Patents

Literature

713results about How to "Eliminate bias" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

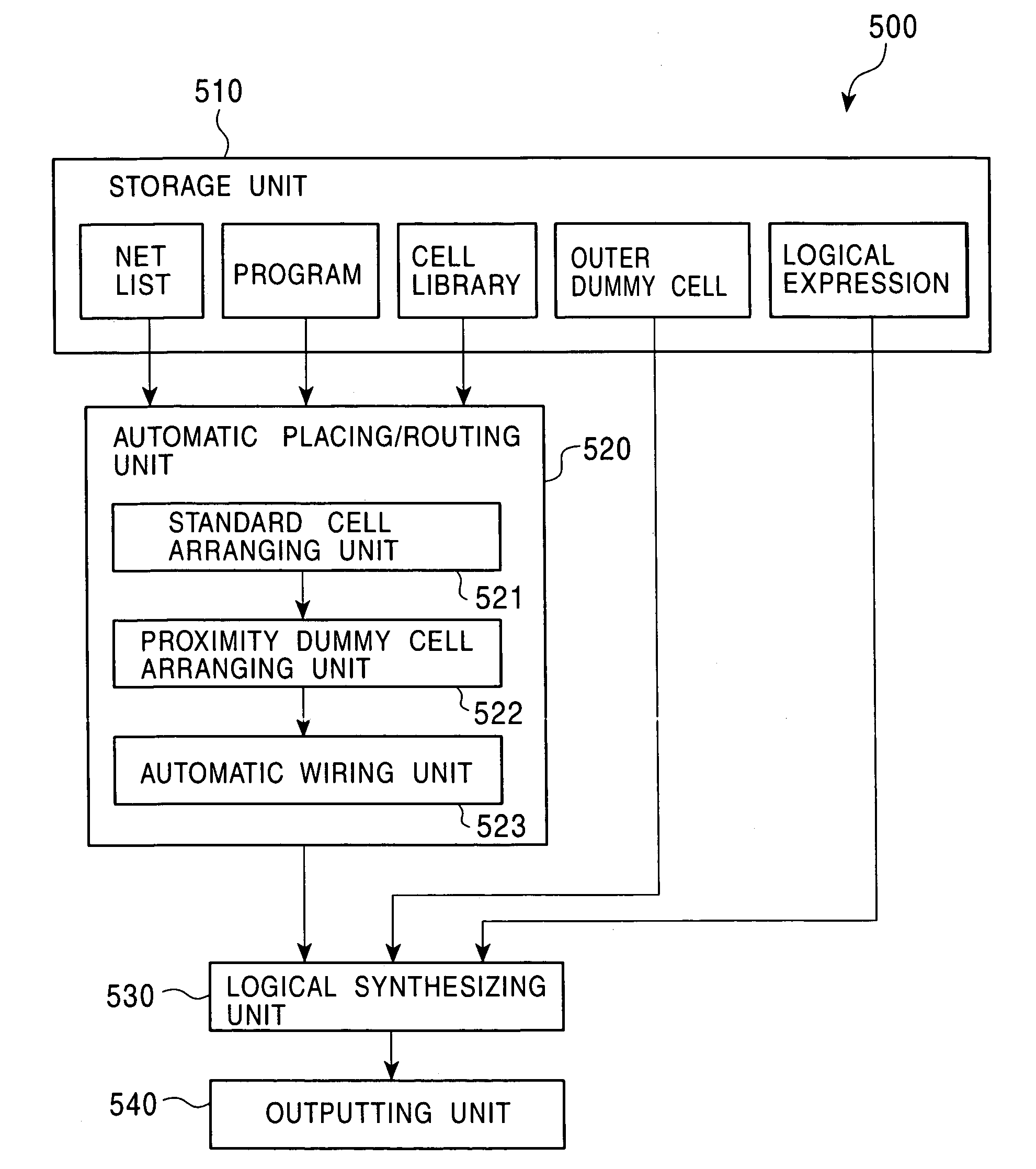

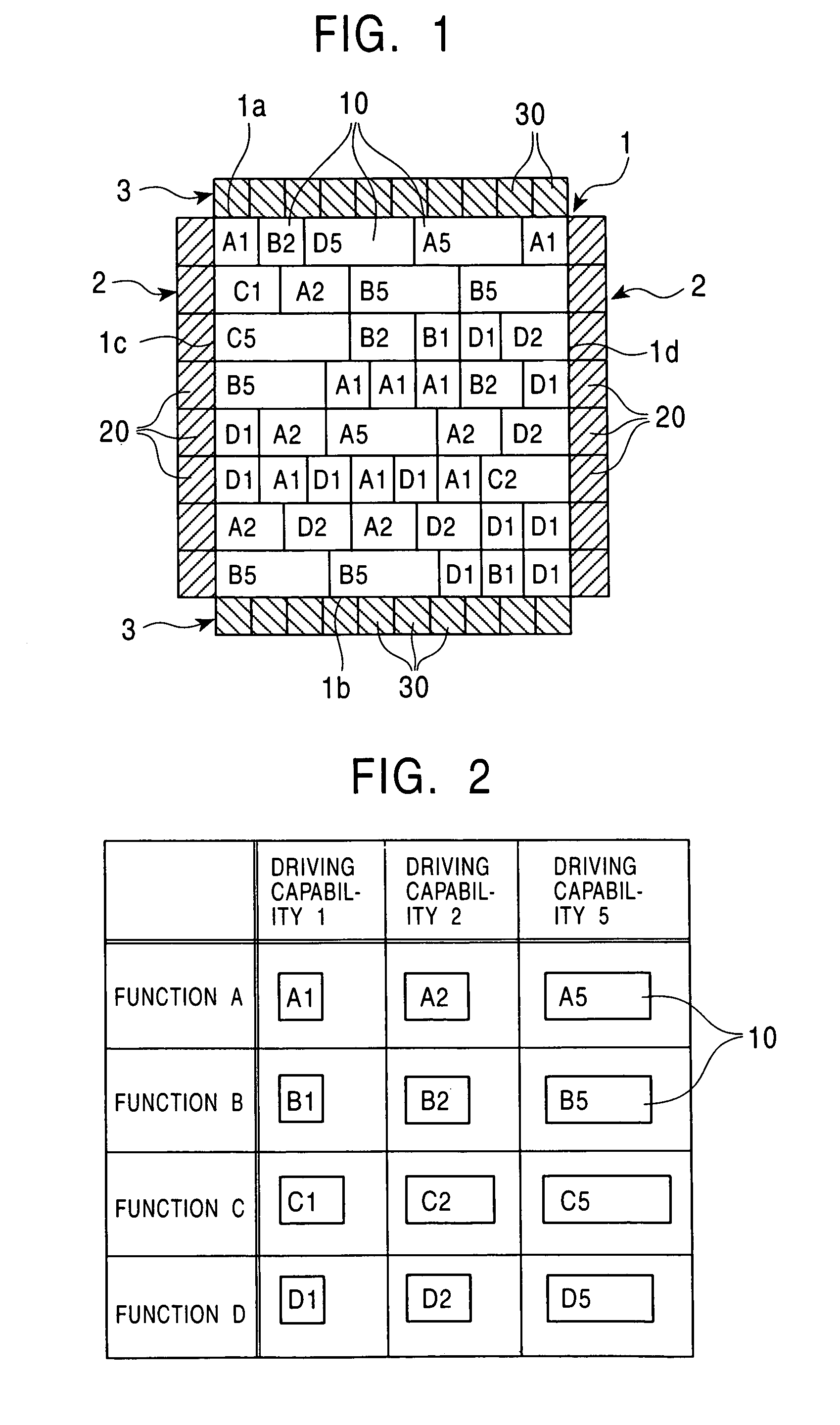

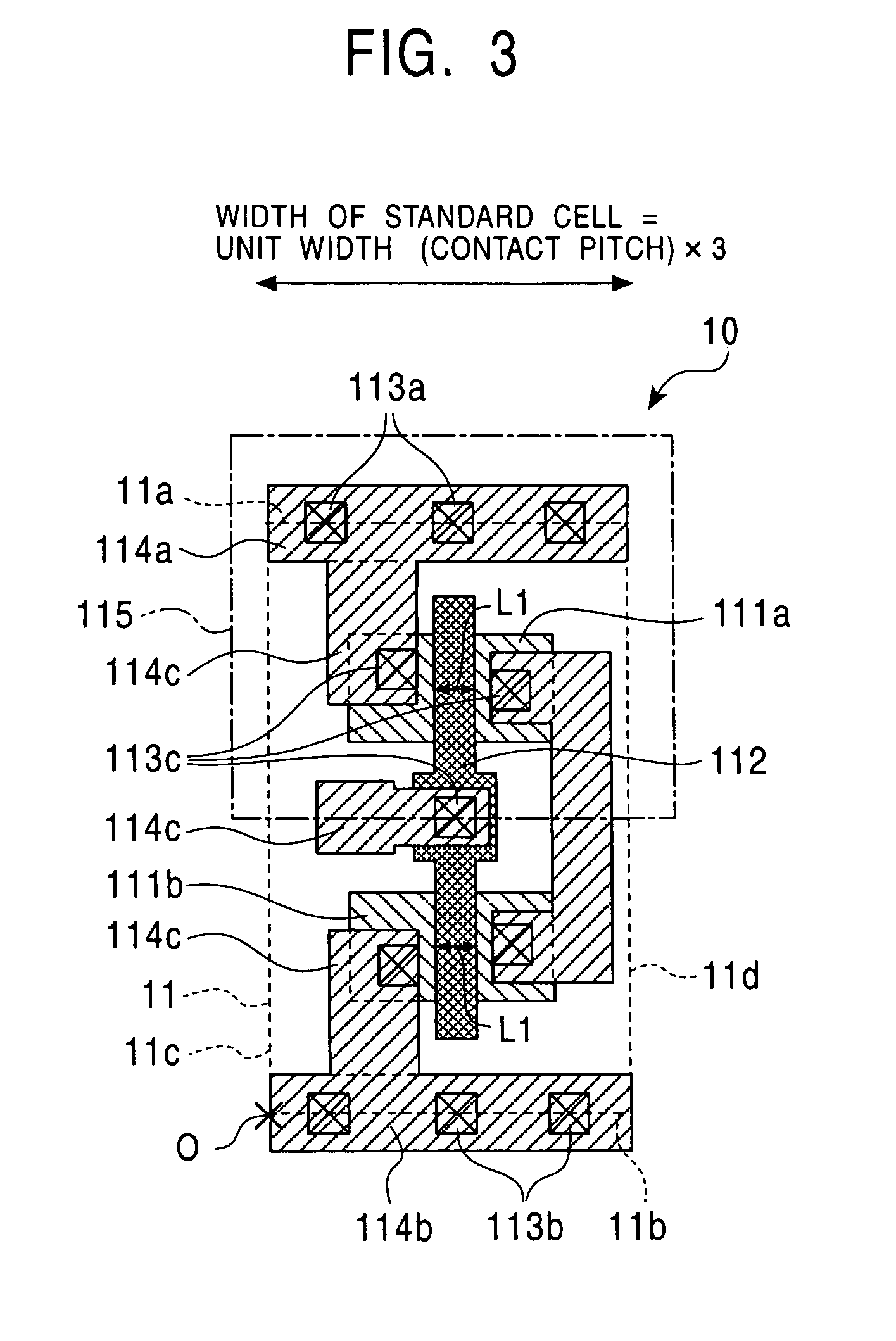

Layout method of semiconductor integrated circuit, layout structure thereof, and photomask for forming the layout structure

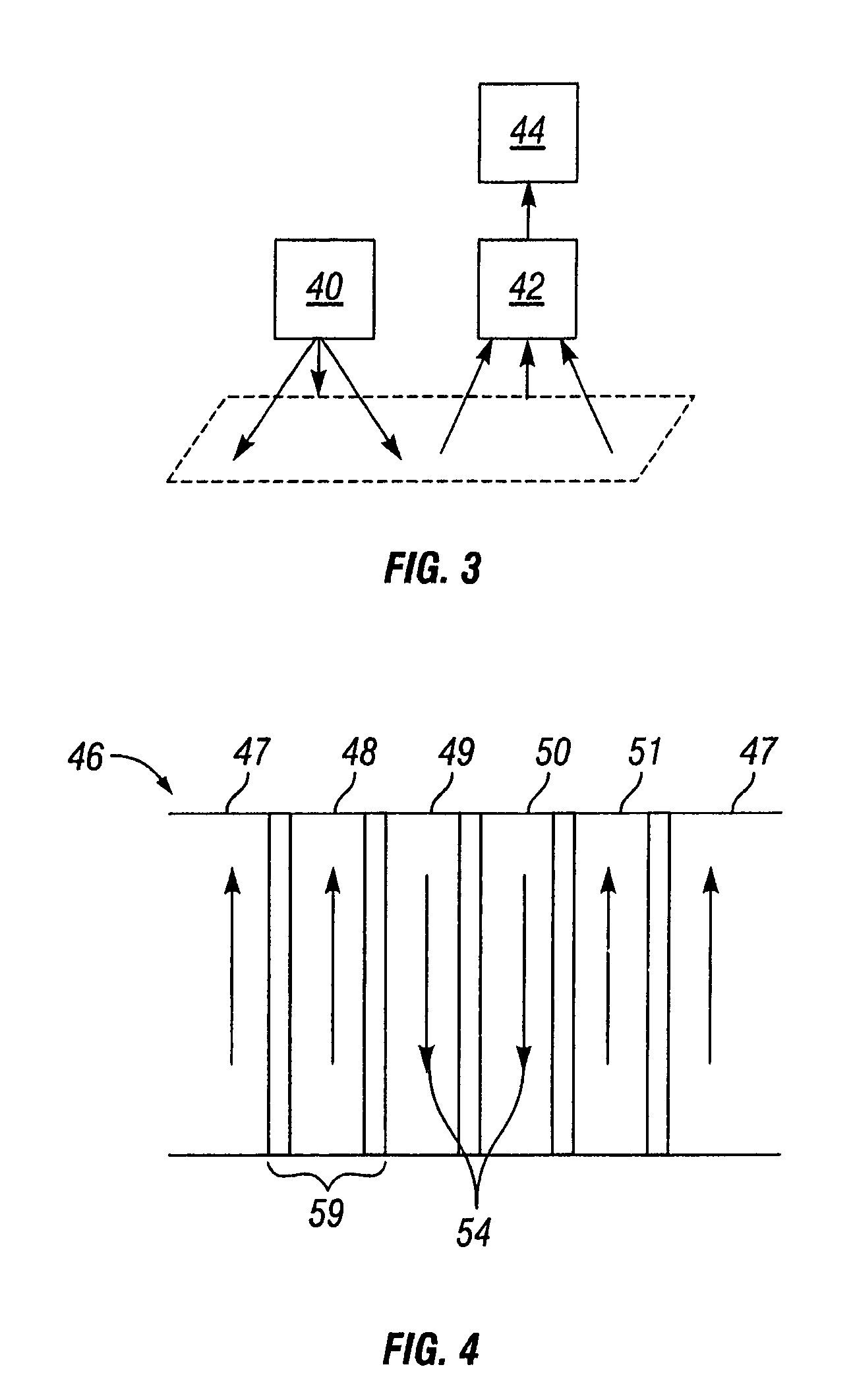

ActiveUS7137092B2Eliminate biasHigh dimensionalSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorPhotomask

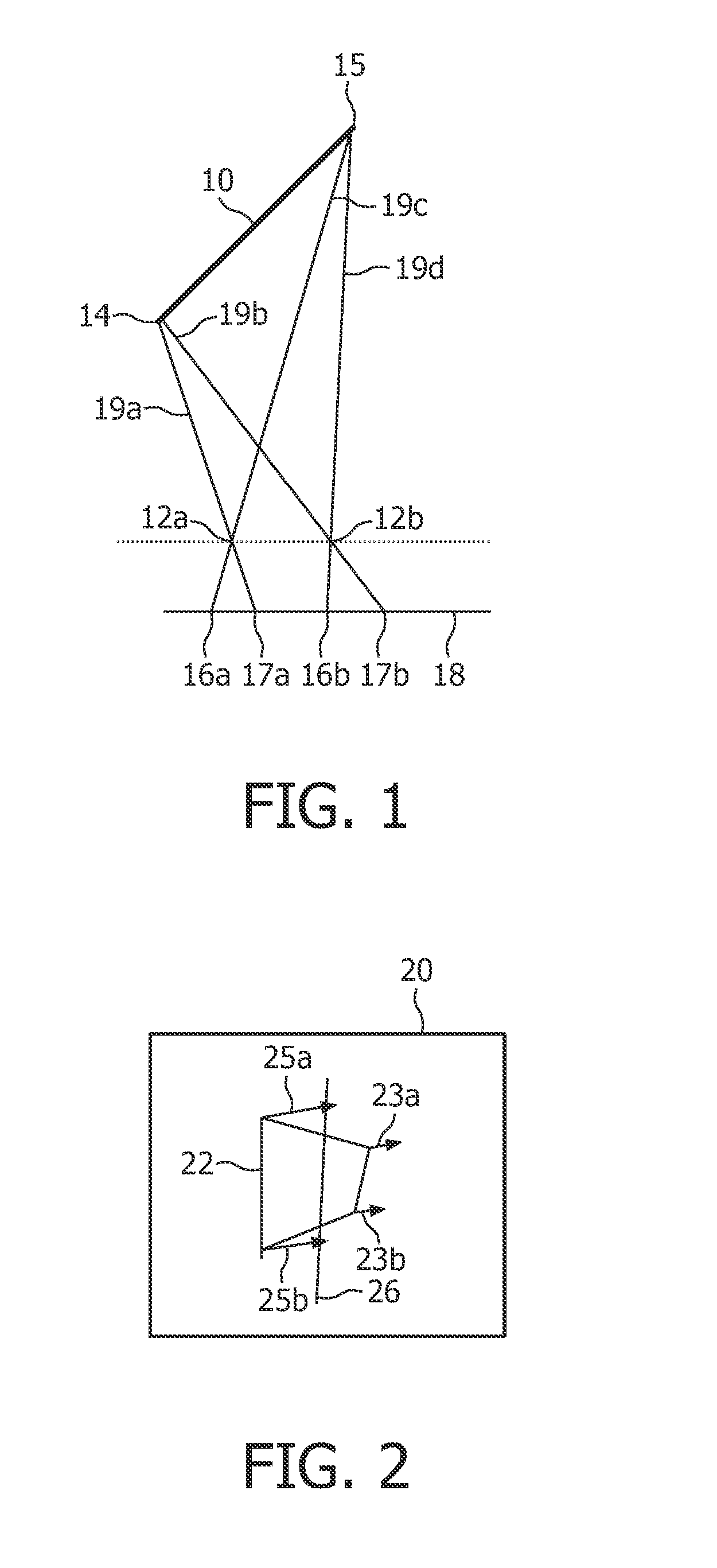

A plurality of standard cells 10 are arranged to form a channel-less standard cell array 1, which has vertical and horizontal sides. A plurality of first proximity dummy cells 20 are arranged along each of the vertical sides of the standard cell array to form a first proximity dummy bands 20 such that the upper and lower sides of the first proximity dummy cells are in contact with each other and such that the left or right side of each of the first proximity dummy cells is in contact with the vertical side of the standard cell array 1. Furthermore, a plurality of second proximity dummy bands are arranged along each of the horizontal sides of the standard cell array to form a second proximity dummy bands such that the upper or lower side of each of the second proximity dummy cells is in contact with the horizontal side of the standard cell 1.

Owner:KAWASAKI MICROELECTRONICS

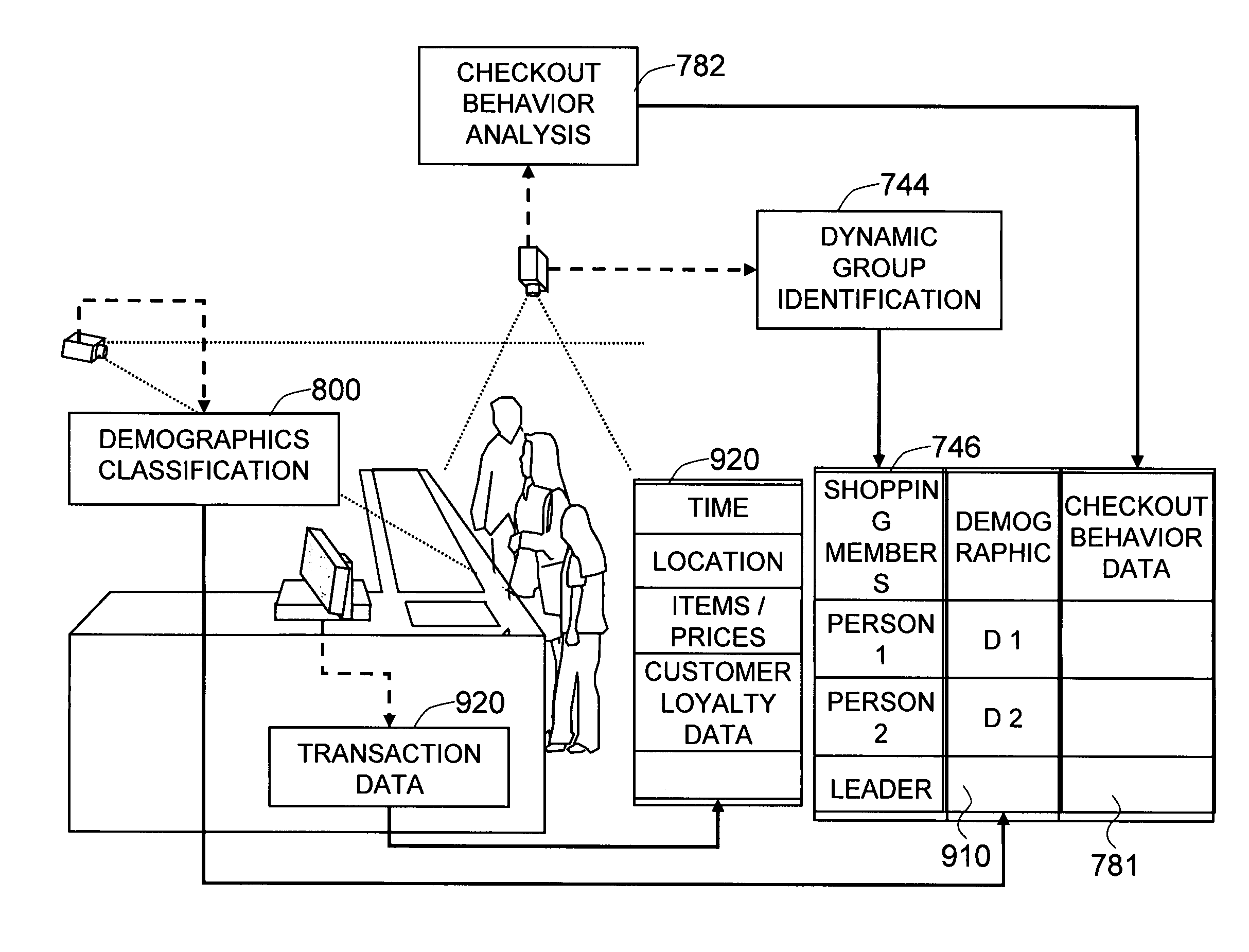

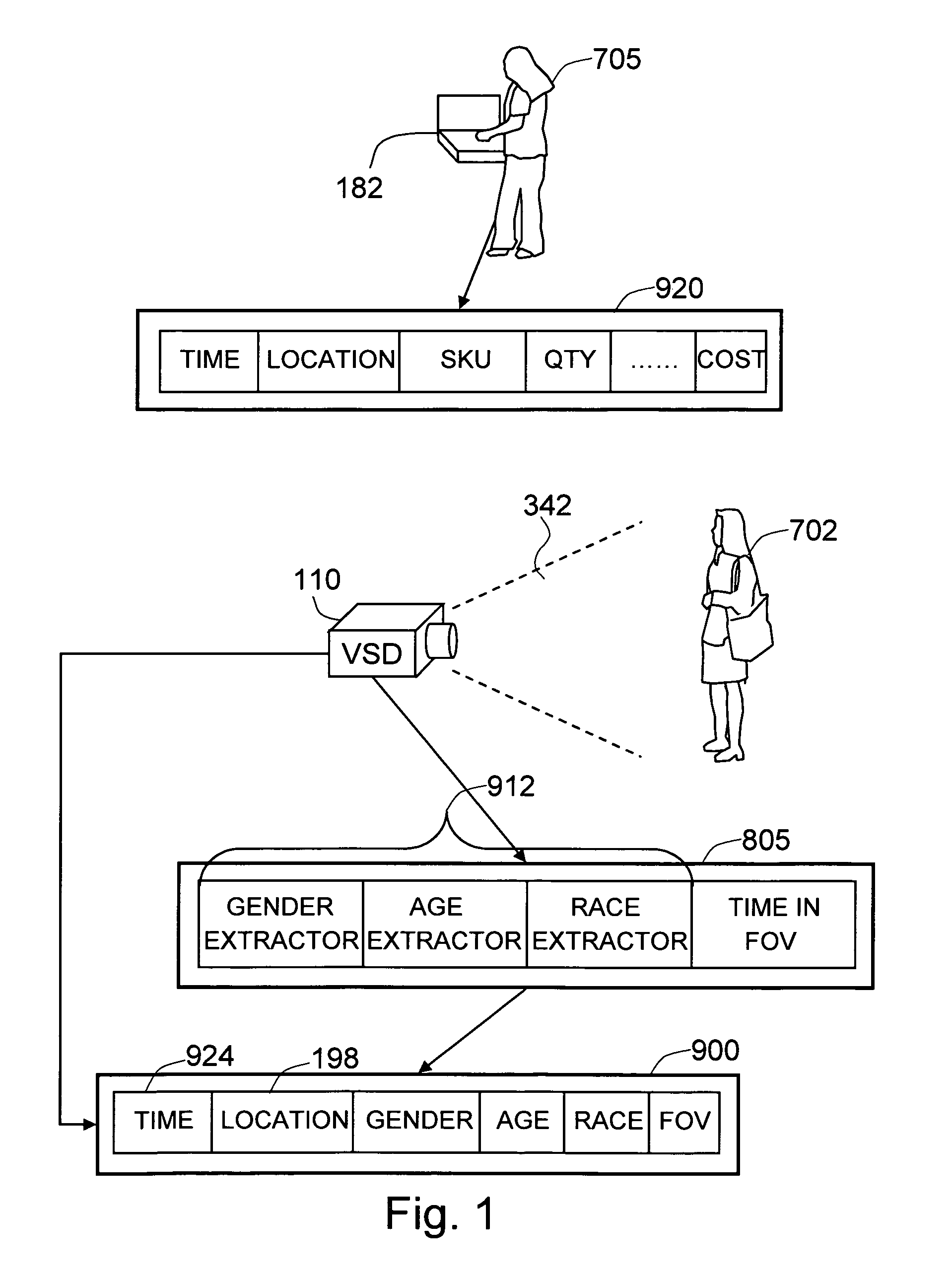

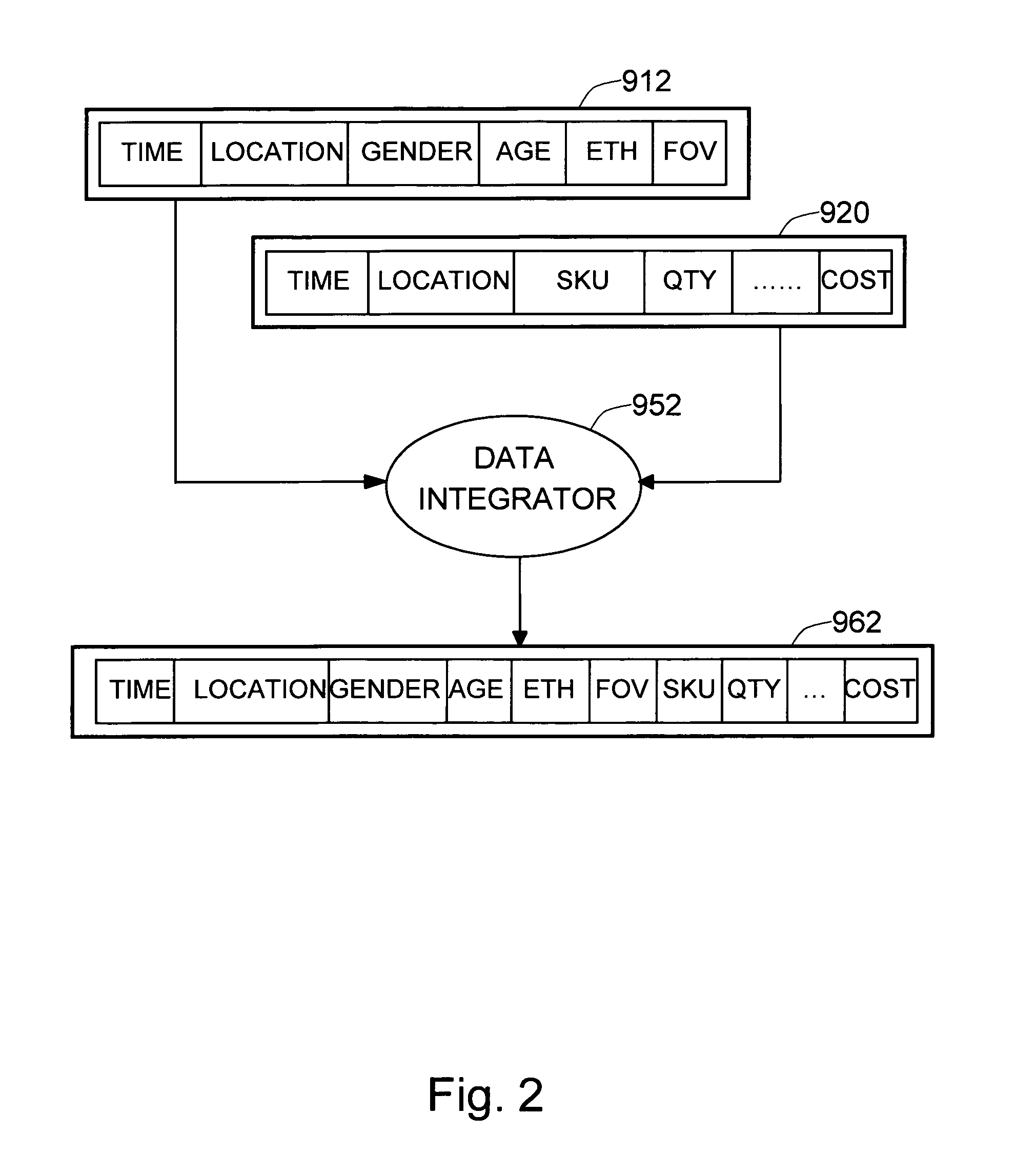

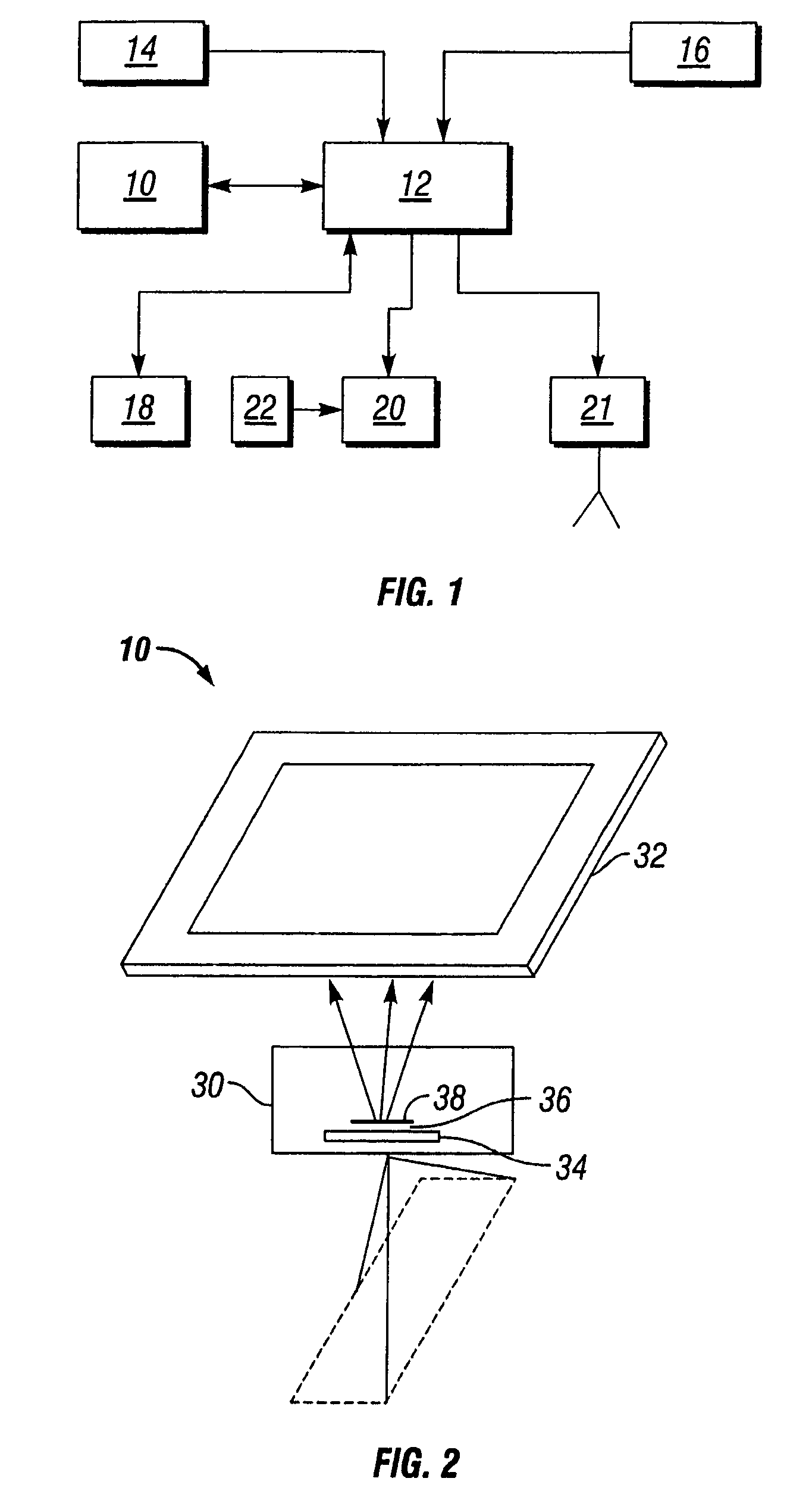

Method for augmenting transaction data with visually extracted demographics of people using computer vision

InactiveUS8010402B1Effectively measure performance of their FLM strategyIncrease profitSpecial data processing applicationsMarket data gatheringFeature vectorTransaction data

The present invention is a system and framework for augmenting any retail transaction system with information about the involved customers. This invention provides a method to combine the transaction data records and a customer or a group of customers with the automatically extracted demographic features (e.g., gender, age, and ethnicity), shopping group information, and behavioral information using computer vision algorithms. First, the system detects faces from face view, tracks them individually, and estimates poses of each of the tracked faces to normalize. These facial images are processed by the demographics classification module to determine and record the demographics feature vector. The system detects and tracks customers to analyze the dynamic behavior of the tracked customers so that their shopping group membership and checkout behavior can be recognized. Then the instances of faces and the instances of bodies can be matched and combined. Finally, the transaction data from the transaction data and the demographics, group, and checkout behavior data that belong to the same person or the same group of people are combined.

