Patents

Literature

177 results about "Morphology control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

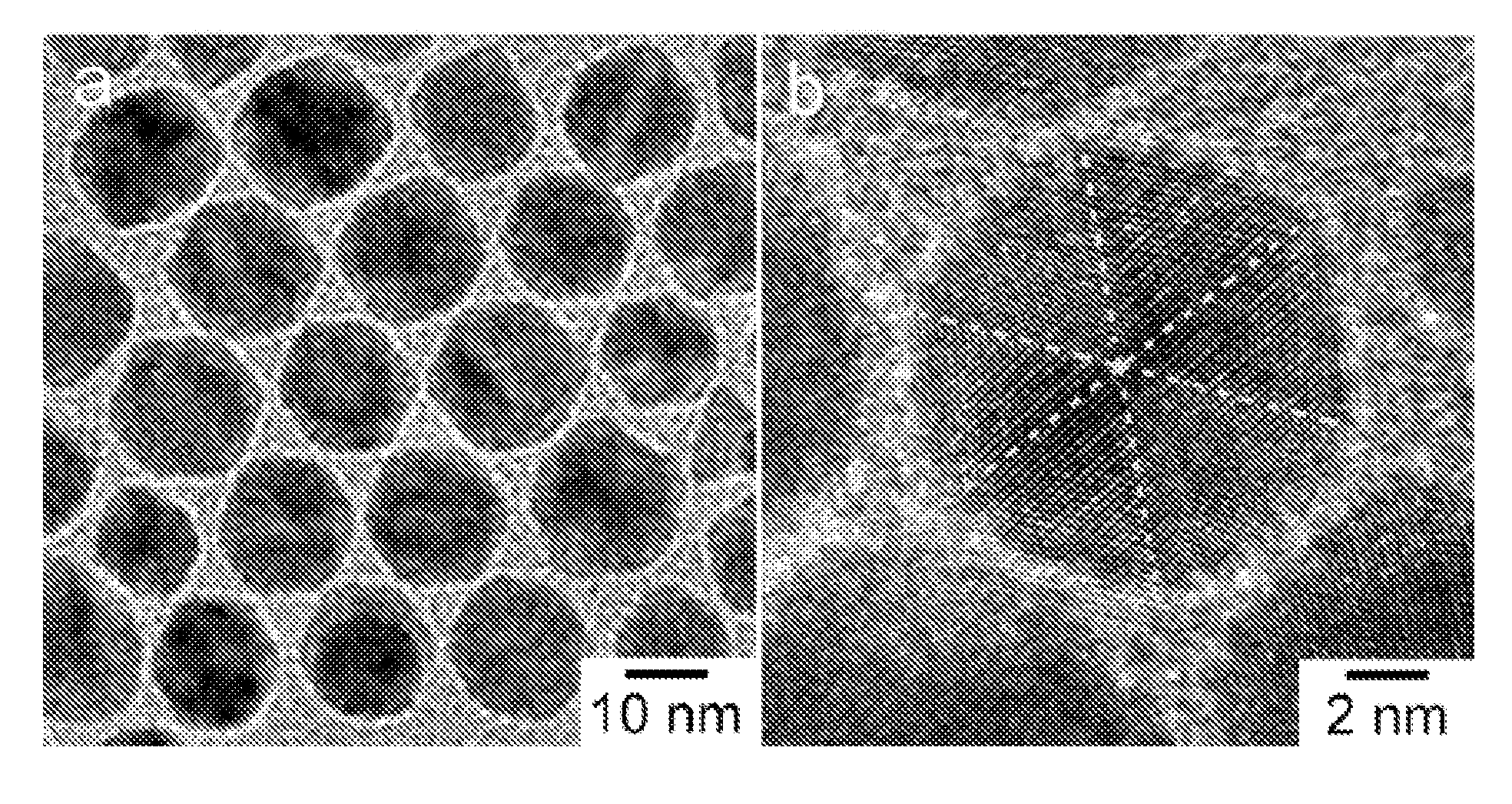

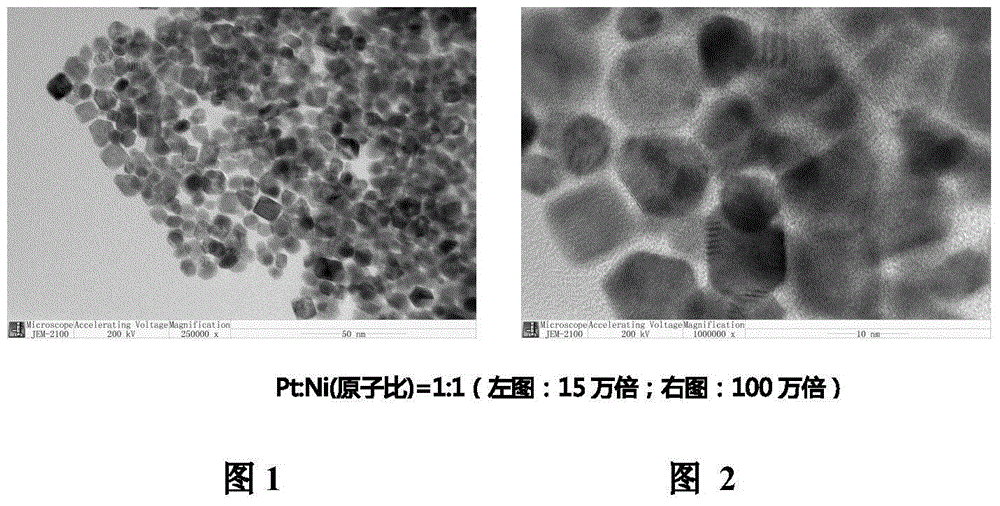

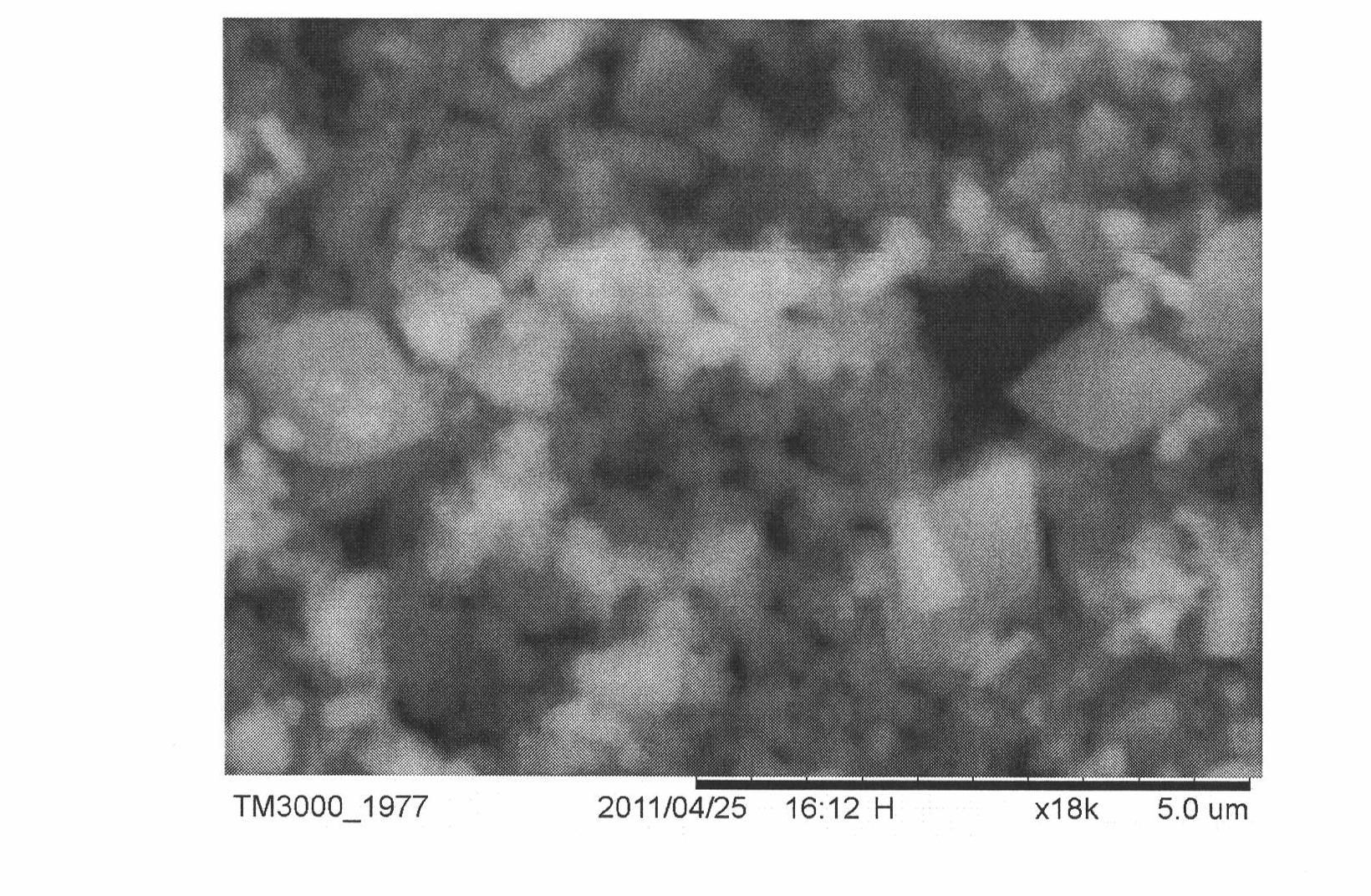

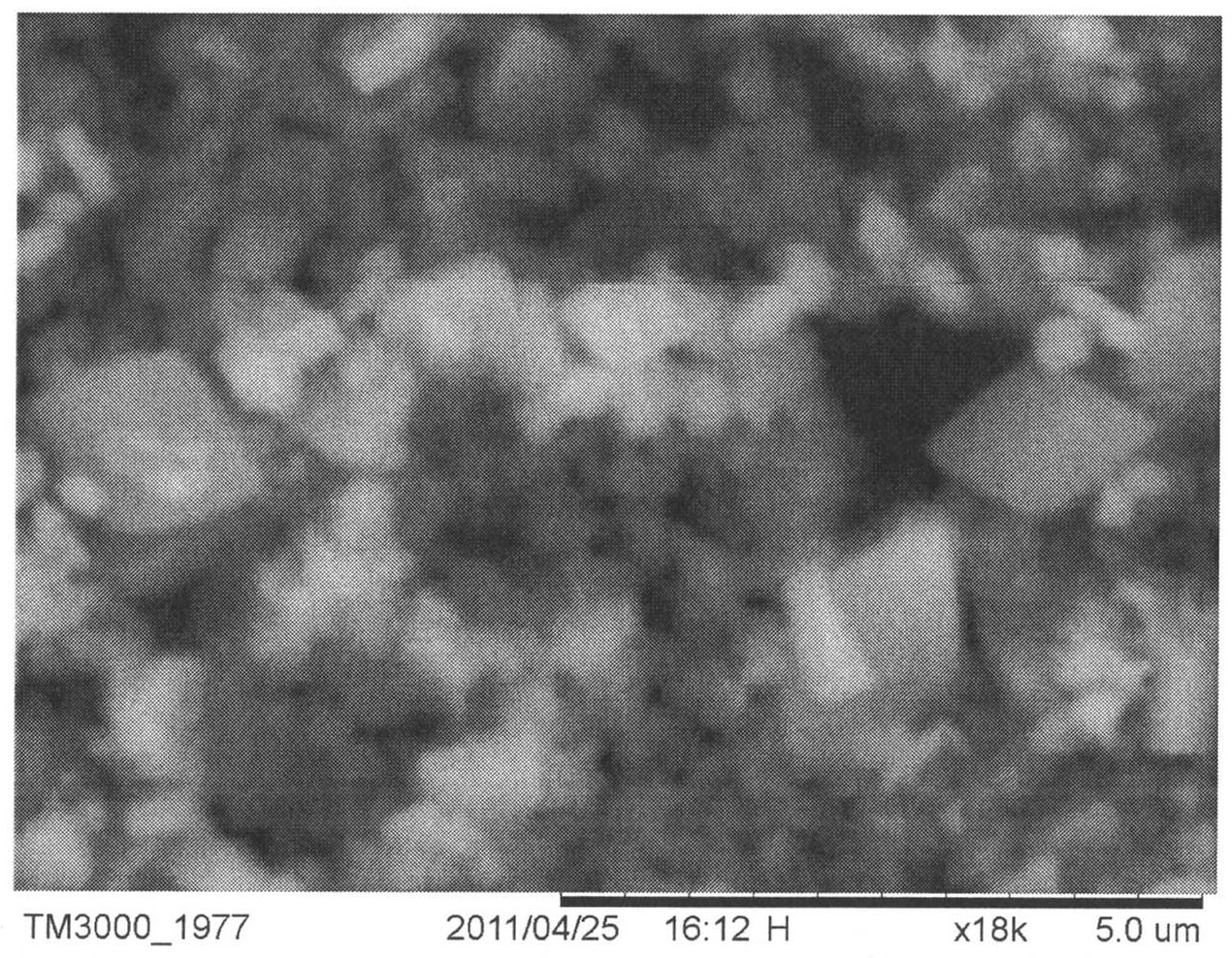

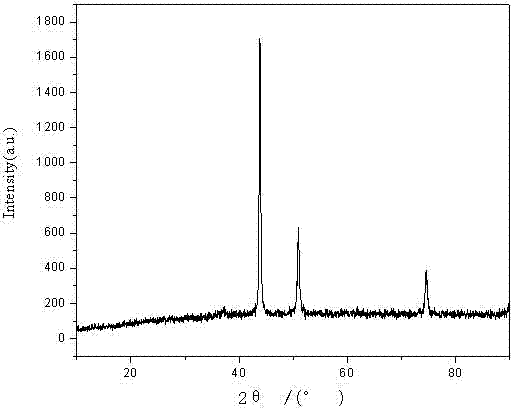

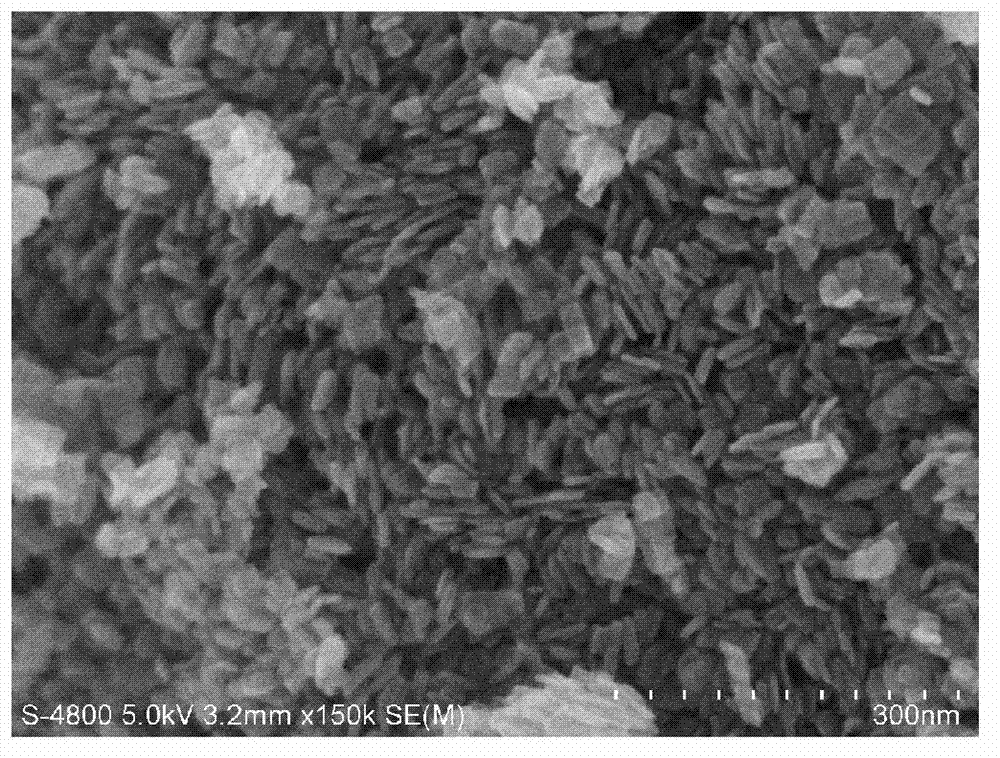

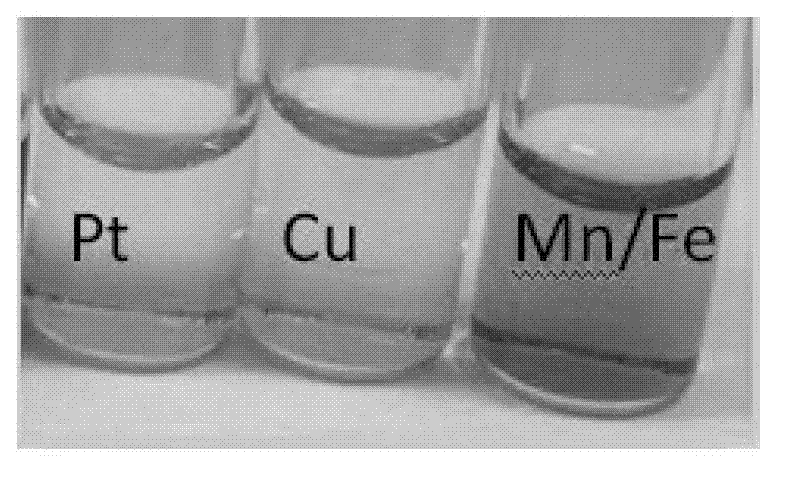

Synthesis of Nanoparticles Using Reducing Gases

Selective gas-reducing methods for making shape-defined metal-based nanoparticles. By avoiding the use of solid or liquid reducing reagents, the gas reducing reagent can be used to make shape well-defined metal- and metal alloy-based nanoparticles without producing contaminates in solution. Therefore, the post-synthesis process including surface treatment become simple or unnecessary. Weak capping reagents can be used for preventing nanoparticles from aggregation, which makes the further removing the capping reagents easier. The selective gas-reducing technique represents a new concept for shape control of nanoparticles, which is based on the concepts of tuning the reducing rate of the different facets. This technique can be used to produce morphology-controlled nanoparticles from nanometer- to submicron- to micron-sized scale. The Pt-based nanoparticles show improved catalytic properties (e.g., activity and durability).

Owner:UNIVERSITY OF ROCHESTER

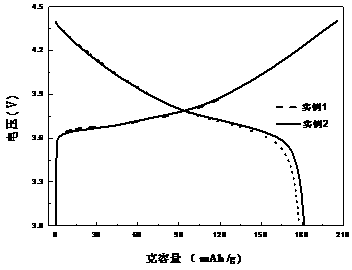

High-energy-density Ni-Co-based lithium ion positive electrode material and preparation method thereof

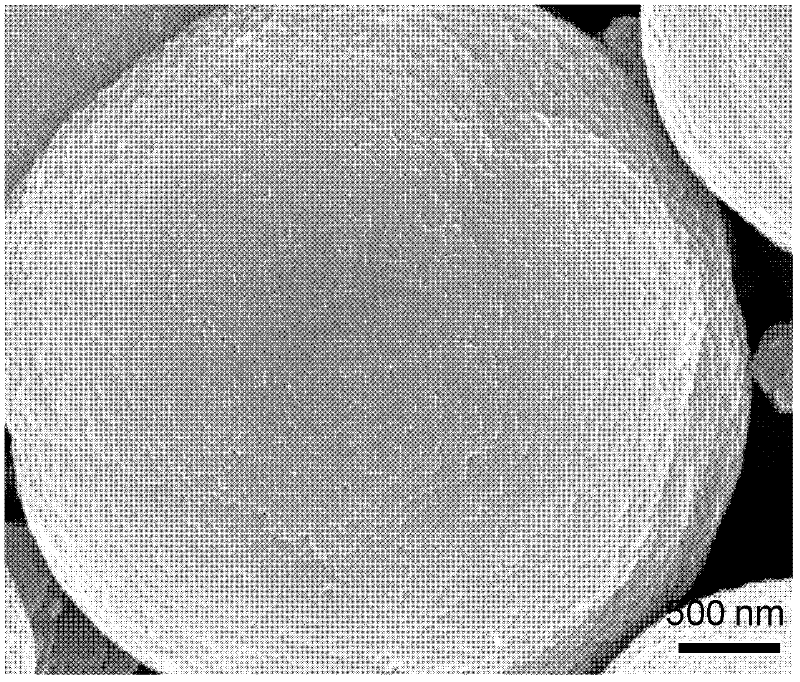

The invention discloses a high-energy-density Ni-Co-based lithium ion positive electrode material. The chemical general formula of a base material is LipNixCo1-xMmO2, M is a doping agent, and a clad material is an active material N; a positive electrode material of a lithium ion secondary battery is composed of second particles formed by gathering of primary particles, or primary particles, or mixed particles of primary particles and second particles. A preparation method of the high-energy-density Ni-Co-based lithium ion positive electrode material comprises the steps of preparation of a precursor of the lithium ion secondary battery positive electrode material and preparation of the lithium ion secondary battery positive electrode material. The Ni-Co binary precursor of the positive electrode material is subjected to a continuous coprecipitation reaction, elements are evenly mixed, the reaction is sufficient, and morphology control is facilitated; the cation mixing phenomenon is reduced through doping of proper elements in a binary high-nickel material, the structure is stabilized, safety and high-temperature performance of the battery material are improved, and the cladding active material improves first-time charge and discharge efficiency and the energy density of the material to a certain extent.

