Patents

Literature

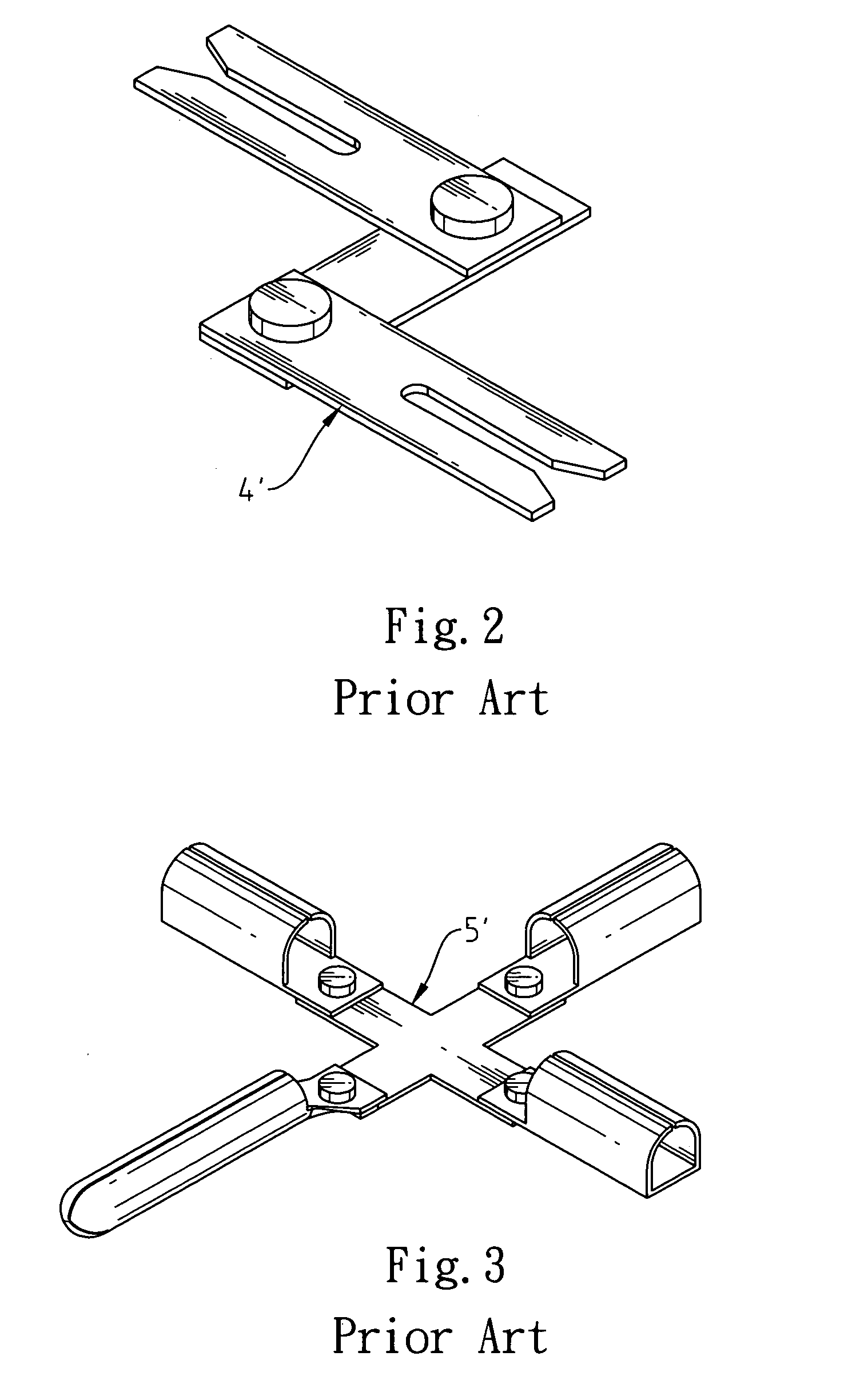

233results about "Riveted connections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

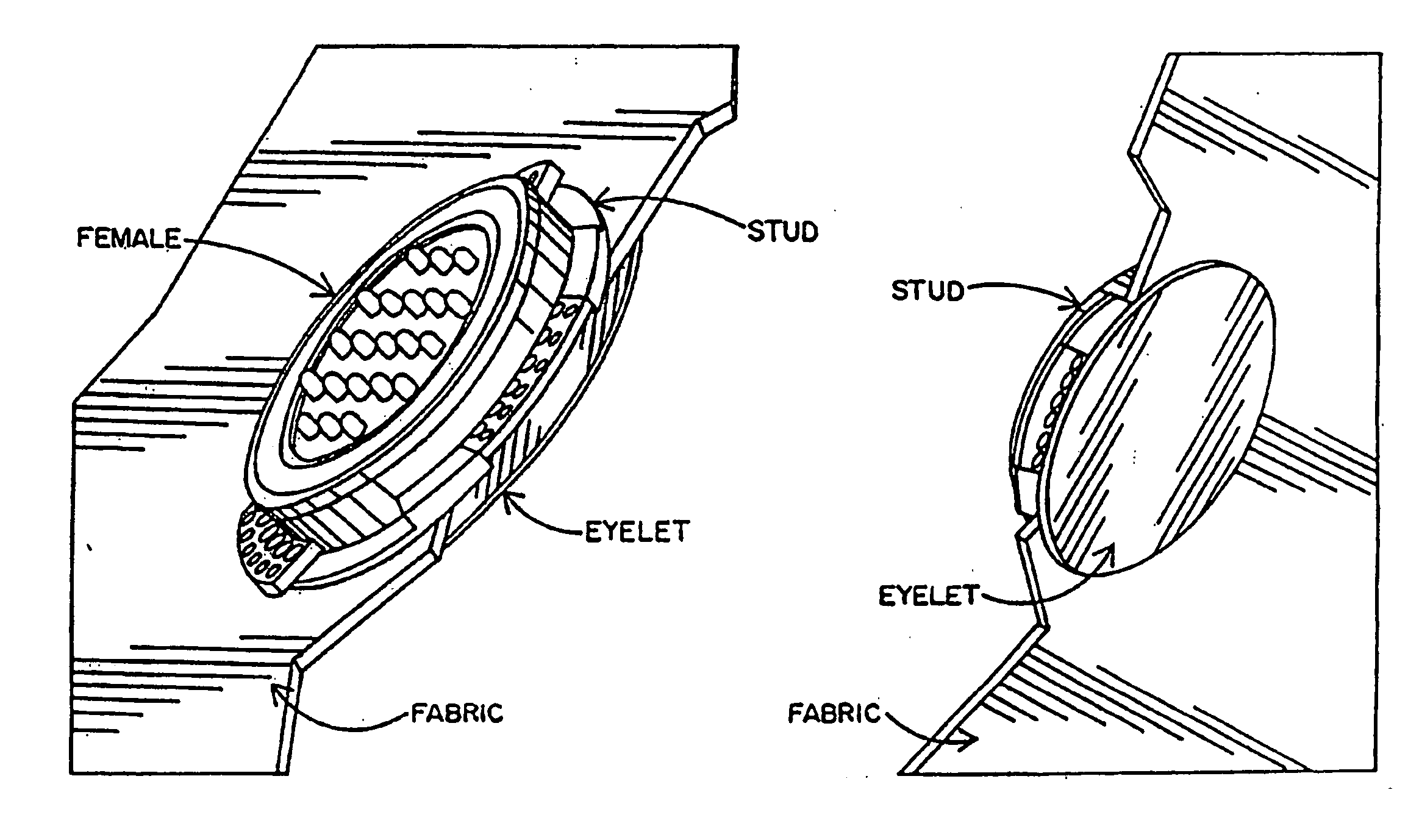

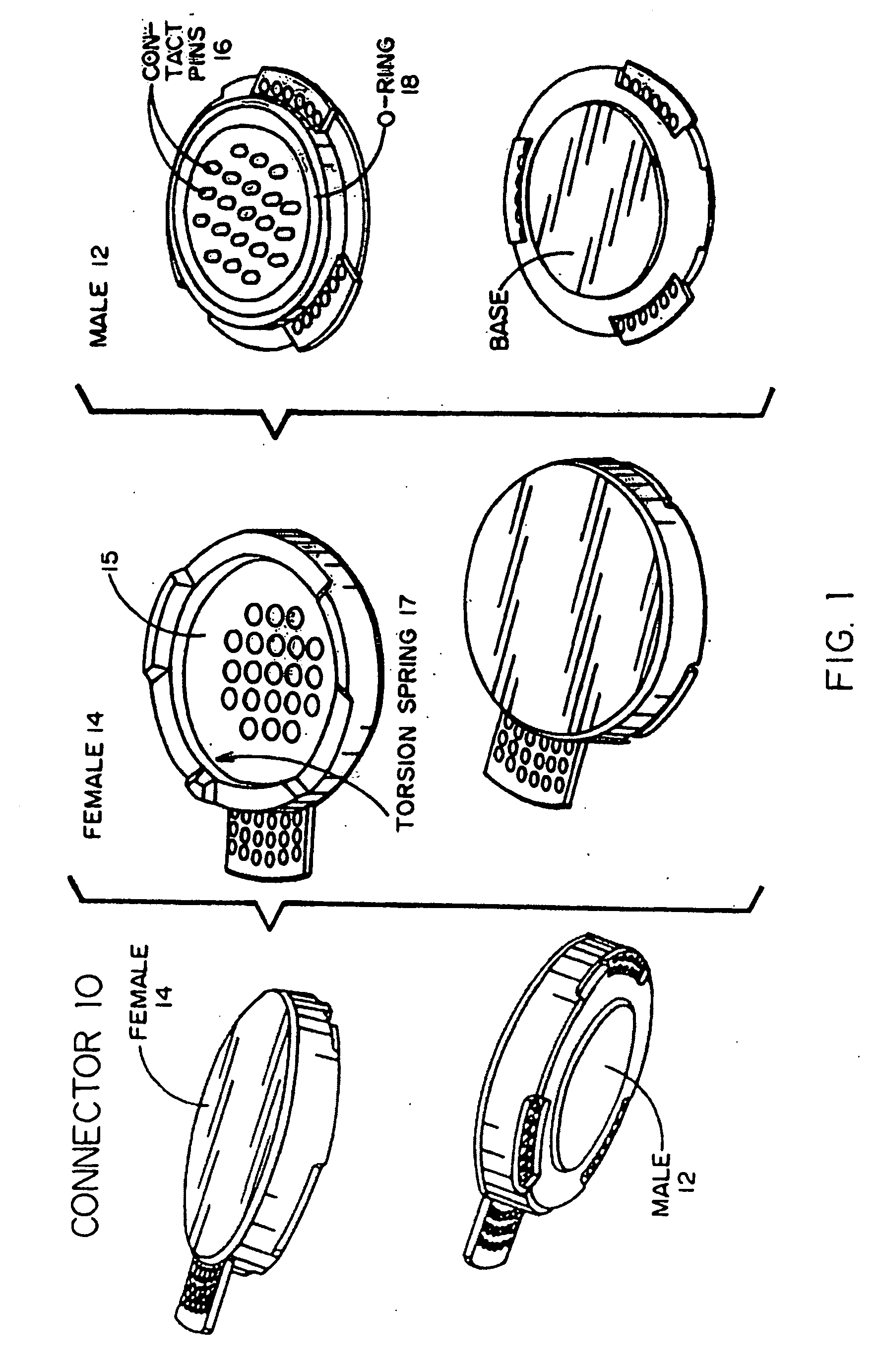

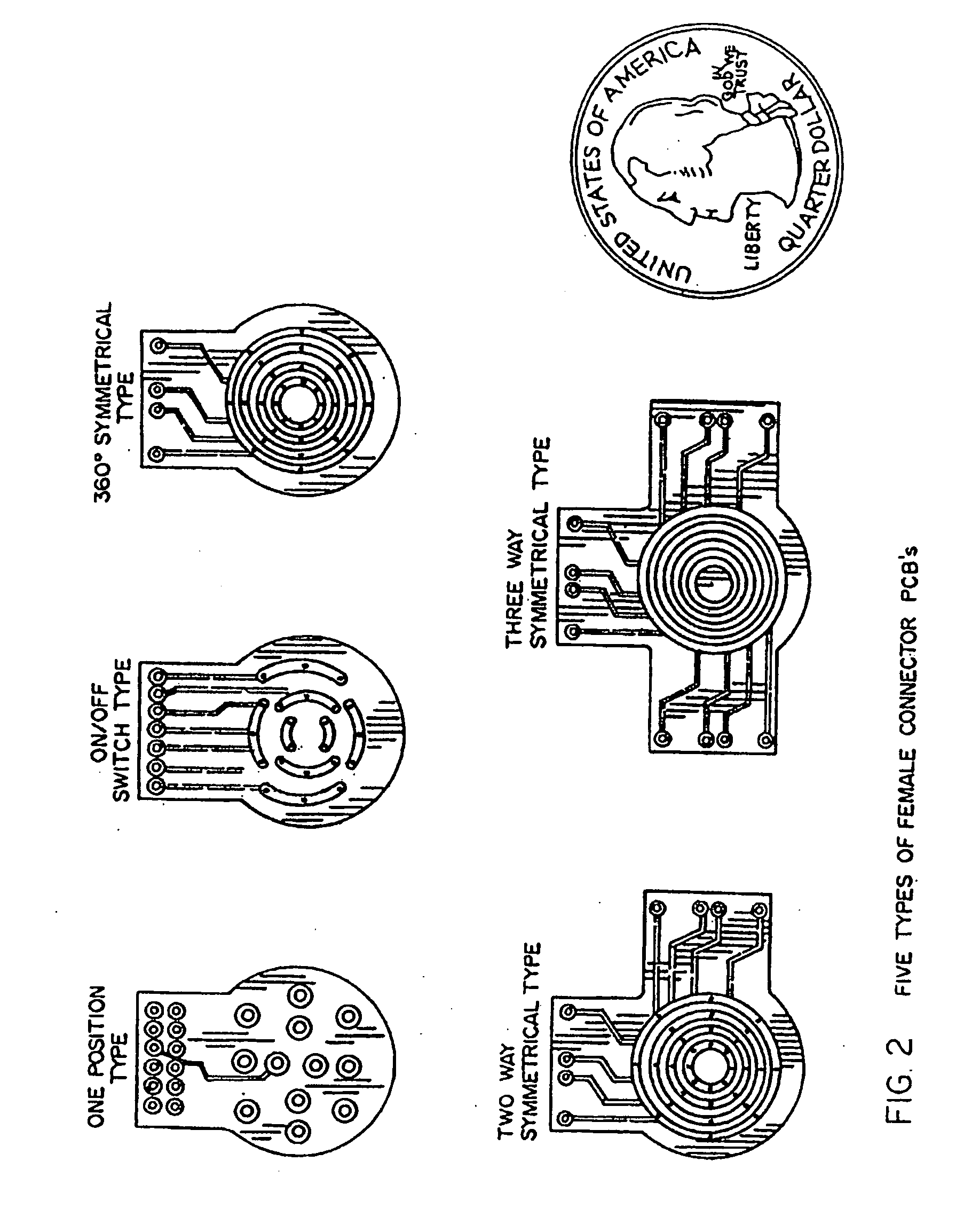

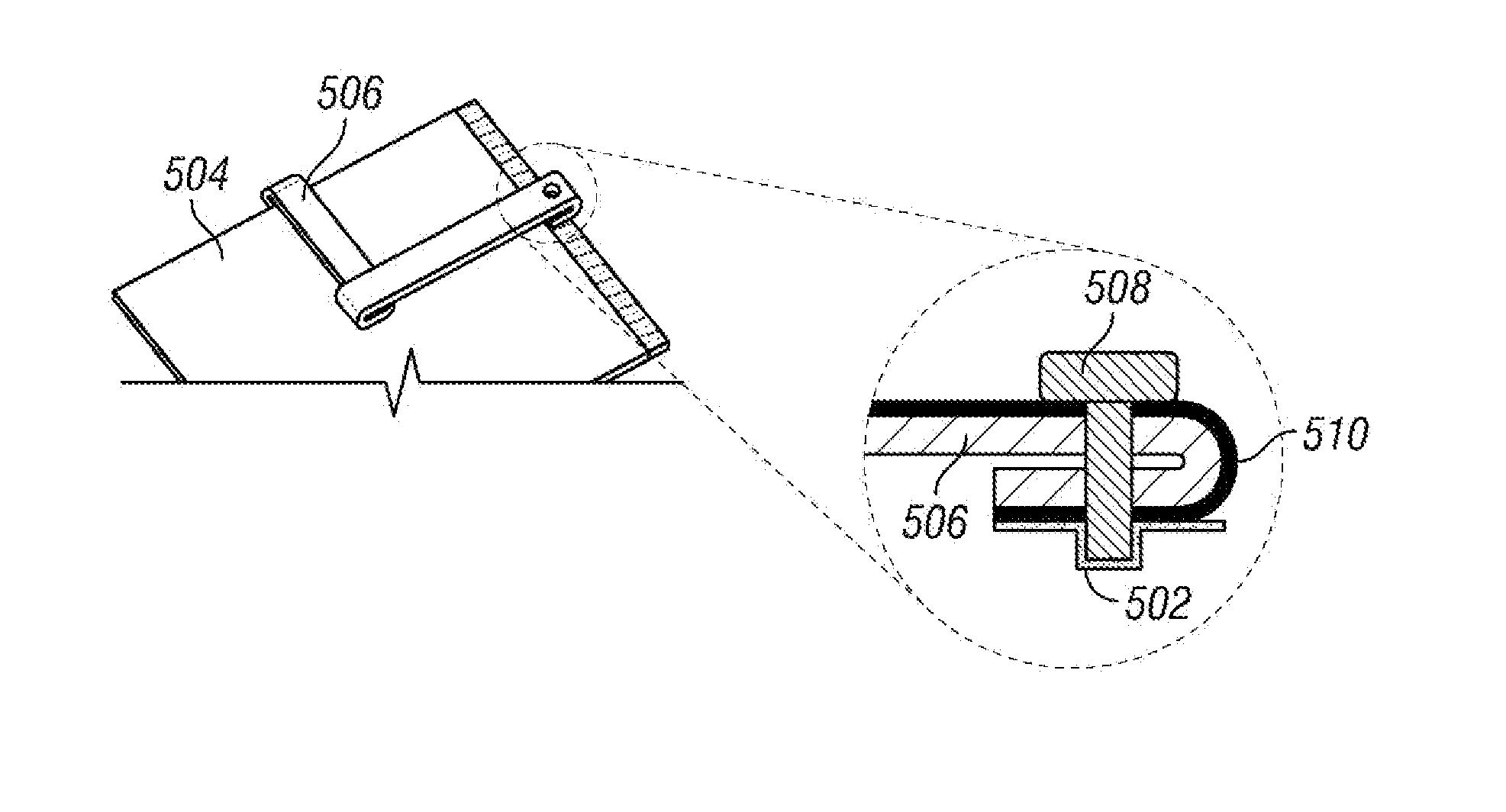

Inherently sealed electrical connector

ActiveUS20090149036A1Easy to operateRotary current collectorNon-rotary current collectorElectricityModularity

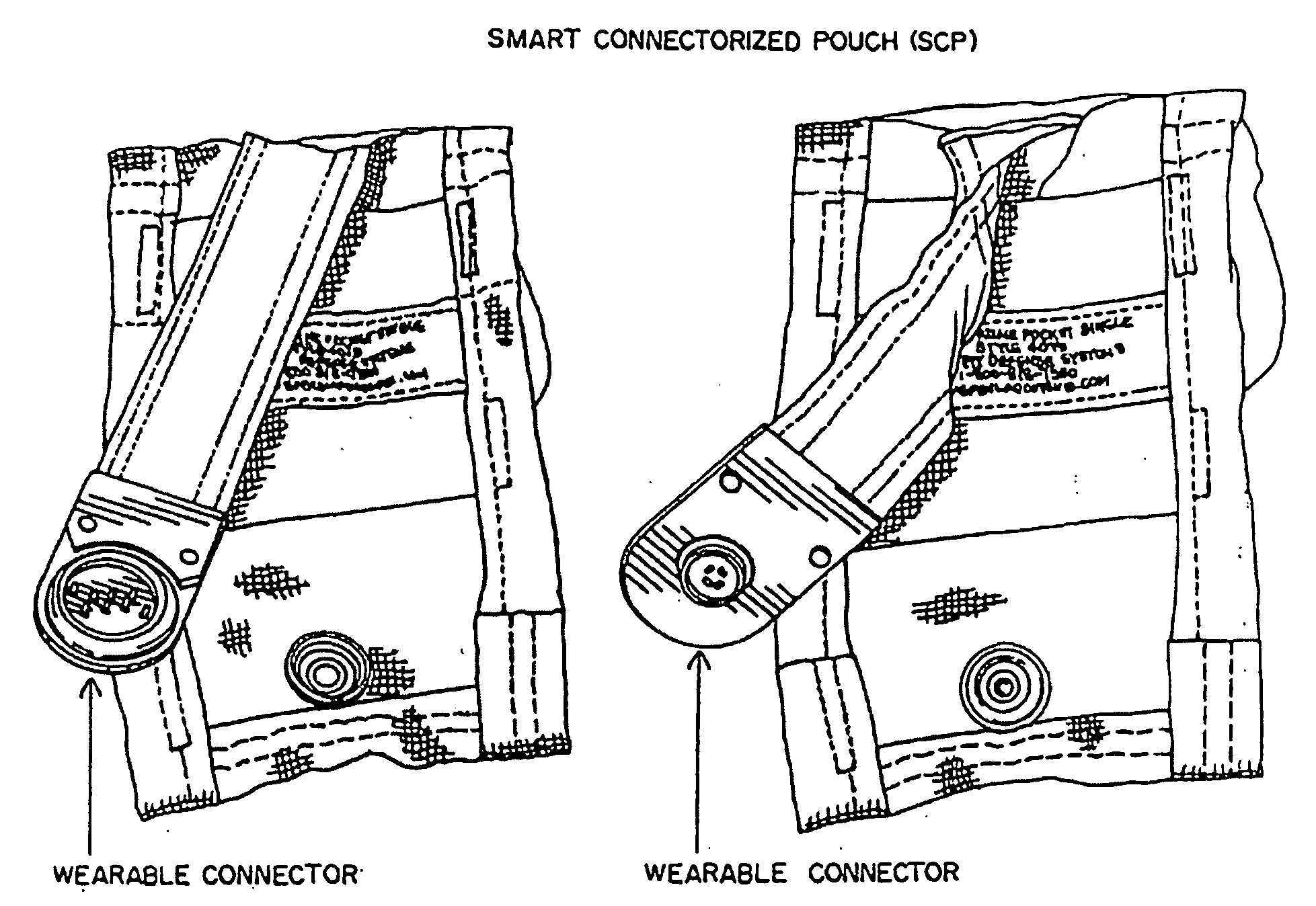

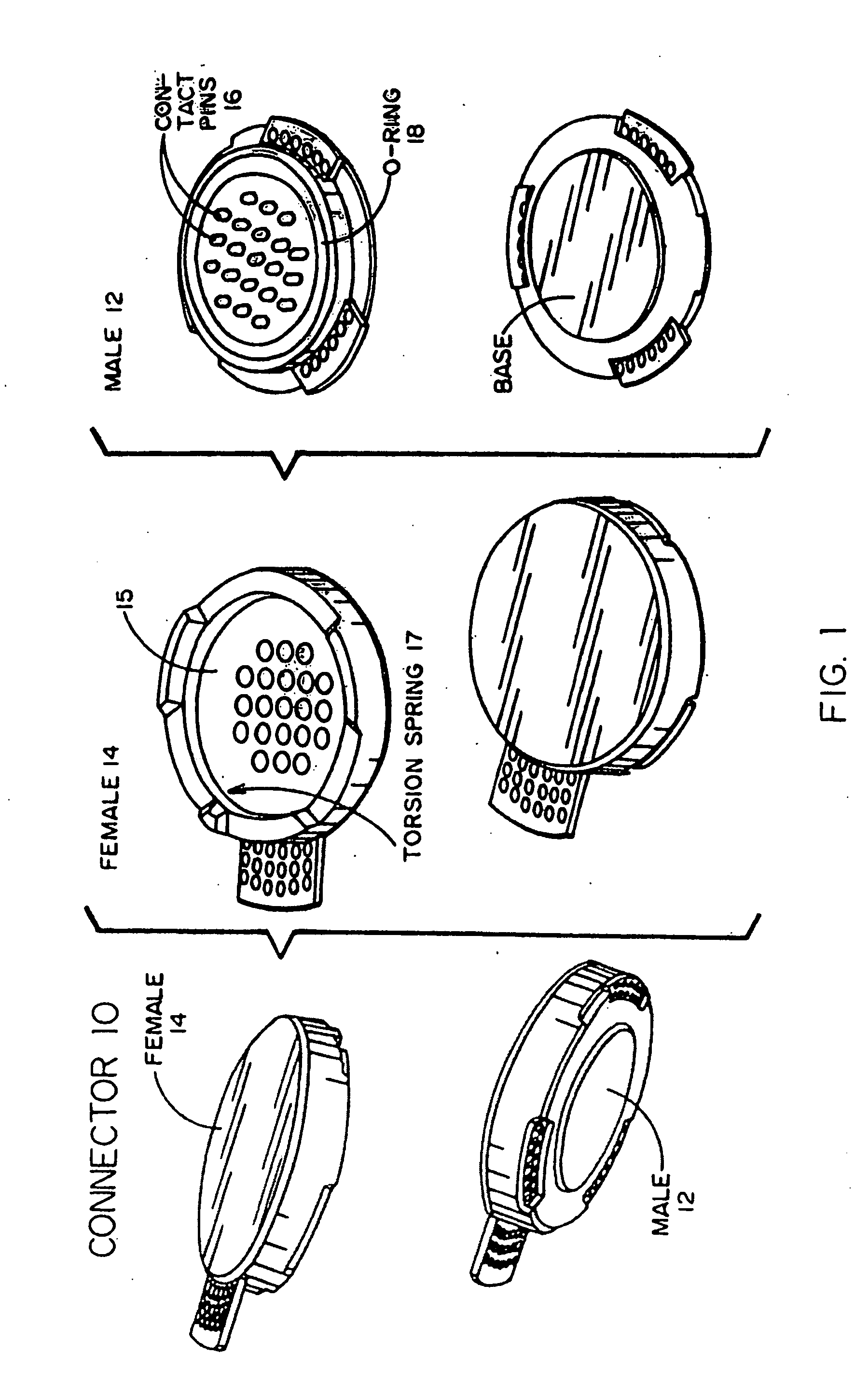

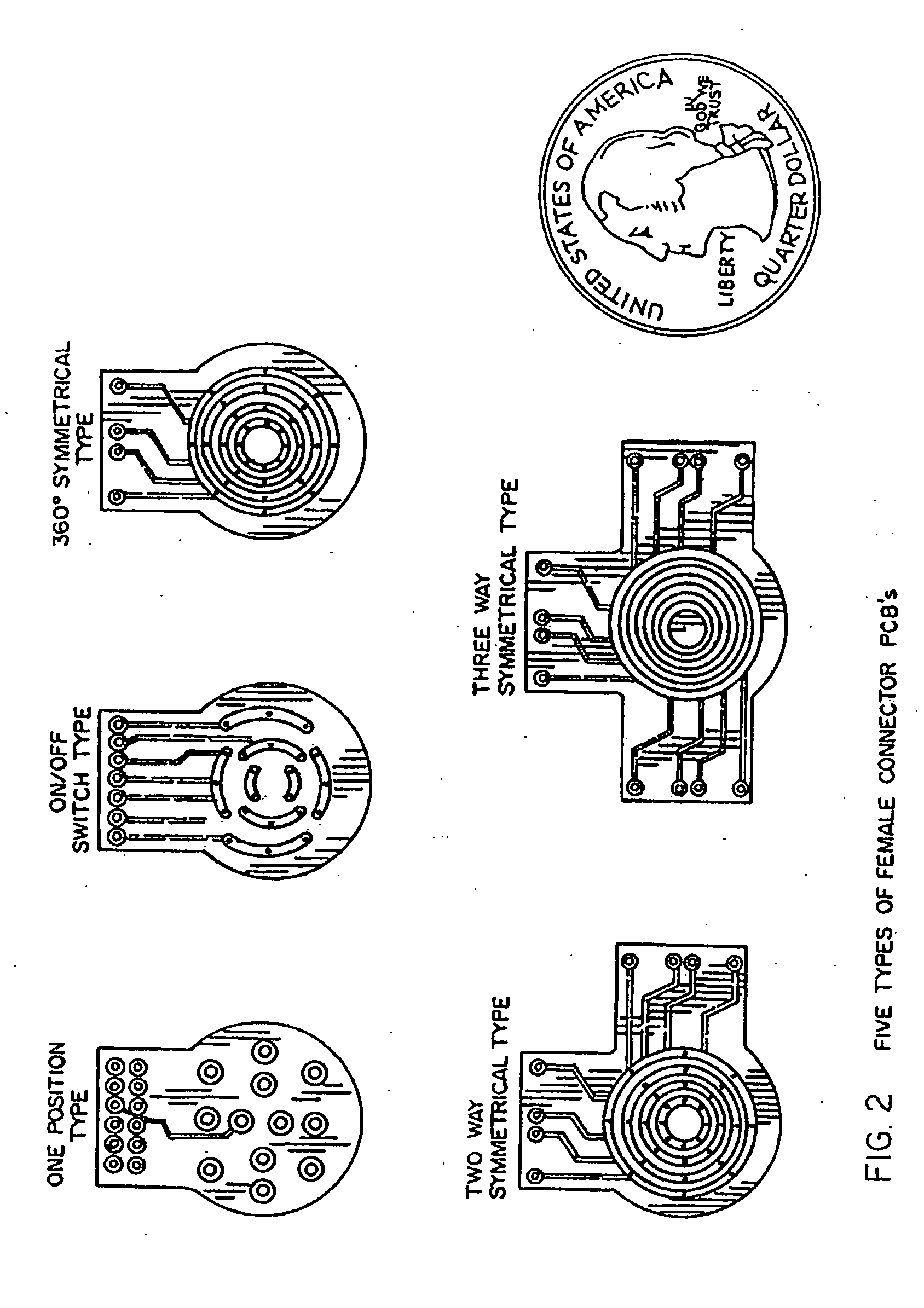

An entirely wearable electrical connector for power / data connectivity. The principal element of a modular network is the wearable electrical connector, which is integrated into a personal area network with USB compatibility. An embodiment comprises a non-conductive elastomeric environmental seal.

Owner:INTELLISENSE SYST INC

Heating element connector assembly with press-fit terminals

ActiveUS20070155255A1Easy constructionLow costHeater elementsSecuring/insulating coupling contact membersEngineeringHeating element

An improved heating element connector assembly includes an insulative, rectangular frame with a central opening and a plurality of conductive terminals which are press fit into openings in the frame. The terminals are spaced apart from each other lengthwise of two opposing sidewalls of the frame, and pairs of terminals are aligned with each other between the two sidewalls. A plurality of conductive strips extend across the frame opening to interconnect the pairs of terminals together. The terminals include compliant pin tail portions for receipt by corresponding holes formed in a circuit board of the assembly and deformable head portions for crimping onto the conductive strips.

