Patents

Literature

38results about How to "Well distributed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-insoluble modified polyvinyl alcohol coating liquor and its preparation process

The invention discloses an insoluble modified polyvinyl alcohol coating liquid and preparing method and film through the coating liquid, which comprises the following parts: polyvinyl alcohol, modifier, inorganics, crosslinking agent, catalyst and water. The coating liquid improves levelling, adhering and even property greatly, which increases obstruct property for kinds of gas.

Owner:刘建林

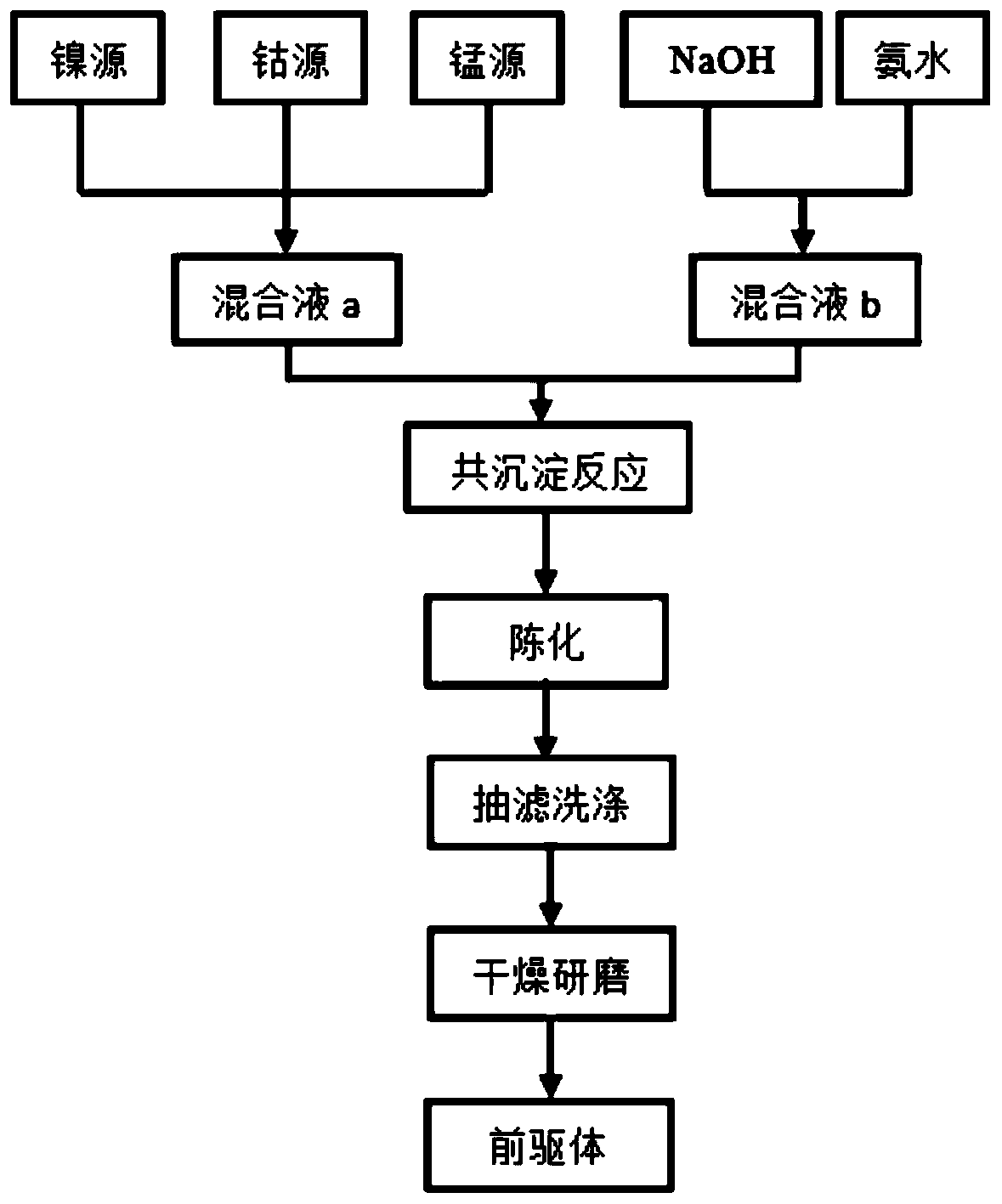

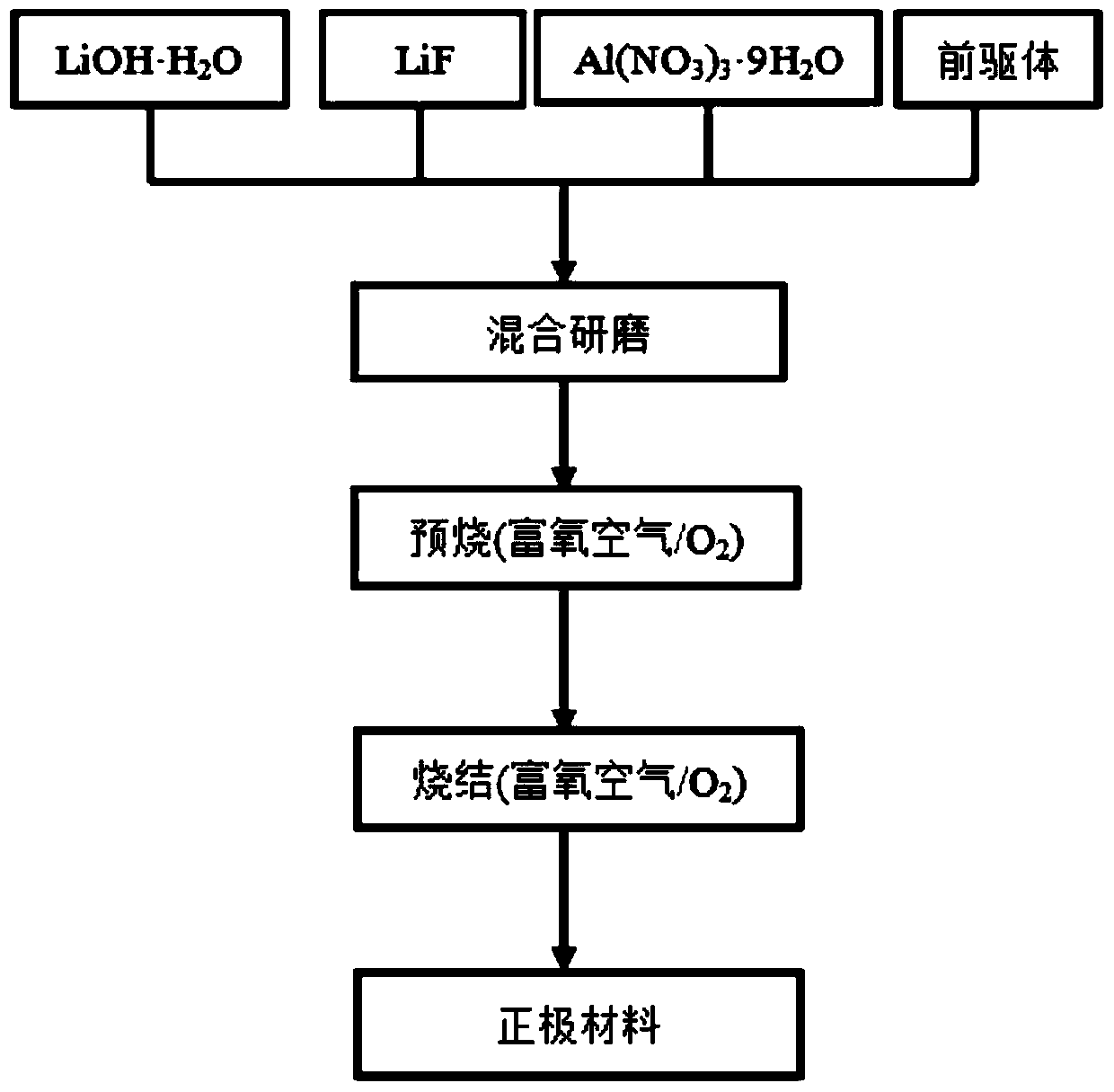

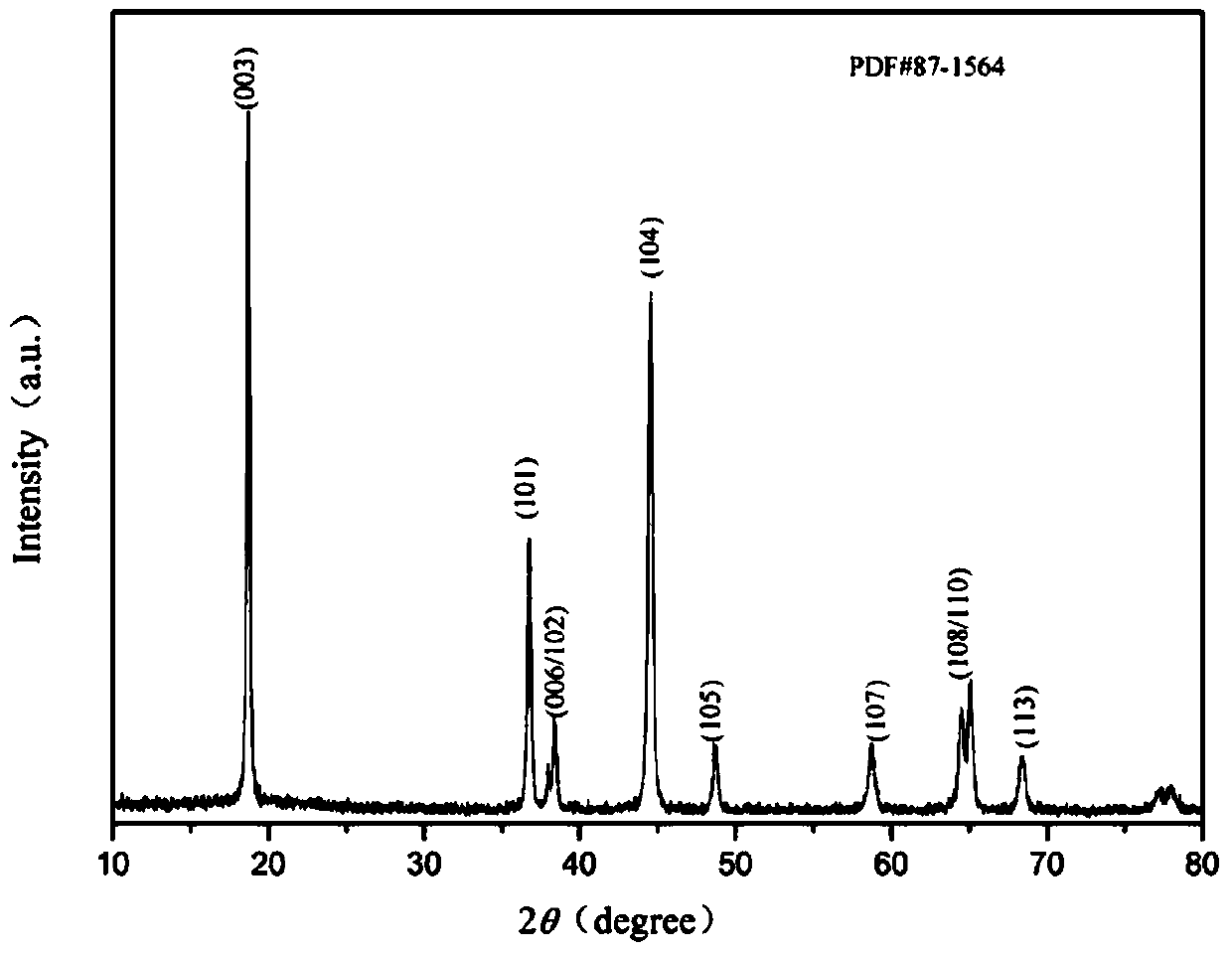

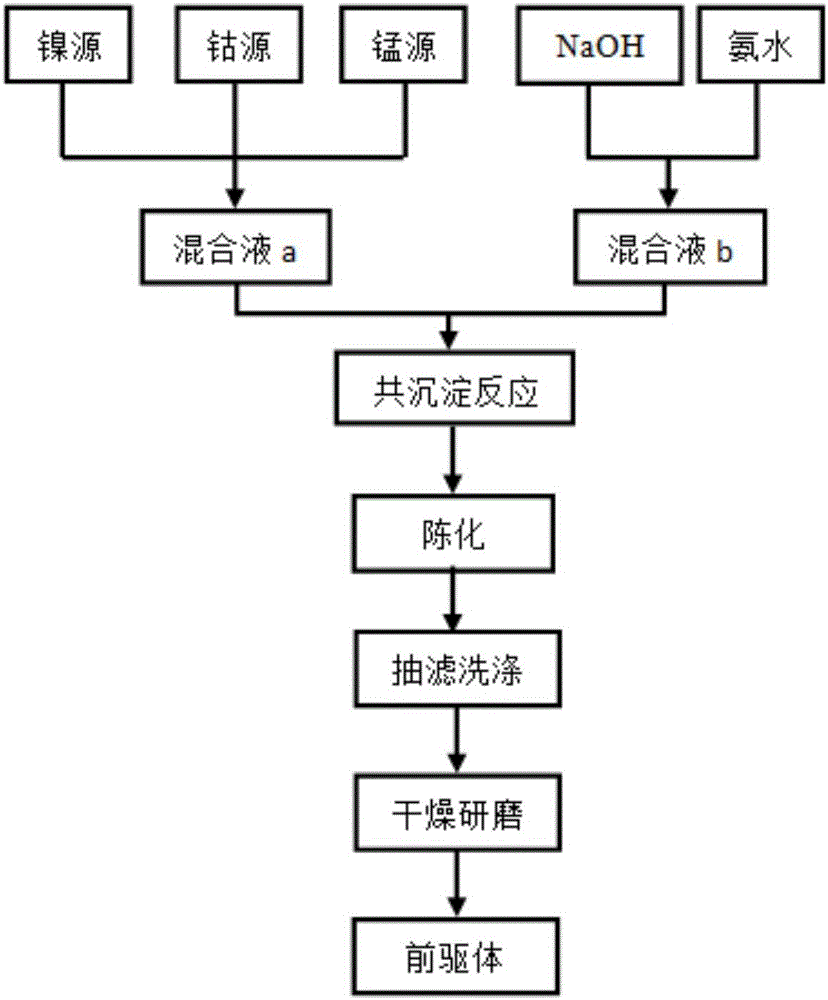

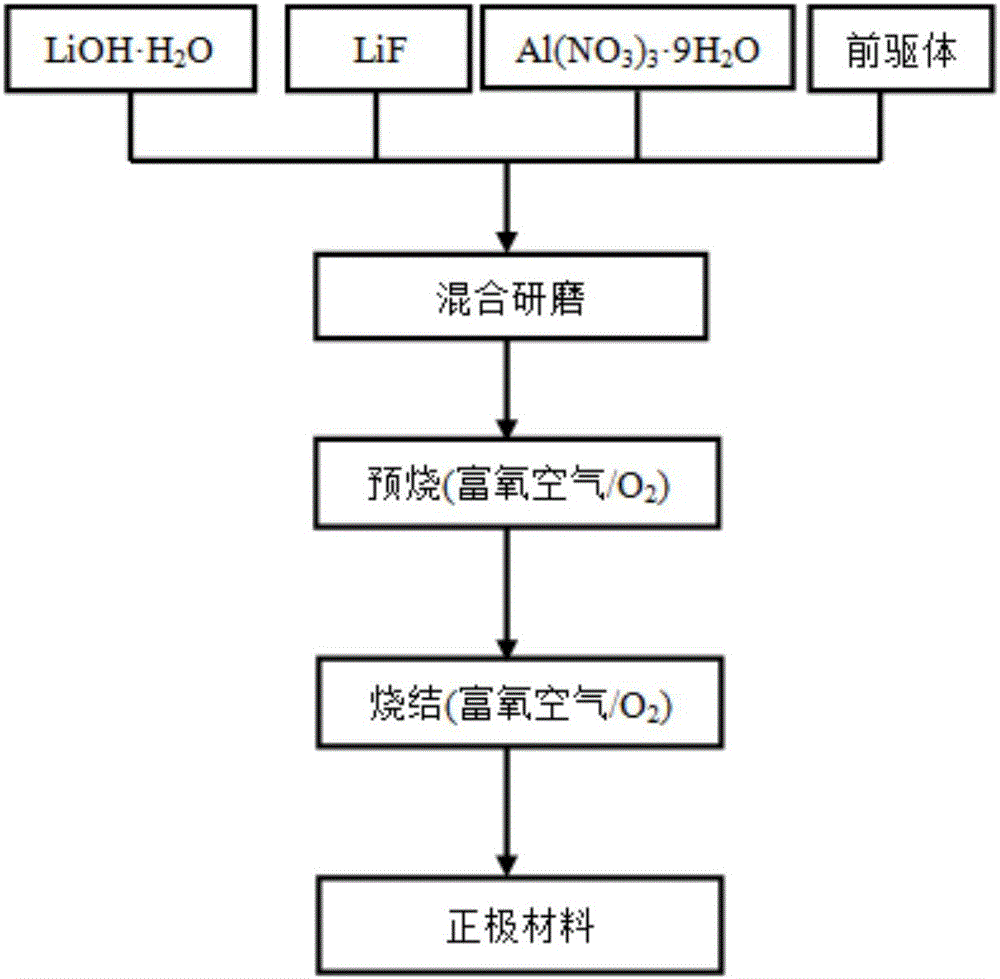

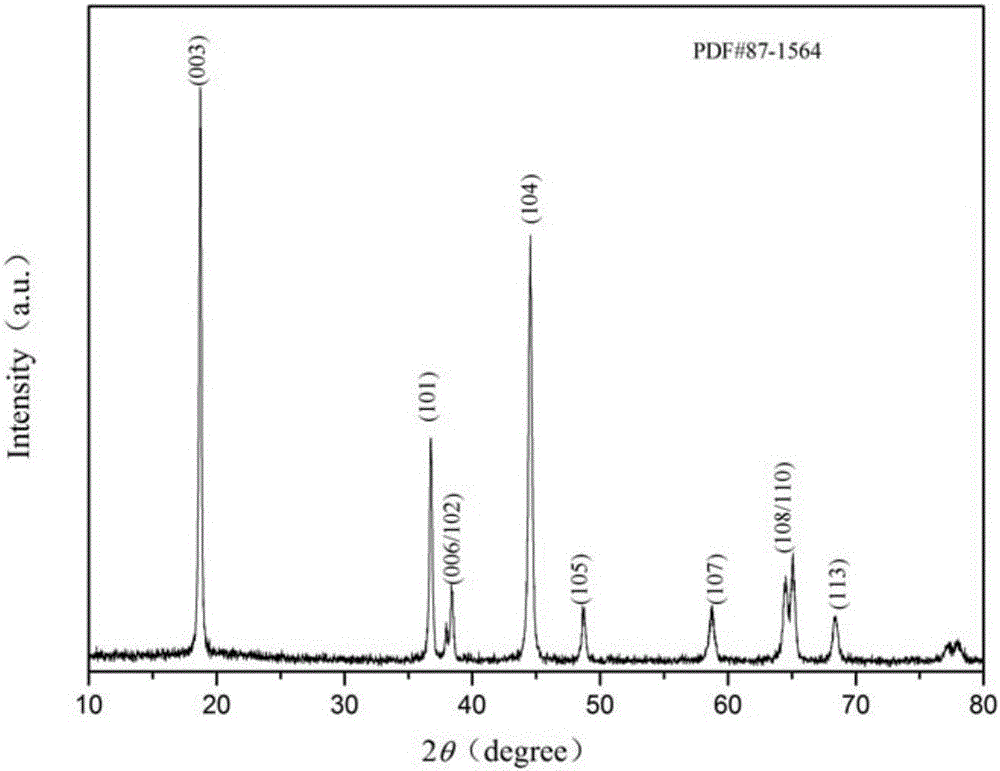

LiNi0.6-xCo0.2Mn0.2AlxO2-yFy positive electrode material for lithium ion cell and preparation method thereof

ActiveCN105990577AImprove structural stabilityHigh discharge specific capacityCell electrodesSecondary cellsAluminiumSpecific discharge

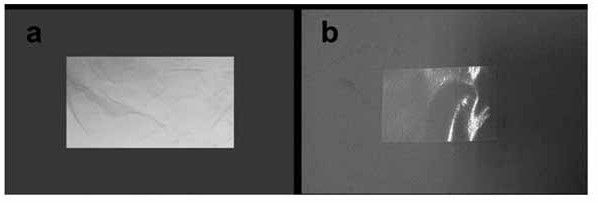

The invention belongs to the field of lithium ion cell and specifically relates to a LiNi0.6-xCo0.2Mn0.2AlxO2-yFy positive electrode material for the lithium ion cell and a preparation method thereof. X is more than 0 and y is less than or equal to 0.05. The positive electrode material is used for overcoming the defect of poor electrochemical performance of the Ni-Co lithium manganate ternary positive electrode material. According to the invention, a minute quantity of aluminum and fluorine are doped, so that the positive electrode material for the lithium ion cell has higher specific discharge capacity and excellent cycle performance; under a room temperature environment, when the voltage scope is 2.7-4.3V and the constant current charge-discharge multiplying power is 0.5C, the specific discharge capacity of the material at the first time can reach 187.9mAh