Patents

Literature

32results about How to "Low and stable contact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

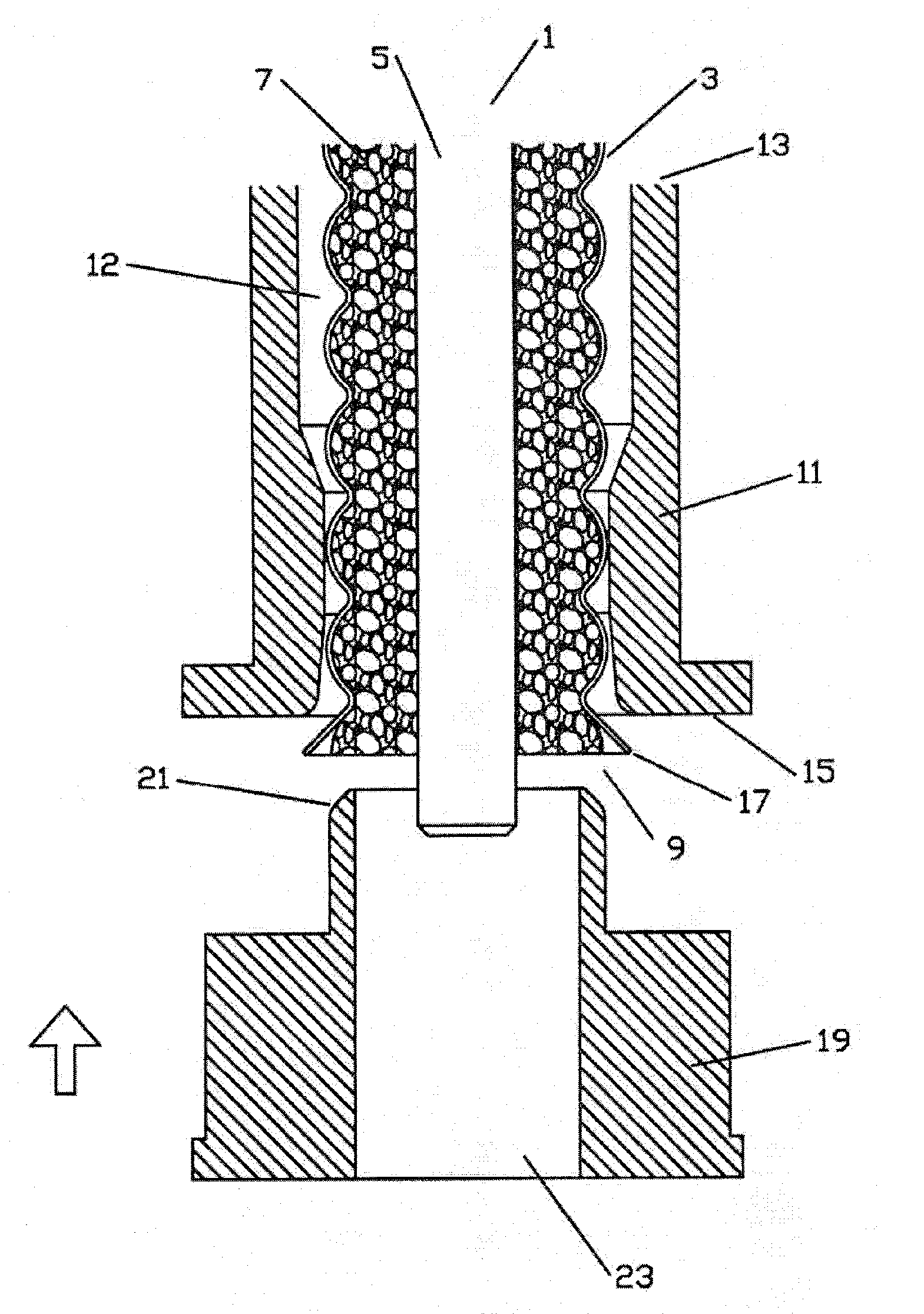

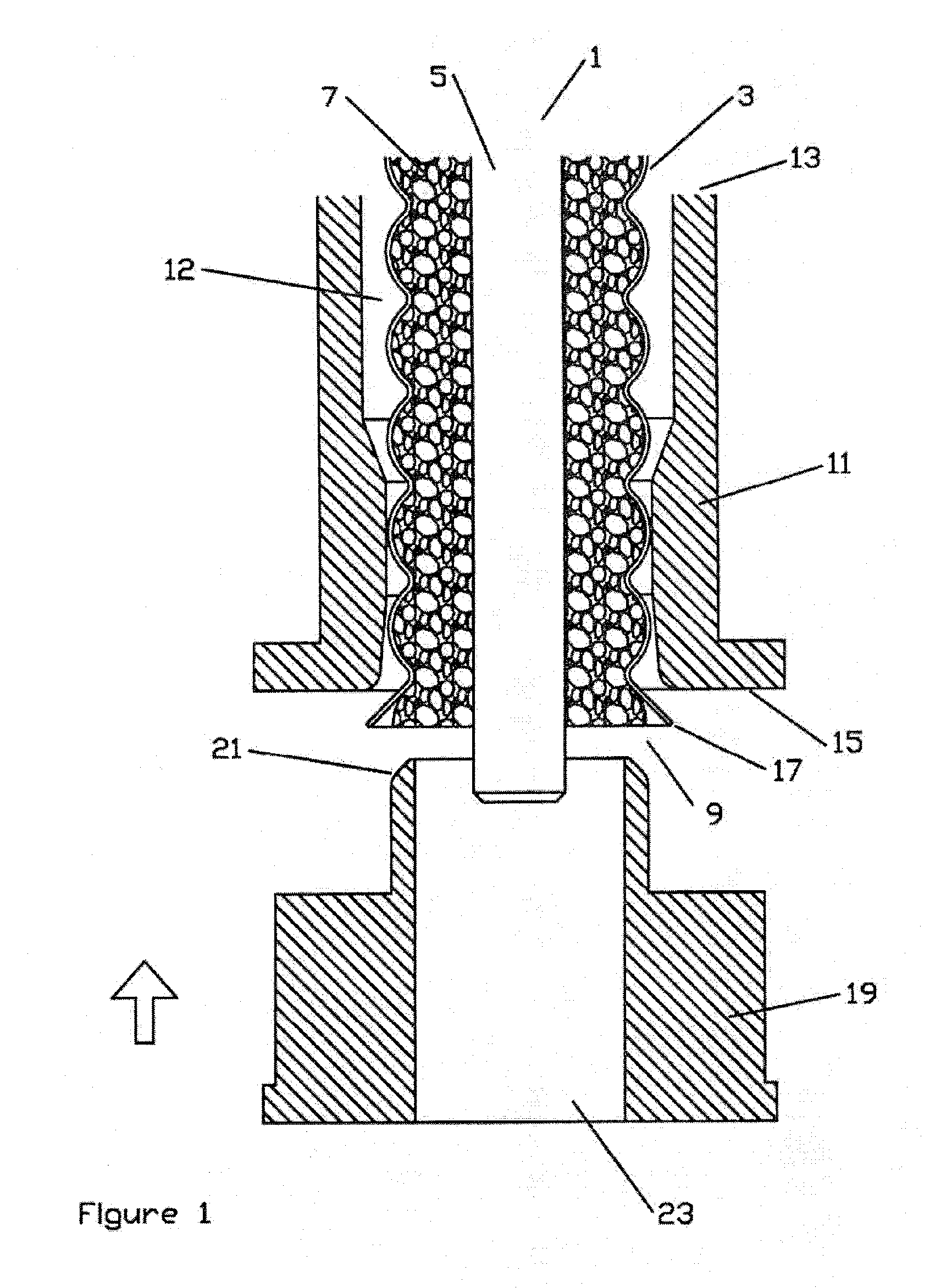

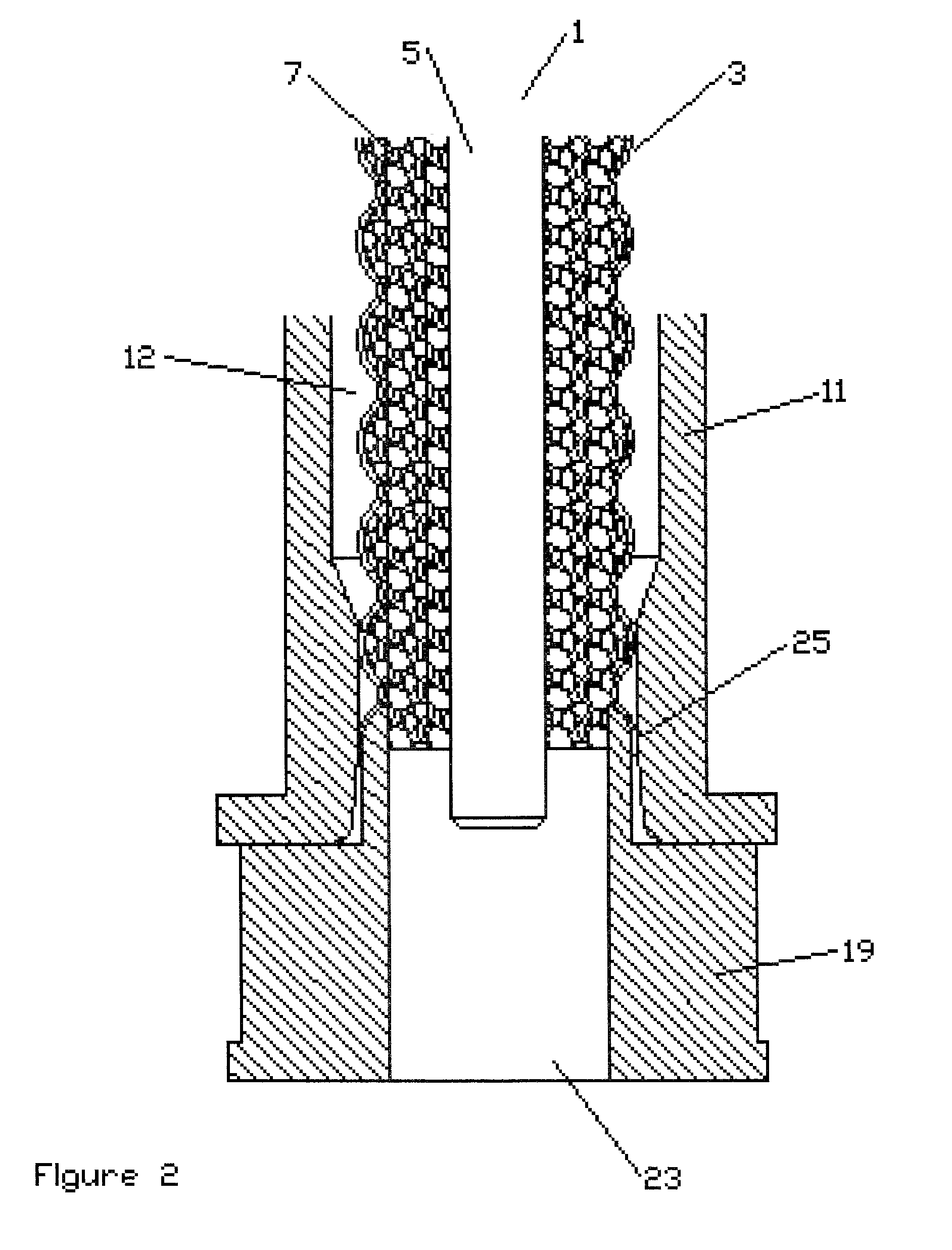

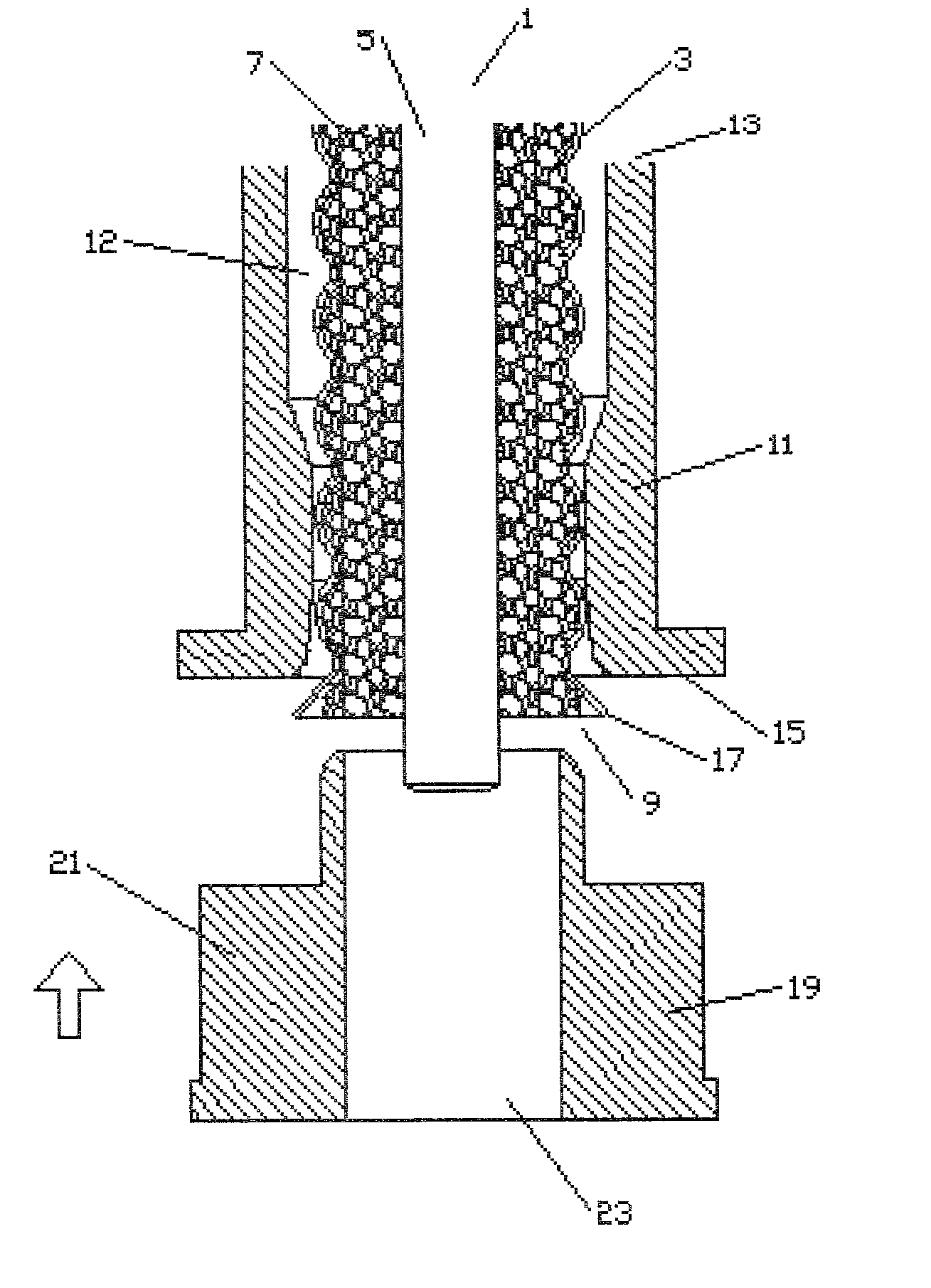

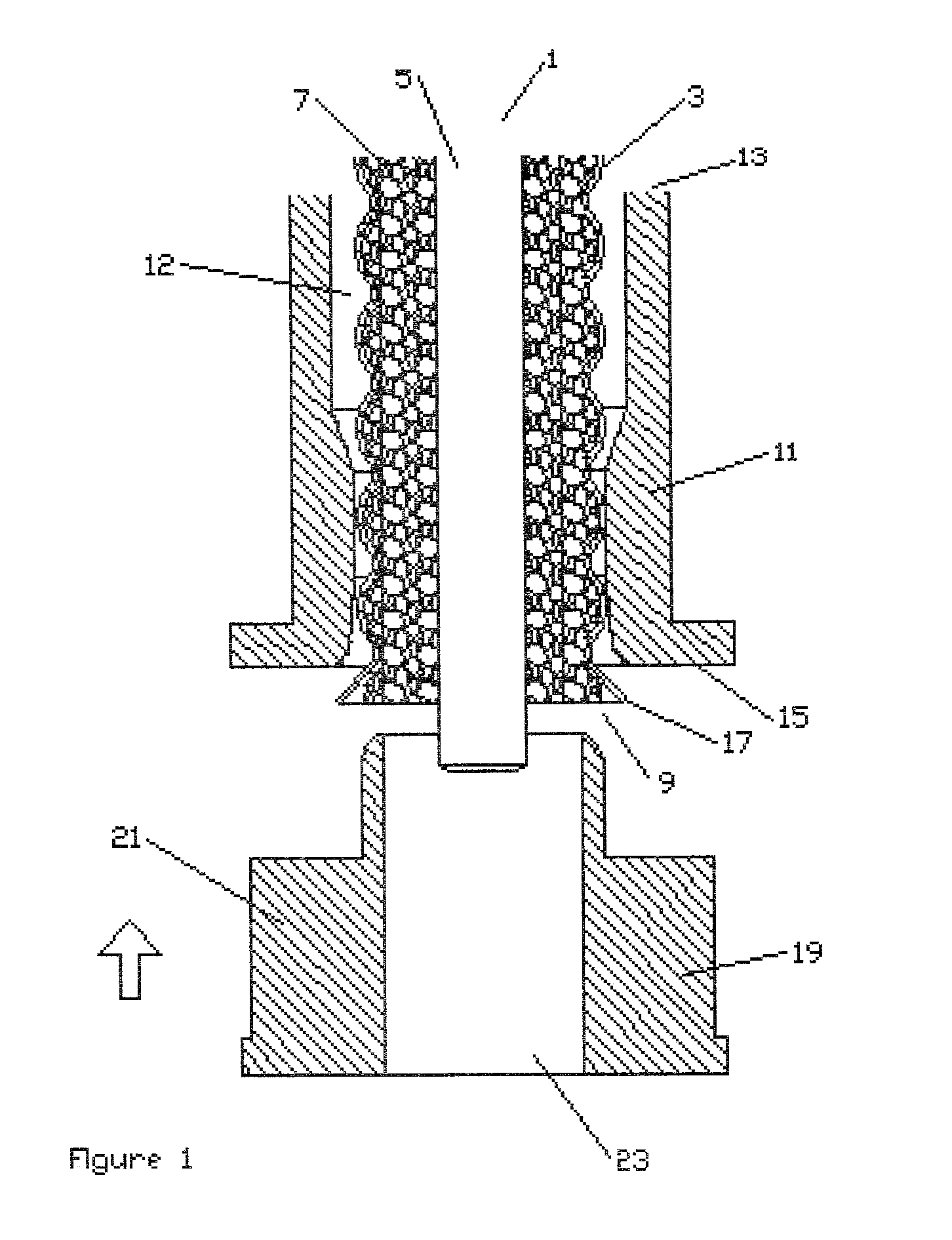

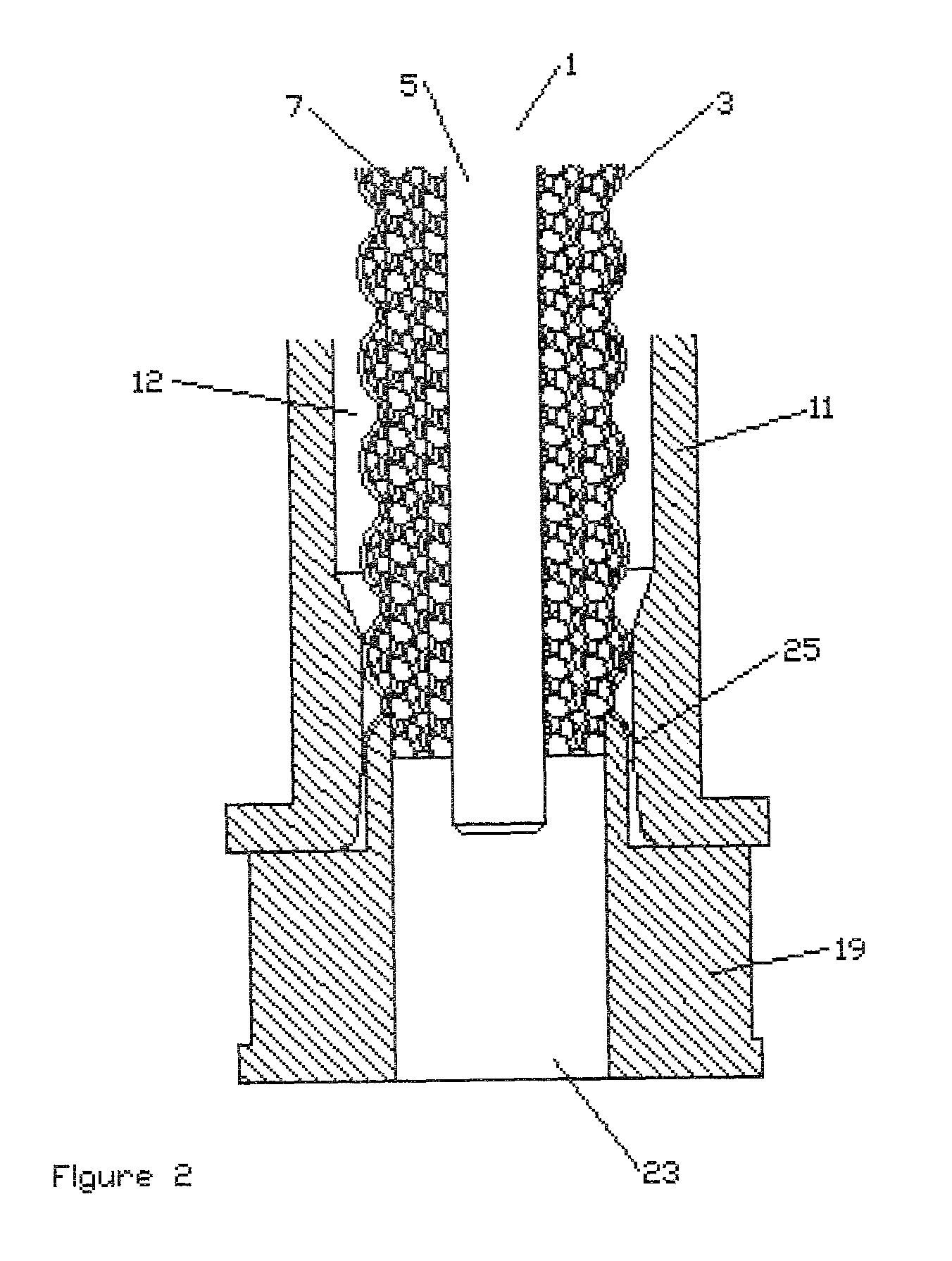

Connector and Coaxial Cable with Outer Conductor Cylindrical Section Axial Compression Connection

InactiveUS20050159044A1Improve electrical performanceReduce material costsElectrically conductive connectionsTwo pole connectionsInterference fitCoaxial cable

A connector and coaxial cable interconnectable via axial compression upon a cylindrical section of a solid outer conductor of the cable. The cylindrical section may be formed in the cable by drawing a cable end into an interference fit between a sleeve and an outer conductor seat formed in the connector body. Alternatively, the cylindrical section may be formed in the outer conductor during cable manufacture and the cylindrical section retained between the outer conductor seat and a crimp ring radially deformed by an angled die face during axial compression. To increase flexibility of a straight walled cable, annular corrugations may be formed in the solid outer conductor with the cylindrical sections at each corrugation peak. The cylindrical section having a length of at least 3 millimeters or 4 times the corrugation depth.

Owner:ANDREW CORP

Connector and Coaxial Cable with Outer Conductor Cylindrical Section Axial Compression Connection

InactiveUS20050159043A1Improve electrical performanceReduce material costsContact member manufacturingElectrically conductive connectionsInterference fitCoaxial cable

A connector and coaxial cable interconnectable via axial compression upon a cylindrical section of a solid outer conductor of the cable. The cylindrical section may be formed in the cable by drawing a cable end into an interference fit between a sleeve and an outer conductor seat formed in the connector body. Alternatively, the cylindrical section may be formed in the outer conductor during cable manufacture and the