Patents

Literature

76results about How to "Loose connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

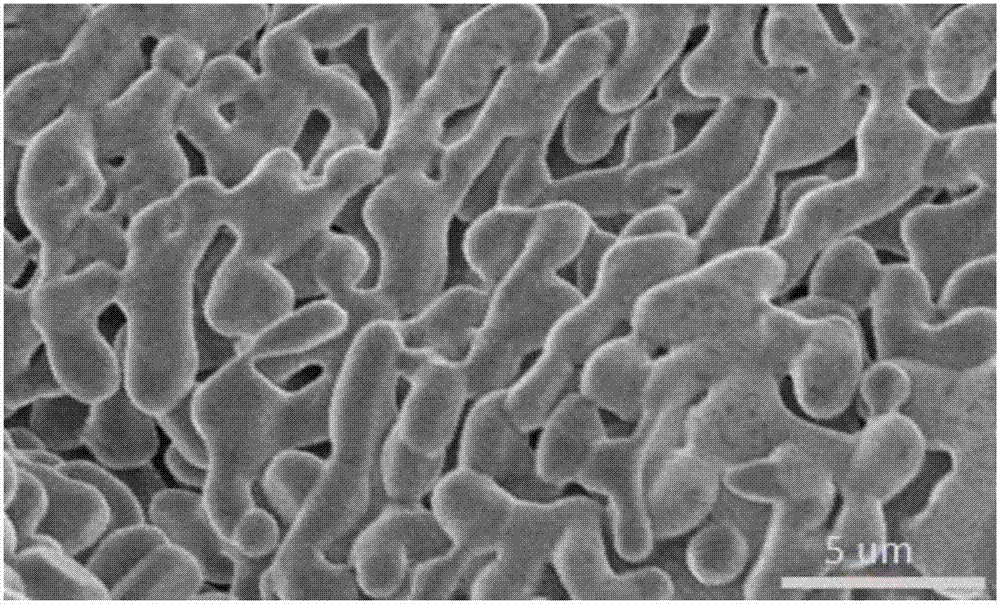

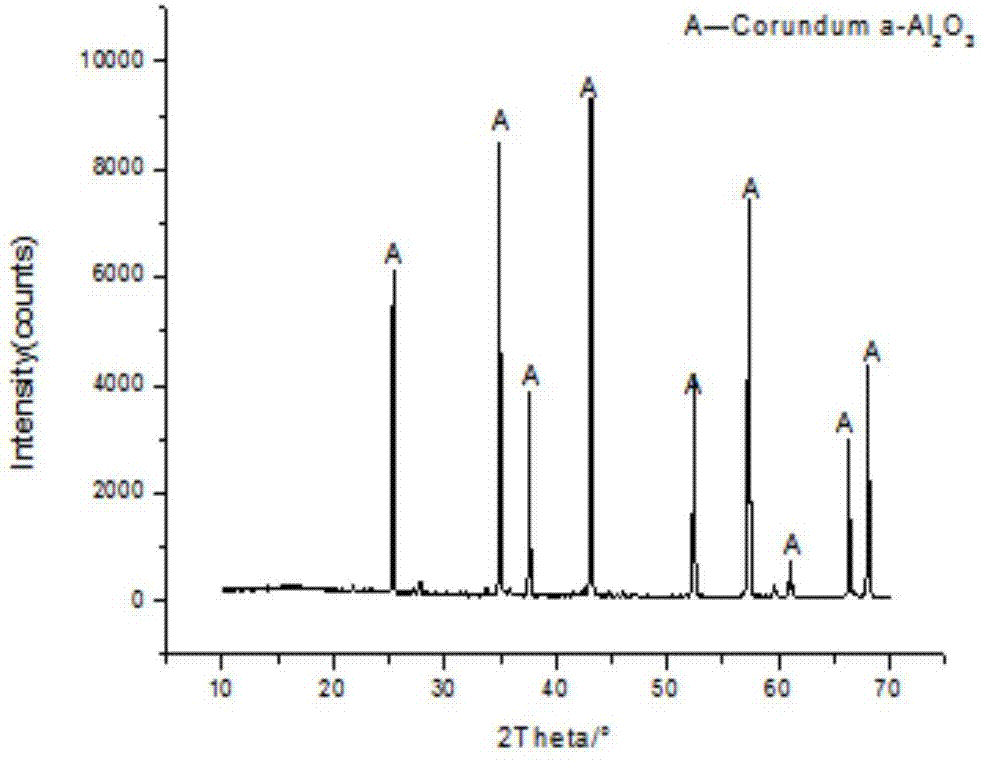

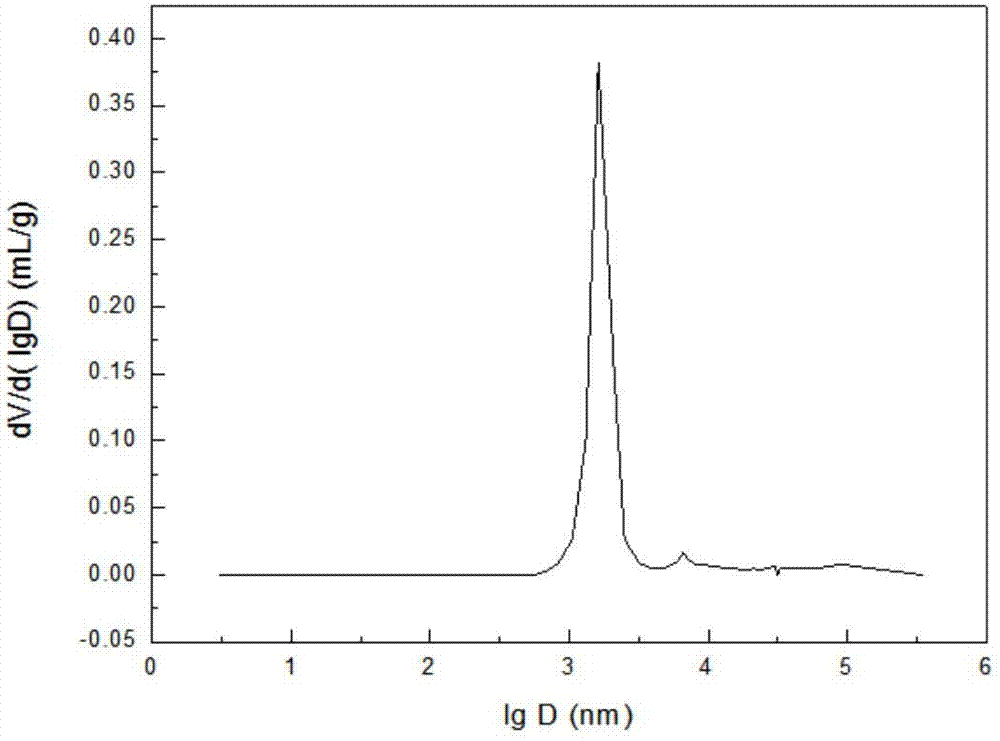

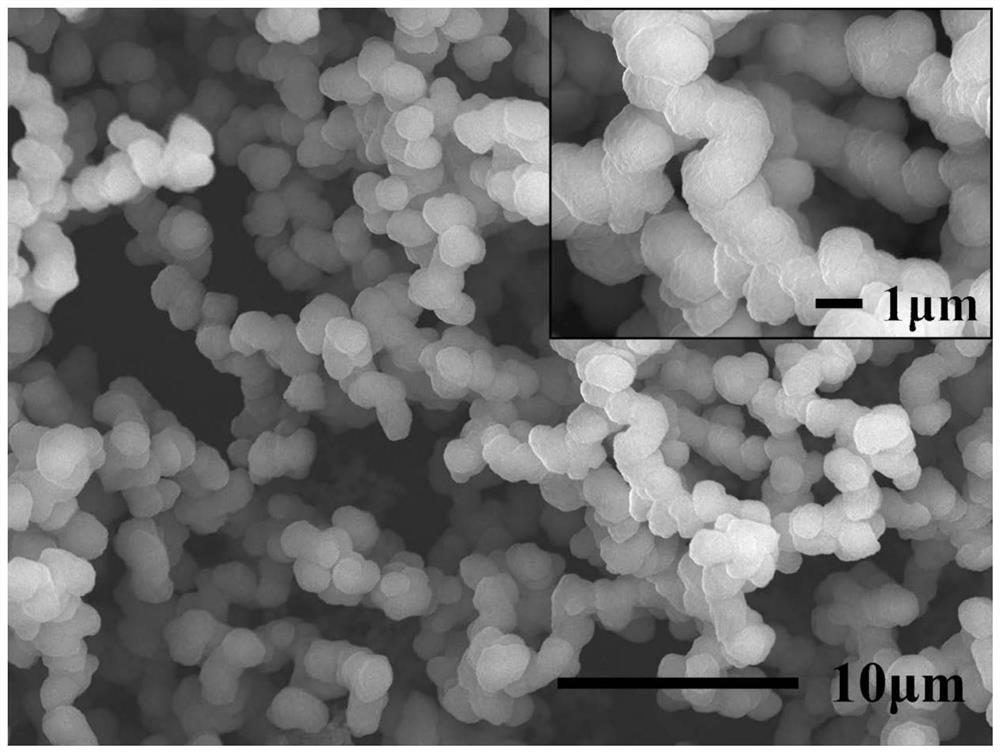

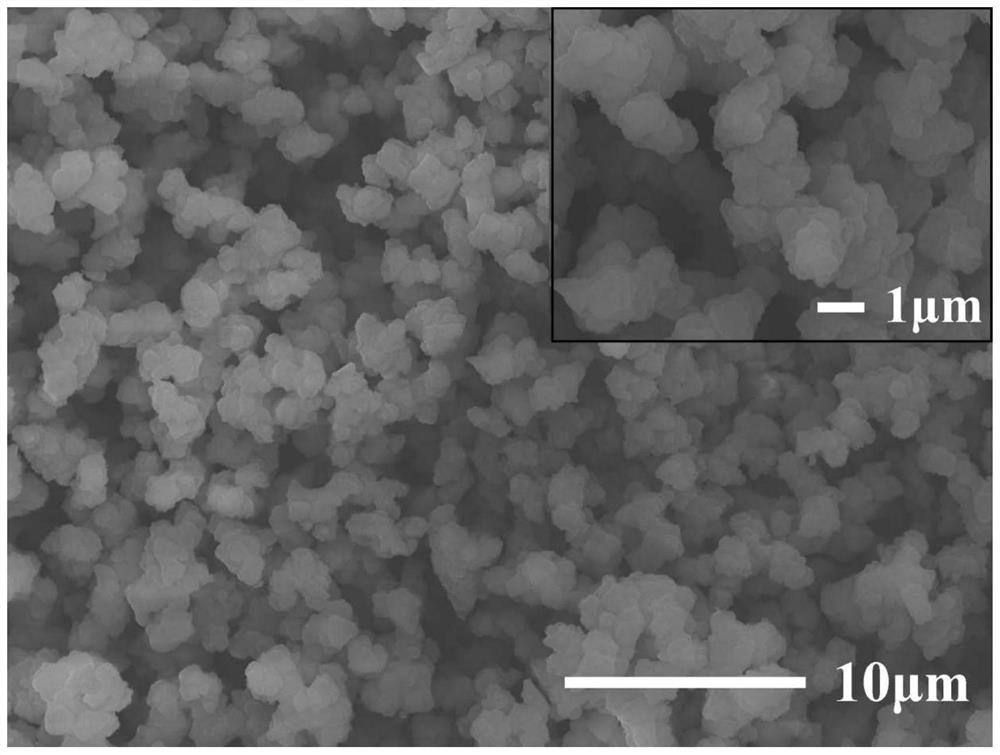

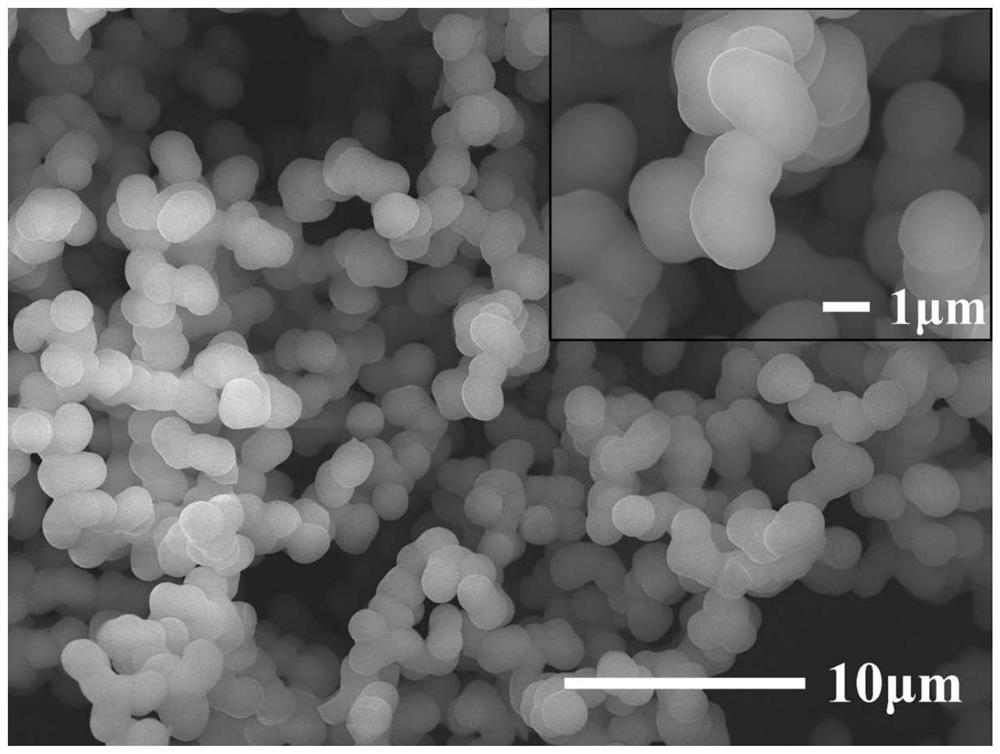

Three-dimensional printing molding preparation method for porous ceramic for filtration

InactiveCN107098717ALoose connectionHigh precisionAdditive manufacturing apparatusDispersed particle filtrationShrinkage rateFiltration

The invention discloses a three-dimensional printing molding preparation method for a porous ceramic for filtration. The method comprises the following steps: S1 preparing a ceramic material for printing in a three-dimensional printer; S2 printing a porous ceramic green body through the three-dimensional printer by using the prepared printing ceramic material; and S3; conducting drying, rubber discharging and sintering on the printed porous ceramic green body to obtain a porous ceramic with a specific shape structure. The three-dimensional printing molding preparation method has the beneficial effects that ceramic particles are loose in connection, the density of the ceramic green body is low, the shrinkage rate after sintering is large, and the defects such as deformation and cracking are easy to occur, and the mechanical properties of the prepared products are lower; and a generated loose porous structure has larger pore size in pores, and the pore size and porosity are difficult to control through a molding process parameter. The ceramic material for printing according to the invention fully mixes solid powder with liquid additive, the ceramic particles are connected closely and the components are uniform, and the printed ceramic green body has high precision and good mechanical performance.

Owner:WUHAN UNIV OF TECH

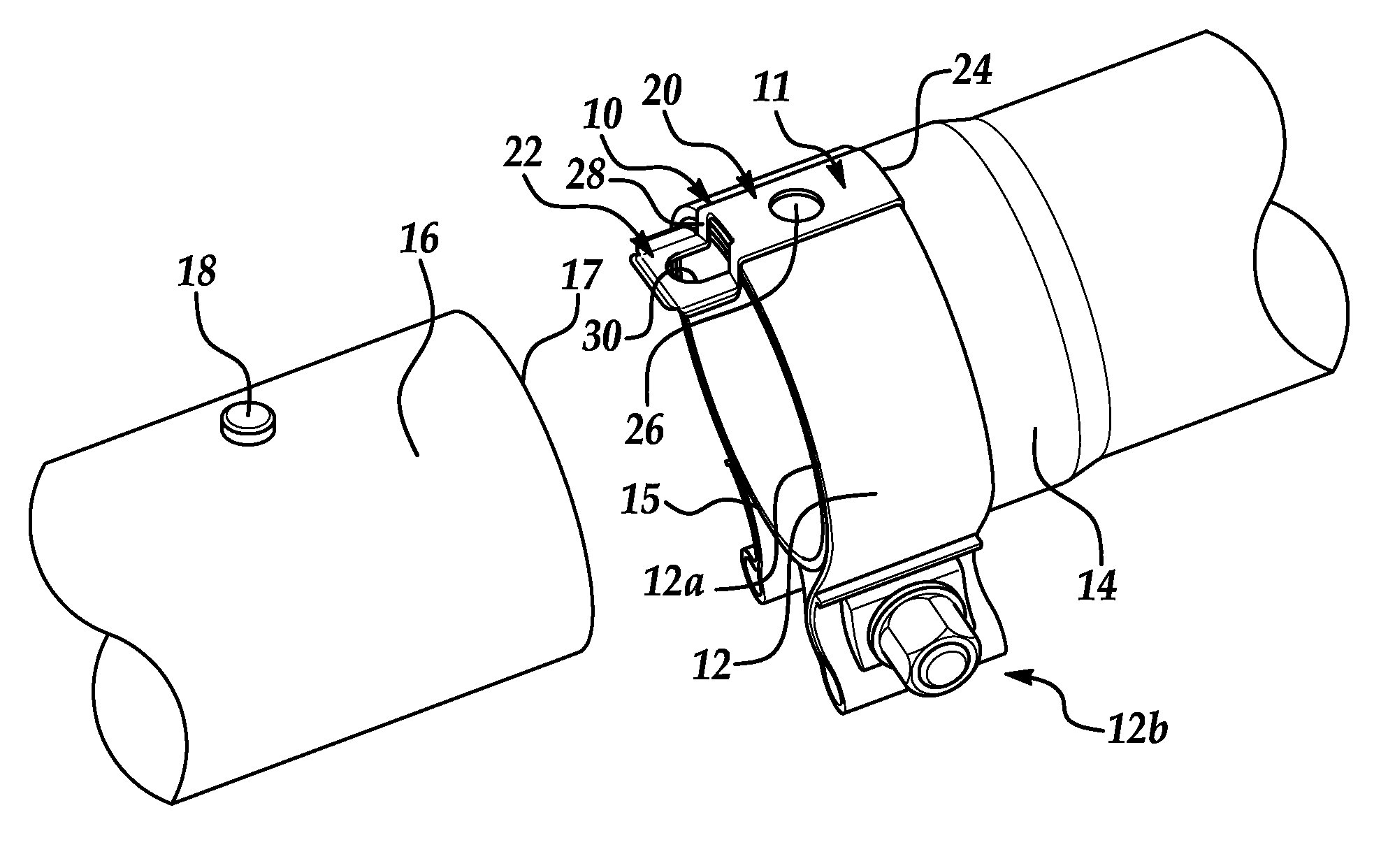

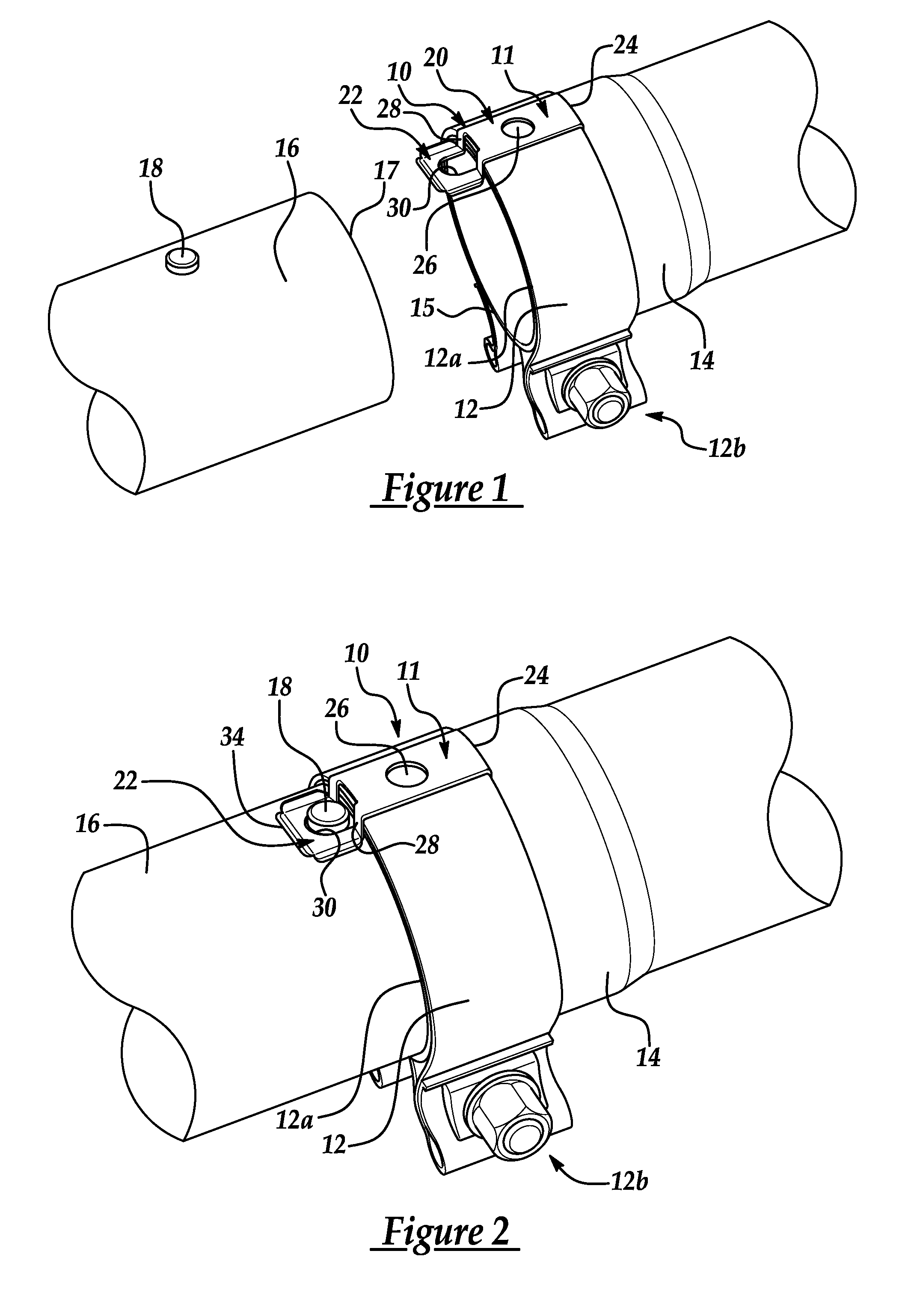

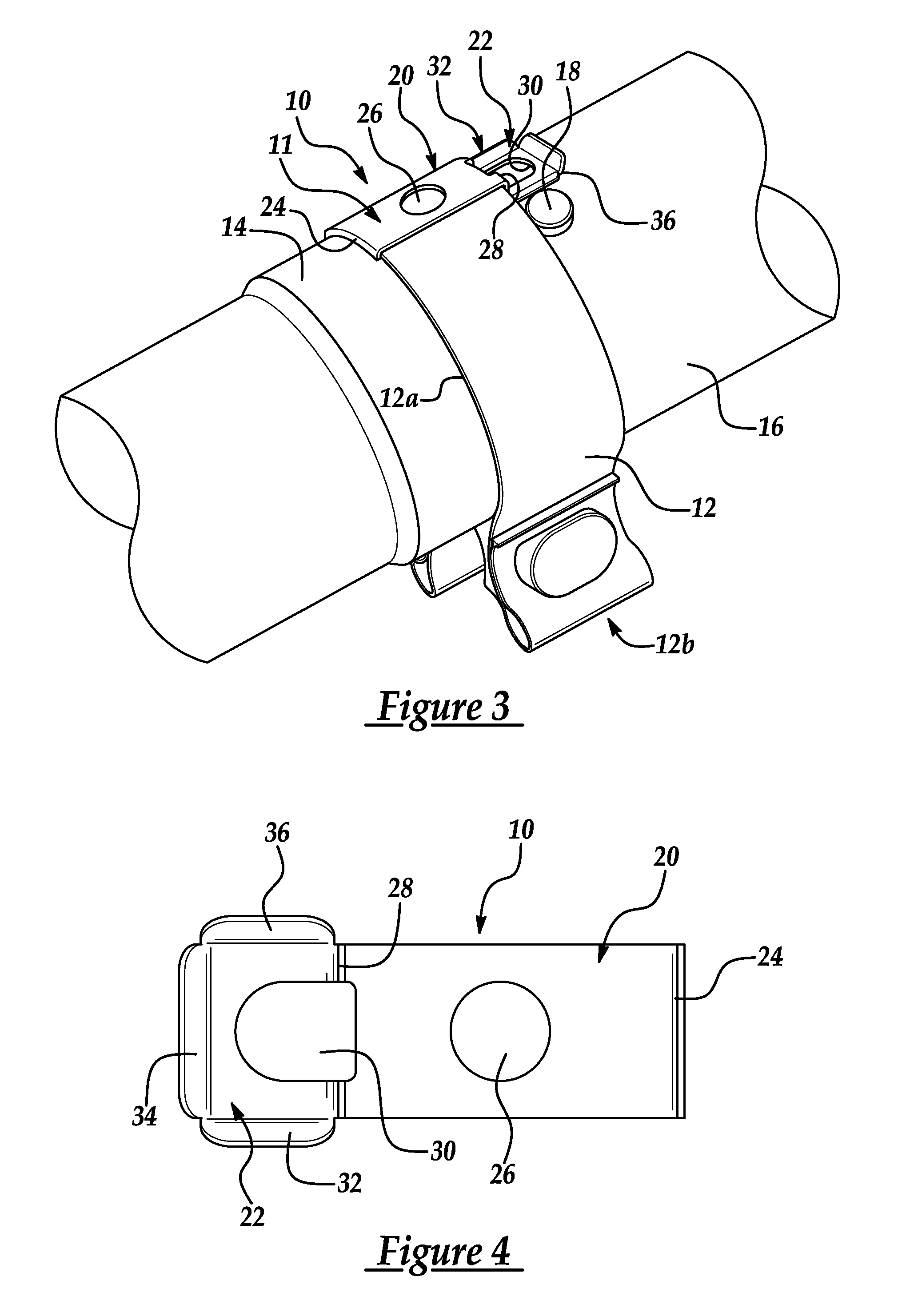

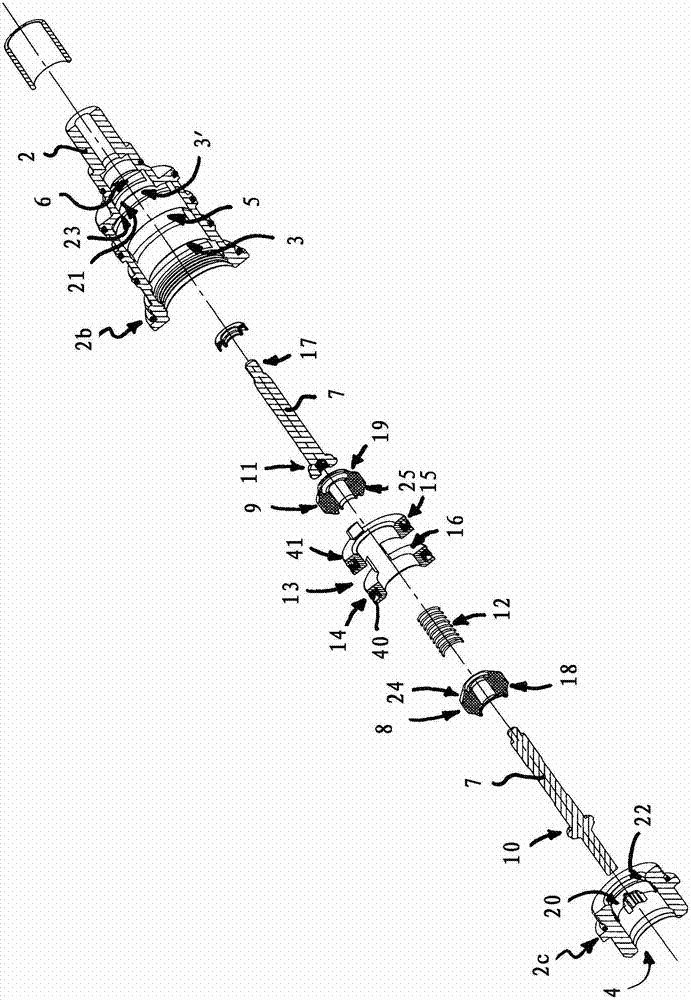

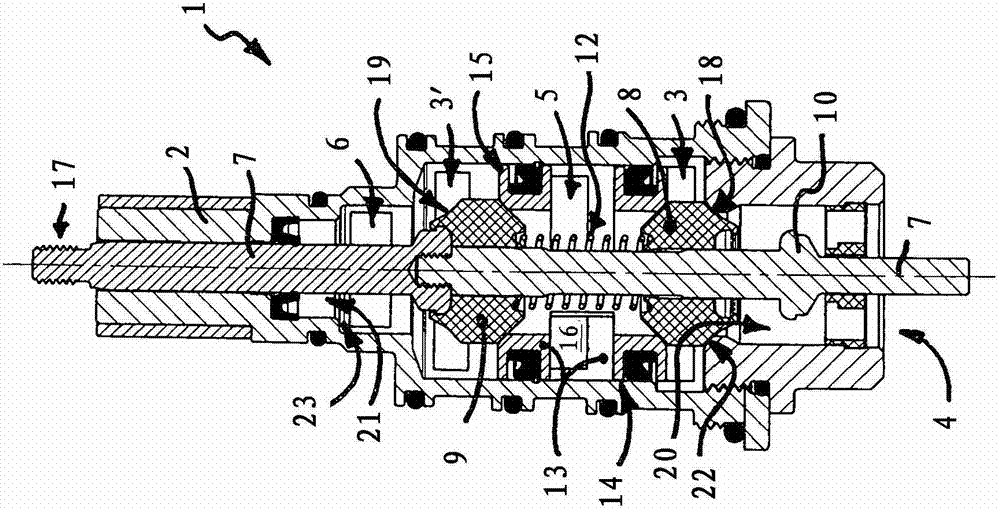

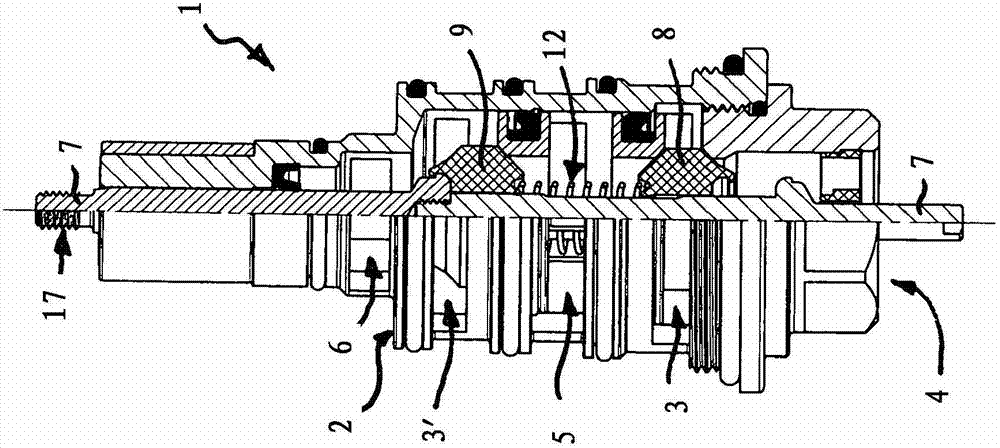

Pipe clamp with integral latch

ActiveUS7458619B2Minimize of to handlingMinimize the possibilitySnap fastenersExhaust apparatusEngineeringMechanical engineering