Owner:ALEXZA PHARMA INC

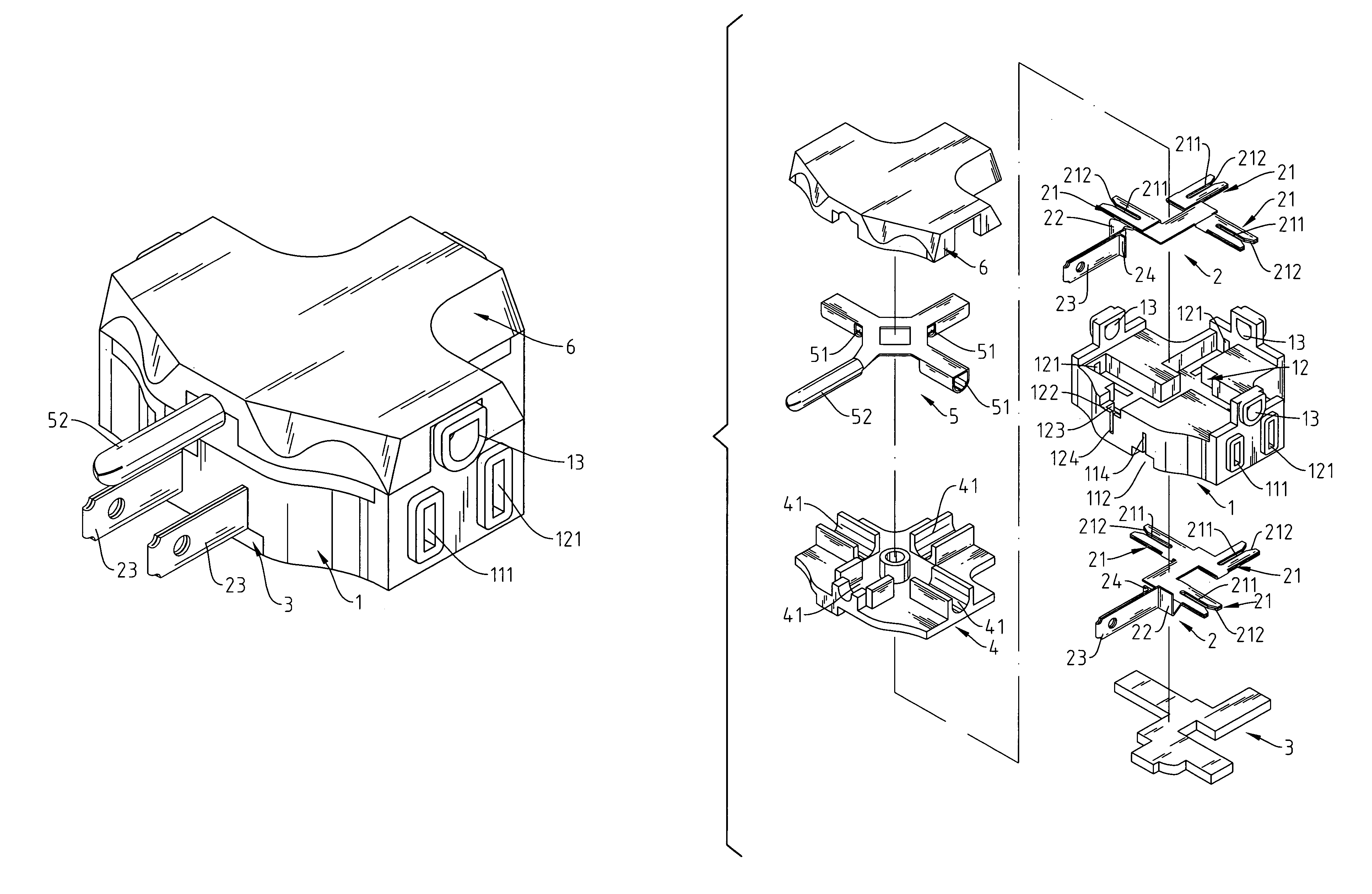

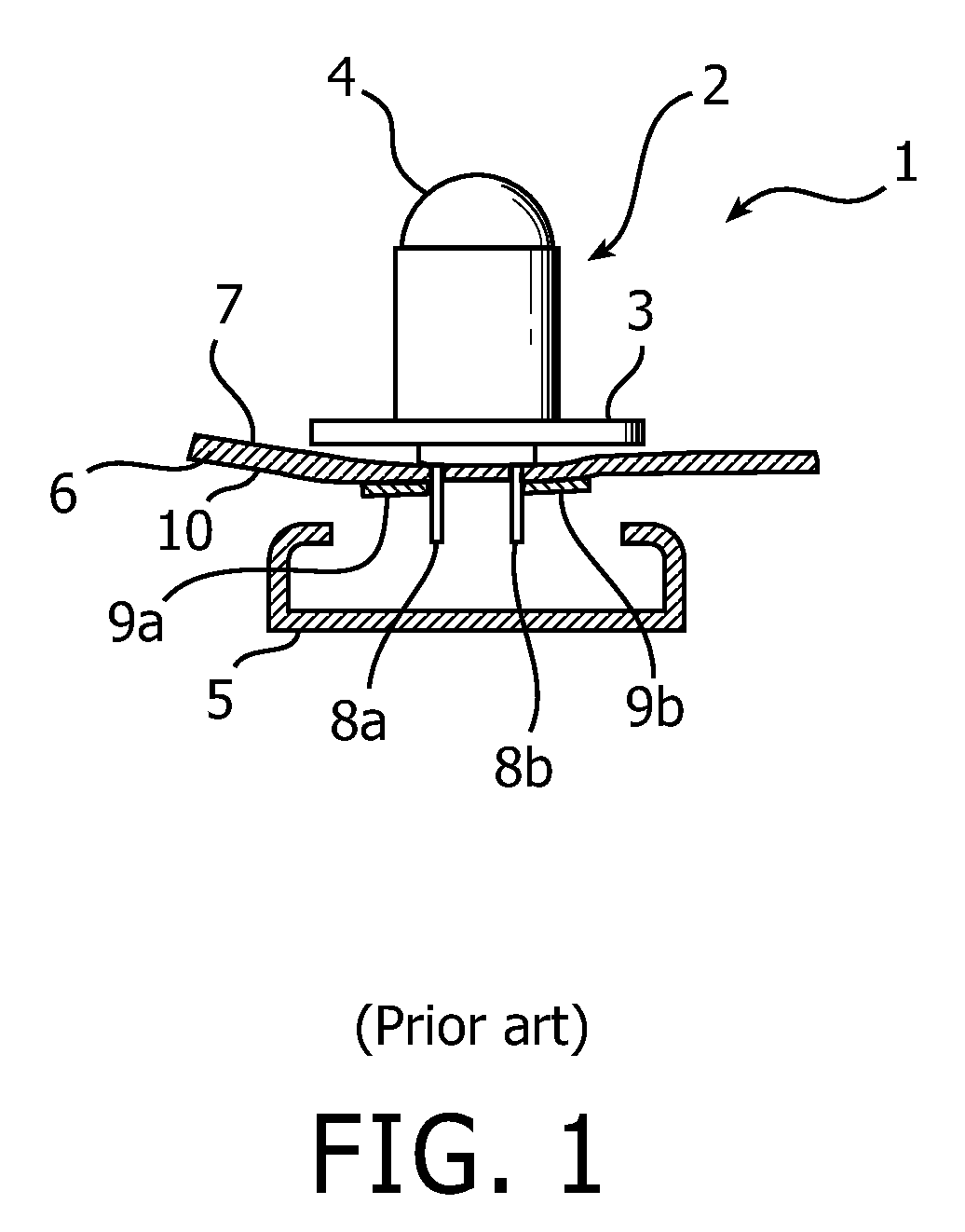

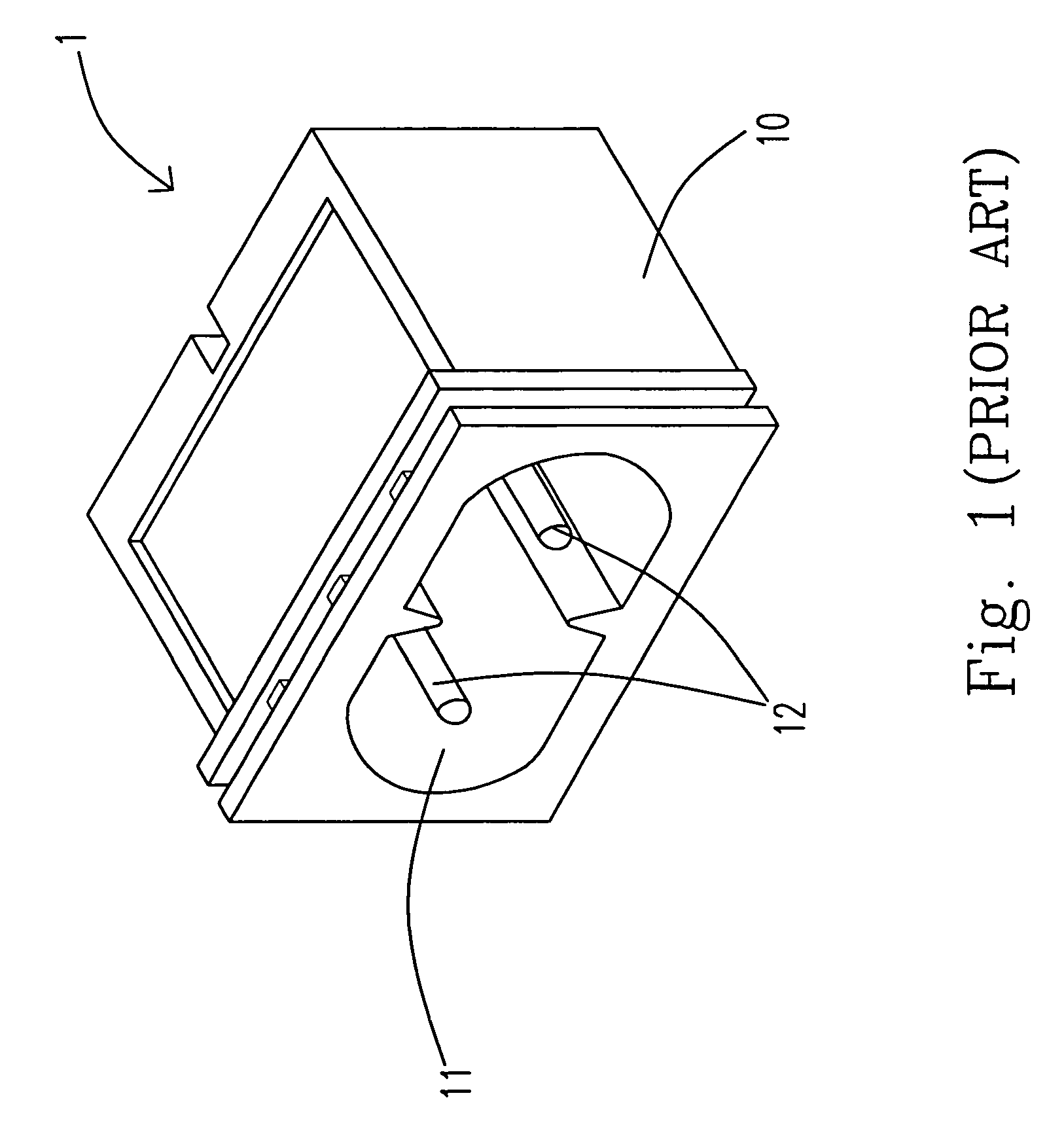

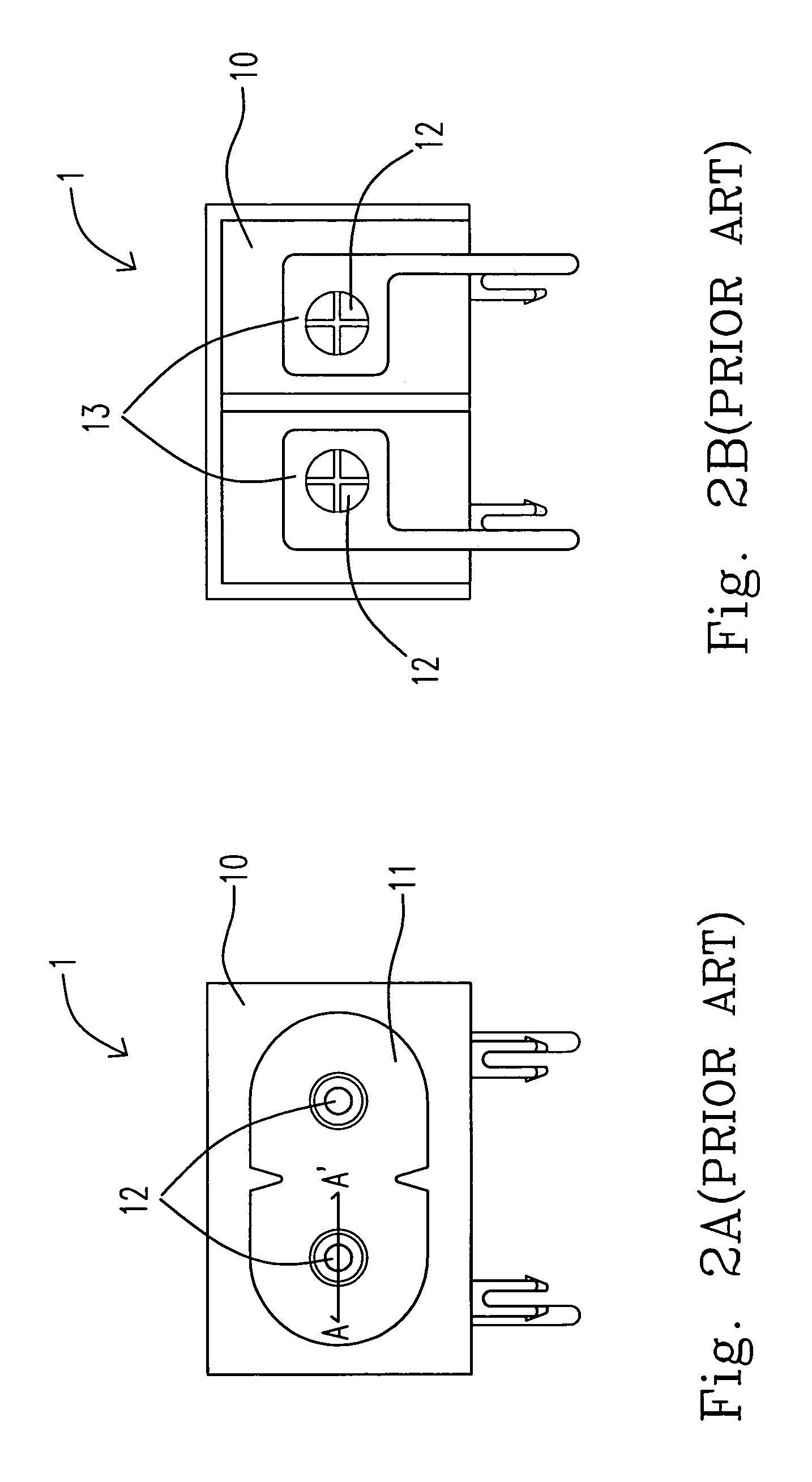

Socket with non-connecting terminal

InactiveUS6929514B1Produced easily and cost-effectivelyProduced cost-effectivelyContact member manufacturingElectric discharge tubesEngineeringTop cap

A socket with non-connecting terminal comprises a socket body, two power terminals, a bottom cover, a support, a ground terminal and a top cover in which the power terminals and the ground prong are integrally stamped without terminal tap. The power terminals are placed in the first receptacle and the second receptacle and sealed with the support and the bottom cover. The power blades are exposed outside to be connected to the wall socket. The three slots serve as a power supply to receive other plugs. The integrally stamped ground terminal is housed in the support and sealed by the top cover; the ground prong is exposed outside for linking to the power supply. The three ground slots on the ground terminal will accept the ground prongs from other plugs. When an electrical current flows through this circuit, there is no resistance encountered and no heat generated.

Owner:CHAO TRADING

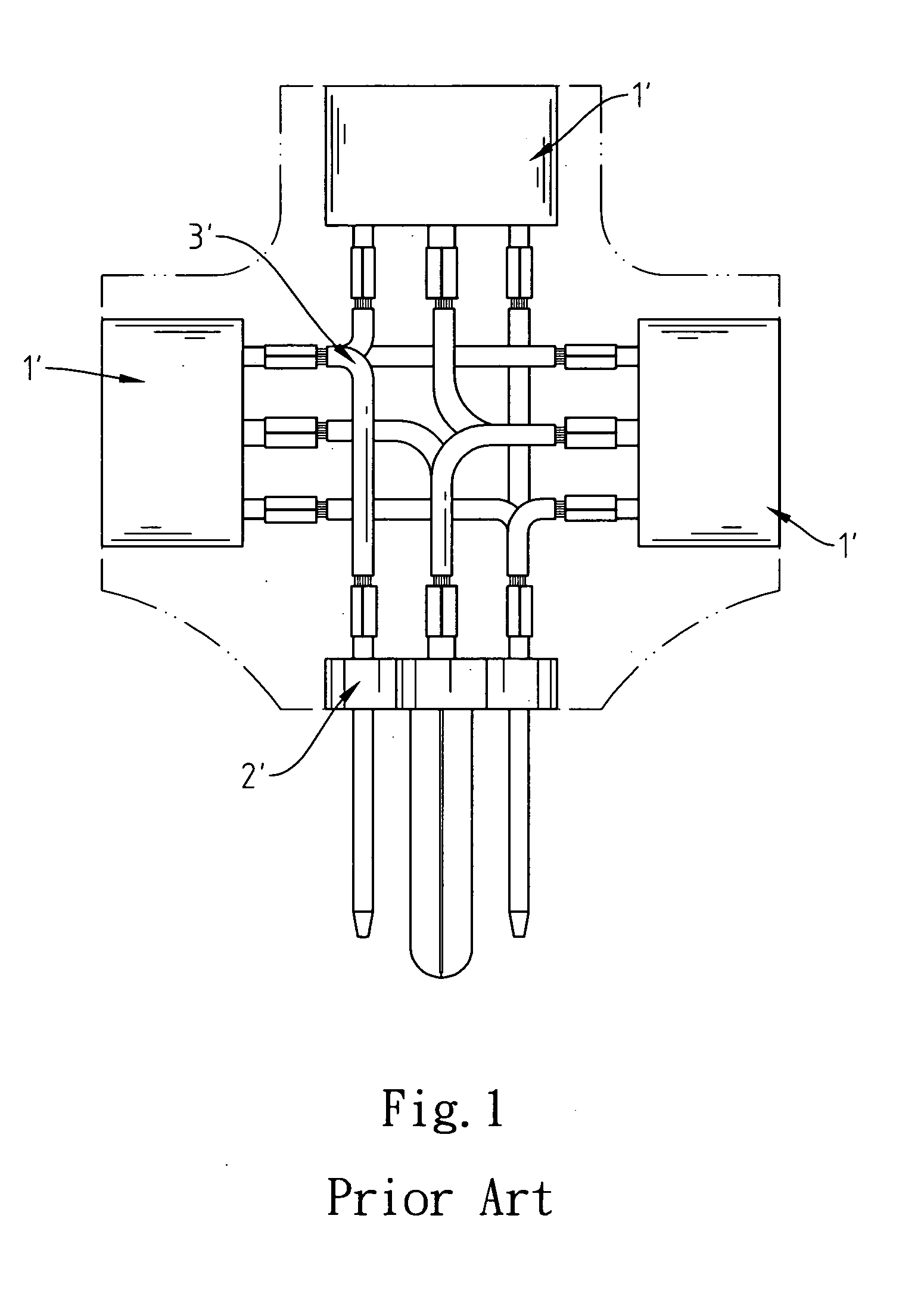

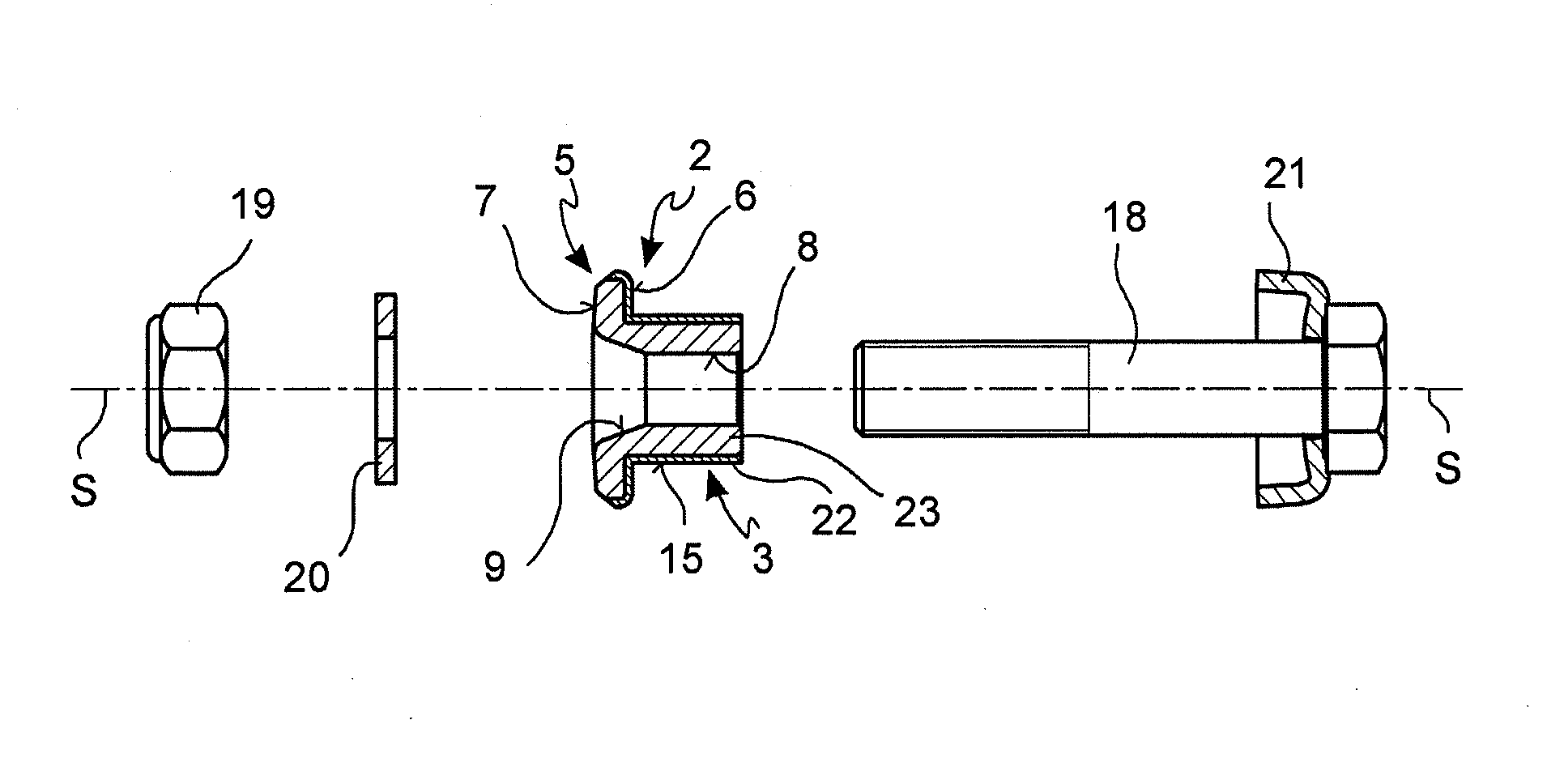

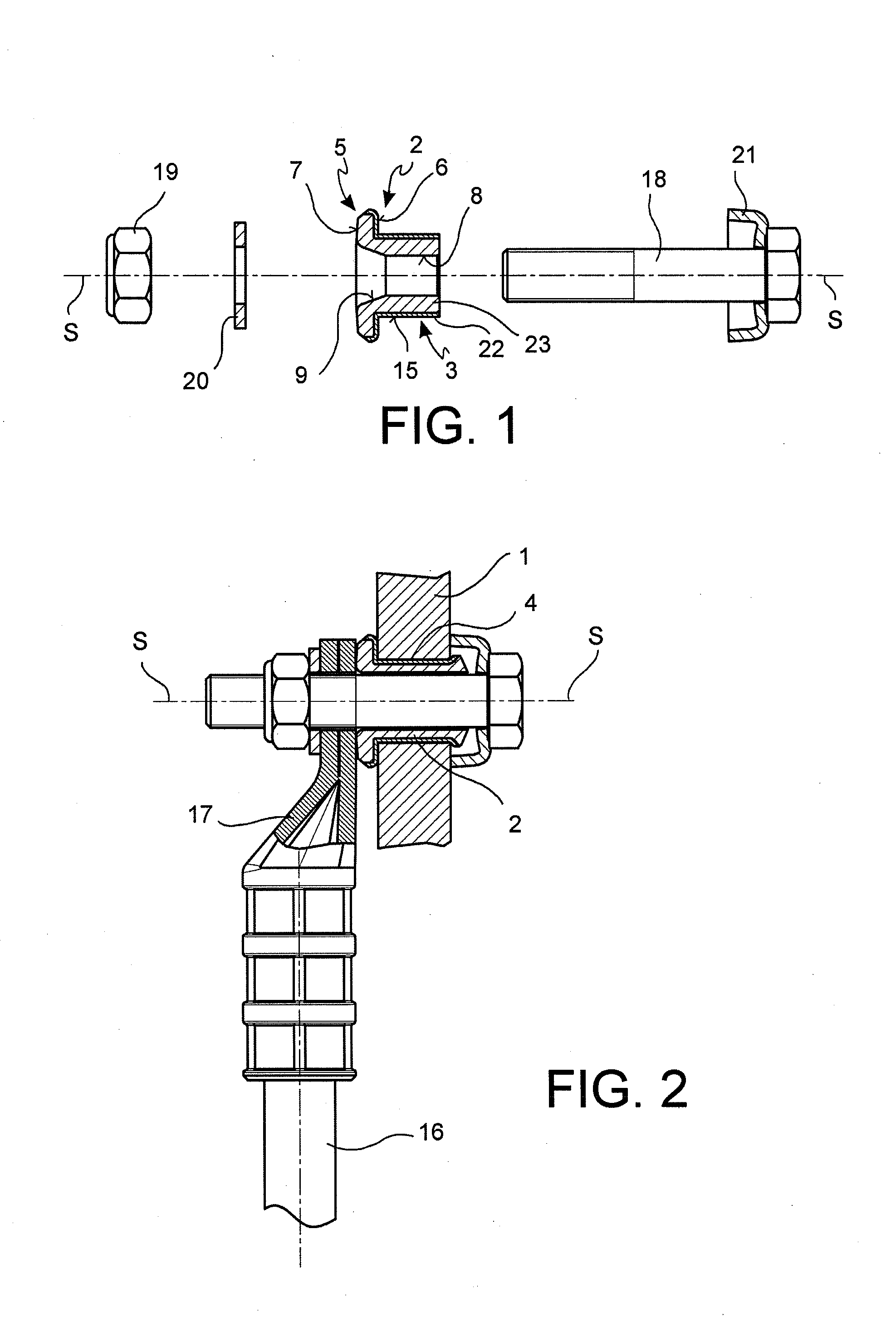

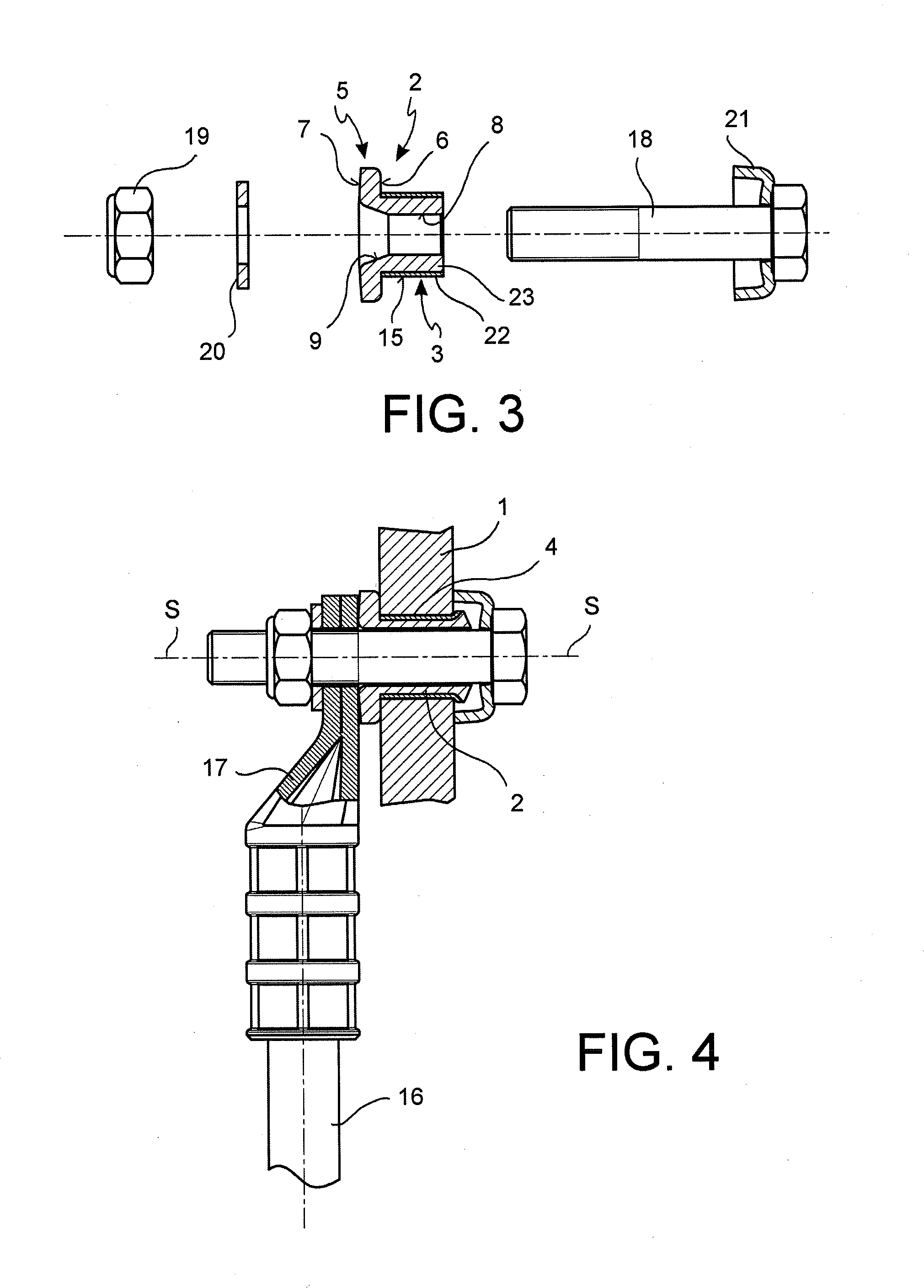

Current distribution device

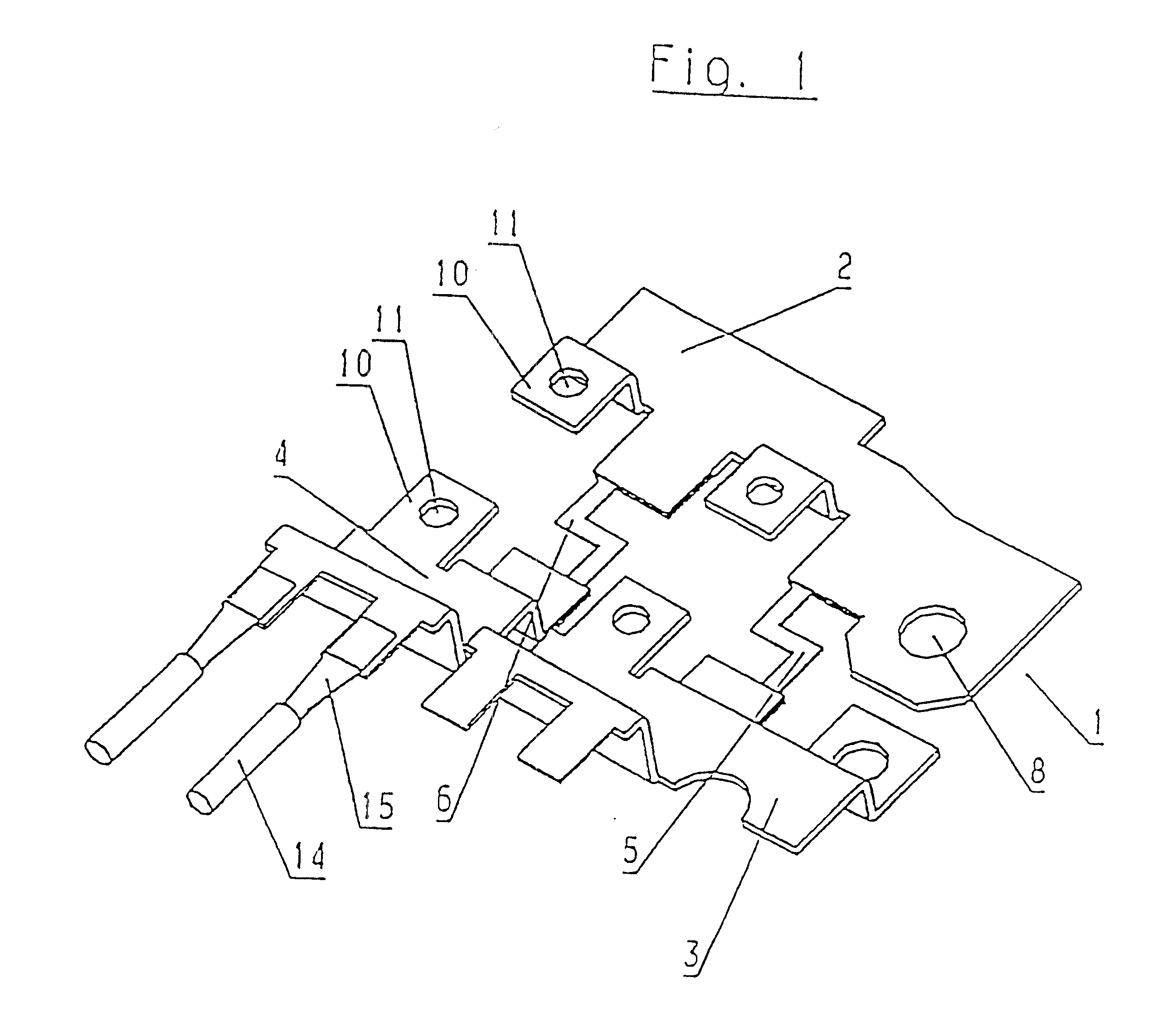

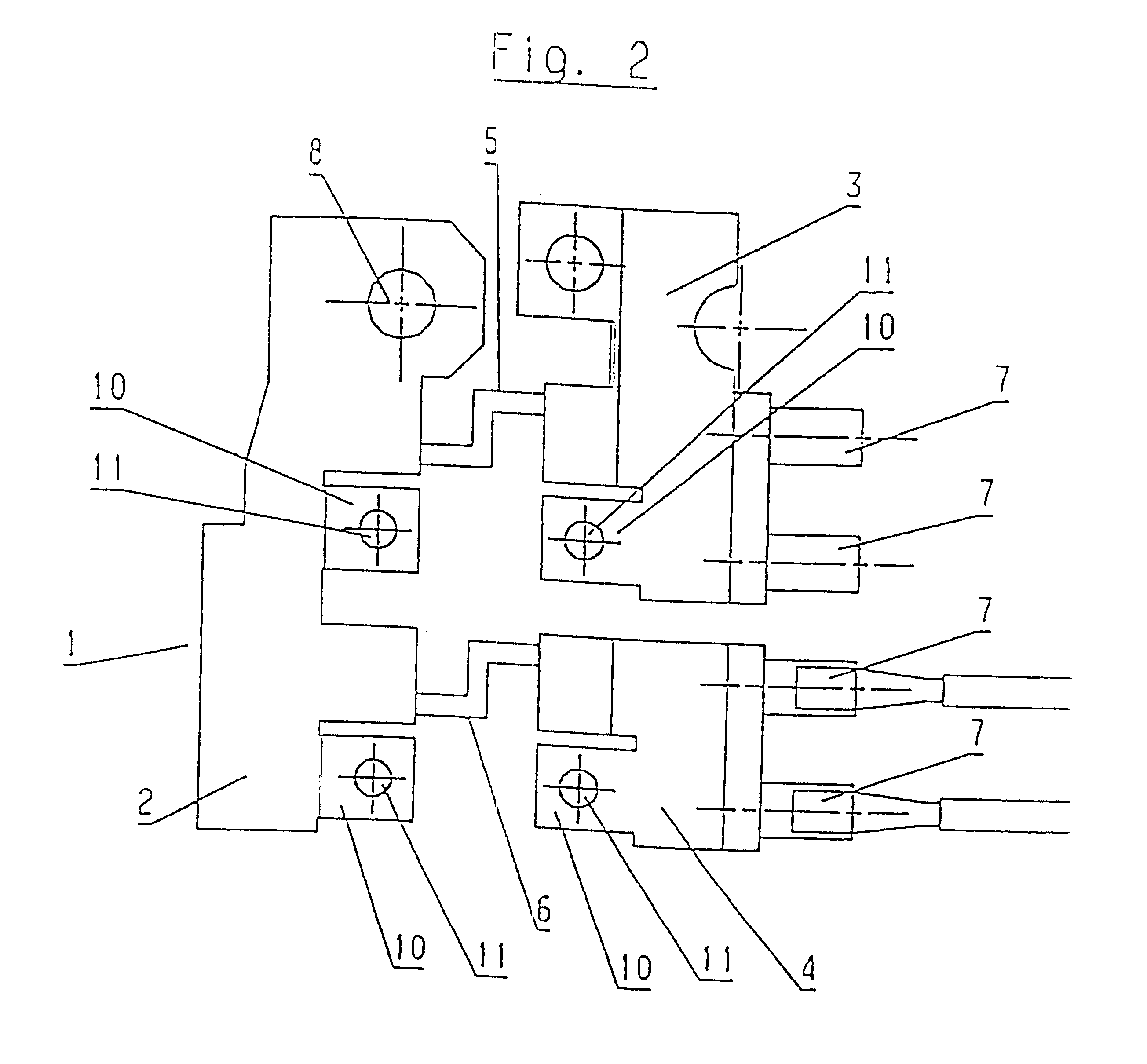

InactiveUS6476705B1Production of the current distribution device is correspondingly simplifiedCompact and weight-saving current distribution devicesBus-bar/wiring layoutsCoupling device detailsCurrent distributionElectrical connection

A voltage distribution device for use especially in motor vehicles, includes a first area (2) made of conductive material and fitted with at least one electrical connection (8), at least two separate second areas (3, 4) made of conductive material and fitted with at least one electrical connection each (7), and bridge-like fuse areas (5, 6) made of conductive material, which each link the second areas (3, 4) with the first (2) and are inseparably connected to the first and associated second area. The bridge-like fuse areas (5, 6) each have a cross-section of material calibrated along a longitudinal section according to material thickness and / or depth. In another embodiment of the invention, in a voltage distribution device for use especially in motor vehicles, a first area (2) made of conductive material and with at least one electrical connection (8), and at least two second areas (3B) made of conductive material and with at least one electrical connection each (4), are linked by bridge-like fuse areas made of conductive material (3), whereby these fuses (3) are inseparably connected to the first area (2) by deep-draw sleeves (5).

Owner:AUDIO OHM DI TONANI CATERINA E C +1

Self-identifying electrical connector

ActiveUS20090149037A1Easy to operateRotary current collectorElectric discharge tubesElectricityEngineering

An entirely wearable electrical connector for power / data connectivity. The principal element of a modular network is the wearable electrical connector, which is integrated into a personal area network with USB compatibility. Several wearable connector embodiments are disclosed. An enhancement to the wearable connector includes OSI Layer 2 (and potentially Layer 3) functionality. Data Link layer functionality is supported by including electronic serial numbers at wearable snap-connector points.

Owner:INTELLISENSE SYST INC

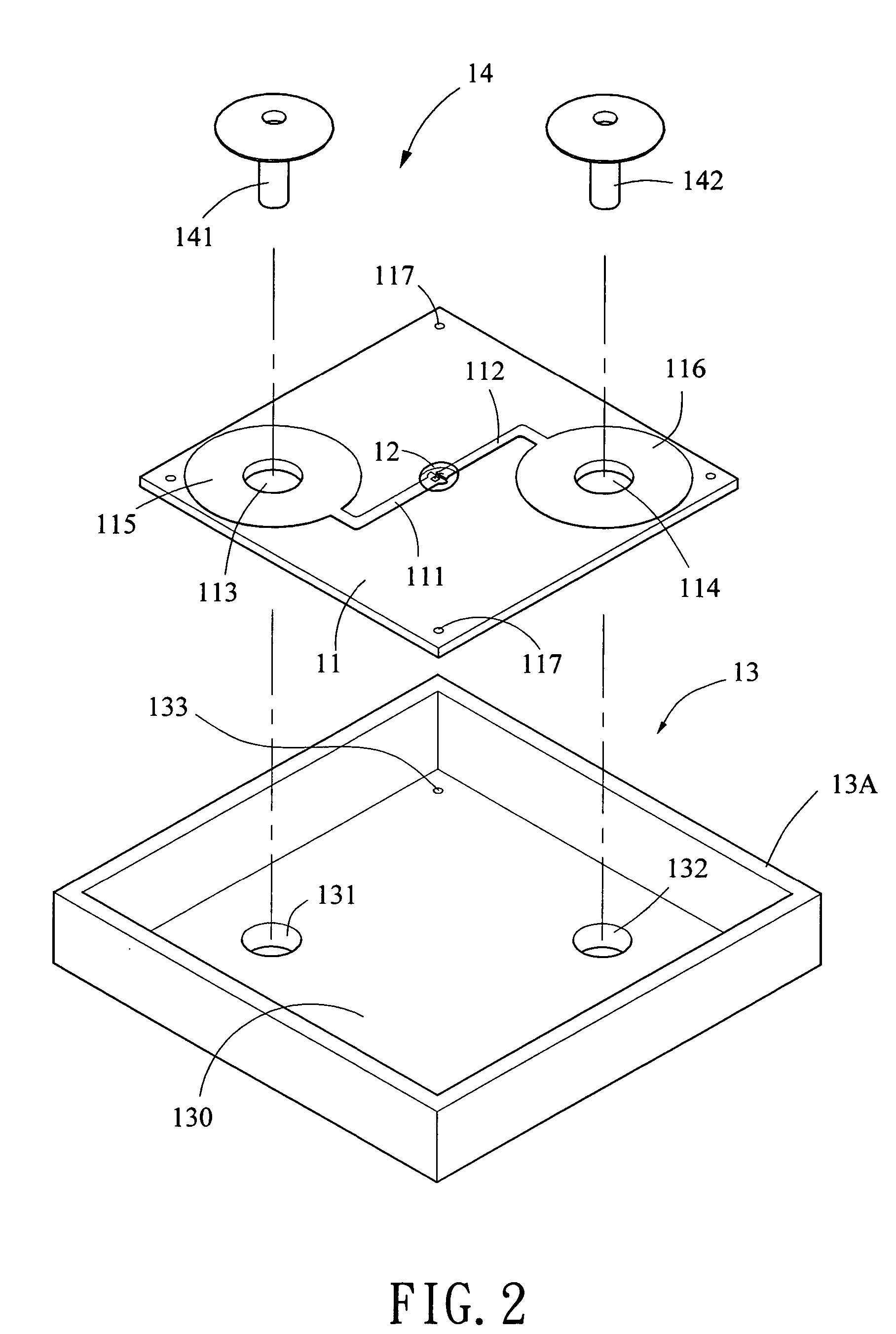

Reflector device and method of manufacturing same

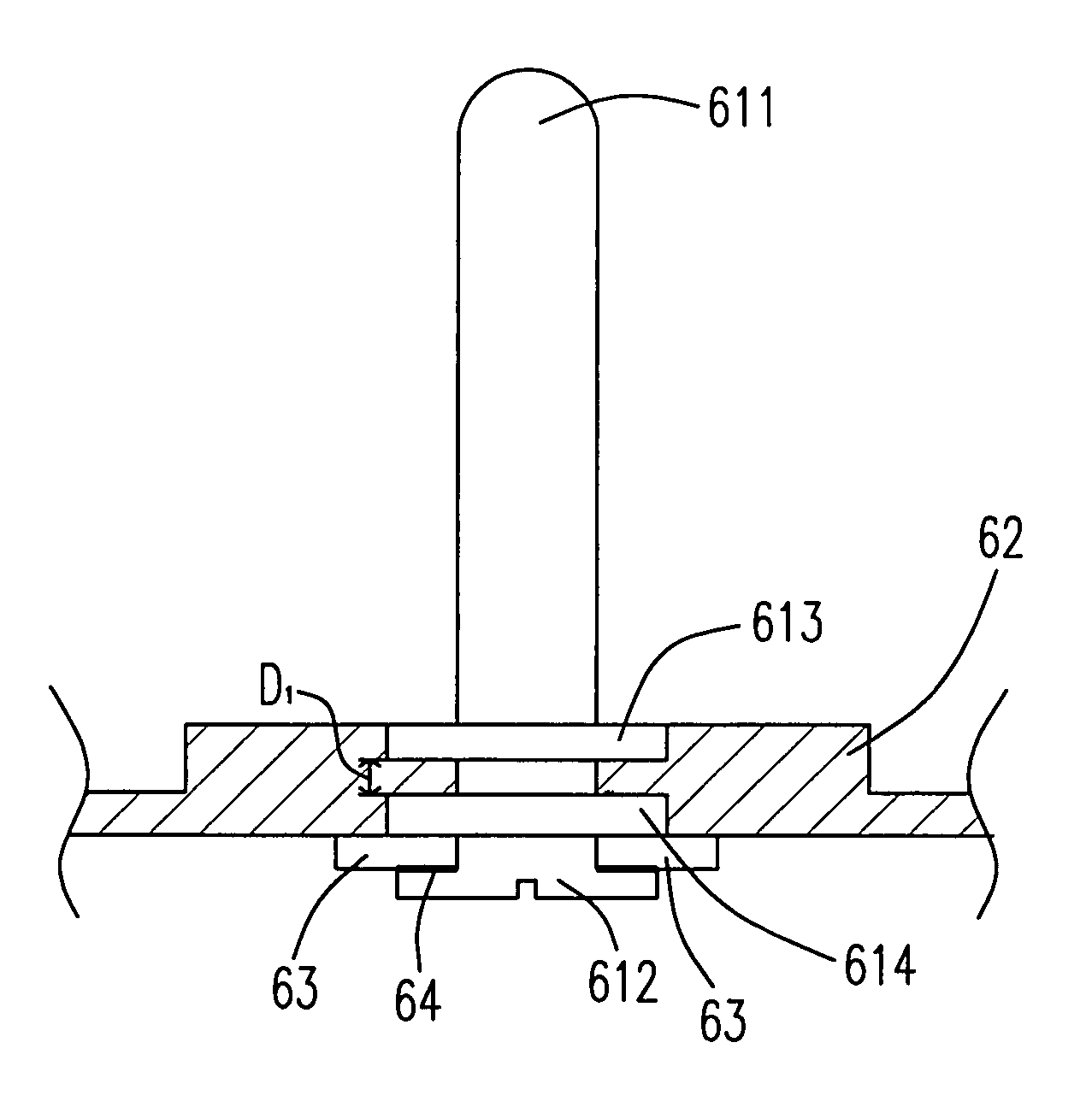

InactiveUS20050117356A1Easy to mass produceIncrease manufacturing costLighting support devicesSolid-state devicesElectrical conductorEngineering

Disclosed is a reflector devise and method manufacturing same. The reflector device comprises a lamp unit comprising a seat assembly, a rivet assembly in the seat assembly, the rivet assembly including rivets projected from an underside of the seat assembly, and a LED lamp in the seat assembly, the LED lamp being electrically coupled to the rivet assembly; and a belt unit comprising an insulating layer and a conductive layer sealed by the insulating layer. The conductive layer comprises conductors and the insulating layer comprises sets of holes along the conductive layer so that the rivets are adapted to pass through the holes into the conductive layer to fasten and electrically connect the lamp and the belt units together. The invention has advantages of mass production and being waterproof and airtight.