g<-1>, and after circulation for 20 times, the specific discharge capacity still can reach 192.1mAh g1 and the capacity retention ratio reaches up to 102.2%; when the voltage scope is increased to 2.7-4.5V and the constant current charge-discharge multiplying power is 0.5C, the initial specific discharge capacity of the material can reach 225.8mAh g<-1>, and after circulation for 20 times, the specific discharge capacity still can reach 190.2mAh g<-1> and the capacity retention ratio reaches up to 84.2%. The preparation technique of the material is simple and controllable, the product purity is high, the chemical uniformity is high, the crystal quality is high, the product grain is small and the size distribution is uniform.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Modified PVA paint and its prepn process

InactiveCN1847334APrevent penetrationImprove densification performanceCoatingsPolymer scienceUltraviolet

The present invention discloses one kind of modified PVA paint, which consists of PVA, regulator, inorganic matter, tackifier and water. The tackifier is polyethylene imine and / or polyoxyethylene; the inorganic matter is clay and / or nanometer titania or the mixture of clay, nanometer silica and nanometer titania. The preparation process includes mixing PVA, regulator, inorganic matter, and water through stirring, heating to and maintaining at 90-95 deg.c to dissolve PVA completely, cooling to normal temperature, and adding tackifier through stirring. The product of the present invention has excellent machinability, and the formed coating has high water resistance, excellent ultraviolet ray and infrared ray reflecting property, high wear resistance and other excellent performance.

Owner:刘建林

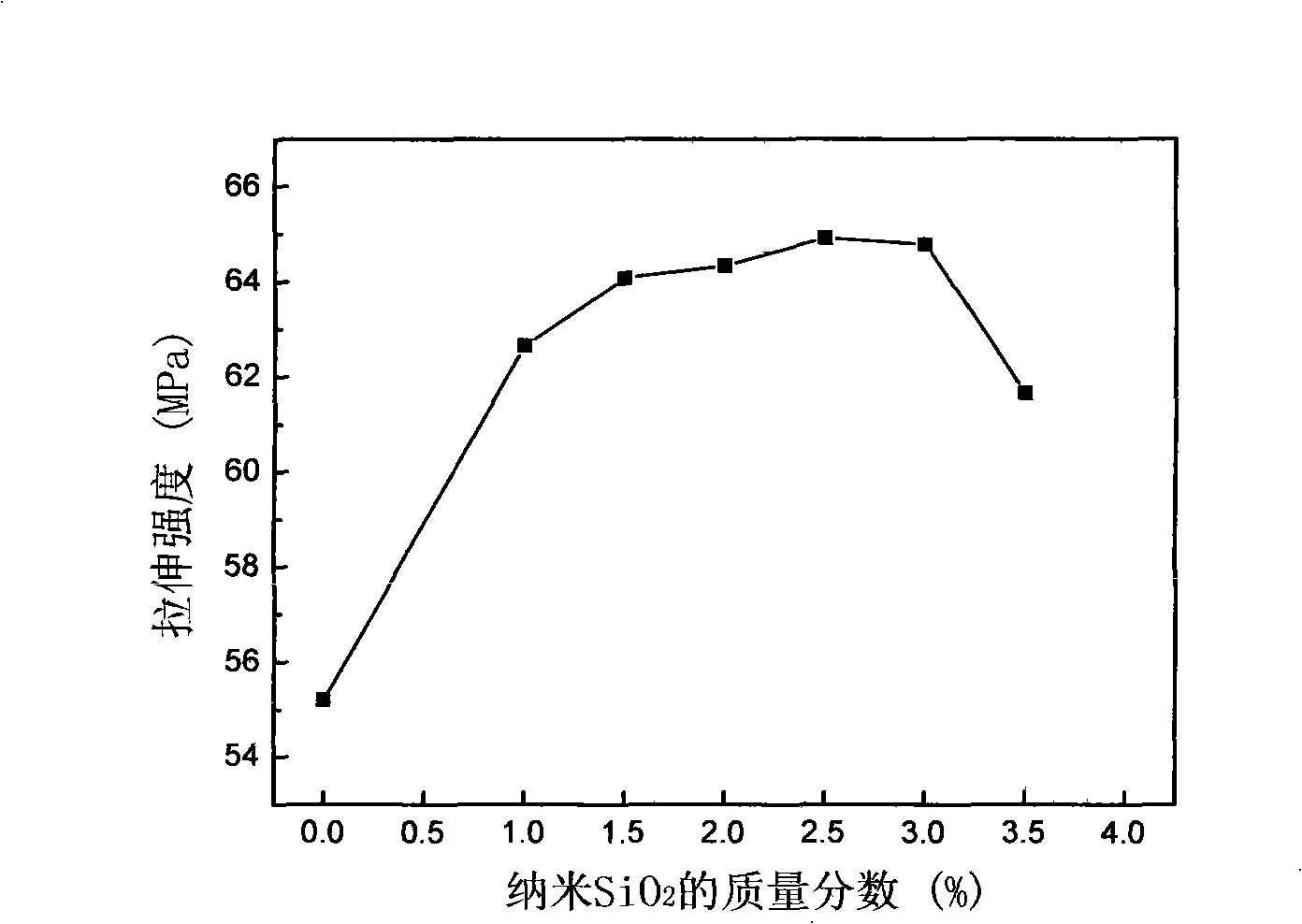

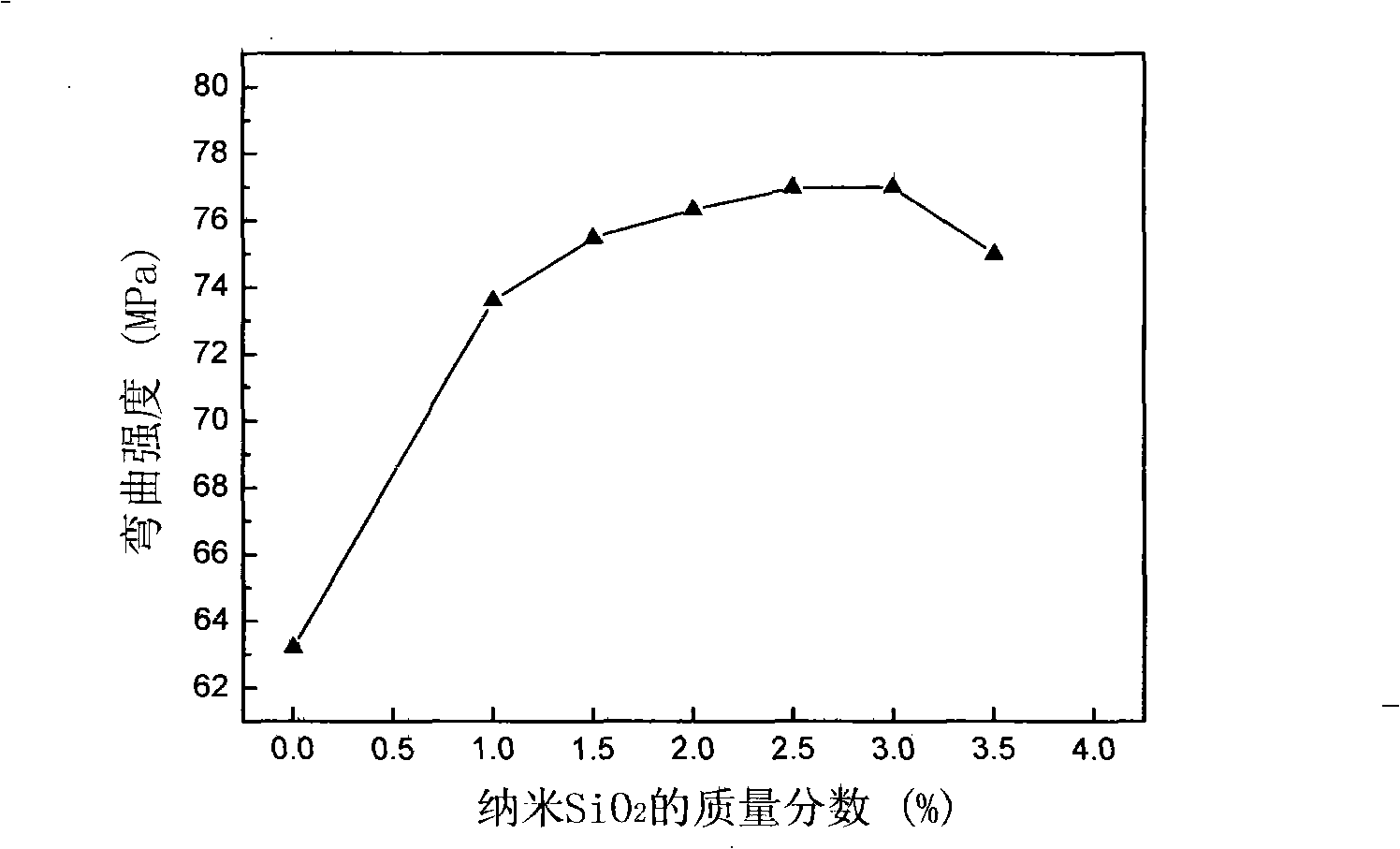

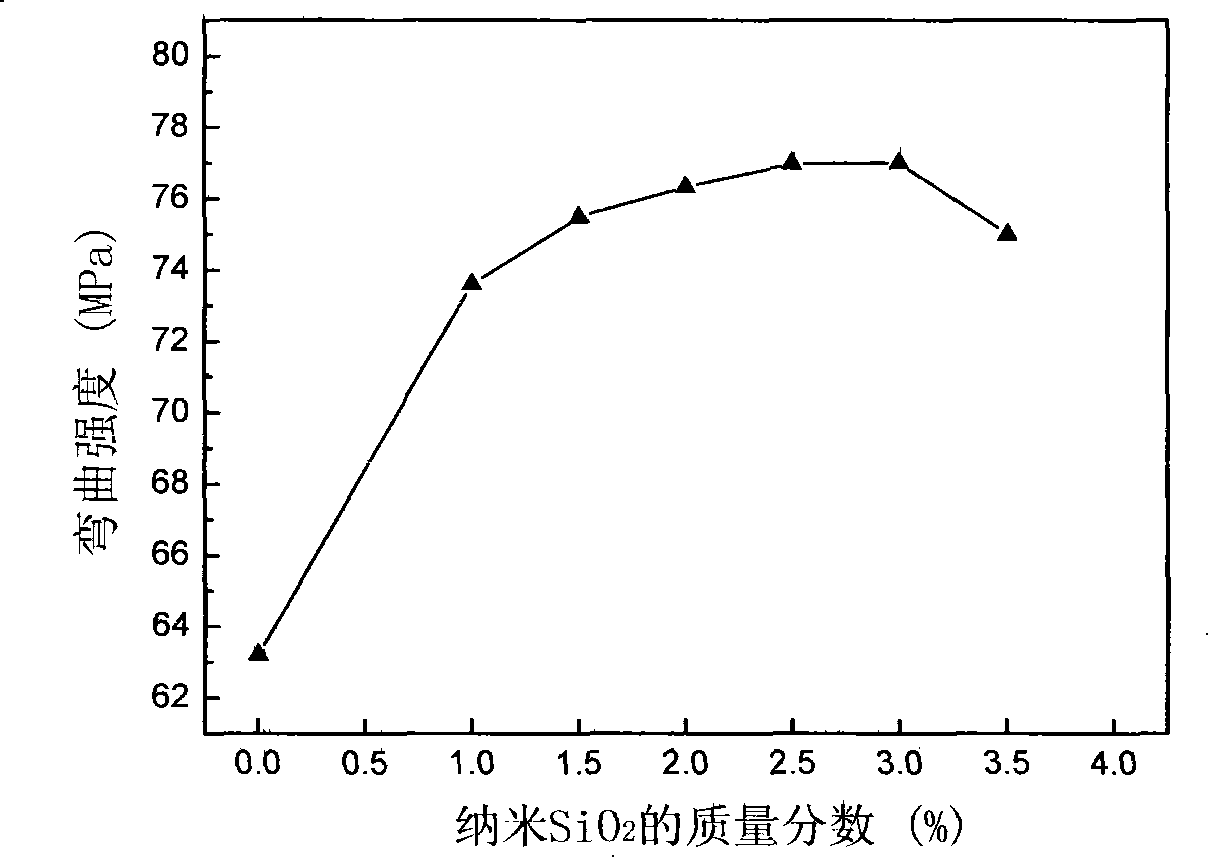

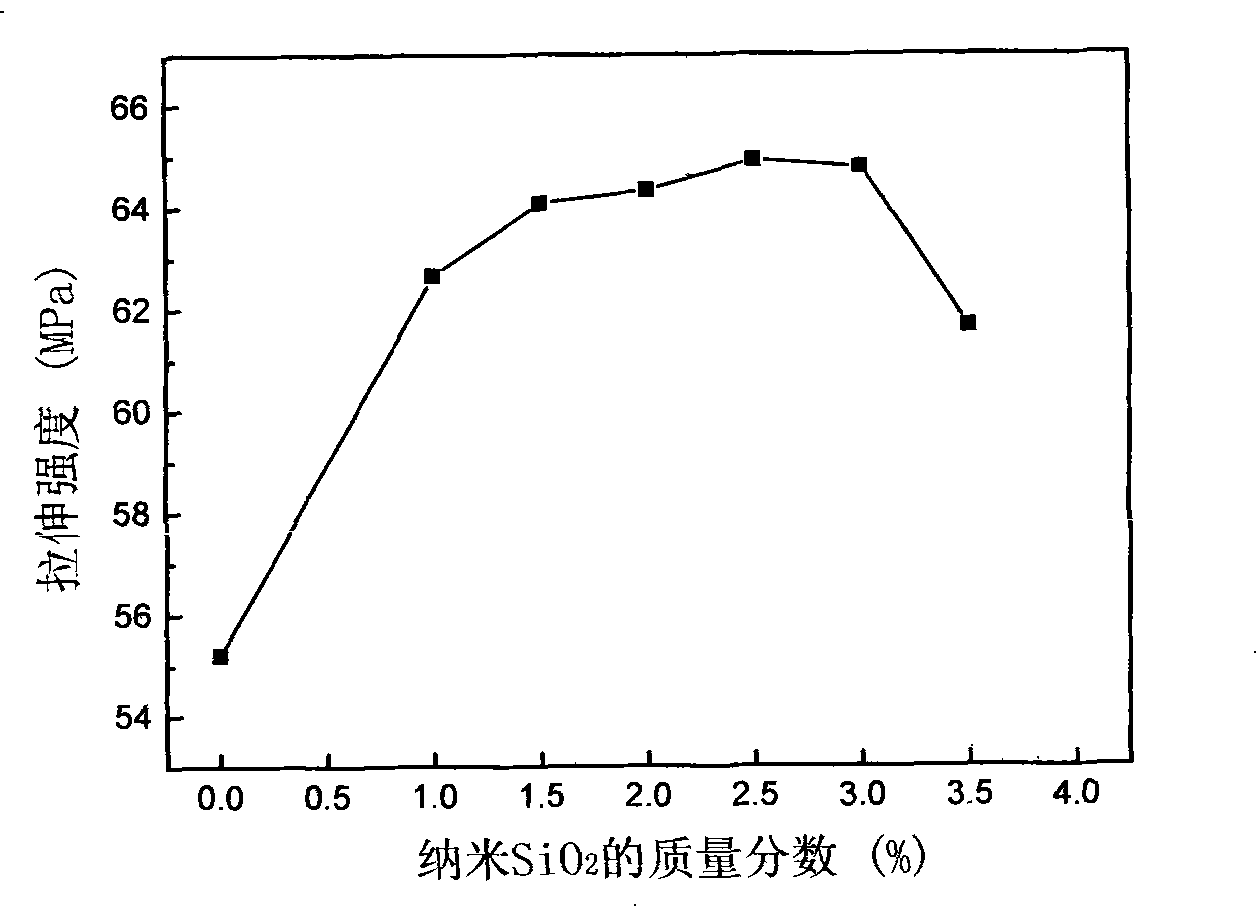

Preparation of nano SiO2 enhanced toughened PET composite material for plastic-steel baling belt

