National standard plug support and manufacturing method thereof

A production method and national standard technology, which are applied in the manufacture of contacts, assembly/disassembly of contacts, and contact parts, etc., can solve the problems of inability to achieve rapid production, high material and labor costs, and cumbersome operation process, and achieve increased stability. The effect of large, safety performance improvement, process and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

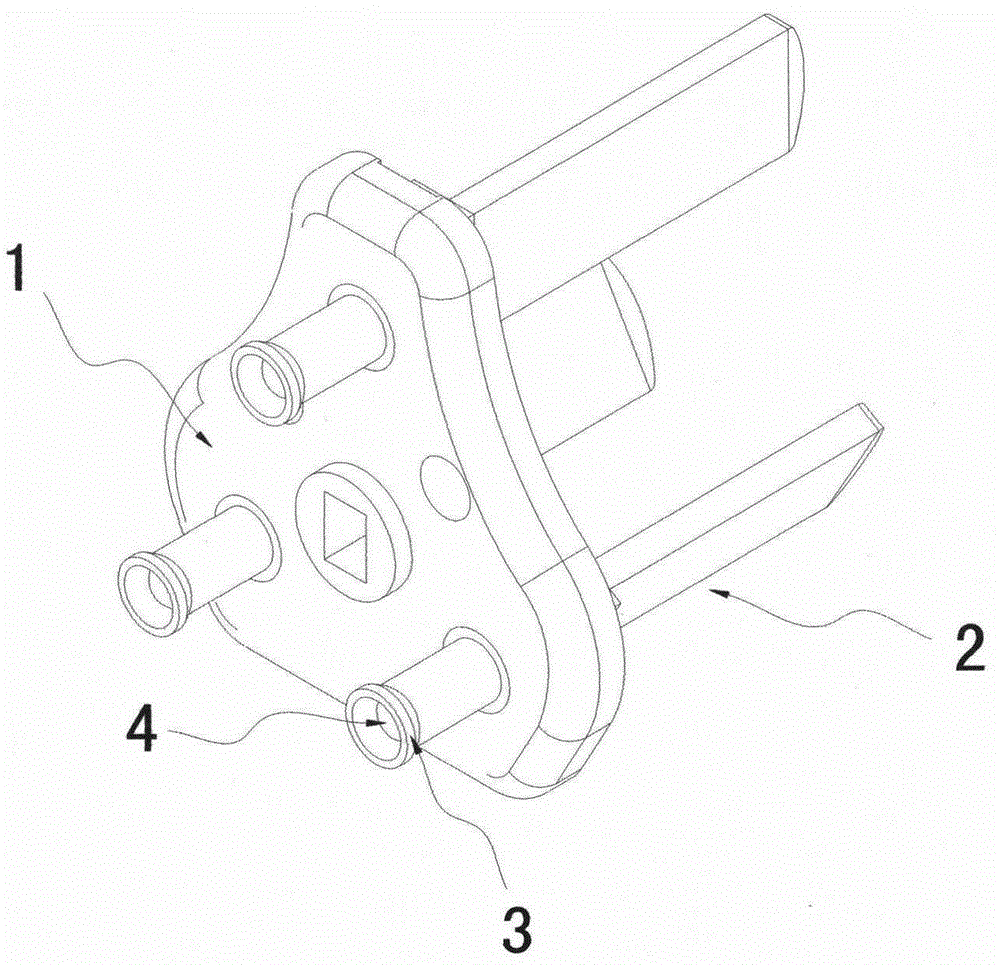

[0014] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

[0015] A method for manufacturing a national standard plug bracket, comprising the following steps:

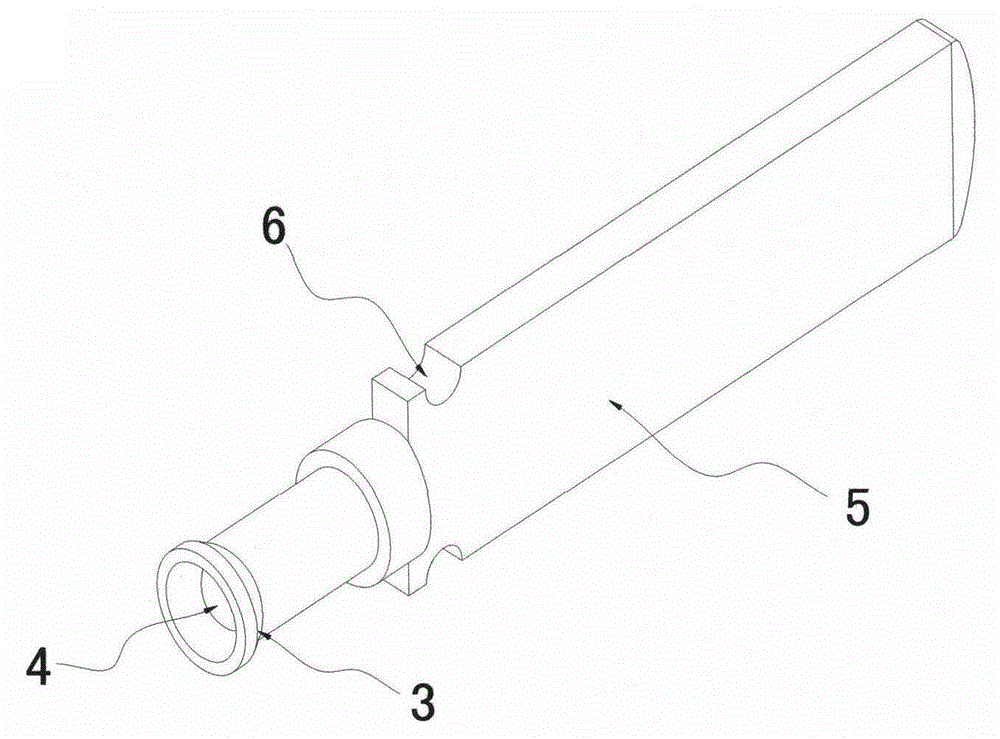

[0016] 1) Using straight rod raw materials, combined with an automatic lathe to turn the bell mouth 3 of the end of the straight rod raw material, and then punch the bell mouth 3, after the punching is completed, cut it off according to the length of the national standard insert to form an insert blank;

[0017] 2) Put the insert blank into the vibrating plate for feeding, and the manipulator sends the insert blank into the stamping die of the automatic punching press to flatten the other end of the straight rod raw material once to form a rough blank, and then carry out the second rough blank. Flatten it for the first time, flatt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com