Polyimide high dielectric composite material and preparation method thereof

A technology of composite material and polyimide, which is applied in the field of polyimide high dielectric composite material and its preparation, can solve problems such as the degradation of the internal structure and performance of composite materials, and achieve improved dielectric properties, easy removal, and reduced volume fractional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

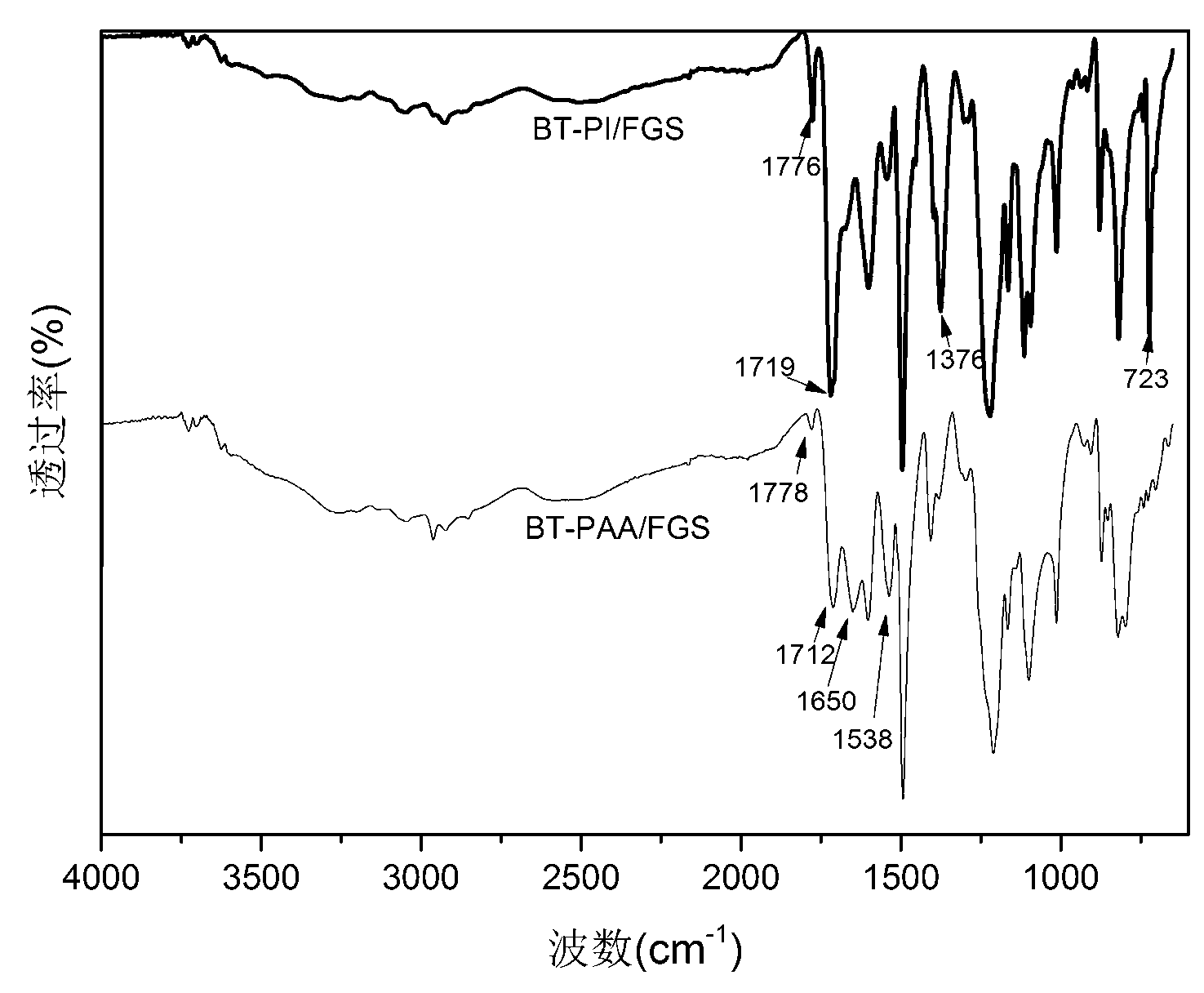

[0043] A preparation method of polyimide high dielectric composite material, comprising the following steps:

