Patents

Literature

70 results about "Photographic plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photographic plates preceded photographic film as a capture medium in photography. The light-sensitive emulsion of silver salts was coated on a glass plate, typically thinner than common window glass, instead of a clear plastic film.

Electroplating copper plughole process of circuit board

ActiveCN101873770AMeets high current connection requirementsImprove performancePrinted element electric connection formationCopper platingPhotographic plate

The invention discloses an electroplating copper plughole process of a circuit board. The process comprises the following steps of: manufacturing a substrate inner layer circuit: arranging an inner layer circuit on a material plate coated with a copper layer, overlapping a plurality of plates and laminating, and drilling a through hole on the multi-layer plate; electroplating the surface of a copper deposition plate: arranging the multi-layer plate in the copper deposition liquid to plate a conductive thin copper layer on the wall of the hole and the external surface of the multi-layer plate; transferring a special plating hole pattern, i.e., transferring the photographic plate image to the multi-layer plate; electroplating the through hole: electroplating the multi-layer plate to fill the through hole with the plated copper; reducing copper and etching: the through hole plated with copper partially exposing out of the plate surface, removing copper exposing out of the plate surface; arranging outer layer circuit: carrying out the arrangement of the outer layer circuit of the multi-layer plate; electroplating pattern; reducing film and etching: removing the dry film and etching; and printing green oil on the naked copper plate and work character, and baking to produce the finished plate.

Owner:广东兴达鸿业电子有限公司

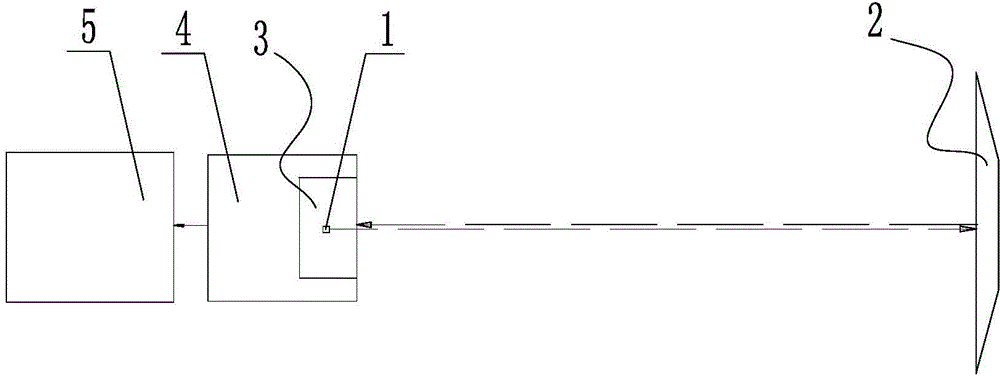

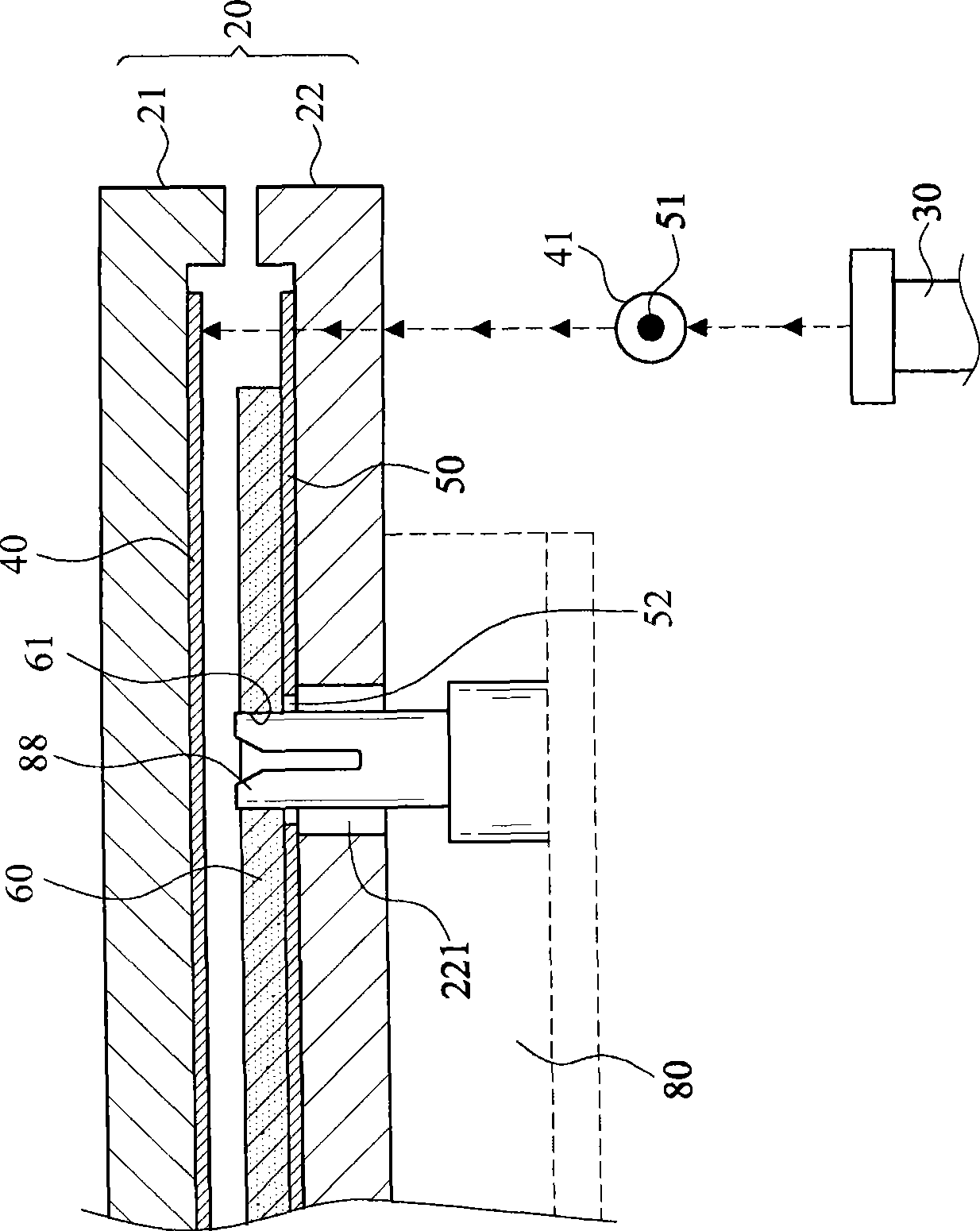

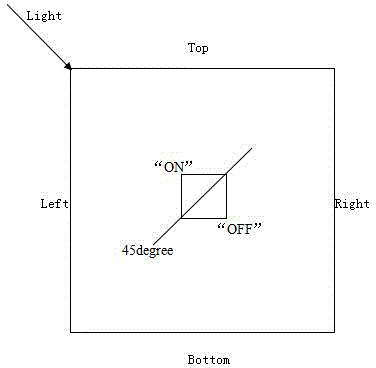

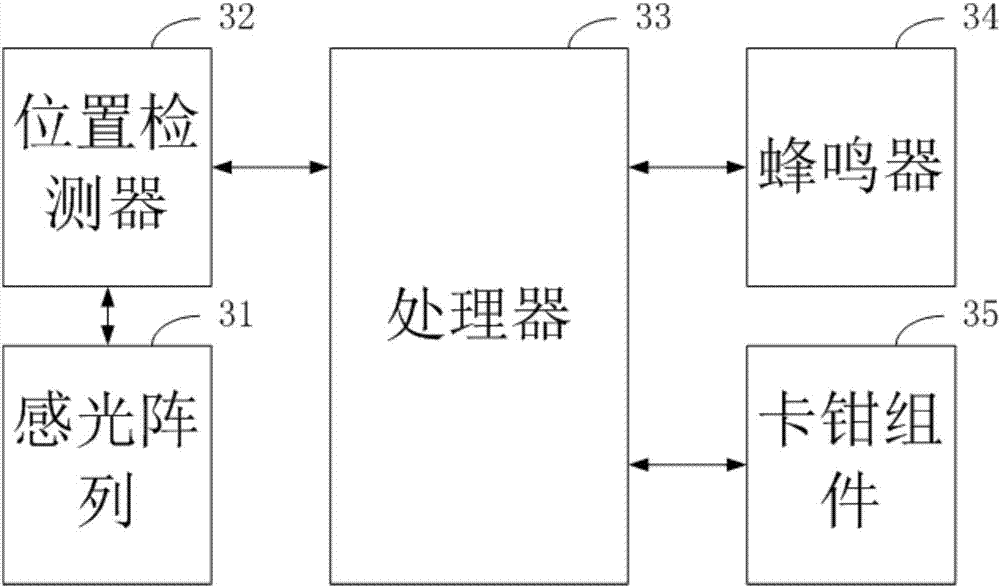

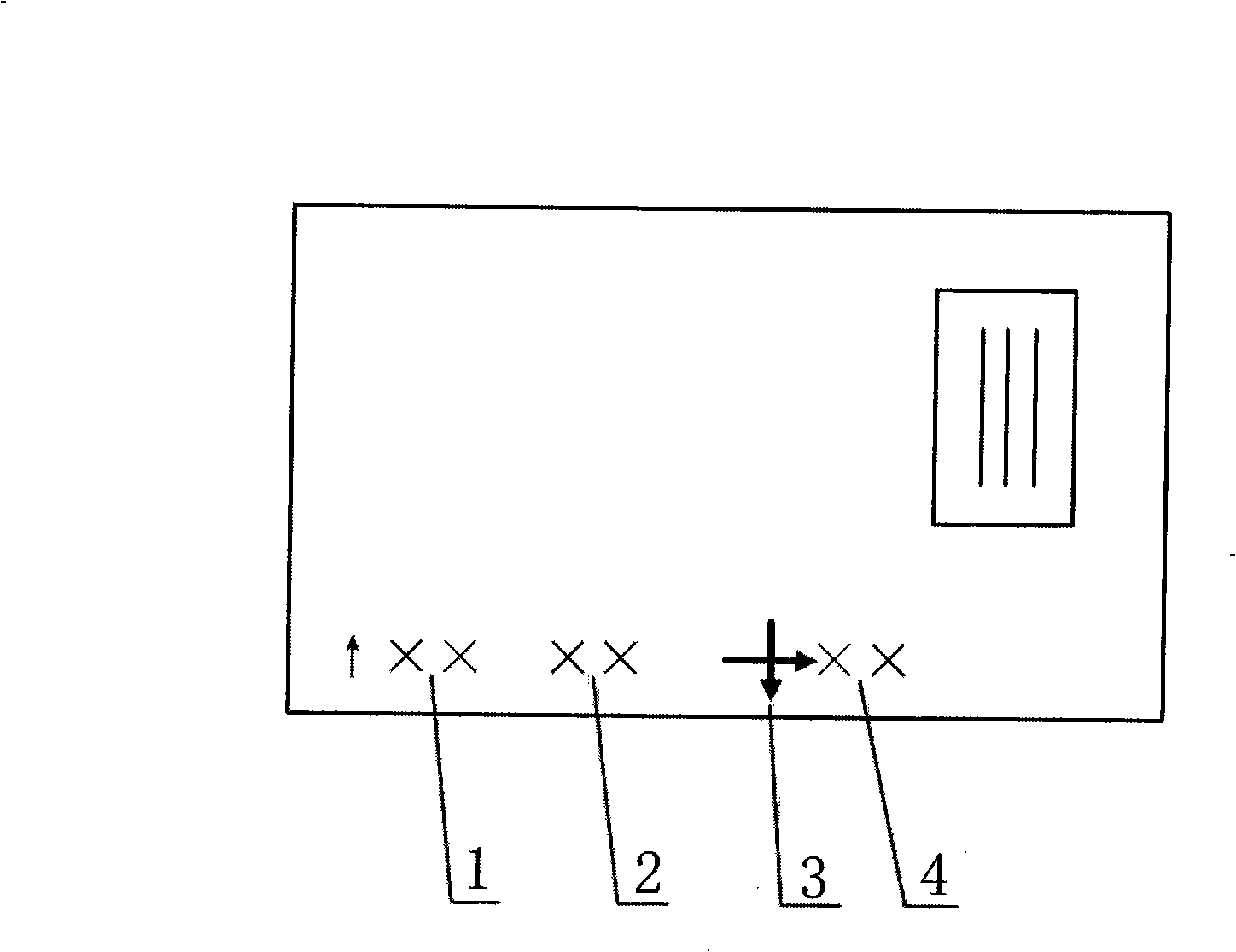

System for detecting error and guiding error correction and method thereof

ActiveCN103604366ASimple structureLow installation accuracy requirementsUsing optical meansElectricityLaser transmitter

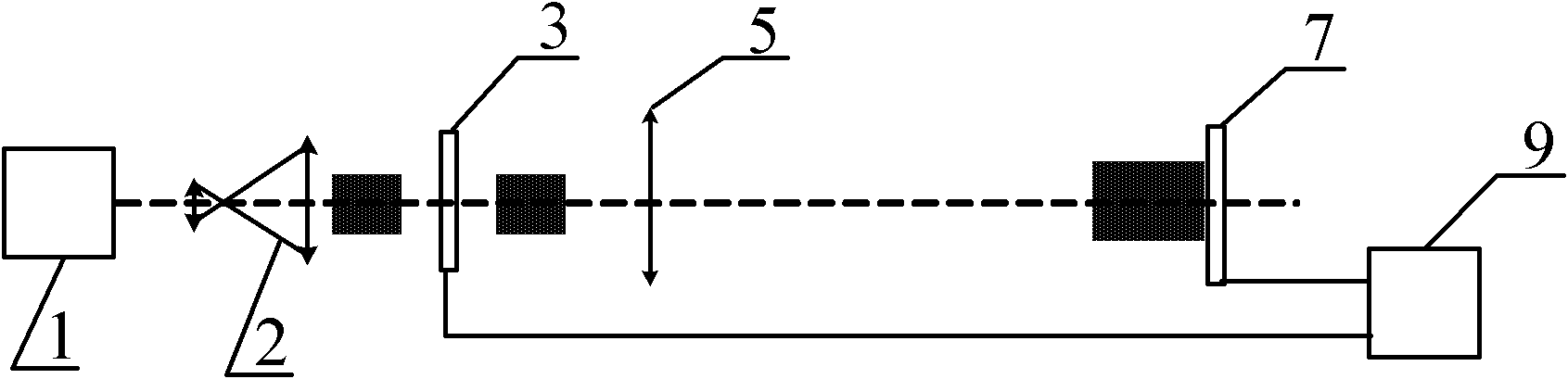

The invention discloses a system for detecting an error and guiding error correction and a method thereof. The system comprises a laser transmitter used for transmitting point laser, a reflection plate used for carrying out specular reflection on laser emitted by the laser transmitter, a photographic plate used for detecting the laser signal emitted by the reflection plate, a signal processor which is electrically connected with the photographic plate and is used for processing the signal transmitted by the photographic plate, a device control center which is electrically connected with the signal processor and displays the result of the signal processor, and a signal processor which receives a reflection laser point position signal transmitted by the photographic plate, compares the signal with a stored center point position, calculates whether a target object position has deviation and a deviation direction, and carries out real-time transmission to the device control center to carry out deviation correction. The system is used for detecting up, down, left and right errors relative to the center and guiding error correction, and the system has the advantages of simple structure, low installation accuracy requirement and low cost.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Digital print making Filin direct printing and digital proofing output system

InactiveCN101380851AHigh edge resolutionAvoid lostTypewritersOther printing apparatusImage resolutionComputer to plate

The invention discloses a comprehensive multitask output system which realizes trinity of CTP(Computer To Plate), CTF(Computer To Film) and CTD(Computer To Digital Proofing) by a high precision control platform, a high resolution inkjet printer, a computer image processing software, etc. No darkroom operation is needed in the invention. A traditional low-cost PS photographic plate is used in digital printing and plate making, thus simplifying the structure of a selenium plate and improving the output quality. Plate making can be carried out directly in a computer digital film output part without a chemical developing machine. By adopting a high resolution inkjet image color management system and a screening technology in printing, the image output by the CTD is exquisite and natural, and the invention is a comprehensive prepress technology of digitalization of a traditional printing device.

