Patents

Literature

61 results about "Methyltetrahydrophthalic anhydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid epoxy resin composition for packaging LED (Light Emitting Diode)

InactiveCN102702682AGood flexibilityImprove crack resistanceSemiconductor devicesCrack resistanceHexahydrophthalic anhydride

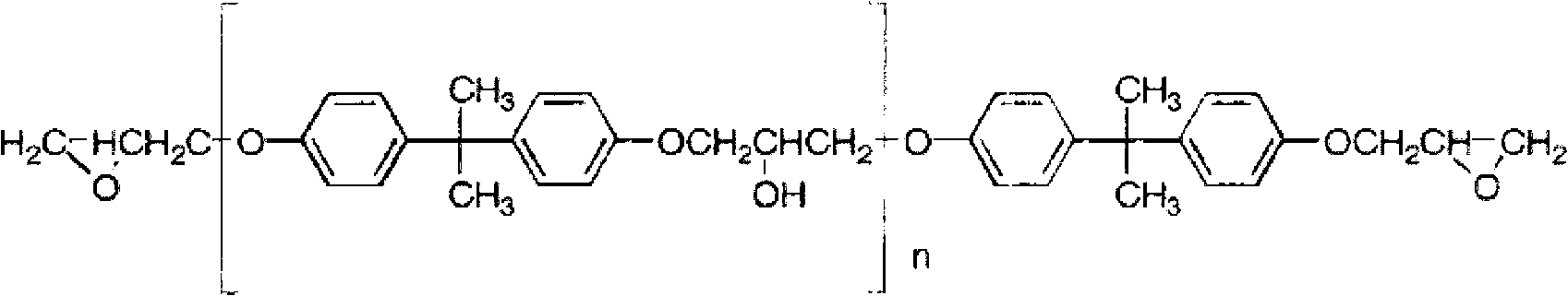

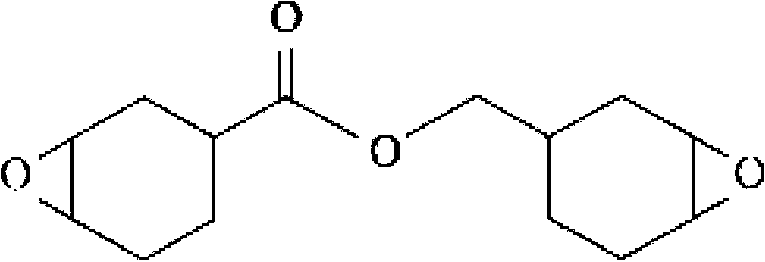

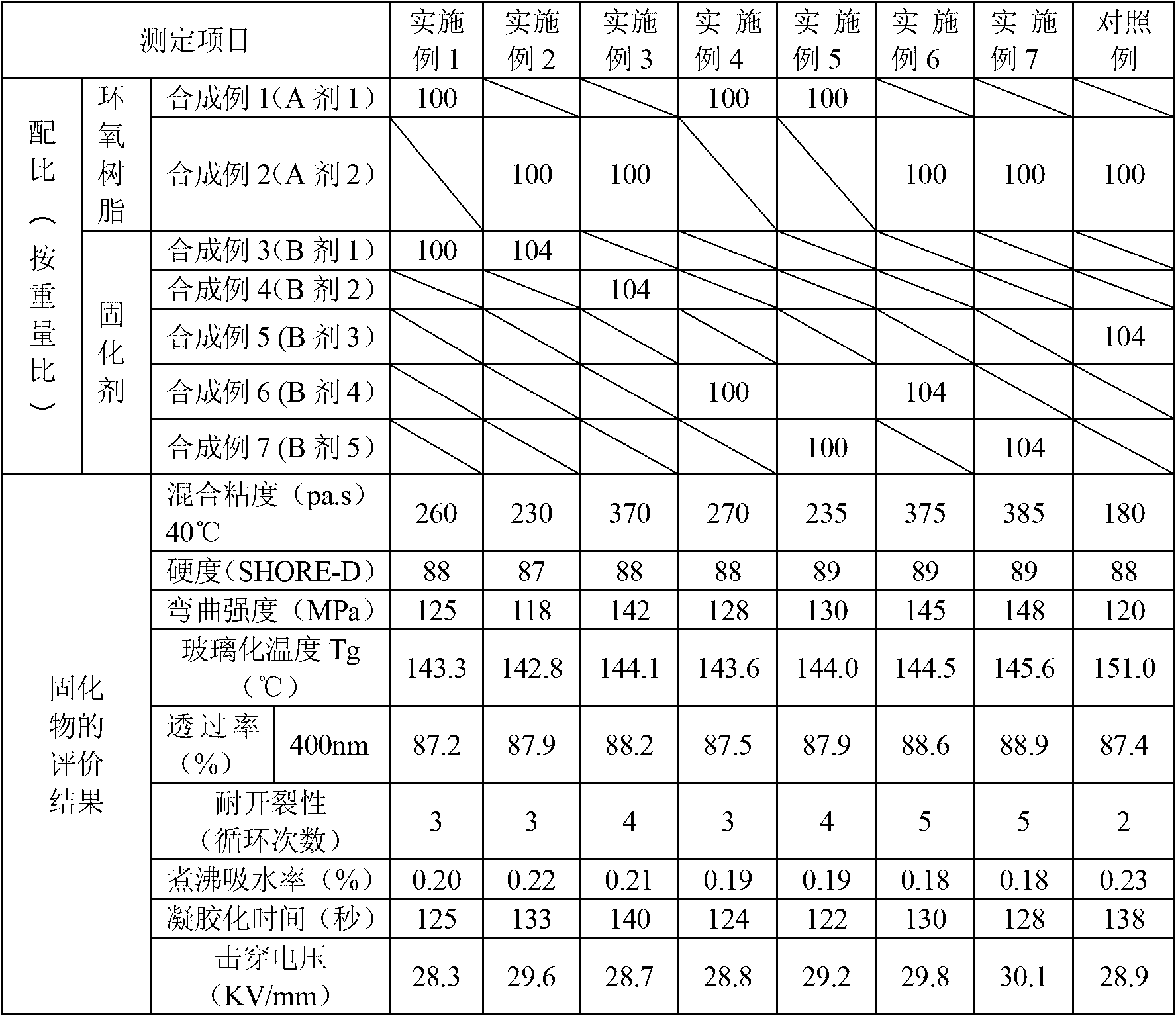

The invention discloses a liquid epoxy resin composition for packaging an LED (Light Emitting Diode). The liquid epoxy resin composition consists of an agent A and an agent B, wherein the agent A comprises 97-99 percent by weight of epoxy resin composition and 1-3 percent by weight of defoaming agent; the agent B comprises 94-97 percent by weight of alicyclic anhydride, 0.02-0.1 percent by weight of antioxidant, 0.02-0.1 percent by weight of ultraviolet absorber, 2-5 percent by weight of toughening modifier and 0.5-1.5 percent by weight of accelerator; and the weight ratio of the agent A to the agent B is 100:(100-105). The epoxy resin composition in the agent A is bisphenol-A epoxy resin and 3,4-epoxy cyclohexylmethyl and 3,4-epoxycyclohexyl carboxylate; and the alicyclic anhydride in the agent B is at least one of methyl tetrahydrophthalic anhydride, methyl hexahydrophthalic anhydride and hexahydrophthalic anhydride; and the toughening modifier is neopentyl glycol. The neopentyl glycol has a structure of a branched chain, so that the flexibility and the cracking resistance of the cured epoxy resin are remarkably improved.

Owner:JIAXING JIAGANG SYNTHETIC MATERIALS

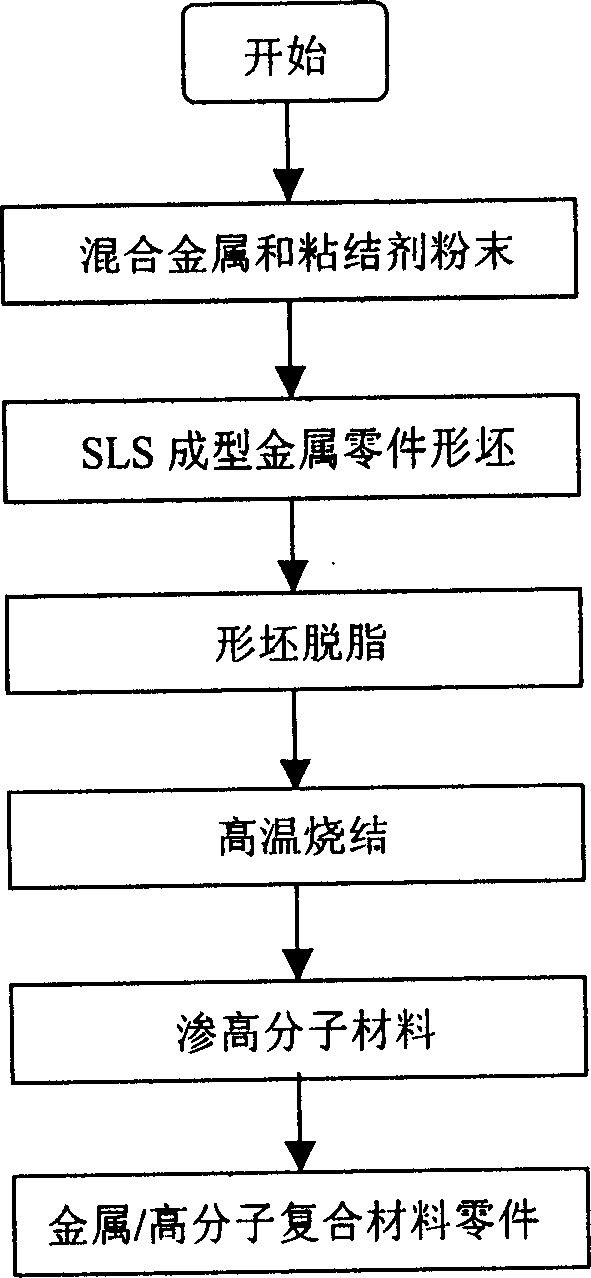

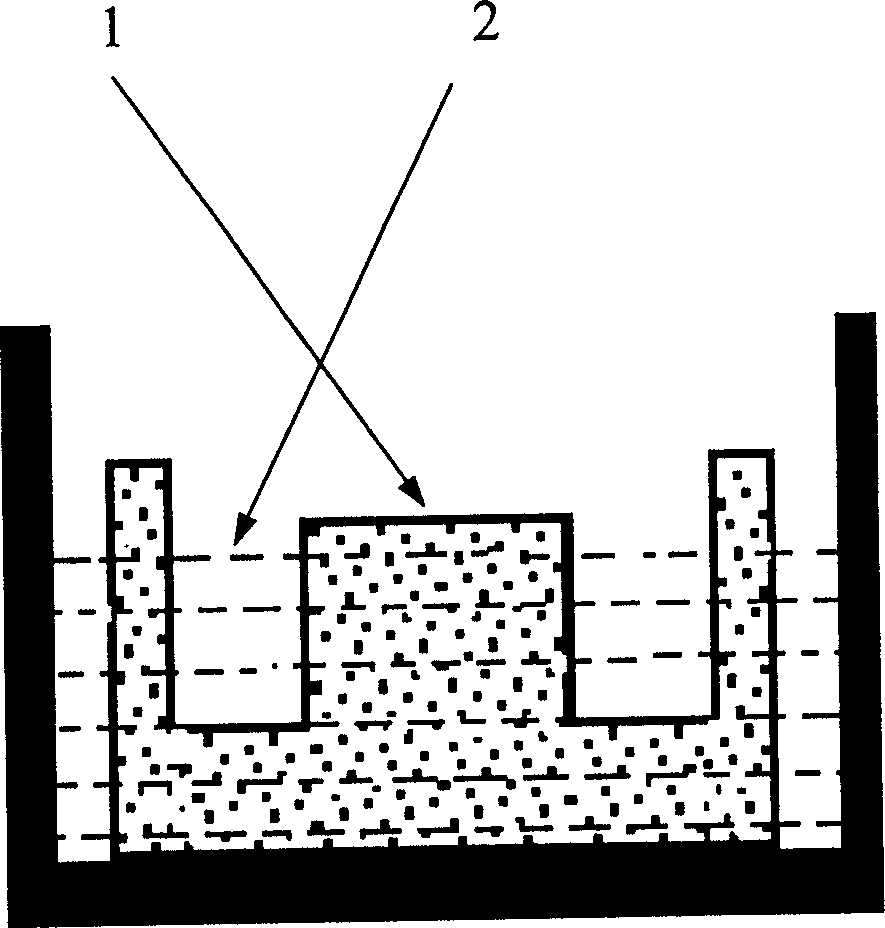

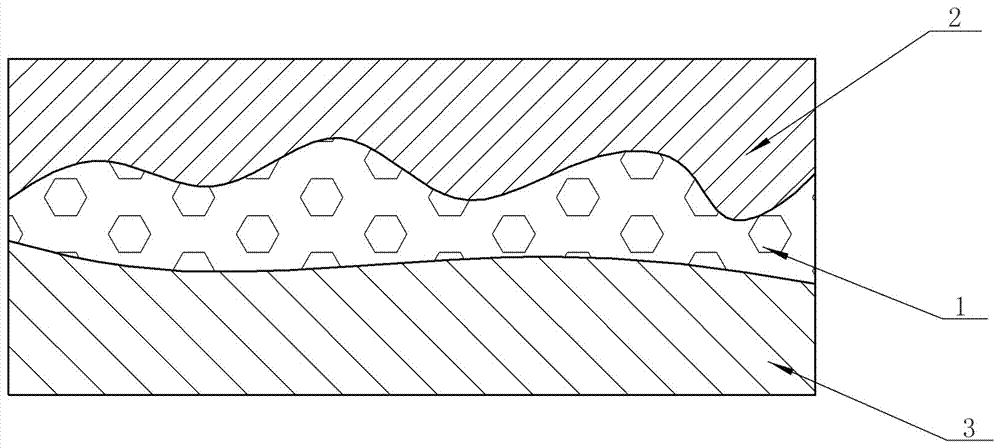

Method for fast mfg. metal/high-molecular composite material parts

A process for quickly preparing the metal / high-molecular material workpiece includes such steps as preparing the immersing liquid through proportionally mixing epoxy resin with phenolic resin or modified organosilicon, heating to 60-80 deg.C, adding methyl tetrahydrophenyl diformic anhydride and stirring, preparing the workpiece blank from metal and high-molecular material, degreasing, sintering to become porous blank, immersing it in said immersing liquid at 90-110 deg.C until no air bubbles, solidifying at 140-180 deg.C, and cooling.

