Patents

Literature

3070 results about "Polyamic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyamic acid is a precursor of polyimide. It is a multi-ionic polymer which contains positive and negative electric charges. Here, analysis under two different mobile phases were compared: (1) NMP alone and (2) with LiBr and phosphoric acid added to NMP.

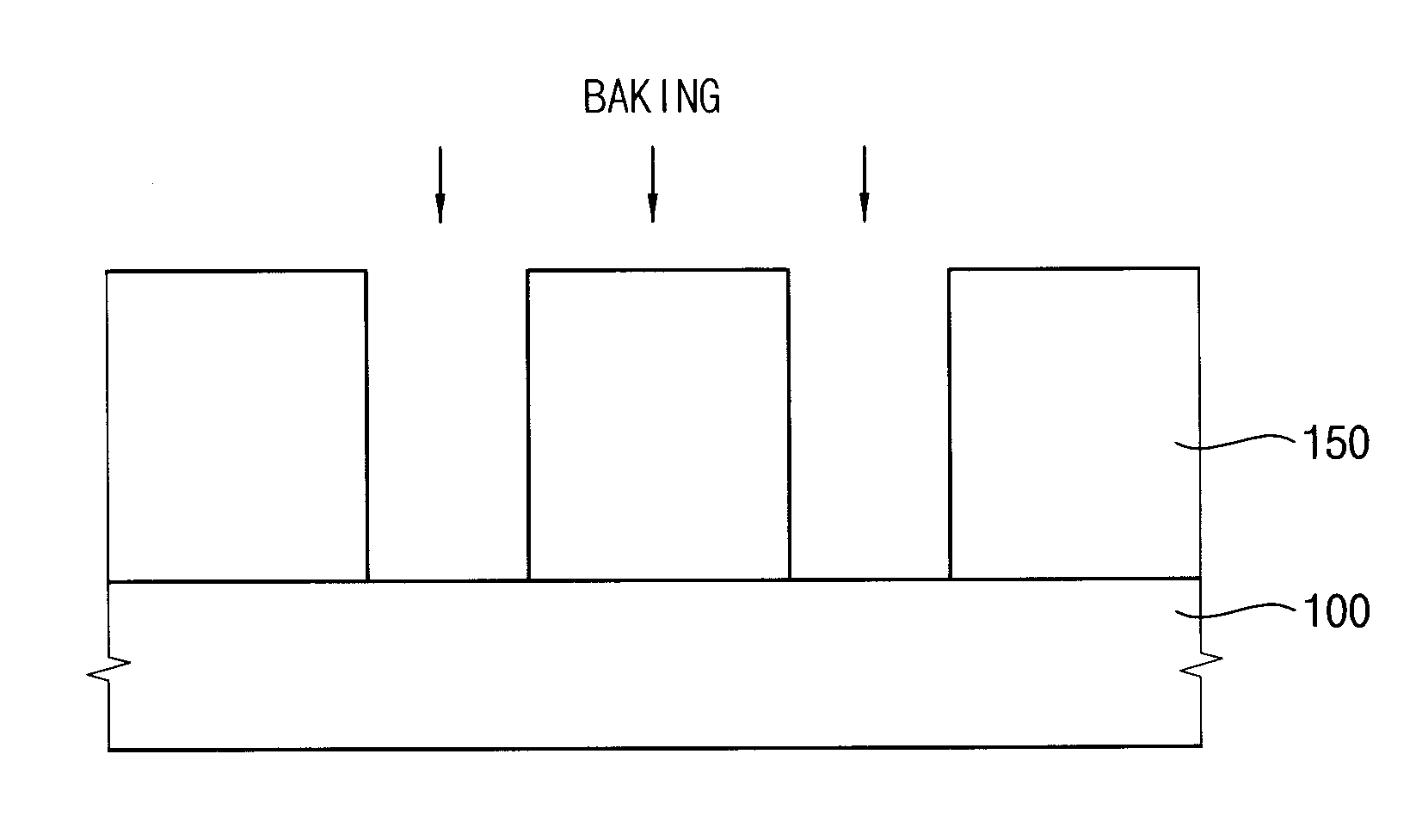

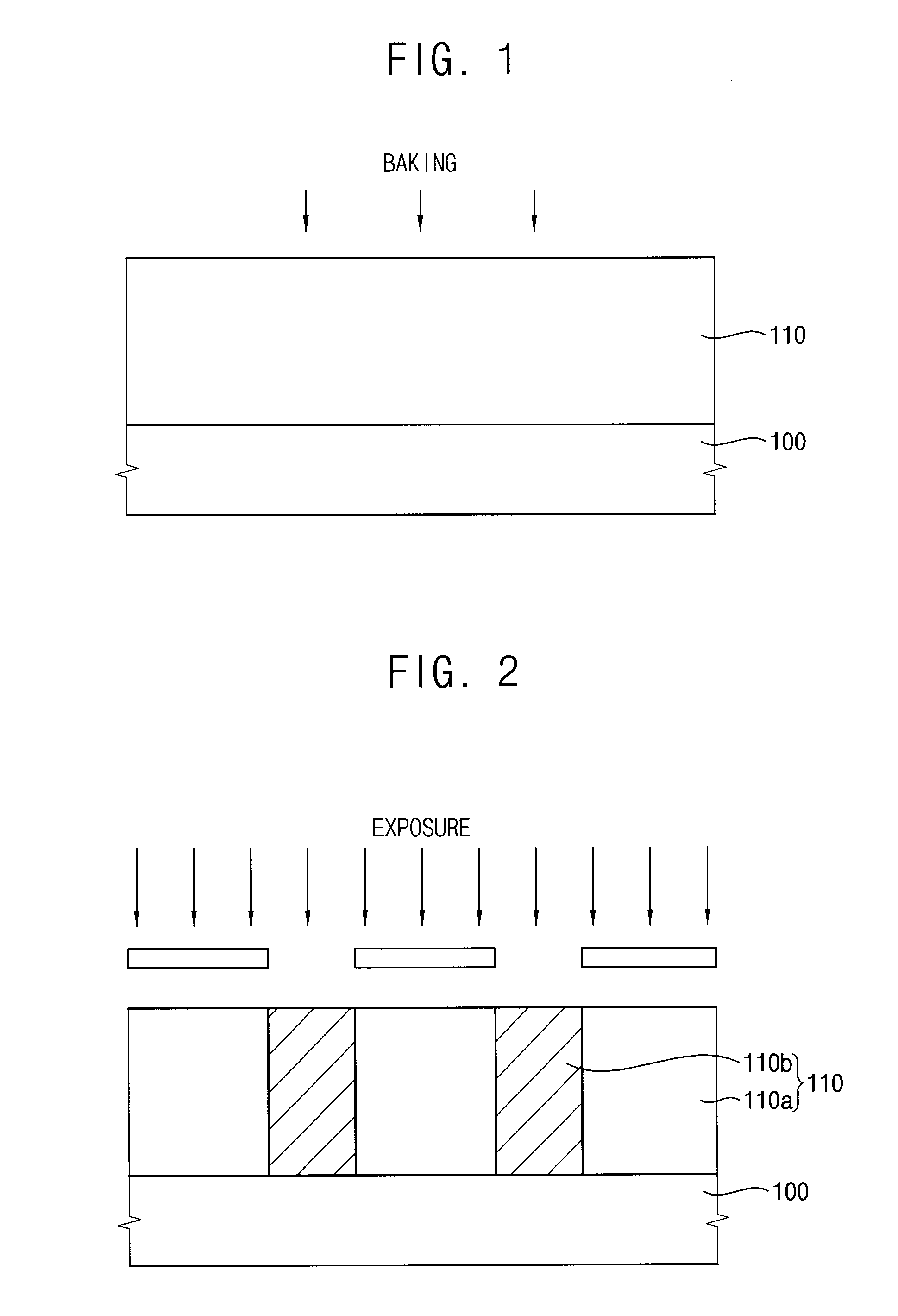

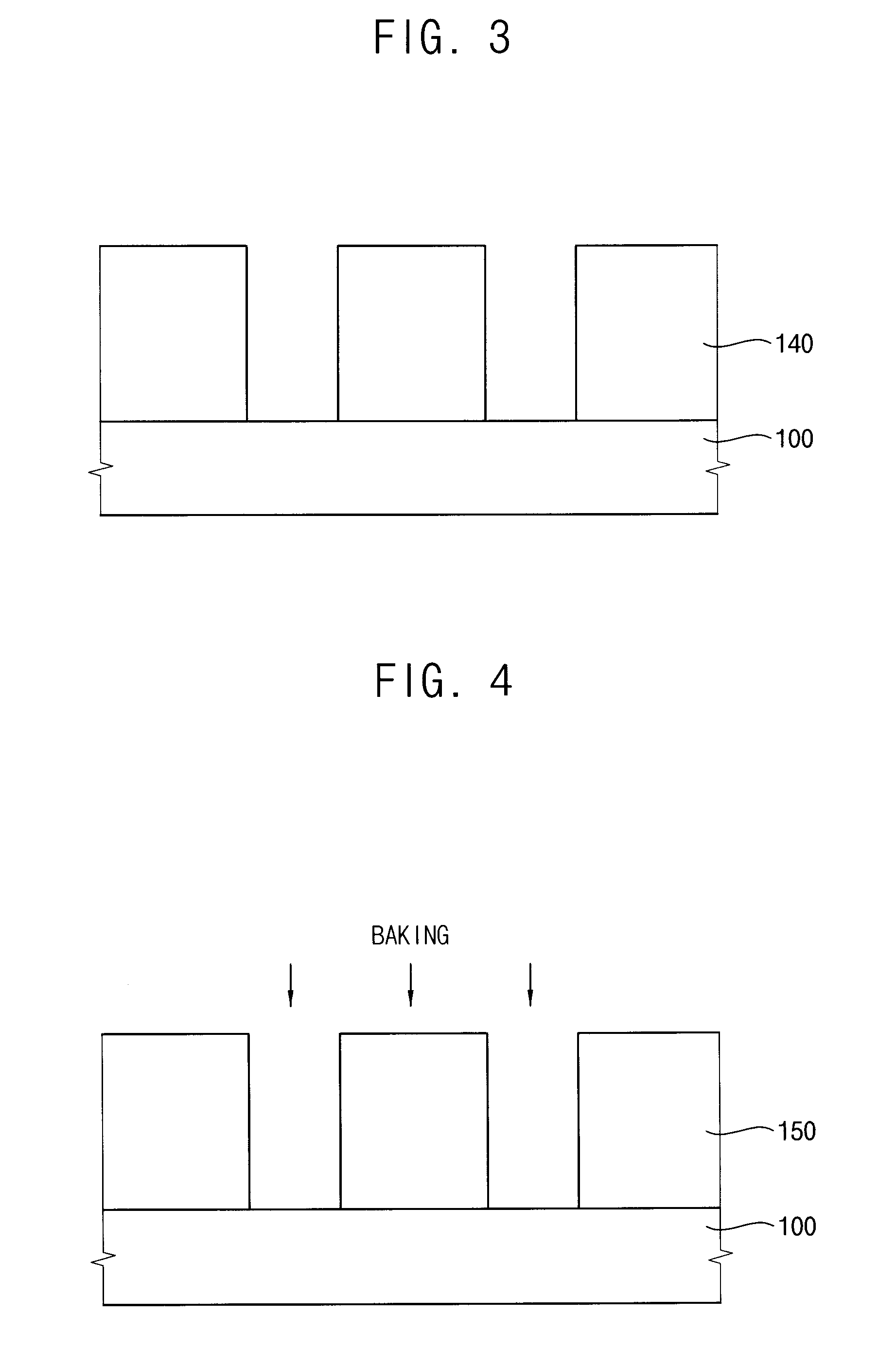

Spin-on carbon compositions for lithographic processing

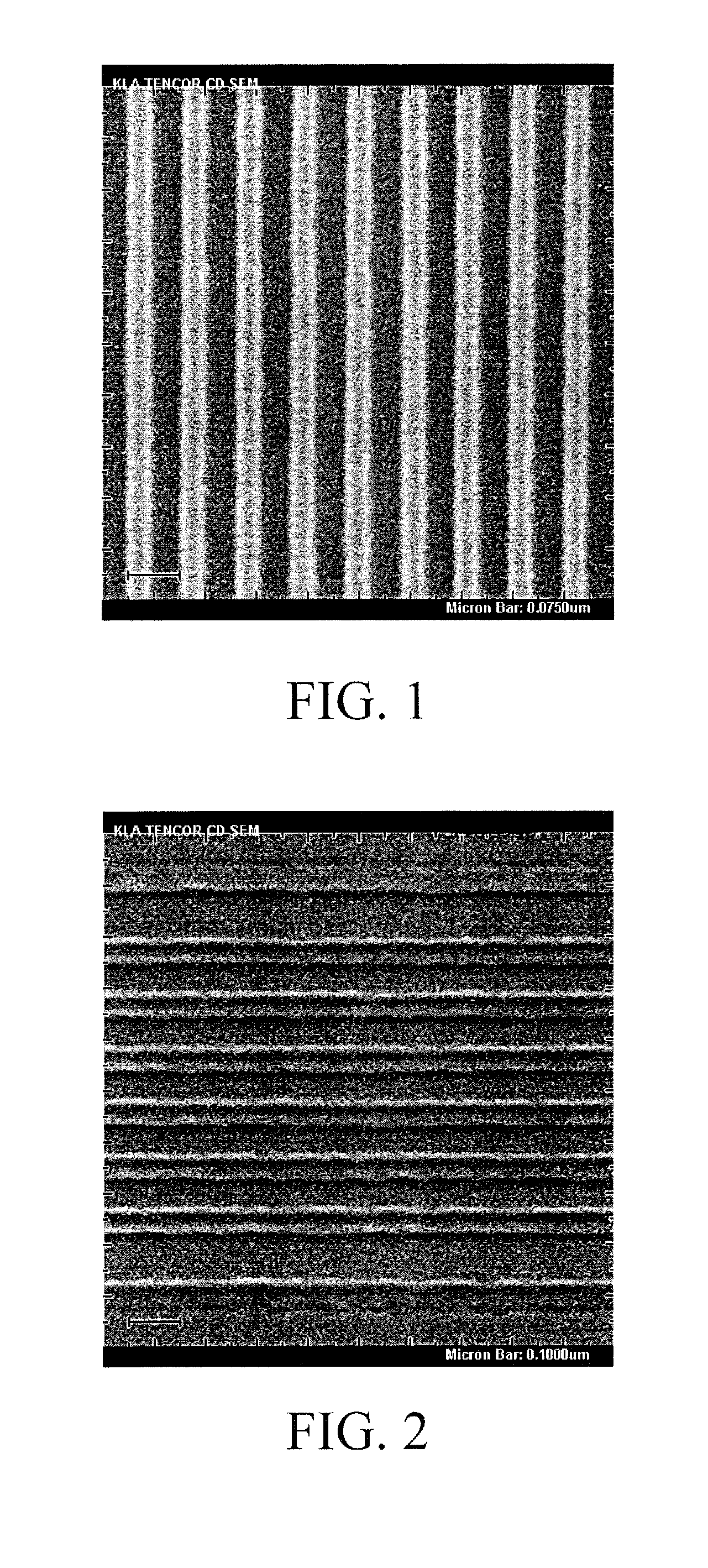

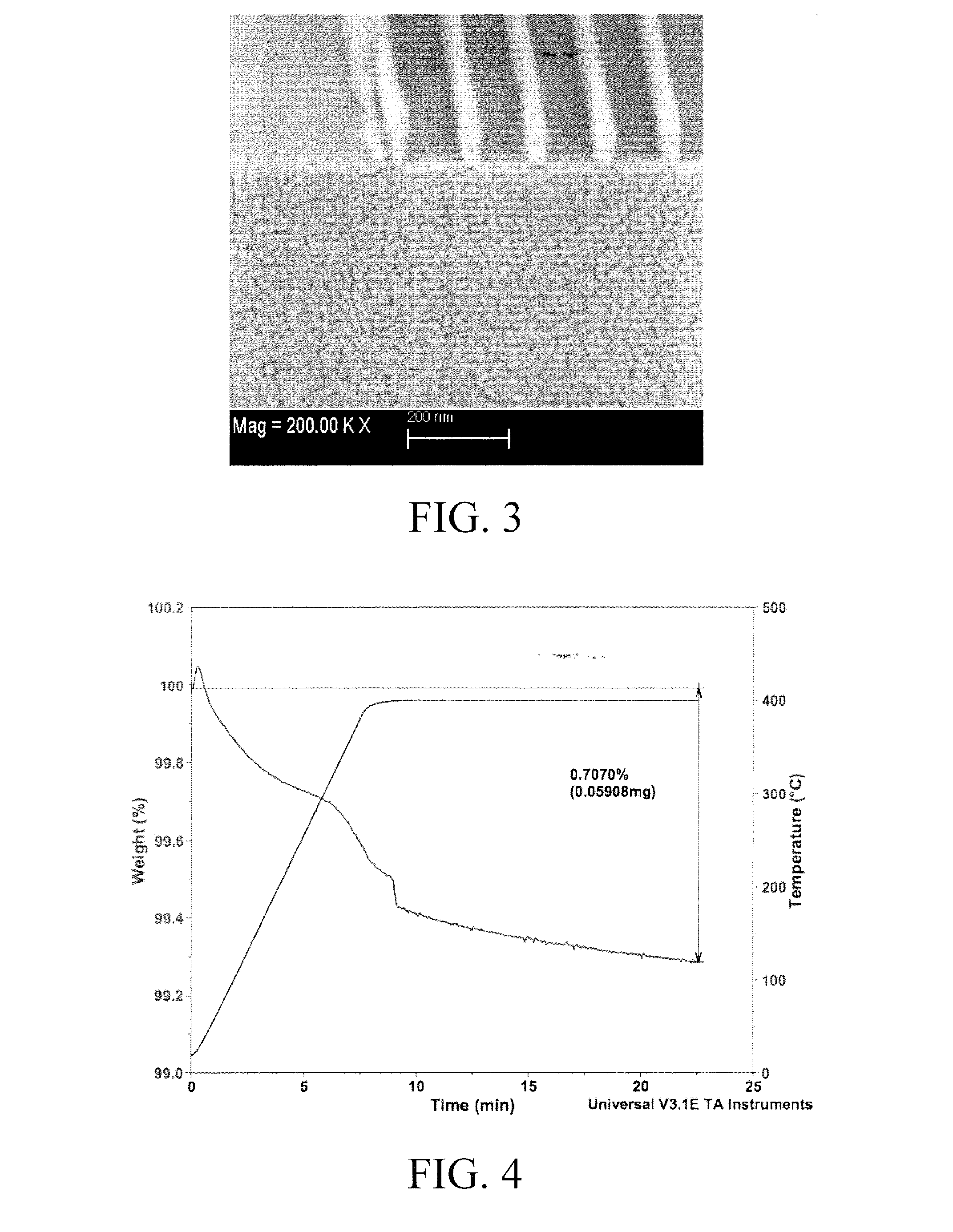

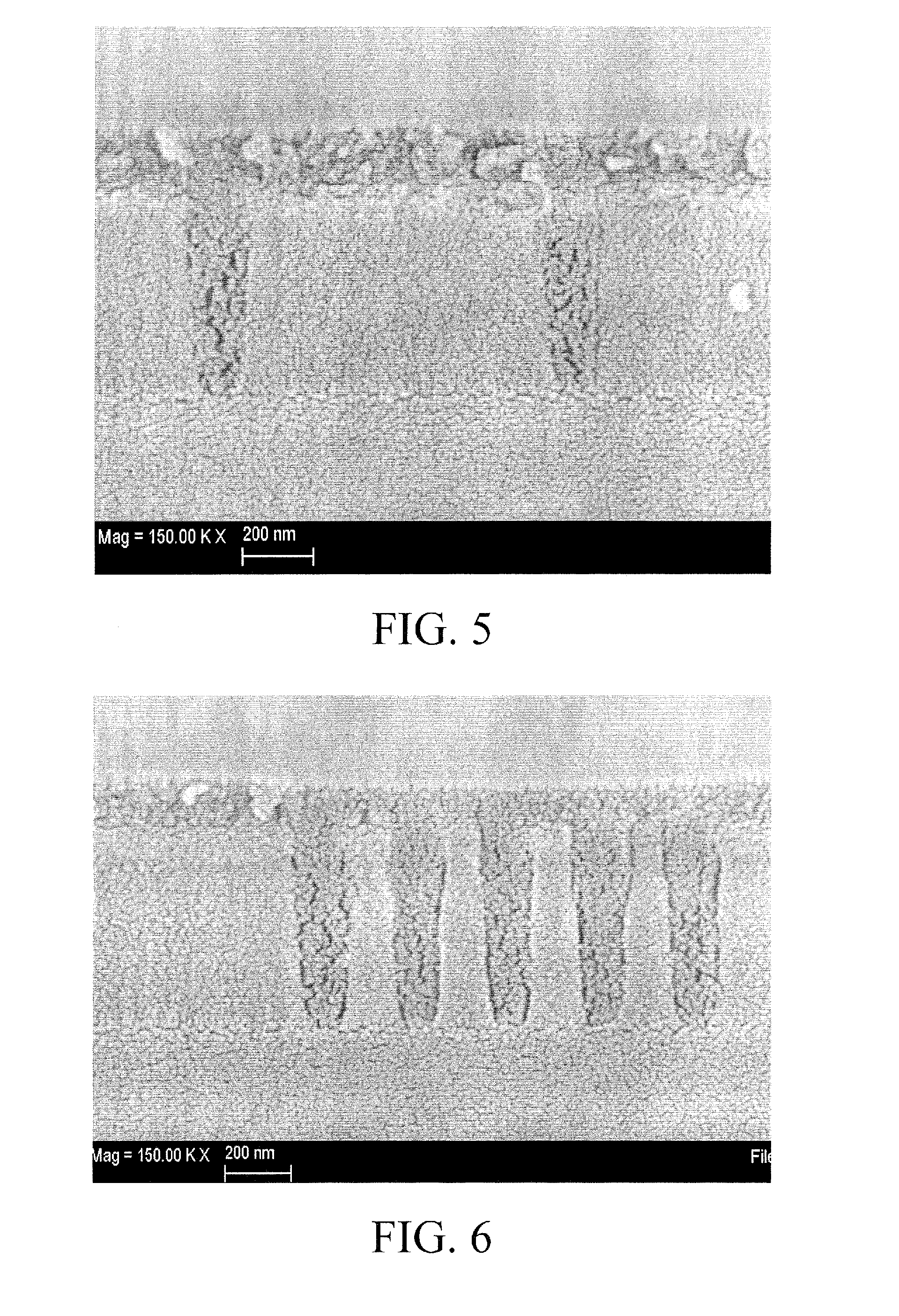

The invention described herein is directed towards spin-on carbon materials comprising polyamic acid compositions and a crosslinker in a solvent system. The materials are useful in trilayer photolithography processes. Films made with the inventive compositions are not soluble in solvents commonly used in lithographic materials, such as, but not limited to PGME, PGMEA, and cyclohexanone. However, the films can be dissolved in developers commonly used in photolithography. In one embodiment, the films can be heated at high temperatures to improve the thermal stability for high temperature processing. Regardless of the embodiment, the material can be applied to a flat / planar or patterned surface. Advantageously, the material exhibits a wiggling resistance during pattern transfer to silicon substrate using fluorocarbon etch.

Owner:BREWER SCI

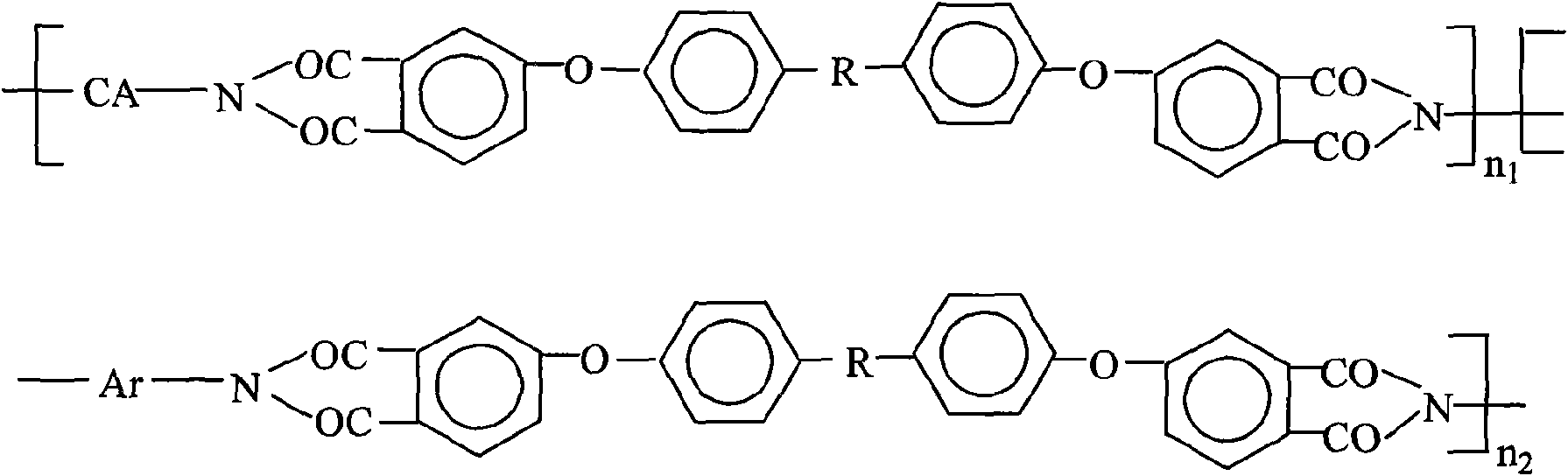

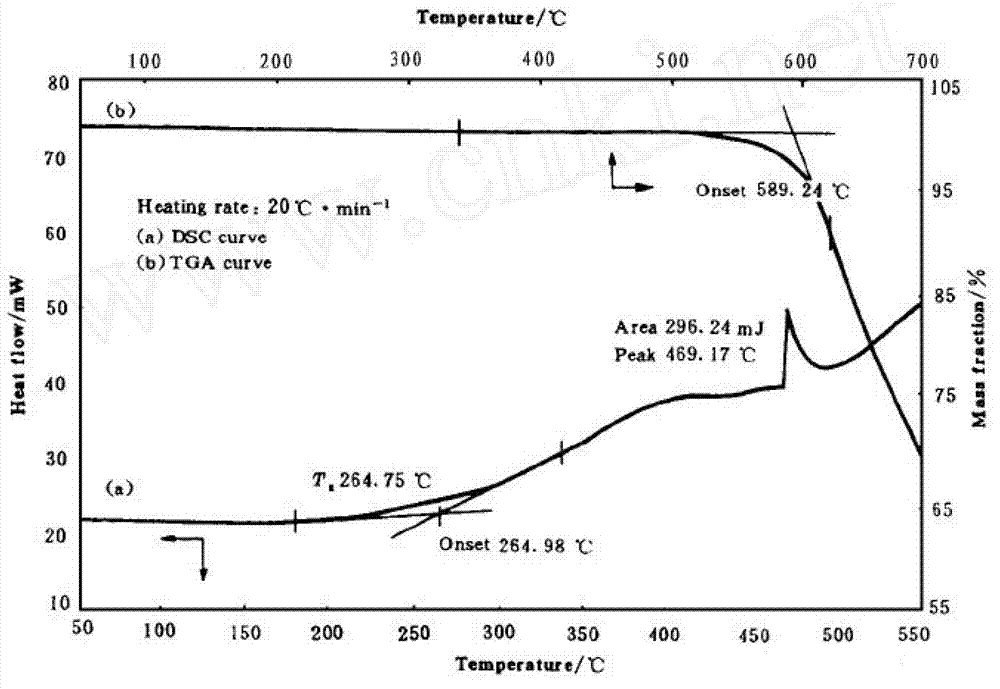

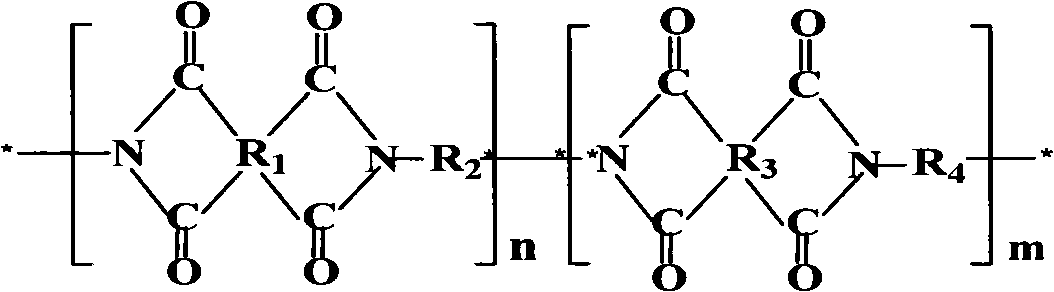

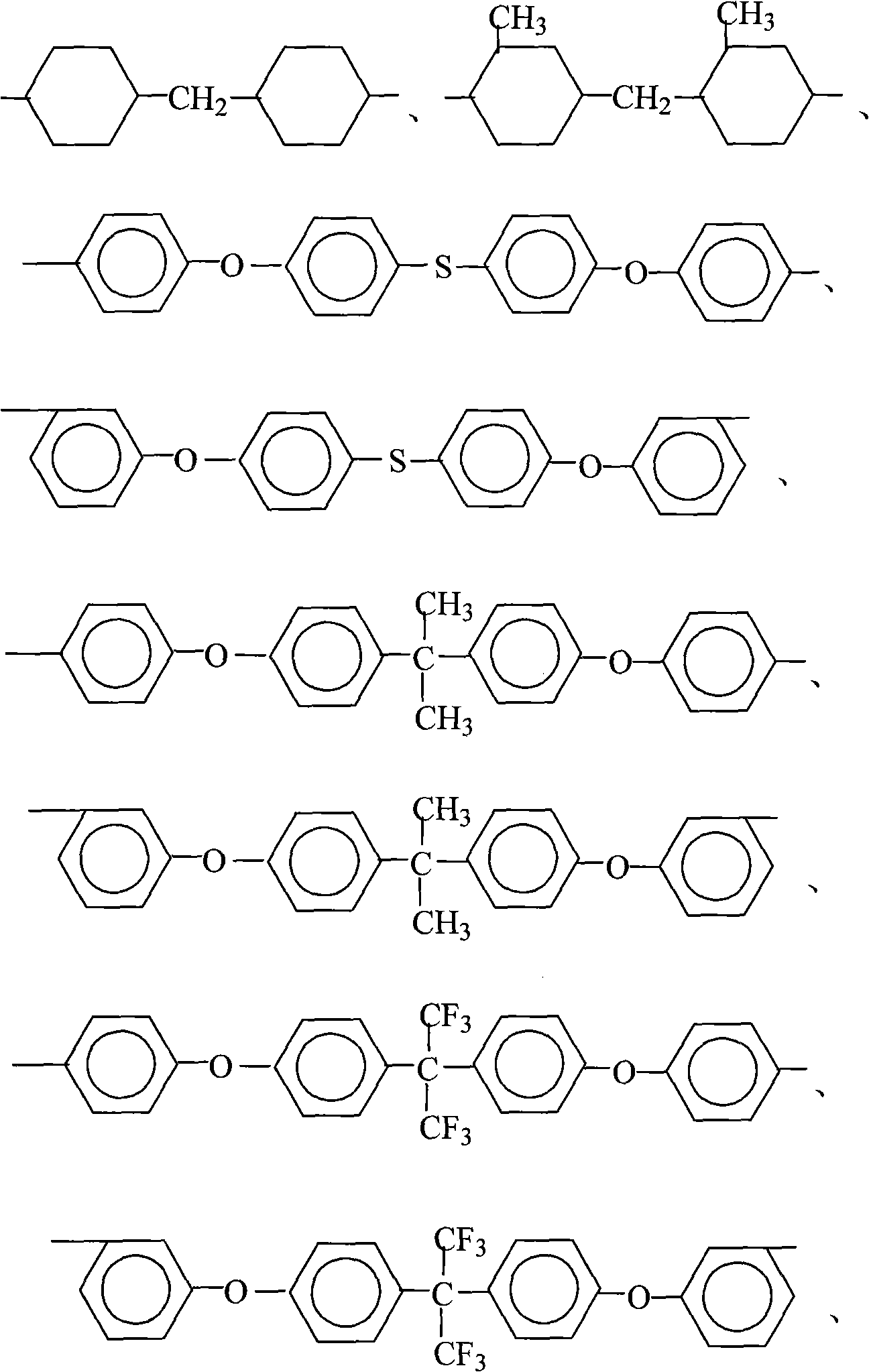

Alicyclic-containing polyimide film and preparation method thereof

InactiveCN101580637AConvenient sourceLow costTelescopesNon-linear opticsOptical communicationPhotochemistry