cylindrical section retained between the outer conductor seat and a crimp ring radially deformed by an angled die face during axial compression. To increase flexibility of a straight walled cable, annular corrugations may be formed in the solid outer conductor with the cylindrical sections at each corrugation peak. The cylindrical section having a length of at least 3 millimeters or 4 times the corrugation depth.

Owner:ANDREW LLC

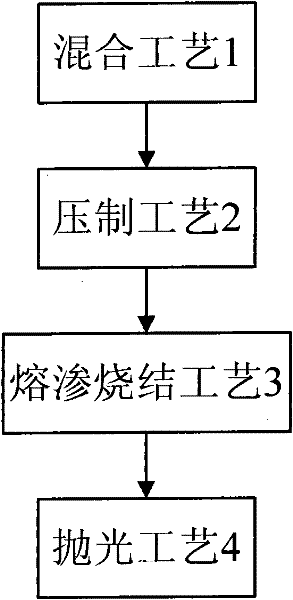

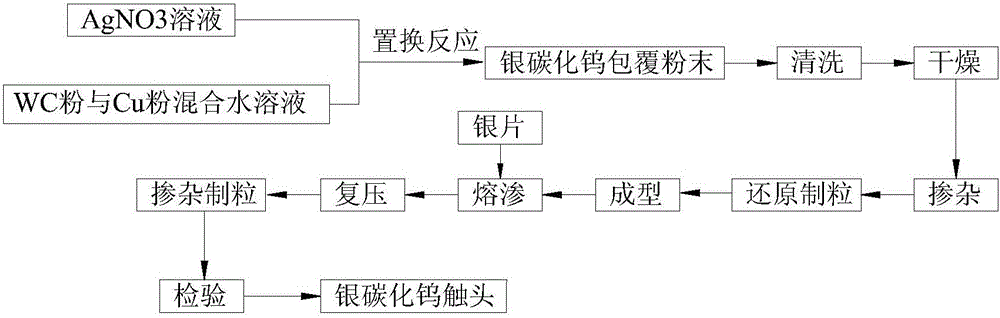

AgWC (wolfram carbide) electrical contact material and manufacturing method thereof

InactiveCN101834070AReduce manufacturing costImprove pass rateContact materialsCarbideHeating furnace

The invention relates to an AgWC (wolfram carbide) electrical contact material and a manufacturing method thereof, in particular to a silver-based electric contact material and a manufacturing method thereof, belonging to the technical field of electrical contact materials. A substrate of the AgWC electrical contact material is infiltrated with silver from upper surface to lower surface. The manufacturing method comprises the following steps of: obtaining Ag and WC mixed powder by applying a powder mixing process; pressing the mixed powder into a powder billet by applying a powder pressing process; then putting a prepared thin silver sheet on the powder billet by applying an infiltration sintering process, conveying into a heating furnace and heating, melting the silver sheet and infiltrating into the powder billet to further obtain an AgWC electric contact; and beautifying the surface of the AgWC electric contact by applying a polishing process. The AgWC electric contact manufactured by adopting the manufacturing process has favorable electric conduction performance and heat conduction performance, high corrosion resistance, strong fusion welding resistance, and the like.

Owner:SHANGHAI DIANKE ELECTRICAL MATERIAL CO LTD

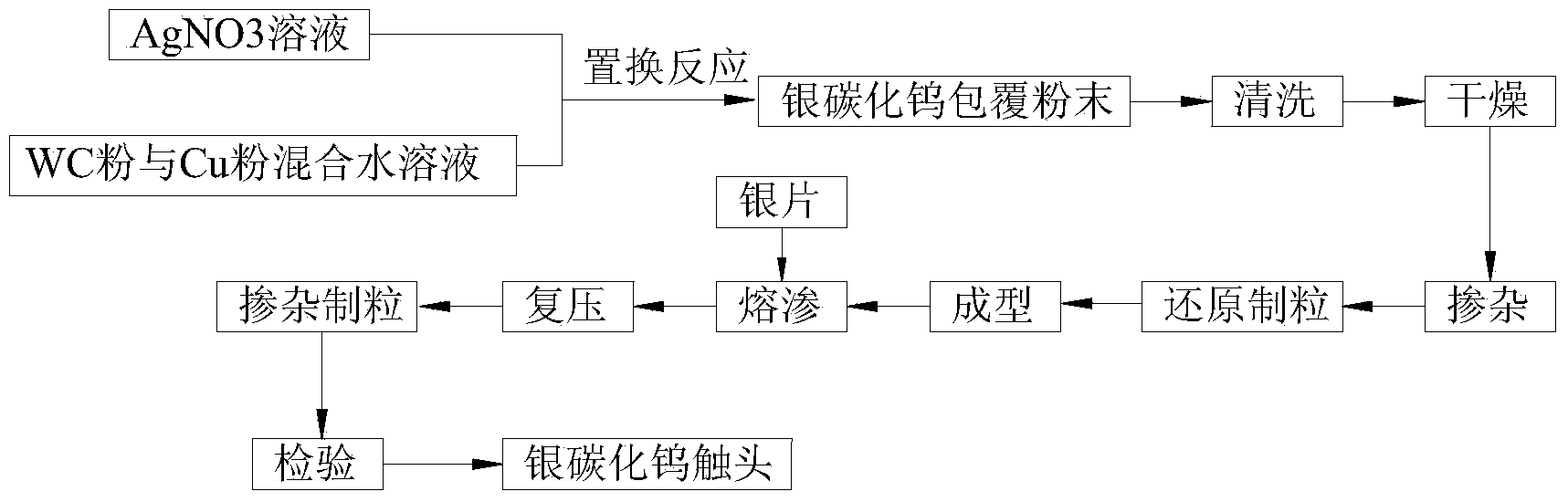

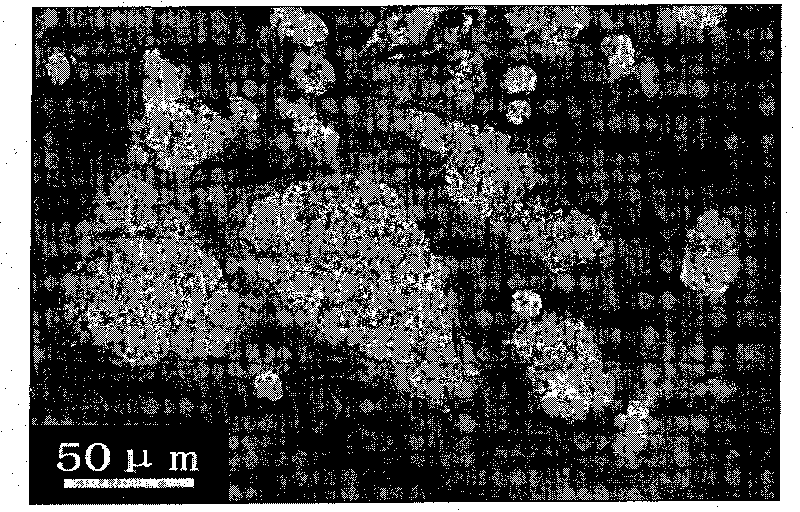

Method for preparing silver-tungsten carbide contact material from silver-coated tungsten carbide powder and silver-tungsten carbide contact material

