Gamma source three-source combined full view exposure method for macrotype spherical storage tank

A spherical storage tank and exposure method technology, which is applied in the direction of using radiation for material analysis, can solve the problems that the exposure effect cannot meet the evaluation requirements, the safety cost increases, and the influence of the radioactive source increases, so as to improve the quality of non-destructive testing and novel construction technology. , the effect of shortened exposure time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

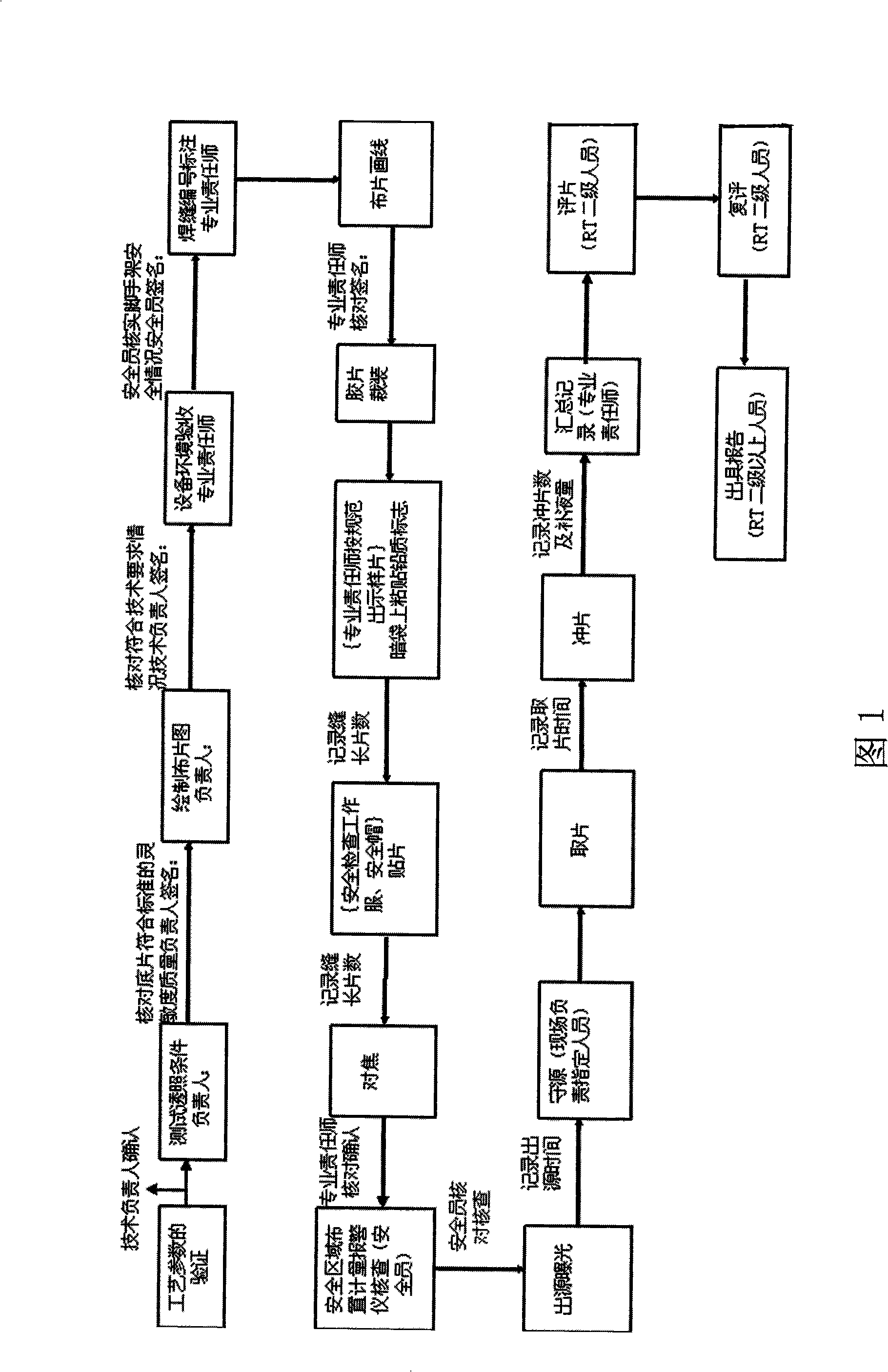

[0016] 1. The specific method steps of the invention and the process parameters in the process

