Preparation method of high-elasticity corrosion-resistant and wear-resistant Cu-Ni-Sn alloy

A corrosion-resistant and high-elasticity technology, which is applied in the preparation of wear-resistant Cu-Ni-Sn alloy, high elasticity, and corrosion-resistant fields. It can solve microscopic cracks in the structure, reduce product fatigue life, and increase the difficulty of plastic forming of materials. Achieve the effects of easy elimination, improvement of product quality and production efficiency, and reduction of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

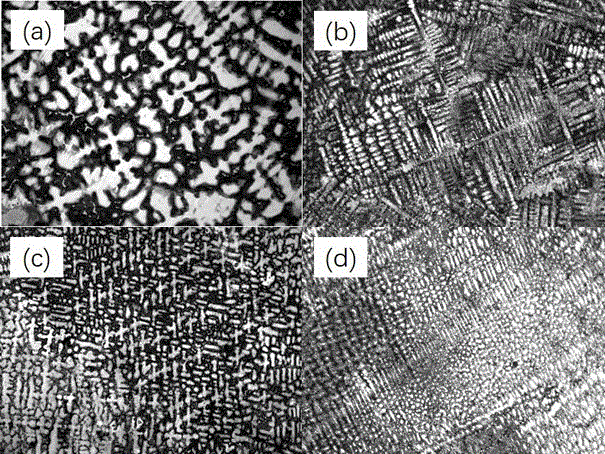

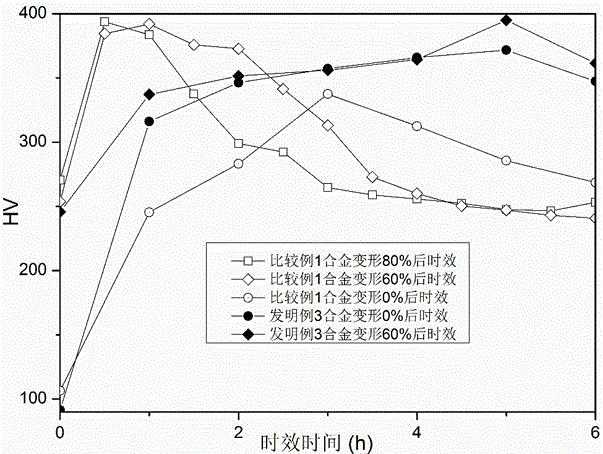

[0019] The present invention relates to a highly elastic, corrosion-resistant, wear-resistant Cu-Ni-Sn alloy preparation method, the steps of the preparation method are:

[0020] Step 1: The percentage by weight of each component to prepare Cu-Ni-Sn alloy is: Ni 3~41%, Sn 1~26%, at least one of trace elements Cr, Mn, Nb, Si, Zr and Ti , and the total amount of Cr, Mn, Nb, Si, Zr, Ti is 0.03%~0.3%; the balance is Cu;

[0021] The selection of Ni and Sn above needs to ensure that the Cu-Ni-Sn alloy can undergo amplitude modulation decomposition;

[0022] Preferably, in this step one: the weight percent content of Ni and Sn is: Ni 14~16%; Sn8.5~10.5%

[0023] Step 2: The above-mentioned alloy is smelted by vacuum induction smelting or non-vacuum smelting with covering protection. The feeding material is that Cu and Ni are added at the same time, and Sn and other trace elements are added after Cu and Ni are melted and refined; Casting; control the furnace temperature to 1100~130...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com