Owner:NANTONG RESHINE NEW MATERIAL

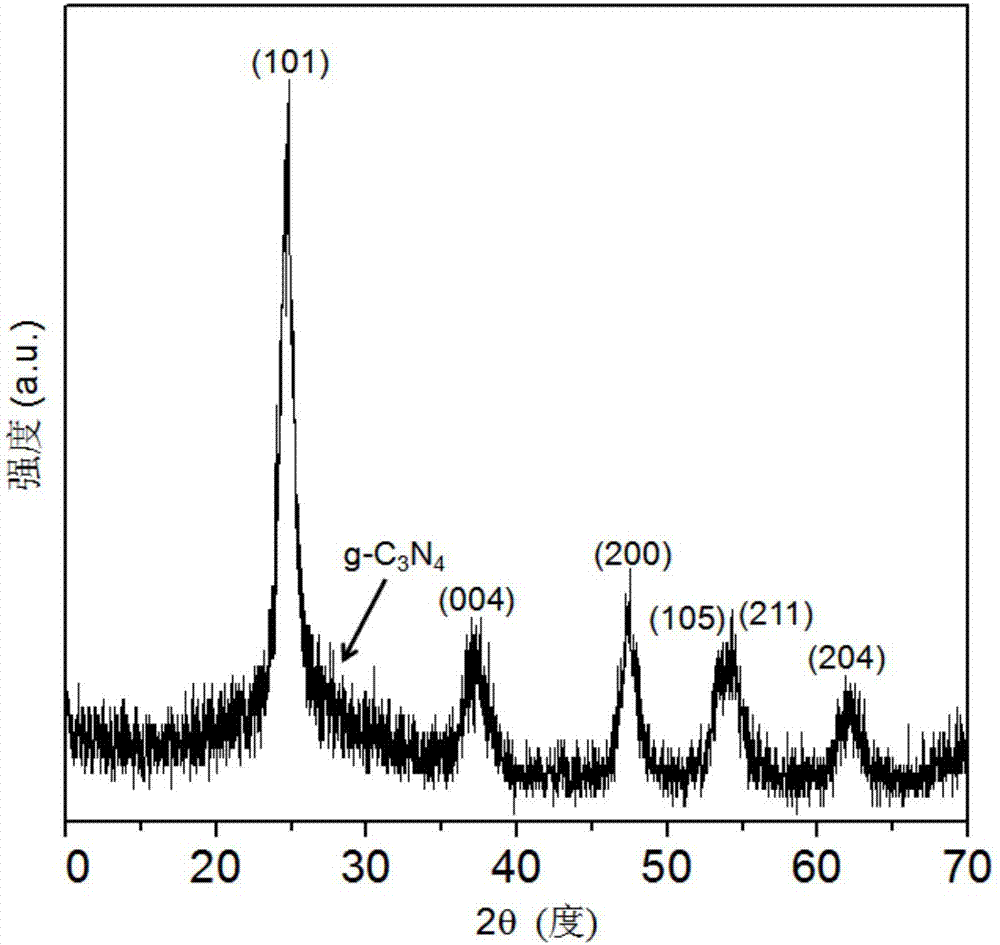

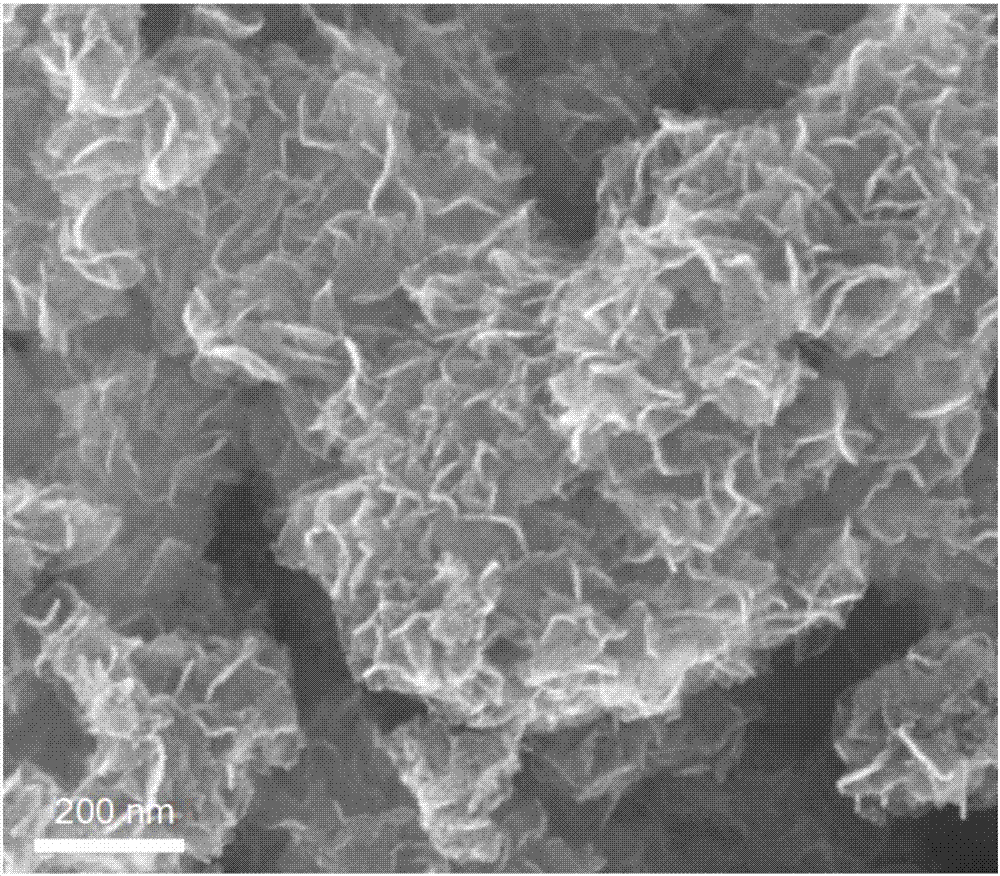

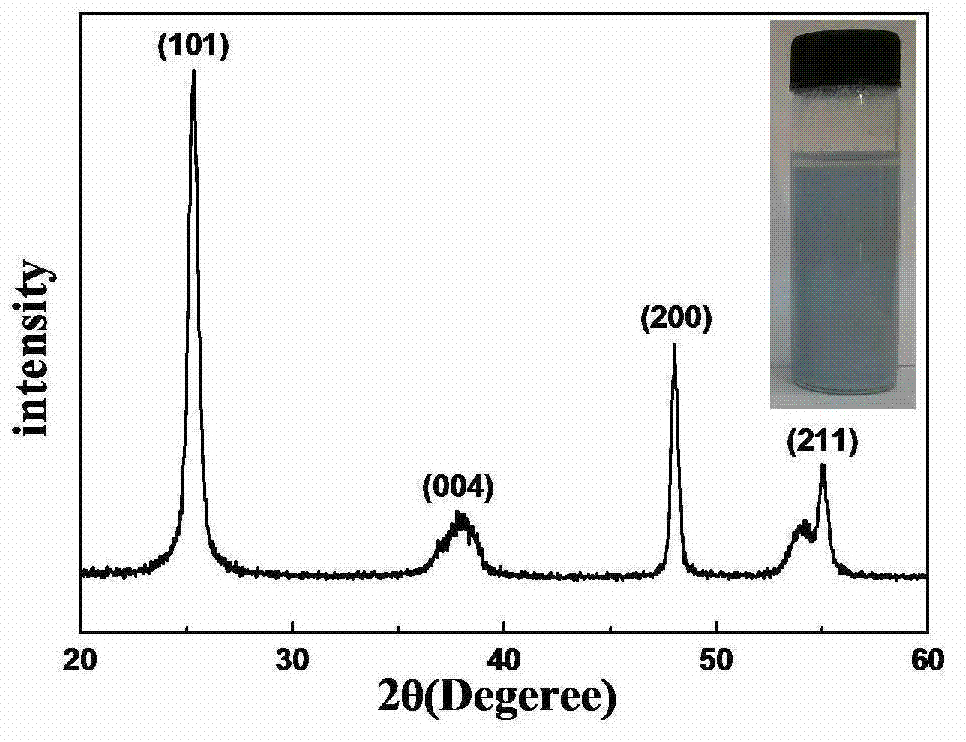

Carbon nitride/titanium dioxide nanosheet array heterojunction photocatalyst and preparation method

InactiveCN106944116AImprove photocatalytic hydrogen production activityImprove photocatalytic activityWater/sewage treatment by irradiationWater treatment compoundsHeterojunctionDiethylenetriamine

The invention relates to a carbon nitride / titanium dioxide nanosheet array heterojunction photocatalyst and a preparation method, belonging to the technical field of photocatalysis of nanometer materials. The catalyst is prepared through the following steps: with g-C3N4 as a carrier, titanium isopropoxide as a titanium source, diethylenetriamine as a morphology controlling agent and isopropanol as a solvent, performing a solvothermal method so as to prepare a g-C3N4 / TiO2 precursor, and carrying out calcination treatment so as to obtain a g-C3N4 / TiO2 nanosheet array heterojunction composite photocatalyst for the first time. The heterojunction composite photocatalyst shows pure and significantly-improved photocatalytic hydrogen production activity to g-C3N4 and anatase TiO2 nanosheet mesoporous spheres in a photocatalytic hydrogen production reaction. The preparation method has the advantages of simple and convenient operation, easy control, greenness, environmental protection and good application prospects. The series of catalysts has multilevel structure; and a g-C3N4 / TiO2 nanosheet array heterojunction structure is formed through vertical and staggered growth of anatase TiO2 nanosheets with regular shape and uniform size on the surface of g-C3N4. The catalyst has excellent photocatalytic hydrogen production activity, good stability, high repeatability and facilitation large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

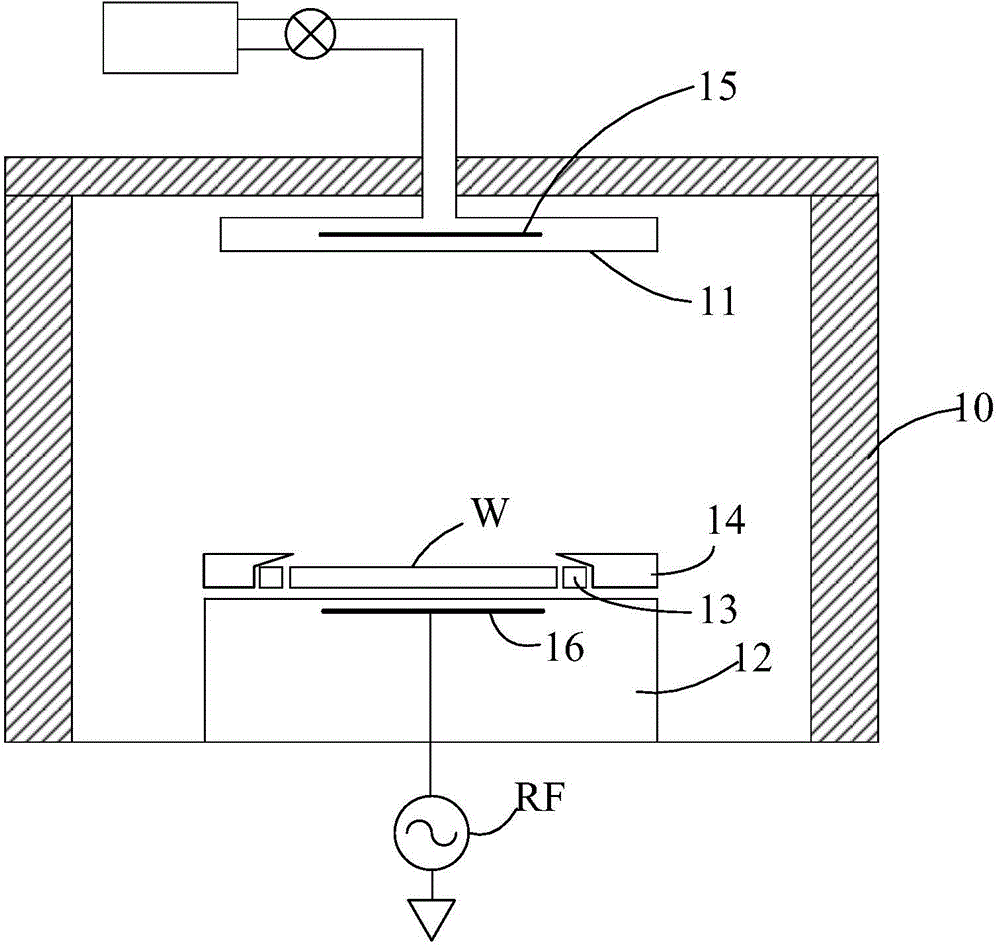

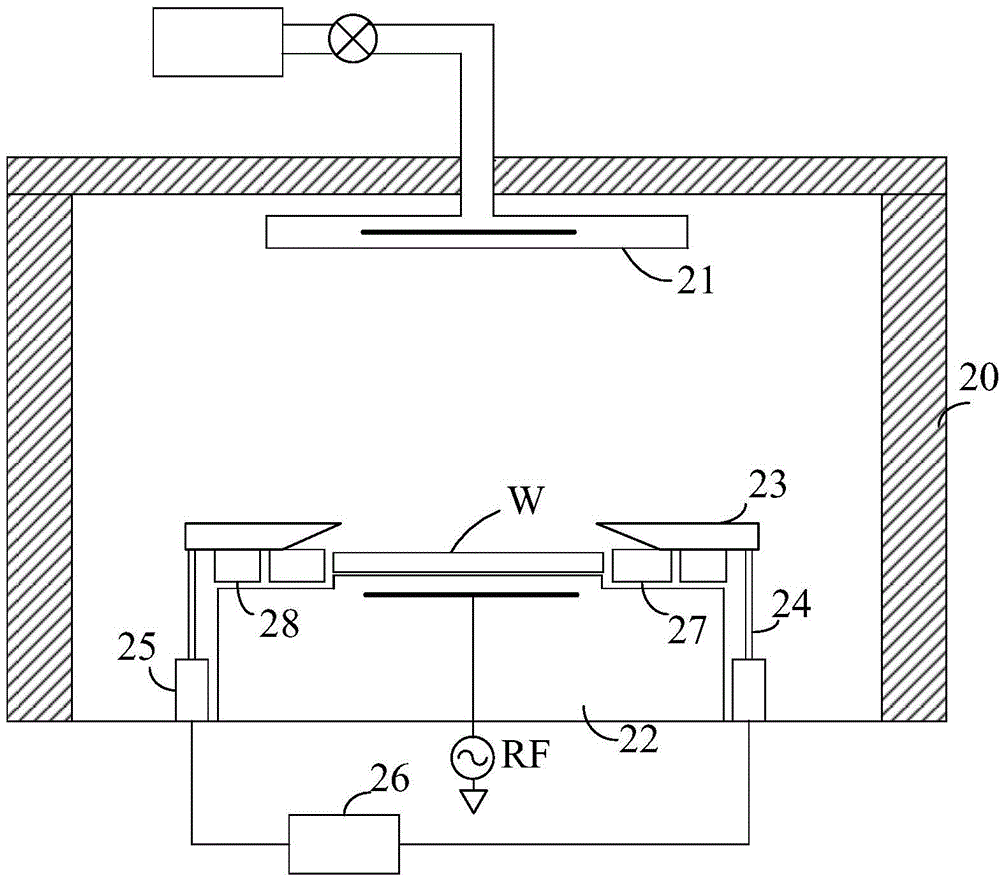

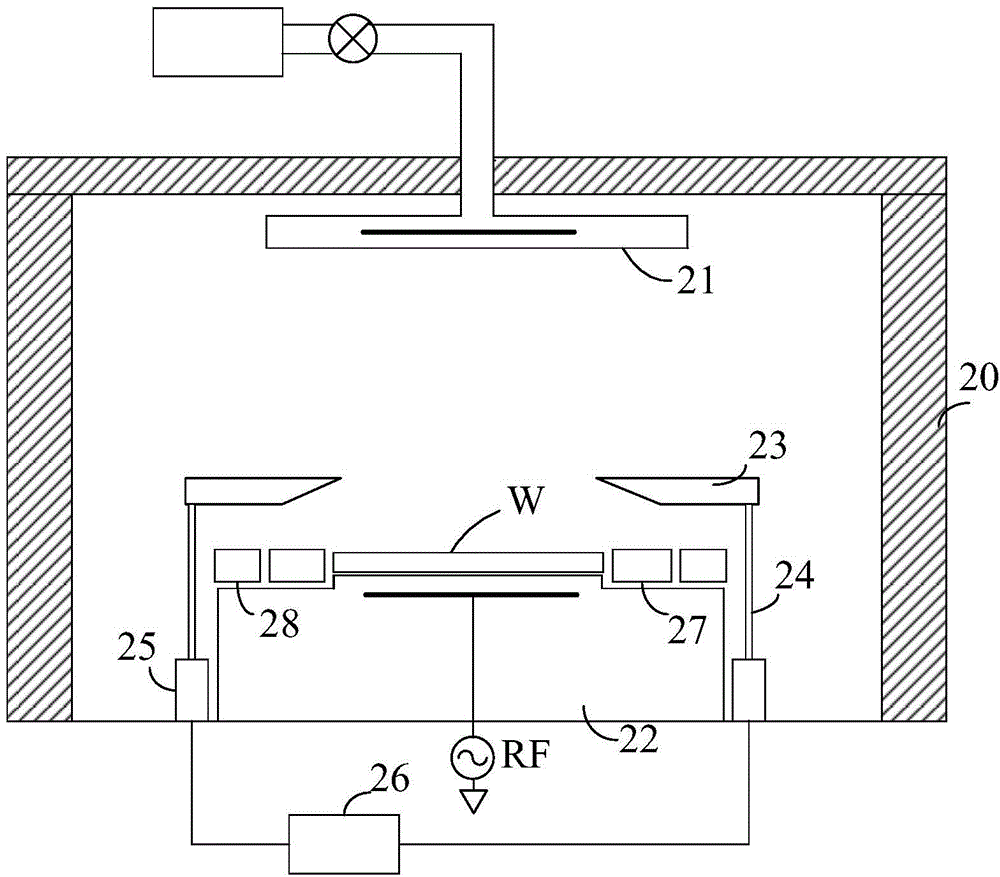

Plasma etching device

ActiveCN105336561AImplement in-place executionMaintain uniformityElectric discharge tubesGraphicsReaction chamber

The invention discloses a plasma etching device capable of executing a deep groove graph etching process in an in situ mode and executing a free-graphics etching process. The device comprises a reaction chamber. The reaction chamber possesses a static chuck clamping a substrate, a mobile annular shielding component arranged on a periphery side of the substrate and located above the substrate, a driving unit used for driving the annular shielding component to move along a vertical direction and a control unit. When the deep groove graph etching process is about to be performed, the control unit makes the driving unit drive the annular shielding component to be positioned at a first position which is far away from the substrate. When the free-graphics etching process is about to be performed, the control unit makes the driving unit drive the annular shielding component to be positioned at a second position close to the substrate. By using the device, morphology control of high-aspect-ratio structure graph etching and uniformity of free-graphics etching can be effectively improved.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

