A surface post-treatment method of 3D printing copper alloy contact material

A contact material and 3D printing technology, applied in the field of metal powder processing, can solve the problems of unsuitable surface treatment of the original parts of 3D printed copper alloy contacts, affecting the reuse of abrasives, and high operator fatigue, achieving low cost and avoiding Over-polished, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

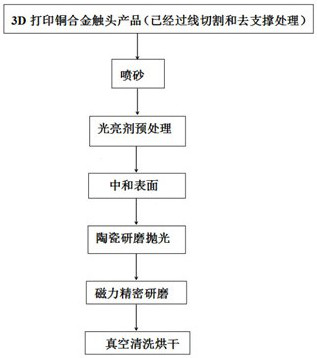

[0044] like figure 1 The surface post-treatment method of a kind of 3D printing copper alloy contact material shown, comprises the following steps:

[0045] S1: sandblasting

[0046] Make the spray gun of the sandblasting equipment 50mm away from the surface of the copper alloy contact, spray sandblasting abrasives to sandblast and polish the surface of the copper alloy contact for 5 minutes; Sandblasting abrasive on the inner wall of the hole;

[0047] The sandblasting abrasive adopts high-strength sandblasting glass beads with a specification of 200 mesh;

[0048] S2: brightener pretreatment

[0049] First put the copper alloy contacts and cleaning tool obtained in step S1 into the PP liquid storage tank, then configure the precision environmental protection cleaning agent and deionized water according to the volume ratio of 1:10 to form an activation solvent, and put them into the PP liquid storage tank , until the liquid surface submerges the copper alloy contact;

[...

Embodiment 2

[0068] A method for post-processing the surface of a 3D printed copper alloy contact material, comprising the following steps:

[0069] S1: sandblasting

[0070] Make the spray gun of the sandblasting equipment 150mm away from the surface of the copper alloy contact, spray sandblasting abrasives to sandblast and polish the surface of the copper alloy contact for 15 minutes; Sandblasting abrasive on the inner wall of the hole;

[0071] The sandblasting abrasive is made of high-strength sandblasting glass beads with a specification of 320 mesh;

[0072] S2: brightener pretreatment

[0073] First put the copper alloy contacts and cleaning tool obtained in step S1 into the PP liquid storage tank, then configure the precision environmental protection cleaning agent and deionized water according to the volume ratio of 1:10 to form an activation solvent, and put them into the PP liquid storage tank , until the liquid surface submerges the copper alloy contact;

[0074] Treat for ...

Embodiment 3

[0092] A method for post-processing the surface of a 3D printed copper alloy contact material, comprising the following steps:

[0093] S1: sandblasting

[0094] Make the spray gun of the sandblasting equipment 100mm away from the surface of the copper alloy contact, spray sandblasting abrasives to sandblast and polish the surface of the copper alloy contact for 10 minutes; Sandblasting abrasive on the inner wall of the hole;

[0095] The sandblasting abrasive adopts high-strength sandblasting glass beads with a specification of 260 mesh;

[0096] S2: brightener pretreatment

[0097] First put the copper alloy contacts and cleaning tool obtained in step S1 into the PP liquid storage tank, then configure the precision environmental protection cleaning agent and deionized water according to the volume ratio of 1:10 to form an activation solvent, and put them into the PP liquid storage tank , until the liquid surface submerges the copper alloy contact;

[0098] Treat for 210s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com