Patents

Literature

151results about How to "Improve plastic processing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sputter target material and method of producing the same

InactiveUS20050230244A1Improve plastic processing performanceGood dispersionCellsTransportation and packagingSputteringElemental composition

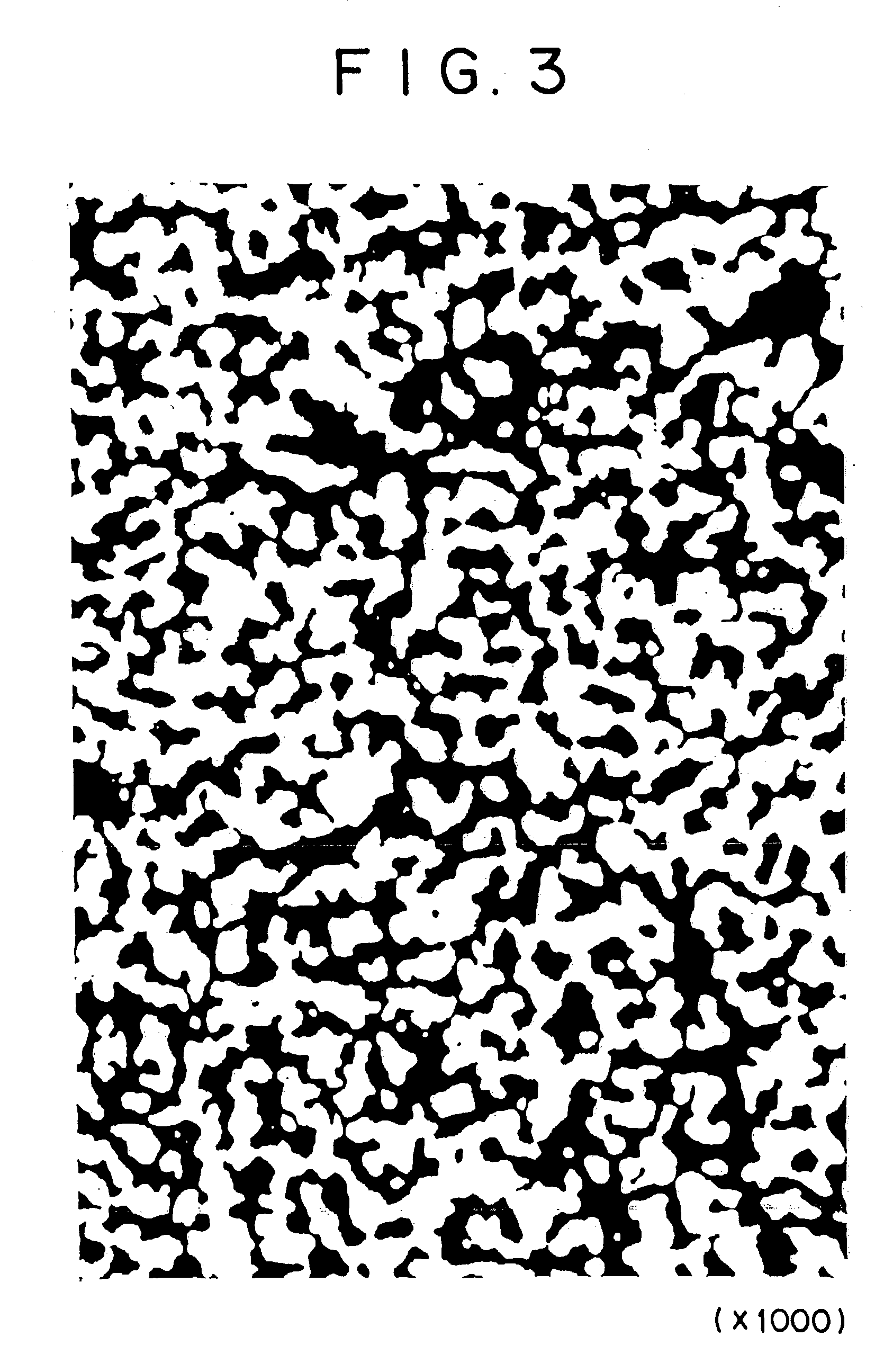

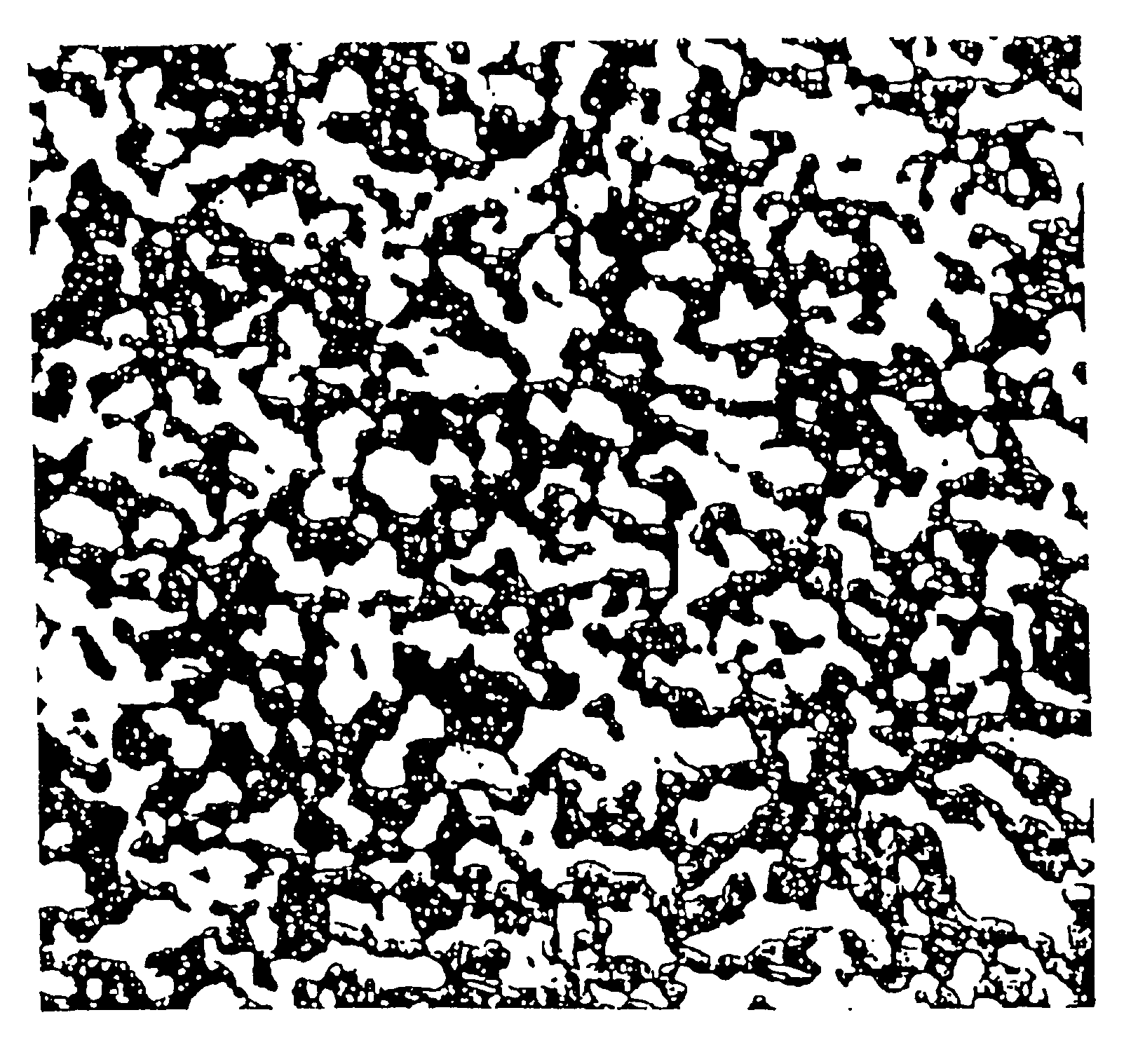

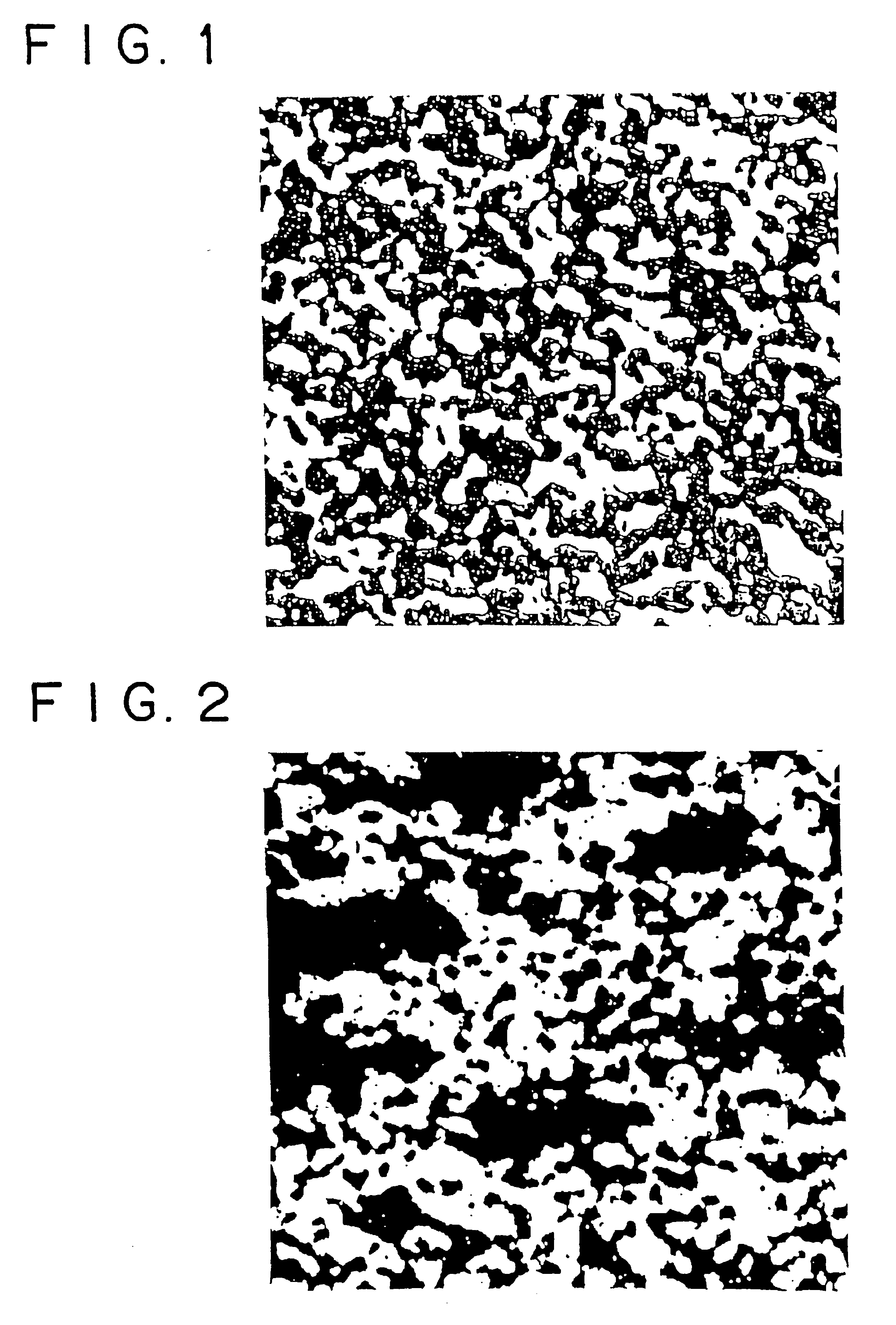

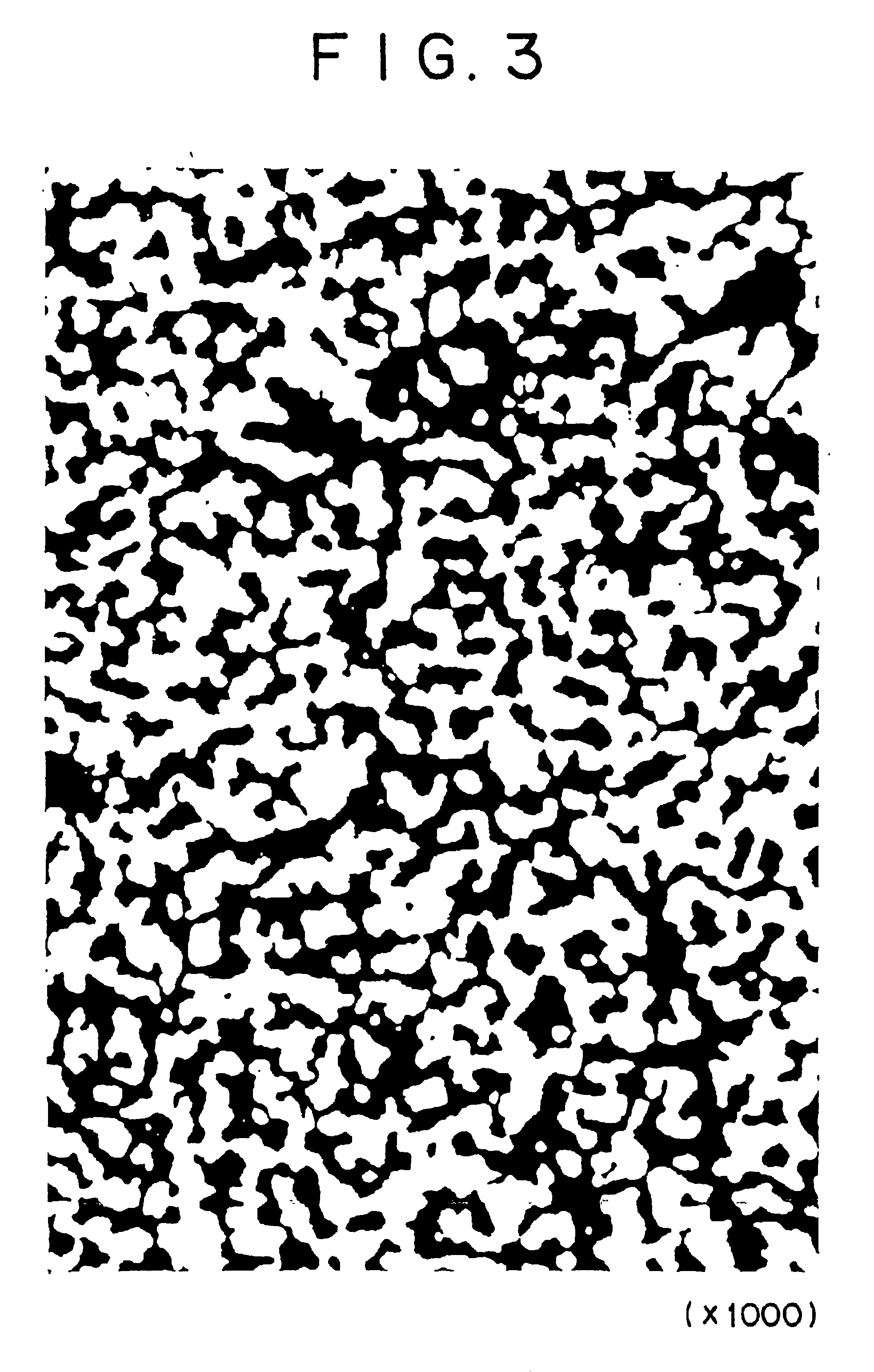

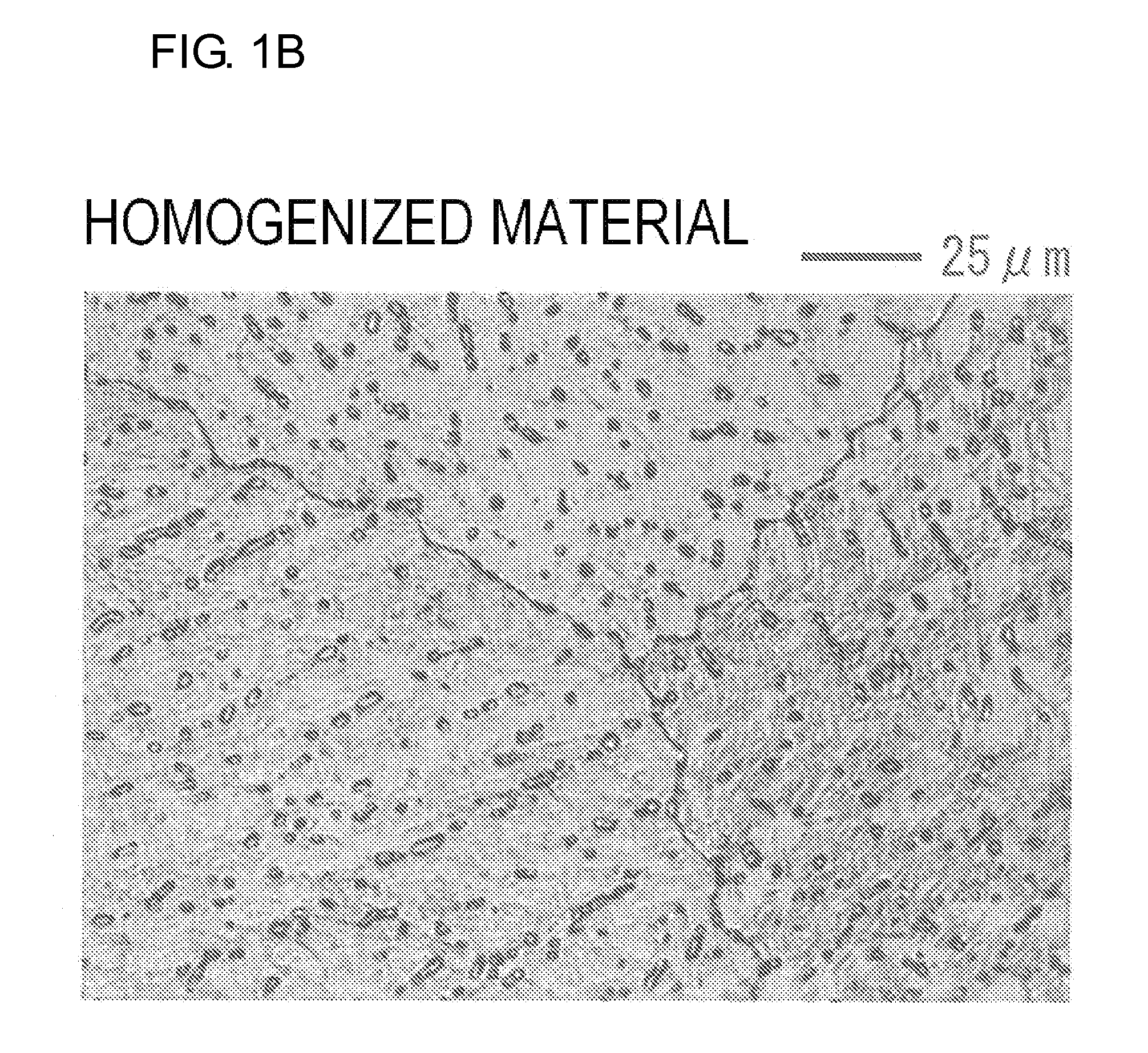

A sputter target material which is of a sintered material, wherein the sputter target material consists of 0.5 to 50 atomic % in total of at least one metal element (M) selected from the group of Ti, Zr, V, Nb and Cr, and the balance of Mo and unavoidable impurities, and has a microstructure seen at a perpendicular cross section to a sputtering surface, in which microstructure oxide particles exist near a boundary of each island of the metal element (M), and wherein the maximum area of the island, which is defined by connecting the oxide particles with linear lines so as to form a closed zone, is not more than 1.0 mm2.