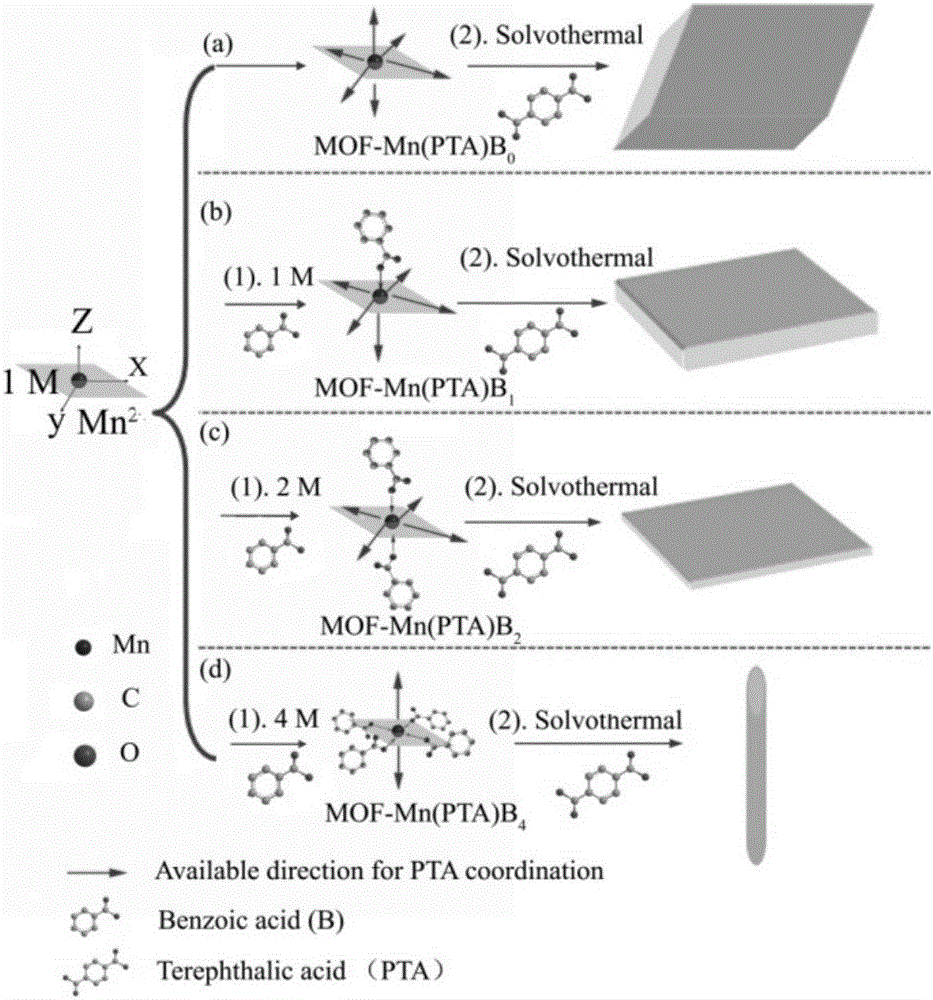

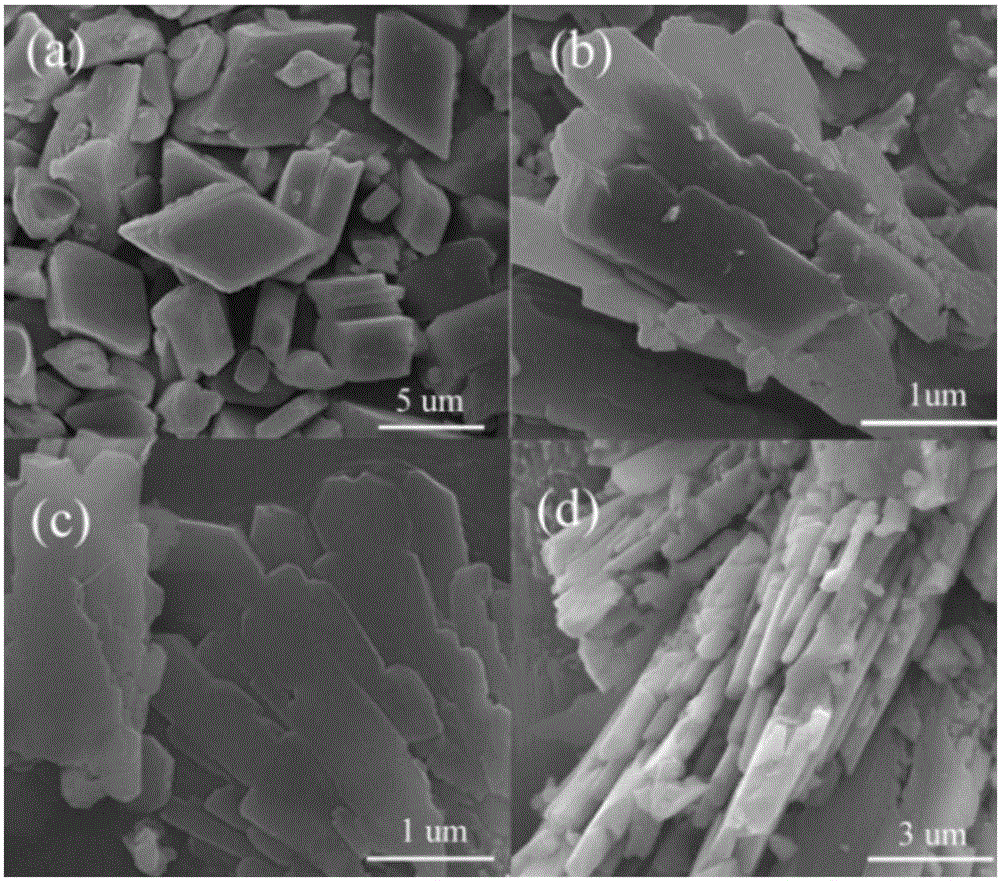

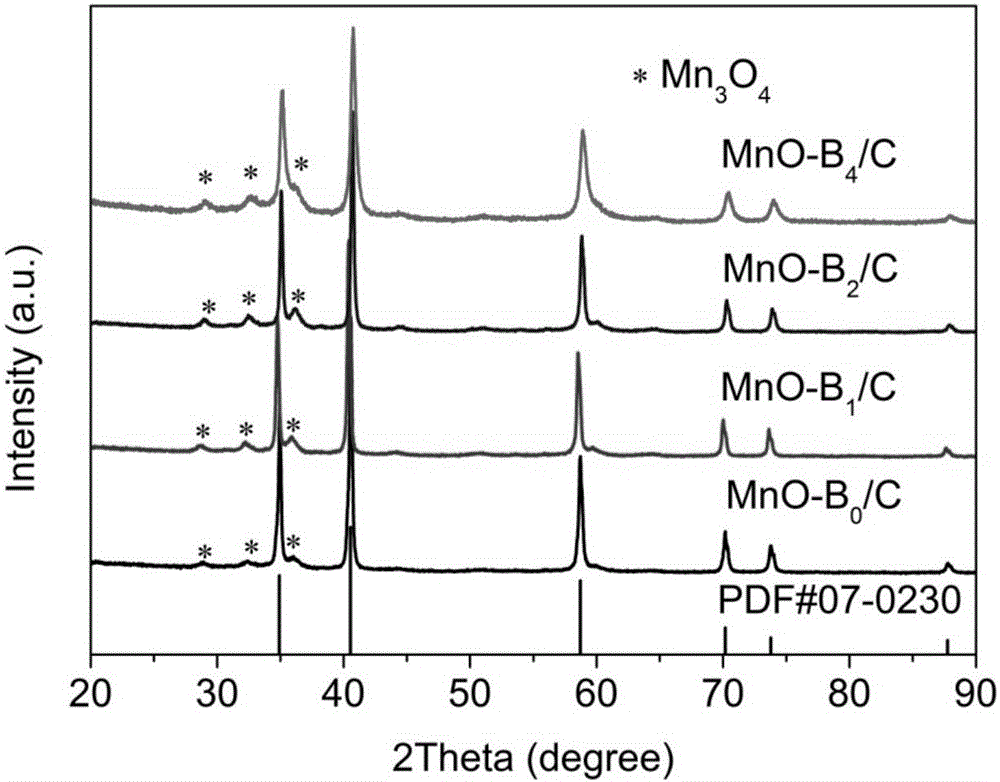

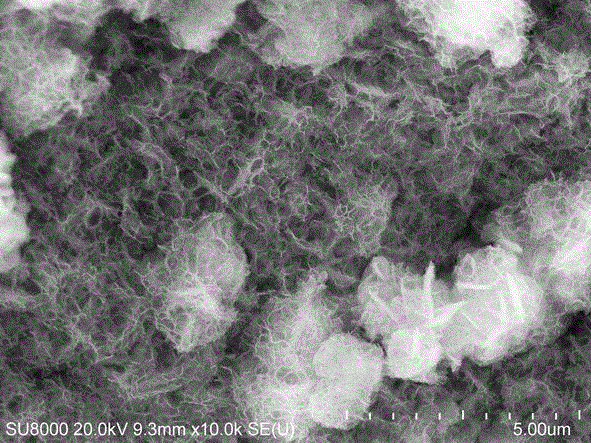

Morphological control method of metal oxide/carbon negative electrode material for lithium ion battery

ActiveCN106784658ALarge specific surface areaSimple processSecondary cellsNegative electrodesAluminium-ion batteryMetal-organic framework

The invention discloses a morphological control method of a metal oxide / carbon (MOx / C) composite material for the negative electrode of a lithium ion battery. The method comprises the following steps: adding metal ions and monodentate ligands with different proportions into a solvent, stirring for a period of time, then adding a multidentate ligand, and heating in a reaction kettle for a period of time to obtain the metal organic framework (MOF) precursor materials with different morphologies; and calcining the precursors in an inert gas atmosphere for a period of time to obtain the MOx / C composite materials with different morphologies. The composite materials disclosed by the invention have relatively high specific surface areas and rich pore structures, and have excellent rate performance and cycling stability as the negative electrode materials of the lithium ion battery. The morphological control method disclosed by the invention is simple to operate, easy to realize large-scale application, and can also be extended to other fields that focus on material morphology control.

Owner:CENT SOUTH UNIV

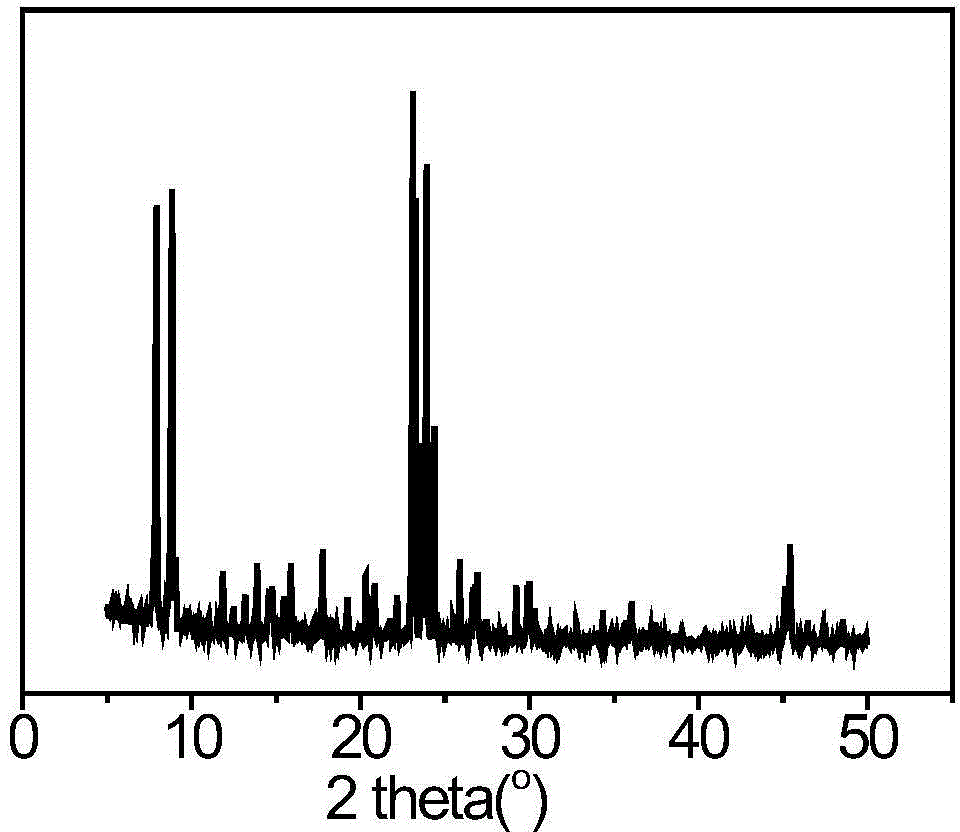

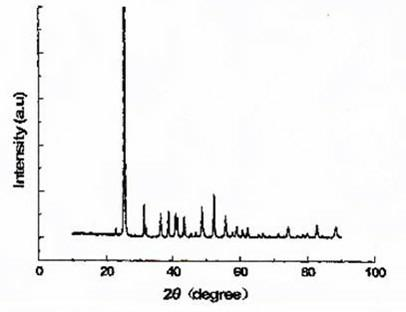

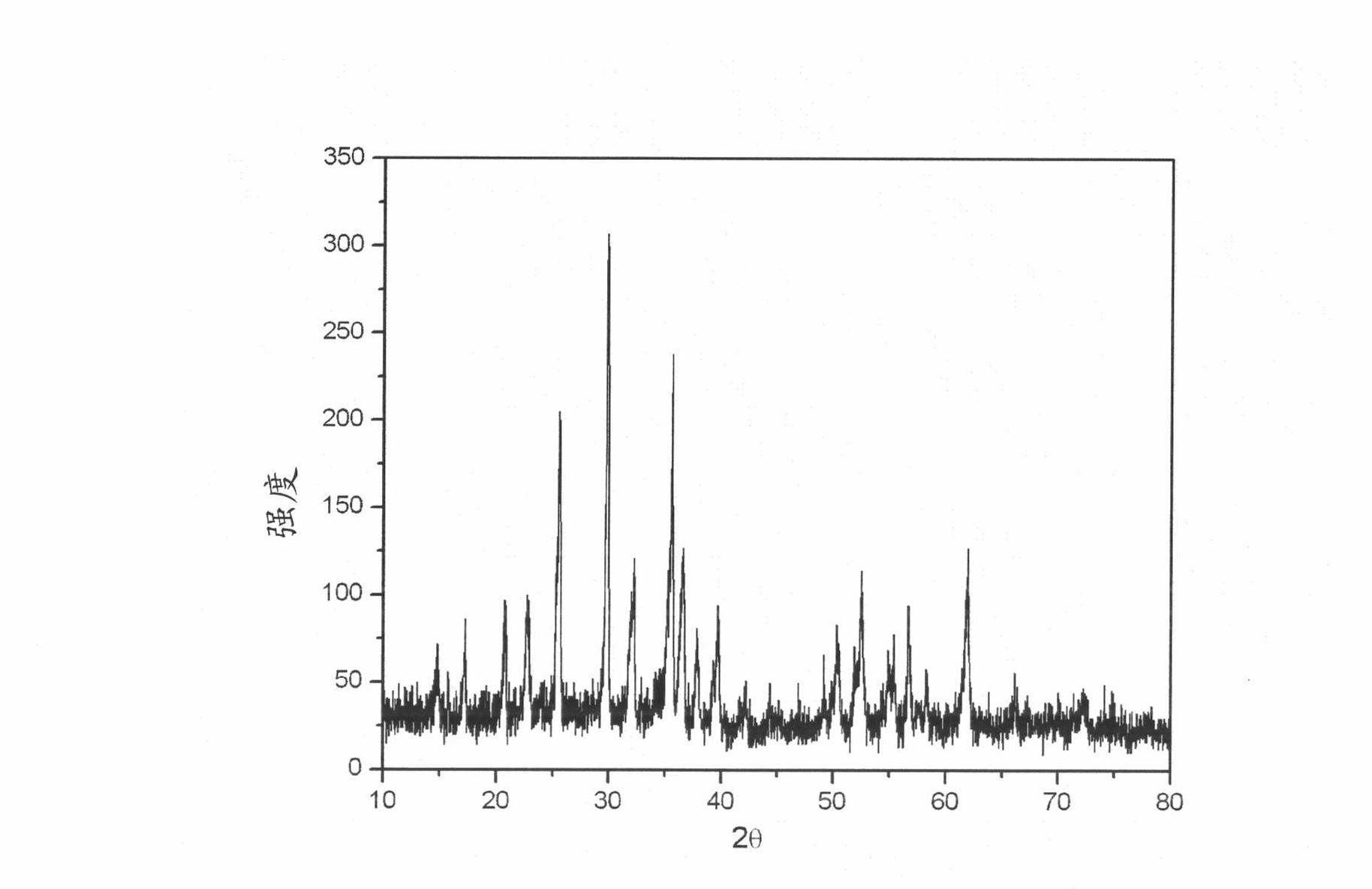

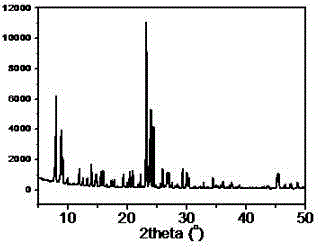

Lamellar ZSM-5 molecular sieve and synthesis method thereof

ActiveCN105523569AEvenly distributedUniform sizePentasil aluminosilicate zeoliteSynthesis methodsCrystallinity

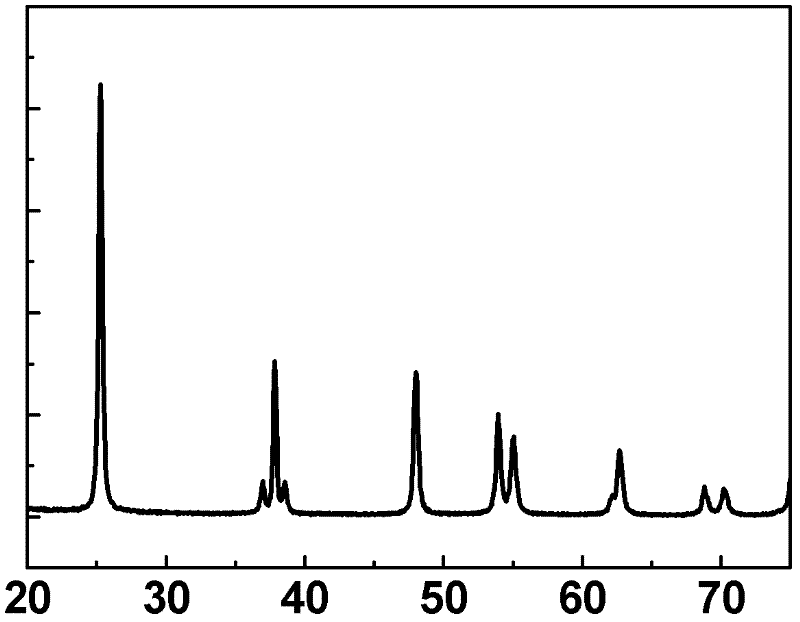

The invention belongs to the technical field of zeolite molecular sieve synthesis and relates to a synthesis method of a lamellar ZSM-5 molecular sieve. Morphology control is important in the field of molecular sieve synthesis, in a catalytic reaction, product selectivity, reaction activity and stability of MFI zeolite molecular sieve catalysts with different morphologies have obvious difference because of morphology difference. The synthesis method mainly utilizes a one kettle way to prepare ZSM-5 zeolite, has simple synthesis processes and can be industrialized easily. Through use of an effective additive, product crystallinity and final morphology can be effectively controlled. A sample XRD shows that the product is the ZSM-5 molecular sieve and has good crystallinity. SEM shows that the zeolite has lamellar morphology and can be used for olefin cracking industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

