Magnesium reduction method for preparing scandium interalloy

A master alloy, aluminum-magnesium technology, applied in the field of preparation of scandium master alloy, can solve the problems of inability to improve the uniformity of scandium distribution, increase the difficulty of operation of process equipment, uneven distribution of scandium, etc., and achieve low cost, simple equipment, and impurity pollution. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

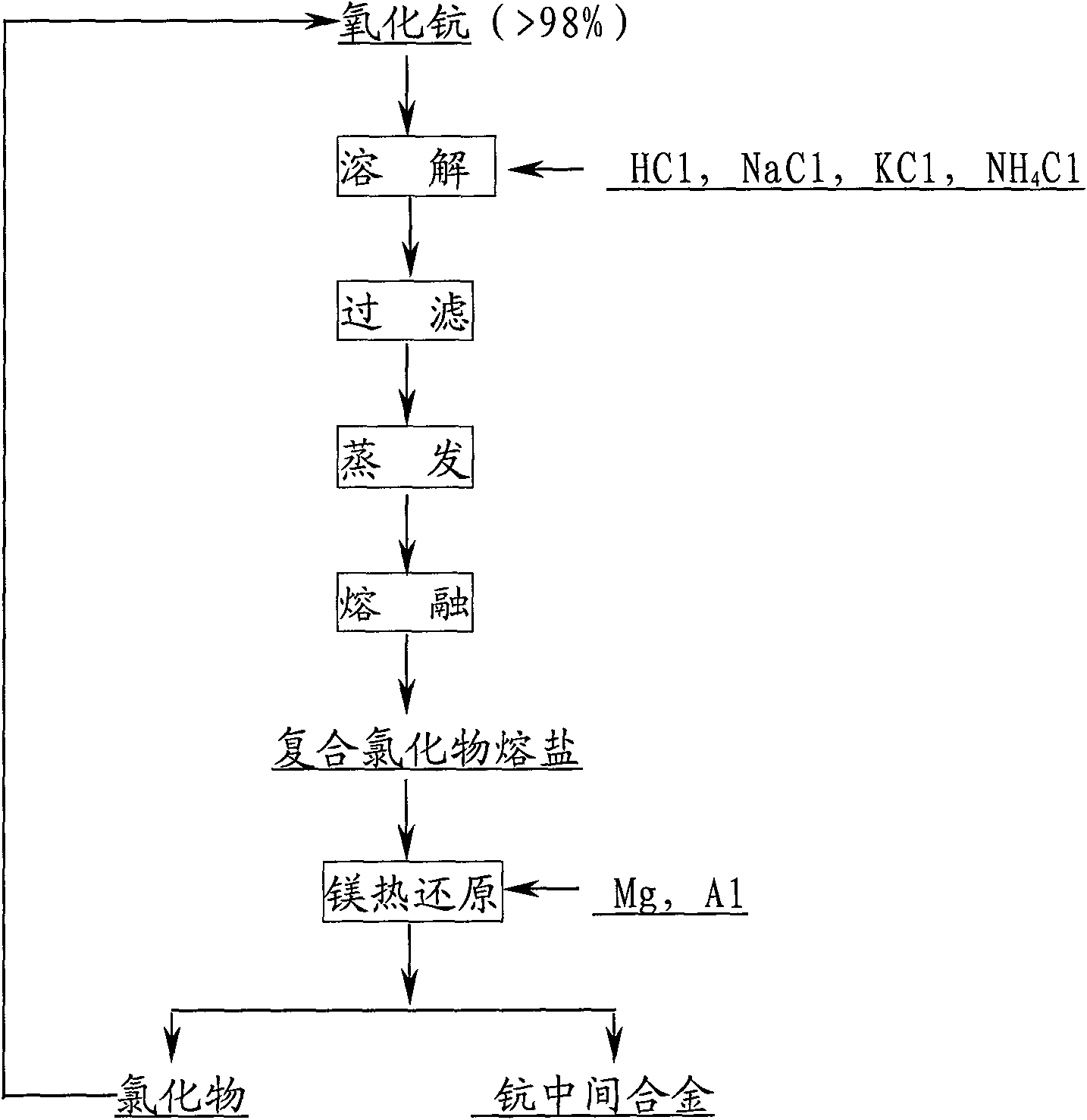

[0014] Embodiment 1 Get 100gSc 2 o 3 , dissolved in concentrated hydrochloric acid (25-30%) under heating conditions, making Sc 2 o 3 Chlorination to ScCl 3 solution; then 216gNaCl, 108gKCl and 184g of stabilizer NH 4 Dissolve Cl respectively in dilute hydrochloric acid solution (2-5%), add to ScCl 3 solution, the resulting solution was mixed and filtered, and the filtrate was evaporated to dryness and then evaporated under negative pressure. The composite chloride after removing the adsorbed water is put into a φ80mm high-purity graphite container and melted in an electric furnace at 800-850°C for 30 minutes to remove the crystal water and the stabilizer in the composite