Owner:NORMA US HOLDING LLC

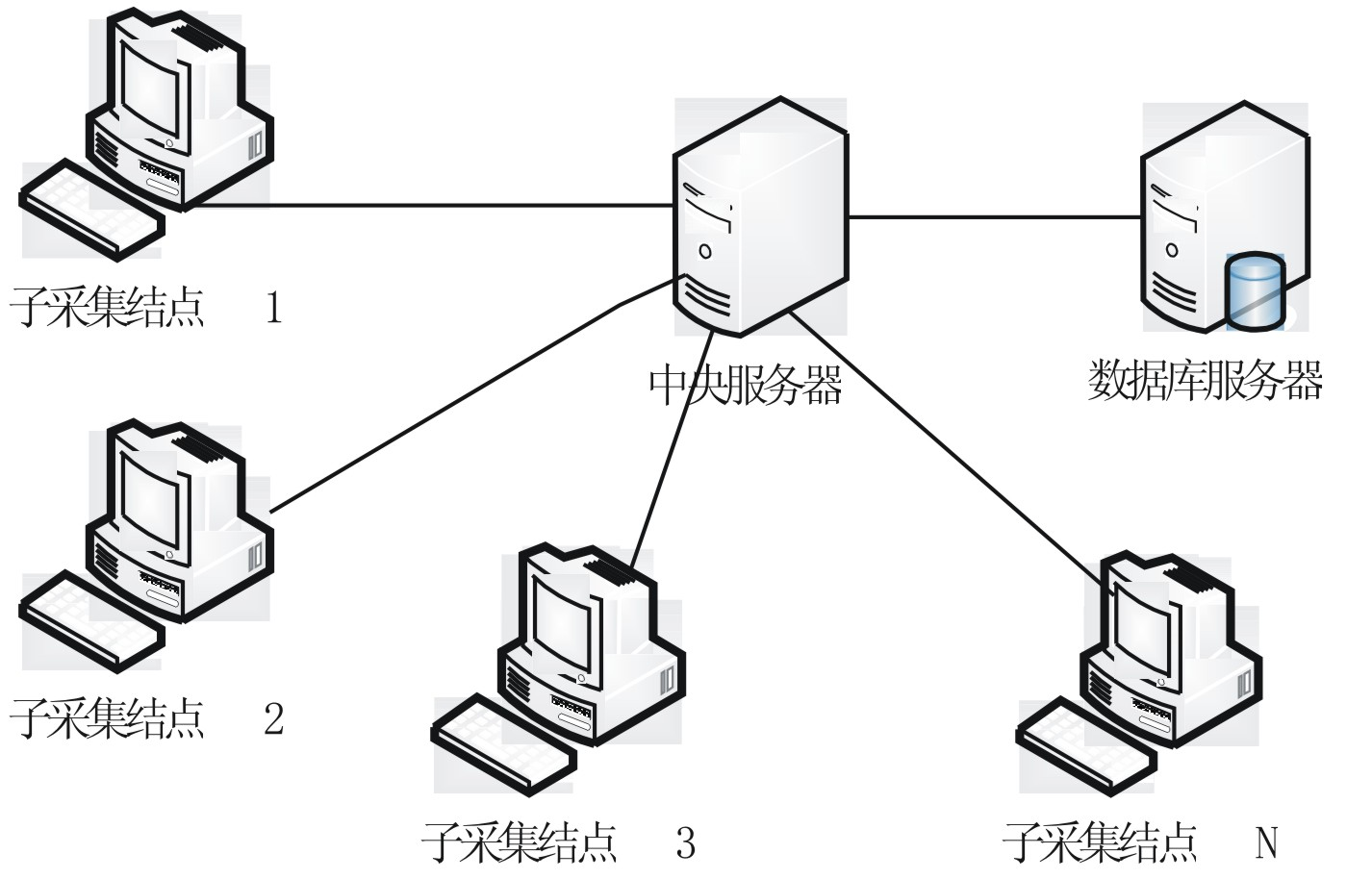

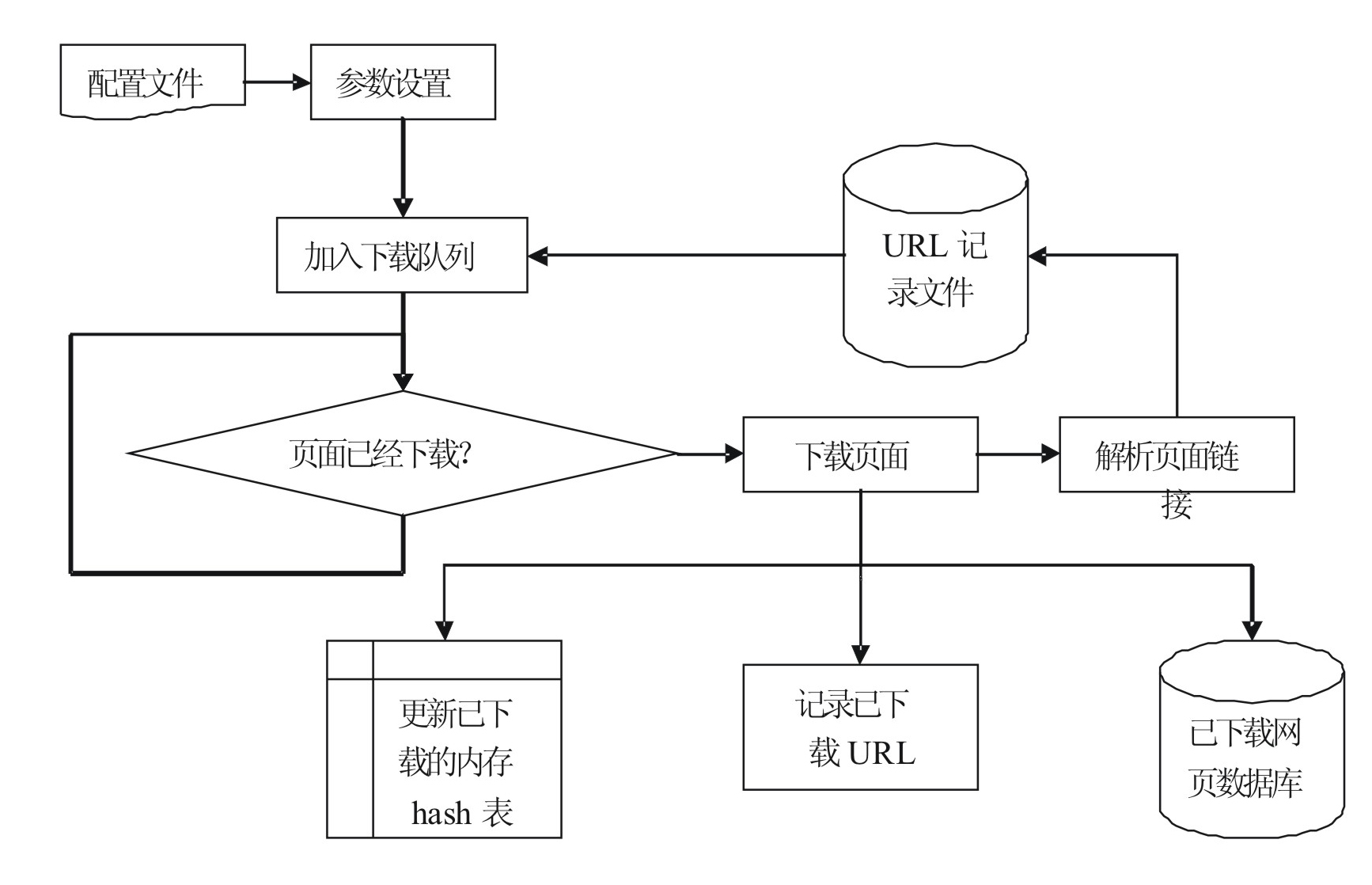

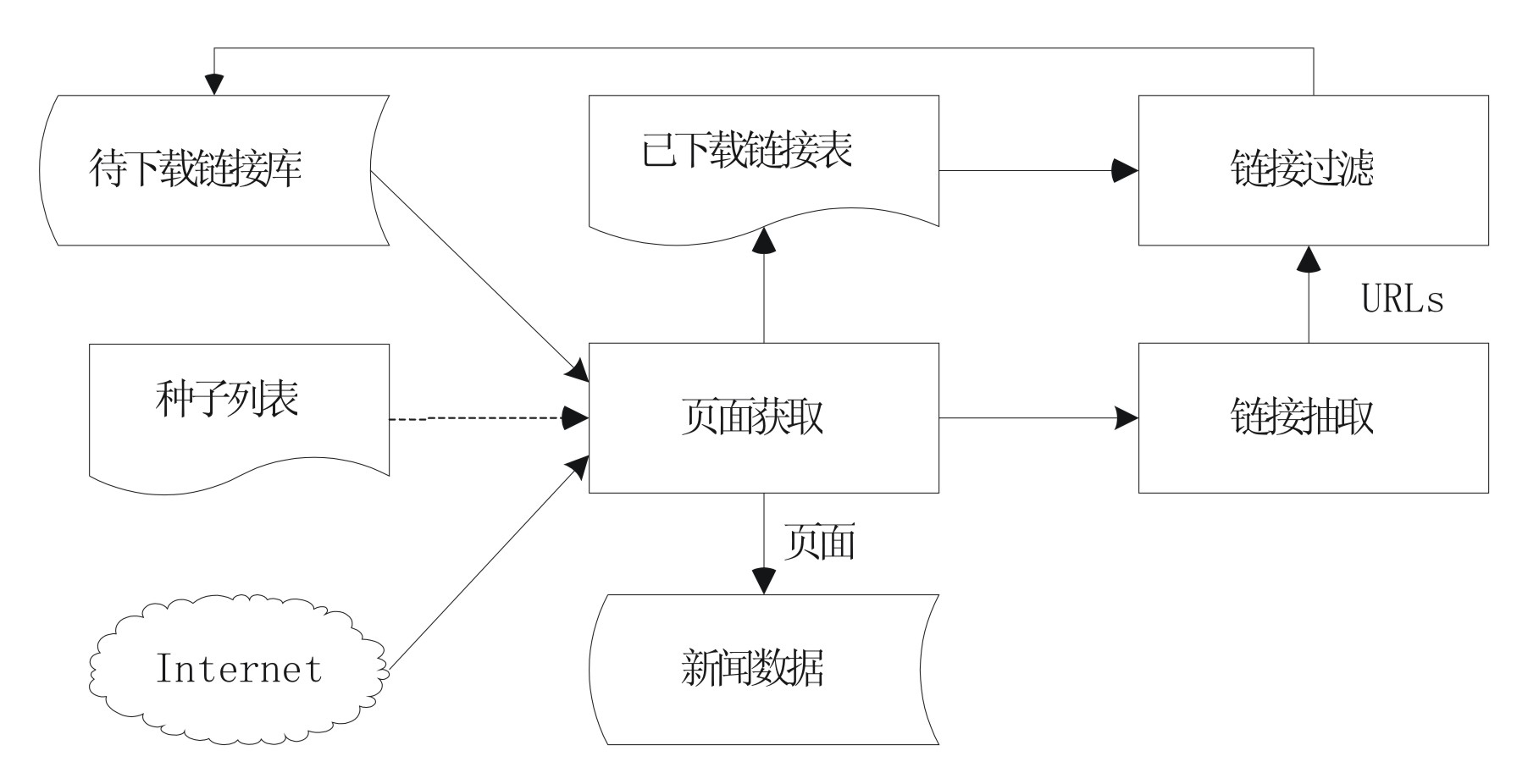

Distributed real-time news information acquisition system

InactiveCN102073683ABig amount of dataLow costSpecial data processing applicationsDatabase serverData library

The invention discloses a distributed real-time news information acquisition system, and the architecture of the system comprises a central server, a plurality of sub-acquisition nodes and a database server, wherein each sub-acquisition node is responsible for acquiring a news page, communicating with the central server through TCP / IP (transmission control protocol / Internet protocol) and transmitting the acquired news page to the central server, and the central server is used for storing all the downloaded news pages into the databse server. The system can overcome the defects of the prior art and is mainly used for performing high-efficient and stable acquisition against the characteristics of a large amount of news data, fast updating speed and high repeatability; furthermore, the cost is low, and the deployment is easy.

Owner:SICHUAN UNIV

Fishscale collagen production process

The invention discloses a fish scale collagen process technology that is made up from the process of twice acid process, alkali neutralized, boiling, enzymolysis, exchanging absorbing, concentrating, filtering, drying and spraying. The invention also supplies the invention to easily produce fish scale collagen produce technology. The invention has low molecular weight, stability, and low content or ash content.

Owner:YANTAI DONGCHENG PHARMA GRP

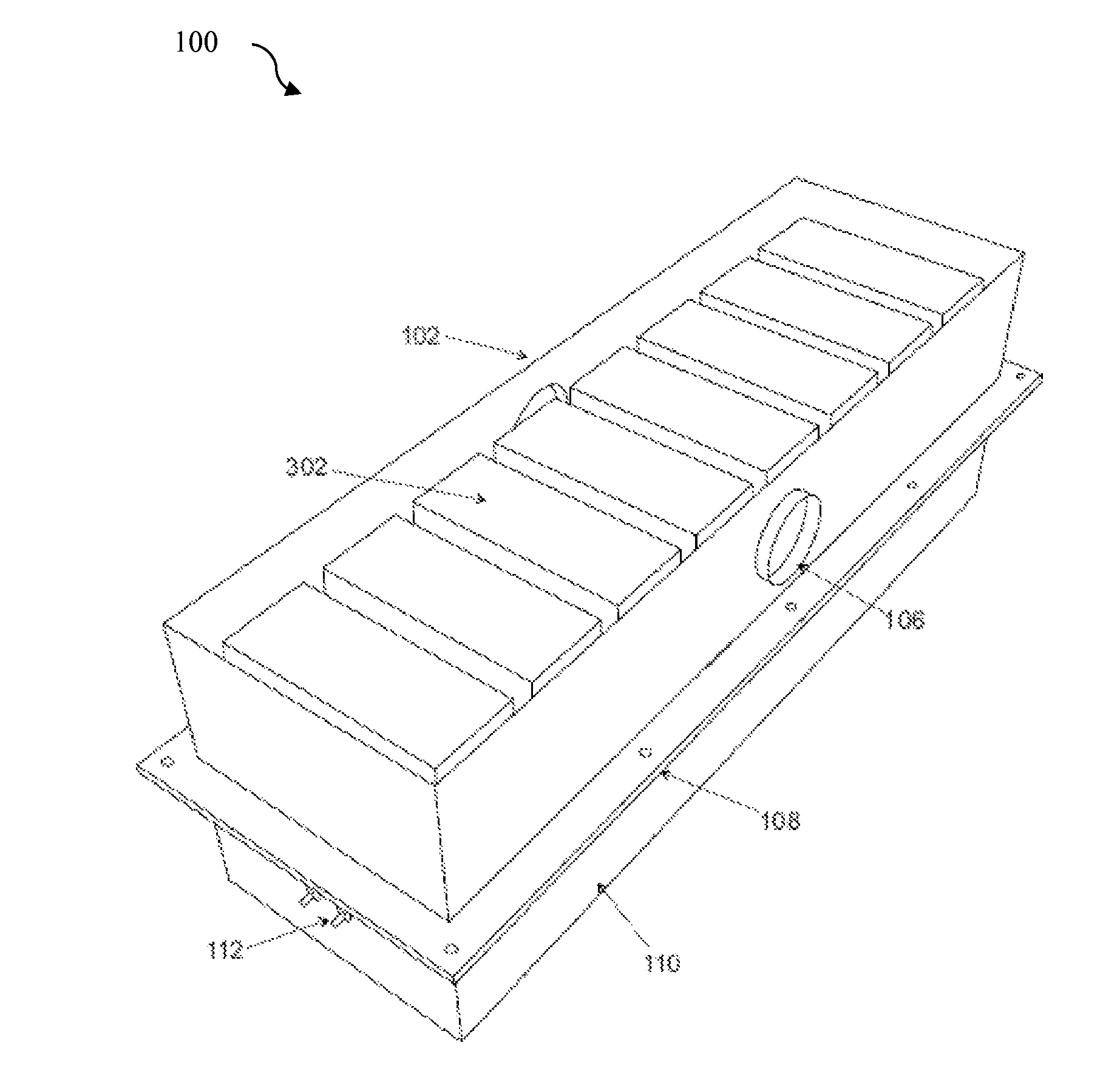

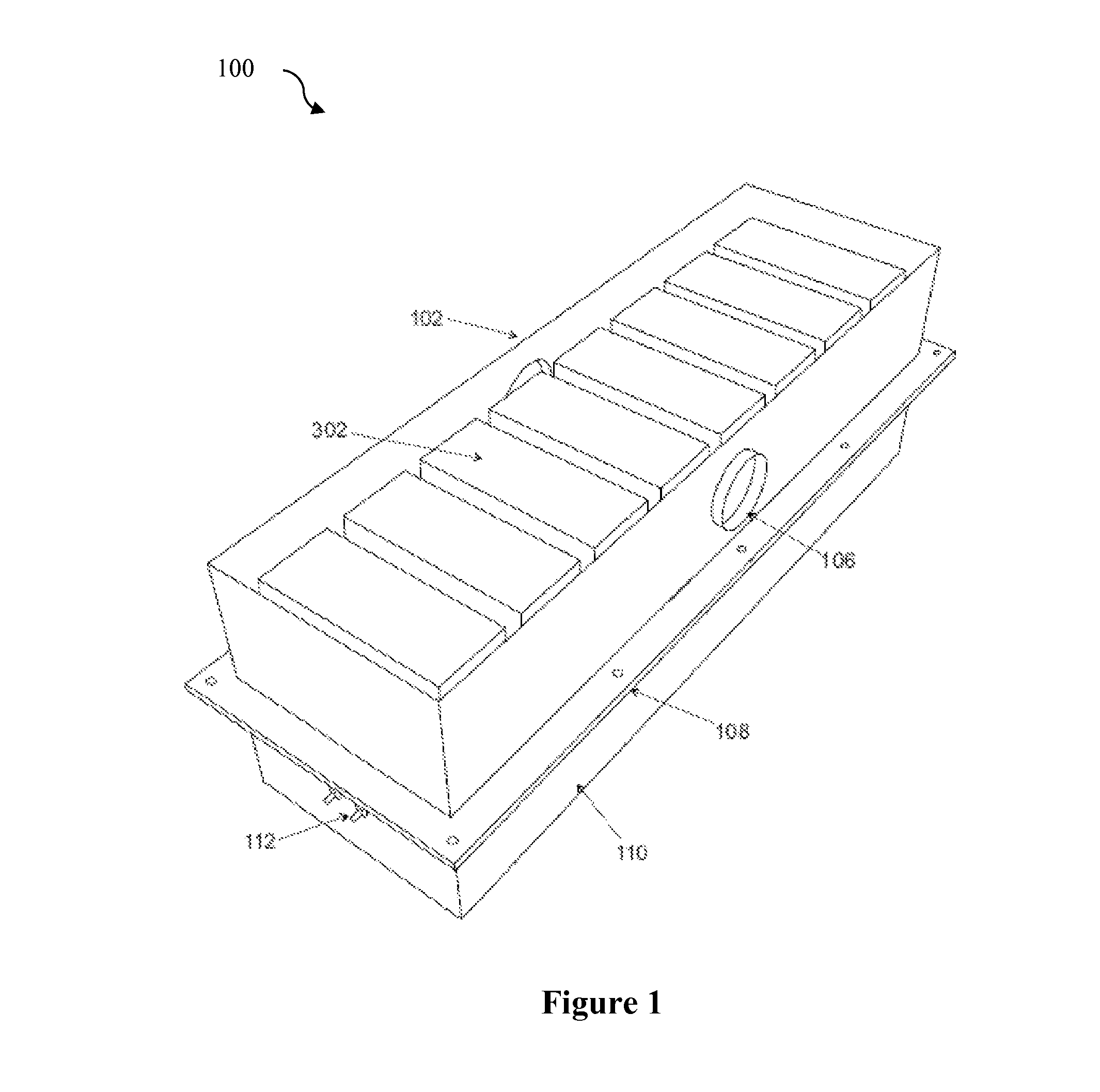

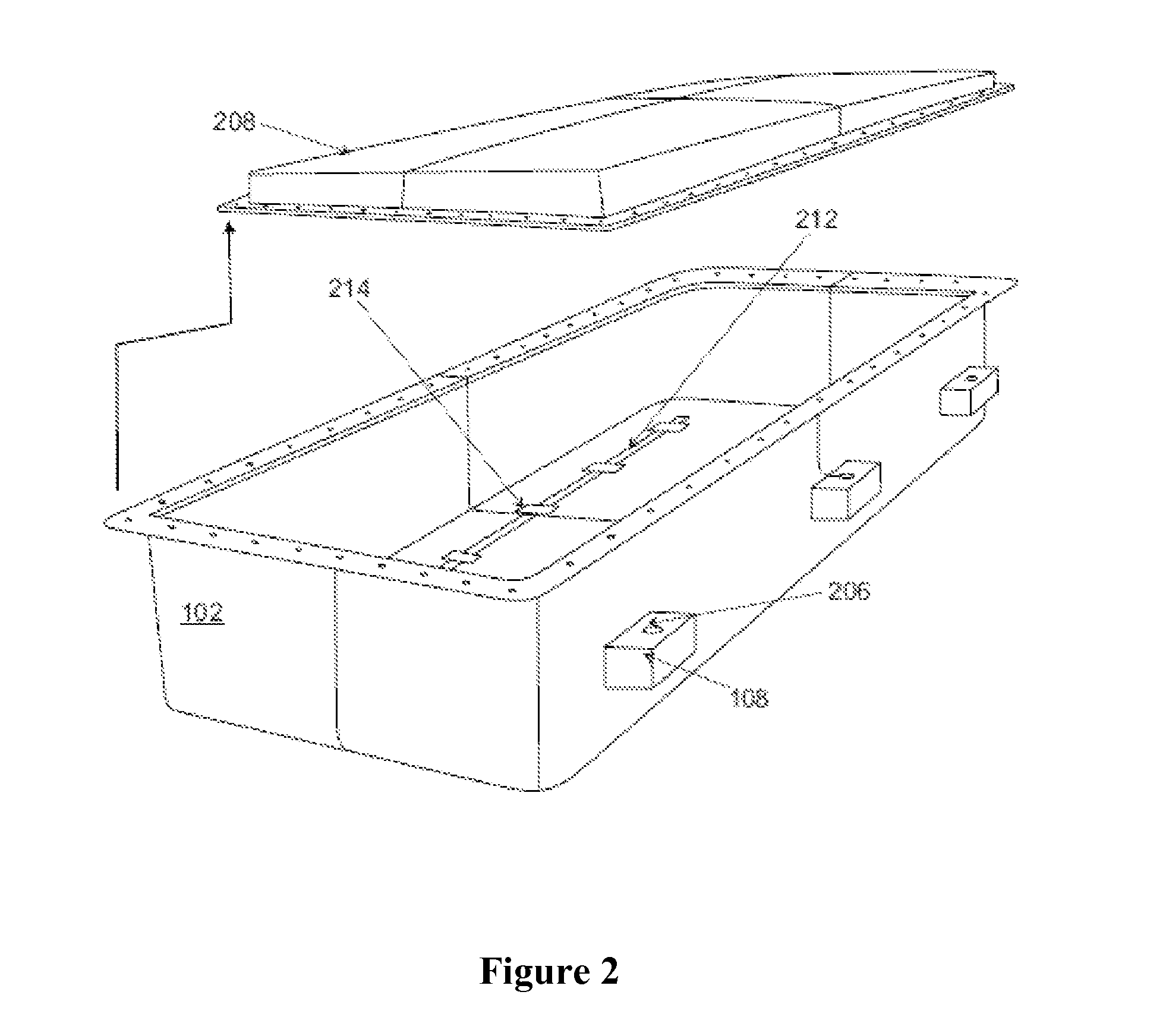

Swappable, configurable and structural battery pack for electric vehicles

InactiveUS9461284B2Improve structural rigidityLoose connectionCharging stationsCell lids/coversElectrical batteryDual purpose

An apparatus for swappable battery packaging for electric vehicle, the apparatus is contributing for dual purpose of protecting the batteries and providing contribution to the overall structural performance of the vehicle. The apparatus offer self repairable battery packing system to even a novice user thereof, offering each of replacement or recharging operations.