InactiveCN101348601AHigh tensile strengthImprove bending strengthFlexible elementsGas phaseNano sio2

The invention discloses a nanometer SiO2 strengthening-toughening PET compound material for plastic-steel packing straps. A melt-blending method is adopted to prepare a master batch of the nanometer SiO2 strengthening PET compound material; the weight percentage content of gas-phase SiO2 is between 25 and 40 percent; a melting system always maintains high-speed shearing dispersion and carries out mixing in a 20KHz ultrasonic environment; a coupling agent KH550 or A1120 is added to the melting system, and the dosage of the coupling agent is 2.5-4 percent of that of the SiO2; the master batch is blended with PET and fed in certain proportion, and then the nanometer SiO2 strengthening-toughening PET compound material can be obtained, wherein the content of nanometer SiO2 is between 1 to 3.5 percent. Due to the adoption of the compound material, nanometer SiO2 particles in PET are uniform in dispersion, good in crystallization property, obvious in strengthening effect, good in the compatibility with the PET, simple to operate and low in cost. The PET master batch is blended with the PET for producing the plastic-steel packing straps, which can raise the strength, toughness, etc. of the PET.

Owner:SOUTHEAST UNIV

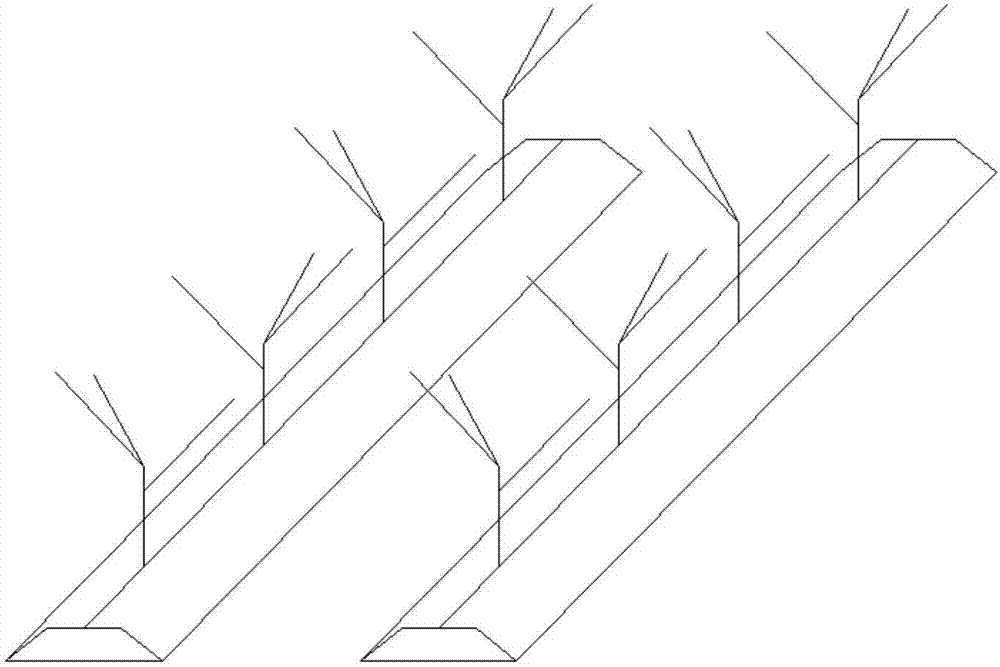

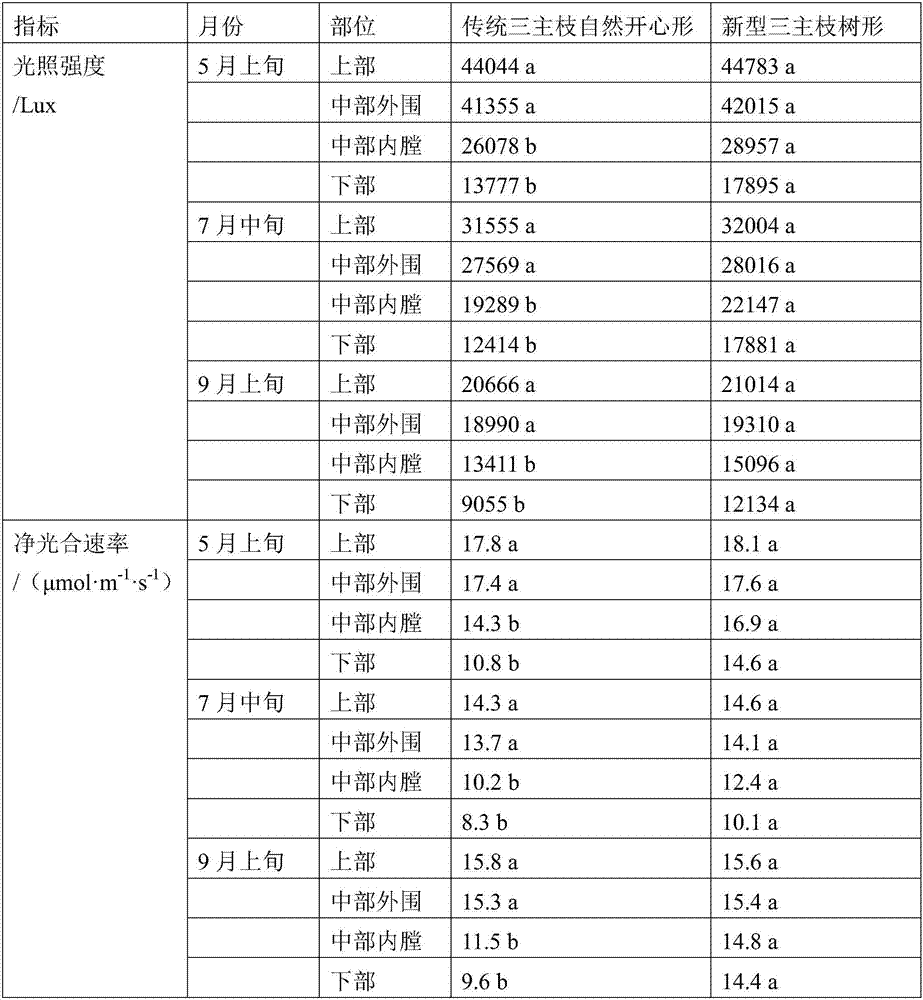

Novel three-main-branch high photosynthetic efficiency cultivation method for peach trees

InactiveCN107873306ATo achieve labor-saving cultivationTake advantage ofCultivating equipmentsHorticulture methodsMain branchRidge

The present invention discloses a novel three-main-branch high photosynthetic efficiency cultivation method for peach trees. Main branches are cultivated from any tree on the same ridge, three main branches with balanced growth vigor are selected and remained from each tree, an included angle between the adjacent main branches is within 40-60 DEG, among the three main branches selected and remained from the tree, the projection of one main branch is oriented to be vertical to lines, and the other two main branches are oriented to the opposite lines. The main branches selected and remained fromthe adjacent trees on the same ridge are constructed to be of the tree form with horizontal rotation of 180 DEG of the tree, the subsequent plant tree forms are successively and alternately constructed according to the above, and the plants at the same field planting point of the adjacent ridges have the same tree form. The space between the lines can be fully utilized, the main branches are staggered, the adjacent plant main branches in the same line and the same row are not interfered with each other, and the purpose of efficiently utilizing the light is truly achieved. Operation between the lines is facilitated, small-sized mechanical work is facilitated, and the purpose of labor-saving cultivation of the peach trees is achieved.

Owner:JIANGSU ACAD OF AGRI SCI

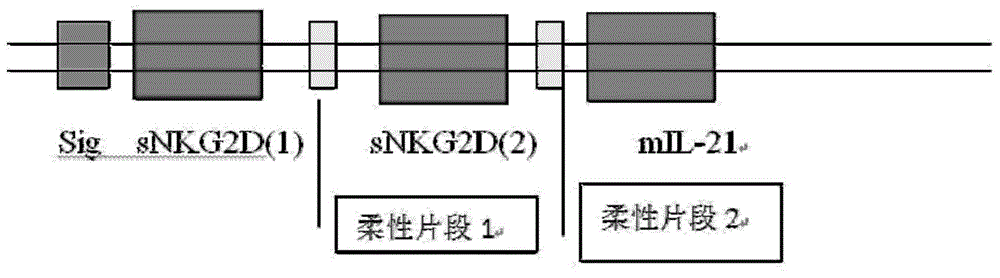

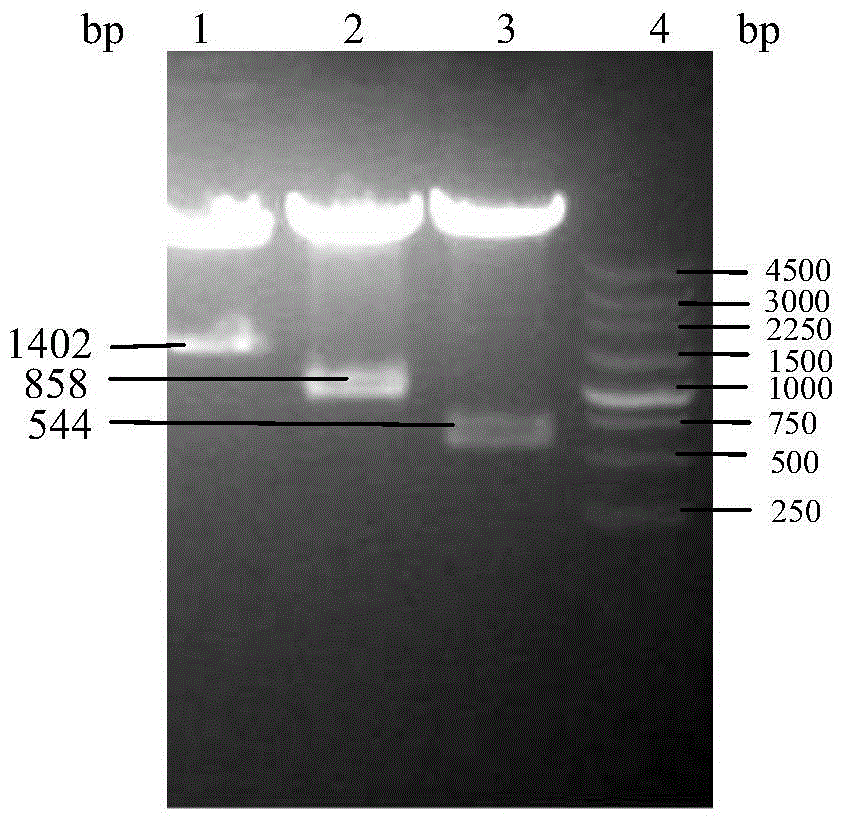

Nano gene drug capable of stimulating lymphocyte activation and preparation method thereof

InactiveCN104894151AActivation functionWell distributedGenetic material ingredientsImmunological disordersSequence signalFusion Protein Expression

The invention relates to a novel nano gene drug capable of stimulating lymphocyte activation and a preparation method thereof. The invention discloses a fusion gene; and a mouse beta-2 microglobulin signal peptide is introduced from the upstream of the fusion gene dsNKG2D-IL-21 gene to obtain the fusion gene ATG-sig-dsNKG2D-IL-21. The invention also discloses a fusion gene expression carrier pcDNA3.1-sig-dsNKg2D-IL-21. The invention also discloses a nano gene vaccine drug which is formed by encapsulating the pcDNA3.1-sig-dsNKg2D-IL-21 fusion protein expression vector with chitosan. The invention also discloses a preparation method of a nano gene vaccine. The nano drug is used for carrying a nano gel of the recombinant dsNKG2D-IL-21 gene vector capable of stimulating lymphocyte activation and in-vivo targeted distribution, and is hopeful to become a drug for resisting tumors and infectious diseases.

Owner:YANGZHOU UNIV

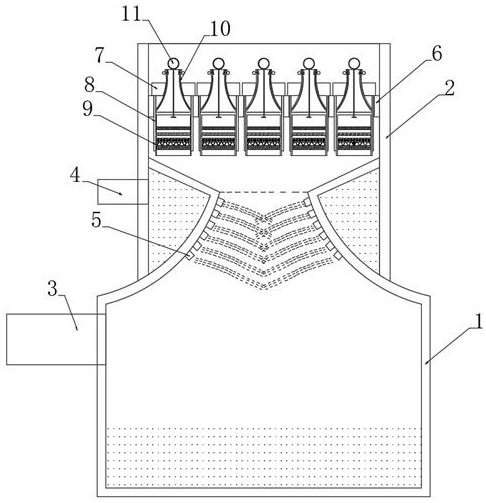

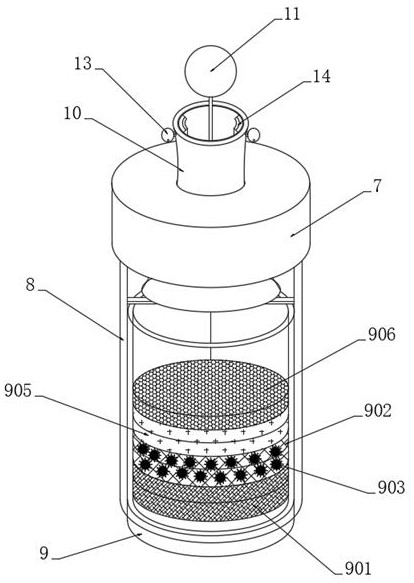

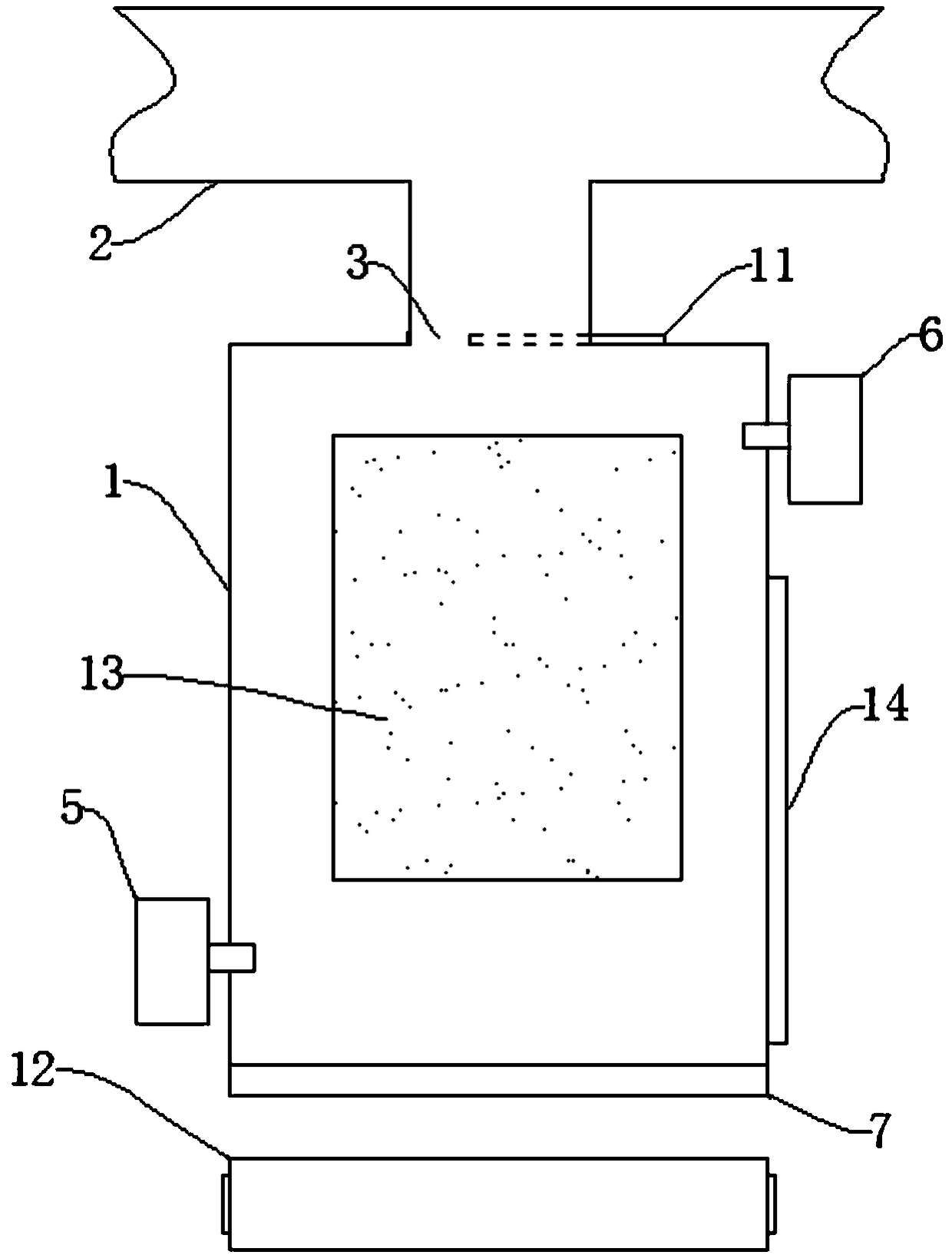

Anti-blocking type particle adsorber for high-temperature waste gas

ActiveCN111659218AImprove adsorption capacityEasy to replaceCombination devicesThermodynamicsEngineering

