Patents

Literature

608results about How to "Alleviate shortages" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

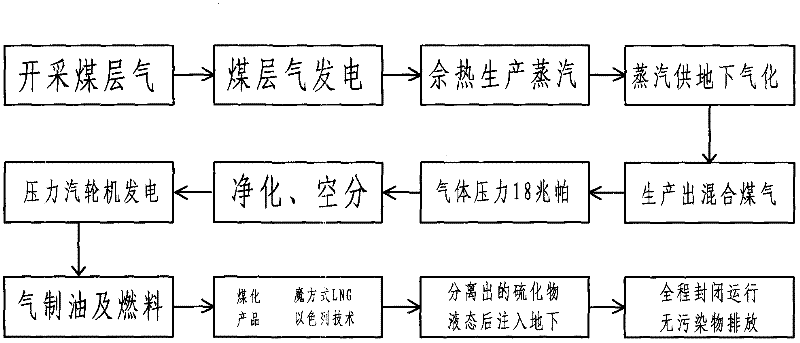

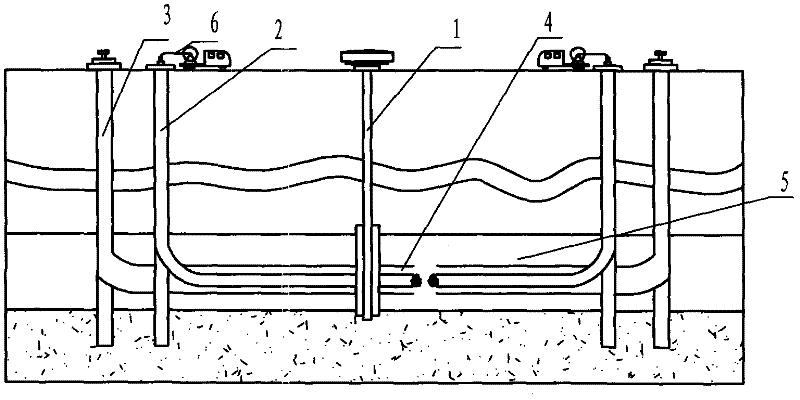

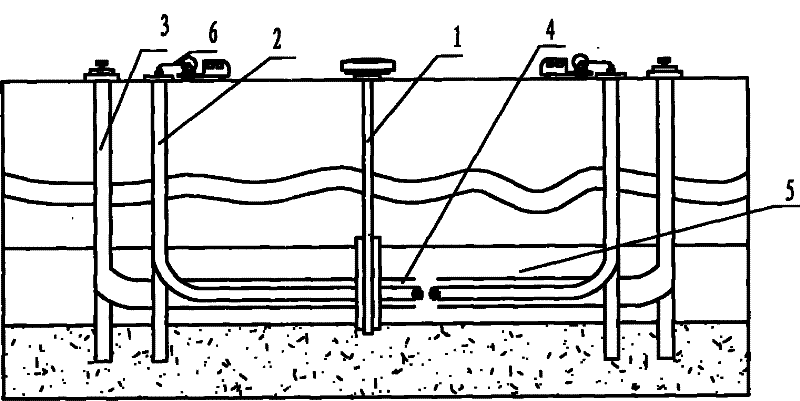

Deep coal and coal bed gas combined mining method

The invention relates to a deep coal resource mining method. When the buried depth of a coal bed is 800 to 3,000 meters, the thickness is more than 3 meters, an inclination angle is less than 10 degrees, and pressure is more than 10 Mpa, the most advanced well drilling and cementing, high-temperature resistant and high-pressure well completion technologies in oil industry, vertical shafts and vertical shafts and gas injection and gas production combined methods are adopted; the method is characterized by comprising the following steps of: drilling three vertical shafts first, wherein the distance between the wells is 500 meters; drilling a horizontal well which is more than 500 meters deep from a secondary well to a central well, combusting a long tunnel which is 1,000 meters long and 10 meters wide by a special combustion method, wherein the tunnel is a gasification tunnel special for gas production, observation, monitoring and the like, and drilling a plurality of overlong horizontal wells in the reverse direction according to the inclination gradient of the coal bed. The deep coal bed gas and the deep coal are gasified underground, and exploited in a combined way, so the problem of shortage in energy resources in China can be greatly improved, the method is a new environment-friendly, low-carbon, innovative new-energy development technology, and low in cost and has great economic value, and investment is reduced.