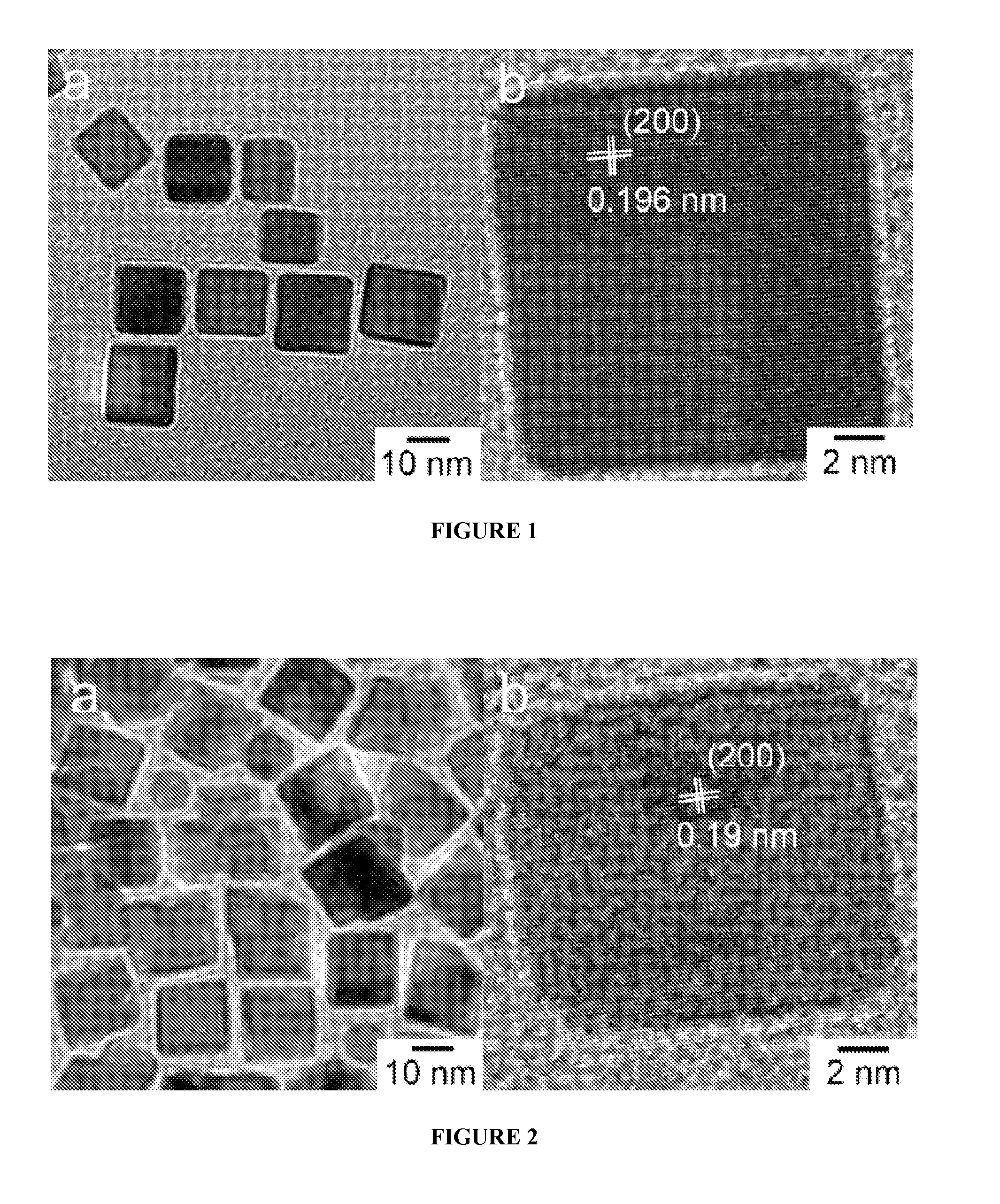

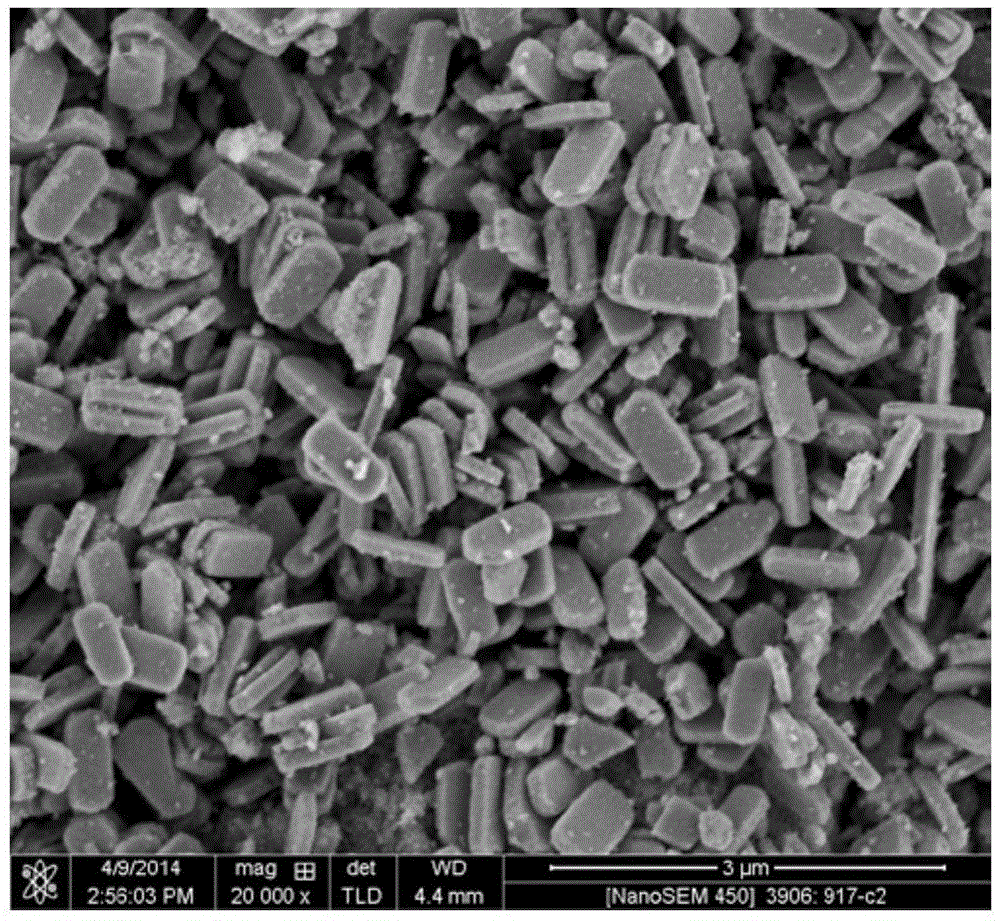

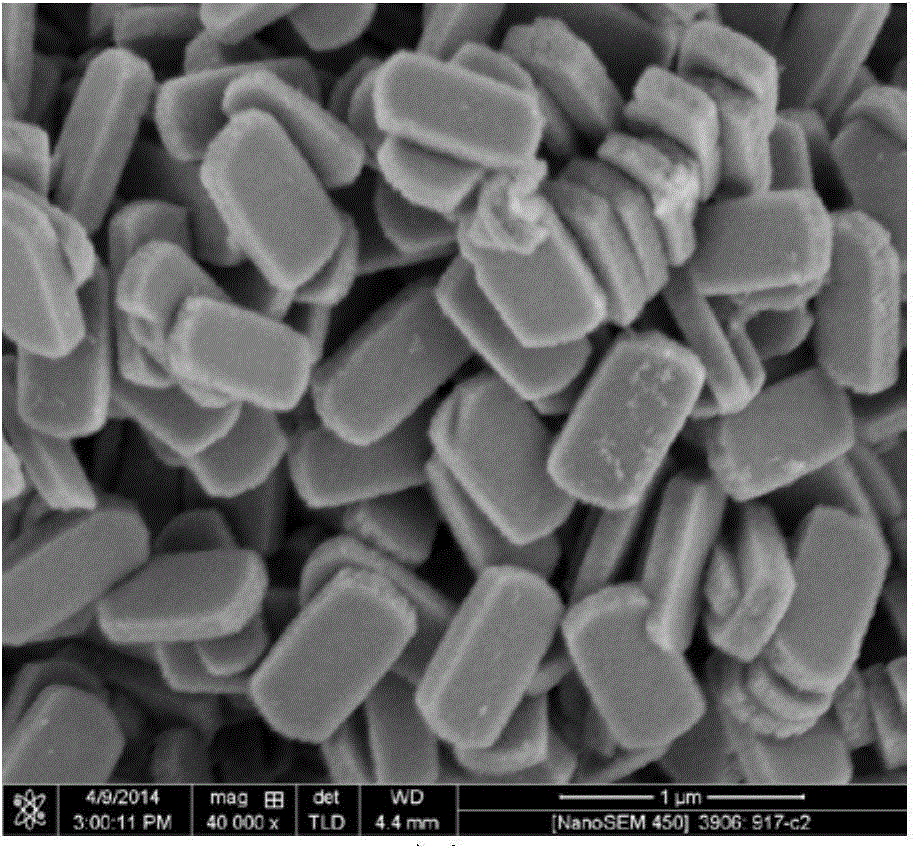

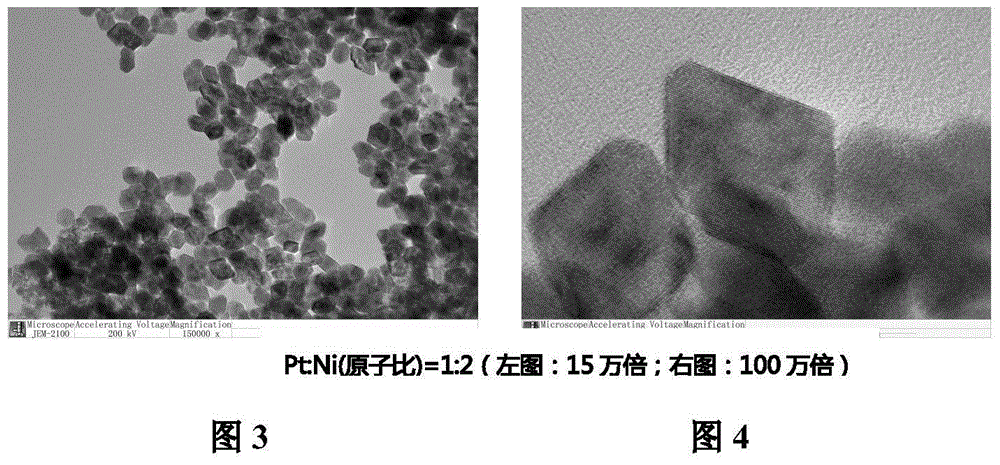

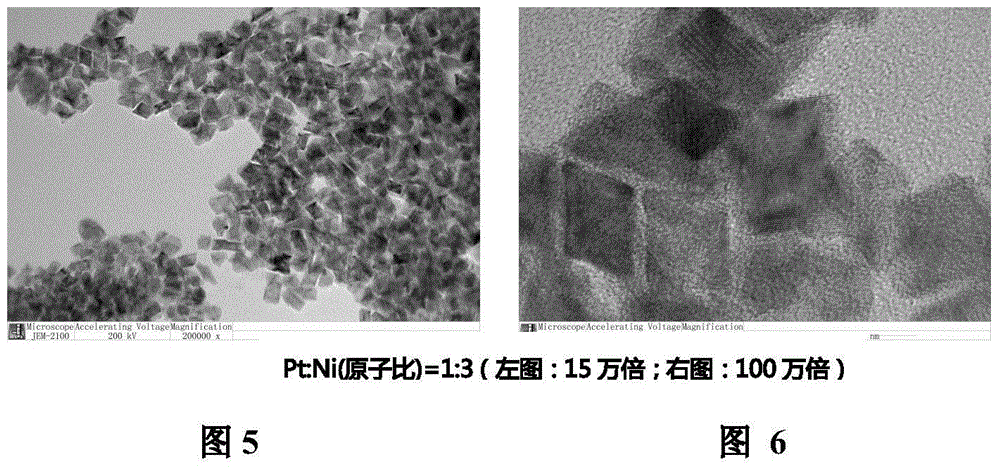

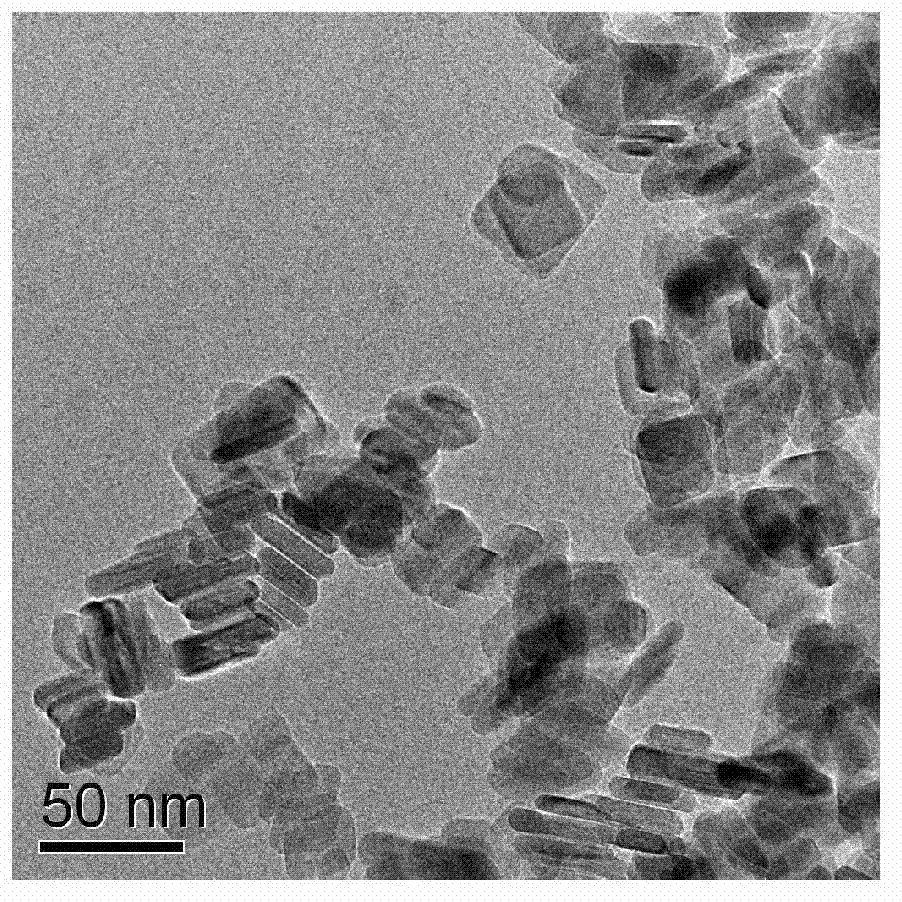

Method for preparing proton-exchange membrane fuel cell oxygen reduction catalyst based on PtNi (111) octahedral single crystal nanoparticles

InactiveCN104998658AHigh catalytic activity for oxygen reductionPt content decreasedCell electrodesMetal/metal-oxides/metal-hydroxide catalystsN dimethylformamideSingle crystal

Owner:昆明贵研催化剂有限责任公司

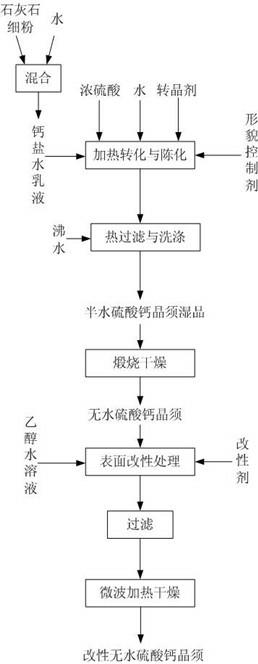

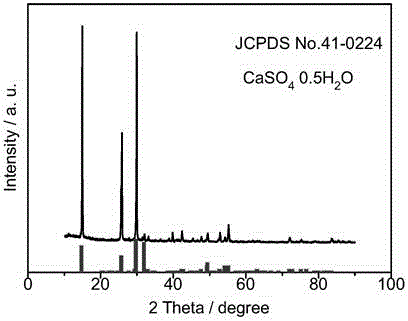

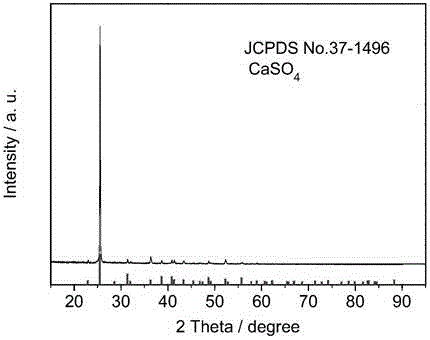

Production method of high-reinforcement modified anhydrous calcium sulfate crystal whiskers

InactiveCN102534773ASimple processThorough responsePolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateCalcium EDTA

The invention discloses a preparation method of high-reinforcement modified anhydrous calcium sulfate crystal whiskers. The method comprises the following steps that: firstly, limestone powder is added into stirred water to be prepared into calcium salt aqueous emulsion; then, sulfuric acid and crystal modifiers are sequentially added into the stirred water to be prepared into sulfuric acid water solution; next, the calcium salt aqueous emulsion containing 1 mol part of Ca<2+> is added into the sulfuric acid water solution containing 2 mol parts of SO4<2-> with the temperature reaching 100 to 110 DEG C, then, morphology control agents are added, the materials are subjected to stirring and aging for 2 to 3.5 hours under the temperature condition being 110 to 120 DEG C, leaching and washing are carried out, and calcium sulfate hemihydrate crystal whisker wet products are obtained; the calcination drying finally is carried out under the temperature condition higher than 200 DEG C to obtain the anhydrous calcium sulfate crystal whiskers; and then, the surface modification treatment is carried out to finally obtain the high-reinforcement modified anhydrous calcium sulfate crystal whiskers. The preparation method has the advantages that the product quality is high, the cost is low, the preparation process is short, the reaction condition is mild, and in addition, green and environmental-friendly effects can be realized.

Owner:四川万润非金属矿物材料有限公司

High-cleaning silica materials made via product morphology control under high shear conditions

InactiveUS20070224133A1Desirable abrasiveIncrease brightnessCosmetic preparationsSilicaSilica gelSilicon dioxide

Unique abrasive materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial, particularly simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels. Such a result thus accords the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Furthermore, the produced abrasive materials also exhibit very high and desirable brightness properties that permit easy incorporation and utilization within dentifrices for aesthetic purposes. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, particularly under high shear conditions, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

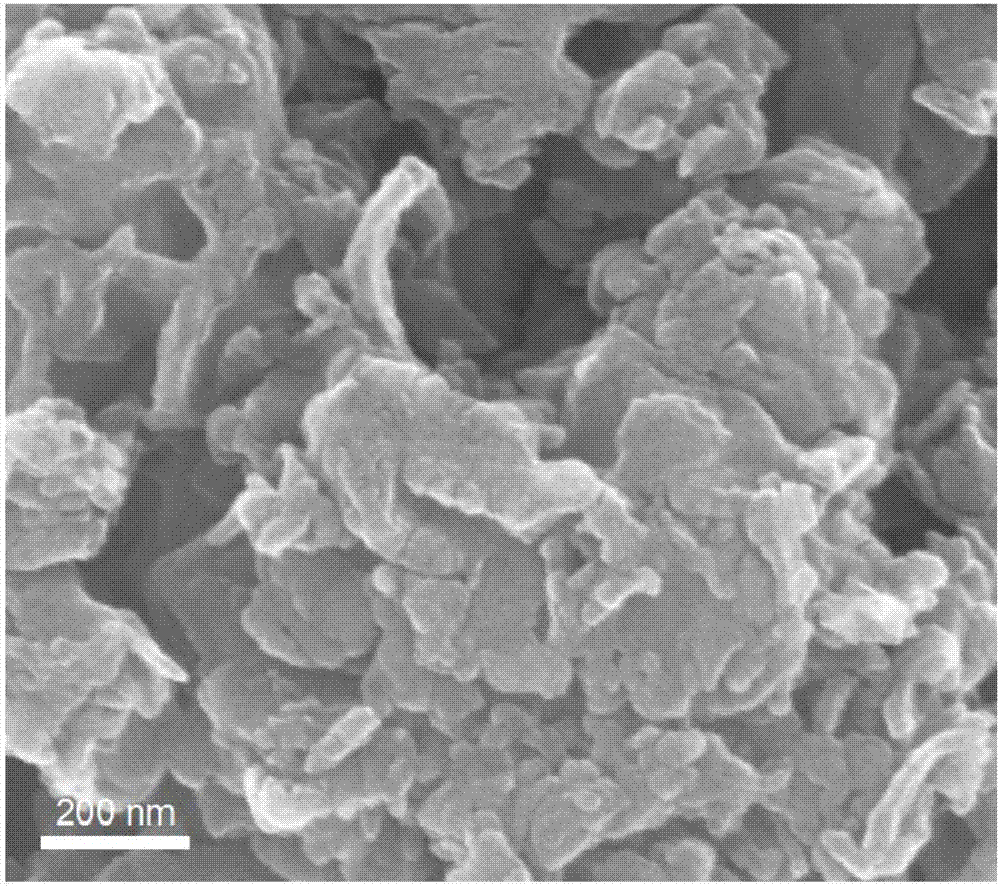

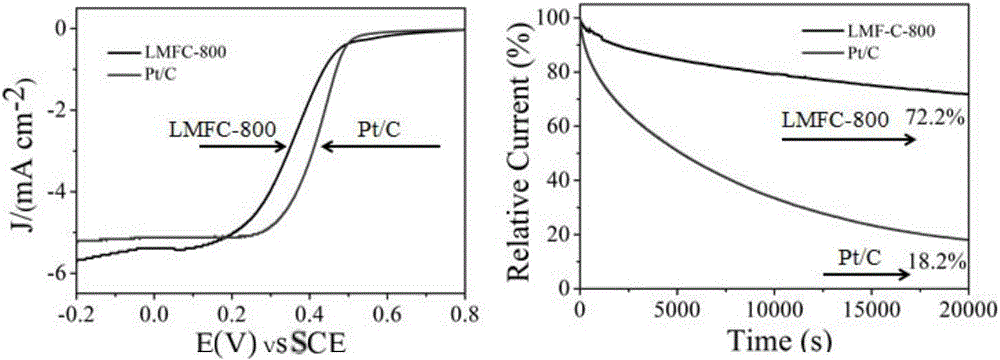

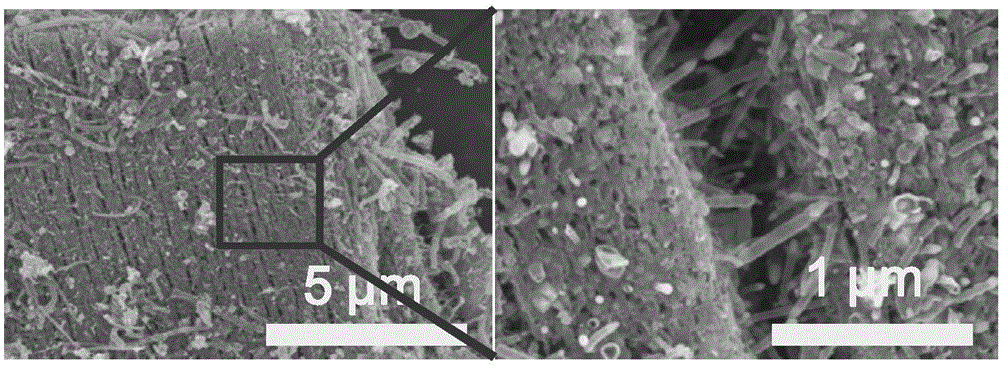

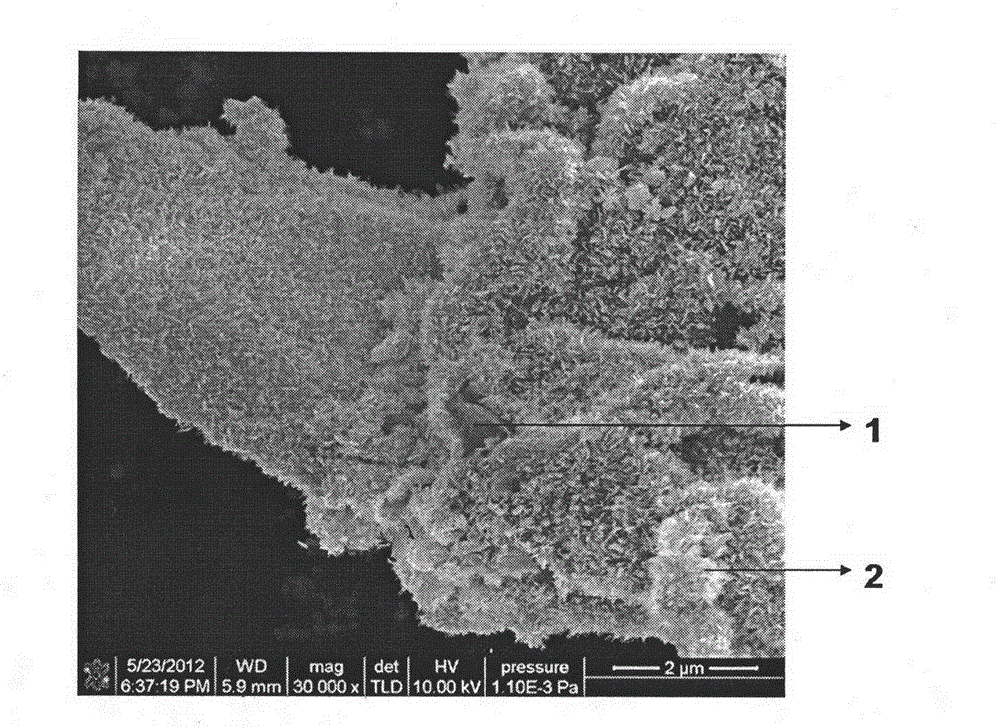

Fe-N-C oxygen reduction catalyst and synthesizing method and application thereof

ActiveCN105921163ASimple activity regulationImprove stabilityPhysical/chemical process catalystsCell electrodesSynthesis methodsFiltration

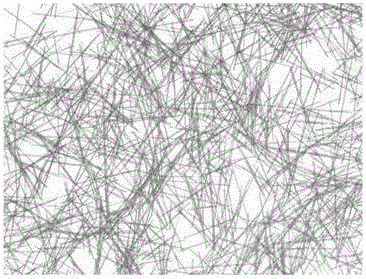

The invention discloses a synthesizing method, a preparation method and application of a Fe-N-C oxygen reduction catalyst. The synthesizing method comprises the following steps that 1, a carbon-nitrogen precursor, a morphology control agent and soluble ferric salt are added into water, heating and stirring are conducted for reacting, suction filtration is conducted after reacting is complete, and drying is conducted to a solid substance; 2, the solid substance obtained in the step 1 is calcined to obtain a catalyst precursor; 3, the catalyst precursor obtained in the step 2 is treated with acid to obtain the Fe-N-C oxygen reduction catalyst. According to the Fe-N-C compound synthesized through the method, the microstructure is a novel multi-layer-steamed-bread-similar structure formed in the mode that a large quality of nanotubes are wound into laminates, and then the laminates are mutually stacked; in addition, due to the fact that Fe metal particles with active centers are wrapped in the nanotubes, the obtained Fe-N-C oxygen reduction catalyst has the good stability and activity.

Owner:ZHEJIANG UNIV

Solvothermal method used for preparing LiFePO4

The invention relates to a solvothermal method used for preparing LiFePO4 with adjustable particle size and controllable morphology. The prepared LiFePO4 can be used as an anode material for a high-rate lithium ion battery. The method comprises steps that: a soluble phosphorous source and divalent ferrite are dissolved in deionized water; lithium salt is uniformly mixed with a surfactant, a reducing agent, and the like; the two solutions are mixed, such that amorphous LiFePO4 is obtained; the amorphous LiFePO4 is subject to centrifugation; a morphology controlling agent is added to the amorphous LiFePO4, and the solution is stirred until the solution reaches a uniform, clarified and stable state; the solution is added into a reaction vessel, and is subject to a reaction for a certain amount of time under high temperature and high pressure; the material is subject to centrifugal washing and drying, such that LiFePO4 with adjustable morphology and size is obtained.