The invention discloses an anti-blocking type particle adsorber for high-temperature waste gas, and belongs to the technical field of waste gas treatment. A gas adsorption device and an embedded plateare installed in an embedded mode. Waste gas which is led out upwards passes through the adsorption layer group in an adsorption cylinder, multiple set adsorption operations are performed, and the adsorption effect of the waste gas is effectively improved; the adsorption layer group reaches a saturated state after being used for a certain time, the gas conduction is difficult to realize continuously; the floating ball which floats upwards is supported by matching with the impact force generated by the conduction gas, when the buoyancy generated by the amount of gas led out upwards is smallerthan the gravity of the floating ball, the floating ball floats upwards, the floating ball sinks and abuts against the top end part of the conical eduction tube, and the outer side wall of the floating ball makes contact with the blockage alarm mechanism to achieve alarm display so that technicians can more easily and visually perceive which adsorption layer set in the adsorption cylinder reachesthe saturation state, the gas adsorption mechanism at the position can be replaced, and replacement by the technicians is facilitated by the embedded installation.

Owner:龙杰机械装备(太仓)有限公司

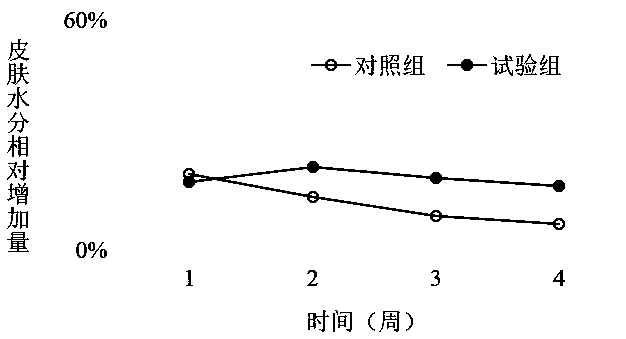

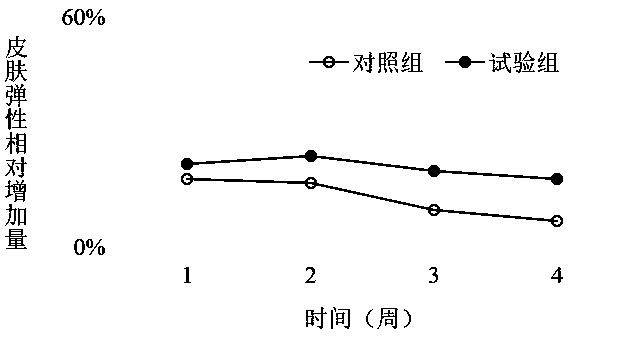

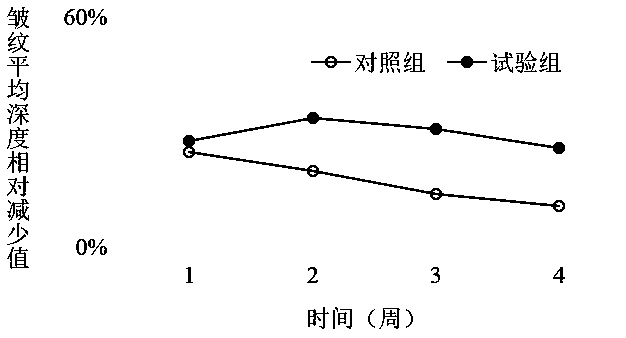

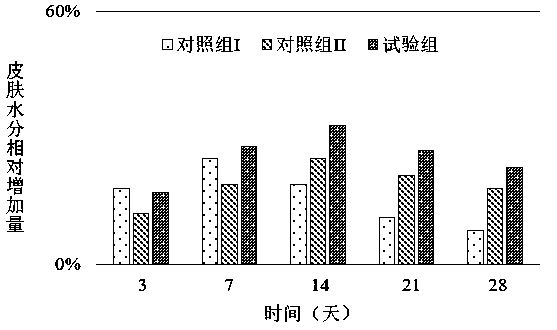

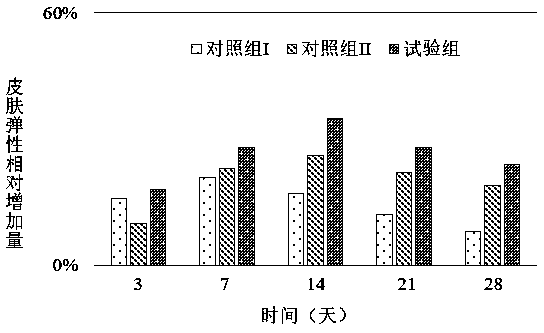

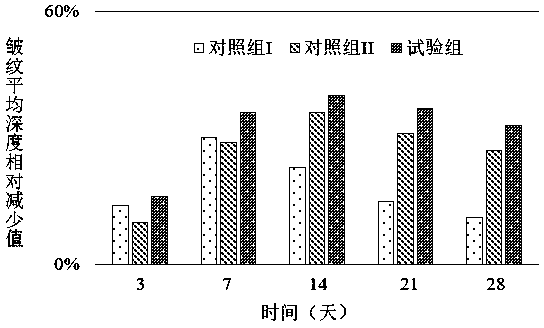

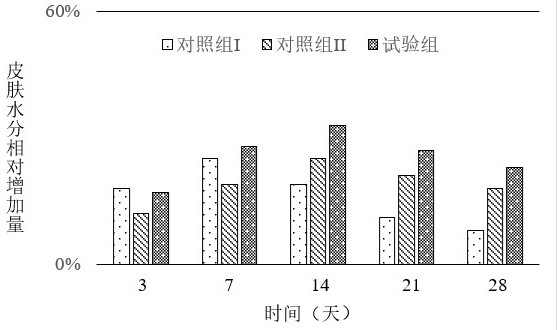

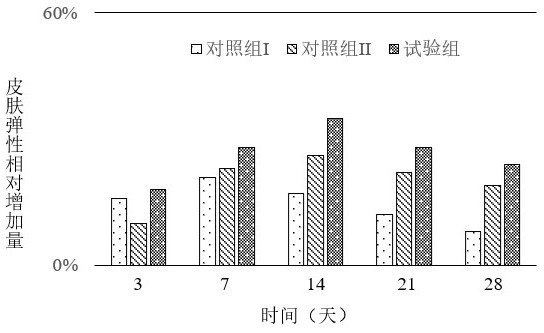

Hyaluronic acid gel for hyaluronic acid injection and use method of hyaluronic acid gel

PendingCN110812253AReduce intensityImprove liquidityCosmetic preparationsToilet preparationsSkin textureBiochemistry

The invention discloses a hyaluronic acid gel for hyaluronic acid injection. The hyaluronic acid gel is a disulfide crosslinked hyaluronic acid, and the content of hyaluronic acid in the gel is not more than 10 mg / mL. The crosslinked hyaluronic acid gel provided by the invention has unique advantages when used for hyaluronic acid injection, is easily injected through a very fine needle head of a hyaluronic acid injection needle, and can realize good and uniform distribution in a subcutaneous layer without bulging; and the hyaluronic acid gel has a moisturizing effect longer than that of uncrosslinked hyaluronic acid, and can effectively improve skin texture.

Owner:BIOREGEN BIOMEDICAL (CHANGZHOU) CO LTD

Water insoluble modified polyvinyl alcohol coating liquid and its producing process

The water insoluble modified polyvinyl alcohol coating liquid consists of polyvinyl alcohol, regulator, inorganic matter, crosslinking agent, catalyst and water. The water insoluble modified polyvinyl alcohol coating liquid includes two components, the component A is prepared through mixing all the material except catalyst and heating at certain temperature, and the component B is catalyst. When used, the two components, A and B, are mixed through stirring, and the mixture forms water insoluble film. The foamed film has excellent processibility, high reflectivity to ultraviolet light and infrared light, high wear resistance, low transmissibility and high adhesion to substrate, and is used in product package.