Owner:VIDEOMINING CORP

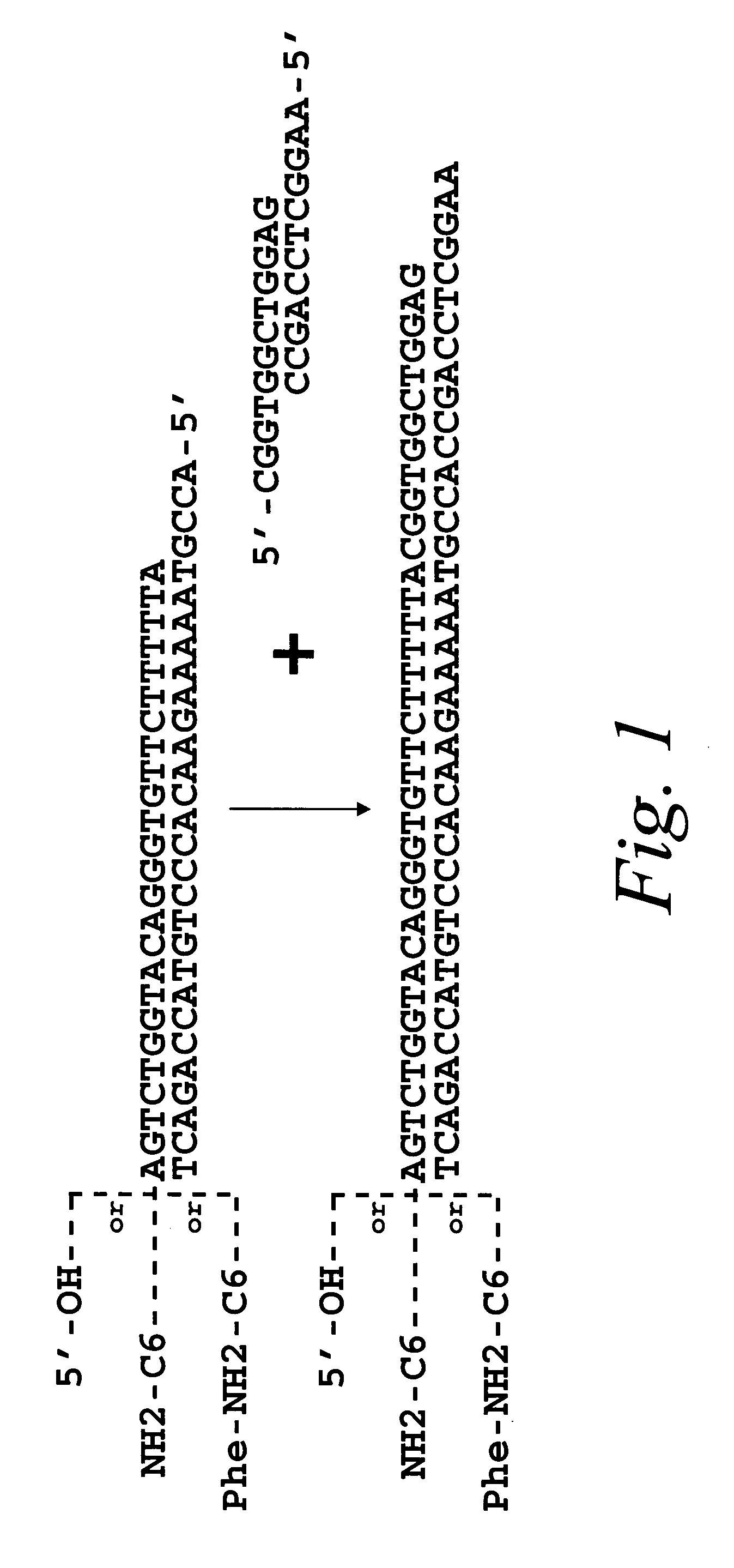

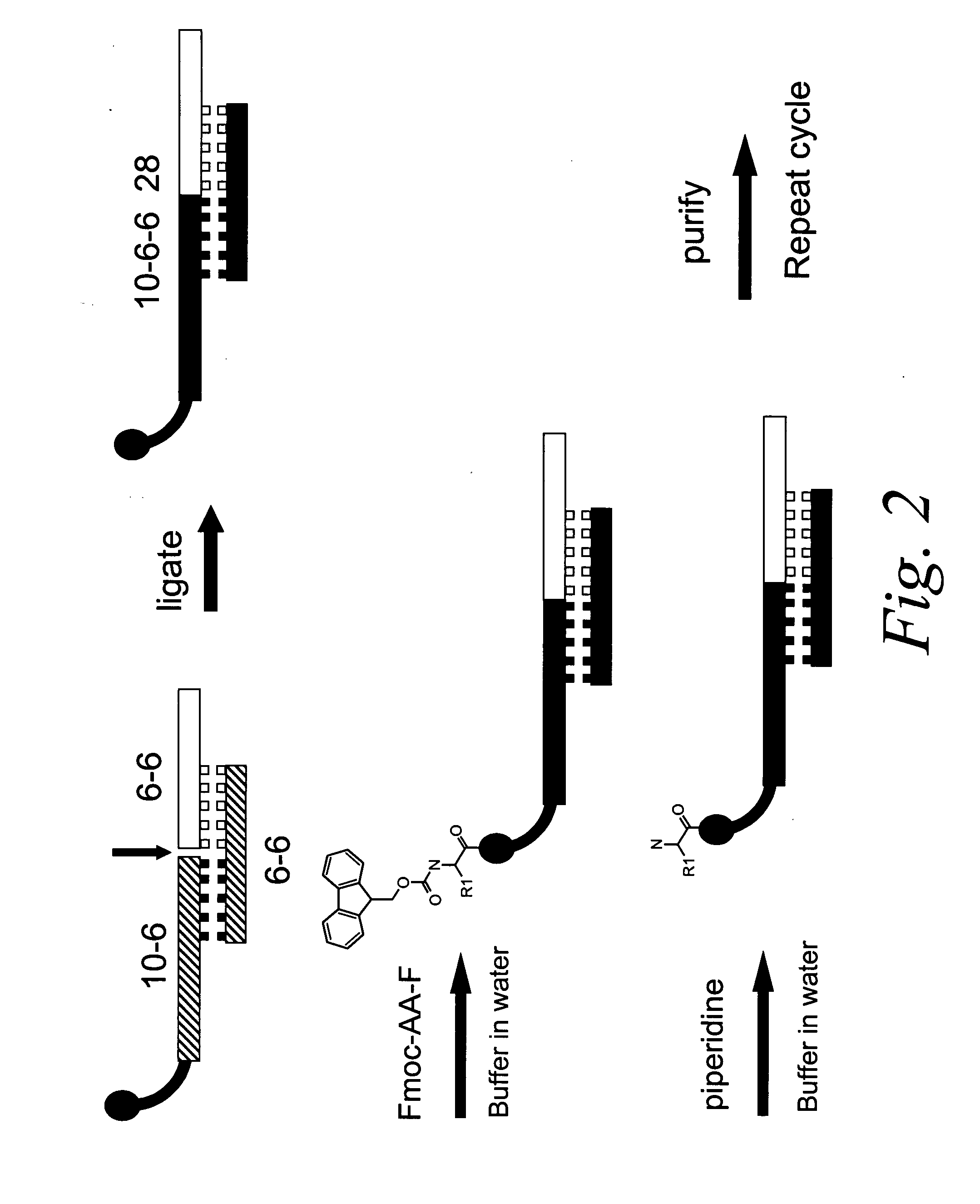

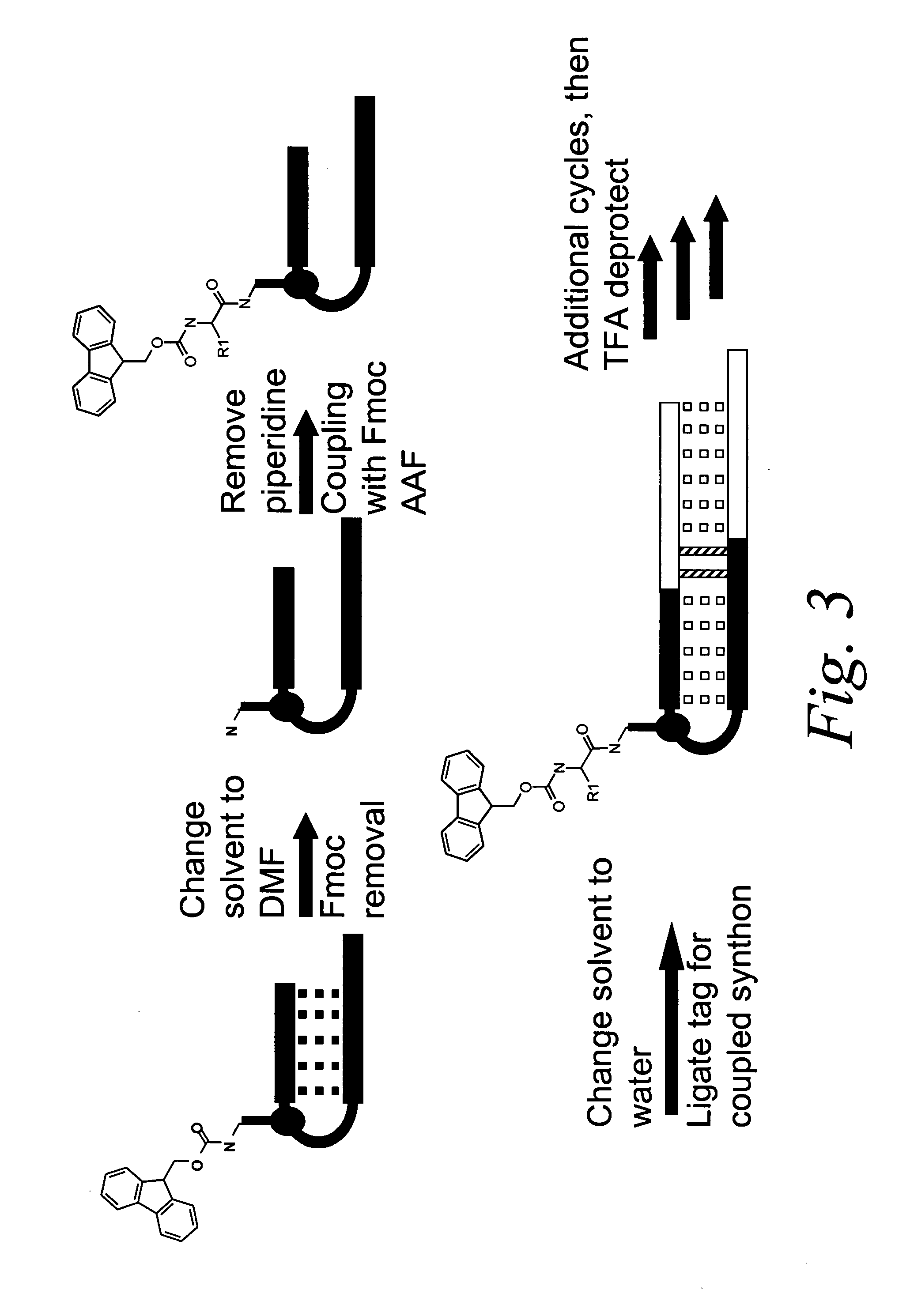

Methods for identifying compounds of interest using encoded libraries

ActiveUS20070224607A1Accurately identifyAccurate identificationPeptide librariesSugar derivativesOligonucleotideBiology

The present invention provides a method for identifying a compound of interest by screening libraries of molecules which include an encoding oligonucleotide tag.

Owner:GLAXO SMITHKLINE LLC

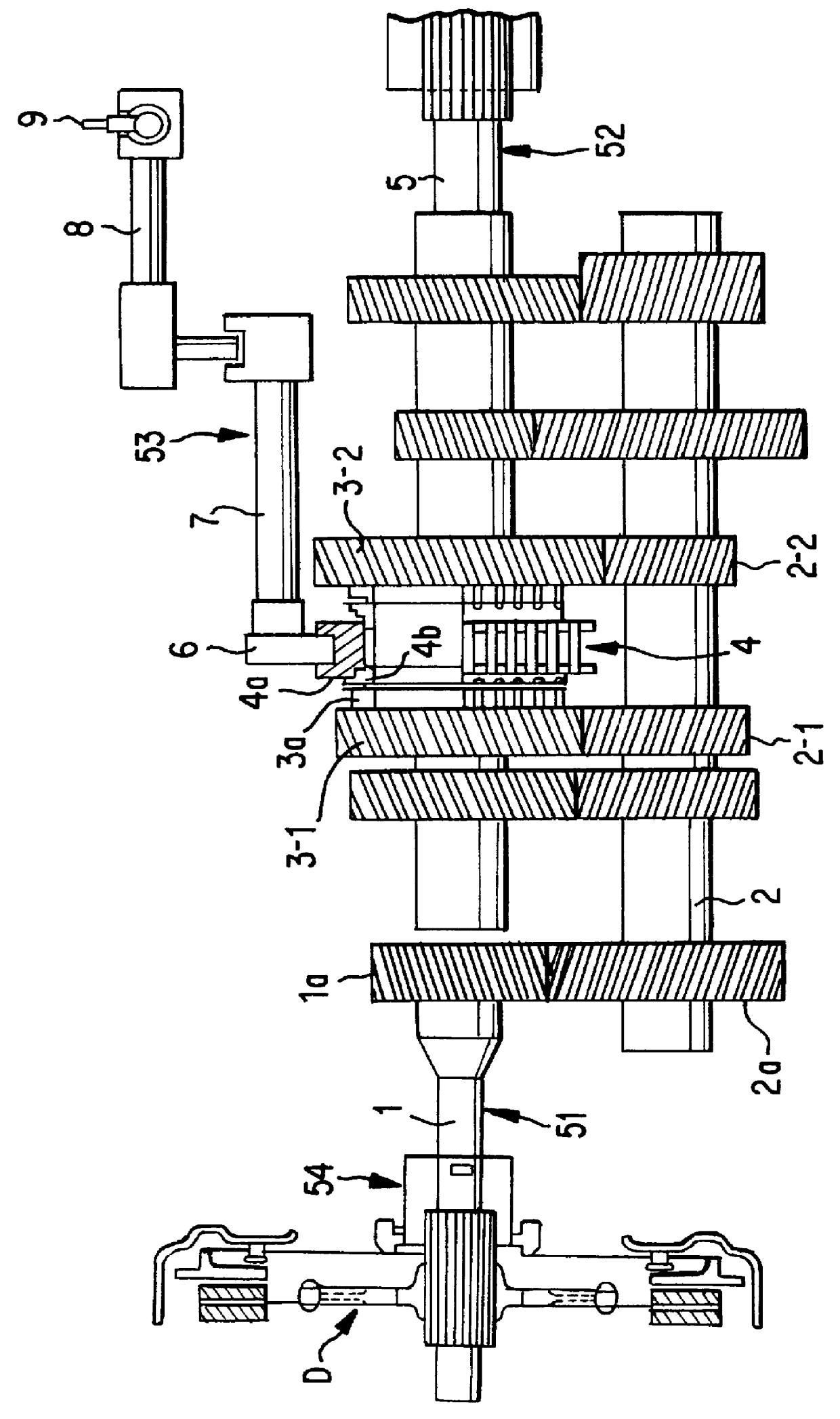

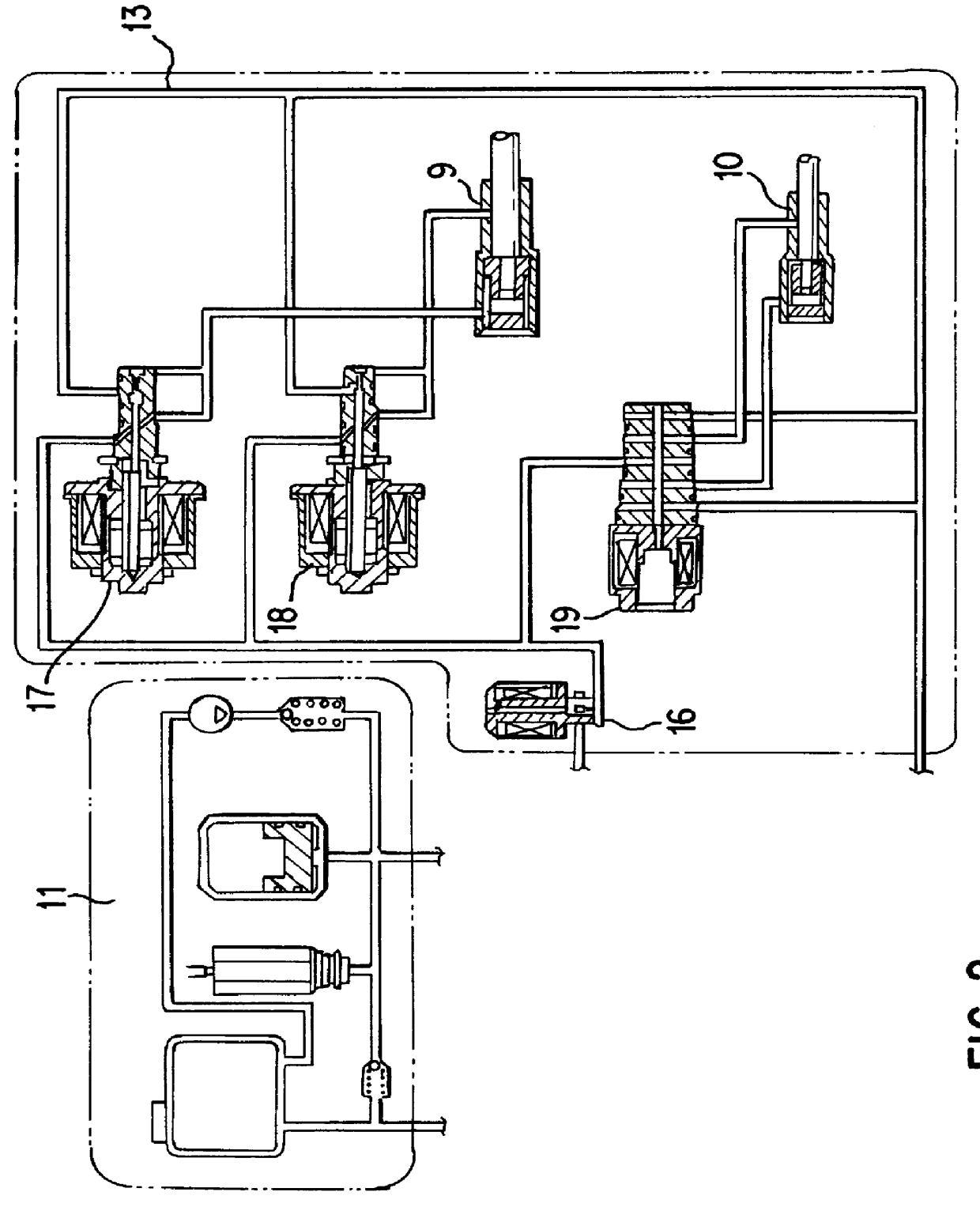

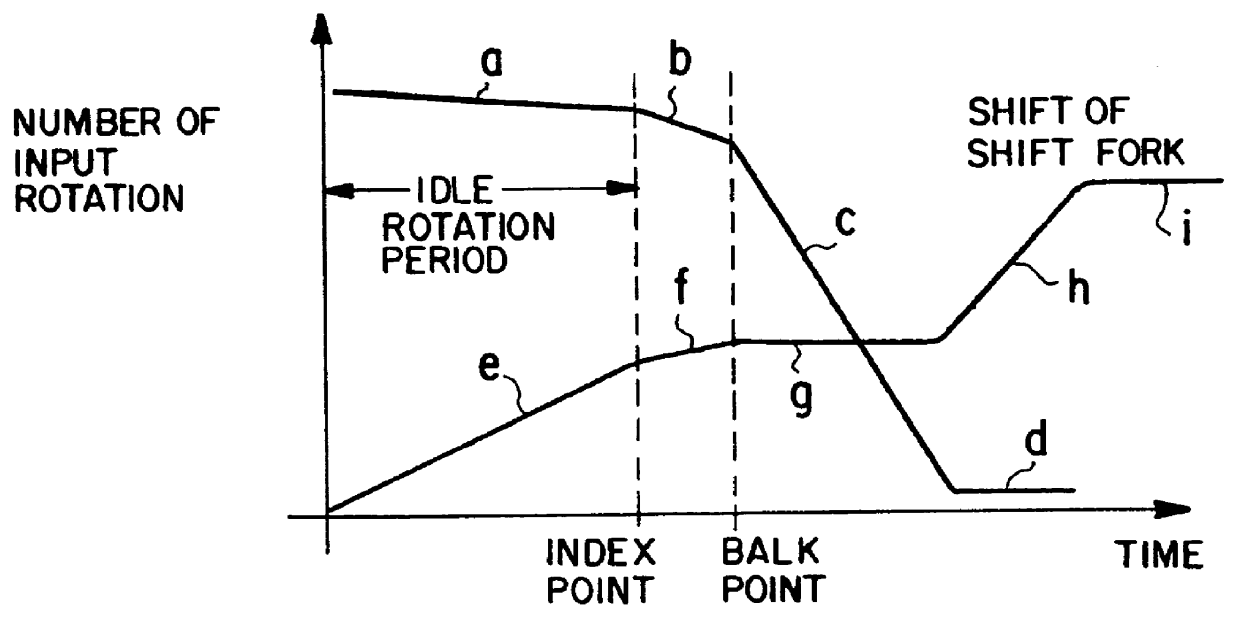

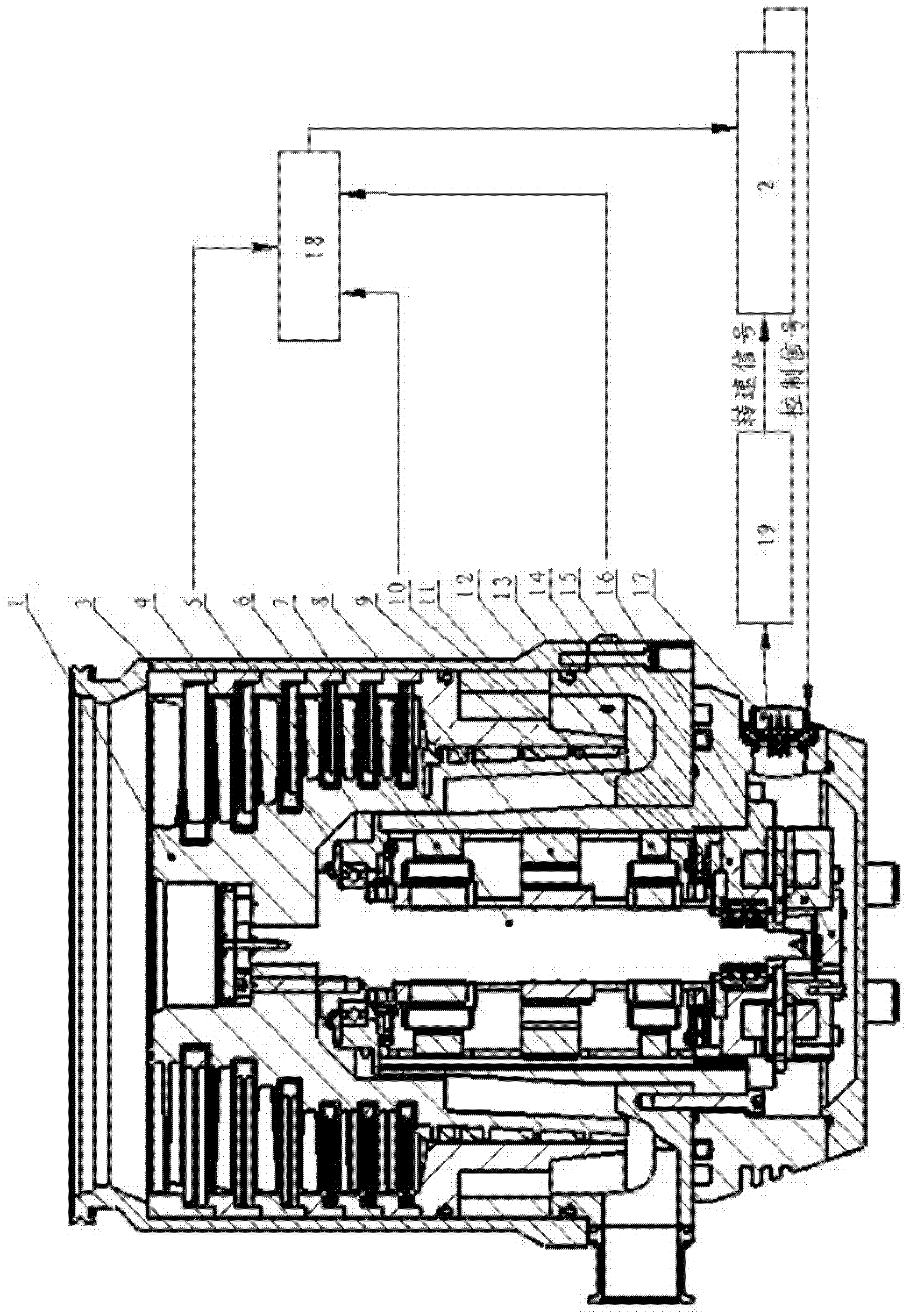

Shifting device for synchromesh-type transmission

InactiveUS6164149AEliminate biasShifting time and enduring character can be further improvedGearing controlEngine controllersDriving currentEngineering

A shifting device for a synchromesh-type transmission is designed to detect an accurate change of the input rotation of each area of the shifting operation, and to set the applying load to the shifting fork based on the change of input rotation. The shifting device for a synchromesh-type transmission includes a detecting device for detecting a rotation change rate of an input shaft, a judging device for judging a balk point based on the rotation change rate of the input shaft detected by said detecting device, and a transmission controlling mechanism including an electric-controlled driving device for driving a shift actuator to shift the shift fork. The driving device controls a drive current to the shift actuator when the balk point is detected by the judging device.

Owner:AISIN AI CO LTD

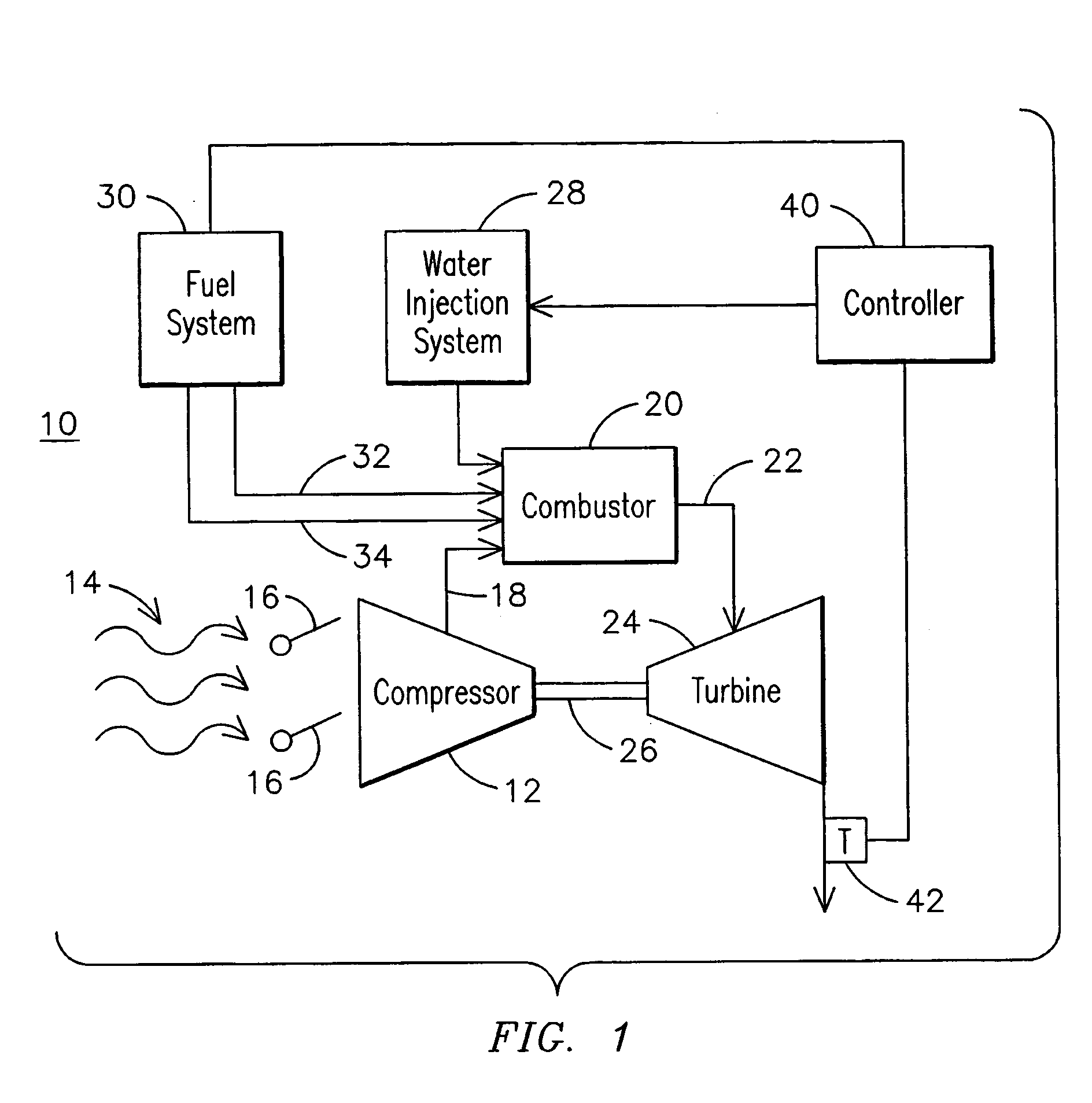

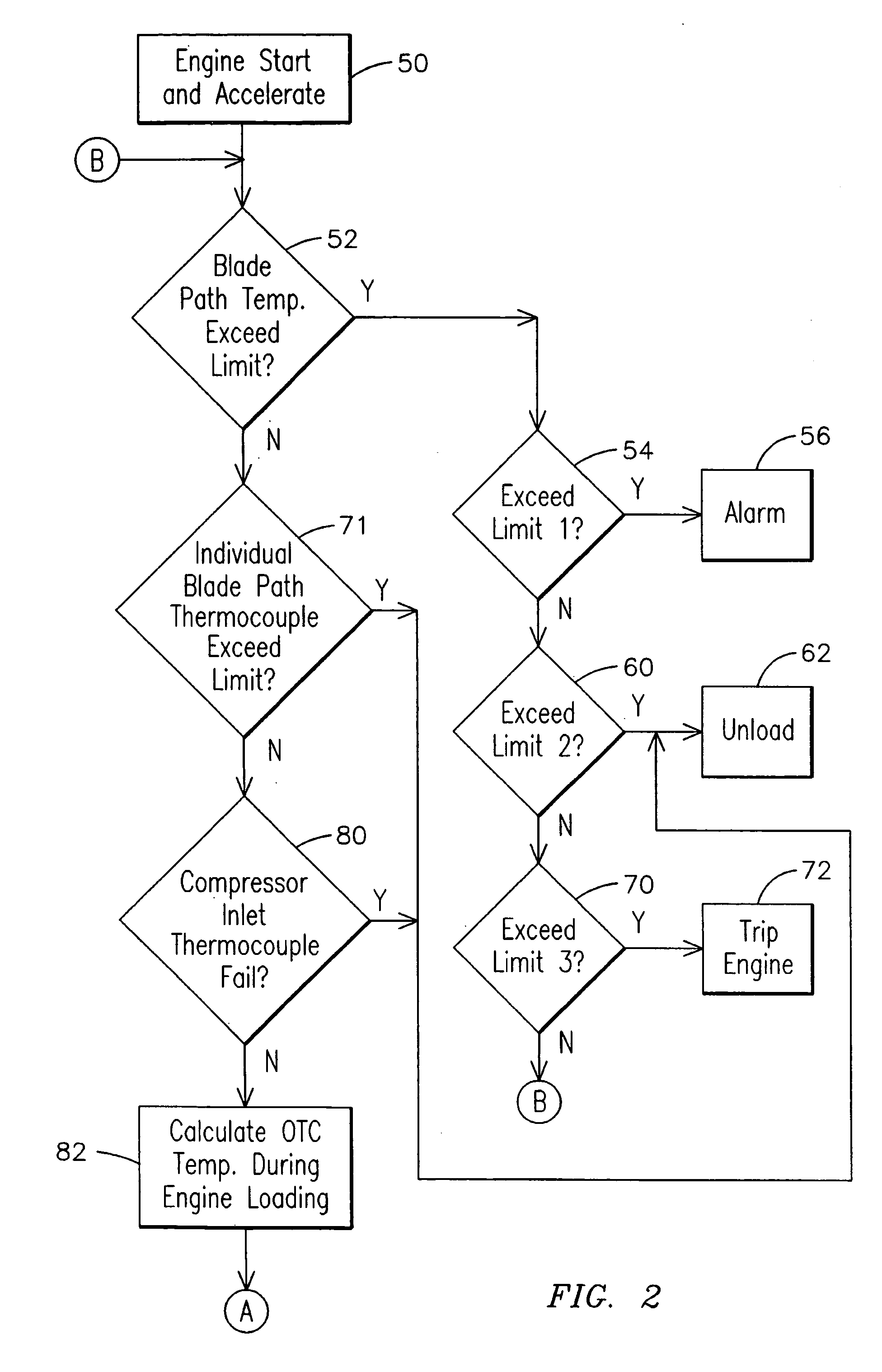

Method of controlling a power generation system

ActiveUS7269953B2Well mixedAccelerate emissionsGas turbine plantsTurbine/propulsion fuel controlCombustorTurbine