Owner:HUAZHONG UNIV OF SCI & TECH

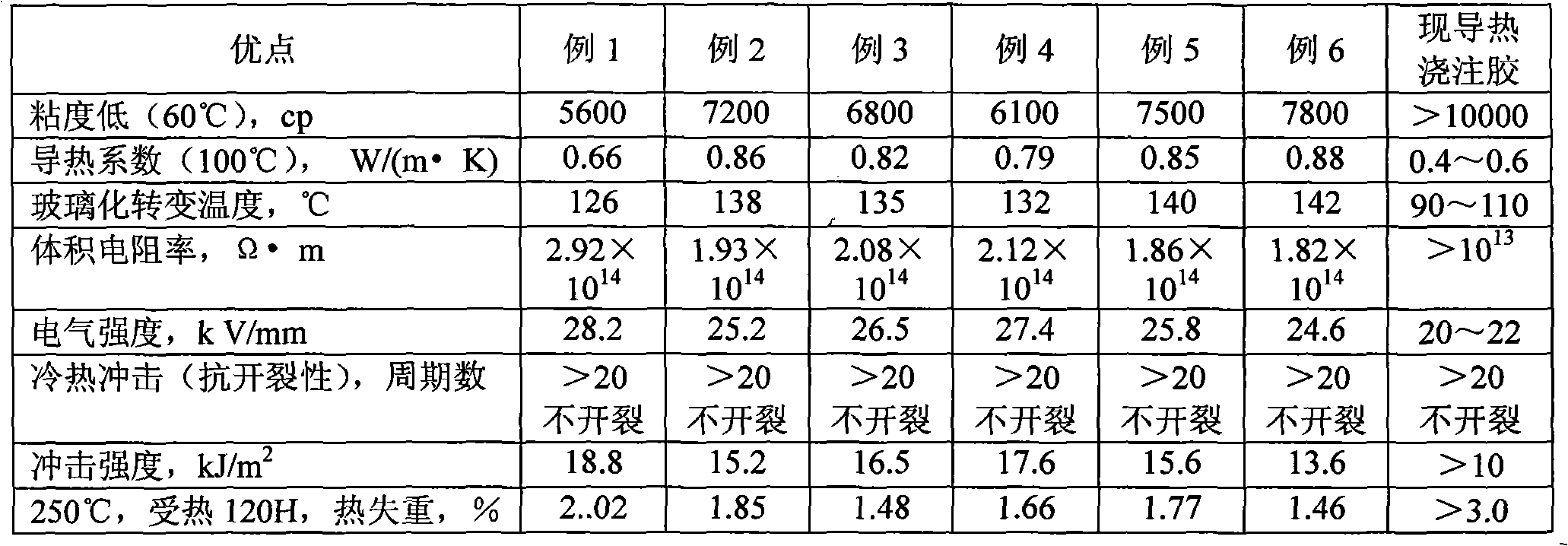

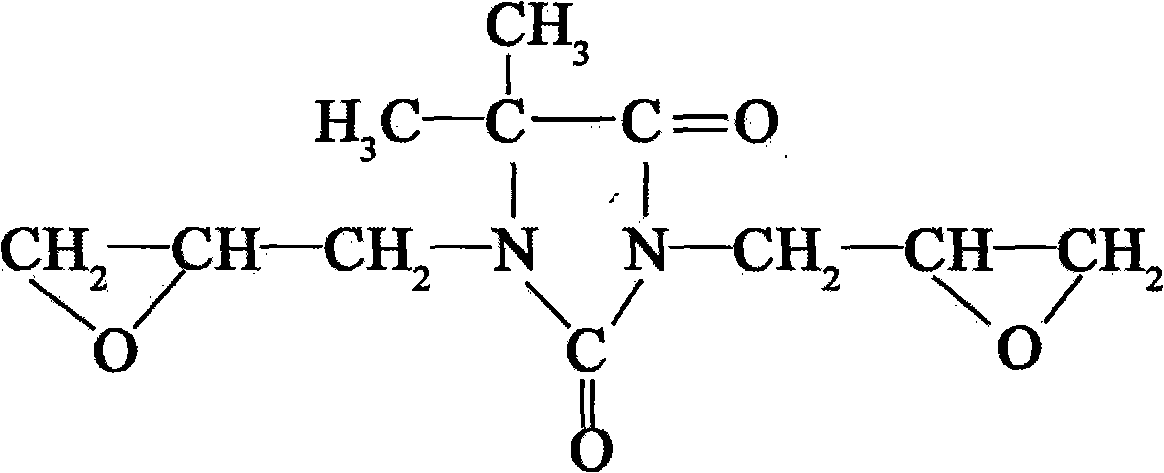

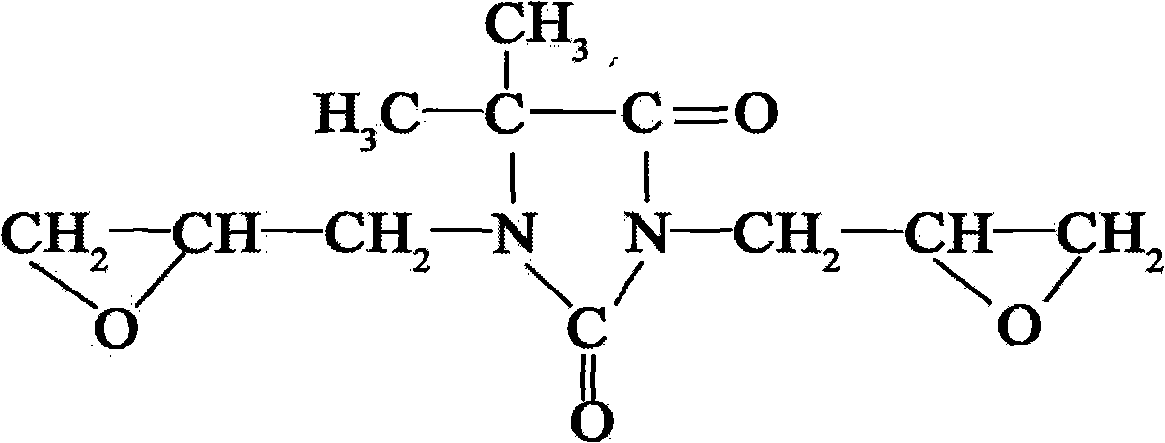

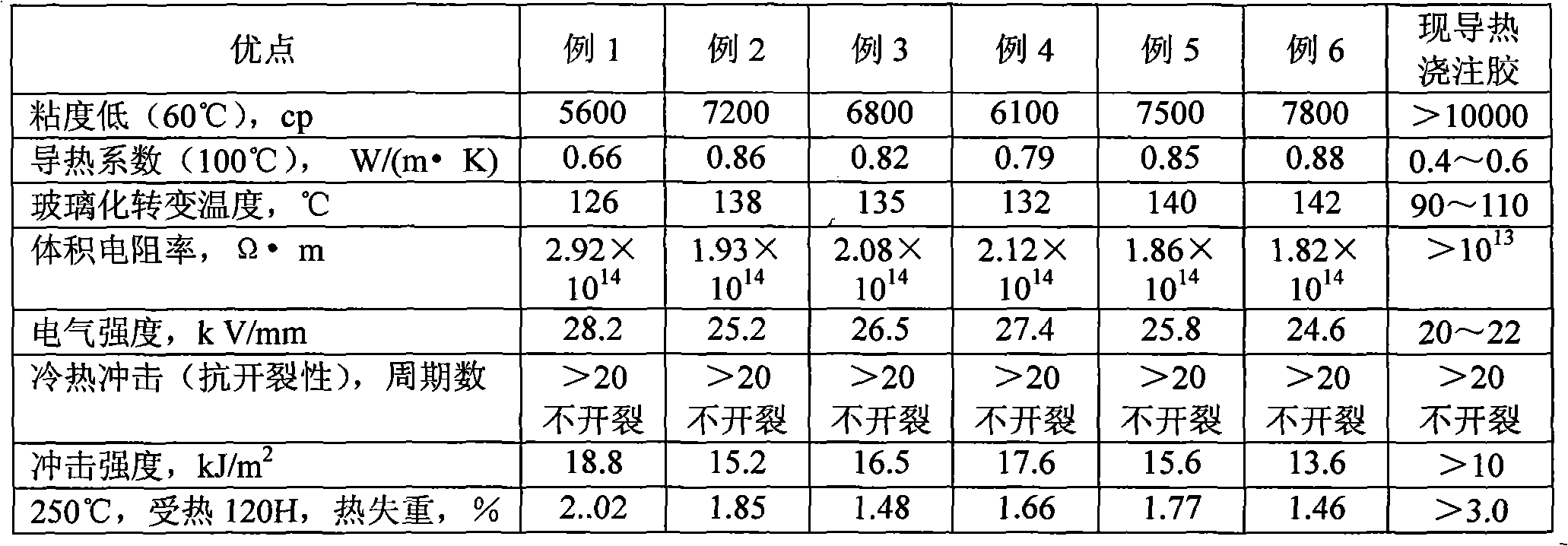

Heat conduction insulating casting glue and preparation method thereof

ActiveCN102093665ALow viscosityGood workmanshipInorganic insulatorsHeat-exchange elementsEpoxyTetrahydrophthalamic acid

The invention relates to a heat conduction insulating casting glue and a preparation method thereof. The casting compound comprises the following main components in parts by weight: (A) 100 parts of hydantoin epoxy resin, (B) 60-120 parts of anhydride curing agent, and (C) 200-400 parts of inorganic heat conductive filler, wherein the component A (per 100 weight parts) contains 10-15 weight partsof alcohol plasticizer; the component B is one or more of hexahydrophthalic anhydride, tetrahydrophthalic anhydride, methyltetrahydrophthalic anhydride, methylhexahydrophthalic anhydride and methylnadic anhydride; and the component C is one or more of silica micropowder, aluminum oxide, aluminum nitride and boron nitride in 300-900 meshes. The preparation method of the casting compound comprises the following steps: mixing A and B proportionally; soaking C in ethanol solution of silane coupling agent, dispersing at a high speed, filtering, and oven-drying; heating the mixture of A and B, adding C, mixing, and debubbling; and casing, and curing. The casting compound provided by the invention has low viscosity, greatly improved heat-conducting property and improved mechanical properties, and is convenient in casting. The preparation method of the casting compound is solvent-free, and has no pollution to the environment.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

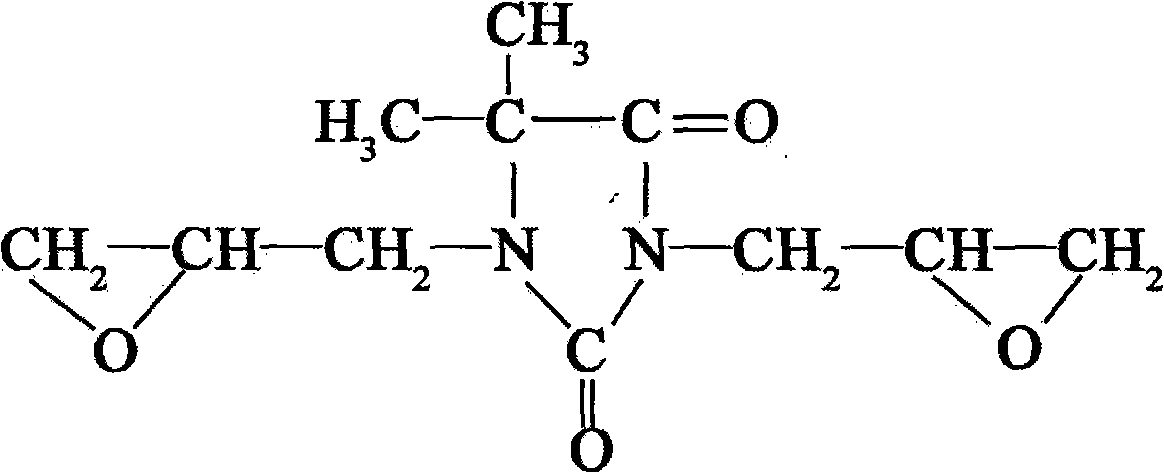

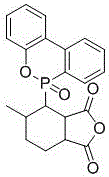

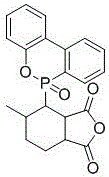

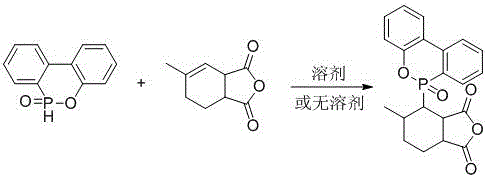

DOPO (9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) modified anhydride epoxy resin flame-retardant curing agent and preparation method thereof

InactiveCN106750183AWith flame retardant effectLow toxicityGroup 5/15 element organic compoundsChemical synthesisPolymer science