Owner:刘建林

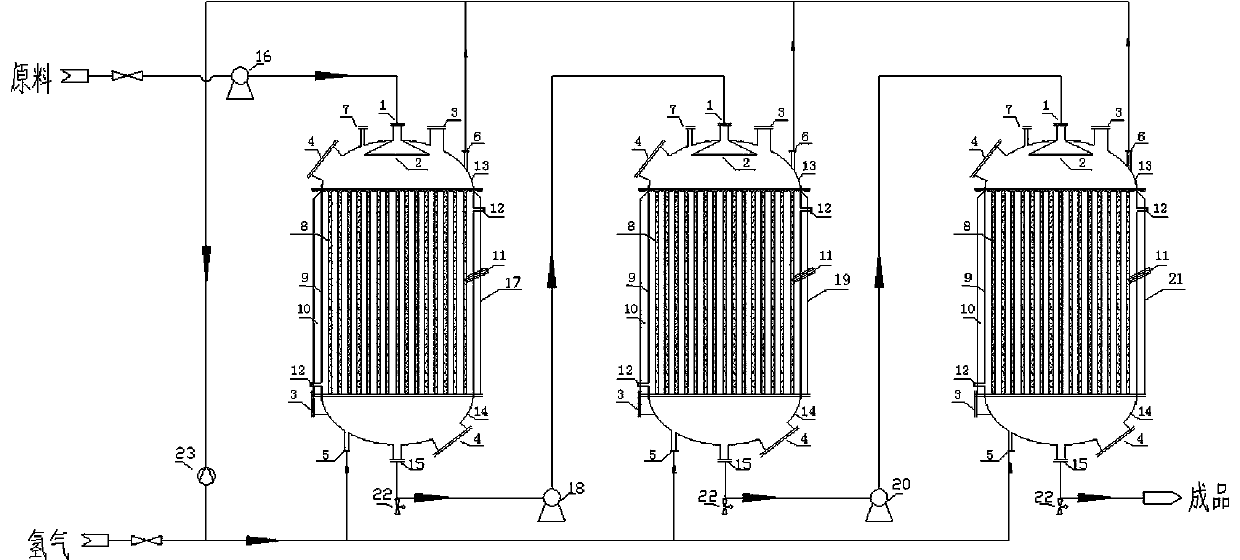

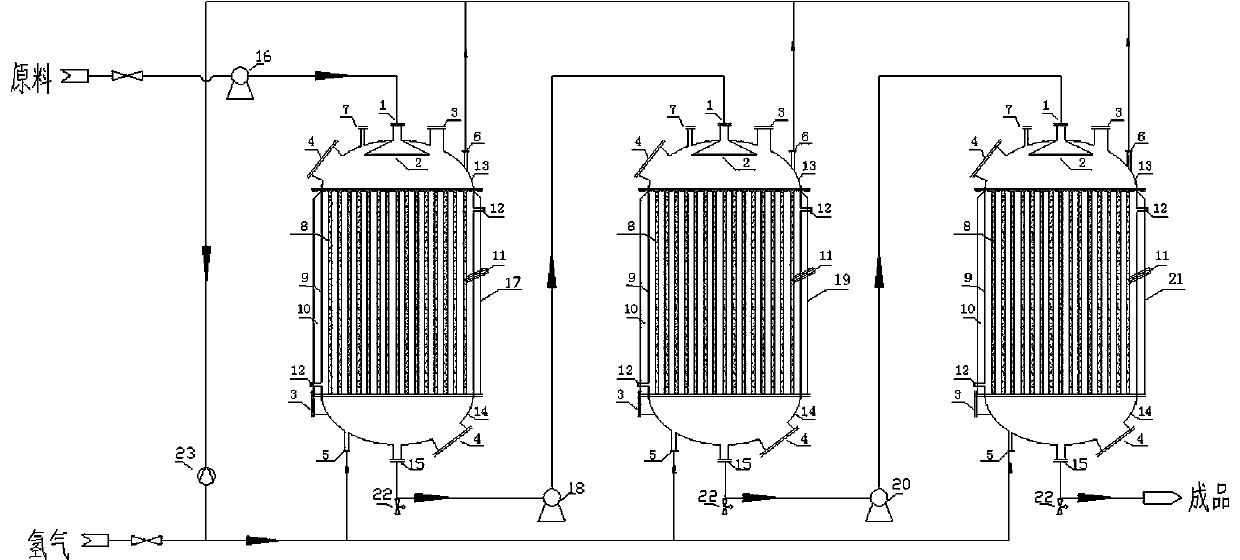

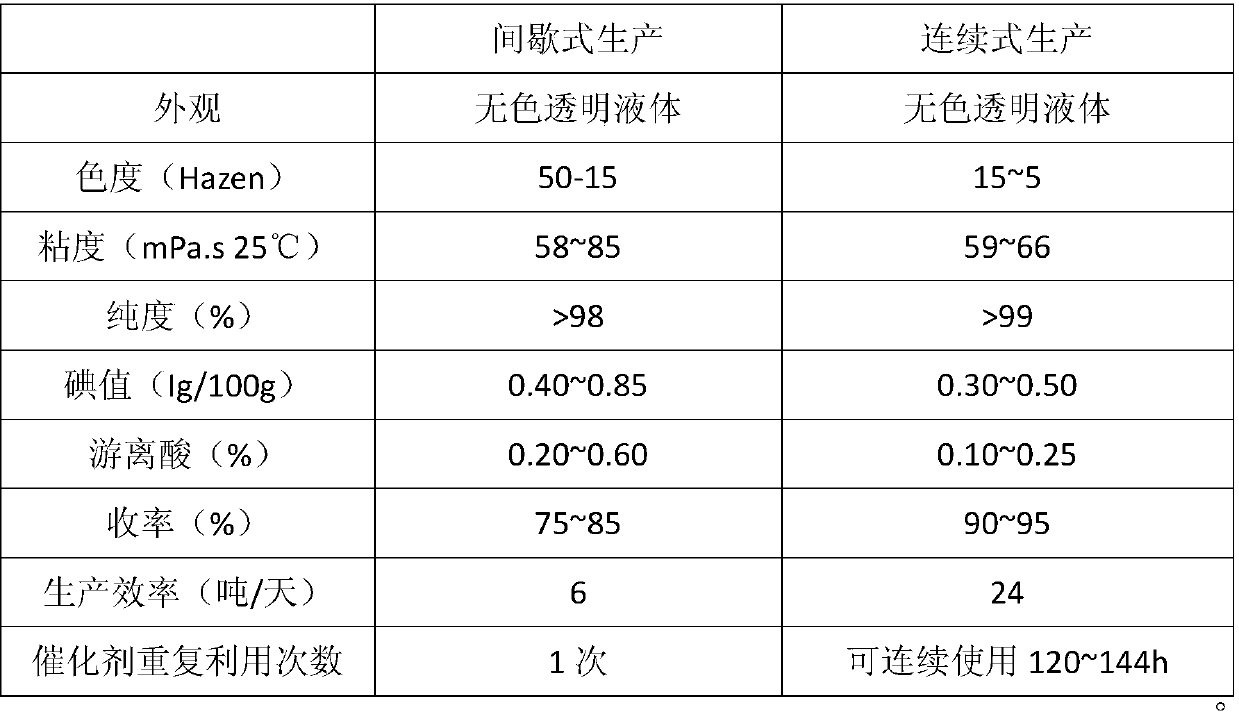

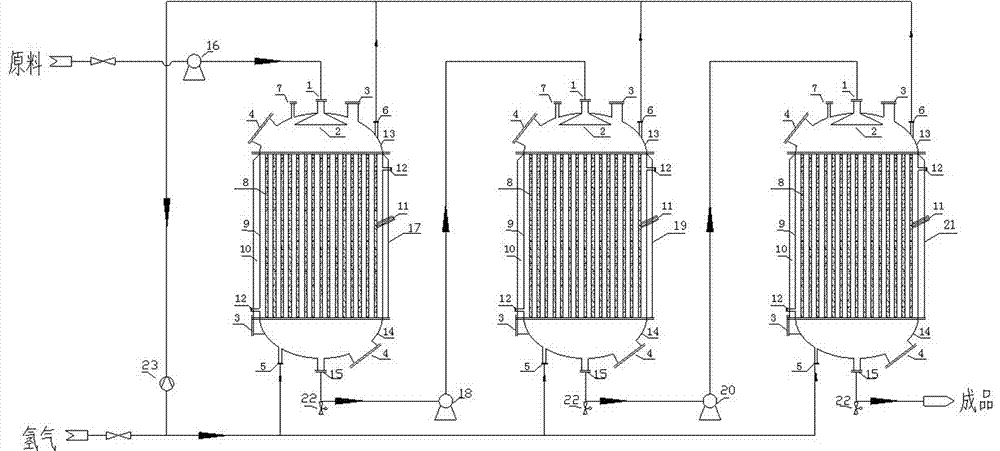

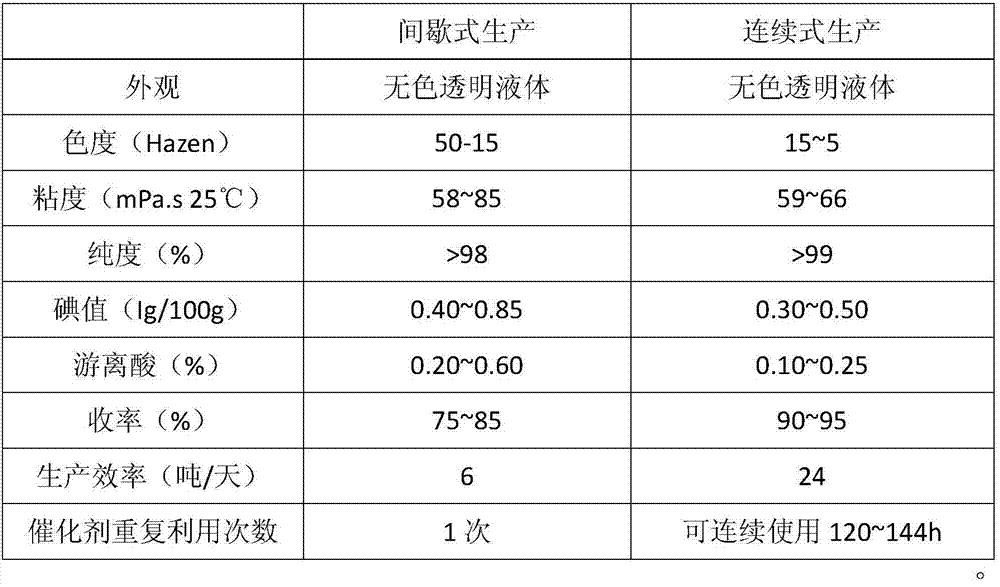

Method for preparing methylhexahydrophthalic anhydride by means of continuous hydrogenation

ActiveCN107089961AWell distributedImprove conversion rateOrganic chemistryChemical/physical processesThree levelFixed bed

The invention discloses a method for preparing methylhexahydrophthalic anhydride by means of continuous hydrogenation and belongs to the field of organic chemicals. A three-level split-tube fixed bed reactor is adopted for circularly continuous hydrogenating; a split-tube type structure is adopted in the split-tube fixed bed reactor; a solid catalyst is arranged between tube passes; a heat medium is arranged in a shell pass; hydrogen respectively enters from the bottom of each level of split-tube fixed bed reactor in parallel; unreacted hydrogen passes by each split tube and then returns to a hydrogen compressor from the upper part of the reactor; the raw material, methyltetrahydrophthalic anhydride, gradually passes by a high pressure pipe pump, is conveyed to the upper part of the split-tube reactor and is sprayed by a distributor located at the top in the reactor so as to be uniformly distributed on the surface of the solid catalyst and react with hydrogen; after circular reaction through the three-level reactor, the hydrogenating conversion rate is close to 100%. According to the method, the production of methylhexahydrophthalic anhydride by means of continuous hydrogenation is realized, the technical process is clean and the catalyst is reused.

Owner:河南惠成新材料有限公司

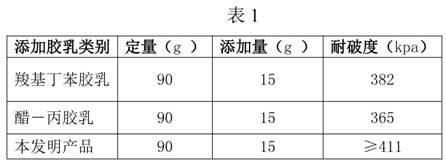

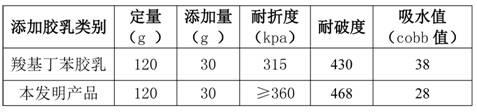

Middle-sole latex and preparation process thereof

The invention discloses middle-sole latex and a preparation process thereof. Raw materials of the middle-sole latex comprise modified starch, cellulose, butyl acrylate, 2-ethylhexyl acrylate, styrene, a functional monomer, an emulsifying agent and appropriated amount of initiator. A middle-sole paper model produced by the middle-sole latex is easy to degrade after being discarded. The middle-solelatex and paper fiber are in good affinity, the latex can be distributed on the paper model easily, and obtained middle-sole sizes are stable. Simultaneously, the used paper model is easy to recycle,the discarded paper model is easy to degrade and the latex is beneficial to environmental protection.

