Composite epoxy asphalt pavement material and preparation method thereof

A pavement material, epoxy asphalt technology, applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of asphalt early strength improvement effect is not obvious, closed for a long time, long curing time, etc., to shorten the open traffic Time, faster curing speed, and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

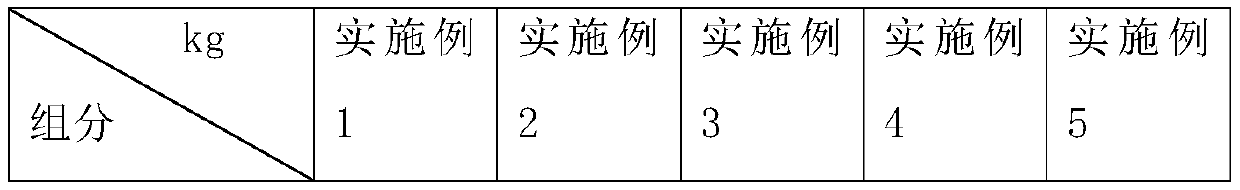

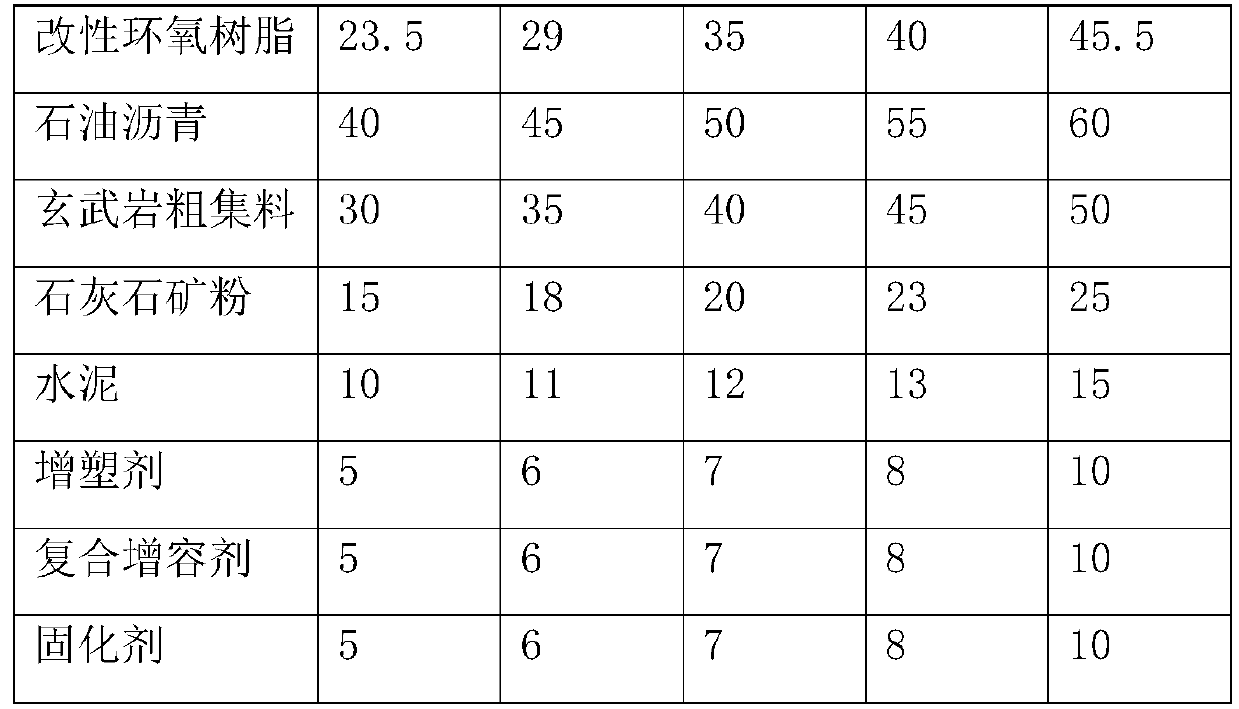

Examples

preparation example 1-3

[0040] In the preparation example 1-3, the bisphenol A epoxy resin is selected from the bisphenol A epoxy resin of the model TC-K51 sold by Wanqian Chemical, and the bismaleimide is selected from Wuhan Lana Bai Pharmaceutical Chemical Co., Ltd., silicon The ketone resin is selected from Dow Corning 805 silicone resin sold by Guangzhou Suoman Trading Co., Ltd., and the glass powder is selected from the glass powder sold by Lingshou County Shunze Mineral Products Processing Factory with a product number of 6502.

preparation example 1

[0041] Preparation Example 1: Stir 3.5kg of bisphenol A epoxy resin and 2.8kg of bismaleimide at 100°C for 2h, cool down to 40°C, add 2.2kg of methyltetrahydrophthalic anhydride, continue to stir for 30min, add 1.4 Mix kg of methyl isobutyl ketone and 1.6 kg of silicone resin evenly, add 0.8 kg of glass powder, 1.2 kg of boron trioxide and 2 kg of strontium chromate, and continue stirring for 1 hour to obtain a modified epoxy resin.

preparation example 2

[0042] Preparation Example 2: Stir 4.5kg of bisphenol A epoxy resin and 3.1kg of bismaleimide at 110°C for 1.5h, cool down to 45°C, add 2.8kg of methyltetrahydrophthalic anhydride, continue to stir for 35min, add Mix 2.1kg of methyl isobutyl ketone and 2.1kg of silicone resin evenly, add 1.2kg of glass powder, 2.0kg of boron trioxide and 2.5kg of strontium chromate, and continue stirring for 1.5h to obtain a modified epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com