Patents

Literature

4381results about How to "Uniform composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

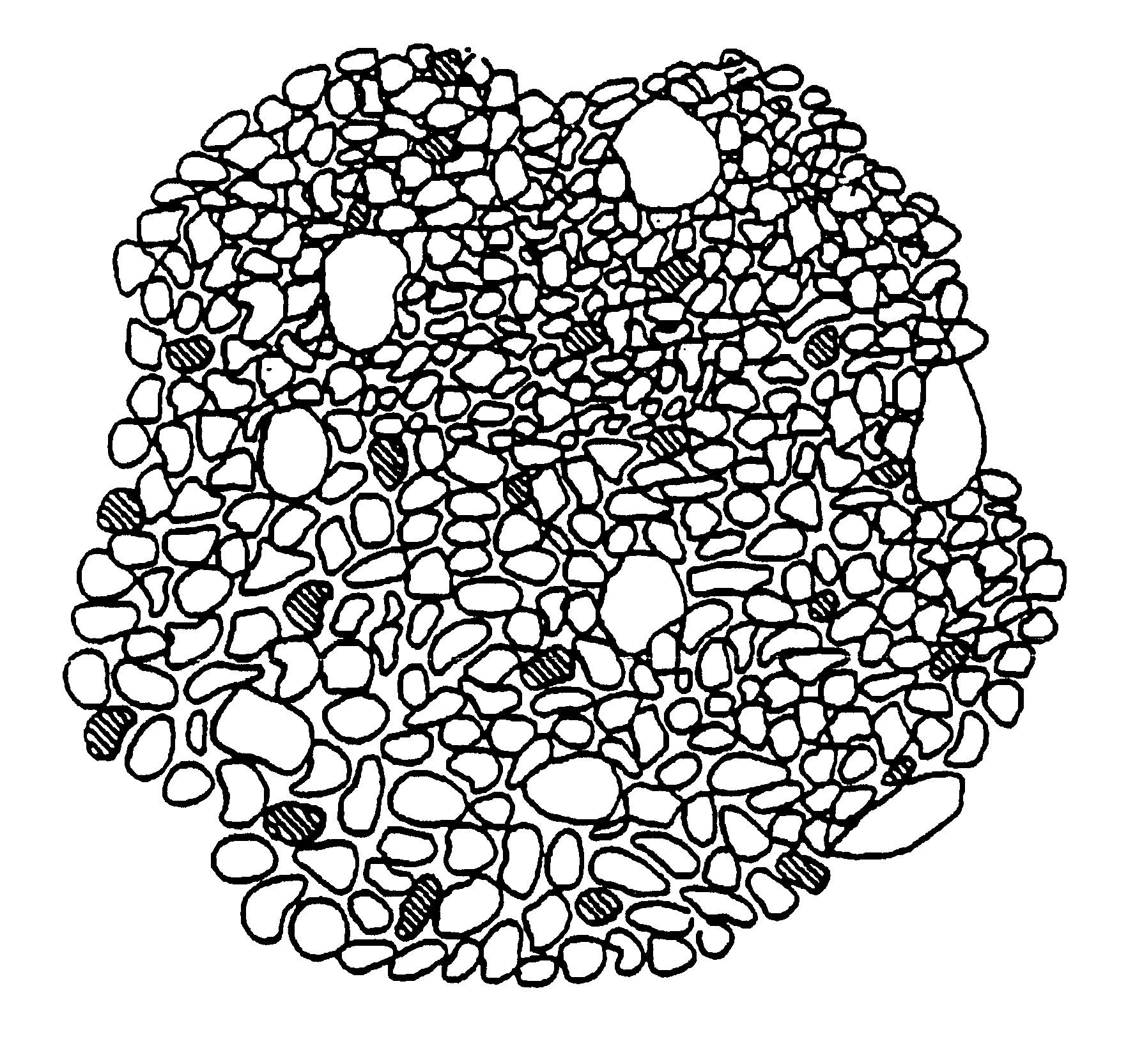

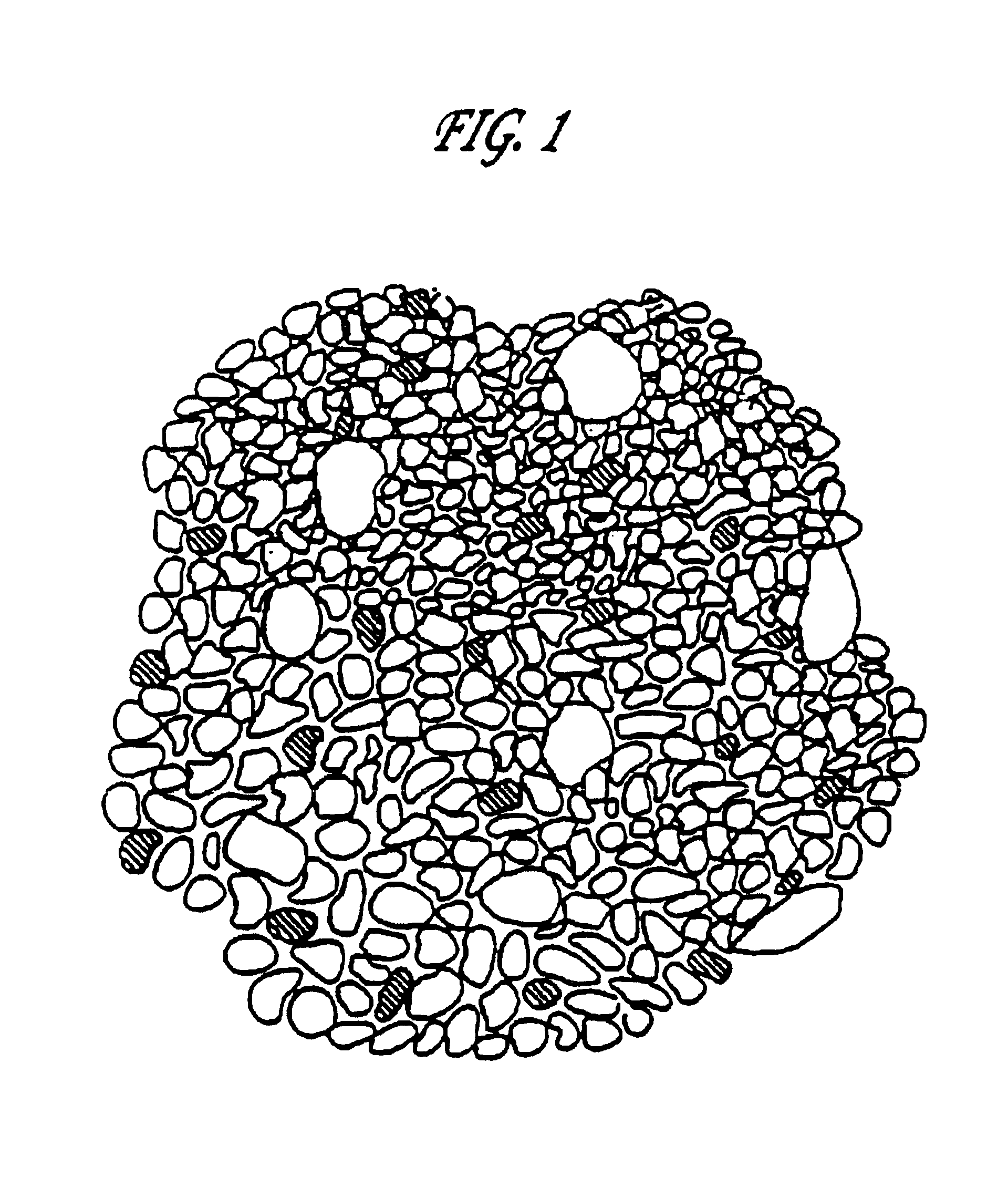

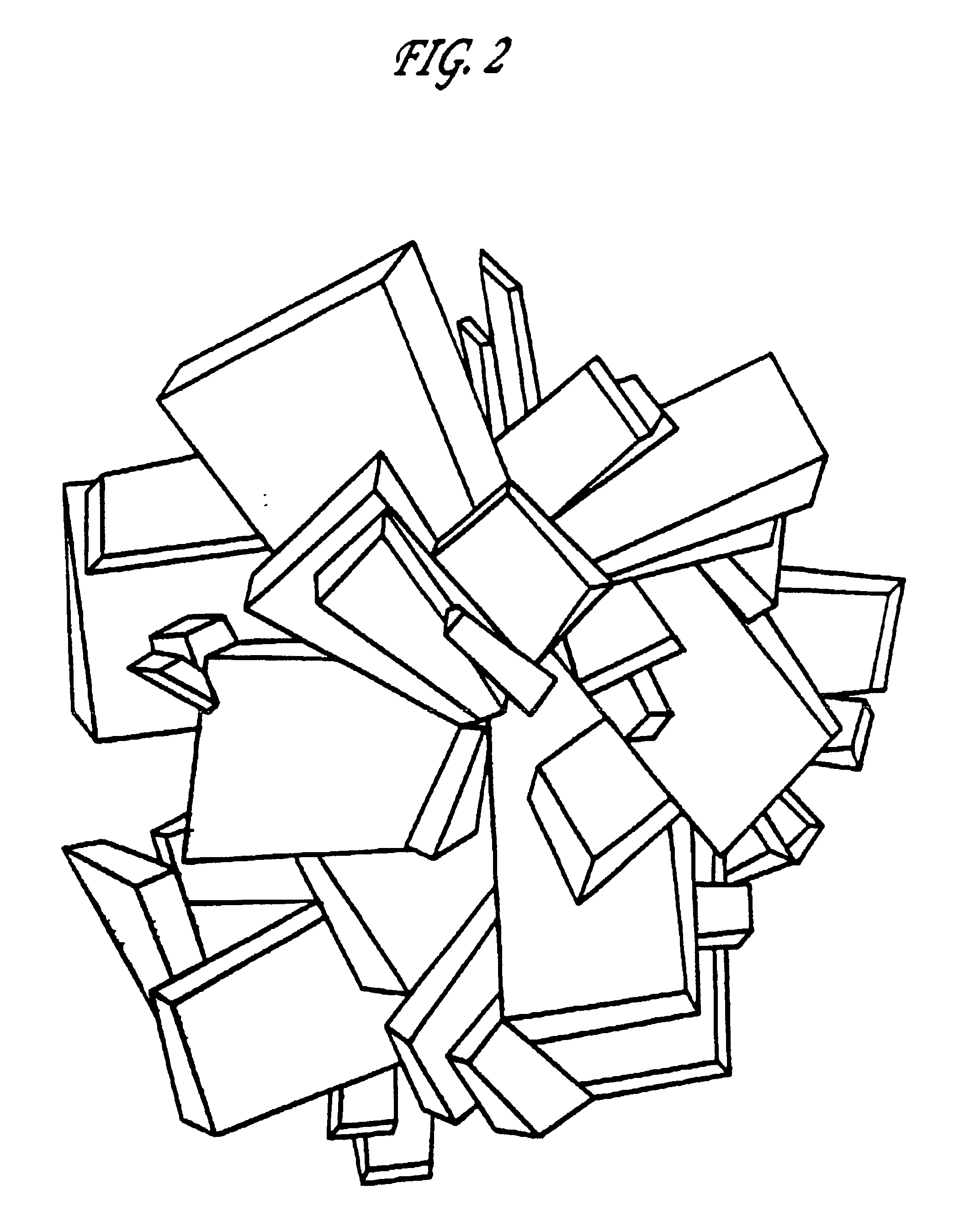

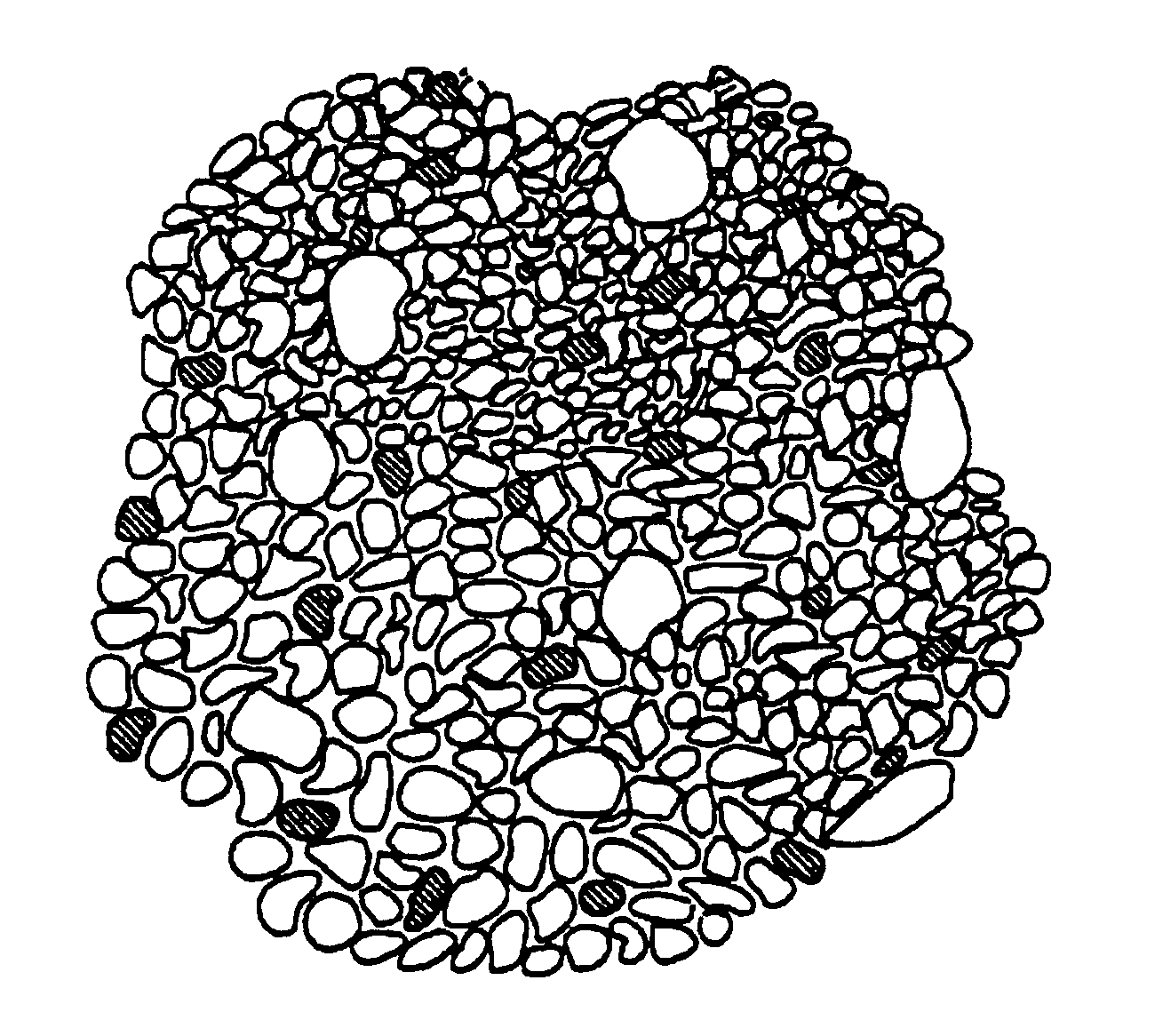

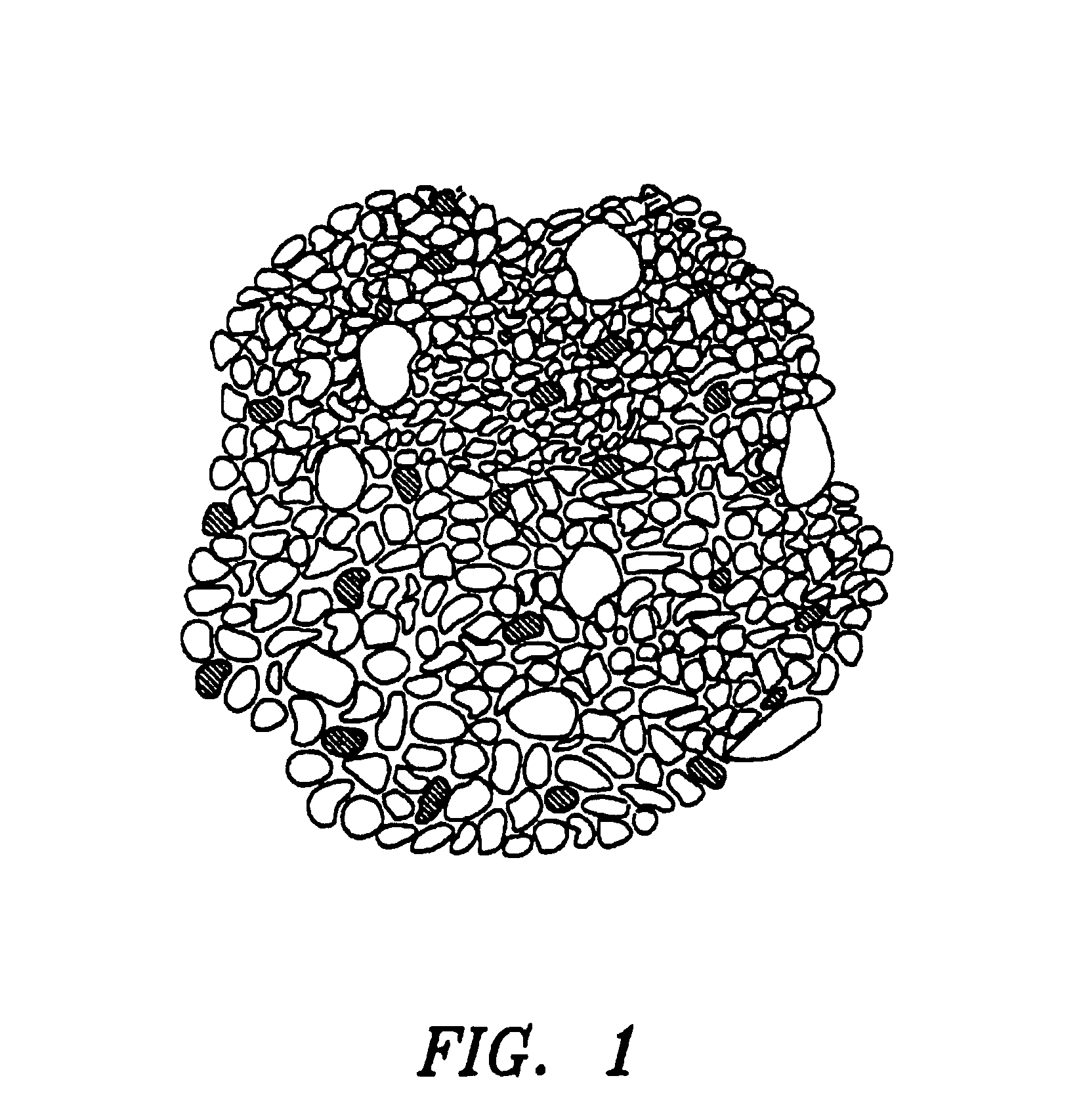

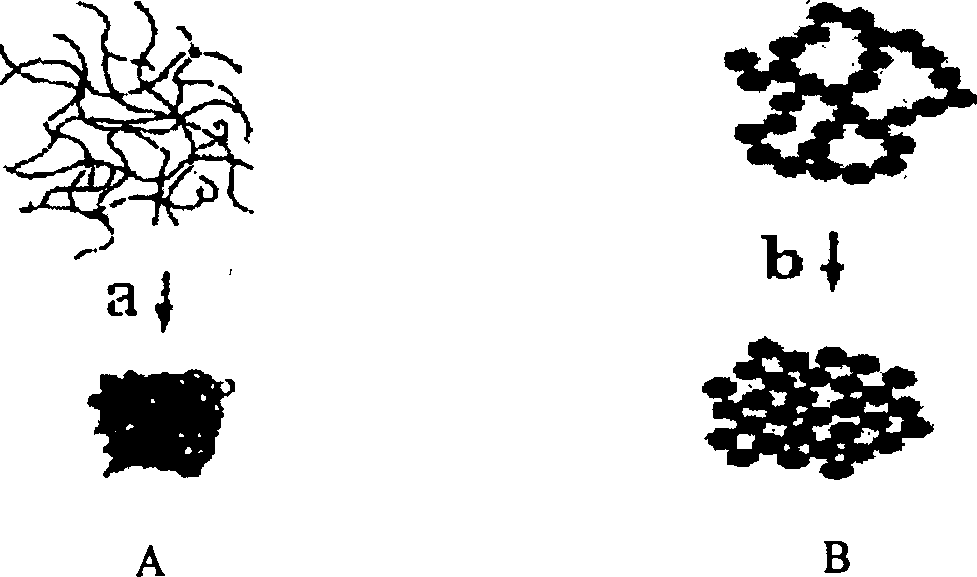

Heterogeneous composite bodies with isolated cermet regions formed by high temperature, rapid consolidation

ActiveUS9943918B2Increase spacingUniform compositionRolling contact bearingsTransportation and packagingNanoparticleNanometre