[0017] 1.1 Process test (mainly to determine the bundling method of the three sources and to verify the possibility of the addition of source strengths)

[0018] 1.1.1 Process Analysis

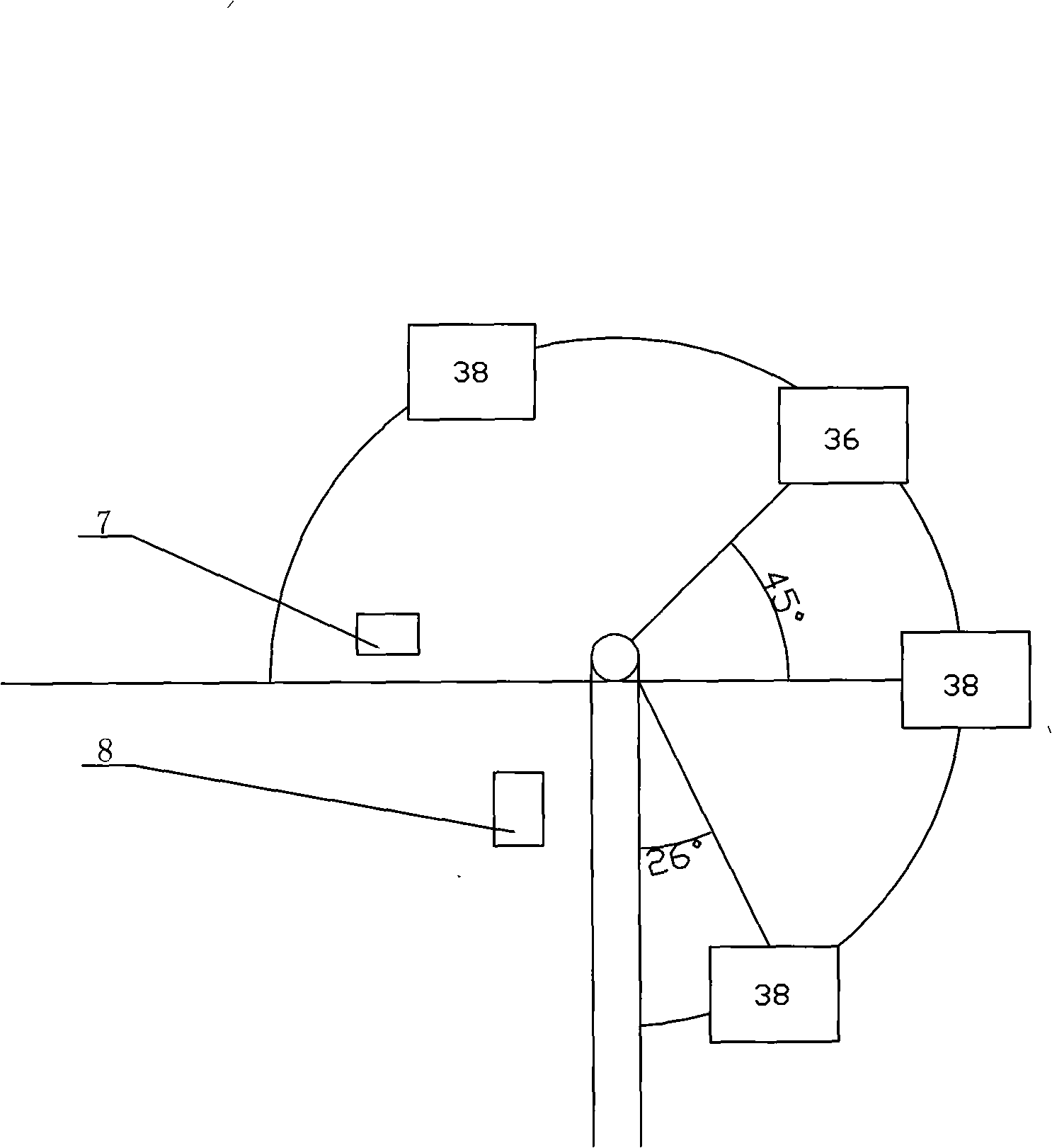

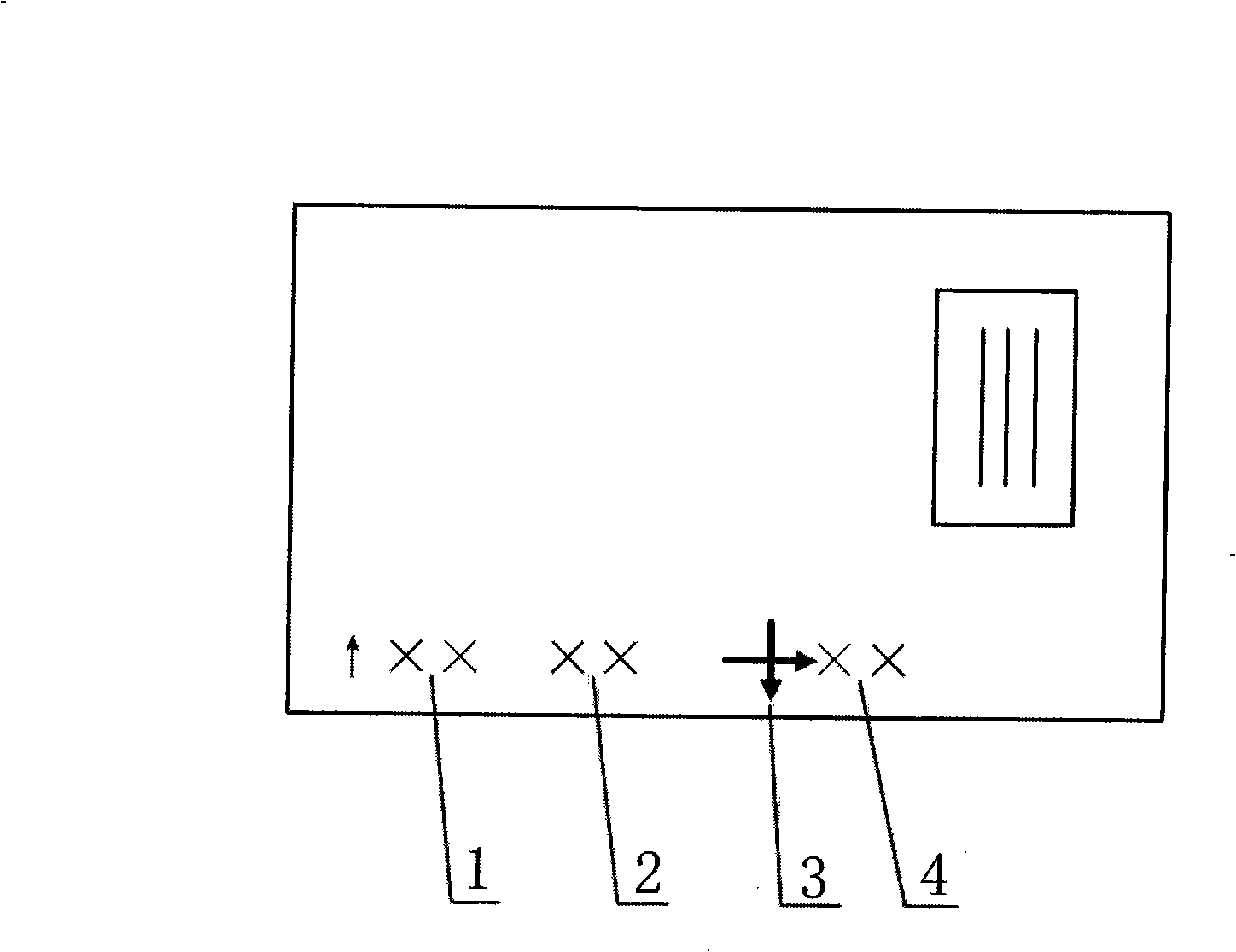

[0019] The spherical tank application γ-ray panoramic exposure is to place the radiation source in the center of the spherical tank, and perform a 360° exposure imaging of the welding seam at the equal diameter position, and one shot can reach more than 70% of the global welding seam. Under normal circumstances, the secondary exposure can complete 100% of the global welding seam, and can run continuously, not affected by the continuous power-on capability of the equipment, small size, light weight, no electricity, no water, greatly reducing manpower and material resources , time, cost, is a method with high efficiency and significant economic benefits. However, gamma sources all have a certain ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com