Owner:谷京陆

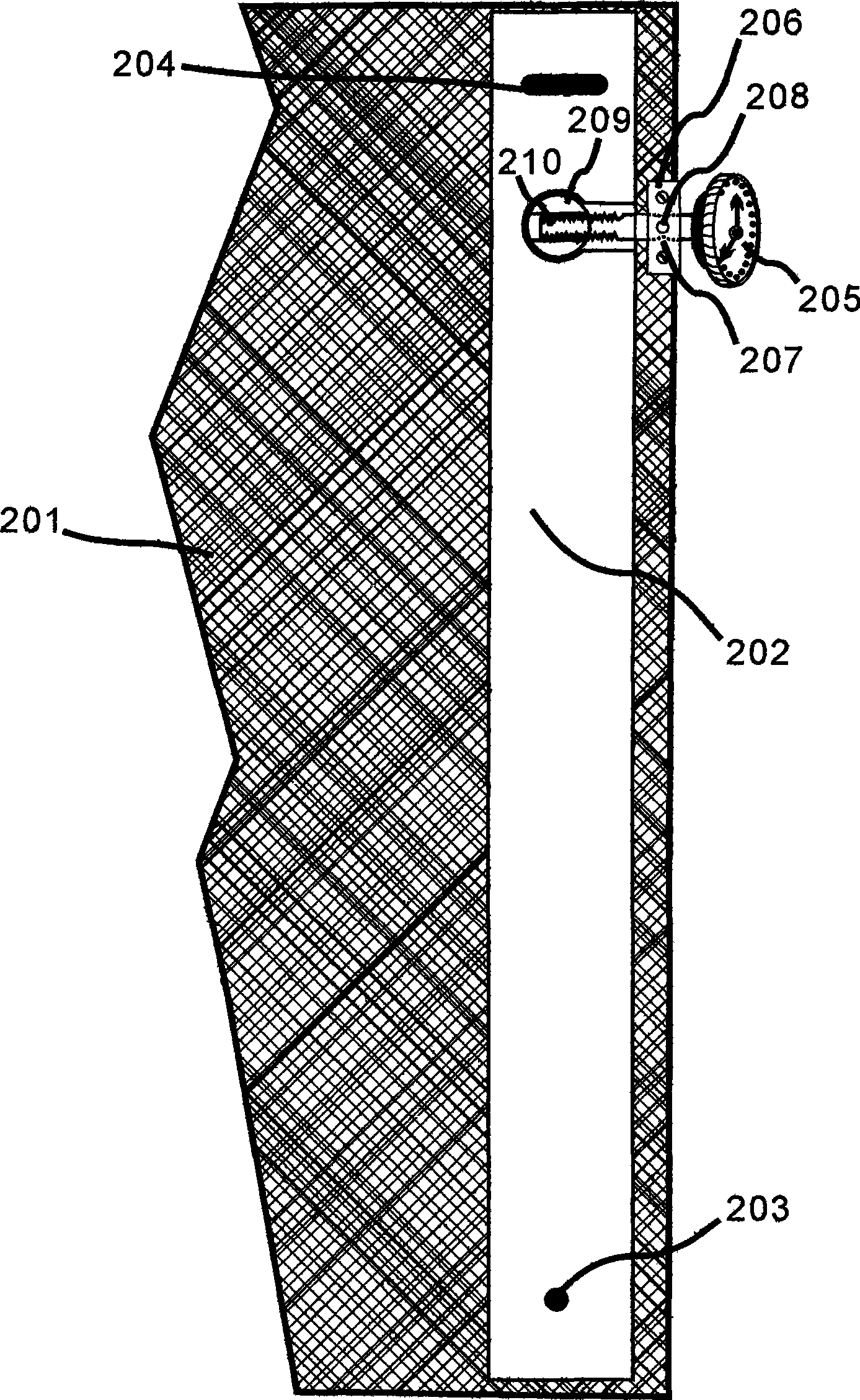

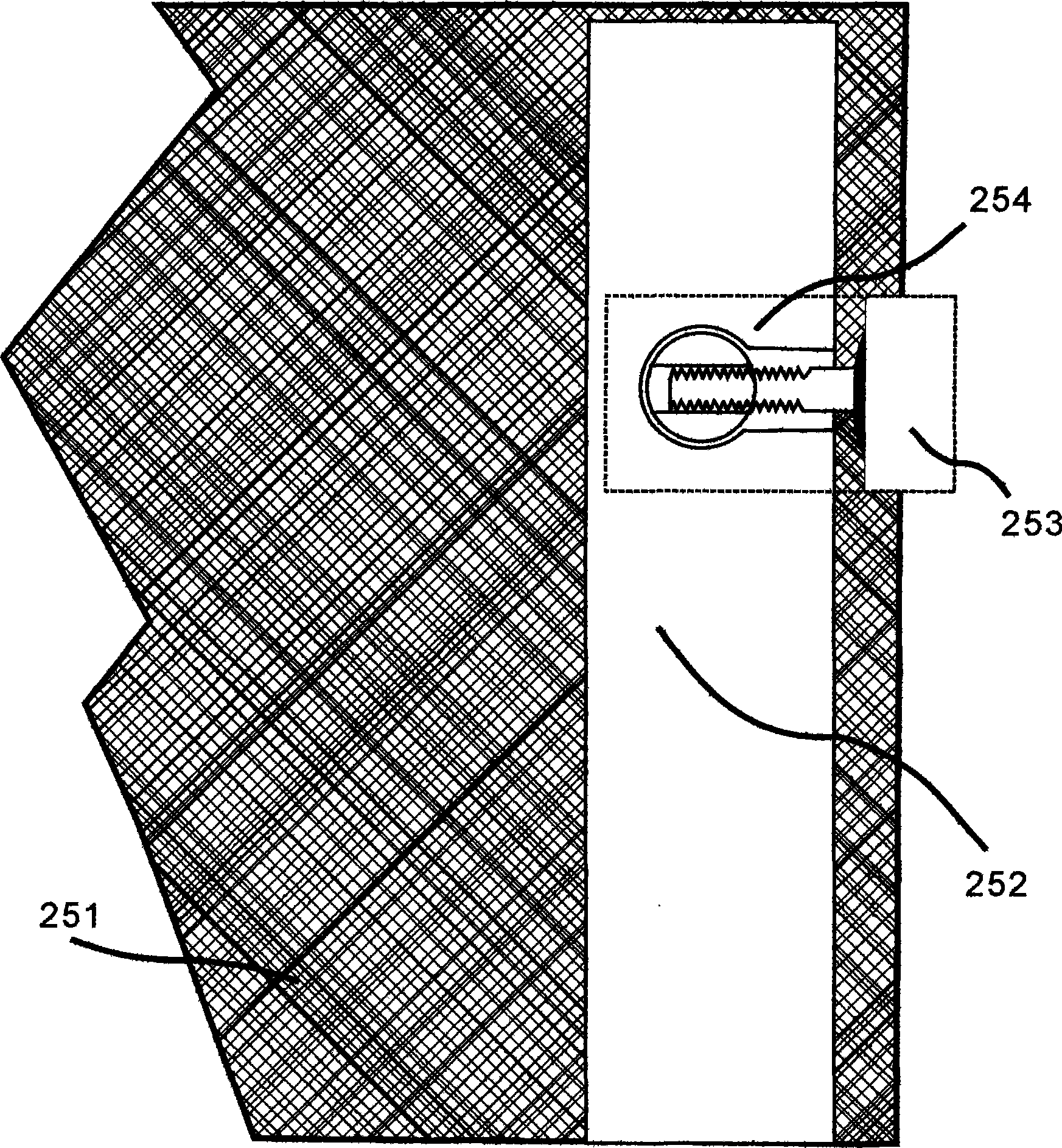

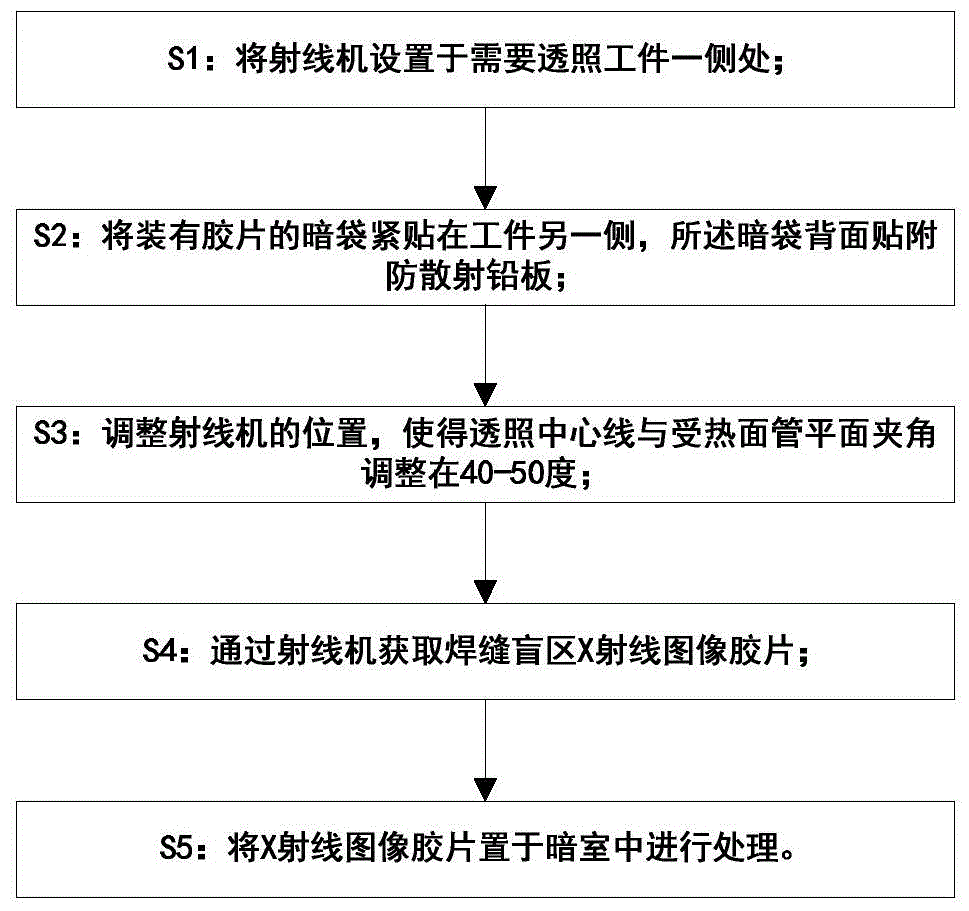

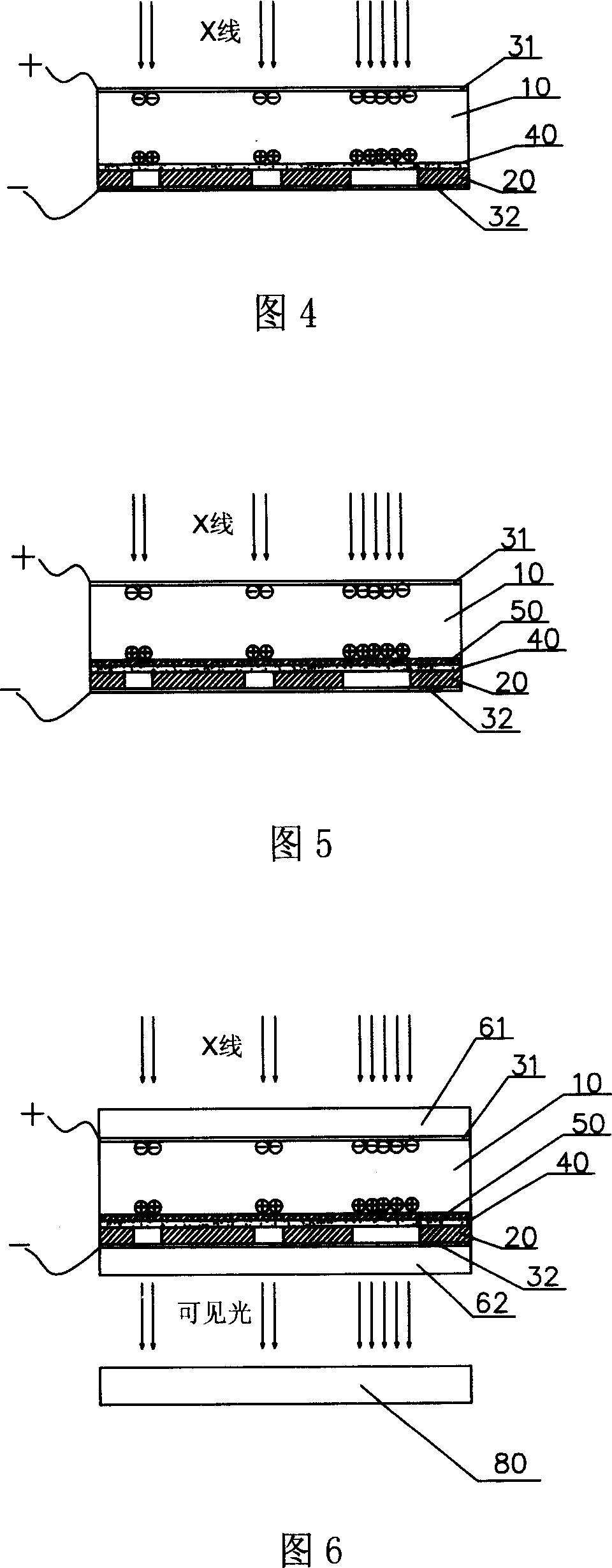

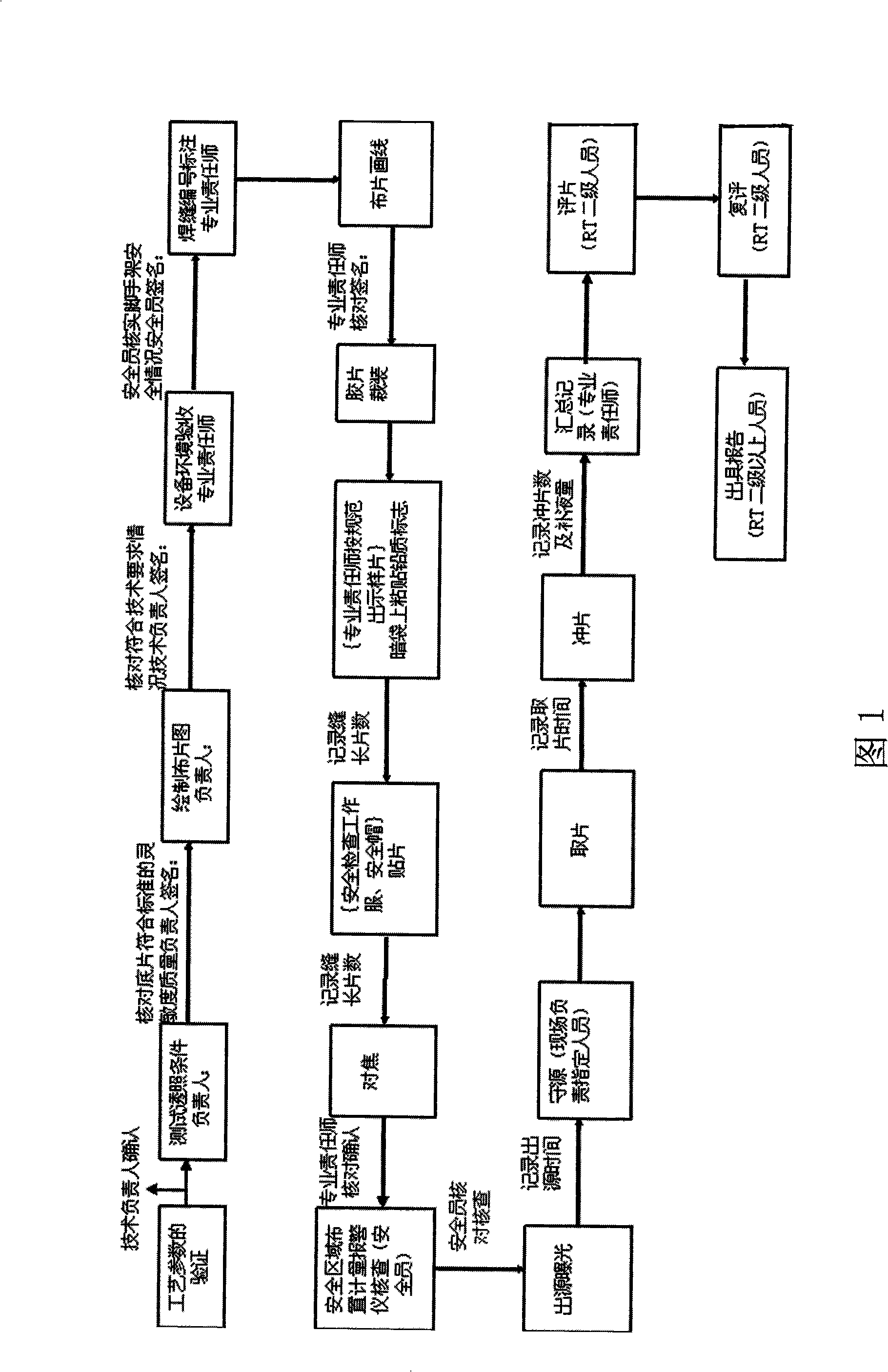

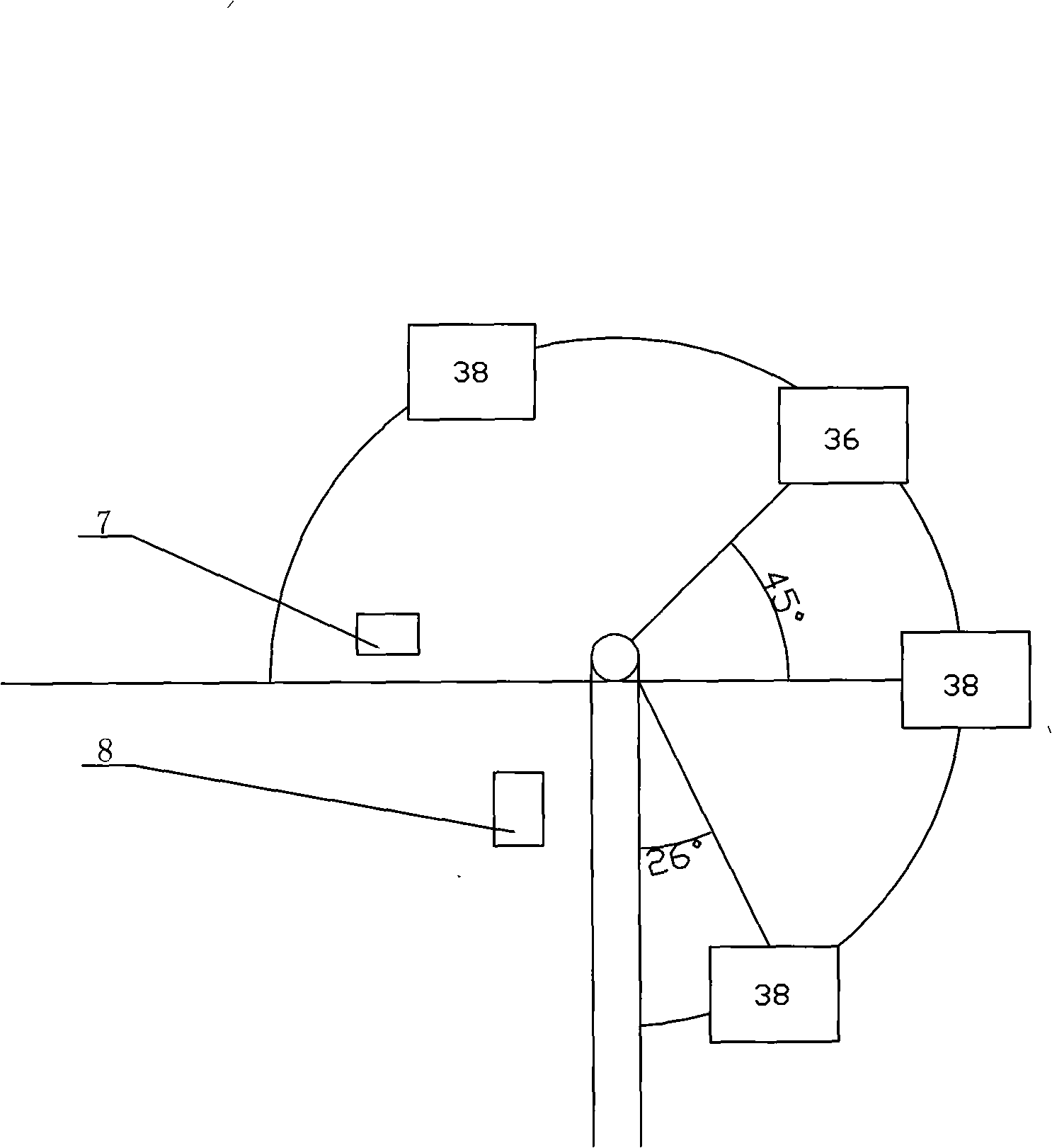

Power station boiler membrane panel welding joint blind area X ray detection method

InactiveCN104698015AReduce spillsGuaranteed operating levelMaterial analysis by transmitting radiationX-rayEngineering

The invention discloses a power station boiler membrane panel welding joint blind area X ray detection method. The method comprises the following steps: firstly, placing a ray machine on one side of a to-be-radiated workpiece; adhering a camera bag containing films to the other side of the workpiece, and adhering the back of the camera bag to an anti-scatter lead plate; then, regulating the position of the X machine so as to regulate an included angle between a radiating centerline and the plane of a heated surface tube to 40-50 degrees; acquiring a welding joint blind area X ray image film by virtue of the X machine; and finally, processing the X ray image film in a darkroom. According to the detection method disclosed by the invention, the XXQ-2505 ray machine is adopted to detect power station boiler membrane panel welding joint blind area X ray and an appropriate radiating angle is selected by virtue of inclined radiation so as to achieve a purpose of detecting out defects; when radiating the membrane panel welding joint, an appropriate angle is kept between the centerline of a ray bundle and the drainage plane of the heated surface tube, so that the definition, sensitivity and welding joint opening distance of a blind area image on a photographic plate can achieve standard requirements, and assessment on defects is not affected.