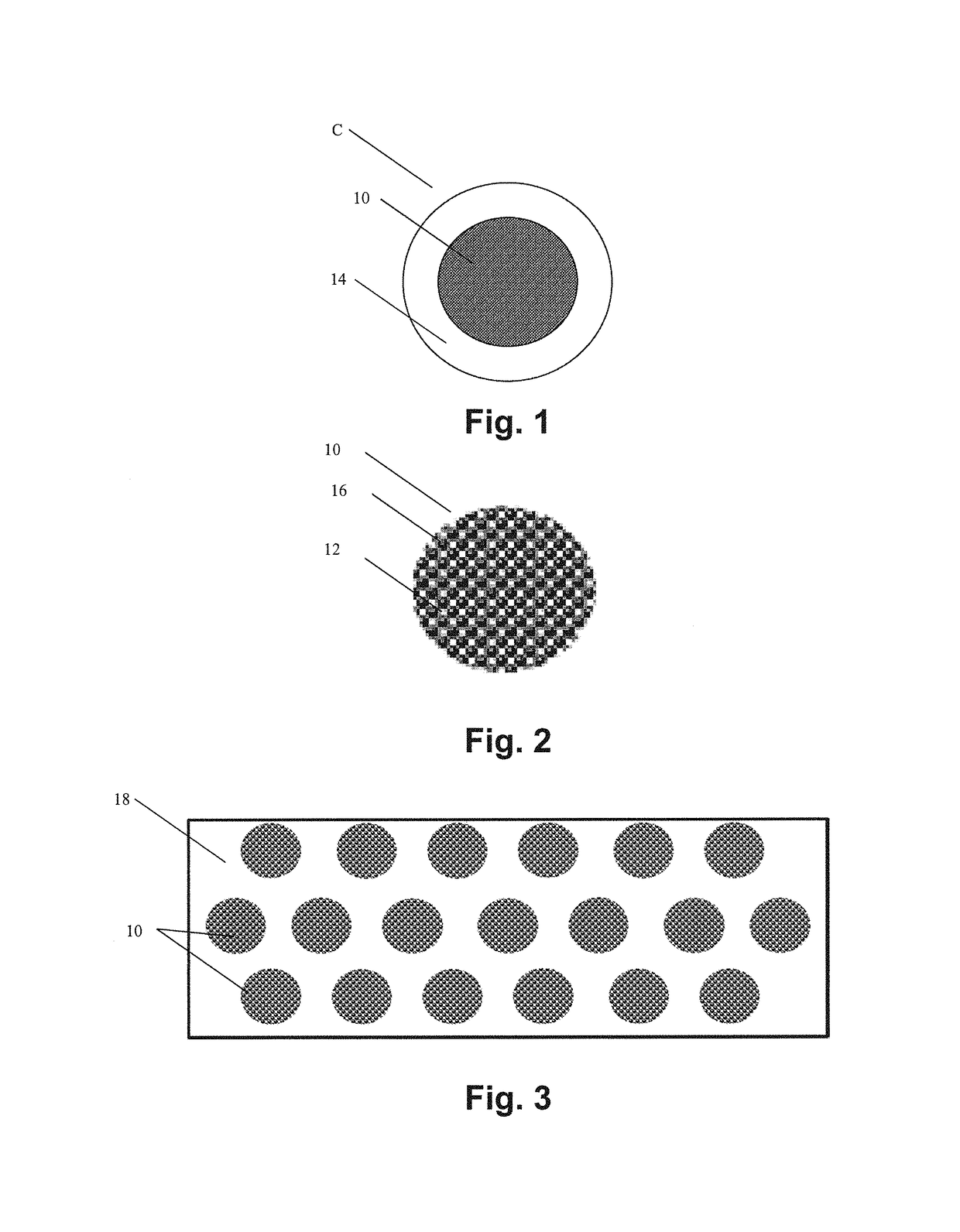

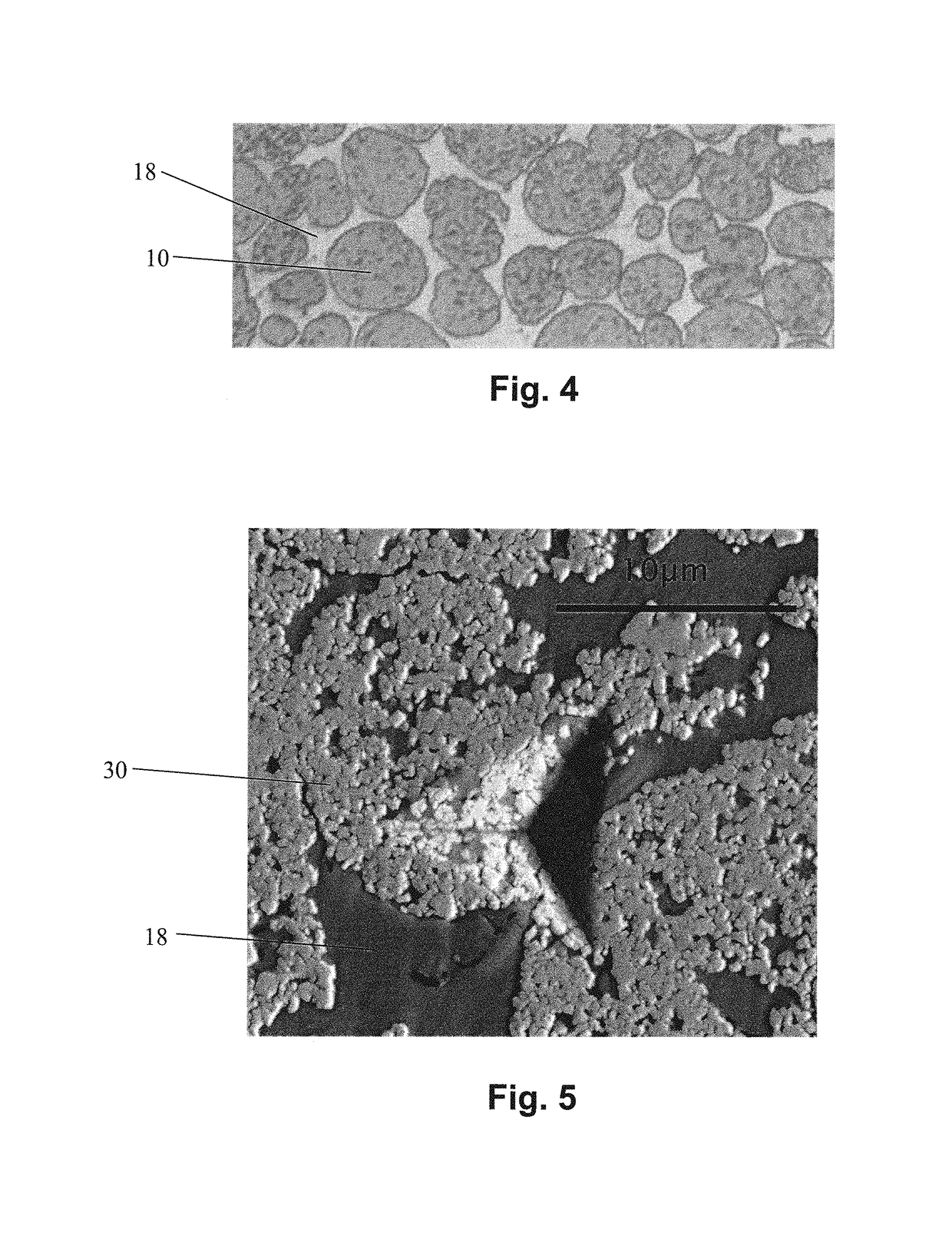

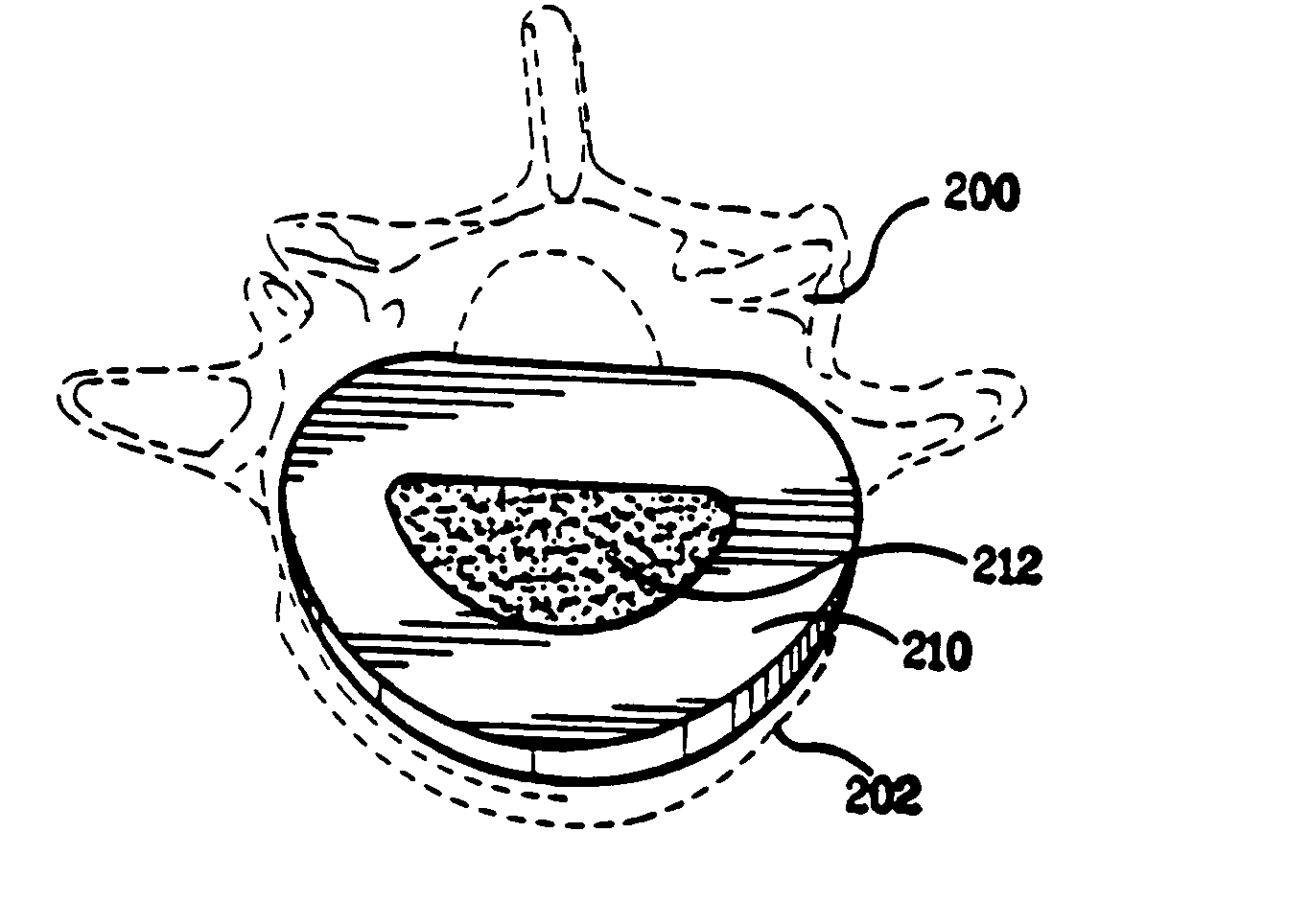

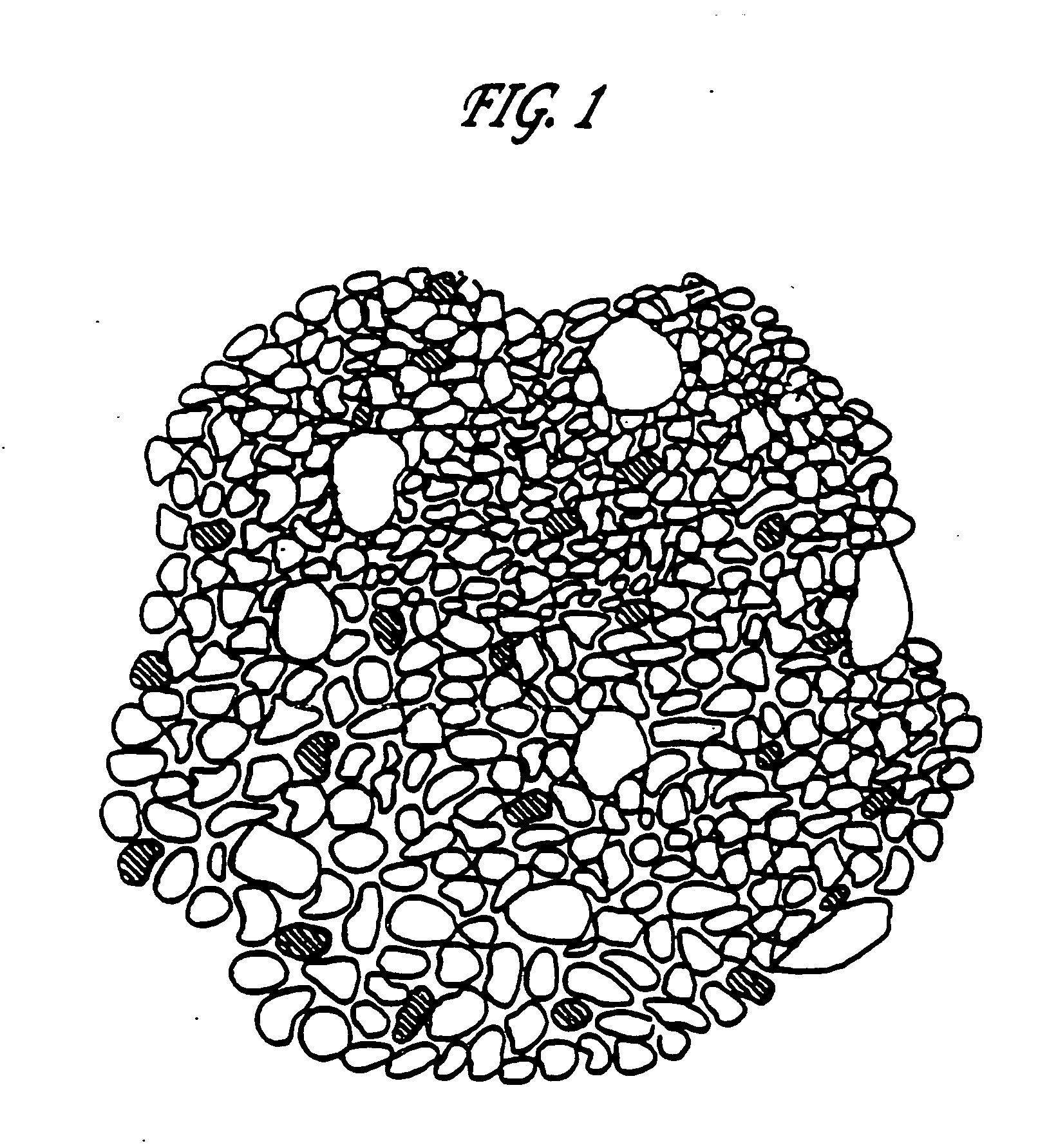

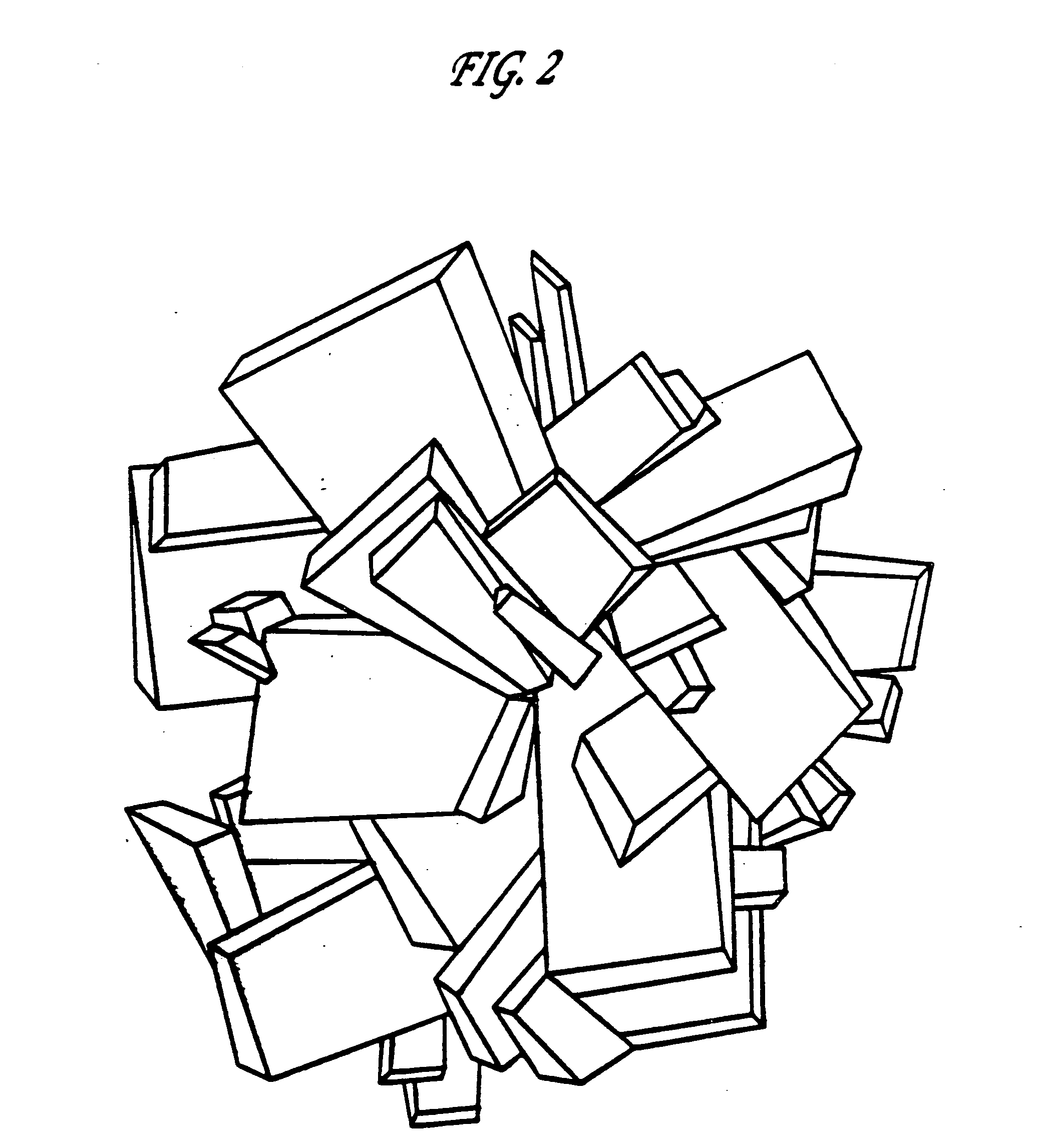

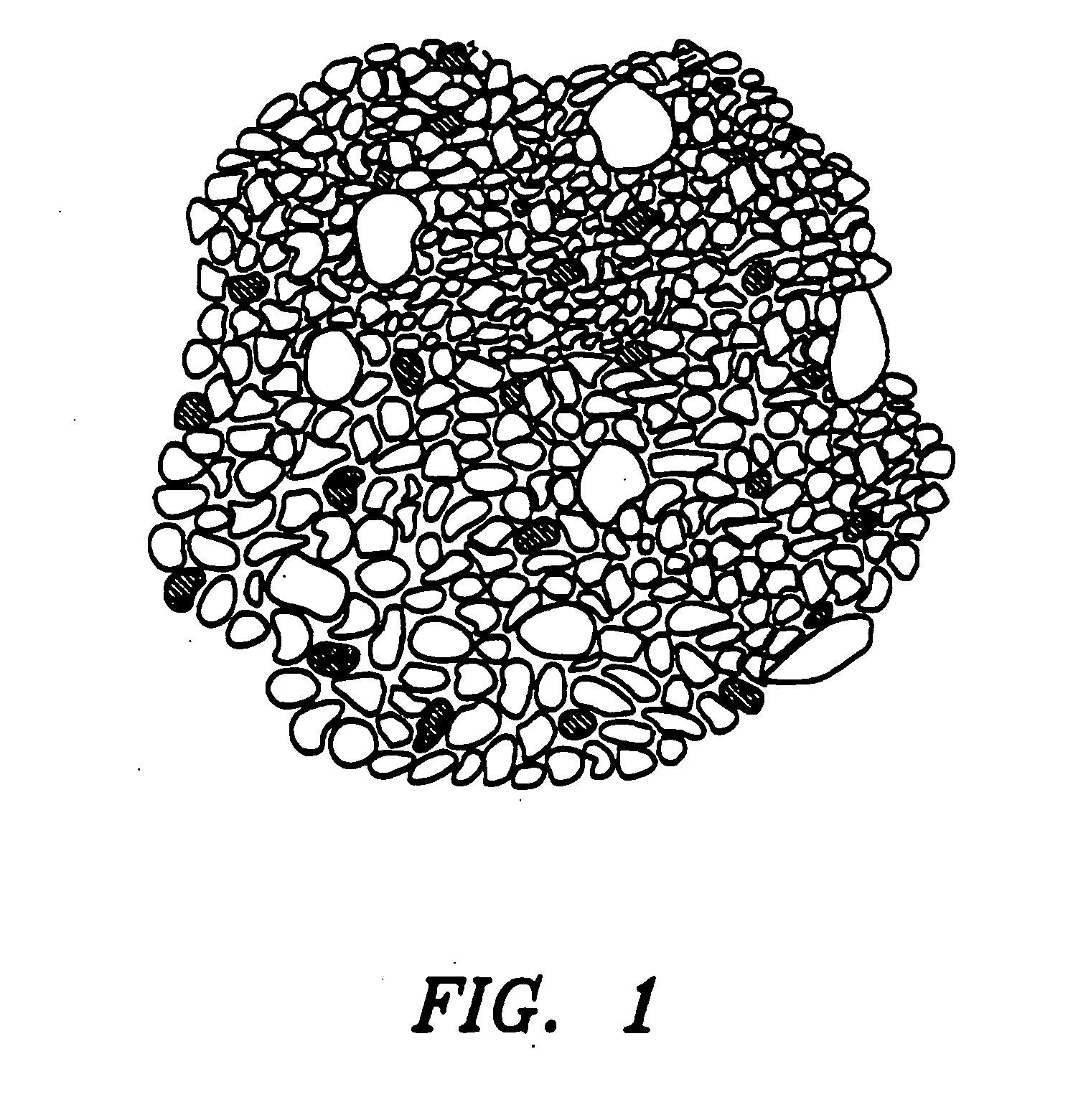

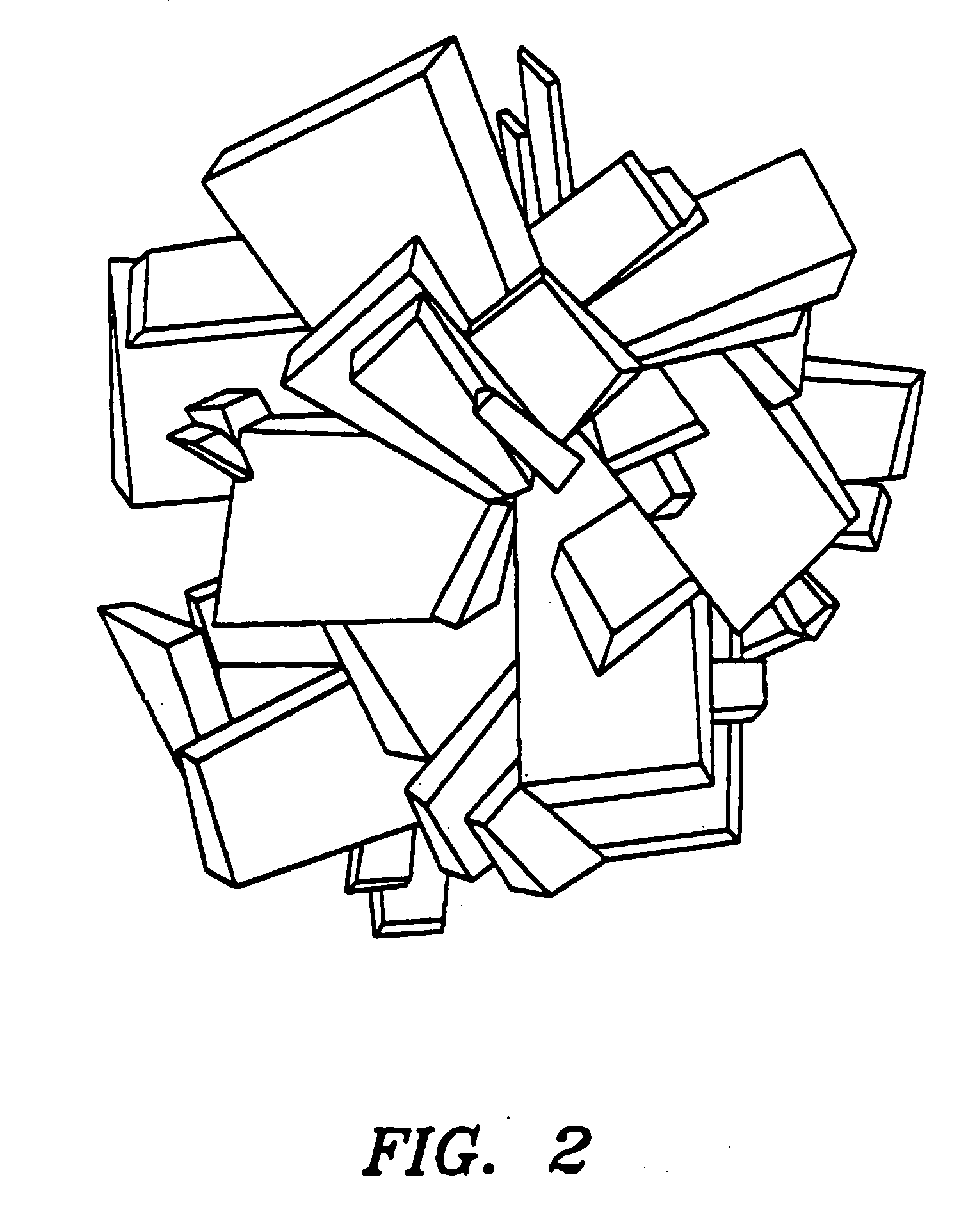

A heterogeneous composite consisting of near-nano ceramic clusters dispersed within a ductile matrix. The composite is formed through the high temperature compaction of a starting powder consisting of a core of ceramic nanoparticles held together with metallic binder. This core is clad with a ductile metal such that when the final powder is consolidated, the ductile metal forms a tough, near-zero contiguity matrix. The material is consolidated using any means that will maintain its heterogeneous structure.

Owner:POWDERMET

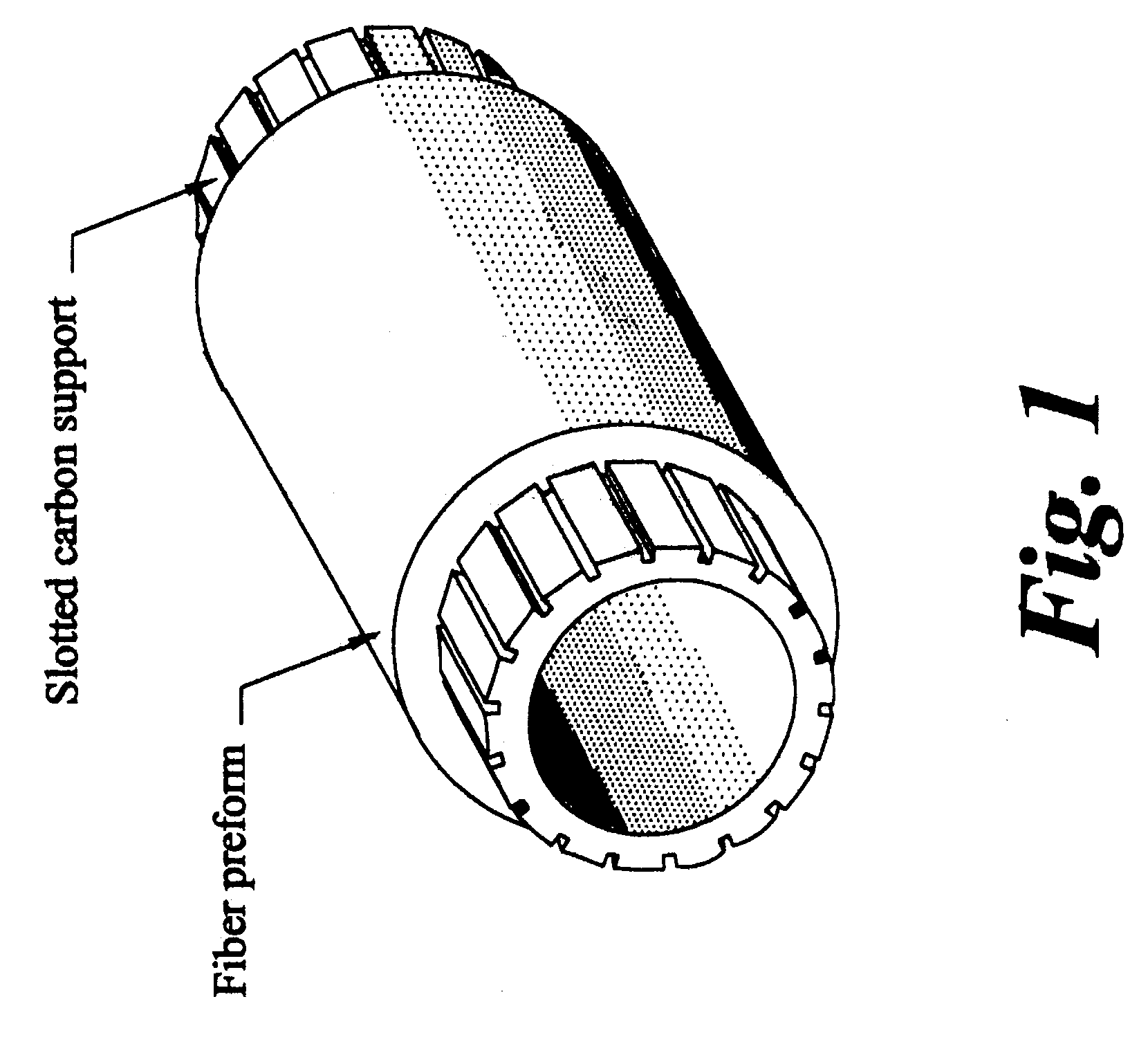

Method for producing melt-infiltrated ceramic composites using formed supports

InactiveUS6503441B2Avoid distortionEvenly distributedPretreated surfacesCeramic shaping apparatusCeramic compositeMetallurgy

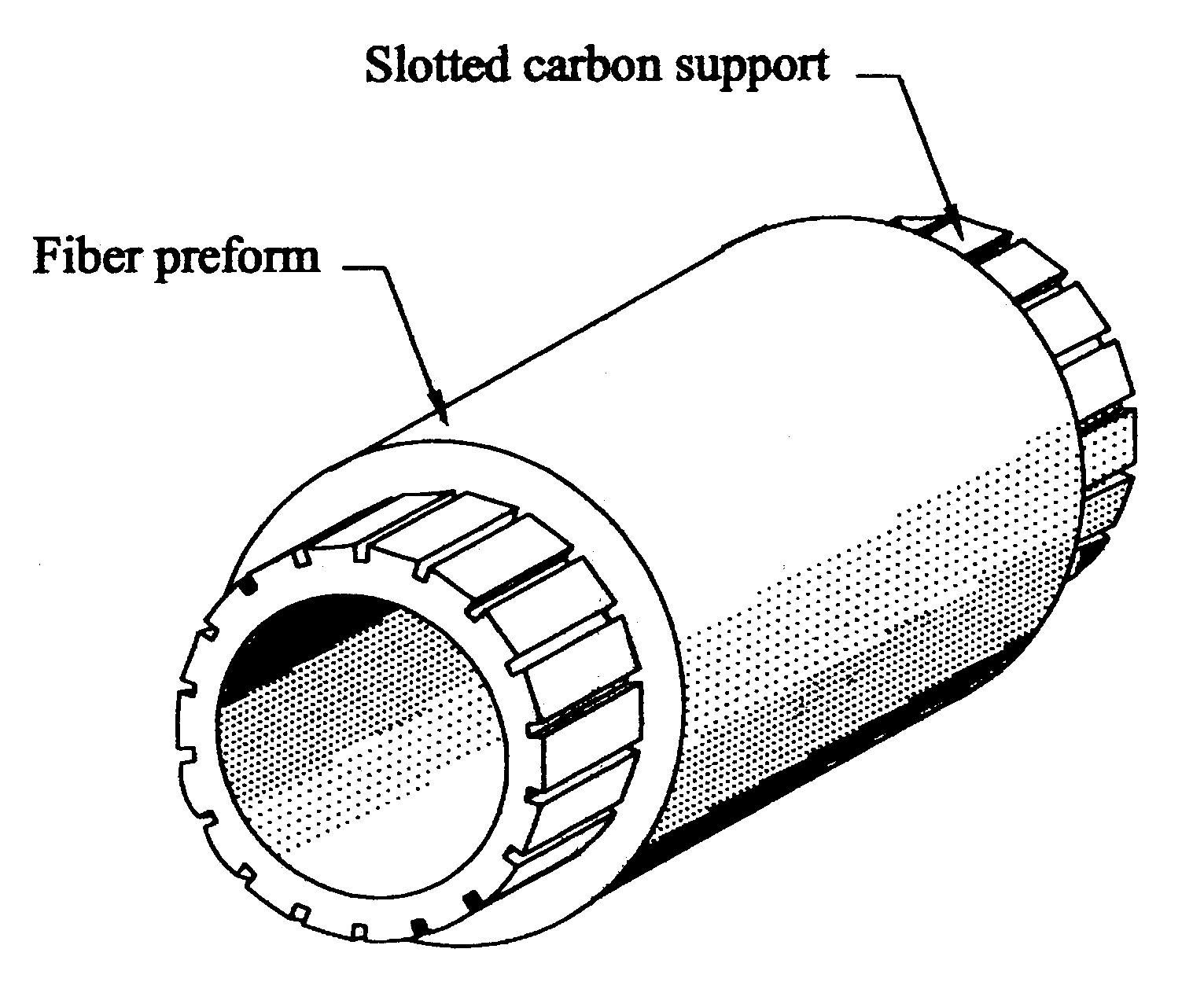

A method for producing shaped articles of ceramic composites provides a high degree of dimensional tolerance to these articles. A fiber preform is disposed on a surface of a stable formed support, a surface of which is formed with a plurality of indentations, such as grooves, slots, or channels. Precursors of ceramic matrix materials are provided to the fiber preform to infiltrate from both sides of the fiber preform. The infiltration is conducted under vacuum at a temperature not much greater than a melting point of the precursors. The melt-infiltrated composite article substantially retains its dimension and shape throughout the fabrication process.