The invention relates to an alicyclic-containing polyimide film. The molecular structure general formula of the film is the right formula, wherein, -CA- is a bivalence connection group of an alicyclic dibasic primary amine, -Ar- is a bivalence connection group of an aromatic dibasic primary amine, and -R- is a bivalence connection group of an aromatic dibasic estolide. The preparation thereof includes: the alicyclic dibasic primary amine and the aromatic dibasic primary amine are dissolved in non-proton organic solvent with strong polarity, the aromatic dibasic estolide is added, the non-proton organic solvent with strong polarity is used for regulating the viscosity of the alicyclic-containing polyamic acid resin solution after reaction for 1-3 hours, forming is carried out in a curtain coating machine, and dehydration fever imidization, cooling and demoulding are carried out so as to obtain the film. The preparation method has mild reaction condition and low cost and is environmentally friendly; and meanwhile, the alicyclic-containing polyimide film has excellent mechanic property and heat resistant property and low water absorption, and the visible light transmission thereof is as high as more than 97%. The film has good application prospect in the fields of optical waveguide material, photorefractive material and photoelectric material in optical communication field and direct action membrane material in the liquid crystal display field and the like.

Owner:DONGHUA UNIV

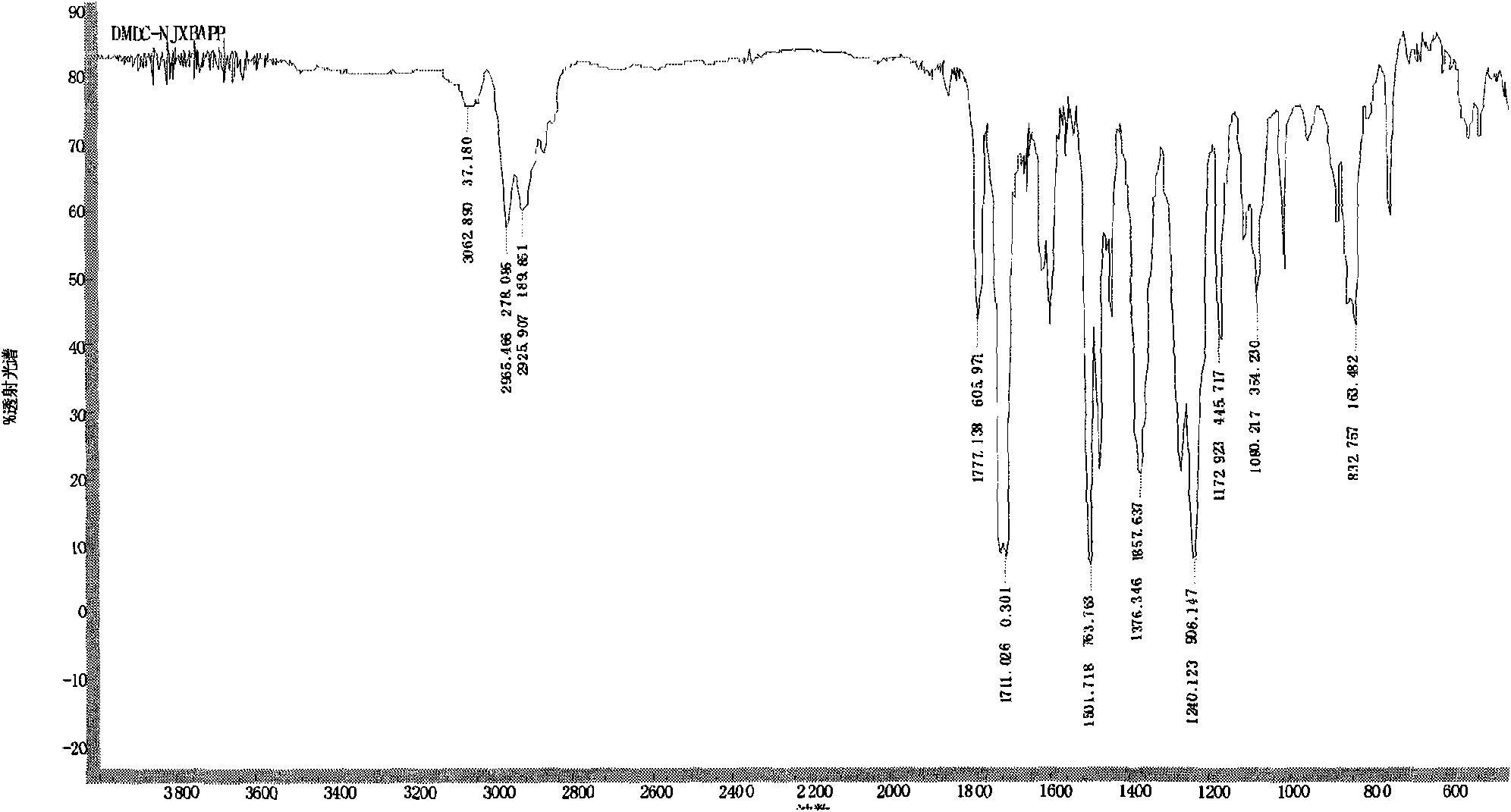

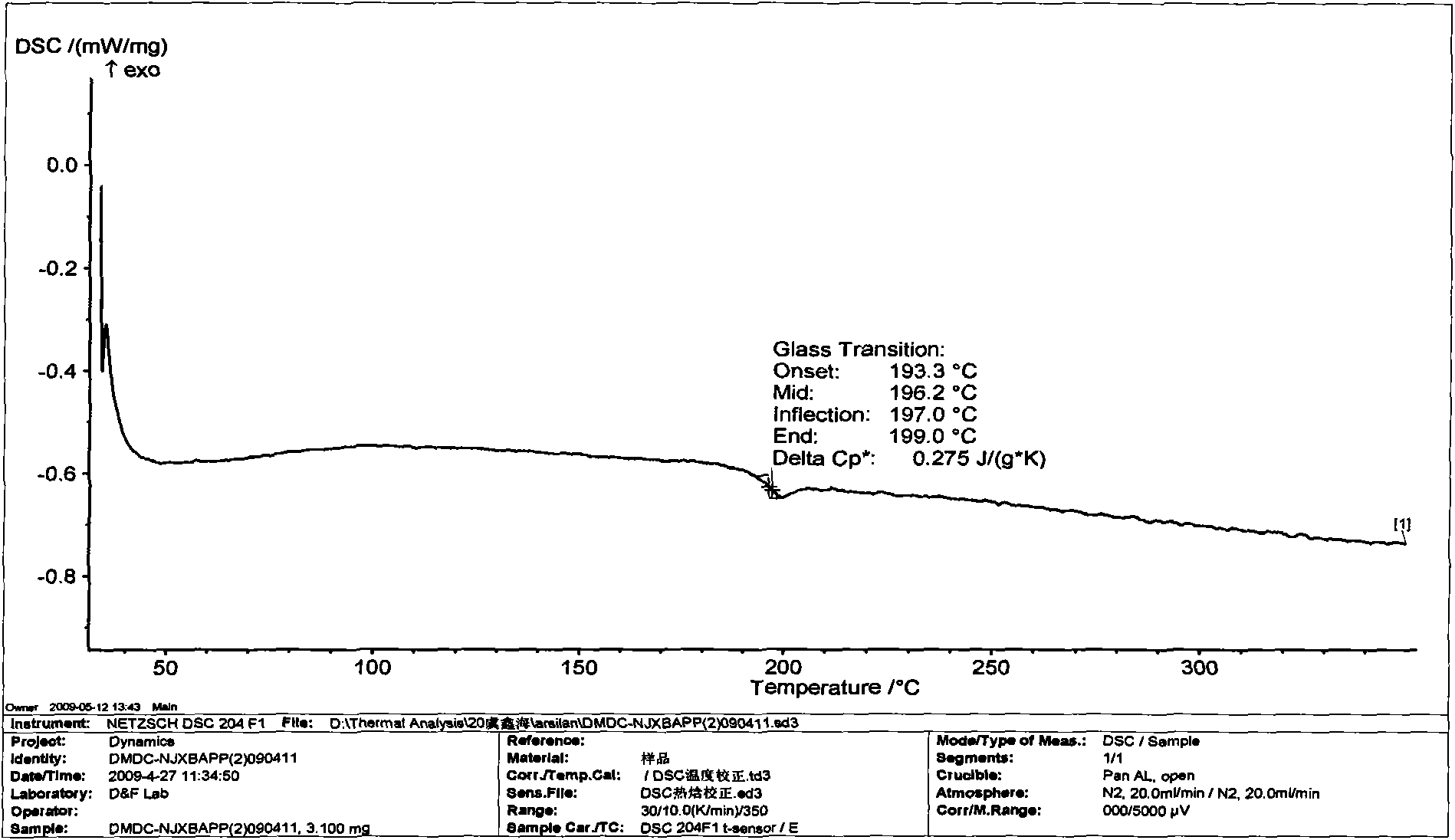

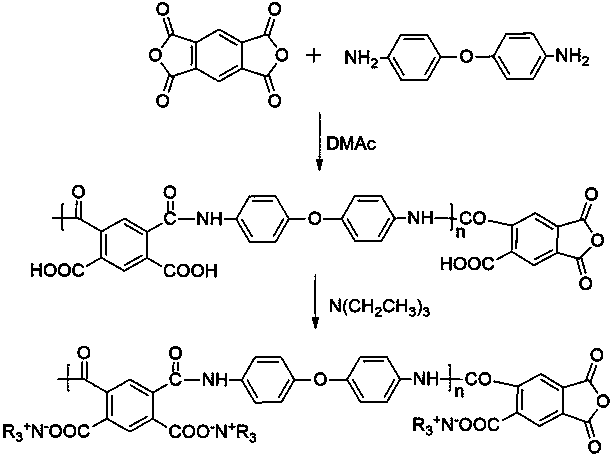

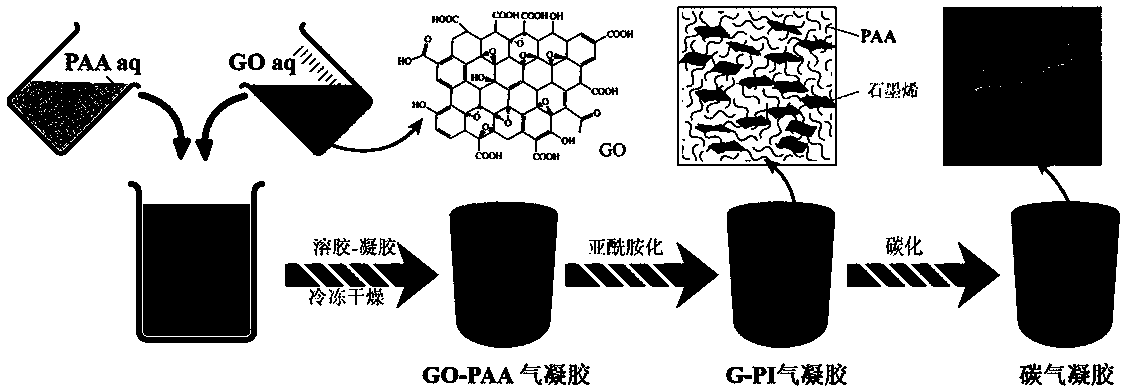

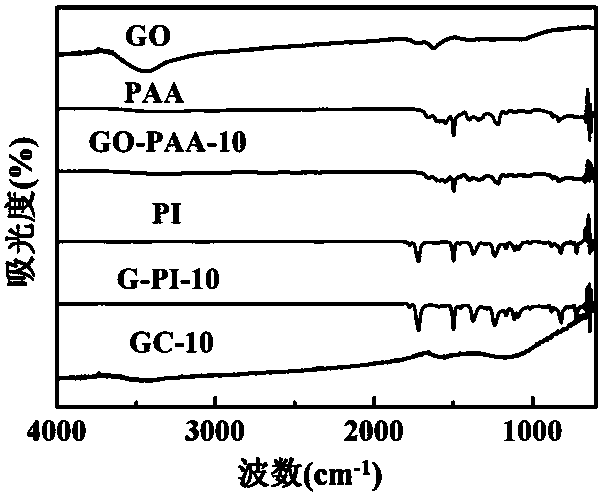

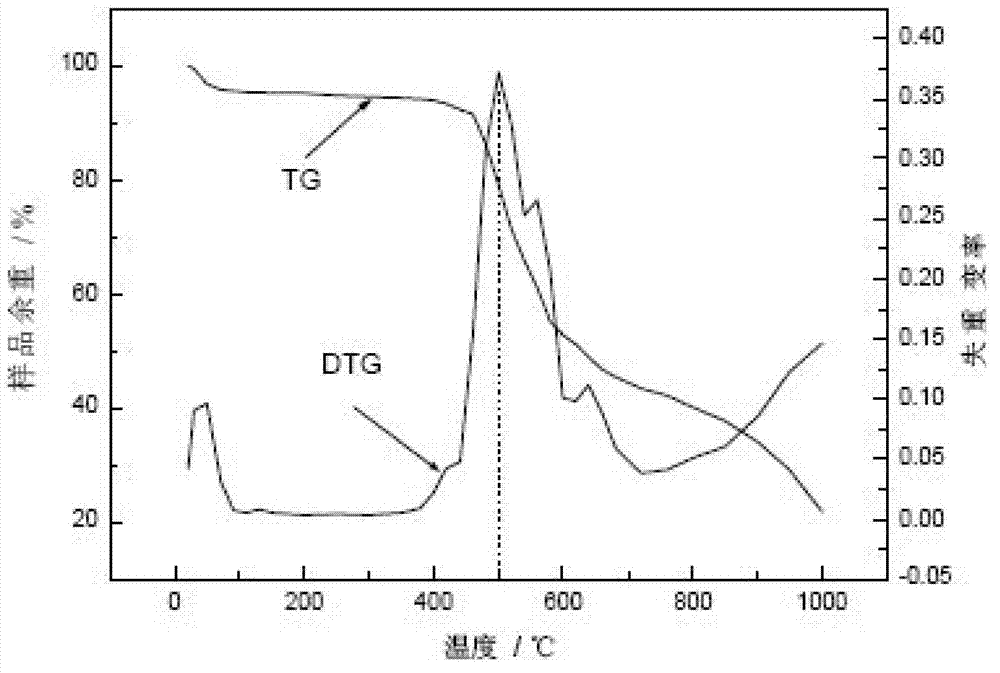

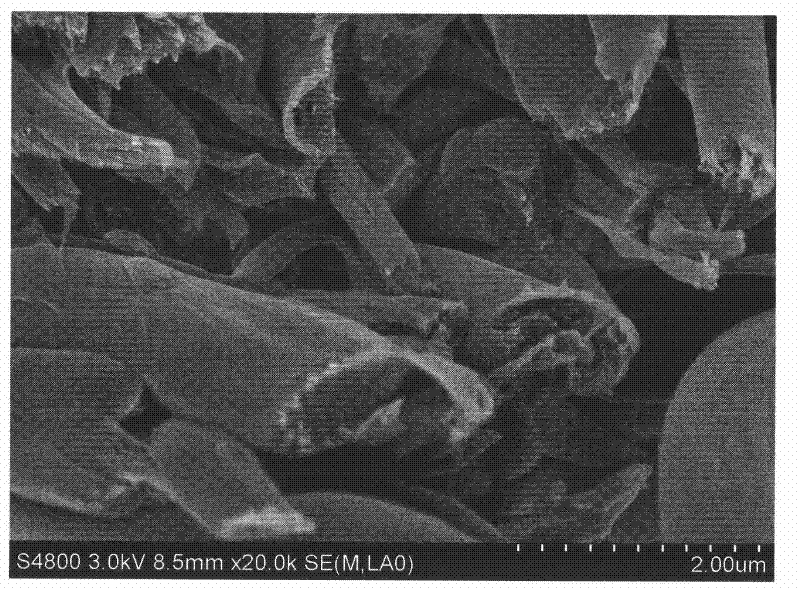

Preparation method of graphene/polyimide-based carbon aerogel

InactiveCN104355302AEasy to makeThe preparation process is environmentally friendlyFreeze-dryingNew energy

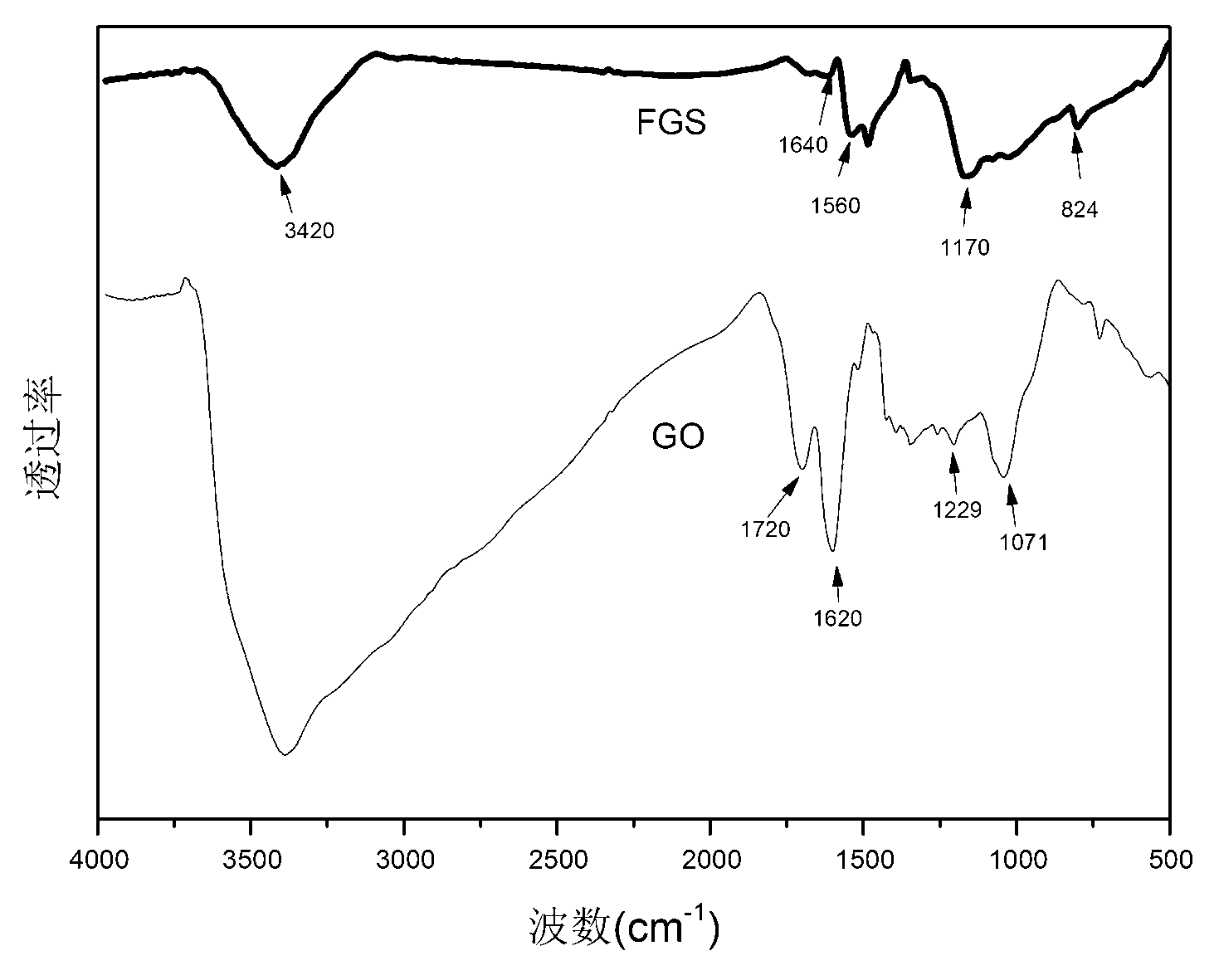

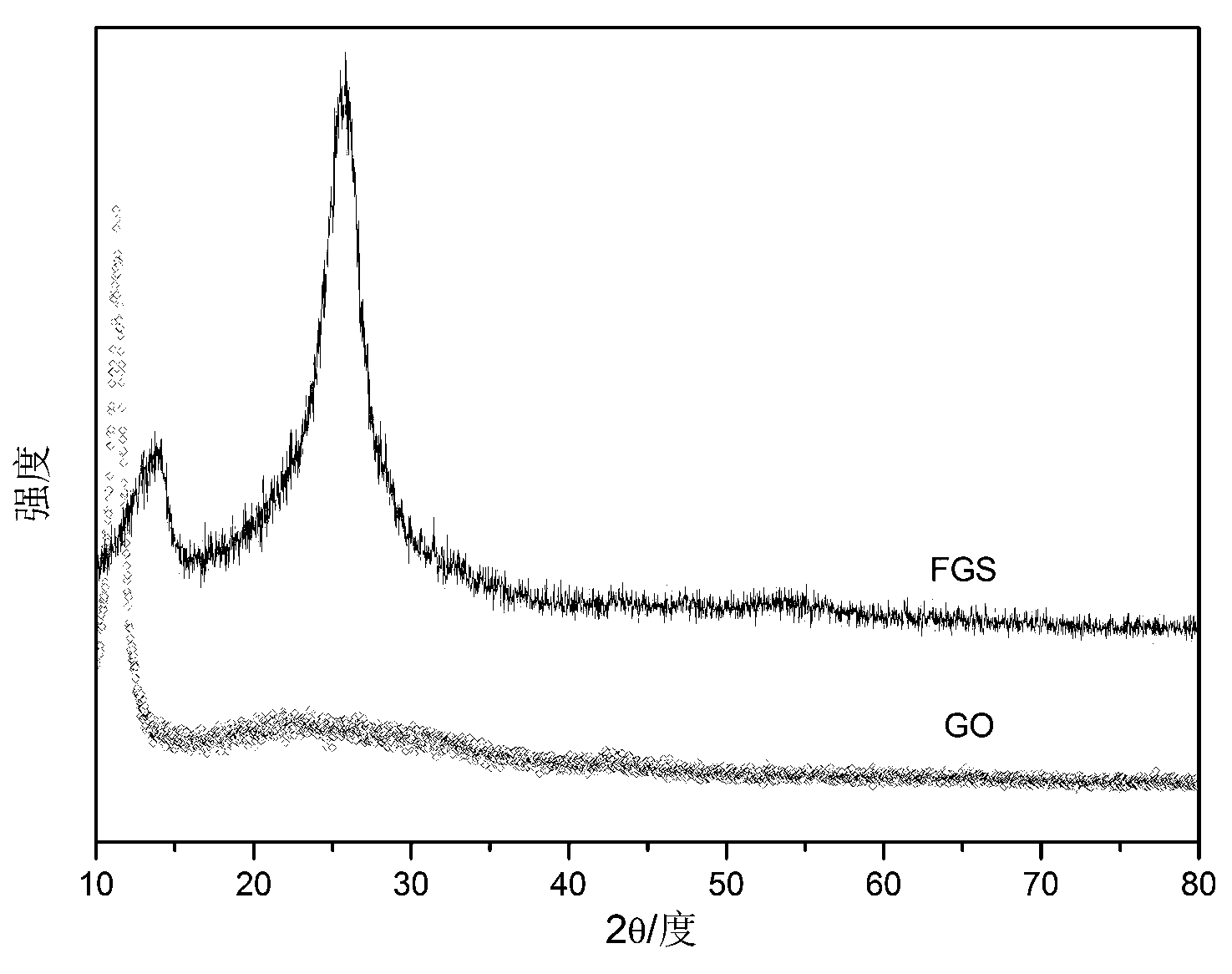

The invention belongs to the technical field of nanoporous material, namely carbon aerogel, and particularly relates to graphene oxide-crosslinked polyimide-based carbon aerogel and a preparation method thereof. The invention carbon aerogel is prepared by crosslinking polyamide acid aerogel by graphene oxide, and comprises the components of graphene oxide and one or more water-soluble polyimide precursor-polyamide acids. The preparation method comprises the following steps: mixing an aqueous graphene oxide solution with the water-soluble polyimide precursor-polyamide acid, and preparing graphene oxide / polyamide acid aerogel through sol-gel and freeze-drying processes; preparing the graphene / polyimide-based carbon aerogel through thermal imidization and high temperature carbonization. According to the preparation method, a toxic reagent formaldehyde is not used; the prepared carbon aerogel has a mesoporous, microporous and macroporous three-level three-dimensional network porous structure, high specific surface area, high conductivity and stable physical and chemical properties, and is an ideal electrode material for preparing a supercapacitor and other new energy devices and a high-performance adsorbent material.