Owner:HAYASHIBARA BIOCHEMICAL LAB INC

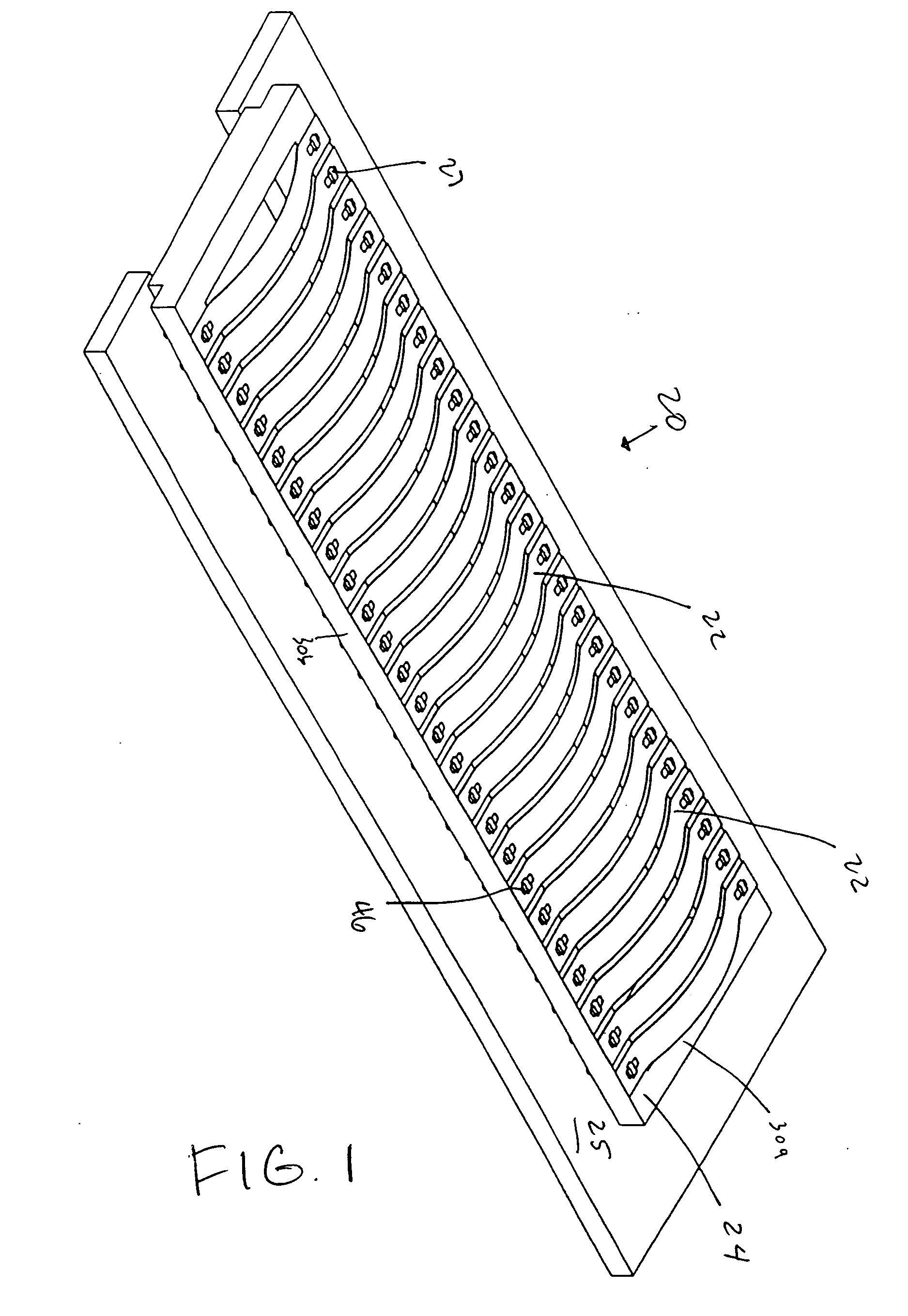

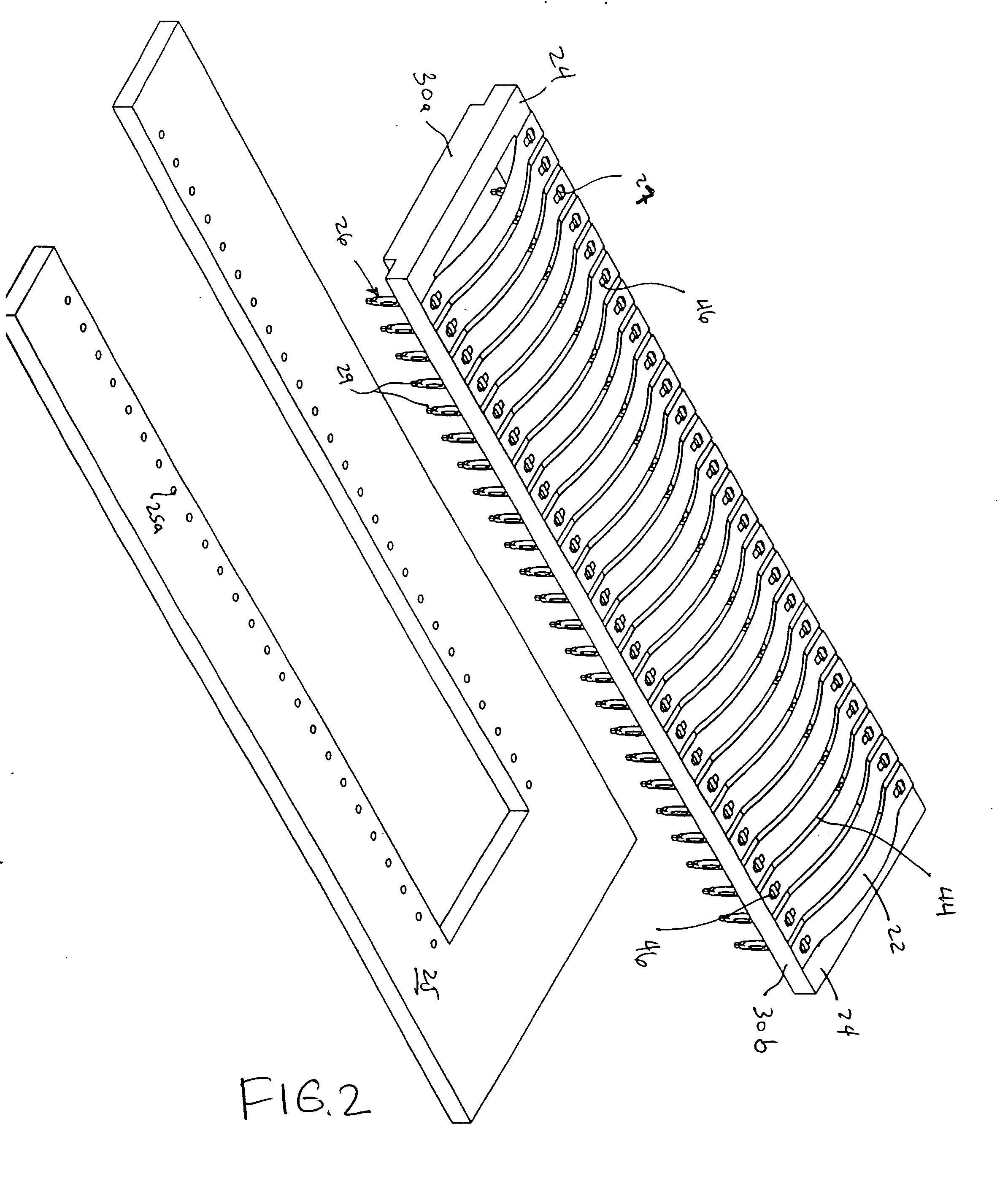

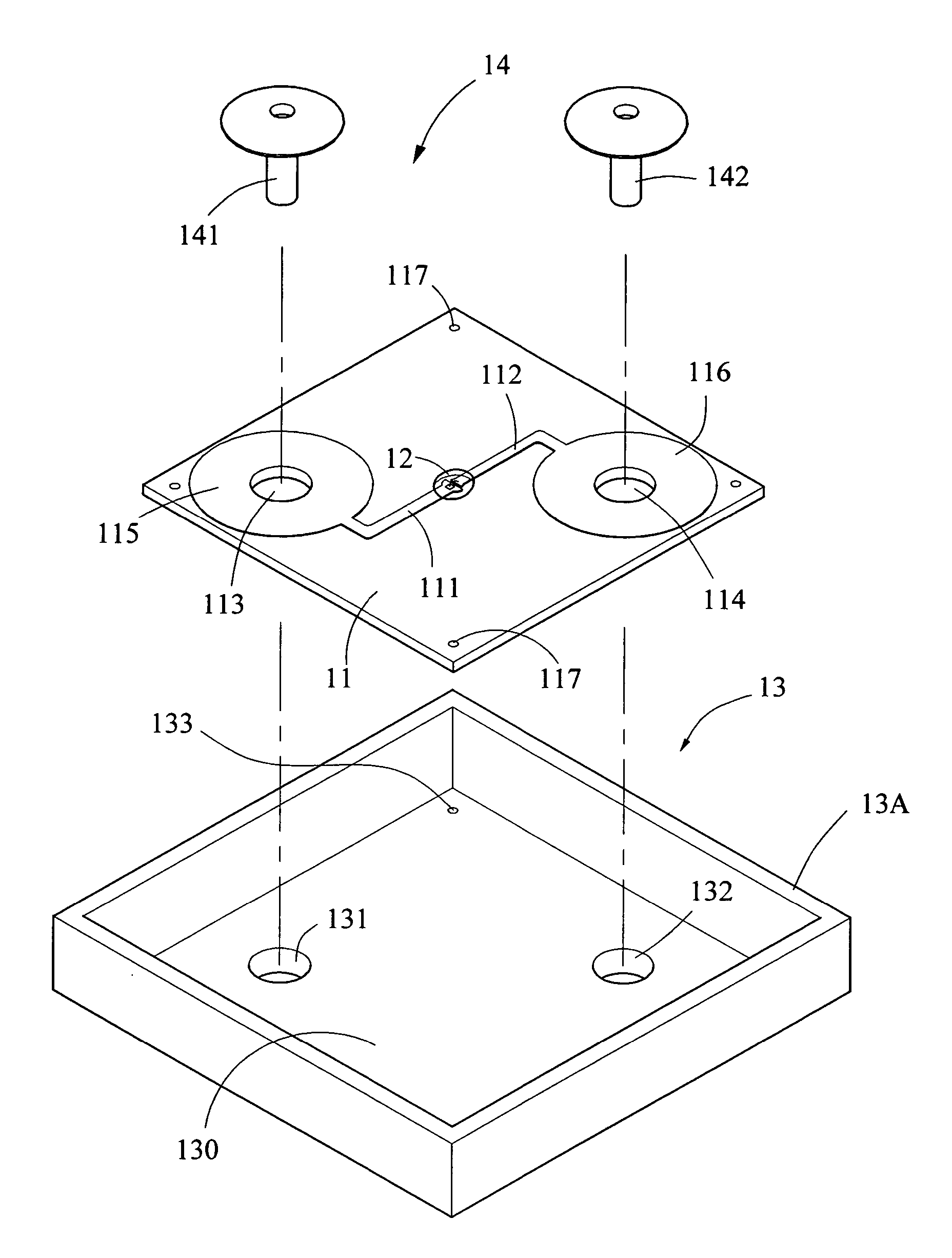

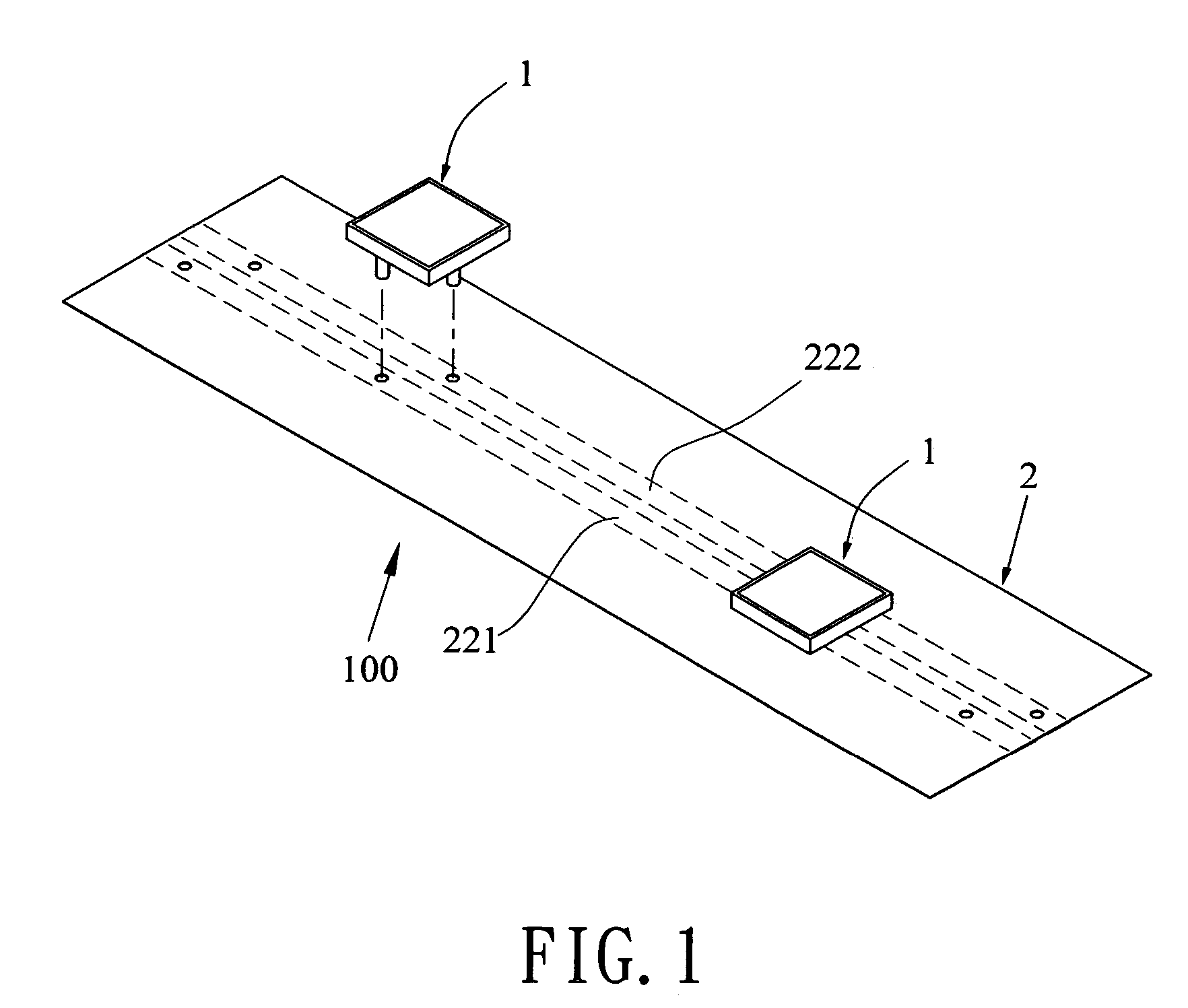

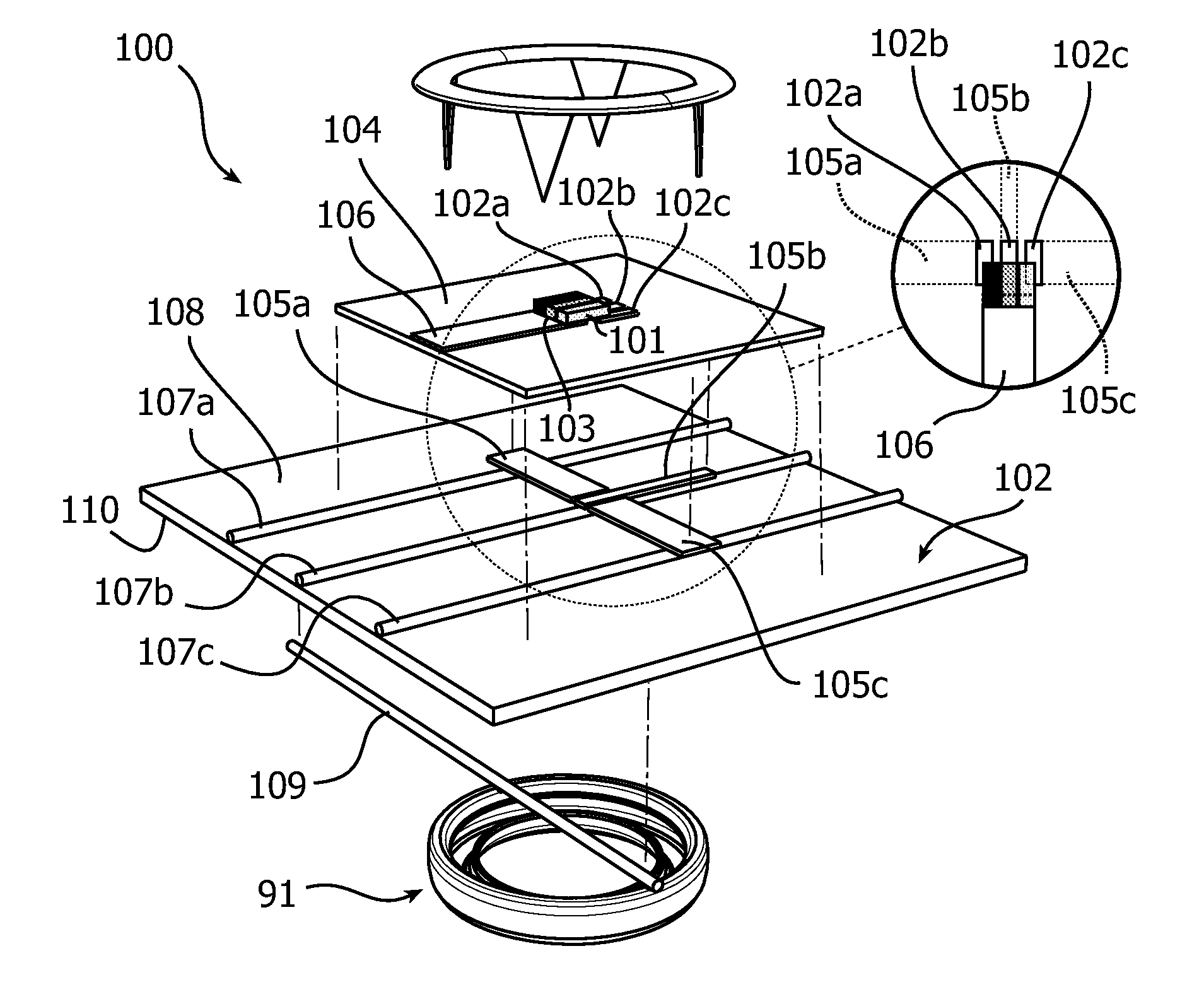

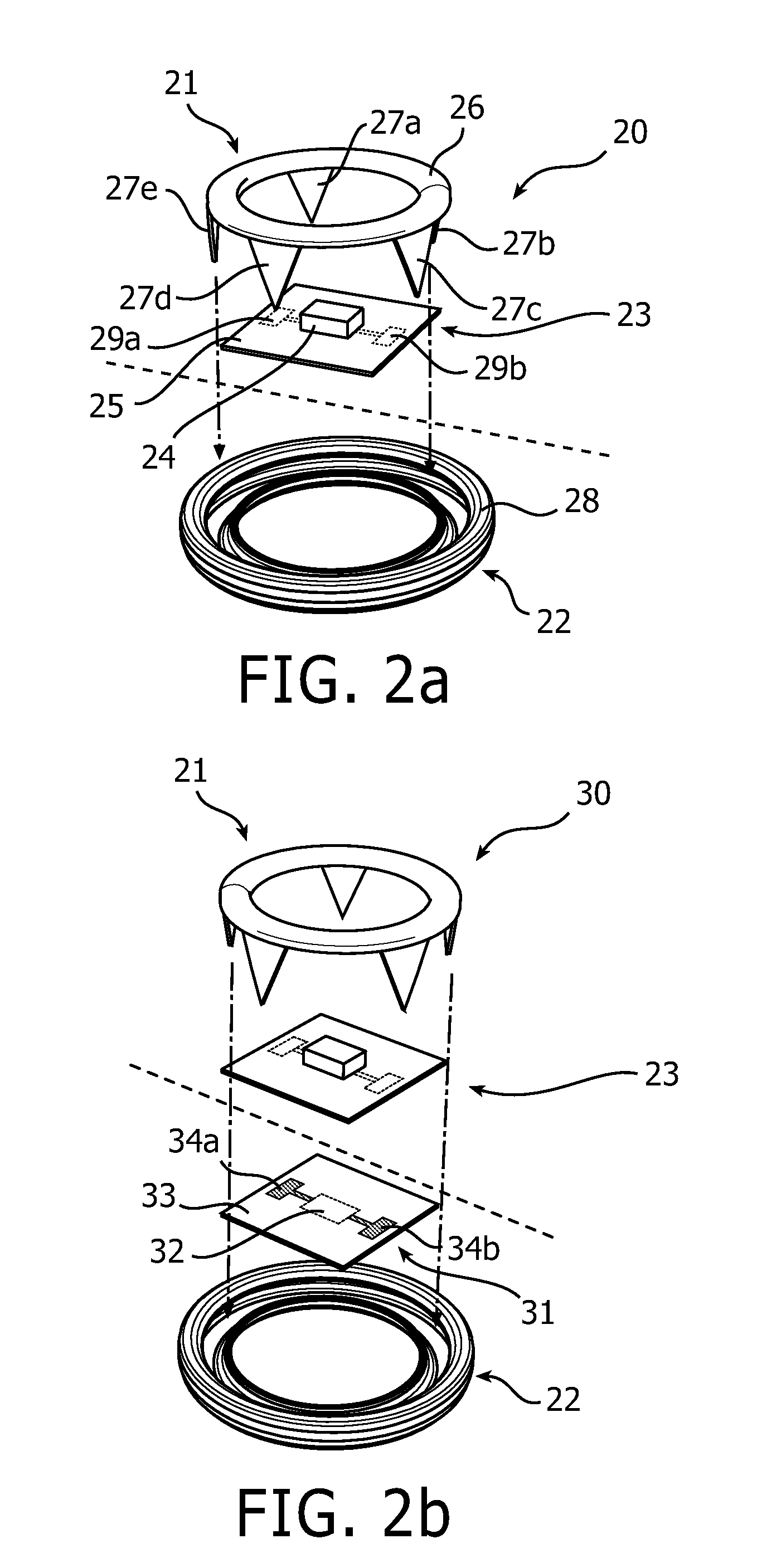

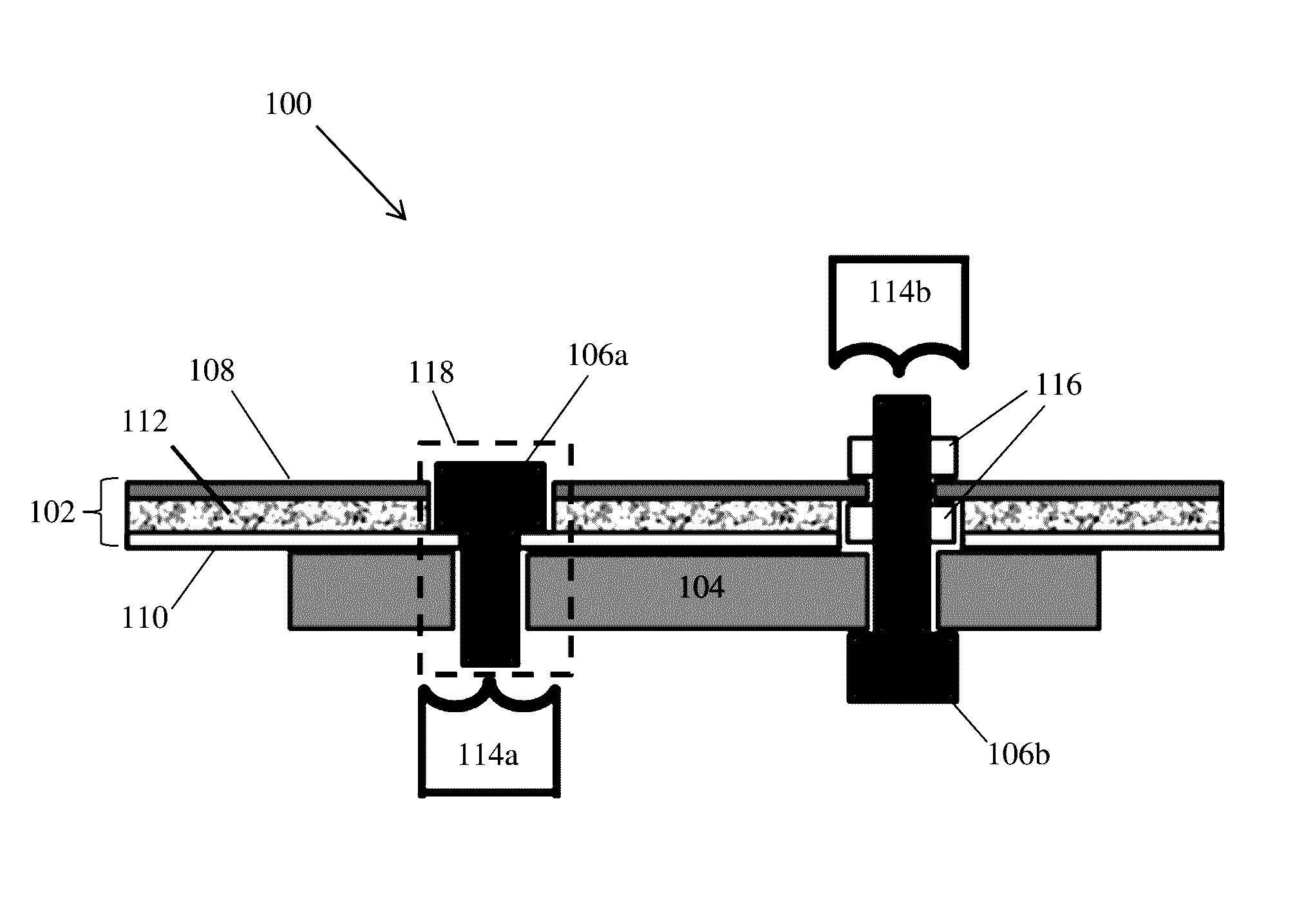

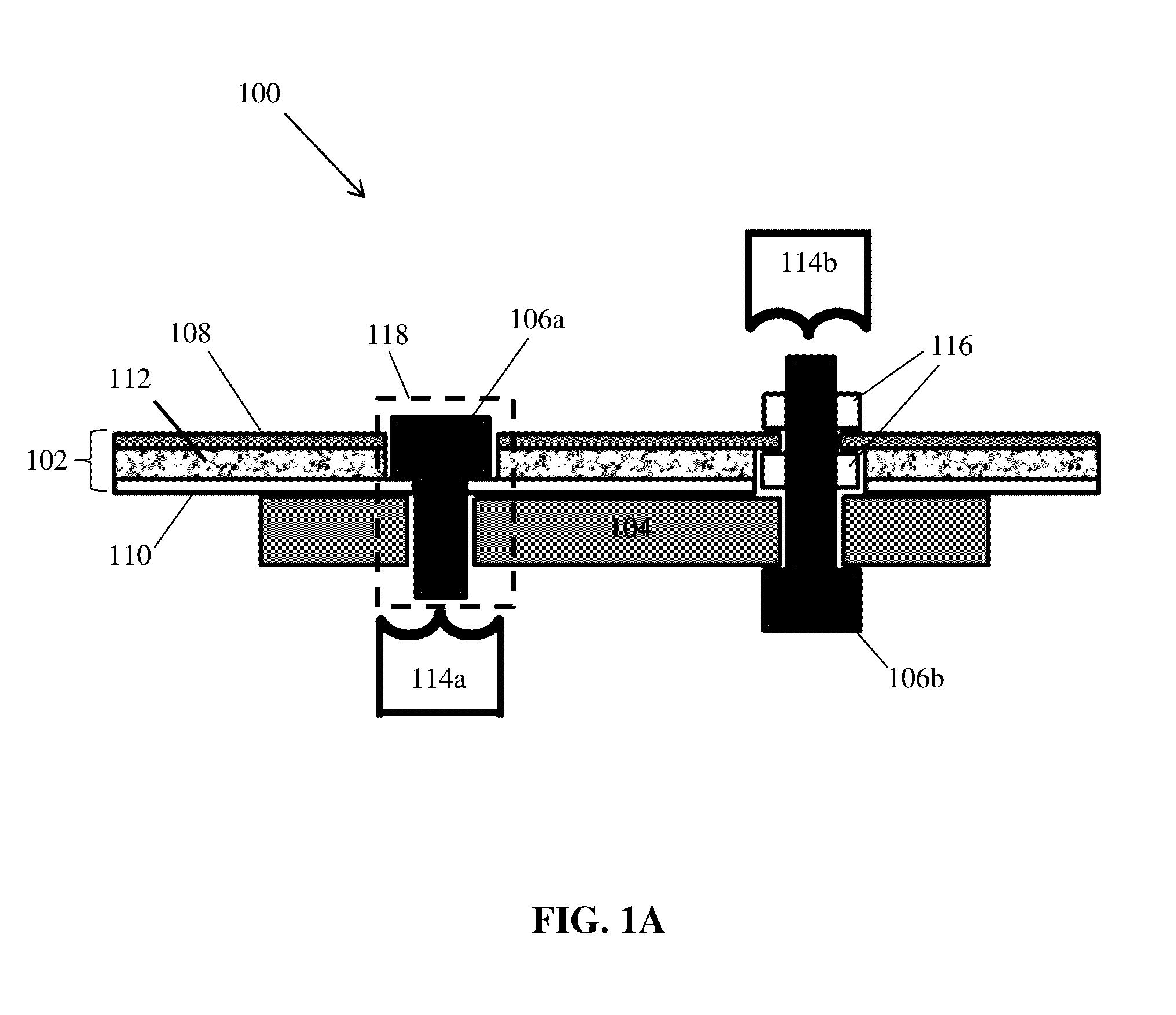

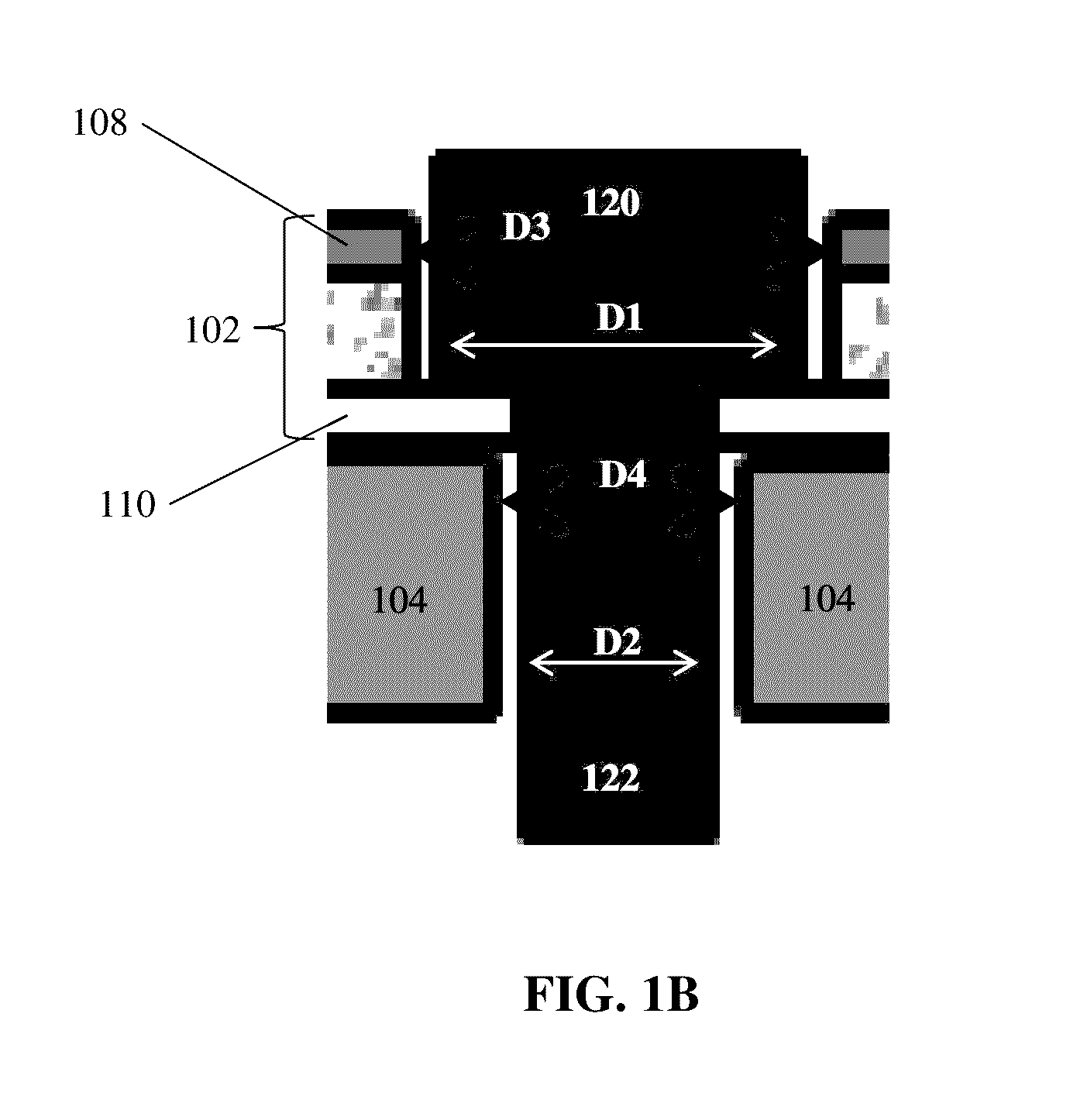

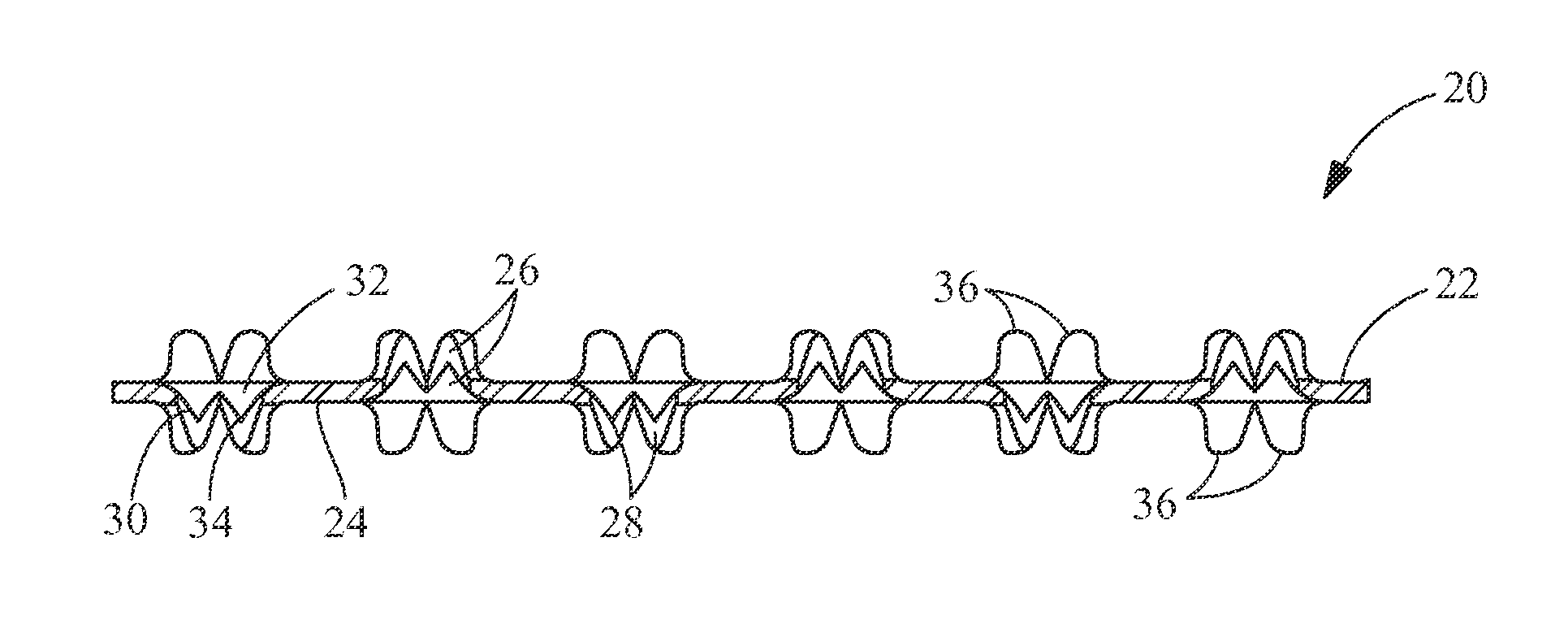

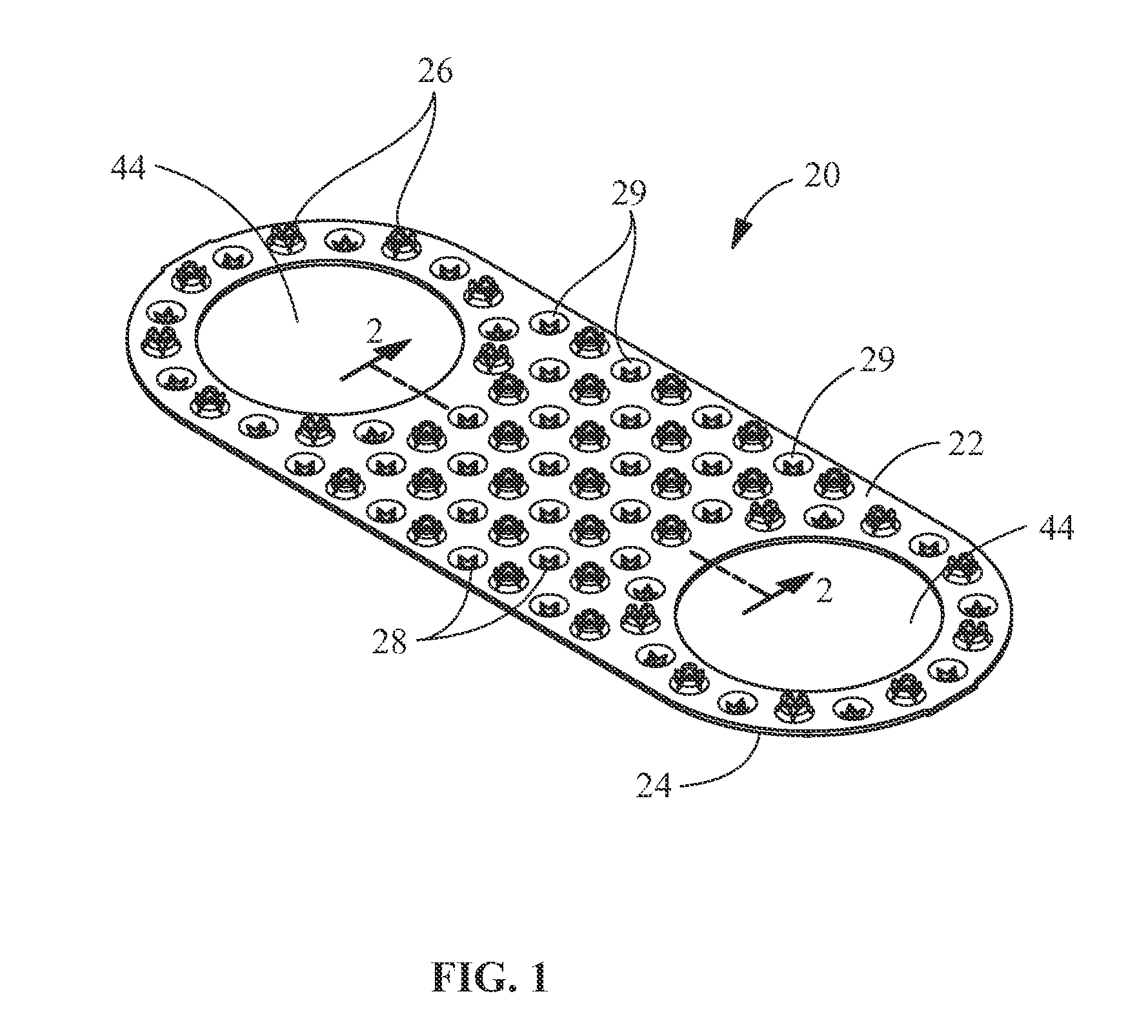

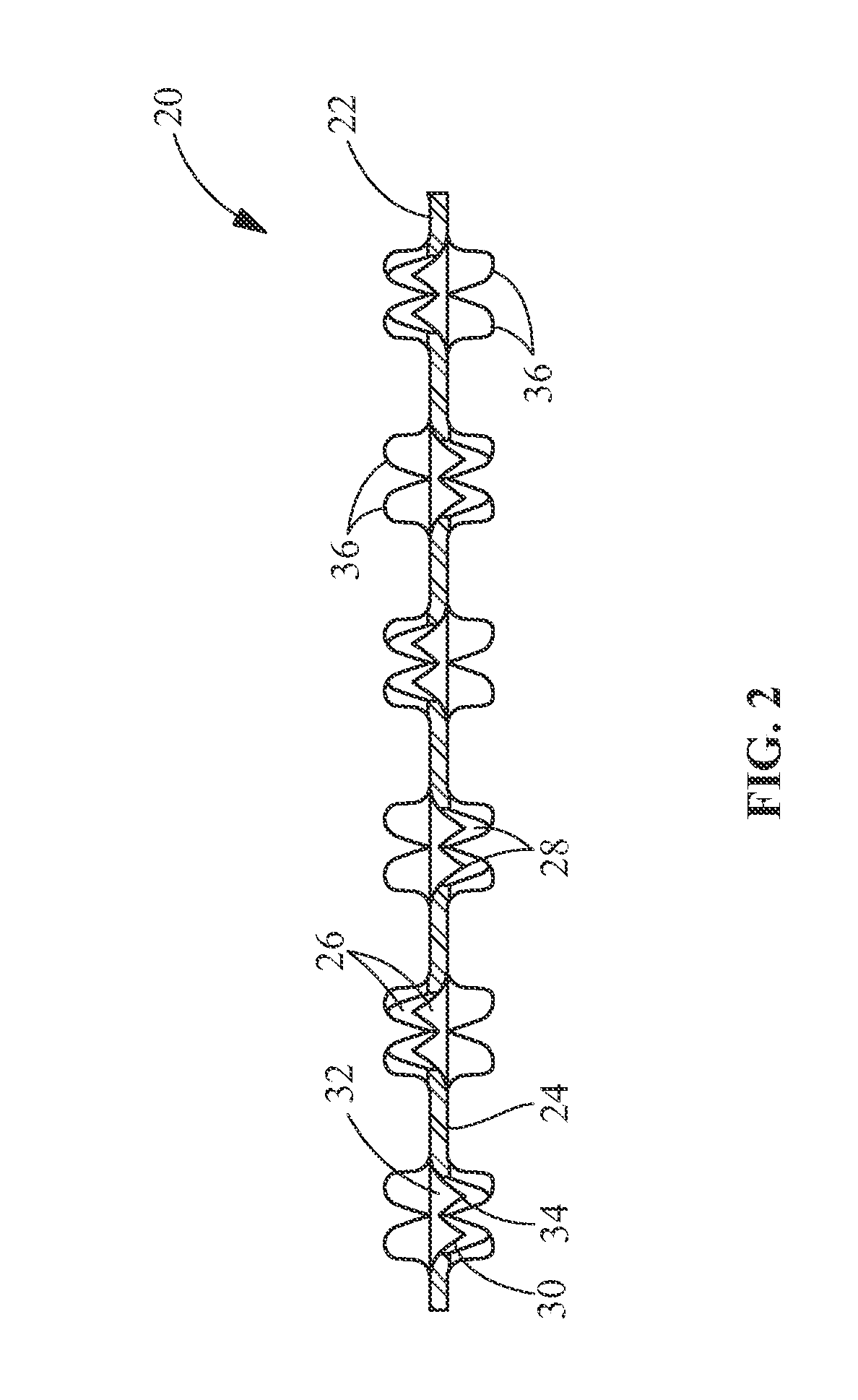

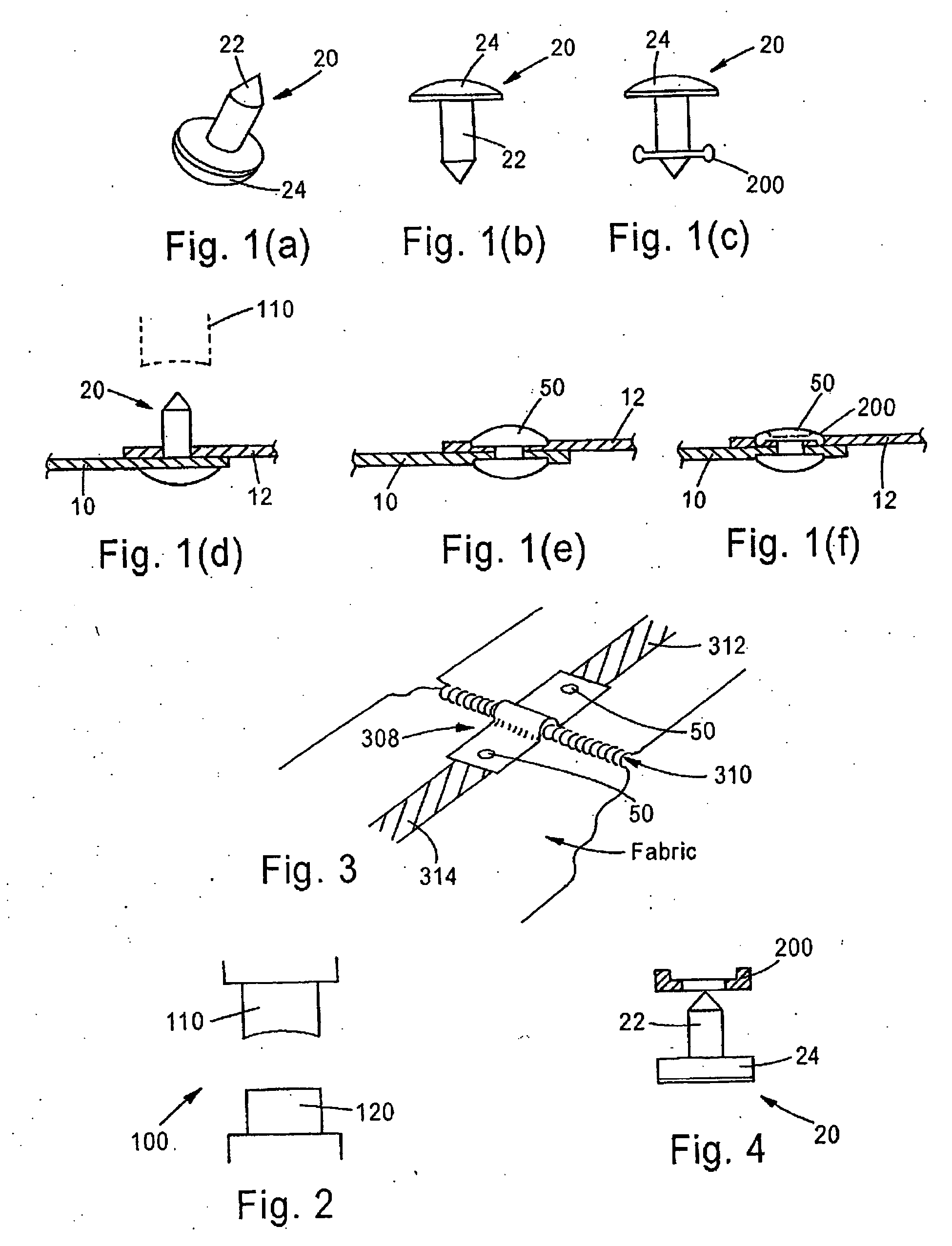

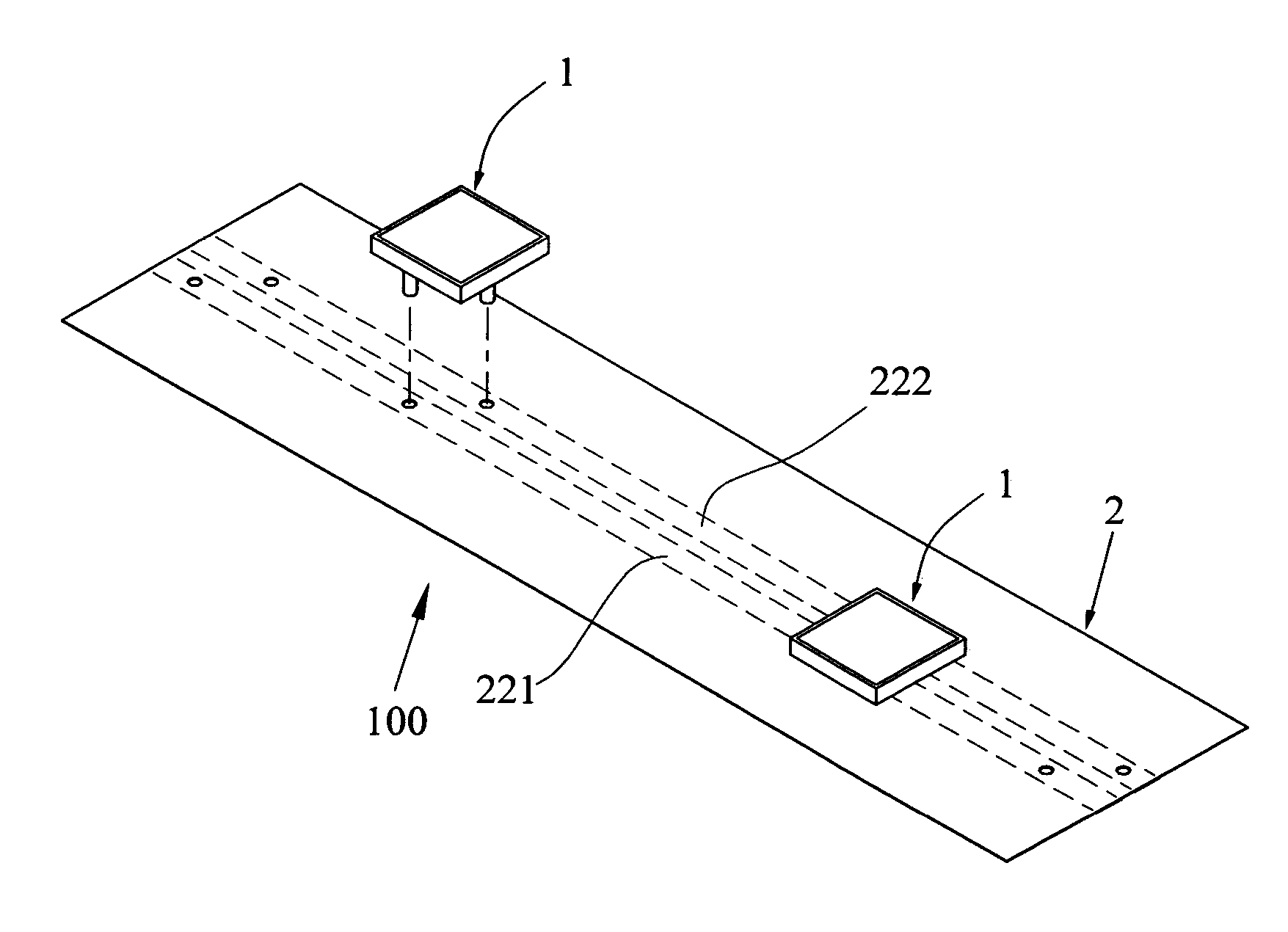

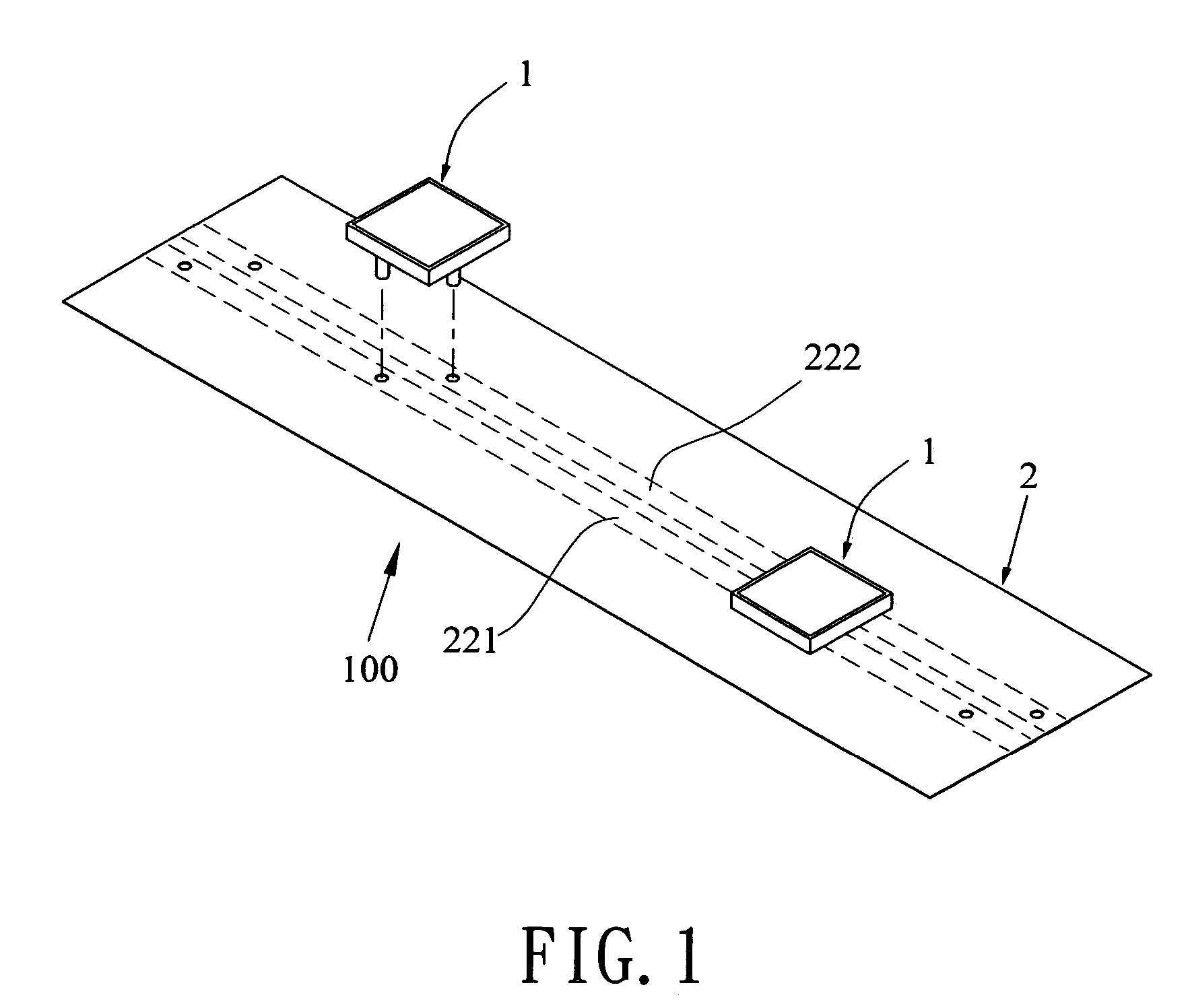

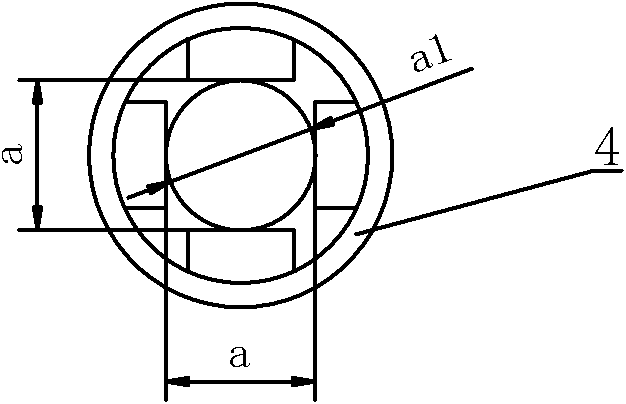

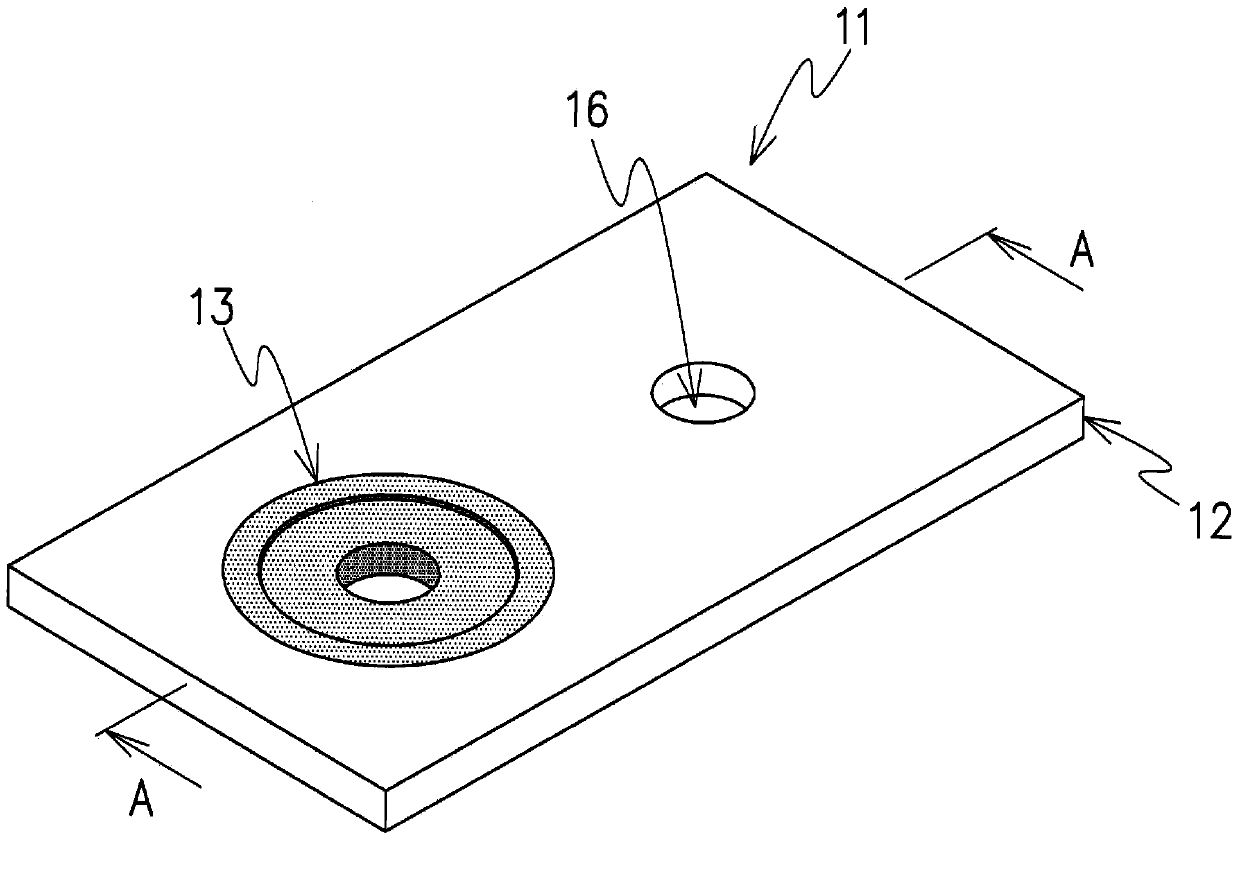

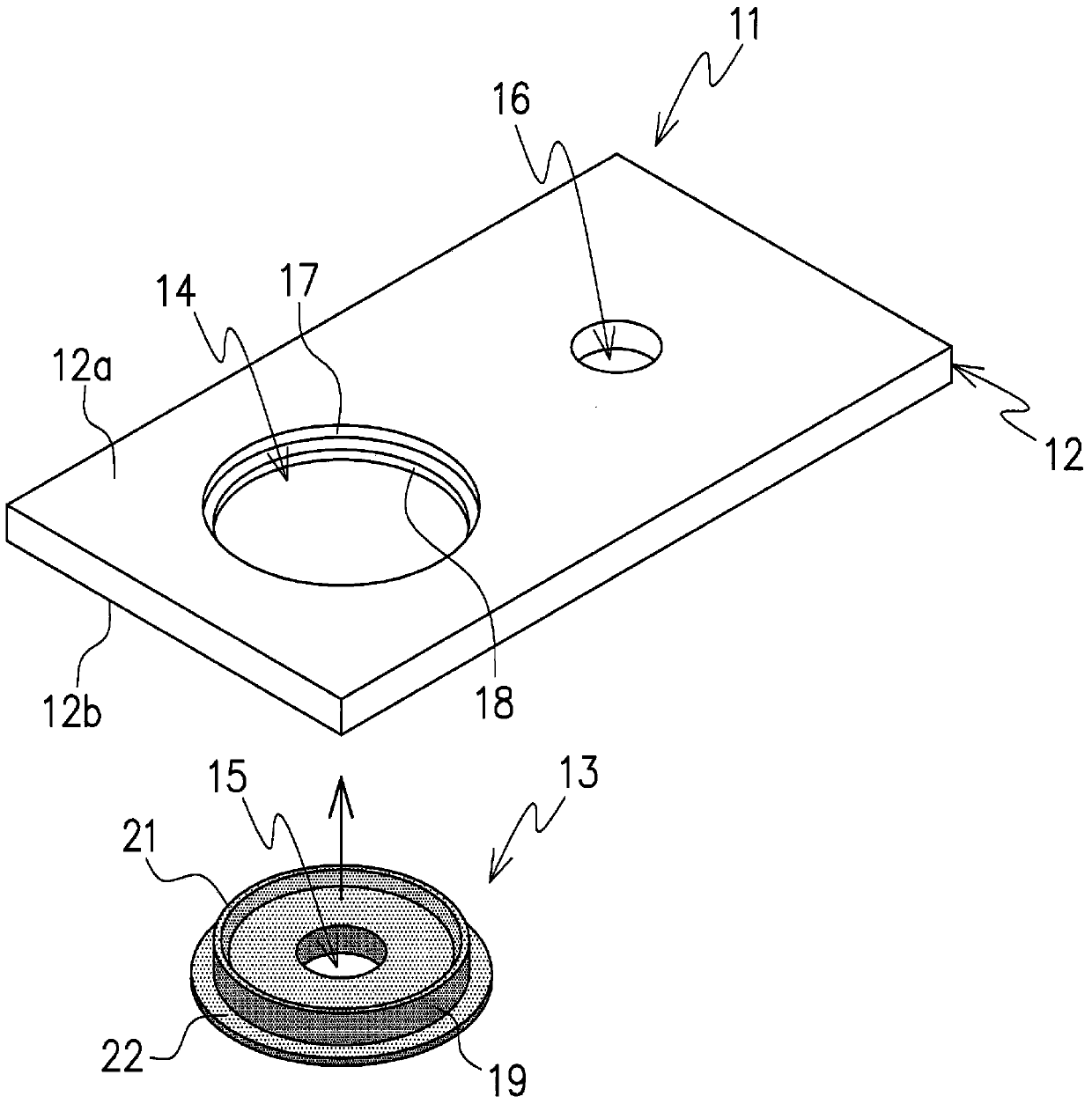

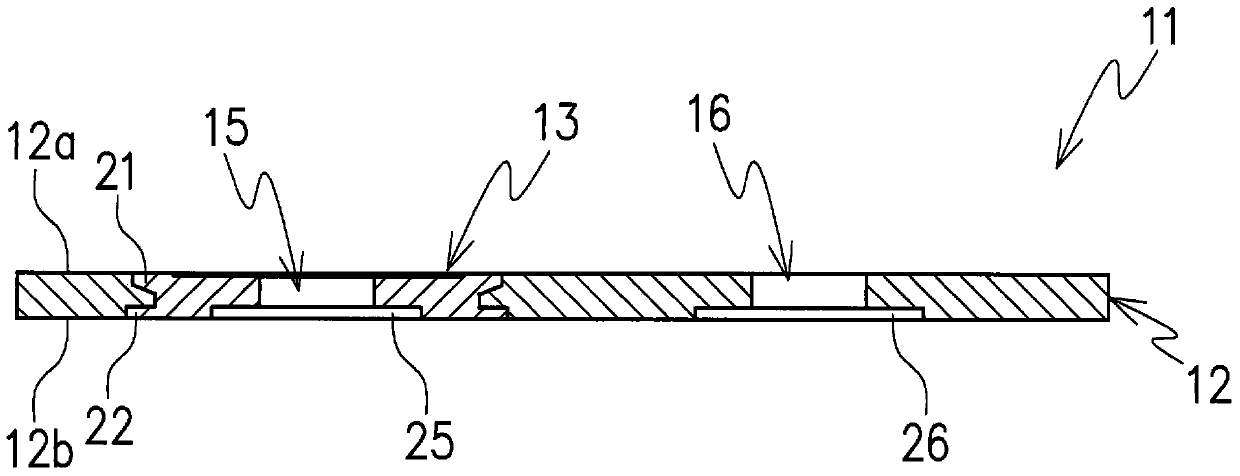

Electronic assembly for attachment to a fabric substrate, electronic textile, and method of manufacturing such an electronic textile

InactiveUS8416579B2Facilitates individual controlLine/current collector detailsWave amplification devicesElectrical conductorElectronic assemblies

An electronic assembly (20; 30; 40; 50) for attachment to a fabric substrate (60; 82, 102) having a conductor pattern (62a-b; 85a-b; 107a-c) on a first side (63; 86; 108) thereof. The electronic assembly comprises an electronic device (23; 42; 64), and at least a first clamping member (21; 41; 65). The electronic assembly is, furthermore, adapted to clamp the electronic device (23; 42; 64) to the first side (63; 86; 108) of the fabric substrate (60; 82, 102) in such a way that the electronic device (23; 42; 64) is electrically connected to the conductor pattern (62a-b; 85a-b; 107a-c).

