Patents

Literature

379 results about "Zr alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Al-Cu-Li-Mg-Ag-Mn-Zr alloy for use as structural members requiring high strength and high fracture toughness

An improved aluminum lithium alloy comprising 0.1 to 2.5 wt. % Li, 2.5 to 5.5 wt. % Cu, 0.2 to 1.0 wt. % Mg, 0.2 to 0.8 wt. % Ag, 0.2 to 0.8 wt. % Mn, up to 0.4 wt. % Zr or other grain refiner such as chromium, titanium, hafnium, scandium or vanadium, the balance aluminum. The present alloy exhibits an improved combination of strength and fracture toughness, over any thickness range. The present invention is further directed to methods for preparing and using Al—Li alloys as well as to products comprising the same.

Owner:CONSTELLIUM ROLLED PROD RAVENSWOOD

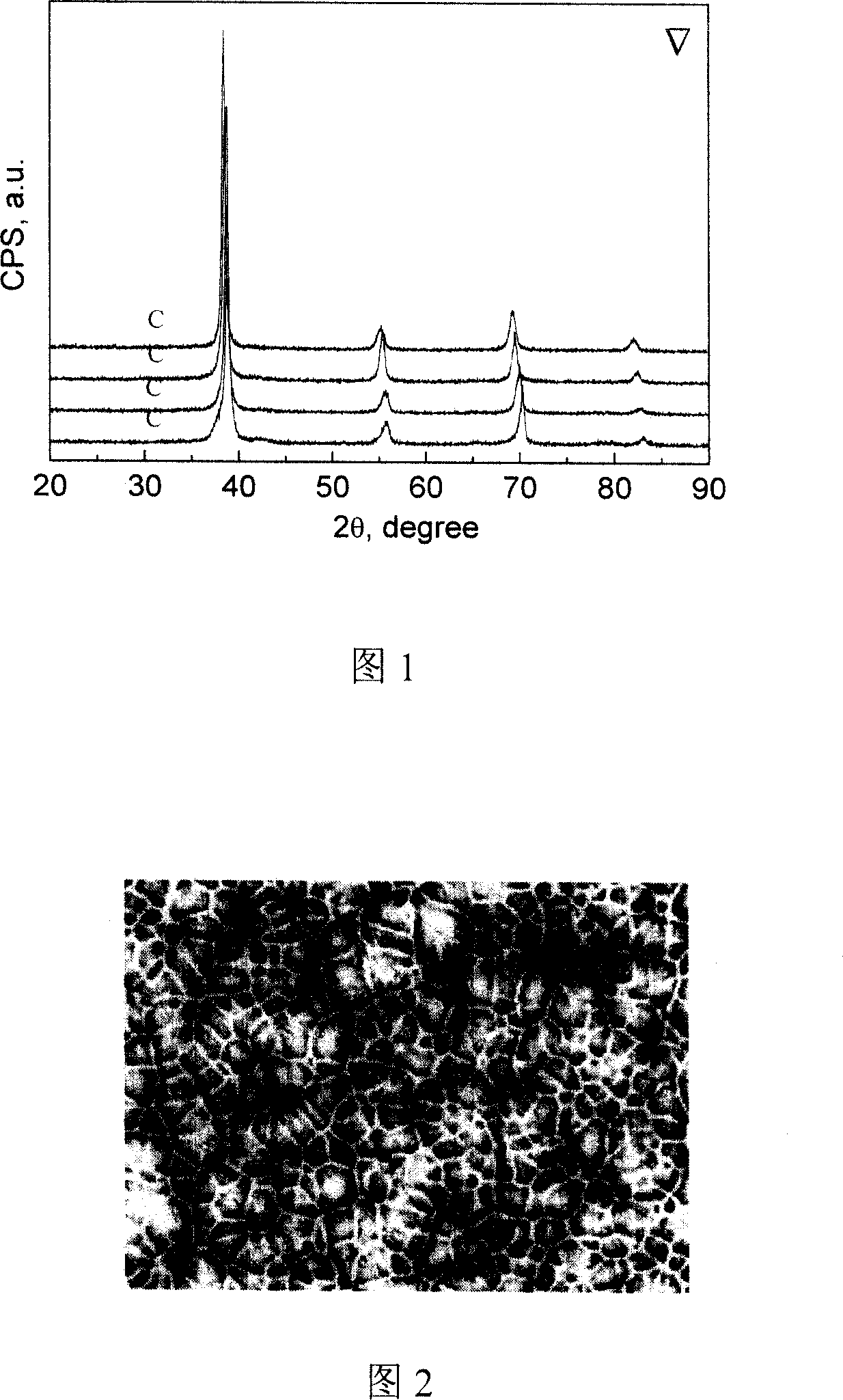

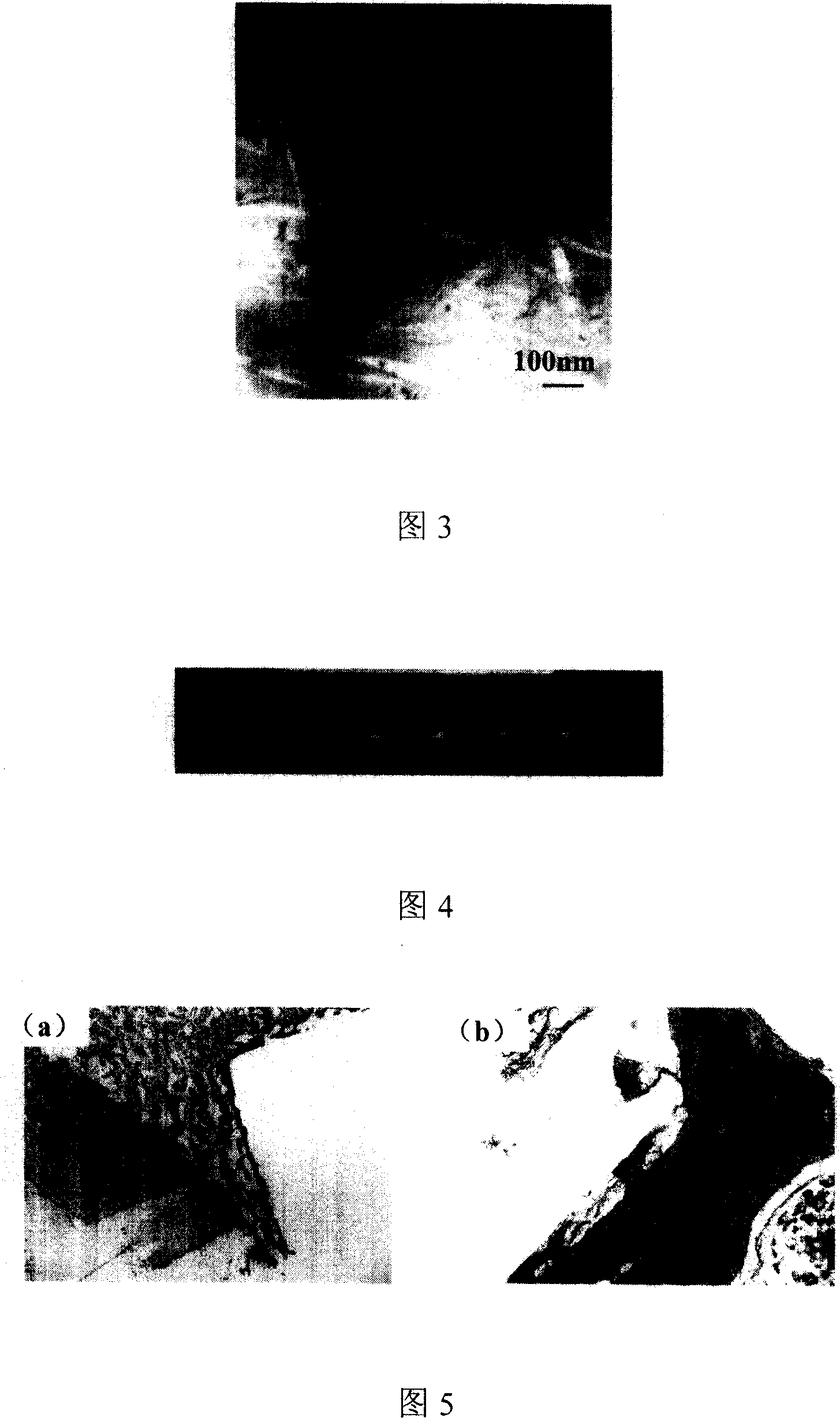

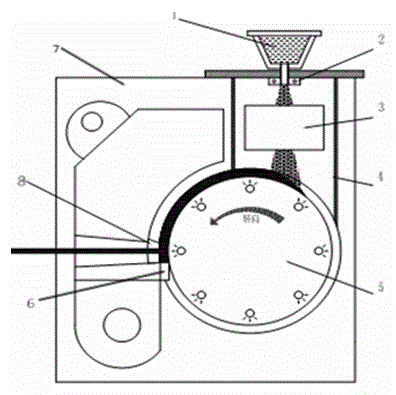

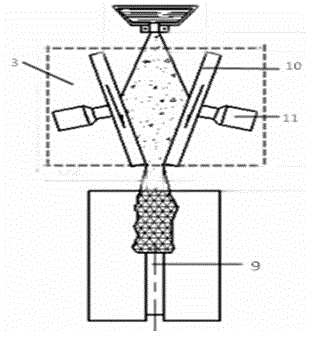

Al-Mg-Sc-Zr series aluminum alloy composition for selective laser melting technology and preparation method for molding part

ActiveCN108486433AImprove performanceIncrease contentAdditive manufacturing apparatusIncreasing energy efficiencySolubilitySelective laser melting

The invention discloses an Al-Mg-Sc-Zr series aluminum alloy composition for selective laser melting technology and a preparation method for a molding part. The composition comprises, by mass, 6-15% of Mg, 0.5-4% of Sc, 0.7-3% of Zr, 0.5-2% of Mn and the balance aluminum. An aluminum alloy molding part are prepared by smelting of master alloy, preparation of metal powder, preparation of aluminum alloy molding parts and heat treatment processes. According to the elective laser melting technology, the solubility of Mg, Sc and Zr alloy elements in aluminum matrix is greatly improved, the concentration of solid solution strengthening elements and dispersion strengthening particles in the aluminum alloy is increased, and the mechanical property of the aluminum alloy is improved. According to the aluminum alloy obtained by preparation of the selective laser melting technology, the highest density is 99.8%, the highest extension strength sigma b reaches 550 MPa, the yield strength sigma0.2 reaches 520 MPa, the plastic deformation rate of about 12 % is maintained, and the Al-Mg-Sc-Zr series aluminum alloy composition for the ctive laser melting technology and the preparation method for themolding part is applied to complicated structural parts with higher mechanical properties.

Owner:JIANGSU UNIV OF SCI & TECH

New Al-Cu-Li-Mg-Ag-Mn-Zr alloy for use as structural members requiring high strength and high fracture toughness

An improved aluminum lithium alloy comprising 0.1 to 2.5 wt. % Li, 2.5 to 5.5 wt. % Cu, 0.2 to 1.0 wt. % Mg, 0.2 to 0.8 wt. % Ag, 0.2 to 0.8 wt. % Mn, up to 0.4 wt. % Zr or other grain refiner such as chromium, titanium, hafnium, scandium or vanadium, the balance aluminum. The present alloy exhibits an improved combination of strength and fracture toughness, over any thickness range. The present invention is further directed to methods for preparing and using Al—Li alloys as well as to products comprising the same.

Owner:CONSTELLIUM ROLLED PROD RAVENSWOOD

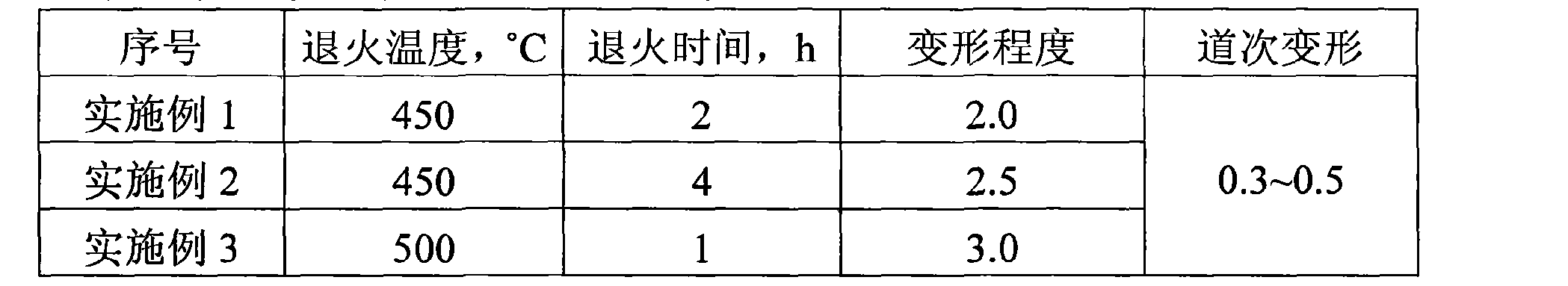

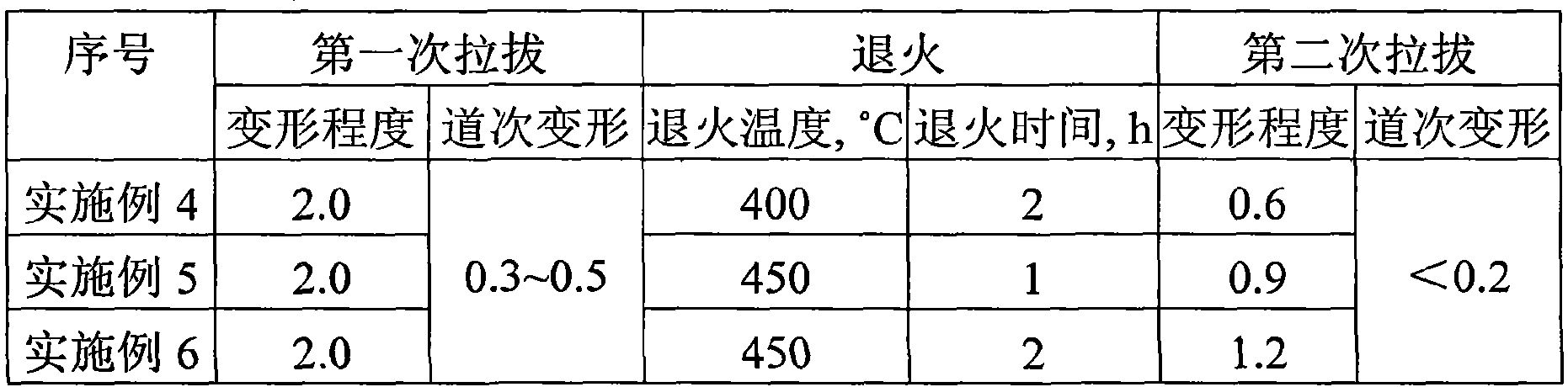

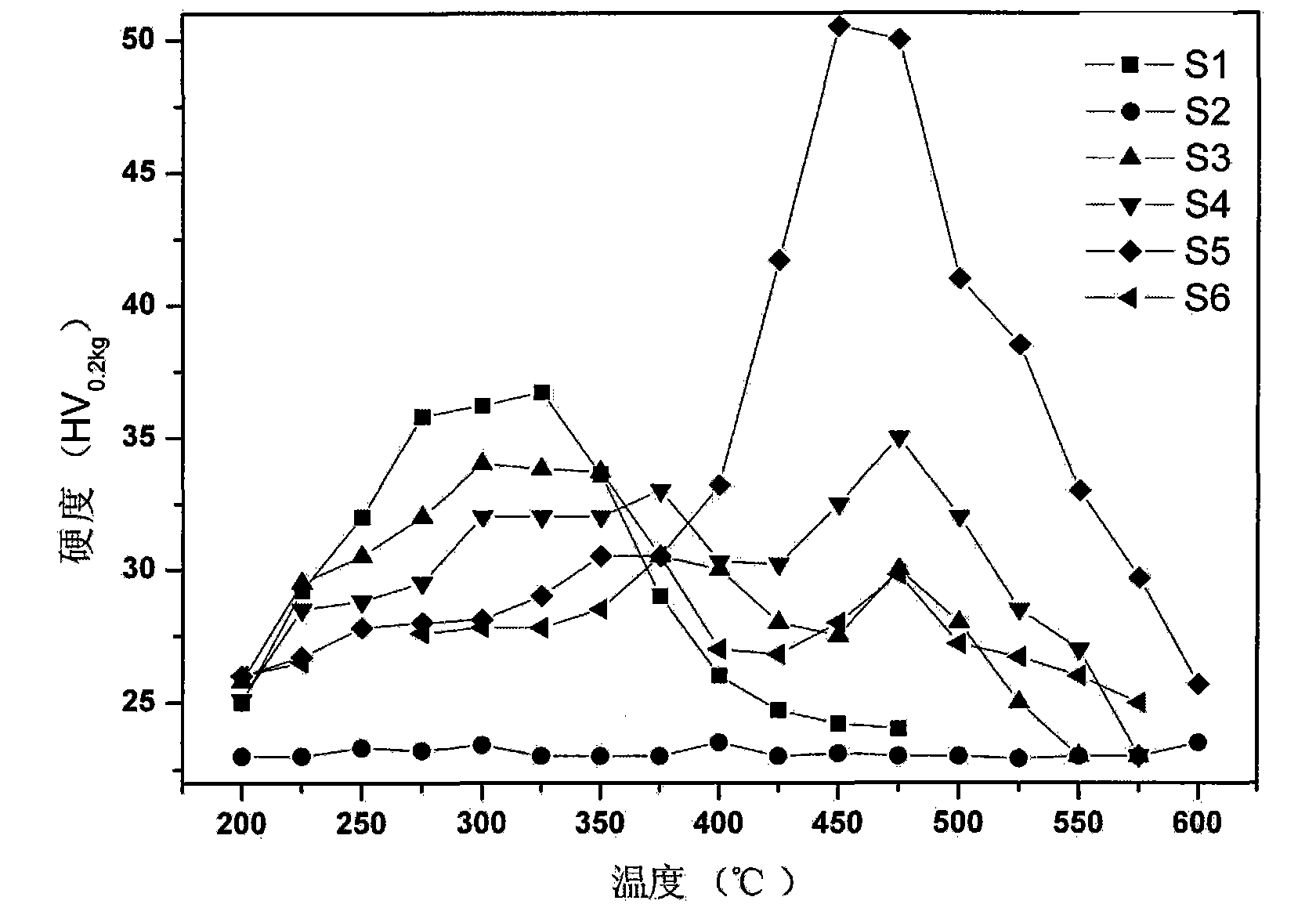

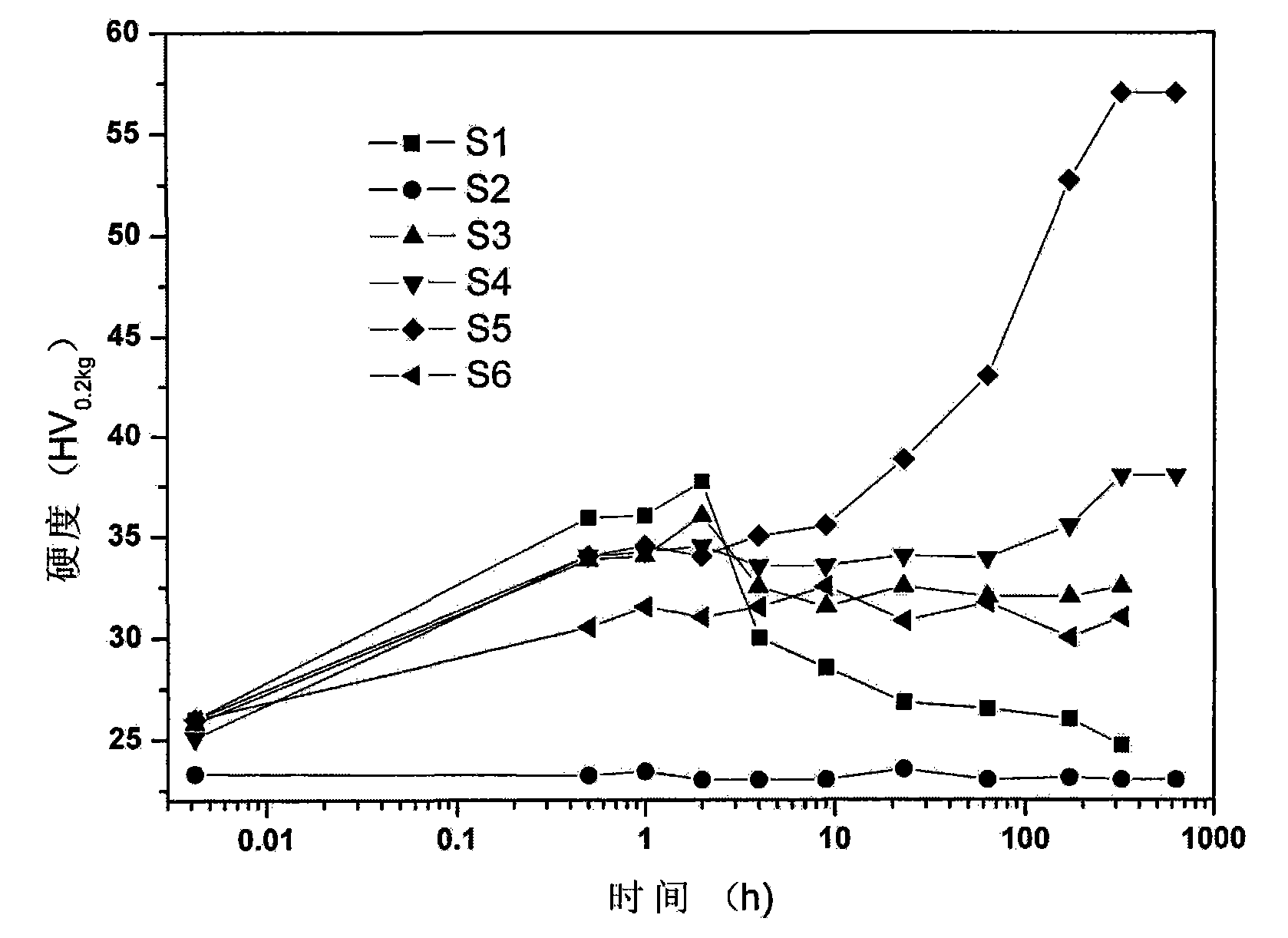

Cu-Cr-Zr alloy preparation technology for contact wire

The invention discloses a process for preparing Cu-Cr-Zr alloys applicable to contact lines. The process comprises the following steps that alloys comprising 0.30 to 0.50 percent of Cu, 0.10 to 0.15 percent of Cr, 0.01 to 0.02 percent of Zr and Si are melt in a vacuum induction furnace, wherein alloy elements, namely Cr, Zr and Si, are added by master alloys; fine casting-state crystal grains and oversaturated matrix tissues having secondary dendritic crystal spaces are obtained by controlling solidification velocity and cooling velocity; rolling in fit, drawing deformation and annealing thermal treatment to the fine casting-state crystal grains and oversaturated matrix tissues are carried out so as to control deformation degrees and parameters for the thermal treatment; and the strain-hardening effect and the precipitation strengthening effect are organically combined. Therefore, the alloys have the advantages of excellent tensile strength, electrical conductivity and high-temperature resistant softening capacity and lower cost under the conditions of simplified process and the simpler apparatus and components, and are applicable to industrial production.