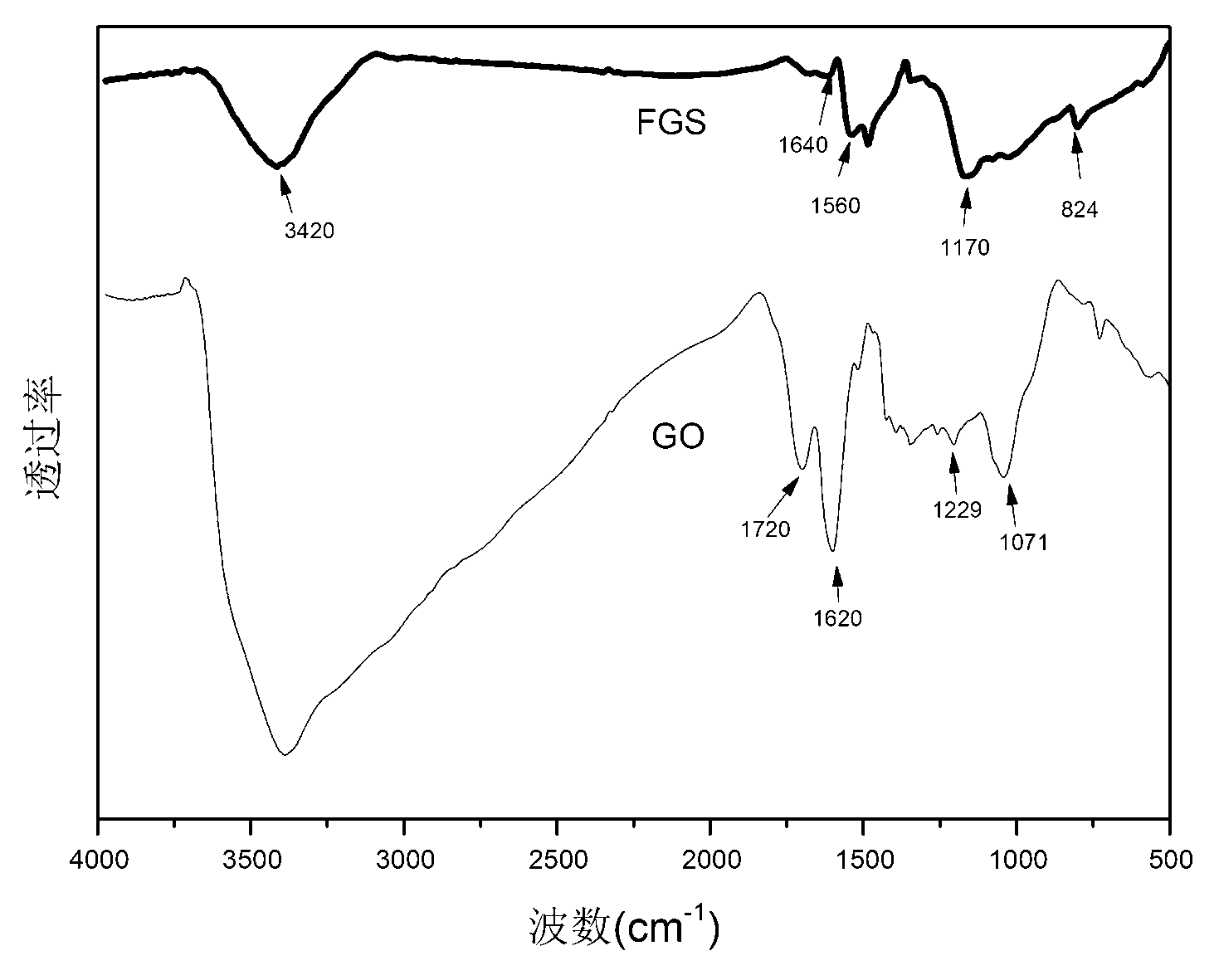

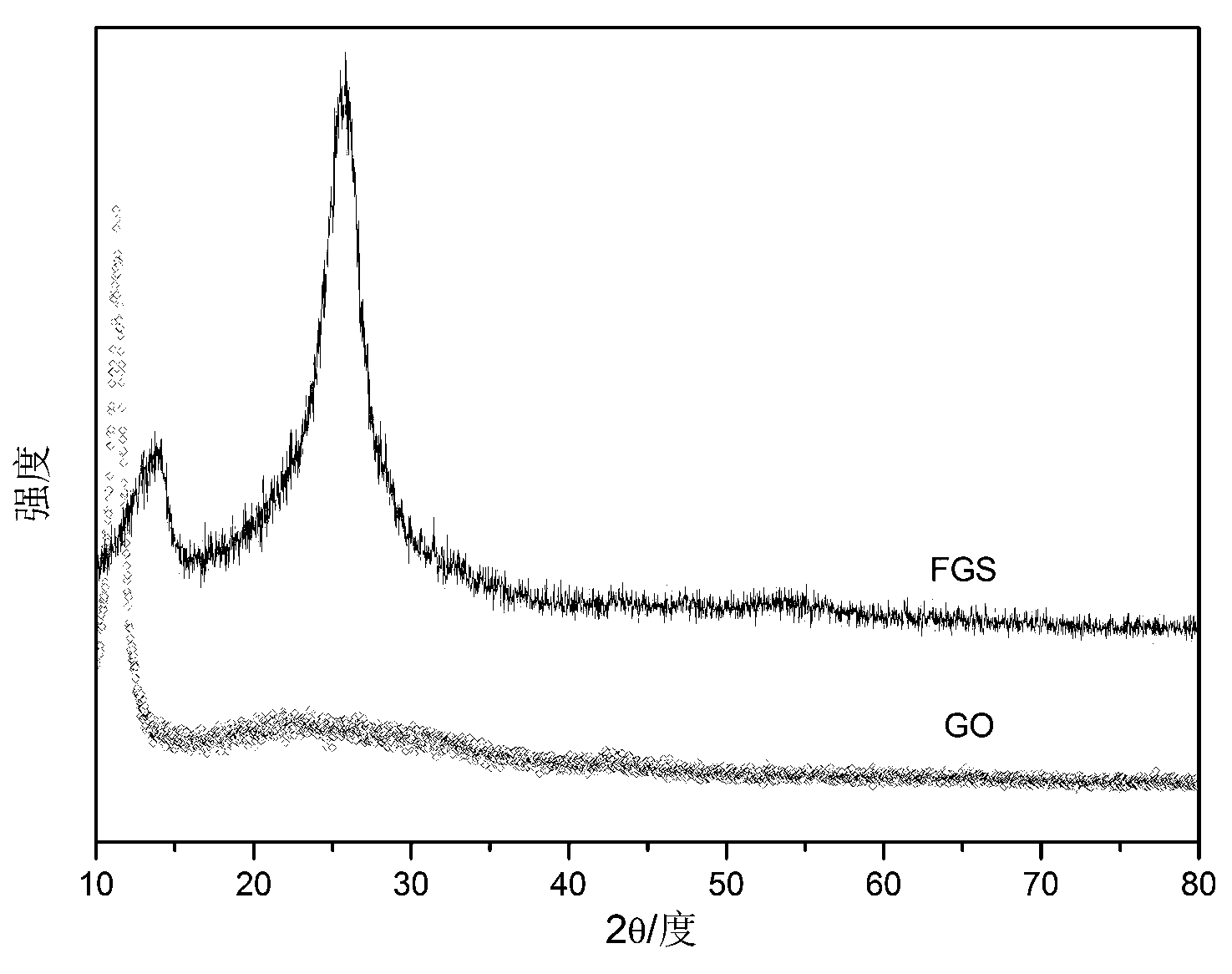

[0044] (1) Modification of graphene oxide

[0045] ① Take 100mg of graphite oxide and add it to the mixed solution of 20ml thionyl chloride and 0.5ml anhydrous dimethylformamide, peel it off by ultrasonic for 30min; under the protection of nitrogen, under the temperature condition of 70℃, react gently for 24 hours , obtain the acid chloride product of graphite oxide;

[0046] Excess thionyl chloride was removed by distillation under reduced pressure.

[0047]② Add 50ml of anhydrous dimethylformamide to the reaction product obtained in step (1)①, seal it and ultrasonically disperse it for later use; dissolve 0.5g of p-phenylenediamine in 10ml of anhydrous dimethylformamide and inject it into the reaction device. Reacted at 120° C. for 24 hours under the protection of nitrogen, suction-filtered, washed, and dried in vacuum at 60° C. for 12 hours to obtain graphene fu...

Embodiment 2

[0056] A preparation method of polyimide high dielectric composite material, comprising the following steps:

[0057] (1) Modification of graphene oxide

[0058] ① Take 200mg of graphite oxide and add it to the mixed solution of 40ml thionyl chloride and 2ml anhydrous dimethylformamide, and peel it off by ultrasonic for 60min; Obtain the acid chloride product of graphite oxide;

[0059] Excess thionyl chloride was removed by distillation under reduced pressure.