Owner:SIGNIFY HLDG BV

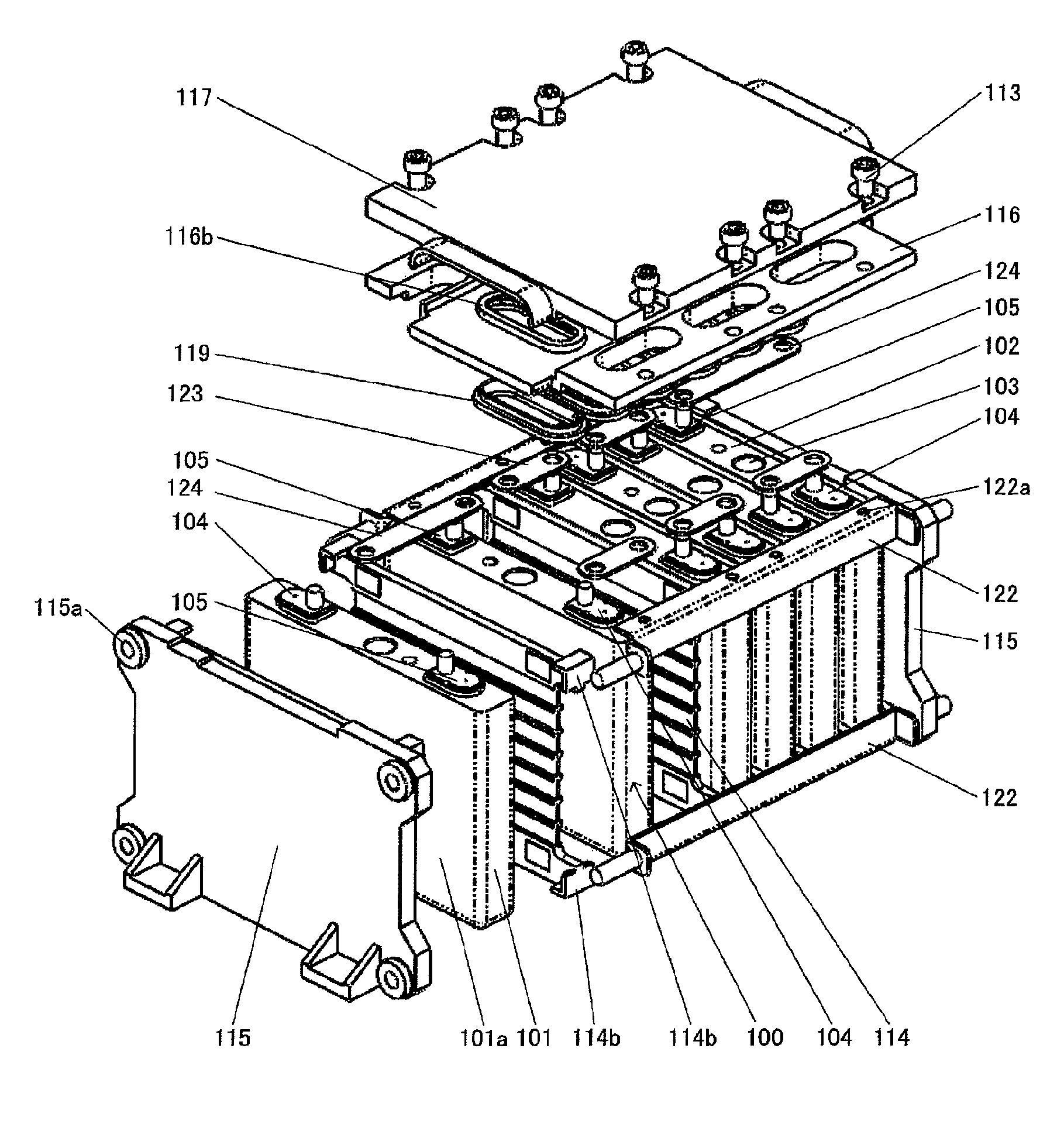

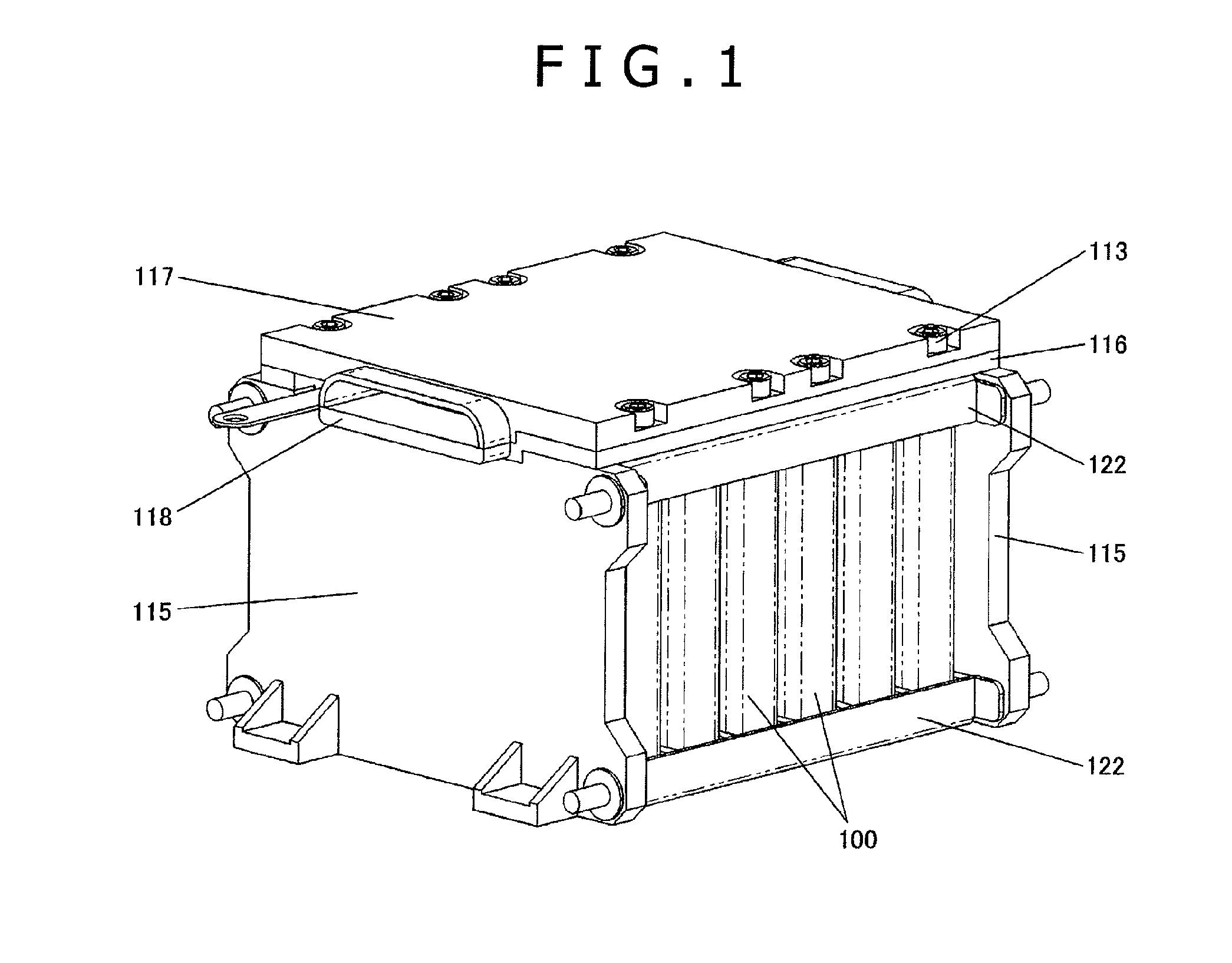

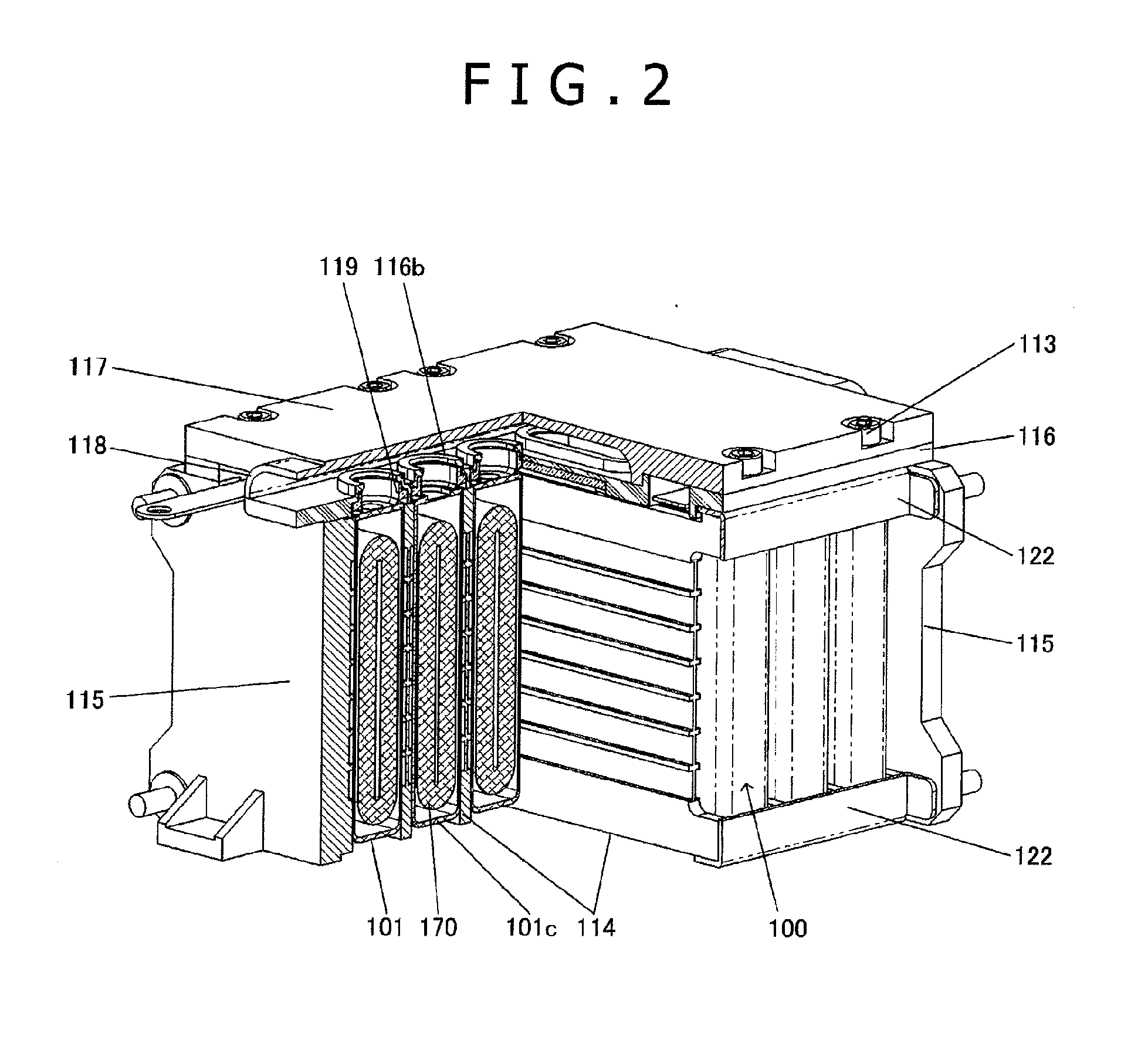

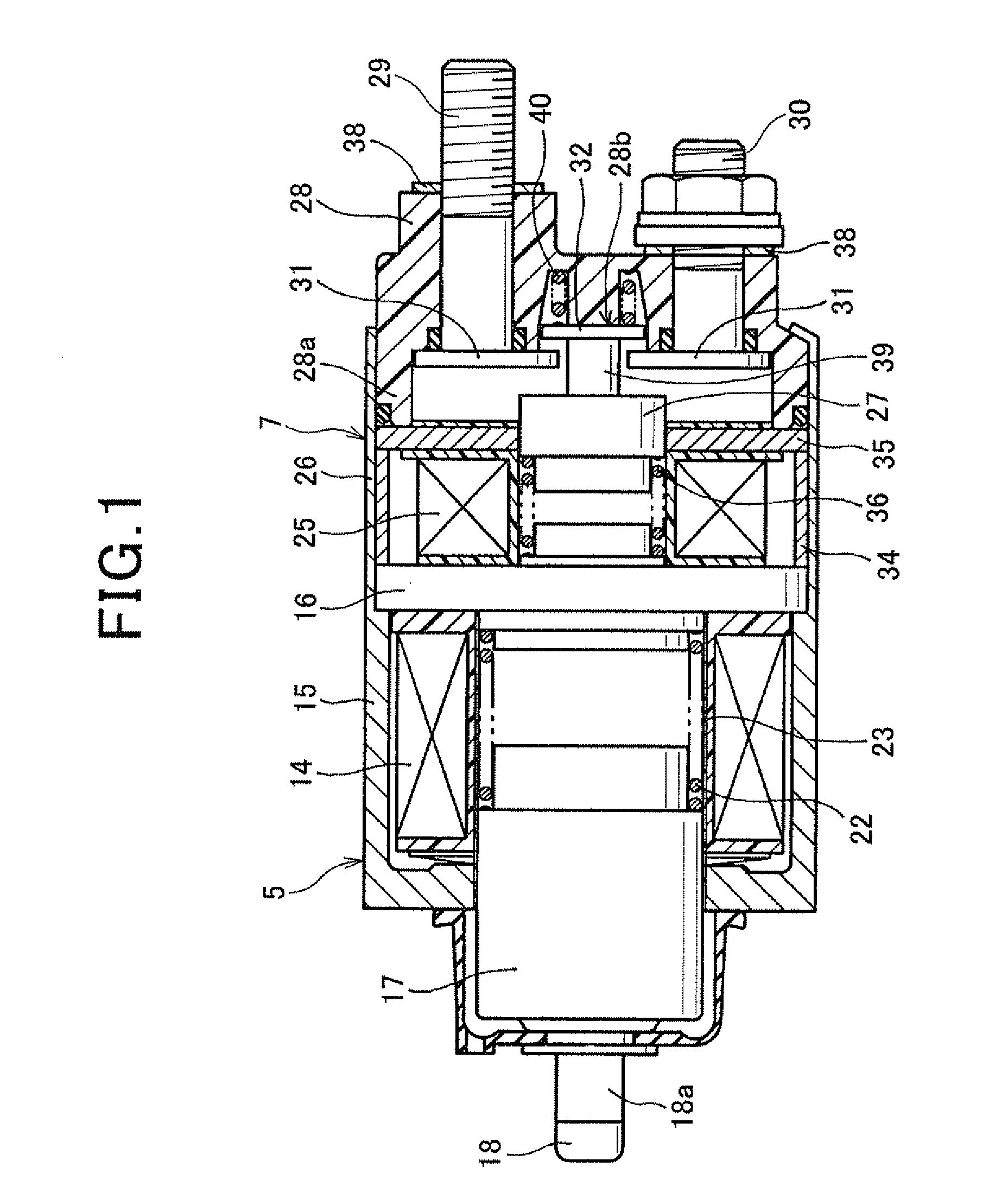

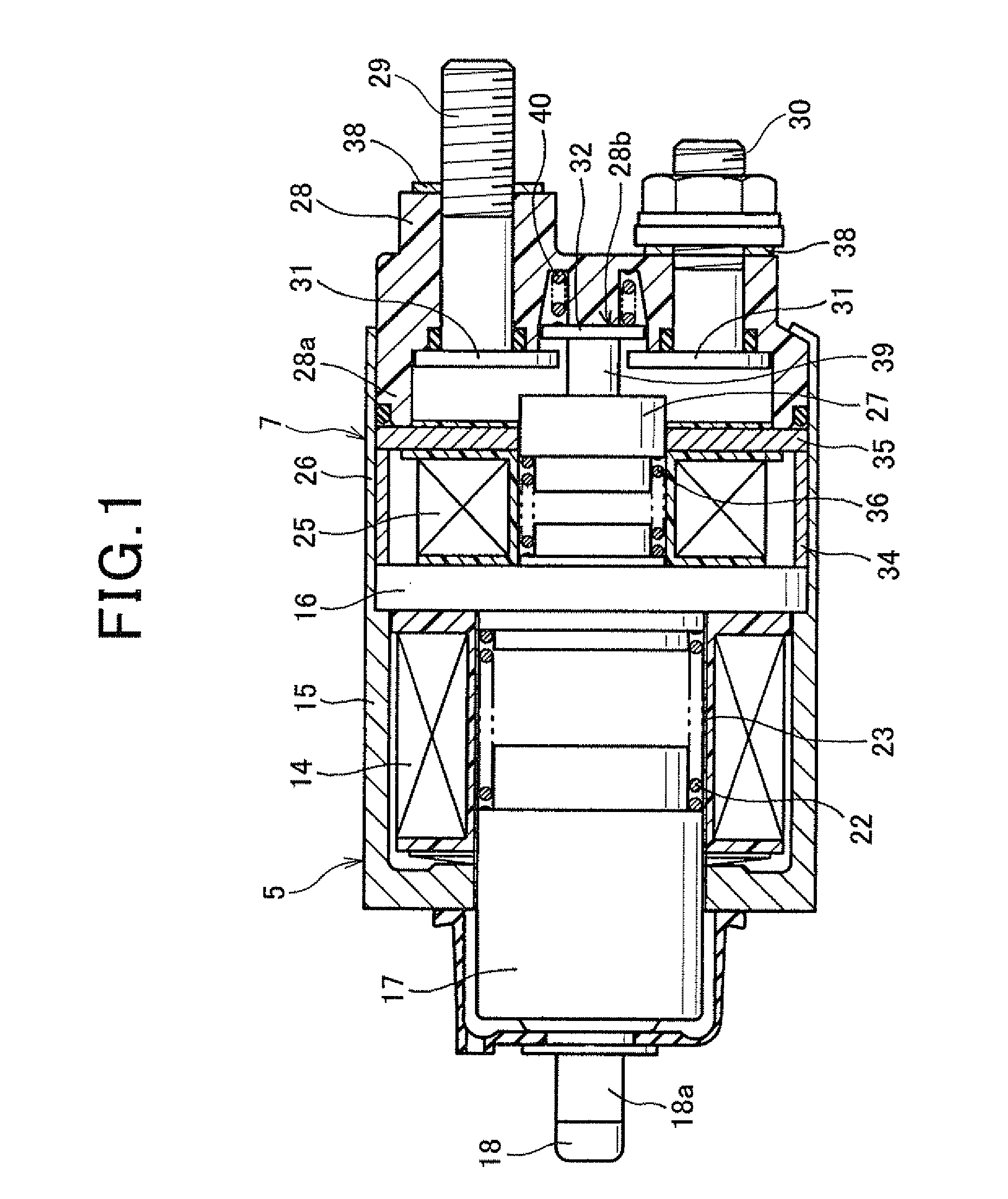

Electric cells and assembled battery

An electric cell comprises: a power generating element including electrodes; a cell container including a cell case for housing the power generating element and a cell cover for sealing an opening of the cell case; two external terminals disposed on the cell cover; and two collector electrodes for connecting the electrodes of the power generating element to the external terminals; wherein each of the external terminals includes: a connector connected to one of the collector electrodes within the cell container; a flat section located right above the connector and exposed to the outside of the cell container; and a bolting section located adjacent to the flat section and having an insertion hole, and wherein the connector, the flat section, and the bolting section are integrally formed. The electric cell allows connection of external terminals to busbars either by bolting or welding.

Owner:HITACHI AUTOMOTIVE SYST LTD

Method for mechnical and electrical connection to display electrodes

An electro-optic display may comprise a front electrode having a first opening defined therein, a rear electrode having a second opening defined therein, an electro-optic layer between the front and rear electrodes and a rigid conductive component passing through the first and second openings and electrically contacting the front electrode but not the rear electrode.

Owner:E INK CORPORATION

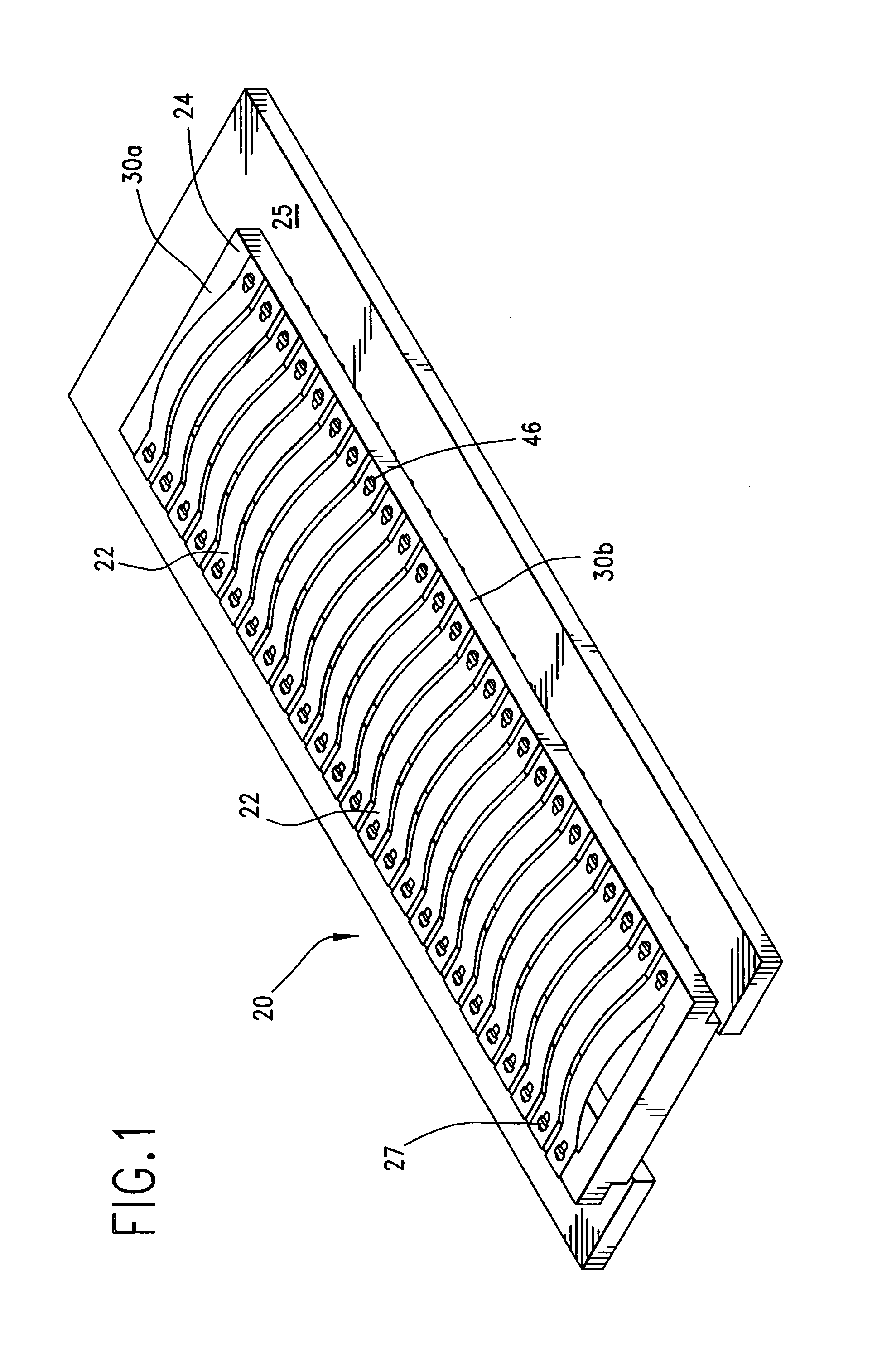

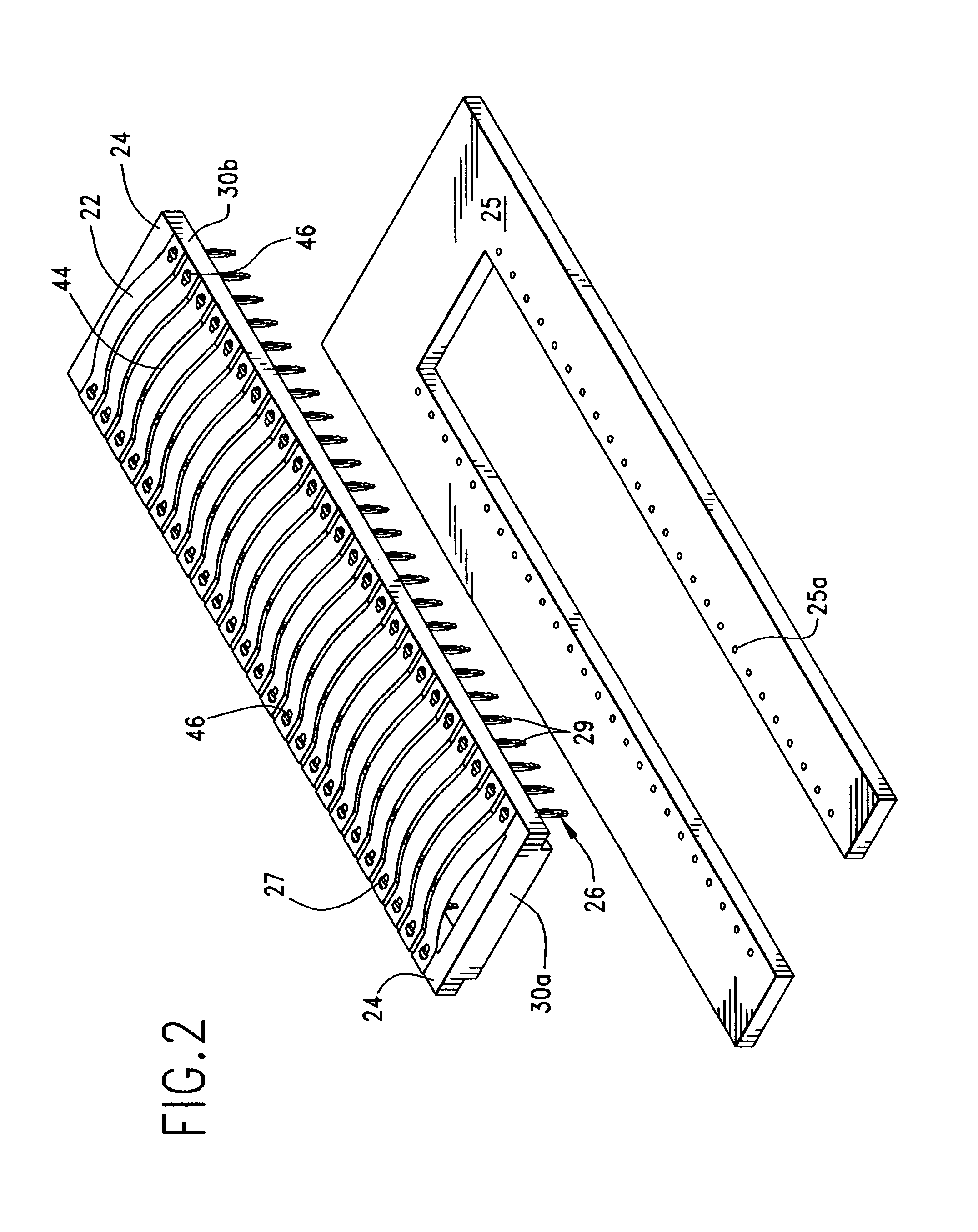

Heating element connector assembly with press-fit terminals

ActiveUS7494344B2Easy constructionLow costHeater elementsSecuring/insulating coupling contact membersEngineeringHeating element

An improved heating element connector assembly includes an insulative, rectangular frame with a central opening and a plurality of conductive terminals which are press fit into openings in the frame. The terminals are spaced apart from each other lengthwise of two opposing sidewalls of the frame, and pairs of terminals are aligned with each other between the two sidewalls. A plurality of conductive strips extend across the frame opening to interconnect the pairs of terminals together. The terminals include compliant pin tail portions for receipt by corresponding holes formed in a circuit board of the assembly and deformable head portions for crimping onto the conductive strips.

Owner:ALEXZA PHARMA INC

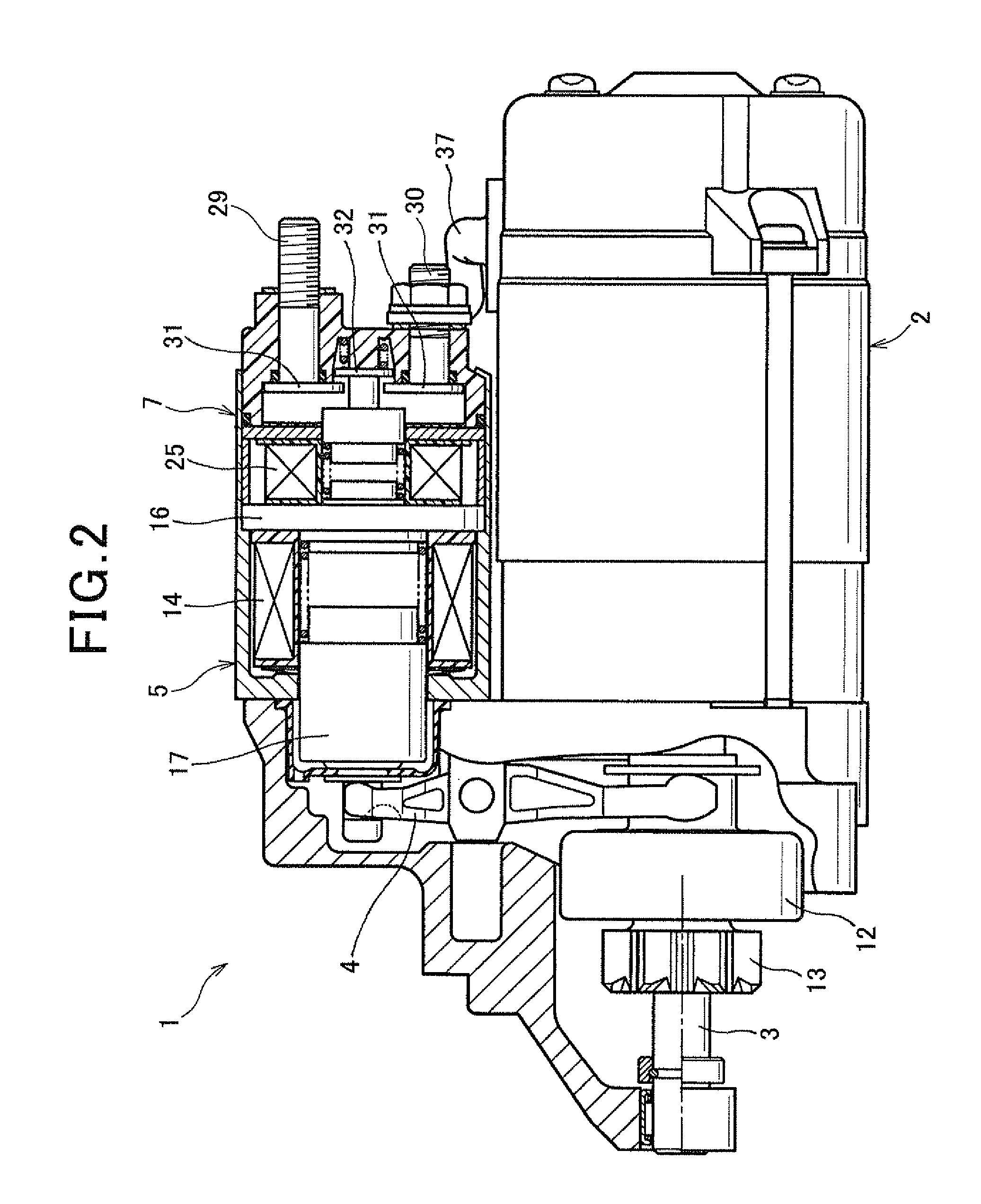

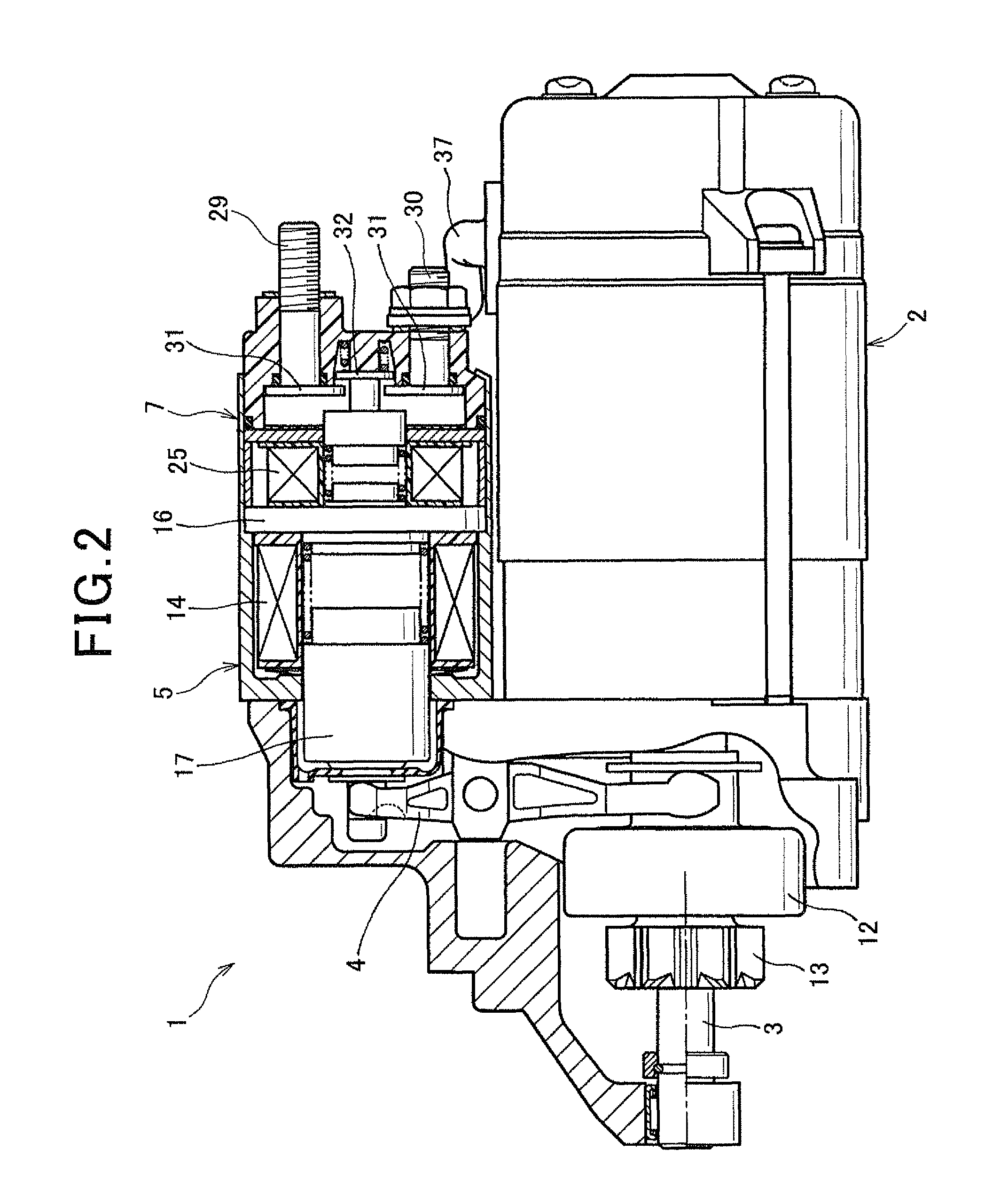

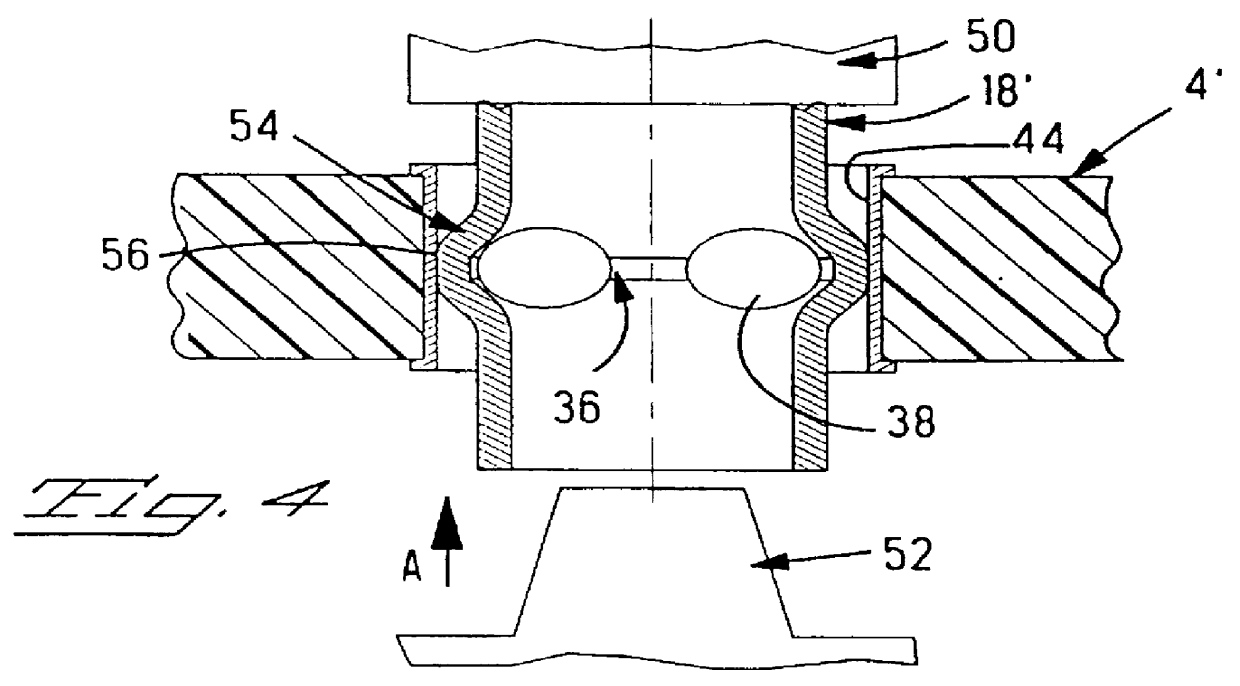

Electromagnetic relay for starters

ActiveUS20110001589A1Simple manufacturing processLoose connectionContact surface shape/structureRiveted connectionsEngineeringRelay

Owner:DENSO CORP

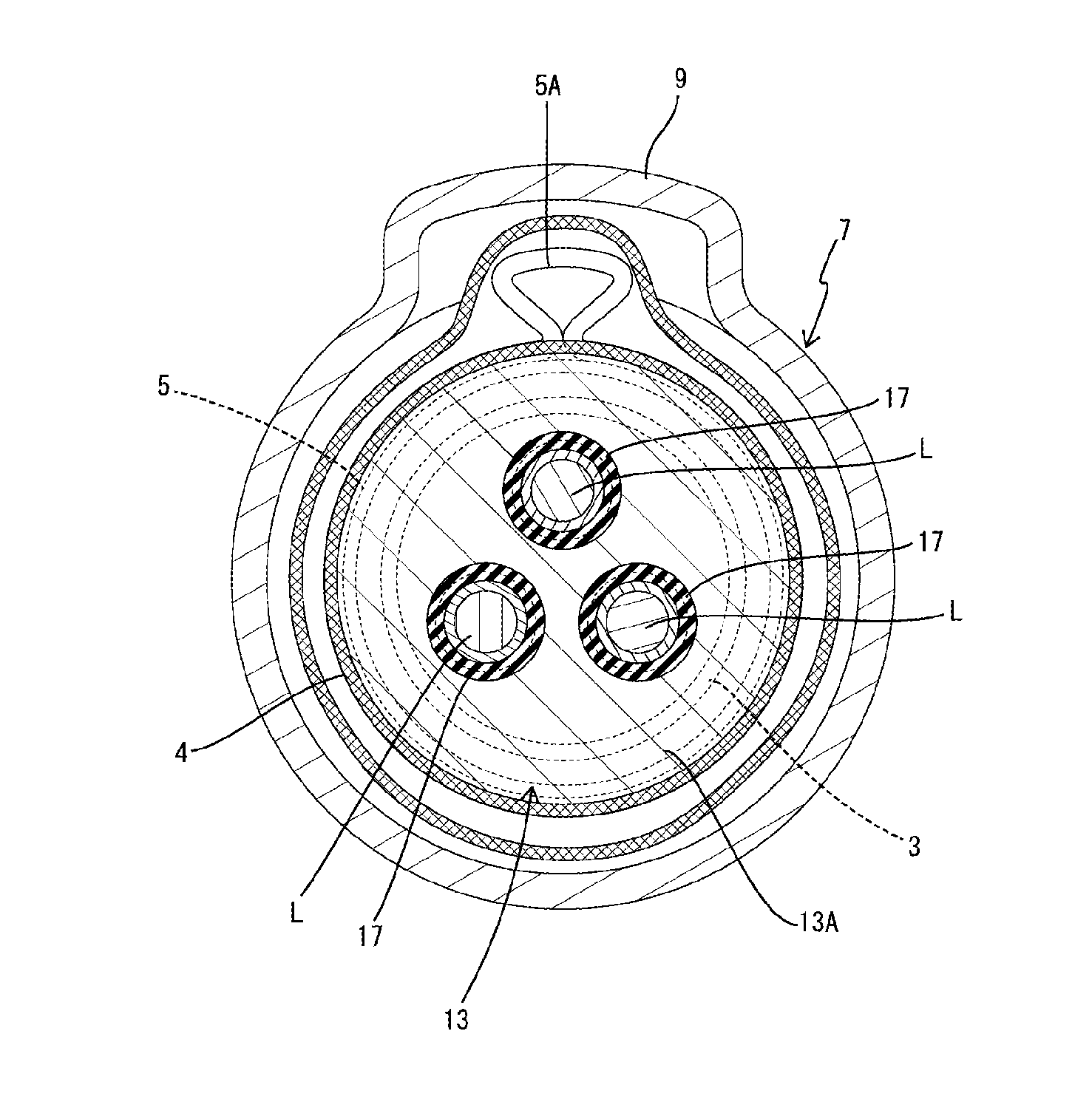

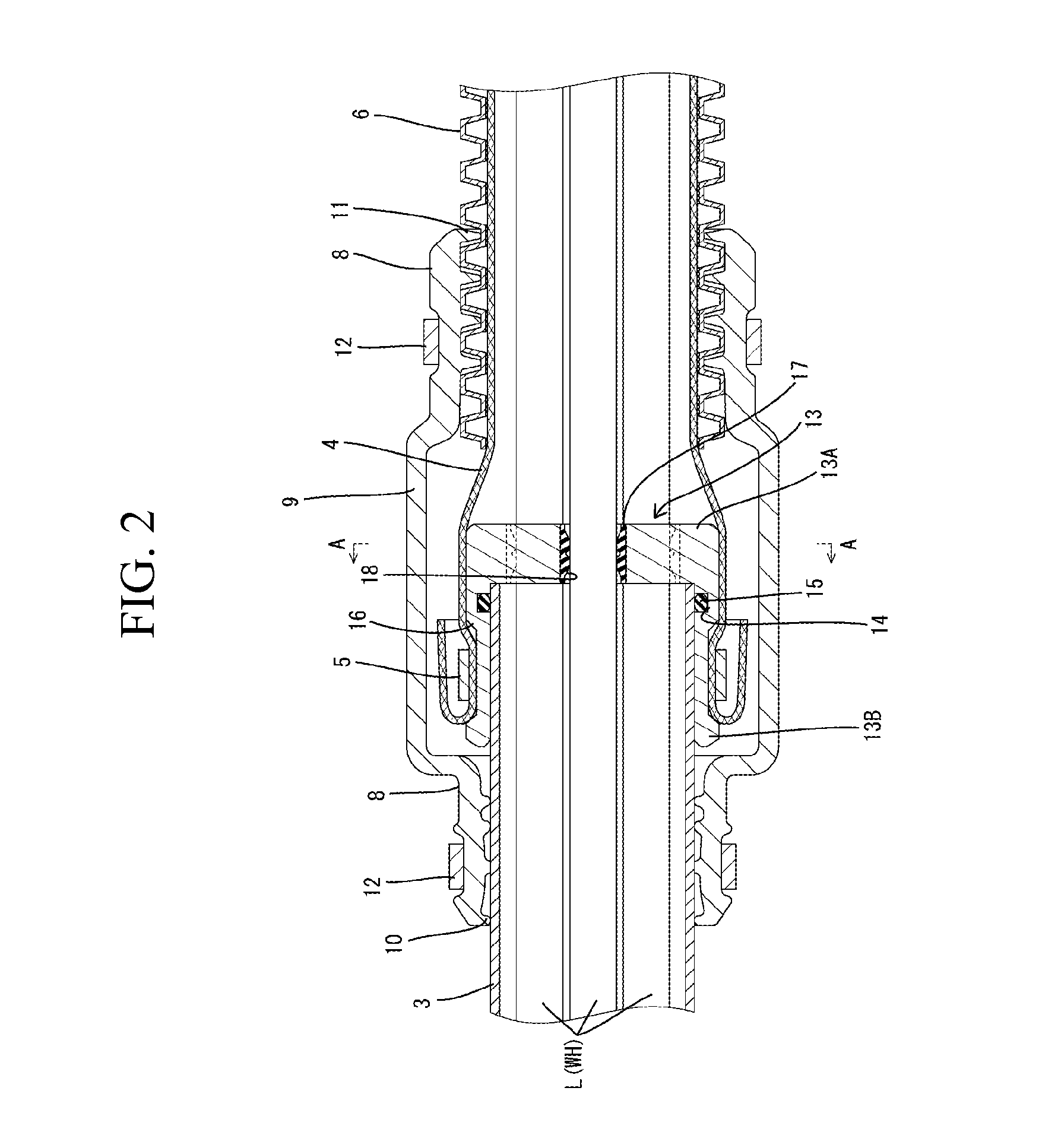

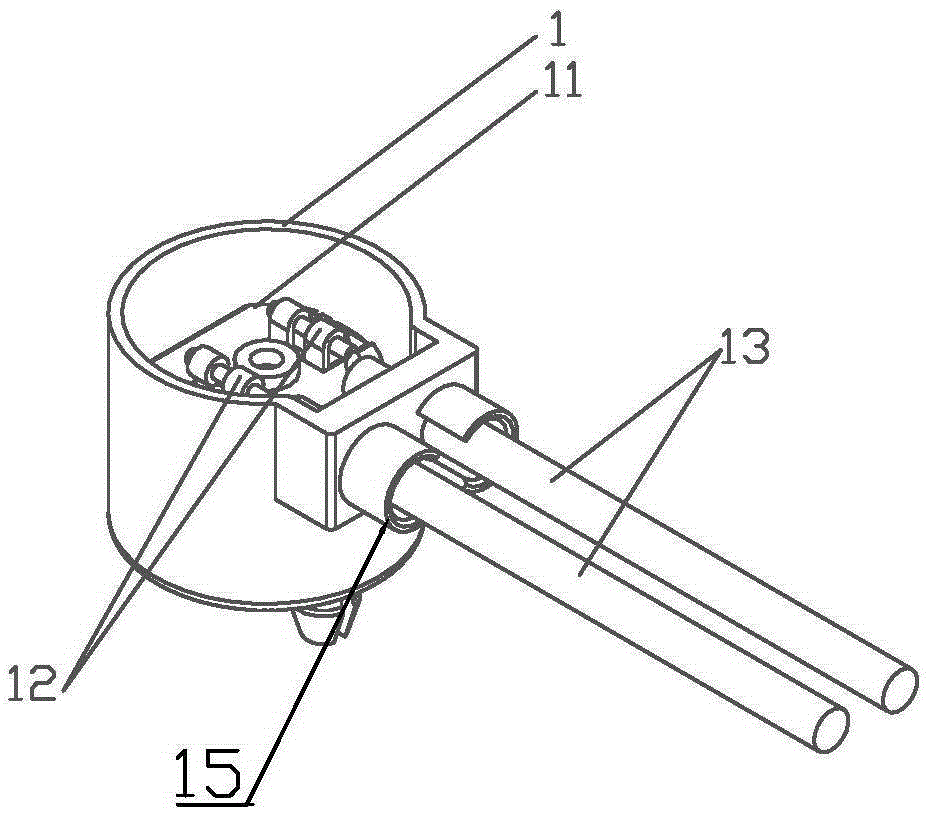

Shield structure for wire harness

ActiveUS20160134090A1Sure easyConvenience to workVehicle connectorsMagnetic/electric field screeningEngineeringConductive materials

A connecting position of a braid portion relative to a shield pipe is stabilized. A shield pipe in which a conductive wire constituting a wire harness is inserted, a braid portion that is connected to an end portion of the shield pipe and in which the conductive wire that is extended out of the shield pipe is inserted, an end member that is formed of a conductive material and that is mounted to an outer circumferential surface of the shield pipe while covering an end surface of the shield pipe, the braid portion being connected to an outer circumferential surface of the end member, and a crimp ring that crimps the braid portion onto the end member are provided. A positioning groove for positioning the crimp ring in an axial direction is formed on the outer circumferential surface of the end member.

