Patents

Literature

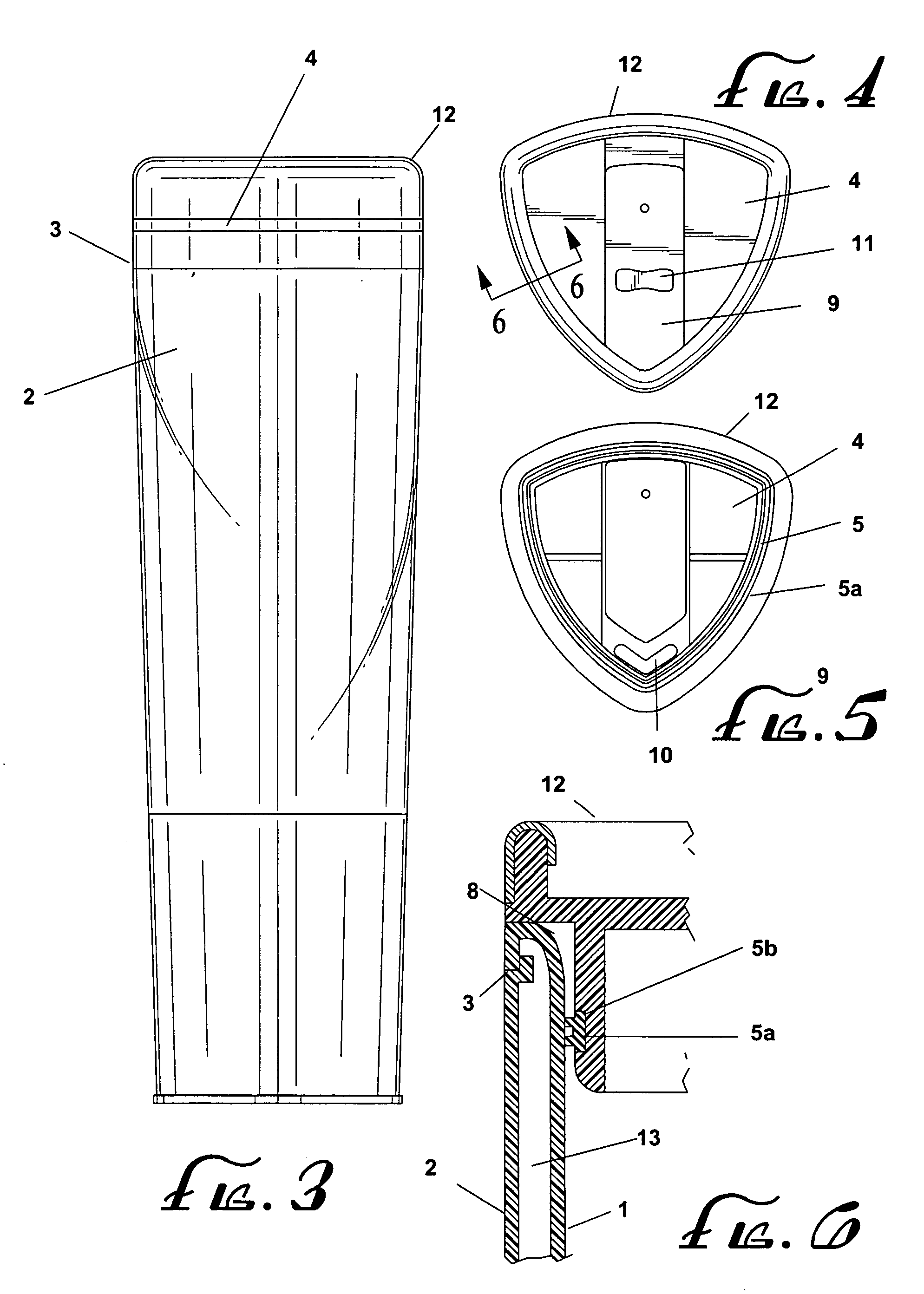

146results about How to "Reduce spills" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

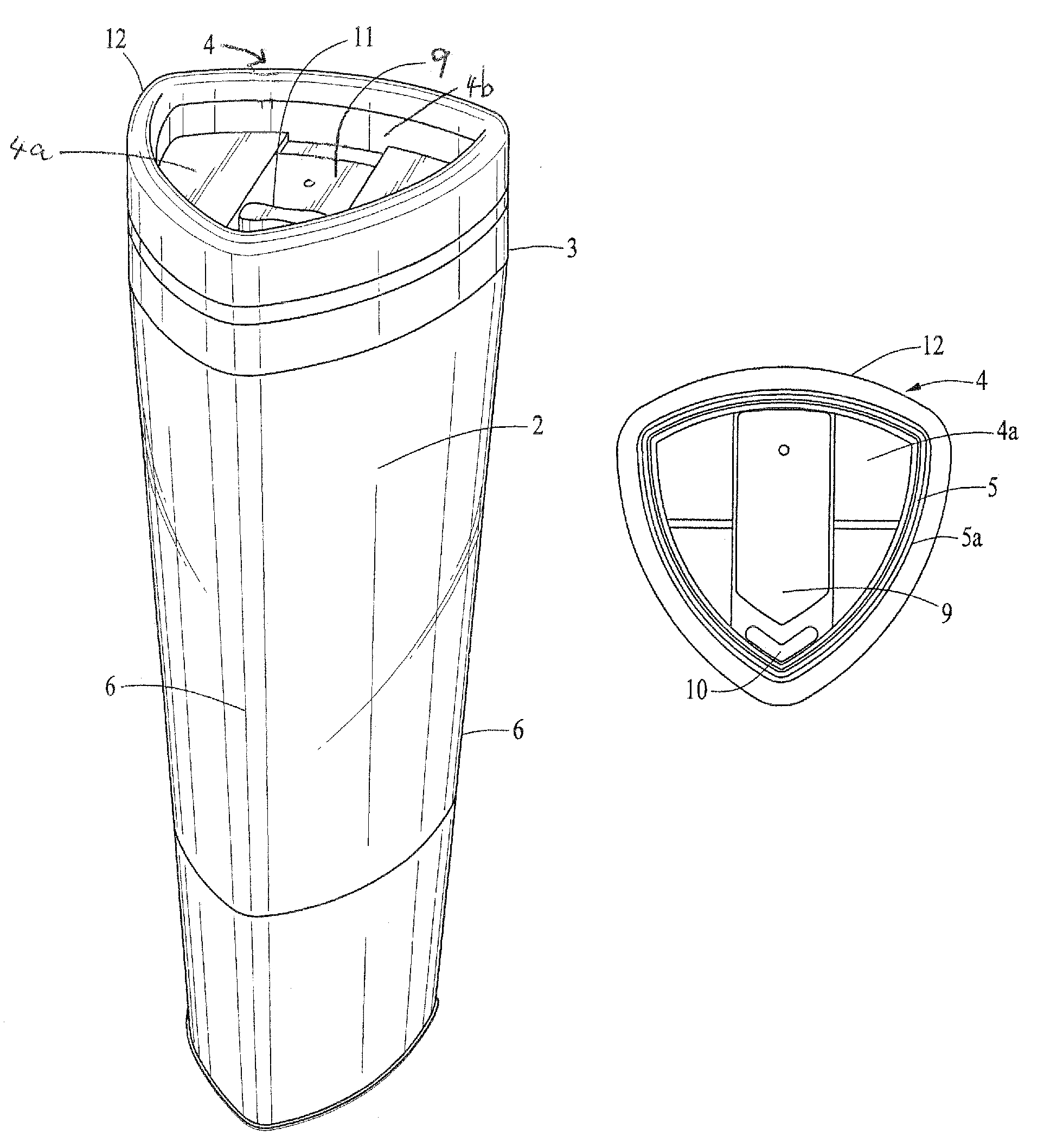

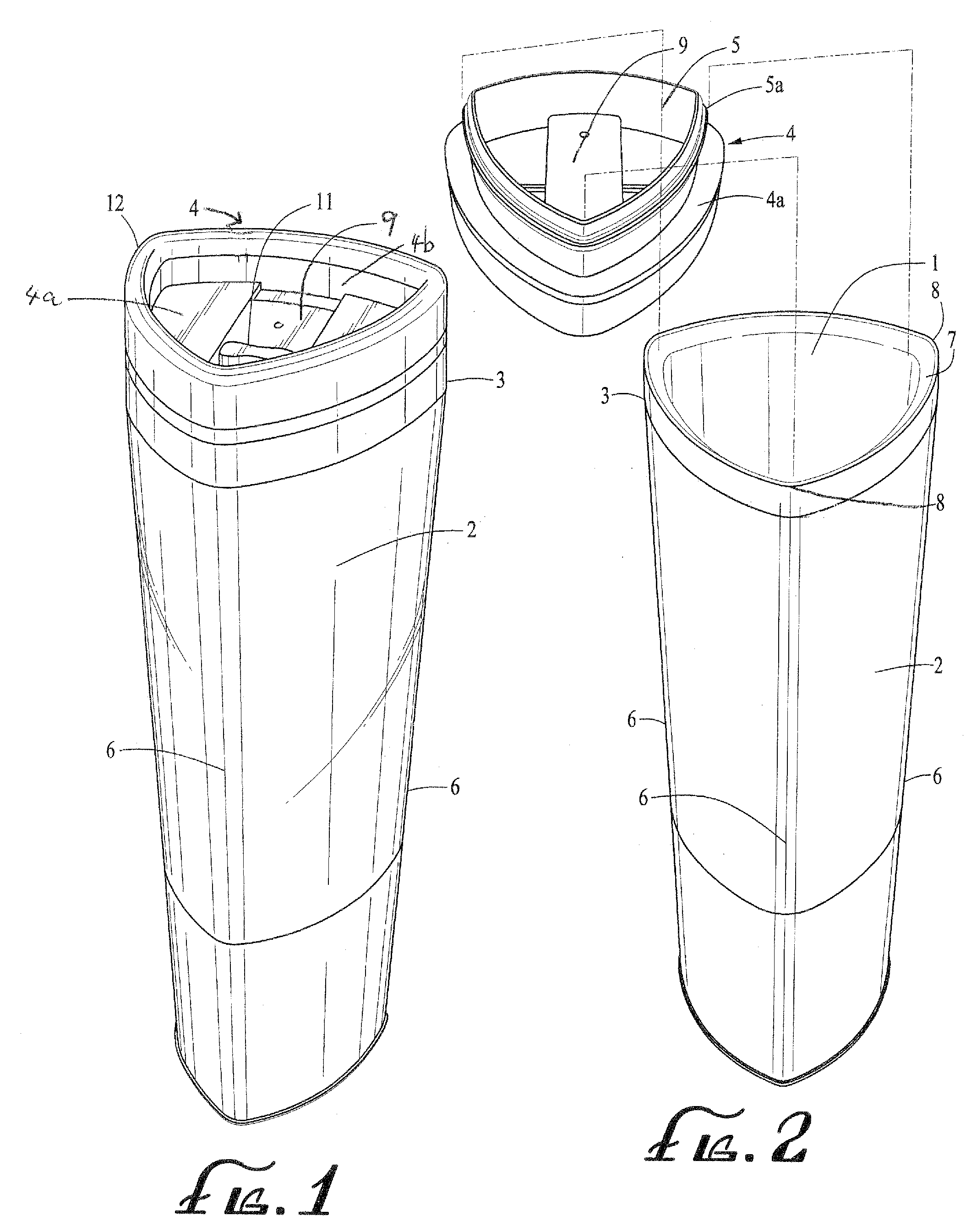

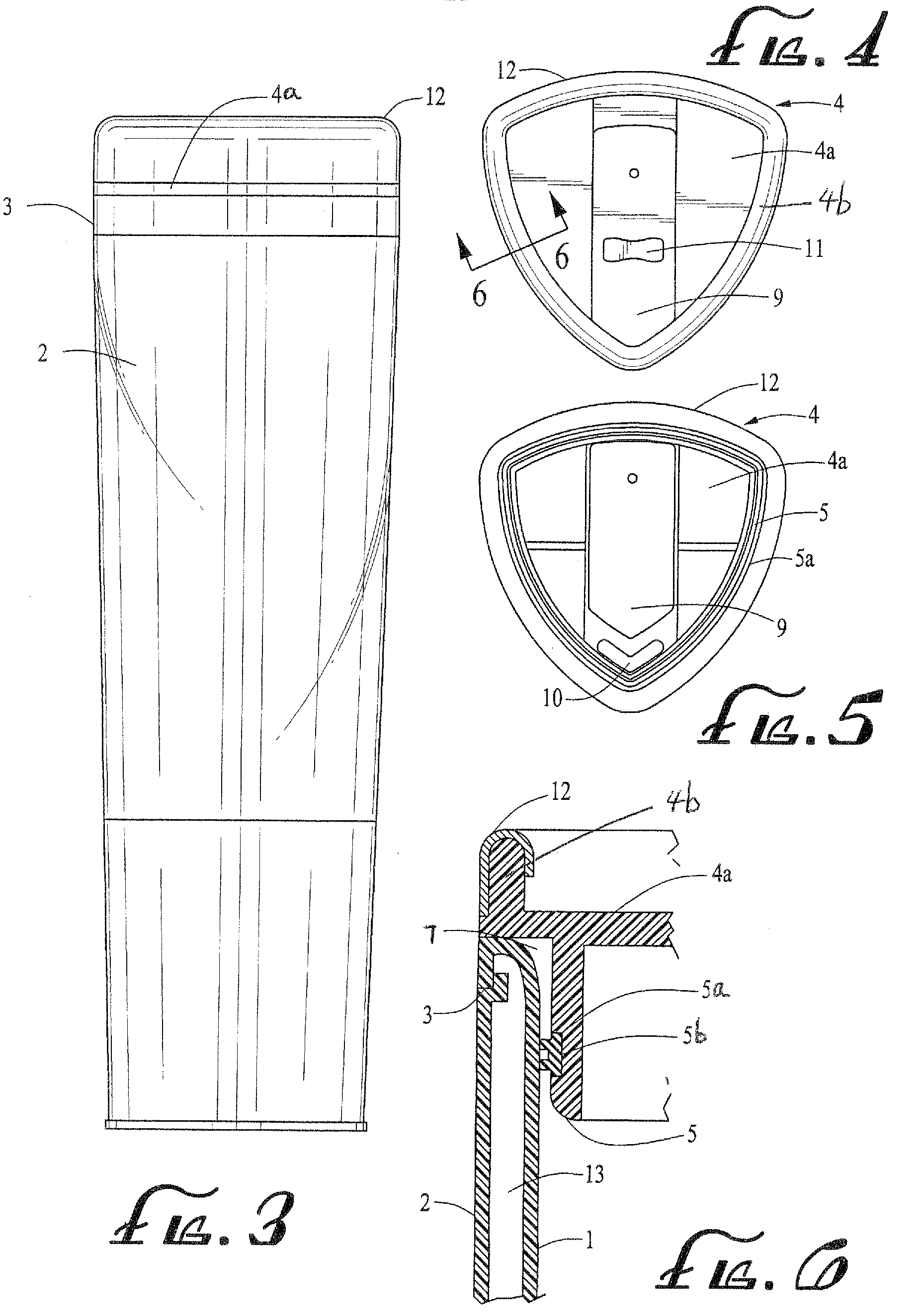

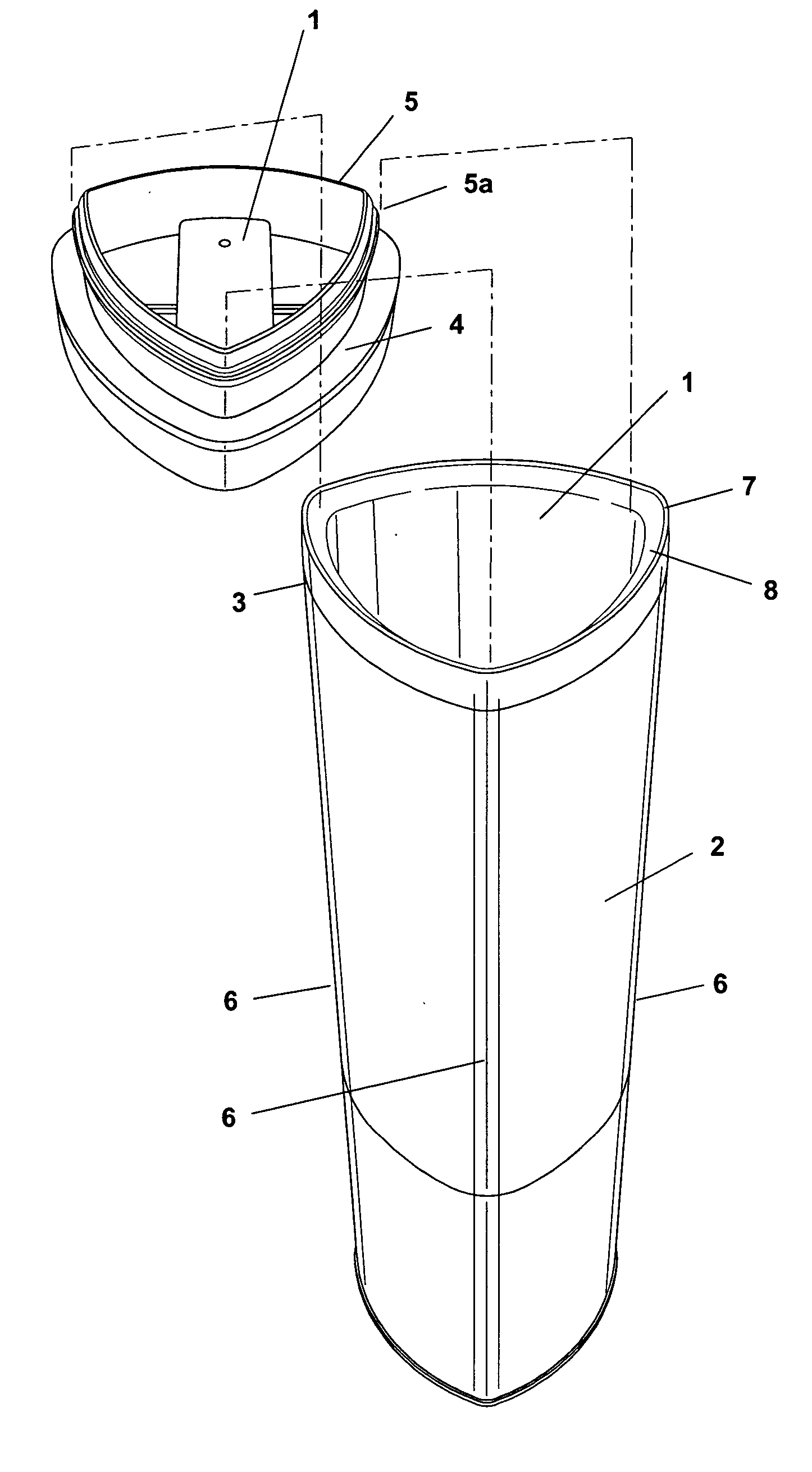

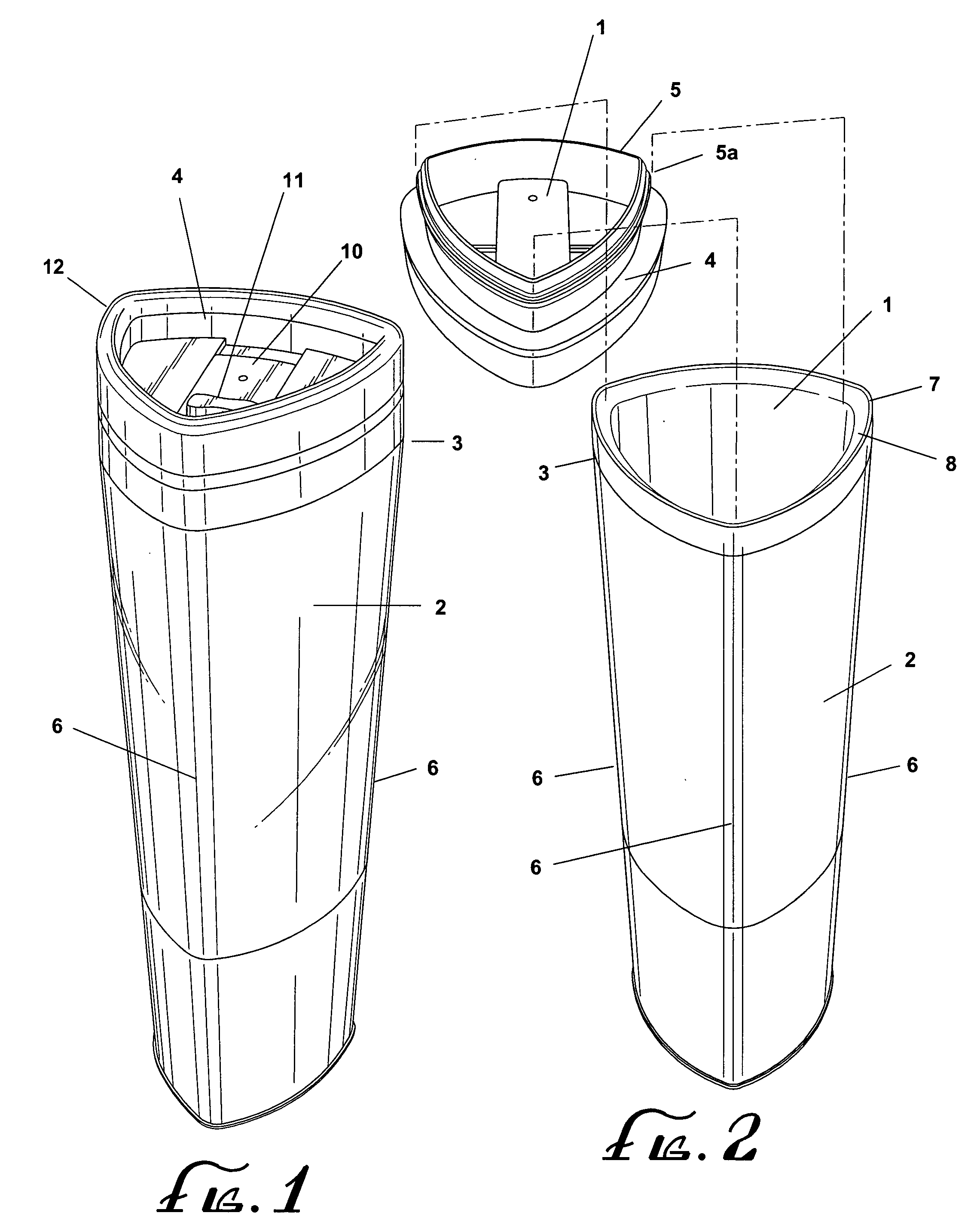

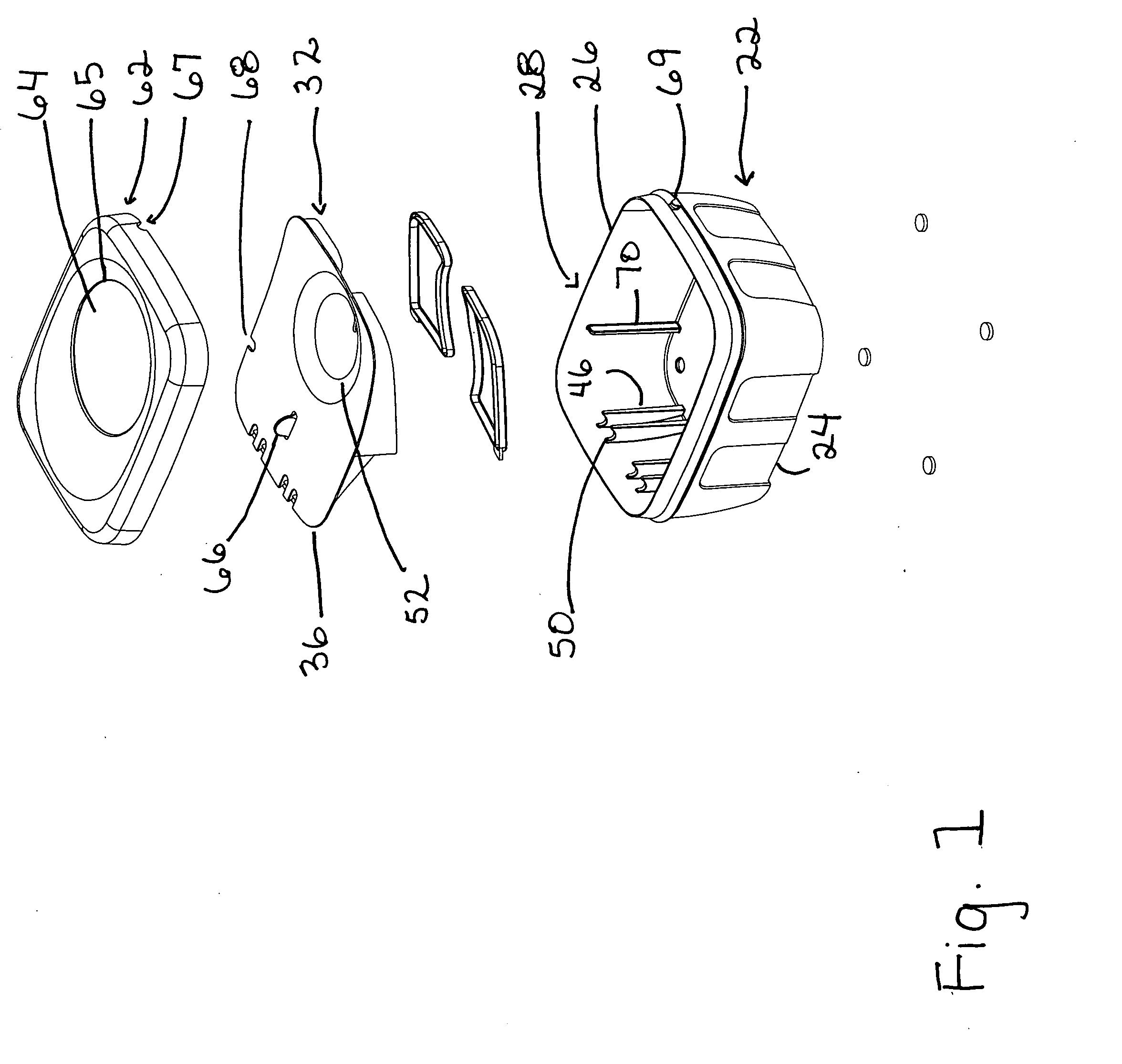

Triangular mug and advertising means

InactiveUS7455191B2Accurate and controlled fashionEasy flow controlDomestic cooling apparatusClosuresTriangular mouthMechanical engineering