Owner:CHONGQING QINENG ELECTRICITY & ALUMINUM

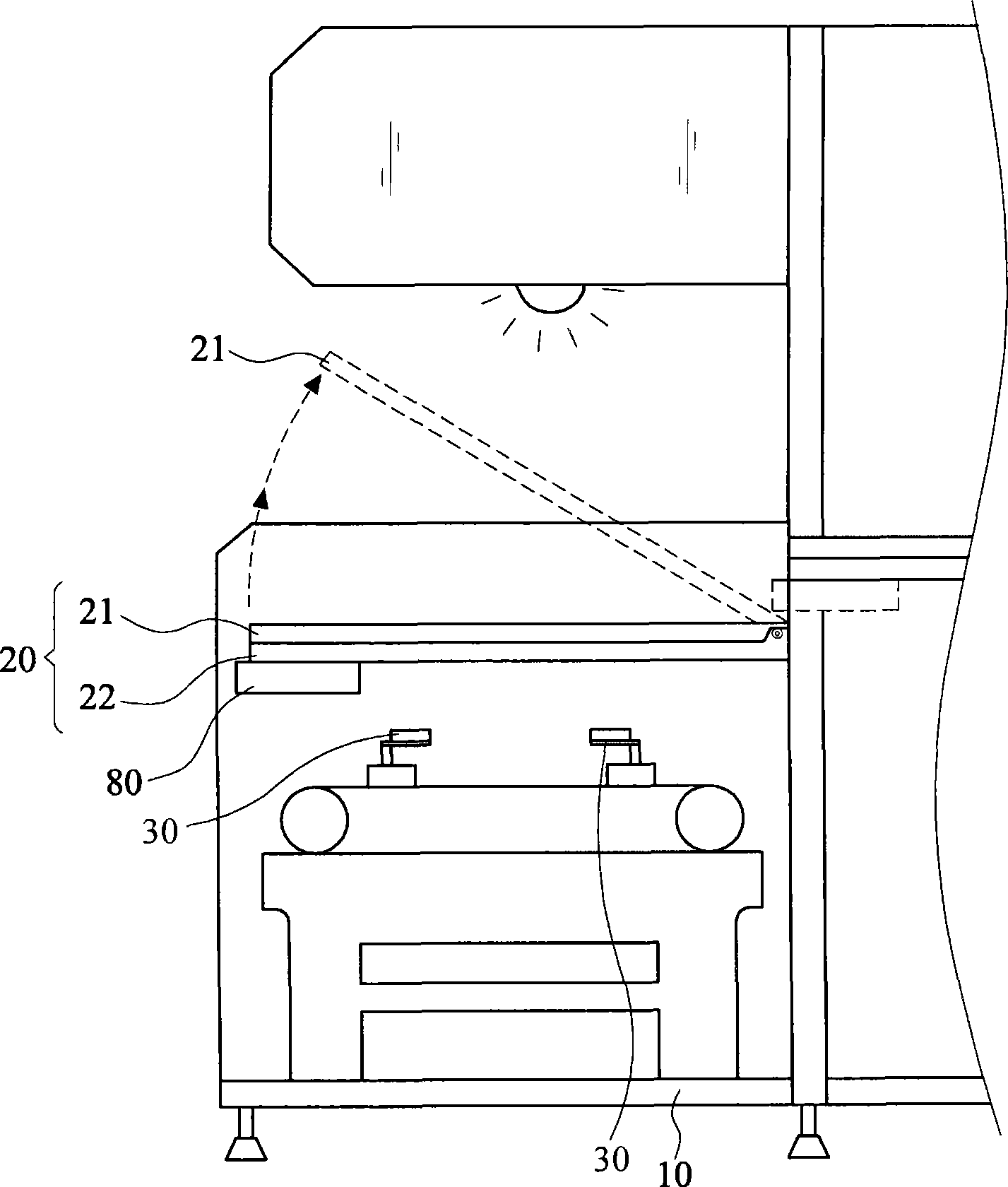

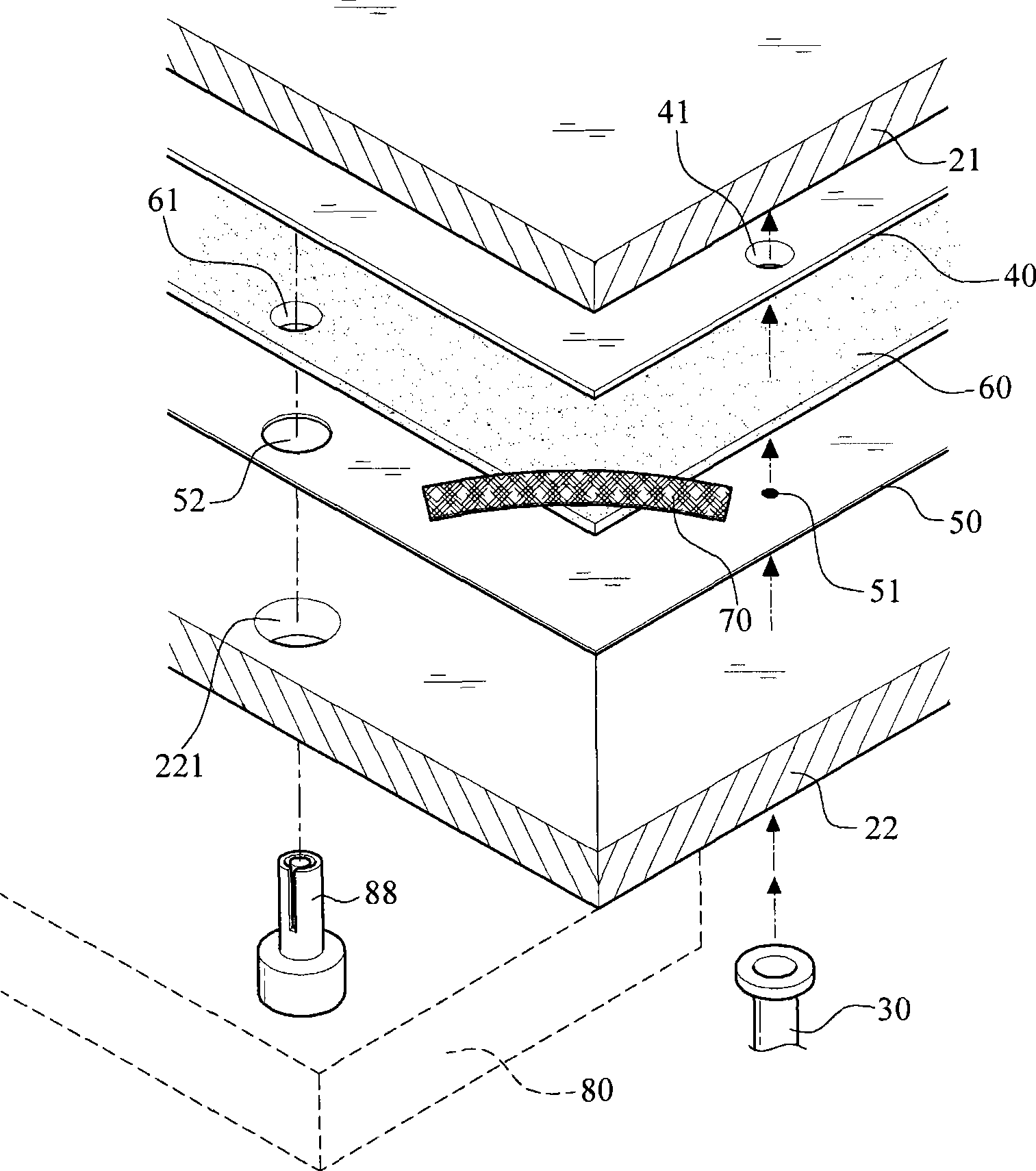

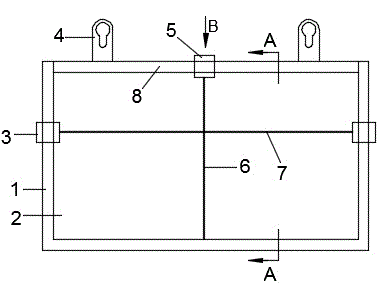

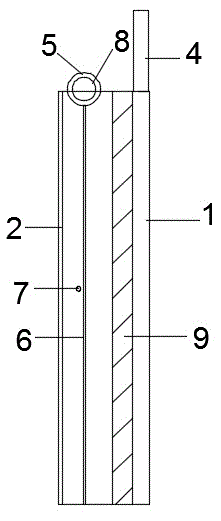

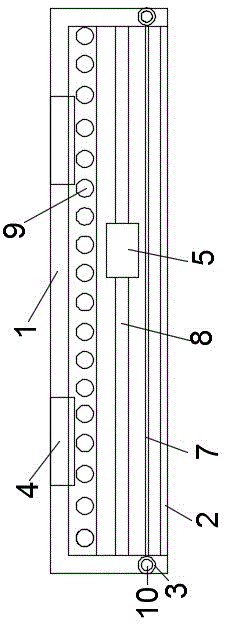

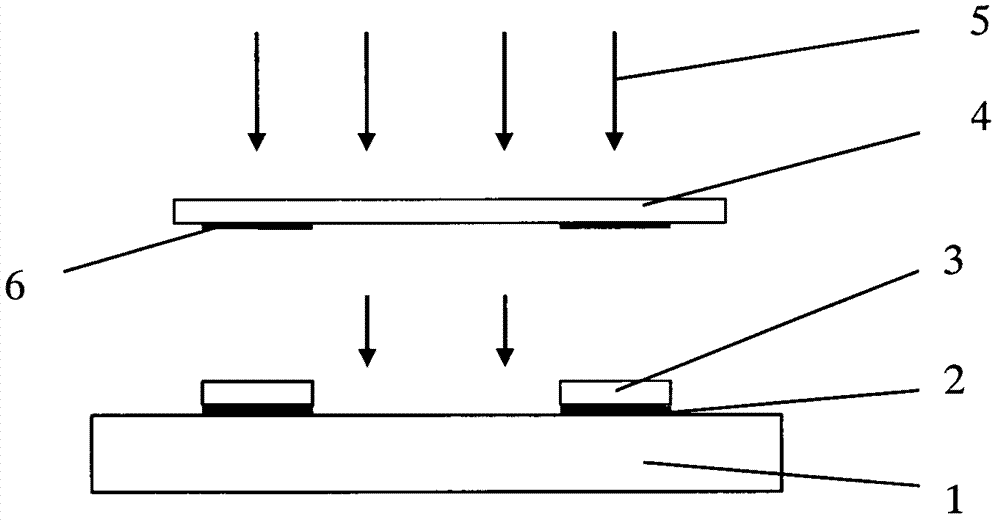

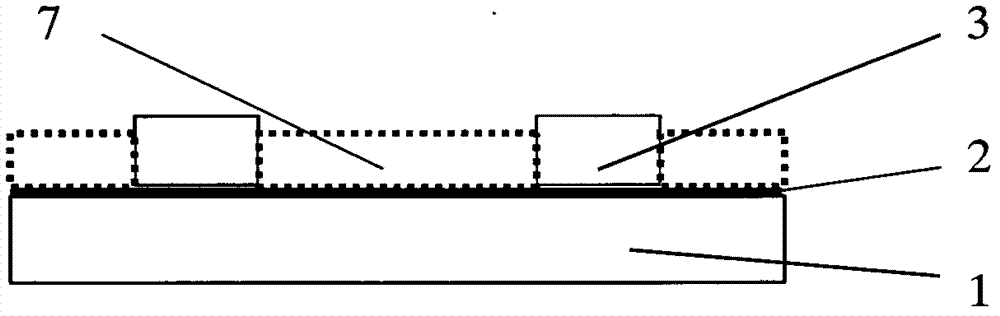

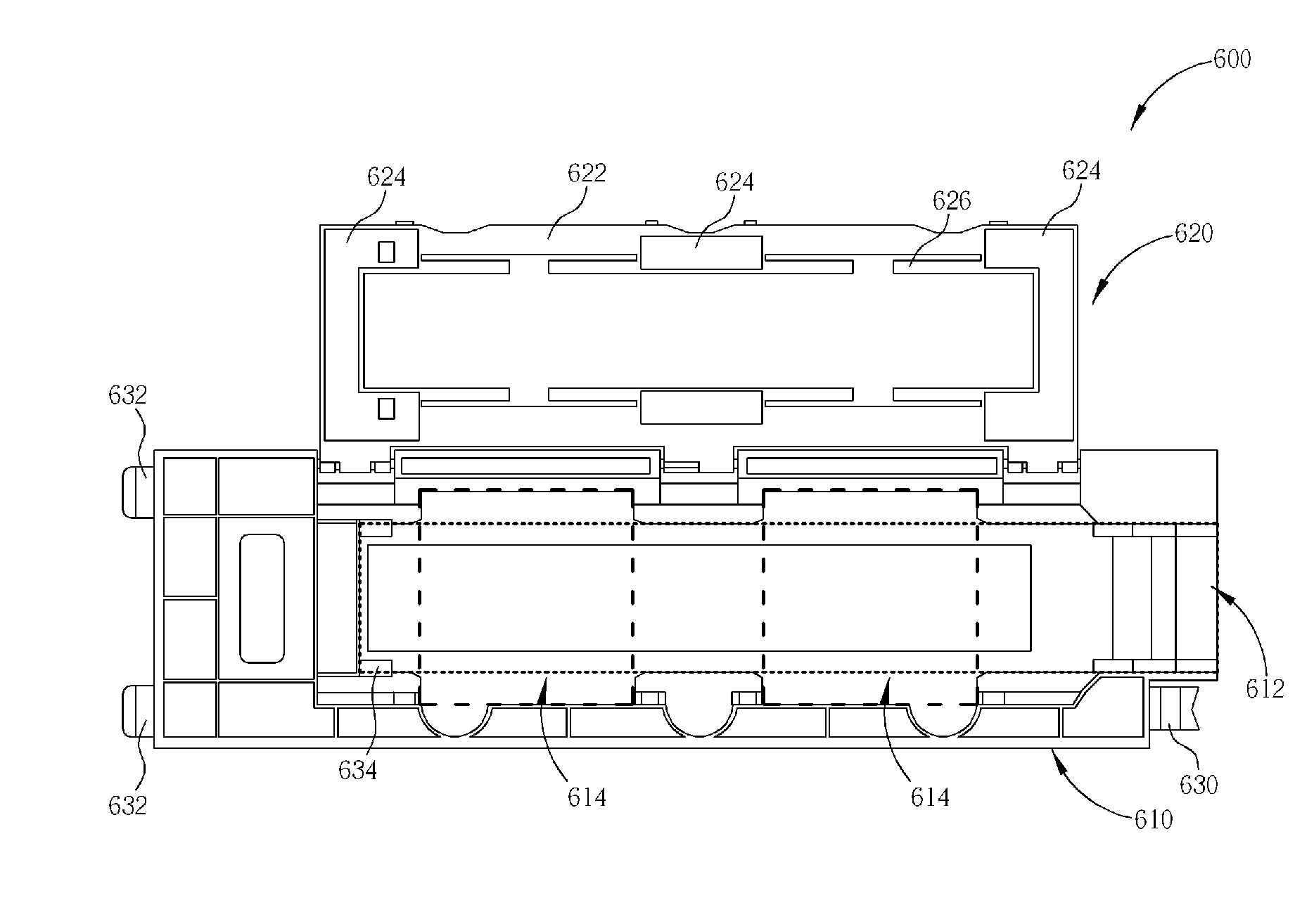

Double-faced exposure architecture and double-faced exposure method of printed circuit board

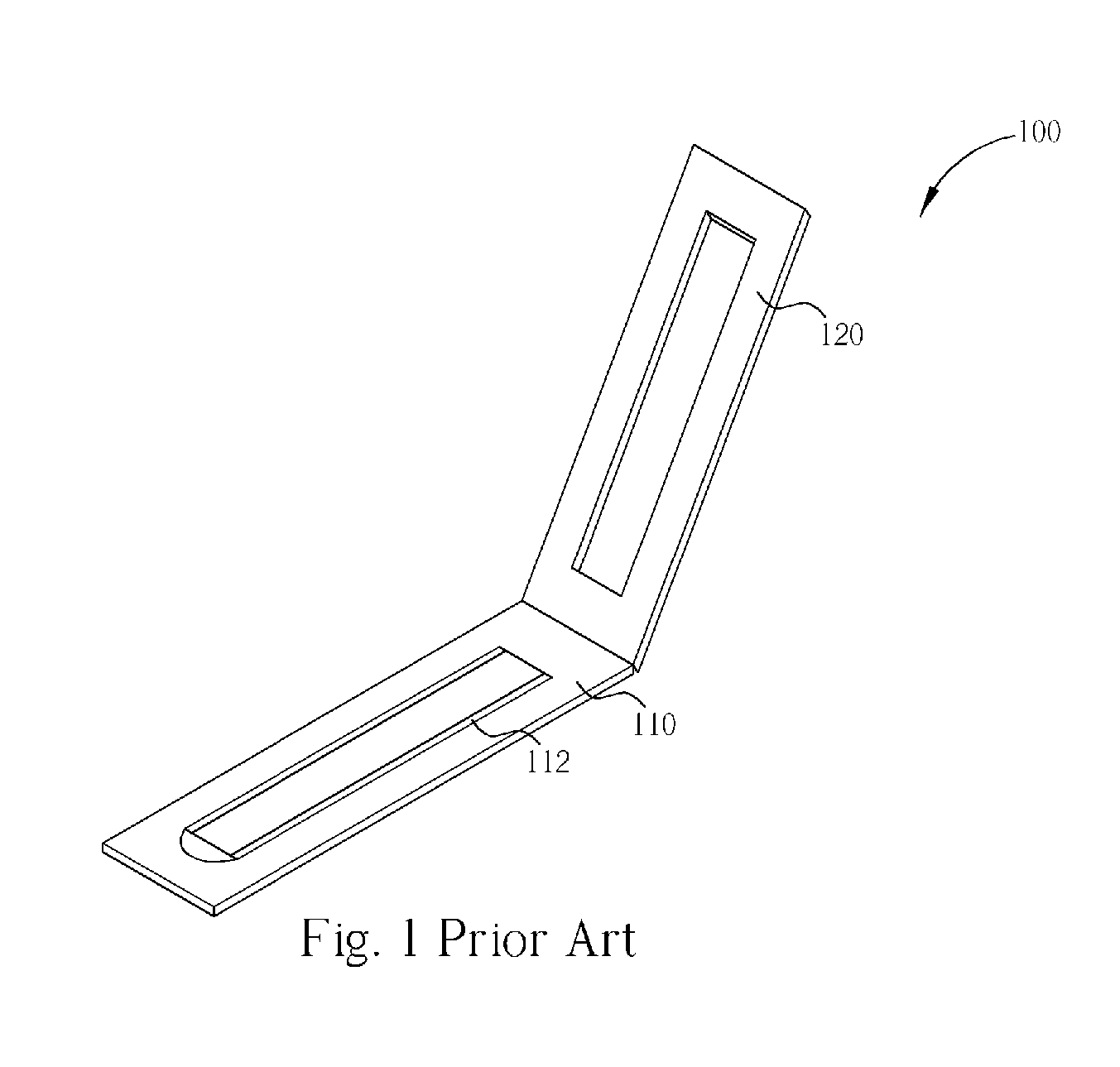

InactiveCN101520607AAchieve the effect of double-sided exposure alignmentAvoid scratchesPhotomechanical exposure apparatusPrinted circuit manufactureEngineeringExposure Location

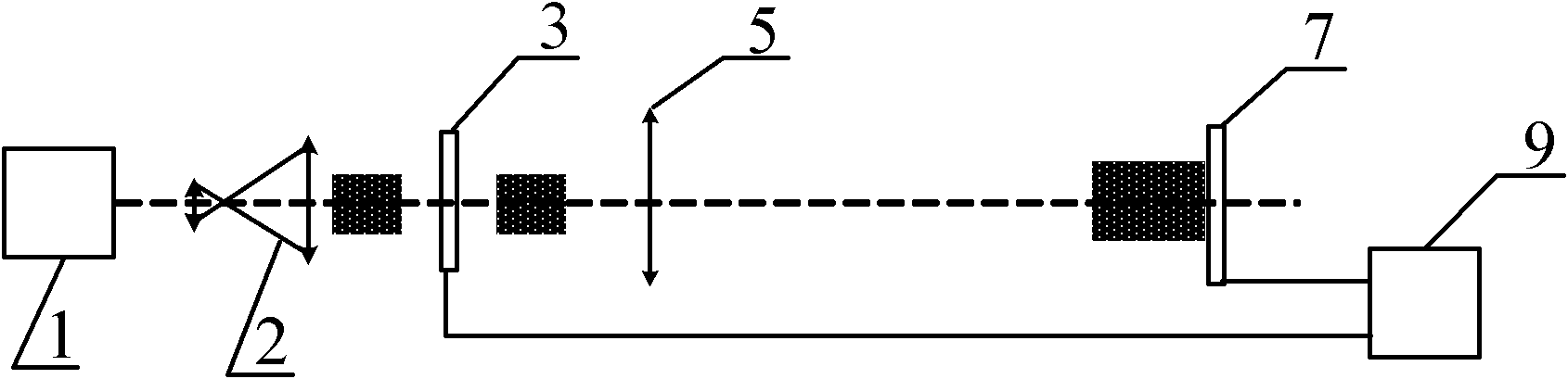

The invention relates to a double-faced exposure architecture and a double-faced exposure method of a printed circuit board. The double-faced exposure architecture at least comprises an exposure frame, an aligning lens, an upper photographic plate, a lower photographic plate, a rigid clapboard and an aligning device, and the upper photographic plate and the lower photographic plate are separated by the rigid clapboard, thus avoiding scratching, and the lower photographic plate is aligned with a previously arranged exposure location of the upper photographic plate through the aligning lens, thus achieving the goal of double-faced exposure aligning of the printed circuit board.

