Patents

Literature

1690 results about "Sodium stearate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium stearate is the sodium salt of stearic acid. This white solid is the most common soap. It is found in many types of solid deodorants, rubbers, latex paints, and inks. It is also a component of some food additives and food flavorings.

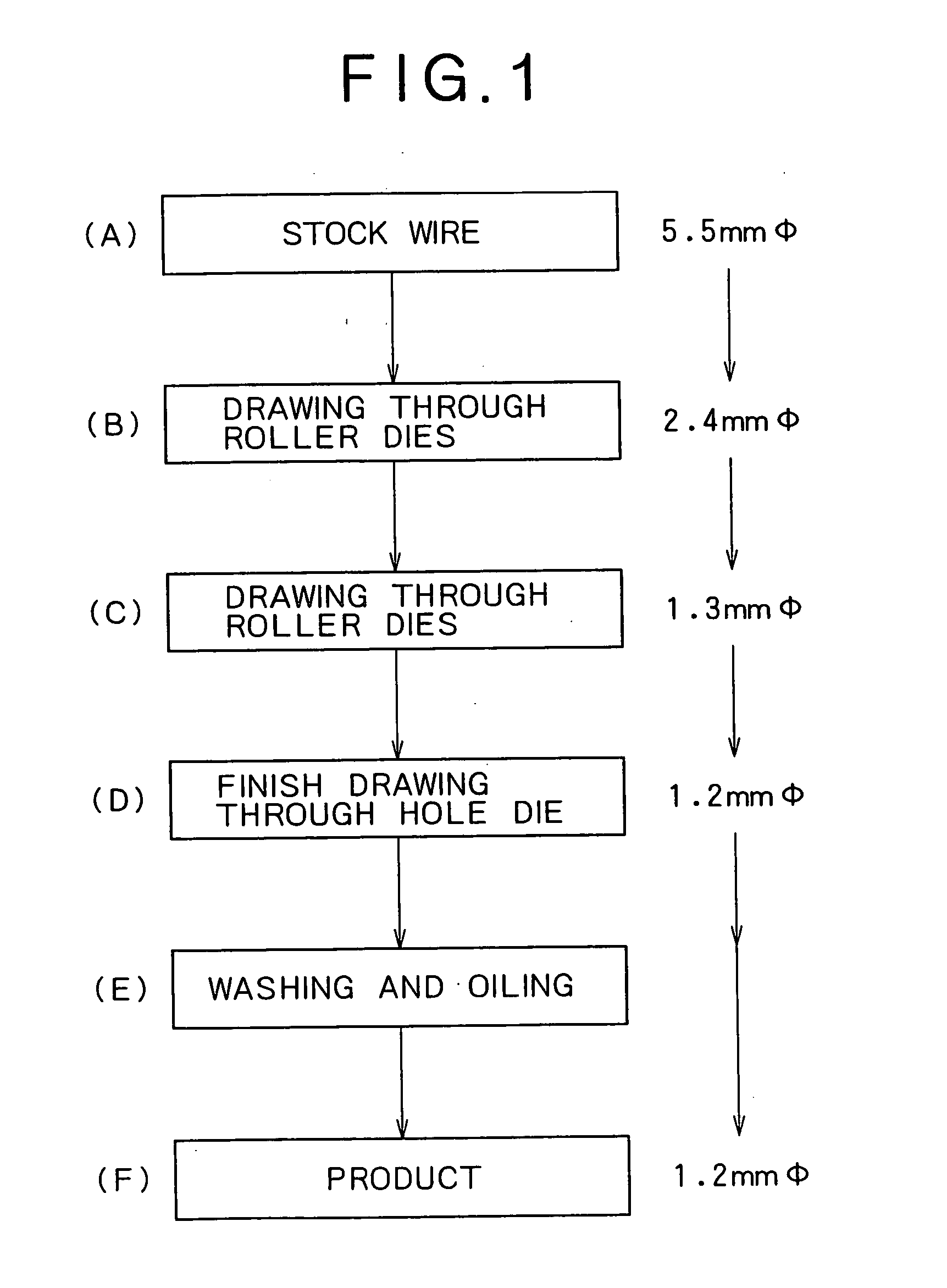

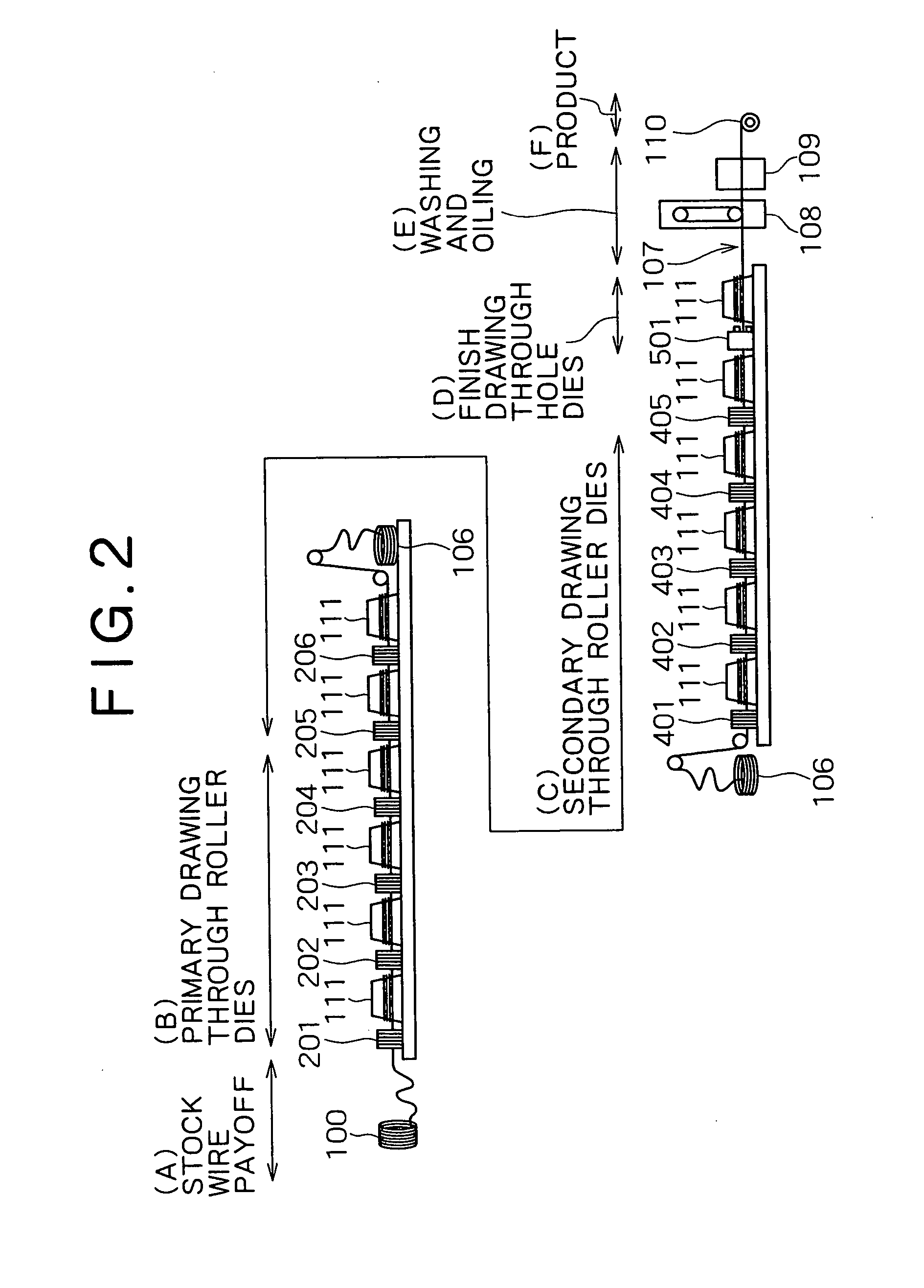

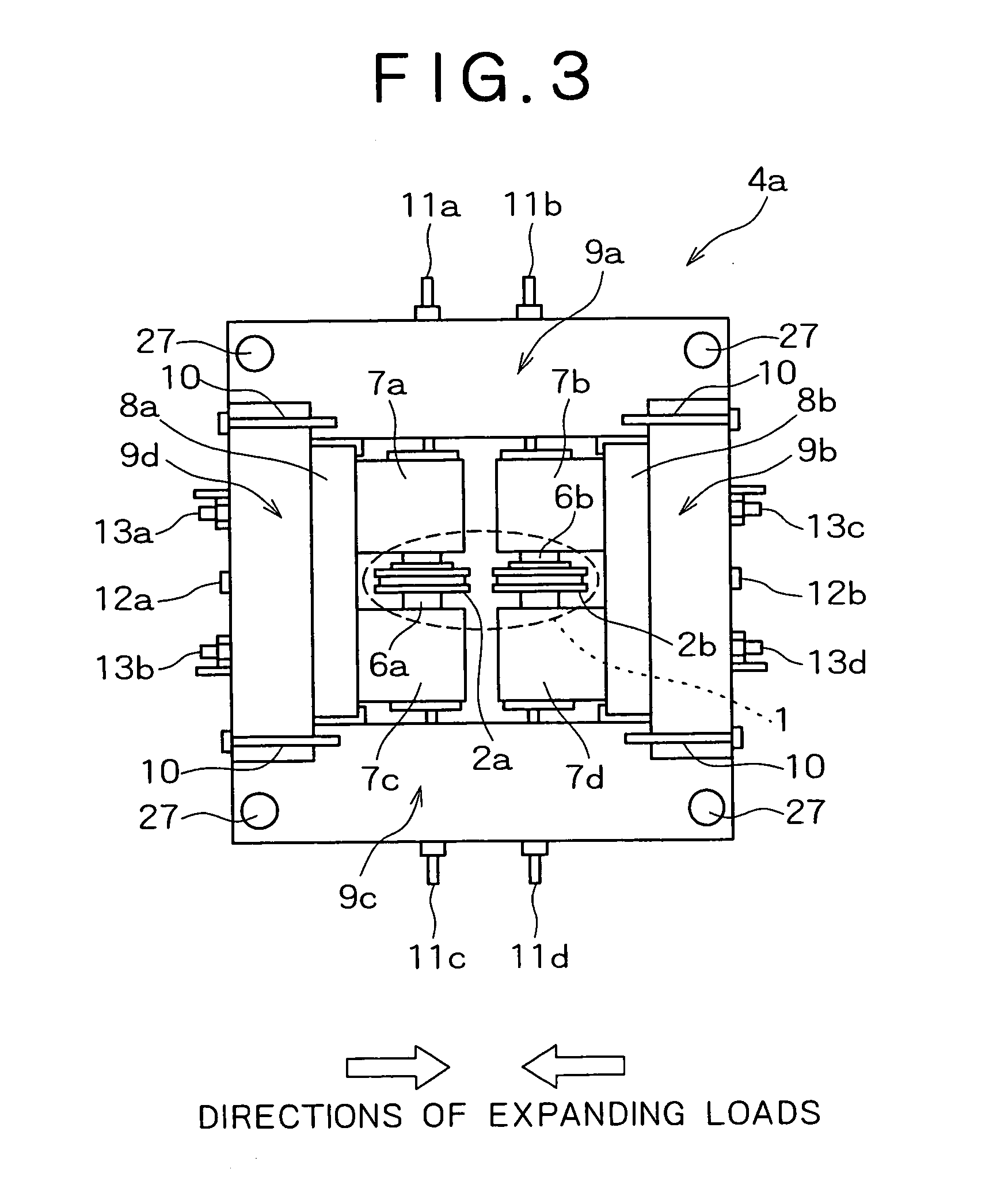

Method of producing solid wire for welding

ActiveUS20050045699A1Uniform applicationEfficient weldingDrawing diesArc welding apparatusCopper platingSodium stearate

A method for efficient production of a welding solid wire free of copper plating. The method consists of drawing by means of roller dies with the help of a dry solid lubricant for drawing which is at least either of sodium stearate or potassium stearate, removing the lubricant from the wire surface by means of a washing device, and applying a lubricant for wire feeding to the surface of the drawn wire by means of an oiling device. High-speed drawing by means of roller dies makes a stock wire into a welding solid wire having the diameter of the finished wire or nearly finished wire. The drawing step is followed by the washing step and the lubricant applying step, which are all accomplished in-line.