Owner:SUMITOMO WIRING SYST LTD

Socket structure and method for forming the same

Owner:DELTA ELECTRONICS INC

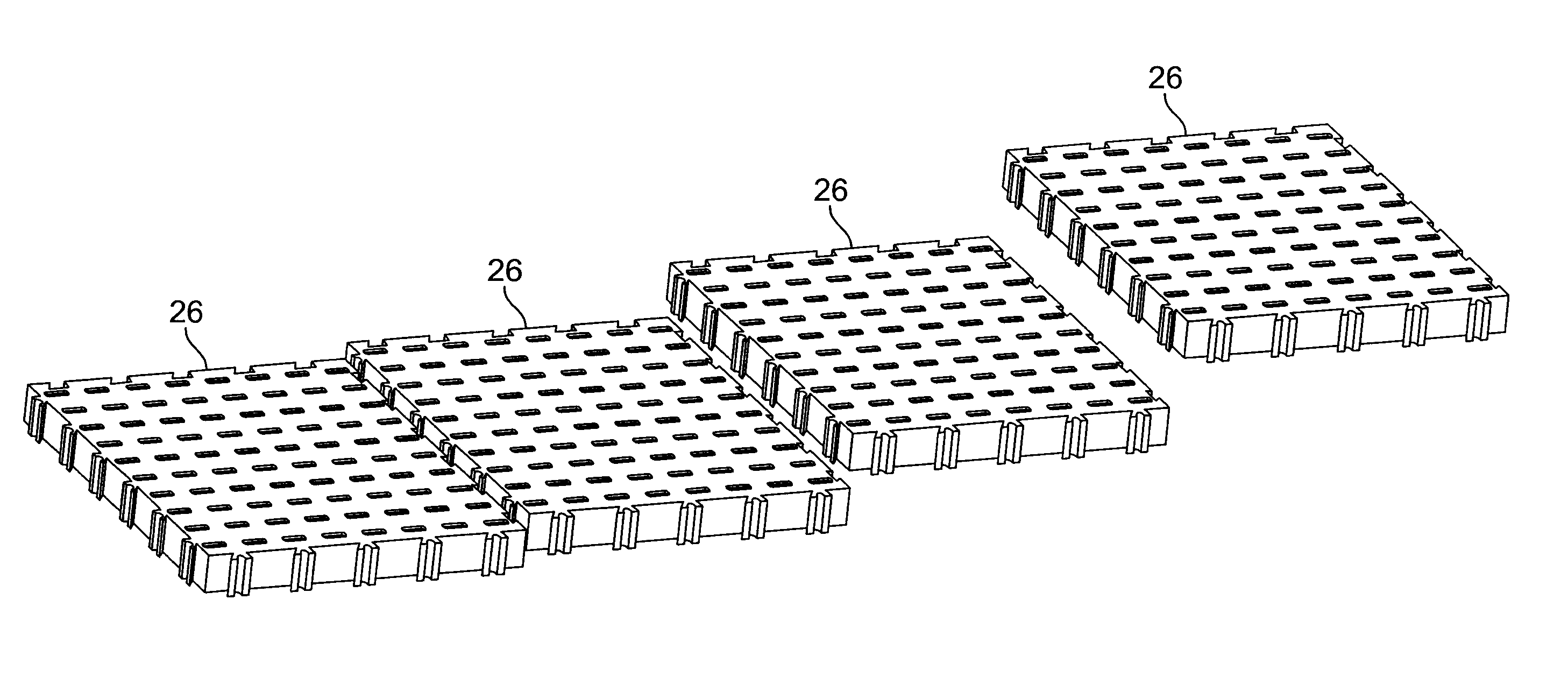

Low resistance insert

ActiveUS20150041211A1Low bond resistanceLower resistanceNon-insulated conductorsConductive materialConductive materialsLow resistance

A conductive insert which provides a low resistance bond between low conductive materials. The insert includes a first surface and an oppositely facing second surface. A plurality of openings extends between the first surface and the second surface. At least one first projection extends from the first surface proximate respective first openings, the at least one first projections extend from the first surface in a direction away from the second surface. At least one second projection extends from the second surface proximate respective second openings, the at least one second projections extend from the second surface in a direction away from the first surface. The insert provides a stable, low resistance electrically conductive path between the conductive materials.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

National standard plug support and manufacturing method thereof

PendingCN105305128AIncrease productivityReduce defective rateContact member manufacturingContact member assembly/disassemblyPunch pressEngineering

The invention relates to a method for manufacturing a national standard plug support. A straight rod raw material is adopted and horn mouth turning is performed on the tip of the straight rod raw material, then punching is performed on the horn mouth, and after punching is completed, automatic cutting is performed according to a national standard inserting sheet length requirement, thereby forming an inserting sheet blank; the inserting sheet blank is fed into a punch press stamping die to perform primary flattening and secondary flattening on the straight rod raw material, stamping edge-cutting is performed on two sides, at the same time, slots are cut on one ends of the two sides close to the horn mouth, and finally punching is performed on the head and chamfering is performed, thereby forming a molded inserting sheet; and three-angle or two-angle integral injection molding is performed on the molded inserting sheet, thereby forming the national standard plug support, one end of the national standard plug support inserting sheet is provided with the integrally formed horn mouth, the horn mouth is internally provided with a guiding circular ring line hole, the horn mouth and the inserting sheet are integrally formed, one end of a sheet body of the inserting sheet, which is close to the horn mouth is provided with symmetrical anti-falling injection molding notches at two sides. The method for manufacturing the national standard plug support improves production efficiency and quality stability, and effectively controls production cost.

Owner:NINGBO YINZHOU JIADI PLASTIC & METAL

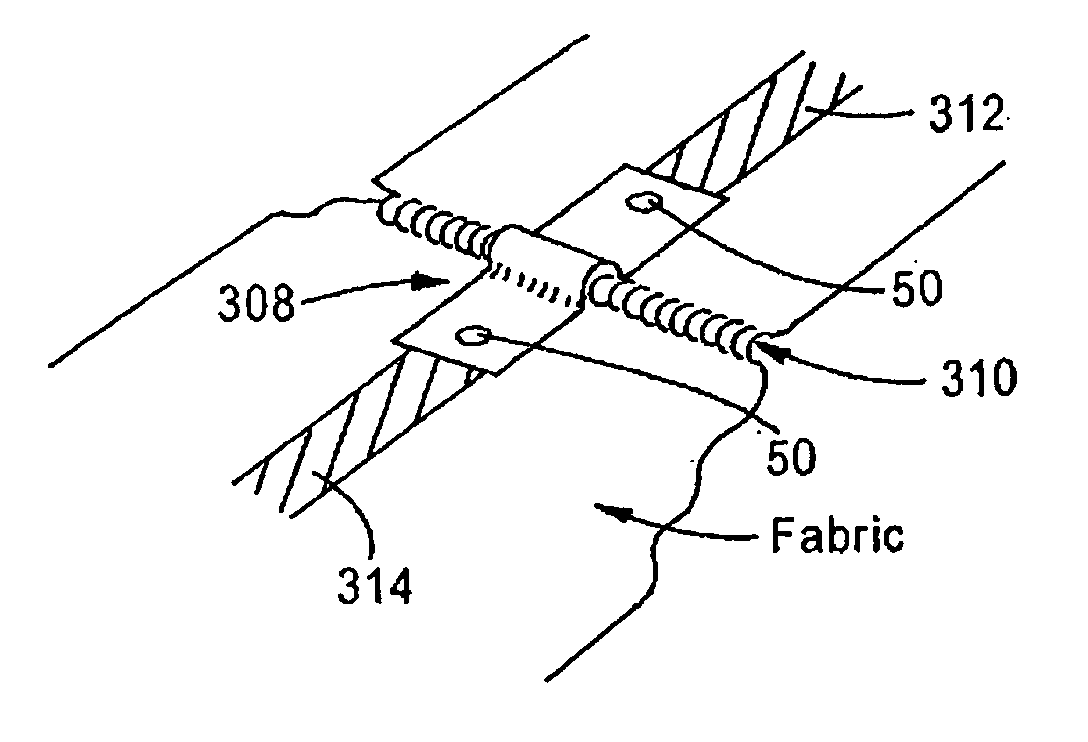

Electrically conductive fabric jumpers

InactiveUS20080066306A1Line/current collector detailsConductive materialUltimate tensile strengthHeat fusion

Disclosed is a heat staking process using a configuration to join two conductive yarn traces or pads by piercing them with a thermo plastic stud shaped somewhat like a rivet with a pointed post to pierce the fabrics. A properly designed tool can be lowered to meet the pointed tip of the stud and by using the proper heat and proper compression will join the two fabric pieces mechanically and electrically. The heat and compression formed stud 50 will provide mechanical strength and actually seal the connection if so required.

Owner:BERNARDINI ALLEN J

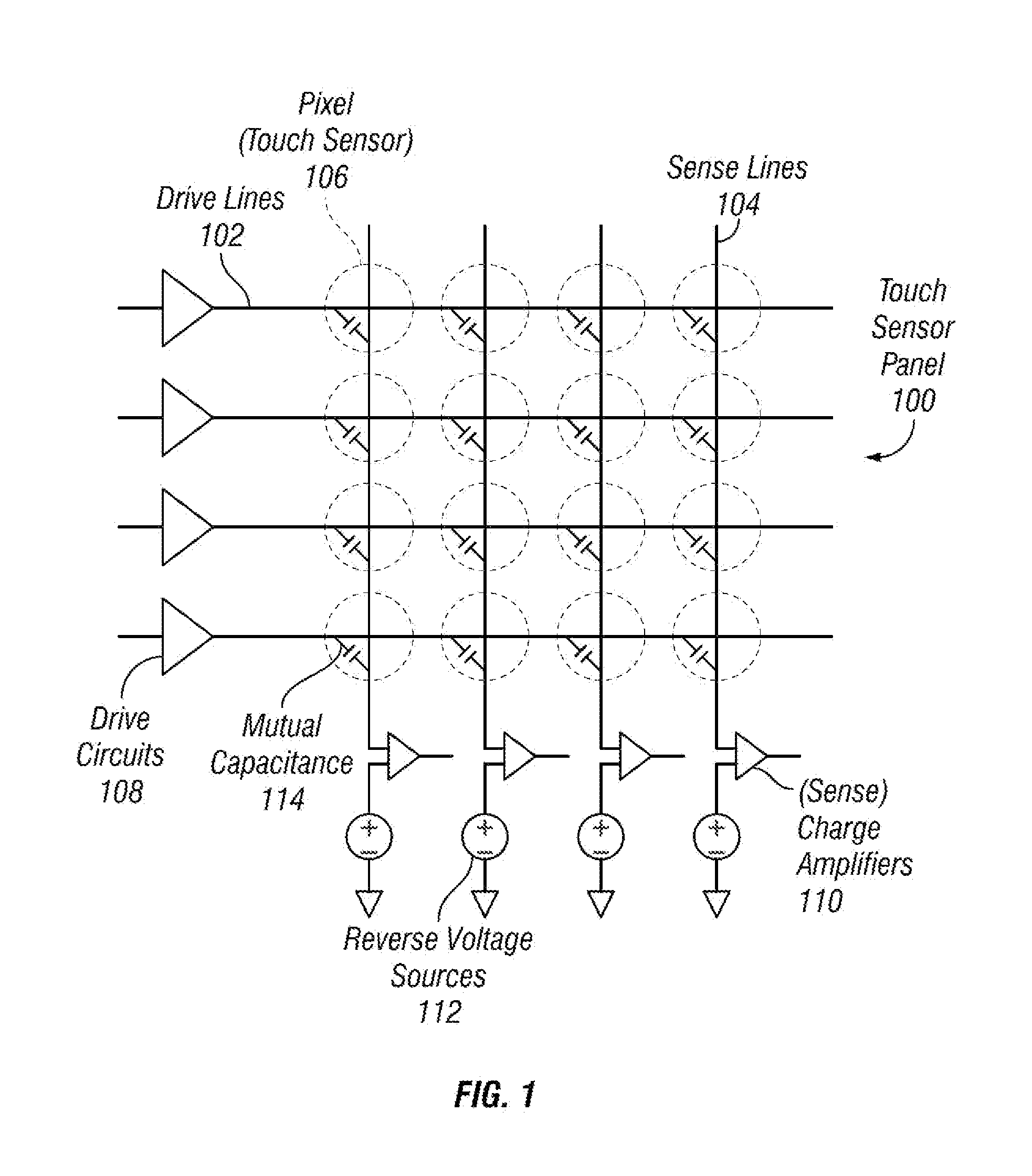

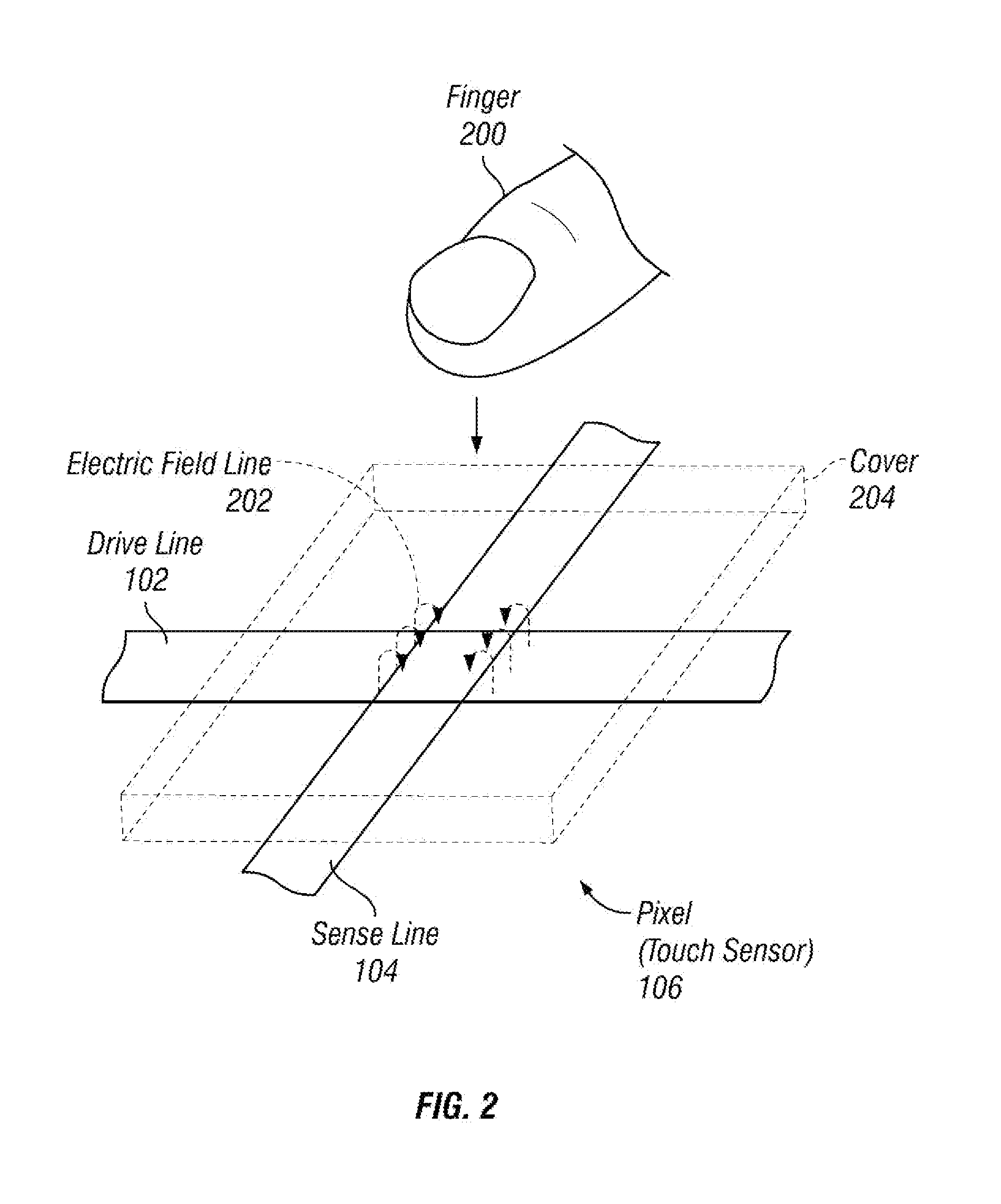

Touch Sensor Back Plane Ground Connection

ActiveUS20130133947A1Riveted connectionsConnections effected by permanent deformationCapacitanceEngineering

Owner:APPLE INC

Conductive rivet for circuit card

The conductive rivet designed to connect the first and second conducting surfaces of circuit board through an aperture in the board. The rivet includes a conical member with an associated insulating washer associated on one side of circuit board. A T-shaped rivet and cooperating insulating sleeve are designed to contact the opposite side of the circuit board and provide a thermal conduction path via tail on the T-shaped rivet to the conical member on the opposing side.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

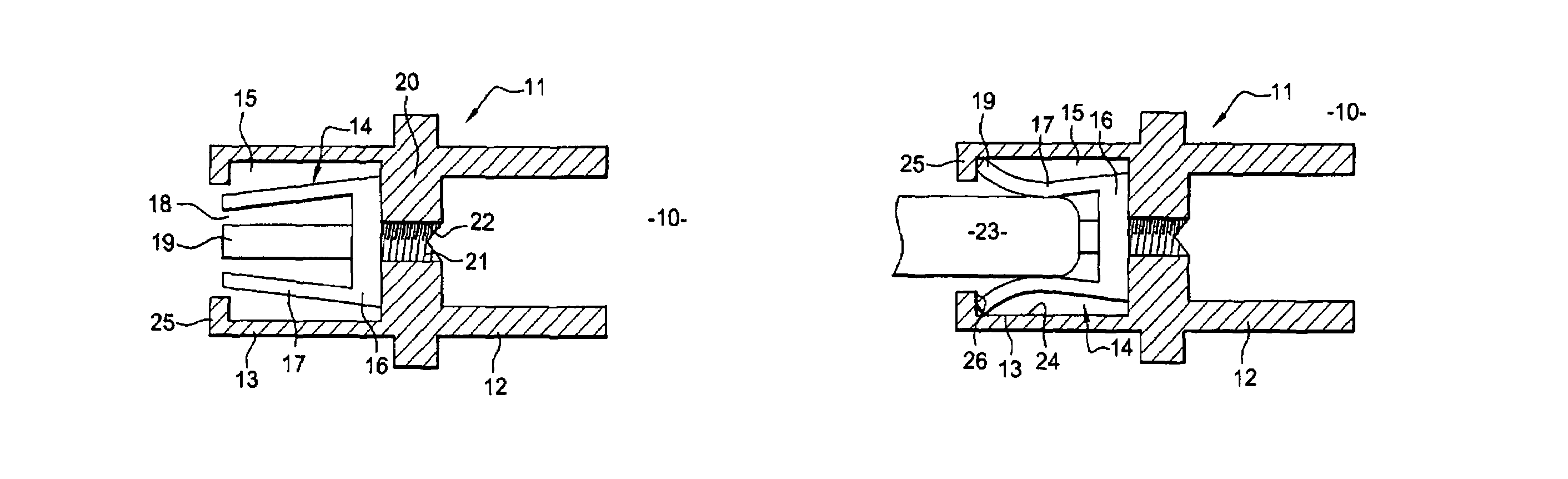

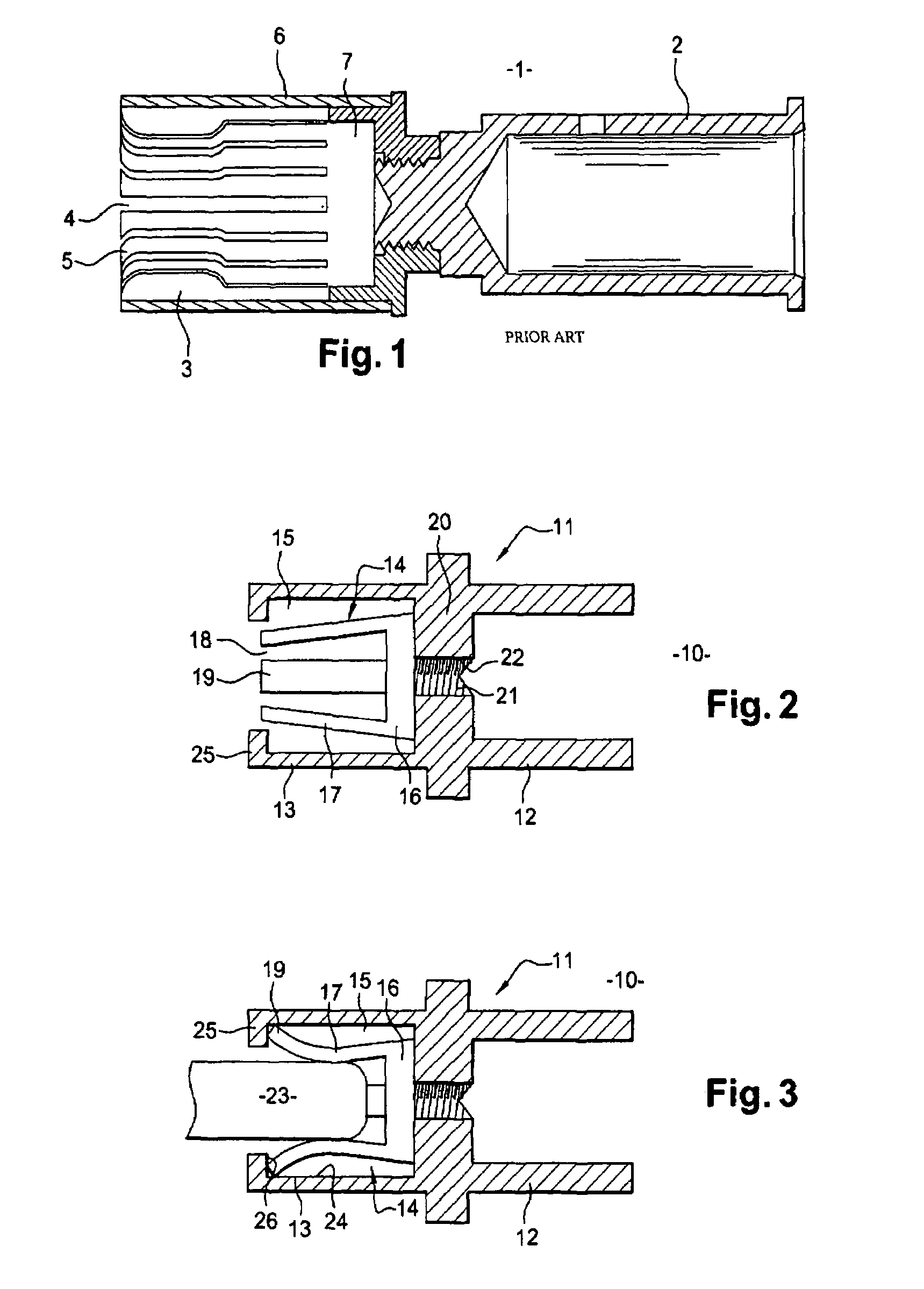

Female electrical contact element and method for making a female electrical contact element

The female contact element comprising a rear shank designed to receive an electrical conductor and a front shank equipped with an elastic socket designed to receive a male contact element. The female contact element is formed from a one-piece tubular body in which the front shank and the rear shank are arranged, the elastic socket being fixed mounted in the front shank. A method for manufacturing such a female contact element.

Owner:SOURIAU

Electromagnetic relay for starters

ActiveUS8143979B2Simple manufacturing processLoose connectionContact surface shape/structureRiveted connectionsEngineeringRelay

Owner:DENSO CORP

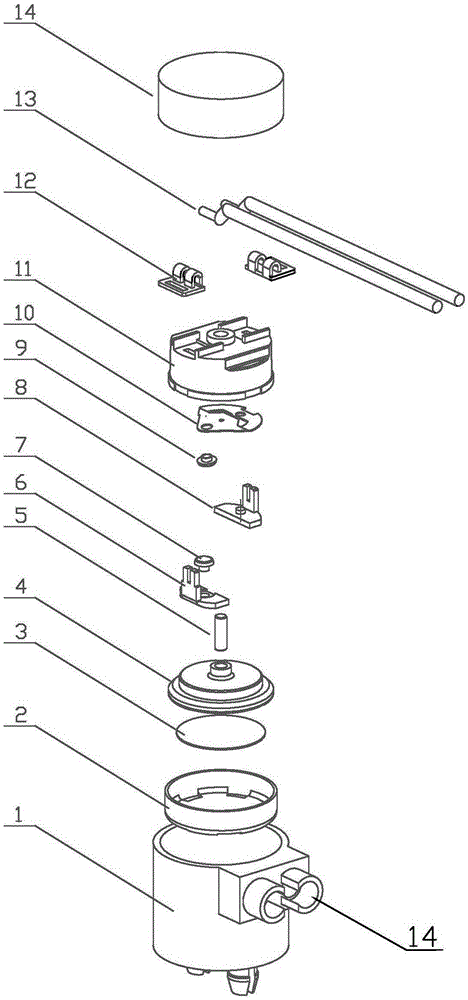

Waterproof temperature controller terminal pin and wire connecting method

InactiveCN105336538ALow costAvoid the hidden danger of pollutionCoupling contact membersRiveted connectionsElectrical and Electronics engineering

Owner:LIGHTCOUNTRY CHANGSHU

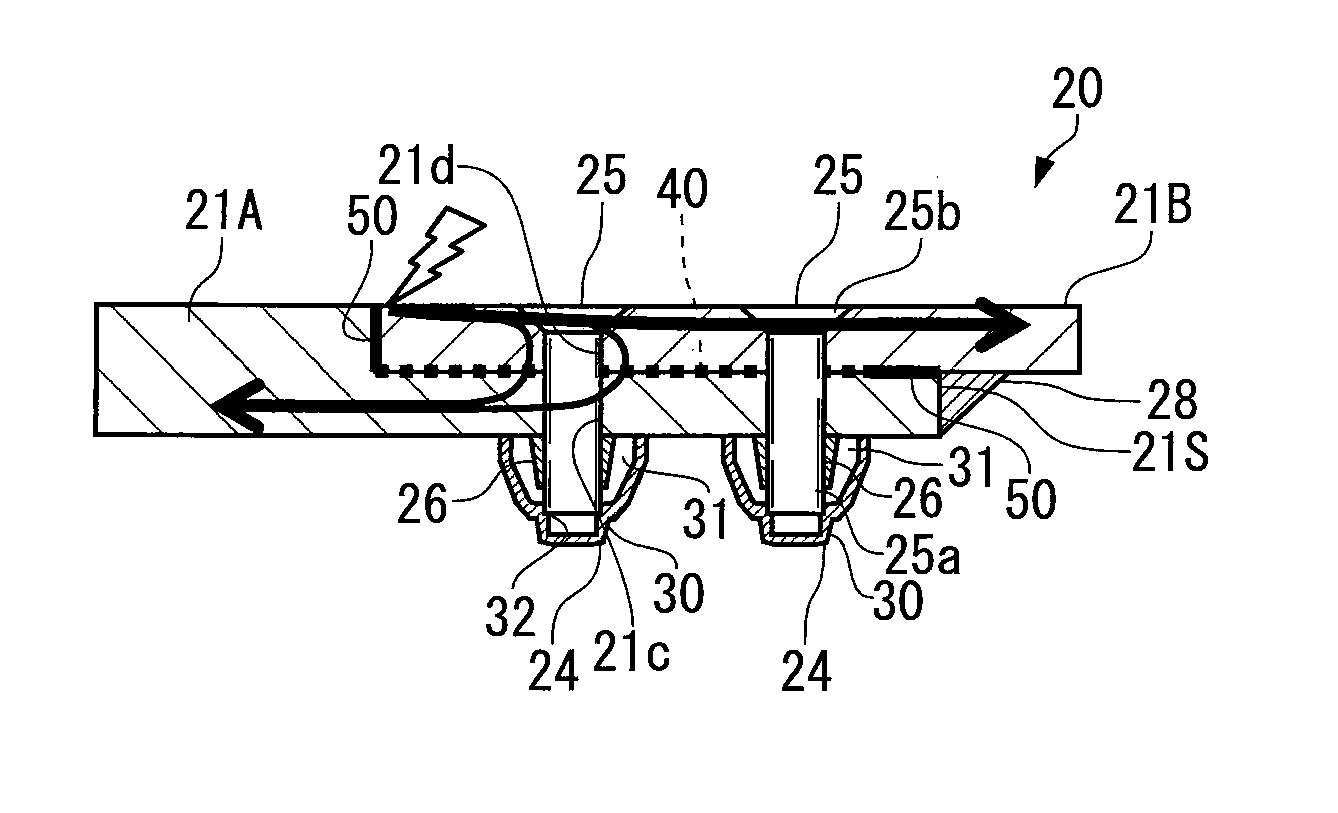

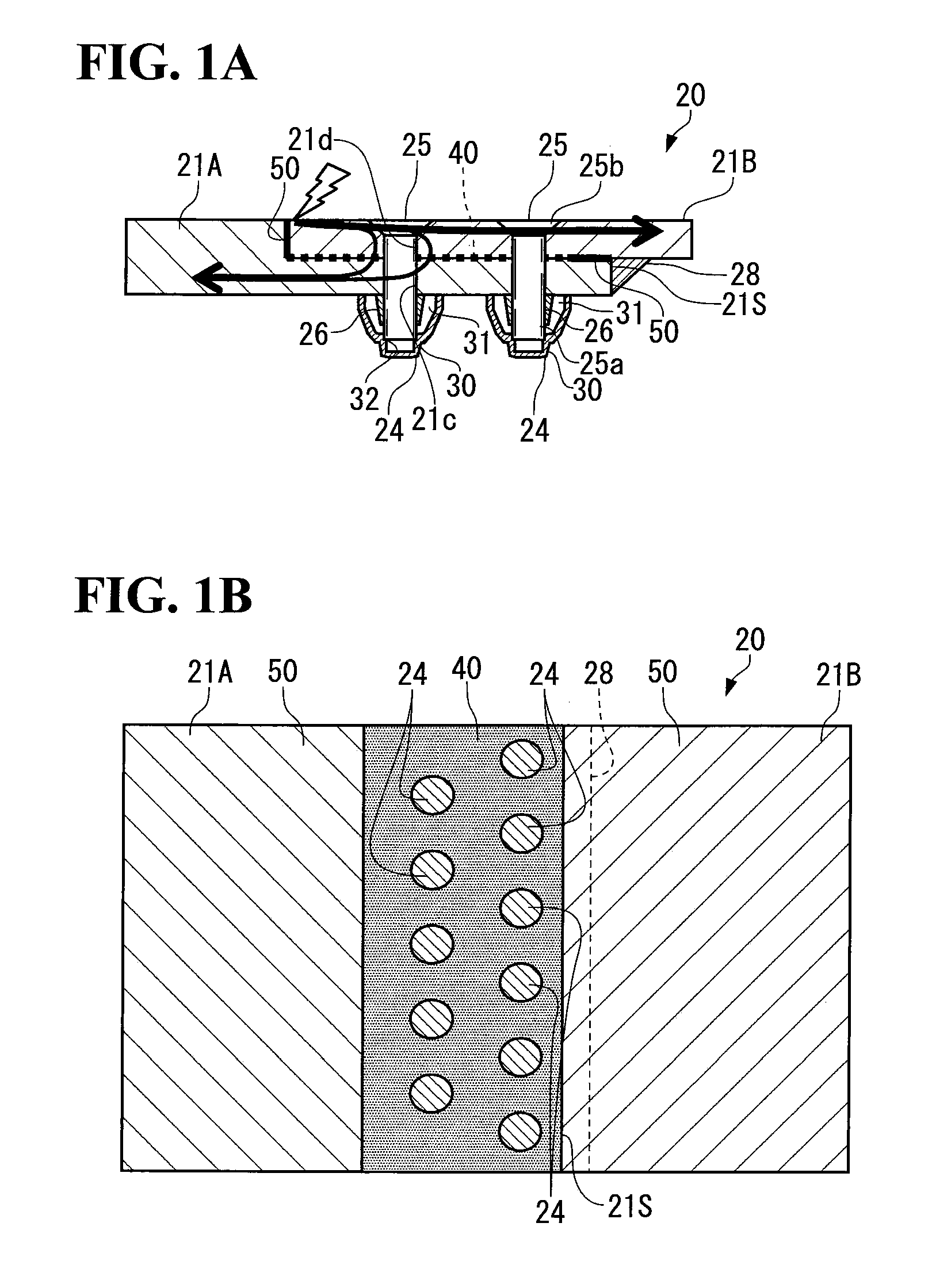

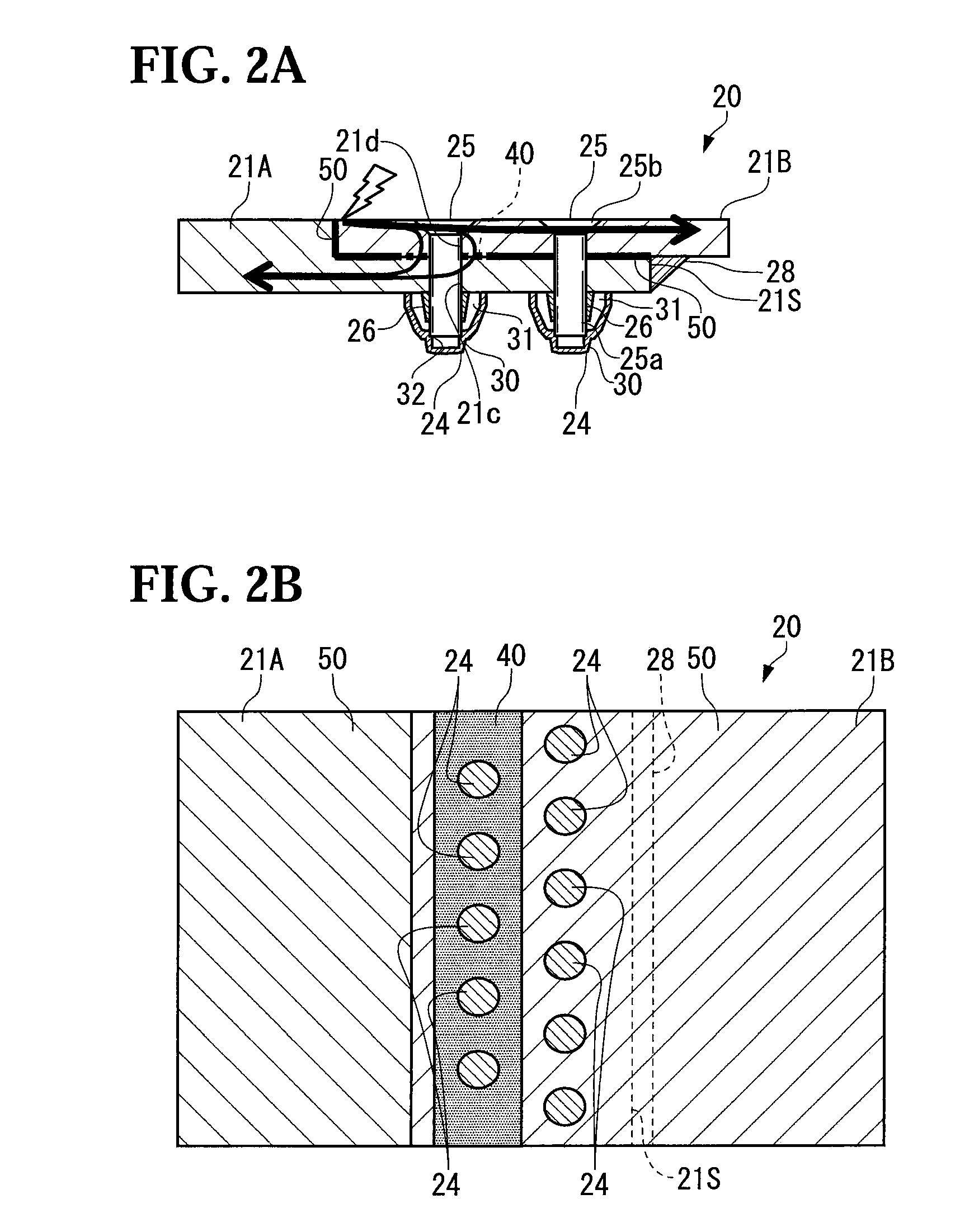

Coupling structure for airframe components

ActiveUS20120234977A1Current can be suppressedReliably achievedFuselage framesAircraft lighting protectorsCouplingConductive materials

Provided is a coupling structure for airframe components that is capable of ensuring sufficient lightning protection capability. A conductive pattern part 40 made of a conductive material is formed around each fastener member 24 between wing surface panels 21A and 21B. The conductive pattern part 40 is formed, for example, around each of holes 21c and 21d on the plane on which the wing surface panel 21A and the wing surface panel 21B abut against each other. Then, the conductive pattern part 40 is pushed against both the wing surface panel 21A and the wing surface panel 21B by the fastening power of the fastener members 24, whereby electrical conduction between the wing surface panel 21A and the wing surface panel 21B can be achieved.