The invention provides a DOPO (9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) modified anhydride epoxy resin flame-retardant curing agent and a preparation method thereof and relates to a chemical synthesis agent and a preparation method thereof. The curing agent comprises the following raw materials: DOPO and 2-methyl tetrahydrophthalic phthalic anhydride. The flame-retardant curing agent is simple in a preparation process and can be prepared only by a one-step reaction, that is, DOPO and 2-methyl tetrahydrophthalic phthalic anhydride are mixed with a solvent under an inert gas atmosphere for a reaction for hours at a certain temperature, and rotary evaporateion and solvent removal are performed, so as to obtain a product; or DOPO reacts with 2-methyl tetrahydrophthalic phthalic anhydride react with each other for hours under the condition of no solvent and then are cooled to the room temperature, so as to obtain an acquired product; and the products obtained under different proportion conditions are colorless liquid to light yellow liquid. In a processing process, the raw materials can be well mixed with epoxy resin and can be cured into one together with the epoxy resin; and the flame-retardant curing agent can be taken as a curing agent of the epoxy resin, and the flame retardant property of the epoxy resin can be effectively improved. The preparation method is simple and convenient, and modified anhydride curing agents with different phosphorus contents can be prepared as required.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

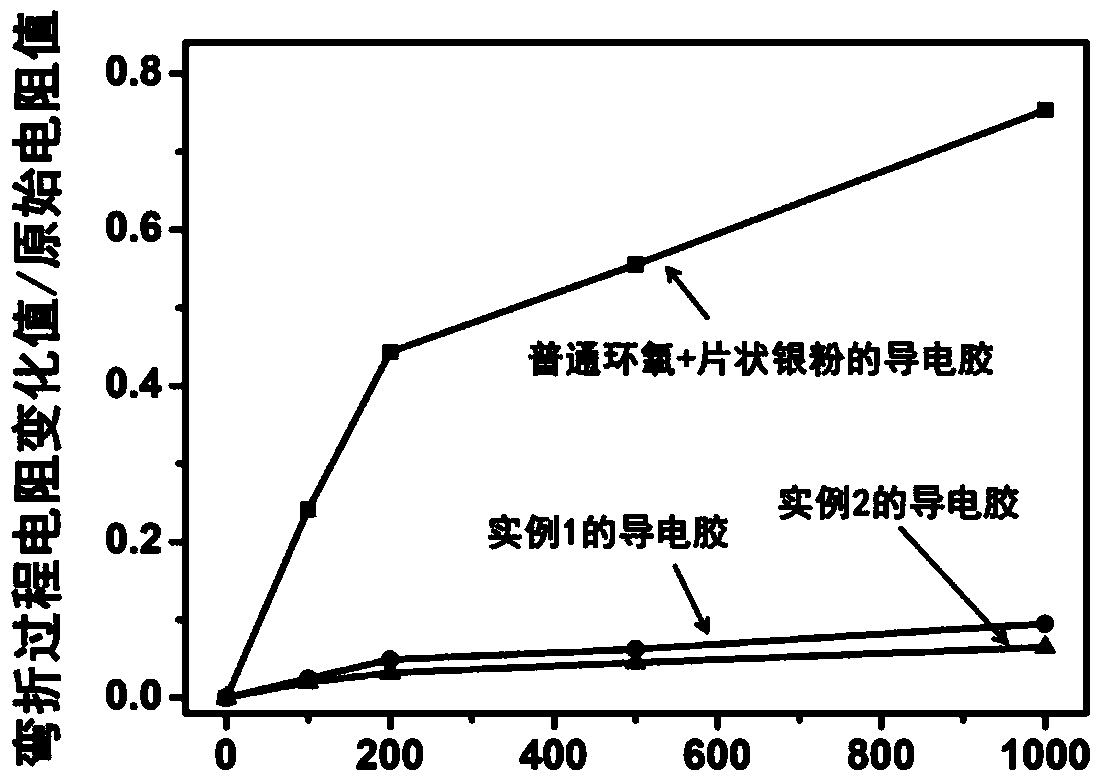

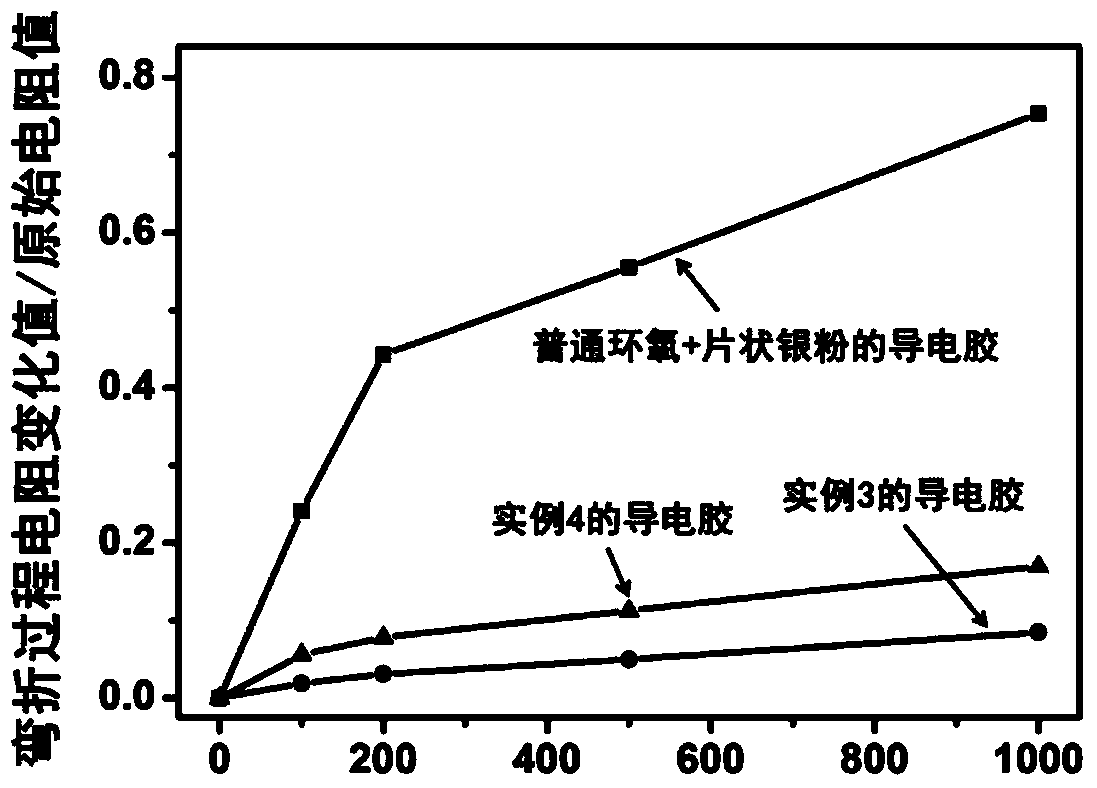

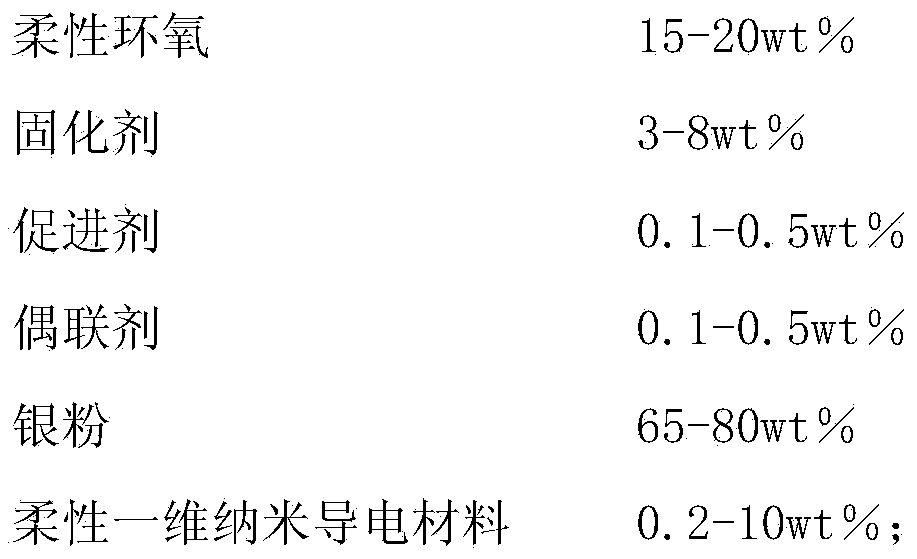

Flexible conductive adhesive capable of being used in direct coating manner and preparation method of flexible conductive adhesive

InactiveCN104263303AImprove conductivityGood flexibilityEpoxy resin adhesivesGraft polymer adhesivesTetrahydrophthalamic acidAdhesive

The invention discloses a flexible conductive adhesive capable of being used in a direct coating manner and a preparation method. The flexible conductive adhesive consists of 15-20wt% of flexible epoxy, 3-8wt% of a curing agent, 0.1-0.5wt% of an accelerant, 0.1-0.5wt% of a coupling agent, 65-80wt% of silver powder and 0.2-10wt% of flexible one-dimensional nano conductive material, wherein the flexible epoxy is a mixture of bisphenol-A epoxy resin with ethylene-vinyl acetate copolymer soft segments grafted and aliphatic glycidyl ether epoxy resin; the curing agent is one or more of methylhexahydrophthalic anhydride, methyl tetrahydrophthalic anhydride and tetrahydrophthalic anhydride; the accelerant is an imidazole compound; the coupling agent is one or more of KH 550, KH560 and KH570; the flexible one-dimensional nano conductive material is a carbon nano tube or a conductive metal nano wire. The flexible conductive adhesive has the excellent conductivity and the good flexibility, the conductivity is almost not changed after being bent repeatedly, and the flexible conductive adhesive can meet requirements of flexible electronic products.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Production method of epoxy resin electronic potting material

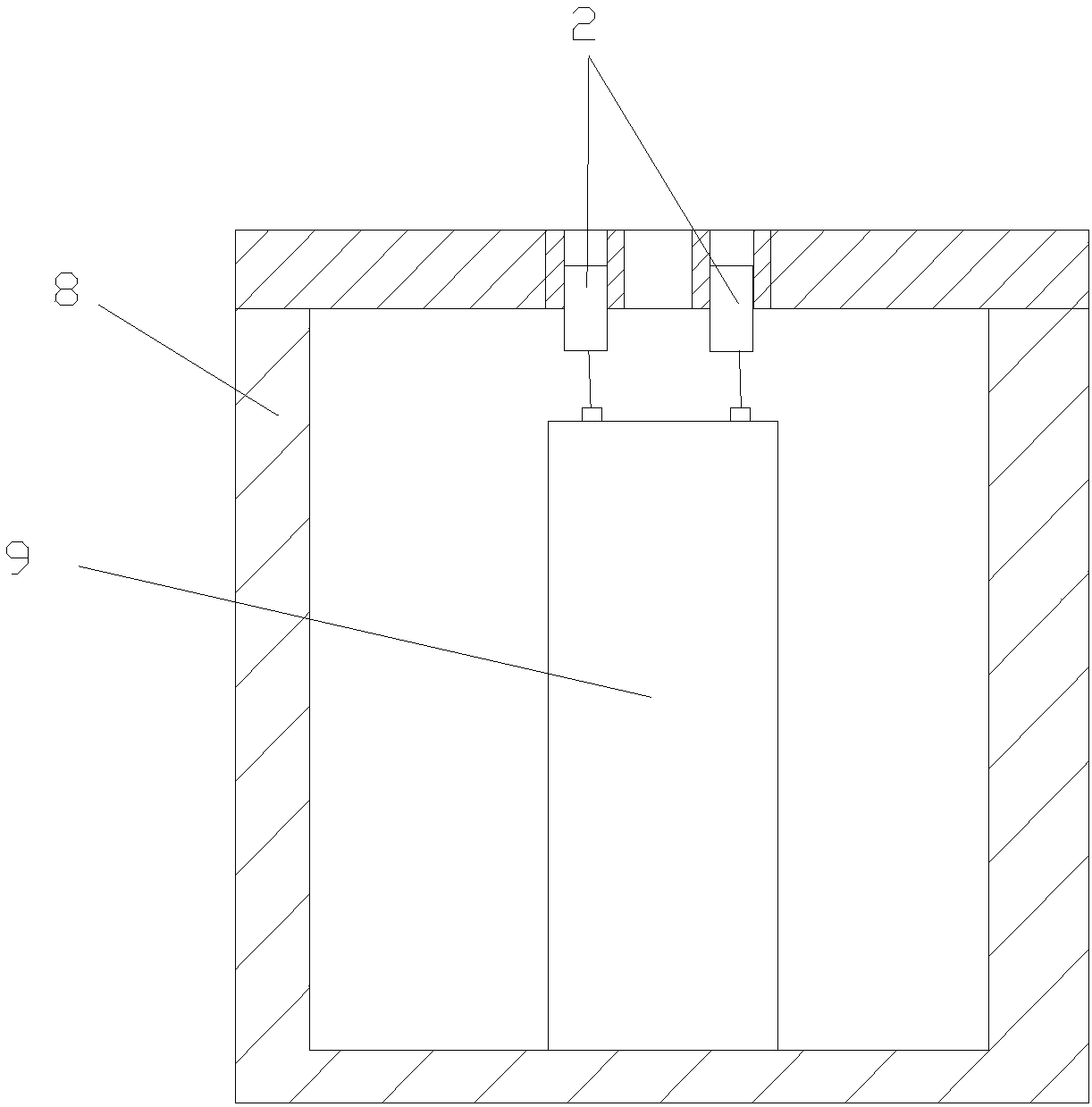

The invention relates to the technical field of potting materials, particularly a production method of an epoxy resin electronic potting material. The epoxy resin electronic potting material comprises a component A and a component B, wherein every 1000kg of the component A comprises the following components in parts by weight: 900-980kg of methyltetrahydrophthalic anhydride and 20-100kg of modifier; and every 1000kg of the component B comprises the following components in parts by weight: 900-950kg of epoxy resin and 50-100kg of modifier. When being used in various electronic components, the epoxy resin electronic potting material has the functions of fixation, moisture protection, corrosion protection, forgery prevention and the like, and has the characteristics of high temperature resistance, high voltage resistance, favorable insulation effect and the like. The adoption of the polyester resin, urea-formaldehyde melamine resin, furfural resin, vinyl resin, isocyanate or silicon resin modifier further enhances the acid resistance, heat resistance and shock strength of the epoxy resin potting material, and improves the chemical resistance and strength of the epoxy resin potting material.