Owner:邢台鑫晖铜业特种线材有限公司 +3

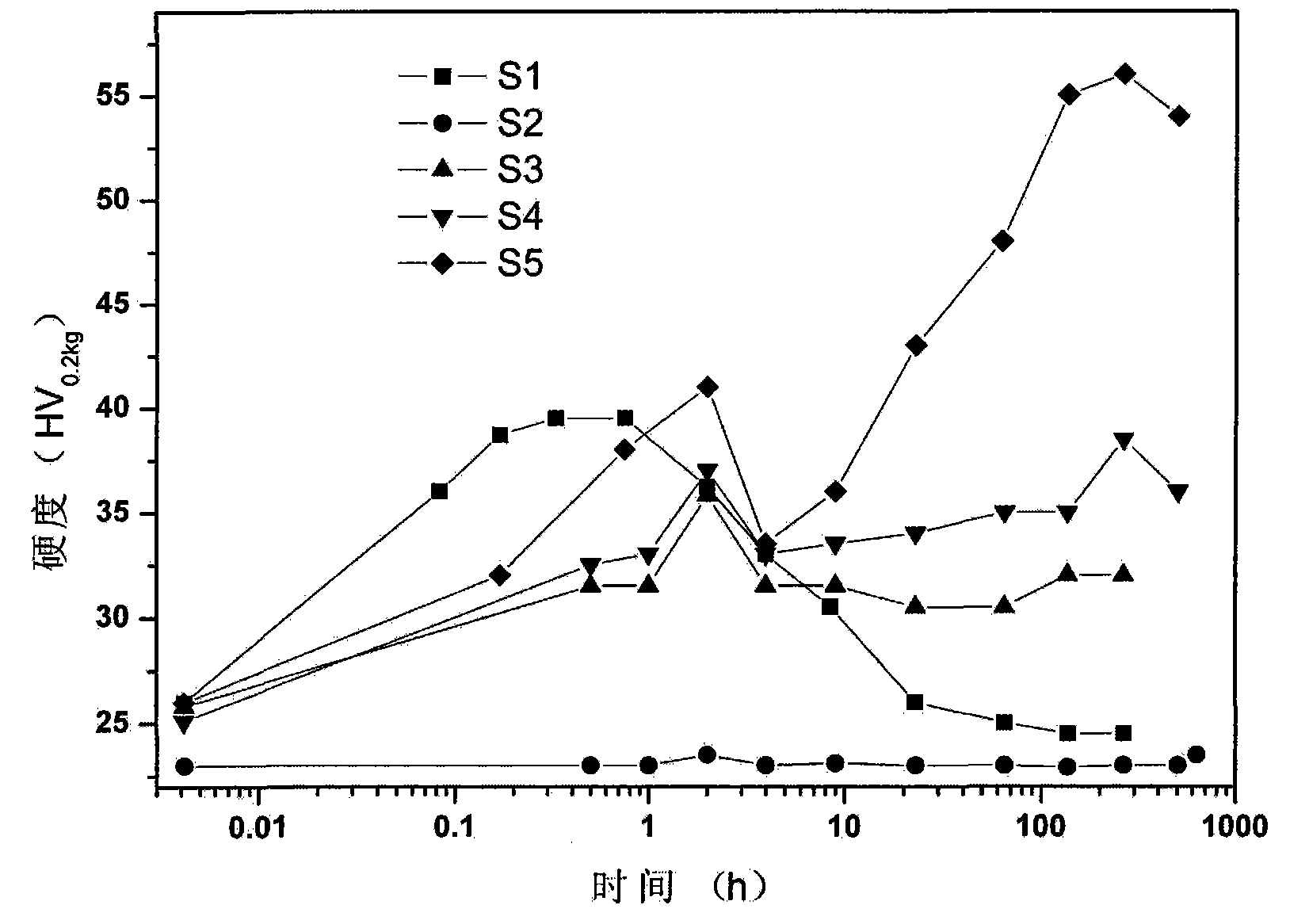

Al-Er-Zr alloy and ageing strengthening process thereof

The invention discloses an Al-Er-Zr alloy and an ageing strengthening process thereof, and belongs to the technical field of alloys. The alloy is prepared by adding 0.09 to 0.3 weight percent of Er and 0.08 to 0.3 percent of Zr into an aluminum substrate. The solid solution ageing heat treatment process of the alloy comprises the following steps of: performing solid solution at the temperature of 640+ / -10 DEG C for 20 to 30 hours, performing water quenching to room temperature, and ageing at the temperature of between 200 and 575 DGE C for 3 hours at intervals of 25 DEG C, or ageing at the constant temperature of between 300 and 450 DEG C, wherein the optimal constant ageing temperature is between 350 and 400 DEG C. Through the composite micro-alloying of Er and Zr, the Al-Er-Zr alloy has obvious ageing strengthening effect; and the ageing strengthening effect and thermal stability of the Al-Er-Zr alloy are higher than those of an Al-Er alloy, and the ageing precipitation speed is obviously higher than that of the Al-Zr alloy.

Owner:BEIJING UNIV OF TECH

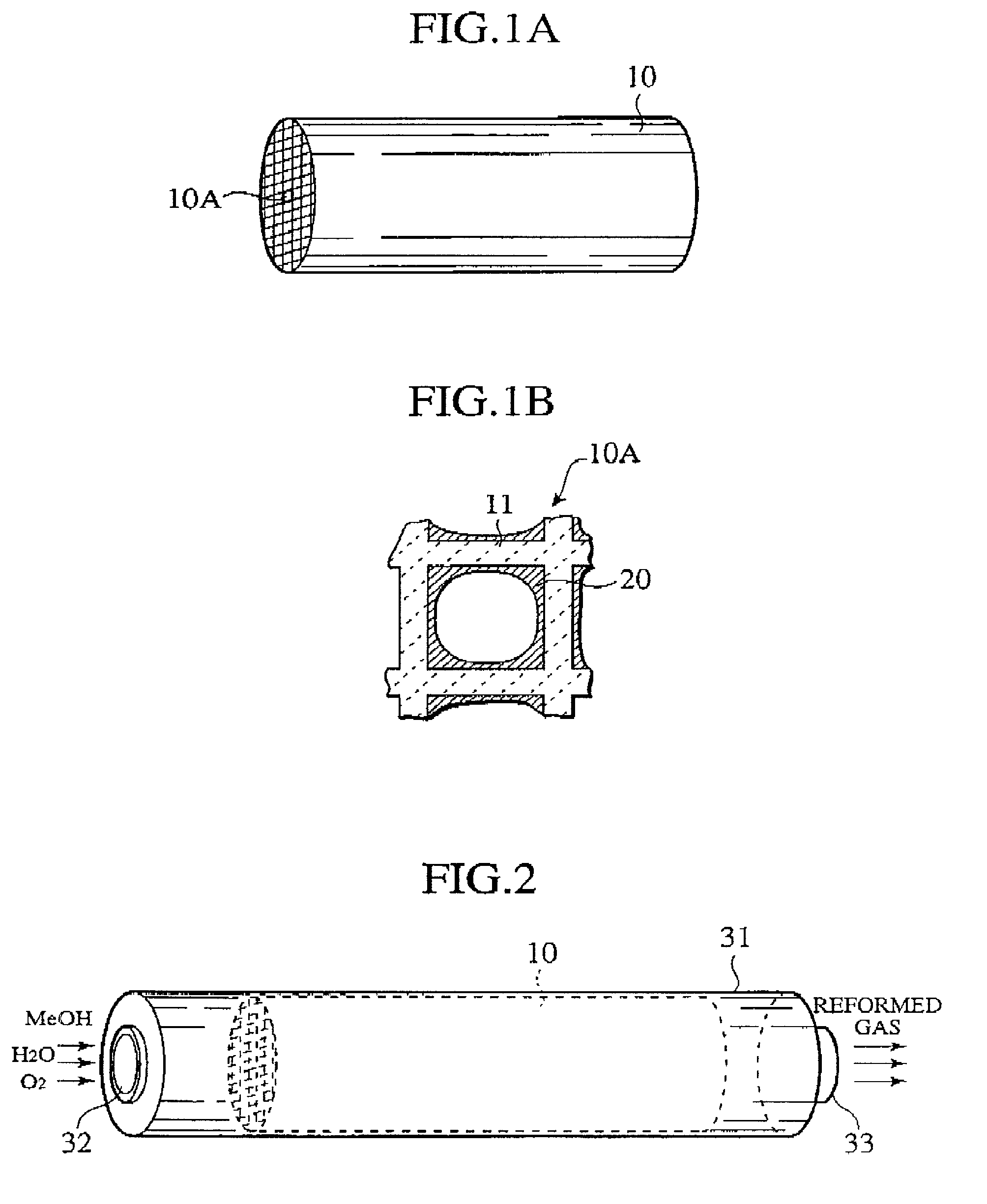

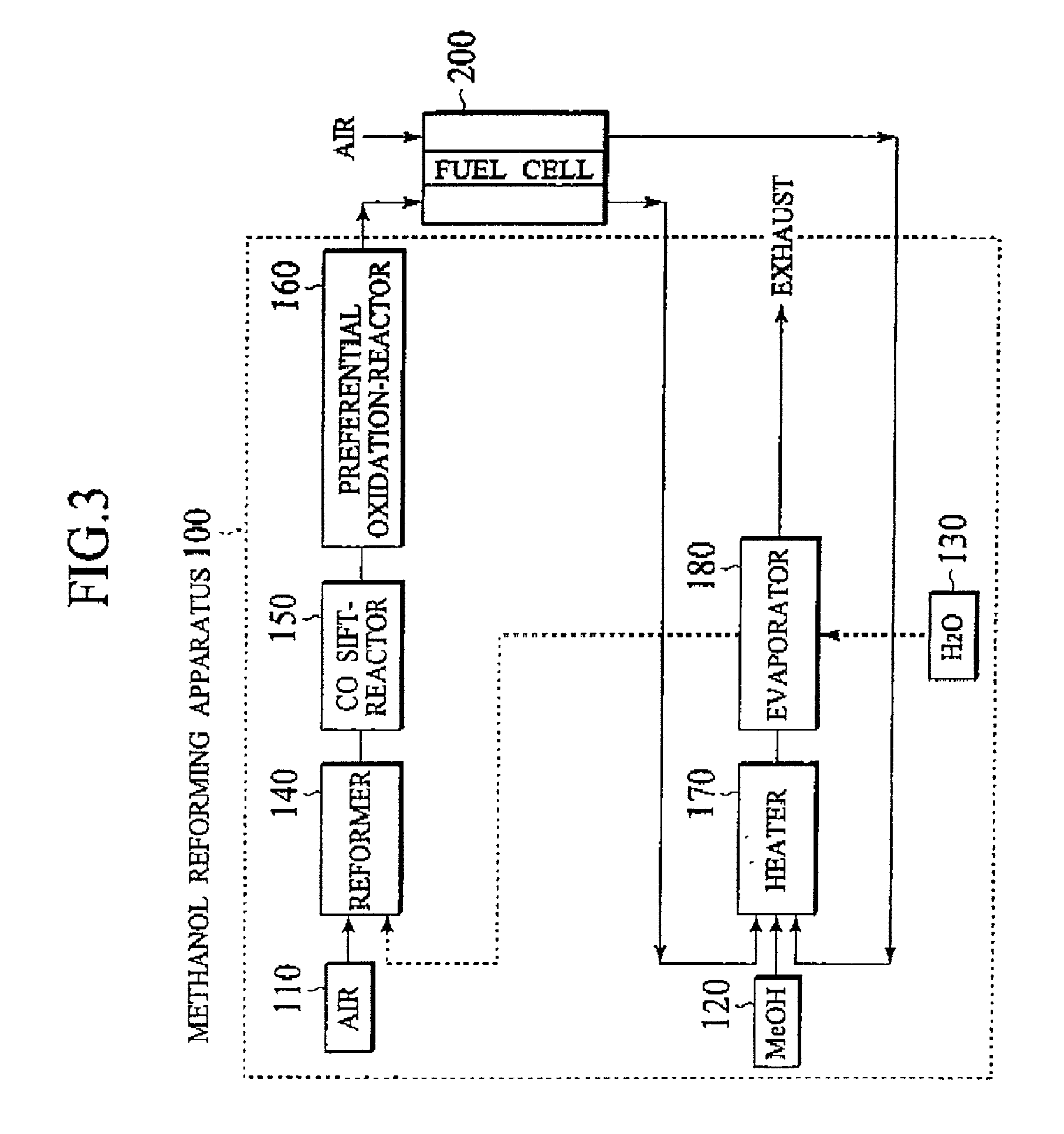

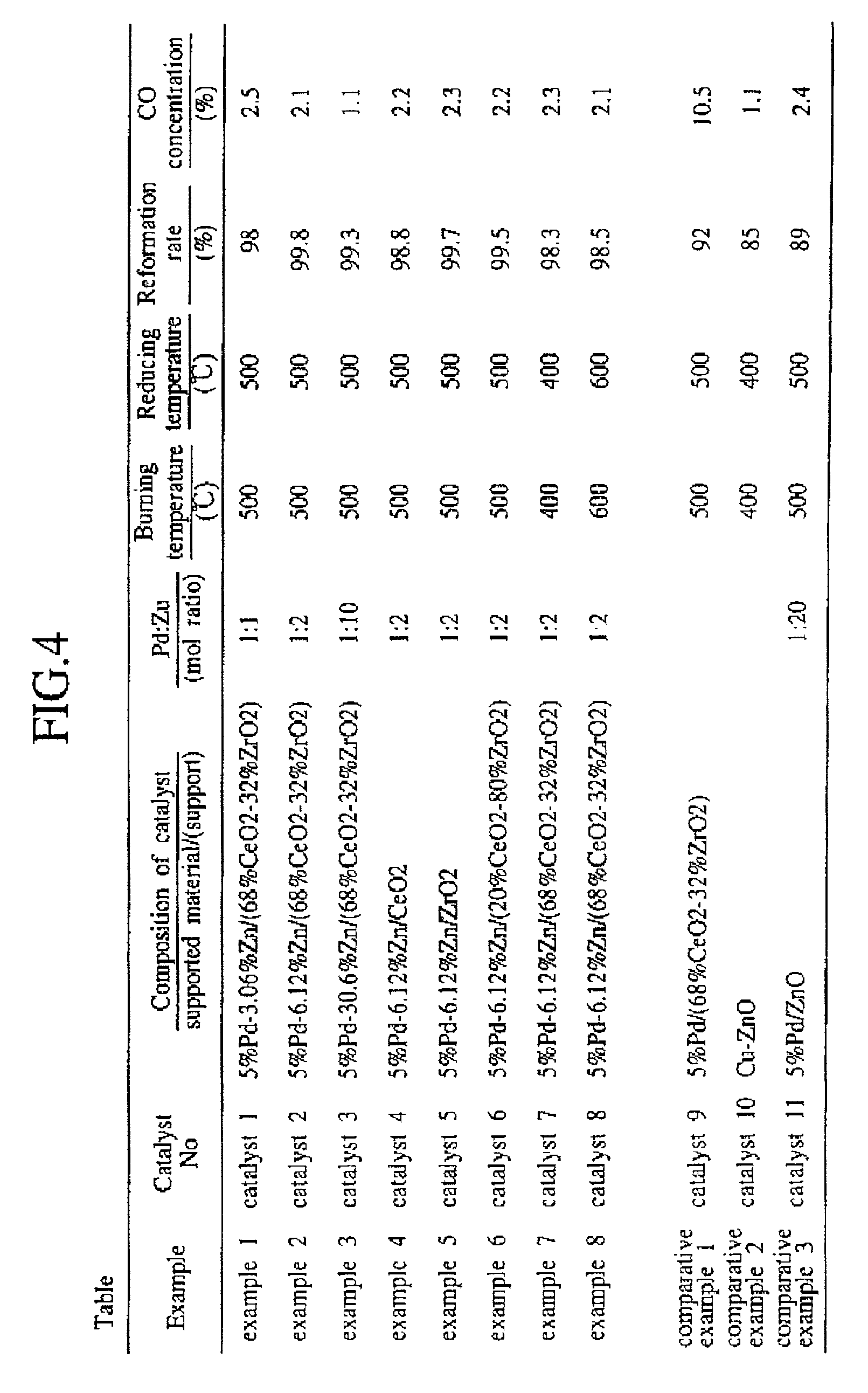

Methanol reforming catalyst

InactiveUS20010021469A1Reformer or the methanol reforming apparatus can be small and simplifiedSmall sizeHydrogenFinal product manufactureSteam reformingHydrogen

A methanol reforming catalyst that generates a reformed gas containing hydrogen by reforming methanol in the atmosphere containing oxygen and steam contains a metal oxide support and Pd-Zr alloy with which the metal oxide support is impregnated. The reforming catalyst accelerate a steam reforming reaction of the methanol as an endothermic reaction and a partial oxidation reaction of the methanol as an exothermic reaction while suppressing generation of CO gas. Also, a methanol reforming apparatus having the methanol reforming catalyst does not need a heater for the reforming reaction.