Owner:GENERAL ELECTRIC CO

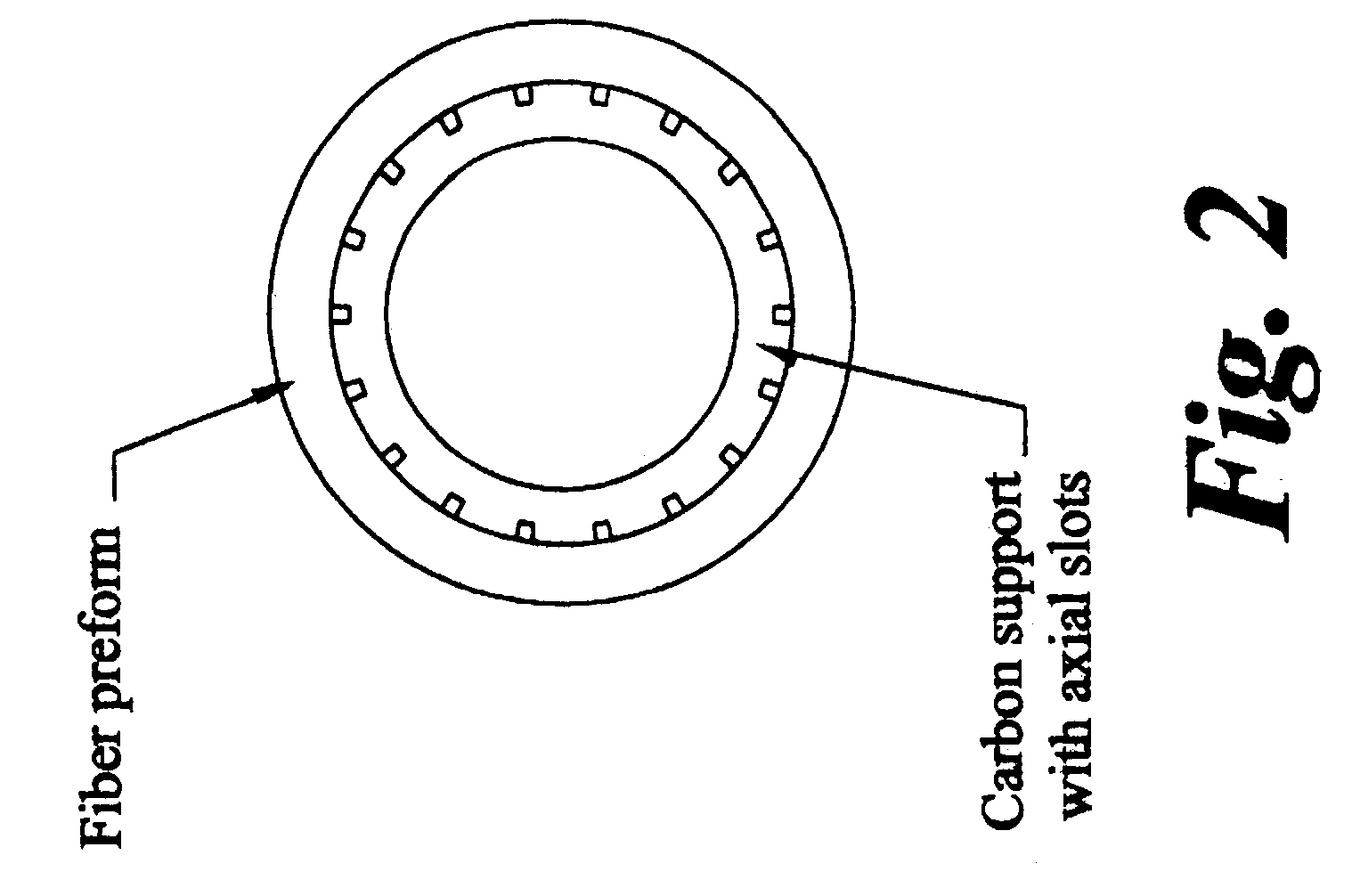

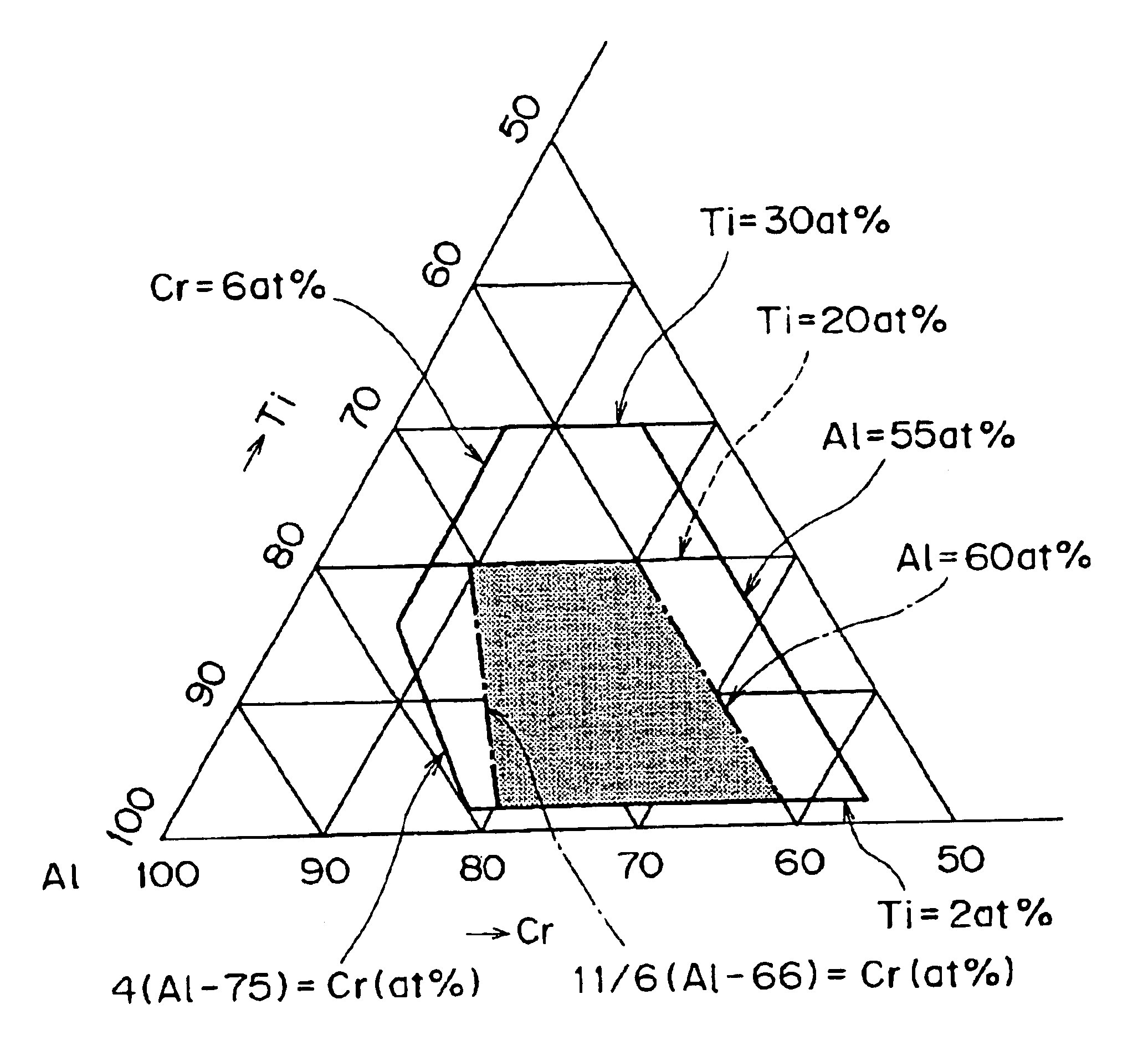

Hard film for cutting tools, cutting tool coated with hard film, process for forming hard film, and target used to form hard film

InactiveUS6824601B2Improve wear resistanceHigh-speed efficient cuttingMolten spray coatingOther chemical processesMetallurgyAtomic ratio

A hard film for cutting tools which is composed of(where a, b, c, and d denote respectively the atomic ratios Al, Cr, Si, and B, and e denotes the atomic ratio of N.)

Owner:KOBE STEEL LTD

Composite shaped bodies and methods for their production and use

InactiveUS6863899B2Overcome the lack of robustnessNovel featuresCosmetic preparationsDental implantsCalcium biphosphatePlastic surgery

Shaped, composite bodies are provided. One portion of the shaped bodies comprises an RPR-derived porous inorganic material, preferably a calcium phosphate. Another portion of the composite bodies is a different solid material, preferably metal, glass, ceramic or polymeric. The shaped bodies are especially suitable for orthopaedic and other surgical use.

Owner:ORTHOVITA INC

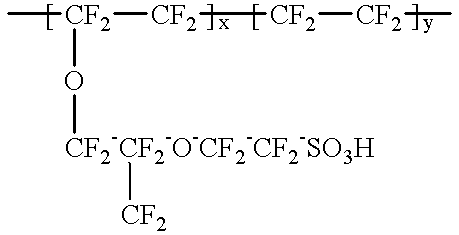

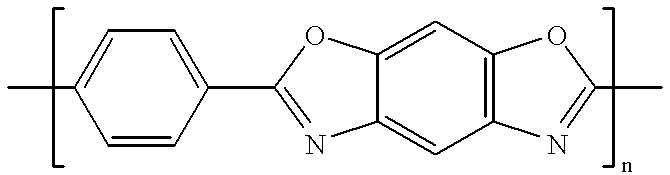

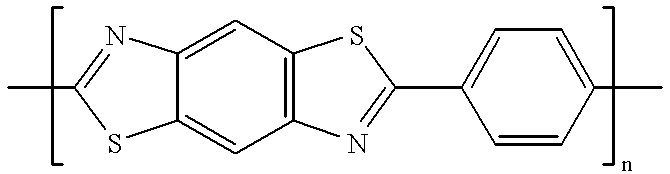

Composite solid polymer elecrolyte membranes

InactiveUS20020045085A1Optimize swellingOptimize fuel crossover resistanceElectrolyte holding meansFinal product manufacturePolymer electrolytesPolymer science

The present invention relates to composite solid polymer electrolyte membranes (SPEMs) which include a porous polymer substrate interpenetrated with an ion-conducting material. SPEMs of the present invention are useful in electrochemical applications, including fuel cells and electrodialysis.

Owner:FOSTER-MILLER

Localized surface volatilization

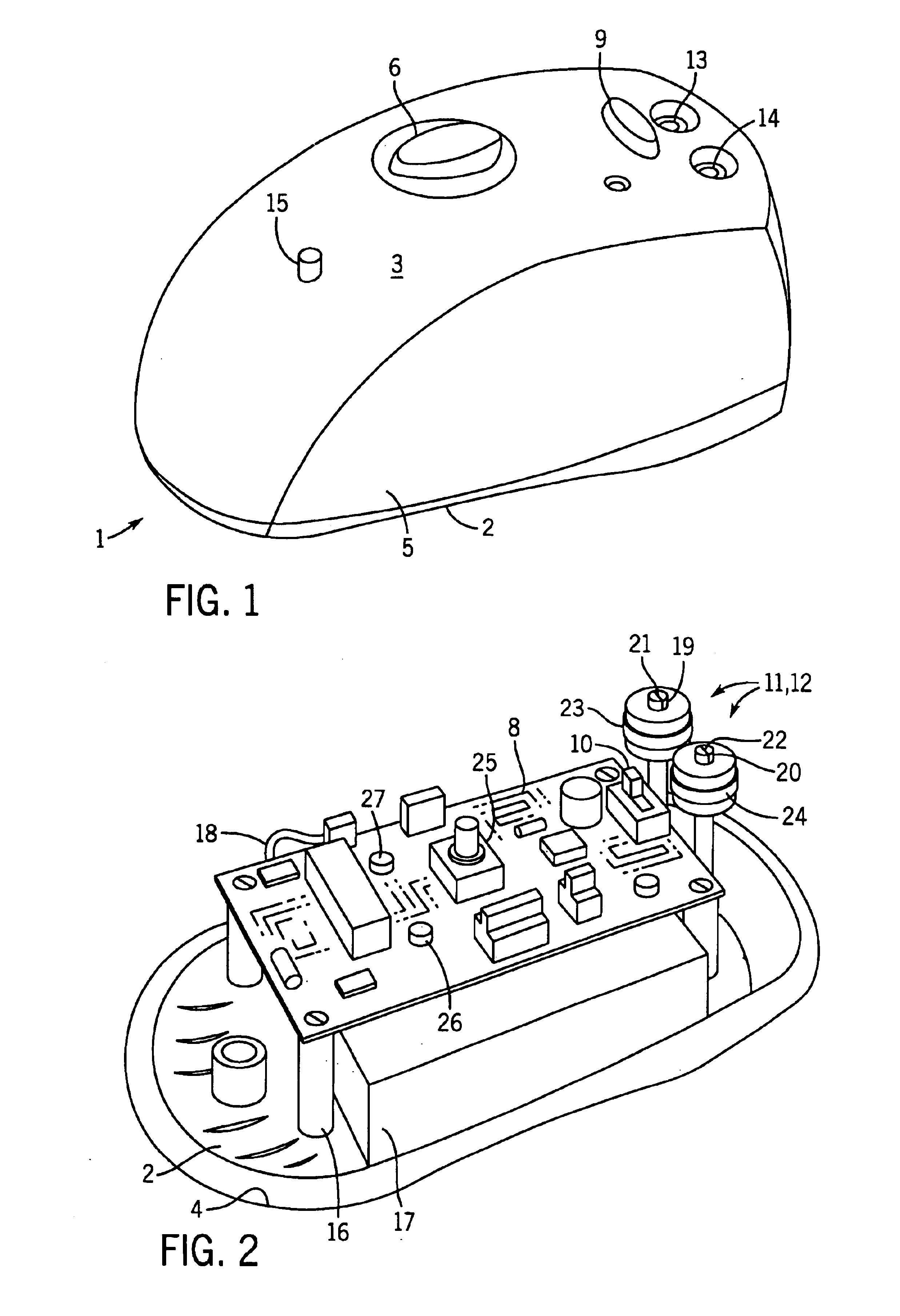

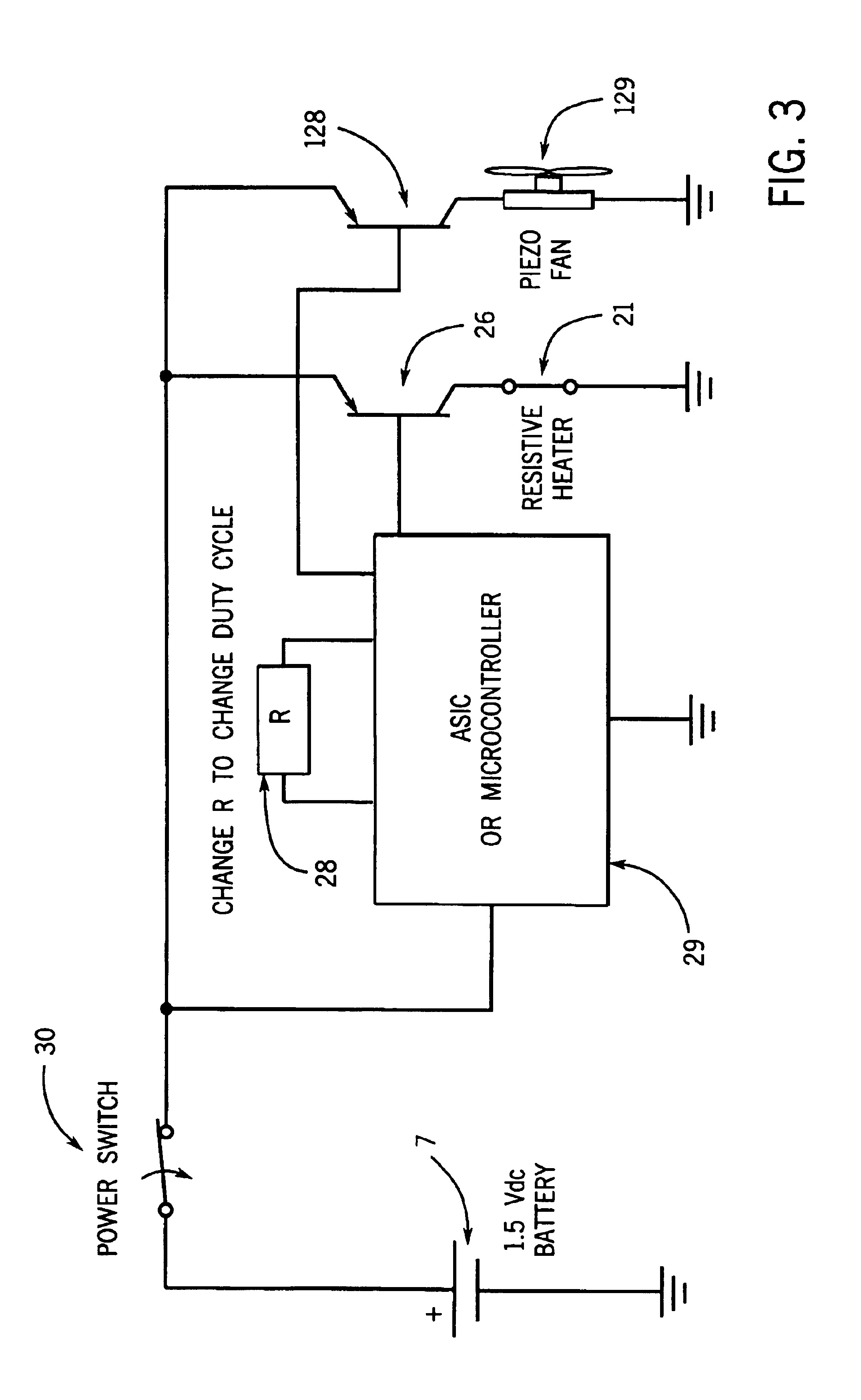

InactiveUS6909840B2Improved vaporizationIncrease vapor pressureDomestic stoves or rangesLiquid heating fuelElectrical resistance and conductanceProduct gas

The present invention relates to an apparatus and method for rapid flash-like volatilization of high and low vapor pressure components from liquid or solid emanators which is in contact with a point or localized heat source. Vaporization is promoted by a geometrically small electrically resistive heating element with variable activation for pulsed or cyclic heating of an emanating surface containing the volatile components. The apparatus is primarily directed towards the treatment of residential air for fragrancing, odor elimination, treatment of insects or pests, air sanitization, air and surface antibacterial or antimicrobial treatment, or other ambient air or surface modification by way of gas or vapor distribution.

Owner:SC JOHNSON & SON INC

Preparation of multi-position doped lithium iron phosphate positive electrode material and application thereof

ActiveCN101339994AWide range of materialsIncrease base capacityElectrode manufacturing processesPhosphorus compoundsElectricityLithium iron phosphate

The invention discloses a preparation method of a multi-place doped lithium iron phosphate anode material and an application thereof, which belong to the technical field of the preparation of electrochemical power materials. The multi-place doped lithium iron phosphate anode material is expressed by the following formula: Li1-xAxFe1-yByP1-zCzO4Ddelta, wherein, at least two of x, y, x and delta can not be expressed zero at the same time. Multi-place doped anode material lithium iron phosphate powder which is used in a secondary lithium-ion battery and has good crystallization performance and even composition is prepared by adopting a solid phase method and a simple mixing and drying process; compared with the method doping in a certain crystal lattice place, the multi-place doped anode material lithium iron phosphate powder has wide doping material source, which can greatly improve the basic capacity and cycling electrical performance of matrix and is applied to a stable industrialized production and non-high-purity materials. The multi-place lithium iron phosphate of the invention is taken as the anode material and is usually used in the secondary lithium-ion battery and the secondary lithium-ion battery is taken as a power source.

Owner:甘肃大象能源科技有限公司

Inorganic shaped bodies and methods for their production and use

InactiveUS6991803B2Overcome the lack of robustnessNovel featuresPowder deliveryDental implantsPorosityCellulose

Shaped, preferably porous, inorganic bodies are provided which are prepared from a reactive blend. In accordance with one preferred embodiment, the solution is absorbed into a porous sacrificial substrate such as a cellulose sponge. The solution-saturated substrate is heated and an oxidation-reduction reaction occurs thereby forming an inorganic solid. A shaped, inorganic body is formed in situ. Optional, but preferred additional thermal treatment of the shaped, inorganic body removes the organic substrate, leaving an inorganic body that faithfully mimics the porosity, shape, and other physical characteristics of the organic substrate. Inorganic substrates may also be used to good effect. Large varieties of shaped bodies can be prepared in accordance with other embodiments of the invention and such shapes find wide use in surgery, laboratory and industrial processes and otherwise. The invention also provides chemically and morphologically uniform powders, including those having uniformly small sizes.

Owner:ORTHOVITA INC

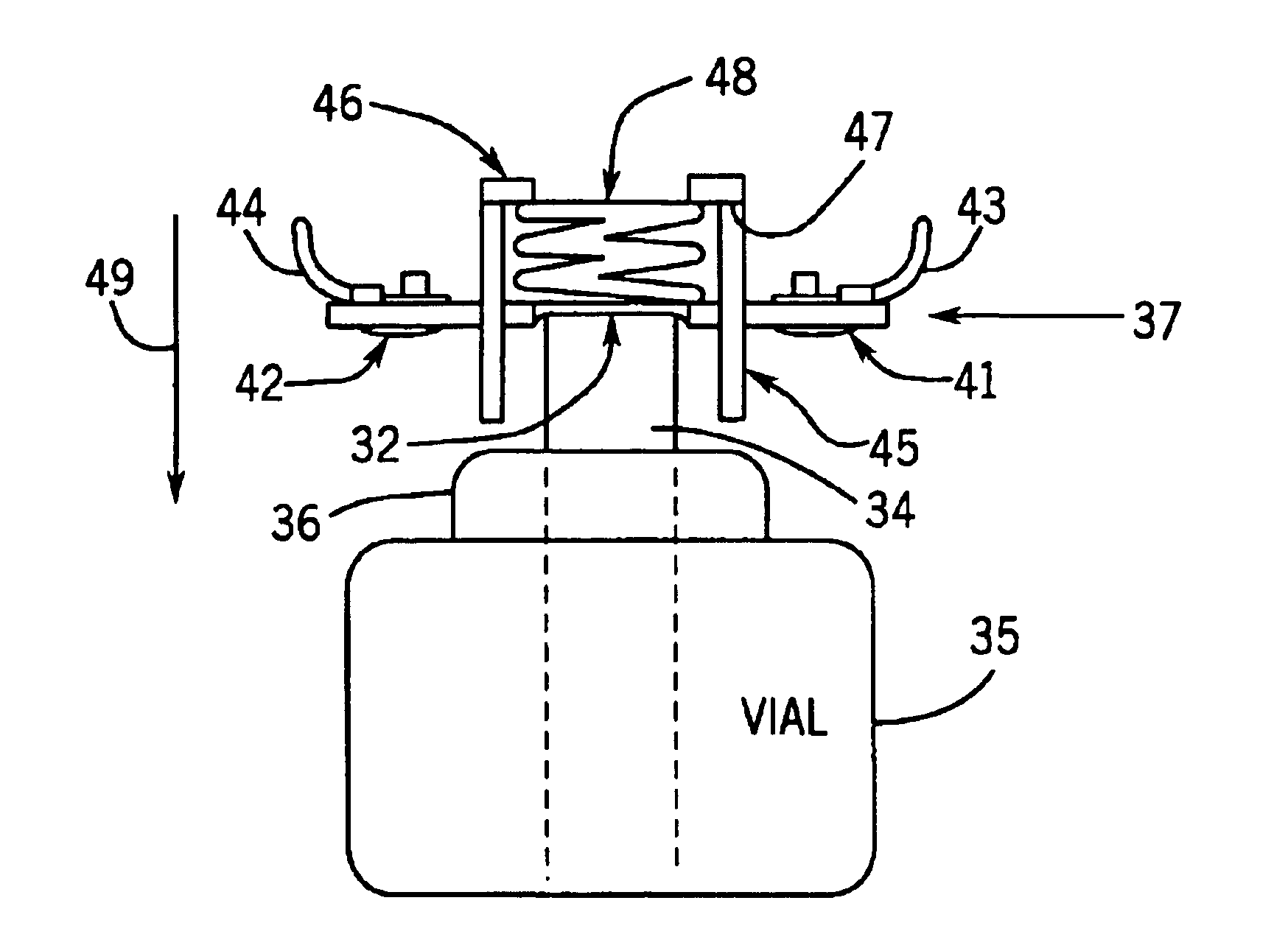

Ribbon feeder and printer

InactiveCN1914045AEliminate wrinklesUniform tensionPrinting mechanismsInking apparatusConductor CoilMechanical engineering

The invention relates to a ribbon feeder of printer. Ribbon tension detecting means (20, 21) each consisting of a plate-like lever body (35) are disposed upstream and downstream, respectively, of a ribbon path from a platen (7). The plate-like lever body (35) has first and second rollers (47, 48) disposed upstream and downstream of the ribbon path and swings around the axis of the rotary shaft of the second roller (48) according to the tension on the ribbon traveling as guided by these rollers (47, 48). When the amount of swing is above or below a fixed vale, a ribbon feed motor (18) or a ribbon winding motor (19) is driven. Further, the ribbon tension detecting means (20, 21) are each provided with a wrinkle eliminating member adapted to contact an ink ribbon (13) so as to eliminate wrinkles formed in the ink ribbon (13).