Owner:HITACHI METALS LTD

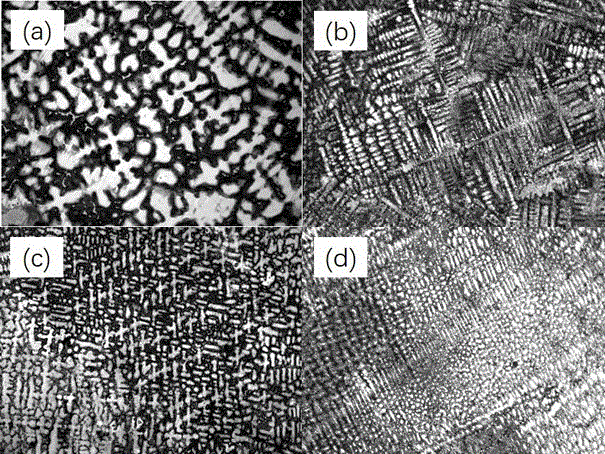

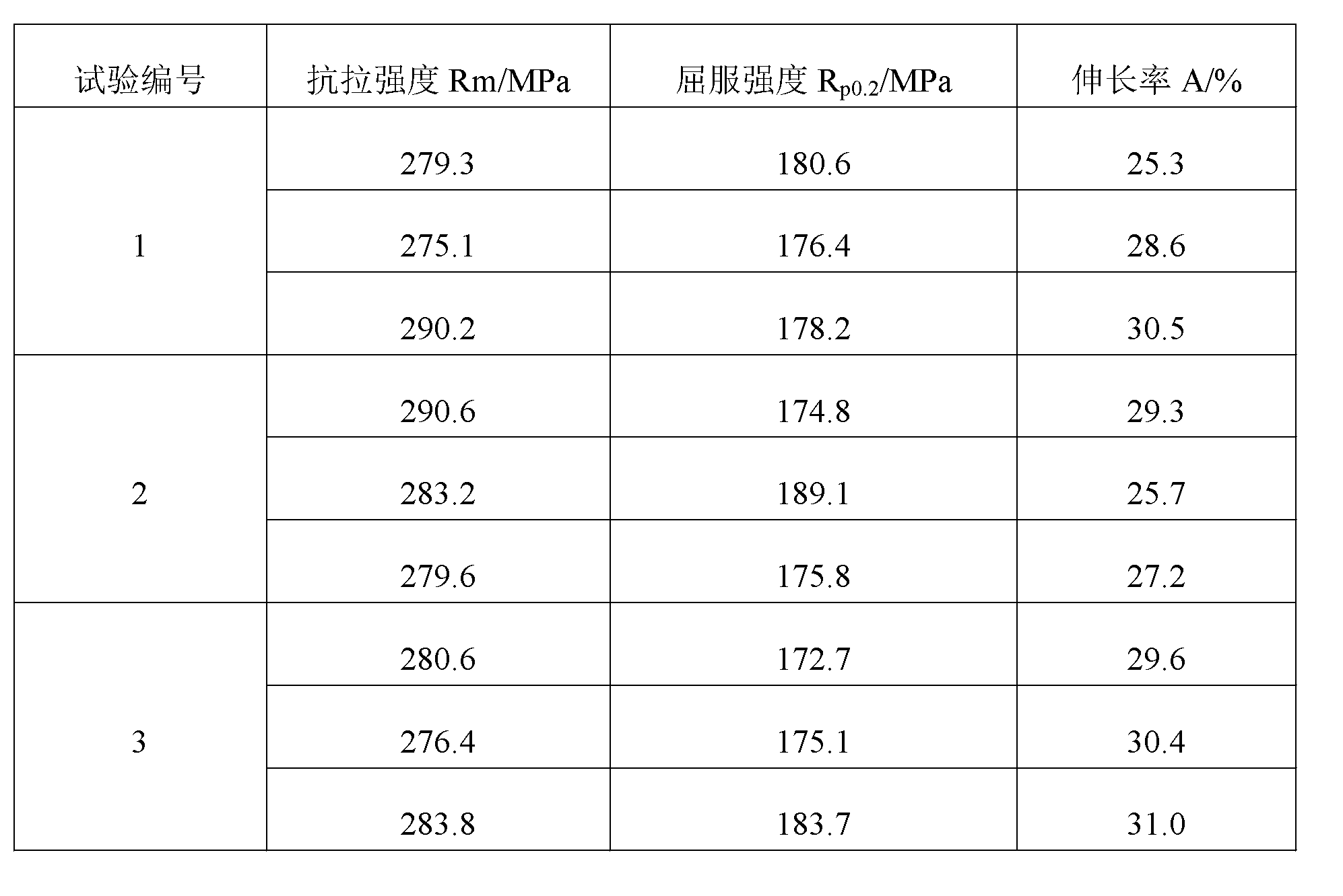

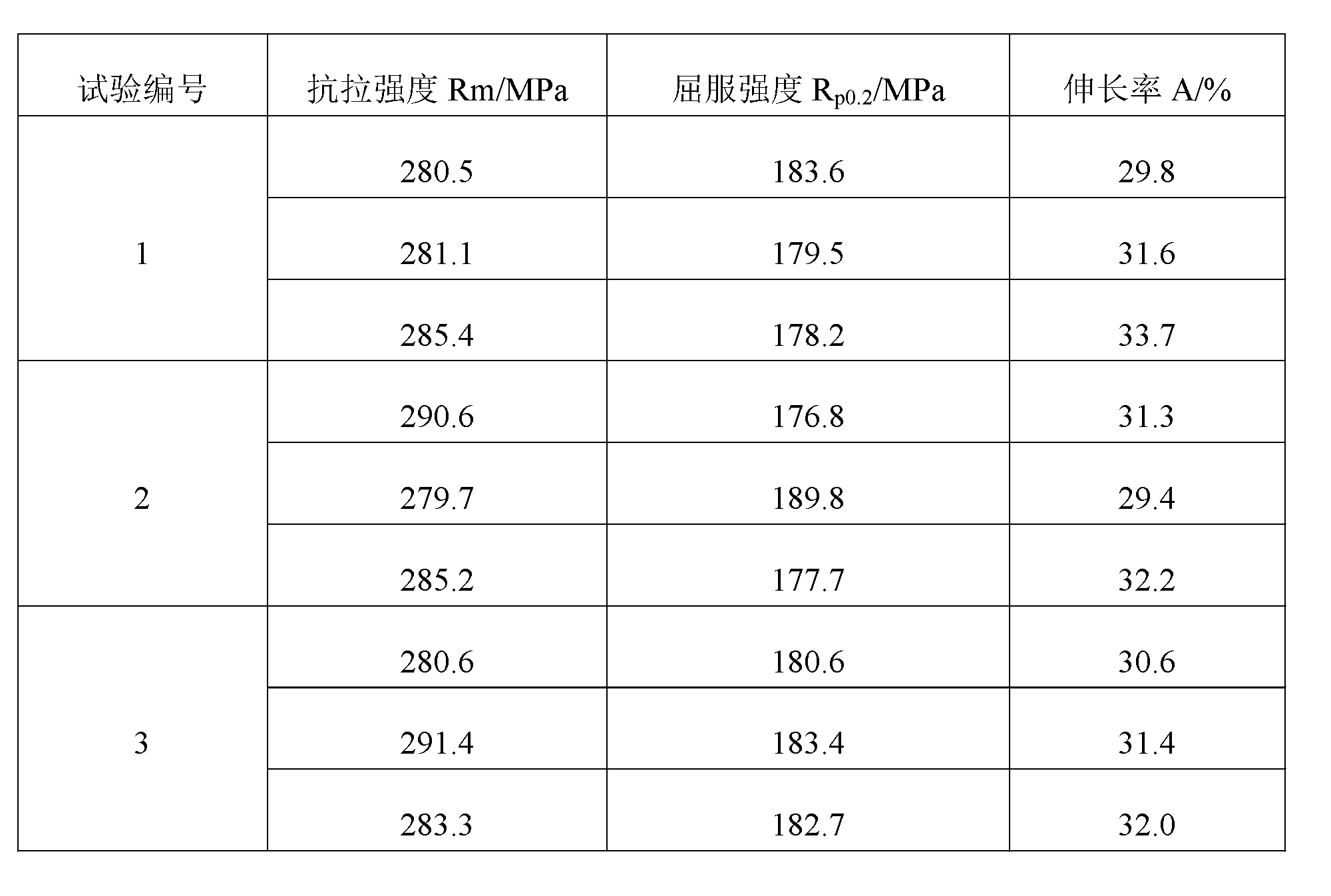

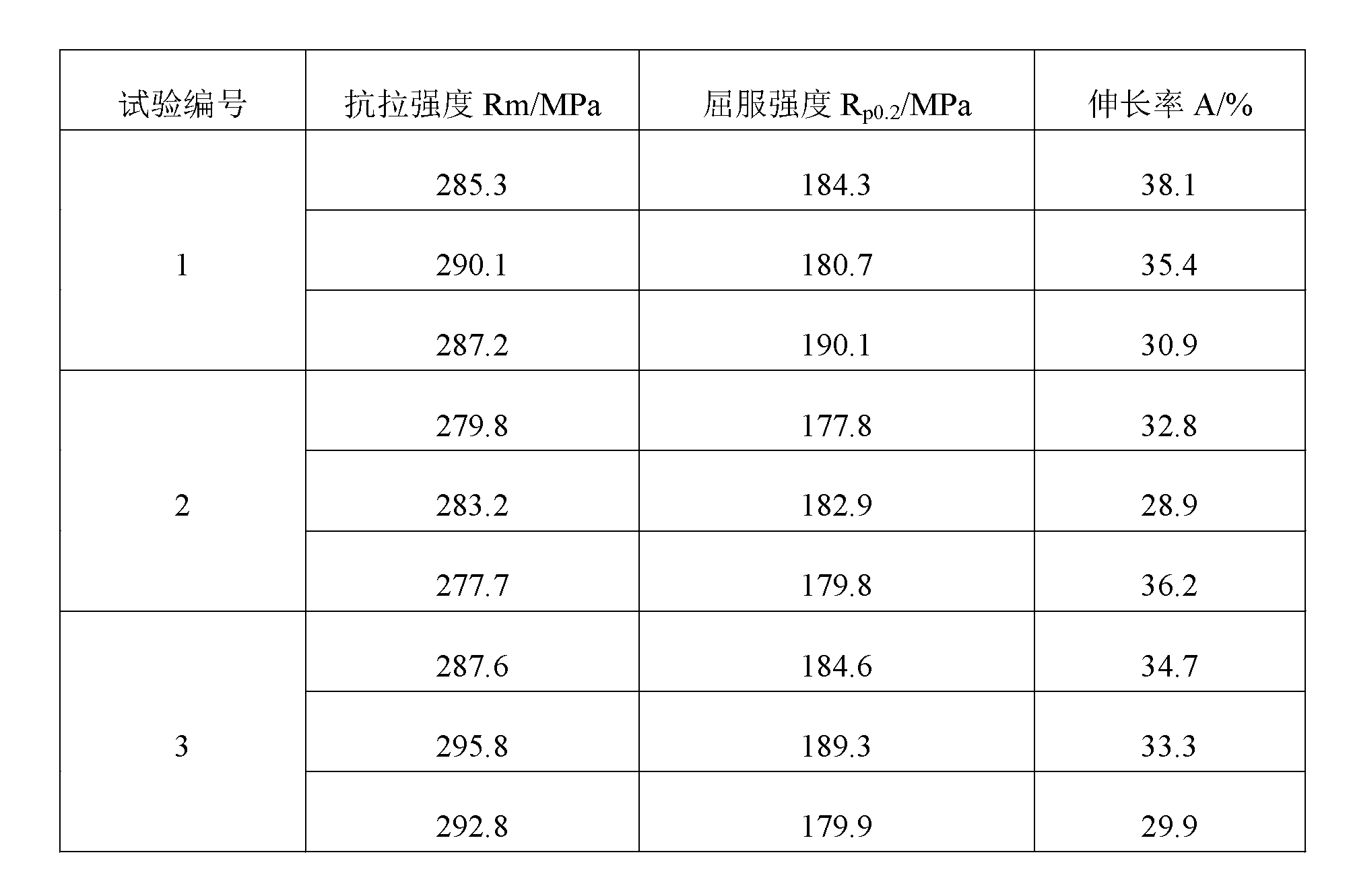

High-toughness heat-resistant Mg-Al-RE-Mn wrought magnesium alloy and preparation method of plate made of same

The invention relates to a high-toughness heat-resistant Mg-Al-RE-Mn wrought magnesium alloy and a preparation method of a plate made of the same. The high-toughness heat-resistant Mg-Al-RE-Mn wrought magnesium alloy comprises aluminum, rare earth, manganese, impurity elements (silicon, iron, nickel and copper) and magnesium. The preparation method comprises the following steps: proportionally preparing pure magnesium, pure aluminum cast ingots, magnesium-manganese (or aluminum-manganese) interalloy and magnesium-rear earth interalloy; smelting and refining by using a smelting furnace, and casting to obtain cast ingots; carrying out homogenizing treatment at 370-410 DEG C, and quenching with water; and before plastic deformation treatment, keeping the temperature at 280-400 DEG C for a period of time, and extruding and rolling, or extruding while rolling, thereby obtaining the high-toughness heat-resistant Mg-Al-RE-Mn wrought magnesium alloy. The high-toughness heat-resistant Mg-Al-RE-Mn wrought magnesium alloy and the plate made of the same provided by the invention have the advantages of high toughness, high heat resistance, high plasticity and favorable hot working properties; and the product can be used as a light-weight high-toughness heat-resistant structural material to satisfy the demands of aviation, spaceflight, civil vehicles and the like for the light-weight high-toughness heat-resistant wrought magnesium alloy material.

Owner:XIAN TECHNOLOGICAL UNIV

Nickel alloy sputtering target

InactiveUS20060037680A1Improve uniformityImprove plastic processing performanceVacuum evaporation coatingSputtering coatingManufacturing technologyNickel alloy

A nickel alloy sputtering target containing 0.5 to 10 at % of tantalum in nickel, in which inevitable impurities excluding gas components are 100 wtppm or less. Provided is a nickel alloy sputtering target, and the manufacturing technology thereof, enabling the formation of a thermally stable silicide (NiSi) film, unlikely to cause the coagulation of films or excessive formation of silicides, having few generation of particles upon forming the sputtered film, having favorable uniformity and superior in the plastic workability to the target, and which is particularly effective for the manufacture of a gate electrode material (thin film).

Owner:JX NIPPON MINING & METALS CO LTD

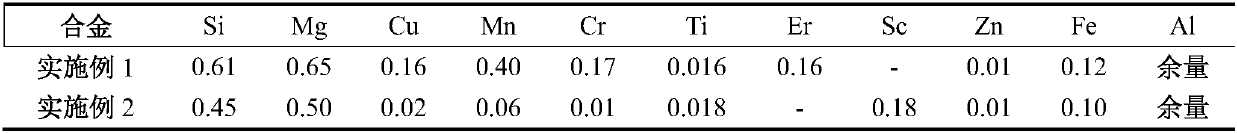

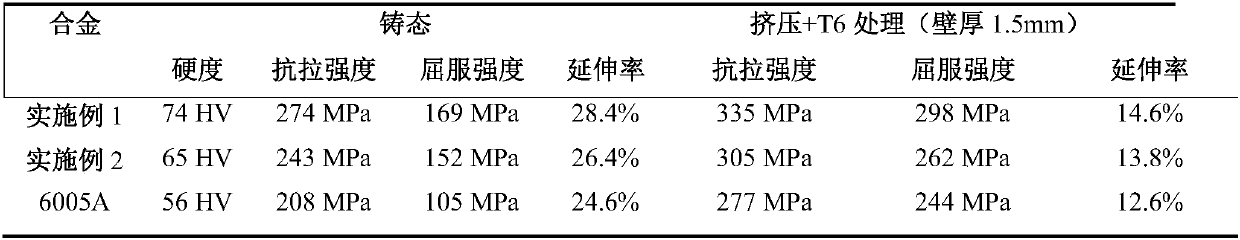

High performance Al-Mg-Si aluminum alloy extrusion material and preparation method thereof

ActiveCN110669964AImprove performanceStrong precipitation strengtheningRare-earth elementSingle element

The invention belongs to the technical field of aluminum alloy materials, and relates to a high performance Al-Mg-Si aluminum alloy extrusion material and a preparation method thereof. The high performance Al-Mg-Si aluminum alloy extrusion material is prepared from the following element components in percent by weight: 0.4-0.7% of Si, 0.5-0.7% of Mg, 0.01-0.2% of Cu, 0.05-0.45% of Mn, 0.01-0.3% ofCr, 0.01-0.02% of Ti, 0.05-0.30% of rare earth elements, less than or equal to 0.1% of Zn, less than or equal to 0.15% of Fe and the balance Al, wherein the content of single elements is less than orequal to 0.05%, the total content of impurities is less than or equal to 0.15%, and any one or two of the rare earth elements Er and Sc are mixed. The preparation method can optimize the alloy components obviously, balance and refine crystal grains, purify and clean a melt, reduce the casting flaws and improve the quality of a cast ingot greatly. In addition, the surface quality of an extruded profile can be better improved, and the extrusion speed and the thermal treatment comprehensive mechanical property of the extruded profile product are improved.

Owner:CHINA ZHONGWANG

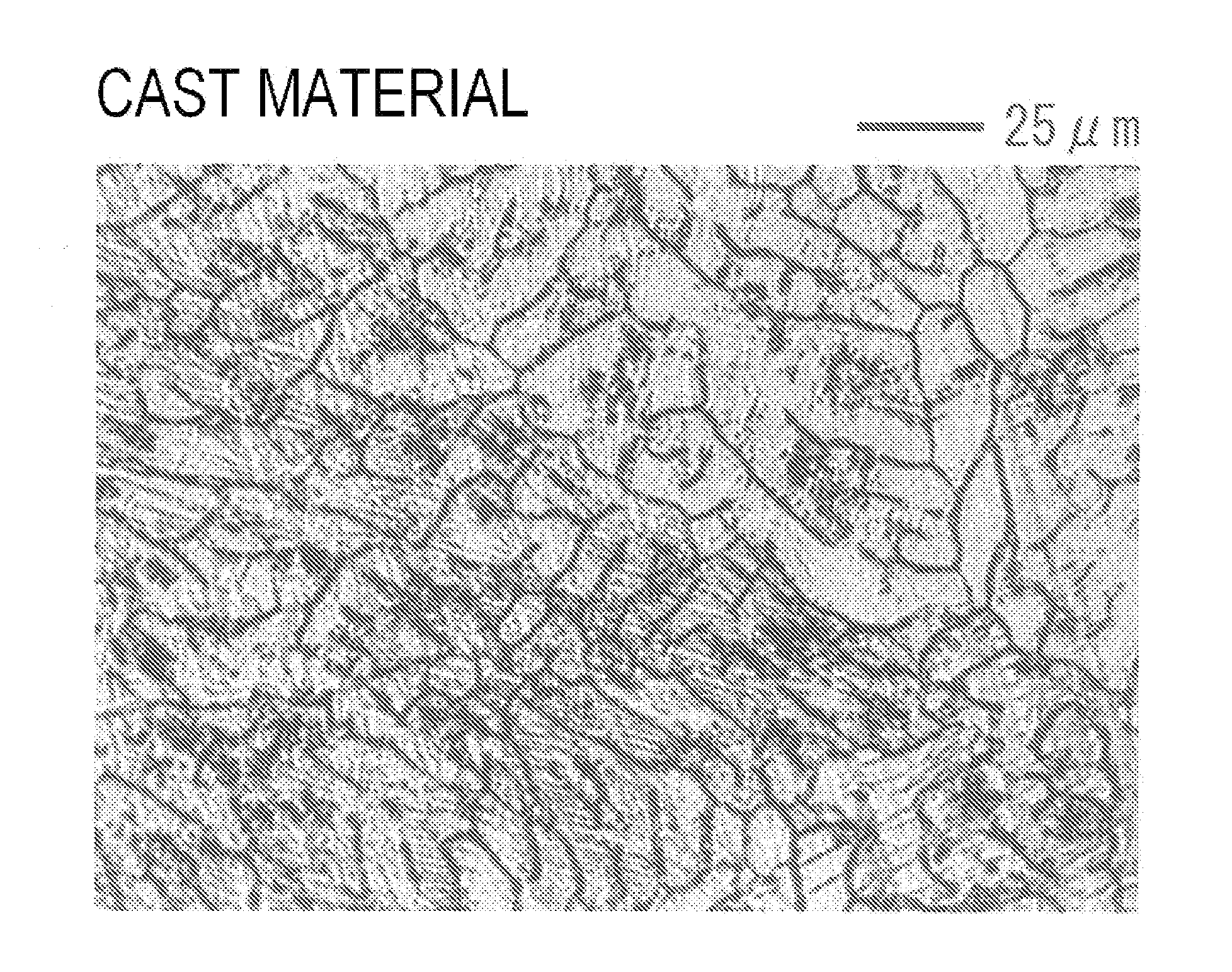

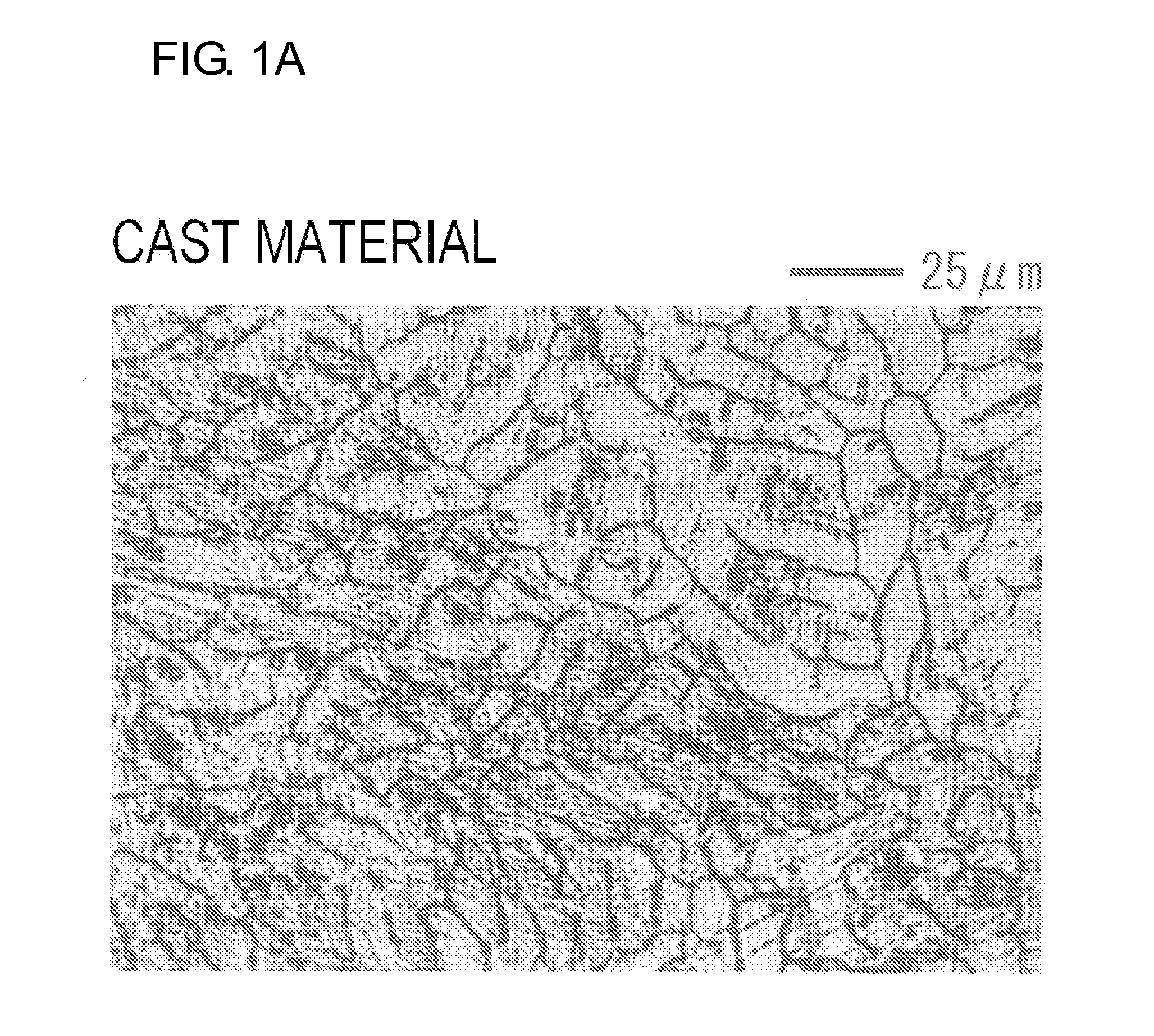

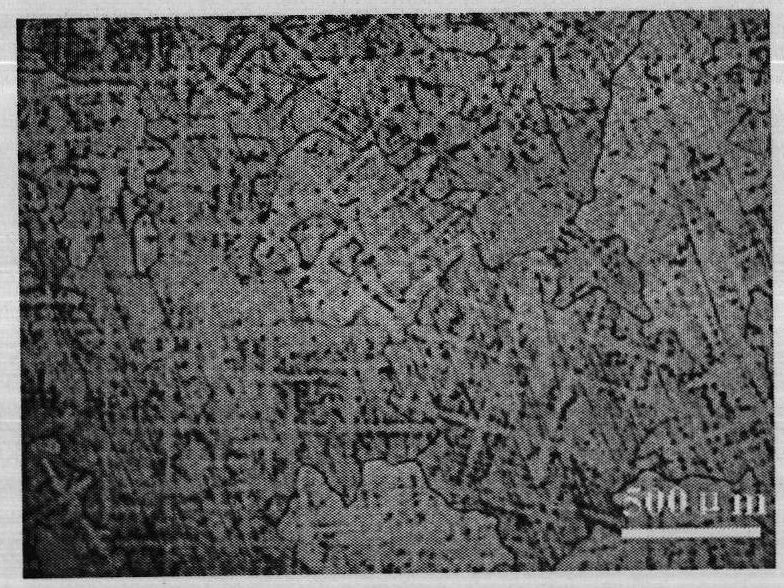

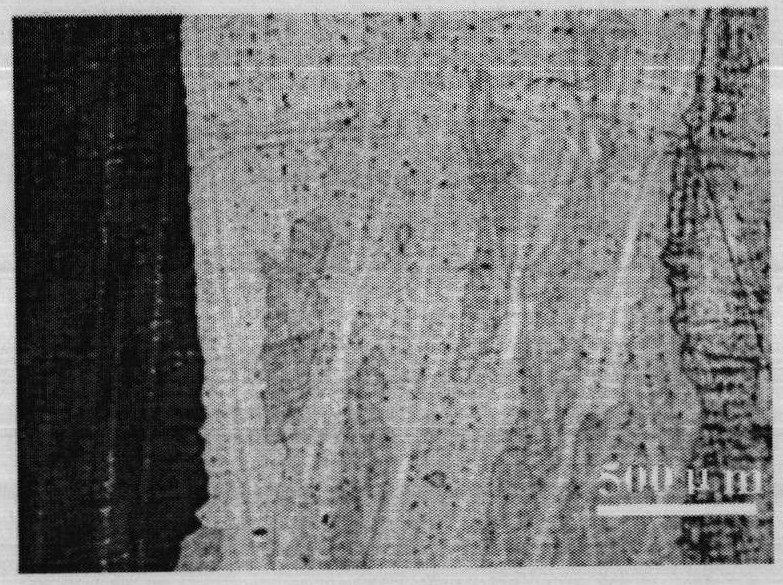

TiAl intermetallic compound-based alloys and methods for preparing same

PCT No. PCT / JP95 / 01349 Sec. 371 Date Mar. 26, 1996 Sec. 102(e) Date Mar. 26, 1996 PCT Filed Jul. 6, 1995 PCT Pub. No. WO96 / 12820 PCT Pub. Date May 2, 1996TiAl intermetallic compound-based alloys comprising Ti, Al, Nb and Cr and, if necessary, further comprising Ni and Co, which have excellent plastic workability, good resistance to oxidation at high temperatures, high strength or good creep resistance.