Owner:FUDAN UNIV

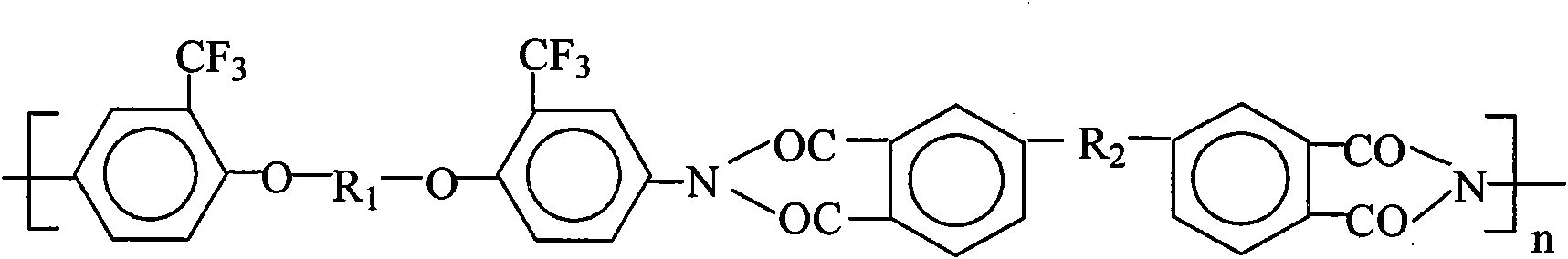

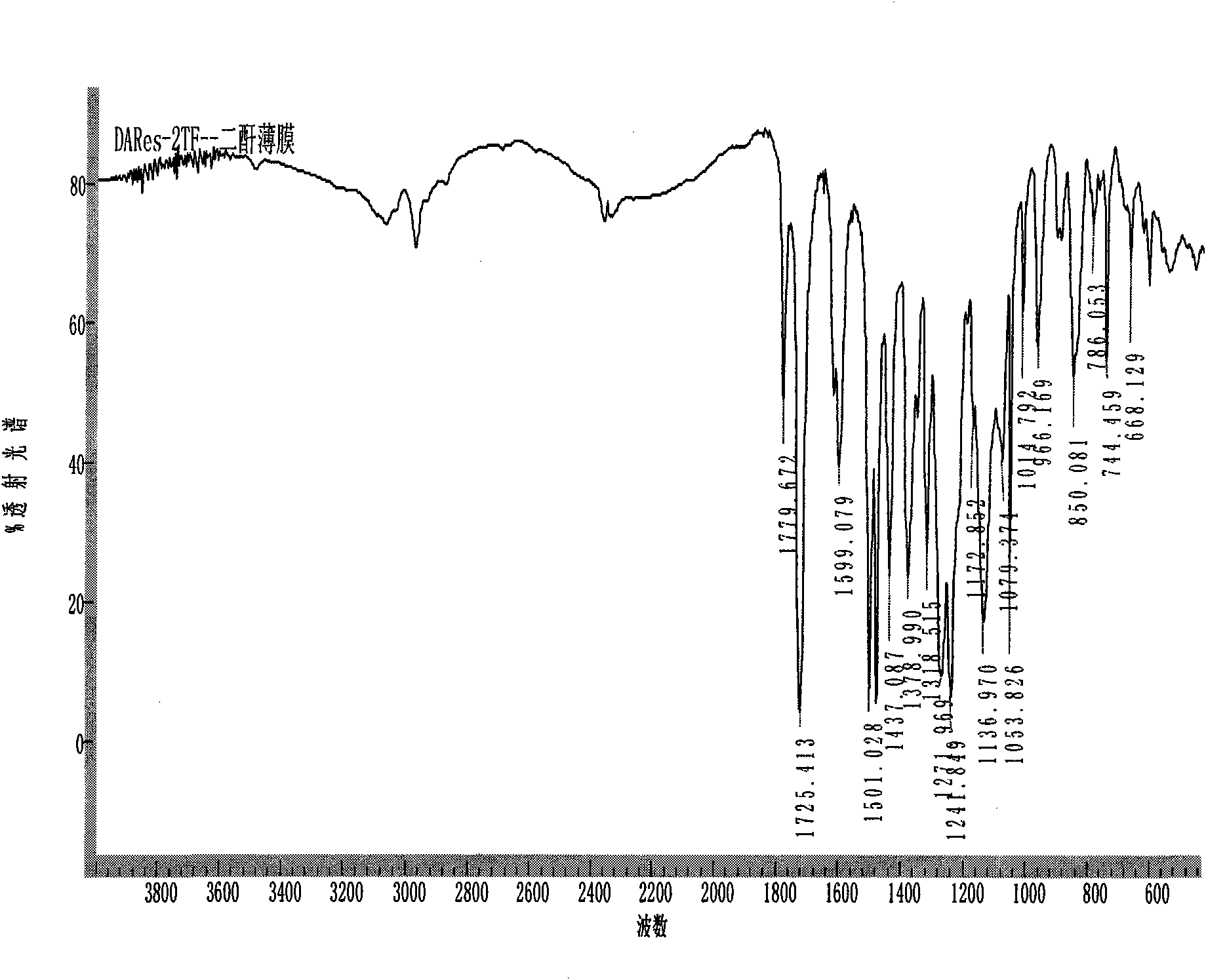

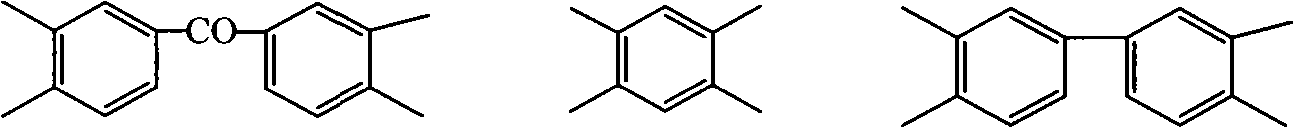

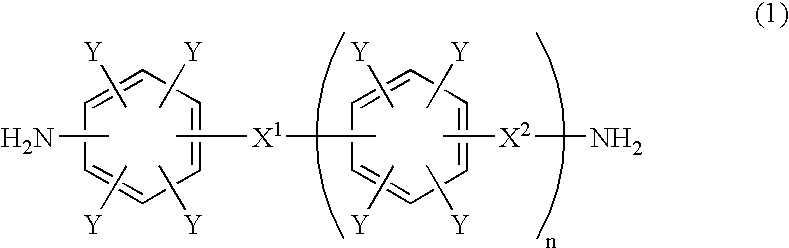

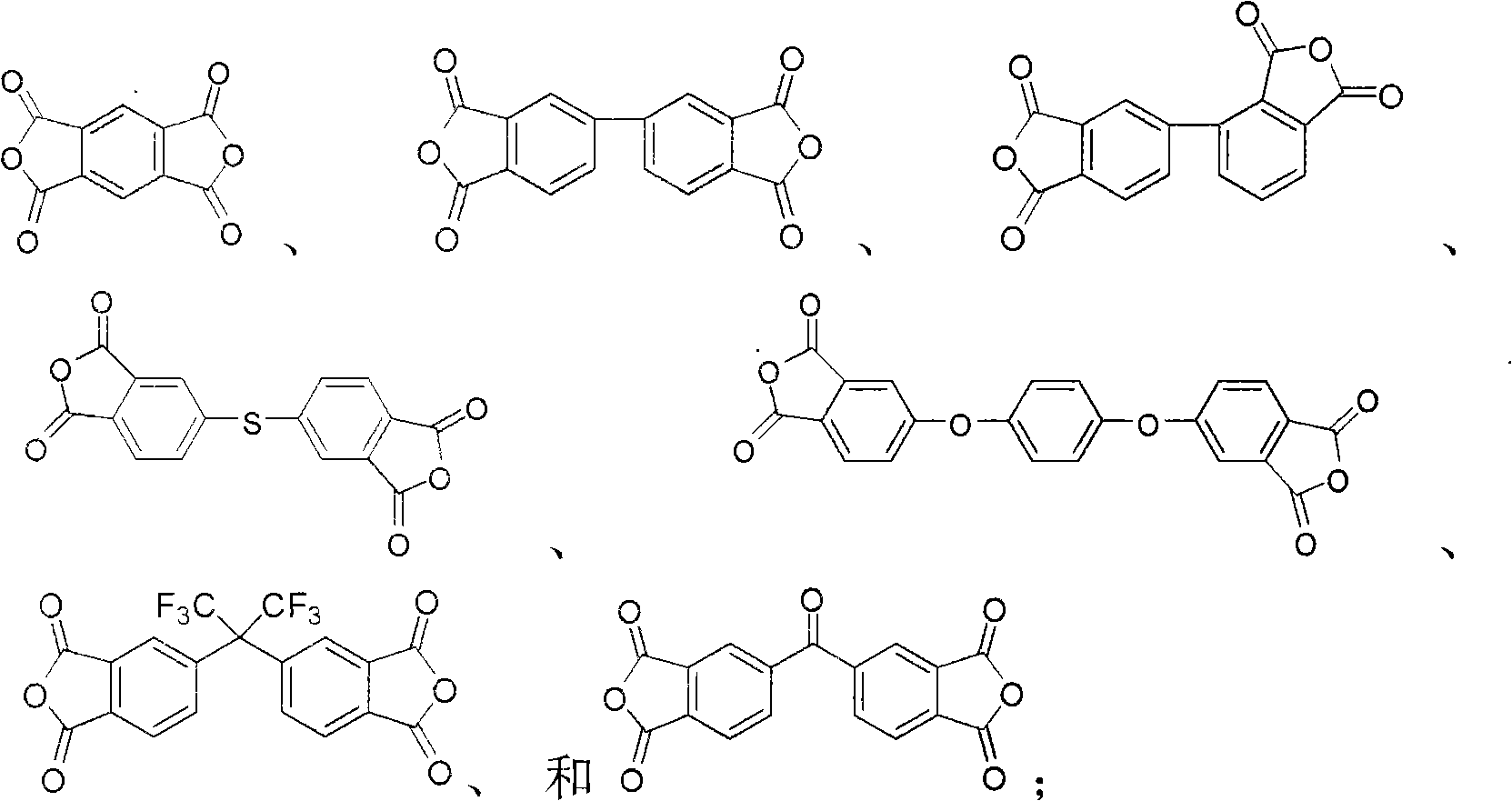

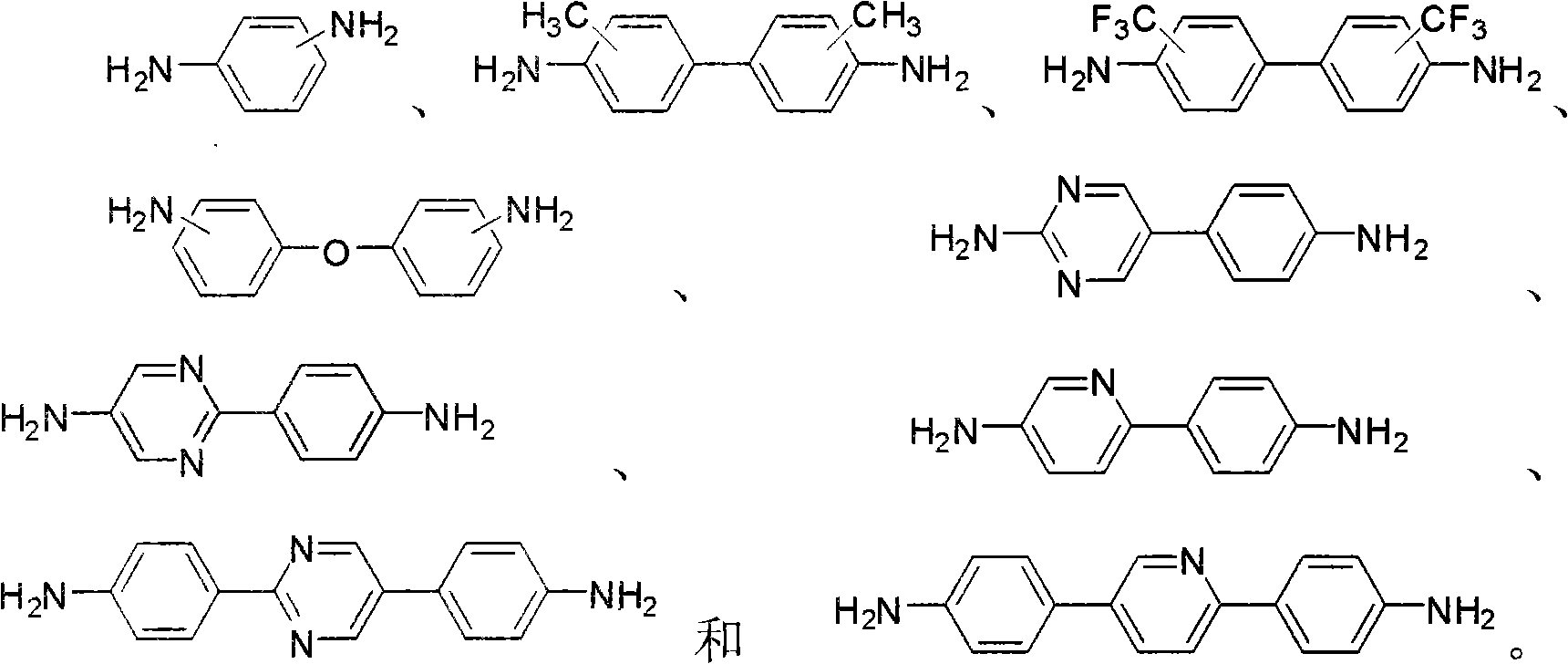

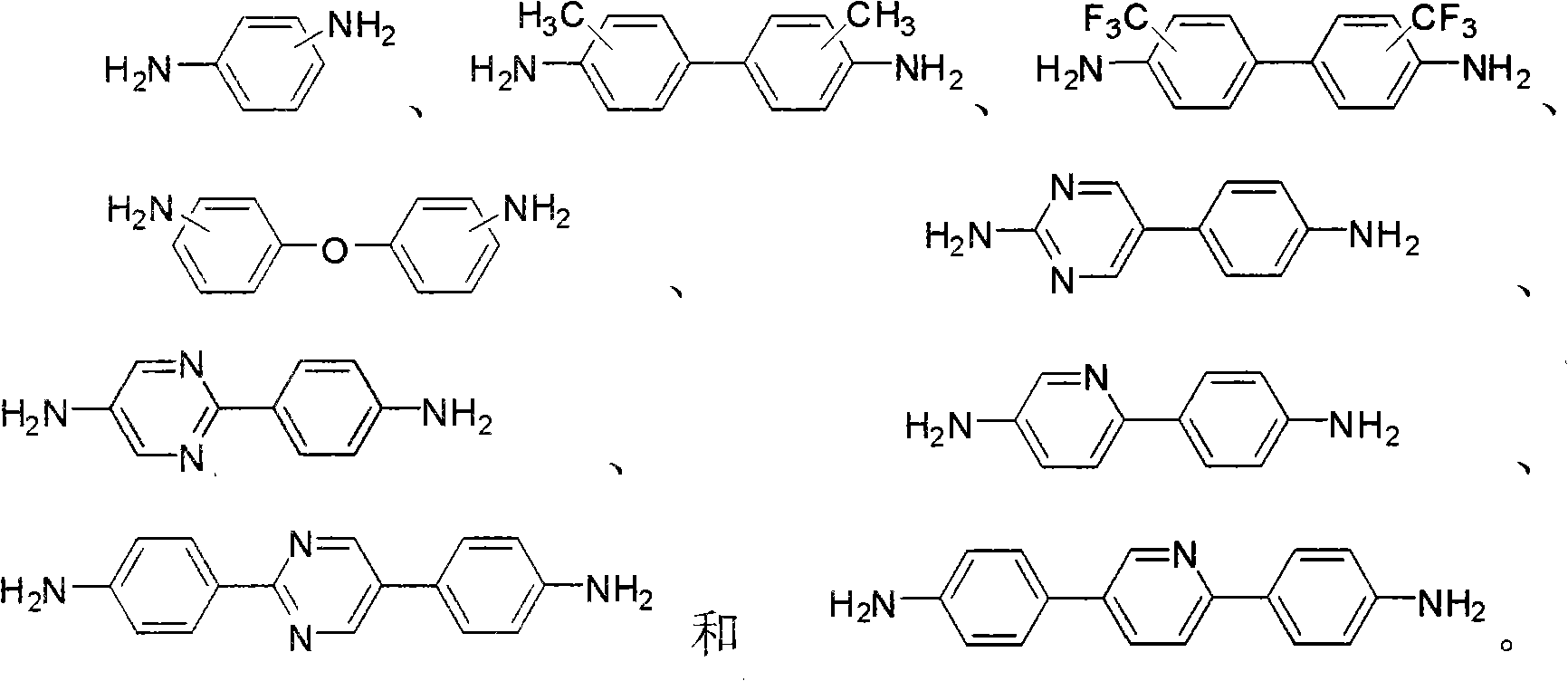

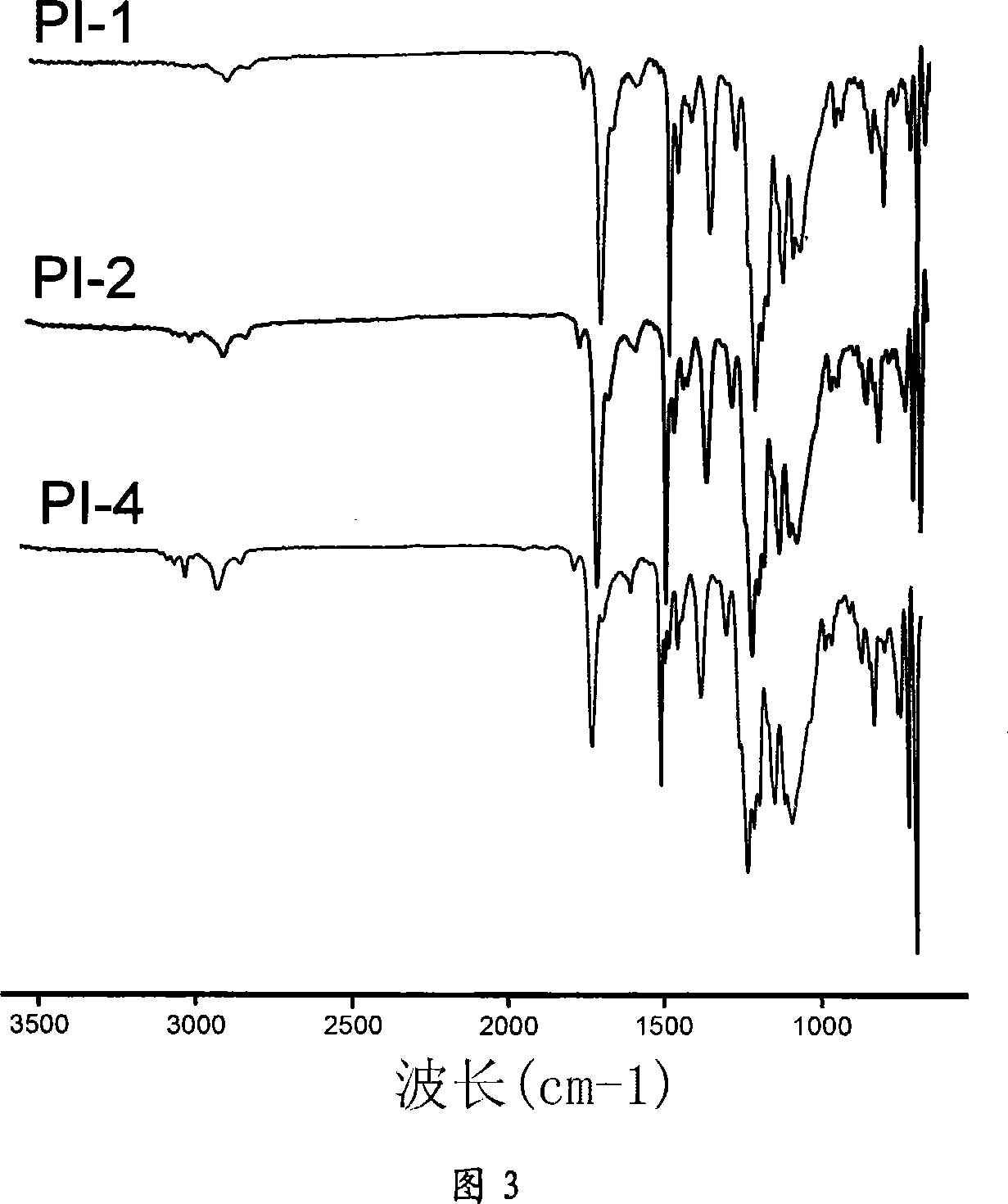

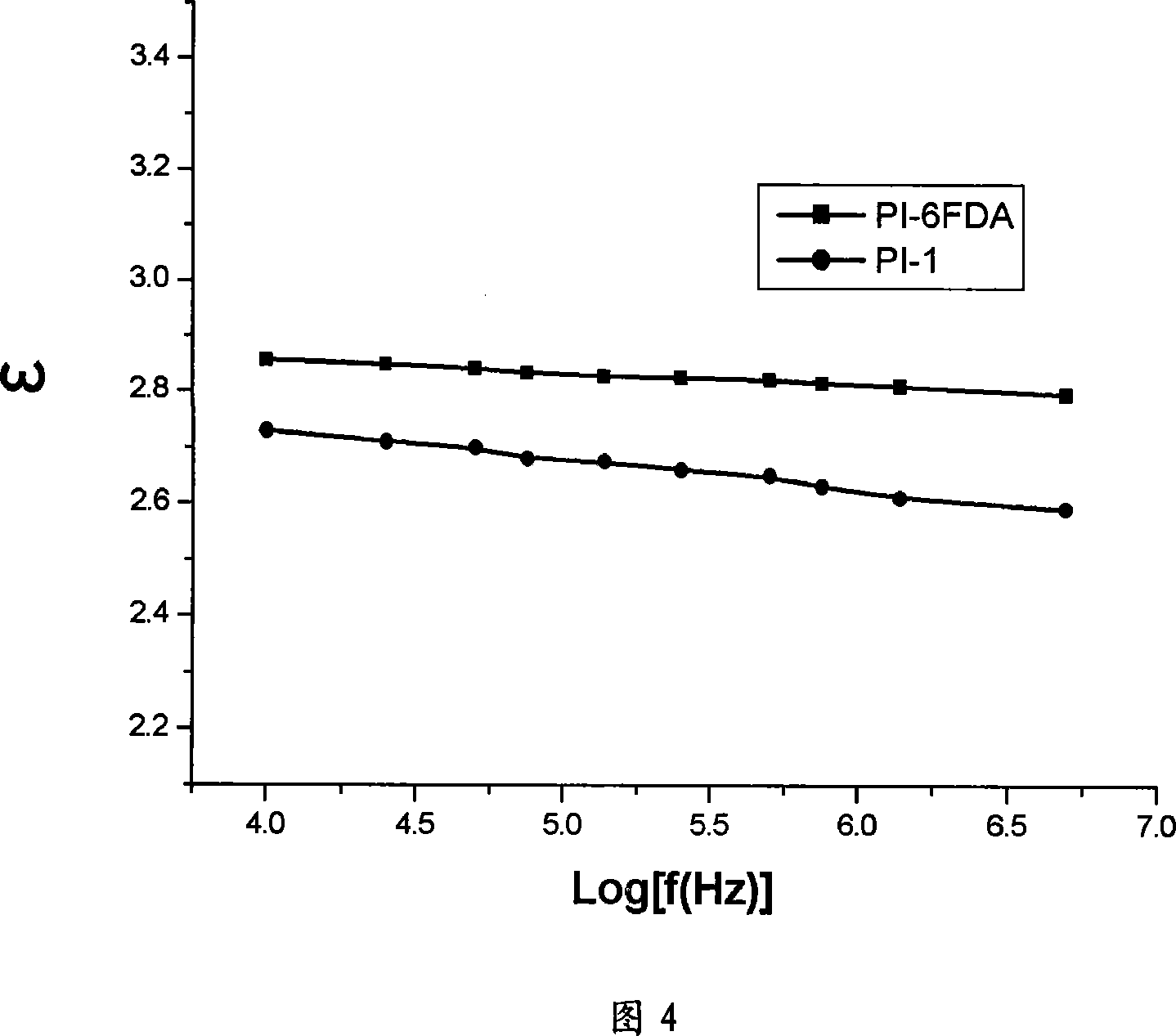

Full aromatic fluorine containing transparent polyimide film and preparation method thereof

The invention relates to a full aromatic fluorine containing transparent polyimide film. Structural formula of molecule thereof is shown above, wherein -R1 is a divalent residue of fluorine containing aromatic binary primary amine, and -R2 is a divalent connecting group of aromatic binary anhydride molecule. The preparation method thereof comprises steps of adding the fluorine containing aromatic binary primary amine and strongly polar non-protonic organic solvent into a polymerizing bottle, stirring at room temperature, after being completely dissolved, adding the aromatic binary anhydride, stirring, after 3 hours reaction, obtaining transparent and thick fluorine containing aromatic polyamide acid resin solution having homogeneous phase; and using the strongly polar non-protonic organic solvent to regulate viscosity of the fluorine containing aromatic polyamide acid resin solution, forming film, heating, carrying out dehydrating hot-imidization reaction, cooling, demoulding, thus obtaining the full aromatic fluorine containing transparent polyimide film. The preparation method has mild reaction condition, simple operation and low cost and is environment friendly. The full aromatic fluorine containing transparent polyimide film has excellent mechanical property and heat tolerance and visible light transmission thereof is up to 95%.

Owner:DONGHUA UNIV

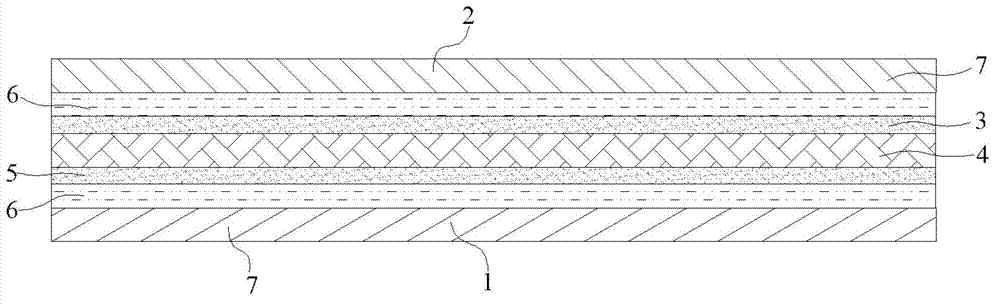

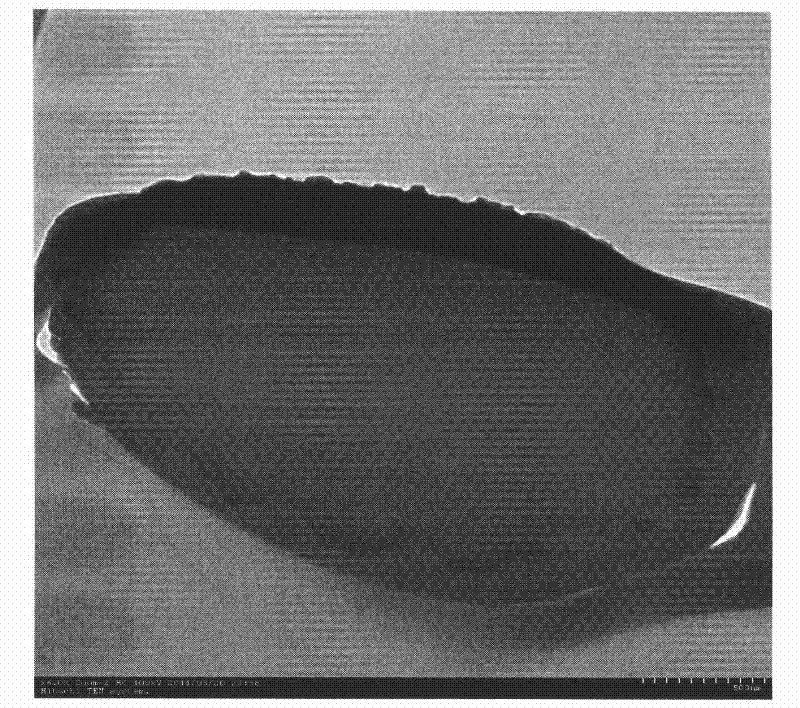

Heat-dissipating double-sided adhesive tape with ultrahigh heat conductivity coefficient

ActiveCN103045119AAvoid local overheatingAchieve uniformityCarbon compoundsFilm/foil adhesivesPolymer sciencePolyamide

The invention discloses a heat-dissipating double-sided adhesive tape with an ultrahigh heat conductivity coefficient. Ethylene glycol or triethylamine is added into a polyamic acid solution, the resulting mixture is put in an oven in a vacuum environment and maintained at 100 DEG C for 0.9-1.1 hours, the temperature is raised to 300 DEG C and maintained for 0.9-1.1 hours, followed by natural cooling, to produce a polyimide film; the polyimide film is heated up to 250 DEG C from room temperature and then heated up to 500 DEG C, and further heated up to 1200 DEG C at a rate of 9-11 DEG C / min, to produce a prefired carbonized film; the prefired carbonized film obtained in the step 4 is rolled by a calendar; the rolled product is heated up to 2400 DEG C at a rate of 19-21 DEG C / min and maintained for 0.9-1.1 hours and then heated up to 2900 DEG C at a rate of 19-21 DEG C / min and maintained for 1.8-2.2 hours, followed by cooling, to produce a fired graphite film; and subsequently the graphite film is rolled to obtain a graphite coating. The heat transfer performance of the double-sided adhesive tape in both the vertical and the horizontal directions are improved, so as to prevent local overheat of the adhesive tape and ensure uniformity of heat transfer performance of the adhesive tape.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