Owner:MITSUBISHI AIRCRAFT

Reflector device and method of manufacturing same

InactiveUS7422345B2Ease of costEase of massLighting support devicesSolid-state devicesElectrical conductorEngineering

Disclosed is a reflector devise and method manufacturing same. The reflector device comprises a lamp unit comprising a seat assembly, a rivet assembly in the seat assembly, the rivet assembly including rivets projected from an underside of the seat assembly, and a LED lamp in the seat assembly, the LED lamp being electrically coupled to the rivet assembly; and a belt unit comprising an insulating layer and a conductive layer sealed by the insulating layer. The conductive layer comprises conductors and the insulating layer comprises sets of holes along the conductive layer so that the rivets are adapted to pass through the holes into the conductive layer to fasten and electrically connect the lamp and the belt units together. The invention has advantages of mass production and being waterproof and airtight.

Owner:HAYASHIBARA BIOCHEMICAL LAB INC

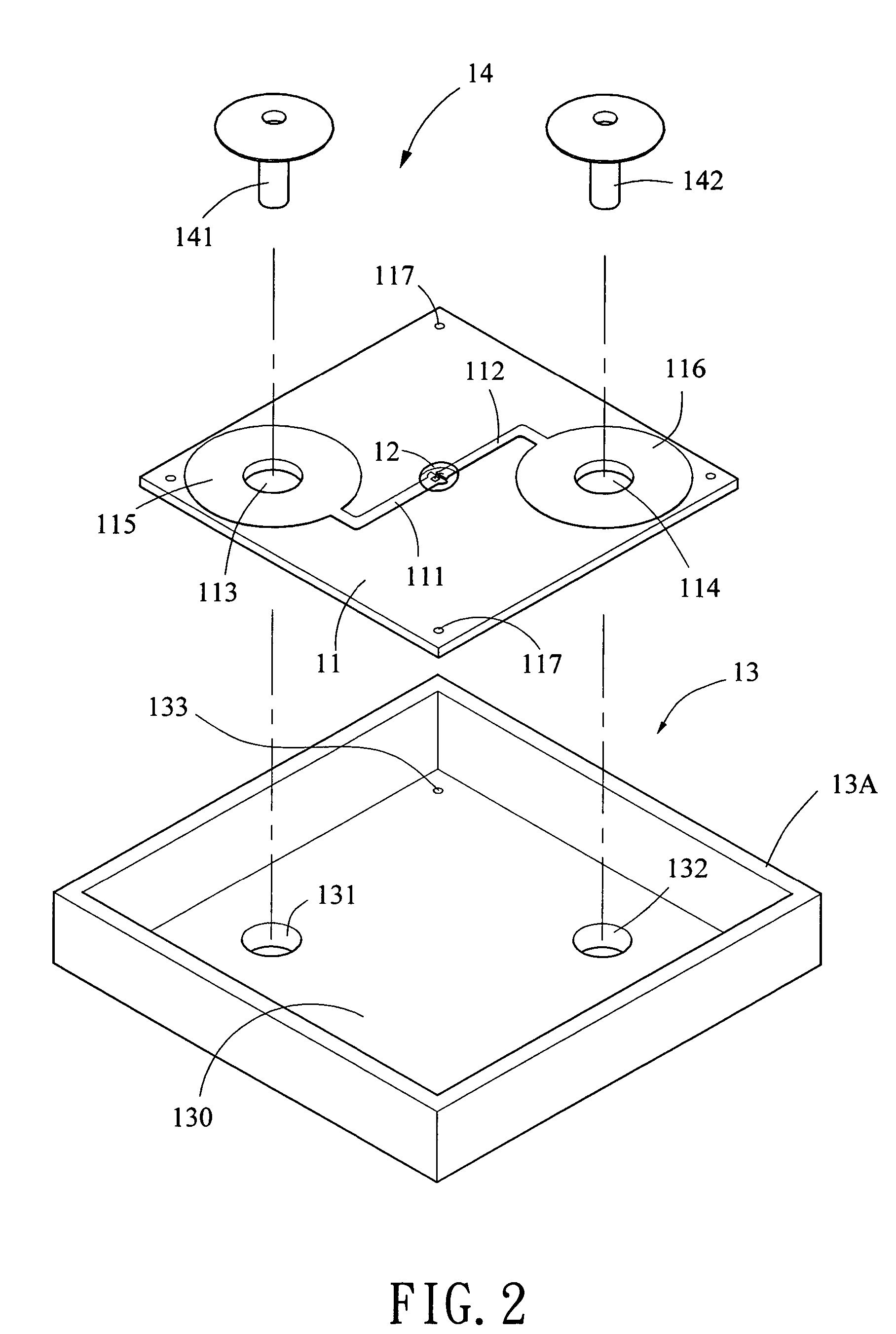

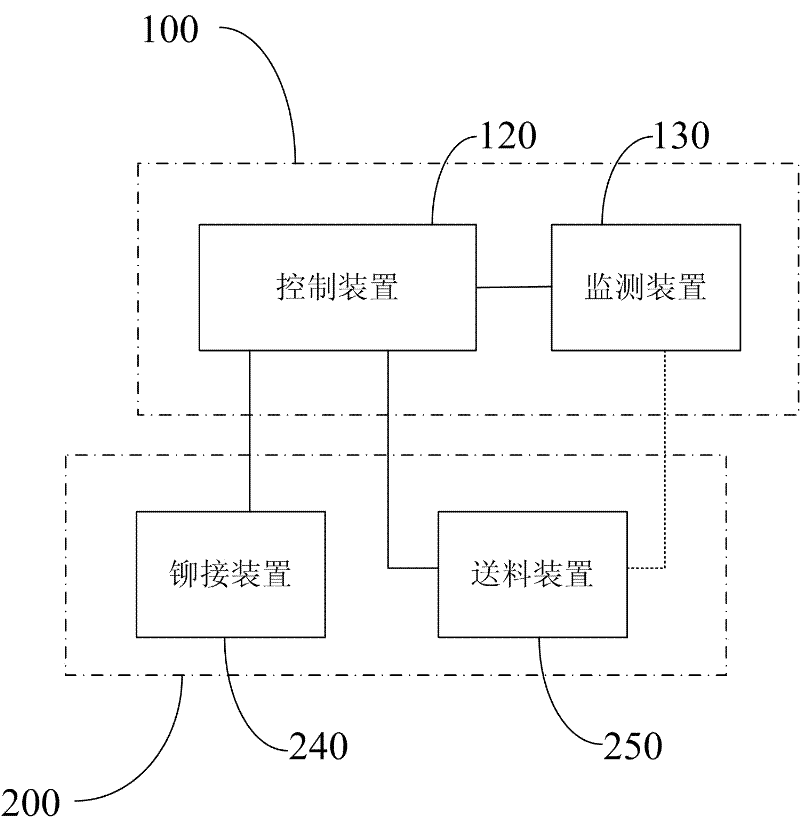

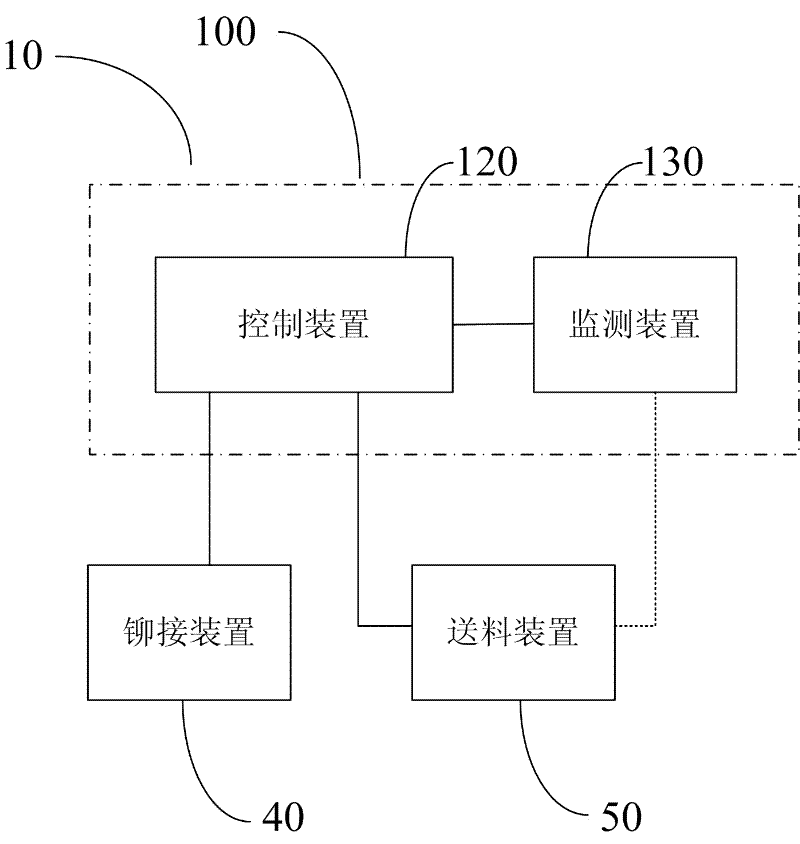

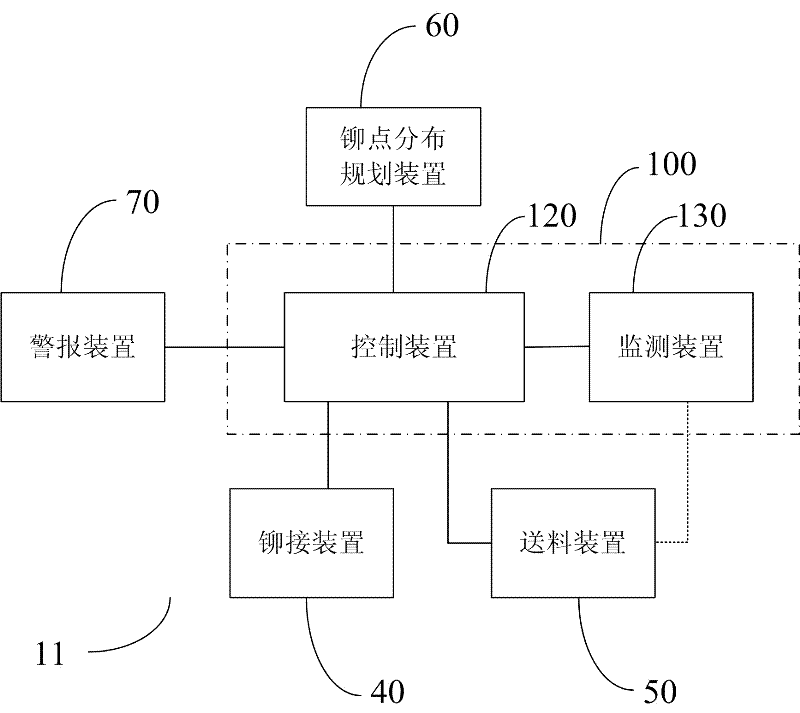

Self-piecing riveting bus bar production machine, self-piecing riveting bus bar production method and monitoring system

ActiveCN102354573AContinuous automatic monitoringOvercoming the disadvantages of manual monitoringRiveted connectionsConnection formation by deformationData controlMonitoring system

The invention relates to a self-piecing riveting bus bar production machine, a self-piecing riveting bus bar production method and a monitoring system. The monitoring system comprises a monitoring device and a controller, the monitoring device is used for measuring the feed data of bus bar components to be riveted, and the controller is connected with the monitoring device, and is used for acquiring the feed data from the monitoring device and controlling the operation of the self-piecing riveting bus bar production machine according to the feed data. When the monitoring system, the production machine and the production method are adopted, the self-piecing riveting bus bar production process can be continuously and automatically monitored on line, the production machine can continuously operate for a long time, and thereby the productivity is increased; meanwhile, a specialized monitoring station is dispensed with, and thereby the human resource cost is reduced.

Owner:成方泳

Permanent electrical contact applicable to the web of rails and the like

A permanent electrical contact applicable to the web of rails. The contact comprises a bush in electrically conductive material having a tubular stem suitable for inserting in a hole in the web of a rail, a flanged head radially widened compared to the stem and suitable for engaging in abutment with a portion surrounding the hole, and an axial through hole in which a punch can be inserted to expand the tubular stem radially and join a radially outer surface of the stem closely with the hole. At least a portion of the outer surface of the stem is substantially made of a first conductive metal and at least a portion of the flanged head is substantially made of a second conductive metal different from the first conductive metal.

Owner:CEMBRE

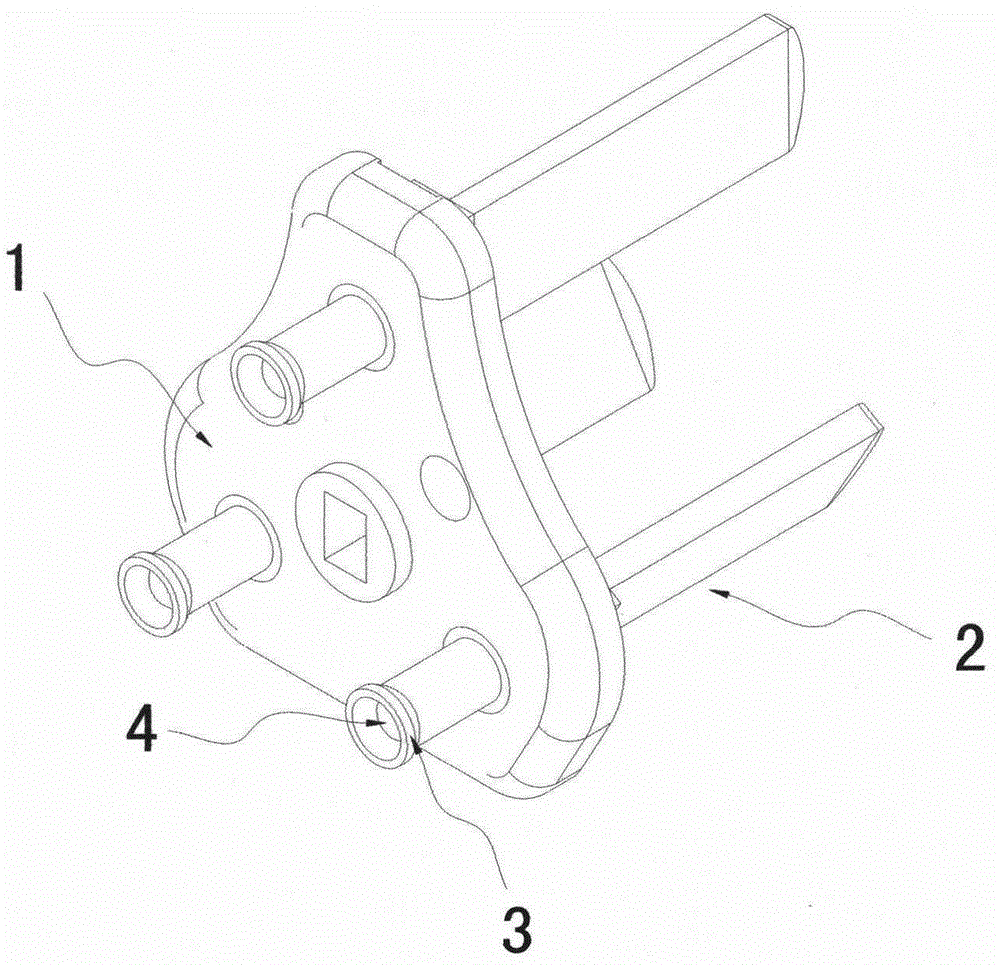

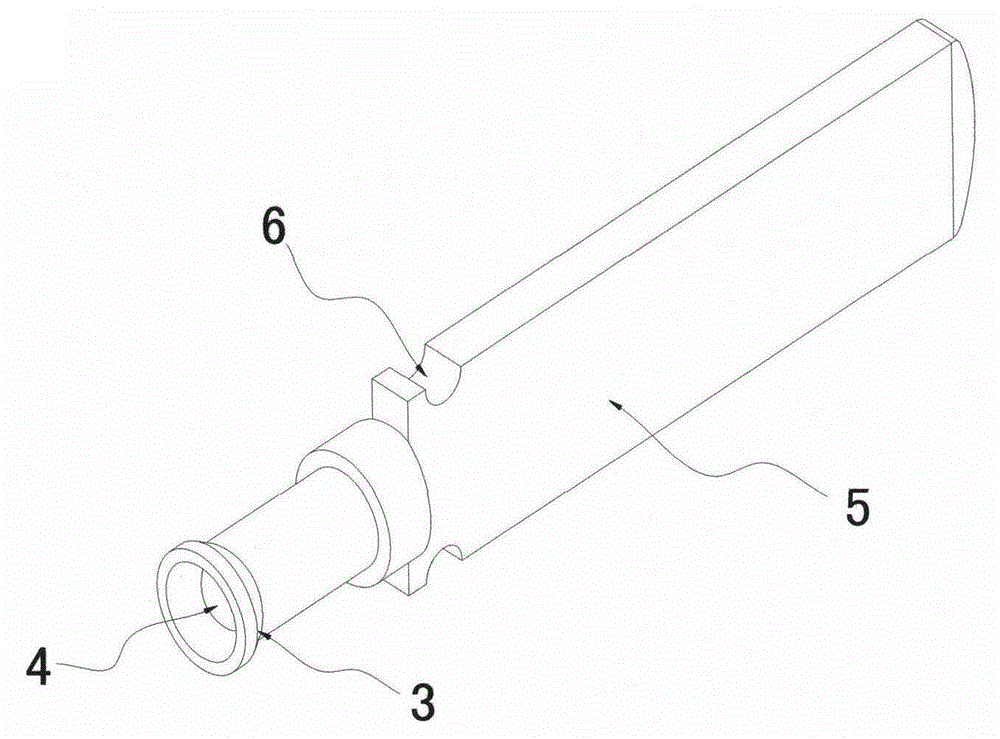

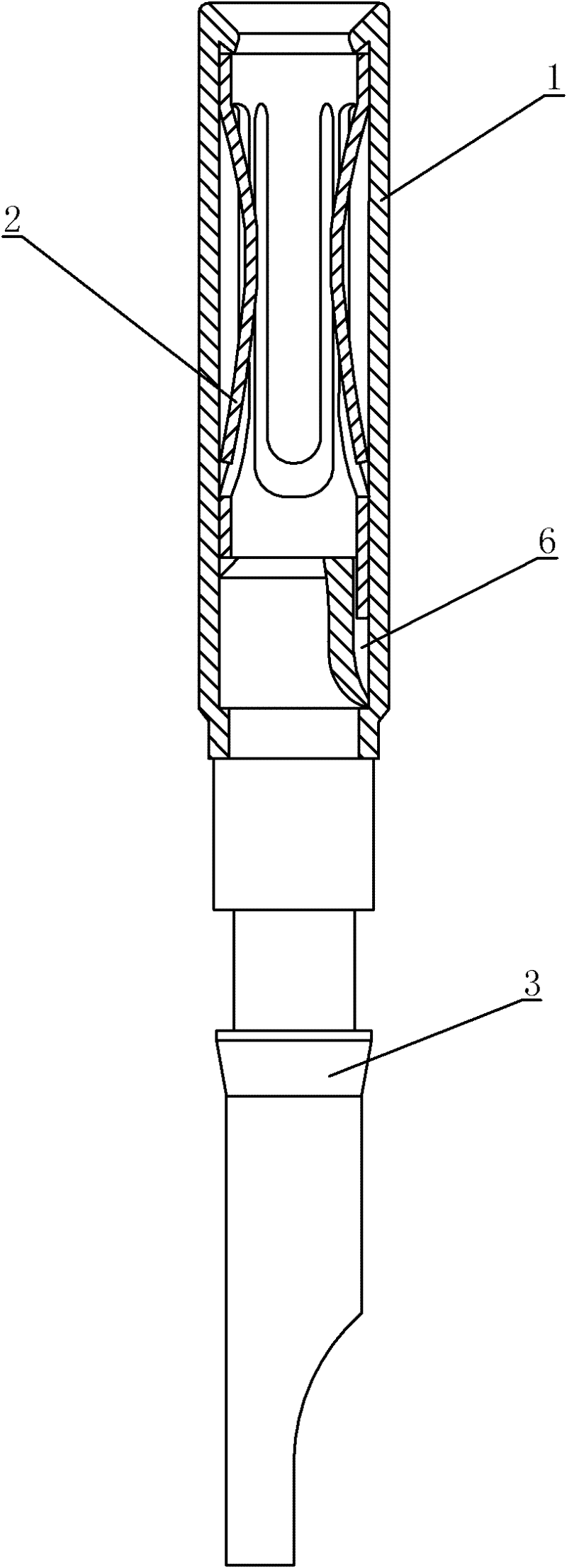

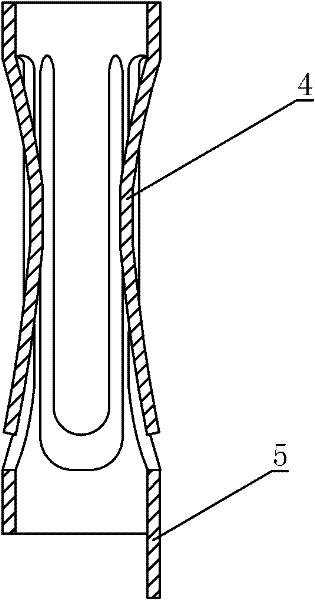

General jack contact element

InactiveCN102544836ASimple structureReasonable designCoupling contact membersRiveted connectionsInterference fitEngineering

The invention discloses a general jack contact element consisting of a jacket, a contact ring arranged in the jacket, and a pin connected with the lower end of the jacket. A locating slot is arranged at the upper end of the pin, the contact ring is a cylindrical part formed by rolling and combining two pairs of parallel elastic arms, the size of the upper end of the contact ring is larger than that of the lower end of the contact ring, the upper end of the contact ring is in interference fit with the jacket, locating teeth used for realizing the peripheral location of the contact ring are arranged at the lower end of the contact ring and are clamped in the locating slot. The general jack contact element is simple in structure, reasonable in design and reliable in contact, can better realize the plugging match with a square contact pin and a circular contract pin, and has stronger novelty and practicability.

Owner:SHAANXI SILING ELECTRONICS

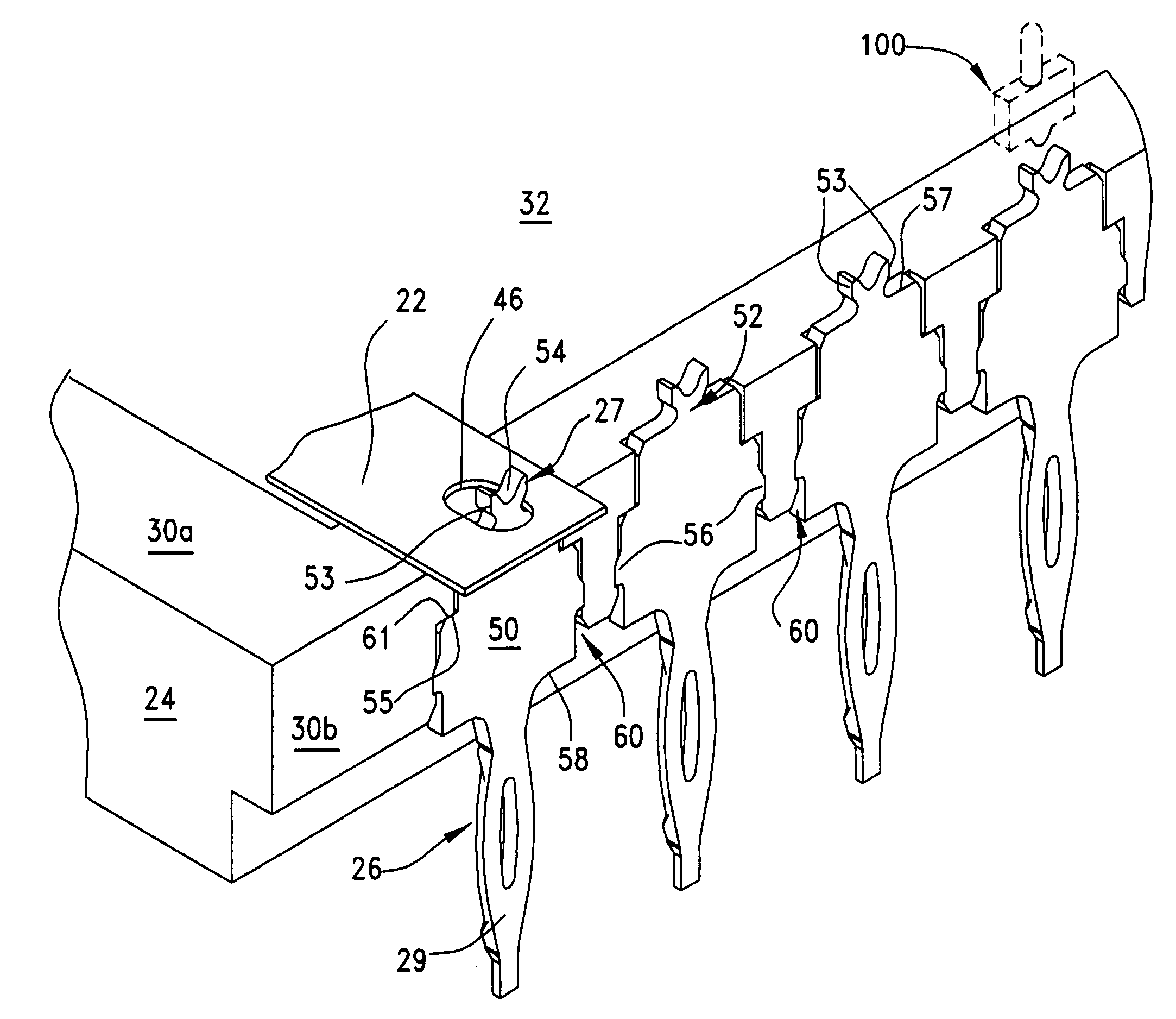

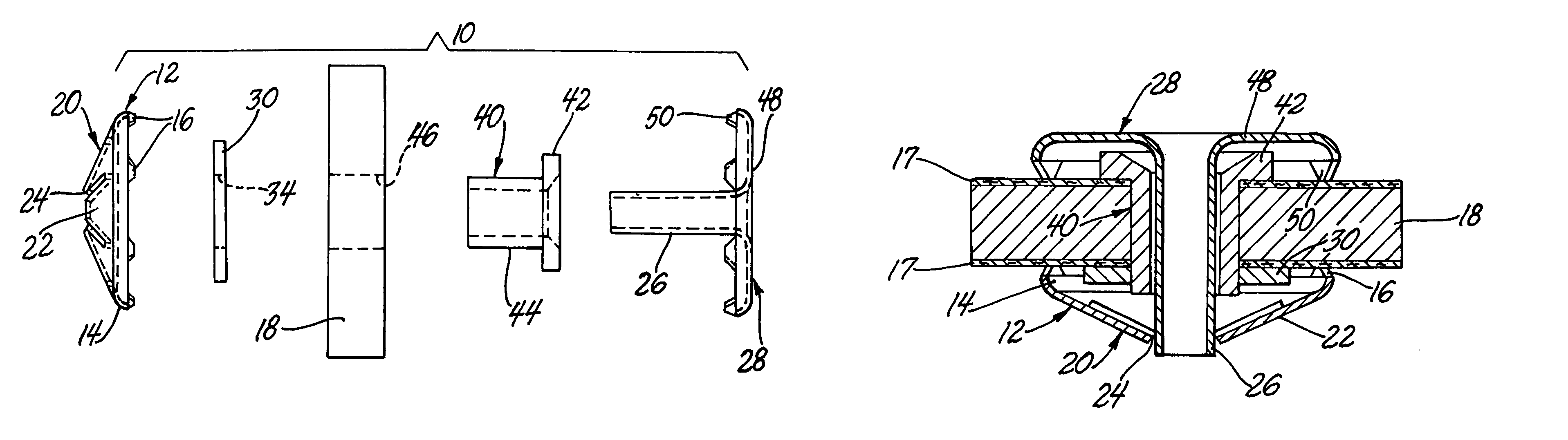

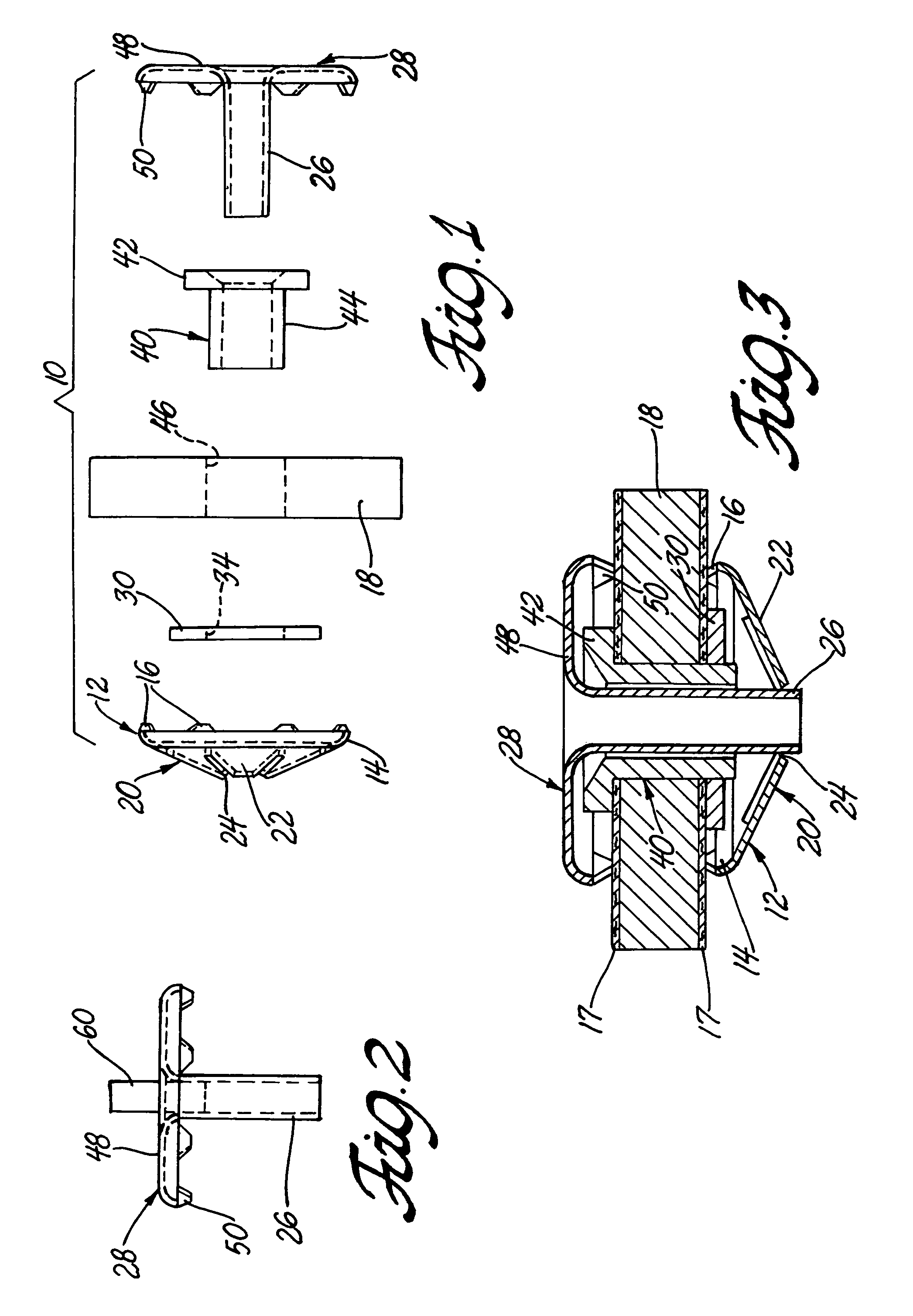

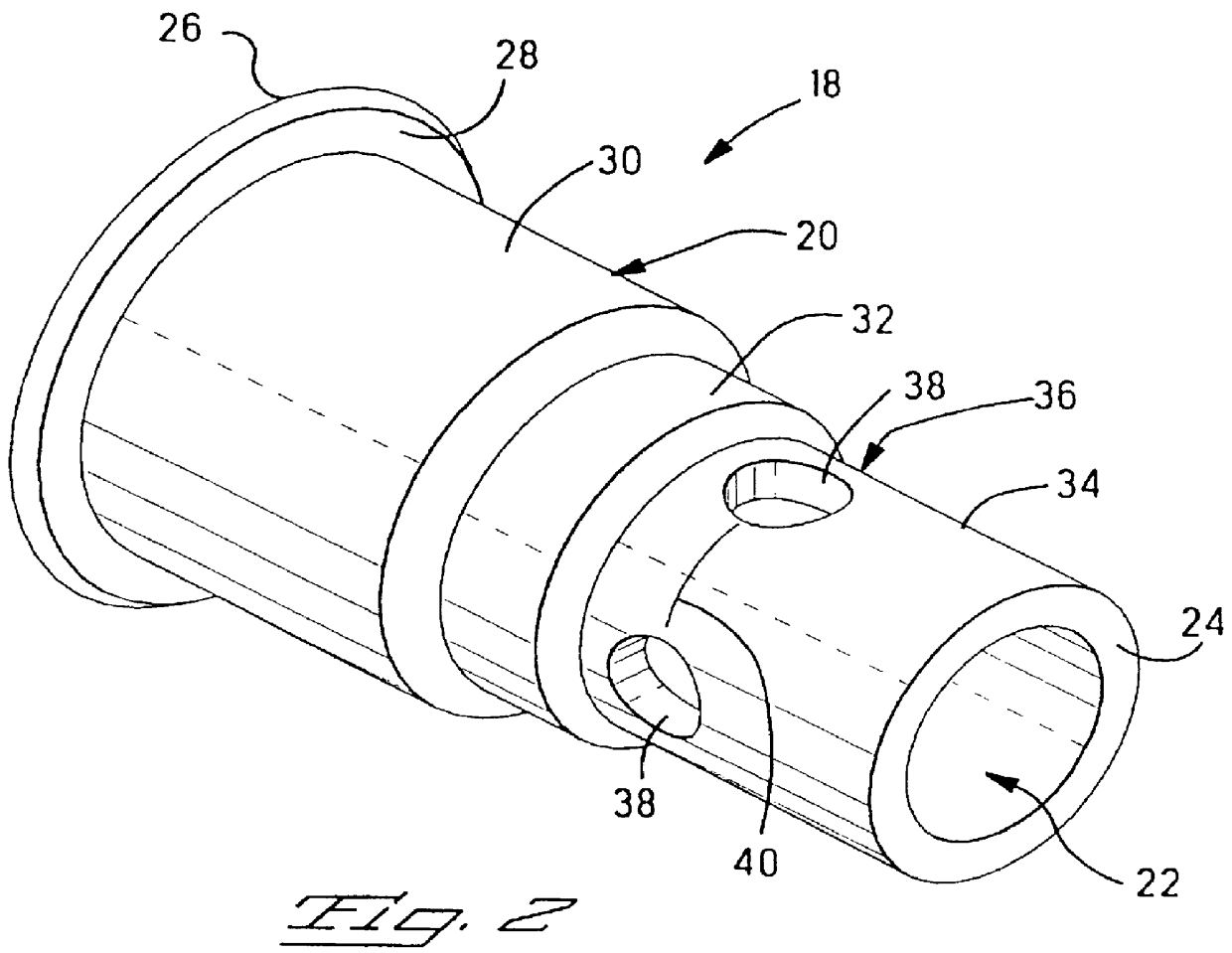

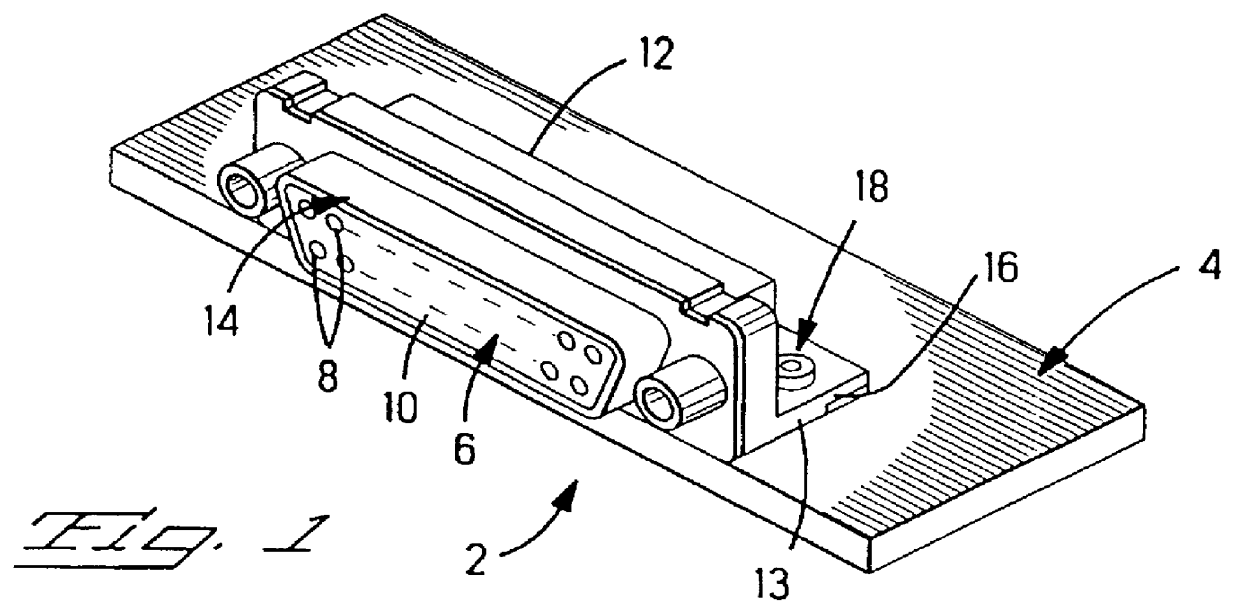

Board lock for electrical connector

InactiveUS6106332AGood mechanical retentionWide rangeSubstation/switching arrangement detailsRiveted connectionsElectrical conductorElectrical connector

PCT No. PCT / IB97 / 01251 Sec. 371 Date Apr. 12, 1999 Sec. 102(e) Date Apr. 12, 1999 PCT Filed Oct. 8, 1997 PCT Pub. No. WO98 / 16977 PCT Pub. Date Apr. 23, 1998An electrical connector assembly mountable to a substrate having an opening therein and configured to mate with a complementary connector, the connector assembly comprising a connector housing having contacts therein for mating with conductors associated with the substrate and the complementary connector, and a board-lock extending outward from the housing and receivable in the opening along a positioning portion; the connector assembly characterized in that the board-lock includes a weakened band along the positioning portion where the weakened band is located within the opening corresponding to the wall thereof, the weakened band including an engagement surface therealong, where the weakened band is constructed such that upon compression the board-lock deforms at the weakened band bringing the engagement surface against the wall of the opening.