ActiveCN103824710AHigh densityHigh hardnessContactsElectrical resistance and conductanceHigh density

The invention discloses a method for preparing a silver-tungsten carbide contact material from silver-coated tungsten carbide powder and the silver-tungsten carbide contact material. According to the technical scheme, a silver-tungsten carbide electrical contact is prepared from raw materials, i.e., a silver nitrate crystal and tungsten carbide powder, by a chemical coating powder preparation process and a liquid-phase infiltration process; the prepared silver-tungsten carbide electrical contact comprises the following components in percentage by weight: 38%-42% of tungsten carbide, 0-0.2% of additives and the balance being silver, wherein the additives are one or more selected from nickel, copper and zirconium. The silver-tungsten carbide contact material prepared by the method has the advantages of high density, high hardness, low and stable contact resistance, uniform metallographic structure, favorable high-temperature oxidation resistance, electric arc erosion resistance, wear resistance and the like.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

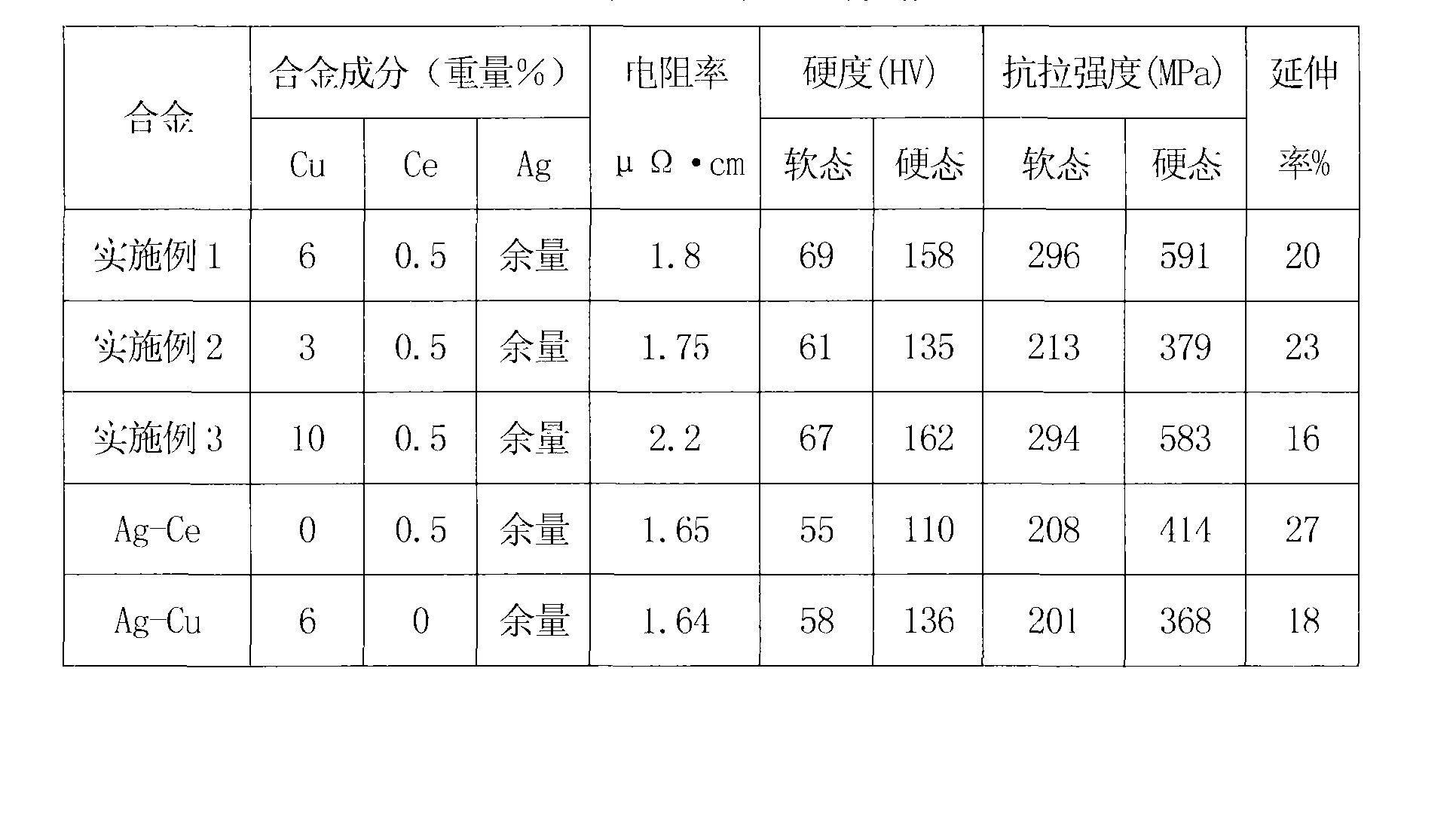

Novel silver alloy electrical contact material

The invention relates to ternary silver alloy of silver, copper and cerium, in particular to breaking contact and sliding contact alloy material of medium and small-load low-voltage electrical appliances. The alloy material contains 3 percent to 10 percent of Cu, 0.3 percent to 0.7 percent of Ce and the rest percent of Ag according to weight. The material has good electrical contact performance and long service life and can respectively serve as the breaking contact and sliding contact alloy material so as to be applied to the medium and small-load low-voltage electrical appliances.

Owner:SINO PLATINUM METALS CO LTD

High-voltage tungsten-base composite contact material and method for making same

The invention relates to the technical field of electrical contact materials, in particular to a tungsten-base electrical contact material and a method for making the same. The high-voltage tungsten-base composite contact material comprises a tungsten substrate, wherein the tungsten substrate comprises nickel, copper and a caking agent, and the copper is infiltrated into the tungsten substrate. The method for making the high-pressure tungsten-base contact material comprises the following the steps of: 1, mixing, namely ball-milling and refining tungsten powder and activated nickel to obtain alloy powder, doping copper powder into the alloy powder and mixing, and adding the caking agent to obtain mixed powder; 2, pressing, namely placing the mixed powder in a mould, and pressing to obtain a press blank; and 3, infiltrating and sintering, namely placing the press blank in a sintering furnace for pre-sintering to form a skeleton, forming pores under the conditions of high temperature and protective atmosphere, melting the copper and casting on the skeleton, and infiltrating into the skeleton. The high-pressure tungsten-base composite contact material produced by the method has the advantages of high electric conduction performance, good heat conduction performance, high corrosion resistance, strong fusion welding resistance and the like.

Owner:SHANGHAI DIANKE ELECTRICAL MATERIAL CO LTD

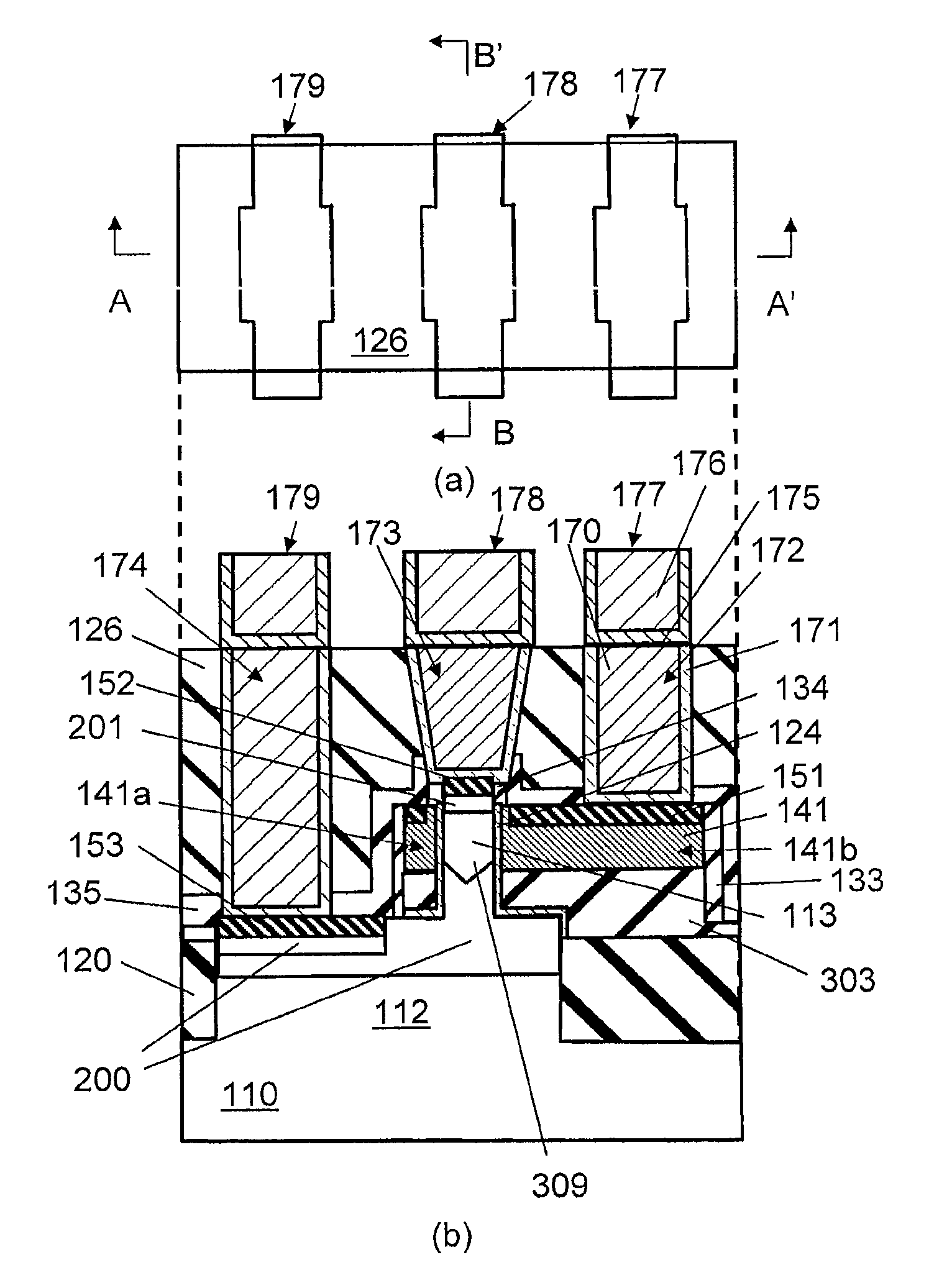

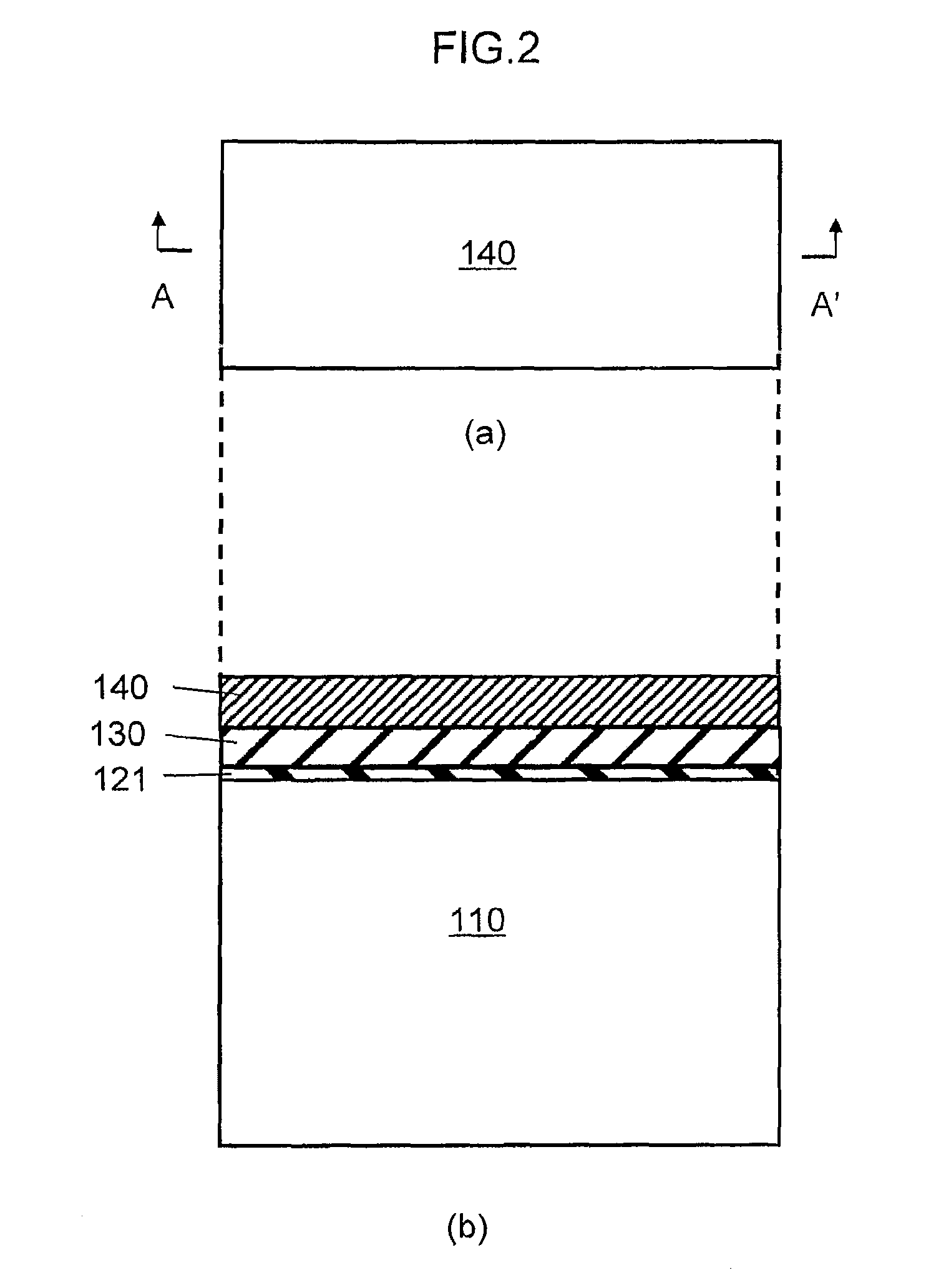

Semiconductor device and production method thereof

ActiveUS8563379B2Low and stable contact resistanceTransistorSemiconductor/solid-state device manufacturingEngineeringContact layer

A method for producing a semiconductor device includes preparing a structure having a substrate, a planar semiconductor layer and a columnar semiconductor layer, forming a second drain / source region in the upper part of the columnar semiconductor layer, forming a contact stopper film and a contact interlayer film, and forming a contact layer on the second drain / source region. The step for forming the contact layer includes forming a pattern and etching the contact interlayer film to the contact stopper film using the pattern to form a contact hole for the contact layer and removing the contact stopper film remaining at the bottom of the contact hole by etching. The projection of the bottom surface of the contact hole onto the substrate is within the circumference of the projected profile of the contact stopper film formed on the top and side surface of the columnar semiconductor layer onto the substrate.