Owner:GUODING DALIAN INVESTMENT

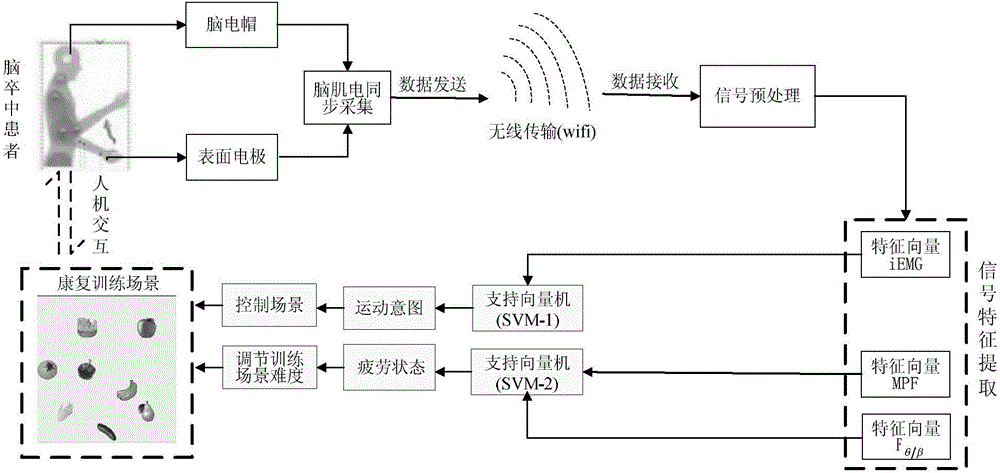

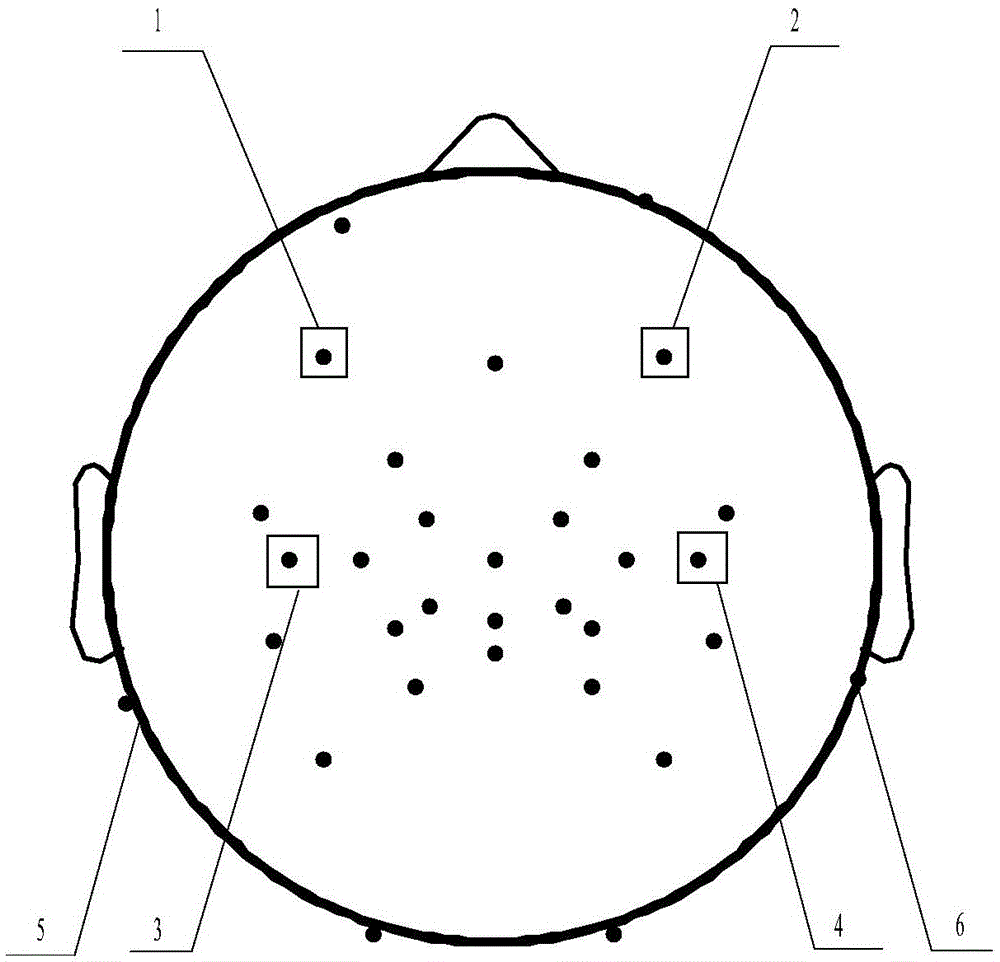

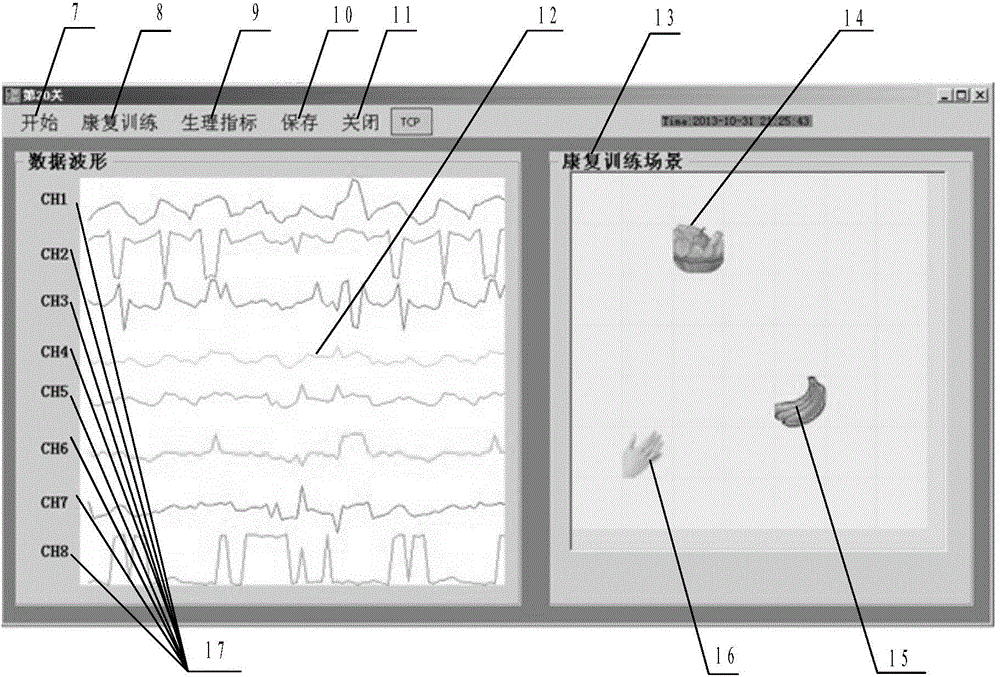

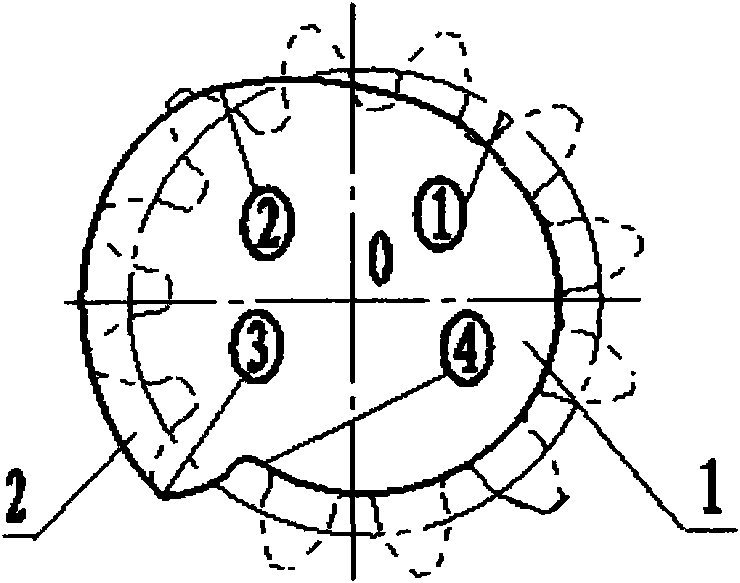

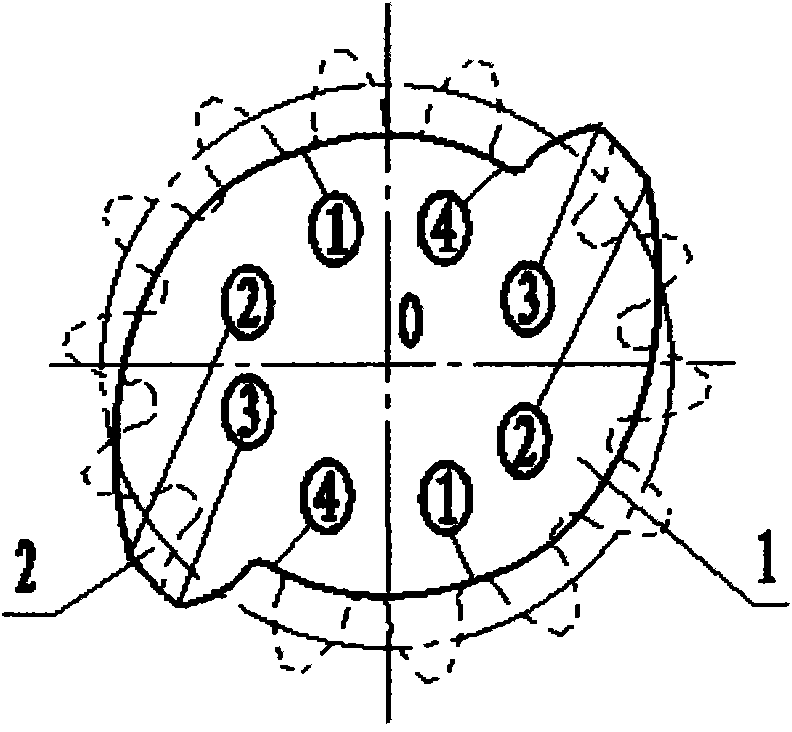

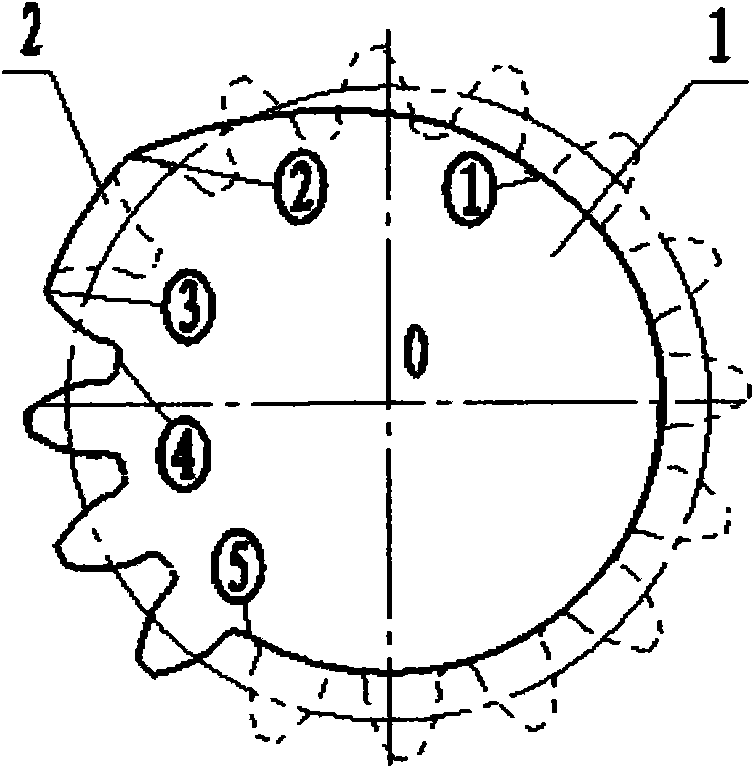

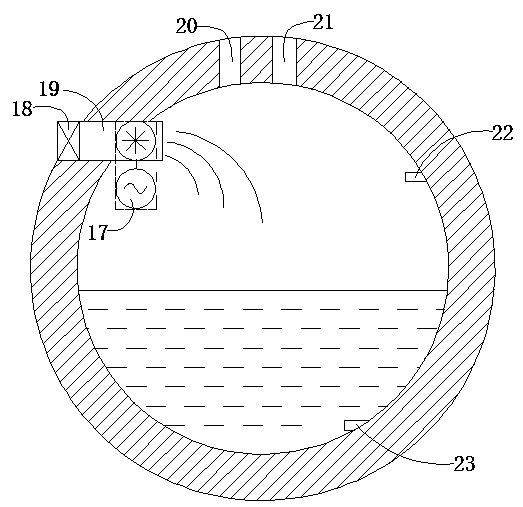

Stroke patient rehabilitation training system and method based on brain myoelectricity and virtual scene

ActiveCN104000586AIncrease initiativeBoost self-confidenceSensorsPsychotechnic devicesRehabilitation physicianSelf adaptive

Provided are a stroke patient rehabilitation training system and method based on brain myoelectricity and a virtual scene. Control over the virtual rehabilitation scene is achieved