Owner:CITIZEN WATCH CO LTD

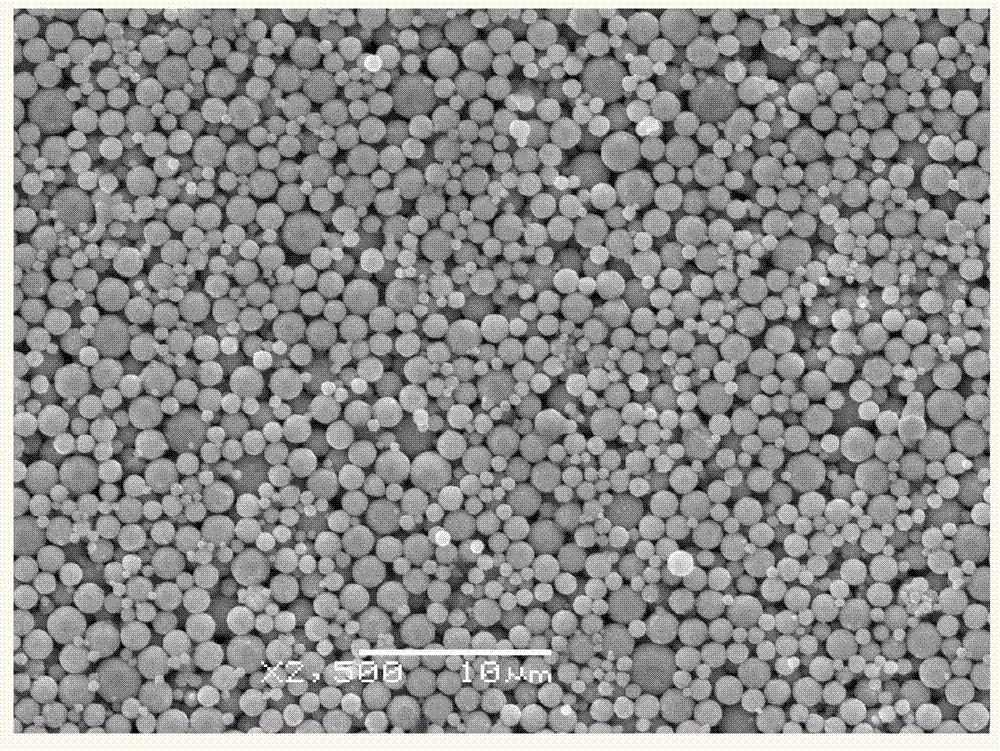

Toner, method of producing same and image forming device

A toner for developing an electrostatic image, including a colorant, a binder resin comprising a modified polyester, and fine resin particles having a weight average particle diameter of 50 to 300 nm and being present on an outer surface of the toner, wherein the toner has a BET specific surface area of 1.5 to 4.0 m2 / g.

Owner:RICOH KK

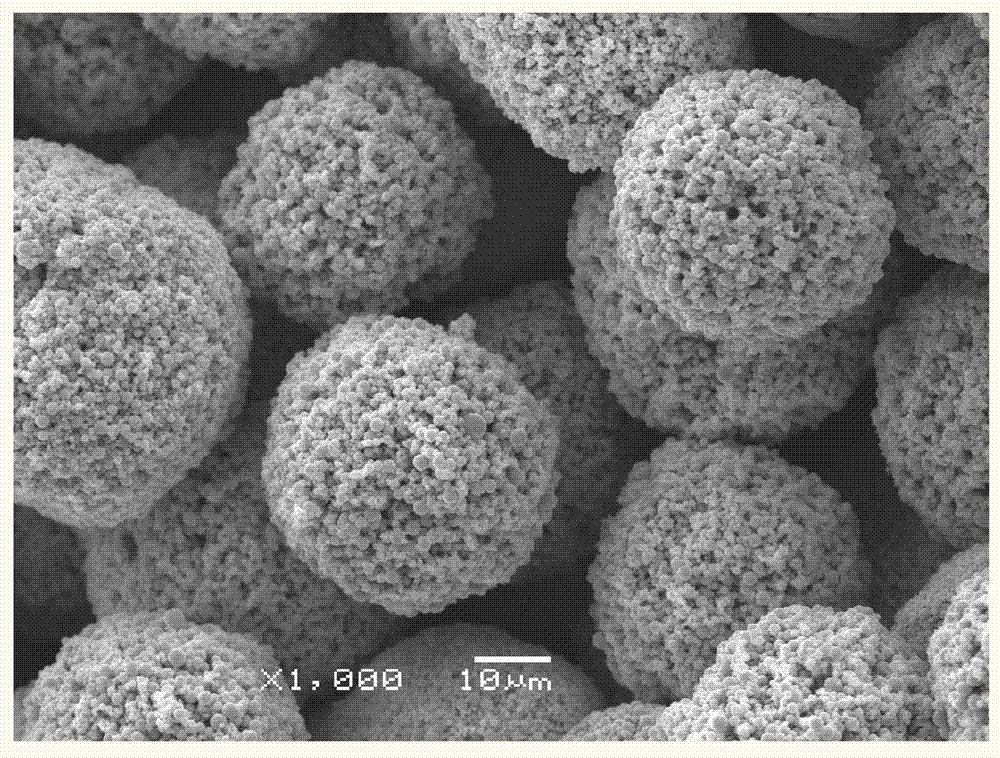

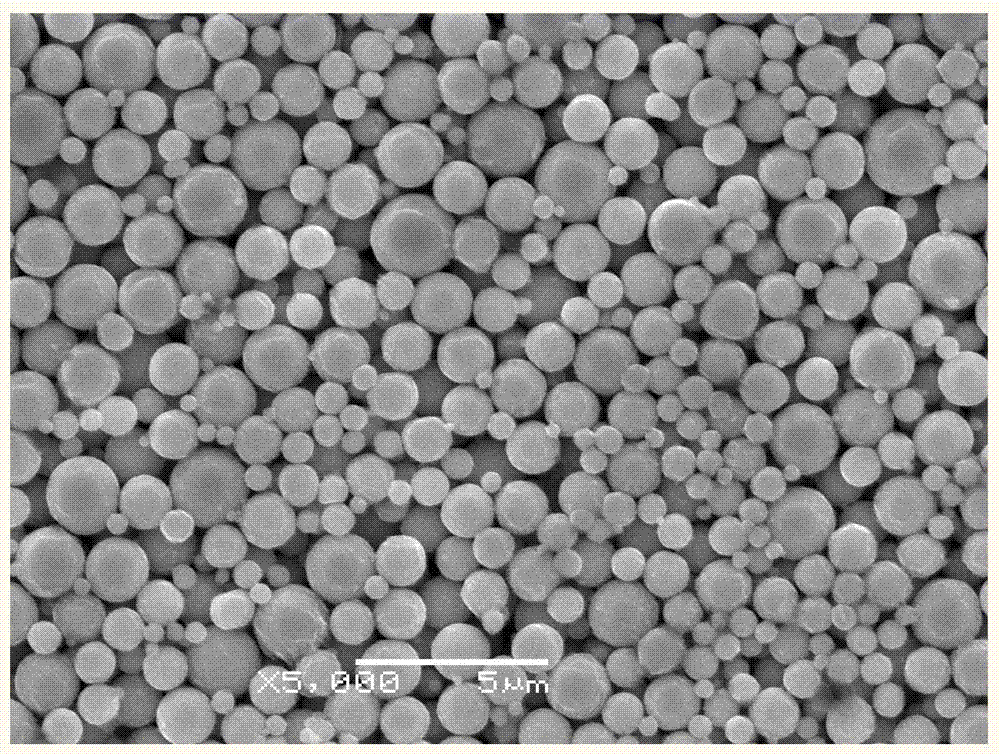

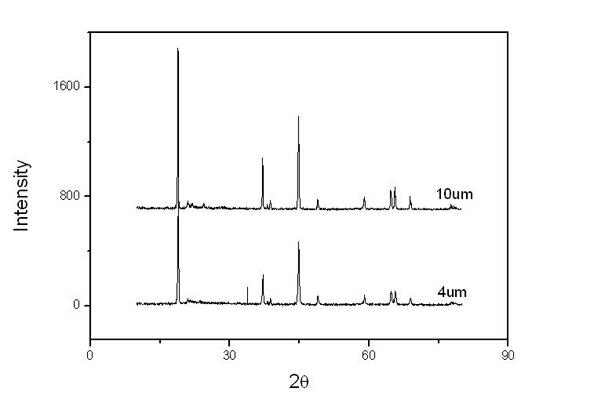

Metal powder for 3D printer and preparing method thereof

ActiveCN103785860AHigh sphericityUniform compositionAdditive manufacturing apparatusTransportation and packagingDispersityMetal particle

Owner:JIANGSU BOQIAN NEW MATERIALS CO LTD

Composite shaped bodies and methods for their production and use

InactiveUS20050042288A1Increase productionLow process temperatureDental implantsPowder deliveryCalcium biphosphatePlastic surgery

Shaped, composite bodies are provided. One portion of the shaped bodies comprises an RPR-derived porous inorganic material, preferably a calcium phosphate. Another portion of the composite bodies is a different solid material, preferably metal, glass, ceramic or polymeric. The shaped bodies are especially suitable for orthopaedic and other surgical use.