Owner:CHINA JILIANG UNIV

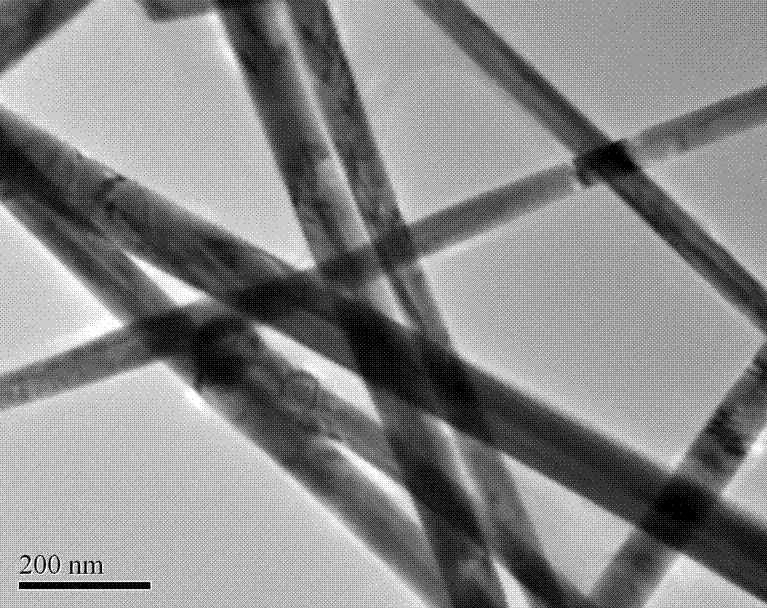

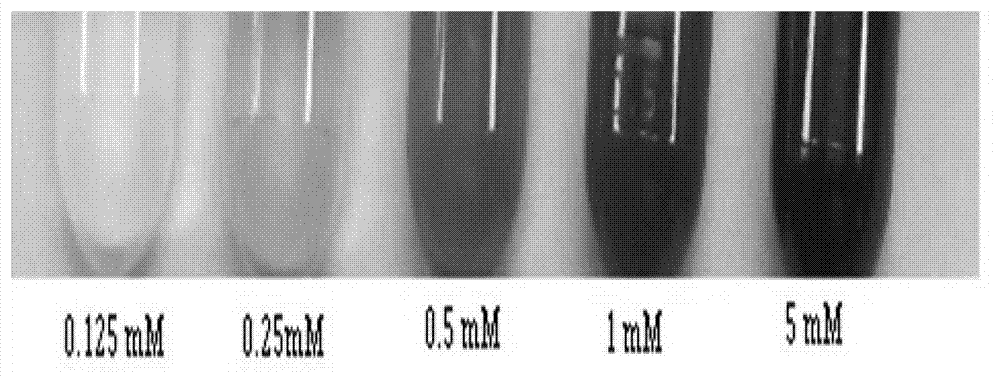

Preparation method for copper nanowire

ActiveCN103084581AEasy to removeVolatilePolycrystalline material growthFrom normal temperature solutionsHydroxylaminePotassium hydroxide

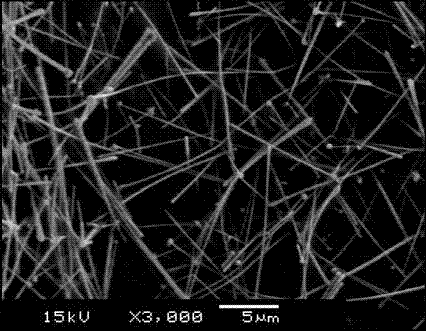

The invention belongs to the technical field of novel function nanometer material preparation, and discloses a preparation method for a copper nanowire. Reducing agent is added to copper source on the premise that morphology control agent and chemical potential control agent are exist in water solution, and the copper nanowire are obtained after separation and under the condition that reaction is carried out for at least one hour in temperature of 25 DEG C to 100 DEG C, wherein the copper source is one or combination of copper hydroxide and copper oxide, the morphology control agent is one kind or combination of more than two kinds of polyethylene polyamine, the chemical potential control agent is one or combination of sodium hydroxide and potassium hydroxide, and the reducing agent is one or combination of hydrazine hydrate and hydroxylamine. The preparation method for the copper nanowire has the advantages of being simple in technology and device, cheap and easy-getting in raw materials, low in cost, high in productivity, suitable for large-scale industrial production, and the like. Prepared copper nanometers are uniform in diameter, diameters and lengths of the copper nanometers can be controlled through changing concentration of the morphology control agent and concentration and reaction temperature of the copper resource.

Owner:HENAN UNIVERSITY

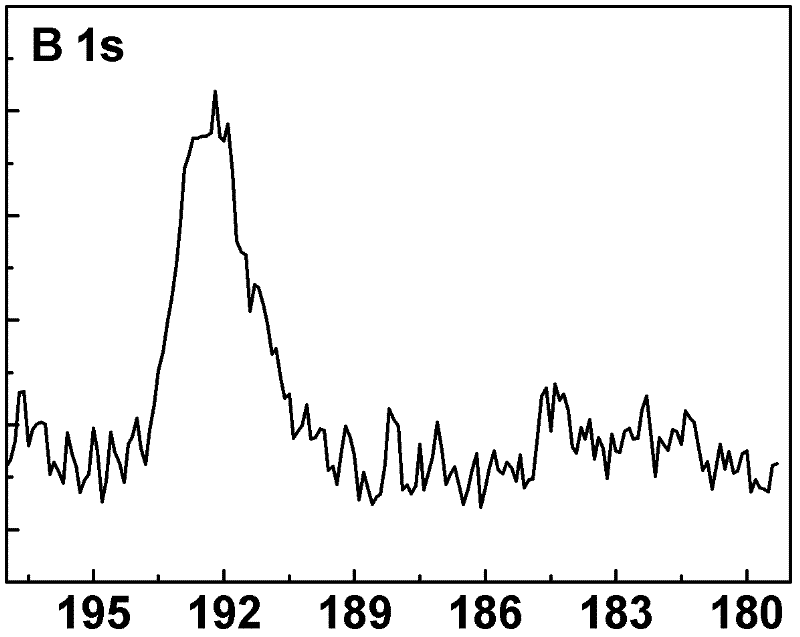

Method for preparing boron-doped titanium dioxide crystal containing specific crystal plane

ActiveCN102343260ASolve the problem of selectivitySolving activityCatalyst activation/preparationCooking & bakingLight Activity

The invention relates to the field of photocatalysis materials, in particular to a method for preparing a boron-doped titanium dioxide crystal containing a specific crystal plane. The method comprises the following steps of: loading titanium boride serving as a precursor into a reaction kettle of an acid solution containing different anions; sealing the reaction kettle; putting the reaction kettle into a baking oven for heating; taking a reaction sample out; washing with deionized water and drying to obtain a boron-doped titanium dioxide crystal containing a specific crystal plane in an acid system containing anions; and further thermally treating the boron-doped titanium dioxide crystal under different atmospheres, adjusting the distribution of boron in the crystal, and introducing a newheteroatom. In the invention, the boron-doped titanium dioxide crystal can be directly prepared by taking the titanium boride as the precursor and taking the anions as a morphology control agent, andthe surface of the boron-doped titanium dioxide crystal consists of an identifiable crystal plane, so that effective adjustment and control of the electronic structure of the photocatalysis material are effectively realized, and the defects of poor reaction selectivity and unavailable invisible light activity of the photocatalysis material are overcome.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

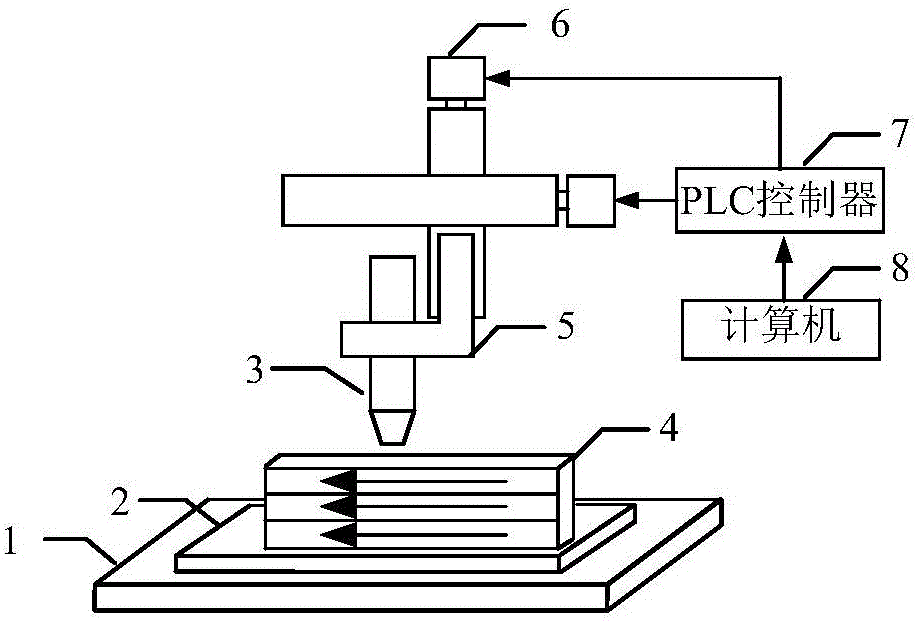

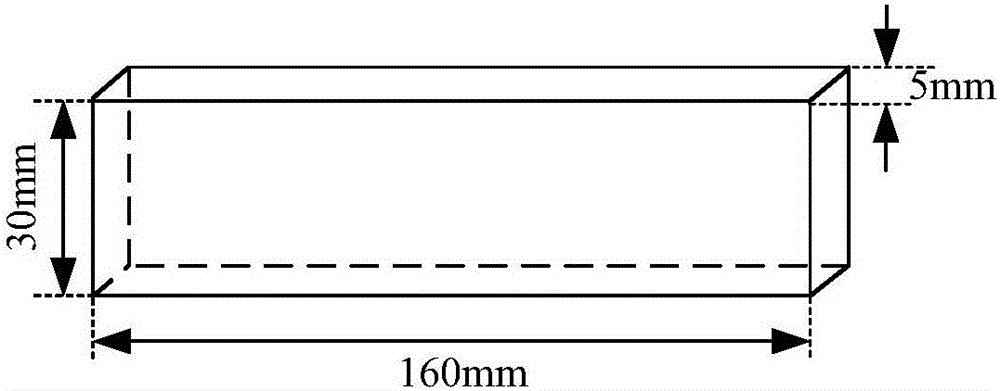

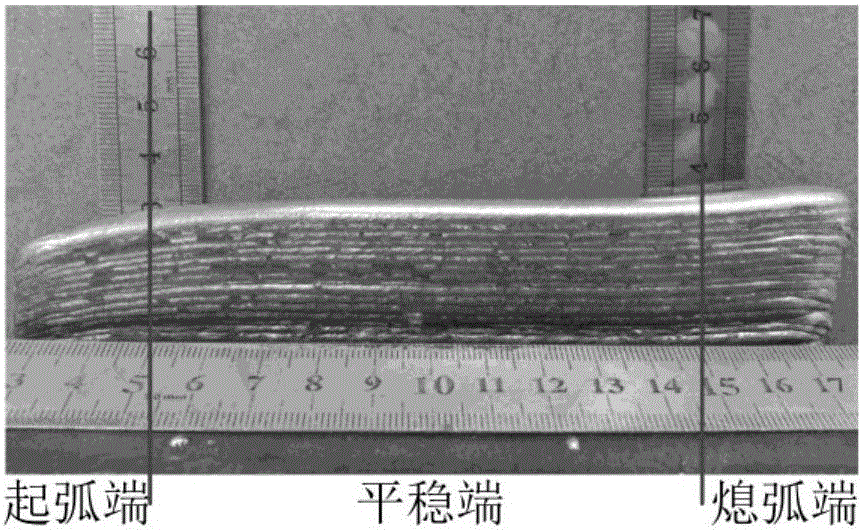

Same-direction forming mode based forming morphology control method for GMAW material increase manufacturing

InactiveCN105880808AHigh forming dimension accuracySuppression of height size differencesArc welding apparatusSize differenceQuality control

The invention provides a same-direction forming mode based forming morphology control method for GMAW material increase manufacturing. The control method includes the steps that arc starting and quenching movement I / O control and given electric signal D / A control of forming current and voltage are completed in the GMAW material increase manufacturing process, and when the forming process is close to the arc quenching end, the forming current, forming speed and forming voltage are gradually decreased within the length range of the arc quenching end; a GMAW welding gun is increased for one layer height and is controlled to return to the forming arc starting end; the upper surface temperature of a formed part is reduced to be 20-300 DEG C; forming of a residual layer is completed till the forming size of the whole structural part meets the requirements. The same-direction forming mode based forming morphology control method can effectively inhibit the height size difference produced by the part end in the same-direction forming process, decreases the defects produced in the forming process, ensures that higher forming size precision is obtained in GMAW material increase manufacturing in the same-direction forming mode and provides a reliable technical support for forming quality control of GMAW material increase manufacturing.

Owner:SOUTHWEST JIAOTONG UNIV

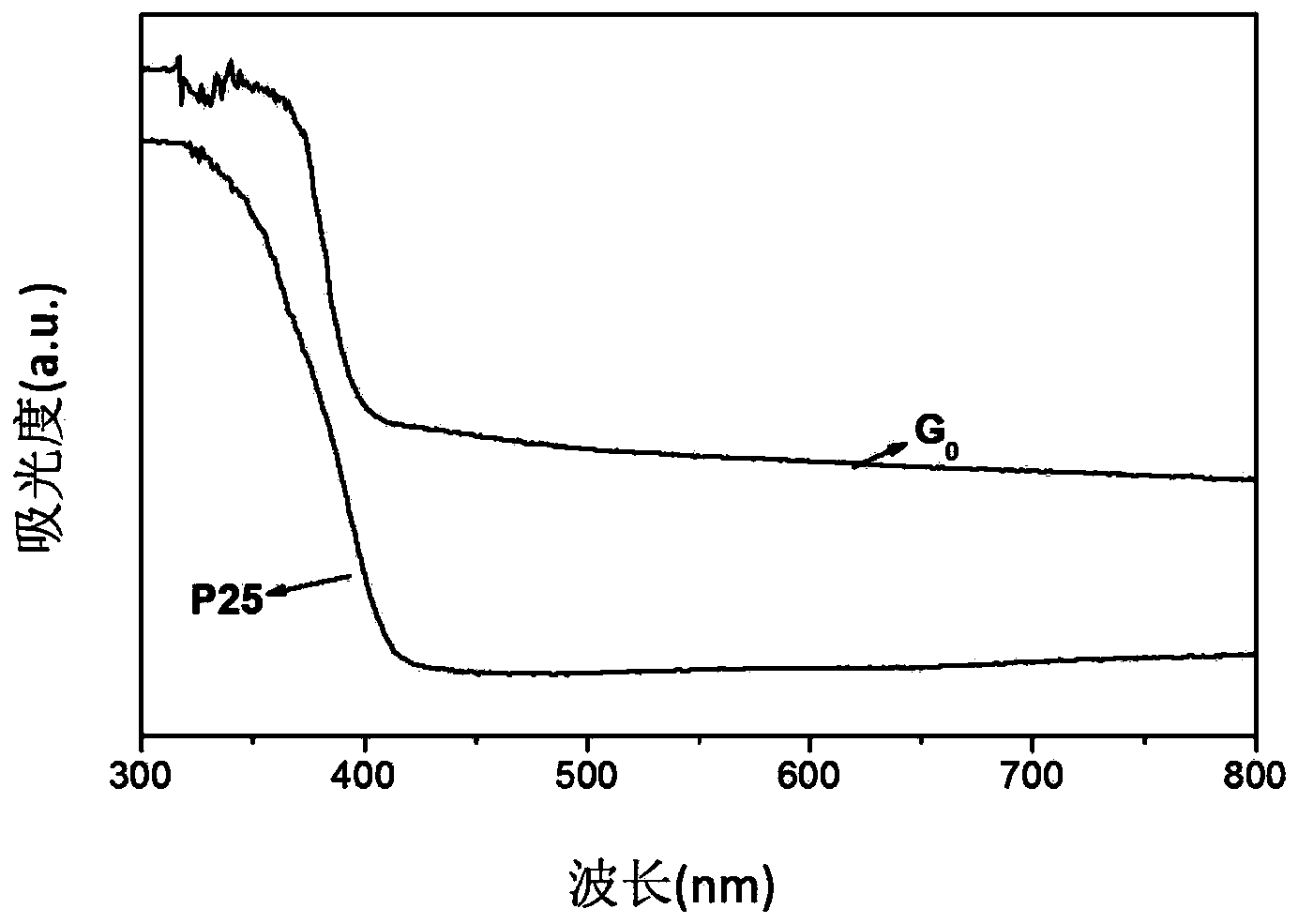

Preparation method for blue sheet-like titanium dioxide nanomaterial

InactiveCN102895964AEasy to operateImprove photocatalytic degradation performancePhysical/chemical process catalystsTitanium dioxideSewage treatmentSolvent

The invention relates to a preparation method for a blue sheet-like titanium dioxide nanomaterial. The preparation method comprises the following specific steps of: dispersing a titanium source in a solvent; then, adding a morphology control agent; stirring to obtain transparent solution; then, transferring the transparent solution into a reaction kettle for reaction; naturally cooling; washing; centrifuging; and drying to finally obtain the blue sheet-like titanium dioxide nanomaterial. The grain size of the material is 10-30nm; the crystal form of the material is an anatase form; and 400-700nm visible light can be absorbed. The blue sheet-like titanium dioxide nanomaterial prepared by the preparation method has the characteristics that the raw material is broad in source; the preparation method is simple; and the material is controllable in color and adjustable in morphology. One more breakthrough that the titanium dioxide nanomaterial is colored from white is realized. The blue sheet-like titanium dioxide nanomaterial is expected to be applied to the sewage treatment industry.

Owner:NANJING UNIV OF TECH

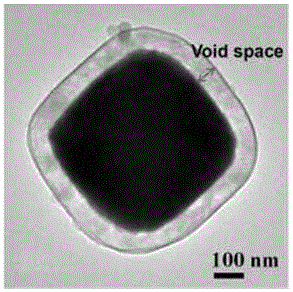

Preparation method of yolk-eggshell structured nitrogen-doped carbon-coated Fe3O4@SnO2 magnetic nanometer box

The invention discloses a preparation method of a yolk-eggshell structured nitrogen-doped carbon-coated Fe3O4@SnO2 magnetic nanometer box, and belongs to the technical field of production of a nanometer material. The preparation method comprises the following steps of firstly, wrapping the surface of a Fe2O3 nanometer cube with a layer of silicon dioxide; secondly, forming a yolk-eggshell structured Fe2O3@SnO2 nanometer box under the effect of potassium stannate trihydrate and urea; and finally, coating dopamine, introducing a carbon source and a nitrogen source, carrying out calcination in an inertia atmosphere to form a conductive carbon layer, and simultaneously converting Fe2O3 to Fe3O4. The instrument equipment adopted by the invention is simple, the preparation cost is low, the operation process is simple and convenient, the required material during the reaction process is low toxic and is not harmful, the stoichiometric ratio of a multi-constituent material can be effectively controlled, and the high-quality yolk-eggshell structured magnetic nanometer material which is uniform in size, uniform in distribution and favorable in morphology control and can be used for industrial production at a large scale is obtained.

Owner:YANGZHOU UNIV

Method for preparing carbon-material-carrying tin dioxide nanosheet composite material

InactiveCN102718250AChange the combinationSolve the uniform dispersionMaterial nanotechnologyGraphiteTin dioxideNew energy

The invention relates to a method for preparing a carbon-material-carrying tin dioxide nanosheet composite material, belonging to the technical field of functional composite materials. According to the method, a carbon material, tin dichloride dihydrate and sodium citrate dihydrate are taken as raw materials and are subjected to mixing, stirring, hydrothermal synthesis, solid-liquid separation, cleaning and drying, and then, the morphology-controlled carbon-material-carrying tin dioxide nanosheet composite material is prepared. The method provided by the invention is simple and is convenient in operation; and water is taken as a solvent, so that the production cost is lower, the environment is not polluted, and the popularization and the application are facilitated. The carbon-material-carrying tin dioxide nanosheet composite material prepared by adopting the method provided by the invention can be widely applied to new-energy devices such as lithium ion batteries, solar batteries and supercapacitors, and can also be applicable to the fields of catalyst carriers, information materials and the like.

Owner:CHONGQING UNIV

High-nickel lithium ion positive electrode material and preparation method thereof

InactiveCN110034297AReduce the mixing degree of lithium and nickelHigh discharge specific capacitySecondary cellsPositive electrodesLithiumCrystal structure

The invention discloses a high-nickel lithium ion positive electrode material. The molecular formula is LiNi<x>Co<y>Mn<1-x-y-z>M<z>O2, wherein M is a doping element, the lithium ion positive electrodematerial is spherical secondary particle formed by gathering primary particle, and the structure of the lithium ion positive electrode material is a homogeneous-phase structure, a core-shell structure and a concentration gradient structure. The preparation method of the lithium ion positive electrode material comprises the steps of preparing a high-nickel positive electrode material precursor andpreparing the lithium ion secondary battery positive electrode. The precursor of the high-nickel positive electrode material is synthesized by a co-precipitation method, uniform mixing of elements can be facilitated, reaction can be more sufficient by adding the aging process, and morphology control is facilitated; and with the adoption of multi-element co-doping, the stability of a material crystal structure can be improved, the content of a Mn element is reduced, other doping elements are introduced, the lithium and nickel mixed arrangement degree of the high-nickel positive electrode material can be reduced, the orderliness of a layered material is ensured, the structure of the material is stabilized, the discharging specific capacity is improved, so that the energy density of the battery is improved.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

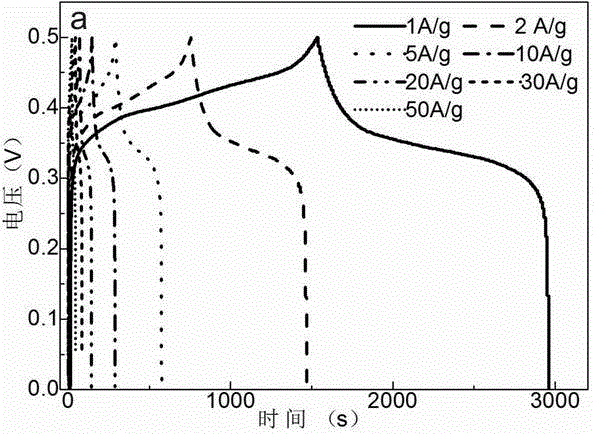

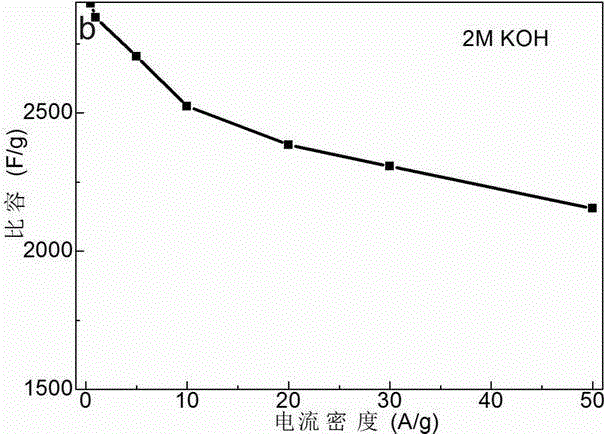

Preparation method of cobalt nickel sulfide/foam nickel super capacitor electrode

InactiveCN106158419AIncrease specific volumeExcellent rate performanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceThiourea

Owner:HENAN NORMAL UNIV

Method for preparing transition metal oxide microspheres with controllable morphology

ActiveCN104743609ASimple stepsExperimental conditions are easy to controlMaterial nanotechnologyManganese oxides/hydroxidesMicrosphereControllability

