TiAl intermetallic compound-based alloys and methods for preparing same

a compound-based alloy and alloy technology, applied in the field oftial intermetallic compound-based alloys, can solve the problems of insufficient plastic ductility, difficult plastic working, and inability to meet the requirements of industrial production, so as to improve oxidation resistance, reduce oxidation resistance, and improve the effect of stabilizing the beta

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

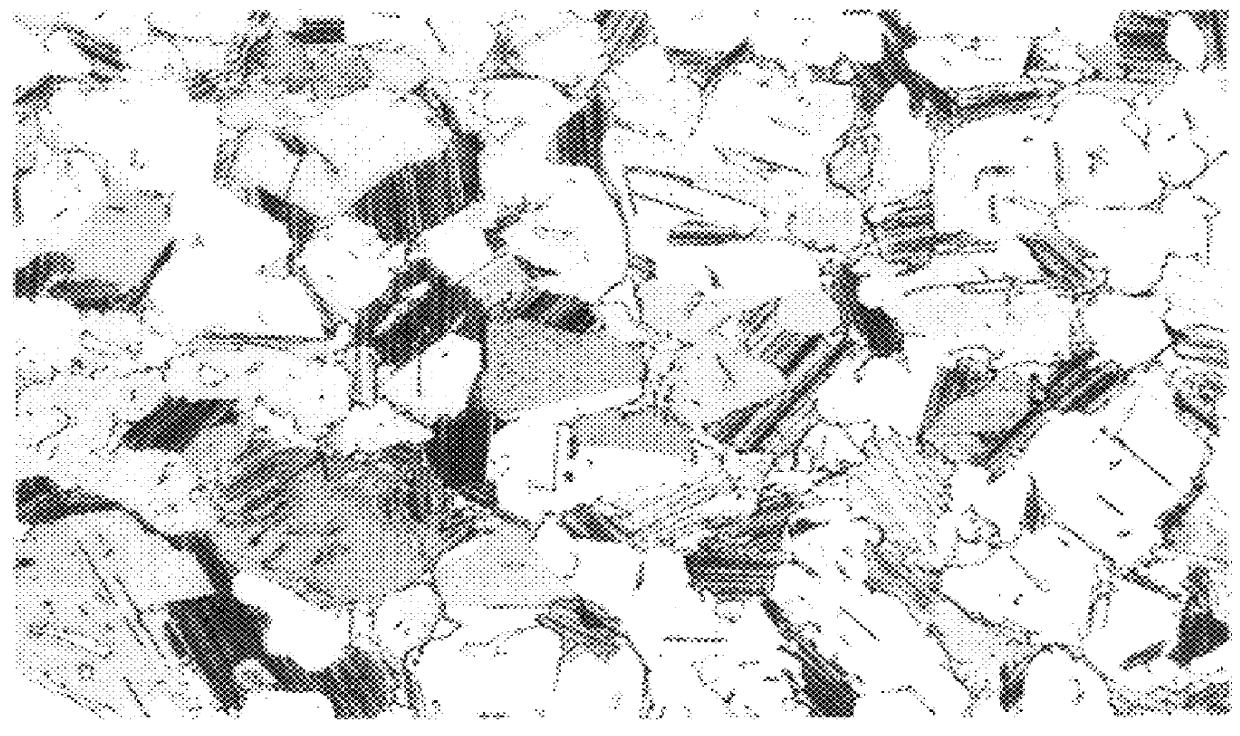

examples 4-6

show the results obtained when an alloy having an Al concentration of 48 atomic percent and additionally containing 3 atomic percent Cr was tested in the as-cast state or after heat treatment at 1200.degree. C. or 1300.degree. C. In all cases, the maximum stress during compression test was 170 MPa or greater and the development of defects was observed. Moreover, the oxidation weight gain was 24.1 mg / cm.sup.2 or greater, indicating that its oxidation resistance was unsatisfactory.