Owner:ORTHOVITA INC

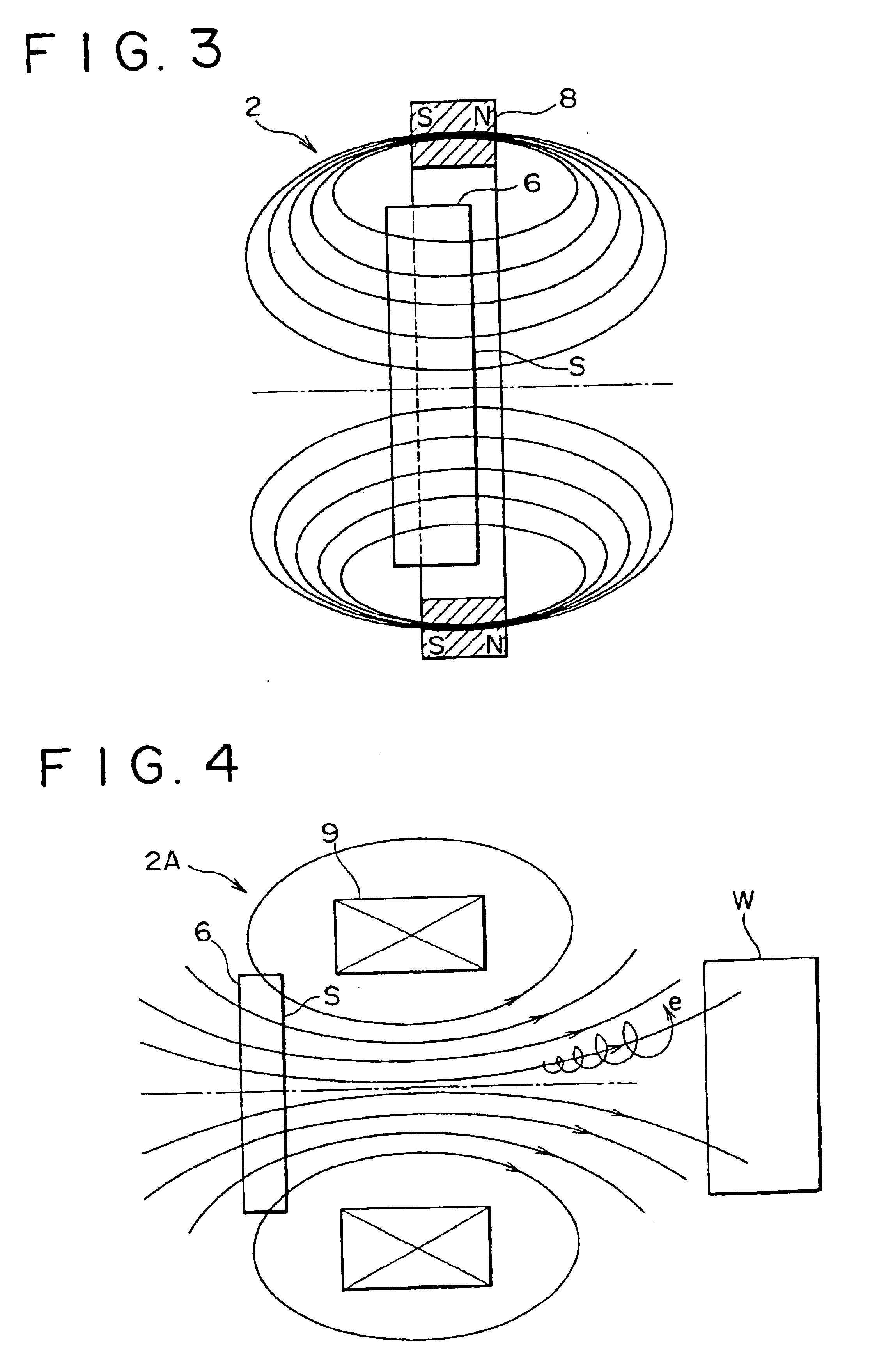

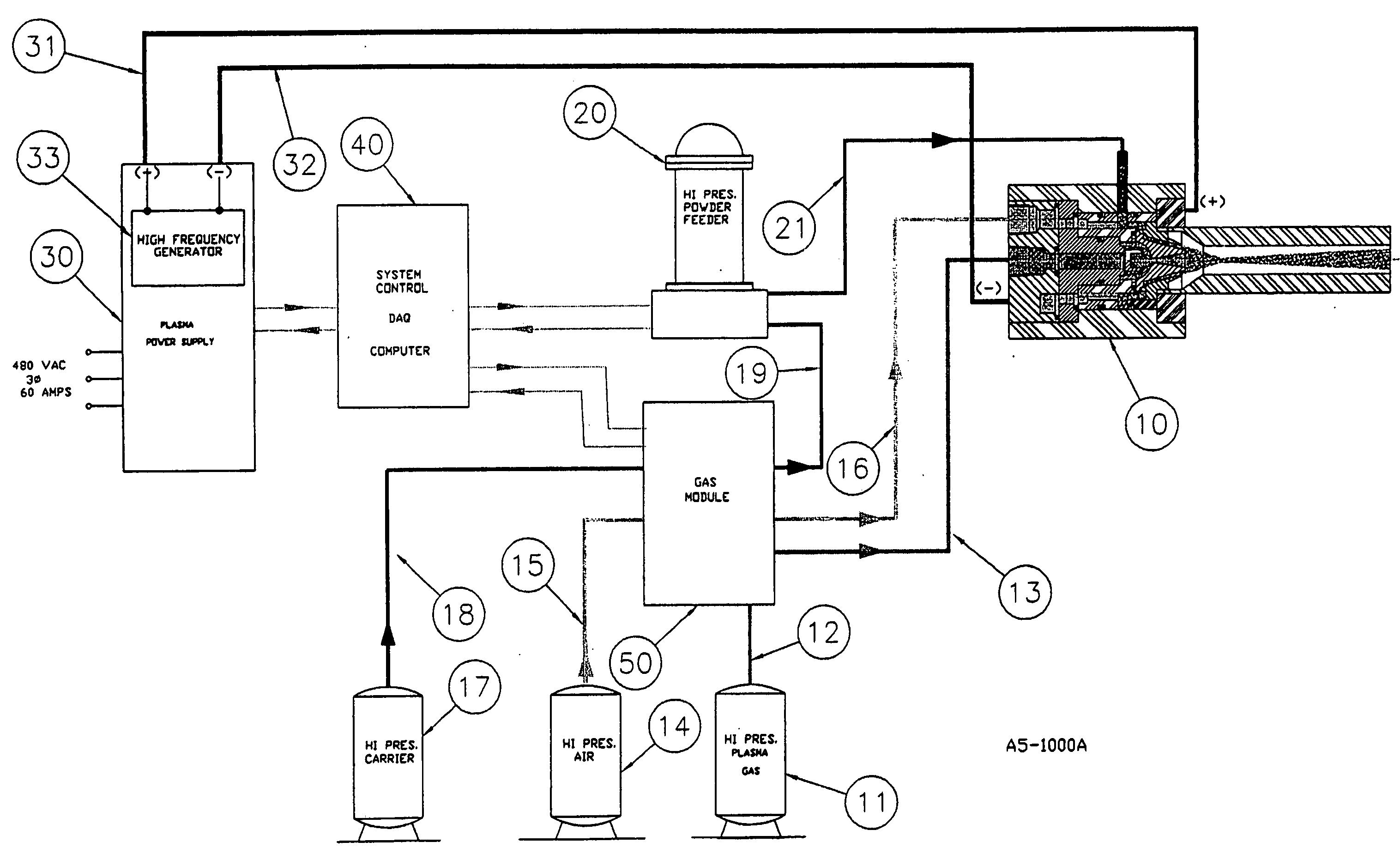

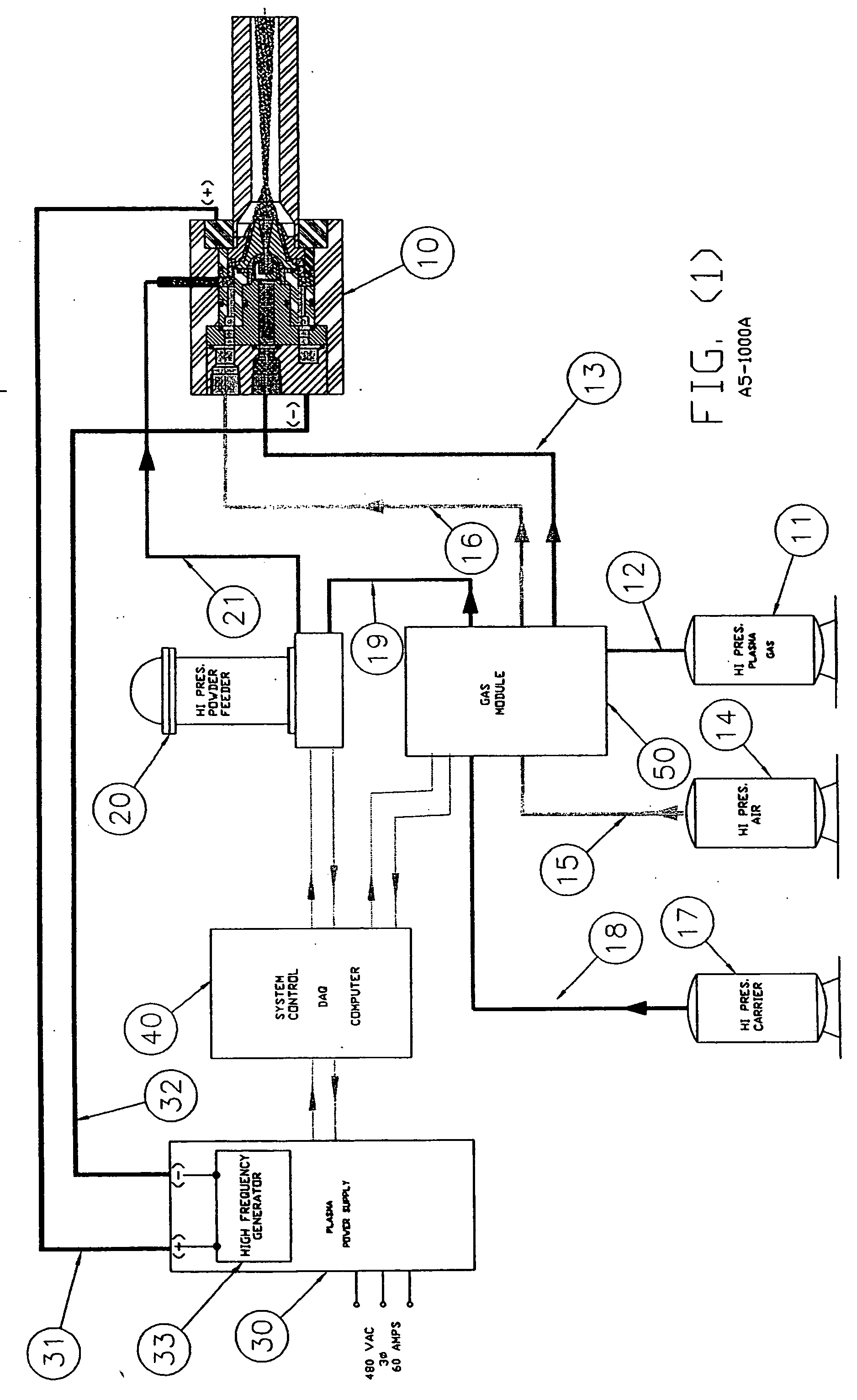

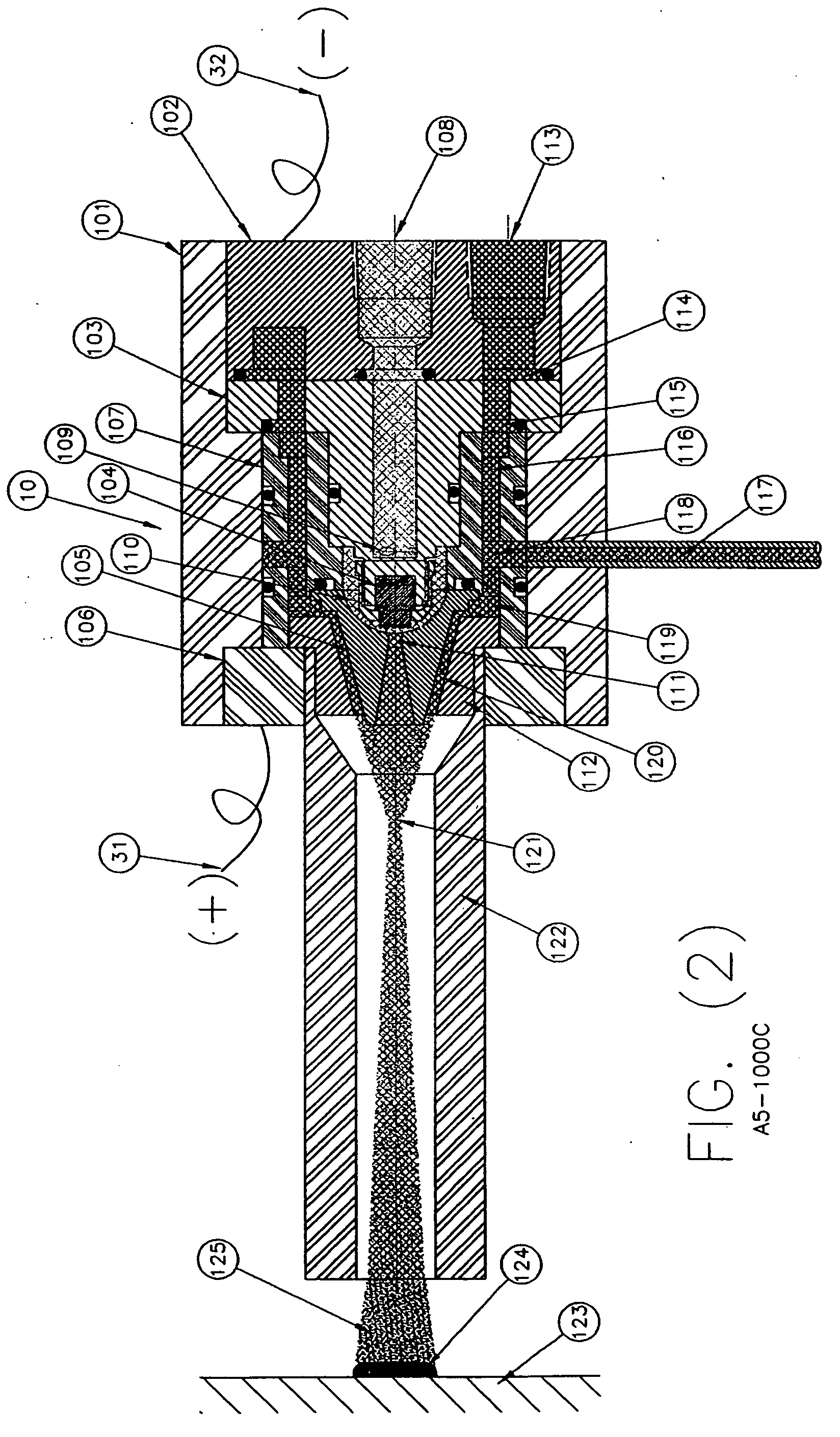

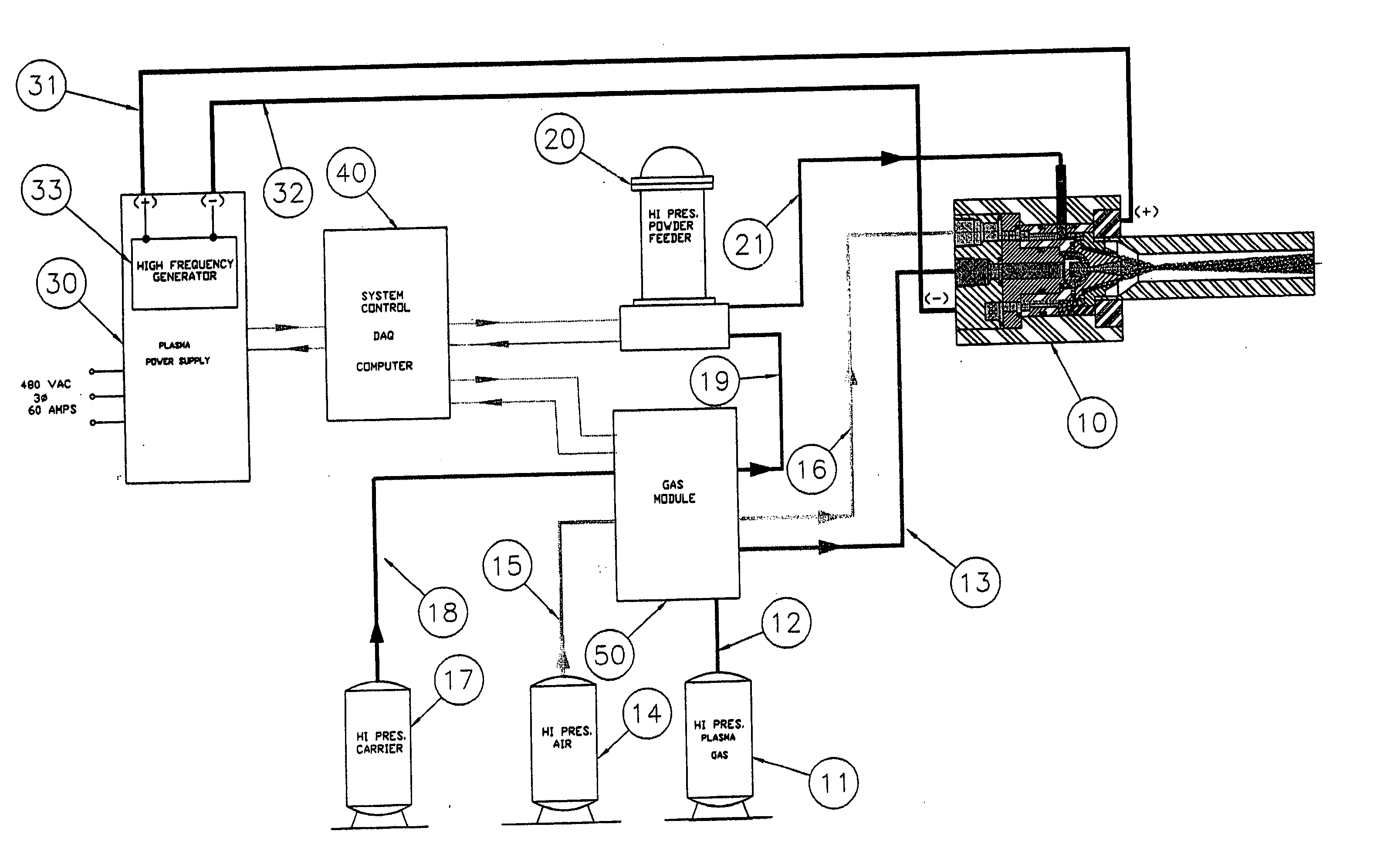

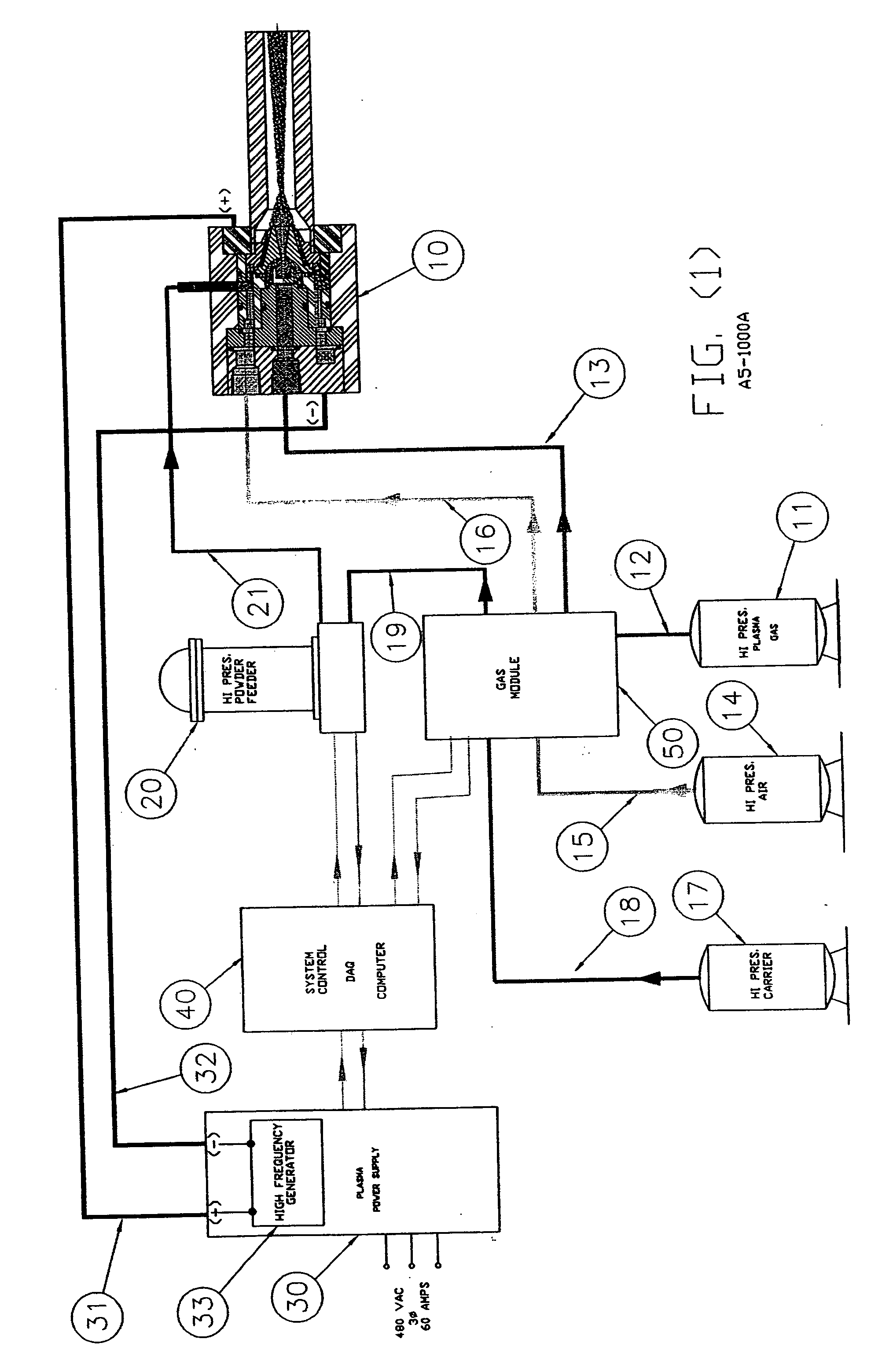

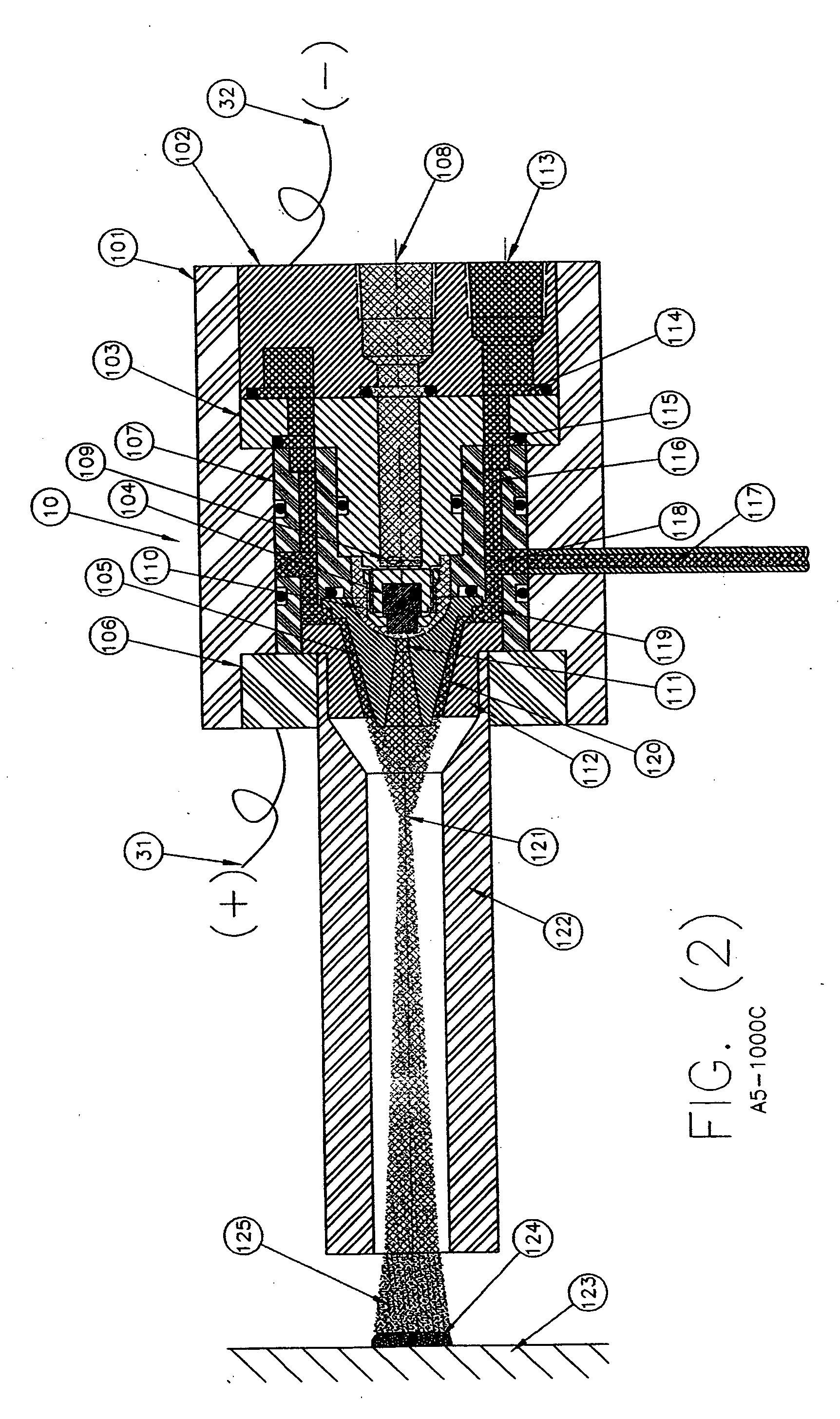

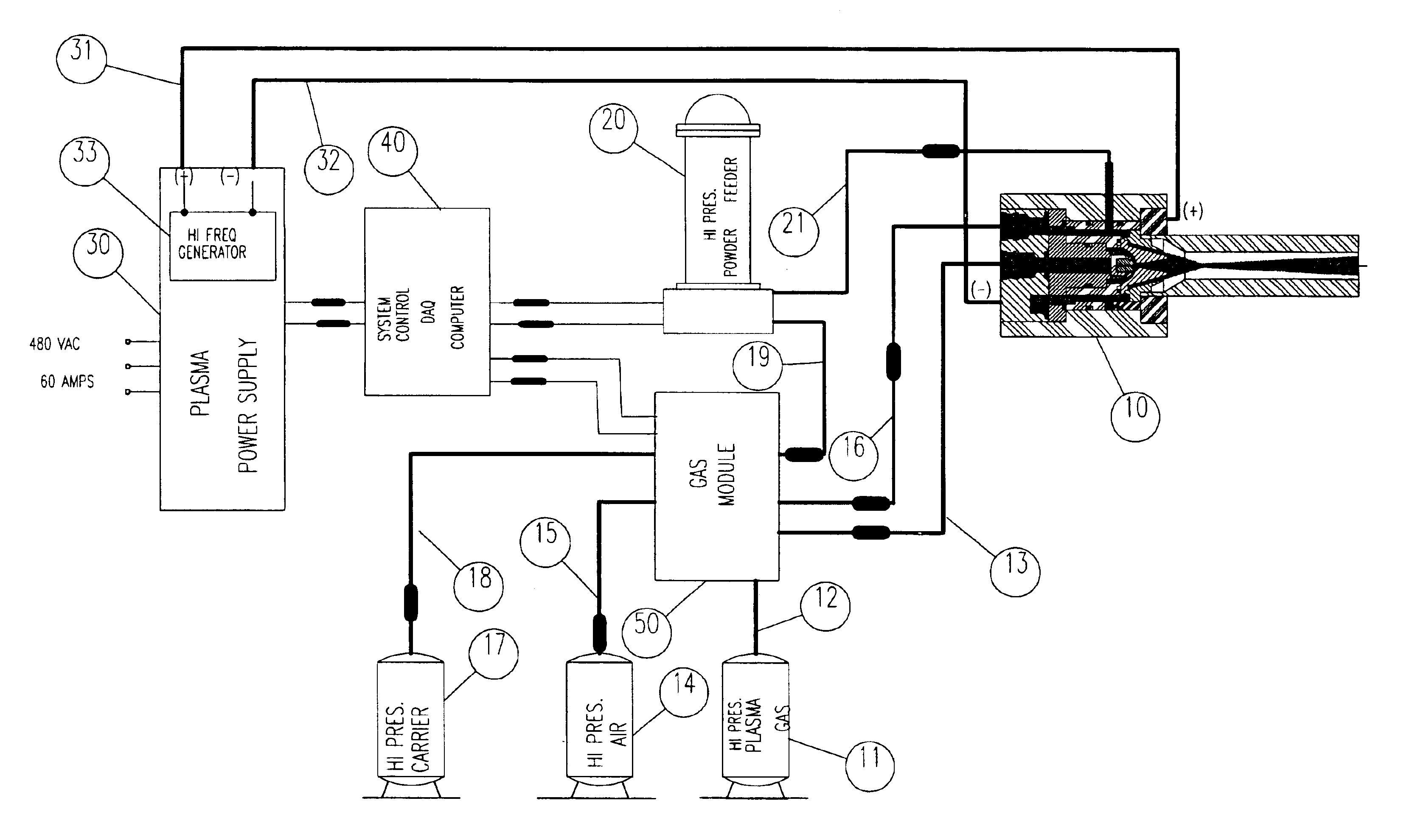

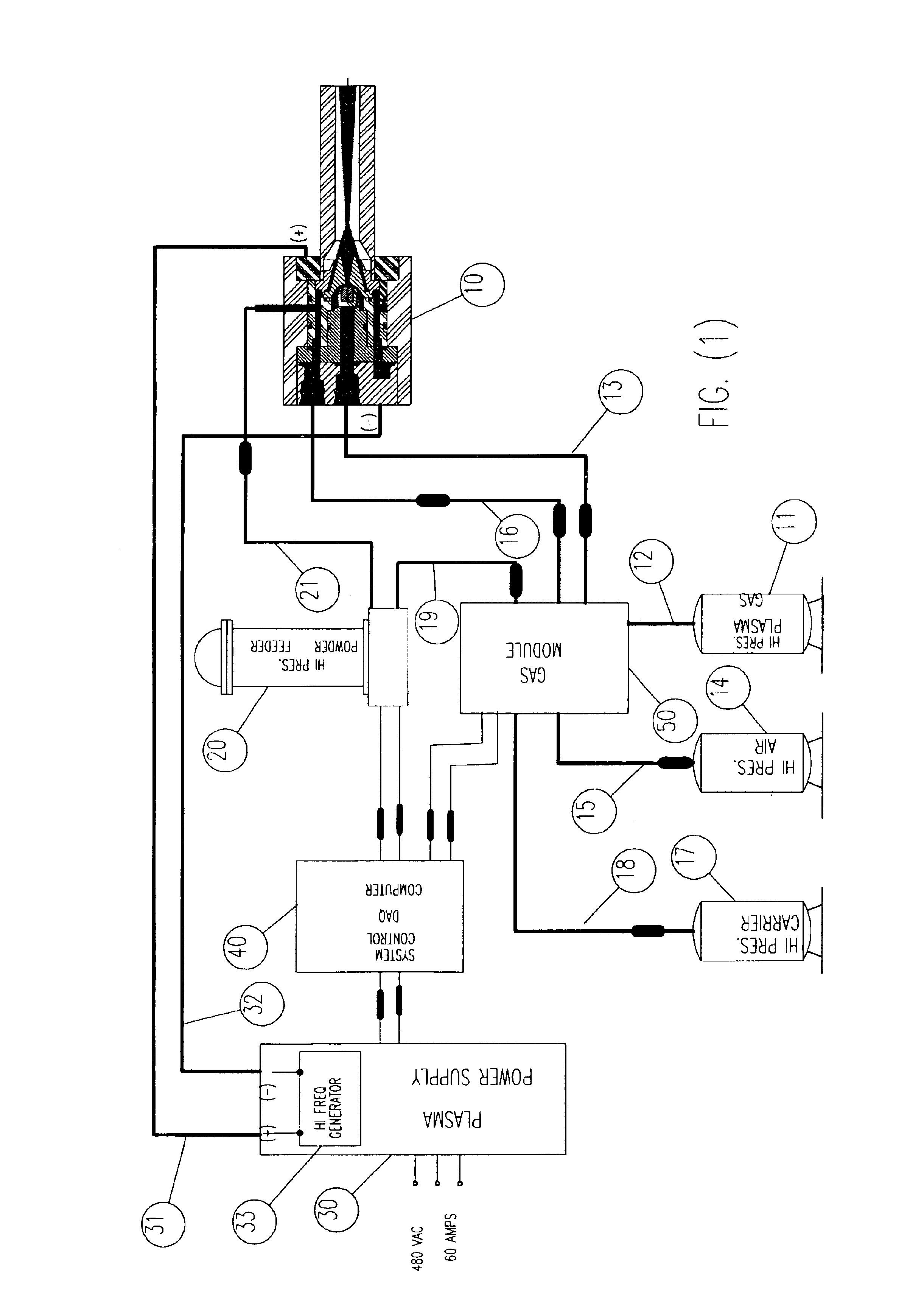

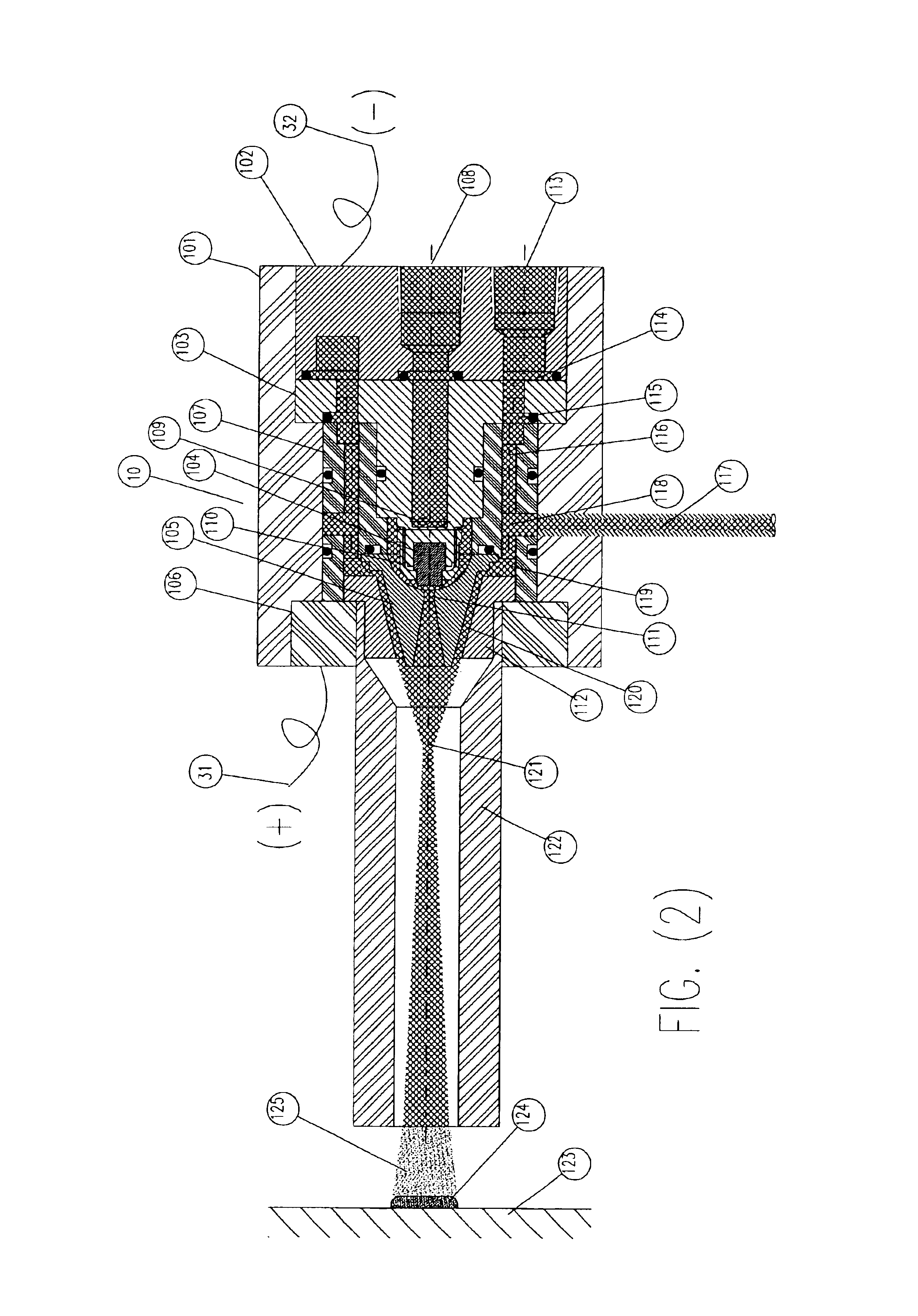

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050252450A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns. The system also includes a rotating member for coating concave surfaces and internal bores or other such devices which can be better coated using rotation.

Owner:FLAME SPRAY IND

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050120957A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns.

Owner:FLAME SPRAY IND

High strength steel plate for big thickness tall building structure and production method thereof

InactiveCN101323929AIncrease thickness specificationLow yield ratioMolten metal pouring equipmentsRoll mill control devicesSheet steelChemical composition

The invention relates to a steel plate with high intensity and used in construction structures of high buildings with large thickness and a production method thereof. The steel plate of the invention consists of the following components according to weight percentage: less than or equal to 0.20 percent of C, less than or equal to 0.55 percent of Si, 1.00 to 1.70 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.70 percent of Ni, less than or equal to 0.70 percent of Cr, less than or equal to 0.20 percent of V, more than or equal to 0.015 percent of Nb, less than or equal to 0.20 percent of Ti, 0.020 to 0.060 percent of Al, and the rest is Fe and inevitable impurity. The produced Q460E-Z35 steel plate with a thickness of 100 to 110 mm is capable of meeting the requirement of high intensity steel of large-thickness construction structure (Ceq is less than or equal to 0.50 percent); the steel plate of the invention can be applied to constructing the structure of high building, has good performance of welding and anti-layer tearing, can meet the requirement of on-site key stress points, has simple production process and is capable of realizing bulk production. The high intensity steel plate of the invention has the following advantages that (1) the steel quality of the invention is purer with less than or equal to 0.025 percent of P and less than or equal to 0.010 percent of S; (2) yield ratio of the invention is relatively low and less than 0.78 actually; (3) the anti-layer tearing performance is good, and Z is larger than or equal to 35 percent in whole thickness direction; (4) low-temperature toughness at the temperature of minus 40 DEG C is good; (5) maximum thickness of the steel plate can reach 110mm.