Owner:南通市福来特化工有限公司

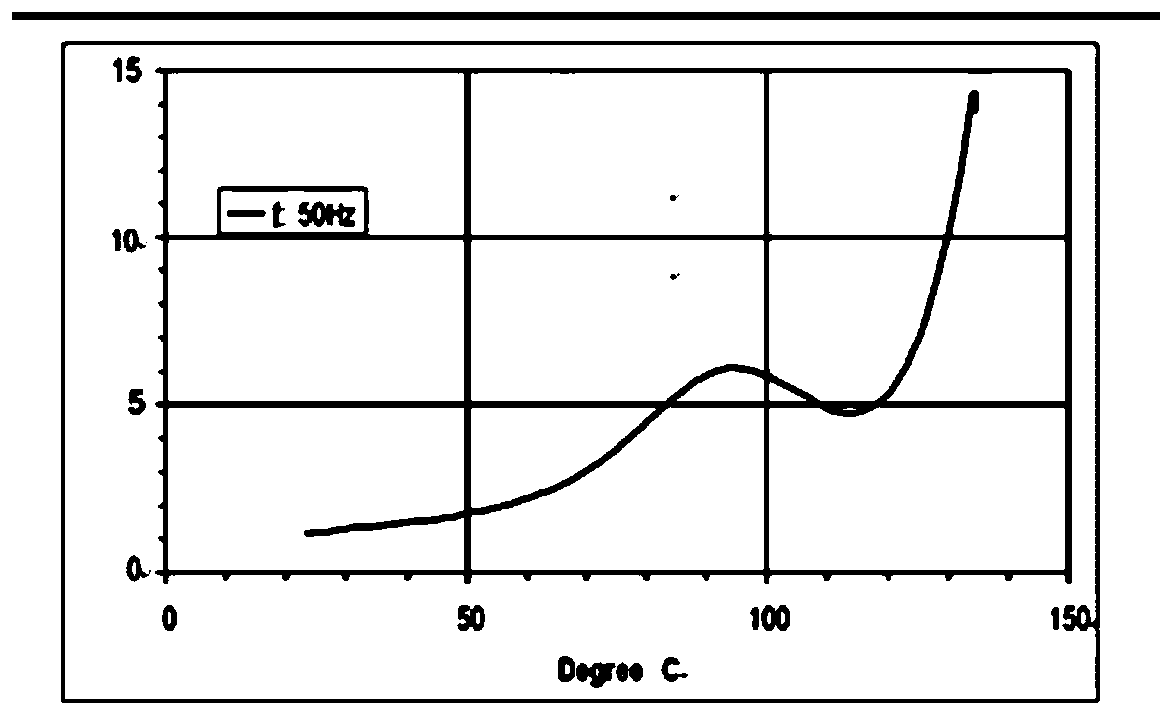

Epoxy resin complex with long chemical storage stability and temperature thixotropy

The invention discloses a category of epoxy resin complexes with long chemical storage stability and temperature thixotropy characterized in that the complexes are prepared by charging acetyl acetone lanthanides group transition metal complexes, methyl tetrohydrogen orthophthalic acid anhydride, silicane coupling agent, nano silica into epoxy resin base through uniform dispersion. The prepared resin system has good wettability with the reinforced material.

Owner:DALIAN UNIV OF TECH

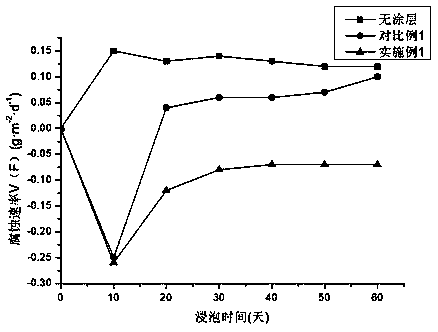

Steel surface composite coating and preparation method thereof

InactiveCN110922865AImprove corrosion resistanceImprove wear resistanceAntifouling/underwater paintsPaints with biocidesMeth-Pyromellitic dianhydride

The invention discloses a steel surface composite coating, and belongs to the technical field of steel corrosion prevention. The steel surface composite coating comprises the following raw materials in parts by weight: 20 to 30 parts of 2-tert-butylamino-4-ethylamino-6-methylthio-1, 3, 5-triazine, 13 to 17 parts of graphene oxide, 300 to 400 parts of water-borne acrylic acid modified epoxy resin,20 to 30 parts of methyl tetrahydrophthalic anhydride, 20 to 30 parts of methyl nadic anhydride and 10 to 20 parts of pyromellitic dianhydride. The steel surface composite coating disclosed by the invention is excellent in corrosion resistance, capable of effectively preventing seawater from corroding steel materials, excellent in friction resistance, also excellent in blue-green algae resistance,and suitable for coating the surfaces of pipelines and ships in the ocean.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

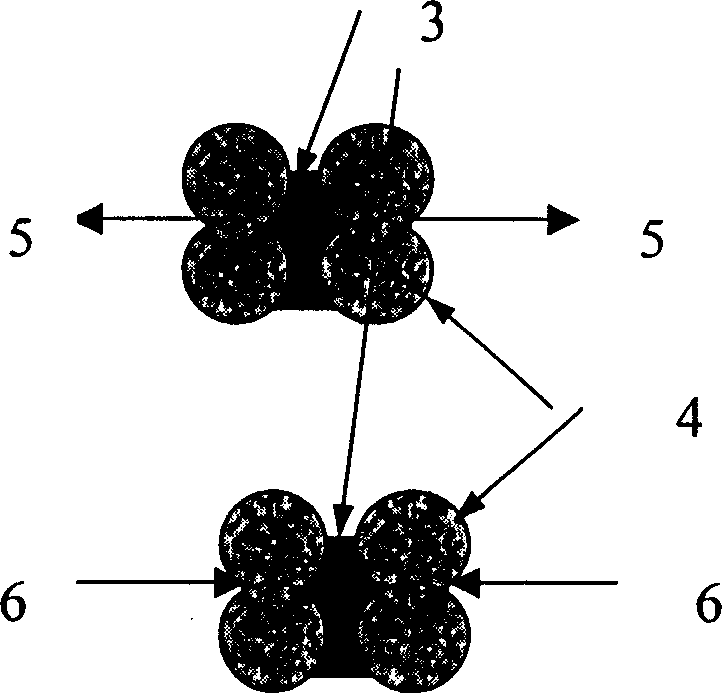

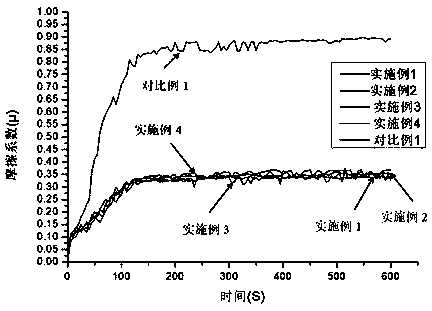

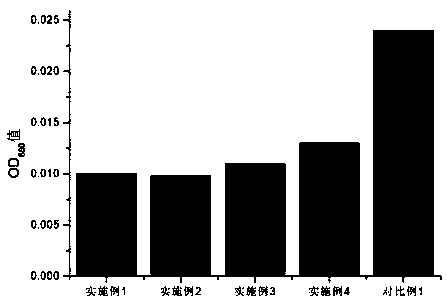

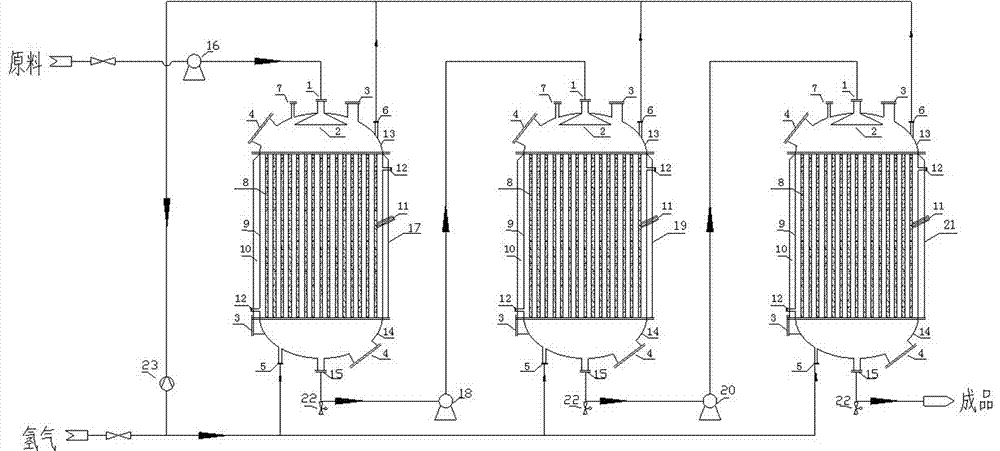

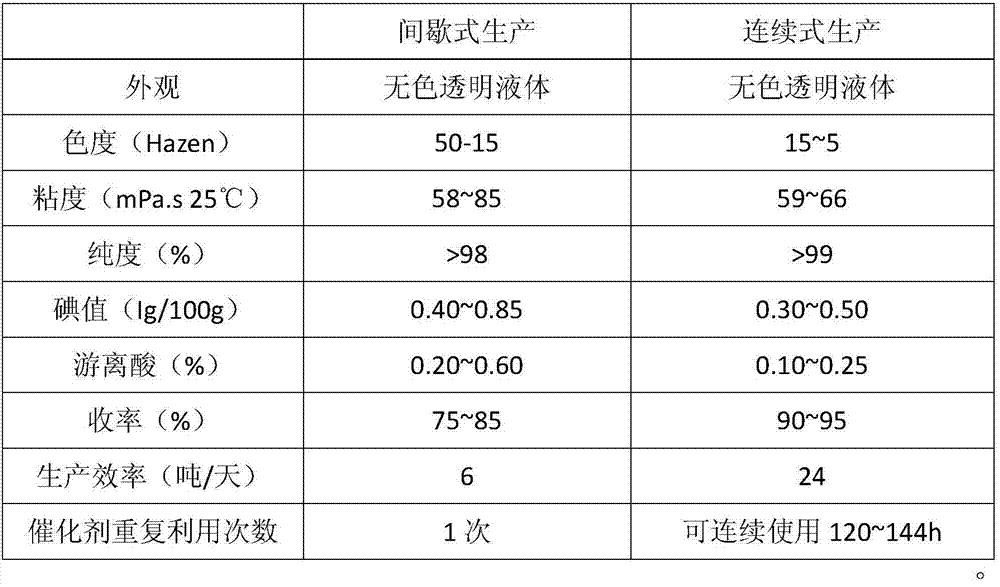

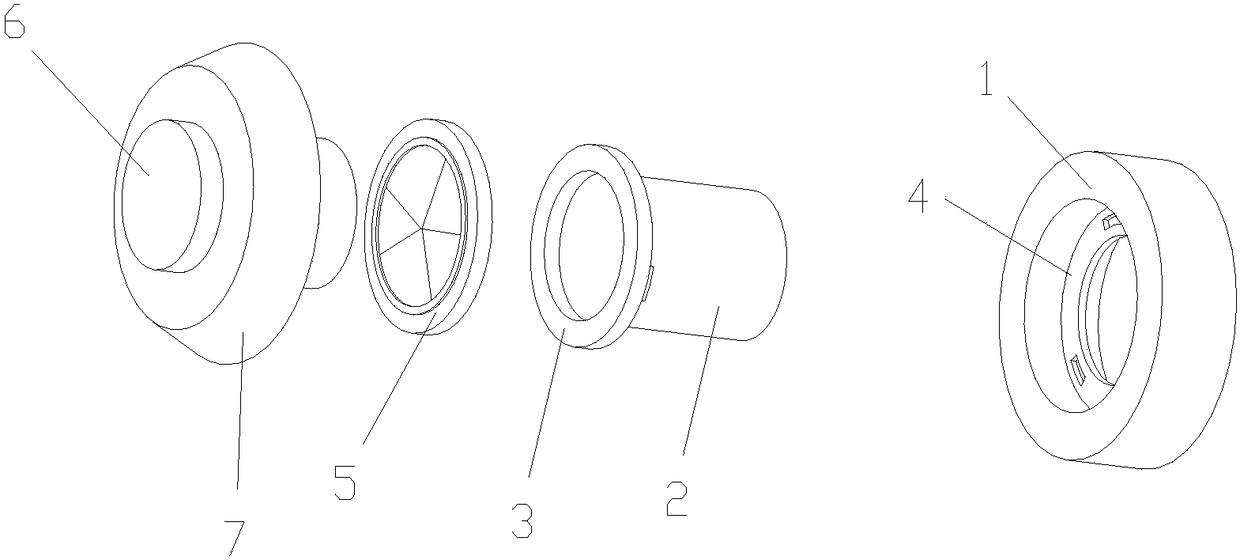

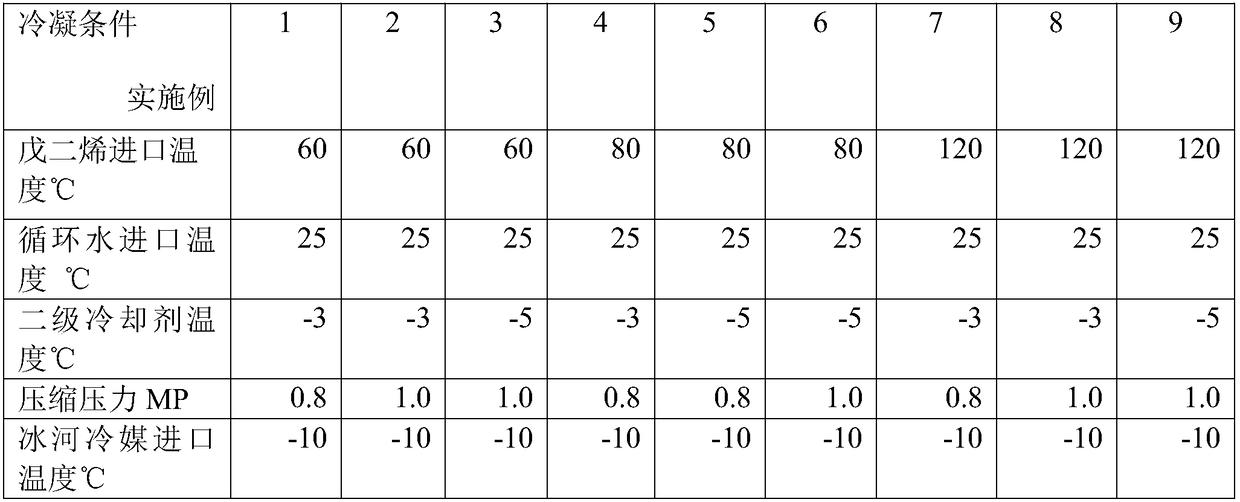

Method for preparing methylhexahydrophthalic anhydride by means of continuous hydrogenation