Owner:JIANGMEN GAOLIYI TECH IND

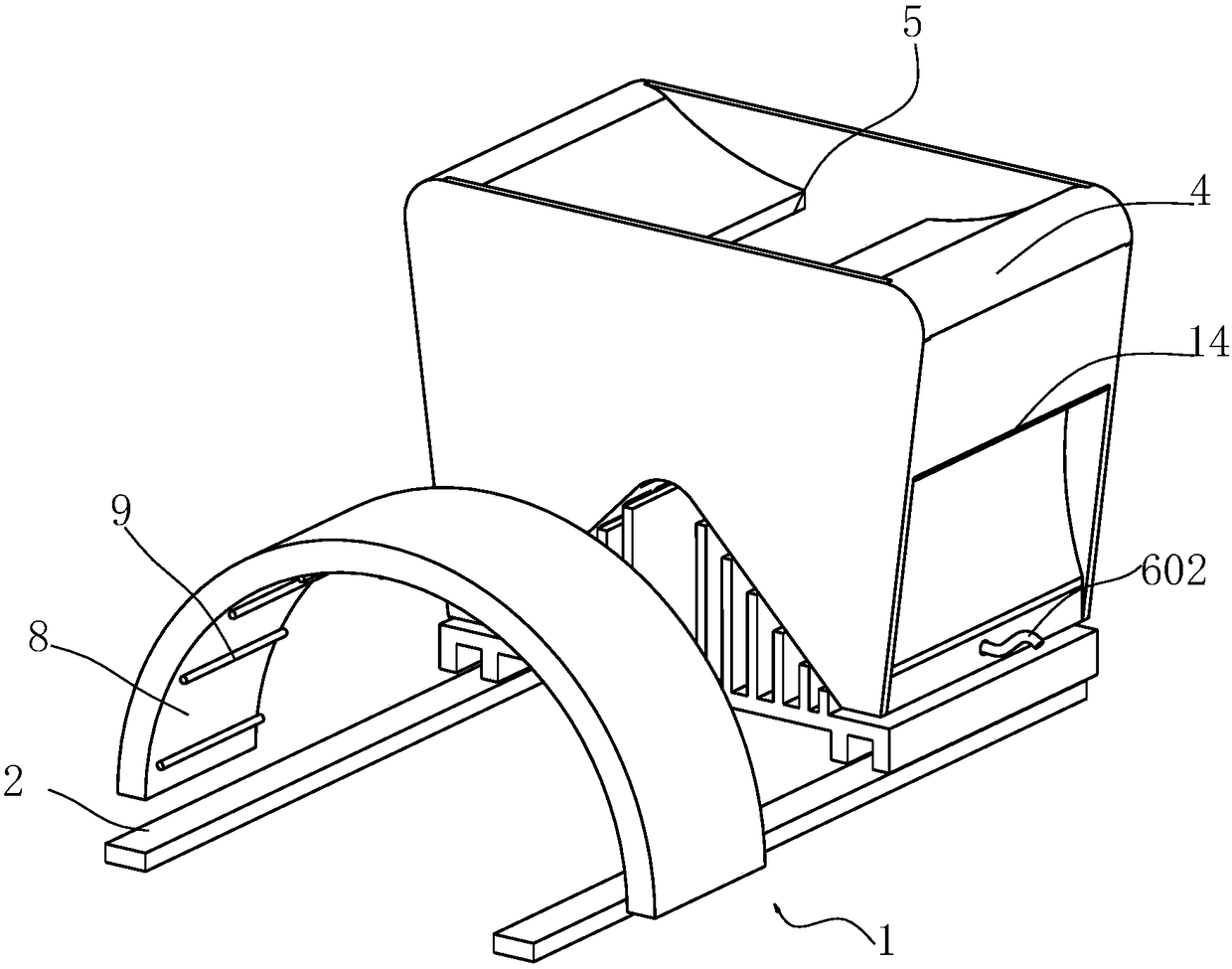

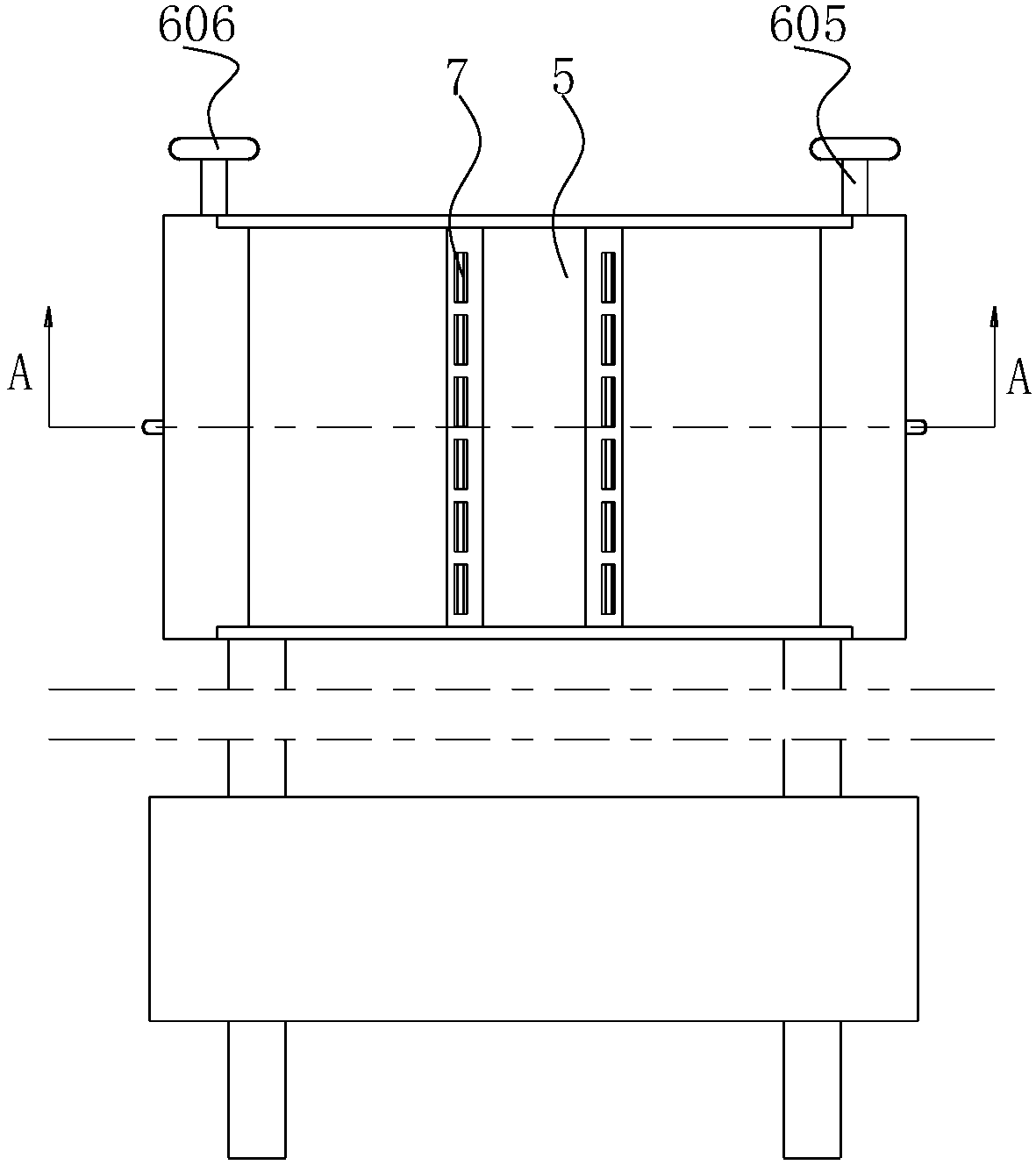

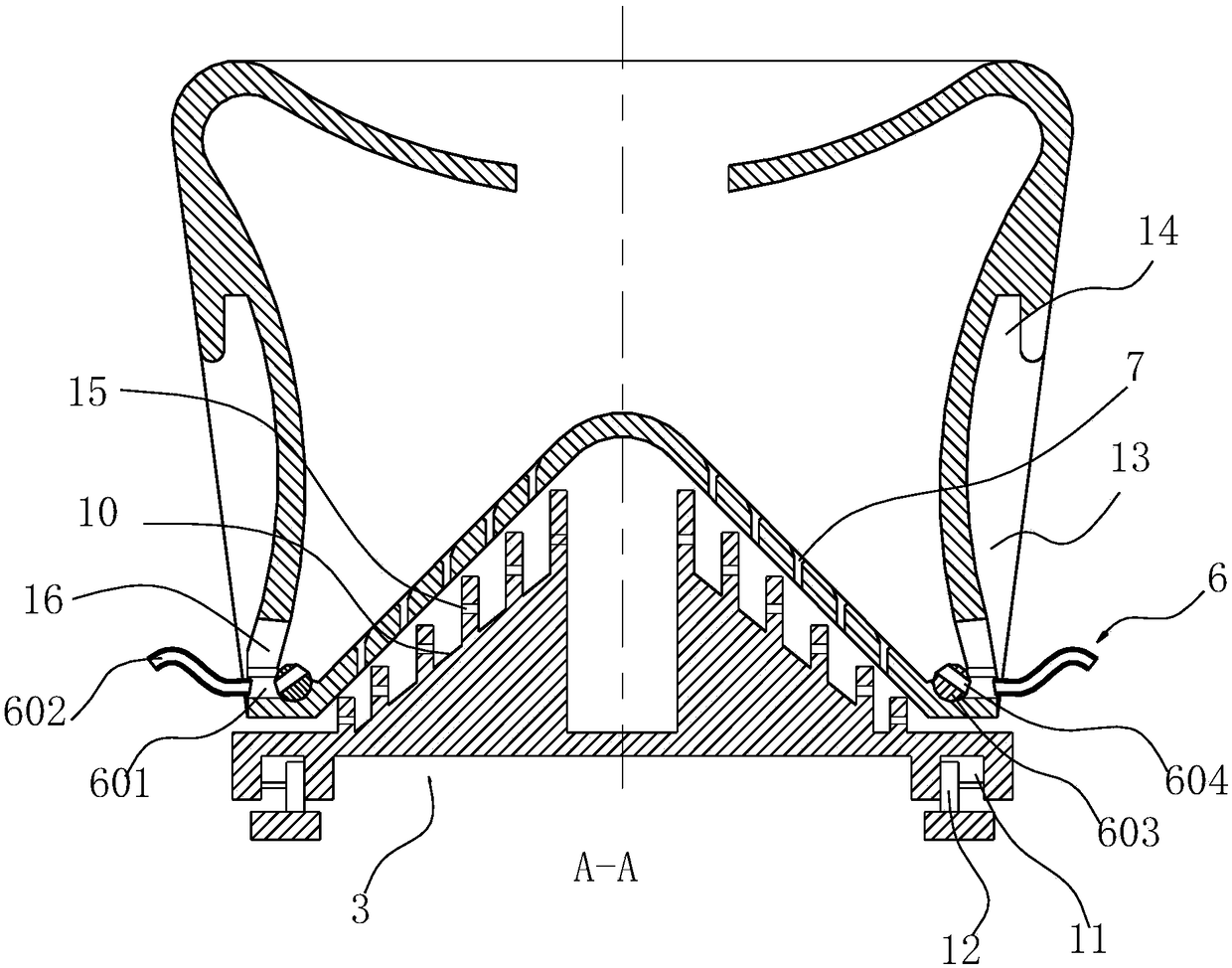

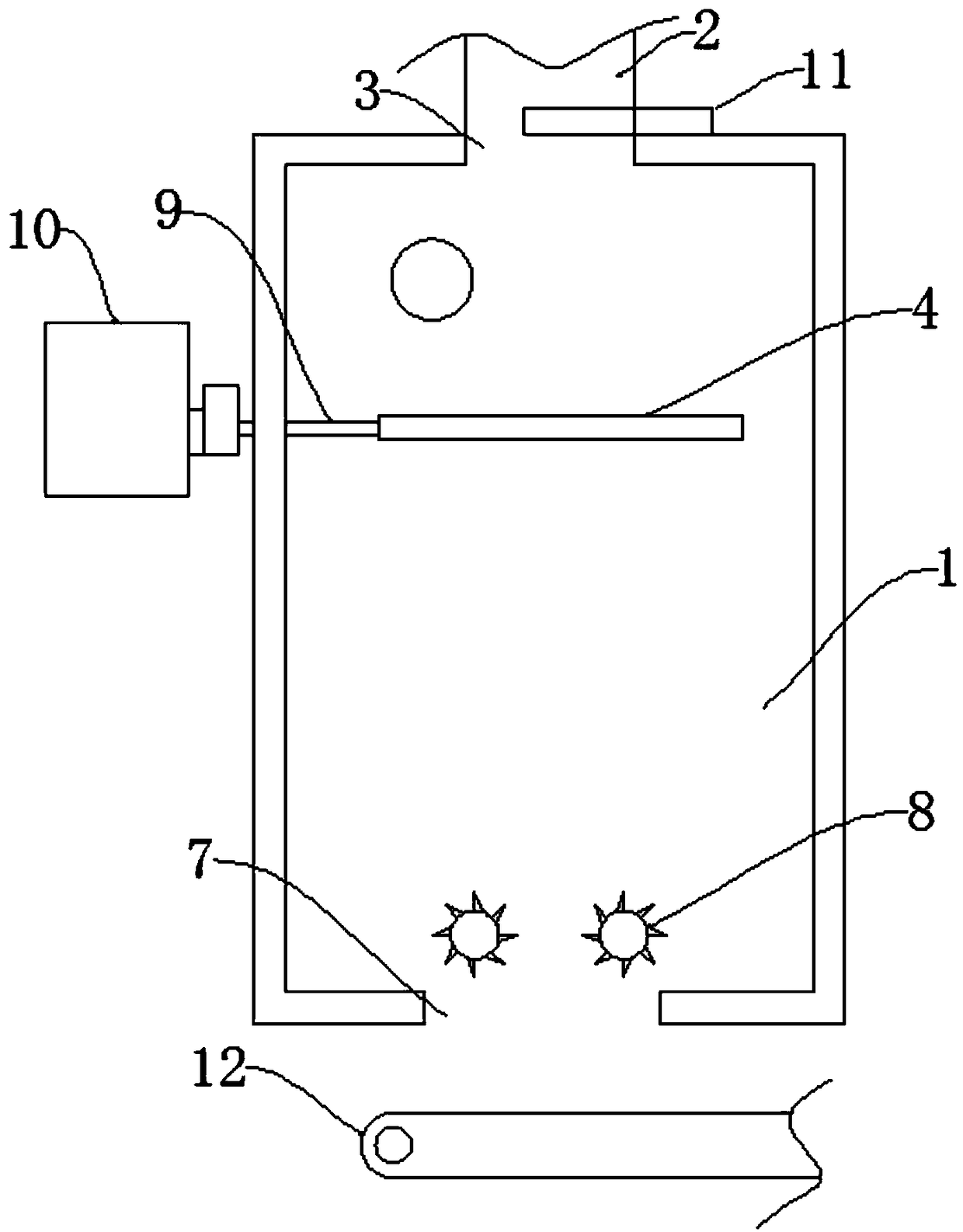

Radix polygonati officinalis slice separating device and using method thereof

ActiveCN108151523ARealize continuous processingRealize streamlined operationDrying gas arrangementsHeating arrangementPolygonum odoratumOfficinalis

The invention relates to a radix polygonati officinalis slice separating device and a using method thereof, and belongs to the technical field of traditional Chinese medicine decoction piece dehydrating equipment. The device comprises a slide rail, and further comprises an edge drying part and a widowing separating box which are arranged along the slide rail as well as a wind pumping mechanism, wherein a radix polygonati officinalis side floor stand is arranged on the slide rail in a sliding mode; the radix polygonati officinalis side floor stand can move to a position below the edge drying part or the windowing separating box; the windowing separating box is of a box body structure with a top opening, and a plurality of strip-shaped holes capable of allowing radix polygonati officinalis slices to pass through are formed in the bottom of the windowing separating box; the bottoms at the two sides of the windowing separating box are equipped with a cavity which communicates with the inner part of the windowing separating box; a wind ball is arranged in the cavity through a rotary shaft; a penetrating gas path is arranged on the wind ball; and the direction of the gas path of the windball can be regulated by rotating the rotary shaft. The radix polygonati officinalis slice separating device realizes preliminary air-drying and raising of radix polygonati officinalis slices, and the raised radix polygonati officinalis slices enter the radix polygonati officinalis slice side floor stand through the strip-shaped holes; and the radix polygonati officinalis slices are conveyed to anext station through the radix polygonati officinalis slice side floor stand, so that continuous processing of the radix polygonati officinalis slices is favorably realized, and streamlined operationis realized.

Owner:亳州市爱开发网络科技有限公司

Hyaluronic acid gel composition for negative-pressure multi-needle injection and preparation method therefor

ActiveCN110812270AImprove skin qualityImprove liquidityCosmetic preparationsToilet preparationsDisulfide bondingMedicine

The invention discloses a hyaluronic acid gel composition for negative-pressure multi-needle injection. The hyaluronic acid gel composition contains 1) disulfide bond cross-linked hyaluronic acid, wherein the content of the hyaluronic acid in gel is not higher than 10mg / mL; and 2) non-crosslinked hyaluronic acid. When the hyaluronic acid gel composition disclosed by the invention is applied to negative-pressure multi-needle injection, the hyaluronic acid gel composition has unique advantages, injection by ultrafine needle heads of negative-pressure multi-needle injection needles is facilitated, good uniform distribution in a subcutaneous shallow surface layer can be achieved, and a bulging phenomenon does not occur; and the effect taking speed is high, water replenishing and moisture preserving effects are long in hold time, and the skin texture of skin can be effectively improved.

Owner:BIOREGEN BIOMEDICAL (CHANGZHOU) CO LTD

Preparation of nano SiO2 enhanced toughened PET composite material for plastic-steel baling belt

InactiveCN101348601BHigh tensile strengthImprove bending strengthFlexible elementsGas phaseNano sio2

Owner:SOUTHEAST UNIV

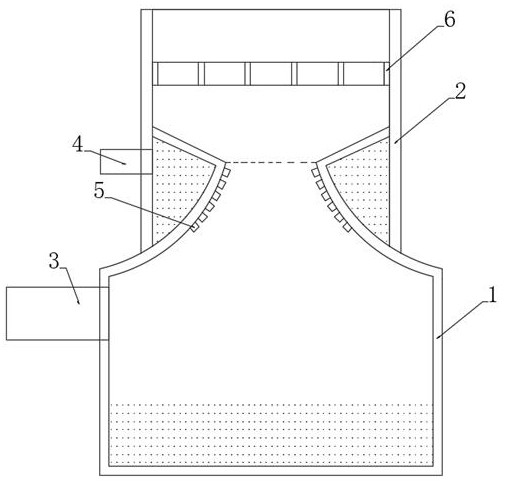

Cotton feeding box of carding machine

The invention relates to a cotton feeding box of a carding machine. The cotton feeding box comprises a box body, the upper end of the box body is provided with a cotton inlet for being communicated with a cotton conveying channel, the box body is provided with a vibration mechanism for scattering cotton falling into the vibration mechanism, the lower portion of one side of the box body is providedwith an air supply device communicated with an inner cavity of the box body, the upper portion of the other side of the box body is provided with an air draft device communicated with the inner cavity of the box body, the bottom of the box body is provided with a cotton outlet, and two parallel and spaced cotton discharging rollers are horizontally and rotatably arranged above the cotton outlet.According to the cotton feeding box of the carding machine, several methods for adjusting the cotton feeding amount are set and include adjustment of the opening degree of the cotton inlet, turning onor turning off of the air draft device and turning on or turning off of the air supply device, the air draft device and the air supply device adjust the air pressure in the box body to adjust the cotton feeding amount of the cotton conveying channel, and the purposes of improving the fluffiness of cotton balls through ventilation and removing fine impurities and dust of the cotton can be achieved.

Owner:湖北德永盛纺织有限公司

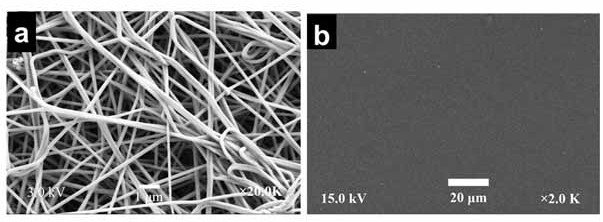

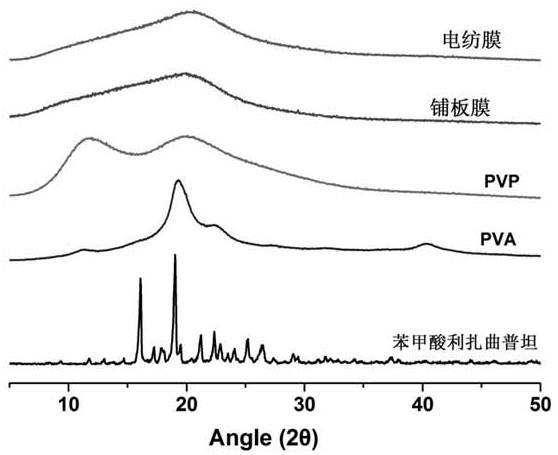

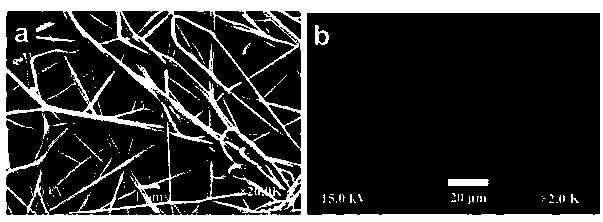

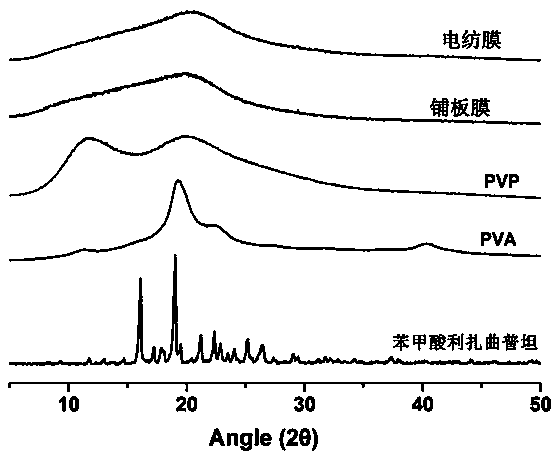

Oral cavity instant membrane agent containing rizatriptan benzoate and preparation method thereof

ActiveCN109730978AFast in vitro dissolution rateLarge specific surface areaOrganic active ingredientsNervous disorderFiberPorosity

The invention belongs to the technical field of medicines, and relates to an oral cavity instant membrane agent containing rizatriptan benzoate prepared by using an electrostatic spinning technology.The formula of the oral cavity instant membrane agent comprises, 1 part of the rizatriptan benzoate, 1-300 parts of a membrane forming material and 0-50 parts of other auxiliaries. An oral cavity instant membrane is obtained through the electrostatic spinning technology, the electrostatic spinning conditions are that the voltage is 5-20 kV, the proceeding speed is 0.1-10 ml / h, the receiving distance is 5-20 cm, the temperature is 5-60 DEG C, and the humidity is 10-70%. The oral cavity instant membrane agent is composed of nano polymer fibers formed by electrostatic spinning, and the diameter of the nano polymer fibers is 10-1000 nm. The rizatriptan benzoate is uniformly distributed without a fixed form state. The oral cavity instant membrane agent containing the rizatriptan benzoate has higher specific surface area and porosity and faster dissolution rate, the effect comes up faster, the biological utilization rate is higher, and the pain of a patient with migraine can be rapidly relieved.

Owner:SHENYANG PHARMA UNIVERSITY

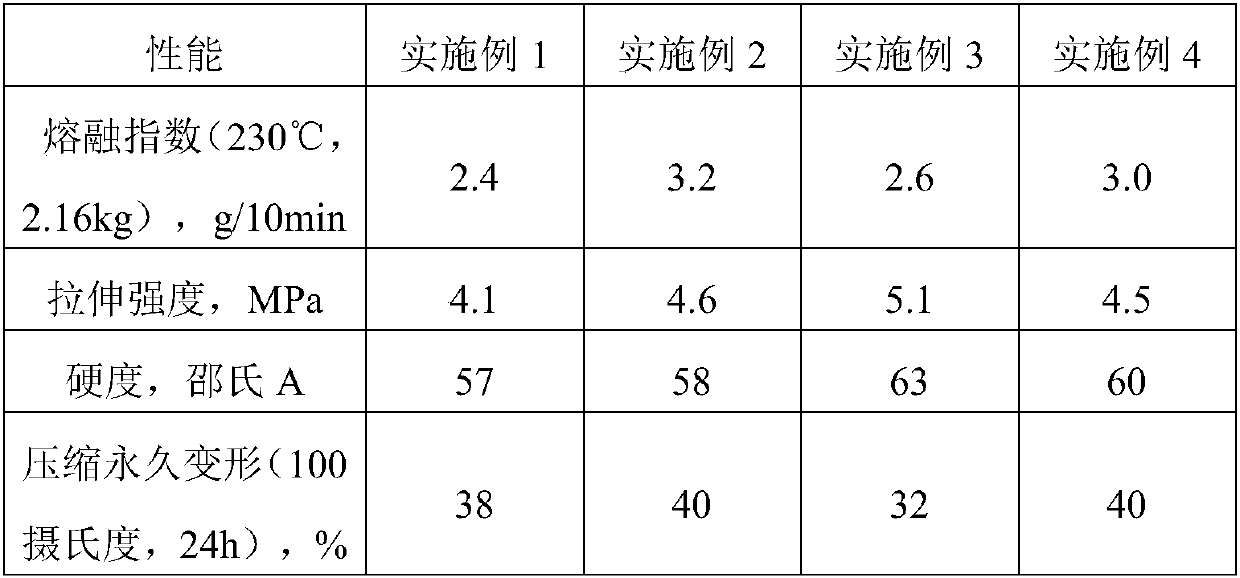

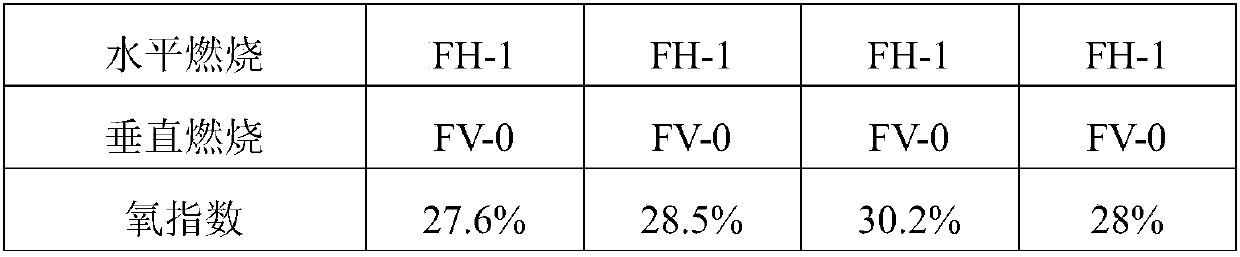

Halogen-free nano flame-retardant TPE material and preparation method thereof

The invention provides a halogen-free nano flame-retardant TPE material and a preparation method thereof and solves the technical problems of characteristic loss and poorer dispersibility of an existing halogen-free nano flame-retardant TPE material elastomer. In every one hundred weight parts, the halogen-free nano flame-retardant TPE material is prepared from the following ingredients in content: 10 to 30 parts of SEBS or SBS, 5 to 40 parts of extending oil, 1 to 5 parts of flame-retardant synergist, 2 to 15 parts of polypropylene and 20 to 50 parts of inorganic nano hydroxide filling masterbatch. The invention further provides a preparation method of the halogen-free nano flame-retardant TPE material.

Owner:威海联桥新材料科技股份有限公司

Recyclable polyethylene single-material high-barrier film bag and processing technology thereof

PendingCN114228289AEasy to processHigh transparencyPackage recyclingFlexible coversPolymer sciencePolyvinyl alcohol

The invention relates to the technical field of plastic flexible packaging, in particular to a recyclable polyethylene single-material high-barrier film bag and a processing technology thereof, the high-barrier bag is easy to process, low in rejection rate, low in non-polyethylene content and good in barrier property and fragrance retention, and equipment used in the processing technology of the high-barrier bag is simple and low in cost. The high-barrier film bag is low in film manufacturing cost, easy to process and high in yield, the high-barrier film bag comprises a printing layer PE film and a heat-sealing layer PE film, the surface of the heat-sealing layer PE film is coated with improved PVA coating liquid, the PVA coating liquid is located on the surfaces of the heat-sealing layer PE film and the printing layer PE film, the printing layer PE film and the heat-sealing layer PE film are compounded through dry compound glue and then cut to manufacture the bag, and the high-barrier film bag is formed. The processing technology of the recyclable polyethylene single-material high-barrier film bag comprises the following steps: S1, preparing a film; s2, PVA (Polyvinyl Alcohol) coating; s3, printing the film cloth; s4, compounding; and S5, bag making.

