A positioning system and method for PCBA automatic testing

An automatic testing and positioning method technology, applied in the direction of electronic circuit testing, etc., can solve problems such as unsatisfactory non-stop production, fast changeover, long adjustment time or calibration time, cumbersome operation, etc., to reduce the teaching workload and shorten the calibration Time, the effect of improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

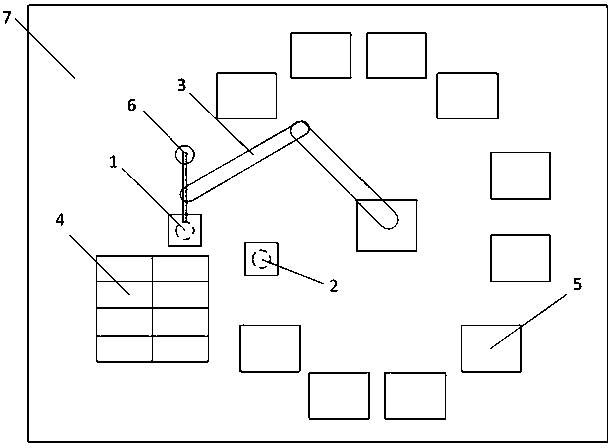

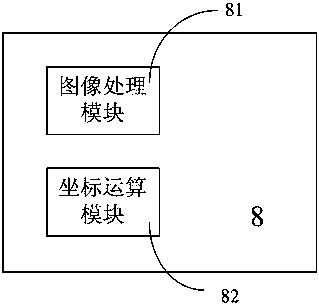

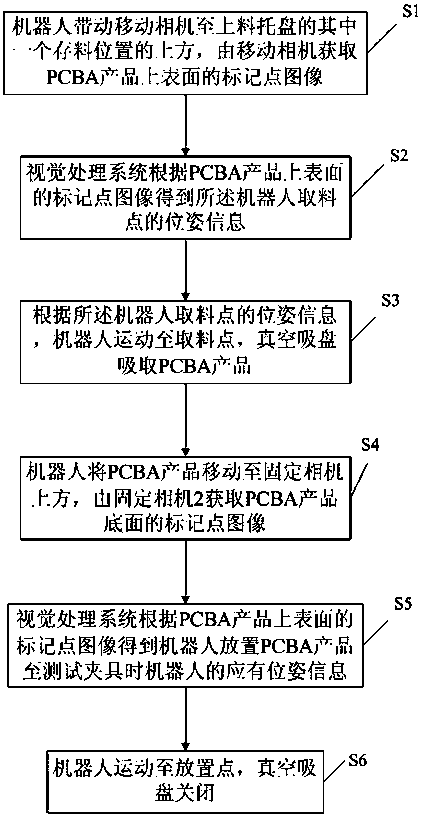

[0047] Such as figure 1 As shown, a positioning system for PCBA automatic testing includes: a workbench 7; a robot 3 arranged on the workbench 7 for performing transfer actions of PCBA products; several test fixtures 5, which are distributed on the robot 3 and located within the operating range of the robot 3; the mobile camera 1, which is fixed at the end of the robot 3, moves dynamically with the robot 3, and is used to collect the mark point images on the upper surface of the PCBA product and the mark point images of the test fixture; the fixed camera 2. It is fixed on the workbench 7 and the shooting direction is perpendicular to the upper surface of the workbench, and is used to collect the mark point image on the bottom surface of the PCBA product; the visual processing system 8 is used to test and test the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com