Owner:UNISANTIS ELECTRONICS SINGAPORE PTE LTD

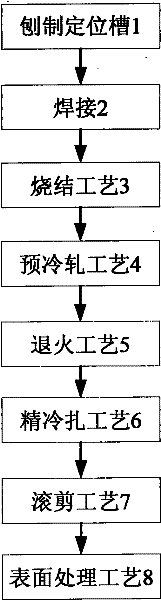

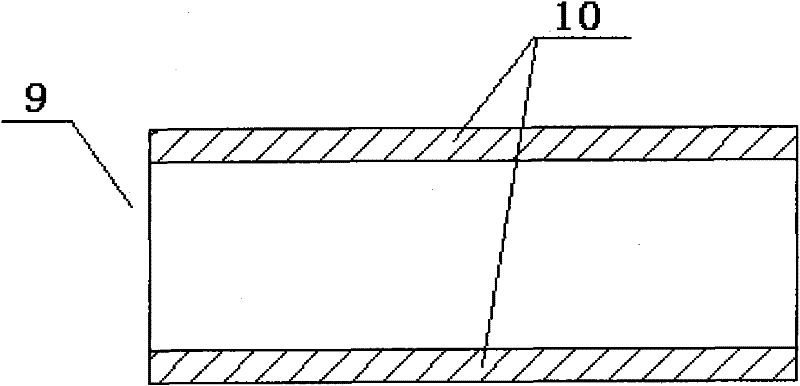

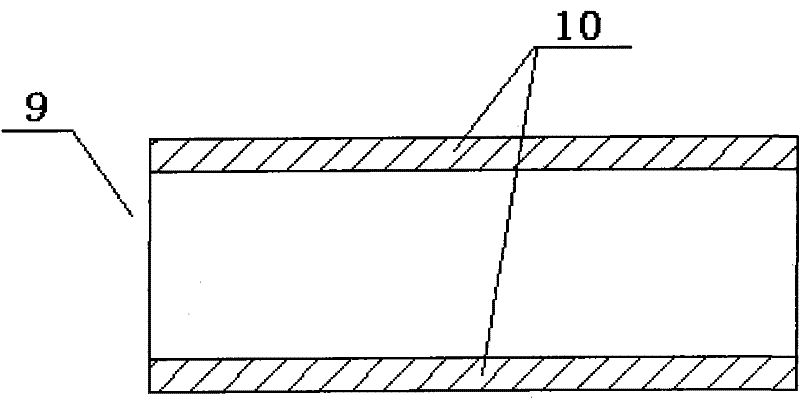

Alloy-copper embedded copying silver material of automobile electric appliance and method for making alloy-copper embedded copying silver material

InactiveCN102237205AImprove conductivityImprove thermal conductivityContact materialsElectricityAlloy

The invention relates to the technical field of electrical contact materials, in particular to a copper copying silver material and a method for making the alloy-copper embedded copying silver material. The alloy-copper embedded copying silver material of an automobile electric appliance comprises a brass plate substrate; a positioning groove is arranged on the brass plate substrate; and a silver bar is arranged on the positioning groove and is fixedly melted with the brass plate substrate into a whole. The method for making the alloy-copper embedded copying silver material of the automobile electric appliance comprises the following steps of: 1, digging the positioning groove; 2, welding; 3, sintering; 4, pre-cold rolling; 5, annealing; 6, finely cold rolling; 7, rolling and shearing; and 8, performing surface treatment. The alloy-copper embedded copying silver material, which is produced by the method of the automobile electric appliance has the advantages of high electric conduction performance, good heat conduction performance, high corrosion resistance, strong fusion welding resistance and the like; a contact bridge and a contact are connected into a whole, so the material can be used in frequently-acted automobile appliances, particularly frequency-acted electric appliances such as automobile brake lamp switches and automobile window switches.

Owner:SHANGHAI DIANKE ELECTRICAL MATERIAL CO LTD

Preparation method for silver-based alloy contact material

InactiveCN108149122AWidely used valueShorten heating timeTransportation and packagingMetal-working apparatusHeating timeInternal oxidation

The invention relates to a preparation method for a silver-based alloy contact material. Silver powder, tungsten powder, nickel powder, copper powder, aluminum powder and titanium carbide are mixed proportionally and them smelted in vacuum, and melted liquid is atomized into powder; the obtained powder is put into an oxidation furnace for internal oxidation treatment, and internally oxidized alloypowder is obtained; and the procedures of cold pressing, high temperature sintering, re-pressing, extruding and drawing of the internally oxidized alloy powder are conducted, and the silver-based alloy contact material is obtained. Through the method, the heating time of materials at a high temperature is greatly shortened, losses of silver materials are reduced, through internal oxidation, oxidephases are diffused and evenly distributed in matrix phases, the alloy reinforcement effect is achieved, meanwhile, through raw material optimization and matching, the oxide phases of the adopted rawmaterials can remarkably improve the electric resistance, fusion welding resistance and abrasion resistance of the alloy material, and the alloy material can be better applied to the field of electronic devices.

Owner:LUOYANG SHENJIA KILN

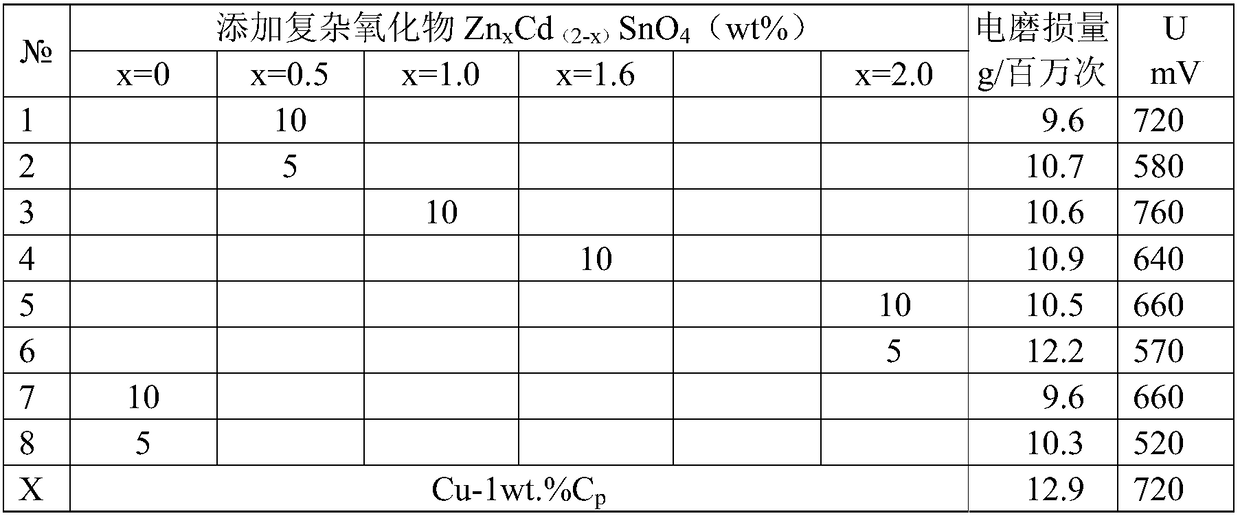

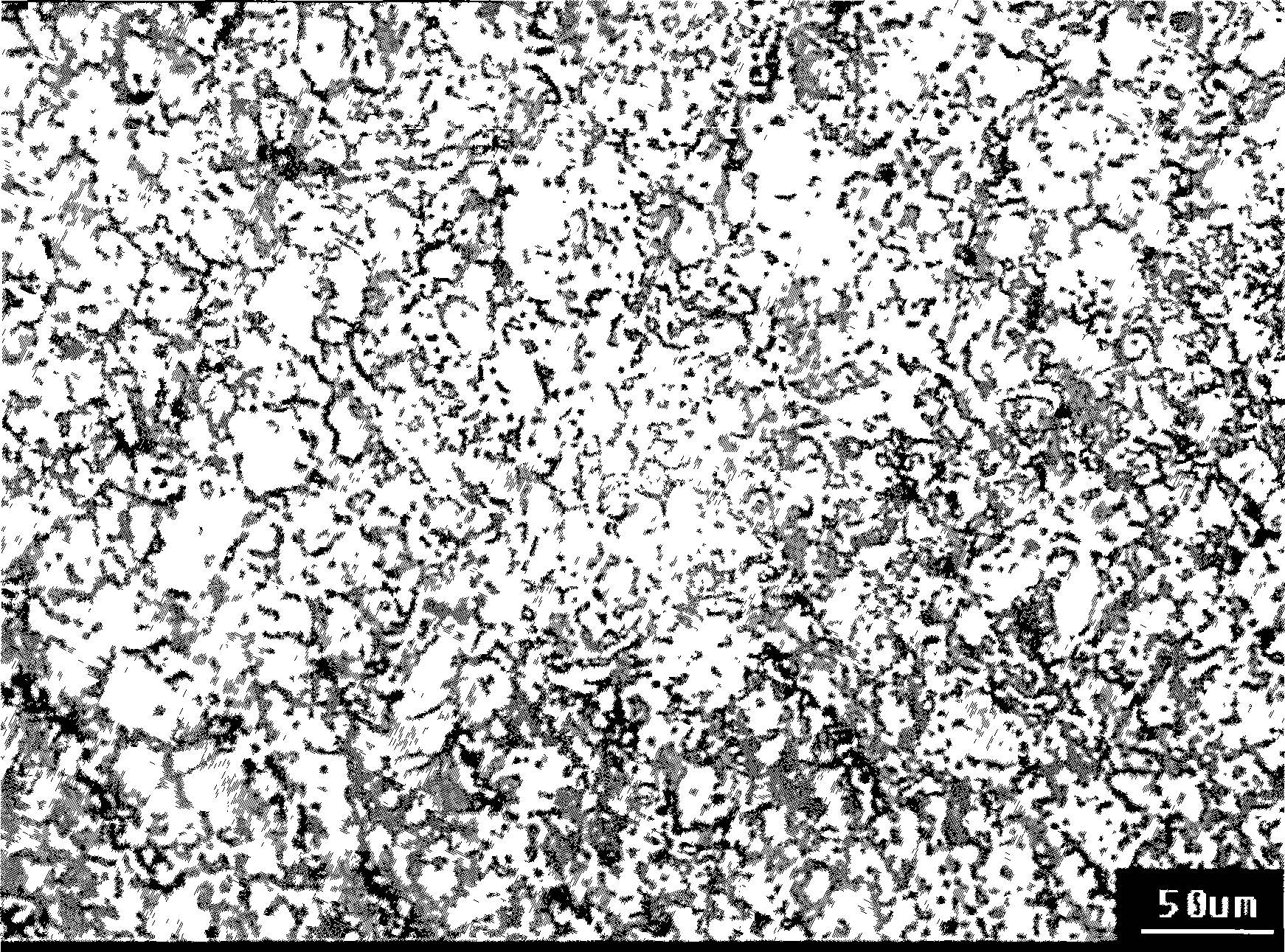

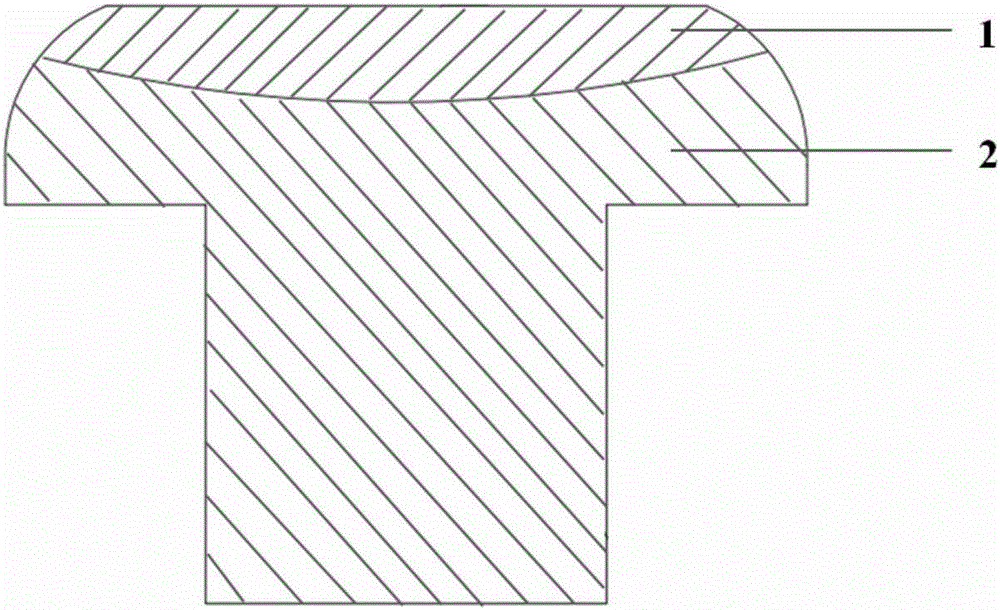

Complex conductive oxide-modified copper-based electric contact material and preparation method thereof

InactiveCN108690920AImproved arc erosion resistanceLow and stable contact resistanceContactsLow voltageLanthanum

The invention discloses a complex conductive oxide-modified copper-based electric contact material and a preparation method thereof, and relates to a copper-based electric contact material and a preparation method thereof. The invention aims at solving the problem of short life of a break contact of a low-voltage electrical appliance switch. The complex conductive oxide-modified copper-based electric contact material is composed of complex conductive oxide, lanthanum, zirconium and the balance copper in percentage by mass; and the molecular formula of the complex conductive oxide is ZnxCd(2-x)SnO4, and x in the molecular formula is 0-2. The preparation method comprises the following steps: weighing cadmium acetate dihydrate, dihydrate dihydrate, tin chloride pentahydrate and copper alloy powder, and dissolving the raw materials into distilled water separately and stirring to obtain a suspension, adjusting the pH value to obtain precipitates, washing, carrying out vacuum drying, calcining, sieving, carrying out cold-pressing molding, sintering, and extruding or rolling. The contact part prepared from the material disclosed by the invention is high in contact conducting capacity, self-arc-extinguishing capacity, matrix wettability and arc erosion resistance. The preparation method disclosed by the invention is applicable to preparation for the copper-based electric contact material.