Owner:NISSAN MOTOR CO LTD

Magnesium-zinc-lanthanon-zirconium magnesium alloy and method for preparing same

ActiveCN101200784AGravity segregation is smallComponent segregation is smallRare earthEconomic benefits

The invention relates to an Mg-based alloy of Mg-Zn-RE-Zr and a preparation method thereof, in particular to an Mg-based alloy of Mg-3wt percent of Zn-3wt percent of RE-Zr alloy which is added with zirconium and a preparation method thereof. In the composition general formula of Mg-3wt percent of Zn-3wt percent of RE-0.6wt percent of Zr, RE is respectively La, Ce, Ce rich rare earth MC, Yttrium rich rare earth MY and mixed dilute MM, the weight ratio of MC to MY of which is 1 to 2. In the casting process of the Mg-Zn-RE alloy with middle Zn content (containing 3wt percent of Zn) and middle RE content (containing 3wt percent of RE), the gravity segregation and the composition segregation are small. Problems that the total amount of alloy with high Zn content or high RE content and strengthening elements are too large, etc. are avoided. At the same time, the ratio of property to price is moderate and the invention is beneficial to meet the market demands. With the five RE combinations adopted, the alloy types of Mg-Zn-RE serial that can be selected and applied in industry are increased. The same process condition can be used for producing five types of RE combinations. The five alloys can be mutually replaced in technology with good technical and economic benefits. The raw material cost is lowed and the RE resource can be utilized effectively.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

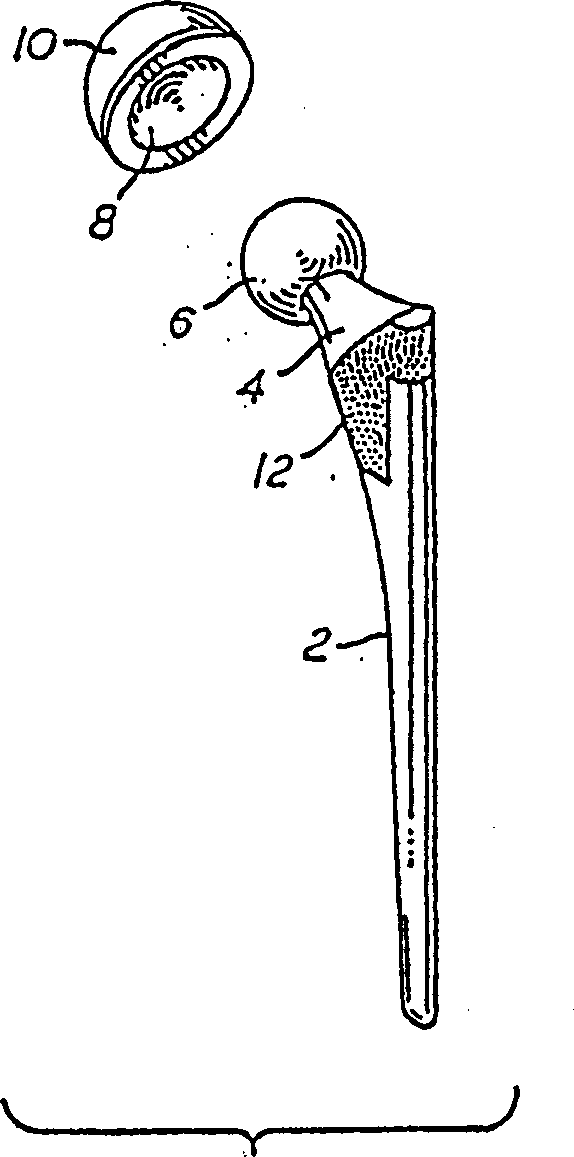

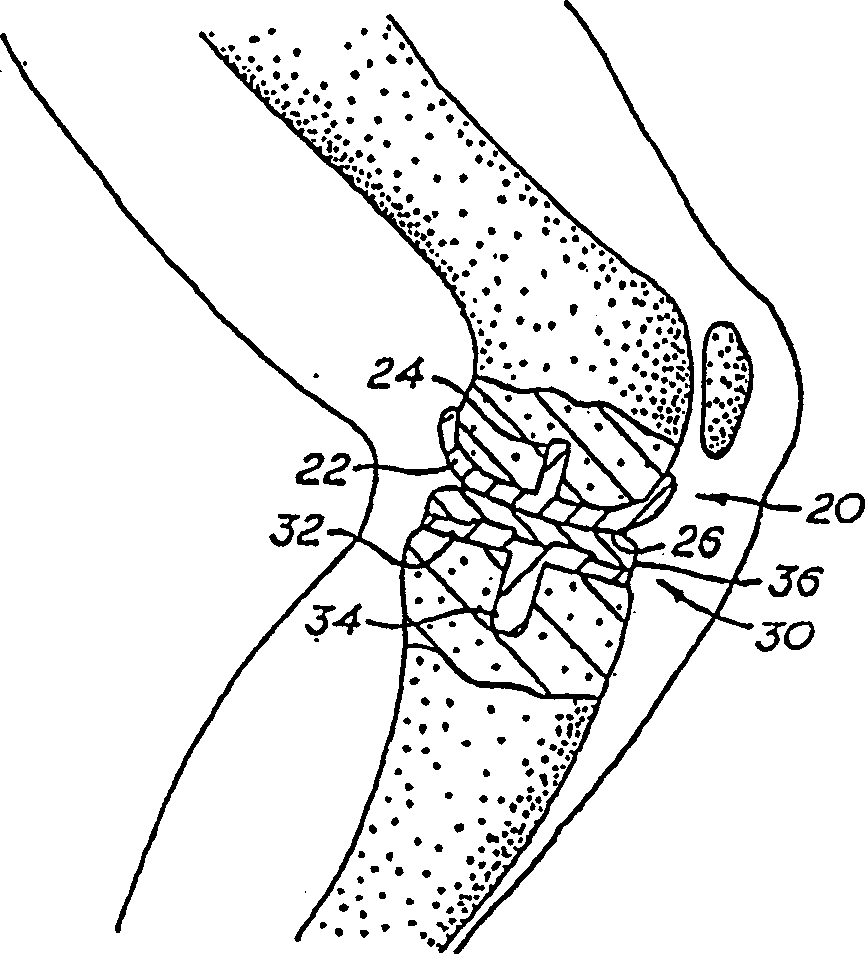

Method of surface oxidizing zirconium and zirconium alloys and resulting product

A coating of blue-black oxidized zirconium of uniform and controlled thickness on a zirconium or zirconium alloy material is accomplished through the use of a single phase crystalline material substrate having an altered surface roughness. An oxidized zirconium coating of uniform and controlled thickness is especially useful on orthopedic implants of zirconium or zirconium-based alloys to provide low friction, highly wear resistant surfaces on artificial joints, such as, but not limited to, hip joints, knee joints, shoulders, elbows, and spinal implants. The uniformly thick oxidized zirconium surface of controlled depth on prostheses provide a barrier against implant corrosion caused by ionization of the metal prostheses. The invention is also useful in non-articulating implant devices such as bone plates, bone screws, etc.

Owner:SMITH & NEPHEW INC

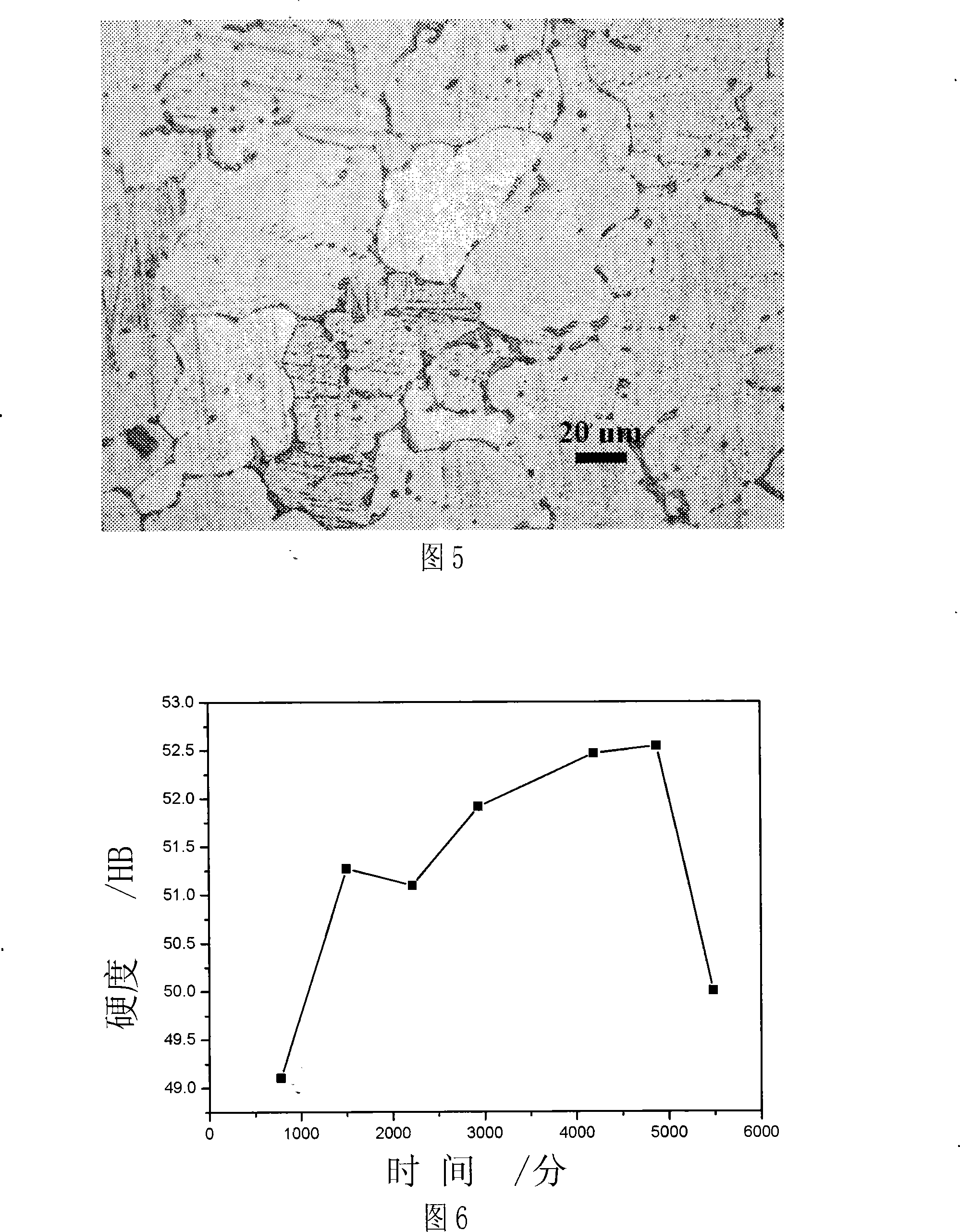

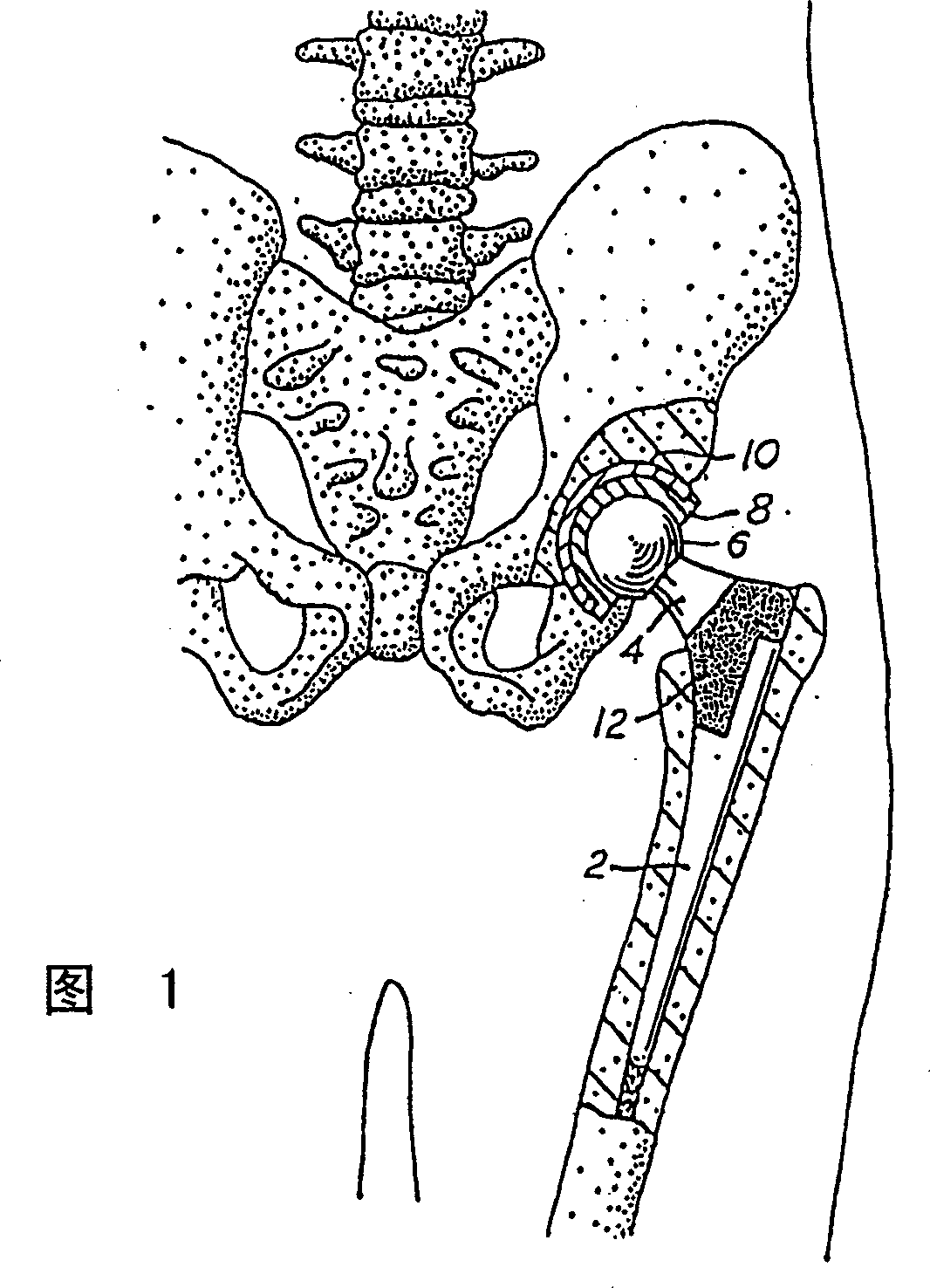

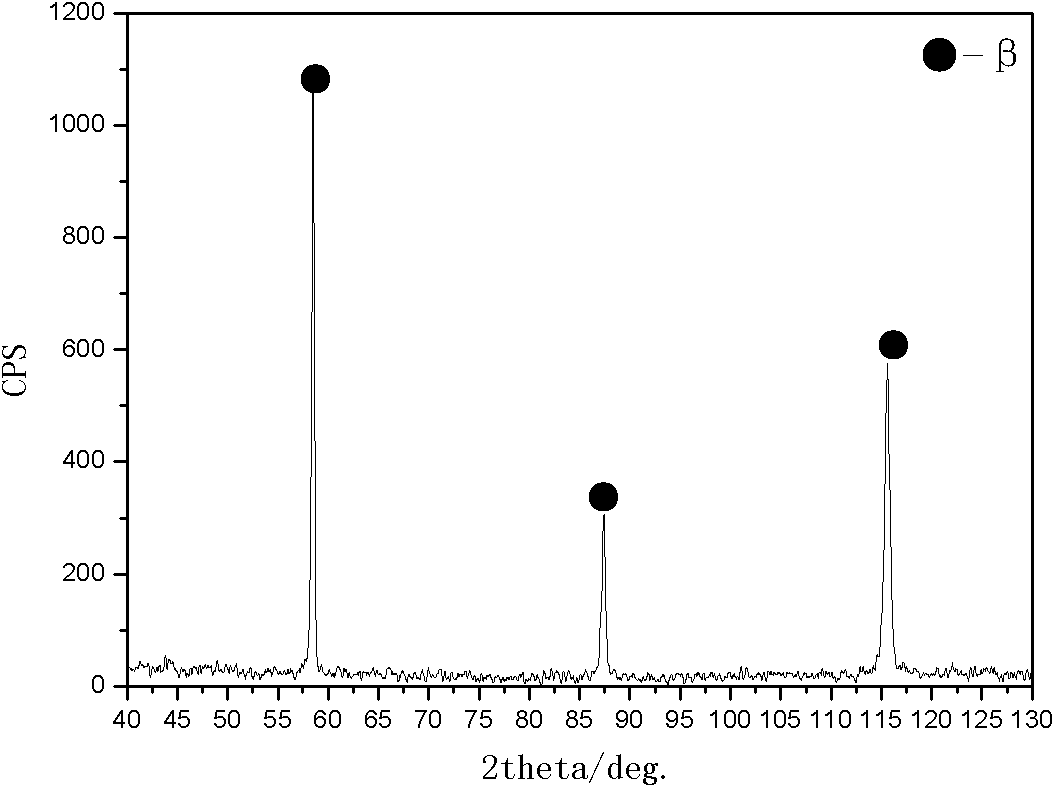

Beta type Ti Nb Zr alloy with low modulus of elasticity, preparation method and application

This invention discloses a beta-type Ti alloy with low elastic modulus for mrdical application. The Ti alloy comprises: Nb 30-37%, Zr 0-20%, and Ti. The cast structure of the Ti alloy is beta phase. The Ti alloy has moderate strength, and can satisfy the strength requirement for clinical bearing material. The elastic modulus of the Ti alloy is only 45-55% that of Ti-6Al-4V alloy. The alloy is a casting alloy, and has no noble metals added such as Ta, thus effectively lowering the cost. Besides, all the added elements have biocompatibility, and toxic elements are avoided. The Ti alloy has high biocompatibility and mechanical compatibility, and can be used to produce bone plates with reduced stress shielding effect.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Method for preparing magnesium alloy

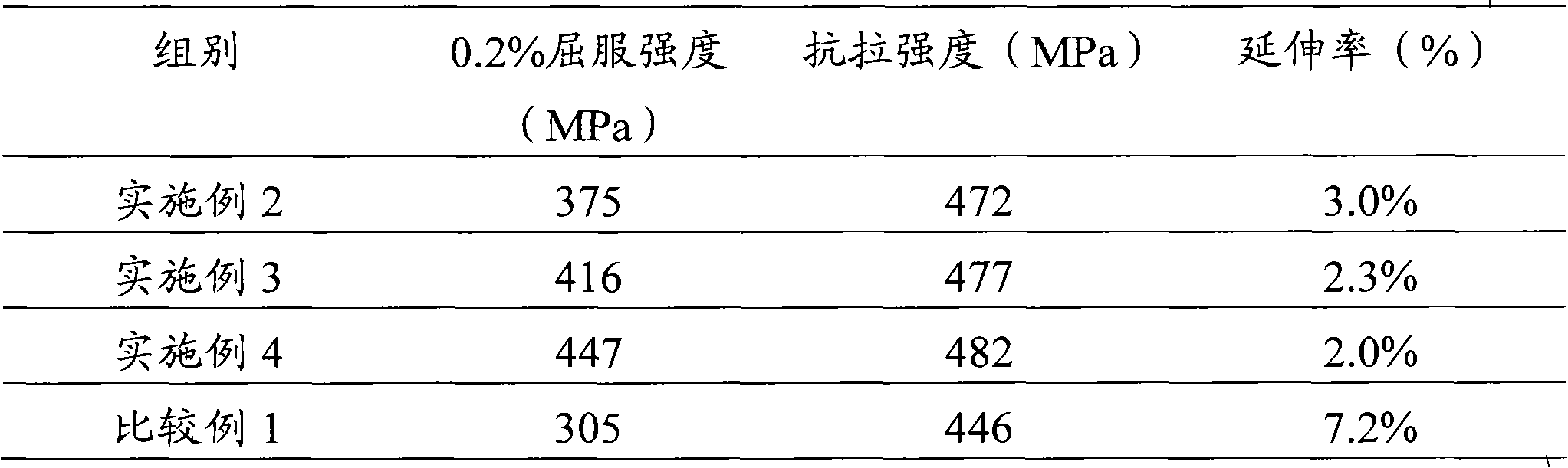

The invention provides a method for preparing a magnesium alloy. The method comprises the following: solution treatment process: heating a cast magnesium alloy to 350 to 550 DEG C and performing heat preservation treatment, wherein the cast magnesium alloy has the following atomic ratio composition: Mg1-a-bREaZrb, wherein RE is one or more of Y, Sc, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu; a is equal to or more than 1 percent and equal to or less than 6 percent; b is equal to or more than 0.05 percent and equal to or less than 0.5 percent; hot extrusion process, performing heat extrusion on the magnesium alloy subjected to the heat preservation treatment at the temperature of between 350 and 550 DEG C and then fast cooling the obtained product to the room temperature; cold rolling process, performing cold rolling on the magnesium alloy subjected to the heat extrusion at the rolling reduction of 5 to 50 percent; and ageing process, performing ageing treatment on the magnesium alloy subjected to the cold rolling. The yield strength of the prepared Mg-Gd-Zr alloy reaches 447MPa.

Owner:CHONGQING UNIV

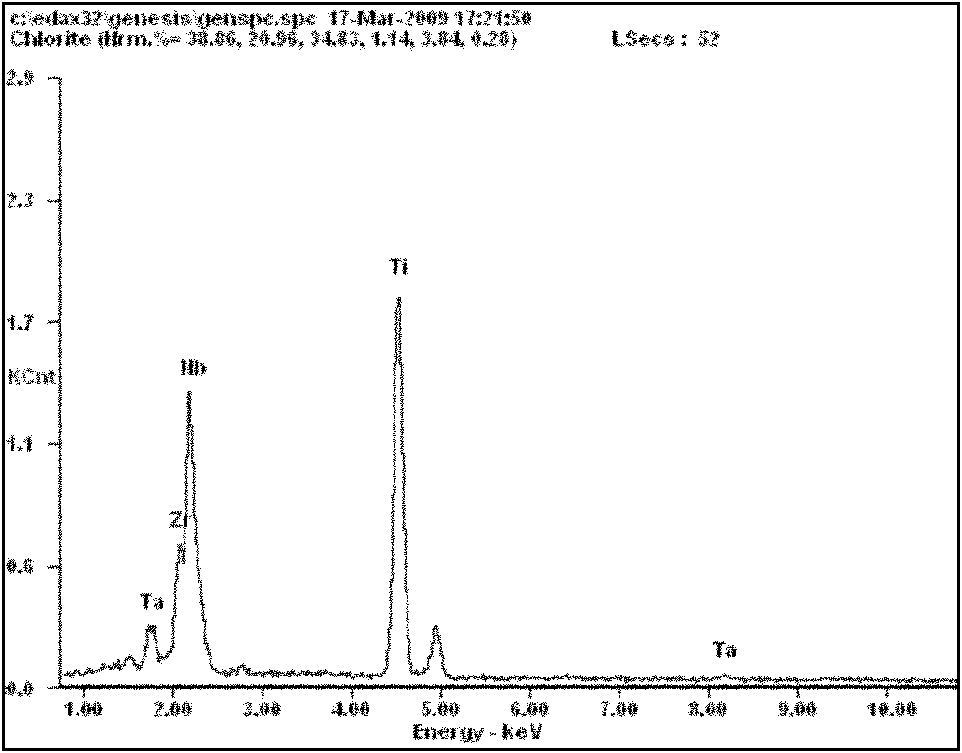

Low-elasticity high-strength near beta-type Ti-Nb-Ta-Zr alloy and preparation method of near beta-type Ti-Nb-Ta-Zr alloy

The invention discloses a low-elasticity high-strength modulus near beta-type Ti-Nb-Ta-Zr alloy. The near beta-type Ti-Nb-Ta-Zr alloy consists of the following components in percentage by weight: 28 to 32 percent of niobium, 4 to 5.5 percent of tantalum, 5 to 15 percent of zirconium and the balance of titanium. A preparation method comprises the following steps of: proportioning the components according to the proportion, and smelting the components into a button-shaped Ti-Nb-Ta-Zr cast ingot through a vacuum non-consumable arc furnace; thermally forging the button-shaped Ti-Nb-Ta-Zr cast ingot into a thin plate with size of 3mm*30mm*70mm; performing solution treatment on a linearly cut sample at the temperature of between 750 and 800 DEG C, and performing water quenching to obtain single-phase beta tissues; and performing ageing treatment on the solution treatment sample at the temperature of between 450 and 500 DEG C, and performing air cooling to obtain two-phase tissues of beta phase and dispersed alpha phase. The alloy can be widely applied to human hard tissue repair, replacement of medicinal materials and other medicinal devices.