Owner:CHIME BALL TECH

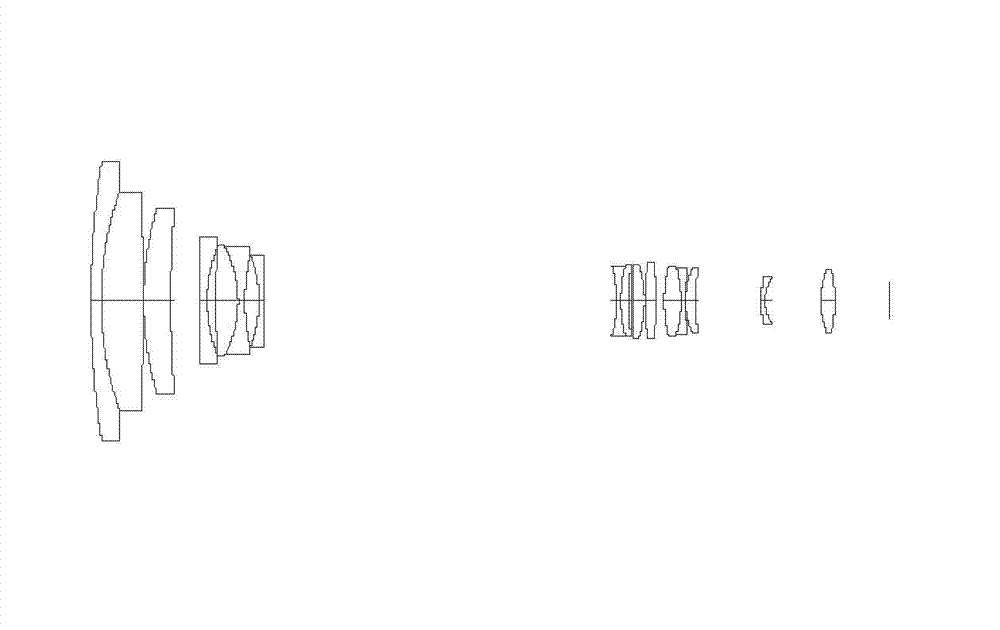

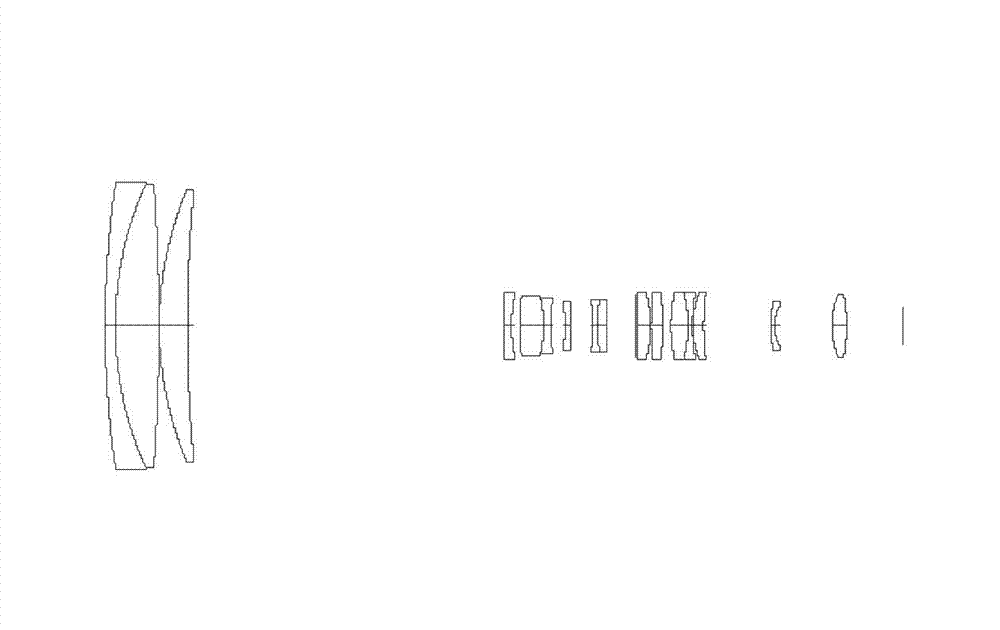

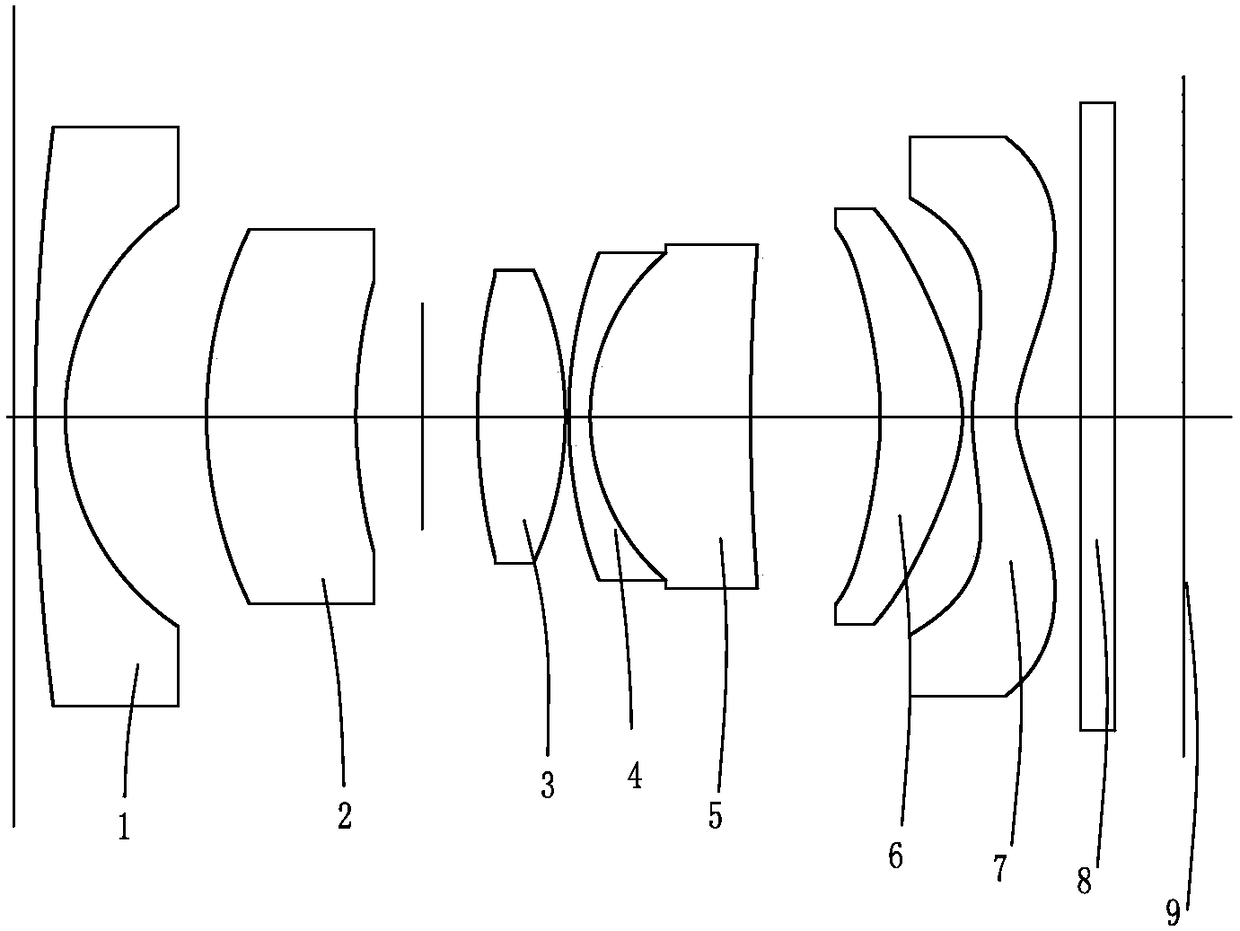

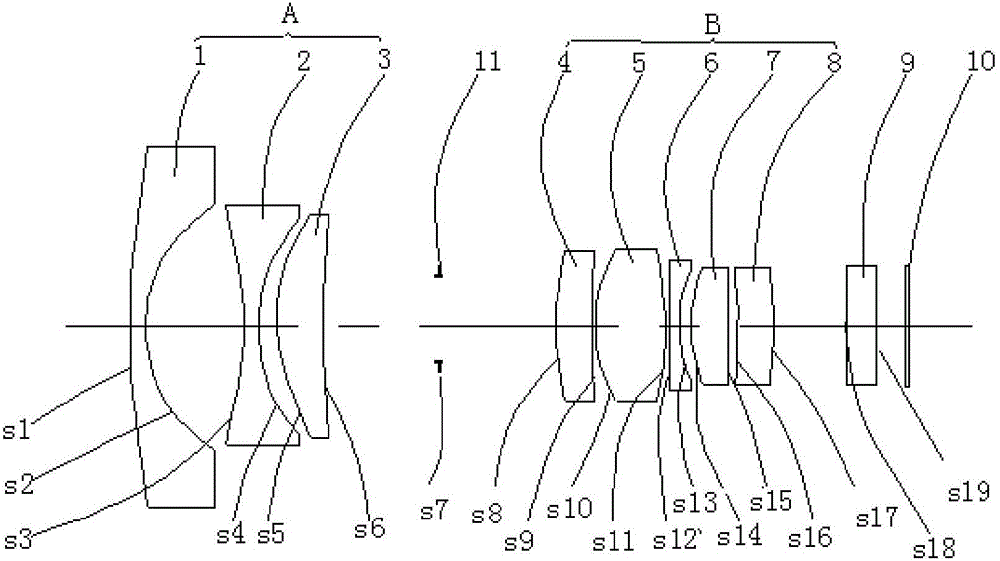

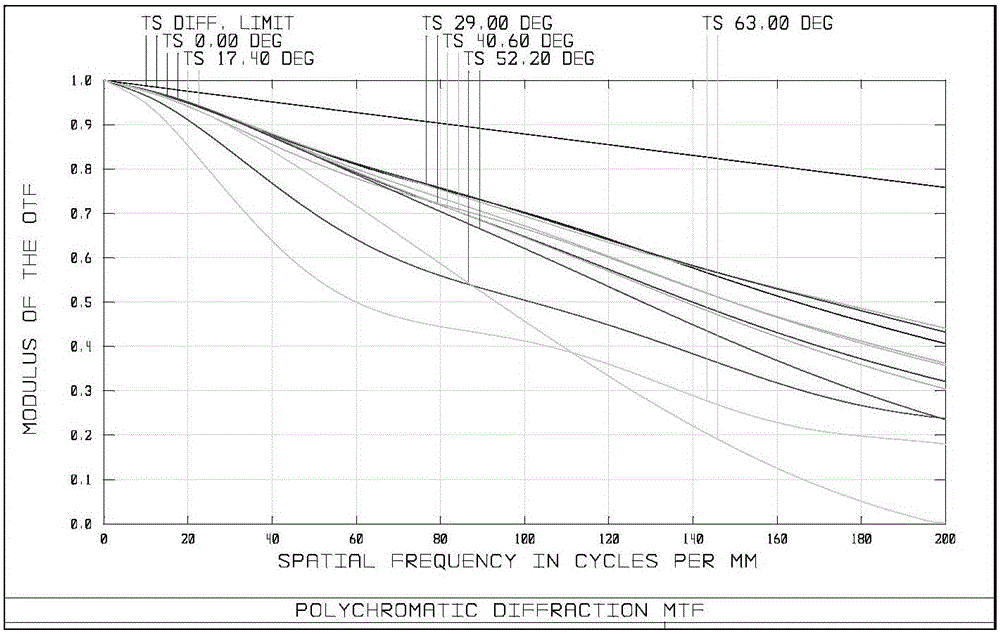

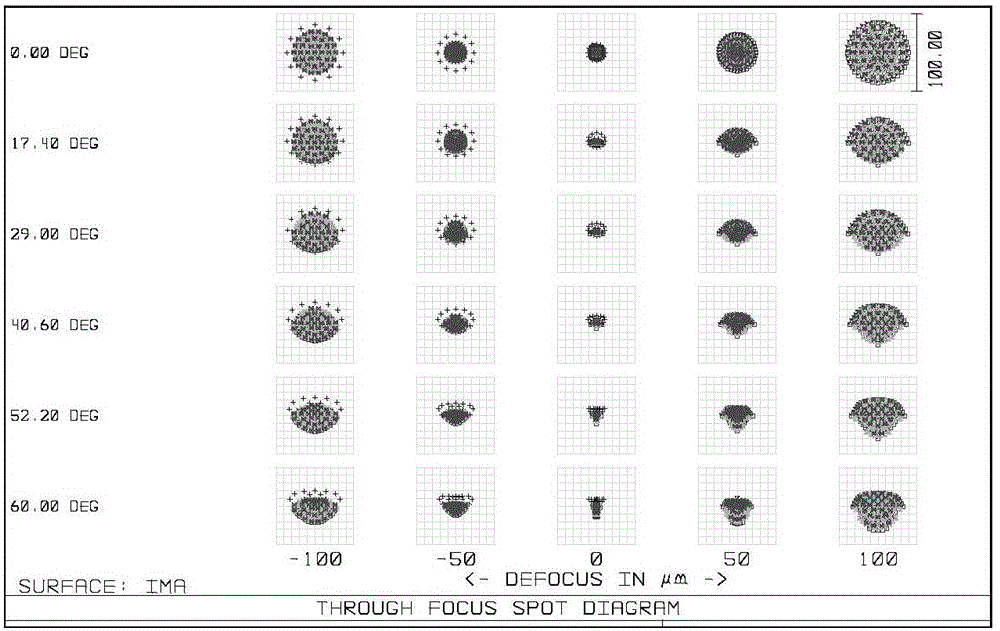

Zoom optical system

The invention discloses an electric zoom lens for electronic monitoring systems. The electric zoom lens is suitable for sensitization devices, such as a CMOS (Complementary Metal-Oxide-Semiconductor) photographic plate or a CCD (Charge Coupled Device) chip. The electric zoom lens is provided with a first lens group with refraction, a second lens group with negative refraction, a third lens group with negative refraction, a fourth lens group with positive refraction and a fifth lens group with positive refraction, which are orderly arranged from an object space to an image space, wherein the positions of the first lens group, the second lens group and the third lens group are variable relative to the sensitization device during a zooming process, and the positions of the fourth lens group and the fifth lens group are fixed relative to the sensitization device during the zoom process. The zoom optical system provided by the invention realizes different zoom ratios under different object distances, and can realize 20x zoom in an infinity object distance and 20x zoom in a 3m object distance; and meanwhile, the optical system further has the characteristics of high resolution, low cost and long back focal length, and the like.

Owner:JIANGXI PHENIX OPTICS TECH CO LTD

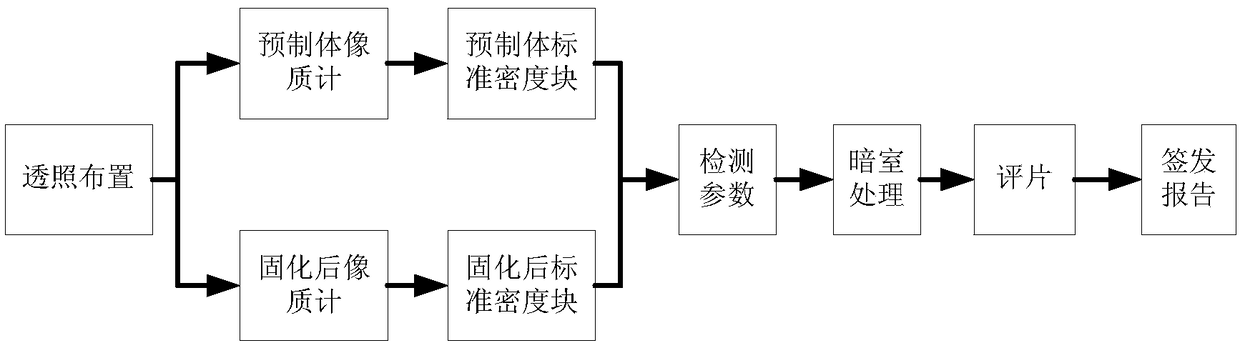

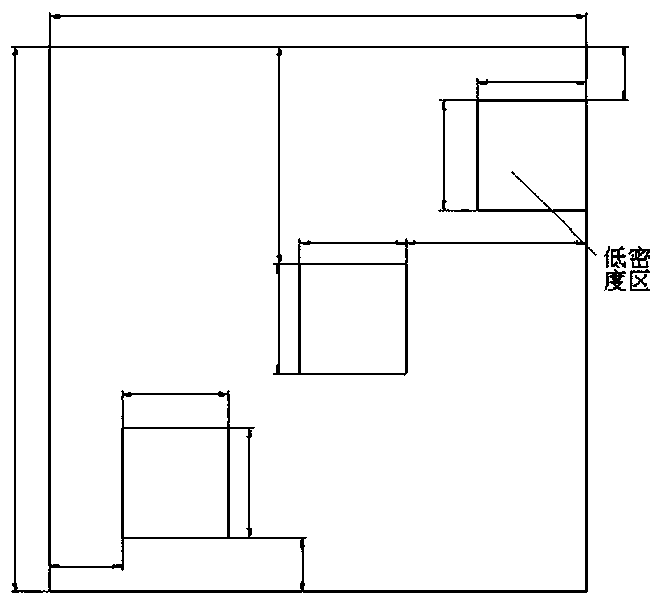

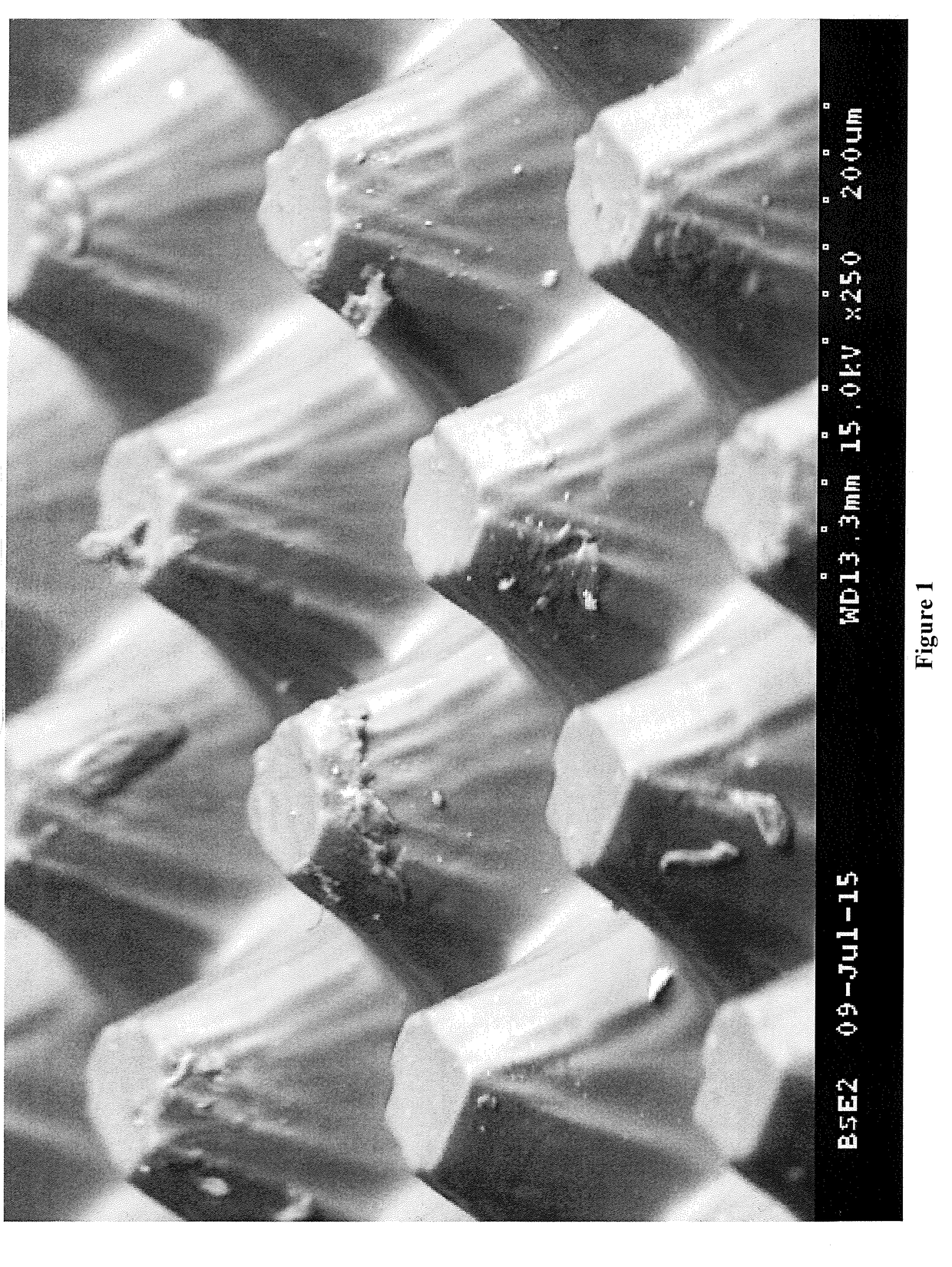

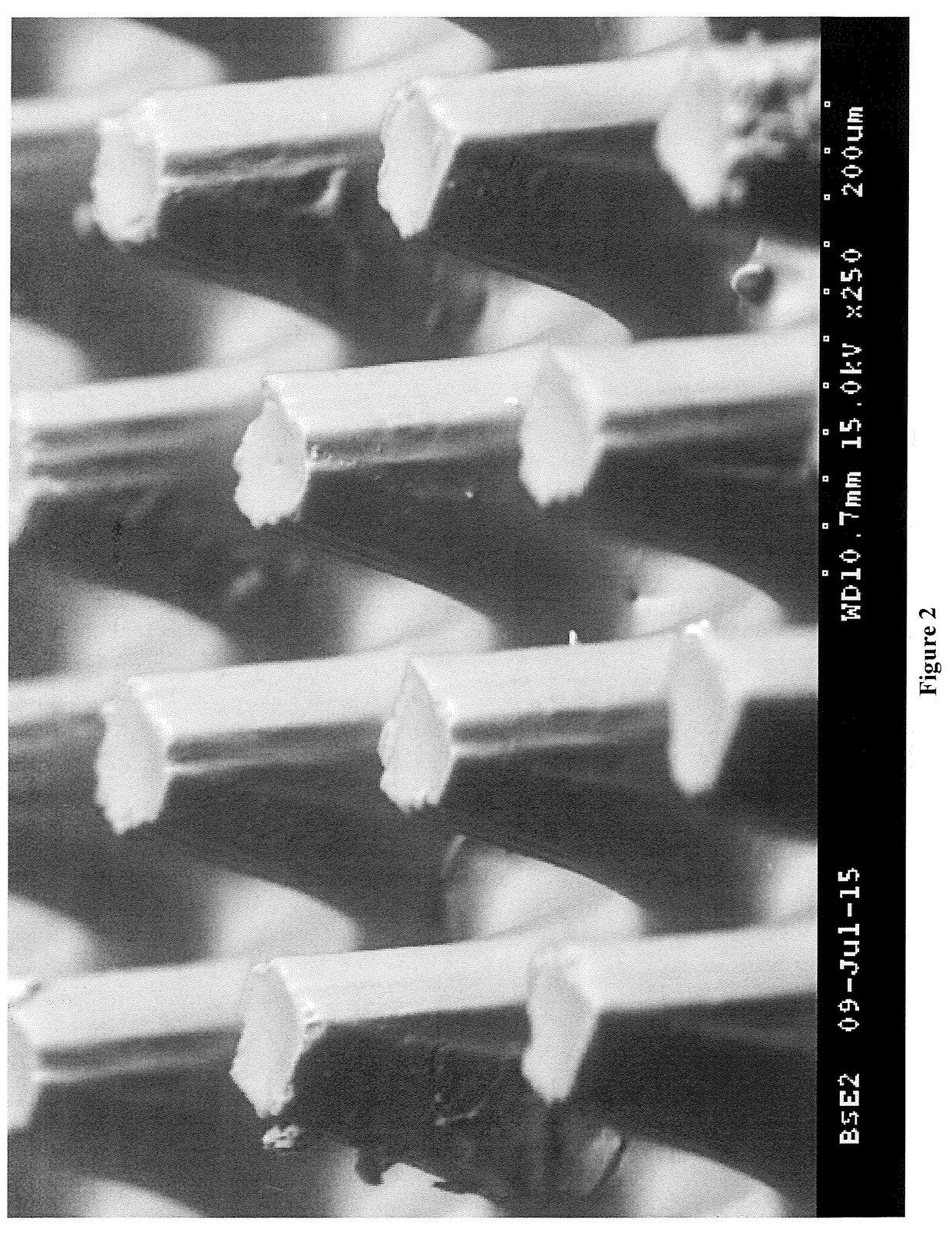

X-ray testing method for NF-series heat-proof material products

ActiveCN109444180AThe recognition effect is accurateAccurate judgmentMaterial analysis by transmitting radiationImaging qualityLow density

Disclosed is an X-ray testing method for NF-series heat-proof material products. The method includes producing a radiographic testing image quality indicator for the pre-fabricated body stage and a density unevenness standard test block for the pre-fabricated body stage, applying the internal-source eccentric single-wall transillumination technology to an X-ray machine to obtain a to-be-tested product, a photographic plate of the radiographic testing image quality indicator for the pre-fabricated body stage, and a photographic plate of the density unevenness standard test block for the pre-fabricated body stage, testing sensitivity, metal inclusions and low-density non-uniformity, producing a radiographic testing image quality indicator for the post-curing stage and a density unevenness standard test block for the post-curing stage to obtain a photographic plate, including the radiographic testing image quality indicator for the post-curing stage and the to-be-tested product, as well as a photographic plate including the density unevenness standard test block for the post-curing stage, and testing inclusions, holes, cracks and density non-uniformity to finally acquire X-ray test results of the NF-series heat-proof material products.

Owner:BEIJING SATELLITE MFG FACTORY

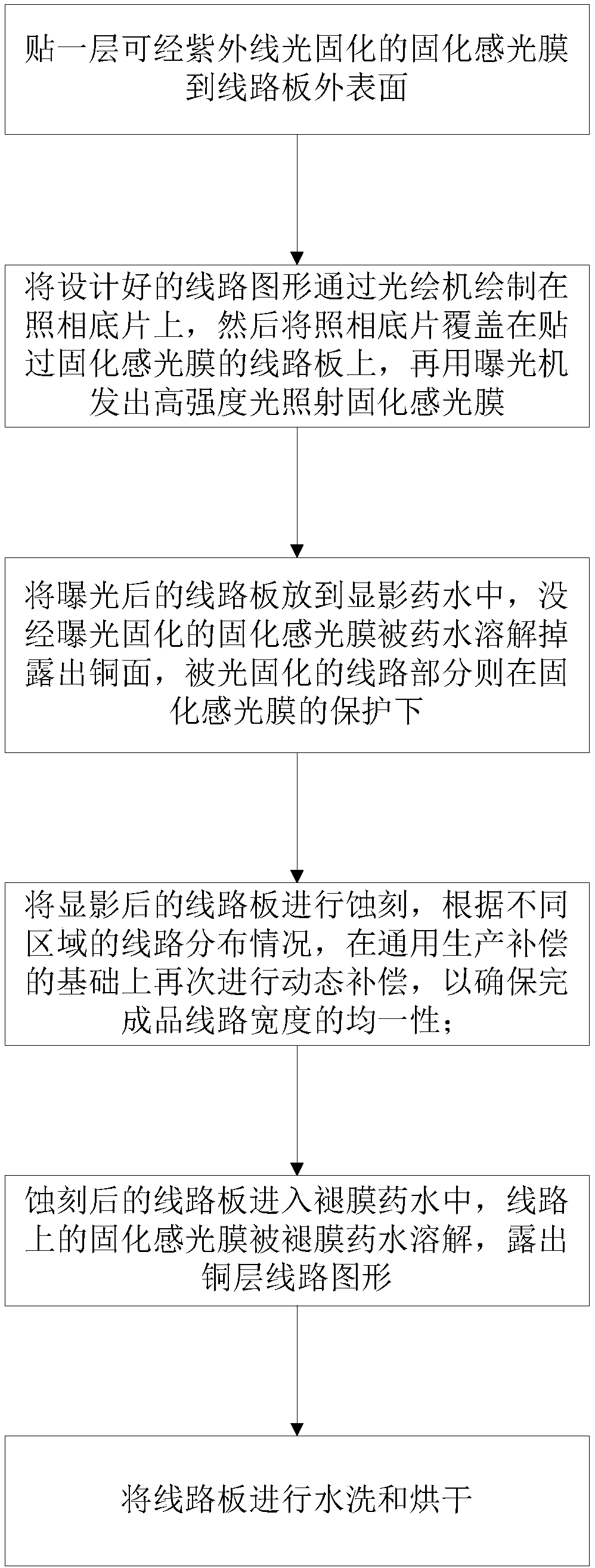

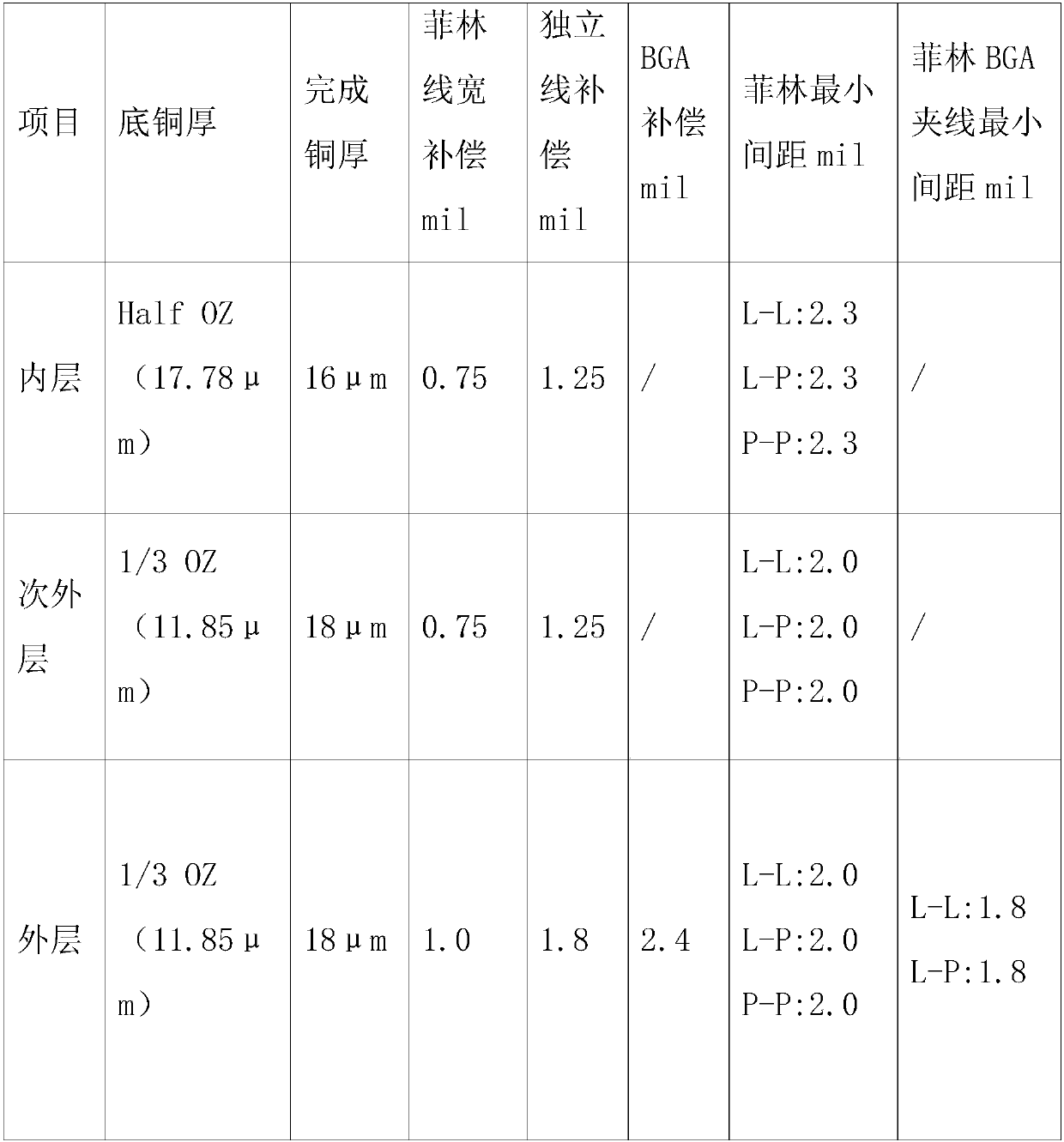

1.5mil circuit board-based line compensation method

InactiveCN108024454AGuaranteed uniformityConductive material chemical/electrolytical removalUltraviolet lightsHigh intensity

The invention discloses a 1.5mil circuit board-based line compensation method. The 1.5mil circuit board-based line compensation method comprises the following steps of S1, pasting a layer of curing photosensitive film which can be cured by ultraviolet light onto an outer surface of a circuit board; S2, drawing the designed circuit pattern onto a photographic plate by a photoplotler, covering the photographic plate on the circuit board pasted with the curing photosensitive film, giving out high-intensity light to irradiate the curing photosensitive film by an exposure machine; S3, etching the developed circuit board, performing dynamic compensation on the basis of universal production compensation according to circuit distribution conditions of different regions so that the width uniformityof the finished line is ensured; S5, allowing the etched circuit board to enter a film removal medium; and S6, washing and drying the circuit board. Classified compensation is performed on differentregions by employing a dynamic compensation technology, and the uniformity of the finished line can be ensured.

