Same-direction forming mode based forming morphology control method for GMAW material increase manufacturing

A technology of additive manufacturing and control method, applied in the field of additive manufacturing, can solve the problem of height difference between arc-starting end and arc-extinguishing end of formed parts, and achieve the effect of reducing defects, reliable technical support, and high forming dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

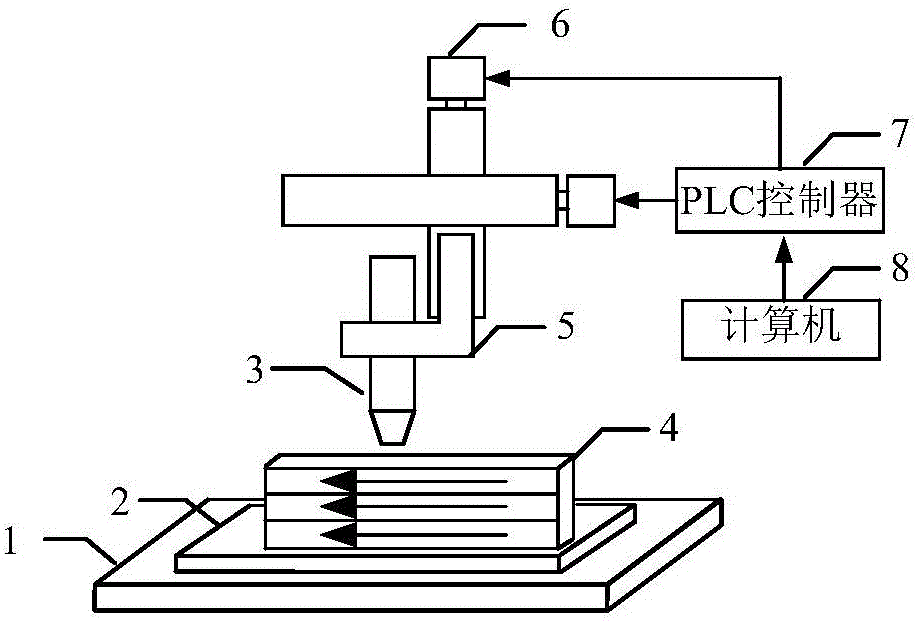

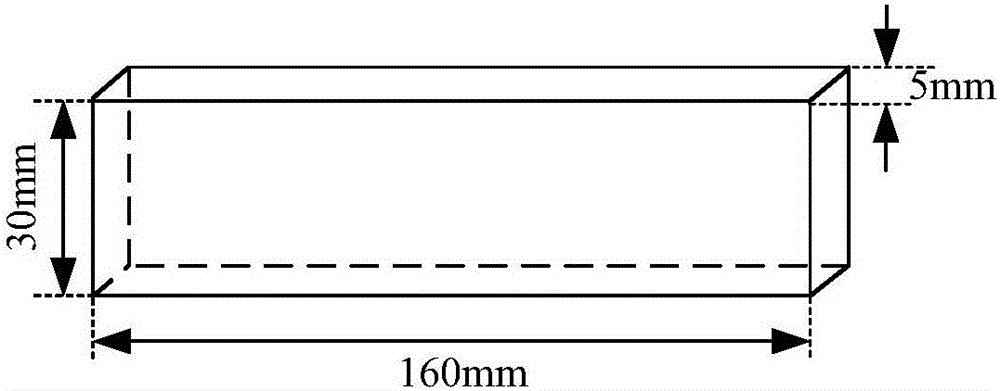

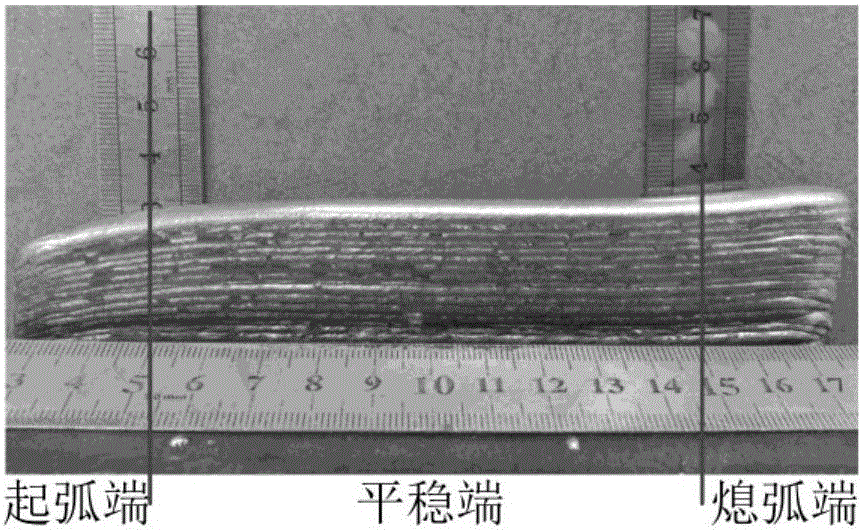

[0062] This embodiment includes the following steps:

[0063] Step 1: Use the PLC controller to complete the I / O control of the arcing and extinguishing action in the GMAW additive manufacturing process, and the electrical signal D / A given control of the forming current and forming voltage, so that the forming speed and forming voltage at the arc starting end are stable. The forming speed, forming current, and forming voltage of the arc-extinguishing end are 0.7 times that of the steady end. The forming length of the arc-starting end is set to 8mm, and the forming length of the arc-extinguishing end is set to 8mm; 4.2mm / s;

[0064] Step 2: Before forming starts, complete the initial setting of forming speed, forming current and forming voltage at the steady end through the PLC man-machine control interface, and gradually reduce the forming speed and forming voltage when reaching the steady end within the forming length of the arc starting end The forming speed and forming vol...

Embodiment 2

[0069] This embodiment includes the following steps:

[0070] Step 1: Use the PLC controller to complete the I / O control of the arcing and extinguishing action in the GMAW additive manufacturing process, and the electrical signal D / A given control of the forming current and forming voltage, so that the forming speed and forming voltage at the arc starting end are stable. The forming speed, forming current and forming voltage of the arc-extinguishing end are 0.95 times that of the steady end. The forming length of the arc-starting end is set to 15mm, and the forming length of the arc-extinguishing end is set to 16mm; 7.3mm / s;

[0071] Step 2: Before forming starts, complete the initial setting of forming speed, forming current and forming voltage at the steady end through the PLC man-machine control interface, and gradually reduce the forming speed and forming voltage when reaching the steady end within the forming length of the arc starting end The forming speed and forming v...

Embodiment 3

[0076] This embodiment includes the following steps:

[0077] Step 1: Use the PLC controller to complete the I / O control of the arcing and extinguishing action in the GMAW additive manufacturing process, and the electrical signal D / A given control of the forming current and forming voltage, so that the forming speed and forming voltage at the arc starting end are stable. The forming speed, forming current, and forming voltage of the arc-extinguishing end are 0.9 times that of the steady end. The forming length of the arc-starting end is set to 10mm, and the forming length of the arc-extinguishing end is set to 9mm; 5mm / s;

[0078] Step 2: Before forming starts, complete the initial setting of forming speed, forming current and forming voltage at the steady end through the PLC man-machine control interface, and gradually reduce the forming speed and forming voltage when reaching the steady end within the forming length of the arc starting end The forming speed and forming volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com