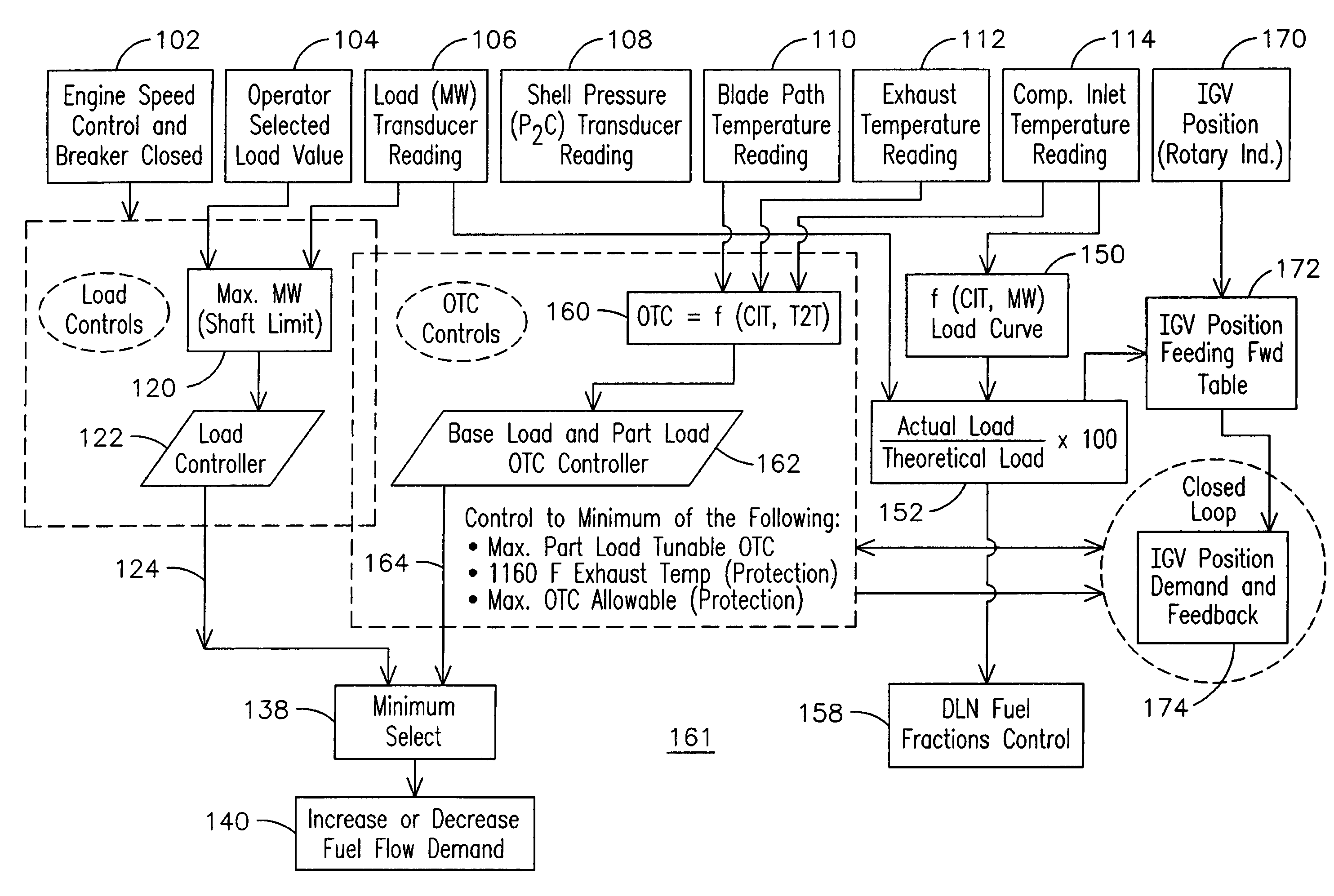

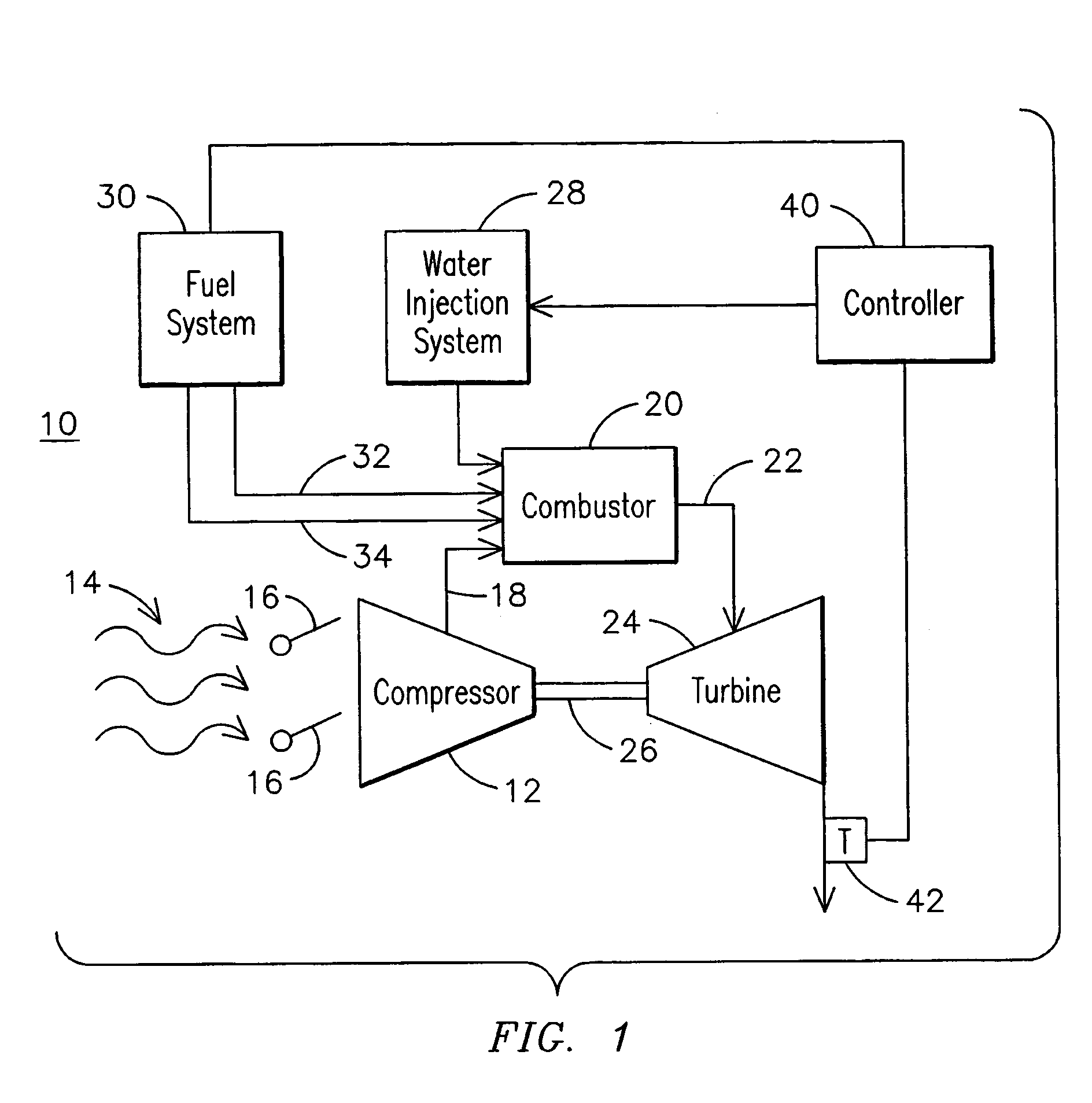

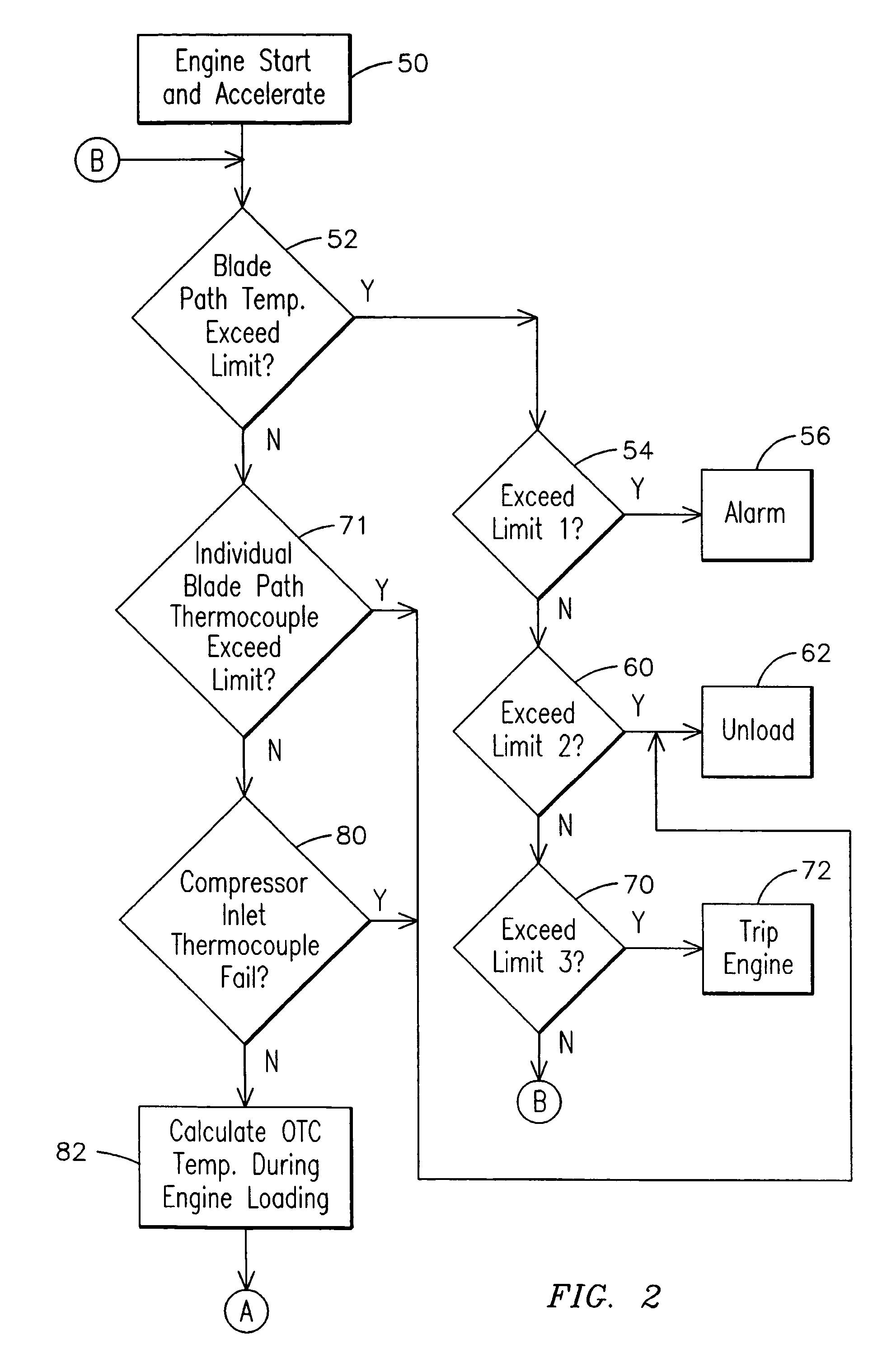

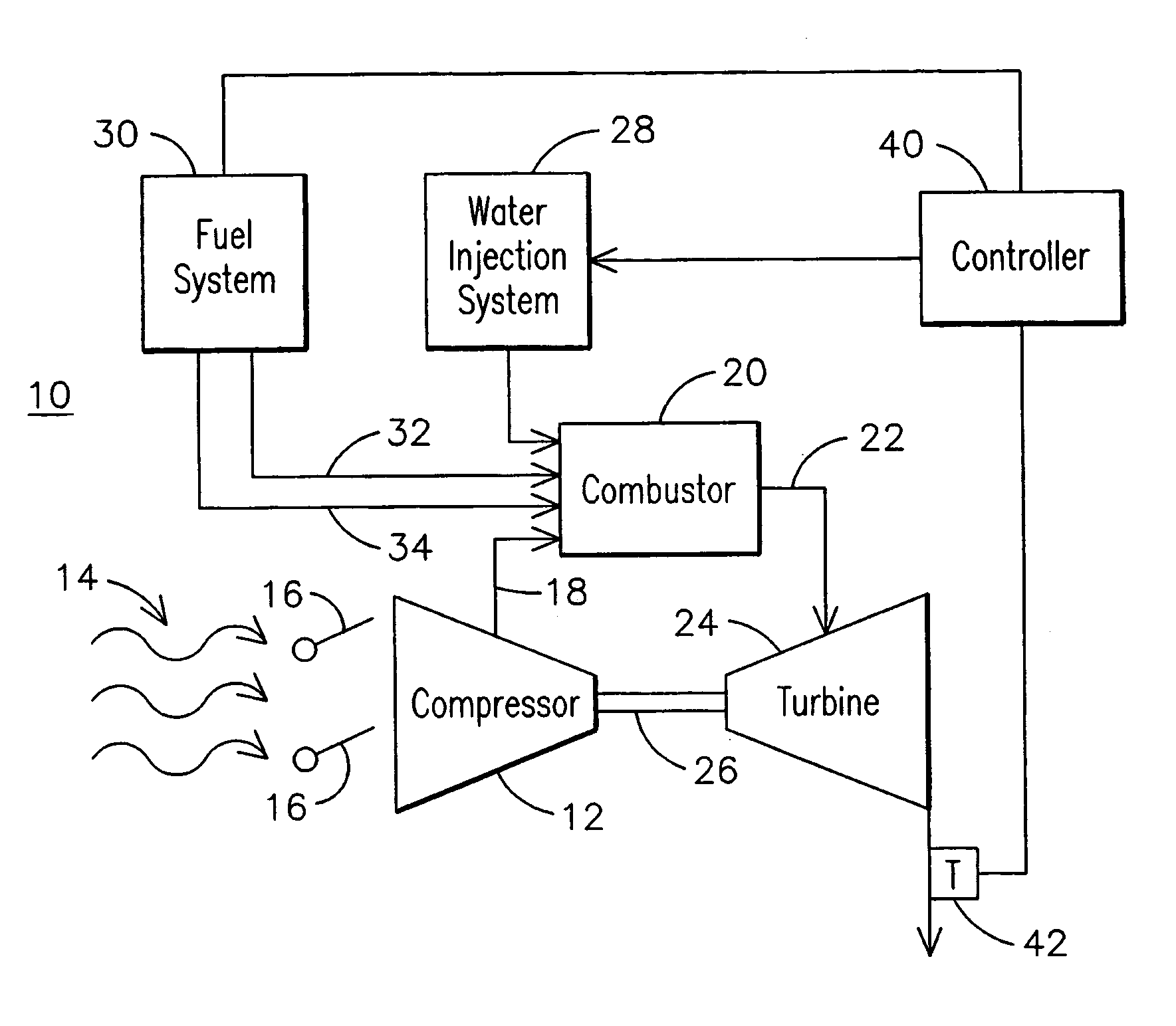

A method of controlling a gas turbine system (10) may include controlling an inlet guide vane position (98) to maintain a turbine (24) exhaust temperature at a corrected value that is a function of a compressor (12) inlet temperature and a turbine (24) normalized load. The method may include selecting the minimum value (138) of a part load tunable value, a part load maximum value and a fixed maximum value of a turbine (24) exhaust temperature for the corrected value. A corrected value setpoint may be determined (94) for the gas turbine system (10) operating at a part load condition where at least one of a fuel flow rate and the inlet guide vane position is controlled (98) so the corrected value does not exceed the corrected value setpoint. The corrected value may prevent a turbine (24) engine from exceeding its firing temperature during operation and ensure the engine operates within combustor dynamics and emissions limits.

Owner:SIEMENS ENERGY INC

Method of controlling a power generation system

ActiveUS20060042258A1Well mixedAccelerate emissionsGas turbine plantsTurbine/propulsion fuel controlCombustorTurbine

A method of controlling a gas turbine system (10) may include controlling an inlet guide vane position (98) to maintain a turbine (24) exhaust temperature at a corrected value that is a function of a compressor (12) inlet temperature and a turbine (24) normalized load. The method may include selecting the minimum value (138) of a part load tunable value, a part load maximum value and a fixed maximum value of a turbine (24) exhaust temperature for the corrected value. A corrected value setpoint may be determined (94) for the gas turbine system (10) operating at a part load condition where at least one of a fuel flow rate and the inlet guide vane position is controlled (98) so the corrected value does not exceed the corrected value setpoint. The corrected value may prevent a turbine (24) engine from exceeding its firing temperature during operation and ensure the engine operates within combustor dynamics and emissions limits.

Owner:SIEMENS ENERGY INC

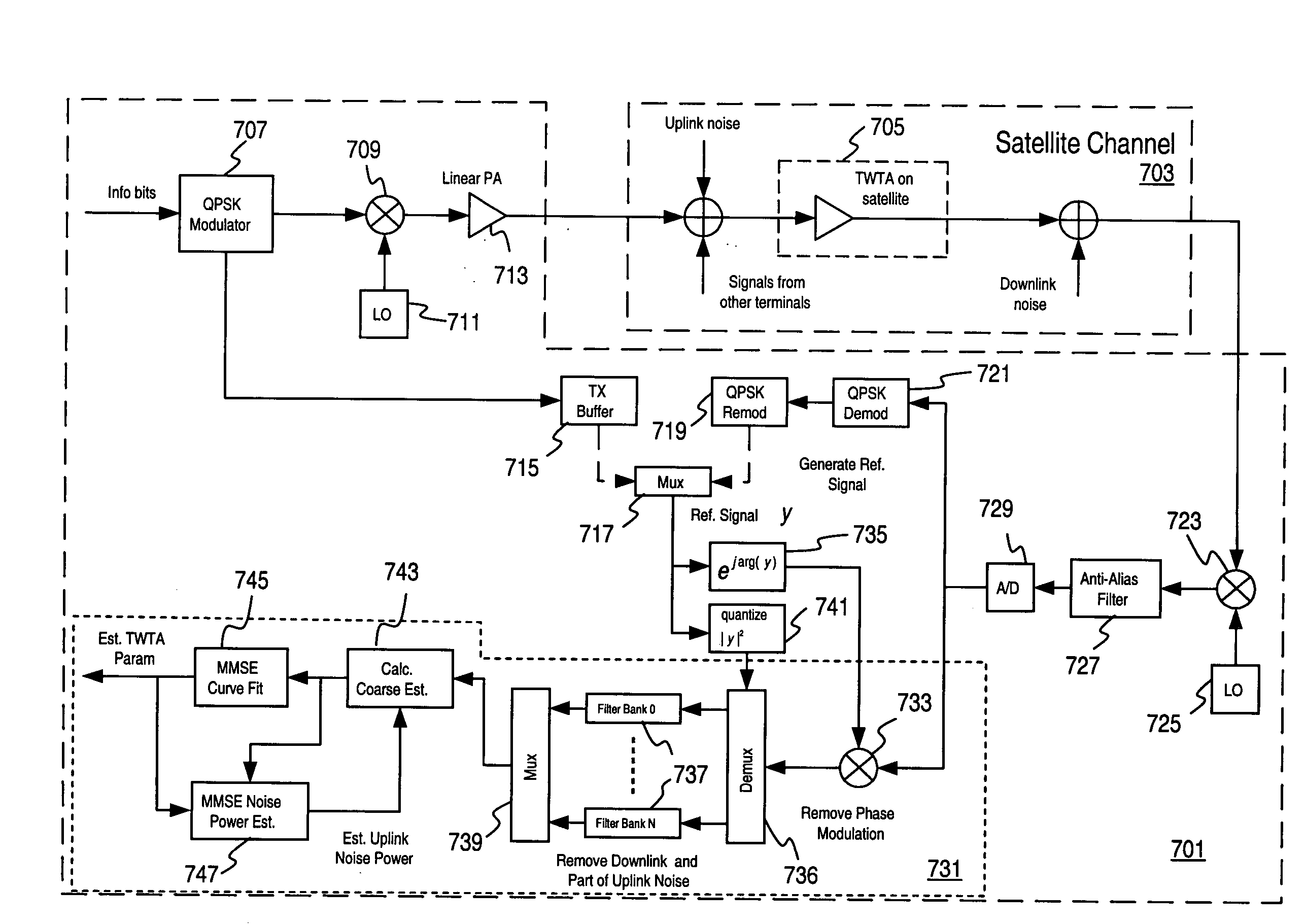

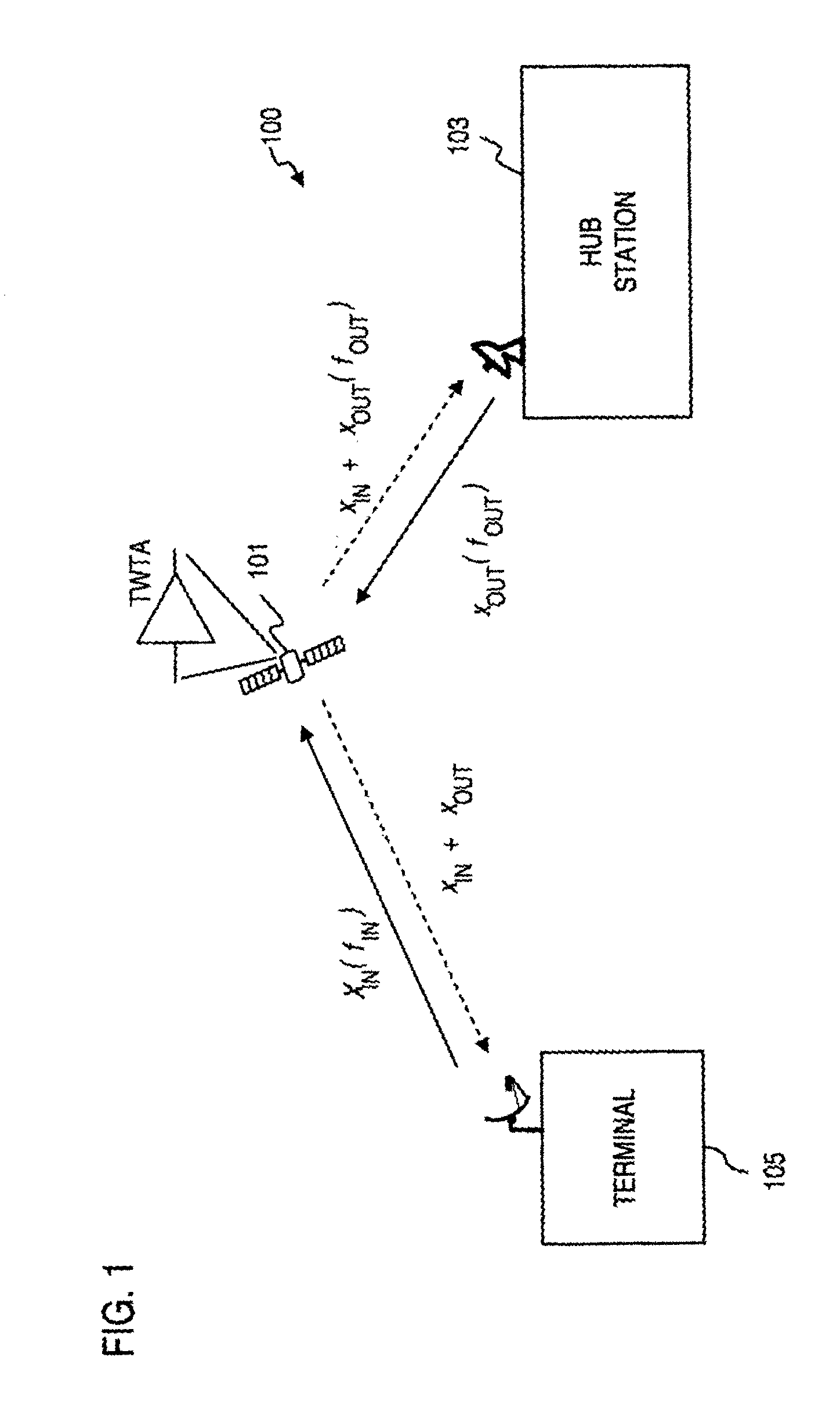

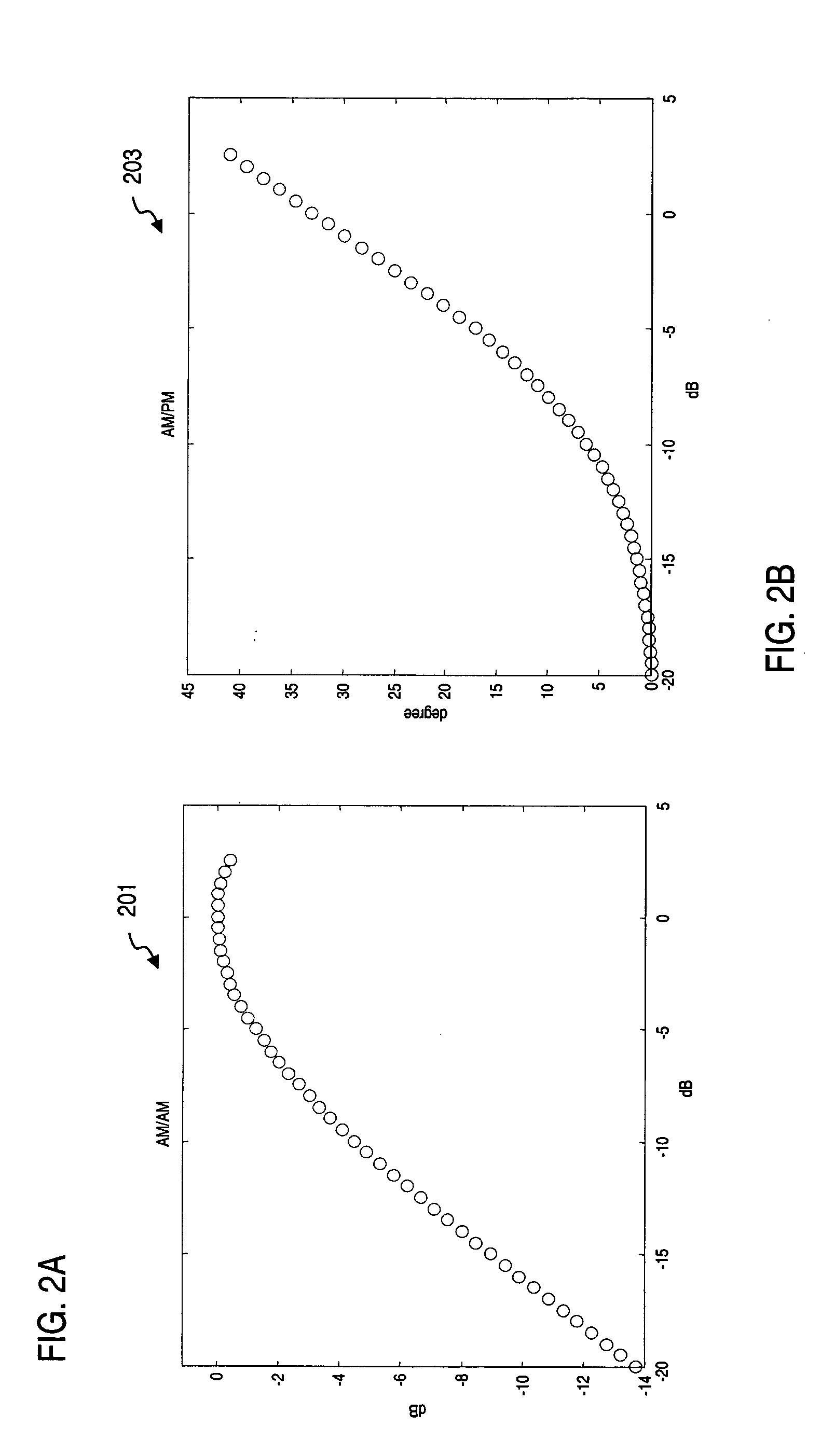

Method and apparatus of estimating non-linear amplifier response in an overlaid communication system

InactiveUS20050032472A1Eliminate biasAccurate reconstructionResonant long antennasRadio transmissionAudio power amplifierCommunications system

An approach is provided estimating non-linear characteristics of an amplifier (such as a Travelling Wave Tube Amplifier) used to amplify a composite signal in a radio communication system. The composite signal, which includes a plurality of inbound signals overlay on an outbound signal, is sampled. The outbound signal is utilized as a training signal. Coarse estimates of the response of the amplifier is generated based on the samples of the composite signal and the training signal. Further, the interference associated with the inbound signals are removed from the estimation of the response of the amplifier by curve-fitting and estimating interference characteristics of the composite signal. An estimated response of the amplifier is thus output, and can be utilized to provide accurate non-linearity compensation and cancellation.

Owner:HUGHES NETWORK SYST

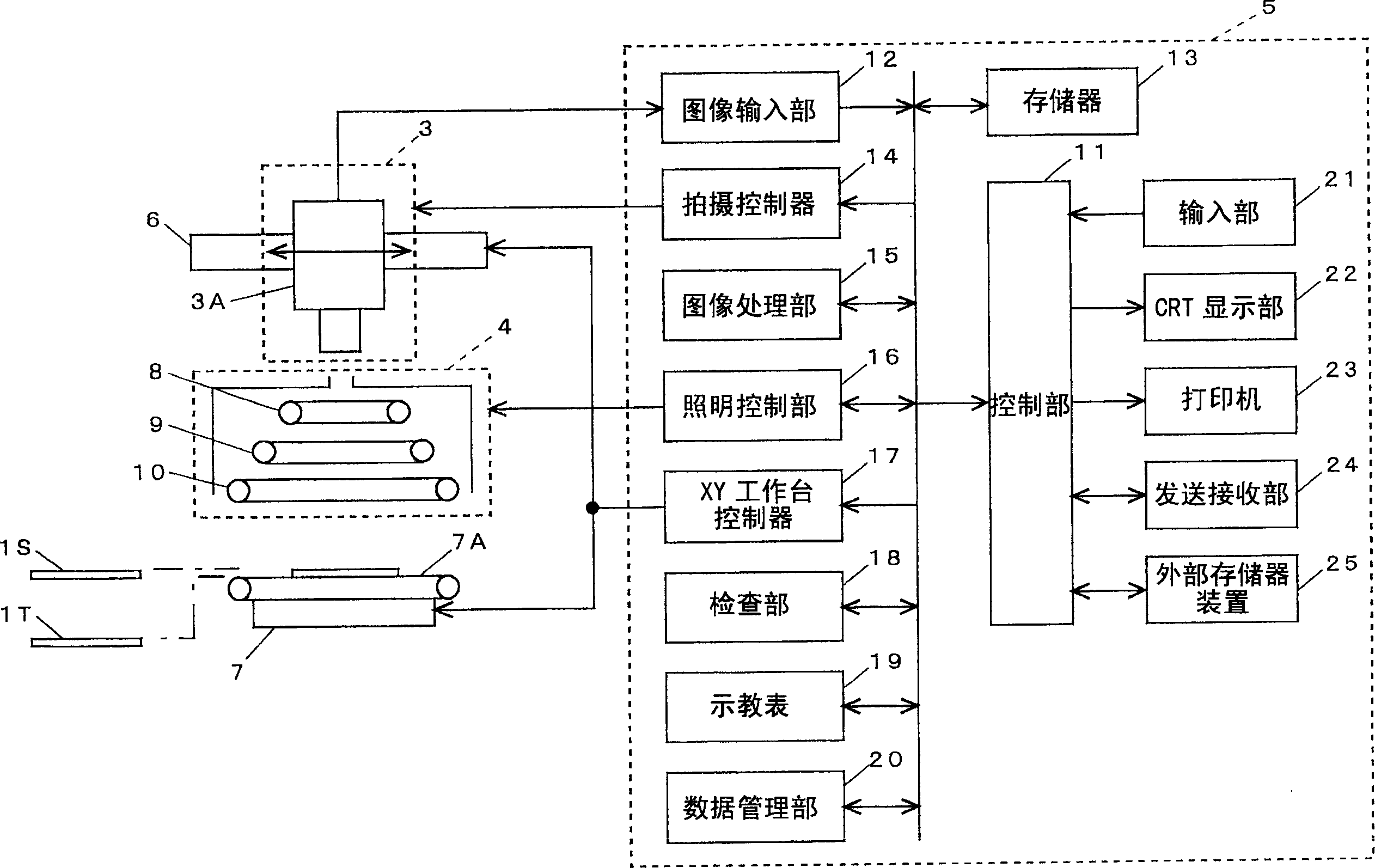

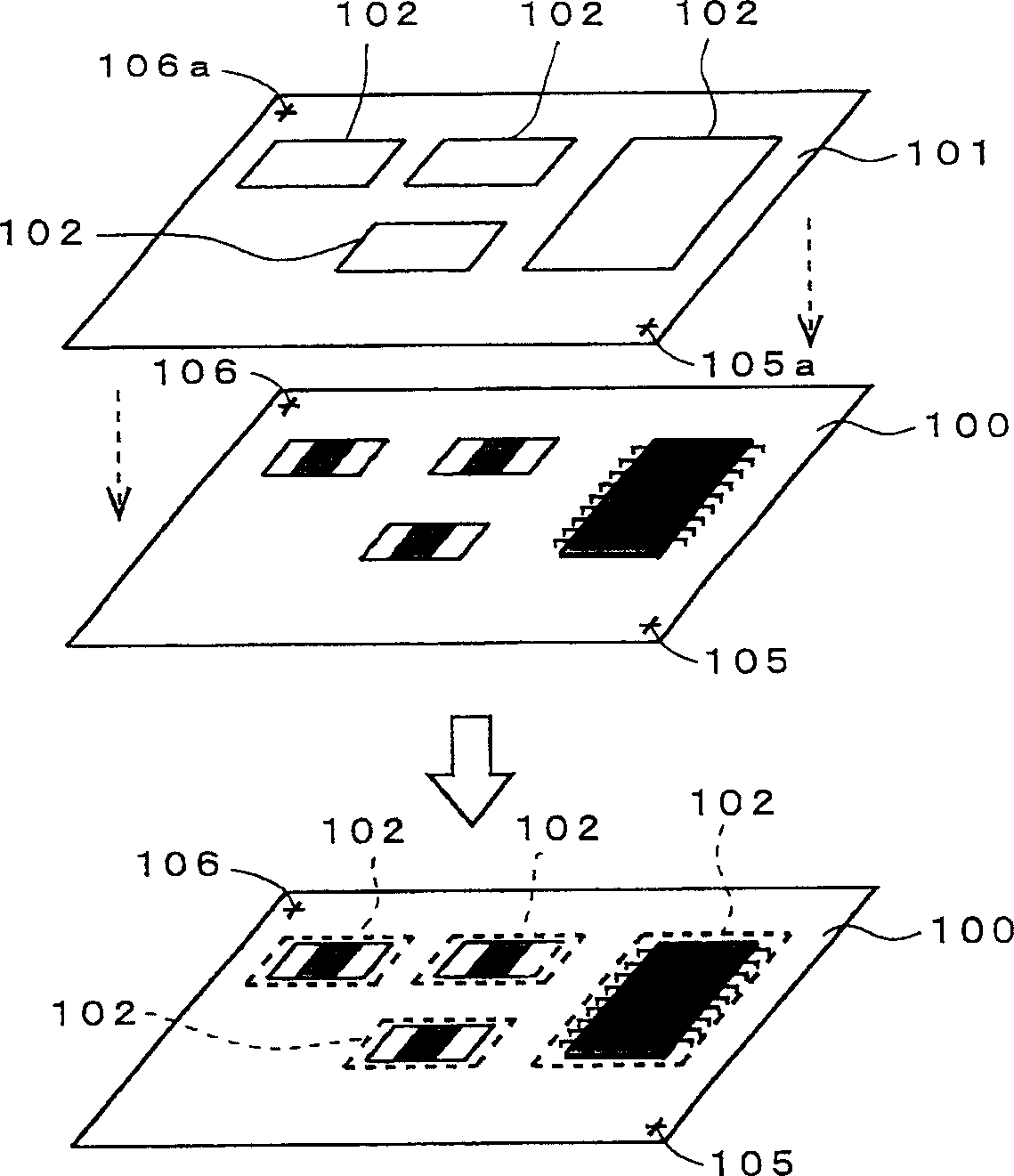

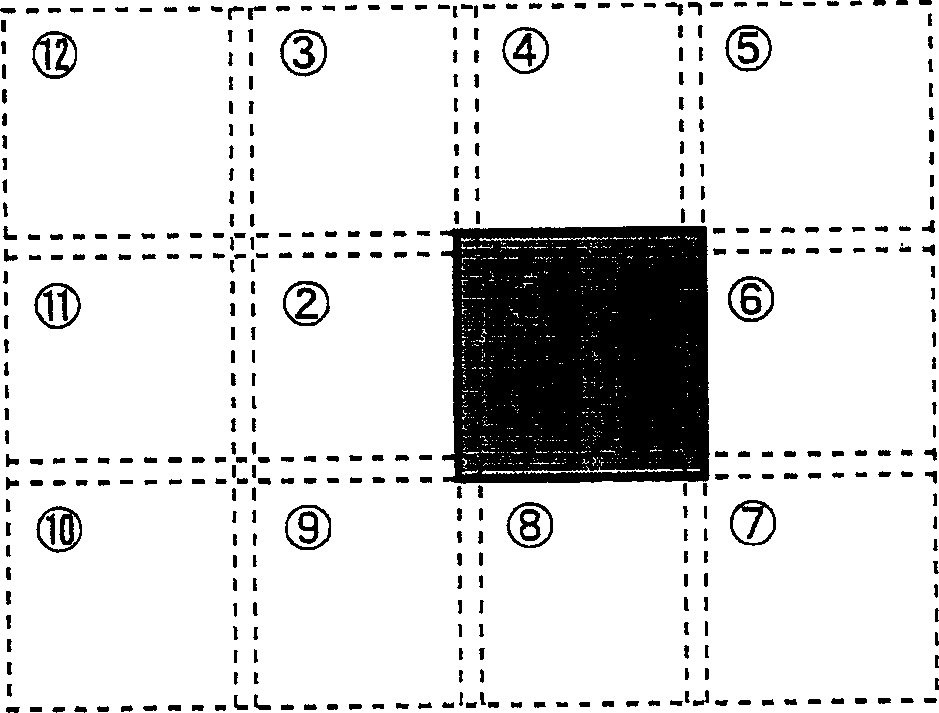

Substrate inspection method and apparatus

ActiveCN1746667AEliminate biasHigh precisionMaterial analysis by optical meansCharacter and pattern recognitionComputer visionInspection method

The invention provides a substrate checking method and a substrate checking device, completing high-precision setting of the checking area of a checked part to improve checking precision. The invention comprises the following steps: an overall image (103) of the substrate of a checking object is made in advance; correspondence is set up in advance between a checking area (31) and the checked part on the overall image (103); during checking, a camera (3A) is located at a position corresponding to a shooting object area (30) to carry out shooting; when a processing object image (40) is obtained, an area (41) corresponding to the processing object image (40) is extracted from the overall image (103); the amount of deviation (Delta x, Delta y) of the shooting object area (30) relative to the area (41) is calculated; in addition, the set location of the checking area (31) is corrected by means of the amount of deviation (Delta x, Delta y), and a checking area is set on the processing object image (40) according to the corrected coordinates.