Owner:SUN COAST MERCHANDISE

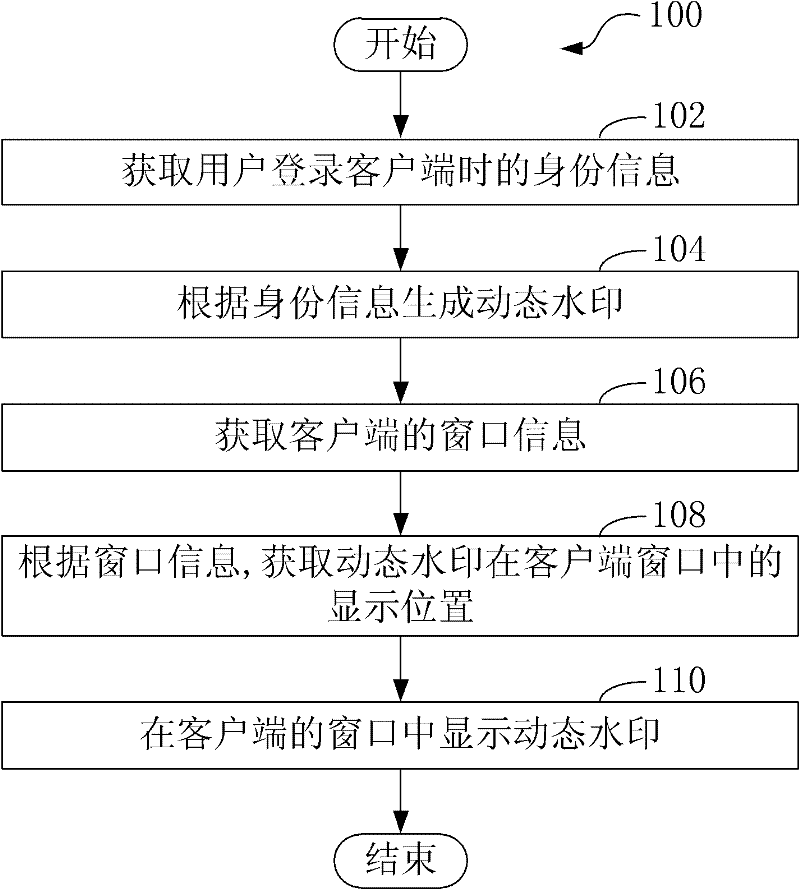

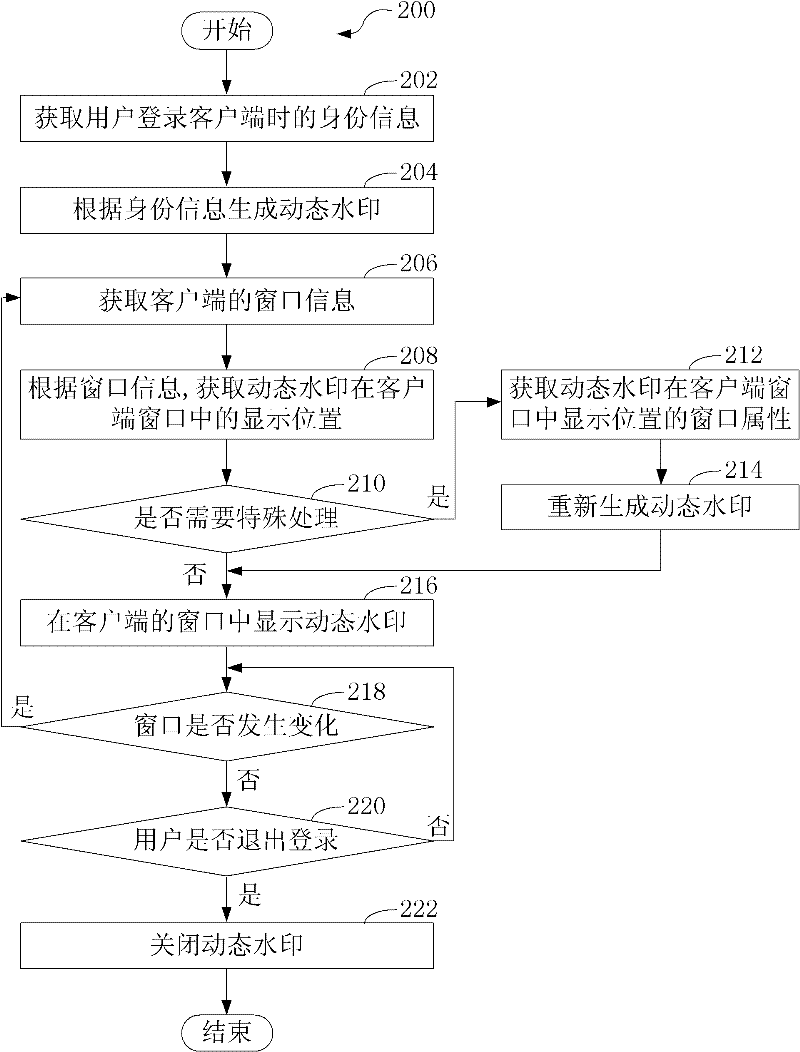

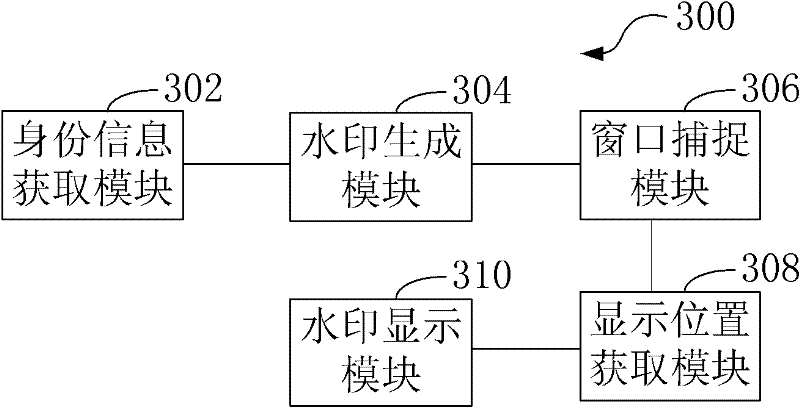

Online information protection method and device

InactiveCN102685076ATo achieve the purpose of protectionImprove security auditTransmissionInternet privacyThe Internet

The invention provides an online information protection method and an online information protection device, relating to an internet technology. The online information protection method comprises the steps of: acquiring identity information of a user when the user logs in a client; generating a dynamic watermark according to the identity information; acquiring window information of the client; acquiring a display position of the dynamic watermark in a window of the client according to the window information; and displaying the dynamic watermark in the window of the client. The method and the device have the advantages that the purpose of protecting online information in the window of the client of an online system can be achieved, a user can trace behaviors of acquiring the online information in abnormally manners such as screen capture and photo taking, so that the safety audit to the online information by enterprises can be enhanced, leakage events of the online information can be reduced, and furthermore, economic losses and negative social impacts brought by such events to the enterprises can be avoided.

Owner:CHINA TELECOM CORP LTD

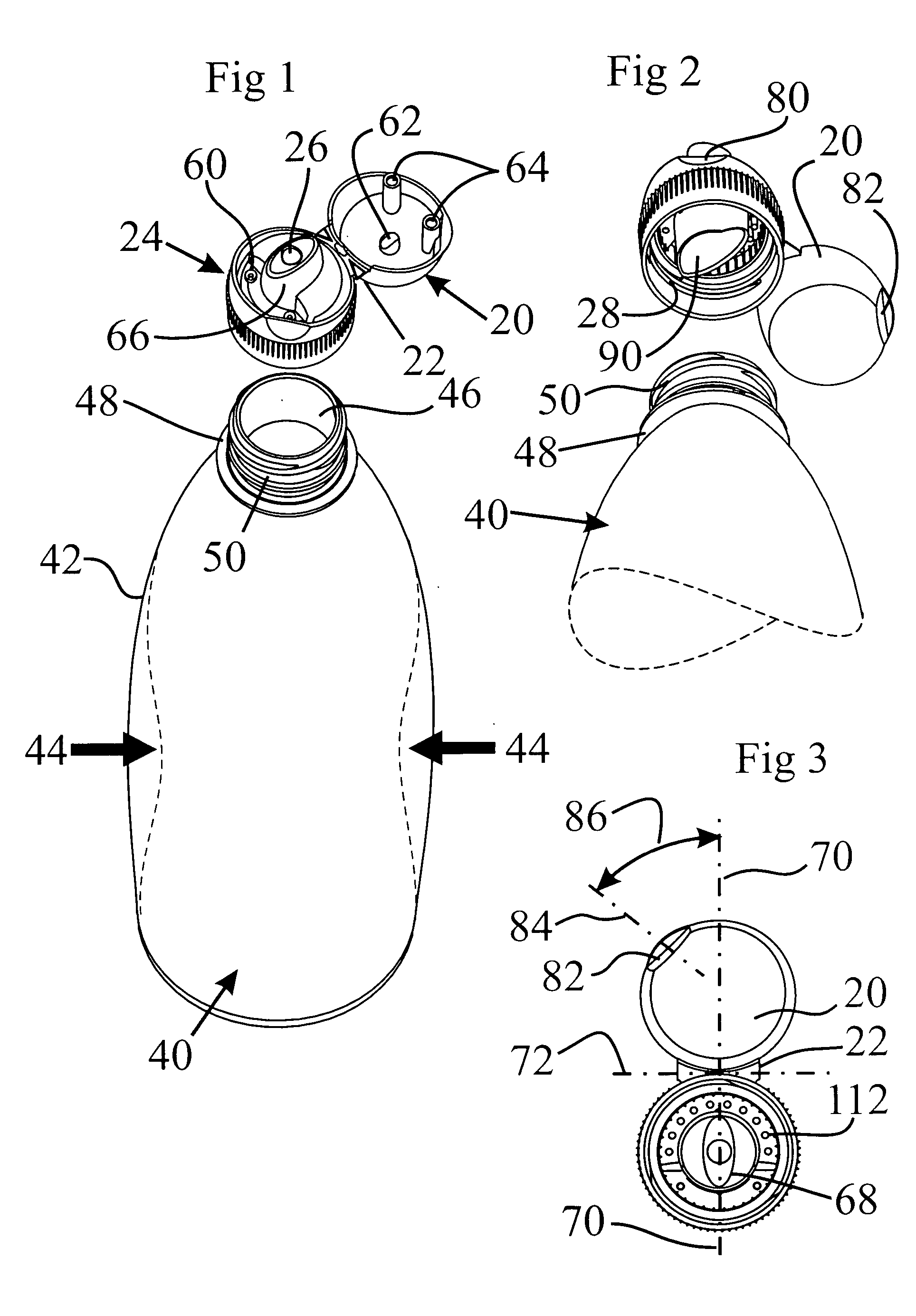

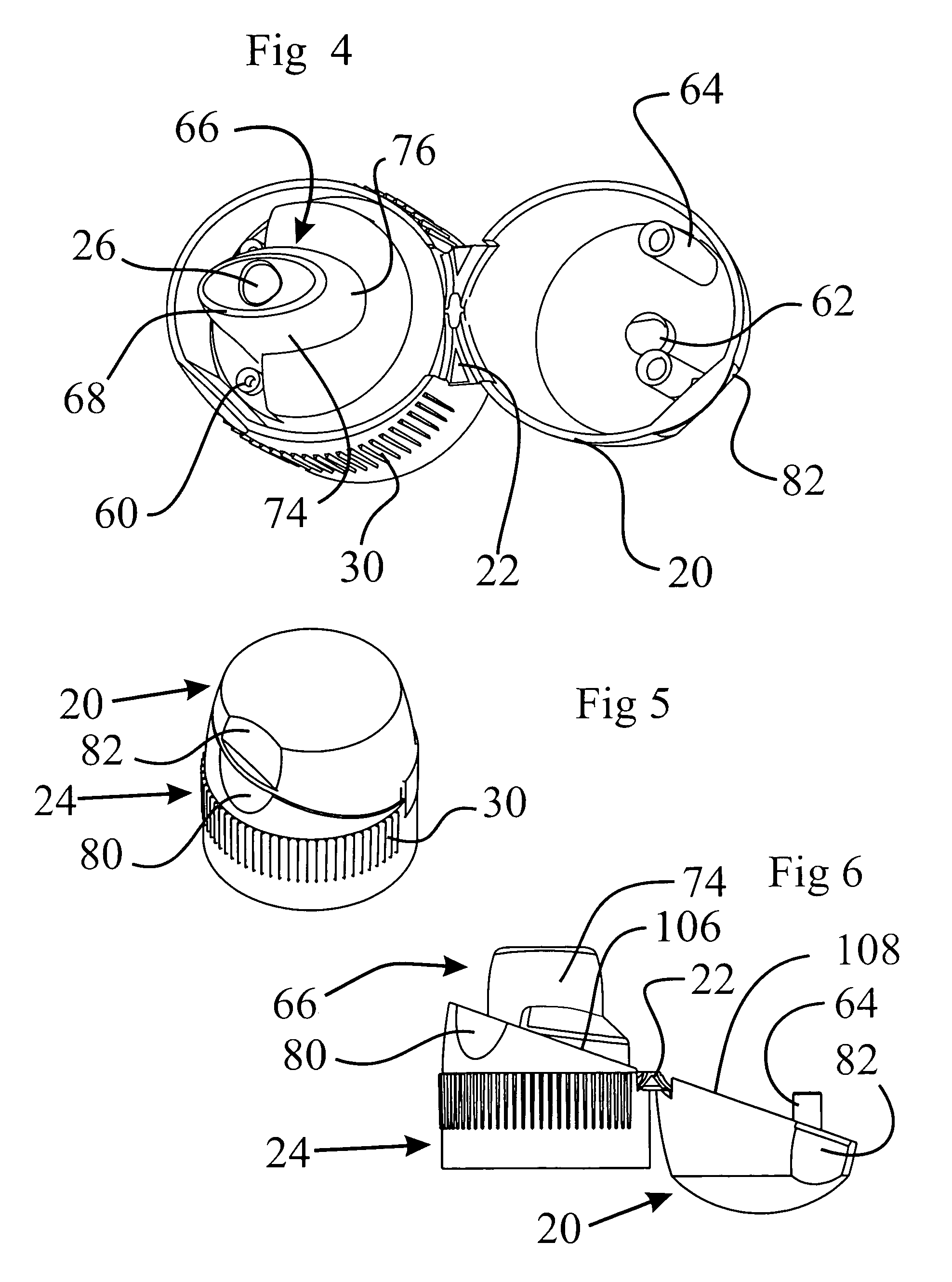

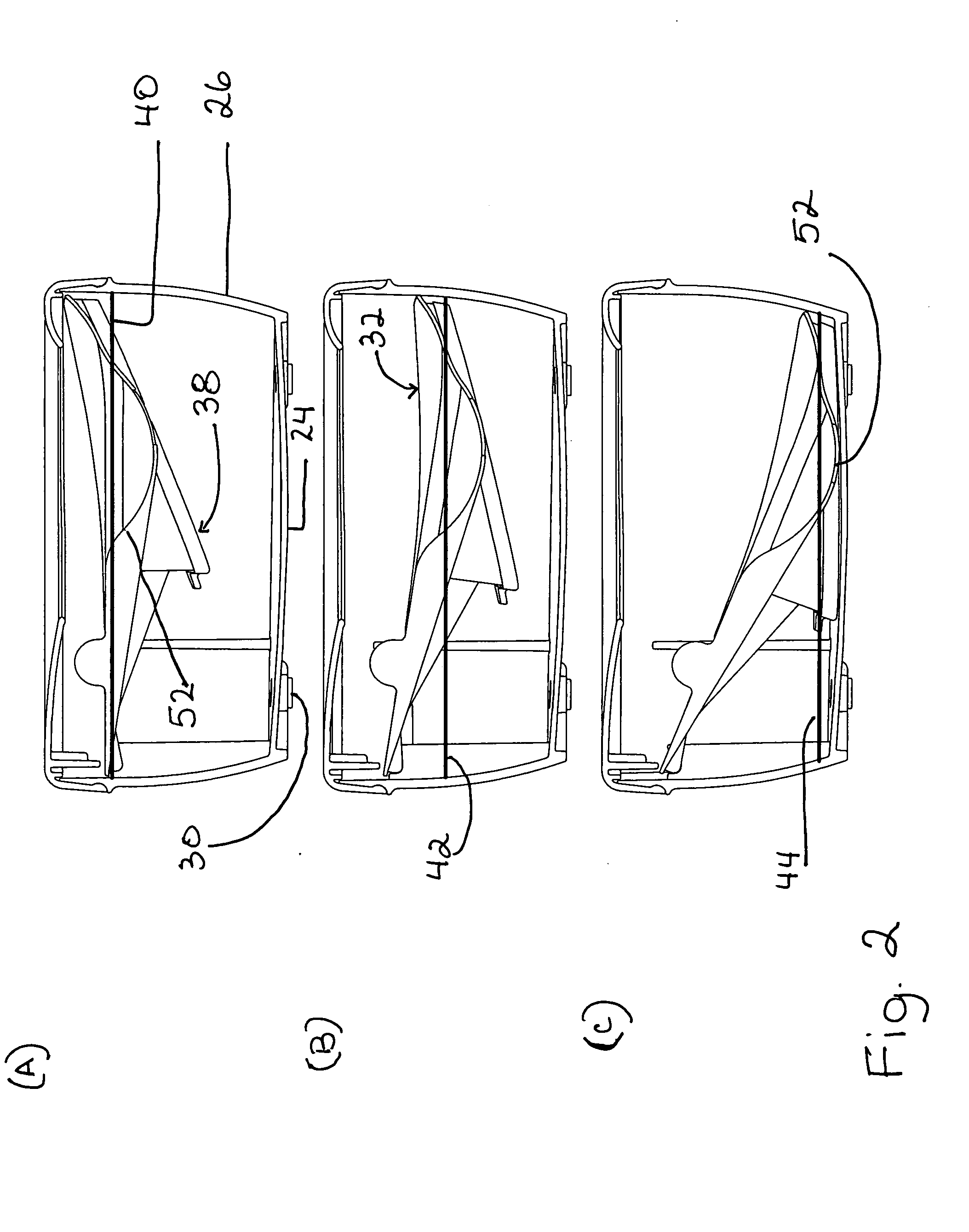

Vented fluid closure and container

InactiveUS20060071040A1Small bubble sizeReduce noiseCapsClosure using stoppersEngineeringMechanical engineering

A vented closure for a liquid container which will not freely pour includes a cap hinged at one side and movable between open and closed positions relative to a base collar. In an open position, a primary fluid passageway extends through a shaped mouthpiece which is elongated and tapered to conform to a user's mouth. One or more air vents of small size are located in a protected floor of the base collar at positions spaced within predetermined ranges of offsets from the dispensing opening so as to convey liquid into contact with the air vents in a manner to self-seal the air vents by surface tension of the liquid until an unbalance force is present. The cap and collar mate along an offset diagonal edge, and a grip area for the user's thumb or finger is offset from a center line. The offsets cause the cap to flip open with additional clearance and without obstructing a user's nose.

Owner:YOUNG JOHN L

Triangular mug and advertising means

InactiveUS20060124651A1Reduce overflowAccurate and controlled fashionClosuresDomestic cooling apparatusMechanical engineeringEngineering

