Patents

Literature

208results about How to "Good arc resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

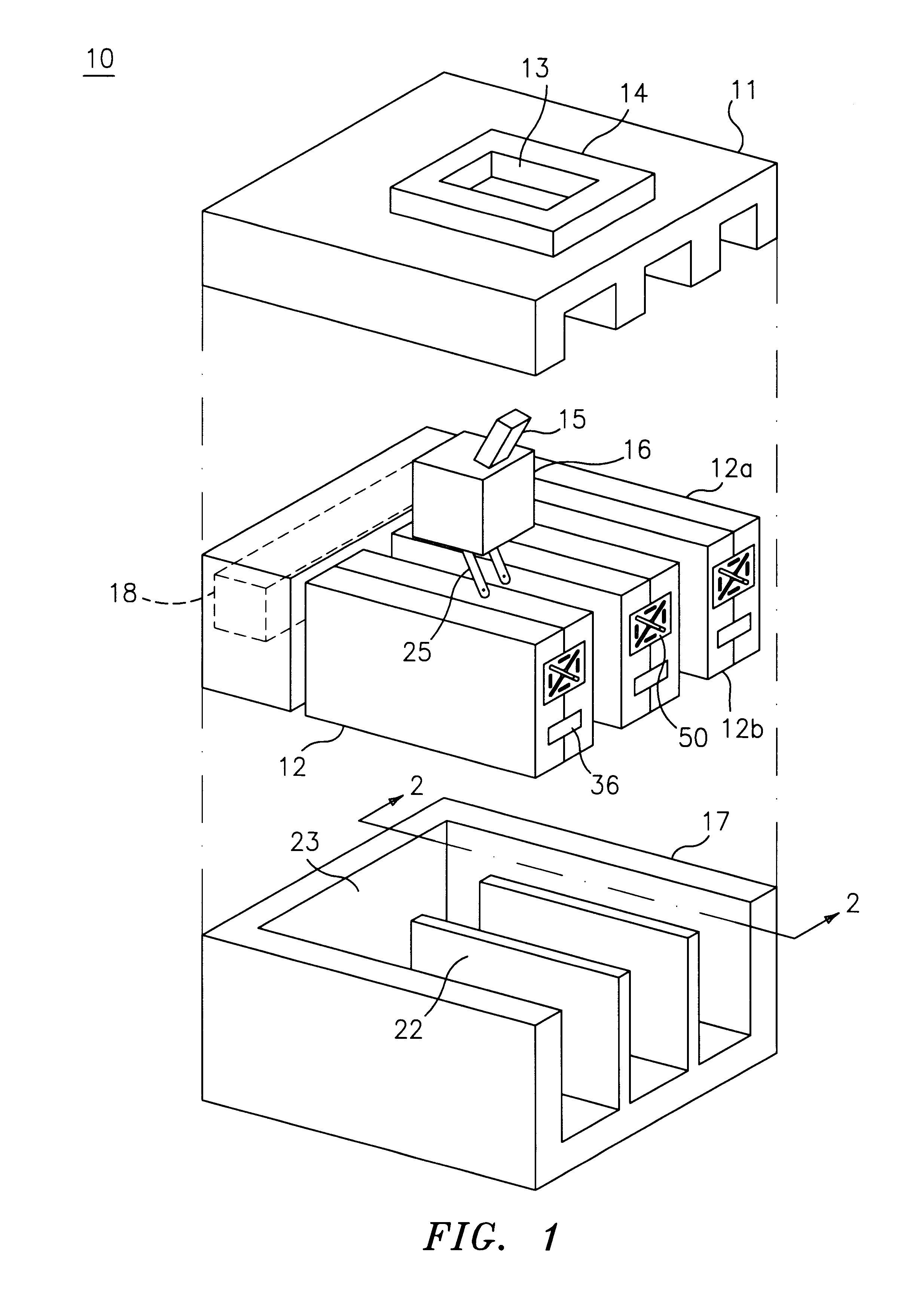

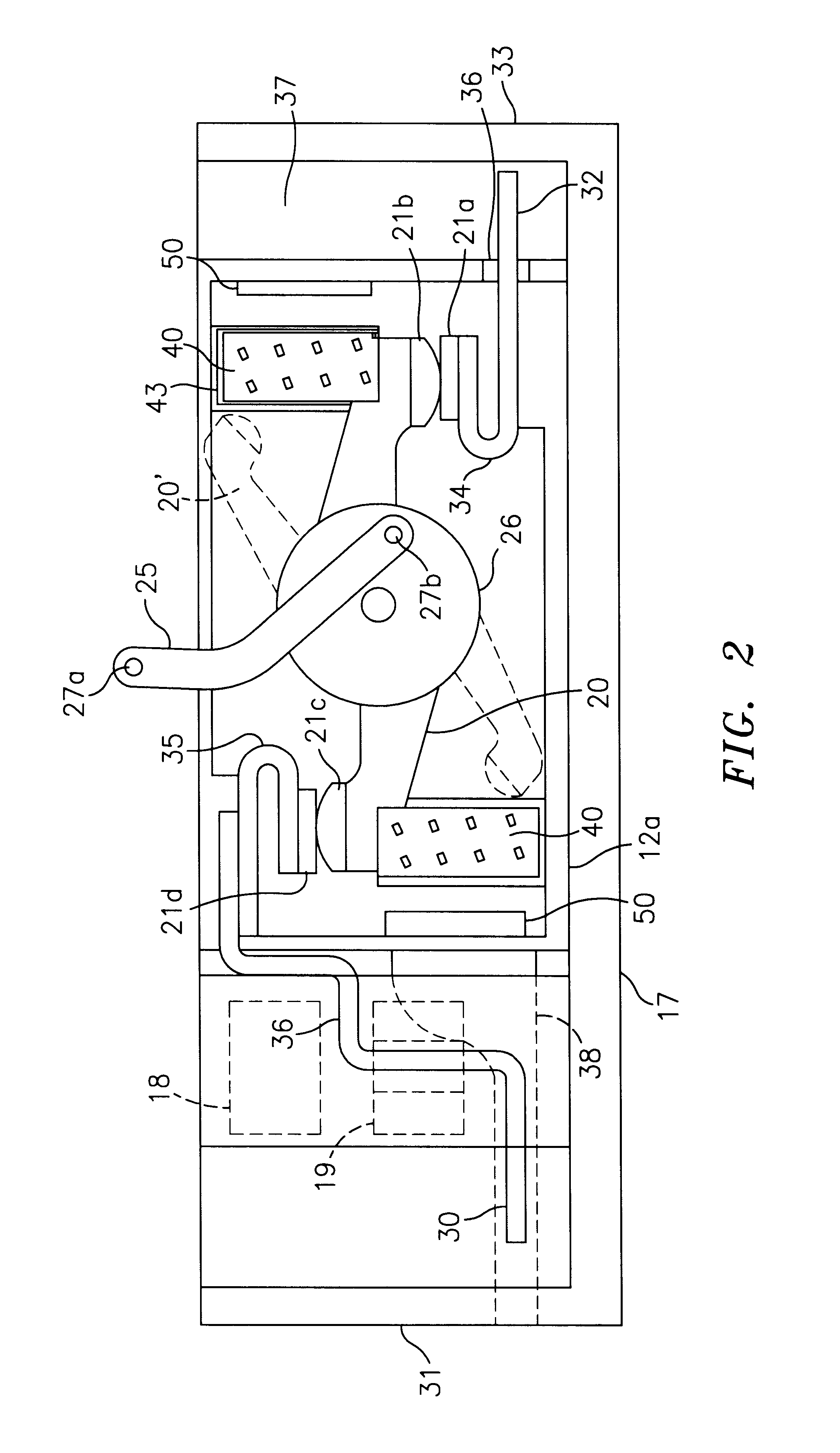

Circuit breaker arc exhaust baffle with variable aperture

InactiveUS6222147B1Reduce stressIncrease pressureProtective switch detailsHigh-tension/heavy-dress switchesCircuit breakerCircuit protection

An improved exhaust baffle for a circuit protective device such as a circuit breaker utilizes material having elastomeric characteristics to provide for variable apertures where the cross-sectional opening of the apertures is dependent on the pressure gradient across the exhaust baffle, thereby effectively controlling arc pressure and arc effluent during short circuit interruption. Fabrication of the exhaust baffle with geometric symmetry about one or more axes or planes also facilitates assembly during product construction.

Owner:ABB (SCHWEIZ) AG

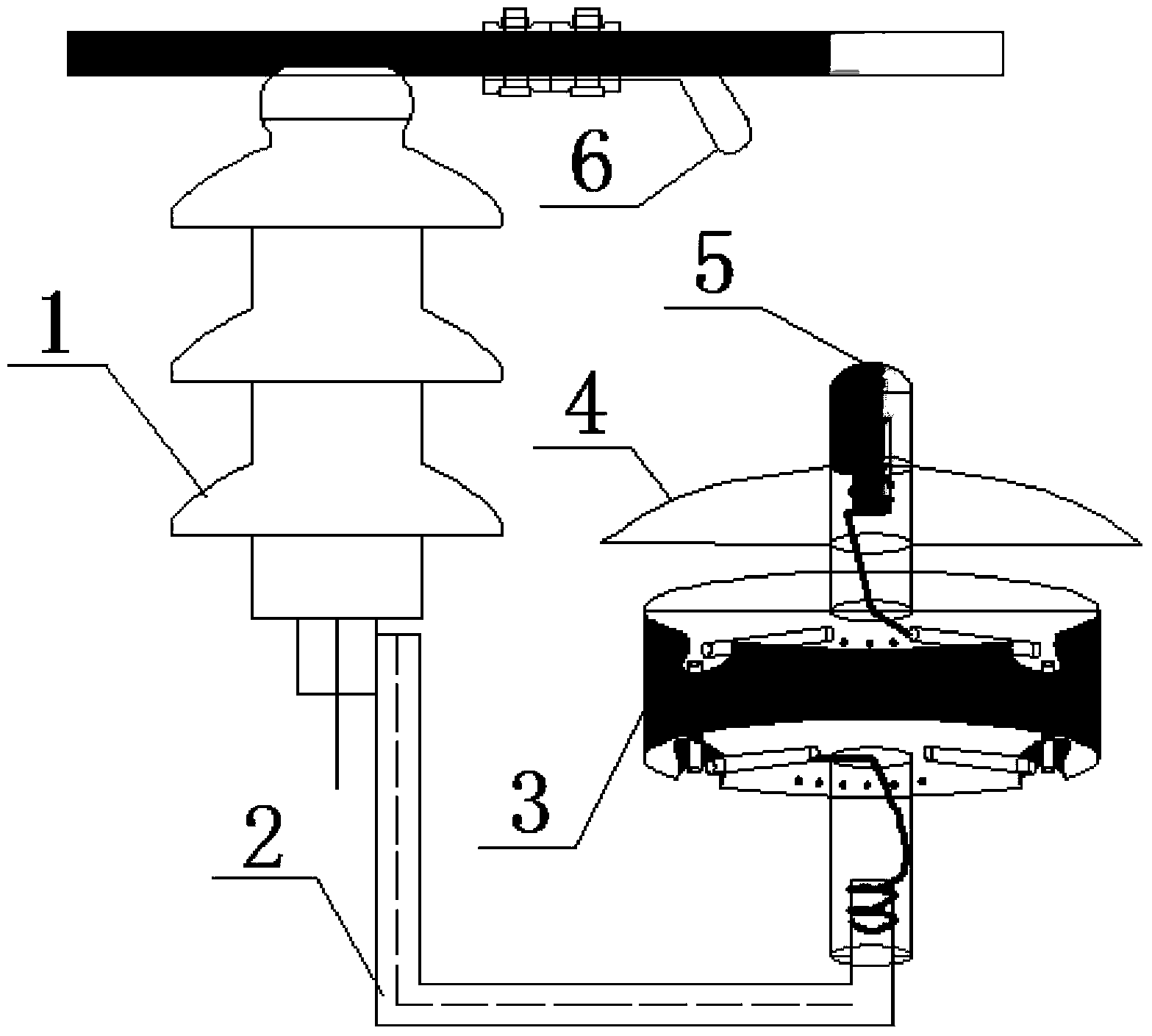

Multi-gap self-swelling strong-air-current longitudinal blow-out arc anti-thunder protecting device

ActiveCN103594210AImprove arc extinguishing effectHigh vulnerabilityInsulatorsCorona dischargeElectricityElectric power system

The invention discloses a multi-gap self-swelling strong-air-current longitudinal blow-out arc anti-thunder protecting device which comprises a longitudinal blow-out arc device arranged at an insulator string earthing terminal through a grounding side connecting hardware fitting, a grounding side electrode arranged on the longitudinal blow-out arc device, and a guide line side electrode arranged on an off-contact guide line. A protecting gap formed by the grounding side electrode and the guide line side electrode is parallel to an insulator string. The longitudinal blow-out arc device comprises an arc extinguishing device body and arc extinguishing tubes. The arc extinguishing device body is provided with a plurality of through holes for placing the arc extinguishing tubes. An angle formed by two arc extinguishing tubes which are arranged in the arc extinguishing device body is 90 degrees, and end portions of the two arc extinguishing tubes are in contact with each other. Each arc extinguishing tube is in a spiral shape. The grounding side electrode is connected with a first arc extinguishing tube through a guide line, and the grounding side connecting hardware fitting is connected with a last arc extinguishing tube through a guide line. The device is simple in structure, low in manufacture cost, safe and reliable, effectively reduces the power system transmission line thunderstrike tripping rate and the accident rate, and improves the stability of a power system.

Owner:王巨丰 +1

Manufacturing method for environment-friendly type insulator shell

InactiveCN101840757AImprove mechanical propertiesImprove insulation performanceInsulatorsEpoxyDark color

The invention relates to a manufacturing method for an environment-friendly type insulator shell, comprising the following steps: firstly mixing the following components uniformly in parts by weight: 100 parts of modified BPA epoxy resin, 280-310 parts of silica powder, 100 parts of curing agent, 40-45 parts of dark color paste and 40-60 parts of fire retardant, and degassing for 1.5-2 hours under the vacuum degree of 0-minus1 MPa; then injecting the degassed mixture into a mold to conduct the primary curing, and curing for 30-40 minutes under the condition of 140 plus or minus 5 DEG C; demolding, conducting the secondary curing, and curing for 8 hours plus or minus 10 minutes under the condition of 128-135 DEG C; and finally, conducting finish machining on the blank after being cured secondarily. The Epoxy resin insulating component manufactured by the method has the advantages of high mechanical strength, strong arc resistance, high compactness, bright and clean surface, better cold-resistant and heat-resistant properties, good electrical insulating property and the like, is widely applied in the power sector, and mainly plays a role in supporting and insulating.

Owner:YANGZHOU DONGYU ELECTRIC

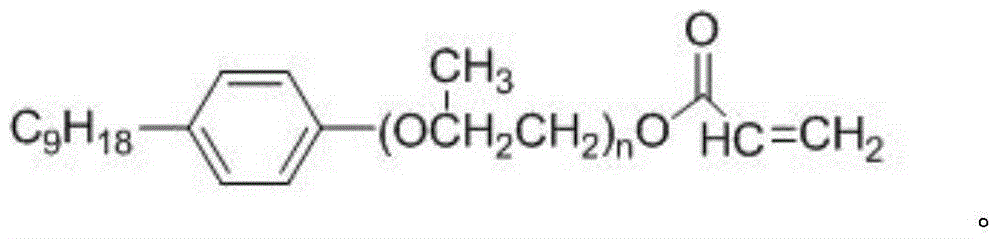

Unsaturated polyester glass fiber felt plate and production method thereof

The invention discloses an unsaturated polyester glass fiber mat board which is obtained by pressing the glass fiber mat immersed with resin paste. The production method thereof comprises: after being stirred evenly, the resin paste is scraped and smeared on a polyethylene film evenly; later a layer of polyethylene film is respectively paved on the upper surface and the lower surface of the glass fiber mat, then a sizing mat is obtained after tight pressing; when the sizing mat is cured, the polyethylene films on the surfaces of the mat are removed; next, the sizing mat is delivered into a press for hot pressing at the temperature of 70 DEG C-145 DEG C and the pressure of 10-20MPa; according to the thickness of the eventually obtained mat board, the mat board with the thickness of each millimeter is hot-pressed for 3-15 minutes; and finally an unsaturated polyester glass fiber mat board is obtained. The unsaturated polyester glass fiber mat board has excellent flame resistance, insulation, electrical and mechanical properties. The production method of the unsaturated polyester glass fiber mat board improves the productivity, reduces the production cost, and can prepare board surfaces with various sizes; and the thickness of the product has large range.