Owner:TATA TECH PTE

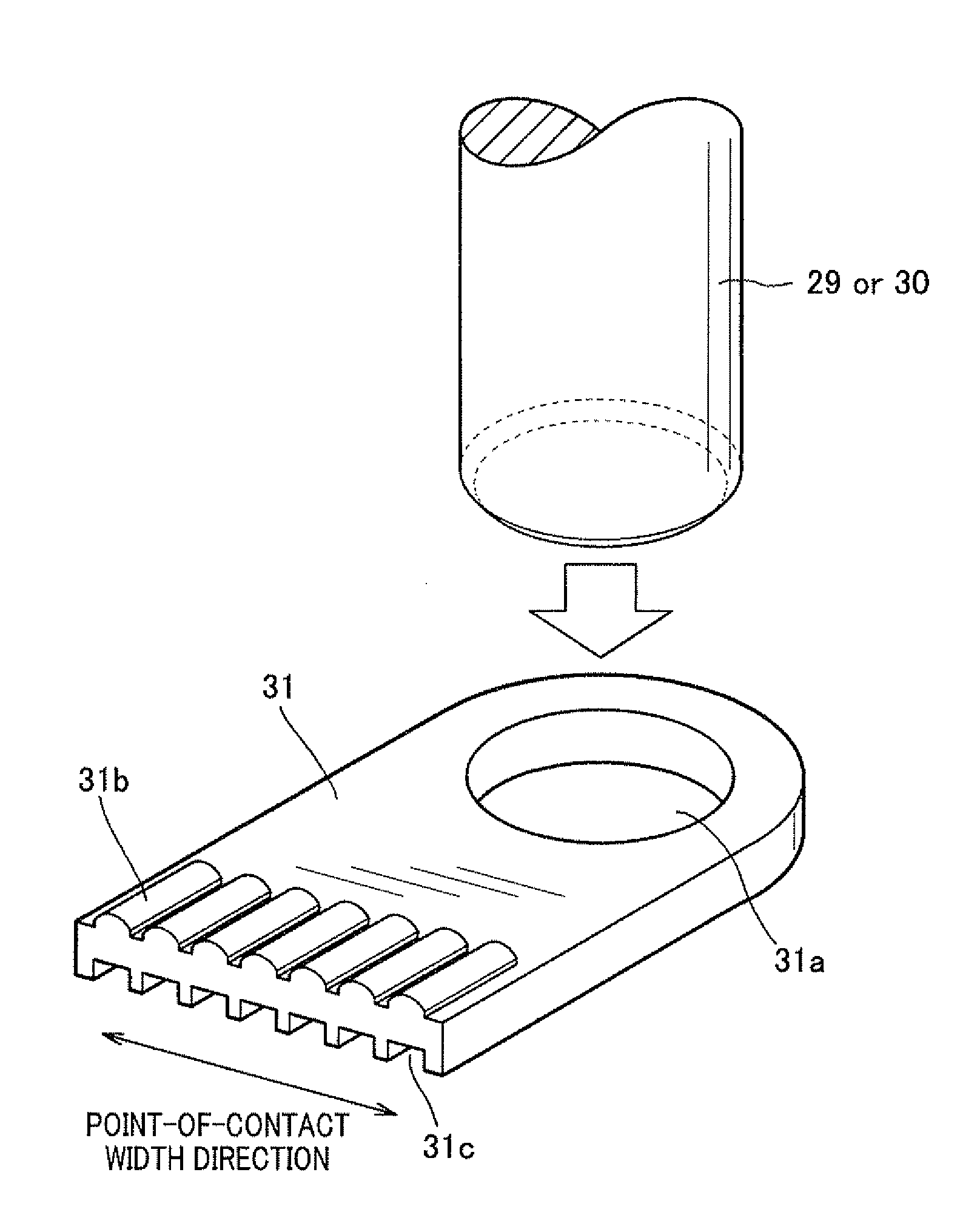

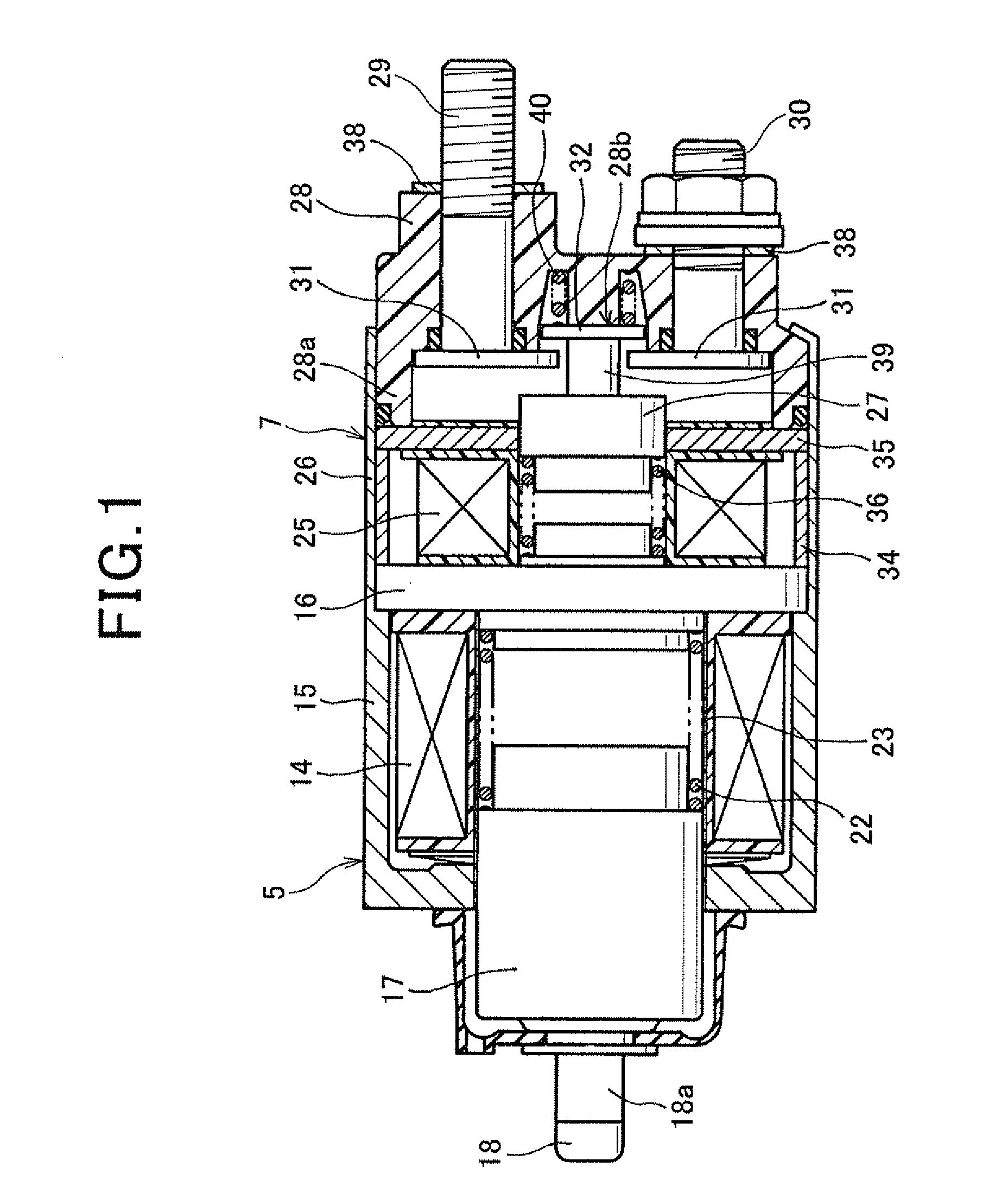

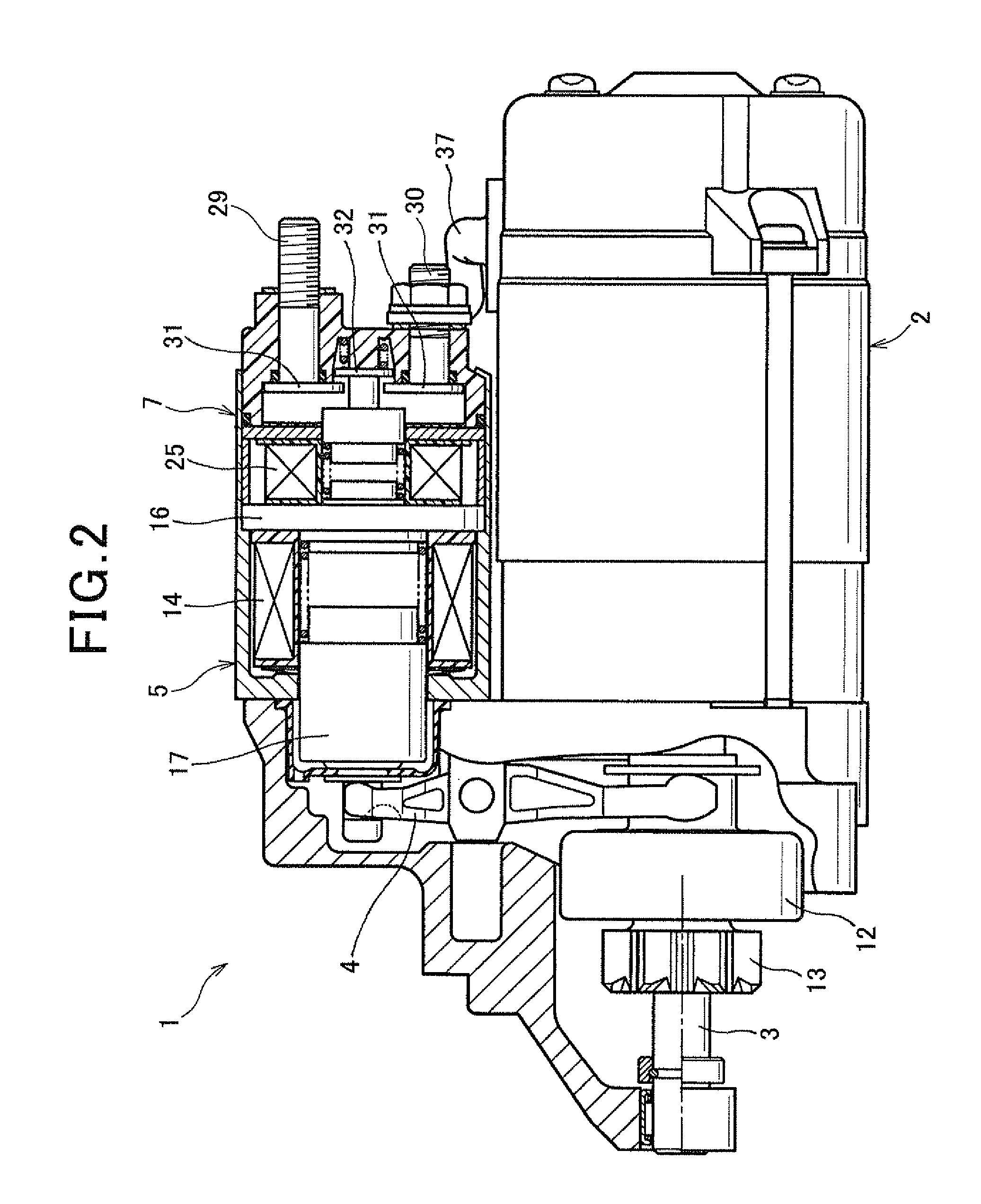

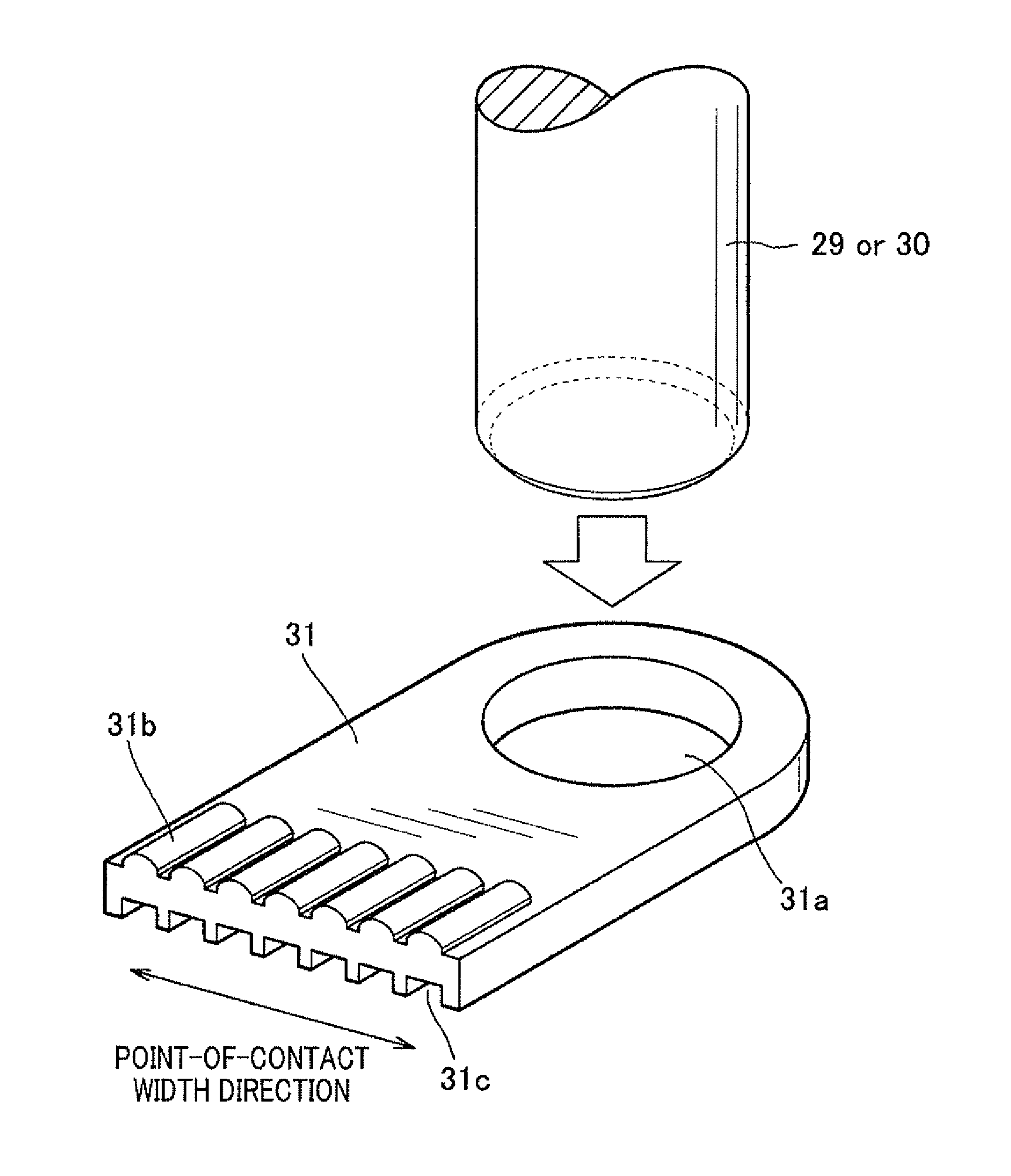

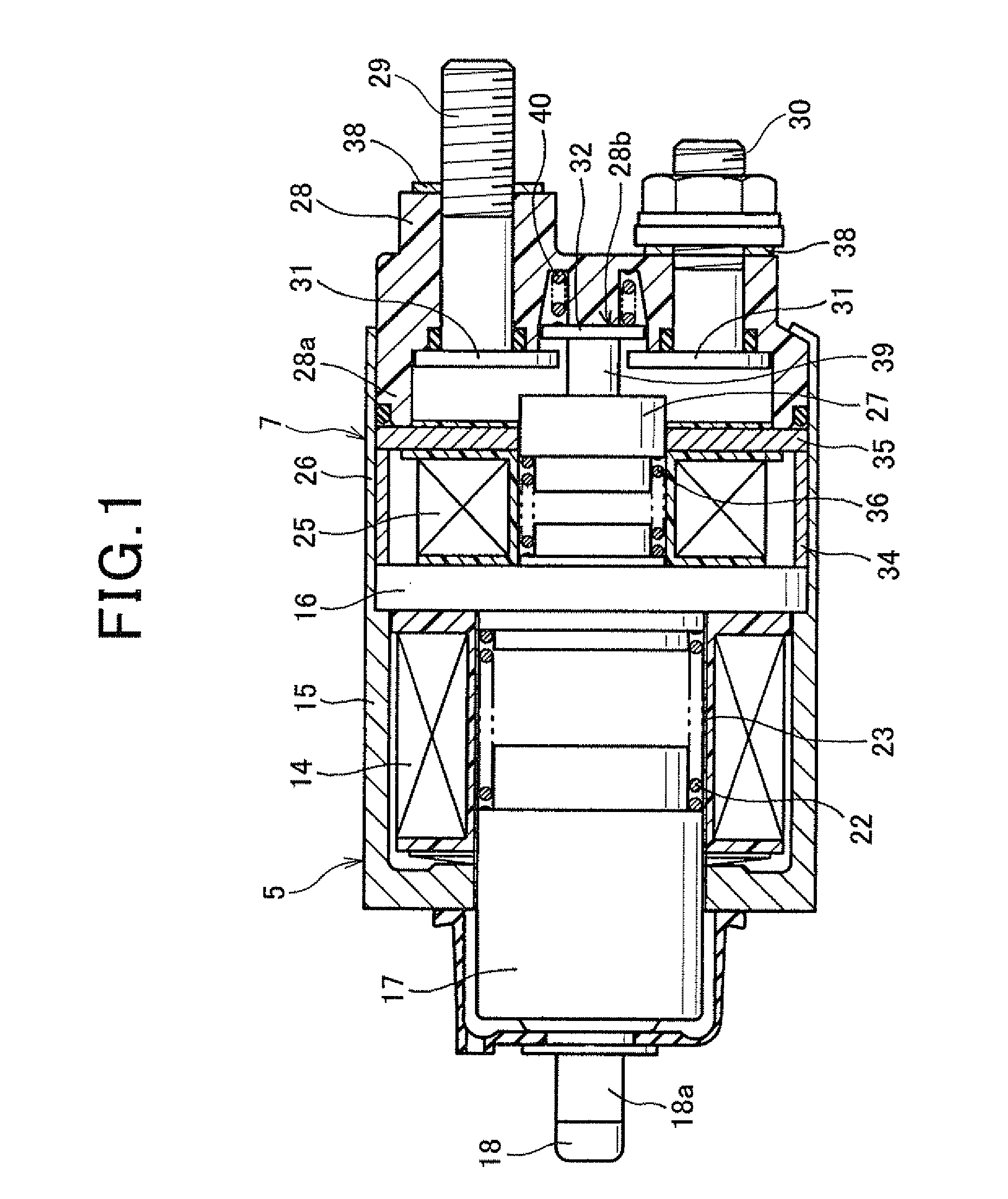

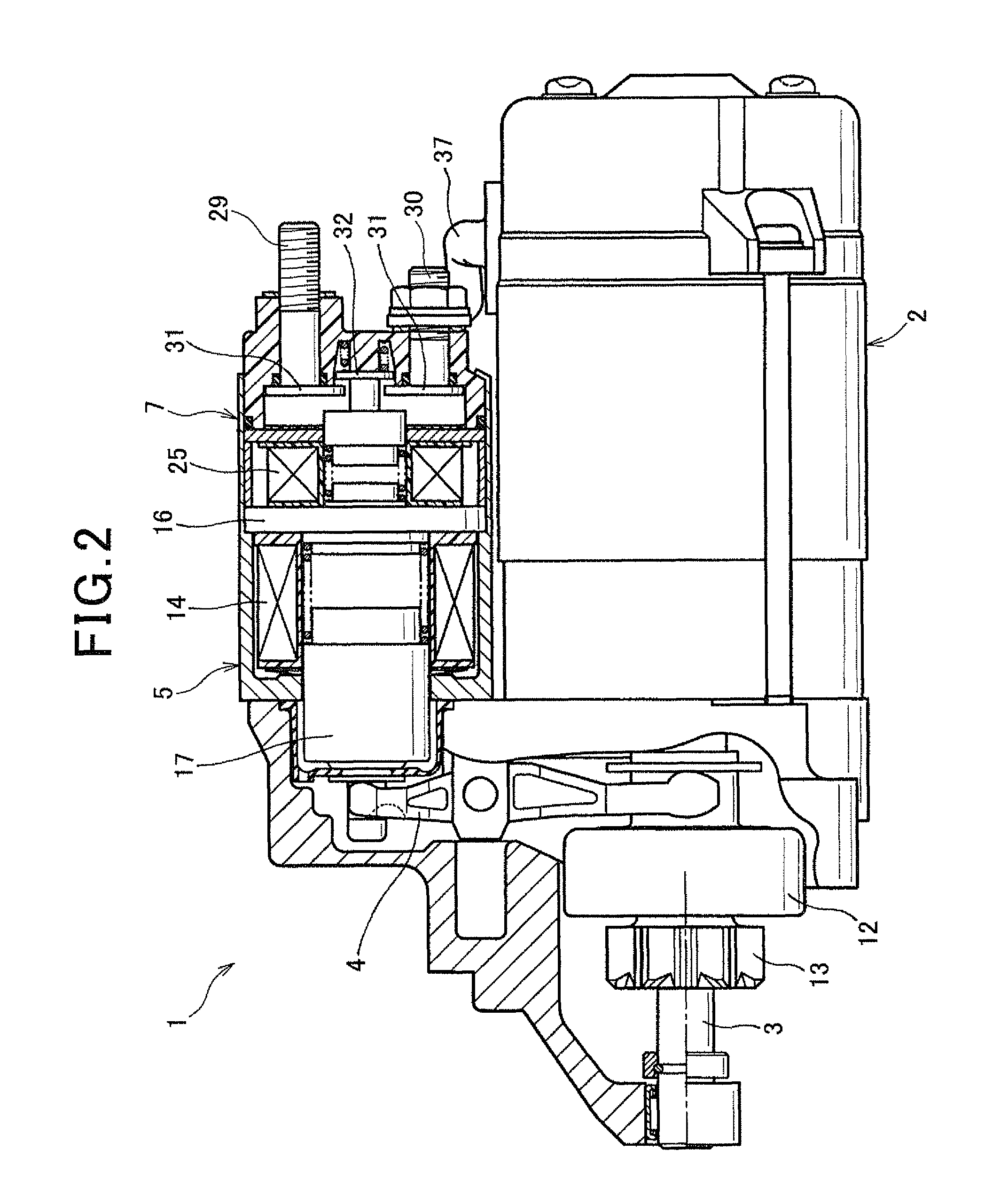

Electromagnetic relay for starters

ActiveUS20110001589A1Simple manufacturing processLoose connectionContact surface shape/structureRiveted connectionsEngineeringRelay

Owner:DENSO CORP

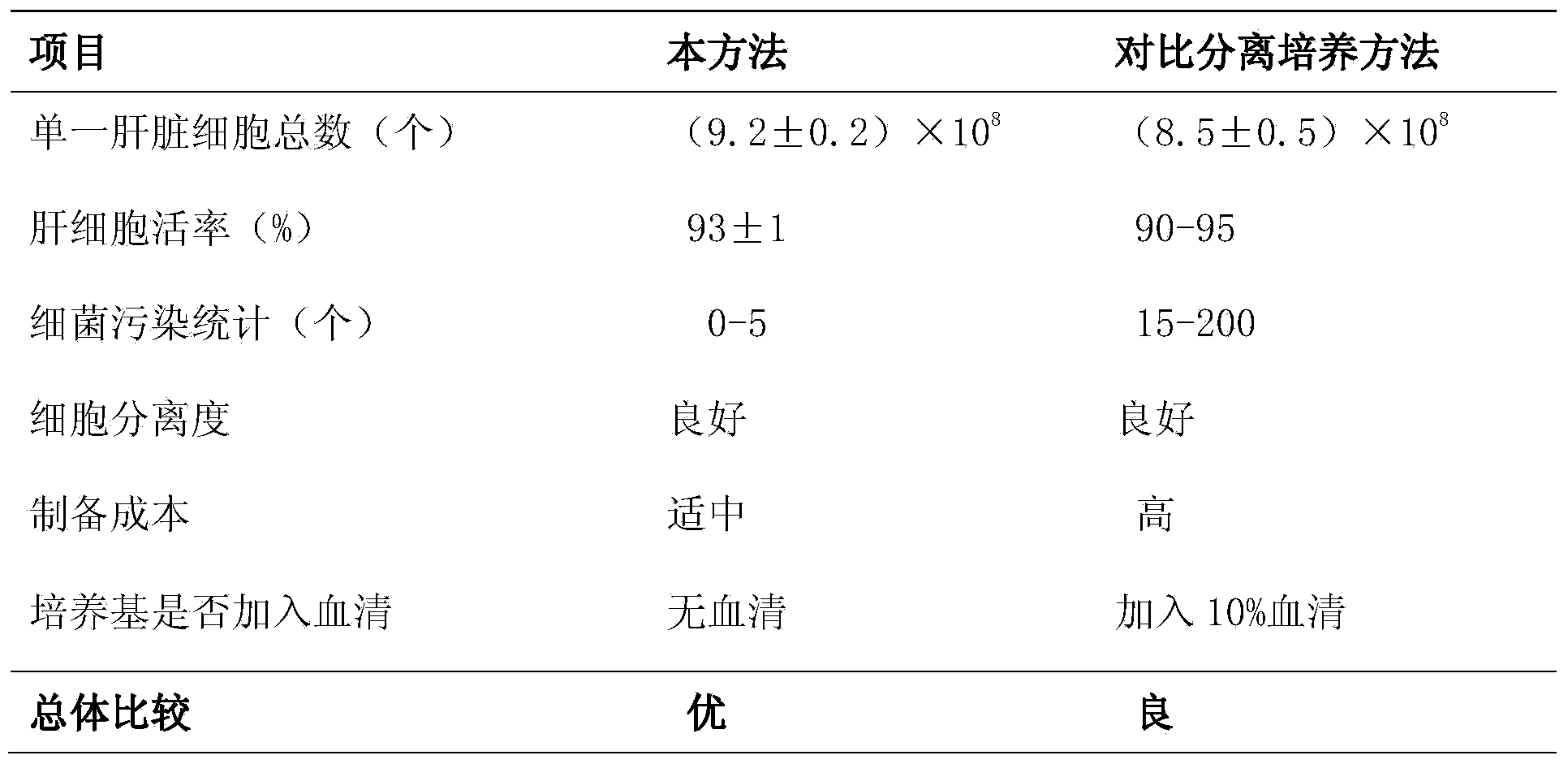

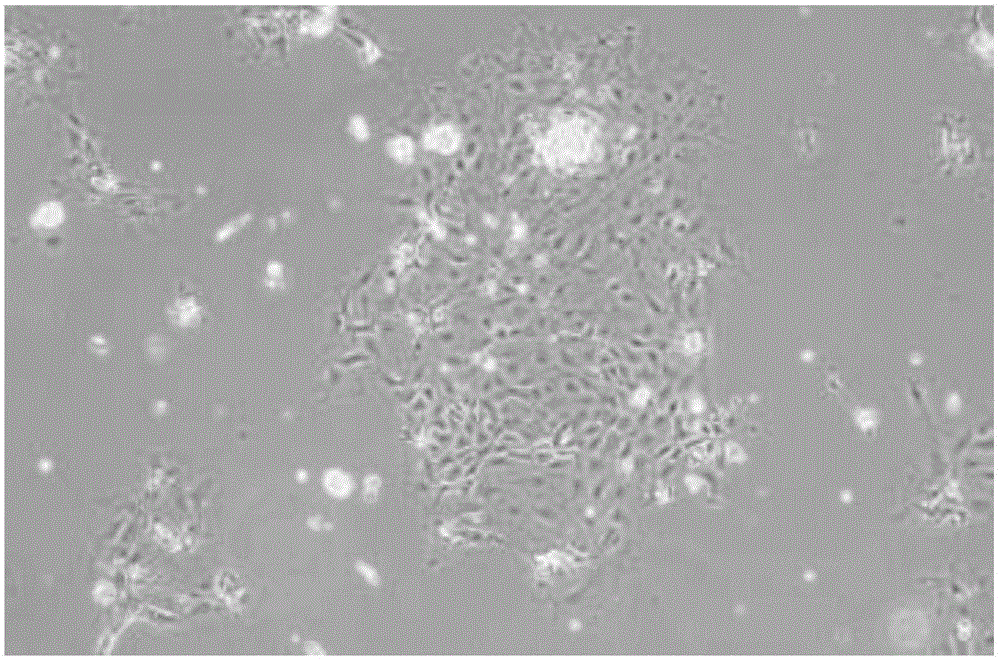

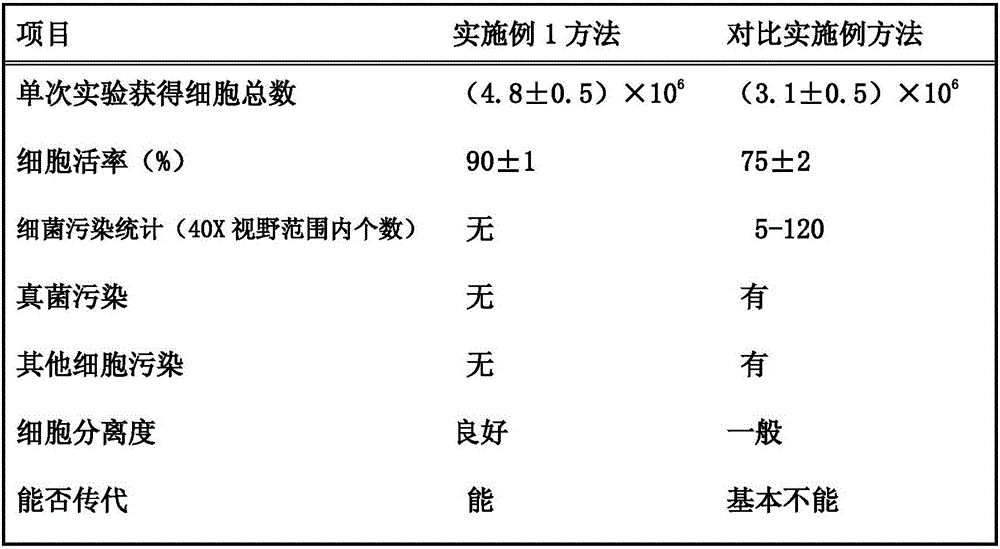

Method for separating and culturing primary chicken hepatocytes

InactiveCN103525756AExtend incubation timeWell differentiatedArtificial cell constructsVertebrate cellsBioproductsEthylene Glycol Tetraacetic Acid

The invention discloses a method for separating and culturing primary chicken hepatocytes. According to the method, EGTA (Ethylene Glycol Tetraacetic Acid) with low hepatotoxicity is added into a perfusate A to loosen the junction between hepatocytes, so that the dispersion degree of the to-be-separated hepatocytes is increased; double resistance is added into the perfusate A, a perfusate B and D-Hanks flushing fluid, so that the pollution is further prevented; and circulating perfusion digestion is adopted during digestion perfusion, so that the perfusion cost is greatly reduced. A serum-free cultural method of the chicken hepatocytes is established; compared with a traditional serum cultural method, the method disclosed by the invention has the same effect on the aspects of cell quantity, activity, function and the like, so that the problems caused by the existence of serum are solved and a foundation is laid for the substance metabolism study and biological product preparation on the basis of the chicken hepatocyte culture.

