Patents

Literature

138results about How to "Adjust viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Leadless electronic slurry composition for solar silicon photovoltaic cell and preparation method thereof

InactiveCN101345263AHigh electrical conductivityRefined nanocrystalline structureFinal product manufactureSemiconductor devicesAdhesiveSlurry

The invention discloses a compounding and a preparation method for lead-free electronic slurry used for a solar silicon photocell; according to the mass percentage, the slurry is obtained by preparing 70 to 75 percent of aluminium powders, 20 to 25 percent of organic adhesive, 1 to 5 percent of inorganic glass powders and 1 to 5 percent of additives; the aluminium powder is ball-shaped aluminium powder with the surface covered by an aluminium nitride protection layer, with the purity not less than 99.9 percent and the average grain size of 2 to 6 microns; simultaneously, organic adhesives consisting of ethyl cellulose, resin, hexadecanol, diethyleneglycol monomethyl ether, diethyleneglycol monobutyl ether, terpineol and n-butyl alcohol are added into the aluminium powder; the inorganic glass powder is silicon dioxide, boracic acid, alumina, antimony oxide and zirconia; the additive consists of Span and pump oil. The product prepared by the method of the invention has no dust generation or aluminium peeling phenomenon and achieves the requirement of no lead and environmental protection.

Owner:NANTONG UNIVERSITY

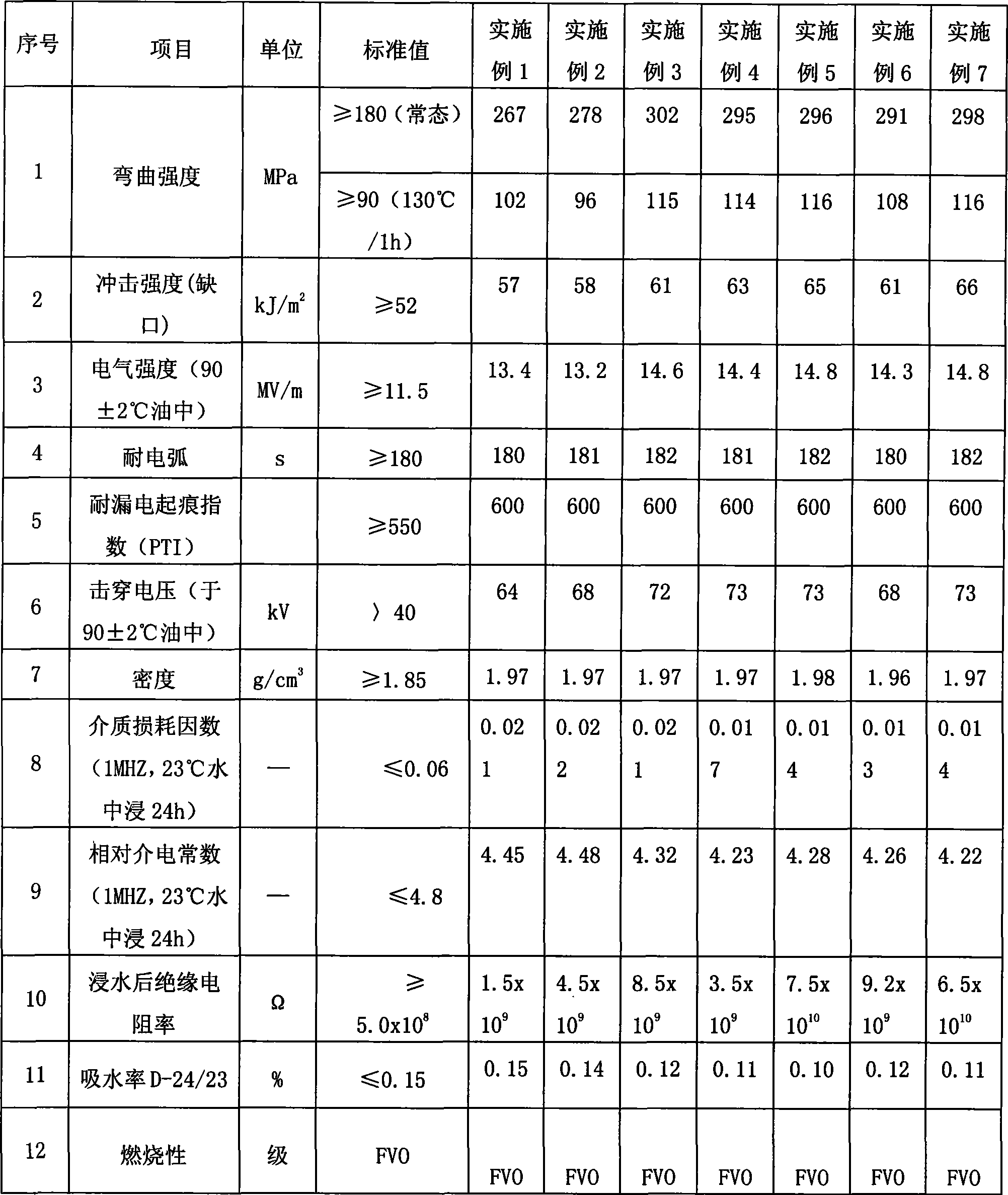

Unsaturated polyester glass fiber felt plate and production method thereof

The invention discloses an unsaturated polyester glass fiber mat board which is obtained by pressing the glass fiber mat immersed with resin paste. The production method thereof comprises: after being stirred evenly, the resin paste is scraped and smeared on a polyethylene film evenly; later a layer of polyethylene film is respectively paved on the upper surface and the lower surface of the glass fiber mat, then a sizing mat is obtained after tight pressing; when the sizing mat is cured, the polyethylene films on the surfaces of the mat are removed; next, the sizing mat is delivered into a press for hot pressing at the temperature of 70 DEG C-145 DEG C and the pressure of 10-20MPa; according to the thickness of the eventually obtained mat board, the mat board with the thickness of each millimeter is hot-pressed for 3-15 minutes; and finally an unsaturated polyester glass fiber mat board is obtained. The unsaturated polyester glass fiber mat board has excellent flame resistance, insulation, electrical and mechanical properties. The production method of the unsaturated polyester glass fiber mat board improves the productivity, reduces the production cost, and can prepare board surfaces with various sizes; and the thickness of the product has large range.

Owner:河北福润达新材料科技有限责任公司

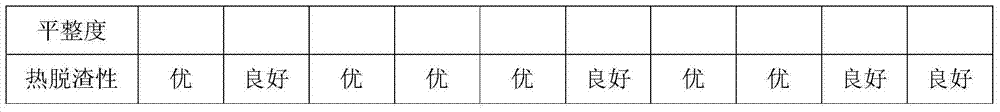

Spray coating capable of preventing slag adhesion

The invention relates to a coating capable of preventing slag adhesion. The coating is characterized by being prepared from, by mass, 8-15 parts of MgO, 15-25 parts of Al2O3, 12-20 parts of SiC, 20-30 parts of SiO2, 2-6 parts of Si, 10-20 parts of C and 0.5-2 parts of Fe2O3, and the coating is prepared by additionally adding 22%-28% of water and conducting stirring through an emulsifying machine. According to the coating capable of preventing the slag adhesion, waste materials of the fire-resistant material industry and the solar energy industry are fully utilized to serve as the main raw materials, and the slag adhesion is prevented by utilizing the non-wetting property of carbon, silicon carbide and the like in the waste raw materials to slags; reactions that metallic silicon is reacted with oxygen to form silicon dioxide, and then the silicon dioxide is reacted with magnesium oxide to form forsterite or reacted with aluminum oxide to form mullite are utilized, and looseness of the materials is caused along with volume expansion, so that the materials are automatically disengaged or easily removed. The coating is used for Baosteel torpedo iron mixing vehicles, Baosteel hot metal ladles, VD shielding caps of the Shanghai steel fifth-factory and LAST immersion covers of the Shanghai steel first factory to enable the service life of fire-resistant materials to be prolonged; the service life is prolonged by 50 percent or above except the hot metal ladles.

Owner:上海柯瑞冶金炉料有限公司

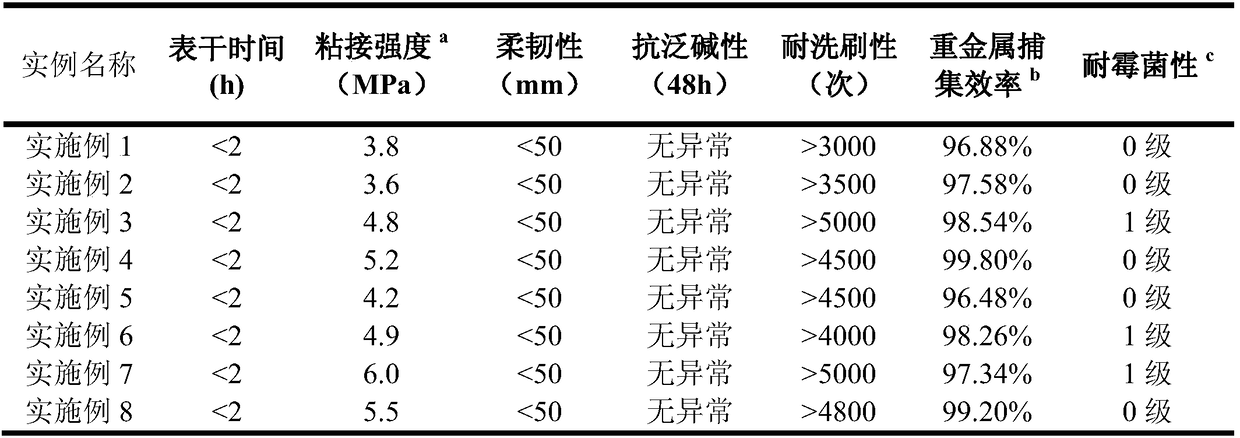

Geopolymer-based mold-proof antibacterial interior wall coating and preparation method thereof

InactiveCN108892978AReduce pollutionGood and long-lasting inhibitory effectAntifouling/underwater paintsPaints with biocidesWater basedBond strength

The invention discloses a geopolymer-based mold-proof antibacterial interior wall coating which is composed of a solid phase S and a liquid phase L, wherein the solid phase S comprises the following components in parts by weight: 10-90 parts of a gel binder, 5-85 parts of pigments and fillers, 0.1-5 parts of a film-forming agent, 0.5-10 parts of an anti-cracking additive and 0.4-5 parts of an anti-settling agent; and the liquid phase L comprises the following components in parts by weight: 5-90 parts of an alkali activator, 0.5-6 parts of a rheological modifier, 0.2-3 parts of an antifoaming agent and 2-90 parts of water. The invention further discloses a preparation method of the geopolymer-based mold-proof antibacterial interior wall coating. The geopolymer-based mold-proof antibacterialinterior wall coating disclosed by the invention realizes the zero-VOC (Volatile Organic Compound) advantage and high-efficiency mold-proof antibacterial functions of the novel water-based inorganicinterior wall coating, and has the advantages of being high in bonding strength with the base plane, excellent in scrubbing resistance, excellent in water resistance and penetration resistance, low inprice and the like, and the mold-proof antibacterial functions have long-term properties.