ActiveCN107089961AWell distributedImprove conversion rateOrganic chemistryChemical/physical processesThree levelFixed bed

The invention discloses a method for preparing methylhexahydrophthalic anhydride by means of continuous hydrogenation and belongs to the field of organic chemicals. A three-level split-tube fixed bed reactor is adopted for circularly continuous hydrogenating; a split-tube type structure is adopted in the split-tube fixed bed reactor; a solid catalyst is arranged between tube passes; a heat medium is arranged in a shell pass; hydrogen respectively enters from the bottom of each level of split-tube fixed bed reactor in parallel; unreacted hydrogen passes by each split tube and then returns to a hydrogen compressor from the upper part of the reactor; the raw material, methyltetrahydrophthalic anhydride, gradually passes by a high pressure pipe pump, is conveyed to the upper part of the split-tube reactor and is sprayed by a distributor located at the top in the reactor so as to be uniformly distributed on the surface of the solid catalyst and react with hydrogen; after circular reaction through the three-level reactor, the hydrogenating conversion rate is close to 100%. According to the method, the production of methylhexahydrophthalic anhydride by means of continuous hydrogenation is realized, the technical process is clean and the catalyst is reused.

Owner:河南惠成新材料有限公司

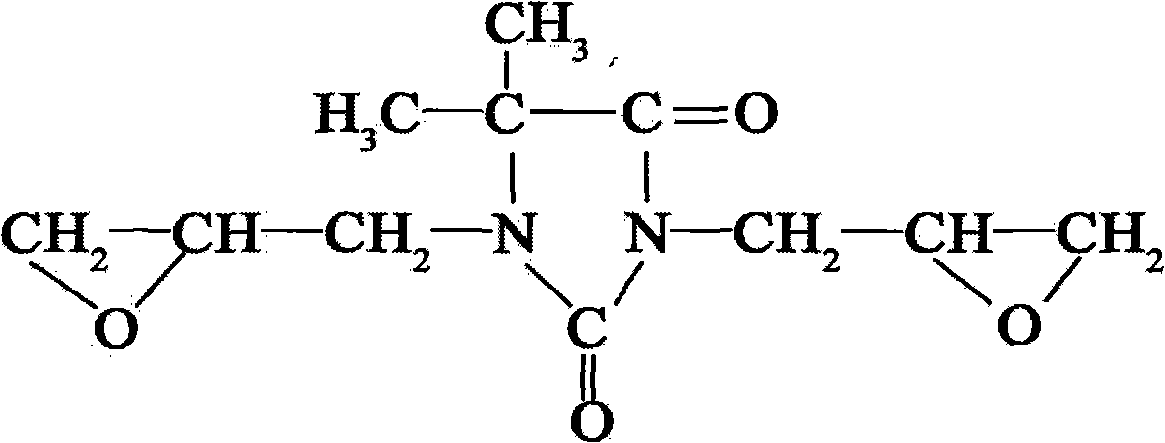

DOPO-modified anhydride-epoxy resin flame-retardation curing agent and preparation method thereof

InactiveCN107383340AWith flame retardant effectLow toxicityGroup 5/15 element organic compoundsEpoxyChemical synthesis

The invention relates to a DOPO-modified anhydride-epoxy resin flame-retardation curing agent and a preparation method thereof, which relate to a chemical compound and a preparation method thereof. The curing agent comprises the following raw materials: DOPO and 2-methyl tetrahydrophthalic anhydride; and the preparation process of the flame-retardation curing agent is simple, the flame-retardation curing agent is prepared by only one step, the method is characterized in that under inert gas atmosphere, DOPO, 2-methyl tetrahydrophthalic anhydride and a solvent are mixed and reacted at certain temperature for several hours, rotary evaporation is carried out to remove the solvent to obtain the product; or the materials are reacted for several hours under solvent-free condition, then the materials are cooled to room temperature to obtain the required product, the obtained products under different ratio conditions are colorless liquid to light yellow liquid. The flame-retardation curing agent is better mixed with epoxy resin, can be cured into a whole body with epoxy resin, can be taken as the curing agent of epoxy resin, and can effectively increase the flame retardation performance of the epoxy resin, the preparation method is simple, and the modified anhydride curing agents with different phosphorus contents can be prepared according to the requirements.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Pouring sealant for automobile igniter and preparation method and application thereof

ActiveCN102936479AAccelerate the process of localizationStrong resistance to crackingNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyCrack resistance

The invention discloses a pouring sealant for an automobile igniter and a preparation method and an application thereof. The pouring sealant for an automobile igniter is prepared by solidifying material A and material B with the mass ratio of 100:(15-50), wherein the material A consists of spare resin, 42mum fusion silica powder, 25mum fusion silica powder, an anti-settling agent, an antifoaming agent, a coupling agent and color paste; and the material B consists of methyl tetralin phthalic anhydride, hexahydrophthalic anhydride, polyether, di-hexyl tetramethyl imidazole and antioxygen. Through formulation of components with a specific proportion, the epoxy resin pouring sealant for automobile igniters produced by a special process is used for insulating and waterproof protective encapsulation of automobile igniters. The pouring sealant for an automobile igniter has the advantages of environmental change resistance to high pressure and high-low temperature, strong cracking resistance and long service life.

Owner:宜兴市普利泰电子材料有限公司

Heat conduction insulating casting glue and preparation method thereof

ActiveCN102093665BLow viscosityGood workmanshipInorganic insulatorsHeat-exchange elementsEpoxyTetrahydrophthalamic acid

The invention relates to a heat conduction insulating casting glue and a preparation method thereof. The casting compound comprises the following main components in parts by weight: (A) 100 parts of hydantoin epoxy resin, (B) 60-120 parts of anhydride curing agent, and (C) 200-400 parts of inorganic heat conductive filler, wherein the component A (per 100 weight parts) contains 10-15 weight partsof alcohol plasticizer; the component B is one or more of hexahydrophthalic anhydride, tetrahydrophthalic anhydride, methyltetrahydrophthalic anhydride, methylhexahydrophthalic anhydride and methylnadic anhydride; and the component C is one or more of silica micropowder, aluminum oxide, aluminum nitride and boron nitride in 300-900 meshes. The preparation method of the casting compound comprises the following steps: mixing A and B proportionally; soaking C in ethanol solution of silane coupling agent, dispersing at a high speed, filtering, and oven-drying; heating the mixture of A and B, adding C, mixing, and debubbling; and casing, and curing. The casting compound provided by the invention has low viscosity, greatly improved heat-conducting property and improved mechanical properties, and is convenient in casting. The preparation method of the casting compound is solvent-free, and has no pollution to the environment.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Low-temperature power battery based on conductive adhesive and preparation method and application of conductive adhesive

ActiveCN108165209APlay a reinforcing roleGood dispersionSmall-sized cells cases/jacketsFixed capacitor terminalsEpoxyFiber

The invention discloses a low-temperature power battery based on a conductive adhesive. The low-temperature power battery based on the conductive adhesive comprises a low-temperature power battery body based on the conductive adhesive, and a positive electrode terminal and a negative electrode terminal which are positioned on the two end surfaces of the battery body, wherein the conductive adhesive is arranged on the positive electrode terminal, or the negative electrode terminal or both the positive electrode terminal and the negative electrode terminal; the conductive adhesive comprises is prepared from the following raw materials in parts by mass: 10-30 parts of epoxy resin, 15-28 parts of butadiene styrene rubber, 3-12 parts of dimethylbenzene, 5-7 parts of methyltetrahydrophthalic anhydride, 27-75 parts of lignin fiber granule-modified silver powder. The low-temperature power battery based on the conductive adhesive has the advantages of uniform dispersion of a conductive medium and good electrical conductivity.

Owner:深圳名飞远科技有限公司

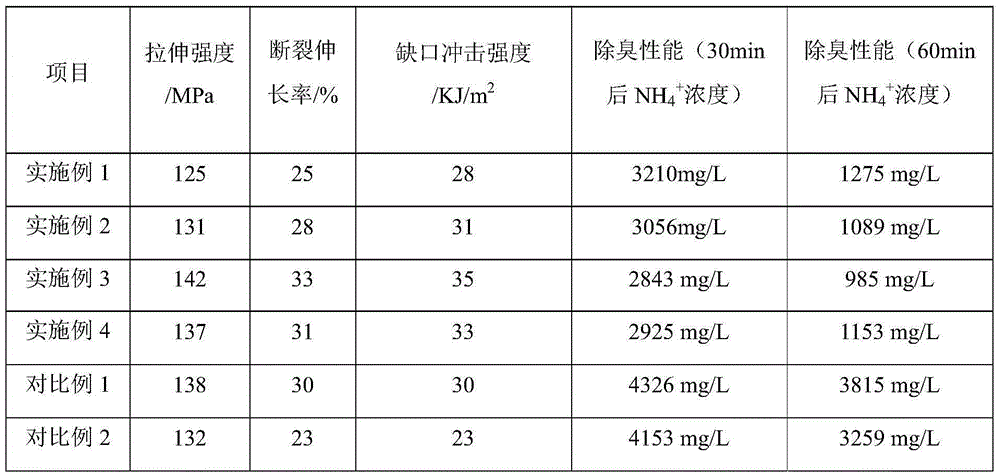

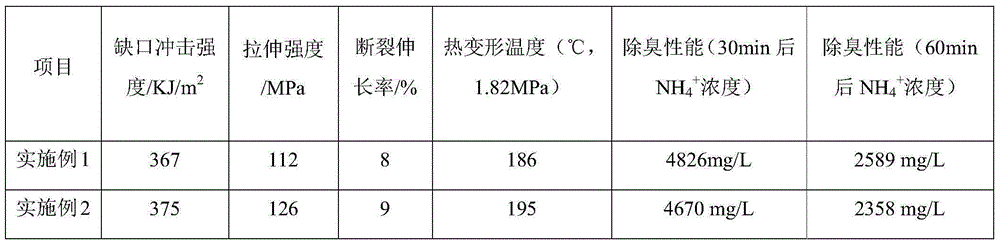

Preparation method of medical deodorization packaging material

The invention discloses a preparation method of a medical deodorization packaging material. According to the method, PVC (polyvinyl chloride), dioctyl phthalate, lauric acid, sodium tripolyphosphate, polycarbonate and barium stearate are added into a mixing stirring machine to be stirred and uniformly mixed; then, the materials are transferred into a reaction kettle; glass fiber, methyltetrahydrophthalic anhydride, aluminium oxide and 3-allene-2-acryloyloxy-1-potassium sulfonate are added; the materials are heated under the negative pressure condition to take reaction; the mixture is dried and crushed; then, ammonia gas is used for suffocating; finally, the extrusion forming is performed through a double-screw extruding machine; the medical deodorization packaging material is obtained. The deodorization packaging material prepared by the preparation method provided by the invention has good mechanical performance and deodorization performance, and can be better applied to the field of medical care and sanitation.