Owner:MITSUBISHI HEAVY IND LTD

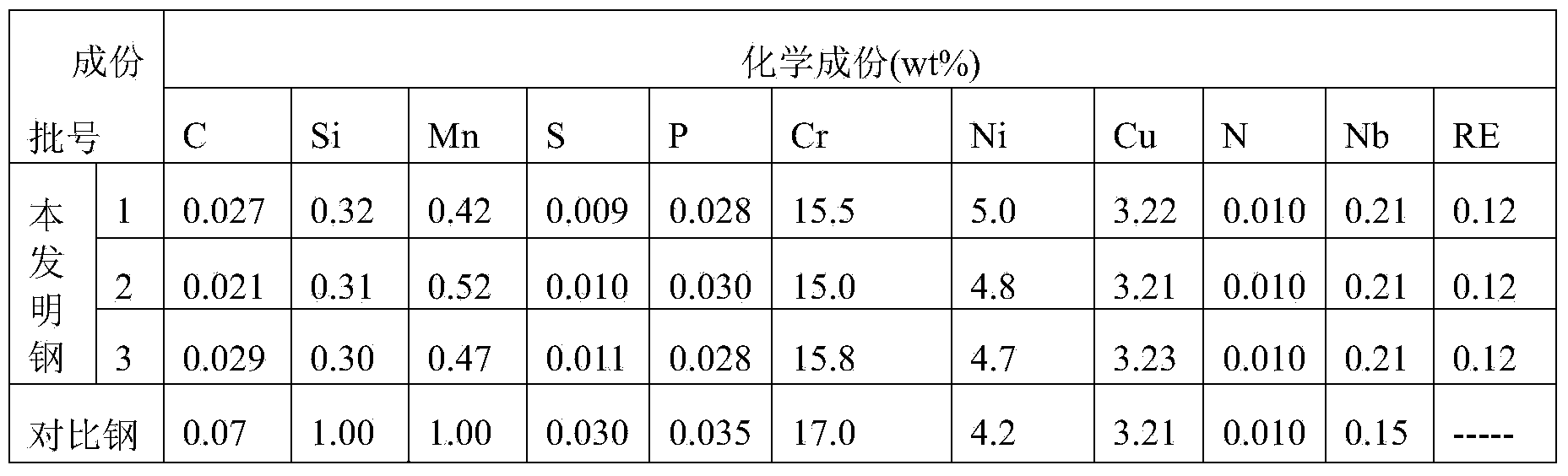

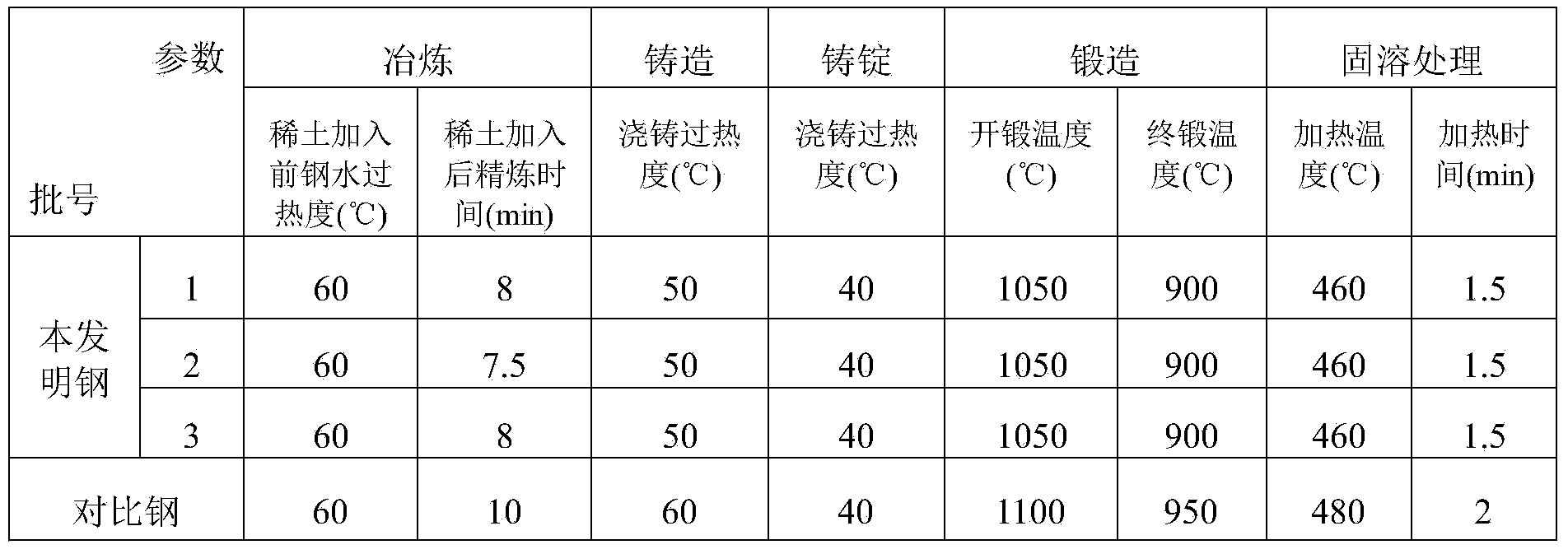

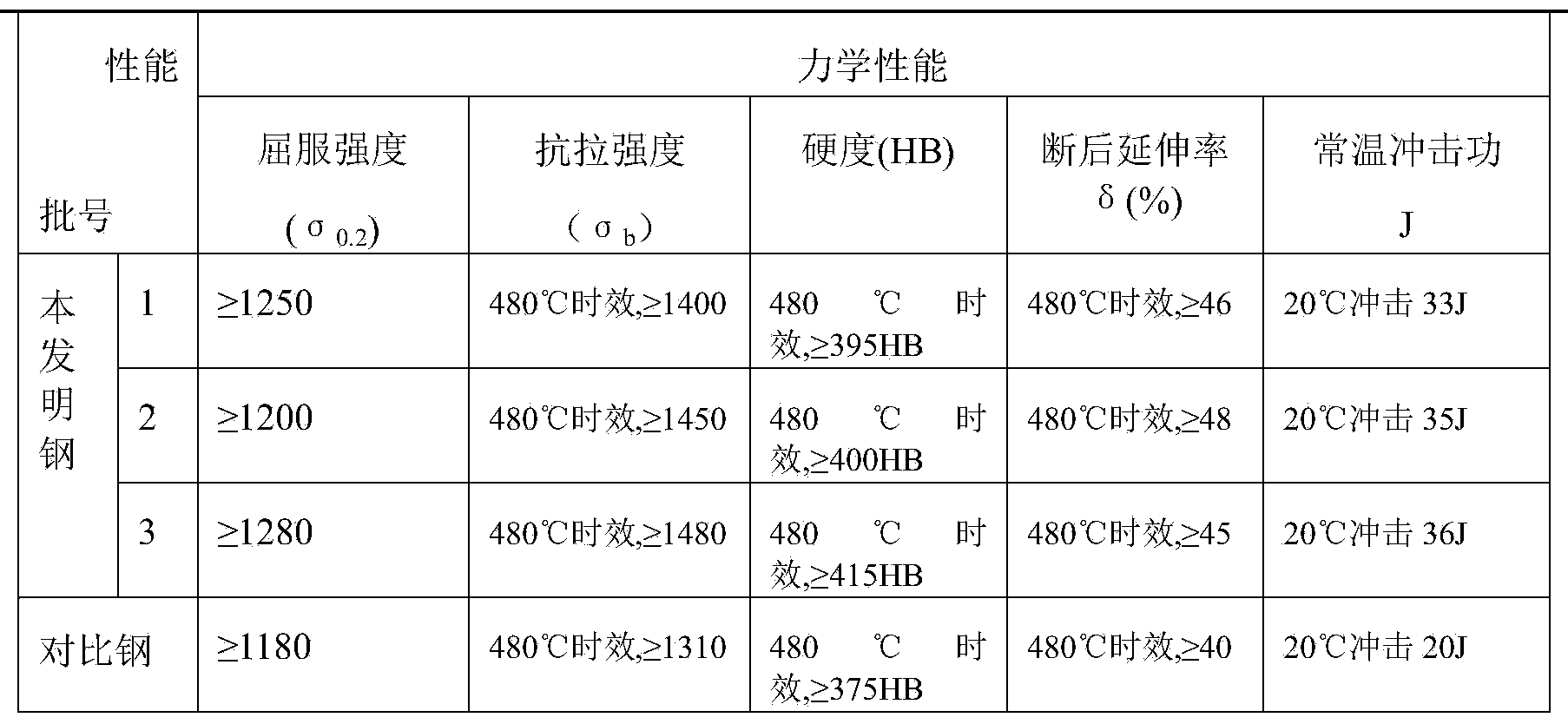

Rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel and preparation method thereof

ActiveCN104328353ARefining solidified tissueImprove performanceSolution treatmentMartensitic stainless steel

The invention discloses rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel is characterized by comprising the following chemical components in percentage by weight: less than or equal to 0.07% of C, less than or equal to 1% of Si, less than or equal to 1% of Mn, less than or equal to 0.035% of P, less than or equal to 0.03% of S, 3.00-5.00% of Ni, 15.5-17.5% of Cr, 3.00-5.00% of Cu, 0.15-0.45% of Nb, 0.05-0.25% of Re and the balance of Fe and belongs to the field of alloy steels. The invention also discloses a preparation method of the rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The preparation method comprises the steps of smelting, casting, carrying out electroslag remelting, casting ingots, forging or rolling, carrying out solution treatment and the like. The rare-earth-type 0Cr17Ni4Cu4Nb special steel, which is disclosed by the invention, as one of precipitation-hardening martensitic stainless steel, has the characteristics of high strength, high hardness, corrosion resistance and the like and is suitable for various technical fields, such as chemical machinery, food machinery, papermaking machinery, aerospace and marine.

Owner:什邡新工金属材料有限公司

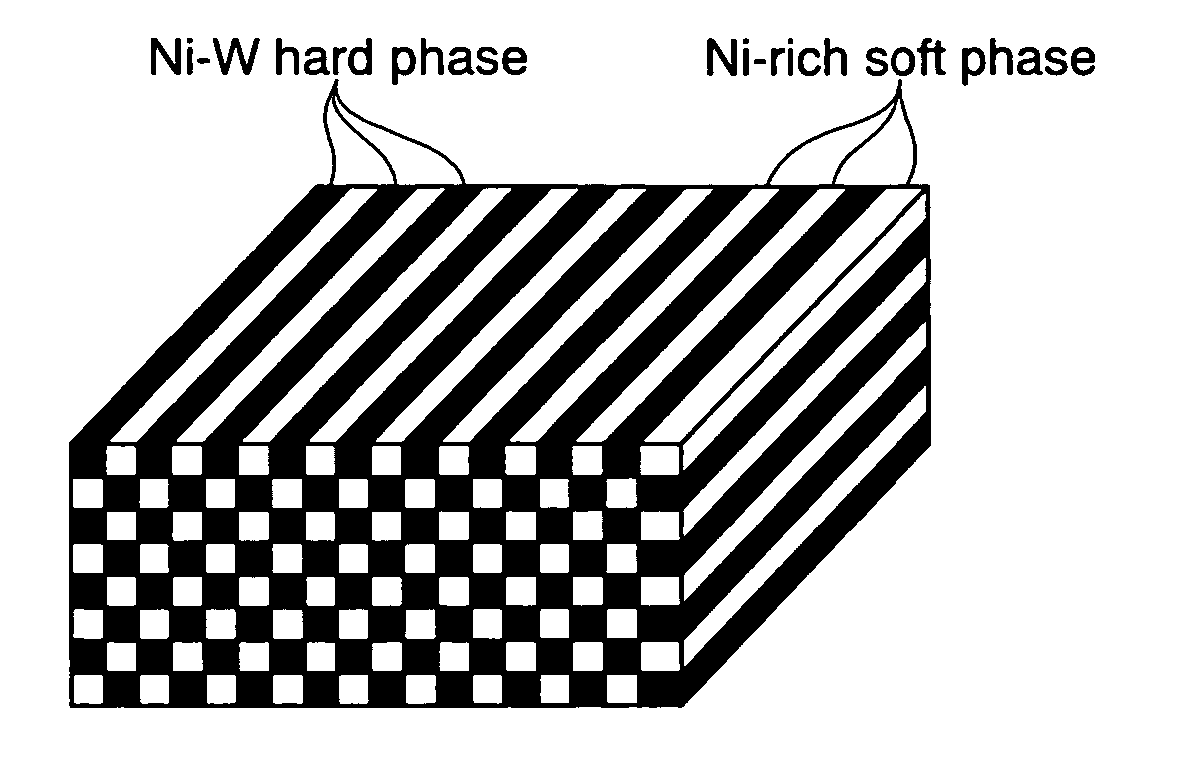

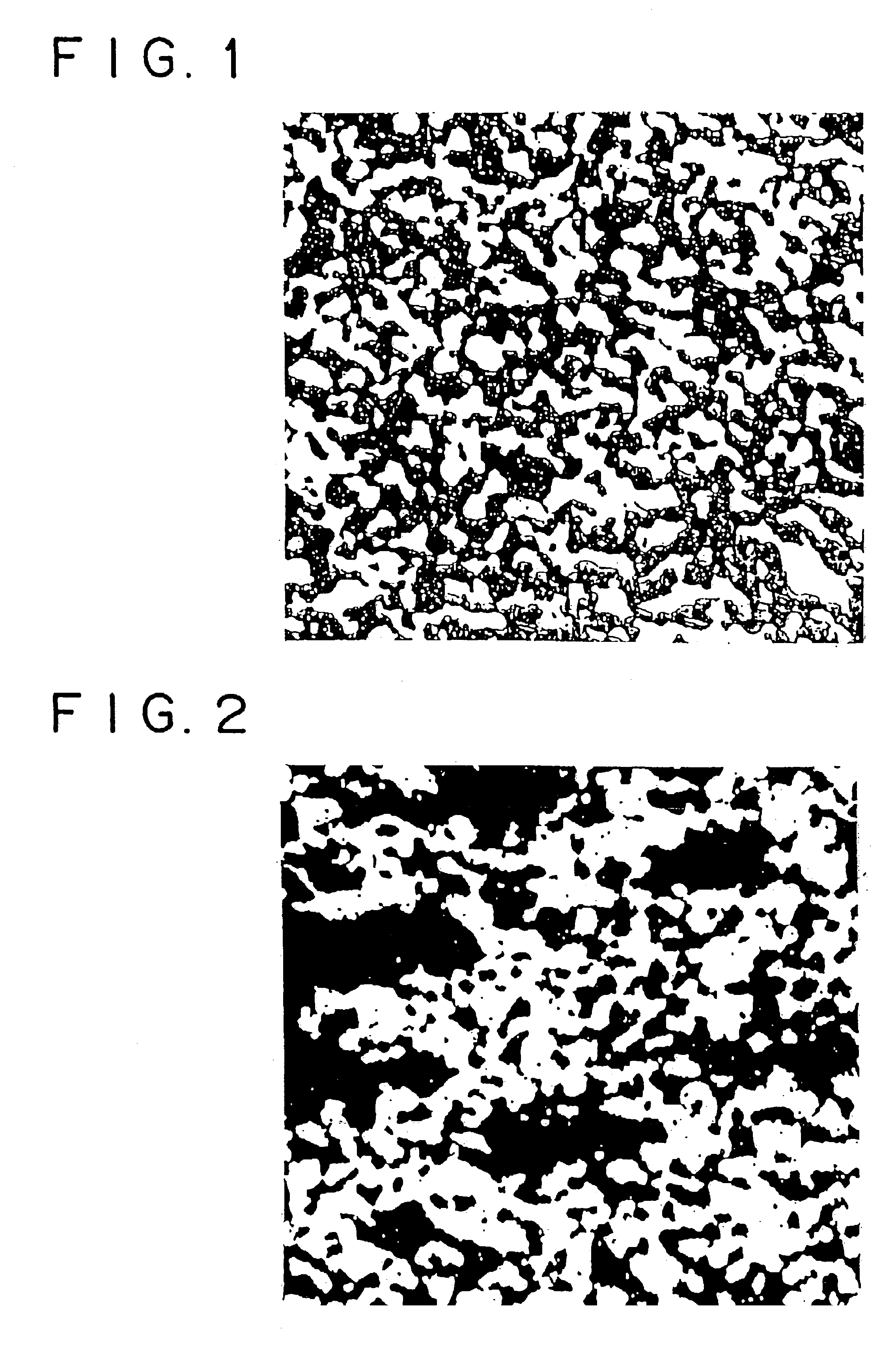

Composite alloy having a three-dimensional periodic hierarchical structure and method of producing the same

