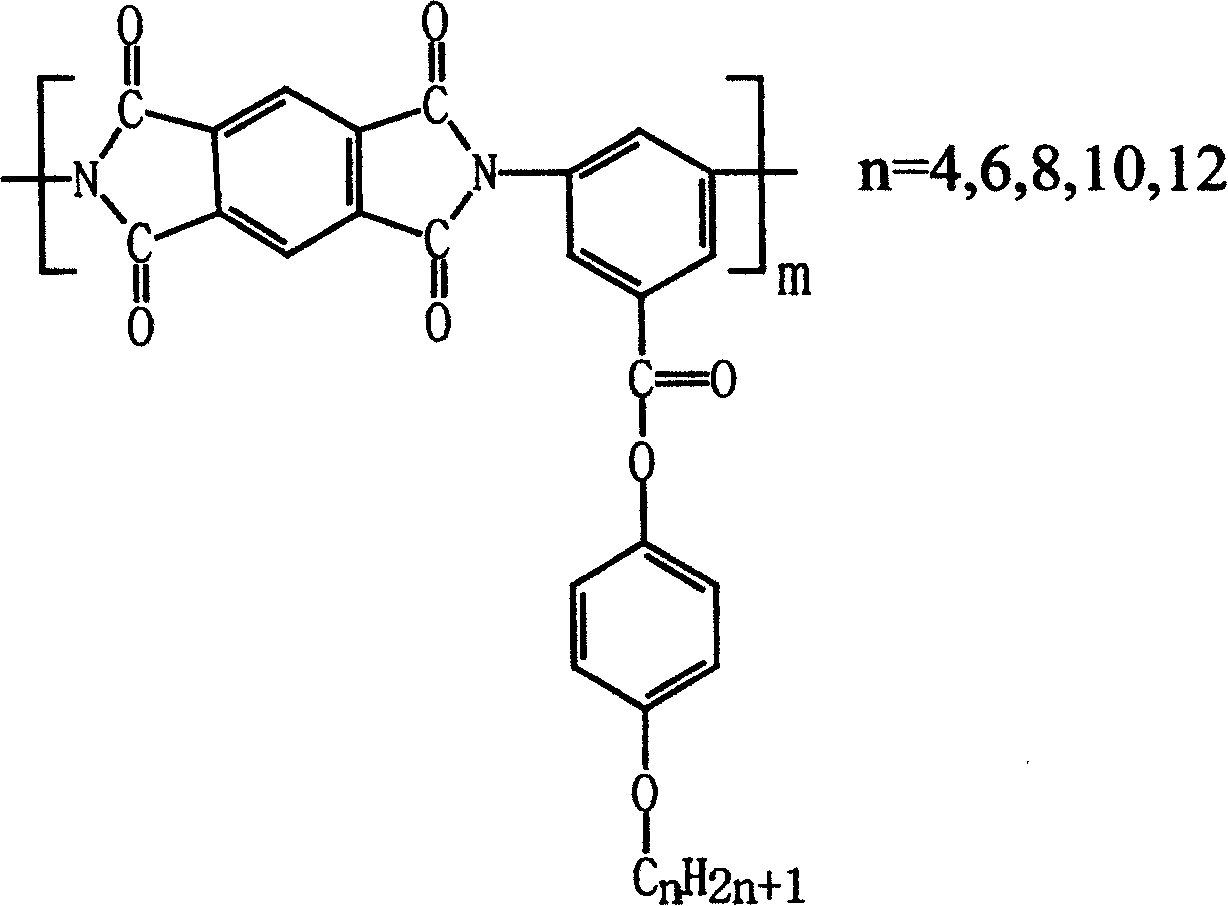

Preparation process of alkoxy side chain polyimide/nanometer silica hybrid

A technology of nano-silica and polyimide, which is applied in the field of preparation of alkoxy side-chain polyimide/nano-silica hybrid materials, can solve the problems of thermal stability decline and achieve thermal stability Reinforcement, reduction of thermal expansion coefficient, small particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] with C 4 -PMDA / SiO2 2 As an example, take polyamic acid solution and a certain amount of silica sol and mix them evenly, spin-lay and imidize to make nano-SiO 2 material (thickness about 0.5mm). prepared under the same conditions without nano-SiO 2 materials compared when SiO 2 When the content is 2% (mass ratio): the maximum light transmittance decreases from 89% to 87%, the tensile strength at room temperature increases to 131.5%, the elongation at break increases from 20% to 33%, and the thermal decomposition temperature increases from 377°C increased to 395°C; when SiO 2 When the content is 4% (mass ratio): the maximum light transmittance decreases from 89% to 84%, the tensile strength at room temperature increases to 140%, the elongation at break increases from 20% to 39%, and the thermal decomposition temperature increases from 377°C increased to 425°C.

Embodiment 2

[0030] with C 12 -PMDA as an example, take polyamic acid solution and a certain amount of silica sol and mix evenly, spin laying, imidization to make nano-SiO 2 material (thickness about 0.5mm). prepared under the same conditions without nano-SiO 2 materials compared when SiO 2When the content is 2% (mass ratio): the maximum light transmittance decreases from 82% to 79%, the tensile strength at room temperature increases to 138.6%, the elongation at break increases from 26% to 41%, and the thermal decomposition temperature increases from 355.6°C increased to 385°C; when SiO 2 When the content is 4% (mass ratio): the maximum light transmittance decreases from 82% to 76%, the tensile strength at room temperature increases to 143%, the elongation at break increases from 26% to 43%, and the thermal decomposition temperature increases from 355.6°C increased to 402°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com