Spherical silica/polyimides composite membrane, preparation thereof and applications

A silicon dioxide and polyimide technology, applied in insulators and other directions, can solve the problems of poor surface morphology consistency, difficult and uniform dispersion of inorganic particles, and decreased material properties and mechanical properties, and achieve low moisture absorption and excellent mechanical properties. , the effect of excellent corona resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

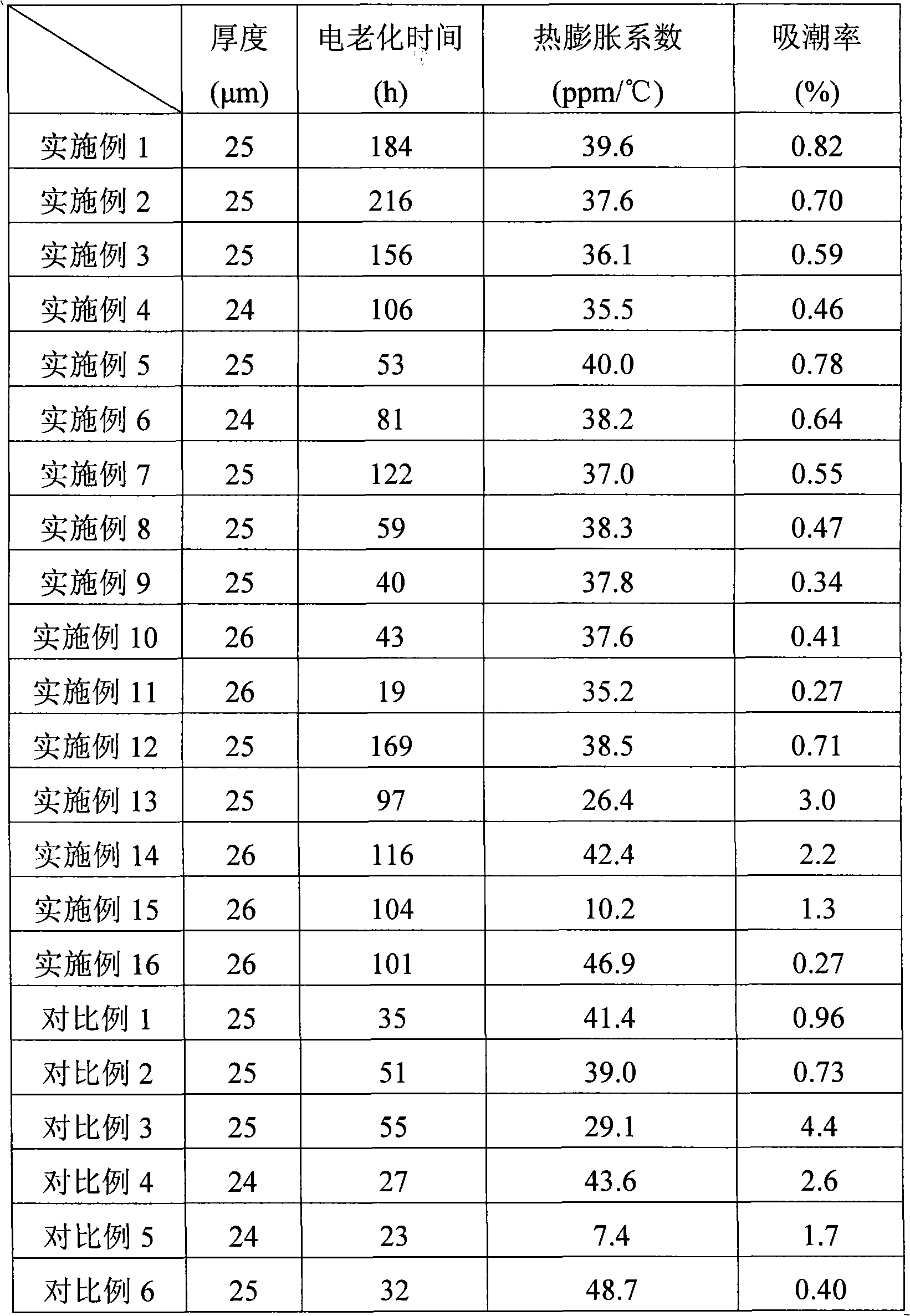

Examples

Embodiment 1

[0047] 1.4080g spherical silica (average particle size: 0.06μm, specific surface area: 55.9m 2 / g, bulk density: 0.09g / cm 3 ) and 0.0704g γ-aminopropyltriethoxysilane were mixed with 170g N, N'-dimethylacetamide, and dispersed for 40 minutes with an ultrasonic disperser. Under the protection of nitrogen, add 14.9488g 1,3-bis(4-aminophenoxy)benzene to the above dispersed system; after the solid is completely dissolved, add 0.4214g bis-(γ-aminopropyl) tetra Methylpolysiloxane; 15.0888g of 3,3',4,4'-biphenyltetraacid dianhydride was added in batches under mechanical stirring. The reaction temperature was controlled at <30° C., and the reaction was stirred for 6 hours to obtain a spherical silica particle / polyamic acid mixed resin solution.

[0048] The prepared spherical silica particles / polyamic acid mixed resin solution was uniformly coated on a clean glass plate. Then, keep at 40°C for 5 hours, 100°C for 1 hour, 150°C for 1 hour, 200°C for 1 hour, 250°C for 1 hour, and 300°...

Embodiment 2

[0050] 2.8160g spherical silica (average particle size: 0.06μm, specific surface area: 55.9m 2 / g, bulk density: 0.09g / cm 3 ) and 0.1408g gamma-aminopropyltriethoxysilane were mixed with 170g N, N'-dimethylacetamide, and dispersed for 40 minutes using an ultrasonic disperser. Under the protection of nitrogen, add 14.9488g 1,3-bis(4-aminophenoxy)benzene to the above dispersed system; after the solid is completely dissolved, add 0.4214g bis-(γ-aminopropyl) tetra Methylpolysiloxane; 15.0888g of 3,3',4,4'-biphenyltetraacid dianhydride was added in batches under mechanical stirring. The reaction temperature was controlled at <30° C., and the reaction was stirred for 6 hours to obtain a spherical silica particle / polyamic acid mixed resin solution.

[0051] The prepared spherical silica particles / polyamic acid mixed resin solution was uniformly coated on a clean glass plate. Then, keep at 40°C for 5 hours, 100°C for 1 hour, 150°C for 1 hour, 200°C for 1 hour, 250°C for 1 hour, and...

Embodiment 3

[0053] 4.2240g spherical silica (average particle size: 0.06μm, specific surface area: 55.9m 2 / g, bulk density: 0.09g / cm 3 ) and 0.2112g gamma-aminopropyltriethoxysilane were mixed with 170g N, N'-dimethylacetamide, and dispersed for 40 minutes using an ultrasonic disperser. Under the protection of nitrogen, add 14.9488g 1,3-bis(4-aminophenoxy)benzene to the above dispersed system; after the solid is completely dissolved, add 0.4214g bis-(γ-aminopropyl) tetra Methylpolysiloxane; 15.0888g of 3,3',4,4'-biphenyltetraacid dianhydride was added in batches under mechanical stirring. The reaction temperature was controlled at <30° C., and the reaction was stirred for 6 hours to obtain a spherical silica particle / polyamic acid mixed resin solution.

[0054] The prepared spherical silica particles / polyamic acid mixed resin solution was uniformly coated on a clean glass plate. Then, keep at 40°C for 5 hours, 100°C for 1 hour, 150°C for 1 hour, 200°C for 1 hour, 250°C for 1 hour, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com