Owner:KOBE STEEL LTD

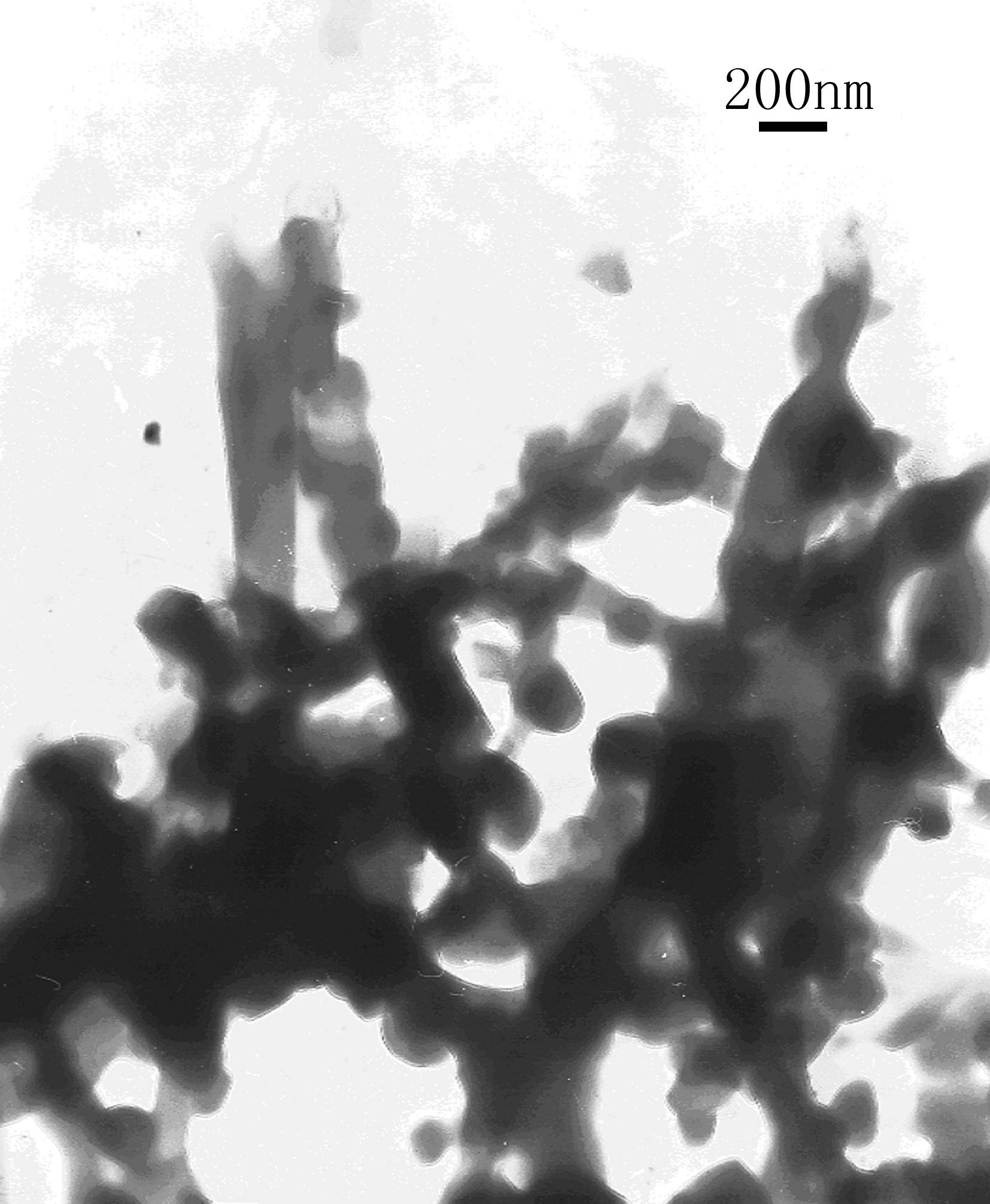

Rod hydrotalcite-like compound and its prepn process

InactiveCN1974399ASimple processLow costCatalyst carriersOther chemical processesSodium stearateCrystal structure

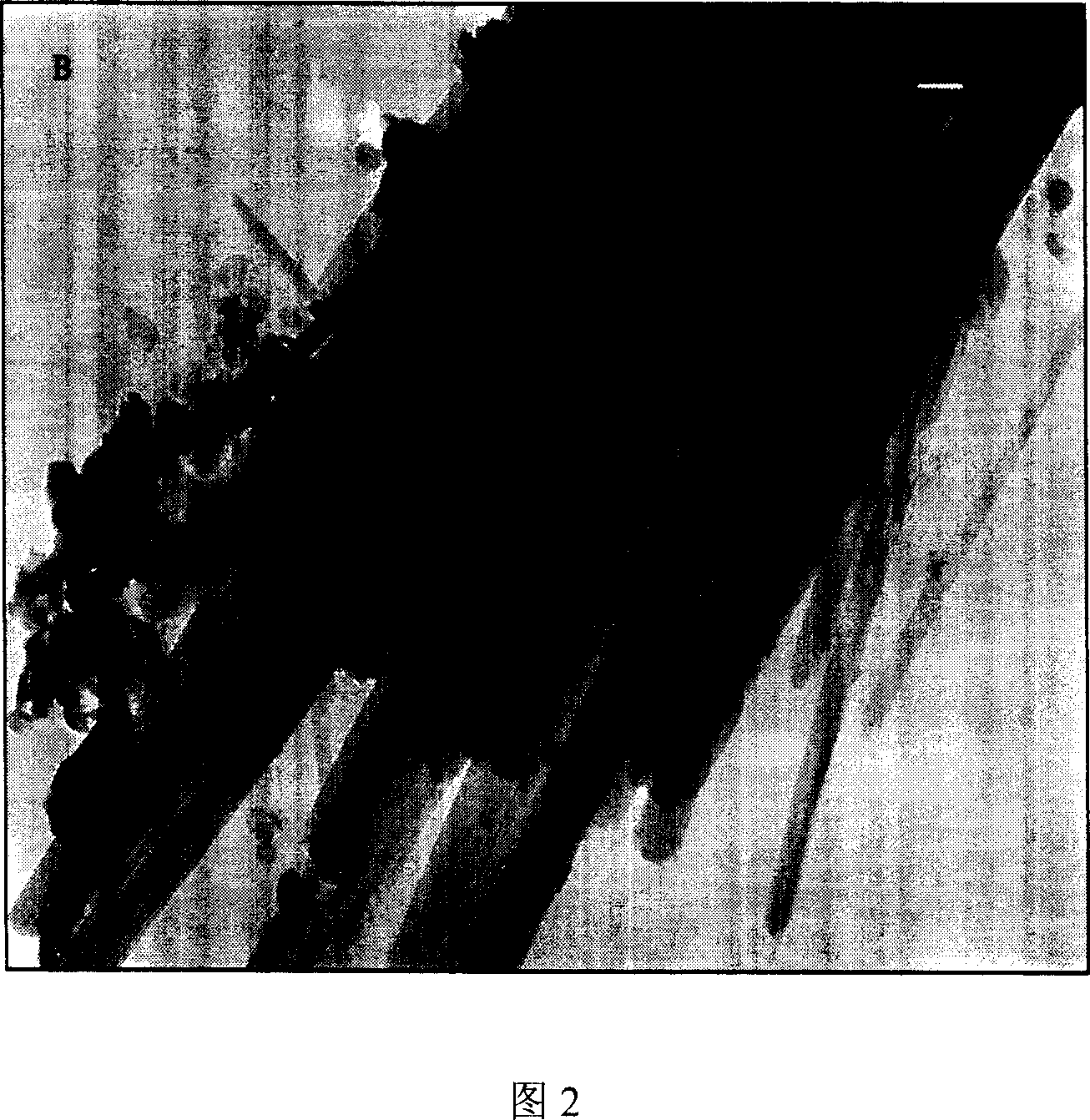

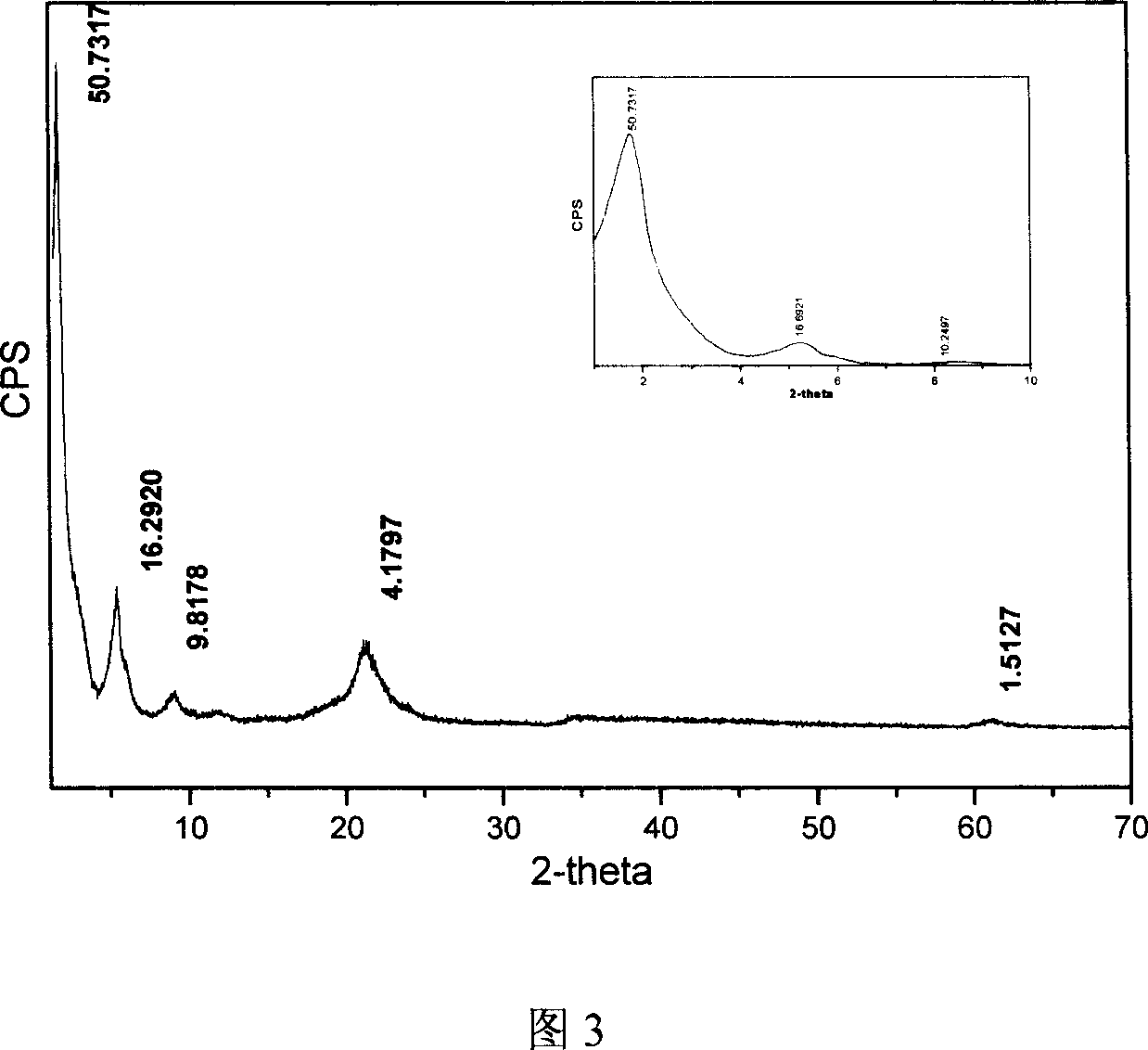

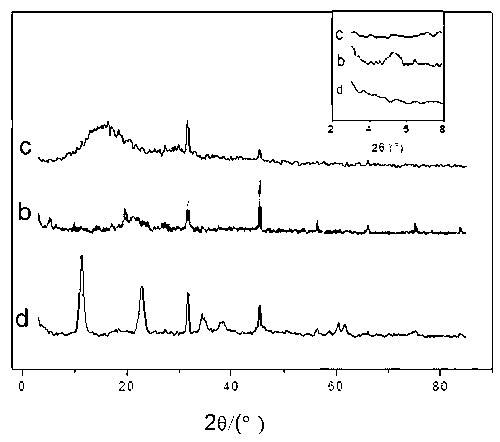

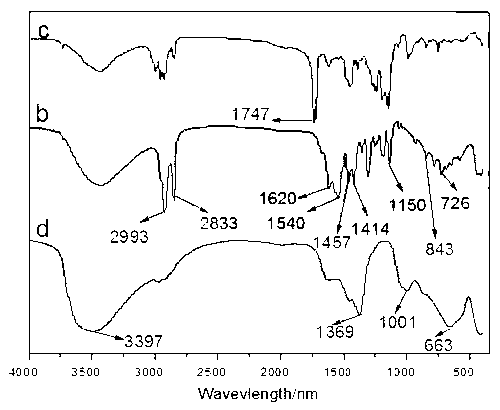

The present invention discloses rod-shaped magnesia alumina hydrotalcite-like compound (HTlc) as one new shaped hydrotalcite-like compound. The rod-shaped magnesia alumina hydrotalcite-like compound has the crystal structure of hydrotalcite and chemical expression of [MII(1-x)MIIIx(OH)2]x+[An-x / n]x-mH2O, where, MII and MIII are bivalent and trivalent metal cation separately, An- is interlayer anion, x is the molar fraction of MIII in HTlc, m is the molar fraction of interlayer crystalline water. It is prepared through a traditional co-precipitation process under the induction of soft template or shape regulating agent sodium stearate. It has simple preparation process and low cost, and may be used as rubber and plastic additive, fire retardant, pesticide release controlling agent, etc.