Owner:河北福润达新材料科技有限责任公司

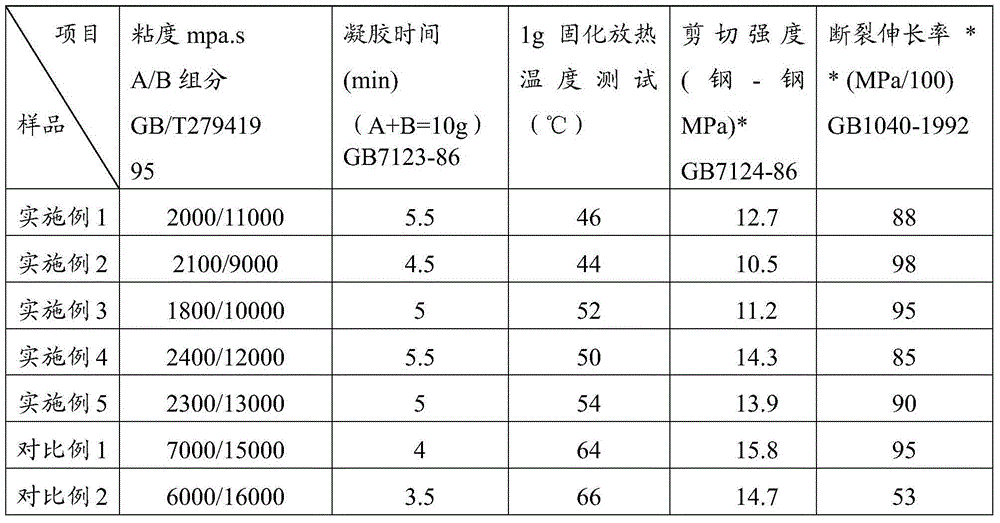

Low-stress transparent epoxy resin adhesive capable of curing fast at room temperature

ActiveCN104479607ALow viscosityEasy to apply glueNon-macromolecular adhesive additivesMacromolecular adhesive additivesShock resistanceBisphenol A

The invention belongs to the technical field of adhesives, and in particular relates to a low-stress transparent epoxy resin adhesive capable of curing fast at room temperature. The low-stress transparent epoxy resin adhesive is prepared by mixing an epoxy resin component A and a curing agent component B at the volume ratio of 1:1, wherein the epoxy resin component A comprises hydrogenated bisphenol A epoxy resin, bisphenol A glycidyl ether epoxy resin, functional acrylate monomer, an acrylate diluent, a tackifying accelerator and a silane coupling agent; the curing agent component B comprises polymercaptan, a tertiary amine accelerator, a vulcanizing accelerator, a stabilizer, a curing accelerator I and a curing accelerator II. While keeping 5-minute fast curing, high transparency and better bonding strength, the adhesive prepared by the invention has low exothermal temperature and small stress during curing, achieves better applicability in assembly of electronic devices, and has excellent electric insulativity, voltage breakdown resistance, shock resistance and aging resistance, and the application range of mercaptan-epoxy resin type adhesives in manufacturing of electronic devices is greatly expanded.

Owner:信泰永合(烟台)新材料有限公司

Boiling-resistant epoxy adhesive as well as preparation method and application thereof

InactiveCN102329584AStrong adhesionEasy to useNon-macromolecular adhesive additivesOther chemical processesPolyolAlcohol

The invention relates to a boiling-resistant epoxy adhesive as well as a preparation method and application thereof. The boiling-resistant epoxy adhesive consists of a component A and a component B; epoxy resin, toughener and coupling agent are mixed, and are stirred and heated, activated inorganic filler and activated inorganic flame retardant are added, polyhydric alcohol or polyhydric phenol is then added, and thereby the component A is prepared; anhydride and catalyst are mixed and heated, activated inorganic filler and activated inorganic flame retardant are then added, and after depressurization for defoaming, the component B is prepared; when in use, the component A and the component B are uniformly mixed according to the proportion by weight of 1 to 3:1, and thereby the boiling-resistant epoxy adhesive is prepared. Compared with the prior art, the boiling-resistant epoxy adhesive has high adhesive force for electronic elements, is convenient to use, and has excellent high-temperature-resistant property, high strength and good weather fastness and impregnating property, the surface properties of solidified product is excellent, and the post-solidification phenomenon caused by cracking is prevented.

Owner:上海海鹰粘接科技有限公司

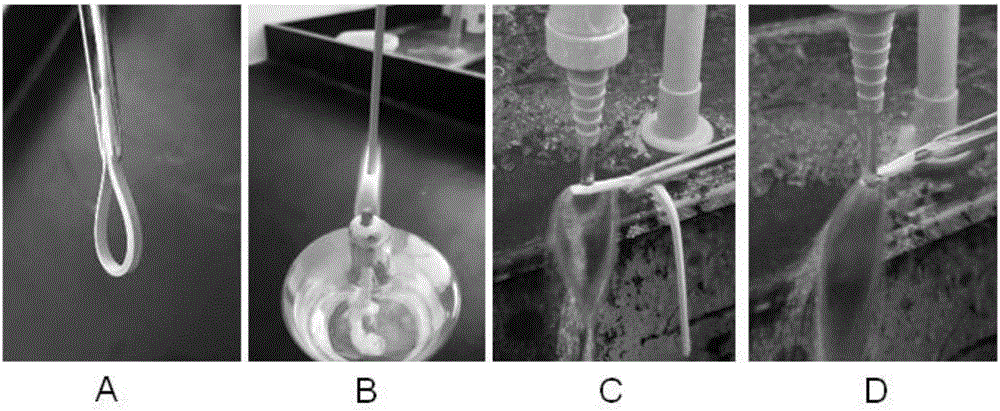

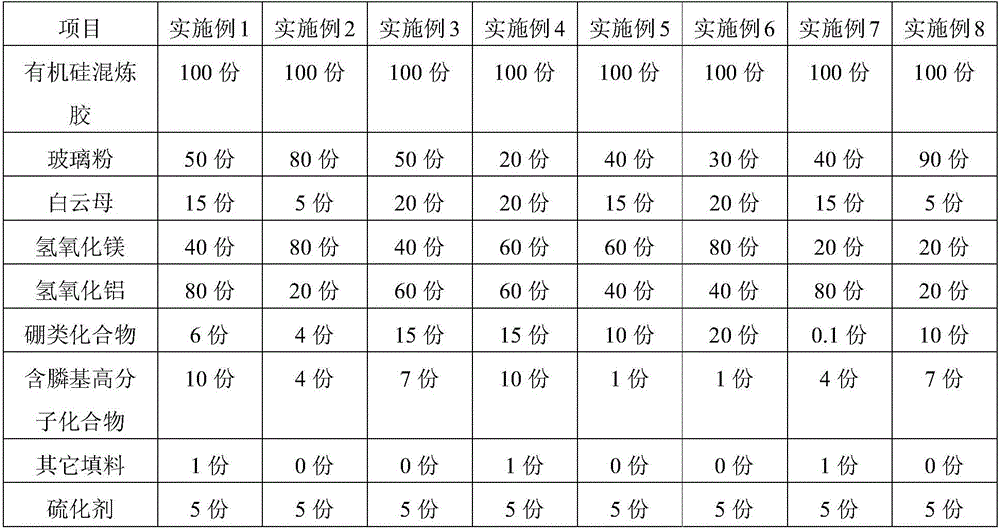

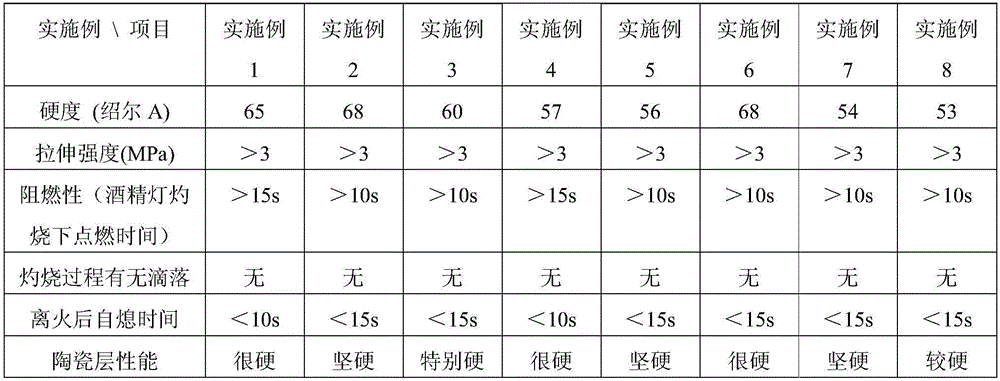

Flame-retardant and drippage-free ceramization silicon rubber and preparation method thereof

ActiveCN105884267AGood physical and mechanical propertiesThe process is simple and easy to controlAluminium hydroxideEconomic benefits

The invention relates to flame-retardant and drippage-free ceramization silicon rubber and a preparation method thereof. The silicon rubber is prepared from components in parts by weight as follows: 100 parts of organic silicon rubber compounds, 1 part to 10 parts of a vulcanizing agent, 100 parts to 150 parts of ceramization powder and 0 to 100 parts of other filler or auxiliaries, wherein the ceramization powder is prepared from raw materials in parts by weight as follows: 1 part to 120 parts of glass powder, 1 part to 20 parts of muscovite, 1 part to 200 parts of magnesium hydroxide, 1 part to 200 parts of aluminum hydroxide, 0.1 parts to 50 parts of boron compounds and 0.1 parts to 20 parts of phosphono-containing polymer compounds. The ceramization silicon rubber prepared with the method has advantages of good flame retardance and self-extinguishment performance; a ceramic layer formed after firing has good compactness and insulativity, external force resistance and the like. The preparation process is simple, raw materials are cheap, and accordingly the silicon rubber is expected to be applied to fields such as wires and cables, the electronic and electrical technology, aerospace engineering and the like and has quite good economic benefits and popularization value.

Owner:SHANDONG UNIV

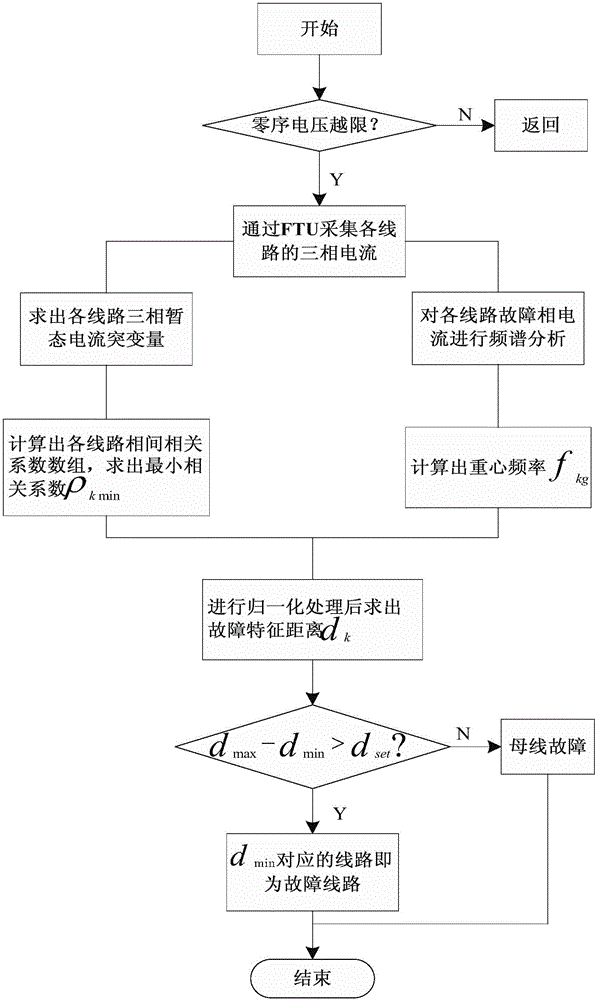

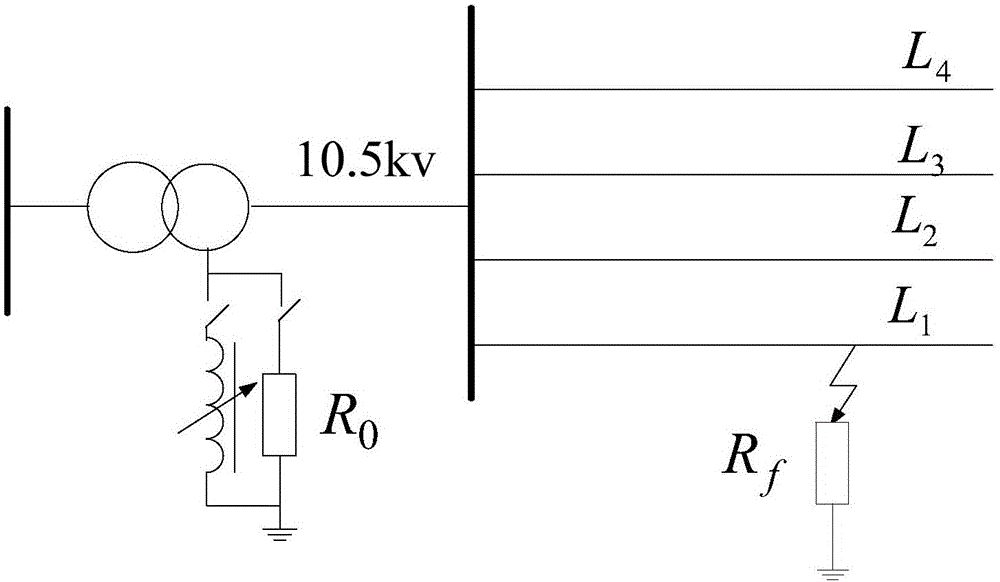

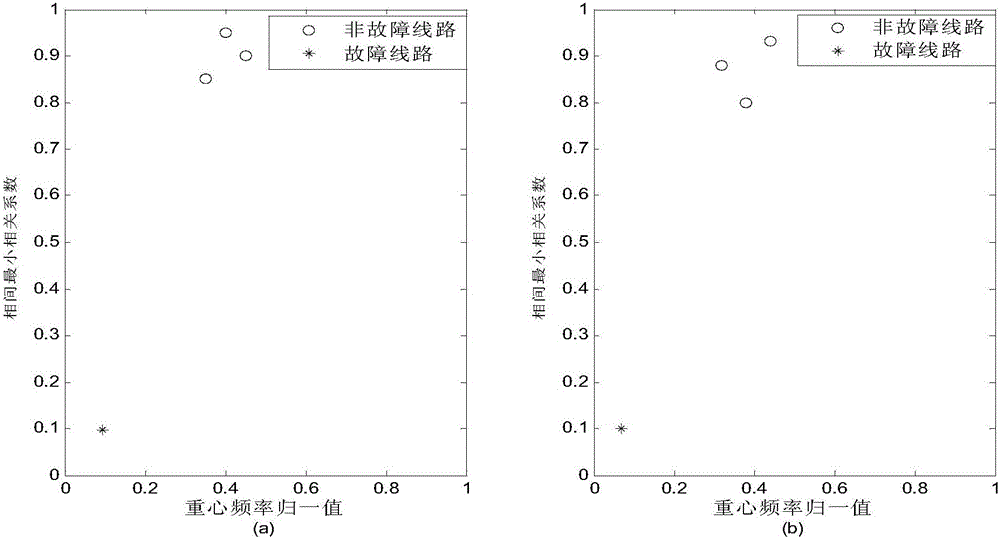

Fault line selection method based on phase current transient characteristic

ActiveCN105974264AEfficient discriminationLine selection is validFault locationPhase currentsCorrelation coefficient

The method discloses a fault line selection method based on a phase current transient characteristic. The method comprises the following steps of S1, continuously measuring a distribution line outlet zero sequence voltage value and determining whether a power distribution network generates a grounding fault; S2, processing collected phase current data, extracting a transient phase-current sudden-change amount of each line, and carrying out interphase pairwise correlation analysis so as to obtain an interphase minimum correlation coefficient rhok min; S3, carrying out spectral analysis on each line fault phase current and calculating a gravity frequency fkg; S4, carrying out normalization processing on a fault characteristic quantity and acquiring normalization values, establishing a two-dimensional coordinate system based on the normalization values, and determining each line fault characteristic coordinate point; and calculating a fault characteristic distance dk between each line fault characteristic coordinate point and a reference point (0, 0) so as to determine a bus fault. The method possesses advantages that a principle is simple; practicality is high; an anti-interference capability is good; accuracy is high and so on.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