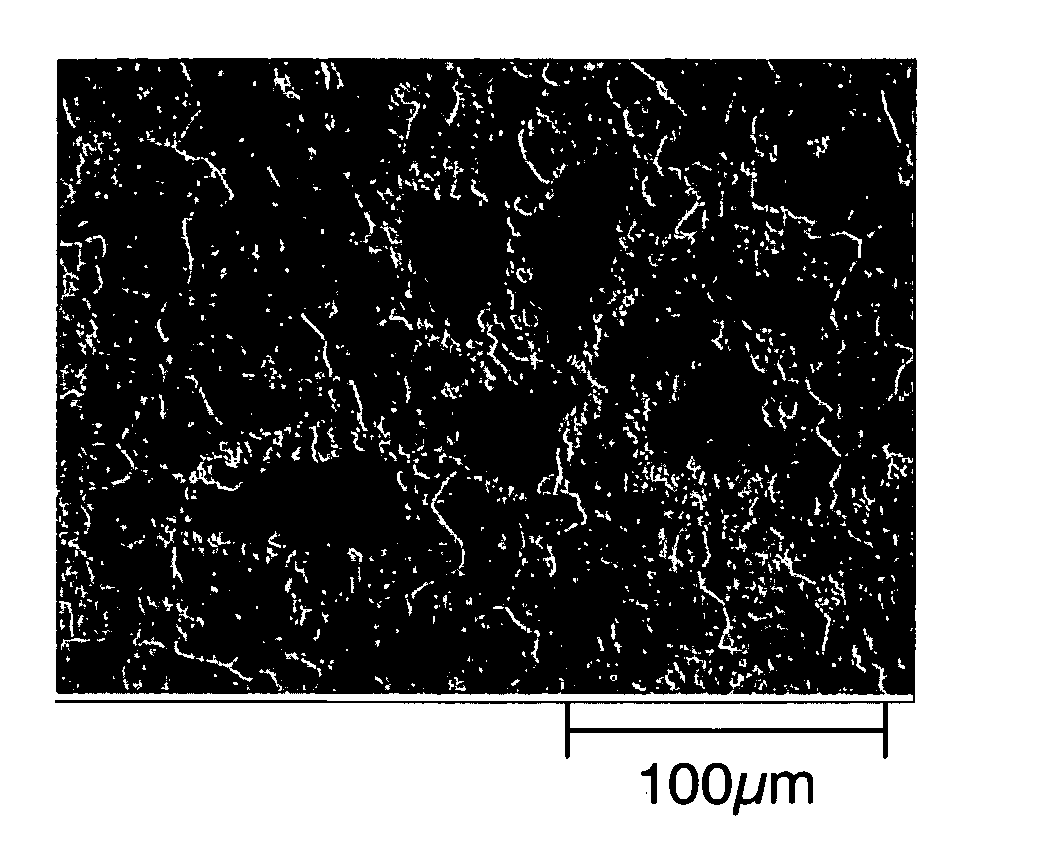

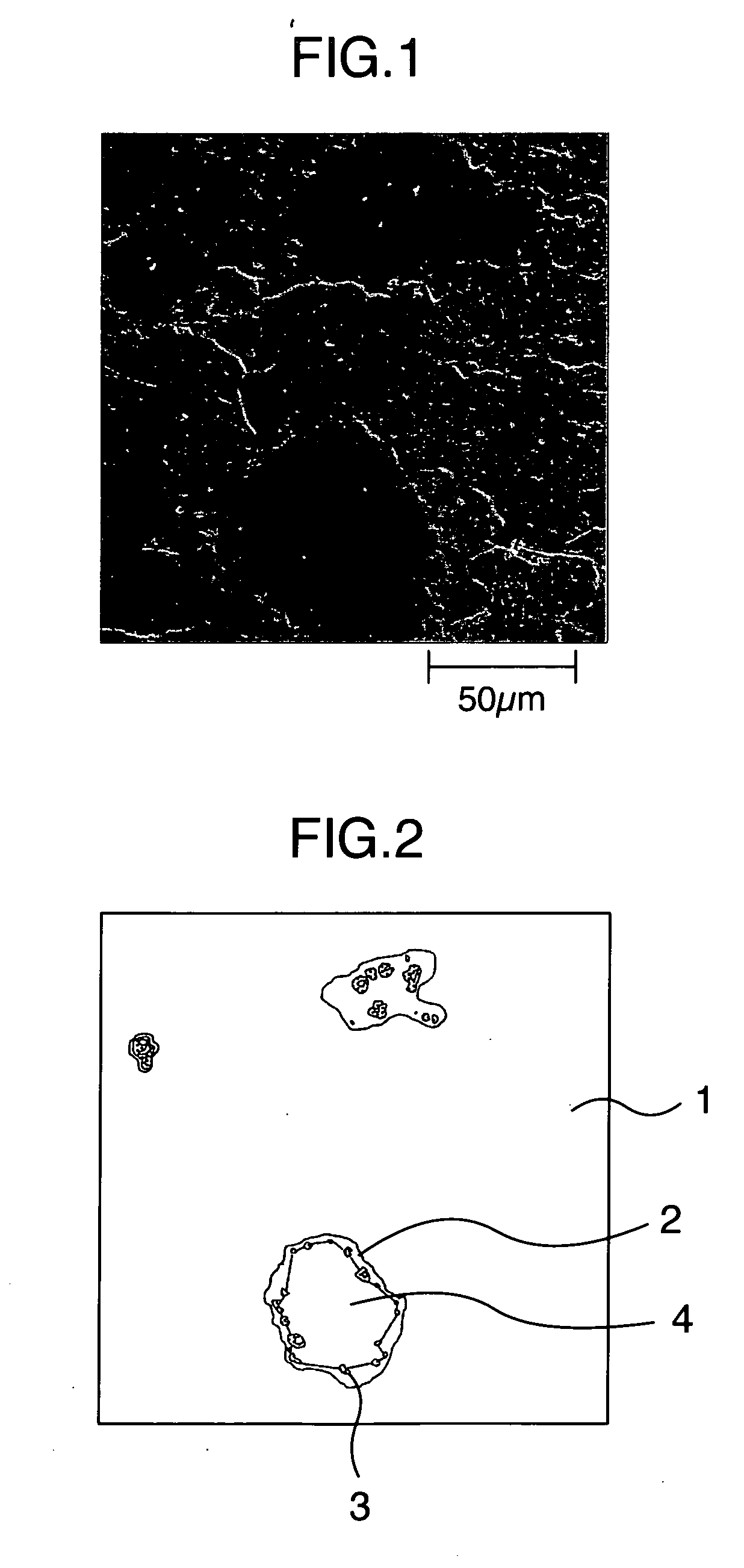

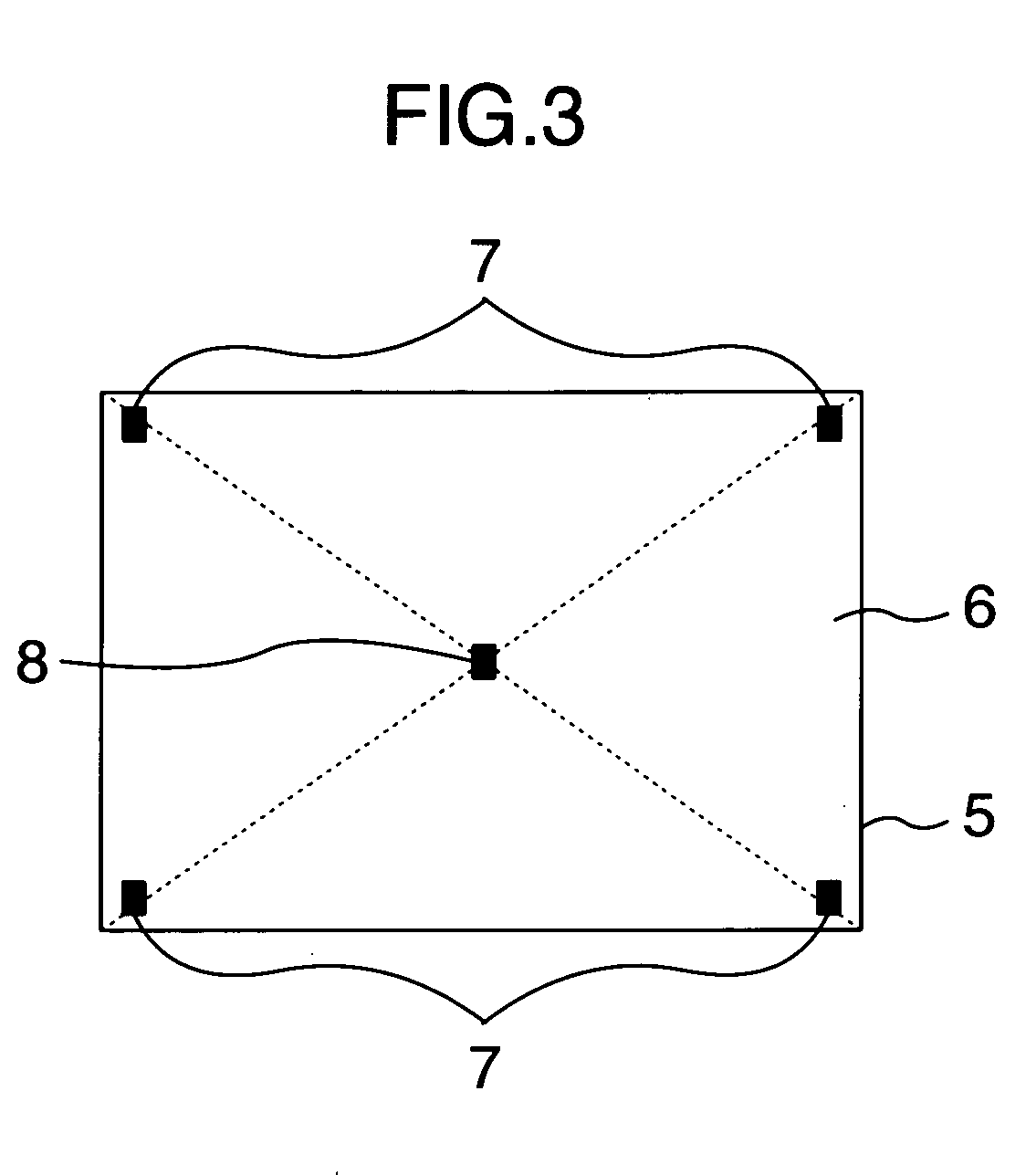

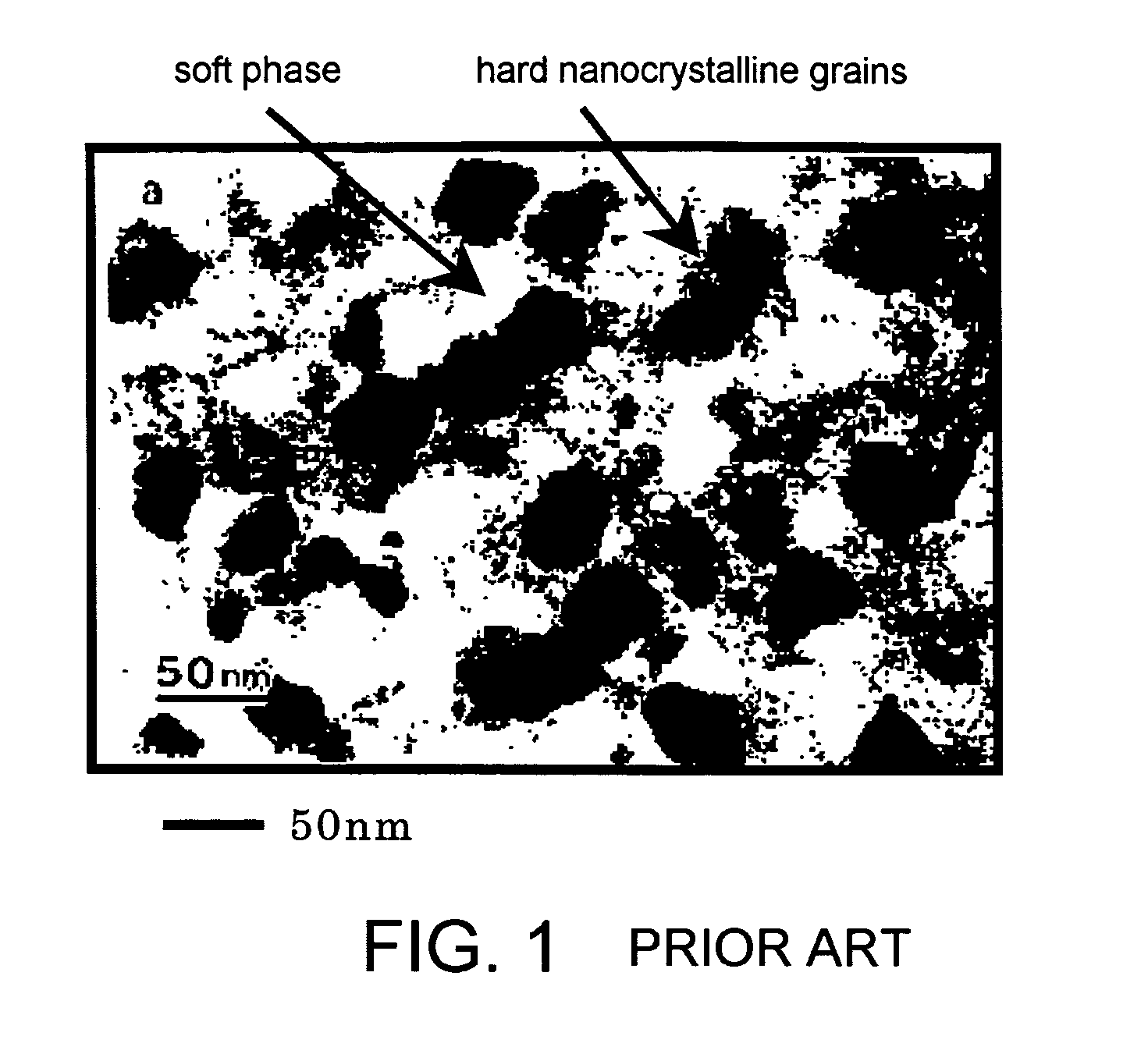

InactiveUS20050045252A1High strengthHigh plastic workabilityCellsTransportation and packagingLayered structureMicroscope

A composite alloy has a three-dimensional periodic hierarchical structure having hard and soft metallic phases periodically arranged with a period having a length ranging from a nanometer scale to a millimeter scale. It is preferable that the three-dimensional periodic hierarchical structure has an alloy composition sloped microscopically within the period. The three-dimensional periodic hierarchical structure may be formed by periodically arranging rod-like hard and soft metallic phases having a width and a thickness ranging from a nanometer scale to a millimeter scale so that their side surfaces are adjacent to one another.