Owner:NANJING AGRICULTURAL UNIVERSITY

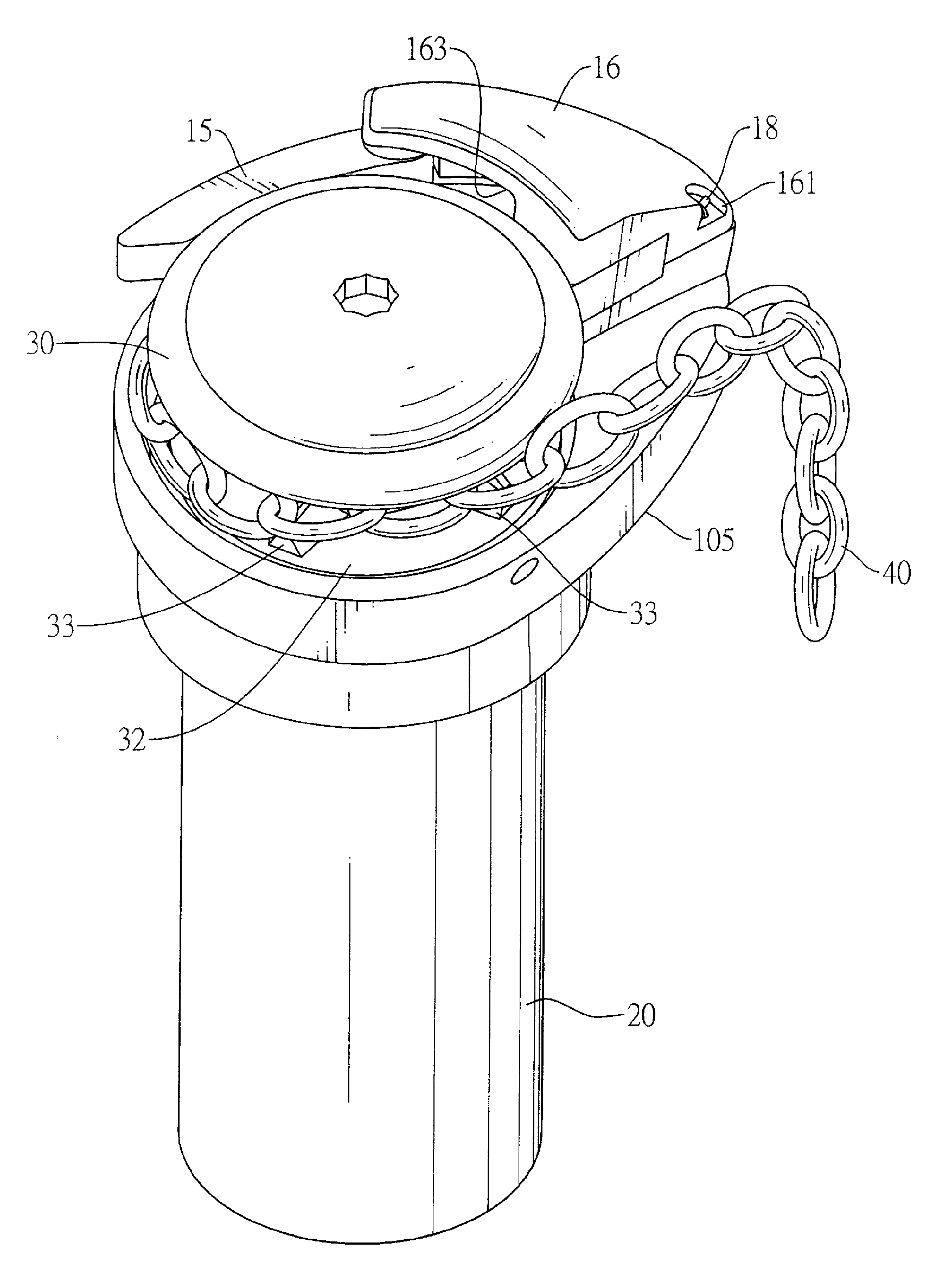

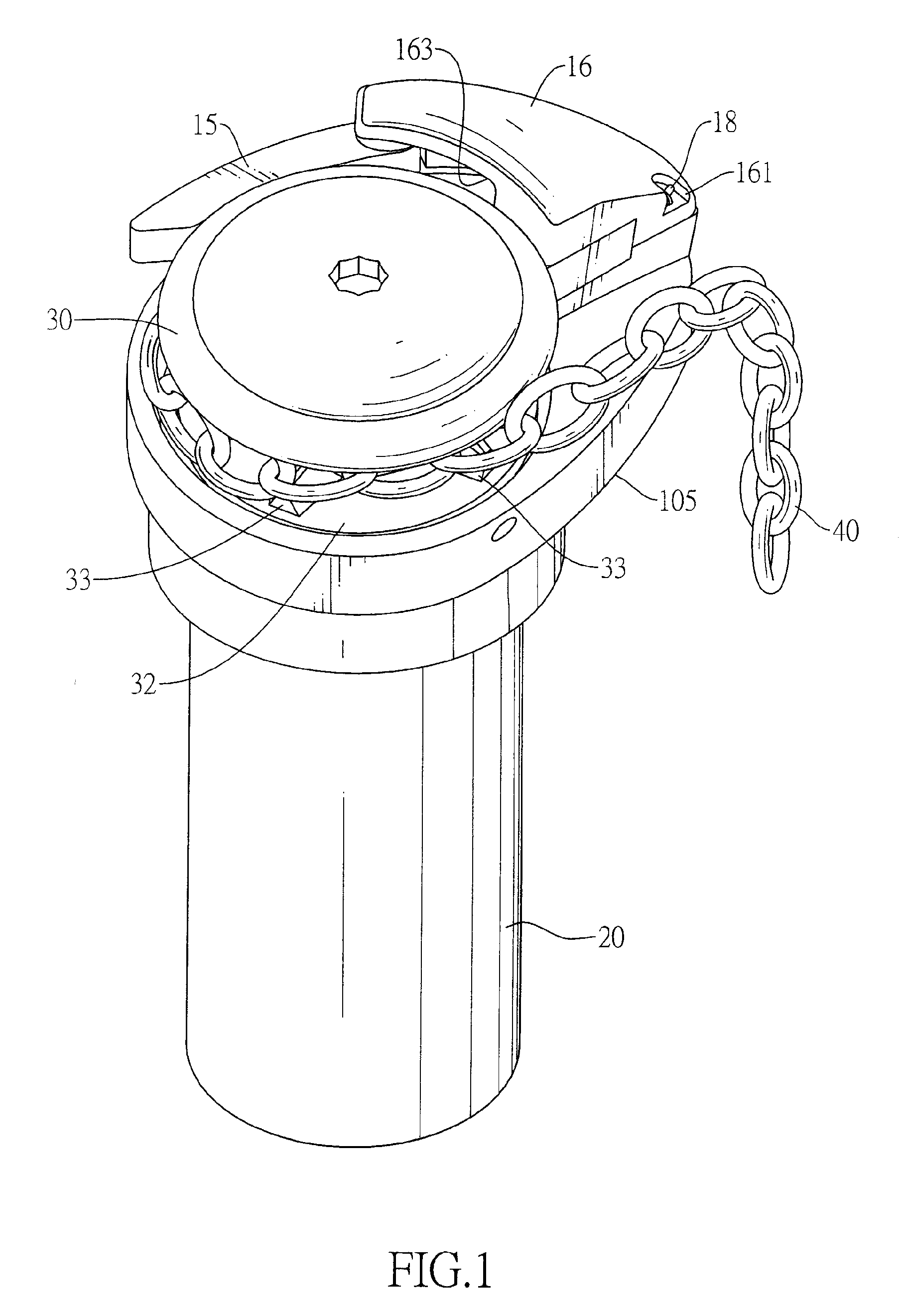

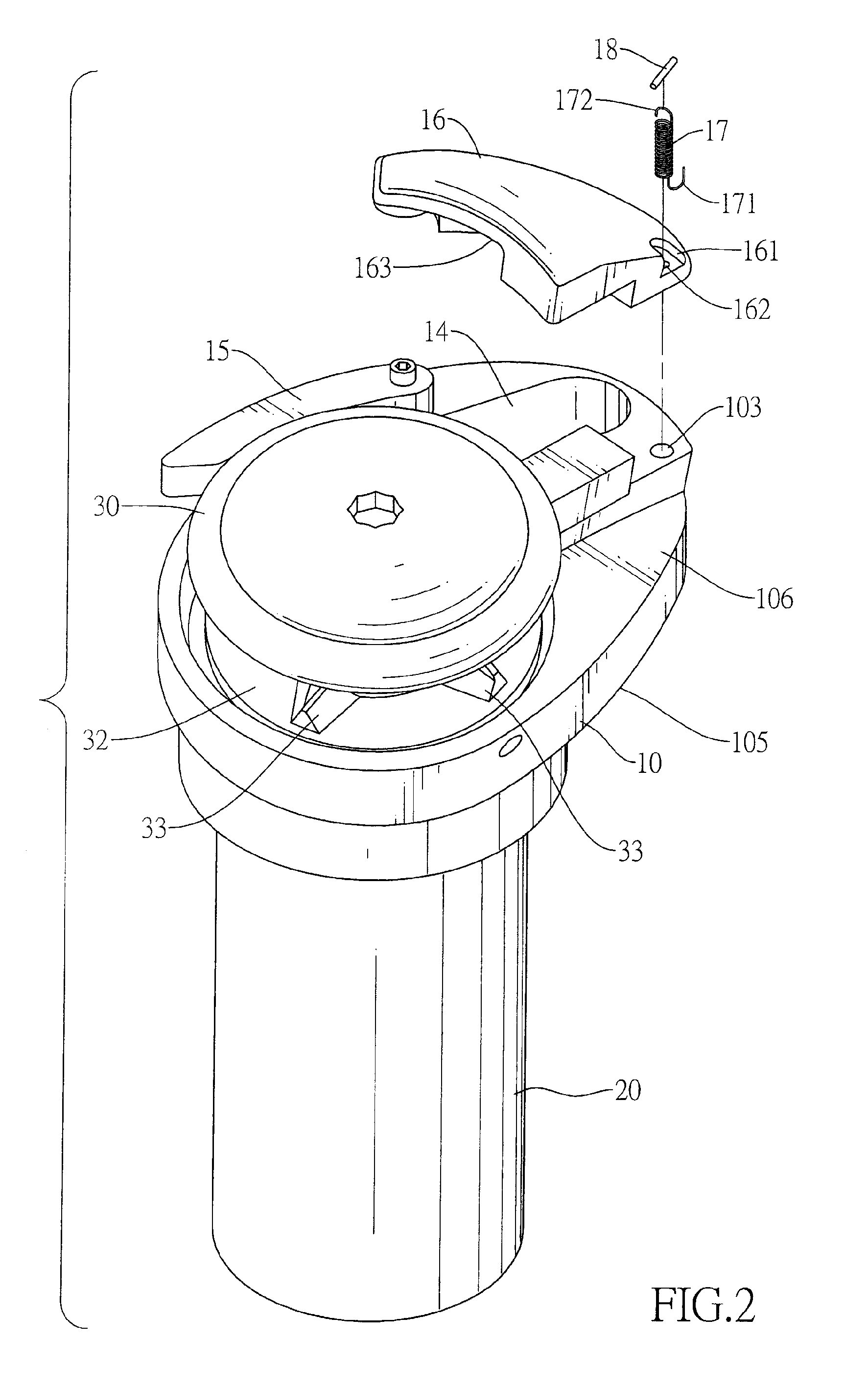

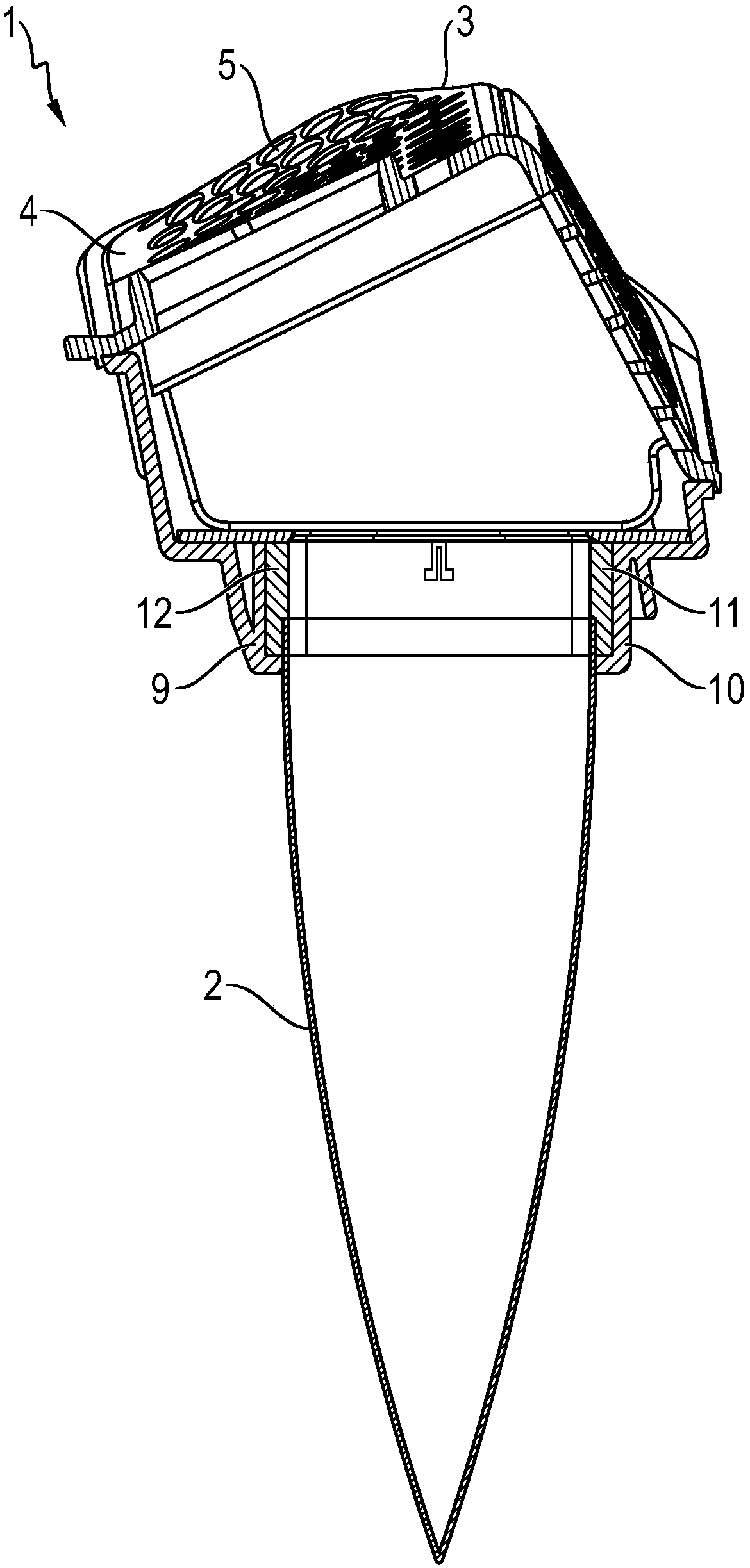

Anchor winch

An anchor winch has a casing assembly, a motor, a capstan and a chain. The casing assembly has a casing, a guiding cover, a spring and a guiding rail. The guiding cover is mounted on the casing and selectively opens. The spring is connected to the casing and the guiding cover and makes to guiding cover to be capable of opening at any angles. The guiding rail is mounted on the casing adjacent to the guiding cover. The motor is mounted on the casing. The capstan is mounted rotatably on the casing and is driven by the motor. The chain is mounted through the casing and is wound on the capstan. The spring achieves a somewhat loose connection between the casing and the guiding cover, which provides a resilient force preventing the guiding cover from being damaged by the inadvertent impact from the moving chain.

Owner:GRAND WINCHES IND

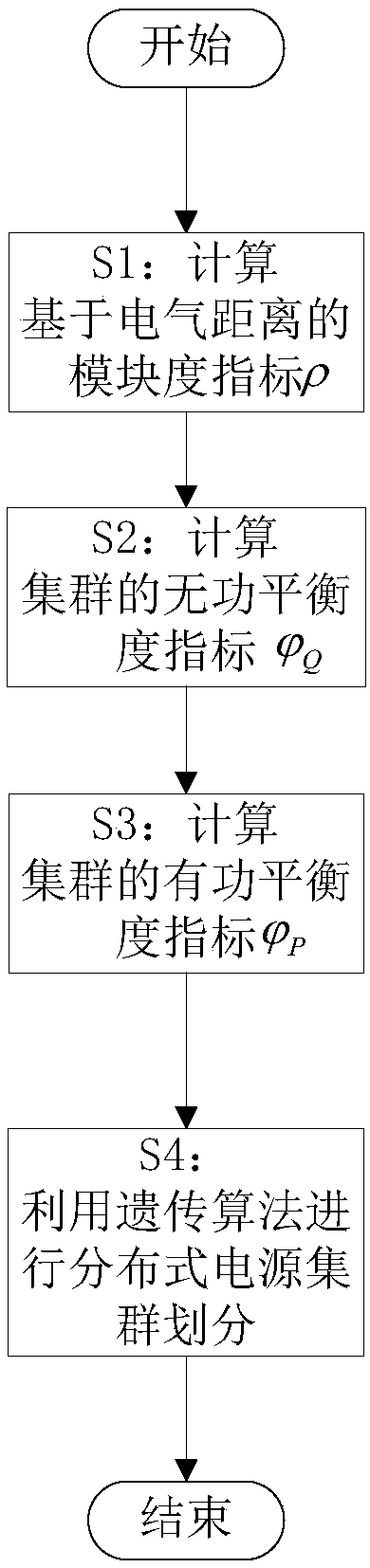

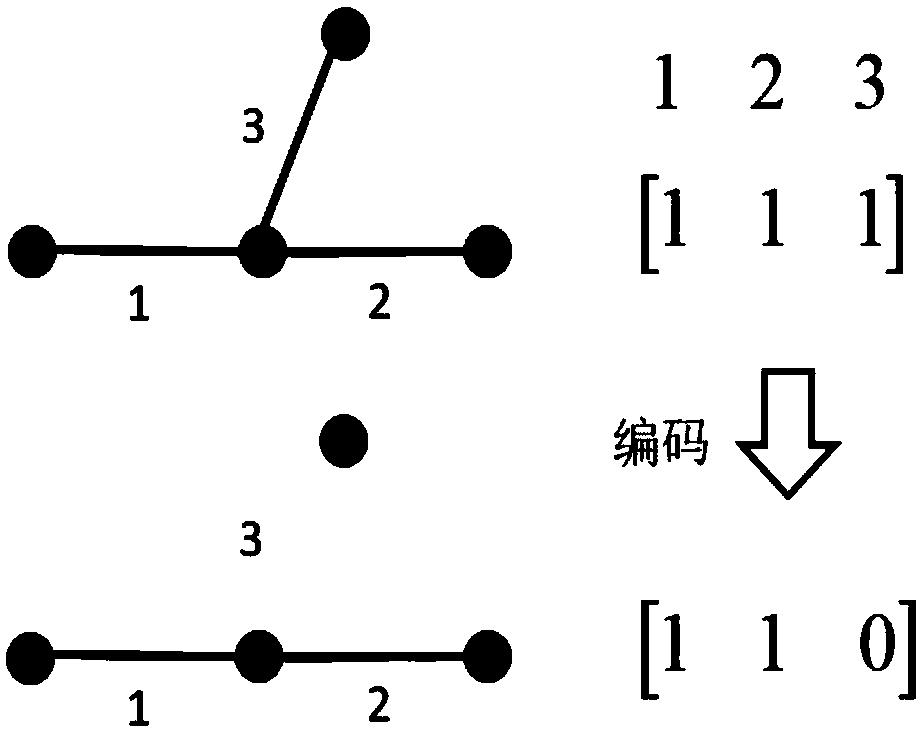

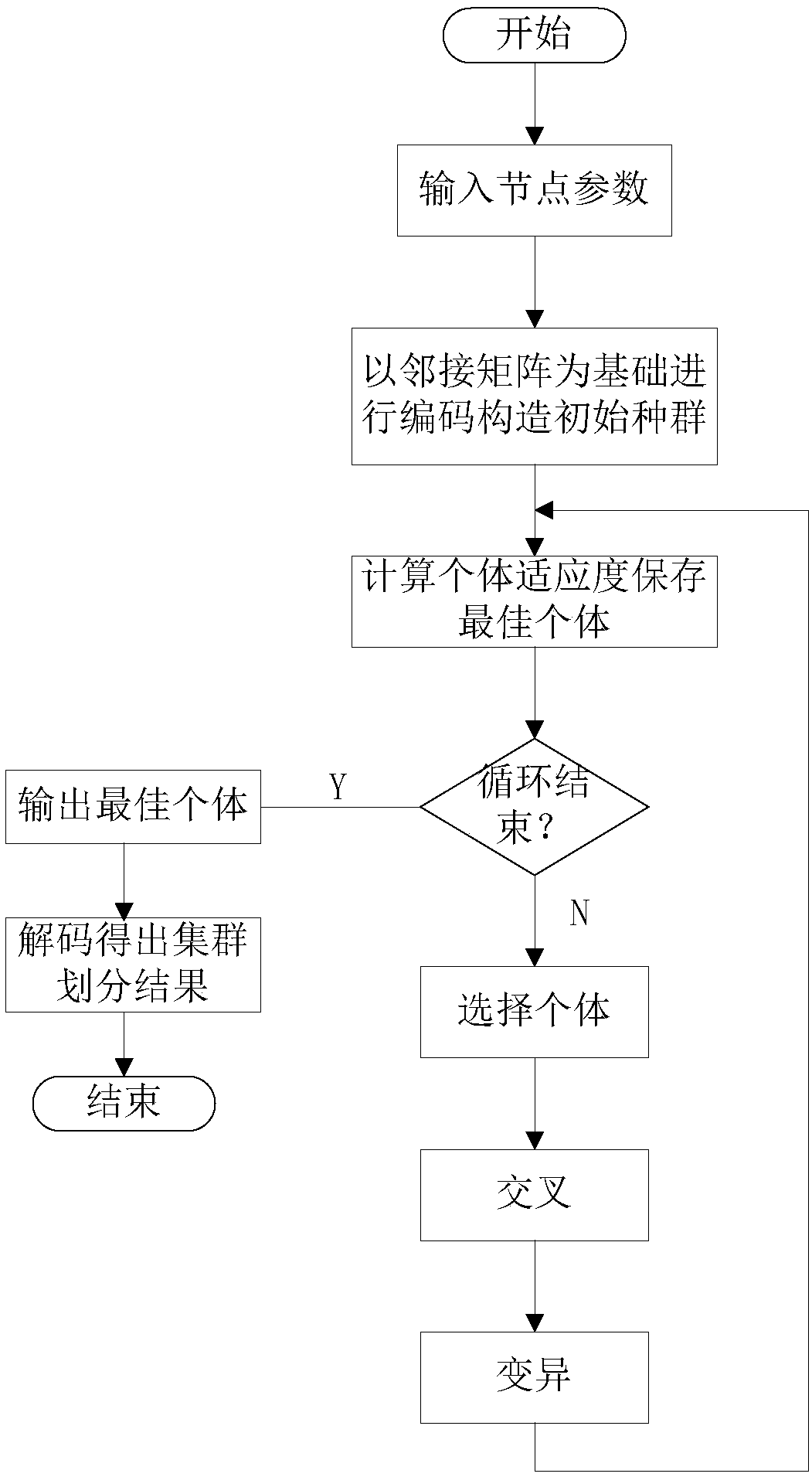

Comprehensive performance index-based high-permeability distributed power supply cluster division method

ActiveCN108448620AEasy to operate and manageGive full play to self-containment abilitySingle network parallel feeding arrangementsNODALPerformance index

The invention discloses a comprehensive performance index-based high-permeability distributed power supply cluster division method, and relates to the technical field of power distribution network planning and control of a renewable energy power supply. A cluster division index system and a cluster division effective algorithm are proposed; the cluster division index is defined as a comprehensiveperformance index; the comprehensive performance index comprises an electrical distance-based modularity index <rho>, a cluster reactive balance degree index formula which is as shown in the specification and a cluster active balance degree index formula which is as shown in the specification; for adapting the calculation expression of the comprehensive performance index system and the objective demand of cluster division, the cluster division effective algorithm performs distributed power supply cluster division based on a genetic algorithm; meanwhile, by improving the basic genetic algorithmand according to the network adjacent relation, a chromosome coding mode is designed; and adaptive crossed mutation probability is adopted. The comprehensive performance index-based high-permeabilitydistributed power supply cluster division method has the advantages as follows: complementarity between nodes and cluster capacity of self-government can be fully played, so that large-scale renewable energy consumption and control can be promoted.

Owner:HEFEI UNIV OF TECH +2

Electromagnetic relay for starters

ActiveUS8143979B2Simple manufacturing processLoose connectionContact surface shape/structureRiveted connectionsEngineeringRelay

Owner:DENSO CORP

Preparation method of iron alloy

The invention relates to a preparation method of an iron alloy, which comprises the following steps: melting one-third weight of iron, all weight of manganese, all weight of aluminum and one-half weight of chromium in a smelting furnace, heating to 1250-1350 DEG C, keeping the temperature for 0.5-1 hour, and cooling to 200-350 DEG C; sequentially adding the rest weight of chromium and all weight of molybdenum, nickel, titanium, zirconium, boron and cobalt, and heating to 1250-1350 DEG C; and adding the rest weight of iron and all weight of carbon, tellurium, silicon and cerium, keeping at the temperature of 1250-1350 DEG C for 1-2 hours, casting, annealing, and carrying out quenching and tempering treatment to obtain the wear-resistant iron alloy. The tissue crystal grain of aluminum in the alloy solution can produce overgrowth to form a similar skeleton structure with manganese and chromium, and the elements added afterwards are sent into the solution in a filling mode.

Owner:宁波市鄞州商业精密铸造有限公司

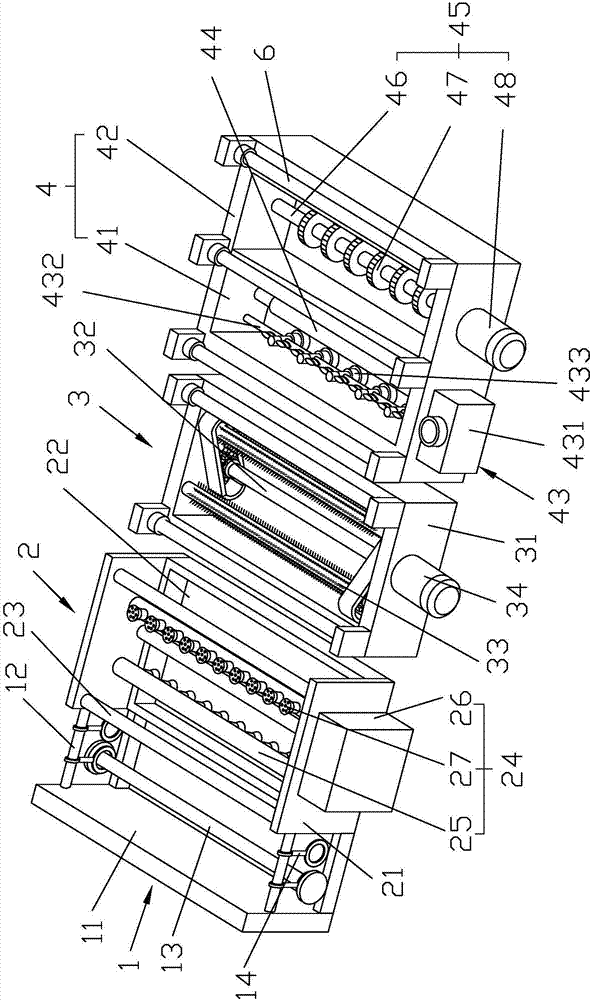

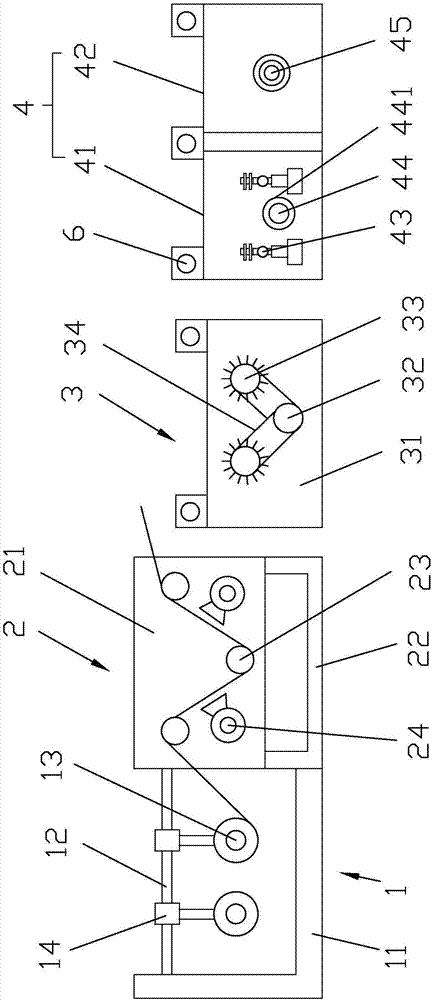

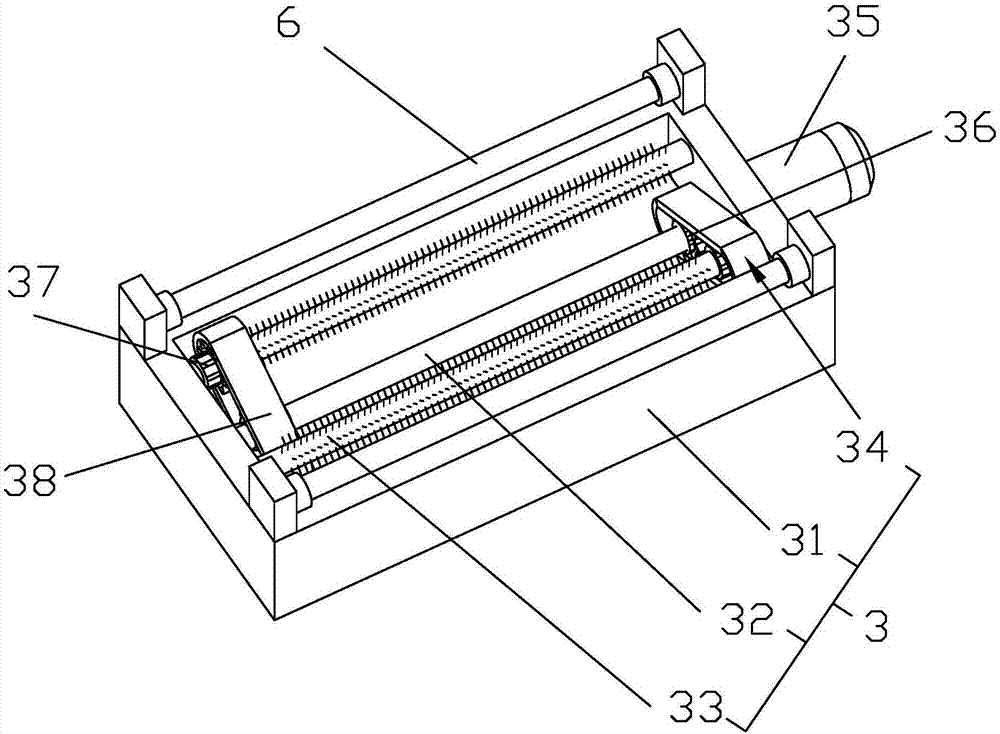

Desizing equipment for spinning fabric

InactiveCN107022860AEasy to feed the clothSave time changing clothMechanical cleaningPressure cleaningFiberPulp and paper industry

The invention mainly discloses a desizing equipment for textile fabrics. Its technical proposal includes a cloth laying rack, a pretreatment device, a scraping device and a desizing box. The pretreatment device includes a pretreatment rack, a water receiving tank, and a transmission roller. And the water spray device, the water receiving tank is located at the bottom of the pretreatment frame, the transmission rollers are distributed on the pretreatment frame in an inverted triangle, the water spray device is located between the adjacent transmission rollers, the scraping device includes a scraping box, the first cloth guide roller , brushing roller and driving device, the driving device respectively drives the first cloth guide roller and brushing roller to rotate, the desizing box includes a trough and an oscillating trough, and a feeding device and a second cloth guide with a heating pipe are arranged in the trough The roller has an oscillating device in the oscillating groove, and the oscillating device includes an oscillating roller, an oscillating wheel and an oscillating motor. The invention has fast desizing speed, high desizing efficiency, less damage to fabric fibers, removes pollutants and symbiotic impurities on fabrics, and is convenient for later processing of fabrics.

Owner:嵊州市靖洁纺织机械有限公司

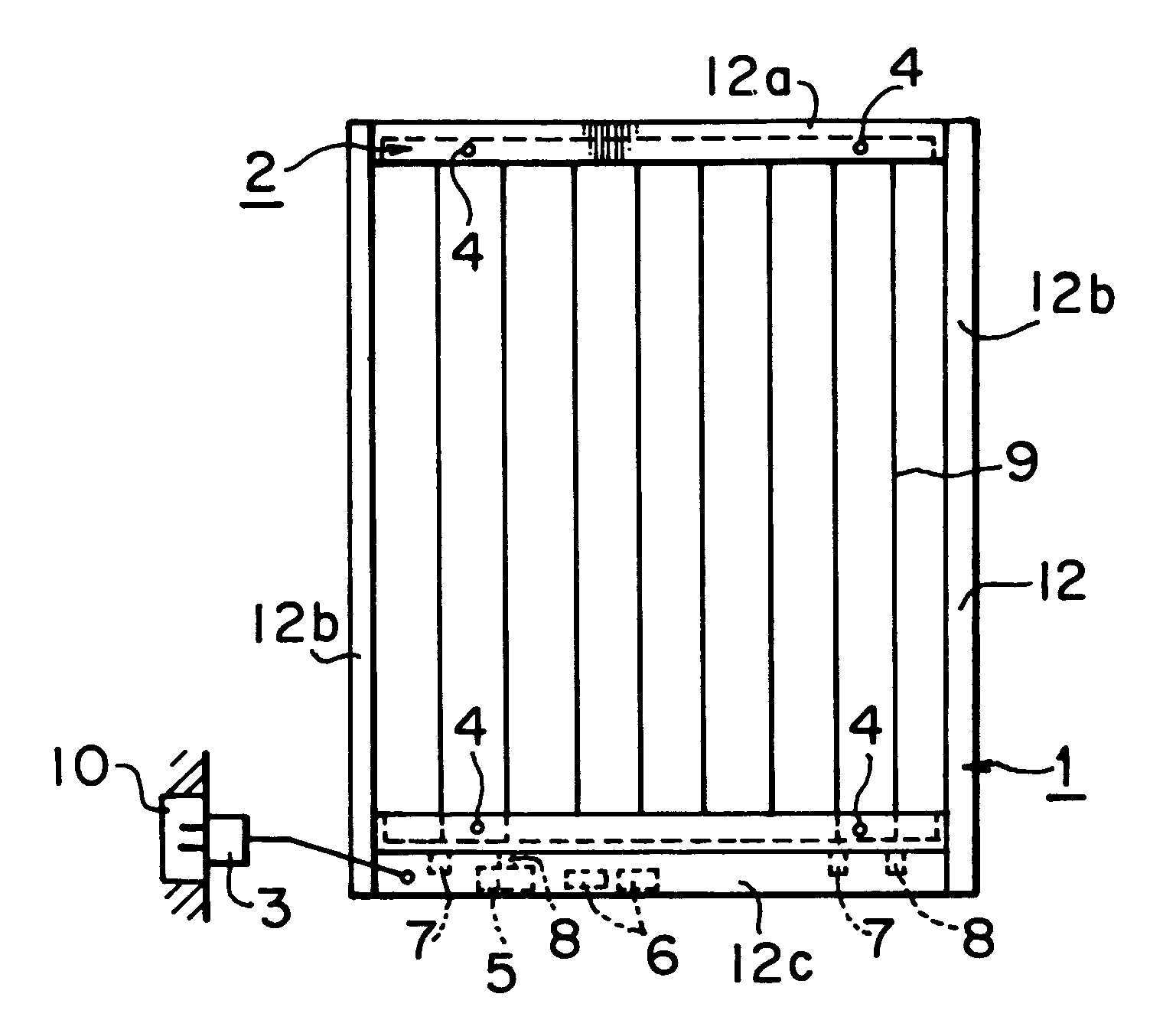

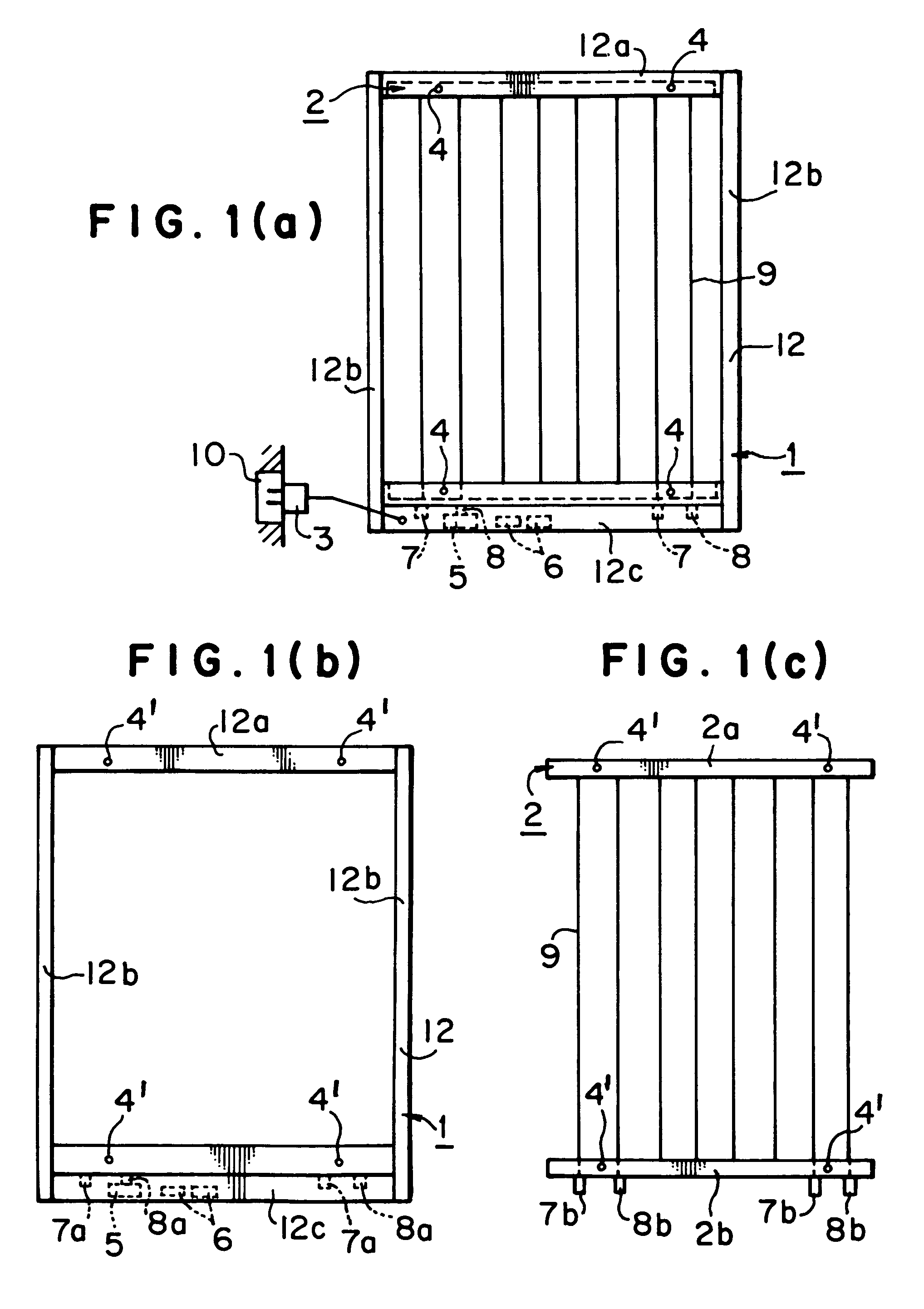

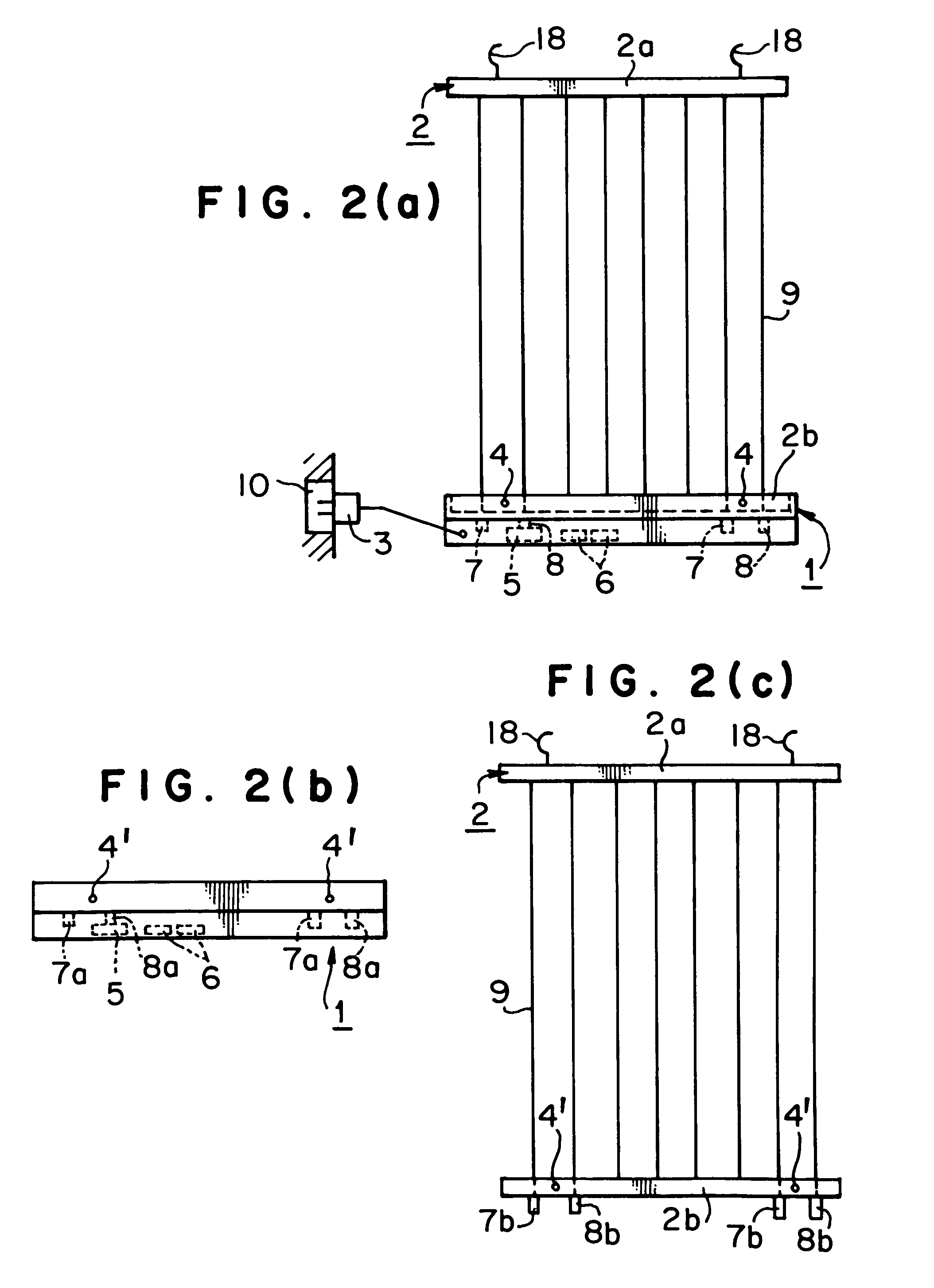

Flotage trapping device using electrostatic field

ActiveUS7833323B2Loose connectionElectrode carrying meansParticle charging/ionising stationsElectricityTrapping