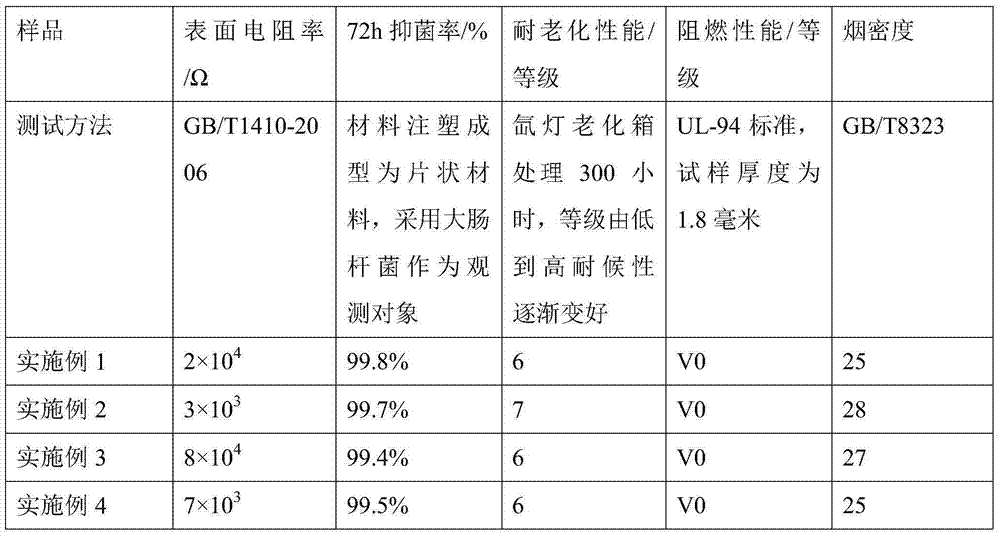

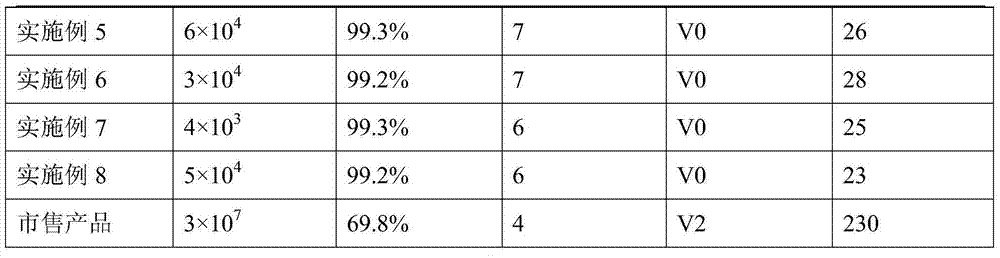

Antistatic antibacterial PC (polycarbonate)/ABS (acrylonitrile-butadiene-styrene copolymer) composite material

The invention discloses an antistatic antibacterial PC (polycarbonate) / ABS (acrylonitrile-butadiene-styrene copolymer) composite material comprising the following components by weight: 63-93 parts of polycarbonate, 57-65 parts of ABS, 33-47 parts of a flame retardant agent, 29-44 parts of a nano antibacterial agent, 41-47 parts of an antiaging agent, 24-32 parts of an antistatic agent, 24-32 parts of a compatibility agent, 22-26 parts of a lubricant, 19-23 parts of a toughening agent, 15-20 parts of a synergistic agent, 10-16 parts of an insulation agent, 10-16 parts of a yellowing resistant agent and 17-24 parts of a wear-resisting agent. The antistatic antibacterial PC / ABS composite material has excellent antistatic performance, avoids the deleterious effects of electrostatic, and also has antibacterial properties, more than 99% bacteriostasis rate can be maintained for a long term, the composite material has good anti-aging properties, is flame retardant, simultaneously reduces the combustion smoke density, has excellent characteristics of wear resistance, yellowing resistance, high voltage resistance and electric arc resistance, and is suitable for different use requirements.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

Insulating wood laminating product and preparation method thereof

ActiveCN101941217AWith self-locking abilityHigh mechanical strengthPlywood pressesTransformers/inductances coils/windings/connectionsTransformerHigh resistivity

The invention relates to a wood laminating material, in particular to a wood laminating material used for manufacturing transformer connecting pieces and a preparation method thereof, and more particularly relates to a material which can be processed into woody bolt or woody nut with an insulating function. The raw materials of the product provided by the invention comprises broad leaf miscellaneous tree veneers the water content of which is less than 4%, wherein, the thickness of the veneer is 1-2mm; and the adjacent veneers are arranged according to a sequential fiber direction or a mutually vertical fiber direction, and are superposed one by one into an assembly after being soaked in the insulating rubber, and formed after being carried out hot-pressing. The wood laminating material of the invention has good mechanical strength, arc resistance, higher resistivity, lower dielectric loss and a certain self-locking performance after being soaking in the oil. The product of the invention can be further processed into bolt plates or nut plates; the bolts and the nuts manufactured by the invention have the following advantages that each layer of rubber plate is soaked with modified alcohol-soluble phenol aldehyde resin, thus leading that the bolts and nuts have higher mechanical strength and uniform inner structure compared with an electric laminating wood board, avoiding the property of partial discharge generated by bubbles, making up for the shortcomings of the bolts prepared by phenolic bakelite and nylon, and being used in the transformer with the voltage more than 220KV.

Owner:ZHALANTUN TONGDE WOOD

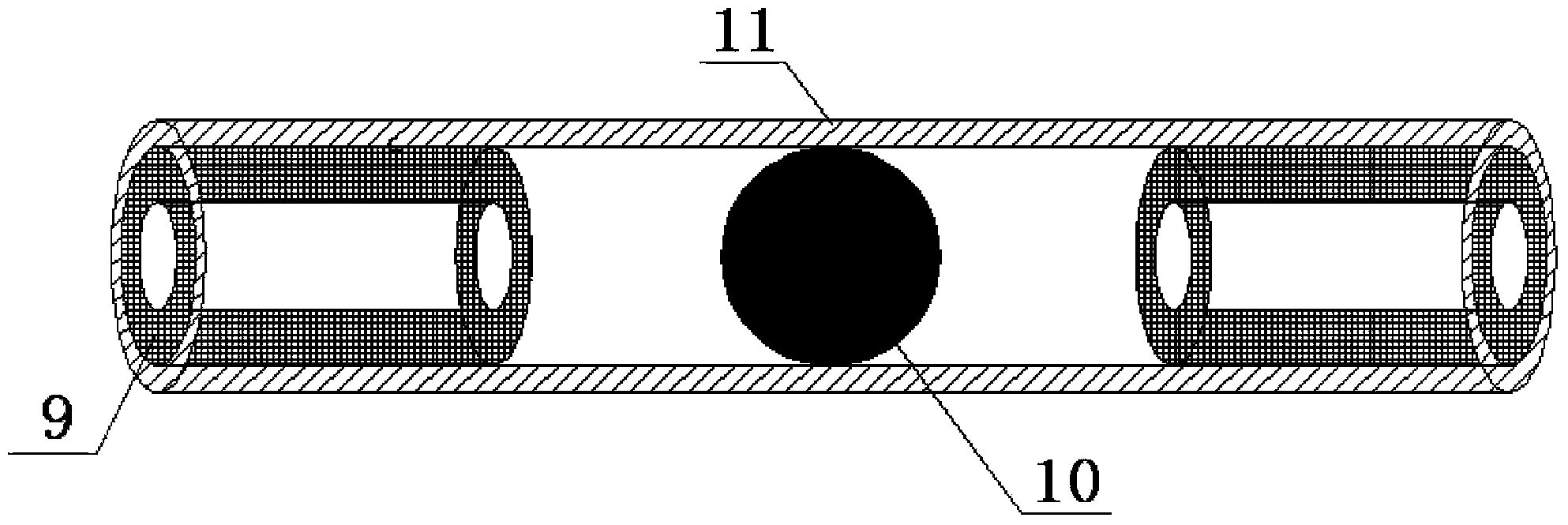

High-strength insulating support beam and preparation method thereof

The invention discloses a high-strength insulating support beam and a preparation method thereof. The problem that the existing insulating support beam is low in mechanical strength and poor in electric performance is solved. The insulating support beam comprises a glass cloth layer, wherein the glass cloth layer is immersed with flame-retardant epoxy resin glue solutions or common epoxy resin glue solutions; the flame-retardant epoxy resin glue solutions are glue solutions which are prepared by adding curing agents, curing accelerators, solvents and flame-retardant agents into flame-retardant epoxy resins; and the common epoxy resin glue solutions are glue solutions which are prepared by adding curing agents, curing accelerators, solvents and flame-retardant agents into common epoxy resins. The insulating support beam has the characteristics of high mechanical strength and high electric performance, can be suitable for supporting large-scale and super-huge type electric equipment in an insulating mode, and can be simultaneously suitable for supporting electric facilities with high voltage and extra-high voltage.

Owner:SICHUAN D&F ELECTRICAL TECH

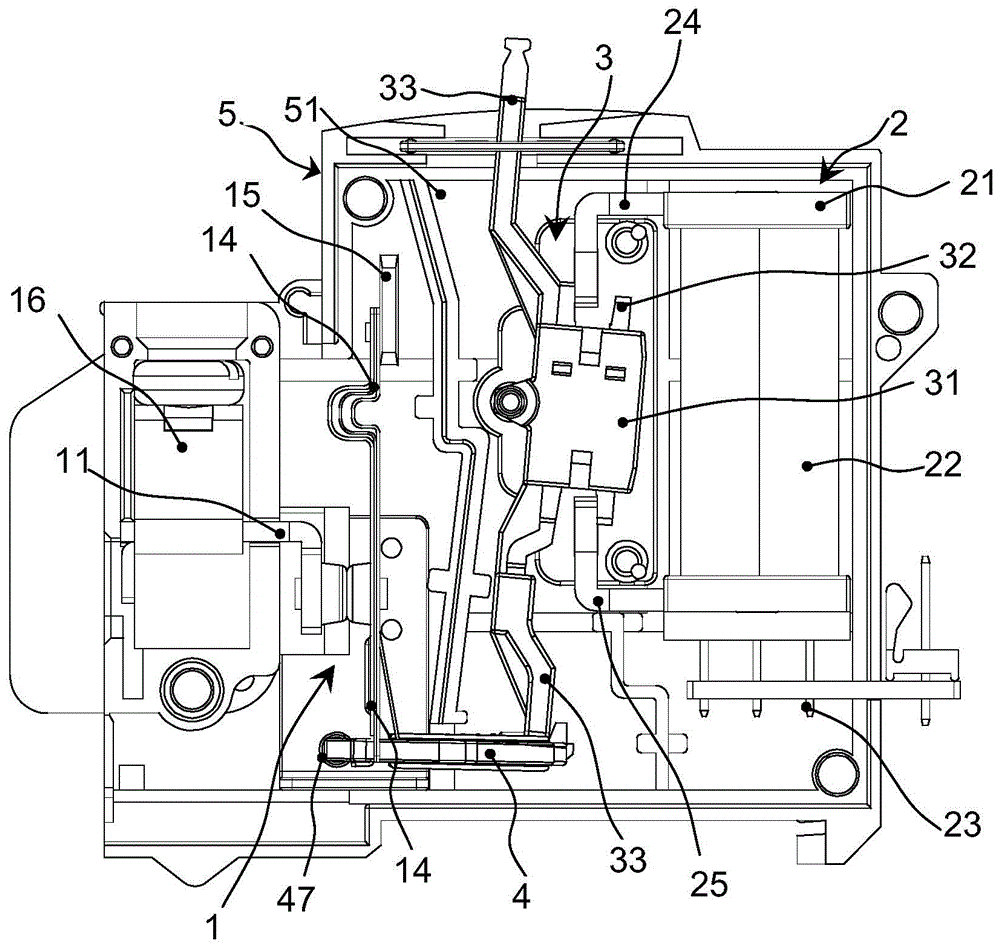

Relay and arc protection structure thereof

ActiveCN104091706AAvoid damageGood arc resistanceElectric switchesElectromagnetic relay detailsElectric arcVoltage

The invention provides a relay and an arc protection structure of the relay. The relay comprises a shell and a contact assembly. The contact assembly comprises at least two lead-out pieces, at least two stationary contacts, at least two movable contacts and a movable reed. The stationary contacts are fixedly installed on the lead-out pieces, and the movable contacts are fixedly installed on the movable reed. The at least two stationary contacts are arranged at certain intervals. A ceramic partition plate is further located between every two adjacent stationary contacts so that the creepage distance between every two contacts can be increased, the voltage withstand performance and the insulation performance of a load output end are improved, and the load capacity of the relay is greatly improved.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