Owner:WUYANG IRON & STEEL

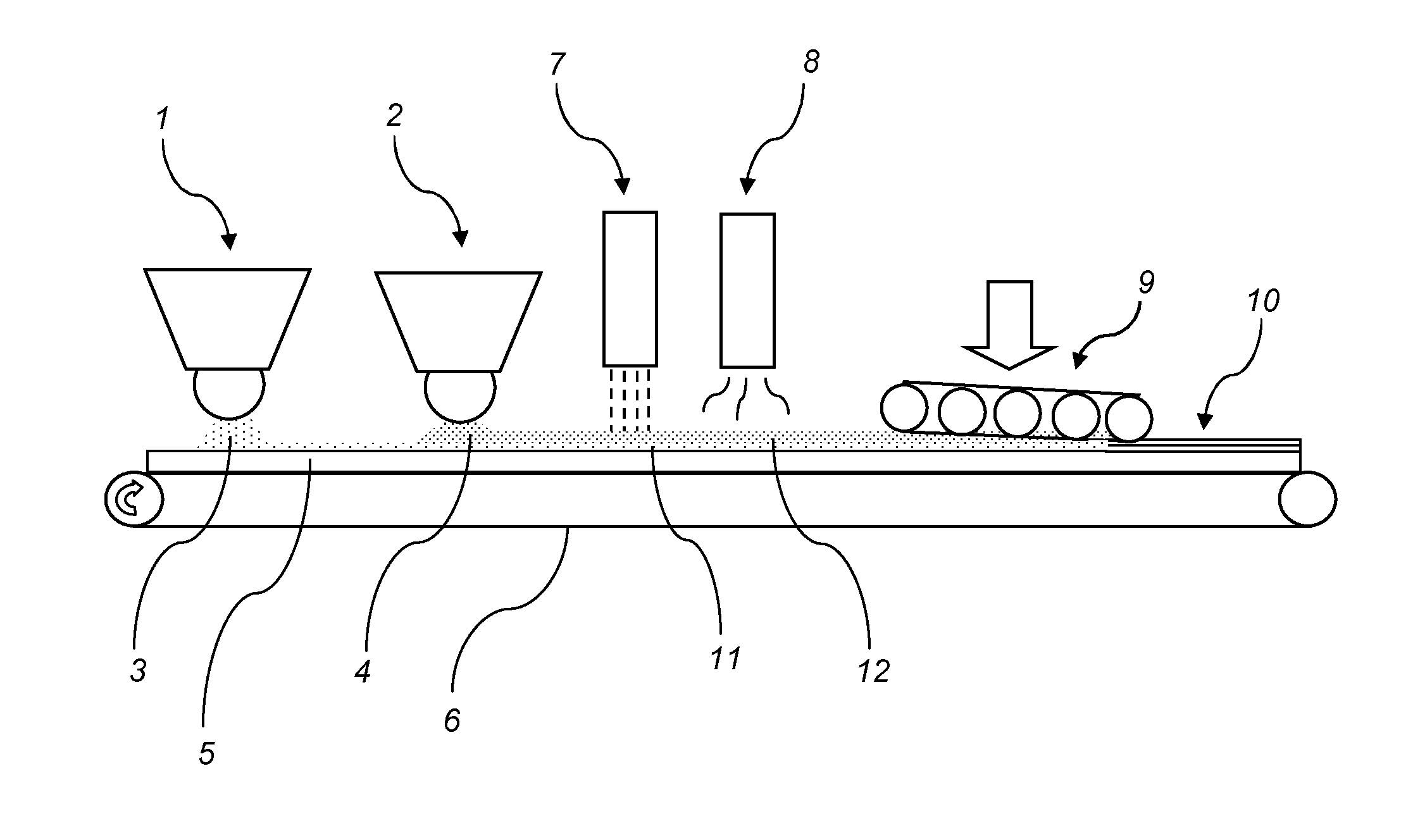

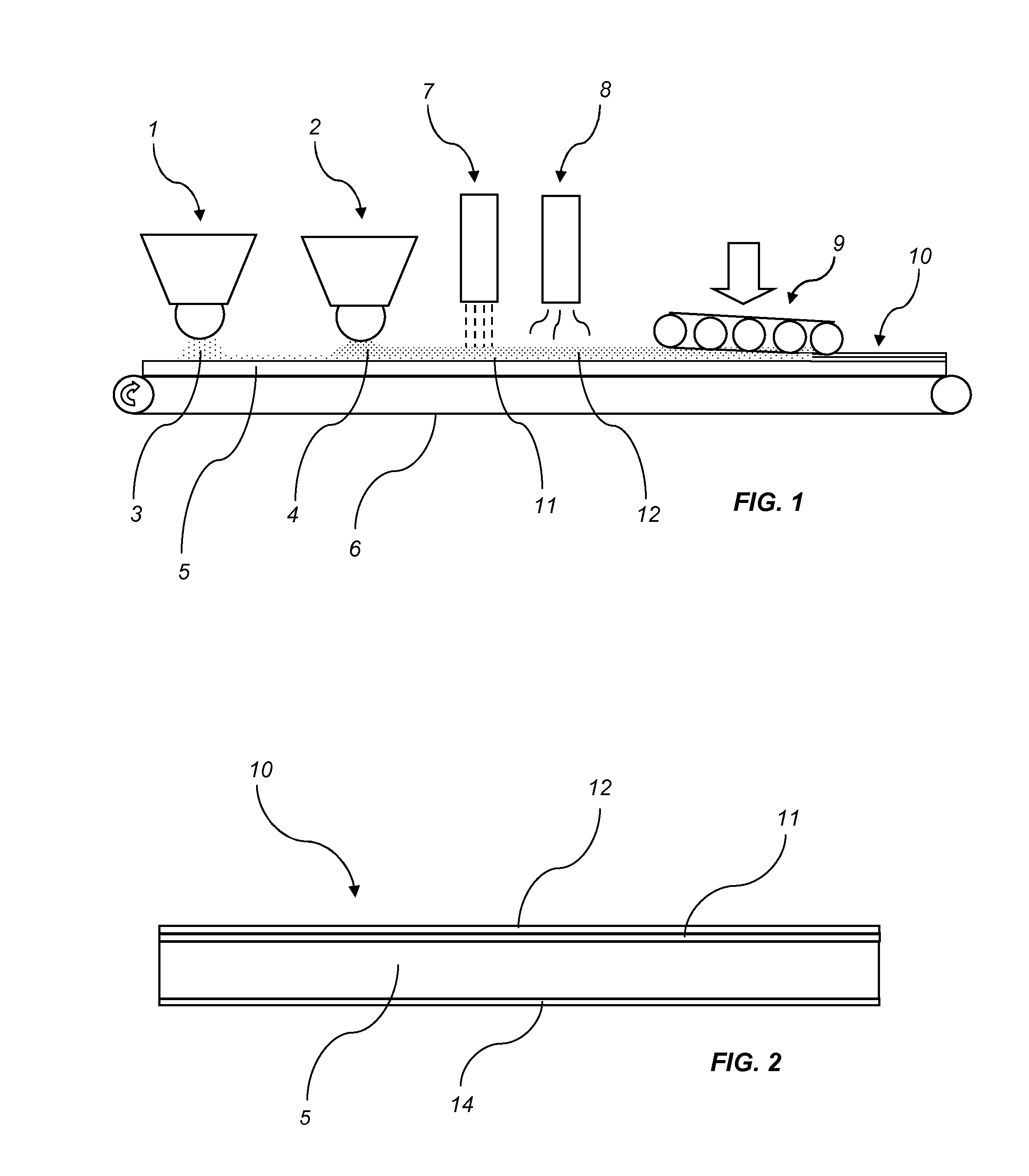

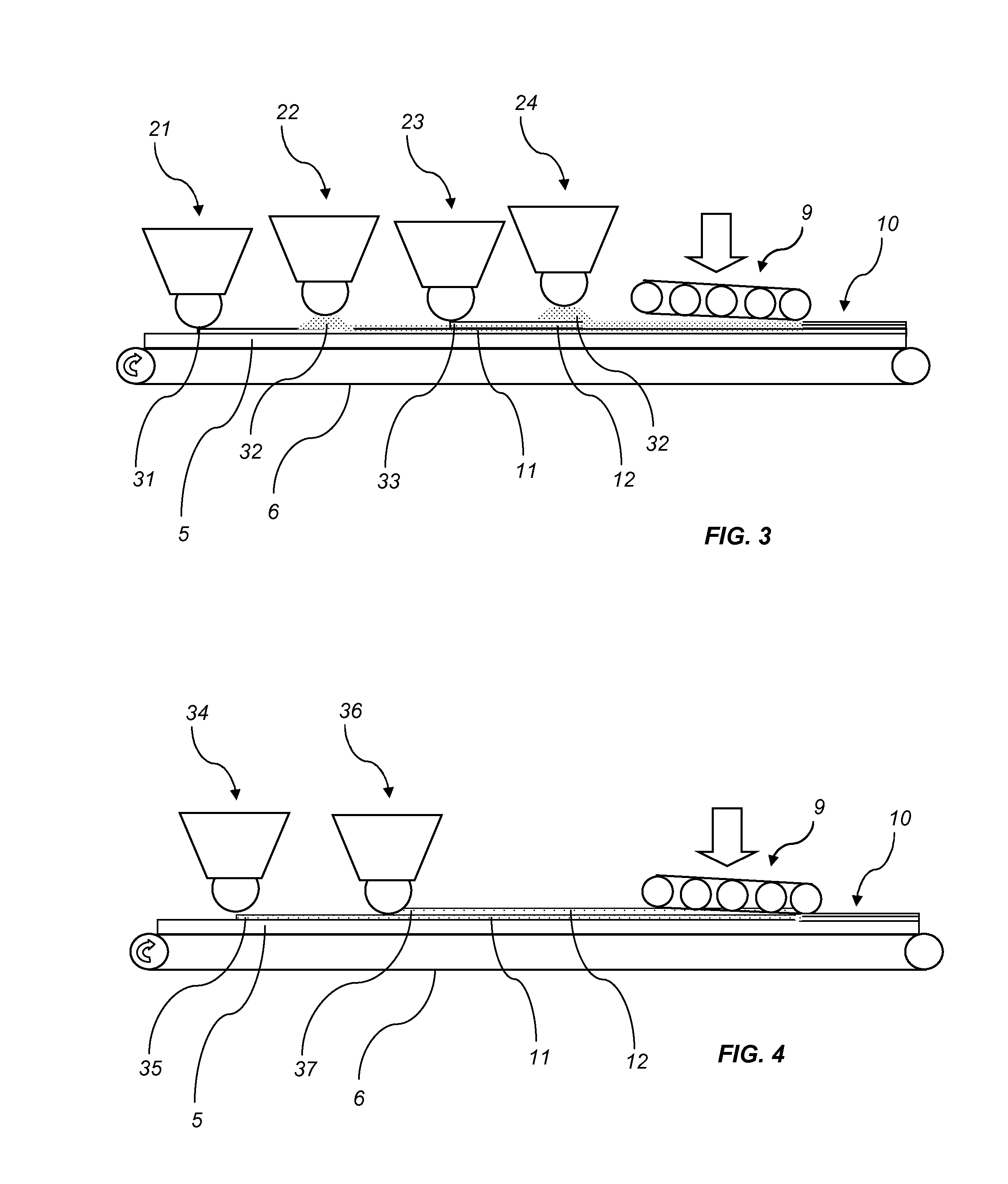

Method of manufacturing a building panel and a building panel

ActiveUS20150017461A1Improve printing effectUniform compositionLiquid surface applicatorsSynthetic resin layered productsMaterials science

A method of manufacturing a building panel (10). The method includes applying a first binder and free lignocellulosic or cellulosic particles on a first surface of a carrier for forming a first layer (11), applying a second binder and free lignocellulosic or cellulosic particles on the first layer (11) for forming a second layer (12), wherein the first binder is different from the second binder, and applying heat and pressure to the first and second layers (11, 12) to form a building panel. Also, such a building panel (10).

Owner:VÄLINGE INNOVATION AB

Plasma spray method for applying a coating utilizing particle kinetics

InactiveUS6861101B1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorHigh pressure

A method of operation of a plasma torch. A cold high pressure carrier gas containing a powder material is injected into a cold main high pressure gas flow and then this combined flow is directed coaxially around a plasma exiting from an operating plasma generator and converging into the hot plasma effluent, mixing with the effluent to form a gas stream with a net temperature, based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, such that the powdered material will not melt. The combined flow with entrained is directed through a supersonic nozzle accelerating the flow to supersonic velocites sufficient that the particles striking the workpiece achieve kinetic energy transformation into elastic deformation of the particles as they impact the workpiece forming a cohesive coating.

Owner:FLAME SPRAY IND

Phosphor single crystal substrate and method for preparing the same, and nitride semiconductor component using the same

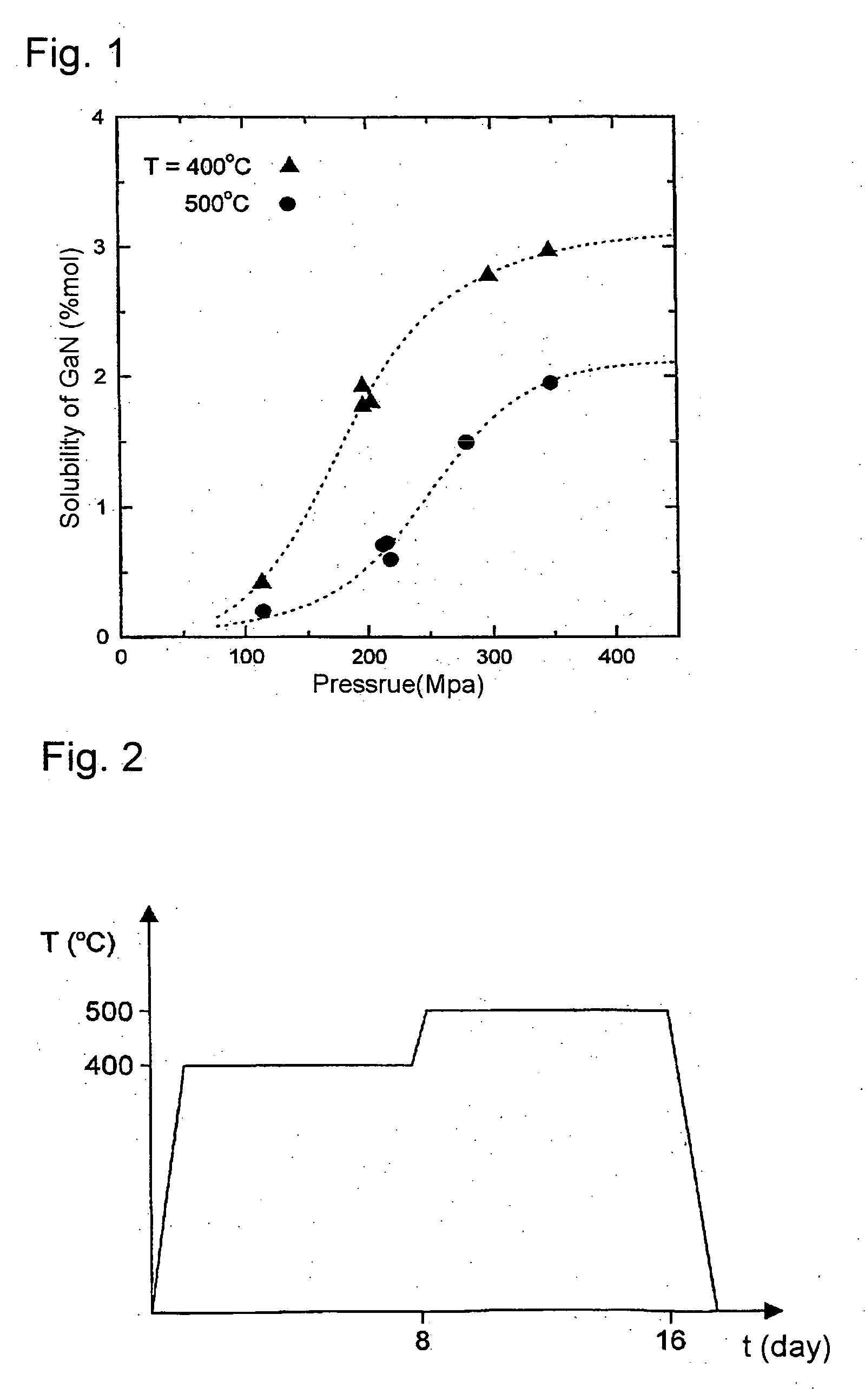

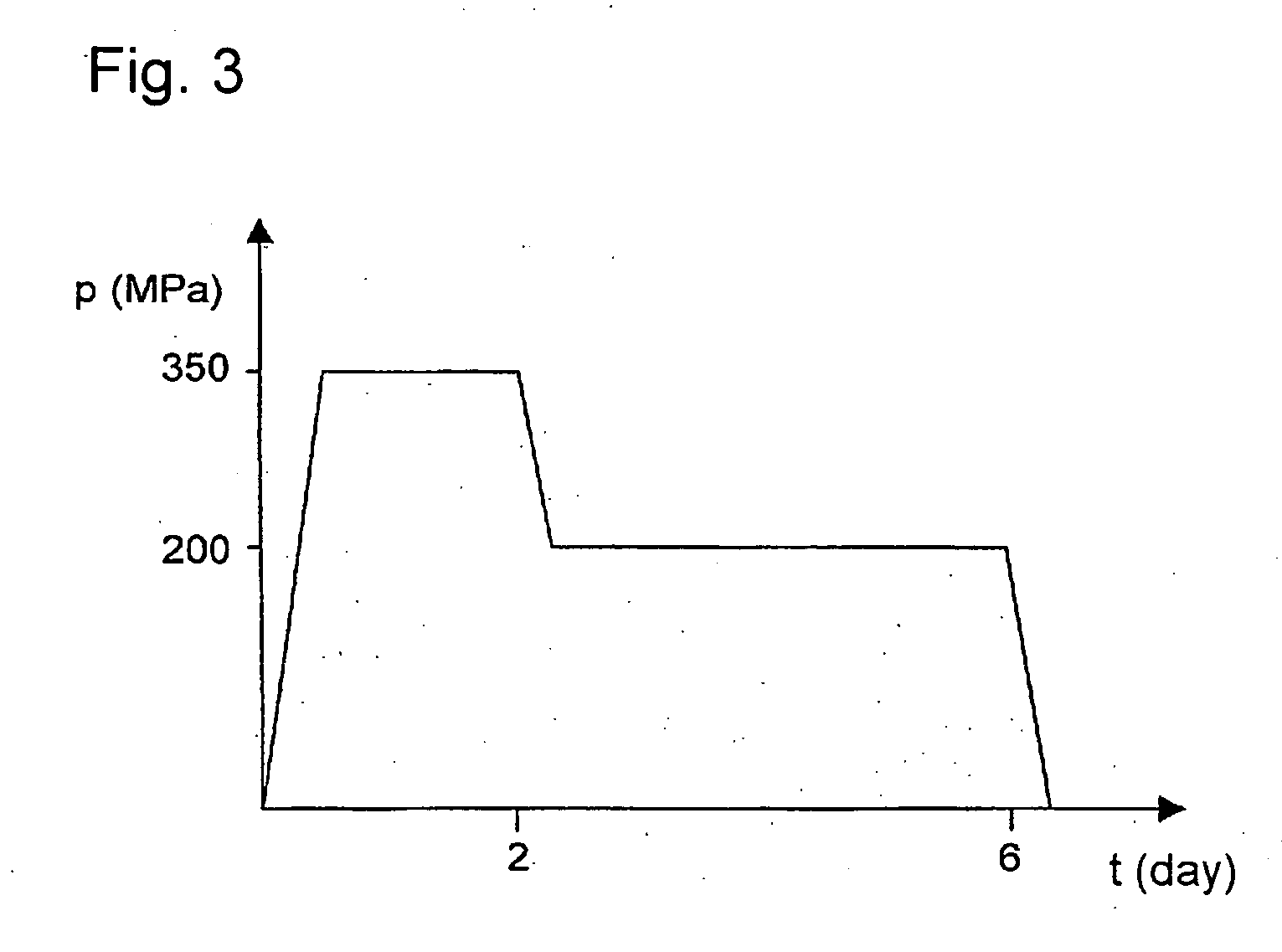

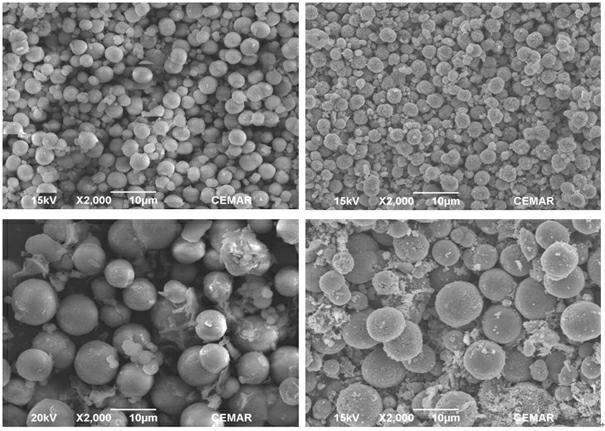

InactiveUS20060054076A1Simple processRapid cooling functionPolycrystalline material growthFrom normal temperature solutionsGas phaseSingle crystal

A light emitting device having a phosphor substrate, which comprises nitride containing at least one element selected from Group XIII (IUPAC 1989) having a general formula XN, wherein X is at least one element selected from B, Al, Ga and In, a general formula XN:Y, wherein X is at least one element selected from B, Al, Ga and In, and Y is at least one element selected from Be, Mg, Ca, Sr, Ba, Zn, Cd and Hg, or a general formula XN:Y,Z, wherein X is at least one element selected from B, Al, Ga and In, Y is at least one element selected from Be, Mg, Ca, Sr, Ba, Zn, Cd and Hg, and Z is at least one element selected from C, Si, Ge, Sn, Pb, O and S. The phosphor substrate is prepared by crystallization from supercritical ammonia-containing solution and the light emitting device is formed by a vapor phase growth on the phosphor substrate so as to obtain a light emitting device which has a wavelength distribution emitting a white light etc. and a good yield.

Owner:AMMONO SP Z O O (PL) +1

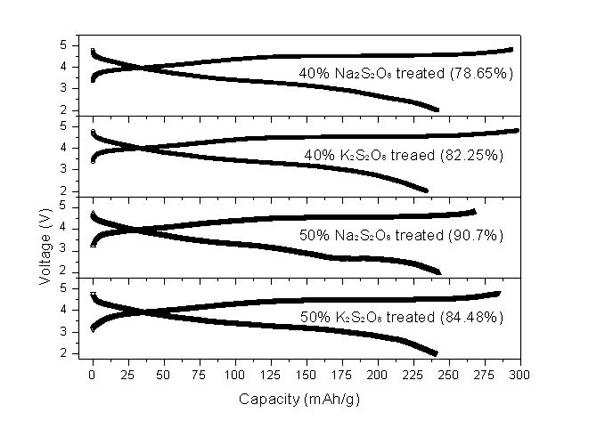

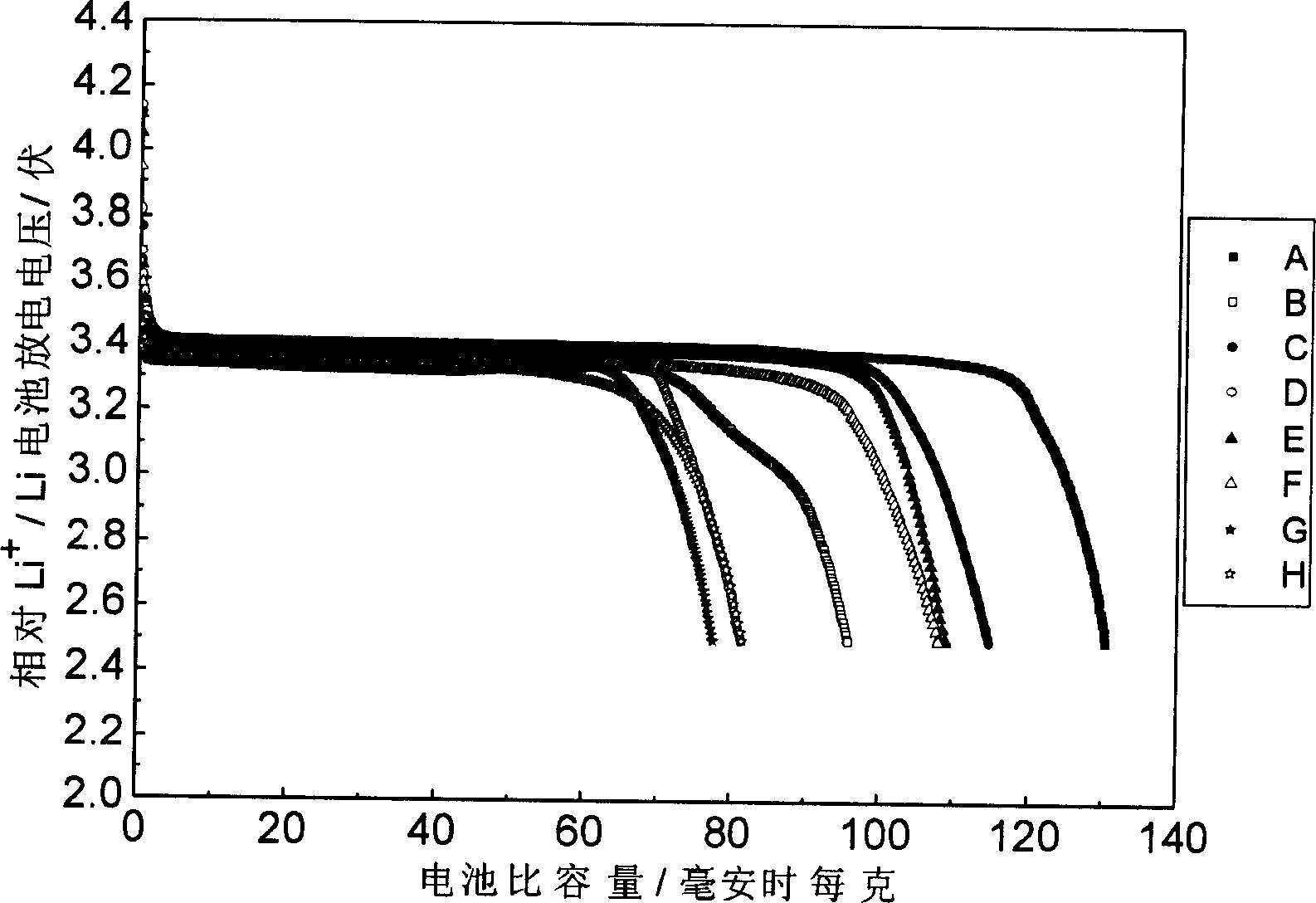

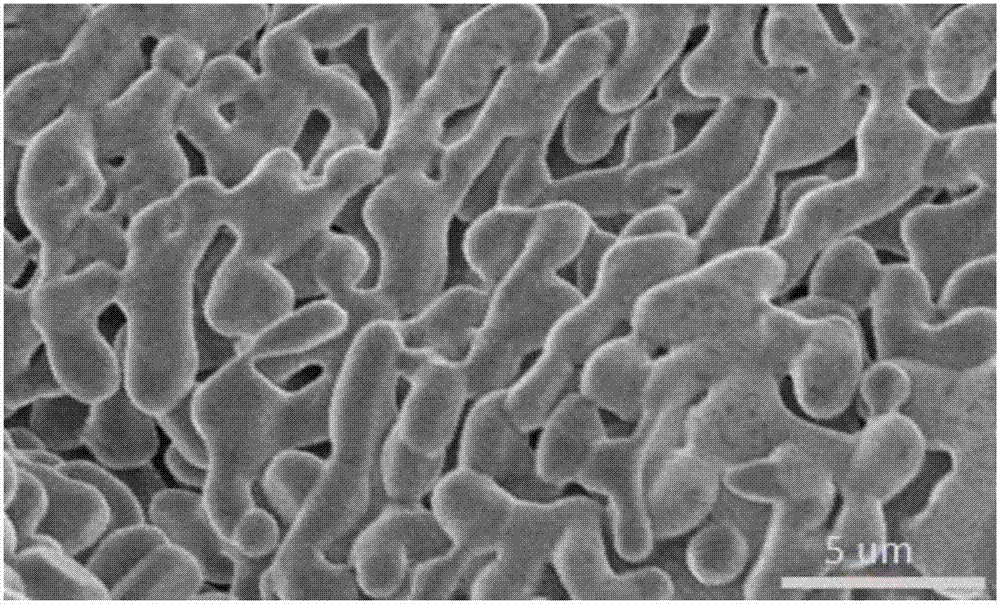

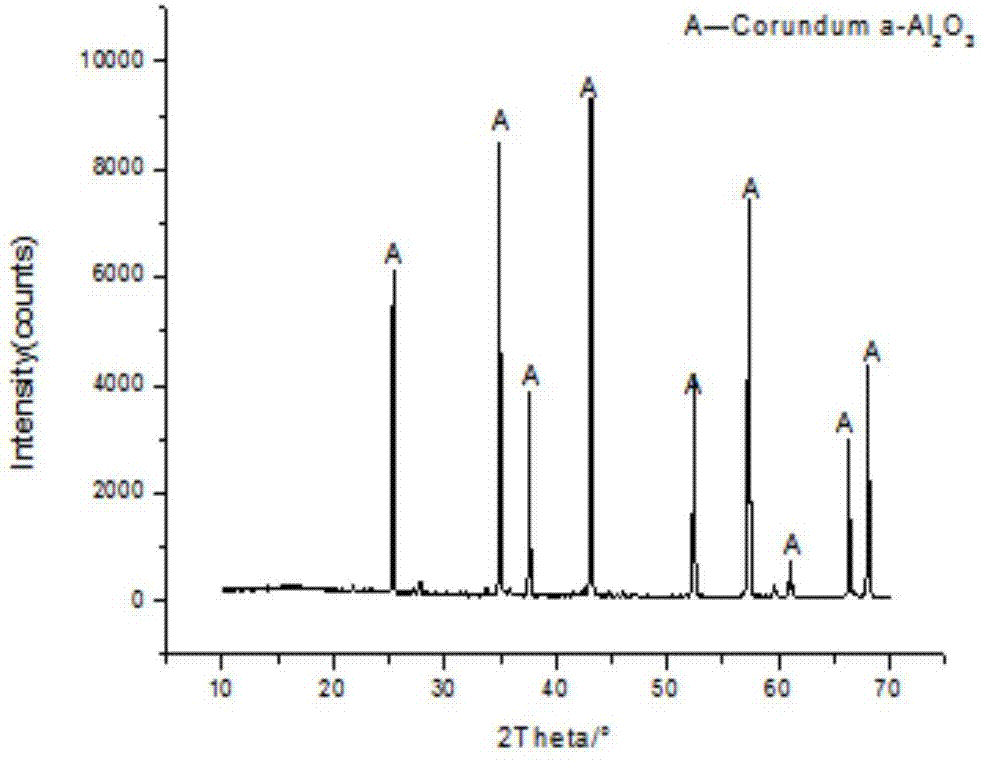

Synthesis and surface modification method of lithium excessive laminar oxide anode material