Owner:YAMASAKI TOHRU +1

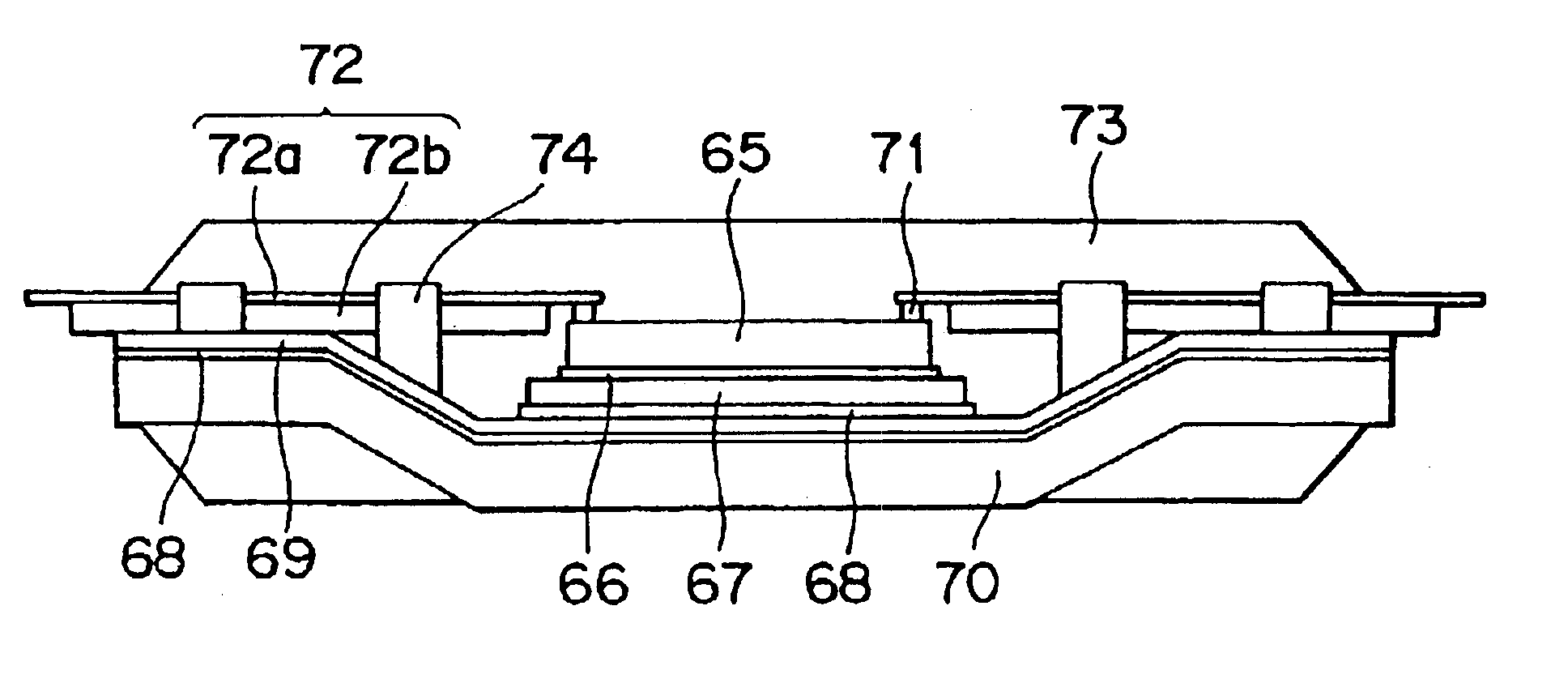

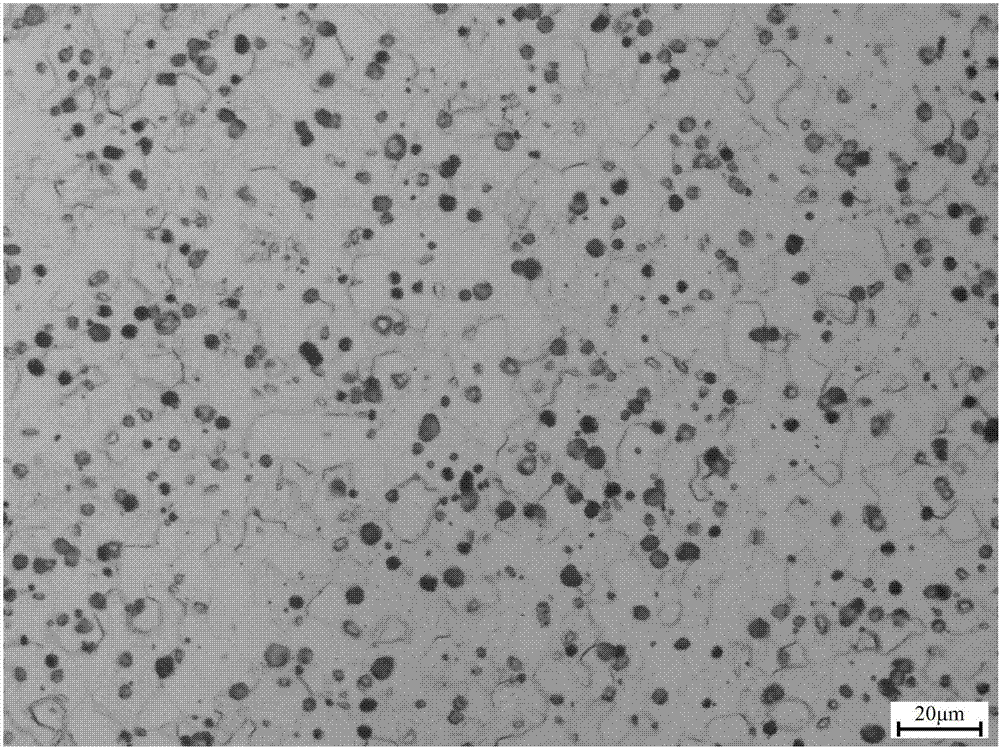

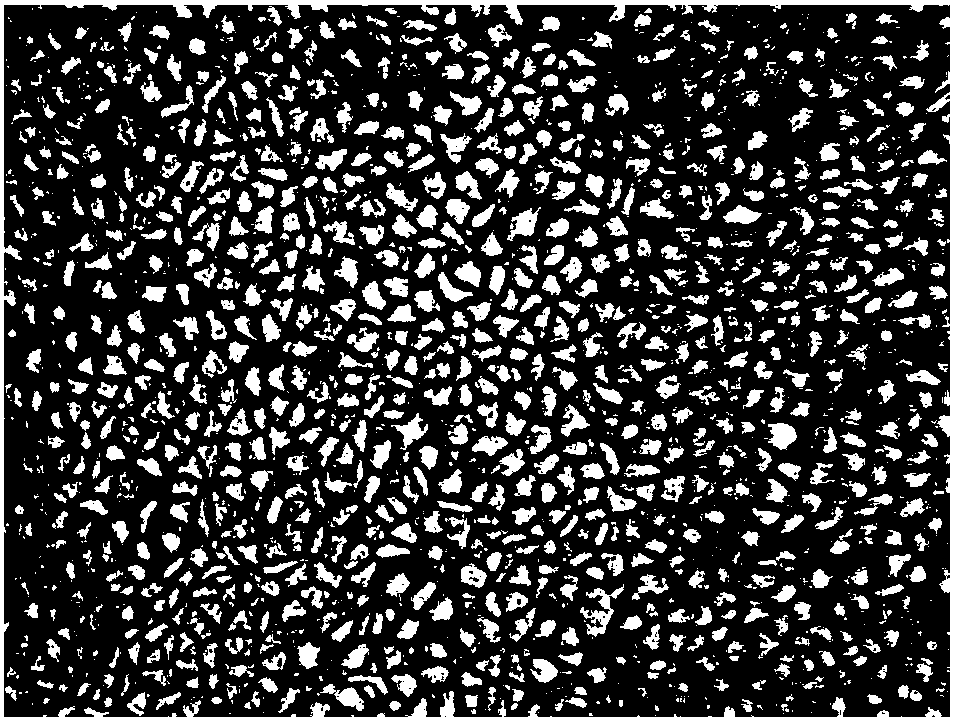

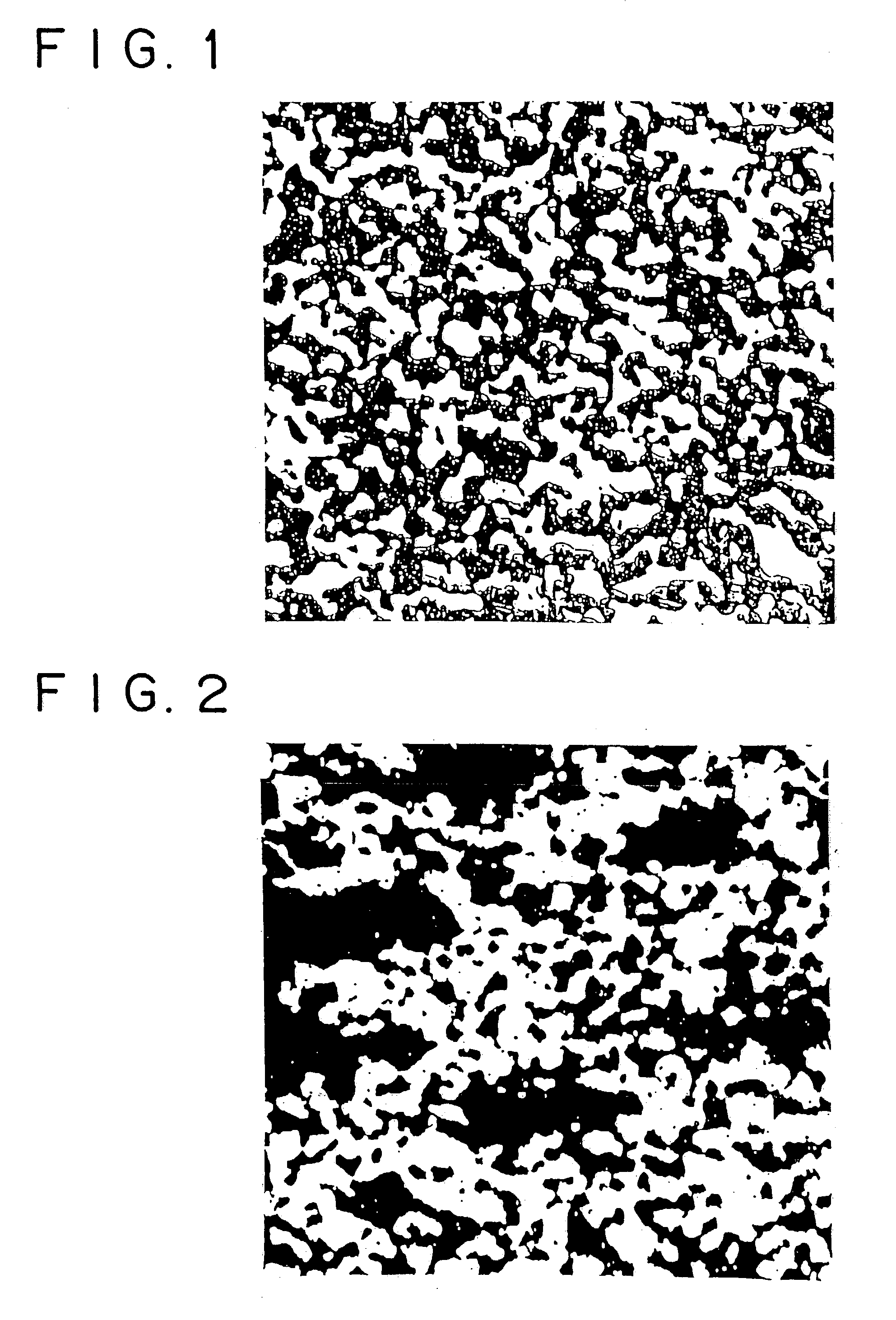

Composite material including copper and cuprous oxide and application thereof

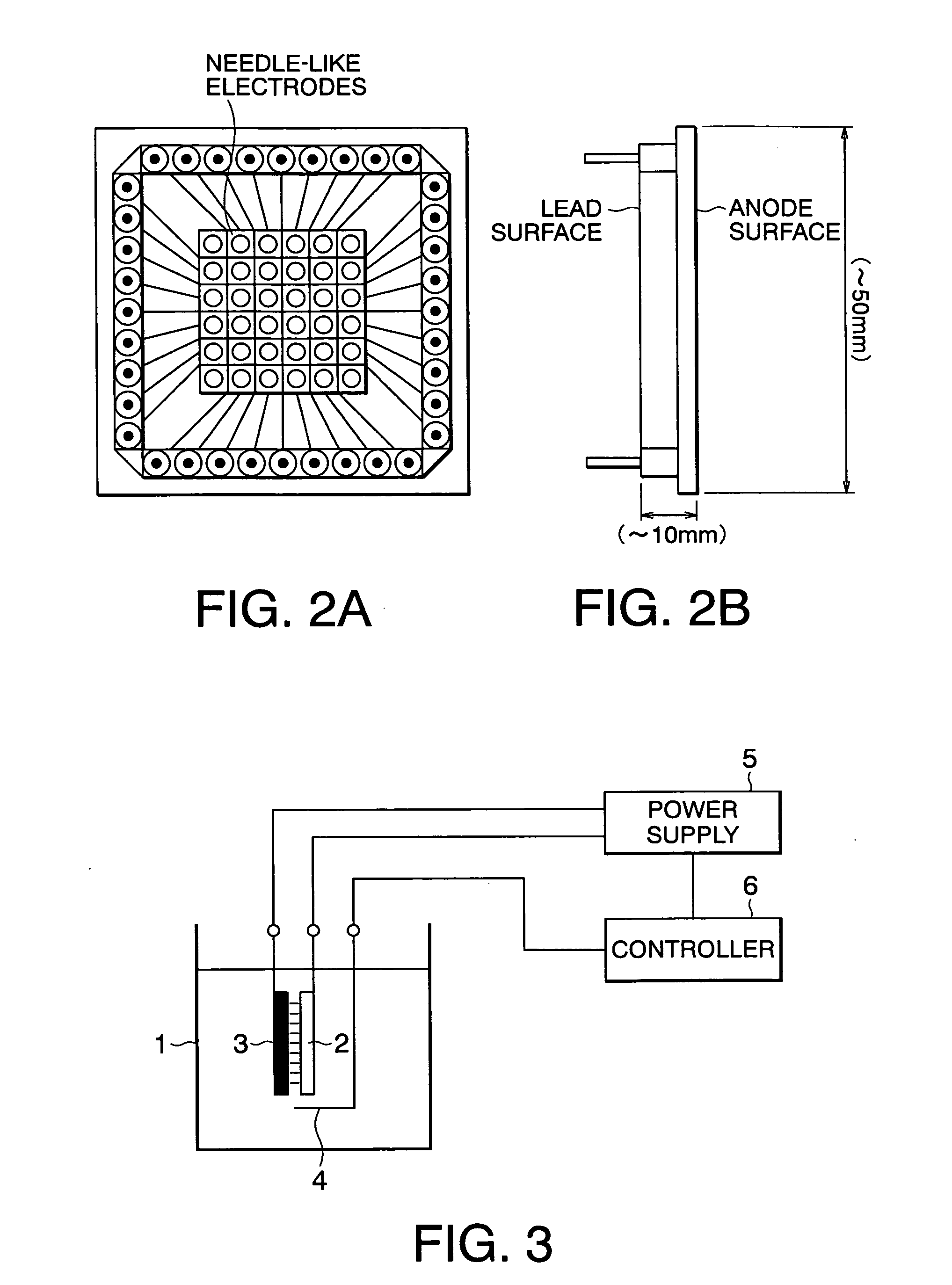

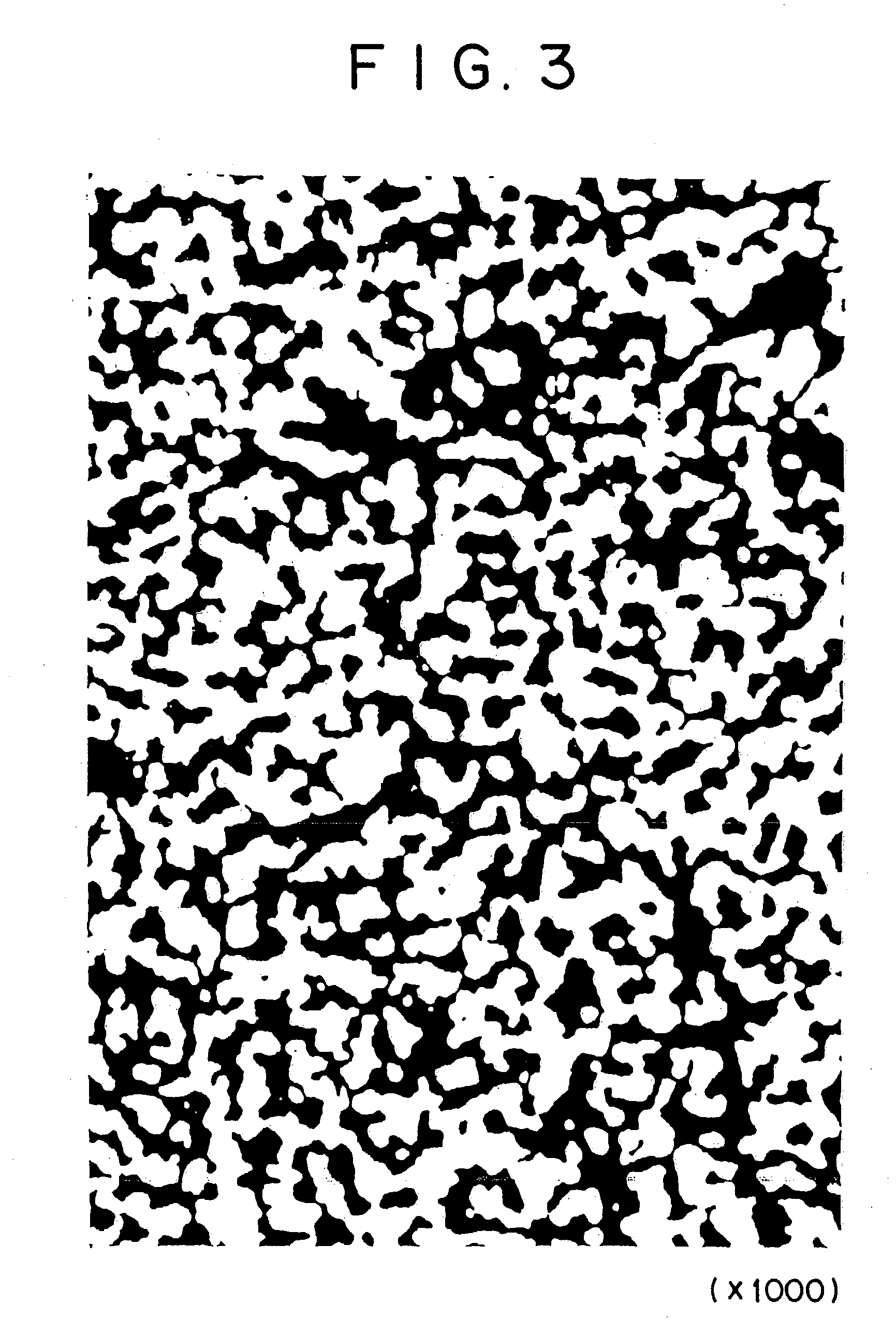

InactiveUS20030146499A1Improve plastic processing performanceShort processing timeSemiconductor/solid-state device detailsSolid-state devicesInorganic particleDielectric plate

It is an object of the present invention to provide a composite material having low thermal expansivity, high thermal conductivity, and good plastic workability, which is applied to semiconductor devices and many other uses. The composite material is composed of metal and inorganic particles having a smaller coefficient of thermal expansion than said metal. It is characterized in that said inorganic particles disperse in such a way that 95% or more of them (in terms of their area in cross-section) form aggregates of complex configuration joining together. The composite material contains 20-80 vol % of copper-oxide, with the remainder being copper. It has a coefficient of thermal expansion of 5x10-6 to 14x10-6 / ° C. and thermal conductivity of 30-325 W / m.K in the range of room temperature to 300° C. It is suitable for the radiator plate of semiconductor devices and the dielectric plate of electrostatic attractors.

Owner:KONDO YASUO +7

Short-flow high-efficiency production method for white brass alloy pipes

The invention relates to a short-flow high-efficiency production method for white brass alloy pipes, belonging to the field of metal materials. In the method, a white brass pipe produced by virtue of a hot-cold-combined casting-mould horizontal continuous casting process is used as a blank; in a straight white brass pipe production process, the pipe blank is directly subjected to cold rolling with the total deformation amount of 50-90% and the single-pass deformation amount of not more than 20-25%; in a white brass coiled pipe production process, the pipe blank is subjected to the cold rolling deformation with the total deformation amount of not more than 50-70% and the single-pass deformation amount of not more than 20-25%, low-temperature recovery annealing is carried out at the temperature of 300-550 DEG C for 1-2 hours after the rolling is completed, an annealing protection atmosphere is formed by 2% of H2 and the balance of N2, and the annealed coiled pipe is bound to be subjected to once finishing in a serial continuous drawing way or triple continuous drawing before coil drawing; and in a subsequent coil drawing process, an average pass lengthening coefficient is 1.2-1.5, and the coil drawing speed is 1-1,000m / min. Compared with the traditional casting and rolling drawing method for producing the white brass pipes, the method provided by the invention has the advantages of short process flow, obviously decreased annealing frequency and low annealing temperature, and is beneficial to energy conservation and production efficiency improvement.

Owner:UNIV OF SCI & TECH BEIJING

Composite material including copper and cuprous oxide and application thereof

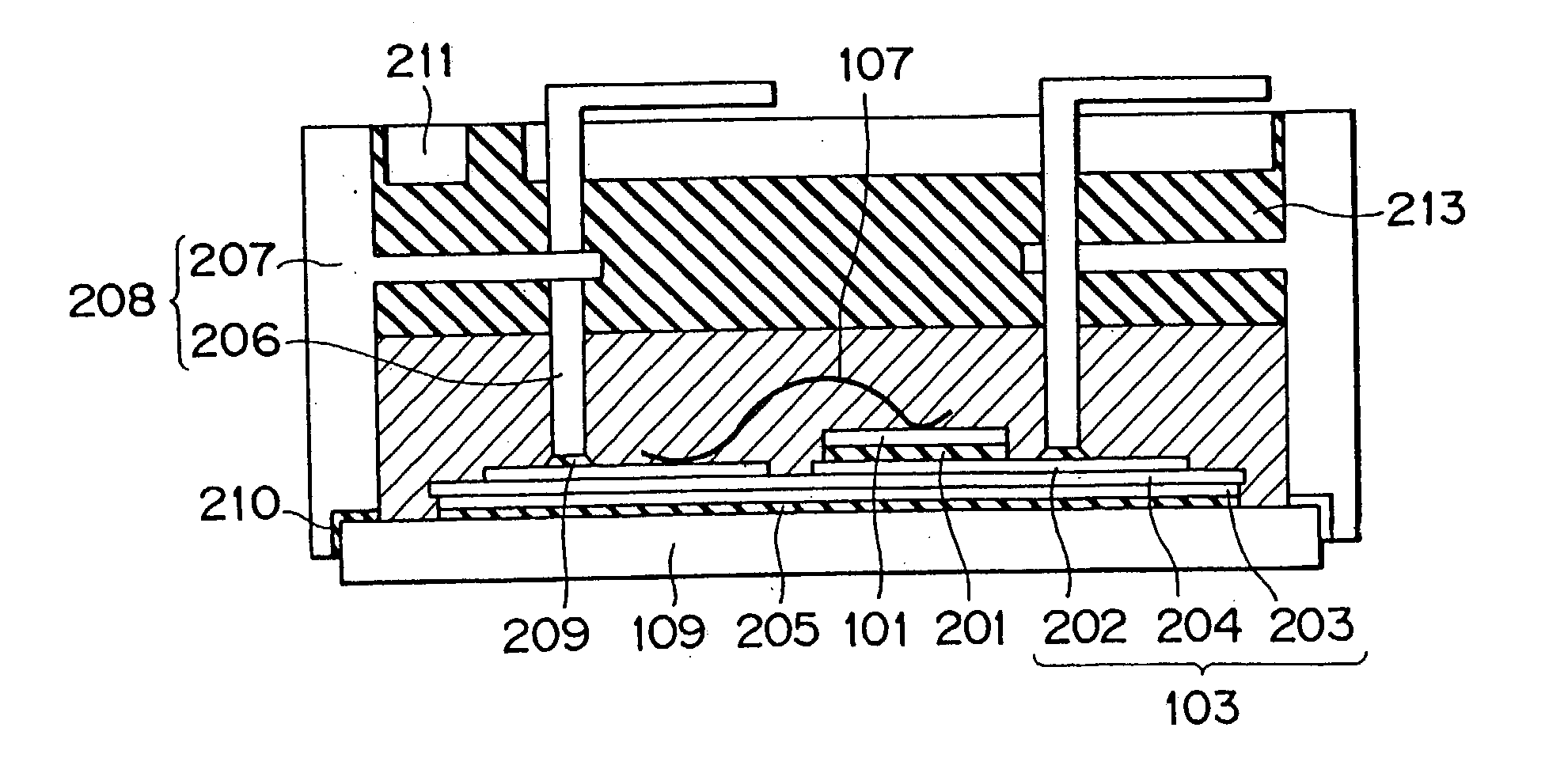

InactiveUS6909185B1Particle diameterLarge mixing energySemiconductor/solid-state device detailsSolid-state devicesDevice materialCopper oxide

A composite material is provided, which has a low thermal expansivity, a high thermal conductivity, and a good plastic workability, which composite material may be applied to semiconductor devices and many other uses. The composite material is composed of metal and inorganic particles having a smaller coefficient of thermal expansion than the metal. It is characterized in that the inorganic particles are dispersed in such a way that 95% or more of them (in terms of their area in cross-section) form aggregates of complex configuration joined together. The composite material contains 20-80 vol % of copper oxide, with the remainder being copper. It has a coefficient of thermal expansion of 5×10−6 to 14×10−6 / ° C. and thermal conductivity of 30-325 W / m·K in the range of room temperature to 300° C. It is suitable for the radiator plate of semiconductor devices and the dielectric plate of electrostatic attractors.

Owner:HITACHI LTD

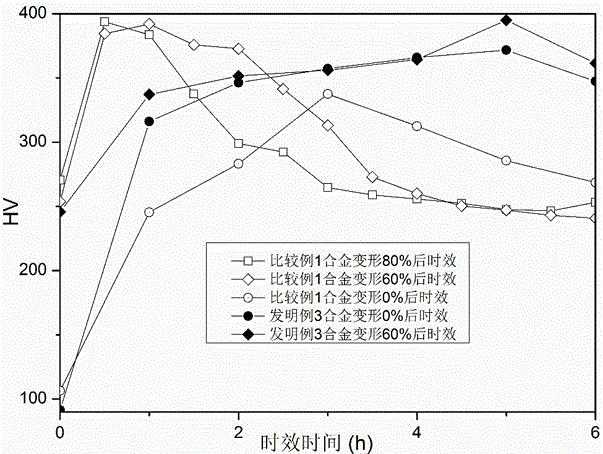

Preparation method of high-elasticity corrosion-resistant and wear-resistant Cu-Ni-Sn alloy

InactiveCN106834795ASolve segregationImprove plastic processing performanceIncreasing energy efficiencyWear resistantWater cooling

The invention relates to a preparation method of a high-elasticity corrosion-resistant and wear-resistant Cu-Ni-Sn alloy. The preparation method comprises the following steps: vacuum induction melting or covering protection type non vacuum melting of a Cu-Ni-Sn ternary alloy, application of electromagnetic stirring until alloy melt is solidified completely in the subsequent solidification process, and homogenization annealing-water cooling-solid solution-cold deformation-aging treatment of as-cast alloy. Through use of the preparation method of a high-elasticity corrosion-resistant and wear-resistant Cu-Ni-Sn alloy, crystal grains can be refined, dendrite spacing can be reduced, macrosegregation and microsegregation of the series of alloy can be eliminated, aging strengthening effect is excellent, plastic processing property of the series of alloy can be improved, the service life of the alloy can be improved, by the application of electromagnetic stirring in the solidification process, the segregation degree of the obtained as-cast structure is small, the segregation is easy to remove, and the method has the advantages of saving energy, improving production efficiency and reducing production cost.

Owner:JIANGYIN SANLING METAL PROD

Tough easy-deforming magnesium alloy

The invention relates to a novel magnesium alloy material, in particular to a magnesium alloy which has strong toughness and is easy to deform, through compounding and adding cerium, yttrium, gadolinium and strontium, the magnesium alloy which has excellent plastic deformation capacity and high mechanical properties is obtained. The percentage by weight of the components are that aluminum is 2.8-3.2, zinc is 0.8-1.1, magnesium is 0.4-0.7, cerium is 0.4-0.8, yttrium is 0.6-1.2, gadolinium is 3-6, and strontium is 0.08-1.2. The percentage by weight of limited impurity elements are that silicon is less than 0.03, ferric is less than 0.004, cuprum is less than 0.003, nickel is less than 0.002, calcium is less than 0.002, and the other content is magnesium. The single pass maximum lower compression ratio of the invention is greater than 35 percent under the homogenization conditions for 4 hours, and the single pass maximum lower compression ratio is greater than 50 percent under the homogenization conditions for 8 hours. The tensile strength of the invention is greater than 330 MPa in room temperature, and the elongation is greater than 8 percent.

Owner:JILIN UNIV

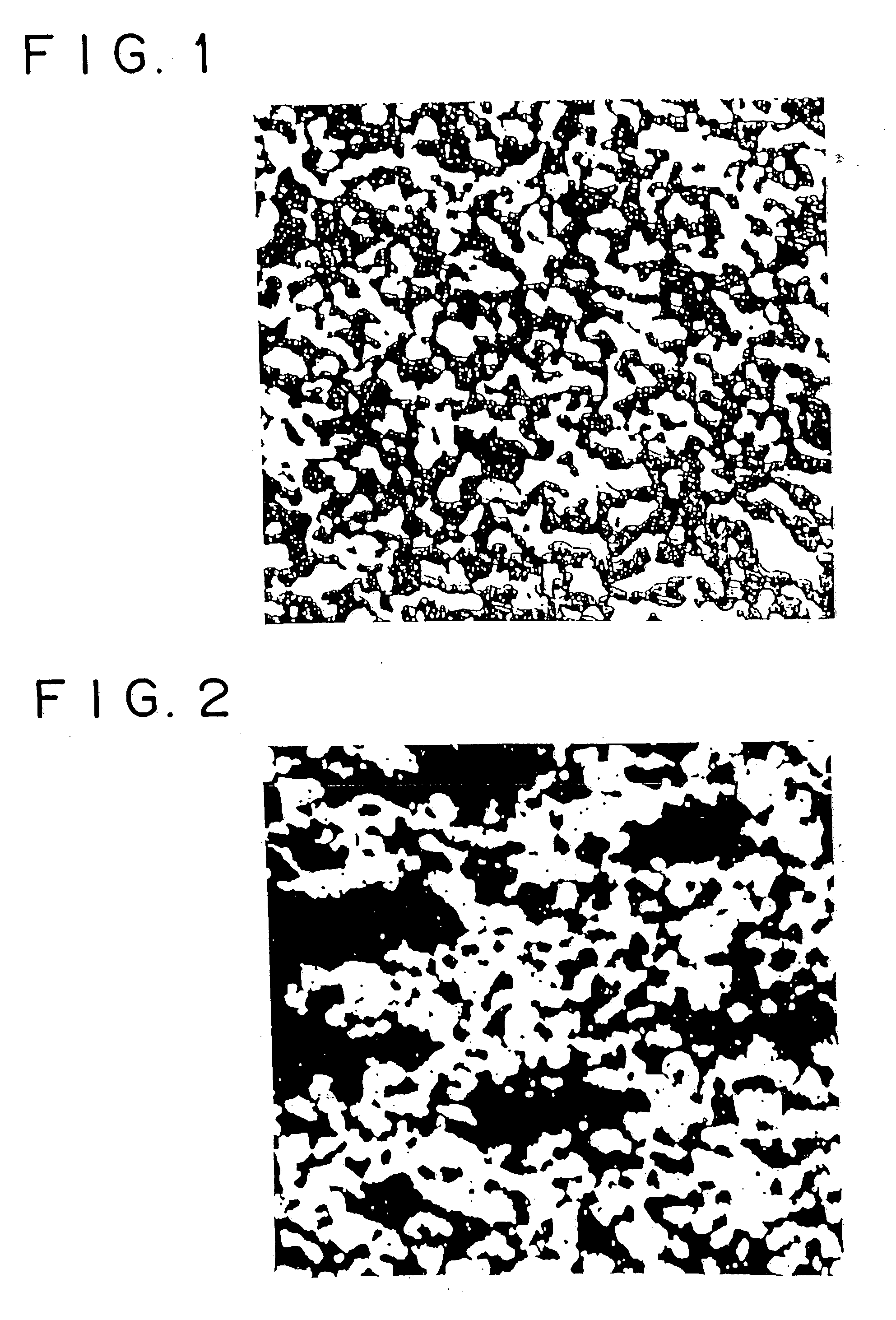

Composite material including copper and cuprous oxide and application thereof

InactiveUS6833617B2High strengthHigh melting pointSemiconductor/solid-state device detailsSolid-state devicesInorganic particleDielectric plate

It is an object of the present invention to provide a composite material having low thermal expansivity, high thermal conductivity, and good plastic workability, which is applied to semiconductor devices and many other uses.The composite material is composed of metal and inorganic particles having a smaller coefficient of thermal expansion than said metal. It is characterized in that said inorganic particles disperse in such a way that 95% or more of them (in terms of their area in cross-section) form aggregates of complex configuration joining together.The composite material contains 20-80 vol % of copper oxide, with the remainder being copper. It has a coefficient of thermal expansion of 5x10<-6 >to 14x10<-6> / ° C. and thermal conductivity of 30-325 W / m.K in the range of room temperature to 300° C. It is suitable for the radiator plate of semiconductor devices and the dielectric plate of electrostatic attractors.