Owner:HARBIN INST OF TECH

Copper-based electric contact material for low-voltage apparatus

The invention discloses design and preparation for a copper base alloy of an electrical contact material for a low-voltage electric appliance. The design is characterized in that the alloy comprises the following compositions in weight percent: 0.5 to 3 percent of Ni, 0.1 to 0.5 percent of Zr, 0.1 to 0.5 percent of Y, and the balance being Cu. The preparation comprises the following process routes: preparing a CuY and CuZr intermediate alloy raw material by Cu+ and Ni+ in vacuum; obtaining CuNiZrY alloy powder by using a self air-water sharp quenching and atomizing powder-preparing technique and equipment under an atmosphere state; preparing formed blank by a powder metallurgy process (forming and sintering, repressing and re-sintering, and CIP and sintering); obtaining semi-finished product blank of wires or sheets by hot extrusion; obtaining semi-finished products through thermal treatment; and obtaining finished products through cold working. The alloy has the characteristics of low but stable contact resistance, high oxidation resistance, strong electric arc erosion resistance and fusion welding resistance property, long electric life, and the like; and can be used for electrical contacts for low-voltage electric appliances.

Owner:KUNMING INST OF PRECIOUS METALS

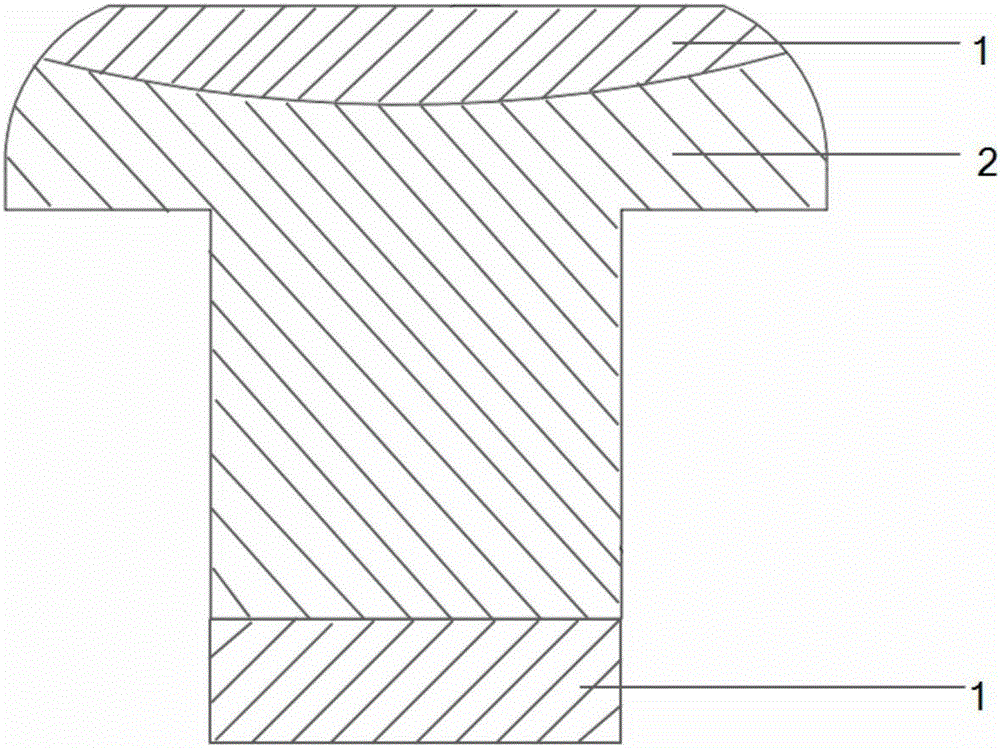

Copper-coated-with-silver graphene composite rivet contact and preparation method therefor

The invention provides a copper-coated-with-silver graphene composite rivet contact and a preparation method therefor. The contact comprises a main body, and the head part and / or tail part of the main body are / is provided with a silver graphene composite layer. Silver graphene is used for a covering material of the head part or tail part of a rivet, and the prepared contact is good in conductivity, is high in hardness, and is long in service life. Meanwhile, the method is simple, is good in technological controllability, is easy to achieve scale production, is uniform in material organization, and is stable in performance.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

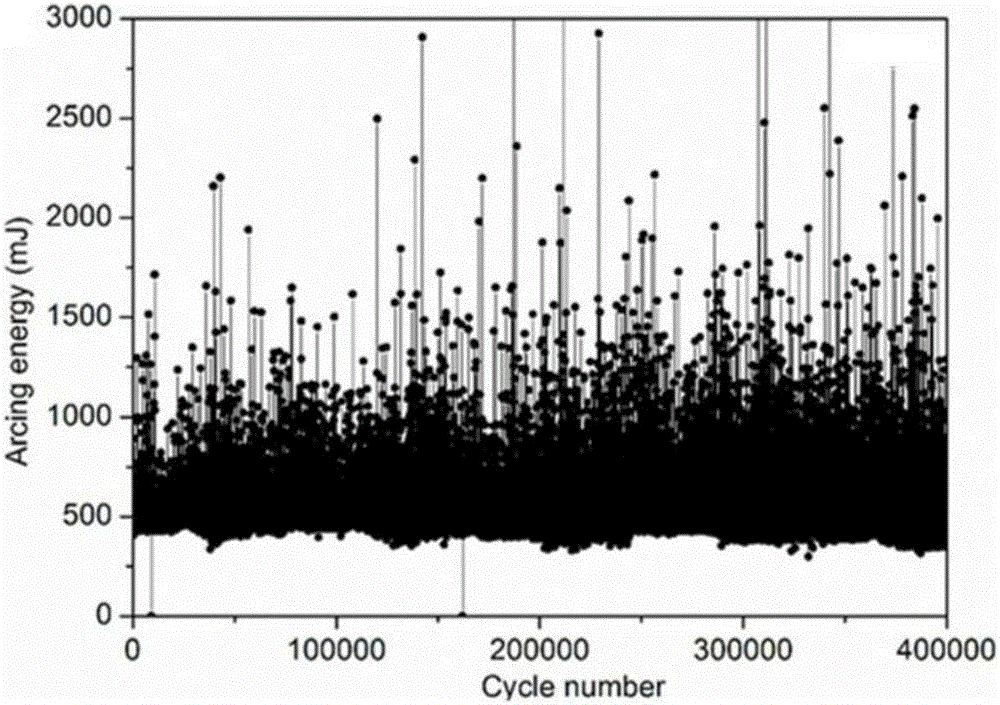

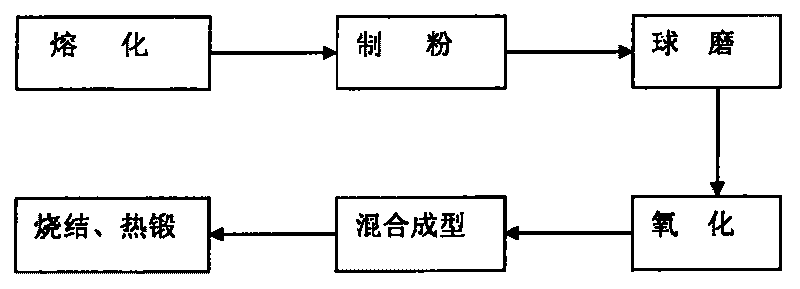

A silver-ZnO electric contact and its making method

InactiveCN101241804BGuaranteed uniformity of distributionChange the internal microstructureContactsElectrical resistance and conductanceAlloy

The present invention provides a silver-zinc oxide electrical contact and the preparing method thereof. The electric contact related by the invention is composed of silver, zinc oxide and additive. The preparing method comprises the following procedures: preparing Ag and Zn in proportion, preparing Ag-Zn alloy powder with gas atomizing after melting, oxidizing the alloy powder after abrasive processing, adding additive, and preparing the thread material or sheet material after the techniques of molding, sintering and hot processing. The silver-zinc oxide prepared with the invention has the advantages of sufficient zinc oxidizing, high oxidation efficiency, dispersed arrangement of zinc oxide at the inner part of the power particle, uniform formation, excellent combination property, excellent fusion welding resistance, excellent electrical arc corrosion resistance, low and stable contact resistance, easy soldering, and no danger to the human body and environment. The invention is suitable for industrial production and can replace the poisonous silver-cadmium oxide contact.

Owner:CENT SOUTH UNIV

Platinum alloy containing Sc for highly-conductive highly-thermal-conductive electric contact material

InactiveCN107653392AReduce the amount of alloying elements usedGood electrical conductivity and mechanical propertiesMetal/alloy conductorsThermal conductivityChemical composition

The invention discloses a platinum alloy containing Sc and used as a high-conductivity and high-heat-conduction electrical contact material. In terms of weight percentage, the chemical composition of the alloy is: Sc:1.5‑2.0wt.%, Y:1.5‑2.0wt.%, Mo:0.8‑1.2wt.%, Sn:0.2‑0.6wt.%, Si:1.2‑ 2.6wt.%, Pd: 0.5‑1.0wt.%, Ho: 0.2‑0.6wt.%, Pr: 0.2‑0.5wt.%, B: 0.2‑0.5wt.%, and the balance is platinum. Compared with traditional electrical contact platinum alloys, this material has excellent mechanical properties, thermal conductivity and electrical conductivity.

Owner:GUANGZHOU YUZHI TECH CO LTD

Copper-based contact material for low-voltage apparatus

InactiveCN102306512AImprove conductivityImprove thermal conductivityMetal/alloy conductorsElectrical resistance and conductanceHazardous substance

The invention discloses a copper-based contact material for a low-voltage apparatus. The copper-based contact material comprises the following components in percentage by mass: 0.01-3 percent of graphite, 0.01-5 percent of boron and the balance of copper alloy. The copper-based contact material has the characteristics of high electric conductivity, heat conductivity, arc burning resistance, welding resistance, excellent anti-oxidant performance, low and stable contact resistance and the like, substitutes a silver alloy contact for the low-voltage apparatus so as to reduce the cost, and meets the European requirement for restriction of the use of certain hazardous substances (ROHS).

Owner:FUDA ALLOY MATERIALS

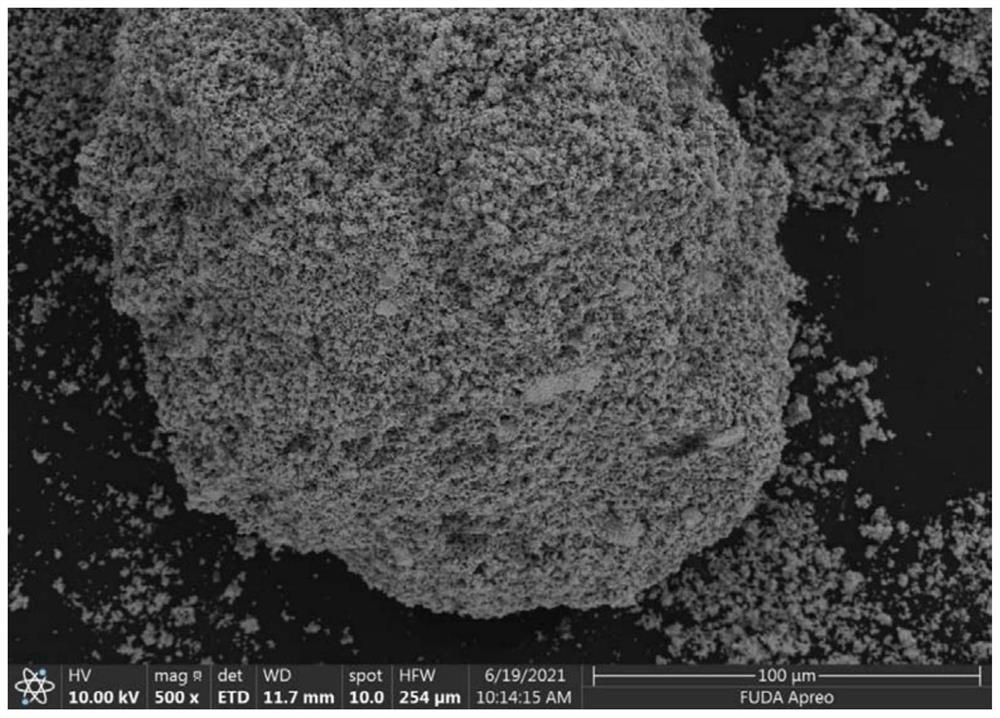

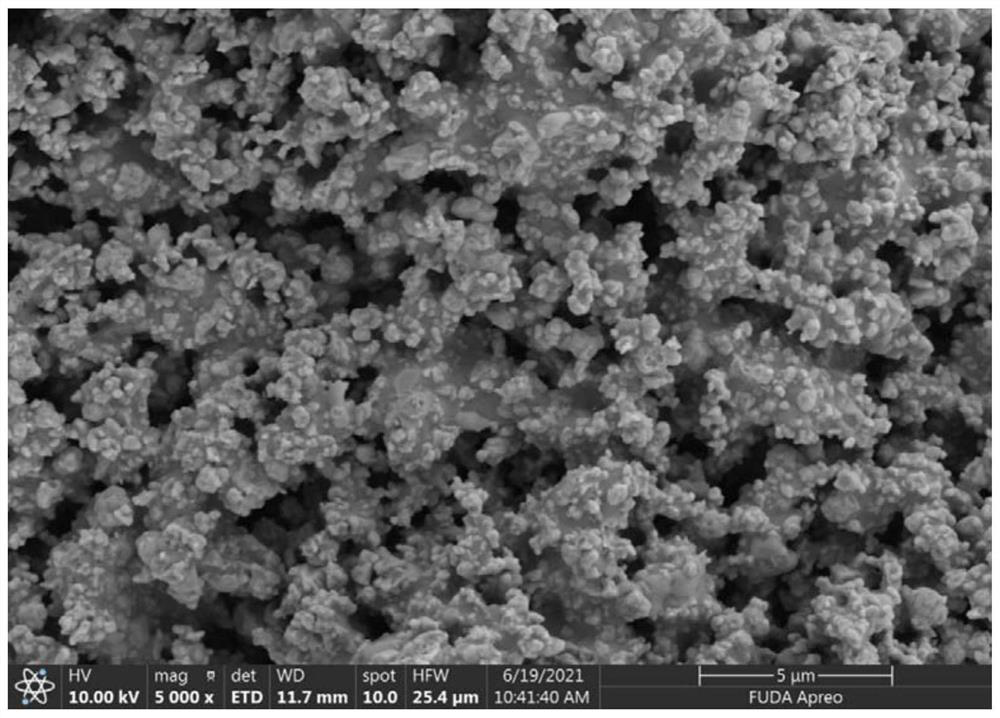

Method and product thereof for preparing silver tungsten carbide contact material from silver-coated tungsten carbide powder

ActiveCN103824710BHigh densityHigh hardnessContactsElectrical resistance and conductanceSILVER NITRATE CRYSTALS