Owner:TRINC

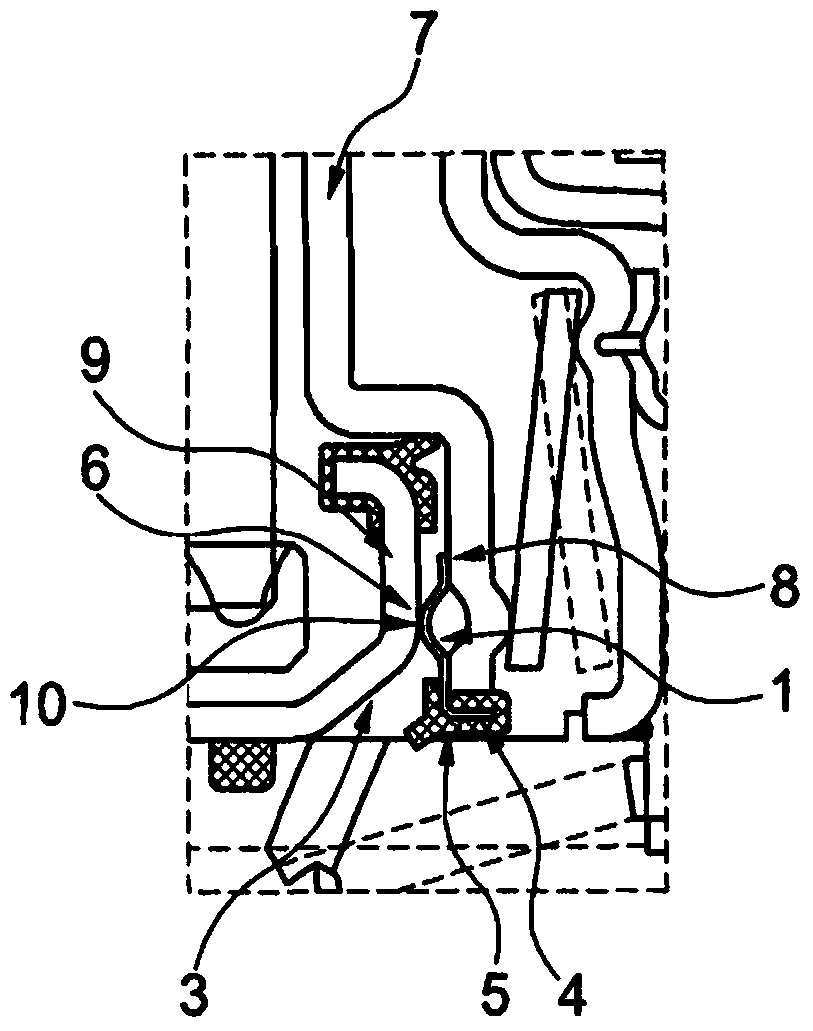

Changeover valve

ActiveCN102808967AGuaranteed automatic resetReduce structural complexityMultiple way valvesThin material handlingEngineeringFront edge

The invention relates to a changeover valve comprising a valve housing, two sealing elements, and a switching tube, wherein an axial actuating movement of the changeover shaft can be transferred at least to one of the two sealing elements in such a way that either both sealing elements bear with outer circumferential sealing surfaces on the sealing surfaces of the valve housing that surround a fluid passage and one of the sealing elements closes the adjacent circumferential front edge of the switching tube with an inner circumferential sealing surface while the other sealing element remains at a distance from the other circumferential front edge of the switching tube, serving as a fluid passage, or both inner circumferential sealing surfaces of the sealing elements bear on the adjacent circumferential front edges of the switching tube while the one sealing element uses the outer circumferential sealing surface thereof to load the adjacent mating sealing surface surrounding the fluid passage, and the other sealing element is spaced apart from the mating sealing surface assigned thereto and surrounding a fluid passage.

Owner:NEOPERL

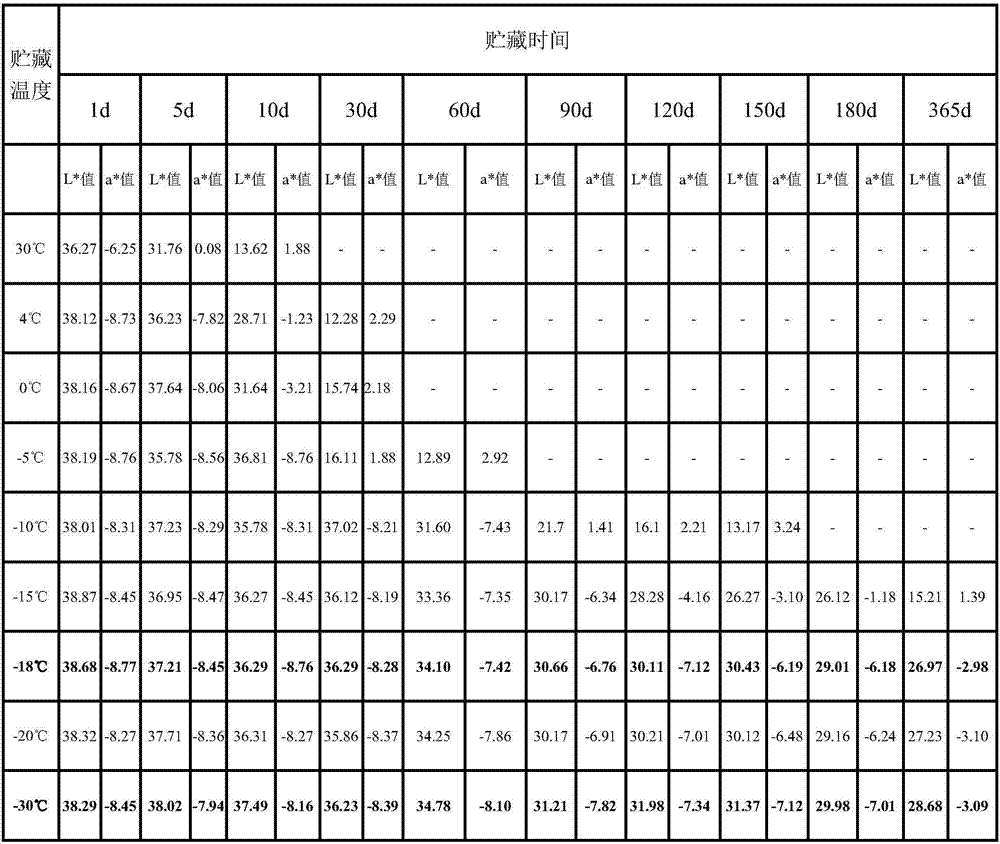

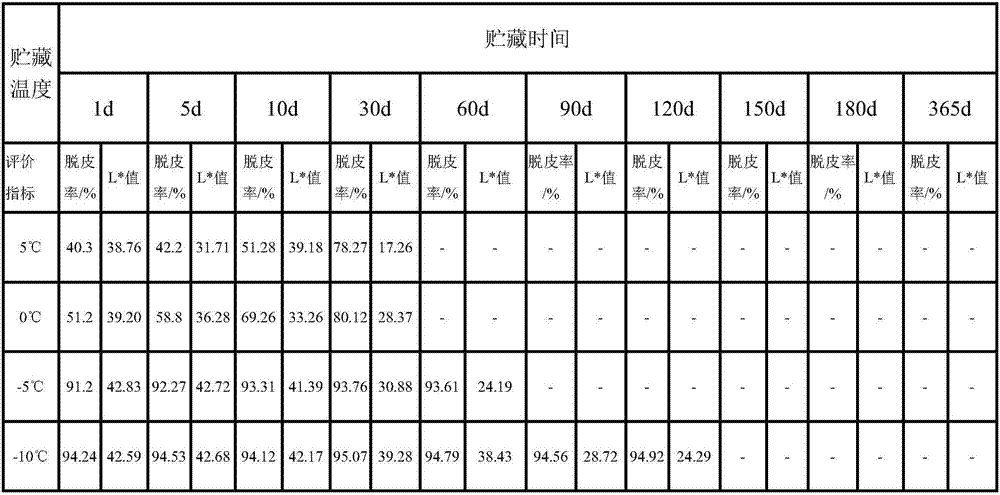

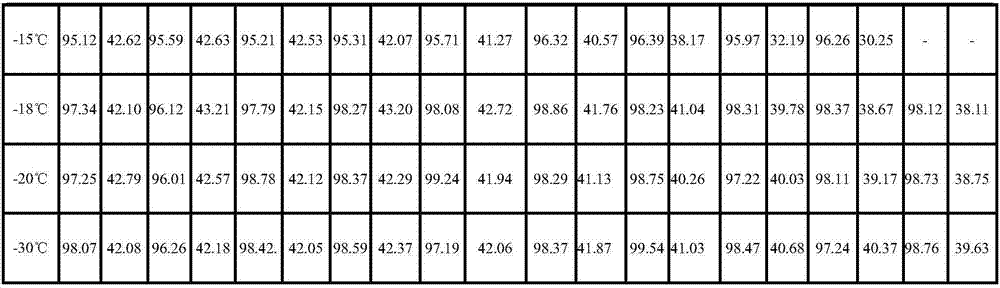

Quick peeling method of piper nigrum fruits through freezing

ActiveCN107028201AColor unchangedNatural colorVegetable peelingFood treatmentPiper lepturumHorticulture

The invention relates to the field of green and safe processing and treating of foods, in particular to a quick peeling method of piper nigrum fruits through freezing. The quick peeling method comprises three steps of precooling, freezing and peeling. According to the peeling method, firstly fresh piper nigrum fruits are frozen, then the frozen piper nigrum fruits are stored, and the unfrozen piper nigrum fruits can be directly peeled through mechanical and electronic integration so that white piper nigrum fruits are prepared. The prepared white piper nigrum fruits are smooth in surfaces, mellow and full in granules, quietly-elegant in color, rich in fragrance and free from any peculiar smell, the fragrance of the white piper nigrum fruits is substantially elevated, the quality of the white piper nigrum fruits is excellent, and the quick peeling method is suitable for large-scale industrialized continuous production.

Owner:HAINAN UNIVERSITY

Primary rat or mouse gastric mucosal epithelial cell isolation and culture method

InactiveCN105907700APlay an anticoagulant rolePrevent adhesionCell dissociation methodsGastrointestinal cellsCell culture mediaDigestion

The invention discloses a primary rat or mouse gastric mucosal epithelial cell isolation and culture method. A perfusion method is innovatively introduced into the primary rat or mouse gastric mucosal epithelial cell isolation and culture method, and sufficient perfusion without dead corners is achieved. Prepared compound enzyme digestive juice avoids the problems of low cell viability and poor yield and is capable of digesting more evenly and thoroughly as compared with preheated digestion of traditional single collagenase. Within 12 hours of cell inoculation adherence, a cell culture medium with a pH value of 6-6.5 is adopted, cell adherence rate can be increased greatly and adherence effects are better. The primary rat or mouse gastric mucosal epithelial cell isolation and culture method has the advantages of large total cell number, high isolation degree, high living rate and low contamination probability by bacteria, fungi and other cells as well as capability of achieving subculture so as to provide a favorable cell culture scheme for related fundamental researches.

Owner:王晓冰

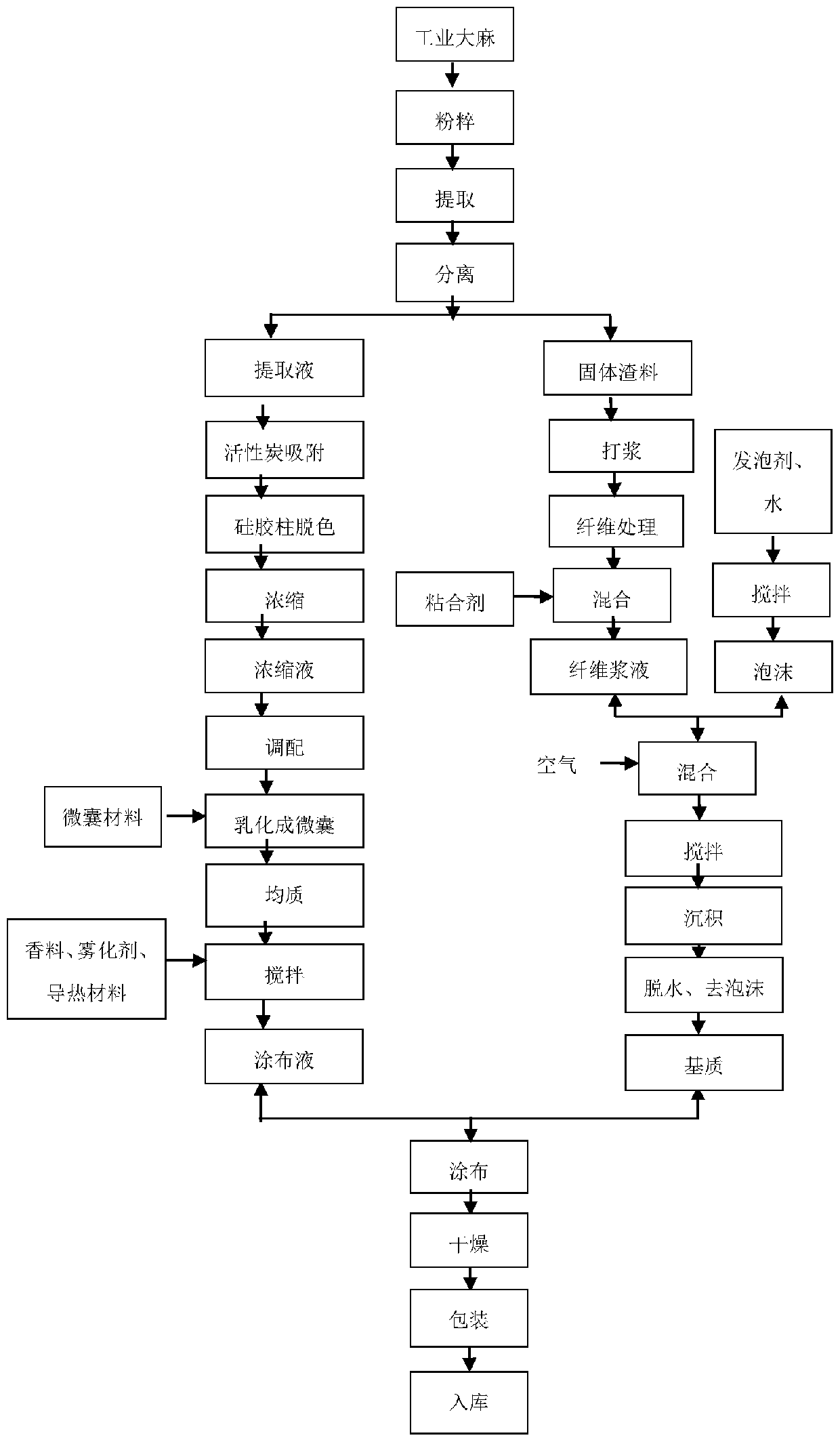

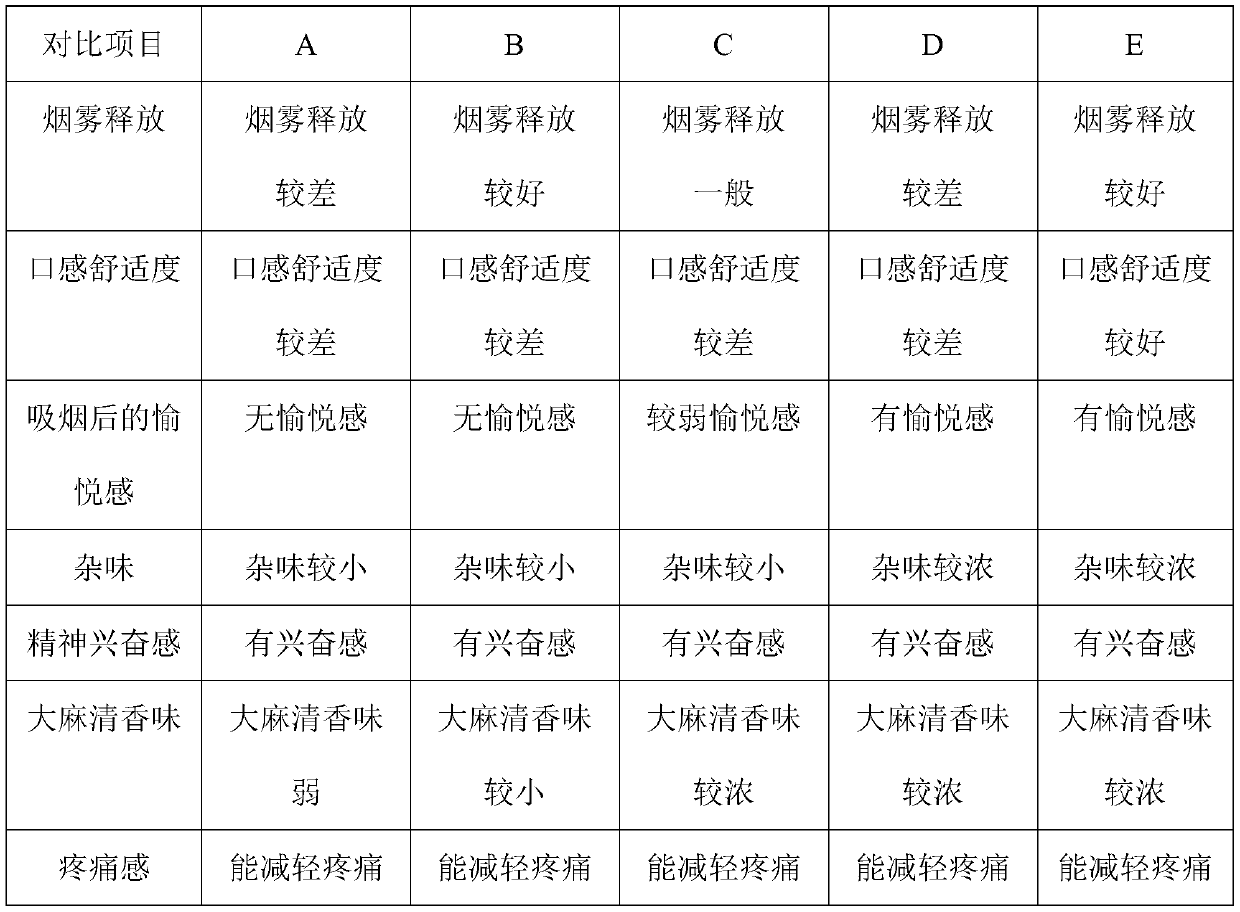

Tobacco product and preparation method thereof

InactiveCN109770411AImprove breathabilityHigh bulkTobacco preparationTobacco treatmentHeat conductingHeat not burn

The invention provides a tobacco product and a preparation method thereof. The preparation method comprises the specific steps that industrial hemp is taken as a raw material, a solid-phase substrateused for the tobacco product is prepared by adopting a foam forming method, a coating liquid containing cannabinoid is sprayed on the solid-phase substrate, and the tobacco product is obtained. The tobacco product has the advantages that the tobacco product replaces a traditional heat-not-burn tobacco product of a cigarette, the volatilization of effective components is fully achieved, the heat-conducting property is good, the smoke amount is large, and the taste is good.

Owner:YUNNAN HANSU BIO TECH CO LTD

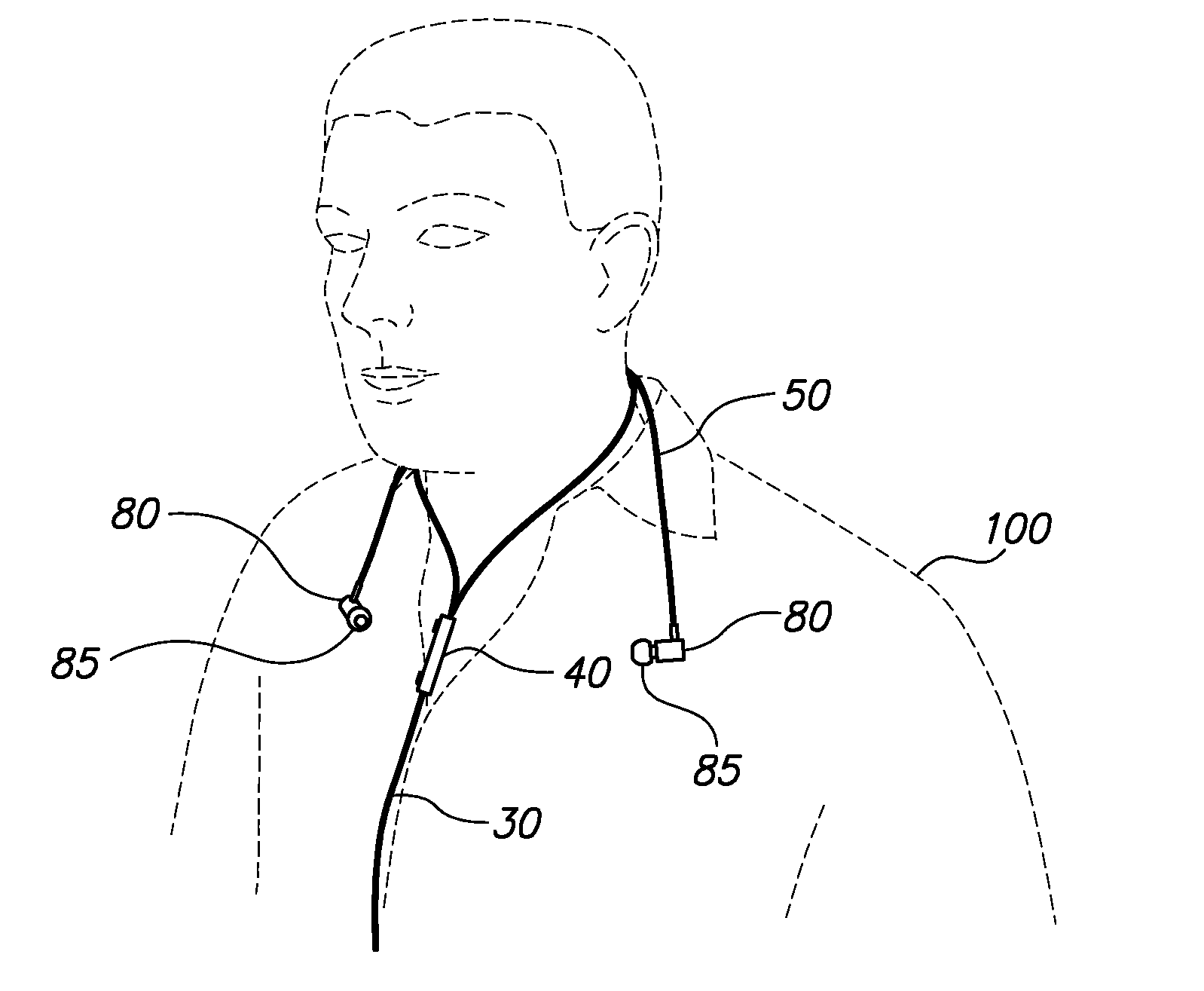

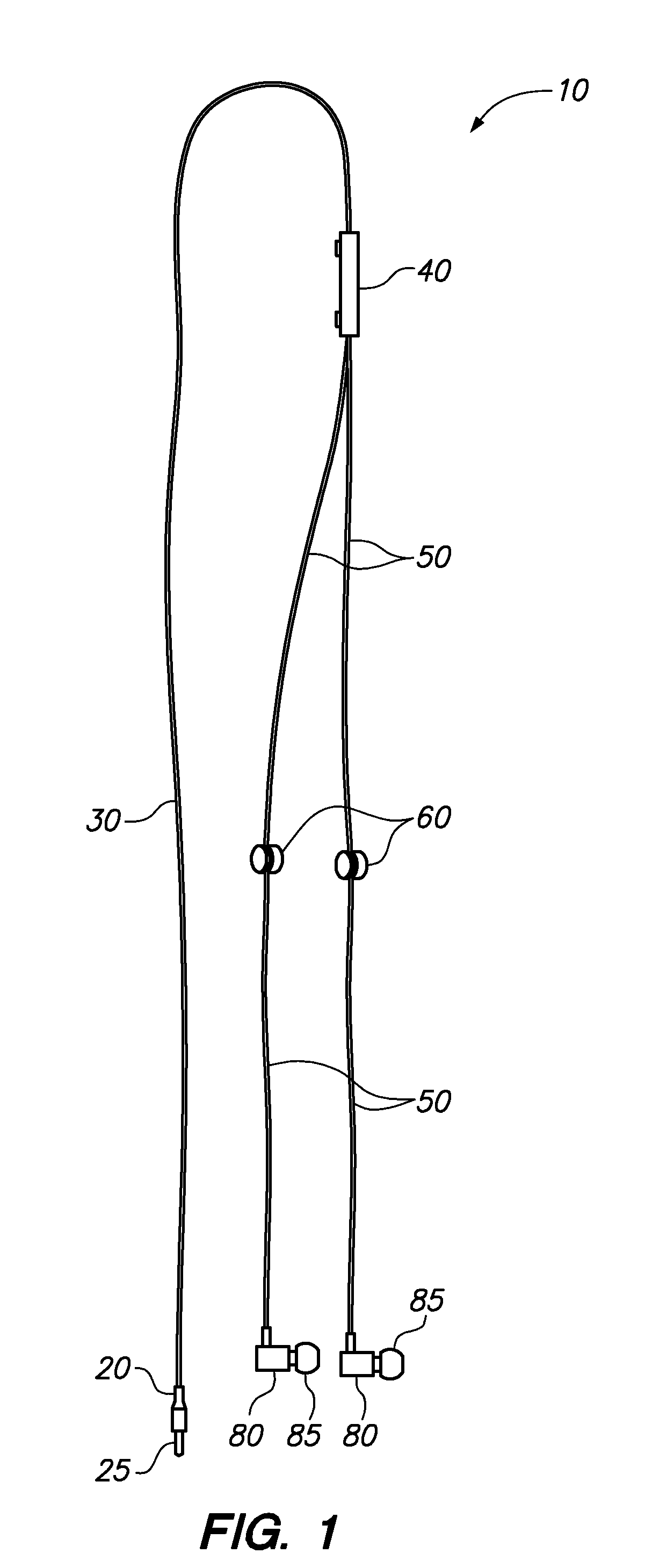

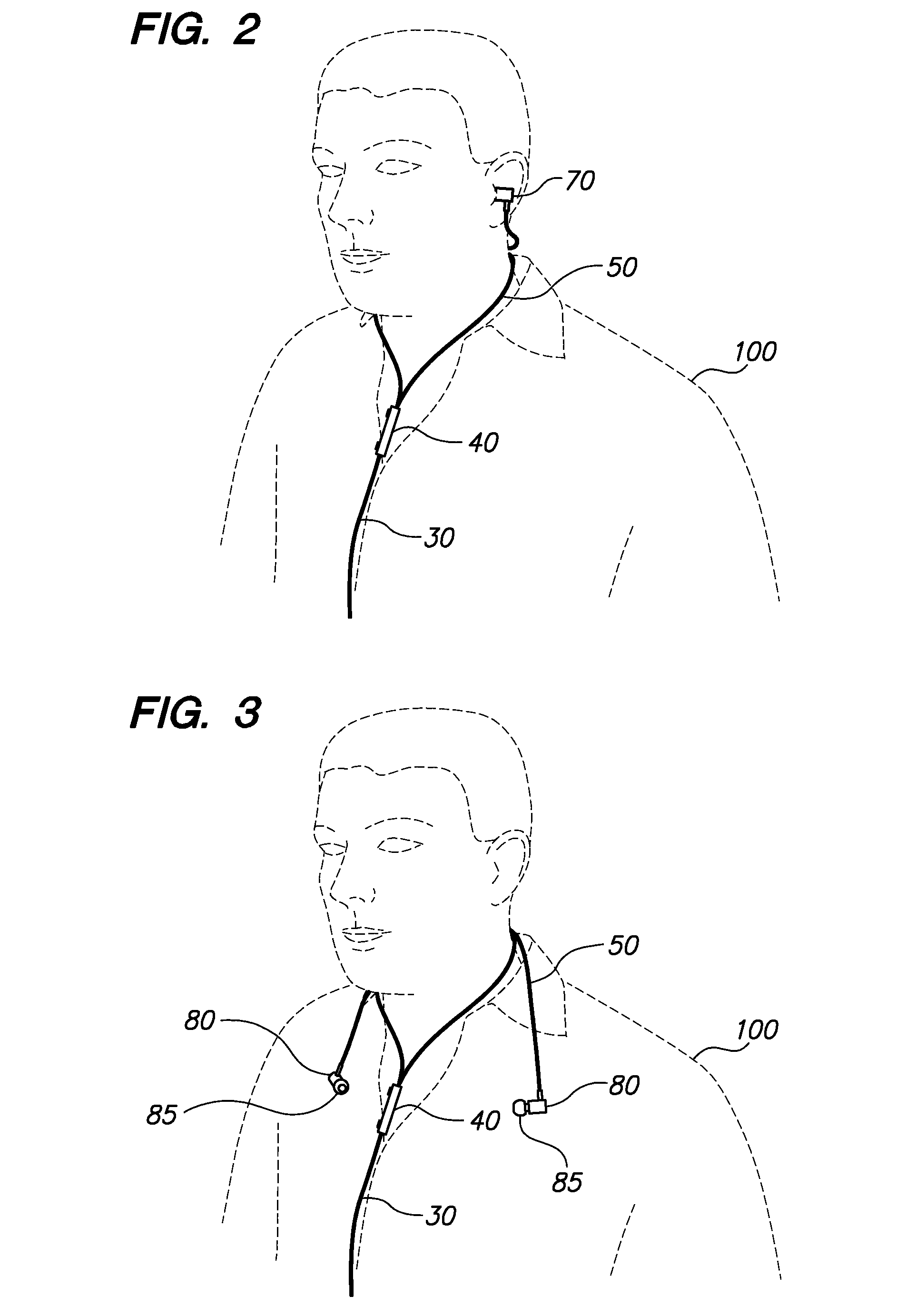

Earbud headphone set with behind-the-neck magnetic speaker wire clamps

InactiveUS20150350763A1Loose connectionEarpiece/earphone cablesDeaf-aid setsElectrical conductorEngineering

An earbud headphone set with adjustable behind-the-neck magnetic speaker wire clamps comprising an audio source electrical connector, a length of four-conductor speaker wire, a Y-junction, a first and second length of two-conductor speaker wire, a first and second adjustable magnetic speaker wire clamp, and a first and second loudspeaker. First and second adjustable magnetic speaker wire clamps are each: (i) permanently attached the substantially longer speaker wire, (ii) reversibly slideably attached and reversibly rigidly attached to the substantially longer speaker wire, or (iii) reversibly rigidly attached to the substantially longer speaker wire. Earbud headphone set with adjustable behind-the-neck magnetic speaker wire clamps may further comprise a microphone located on the length of four-conductor speaker wire, the Y-junction, or the first or second length of two-conductor speaker wire.