Owner:SHANDONG UNIV

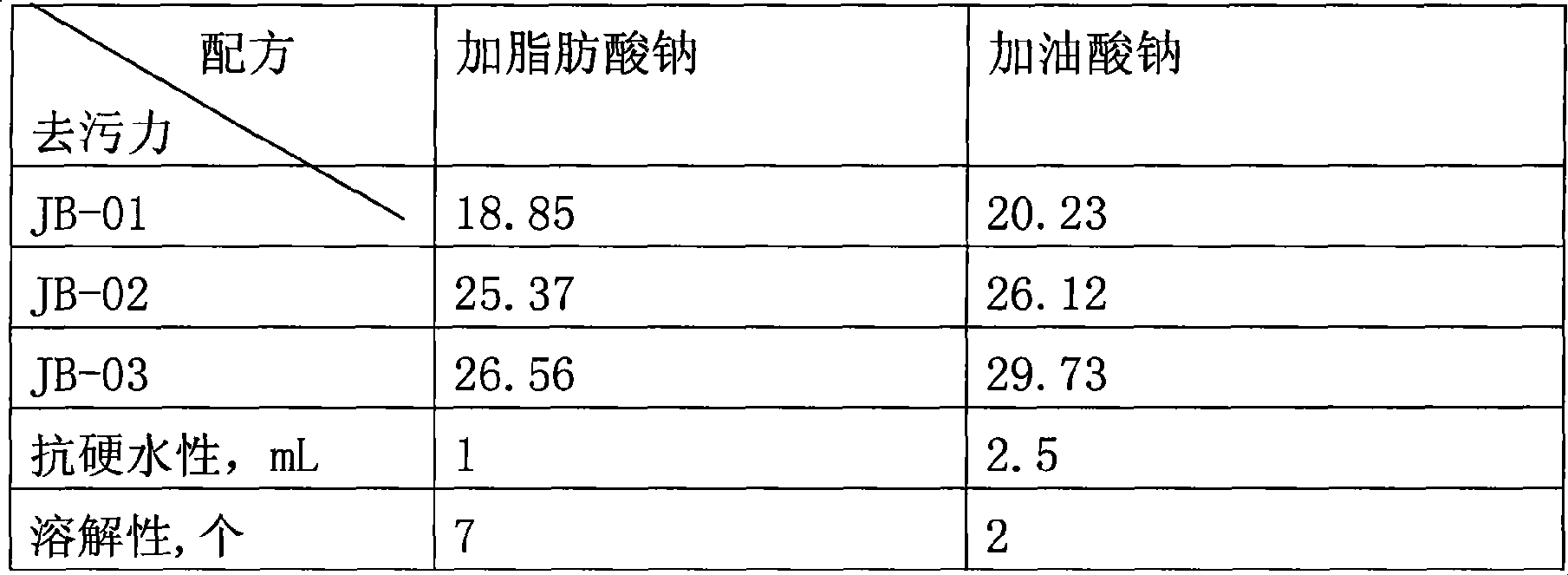

Neat soap washing powder and preparing technique thereof

InactiveCN101368147AImprove decontamination abilityNo stimulationSoap detergent compositionsSolubilitySodium stearate

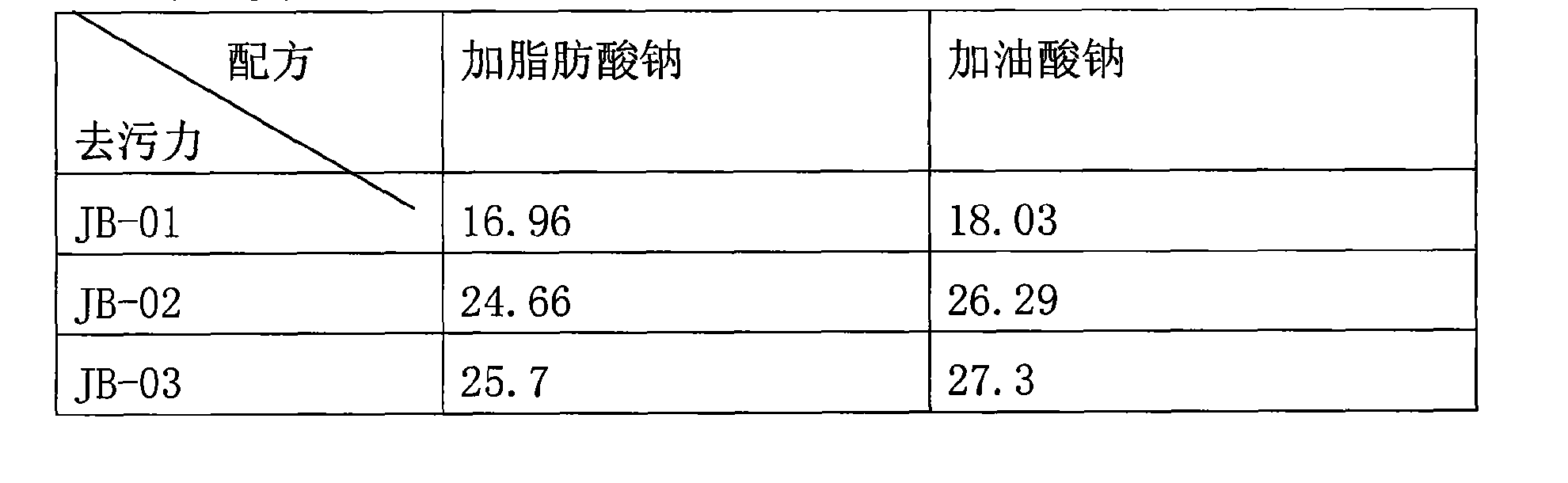

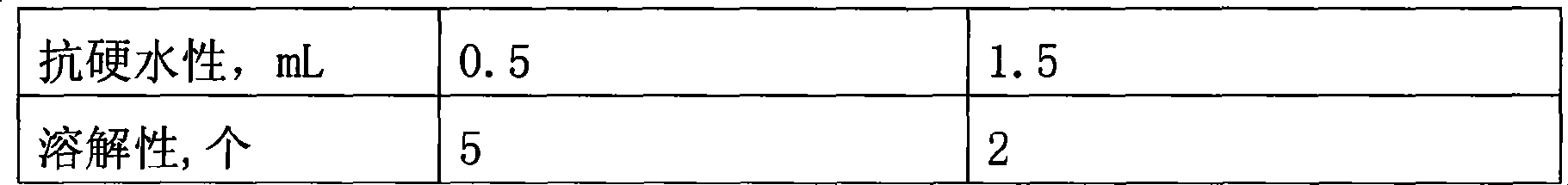

The invention relates to a household chemicals manufacturing technique, in particular to a genuine soap washing-powder manufacturing technique, which solves the problems of no hard water tolerance, low solubility and weak detergency caused by sodium stearate added into the powder in the genuine soap washing-powder of the prior art. The weight percentages of integrants comprised in the genuine soap washing-powder are 5-30 portions of surface active agent, 2-40 portions of eunatrol, 20-70 portions of washing auxiliary detergent, 0.1-10 portions of auxiliary material and 5-50 portions of sodium sulfate used as plugging compound. Different manufacturing techniques are applied for adding the oleic acid or eunatrol into the washing-powder. The invention has the advantages of strong detergency, no skin irritation, no environment pollution, simple application, easy manufacturing, environment protection, high efficiency and low production cost.

Owner:山西焦煤运城盐化集团有限责任公司

Semi-hard dentifrice

InactiveUS20050152851A1Extended shelf lifeHigh melting pointCosmetic preparationsToilet preparationsSodium bicarbonateSodium stearate

The invention comprises a formulation for a semi-hard stick-type dentifrice optimally for use in an oral hygiene device which utilizes such semi-hard stick-type dentifrice, most often used when traveling. The dentifrice includes a primary base material such as glycerin. Sodium benzoate is included as a preservative. Sodium coco-sulfate and a mixture of wheat gluten proteins and potassium cocoate provide a foaming material. Cleansers are included and the dentifrice is strengthened by vegetal-based sodium stearate and vegetal-based stearyl alcohol. Whitening materials are included, as is an absorption material and sodium bicarbonate as an abrasive.

Owner:KAMINSKI BASIA

Production of superfine calcium carbonate from carbide slag

InactiveCN1854069ASimple production processLow costCalcium/strontium/barium carbonatesSal ammoniacSodium stearate

Production of superfine calcium carbonate from carbide slag is carried out by dissolving dried carbide slag by NH4Cl solution, removing residue, adding into sodium stearate, inducing CO2 in range of 2-100 degree and obtaining slab, spherical and acicular calcium carbonate. It is cheap, has higher additional value and no second environmental pollution.

Owner:卢忠远

Preparation process of wet-process superfine modified calcium carbonate

InactiveCN104744971AIncrease productivityHigh activityInorganic compound additionPigment treatment with macromolecular organic compoundsSodium stearateMicrosphere

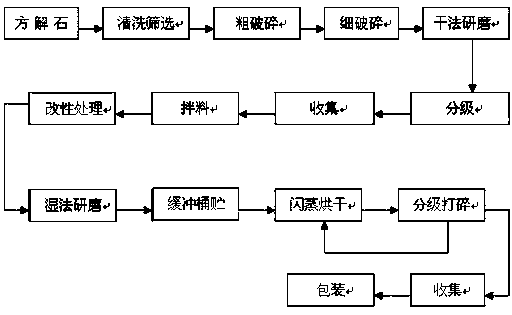

The invention discloses a preparation process of wet-process superfine modified calcium carbonate. The preparation process comprises the following steps: performing cleaning and screening, rough crushing, fine crushing, dry grinding and grading on calcite ores; collecting fine powder of 600 meshes and preparing slurry with water in such a manner that the solid content is 70%-80%; adding a modifier sodium stearate to the slurry for modification treatment and then performing wet grinding, and adding a grinding medium zirconium oxide microspheres and a dispersant sodium polyacrylate during grinding, wherein the volume ratio of the grinding medium to the slurry is 1: 1.5, and the dosage of the modifier is 0.6%-1.2% of the solid content; and putting the slurry obtained after the wet grinding through a vibrating screen, collecting the obtained wet-process superfine modified calcium carbonate slurry into a slurry barrel for flashing drying, collecting the finished product and packaging. The new preparation process is adopted; the wet grinding-modifying integrated technique and the flashing drying technique are adopted so that the production efficiency is high and the production cost is low; the product has the advantages of small particle size, low oil absorption value, high activity and the like; and the major product quality indices are at the international leading level.

Owner:江西科越科技有限公司

High strength polylactic acid thin film and preparation method thereof

The invention provides a high strength polylactic acid thin film and a preparation method thereof. The thin film comprises: by weight, 80 to 93 parts of polylactic acid, 3 to 16 parts of a modified nanoscale silica, 0 to 5 parts of one or more plasticizers, 0 to 2 parts of one or more anti-oxidants, and 0 to 2 parts of one or more lubricants. The modified nanoscale silica is prepared through the process that nanoscale silica particles are mixed with one or more modifiers of sodium stearate, calcium stearate and silane coupling agent and are modified by the one or more modifiers. The polylactic acid thin film is biodegradable, has an improved greatly tensile strength and a breaking elongation rate, can be utilized directly in the preparation of finished products such as food packaging bags, vest bags, agricultural thin film materials and the like, and can be utilized widely in the field such as a sheet material field where a flexibility requirement is high.