Owner:SOUTHEAST UNIV

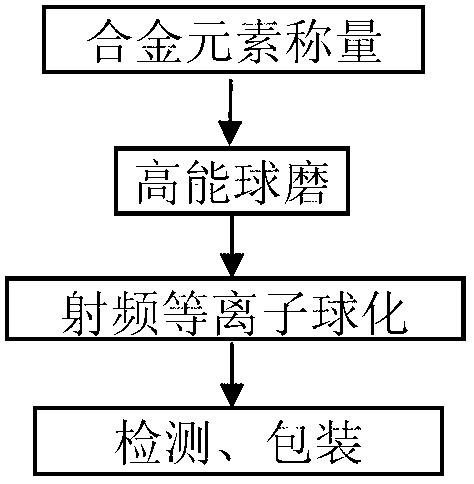

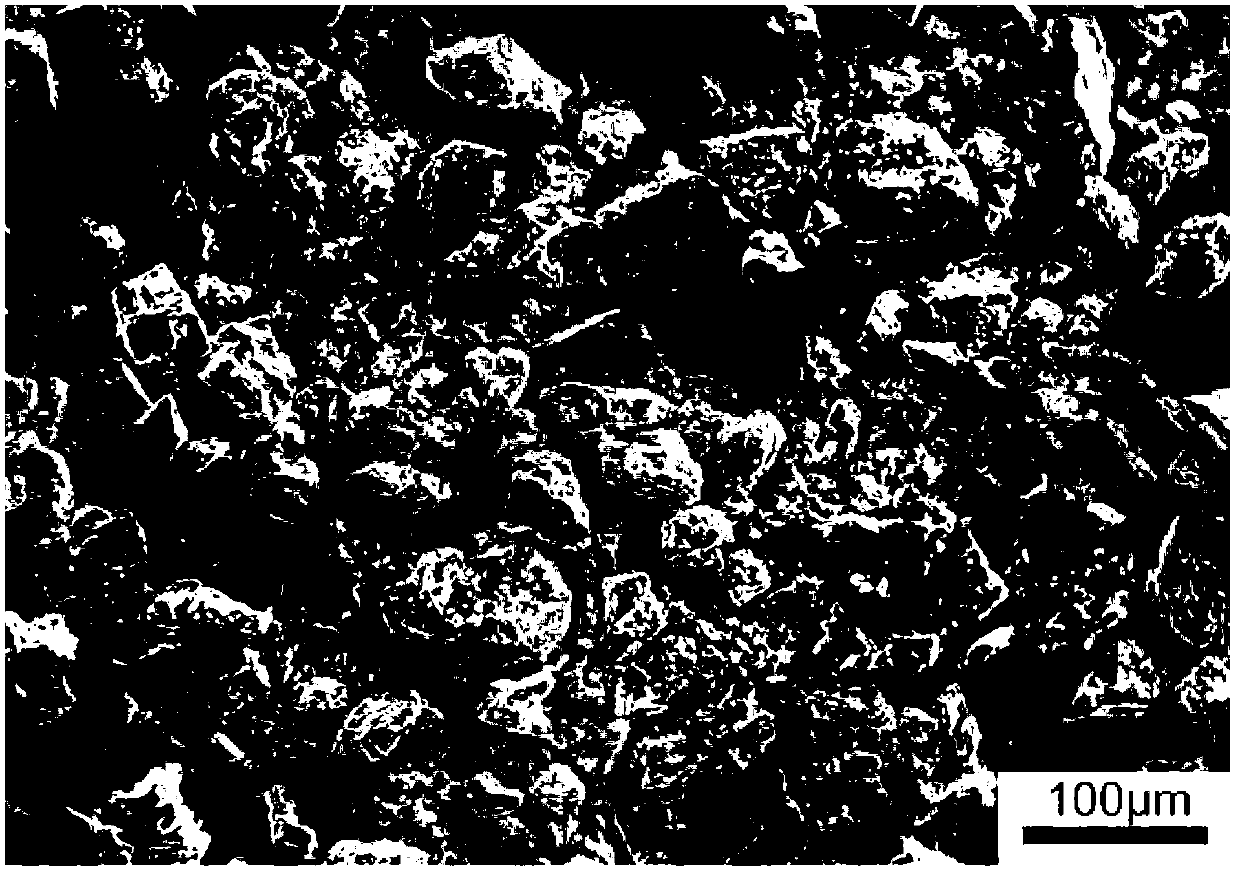

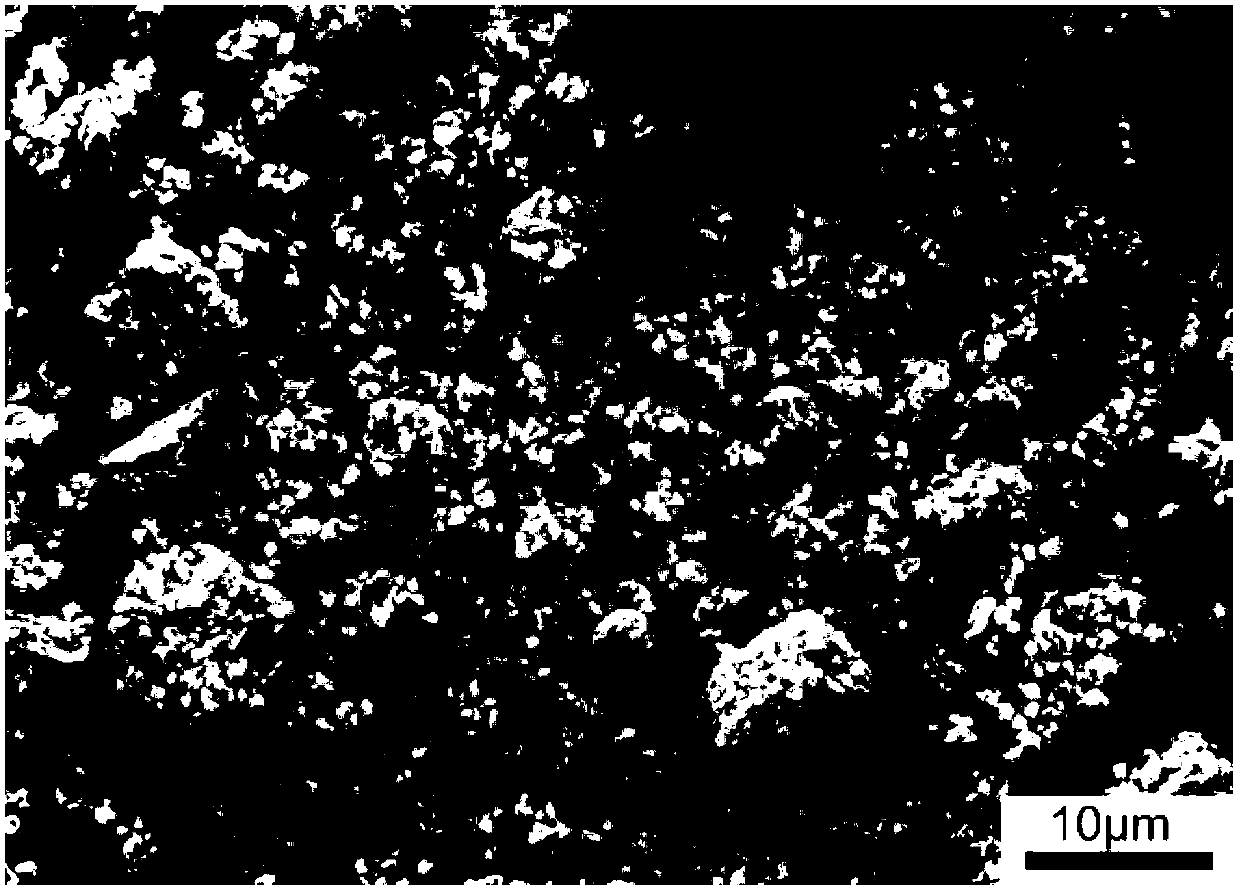

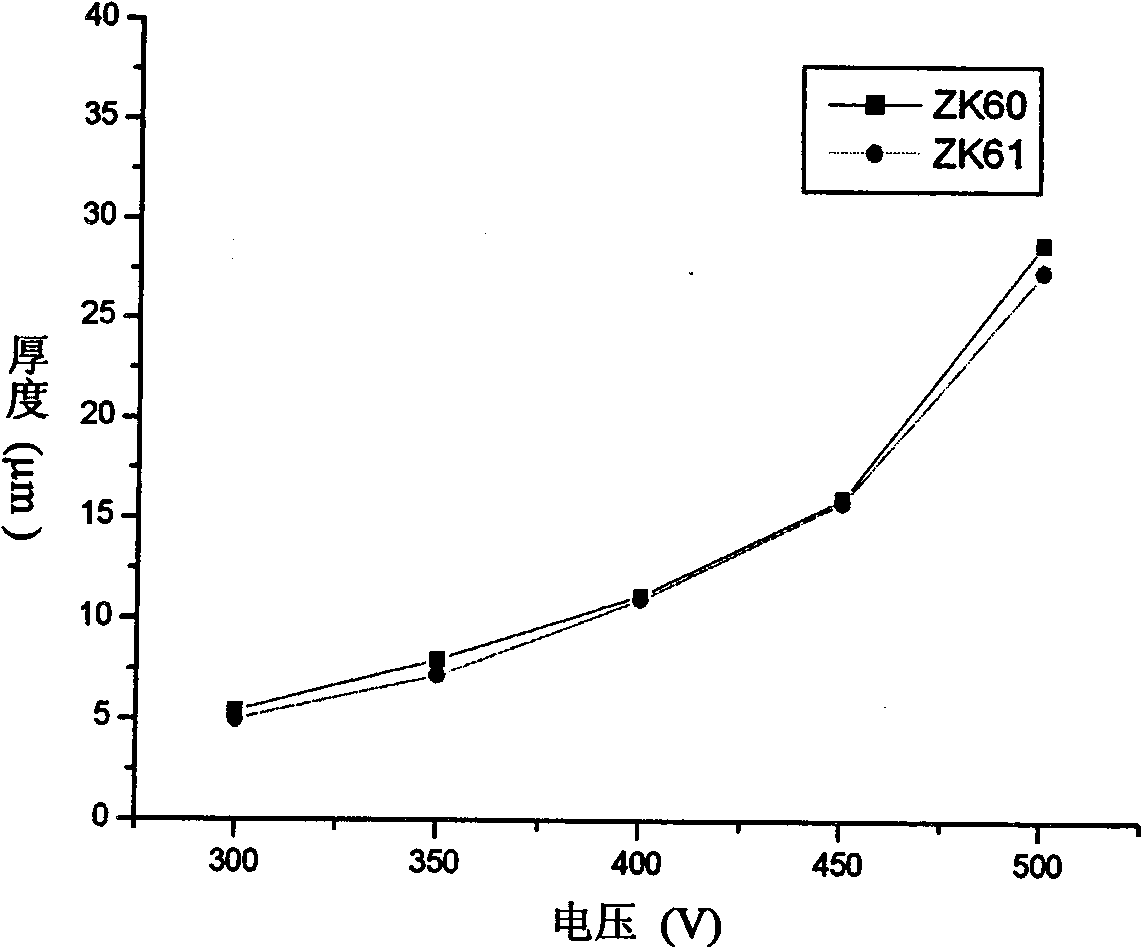

Method for preparing micro spherical niobium (Nb)-wolfram (W)-molybdenum (Mo)-zirconium (Zr) alloy powder

Owner:UNIV OF SCI & TECH BEIJING

High-strength and high-conductivity rare-earth copper alloy and preparation method thereof

The invention discloses a high-strength and high-conductivity rare-earth copper alloy and a preparation method of the high-strength and high-conductivity rare earth copper alloy. The high-strength and high-conductivity rare-earth copper alloy belongs to the technical field of an alloy material. Silver, phosphorus and a trace of rare-earth elements are added on the basis of a traditional Cu-Cr-Zr alloy. The copper alloy is prepared from the following components in percentage by weight: 0.2-1.0% of chrome, 0.1-0.4% of zirconium, 0.1-0.2% of silver, 0.02-0.03% of phosphorus, 0.02-0.16% of the rare-earth elements, and the balance of copper and inevitable impurity elements; the rare-earth elements are one or two or three of cerium, iridium and neodymium; a material is carried out processes such as hot forging, solid-solution treatment, cold rolling and aging treatment; prepared copper alloy has a good overall performance; tensile strength is greater than 550MPa; hardness is greater than 150HV; an elongation rate is greater than 10%; electric conductivity is greater than 80% IACS (International Annealed Copper Standard), and a softening temperature is greater than 450 DEG C. A requirement of the material for an electronic industrial field on the performance of the copper alloy can be better met; the high-strength and high-conductivity rare-earth copper alloy can be used for a lead frame material for a large-scale integrated circuit, a contact line of an electric car or an electric locomotive, an electrode alloy connector and the like.

Owner:HENAN UNIV OF SCI & TECH

Mg-gd-y-zn-zr alloy and process for preparing the same

A Mg—Gd—Y—Zn—Zr alloy with high strength and toughness, corrosion resistance and anti-flammability and a process for preparation thereof are disclosed. The components and the mass percentages thereof in the Mg—Gd—Y—Zn—Zr alloy are: 3.0%≤Gd≤9.0%, 1.0%≤Y≤6.0%, 0.5%≤Zn≤3.0%, 0.2%≤Zr≤1.5%, the balance being Mg and inevitable impurities. The process for preparation thereof comprises: adding pure Mg into a smelting furnace for heating, then introducing mixed gases of CO2 and SF6 into the furnace for protection; adding other raw materials in sequence when the pure Mg is completely melted; preparing an ingot; conducting a homogenization treatment on the ingot prior to extrusion; conducting an aging treatment on the extruded alloy. A wrought magnesium alloy having superior overall performances and good fracture toughness, corrosion resistance and anti-flammability, with a small amount of rare earth element is obtained by adjusting the proportion of the alloy elements and by conventional casting, extrusion and heat treatment processes. The cost of the alloy is reduced while the strength of the alloy is maintained.

Owner:THE BOEING CO

Magnesium base degradable implant material and preparation method thereof

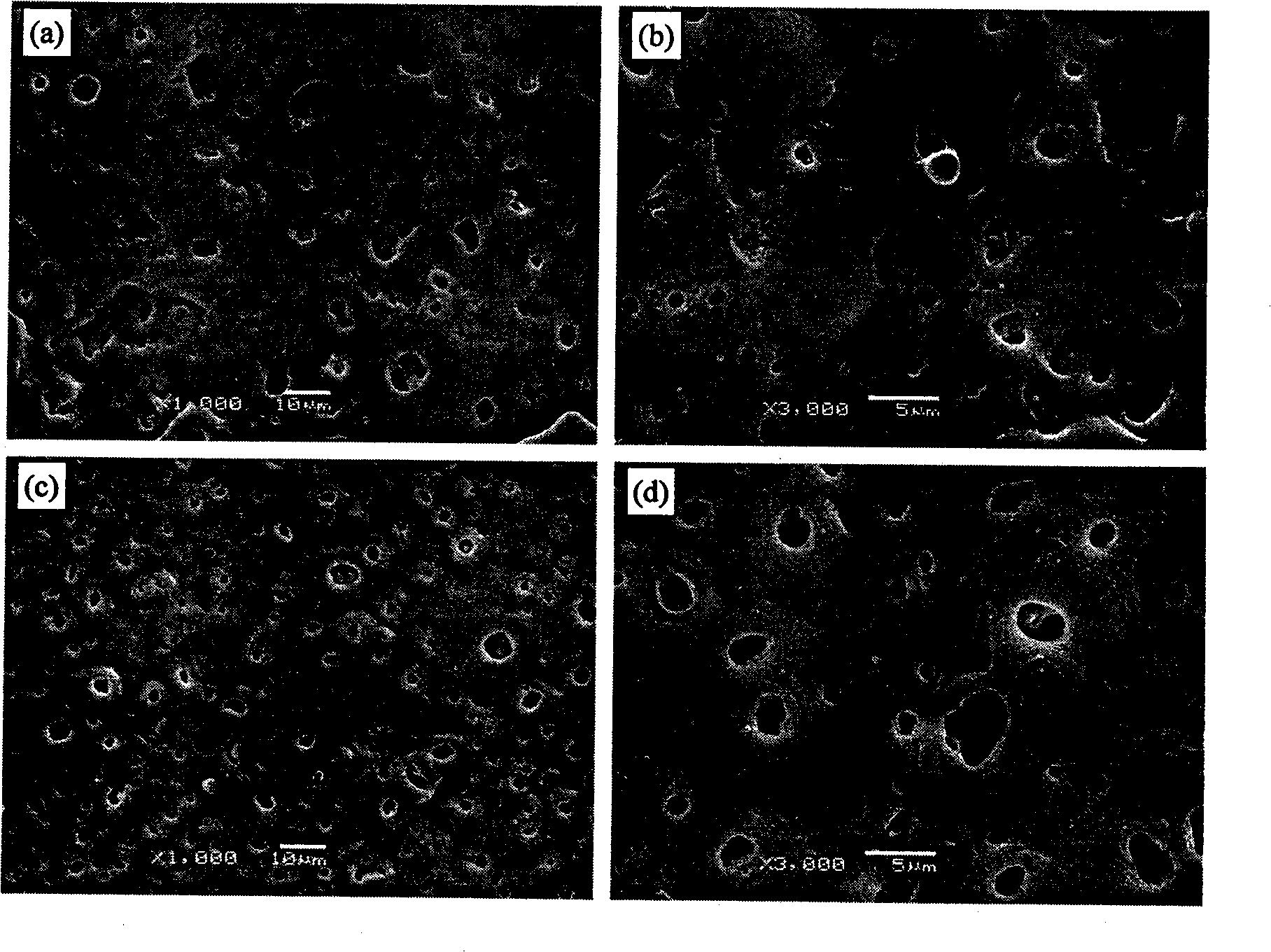

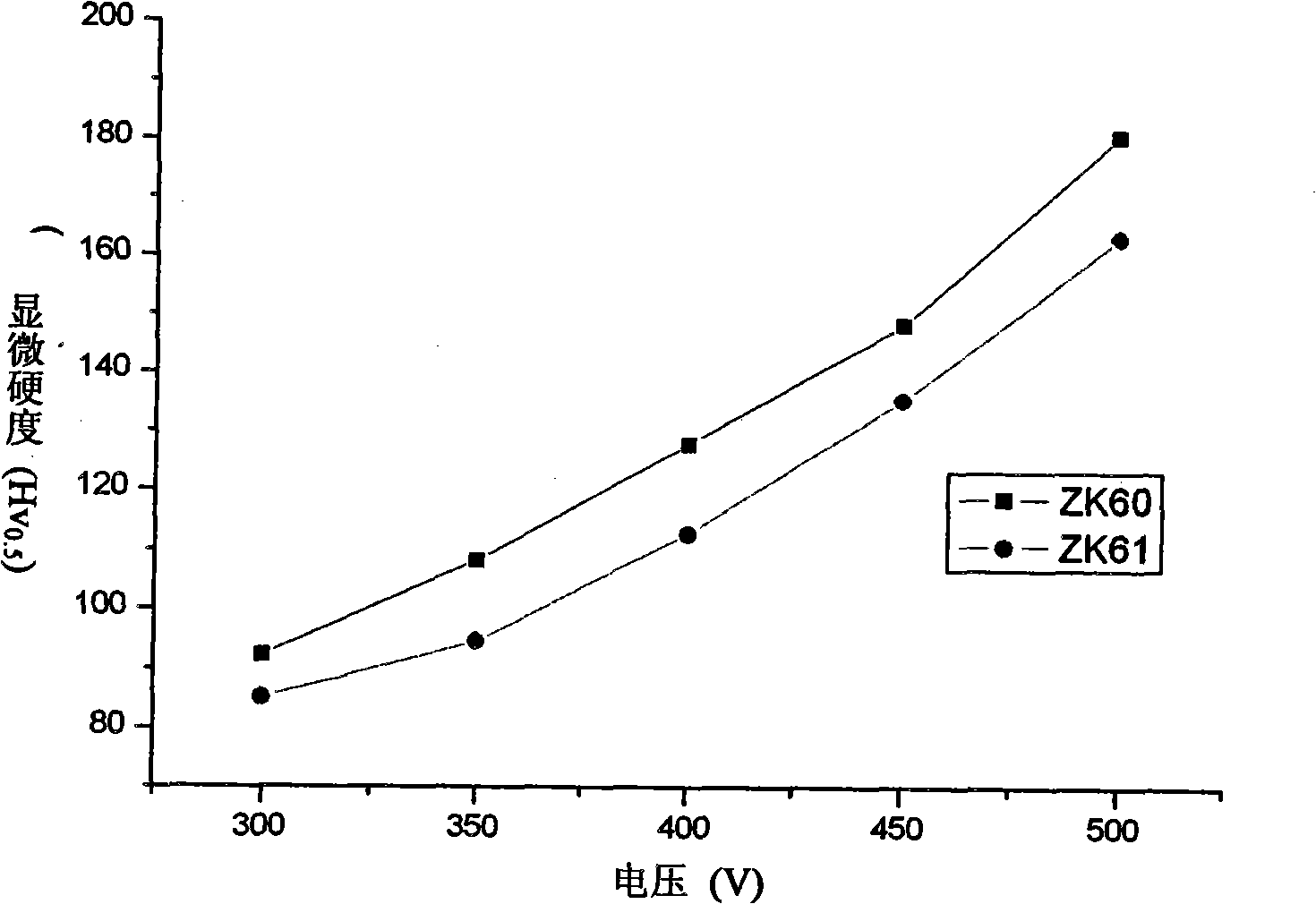

InactiveCN101559239AImprove biological activityIncreased microhardnessAnodisationProsthesisMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a magnesium base degradable implant material, belonging to the technical field of biological materials. The implant material is composed of Mg-Zn-Zr alloy matrix and micro-arc oxidation coating; the micro-arc oxidation coating is formed by micro-arc oxidation treatment by electrolyte formed by solving the sodium silicate, potassium hydroxide, potassium fluoride, soluble phosphate and trolamine in pure water; each liter of electrolyte contains 12-18g of sodium silicate, 3-8g of potassium hydroxide, 2-7g of potassium fluoride, 5-20g of soluble phosphate and 5-10ml of trolamine. The implant material has not only high micro hardness but also excellent decay resistance; and after dipping in simulated body fluid, the surface has phosphorite deposition, which shows that the material has certain biological activity.