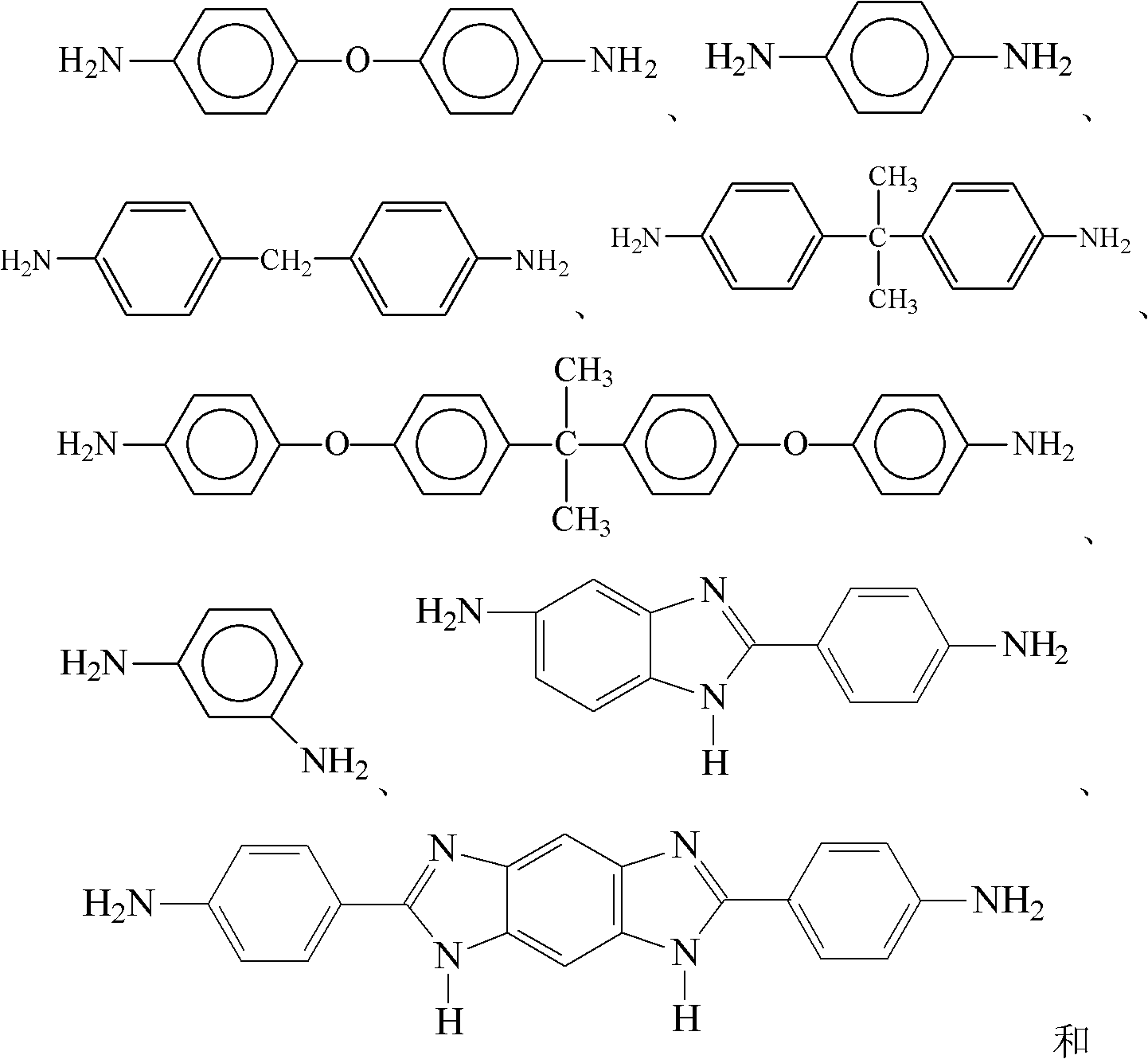

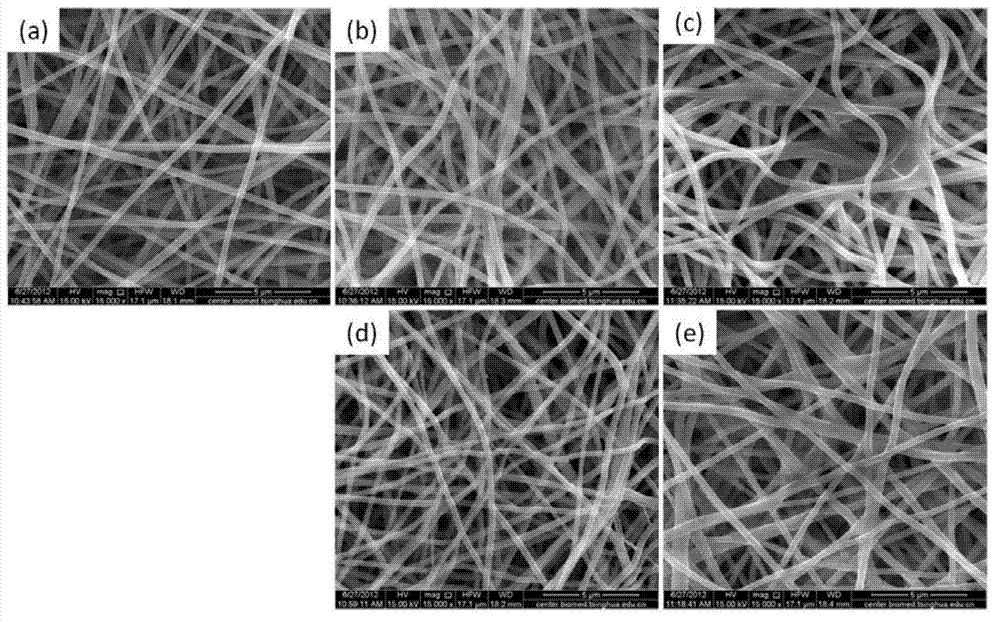

Copolymerized polyimide nanofiber nonwoven and preparation method and application thereof

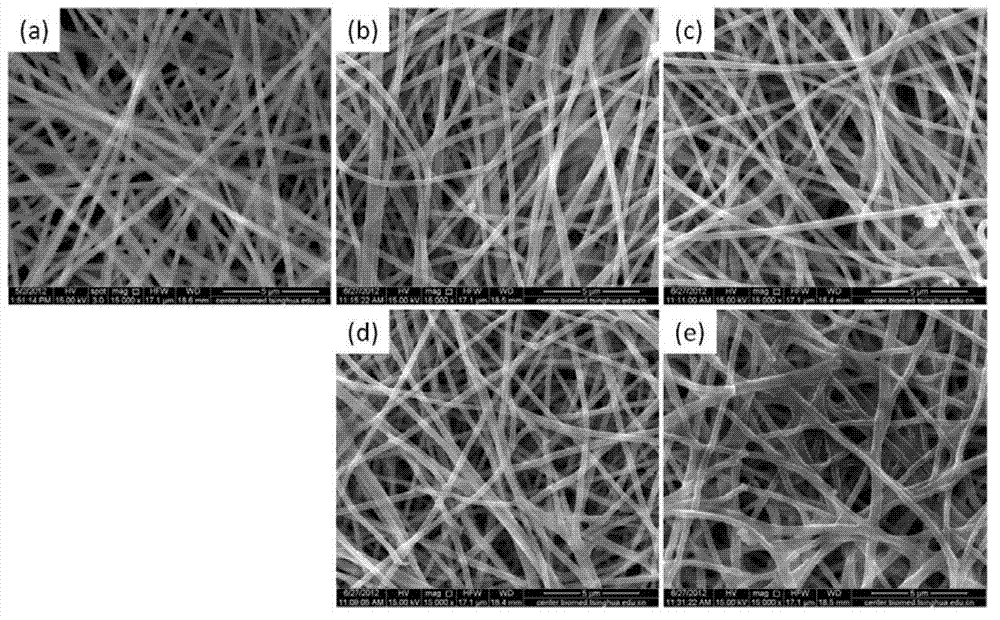

ActiveCN101974828AHigh mechanical strengthElectrospun copolyimide nanofiber nonwovens with this property are tear-resistantMonocomponent synthetic polymer artificial filamentCell component detailsPorosityTear resistance

The invention relates to a copolymerized polyimide nanofiber nonwoven and a preparation method and application thereof. The preparation method comprises the following steps of: reacting a tetracid dianhydride monomer with a diamine monomer by taking a high-polar solvent as a reaction medium; performing condensation polymerization through mechanical agitation in a reaction kettle to form copolymerized polyimide acid solution; performing electrostatic spinning on the copolymerized polyimide acid solution in a high-voltage electric field so as to obtain the copolymerized polyimide nanofiber nonwoven; performing imidization on the nonwoven at a high temperature to prepare the copolymerized polyimide nanofiber nonwoven which has the characteristics of high tear resistance, high porosity, high temperature and low temperature resistance and high mechanical properties. The copolymerized polyimide nanofiber nonwoven is mainly used for battery diaphragms and capacitor diaphragms.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

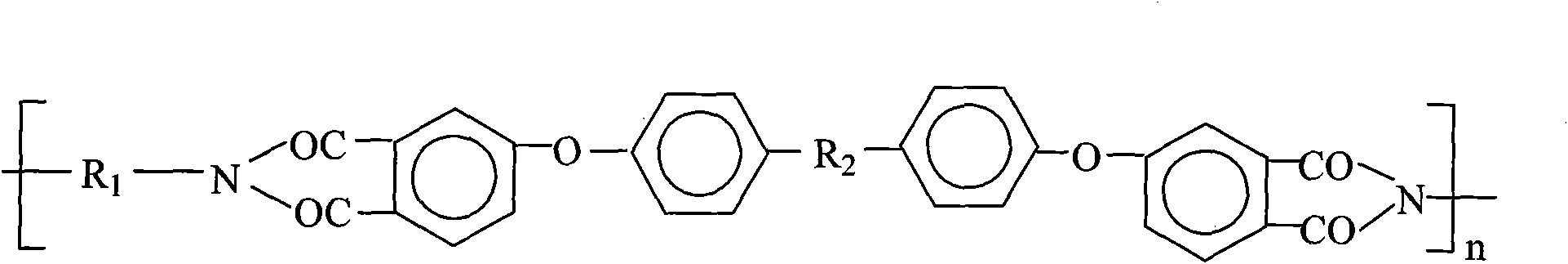

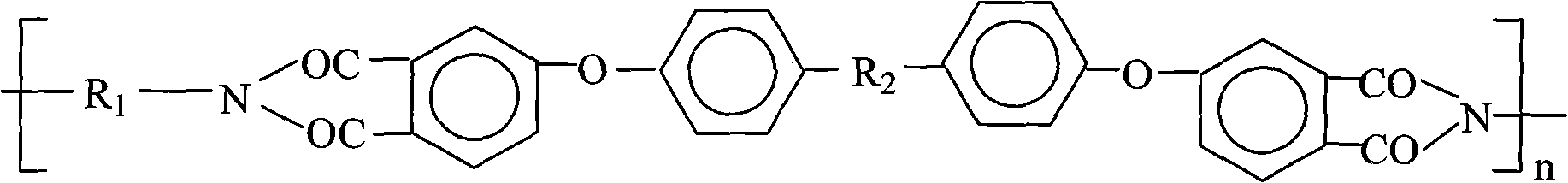

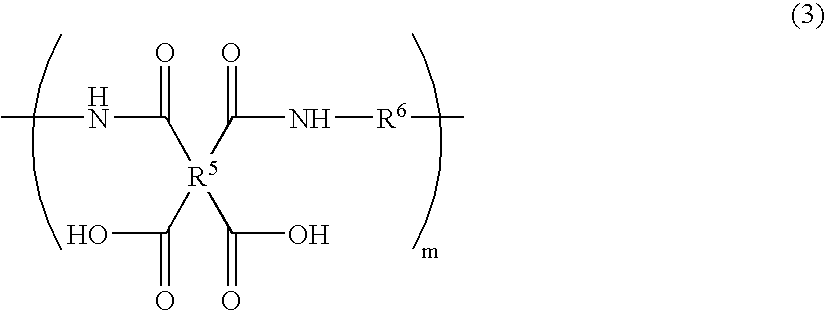

Polyimide film with high visible light permeability and preparation thereof

The invention related to a polyimide film with high visible light permeability, molecular structure formula of which is: (shown in figure). Preparation comprises steps of: dissolving primary diamine in a strongly polarnon-proton solvent, cooling the same by cold water to 5 DEG. C to 10 DEG. C, adding aromatic dianhydride, mixing, reacting 4h to 10h at 5 DEG. C to 10 DEG. C, acquiring homogeneous, transparent, sticky polyamic acid resin solution; wherein mol number of aromatic dianhydride is equal to that of primary diamine; adjusting viscosity of polyamic acid resin solution by N,N-dimethyl acetamide, forming film in a casting machine, heating to raise temperature, processing dehydration heat imidization, cooling, deciduating to acquire homogeneous and transparent polyimide thin film. The preparation method has mild reaction condition, sample to operate, low in cost and environmental friendly; mechanical property and thermal stability of the polyimide thin film are excellent with high visible light permeability reaching 94% and film thickness 50 micrometers.

Owner:DONGHUA UNIV +1

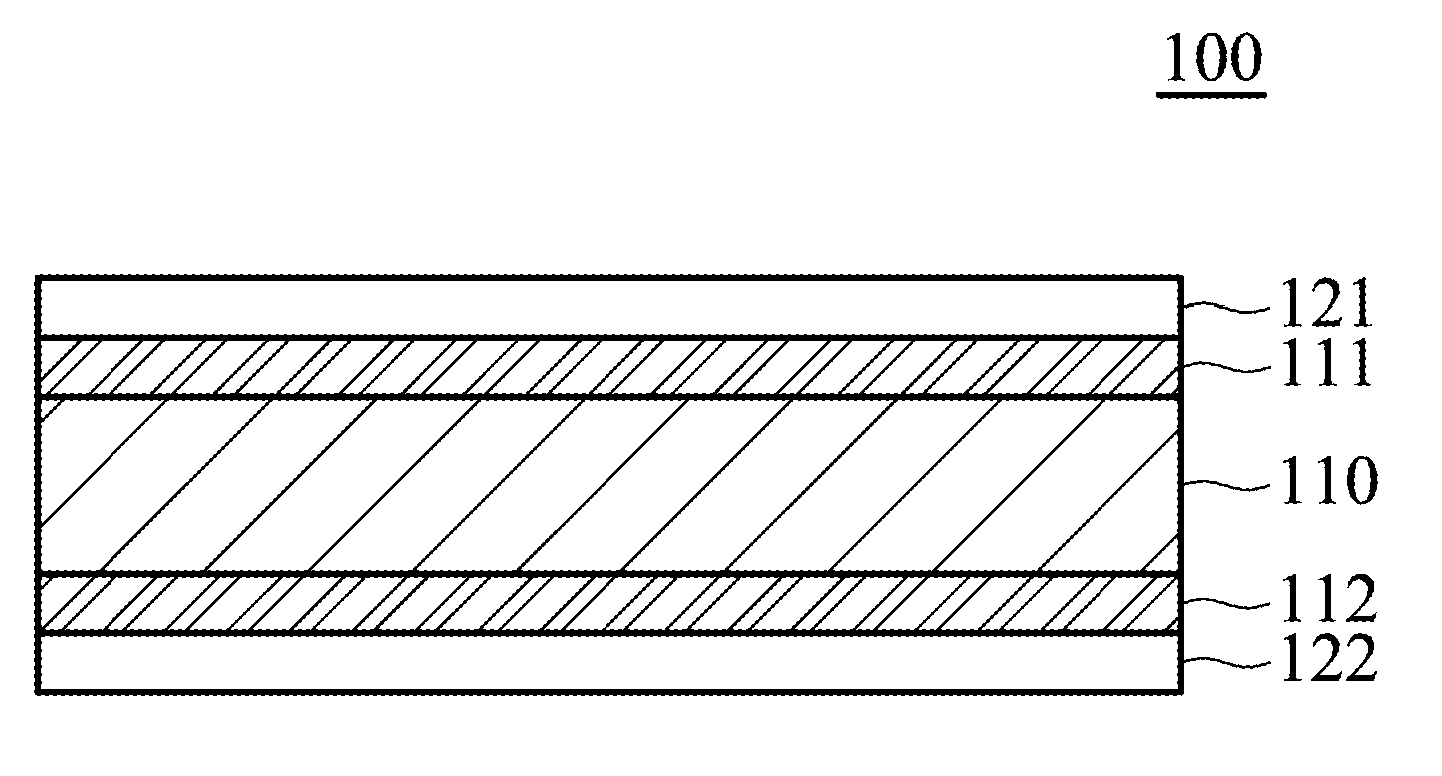

Polyimide metal laminate

InactiveUS20050048297A1High modulus of elasticityEasy to useSynthetic resin layered productsPrinted circuit aspectsPartial hydrolysisPolyamic acid

The polyimide metal laminate has at least one resin layer produced from a silica-dispersed polyimide composition obtained by reacting (A) alkoxysilane and / or its partial hydrolysis polycondensate with (B) an amino-containing compound having a functional group capable of forming a bond with silica, in the presence of water in a polyimide solution and / or a polyamic acid solution.

Owner:MITSUI CHEM INC

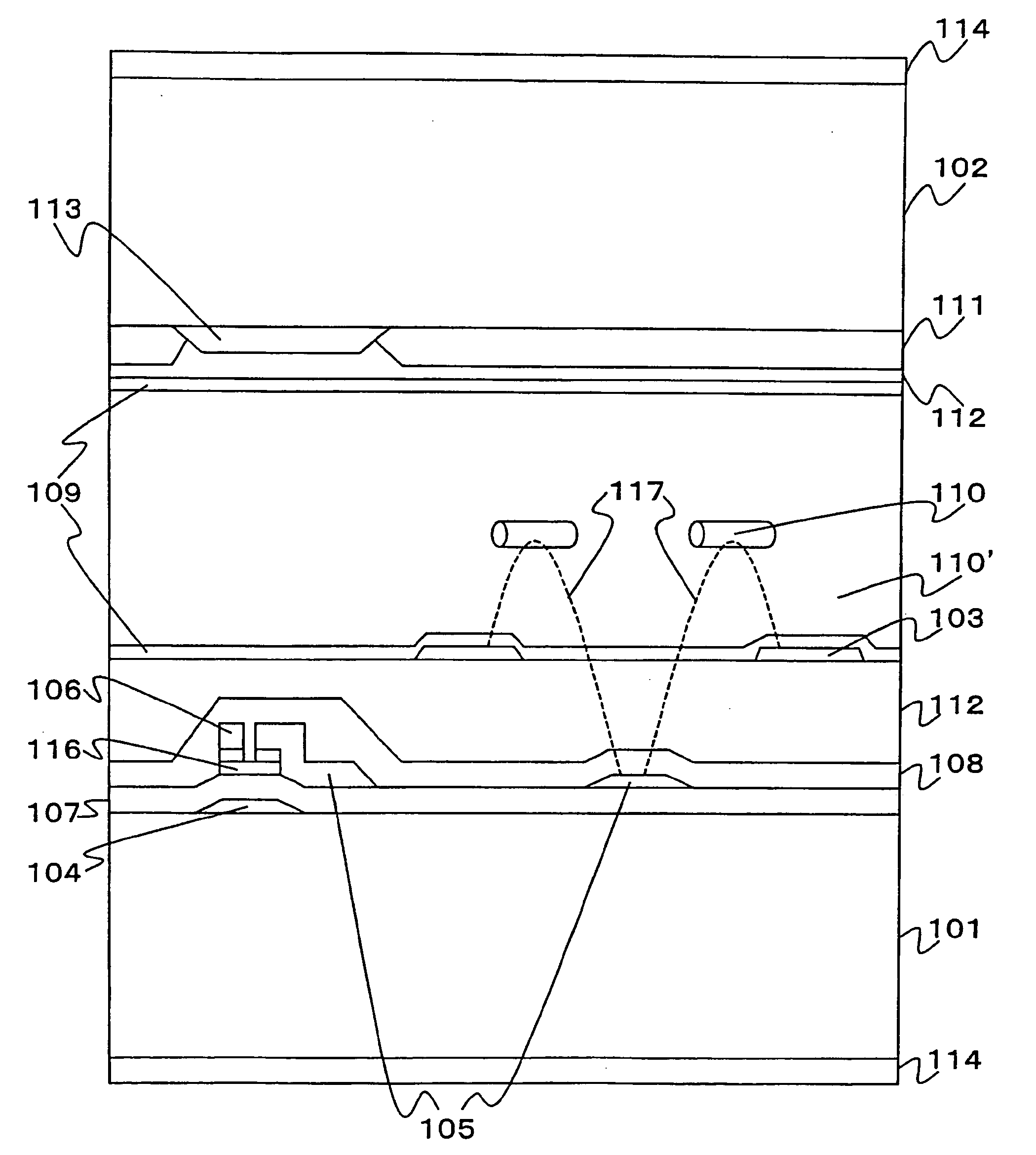

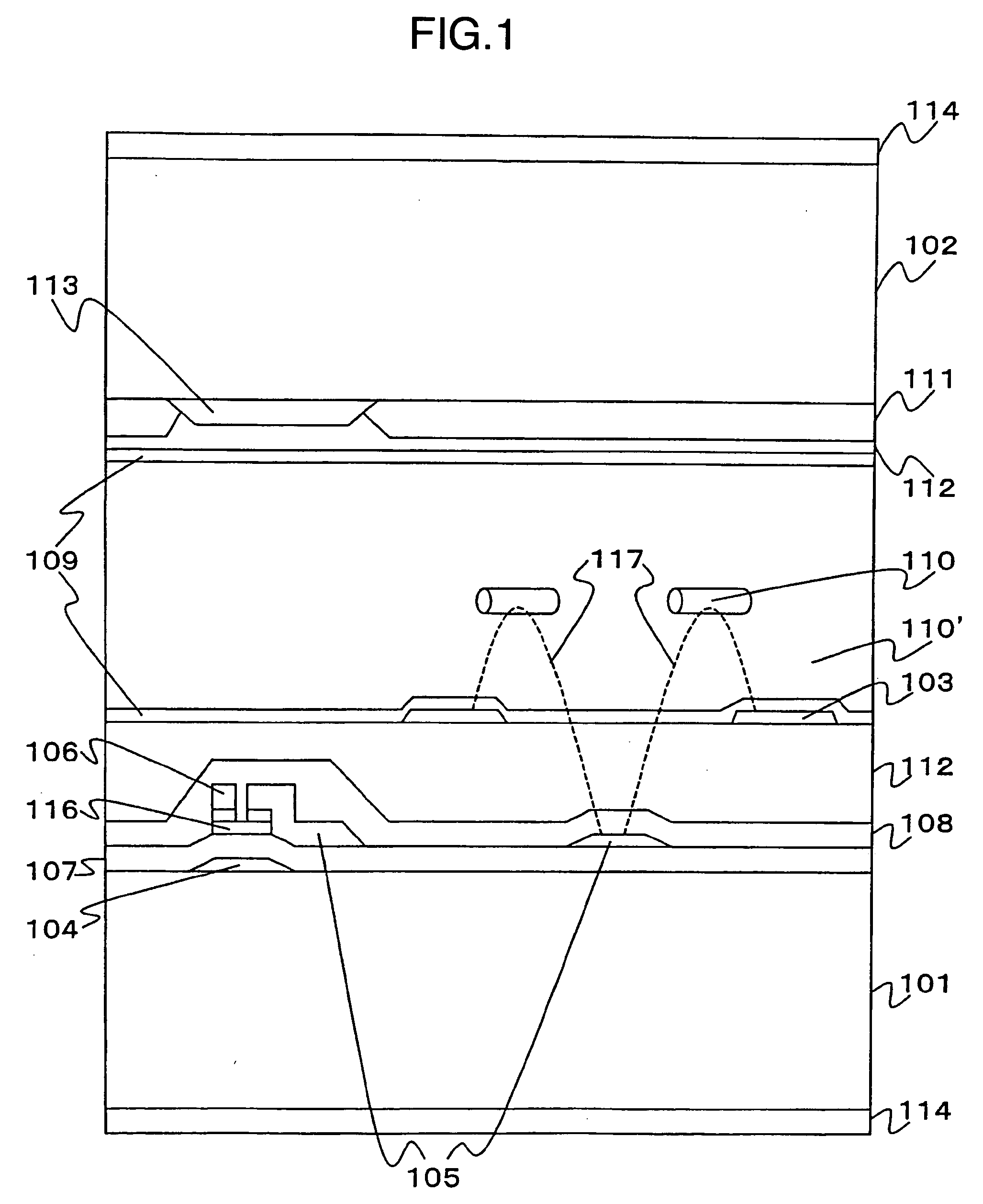

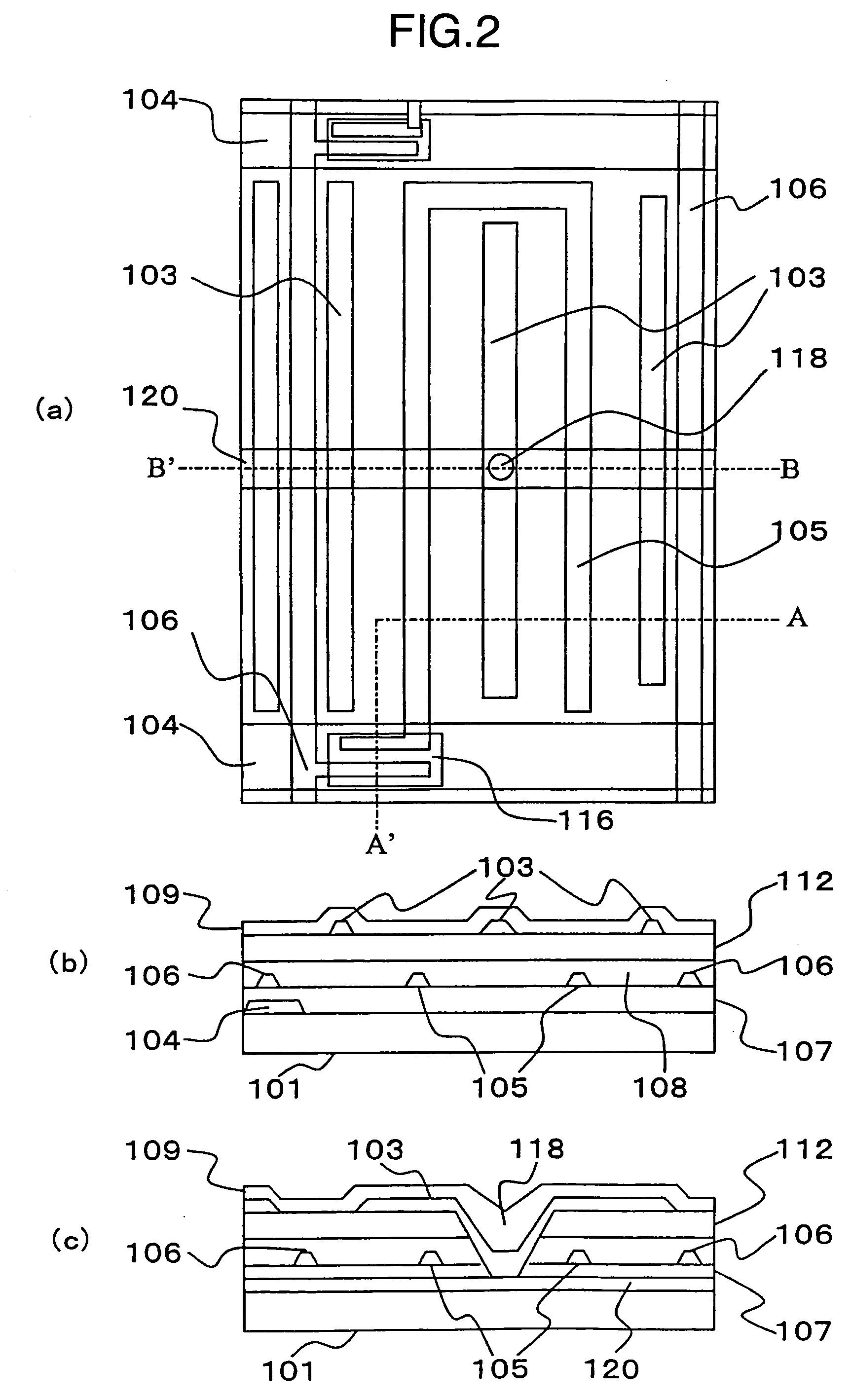

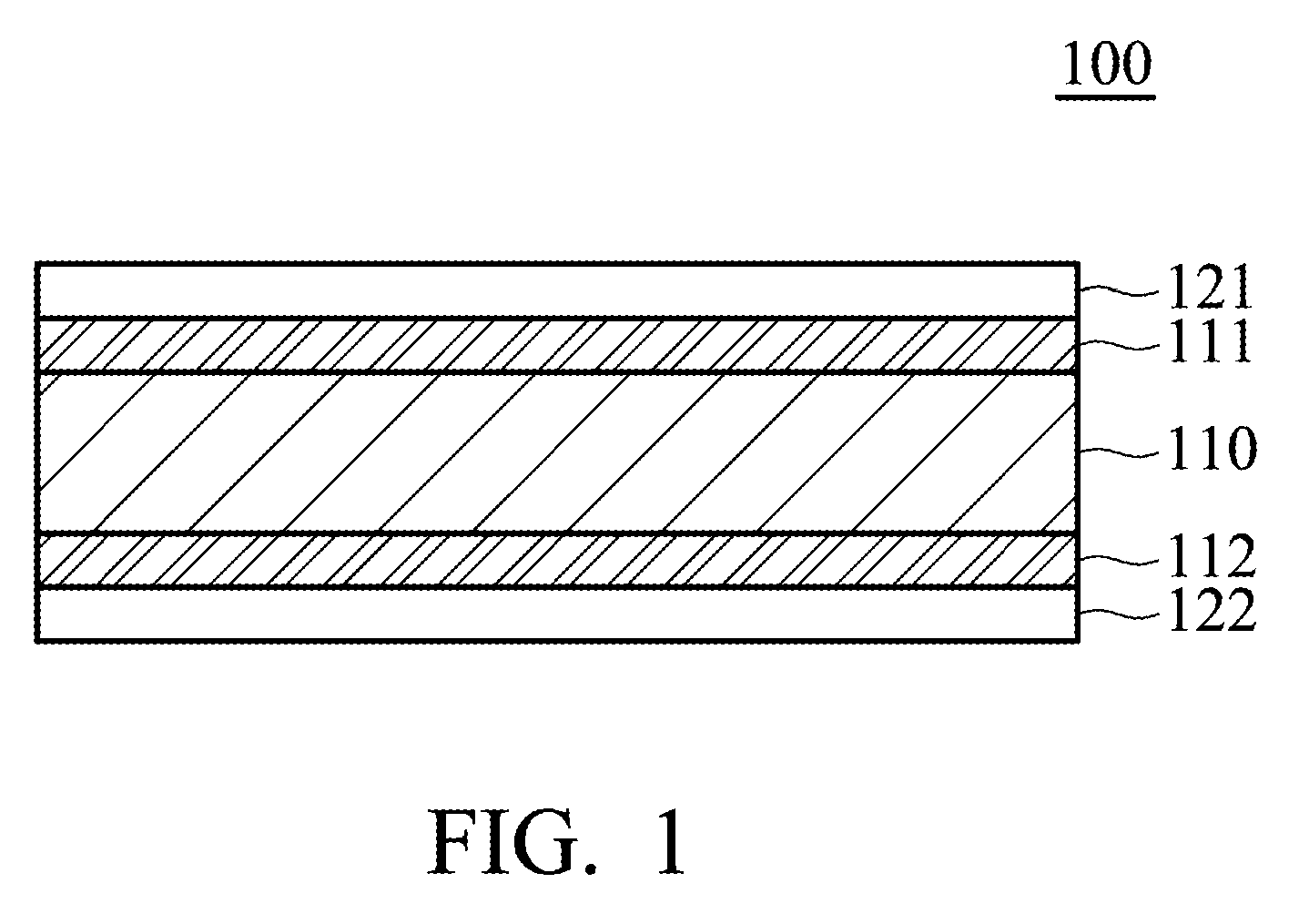

Liquid crystal display

ActiveUS20050271833A1Promoting and stabilizing capacityImprove responseLiquid crystal compositionsPhotosensitive materialsLiquid-crystal displayHigh volume manufacturing