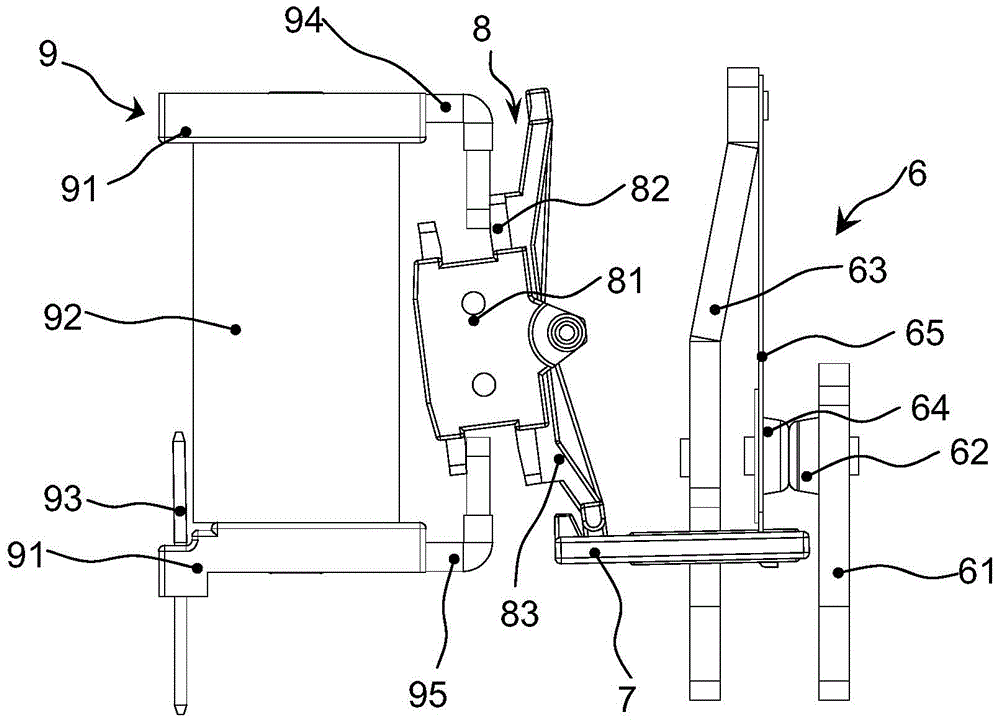

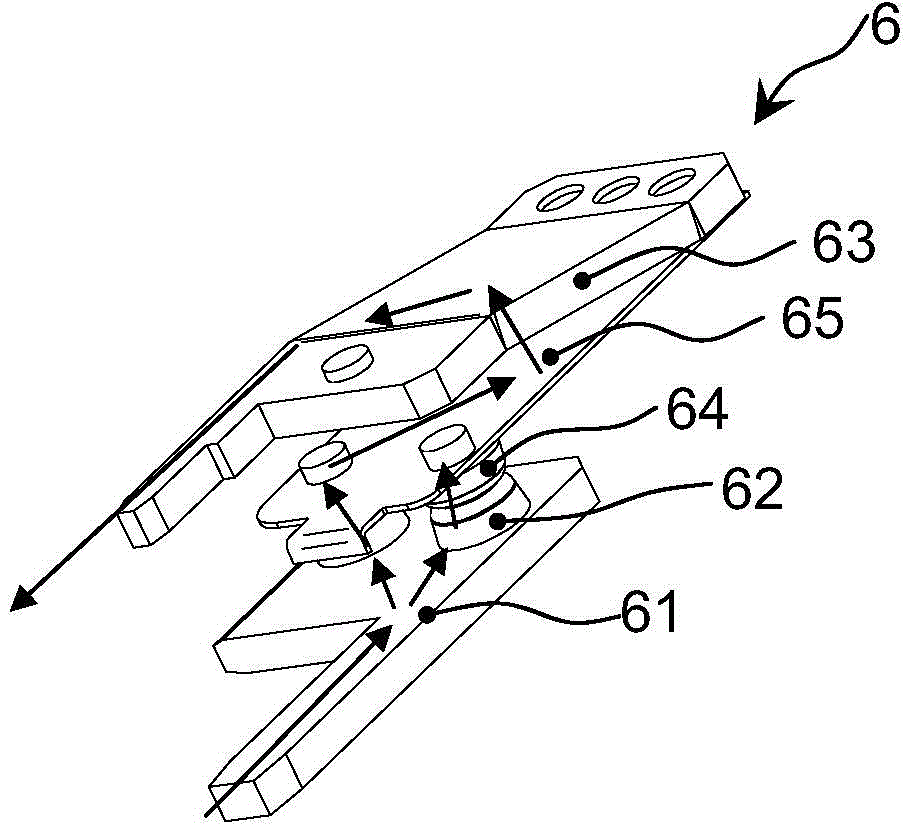

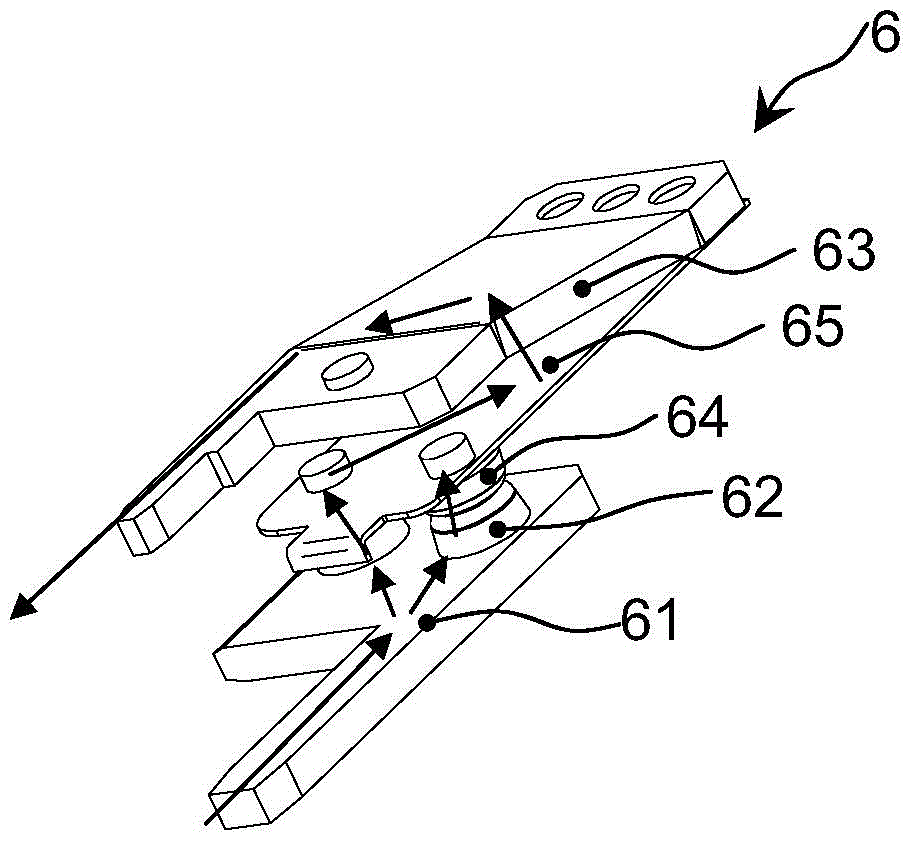

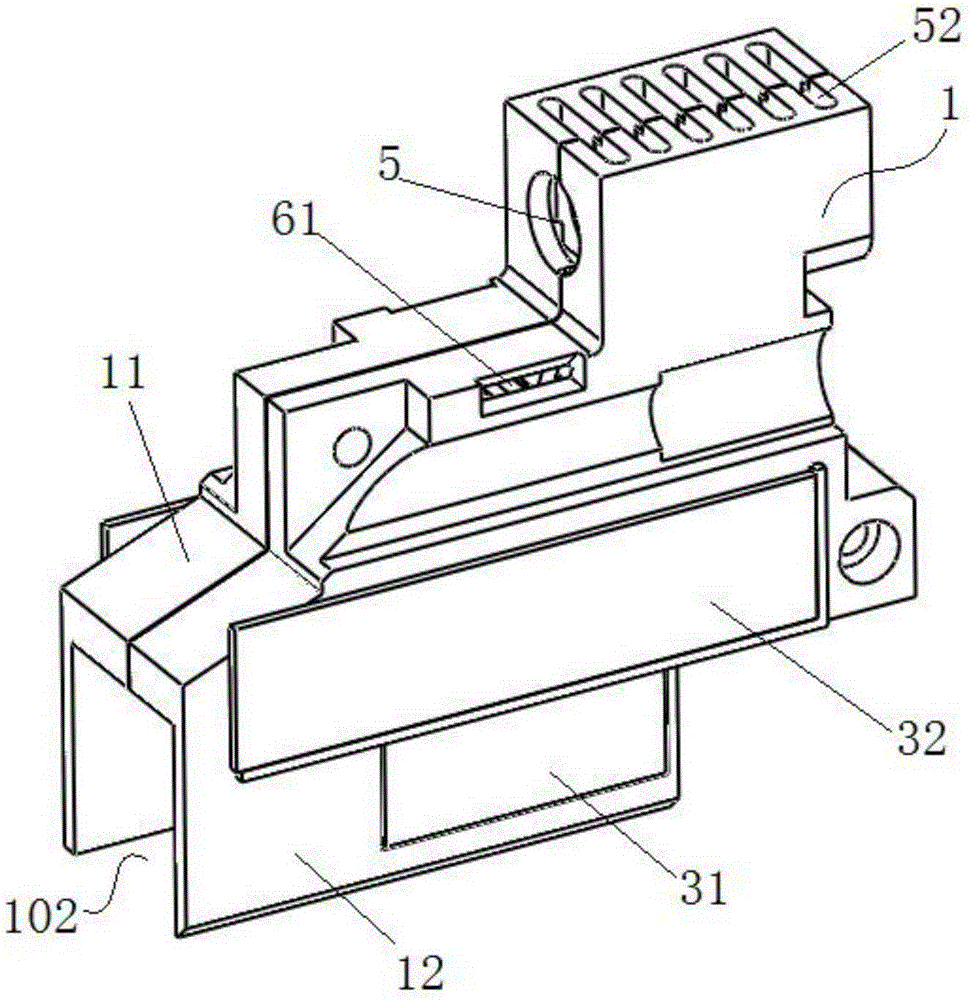

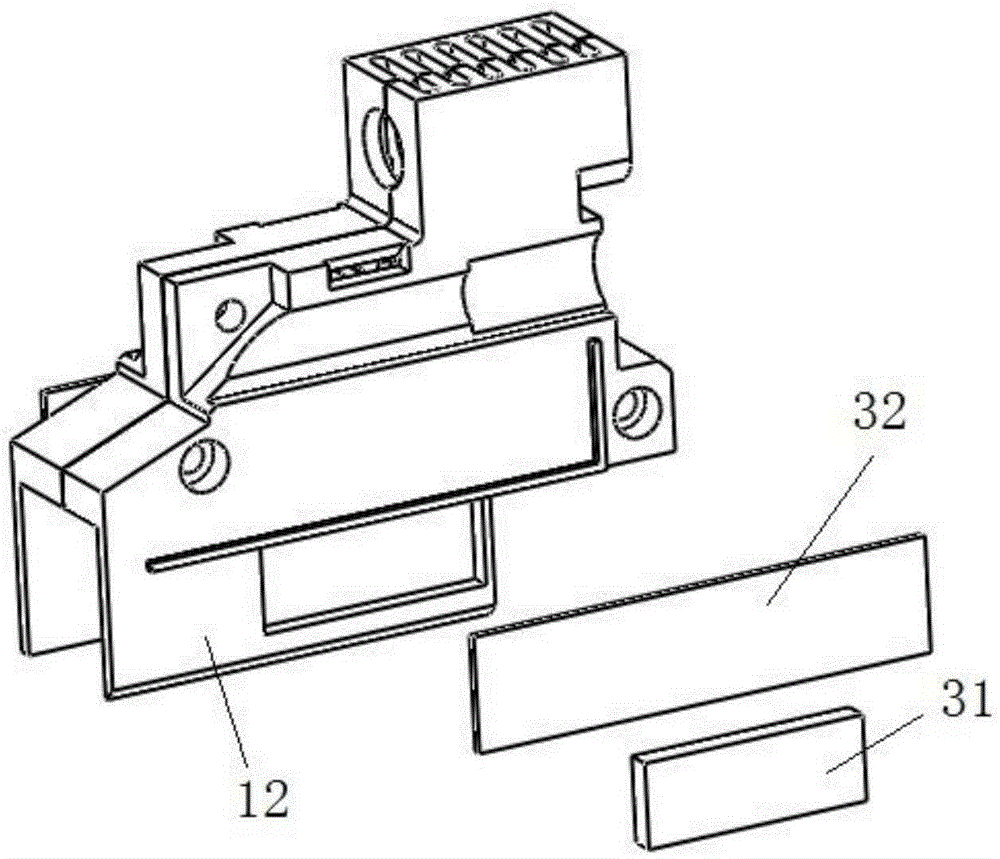

Large-current magnetic latching relay, movable contact spring of large-current magnetic latching relay, and contact assembly of large-current magnetic latching relay

ActiveCN104091725AImprove pressure resistanceExtend your lifeElectromagnetic relay detailsNon-polarised relaysEngineeringConductive materials

The invention provides a large-current magnetic latching relay, a movable contact spring of the large-current magnetic latching relay, and a contact assembly of the large-current magnetic latching relay. The large-current magnetic latching relay comprises the contact assembly, an electromagnetic assembly, an armature assembly and a pushing clamp, and under the magnetic attraction action of permanent magnet steel inside the armature assembly, the contact assembly keeps in the normally open state or in the normally closed state; the contact assembly is triggered by pulse electric signals to be switched between the normally open state and the normally closed state, so that the electromagnetic assembly drives the armature assembly to drive the pushing clamp to shift, and the contact assembly is switched between the normally open state and the normally closed state through shifting of the pushing clamp. The movable contact spring of the large-current magnetic latching relay is made of elastic conductive materials and is fixedly provided with at least two movable contacts, the movable contact spring is provided with a fixed first end portion and a second end portion capable of elastically swinging, the movable contacts are fixed to the second end portion and are electrically connected through the movable contact spring, and the second end portion of the movable contact spring is driven by the pushing clamp to swing.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

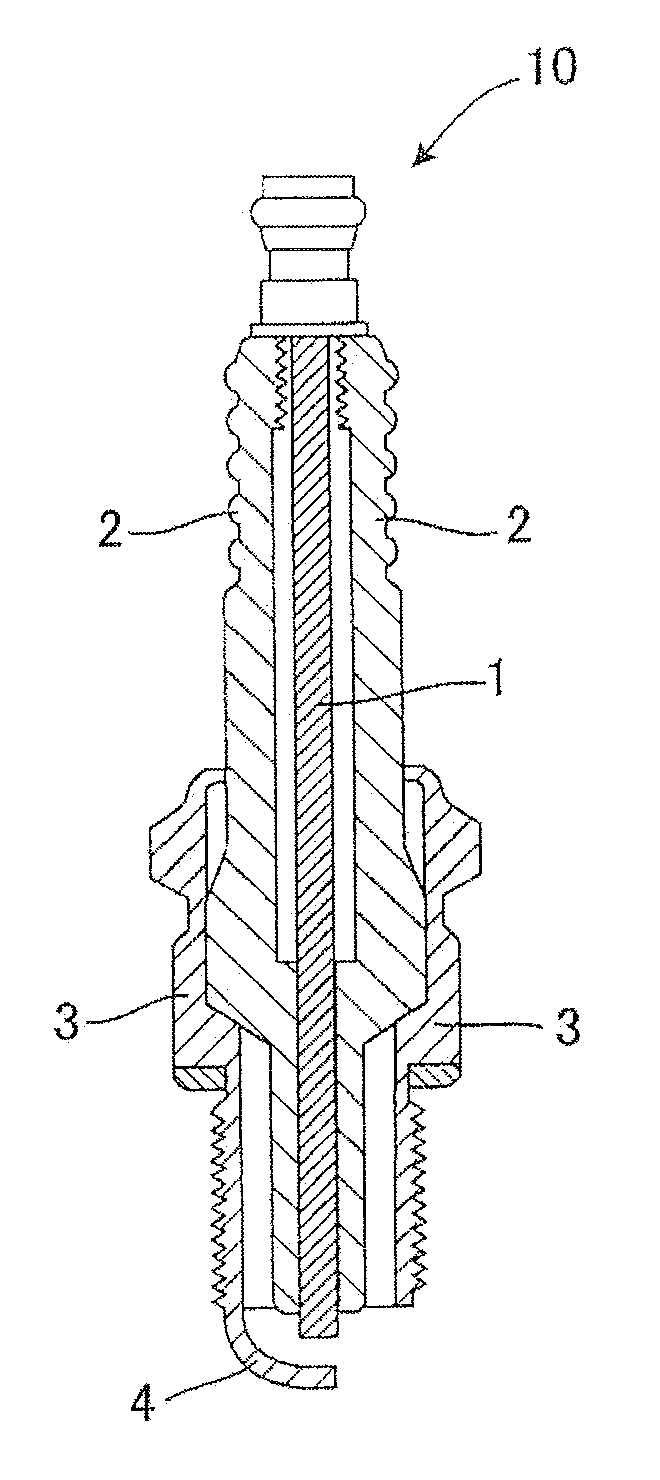

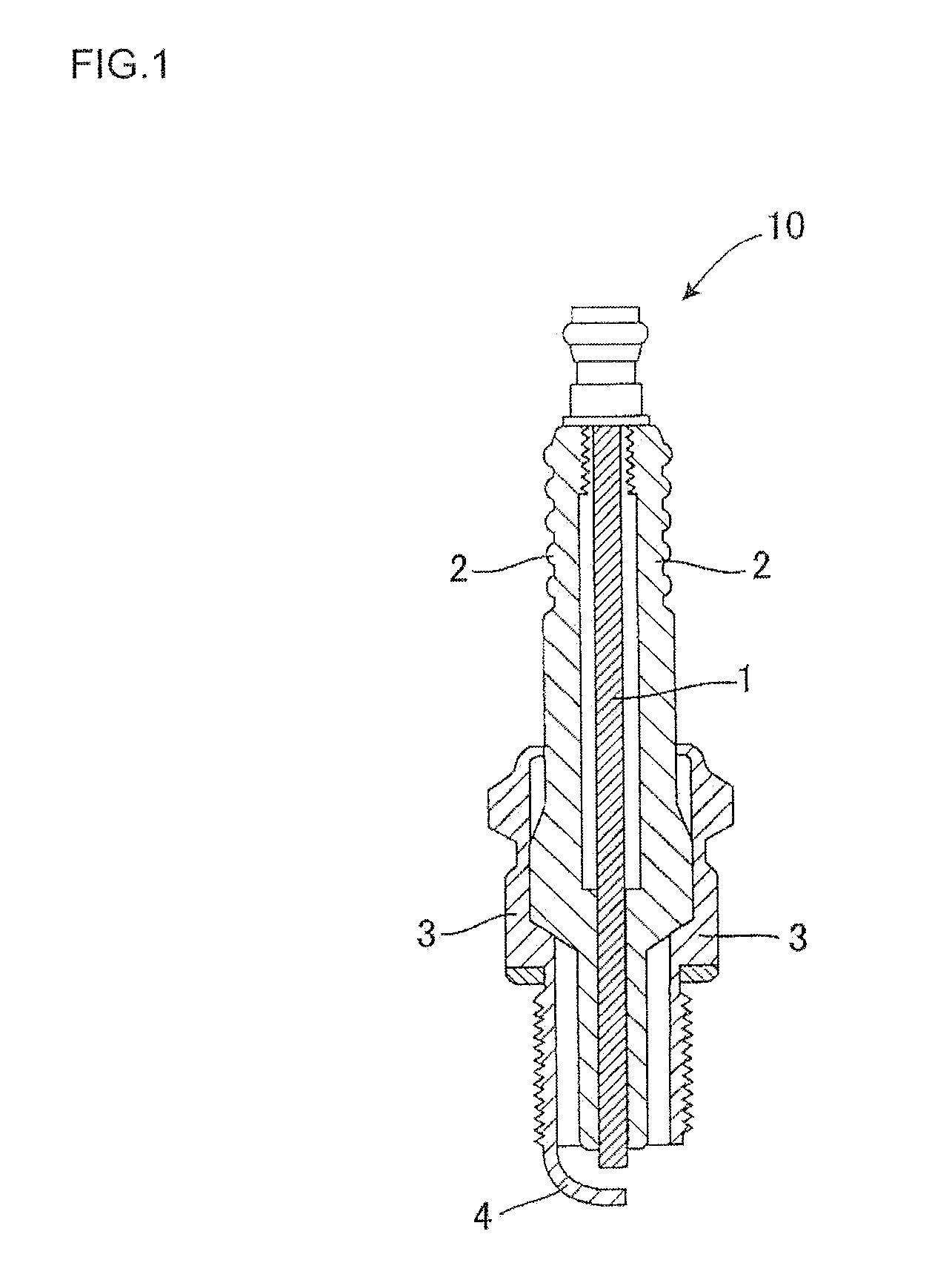

Ti3SiC2 BASED MATERIAL, ELECTRODE, SPARK PLUG AND MANUFACTURING METHOD THEREOF

ActiveUS20120186723A1Improve arc resistanceReducing TiC (heterophase) content and open porosityConductive materialCeramic shaping apparatusSpark plugPorosity

The present invention provides a Ti3SiC2 based material that exhibits excellent arc resistance, an electrode, a spark plug, and methods of manufacturing the same. A Ti3SiC2 based material according to the present invention includes Ti3SiC2 as a main phase, the Ti3SiC2 based material having a TiC content of 0.5 mass % or less and an open porosity of 0.5% or less. It may be preferable that 0 to 30 mol % of Si contained in the main phase Ti3SiC2 be substituted with Al. A spark plug according to the present invention includes an electrode formed using the Ti3SiC2 based material.