Owner:浙江航通舟新材料科技股份有限公司

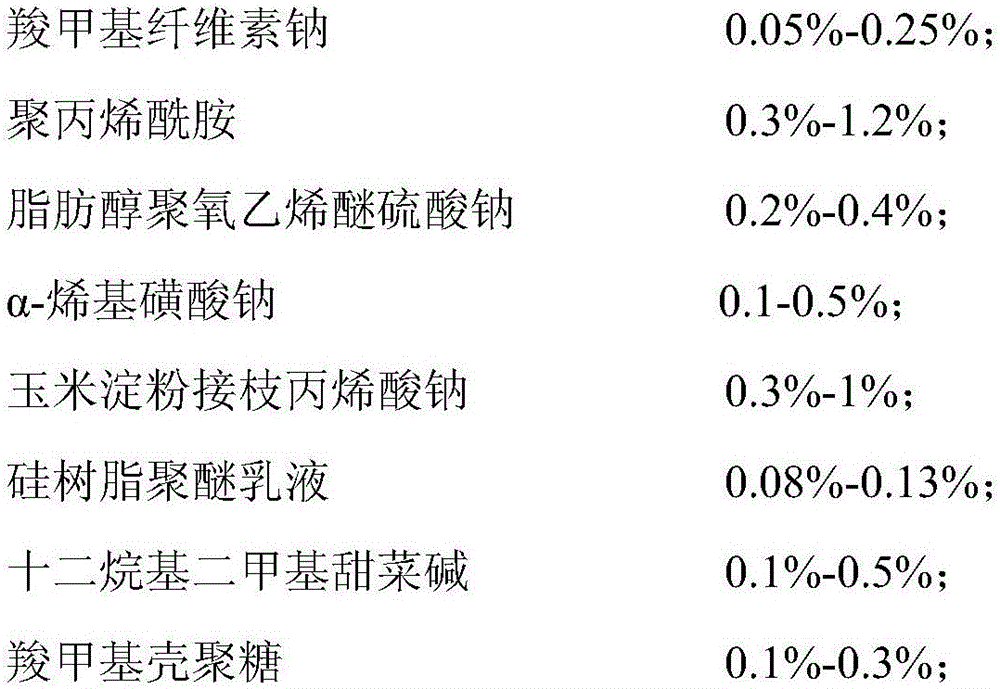

Wetting agent capable of inhibiting dust flying

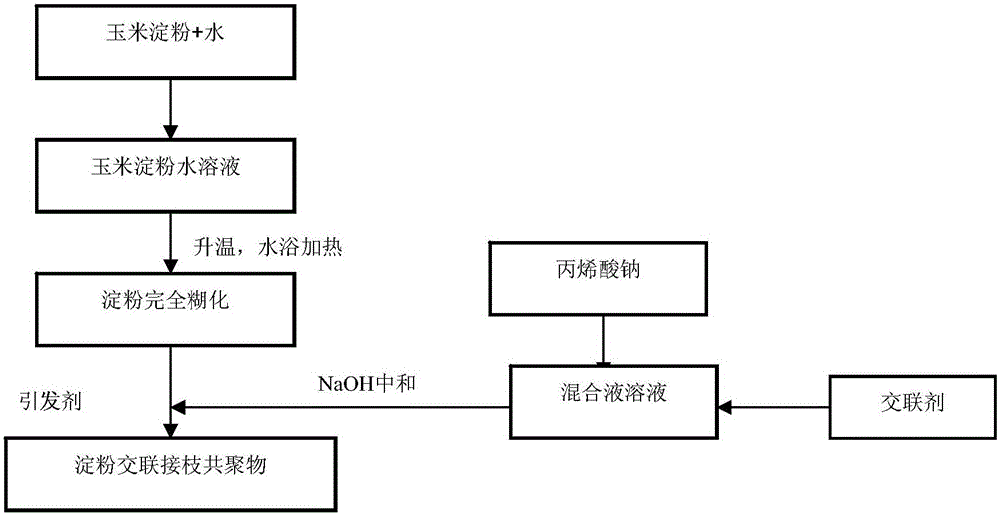

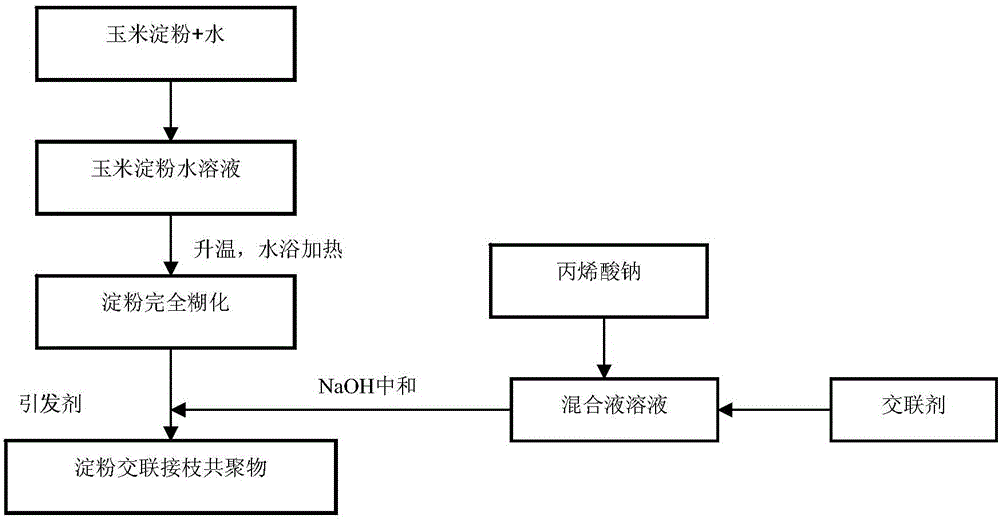

ActiveCN105860933AReduce surface tensionImprove wettabilityOther chemical processesTransportation and packagingCorn starchSodium carboxymethylcellulose

The invention discloses a wetting agent capable of inhibiting dust flying. The wetting agent comprises 0.05-0.25% of sodium carboxymethyl cellulose, 0.3-1.2% of polyacrylamide, 0.2-0.4% of polyoxyethylene fatty alcohol sodium sulfate, 0.1-0.5% of sodium alpha-alkenylsulfonate, 0.3-1% of corn starch grafted sodium acrylate, 0.08-0.13% of silicone resin polyether emulsion, 0.1-0.5% of dodecyldimethylbetaine, 0.1-0.3% of carboxymethyl chitosan, 0.05-0.1% of dioctyl sodium sulphosuccinate, 0.4-0.6% of ethanediol, 0.2-0.4% of calcium chloride and the balance of water. The sprayed fog drops can quickly capture and wrap the dust particles, thereby increasing the particle settling speed. The sprayed fog drops can be covered on the dust on the coal rock surface and ground surface to prevent secondary flying dust, thereby enhancing the dust removal efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

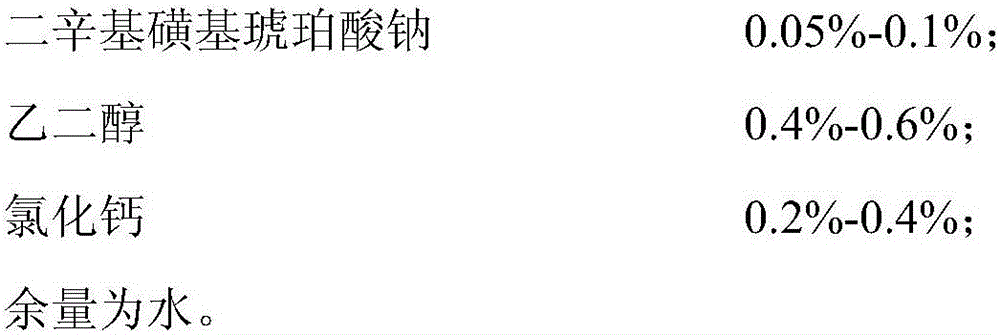

Healant for chemical pipes and preparation method thereof

ActiveCN102311715AGood chemical resistanceWide range of chemical mediaNon-macromolecular adhesive additivesOther chemical processesEpoxyAdhesive

The invention relates to a healant for chemical pipes and a preparation method thereof. The healant comprises the components in parts by weight as follows: modified epoxy resin 40-60, a coupling agent 1-8, a thixotropic agent 1-5, nano chemical resistant powder 10-40, an anti-aging agent 0.5-10 and pigment cream 0-5. The preparation method comprises the steps of: adding the modified epoxy resin obtained through synthesizing into a reaction kettle; adding the coupling agent; heating and gradually adding the nano chemical resistant powder; keeping the temperature in vacuum and dispersedly mixing at a high speed for 2-4 h; re-adding the anti-aging agent, the pigment cream and the thixotropic agent; and continuously sealing the reaction kettle and dispersedly mixing at a high speed in vacuum for 1-2 h to obtain the product. Compared with the prior art, the healant for chemical pipes is added with adhesive capacity of adhesives and greatly improved in tensile strength and impact resistance, can be applied to more chemical mediums, specifically aims at the repairing of the chemical pipes, and is attractive in appearance.