Owner:ORMON CORP

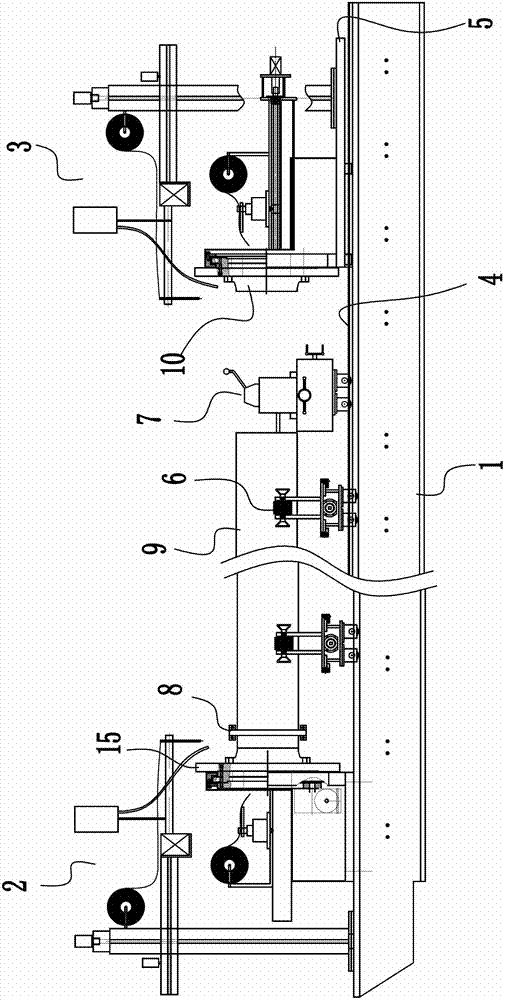

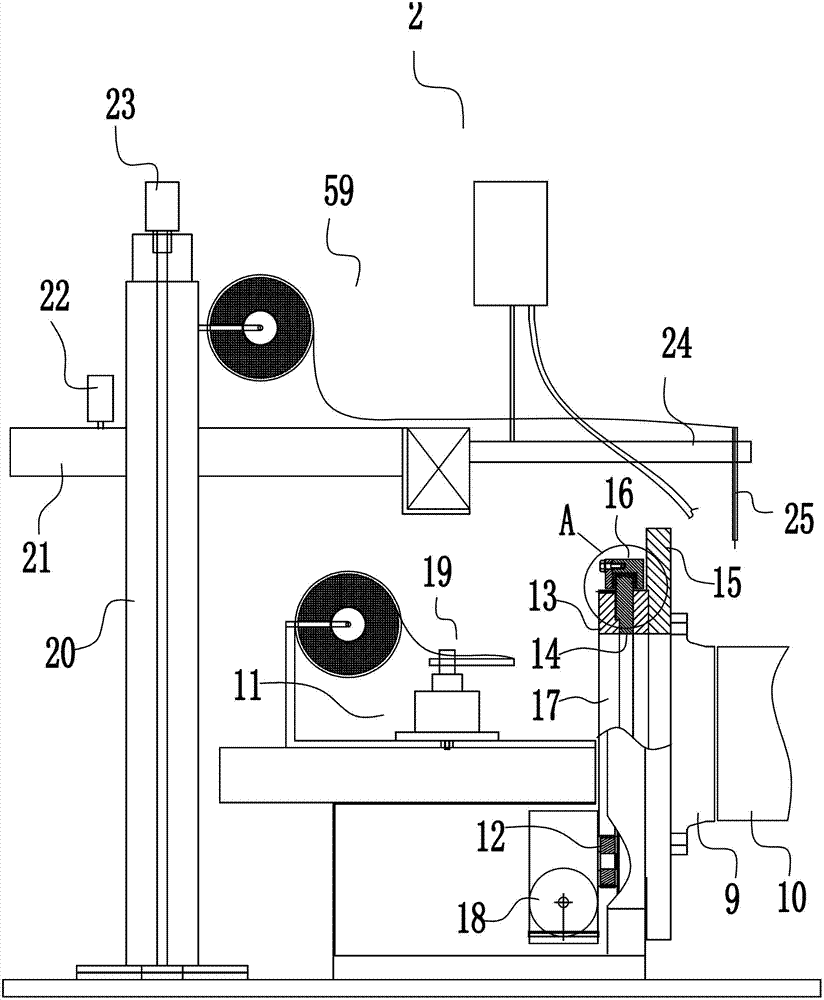

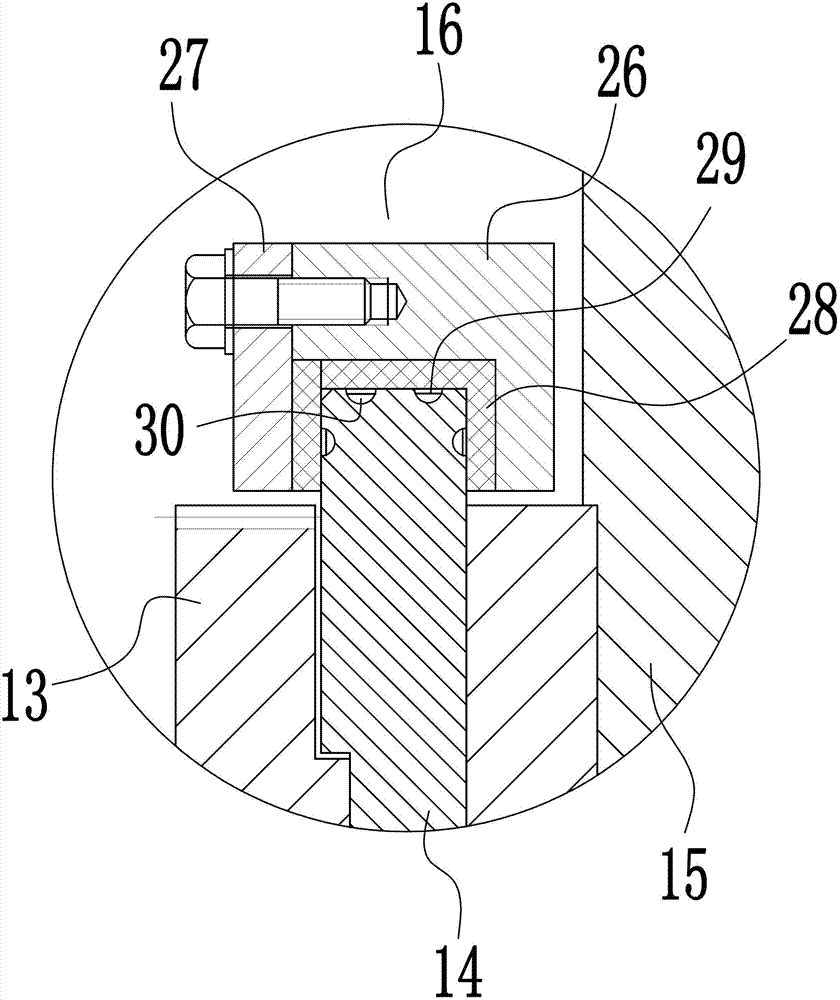

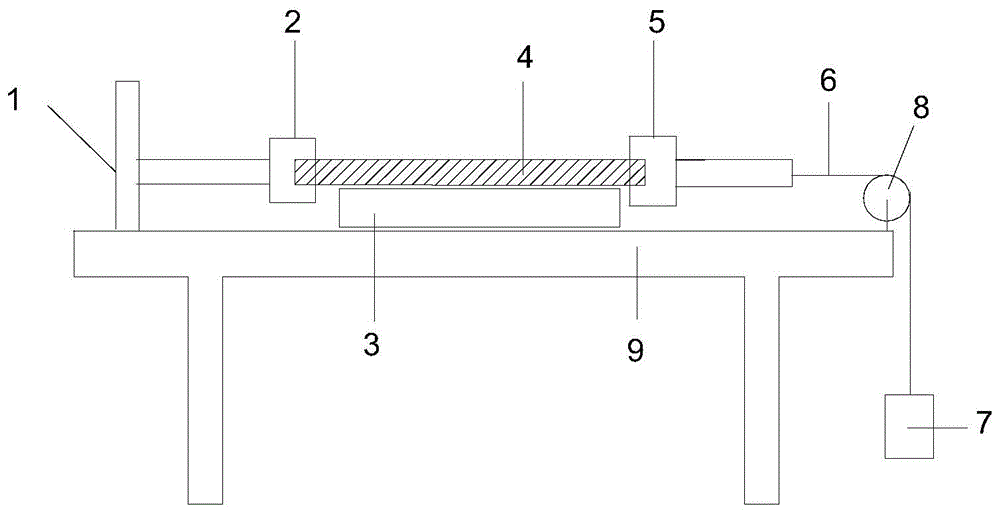

Integrated steel pipe and flange splicing and machining machine and machining process thereof

InactiveCN102729045ALarge amount of welding depositionImprove welding speed and qualityArc welding apparatusOther manufacturing equipments/toolsSteel tubeMachining process

The invention discloses an integrated steel pipe and flange splicing and machining machine and a machining process thereof and aims to provide an integrated steel pipe and flange splicing and machining machine which can improve the manufacturing precision and the production efficiency and reduce the labor intensity and is high in steel pipe and flange welding quality and a machining process of the machine. The integrated steel pipe and flange splicing and machining machine comprises a working platform, and a supporting bracket which is arranged on the working platform and is used for supporting a steel pipe, wherein one end of the working platform is provided with a first welding device; a first guide rail which extends to the other end of the working platform is arranged on the top of the working platform; a first mounting plate is arranged on the first guide rail in a sliding mode; a second welding device is arranged on the first mounting plate; and flange fixing templates are arranged on the first welding device and the second welding device. The machining process comprises the following steps of: lifting the steel pipe to the supporting bracket, and fixing the flange to a flange fixing template; and welding annular gaps of the inner and outer side faces of the steel pipe and the flange through the first welding device and the second welding device.

Owner:戴刚平

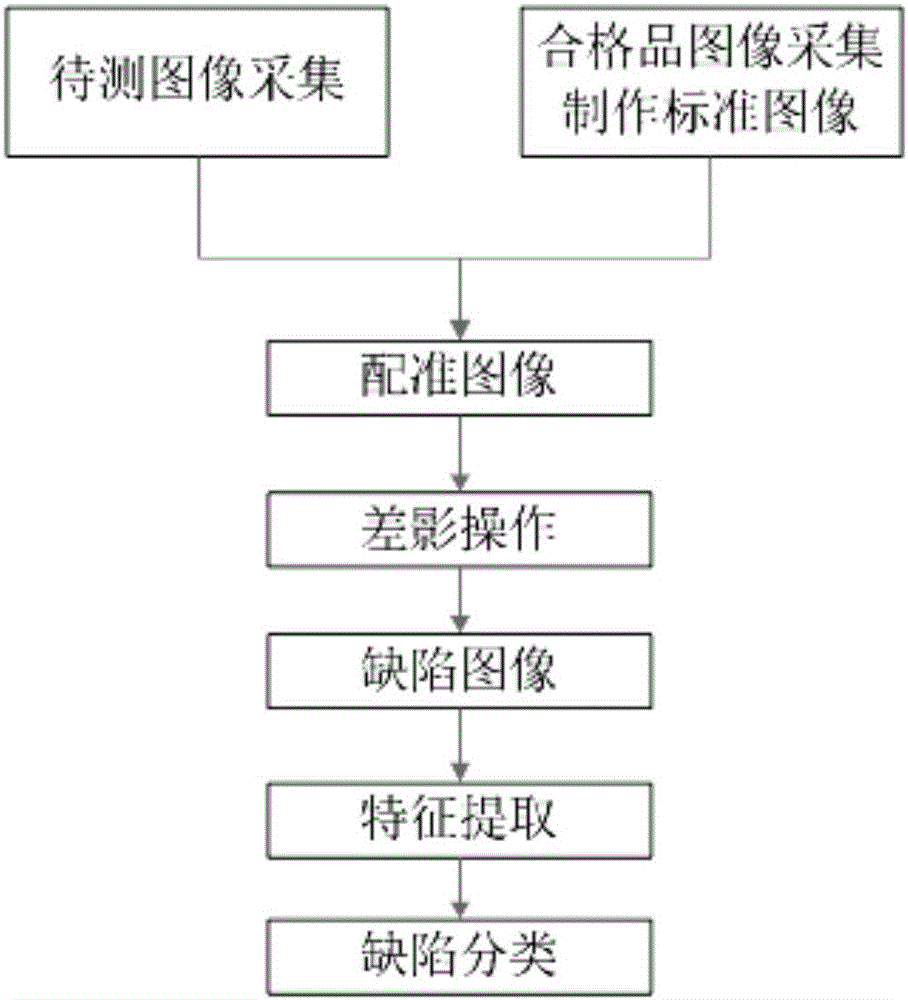

Product packaging surface defect detection and classification method based on machine vision

InactiveCN106204618AAvoid human interferenceAvoid trainingImage enhancementImage analysisColor imageFeature extraction

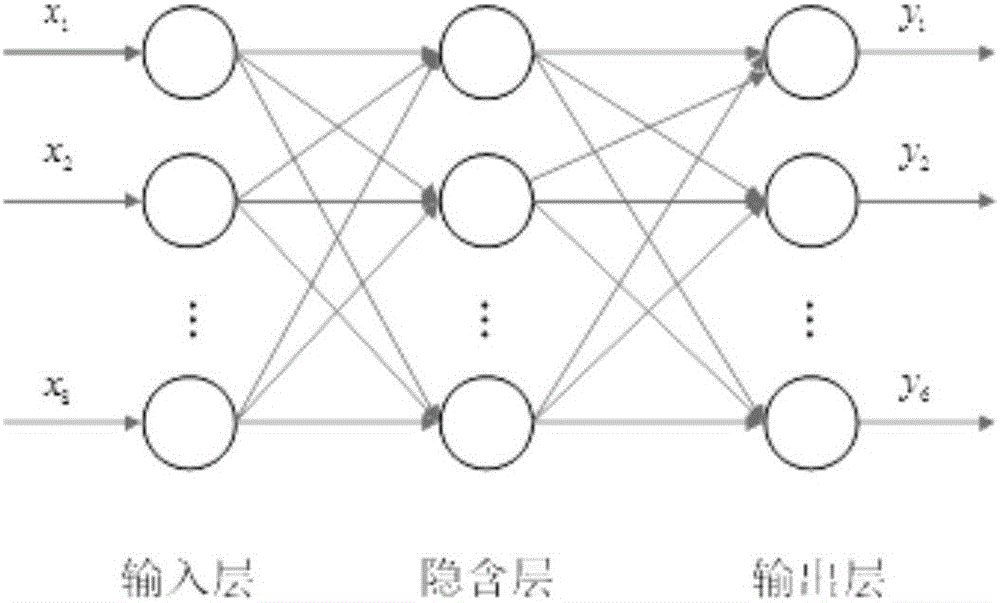

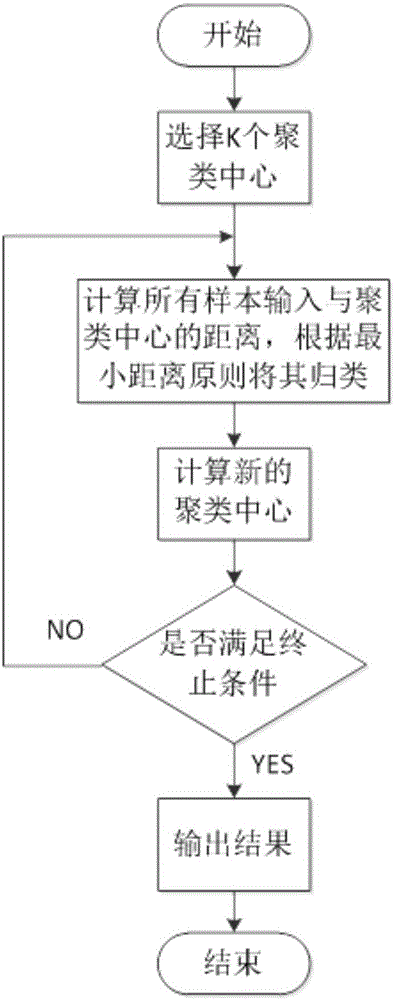

The invention discloses a product packaging surface defect detection and classification method based on machine vision. The method comprises the steps of 1, acquiring a high-definition color image of defect-free product packaging, making the high-definition color image into a standard image, conducting real-time shooting with a camera, conducting online acquisition of a high-definition color image of product packaging to be detected, and making the high-definition color image as an image to be detected; 2, conducting image matching on the image to be detected and the standard image based on SURF algorithm; 3, conducting difference image operation on the two images matched in step 2 to obtain a defective image; 4, conducting feature extraction on the defective image to obtain the geometrical features and color features of the defective image; 5, classifying product packaging surface defects by means of RBF neural network algorithm. Automatic defect detection and classification are conducted by means of a machine vision system, human factor interference can be avoided, labor cost is reduced greatly, and then huge hidden cost caused by training and management when artificial detection is adopted is avoided.

Owner:NANJING WENCAI SCI & TECH

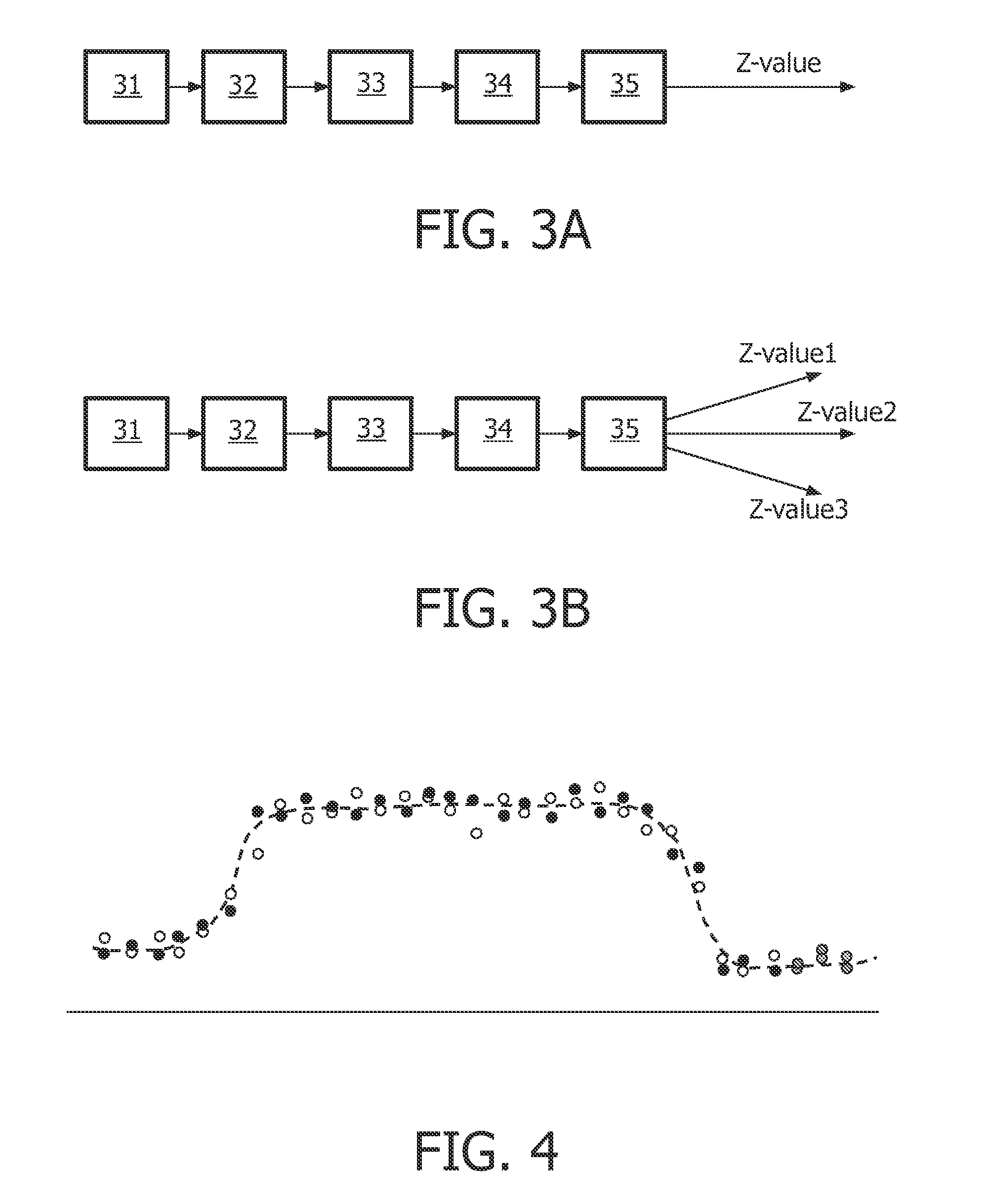

Method for determining a depth map from images, device for determining a depth map

InactiveUS20090324059A1Promote resultsConvenient ArrangementImage analysisCharacter and pattern recognitionDepth mapSurface filter

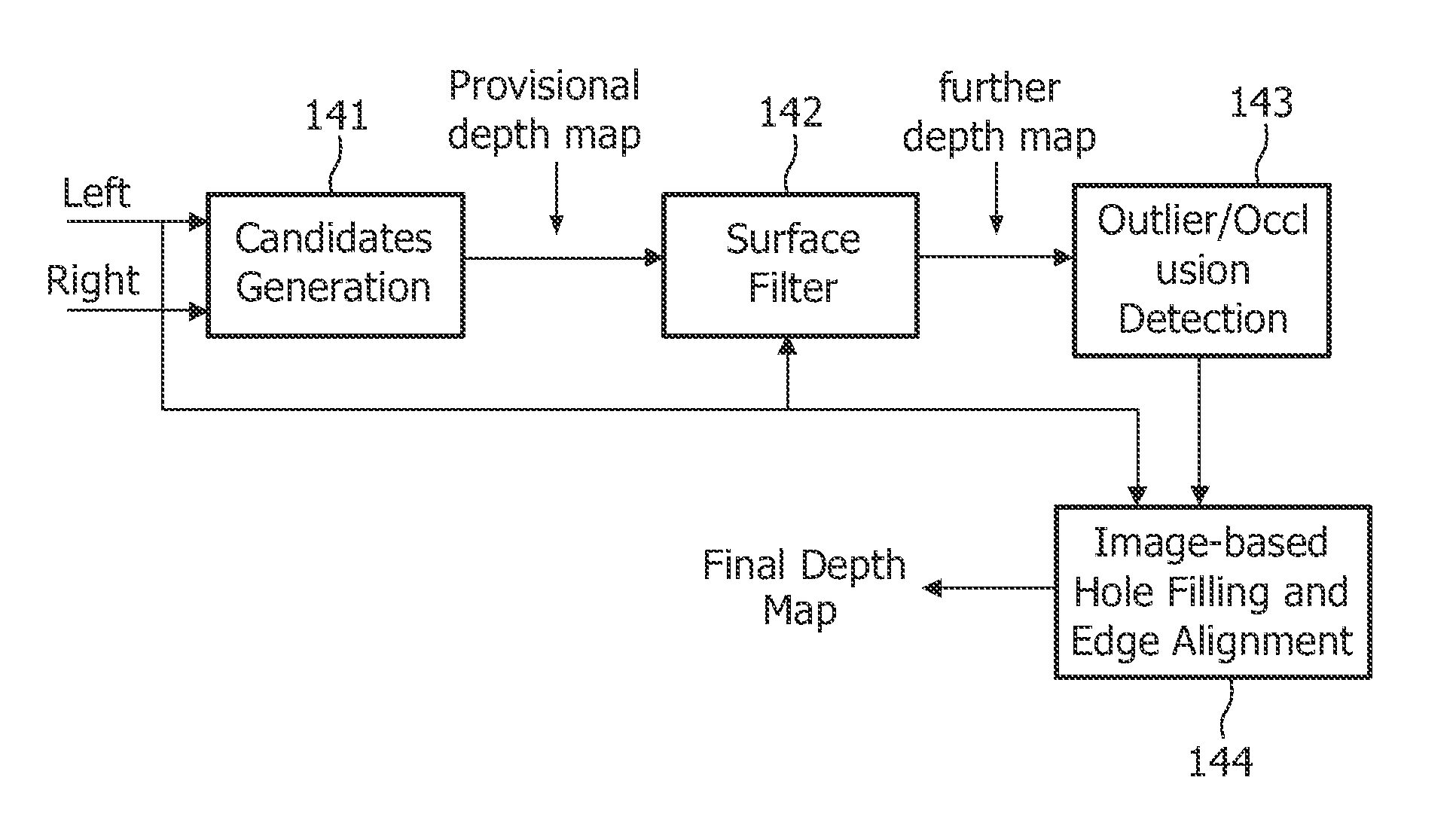

Window based matching is used to determine a depth map from images obtained from different orientations. A set of matching windows is used for points of the image for which the depth is to be determined. A provisional depth map is generated wherein to each point more than one candidate disparity value is attributed. The provisional depth map is filtered by a surface filtering wherein at least the z-component of a norm of a sum of unit vectors pointing from the candidate disparity values for neighboring points to a point of interest.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

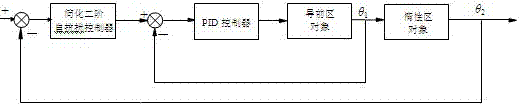

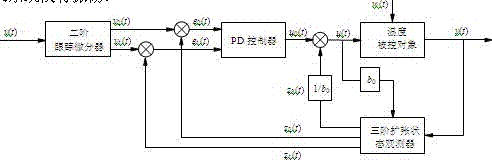

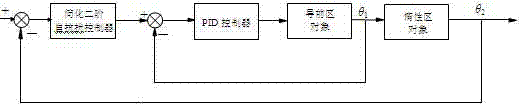

Method for controlling main steam temperature in power plant based on simplified second-order auto disturbance rejection controller

InactiveCN102360176AEasy to adjustRealize decoupling controlControllers with particular characteristicsCompensation effectControl manner

The invention discloses a method for controlling a main steam temperature in a power plant based on a second-order simplified auto disturbance rejection controller. In the method, a cascade control mode is used for forming a cascade steam temperature mediation and control system; in an inner ring, proportion integration differentiation (PID) adjustment is used for eliminating the deviation of an advance timing steam temperature to achieve a coarse tuning effect on an overheating steam temperature; in an outer ring, the simplified second-order auto disturbance rejection controller is used for controlling the outlet temperature of an overheater, so that the defects of large inertia and large delay of a temperature object in an inertia area are fully overcome; and by a disturbance compensation effect of the simplified second-order auto disturbance rejection controller, the disturbance of factors such as loads, flue gas and the like is eliminated, so that the stability of the main steam temperature is ensured. In the method, an algorithm is simple, a parameter is easy to adjust, and a higher response speed, higher steady state accuracy, higher disturbance resistance and higher robustness can be well acquired without dependence on a mathematical model with an accurate main steam temperature in the power plant.

Owner:SHANDONG ELECTRIC POWER SCHOOL

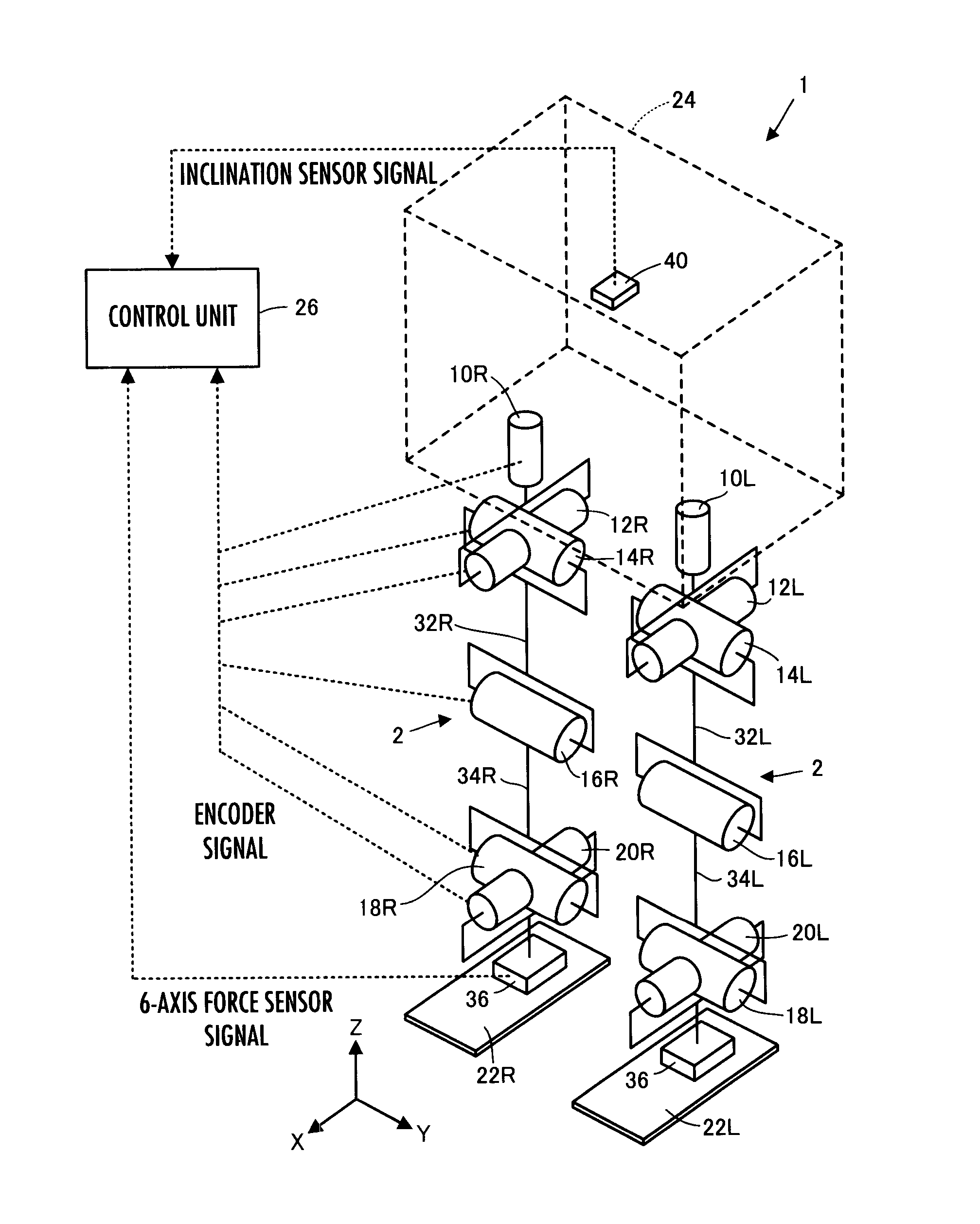

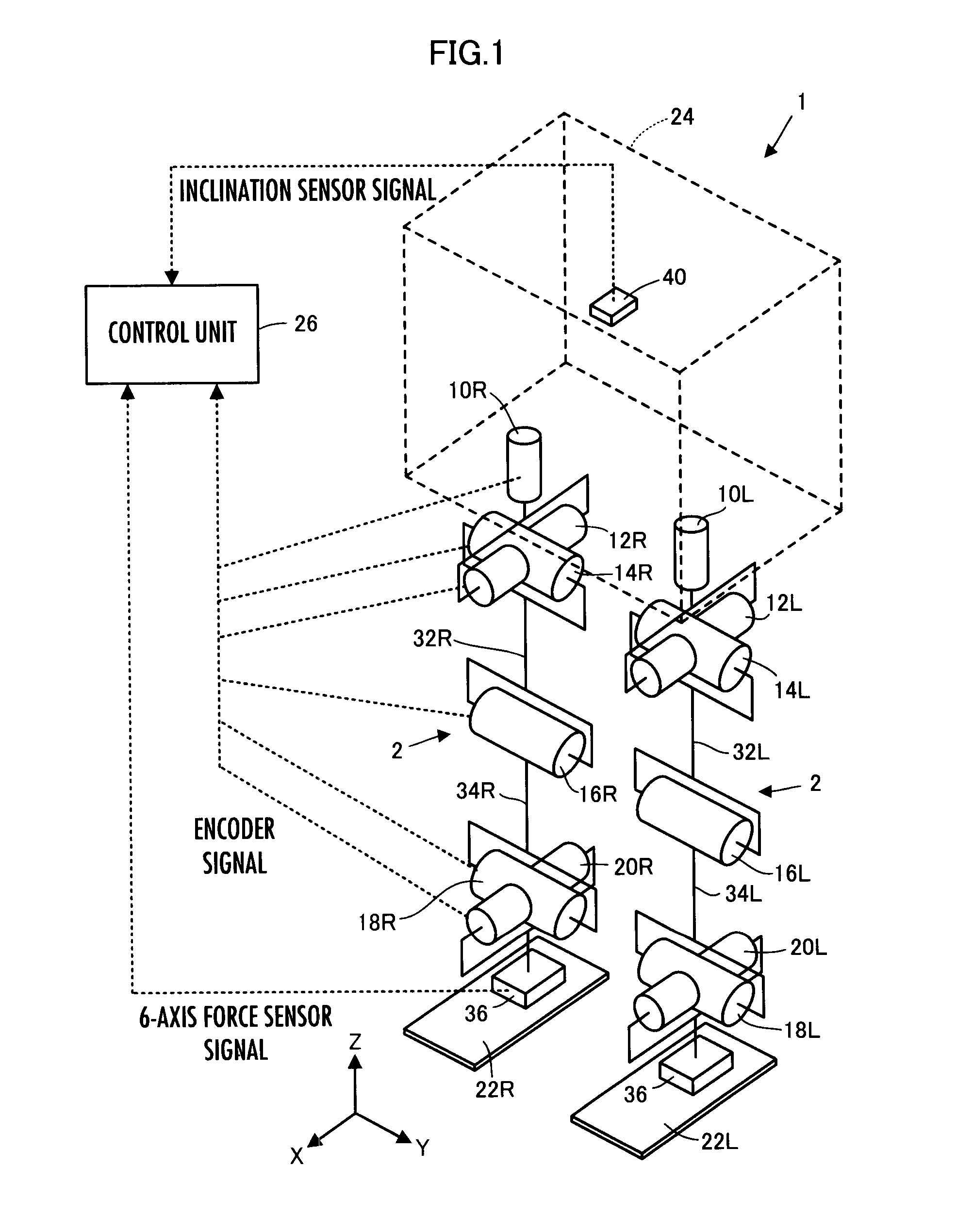

Control device for mobile body

ActiveUS20110022232A1Eliminate deviationSmoothly deviationSolid-state devicesMaterial analysis by optical meansCurrent timeTime of use

A control device for a mobile body makes it possible to smoothly correct the deviation of an actual posture of a base body of a mobile body, which travels with the base body thereof moving up and down, from a desired posture of the base body while restraining an overshoot or an undershoot from occurring. To determine a required manipulated variable according to a feedback control law in order to converge a state amount deviation related to the posture of the base body of the mobile body to zero, the feedback gain of the feedback control law is determined by using the time series in a period from current time to predetermined time in the future in the time series of a desired inertial force of the mobile body or the base body. The required manipulated variable is determined by the calculation of the feedback control law on the basis of the determined feedback gain and an observed value of the state amount deviation.

Owner:HONDA MOTOR CO LTD

BIM-based pre-assembling method for double-curved glass curtain wall

ActiveCN106013535AEliminate biasImprove installation accuracyWallsBuilding material handlingSolid componentPoint cloud

The invention relates to a BIM-based pre-assembling method for a double-curved glass curtain wall. The method includes the following steps that three-dimensional models of glass curtain wall components are established according to a modeling standard; detailed glass curtain wall component drawings are guided out and numbered, and then processing and production are carried out; three-dimensional scanning is carried out on the processed glass curtain wall components, point cloud data are obtained, and three-dimensional point cloud models are established through the point cloud data; the three-dimensional point cloud models and the three-dimensional models are compared to obtain deviation values of glass curtain wall component solid bodies, and glass curtain wall component information is adjusted till the deviation values meet glass curtain wall standard requirements; and overall pre-assembling of the three-dimensional point cloud models meeting the requirements is simulated in Revit, accumulative errors in the assembling process are eliminated till the pre-assembled three-dimensional point cloud models are completely matched with the three-dimensional models, and then the glass curtain wall components are delivered out of a factory and delivered to a construction site for solid component installation. By means of the method, the problems that the double-curved glass curtain wall is large in field installation difficulty, low in installation efficiency and low in precision are solved.

Owner:SHANGHAI BAOYE GRP CORP

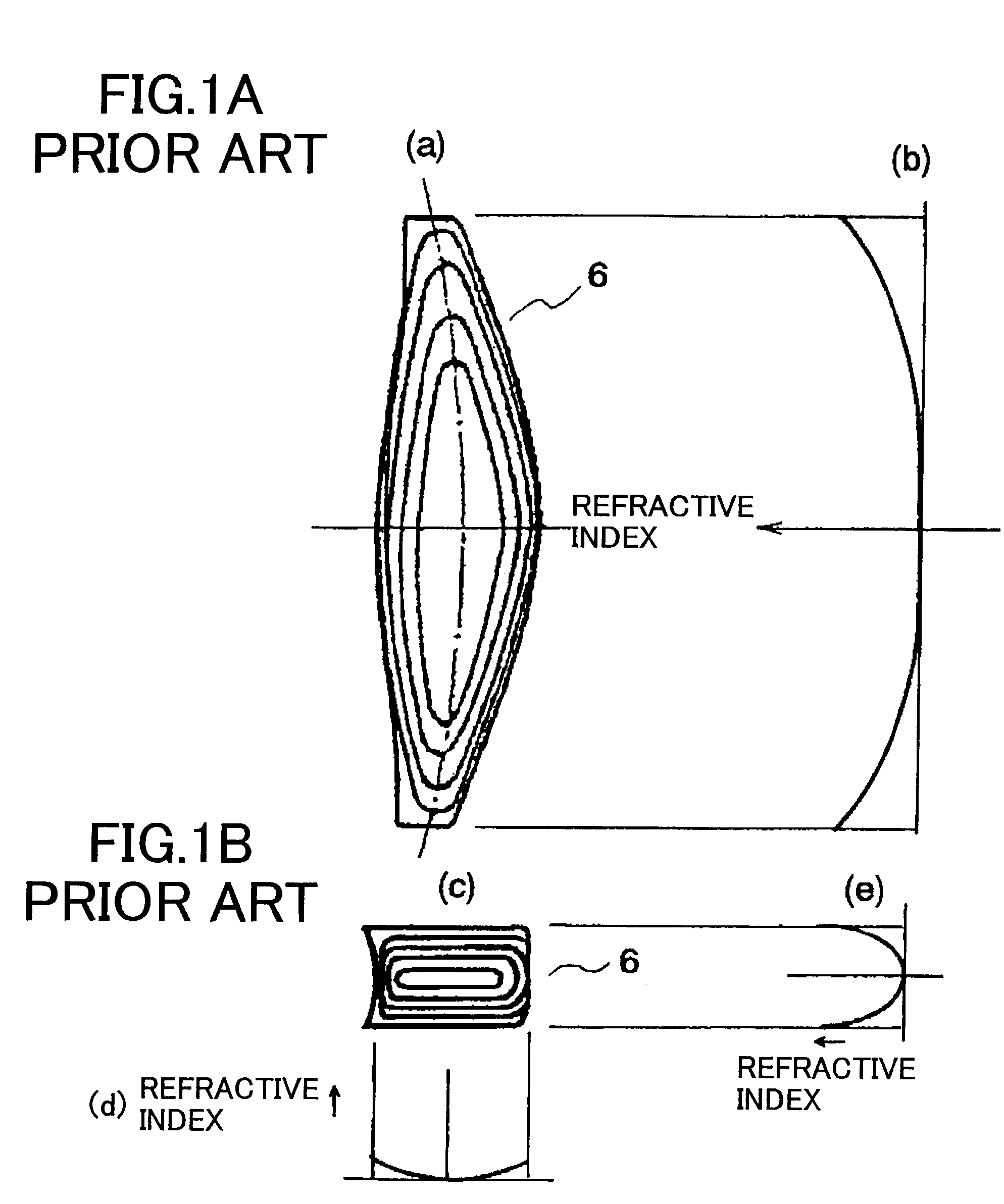

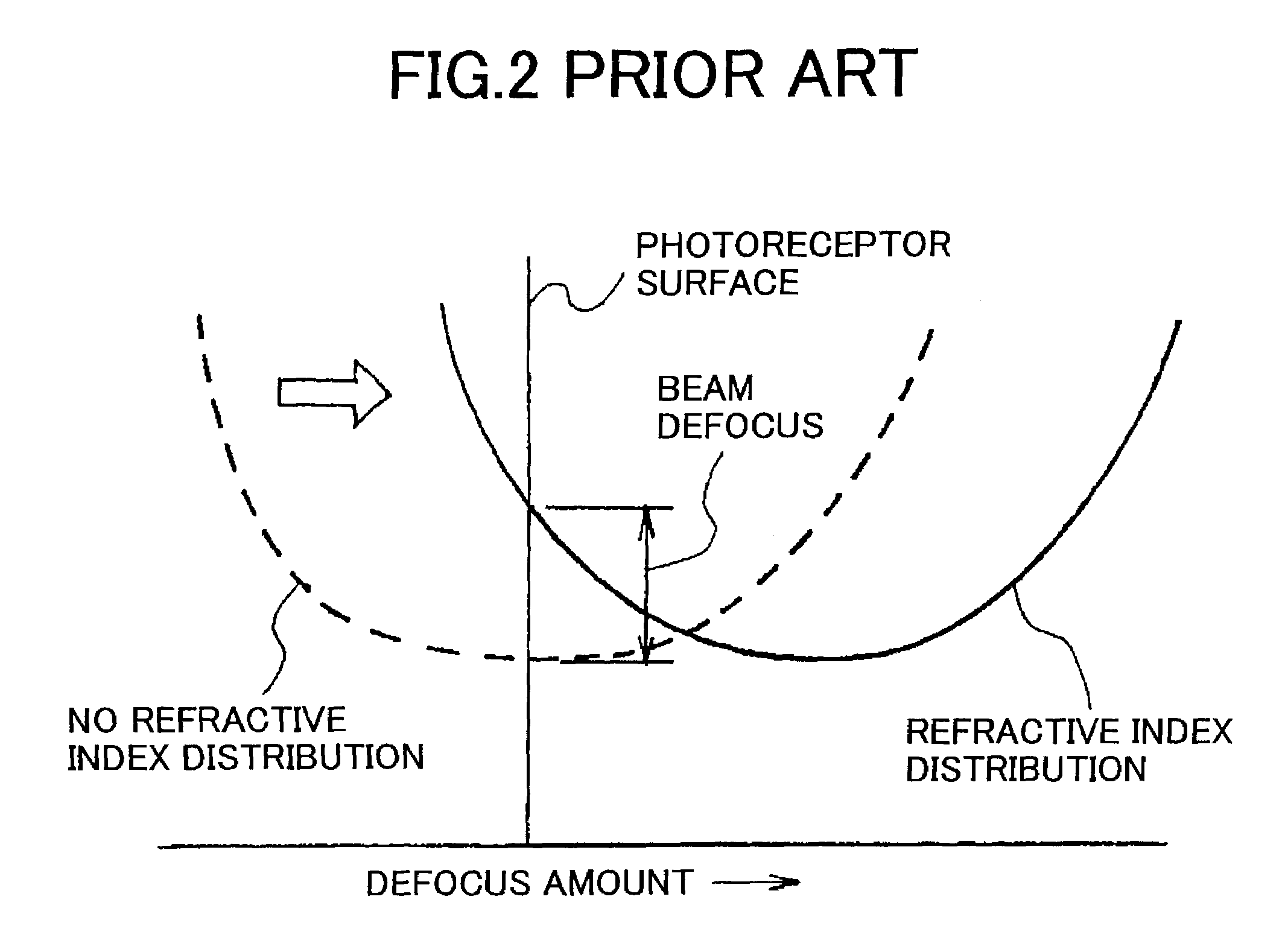

Optical element, optical scanner and image forming apparatus

InactiveUS7038822B2Correct misalignmentEliminate biasInking apparatusOther printing apparatusOptical scannersImage formation

An optical element can effectively correct misalignment of focused positions of optical spots and an optical spot pitch deviation with respect to image heights due to a refractive index distribution therein. The optical element includes a lens, which serves as an optical system in an optical scanner, is shaped in such a profile that misalignment of a focused position of the optical spot due to the refractive index distribution is corrected for image heights.