Owner:JIANGSU LANWAN BIOTECH

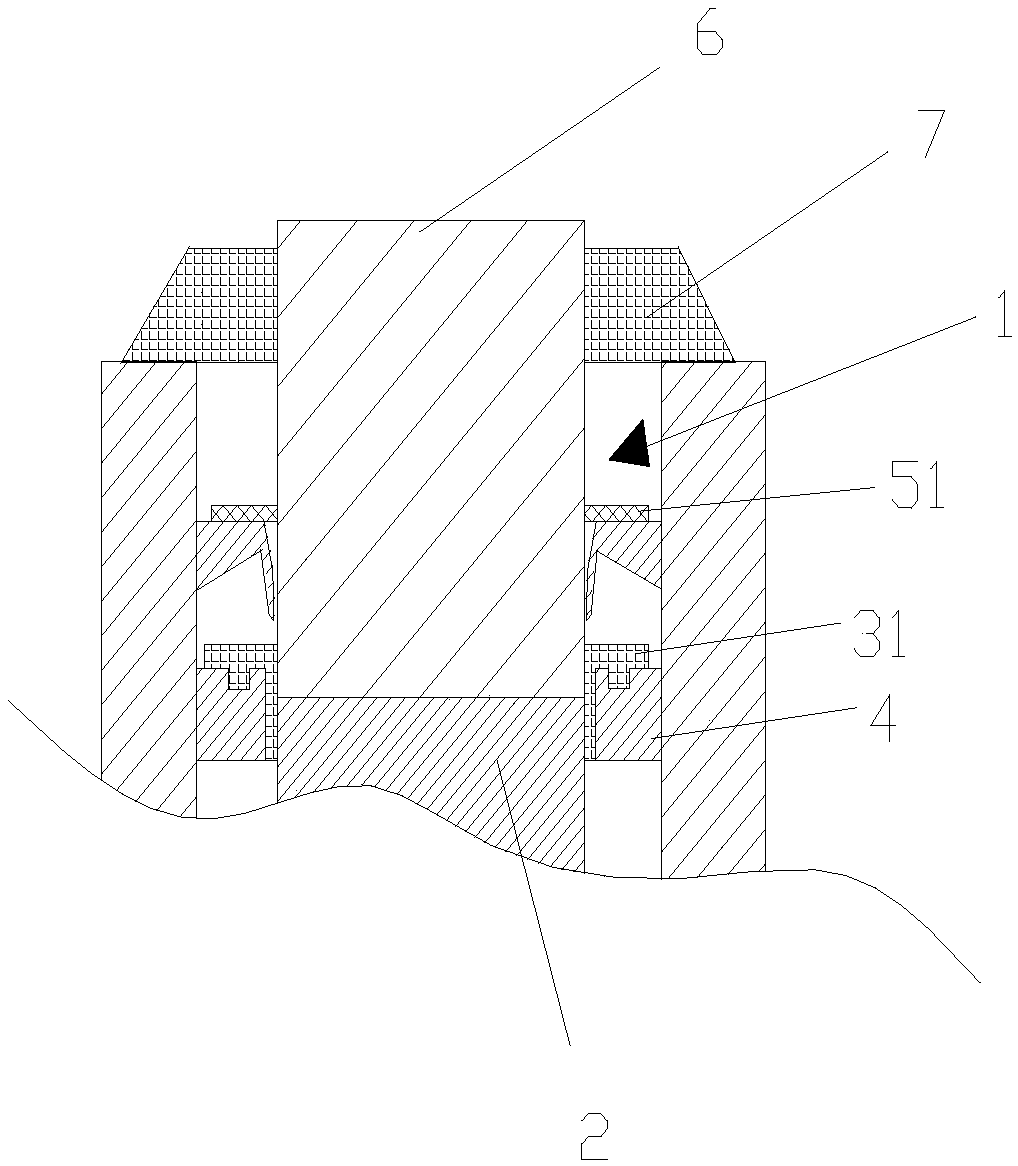

Toughening modified epoxy curing agent for dry-type transformer and preparation method of toughening modified epoxy curing agent

ActiveCN114853983APlay the role of toughening and strengtheningImprove impact resistanceChemical industryPolymer sciencePtru catalyst

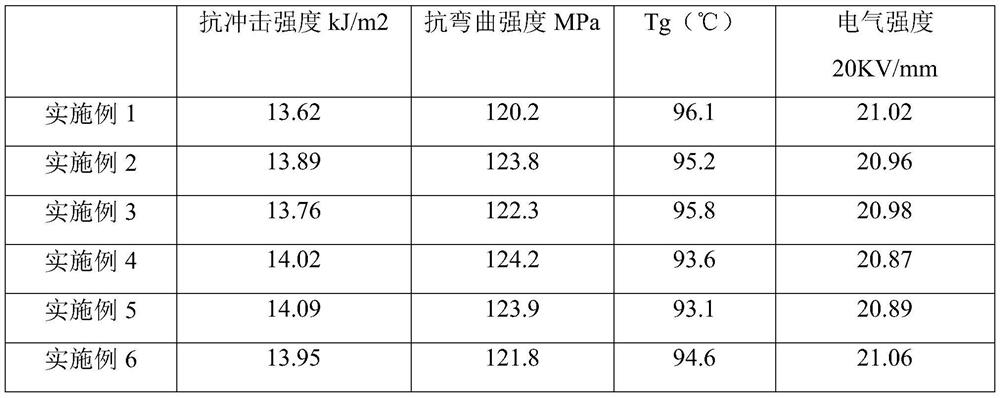

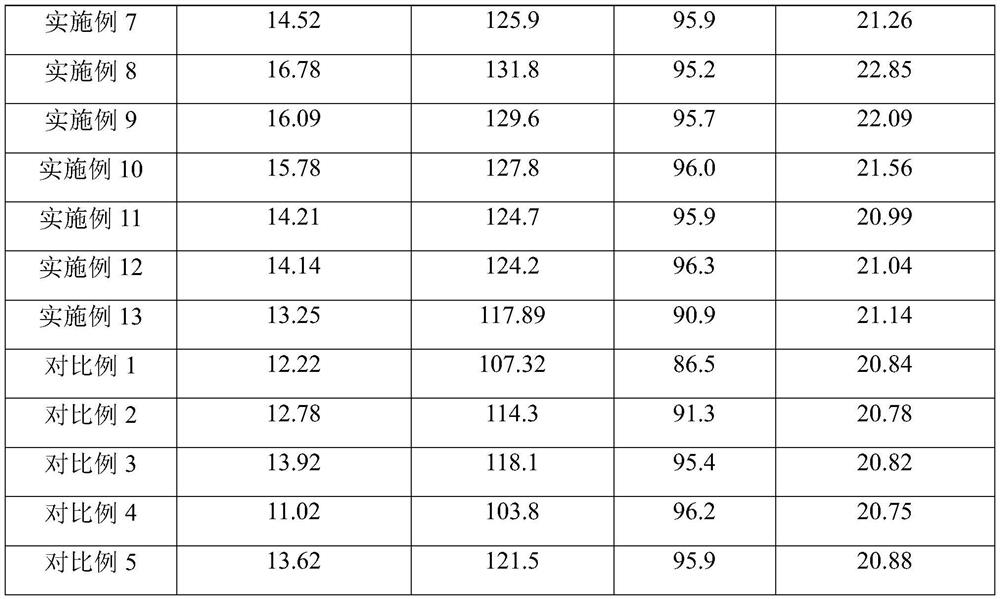

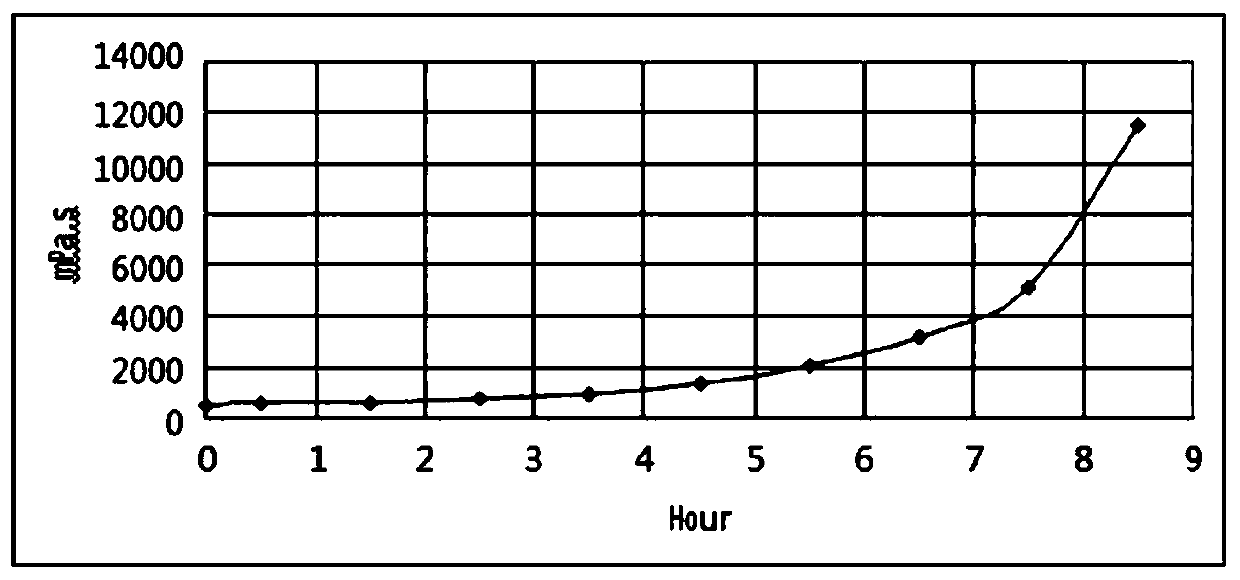

The invention relates to the technical field of epoxy hardeners, in particular to a toughening modified epoxy hardener for a dry-type transformer, a preparation method and an epoxy resin potting material prepared from the toughening modified epoxy hardener. The invention discloses a toughening modified epoxy curing agent for a dry-type transformer. The weight-average molecular weight of the toughening modified epoxy curing agent is 6000-8000. The toughening modified epoxy curing agent is prepared from the following raw materials: methyl tetrahydrophthalic anhydride, a catalyst and polyol; the weight-average molecular weight of the polyhydric alcohol is 2000 to 4000; the proportion of a trans structure in the methyl tetrahydrophthalic anhydride is controlled to be 35 to 45 percent. The toughened and modified epoxy curing agent can play a role in toughening and reinforcing the epoxy resin potting material, the impact strength can be improved by 8-20%, the bending strength can be improved by 15-20%, and the Tg temperature is controlled to be 90-100 DEG C.

Owner:嘉兴南洋万事兴化工有限公司

Flame-retardant high toughness epoxy resin casting material and preparation method thereof

InactiveCN110128788AGood mechanical properties of epoxyImprove mechanical propertiesCore shellToughness

The invention discloses a flame-retardant high toughness epoxy resin casting material. The epoxy resin casting material comprises 100 wt% of a resin and 80 wt% of a curing agent; the resin includes 5-85 wt% of a bisphenol A type epoxy resin 128 and 15-95 wt% of a core-shell toughening agent DY040; and the curing agent includes 1-40 wt% of methyltetrahydrophthalic anhydride, 1-60 wt% of methylhexahydrophthalic anhydride, 0.1-0.4 wt% of N,N-dimethylbenzylamine and 1-35 wt% of an OD-PN reactive flame retardant. The epoxy resin casting material has the good mechanical properties and good processability of the bisphenol A epoxy resin; and the curing agent of the epoxy resin system is modified, so the flame retardation performance of a cured material of the whole casting material is enhanced.

Owner:福建克雷斯波精细化工有限公司

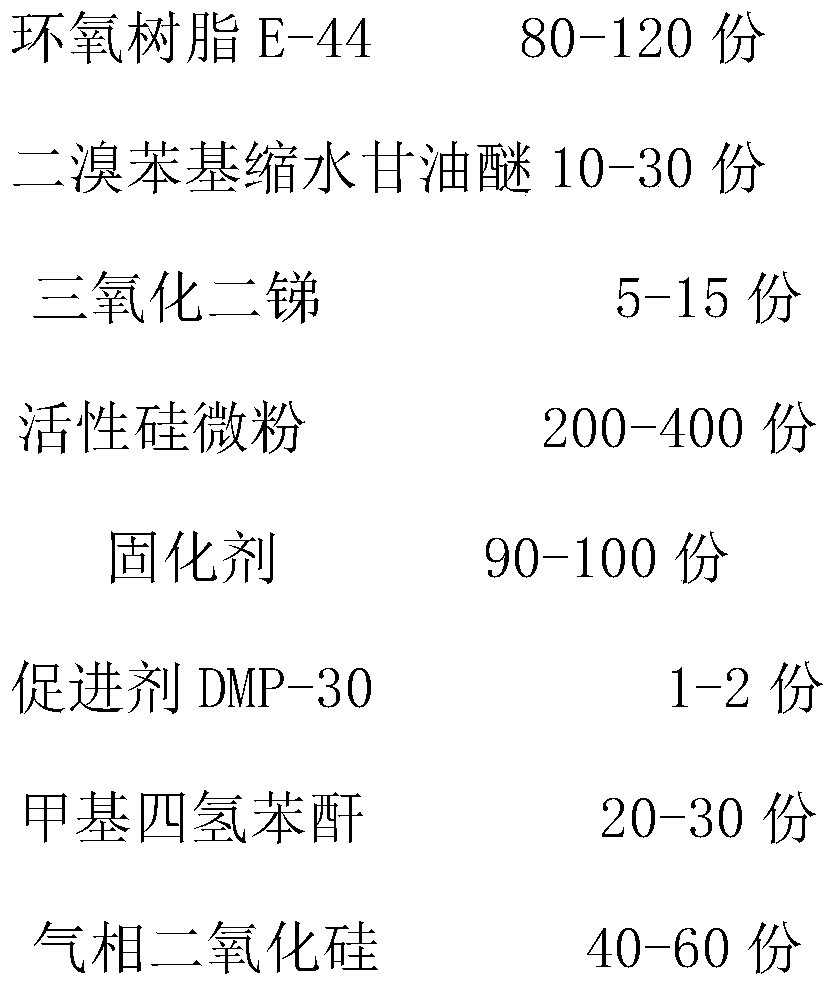

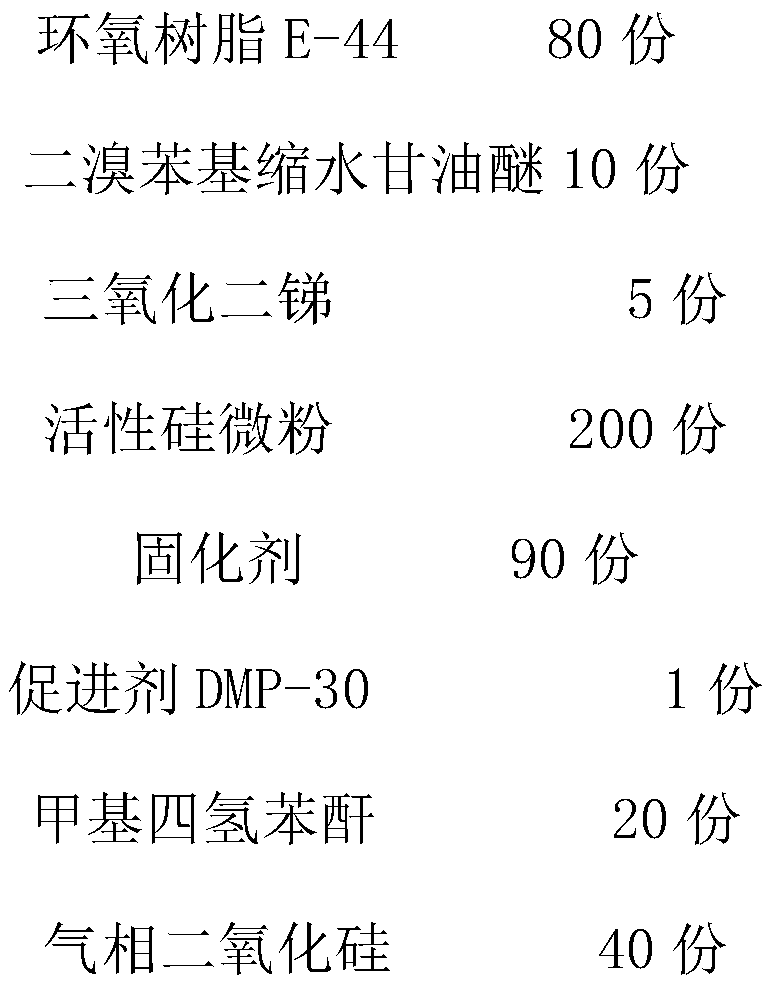

Environment-friendly insulating material

InactiveCN109880291AReduce sedimentation rateModerate viscosityEnvironmental resistanceAntimony trioxide