Owner:上海海鹰粘接科技有限公司

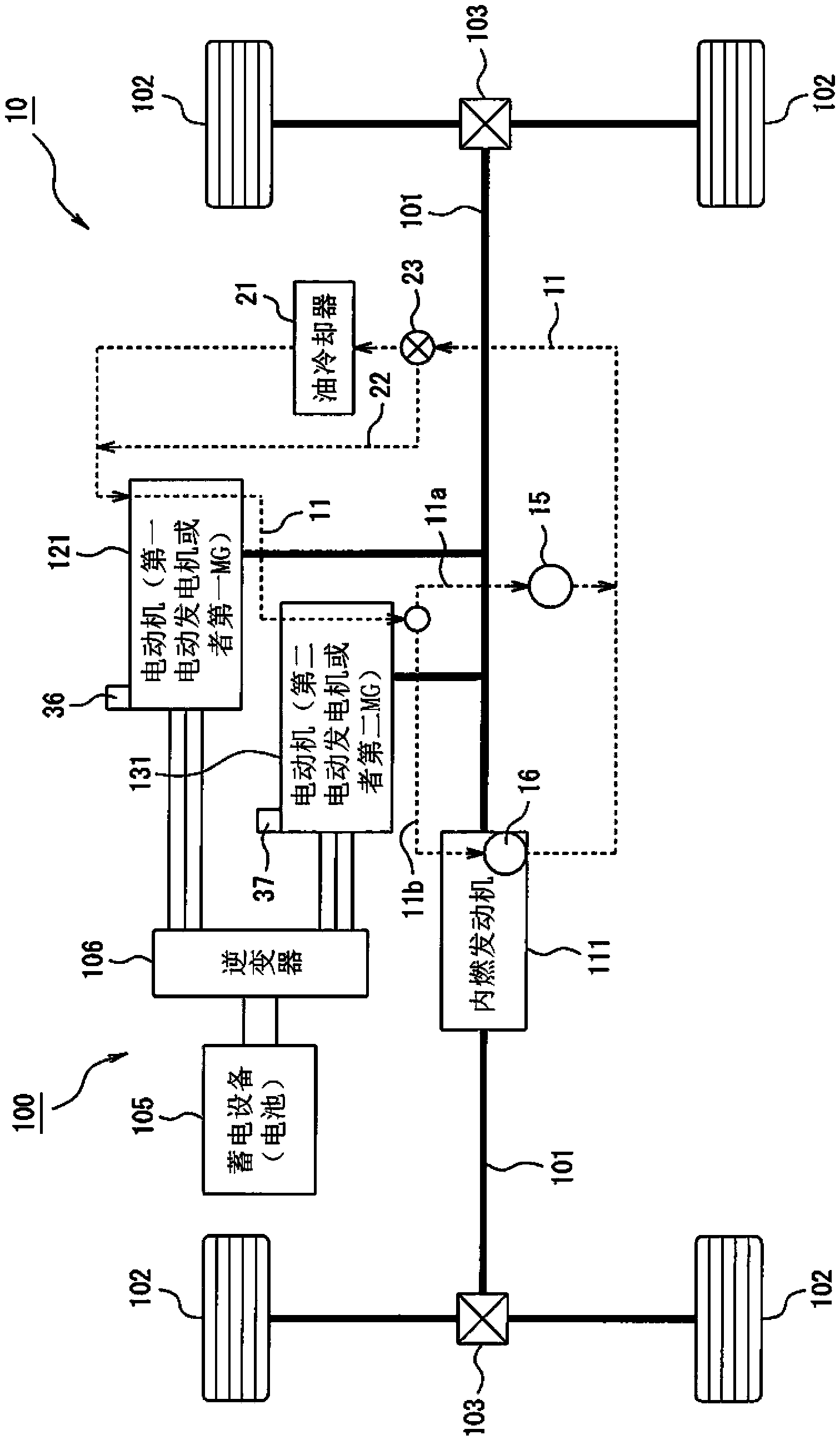

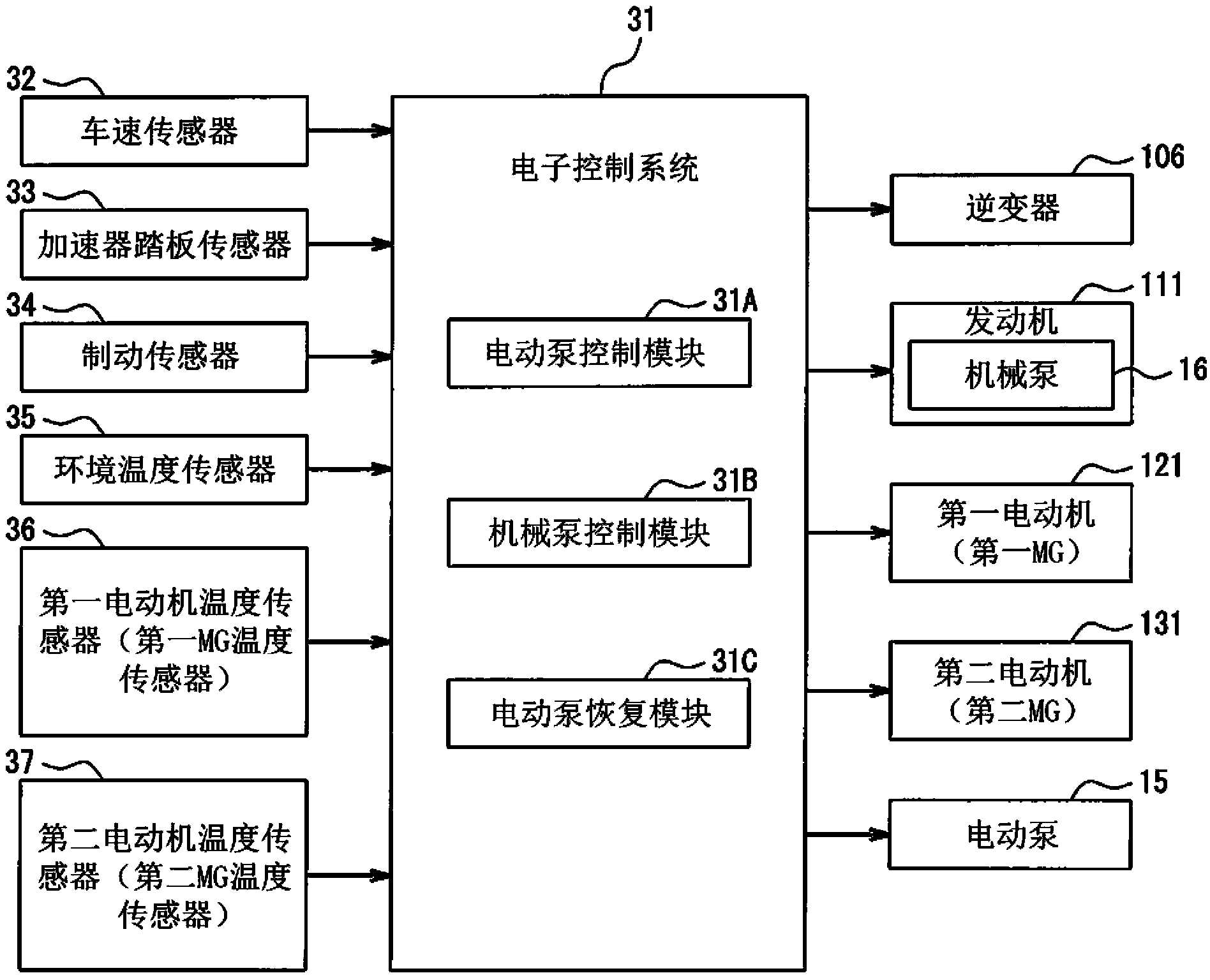

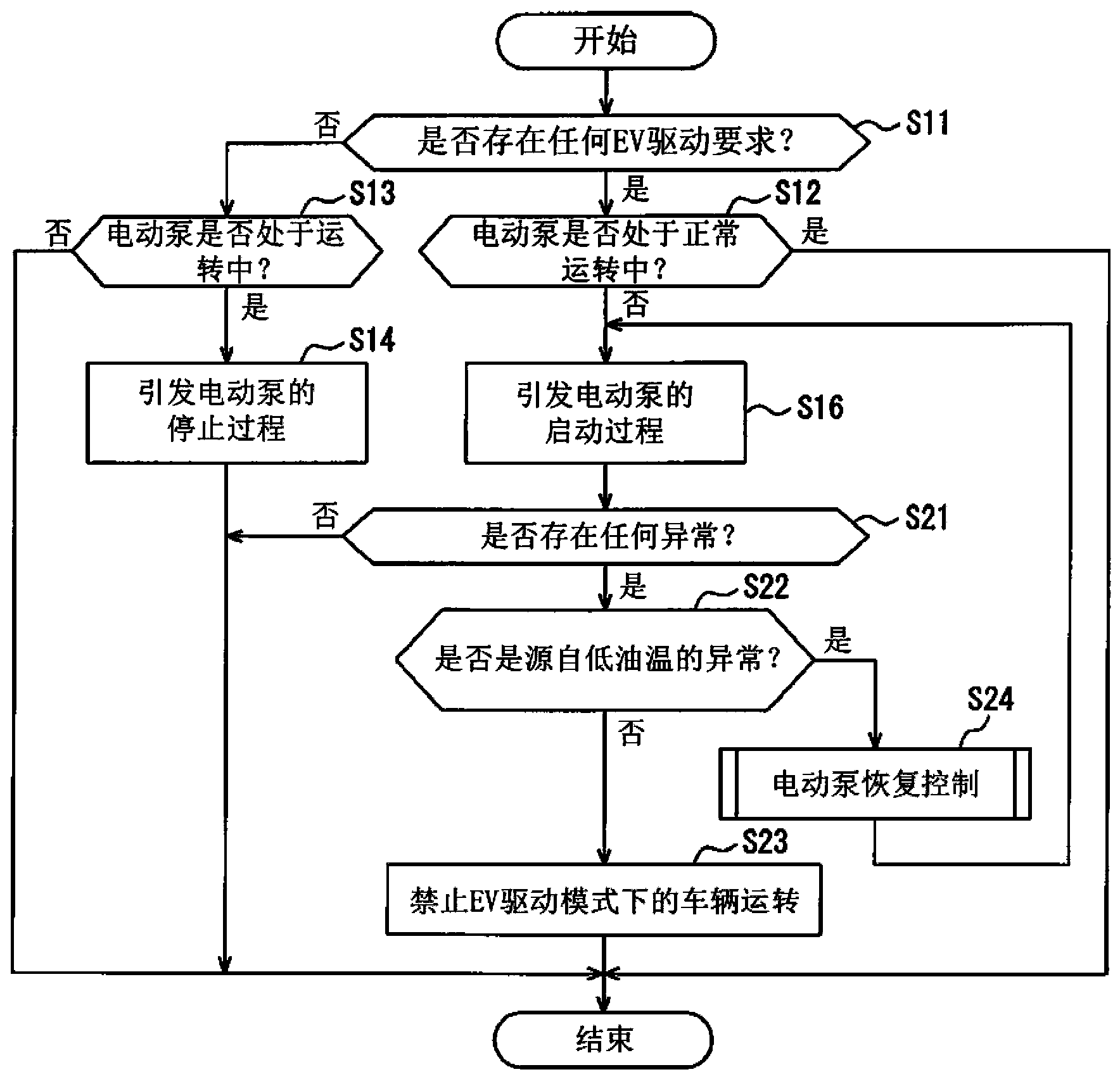

Oil circulation system for electric motor in a hybrid electric vehicle

ActiveCN103448638AEfficient rotationEnsure adequate lubricationPump controlLubricating systemExternal combustion engineInternal combustion engine

An oil circulation system for electric motors in a hybrid electric vehicle having, as a power source, an internal combustion engine is disclosed. Provision is made to start oil circulation under high reliability even though an electric pump cannot circulate lubricant oil through the electric motors due to increased viscosity at low temperatures. The oil circulation system includes the electric pump in fluid communication with an oil flow path for the electric motors;a mechanical pump, in fluid communication with the oil flow path, operable on driving power of the engine;and a controller for control of operation of the electric pump and that of the mechanical pump. The controller utilizes operation of the mechanical pump upon detection of abnormality in operation of the electric pump derived from viscosity of the lubricant oil in order to recover the electric pump.

Owner:SUZUKI MOTOR CORP

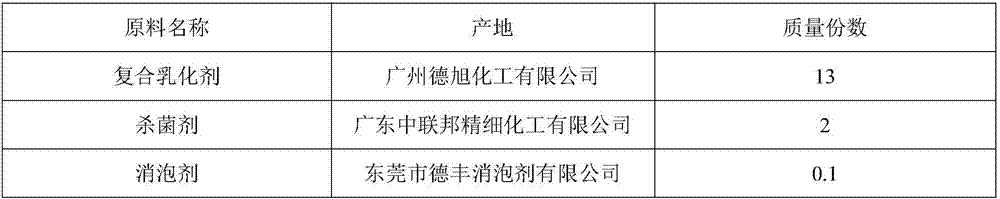

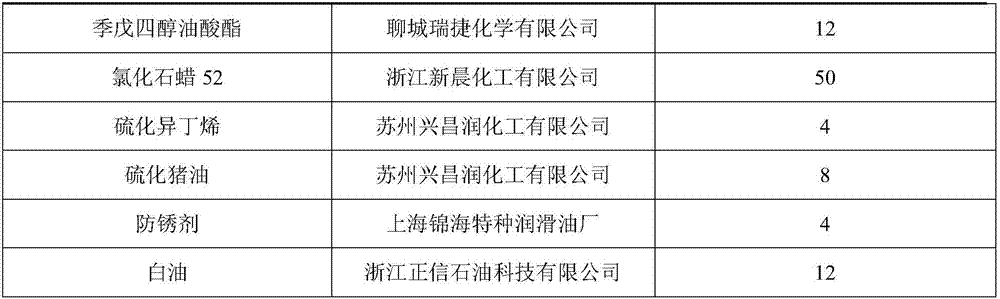

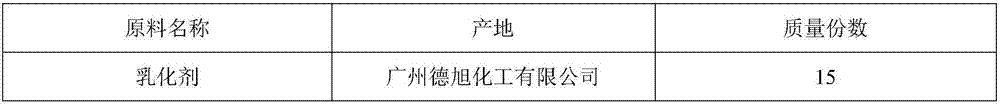

Stamping drawing oil used for water-based stainless steel and preparation method of stamping drawing oil

InactiveCN107502425AImprove the lubrication effectImprove stabilityLubricant compositionWater basedPentaerythritol

The invention discloses stamping drawing oil used for water-based stainless steel and a preparation method of the stamping drawing oil. The stamping drawing oil comprises 10-15 parts of an emulsifier, 1-3 parts of a bactericide, 0.1 part of a defoaming agent, 10-15 parts of pentaerythritol oleate, 40-60 parts of chlorinated paraffin, 5-10 parts of sulfurized isobutylene, 5-10 parts of sulfurized lard oil or sulfurized cotton oil, 3-5 parts of an anti-rust agent and 10-15 parts of white oil or non-standard mechanical oil. The formula and preparation steps of the stamping drawing oil provided by the invention are simple; stainless steel products processed by using the stamping drawing oil used for stainless steel provided by the invention are easy to wash; the stamping drawing oil has no organic phosphorus, has no toxicity, is environmentally friendly, has a good lubrication property, and meets the requirements of stamping drawing processing of all stainless steel; the products finally processed by the stamping drawing oil are bright, and have no burr; the damage rate is effectively reduced, the qualified rate of products is increased; and compared with the cost of stamping drawing oil in the prior art, the cost according to the formula of the stamping drawing oil provided by the invention is decreased greatly.

Owner:嘉兴市国龙石油化工股份有限公司

Method for preparing low-temperature cured conductive paste

InactiveCN101697292AAdjust printabilityChange viscosityConductive materialMetal/alloy conductorsConductive pasteScreen printing

The invention discloses a method for preparing low-cost low-temperature cured conductive paste for screen printing. In the preparation method, base metal nickel (Ni) is used to replace part of used precious metal silver (Ag); nickel powder and silver powder form a conductive function phase of the conductive paste together, wherein the change of the adding proportion of the nickel powder not only can adjust the final electrical property, but also can adjust the printing performance of the paste well; the change of the adding proportion of an organic carrier can adjust the viscosity and the electric conductivity of a product; and the change of the adding proportion of a thickening agent can adjust the viscosity, the leveling property and the printing performance of the product. The quick drying and curing can be performed at a constant temperature of between 120 and 150 DEG C to form the product with good electrical property. The conductive paste of the invention adopts the base metal to replace partial precious metal silver, so the production cost is greatly reduced, and the performance reaches the level of high silver content.

Owner:IRICO

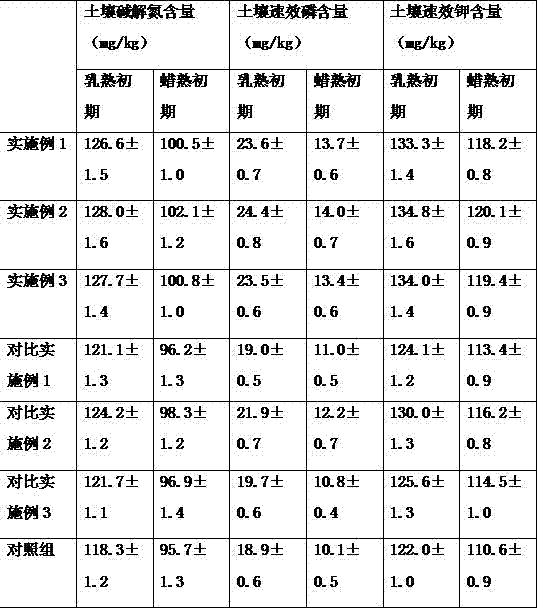

Special microorganism compound fertilizer for reproduction and growth period of rice

InactiveCN106938946AImprove soil environmental conditionsPrevent soil compactionBio-organic fraction processingMagnesium fertilisersAmmonium sulfateChemistry

The invention discloses a special microorganism compound fertilizer for the reproduction and growth period of rice, and relates to a fertilizer which is made from the following materials: urea, ammonium sulfate, ammonium dihydrogen phosphate, potassium sulfate, magnesium sulfate, calcium nitrate, zinc chloride, copper chloride, manganese sulfate, ferric sulfate, ferrous sulfate, sodium molybdate, boric acid, decomposed farmyard manure, animal viscera leftovers, fermented rapeseed meal, corn straws, filler and a microbial agent. The special microorganism compound fertilizer can effectively improve the ratio of content of each element in the soil, can well fit with the nutrition demand law of the reproduction and growth period of the rice, and can ensure the growth quality of the rice in the reproduction and growth period, the material utilization rate of the fertilizer is enhanced, the rice grain quality is improved, and the special microorganism compound fertilizer has very good promotion use value.

Owner:安徽省卫国农业科技有限公司

Lead-free aluminum paste for solar cell and preparation method thereof

InactiveCN103177792AImprove conversion efficiencyReduce warpageNon-conductive material with dispersed conductive materialCable/conductor manufacturePlasticizerOhmic contact

The invention discloses a lead-free aluminum paste for a solar cell and a preparation method thereof. The lead-free aluminum paste comprises, by weight, 0.5%-3% of lead-free glass powder, 65%-80% of fine spherical aluminum powder, 10%-28% of an organic vehicle, 4%-10% of a solvent, 1%-3% of a plasticizer, 0.3%-1% of a dispensing agent and 0.1%-1% of an inorganic additive. The invention further discloses a preparation method of the lead-free aluminum paste for the solar cell. According to the lead-free aluminum paste for the solar cell and the preparation method thereof, the excellent printability is provided, and mesh clogging and mesh drying in the printing process can be avoided; and the lead-free aluminum paste forms good ohmic contact with silicon chips after sintering, aluminum beads and aluminum blisters can be avoided, the warp degree of the cell is reduced, and the open-circuit voltage and the conversion efficiency are increased.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