It is an object to provide a liquid crystal display which reduces unsatisfactory display caused by distorted initial alignment direction in a liquid crystal alignment layer for IPS type displays, realizes stable liquid crystal alignment, is high in mass-productivity, and produces high-quality images of increased contrast ratio. The liquid crystal display contains alignment layers 109 placed between a pair of substrates 101 and 102, at least one of which is transparent, liquid crystal layer 110′ sealed between the alignment layers, common electrode 103 and source electrode 105 for applying an electrical field to the liquid crystal layer, thin-film transistors connected to each of these electrodes, polarizer plate 114 provided on at least one of the substrates, wherein at least one of the alignment layers 109 is composed of a photo-reactive polyimide and / or polyamic acid which can be provided with a liquid crystal alignment capacity by being irradiated with essentially linearly polarized light.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

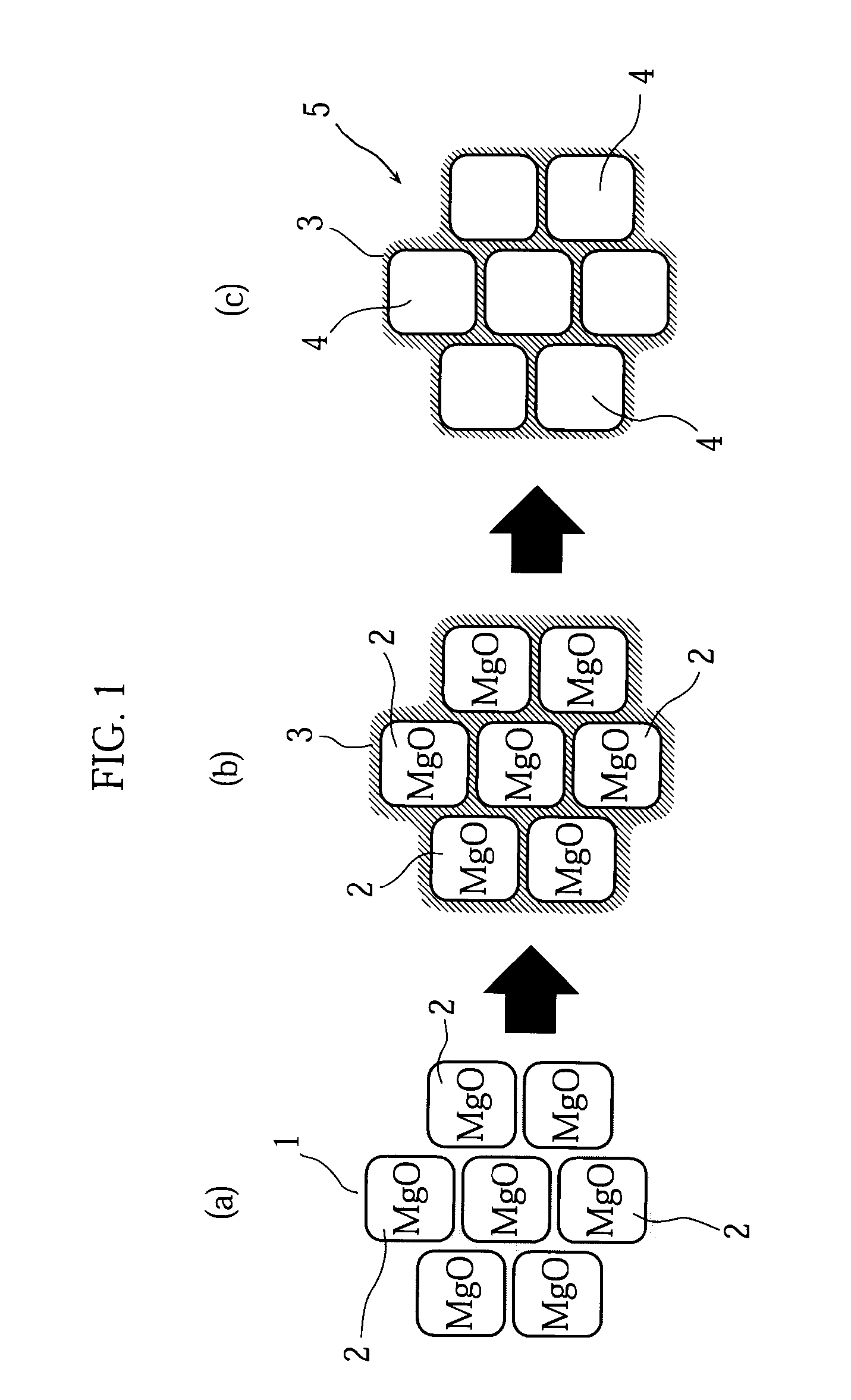

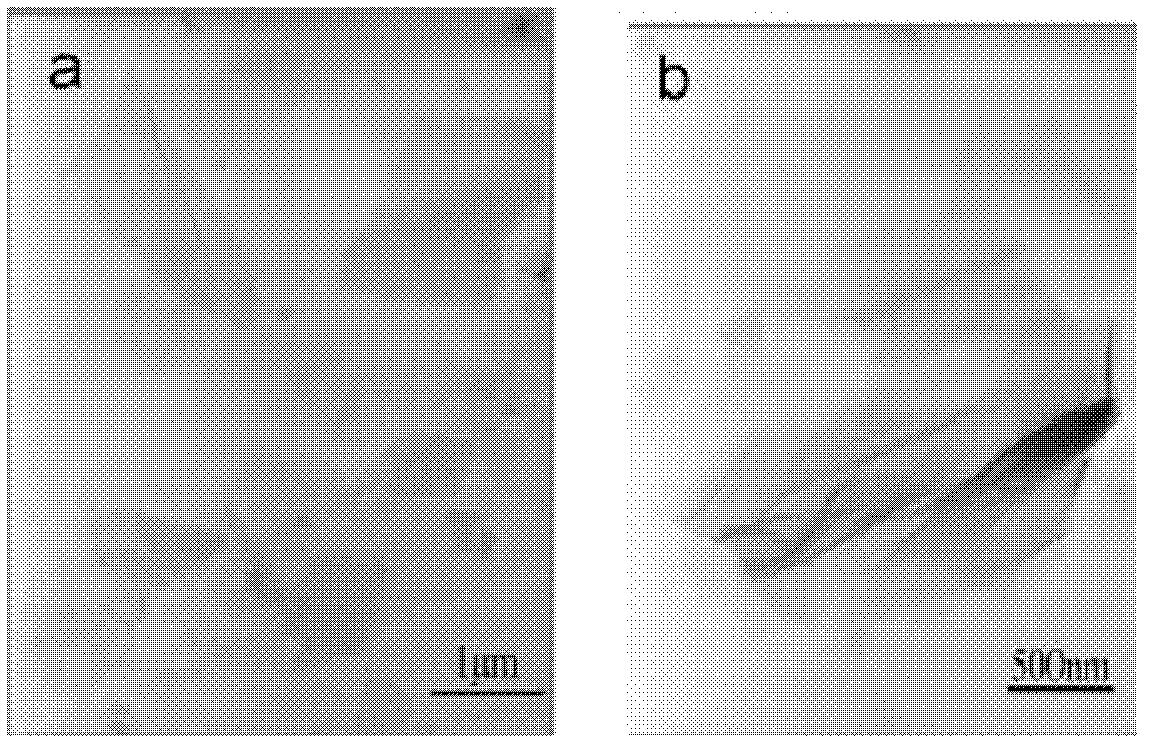

Porous carbon and method of manufacturing same

InactiveUS20110318254A1Pore diameter can be easilyEasy to controlMaterial nanotechnologyCarbon compoundsDecompositionPorous carbon

A porous carbon that retains a three-dimensional network structure and enables the pore diameters of mesopores and micropores to be controlled easily is provided. A method of manufacturing the porous carbon is also provided. The porous carbon is fabricated by mixing a polyamic acid resin 1 as a carbon precursor with magnesium oxide 2 as template particles, heat-treating the mixture in a nitrogen atmosphere at 1000° C. for 1 hour to cause the polyamic acid resin to undergo heat decomposition, and washing the resultant sample with a sulfuric acid solution at a concentration of 1 mol / L to dissolve MgO away.

Owner:TOYO TANSO KK

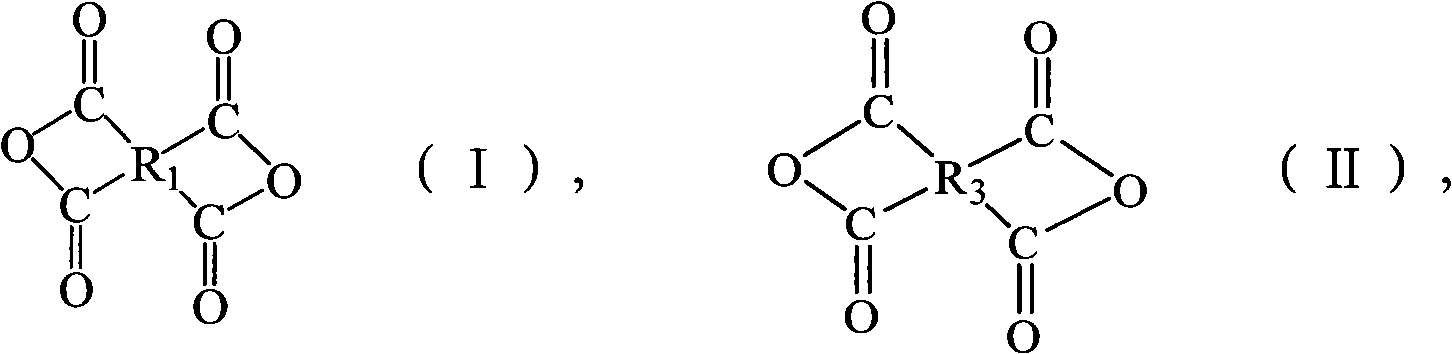

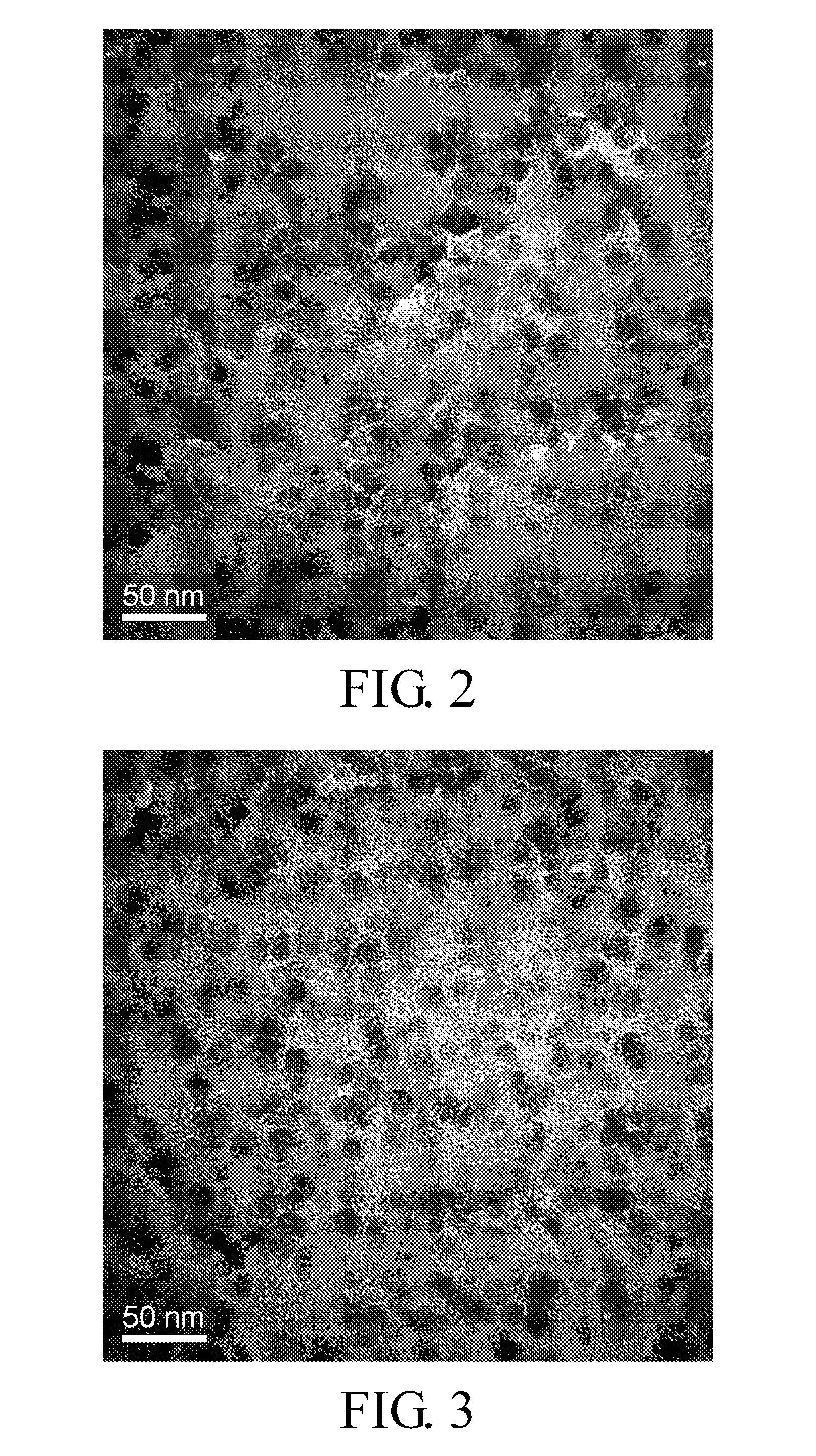

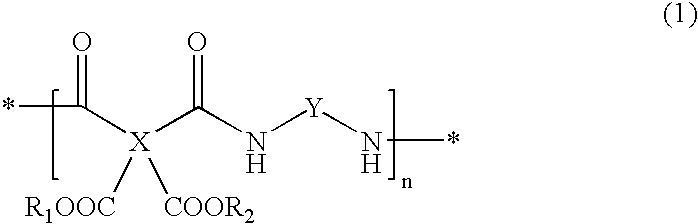

Polyamic acid resin composition and polyimide film prepared therefrom

A polyamic acid resin composition, and a polyimide film and laminate prepared therefrom are provided. The polyamic acid resin composition includes a polyamic acid resin, a solvent, and a polar aprotic solution containing nanoscale silica, with surface hydroxyl groups, modified by a surface modification agent. Particularly, the surface modification agent has a structure represented by formula (I):R1—Si—(OR2)3 formula (I)wherein, R1 is an aliphatic group or an aryl group, and R2 is a C1-8 alkyl group.

Owner:IND TECH RES INST

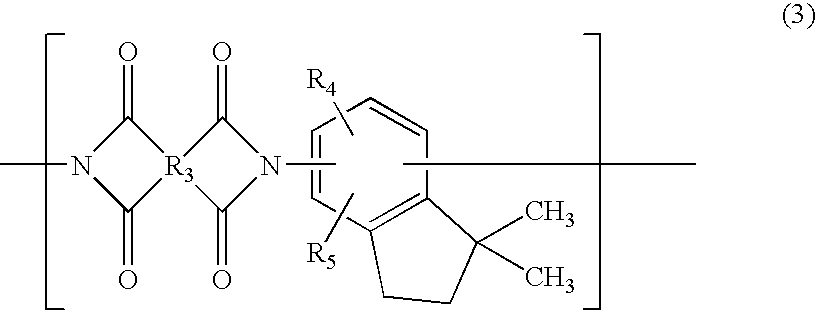

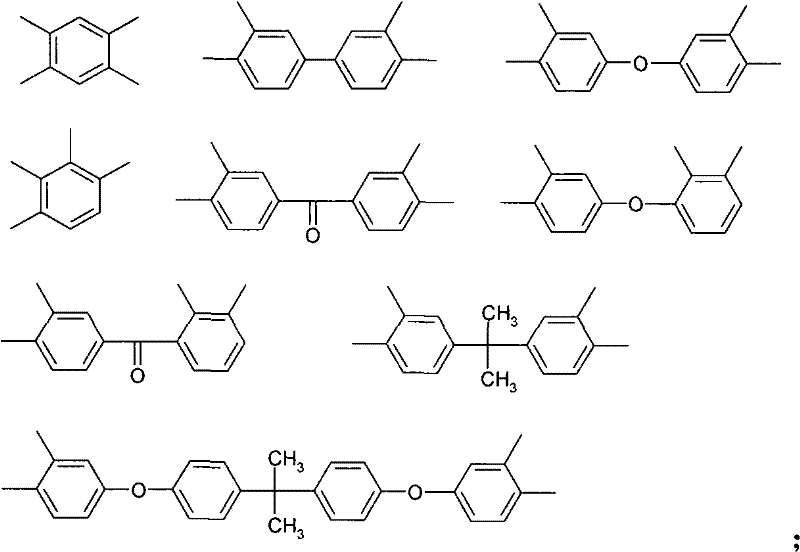

Positive photosensitive polyimide resin composition

InactiveUS6875554B2Low viscosityDiazo compound compositionsPhotosensitive materials for photomechanical apparatusOrganic groupPolyamic acid

A positive photosensitive polyimide resin composition comprising:(a) a solvent-soluble polyimide comprised of from 1 to 100 mol % of a bivalent organic group derived from a diamine, that has at least one solvent solubilizing functional group, the polyimide having a reduced viscosity ranging from 0.05 to 5.0 dl / g,(b) a photosensitive orthoquinonediazide compound, and(c) from 0.1 to 50 wt %, based on the total weight of all polymers of the composition, of a component (c1) or (c2), wherein:component (c1) is a solvent-soluble polyimide comprised of from 1 to 100 mol % of a bivalent organic group derived from a diamine, that has at least one functional group selected from the group consisting of a long chain alkyl group having at least 6 carbon atoms and a fluorinated alkyl group, the polyimide having a reduced viscosity ranging from 0.05 to 5.0 dl / g, andcomponent (c2) is a polyamic acid comprised of from 1 to 100 mol % of a bivalent organic group derived from a diamine, that has at least one functional group selected from the group consisting of a long chain alkyl group having at least 6 carbon atoms and a fluorinated alkyl group, the polyimide having a reduced viscosity ranging from 0.05 to 5.0 dl / g.

Owner:NISSAN CHEM IND LTD

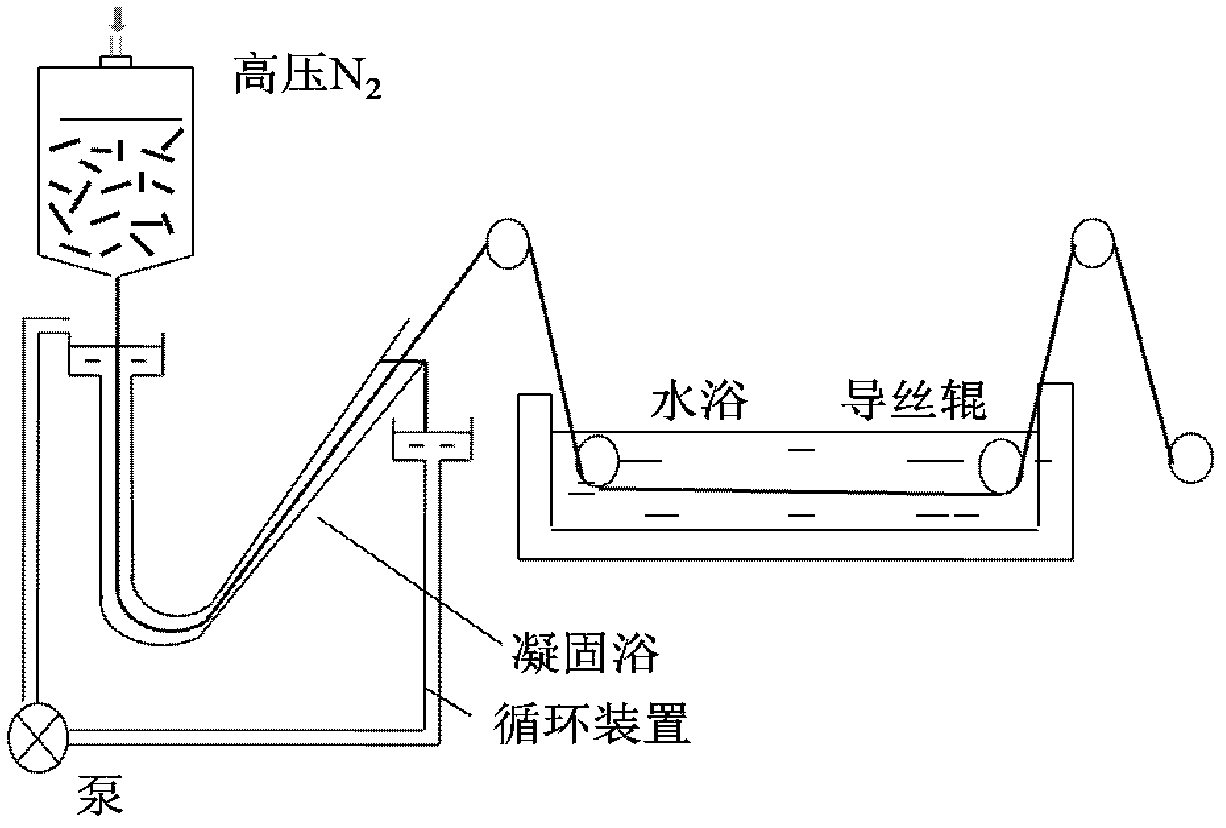

Method for preparing polyimide fiber

ActiveCN101338462AHigh strengthHigh modulusSynthetic polymer filament chemical after-treatmentMonocomponent polyamides artificial filamentFiberTemperature control

The invention relates to a preparation method of polyimide fiber. The procedures and conditions of the preparation method are as follows: (1) precursor acid polyamine solution used for spinning is made by fasculating diamine and dianhydride monomer; (2) the preparation of the polyimide fiber adopts dry-wet spinning process; (3) the polyimide fiber is imidized; and (4) the polyimide fiber undergoes the heat drawing under the temperature of 300 to 500 DEG C, and the drawing multiple of the fiber is 1 to 7 times. Imide process adopts a gradient heating-up thermal treatment furnace so as to overcome the defects of the inaccurate temperature control and the non-feasibility of the prior double thermal furnace process. The preparation method has simple process and is easy for continuous production. The prepared polyimide fiber has stronger strength and high modulus and can be used under the temperature of over 300 DEG C. In addition, the polyimide fiber has UV irradiating resistance property, a higher limited oxygen index and corrosion resistance, so the polyimide fiber can be widely applicable for the reinforced fiber of composite materials, a cable sheath, a cable reinforcing core, the mooring rope of vehicle and vessel and the filtering materials of high temperature or radioactive substance, etc.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Polyimide porous membrane and lithium ion battery comprising same

ActiveCN101665580AUniform hole diameter distributionImprove breathabilitySecondary cellsCell component detailsBenzoic acidChlorinated paraffins

The invention discloses a polyimide porous membrane and a lithium ion battery comprising the same. The polyimide porous membrane is prepared by the following method, and the method comprises the following steps: forming a polyamic acid membrane by using the mixture of a mixture containing polyamic acid, pore-forming substance and solvent, and subjecting the polyamic acid membrane to amidation at the temperature higher than the decomposing temperature of the pore-forming substance, wherein the solvent is a solvent which dissolves the polyamic acid but slightly dissolves or does not dissolve thepore-forming substance; and the pore-forming substance may be one or combination of benzoic acid polyol ester, phthalic acid dialkyl ester, polyprotic acid alkyl ester, phenyl alkysulfonate, chlorinated paraffin and epoxidized soybean oil. The service life and the processing yield of the lithium ion battery made of the polyimide porous membrane serving as a battery membrane are improved. Moreover, the polyimide porous membrane also has higher thermal stability, and greatly improves the safety performance of the battery.

Owner:BYD CO LTD

Method for preparing polyimide/ silicon dioxide hollow micro-sphere composite film

The invention discloses a method for preparing polyimide / silicon dioxide hollow microballoon laminated film which has low dielectric constant and keeps thermal property, and steps of reaction are that: silicon dioxide hollow microballoon is put into ethanol solution, amino-containing silane coupling agent is added after ultra sonic dispersion, stirred for reaction, separated centrifugally, washed and dried; then under the protection of nitrogen flow, the dianhydride and the diamine with a mole-ratio 1:1 are added into the high boiling polarity aprotic solvent to prepare solvent containing 10 percent (wt / wt) of solid-content; the silicon dioxide hollow microballoon modified by silane coupling agent is put into the solvent, and the weight of the silicon dioxide hollow microballoon modified by the silane coupling agent is 2-50 percent of the weight of laminated film, the polyamide acid viscous fluid is prepared upon ultra sonic dispersion and a reaction of twenty-four hours at room temperature; the polyamide acid viscous fluid is taken and poured into the glass plate mould; finally the mould is put in vacuum to dry, the temperature is heated up continuously after the solvent is removed for cyclic reaction. Thus, the polyimide / silicon dioxide hollow microballoon laminated film is prepared..