The invention discloses a method for preparing a silver-tungsten carbide contact material from silver-coated tungsten carbide powder and the silver-tungsten carbide contact material. According to the technical scheme, a silver-tungsten carbide electrical contact is prepared from raw materials, i.e., a silver nitrate crystal and tungsten carbide powder, by a chemical coating powder preparation process and a liquid-phase infiltration process; the prepared silver-tungsten carbide electrical contact comprises the following components in percentage by weight: 38%-42% of tungsten carbide, 0-0.2% of additives and the balance being silver, wherein the additives are one or more selected from nickel, copper and zirconium. The silver-tungsten carbide contact material prepared by the method has the advantages of high density, high hardness, low and stable contact resistance, uniform metallographic structure, favorable high-temperature oxidation resistance, electric arc erosion resistance, wear resistance and the like.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

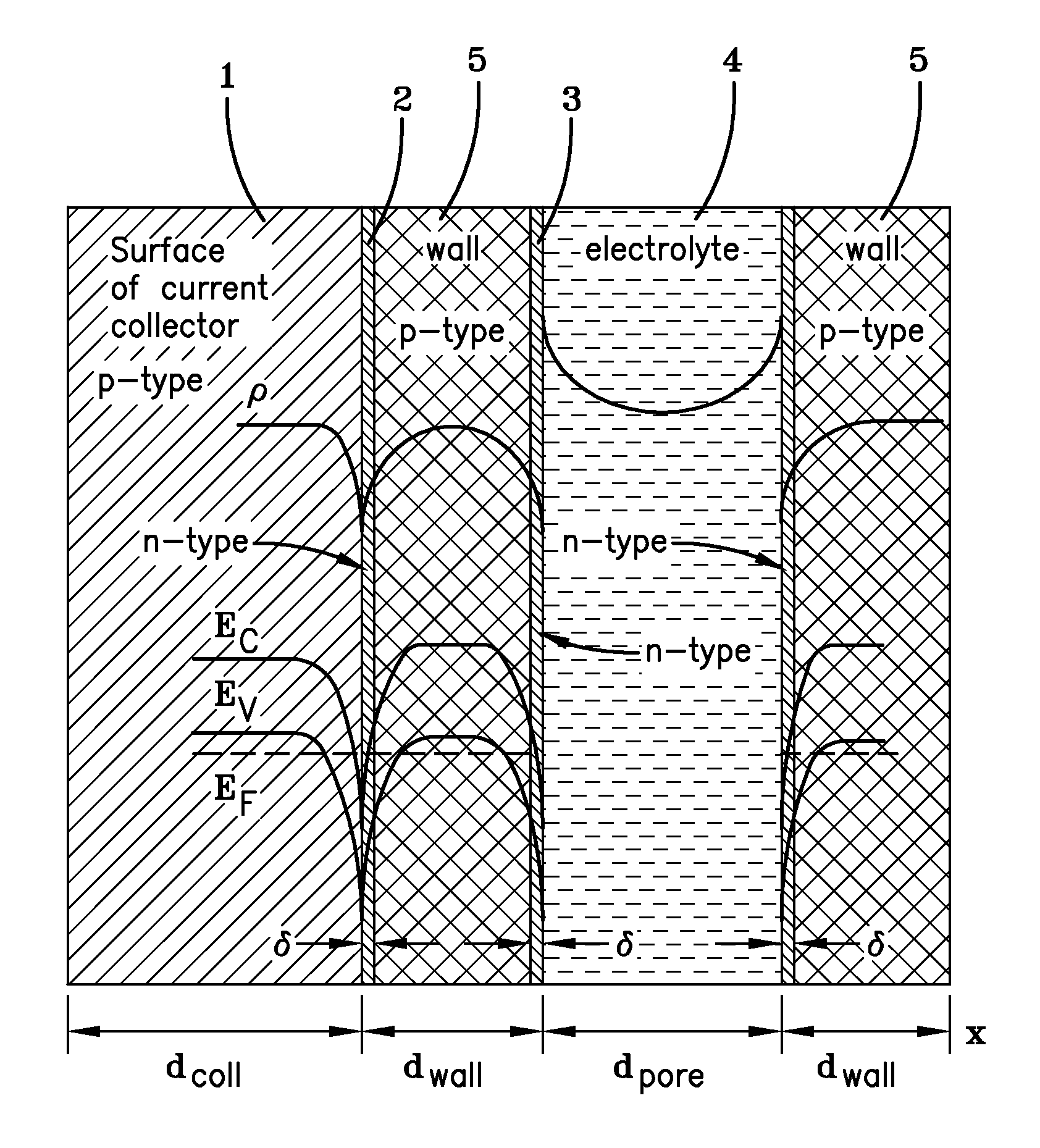

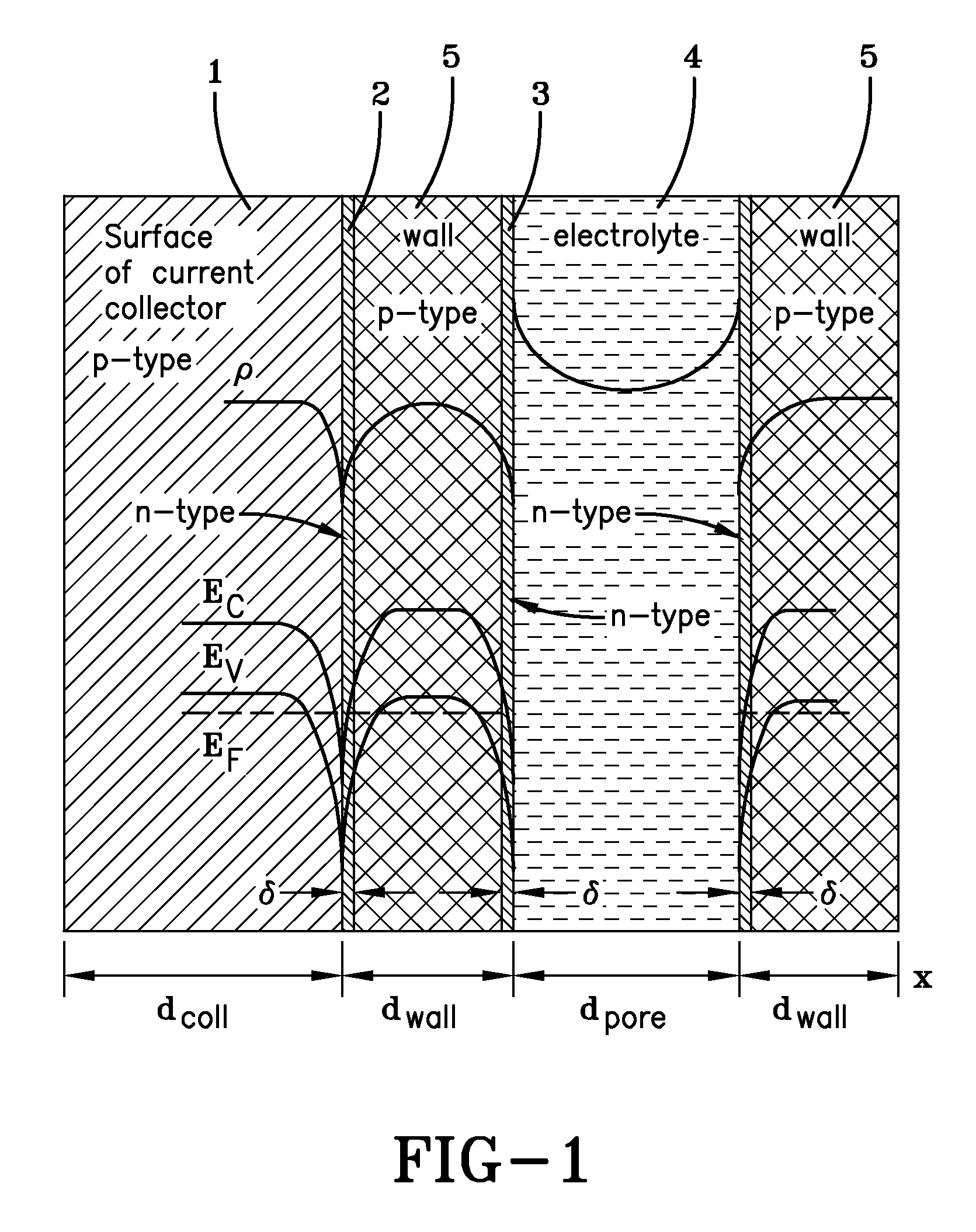

Negative electrode current collector for heterogeneous electrochemical capacitor and method of manufacture thereof

InactiveUS8472163B2Improve stabilityLower resistanceHybrid capacitor electrolytesHybrid capacitor electrodesGraphiteCapacitor

Owner:UNIVERSAL SUPERCAPACITORS LLC

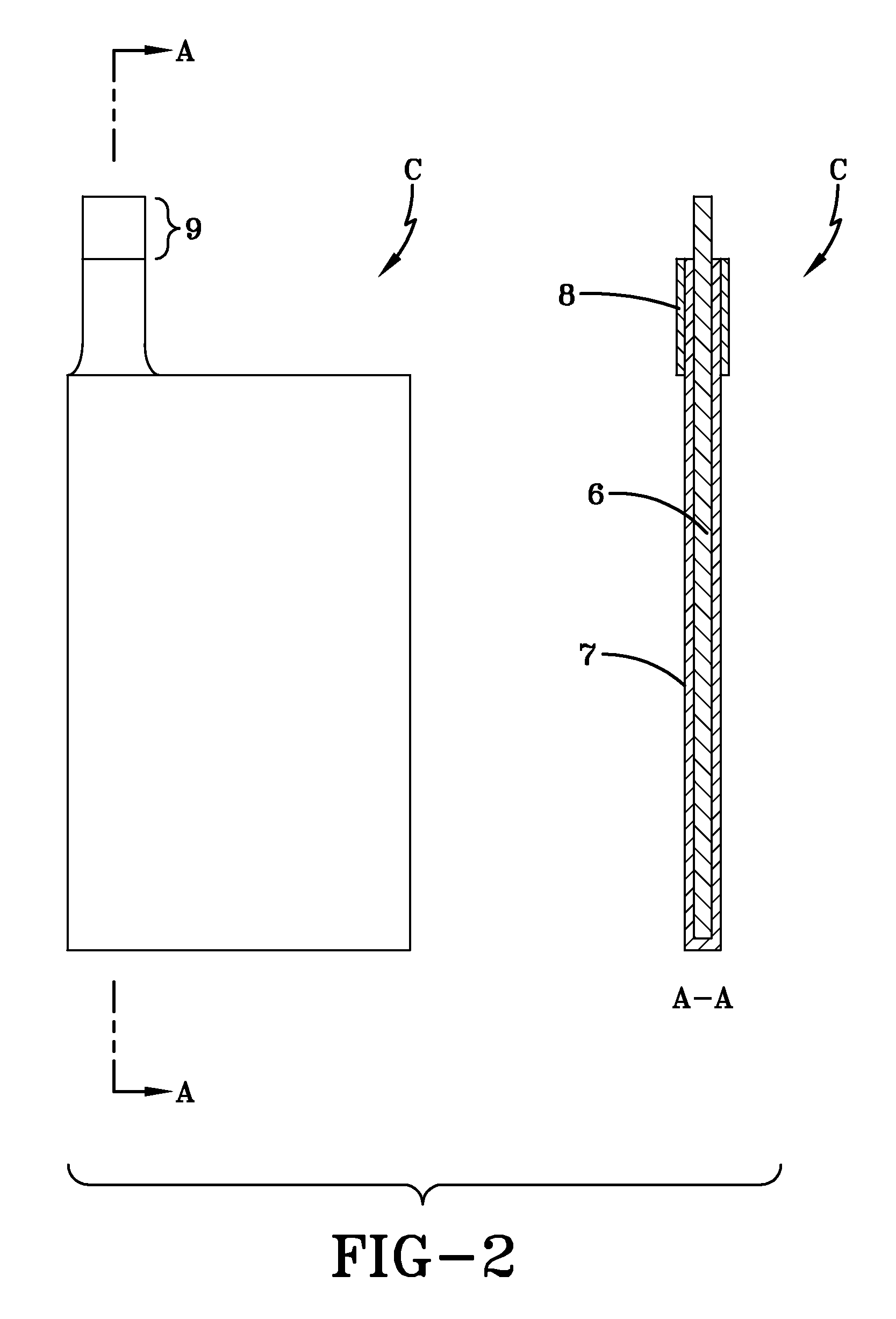

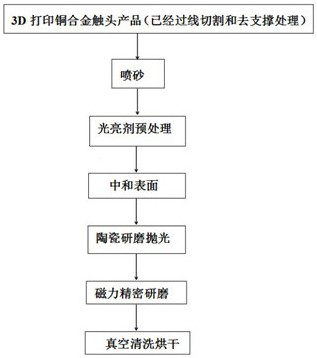

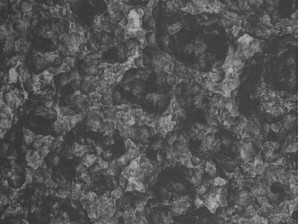

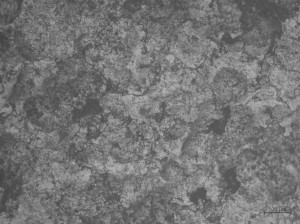

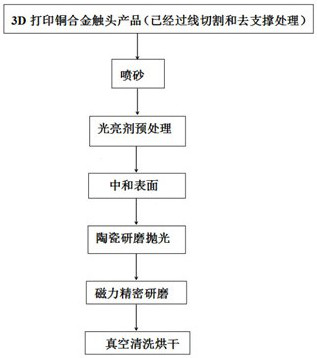

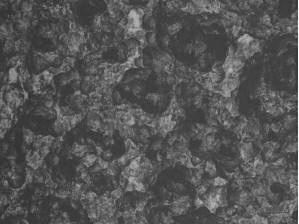

Surface post-treatment method for 3D printing copper alloy contact material

ActiveCN113369498AImprove surface qualityReduce roughnessAdditive manufacturing apparatusIncreasing energy efficiencySand blastingLiquid storage tank

The invention relates to the technical field of metal powder processing, and discloses a surface post-treatment method for a 3D printing copper alloy contact material. The surface post-treatment method comprises the following steps that S1, sand blasting grinding materials are sprayed out by sand blasting equipment to conduct sand blasting grinding on the surface of a copper alloy contact; S2, the copper alloy contact obtained after sand blasting and a cleaning tool are put into a PP liquid storage tank to be cleaned; S3, the surface is neutralized by using a degradable environment-friendly solvent; S4, rough polishing is conducted for 20-30 min at first, and then fine polishing is conducted three times through an Al2O3 and SiO2 ceramic abrasive material; S5, magnetic precision grinding is carried out, the frequency ranges from 20 Hz to 60 Hz, the time ranges from 60 min to 180 min, and the magnetic field exchange time ranges from 1 min to 3 min; and S6, vacuum cleaning and drying are conducted. The surface post-treatment method for the copper alloy contact can meet the requirements of the market on the appearance quality of the copper alloy contact, and has the advantages of low cost and high efficiency.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Method for preparing rare-earth contact material

The invention discloses a method for preparing a rare-earth contact material. The method comprises the following steps: (1) smelting, namely smelting silver, cadmium, and rare earth materials at 1200-1250 DEG C; (2) casting an ingot, namely a casting molten liquid into the ingot in the presence of an inert gas; (3) machining; (4) carrying out hot extrusion at a hot extrusion temperature of 780-820 DEG C; (5) carrying out pre-oxidation treatment at 680-750 DEG C for 24-48 hours, wherein the oxygen pressure is 0.4-0.6MPa; (6) crushing and molding; (7) carrying out secondary hot extrusion at 860-890 DEG C, wherein the retention time is greater than or equal to 3 hours, and the extrusion ratio is greater than 240 to 1; and (8) processing a wire rod, namely carrying out annealing treatment on the wire rod at no less than 650 DEG C for more than an hour, and carrying out homogenization treatment on the wire rod at 250-380 DEG C for more than an hour. The AgCdO contact material prepared by the method is relatively excellent in melting-welding resistance, relatively low and stable in contact resistance, relatively low in temperature rise, and relatively excellent in melting-welding resistance.