Owner:NGK INSULATORS LTD

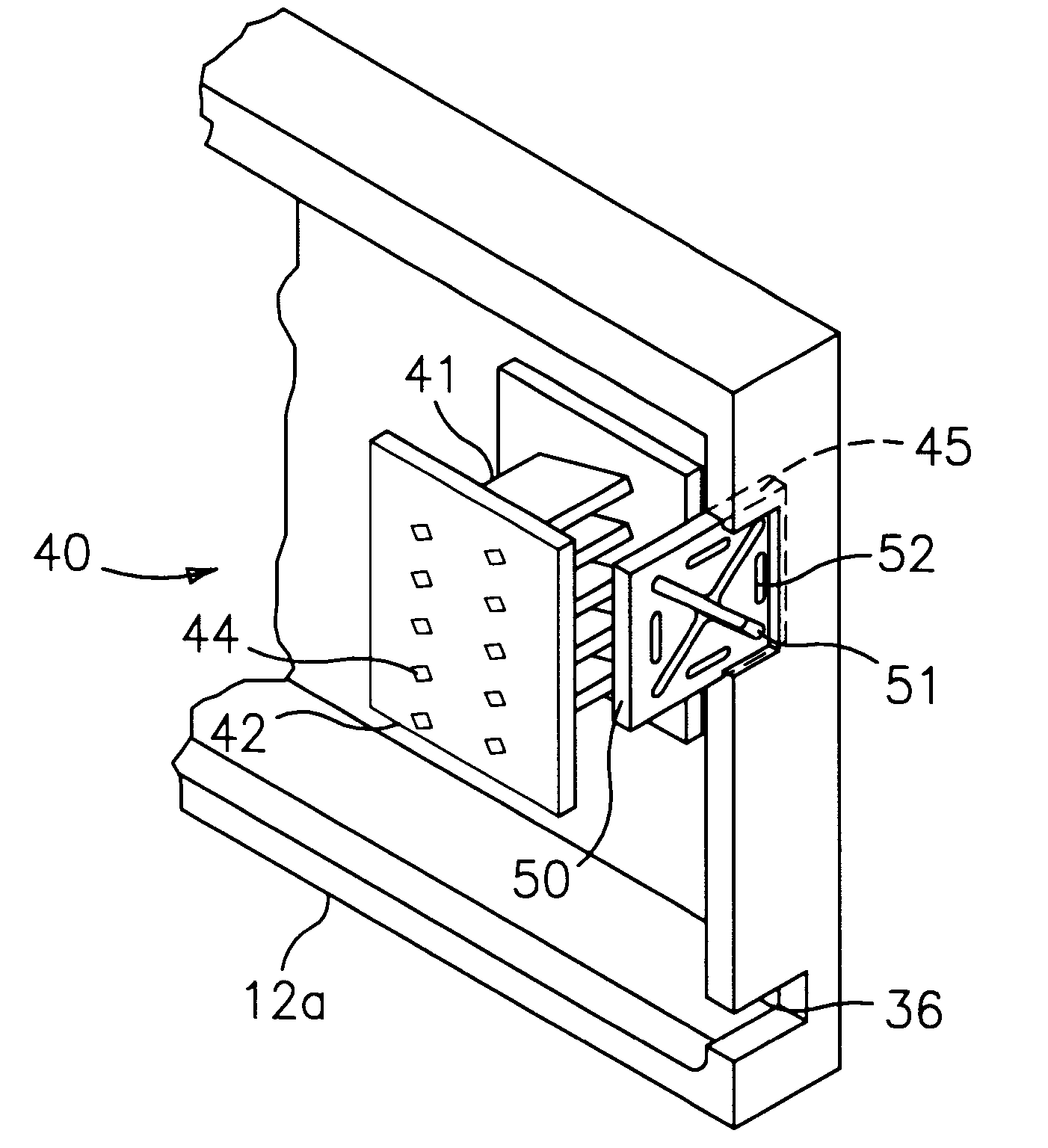

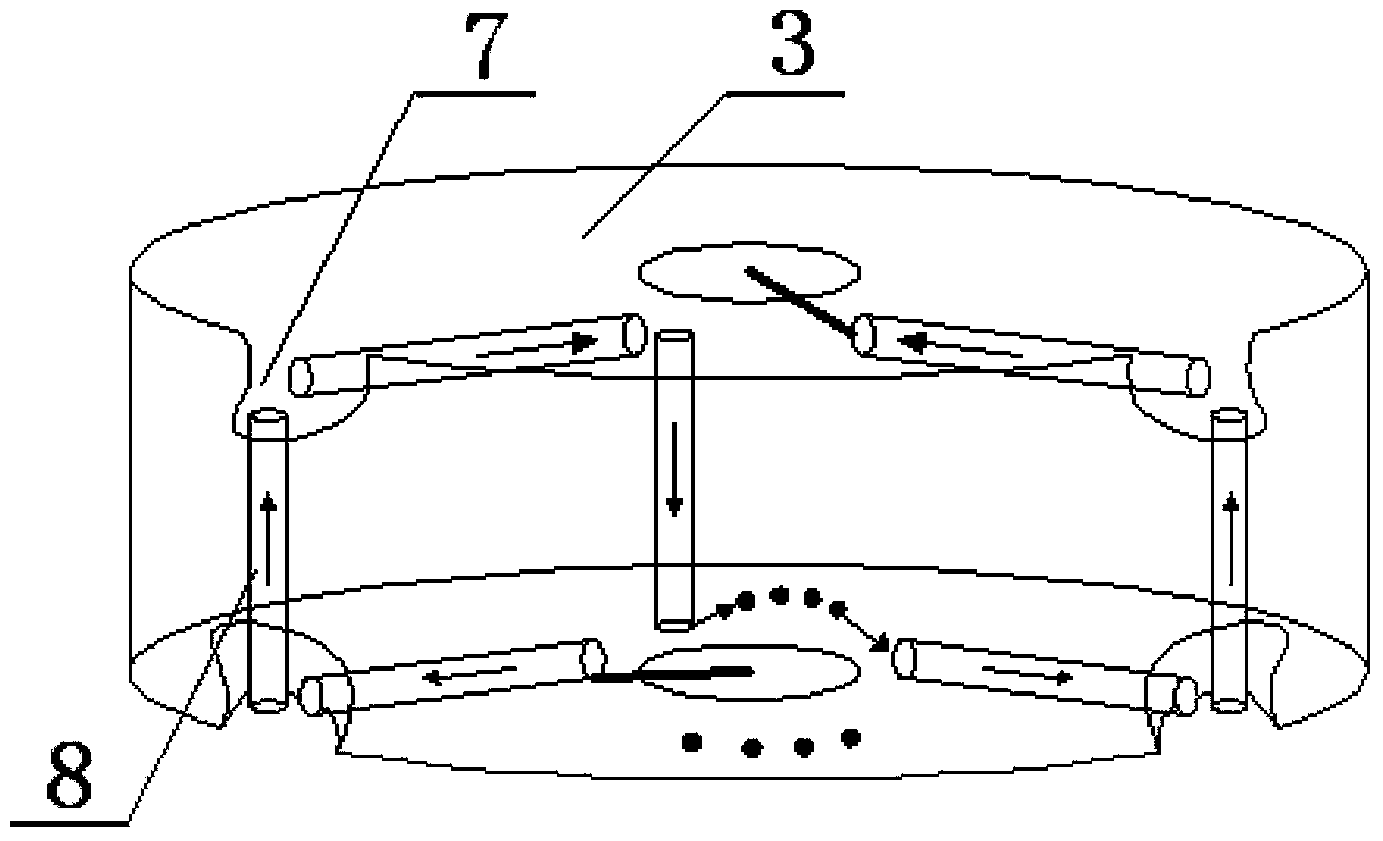

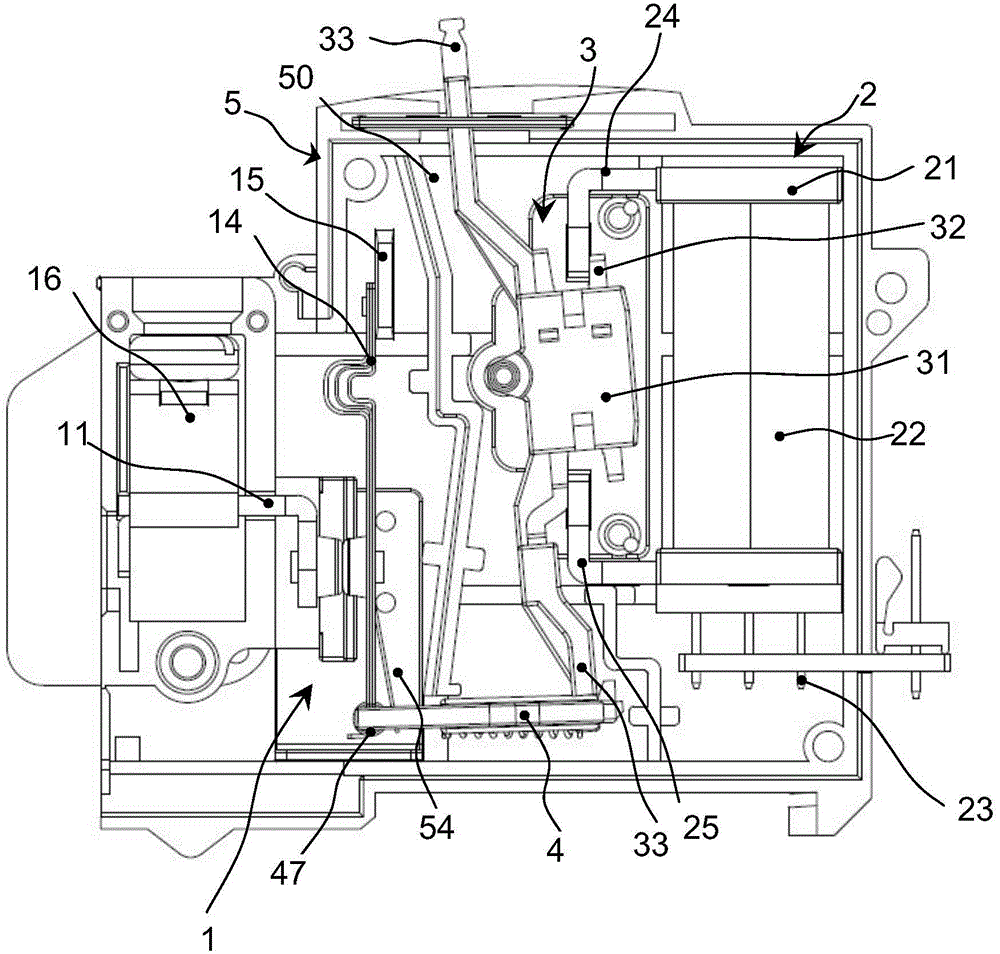

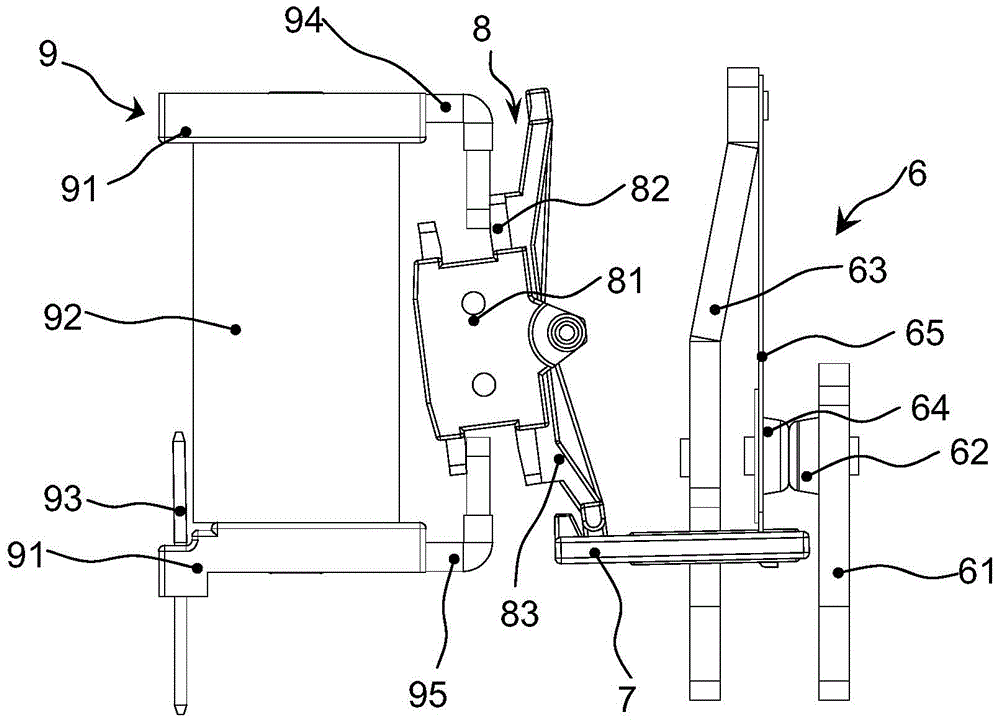

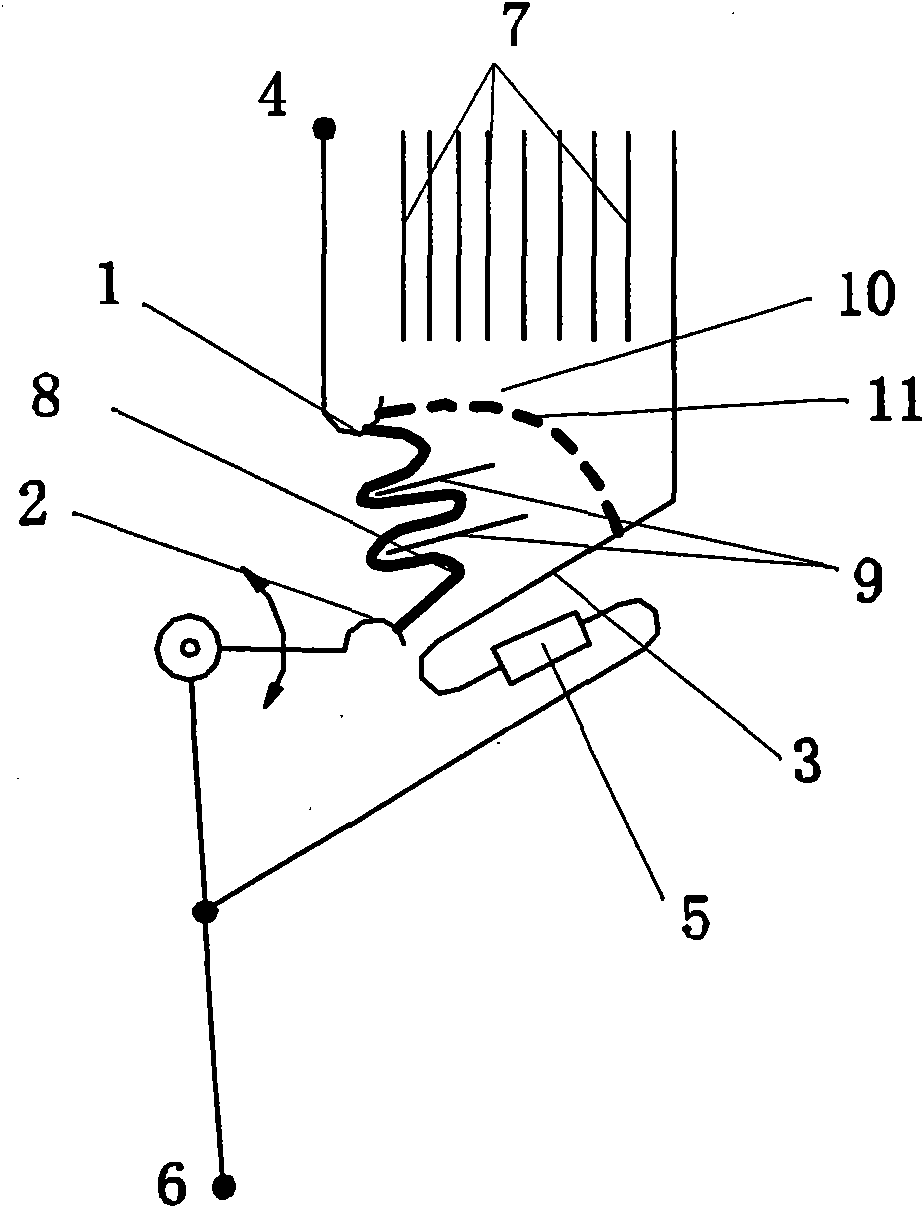

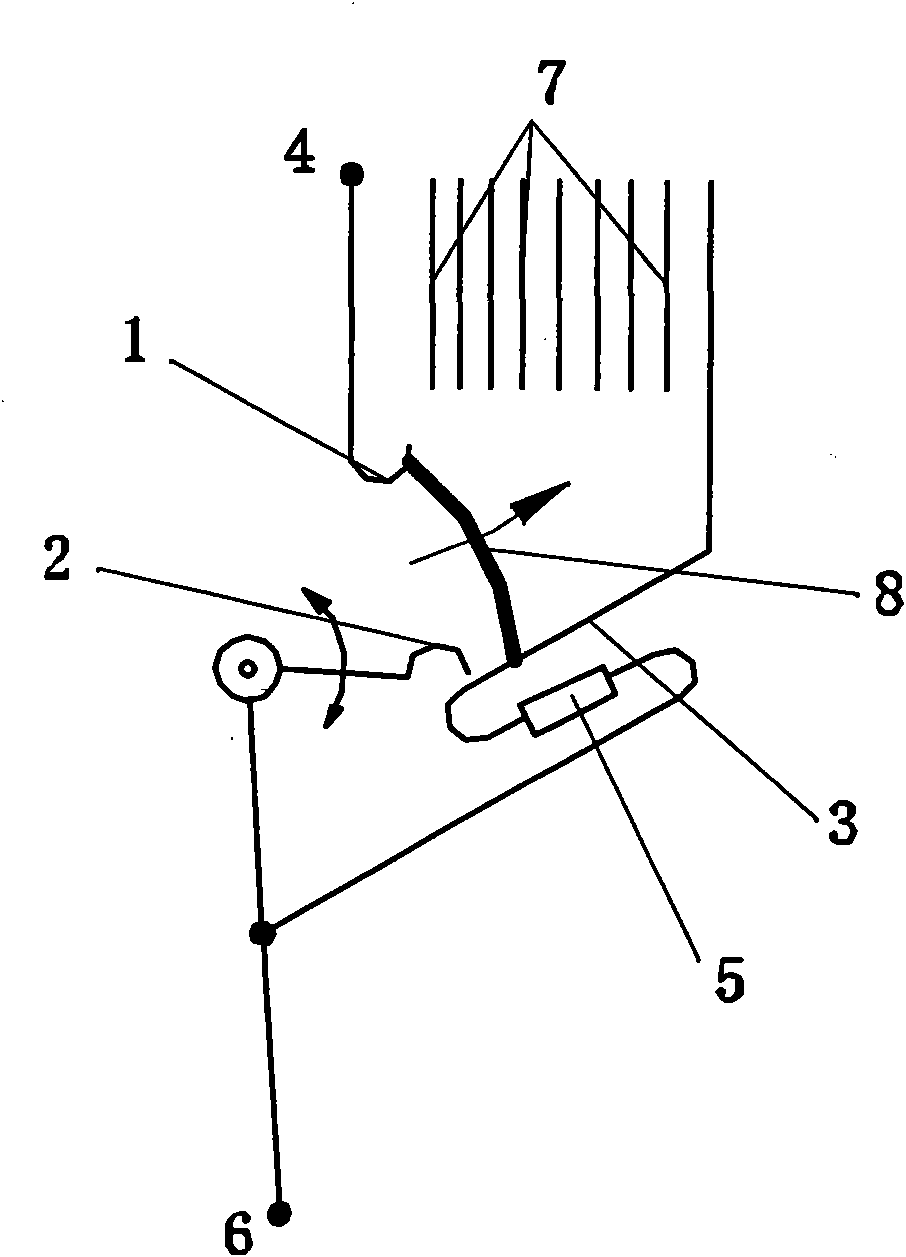

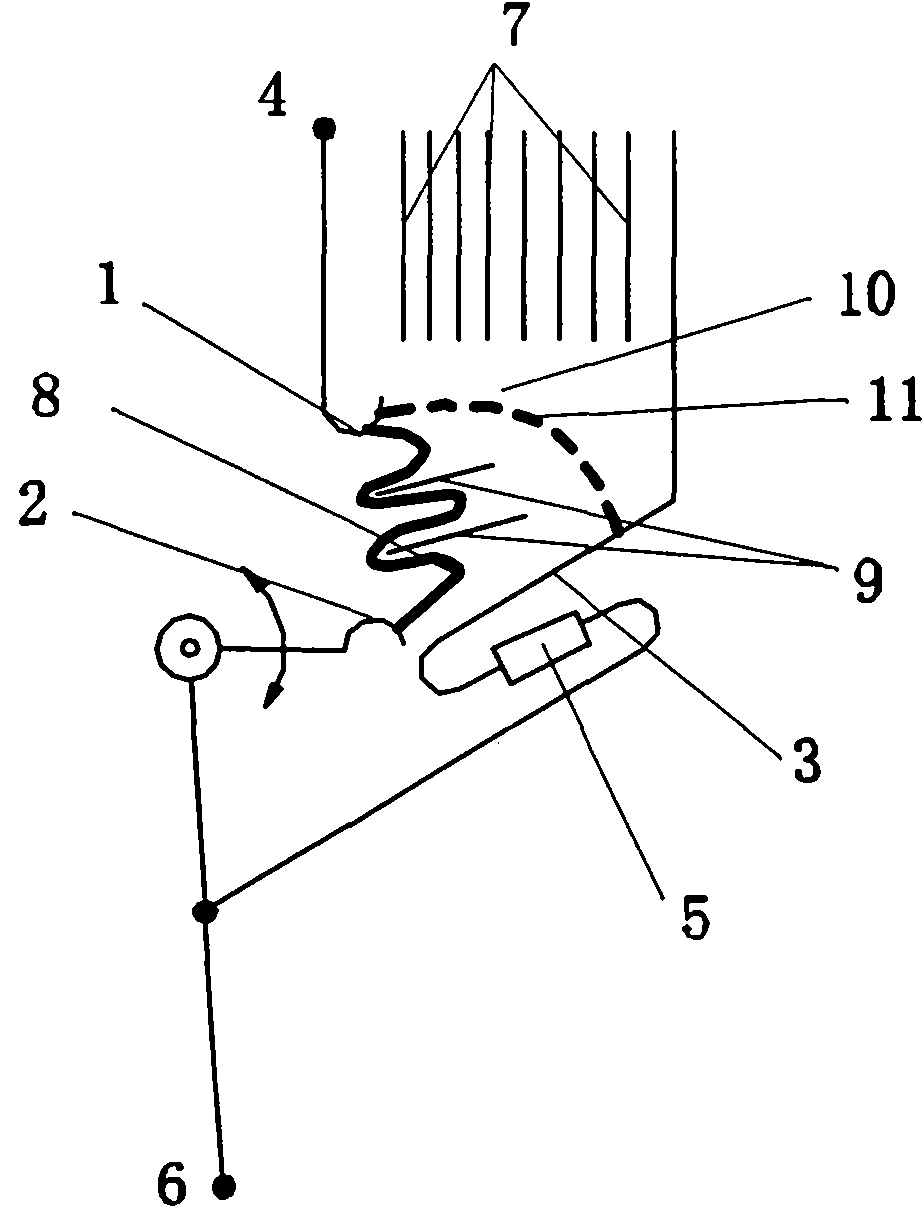

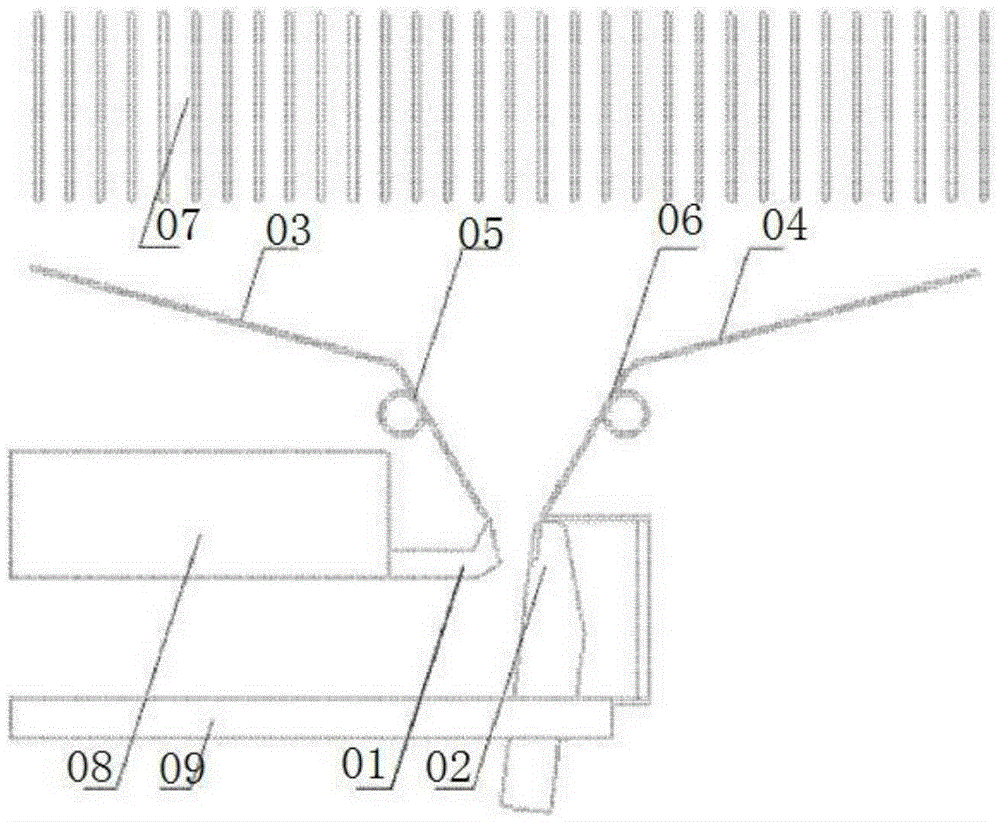

Arc striking/extinguishing mechanism of low-voltage circuit breaker

InactiveCN102024633AImprove current limiting performanceImprove breaking capacityCircuit-breaking switch detailsElectricityLow voltage circuits

The invention discloses an arc striking / extinguishing mechanism of a low-voltage circuit breaker, which belongs to the technical field of low-voltage apparatus. The mechanism comprises a moving contact, a stationary contact, an arc-extinguishing grid, and a moving-contact arc striking plate, wherein the moving contact is arranged in a shell and electrically connected with a first connecting terminal; the stationary contact is also arranged in the shell and electrically connected with a second connecting terminal; the arc-extinguishing grid is arranged in the shell and used for extinguishing electric arcs produced by disconnecting the moving contact and the stationary contact; and the moving-contact arc striking plate is arranged corresponding to the moving contact, one end of the moving-contact arc striking plate extends to the arc-extinguishing grid, and the other end of the moving-contact arc striking plate is electrically connected with the first connecting terminal. The mechanism provided by the invention is characterized in that a part which is arranged in the shell, between the moving contact and the stationary contact and corresponding to the motion trail of the moving contact is provided with at least an auxiliary arc-extinguishing grid. The mechanism provided by the invention has the advantage of improving the current limiting capacity, breaking capacity and electrical life of the circuit breaker.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

Production technique for phosphor copper strip for electrical purposes