Owner:SHANDONG UNIV

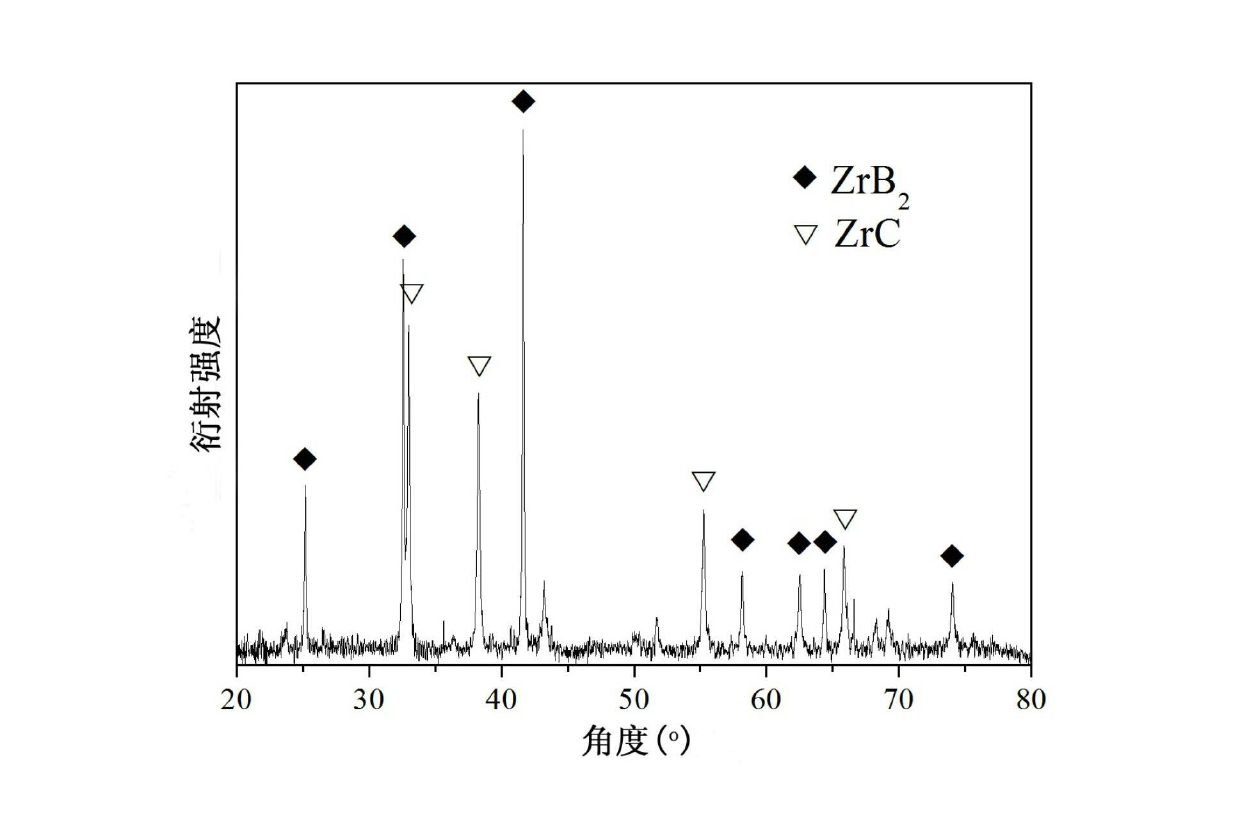

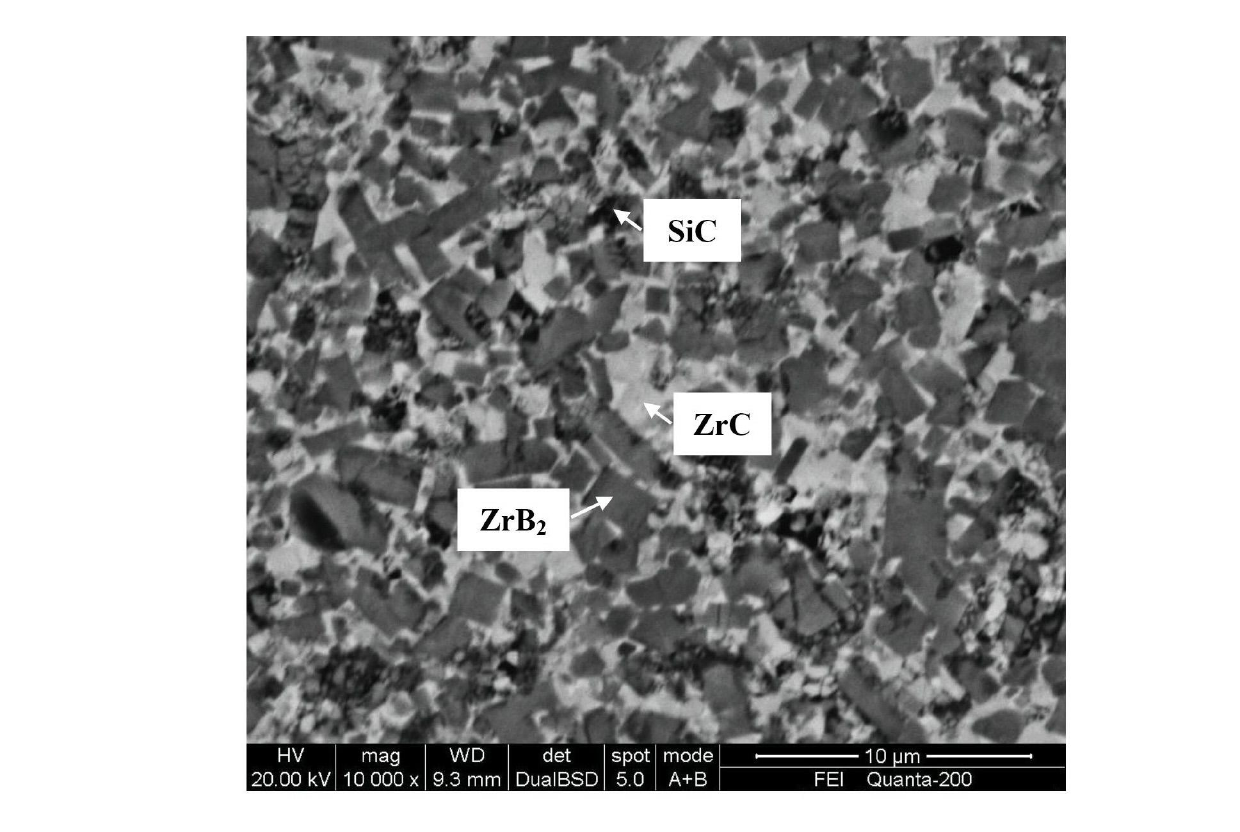

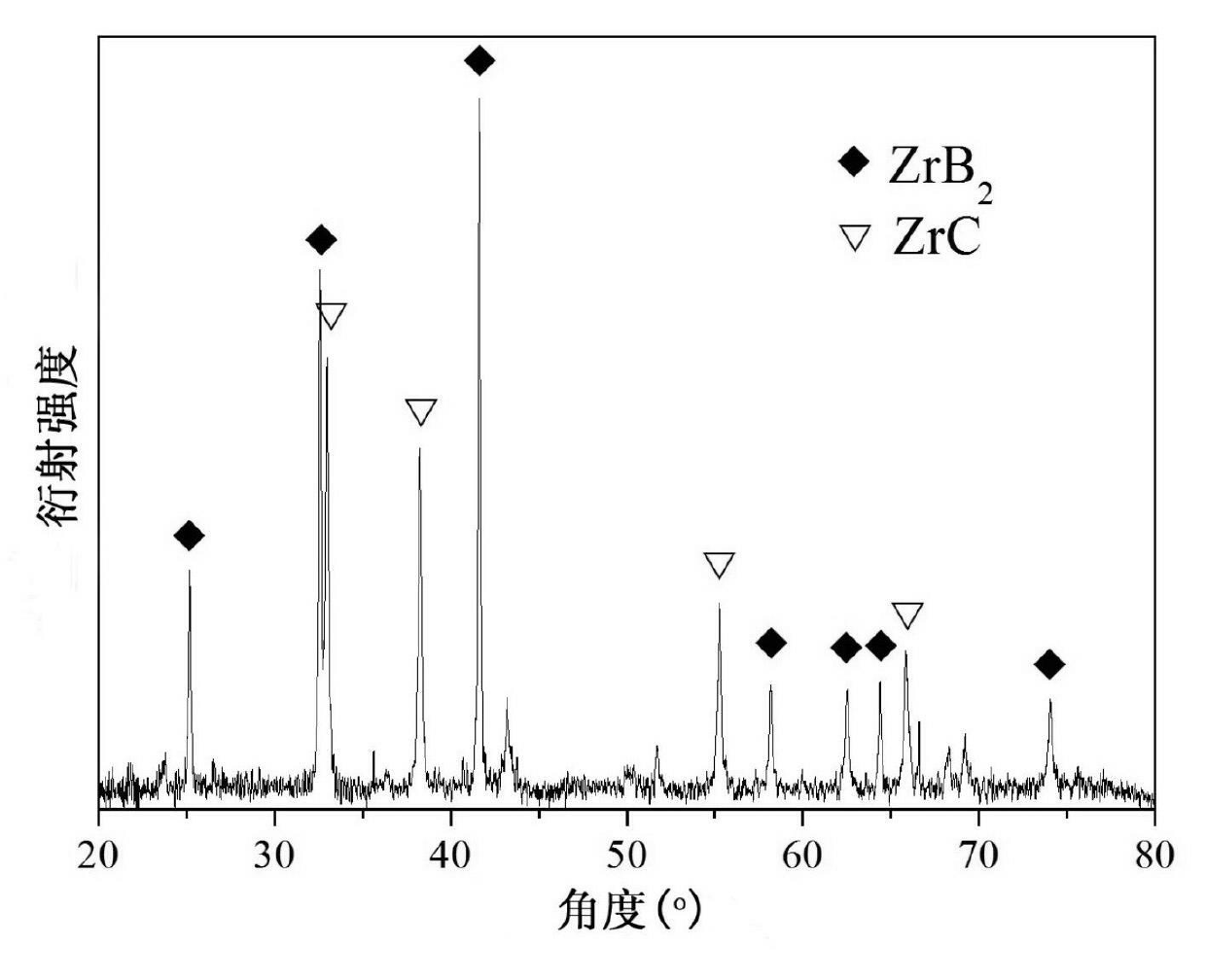

Preparation method of ZrB2-ZrC-based ultrahigh-temperature-resistant ceramic

The invention discloses a preparation method of ZrB2-ZrC-based ultrahigh-temperature-resistant ceramic. The preparation method comprises the following process steps of: weighing raw materials, mixing by ball milling, and performing die pressing or crosslinking molding to obtain a green body; performing high-temperature cracking and heat preserving on the green body to obtain a porous rigid prefabricated body; undergoing an infiltration reaction by taking the porous rigid prefabricated body as a substrate and taking a zirconium-containing alloy as an infiltration agent to obtain semi-finished ZrB2-ZrC-based ultrahigh-temperature-resistant ceramic; and embedding the semi-finished ZrB2-ZrC-based ultrahigh-temperature-resistant ceramic with B4C powder or SiC powder and performing high-temperature treatment to obtain the ZrB2-ZrC-based ultrahigh-temperature-resistant ceramic. The process of the invention has the advantages of low preparation temperature and low cost. By adopting the preparation method, a ceramic product with high density, high mechanical property and high temperature resistance can be obtained.

Owner:NAT UNIV OF DEFENSE TECH

Degradable magnesium alloy plate and bar for fracture internal fixation and preparation methods thereof

InactiveCN104630587AReduce the chance of infectionGood biocompatibilitySurgeryFernicoPhysical chemistry

The invention relates to a degradable magnesium alloy plate and a bar for fracture internal fixation. The degradable magnesium alloy plate and bar are prepared by adding one or two of Sr, Ca and Ag based on a Mg-Zn-Zr alloy, wherein the degradable magnesium alloy plate comprises the following components in percentage by mass: 3.0wt% of Zn, 0.5wt% of Zr, 0.0-1.0 wt% of Ca, 0.0-1.0wt% of Ag, 0.0-1.5wt% of Sr, and the balance of Mg, wherein the content of each of iron, nickel, copper, aluminum single impurity element is less than 0.05% and the total amount of the impurities is not more than0.4%. The degradable magnesium alloy plate and the bar have the advantages of high purity, good uniformity composition and microstructure and higher strength and corrosion resistance; the contained elements such as calcium and strontium can promote bone growth so that the alloy has better biocompatibility; the silver element is added so as to improve antibacterial property of an implant; and the degradable magnesium alloy plate and the bar is suitable for being applied in fracture fixation materials.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Preparation method of Cu-Cr-Zr alloy contact wire

ActiveCN105039883AImprove performanceReduce segregationCable/conductor manufactureStructure propertyUltimate tensile strength

The invention discloses a preparation method of a Cu-Cr-Zr alloy contact wire, and belongs to the technical field of copper alloy processing and preparation. The contact wire with a cross section area of 110 to 150 mm2 is prepared through steps of melting, spray deposition and continuous extrusion, planetary rolling, aging, and drawing. In the provided method, the product structure property and overall dimension can be controlled in one technology. The Cu-Cr-Zr alloy contact wire prepared by the spray deposition and continuous extrusion method has the advantages of high strength, good conductivity, and excellent high temperature softening resistant property. The preparation method has the advantages that the process flow is short, the material utilization rate is high, the product performance can be guaranteed, at the same time, the production cost is reduced, the contact wire can be made into any length in theory, and the contact wire is suitable for industrial application.

Owner:北京兴荣源科技有限公司

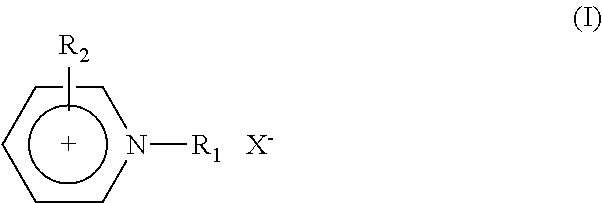

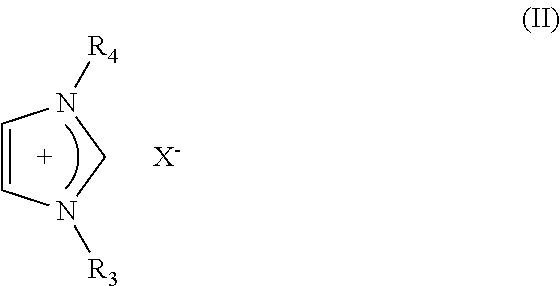

Electric Al-Zr Alloy Plating Bath Using Room Temperature Molten Salt Bath and Plating Method Using the Same

InactiveUS20100285322A1Improve corrosion resistanceImprove powerThin material handlingMetal layered productsOrganic solventRoom temperature

Disclosed is an electric Al—Zr alloy plating bath containing an aluminum halide (A), one or more compounds (B) selected from the group consisting of N-alkylpyridinium halides, N-alkylimidazolium halides, N,N′-alkylimidazolium halides, N-alkylpyrazolium halides and N,N′-alkylpyrazolium halides, and a zirconium halide (C). The molar ratio between the aluminum halide (A) and the compounds (B) is from 1:1 to 3:1. The electric Al—Zr alloy plating bath further contains an aromatic organic solvent (D), an organic polymer (E) and one or more additives (F) selected from brightening agents.

Owner:DISPOL CHEMICALS CO LTD +1

Degradable Mg-Zn-Zr alloy endovascular stent and comprehensive processing technique thereof

InactiveCN101485900AMeet the requirements of mechanical support timeReasonable degradation rateStentsMetallic material coating processesBiocompatibility TestingIn vivo

The invention relates to technology for processing and treating endovascular stent materials, in particular to heat treatment and surface hydrofluoric acid treatment technology for biodegradable Mg-Zn-Zr alloy endovascular stents, wherein the homogenizing temperature is between 400 and 450 DEG C, and the homogenizing time is between 20 and 24 hours; the hot extrusion ratio is between 40 and 60; the forming temperature of capillary tubes is between 150 and 200 DEG C, and flower patterns of the tube wall are engraved by laser; the temperature of time effect treatment technology is between 150 and 200 DEG C, and the time is between 18 and 24 hours; and the surface treatment technology comprises that: the concentration of hydrofluoric acid is between 10 and 40 percent, the treatment temperature is between 20 and 60 DEG C, and the treatment time is between 12 and 24 hours. The comprehensive treatment technology not only can guarantee to process the alloys into clinically required endovascular stents but also can guarantee that the endovascular stents have reasonable degradation rate and good biocompatibility in a biological in vivo blood environment, particularly can guarantee the corrosion rate of thickness regulation and control alloys of surface MF2 layers after hydrofluoric acid treatment, makes the degradation rate of the stents be between 0.1 and 0.2 mm / yr, and meets the requirement on the mechanical supporting time of the endovascular stents in treatment.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

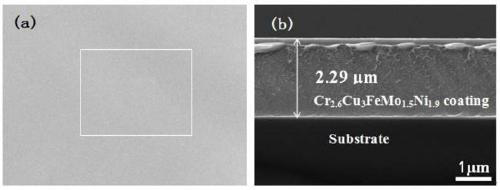

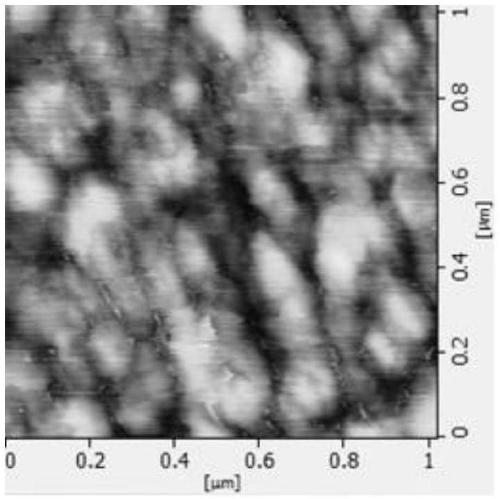

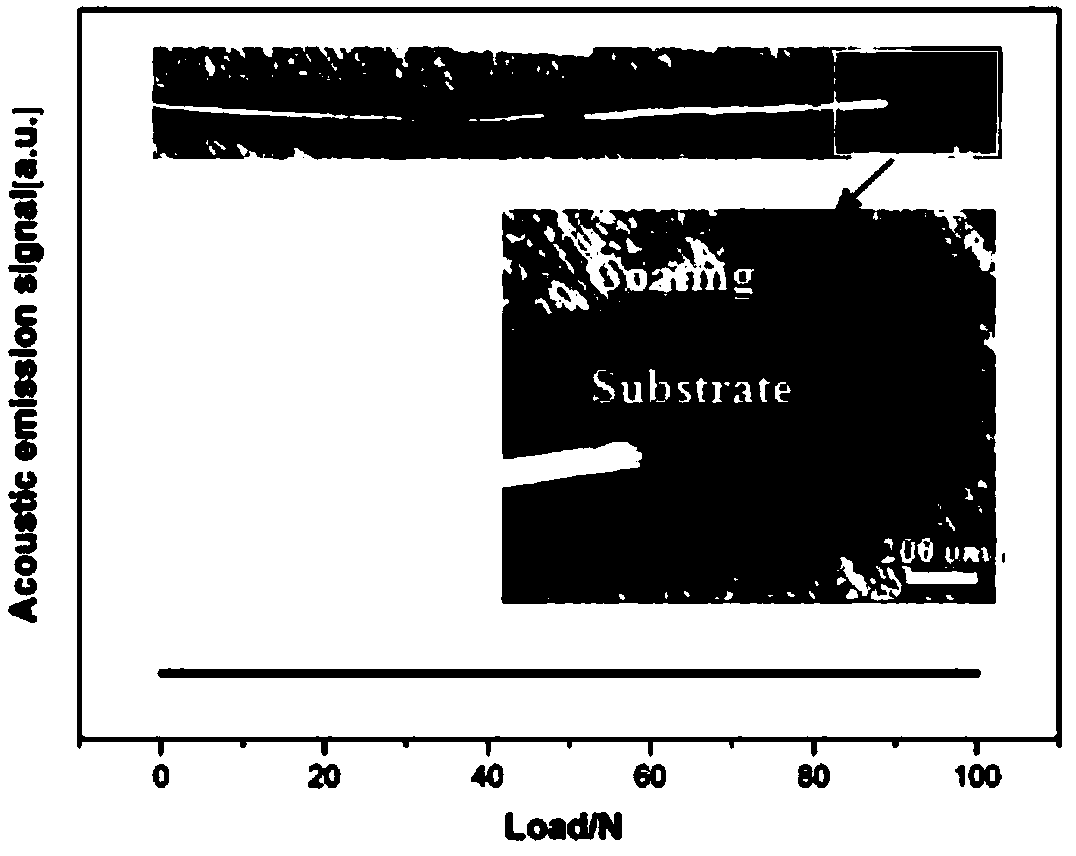

Nuclear zirconium alloy cladding surface high temperature and corrosion resisting high-entropy alloy coating and preparing method thereof