Owner:河北上东包装科技有限公司

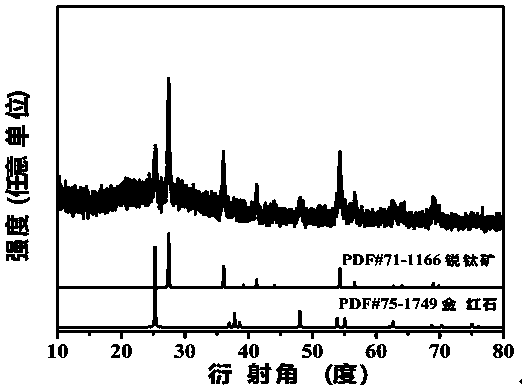

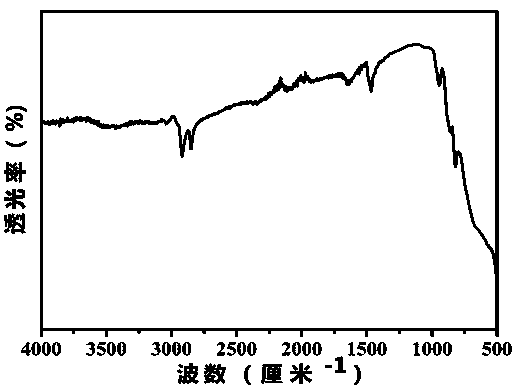

Composite nanofibers as well as preparation method and application thereof

ActiveCN108855232AWell distributedSolve the problem of polyacid agglomerationOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsFiberN dimethylformamide

The invention discloses composite nanofibers, and the molecular formula of the composite nanofibers is (OTA)10[Co4(H2O)2(VW9O34)2] / TiO2. A preparation method of the composite nanofibers comprises thefollowing steps: (1) dissolving Co(NO3)2.6H2O and Na2WO4.2H2O in 0.5M NaAC / HAC buffer solution under the condition of magnetic stirring, then adding NaVO3, heating, carrying out hot filtration, and drying to obtain Na10[Co4(H2O)2(VW9O34)2].35H2O; (2) dissolving butyl titanate and polyvinylpyrrolidone in a mixed solvent of N, N-dimethylformamide, glacial acetic acid and acetylacetone, and using anelectrospinning method to obtain TiO2 nanofibers; (3) dispersing the TiO2 nanofibers in 30-50mL of ethanol, stirring, adding C18H37N(CH3)3.Cl, and continuously stirring to obtain a solution A; dissolving the Na10[Co4(H2O)2(VW9O34)2].35H2O in 20-40mL of water to obtain a solution B; slowly dropwise adding the solution B into the solution A, stirring for 20-30 hours, washing with water and ethanol,and drying under the vacuum condition to obtain the composite nanofibers. The composite nanofibers effectively solve the problem of polyacid agglomeration; the catalytic efficiency is not significantly reduced after 5 cycles of use; the composite nanofibers form an extraction catalytic oxidative desulfurization system together with hydrogen peroxide and ionic liquid [Bmim] PF6, thus showing higherdesulfurization efficiency and excellent reusability.

Owner:NORTHEAST NORMAL UNIVERSITY

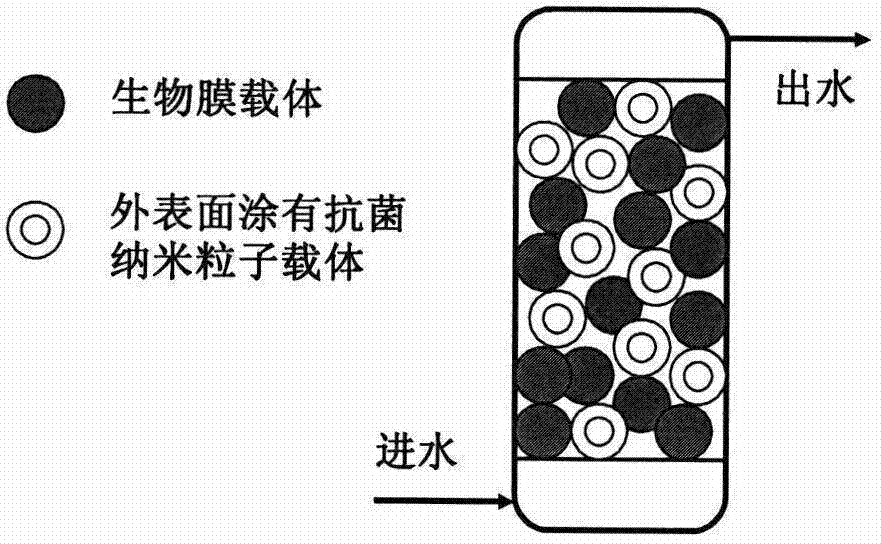

A double carrier fixed bed biofilm reactor

InactiveCN104649410BGrowth inhibitionImprove the distribution effectBiological treatment apparatusSustainable biological treatmentNanoparticleFixed bed

Owner:汉尼科(南京)环保有限公司

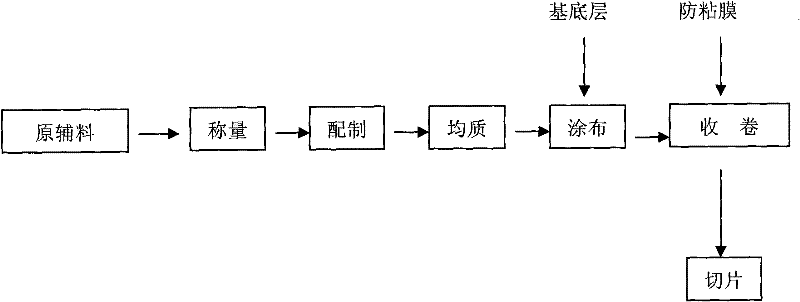

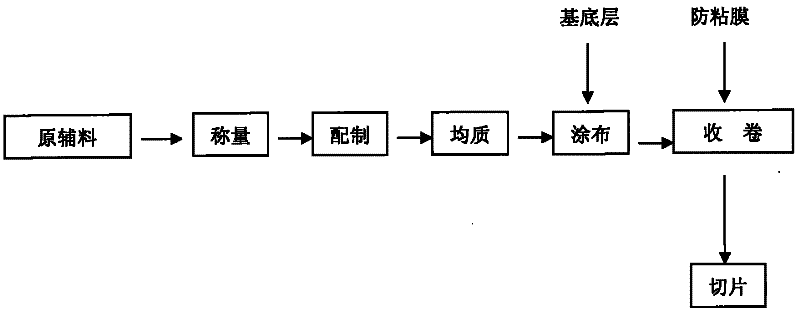

Transdermal nitrendipine adhesive patch and preparation method thereof

ActiveCN101703494BImprove solubilityWell distributedOrganic active ingredientsPharmaceutical non-active ingredientsMedicineCurative effect

The invention relates to a transdermal nitrendipine adhesive patch and a preparation method thereof. The invention prepares a nitrendipine adhesive patch with more uniform drug distribution by selecting polyacrylic acid resin IV as skeleton, simultaneously adopting the skeleton function and adhesive function of the pressure sensitive adhesive to solve the adhesive problem between the drug layer and the substrate layer and using a homogenizer to perform low pressure homogenization to distribute all components evenly. Compared with the prior art, the transdermal nitrendipine adhesive patch of the invention has uniform nitrendipine release rate and better curative effect; and the method of the invention can be used to greatly reduce the production time, increase the production capacity, reduce the energy consumption and simplify the production process.

Owner:蚌埠丰原涂山制药有限公司

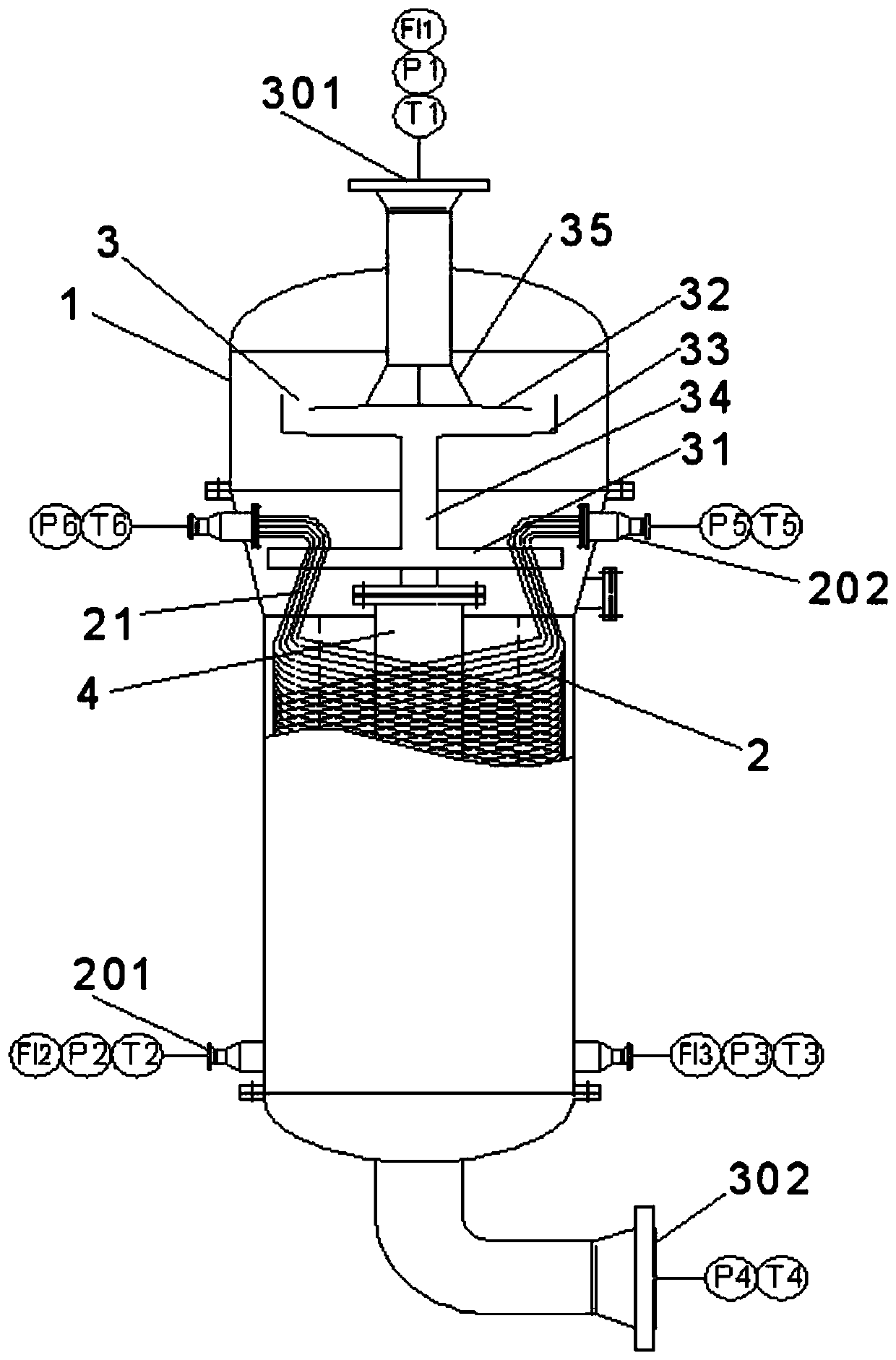

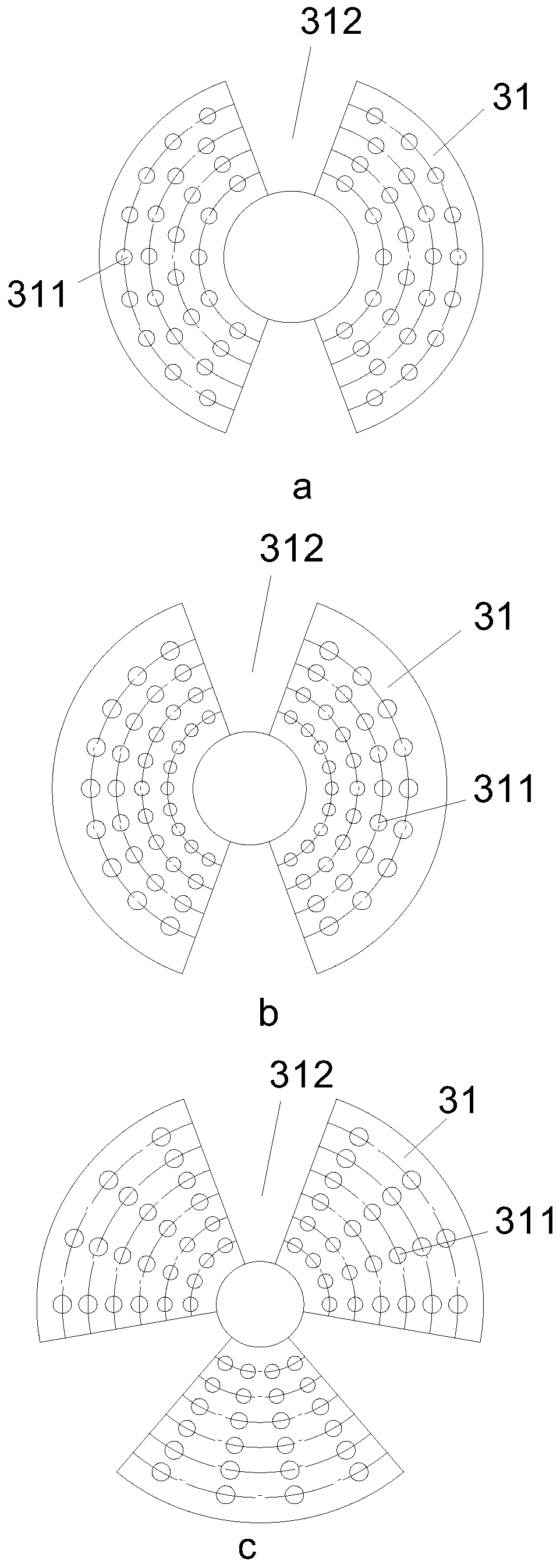

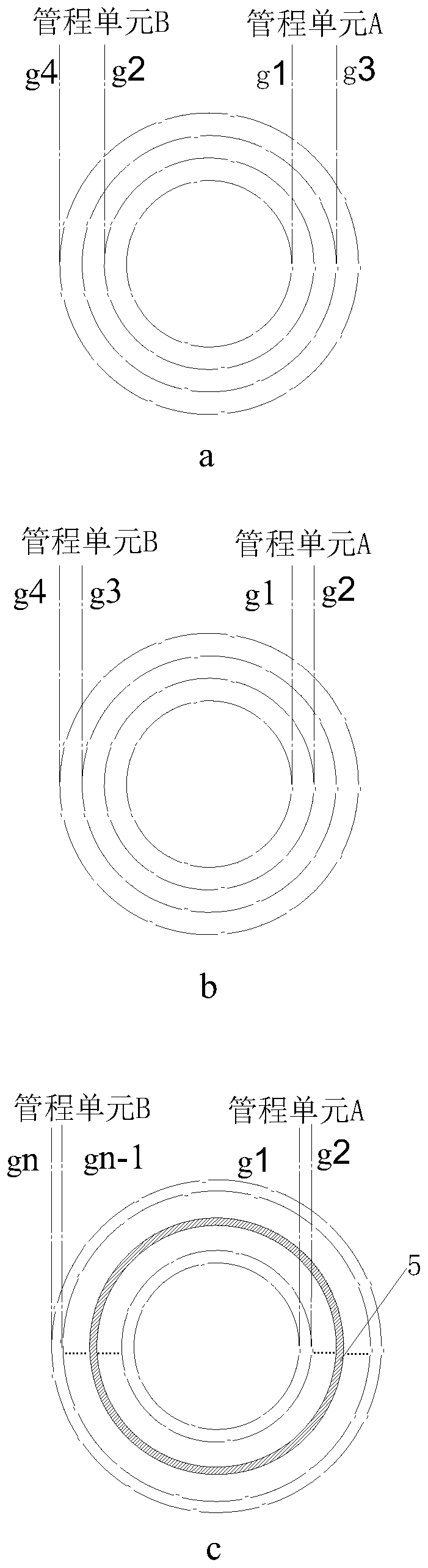

A heat transfer structure and measurement and control method for optimizing heat transfer efficiency

ActiveCN109357551BWell distributedEasy to replaceStationary conduit assembliesHeat exchange apparatusHeat transfer efficiencyMechanical engineering

The invention relates to a heat exchange structure capable of optimizing the heat transfer efficiency and a testing control method, and relates to the technical field of heat exchange devices. The heat exchange structure comprises a heat exchange tube arranged inside a shell body and used for allowing a tube pass fluid to flow through, and a spraying device used for distributing a shell pass fluid; a tube pass inlet and a tube pass outlet which are correspondingly connected to the two ends of the heat exchange tube are arranged on the shell body, a shell pass inlet and a shell pass outlet which are correspondingly connected to the two ends of the spraying device are arranged on the shell body, the spraying device comprises a spraying part, spraying holes are formed in the bottom of the spraying part, the spraying areas of the spraying holes are matched with the arrangement area of the heat exchange tube, the hole diameter of the part, close to the liquid inlet end of the spraying part,of the spraying holes is relatively small, and the hole diameter of the part, far away from the liquid inlet end of the spraying part, of the spraying holes is relatively large. The heat exchange structure has the advantages that dismounting and replacement are convenient, the heat transfer effect is good, and the shell pass fluid is easy to distribute.