Owner:SUN COAST MERCHANDISE

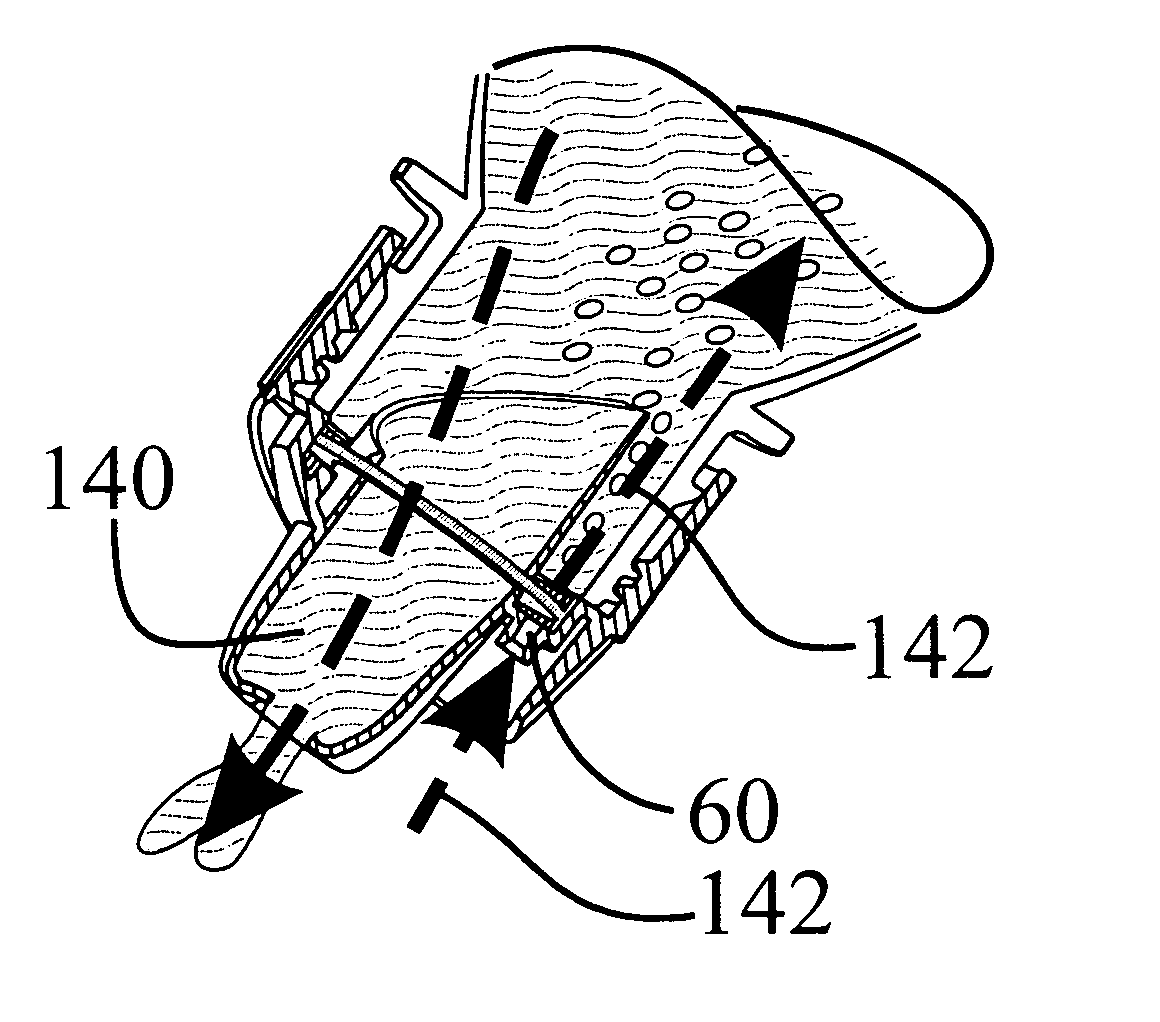

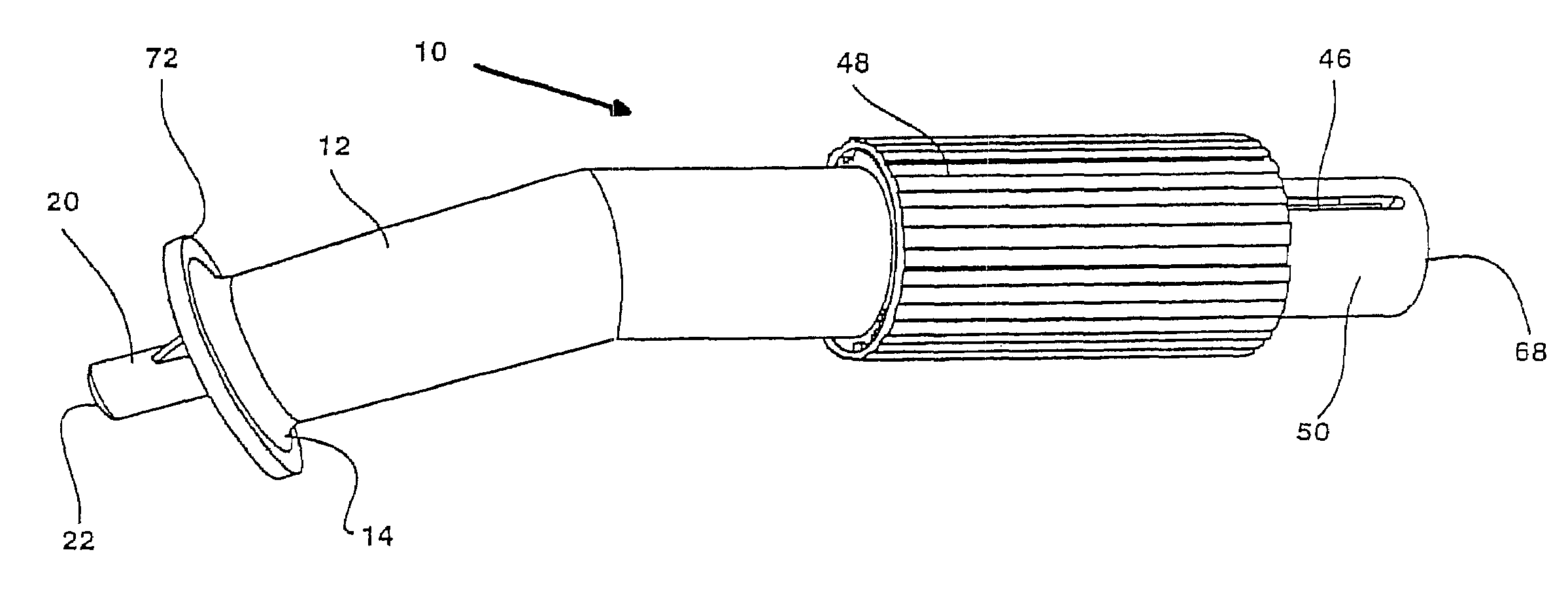

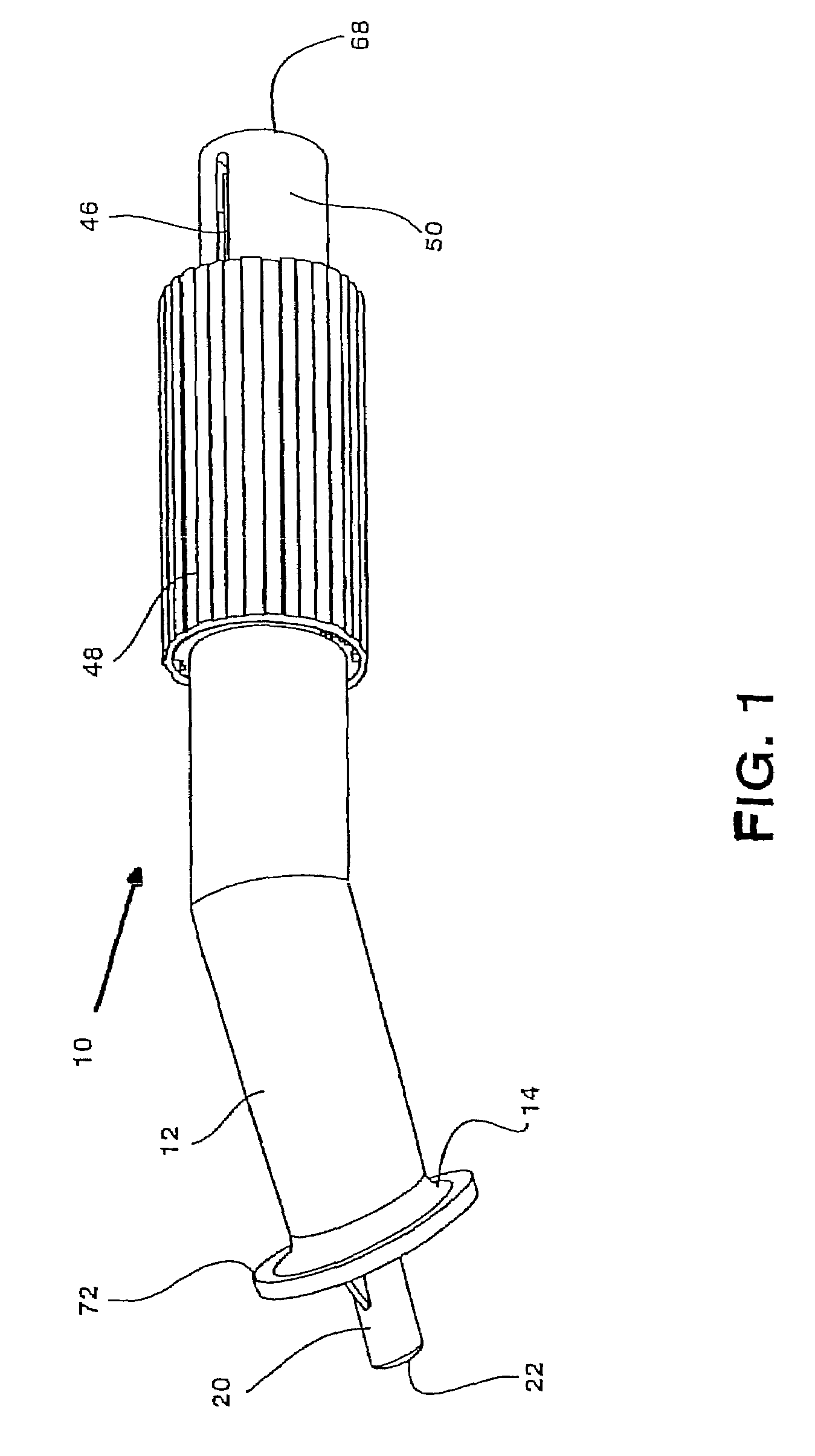

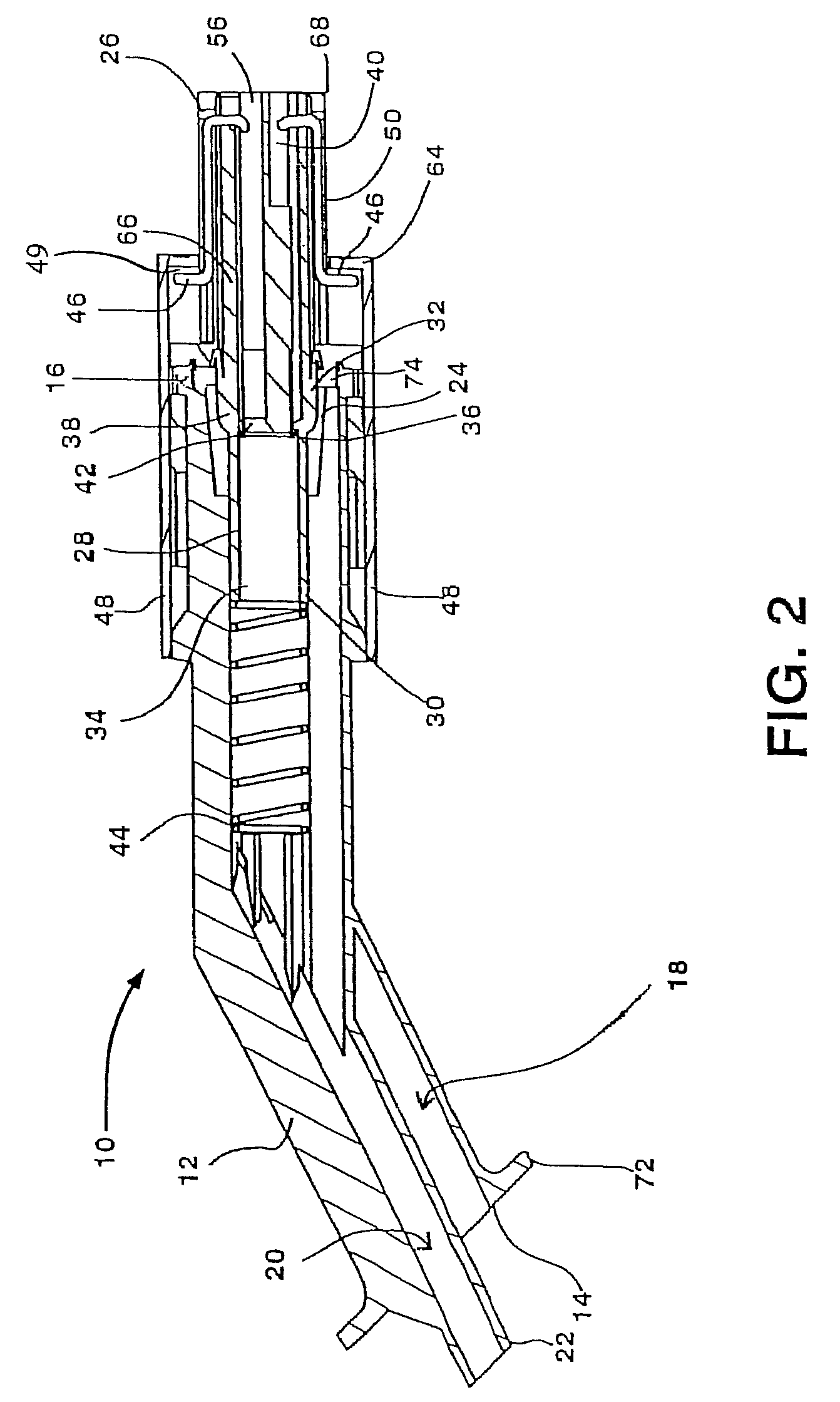

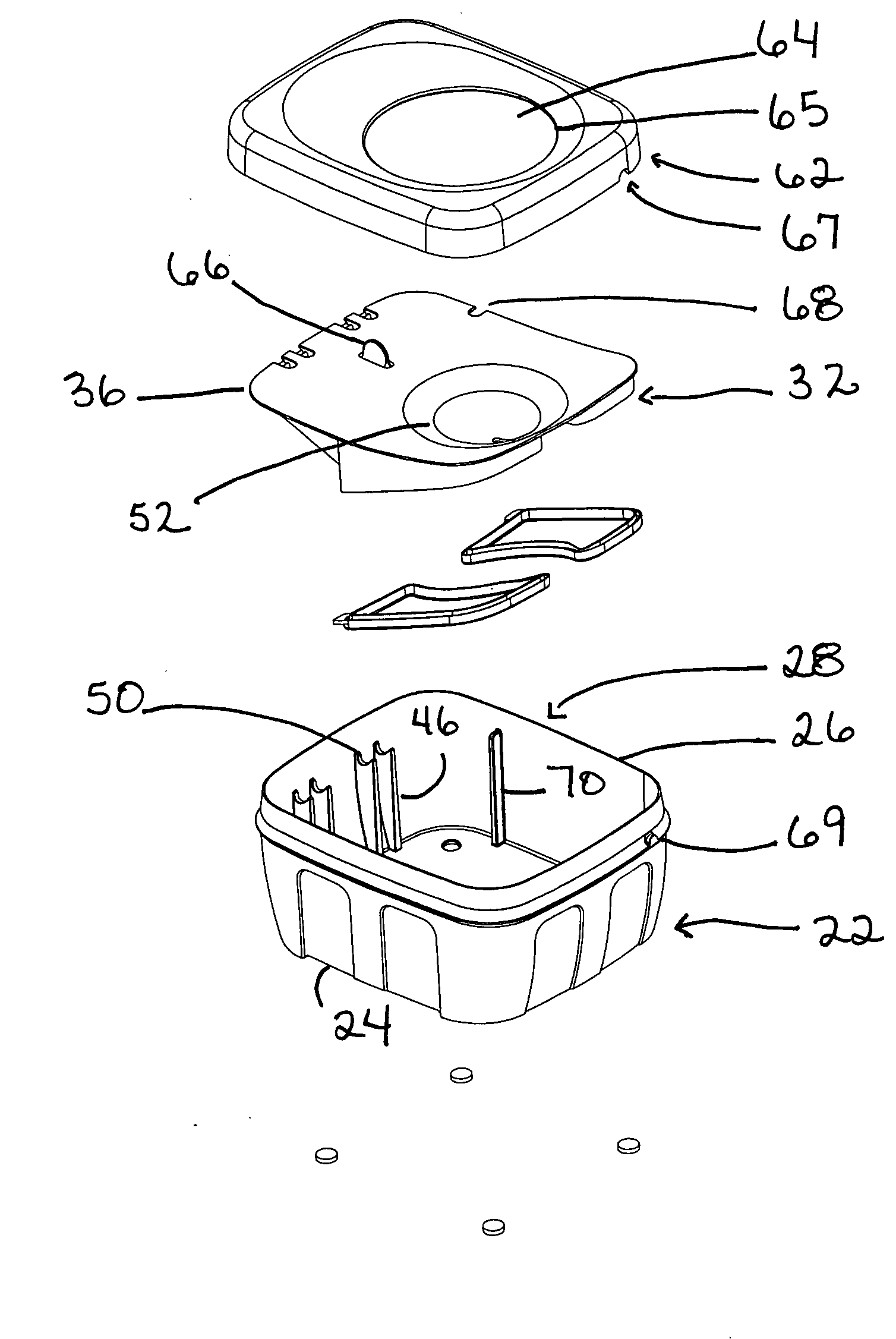

Closeable self-venting spout

InactiveUS7621304B2Avoid insufficient lengthSufficient shapeLiquid transferring devicesSolid materialEngineeringGuide tube

A non-spilling, detachable pouring spout is configured to transfer liquid from a non-vented filling container to a receiving container. The spout has a spout body defining a first hollow passageway extending from an open first end to an open second end, wherein this open passageway having a generally tubular hollow inner conduit positioned within the first hollow passageway and defining a second hollow passageway. An intermediate sleeve is received in the spout and seals against portions of the spout body and the inner conduit so as to variously control the flow of materials out of the spout body, preferably the flow of liquid out of the spout and air into the spout as a venting system. The movement of said sleeve may be controlled by movement of an external sheath and may include child-resistant features. The preferred spout may achieve smooth air venting and liquid flow, and minimizes transverse / sideways flow and openings that tend to cause splash and leaks. The preferred spout does not use any O-ring members, which are prone to failure when used with gasoline, but instead uses a slidable sleeve with inner and outer seal surfaces provided by a flared or bell-shaped seal member.

Owner:NITEC NIELSEN IDAHO TOOL & ENG

Liquid container for animals

InactiveUS20090266302A1Reduce spillsReduce splashAnimal watering devicesSecuring devicesEngineeringMechanical engineering

Owner:VAN EESSEL CHARLES

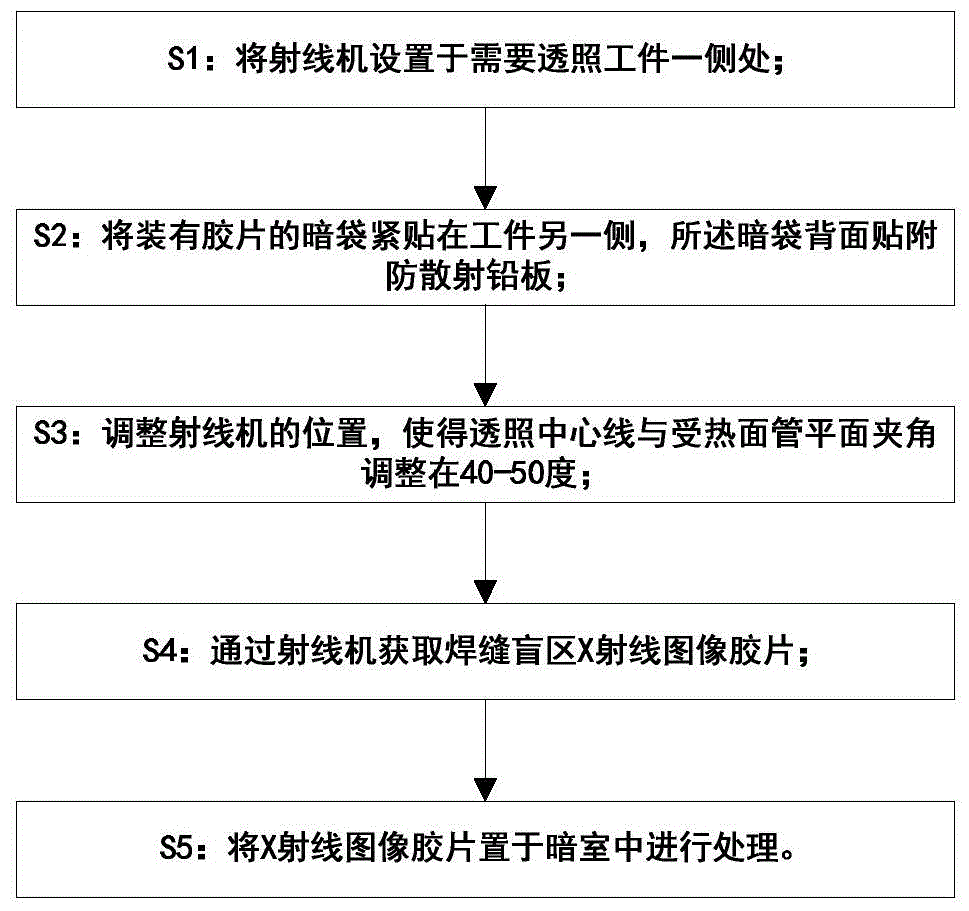

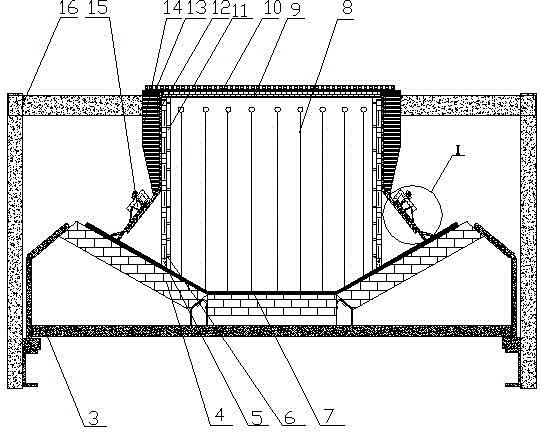

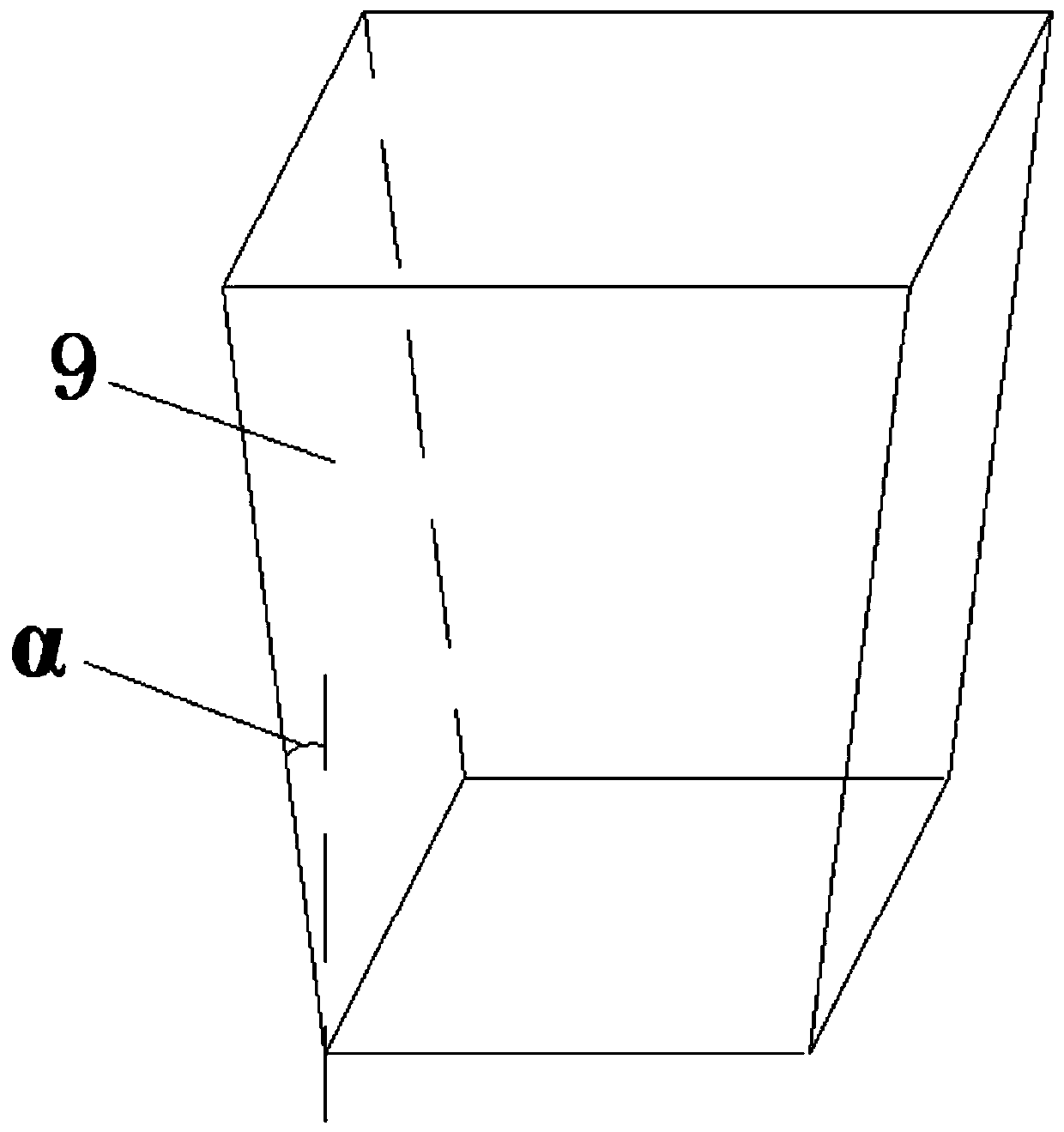

Power station boiler membrane panel welding joint blind area X ray detection method

InactiveCN104698015AReduce spillsGuaranteed operating levelMaterial analysis by transmitting radiationX-rayEngineering

The invention discloses a power station boiler membrane panel welding joint blind area X ray detection method. The method comprises the following steps: firstly, placing a ray machine on one side of a to-be-radiated workpiece; adhering a camera bag containing films to the other side of the workpiece, and adhering the back of the camera bag to an anti-scatter lead plate; then, regulating the position of the X machine so as to regulate an included angle between a radiating centerline and the plane of a heated surface tube to 40-50 degrees; acquiring a welding joint blind area X ray image film by virtue of the X machine; and finally, processing the X ray image film in a darkroom. According to the detection method disclosed by the invention, the XXQ-2505 ray machine is adopted to detect power station boiler membrane panel welding joint blind area X ray and an appropriate radiating angle is selected by virtue of inclined radiation so as to achieve a purpose of detecting out defects; when radiating the membrane panel welding joint, an appropriate angle is kept between the centerline of a ray bundle and the drainage plane of the heated surface tube, so that the definition, sensitivity and welding joint opening distance of a blind area image on a photographic plate can achieve standard requirements, and assessment on defects is not affected.

Owner:CHONGQING QINENG ELECTRICITY & ALUMINUM

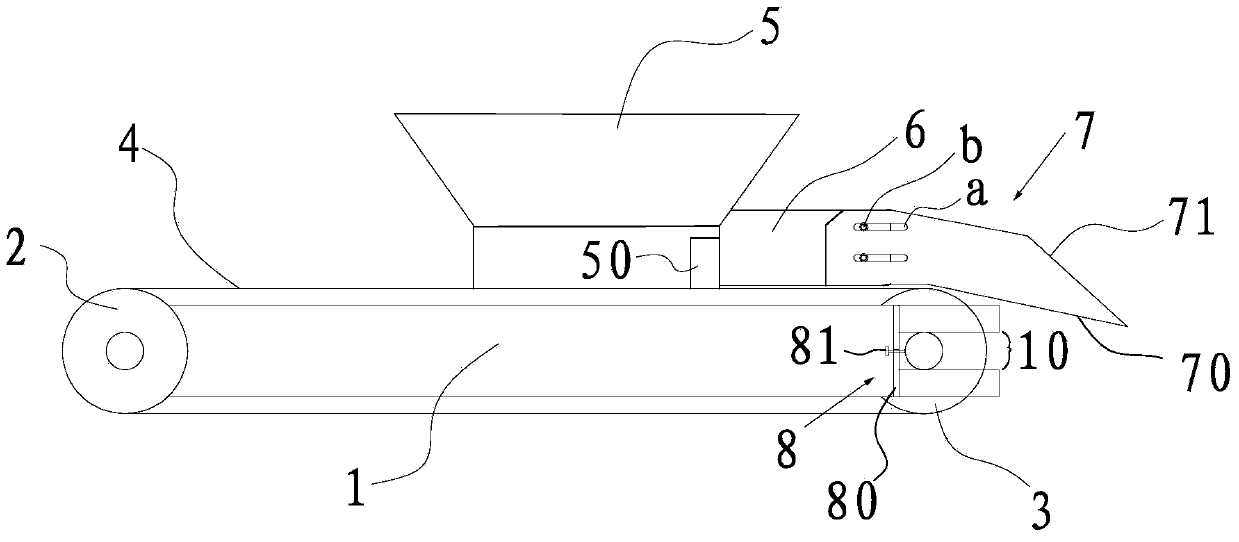

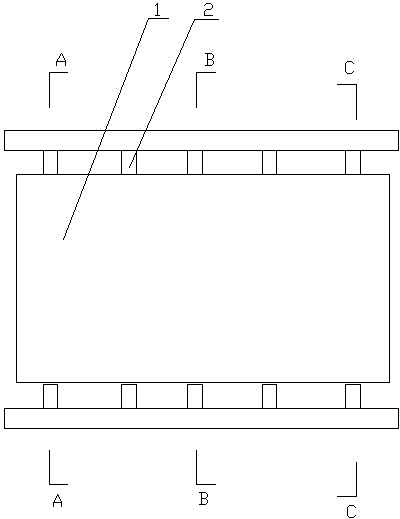

Material conveying device

ActiveCN103420127AImprove concentrationReduces the tendency to spill from both sides of the conveyor beltConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses a material conveying device which comprises a first roll, a second roll, a conveyer belt, a driving mechanism used for driving the first roll and the second roll to rotate, a hopper, material baffles and a mechanism for regulating the distance between the first roll and the second roll, wherein the first roll and the second roll are respectively arranged at two ends of a rack and can rotate around respective axes; the conveyer belt is sleeved on the first roll and the second roll; the hopper is positioned above the conveying belt between the first roll and the second roll; the material baffles are arranged along the conveying direction of the conveying belt and positioned on two sides of the hopper; the hopper is arranged on the rack, and the direction of the discharge port of the hopper is consistent with the conveying direct of the conveying belt; the material baffles are connected to two sides of the discharge port, and one end parts of the material baffles on two sides are respectively connected to the hopper. According to the material conveying device, the hopper and the material baffles are arranged, so that materials can be gathered conveniently, a phenomenon that the materials fall off from two sides of the conveying belt easily can be reduced, the material conveying efficiency is improved; meanwhile, the regulating mechanism is adopted for regulating the tightness of the conveying belt; in addition, the conveying device is simple in structure, convenient to implement and lower in cost.