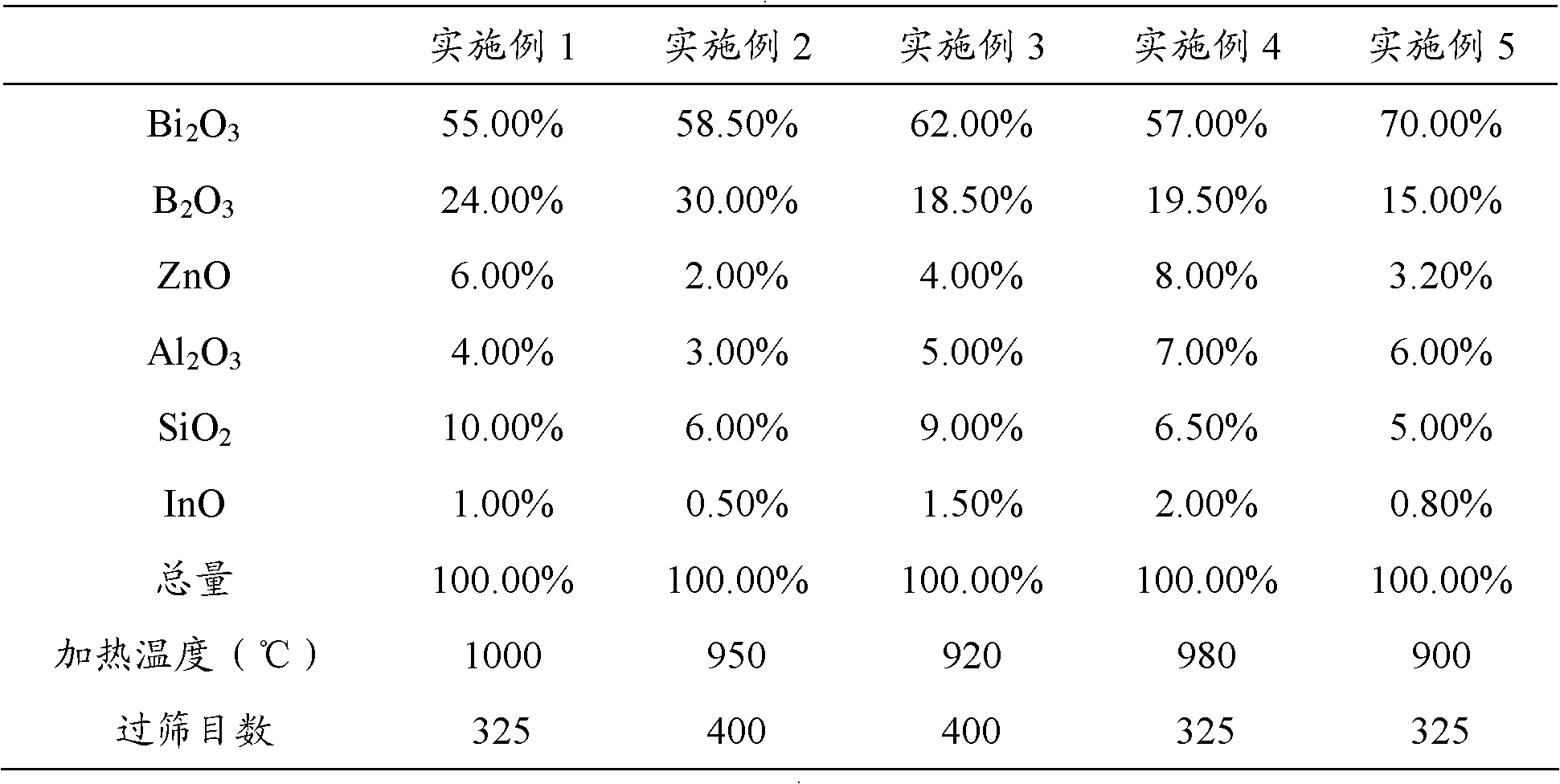

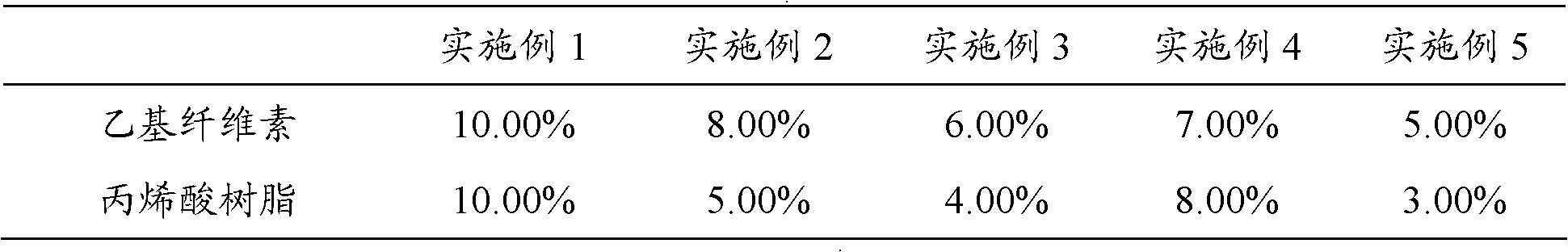

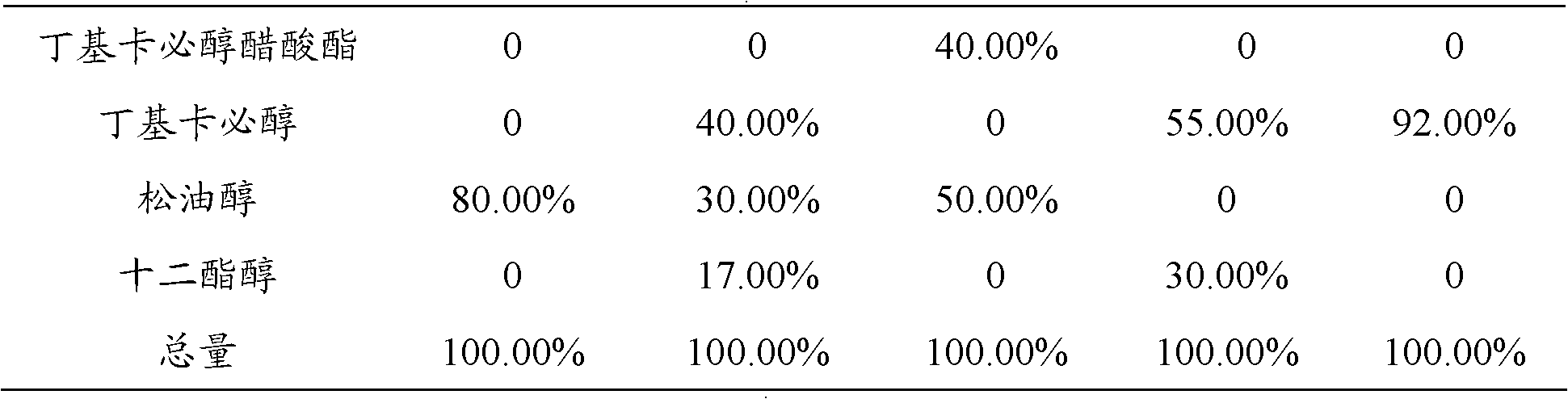

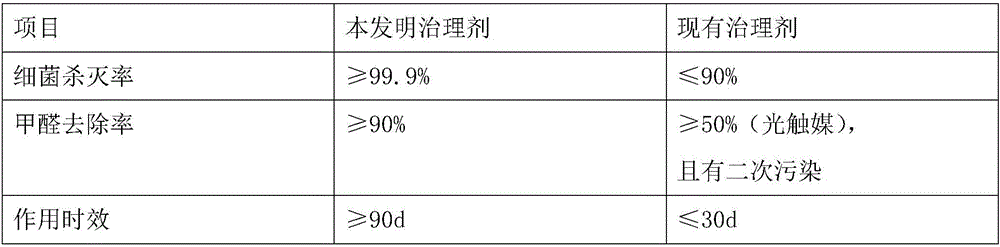

Indoor and intra-vehicle slow-release air treating agent

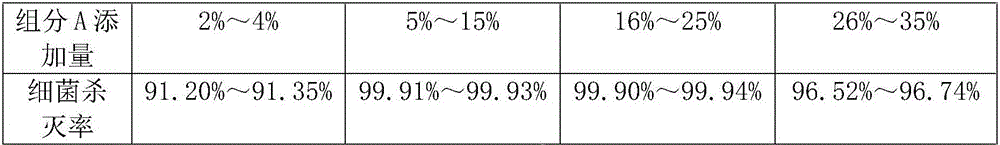

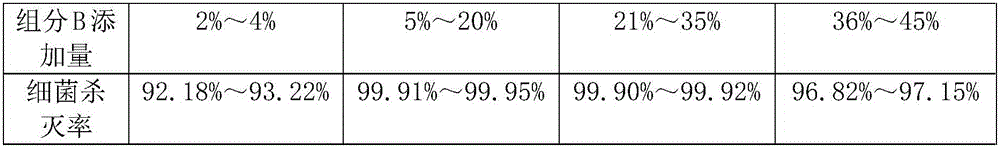

The invention discloses an indoor and intra-vehicle slow-release air treating agent, made from gel A and gel B both comprising a matrix, active ingredients and a control ingredient; the active ingredients of the gel A are a medium-strong acid and component A, the medium-strong acid is one or more of sulfurous acid, dilute sulfuric acid, acetic acid, benzoic acid, citric acid, malic acid, and benzene sulfonic acid or hydrogen phosphate di-salt, the active ingredients of the gel B are sodium chlorite and component B or 3-8 g / L chlorine dioxide alkaline solution and component B.The indoor and intra-vehicle slow-release air treating agent provided herein can remove pollutants in air continuously and has the multiple functions of air refreshing, bacteria killing and inhibiting and pollution removing.A preparation method of the slow-release air treating agent is simple, the materials are easy to obtain and low in cost, the slow-release air treating agent is convenient to use and can last for longer than 90 days, has a removal rate of higher than 90% for formaldehyde pollutants 5 times over the standard and has a killing rate of higher than 99% for common pathogenic bacteria.

Owner:SHENZHEN PURE WORLD ENVIRONMENTAL PROTECTION TECH CO LTD

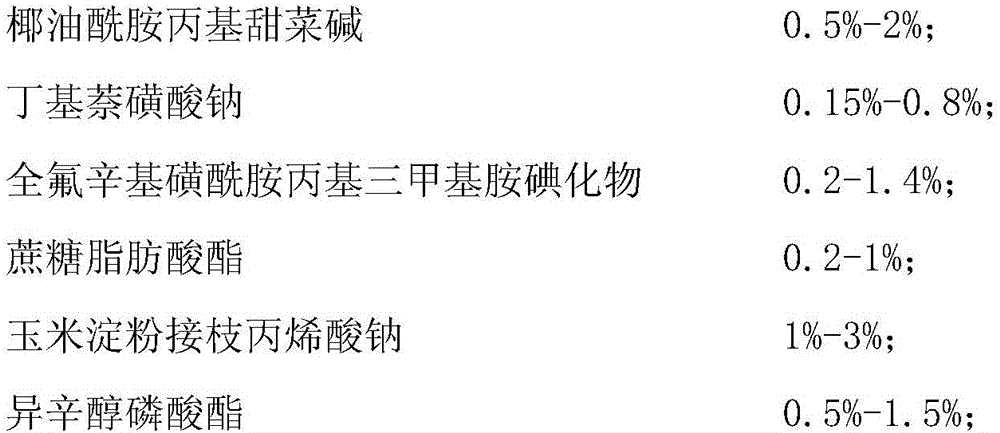

Permeability-increasing and coagulation-accelerating wetting agent for wet-type dust control

ActiveCN105778867AReduce surface tensionIncrease surface tensionOther chemical processesDust removalSucrosePhosphate