Owner:宁波科扬贵金属合金科技有限公司

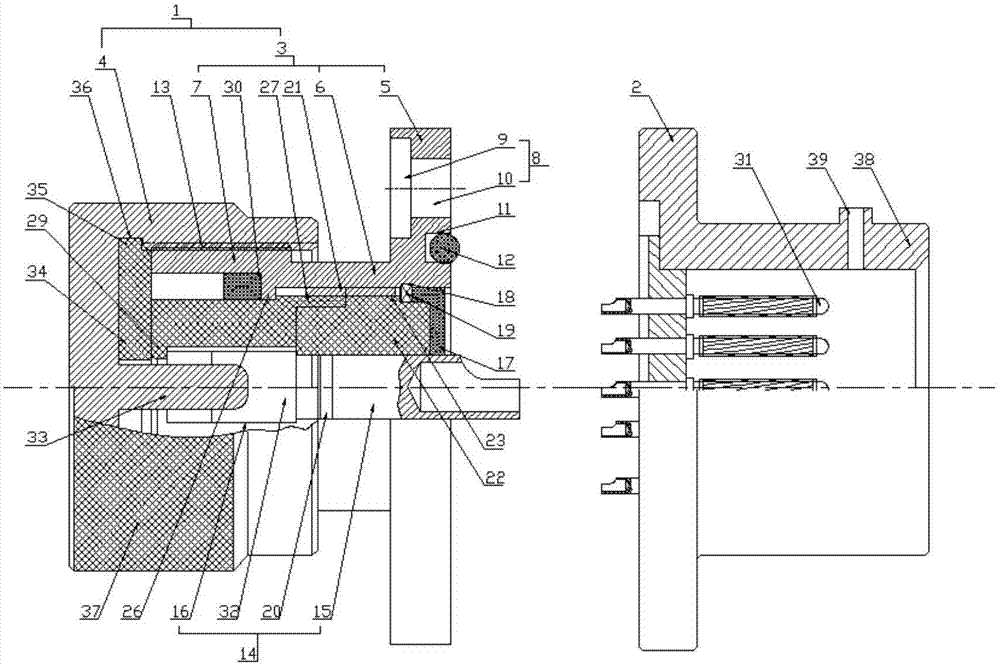

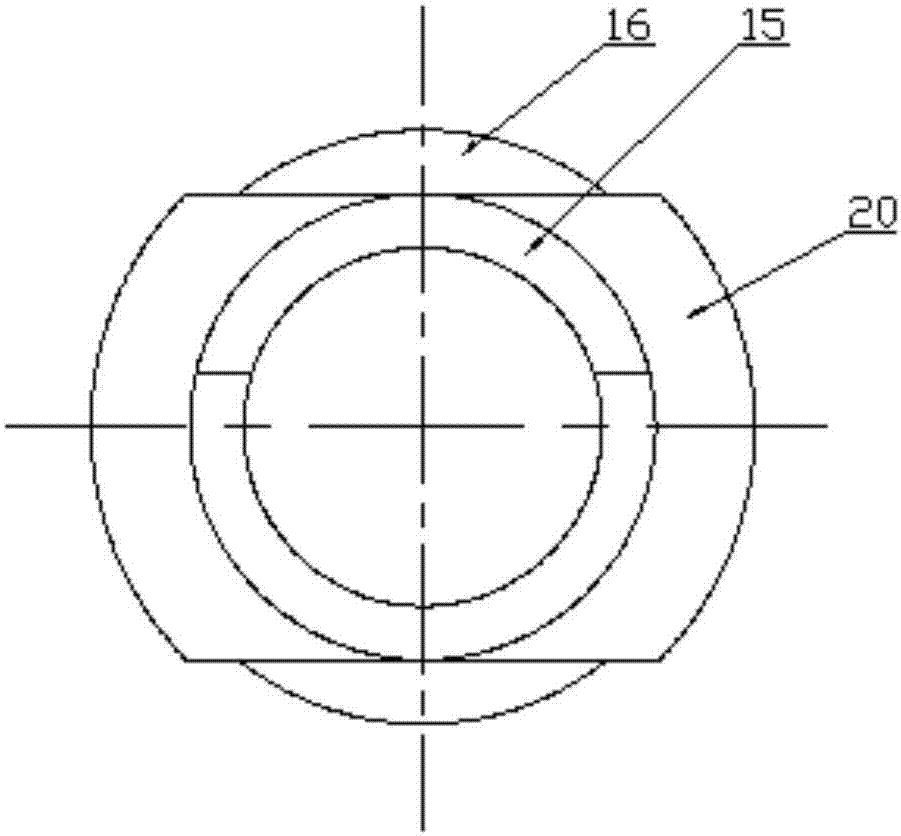

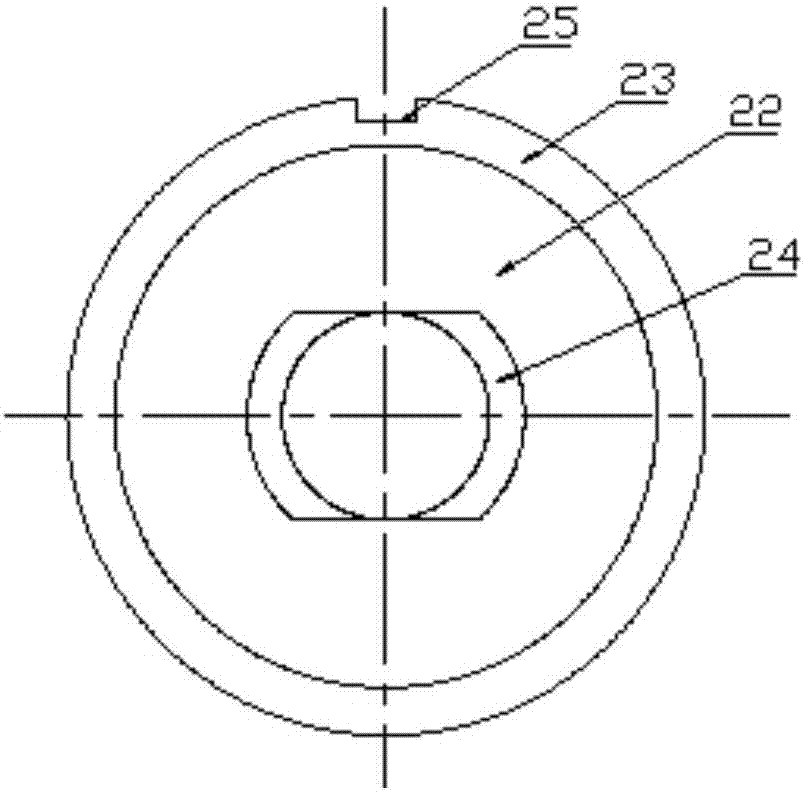

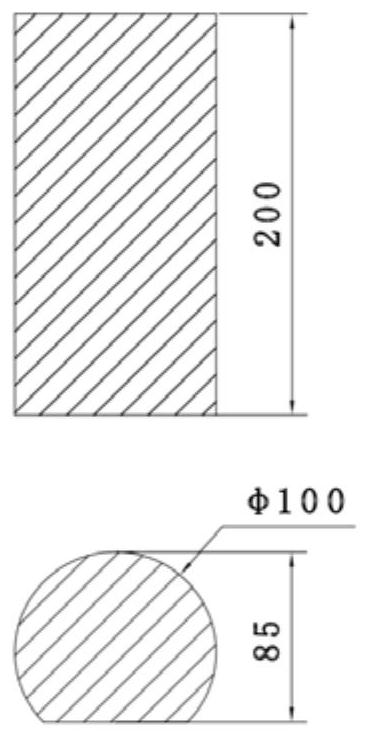

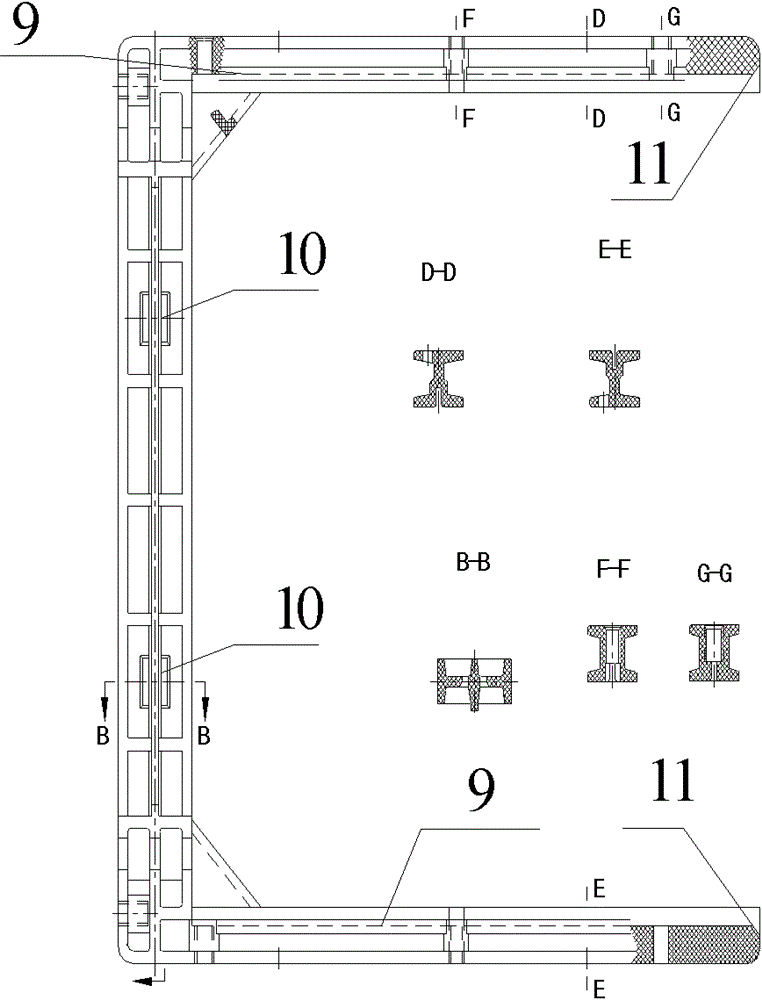

Anti-compression air-tight seal aviation electric connector

InactiveCN107978892AGuaranteed tightnessGuaranteed insulation performanceCouplings bases/casesCoupling parts mountingAviationEngineering

The present invention relates to an anti-compression air-tight seal aviation electric connector. The electric connector comprises a socket and a plug, the socket comprises a round base and a protective cover, the round base comprises a flange, a connecting sleeve and a thread bush which are connected to an integrated structure, the round base is internally provided with a first contact, the firstcontact comprises a guide sleeve and an inner sleeve which are connected to an integrated structure, a hole cover plate is arranged between the inner side of a first seal body and the guide sleeve, asecond seal body is arranged between a hole insulator and the inner wall of the thread bush, the plug is internally provided with a plurality of second contacts, the second contacts and the first contact are internally provided with wire spring jacks, the protective sleeve is internally provided with a limited pillar, the end portion of the limited pillar is arranged in the wire spring jack of thefirst contact, and a rubber mat is arranged between the external portion and the thread bush. The anti-compression air-tight seal aviation electric connector is convenient and rapid in operation andinstallation, good in compression resistance and seal insulation performances, and low and stable in contact resistance, can still remain high-reliability electric contact performances in a strong vibration impact environment, is small in insertion and extraction force and low in wearing, can be suitable for various field of working condition environments with high pressure, high vacuum and high gas tightness.

Owner:泰兴市航海电连接器有限公司

High-conductive high-strength platinum alloy containing Ti and used for electrical contact material

InactiveCN107881358AHigh yieldImprove conductivityMetal/alloy conductorsPlatinumChemical composition

The invention discloses a high-conductive high-strength platinum alloy containing Ti and used for an electrical contact material. The alloy comprises, by weight, 2.5-3.0% of Ti, 1.5-3.0% of Sn, 0.2-0.4% of Sc, 0.2-0.5% of Ru, 1.0-1.5% of Si, 0.4-0.5% of Cu, 0.2-0.6% of Re, 0.2-0.4% of Er, 0.5-0.9% of B, and the balance platinum. Compared with a traditional electric contact platinum alloy, the material has excellent mechanical and conductive properties.