Owner:SOUTHEAST UNIV

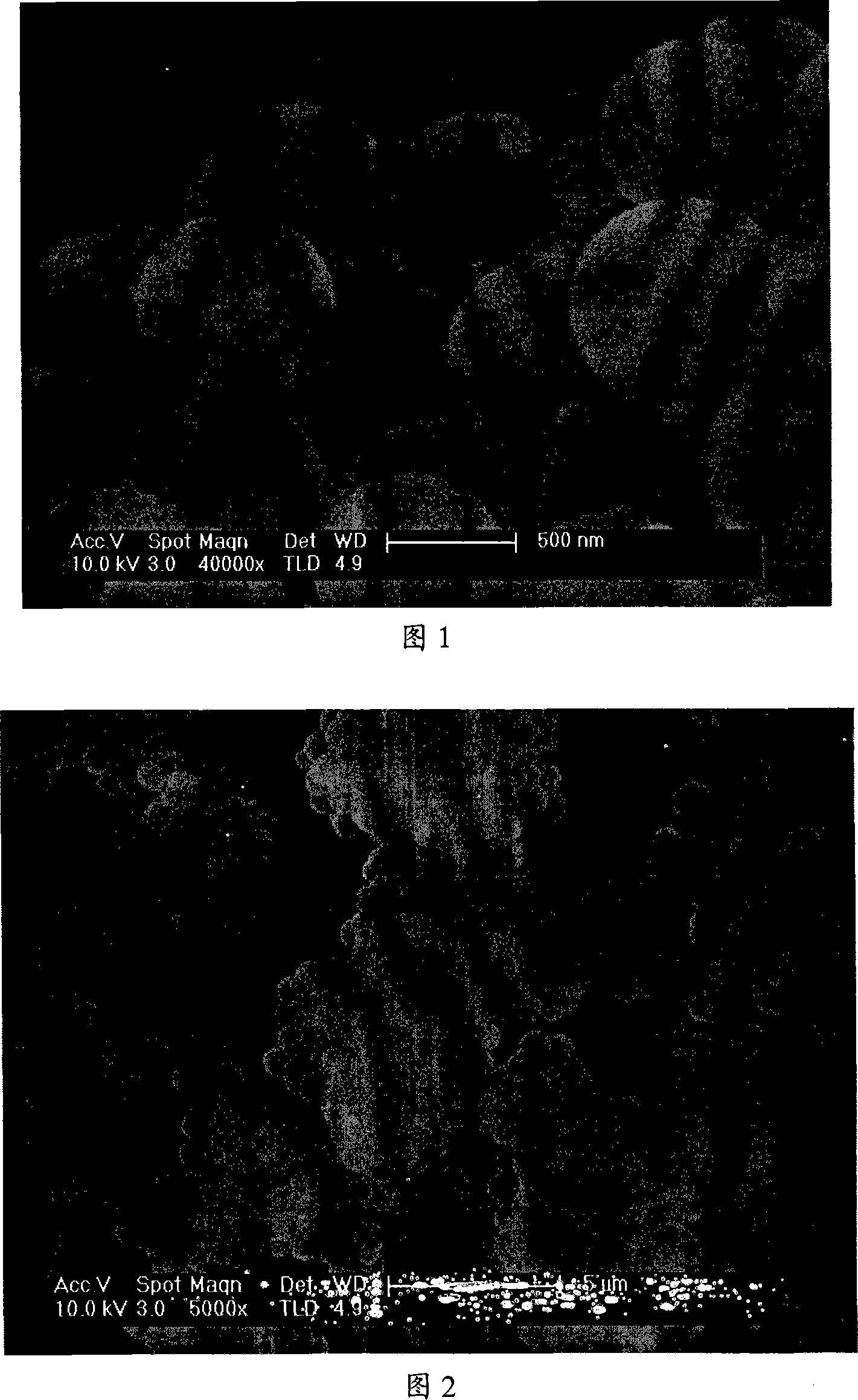

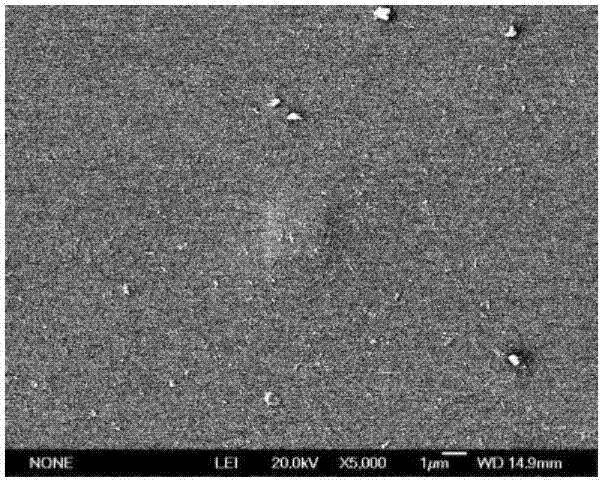

Spherical silica/polyimides composite membrane, preparation thereof and applications

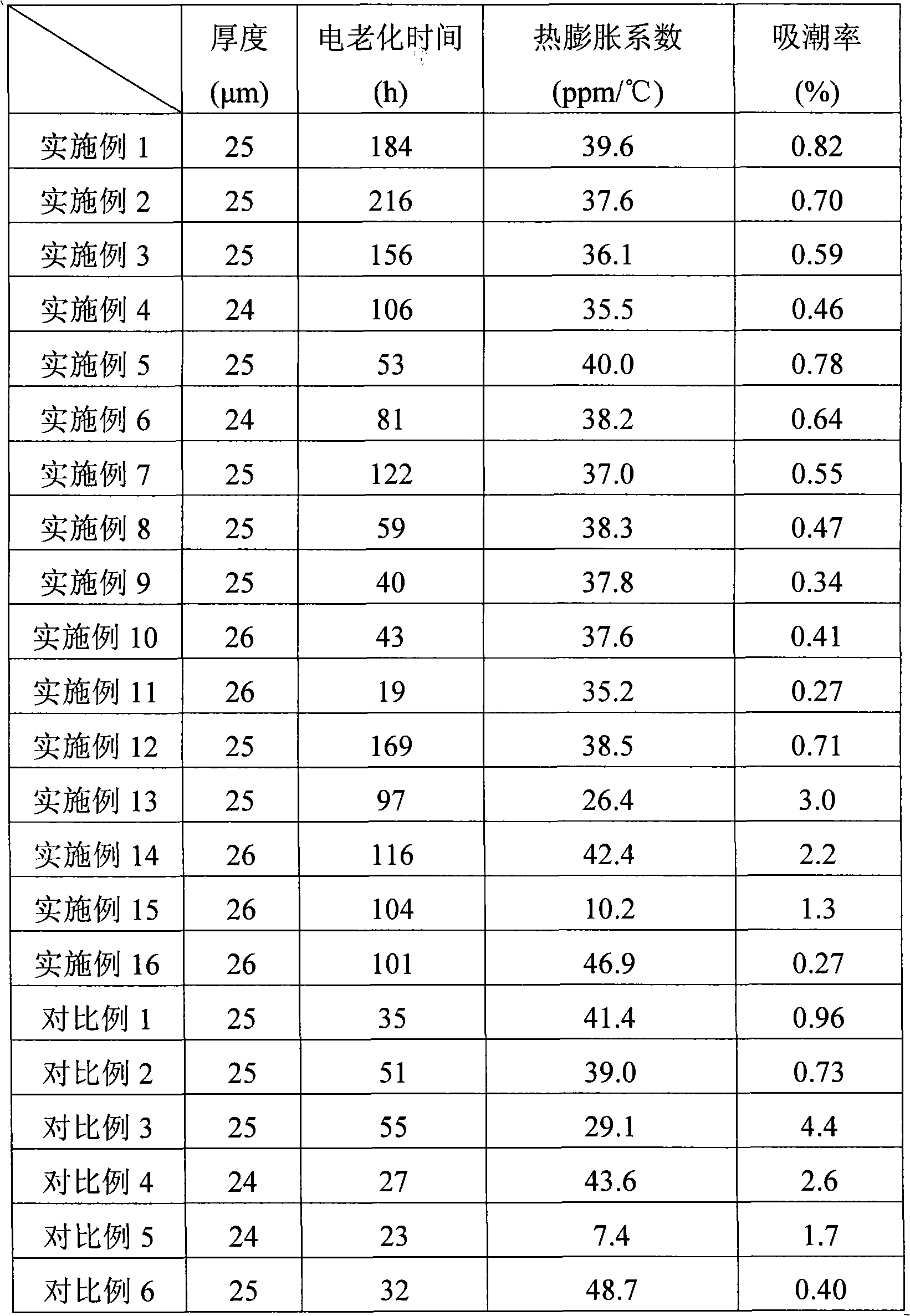

ActiveCN101289542ACorona resistantImprove corona resistanceInsulating bodiesAdhesiveThermal coefficient

The invention discloses a spherical silicon dioxide / polyimide composite film and a method for making the same as well as an application. The method for making the spherical silicon dioxide / polyimide composite film comprises the following steps that: 1) spherical silicon dioxide particles are scattered into an organic solvent evenly to obtain the spherical silicon dioxide particle suspension liquid; 2) a surface treatment agent, a molecular weight modifying agent, an auxiliary adhesive, a flatting agent and aromatic series diamine are dissolved inside the spherical silicon dioxide particle suspension liquid; organic dicarboxylic anhydride is added to be stirred in order to obtain a spherical silicon dioxide / polyamide acid mixing resin solution; 3) the mixing resin solution is coated on the surface of a flat substrate and is heated up to make the solvent volatilize and complete the imide reaction to obtain the spherical silicon dioxide / polyimide composite film. The spherical silicon dioxide / polyimide composite film has good mechanical property, good corona resistance, low thermal coefficient of expansion and low moisture absorption ratio, and has important application value in an insulating system of a frequency conversion speed motor.

Owner:INST OF CHEM CHINESE ACAD OF SCI

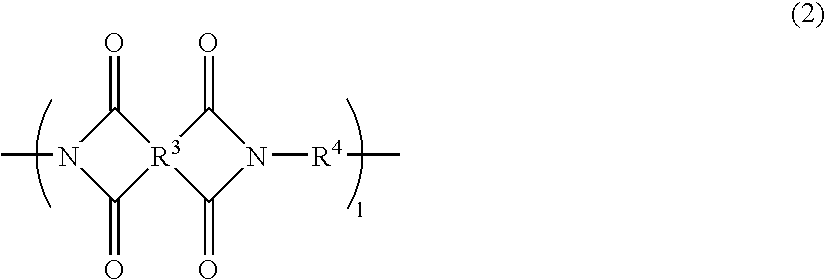

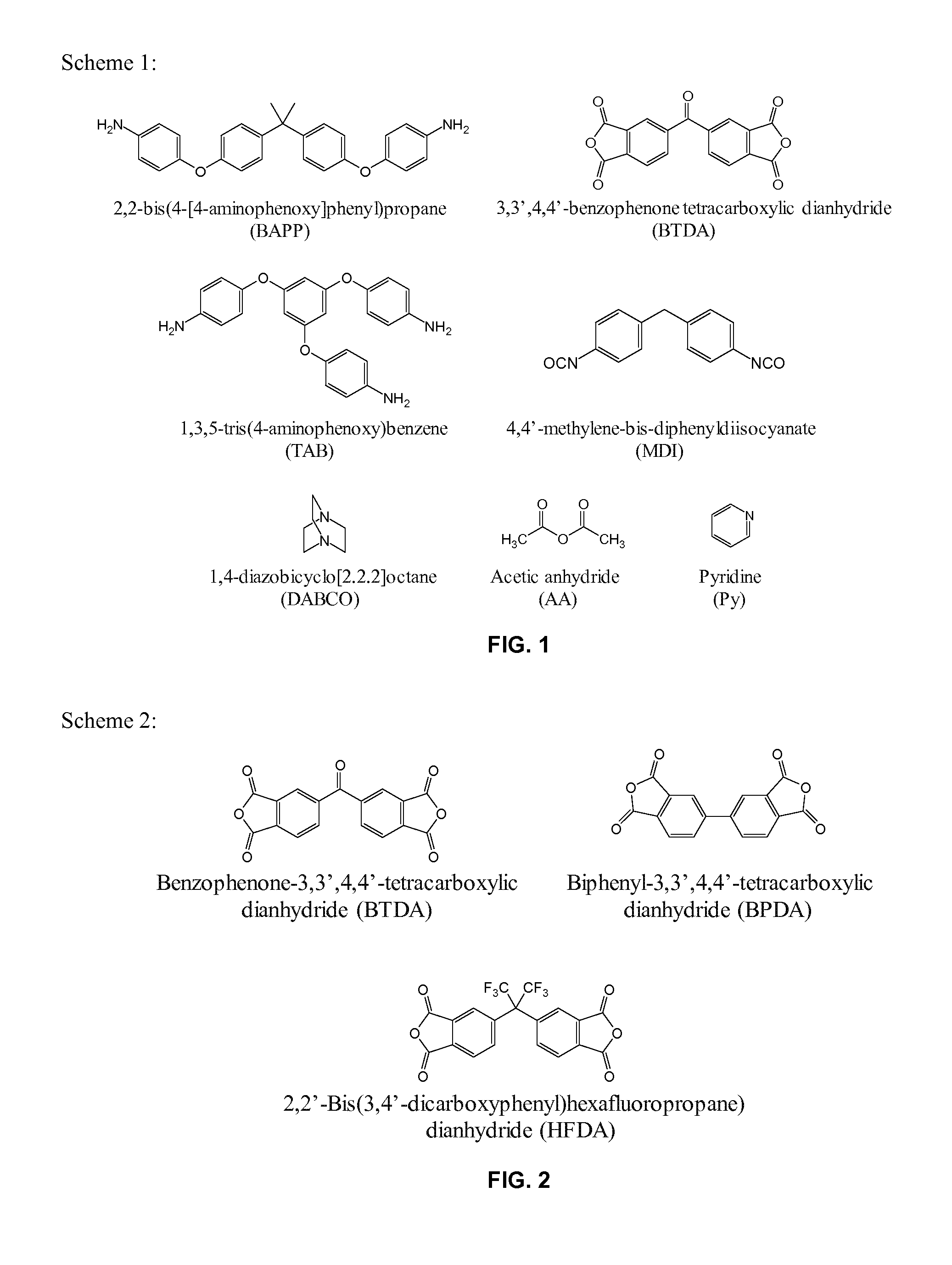

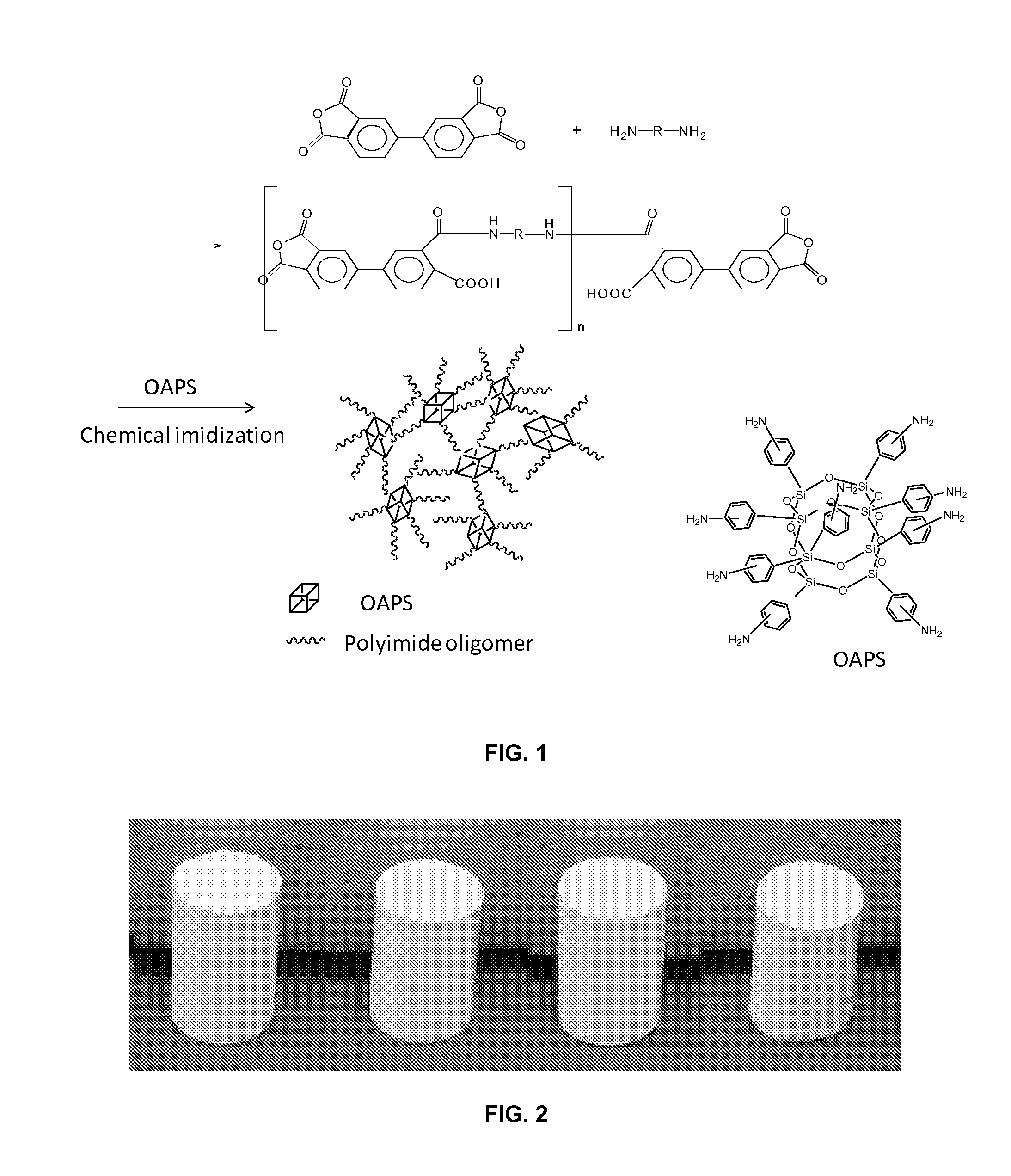

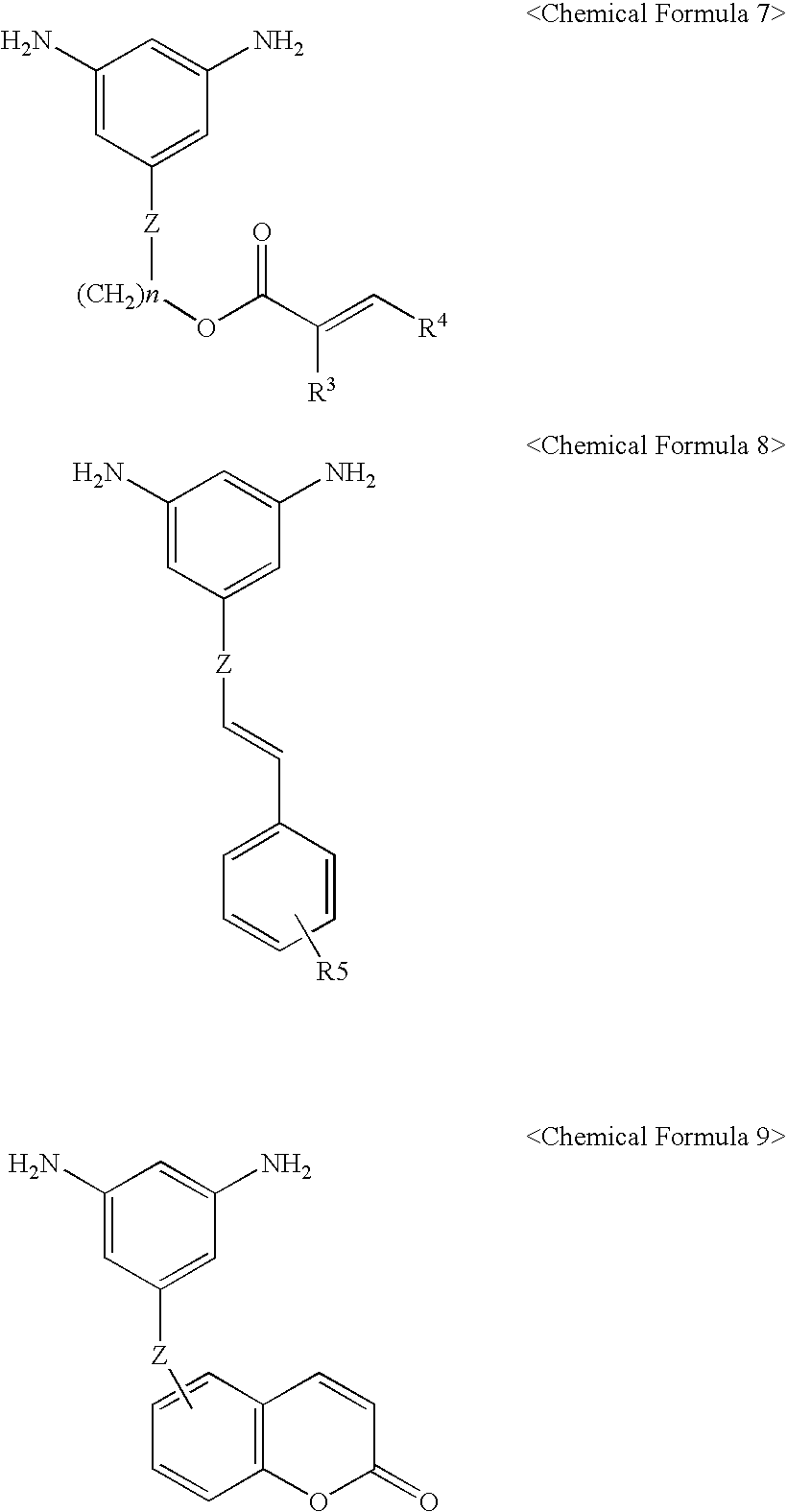

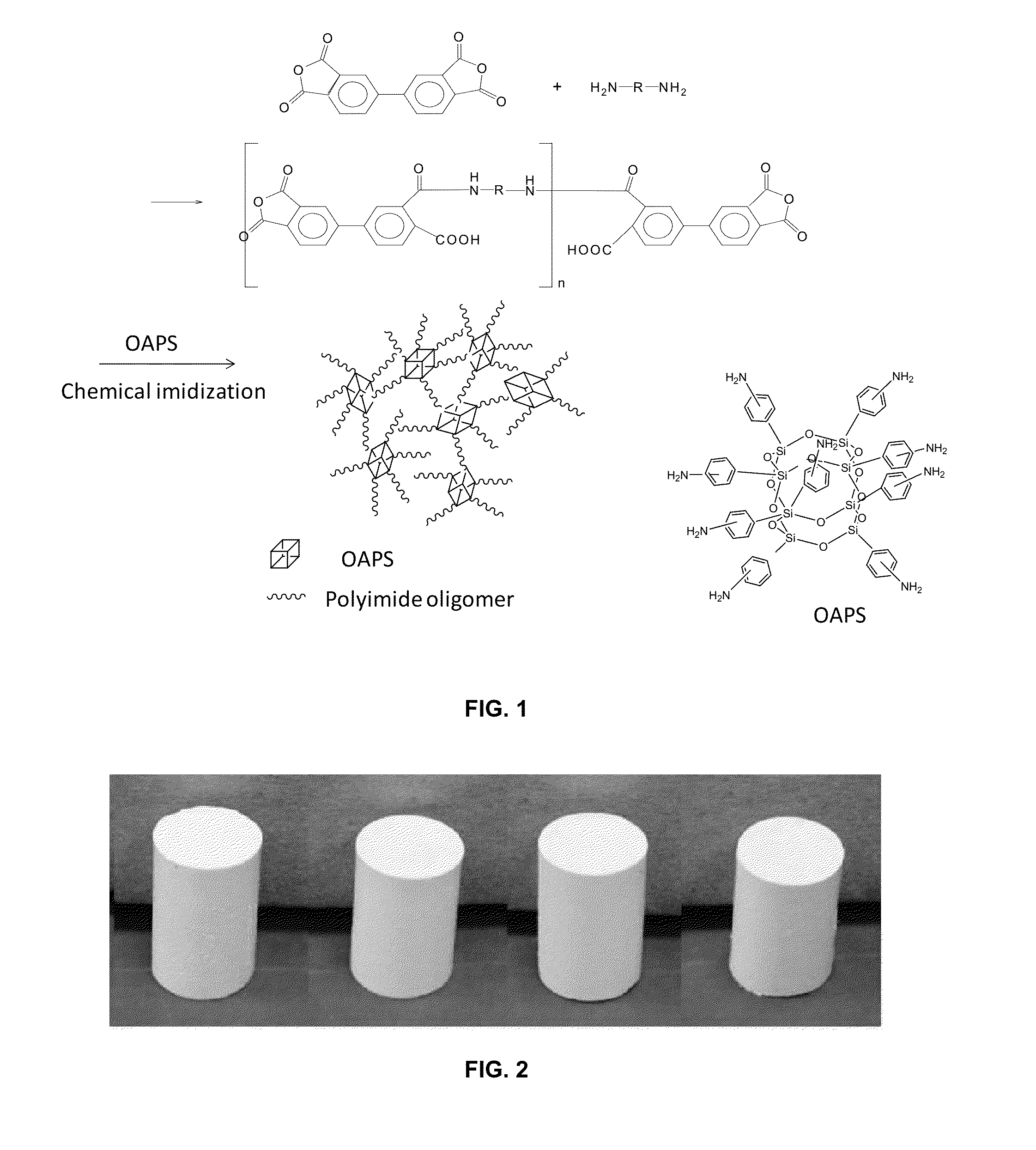

Porous cross-linked polyimide-urea networks

Porous cross-linked polyimide-urea networks are provided. The networks comprise a subunit comprising two anhydride end-capped polyamic acid oligomers in direct connection via a urea linkage. The oligomers (a) each comprise a repeating unit of a dianhydride and a diamine and a terminal anhydride group and (b) are formulated with 2 to 15 of the repeating units. The subunit was formed by reaction of the diamine and a diisocyanate to form a diamine-urea linkage-diamine group, followed by reaction of the diamine-urea linkage-diamine group with the dianhydride and the diamine to form the subunit. The subunit has been cross-linked via a cross-linking agent, comprising three or more amine groups, at a balanced stoichiometry of the amine groups to the terminal anhydride groups. The subunit has been chemically imidized to yield the porous cross-linked polyimide-urea network. Also provided are wet gels, aerogels, and thin films comprising the networks, and methods of making the networks.

Owner:UNITED STATES GOVERNMENT ADMINISTRATOR OF NASA +1

A preparation method of gum-free flexible copper-coating plate

PendingCN101157077AImprove heat resistanceGood flexibilityPretreated surfacesCoatingsDielectricCopper foil

The invention discloses a preparation method for a non-glue type flexible copper clad laminate. The invention has the method that monomer aromatic diamine is dissolved in non-protonic polar solvent, and aromatic tetracid dianhydride with the equal molar is added into the solution, thereby generating polyamic acid solution with 10 to 30 percent of the solid content in a polyamic way; dehydrating agent and catalyst are dropwise added into the solution, and the chemical imidization is performed at 10 to 80 DEG C, thereby obtaining polyimide precursor solution; the polyimide precursor solution is coated on the copper foil surface with the 60 to 70 micron thickness, and heated to remove the solvent, and the thermal imidization is further performed at 250 to 300 DEG C, thereby obtaining the non-glue type flexible copper clad laminate. The non-glue type flexible copper clad laminate of the invention has the excellent heat resistant performance, is suitable for the non-lead welding meeting the environmental protective requirement, has small crimpability, good dimensional stability, better mechanical strength, high peel strength, and high flexibility resistance, and simultaneously has lower thermal expansion coefficient, dielectric constant, and water absorption.

Owner:湖北省化学研究院

Methods of forming a passivation layer

ActiveUS20110263136A1Improve featuresSemiconductor/solid-state device manufacturingPhotosensitive material processingCross-linkBenzoxazole

In a composition of forming a passivation layer, the composition includes about 30 to about 60 percent by weight of a mixed polymer resin formed by blending polyamic acid and polyhydroxy amide, about 3 to about 10 percent by weight of a photoactive compound, about 2 to about 10 percent by weight of a cross-linking agent and an organic solvent. The passivation layer formed by using the composition has superior mechanical and physical properties, in which disadvantages of polyimide and polybenzoxazole are compensated by mixing both materials.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for preparing graphene/polyimide composite fibers

InactiveCN102534858ASolve for uniformitySolve adhesivenessElectroconductive/antistatic filament manufactureWet spinning methodsFiberPolymer science

The invention relates to a method for preparing graphene / polyimide composite fibers. The method comprises the following steps of: (1) preparing graphene or graphene oxide; (2) preparing a graphene / polyamic acid spinning solution; and (3) preparing graphene / polyimide or graphene oxide / polyimide composite fibers. According to the method, through adopting stripped graphene layers as addition materials of polyimide fibers, the spinnability of the polyamic acid spinning solution is improved, the stability of the polyamic acid fibers is improved, the improvement on the performance of the fibers is facilitated, and thus, the polyimide fibers with excellent performance are prepared; and with the adoption of the method, the problem of difficulty in the spinning and the forming of the polyamic acid fibers is solved, the mechanical properties of the composite fibers is improved, meanwhile, the problems of uneven dispersion and interfacial adhesiveness of the graphene in a matrix polymer are solved.