Owner:CHADBOURNE JEFF +1

Preparation method of wear-resistant ferroalloy

The invention relates to a preparation method of a wear-resistant ferroalloy. The method comprises steps as follows: in the ratio, placing 1 / 3 parts of iron by weight, 1 part of manganese by weight, 1 part ofaluminum by weight and 1 / 2 parts of chromium by weight into a smelting furnace for melting, heating the smelting furnace to the temperature of 1250-1350 DEG C for 0.5-1 h, and then cooling the smelting furnace to the temperature of 200-350 DEG C; then sequentially adding the rest chromium by weight, 1 part ofmolybdenum by weight,1 part of nickel by weight, 1 part of titanium by weight, 1 part of vanadium by weight, 1 part of boron by weight and 1 part of cobalt by weight, and heating the mixture to the temperature of 1250-1350 DEG C; then adding the rest iron by weight, 1 part of carbon by weight, 1 part of silicon by weight and 1 part of ceriumby weight at the temperature of 1250-1350 DEG C for 1-2 h, and performing casting, annealing, quenching and tempering to obtain the wear-resistant ferroalloy. Structural grains of the aluminum can grow excessively in an alloy liquid, the aluminum, the manganese and the chromium form a framework-like structure, and elements added later enter the liquid in a filling manner.

Owner:NINGBO HENGYUAN CASTING

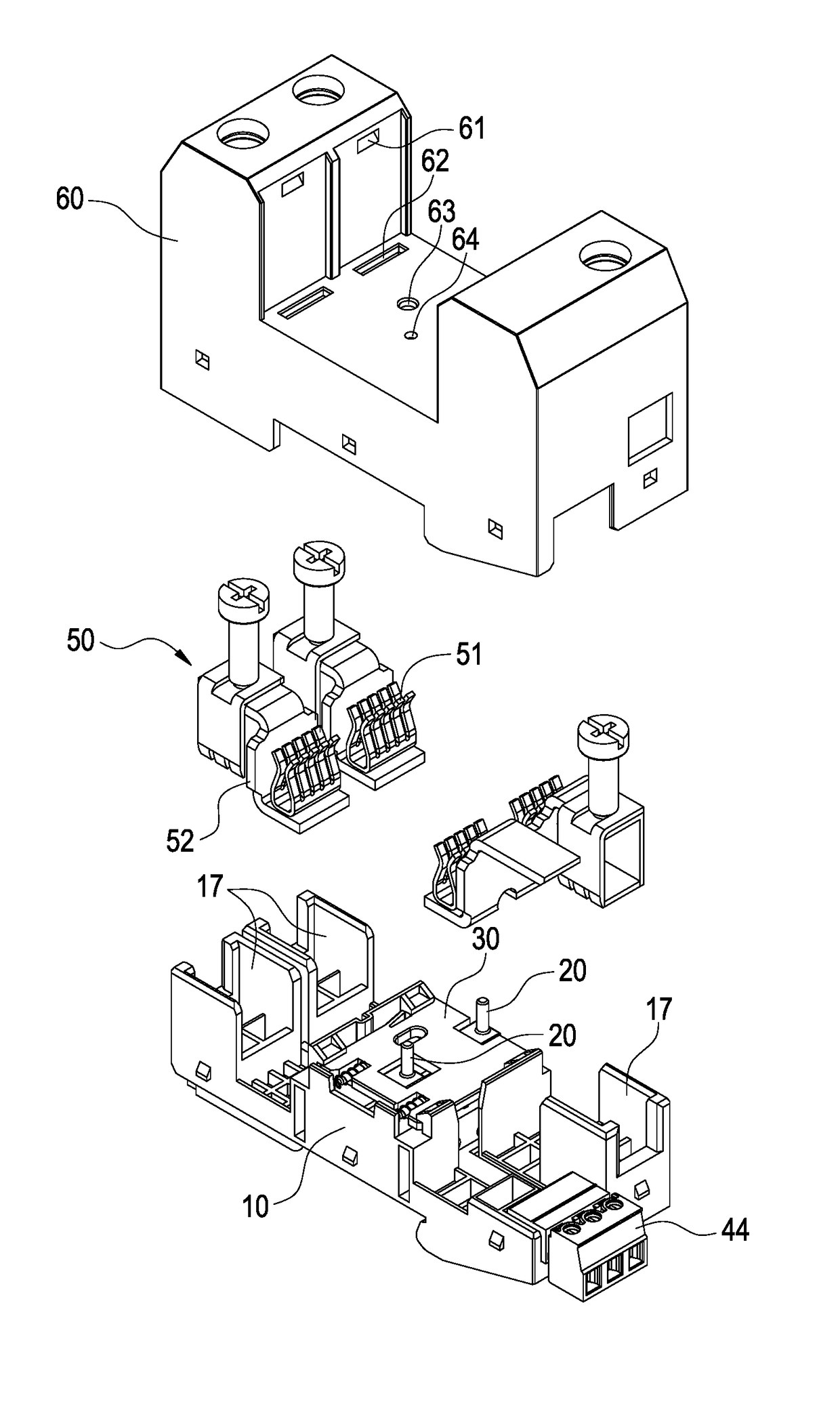

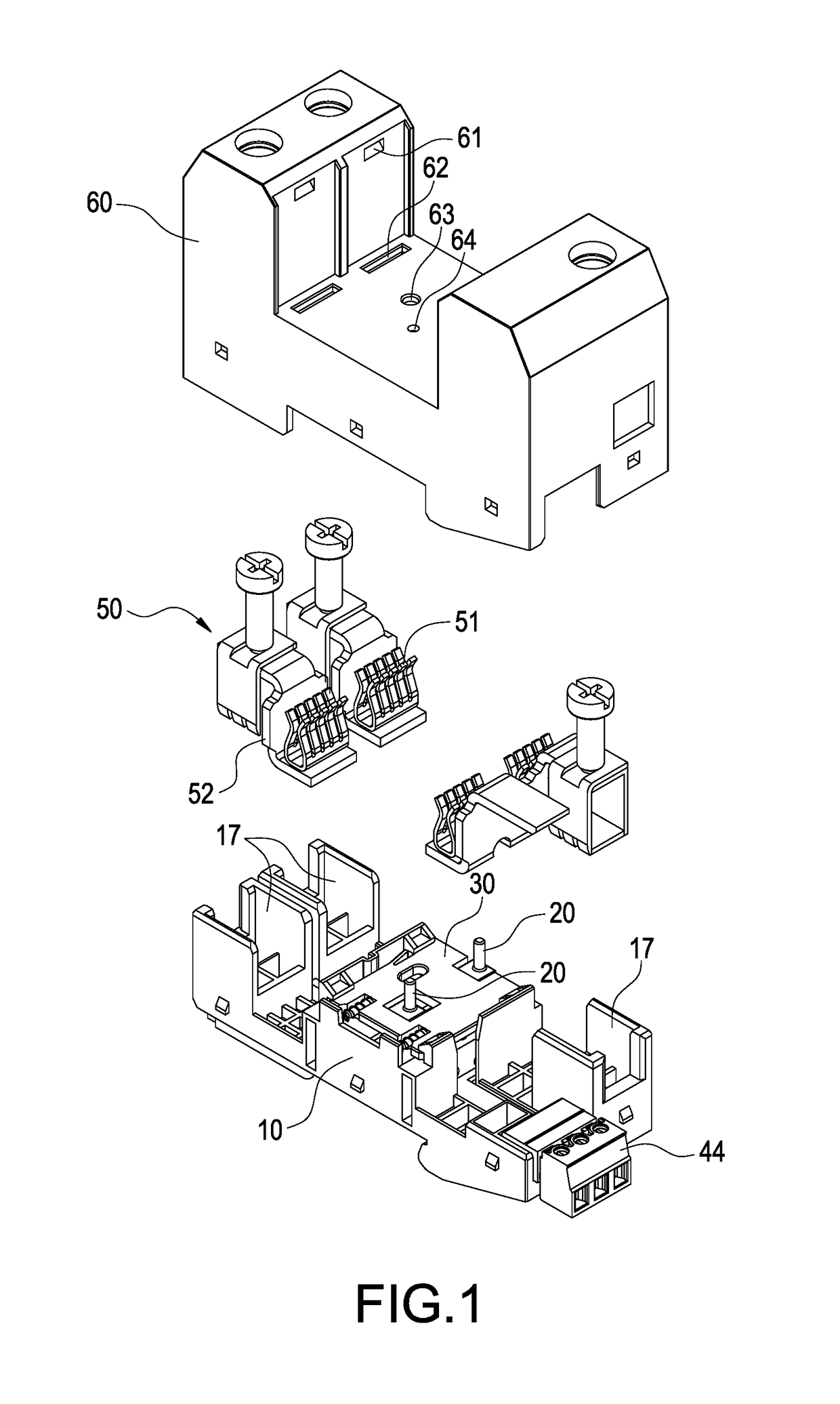

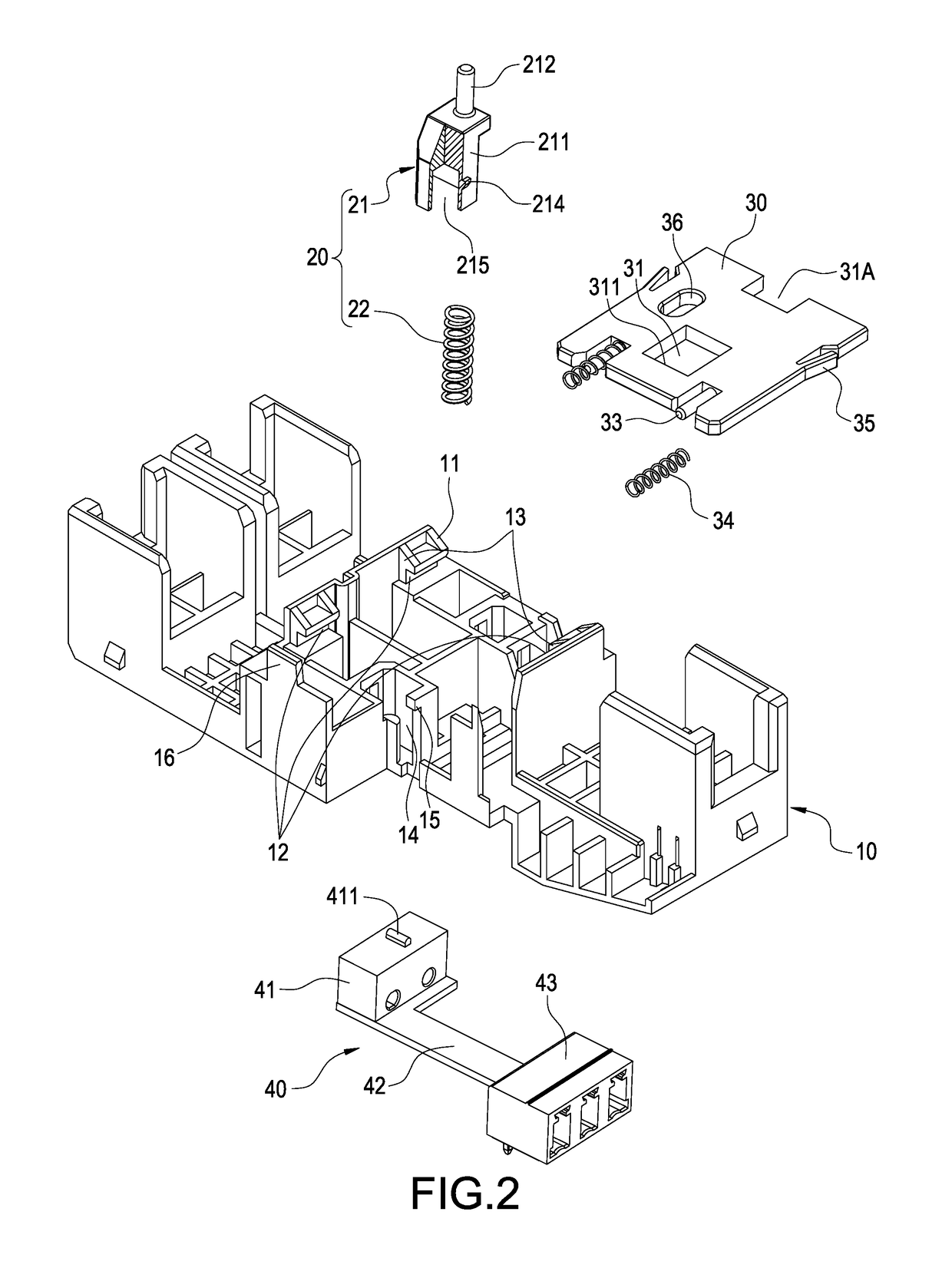

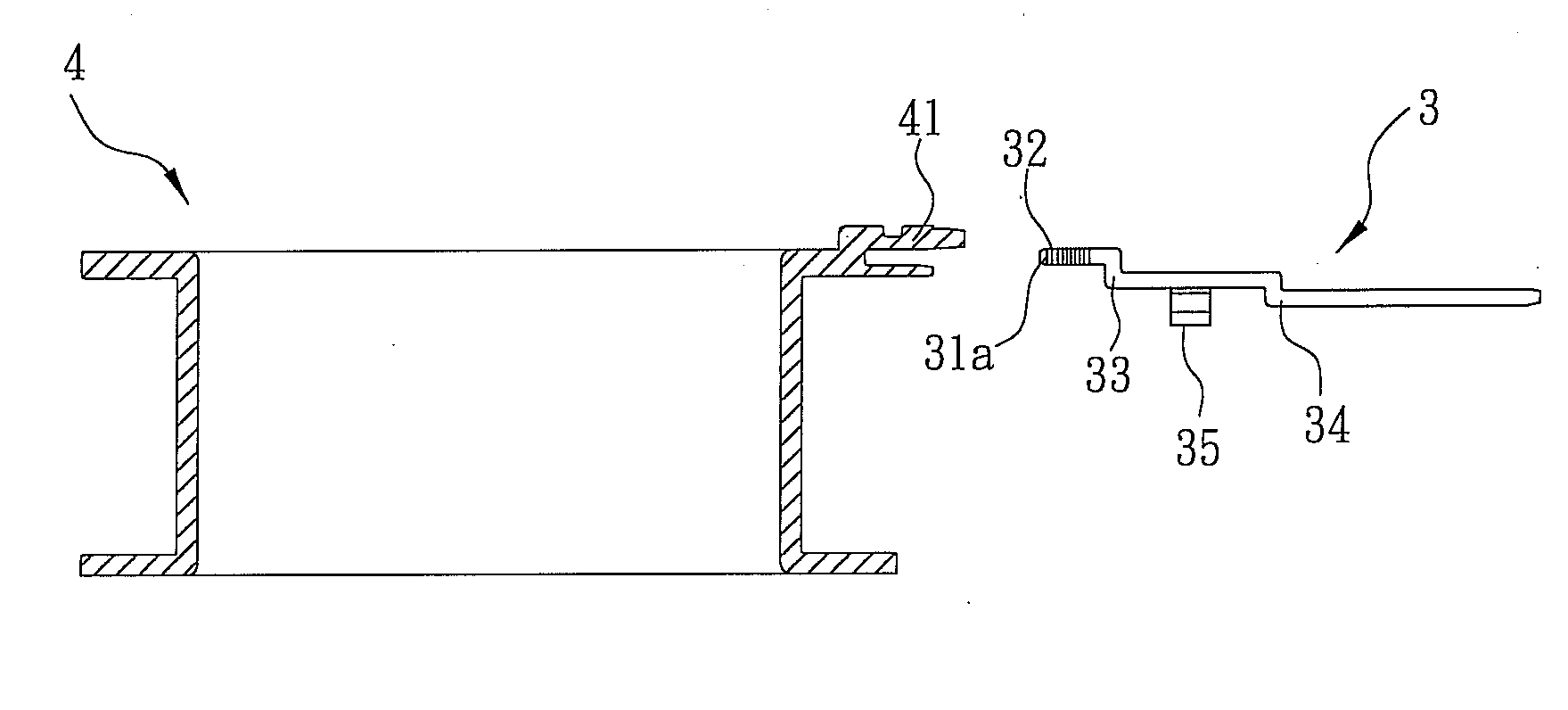

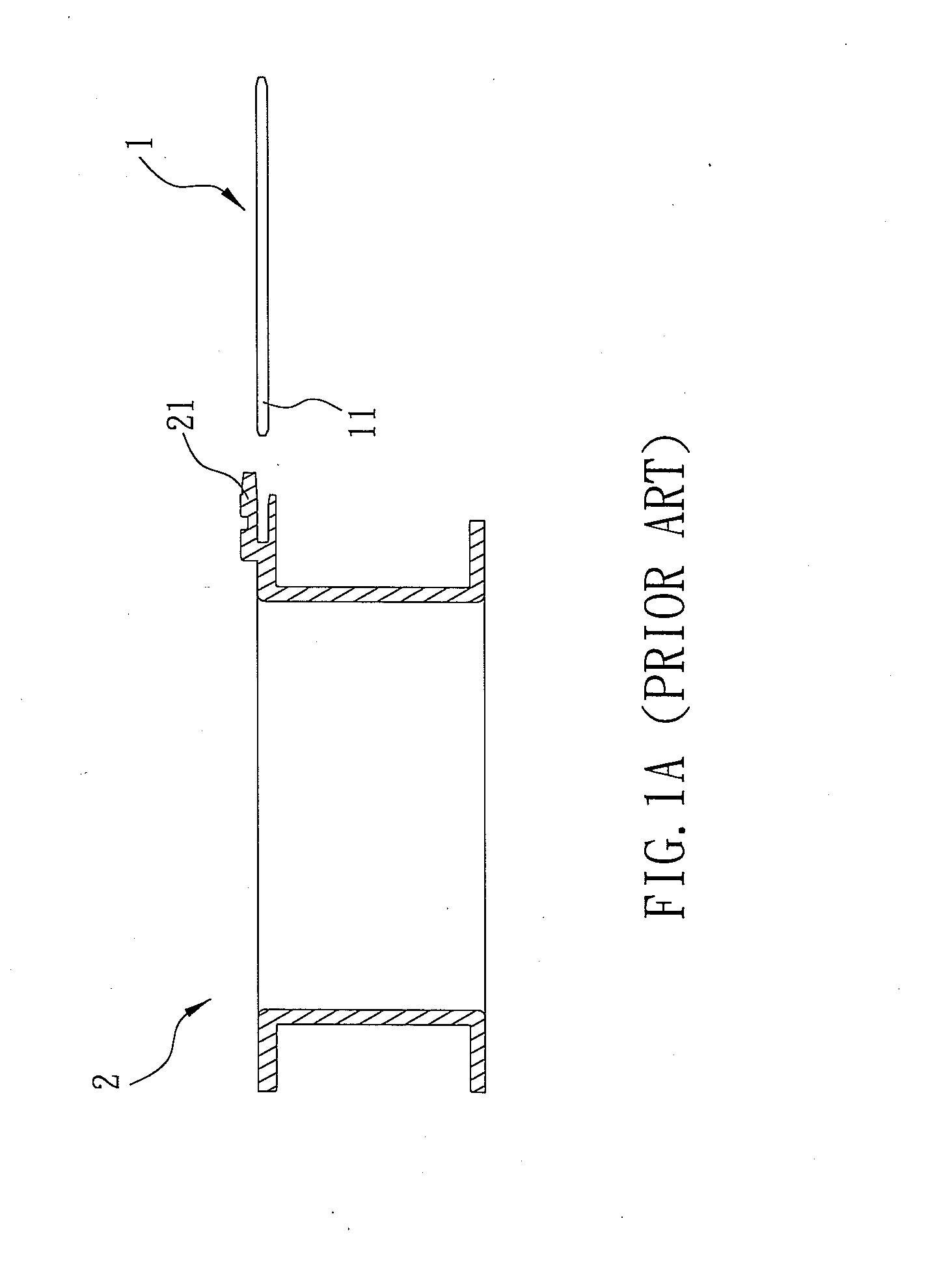

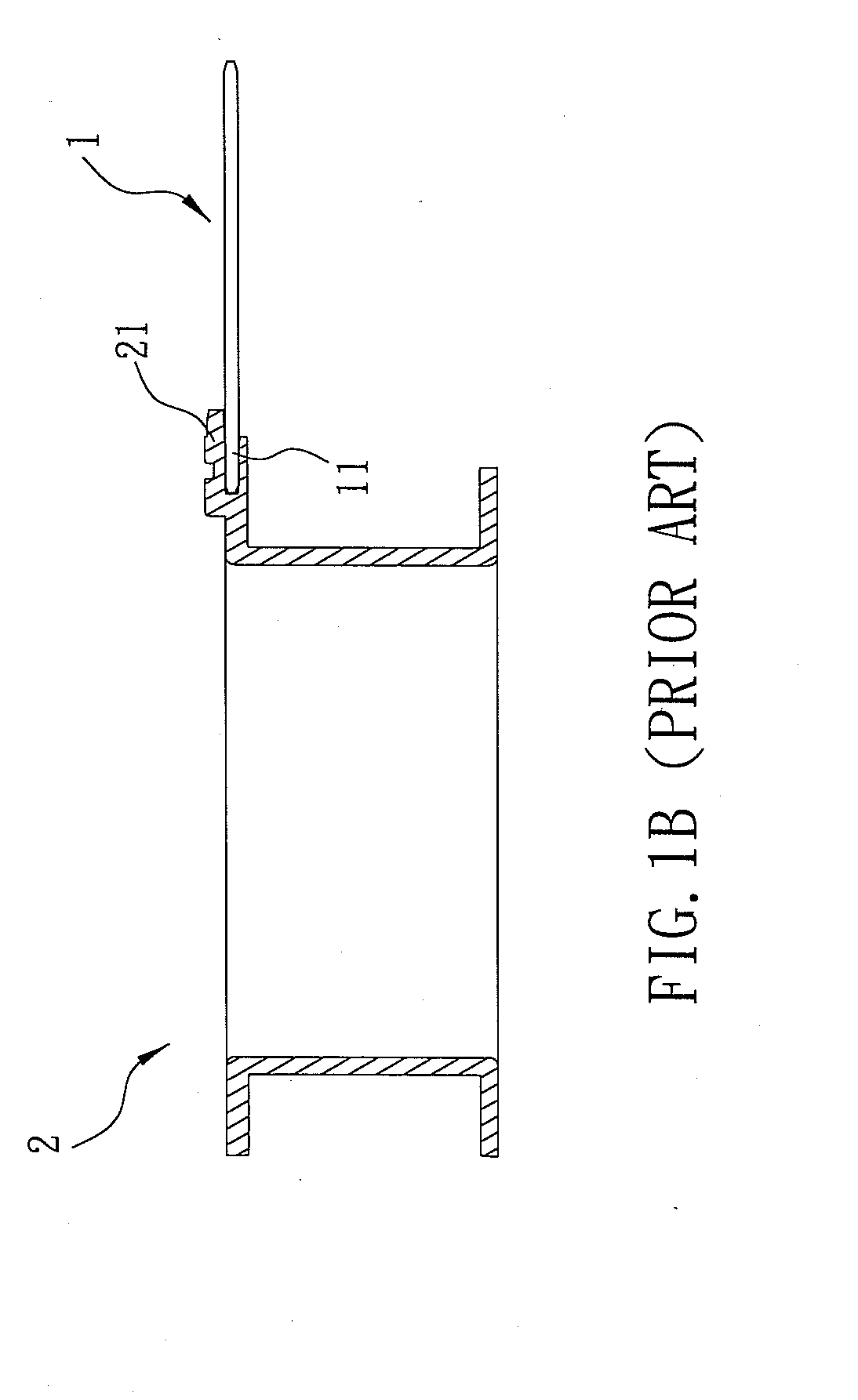

Signal feedback apparatus

ActiveUS10121615B1Improve securityImprove reliabilityElectric switchesEmergency springsMechanical engineeringSignal monitoring

A liquid-cooled heat dissipation apparatus includes a base (10), a telesignaling linkage member (20), a sliding plate (30) and a switch module (40). The telesignaling linkage member (20) is moveably installed on the base (10). The sliding plate (30) is installed corresponding to the telesignaling linkage member (20) and generates a movement along with the telesignaling linkage member (20). The switch module (40) includes a microswitch (41) arranged corresponding to the sliding plate (30) such that the microswitch (41) is operably opened or closed based on the movement of the sliding plate (30). Accordingly, through the opening and closing of the microswitch, the telesignaling monitoring on the functional module state can be achieved.

Owner:DINKLE ENTERPRISE CO LTD

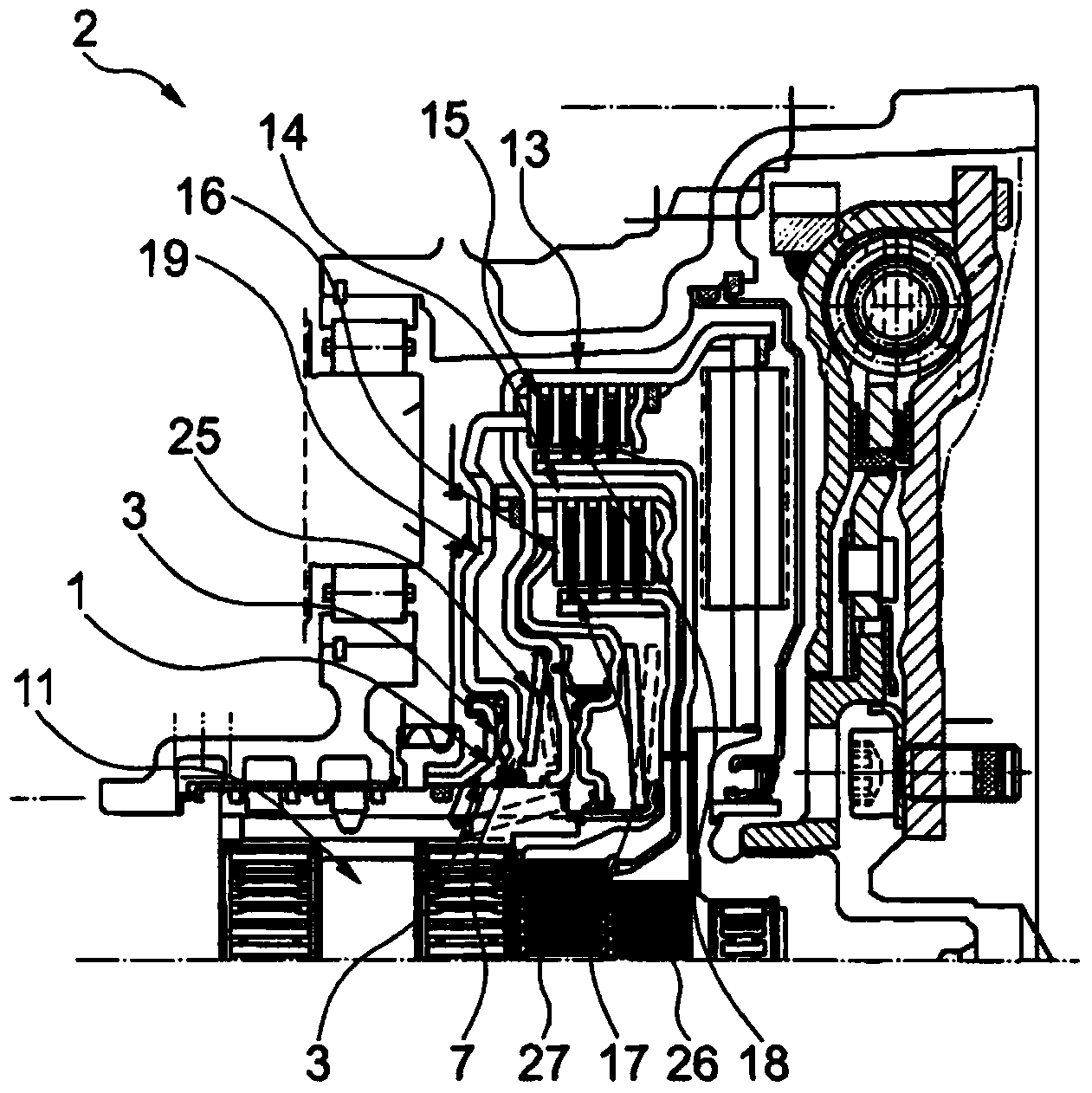

Carrier element for pressure chamber of friction clutch

The present invention relates to a carrier element for a pressure chamber of a friction clutch. The carrier element is provided with at least a receiving element for a sealing device and a stopping element for an operation element of a pressure chamber. The carrier element is characterized by employing an integral structure. By employing the carrier element, a plurality of elements can be replaced by the carrier element which is very light in weight and simple in structure.