The invention discloses an environment-friendly insulating material. The insulating material comprises the following components in parts by weight: 80-120 parts of epoxy resin E-44, 10-30 parts of dibromophenyl glycidyl ether, 5-15 parts of antimonous oxide, 200-400 parts of active silica micropowder, 90-100 parts of a curing agent, 1-2 parts of an accelerant DMP-30, 20-30 parts of methyl tetrahydrophthalic anhydride and 40-60 parts of fumed silica. According to the invention, epoxy resin E-44, dibromophenyl glycidyl ether, antimonous oxide, active silica micropowder, the curing agent, the accelerant DMP-30 and methyltetrahydrophthalic anhydride are mixed for processing according to a specific ratio, thus the insulating material has a high-voltage insulating function, meanwhile, by addingfumed silica, the moderate viscosity of a system is guaranteed, the settling rate of silicon micropowder can be greatly reduced, and the situation that the insulating material is uneven in property, generates large internal stress and cracks is avoided.

Owner:DONGGUAN YUMAO NANO TECH

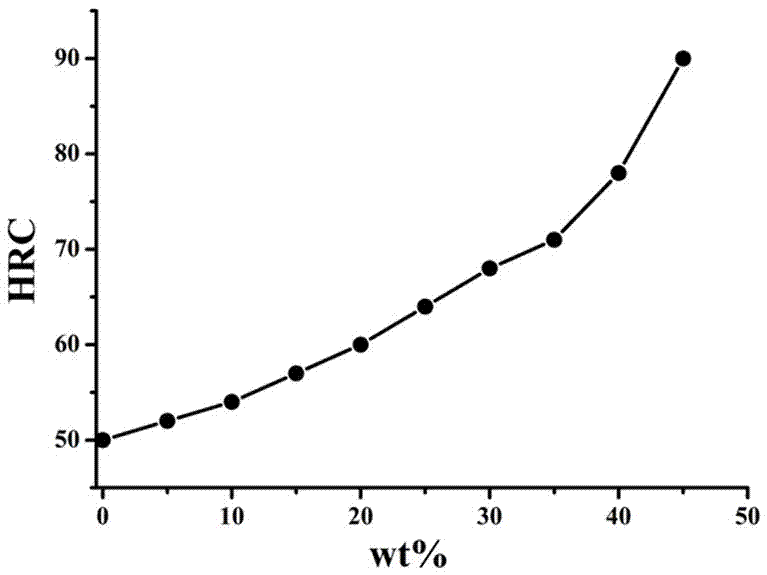

Novel consolidated nano-diamond butadiene grinding disc and preparation technology thereof

A novel consolidated nano-diamond butadiene grinding disc is manufactured by a basic raw material and added nano-diamond butadiene, wherein the basic raw material is prepared from the following components in percentage by weight: 55-60% of modified E-54 epoxy resins and methyl tetrahydrophthalic anhydride, 0.5-1% of N,N-dimethylbenzylamine, 3.5-4% of a plasticizer, 30-35% of a filler and 5-6% of a pore-forming agent, the addition quantity of the nano-diamond butadiene is 15-33wt% of the basic raw material, and the mass ratio of E-54 epoxy resins to methyl tetrahydrophthalic anhydride is 10:9. The consolidated nano-diamond butadiene grinding disc of the invention is high in processing efficiency; in the grinding process of the consolidated nano-diamond butadiene, the utilization rate of grinding materials is high, the cost is low and the pollution to environment is low; and after the grinding of the consolidated nano-diamond butadiene grinding disc, the grinding materials cannot be embedded into the surface of a processed workpiece, and the subsequent cleaning and processing of the workpiece are conveniently carried out.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

High-temperature-resistant electrical wiring harness protective sleeve

InactiveCN109897252AExtended service lifeGuaranteed stabilityRubber insulatorsPhytic acidEngineering

The invention relates to a high-temperature-resistant electrical wiring harness protective sleeve. The high-temperature-resistant electrical wiring harness protective sleeve is characterized in that the components of the electrical wiring harness protective sleeve are as follows in parts by weight: 20-30 parts of rubber, 20-30 parts of phytic acid, 10-15 parts of alkenyl succinate, 5-10 parts of polycarbonate, 5-10 parts of zinc borate, 1-2 parts of methyltetrahydro phthalic anhydride, 1-2 parts of coupling agent, 0.5-1 part of anti-aging agent, 0.2-0.5 part of antistatic agent and 0.5-1 partof sulfur. The high-temperature-resistant electrical wiring harness protective sleeve involved in the invention has the advantages that the problems that a signal or power source transmitted by an electrical wiring harness is unstable or even unable to be transmitted in a humid environment, dust is easily subjected to electrostatic adsorption, and the electrical wiring harness is easy to burn at high temperature are solved; and the protective sleeve prolongs the service life of the electrical wiring harness, and ensures stability and continuity of power source and signal transmission by the electrical wiring harness.

Owner:常州德瑞电子有限公司

Preparation method of high temperature resistant medical deodorization material

The invention discloses a preparation method of a high temperature resistant medical deodorization material. The preparation method comprises the steps of firstly adding PVC, PET, dioctyl phthalate, lecithin, polycarbonate and barium stearate into a mixer, stirring and mixing uniformly, then adding the mixture into a reaction still, adding fiberglass, 3a-methyl-5,6-dihydro-4H-isobenzofuran-1,3-dione, aluminium oxide, polyester fiber and potassium 3-sulphonatopropyl acrylate, heating and stirring under a negative pressure condition, then performing temperature rise reaction under a normal pressure condition, then cooling to 0 DEG C, then drying, smashing, stifling by using ammonia gas, and then performing extrusion molding in a twin-screw extruder, thus obtaining the high temperature resistant medical deodorization material. The high temperature resistant medical deodorization material prepared by the preparation method provided by the invention has good high temperature resistance and deodorization performance, thus further expanding the application of the material.

Owner:JIANGSU LANWAN BIOTECH

Anti-aging flame-retardant corrugated pipe

InactiveCN109749329AExtended service lifeReduce manufacturing costSodium fluorosilicateFire retardant

The invention relates to an anti-aging flame-retardant corrugated pipe. The anti-aging flame-retardant corrugated pipe comprises the following components in parts by weight: 15-25 parts of coumarone resin, 15-20 parts of polypropylene resin, 10-15 parts of calcium stearate, 5-10 parts of sodium fluorosilicate, 3-7 parts of aluminum oxide micropowder, 2-5 parts of triethylene glycol diisooctanoate,1-3 parts of methyl tetrahydrophthalic anhydride, 1-2 parts of a curing agent, 1-3 parts of an anti-aging agent and 0.5-2 parts of a flame retardant. The anti-aging flame-retardant corrugated pipe has the advantages of low manufacturing cost, good anti-aging effect, prolonged service life of the corrugated pipe and wide application prospect.

Owner:丹阳贝尔特传动科技有限公司

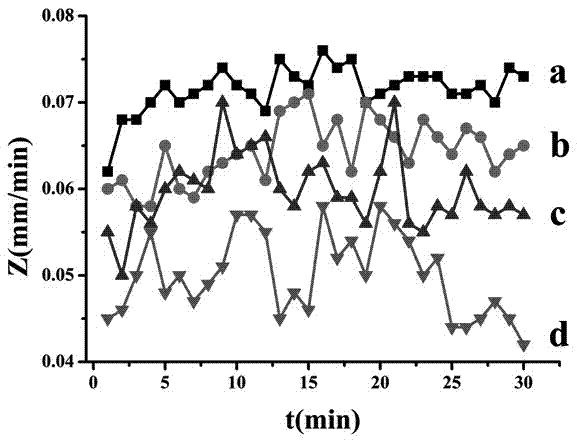

Preparation method for improving conductivity of composite epoxy resin matrix

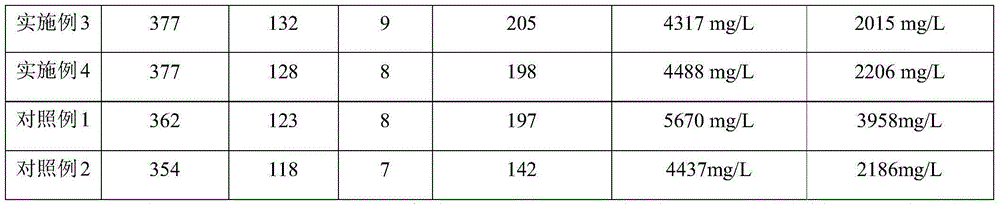

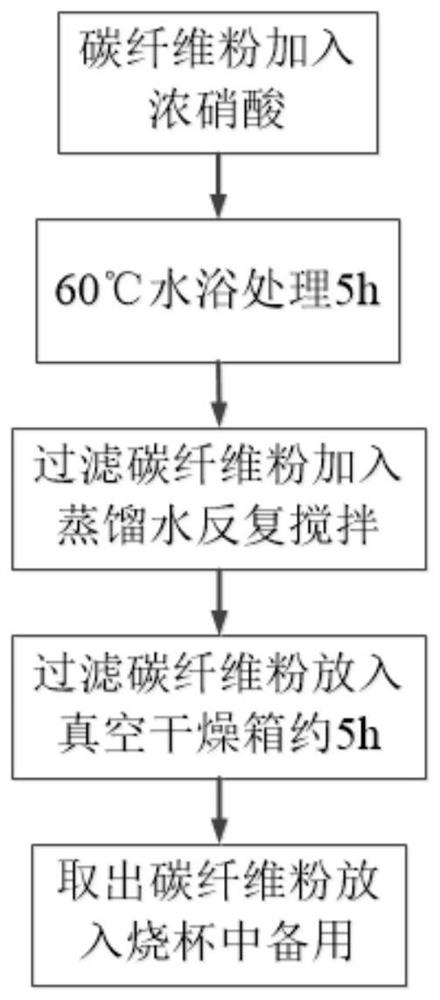

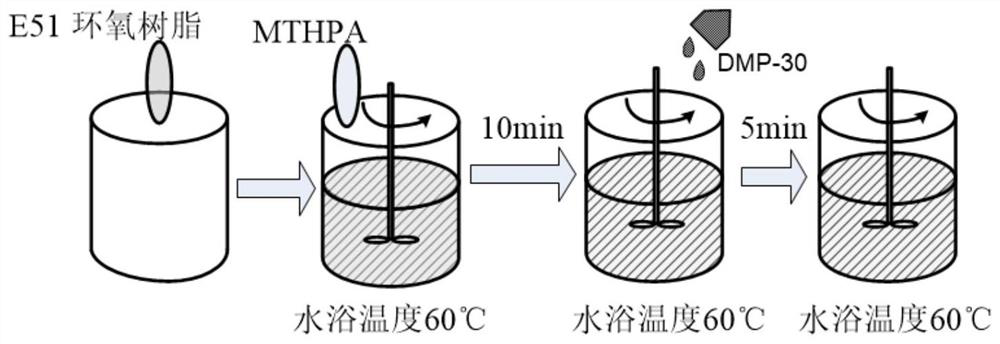

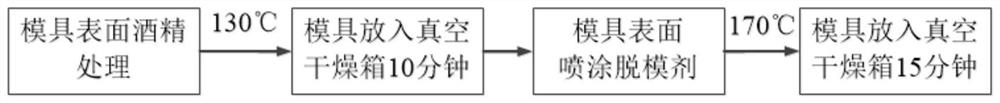

The invention relates to a preparation method for improving the conductivity of a composite epoxy resin matrix. The preparation method specifically comprises the following steps: S1, weighing raw materials in proportion, S2, putting carbon fiber powder into nitric acid, washing the carbon fiber powder with pure water to remove nitric acid, and putting the carbon fiber powder into a vacuum drying oven for drying treatment, S3, putting epoxy resin and a methyl tetrahydrophthalic anhydride curing agent into a flask, stirring and then adding DMP-30 into the flask, S4, treating the surface of a metal mold with ethyl alcohol, then putting the metal mold into a vacuum drying box to be dried, spraying a release agent to the surface of the metal mold, and then putting the metal mold into the vacuumdrying box again to be subjected to vulcanization treatment, and S5, adding the mixed solution of the carbon fiber powder and the epoxy resin matrix into a ball mill to be fully mixed, then introducing the fully mixed solution into the vulcanized metal mold to wait for molding, and carrying out demolding treatment after molding to obtain the modified epoxy resin matrix.