Owner:GUANGZHOU YUZHI TECH CO LTD

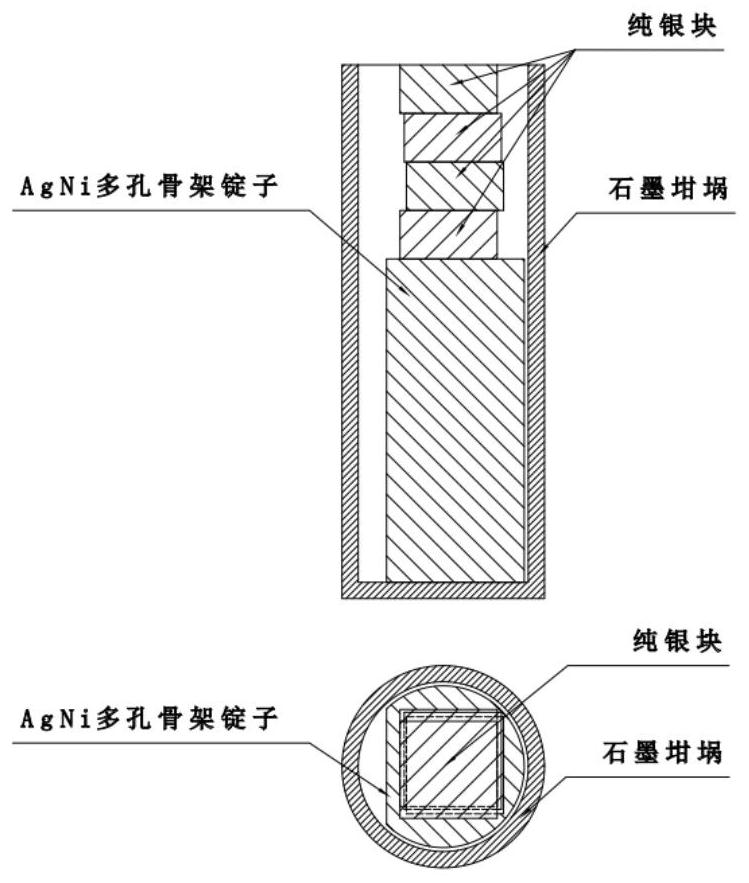

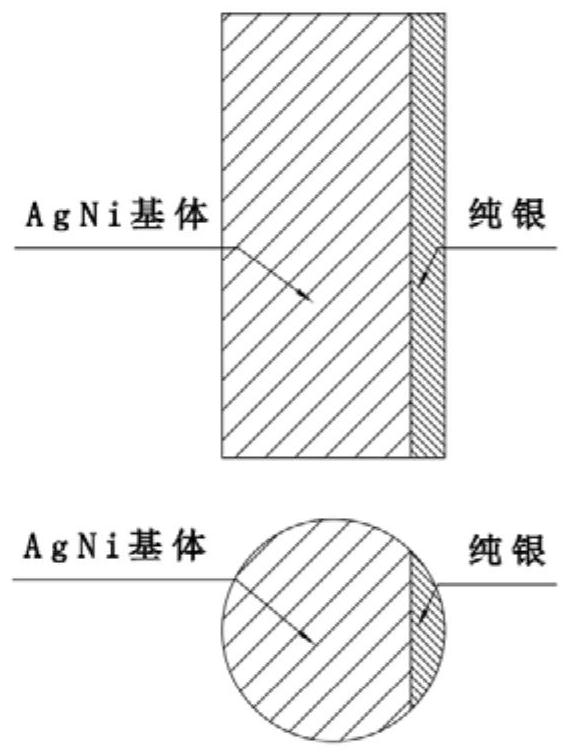

Method for preparing agni electrical contact material based on foaming infiltration process and product thereof

ActiveCN114086014BLow and stable temperature riseGuaranteed mechanical propertiesTransportation and packagingMetal-working apparatusFoaming agentIngot

The invention discloses a method and a product for preparing AgNi electrical contact materials based on a foaming infiltration process. The technical scheme is that a foaming agent is added to AgNi mixed powder for sintering strengthening, and the sintering-strengthened AgNi powder is wrapped with a separator and sintered Above the liquid phase, it is crushed and sieved to obtain high-strength porous AgNi powder. The porous AgNi powder is isostatically pressed into a special columnar porous skeleton ingot, and then the pure silver sheet is placed above the skeleton and placed in a graphite crucible. The skeleton ingot is infiltrated at high temperature to obtain AgNi / Ag composite ingot with high silver content and low resistivity, and the ingot is extruded into a thin strip and finally punched into AgNi electrical contact material. The invention simultaneously solves the problem of composite extrusion of thin strips and the problem that low-nickel and high-silver AgNi electrical contacts can only be made by solid-phase sintering process. The service life and other performance have been greatly improved.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

A surface post-treatment method of 3D printing copper alloy contact material

ActiveCN113369498BImprove surface qualityReduce roughnessAdditive manufacturing apparatusIncreasing energy efficiencyAbrasive blastingLiquid storage tank

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

High conductivity corrosion resistance platinum alloy containing Ru and used for electrical contact material

InactiveCN107881359AHigh yieldImprove conductivityMetal/alloy conductorsPlatinumChemical composition

The invention discloses a platinum alloy containing Ru and used as a highly conductive and corrosion-resistant electrical contact material. In terms of weight percentage, the chemical composition of the alloy is: Ru:2.5‑4.0wt.%, Ti:1.0‑3.0wt.%, Ge:0.4‑0.8wt.%, Mn:0.2‑0.5wt.%, Al:0.5‑ 0.8wt.%, Pd: 0.5‑1.0wt.%, W: 0.2‑0.5wt.%, Pr: 0.4‑0.8wt.%, B: 0.2‑0.5wt.%, and the balance is platinum. Compared with traditional electrical contact platinum alloys, this material has excellent corrosion resistance and electrical conductivity.

Owner:GUANGZHOU YUZHI TECH CO LTD

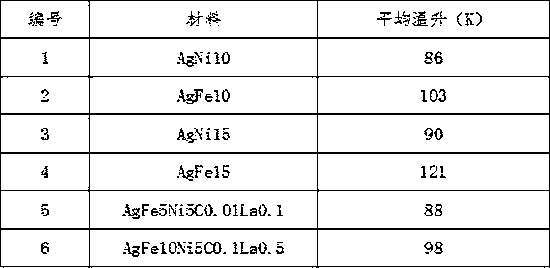

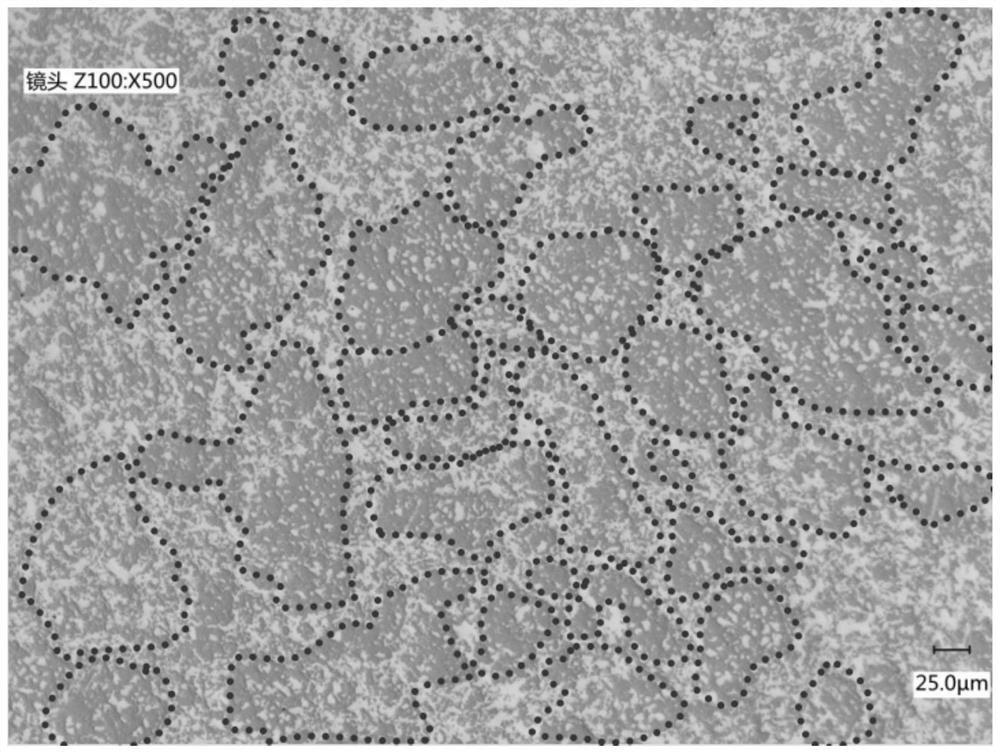

A kind of silver-iron-nickel electrical contact material and preparation method thereof

ActiveCN107675017BSolve the problem of high contact resistanceLow and stable contact resistanceContactsSurface oxidationLanthanum

The invention discloses a silver-iron-nickel electric contact material, the material composition and mass percentage of which are as follows: the mass percentage of each component is: 5%≤the total amount of iron and nickel≤30%, 0.01%≤graphite≤ 1%, 0.01%≤lanthanum≤2%, the balance is silver; the mass percentage of iron in the total amount of iron and nickel is 1%≤iron≤29%, and the balance is nickel. This silver-iron-nickel electrical contact material is produced using a co-powder-extrusion process. The invention reduces the continuity and thickness of the oxide film on the surface during the electrical contact process by adding nickel element and trace amounts of graphite and lanthanum, so as to reduce the contact resistance and temperature rise and improve the welding resistance of the material. The material prepared by the invention can be used to replace silver-iron materials and silver-nickel materials, and is applied to AC contactors and relays.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

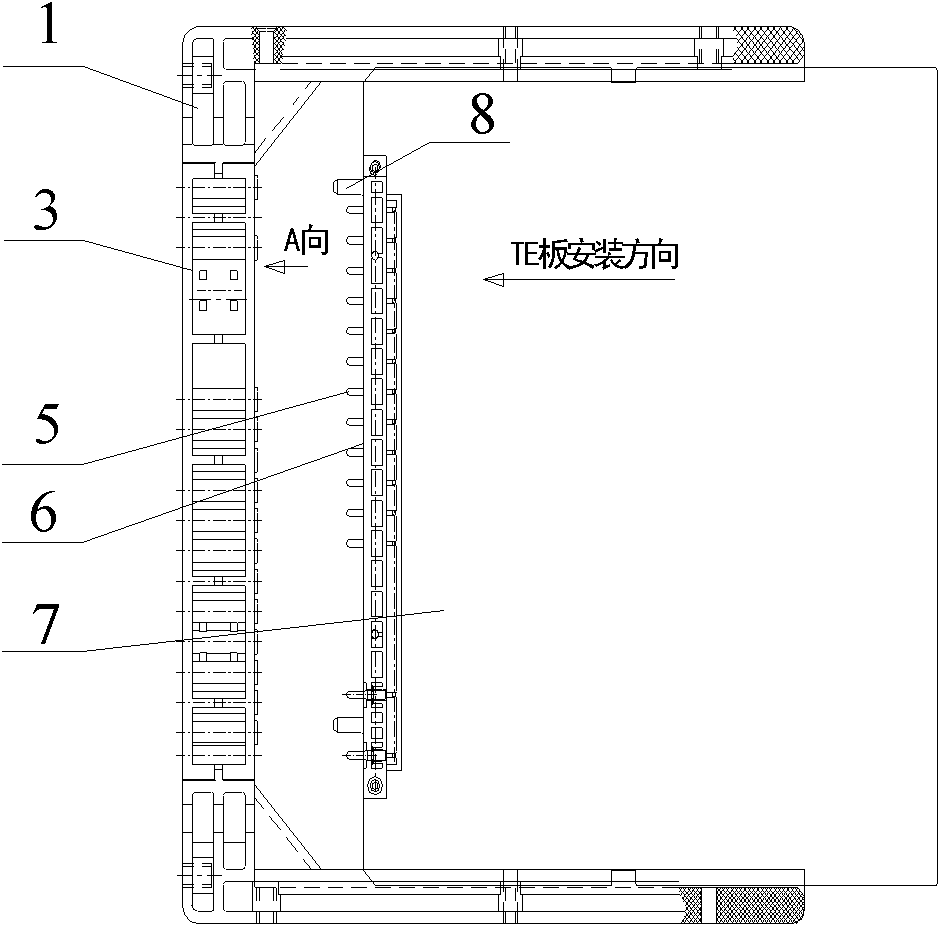

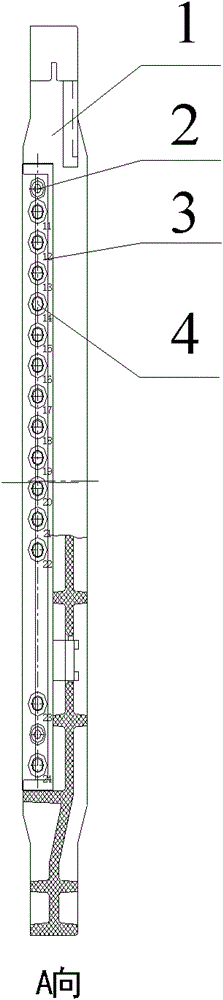

Slot type connector for high potential trigger plate

ActiveCN102544845BRealize detachable connectionReliable cooperationCoupling contact membersElectricityEngineering

Owner:CHINA EPRI SCIENCE & TECHNOLOGY CO LTD +2

Composite electrically contacting silver-conducting ceramic material

InactiveCN1124621CSimple production processLow costOxide conductorsMetal/alloy conductorsFusion weldingContact resistance

The silver-conductive ceramics composite contact material belongs to the field of new material technology, and its main composition contains 60%-90% of silver and 40%-10% of conductive ceramics. Said invention possesses good arc-suppressing property, fusion welding resistance, loss resistance, antisticking property and silver mobility resistance, also has the low and stable contact resistance and small temp. rise.

Owner:SHANDONG UNIV

A kind of manufacturing method of rare earth contact material

The invention discloses a method for preparing a rare-earth contact material. The method comprises the following steps: (1) smelting, namely smelting silver, cadmium, and rare earth materials at 1200-1250 DEG C; (2) casting an ingot, namely a casting molten liquid into the ingot in the presence of an inert gas; (3) machining; (4) carrying out hot extrusion at a hot extrusion temperature of 780-820 DEG C; (5) carrying out pre-oxidation treatment at 680-750 DEG C for 24-48 hours, wherein the oxygen pressure is 0.4-0.6MPa; (6) crushing and molding; (7) carrying out secondary hot extrusion at 860-890 DEG C, wherein the retention time is greater than or equal to 3 hours, and the extrusion ratio is greater than 240 to 1; and (8) processing a wire rod, namely carrying out annealing treatment on the wire rod at no less than 650 DEG C for more than an hour, and carrying out homogenization treatment on the wire rod at 250-380 DEG C for more than an hour. The AgCdO contact material prepared by the method is relatively excellent in melting-welding resistance, relatively low and stable in contact resistance, relatively low in temperature rise, and relatively excellent in melting-welding resistance.

Owner:宁波科扬贵金属合金科技有限公司

Method and product thereof for preparing ag-based tungsten-containing electrical contact material based on foaming infiltration process

ActiveCN114086022BGuaranteed mechanical propertiesImprove electrical lifeTransportation and packagingMetal-working apparatusFoaming agentElectric resistivity

The invention discloses a method for preparing an Ag-based tungsten-containing electrical contact material based on a foaming infiltration process and a product thereof, specifically a method for preparing an Ag (W, WC) electrical contact material with a high silver content and low resistivity by an infiltration process method. Add a foaming agent to the Ag-based mixed powder for sintering strengthening, and sinter the sintered-strengthened Ag-based powder to wrap the spacer above the liquid phase and then crush and sieve to obtain a high-strength porous Ag-based powder. The body is pressed into a skeleton, and then a pure silver sheet is placed on the skeleton, and the skeleton is infiltrated in liquid phase at a high temperature to obtain an Ag-based electrical contact material with high silver content and low resistivity. The invention solves the problem that Ag-based electrical contact materials with high silver content can only be produced by solid-phase sintering process, and has higher density and anti-burning loss compared with Ag-based electrical contact materials with the same silver content prepared by sintering process Capability, lower resistivity, electrical life and other performance have been greatly improved.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Alloy material

InactiveCN108715968AGood electrical conductivityReduce contact resistanceContactsTungstenTitanium carbide

The invention discloses an alloy material. The alloy material is characterized by comprising, by weight, 15-20 parts of epoxy resin, 20-30 parts of silver, 5-8 parts of stannum, 15-20 parts of tungsten, 10-30 parts of nickel, 5-30 parts of copper, 5-30 parts of aluminum, 3-5 parts of molybdenum, 2-4 parts of phosphorus and 10-20 parts of titanium carbide. The alloy material provided by the invention has excellent electrical conductivity and heat conducting property, is low and stable in contact resistance and high in electrical loss resistance, improves the fusion welding resistance of electrical contact materials and can be applied to high-capacity electrical contact materials.

Owner:HUZHOU WUSHI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com