Owner:TIGERBUILDER CIRCUIT SUZHOU

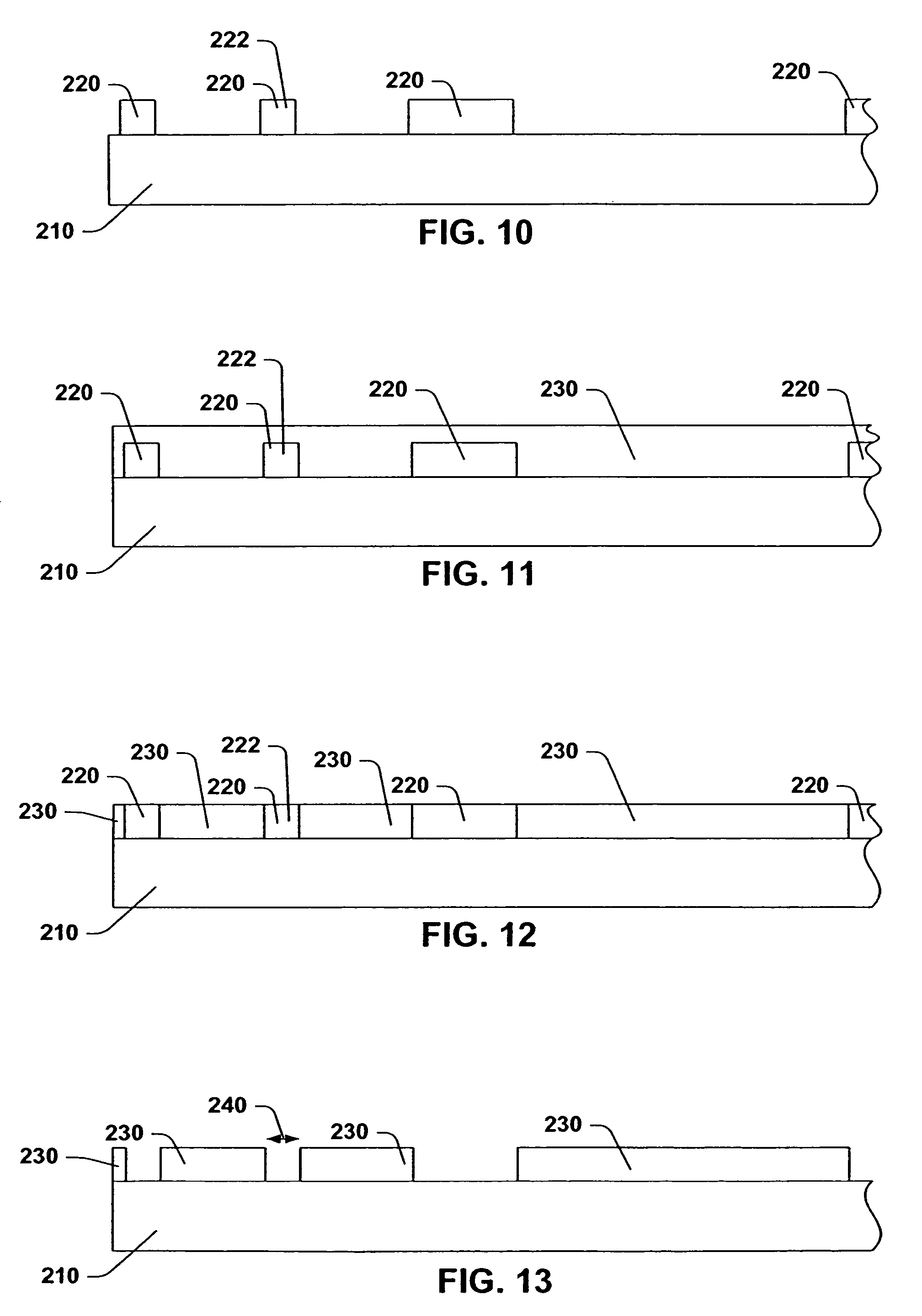

Inverse resist coating process

InactiveUS7943289B2Simple and efficient and high fidelitySmall sizeSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistPhotographic plate

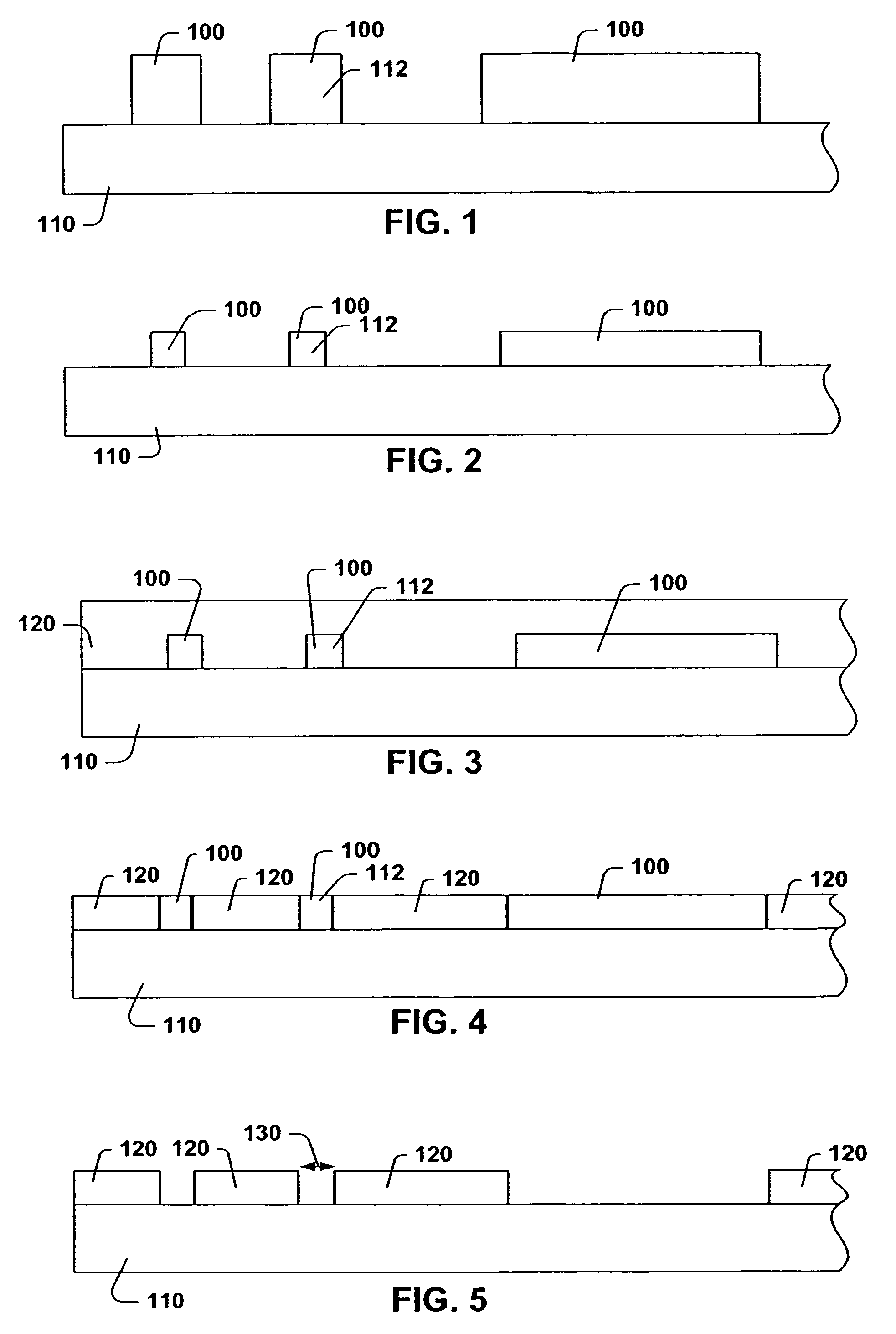

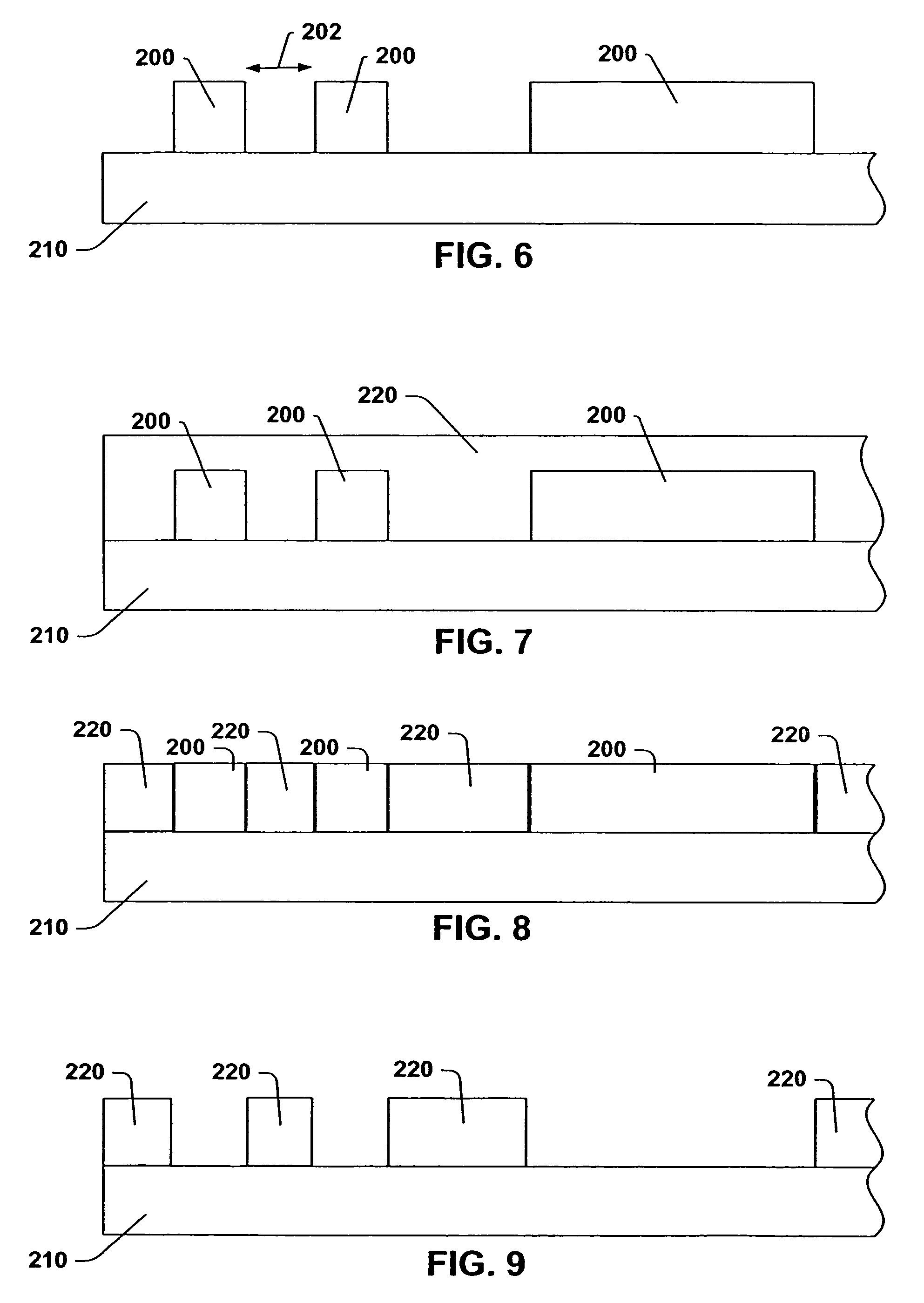

The invention provides systems and processes that form the inverse (photographic negative) of a patterned first coating. The patterned first coating is usually provided by a resist. After the first coating is patterned, a coating of a second material is provided thereover. The uppermost layer of the second coating is removed, where appropriate, to expose the patterned first coating. The patterned first coating is subsequently removed, leaving the second coating material in the form of a pattern that is the inverse pattern of the first coating pattern. The process may be repeated with a third coating material to reproduce the pattern of the first coating in a different material. Prior to applying the second coating, the patterned first coating may be trimmed by etching, thereby reducing the feature size and producing sublithographic features. In addition to providing sublithographic features, the invention gives a simple, efficient, and high fidelity method of obtaining inverse coating patterns.

Owner:GLOBALFOUNDRIES INC

Method for producing substrate of precoated sensitive plate from aluminum alloy

InactiveCN101338393ASolve the technical problems of softeningHigh strengthMetal rolling arrangementsIngotPhotographic plate

The invention discloses a method for producing a pre-coated photographic plate substrate by adopting an aluminum alloy which mainly includes the following components of: 0.15 to 0.30 percent of Fe, less than 0.10 percent of Si, less than 0.03 percent of Cu, less than 0.03 percent of Mn, 0.13 to 0.25 percent of Mg, less than 0.03 percent of Zn, 0.01 to 0.02 percent of Ti, the signal content of other impurities is less than 0.03 percent, the total amount is equal to or less than 0.15 percent; the Al is equal to or more than 99.45 percent; the pre-coated photographic plate is mainly produced by a cast ingot by adopting the methods of thermal rolling and cold rolling; the method of the invention adopts the methods of thermal rolling and cold rolling to roll and the adjusting of the alloy components to solve the technical difficulty that a medical foil turns soft when passes through an oven and improve the intensity of the medical foil.

Owner:中铝河南铝业有限公司

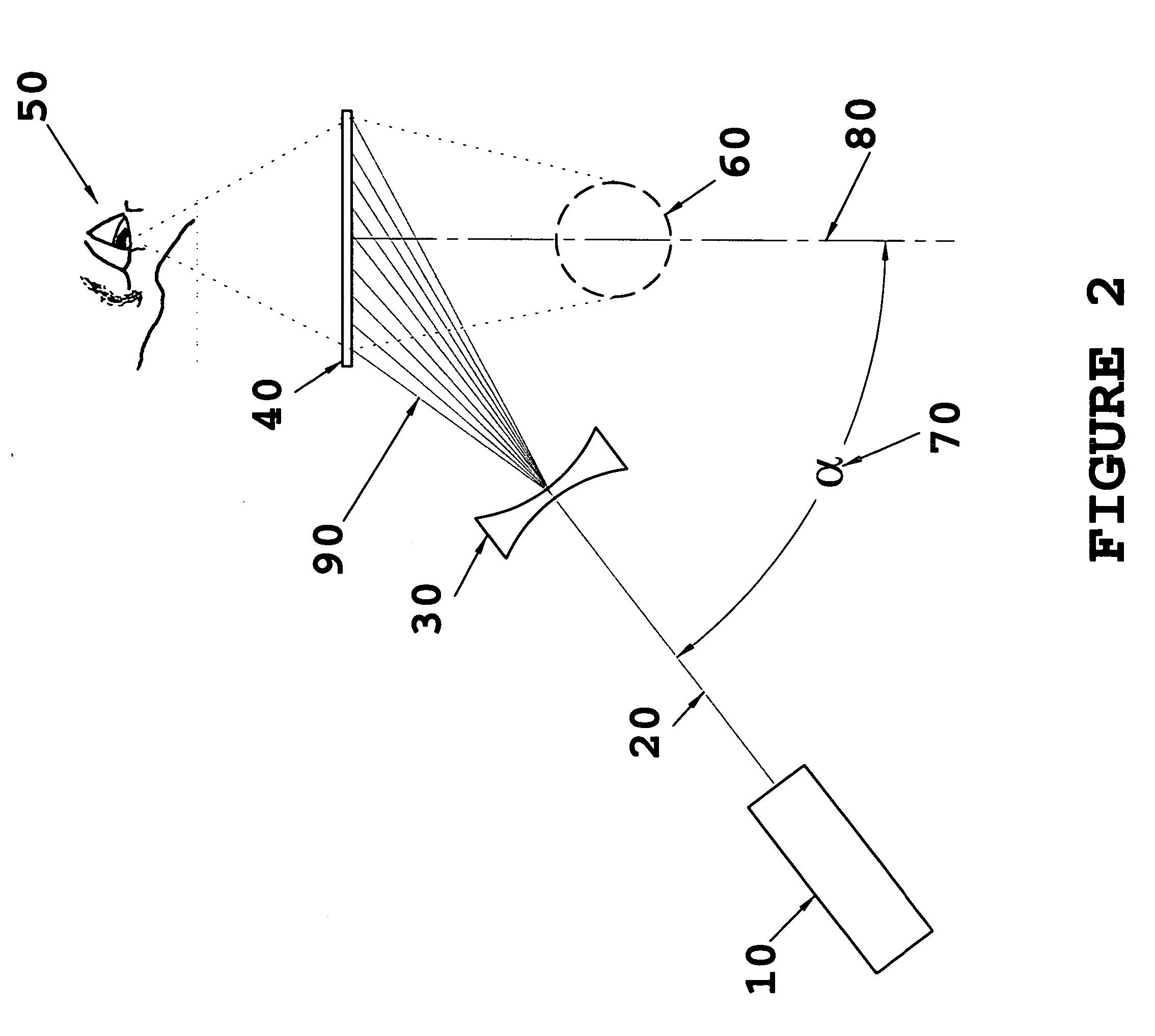

Method of producing and viewing 3-dimentional images and secure data encryption/decryption based on holographic means

InactiveUS20050074119A1Equal length code transmitterPublic key for secure communicationWeb siteEmulsion

The invention provides improvements in the way that holograms are created and viewed, and enables the storage of said holograms by digital means, thereby eliminating the requirement of photographic plates or emulsion. The invention also makes possible secure and robust correspondence based on holographic methods and has potential applications to the realization of holographic television, movies, computer displays, cameras, and the enhancement of web sites and virtual reality schemes.

Owner:CONNECTICUT ANALYTICAL

Product with holographic pattern and manufacturing method thereof

InactiveCN101633288AFeel goodReduce productionOther printing matterDecorative surface effectsLaser holographyPhotographic plate

The invention provides a product with a holographic pattern and a manufacturing method thereof. The product comprises a substrate and a holographic pattern layer, wherein the substrate and the holographic pattern layer made of the same material form an integrated structure. The method comprises the following steps: recording a required pattern onto a photographic plate through laser holography and manufacturing an optical mask plate with the holographic pattern; copying the holographic pattern on the optical mask plate and forming a metal plate with the holographic pattern; and transferring the holographic pattern on the metal plate onto the surface of the substrate by a mould pressing method, and forming the holographic pattern layer. Compared with the prior TPU product with the holographic pattern, the product with the holographic pattern is made of a material with better handfeel. Compared with the manufacturing method for the TPU product with the holographic pattern, the manufacturing method provided by the invention decreases working procedures of the manufacture of laser release paper or a laser release film and hot-pressing release transfer, and simplifies manufacturing process.

Owner:BYD CO LTD

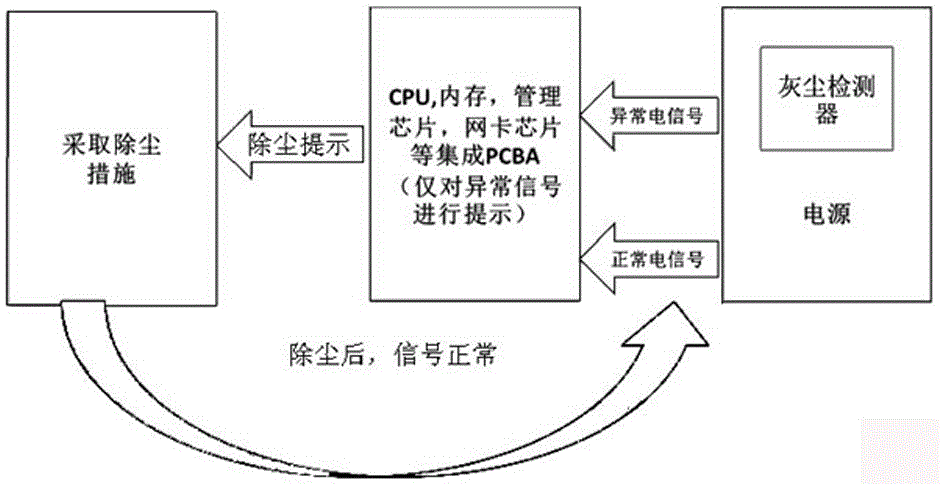

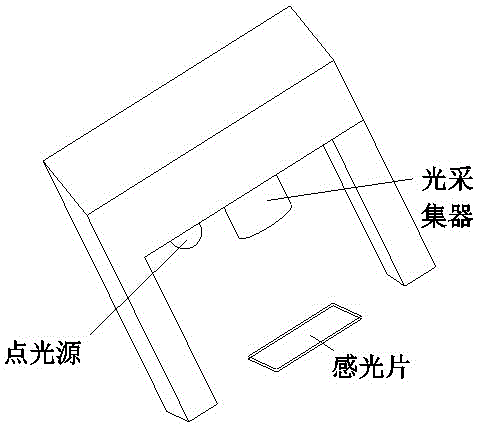

Design method for dust removing prompt of PCBA

InactiveCN105045703ABlock the impactRealize the protection functionHardware monitoringOptoelectronicsPhotographic plate

The invention provides a design method for dust removing prompt of a PCBA and relates to the field of servers, as well as hardware and software of a PC. A dust detector composed of three parts including a photographic plate, a point light source and a light collector (comprising a photosensitive sensor) is additionally arranged on a plate card; and when reflected light collected on the photographic plate by the light collector is lower than certain limit, an prewarning electric signal is transmitted by the collector and then is sent to a central management chip of a system to prompt a user to perform dust removal, so as to realize measures for protecting the PCBA.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

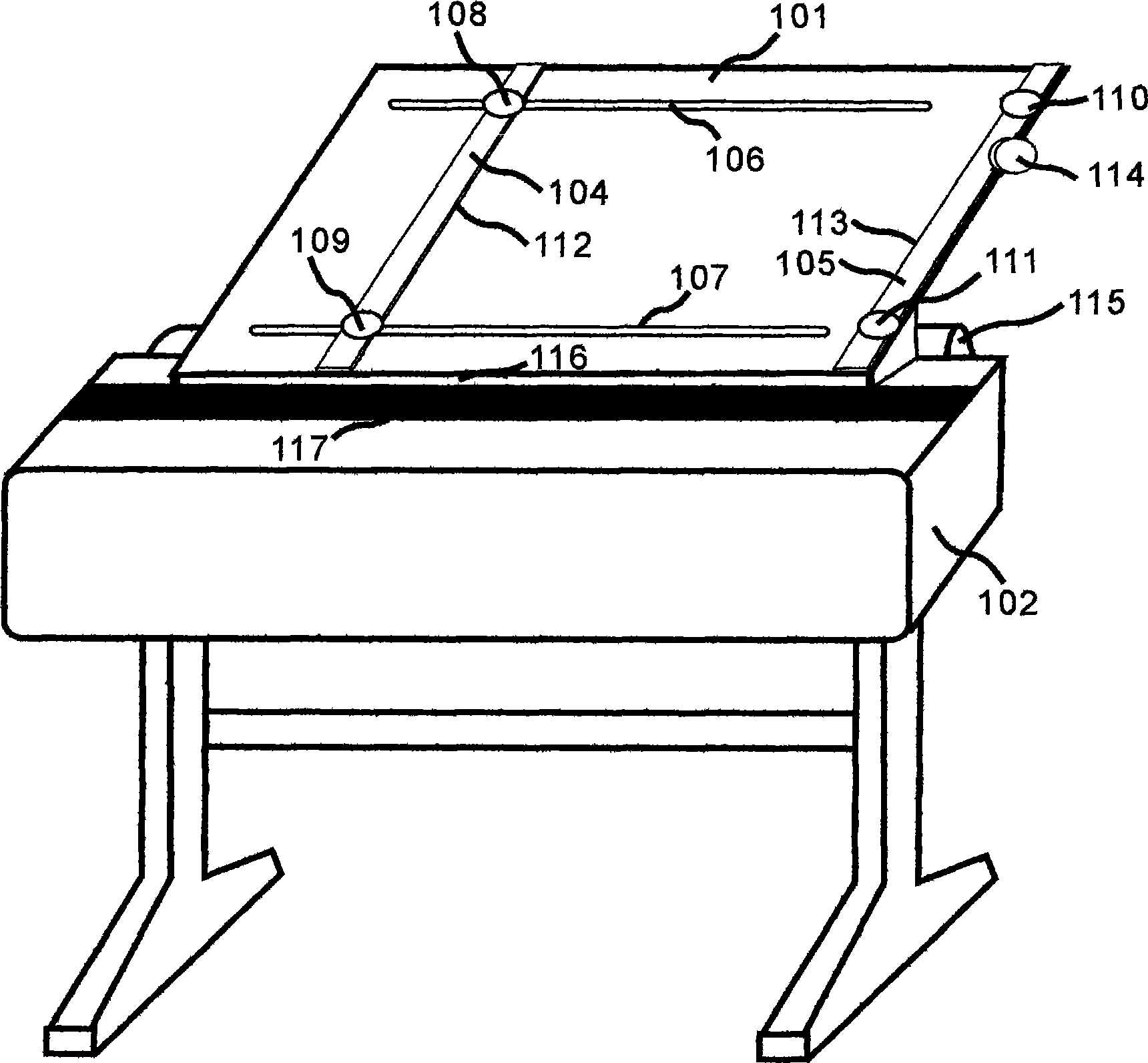

Medical film viewer capable of longitudinal and transverse orientation

The invention discloses a medical film viewer capable of longitudinal and transverse orientation, wherein a lamp frame plate is arranged on one side surface of a lamp frame; a transparent plate is arranged on the side surface opposite to the lamp frame plate; several lamp tubes are arranged between the lamp frame plate and the transparent plate; a top rod is arranged at the top of the lamp frame; several longitudinal line adjusting rings are arranged on the top rod in a penetrating manner, wherein a longitudinal line is fixedly arranged under each longitudinal adjusting ring; side rods are symmetrically arranged on both sides of the lamp frame respectively; each side rod is provided with several transverse line adjusting rings in a penetrating manner; and transverse lines are fixedly arranged between longitudinal line adjusting rings respectively at the same height on two side rods. According to the medical film viewer capable of longitudinal and transverse orientation, the reference of longitudinal and transverse lines can be provided, and the observation needs of various X-ray photographic plates or CT imaging plates can be satisfied on the premise of ensuring functions of normal film viewers.

