High-damping Mn-Cu damping alloy and manufacturing method thereof

A vibration-damping alloy and high-damping technology, applied in the field of high-damping manganese-copper vibration-damping alloys and their manufacturing, can solve problems such as limited effect and reduced damping performance, and achieve high operating temperature, reducing vibration transmission, and wide operating temperature range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

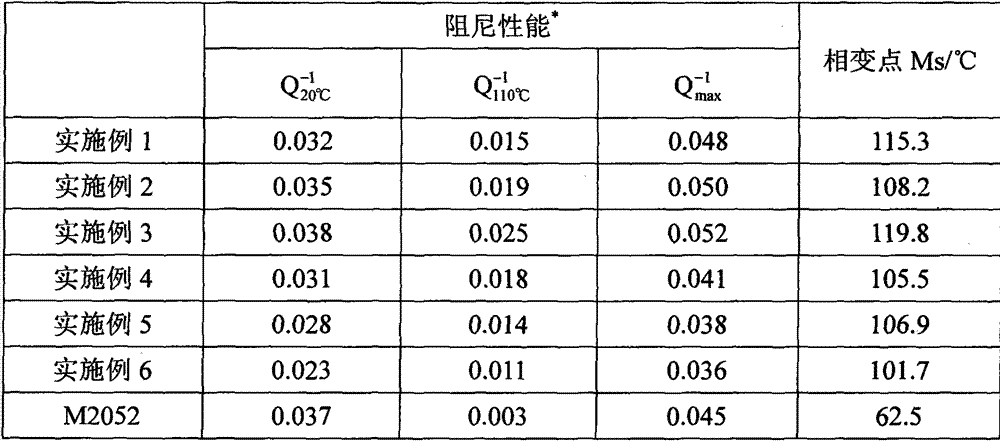

Examples

Embodiment 1

[0021] The composition is Mn71.17%, Ni2.23%, Al2.68%, Fe2.27%, C0.005%, Si0.08%, P0.017%, S0.0043%, N0.030%, O0.006 %, the rest is Cu alloy, which is smelted in an electric furnace. The refining temperature of the alloy is 1220°C, the refining time is 25min, and the tapping temperature is 1210°C. After the ingot is demoulded and cooled to room temperature, it is heated to 850°C in a protective atmosphere or vacuum , heat preservation for 9 hours to make it homogeneous, and then the ingot is heated at 840°C, and forged into a 85mm×85mm profile with a forging press, and the final forging temperature is 750°C. Material heat treatment system: Heating to 800°C in a hydrogen atmosphere, holding for 1 hour, cooling to 400°C at a rate of 5°C / min, holding for 4 hours, cooling to room temperature at a rate of 3°C / min.

Embodiment 2

[0023] The composition is Mn70.03%, Ni3.88%, Al1.52%, Fe1.99%, C0.006%, Si0.05%, P0.015%, S0.0053%, N0.034%, O0.009 %, Zr0.20%, Ti0.25%, Mm0.15%, and the rest is an alloy of Cu. It is smelted in an electric furnace. The refining temperature of the alloy is 1220°C, the refining time is 25min, and the tapping temperature is 1220°C. After the ingot is demolded and cooled to room temperature, it is heated to 850°C in a protective atmosphere or under vacuum, and kept for 10 hours to make it homogeneous, and then the ingot is heated at 855°C, forged into a 90mm×90mm billet with a forging press, and the surface is ground. After that, it is hot forged at 860°C to form a φ50mm profile, and the final forging temperature is 700°C. Material heat treatment system: Heating to 900°C in a hydrogen atmosphere, holding for 1 hour, cooling to 450°C at a rate of 2°C / min, holding for 2 hours, cooling to room temperature at a rate of 3.5°C / min, and leaving the furnace.

Embodiment 3

[0025] The composition is Mn73.25%, Ni2.36%, Al3.00%, Fe1.88%, C0.008%, Si0.05%, P0.018%, S0.0045%, N0.041%, O0.005 %, La0.15%, Ce0.10%, and the rest is Cu alloy, which is smelted in an electric furnace. The refining temperature of the alloy is 1225°C, the refining time is 20min, and the tapping temperature is 1200°C. After the ingot is demolded and cooled to room temperature, it is heated to 900°C in a protective atmosphere or under vacuum, and held for 8 hours to make it homogeneous, and then the ingot is heated at 865°C, forged into a 90mm×90mm square billet with a forging press, and the surface is ground. After that, it is heated and forged at 850°C to form a φ20mm profile, and the final forging temperature is 730°C. Material heat treatment system: Heating to 800°C in a hydrogen atmosphere, holding for 1 hour, cooling to 500°C at a rate of 0.5°C / min, holding for 2 hours, cooling to room temperature at a rate of 1°C / min, and leaving the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com