Owner:SCHAEFFLER TECH AG & CO KG

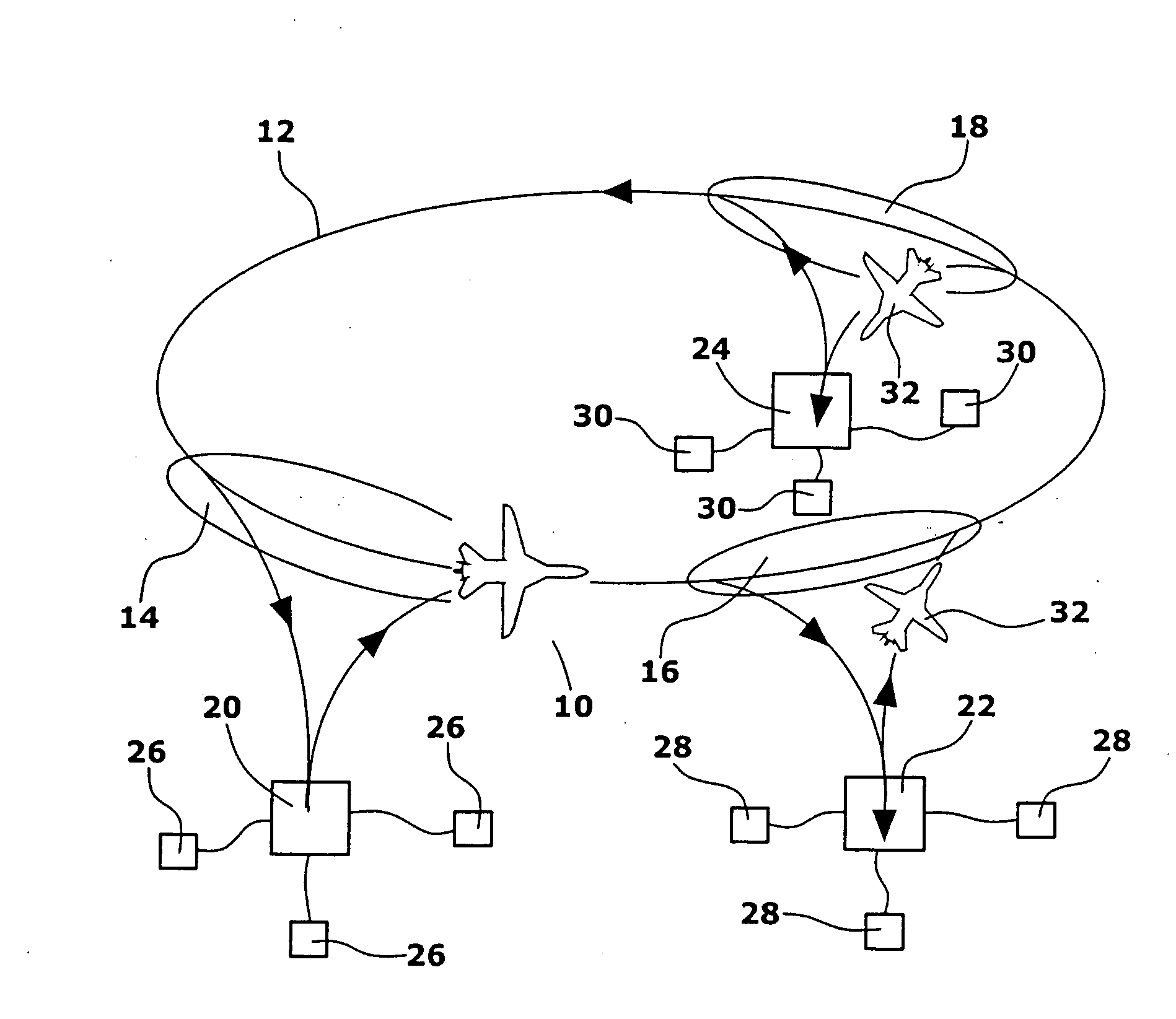

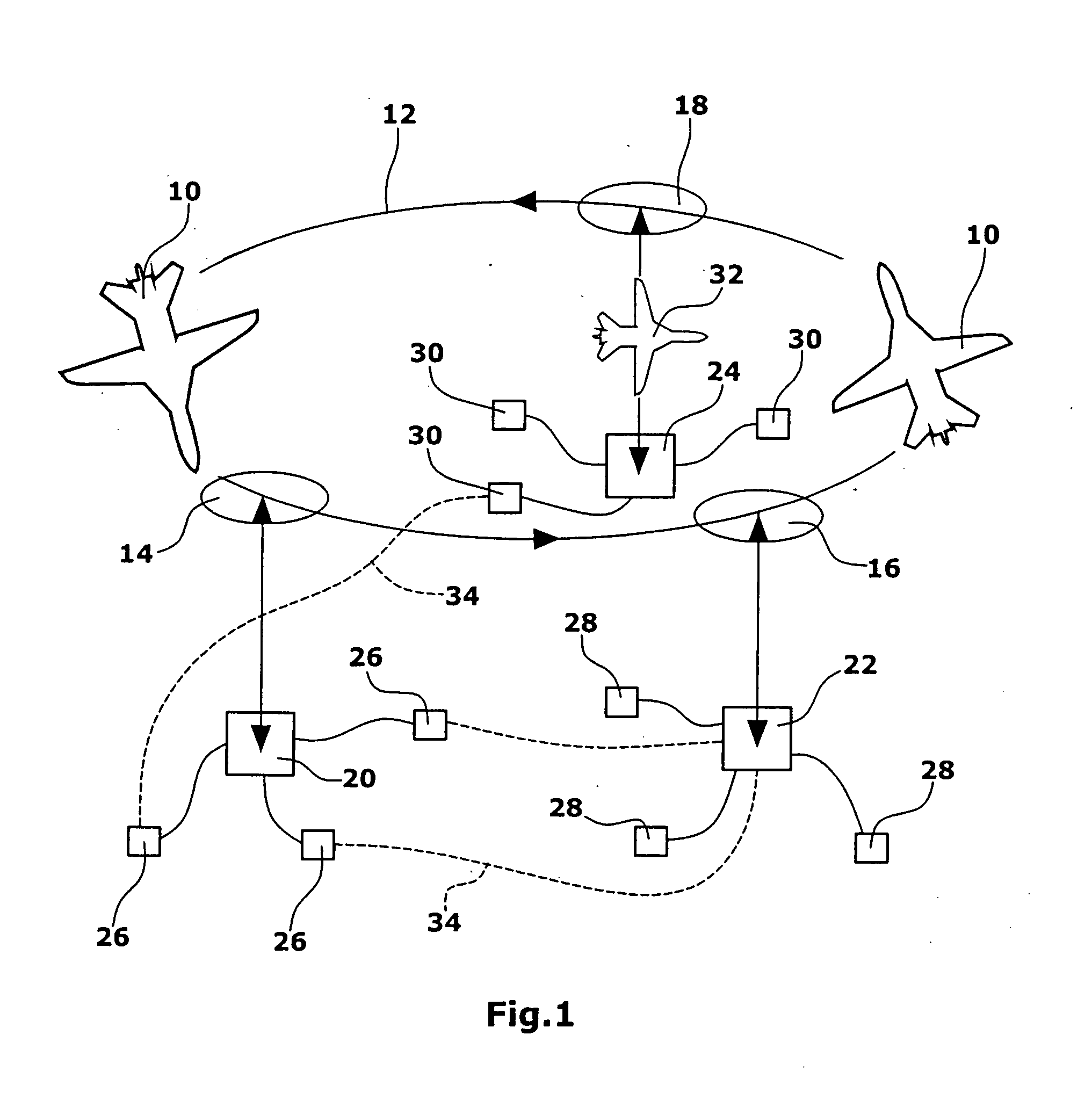

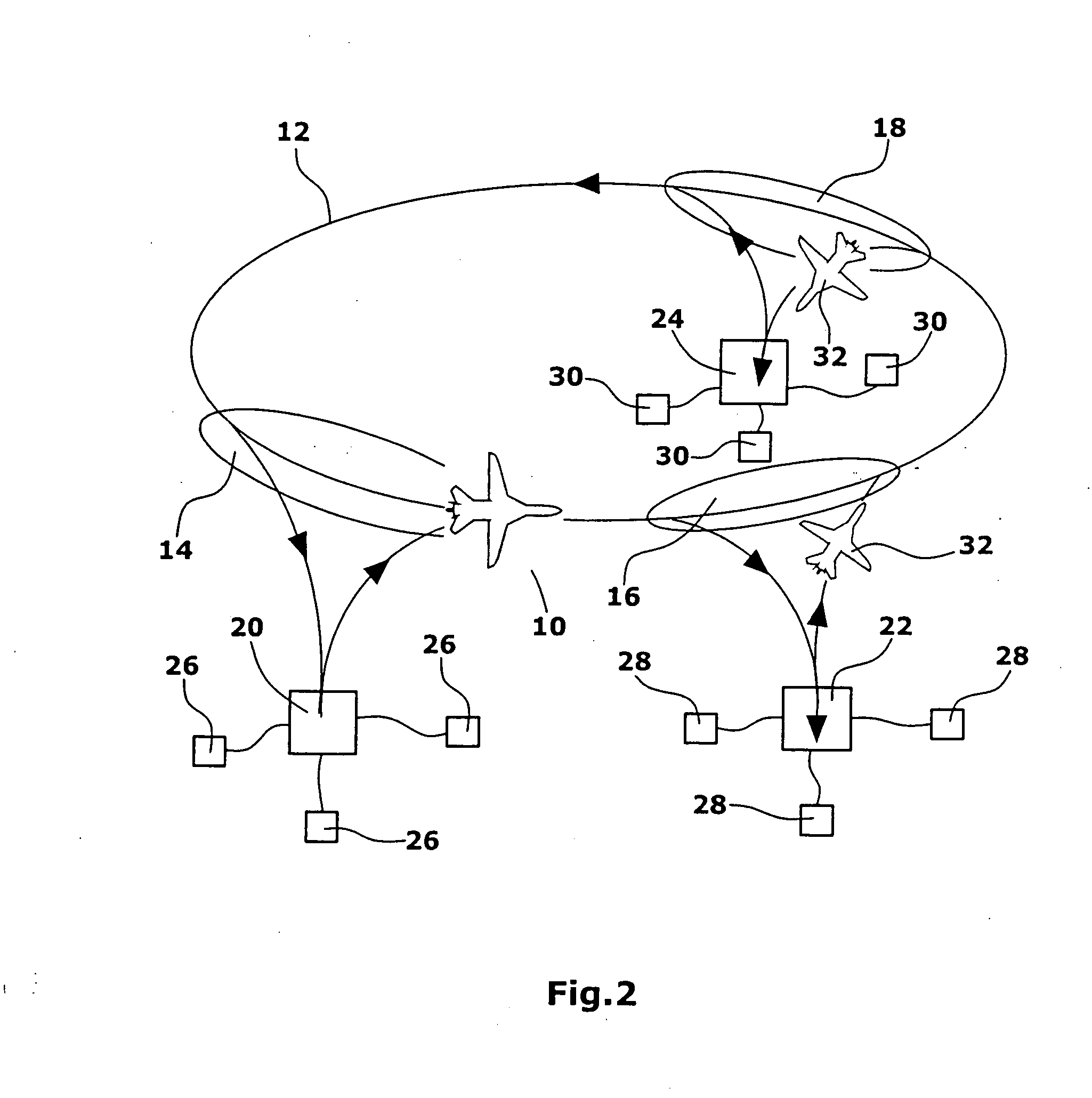

Air Freight Transport Method, Transport Aeroplane and Air Freight Transport System

InactiveUS20080296428A1Few or no effectsReduce loadConvertible aircraftsEfficient propulsion technologiesTransport systemMode of transport

An air cargo transportation method, a transport plane and an air cargo transport system. In the air cargo transportation method for the transport of various cargoes to different destinations, a transport plane is provided first that flies through at least three air regions respectively associated to a station. The transport plane does not land at one of the stations. Instead, the cargo is transported between the transport plane and one of the stations by an airworthy feeders, the cargo being transferred between the feeder and the transport plane while in the air. The transport plane and two feeders form the air cargo transport system, wherein the transport plane may comprise two interconnected feeders. With the air cargo transportation method, the utilization of the transport plane is enhanced. Further, the transport ways for individual cargo items can be shortened so that the efficiency is improved.

Owner:GABY TRAUTE REINHARDT

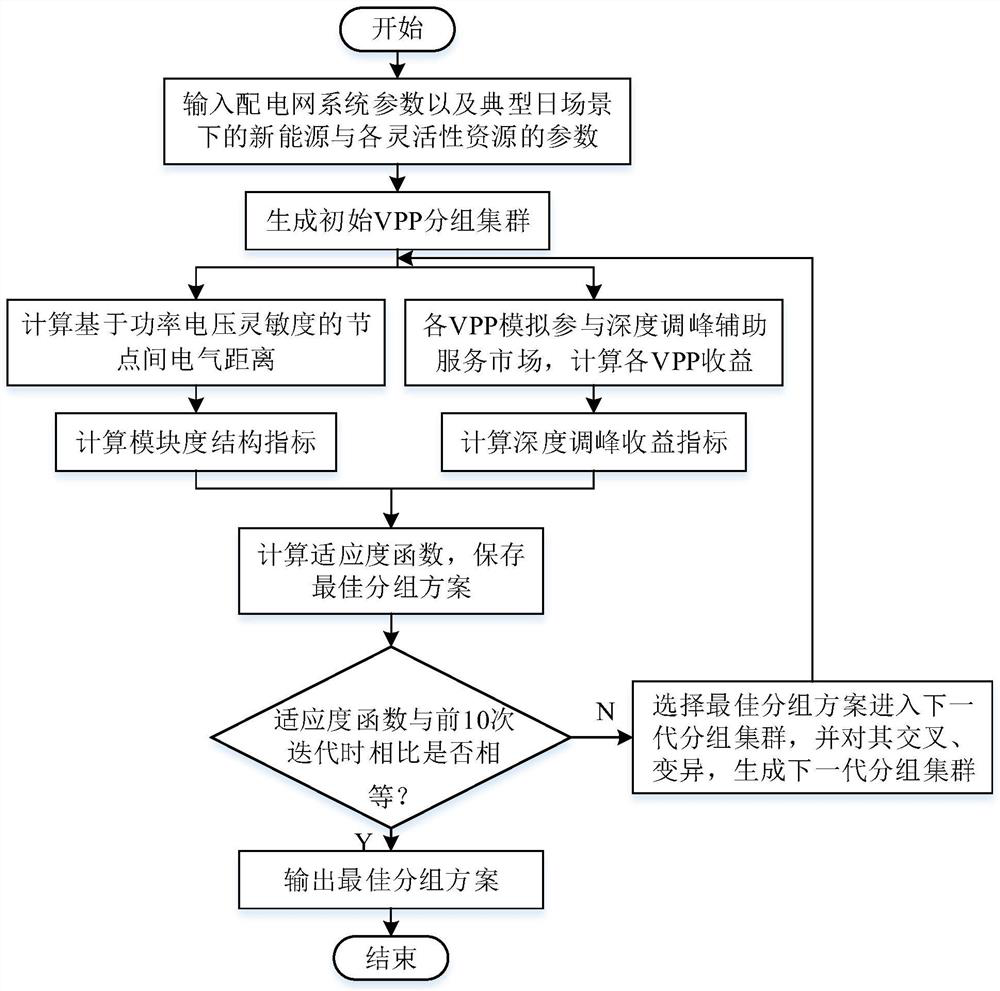

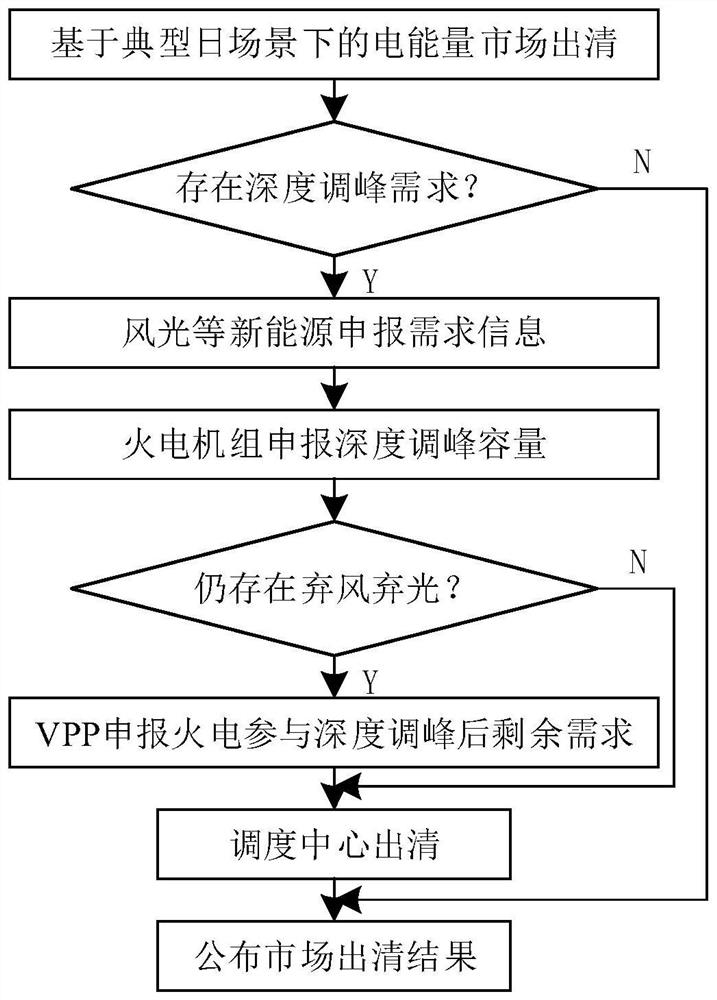

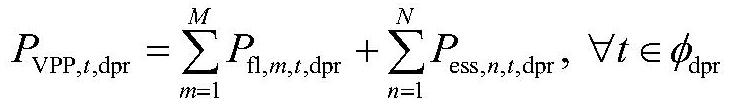

Virtual power plant optimization building method for power grid deep peak regulation auxiliary service

PendingCN114742421AEasy to operate and manageClose electrical connectionForecastingResourcesDirect controlReliability engineering

The invention relates to a virtual power plant optimization establishment method for power grid deep peak regulation auxiliary service, which comprises the following steps of: firstly, randomly generating an initial virtual power plant establishment scheme population by using a genetic algorithm; secondly, simulating each virtual power plant to participate in a peak regulation auxiliary service market based on a typical day scene, solving a clearing result by using a linear programming solver ILOG CPLEX in a unified marginal clearing mode, and calculating a peak regulation income index; then, calculating an electrical distance between nodes of the power distribution network based on power voltage sensitivity to obtain a modularity index reflecting the structural characteristics of the virtual power plant; and finally, establishing a virtual power plant optimization establishment model by taking the maximum value of the weighted sum of the peak regulation income index and the modularity index as a target function, and performing iterative solution by using a genetic algorithm to formulate a virtual power plant optimization establishment scheme. The method provided by the invention solves the problem of aggregation and construction of flexible resources with scattered demand sides and poor direct control performance, and meets the deep peak regulation auxiliary service demand of the power grid.

Owner:HOHAI UNIV +3

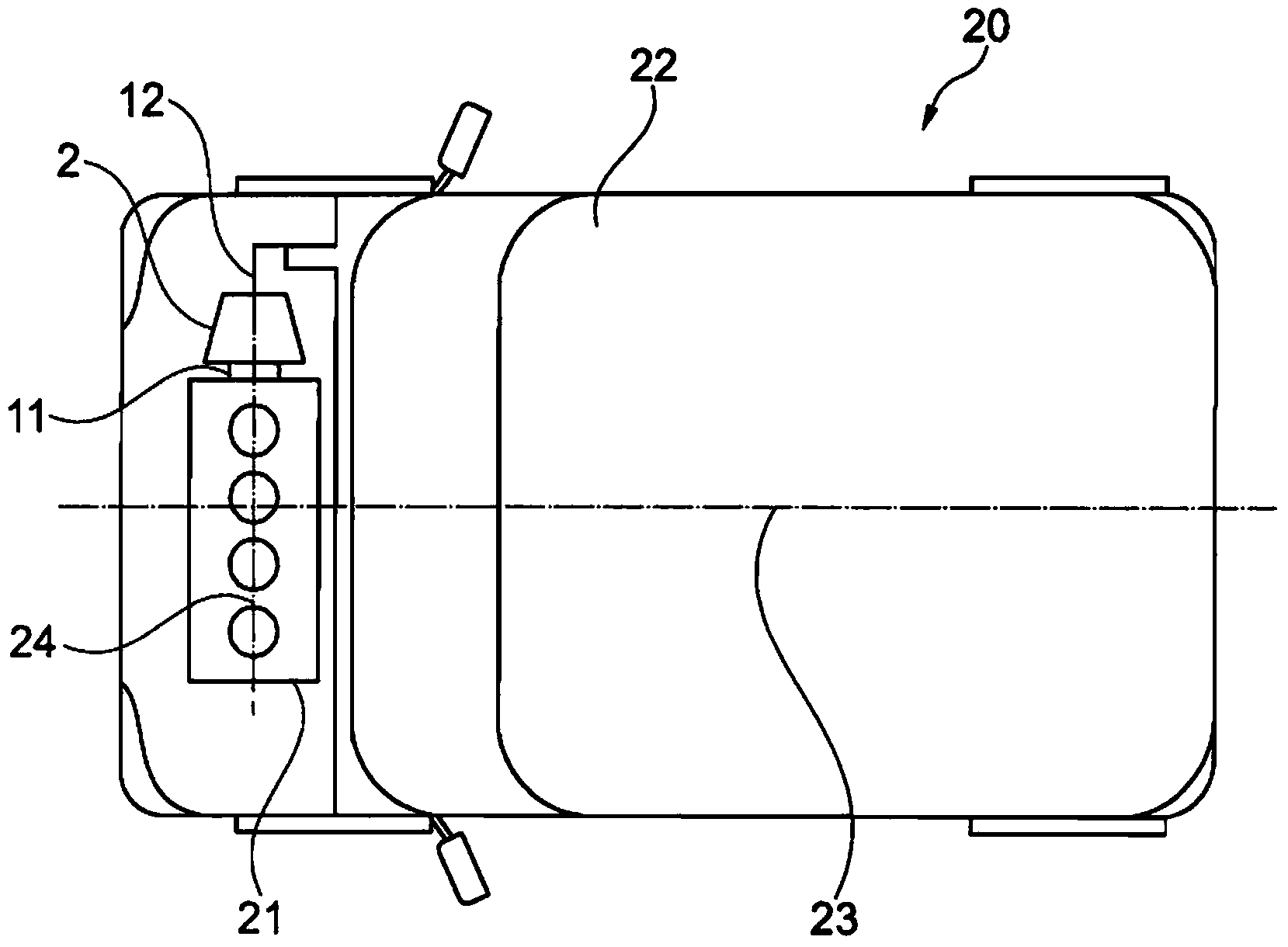

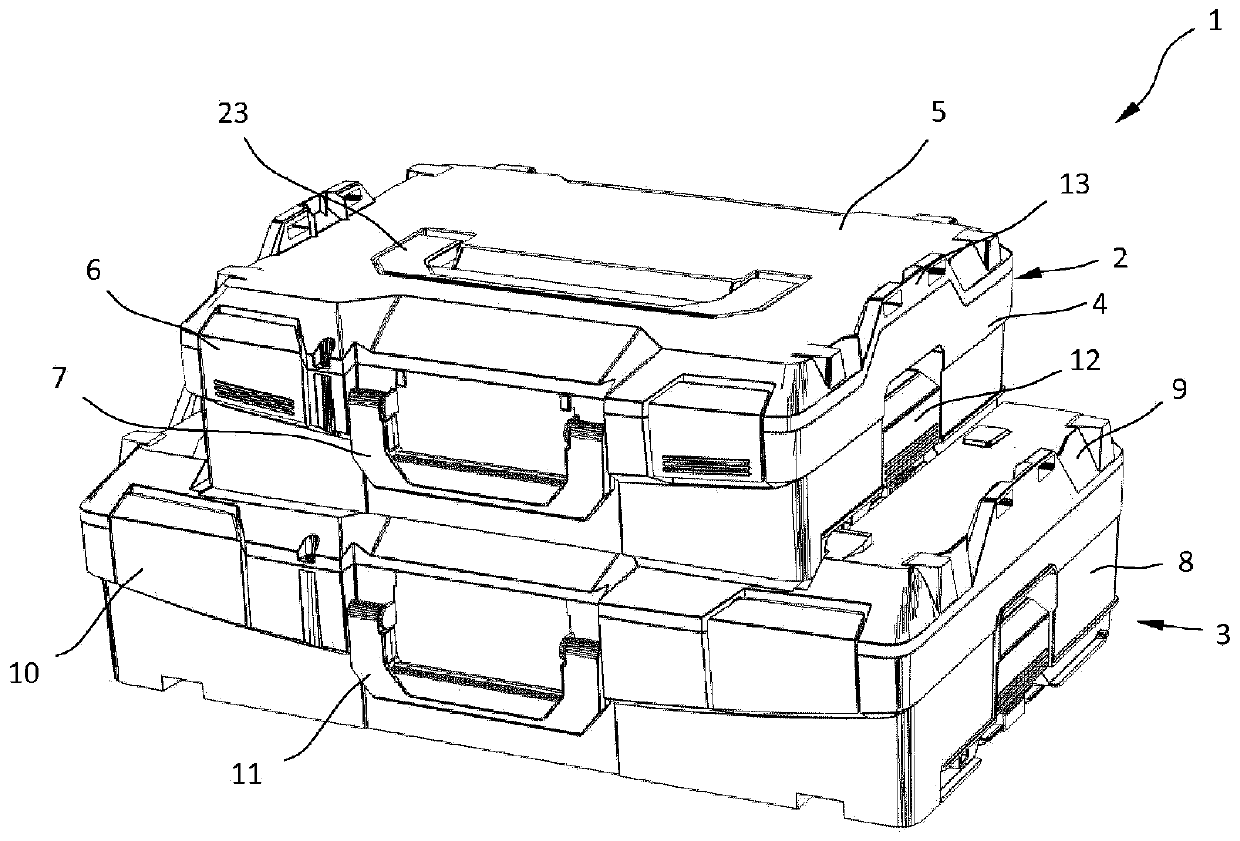

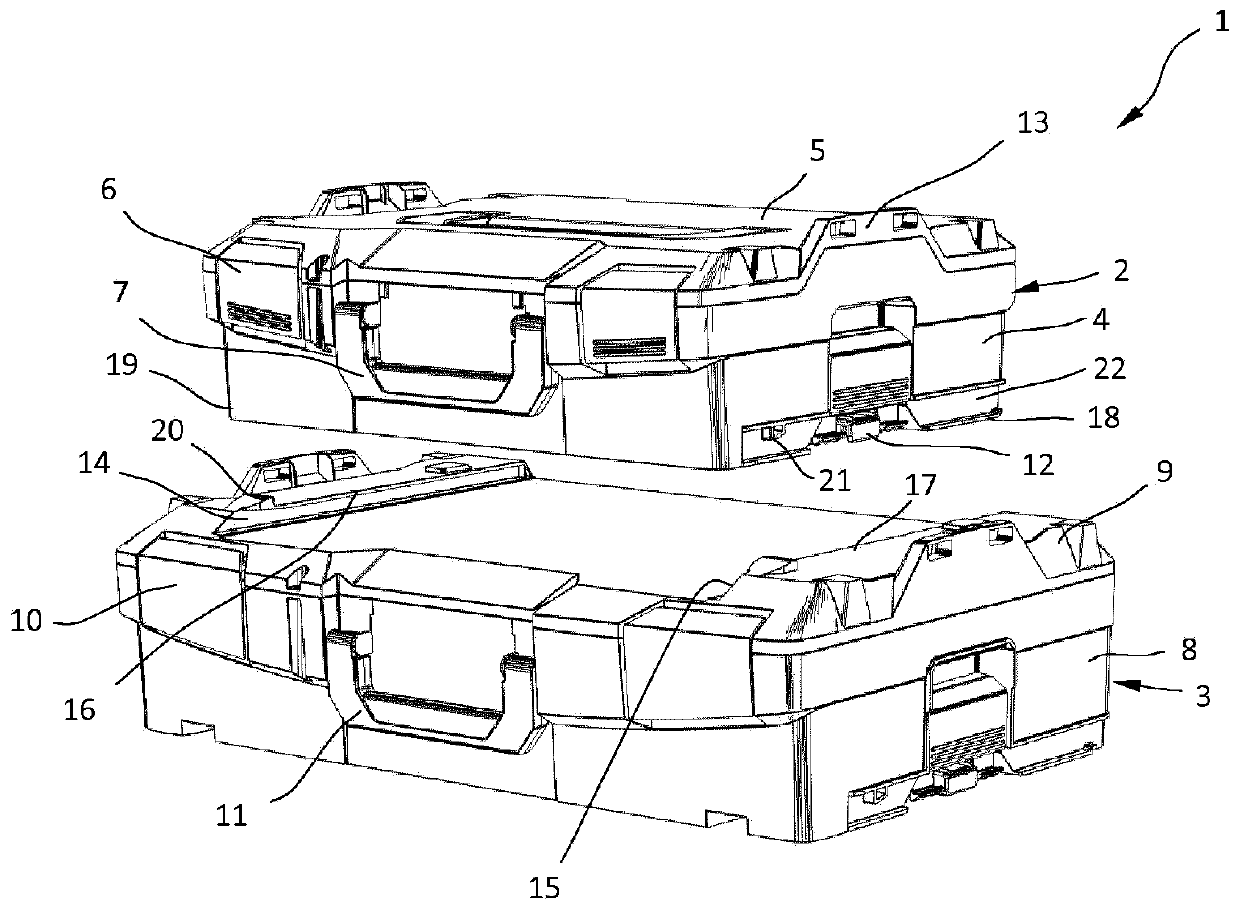

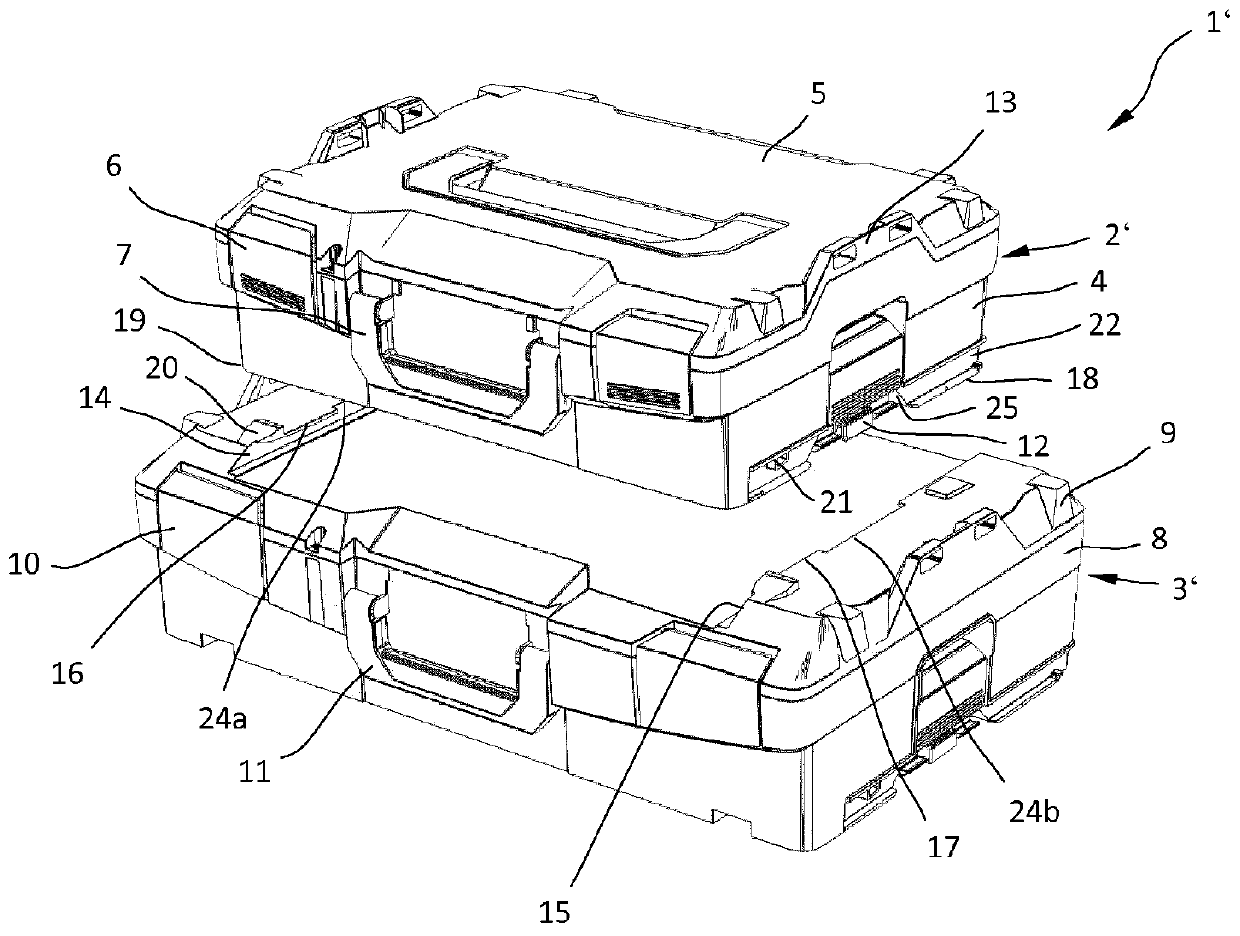

Stackable system container and transport system

ActiveCN111406026AEasy to stackLoose connectionLuggageOther accessoriesTransport systemTransit system

The invention relates to a stackable system container (3) and a corresponding transport system (2). The known system containers or transport systems have the disadvantage that a precise prior adjustment is necessary for the purpose of connecting the system containers. The aim of the invention is to configure a system container or transport system in such a way that a particularly stable and intuitive mutual fastening is made possible. The aim is achieved in that catwalks (16; 17) of the system container project in the opposite directions, and at least one upwardly protruding locking nose (20)is provided on a lid part (9).