Owner:HEFEI UNIV OF TECH +1

Method for preparing 4-methyl benzene anhydride

The invention discloses a method for preparing 4-methyl benzene anhydride. The method comprises utilizing 4-methyl-1,2,3,6-tetra hydro phthalic anhydride as raw materials, and performing dehydrogenation on raw materials through the bromine to prepare the 4-methyl benzene anhydride. RCOOM or R(COOM)2 is utilized in the dehydrogenation reaction to serve as an acid-binding agent, quaternary ammonium salt is utilized to serve as a phase transfer catalyzer, benzene, chlorobenzene, orthodichlorobenzene, dibutyl ether and diisopropyl ether are utilized to serve as solvents, and the feeding molar ratio of 4-methyl tetrahydrophthalic anhydride to the acid-binding agent to the bromine is 1:2-4.4:2-2.2. The method is simple in synthesis process, less in wastewater, few in waste gases and residues, high in yield and suitable for industrialization production.

Owner:BEILI CHEM ZHANGJIAGANG

Molding resin for improving insulation performance and heat deformation temperature of outdoor electrical appliance, and preparation method thereof

PendingCN109575256AHigh tensile strengthHigh modulus of elasticity in tensionHeat deflection temperaturePlasticizer

The invention discloses molding resin for improving the insulation performance and heat deformation temperature of an outdoor electrical appliance. The molding resin comprises 28.5-37.5 parts of diol,3-4.5 parts of phthalic anhydride, 21.5-26.5 parts of maleic anhydride, 4-8.5 parts of methyltetrahydrophthalic anhydride, 23-28 parts of styrene, 0.07-0.13 part of polymerization inhibitor, 0.08-0.41 part of retarder, 0.08-0.11 of antioxidant, 0.18-0.35 part of plasticizer and 7-15 parts of chelating agent. The invention also discloses a preparation method of the molding resin for improving theinsulation performance and heat deformation temperature of the outdoor electrical appliance.

Owner:镇江利德尔复合材料有限公司

Novel fiberboard with heat storage function

ActiveCN113858373AImprove heat transfer performanceImprove the wrapping effectHeat-exchange elementsFlat articlesBenzoic acidCellulose

The invention discloses a novel fiberboard with a heat storage function, and relates to the technical field of fiberboard processing. A method comprises the following steps that (1), sodium alginate and chitosan are adopted as wall materials, pretreated flaky aluminum oxide particles obtained after stearic acid surface treatment are introduced, and an outer wall material solution is obtained; (2), the pretreated zirconium oxide nanoparticles modified by benzoic acid are introduced into a polyacrylate emulsion, and a polymerization reaction is carried out with a phase change material, an initiator and an aqueous solution containing a dispersant and a surfactant to form a suspension; (3), the outer wall material solution is dropwise added into the suspension, and a glutaraldehyde solution is added to obtain a capsule phase change material; and (4), the plant fiber, the capsule phase change material, solid paraffin, urea-formaldehyde resin adhesive, carboxymethyl cellulose and methyl tetrahydrophthalic anhydride are evenly mixed and then laid, and the fiberboard with the heat storage function is obtained. The fiberboard is excellent in performance, and the heat release time is prolonged by 85% or above compared with a common fiberboard.

Owner:阜阳大可新材料股份有限公司

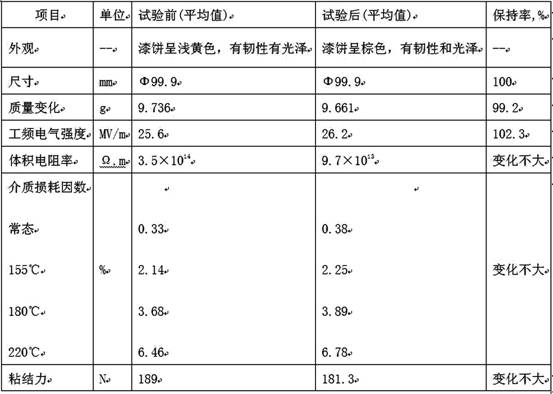

High heat-resistant environment-friendly refrigerant-resistant insulating impregnation resin and preparation method thereof

ActiveCN111440518BAvoid pollutionNon-volatileFireproof paintsEpoxy resin coatingsEpoxyPolymer science

The invention belongs to the technical field of electrical insulating impregnating varnish, and provides a high heat-resistant and environment-friendly refrigerant-resistant insulating impregnating resin and a preparation method thereof. It is prepared from unsaturated polyester resin; imide epoxy resin solution with a solid content of 50%~60%; crosslinking agent; curing agent; initiator and polymerization inhibitor according to a certain proportion, the raw material of unsaturated polyester resin The formula includes a first monomer and a second monomer, the first monomer is one or more selected from diethylene glycol, propylene glycol, and neopentyl glycol; the second monomer is selected from butene One or more of dianhydride and phthalic anhydride, tetrahydrophthalic anhydride, methyltetrahydrophthalic anhydride, isophthalic acid and adipic acid. The insulation impregnation resin of the present invention is resistant to high temperature of 240°C, has no volatilization, no odor, low VOC content, is resistant to new refrigerants such as R134a and R1234ze, and can be used for impregnation and insulation treatment of various high and low voltage refrigerant-resistant motors, transformers and other motor electrical winding coils.

Owner:山西博拉哲绝缘技术有限公司

Pouring sealant for automobile igniter and preparation method and application thereof

ActiveCN102936479BAccelerate the process of localizationStrong resistance to crackingNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyCrack resistance

The invention discloses a pouring sealant for an automobile igniter and a preparation method and an application thereof. The pouring sealant for an automobile igniter is prepared by solidifying material A and material B with the mass ratio of 100:(15-50), wherein the material A consists of spare resin, 42mum fusion silica powder, 25mum fusion silica powder, an anti-settling agent, an antifoaming agent, a coupling agent and color paste; and the material B consists of methyl tetralin phthalic anhydride, hexahydrophthalic anhydride, polyether, di-hexyl tetramethyl imidazole and antioxygen. Through formulation of components with a specific proportion, the epoxy resin pouring sealant for automobile igniters produced by a special process is used for insulating and waterproof protective encapsulation of automobile igniters. The pouring sealant for an automobile igniter has the advantages of environmental change resistance to high pressure and high-low temperature, strong cracking resistance and long service life.

Owner:宜兴市普利泰电子材料有限公司

Anti-corrosion spraying mechanical arm

ActiveCN105820709AImprove corrosion resistanceQuality improvementSpraying apparatusAnti-corrosive paintsEpoxySilanes

The invention discloses an anti-corrosion spraying mechanical arm. The anti-corrosion spraying mechanical arm comprises a metal base, a polymer coating and an anti-corrosion coating, wherein the polymer coating contains the following ingredients: epoxy resin, modified graphene, methyltetrahydrophthalic anhydride, feldspar powder, silica and methyl acryloyloxy trimethoxy silane, and the anti-corrosion coating comprises TiO2, TiN, SiC, Ni and Fe. The anti-corrosion spraying mechanical arm has the advantages that binding force between layers is good, the surface of the prepared spraying mechanical arm is good in corrosion resistance and quality, and the service life of the spraying mechanical arm is prolonged.

Owner:HEXIAN LONGSHENG PRECISION MACHINERY CO LTD

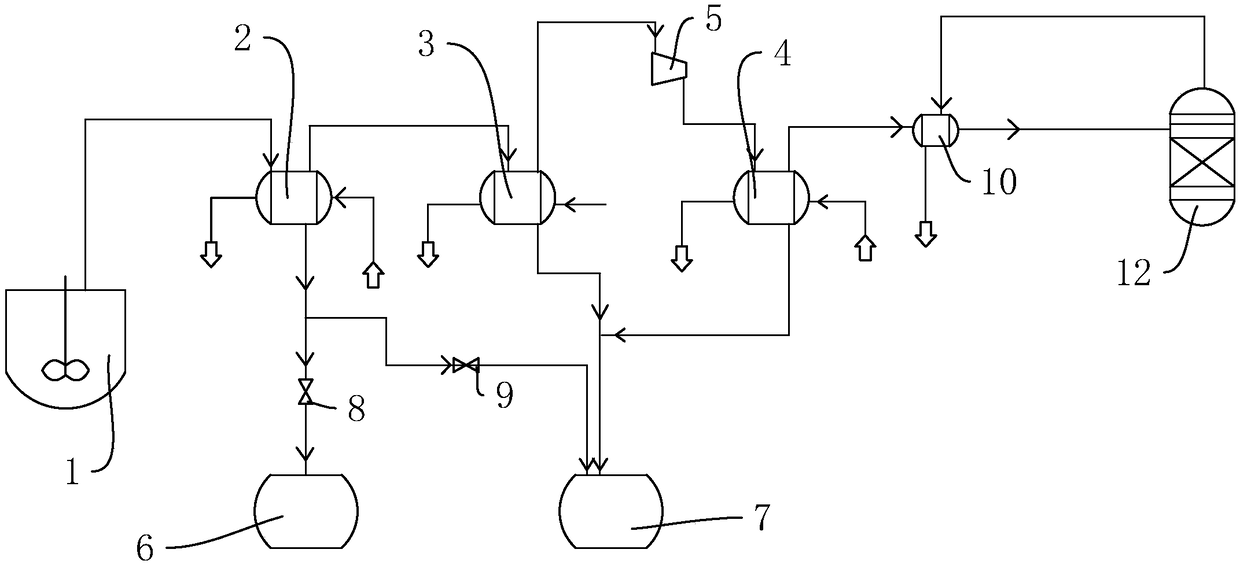

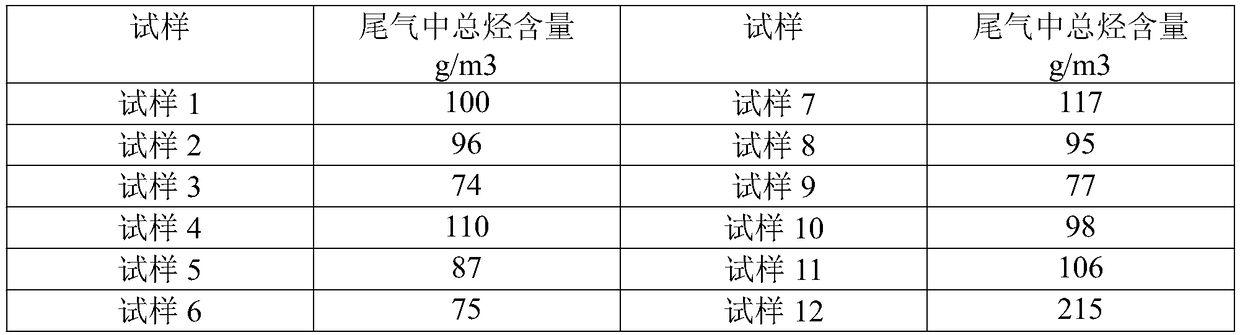

Condensation recovery process of pentadiene in production of methyl tetrahydrophthalic anhydride

InactiveCN109134183AEasy to condenseHigh recovery rateDistillation purification/separationHydrocarbonsAlcoholMethyltetrahydrophthalic anhydride

The invention relates to a condensation recovery process of pentadiene in the production of methyl tetrahydrophthalic anhydride, and belongs to the technical field of gas condensation recovery. The technical key points include: step A, pentadiene steam passes through a primary condenser, a coolant is circulating water, liquid pentadiene enters a recovery tank from the bottom of the condenser, andthe residual gas is discharged from the upper end of the condenser; step B, the residual gas enters a secondary condenser, the coolant is a salt and alcohol solution, liquid pentadiene enters the recovery tank from the bottom of the condenser, and the residual gas is discharged from the upper end of the condenser; and step C, the residual gas is pressurized and then enters a tertiary condenser, liquid pentadiene enters the recovery tank from the bottom of the condenser, and the residual gas enters a tail gas treatment device. The condensation recovery process of pentadiene in the production ofmethyl tetrahydrophthalic anhydride has the advantages of simple operation, improved pentadiene recovery rate through multistage condensation, and improved energy utilization rate through heat exchange between material flows.

Owner:嘉兴南洋万事兴化工有限公司

A graphene RFID electronic tag suitable for gravure printing

ActiveCN113789082BImprove mobilityTransfer in timeInksRecord carriers used with machinesEpoxyToluene diisocyanate

This application relates to the technical field of RFID electronic tags, and specifically provides a graphene RFID electronic tag suitable for gravure printing, including a substrate and a graphene conductive paste printed on the substrate by gravure printing, The graphene conductive paste comprises the following components by weight: 5-10 parts of graphene, 1-3 parts of surfactant, 5-10 parts of dispersant, 15-25 parts of cured resin; the mass ratio of cured resin is (70 ~90): (10~30): (18~23): (1.8~5.5): (0.5~1.6) o-cresol novolac epoxy resin, polyurethane, methyl tetrahydrophthalic anhydride, trimethylolpropane and toluene ‑2,4‑diisocyanate is prepared; the surfactant includes sodium dodecylbenzenesulfonate and sodium fatty alcohol polyoxyethylene ether sulfate with a mass ratio of (0.5~0.8): (1.2~1.5). The graphene slurry provided by this application is dispersed in a cured resin in the presence of a specific surfactant, and then supplemented with a specific dispersant and auxiliary agent to make a printing slurry for the gravure printing technology to prepare RFID electronic tags Antistatic.

Owner:SHANDONG HUAGUAN SMART CARD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com