[0060] ② Add 100ml of anhydrous dimethylformamide to the reaction product obtained in step (1) ①, seal and ultrasonically disperse for later use; dissolve 1g of p-phenylenediamine in 10ml of anhydrous dimethylformamide and inject into the reactor , reacted at 100° C. for 24 hours under the protection of nitrogen, suction-filtered, washed, and dried in vacuum at 60° C. for 24 hours to obtain graphene functionalized with p-phenylenediamine.

[0061] (2) Preparation of polyamic acid prepolymer

[0062] ① Take 143mg (...

Embodiment 3

[0069] A preparation method of polyimide high dielectric composite material, comprising the following steps:

[0070] (1) Modification of graphene oxide

[0071] ① Add 100mg of graphite oxide to a mixed solution of 20ml of thionyl chloride and 0.5ml of anhydrous dimethylformamide, and peel it off by ultrasonic for 40min; Obtain the acid chloride product of graphite oxide;

[0072] Excess thionyl chloride was removed by distillation under reduced pressure.

[0073] ② Add 50ml of anhydrous dimethylformamide to the reaction product obtained in step (1) ①, seal and ultrasonically disperse for later use; dissolve 1g of p-phenylenediamine in 10ml of anhydrous dimethylformamide and inject into the reactor ; Under the protection of nitrogen, react at 80°C for 48 hours, filter the generated product, wash, and vacuum dry at 70°C for 12 hours to obtain graphene functionalized with p-phenylenediamine.

[0074] (2) Preparation of polyamic acid prepolymer

[0075] ① Take 30mg (0.5wt%) o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com