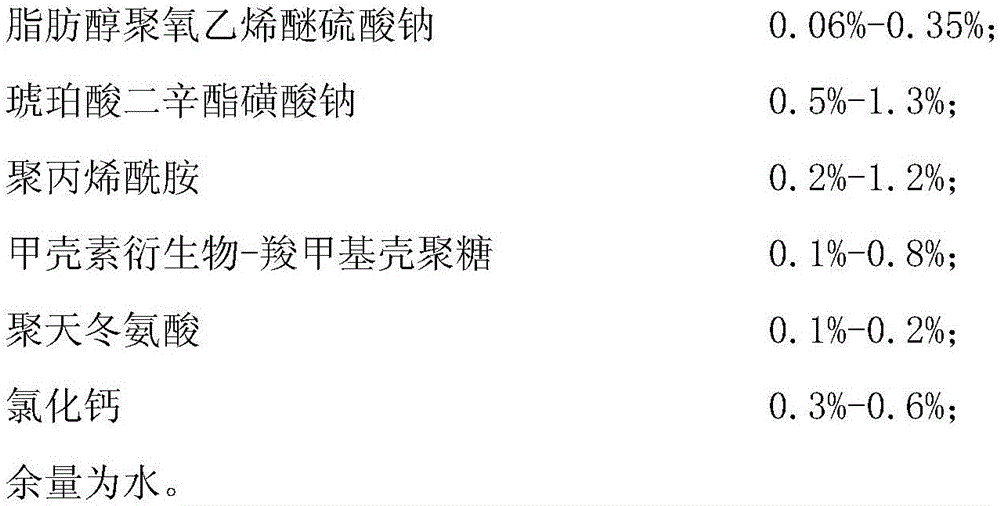

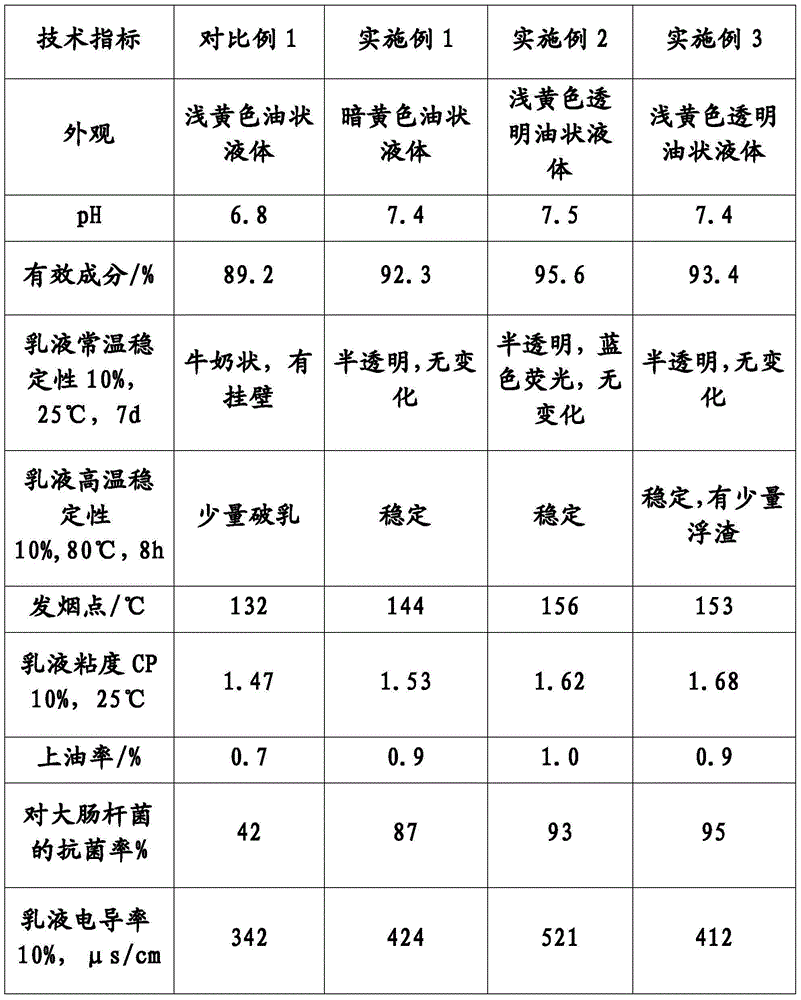

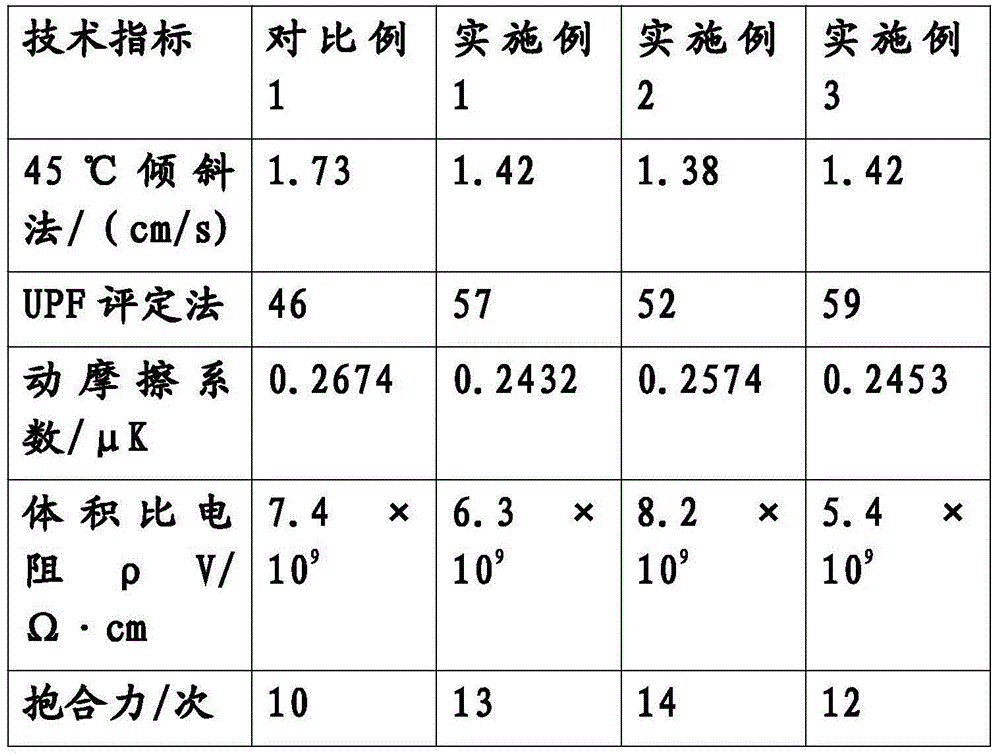

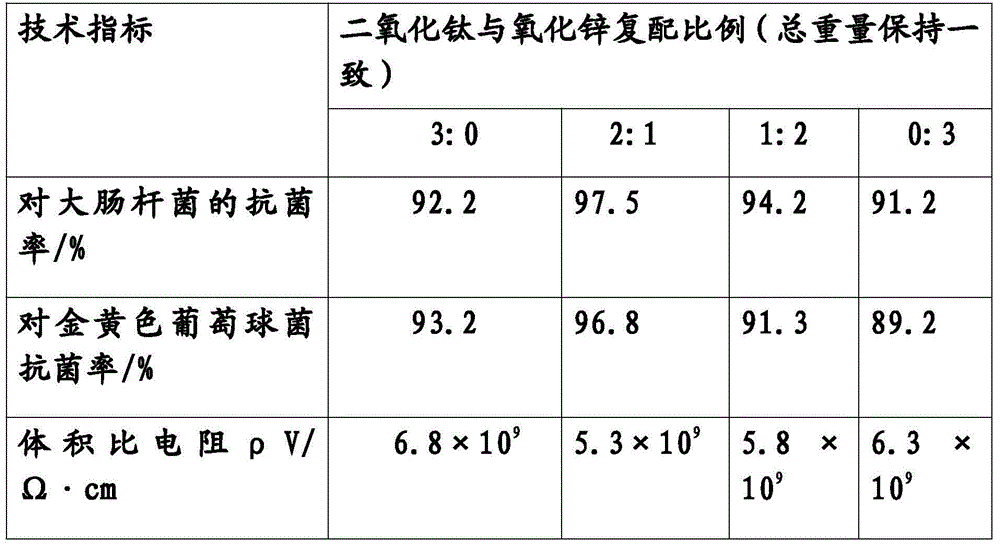

The invention discloses a permeability-increasing and coagulation-accelerating wetting agent for wet-type dust control. The permeability-increasing and coagulation-accelerating wetting agent comprises 0.5%-2% of cocamidopropyl betaine, 0.15%-0.8% of butylnaphthalenesulfonic acid sodium salt, 0.2%-1% of trimethyl-1-propanaminium iodide, 0.2%-1% of sucrose fatty acid ester, 1%-3% of corn starch grafting sodium acrylate, 0.5%-1.5% of isooctanol phosphate, 0.06%-0.35% of sodium alcohol ether sulphate, 0.5%-1.3% of sodium diethylhexyl sulfosuccinate, 0.2%-1.2% of polyacrylamide, 0.1%-0.8% of chitin derivative-carboxymethyl chitosan, 0.1%-0.2% of polyaspartic acid, 0.3%-0.6% of calcium chloride and the balance water. The ermeability-increasing and coagulation-accelerating wetting agent for wet-type dust control has the advantages that wetting ability of water for coal is enhanced and water molecules can wrap coal dust particles quickly, so that coagulation and falling of the coal dust particles are facilitated.

Owner:SHANDONG UNIV OF SCI & TECH

Method for preparing resin for high water resistant waterborne glass ink

The invention discloses a preparation method of a water-based glass ink-used resin with high water resistance, which comprises the following steps: step A. under the protection of nitrogen, dehydrated polyether dihydric alcohol, modified epoxy polyester polyol and IPDI react with each other at certain temperature; during the reaction course, the end of the reaction is judged by measuring the content of NCO; when the reaction ends, an emulsifying hydrophilc agent is added to react for a period of time and then the temperature is reduced; step B. after aqueous alkali is added for neutralization, a diluting solvent is added for dilution so as to reduce the viscosity of the solution after neutralization; then, emulsification is carried out at normal temperature, the chain is extended by a chain extender and the diluting solvent is removed in vacuum to obtain a water-based polyurethane dispersoid; and step C. core-shell copolymerization is carried out after high-speed emulsification by adding polymerized monomers into the water-based polyurethane dispersoid, and then the acroleic emulsion resin modified by the polyurethane is obtained after the temperature is reduced.

Owner:王兆进

Chinlon spinning additive

ActiveCN104611912AHas UV protection propertiesThe solution function is relatively simpleFibre typesMontmorilloniteUltraviolet protection

The invention provides a chinlon spinning additive which includes the following constituents in parts by weight: 5-10 parts of zinc oxide, 3-5 parts of titanium dioxide, 2-6 parts of montmorillonite, 3-6 parts of vermiculite and 1-3 parts of a dispersing agent. The prepared additive is small in grain size and good in dispersing performance, improves the stability, ultraviolet protection and mold resistance of spinning oil after being added in the mold spinning oil.

Owner:JIANGSU WENFENG CHEM FIBER GROUP

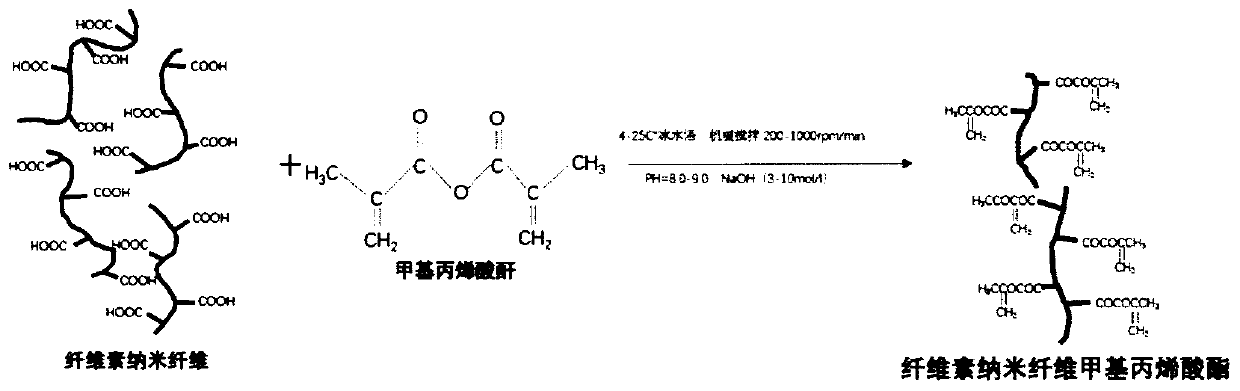

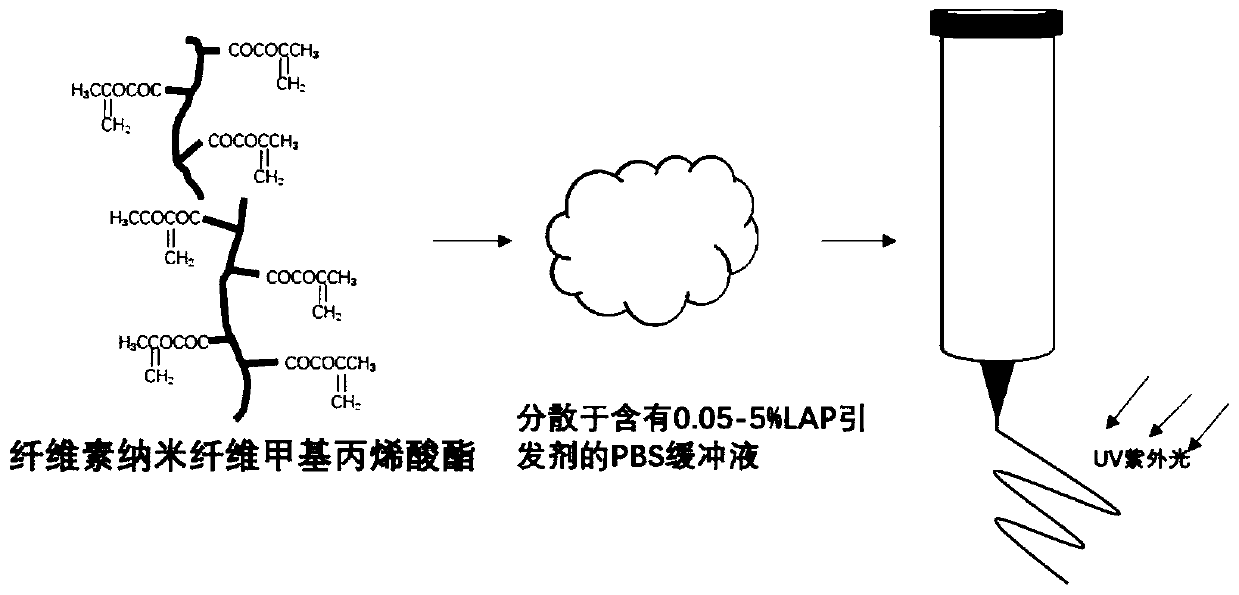

Preparation for direct writing forming 3D printing bioink, and 3D printing method capable of adopting direct writing forming 3D printing bioink

ActiveCN110787320AAdjust viscosityStructurally orientedAdditive manufacturing apparatusTissue regenerationCelluloseDirect writing

The invention discloses preparation for a direct writing forming 3D printing bioink, and a 3D printing method capable of adopting the direct writing forming 3D printing bioink. The 3D printing bioinktakes a cellulose nanofiber as a main body, and methacrylic anhydride is grafted to a main body chain segment to synthesize cellulose nanofiber methacrylate. By use of the shear thinning characteristic of a cellulose nanofiber hydrogel and a characteristic that a methacrylate polymer is photocurable, the degradable 3D printing bioink which has high biocompatibility, high mechanical properties, notoxins and structure orientations and has a capability of guiding biological cells to grow and differentiate is prepared. A biological bionic structure printed by the 3D printing bioink is suitable for biological cells to adhere, proliferate and differentiate in the biological bionic structure, and the biological bionic structure is an ideal biological tissue reconstruction and repairing substitute.

Owner:SOUTHERN MEDICAL UNIVERSITY

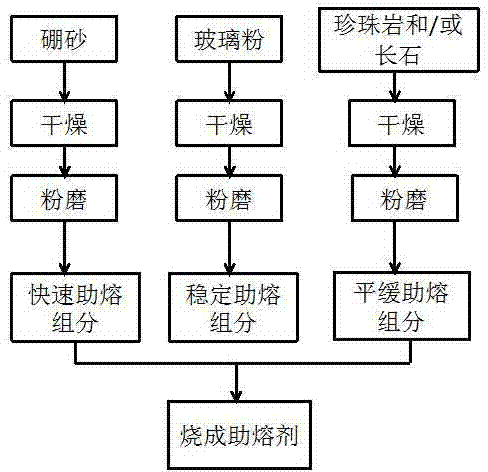

Sintering flux for solid waste sintered porous heat insulation sheets, and preparation method and application thereof

ActiveCN104774029AWide firing rangeImprove physical and mechanical propertiesSolid waste disposalCeramicwareToxic industrial wasteIndustrial waste

The invention relates to a sintering flux for solid waste sintered porous heat insulation sheets, and a preparation method and an application thereof. The sintering flux comprises a rapid fluxing component, a stable fluxing component and a mild fluxing component; a mass ratio of the rapid fluxing component to the stable fluxing component is 0.5-2:1, and a mass ratio of the mild fluxing component to the stable fluxing component is 0.5-2:1; and the rapid fluxing component is borax, the stable fluxing component is glass powder, and the mild fluxing component is one or two of perlite and feldspar. The invention also provides the preparation method and the application of the sintering flux for solid waste sintered porous heat insulation sheets. The flux is added in the sintering process of the sintering flux for solid waste sintered porous heat insulation sheets to decrease the sintering temperature by 50-150DEG C, a large amount of waste mine tailings and industrial waste residues are used, and the utilization rate reaches 80%, so environment protection is facilitated, resources are saved, and waste discharge is reduced.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

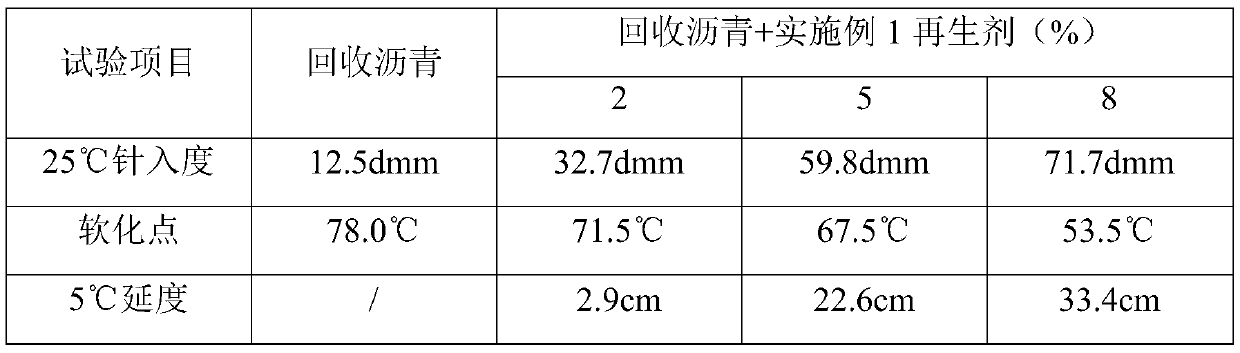

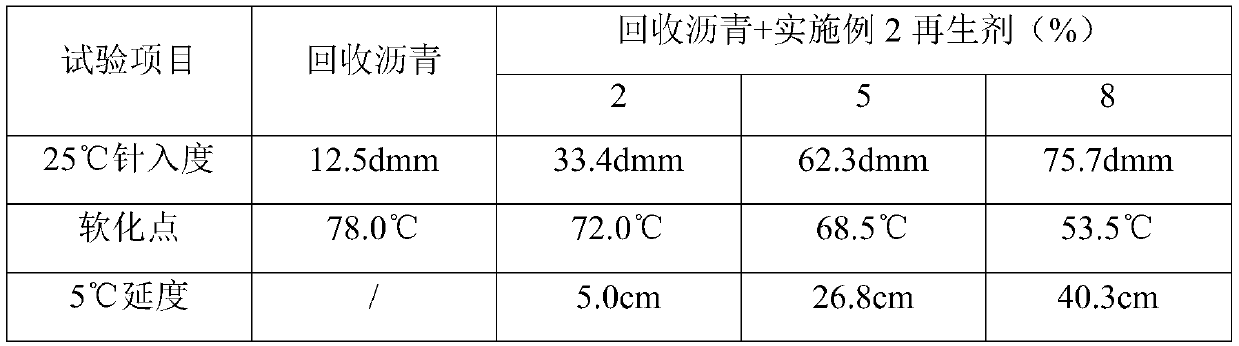

Regeneration activator for old asphalt mixture of high type asphalt pavement

ActiveCN103360772AHigh flash pointSuitable for thermal recyclingBuilding insulationsChemical compositionPavement engineering

The invention discloses a recycling utilization technology of an old asphalt mixture of a high type asphalt pavement. According to the invention, for the chemical composition change condition of the old asphalt mixture in the asphalt pavement, saturates, aromatics, colloids and asphaltenes in the asphalt are analyzed by a component method; the missing part in the old asphalt is adjusted by adding an activator according to the change of each component of the aged asphalt; the component transfer problem (commonly known as aging) of the old asphalt material in the asphalt pavement is solved from the aspect of recovering the chemical components of the old asphalt; as a result, the chemical components of the old asphalt material are re-activated, the old asphalt mixture is caused to obtain new technological performance, the original mechanical properties and pavement performance indicators of the old asphalt mixture are recovered, and the old asphalt mixture can be better utilized by pavement engineering again.