Owner:邹俊

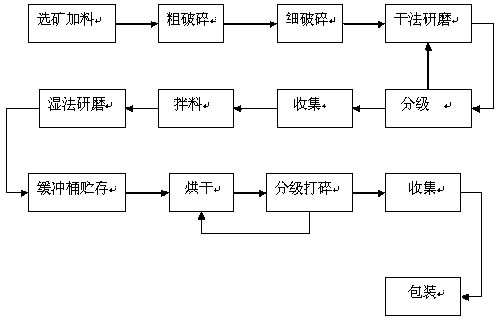

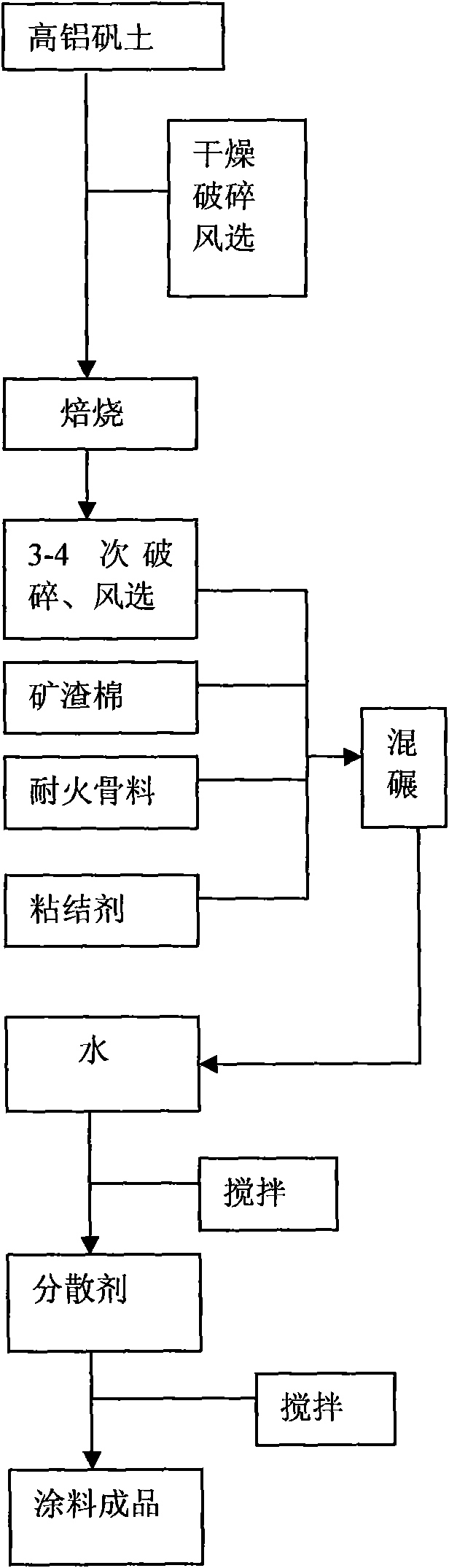

Centrifugal casting coating for cylinder liners and preparation method thereof

InactiveCN101554643AImprove sinterabilityImprove high temperature resistanceFoundry mouldsFoundry coresSulfonateSodium stearate

The invention discloses a centrifugal casting coating for cylinder liners and a preparation method thereof. The centrifugal casting coating comprises the following components according to parts by weight: 100 parts of refractory aggregate, 12 to 20 parts of binder, 22 to 30 parts of heat-insulating agent, 0.7 to 1.15 parts of dispersant and 150 to 200 parts of water. The preparation method comprises the following steps: mixing and milling the refractory aggregate, the binder and the heat-insulating agent in a sand roller mill; feeding the mixed and milled components and the water into a stirring cask and stirring for 5 to 6 hours at the rotating speed of 120 to 180 rp / min; and adding sodium alkylbenzene sulfonate or sodium stearate and further stirring for 20 to 30 min to obtain the centrifugal casting coating for cylinder liners. The invention has the advantages that the selected materials are scientific and reasonable, the process is simple and advanced, and the coating has good sintering performance, high-temperature resistance and heat-insulation performance. Compared with the existing coatings, the coating layer, which is thinner and easily dried, has good heat-insulating effect, ensures that the castings can easily obtain good metallurgical structure, prolongs the service life of moulds and realizes the shape-following casting of the centrifugal casting cylinder liners.

Owner:YANGZHOU WUTINGQIAO CYLINDER LINER

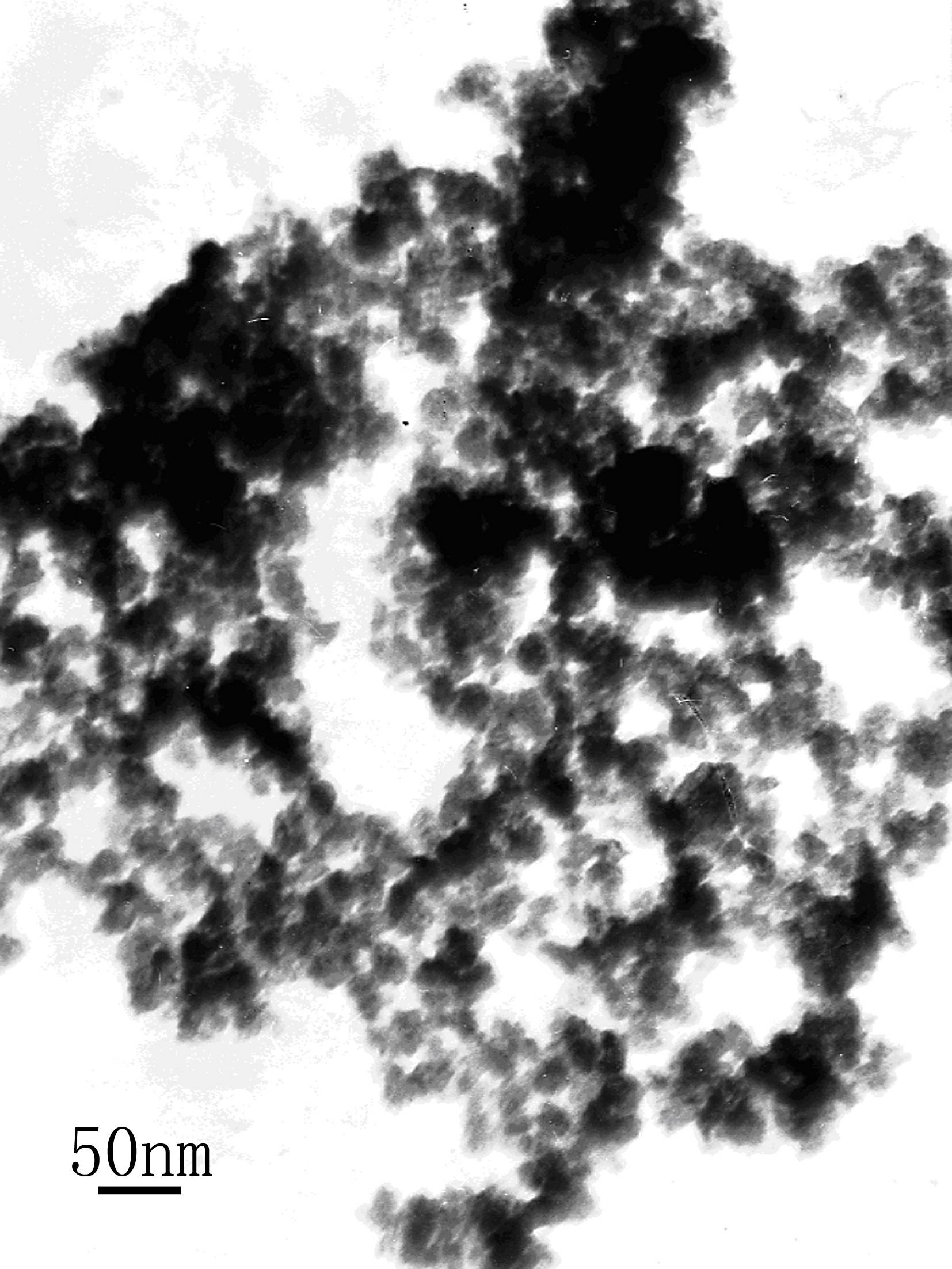

Preparation method of spherical nano calcium carbonate

InactiveCN102557100AUniform size distributionSuitable for industrial productionCalcium/strontium/barium carbonatesNanotechnologyPentaerythritolSodium stearate

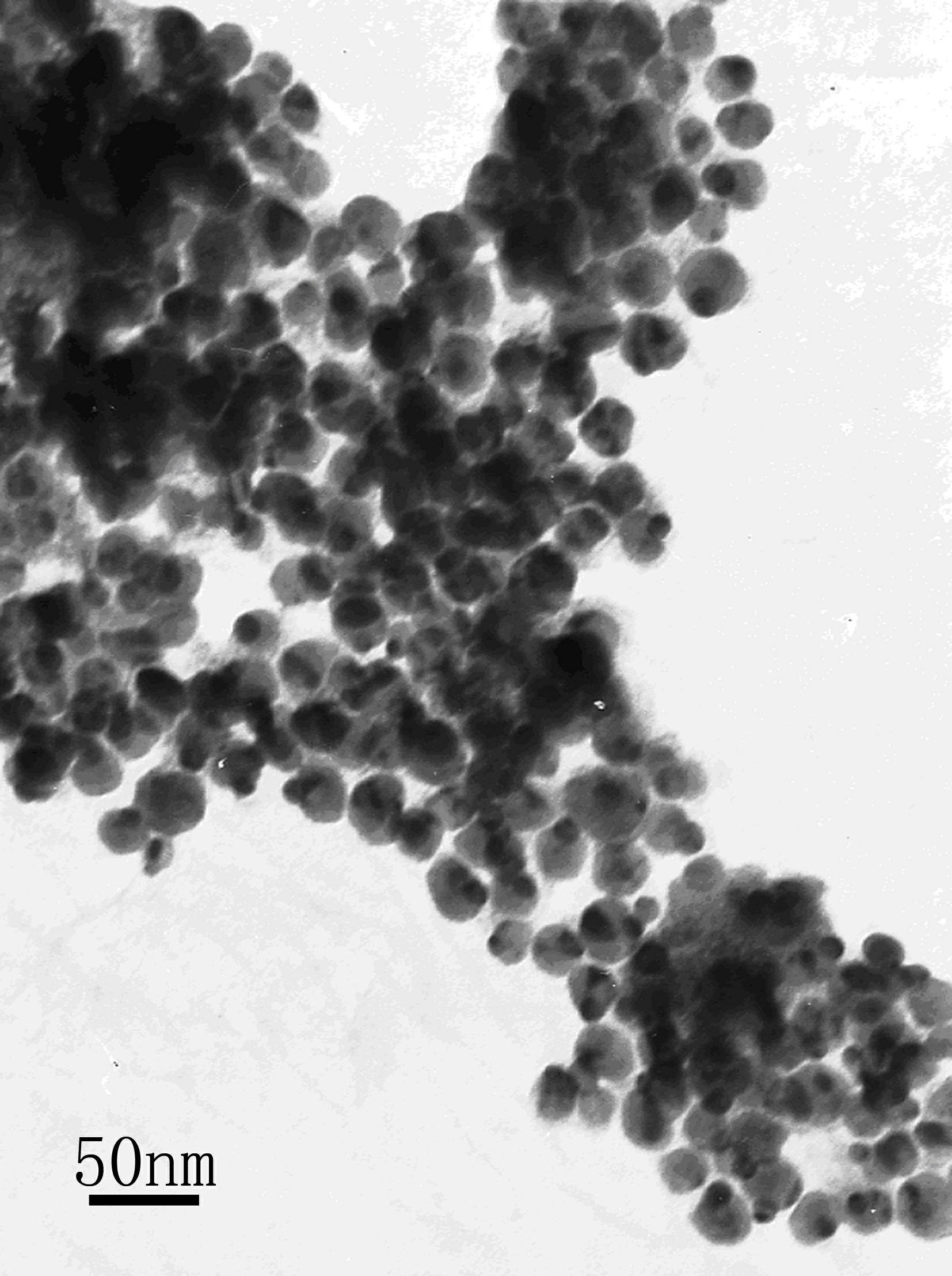

The invention provides a preparation method of spherical nano calcium carbonate, which is characterized by enabling pentaerythritol to be added in 0.05-0.10 mol / L of sodium carbonate solution to completely dissolve, and slowly adding 1.0-2.0mol / L of calcium chloride solution under blending for reaction to obtain the spherical nano calcium carbonate, wherein the dosage of the pentaerythritol is 0.1-2% of the quality of the product calcium carbonate. Grain size of the btained spherical nano calcium carbonate is about 25nm, size and distribution are even, the whole preparation process is simple,a used crystal form control agent is slow in cost, simultaneously serous fluid obtained by reaction is added in sodium stearate according to 1-5% of the quality of the calcium carbonate, the nano calcium carbonate coated with the sodium stearate is obtained, and the method is applicable to industrialization production of the spherical nano calcium carbonate.