Owner:HITACHI LTD

Rare earth magnesium-lithium alloy sheet and preparation method thereof

The invention discloses a rare earth magnesium-lithium alloy sheet and a preparation method thereof, belonging to the field of metal processing. The rare earth magnesium-lithium alloy sheet is characterized by comprising the following components in percentage by weight: 11-15% of Li, 0.5-2% of Y, 0.5-2% of Gd, 0.1-1% of Sc, 7-9% of Al and the balance of magnesium. The preparation method comprises the following steps of: melting magnesium and intermediate alloy by using an industrial medium-frequency or line-frequency induction melting furnace, adjusting the furnace temperature for heat preservation treatment, sampling from the furnace and carrying out rapid on-the-spot sample analysis after the heat preservation time is reached, and detecting whether the components are qualified; and hot rolling and cold rolling a pouring and rolling sheet, carrying out T6 treatment, then, making a mechanical sample, and measuring the mechanical property. By using the rare earth magnesium-lithium alloy sheet and the preparation method thereof, the strength of magnesium-lithium alloy is ensured, the plastic deformation capability of the magnesium-lithium alloy is also greatly enhanced, the production difficulty of the deformed magnesium-lithium alloy sheet is lowered, and the production efficiency is increased. The alloy smelting process is simple, convenient and reliable, convenient to operate and free of special processing process and alloy adding methods. A cast ingot is fine and uniform in tissue, free of meshy and thick sheet-like Mg17Al12 phase and uniform in precipitated phase. The rolling process is simple, convenient, reliable and feasible, and the sheet has favorable comprehensive mechanical property.

Owner:INNER MONGOLIA 52 SPECIAL MATERIAL ENG TECH RES CENT

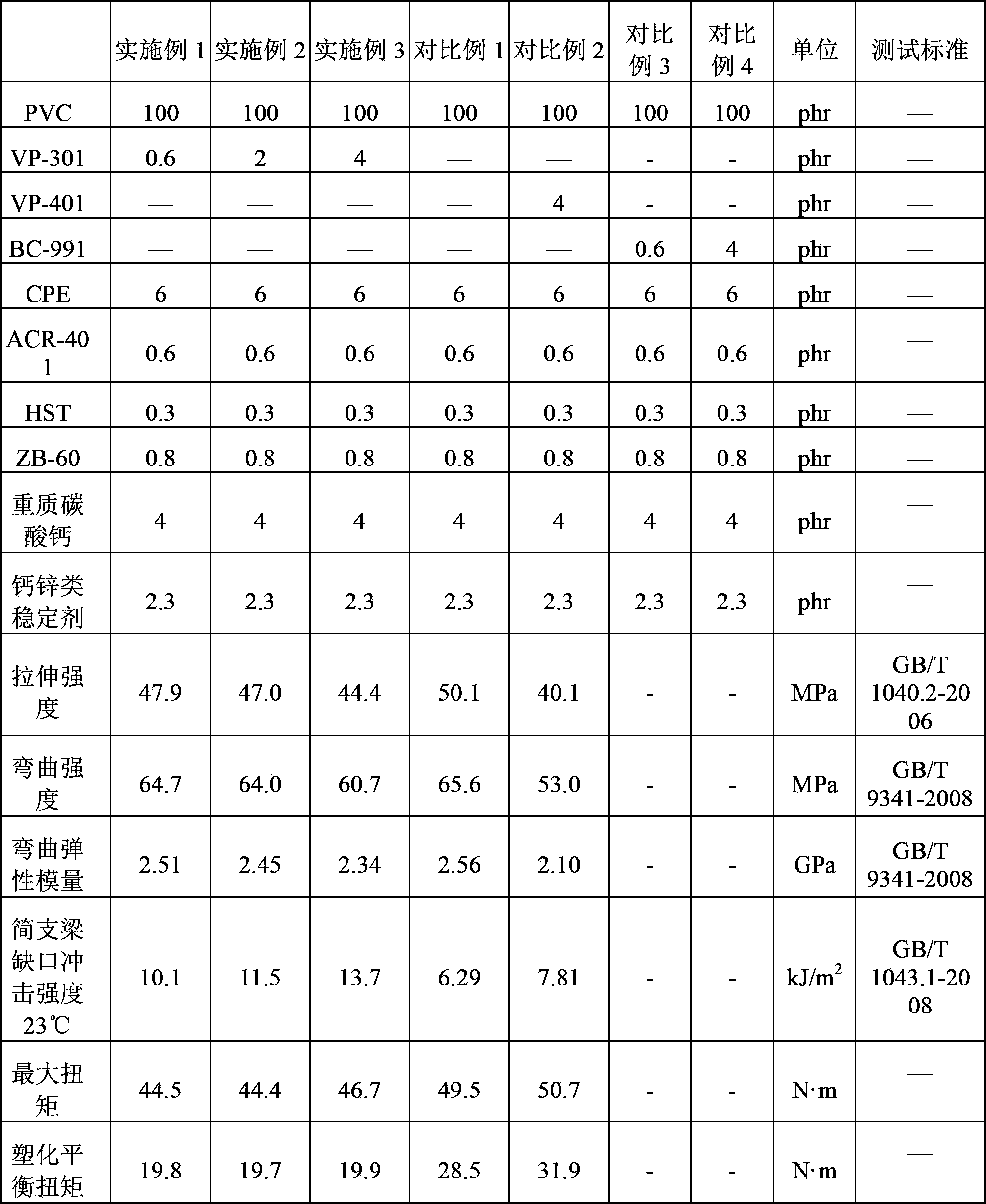

Hard impact-resistant polyvinyl chloride composition and preparation method thereof

The invention provides a hard impact-resistant polyvinyl chloride composition and a preparation method thereof, and relates to the field of polyvinyl chloride material. The composition comprises following mixed materials: polyvinyl chloride resin, a stabilizer, and completely-vulcanized acrylate rubber powder; wherein by taking the weight of polyvinyl chloride as 100 parts, the weight of the completely-vulcanized acrylate rubber powder is 0.1 to 40 parts; the polymerization degree of the polyvinyl chloride is larger than 700; the average particle size of the completely-vulcanized acrylate rubber powder is in the range of 20 to 200 nm, and the gel content of the completely-vulcanized acrylate rubber powder is 60 wt% or more. Compared to those of nitrile rubber modified hard compact-resistant polyvinyl chloride composition in the prior art, the polyvinyl chloride composition mentioned in the invention has higher strength and impact-resistant performance and lower maximum torque and plasticizing balance torque, can improve the mechanical property and plasticization processing property of the polyvinyl chloride material at the same time, and has the advantages of simple technology, easy operation, and suitability for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aluminum alloy material for manufacturing doors and windows

The invention relates to aluminum alloy, and discloses an aluminum alloy material for manufacturing doors and windows. The aluminum alloy material includes, by mass, 4.30-5.80 parts of copper, 0.45-0.80 part of silicon, 1-5 parts of nickel, 2.30-4.30 parts of magnesium, 4.60-8.60 parts of zinc, 0.60-0.80 part of manganese, 0.20-0.40 part of iron, 0.04-0.06 part of titanium, 0.02-0.035 part of boron, 0.10-0.20 part of chrome, 0.03-0.05 part of strontium, 0.15-0.25 part of zirconium, 0.05-0.08 part of composite rare earth, and the balance aluminum and 0.09 part or less of impurities, wherein the composite rare earth includes, by mass, 17.00-18.60 parts of lanthanum, 12.40-15.30 parts of cerium, 9.80-11.70 parts of praseodymium, 12.30-14.20 parts of neodymium, 1.10-1.20 parts of ytterbium, 13.40-14.50 parts of thulium and the balance holmium. The aluminum alloy material for manufacturing doors and windows is high in intensity and yield strength, good in tensile strength, friction resistance and corrosion resistance, and long in fatigue life, and the problems that existing aluminum alloy materials are too hard, poor in plasticity, not enough in intensity and the like are solved.

Owner:CHONGQING SHUANGCHI DOORS & WINDOWS

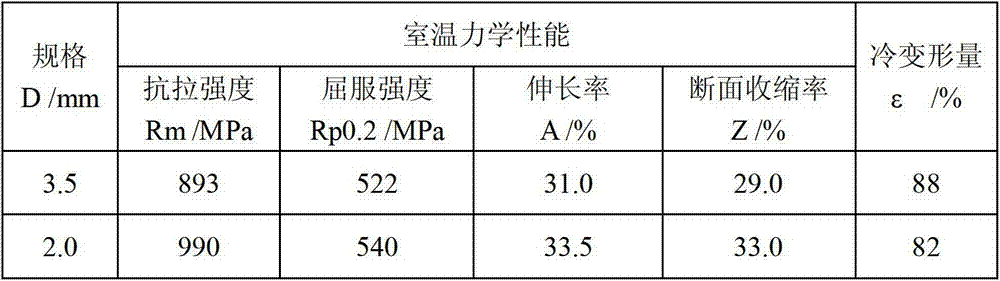

Preparation method of high-plasticity TiNi51 alloy wire material

The invention discloses a preparation method of a high-plasticity TiNi51 alloy wire material. The method comprises steps of: carrying out medium frequency induction smelting and vacuum self-consuming smelting so that the casting defects of primary ingots are eliminated to obtain pure and uniform cast ingots and moreover titanium and nickel alloy large-scale ingot casting are obtained and the production efficiency and material batch stability are improved further; then, homogenizing the cast ingot at a high temperature so as to reduce the brittle phase of the materials; forging and rolling to form wire blanks; and finally, drawing and correcting to produce the finished wire materials. Compared with the prior art, the method has the following advantages that the technology combining medium frequency induction smelting with vacuum self-consuming smelting is adopted so as to obtain the uniform, pure and large-scale titanium-nickel cast ingots; the brittle phase of the materials is reduced through high-temperature homogenizing treatment; and reasonable heating and finished product correcting technologies are adopted so as to improve the plastic processing performance of the materials. The TiNi51 alloy wire materials with large ingot shape, uniformity, stability and high plasticity are prepared.

Owner:西安赛特金属材料开发有限公司

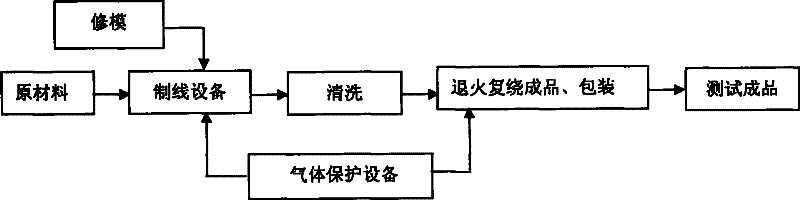

Method for preparing single-crystal copper bonding wire

InactiveCN101524721AHigh strengthHigh elongationPolycrystalline material growthSolid-state devicesMegasonic cleaningSingle crystal

The invention relates to a method for preparing a single-crystal copper bonding wire, which uses copper as a raw material. The method comprises the following steps: melting high purity copper of which the purity is higher than 99.995 percent by using a high-vacuum furnace, raising the temperature to between 1,100 and 1,180 DEG C, refining the copper for 60 to 120 minutes, and adopting high purity argon for protection in the whole melting process; broaching single-crystal copper rods of phi 4 to phi 8 mm in a directional solidification mode, and then coldworking the single-crystal copper rods to between phi 0.95 and phi 1.102 mm with the broaching working rate of 15 to 25 percent for each gate; broaching the single-crystal copper rods to between 0.020 and 0.05 mm with 47 to 70 gates and the working rate of 7.59 to 17.82 percent for each gate; and carrying out sonicleaning on the surface of the single-crystal copper bonding wire when the wiredrawing temperature is between 35 and 45 DEG C, carrying out heat treatment on the cleaned single-crystal copper bonding wire, and using H2+Ar2 for protection with the temperature of between 410 and 425 DEG C, the time of between 0.7 and 2.0s and the annealing rewinding tension of between 0.6 and 2.8g.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Linear object composed of magnesium alloy, bolt, nut, and washer

InactiveUS20130209195A1Improve plastic processing performanceImprove heat resistanceWashersNutsCreep strainHeat resistance

A linear object is composed of a magnesium alloy including, in percent by mass, 0.1% to 6% of Zn, 0.4% to 4% of Ca, and the balance being Mg and incidental impurities, in which, when a creep test is performed on the linear object under conditions of a temperature of 150° C., a stress of 75 MPa, and a holding time of 100 hours, the linear object has a creep strain of 1.0% or less. Zn and Ca interact with each other to improve heat resistance, and thus it is possible to obtain the linear object having an excellent creep property. By incorporating Zn and Ca, in amounts in specific ranges, into the magnesium alloy, it is also possible to obtain the linear object having excellent plastic workability.

Owner:SUMITOMO ELECTRIC IND LTD

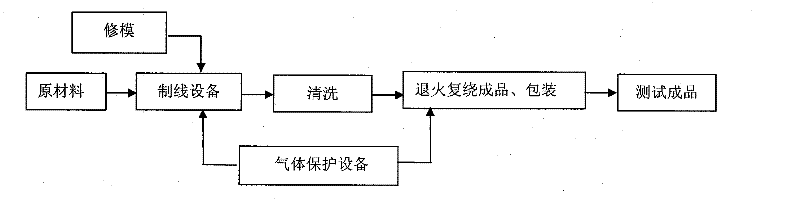

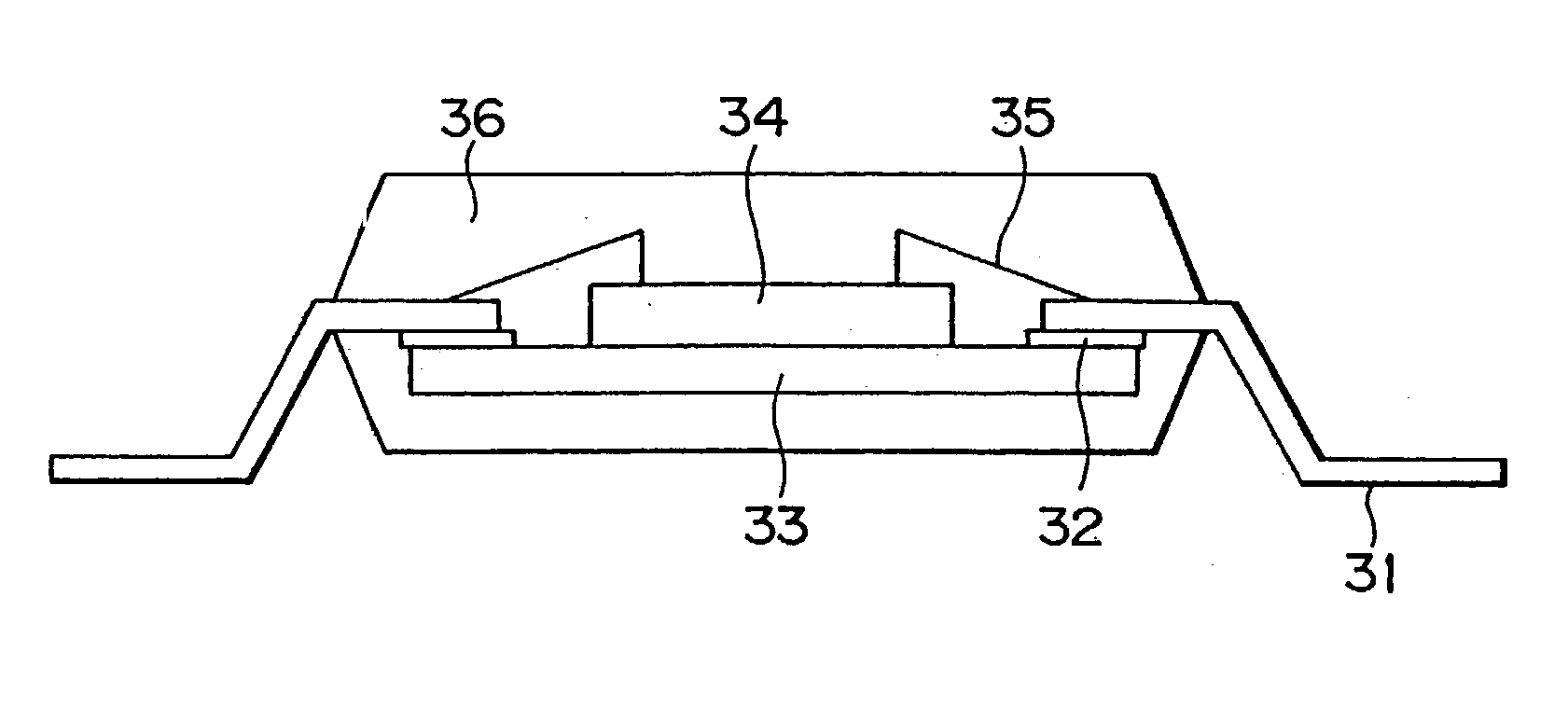

Single crystal copper bonding lead and preparation method thereof

InactiveCN102637657AHigh strengthHigh elongationSemiconductor/solid-state device detailsSolid-state devicesCopper wireDying processes

The invention discloses a single crystal copper bonding lead and a preparation method thereof, relating to the field of production of microelectronic materials. The production technology integrates a metal material preparation process, a heat treatment process and a diamond die process, ensures the production consistency and reliability and realizes the large-scale production. The adopted production process comprises the steps of providing die repair and gas protection equipment, smelting, wiredrawing, cleaning, and compounding, packaging and testing a finished product. The single crystal copper bonding lead has the beneficial effects that as a signal crystal copper material has a compact solidification structure, lateral crystal boundaries are eliminated, the casting defects of shrinkage cavities, pores and the like are avoided, the plastic working performance, the mechanical performance, the electric performance and the like of the signal crystal copper material are obviously higher than those of the conventional oxygen-free copper, the defects of more end breakage, low quality and low productivity in the wiredrawing process of the conventional copper wire are overcome, and an electronic packaging bonding wire with the wire diameter reaching 0.015m, high strength, high elongation and stable performance can be prepared.

Owner:宋东升

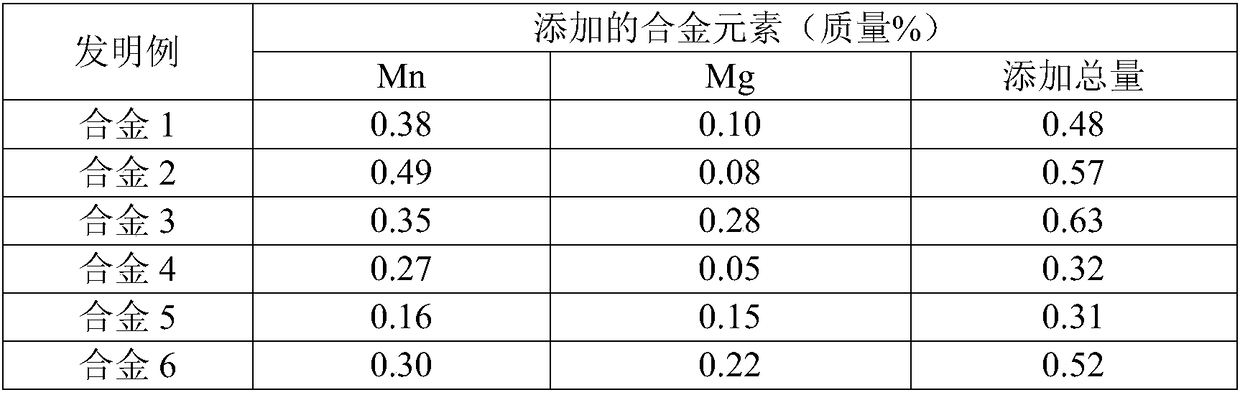

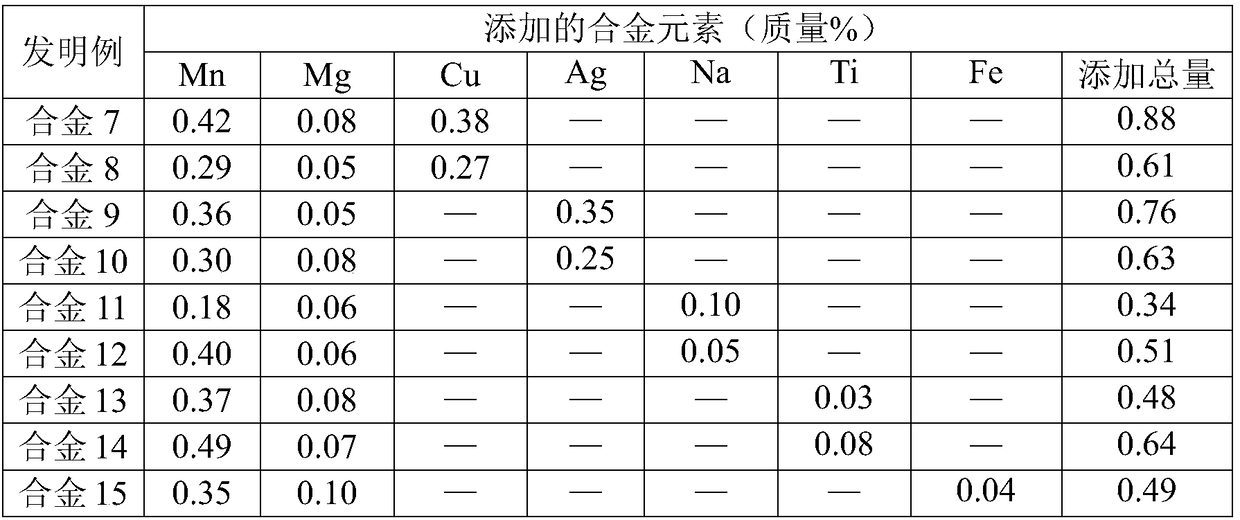

High-strength high-ductility biodegradable Zn-Mn-Mg series zinc alloy and preparation method thereof

The invention relates to high-strength high-ductility biodegradable Zn-Mn-Mg series zinc alloy and a preparation method. The alloy is prepared from the 0.02 to 0.49% of Mn and 0.001 to 0.3% of Mg, wherein Mn is a main alloying element, Mg is a secondary alloying element, and the Mn content is not lower than the Mg content in the alloy; at least one of Na, K, Ca, Sr, Ti, Fe, Cu and Ag elements is selected, the total content of the alloying elements added to the Zn-Mn-Mg series zinc alloy does not exceed 2%, and the balance is Zn. The basic preparation process of the zinc alloy comprises the steps of vacuum directional solidification and extrusion; on the basis of the steps, at least one of the following processing methods can be selected for processing again: two-stage heat treatment, extrusion, rolling, drawing and annealing. According to the preparation process, the processing plasticity of the zinc alloy can be given to the maximum, and multiphase multiscale directional tissues can be obtained, so that the alloy has excellent overall performance. The tensile mechanical properties of the zinc alloy at room temperature include the yield strength of 260 to 430 MPa, the tensile strength of 305 to 580 MPa and the elongation of 18.5 to 55%, and the zinc alloy is suitable for medical implants and is especially suitable for biodegradable stents.