Owner:石城祥

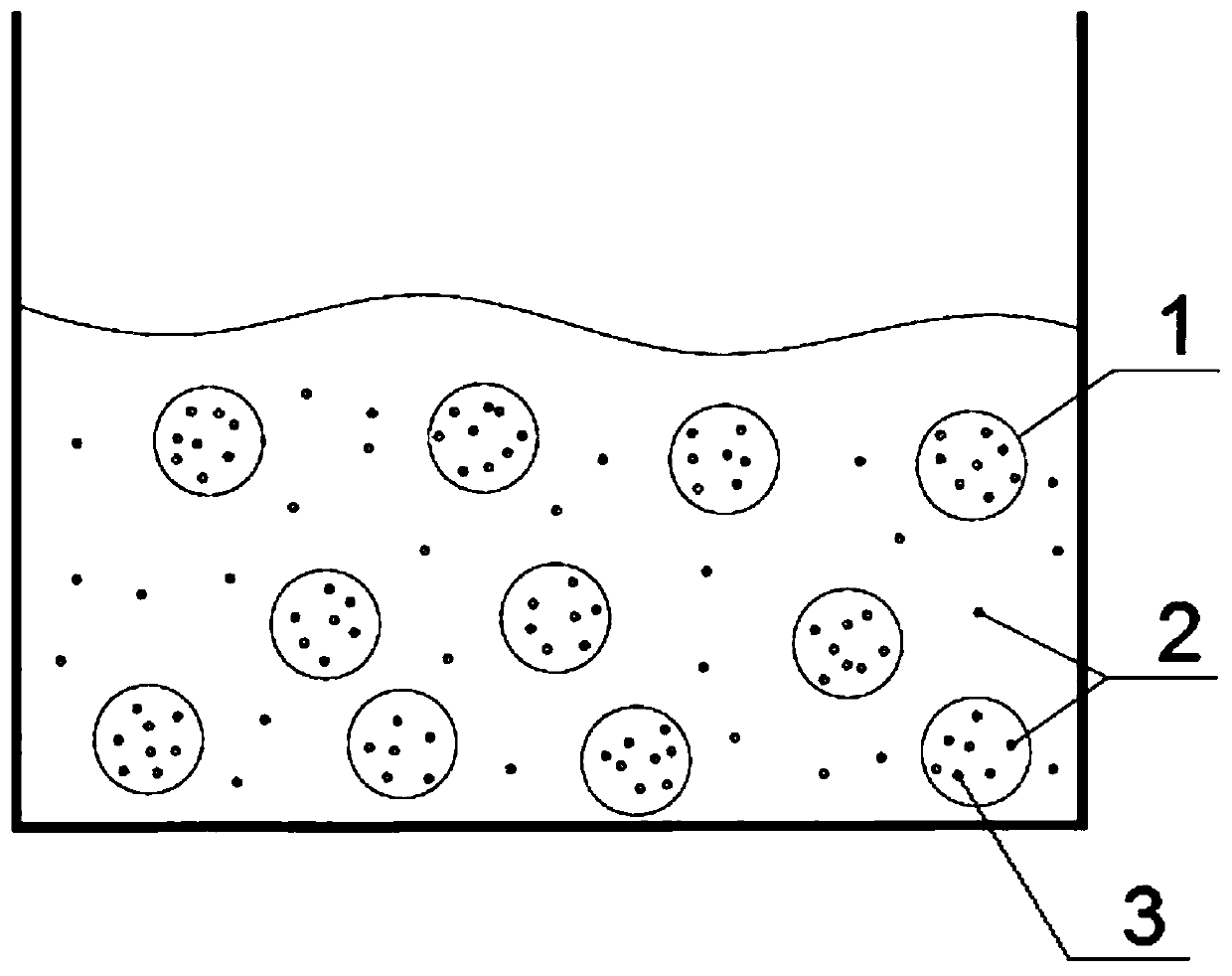

Slow-release asphalt modified regenerant and preparation method thereof

ActiveCN110669345AImprove performanceStrong environmental protectionBuilding insulationsPlasticizerProcess engineering

The invention discloses a slow-release asphalt modified regenerant and a preparation method thereof. The regenerant comprises the following components in parts by mass: 30-80 parts of modified base oil, 30-50 parts of matrix asphalt, 10-30 parts of an added oil, 1-5 parts of a plasticizer, 1-5 parts of an anti-aging agent, 1-5 parts of a modifier and 1-10 parts of a capsule modifier. The regenerant provided by the invention is capable of adjusting the viscosity of new and old asphalt and mixture systems, enhancing the anti-stripping performance of systems, slowly releasing light components, realizing lasting regeneration, saving the dosage of new asphalt, increasing the compatibility of the new and old asphalt through active points, improving the performance of the asphalt, resisting agingand the like. In addition, the regenerant provided by the invention can realize waste recycling, and solve the problems of single performance and poor long-term regeneration effect of traditional regenerants. In addition, the regenerant is simple in preparation process and convenient for industrial production.

Owner:山西交通科学研究院集团有限公司 +1

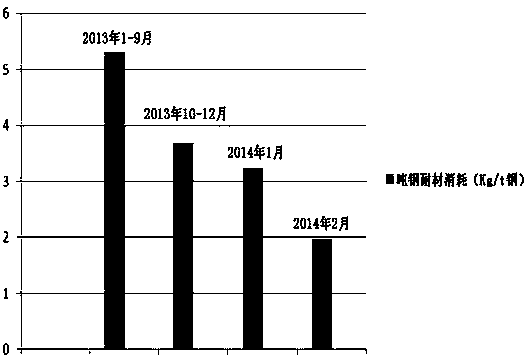

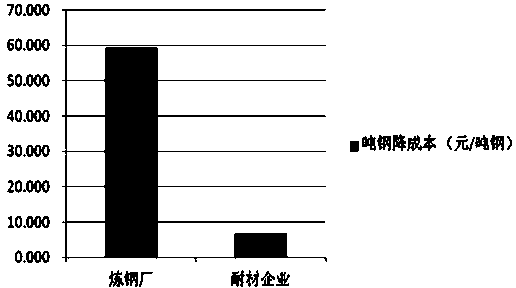

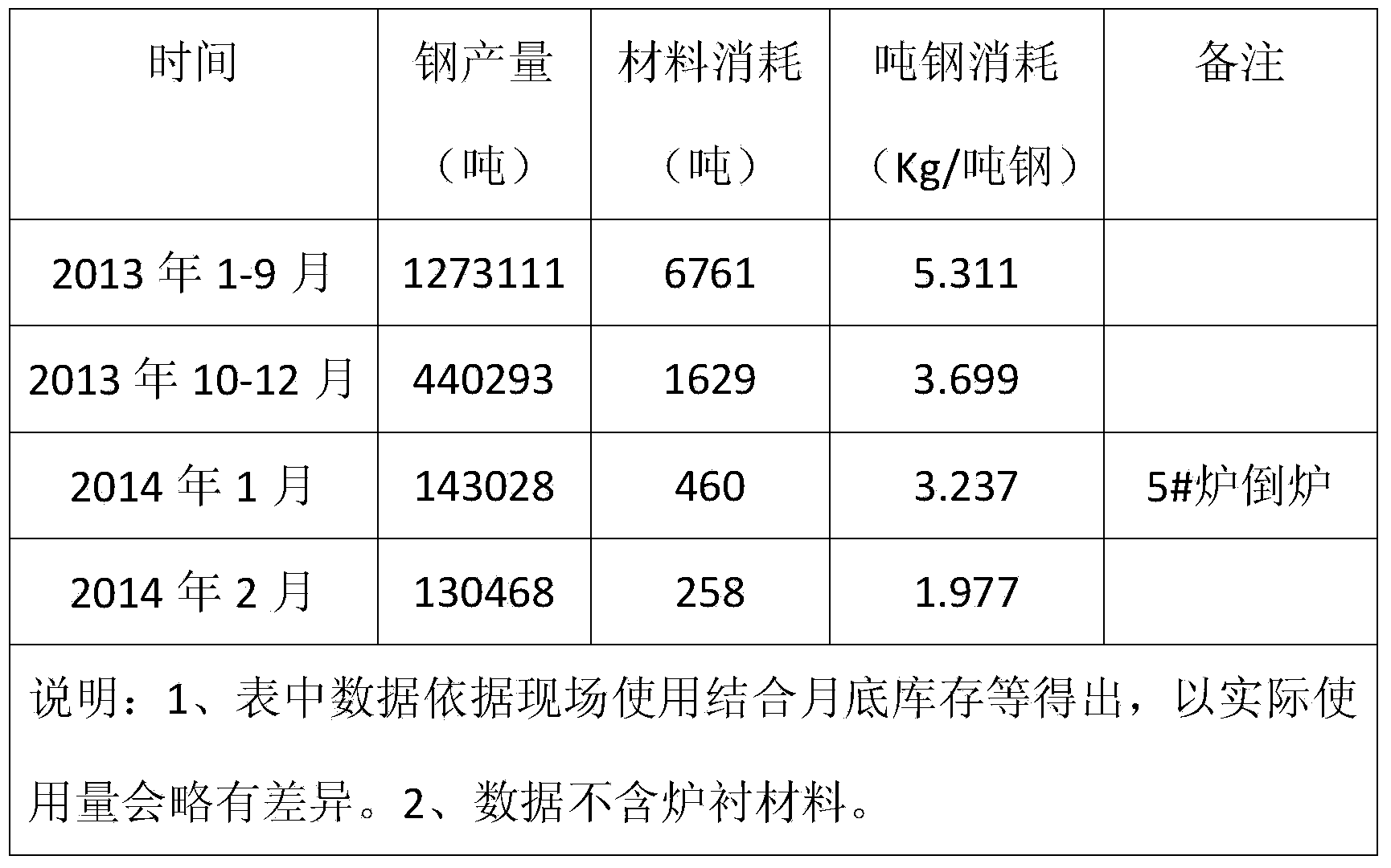

Comprehensive furnace protecting method for steelmaking convertor furnace

The invention belongs to the field of steel smelting and particularly relates to a comprehensive furnace protecting method for a steelmaking convertor furnace. Light-roasted dolomite and raw dolomite are selected as splashed slag materials, and a ratio of the splashed slag materials to adding amount of lime is 1 to 1, 25-35kg / t each. Light-roasted magnesium balls which are high in price and are extremely great in waste residue amount and a modifier are cancelled, and the furnace is protected by adopting a three-in-one combination furnace protecting method of curing the furnace by formed slag, protecting the furnace by splashed slag and cushioning furnace by left slag. On the basis of the conventional splashed slag furnace protecting process, the comprehensive furnace protecting method disclosed by the invention properly lowers application conditions of the splashed slag furnace protecting technology, and adopts the method of adjusting measures to local conditions and replacing to satisfy needs of the splashed slag furnace protecting process according to practical production conditions of each steel plant, so that effects of the furnace protecting by splashed slag are brought into play to the greatest extent, manual tiling and fettling by a great shovel are completely cancelled, fettling materials are lowered to be lowest, and therefore, cost decreasing and benefit increasing of the steel plant realize maximization. The comprehensive furnace protecting method is perfection and supplementation of the conventional splashed slag furnace protecting process, so that the comprehensive furnace protecting method is more universal, and therefore, more than half steel mills in China are benefited.