Owner:ZHANGJIAGANG XIAFEI PLASTIC

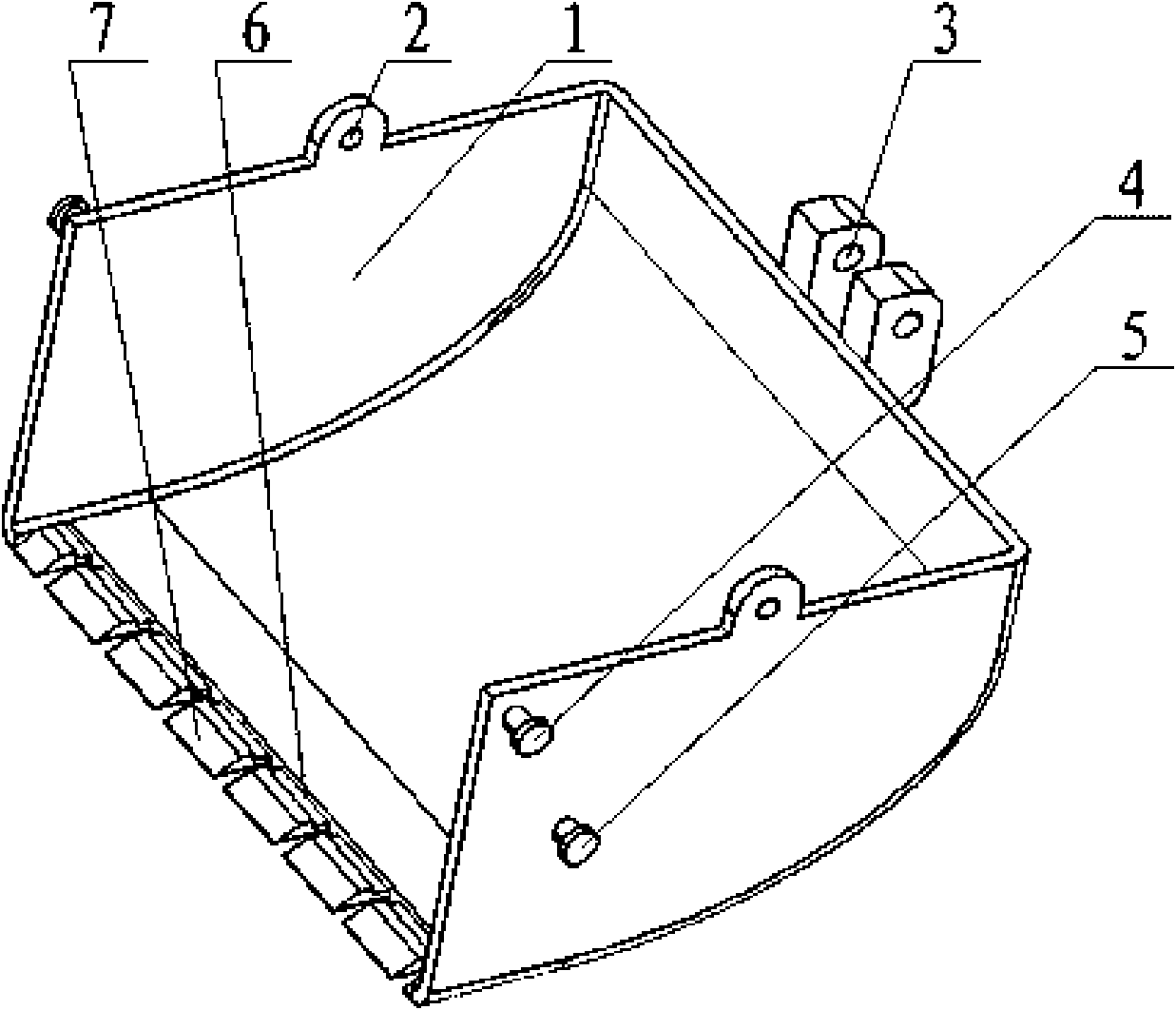

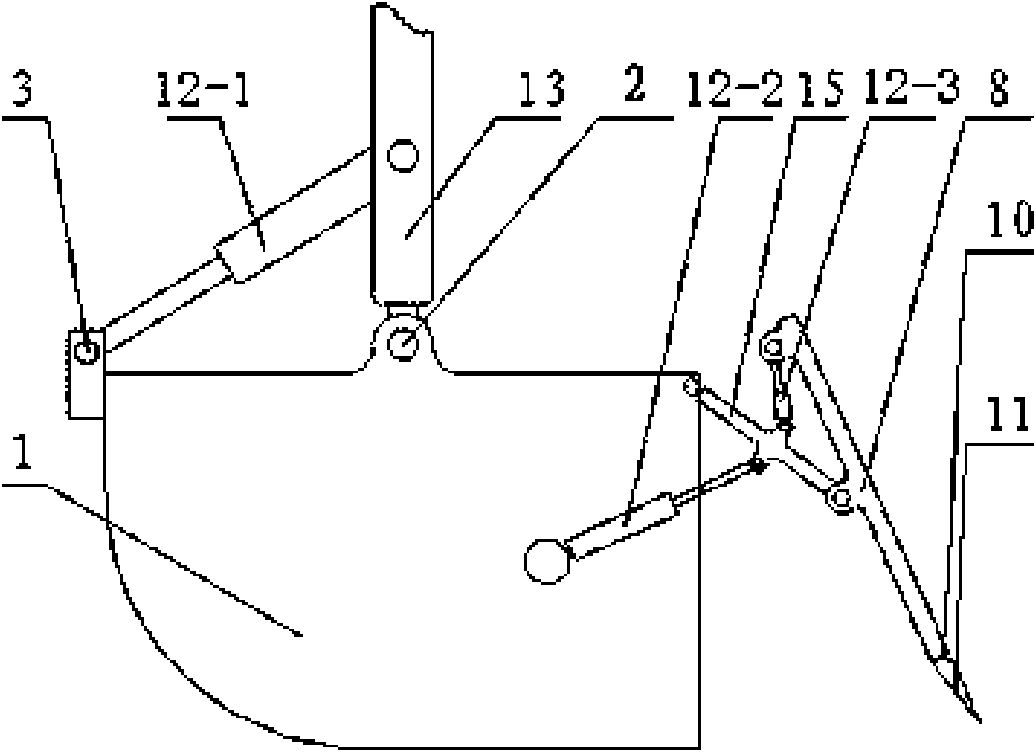

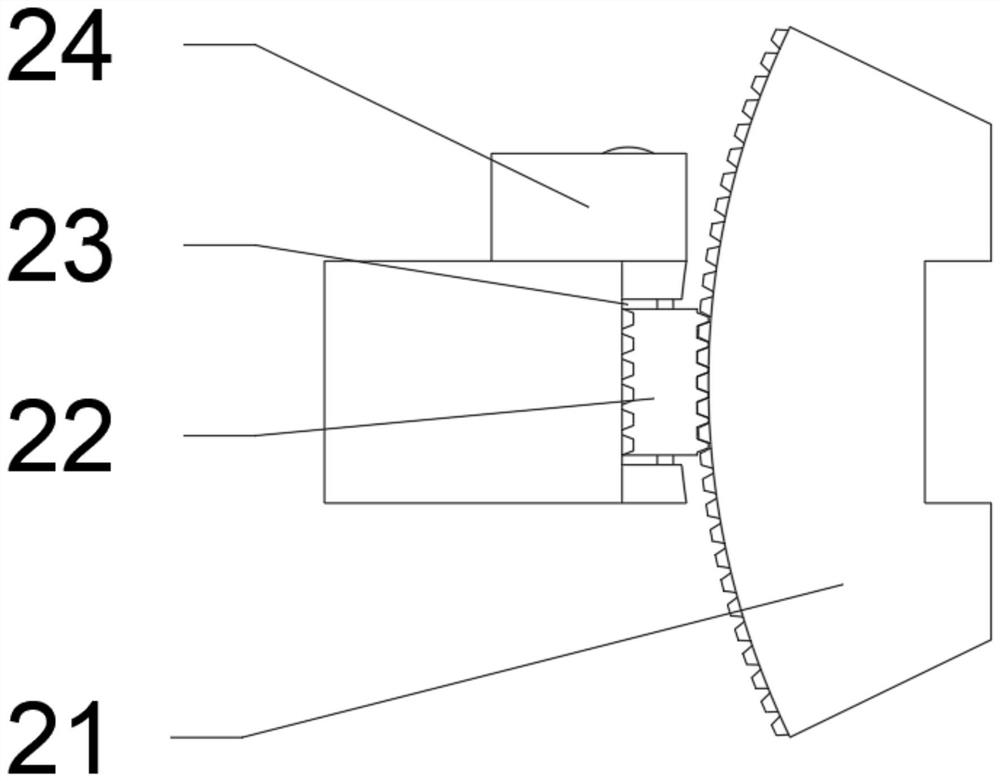

Multifunctional tipping-bucket hydraulic excavator bucket

InactiveCN101649627ALarge single bucket capacityReduce spillingMechanical machines/dredgersAutomatic controlEngineering

The invention discloses a multifunctional tipping-bucket hydraulic excavator bucket, comprising a tipping bucket connected with an extension arm of an excavator by pulling back a bidirectional hydrocylinder. The multifunctional tipping-bucket hydraulic excavator bucket is characterized in that a multifunctional shovel plate is arranged in the front end of the tipping bucket; a fixed hole in the middle of the multifunctional shovel plate is connected with the tipping bucket via a connecting rod; the middle of the connecting rod is connected to one end of the two bidirectional hydrocylinders respectively; and the other ends of the two bidirectional hydrocylinders are connected with the tipping bucket and the multifunctional shovel plate respectively. By adopting a structure combining the tipping bucket with the multifunctional shovel plate, the invention can excavate and shove excavated objects by using the multifunctional shovel plate and has large capacity for a single bucket so as toobviously reduce the falling of excavated objects during excavation. The invention further can level the ground by using the multifunctional shovel plate by adjusting the position of each assembly, enlarge the application range of the excavator, greatly improve the work efficiency and has compact structure as well as flexible and convenient operation through fully hydraulic automatic control.

Owner:黄银飞

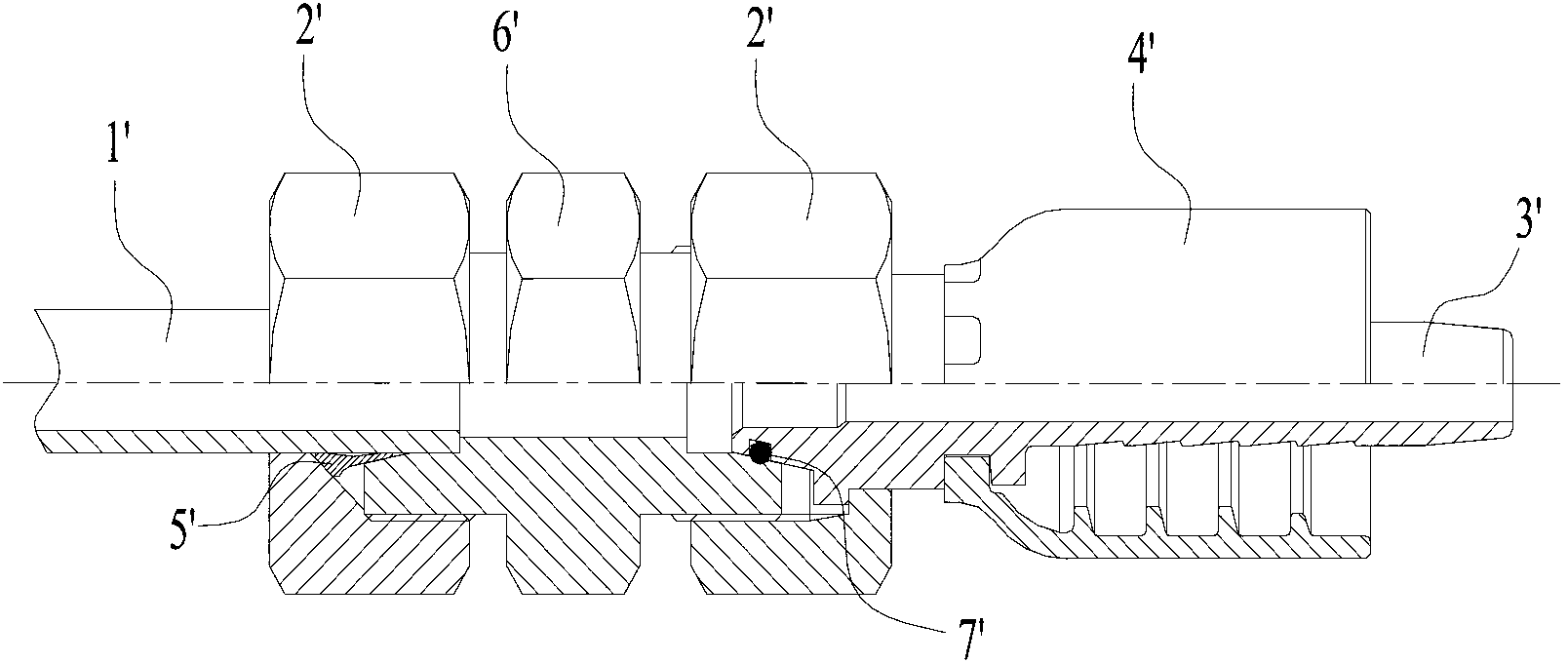

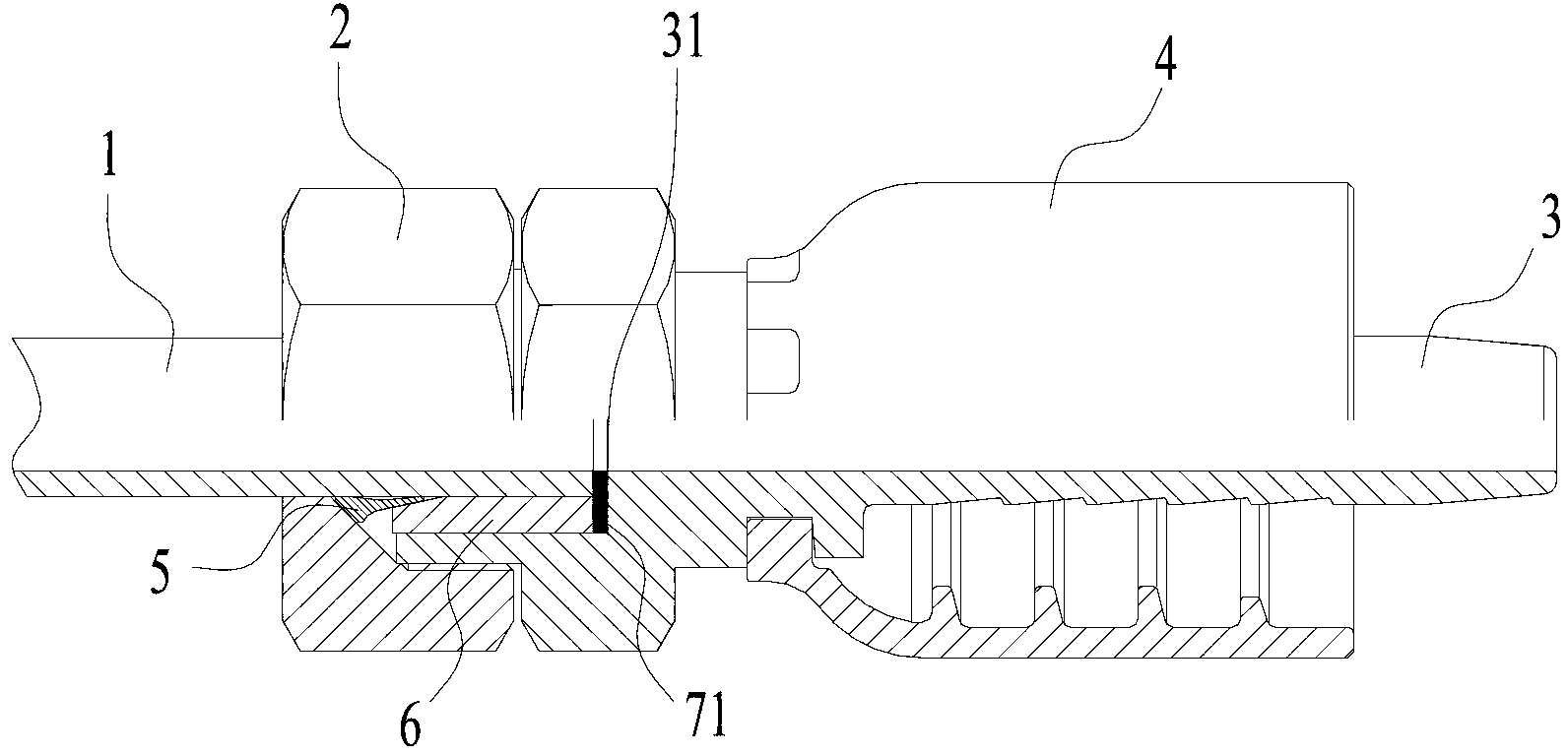

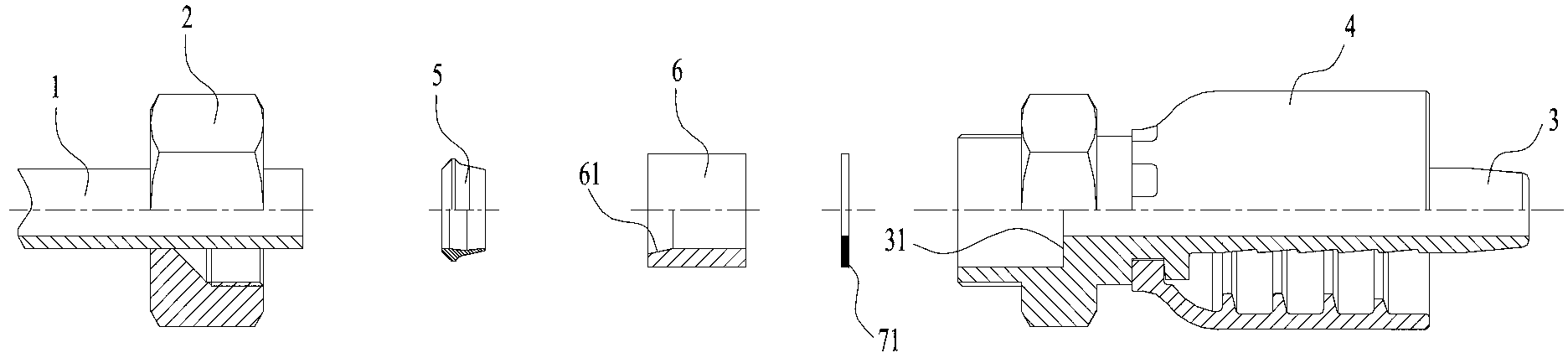

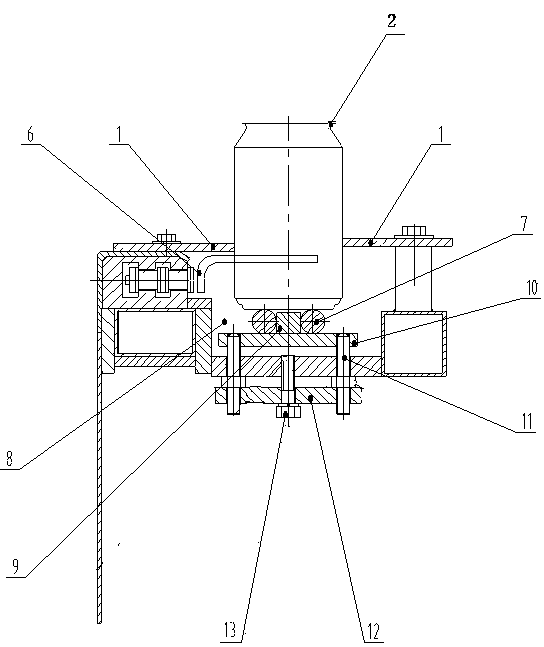

Pipeline connection structure and hydraulic pipeline

ActiveCN103016863AReduce in quantityIncrease varietyJoints with sealing surfacesHose connectionsButt jointSteel tube

The invention discloses a pipeline connection structure, which comprises a steel pipe (1), a connecting nut (2) clamped on the steel pipe (1), a rubber tube, a wrap (4), a joint core (3) and a matching sleeve (6). According to the pipeline connection structure provided by the invention, the matching sleeve which can be selected along with the diameter of a steel pipe is additionally arranged in the joint core, so that the joint core can be directly connected with steel pipes of different diameters, the traditional structure characterized in that connection can only be realized by a transition joint is changed, the amount of parts is reduced, connection points in the integral pipeline are reduced, and leakage accidents are reduced. Different types of matching sleeves are used for sheathing the steel pipes of the corresponding types, the types of the steel pipe which can be subjected to butt joint with the joint core are expanded, the types of connecting accessories between the steel pipe and the joint core are reduced, unnecessary resource waste caused by excessive accessories is avoided, complex work of selecting the accessories due to assembling is omitted, and the assembling time is saved. The invention also discloses a hydraulic pipeline applying the pipeline connection structure.

Owner:ZOOMLION HEAVY IND CO LTD

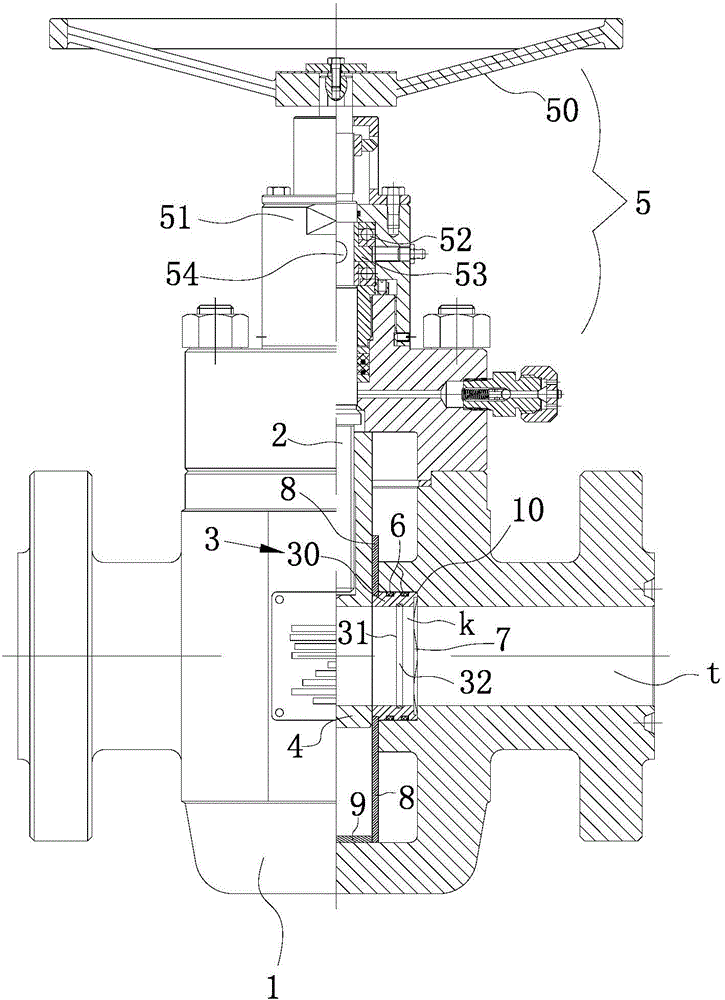

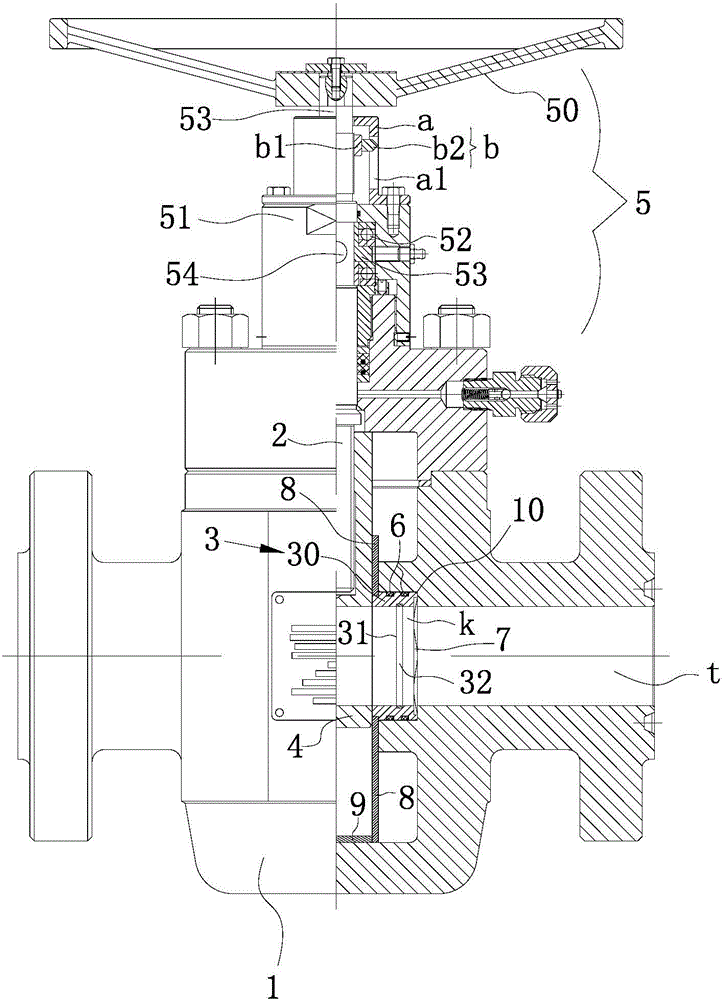

Flat gate valve

The invention relates to a flat gate valve which comprises a valve body, a valve rod, valve seats arranged at channel openings in the two sides of the interior of the valve body in a sealed manner, a valve plate located between the valve seats on the two sides and arranged on the valve rod, and a driving mechanism used for driving the valve rod to rotate around the axis of the valve rod so as to enable the valve plate to conduct the vertical lifting movement to intercept or open channels. Each valve seat comprises a seat body internally provided with a through hole communicating with the corresponding channel. A screw-nut structure is composed of the valve rod and the valve plate. Particularly, each valve seat further comprises installation grooves which are formed in the seat body and arranged in the circumferential direction of the seat body, and expansion rings arranged in the installation grooves to make the connecting position of the valve seat and the corresponding channel opening tend to be expanded. According to the flat gate valve, due to the arrangement of the expansion rings, the sealing performance between the valve seats and the valve body is high, leakage accidents are reduced, meanwhile, the structure is simple, implementation is convenient, and cost is low.

