Arc fuse additive manufacturing method for a disc-shaped support

An additive manufacturing and support technology, applied in the field of additive manufacturing, arc fuse additive manufacturing of TIG power supply, and arc fuse additive manufacturing, which can solve the problem of heavy programming workload, repeated positioning and difficulty in finding, Low level of intelligence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

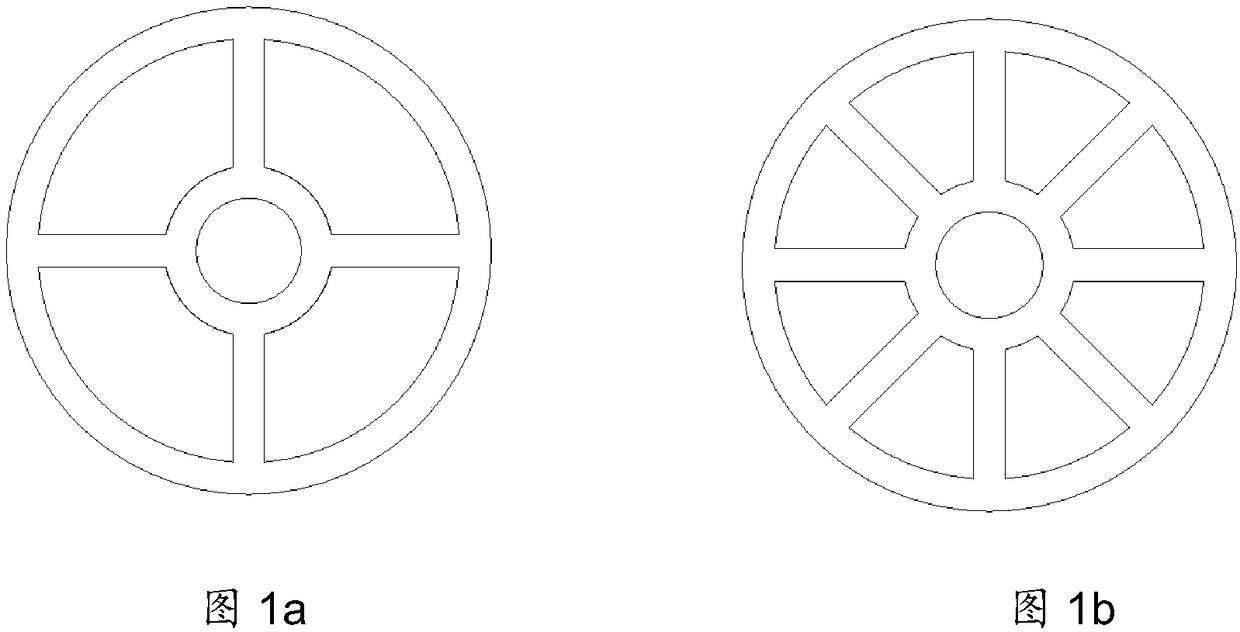

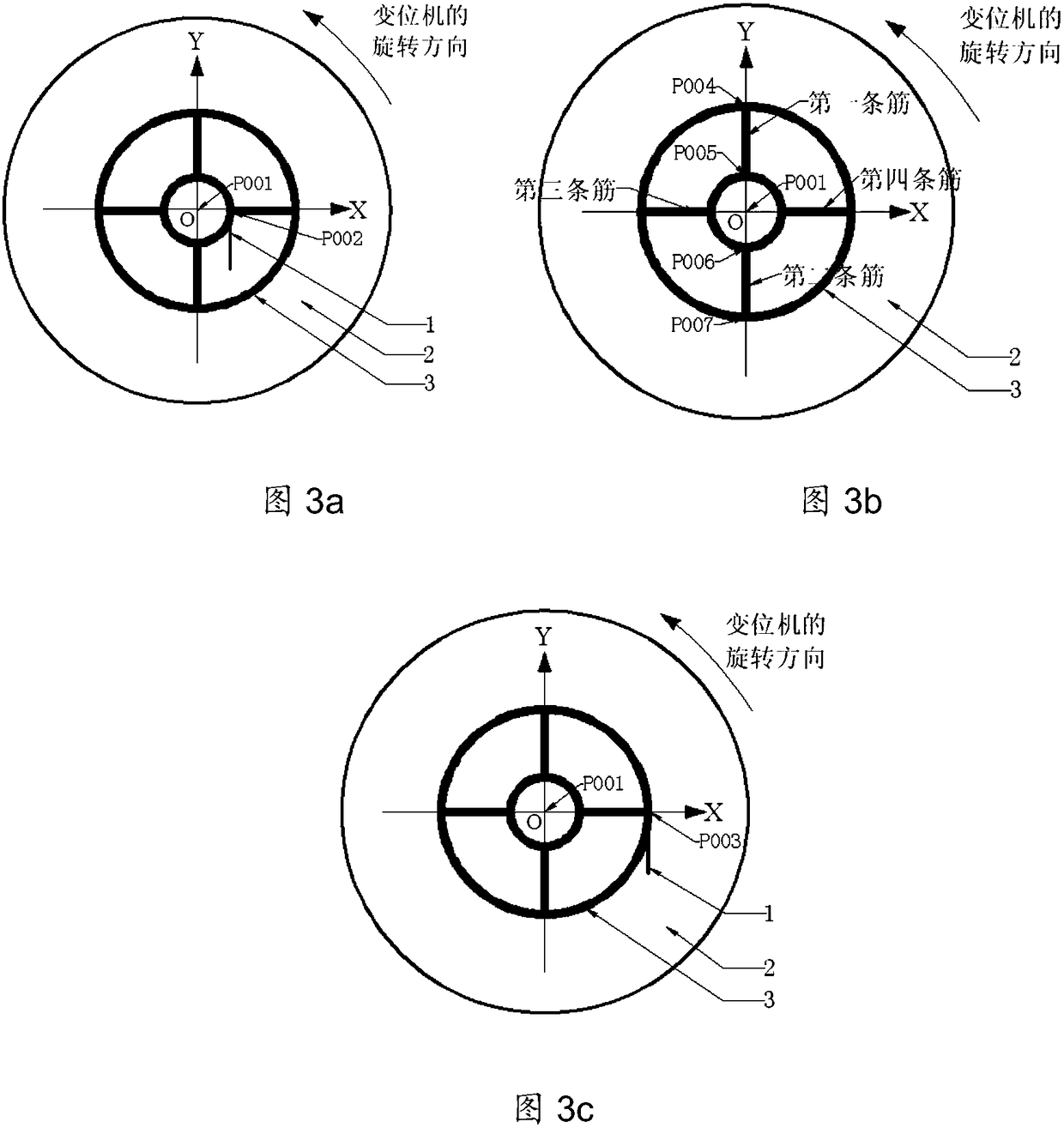

[0059] Such as figure 1 Shown is the structural representation of the disc-shaped support to be prepared in the present invention, wherein figure 1 a is the diagram of 4 connecting bars; figure 1 b is a diagram