Owner:张洪武 +1

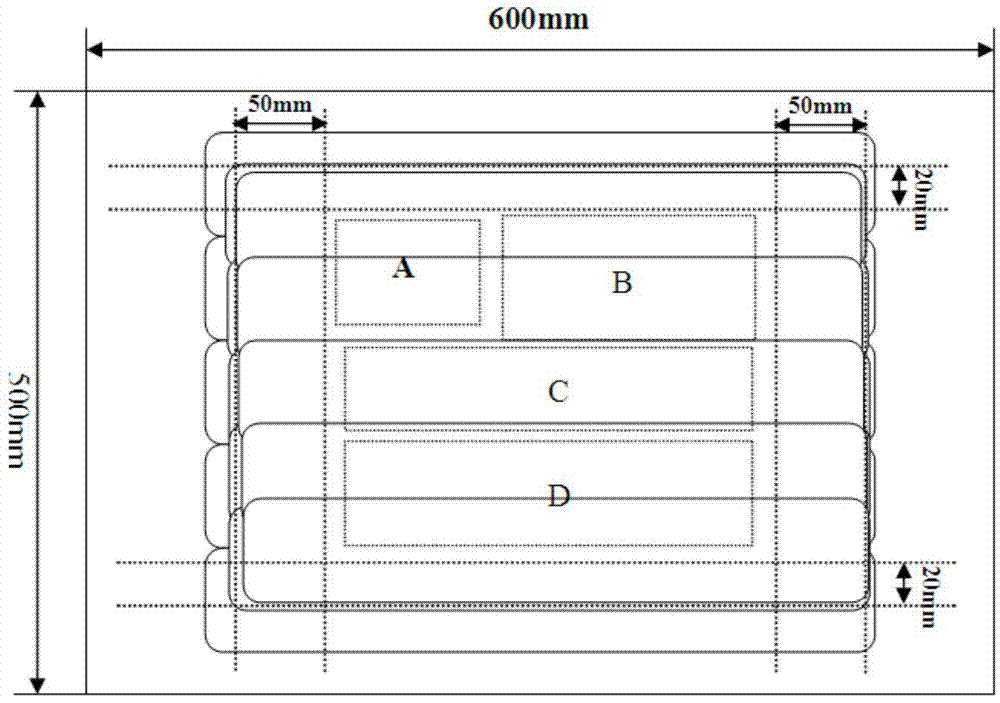

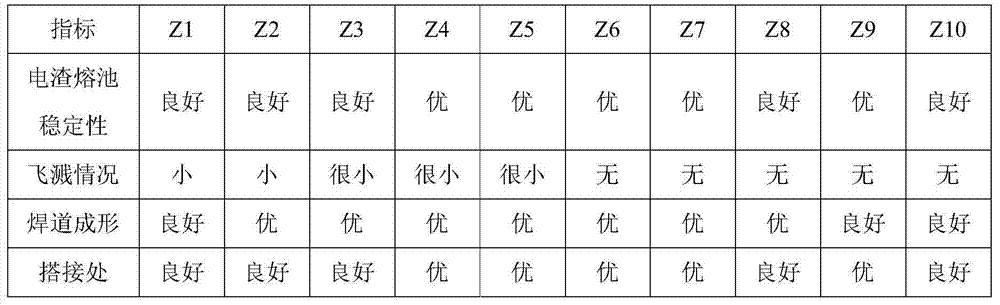

Sintered flux for nickel base strip electrode electro-slag welding

ActiveCN104708231AReduce burning lossImprove the transition coefficientWelding/cutting media/materialsSoldering mediaFerroniobiumSlag

The invention relates to sintered flux for nickel strip electrode electro-slag welding. The sintered flux for the nickel strip electrode electro-slag welding is characterized in that the intered flux is prepared from dry powder components and binder water glass; the dry powder components comprise, by mass, 45-75% of CaF2, 15-35% of Al2O3, 1-5% of SiO2, 1-5% of CaO, 1-5% of MgO, 1-10% of sodium fluoroaluminate, 1-5% of rare earth fluoride and 1-5% of ferroniobium alloy powder; the ratio of potassium to sodium of the binder water glass is 1 to 1, the molar ratio is 2.2-3.5, the baume degree at room temperature is 38-50, and the dosage is 15-25% of the weight of the dry powder. The sintered flux can be used through being matched with various nickel base welding strip such as EQNiCrMo-3 and EQNiCr-3, when strip electrode electro-slag surfacing is conducted through matching with the nickel base welding strip, stable electro-slag process and welding technological property can be maintained at the quick welding condition of 250 mm / min, the quality of formation of surfacing layers is good, defects do not exist in lap joint, and various indexes of the surfacing layers can meet usage requirements of users.

Owner:BEIJING JINWEI WELDING MATERIAL +1

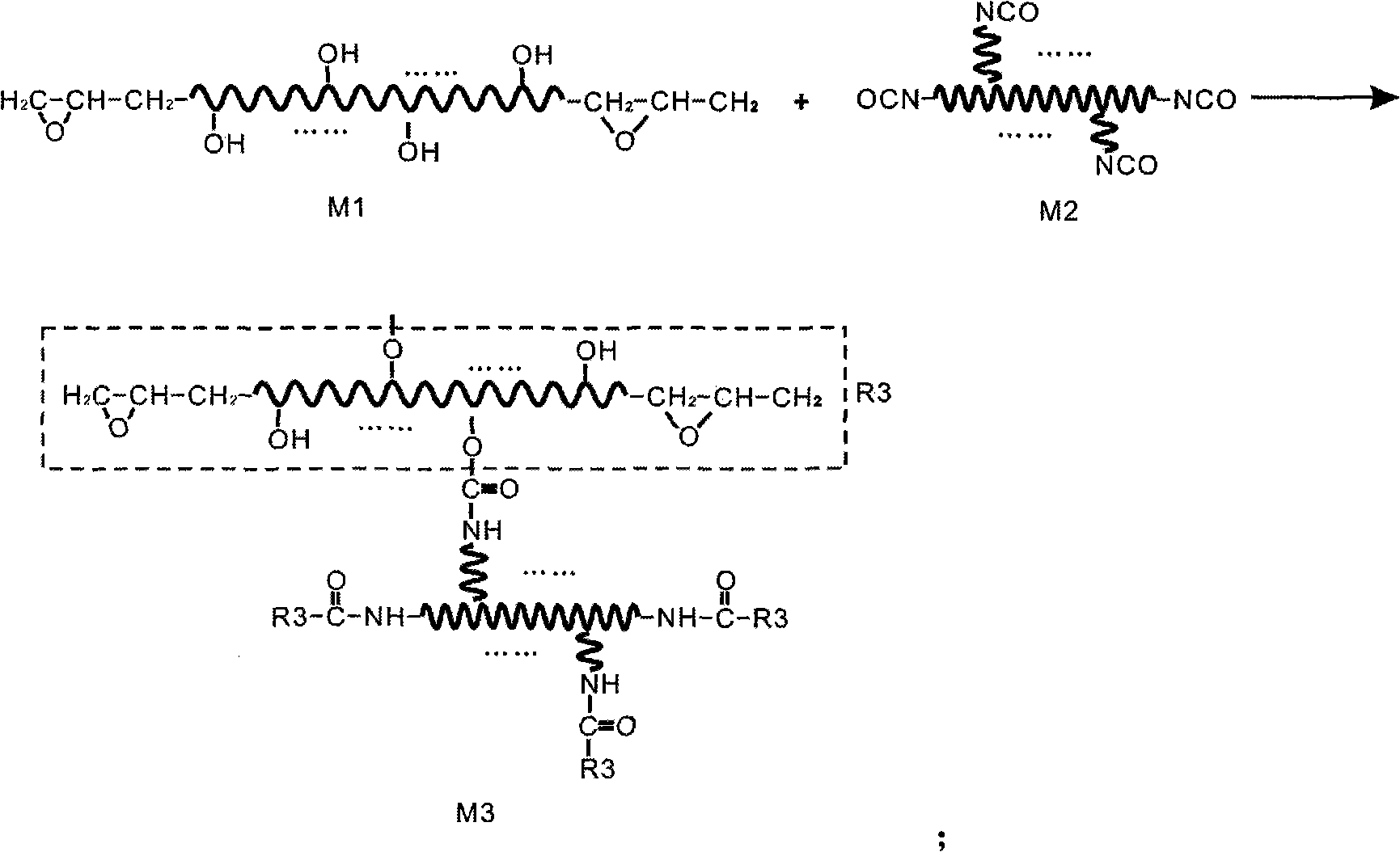

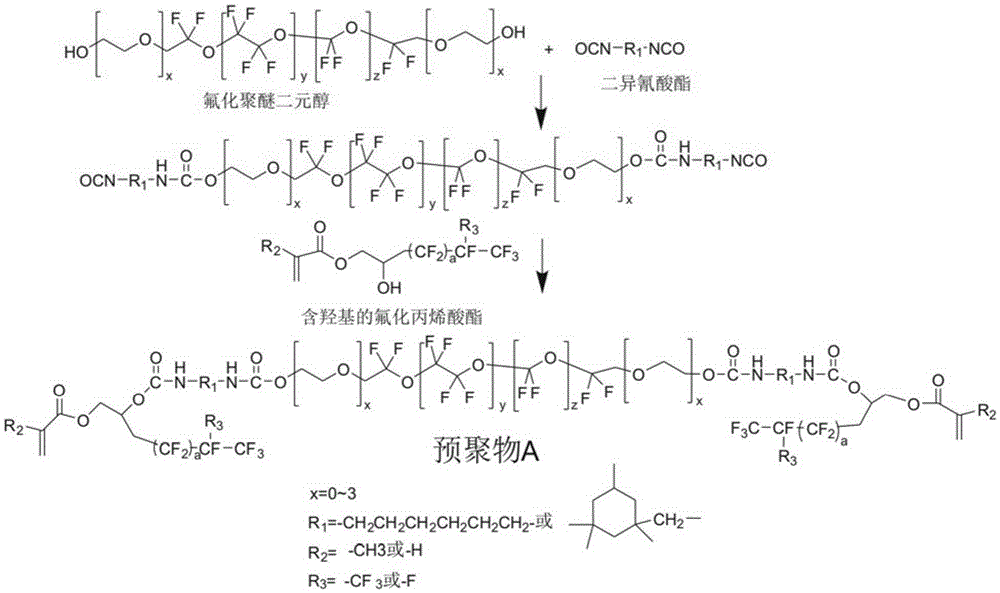

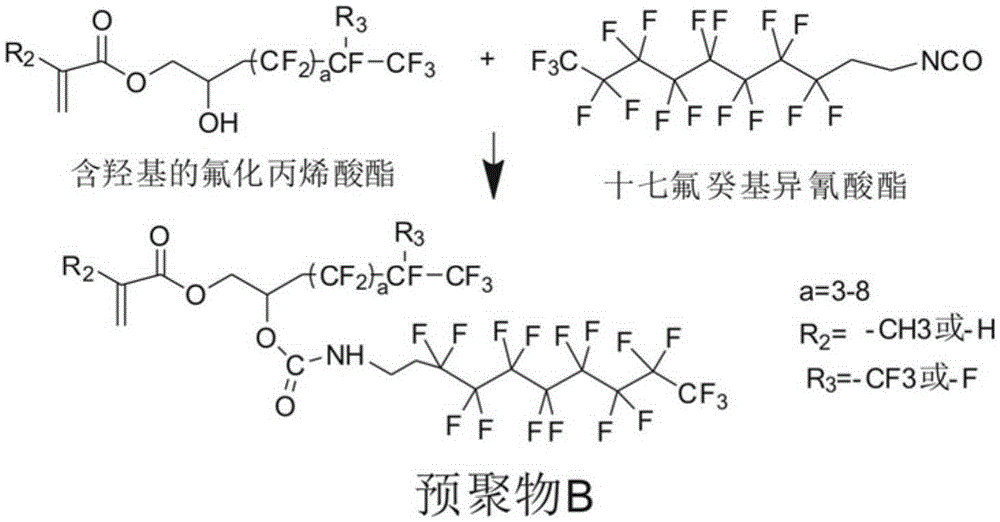

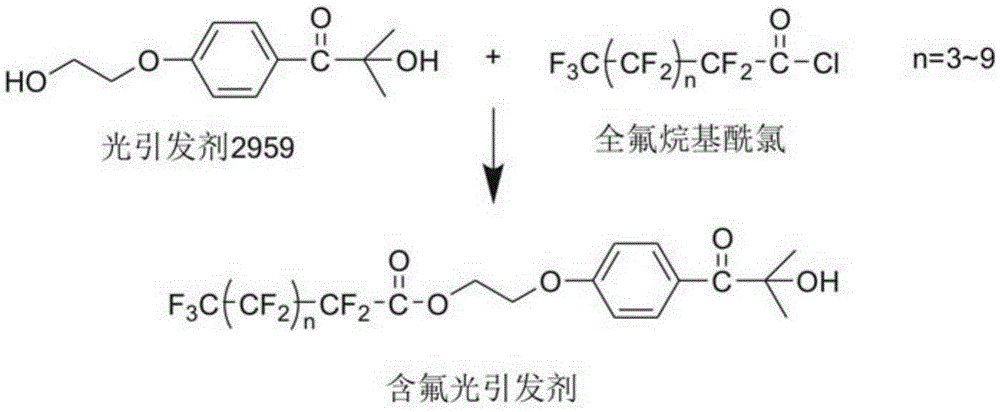

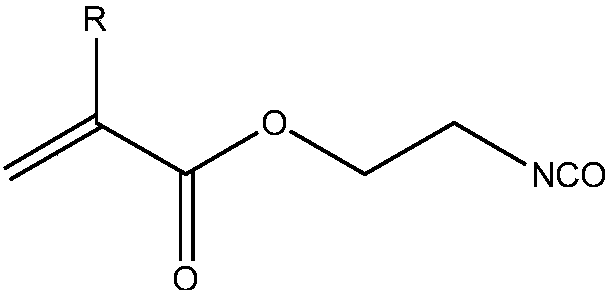

Low-refractive optical fiber coating resin

ActiveCN105273613AAvoid breakingLow refractive indexPolyurea/polyurethane coatingsRefractive indexPhotoinitiator

The invention relates to low-refractive optical fiber coating resin. The low-refractive optical fiber coating resin is prepared from, by weight, 30-65% of prepolymer A, 0-40% of prepolymer B, 2-8% of a photoinitiator, 20-40% of an active diluent and 0.5-2% of a silane coupling agent, and the sum of the weight percentages of all the components is 100%. The low-refractive optical fiber coating resin is high in adhesive power, optical fiber is not likely to be broken when bent, and the low-refractive optical fiber coating resin is low in refractive rate and can enlarge the digital transmission aperture of the optical fiber.

Owner:武汉长盈鑫科技有限公司

Medium-trace element fertilizer suitable for planting paddy rice in soil polluted by cadmium

InactiveCN106883030AEliminate side effectsImprove antagonistic abilityCalcareous fertilisersMagnesium fertilisersFertilizerChemistry

The invention discloses medium-trace element fertilizer suitable for planting paddy rice in soil polluted by cadmium, which relates to fertilizer. The medium-trace element fertilizer is prepared from the following substances: calcium chloride, magnesium chloride, zinc sulfate, copper chloride, iron sulfate, ferrous sulfate, manganese chloride, borax, additives and filler. Not only can the medium-trace element fertilizer provide a great amount of medium trace elements to the paddy rice and improve the growth quality of the paddy rice, but also can play a role in well inhibiting the heavy metal cadmium; and when the medium-trace element fertilizer is applied to the paddy rice planted in the soil with severe pollution of heavy metal cadmium, the cadmium content in paddy rice grains can be reduced by a half or more, the application utilization effect is good, and the popularization value is high.

Owner:安徽省卫国农业科技有限公司

Methods of preparing hydrocarbon, water and organophilic clay emulsions and compositions thereof

InactiveCN101421371AIncrease stickinessReduce viscosityTransportation and packagingMixingFoundryPolyester

This invention relates to compositions and methods for improving the performance of organophilic organic-clay complexes, which are dispersible in organic liquids to form a gel therein. Depending on the composition of the gel, such gels may be useful as lubricating greases, oil-based muds, oil base packer fluids, paint-varnish-lacquer removers, paints, foundry molding sand binders, adhesives and sealants, inks, polyester laminating resins, polyester gel coats, cosmetics, detergents, and the like.