Owner:NANTONG KANGSHENG MEDICAL EQUIP

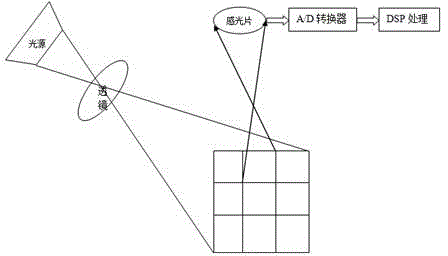

Compressed sensing point-by-point scanning camera for inside of divided array blocks

InactiveCN104702828AFast imagingHigh potential application valueTelevision system detailsColor television detailsData acquisitionShooting method

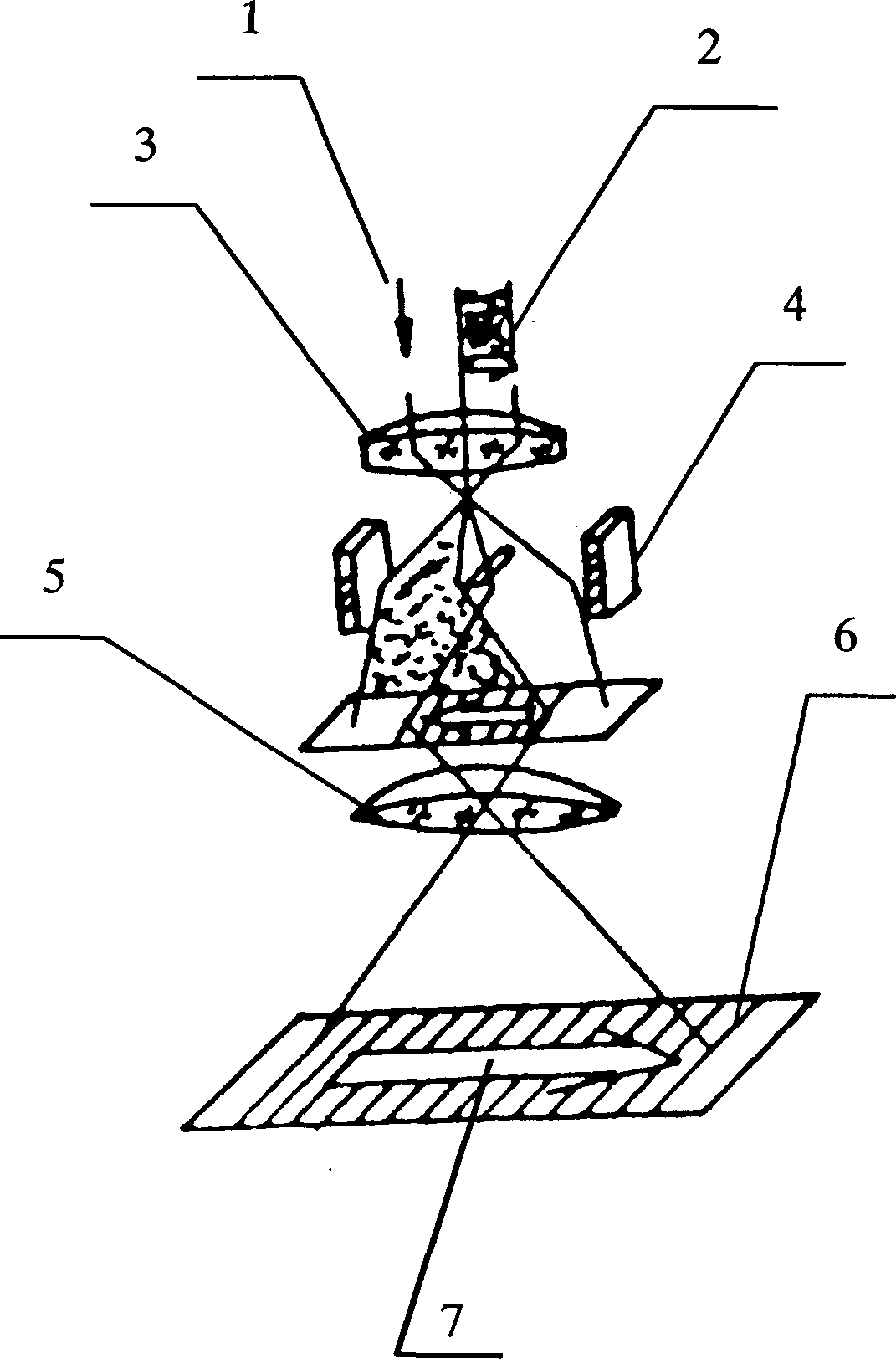

The invention provides a compressed sensing point-by-point scanning camera for the inside of divided array blocks. The camera comprises an object light source, a lens group, a DMD (Digital Mirror Device) array, a photographic plate, an A / D converter and a DSP (Digital Signal Processor). The DMD array is divided into a plurality of small square blocks in advance; the lens group shoots scenery light rays to the DMD array; the divided point-by-point scanning to the scenery light rays is realized by controlling a digital micromirror on the DMD array to turn point by point, that is, compressed sampling is respectively performed in each small square block. Original signals are reconstructed according to a reconstruction algorithm; the DMD array reflects the reconstructed scenery image subjected to point-by-point scanning on the photographic plate for imaging. The imaging speed is accelerated by means of the point-by-point scanning of the DMD array; a new shooting method with great potential application value is provided; the bottleneck of Shannon's sampling theorem is broken; an original image is reconstructed precisely from a small quantity of sampling and measuring values; the acquisition and compression of traditional data become one and the storage resource is saved.

Owner:SICHUAN UNIV

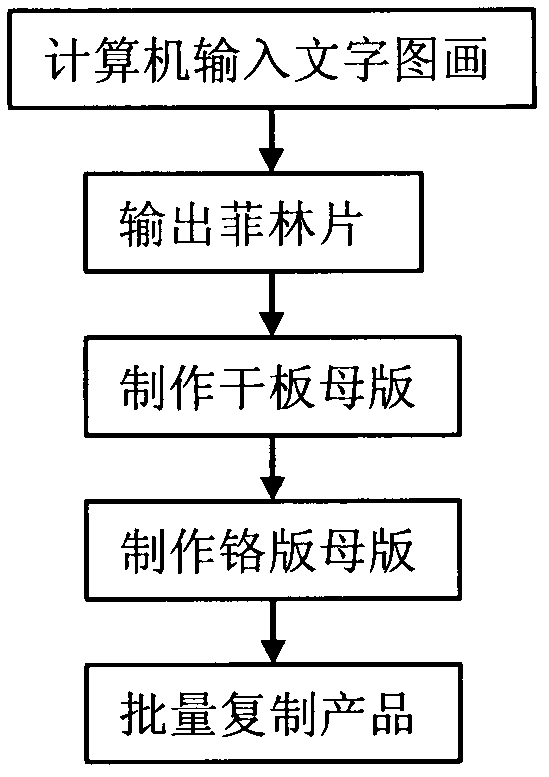

Making method of micro characters and pictures

ActiveCN103246160AShorten the timeShorten production timePhotomechanical apparatusSquare MillimeterChinese characters

The invention discloses a making method of micro characters and pictures. The making method is characterized by comprising the following steps: firstly inputting characters and pictures into a computer and preparing a film, preparing a photographic plate motherboard through using an optical microimaging and step repeating technology, engraving the photographic plate motherboard to a chromium plate motherboard through using a modern micro-photoetching technique, and copying the micro characters and pictures on a target file in batches through using methods of photoetching and corroding, photoetching and stripping, photoetching and electroforming, and electroforming and mould pressing by utilizing the motherboard. The making method disclosed by the invention is high in making efficiency, short in technique procedure and small in equipment investment. By adopting the making method disclosed by the invention, the heights of the characters can be shortened to be smaller than 150 microns, more than 44 characters can be arranged on an area of 1 square millimeter, and the micro proportion for the characters is suitable for enjoyment and identification. A made product of the micro characters and pictures can well keep the original style and characteristic, so that the making method can be not only used for making a piece of high-end artware, but also used for encrypting and anti-counterfeiting of common goods.

Owner:吴强

Method of making relief image printing plates

ActiveUS9703201B2Widen meansExtension of timePhotomechanical exposure apparatusPhotosensitive material processingPhotopolymerEngineering

A method of selectively exposing a liquid photopolymer printing blank to actinic radiation to create a relief image printing plate. The printing blank is produced by (i) placing a photographic negative on a bottom glass platen and placing a coverfilm over the negative, (ii) disposing a layer of liquid photopolymer on top of the coverfilm and negative, and (iii) placing a backing sheet over the liquid photopolymer layer. The method includes the steps of scanning a light bar across an upper surface of the liquid photopolymer printing blank through the backing sheet to cure the layer of liquid photopolymer in selected areas, creating islands of cured polymer adjacent to the backing sheet, and imaging the photopolymer through the bottom of the liquid photopolymer printing blank to crosslink and cure selective portions of the liquid photopolymer and create a relief image therein. The relief image is created on the cured islands.

Owner:MACDERMID PRINTING SOLUTIONS

Large-image-surface and high-resolution video conference optical imaging system

The invention discloses a large-image-surface and high-resolution video conference optical imaging system. The large-image-surface and high-resolution video conference optical imaging system sequentially comprises a first lens 1, a second lens 2, a third lens 3, a fourth lens 4, a fifth lens 5, a sixth lens 6 and a seventh lens 7 from the object surface to the image surface, wherein the first lensis a negative-focal-length lens, the object side of the first lens 1 is a convex surface, and the image side of the first lens 1 is a concave surface; the second lens 2 is a positive-focal-length lens, the object side of the second lens 2 is a convex surface, and the image side of the second lens 2 is a concave surface; the third lens 3 is a positive-focal-length lens, and both the object side and image side of the third lens 3 are convex surfaces; the sixth lens 6 is a positive-focal-length crescent lens, the object side of the sixth lens 6 is a concave surface, and the image side of the sixth lens 6 is a convex surface; the seventh lens 7 is a negative-focal-length lens, the object surface and the image surface of the seventh lens 7 are nonspherical surfaces, and the image surface of the seventh lens 7 is provided with at least one inflexion point. The large-image-surface and high-resolution video conference optical imaging system has the advantages that the seven lenses combining nonspherical, spherical and adhering lens are adopted, the height of a photographic plate is IMC, the total focal length of the optical lenses is f, 0.4<f / IMC<0.5, and IMC>17mm; large-dimension imagingrequirements are satisfied, high-resolution imaging of 21 million pixels is achieved, and clear imaging is achieved.

Owner:UNION OPTECH

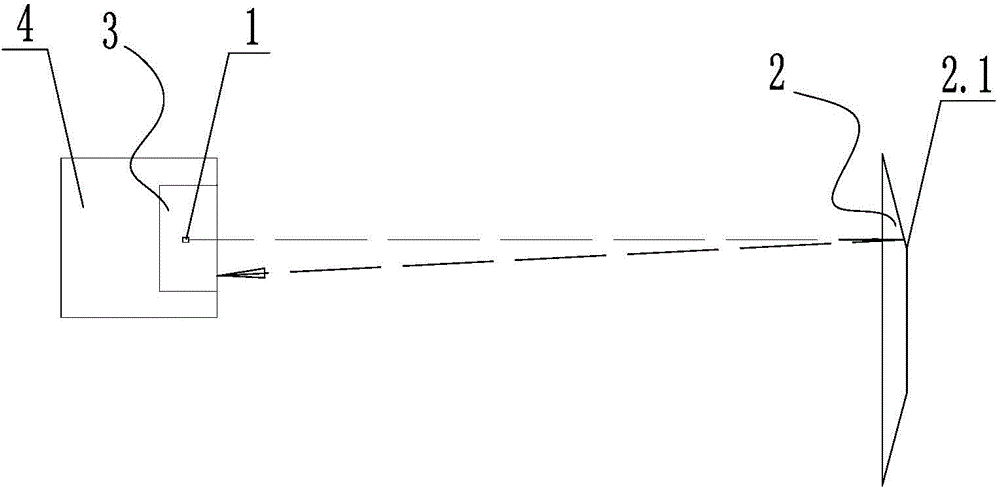

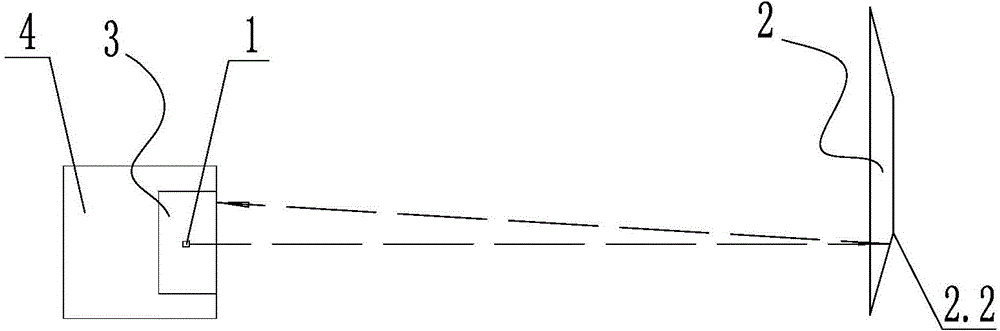

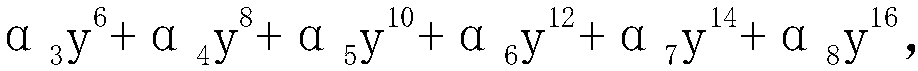

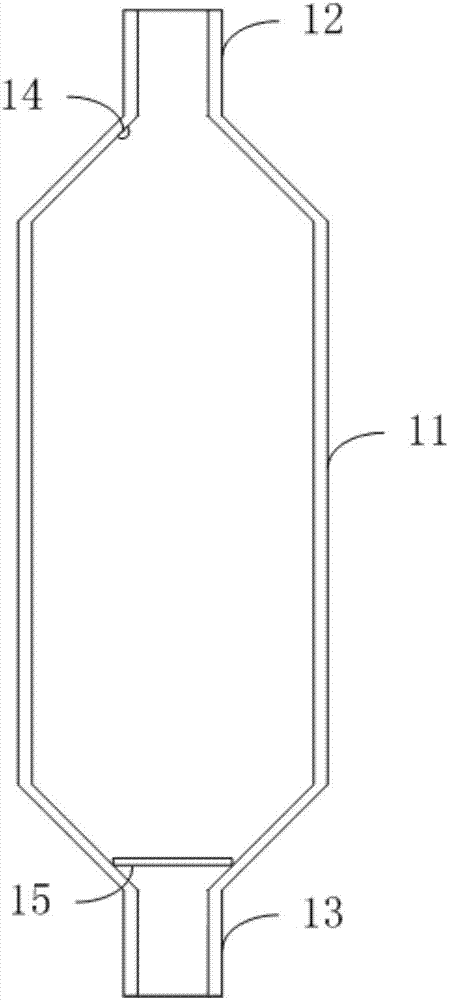

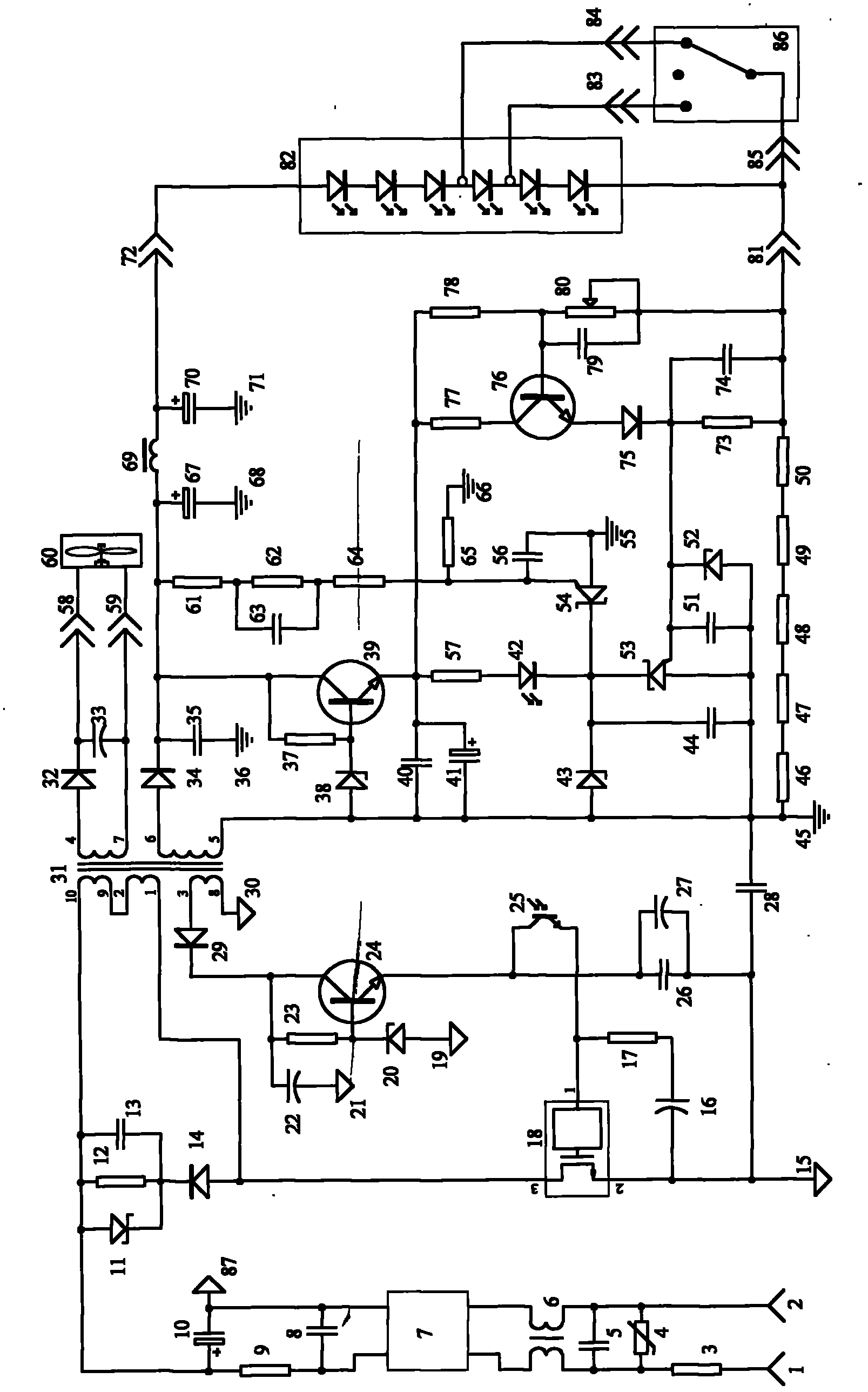

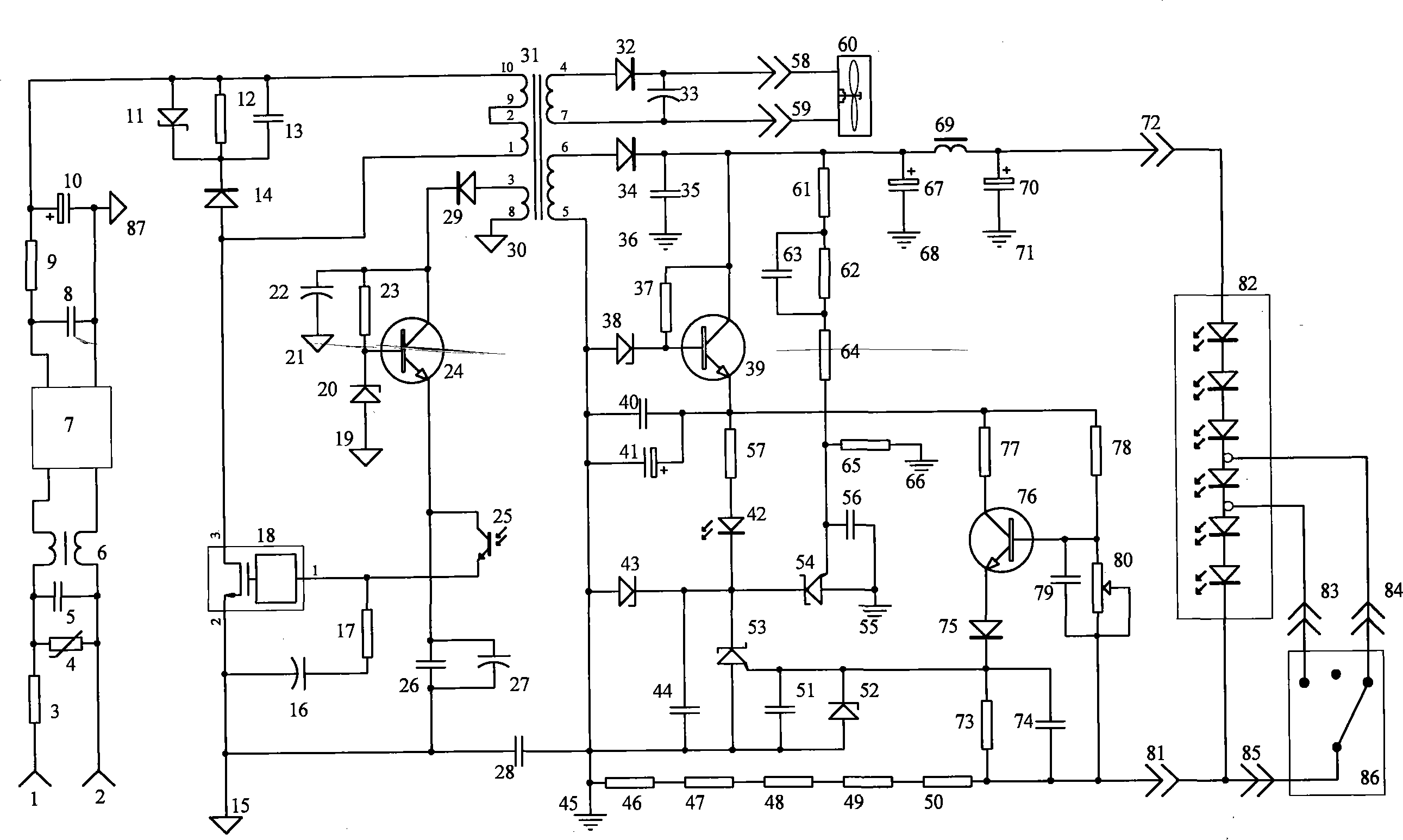

Transfusion state monitoring device

The embodiment of the invention discloses a transfusion state monitoring device which comprises a liquid dropping cavity, wherein a laser transmitter is arranged at one end of the liquid dropping cavity; a photographic plate is arranged at the end of the liquid dropping cavity; the change of the liquid level in the liquid dropping cavity is judged by detecting a photographic point of laser emitted by the laser transmitter, which is protected on the photographic plate after the laser is refracted by the liquid level. The transfusion state monitoring device provided the embodiment of the invention has the advantage that false alarms are effectively reduced during monitoring of a transfusion state.