The invention relates to a production technique for a phosphor copper strip for electrical purposes. The production technique comprises the first step of introduction of a copper bar onto a tractor unit with high-purity cathode copper as a raw material, the second step of continuous extrusion of a copper strip blank, the third step of cold rolling, the fourth step of annealing, the fifth step of finish rolling, the sixth step of cleaning and passivation, and the seventh step of splitting. The produced phosphor copper strip for electrical purposes has high purity, low oxygen content, high electric conduction and high surface quality. The technique is short in process, high in efficiency and capable of saving energy.

Owner:惠州市一电电池技术有限公司

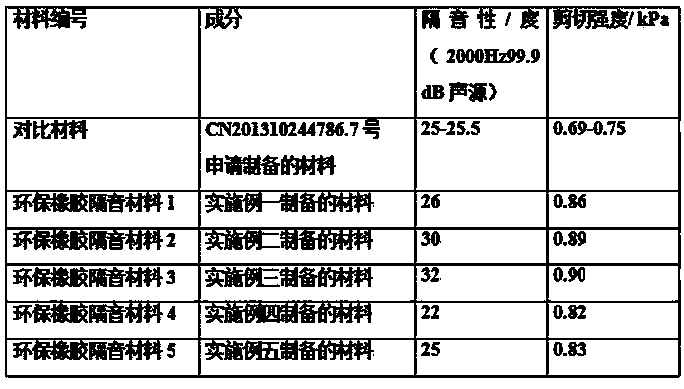

Environment-friendly rubber sound-insulation material and preparation method thereof

ActiveCN104194338AGood mechanical propertiesGood alkali resistanceClimate change adaptationEpoxySilicon oxide

The invention belongs to the field of functional materials, and particularly relates to an environment-friendly rubber sound-insulation material and a preparation method thereof. The material comprises the following components in percentage by weight: 1-3% of dibenzoyl peroxide, 1-3% of silicon oxide, 5-15% of recovered epoxy resin, 5-15% of composite rare-earth oxide and the balance of silicon rubber. No abundant rare materials are used in the preparation process, so the raw material cost is lowered; and the wastes are used as the raw materials, so the material preparation method is convenient in technique and simple in process. The prepared material can effectively absorb energies, can be used in the fields of transportations, architecture, military affairs and the like, has the functions of shock resistance, impact buffering, heat insulation, sound insulation and the like, and is especially suitable to be used as a saloon car damping fin.

Owner:江苏金泰祥内外门业有限公司

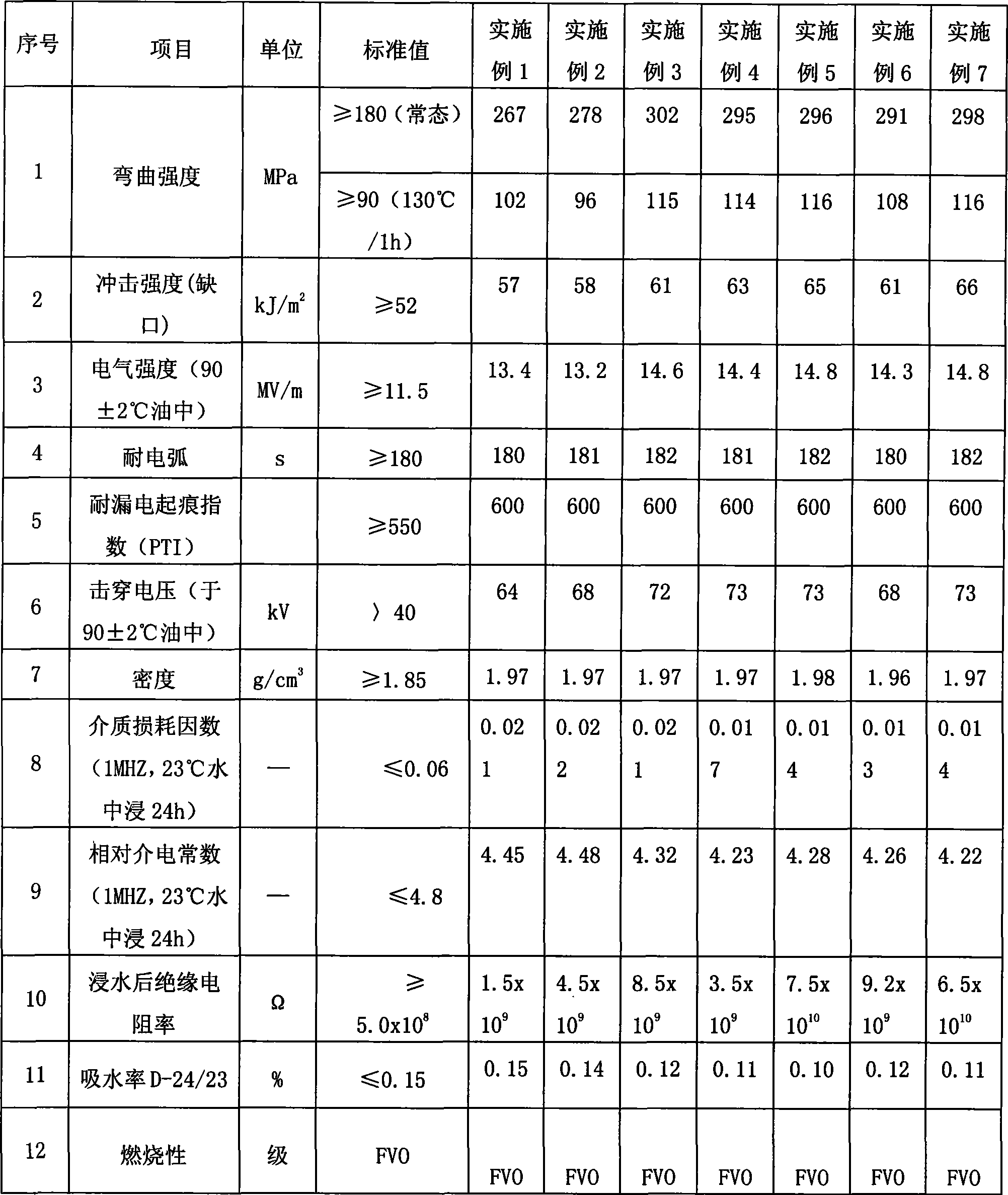

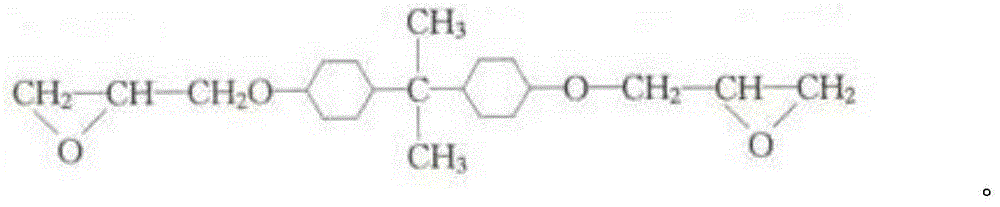

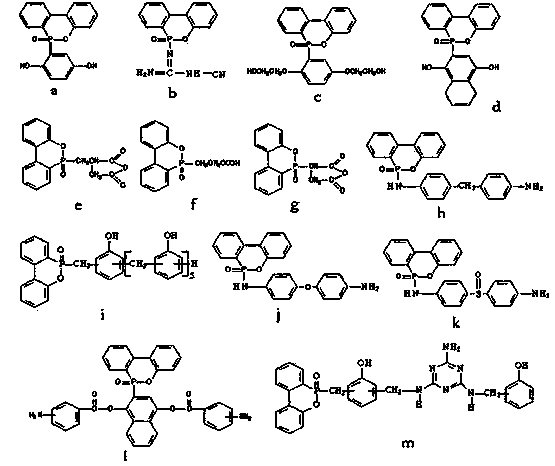

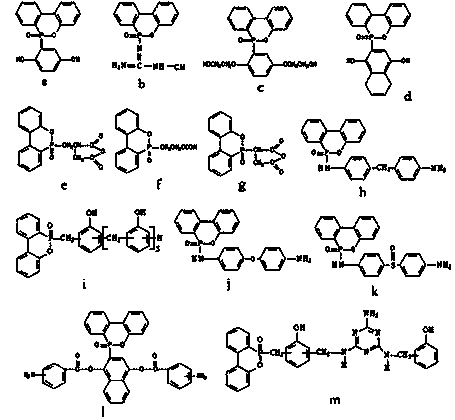

High-arc resistance epoxy insulating material and preparation method thereof and insulator