Owner:RICOH KK

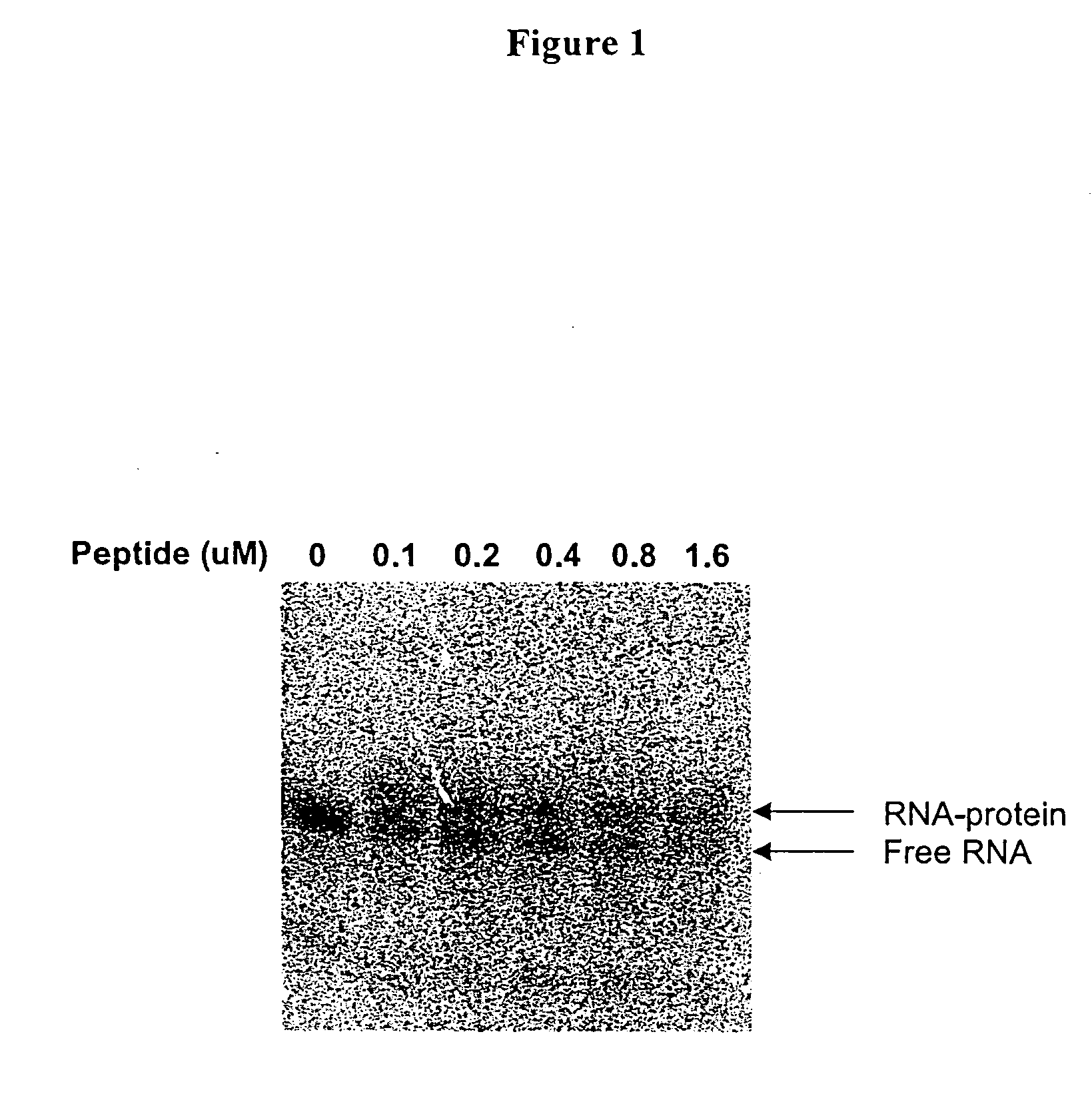

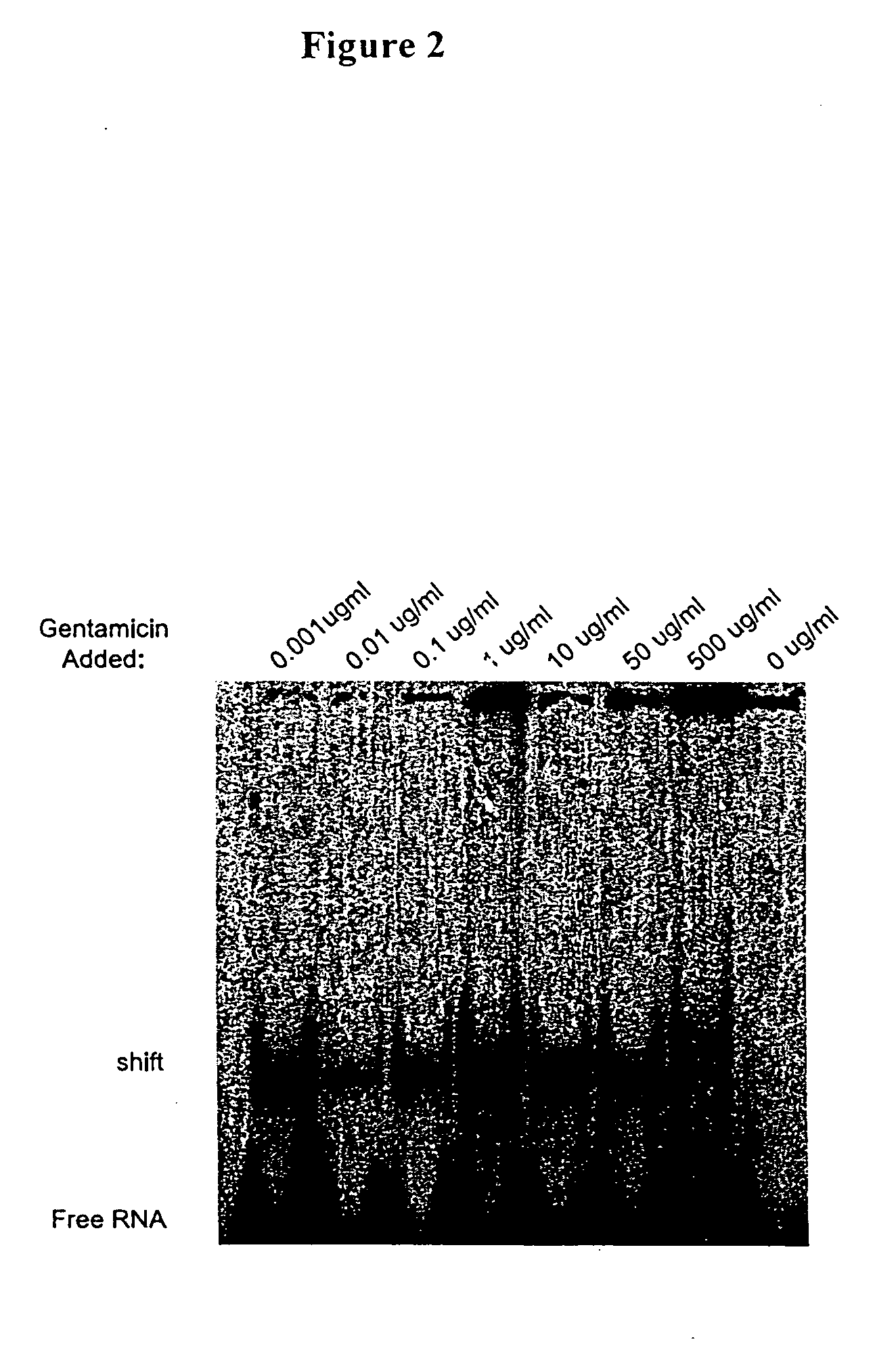

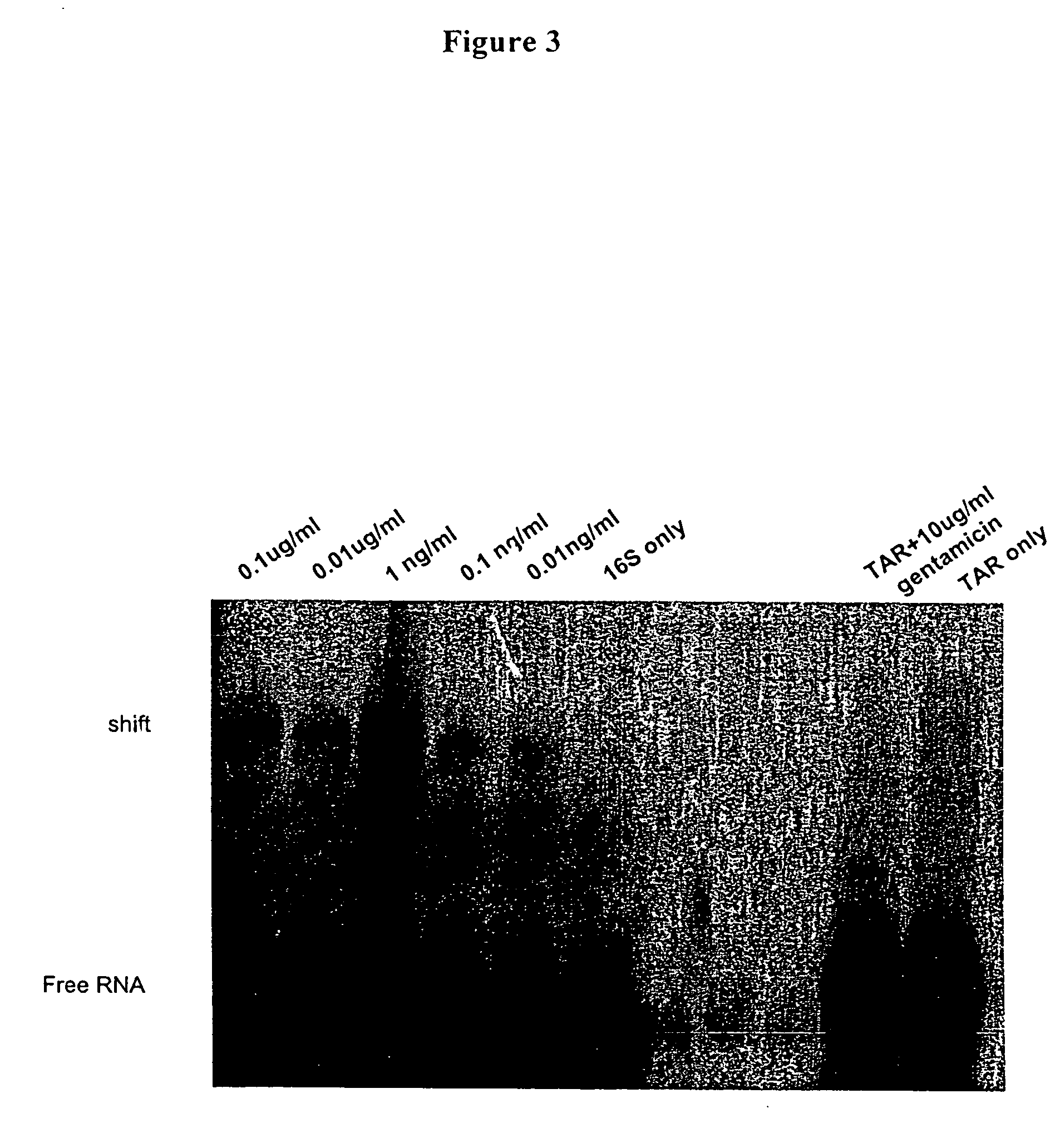

Methods for identifying small molecules that bind specific rna structural motifs

InactiveUS20040219545A1Easy to identifyEliminate biasMaterial nanotechnologyMicrobiological testing/measurementHigh-Throughput Screening MethodsBiology

The present invention relates to a method for screening and identifying test compounds that bind to a preselected target ribonucleic acid ("RNA"). Direct, non-competitive binding assays are advantageously used to screen libraries of compounds for those that selectively bind to a preselected target RNA. Binding of target RNA molecules to a particular test compound is detected using any physical method that measures the altered physical property of the target RNA bound to a test compound. The structure of the test compound attached to the labeled RNA is also determined. The methods used will depend, in part, on the nature of the library screened. The methods of the present invention provide a simple, sensitive assay for high-throughput screening of libraries of compounds to identify pharmaceutical leads.

Owner:RANDO ROBERT F +1

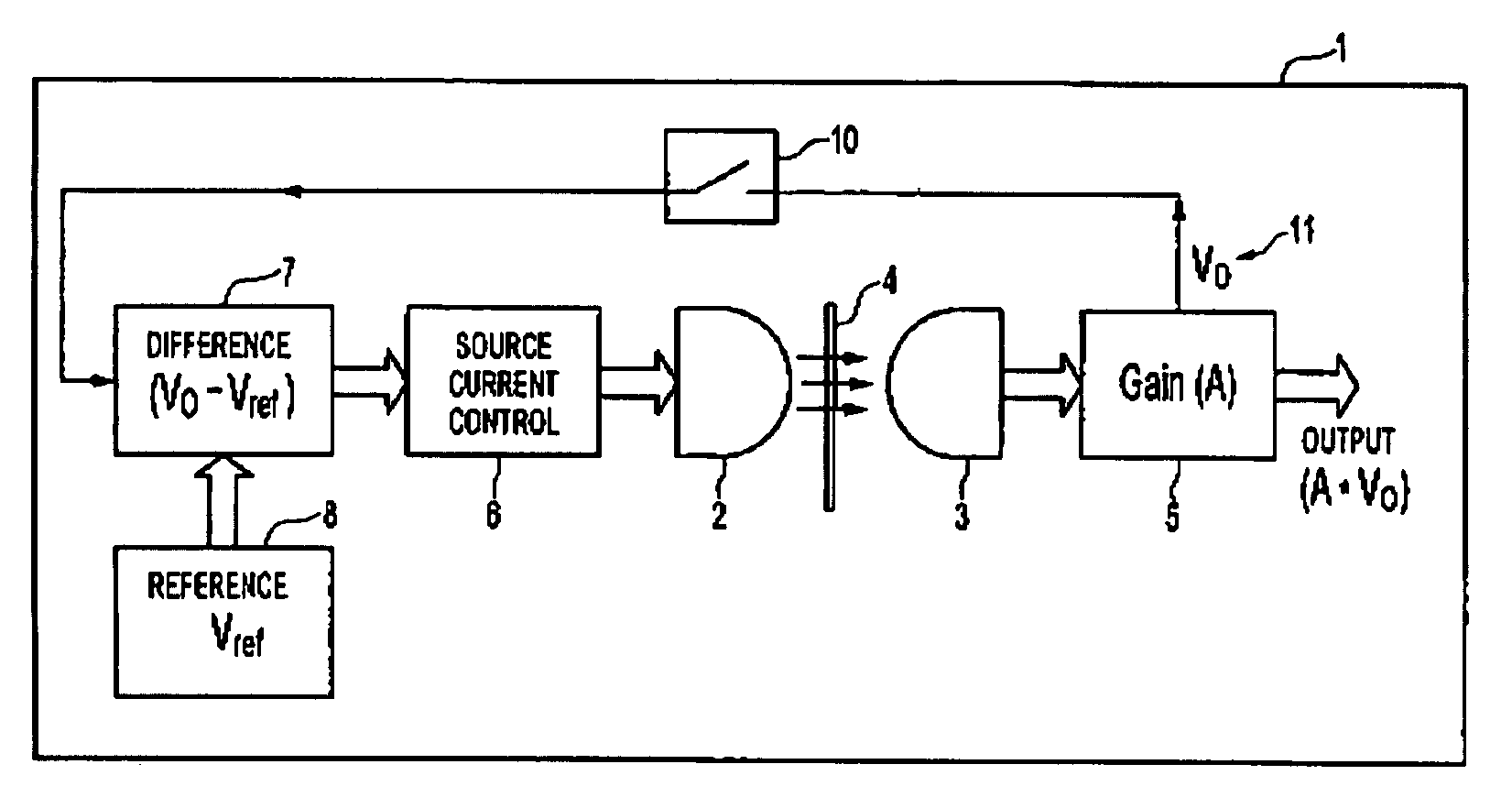

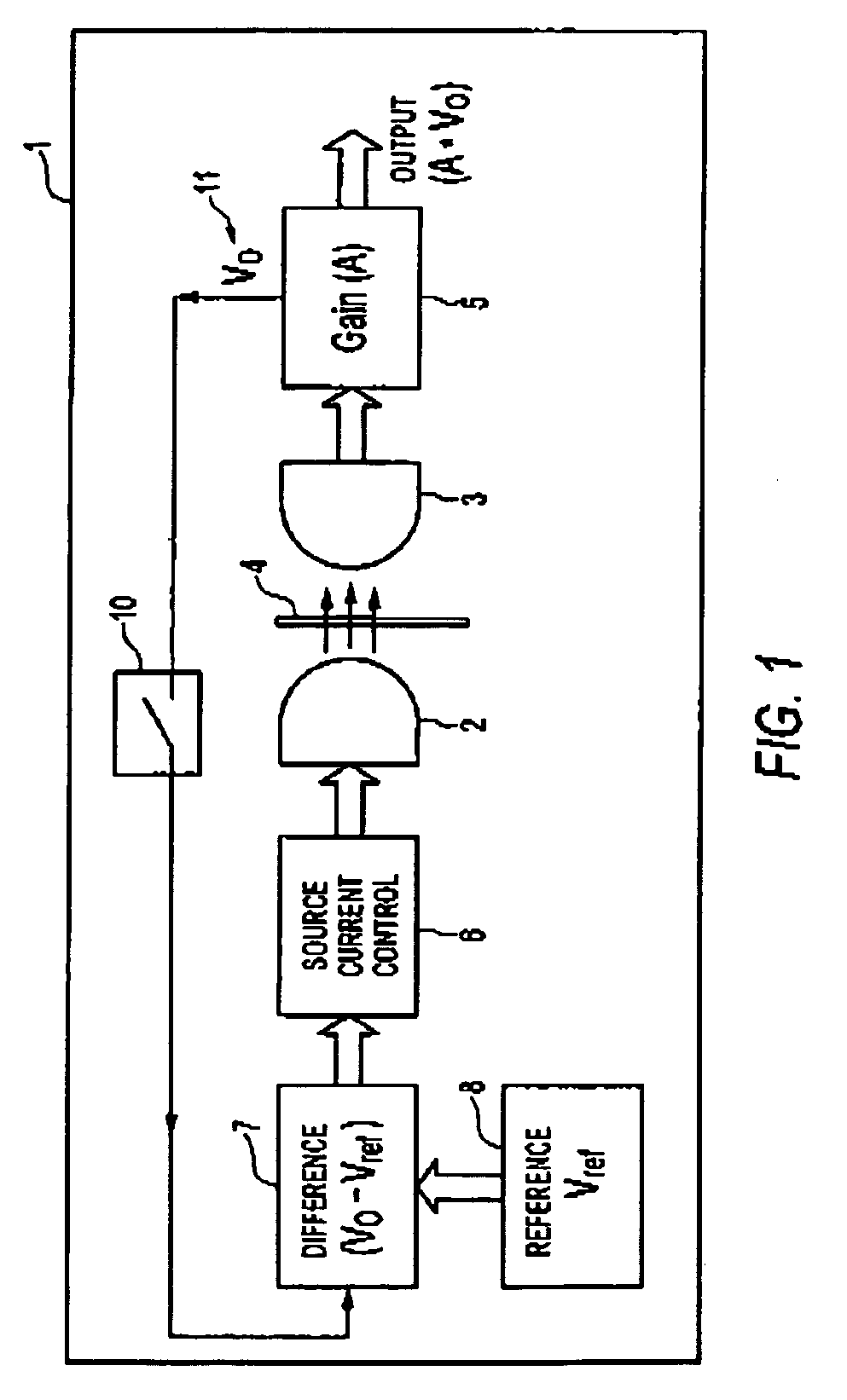

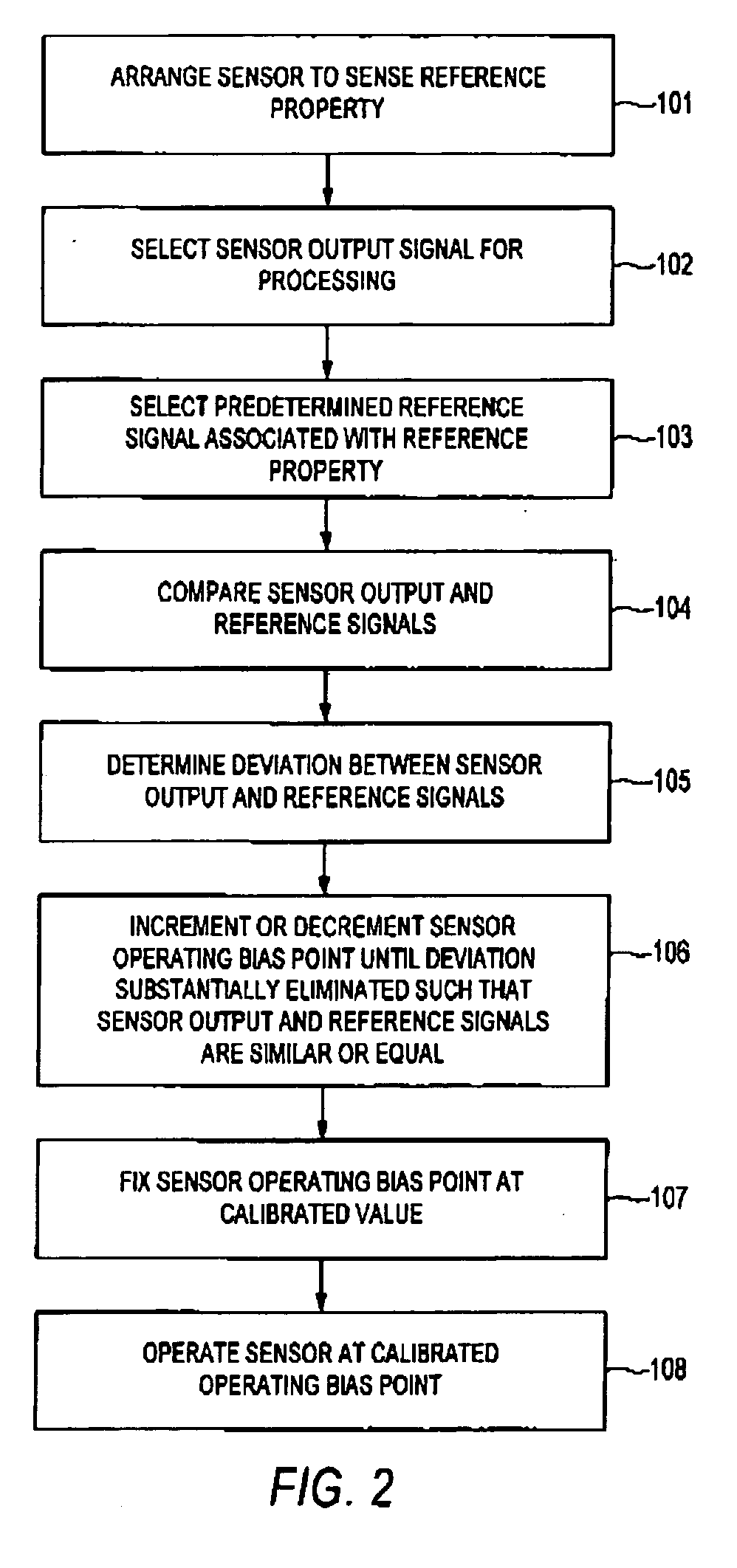

Self-calibrating sensor

InactiveUS20070032974A1Low costEasy to embedApparatus with stored calibration coefficientsElectrical measurementsVoltage referenceLogic circuitry

A method for self-calibrating a sensor can be implemented in a system having a calibration circuit. The calibration circuit has differential circuitry which compares an output signal of the sensor with a predetermined reference signal associated with a reference property. A bias controller increments or decrements the sensor operating bias according to the deviation between the predetermined reference signals and sensor output signal such that the sensor output corresponds to the predetermined reference voltage. The calibration circuit can be embedded in the sensor to provide a self-calibrating sensor. Logic circuitry can be used to form the calibration circuit.

Owner:HONEYWELL INT INC

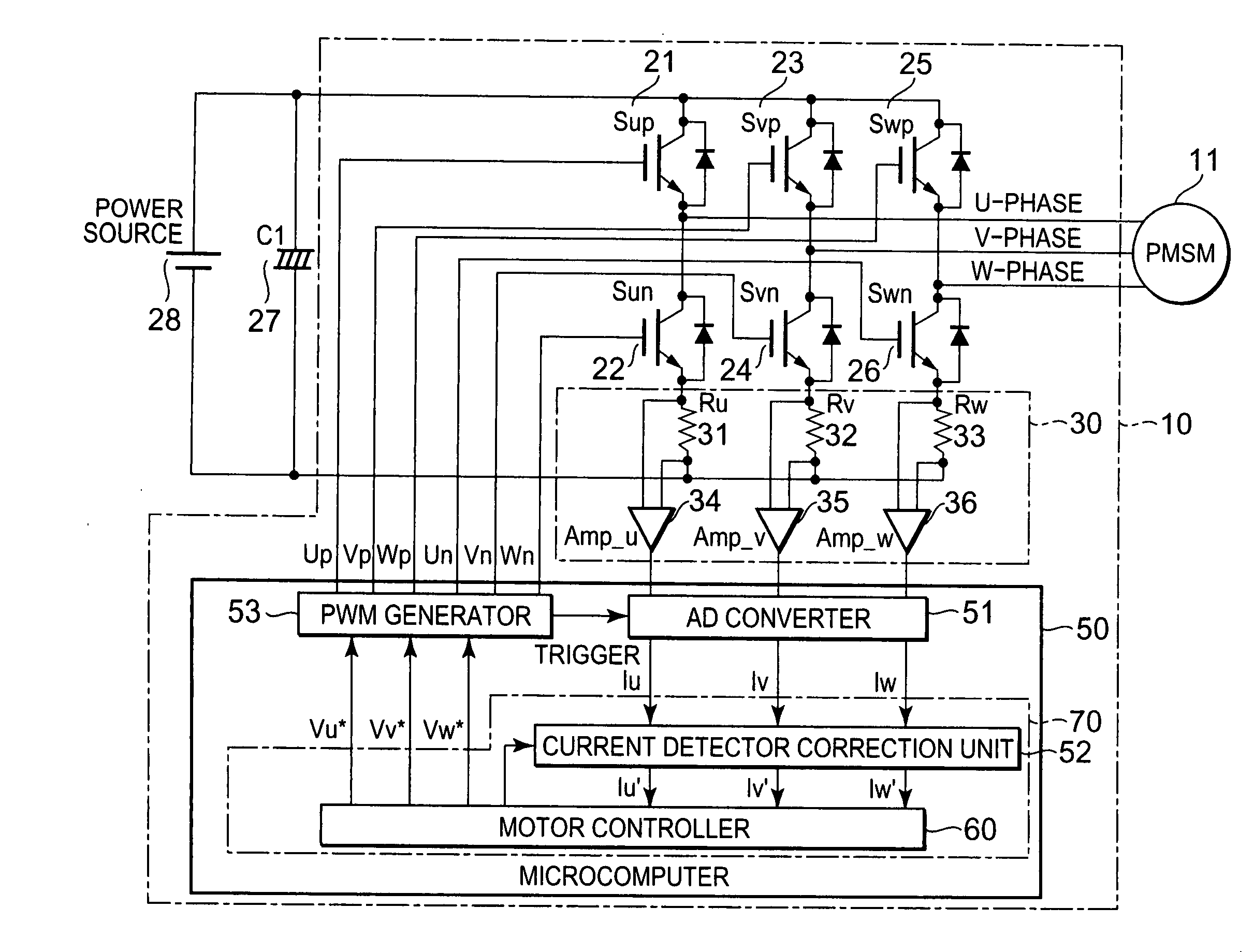

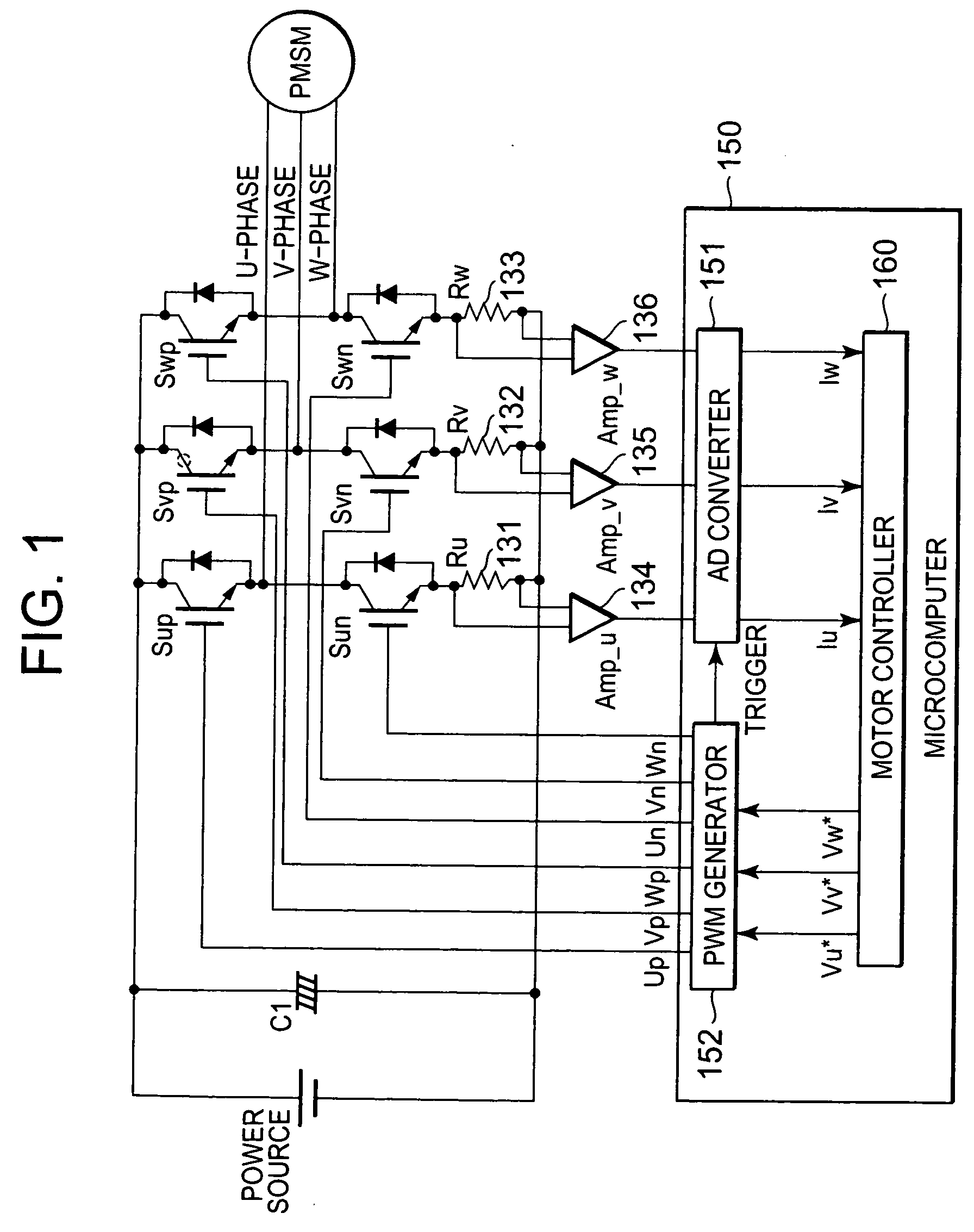

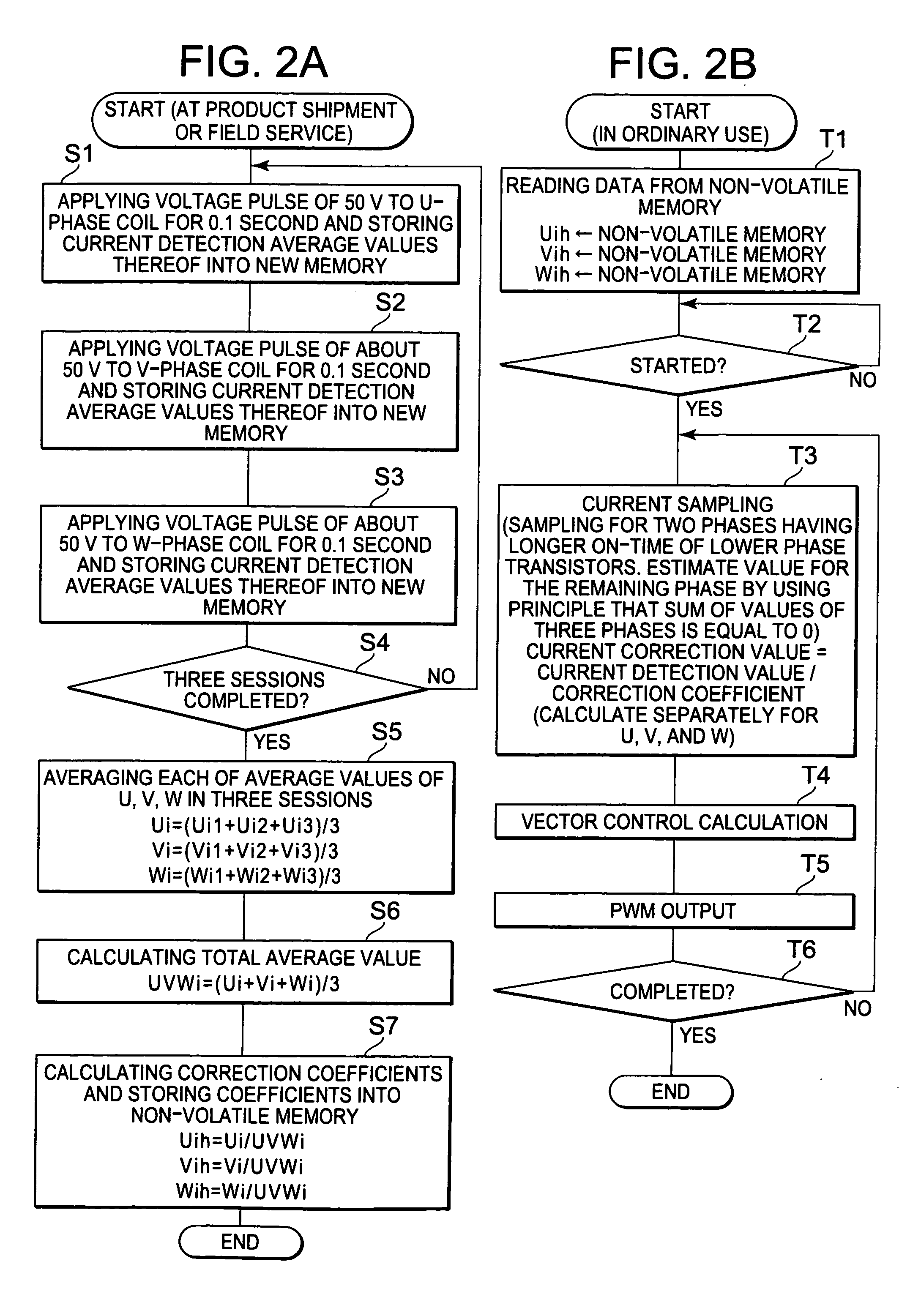

Inverter apparatus and a semiconductor device used for the same

ActiveUS20080265829A1Low costIncrease torqueSingle-phase induction motor startersDC motor speed/torque controlThree-phaseSemiconductor

FIGS. 4A and 4B are principle diagrams for correcting deviations among current detectors of a three-phase motor 19 in an inverter apparatus of the present invention, which includes bidirectional switching elements 13 to 18. FIG. 4C shows on and off states of switches in the cases of FIGS. 4A and 4B, in which 1 and 0 mean on- and off-states, respectively. The states shown in FIGS. 4A and 4B are alternately repeated by controlling the switches, and measurement for correcting the deviations among the current detectors are obtained in the state shown in FIG. 4B. Specifically, in FIG. 4B, currents having the same amplitude flow on a U phase and a V phase. Accordingly, a difference in the measured data represents a difference in performances of the current detectors. In the state of normal use, the inverter apparatus is operated by correcting detected current values based on the measurement data.