Owner:张坚

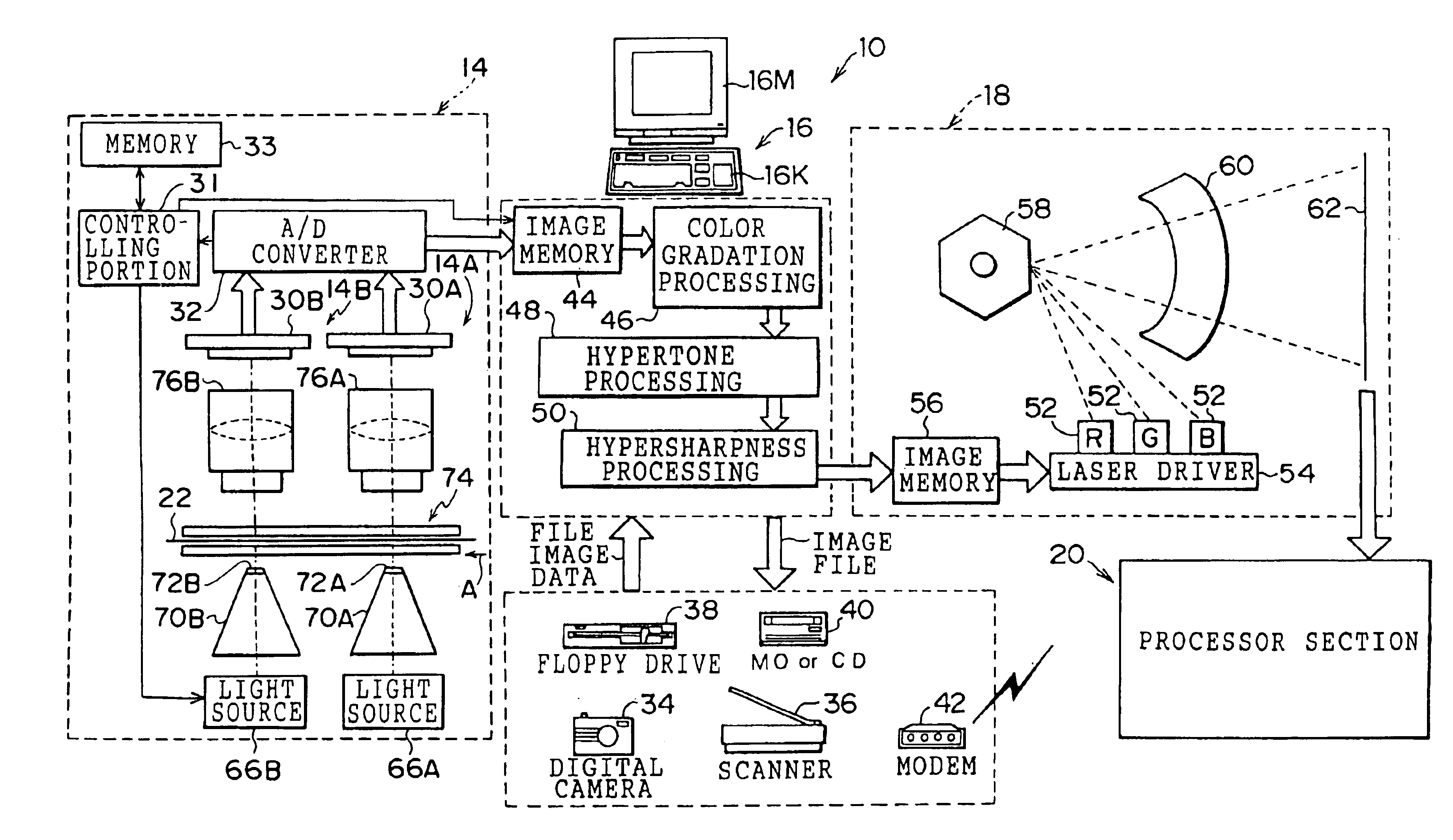

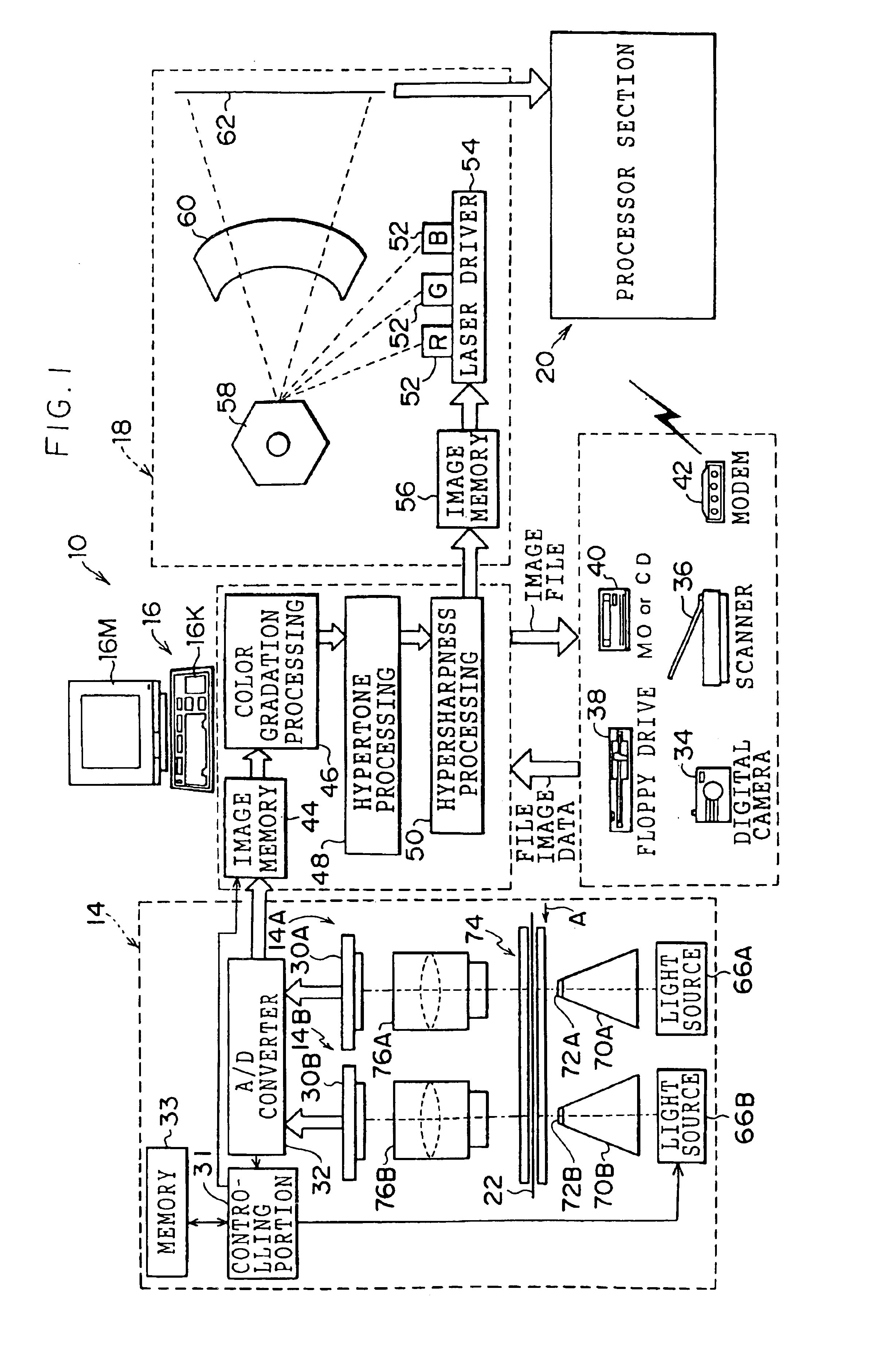

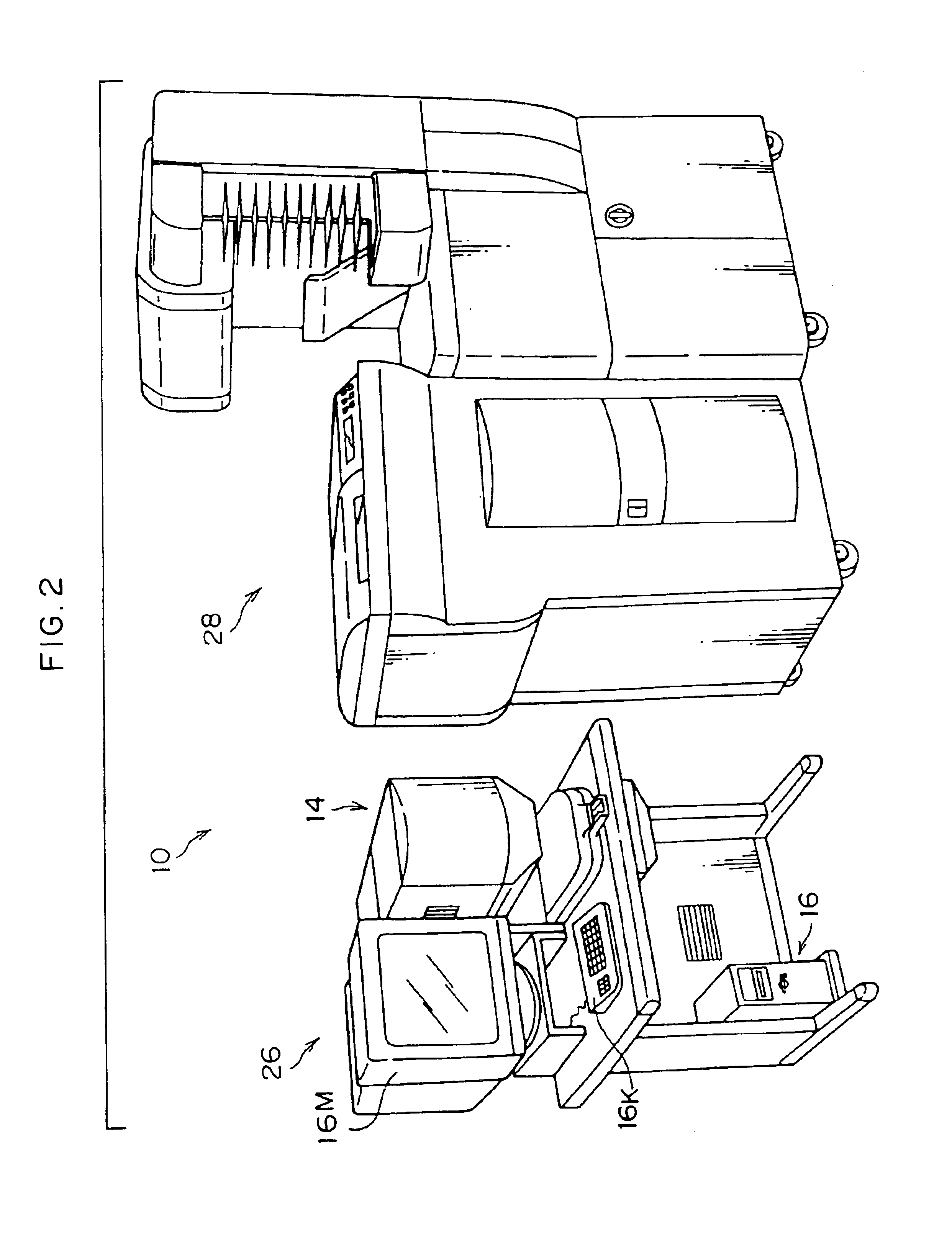

Constant speed image reading device and method

InactiveUS6906833B1Improve directivityShorten the timePhotographic printingPictoral communicationFilm (photographic)Light source

An image reading device in which a processing time required for prescanning and fine-scanning of a film can be shortened. A reading system for prescanning which performs prescanning and a reading system for fine-scanning which performs fine-scanning are adjacently juxtaposed on a conveying path of a photographic film. Prescanning is carried out by the reading system for prescanning, which is structured such that light that is emitted from a light source is transmitted through the photographic film, which is conveyed at a constant speed which is suitable for fine-scanning, the light is detected by a linear CCD, and frame images at the photographic film are thereby preliminarily read. Then, fine-scanning is carried out with the photographic film being conveyed at the same speed and the frame images on the photographic film being read at the reading system for fine-scanning by a quantity of light controlled on the basis of reading results of prescanning.