Owner:US DIAMOND OIL DRILLING SYST ENG (SHANGHAI) CO LTD

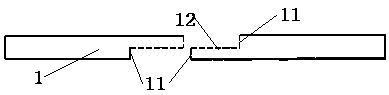

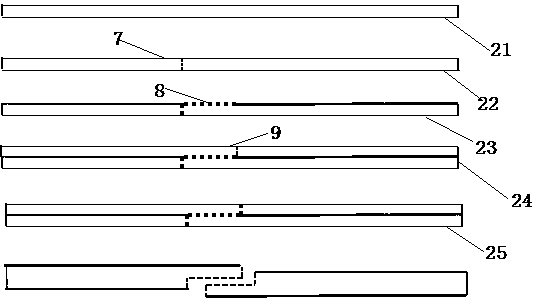

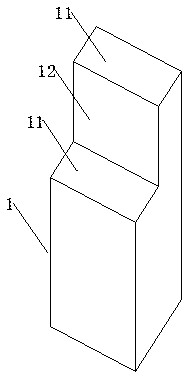

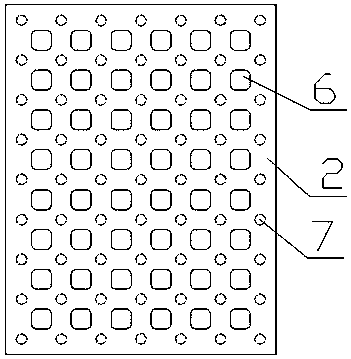

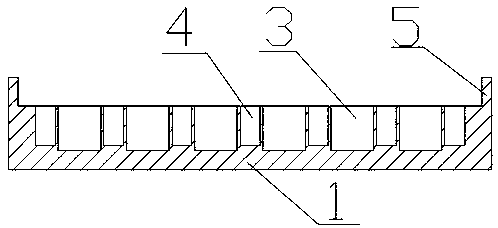

Technological cover plate of combined structure and preparation method

The invention discloses a technological cover plate of a combined structure. The technological cover plate comprises a plurality of split shaped panels in lap joint, and the split shaped panels comprise border parts provided with step surfaces and connecting parts connected with the ends, away from the step surfaces, of the border parts; the border parts and the connecting parts are molded throughone-time curing; and the split shaped panels are in lap joint through the step surfaces. According to the technological cover plate, the border parts with the step surfaces are adopted, motion coordination of internal structures of the technological cover plate is improved, the fitting degree of the technological cover plate and skin green bodies is optimized, and internal quality is guaranteed;lap joint clearances are prevented from being generated, the possibility of the material overflow problem is reduced, even though the material overflow problem occurs, only resin overflows, and overflowed materials can be treated through simple polishing; and the operation program is effectively simplified, the separated lap joint effect of the split shaped panels is improved, the possibility of material overflow at lap joint zones of the split panels is reduced, the structure is unique, the concept is novel, and the prepared technological cover plate of the combined structure has high structure motion coordination of rubber technological cover plates.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

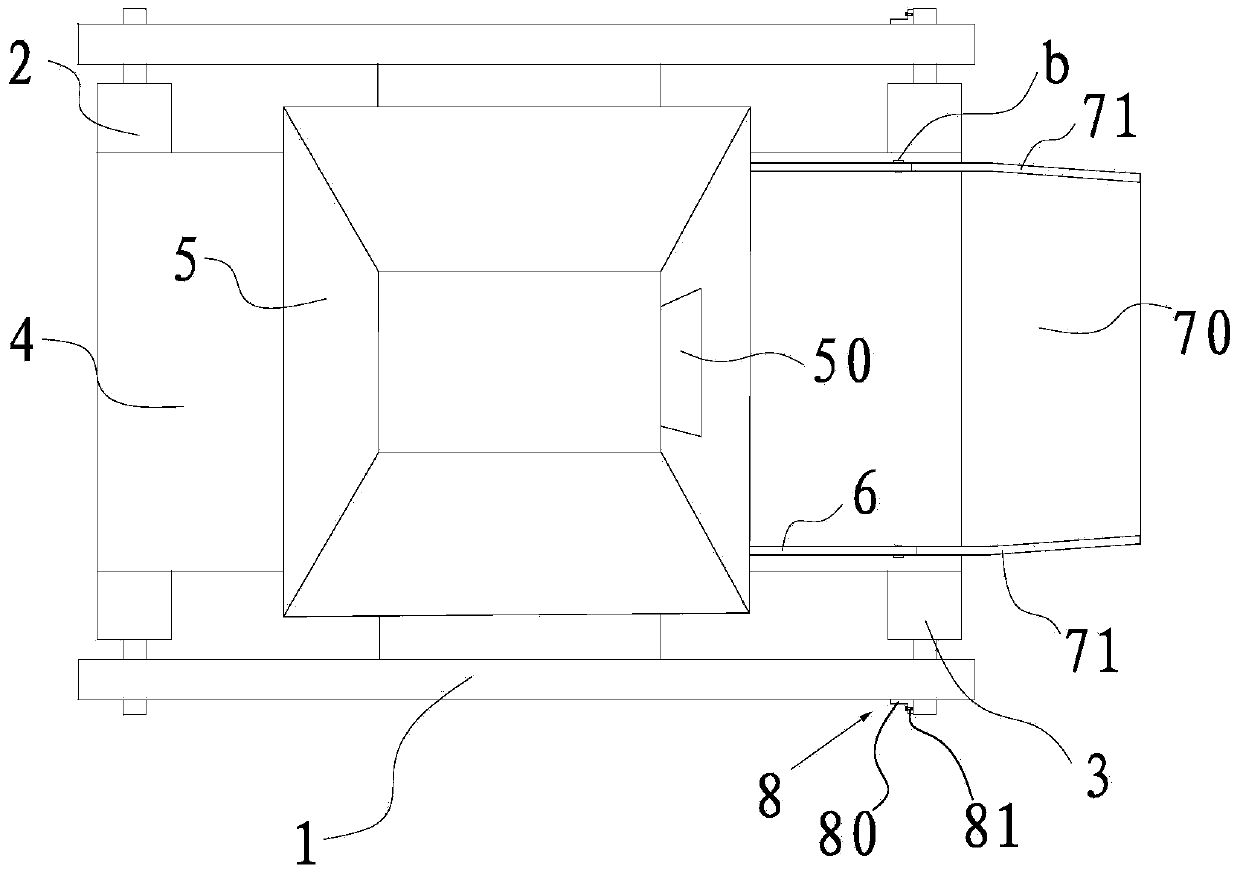

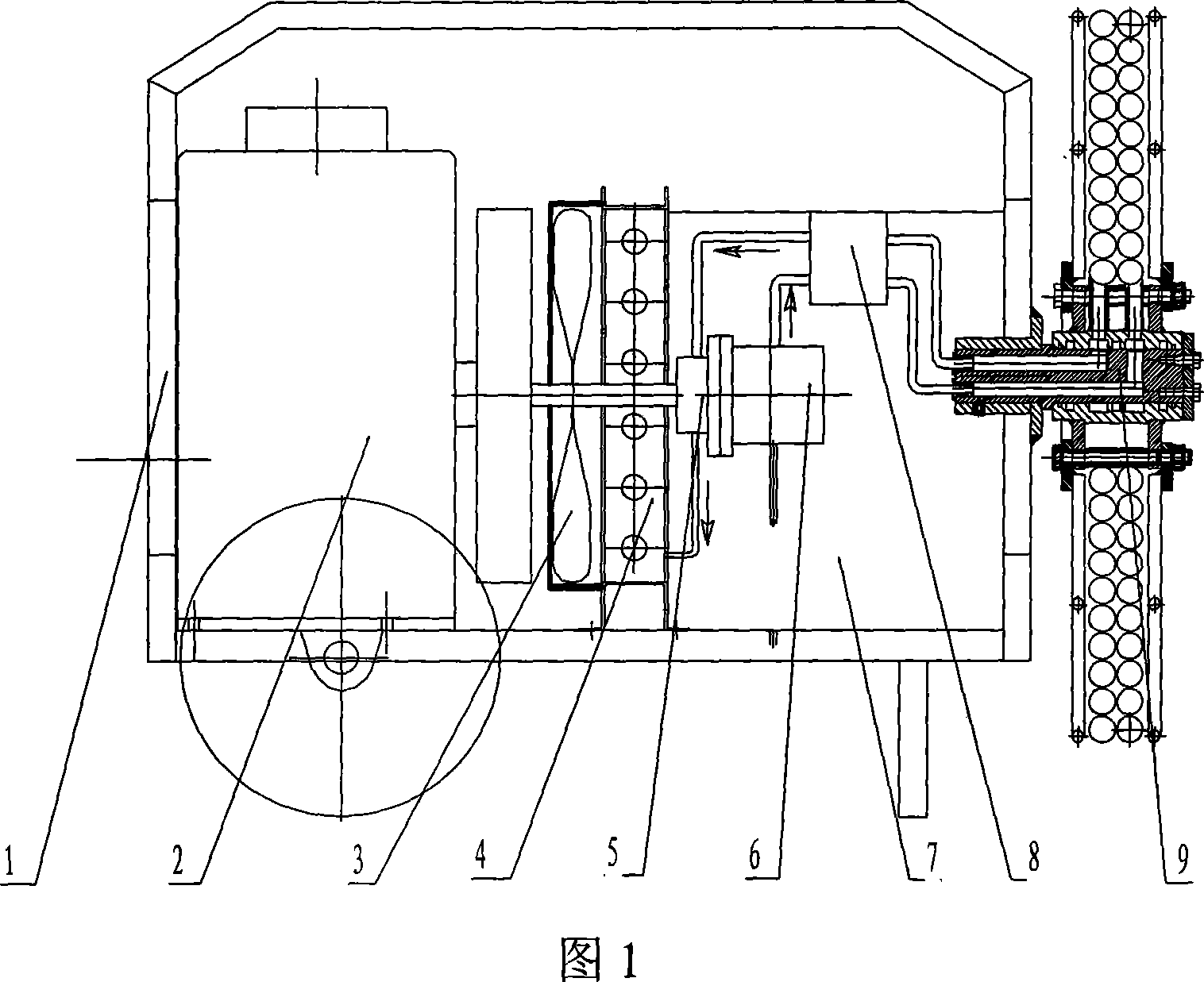

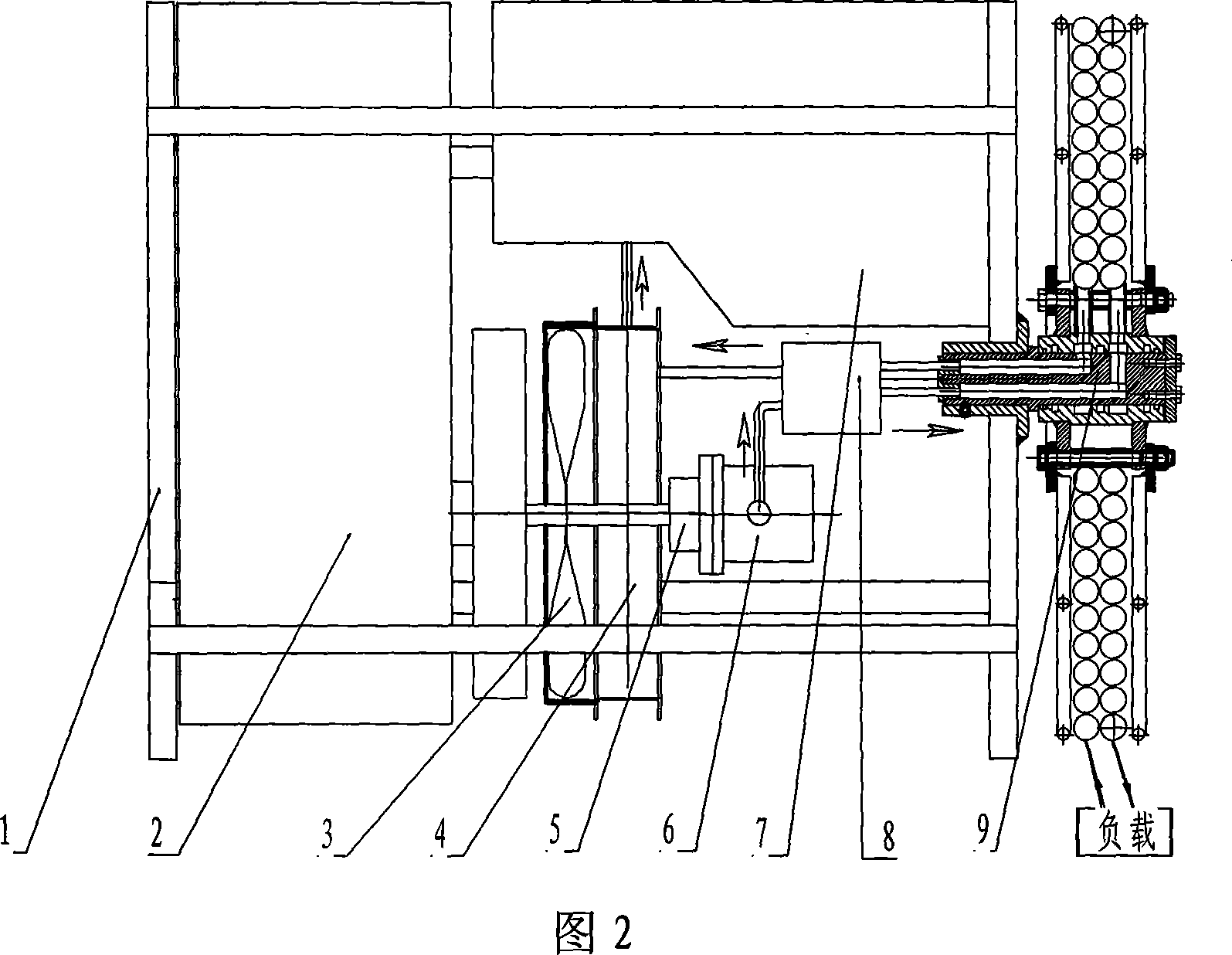

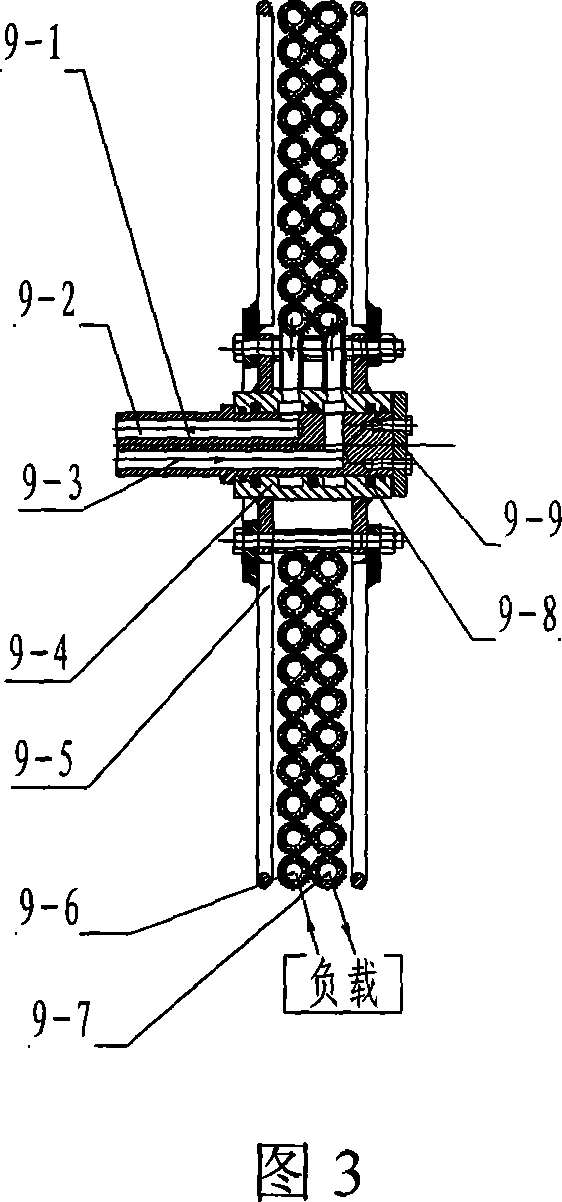

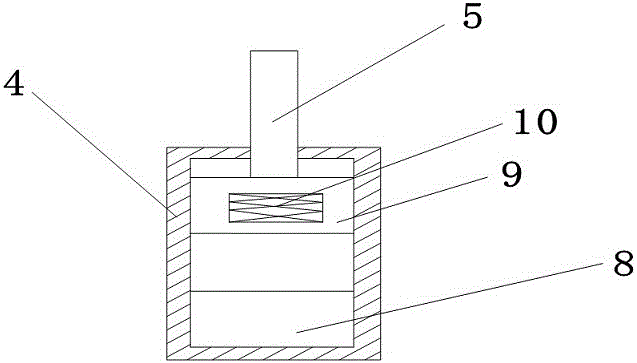

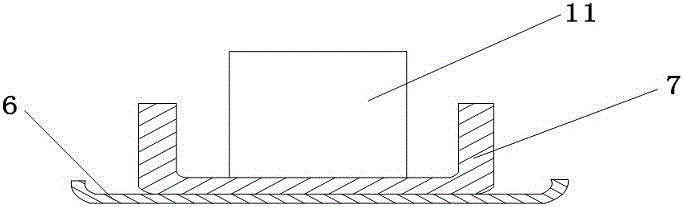

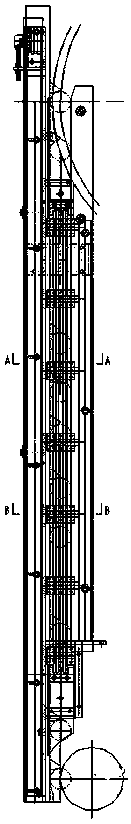

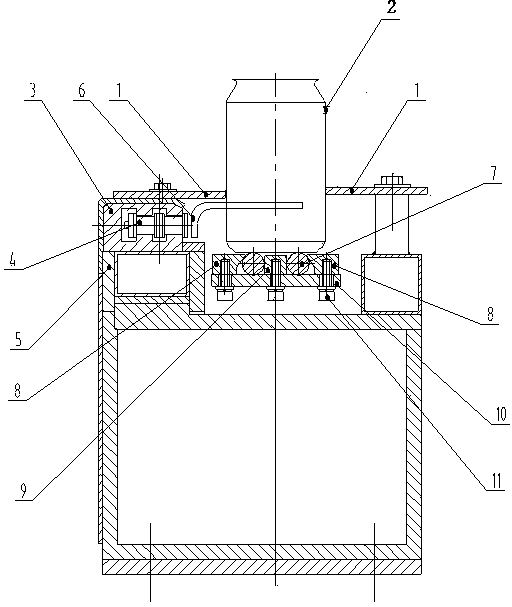

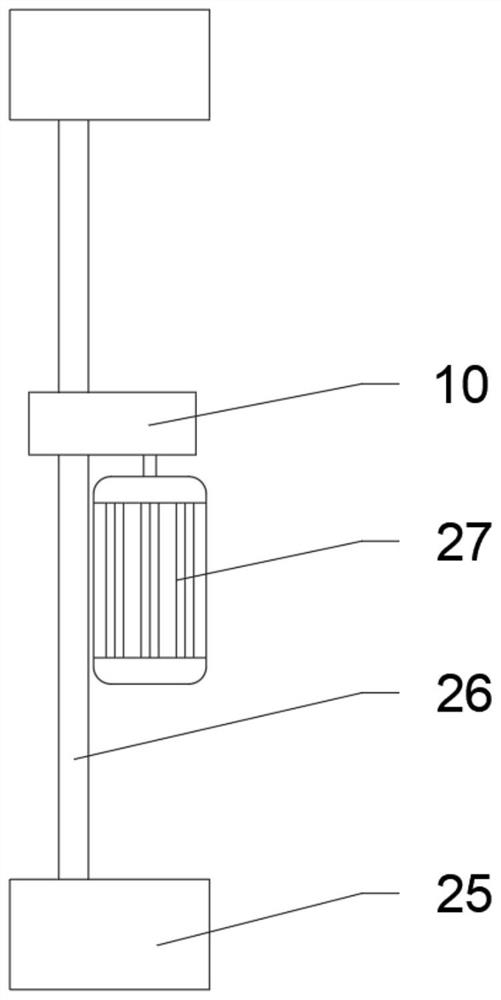

Movable type hydraulic pumping station

InactiveCN101059137AReduce spillsCompact structureAccumulator installationsFluid-pressure actuatorsVehicle frameFuel tank

A mobile hydraulic pump station belongs to hydraulic pump station. The hydraulic pump station consists of car frame, power machine, fuel tank, fan, radiator, junction box, oil pump, hydraulic pressure control valve and tube-bound device; the car frame is equipped with diesel engine, fuel tank, fan, radiator, junction box, oil pump, hydraulic pressure control valve, the fuel tank, oil pump, hydraulic pressure control valves, tube-bound device and radiator are sequentially connected through pipelines; the axle of junction box one end is connected with diesel engine and another end is connected with oil pump, the tube-bound device is installed on the car frame, and hydraulic port of tube-bound device is connected with hydraulic pressure control valve through pipelines; the tube-bound device consists of mandrel, mandrel outer sleeve and tube-bound frame, the mandrel outer sleeve is nested on the mandrel, and sealing ring is installed between the mandrel and the mandrel outer sleeve; the tube-bound frame is installed on the outer end of tube-bound device. The hydraulic pump station has compact structure and volume, only is the hydraulic rubber hose with work device pulled out from tube-bound device when works, inactive and repetitive operation is not needed, it saves labor and time, the use is easy, it ensures the cleanliness of hydraulic oil effectively and saves use cost significantly .

Owner:侯学礼

Preparation method of sodium butyrate

InactiveCN102070435AConvenient sourceLow priceCarboxylic acid salt preparationSide reactionButyric acid

The invention provides a preparation method of sodium butyrate, and the method comprises the following steps: dropwisely adding butyric acid into an NaOH water solution to react; and after the reaction finishes, evaporating out water in the system, and drying to obtain the sodium butyrate. By using the preparation method provided by the invention, after the reaction finishes, all the water is evaporated out, and drying is carried out so as to obtain the target product. The process route is optimally selected, and special drying equipment capable of ensuring fewer side reaction impurities and large-scale production is directly used for drying, thereby reducing the labor intensity, saving the production time and greatly increasing the yield which can be higher than 98%.

Owner:BEIJING CHALLENGE AGRI SCI & TECH CO LTD

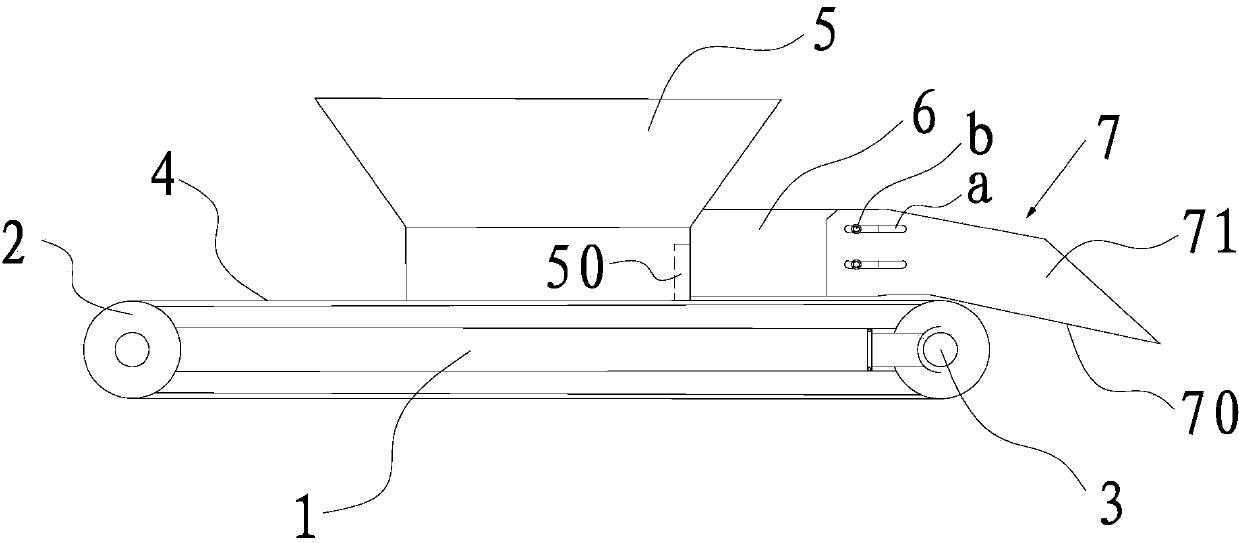

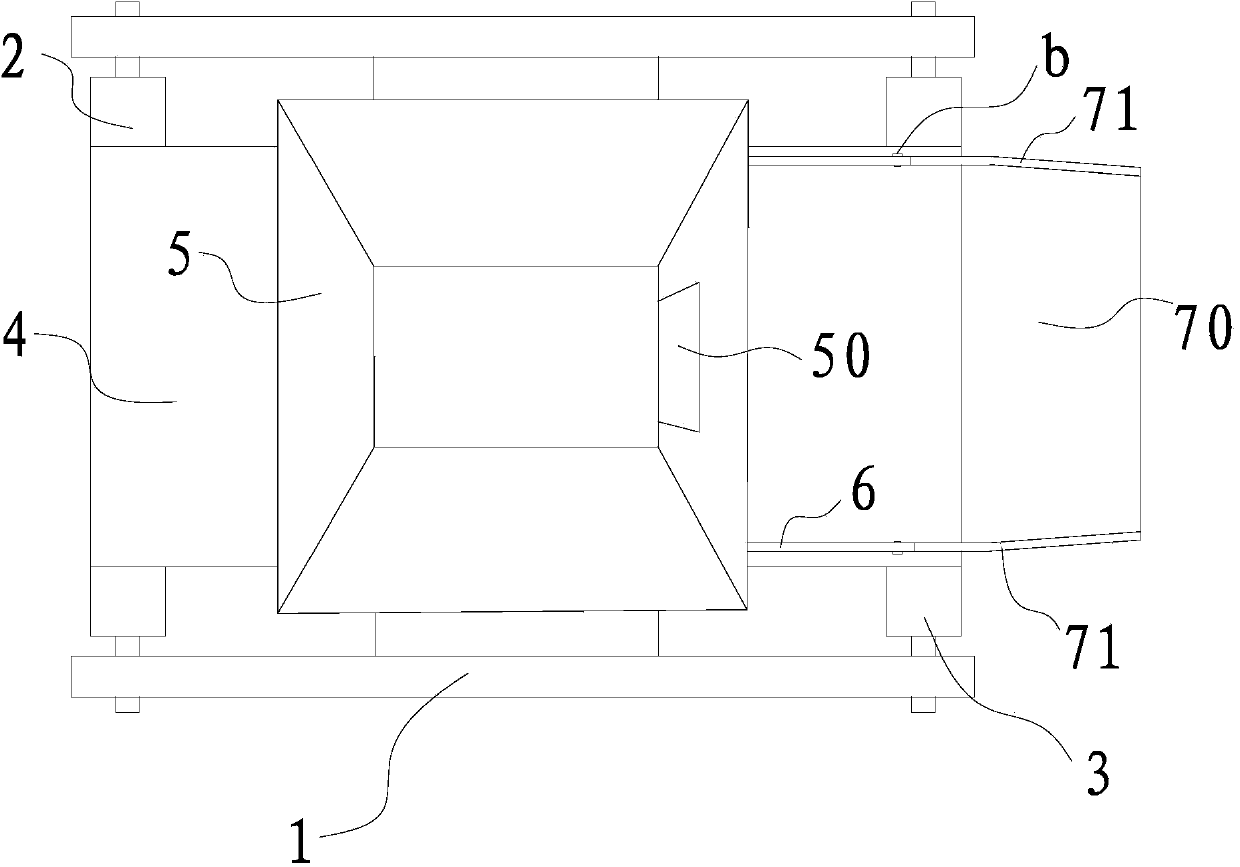

Material conveying device

ActiveCN103420129AImprove concentrationReduces the tendency to spill from both sides of the conveyor beltConveyorsConveyor partsMechanical engineeringEngineering

The invention discloses a material conveying device, which comprises a first roll shaft, a second roll shaft, a conveying belt, a driving mechanism, a hopper and material-blocking plates, wherein the first roll shaft and the second roll shaft are respectively arranged at two ends of a rack and can rotate around the self shaft axes; the conveying belt is sheathed on the first roll shaft and the second roll shaft; the driving mechanism drives the first roll shaft or the second roll shaft to rotate; the hopper is arranged above the conveying belt arranged between the first roll shaft and the second roll shaft; and the material-blocking plates are arranged at two sides of the hopper along the conveying direction of the conveying belt. The hopper is arranged on the rack, and the direction of the discharge port of the hopper and the conveying direction of the conveying belt are consistent. The material-blocking plates are connected to two sides of the discharge port, and one end parts of the material-blocking plates of the two sides are respectively connected onto the hopper. Due to the hopper and the material-blocking plates, the material concentration is convenient, the phenomenon that the materials are easily spilled from the two sides of the conveying belt is reduced, and the conveying efficiency of materials is increased. Meanwhile, the conveying device has the advantages of simple structure and convenience in implementation.