The invention relates to a synthesis and surface modification method of a lithium rich anode material Li1+xM1-xO2 (M is one or more of Ni, Co and Mn, and X is more than or equal to 0 and less than or equal to 1 / 3) for a lithium ion battery. The method comprises the following steps of: synthesizing a precursor by using a carbonate precipitation method, mixing the precursor and a lithium salt, and calcining for 2 to 20 hours at the temperature of between 800 and 1,100 EG C to obtain a lithium rich material, wherein the prepared lithium rich material has controllable particle size and higher reversible capacity; and dissolving persulfate or sulfate in an amount which is 5 to 80 mass percent of the lithium rich material into deionized water, adding the lithium rich material, stirring for 2 to 100 hours at the temperature of between 25 and 80 DEG C, heating the materials to the temperature of between 100 and 500 DEG C in a muffle furnace, calcining the materials for 2 to 20 hours, fully filtering the obtained materials, and washing off impurities to obtain the surface modified anode material Li1+x-yM1-xO2. The synthesized lithium rich material has controllable particle size; the first charge / discharge efficiency of the lithium rich material and the discharge specific capacity and the cyclical stability under high magnification can be improved; and the method is simple, low in cost, convenient for operation and suitable for industrialized production.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

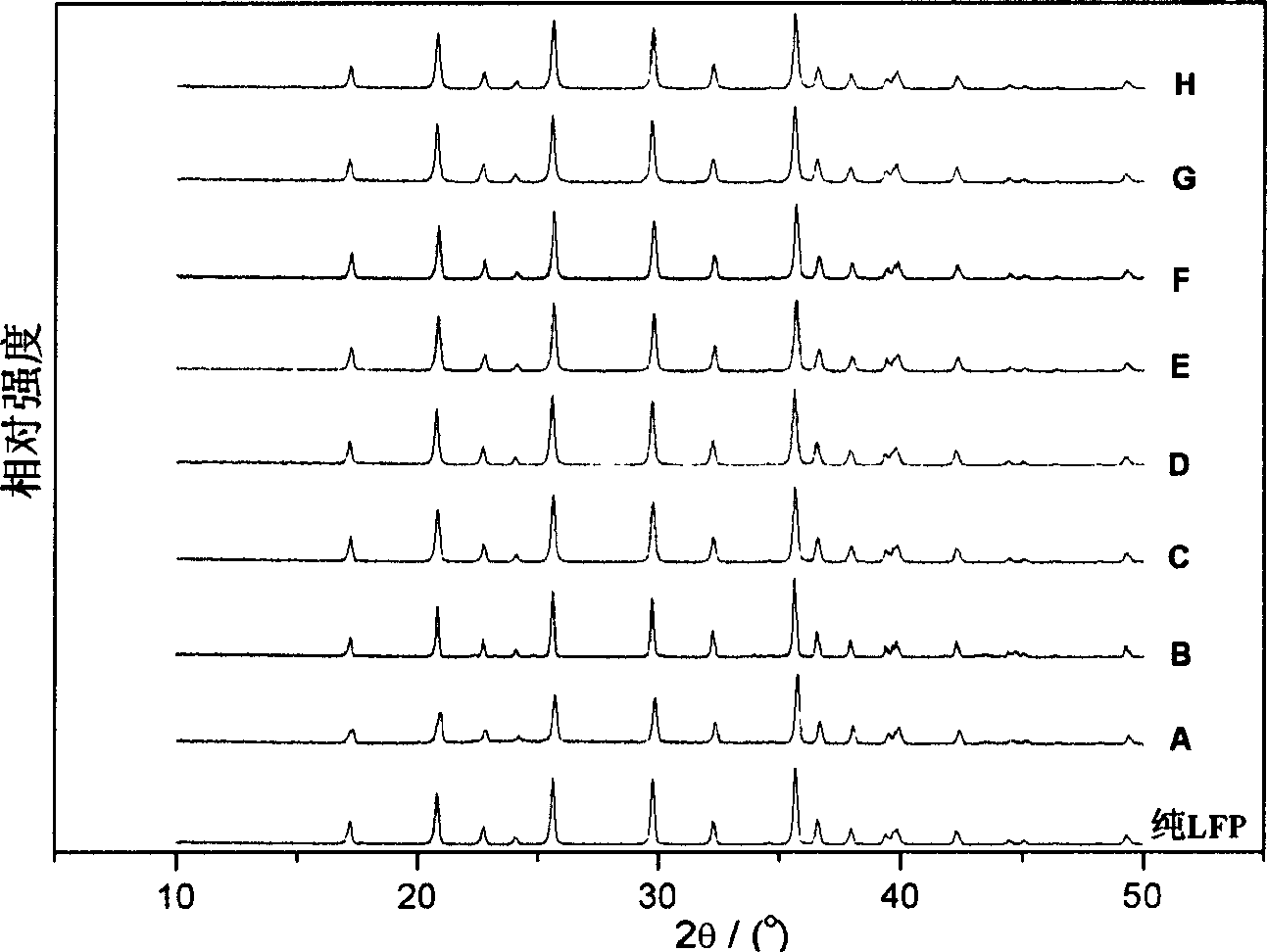

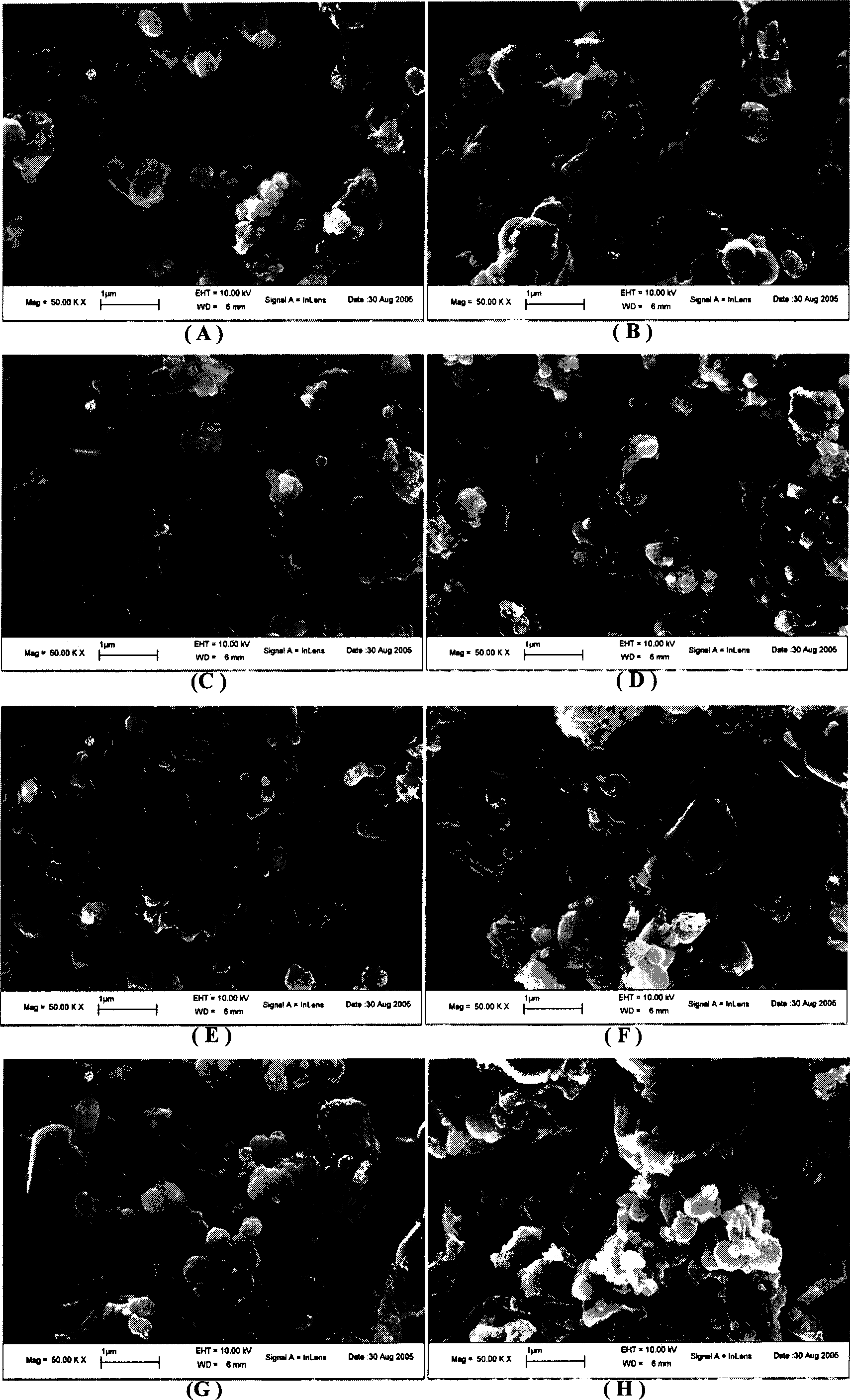

Preparation method of phosphorus position partly substituted iron lithium phosphate powder

InactiveCN1785823AGood crystallization performanceUniform compositionSulfur compoundsLithium compoundsTungstenPhosphate

The present invention discloses a preparation method of phosphorus position partial substituted type iron lithium phosphate powder body, belonging to the field of electrochemical power supply material preparation technology. The molecular formula of said positive electrode iron lithium phosphate of lithium ion cell is LiFeP1-yDyO4. Its preparation method includes the following steps: mixing lithium salt, ferrous salt, phosphate and substitution compound according to a certain mole ratio, drying, low-temperature prefiring and high-temperature secondary calcining so as to obtain the phosphorus position partial substituted type iron lithium phosphate powder body. Said invention uses the compound of boron, tungsten, sulfur and silicon or elementary substance as substitution compound.

Owner:TSINGHUA UNIV

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

Preparation method of transition element doped iron lithium phosphate powder

InactiveCN1785799AIncrease capacityImprove capacity cycling performancePhosphorus compoundsMaterials preparationLithium iron phosphate

The present invention discloses a preparation method of transition element Mn, Co and Ni doped iron lithium phosphate powder body, belonging to the field of electrochemical power supply material preparation technology. Its molecular formula is Li1-x TRxFePO4, and its preparation method includes the following steps: weighting lithium salt, ferrous salt, phosphate and adulterant according to mole ratio, mixing them, drying, low-temperature prebaking and high-temperature secondary calcining so as to obtain the invented product which can be used as positive electrode material of lithium ion cell.

Owner:TSINGHUA UNIV

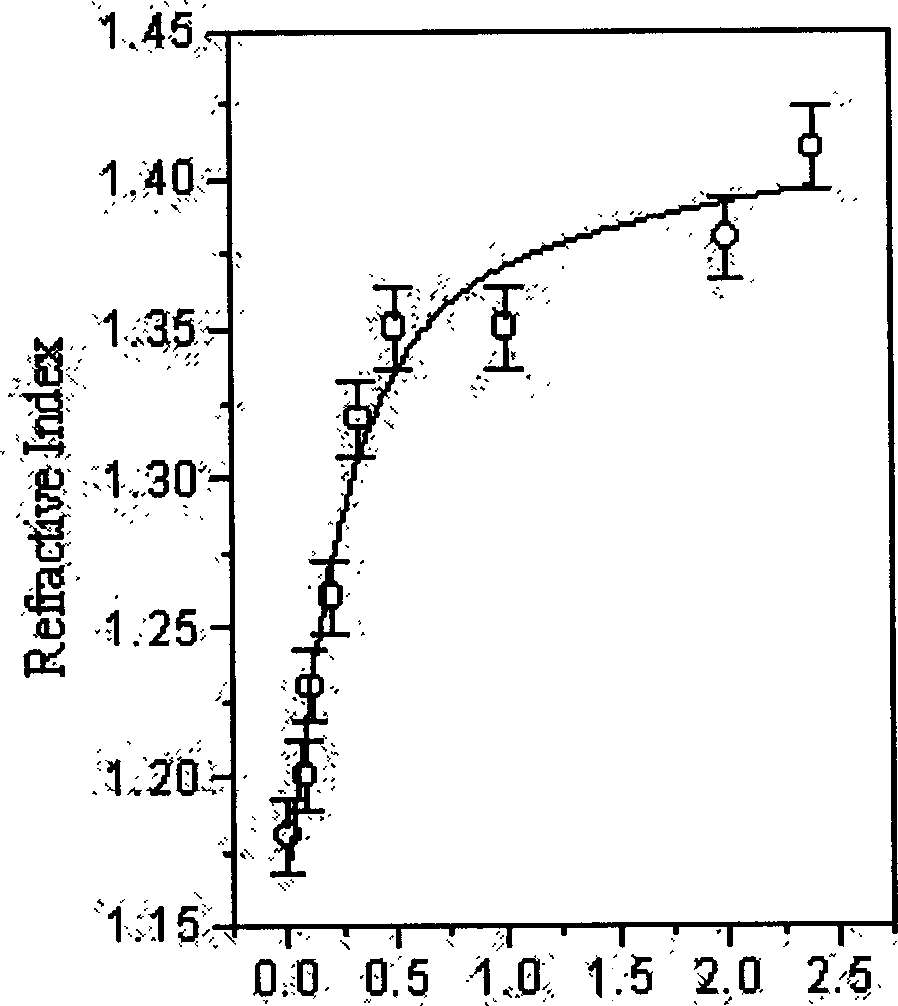

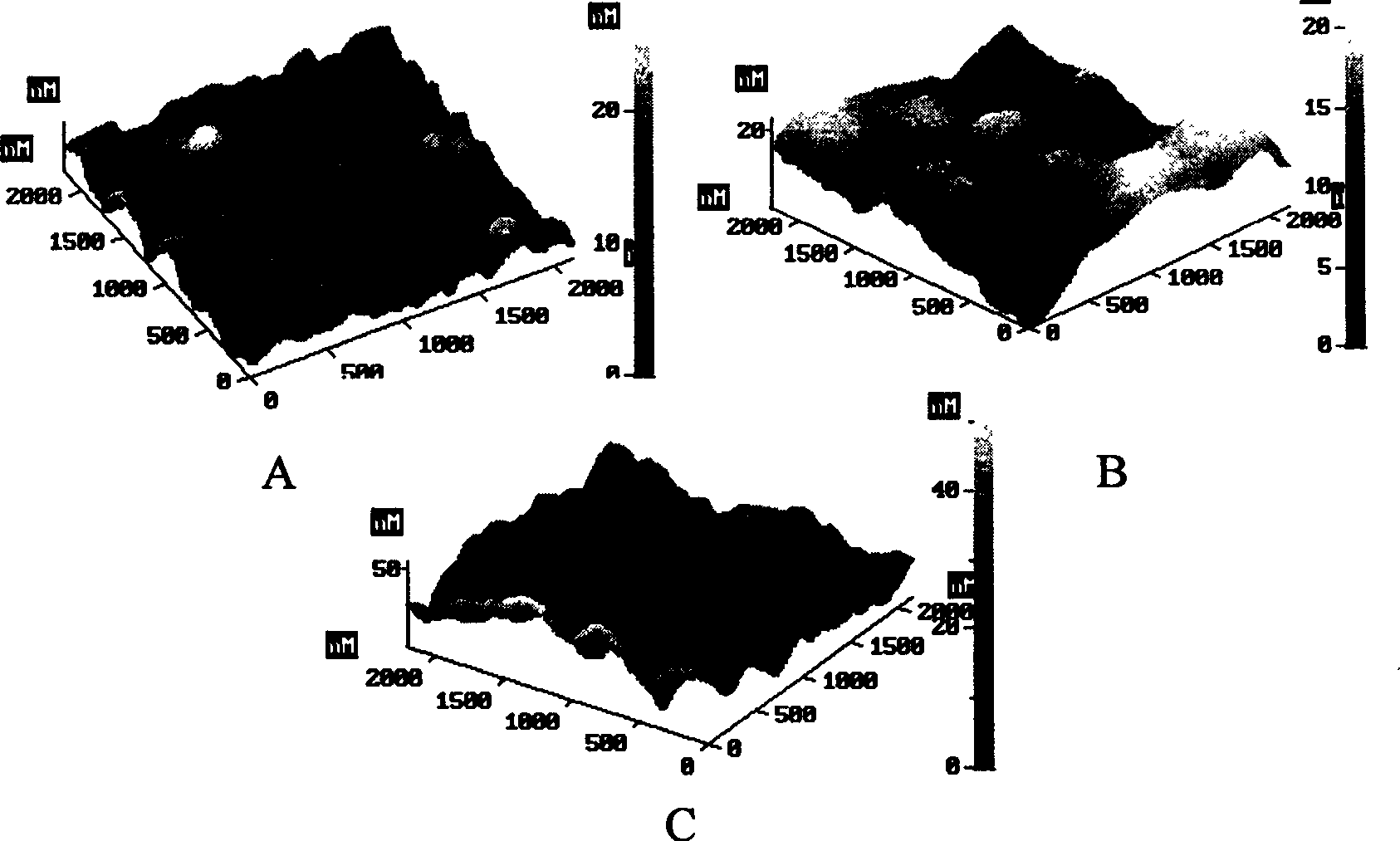

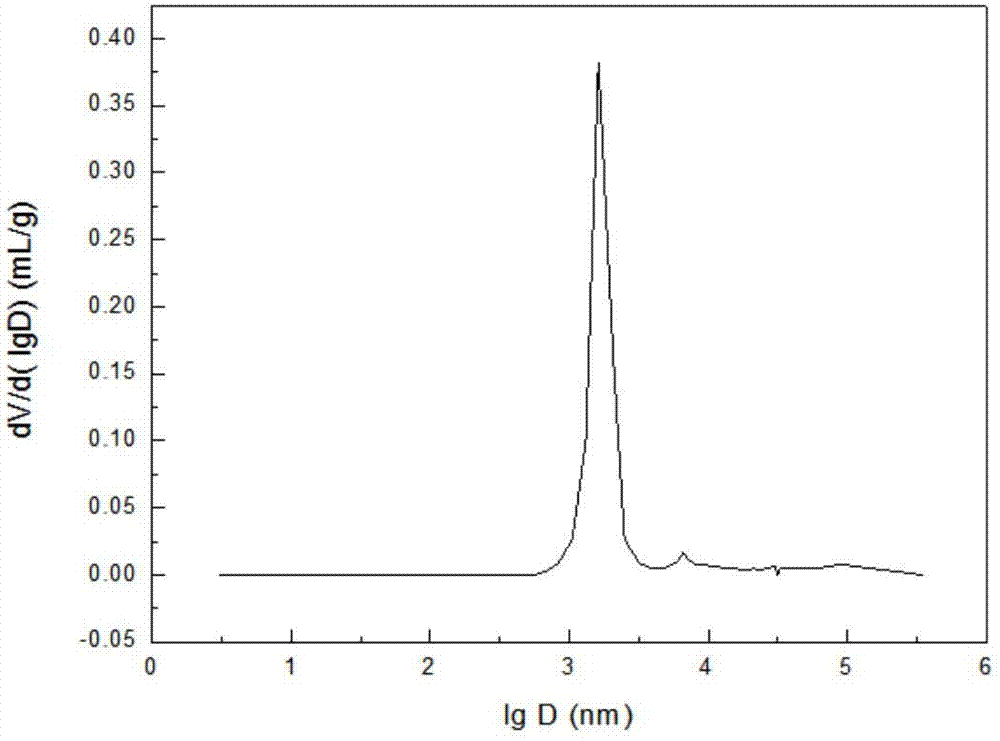

Preparing method for nanometer porous silica thin-membrane

InactiveCN1553219AHigh refractive indexLow refractive indexOptical elementsPtru catalystSilicic acid

The preparing method is as the follows, positive silester is used as presoma alcohol as solvent and ammonia water as well as hydrochloric acid as catalysts, they are become basic and acidic soliquid after hydrolyzation and polycondensation are carried out silica soliquid can be obtained by further polycondensation and hydrolyzation after basic silica soliquid is agitated in some acidic soliquid, a complete nanomultihole network structure which is not simply piled up can be formed by closely combining particles to be film when using acidic soliquid as coupling agent to link basic soliquid particles together.

Owner:TONGJI UNIV

Inorganic shaped bodies and methods for their production and use

InactiveUS20060039951A1Overcome the lack of robustnessNovel featuresDental implantsCosmetic preparationsCellulosePorosity

Owner:ORTHOVITA INC

Three-dimensional printing molding preparation method for porous ceramic for filtration

InactiveCN107098717ALoose connectionHigh precisionAdditive manufacturing apparatusDispersed particle filtrationShrinkage rateFiltration

The invention discloses a three-dimensional printing molding preparation method for a porous ceramic for filtration. The method comprises the following steps: S1 preparing a ceramic material for printing in a three-dimensional printer; S2 printing a porous ceramic green body through the three-dimensional printer by using the prepared printing ceramic material; and S3; conducting drying, rubber discharging and sintering on the printed porous ceramic green body to obtain a porous ceramic with a specific shape structure. The three-dimensional printing molding preparation method has the beneficial effects that ceramic particles are loose in connection, the density of the ceramic green body is low, the shrinkage rate after sintering is large, and the defects such as deformation and cracking are easy to occur, and the mechanical properties of the prepared products are lower; and a generated loose porous structure has larger pore size in pores, and the pore size and porosity are difficult to control through a molding process parameter. The ceramic material for printing according to the invention fully mixes solid powder with liquid additive, the ceramic particles are connected closely and the components are uniform, and the printed ceramic green body has high precision and good mechanical performance.