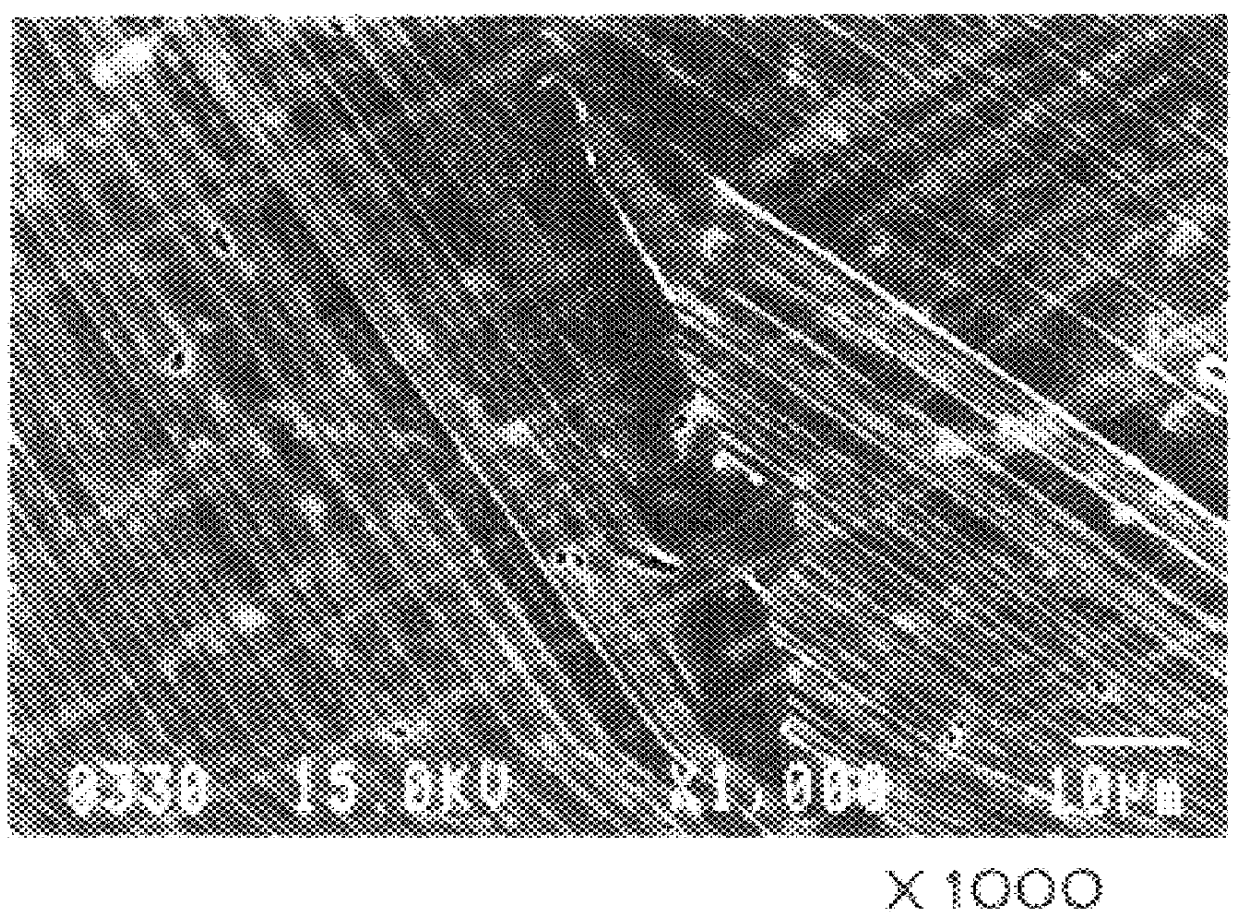

examples 7-12

relate to an alloy in accordance with the present invention and show the results obtained when an alloy comprising 42 atomic percent Ti, 47 atomic percent Al, 9 atomic percent Nb and 2 atomic percent Cr was tested in the as-cast state or after heat treatment at 1100.degree. C., 1150.degree. C., 1200.degree. C., 1250.degree. C. or 1350.degree. C. After heat treatment at 1150.degree. C. or 1200.degree. C., the maximum stress was 140 MPa or less and no defects were developed. On the other hand, in the as-cast state and after heat treatment at 1100.degree. C., 1250.degree. C. or 1350.degree. C., the maximum stress was 170 MPa or greater and the development of defects was observed. The oxidation weight gain was 3.5 mg / cm.sup.2 or less, indicating that its oxidation resistance was markedly superior as compared with Examples 1-6.