The invention discloses a method for preparing transition metal oxide microspheres with controllable morphology. According to the method for preparing the transition metal oxide microspheres, the transition metal oxide microspheres are produced according to the steps of introducing catechol compounds into a reaction system and then performing simple hydrothermal reaction, and preferably, a morphology control agent can also be added in the hydrothermal reaction system to control the morphology of the transition metal oxide microspheres. According to the method for preparing the transition metal oxide microspheres with controllable morphology disclosed by the invention, the transition metal oxide microspheres with controllable morphology are produced by adding a special morphology control agent into the hydrothermal reaction system to control the anisotropic growth of the material, not only the technology is simple, the controllability is good and the yield is high, but also the product produced according to the method has uniform size, larger specific surface area and high reaction activity and is suitable for large-scale preparation.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

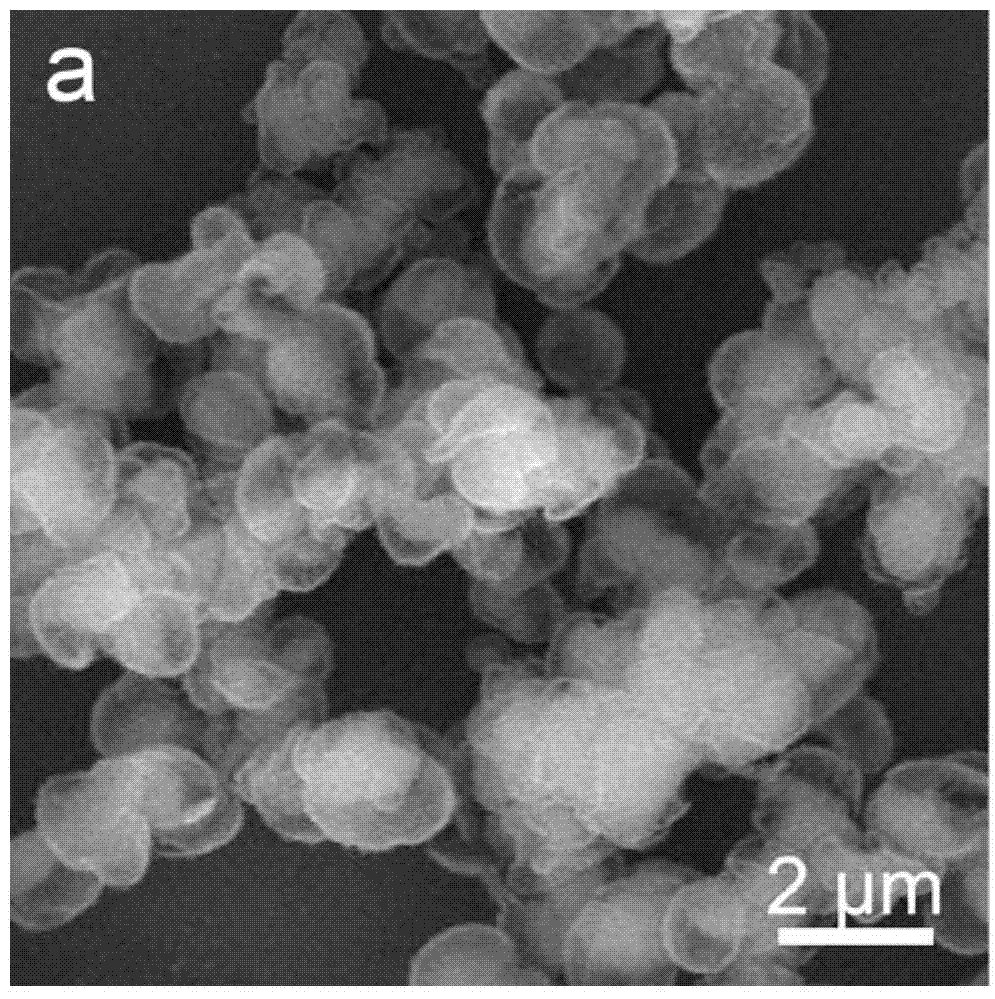

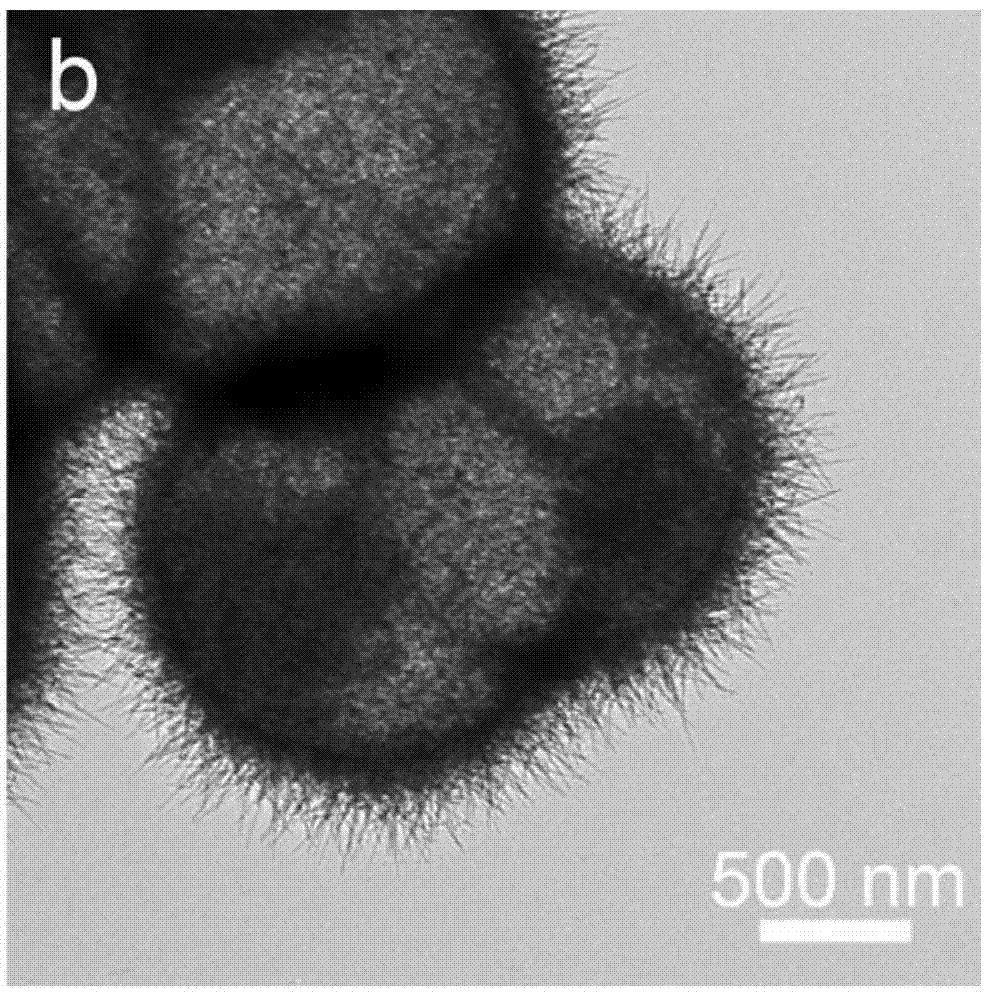

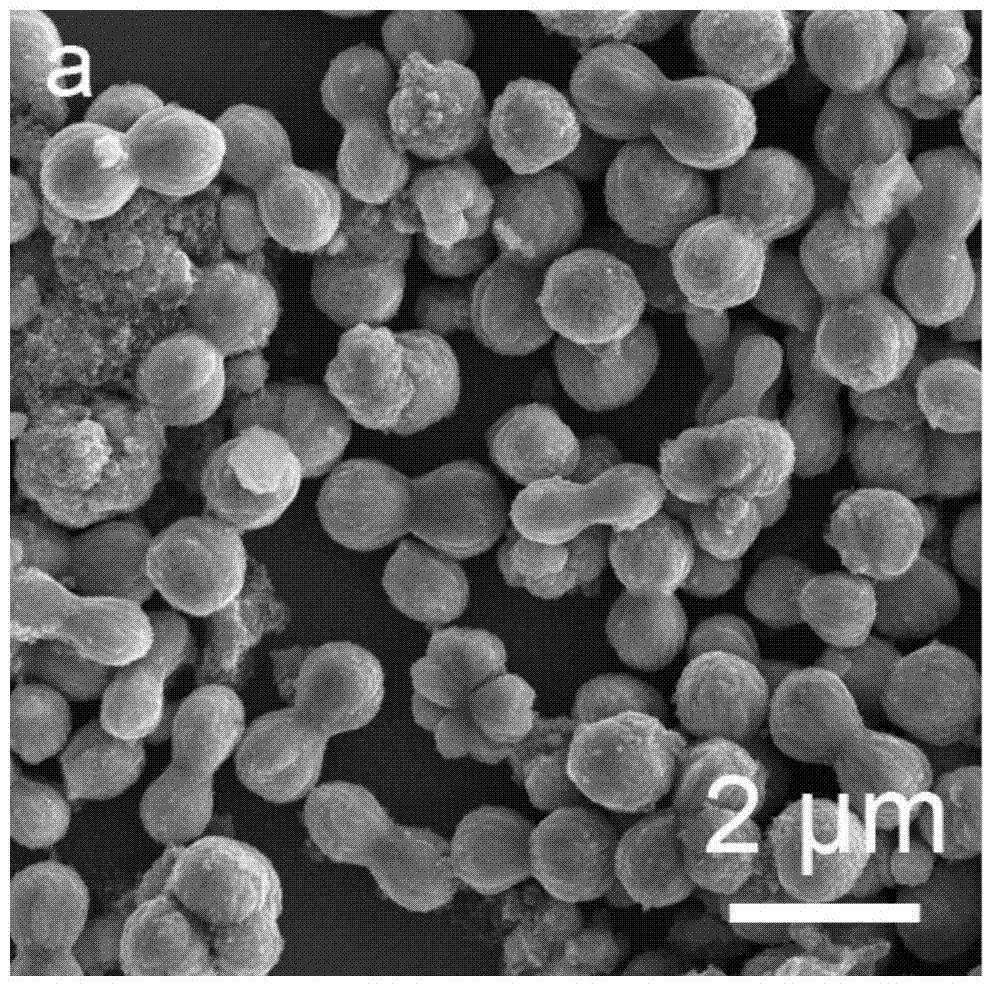

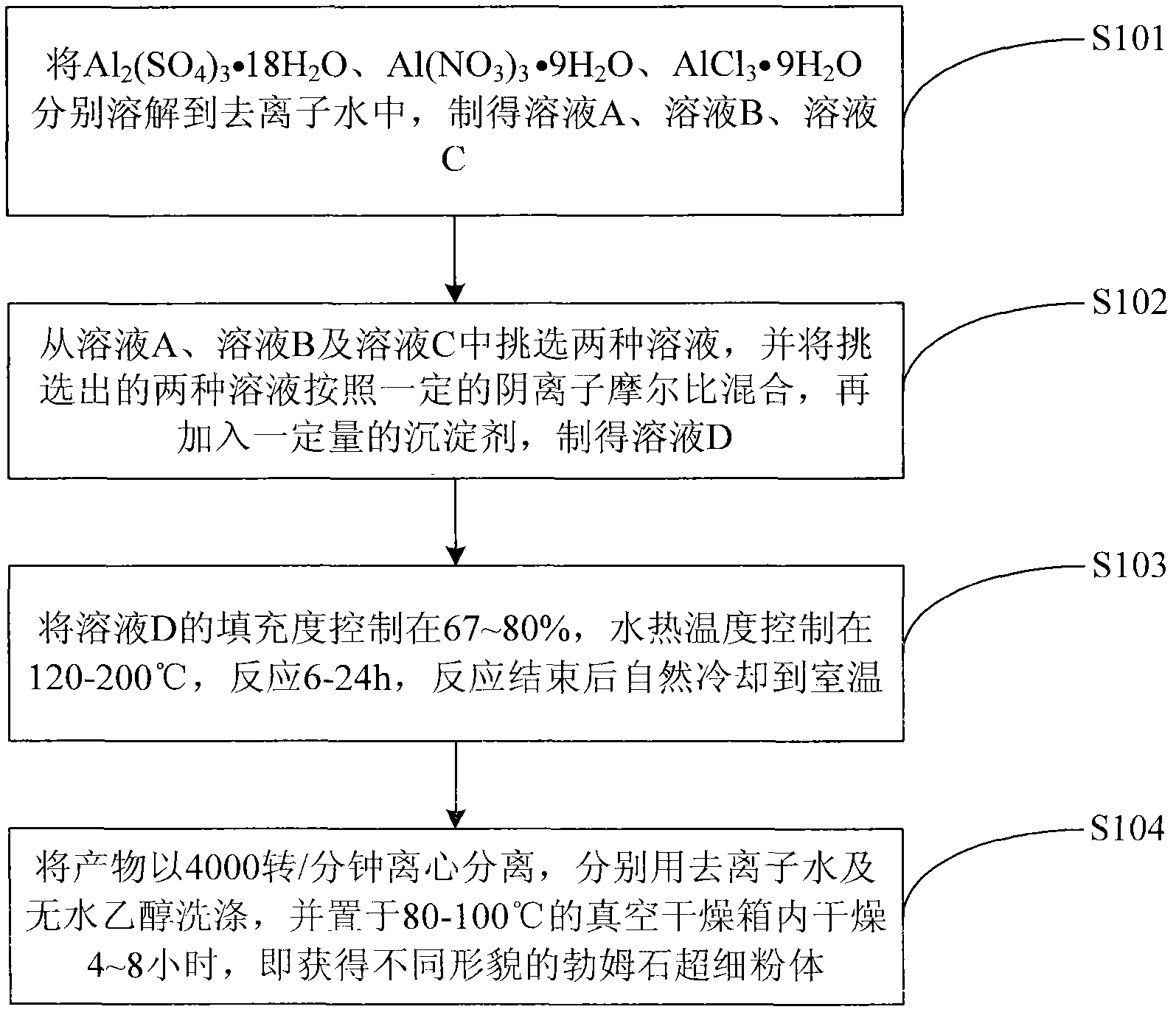

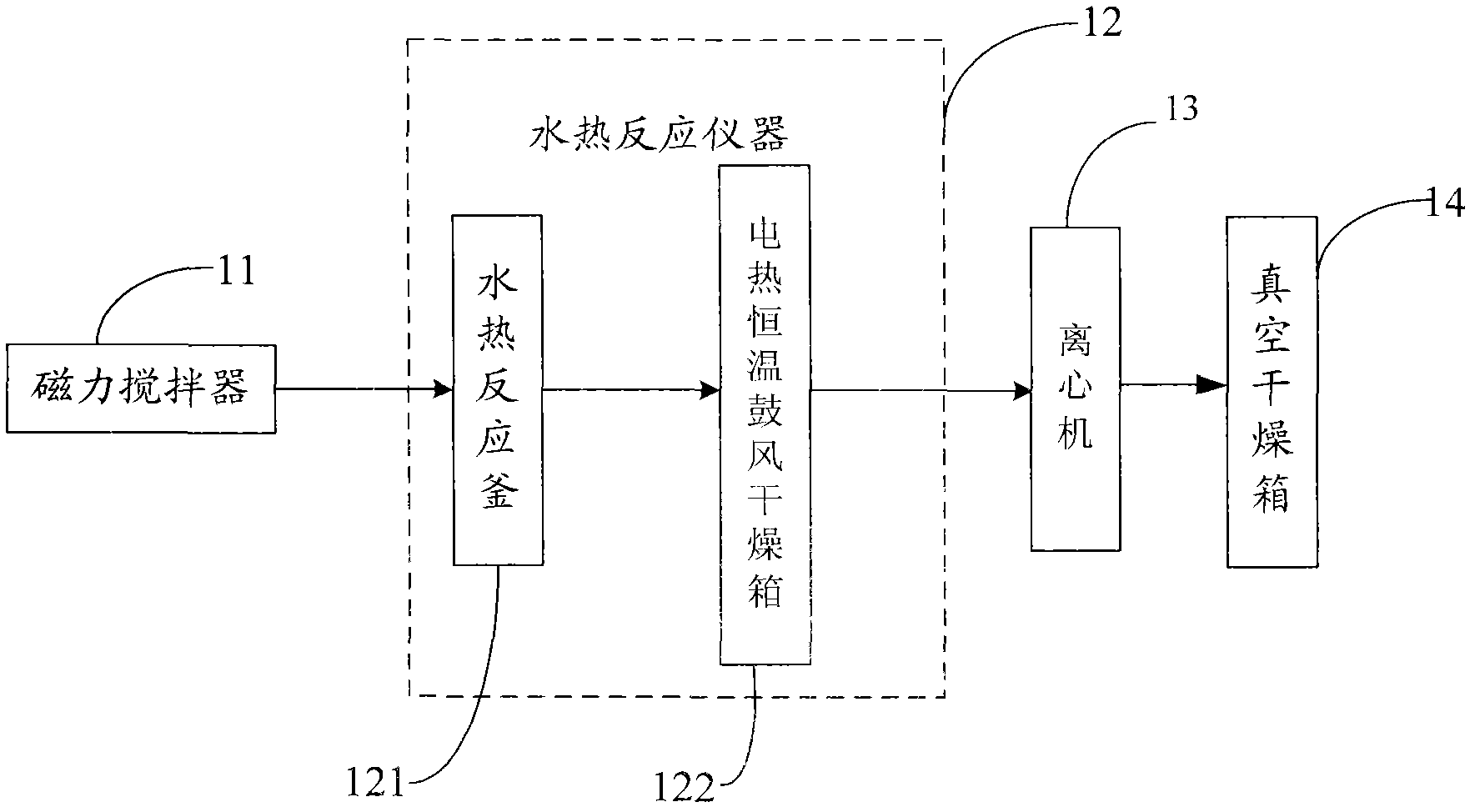

Method and device for controlling morphology of boehmite

ActiveCN102701244AIntergranular porosityRich shape typeAluminium oxides/hydroxidesVacuum dryingMorphology control

The invention belongs to the technical field of chemical production, and provides a method and a device for controlling the morphology of boehmite. The method comprises the following steps of: respectively dissolving two analytically pure aluminum salts in deionized water to prepare solutions; adding the two aluminum salt solutions into a hydrothermal reaction kettle according to a certain anion mole ratio, adding a certain amount of precipitant and controlling the filling factor of the mixed liquor in the hydrothermal reaction kettle within 67-80%; sealing the hydrothermal reaction kettle, controlling the hydrothermal temperature within 120-200 DEG C and reacting for 4-24h; centrifugally separating sediment products at a revolving speed of 4000rpm; respectively washing the sediment products by using deionized water and absolute ethyl alcohol; and placing in a vacuum drying oven of 80-100 DEG C to dry for 4-8h, so as to obtain boehmite superfine powder with different morphologies. The preparation of the boehmite superfine powder is finished in liquid phase at once, the raw materials are inexpensive and easy to get, no additive is needed, the morphology control method is simpler and more convenient, the after-treatment process is simple, and the product dispersion is even and the morphology change is rich.