ActiveCN109666911AHigh hardnessImprove high temperature resistanceVacuum evaporation coatingSputtering coatingFault toleranceSputtering

The invention discloses a nuclear zirconium alloy cladding surface high temperature and corrosion resisting high-entropy alloy coating and a preparing method thereof. The high-entropy alloy coating deposited on the surface of a Zr alloy is a CrCuFeMoNi high-entropy alloy, and according to the atomic percents of Cr, Cu, Fe, Mo and Ni in the high-entropy alloy, Cr is 25%-35%, Cu is 20%-30%, Fe is 10%-14%, Mo is 15%-20%, and Ni is 15%-20%. The high-entropy alloy coating is deposited on the surface of the Zr alloy through the multi-target magnetron sputtering technology. According to the CrCuFeMoNi high-entropy alloy coating, the surface hardness of the Zr alloy is improved, corrosion resistance and radiation resistance are improved, good high-temperature resisting performance and corrosion resisting performance are shown, the actual engineering application can be achieved, and the CrCuFeMoNi high-entropy alloy coating is the potential alternative material for accident fault tolerance fuelcladding coatings. The adopted multi-target magnetron sputtering technology is mature, operation is simple, industrial production of the nuclear zirconium alloy cladding surface high temperature andcorrosion resisting high-entropy alloy coating to the engineering field can be achieved, and good development prospects are achieved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

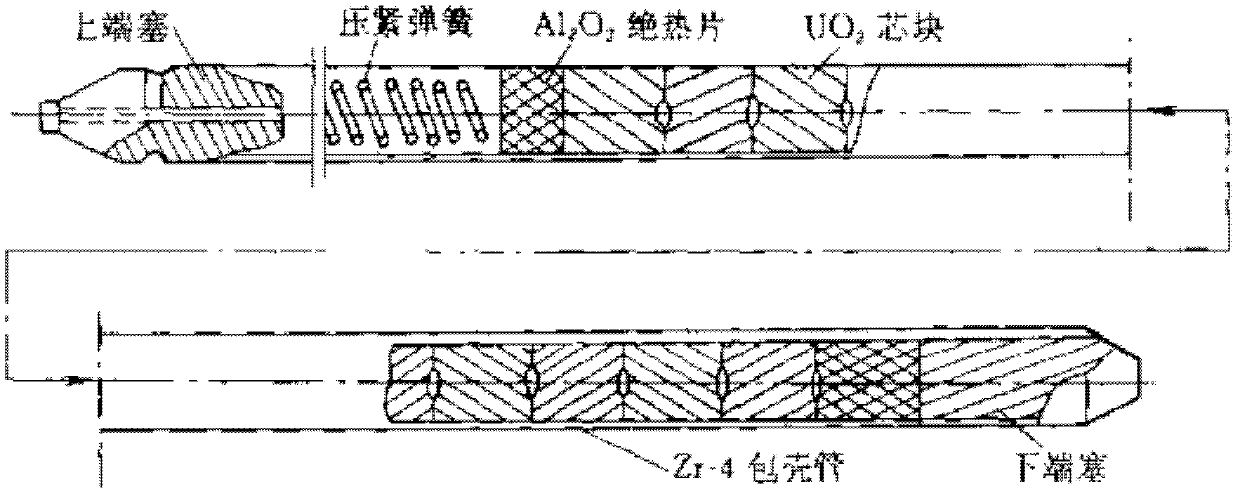

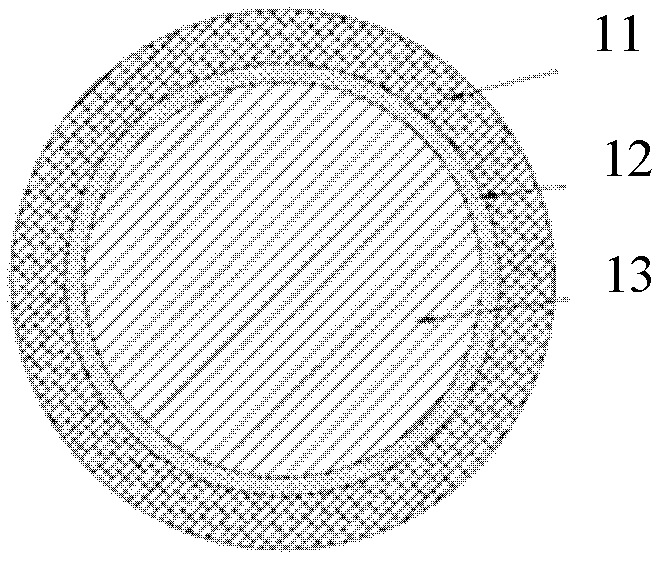

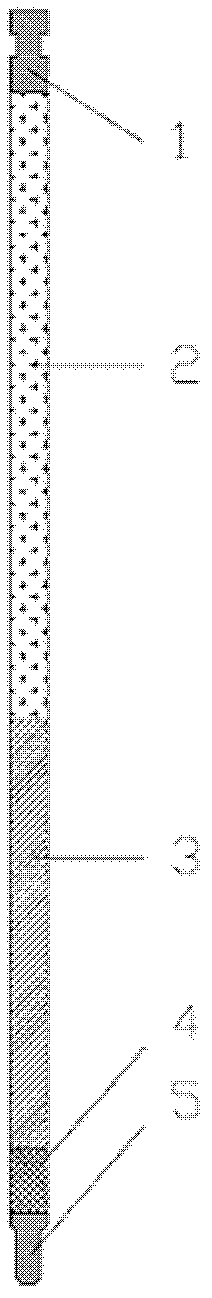

Nuclear fuel rod with ceramic cladding and metallic pellet

ActiveCN103295652AImprove mechanical propertiesReduce breakageOptical rangefindersNuclear energy generationHeat conductingComposite ceramic

The invention aims at providing a nuclear fuel rod with ceramic cladding and metallic pellet. The nuclear fuel rod with ceramic cladding and metallic pellet has the advantages that the heat-conducting property of the nuclear fuel rod can be improved, the central temperature of the fuel pellet is lowered or the fuel power density is effectively improved, the fuel rod cladding mechanical property, corrosion resistance and radiation resistance are greatly improved, the breakage rate of the fuel rod is lowered, the discharge burnup of the fuel rod is remarkably increased and the fuel utilization rate is greatly improved; meanwhile, the fuel rod has good neutronics performance, and can be widely used in a fast reactor or a thermal reactor. The cladding of the nuclear fuel rod provided by the invention is a SiCf / SiC composite ceramic material cladding, the metallic fuel pellet adopts a U-Zr or U-Pu-Zr alloy fuel pellet; a gap between the cladding and the fuel pellet is filled with low-melting-point metal; and a lengthened air cavity is designed at the upper part of the fuel rod.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

Wrought magnesium alloys in high intensity, high plasticity, and preparation method

This invention discloses a method for preparing Mg alloy with high strength and high plastic deformation. The compositions of the Mg alloy are: Zn 4.5-5.5 wt.%, Ce 0.5-2.5 wt.%, Ti 0.01-0.20 wt.%, Si less than or equal to 0.08 wt.%, Fe less than or equal to 0.01 wt.%, Cu less than or equal to 0.01 wt.%, Ni less than or equal to 0.002 wt.%, impurities less than or equal to 0.05 wt.%, and Mg as balance. The method adds rare earth element Ce to Mg-Zn-Zr alloy, and replaces Zr with Ti, thus can refine the alloy grains. Besides, Mg forms a dispersed reinforcing phase, which can effectively improve the comprehensive properties of the Mg alloy. The surface quality of the extruded product of the Mg alloy is obviously improved when compared with ZK series deformed Mg alloys. The average tensile strength, yield strength and elongation at breakage of the Mg alloy at room temperature are 360 MPa, 245 MPa and 7%, respectively. The average tensile strength and elongation at breakage of the Mg alloy at 150 deg.C are 250 MPa and 11%, respectively.

Owner:NANJING YUNHAI SPECIAL METALS CO LTD

High-temperature-resistant ceramic-based composite member and connecting method thereof

The invention relates to a high-temperature-resistant ceramic-based composite member and a connecting method thereof. The method comprises the following steps: (1) uniformly mixing silicon powder, chopped carbon fibers, an organic dispersing agent and a phenolic resin to obtain mixed slurry; (2) coating a joint face of a first to-be-connected prefabricated member and / or a second to-be-connected prefabricated member with the mixed slurry, and laminating and connecting the joint face of the first to-be-connected prefabricated member and the second to-be-connected prefabricated member so as to obtain a pre-connecting piece, wherein the first to-be-connected prefabricated member and / or the second to-be-connected prefabricated member are / is made from fiber preforms; (3) at least impregnating the joint of the pre-connecting piece with the mixed slurry, and sequentially curing and splitting the impregnated pre-connecting piece so as to obtain a pre-connected member; and (4) carrying out a silicon-zirconium alloy infiltration reaction on the pre-connected member, thereby obtaining the high-temperature-resistant ceramic-based composite member. The method disclosed by the invention has the advantages of being simple in process, capable of obviously enhancing the member connection strength and enabling the overall member to be high-temperature-resistant, and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

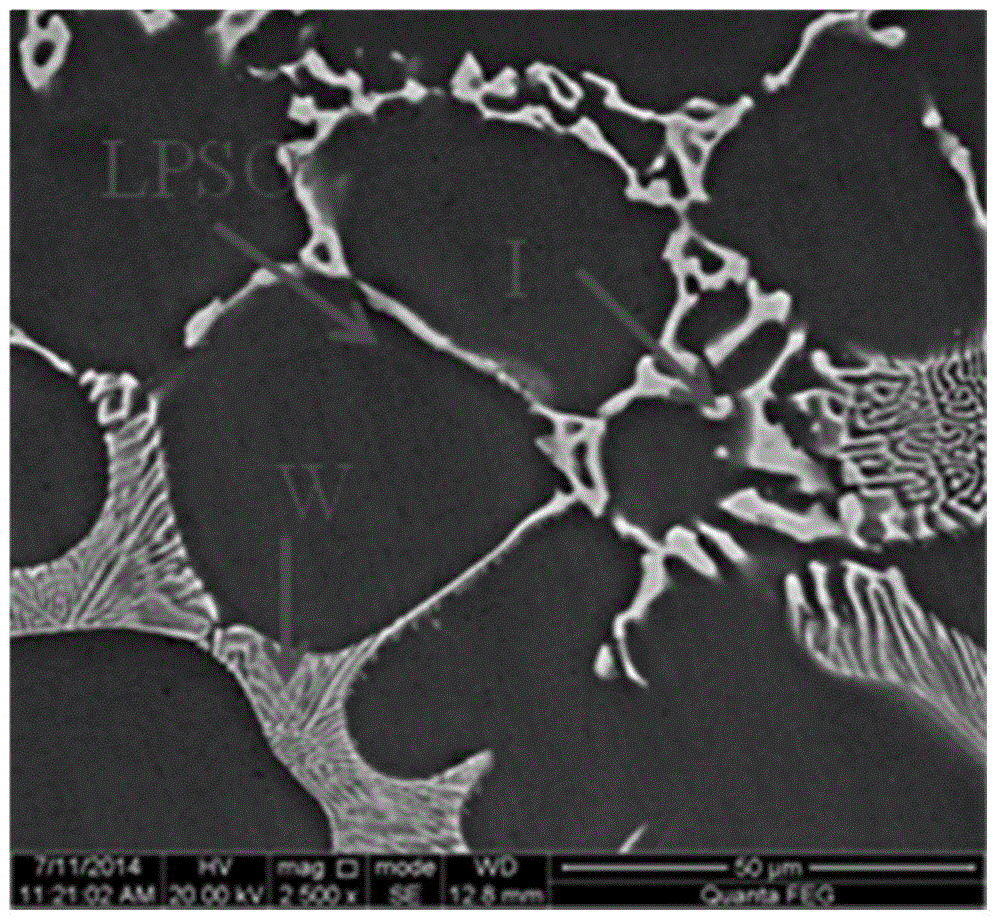

High-intensity high-toughness Mg-Zn-Y-Gd-Zr alloy and preparation method thereof

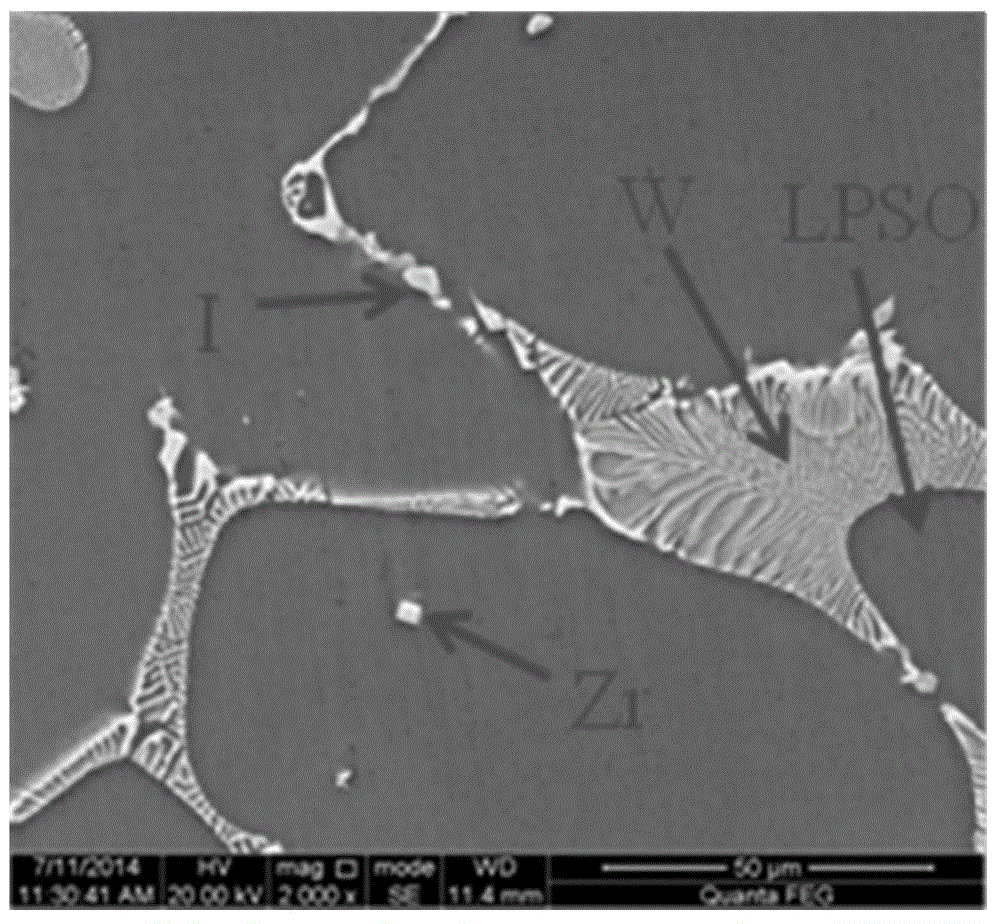

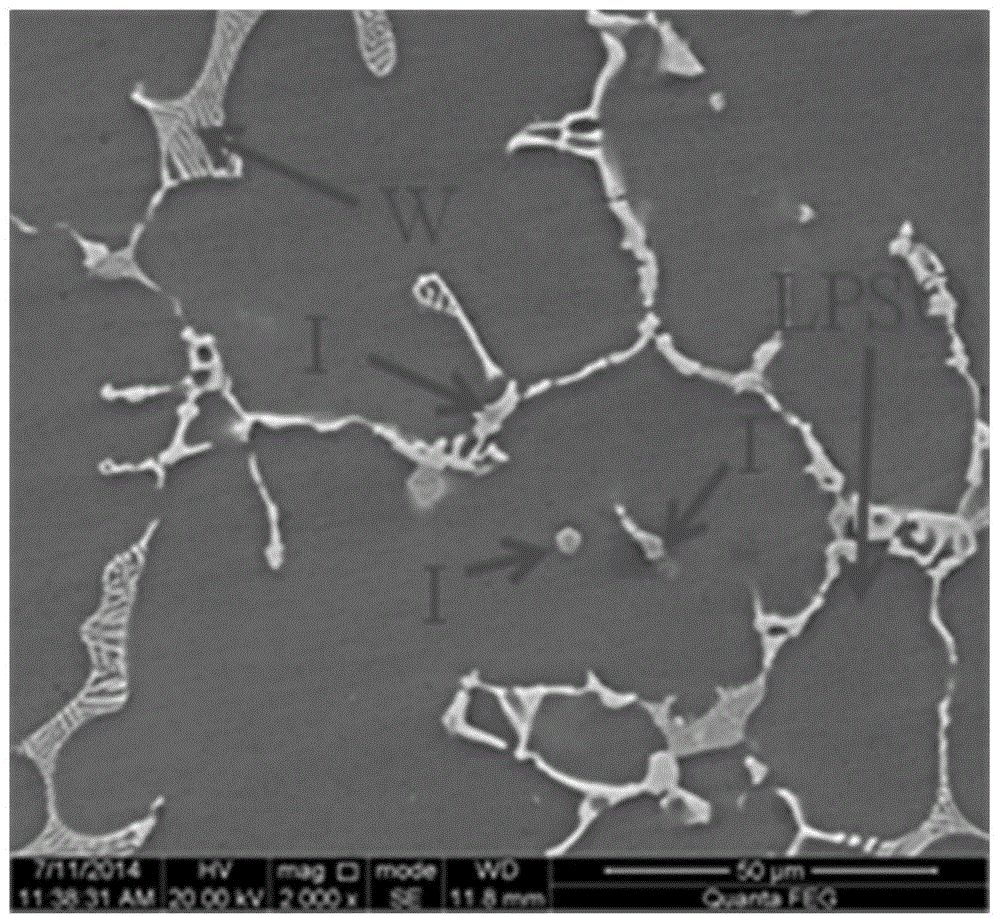

The invention discloses a high-intensity high-toughness Mg-Zn-Y-Gd-Zr alloy and a preparation method thereof and relates to an alloy and a preparation method thereof. The invention aims to solve the technical problem of high rare earth content in an alloy prepared by an existing method. The alloy disclosed by the invention consists of Zn, Y, Gd, Zr and Mg. The preparation method comprises the following steps: weighing raw materials, adding pure magnesium into a crucible, heating the crucible and then filling mixed gas of CO2 and SF6 into the crucible to carry out protection; after the pure magnesium is completely molten, sequentially adding other raw materials; preparing a cast ingot; homogenizing and extruding the cast ingot, carrying out heat preservation at an aging temperature and cooling to obtain the high-intensity high-toughness Mg-Zn-Y-Gd-Zr alloy. The total rare earth content of the high-intensity high-toughness Mg-Zn-Y-Gd-Zr alloy is lower than 6 weight percent; by improving zinc content and a Zn / RE atomic ratio, a stable quasicrystalline phase and a long-period ordered structural phase (LPSO) are obtained; tensile intensity of the alloy disclosed by the invention is higher than 500MPa; elongation of the alloy disclosed by the invention is greater than 5 percent. The invention belongs to the field of preparation of alloys.

Owner:HARBIN INST OF TECH

Body-centered cubic (BCC) Zr-Ti-Mo-Sn-Nb alloy with low modulus and low magnetic susceptibility

The invention discloses a body-centered cubic (BCC) Zr-Ti-Mo-Sn-Nb alloy with low modulus and low magnetic susceptibility, and the BCC Zr-Ti-Mo-Sn-Nb alloy belongs to the technical field of new materials. The BCC Zr-Ti-Mo-Sn-Nb alloy is characterized by comprising the following elements in percentage by weight: Zr-(0-3.3%)Ti-(0-6.5%)Mo-(0-7.1%) Sn-(6.3-17.2%)Nb. The alloy has the material performances that the elastic modulus E=77-91 GPa, the magnetic susceptibility chig=2.12-3.01cm<3>g<-1>, and the hardness HV=243-311kgf.mm<-2>. The alloy has the effects and benefits that the BCC Zr-Ti-Mo-Sn-Nb alloy with low elastic modulus and low magnetic susceptibility is obtained on the basis that a Zr alloy has a single-phase BCC structure; the constituent elements of the BCC Zr-Ti-Mo-Sn-Nb alloy are reasonably added, and the BCC Zr-Ti-Mo-Sn-Nb alloy has ensured excellent alloy performances and is a low-cost alloy material; and the constituent elements of the BCC Zr-Ti-Mo-Sn-Nb alloy are non-toxic elements and harmless to human bodies, and the BCC Zr-Ti-Mo-Sn-Nb alloy can be used as a biomedical material with low magnetic susceptibility.