Owner:北京尚宁科智医疗器械有限公司

Composite material including copper and cuprous oxide and application thereof

InactiveUS20030146498A1Improve plastic processing performanceShort processing timeSemiconductor/solid-state device detailsSolid-state devicesInorganic particleDielectric plate

It is an object of the present invention to provide a composite material having low thermal expansivity, high thermal conductivity, and good plastic workability, which is applied to semiconductor devices and many other uses. The composite material is composed of metal and inorganic particles having a smaller coefficient of thermal expansion than said metal. It is characterized in that said inorganic particles disperse in such a way that 95% or more of them (in terms of their area in cross-section) form aggregates of complex configuration joining together. The composite material contains 20-80 vol % of copper oxide, with the remainder being copper. It has a coefficient of thermal expansion of 5x10-6 to 14x10-6 / ° C. and thermal conductivity of 30-325 W / m.K in the range of room temperature to 300° C. It is suitable for the radiator plate of semiconductor devices and the dielectric plate of electrostatic attractors.

Owner:HITACHI LTD

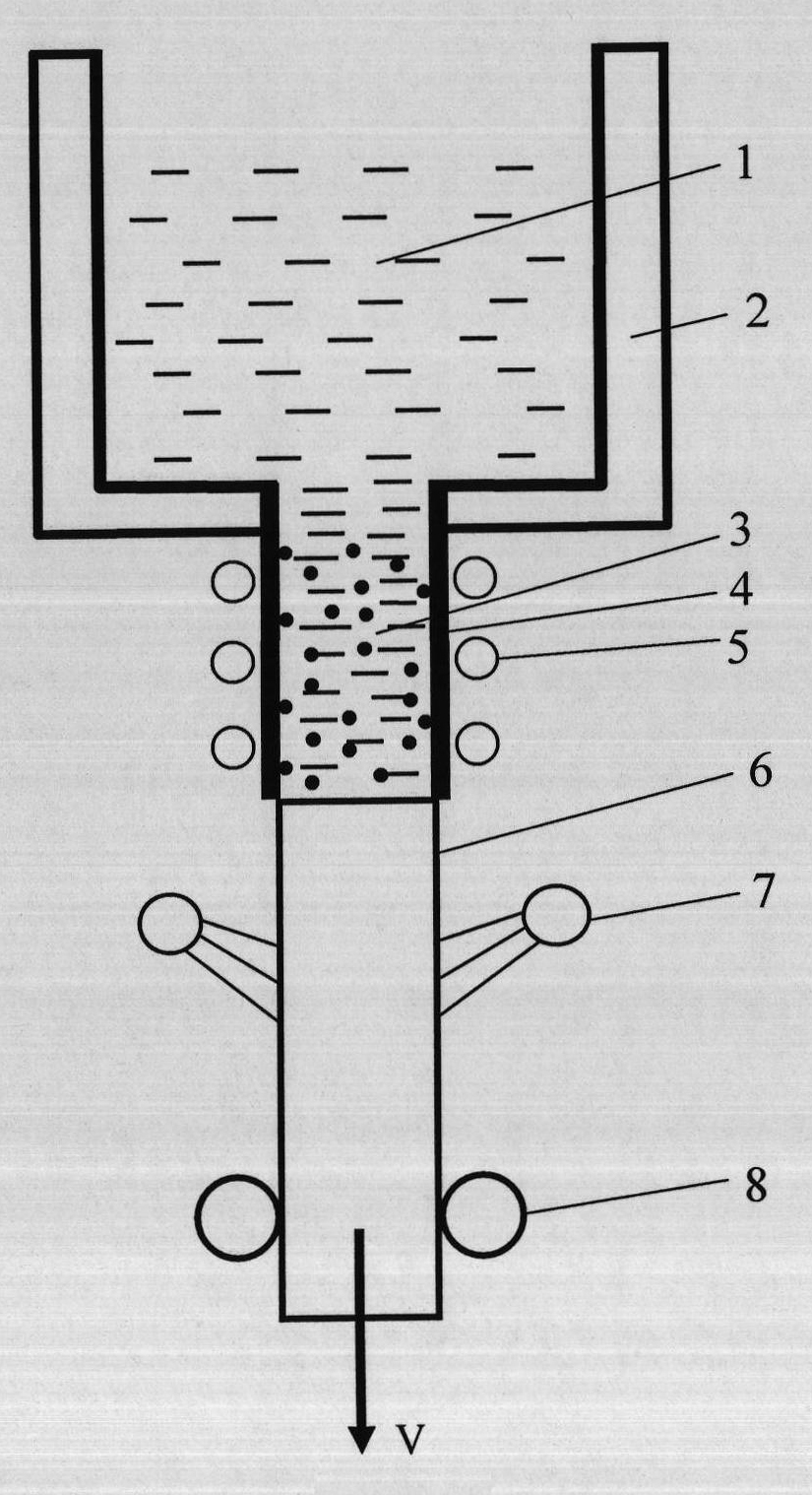

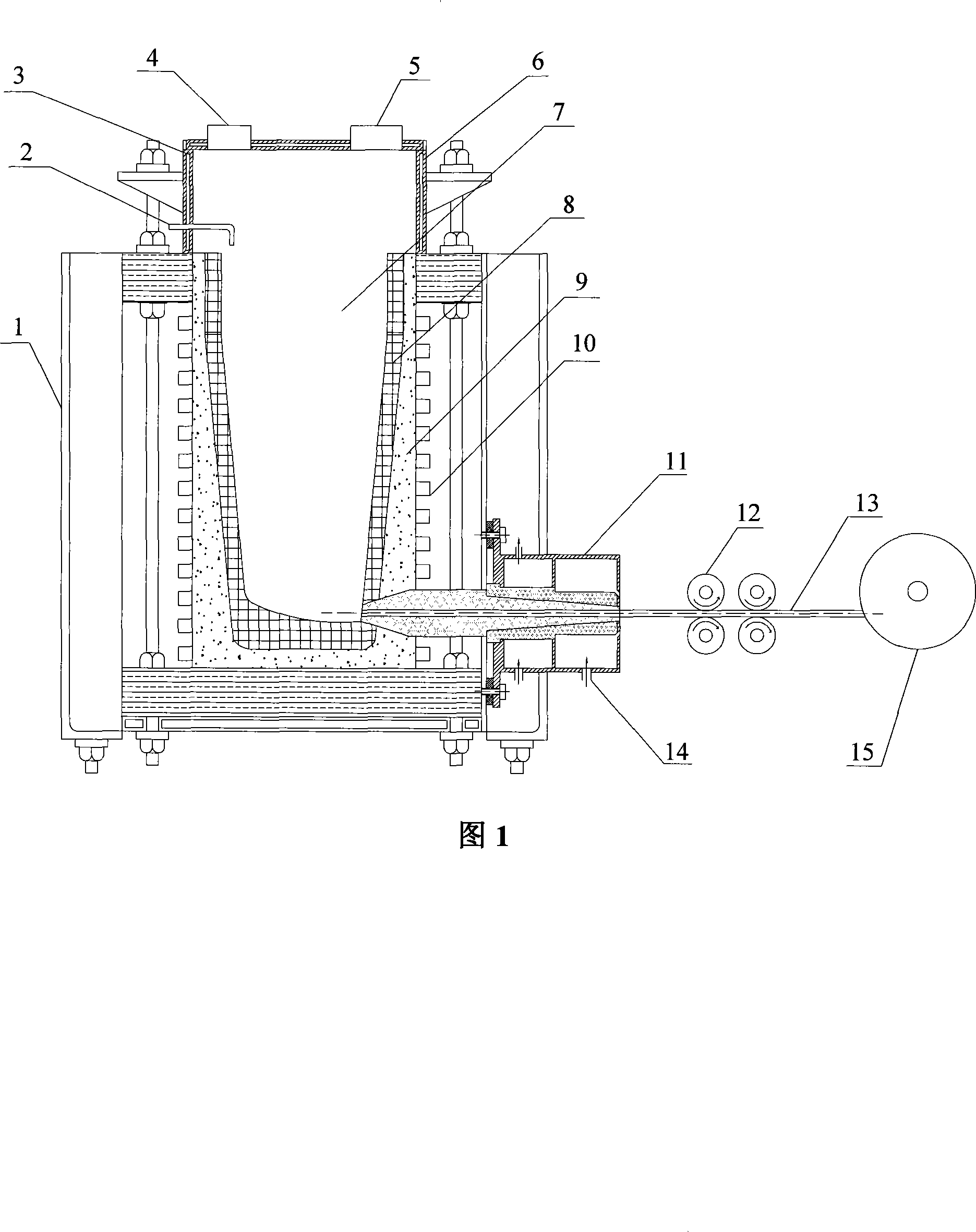

Casting equipment and method using solid-liquid two-phase region temperature as casting mold temperature

The invention discloses casting equipment and a casting method using solid-liquid two-phase region temperature as casting mold temperature, and belongs to the technical field of metal casting. The casting equipment is characterized by consisting of a crucible, two-phase region casting molds, a heater, a cooler and a traction mechanism, wherein one or more two phase region casting molds are arranged below, above or beside the crucible; the casting mold is insulated and heated through the heater or heated by using the heat which is conducted by the cast metal melt before entering the casting mold so as to keep the casting mold temperature between the solidus temperature and the liquidus temperature of the cast metal; the cast metal is forcibly cooled through the cooler which is arranged close to the outlet of the casting mold or a cooling device which is arranged at the outlet of the casting mold and can move along the casting direction; and the traction mechanism is used for drawing a metal casting blank. The equipment of the invention has the advantages of simple structure, convenient operation and repair, high production efficiency and wide application range and can industrially produce the high-quality metal casting blank with high strength, high plasticity, high surface finish, high dimensional accuracy, high compactness and low or no segregation in batches.

Owner:UNIV OF SCI & TECH BEIJING

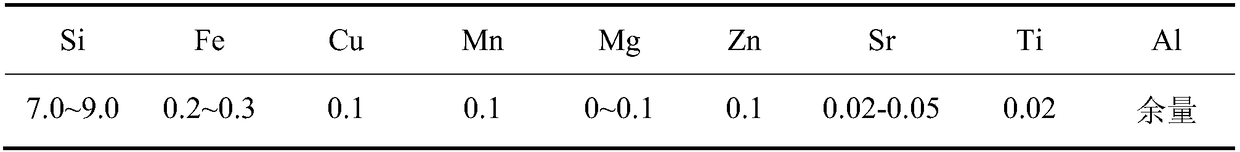

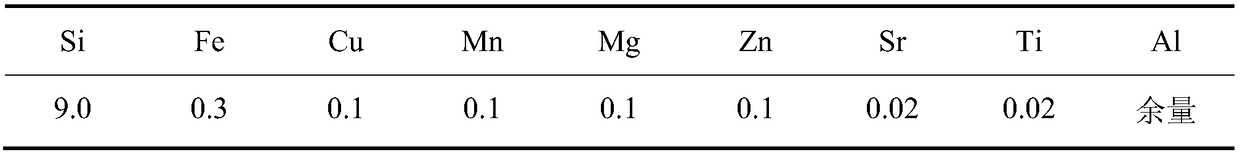

Preparation method and application for hypo eutectic aluminum-silicon alloy slab

The invention belongs to the technical field of processing of aluminum alloy plate sheets, and particularly relates to a preparation method and application for a hypo eutectic aluminum-silicon alloy slab. The method for preparing the hypo eutectic aluminum-silicon alloy slab comprises the following steps that an alloy is prepared by adopting an industrial pure aluminum ingot, an aluminum-silicon intermediate alloy and other alloy element additives, after melting is carried out in a melting furnace, a slagging agent and a refining agent are added separately, and then refining treatment is carried out; obtained metal melt is guided into a still furnace, a modificator and the refining agent are added, then secondary refining treatment is carried out, and a titanium wire is added and is guidedinto a degasification tank and a filter tank; aluminum alloy liquid is guided into the degasification tank, and cast rolling treatment is carried out so as to obtain an aluminum-silicon alloy cast-rolling blank; and uniform annealing treatment is carried out so as to obtain the hypo eutectic aluminum-silicon alloy cast-rolled slab. According to the preparation method and application for the hypoeutectic aluminum-silicon alloy slab, the melt treatment quality and efficiency are improved, so that the technological parameters are changed and optimized, and therefore the yield is increased, andthe production cost is lowered; and meanwhile, the material plasticity and machinability of the slab prepared through the method are enhanced, and the slab is expected to be widely used for processingthe cold-rolled sheets.

Owner:JIANGSU UNIV

High-strength anticorrosion aluminum-alloy material and production process thereof

InactiveCN104674087AImprove antioxidant capacityAccelerated corrosionUltimate tensile strengthCorrosion resistant

The invention discloses a high-strength anticorrosion aluminum-alloy material. The aluminum-alloy material comprises the following chemical components by weight percent: 1.23 to 1.45 percent of Sr, 1.34 to 1.36 percent of Si, 1.25 to 2.28 percent of Nb, 4.52 to 4.55 percent of Cu, 1.56 to 3.27 percent of Ti, 0.22 to 0.24 percent of Mg, 0.01 to 0.02 percent of C, 16.1 to 16.8 percent of Cr, 1.25 to 2.24 percent of V, 12.1 to 13.3 percent of Ni, 0.015 to 0.018 percent of B, 3.35 to 3.38 percent of Mn, 2.51 to 2.85 percent of composite rare earth and the balance of Al and impurities; the composite rare earth comprises the following ingredients by weight percent: 12.5 to 13.8 percent of Tm, 1.1 to 1.5 percent of Tb, 11.8 to 14.9 percent of Pr, 14.3 to 15.5 percent of Nd, 2.8 to 3.2 percent of Lu, 17.2 to 17.3 percent of Sm and the balance of Ho. The high-strength anticorrosion aluminum alloy material is long in service life, high in strength, good in safety and high in friction resistance and corrosion resistance; by adopting the production process, the processing cost is reduced, the processing period is shortened, and the anticorrosion property and the welding property of the aluminum alloy can be improved.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

Short-process efficient production method of copper-sliver alloy wire

The invention relates to a short-process efficient production method of a copper-sliver alloy wire, and belongs to the technical field of metal material preparation. The production method is characterized in that a warm type continuous casting method is used to prepare a copper-sliver alloy wire billet with a columnar crystal structure having the high orientation degree along a length direction and a diameter of 1-30 mm, wherein the billet drawing speed of the warm type continuous casting is 1-600 mm / min; and at a room temperature or 20-50 DEG C below the wire billet re-crystallization temperature, the wire billet is subjected to rolling or rough drawing, and then fine drawing is performed to obtain the wire with a diameter of 10-50 [mu]m. The production method of the present invention has the following advantages that: the warm type continuous casting method is used to prepare the copper-sliver alloy wire billet having the columnar crystal structure having the high axial orientation degree, the cold processing extending deformation capability is excellent, the pull-off is not easily generated during the wire drawing process, the intermediate annealing step even can be eliminated, the process is short, the material utilization rate is high, the energy source is saved, the production efficiency is high, the cost is low, and the wire quality and the wire performance are excellent.

Owner:UNIV OF SCI & TECH BEIJING

Apparatus for preparing easy-oxidizing hard-distortion alloy wire staff

InactiveCN101157119AAvoid various problems of vacuum production processShort processWire rodProduct demand

The invention relates to equipment for preparing an alloyed wire rod which is easy to be oxidated and difficult to be distorted. A smelting furnace adopts a non-vacuum induction smelting furnace protected by the atmosphere, holes are arranged on the side of the smelting furnace body, horizontal continuous casting crystallizers with different cross sections and specifications are installed at the side hole positions, the sprues of the horizontal continuous casting crystallizers are communicated with the smelting furnace body, draughting mechanisms are arranged at the outlet openings of the horizontal continuous casting crystallizers, and curling mechanisms are connected with the draughting mechanisms end to end. The horizontal continuous casting alloyed wire rod is realized through installing the horizontal continuous casting crystallizers with different cross sections and specifications at the side hole positions, for the sizes of the horizontal continuous casting crystallizers, different specifications and different cross sections are determined according to product demand, the draughting mechanisms realize that the wire rod advances at the specified casting draughting speed, the curling mechanisms realize to collect the alloyed wire rod, so that the length of the wire rod can be expanded, the invention is widely suitable for production equipment of the wire rod of easily oxidable alloys of Cu-Cr-Zr, Cu-Ti, etc., and difficultly distorted alloys of Cu-Ti, etc.

Owner:苏州有色金属研究院有限公司

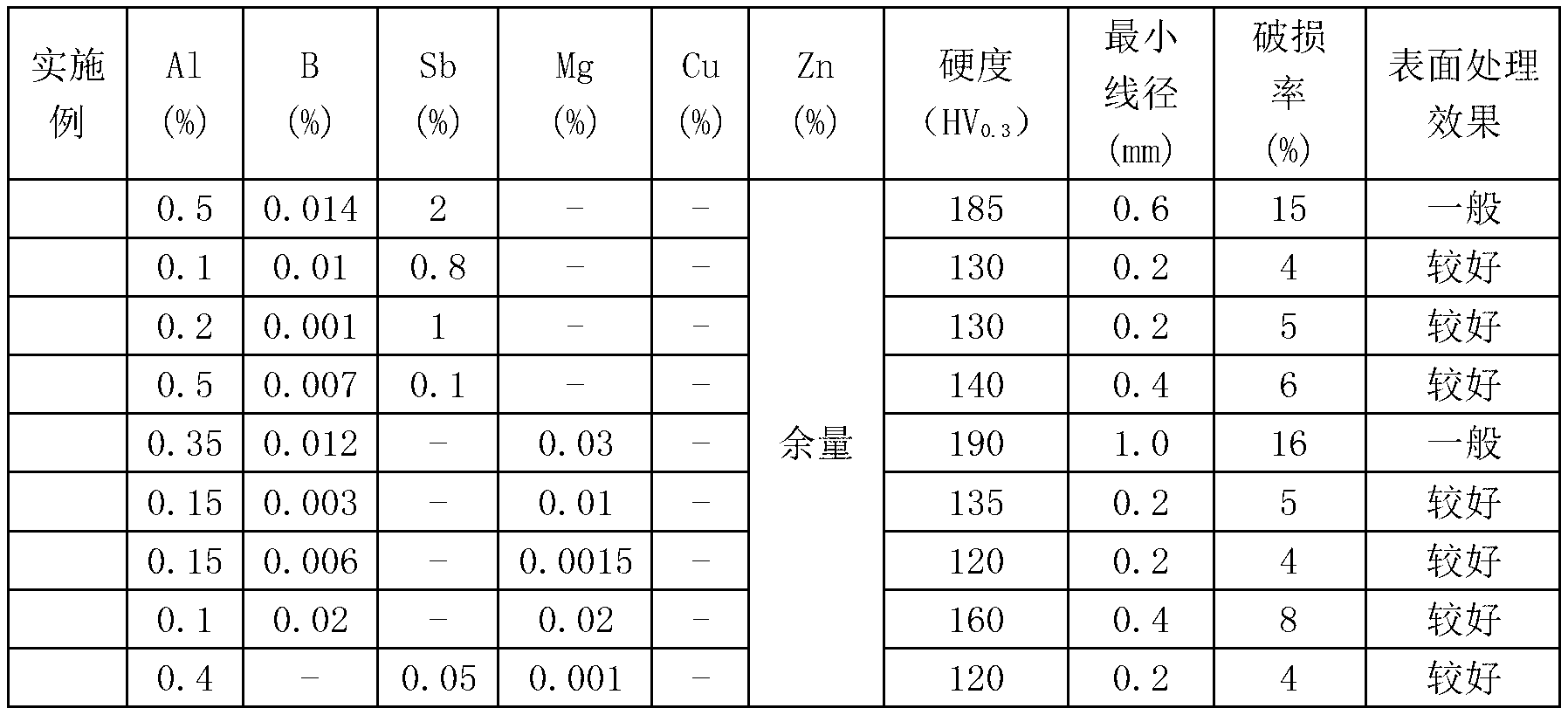

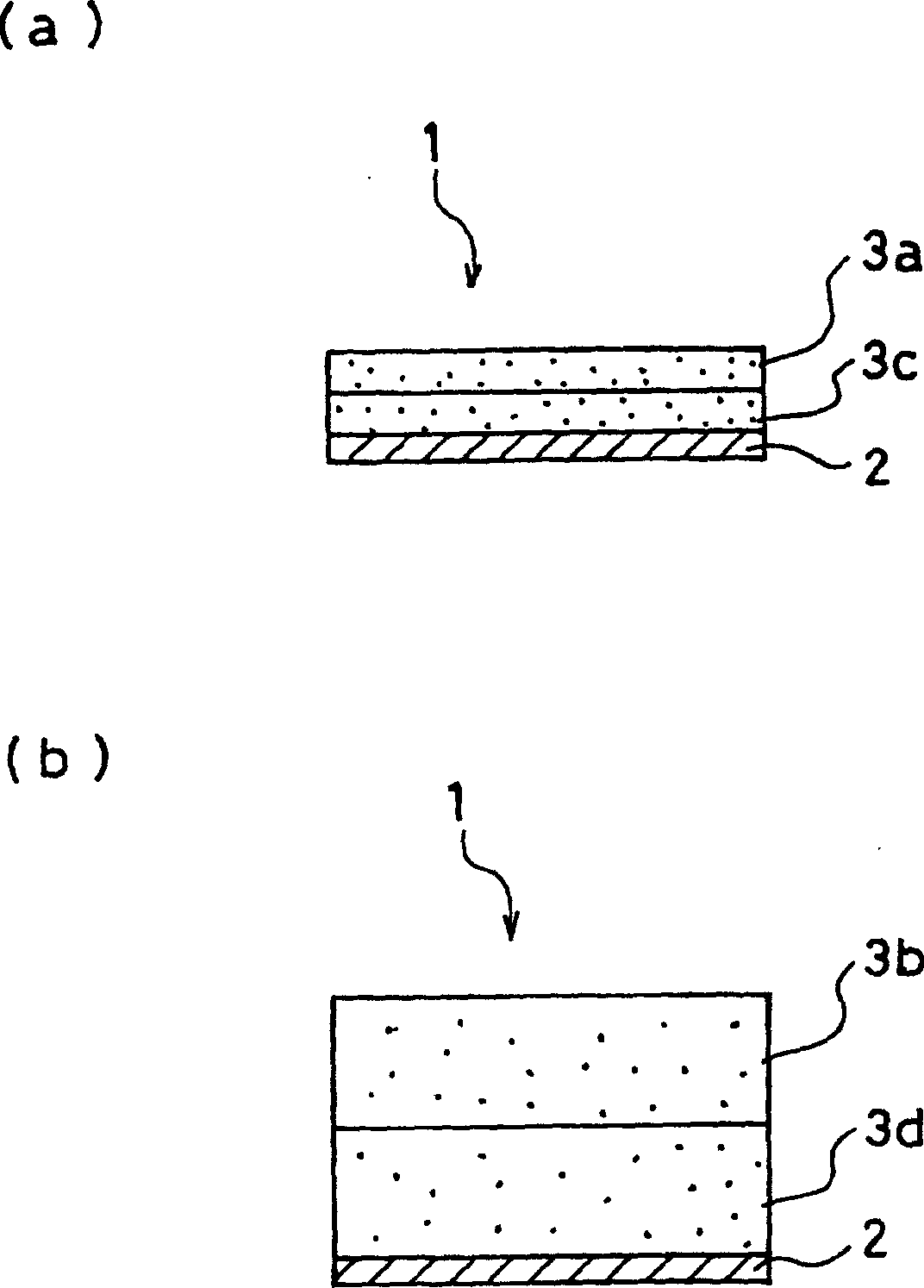

Zinc alloy

The invention discloses a zinc alloy which uses the zinc as a base, and is added with two or all of boron, antimony and magnesium, and a little aluminium. The zinc alloy is characterized by comprising the following components by weight percent: 0.1-0.5 % of the aluminium, 0.001-0.02 % of boron, 0.05-2 % of the antimony, 0.0005-0.05 % of the magnesium, not more than 0.05 % of impurities, and the balance being zinc; and a sum of the weight percent of each component is 100 %. The zinc alloy is high in yield, good in plasticity, small in breakage rate, high in recycling rate; good in corrosion resistance, small in tendency of intergranular corrosion, high in dimension stability; high in product intensity being up to 300 MPa; good in cold plastic processing performance, so that the zinc alloy can be prepared through a drawing technology and a minimum diameter reaches [phi]0.2 mm; and simple in processing technology; and can realize industrial continuous production. Raw materials are cheap and easily available, and a comprehensive cost is low.