Owner:LANZHOU JIAOTONG UNIV

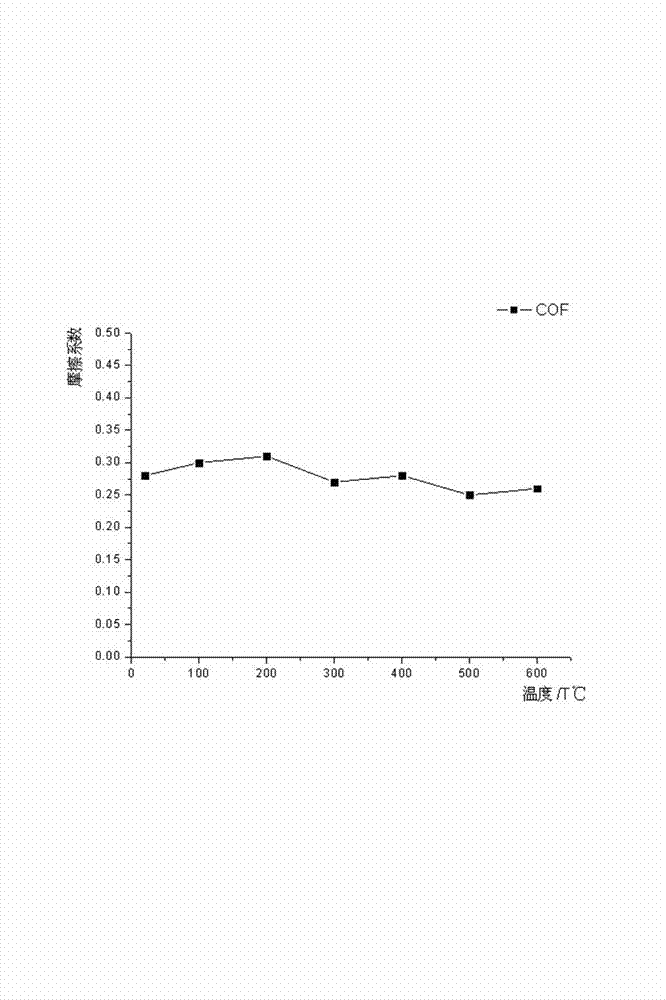

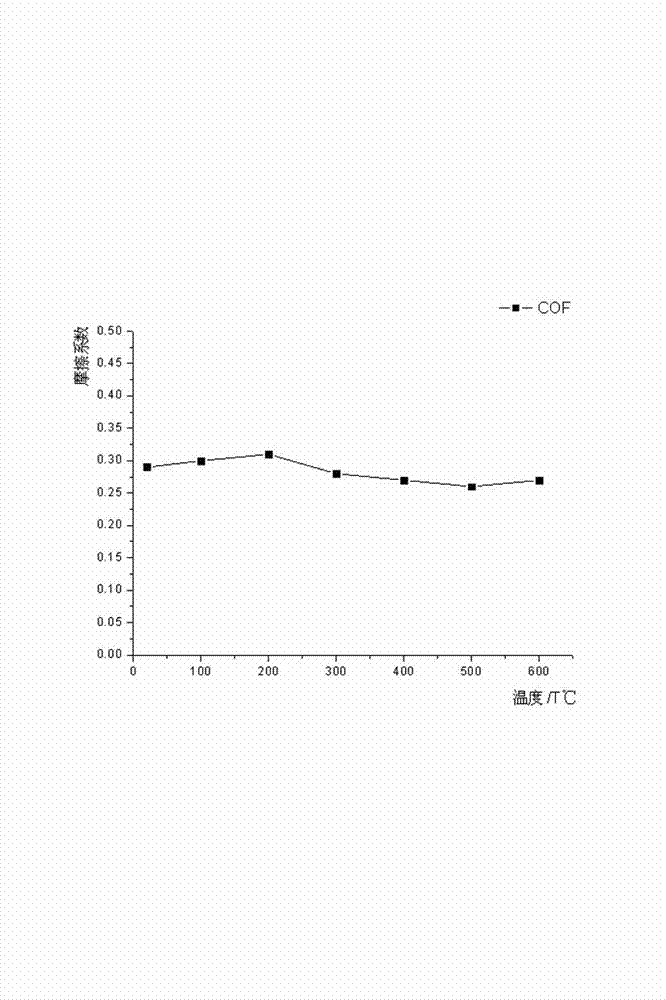

High temperature resistant self-lubricating bearing material and preparation method thereof

The invention discloses a high temperature resistant self-lubricating bearing material and a preparation method thereof. The method comprises: mainly taking 06Cr19Ni10 stainless steel powder as the matrix material, selecting high purity (greater than or equal to 95%) Cu, Mo, and Co metal powder as the reinforcement phase, selecting MoS2 and CaF2 as the lubricating friction reduction phase, and simultaneously adding a proper amount of sodium stearate as the binder, then performing cold press molding and pressureless vacuum sintering, thus obtaining the bearing material. The high temperature resistant self-lubricating bearing material prepared by the method provided in the invention can still have a low friction coefficient and good abrasion resistance under a high temperature environment of 600DEG C, can be applied in steel, metallurgy and other heavy machinery equipment, and is especially suitable for occasions requiring oil-free lubrication.

Owner:JIANGSU JINGU STAINLESS STEEL

Rubber framework grease seal for automobile gear box and manufacturing method thereof

InactiveCN101319082APrevent leakageSolve the problem of oil leakageEngine sealsDomestic articlesSodium stearateSulfur

The invention provides a rubber framework oil seal used for a gear box of an automobile and a manufacturing method thereof. The rubber framework oil seal comprises the following compositions in weight portion: 100 portions of activated chlorine type acrylate adhesive AR840, 0.5 to 1 portion of a vulcanizing activator stearic acid, 1.5 to 2 portions of a process additive TM-80, 2 to 3 portions of a vulcanizing agent sodium stearate, 0.5 to 0.6 portion of an accelerating agent sulfur and potassium stearate, 1 to 2 portions of an age inhibitor 445, 1 to 2 portions of MB, 4 to 6 portions of a strengthening agent carbon soot and 22 to 28 portions of a siliceous reinforcing agent. The rubber framework oil seal has the characteristics of stable size of hypoid gear oil of the gear box, oil resistance, anti-aging property, and sealing reliability, etc.

Owner:青岛茂林橡胶制品有限公司

A water-based metal cleaning agent and a preparing method thereof

InactiveCN107779893AThe formula is scientific and reasonableStrong degreasing abilityWater basedSodium stearate

A water-based metal cleaning agent and a preparing method thereof are disclosed. The cleaning agent includes, by weight, 15-20 parts of polyoxyethylene alkyl ether, 15-20 parts of octylphenol polyoxyethylene ether, 10-12 parts of sodium citrate, 10-12 parts of sodium stearate, 10-15 parts of sodium dodecyl sulfonate, 8-15 parts of triethanolamine oleate, 15-20 parts of coconut fatty acid diethanolamide, 3-5 parts of sodium silicate, 3-5 parts of carboxymethylcellulose, 2-4 parts of a defoamer and 80-100 parts of water. The polyoxyethylene alkyl ether, the octylphenol polyoxyethylene ether, thesodium dodecyl sulfonate are firstly dissolved into the water, then the sodium citrate, the sodium stearate, the sodium silicate, the triethanolamine oleate, the coconut fatty acid diethanolamide andthe carboxymethylcellulose are added in order according to the ratio, the mixture is stirred until the mixture is in a semitransparent state, finally the defoamer is added into the mixture, and the mixture is fully stirred. The cleaning agent is scientific and reasonable in formula, high in cleaning power, safe, environmentally friendly, simple and convenient to operate and low in cost.

Owner:天佑京铁轨道技术有限公司 +1

Acrylic ester rubber and preparation method thereof

InactiveCN101633768AImprove the defect of sticky rollerReasonable ratioSodium stearatePolymer science

The invention provides acrylic ester rubber and a preparation method thereof. The acrylic ester rubber is characterized by comprising the following components by weight: 70-90 portions of tri-acrylate rubber AR840, 10-30 portions of butyronitrile rubber NBR, 55-75 portions of fast extruding carbon black N550, 1-2 portions of anti-aging agent RD, 1-2 portions of anti-aging agent MB, 0.5-1 portion of anti-scorching agent CTP, 3-5 portions of dioctyl phthalate DOP, 1-2 portions of dispersant rhine powder-42, 0.3-0.5 portion of common sulphur, 0.2-0.4 portion of tetramethyl thiuram disulfide TMTD, 3.5-4.0 portions of sodium stearate and 0.3-0.5 portion of potassium stearate. The sticking phenomenon is reduced and the elasticity, extensile intensity and low temperature resistance of the acrylic ester rubber are improved.

Owner:QINGDAO HILYWILL ADVANCED MATERIALS TECH

Allochroic solid adhesive and preparation method thereof

InactiveCN101608103ASimple recipeEasy to produceEster polymer adhesivesN-vinyl-pyrrolidone polymer adhesivesTO-18Phenolphthalein

The invention discloses a high-stability allochroic solid adhesive and a preparation method thereof. The allochroic solid adhesive is prepared by the method according to the following steps: adding all the following raw materials in portion by weight into a reaction kettle of which the temperature is between 50 and 100 DEG C: 50 to 75 portions of dispersant water, 10 to 45 portions of bonding agent such as polyvinyl pyrrolidone, 5 to 18 portions of excipient such as sodium stearate, 5 to 15 portions of humectant such as glycerol, 0.1 to 1 portion of developer phenolphthalein, and proper amount of color stabilizer; stirring the raw materials at a temperature of between 80 and 100 DEG C for one hour, and then adjusting the pH to between 9 and 11; and then standing the mixture at a constant temperature, and bottling the mixture to obtain a purple solid adhesive. The allochroic solid adhesive has a reasonable and simple formulation, easy manufacture and production and low cost; the colloid is purple when the allochroic solid adhesive is coated on a substrate material, and the purple disappears in a short time to meet the requirements in specific fields; besides, the allochroic solid adhesive has the most prominent characteristic that the color is stable during storage and is basically unchanged for more than two years.

Owner:NINGBO SONGHE STATIONERY

Environmental protection type transparent solid glue and preparation method thereof

ActiveCN102321443AColor transparentHigh hardnessNon-macromolecular adhesive additivesN-vinyl-pyrrolidone polymer adhesivesSodium stearatePreservative

The present invention discloses environmental protection type transparent solid glue. The glue comprises the following components, by weight, 40-50 parts of deionized water, 6-10 parts of an activator, 0.5-2 parts of an antifoaming agent, 15-20 parts of a lubricant, 20-30 parts of a moisturizing agent, 6-10 parts of sodium stearate, 20-30 parts of polyvinylpyrrolidone and 0.2-1 parts of a preservative. In addition, the present invention further provides a preparation method for the environmental protection type transparent solid glue. Compared to the prior art, the environmental protection type transparent solid glue provided by the present invention has characteristics of transparent color, high hardness, good moisture retention, smooth coating without dreg dropping, good oxidation resistance, environmental protection and no toxicity.

Owner:JIANGSU XINGDA STATIONERY GRP

Production method for coarse-cereal artificial rice

The invention relates to a production method for coarse-cereal artificial rice, which comprises the following steps: coarse cereals, starch, flour, glutinous rice flour, cassava flour and the like are mixed, then calcium chloride and tripolyglycerol sodium monostearate are added into the mixture by stirring, the obtained mixture is pressed by a flour press machine to be wide noodles, the wide noodles are delivered to a grain press machine with rice grain shape parts and are pressed to form artificial rice grains; and the artificial rice is produced from the artificial rice grains after being dried, cooked, polished and the like. The artificial rice produced by the method is made from coarse cereals and contains various nutrient elements and trace elements; moreover, the artificial rice produced by the method is similar to real rice in the aspects of appearance and mouth feel and is not deformed or broken easily when the artificial rice is soaked, steamed and boiled.