Owner:DONGHUA UNIV

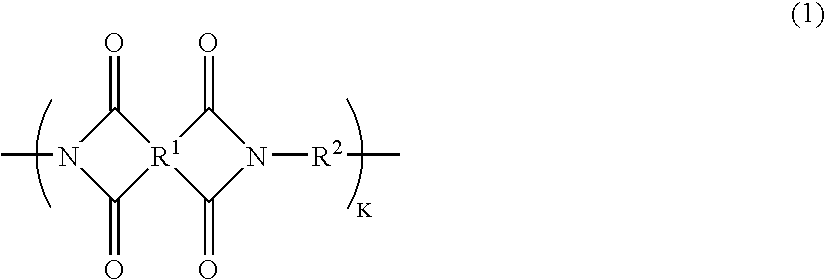

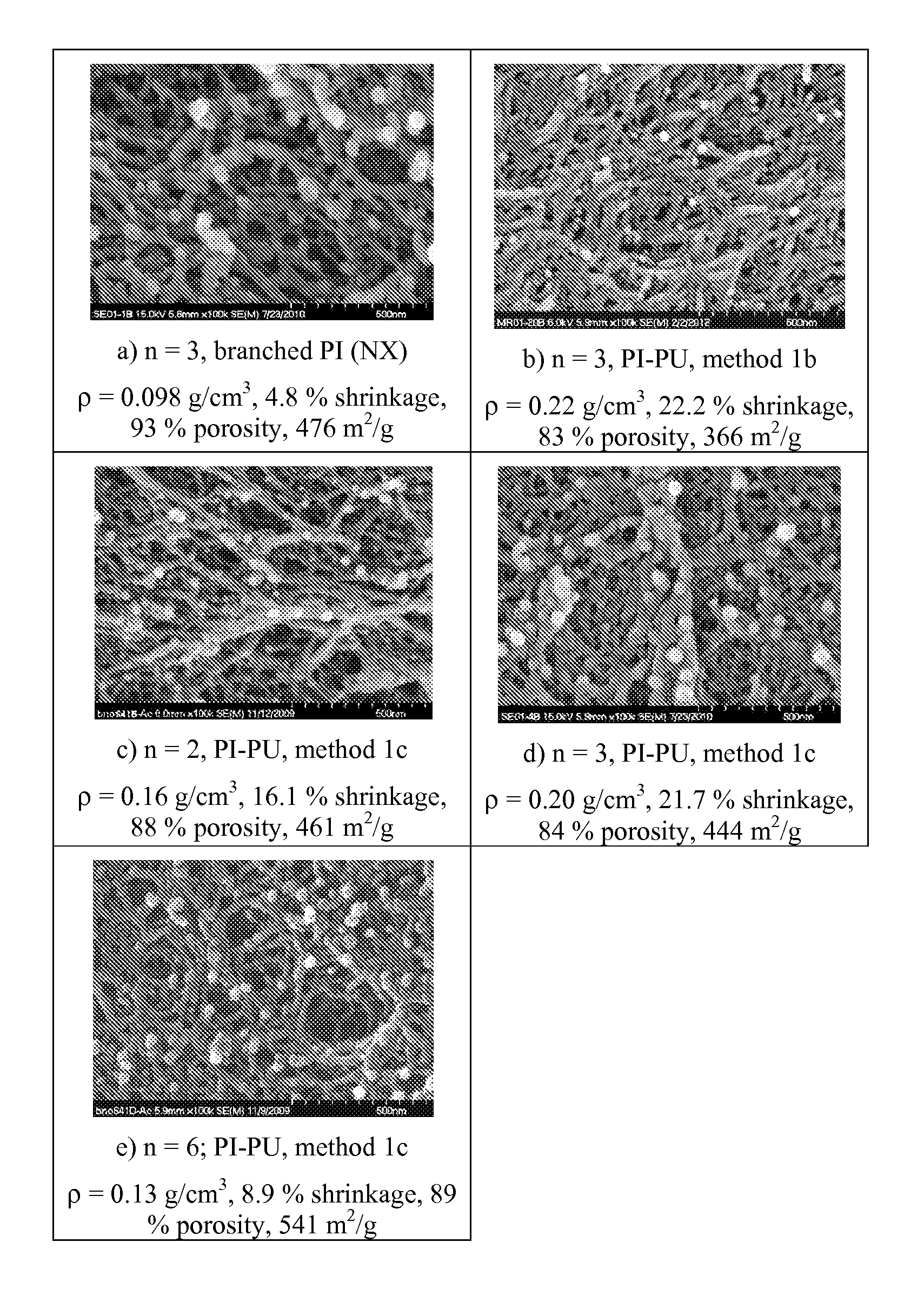

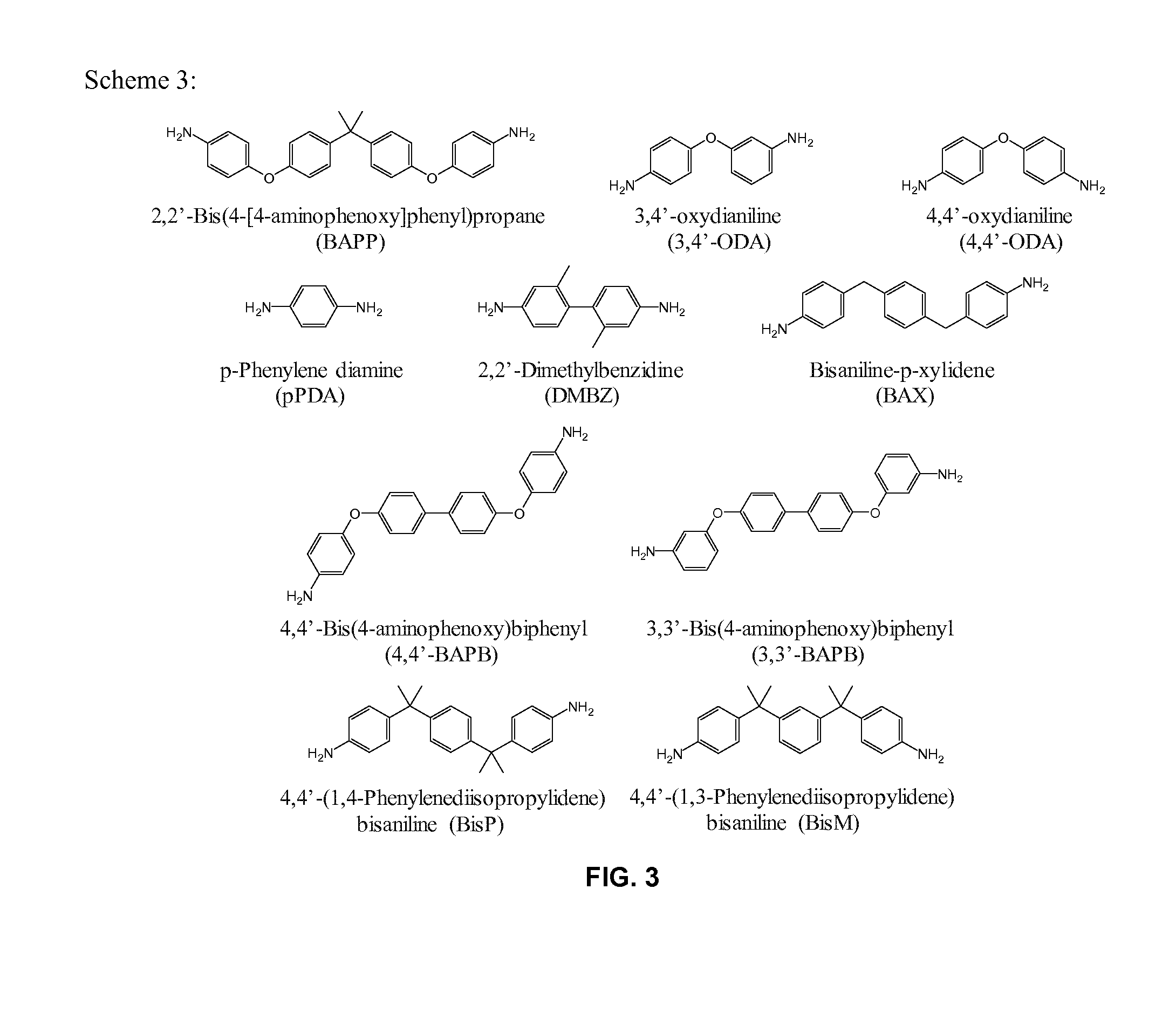

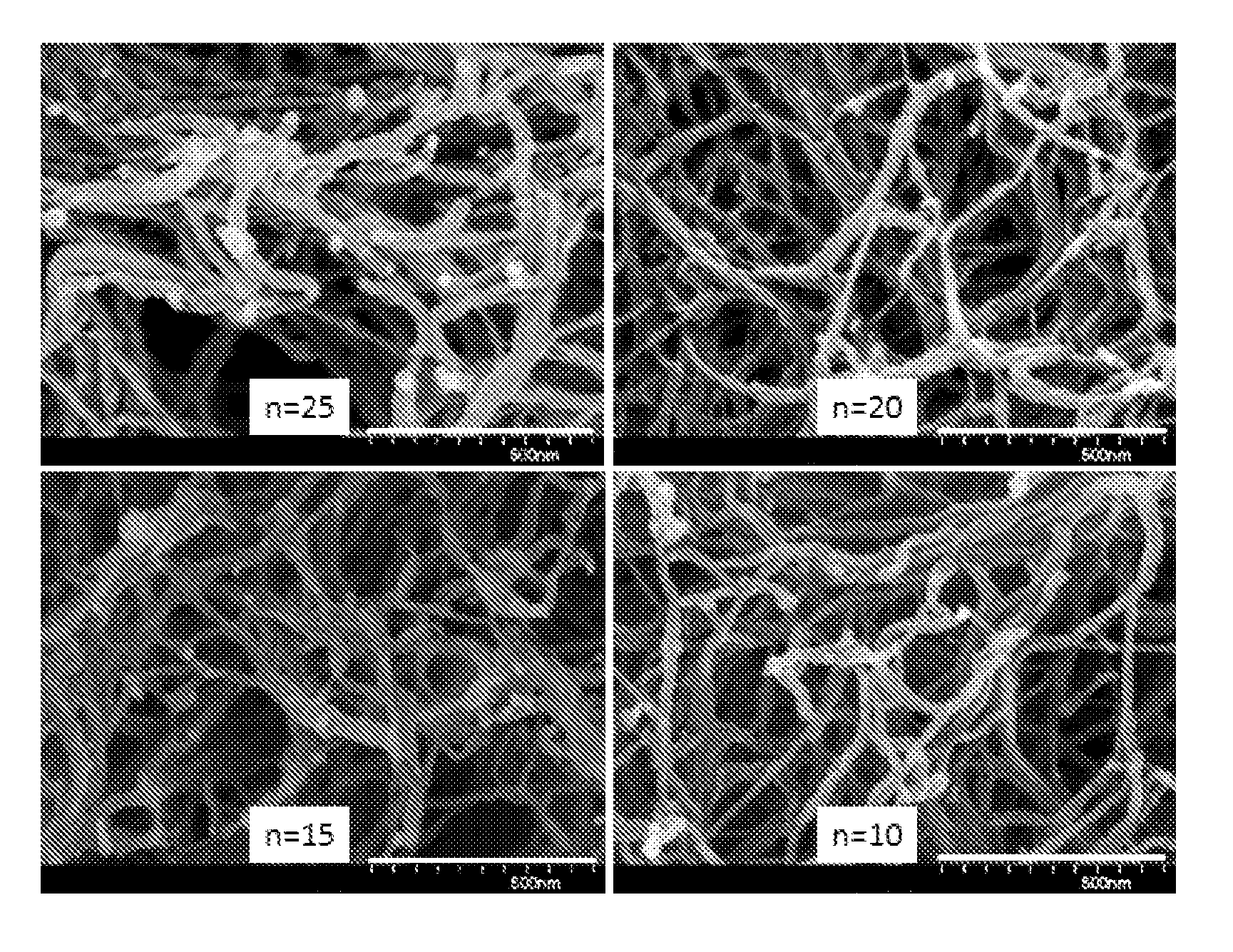

Porous cross-linked polyimide networks

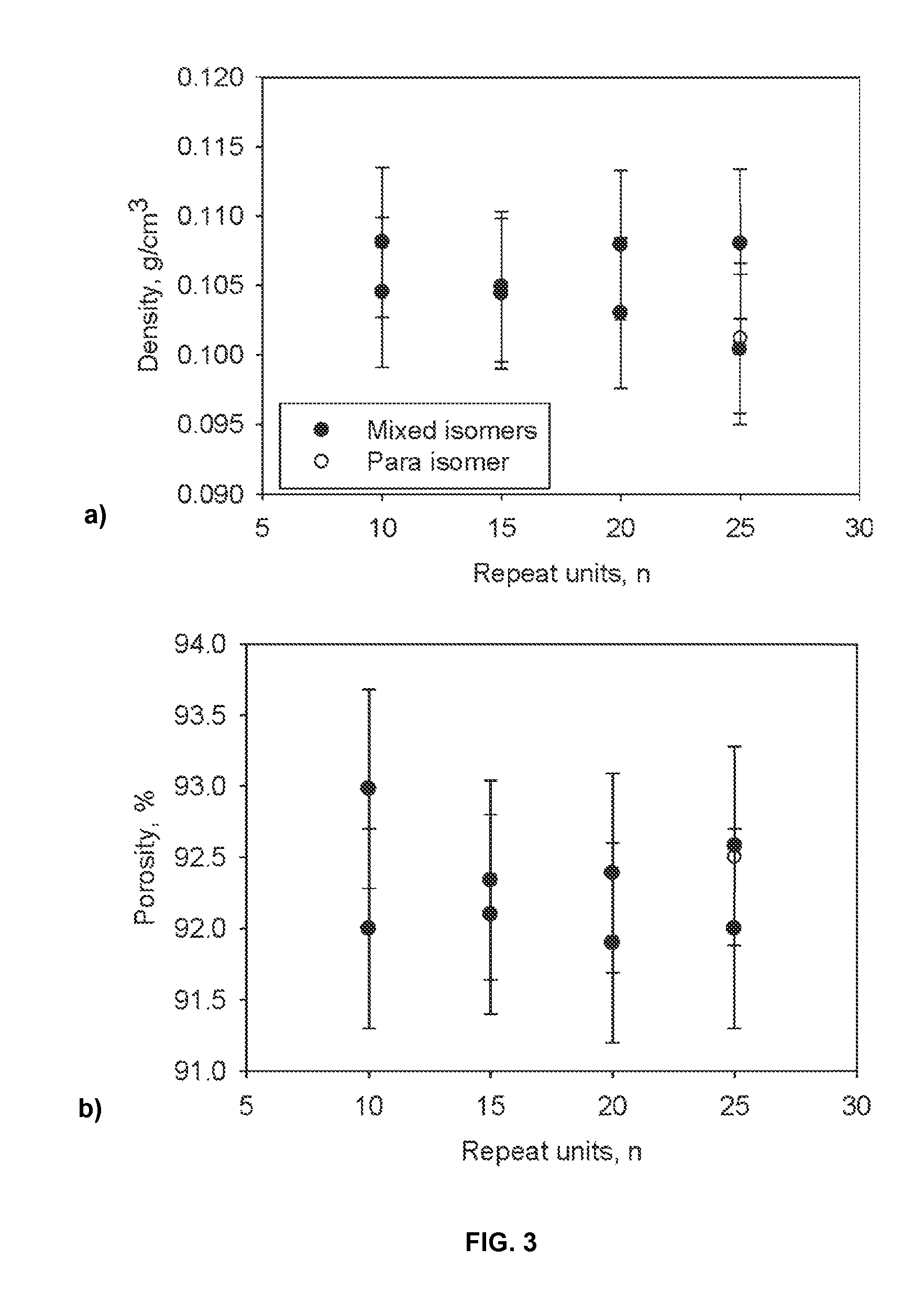

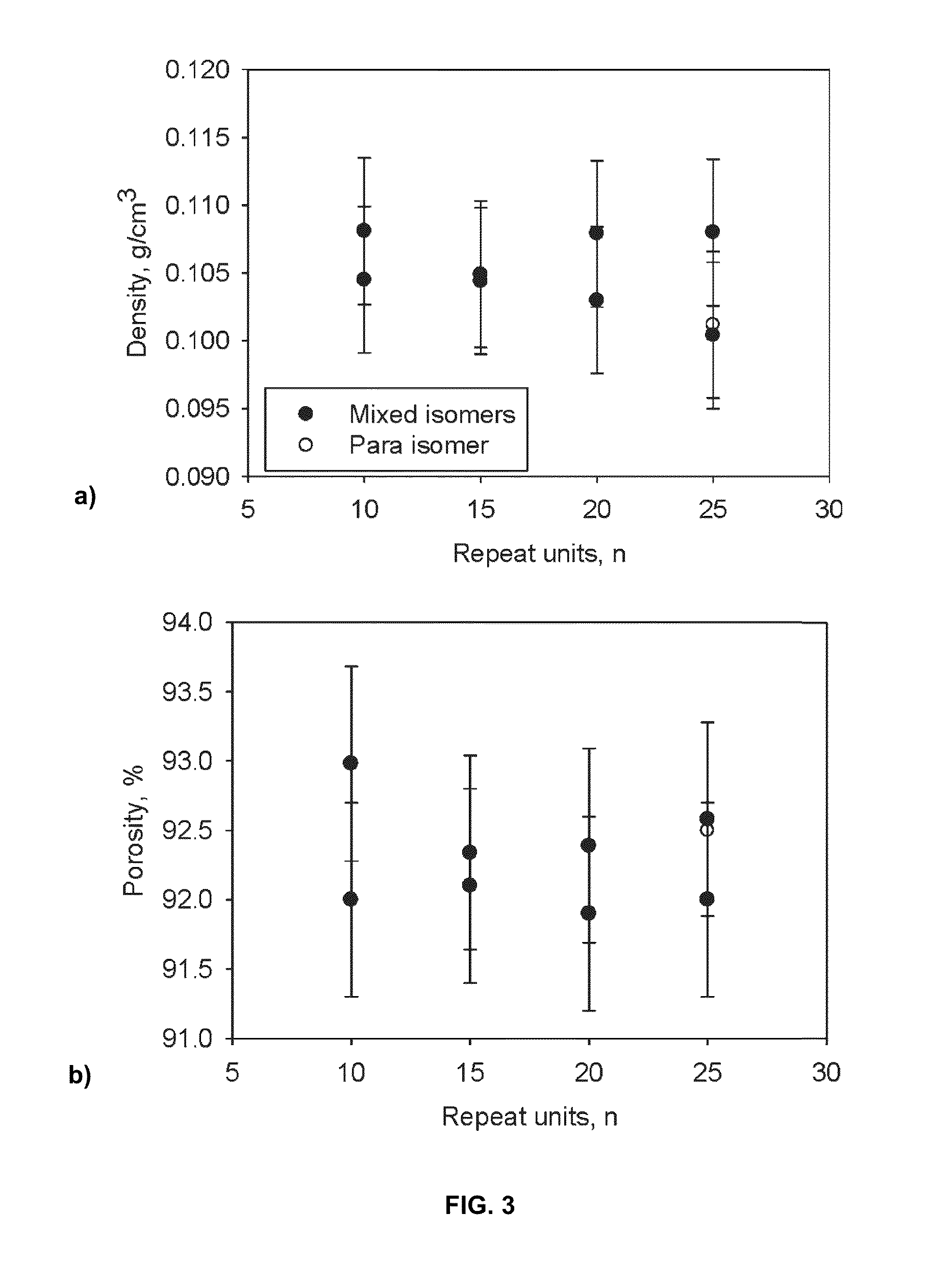

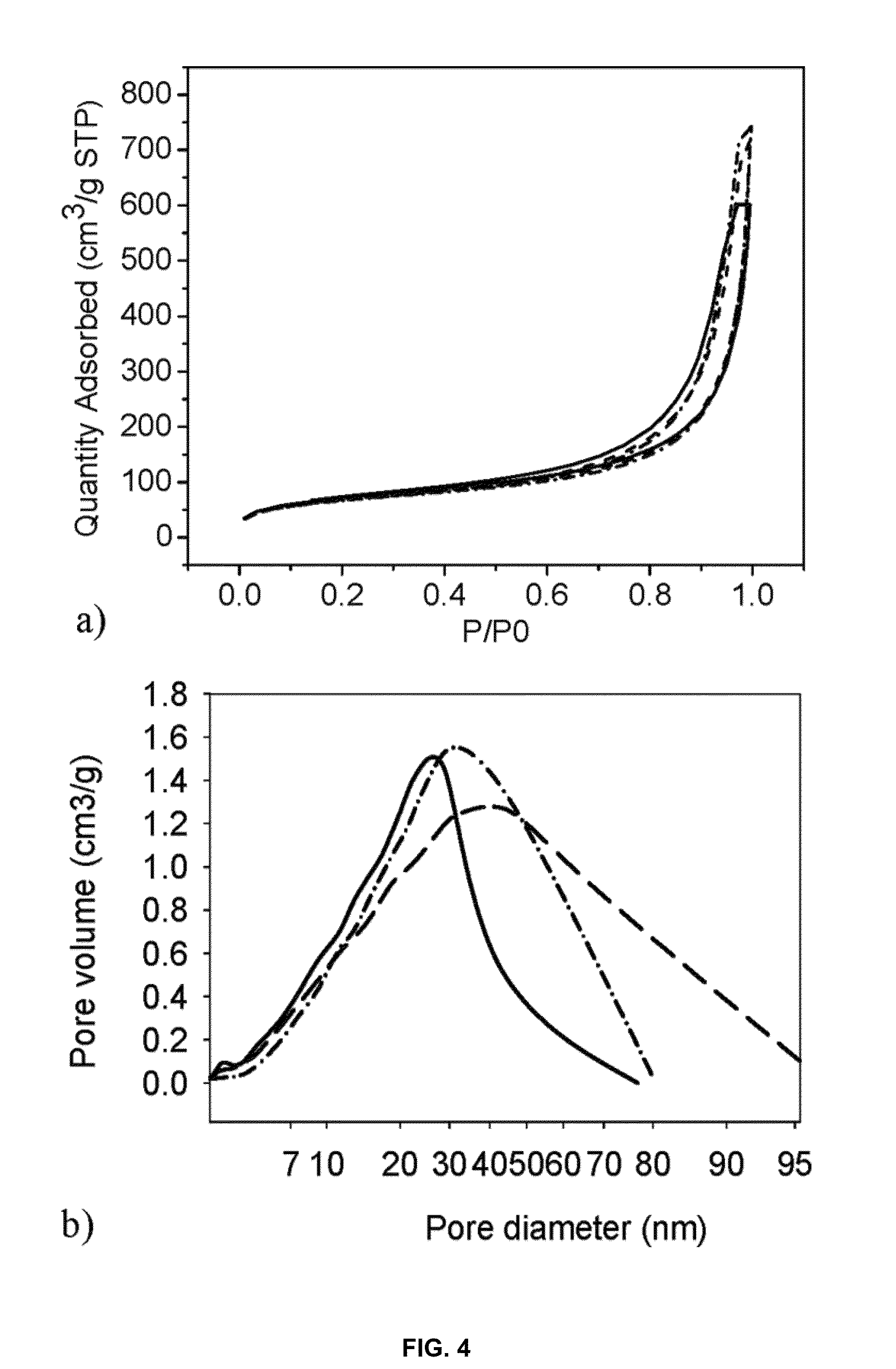

Porous cross-linked polyimide networks are provided. The networks comprise an anhydride end-capped polyamic acid oligomer. The oligomer (i) comprises a repeating unit of a dianhydride and a diamine and terminal anhydride groups, (ii) has an average degree of polymerization of 10 to 50, (iii) has been cross-linked via a cross-linking agent, comprising three or more amine groups, at a balanced stoichiometry of the amine groups to the terminal anhydride groups, and (iv) has been chemically imidized to yield the porous cross-linked polyimide network. Also provided are porous cross-linked polyimide aerogels comprising a cross-linked and imidized anhydride end-capped polyamic acid oligomer, wherein the oligomer comprises a repeating unit of a dianhydride and a diamine, and the aerogel has a density of 0.10 to 0.333 g / cm3 and a Young's modulus of 1.7 to 102 MPa. Also provided are thin films comprising aerogels, and methods of making porous cross-linked polyimide networks.

Owner:UNITED STATES GOVERNMENT ADMINISTRATOR OF NASA +1

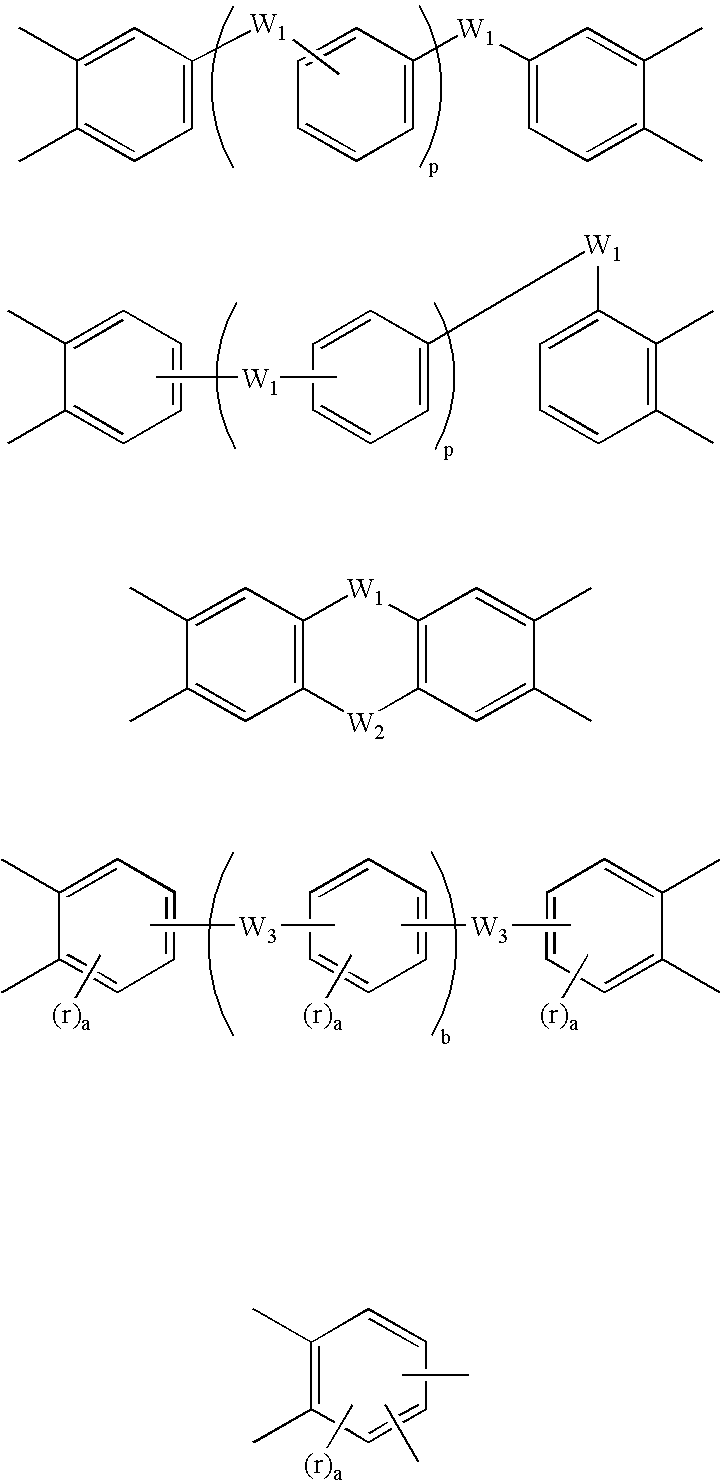

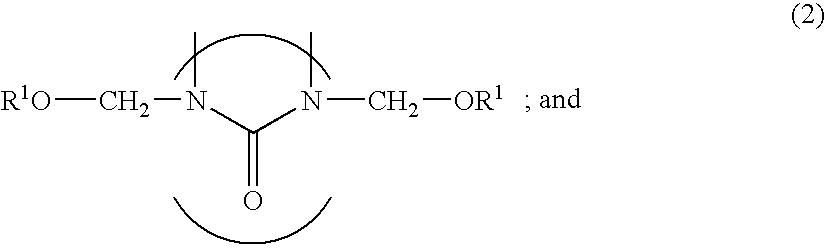

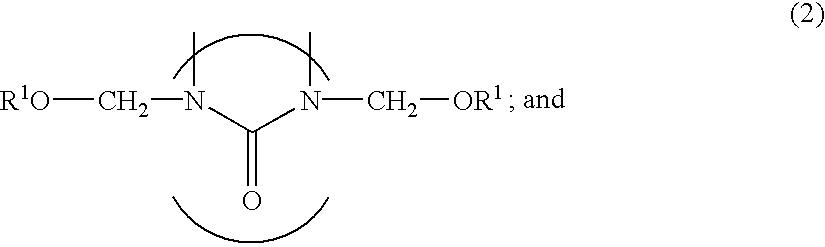

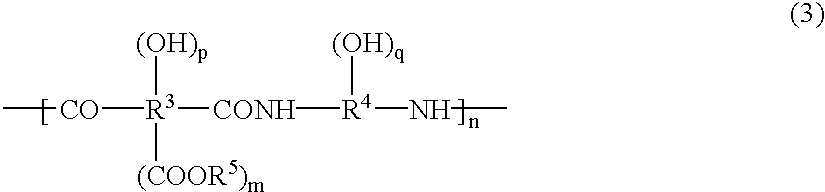

Precursor composition for positive photosensitive resin and display made with the same

InactiveUS20030194631A1Raise the ratioImprove resolutionRadiation applicationsPhotoprinting processesQuinoneHydrogen atom

A positive photosensitive resin precursor composition which can be can be developed in an alkaline developer is provided. The positive photosensitive resin precursor composition comprises (a), one of (b1) and (b2), and (c): (a) a polyamic acid ester and / or a polyamic acid polymer, both of which are soluble in an alkaline aqueous solution; (b1) a phenolic-hydroxyl-group-containing thermally crosslinkable compound comprising an organic-group-R<superscript>1>-substituted methylol group represented by formula (1) (wherein R<superscript>1 >is not a hydrogen atom),CH<subscript>2< / highlight>-OR<superscript>1>) (1);(b2) a thermally crosslinkable compound containing a ureal organic group substituted by an organic group R<superscript>1 >and represented by formula (2) (c) an esterified quinone diazide compound.