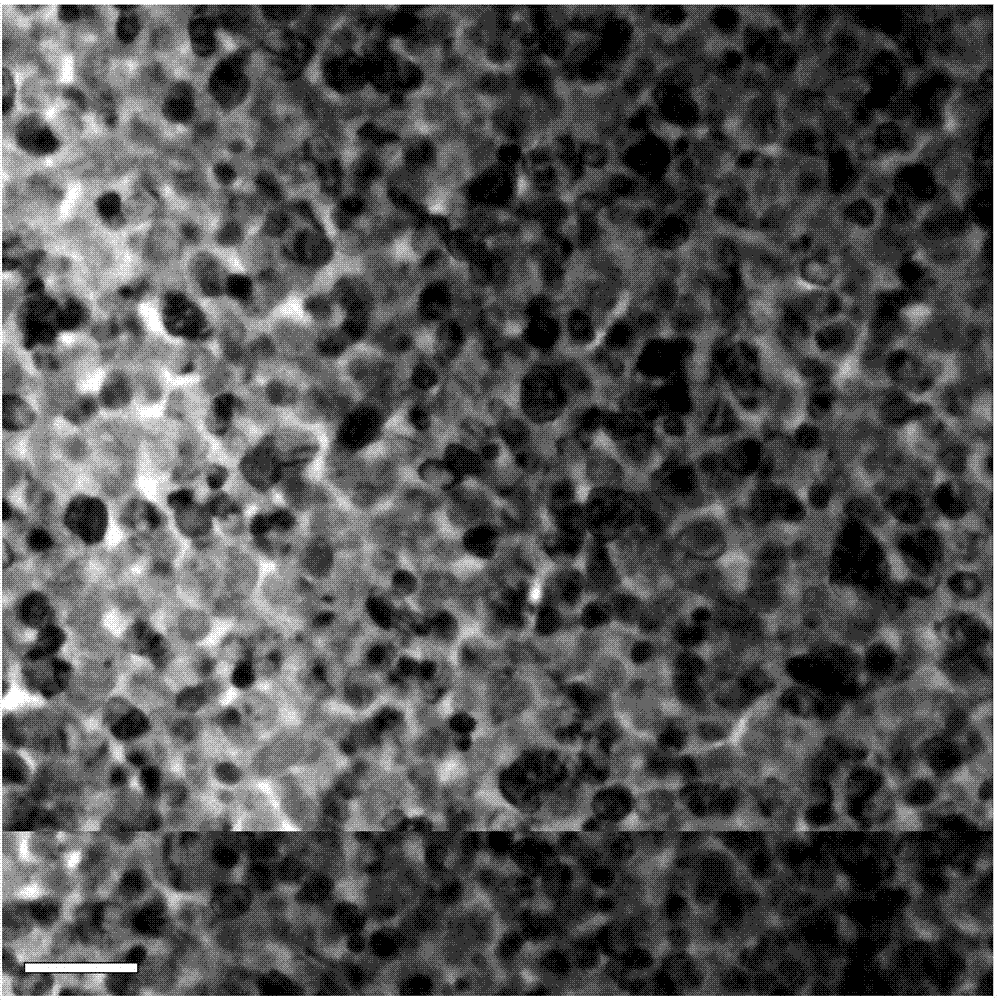

ActiveCN105504685AGood arc resistanceIncrease the number of pressure operationsPlastic/resin/waxes insulatorsMetallic oxidesPolyethylene glycolGlass transition

The invention discloses a high-arc resistance epoxy insulating material and a preparation method thereof and an insulator. The epoxy insulating material is prepared from the following raw materials in parts by mass: 1 part of composite epoxy resin, 0.51-0.55 part of curing agent methyl tetrahydrophthalic anhydride and 3.25-3.45 parts of aluminum oxide, wherein the composite epoxy resin is a mixture of phenolic aldehyde modified bisphenol A epoxy resin, polyethylene glycol modified bisphenol A epoxy resin and diphenolic acid modified bisphenol A epoxy resin. The epoxy insulating material is equivalent to traditional materials in glass-transition temperature, tensile strength and electric strength, the arc resistance reaches 237s, and after a 252kV circuit breaker is switched on / off under voltage for over 3243 times, flashover appears behind; and the epoxy insulating material has excellent arc resistance, the operation times of a high-voltage circuit breaker under voltage is remarkably increased, the service lives of internal epoxy insulating components are prolonged and reliability of the internal epoxy insulating components is improved, and the maintenance and overhauling cost of a power station is reduced.

Owner:PINGGAO GRP +2

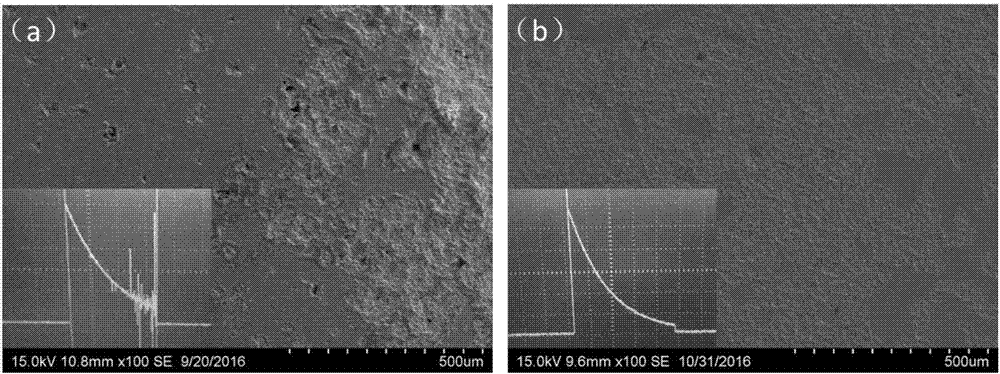

Surface clad layer treatment method of copper tungsten electrical contact material for arc extinguish chamber

ActiveCN106978586AExtended service lifeImprove abnormal breakdown discharge phenomenonVacuum evaporation coatingSputtering coatingDistributed structureArgon atmosphere

The invention discloses a surface clad layer treatment method of a copper tungsten electrical contact material for an arc extinguish chamber. The method includes the steps that the copper tungsten alloy contact material is prepared to serve as a substrate material; mechanical buffing, washing and drying are carried out; the substrate material is placed into a vacuum chamber to deposit a chromium layer, a nickel layer or a titanium layer on a base body through a chromium target, a nickel target or a titanium target under the argon atmosphere; a copper target and a tungsten target are used for codeposition of a copper-tungsten clad layer on the substrate deposited with the chromium target, the nickel target or the titanium target continuously, and a copper tungsten-tungsten clad layer with a certain film thickness is obtained; and annealing is carried out under protection of a mixed atmosphere of inert gas and hydrogen, furnace cooling is carried out, a sample is taken out, and a copper tungsten electrical contact material surface clad layer is obtained. By means of the two-phase nanoscale uniform distributed structure, the ablation uniformity can be greatly improved, the ablation pit depth is reduced, and the service life is prolonged; meanwhile, a provided nanocrystalline tungsten framework can improve the arc ablation resistant capacity. By means of the method, equipment is simple and convenient to operate, the effect is obvious, and the good industrial application prospect is achieved.

Owner:XI AN JIAOTONG UNIV

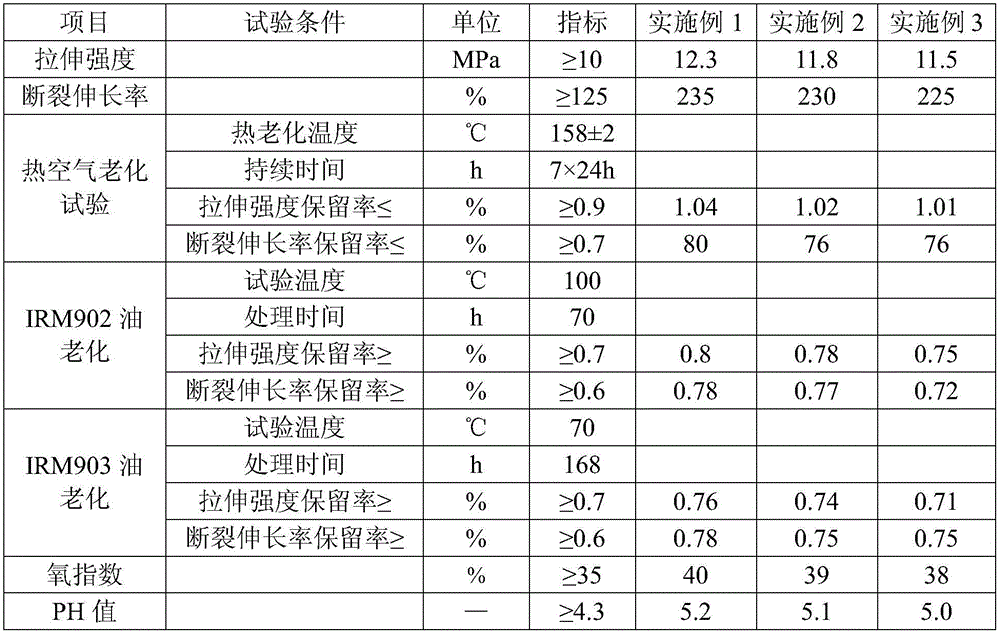

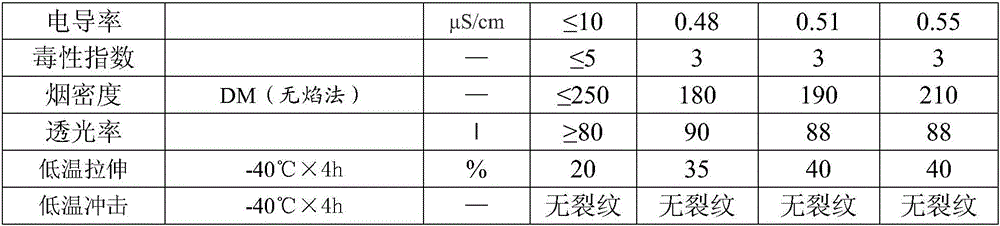

Environmental-protection flame retardant cable material and preparation method thereof

InactiveCN106243479AImprove low temperature performanceImproved low temperature winding performance and low temperature impact performanceRubber insulatorsPlastic/resin/waxes insulatorsCarbon blackAntioxidant

The invention discloses an environmental-protection flame retardant cable material and a preparation method of the environmental-protection flame retardant cable material. The preparation method comprises the following steps: putting EPDM (Ethylene-Propylene-Diene Monomer) rubber and ethylene-vinylacetate rubber into an internal mixer to be mixed, then putting zinc oxide, antioxidants, lubricants, zinc borate and auxiliary crosslinking agents into the internal mixer to be mixed, then putting carbon black pigment, reactive flame retardants, silane coupling agents and processing aids into the internal mixer to be mixed, finally discharging rubber compounds which are uniformly mixed from the internal mixer after the processing aids and peroxide crosslinking agents are put into the internal mixer to be mixed, packaging into triangle bags through an open mill and carrying out fine grinding, and then performing calendaring through a calender to be prepared into slices, thus obtaining the environmental-protection flame retardant cable material. The environmental-protection flame retardant cable material disclosed by the invention has good low-temperature rolling performance and low-temperature impact properties, can effectively lower the production cost of the environmental-protection flame retardant cable material and solve the problem of roll sticking in the EVM mixing process, has good elasticity and flexibility, excellent transparency and surface glossiness and further has good chemical stability, aging resistance and ozone resistant intensity.

Owner:HENGYANG HENGFEI CABLE CO LTD

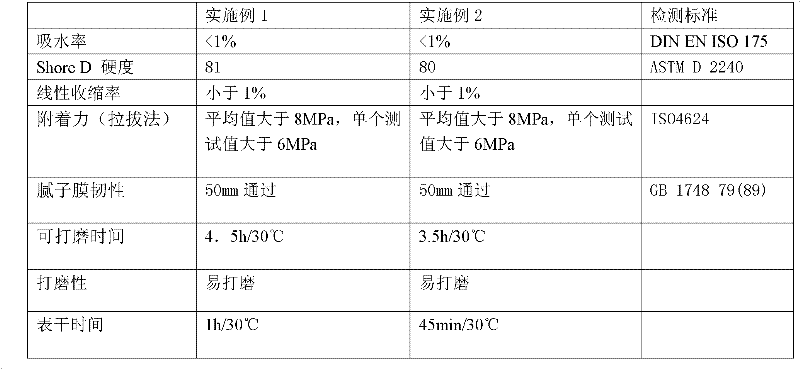

Epoxy ash for high performance megawatt wind turbine blades and preparation method thereof

The invention discloses a high-performance epoxy ash for megawatt wind power blades and a preparation method. The epoxy ash is formed by mixing a putty part and a curing agent part, wherein the mass composition of the putty part is: Epoxy resin 20-65%, reactive diluent 5-20%, pigment and filler 40-70%, wetting and dispersing agent 1-5%, leveling agent 0.1-5%, defoamer 1-4%, thixotropic The curing agent is 0.5-10%; the curing agent part is formed by mixing amine substances and thixotropic agents. The product of the invention has the advantages of convenient curing, strong adhesion, low shrinkage, excellent mechanical properties, good electrical properties, chemical stability and the like.

Owner:江苏普兰纳涂料有限公司

Epoxy resin casting insulating material and preparation method thereof

The invention relates to an epoxy resin casting insulating material. The epoxy resin casting insulating material comprises the following raw materials in parts by mass: 7-13 parts of epoxy resin, 5-11parts of a curing agent, 20-30 parts of modified silicon dioxide powder and 2-8 parts of mica powder. The epoxy resin casting insulating material has an excellent formation processing property, is suitable for an APG technology and a vacuum casting technology, and suitable for manual casting moulding. An insulating component prepared by the material has a good insulating property and excellent arc resistance, and is capable of solving a technical problem that the arc resistance of an epoxy casting material is poor, wherein the arc resistance of the material can reach more than 210 s. The material has a lower curing shrinkage rate which is 0.1%-0.05% only. An overlarge stress is prevented from being generated between a metal insert and an insulator through the smaller curing shrinkage rate, and a problem that a product is cracked in a place of the metal insert is prevented from happening. The insulating component formed and prepared by using the insulating material has higher strengthand toughness, and is good in secondary machining property.

Owner:株洲电力机车广缘科技有限责任公司

Micromotor commutator electric contact material for raising wear resistance and arc erosion resistance

The invention discloses a micromotor commutator electric contact material for raising wear resistance and arc erosion resistance. The material provided by the invention comprises the following components of: by weight, 1-8% of Cu, 0.1-0.5% of Ni, 0-5% of Zn, 0.5-2% of an oxide, and the balance being silver, wherein the oxide is any one selected from Al2O3, ZrO2, CeO2 and Cr2O3, and the granularity of the oxide needs to be controlled below 3 microns. Prepared by a powder metallurgic technique, the material has excellent wear resistance, arc resistance and welding resistance, can be used to effectively prevent short circuit caused by aggregation of abrasive dust in a groove of a commutator, and is suitable for manufacturing a micromotor commutator with large arc during the commutation stage.

Owner:CHONGQING CHUANYI AUTOMATION

Sliding electrical contact material and electrical contact metal composite material

ActiveCN101677170AImprove wear resistanceImprove pollutionRotary current collectorElectricityTrace element

The invention discloses two Au-containing sliding electrical contact materials which respectively comprise the main components: Au, Ag, Cu and Y as well as Au, Ag, Cu, Pd and Y; and on that basis, thetwo materials are respectively added with one or more of the trace elements Zr, Cr, Ta and Ti, and the total content of the trace elements does not exceed 2%. The alloy has good wear resistance, arcresistant capability and organic pollution resistance, so as to be excellent sliding electrical contact material, thus being suitable for manufacturing a commutator of a DC motor.