chloride to obtain a composite chloride molten salt. Put the graphite crucible with 2.5KgAl and 0.45KgMg into the vacuum intermediate frequency furnace, raise the temperature to 900°C under the protection of argon atmosphere, add the compound chloride melt in batches (about 50g for each batch, and the in...

Embodiment 2

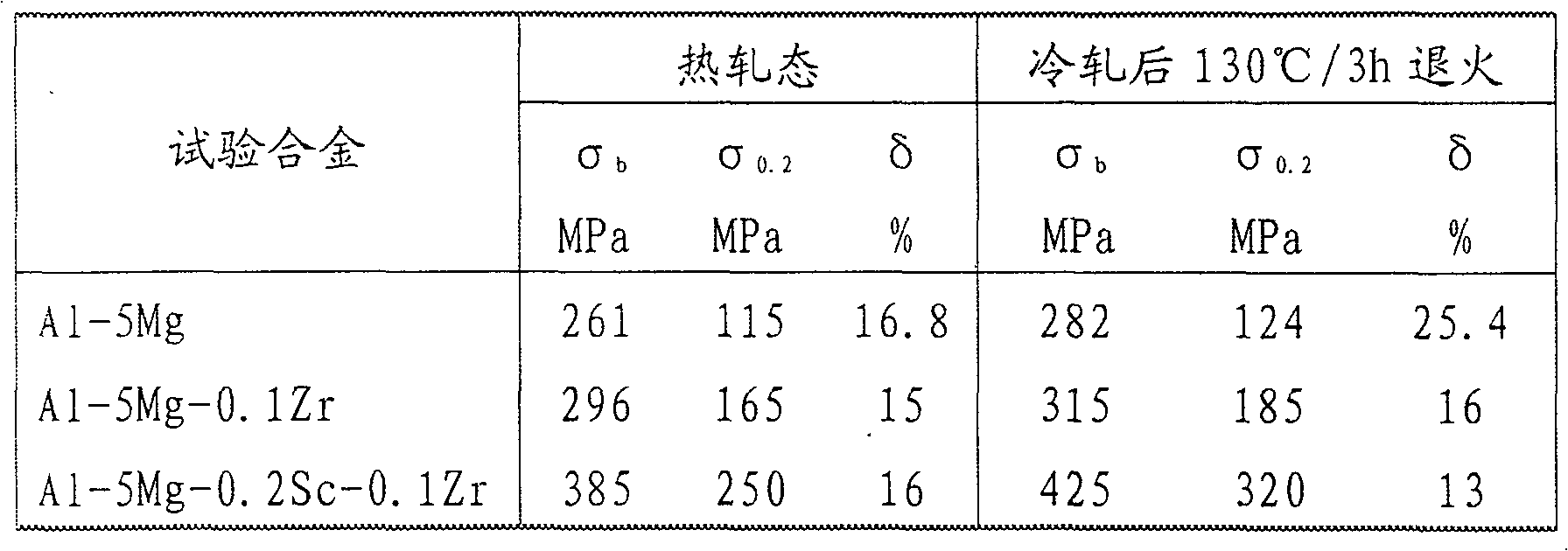

[0015] Example 2 Take 2580g of pure aluminum ingot, 105g of pure magnesium ingot, 80g of Al-3.8%Zr master alloy, and 320g of Al-14.1Mg-1.89Sc master alloy prepared by the above method, and protect them with flux in the graphite crucible of resistance crucible boiler Melt and refine under high pressure, then cast into a 60mm thick ingot, after the ingot is homogenized, it is hot rolled at 470°C into a 3mm thick plate, and part of the hot rolled plate is cold rolled to a thickness of 2mm, and then stabilized at 130°C / 3h , and then test and inspect the mechanical properties and microstructure of alloys in different treatment states. Table 1 shows the mechanical properties and microstructure of the prepared Al-Mg-Sc master alloy in different treatment states.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com