Owner:DALIAN UNIV OF TECH

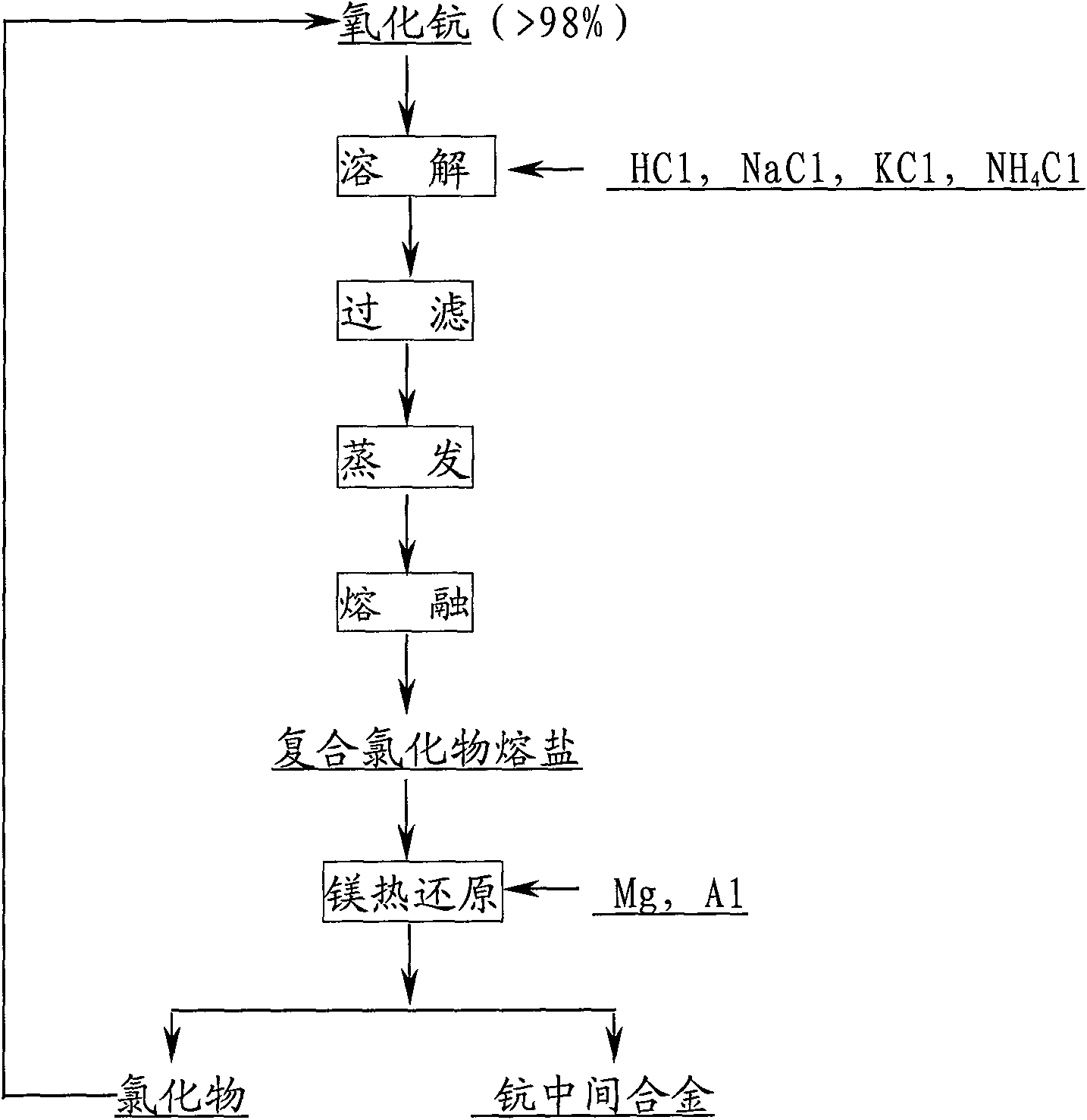

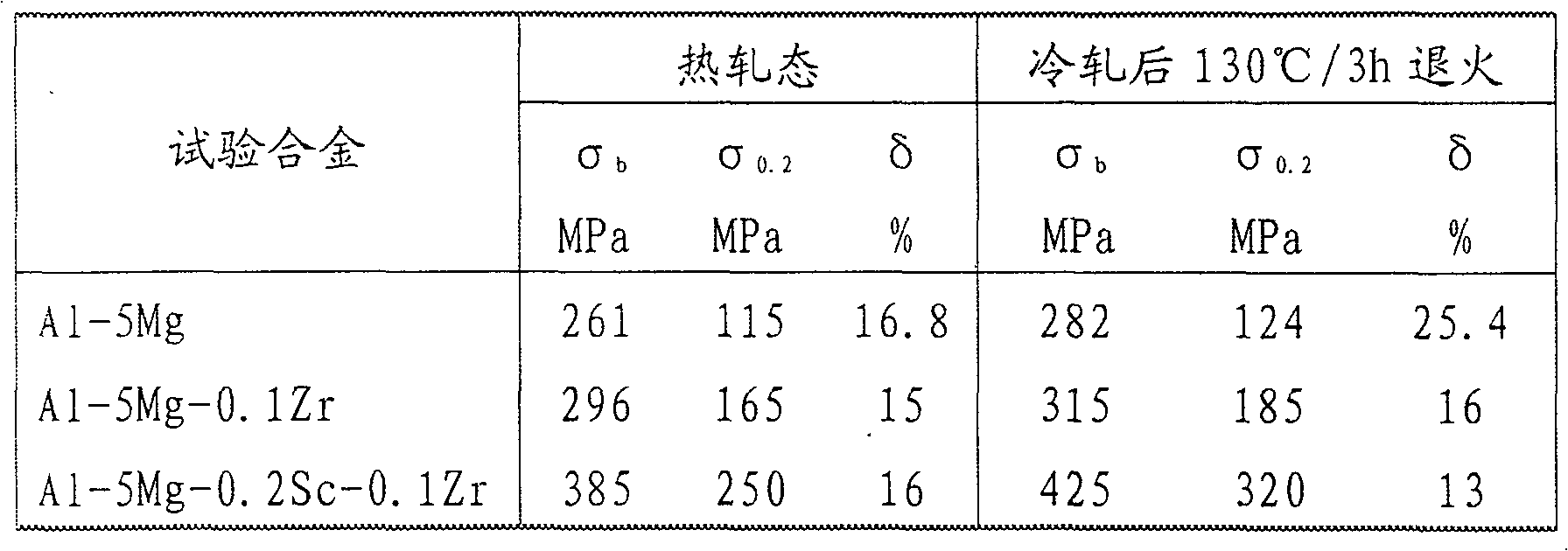

Magnesium reduction method for preparing scandium interalloy

The invention relates to a preparation method of an aluminum-magnesium-scandium master alloy. The invention uses non-high-purity scandium oxide as a raw material, and the scandium oxide becomes scandium chloride after being chlorinated, and the above-mentioned scandium-containing composite chloride is prepared by a metallothermal reduction method to prepare an aluminum-magnesium-scandium master alloy. Al-Mg-Sc master alloys with a scandium content of 1.5%-3% (weight percent) can be prepared by this method. The method for preparing scandium master alloy has simple process, uniform composition, and the recovery rate of scandium reaches 98%. The cost of scandium master alloy can be reduced by 25%. For the Al-Mg-Sc-Zr alloy prepared from the above-mentioned master alloy, the tensile strength of the finished plate is increased by 35%, the yield strength is increased by 73%, and the elongation remains at a high level of 13%.