Owner:WUHAN UNIV OF TECH

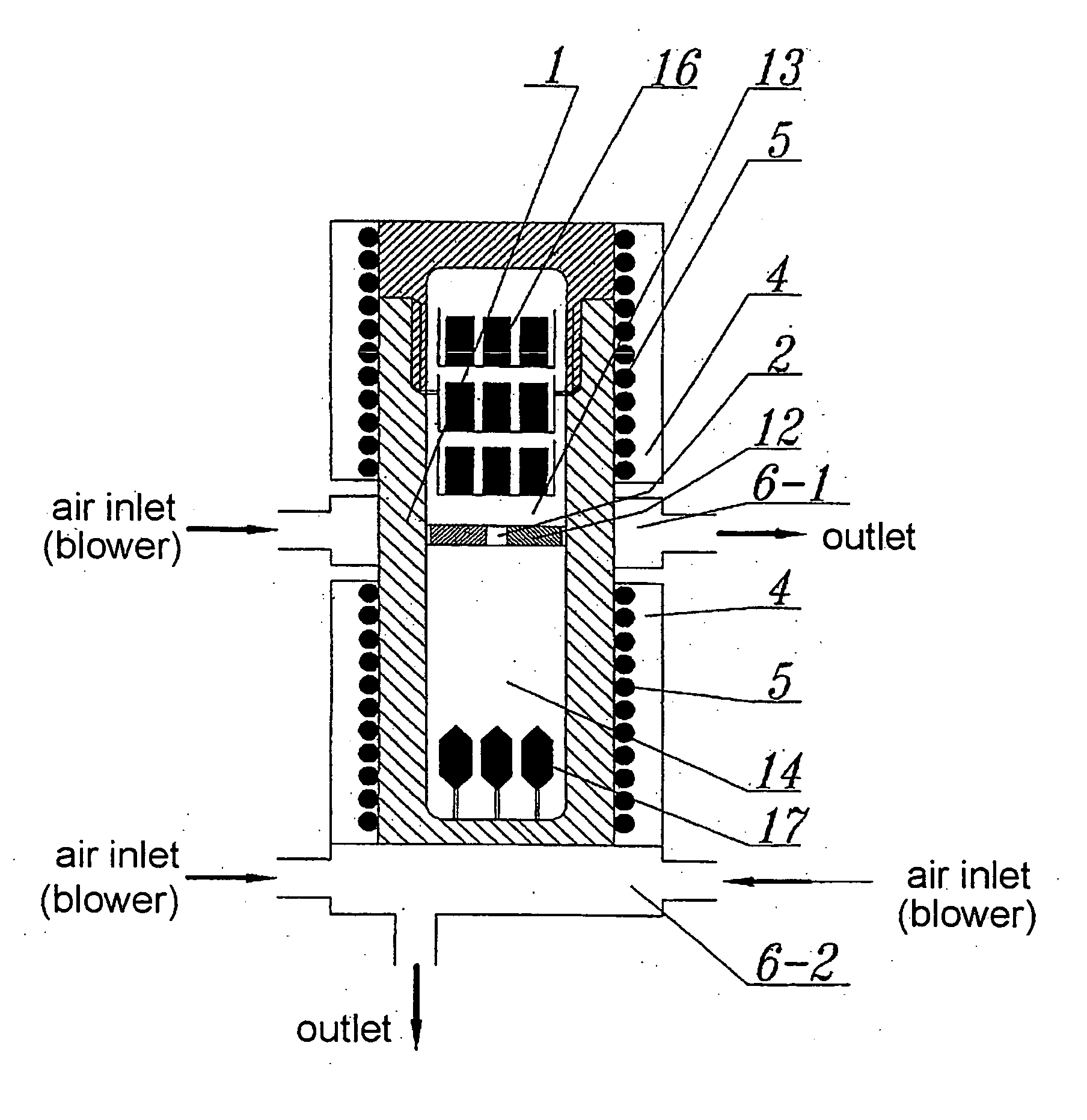

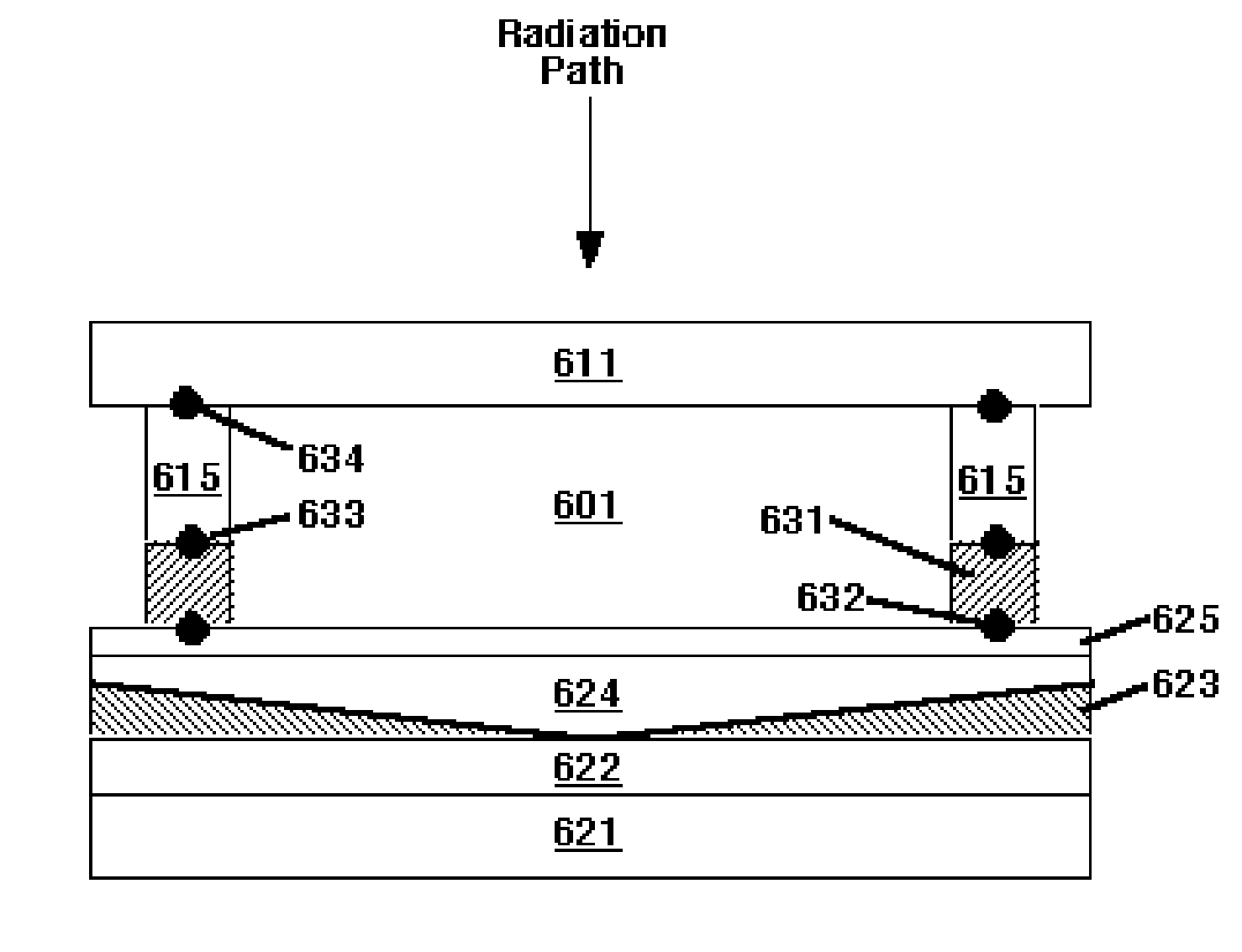

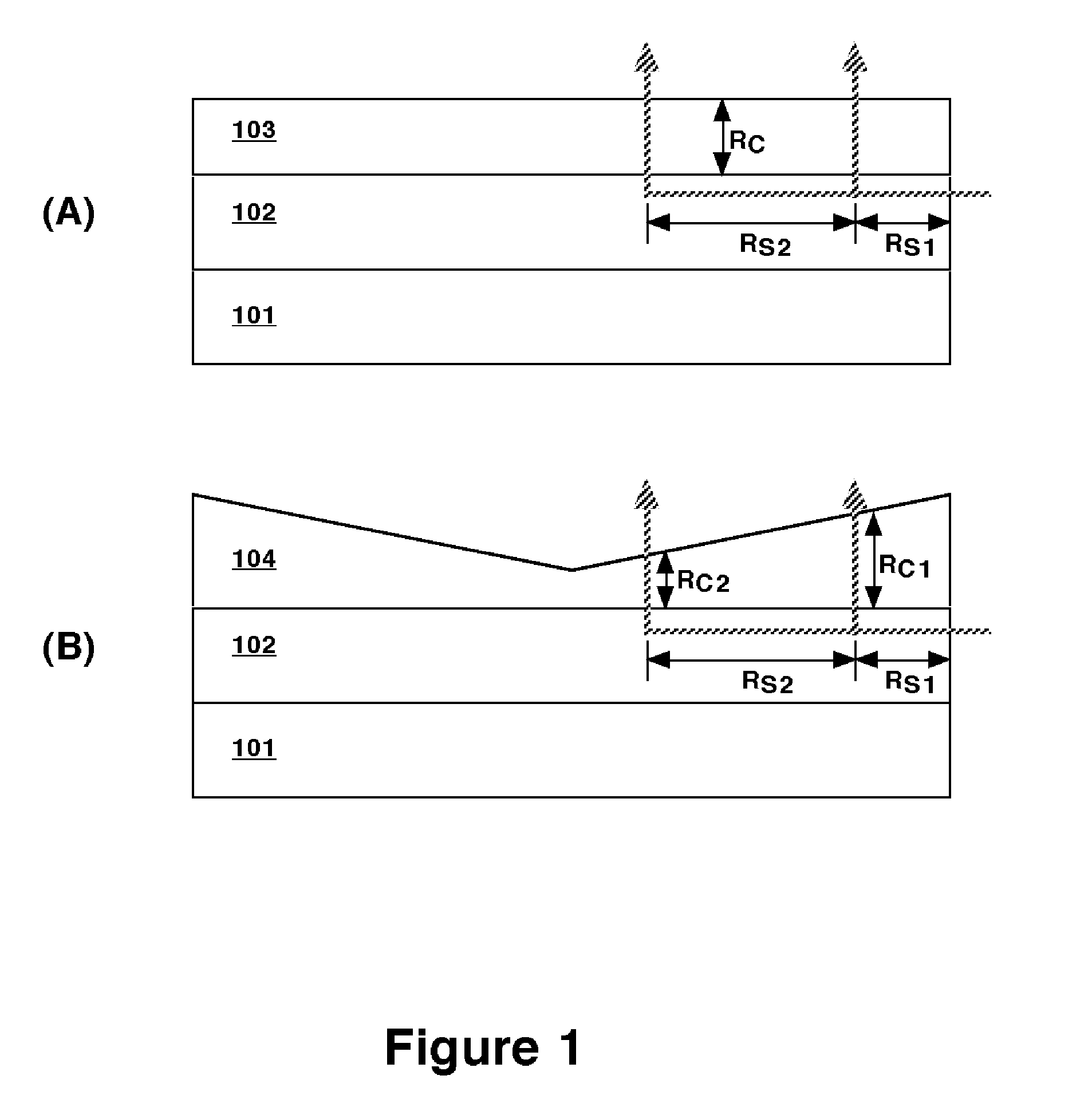

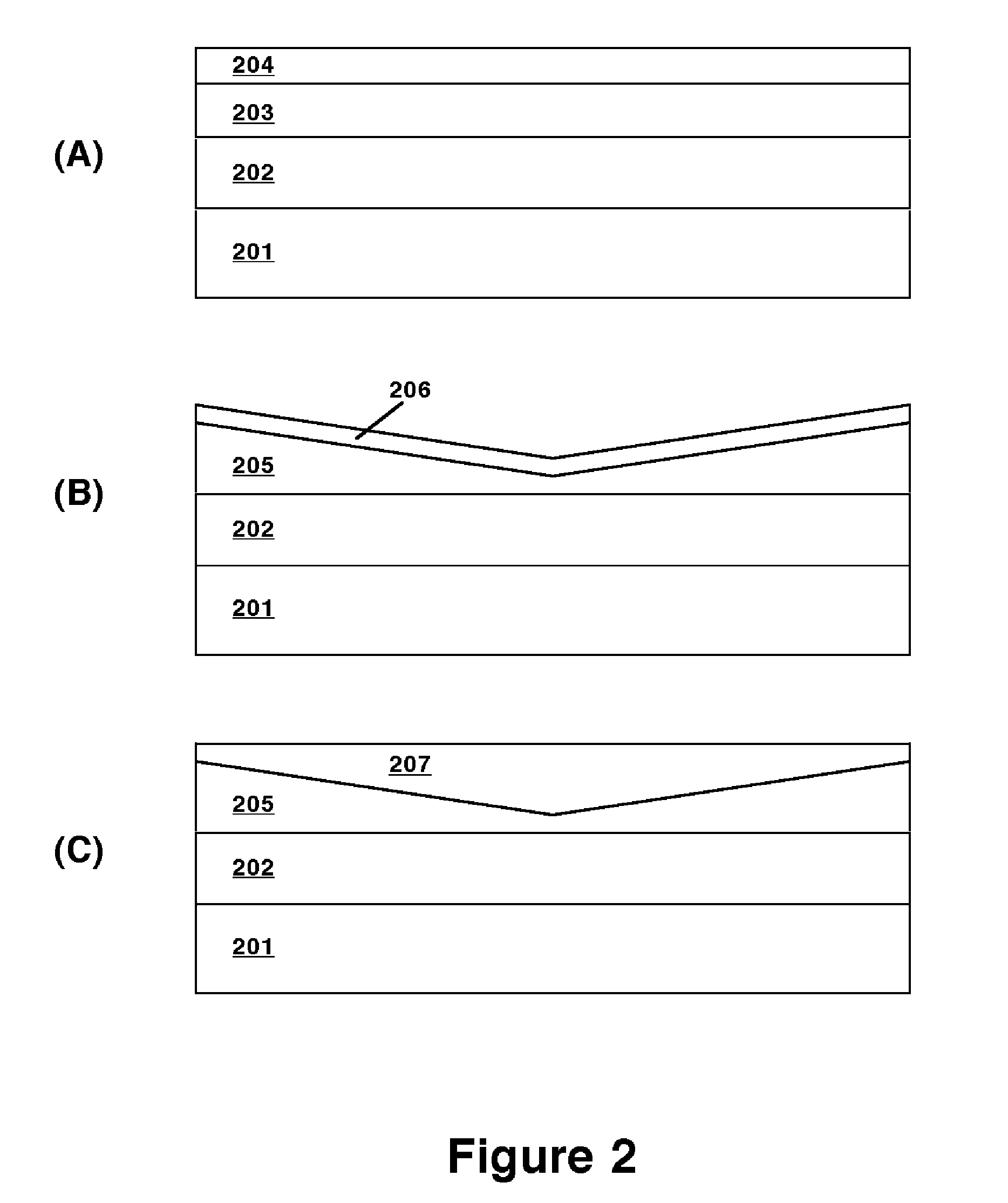

Electrode With Transparent Series Resistance For Uniform Switching Of Optical Modulation Devices

InactiveUS20070053046A1Improve reflectivityReduce transmissionNon-linear opticsOptical elementsElectrical resistance and conductanceElectrical conductor

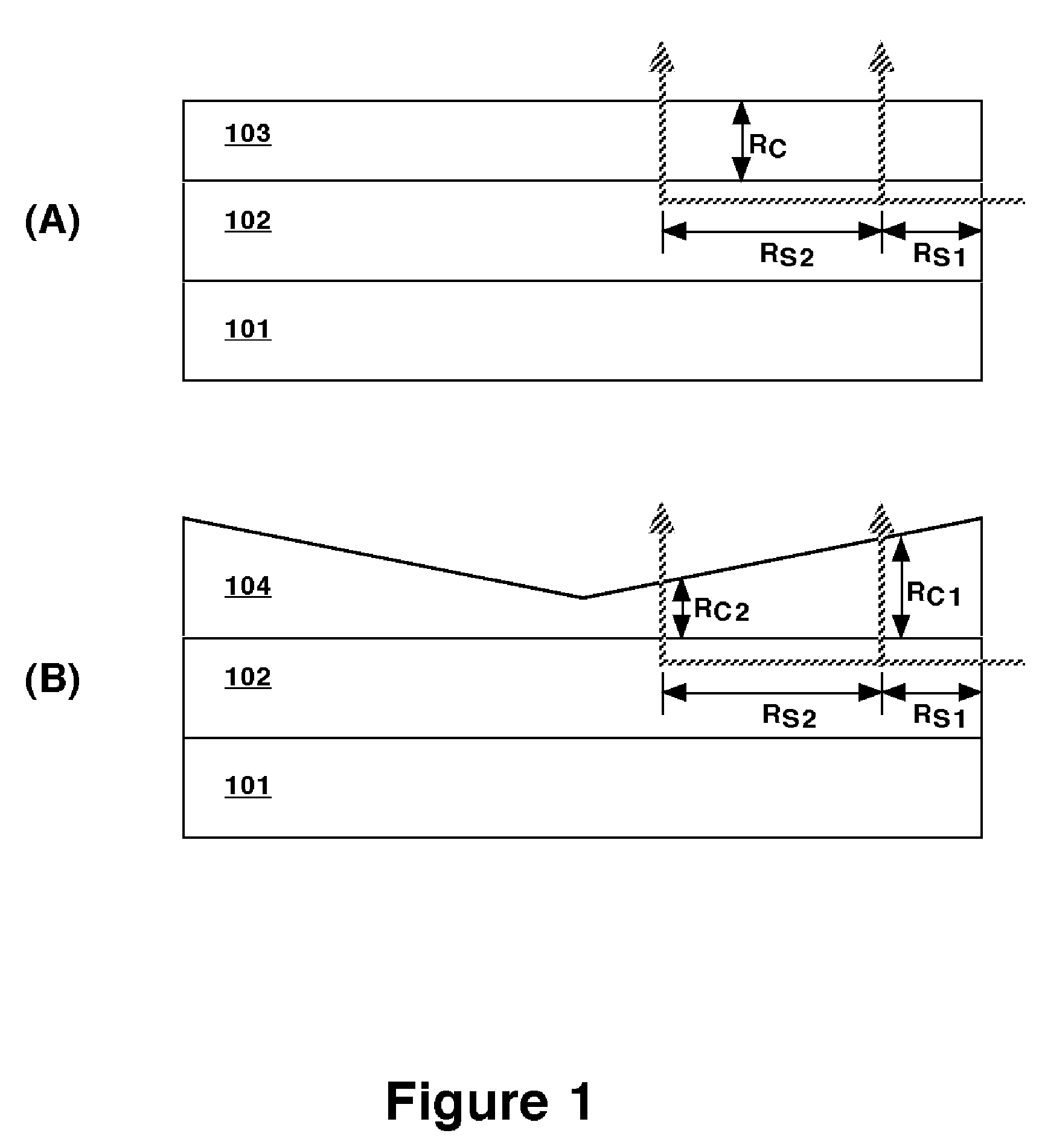

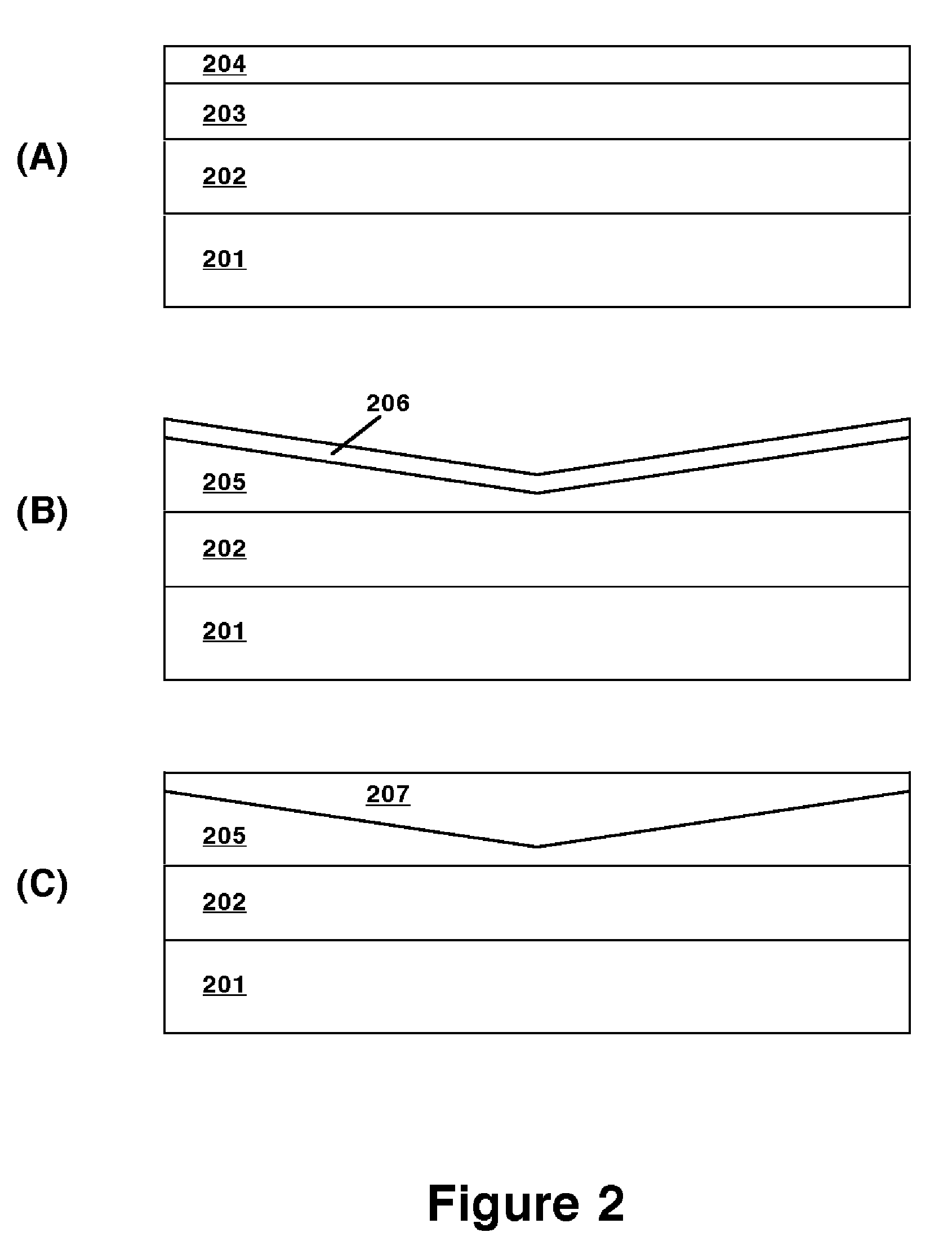

Switching uniformity of an optical modulation device for controlling the propagation of electromagnetic radiation is improved by use of an electrode comprising an electrically resistive layer that is transparent to the radiation. The resistive layer is preferably an innerlayer of a wide-bandgap oxide sandwiched between layers of indium tin oxide or another transparent conductor, and may be of uniform thickness, or may be graded so as to provide further improvement in the switching uniformity. The electrode may be used with electrochromic and reversible electrochemical mirror (REM) smart window devices, as well as display devices based on various technologies.

Owner:TELEDYNE SCI & IMAGING

Electrode with transparent series resistance for uniform switching of optical modulation devices

InactiveUS7317566B2Improves switching uniformityIncrease resistanceMachining electrodesMultiplier circuit arrangementsElectrical resistance and conductanceElectrical conductor

Switching uniformity of an optical modulation device for controlling the propagation of electromagnetic radiation is improved by use of an electrode comprising an electrically resistive layer that is transparent to the radiation. The resistive layer is preferably an innerlayer of a wide-bandgap oxide sandwiched between layers of indium tin oxide or another transparent conductor, and may be of uniform thickness, or may be graded so as to provide further improvement in the switching uniformity. The electrode may be used with electrochromic and reversible electrochemical mirror (REM) smart window devices, as well as display devices based on various technologies.

Owner:TELEDYNE SCI & IMAGING

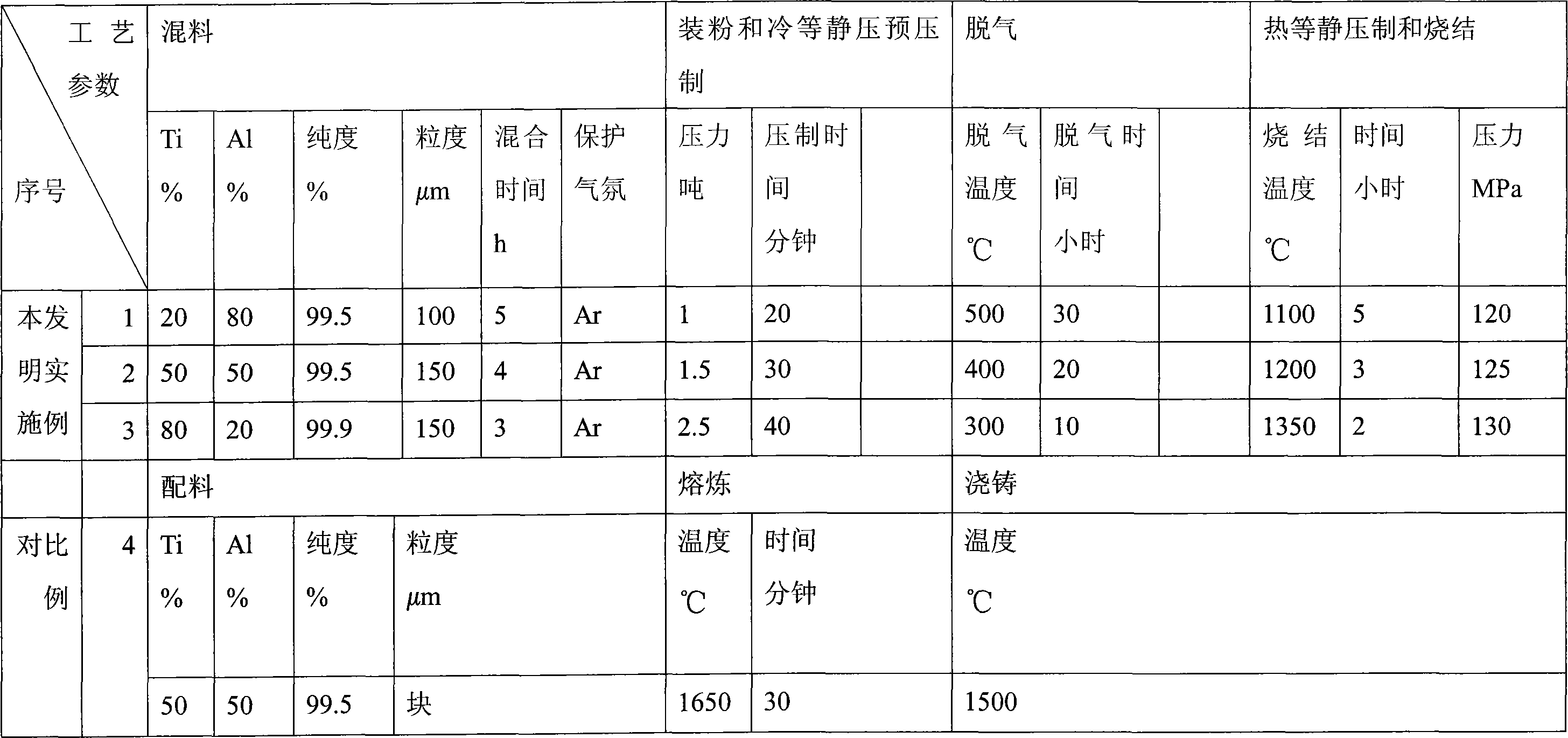

Method for preparing powder metallurgy of titanium-aluminium alloy target material

The invention belongs to the preparing field of powder metallurgy, in particular to the powder metallurgy preparing method for titanium aluminum alloy target material. The components of the titanium aluminum alloy target material relates to: Ti to Al is equal to 80 percent to 20 percent or Ti to Al is equal to 20 to 80 percent. The powder metallurgy preparing method for the titanium aluminum alloy target material is to adopt a pulverization method to acquire the titanium aluminum alloy or mix the titanium powder and the aluminum powder and then pre-pressing through powder mounting and isostatic cool pressing, and then carries out hot isostatic pressing forming after the technique of desaeration and finally carries out sintering process and machining to acquire the titanium aluminum alloy target material. Compared with the exiting casting target material, the titanium aluminum alloy target material of the invention has the advantages of good compactness, no air holes, no loosening and aliquation, uniform component, petty crystal particle, big specification dimension, etc., and is suitable for hard coat needed by various tools and dies.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Preparation method of rare earth doped iron lithium phosphate powder

InactiveCN1785800AIncrease capacityHigh crystallinityPhosphorus compoundsRare-earth elementMaterials preparation

The present invention discloses a preparation method of rare earth doped iron lithium phosphate powder body, belonging to the field of electrochemical power supply material preparation technology. Its molecular formula is Li1-xRExFePO4, and its preparation method includes the following steps: mixing lithium salt, ferrous salt, phosphate and adulterant according to a certain mole ratio, drying, low-temperature prebaking and high-temperature secondary calcining so as to obtain the invented product which can be used as positive electrode material of secondary lithium ion cell and power energy source cell. Said invention uses lanthanide series rare earth element compound as adulterant.

Owner:TSINGHUA UNIV

Method of improving and optimizing the hydrogen permeability of a palladium-copper membrane and novel membranes manufactured thereby

InactiveUS6372363B1Improve membraneUniform compositionMembranesSemi-permeable membranesPalladiumCopper alloy

Owner:WALTER JUDA ASSOCS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com