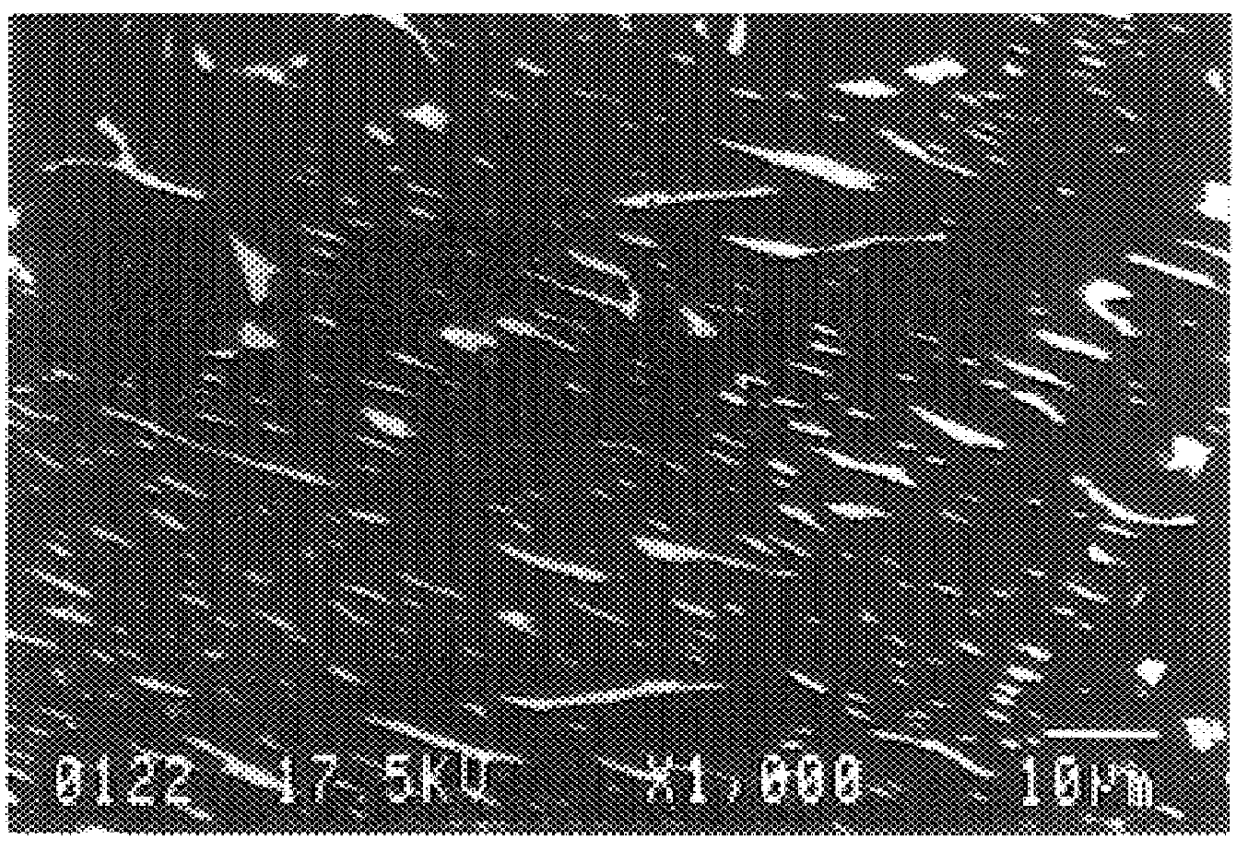

examples 13-18

relate to an alloy in accordance with the present invention and show the results obtained when an alloy comprising 45 atomic percent Ti, 45 atomic percent Al, 8 atomic percent Nb and 2 atomic percent Cr was tested in the as-cast state or after heat treatment at 1100.degree. C., 1150.degree. C., 1200.degree. C., 1250.degree. C. or 1350.degree. C. After heat treatment at 1150.degree. C. or 1200.degree. C., the maximum stress was 120 MPa or less and no defects were developed. On the other hand, in the as-cast state and after heat treatment at 1100.degree. C., 1250.degree. C. or 1350.degree. C., the maximum stress was 160 MPa or greater and the development of defects was observed. The oxidation weight gain was 3.3 mg / cm.sup.2 or less, indicating that its oxidation resistance was markedly superior as compared with Examples 1-6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com