Ultra-high-strength and ultra-fine-grain TiB2 reinforced Al-Zn-Mg-Cu composite material and preparation method thereof

A composite material and ultra-fine grain technology, applied in the field of composite materials, can solve the problems of alloy loss, difficulty in further improving tensile strength, alloy stress corrosion cracking, etc., and achieve strength improvement, optimization of rapid solidification process and hot extrusion process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

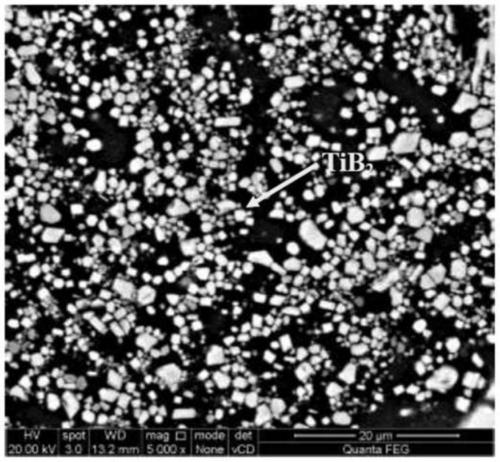

[0022] Preparation of ultra-high-strength, ultra-fine-grained TiB 2 / Al-Zn-Mg-Cu composite material process is as follows:

[0023] (1) The ratio of the composite material is: 5% TiB 2 , 10% Zn, 1.7% Mg, 1.0% Cu, 0.12% Zr, and the balance is Al. Al-TiB 2 The master alloy consists of high-purity aluminum ingot, Al powder, Ti powder, TiO 2 、H 3 BO 3 Prepare, wherein the molar ratio of Ti / B is 1:3.5, Al powder, Ti powder and TiO 2 The mass ratio of Al-Zn-Mg-Cu-Zr is 2:2:3, and the Al-Zn-Mg-Cu-Zr matrix is prepared from pure aluminum ingots, pure zinc ingots, pure magnesium ingots, Al-50% Cu and Al-4% Zr master alloys.

[0024] (2) Preparation of Al-TiB 2 Master alloy, weigh TiO as required 2 、H 3 BO 3 , mix the two powders evenly, and heat at 200°C for 2h to remove H 3 BO 3 moisture in. The heated TiO 2 and H 3 BO 3 The mixed powder is uniformly mixed with the aluminum powder and titanium powder required to be weighed, and the uniformly mixed powder is placed i...

Embodiment 2

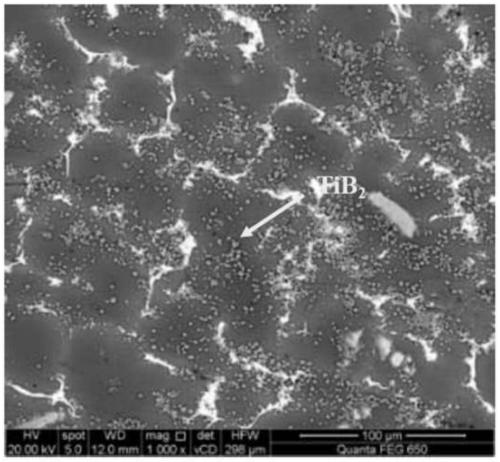

[0030] (1) The ratio of composite materials is: 2% TiB 2 , 11% Zn, 2.0% Mg, 1.2% Cu, 0.12% Zr, and the balance is Al. Al-TiB 2 The master alloy consists of high-purity aluminum ingot, Al powder, Ti powder, TiO 2 、H 3 BO 3 Prepare, wherein the molar ratio of Ti / B is 1:3.5, Al powder, Ti powder and TiO 2 The mass ratio is 2:2:3, and the aluminum ingot is 2Kg. The Al-Zn-Mg-Cu-Zr matrix is prepared from pure aluminum ingots, pure zinc ingots, pure magnesium ingots, Al-50% Cu and Al-4% Zr master alloys.

[0031] (2) Preparation of Al-TiB 2 Master alloy, same as step (2) in embodiment 1.

[0032] (3) The matrix components designed in step (1) are mixed with pure aluminum ingots, pure zinc ingots, pure magnesium ingots, Al-50% Cu and Al-4% Zr master alloys.

[0033] (4) is the same as step (4) in Example 1.

[0034] (5) is the same as step (5) in Example 1.

[0035] (6) T6 heat treatment (solid solution 460°C / 2h, aging 120°C / 24h) on the composite material after hot extrus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com