General jack contact element

A technology of socket contacts and contact rings, which is applied to contact parts, riveted connections, etc., can solve the problems affecting the promotion and use of contacts and low contact reliability, and achieve strong novelty and practicability, reliable contact, Good simultaneous mating and matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

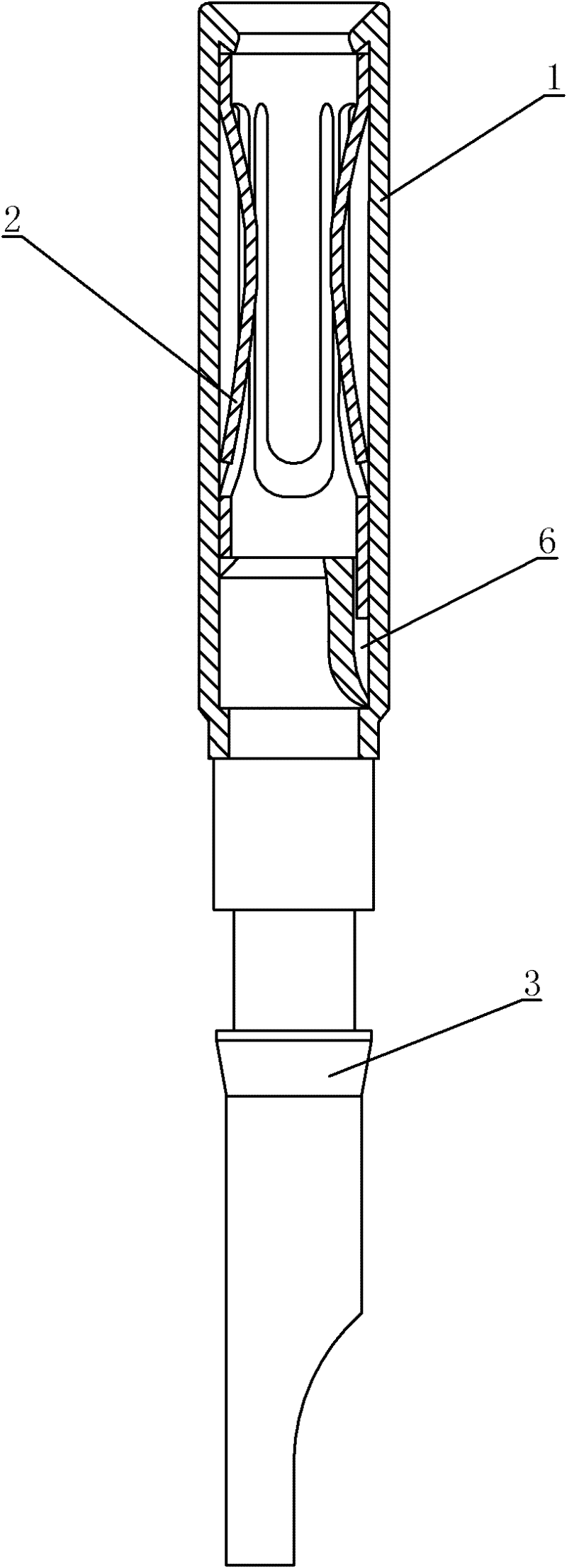

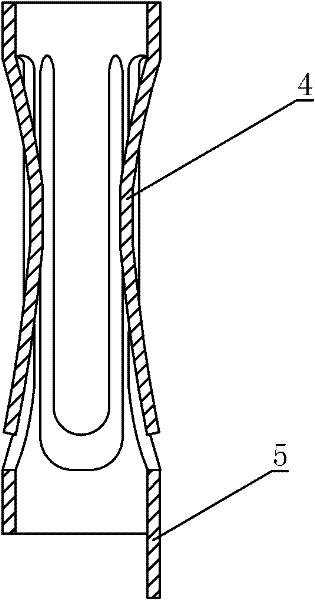

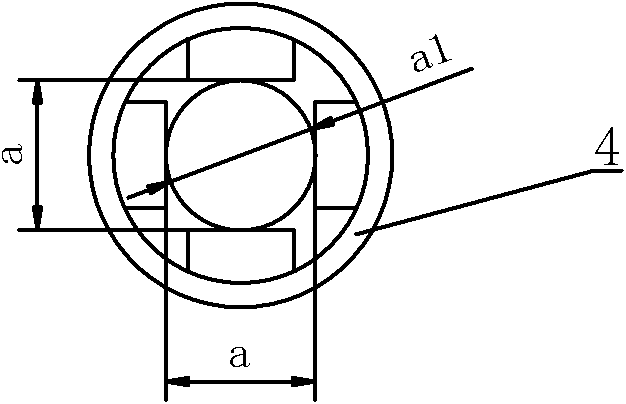

[0017] Such as figure 1 , 2 A universal jack contact shown in and 3 consists of three parts: a sheath 1, a contact ring 2 arranged inside the sheath 1, and a pin 3 connected to the lower end of the sheath 1, and the upper end of the pin 3 A positioning groove 6 is provided, and the contact ring 2 is rolled up by two pairs of parallel elastic arms 4 to form a cylindrical part. There is an interference fit between them, and the lower end of the contact ring 2 is provided with positioning teeth 5 for realizing the circumferential positioning of the contact ring 2 , and the positioning teeth 5 are snapped into the positioning groove 6 .

[0018] The connection method between the pin 3 and the sheath 1 is riveting.

[0019] In the present invention, the contact ring 2 is the core part of the universal jack contact, which is formed into a cylindrical shape with two pairs of parallel elastic arms 4 after blanking, bending, rolling and punching of a 0.1mm thick beryllium copper stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com