Owner:TAISHAN MEDICAL UNIV

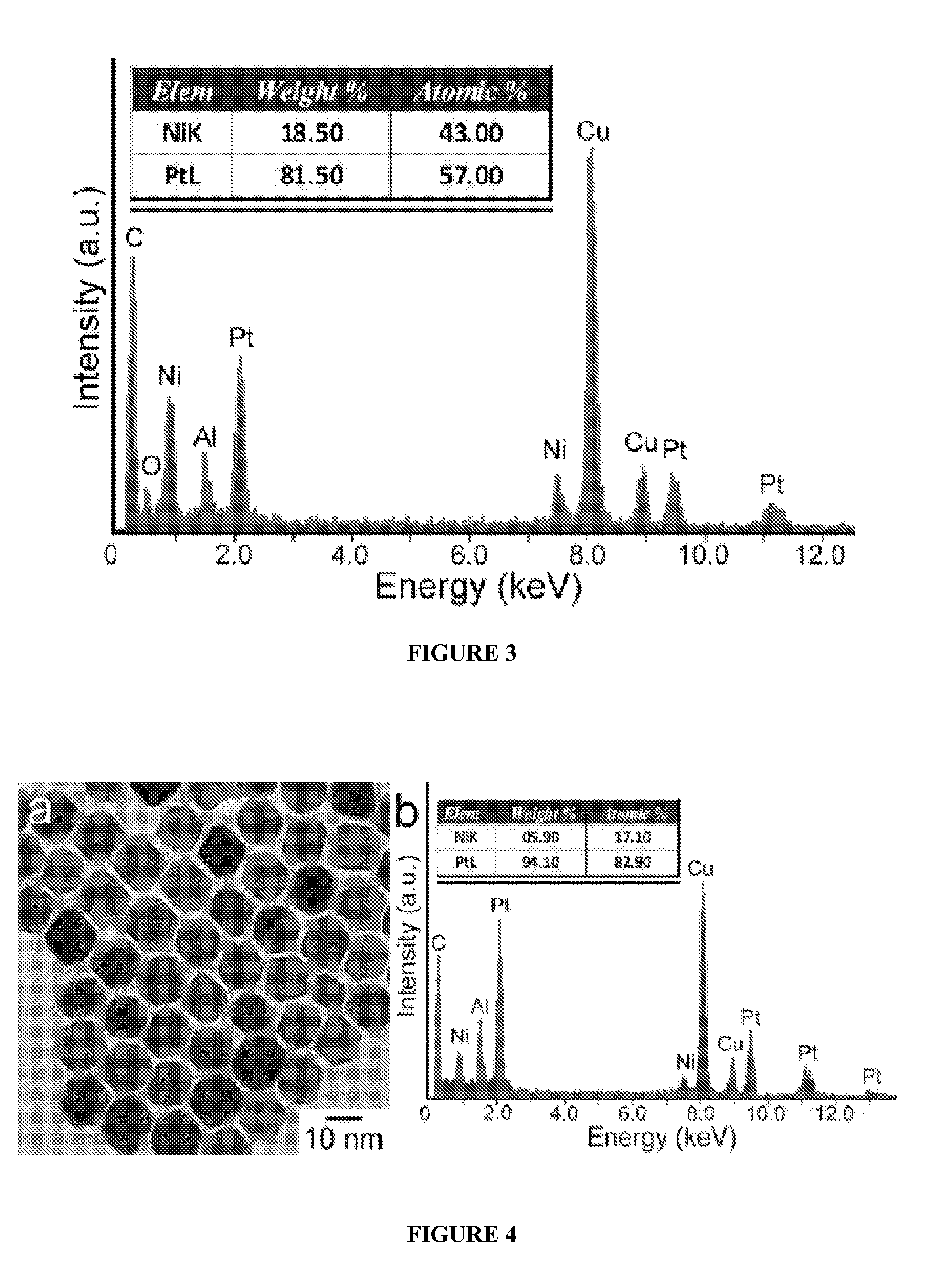

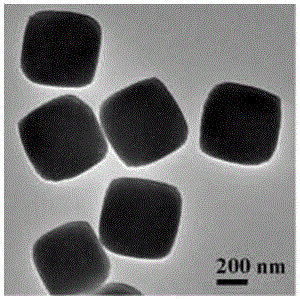

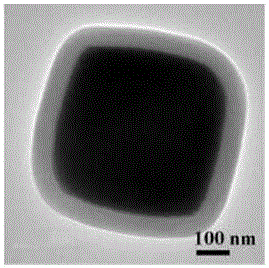

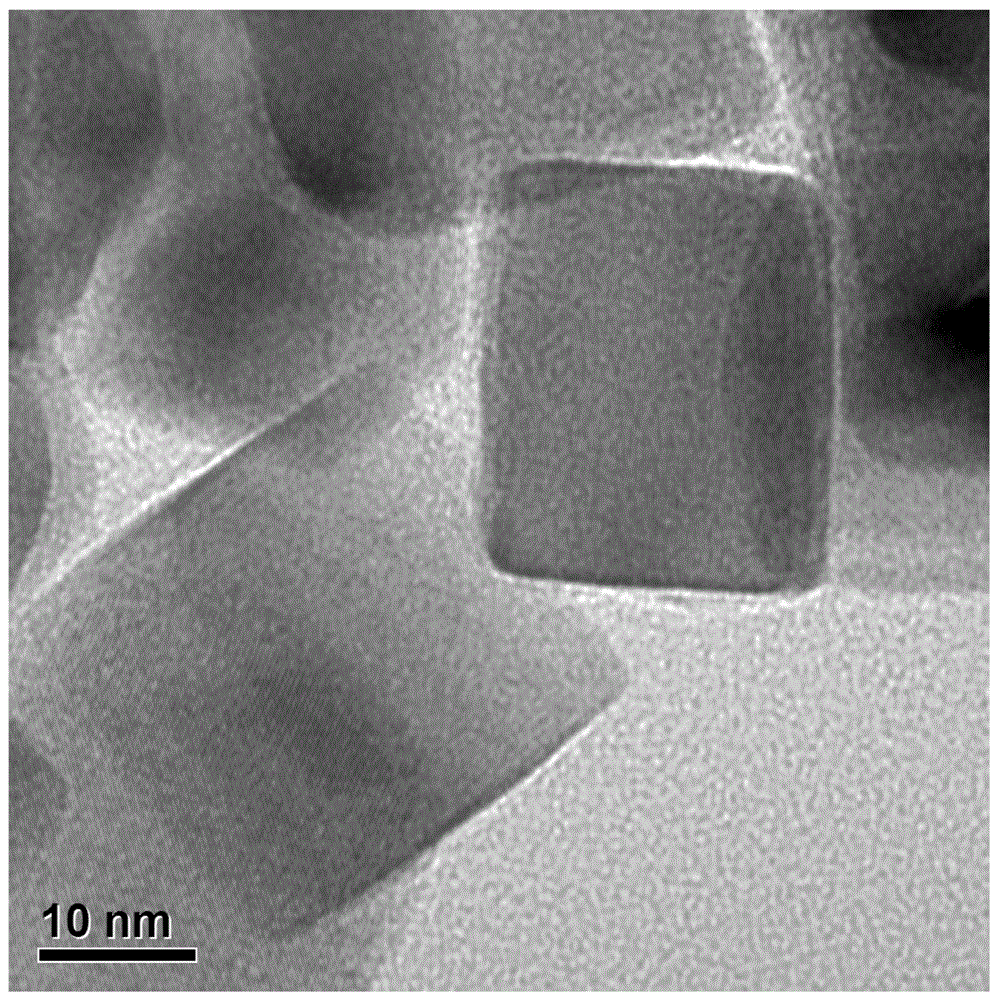

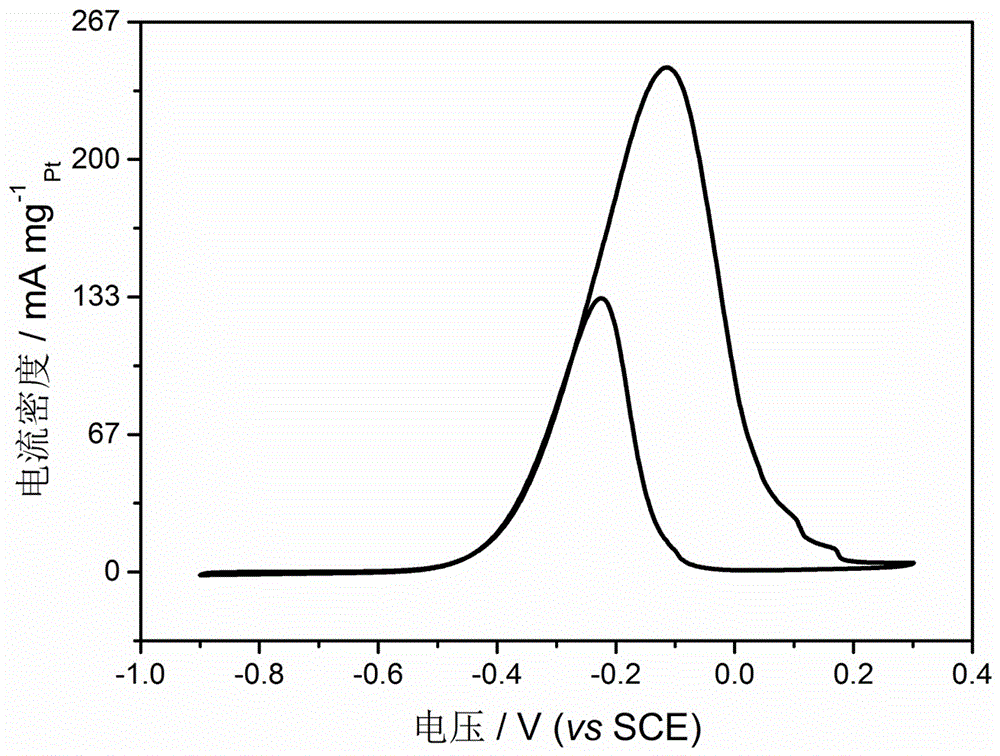

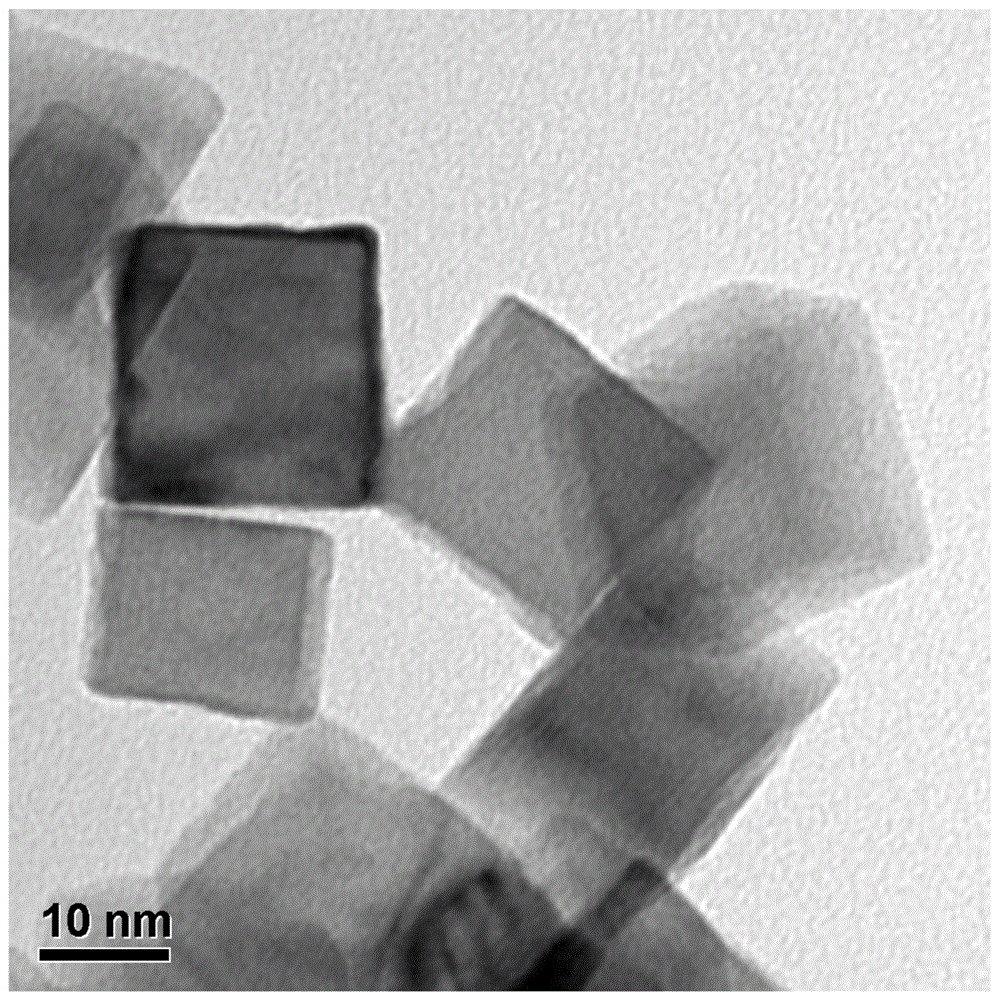

PtCu electric catalyst for fuel battery, preparation method and application thereof

ActiveCN106058274AUnique regular cube shapeExcellent performance in electrocatalytic oxidation of methanolCell electrodesSynthesis methodsPotassium iodine

The invention relates to a PtCu electric catalyst for a fuel battery and a preparation method thereof. The method adopts the one-step hydro-thermal synthesis technology, the synthesis method comprises the following steps: dissolving triblock copolymer P123 in the secondary distilled water; adding chloroplatinic acid hexahydrate, cupric chloride and potassium iodide in a P123 solution, stirring, ultrasonically dissolving; transferring the mixed solution to a liner of a polytetrafluoroethylene reaction kettle in 50mL, tightly sealing the reaction kettle, and placing the reaction kettle in a blast drying oven, reacting for 6-12 hours at 120-200 DEG C; naturally cooling to room temperature, centrifuging, washing for three to five times to obtain the PtCu electric catalyst for the fuel battery. The triblock copolymer P123 is simultaneously used as the protection agent and the reducing agent, the potassium iodide is used as the morphology control agent, the obtained PtCu electric catalyst is good in dispersibility, has a regular cubic appearance, and excellent performance of electrically catalyzing and oxidizing methanol, and is a fuel battery catalyst which has excellent development prospects.

Owner:CHINA THREE GORGES UNIV

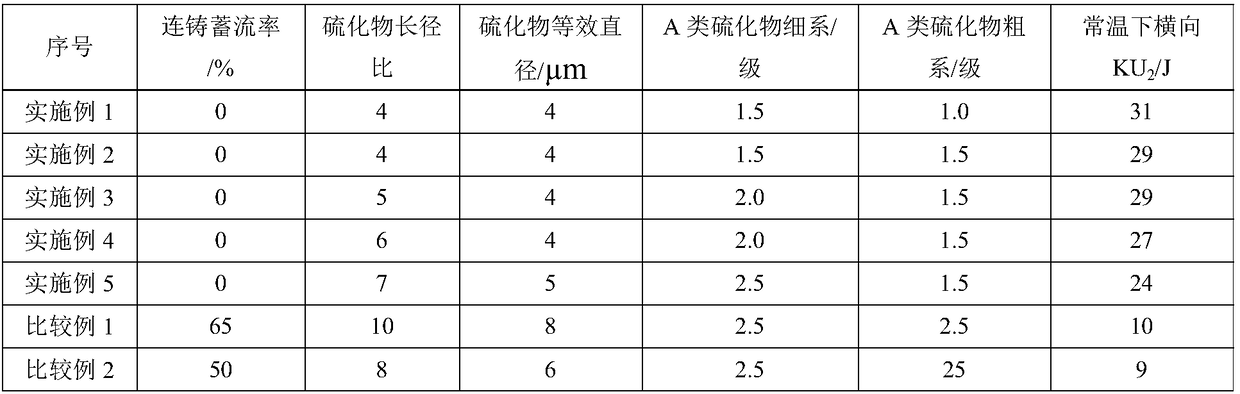

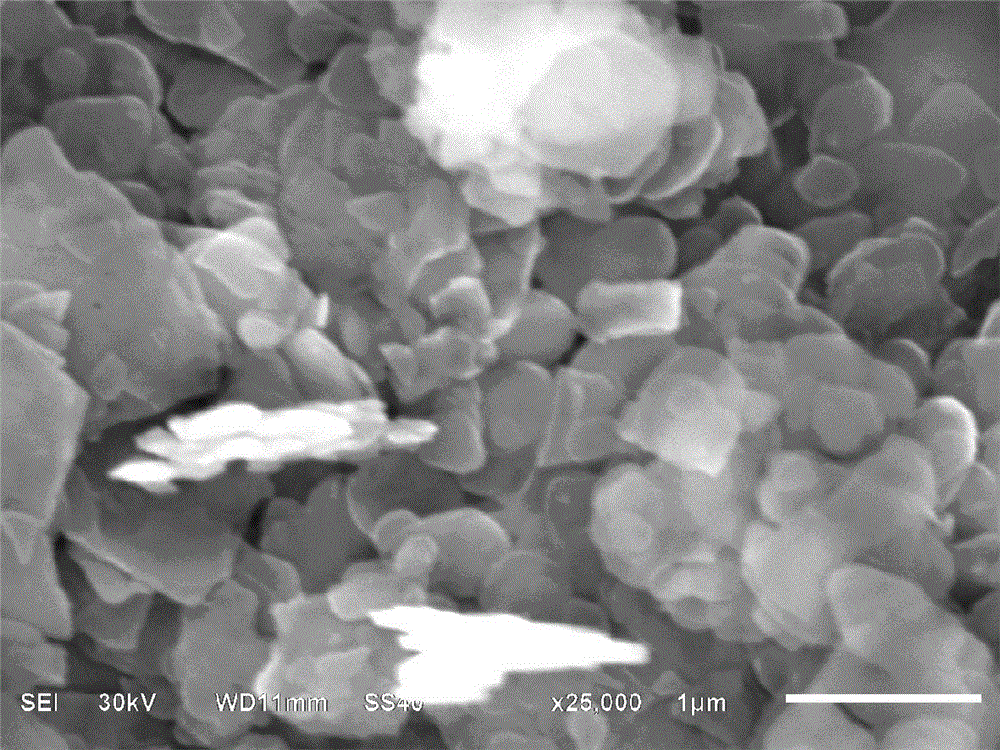

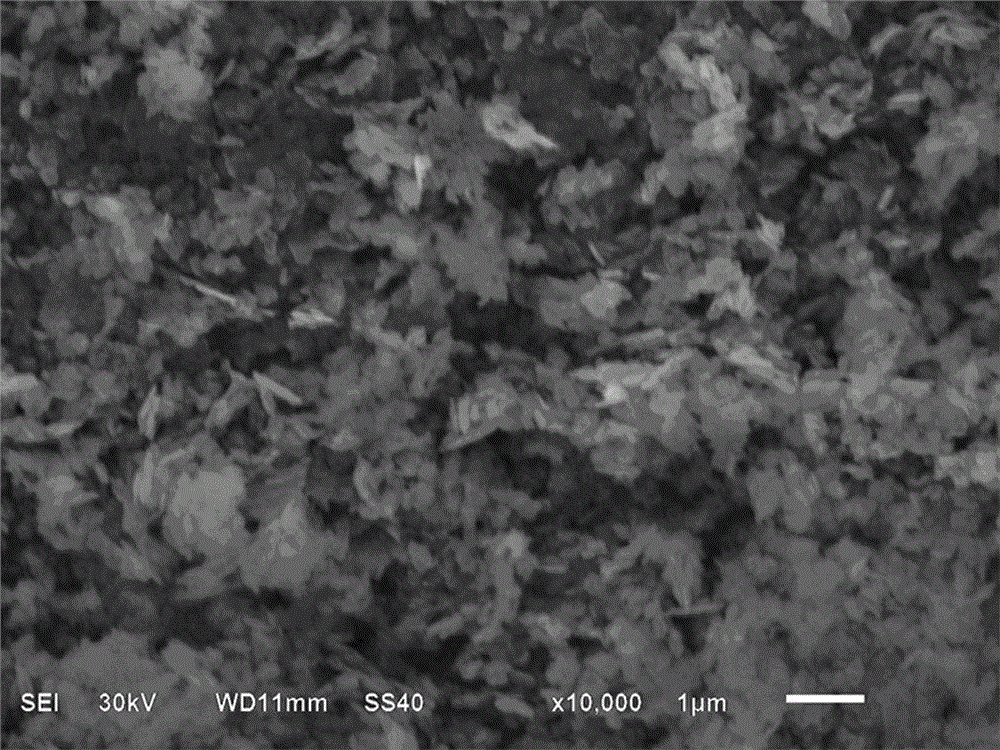

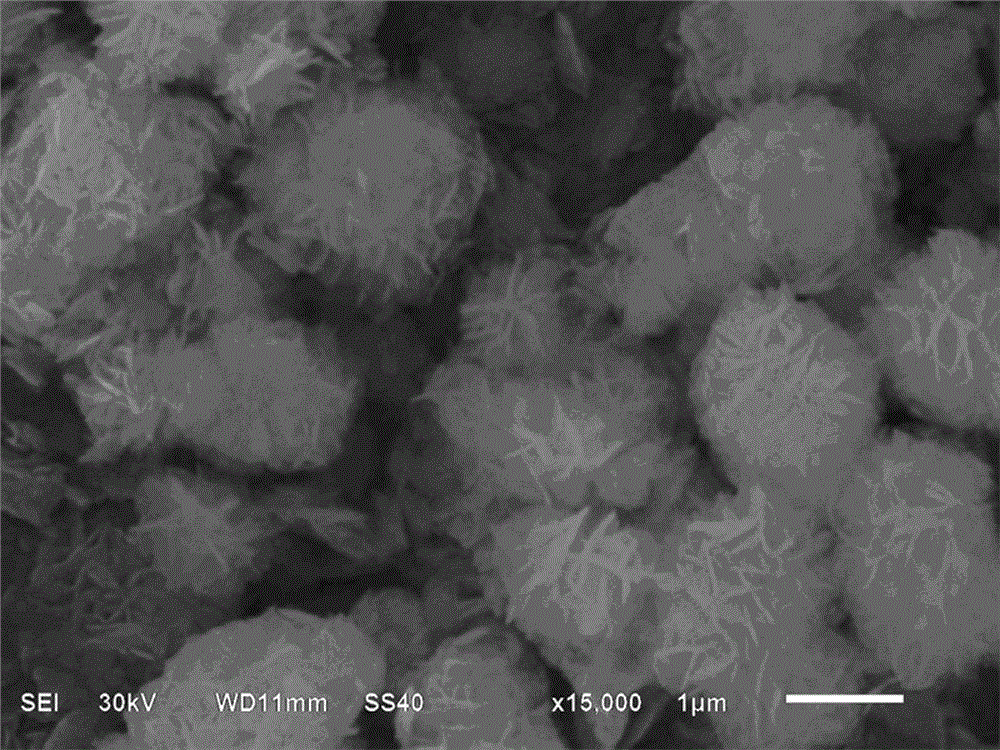

Killed non-tempered steel containing sulfur and aluminum and morphology control method of sulfides thereof

The invention provides a killed non-tempered steel containing sulfur and aluminum and a morphology control method of sulfides thereof. The killed non-tempered steel comprises following chemical components in percentage by weight: 0.30 to 0.50% of C, 0.45 to 0.75% of Si, 1.20 to 1.60% of Mn, 0.10 to 0.30% of V, 0.010 to 0.050% of Ti, 0.10 to 0.50% of Cr, 0.020 to 0.080% of S, 0.015 to 0.060% of Al,0.005 to 0.040% of Te, 0.010 to 0.015% of [N], not more than 0.015% of P, not more than 0.0012% of T.O, not more than 0.30% of Ni, not more than 0.15% of Mo, not more than 0.25% of Cu, not more than0.010% of As, not more than 0.010% of Sn, not more than 0.010% of Sb, not more than 0.005% of Pb, and the balance being Fe and inevitable impurities. The production technology comprises steps of carrying out primary steel making in an arc furnace or a converter, performing LF refining, carrying out RH / VD vacuum degassing, and performing continuous casting. The length-diameter ratio of sulfides inthe killed non-tempered steel, which is processed by the morphology control method, is not more than 8, the equivalent diameter is not more than 5 [mu]m, the cleanness of molten steel is high, T.O isnot more than 0.0012%, the grain size of the steel is not less than 7.0 grades, and the clogging rate is 0 in continuous casting.

Owner:MAANSHAN IRON & STEEL CO LTD

Preparation method for BiOCl photocatalyst with controllable morphology and crystal face

InactiveCN104689838ASimple methodEasy to operatePhysical/chemical process catalystsMethyl orangeWater treatment

The invention provides a preparation method for a BiOCl photocatalyst with a controllable morphology and a crystal face, and belongs to the technical field of environmental chemical engineering photocatalysis water treatment. The preparation method is characterized by comprising the following steps: adding Bi(NO3)3.5H2O into a certain amount of water, ethyl alcohol or a dimethyl formamide solvent, uniformly stirring, then adding a certain amount of chlorination-1-butyl-3-methylimidazole, stirring for 20min for uniform mixing, performing ultrasonic treatment under room temperature for 10-60min, and reacting to generate white precipitate; washing the precipitate by water and ethyl alcohol, and drying the precipitate under the temperature of 60 DEG C to obtain BiOCl photocatalyst powder with different morphologies. According to the preparation method provided by the invention, the BiOCl preparation period is short, and the use of a surfactant is avoided; by control on the solvent, the preparation method for implementing BiOCl crystal surface control (101 and 102) and morphology control (a nano sheet shape, a flower-like structure and an irregular disk shape) can be conveniently realized. The preparation method is completed in the next step under the room temperature, has the advantages of simple process, extremely short preparation period, environment friendliness and the like and is favorable for engineering large-scale preparation. The catalyst has outstanding degrading effects on rhodamine B, methyl orange, quinoline blue and the like by visible light and sunshine and has an actual application prospect.

Owner:XIANGTAN UNIV

Morphology control of substituted diacetylenic monomers for shelf life monitoring systems

ActiveUS7161023B2Improve consistencySmall particle sizeCarbamic acid derivatives preparationOrganic compound preparationMonitoring systemQuenching

A system for recovering a diacetylenic monomer shelf life monitoring compound of reduced particle size and narrow size distribution range which comprises quenching a solution of the monomer by mixing the solution in a lower temperature quenching fluid having a base temperature which is at least about 30° C. below the nominal temperature at which the monomer compound recrystallizes from solution, the mixing being effected in such a manner as to limit the resulting quenching mixture temperature to one which is not higher than a maximum of about 15° C. above the quenching fluid base temperature.