Owner:BS SYST GMBH &CO KG

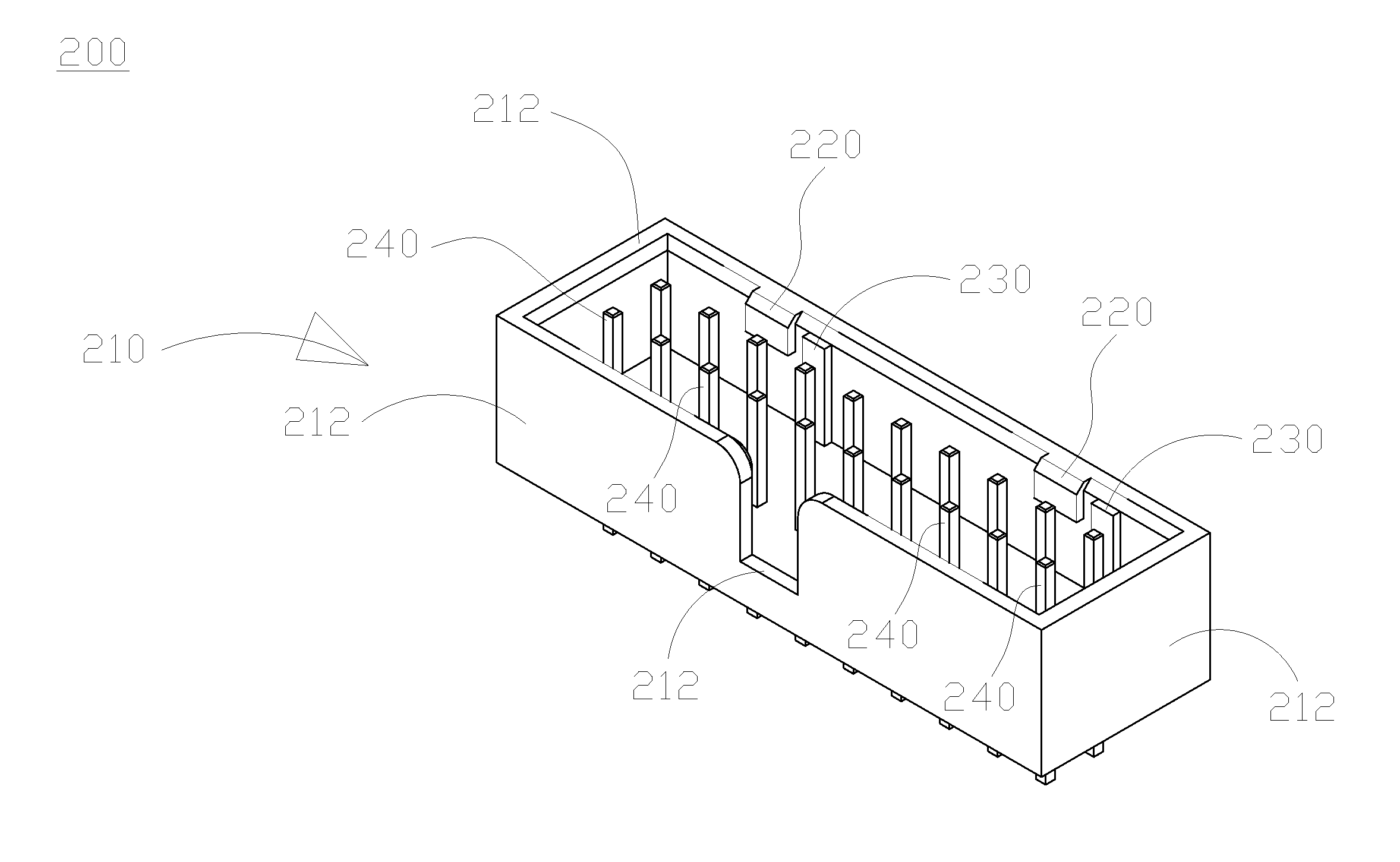

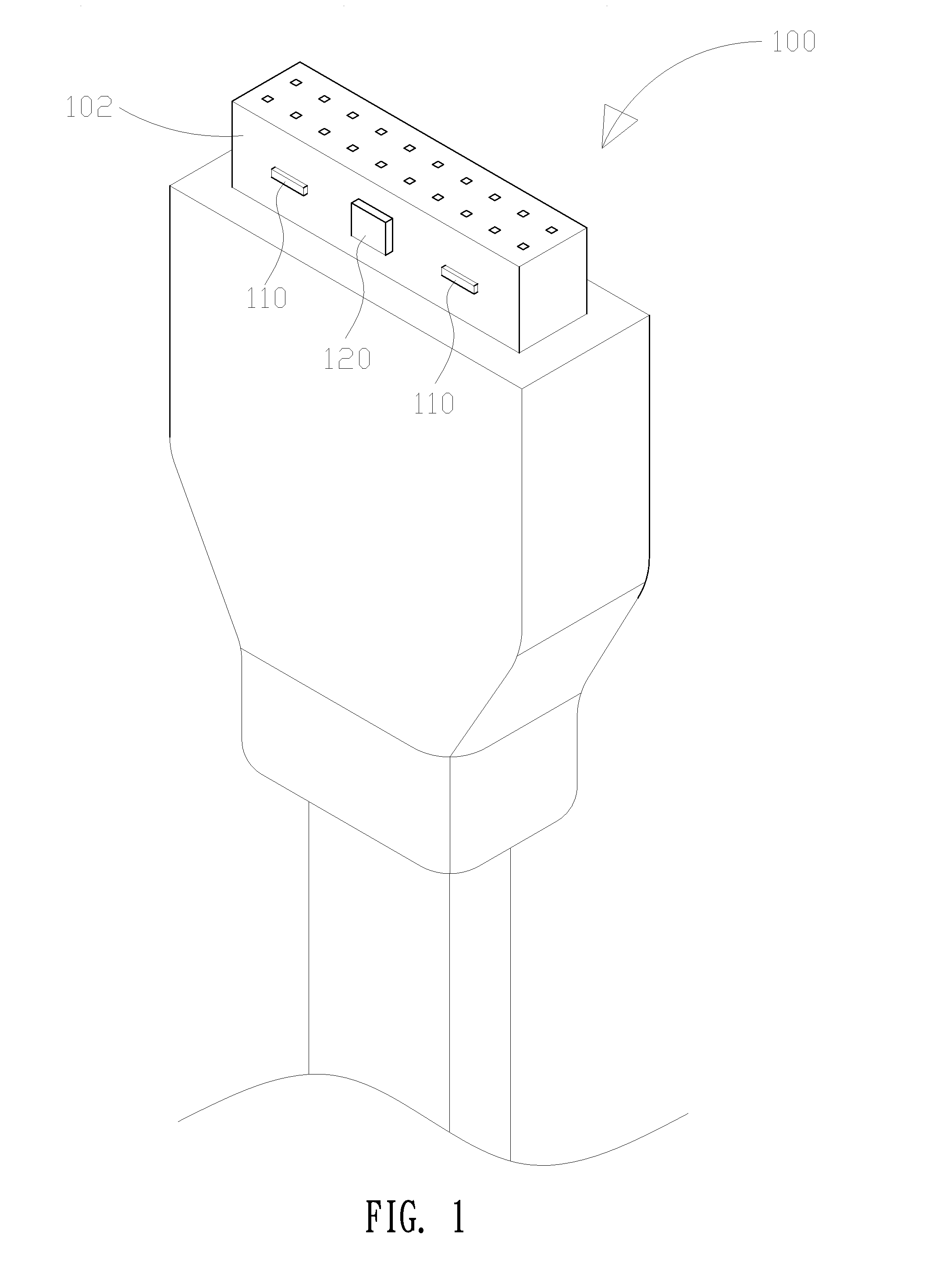

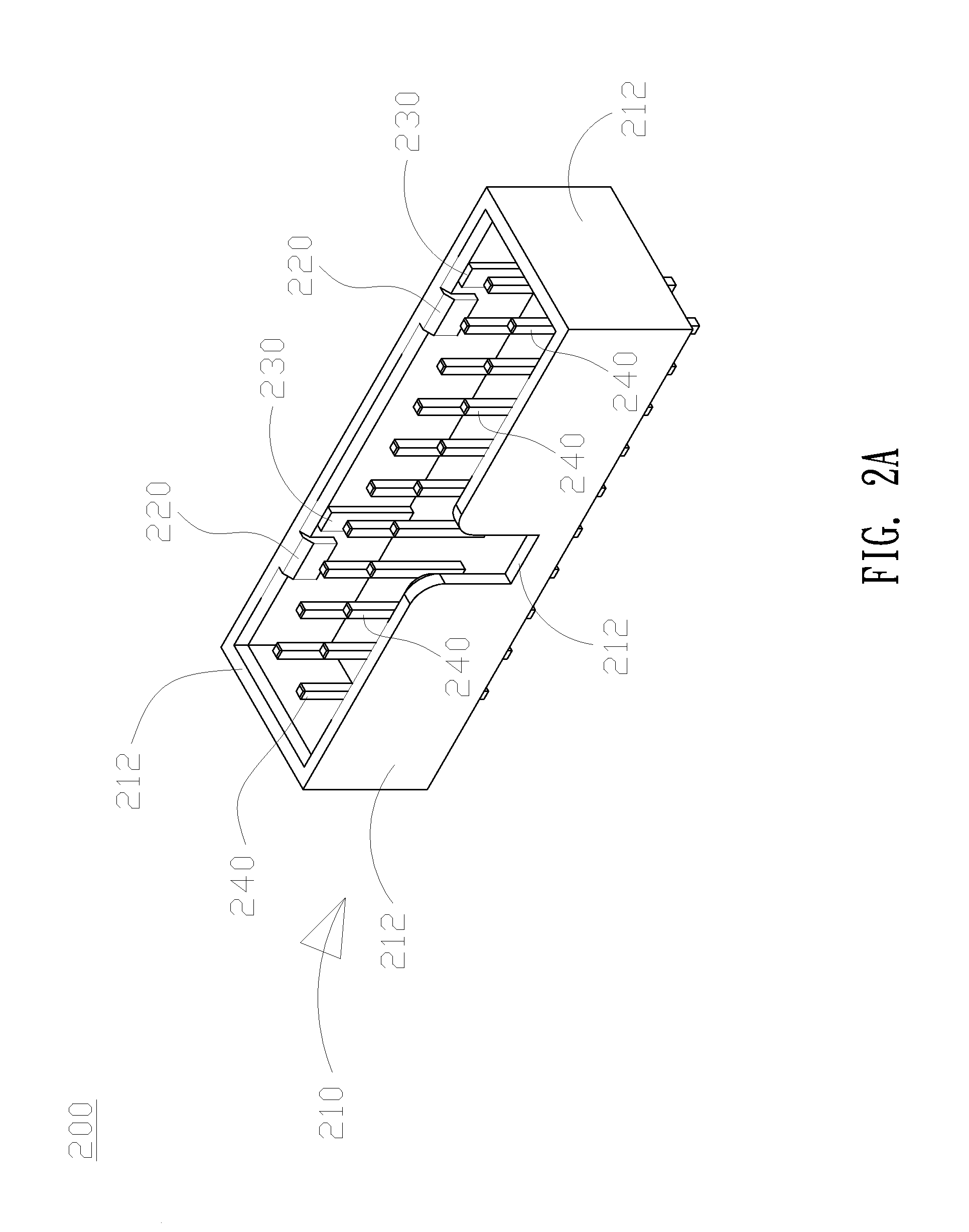

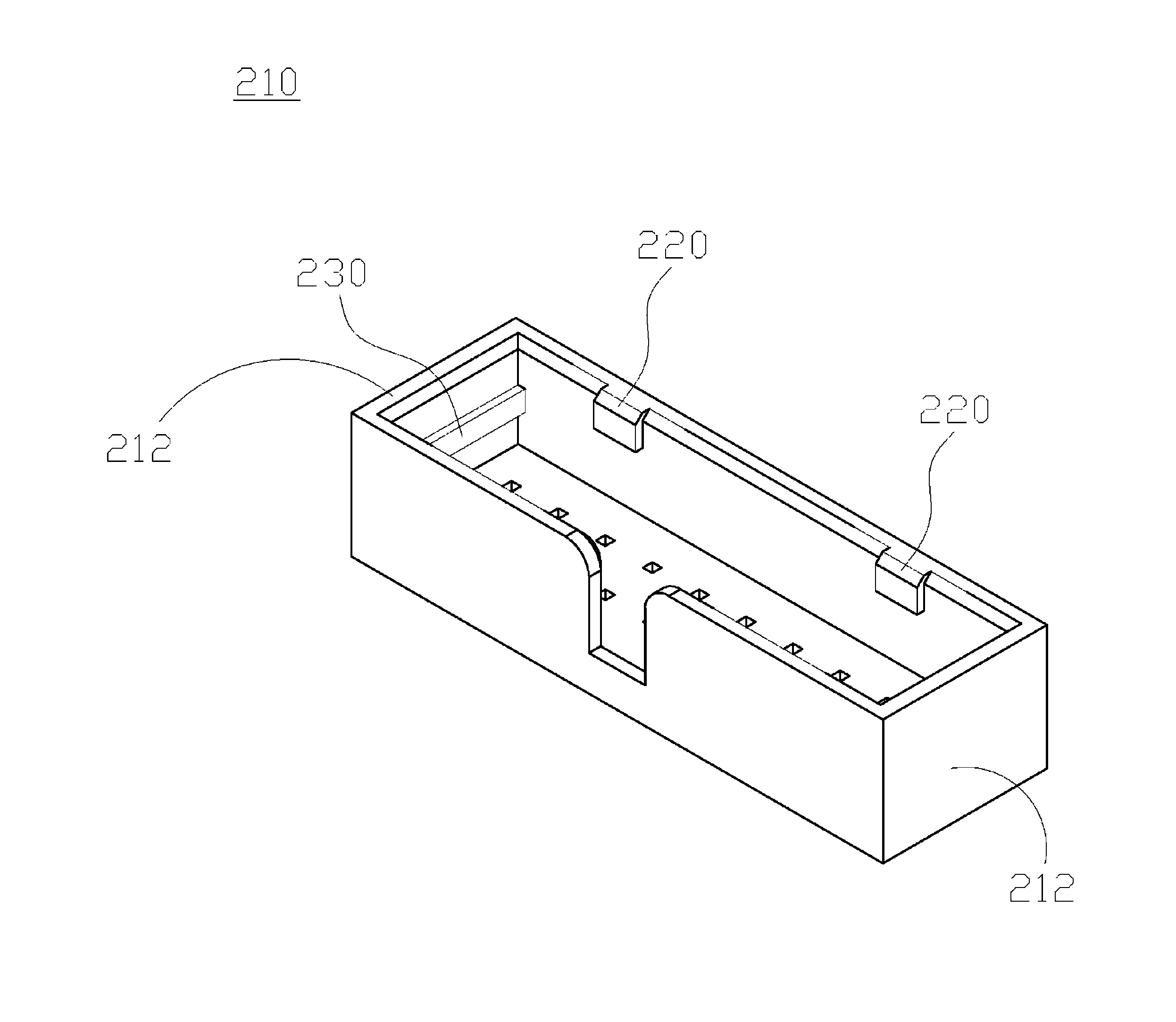

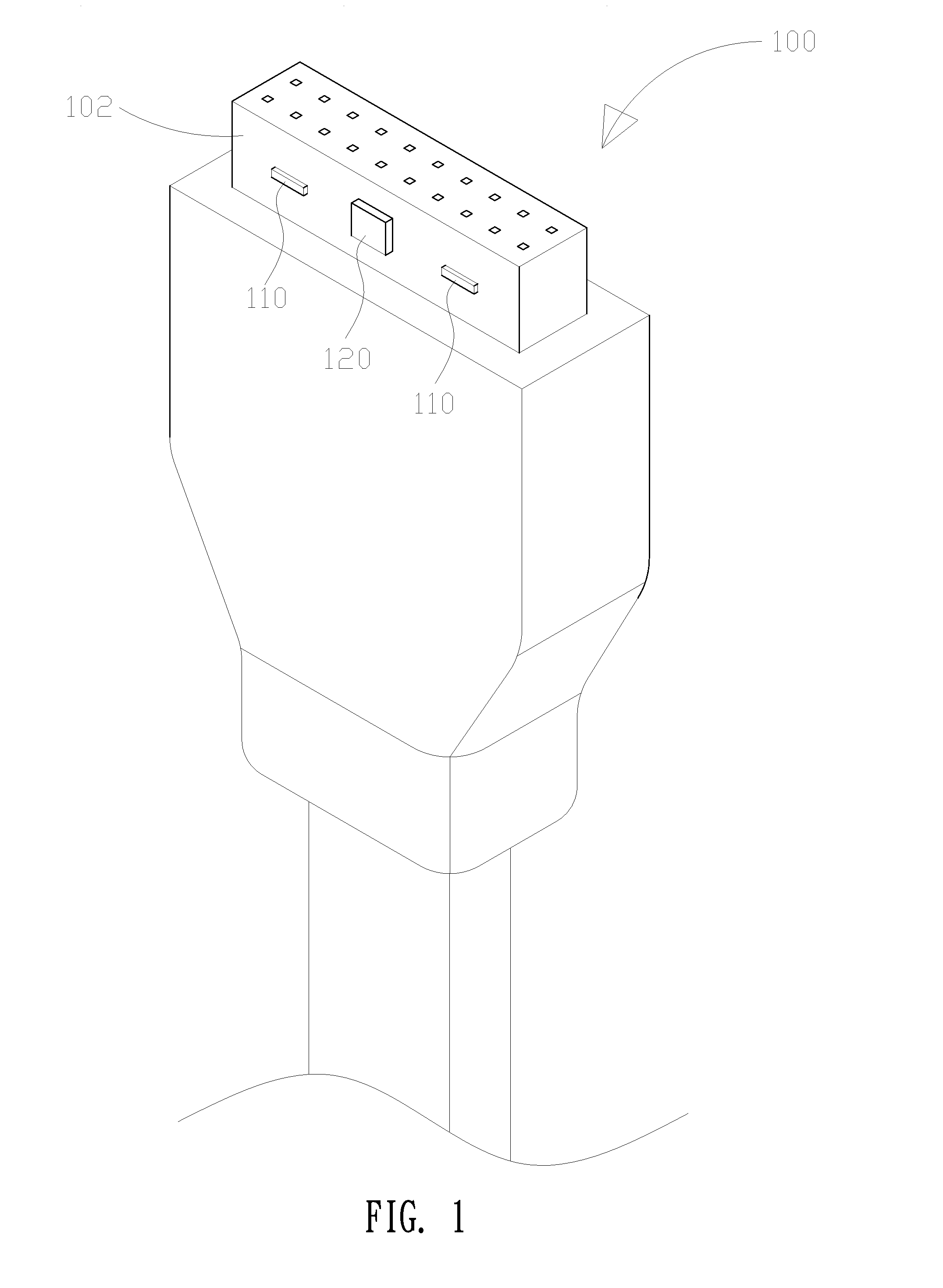

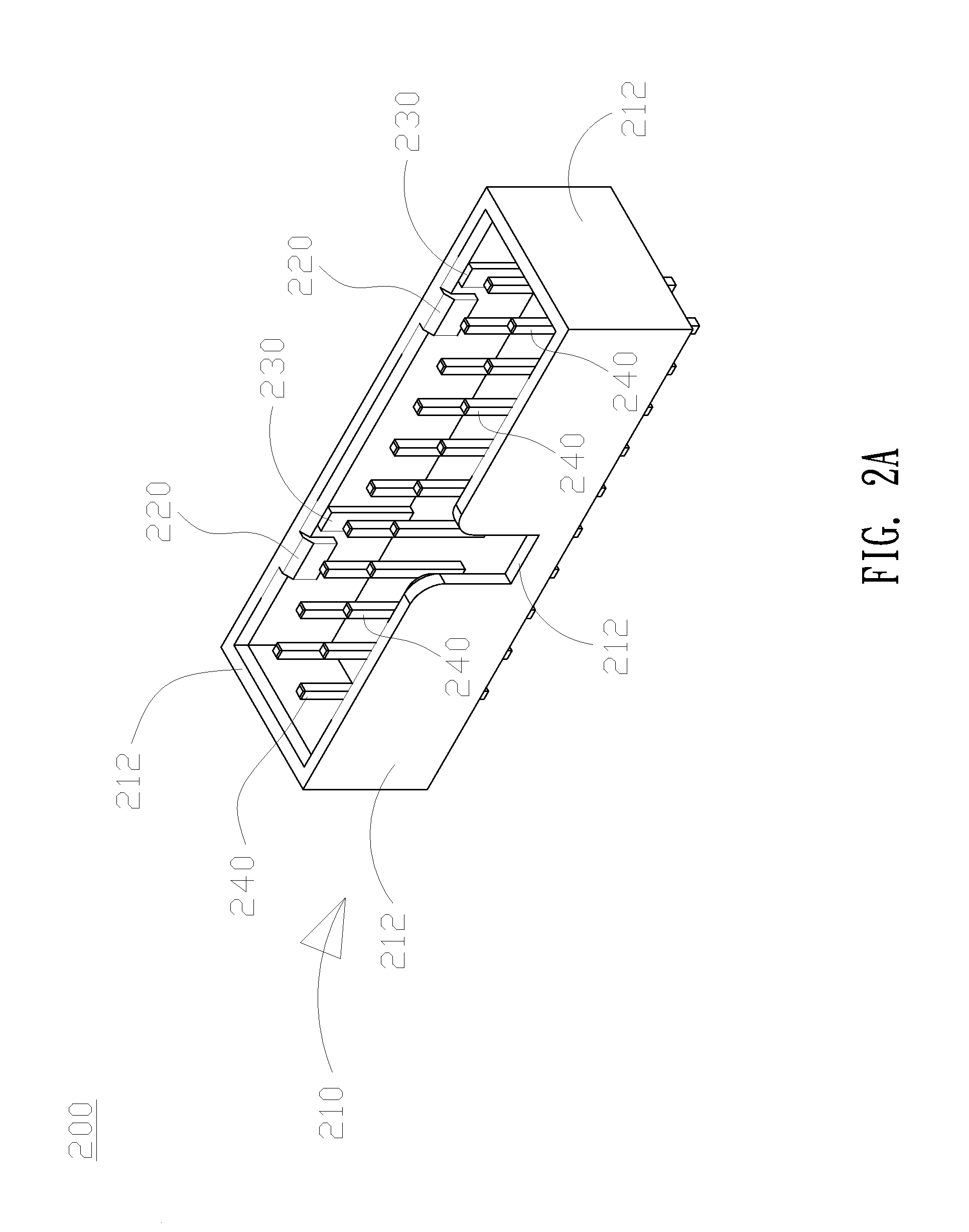

Electric socket and bearing body therefor

ActiveUS20120322291A1Avoid damageLoose connectionEngagement/disengagement of coupling partsClamped/spring connectionsElectricityFastener

The invention provides an electric socket and a bearing body therefor. The bearing body includes a housing for accommodating the electrically connecting terminal, having a plurality of sidewalls that are connected and a bottom; a baffled portion on one of the sidewalls; a rib provided on the sidewall and extending longitudinally from one side to the other side of the one of the sidewalls; and a plurality of conductive pins penetrating the bottom. When the electrically connecting terminal is fit into the housing, the baffled portion opposes against the fastener of the electrically connecting terminal, and the rib is located against an outer surface of the electrically connecting terminal, thereby preventing detachment of the electrically connecting terminal from the electric socket.

Owner:GIGA BYTE TECH CO LTD

Fishscale collagen production process

ActiveCN100370033CSignificant positive effectGuaranteed complete enzymatic digestionFermentationWaste materialFish scale

The invention discloses a fish scale collagen process technology that is made up from the process of twice acid process, alkali neutralized, boiling, enzymolysis, exchanging absorbing, concentrating, filtering, drying and spraying. The invention also supplies the invention to easily produce fish scale collagen produce technology. The invention has low molecular weight, stability, and low content or ash content.

Owner:YANTAI DONGCHENG PHARMA GRP

Motor winding bobbin and terminal structure thereof

InactiveUS20090079288A1Improve connection strengthLoose connectionSynchronous generatorsWindingsBobbinEngineering

A motor winding bobbin and terminal structure there are disclosed. The terminal structure includes a fixing portion and at least one positioning portion. The fixing portion is disposed at one end of the terminal structure and has at least one fixing pattern. The fixing portion is connected with a connecting end of the motor winding structure. The positioning portion is disposed adjacent to the fixing portion and urged against the motor winding structure for positioning the fixing portion while it is connected with the connecting end.

Owner:DELTA ELECTRONICS INC

Preparation method of flexible silicon dioxide aerogel

ActiveCN111908478AIncrease contact surfaceGuaranteed flexibilitySilicon compoundsPhysical chemistrySilicon oxide

The invention discloses a preparation method of flexible silicon dioxide aerogel, which comprises the following steps: S1, dissolving CTAB in a mixed solvent to obtain a mixed solution which comprisesethanol, water and hydrochloric acid; S2, sequentially adding TEOS, MTES and DEDMS into the mixed solution under a stirring condition, and mixing and stirring to obtain silicon dioxide sol; S3, dropwise adding ammonia water with the concentration of 2-3 mol / L into the silicon dioxide sol under a stirring condition, and mixing and stirring to obtain silicon dioxide gel, with the molar ratio of theammonia water to the DEDMS added in the S2 being (0.008-0.012): (0.015-0.025); and S4, carrying out aging treatment, cleaning and drying on the silicon dioxide gel to obtain the flexible silicon dioxide aerogel. The connection strength of an aerogel skeleton can be improved, the preparation time is shortened, and the preparation efficiency is improved.

Owner:SOUTHWEST UNIV

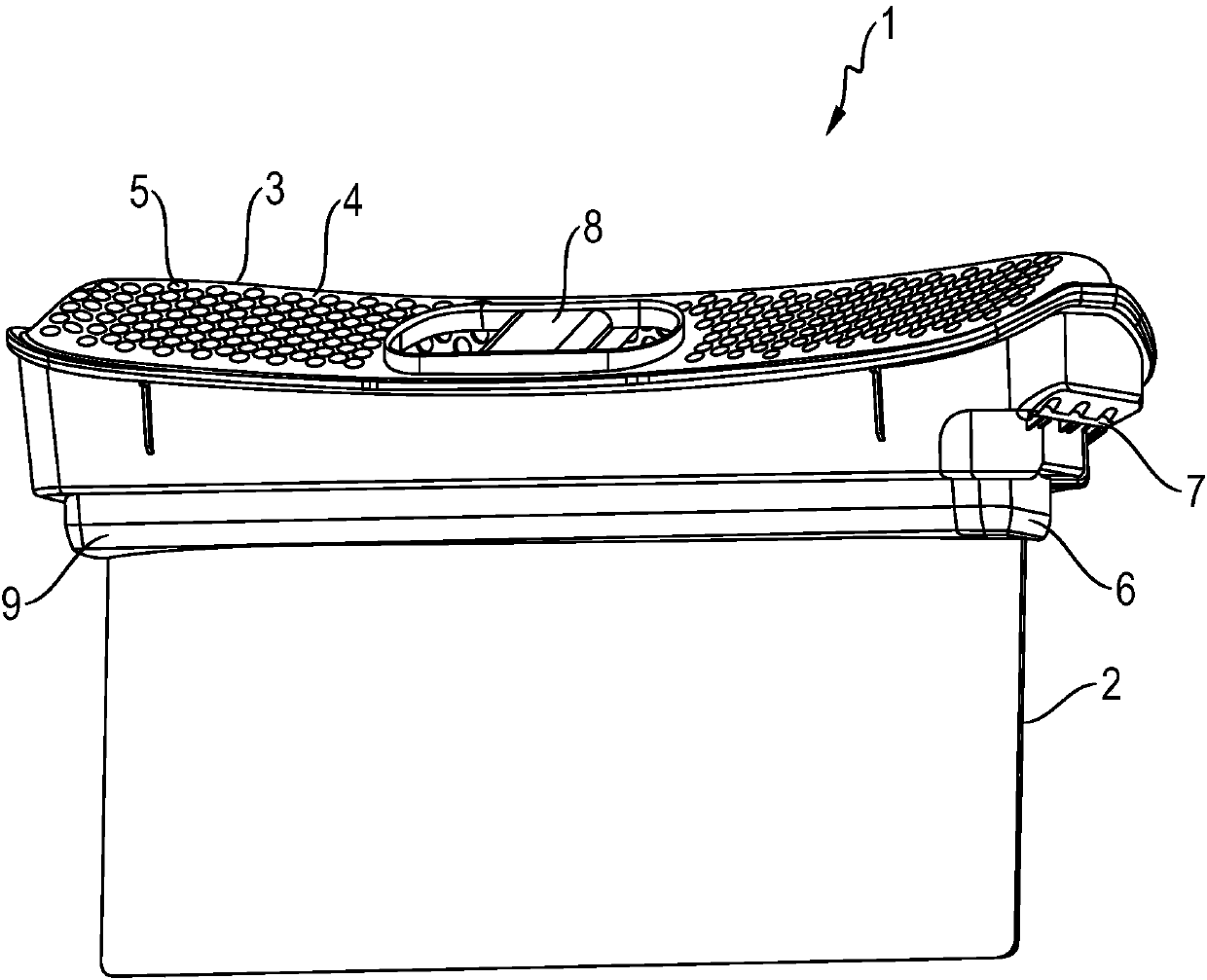

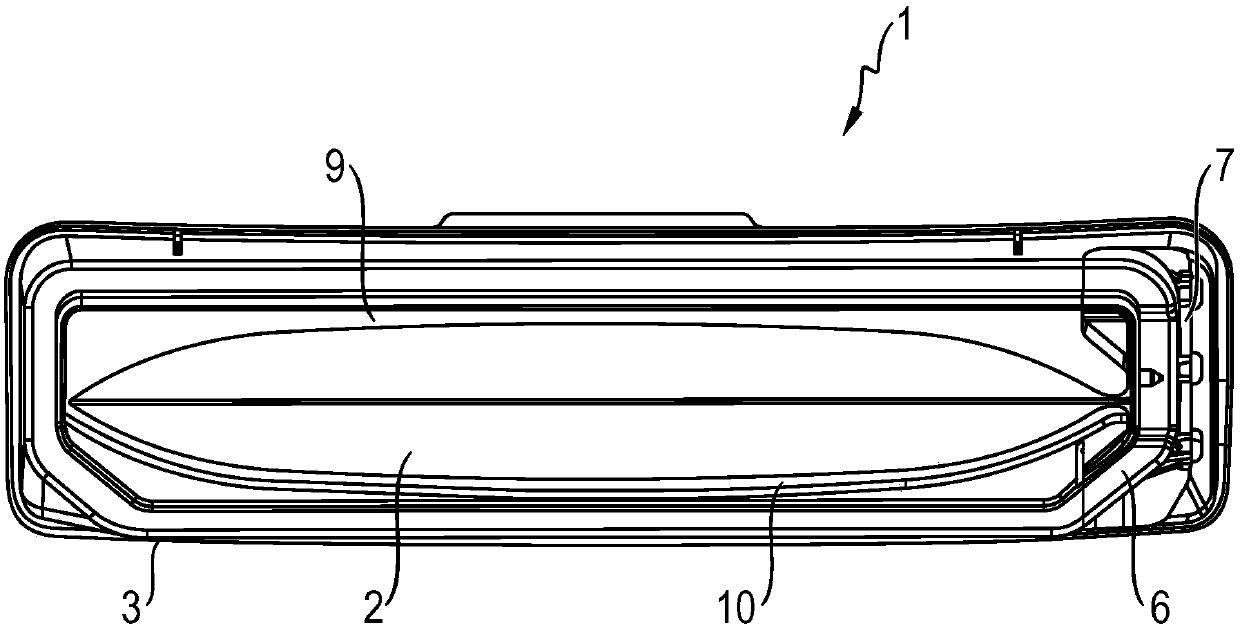

Filter cartridge and device for treating laundry

ActiveCN107641948APrevent from reachingLoose connectionTextiles and paperLaundry driersLaundryEngineering

A filter cartridge is provided with a filter bag and an attachment unit non-destructively releasably connected to the filter bag and used for attaching the filter cartridge to a component of the device. The attachment unit has an air inlet section. The filter cartridge comprises two elastic and buckling-resistant rails which are arranged on mutually opposite sections of the filter bag and at the mutually facing sides each have a connection member extending over at least a part of the longitudinal extension of the correspond rails and non-destructively detachably connected with the connecting member of the correspond other rail; two guide devices which are arranged on one side, of the attachment unit, facing the filter bag, wherein the rails are guided into the guide devices, and the guidedevices extend on the mutually-departing sides of the rails; and at least one releasing member which is arranged between the guide devices at the guiding-in side, and is arranged relative to the guidedevices in a way that when the rails which are connected with each other through the connection members are guided into the guide devices, the releasing member reaches between the rails and pushes the rails to be separated from each other and releases the connection members which are connected with each other.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Electric socket and bearing body therefor

ActiveUS8758037B2Avoid damageLoose connectionEngagement/disengagement of coupling partsIncorrect coupling preventionFastenerElectrical and Electronics engineering

The invention provides an electric socket and a bearing body therefor. The bearing body includes a housing for accommodating the electrically connecting terminal, having a plurality of sidewalls that are connected and a bottom; a baffled portion on one of the sidewalls; a rib provided on the sidewall and extending longitudinally from one side to the other side of the one of the sidewalls; and a plurality of conductive pins penetrating the bottom. When the electrically connecting terminal is fit into the housing, the baffled portion opposes against the fastener of the electrically connecting terminal, and the rib is located against an outer surface of the electrically connecting terminal, thereby preventing detachment of the electrically connecting terminal from the electric socket.

Owner:GIGA BYTE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com