Owner:CHONGQING CHUANYI AUTOMATION

Sliding electrical contact material containing rare earth and electrical contact metal composite material

InactiveCN101676422AImprove wear resistanceImprove antioxidant capacityContactsRare earthWear resistance

The invention relates to a sliding electrical contact material containing rare earth, which comprises the components by mass percent: 0.5-1.5% of Pd, 3.0-9.0% of Cu, 0.2-0.9% of Ni, 0.02-0.50% of rareearth elements and the rest of Ag. The material has good wear resistance and arc resistant capability, so as to be excellent sliding electrical contact material, thus being suitable for manufacturinga commutator of a DC motor.

Owner:CHONGQING CHUANYI AUTOMATION

DC circuit breaker arc extinguishing chamber

The present invention provides a DC circuit breaker arc extinguishing chamber which comprises a shell with a mounting inner cavity and a plurality of metal gates which are installed in the mounting inner cavity side by side. An arc extinguishing space with two through ends is formed between any two adjacent metal gates. The shell also comprises a containing inner cavity for containing DC circuit breaker moving and static contacts, and the containing inner cavity communicates with one end of the arc extinguishing space. The shell side wall which forms the containing inner cavity is also provided with a first magnetic shield plate for shielding a magnetic field. When the moving and static contacts of the DC circuit breaker are disconnected to generate an electric arc, the first magnetic shield plate can protect the electric arc from being interrupted by an external magnetic field, the magnetic field generated at moving and static contact positions is gathered in the containing inner cavity such that the electric arc is rapidly and stably driven to the metal gates to extinguish the arc under the effect of the magnetic field generated at moving and static contact positions, and thus the stability of arc extinguishment is improved.

Owner:ANDELI GRP

Alkali metal-added silver-based sliding contact material containing rare earth

ActiveCN101924312AGood arc resistanceEasy to implementRotary current collectorDynamo-electric machinesElectricityHigh humidity

The invention discloses an alkali metal-added silver-based sliding contact material containing rare earth, which is prepared by adding a little amount of alkali metal elements in AgCuNiRE, AgCuPdNiRE, AgCuZnNiRE and AgCuPdZnNiRE, wherein the additive amount of alkali metals Li, Na, K is 0.01-3.0% by mass. The elements can be respectively added solely or two or three of the elements are added in amatching manner, and the total additive amount is not greater than 3.0%. The material of the invention has good self-lubricating and arc suppressing properties, can be used for manufacturing commutators of DC motors, can prolong the service life and improve the contact stability and the reliability under high temperature and high humidity conditions, and can meet the requirements of small DC motors with long service life.

Owner:CHONGQING CHUANYI AUTOMATION

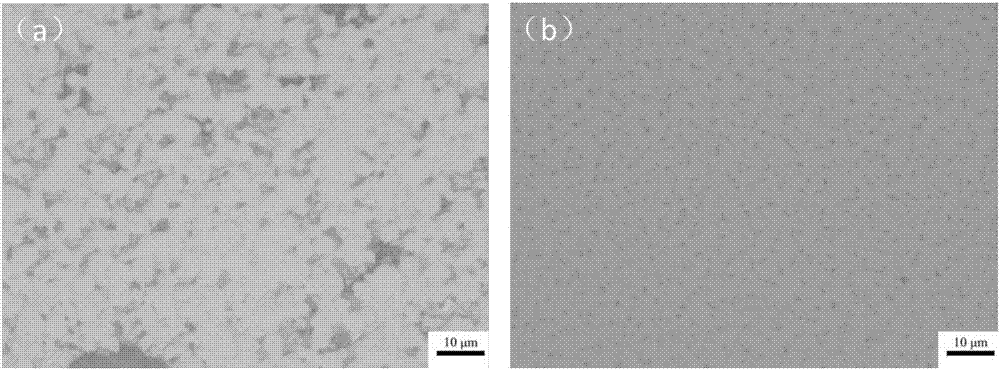

Silicon rubber insulation composite material, preparation method and purpose thereof

ActiveCN108962426AImprove breakdown resistanceGood arc resistanceRubber insulatorsInorganic insulatorsVulcanizationComposite insulators

The invention provides a silicon rubber insulation composite material, a preparation method and a purpose thereof. The silicon rubber insulation composite material comprises, by weight, 100-120 partsof a silicone rubber, 20-40 parts of a layered inorganic particle, 0.5-20 parts of a nanometer silicon ball, 1-3 parts of a vinyl silane coupling agent, 0.5-2 parts of a vulcanizing agent and 5-10 parts of an addition agent. The preparation method of the silicon rubber insulation composite material comprises the following steps of firstly, mixing the formula amounts of the silicone rubber, the nanometer silicon ball and the vinyl silane coupling agent; then, adding a residual raw material to mix; and finally using a vulcanization method to prepare the material. The silicon rubber insulation composite material provided in the invention has the advantages of high breakdown resistance, high arc resistance and a low dielectric loss and has a good mechanical property. The material can be used as the material of a direct current power transmission line composite insulator and is especially suitable for being used as the material of the composite insulator in a direct current casing pipe.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

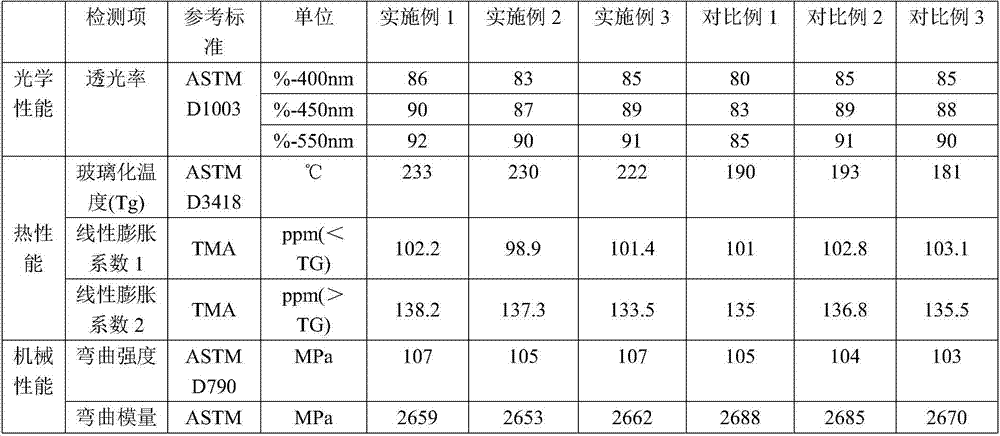

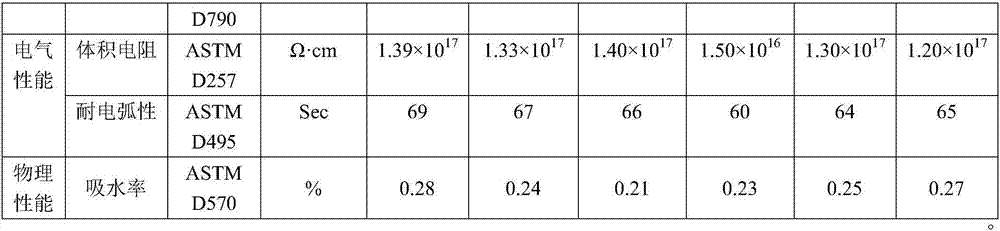

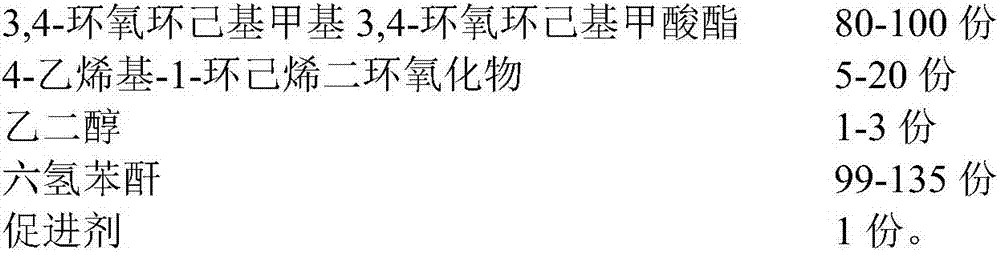

Heat-resistant alicyclic epoxy resin cured product and preparation method thereof

ActiveCN108003328AHigh light transmittanceHigh glass transition temperatureHexahydrophthalic anhydrideGlass transition

The invention relates to a heat-resistant alicyclic epoxy resin cured product. The cured product comprises the following raw materials in parts by weight: 80-100 parts of 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexanecarboxylate, 5-20 parts of 4-vinyl-1-cyclohexene dioxide, 1-3 parts of ethylene glycol, 99-135 parts of hexahydrophthalic anhydride and 1 part of an accelerator. The invention also relates to a preparation method of the heat-resistant alicyclic epoxy resin cured product. According to the heat-resistant alicyclic epoxy resin cured product provided by the invention, the light transmittance and glass transition temperature (Tg) are obviously improved, and the properties such as volume resistance, arc resistance and the like are superior to the properties of prior alicyclic epoxyresin cured products.

Owner:JIANGSU TETRA NEW MATERIAL TECH

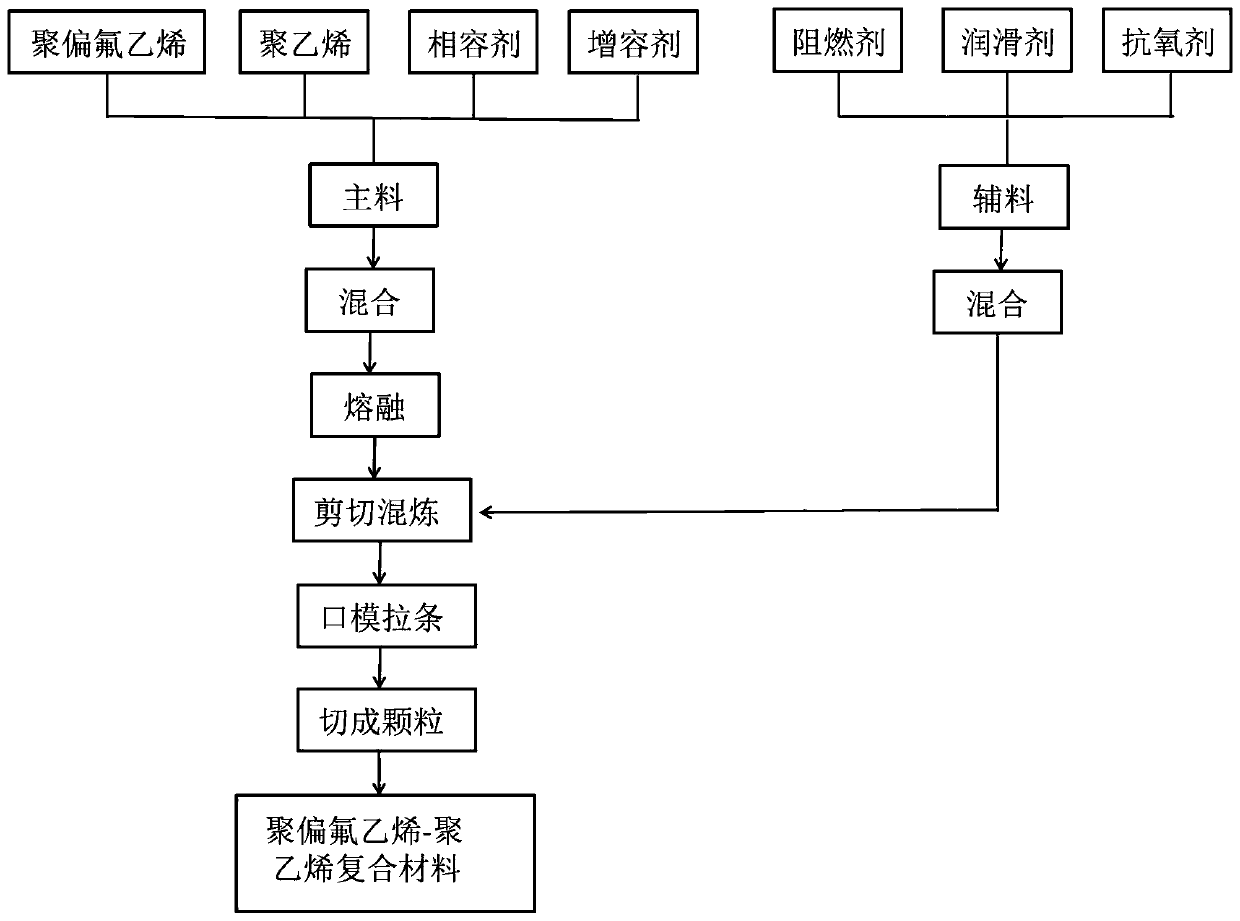

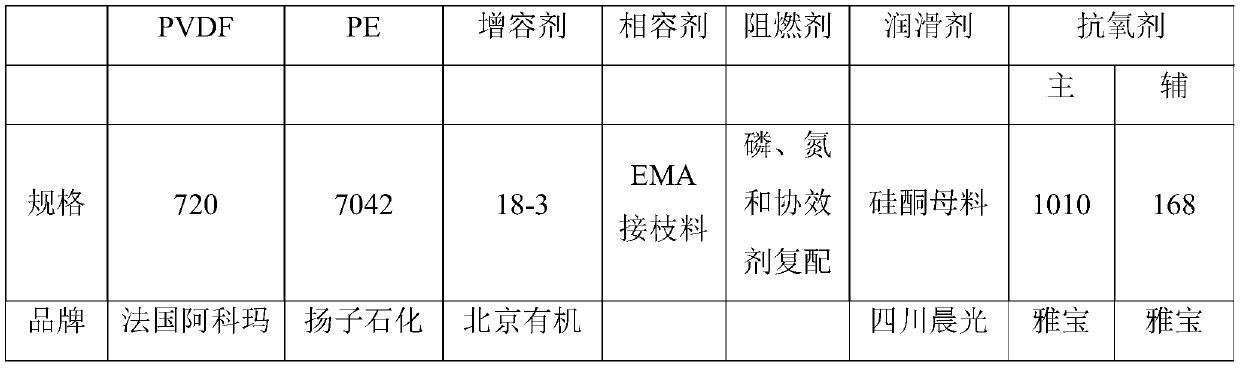

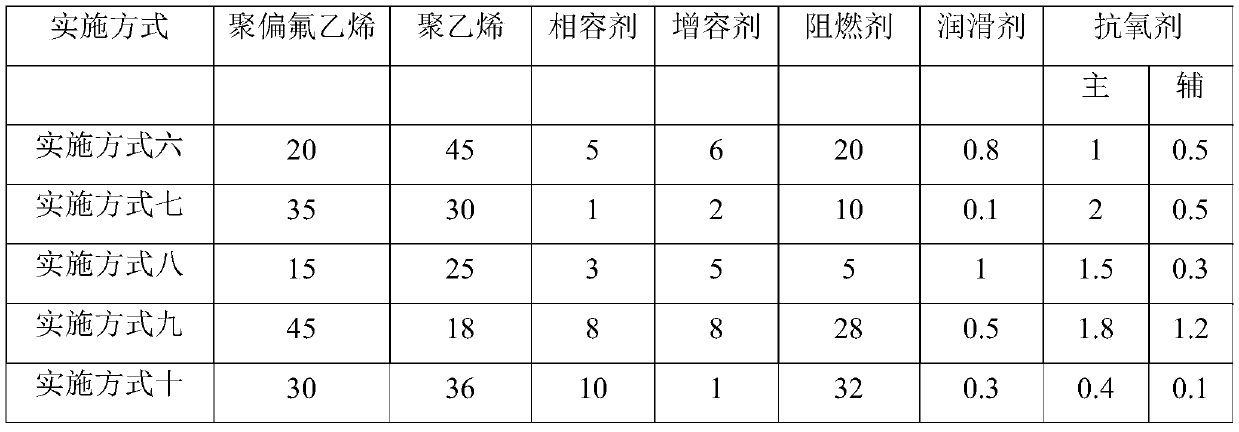

Polyvinylidene fluoride-polyethylene composite material, preparation method thereof and insulator sheath

InactiveCN110204820AAnti-humidity goodImproved arc resistance and flame retardancyPlastic/resin/waxes insulatorsPolyvinylidene fluorideAntioxidant

The invention belongs to the field of materials, and particularly relates to a flame-retardant high-pressure resistant polyvinylidene fluoride-polyethylene composite material, a preparation method thereof and an insulator sheath. The polyvinylidene fluoride-polyethylene composite material comprises the following components in parts by weight: 10-50 parts of polyvinylidene fluoride; 10-50 parts ofpolyethylene; 1-10 parts of a compatilizer; 1-10 parts of a compatibilizer; 5-35 parts of a flame retardant; 0.1 to 1 part of a lubricant; and 0.5 to 3 part of an antioxidant. The polyvinylidene fluoride-polyethylene composite material has better moisture flash prevention and anti-pollution flash prevention capabilities, and the arc resistance and flame retardancy of the composite material are improved by adding the flame retardant into the raw material formula. In addition, the raw materials in the composite material are nontoxic, no waste gas, waste material and waste water are generated inthe production process, and no pollution is caused to the environment.

Owner:CHANGZHOU INST OF LIGHT IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com