Owner:ZHANGJIAGANG XIAFEI PLASTIC

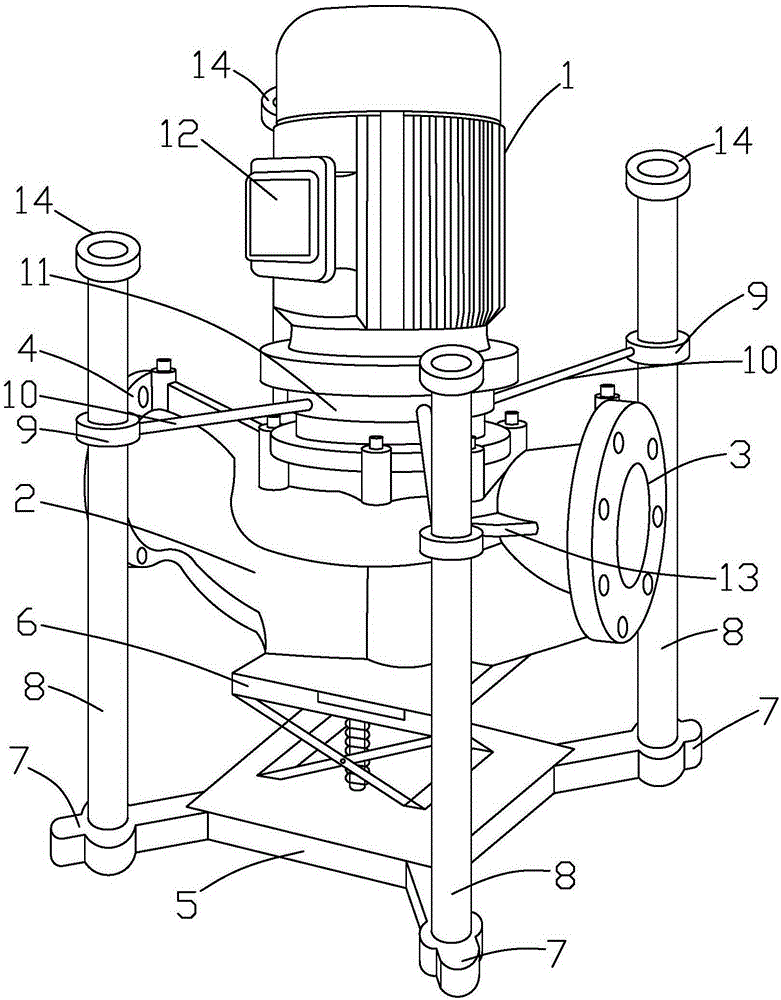

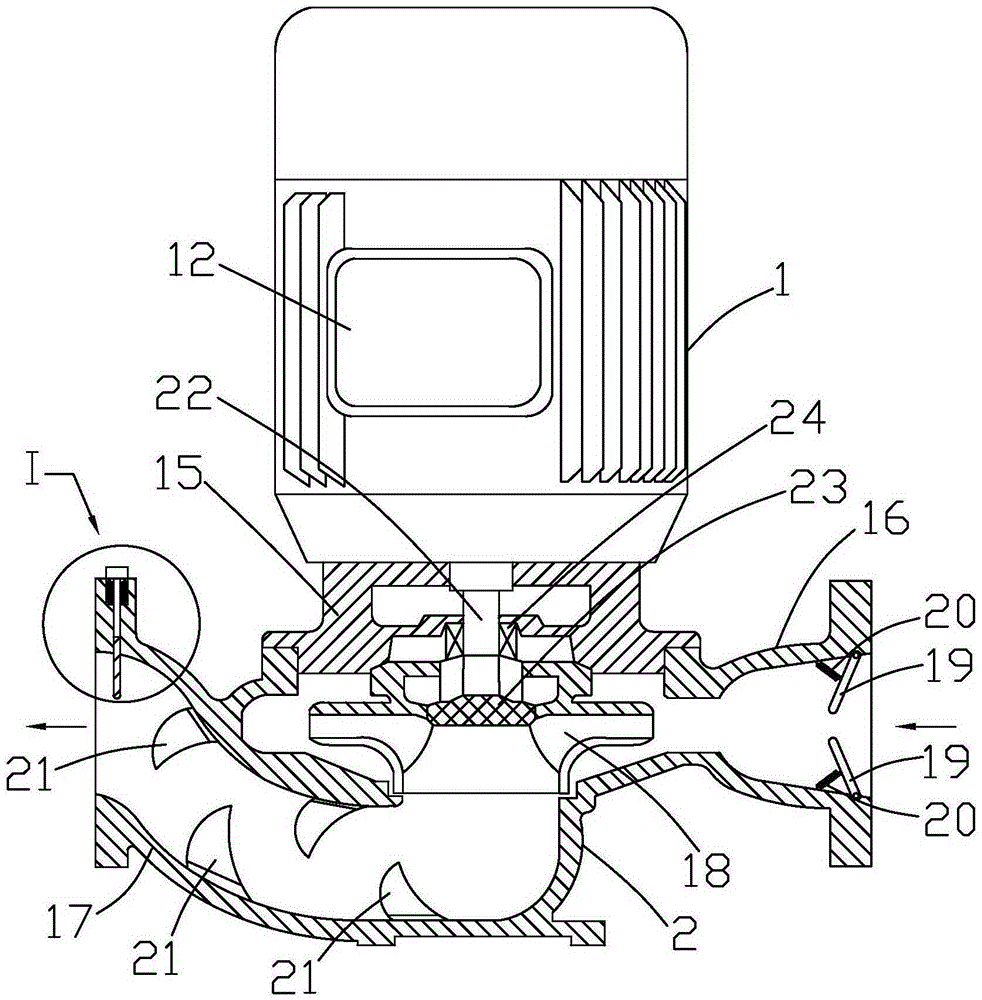

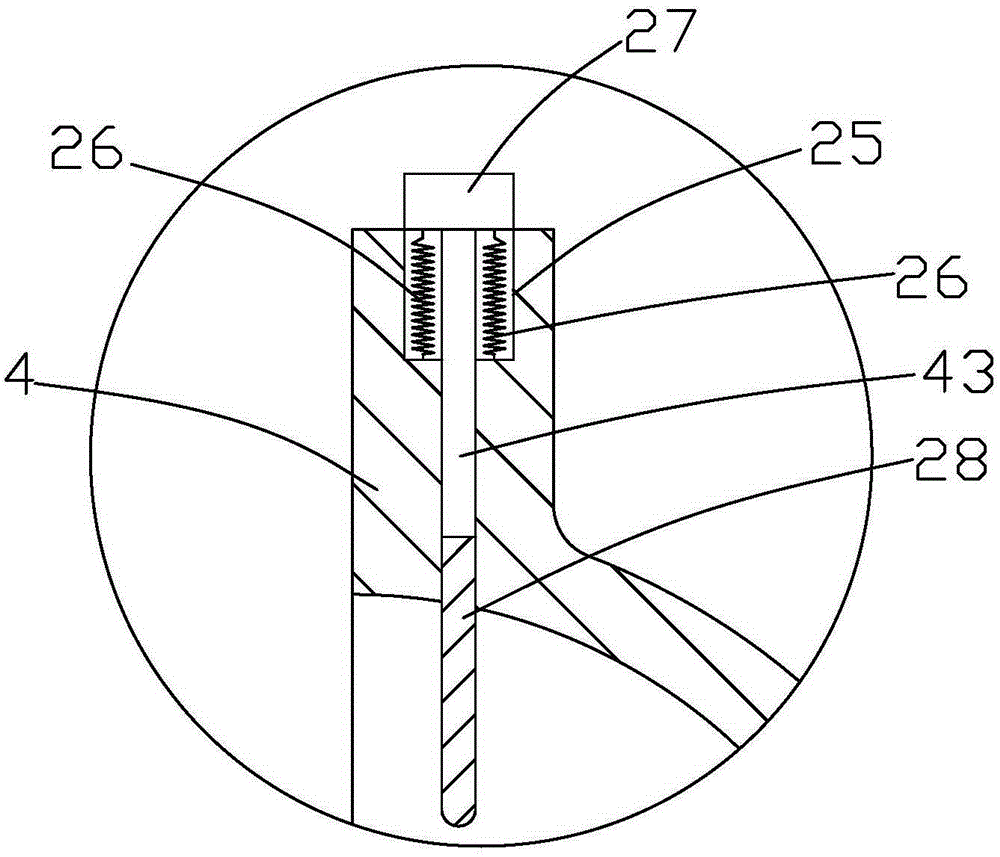

Lifting vertical vortex pipeline pump

InactiveCN105221442AMeet connectionAvoid bendingPump componentsPump installationsImpellerEngineering

The invention discloses a lifting vertical vortex pipeline pump. The lifting vertical vortex pipeline pump comprises a first motor and a pump body. The first motor and the body are fixedly connected through a bearing seat. A liquid outflow pipe and a liquid inflow pipe are arranged on the left side and the right side of the pump body respectively. A liquid outflow flange plate and a liquid inflow flange plate are arranged at the end of the liquid outflow pipe and the end of the liquid inflow pipe respectively. An impeller is arranged in the pump body. A lifting device is arranged at the bottom of the pump body. At least four supporting guide rods are symmetrically arranged on the periphery of the lifting device. The supporting guide rods are connected with the first motor through limiting mechanisms. One-way flow guide plates are rotationally connected to the inner wall of the liquid inflow pipe. Vortex generating bodies are arranged in the liquid outflow pipe. The lifting vertical vortex pipeline pump is simple in structure and high in practicality; the lifting device is arranged outside the pump body, the requirement of erection joint of pipelines of different heights can be met, the pipelines are prevented from being bent, and connecting accuracy and strength are improved; and liquid can flow in a vortex manner through the vortex generating bodies in the pump body, and pressure and speed in the liquid flowing process are increased.

Owner:绍兴泰克精工机电有限公司

Flat gate valve with valve plate position indication function

The invention relates to a flat gate valve with a valve plate position indication function. The flat gate valve comprises a valve body, a valve rod, a valve seat, a valve plate and a drive mechanism for making the valve plate rise and fall so that a passageway can be blocked or opened. The drive mechanism comprises a hand wheel, a bearing pedestal, a shaft sleeve driven by the hand wheel and arranged on the bearing pedestal through a bearing, and a pin shaft used for oppositely locking the shaft sleeve and the valve rod. The valve seat comprises a seat body, an installation groove formed in the seat body in the circumferential direction of the seat body, and a tensioning ring arranged in the installation groove and making the connection position of the valve seat and an opening of the passageway have the tensioning tendency. The flat gate valve further comprises an indicator cover and a pointer arranged on the shaft sleeve in a sleeving manner and moving up and down along with rotation of the shaft sleeve, wherein the pointer and the valve plate synchronously move. Due to the fact that the tensioning ring is arranged, the leakproofness of the valve seat and the valve body can be high, and leakage accidents are reduced. Meanwhile, because the pointer and the valve plate synchronously move, the position of the valve plate can be directly judged, and control over the flowing speed is facilitated.

Owner:US DIAMOND OIL DRILLING SYST ENG (SHANGHAI) CO LTD

Method for preparing modified phenolic resin

The invention provides a method for preparing modified phenolic resin. The method comprises the following steps: heating phenolic compounds, aldehyde compounds and water to carry out a first reaction in the presence of a catalyst to obtain a reaction mixture; mixing the reaction mixture obtained in the abovementioned step with phenol and formaldehyde to carry out a second reaction in the presence of an alkaline catalyst to obtain the modified phenolic resin, wherein the catalyst is a bivalent metal salt or a divalent metal oxide. The method provided by the invention is used for preparing the modified phenolic resin with short curing time and low warpage in two steps of segmented reactions under special reaction conditions according to a special feeding sequence.

Owner:山东圣泉新材料科技有限公司

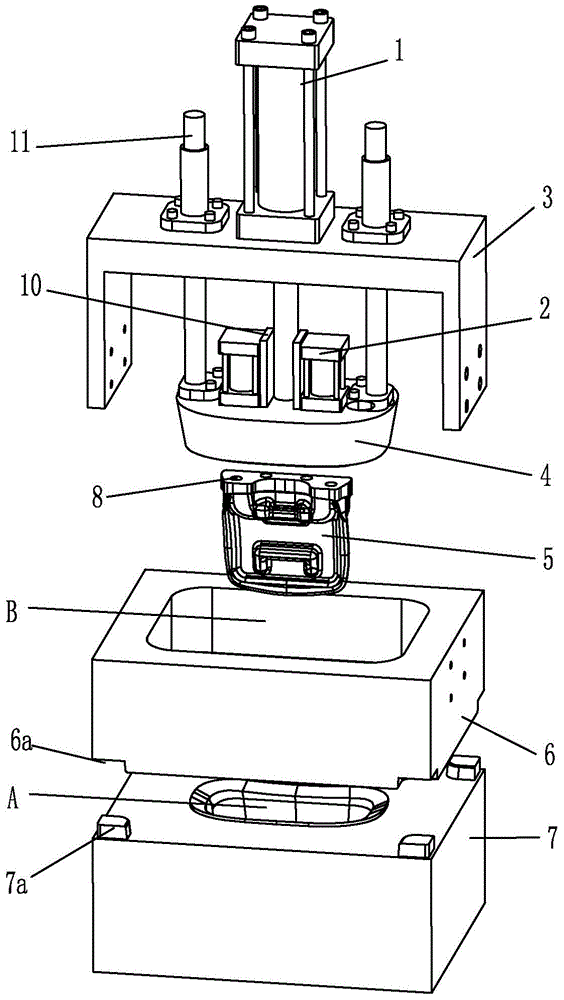

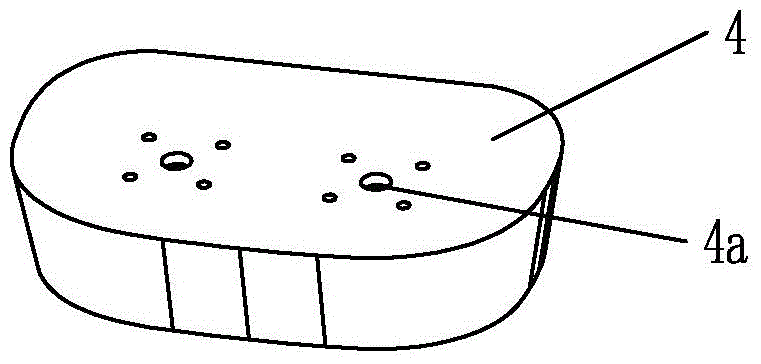

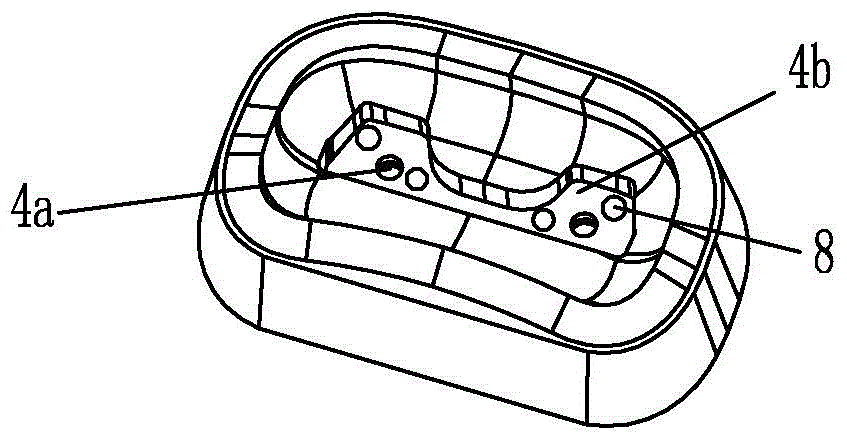

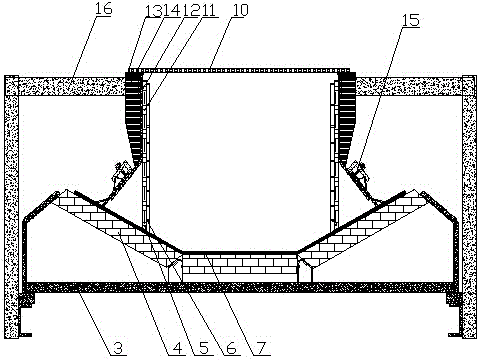

Seat headrest vertical foaming mold

The invention discloses a seat headrest vertical foaming mold. An upper mold and a lower mold are buckled together to form a headrest foaming cavity; a large cylinder is arranged at the top of a cylinder bracket, a small cylinder is arranged at the top of an upper mold insert, the left end and right end of the cylinder bracket extends downwards vertically so as to be fixedly connected with the left side wall and right side wall of the upper mold, the lower end of a piston rod of the large cylinder is connected with the upper mold insert which is internally provided with a vertically-through round hole, and the piston rod passes through the round hole; the top of a movable inserting block extends into a groove matched with the bottom of the upper mold insert, and the top of the movable inserting block and the top of the groove are fixed together by virtue of the magnetic force of a magnet; the upper mold insert drives the movable inserting block to move from top to bottom together; the upper mold insert extends into the top cavity of the upper mold, and the movable inserting block extends into the headrest foaming cavity. According to the seat headrest vertical foaming mold, material overflow and hard edges are avoided, the product stability is improved and the workload of operators is reduced.