Owner:RENESAS ELECTRONICS CORP

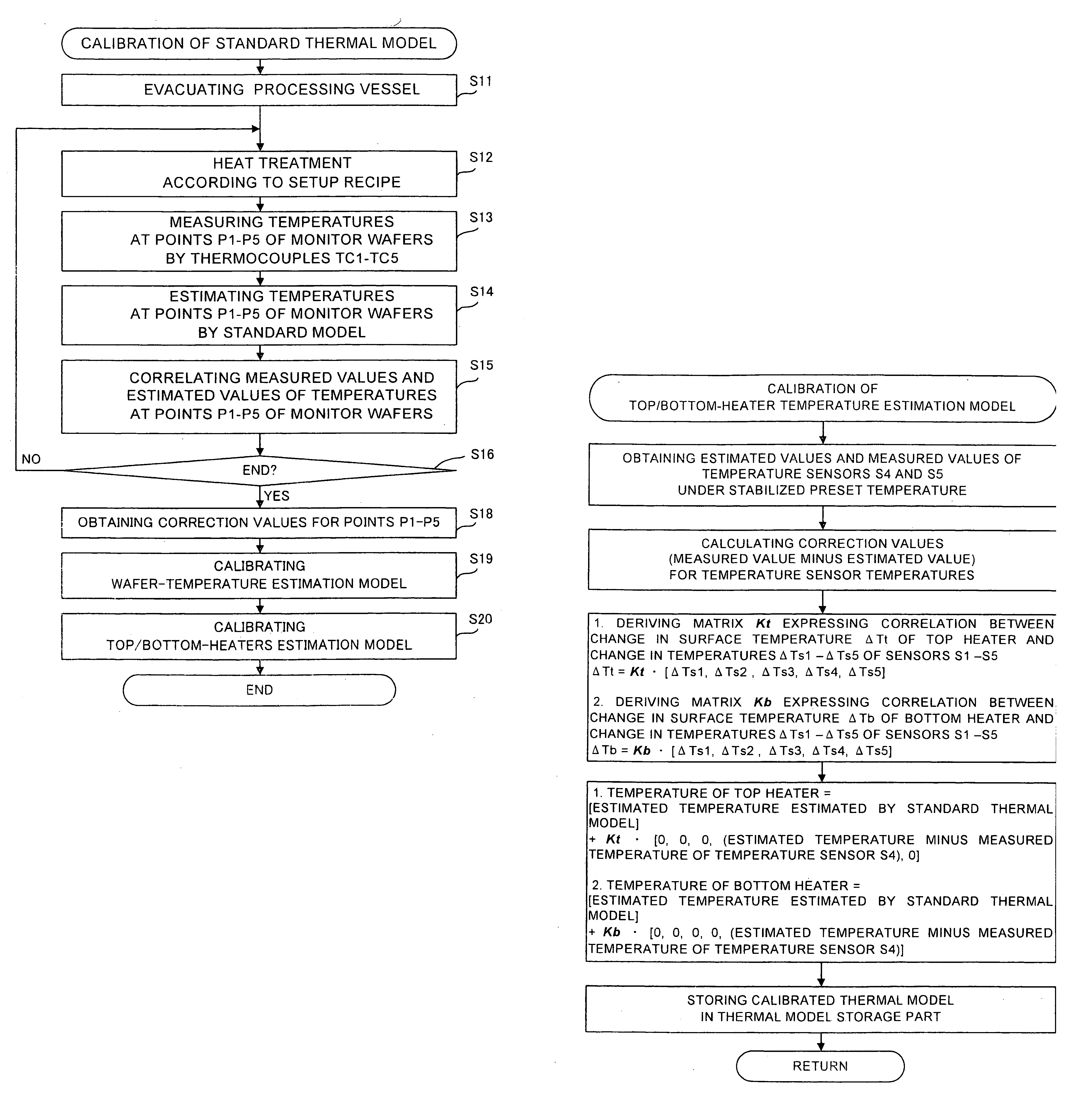

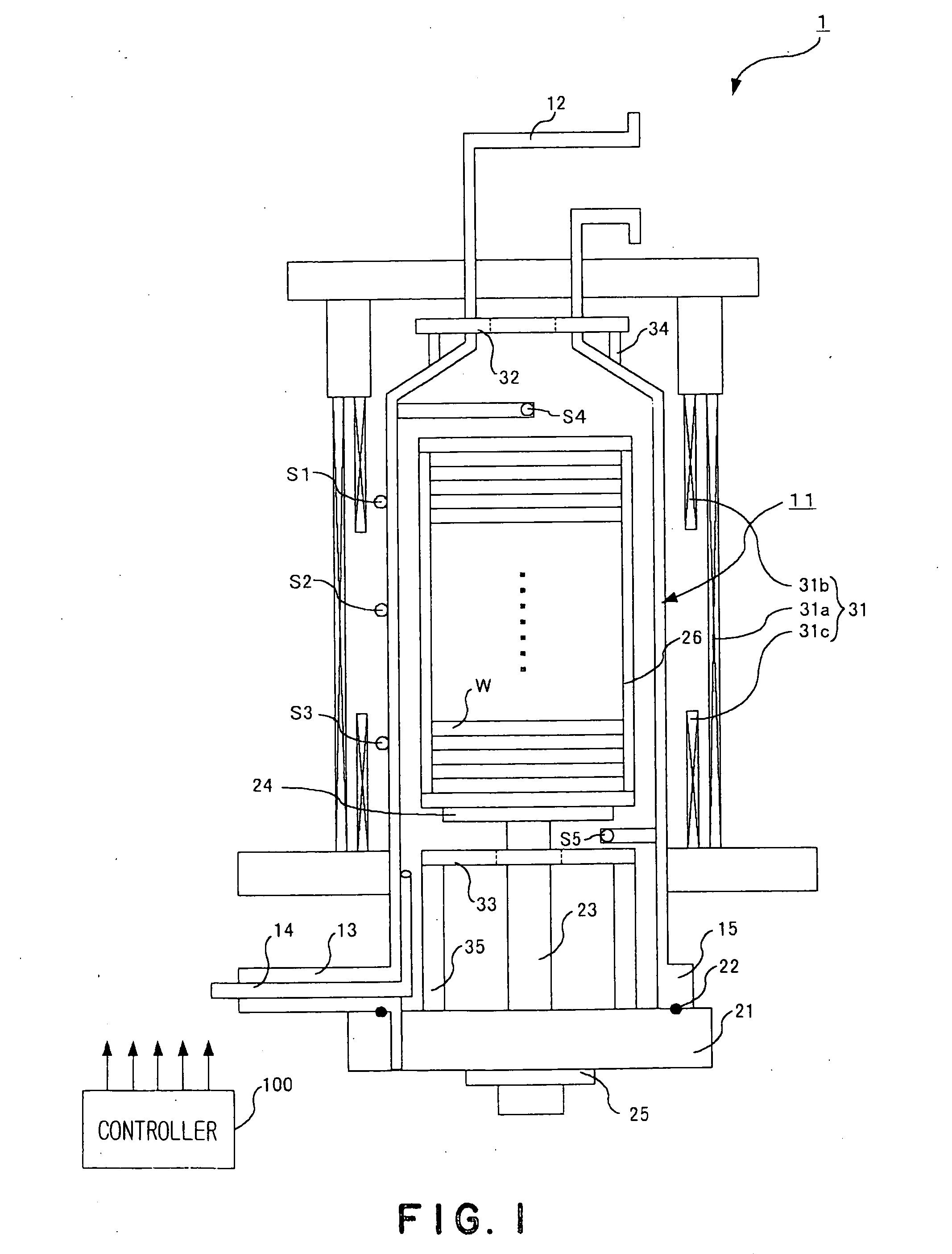

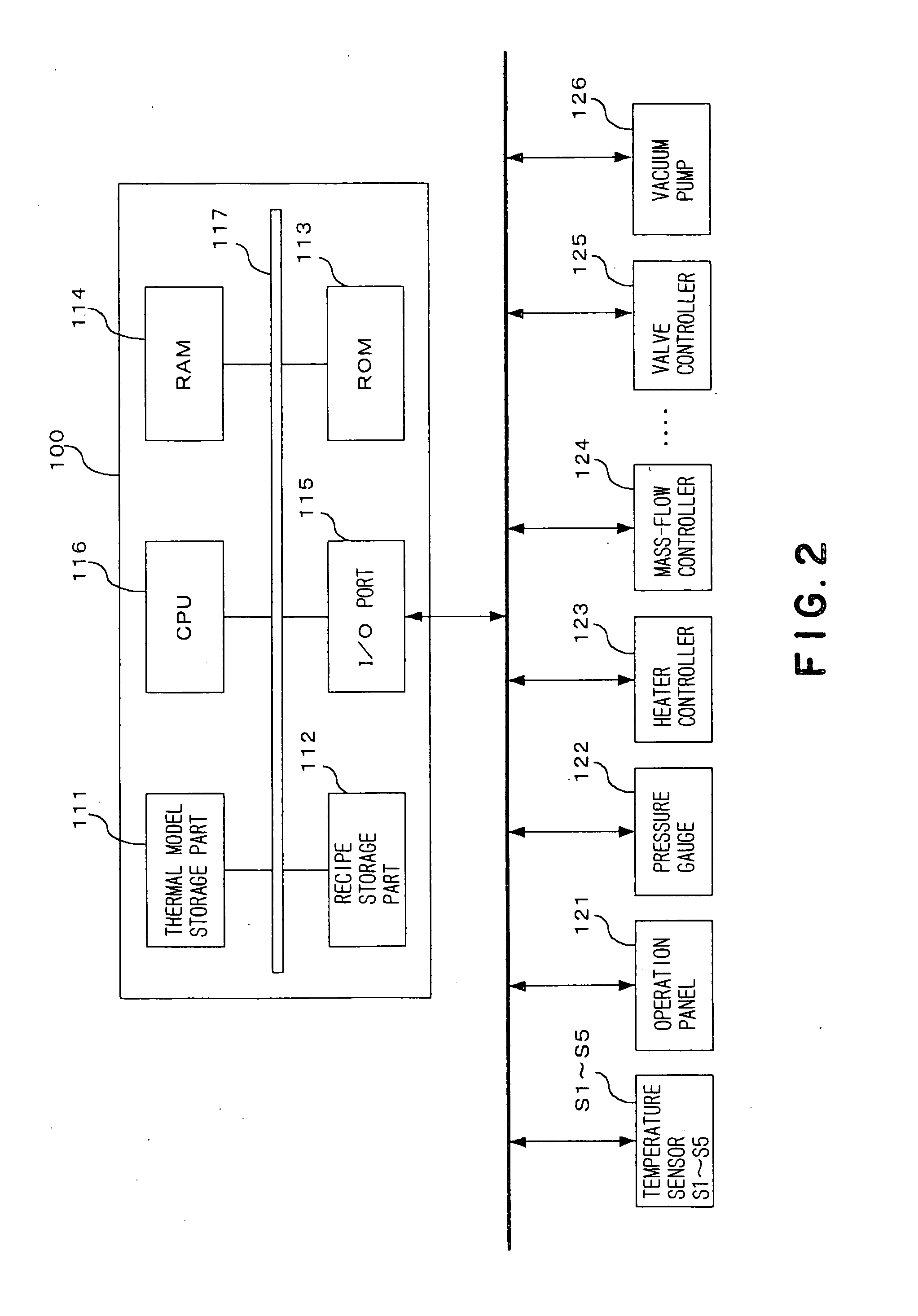

Heat treatment apparatus and method of calibrating the apparatus

ActiveUS20070195853A1Accurate temperature estimationAccurate estimateSemiconductor/solid-state device manufacturingCharge manipulationTemperature controlEngineering

The present invention provides precise temperature estimation in a heat treatment apparatus that estimates temperatures of process objects by using a thermal model and performs a heat treatment while performing a temperature control based on the estimated temperatures. The heat treatment apparatus 1 includes a processing vessel 11 accommodating plural wafers W, plural heaters 31 to 33 and plural temperature sensors S1 to S5, and stores the thermal model. The heat treatment apparatus 1 estimates temperatures of the wafers W based on outputs of the temperature sensors S1 to S5 by using the thermal model and controls the heaters 31 to 33 based on the estimated temperatures, applying a heat treatment to the wafers W. The thermal model for an individual apparatus is made by calibrating a standard thermal model designed for a standard apparatus. The standard model calibration is performed by heating an interior of the processing vessel 11, measuring the temperatures of the wafers W in the processing vessel 11, estimating the temperatures of the wafers W by using the thermal model, comparing the measured temperature and the estimated temperature, and calibrating the standard thermal model so that the measured temperature substantially coincide with the estimated temperature.

Owner:TOKYO ELECTRON LTD

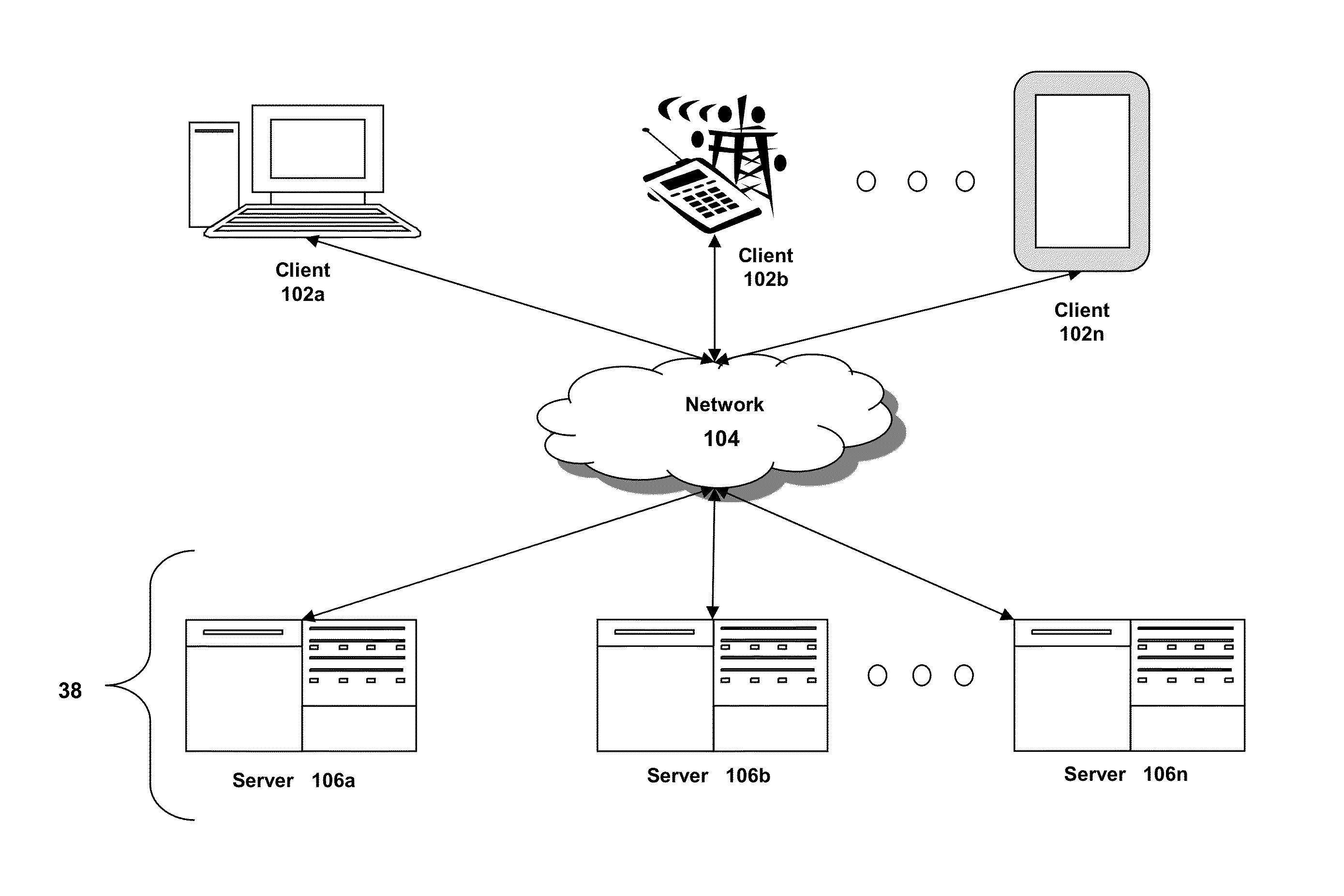

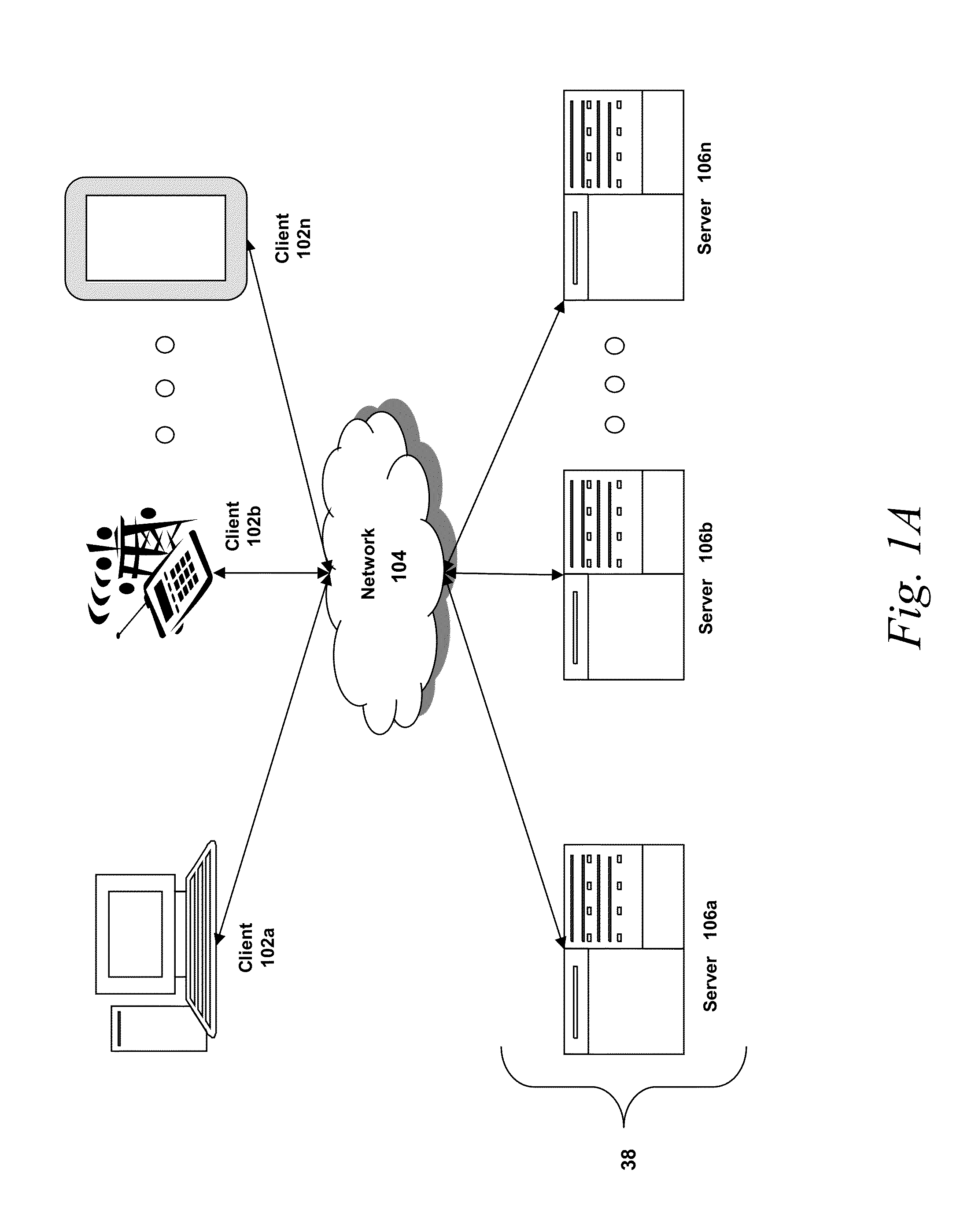

Systems and methods of applying high performance computational techniques to analysis and execution of financial strategies

Systems and method of the present disclosure are directed to a strategy assessment tool that facilitates developing a financial strategy, testing the financial strategy on historical data, and applying the strategy in real time to activate trades. The strategy assessment tool can retrieve, obtain, or otherwise identify financial data related financial instruments. The tool can store the financial data in a database or data structure such that the tool can efficient analyze the data using one or more financial strategies running on multiple threads of a GPU.

Owner:ELSEN

Unidirectional carbon fiber cloth tension property testing sample preparation method

InactiveCN104819877AAchieve brokenImprove accuracyPreparing sample for investigationStress concentrationCarbon fibers

Embodiments of the present invention disclose a unidirectional carbon fiber cloth tension property testing sample preparation method. According to the present invention, a tension device is used to apply tension force along a weft direction so as to make the silk beam maintain a parallel and straightening state during a carbon fiber cloth sheet forming process, increase the accuracy and the reliability of the tensile strength of the tension property testing sample strip, and make the qualification rate of the tension property testing sample strip achieve 100%; a scale ruler is placed on a glass flat plate, such that the distribution of the unidirectional carbon fiber cloth sheet and the unidirectional carbon fiber cloth sample strip resin is uniform, the deposition can not be generated, the stress centralization phenomenon during the tension property testing process can be eliminated, and the probability of the advanced damage on the sample is reduced; and both ends of the unidirectional carbon fiber cloth sample strip are subjected to one-time curing forming to form the resin type reinforcement sheet so as to replace the external-adhesion aluminum sheet or fiber reinforced resin and other traditional reinforcement sheet, eliminate the technical problems of deviated tension, irregular stress-deformation curve and the like caused by the external-adhesion and the improper roughening treatment on the traditional reinforcement sheet, and improve the accuracy and the reliability of the testing result.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

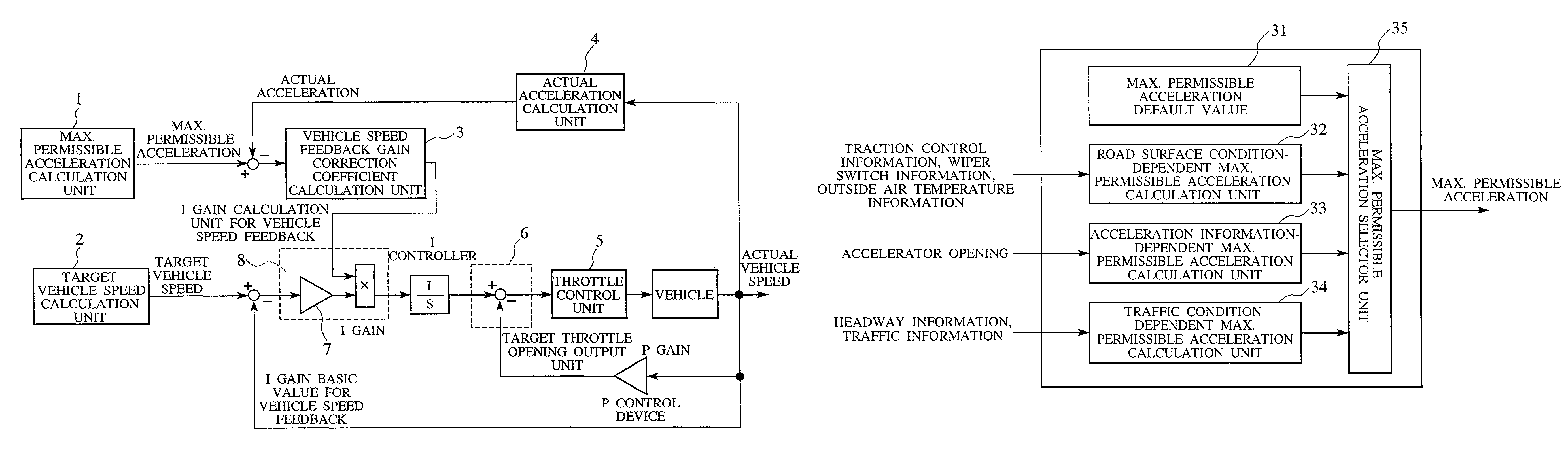

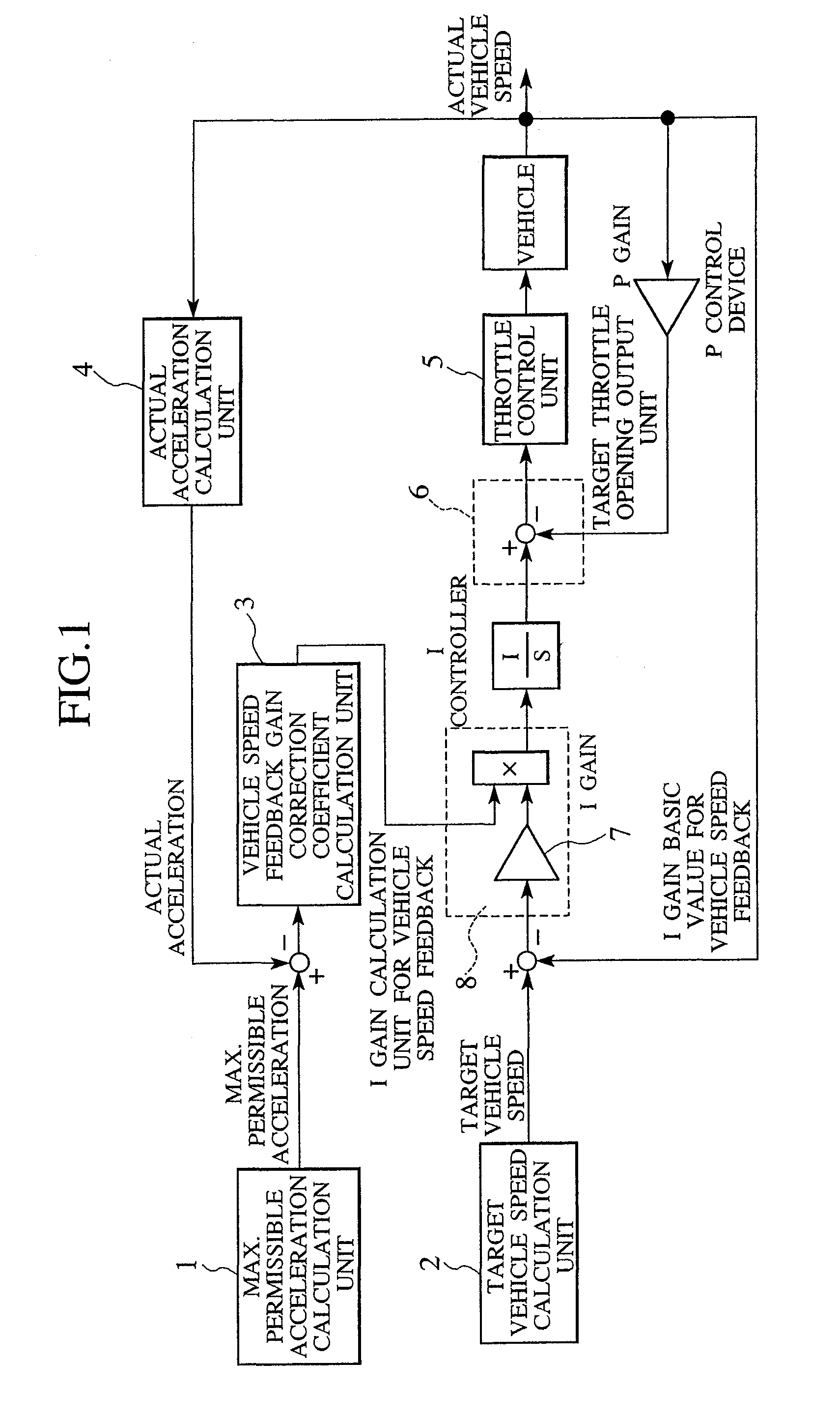

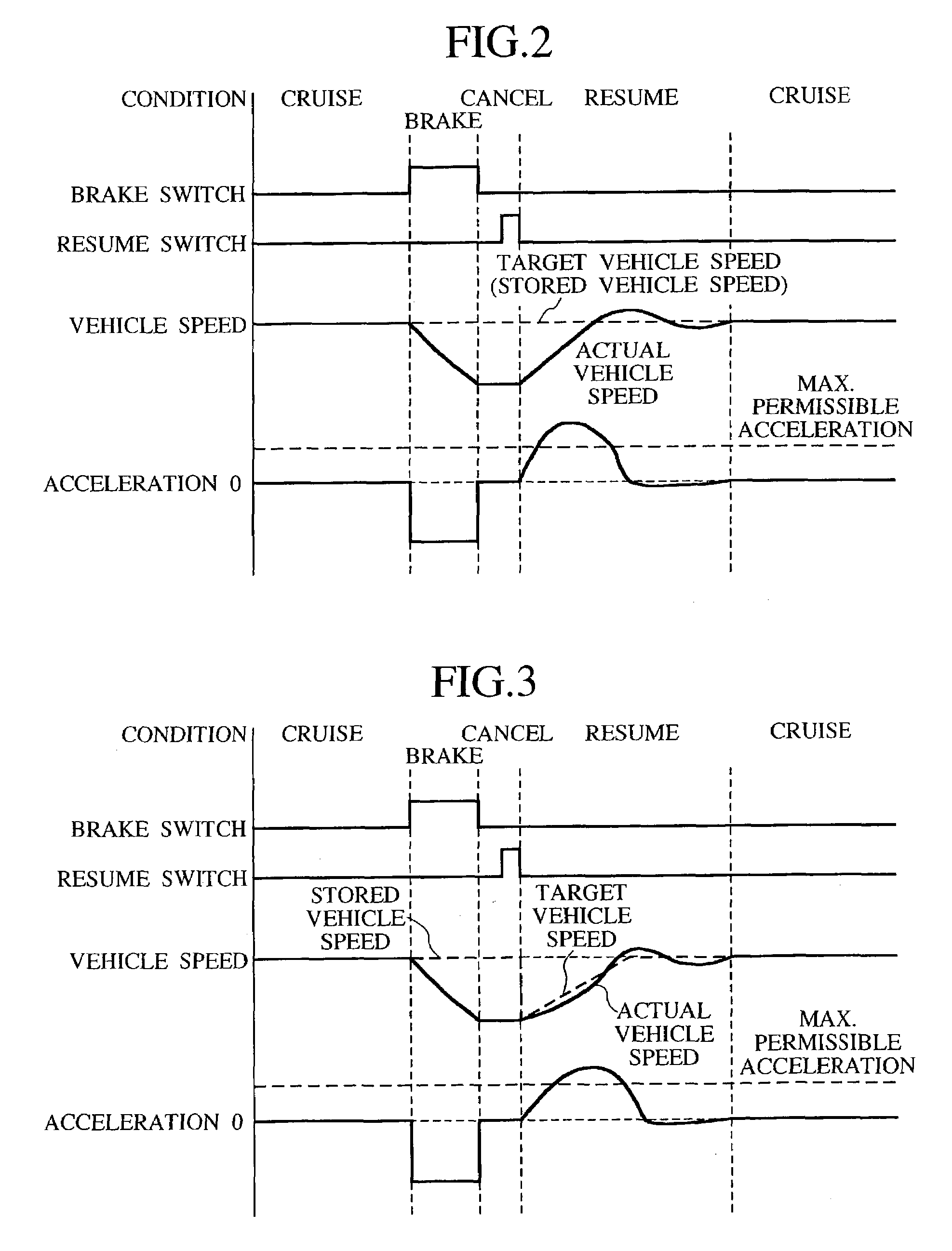

Vehicle cruise control device and method

InactiveUS7308961B2Easy to controlEliminate biasVehicle fittingsDigital data processing detailsCruise controlIn vehicle

A maximum permissible acceleration is calculated so as to take into account vehicle stability, driver's comfort, road surface information and traffic information, driver's specific taste in acceleration and deceleration, and the like. An acceleration limiting process is carried out, in which a feedback gain in vehicle speed feedback control is corrected as may be necessary based on a relationship between the maximum permissible acceleration and actual acceleration information so as to keep the actual acceleration within the maximum permissible acceleration. The present invention thereby makes it possible to control a vehicle speed within a desired acceleration range even under conditions, in which there is a large vehicle speed deviation as in a resume mode, causing an excessively large acceleration or deceleration to tend to occur. Auto cruise control offering an outstanding safety and comfort can thus be implemented.

