System for detecting error and guiding error correction and method thereof

An error correction and error detection technology, which is applied in the field of position detection systems, can solve problems such as high installation accuracy requirements, high cost, and inability to determine errors, and achieve the effects of low installation accuracy, simple structure, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

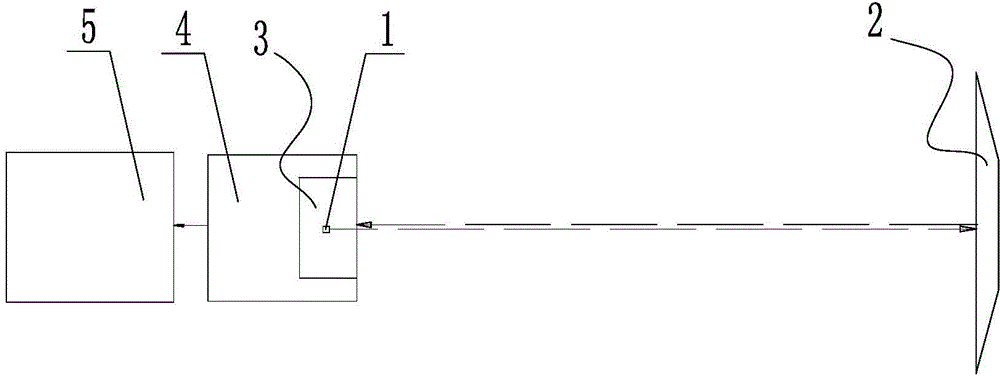

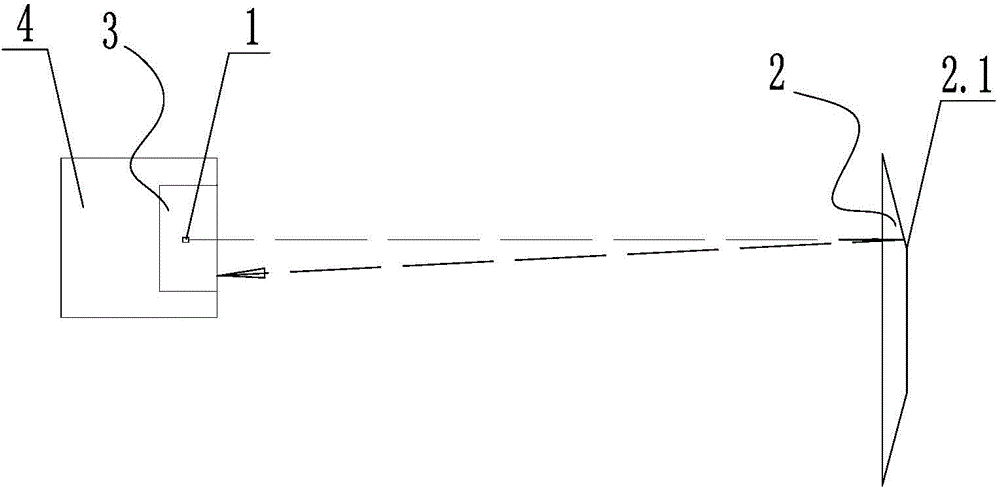

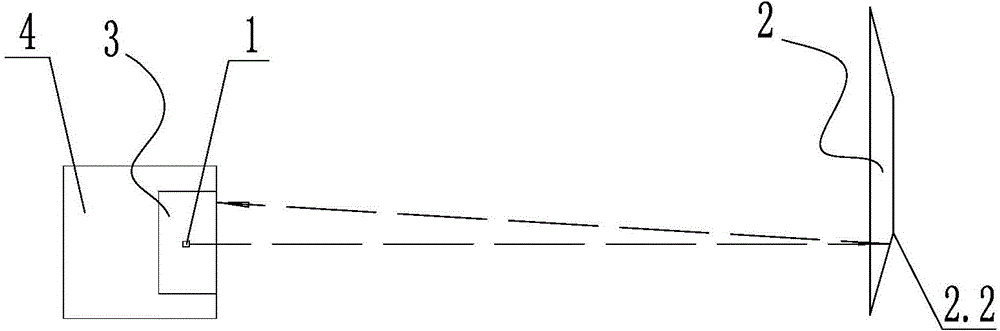

[0023] Such as figure 1 Shown is a specific embodiment of the system of the present invention for detecting errors and directing error correction. In this embodiment, the system for detecting errors and directing error correction includes:

[0024] Laser emitter 1, used to emit point laser;

[0025] The reflector 2 is used for specular reflection of the laser light emitted by the laser emitter 1 .

[0026] The photosensitive plate 3 is used to detect the laser signal reflected by the reflective plate 2 . In this embodiment, the photosensitive plate 3 is a CCD photosensitive plate.

[0027] A signal processor 4, electrically connected to the photosensitive plate 3, for processing the signal transmitted by the photosensitive plate 3;

[0028] The equipment control center 5 is electrically connected with the signal processor 4 and displays th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com