Owner:绍兴市天龙锡材有限公司

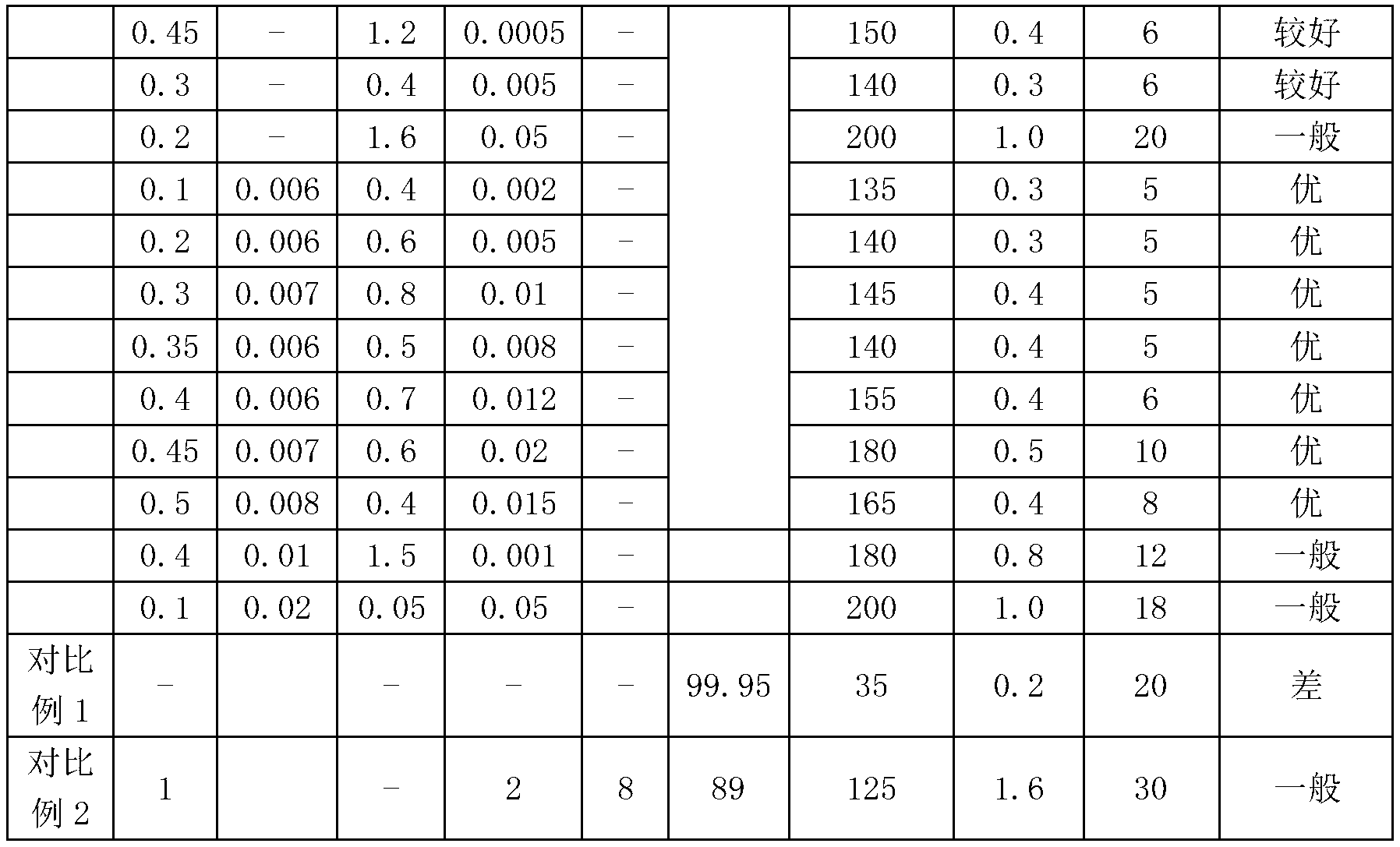

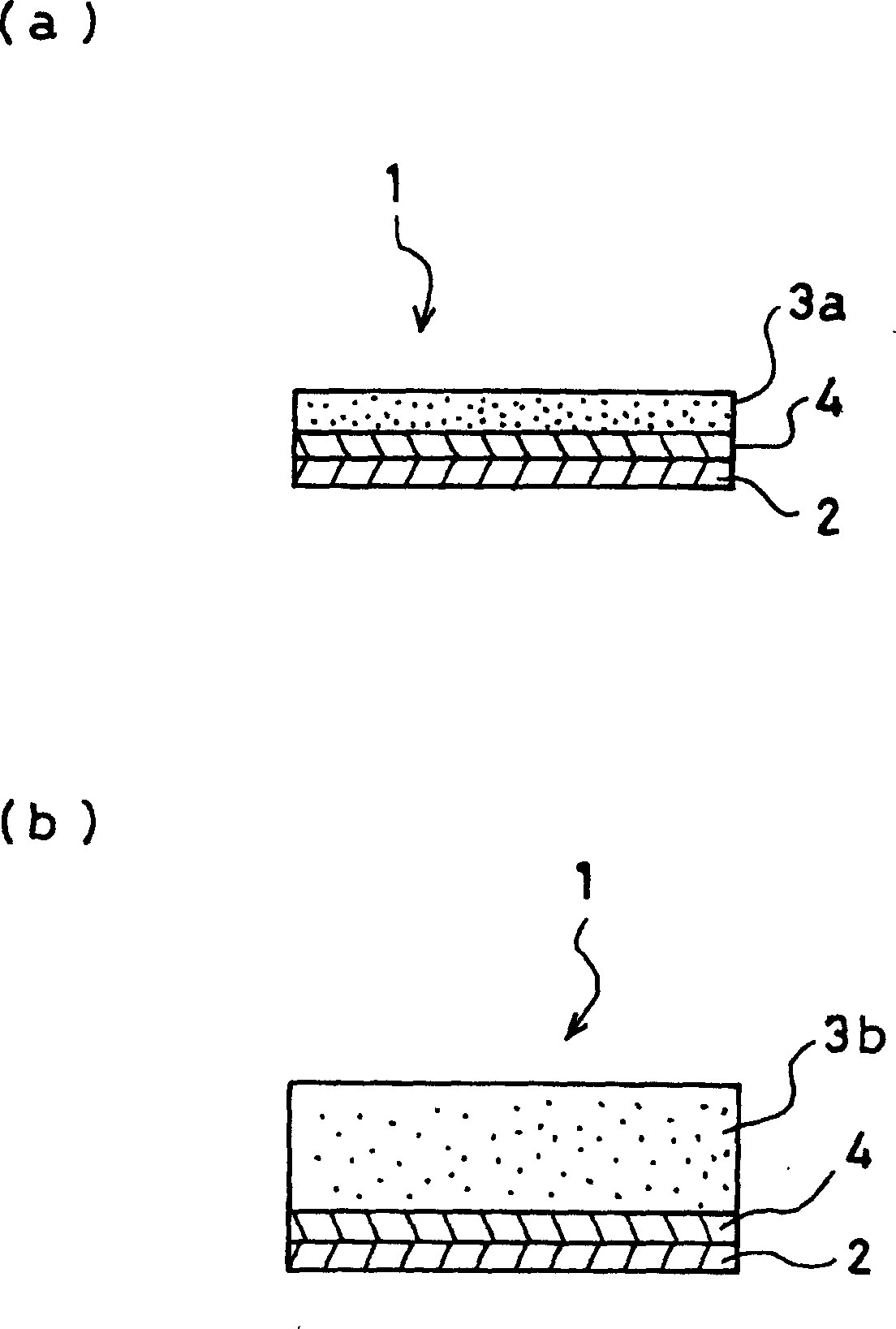

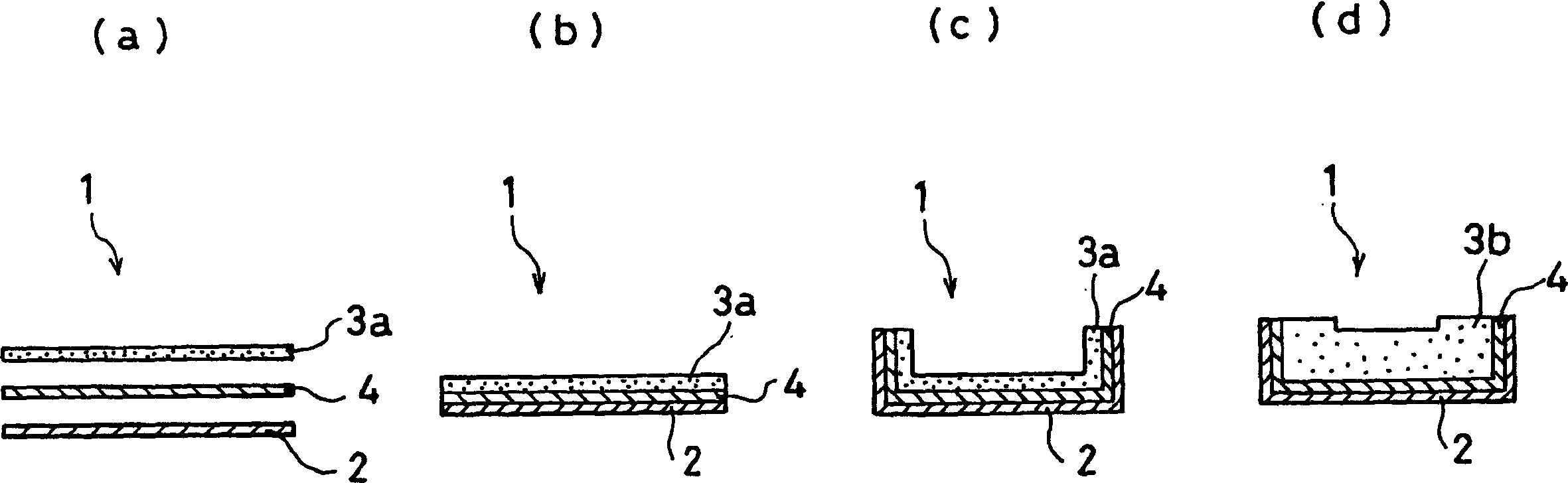

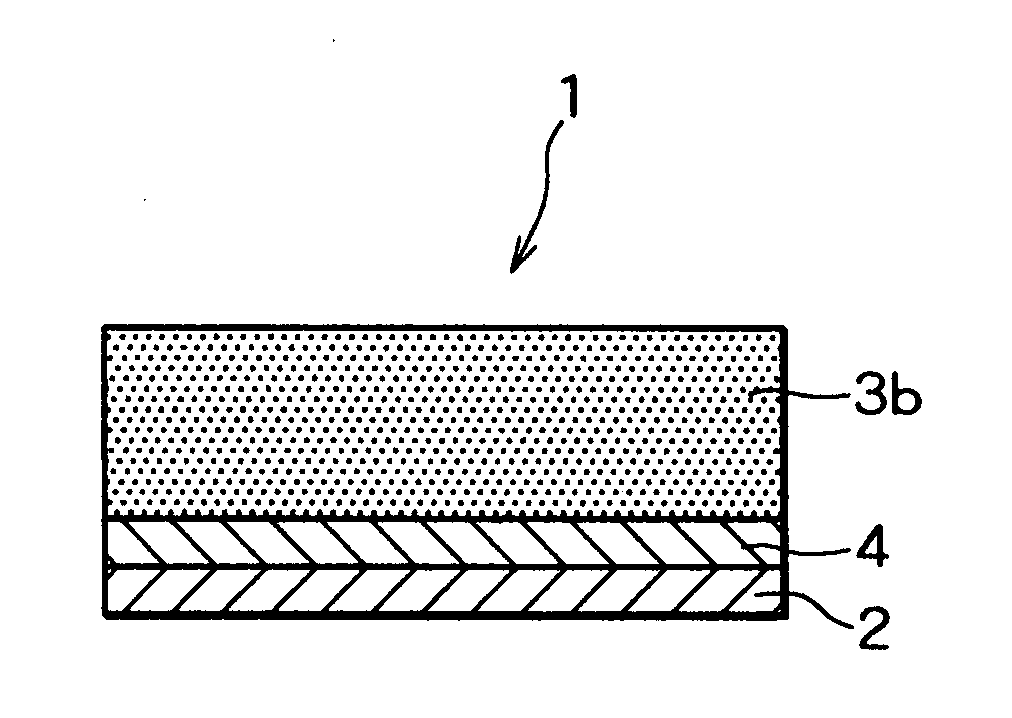

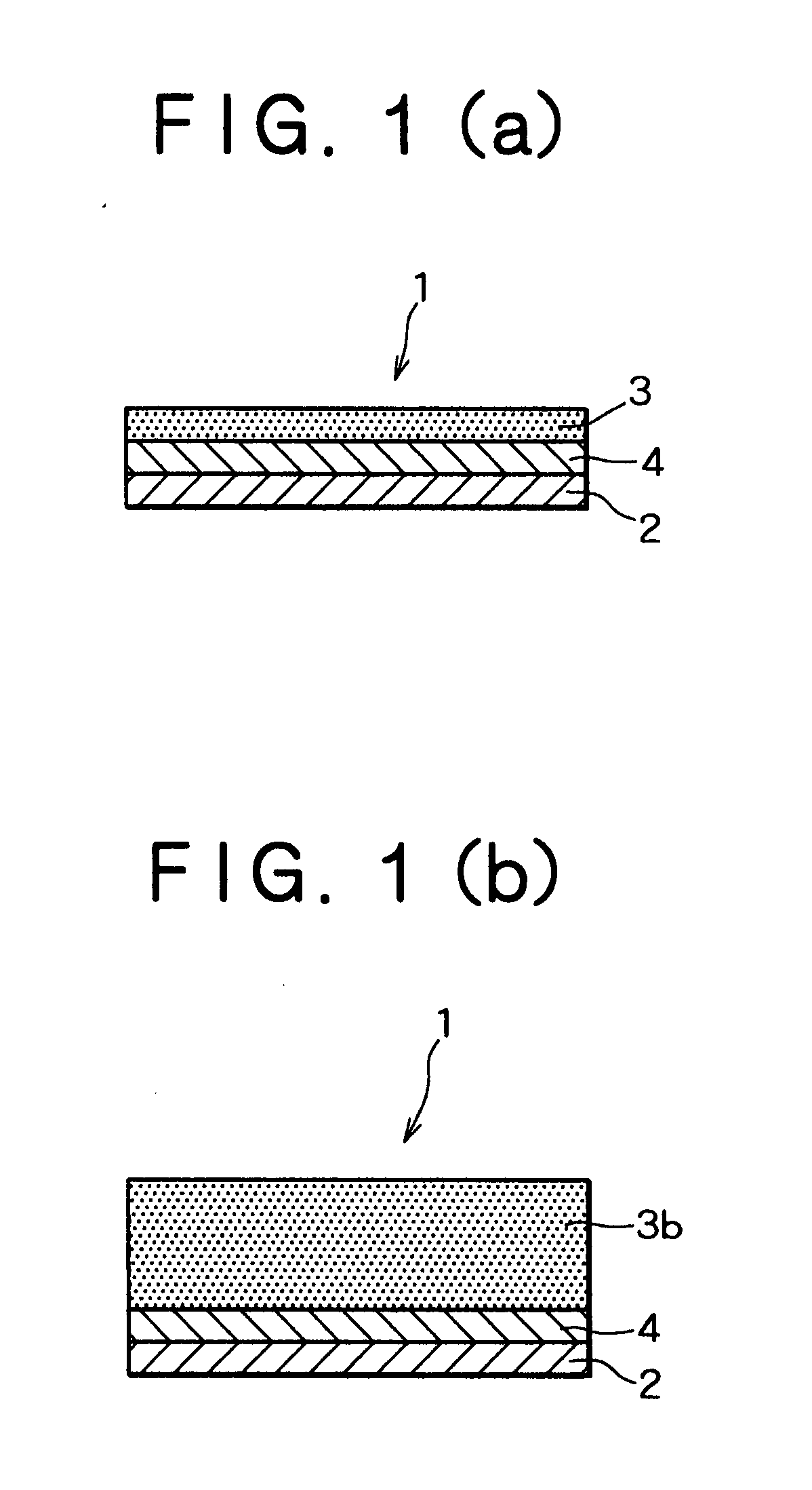

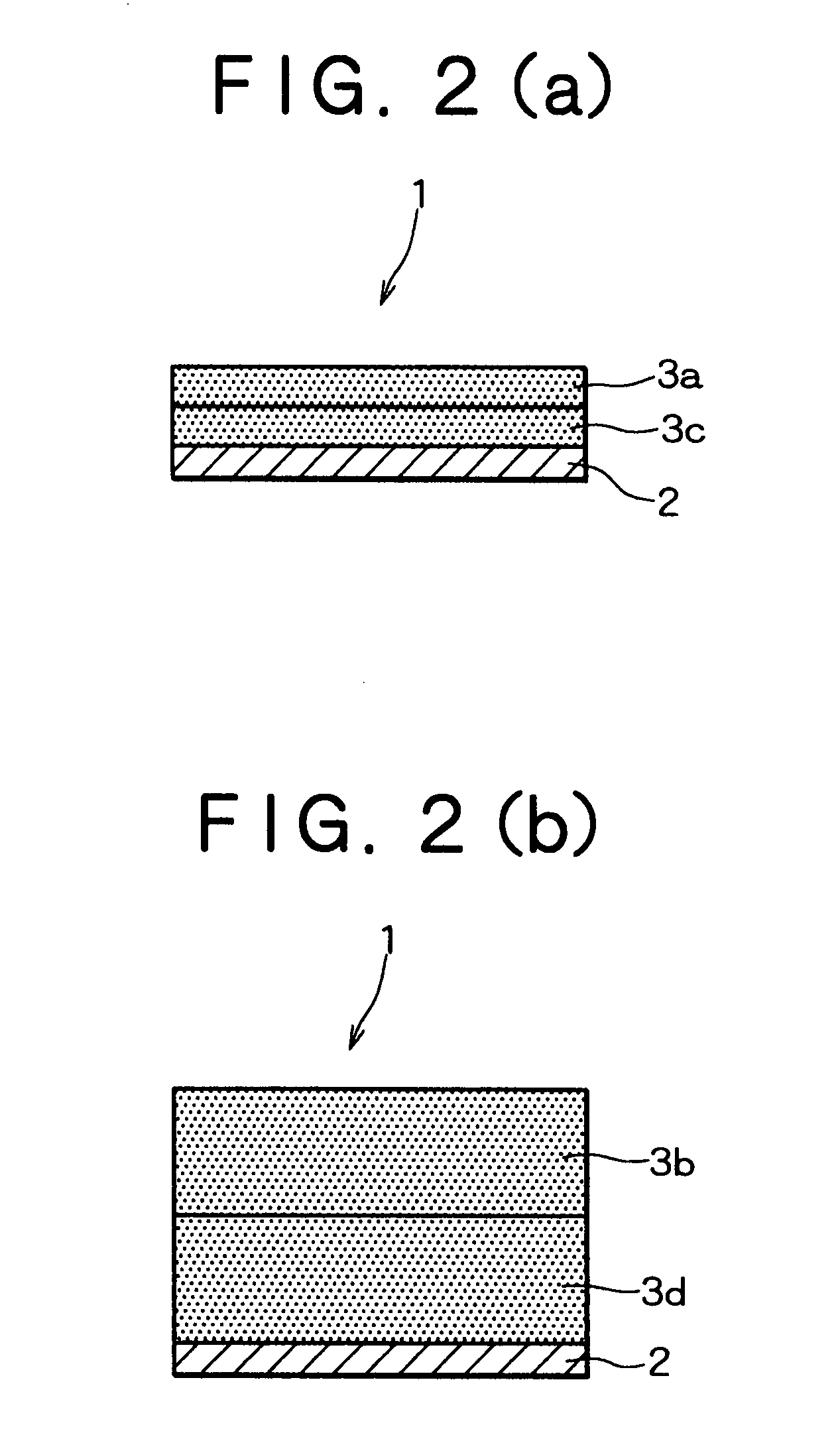

Foam resin laminated sound insulating plate and producing method thereof

InactiveCN1468705ASufficient vibration dampingImprove plastic processing performanceLamination ancillary operationsSynthetic resin layered productsEngineeringAcoustic board

Owner:KOBE STEEL LTD

Foamed resin laminate sound insulation board and method for manufacturing the same

InactiveUS20070289689A1Sufficient damping performanceImprove plastic processing performanceLamination ancillary operationsLaminationEngineeringHardboard

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com