Owner:HITACHI LTD

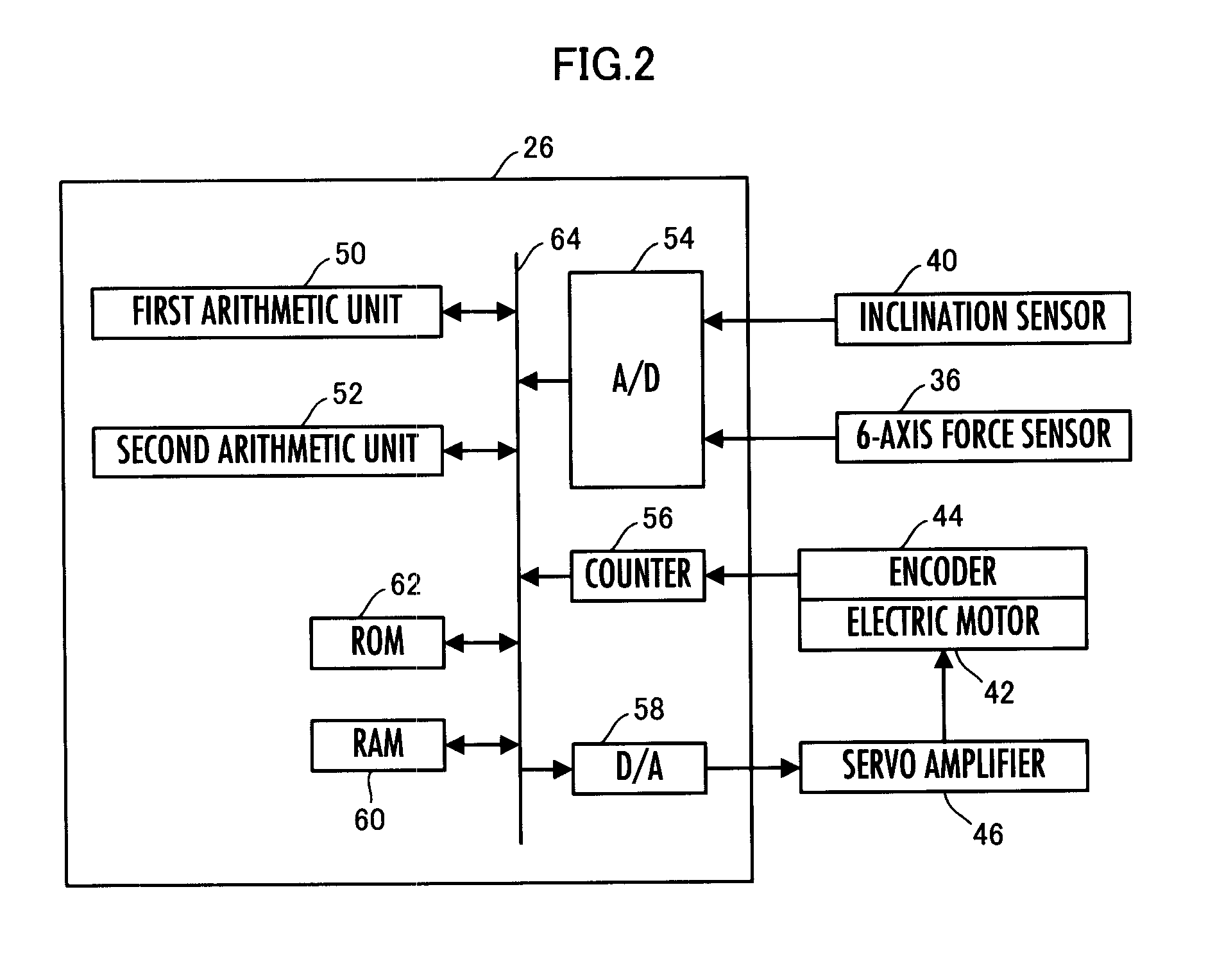

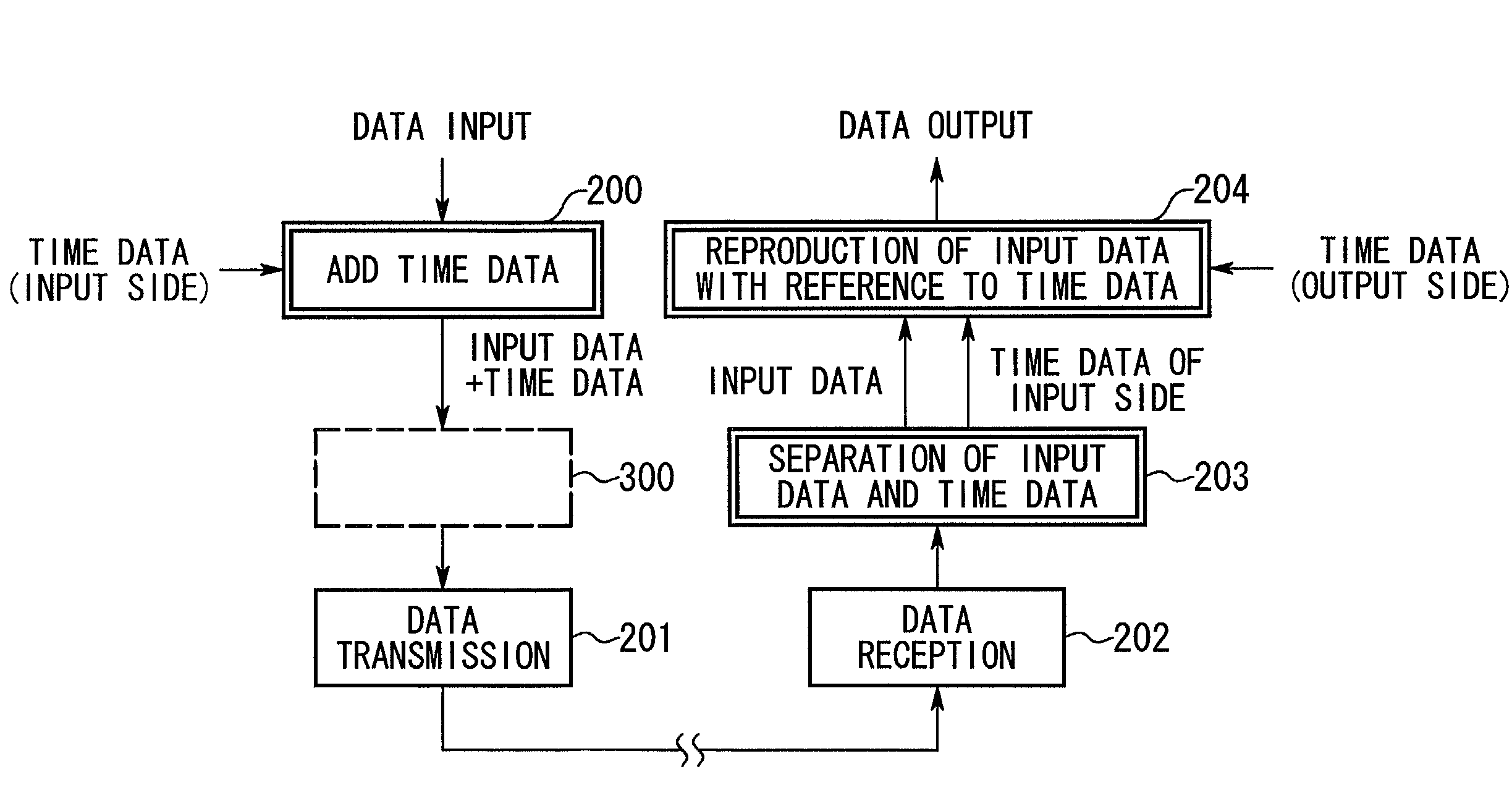

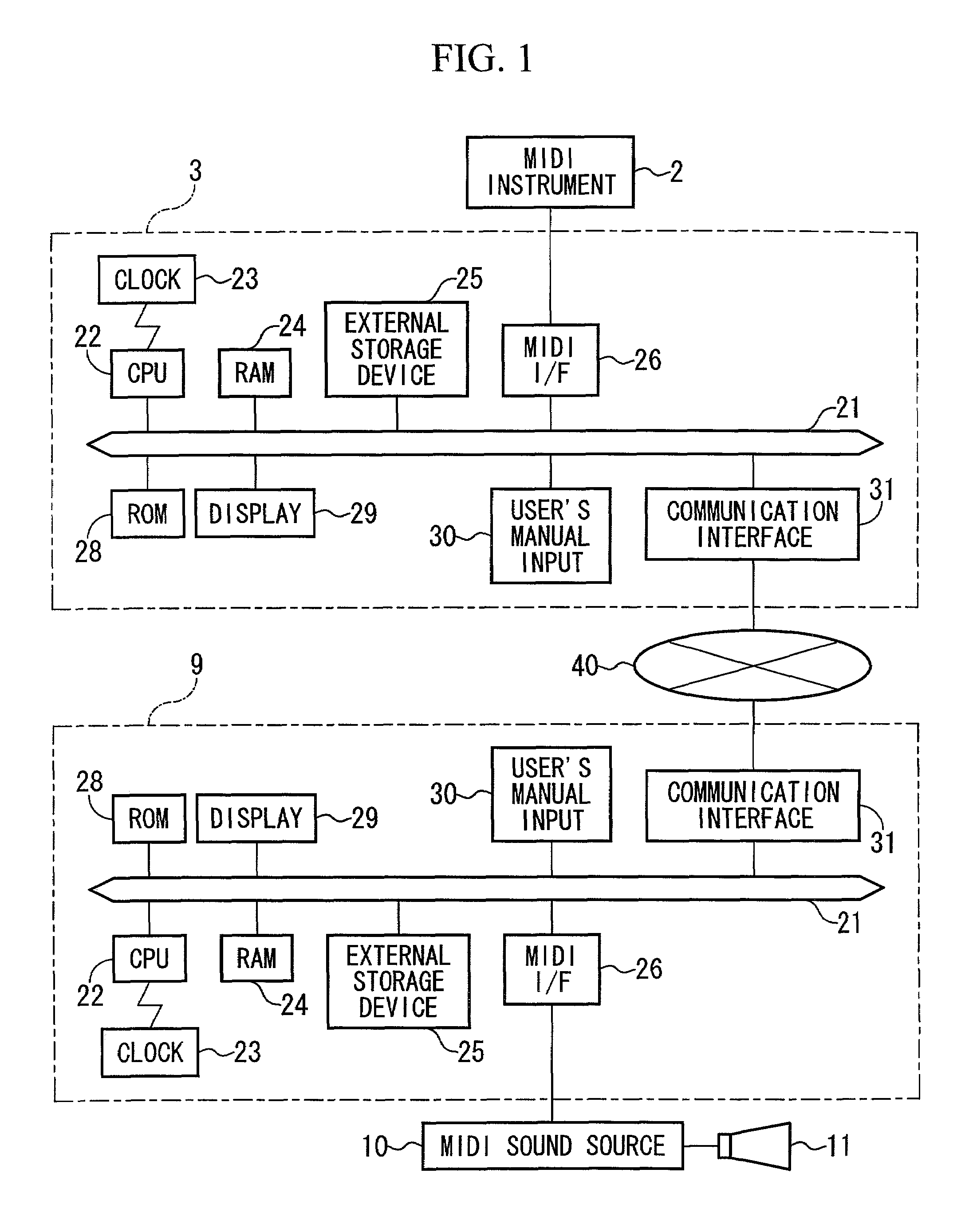

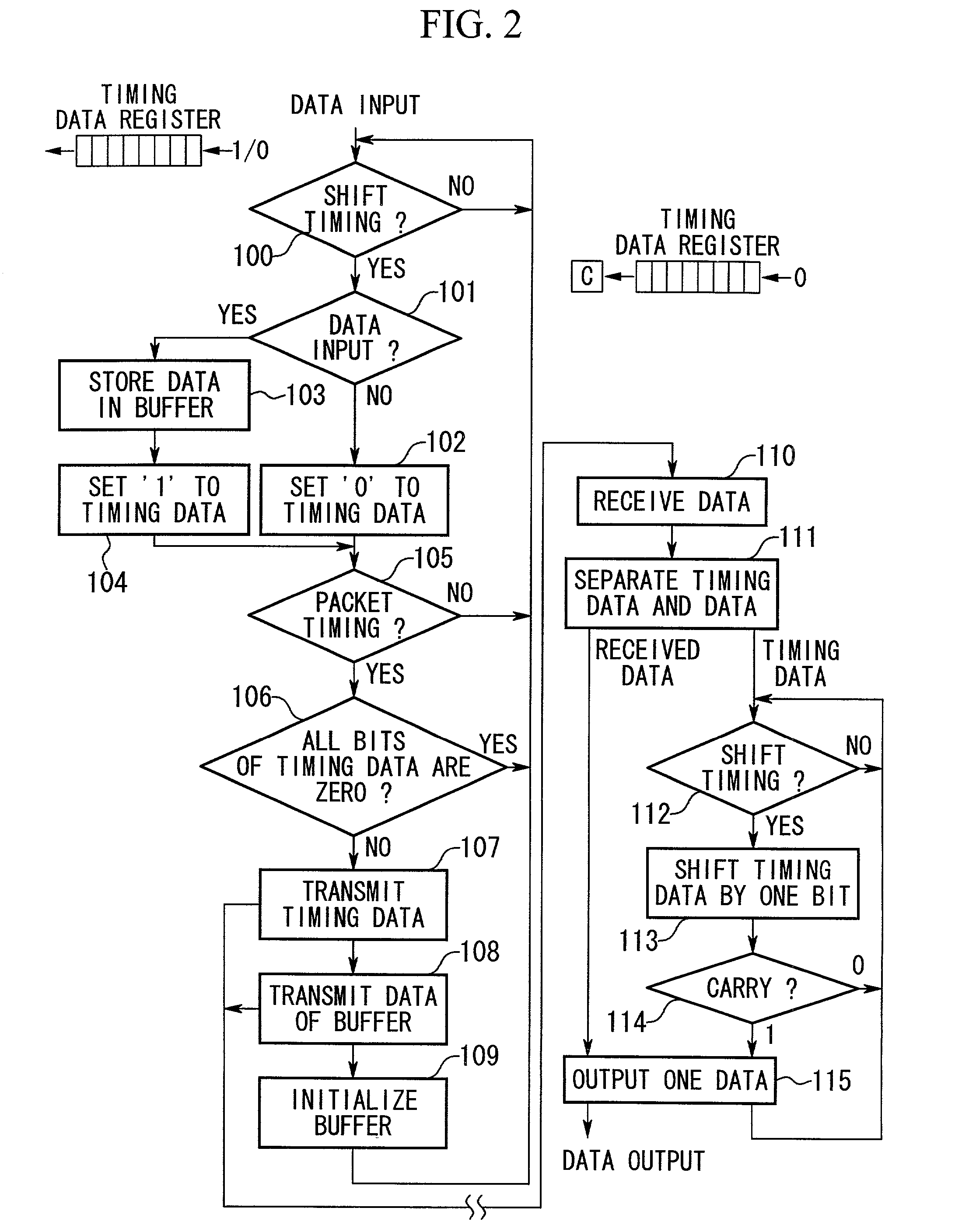

Communication method and system for transmission and reception of packets collecting sporadically input data

InactiveUS7254644B2Eliminate dispersionEliminate deviationElectrophonic musical instrumentsMultiple digital computer combinationsPacket communicationThe Internet

A server / client system provides packet communications between a server and a client by way of a network such as the Internet. The server inputs data such as MIDI data in a sporadic manner while storing timing data representing their input timings. Then, the server performs packetizing of the sporadically input data, which accompany the timing data and are subjected to transmission to the client. The client receives the packetized input data and then outputs them at timings based on the timing data. Thus, it is possible to completely secure the same time relationship of data during transmission and reception of the sporadically input data even though the client differs from the server on a time-axis basis.

Owner:YAMAHA CORP

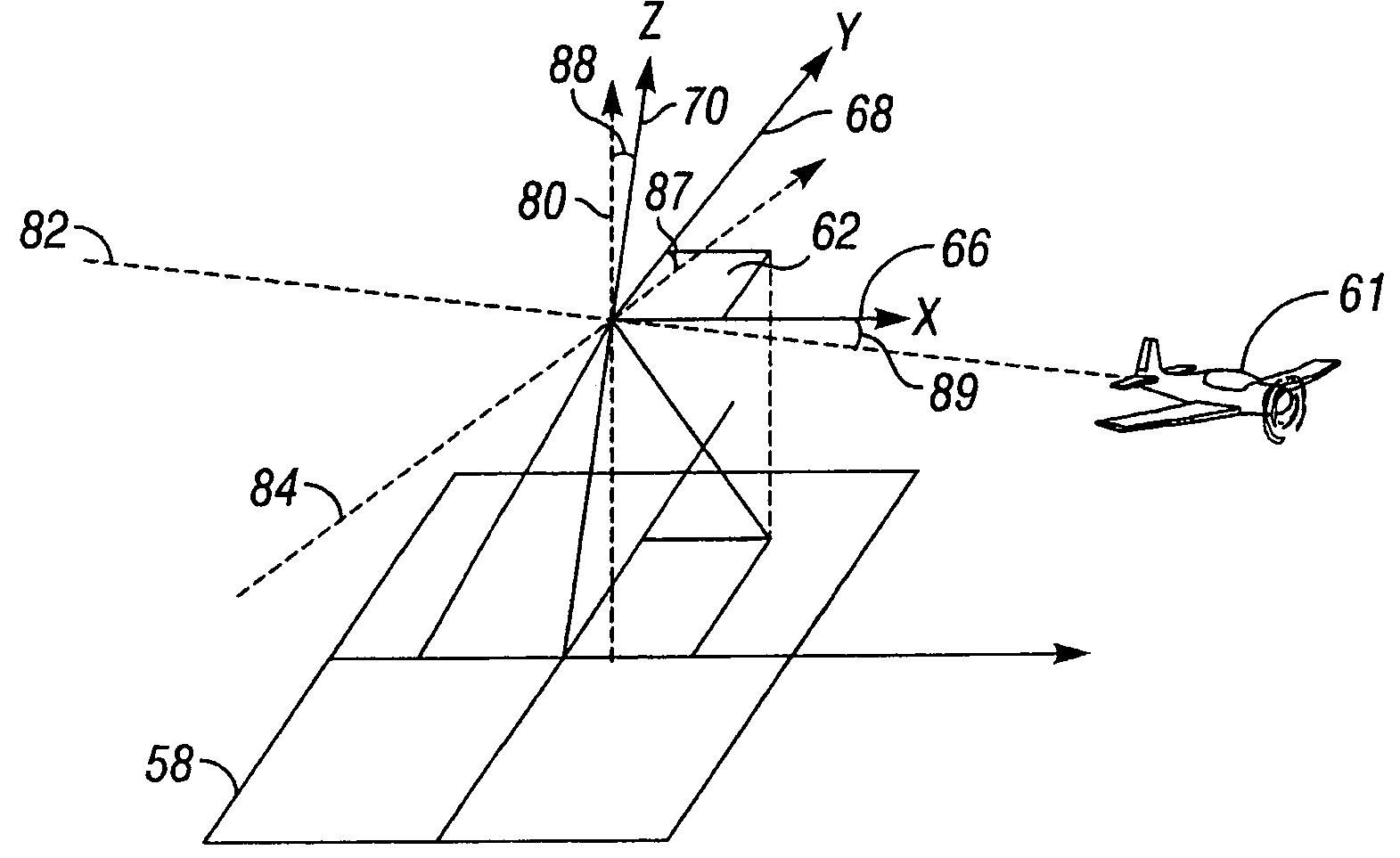

Method of using a self-locking travel pattern to achieve calibration of remote sensors using conventionally collected data

InactiveUS7212938B2Eliminate biasWave based measurement systemsTesting/calibration apparatusSensing dataOn board

The present invention provides a method to calibrate an on-board remote sensing system using a self-locking travel pattern and target remote sensing data. The self-locking travel pattern includes a number of parallel travel lines having overlapping swath widths between adjacent travel lines. The overlapping swath widths are used to determine the boresight angles and range offset of the remote sensor device. In addition, the method can be used to generate estimated horizontal and vertical displacement errors. These estimated errors can be used as correction factors for the range offset and boresight angles.

Owner:VI TECH LLC

System for detecting error and guiding error correction and method thereof

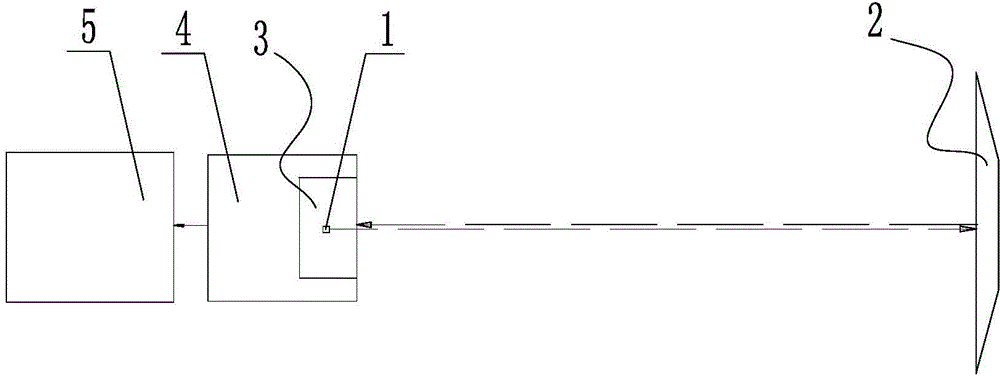

ActiveCN103604366ASimple structureLow installation accuracy requirementsUsing optical meansElectricityLaser transmitter

The invention discloses a system for detecting an error and guiding error correction and a method thereof. The system comprises a laser transmitter used for transmitting point laser, a reflection plate used for carrying out specular reflection on laser emitted by the laser transmitter, a photographic plate used for detecting the laser signal emitted by the reflection plate, a signal processor which is electrically connected with the photographic plate and is used for processing the signal transmitted by the photographic plate, a device control center which is electrically connected with the signal processor and displays the result of the signal processor, and a signal processor which receives a reflection laser point position signal transmitted by the photographic plate, compares the signal with a stored center point position, calculates whether a target object position has deviation and a deviation direction, and carries out real-time transmission to the device control center to carry out deviation correction. The system is used for detecting up, down, left and right errors relative to the center and guiding error correction, and the system has the advantages of simple structure, low installation accuracy requirement and low cost.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

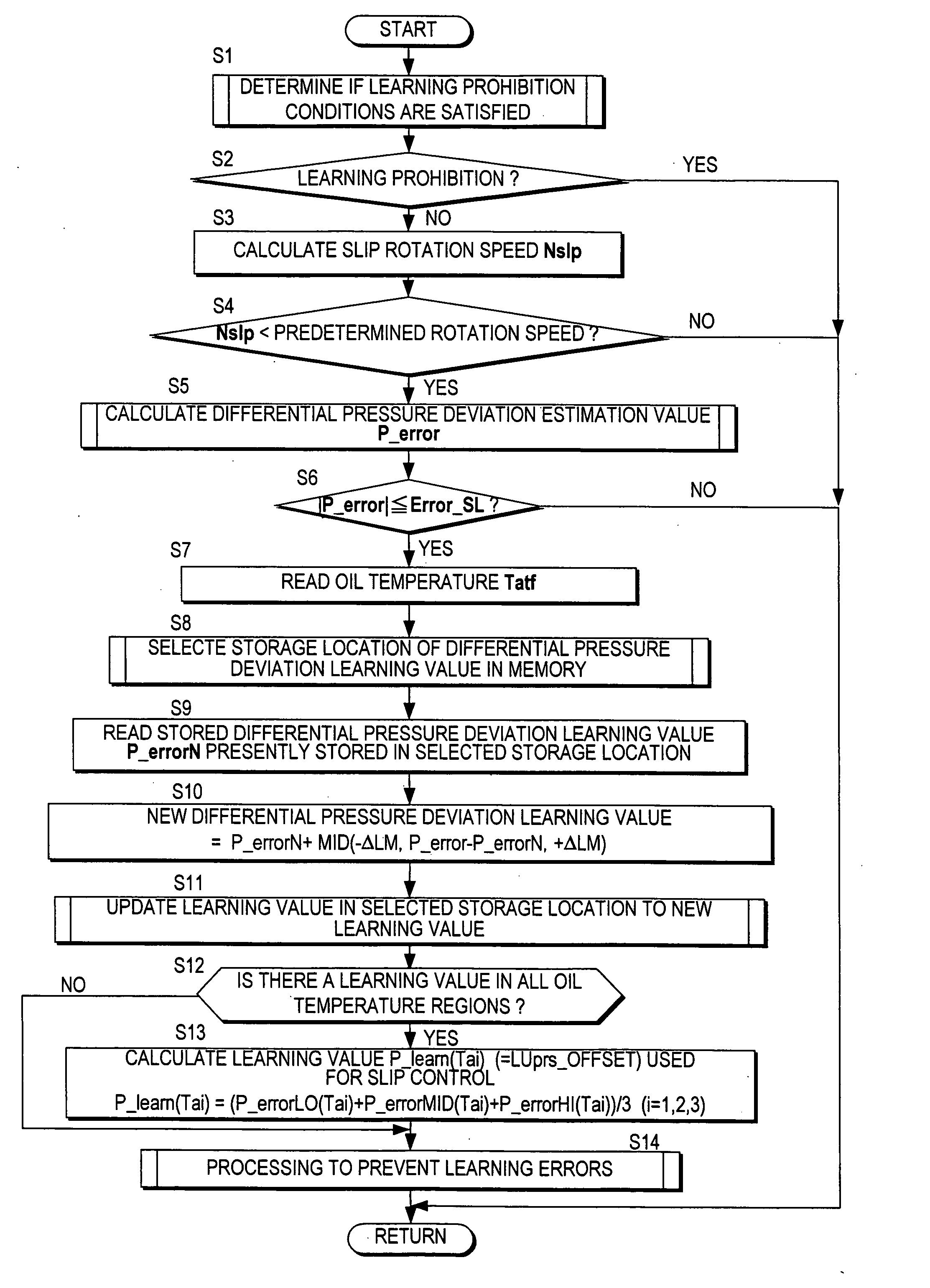

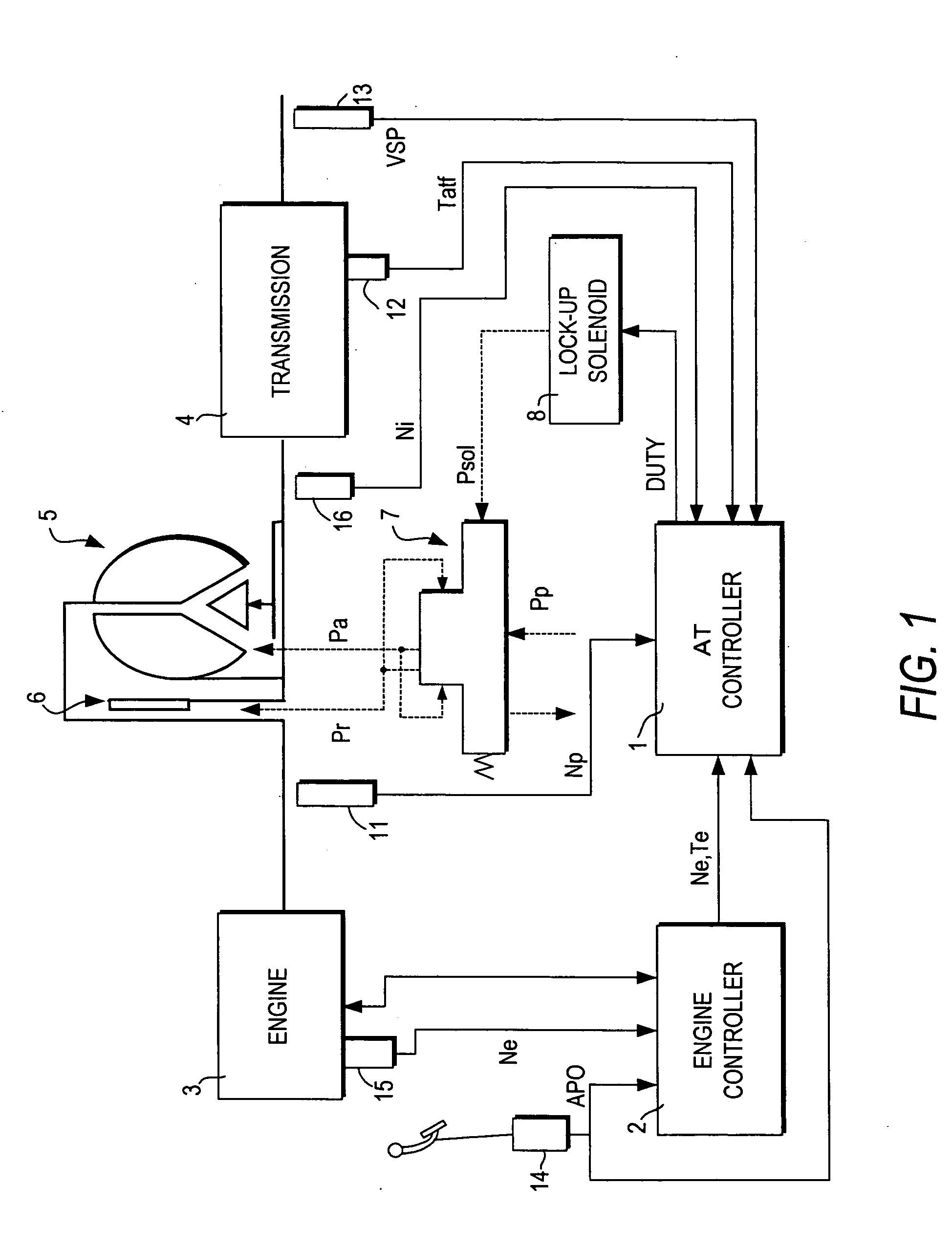

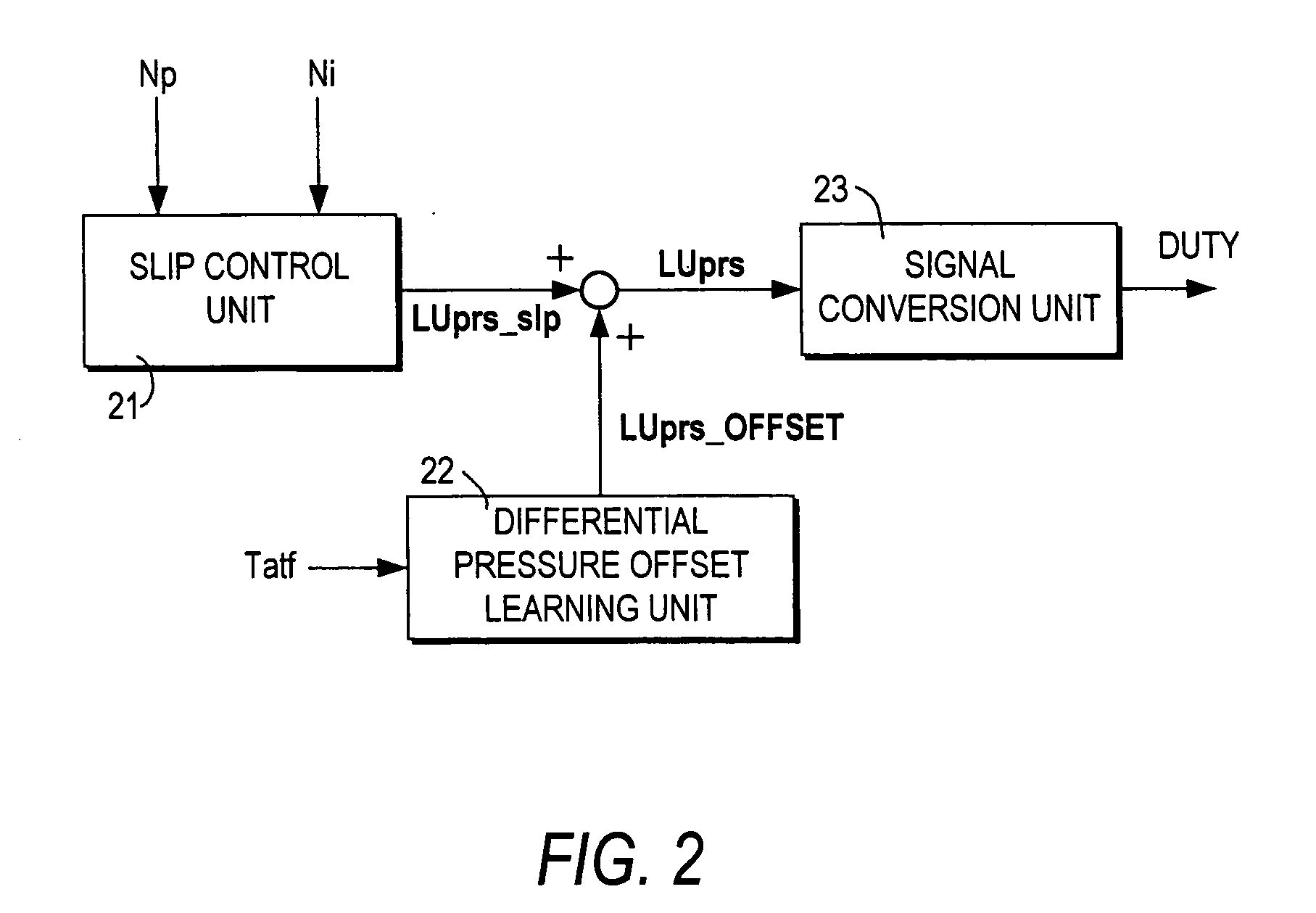

Lock-up control for torque converter

ActiveUS20050222738A1Fast learningEliminate biasAnalogue computers for trafficGearing controlVariatorClutch control

A lock-up clutch control device which controls a lock-up clutch provided in a torque converter installed between an engine and a transmission, is disclosed. The lock-up clutch control device changes over between a converter state and a lock-up state of the torque converter according to a differential pressure command value (LUprs) relating to a differential pressure supplied to the lock-up clutch. The lock-up clutch control device includes a differential pressure generating device (7,8) which generates the differential pressure supplied to the lock-up clutch; input torque detection means (2,14,15) which detects an input torque (Te) to the torque converter; and a controller (1). The controller (1) is programmed to compute a real differential pressure (P_lu) based on the detected input torque (Te) upon completion of the engagement of the lock-up clutch; compute a learning value (P_learn(Tai)) relating to a differential pressure deviation, based on the difference between the computed real differential pressure (P_lu) and differential pressure command value (P_ref) upon completion of the engagement of the lock-up clutch, and store the learning value (P_learn(Tai)); correct a present differential pressure command value (LUprs_slp) based on the learning value (P_learn(Tai)); and send the corrected differential pressure command value (LUprs) to the differential pressure generating device (7, 8).

Owner:NISSAN MOTOR CO LTD

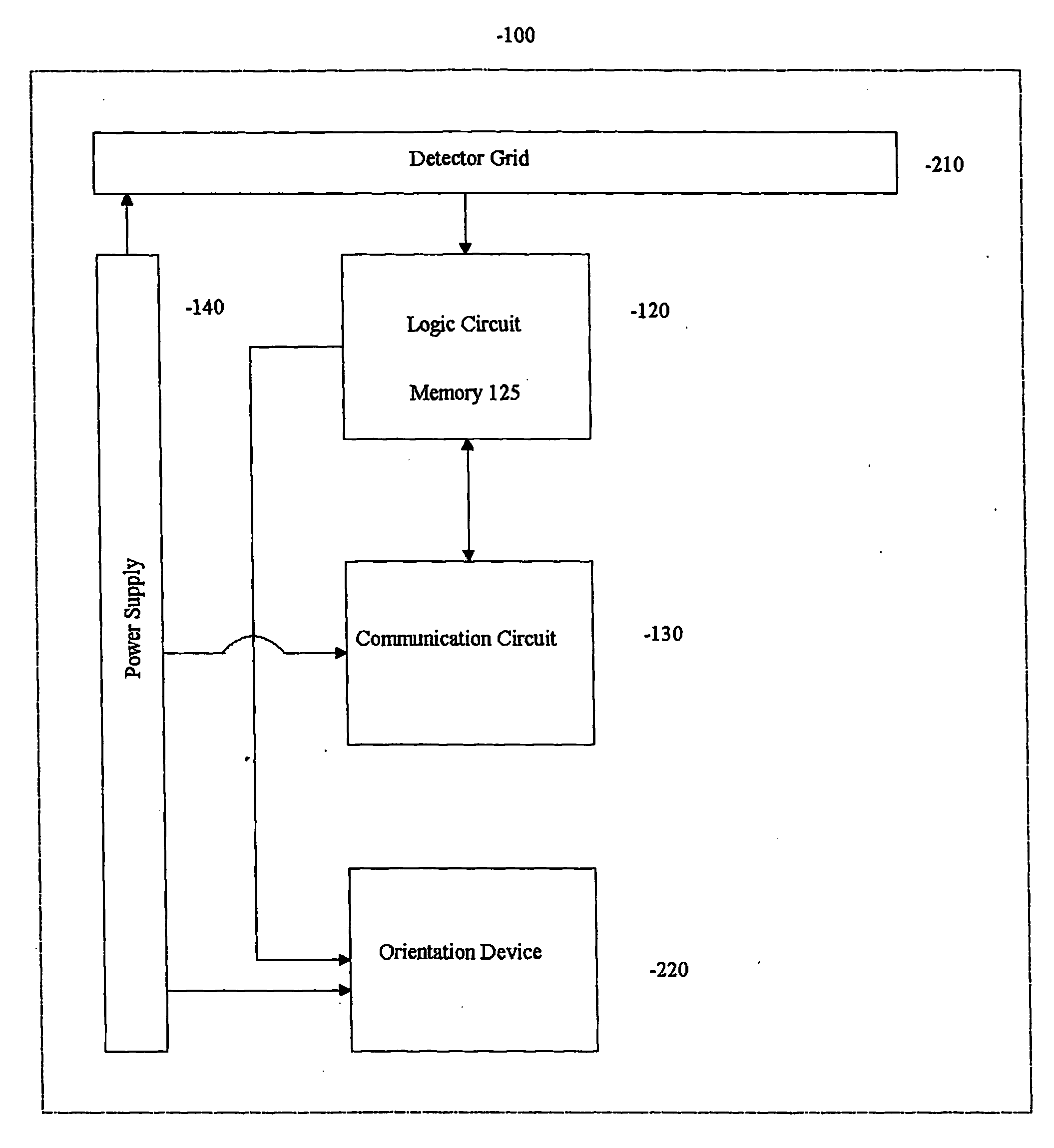

Systems and methods for generating random numbers from astronomical events

InactiveUS20060235917A1Eliminate biasLottery apparatusRandom number generatorsGamma rayAcousto-optics

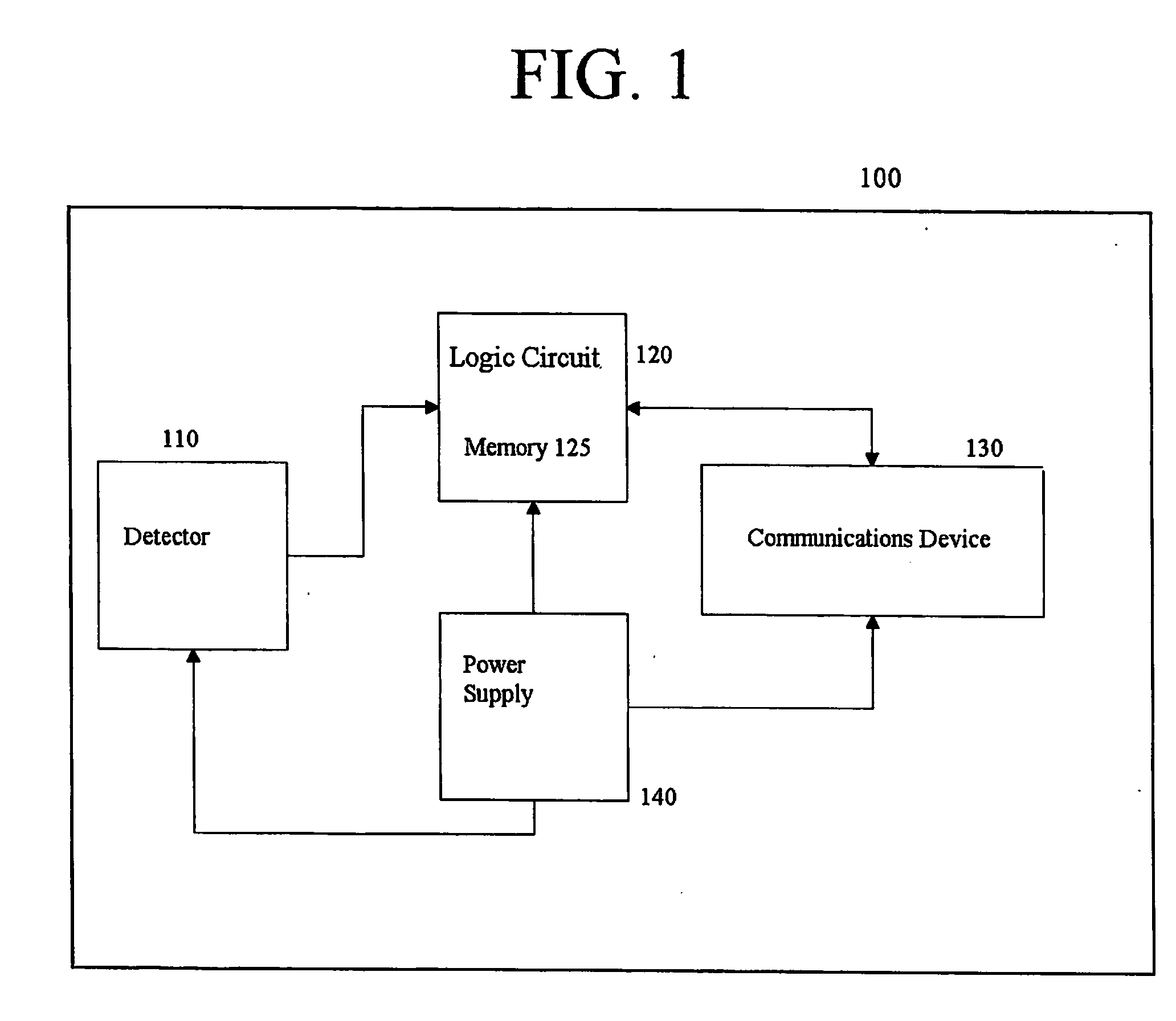

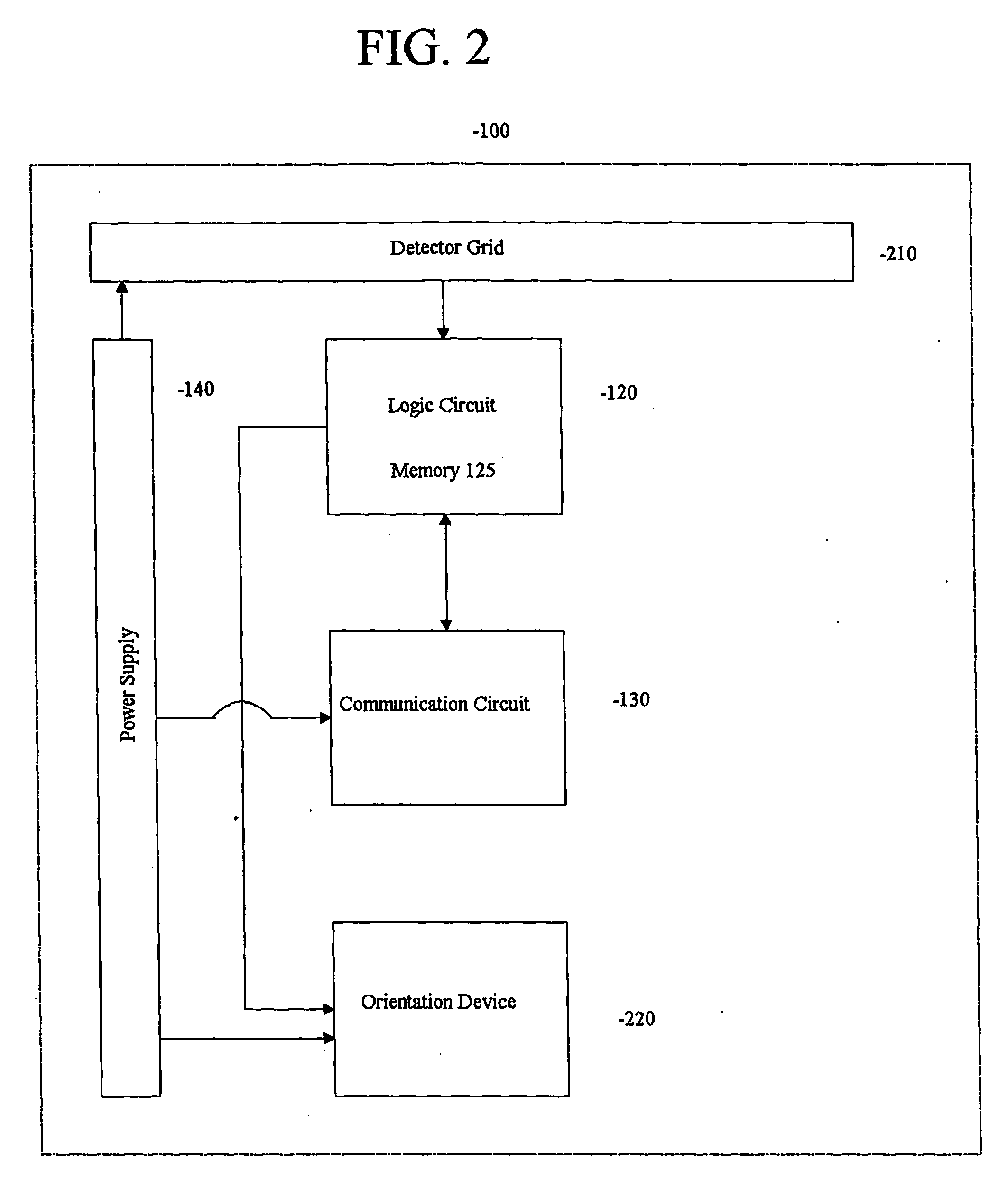

The invention discloses systems and methods for generating pure random numbers from astronomical events, such as cosmic radiation or solar events. The invention includes a detector, a logic circuit, memory, power supply and a communication device. The detector may be, for example, a solar wind particle detector, an alpha ray detector, a gamma ray etector, or the like. The memory stores data from the detector. The communication device transmits the data. In addition, the logic circuit applies predetermined mathematical rules to the collected data to generate pure random numbers suitable for use in games of chance, horoscopes, astrology, sound or light displays, or other activities. In addition, the logic circuit may encrypt these random numbers before the numbers are transmitted to a receiving device.