Owner:CHONGQING ZONGSHEN HONGLI CUSHION MFG

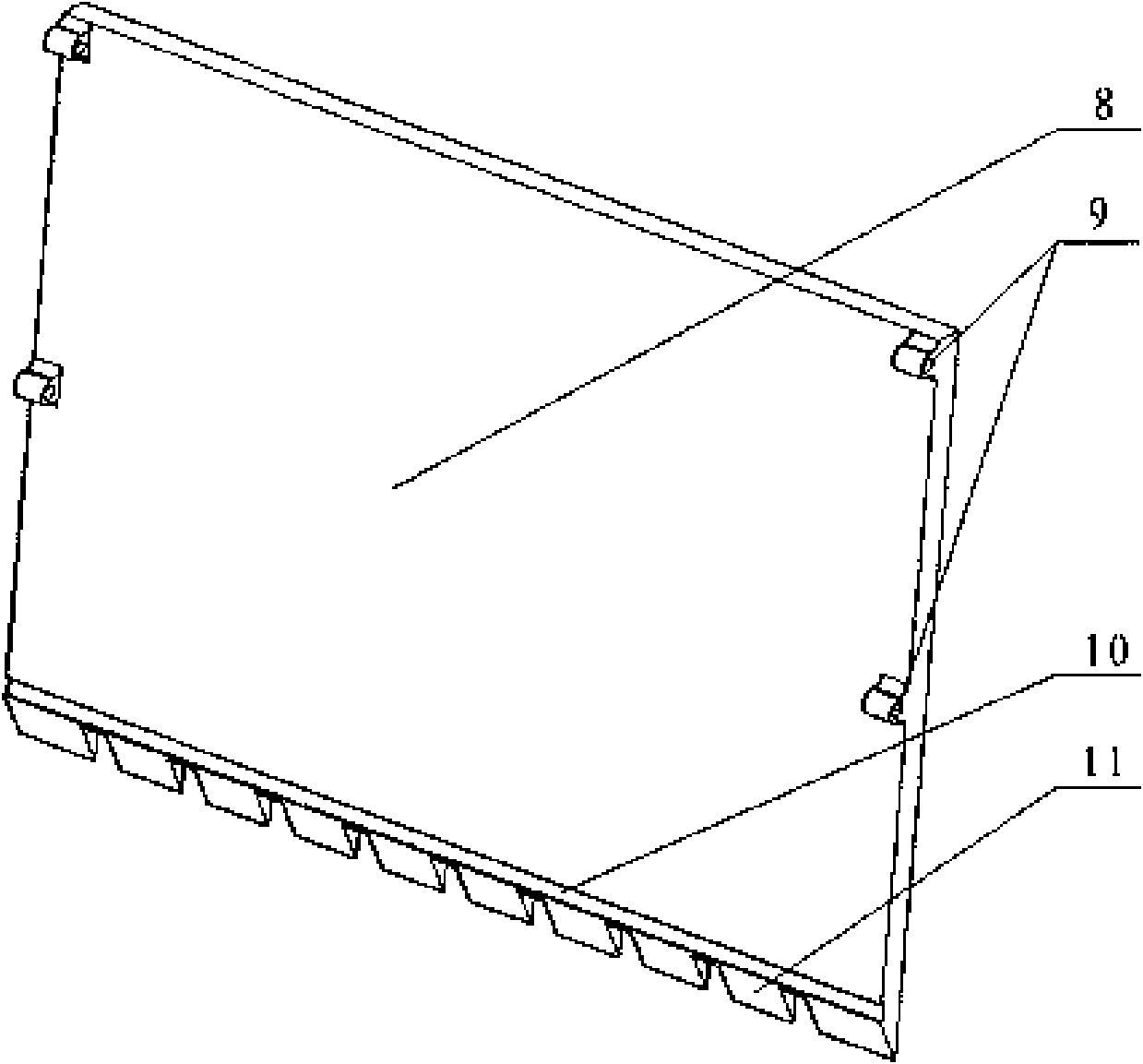

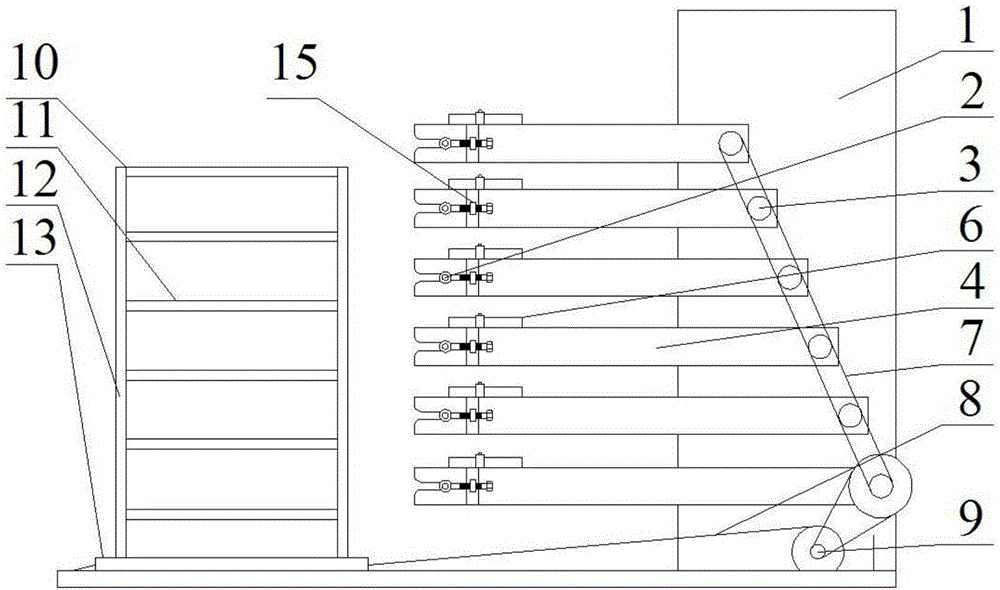

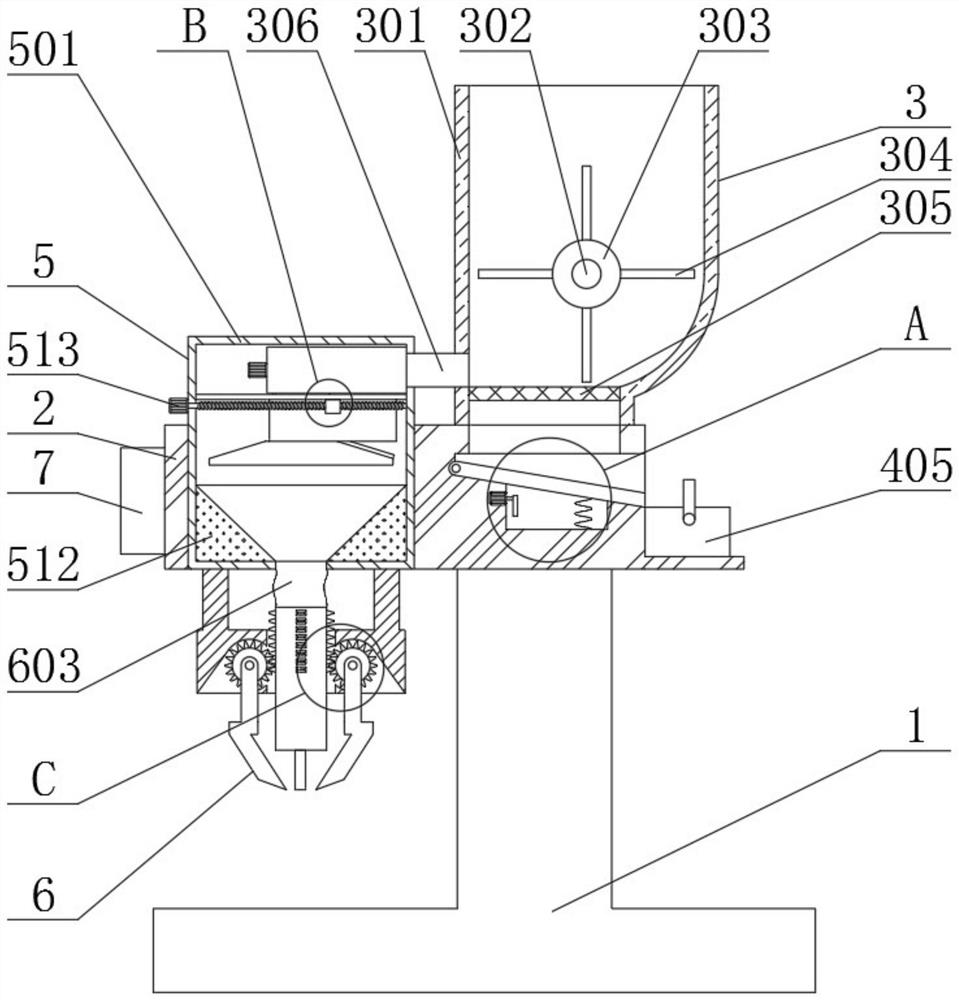

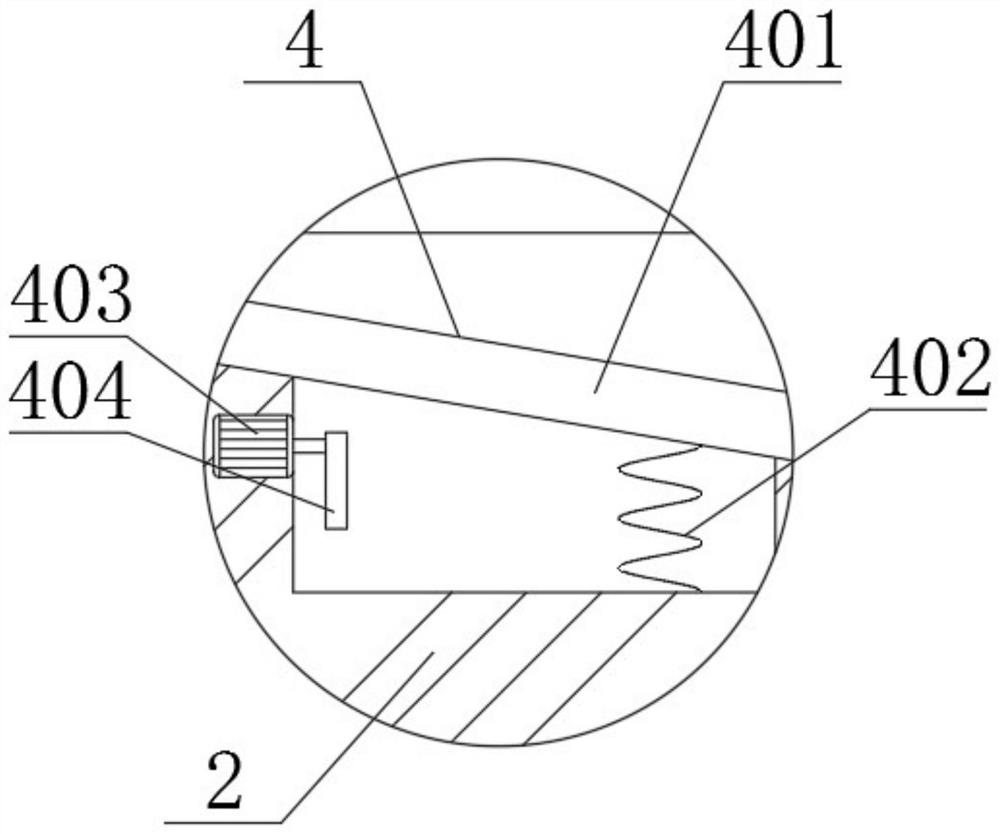

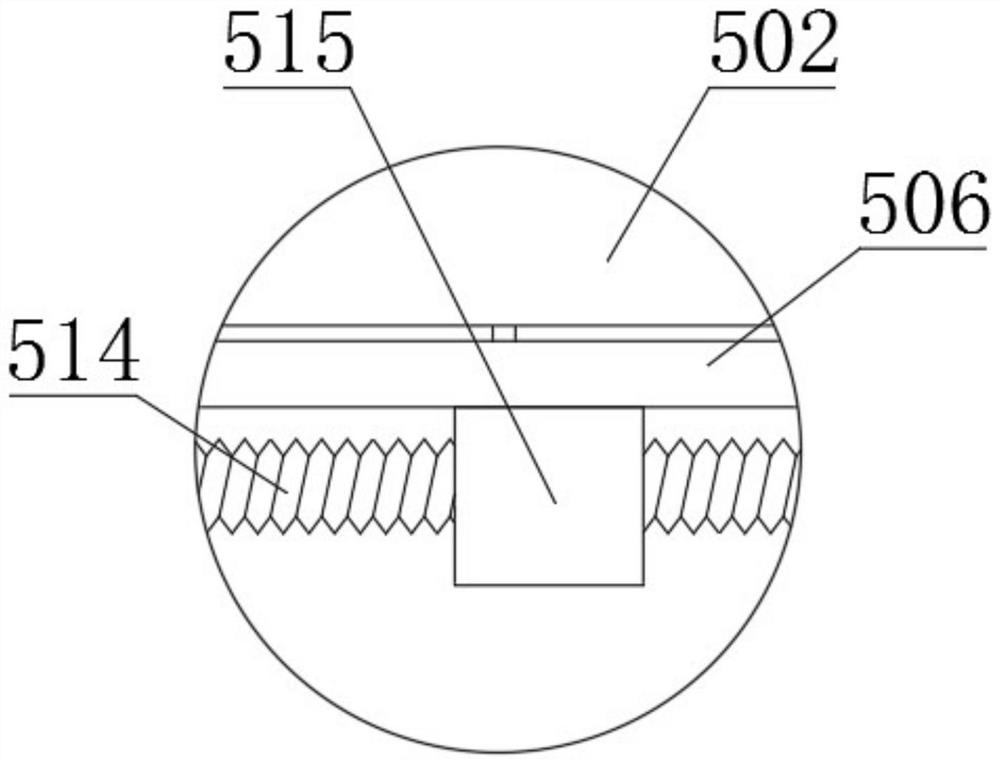

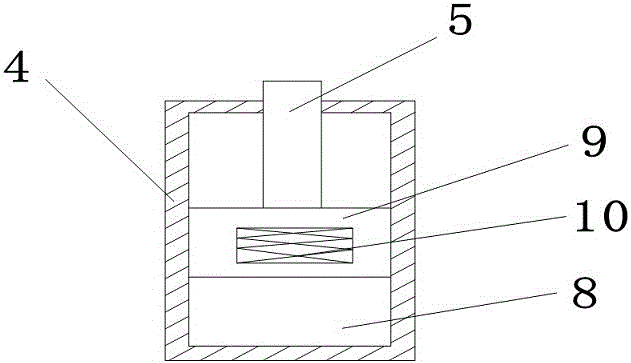

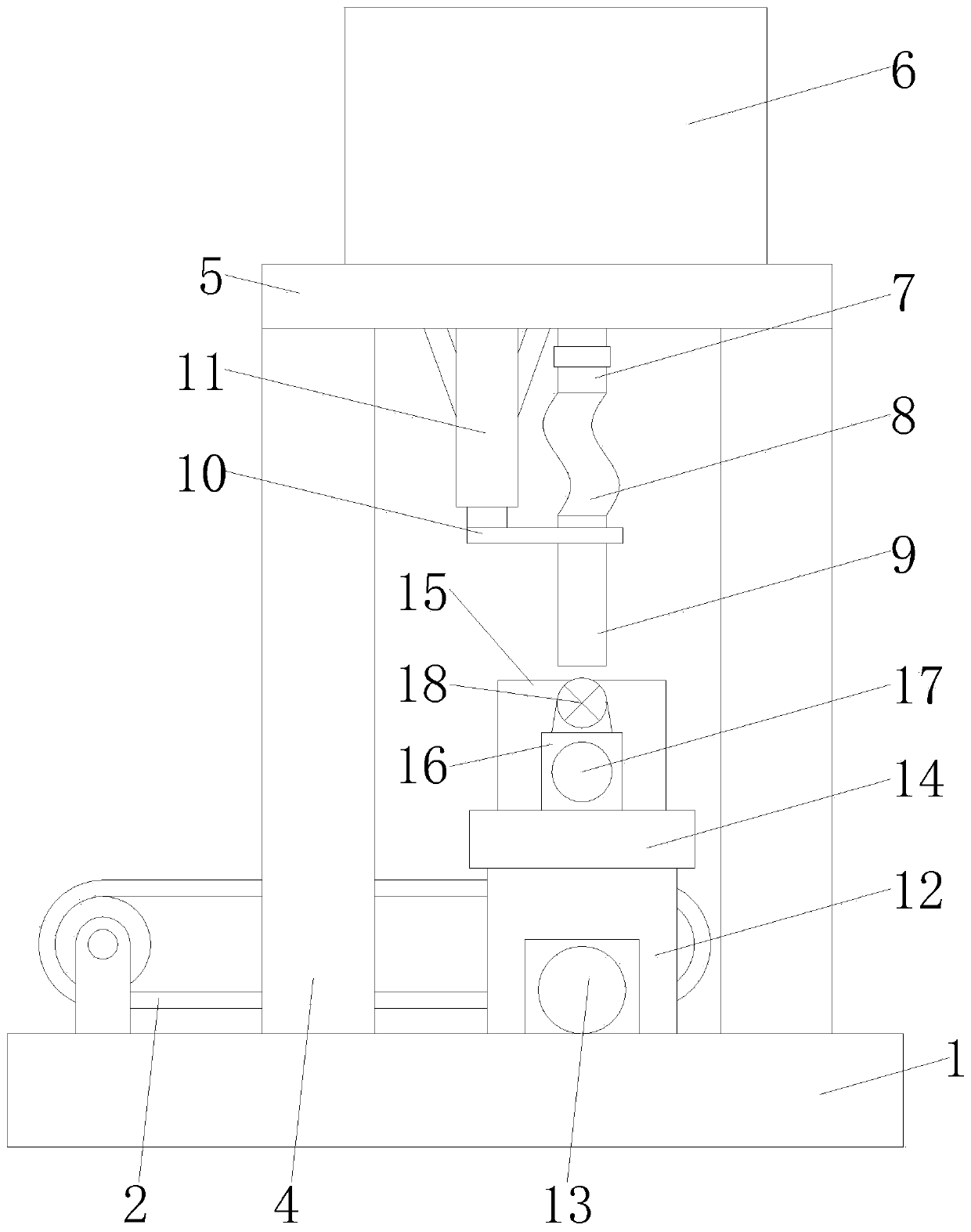

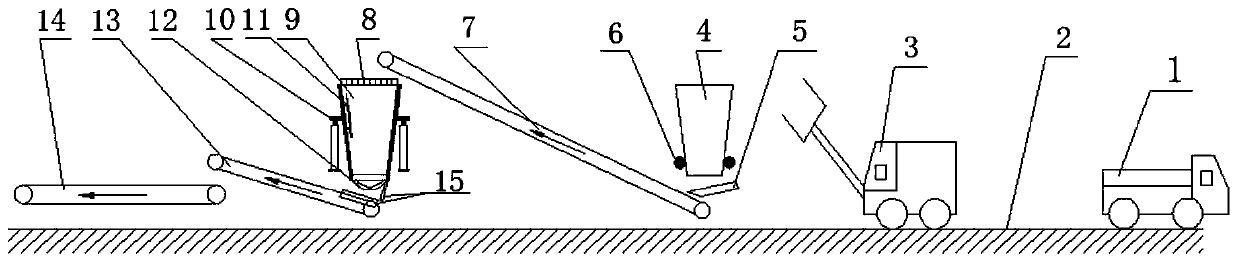

Industrialized mushroom production compost charging machine

ActiveCN106241331AImprove efficiencyUniform feedingCleaningCultivating equipmentsPulp and paper industryMushroom

The invention discloses an industrialized mushroom production compost charging machine. The industrialized mushroom production compost charging machine comprises a stock bin, a transmission device, culture frames, a culture frame pulley and a power system, wherein after compost enters the stock bin, the compost is conveyed to the culture frames continuously through the power system and the transmission device. The industrialized mushroom production compost charging machine has the advantages that (1) charging of 4 to 8 layers of culture frames can be finished by one charging action, so that the efficiency is increased; (2) each layer of culture disk is charged uniformly, and channels are consistent, so that standardized production demands are met; (3) spraying of the compost is reduced, and materials are saved.

Owner:江苏江南生物科技有限公司

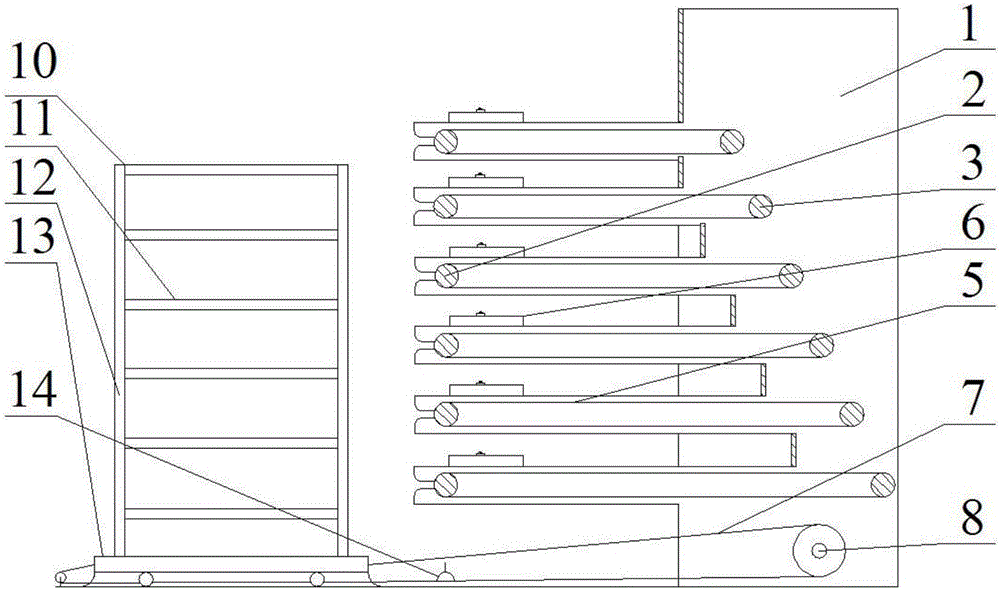

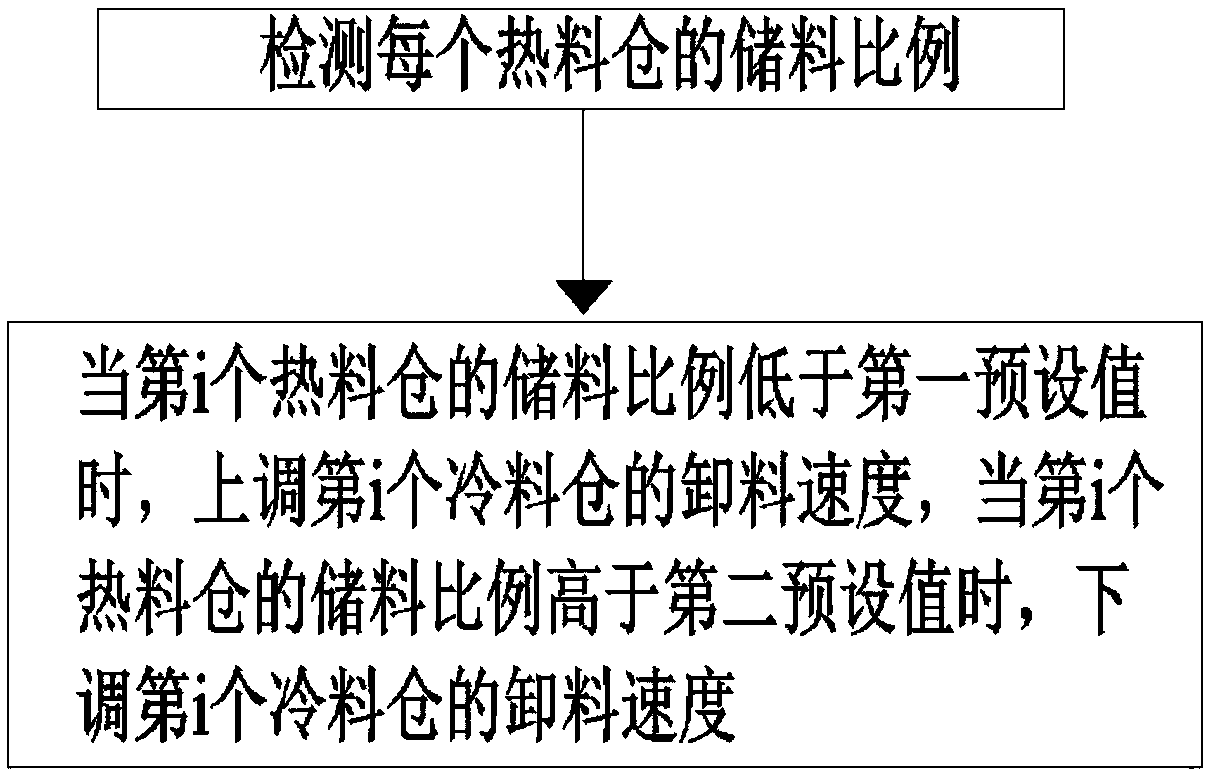

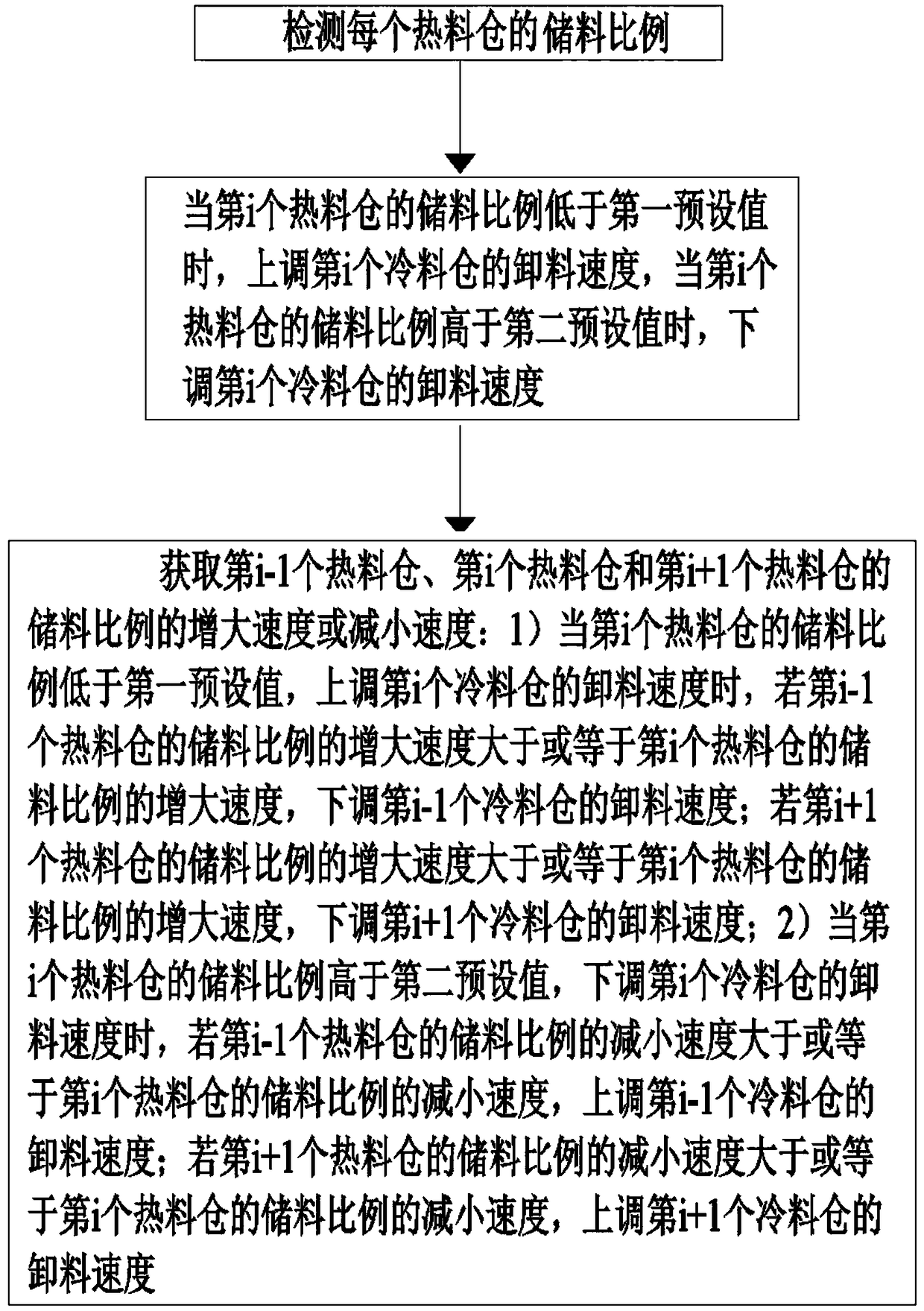

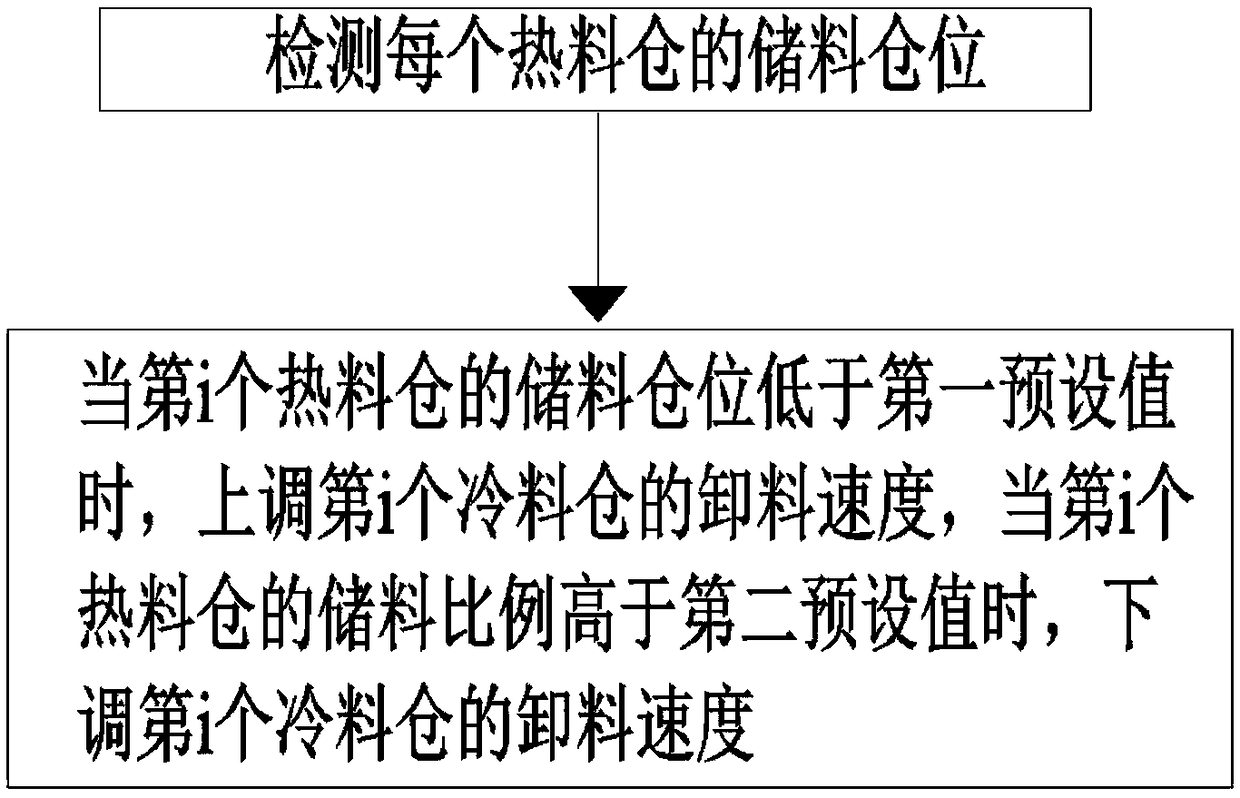

Automatic batching method and automatic batching system for asphalt mixing station and asphalt mixing station

The invention provides an automatic batching method of an asphalt mixing station, the asphalt mixing station comprises N cold material silos and N hot material silos, 1st cold bunker, the average particle size of aggregate stored in the 1-th cold silo, the 2-th cold silo...the N-th cold silo is increased in turn, The average particle size of aggregates stored in the 1-th cold silo, the 2-th cold silo...the N-th hot material bin is increased in turn, the first cold material bin corresponds to the first hot material bin, and the second cold material bin corresponds to the second hot material bin. The automatic batching method comprises the following steps: step 102: the storage amount of each hot material bin is acquired; Step 104: When the storage quantity of the i-th hot material bin is lower than the first preset value, the discharge speed of the i-th cold material bin is increased, and when the storage quantity of the i-th hot material bin is higher than the second preset value, thedischarge speed of the i-th cold material bin is decreased, wherein, i is selected from An integer of 1-N, the first preset value being smaller than the second preset value. The invention additionallyprovides an automatic batching system of an asphalt mixing station and an asphalt mixing station.

