Rod hydrotalcite-like compound and its prepn process

A hydrotalcite and rod-shaped technology, which is applied in the field of new morphology-rod-like hydrotalcite and its preparation, to achieve the effects of low cost, simple process and mild reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Step a: Dissolve 3.83g (0.0125mol) of sodium stearate in 250ml of water and heat to 75°C.

[0047] Step b: 3.05g (0.015mol) of solid MgCl 2 .6H 2 O and 1.81 g (0.0075 mol) of solid AlCl 3 .6H 2O was dissolved in 45ml of water.

[0048] Step c: Dissolve 2.1g NaOH in 27ml water to prepare 2.0M alkaline solution.

[0049] Step d: After the solution in step a reaches a temperature of 75°C, add the solution in step b to the solution in step a to obtain a mixed solution;

[0050] Step e: Add the solution of step c to the above-mentioned mixed solution dropwise, stir, and control the pH range to 10. After the dropwise addition, age at 80°C for 18 hours, filter, wash with water until neutral, and age at 80°C for 24 hours, a rod-shaped magnesium-aluminum hydrotalcite material is obtained.

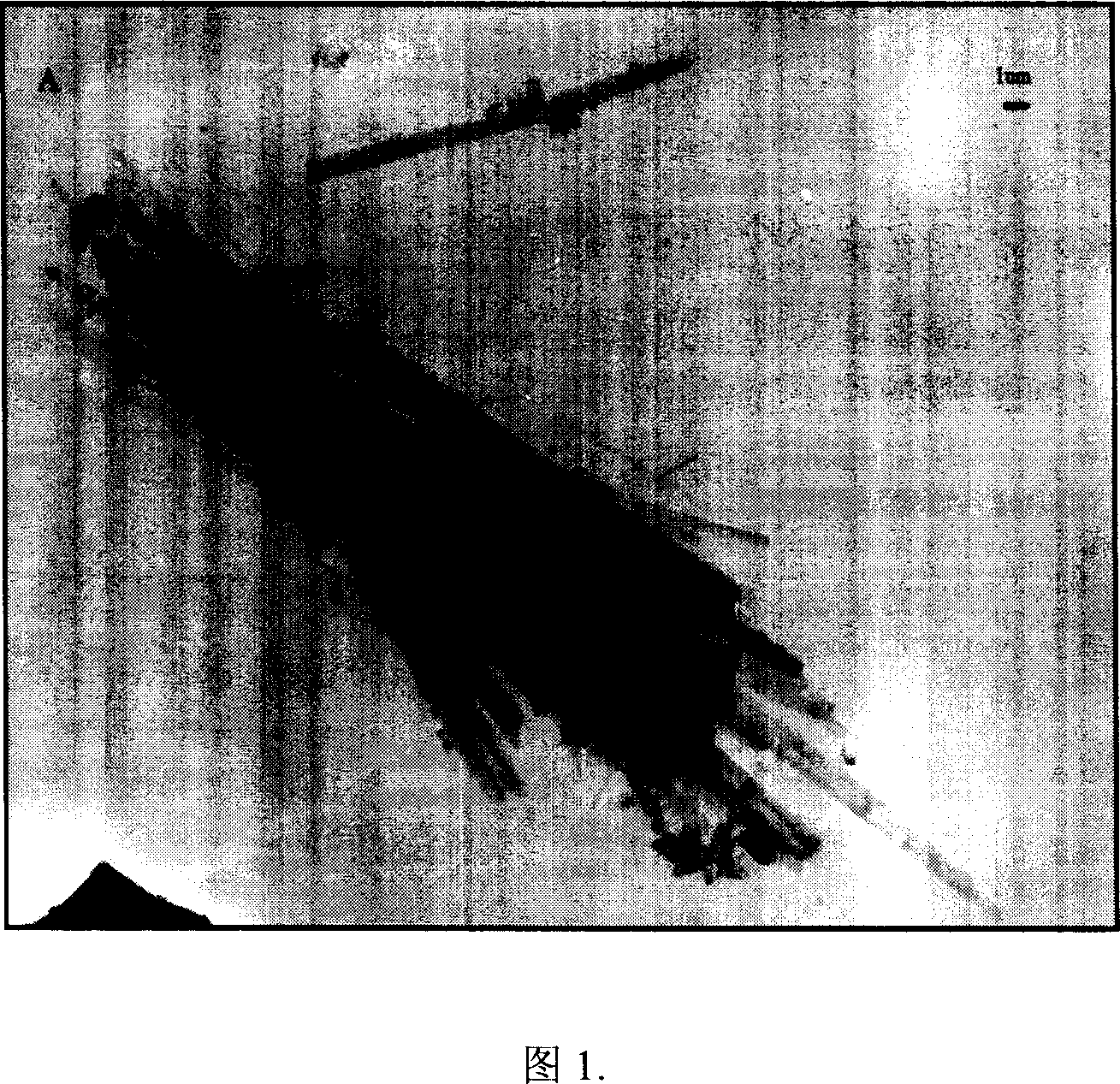

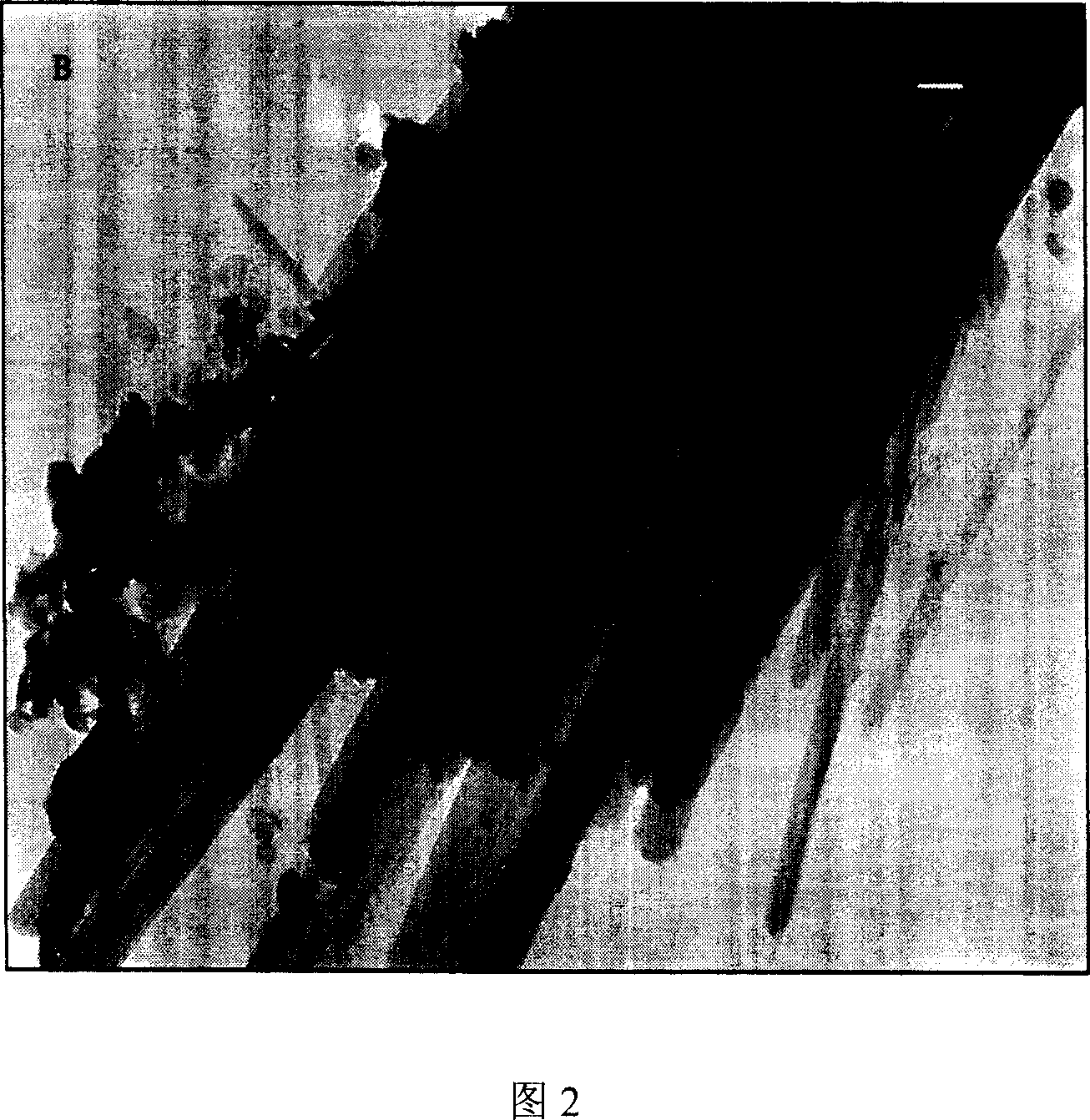

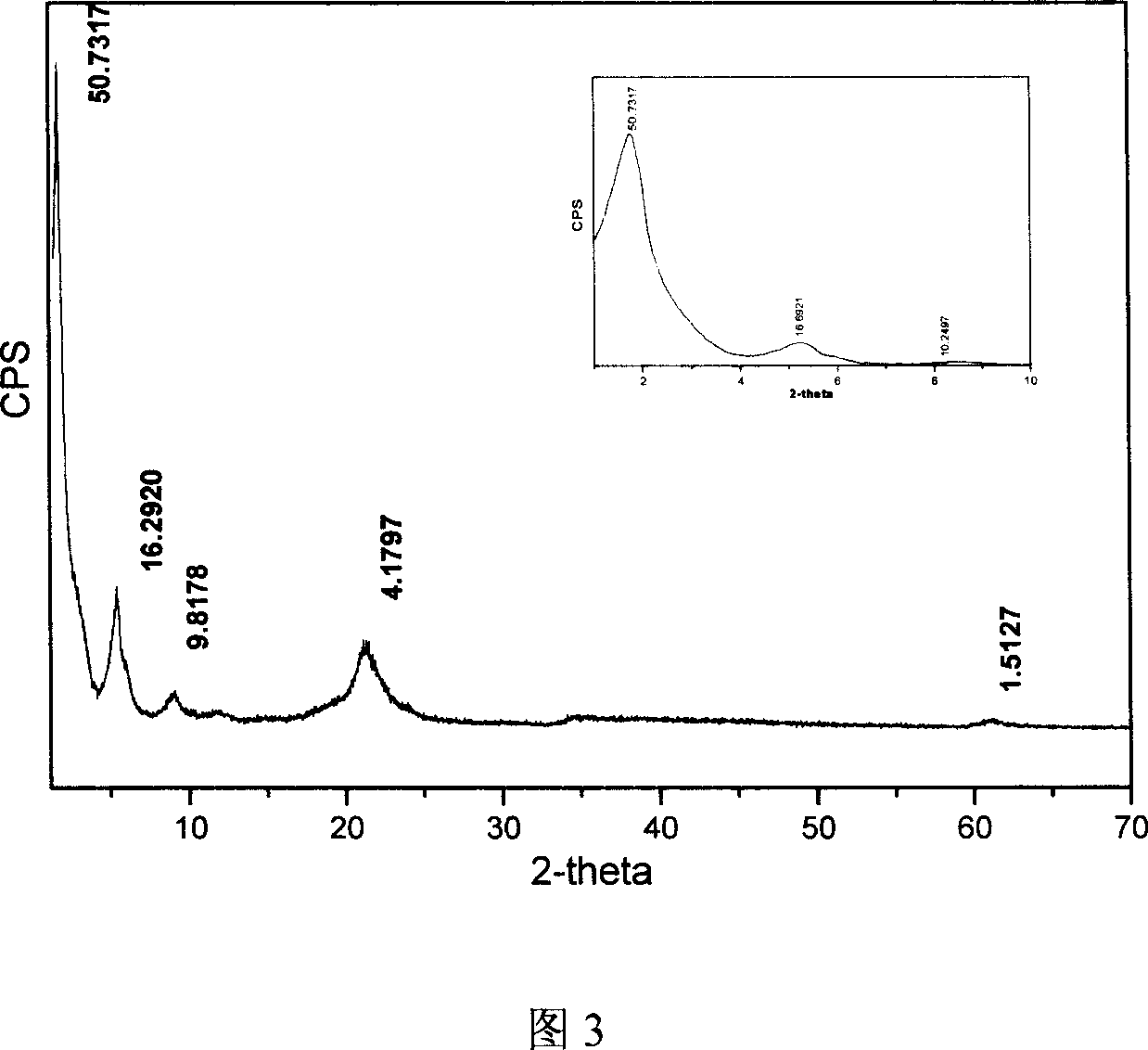

[0051] From the TEM results (Fig. 1 and Fig. 2), it can be seen that the morphology of the obtained material is rod-like, the average length of the rods is tens of microns, and the aver...

Embodiment 2

[0055] Step a: Dissolve 4.32g (0.015mol) of sodium lauryl sulfate in 150ml of water and heat to 60°C.

[0056] Step b: 8.91g (0.03mol) of solid Zn(NO 3 ) 2 .6H 2 O and 5.64g (0.015mol) of solid Al(NO 3 ) 3 .9H 2 O was dissolved in 40ml of water.

[0057] Step c: Dissolve 4.2g in 54ml of water to prepare a 2.0M alkaline solution.

[0058] Step d: After the solution of step a reaches the temperature of 75°C, simultaneously add the solution of step b and the solution of step c to the solution of step a dropwise, adjust the speed of both to complete the dropwise addition, and then adjust the pH range to 10.

[0059] Step e: aging the slurry obtained in step d at 70° C. for 18 hours, filtering, washing with water until neutral, and aging at 80° C. for 24 hours to obtain a rod-shaped zinc-aluminum hydrotalcite material.

Embodiment 3

[0061] Step a: Dissolve 4.32g (0.015mol) of sodium lauryl sulfate in 150ml of water and heat to 65°C.

[0062] Step b: 6.10 g (0.03 mol) of solid MgCl 2 .6H 2 O and 4.05 g (0.015 mol) of solid FeCl 3 .6H 2 O was dissolved in 40ml of water.

[0063] Step c: Dissolve 4.2g in 54ml of water to prepare a 2.0M alkaline solution.

[0064] Step d: After the solution of step a reaches the temperature of 75°C, simultaneously add the solution of step b and step c to the solution of step a dropwise, adjust the speed of both to complete the dropwise addition, and then adjust the pH range to 10.5.

[0065] Step e: aging the slurry obtained in step d at 65° C. for 18 hours, filtering, washing with water until neutral, and aging at 80° C. for 26 hours to obtain a rod-shaped mafic-iron hydrotalcite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com