Owner:MANBER JEFFREY MR +1

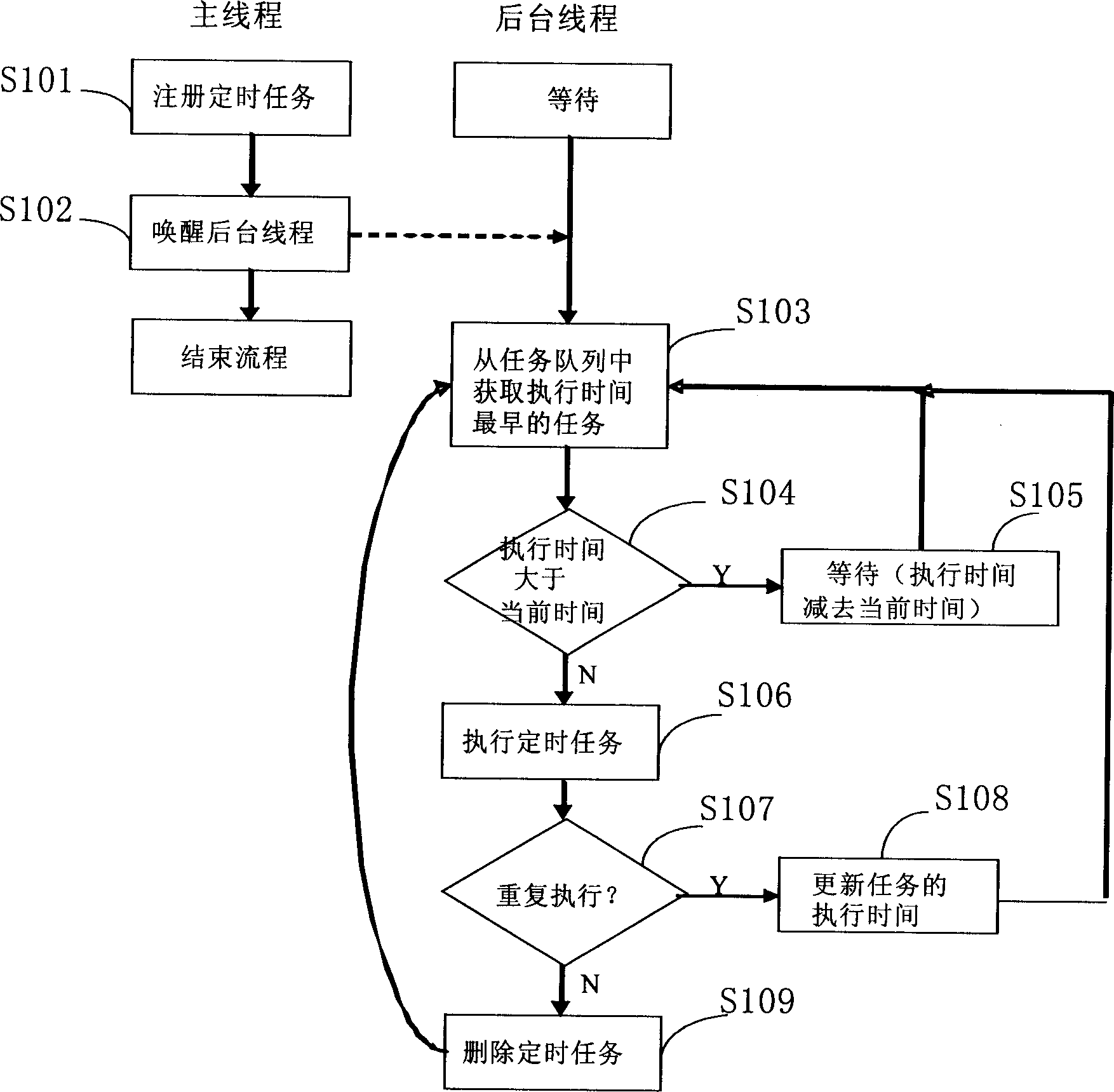

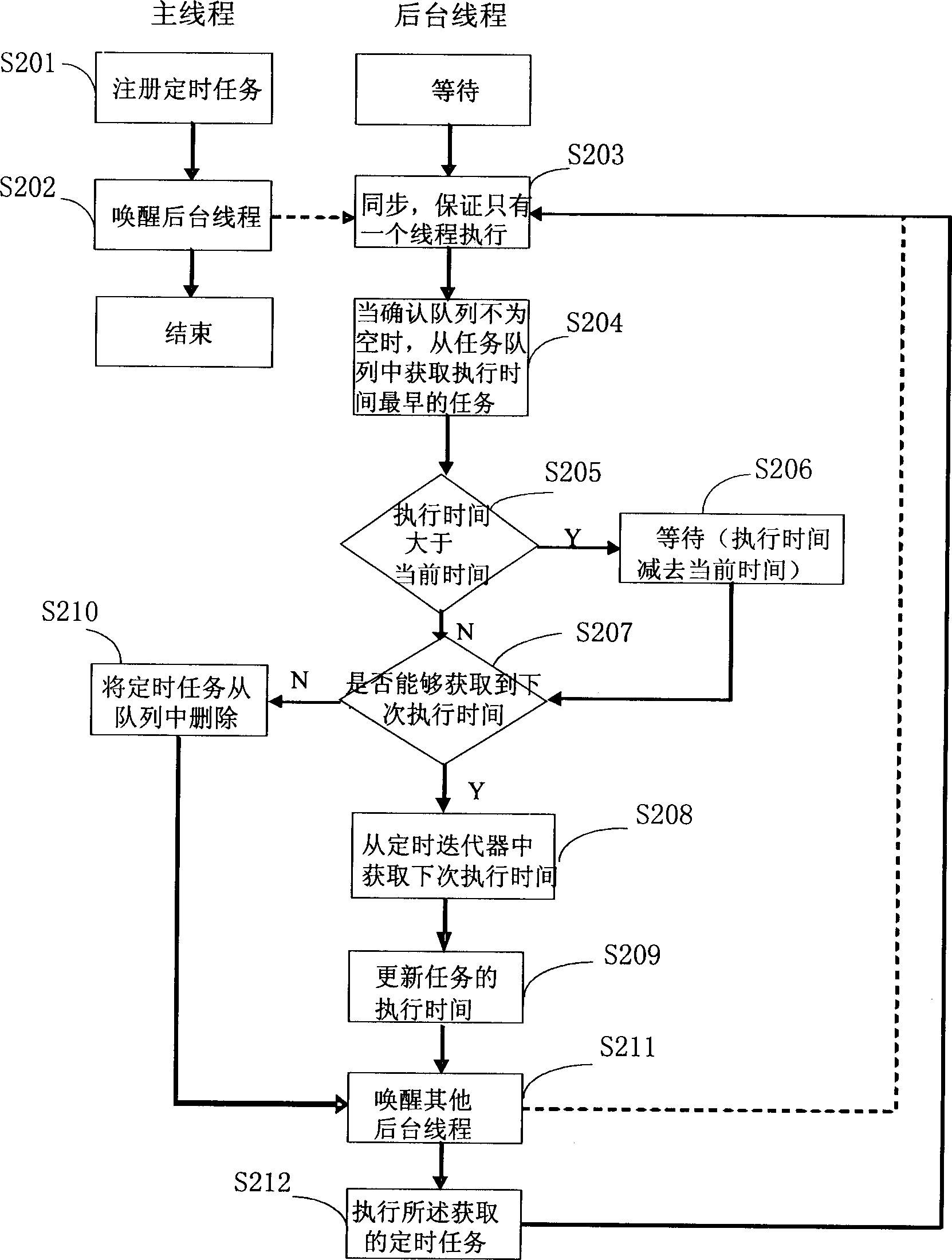

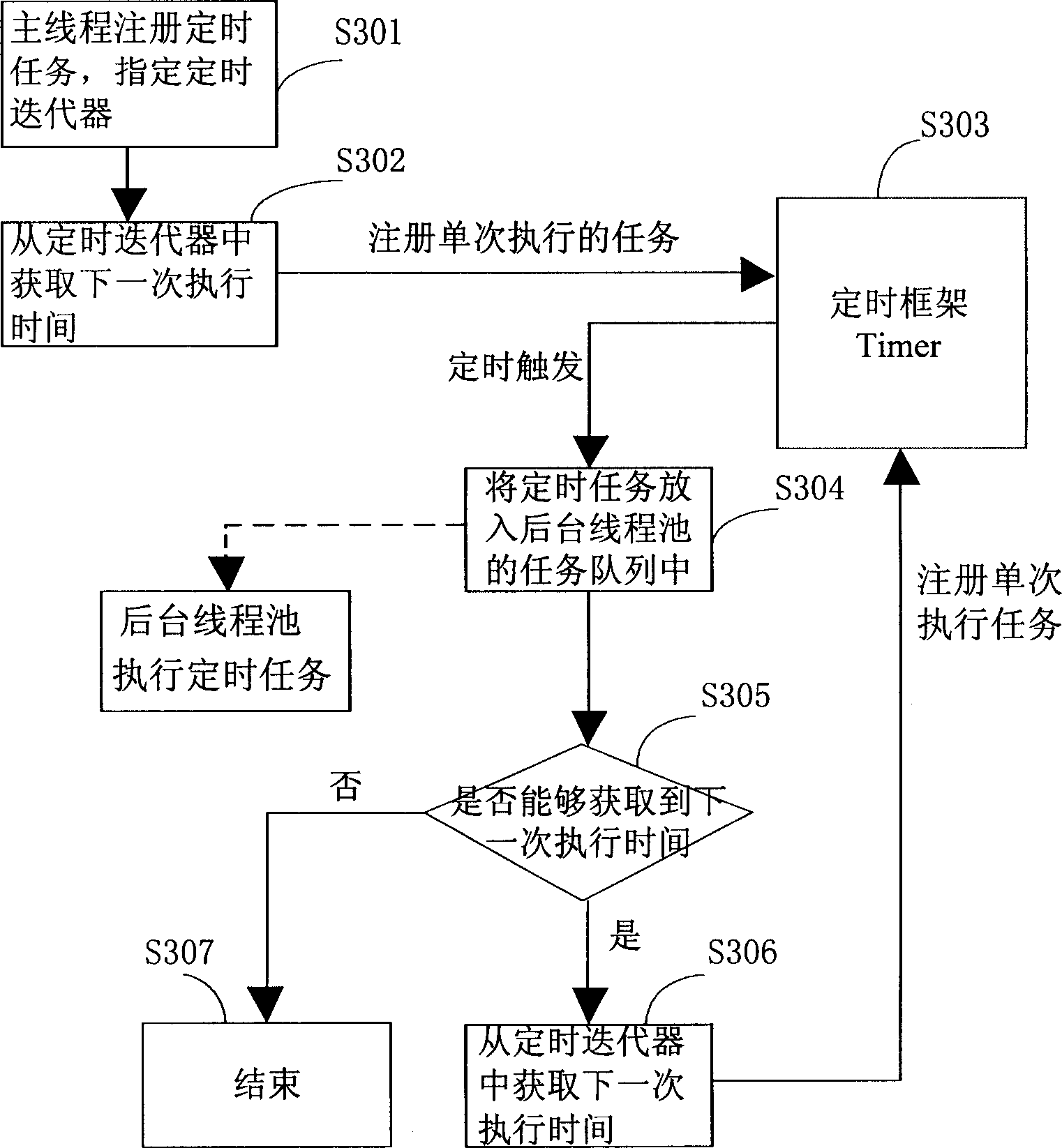

Method for planing dispatching timing task

InactiveCN1862575AGuaranteed accuracyEliminate biasMultiprogramming arrangementsResourcesExecution planIterator

The present invention relates to a method for planning and scheduling timed task. Its kernel lies in that based on timing iterator it utilizes at least two line processes to schedule and execute plan-scheduled timed task. Said invention can make the plan be self-contained by means of mode of timed iterator, so that it is favorable for implementing any complex plan. Besides, when the timing iterator is implemented, it can use a calendar algorithm, so that it can eliminate deviation of daylight saving time, and can ensure planning accuracy.

Owner:HUAWEI TECH CO LTD

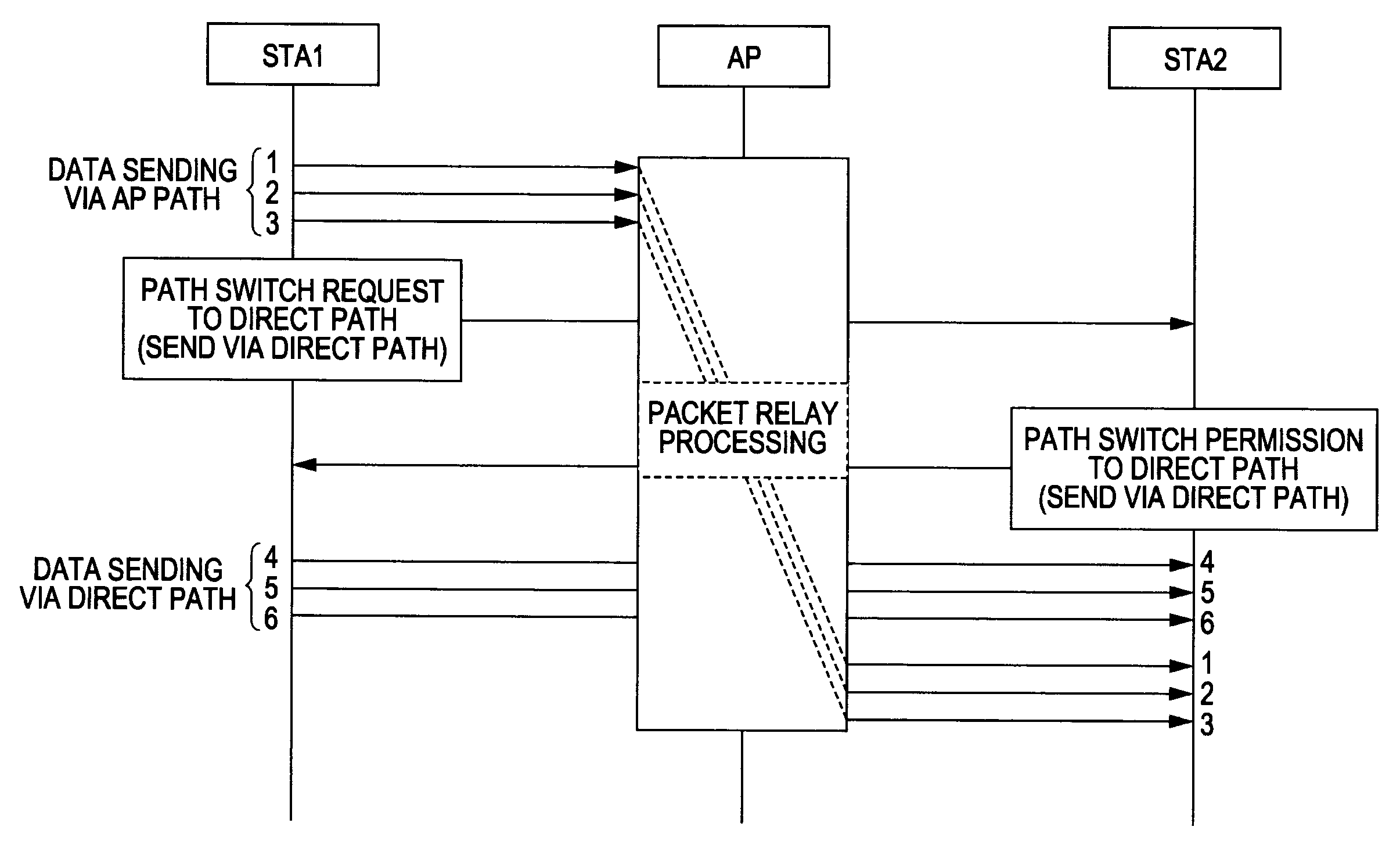

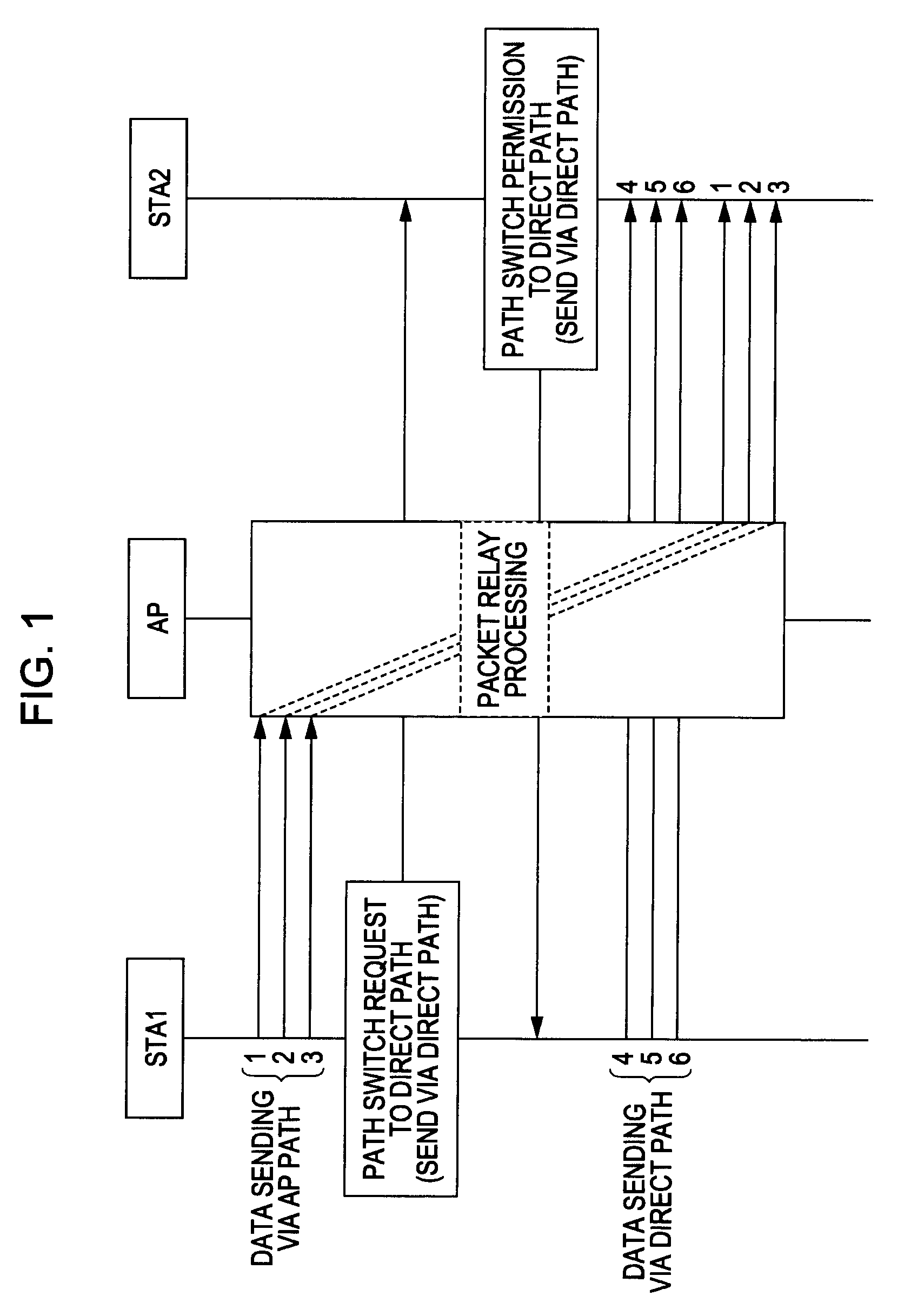

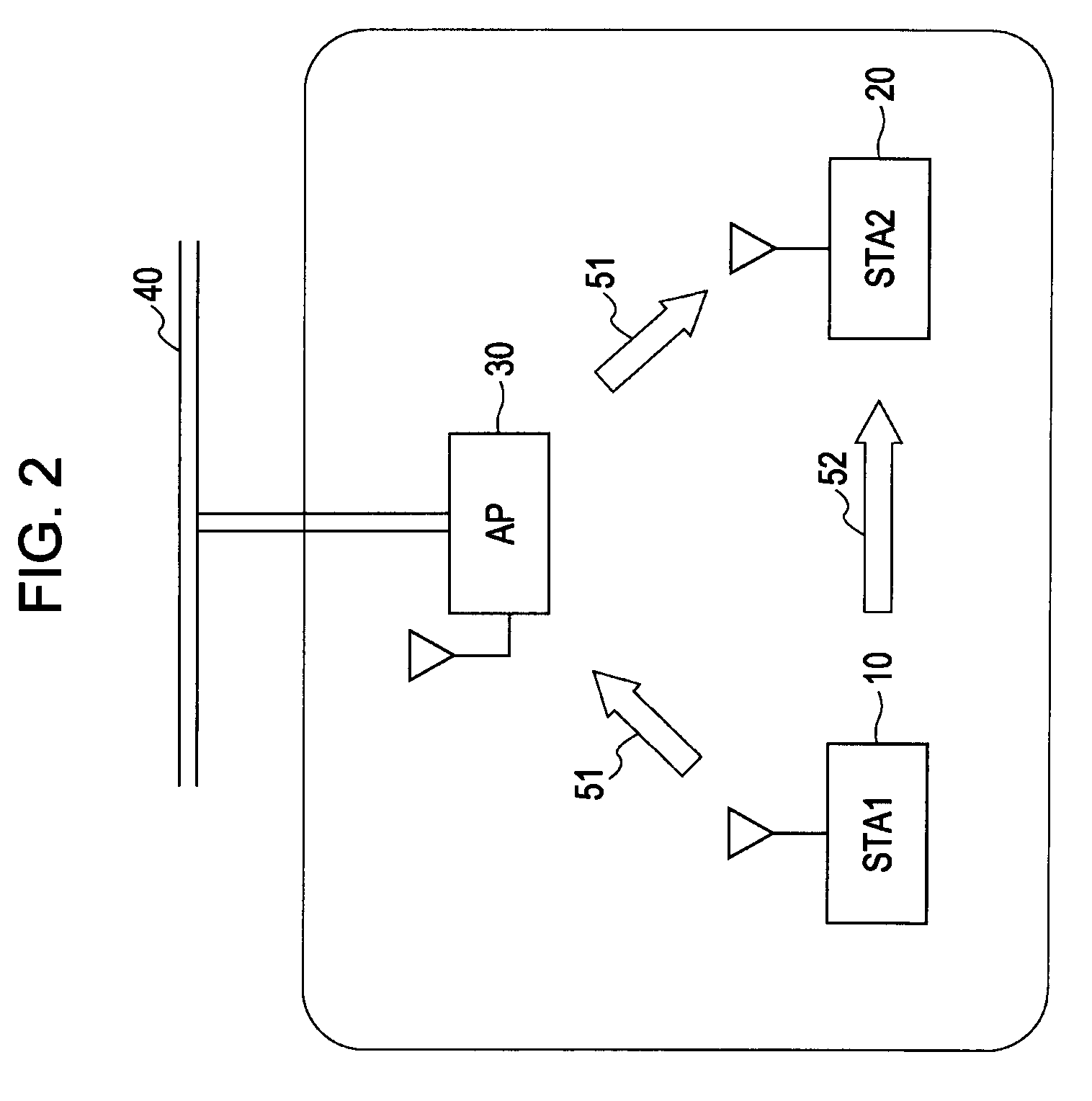

Wireless Communication Device, Communication System, and Communication Control Method, and Program

InactiveUS20100040007A1Eliminate biasNetwork traffic/resource managementWireless commuication servicesCommunications systemPath switching

Owner:SONY CORP

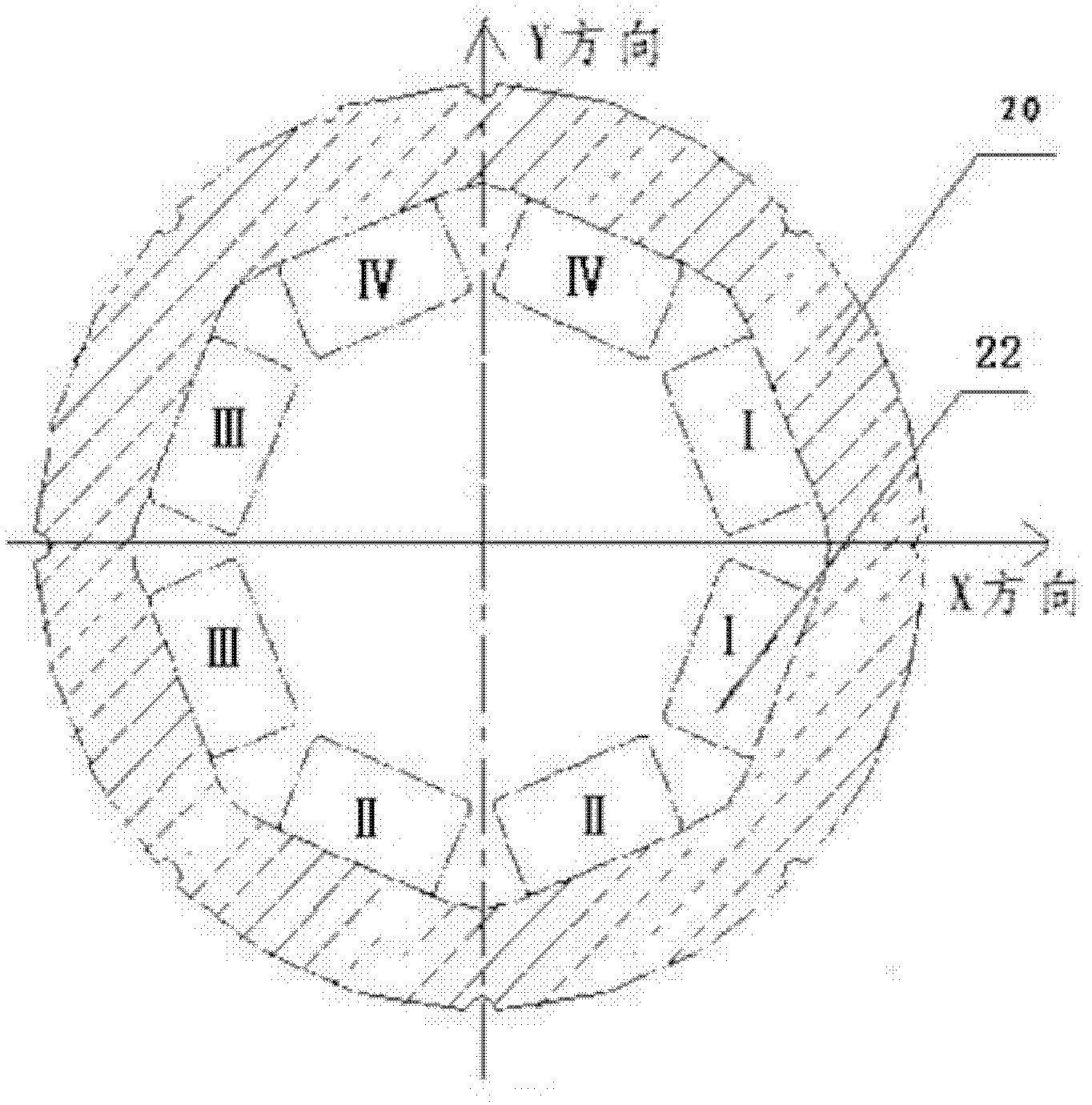

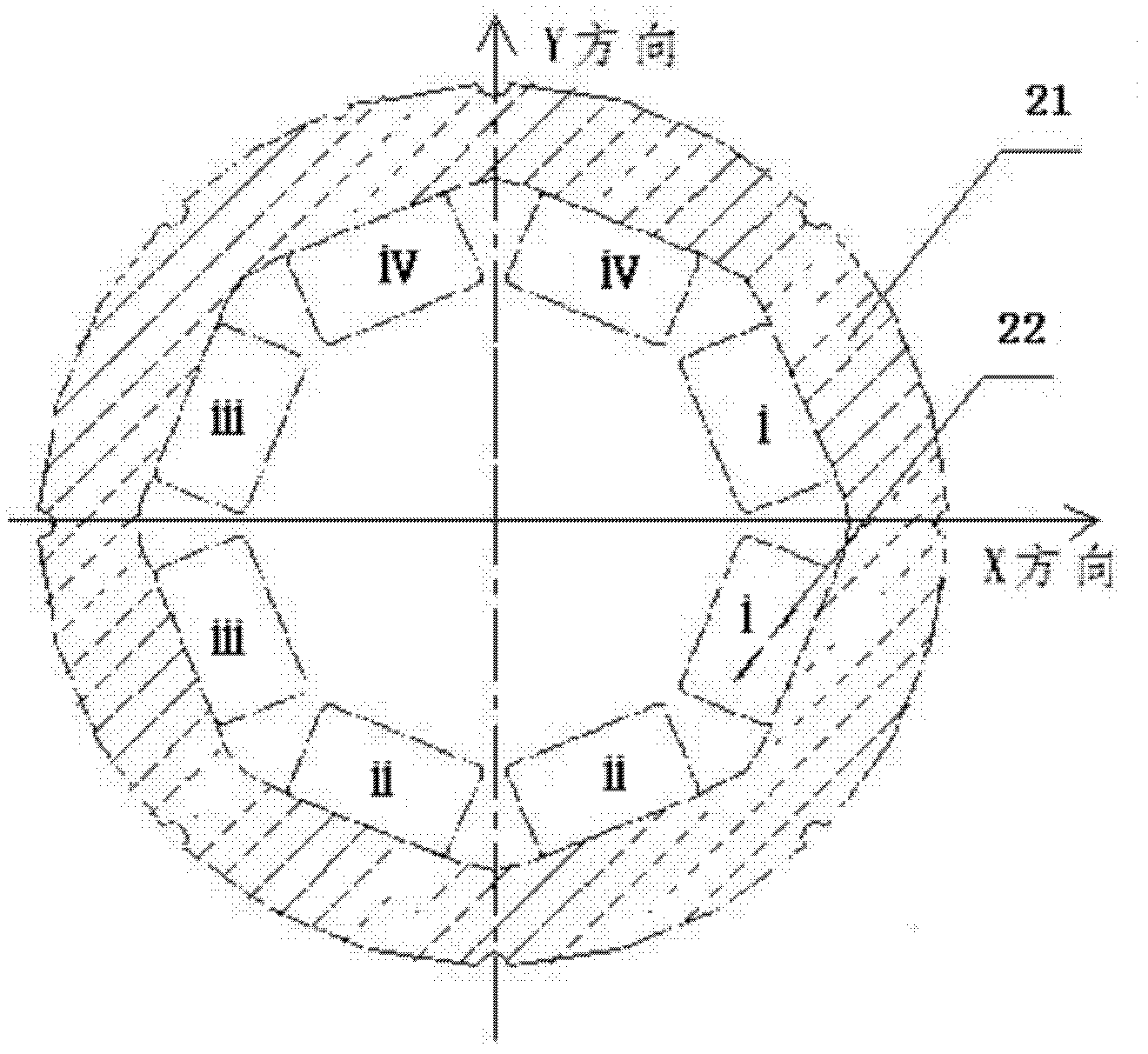

Method for obtaining radial suspension centers of rotor of magnetic molecular pump

ActiveCN102425555AEliminate biasGuaranteed uptimePump controlAxial flow pumpsMagnetic bearingEngineering

The invention discloses a method for obtaining radial suspension centers of a rotor of a magnetic molecular pump. The method is characterized by establishing a radial magnetic bearing coordinate system and a radial displacement sensor coordinate system with the radial magnetic bearing stator inner circle center and the radial displacement sensor stator inner circle center as the origins; obtaining deviations between the radial magnetic bearing stator inner circle center and the radial protection bearing stator inner circle center in the X and Y directions by obtaining a radial protection bearing stator inner circle center coordinate in the radial magnetic bearing coordinate system; obtaining the radial magnetic bearing stator inner circle center in the radial displacement sensor coordinate system according to the deviations; and adjusting the first and second radial suspension centers of the rotor to be in the first and second radial magnetic bearing stator inner circle centers through the above processes. The method has the effect of ensuring stable operation of the magnetic molecular pump system.

Owner:KYKY TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com