Owner:SANY AUTOMOBILE MFG CO LTD

Quantitative discharging device for tea packaging

InactiveCN112498764AConvenient for quantitative dischargeQuantitative discharge is fastSievingScreeningStructural engineeringMechanical engineering

The invention relates to the technical field of tea packaging, in particular to a quantitative discharging device for tea packaging. The device comprises a support frame and a fixing plate, the top end of the support frame is fixedly connected with the fixing plate, and a quantitative distributing mechanism is penetratingly arranged on the inner side of the left end of the fixing plate. The quantitative material distributing mechanism comprises a material distributing box, a conveying box, a discharging groove plate, a material limiting plate, a quantitative box, a middle partition plate, a discharging rotating plate and a material guiding concentration block, the conveying box is fixedly connected to the top end of the inner side of the material distributing box, the material limiting plate is fixedly connected to the inner side of the material distributing box, and the discharging groove plate is fixedly connected to the center of the material limiting plate; The quantitative box isarranged on the outer side of the bottom end of the discharging groove plate, and the middle partition plate is fixedly connected to the inner side of the quantitative box. According to the device, through the arrangement of the quantitative material distributing mechanism, tea leaves can fall into the material distributing box after being driven by a conveying rod, so that quantitative discharging during tea leaf packaging is facilitated, the time interval between material distributing and discharging is shortened, and quantitative discharging of the tea leaves is faster.

Owner:漳州市索兰德茶叶有限公司

Multi-functional tea table

The invention belongs to the field of the furniture articles, and particularly relates to a multi-functional tea table. The multi-functional tea table comprises the tea table. The table top of the tea table is provided with a control device. The control device is provided with a plurality of controllers. The control device is provided with switches corresponding to the controllers. A magnet is installed in each controller. An electromagnet is installed above the magnet. A coil is installed in the electromagnet. The electromagnet is provided with an extension bar, and the extension bar is protruded out of the controllers. The extension bar is provided with a support plate. The support plate is provided with a limiting block. Based on the solution, the extension bar is driven to be protruded by the electromagnetism function, so a tea cup is moved in the uniform velocity along with the support plate, and the tea cup is limited by the limiting block, the tea water is prevented from sputtering from the tea cup.

Owner:MINGFENG DOORS

Can conveying device

The invention provides a can conveying device which is applicable to conveying various ring-pull cans between a filling machine and a capping machine. The can conveying device comprises a can conveying table support and a can conveying guide rail. A conveying chain guide rail with a conveying chain is arranged in the can conveying table support. A conveying chain is connected with a shifting pawl, a ring-pull can is driven by the shifting pawl to move along the upper surface of the can conveying guide rail, can protection plates are arranged on the two sides of the ring-pull can, and the can conveying guide rail comprises a supporting plate and a plurality of round steel guide rails fixed to the supporting plate. According to the can conveying device, the round steel guide rails replace traditional nylon plates or stainless steel plates, the contact face between the can bottom and the guide rails is small, the friction force is small, the phenomenon that materials are spilled is reduced, the round steel guide rails rotating by an angle can be used again after one sides of the round steel guide rails are abraded, and the service life is long; the height and interval of the round steel guide rails can be adjusted, and requirement for filling and conveying different ring-pull cans can be met, and applicability is good.

Owner:南京轻机包装机械有限公司

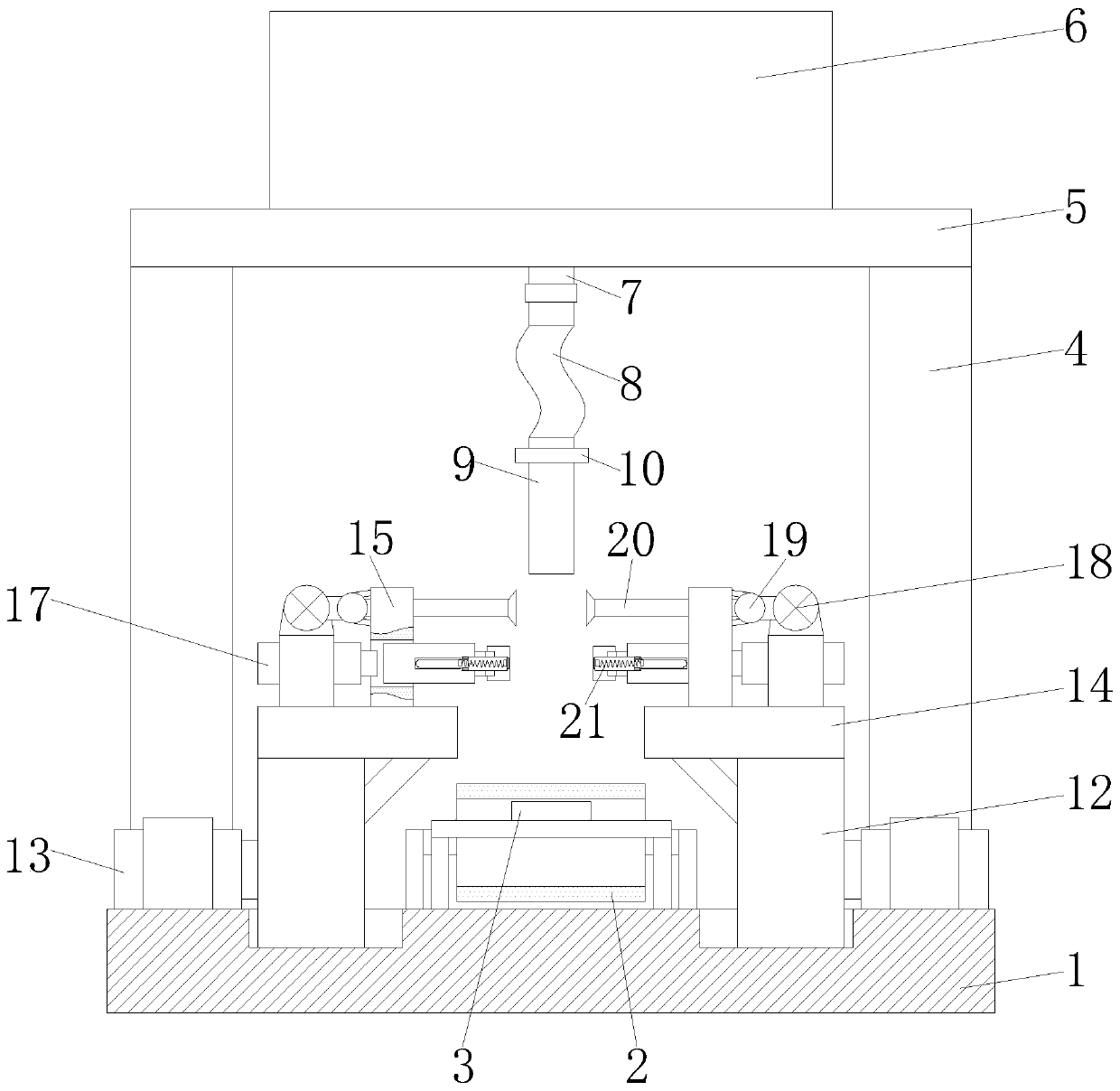

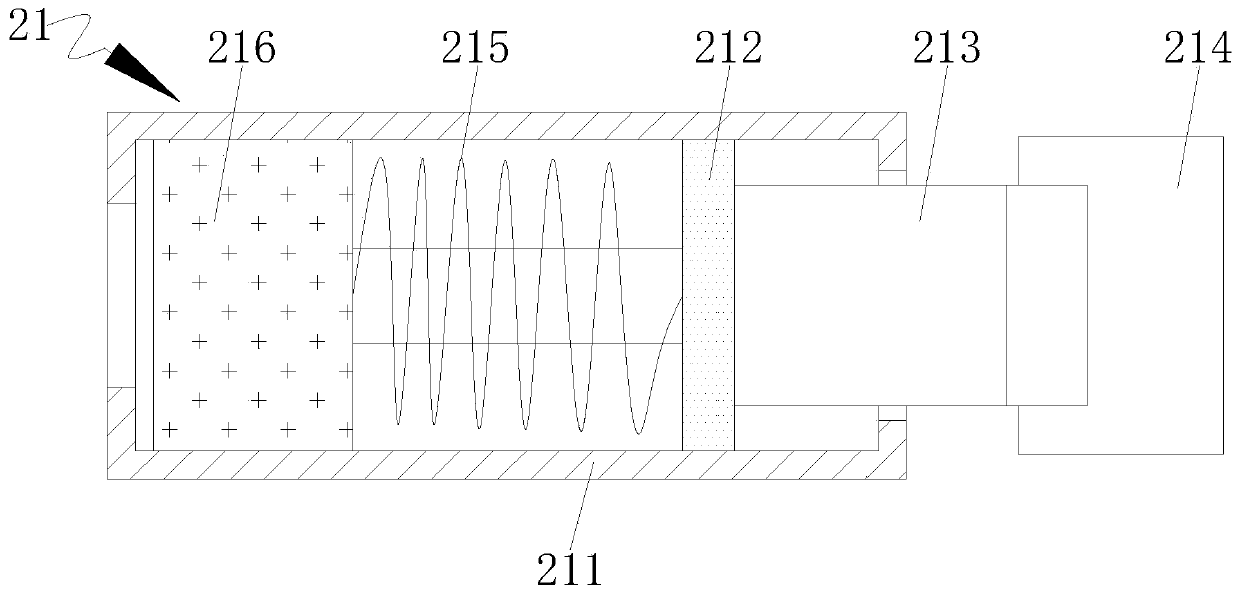

Leakage-proof glass fiber powder filling device

ActiveCN111003285AReduce labor intensityImprove efficiencyPackaging automatic controlSolid materialGlass fiberPhysical health

The invention belongs to the technical field of glass fiber powder filling and discloses a leakage-proof glass fiber powder filling device. The device comprises a base; the top of the base is fixedlyconnected with a conveying belt; the bottom of the base is fixedly connected with a force sensor through a mounting frame; two sets of supporting rods are symmetrically and fixedly connected to the top of the base; a supporting plate is fixedly connected between the top ends of the supporting rods; the top of the supporting plate is fixedly connected with a material storage box; the bottom of thematerial storage box is communicated with a material discharging pipe; the bottom end of the material discharging pipe penetrates through the top of the supporting plate and is communicated with a feeding pipe; the bottom end of the feeding pipe is communicated with a filling pipe; and the outer circular surface of the filling pipe is fixedly sleeved with a connecting plate. According to the priorart, most existing glass fiber powder filling devices adopt no leakage-proof design, as a result, glass fiber powder will be wasted and inhaled into the bodies of workers, and the physical health ofthe workers is harmed. However, with the device of the invention adopted, the problem in the prior art can be solved.

Owner:天长市天意玻璃制品有限公司

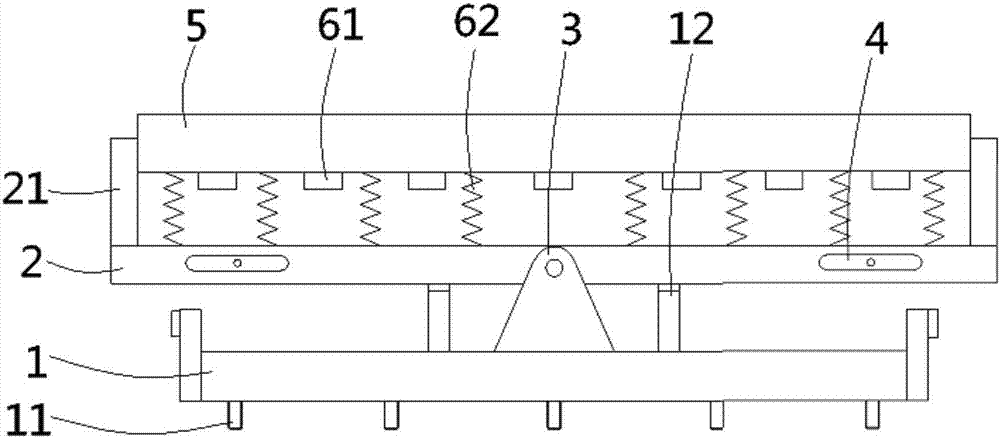

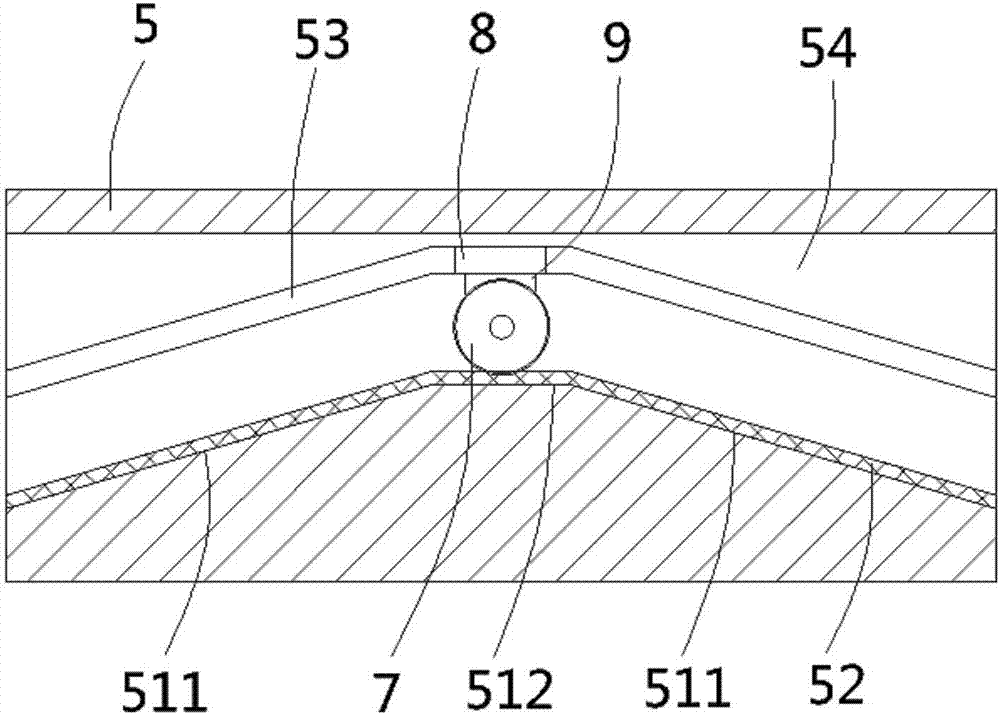

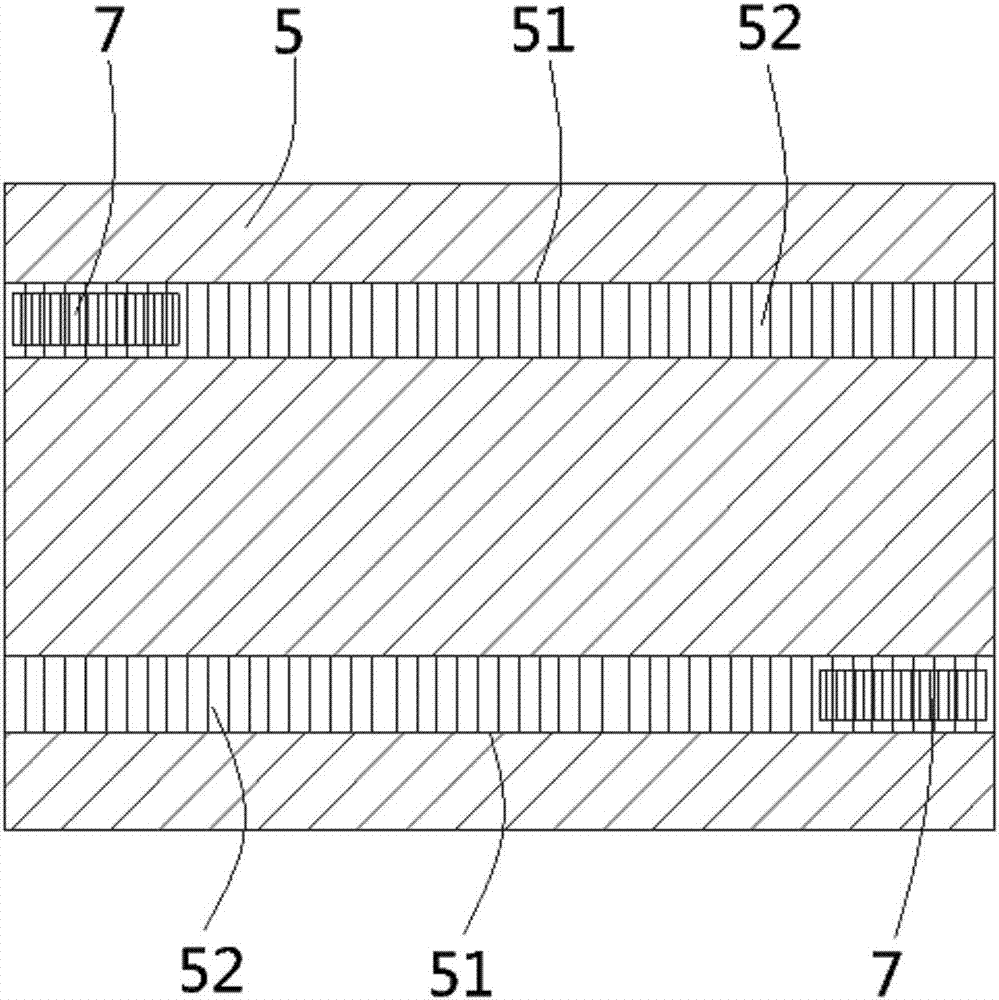

Balancing support frame for meal delivery robot

The invention discloses a balancing support frame for a meal delivery robot. The balancing support frame comprises a base and a supporting plate; a hinge seat is installed at the middle part of the base; the middle part of the supporting plate is hinged to the hinge seat; level meters are arranged on the two sides of the supporting plate respectively; a tray is installed on the supporting plate; two moving guide rail grooves, each of which is formed by slope parts on the left and right sides and a horizontal part at the middle part and is provided with a rack guide rail, are formed in the two sides of the tray respectively; each rack guide rail is connected with a moving gear in an engaging manner; the two moving gears are arranged at the left end and the right end of the two moving guide rail grooves respectively and are installed on the support plates; a drive motor is fixed on each support plate; a rotary shaft of each drive motor is connected with the corresponding moving gear; an insertion connection groove is formed in the tray on one side of the each moving guide rail groove; and one end of each support plate is connected into the corresponding insertion connection groove in an insertion manner. The balancing support frame can regulate balance of the meal delivery robot and reduce vibration when encountering an obstacle, so that dishes can be prevented from being spilled out.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

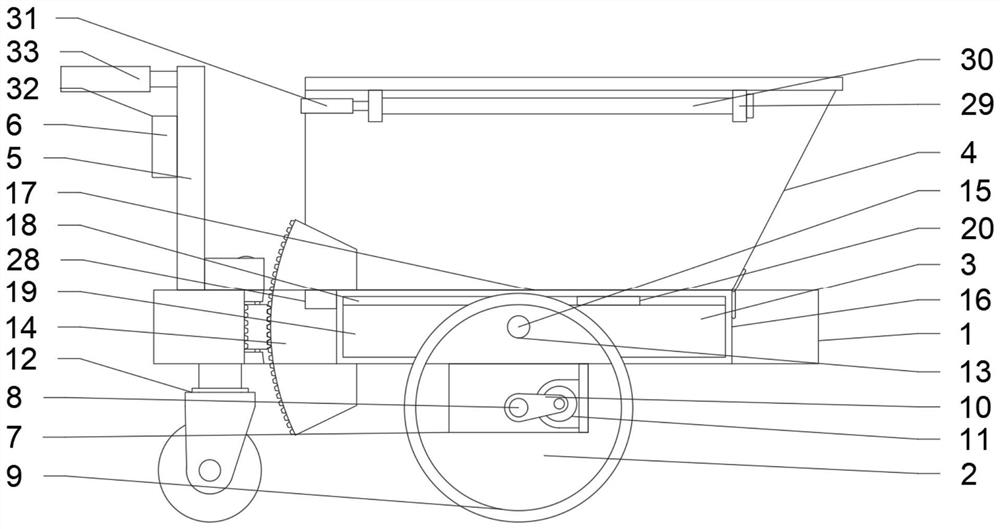

Automatic trolley for constructional engineering

InactiveCN113147856AReduce labor intensityReduce spillsHand carts with multiple axesHand cart accessoriesAuto regulationArchitectural engineering

The invention belongs to the technical field of building construction equipment, and discloses an automatic trolley for constructional engineering. The automatic trolley comprises a fixing frame and a hopper, a supporting wheel mechanism and a horizontal adjusting mechanism are arranged on the fixing frame, the fixing frame is adjustably connected with the hopper through the horizontal adjusting mechanism, and the end, close to the hopper, of the fixing frame is fixedly connected with a fixing base. And a controller and a control rotary handle are fixedly connected to the fixing base. Compared with trolleys in the prior art, the trolley has the beneficial effects that the trolley is simple in structure and convenient to use, certain assistance is provided through the supporting wheel mechanism, the labor intensity of workers is relieved, the hopper is automatically adjusted to be horizontal through the horizontal adjusting mechanism, it is guaranteed that the situation that materials are scattered when the trolley goes uphill or downhill is avoided, building materials can be saved, and the ground of a building construction site can be kept clean and tidy.

Owner:山东国建工程集团有限公司

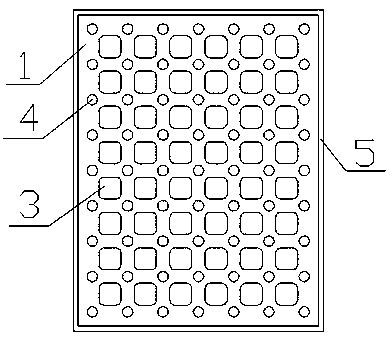

Belt conveyor material guide groove

The invention provides a belt conveyor material guide groove, which comprises a material guide groove body, wherein the material guide groove body comprises a support roller, a support roller support frame and a rubber belt surface arranged on the support roller, the left end and the right end of the material guide groove body are respectively provided with double front curtains, the right sides of the double front curtains arranged at the right side are also provided with a baffle plate, side plates are respectively arranged at the front side and the back side inside the material guide groove body, a cover plate is arranged at the upper end of the material guide groove body, a press plate is also arranged under the cover plates arranged at the left and right ends, a lattice making lining plate is arranged on the surface, in contact with the materials, of the upper section side plate, and an overflowing-proof skirt edge is arranged on the lower section side plate; a first sealing plate is arranged between the cover plate and the side plates, and a second sealing plate is arranged at a surface contact part of the lattice making lining plate and the rubber belt surface; the support roller support frame and the side plates are connected through adjustable angle steel, and reinforcing ribs are also arranged between the side plate and the adjustable angle steel. The belt conveyor material guide groove provided by the invention has the advantages that the structure is simple, the cost is low, the sealing is tight, the wear resistance of the side plates is high, and the like.

Owner:HENGYANG CONVEYING MACHINERY

Steel scrap adding device for blast furnace and adding method thereof

PendingCN110607408AEasy to operateLess frequent interruptionsBlast furnace componentsBlast furnace detailsScrapLeather belt

The invention provides a steel scrap adding device for a blast furnace and an adding method thereof. The steel scrap adding device for the blast furnace comprises a material receiving mechanism, a weighing mechanism and a conveying belt, wherein the material receiving mechanism comprises a material receiving hopper and a feeding machine, the weighing mechanism is used for weighing steel scrap conveyed to the weighing mechanism by the material receiving mechanism, and comprises a weighing hopper, a metering device and an opening and closing device, the conveying belt comprises a material receiving belt and a feeding belt, the feeding machine continuously and uniformly distributes the steel scrap on the material receiving belt, and then conveys the steel scrap to the weighing mechanism, andthe steel scrap flows out from an opening and closing position of the opening and closing device, is conveyed onto a feeding main belt of the blast furnace through the feeding belt, and then is transported into the blast furnace. The steel scrap adding device for the blast furnace is simple, easy to operate, high in automatic degree and efficient in running. The material receiving hopper and the weighing hopper are self-made devices, and all the other auxiliary tools can utilize used tools, and furthermore the conveying belt is a sintering or blast furnace feeding used material, and thereforemanufacture cost is low.

Owner:DAYE SPECIAL STEEL CO LTD

Seedling cultivation tray

The invention discloses a seedling cultivation tray. The seedling cultivation tray comprises a seedling cultivation tray body and a cover plate, the cover plate is clamped on the upper surface of theseedling cultivation tray body which is provided with seedling cultivation holes and grooves, the outer periphery of the seedling cultivation tray body is provided with a convex plate circularly, thecover plate is provided with fixing through holes and convex columns, the lower surface of the cover plate is provided with a wool felt layer, the convex columns are internally provided with heating cavities, and heating resistance wires are arranged in the heating cavities. The seedling cultivation tray is integrally simple in structure, convenient to use, capable of well guaranteeing healthy growth and development of seedlings and high in popularization and utilization value.

Owner:王艳平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com