Owner:ENGINEERED DRILLING SOLUTIONS

High-refractive index and low-dispersion heavy lanthanum flint optical glass

The invention relates to a high-refractive index and low-dispersion heavy lanthanum flint optical glass which is prepared from the following components in percentage by mass of oxides: 9.25-13.37 percent of B2O3, 5.48-7.34 percent of SiO2, 43.60-51.63 percent of La2O3, 3.53-9.12 percent of Y2O3, 4.18-10.23 percent of Gd2O3, 3.47-6.52 percent of Nb2O5, 3.47-6.62 percent of ZrO2, 0.81-1.50 percent of WO3, 3.96-6.95 percent of TiO2, 3.28-6.79 percent of ZnO and 0.61-1.52 percent of Al2O3; and in the composition, the following conditions are also met: B / Si is larger than 1.33 and smaller than 2.54 (by mass percentage), a sum of the mass percentages of La2O3, Y2O3 and Gd2O3 is 58.61-60.32 percent, and a sum of the mass percentages of WO3 and TiO2 is 4.85-8.34 percent. The optical glass does not contain Ta2O3 with high cost to facilitate reduction of the cost of the glass, does not contain alkali metals, alkaline-earth metals and toxic components including Pb, As and Cd either, has the refractive index nd being 1.883-1.915 and an abbe number vd being 35.65-38.32, is excellent in crystallization resistance and is suitable for batch production.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Conductive ink used for ink-jet printing, and preparation method and applications thereof

InactiveCN110093066AImprove evaporation gradientAdjust viscosityConductive layers on insulating-supportsInksUV curingBoiling point

The invention embodiment provides a conductive ink used for ink-jet printing, and a preparation method and applications thereof. The conductive ink used for ink-jet printing comprises, by weight, 30 to 70 parts of nano metal, 10 to 40 parts of a high-boiling UV monomer humectant, 10 to 60 parts of a fast-drying solvent, 0 to 5 parts of a binder, 0.5 to 2 parts of a UV curing agent, and 0 to 2 parts of an auxiliary agent.

Owner:北京大华博科智能科技有限公司

Collapsible loess reinforcing grouting slurry, preparation method and application thereof

ActiveCN109369113AAdjust viscosityReasonable formula designBuilding repairsFoundation engineeringSodium BentoniteSlurry

The invention relates to collapsible loess reinforcing grouting slurry. The collapsible loess reinforcing grouting slurry comprises the following components in parts by weight: 30-40 parts of Portlandcement, 160-210 parts of fine aggregate, 70-100 parts of a gel material, 15-20 parts of bentonite, 5-15 parts of paraffin, 10-15 parts of magnetic powder, 2-10 parts of additive, and 35-47 parts of water; the density of the mixture obtained by mixing the components is 2050-2800 kg / m<3>. The collapsible loess reinforcing grouting slurry is capable of improving and reinforcing a loess foundation; the slurry is simple to prepare, convenient to construct, and low in manufacturing cost; the viscosity of the slurry can be changed by applying an additive magnetic field as required, to meet the requirements of various foundation conditions.

Owner:南京康泰建筑灌浆科技有限公司

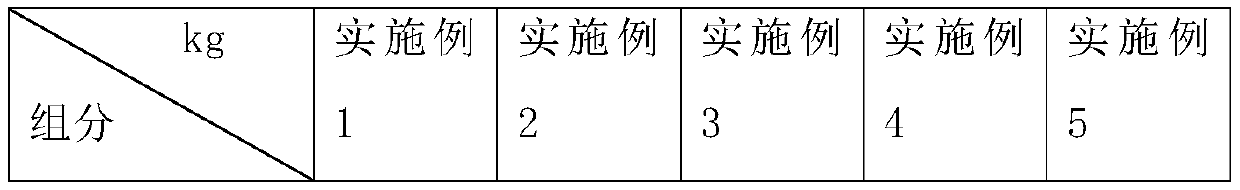

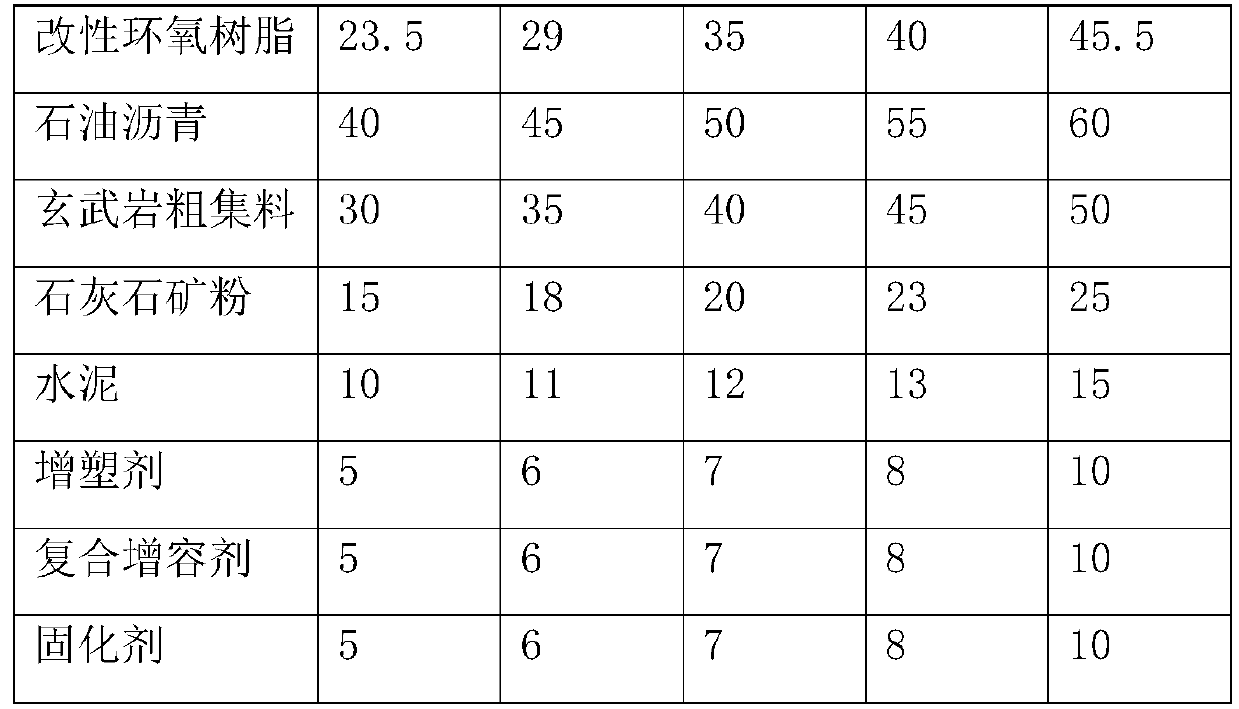

Composite epoxy asphalt pavement material and preparation method thereof

The invention discloses a composite epoxy asphalt pavement material and a preparation method thereof. The composite epoxy asphalt pavement material comprises, by weight, 23.5-45.5 parts of modified epoxy resin, 40-60 parts of petroleum asphalt, 30-50 parts of basalt coarse aggregate, 15-25 parts of limestone mineral powder, 10-15 parts of cement, 5-10 parts of a plasticizer, 5-10 parts of a composite compatibilizer and 5-10 parts of a curing agent; and the curing agent is prepared from, by weight, 3.6-5.8 parts of tung oil anhydride, 2.2-3.4 parts of 2-methyl-4-ethylimidazole, 1.2-2.6 parts of4,4'-diaminodiphenylsulfone and 2.8-3.6 parts of polyamide acid. The composite epoxy asphalt pavement material has the advantages of short curing time, high early strength, shortening of the trafficopening time, absorbing of automobile exhaust, purifying of air and reduction of air pollution.

Owner:江苏中新苏通市政工程有限公司

Fireproof and heat-insulating building material and preparation method thereof

InactiveCN108821648AImprove thermal insulation performanceImprove fire performanceCeramic shaping apparatusCeramicwareFiberCalcium silicate

The invention provides a fireproof and heat-insulating building material and a preparation method thereof, and relates to the field of building materials. The fireproof and heat-insulating building material comprises nanometer silicon carbide, stearyl alcohol, sepiolite powder, asbestos, calcium silicate powder, polyurethane, silk fibroin fibers, 1,4-butylene glycol, waste polyethylene plastics, phosphate slag, diatomaceous earth, activated carbon particles, glass wool, a cementing material, a set retarder, a thickener, a foaming agent, a water reducer and water. The preparation method comprises the following steps: (1) weighing of above raw materials; (2) crushing; (3) stirring; and (4) casting molding, demolding, piling and curing. The fireproof and heat-insulating building material prepared in the invention has the advantages of good heat insulation property, good fireproof property, environmental protection, energy saving and high compressive strength.

Owner:张建

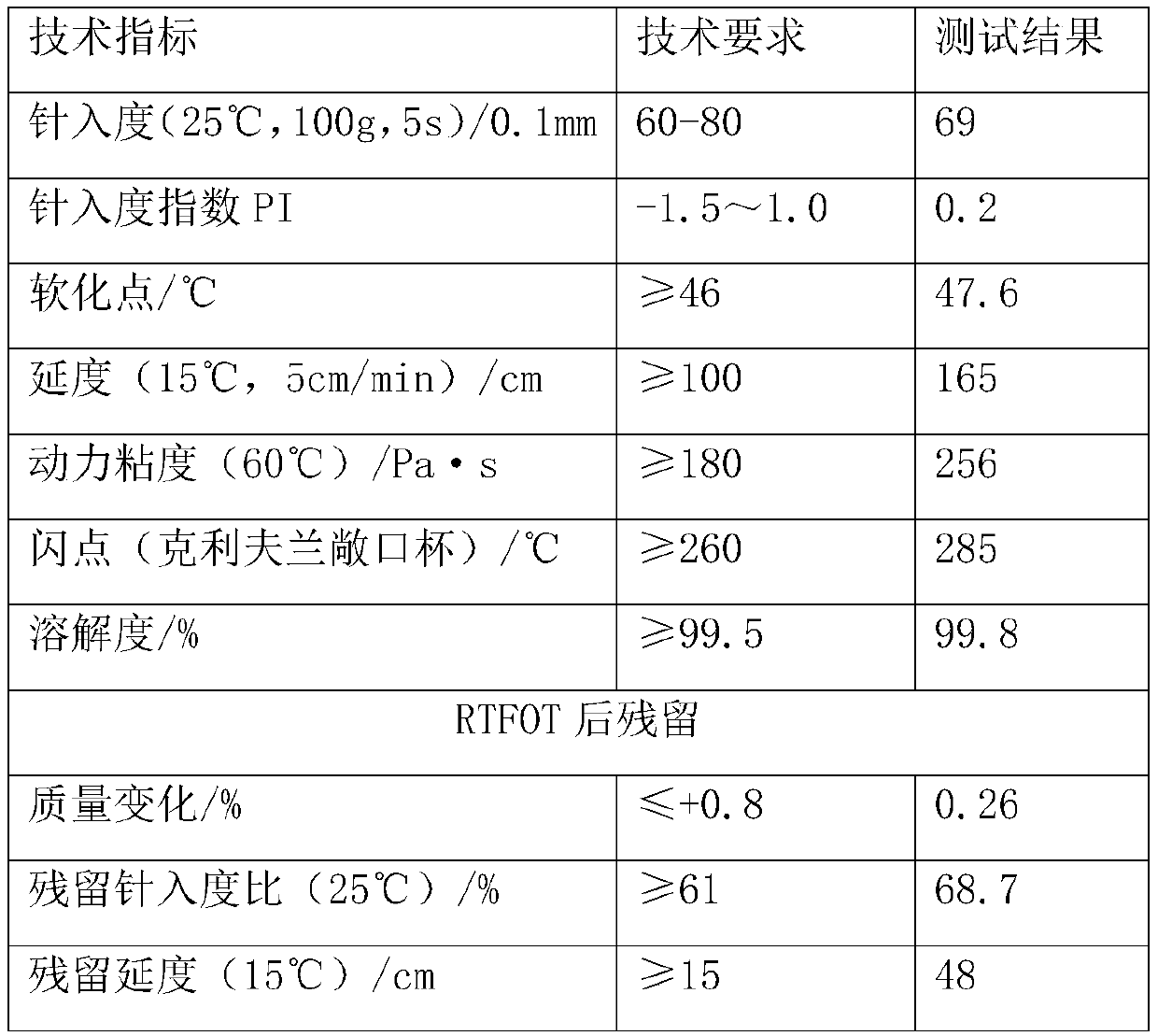

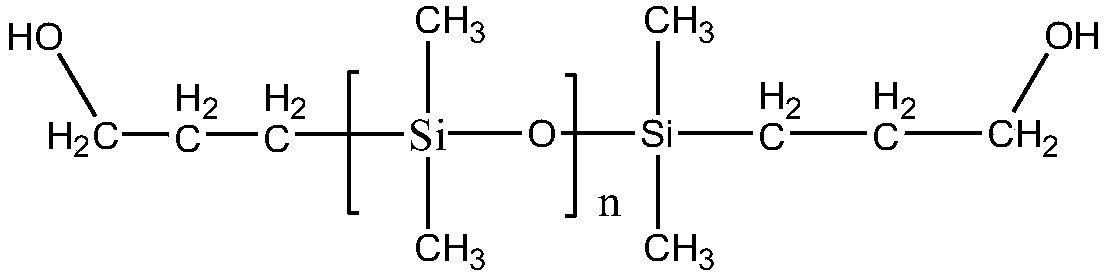

UV light-cured organic silicon polyurethane acrylate monomer and preparation method thereof

The invention relates to a UV light-cured organic silicon polyurethane acrylate monomer and a preparation method thereof. The preparation method comprises the following steps: dissolving a certain amount of hydroxyalkyl dual end-capped polydimethylsiloxane and an AOI-VN monomer into an organic solvent, adding a certain amount of polymerization inhibitor, reacting under action of a catalyst for 4-6hours at a reaction temperature of 40-60 DEG C; after reaction is ended, adsorbing through active carbon, wherein dosage of the active carbon is 2-4% of mass of a mixture system; filtering and removing the solvent to obtain the organic silicon polyurethane acrylate monomer. The monomer prepared by the invention can be directly used as prepolymer, and further can be added into a resin or paint formula as an additive. After being light-cured, the product has performance such as water resistance and high temperature resistance of an organic silicon material.

Owner:YANTAI DEBANG ADVANCED SILICON MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com