Composite nanofibers as well as preparation method and application thereof

A composite nanofiber, nanofiber technology, applied in chemical instruments and methods, refining with oxygenated compounds, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of polyacid agglomeration, difficult separation and recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

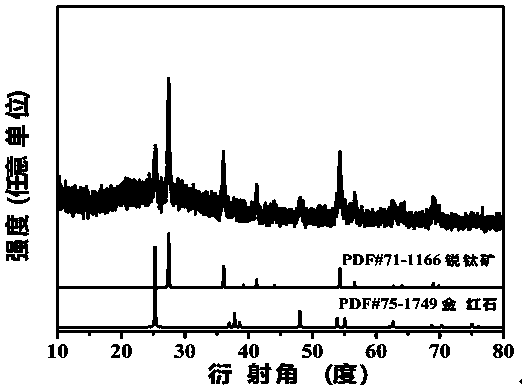

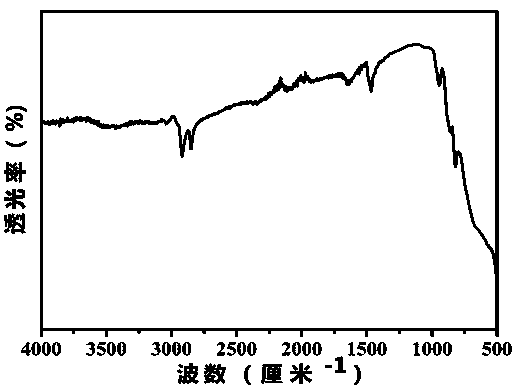

[0033] Example 1 (OTA) 10 [Co 4 (H 2 O) 2 (VW 9 o 34 ) 2 ] / TiO 2 Preparation of composite nanofibers

[0034] A (OTA) 10 [Co 4 (H 2 O) 2 (VW 9 o 34 ) 2 ] / TiO 2 Composite nanofiber synthesis steps are as follows:

[0035] (1) Na 10 [Co 4 (H 2 O) 2 (VW 9 o 34 ) 2 ] 35H 2 Synthesis of O:

[0036] 1.2g Co(NO 3 ) 2 ·6H 2 O and 6g Na 2 WO 4 2H 2 O was completely dissolved in 120mL 0.5M NaAC / HAC buffer solution (pH=4.8) under magnetic stirring, and then 0.27g NaVO 3 , the mixed solution was heated to 80°C and kept for 2h, and the hot filtered brown solid was vacuum-dried in a drying oven for 24h, and finally, Na 10 [Co 4 (H 2 O) 2 (VW 9 o 34 ) 2 ] 35H 2 O;

[0037] (2) TiO 2 Synthesis of Nanofibers:

[0038] Using butyl titanate as a titanium source, it was completely dissolved in a mixed solvent formed by N,N-dimethylformamide, glacial acetic acid and acetylacetone, and then polyvinylpyrrolidone with a molecular weight of 1,300,000 was added ...

Embodiment 21

[0043] Example 2 1 (OTA) 10 [Co 4 (H 2 O) 2 (VW 9 o 34 ) 2 ] / TiO 2 Preparation of composite nanofibers

[0044] A (OTA) 10 [Co 4 (H 2 O) 2 (VW 9 o 34 ) 2 ] / TiO 2 Composite nanofiber synthesis steps are as follows:

[0045] (1) Na 10 [Co 4 (H 2 O) 2 (VW 9 o 34 ) 2 ] 35H 2 Synthesis of O:

[0046] 1.2g Co(NO 3 ) 2 ·6H 2 O and 6g Na 2 WO 4 2H 2 O was completely dissolved in 120mL 0.5M NaAC / HAC buffer solution (pH=4.8) under magnetic stirring, and then 0.27g NaVO 3 , the mixed solution was heated to 75°C and kept for 2.5h, and the hot filtered brown solid was vacuum-dried in a drying oven for 30h, and finally, Na 10 [Co 4 (H 2 O) 2 (VW 9 o 34 ) 2 ] 35H 2 O;

[0047] (2) TiO 2 Synthesis of Nanofibers:

[0048] Using butyl titanate as a titanium source, it was completely dissolved in a mixed solvent formed by N,N-dimethylformamide, glacial acetic acid and acetylacetone, and then polyvinylpyrrolidone with a molecular weight of 1,300,000 was ad...

Embodiment 3

[0053] Example 3 Extraction Catalytic Oxidative Desulfurization Experiment of Simulated Oil Containing Benzothiophene

[0054] Completely dissolve 0.10g of biphenyl and 0.21g of benzothiophene in 100mL of n-octane to obtain 100mL of simulated oil containing 500ppm benzothiophene; first, add 5mL of simulated oil to 25mL of Place the round bottom flask in a temperature-controlled water bath and activate it for 15 min; then, add 21 μL hydrogen peroxide, 1 mL ionic liquid [Bmim]PF to the above flask 6 and 0.01g of the composite nanofiber prepared in Example 1, magnetically stirred for 90min, and the upper oil sample was taken out every 10min for gas chromatography analysis. The results showed that adding 21 μL of H 2 0 2 , after 90 minutes of reaction, the catalytic efficiency of 0.01g of this catalyst at 50°C is 79%, see Figure 4 Shown; after the reaction finishes, the upper strata simulated oil product is dumped as much as possible, then with dichloromethane the residue in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com