Owner:ANHUI YANZHIFANG FOOD

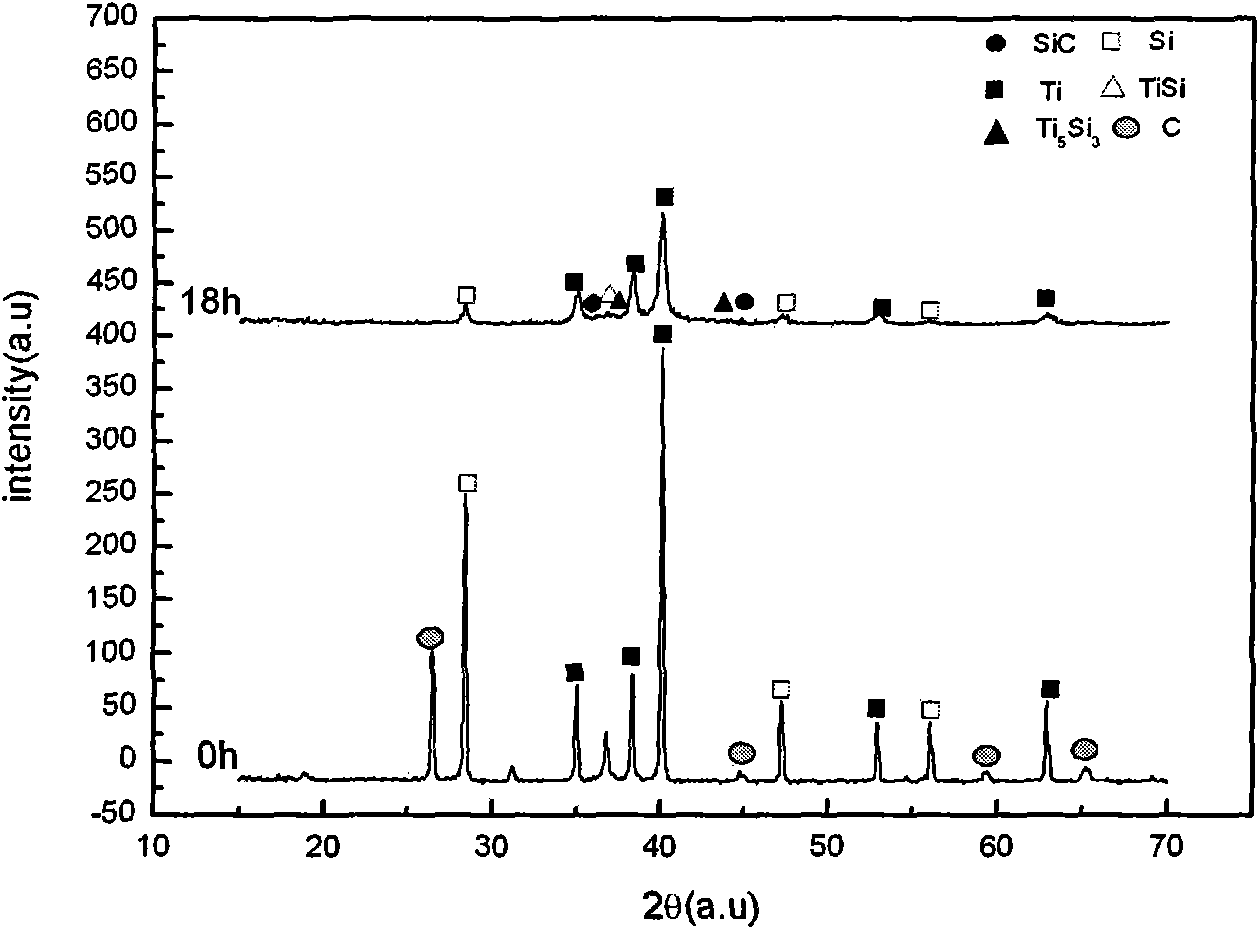

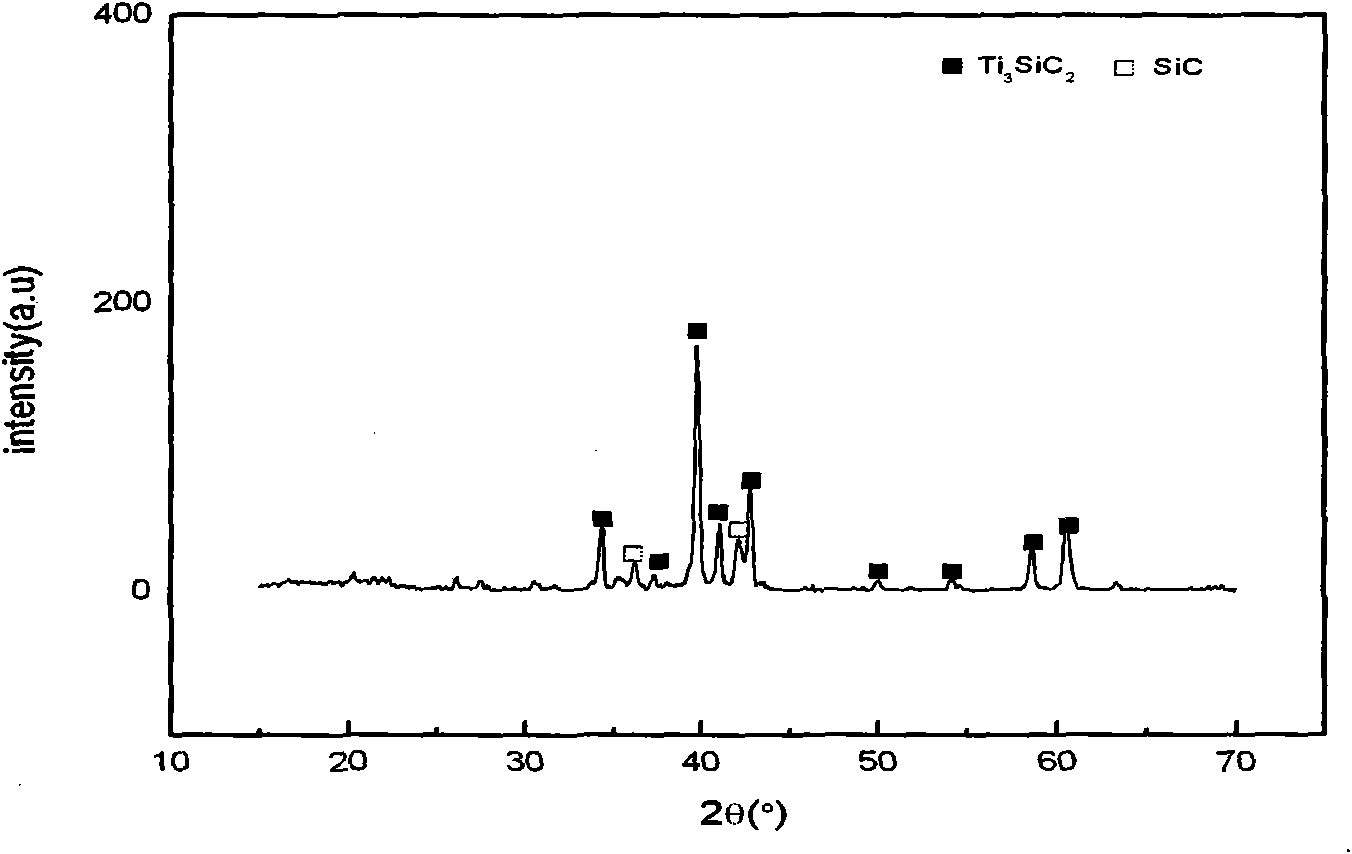

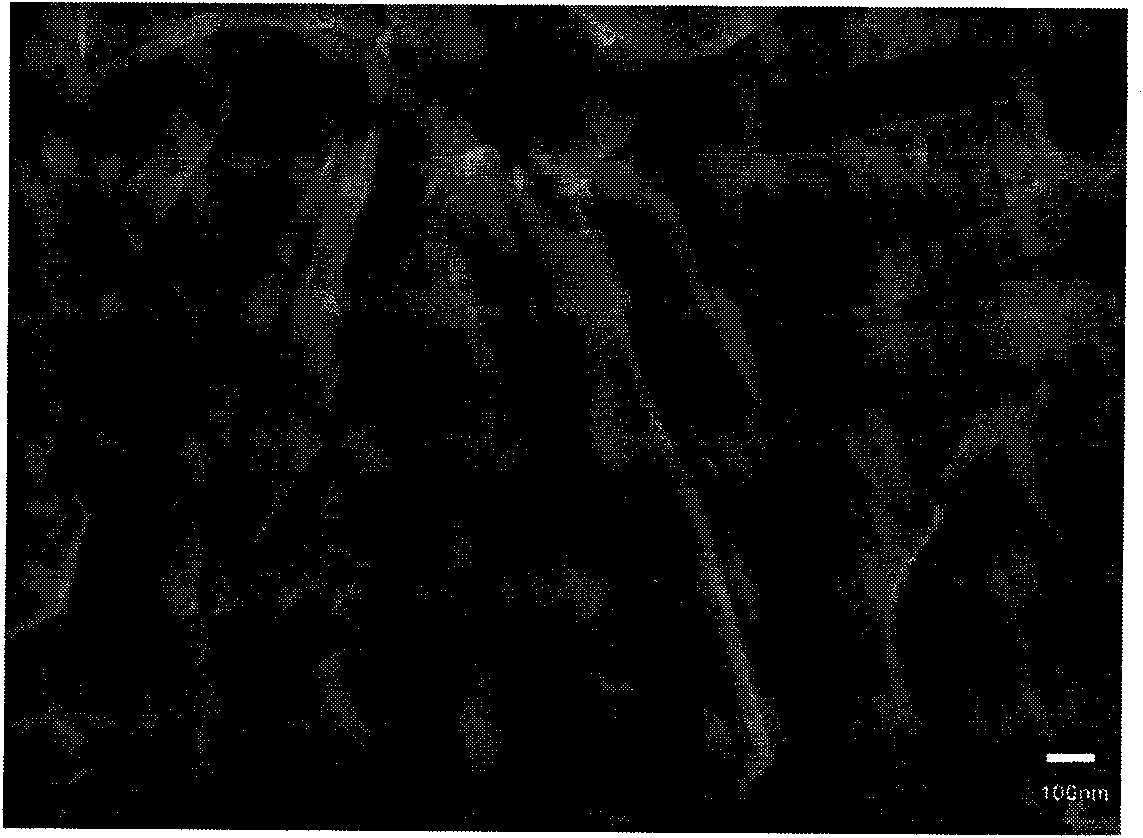

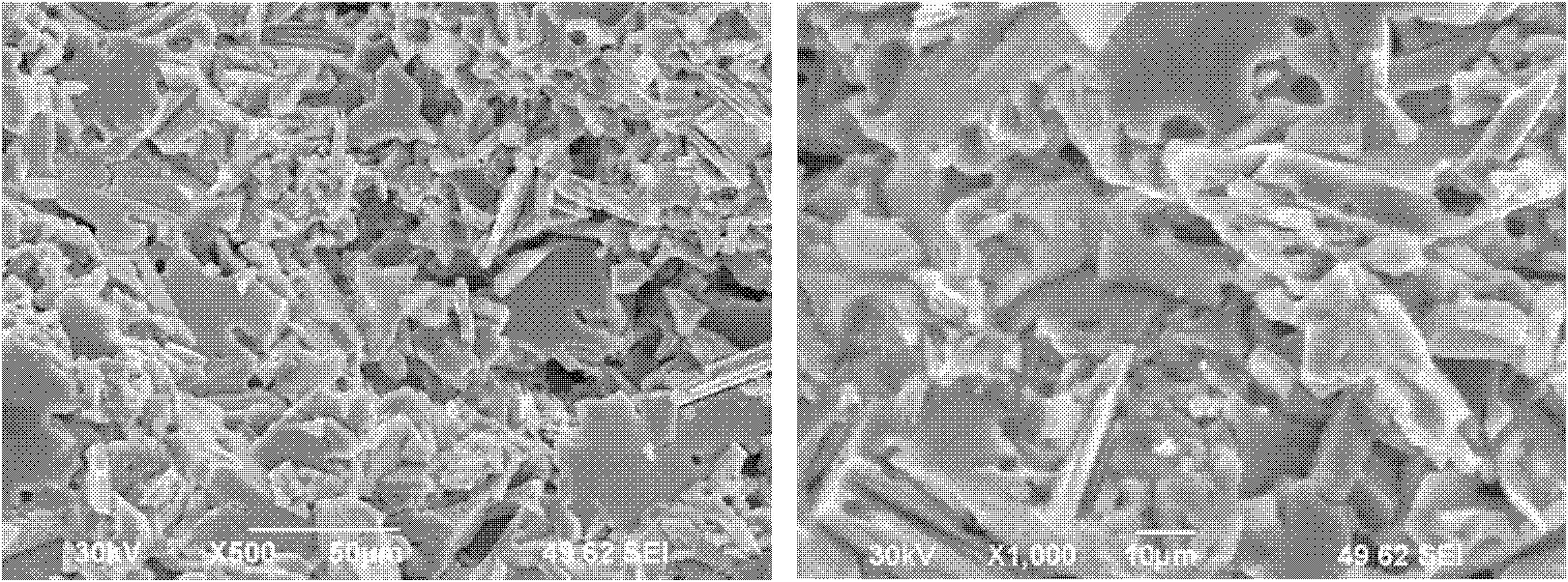

Preparation method for Ti3SiC2 ceramic material

The invention relates to a preparation method for a Ti3SiC2 ceramic material, which comprises the following steps of: firstly, preparing Ti, Si and C into mixture, adding sodium stearate dispersing agent and little amount of A1 into the mixture for enhancing sintering, adopting a dry method for ball milling to lead the mixture to be mechanically alloyed to form main phases such as Ti, Si and little amount of SiC as well as Ti5Si3 fine powder, using an alcohol wet method to take materials from the ball-milled powder, and vacuum-drying; putting the dried powder into a graphite grinding tool, and carrying out hot-pressing and sintering under the condition of argon or vacuum. The preparation method uses Ti powder, Si powder, C powder and little amount of additives for high-energy ball milling, fining crystalline grain, simultaneously carrying out in situ reaction to generate little amount of SiC, Ti5Si3 intermediate phase. The compound powder forms a machinable ceramic material with the main phases of Ti3SiC2 after hot-pressed and sintered. The preparation method has simple technique and low firing temperature, and the prepared material has even and compact structure.