Owner:FUJIFILM HLDG CORP +1

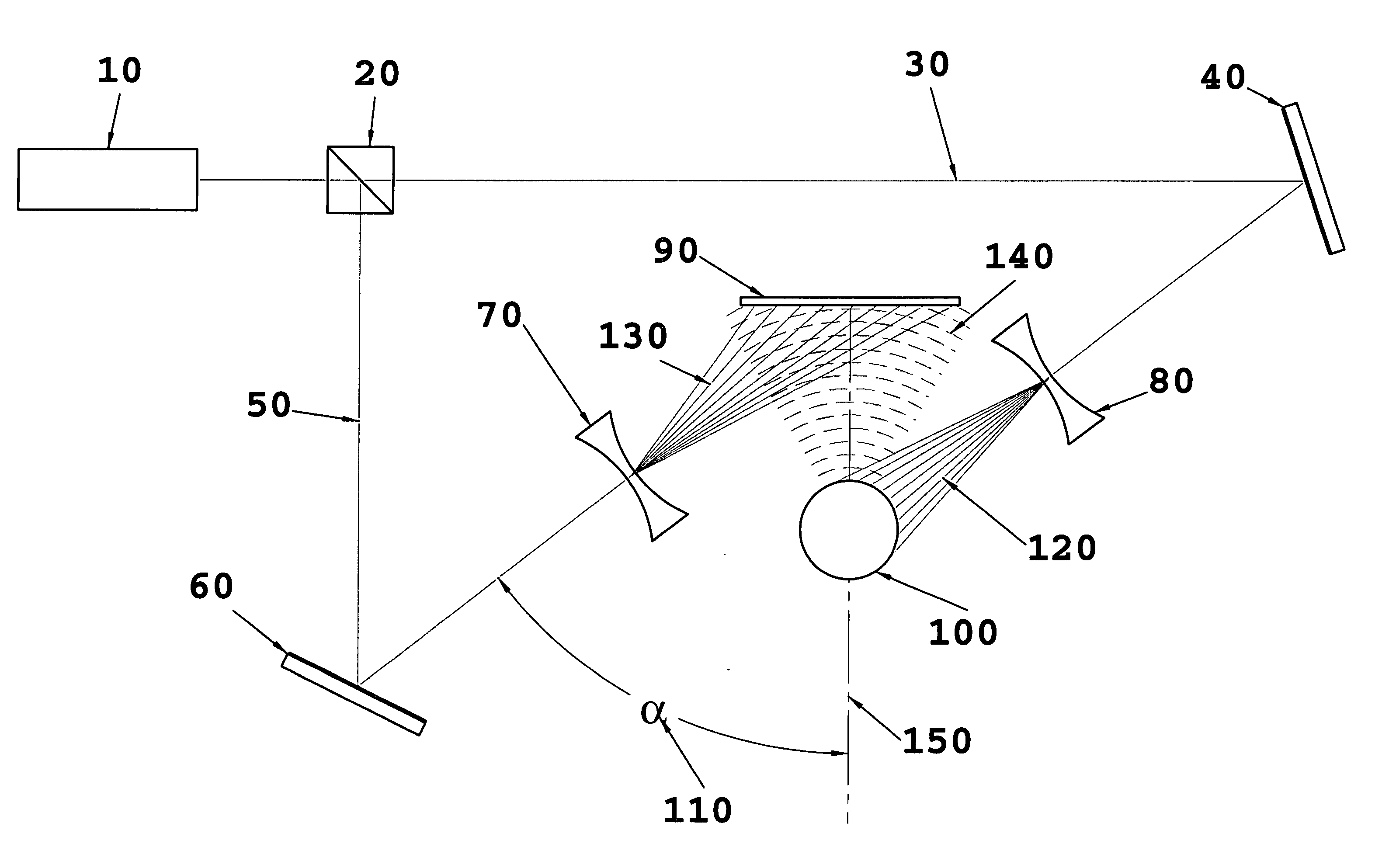

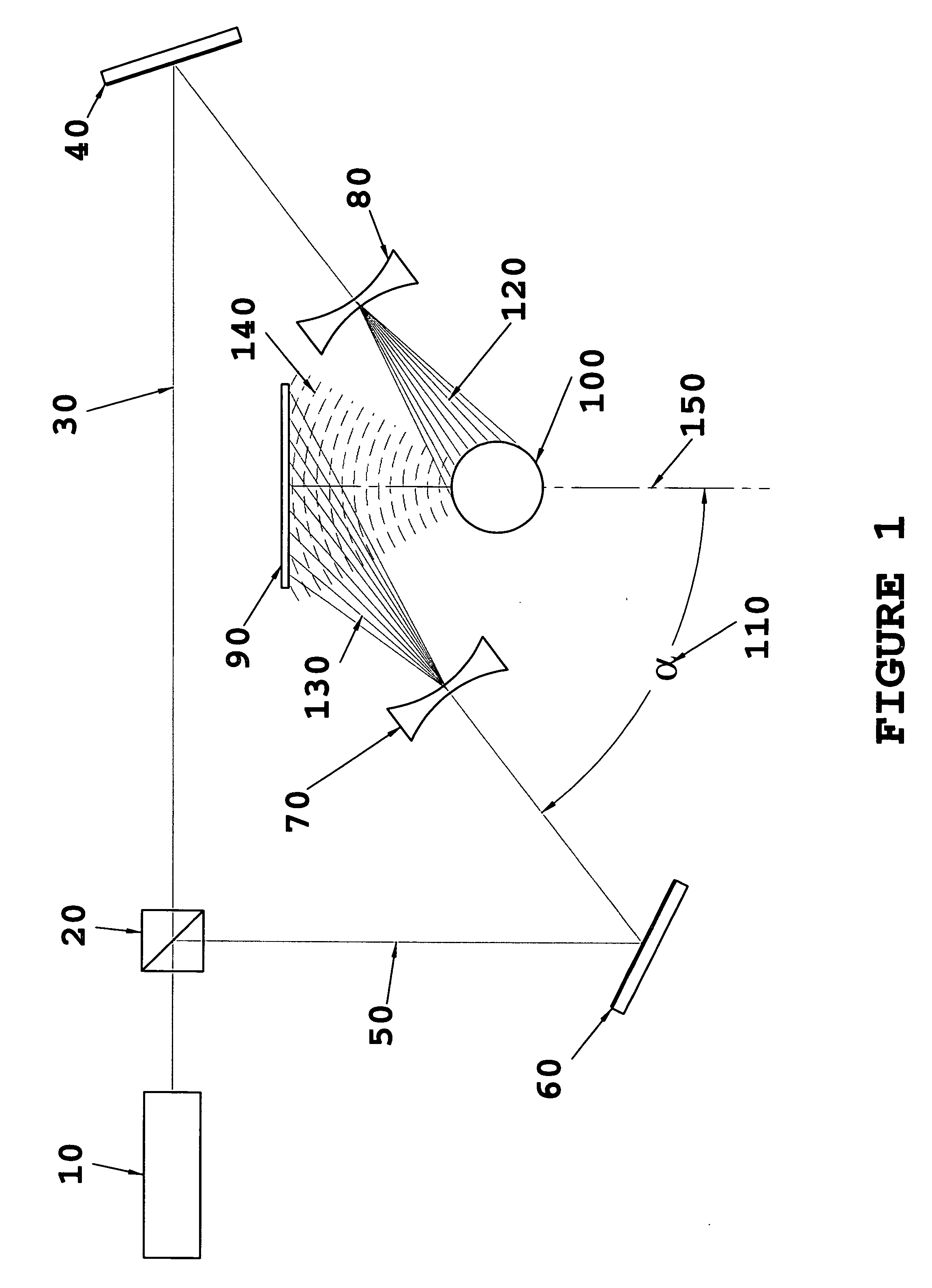

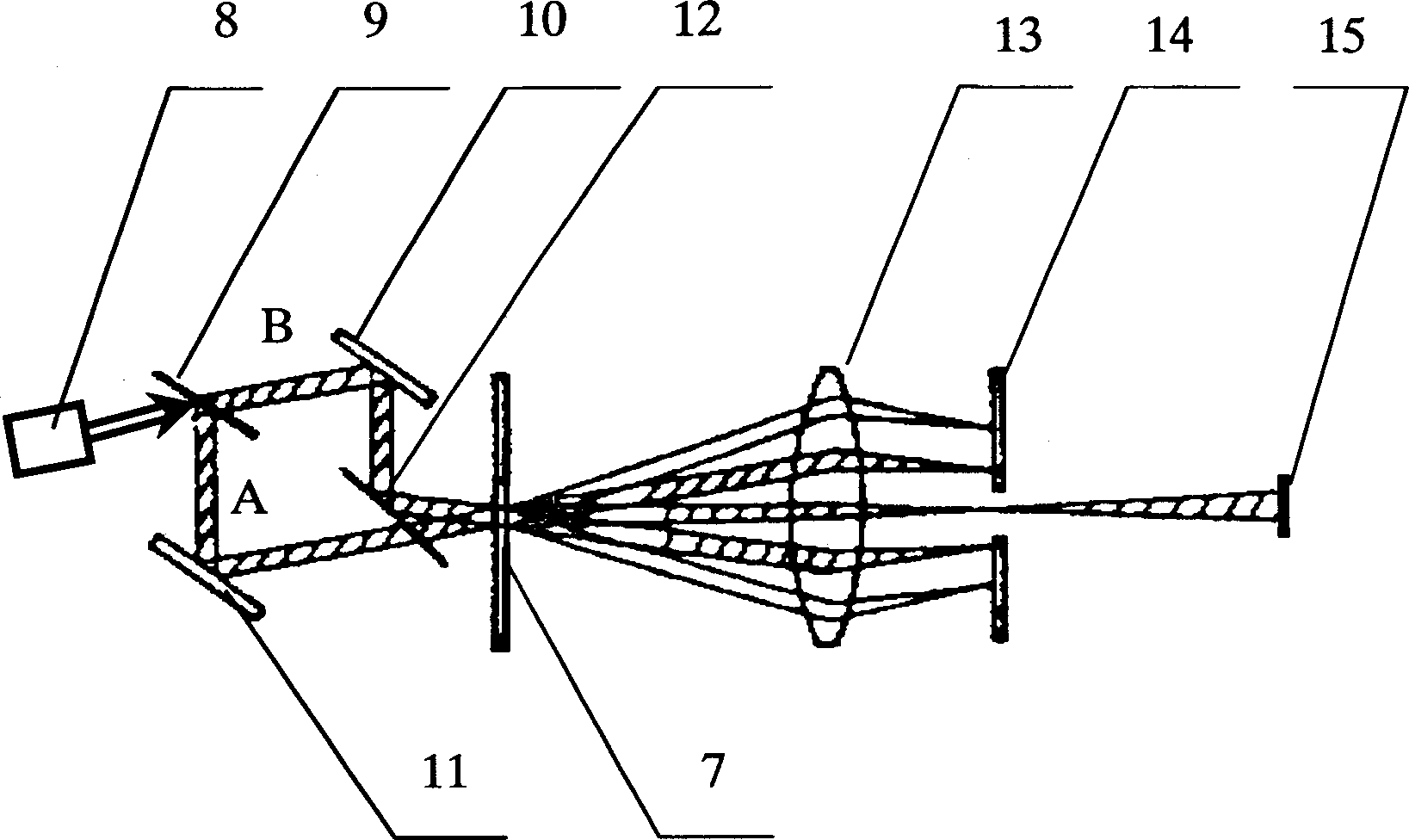

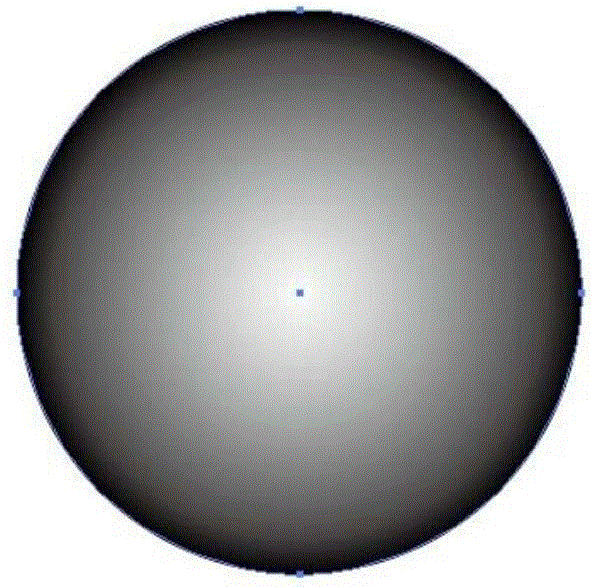

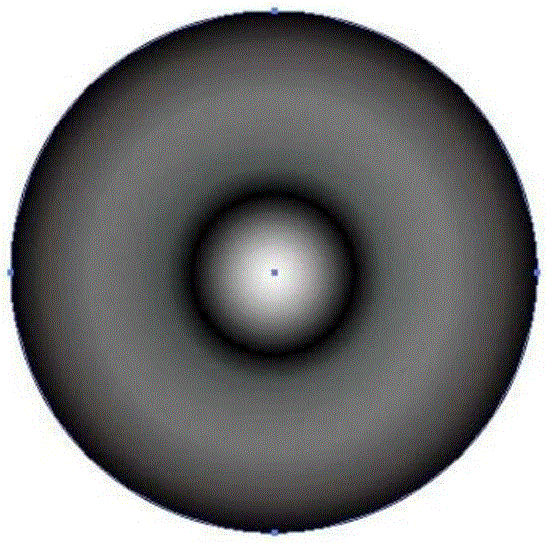

Particle field optical holographic high-precision reproduction collecting system and method

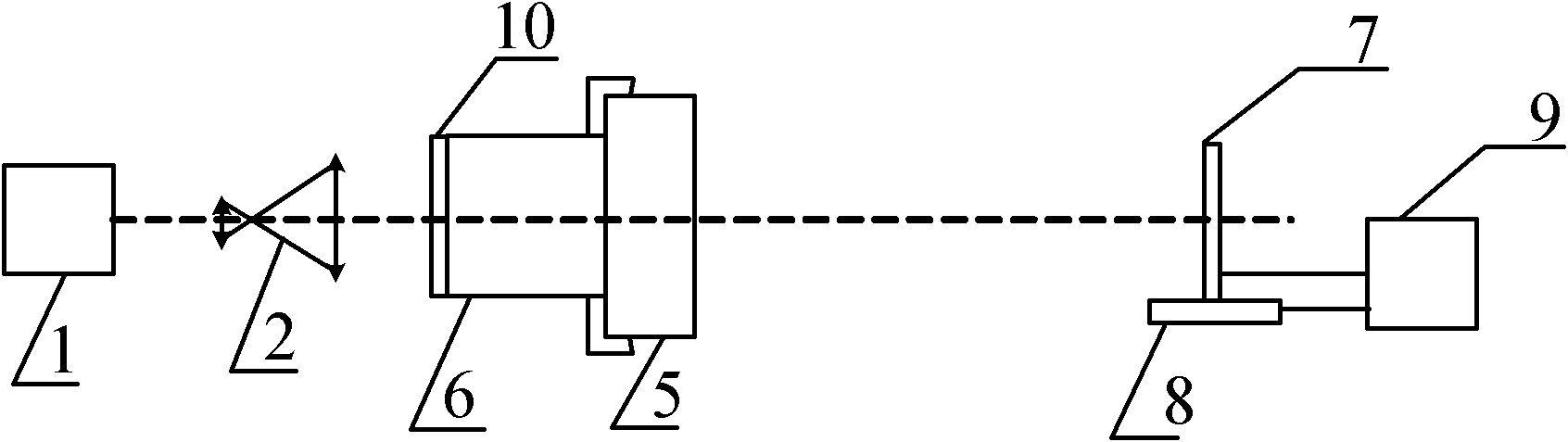

InactiveCN102096091AEasy to adjustSolve efficiency problemsRadiation intensity measurementImaging lensPhotographic plate

The invention relates to a particle field optical holographic high-precision reproduction collecting system and a particle field optical holographic high-precision reproduction collecting method. A beam expanding alignment unit, a particle field information carrier, an imaging lens, and a charge coupled device (CCD) are arranged on the output optical path of a laser in turn, and the CCD is connected with a computer; the sensitive face of the CCD is positioned at the rear focusing face of the imaging lens; the particle field information carrier is a holographic photographic plate carrying particle field information; a carrier positioning and moving device comprises a three-dimensional translation platform; a CCD positioning and moving device comprises a one-dimensional translation platform and a lens focusing face positioning device; the lens focusing face positioning device comprises a positioning part and a standard partition plate; and the standard partition plate is arranged on one end face of the positioning part, while the other part of the positioning part is connected with an object face side of the imaging lens. The device and the method solve the problems of low efficiency and low precision of the conventional optical path adjustment and low final data precision of the system caused thereby, realize accurate adjustment to the system optical path according to the lens imaging principle and improve the final data precision of the system.

Owner:NORTHWEST INST OF NUCLEAR TECH

Method for measuring weak micromagnetic field

InactiveCN1395113AHigh measurement sensitivityMagnitude/direction of magnetic fieldsPhase differenceMagnification

The invention relates to a method for measuring very weak magnetic field, especially the weak magnetic field with its flux less than 10 to the power -15 Wb. The sample to be tested is made from magnetic material with thickness less than or equal to 500 nano. First, the said sample is palced on the electron microscope to take electric holograph. Then, the electric photographic plate is put to the optical Mach-Rehnder interferometer for carrying out the phase difference magnification to obtain the interference pattern. The flux of the sample to be tested can be obtained by reading out the number of the interference fringe in the interference pattern. Comparing with the prior art, the invention possesses the features of high sensitivity, measuring the magnetic leakage field and very weak magnetic field as well as validating the Ahalanov-Boehm effect.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Manufacturing method for hot-stamped and transferred film with Fresnel lens visual effect

InactiveCN105904864AWith visual impactPattern printingOther printing apparatusFresnel lensHigh energy

The invention discloses a manufacturing method for a hot-stamped and transferred film with a Fresnel lens visual effect. The manufacturing method includes the steps that firstly, a lens gray scale pattern is manufactured; secondly, a control computer is used for reading each concentric circle gray scale of the gray scale pattern, and the output power of a high-energy light beam is set to be a laser which outputs different kinds of power according to control of a waveform generation circuit; thirdly, the circumference of each circle is calculated through the computer, and the circumferences are converted into stepping numbers of a rotation platform till the gray scale pattern designed in the second step is completed; fourthly, a photographic plate obtained after photoetching is subjected to developing, and etched lines are developed; fifthly, a photoetching plate is copied into a plate capable of being used for die pressing; sixthly, the die pressing plate is loaded on a die press to be subjected to die pressing; and seventhly, the plate obtained after die pressing is made into a coating film. By means of the method, the unique, effective and visual three-dimensional image-text film can be manufactured and used for achieving fake preventing of currencies, negotiable securities and products and achieving a visual impact effect of printed products.

Owner:珠海市瑞明科技有限公司 +1

Clamp for fixing a photographic slide or negative

Owner:TRANSPACIFIC PLASMA

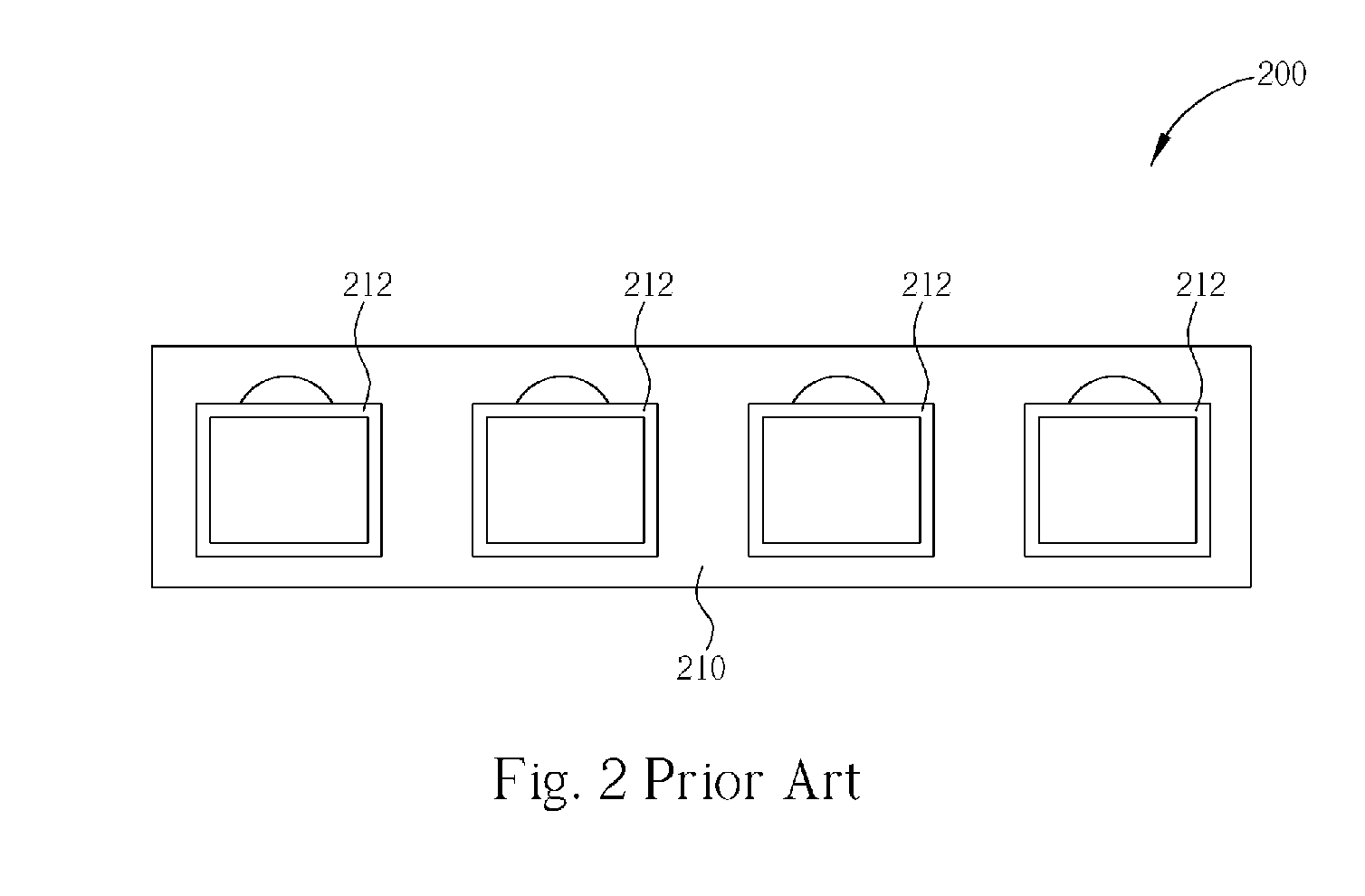

Lighting area-selectable background lighting device for picture viewing machine

InactiveCN102625533AEasy to watchEasy to viewElectric light circuit arrangementEnergy saving control techniquesEffect lightLighting ratio

A lighting area-selectable background lighting device for a viewing industrial crack detection photographic plate viewing machine is composed of an active controller, an LED lighting plate and a wave-band switch, and is characterized in that the input end of the active controller is connected with a 220VAC power supply; the output end of the active controller is connected with the positive end and the negative end of a lighting plate and built-in sectional connection points of the lighting plate; and the connecting points of the wave-band switch are respectively connected with the built-in sectional connection points of the lighting plate. By utilizing the picture viewing machine provided by the invention, the lighting area of the background lighting device can be selected in a sectional manner, therefore, when viewing standard photographic plate, the size of the background lighting can be selected according to the specification of the standard photographic plate, so that a user is facilitated to view the photographic plate, the energy is saved, requirements on production, life, energy conservation and low carbon of modern social are met, the development prospect is active, and the market demand is large.

Owner:辽宁省安全科学研究院

Making method of embossment type color metal etchings

ActiveCN102774219ARich three-dimensional senseRich visual senseDecorative surface effectsSpecial artistic techniquesEtchingPrinting ink

The invention discloses a making method of embossment type color metal etchings. The method comprises the following steps: firstly, grinding metal plates; then making canvas shadings and image films according to pictures, etching back on grinded metal plates to making the canvas shadings and image films; then mixing photosensitive printing ink with thickness texture according to color separation photographic plates of pictures; then making thickness photographic films capable of acquiring picture stroke and thickness texture effects according to picture effect; carrying out sensitization to obtain bottom slabs with abundant stroke texture; finally, making 4-color photographic films; spraying colorful photosensitive printing ink on the metal plates by a spraying method; and performing sensitization by using the 4-color photographic films respectively, so as to obtain the embossment type color metal etchings. By means of the making method of the embossment type color metal etchings, the thickness feeling and volume feeling of the pictures can be made on the metal plates, so that colorful metal printmaking has more abundant stereoscopic impression and texture is more close to vivid oil painting in visual effect and abundant visual impression of people is met.

Owner:刘明祥 +1

Day-night dual-purpose zoom lens capable of eliminating heat difference

ActiveCN105137580AReduce manufacturing costOvercome the defect of large focus driftOptical elementsCamera lensImaging quality

The invention discloses a day-night dual-purpose zoom lens capable of eliminating a heat difference. The day-night dual-purpose zoom lens comprises a first lens group, an automatic aperture, a second lens group, an optical filter and a photographic plate. The first lens group is composed of three glass lenses. The second lens group is composed of five lenses, and at least three lenses of the second lens group are plastic aspherical lenses. According to the invention, the production cost of the lens provided by the invention is lowered, the market competitiveness of the lens is enhanced; each lens is optimally configured, and the heat difference elimination design is adopted, so that the defect that the focus drifting amount of the plastic lenses is large under high-low temperature environments is effectively overcome, and the lens provided by the invention has the advantage of stable analysis under different temperature usage conditions; in addition, the lens provided by the invention can realize triple zooming, the day-night dual-purpose function is achieved, and the resolving power can realize the image quality of three million pixels.

Owner:舜宇光学(中山)有限公司

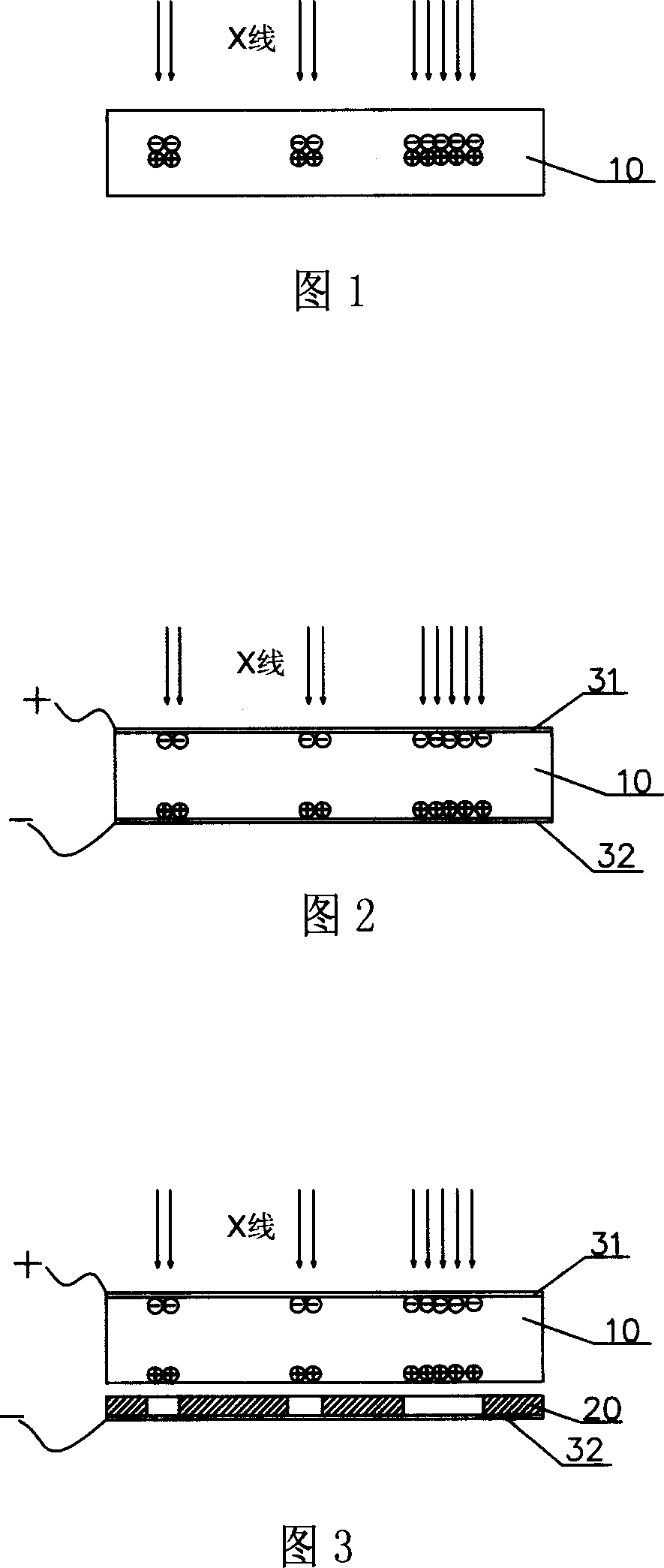

X-ray detecting method and X-ray detector therefor

The invention relates to x ray detecting method and detector. It uses photographic plate to capture x ray to convert it to electric charge, forming corresponding voltage signal using electrode, using voltage signal to control LCD layer forming and capturing x ray corresponding visible light through status, reading the status information to get electric signal. Without using TFT technique, it can effectively reduce X ray detector cost, reaching the same effect with the detector based on TFT tech. Using non contact electric charge reading technique, it can avoid physical damage and impact to feature of the photographic plate.

Owner:珠海友通科技有限公司

Method of Making Relief Image Printing Elements

ActiveUS20170322494A1Reduced print gainPhotomechanical exposure apparatusMicrolithography exposure apparatusDigital imagingEngineering

A method of flood exposing a photocurable printing blank to actinic radiation from a UV LED light source, wherein a high intensity UV LED light source is modulated to a lower intensity. The method includes the steps of: (a) positioning the photocurable printing blank in an exposure unit, wherein the exposure unit comprises one or more high intensity UV LED light sources; (b) modulating intensity of the one or more high intensity UV LED light sources to a lower intensity; and (c) flood exposing the photocurable printing blank through the photographic negative or the digitally imaged mask layer to actinic radiation from the one or more modulated UV LED light sources.

Owner:MACDERMID PRINTING SOLUTIONS

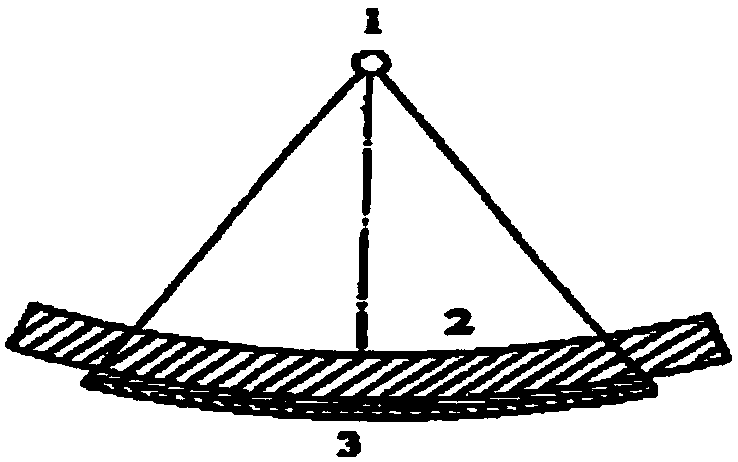

Gamma source three-source combined full view exposure method for macrotype spherical storage tank

InactiveCN101344496ASatisfied with the quality effectBasically uniform panoramic radiation fieldMaterial analysis by transmitting radiationRadiation fieldPhotographic plate

The invention relates to a panoramic exposure method with three-source Gamma source combination of a large-scale spherical storage tank, which adopts the irradiation with three-source bound combination, can obtain a basically even panoramic radiation field, completely satisfies the standard fog density and sensitivity requirements of photographic plates, has greatly shortened irradiation time and novel techniques, is simple, convenient, safe, reliable and environment-protective, and can improve the nondestructive examination quality. The panoramic exposure method comprises the following technical steps: a central point of the spherical storage tank is obtained by measurement, a Gamma source head is packed on a nylon belt and positioned at the central point of the spherical storage tank, and the nylon belt is fixed in centers of an upper inlet orifice and a lower inlet orifice and strung by an euphroe, thus avoiding swinging; a source tank is connected with a drive device, and source transmission pipes and a drive hose are straightly positioned with the bend radius no less than the least Phi 500; the three source transmission pipes are bound together, and under the precondition that the geometric unsharpness is ensured, three irradiation heads turn outward in a petal shape so as to reduce mutual influence, increase irradiation area and reduce fade zone.

Owner:陕西化建工程有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com