Owner:TEMPTIME CORP

Mixed additives and method for producing anhydrous dead-burned type of calcium sulfate whisker

ActiveCN104928758AReduce energy consumptionReduce environmental stressPolycrystalline material growthFrom normal temperature solutionsFiltrationCalcination

The invention relates to a mixed additive for producing an anhydrous dead-burned type of calcium sulfate whisker, and belongs to the technical field of inorganic chemical materials production. The mixed additive of the invention comprises a morphology controlling agent, an auxiliary controlling agent and a reaction system pH controlling agent. The mass ratio of the morphology controlling agent, the auxiliary controlling agent and the reaction system pH modulator is 1:0-20:30-70. The mixed additive can speed up growth of crystals, shorten reaction time, and at the same time can implement control of whisker morphology to acquire high aspect ratio hemihydrate calcium sulfate whisker. The invention further relates to a method for producing an anhydrous dead-burned type of calcium sulfate whisker. The method comprises: using calcium sulfate dihydrate, water and the mixed additive as raw materials, performing a hydrothermal reaction to acquire hemihydrate calcium sulfate whisker; after filtration, drying,calcination and cooling, acquiring the anhydrous dead-burned type of calcium sulfate whisker with calcium sulfate content being more than 98wt%. The invention is simple in process, zero in pollution, low in production cost, high in operability, good in product quality and good in stability.

Owner:四川康升晶须科技有限公司

Synthesis method for ZSM-5 molecular sieve of special morphology

ActiveCN105293520AAdjust grain sizeControl shapePentasil aluminosilicate zeoliteMolecular sieveCrystal morphology

The invention belongs to the technical field of zeolite molecular sieve synthesis, in particular to a synthesis method for a ZSM-5 zeolite molecular sieve of a petaloid morphology. According to the synthesis method, morphology control is an important aspect in the field of molecular sieve synthesis; when MFI zeolite molecular sieve catalysts of different crystal morphologies are adopted in a catalytic reaction, all of the product selectivity, the reaction activity, the reaction stability and the like can be changed obviously along with the morphology difference. The invention further relates to a preparation method for ZSM-5 zeolite. The synthesis method provided by the invention has the advantages that the synthesis process is simple and convenient, and industrialization is easy to realize; meanwhile, a plurality of templates are applied, so as to effectively control the product crystallinity and the final morphology; sample XRD shows that the obtained product is the ZSM-5 molecular sieve of which the product crystallinity is high; sample SEM shows that zeolite has a special petaloid morphology, and thus can be utilized for industrial production of ZSM-5 zeolite of the special petaloid morphology.

Owner:CHINA PETROLEUM & CHEM CORP +1

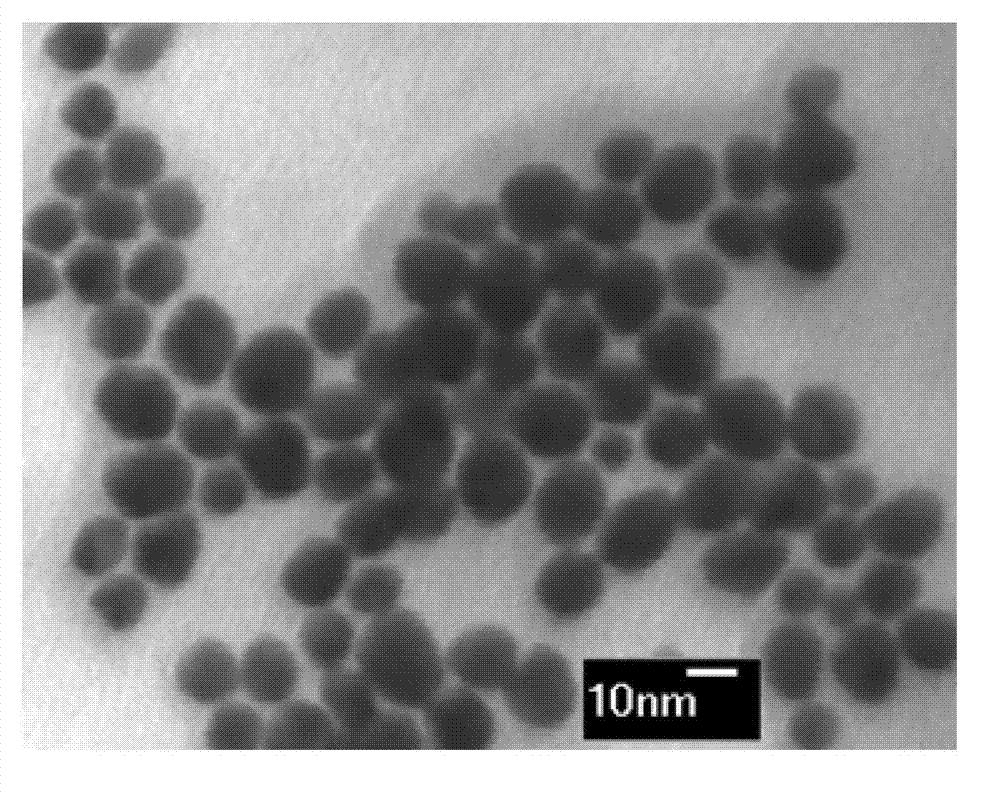

Environmentally-friendly synthetic method for metal nanoparticle

ActiveCN103071808ANarrow particle size distributionEasy to controlNanotechnologyDipotassium phosphateNutrient solution

The invention discloses an environmentally-friendly synthetic method for the metal nanoparticle, and belongs to the field of the nanometer material. The existing ingredients in a microorganism nutrient solution are used as reducing agent, stabilizing agent and morphological control agent to synthetize metal nanometer material in one step. The environmentally-friendly synthetic method for the metal nanoparticle comprises the following steps of: (1) blending a reducing stable morphology control agent solution, and meanwhile, adding sodium chloride or dipotassium phosphate; (2) regulating the pH (potential of hydrogen) value of the solution to 2-13; (3) adding the soluble metal salt water solution of the metal nanoparticle while stirring the solution; and (4) at the temperature of 15-50DEG C, reacting for 5 seconds to 24 hours to obtain the metal nanoparticle. The environmentally-friendly synthetic method for the metal nanoparticle, which is disclosed by the invention, has the moderate reaction condition, short synthesis time and low production cost, the particle diameter of the obtained metal nanoparticle is 1-100nm, the particle diameter of the nanometer material is relatively even, and the morphology of the generated metal nanoparticle can be controlled. Compared with the biosynthesis method, the environmentally-friendly synthetic method for the metal nanoparticle is simpler, efficient and environmentally-friendly.

Owner:上海穗杉实业股份有限公司

Grey titanium dioxide nano-material, as well as preparation method and application thereof

ActiveCN103657624APhysical/chemical process catalystsWater/sewage treatment by irradiationSolventHigh pressure

The invention relates to a grey titanium dioxide nano-material, as well as a preparation method and application of the grey titanium dioxide nano-material. The material is characterized in that the color is grey, the crystal form is anatase type, the grain size is 50-70nm, and the material can absorb visible light with wavelength in a range of 400-800nm. A titanium source and a morphology control agent react in a high-pressure kettle by adopting a solvothermal method, and calcined in a certain atmosphere to obtain the grey titanium dioxide. The flake-shaped titanium dioxide nano-material is grey, which is a breakthrough of changing white and blue titanium dioxide to grey titanium dioxide. The material has the characteristics of simple preparation method, low cost, adjustable morphology and crystal form and excellent photocatalysis performance, and expected to be applied to paint, water pollution treatment and other industries.

Owner:NANJING UNIV OF TECH

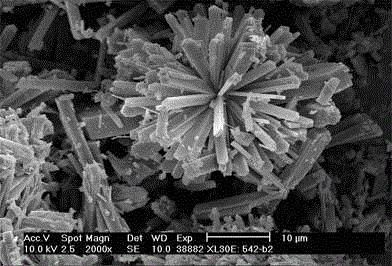

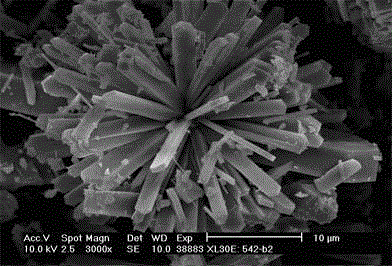

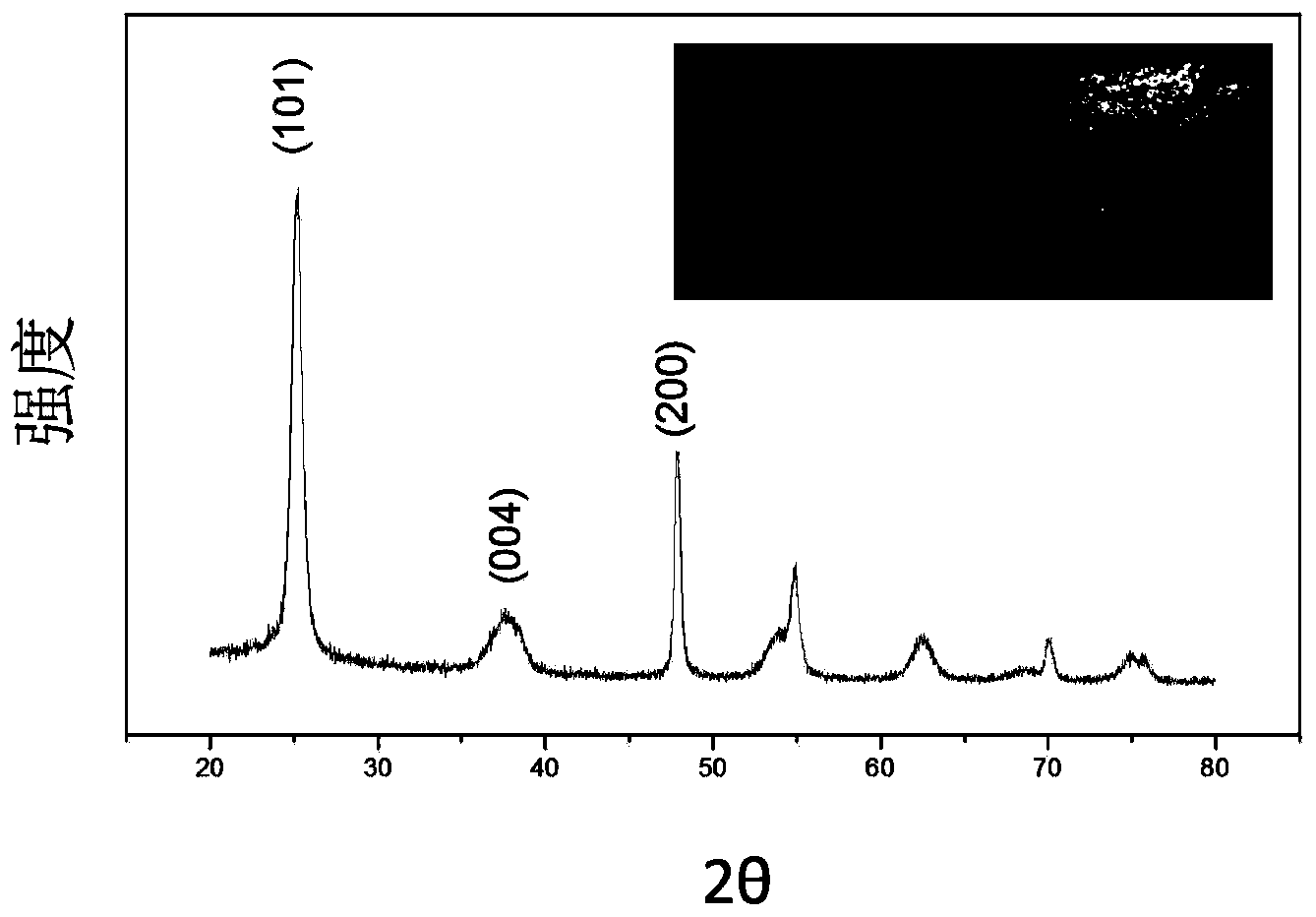

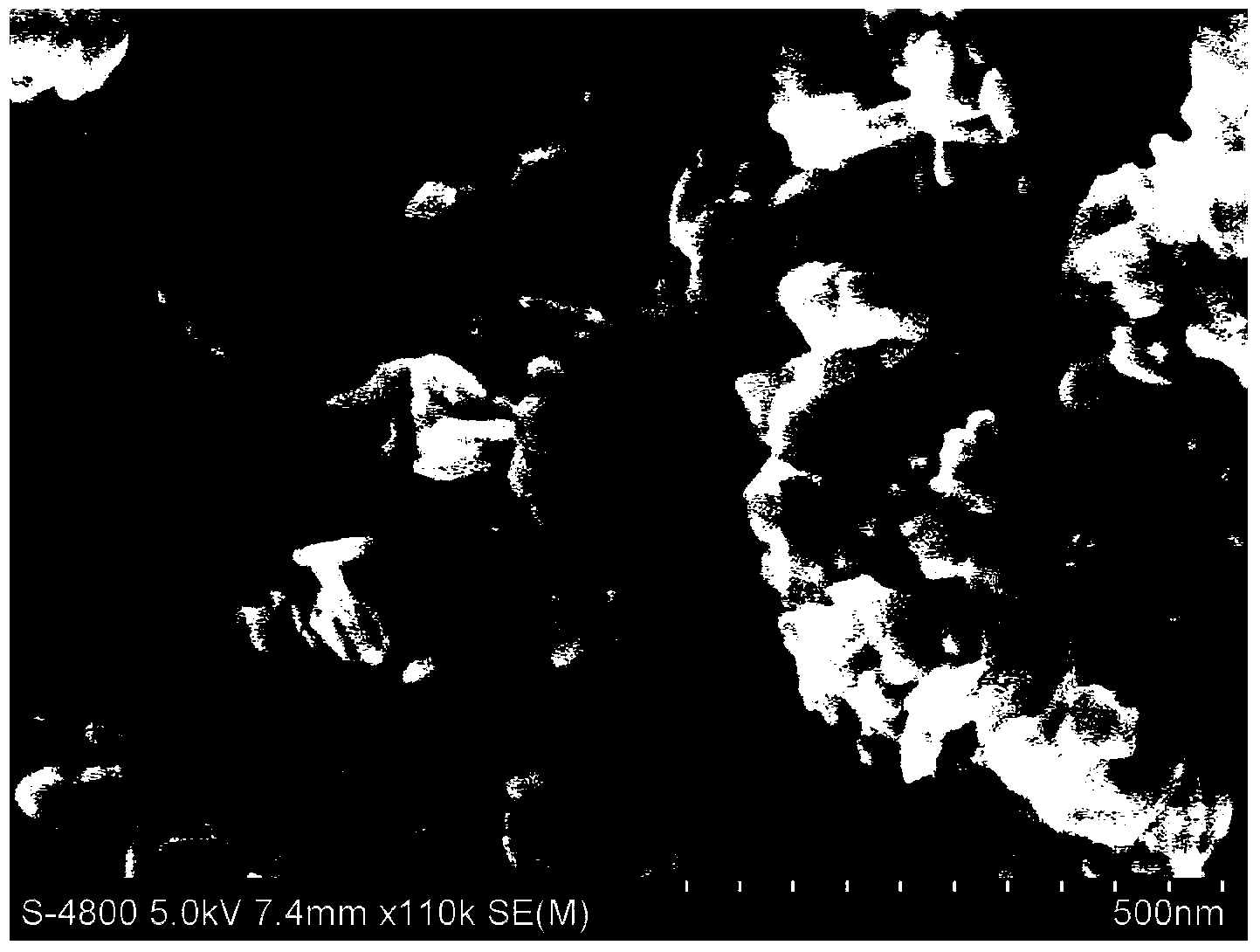

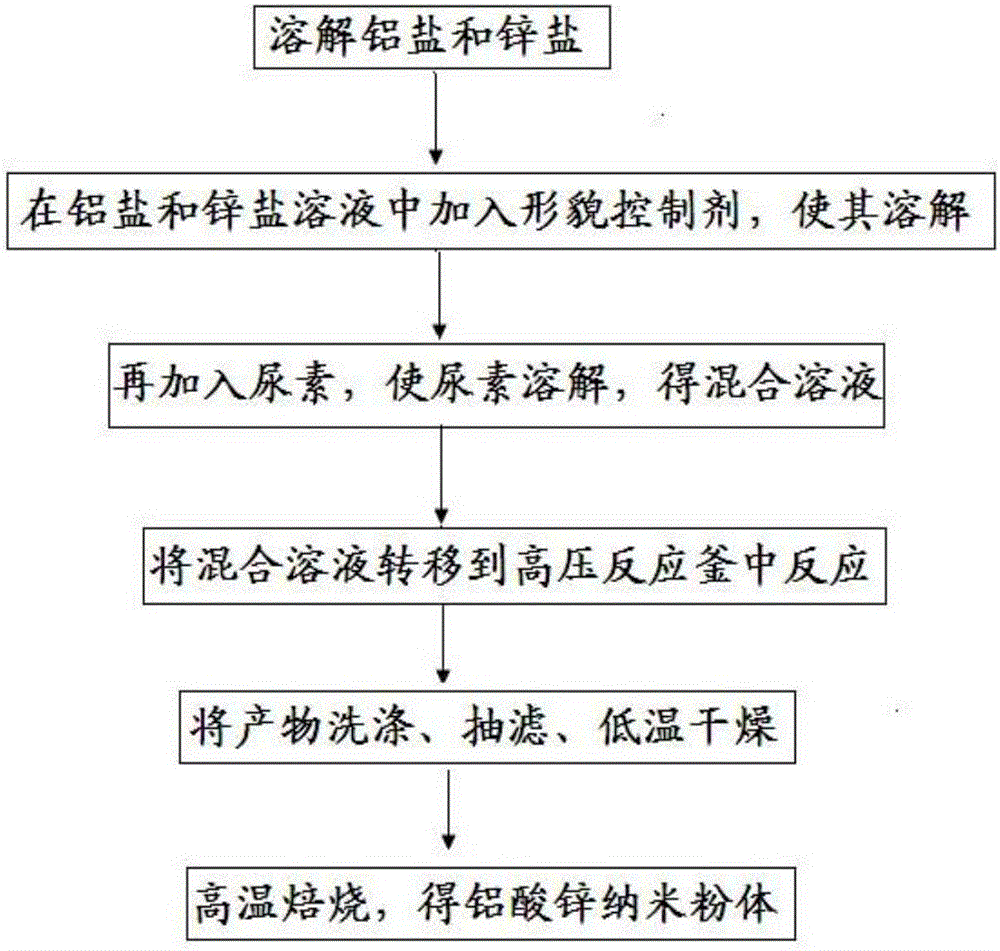

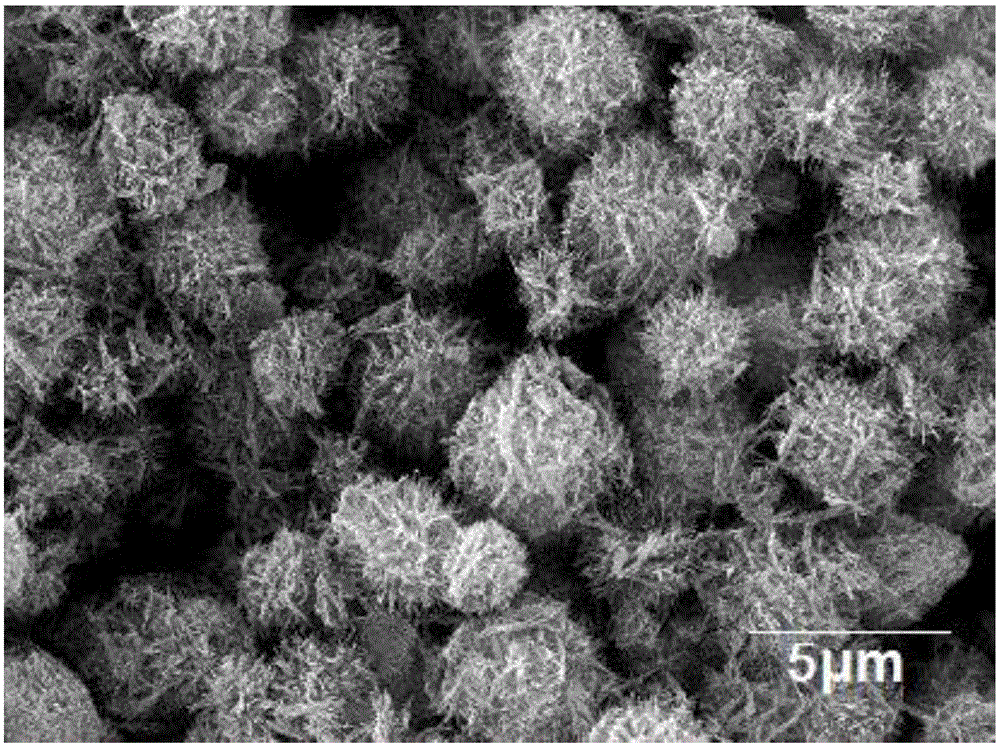

Zinc aluminate nanometer powder and preparing method thereof

The invention provides a zinc aluminate nanometer powder and a preparing method thereof. The preparing method includes the steps that 1, soluble aluminum salt and zinc salt are added into a water solution, the mixture is heated to be at the temperature of 40 DEG C to 70 DEG C under stirring, a water bath is carried out for 20 min to 60 min at the constant temperature, and a mixed solution is obtained; 2, a morphology control agent is added into the mixed solution obtained in the step 1, and dissolved under stirring, wherein the concentration of the morphology control agent is 0.01 mol / L to 2 mol / L; 3, urea is added into the mixed solution obtained in the step 2, and the constant temperature of 40 DEG C to 70 DEG C is kept for 1 h to 5 h, wherein the molar ratio of the morphology control agent to the urea is 1:100-1:10; 4, the mixed solution obtained in the step 3 is transferred to a high-pressure reaction vessel, and is reacted for 2 h to 8 h at the temperature of 120 DEG C to 180 DEG C, the obtained product is washed, subjected to suction filtration, dried at the low temperature, and subjected to high-temperature roasting, and the zinc aluminate nanometer powder is obtained. The zinc aluminate nanometer powder prepared with the method is of a fluffy-sea-urchin-shaped structure, and has the high specific surface area and high fluffiness.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com