Owner:THE WHITAKER CORP

Crimping structure for metal materials, and bus bar using said crimping structure

ActiveCN103733385AEnlarging joint cross sectionImprove conductivityCoupling device connectionsCurrent conducting connectionsElectrical resistance and conductanceMetal

To provide a crimping structure for metal materials, wherein it is possible to stably and tightly join metal materials and to reduce the electrical resistance even when the joined metal materials are formed from different materials. A crimping structure for metal materials, the crimping structure being provided with a metal plate (12) on which a hole (14) is formed, and a disk-shaped conductive member (13) which is crimped to the periphery of the hole (14) after being inserted into the hole (14), wherein a groove (17) is disposed on at least one surface in the periphery of the hole (14), and a perpendicular flange (21) protruding from at least one surface is disposed on the outer circumference of the conductive member (13). When the conductive member (13) is inserted into the hole (14) and is crimped to the metal plate (12), the perpendicular flange (21) of the conductive member (13) becomes crushed, and the groove (17) on the metal plate (12) becomes filled with the crushed perpendicular flange (21).

Owner:SANCALL

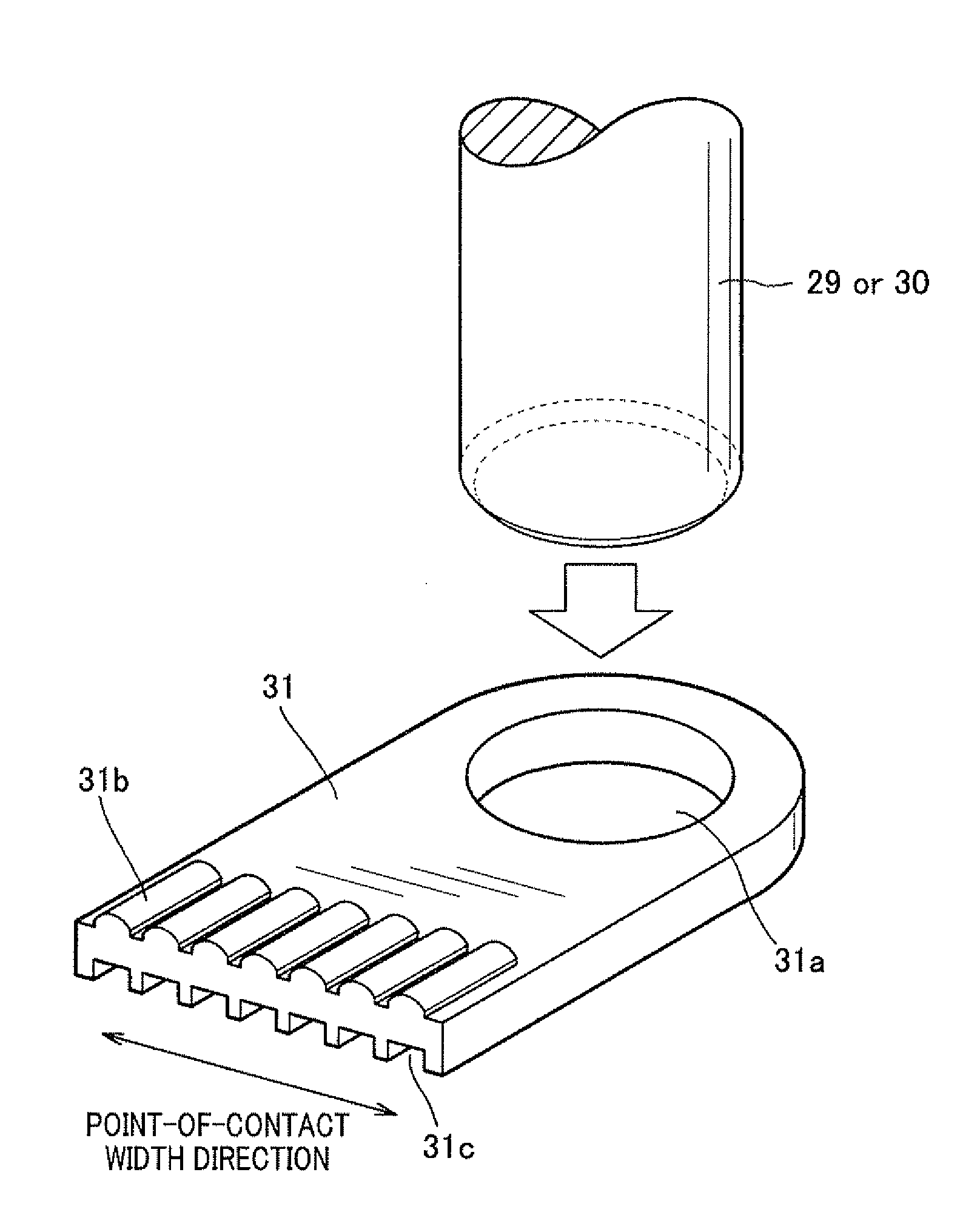

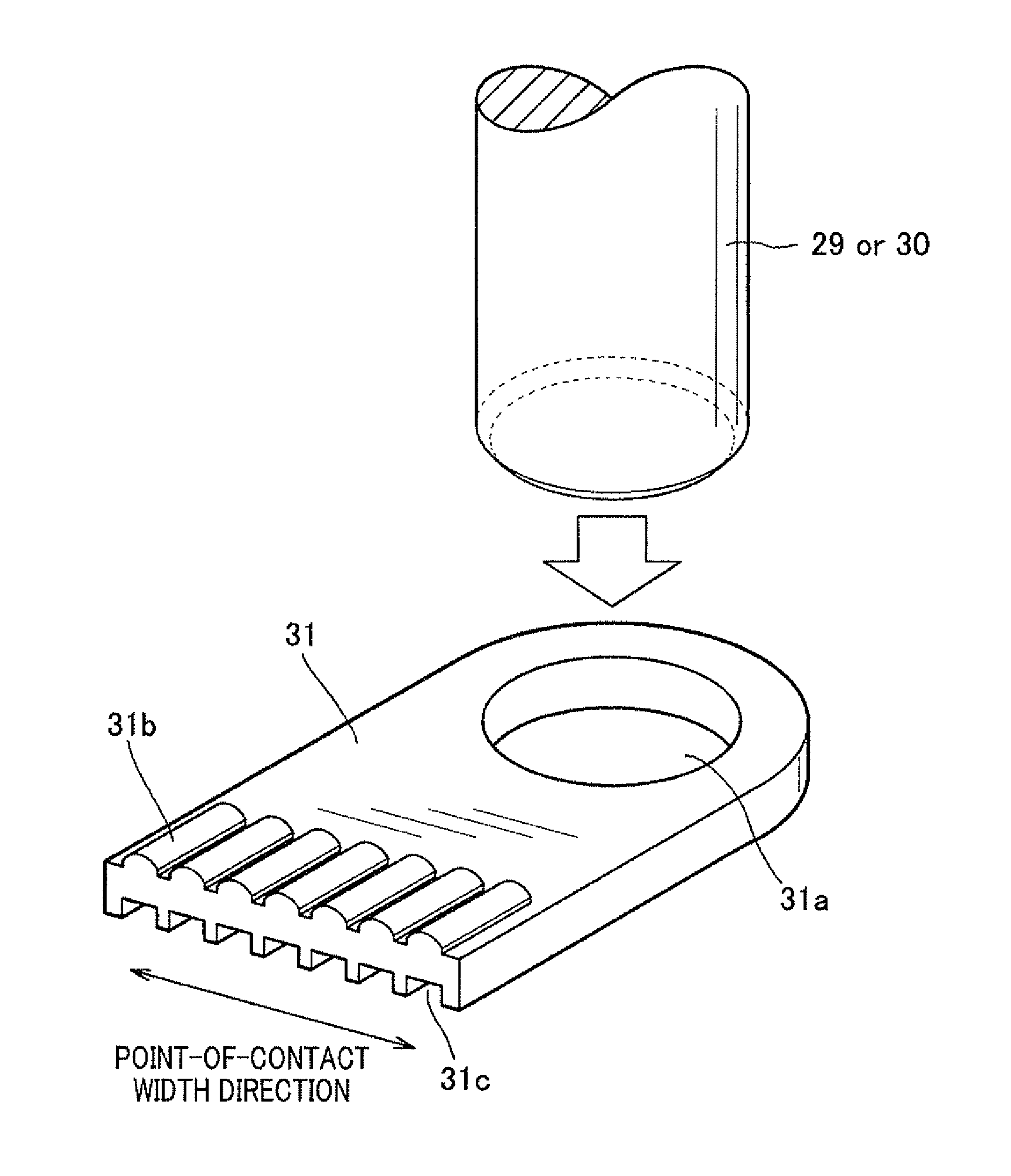

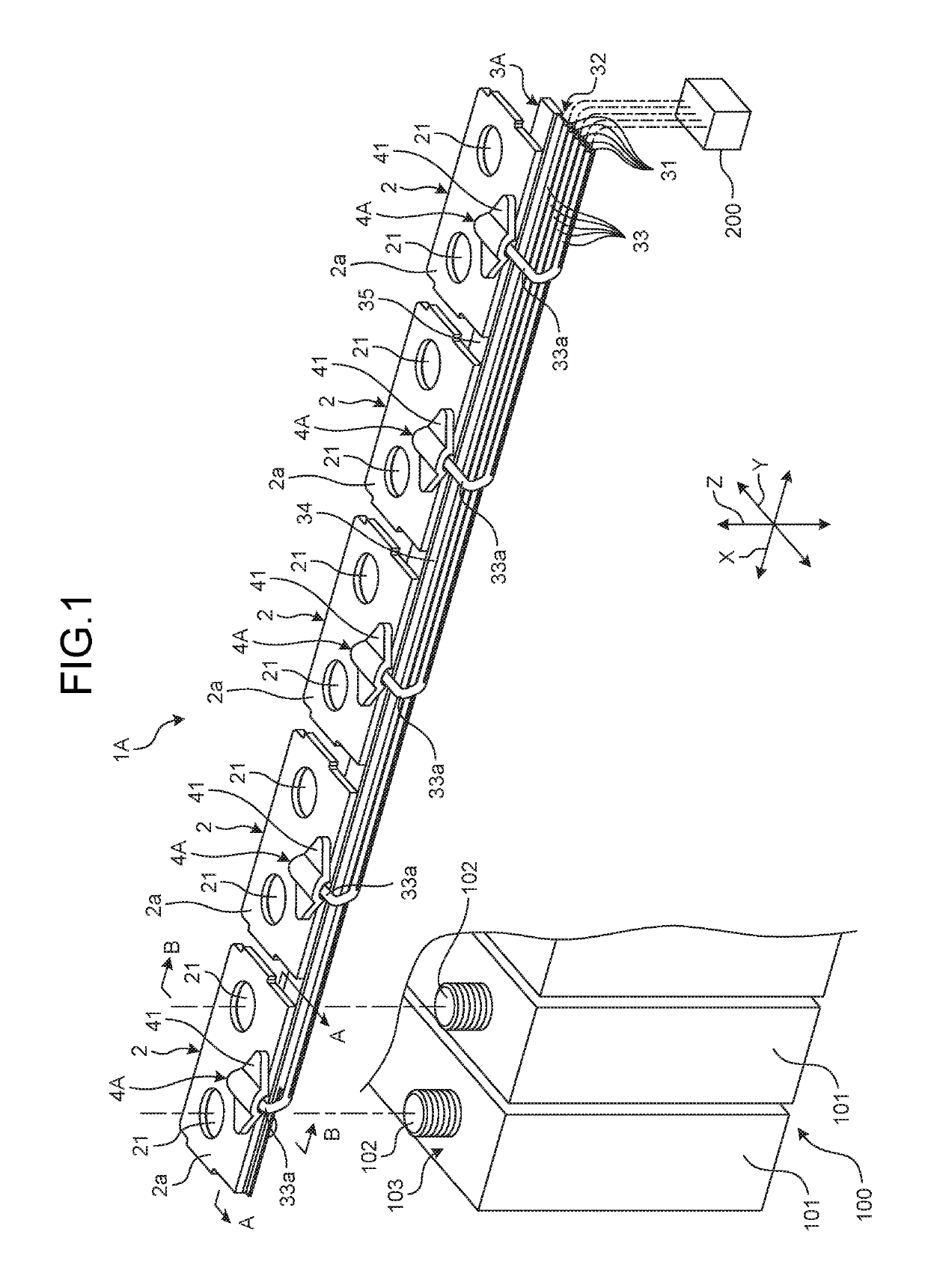

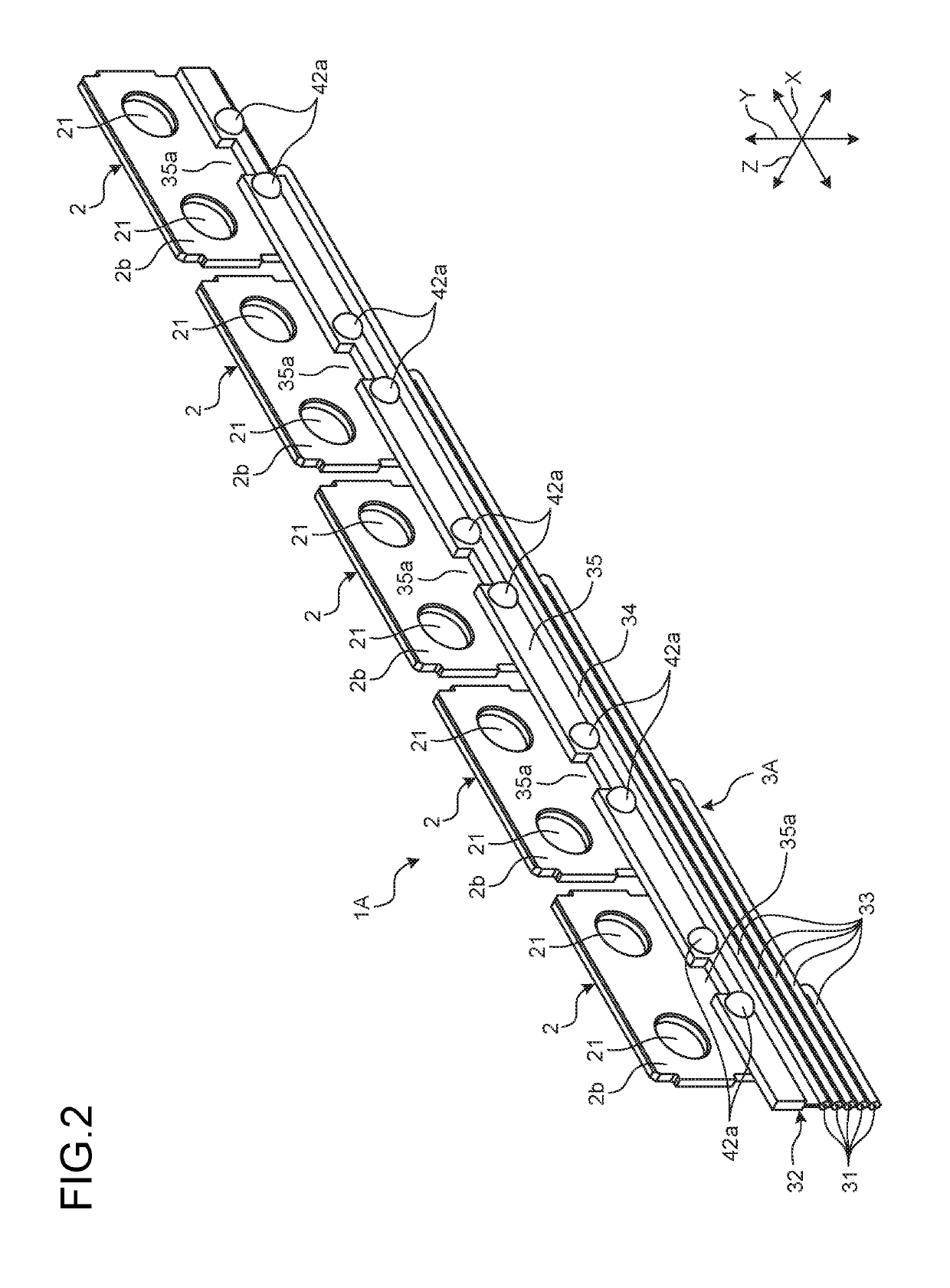

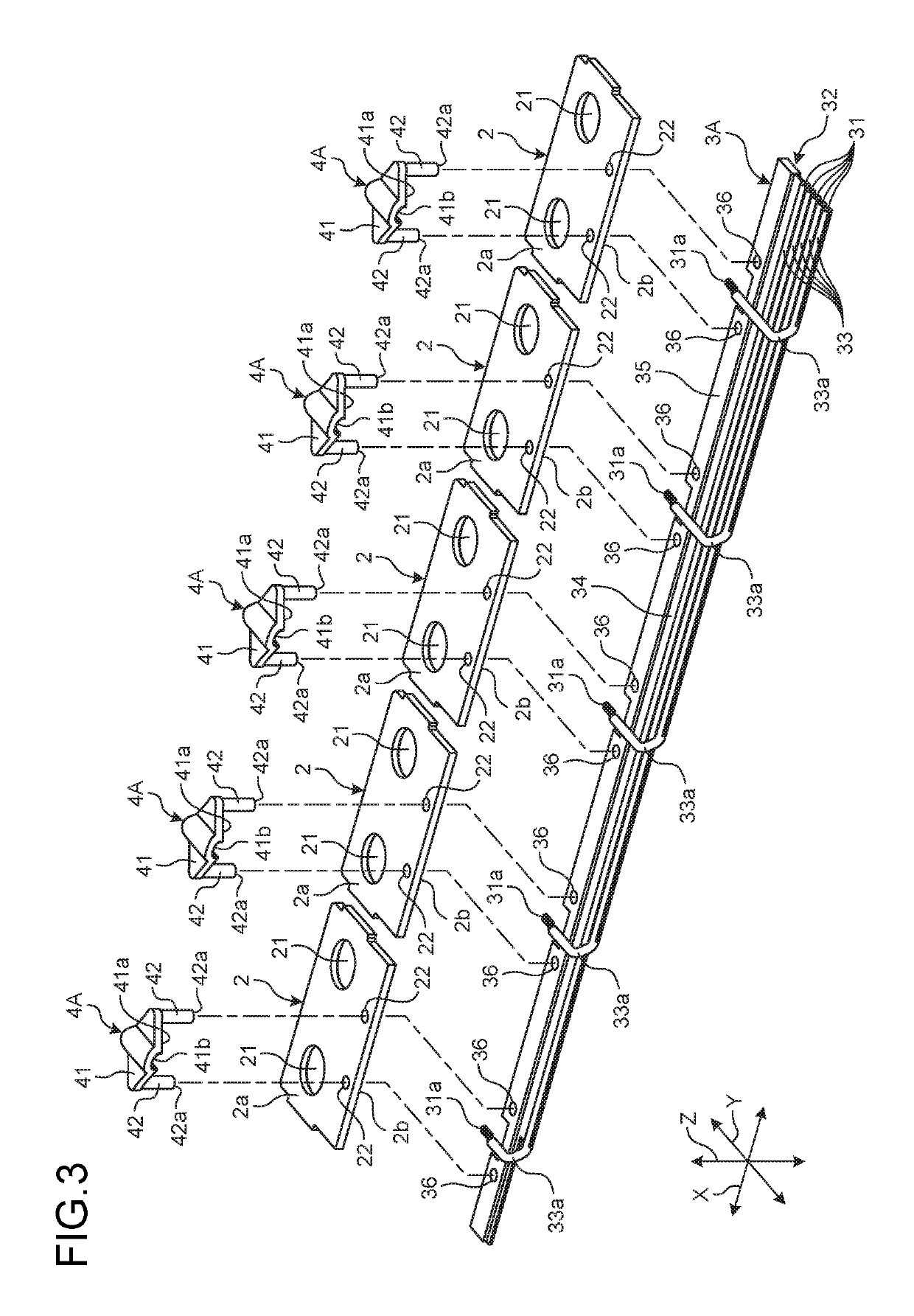

Conductor module for terminal

ActiveUS20190273239A1Reduced connection reliabilityImprove connection reliabilityCurrent conducting connectionsSecondary cellsElectrical conductorEngineering

A conductor module for terminal includes a bus bar, a state detector including a detection conductor, and a fixing member fixing the state detector to the bus bar. The bus bar includes a connection surface to which the detection conductor is electrically connected, and two fixing holes formed with the placed state detector interposed therebetween. The fixing member includes a main body that the state detector is made contact with, and plastically deformable fixing legs. Each of the fixing legs is inserted in the fixing hole from the connection surface side and projects from the fixed surface. In a fixed state, when the fixing leg is seen from an axis direction of the fixing hole, a tip of the fixing leg is disposed on the outside in a radial direction than the fixing holes.

Owner:YAZAKI CORP

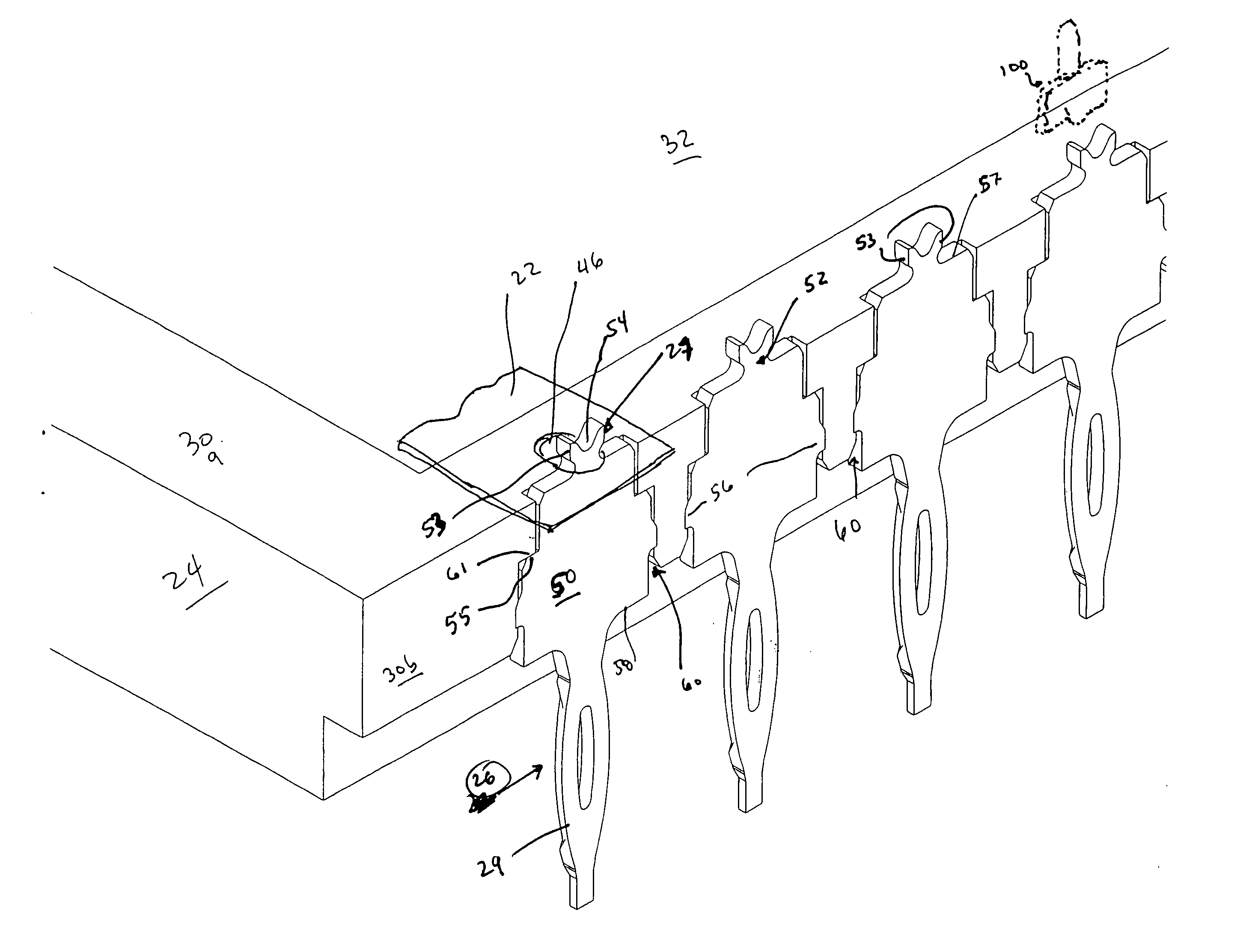

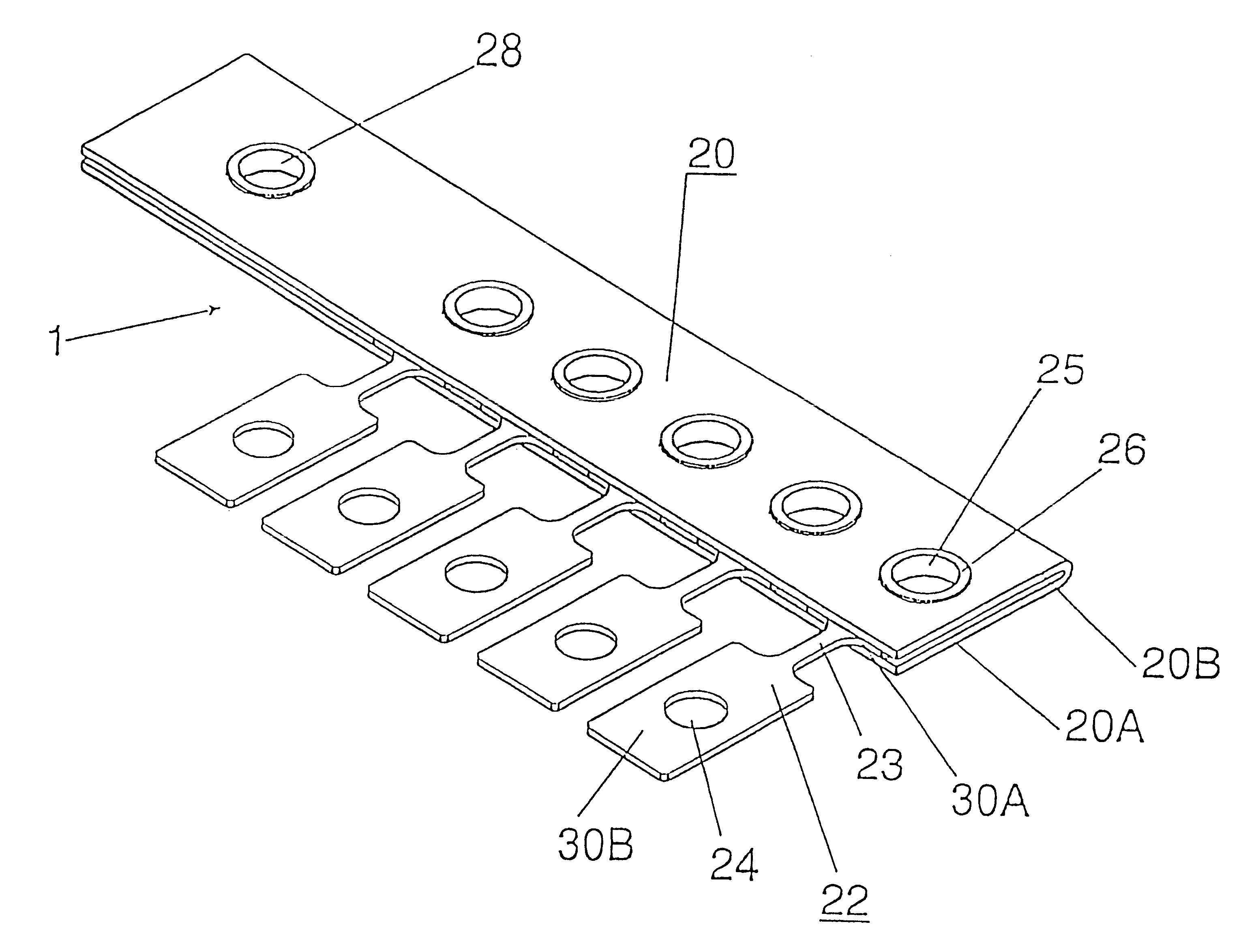

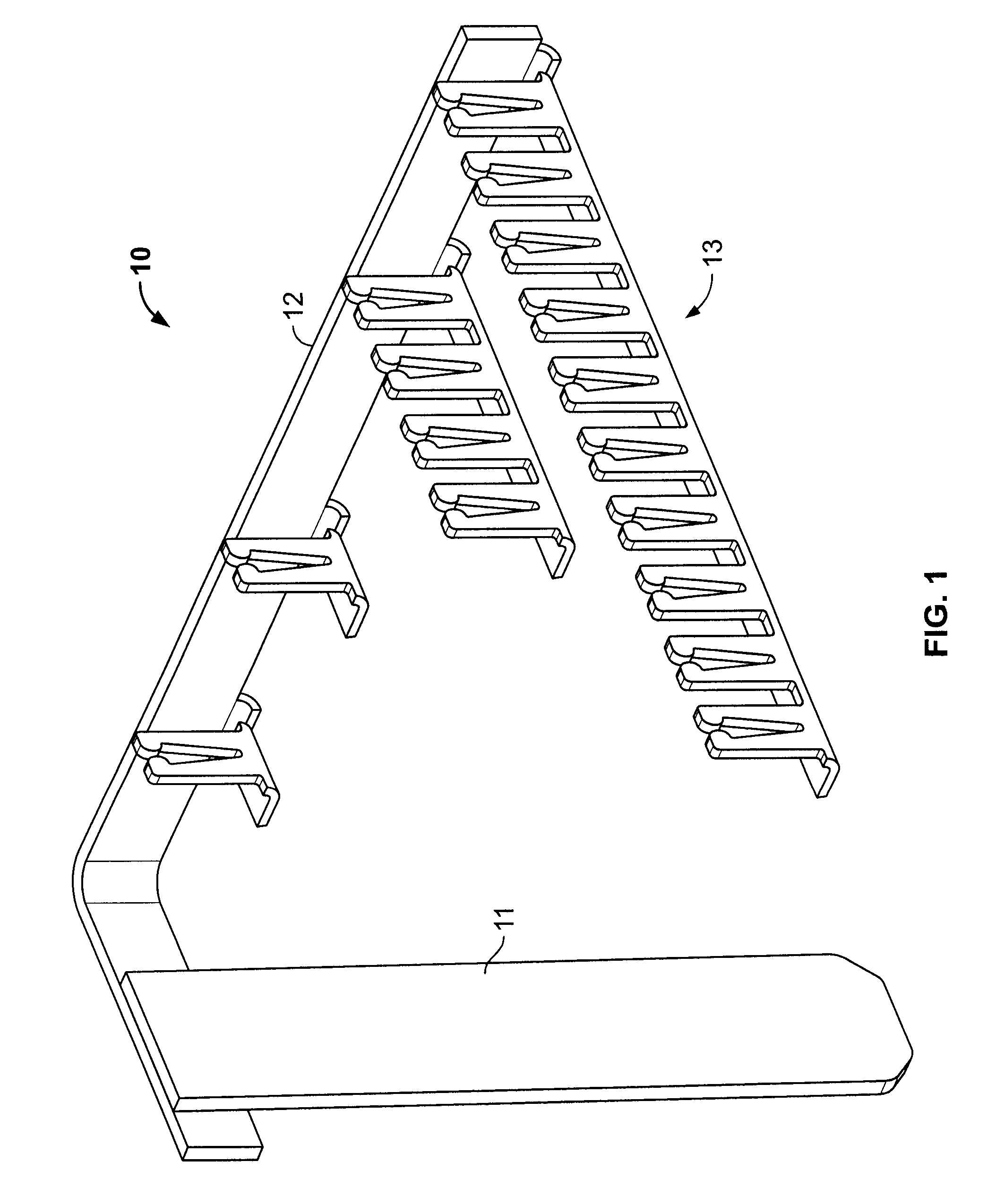

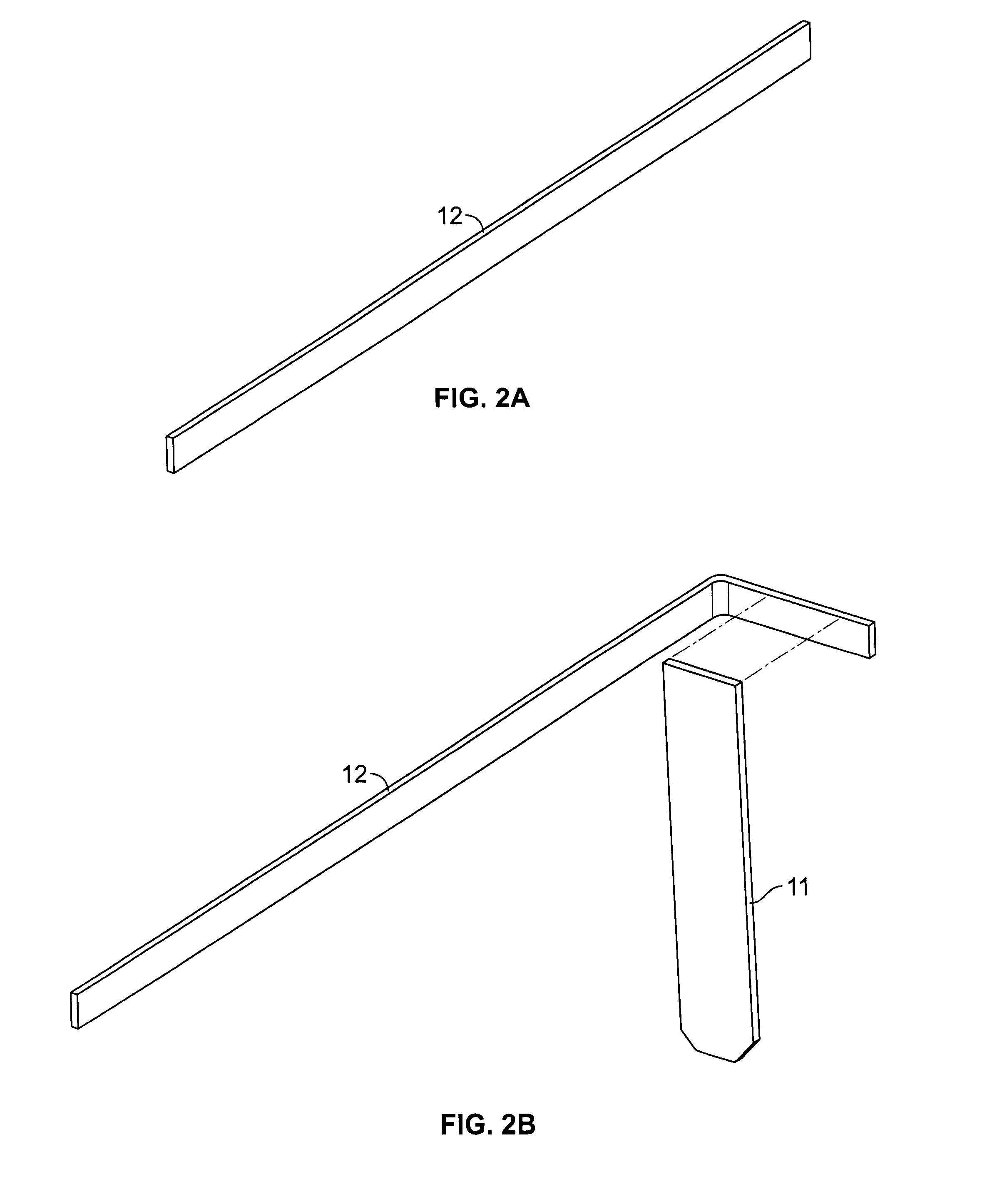

Modular power distribution center

ActiveUS7591653B2Riveted connectionsClip conductor connectionInterconnectivityPower distribution center

There is disclosed a modular power distribution center that utilizes connectors for interconnectivity, as opposed to hard wiring and allows for the integration of electronics modules onto printed circuit board architecture.

Owner:AEES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com