of 8 connecting ribs; the disc-shaped support is mainly composed of two types of structures, a ring and a connecting rib, wherein the ring has two inner rings and outer rings; the number of connecting ribs is 2n, Every two symmetrical connecting ribs are on the same straight line. The connecting ribs are evenly distributed on the ring, and the angular interval value is α=360° / 2n.

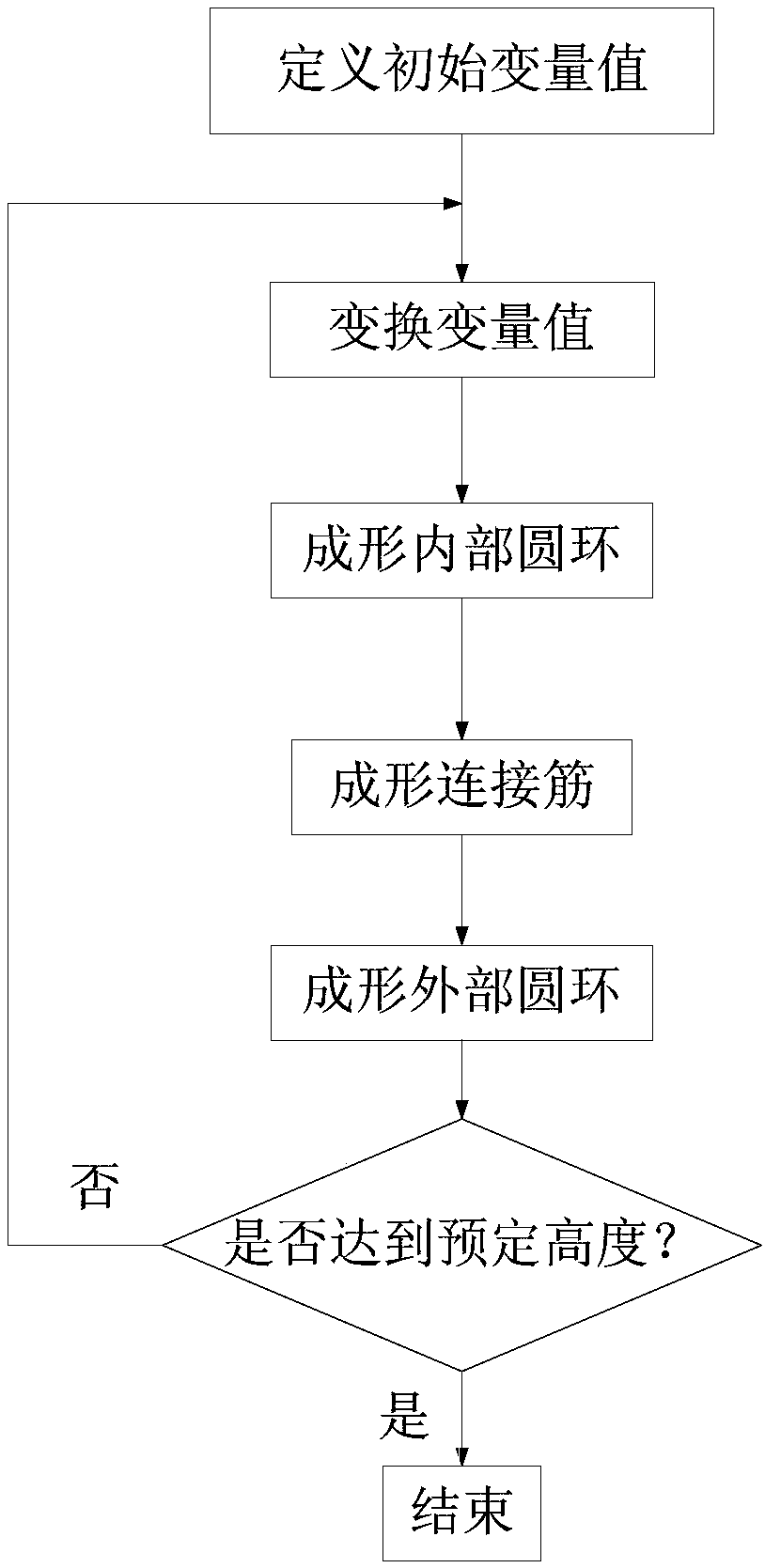

[0060] The forming method of the disc-shaped support in the present invention is divided into a ring forming method and a connecting rib forming method according to its main structural features.

[0061] ① Forming method of the ring: The forming of the ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com