Owner:CENT SOUTH UNIV

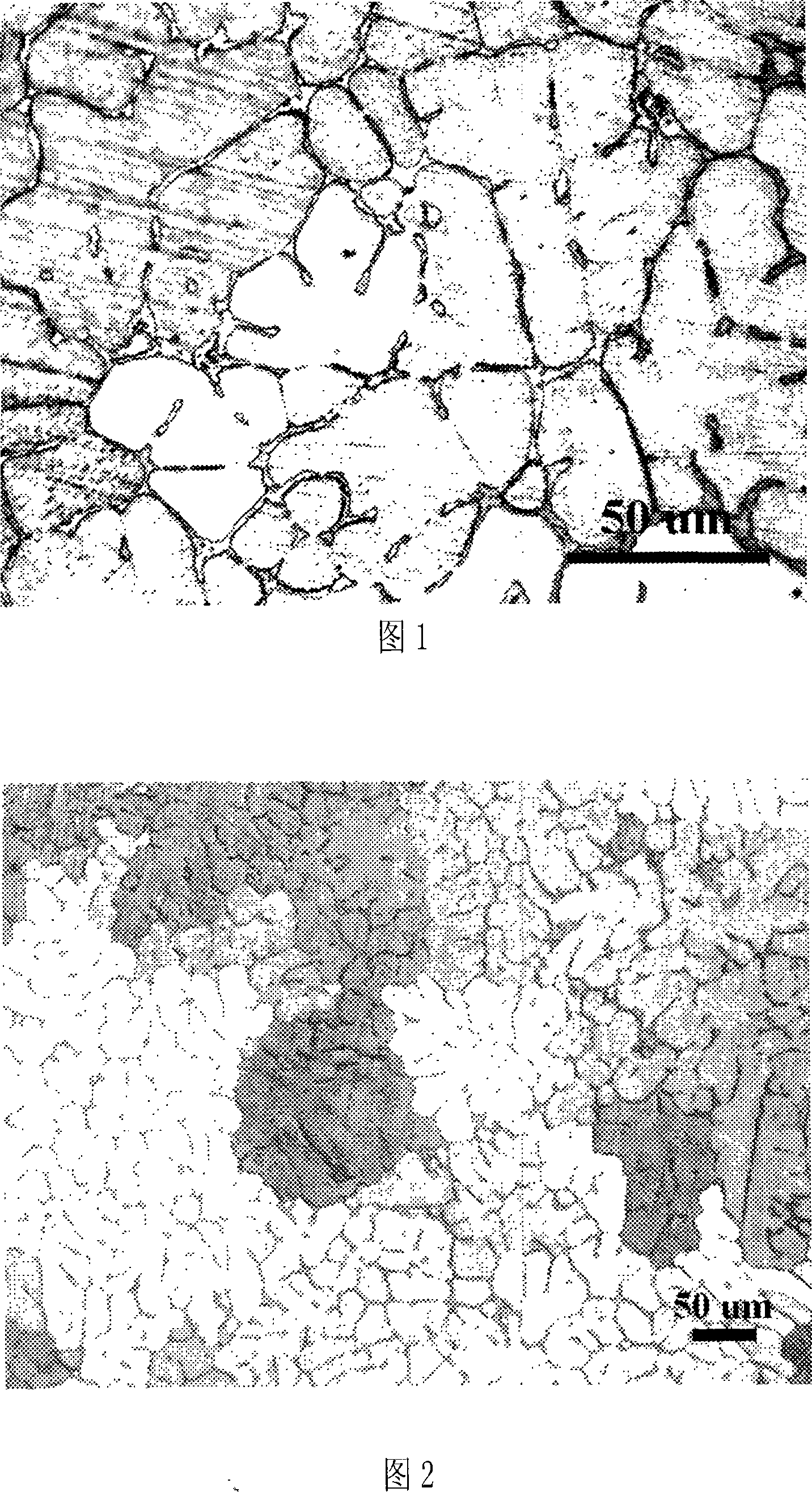

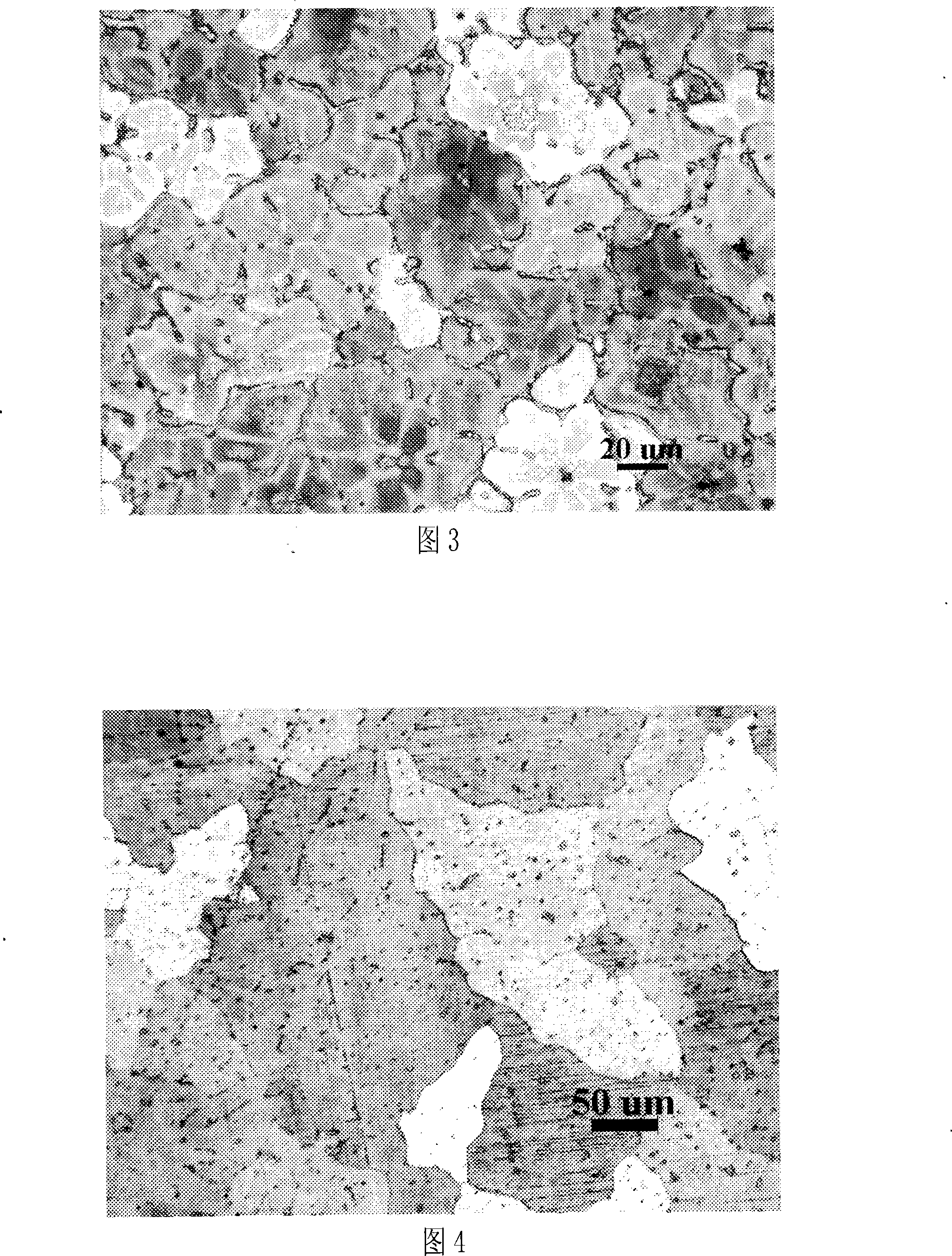

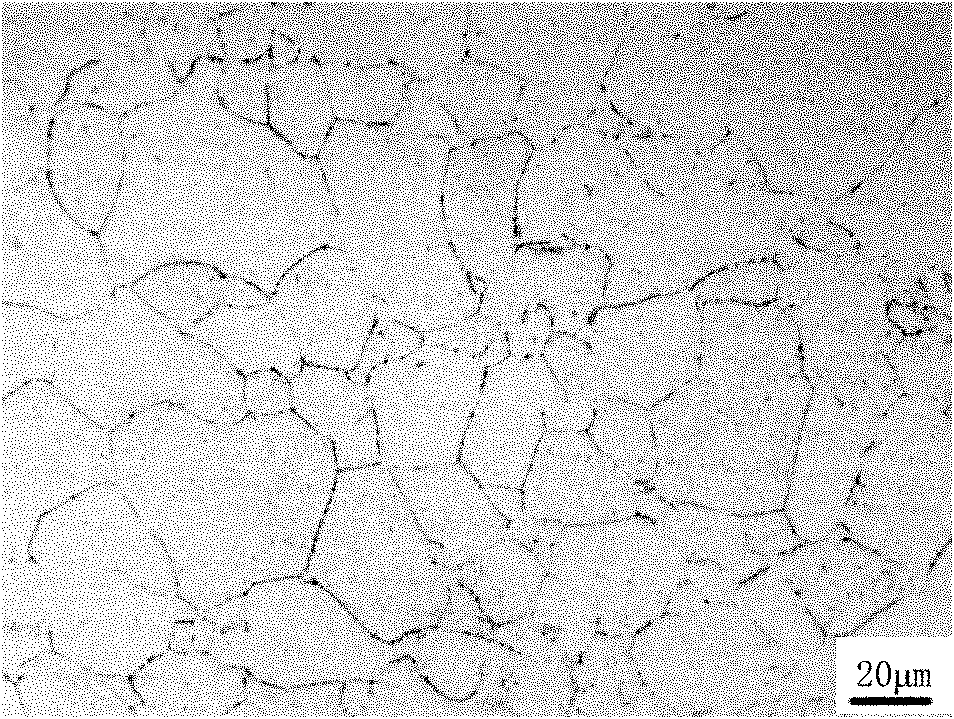

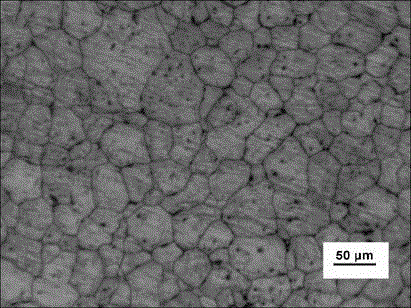

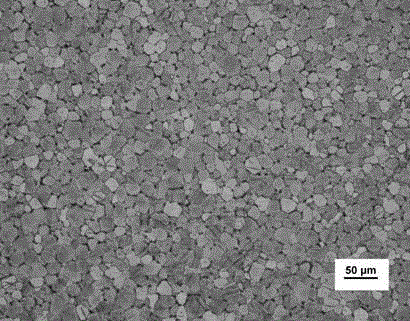

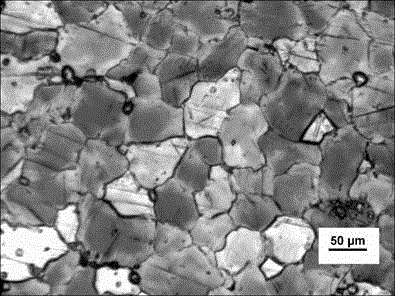

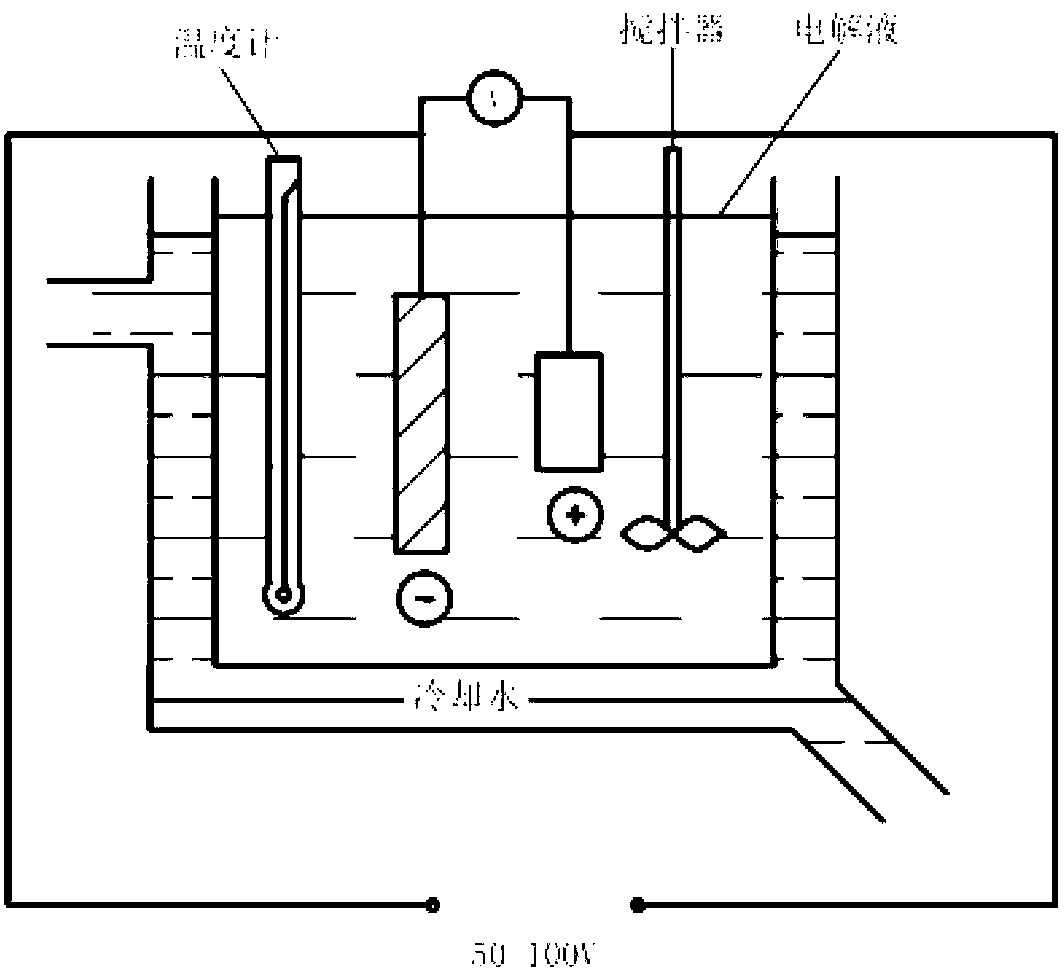

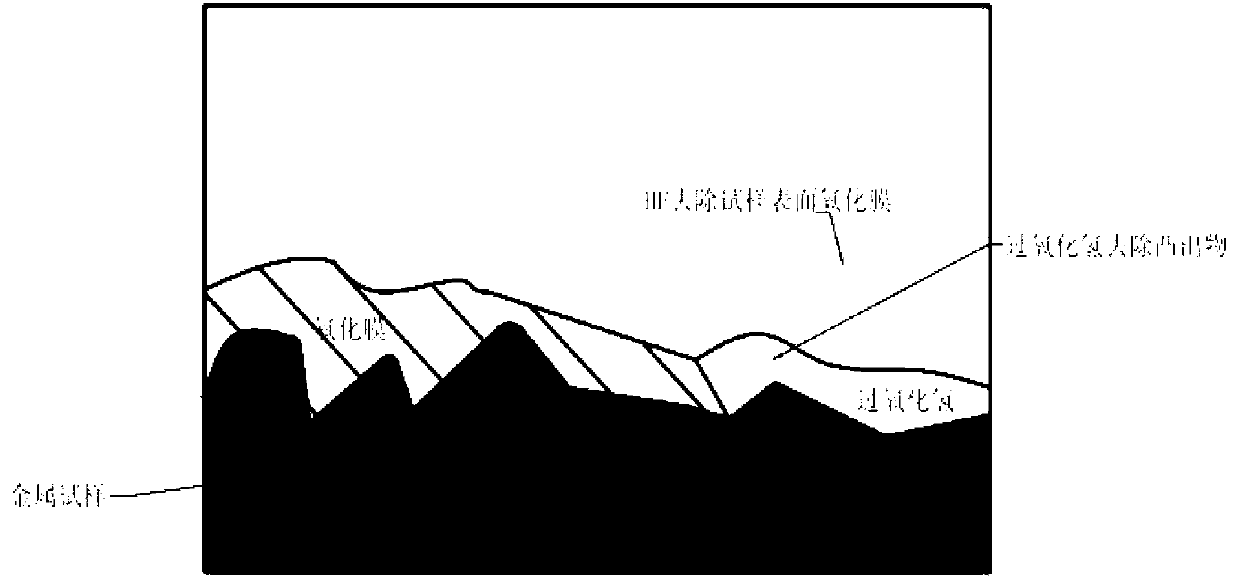

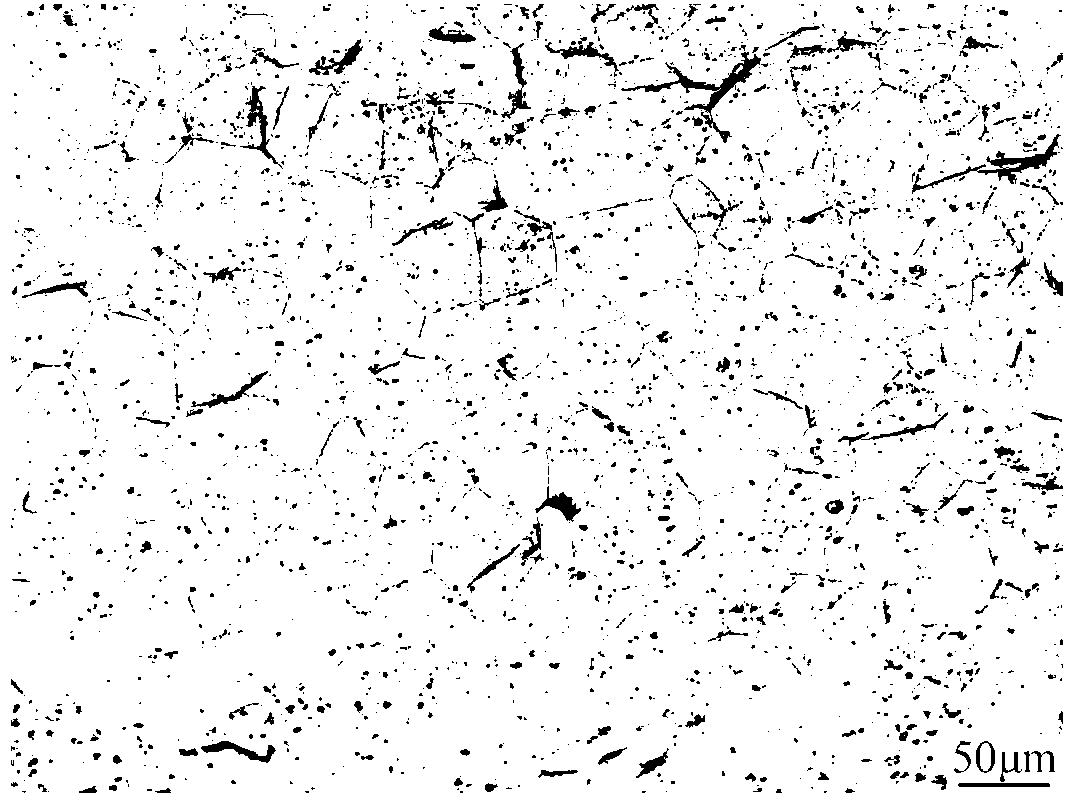

Preparation method for metallographic sample of zirconium and zirconium alloy microstructures

InactiveCN102998162AGood effectClear grainPreparing sample for investigationZr alloySample preparation

The invention discloses a preparation method for a metallographic sample of zirconium and zirconium alloy microstructures. The method comprises the following steps of pre-cleaning the metallographic sample; successively performing pre-grinding, rough-grinding and fine-grinding on the metallographic sample after the sample surface is cleaned; preparing a solution according to a volume ratio of H2O2 : HF : H2O of 0.8-1.2 : 1 : 2; wiping the sample surface for 30-40 seconds by using the solution; chemical-etching the sample without a scratch on the surface in a solution with the volume ratio of H2O2 : HF : H2O being 0.8-1.2 : 2 : 17 and with the etching time of 40-50 minutes; cleaning the etched sample; draining water; and performing metallographic observation and grain size evaluation. The microstructure diagrams of the zirconium and zirconium alloy have good effect, clear crystal grains, and are helpful for analysis and the grain size evaluation for the zirconium and zirconium alloy microstructures and intermetallic compound forms. The whole operation process is simple and a procedure is relatively short. The corrosivity for H2O2 solution is lower than that of HNO3, so that the method has small harm to health of an operator; equipment investment can be reduced; the quality and speed for sample preparation are increased; and the method is suitable for the analysis and the grain size evaluation for the zirconium and zirconium alloy microstructures.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

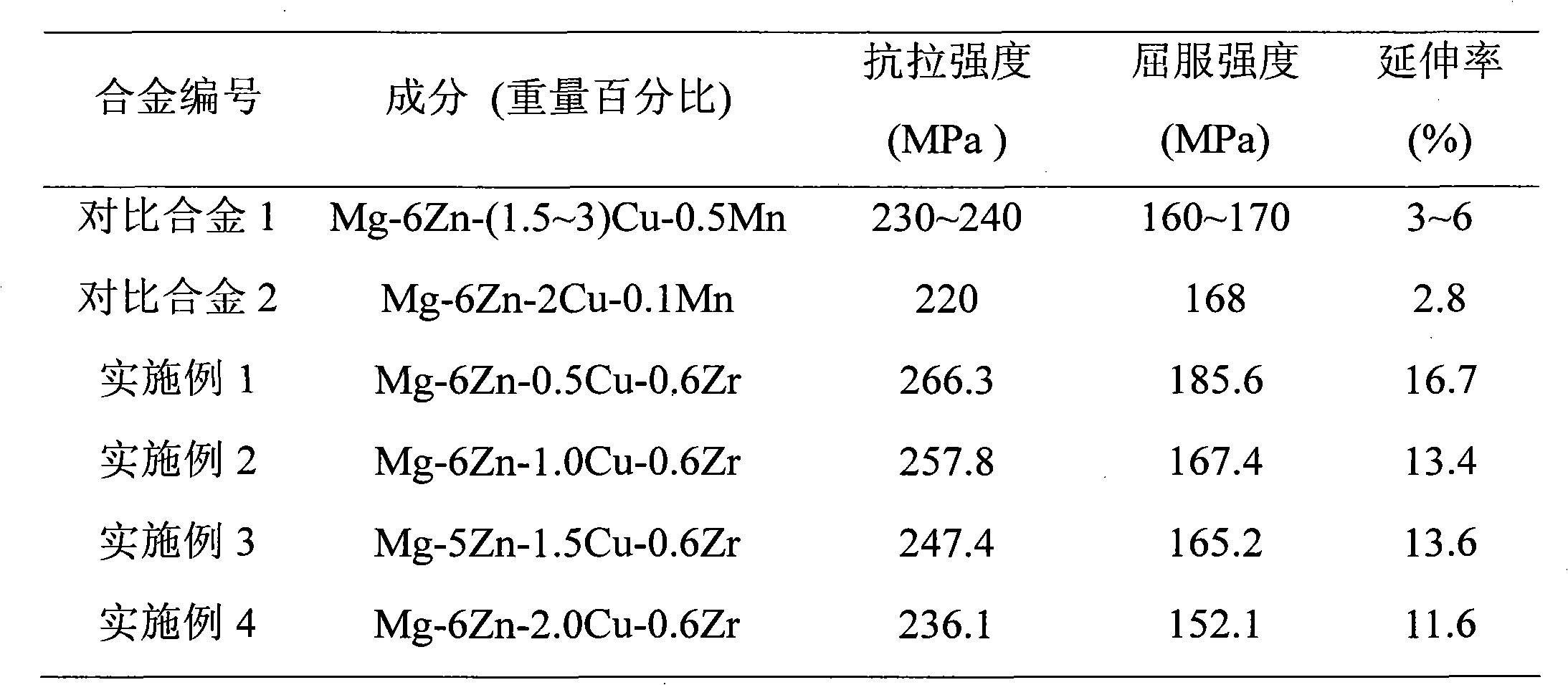

Mg-Zn-Cu-Zr alloy

The invention discloses an Mg-Zn-Cu-Zr alloy. The alloy comprises the following components in percentage by weight: 5 to 7 percent of Zn, 0.5 to 2 percent of Cu, 0.3 to 0.8 percent of Zr and the balance of Mg. The alloy is prepared by adopting relatively cheap alloy elements, a common casting method and subsequent heat treatment; and the operating process is simple, and the production efficiency is high. The alloy has good casting performance and excellent comprehensive mechanical property.

Owner:SOUTH CHINA UNIV OF TECH

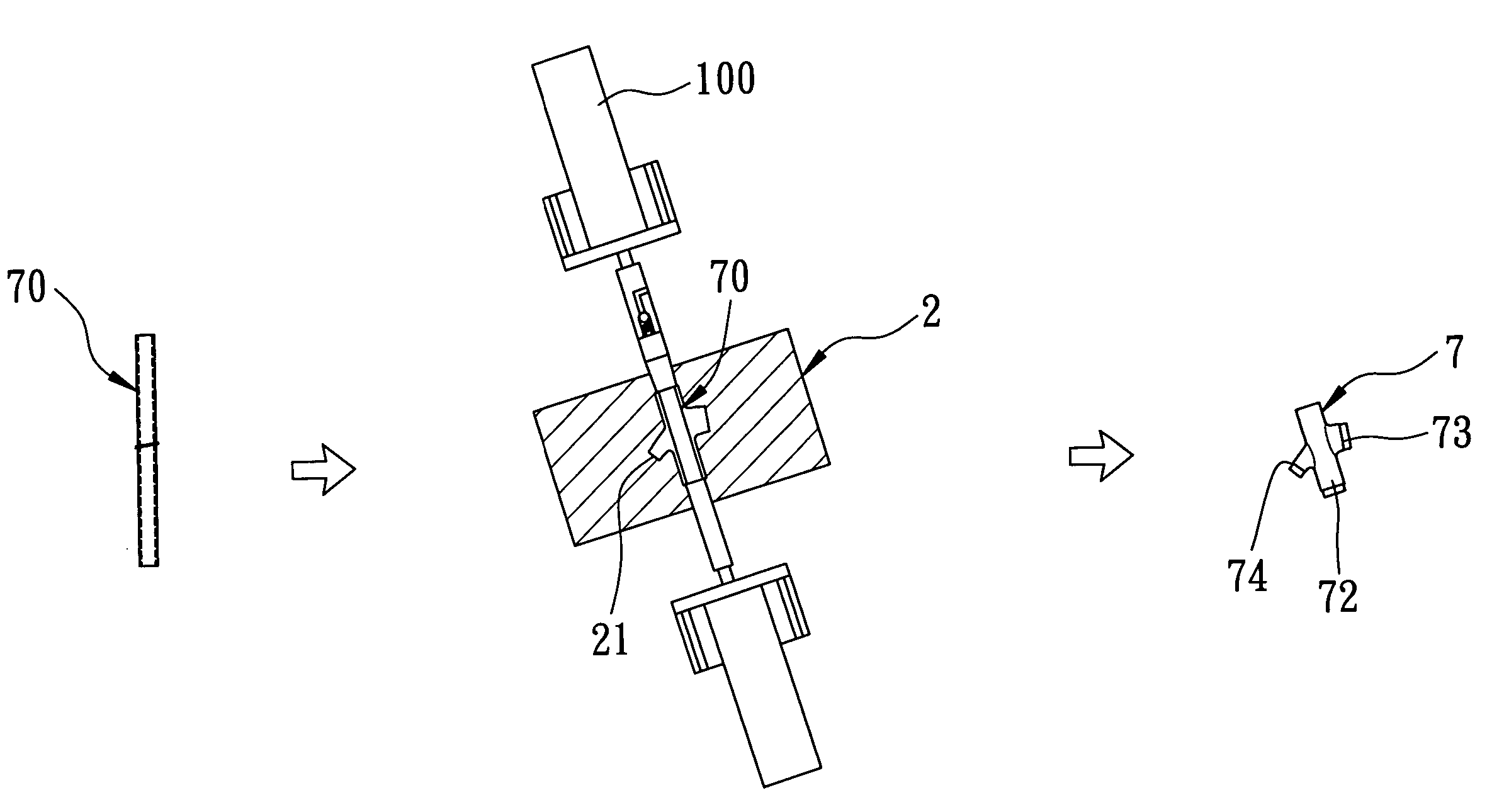

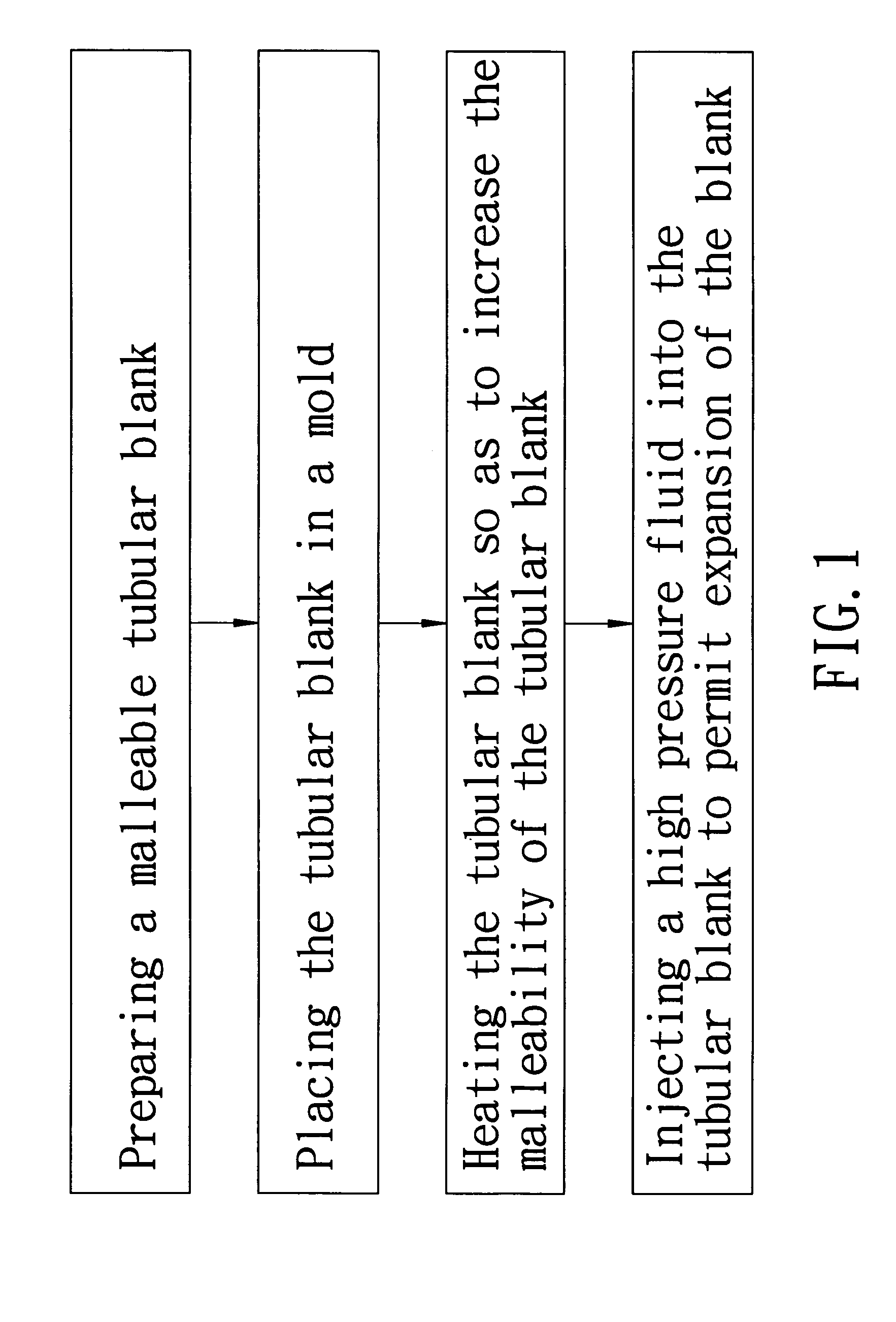

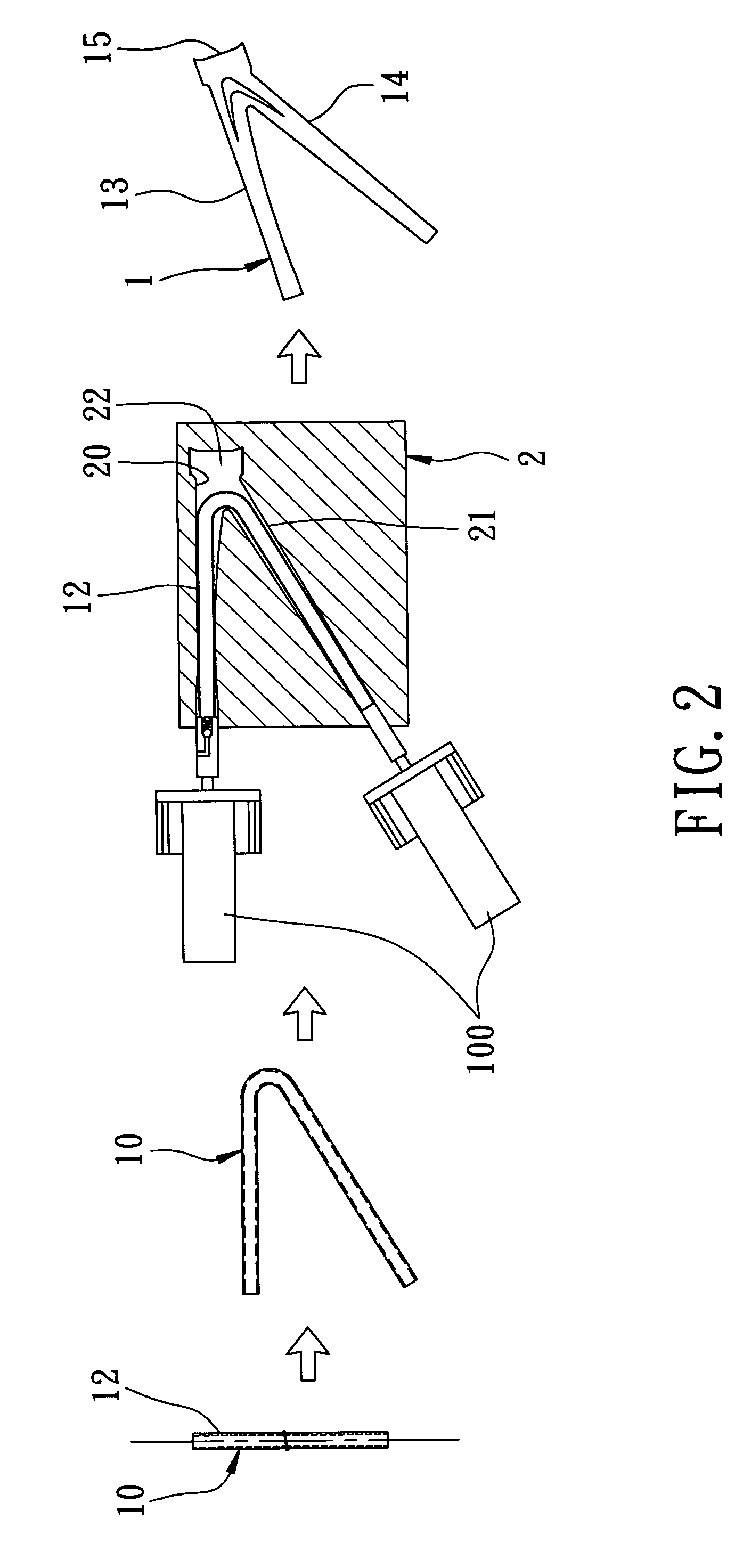

Method for making a bicycle frame part

A method for making a bicycle frame part includes the steps of preparing a malleable tubular blank that has an outer surface and that is made from an alloy selected from the group consisting of Al—Mg—Sc alloy, Al—Mg—Zr alloy, and Al—Mg—Li—Zr alloy; placing the tubular blank in a mold such that the tubular blank is surrounded by an inner surface of the mold; heating the tubular blank to a working temperature ranging from 200 to 500° C; and injecting a high-pressure fluid into the tubular blank so as to permit expansion and permanent deformation of the tubular blank in the mold to an extent that the outer surface of the expanded tube abuts against and conforms to the inner surface of the mold.

Owner:GIANT MFG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com