Owner:HEFEI GENERAL MACHINERY RES INST

A kind of hyaluronic acid gel composition for hydrolight injection and preparation method thereof

ActiveCN110812270BImprove skin qualityImprove liquidityCosmetic preparationsToilet preparationsDisulfide bondingSkin texture

Owner:BIOREGEN BIOMEDICAL (CHANGZHOU) CO LTD

4-tert-butylcalix[6]arene derivative as well as preparation method and application thereof

ActiveCN102276507BLow toxicityPromote absorptionSulfonic acids salts preparationAntinoxious agentsSalting outStructural formula

The invention discloses a 4-tert-butylcalix[6]arene derivative as well as a preparation method and an application thereof. The 4-tert-butylcalix[6]arene derivative has a structural formula shown in a formula I. The preparation method of the 4-tert-butylcalix[6]arene derivative shown in the formula I comprises the following steps of: uniformly mixing 4-tert-butylcalix[6]arene with a concentrated sulfuric acid water solution for carrying out a sulfonation reaction, and salting out after the reaction is ended to obtain the 4-tert-butylcalix[6]arene derivative shown in the formula I. The 4-tert-butylcalix[6]arene derivative shown in the formula I can be efficiently complexed with a uranium-bearing material, has low toxicity, can be orally taken or injected, is capable of remarkably promoting the uranium-bearing material to be discharged out of a human body, and has important application value in coping with uranium related emergencies in the field of military and civilian use.

Owner:INST OF RADIATION MEDICINE ACAD OF MILITARY MEDICAL SCI OF THE PLA

Lithium-ion battery cathode material lini 0.6-x co 0.2 mn 0.2 al x o 2-y f y and its preparation method

ActiveCN105990577BImproved reversible de-intercalation/intercalation capabilitiesStable internal structureCell electrodesSecondary cellsCharge dischargeRetention ratio

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A kind of oral instant film containing rizatriptan benzoate and preparation method thereof

ActiveCN109730978BPromotes even distributionWell distributedOrganic active ingredientsNervous disorderBenzoic acidElectrospinning

The invention belongs to the technical field of medicine, and relates to an oral instant film preparation containing rizatriptan benzoate prepared by an electrospinning process. The oral instant film prescription comprises 1 part of rizatriptan benzoate, 1-300 parts of film-forming material and 0-50 parts of other auxiliary materials. Oral instant film is obtained through electrospinning process. The conditions of electrospinning are: voltage 5-20kV, advancing speed 0.1-10ml / h, receiving distance 5-20cm, temperature 5-60℃, humidity 10-70%. The oral instant film is composed of nano-polymer fibers formed by electrospinning, and the diameter of the nano-polymer fibers is 10-1000nm. The rizatriptan benzoate is uniformly distributed in an amorphous state in the film preparation. The oral instant film containing rizatriptan benzoate protected by the present invention has higher specific surface area and porosity and faster dissolution rate, more rapid onset, higher bioavailability, and can quickly relieve migraine patient suffering.

Owner:SHENYANG PHARMA UNIVERSITY

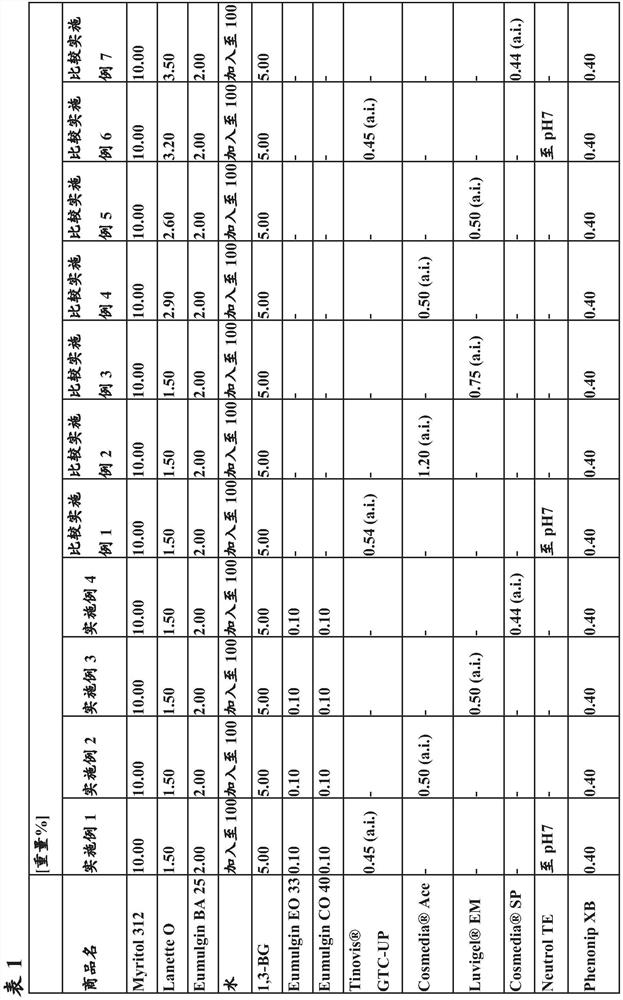

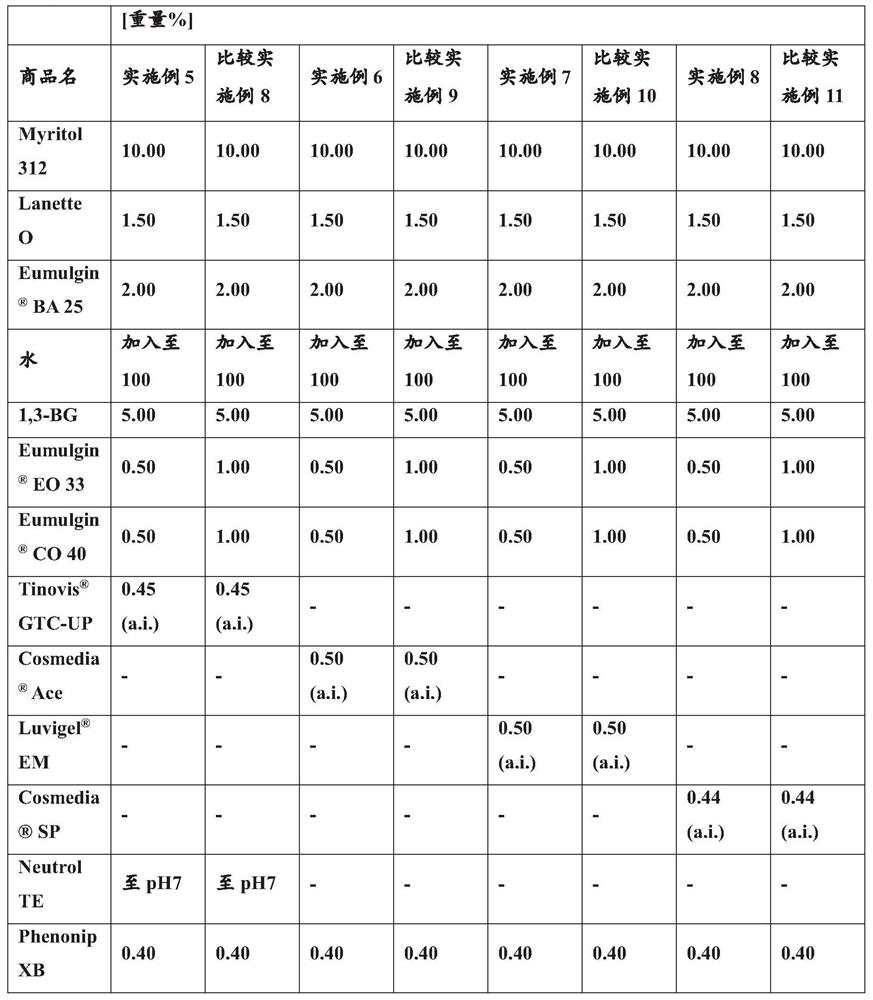

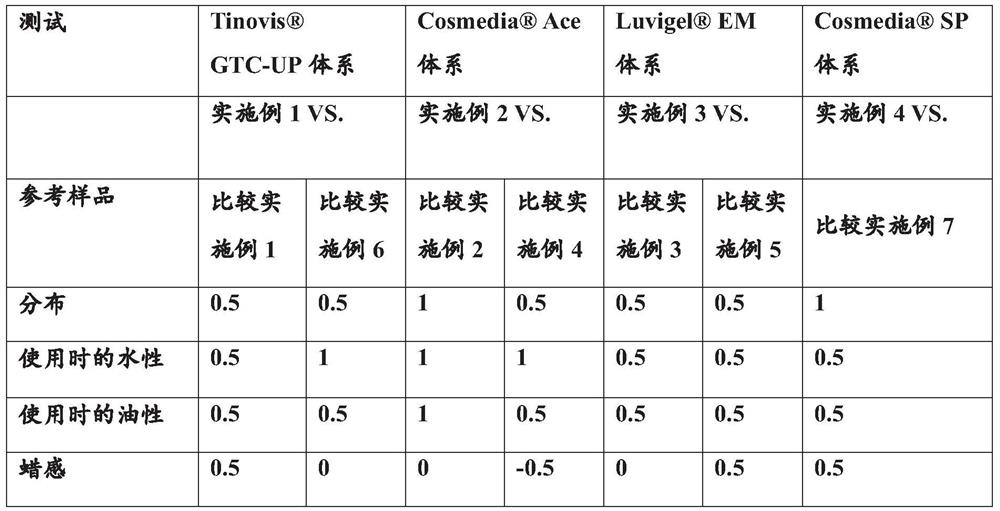

Cosmetic composition, use thereof and method for improving organoleptic properties

PendingCN114746154AWell distributedBroaden applicationCosmetic preparationsHair cosmeticsPolymer sciencePolythylene glycol

The present invention provides a cosmetic composition comprising (a) 0.01 wt% to 2.0 wt% of at least one gel-forming (meth) acrylic polymer, (b) 0.01 wt% to 1.0 wt%, excluding 1.0 wt%, of at least one non-ionic emulsifier, and (c) water, the present invention relates to a cosmetic composition, selected from the group consisting of polyethylene glycol diesters of fatty acids, polypropylene glycol diesters of fatty acids and poly (ethylene glycol-co-propylene glycol) diesters of fatty acids, (c) 0.01% to 1.0% by weight of at least one solubilizer having an HLB value in the range of 12 to 20, and (d) water, each based on the total weight of the cosmetic composition wherein the composition is in the form of a gel or an oil-in-water emulsion, preferably in a gel form. The cosmetic composition of the present invention is in a form that is refreshing, non-greasy and easier to distribute.

Owner:BASF AG

A kind of method for producing methyl hexahydrophthalic anhydride by continuous hydrogenation

ActiveCN107089961BWell distributedImprove conversion rateOrganic chemistryChemical/physical processesThree levelFixed bed

The invention discloses a method for preparing methylhexahydrophthalic anhydride by means of continuous hydrogenation and belongs to the field of organic chemicals. A three-level split-tube fixed bed reactor is adopted for circularly continuous hydrogenating; a split-tube type structure is adopted in the split-tube fixed bed reactor; a solid catalyst is arranged between tube passes; a heat medium is arranged in a shell pass; hydrogen respectively enters from the bottom of each level of split-tube fixed bed reactor in parallel; unreacted hydrogen passes by each split tube and then returns to a hydrogen compressor from the upper part of the reactor; the raw material, methyltetrahydrophthalic anhydride, gradually passes by a high pressure pipe pump, is conveyed to the upper part of the split-tube reactor and is sprayed by a distributor located at the top in the reactor so as to be uniformly distributed on the surface of the solid catalyst and react with hydrogen; after circular reaction through the three-level reactor, the hydrogenating conversion rate is close to 100%. According to the method, the production of methylhexahydrophthalic anhydride by means of continuous hydrogenation is realized, the technical process is clean and the catalyst is reused.

Owner:河南惠成新材料有限公司

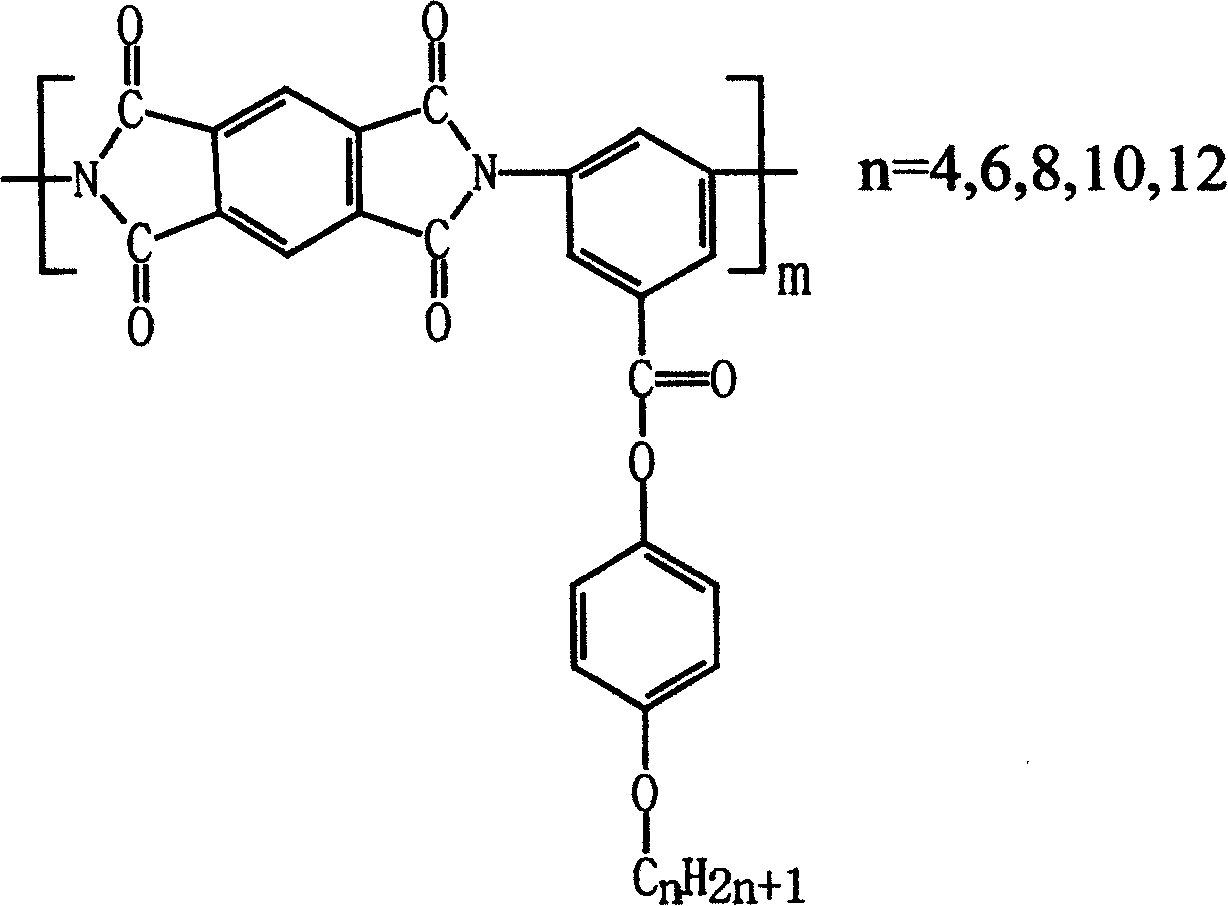

Preparation process of alkoxy side chain polyimide/nanometer silica hybrid

The preparation process of alkoxy side chain polyimide / nanometer silica hybrid material includes: dissolving 4'-butoxy phenyl-3, 5-diamino benzoate in N, N-dimethyl acetamide to compound solution through stirring; adding pyromellitic dianhydride in the same molar amount as that of 4'-butoxy phenyl-3, 5-diamino benzoate into the solution through stirring to obtain polyamic acid solution; adding silica sol to the solution to prepare mixed sol solution; and final vacuum drying to obtain the alkoxy side chain polyimide / nanometer silica hybrid material. The present invention has high heat stability, mechanical stability, high toughness and other advantages, and is used in specific technological field and for modifying other common polyimide.

Owner:SOUTHEAST UNIV

Water insoluble modified polyvinyl alcohol coating liquid and its producing process

The water insoluble modified polyvinyl alcohol coating liquid consists of polyvinyl alcohol, regulator, inorganic matter, crosslinking agent, catalyst and water. The water insoluble modified polyvinyl alcohol coating liquid includes two components, the component A is prepared through mixing all the material except catalyst and heating at certain temperature, and the component B is catalyst. When used, the two components, A and B, are mixed through stirring, and the mixture forms water insoluble film. The foamed film has excellent processibility, high reflectivity to ultraviolet light and infrared light, high wear resistance, low transmissibility and high adhesion to substrate, and is used in product package.

Owner:刘建林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![4-tert-butylcalix[6]arene derivative as well as preparation method and application thereof 4-tert-butylcalix[6]arene derivative as well as preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/5ec562a8-8dd0-4d17-940a-077512833fbd/BSA00000159939700011.png)

![4-tert-butylcalix[6]arene derivative as well as preparation method and application thereof 4-tert-butylcalix[6]arene derivative as well as preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/5ec562a8-8dd0-4d17-940a-077512833fbd/BSA00000159939700021.png)

![4-tert-butylcalix[6]arene derivative as well as preparation method and application thereof 4-tert-butylcalix[6]arene derivative as well as preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/5ec562a8-8dd0-4d17-940a-077512833fbd/BSA00000159939700051.png)