Owner:SHAANXI UNIV OF SCI & TECH

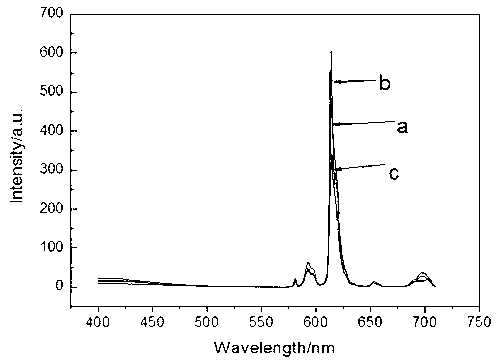

Preparation method of rare earth hydrotalcite-like compound/polymer nanocomposite

InactiveCN102796216AImprove thermal stabilityEasy to processLuminescent compositionsSodium stearateUltrasound - action

The invention relates to a rare earth hydrotalcite-like compound / polymer nanocomposite and a preparation method thereof. The method comprises the following steps: firstly prefabricating: dissolving sodium metaaluminate and sodium hydroxide in deionized water to prepare a solution A, dissolving magnesium chloride in deionized water to prepare a solution B, dissolving rare earth oxide with dilute hydrochloric acid and then putting them into the solution B to prepare a solution C, and dissolving a single ligand or a mixed ligand in sodium stearate to prepare a mixed slurry D; then under the action of strong stirring or ultrasonic wave, simultaneously adding the solution A and the solution C dropwisely in the mixed slurry D to prepare a mixed slurry E, aging, conducting pumping filtration, drying the filter cake to obtain a bright fluorescent rare earth hydrotalcite-like compound; and immersing the rare earth hydrotalcite-like compound in a polymer monomer and initiator for 24 hours, and then conducting polymerization to obtain the nanocomposite. The materials disclosed herein has excellent luminescence property of original rare earth complex, and has the advantages of good formability, strong impact resistance, light weight, low cost, easiness in film formation and the like of organic polymer materials.

Owner:FUJIAN NORMAL UNIV

High-heat-resisting glass-fiber reinforced polyester composite material and preparing method

The present invention discloses a kind of high-heat-resistant, glass-fiber-enhanced, polyester composite and its preparation method. The components (weight percentage) are: polyester 45-95%; nucleating agent-sodium stearic acid 0.3-5%; brominated flame retardant 5-30%; flame retardant synergist 4-10%; toughening agent 1-6%; antioxidant 0.1-1%; lubricant 0.1-5%; glass fiber 5-50%. The present invention uses organic-nucleating-agent sodium stearic acid, acrylic core-shell copolymer toughening agent and epoxy-group-containing material as chain extender, thus, increases the crystallization rate of PET, makes the prepared composite forming at a lower temperature, that is 70-100 degree C. Therefore, no oil heating machine needs to be added, which reduces the energy consumption, and meanwhile ensures the material's high heat resistance, high strength and high impact resistance; the material is low in cost, simple in preparation process, and easy to control its production process.

Owner:SHENZHEN KEJU NEW MATERIAL

Water-based graphite core rod lubricant

The water plumbago mandril lubricant which applies to metal thermoplastic processing, especially applies to roller mandril uses plumbago powder as lubricant, uses compound resin latex as film agent, uses borax or tripoly sodium phosphate as antioxidant, hexa sodium phosphate as dispersant, natrium stearate calcium soap as stabilizing agent, phosphate butyl tri-ester as antifoam, carboxyl ethyl fibrin as thick-increasing agent, 1,2-propyl diethanol as film assistant agent, the residual is water.

Owner:JINHUA INDAL HENGYANG CITY HIGH NEW TECH AREA

Nano silver facial perfuming soap

PendingCN101130719AGuaranteed healthy skinGood effectInorganic/elemental detergent compounding agentsSodium laurateSodium stearate

The invention discloses a beauty soap of nanometer silver, which comprises the following steps: 1. 5-2. 5% nanometer colloid silver, 2. 0-3. 0% pure embryo element, 0. 05-0. 15% collagen, 0. 05-0. 15% ursin, 6. 0-8. 0% deep sea, 7. 0wt% coagulant, 12. 0-14. 0% water, 21. 5-22. 5% glycerin, 8. 0-9. 0% sodium oleate, 21. 0-23. 0% sodium stearate, 11. 0-13. 0% sodium laurate and 3. 0-4. 0 essence. The invention not only has strong detergency, but also possesses the function of antibiotic and disinfection to maintain the oil-water balance of skin, prevent skin from aging with skin beauty.

Owner:全昌均 +1

Novel fishing net

InactiveCN104558793AHigh strengthGood knot strengthLow-density polyethyleneLinear low-density polyethylene

The invention relates to a novel fishing net which comprises high-density polyethylene, linear low-density polyethylene, triphenyltin, titanium dioxide, zinc oxide, dibutyl phthalate and sodium stearate. The diameter of the fishing line of the fishing net uniformly decreases from the traction part to the bottom; and the reduction of diameter of every 10m-long fishing line is 0.025-0.2mm. The novel fishing net provided the invention has the advantages of higher strength and sectional strength, higher fishing effect, greatly higher corrosion resistance and ultraviolet resistance, and longer service life.

Owner:巢湖市瑞强渔具有限责任公司

Negative ion environment-friendly latex pillow and preparing method thereof

InactiveCN105037838AEasy to prepareWith sedative sleepPillowsEnvironmental resistanceSodium stearate

The invention relates to a negative ion environment-friendly latex pillow and a preparing method thereof. The negative ion environment-friendly latex pillow comprises, by weight, 100 parts of natural latex, 0.5-2 parts of vulcanizing agent, 10-15 parts of honeysuckle, 10-15 parts of Juncus effusus L, 10-15 parts of green tea, 10-15 parts of jasmine flowers, 0.5-2 parts of antioxidants, 10-20 parts of negative ion powder, 1-5 parts of carrageenan and 1-5 parts of sodium stearate. The negative ion environment-friendly latex pillow is simple in preparing method and has the effects of tranquilizing, assisting in sleeping, releasing negative ions, degerming and the like.

Owner:上海婉静纺织科技有限公司

Solid glue stick and method for producing the same

InactiveCN101220252AImprove mechanical propertiesImprove performancePolyureas/polyurethane adhesivesN-vinyl-pyrrolidone polymer adhesivesSodium stearatePolyurethane adhesive

The invention discloses a solid glue stick, and is prepared with watercraft polyurethane latex as a major glue component, water as solvent, sodium stearate as gel, and polyvinyl alcohol and polyethylene pyrrole azululanone as accessory ingredients, and moderate glycerol added as humectant, wherein a self-emulsion method is adopted for the preparation of the watercraft polyurethane latex. The invention has the advantages that coated surface of the watercraft polyurethane adhesive adopted in preparing the solid glue stick is not easy to be damaged; the mechanical property is excellent; the modification is easy; the compatibility with paint is good; the prepared solid glue stick has obvious advantages in properties of assigned model, hardness, coating, and splicing, etc.; the exterior is pure white; the feeling is subtle; the splicing property is good; the drying speed is high; time for paper tearing is less than one minute; the hydrating period is as long as one year; the reserve property is fine.

Owner:ZHONGBEI UNIV +1

Chinese caterpillar fungus ginseng dan drop pills and preparing process thereof

InactiveCN1520879AImprove sleepingVigorousOrganic active ingredientsUnknown materialsSodium stearateAdditive ingredient

The present invention discloses one kind of immunity-raising aweto-American ginseng-glossy ganoderma dripping pill and its preparation process, and belongs to the field of Chinese medicine preparing technology. The medicine has ingredients including aweto extractive 1-60 weight portions, glossy ganoderma extractive 1-60 weight portions, American ginseng extractive 1-60 weight portions and matrix 20-80 weight portions. The said matrix is polyglycol or sodium stearate. The preparation process includes taking medicine material based on the recipe, crushing, mixing with matrix, heating to melting state, stirring, dropping the medicine liquid into liquid paraffin via holes in stainless steel mold, cooling under room temperature to form, shaping and demolding. The medicine is suitable for patient of cardiac and cerebral vascular diseases, diabetes, kidney disease, tumor, etc. to raise immunity and has fast absorption and obvious curative effect.