Owner:TORAY IND INC

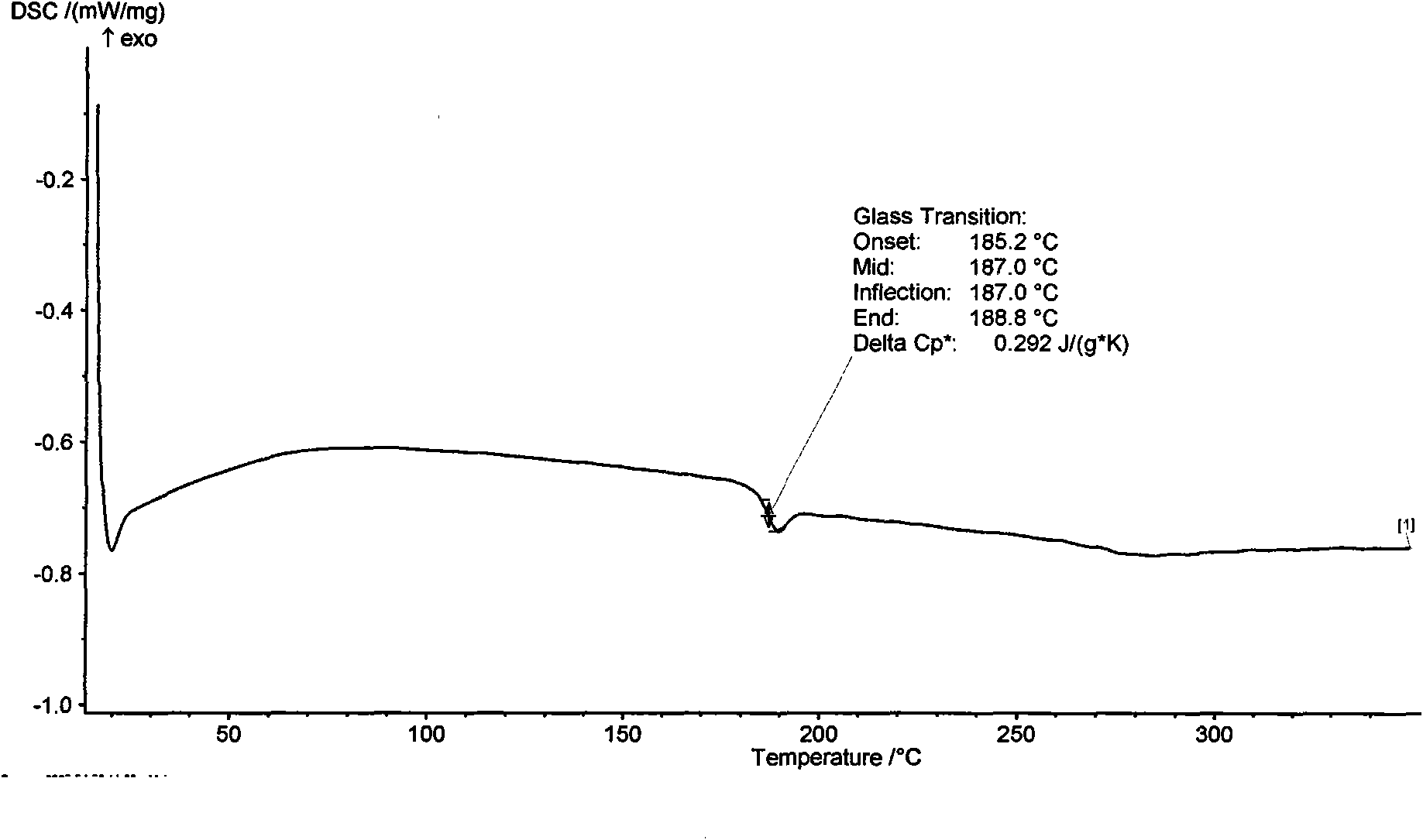

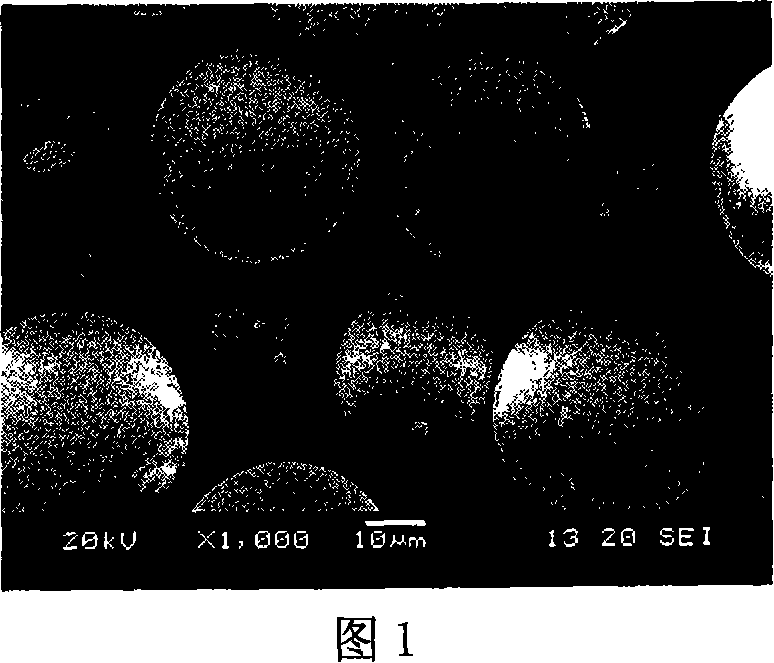

Prepn process of polyimide microsphere

The present invention relates to dispersive polymerization process of preparing polyimide microsphere in monomer solution. The process includes the following steps: dissolving monomer diamine and dispersant in organic solvent through stirring; stage adding monomer diamine and heating for polymerizing to prepare polyamic acid solution; adding catalyst and dewatering agent successively for chemical imination; dropping water solution of dispersant to separate out solid grains, centrifugally filtering, washing and stoving to obtain polyimide microsphere. Thus prepared polyimide microsphere has glass transition temperature Tg of 200-300 deg.c, and grain size of 0.1-100 micron. The process has high polyimide yield, low cost and controllable grain shape and size distribution.

Owner:NANJING UNIV OF TECH

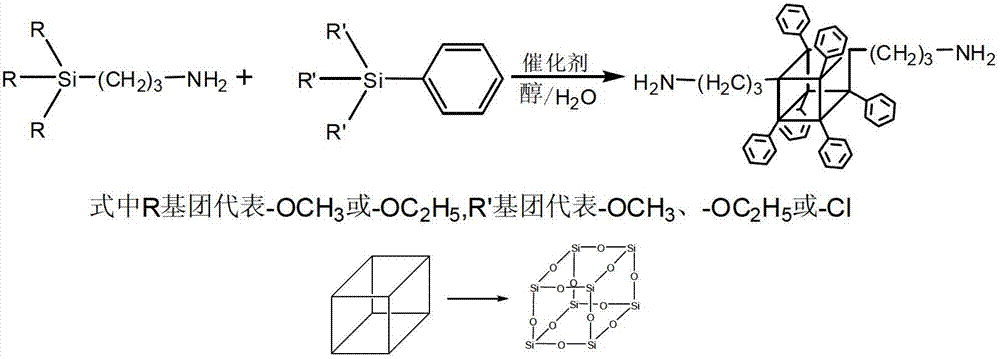

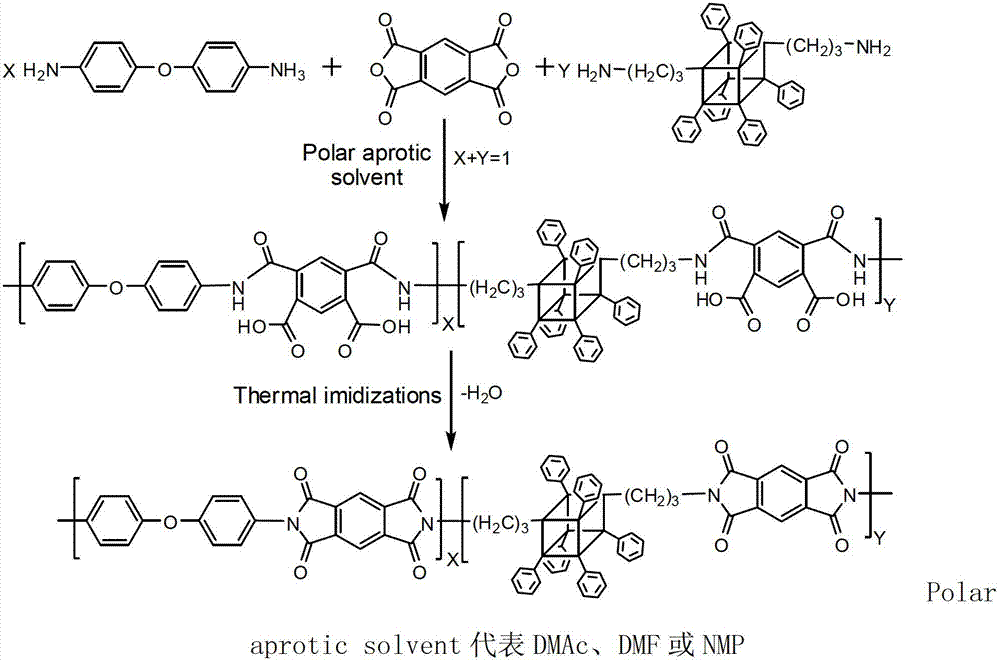

Preparation method of atomic oxygen-resistant polyimide hybrid films containing POSS (polyhedral oligomeric silsesquioxanes) structures

InactiveCN102731809AImprove anti-atomic oxygen performanceMild reaction conditionsSilicon organic compoundsAviationAlcohol

The invention relates to a preparation method of atomic oxygen-resistant polyimide hybrid films containing POSS structures. The preparation method comprises the following steps: reacting phenyl-containing monomers with aminopropyl-containing silane monomers in an alcohol / water cosolvent system under the action of a catalyst, volatilizing the solvent, washing, lyophilizing to obtain diamine POSS, modifying a polyimide material with the diamine POSS to prepare polyamide acid containing the POSS structure, and carrying out thermal imidization to obtain a series of polyimide hybrid films with different contents of the diamine POSS. Reaction conditions for synthesizing the diamine POSS are mild, the cost is low, and the POSS structure is introduced to the main chain of a polyimide molecule in a chemical bond manner, so the polyimide material has an excellent intrinsic atomic oxygen resistance, the hybrid films have excellent comprehensive performances, and the atomic oxygen resistances of the hybrid films are 6 times higher than that of unmodified Kapton polyimide films, thereby the hybrid films of the invention have important meanings to the development of the aviation and space industry.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Coaxial compound nanometre fibre film as well as preparation method and application thereof

ActiveCN102230257AImprove permeabilityHigh tensile strengthFilament/thread formingCell component detailsFiberPolymer science

The invention discloses a coaxial compound nanometre fibre film composed of compound nanometre fibres of a fluorine-containing polymer skin layer and a polyimide core layer, wherein the upper and the lower surfaces and inner holes of the film are distributed symmetrically. The coaxial compound nanometre fibre film is prepared from a fluorine-containing polymer solution and a polyamic acid solution through coaxial static spinning compounding, mechanical roller pressing and thermal imidization; the nanometre fibre film provided by the invention integrates the advantages of fluorine-containing polymer and polyimide; the fluorine-containing polymer has excellent electrolyte wetting property, liquid maintaining property and ion conductivity; and the polyimide has high mechanical strength and high heat resistance. The compound nanometre film provided by the invention is fit for high-energy lithium ion energy storage batteries and high-power electrokinetic cells.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Polyimide nano-fiber membrane with crosslinked structure and preparation thereof

ActiveCN102766270AImprove mechanical propertiesThe degree of cross-linking can be controlledMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention provides a polyimide nano-fiber membrane with a crosslinked structure and preparation thereof, belonging to the technical field of polyimide nano-fiber membrane. Polyamide acid solution which is a prepolymer of polyimide is synthesized from diamine and a dibasic acid anhydride monomer. And polyimide nano-fiber membrane is prepared by the electrospinning technology. The polyimide nano-fiber membrane is then treated in alkali lye with PH of 8.5-10.5 for 10s-3h, washed and dried, which is then thermal-imidized through gradient heating up and cooled down to obtain polyimide nano-fiber membrane with the crosslinked structure. The polyimide nano-fiber membrane with the crosslinked structure prepared by the invention has the advantages of high strength, simple implementation process, easiness in processing and good application prospect.

Owner:BEIJING UNIV OF CHEM TECH

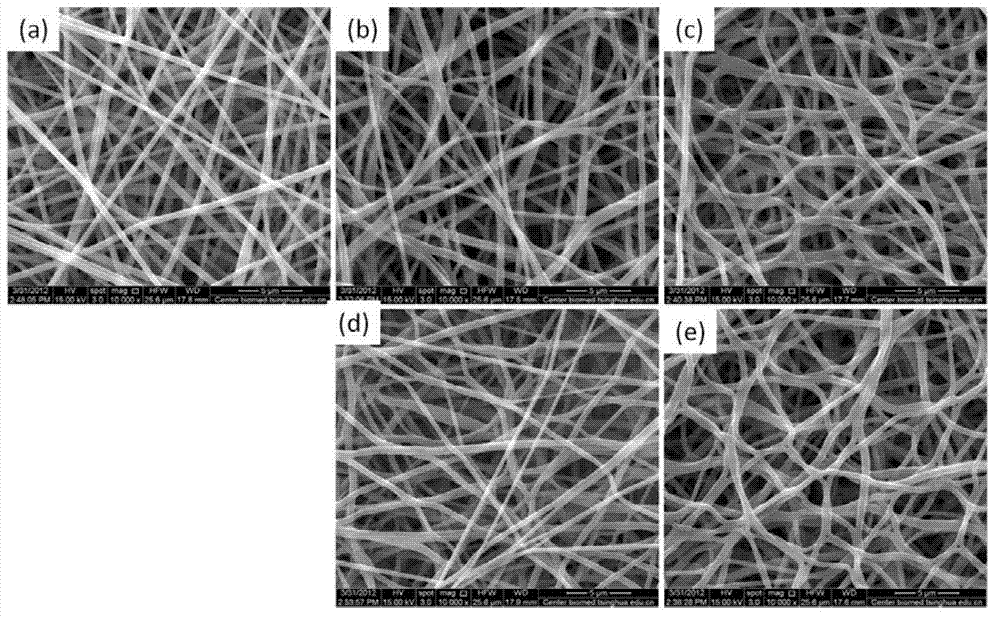

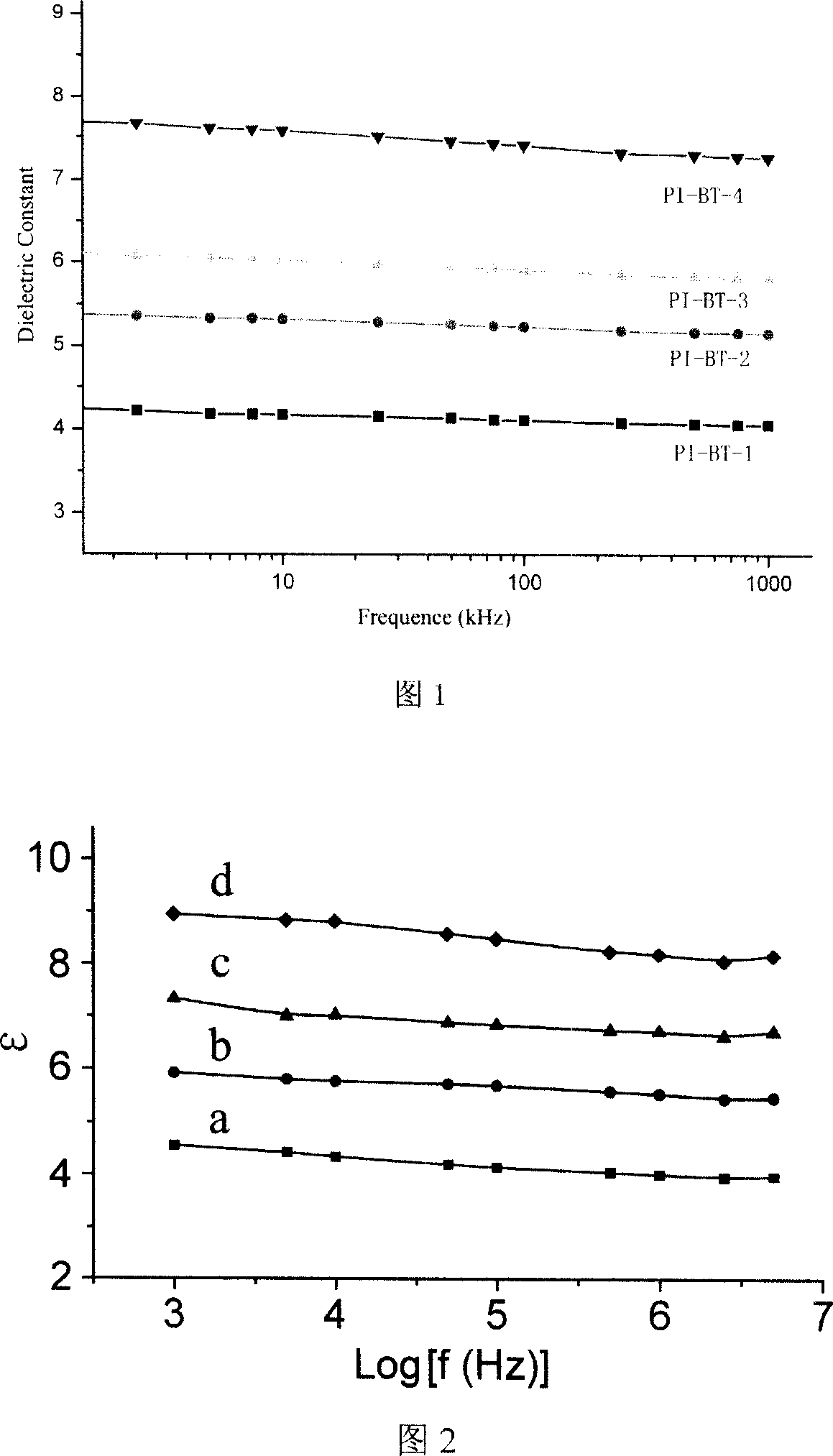

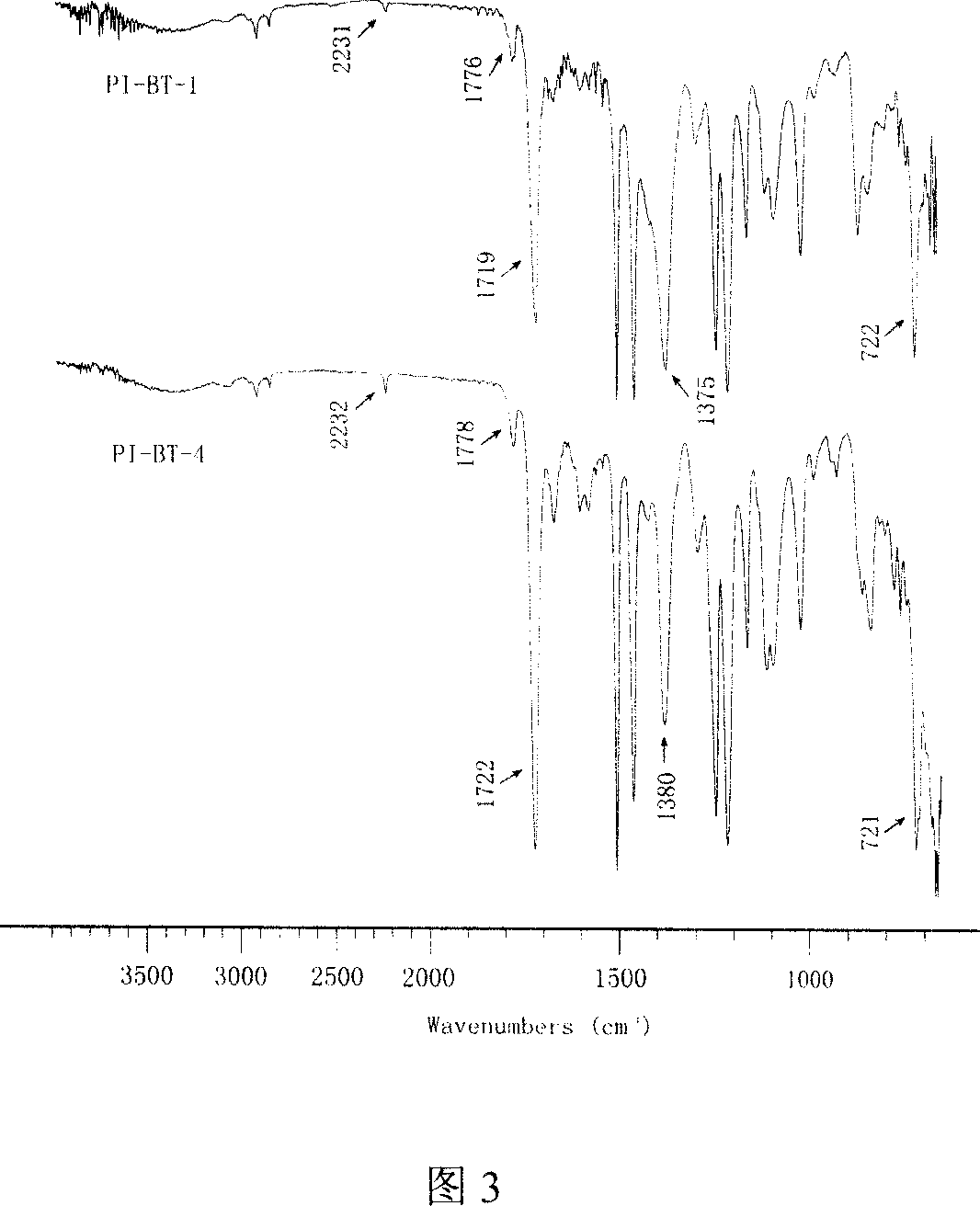

Process for synthesizing composite film of polyacylimide/nano barium phthalate with high deelectric constant

The process of synthesizing composite polyimide / nanometer barium titanate film with high dielectric constant includes the following steps: adding maleic anhydride and diamine in the same molar amount into N-methyl-2-pyrrolidone or N, N-dimethyl acetamide as solvent to compound solution with solid content of 10-20 %, adding nanometer modifying barium titanate particle in the amount less than 40 % of the composite film weight into the solution and ultrasonically dispersing, stirring continuously at room temperature for 18-24 hr to obtain polyamic acid, pouring the polyamic acid on glass plate mold, and vacuum heating to eliminate solvent and iminate to obtain the composite polyimide / nanometer barium titanate film. Thus prepared film has excellent heat stability, high oxidative degradation resistance, high dielectric constant and low dielectric loss, and may be used for wound film capacitor, printed circuit board, semiconductor device, etc.

Owner:SOUTHEAST UNIV

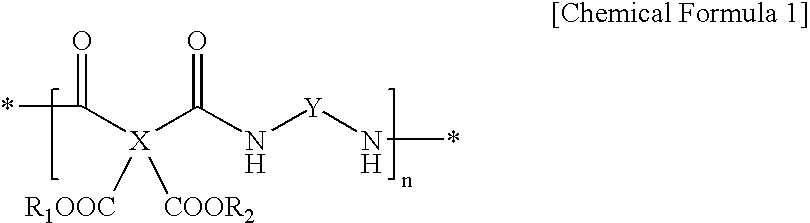

Transparent, highly heat-resistant polyimide precursor and photosensitive polyimide composition thereof

ActiveUS20070093640A1Good chemical resistanceImprove heat resistancePhotosensitive materialsPhotomechanical apparatusNegative typeInsulation layer

The present invention relates to an aqueous alkali-developable photosensitive polyimide precursor resin composition that is appropriate for highly heat-resistant transparent protection layers and insulation layers for liquid crystal display devices. In more detail, the present invention relates to a negative-type photosensitive transparent polyimide precursor resin composition manufactured in two steps. The first step is the manufacture of a transparent linear polyamic acid (A) from (a-1) one or more kinds of tetracarboxylic acid dianhydrides selected from alicyclic tetracarboxylic acid dianhydrides having 3 to 30 carbon atoms; and (a-2) one or more kinds of diamines selected from aliphatic, alicyclic, or non-conjugated aromatic diamines, having 3 to 30 carbon atoms, having one or more ethylenically unsaturated bonds at side chains as essential components; and the second step is the manufacture of reactive transparent polyimide precursors shown in the following Chemical Formula 1 according to the esterification reaction of the above polyamic acid (A) with ethylenically unsaturated compound (B) containing an epoxy group in the same molecule as the main component. The photosensitive transparent polyimide precursor resin compositions according to the present invention have a superior photosensitivity, and thus, may be used for transparent protection layers and insulation layers of liquid crystal display devices having superior heat resistance, chemical resistance, mechanical strength, and electricity insulation.

Owner:LG CHEM LTD

Porous cross-linked polyimide networks

Porous cross-linked polyimide networks are provided. The networks comprise an anhydride end-capped polyamic acid oligomer. The oligomer (i) comprises a repeating unit of a dianhydride and a diamine and terminal anhydride groups, (ii) has an average degree of polymerization of 10 to 50, (iii) has been cross-linked via a cross-linking agent, comprising three or more amine groups, at a balanced stoichiometry of the amine groups to the terminal anhydride groups, and (iv) has been chemically imidized to yield the porous cross-linked polyimide network. Also provided are porous cross-linked polyimide aerogels comprising a cross-linked and imidized anhydride end-capped polyamic acid oligomer, wherein the oligomer comprises a repeating unit of a dianhydride and a diamine, and the aerogel has a density of 0.10 to 0.333 g / cm3 and a Young's modulus of 1.7 to 102 MPa. Also provided are thin films comprising aerogels, and methods of making porous cross-linked polyimide networks.

Owner:UNITED STATES GOVERNMENT ADMINISTRATOR OF NASA +1

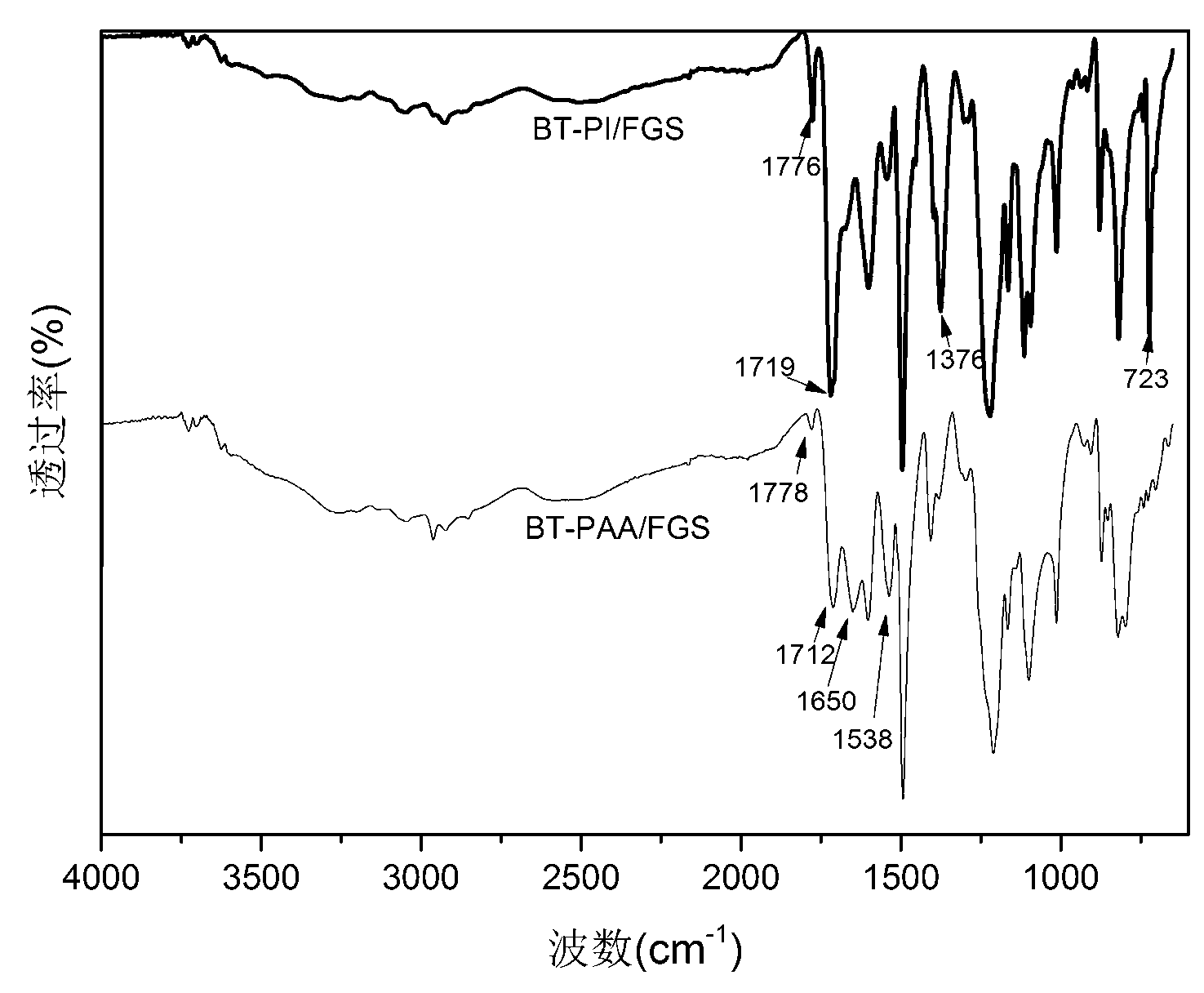

Polyimide high dielectric composite material and preparation method thereof

The present invention relates to a polyimide high dielectric composite material, wherein polyimide is adopted as a matrix phase, modified graphene and nanometer barium titanate are adopted as inorganic phases, components comprise, by mass, 0.5-3.0 w% of modified graphene, 9.6-29.8 w% of nanometer barium titanate, and 69.7-87.4 w% of polyimide, the modified graphene is p-phenylenediamine graft modified graphene, and the surface of the modified graphene contains chemically grafted polyimide. The preparation method comprises the following steps: (1) graphene oxide modification, (2) polyamic acid prepolymer preparation, and (3) composite material thermal cross-linking. According to the preparation method, the functionalized graphene and the polyimide molecules can be combined through a covalent bond form, electric conductivity of the graphene can directly affect dielectric property of the composite material, and a volume fraction of the barium titanate can be effectively reduced. In addition, the conventional solution blending technology is adopted, the preparation process is simple, operation is easy, and the method can be widely promoted and applied.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com