Owner:张永 +1

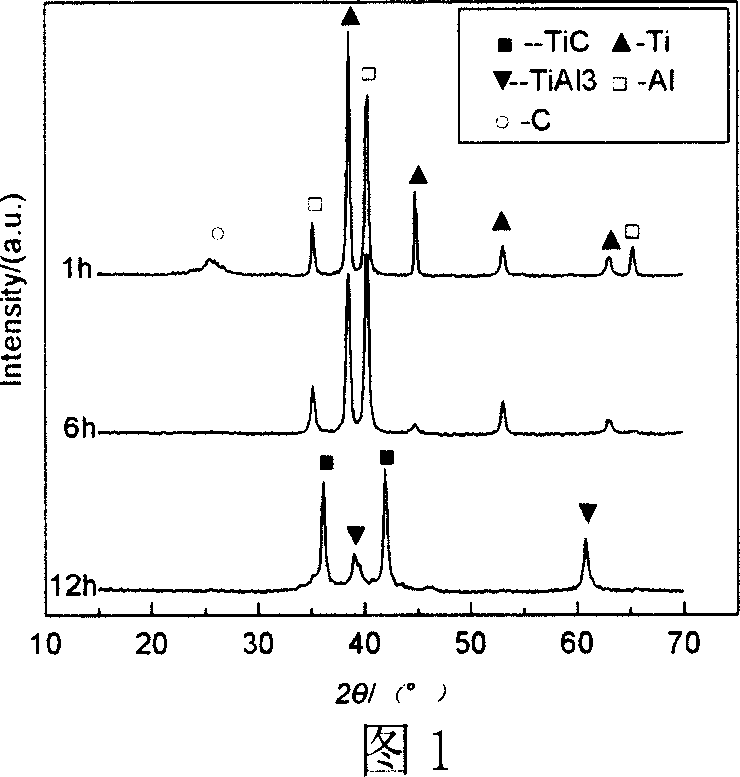

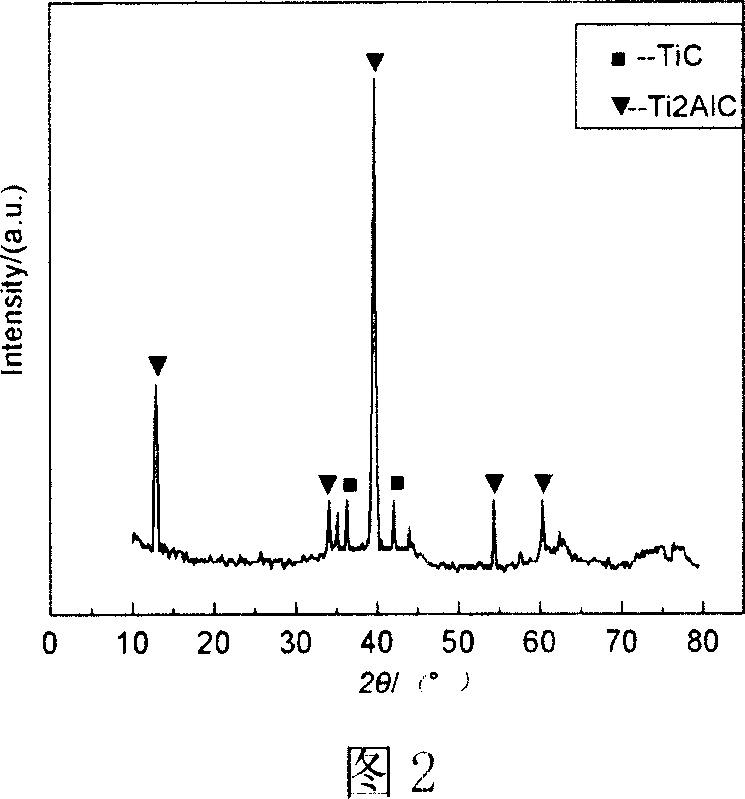

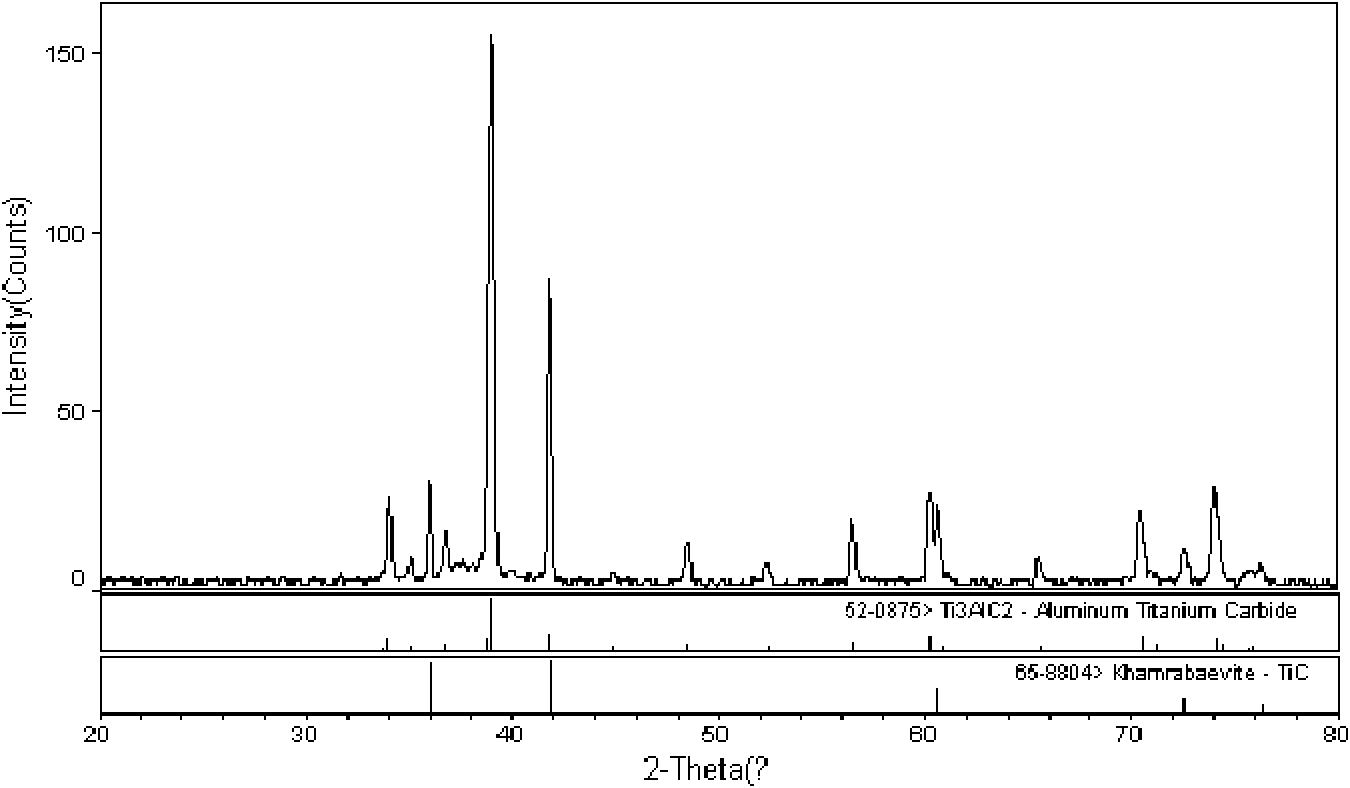

Method for preparing Ti2AlC ceramic material

This invention discloses a method for preparing Ti2AlC ceramic material. The method comprises: (1) preparing a mixture of Ti, Al and C, adding sodium stearate dispersant into the mixture, performing dry ball-milling for mechanically alloying and obtained fine powder of TiAl, TiC, and minor Ti and Al, and vacuum-drying; (2) loading the dried powder into a graphite mold, and hot-pressing sintering in Ar or vacuum. After ball-milled, Ti, Al and C powder can perform in situ reaction to form TiC intermediate phase, which is then hot-pressing sintered to form processable ceramic material with Ti2AlC as the major crystalline. The method has such advantages as simple process and low sintering temperature. The prepared Ti2AlC ceramic material is uniform and compact.

Owner:SHAANXI UNIV OF SCI & TECH

Brightness-retaining agent for silverware

The invention discloses a brightness-retaining agent for silverware and belongs to the technical field of silverware maintenance. The brightness-retaining agent is used for solving the problem that the surface of the silverware is easily oxidized, vulcanized and discolored. The brightness-retaining agent is prepared from the following components in parts by weight: 5-10 parts of sodium hypophosphite or sodium phosphite, 1-5 parts of coconut oil fatty acid diethanolamide, 1-3 parts of deionized water, 1-2 parts of Tween-20, 1-3 parts of potassium dihydrogen phosphate, 1-3 parts of sodium dihydrogen phosphate, 3-5 parts of sodium carbonate, 1-3 parts of methyl benzotriazole, 1-3 parts of 2-mercaptobenzothiazole thiadiazole, 1-2 parts of sodium lauryl sulfate and 0.5-1 part of sodium stearate. During use, the brightness-retaining agent is dissolved in deionized water to obtain a 5-10% aqueous liquid. The brightness-retaining agent is stably stored, is convenient to operate and is free of potential safety hazard and the surface texture of the silverware is not affected.

Owner:HANDAN COLLEGE

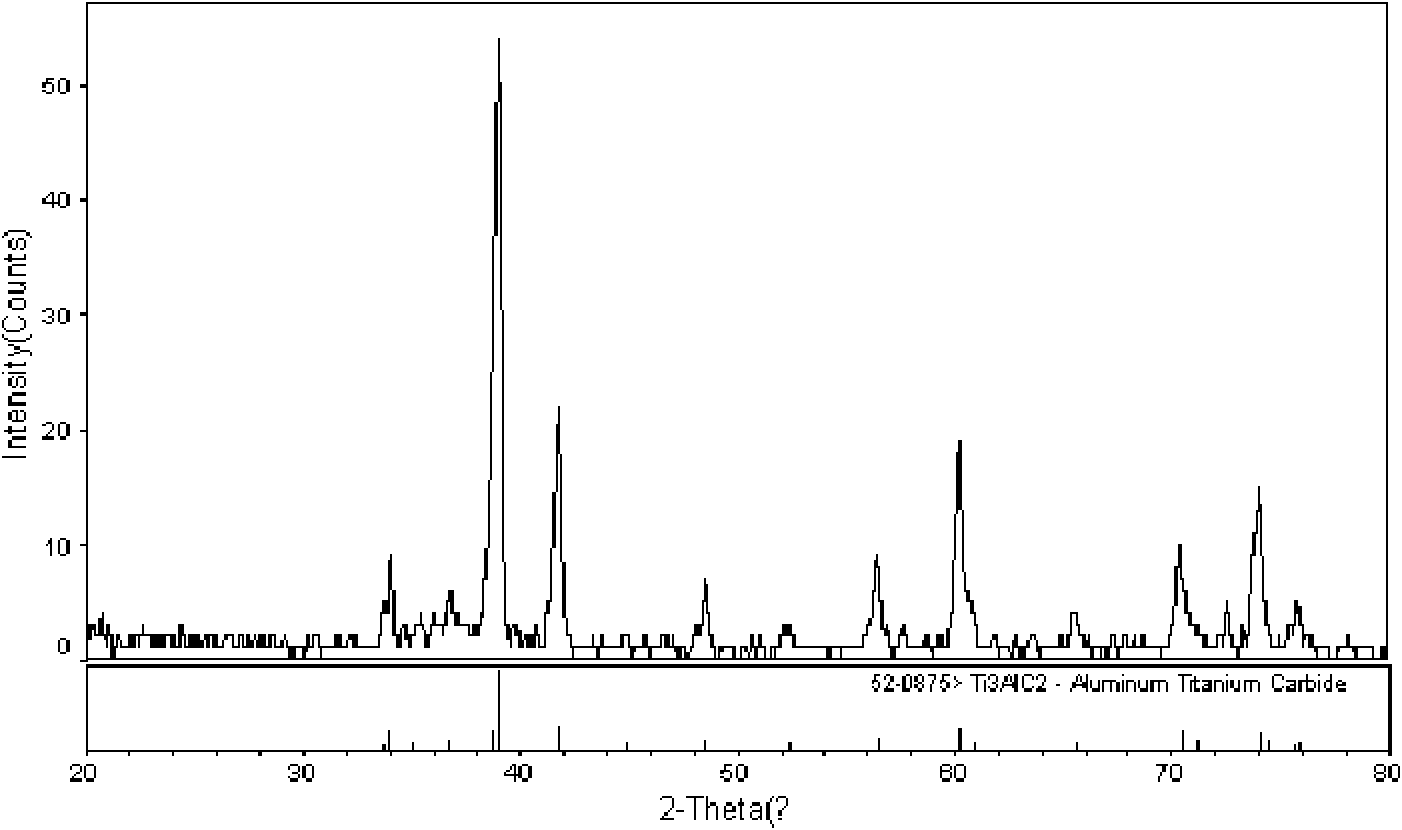

Method for preparing high-purity Ti3AlC2 ceramics

The invention relates to a method for preparing high-purity Ti3AlC2 ceramics, comprising the following steps: carrying out wet milling on TiC powder, Ti powder and Al powder which serve as raw materials in the presence of sodium stearate serving as dispersing agent and ethanol serving as ball-milling assistant; cooling the mixture at room temperature, sieving and prepressing into a cake-shaped material; and placing the cake-shaped material into a graphite mould, heating to 1300-1500 DEG C at a heating rate of 5 DEC C / min-20 DEG C / min, carrying out heat preservation for 0.5-3 hours at a hot-pressing pressure of 10-25MPa, and then cooling to room temperature. In the invention, the process is simple, and the ball-milling assistant and the dispersing agent are added, thus the ball-milling mixing efficiency is obviously improved, the reactivity can be enhanced, and the prepared product is uniform in crystallite dimension; and simple substances Ti powder and C powder are replaced by TiC, thus the cost is lowered, the product purity is higher, and the main crystalline phase is Ti3AlC2.

Owner:SHAANXI UNIV OF TECH

High-fire-retardant and wear-resistant modified silicone rubber cable material

InactiveCN105885428AImprove flame retardant performanceImprove wear resistanceRubber insulatorsInsulated cablesLow-density polyethylenePolymer science

The invention discloses a high-fire-retardant and wear-resistant modified silicone rubber cable material. The high-fire-retardant and wear-resistant modified silicone rubber cable material is prepared from the following raw materials in parts by weight: 30 to 60 parts of modified silicone rubber, 5 to 15 parts of urea formaldehyde resin, 3 to 9 parts of epoxy resin E-51, 2 to 8 parts of polyamide resin, 1 to 6 parts of dicumyl peroxide, 2 to 8 parts of maleic anhydride, 3 to 7 parts of acrylic acid, 1 to 4 parts of methacrylic acid, 2 to 5 parts of zinc oxide, 3 to 5 parts of sodium stearate, 4 to 8 parts of polyphosphate, 1 to 6 parts of low density polyethylene, 3 to 5 parts of liquid paraffin, 2 to 4 parts of styrene, 1 to 5 parts of mica iron oxide, 3 to 8 parts of zinc phosphate, 1 to 6 parts of nano titania, 2 to 5 parts of nano silica, 3 to 5 parts of silicon carbide, 3 to 6 parts of aluminum oxide, 2 to 8 parts of accelerator, 2 to 5 parts of tetraethyl orthosilicate, 3 to 6 parts of dibutyltin dilaurate, 1 to 4 parts of phase solvent and 2 to 6 parts of antioxidant. The cable material disclosed by the invention has excellent fire-retardant and wear-resisting properties.

Owner:安徽华海特种电缆集团有限公司

High strength wear resistant rubber material

The invention discloses a high strength wear resistant rubber material, which comprises the following raw materials: epoxy natural rubber, ethylene propylene diene monomer, butyl rubber, nano zinc oxide, sodium stearate, novel modification fortifier, carbon black N330, sulfur, promoter DM, promoter DOTG, meerschaum powder, grinded polypropylene fiber, mica powder, molybdenum disulfide, silane coupling agent KH-792, trioctyl trimellitate (TOTM), chlorinated paraffin, antioxidant 1010, and antioxidant 264. The high strength wear resistant rubber material has the advantages of good elasticity, high strength, good wear resistant performance, and long service life.

Owner:宁国市开源橡塑汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com