through myoelectric signals, and rehabilitation training intensity is adjusted in a self-adaptation mode with a brain myoelectricity fatigue index combined. The design of the virtual rehabilitation scene is completed with the needs of stroke patient rehabilitation training and the advice of a rehabilitation physician combined, the brain fatigue index is provided, and quantitative evaluation on brain region fatigue is achieved. The surface myoelectric signal features under different motion modes of an arm are extracted, the motion intention of a patient is obtained, and control over the virtual rehabilitation scene is achieved. The muscle fatigue and brain fatigue index comprehensive features are extracted, the fatigue state of a rehabilitation patient is obtained, self-adaptation rehabilitation training scene adjusting is achieved, rehabilitation training intensity is relieved or enhanced, and secondary damage caused by improper training is avoided. The system and method have the advantages of being high in safety, high in intelligence and scientific in training, and damage cannot happen easily.

Owner:YANSHAN UNIV

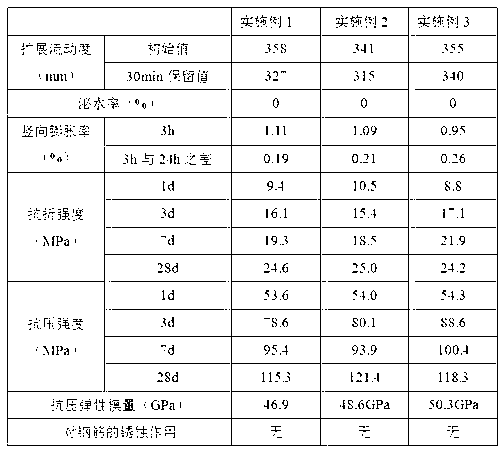

Ultrahigh-strength grouting material based on iron tailing sand and cement and preparation method of grouting material

InactiveCN102992722AGood dispersionImprove liquiditySolid waste managementCompressive strengthUltimate tensile strength

The invention relates to an ultrahigh-strength grouting material based on iron tailing sand and cement and a preparation method of the grouting material. The ultrahigh-strength grouting material is composed of the following components in proportion by weight: 30%-45% of cement, 45%-55% of iron tailing sand, 6%-15% of multielement mineral admixtures, 0.35%-1% of water reducing agent, 0.1%-1% of plastic retaining agent, 0.01%-0.1% of plastic expanding agent, and 2%-6% of shrinkage-compensating expanding agent. The preparation method comprises the steps of uniformly mixing all the components and then uniformly stirring the mixed components in water, wherein the ratio of the water to the materials is 0.09-0.11. The grouting material is good in flowability, is good in stability in a plastic stage, is free from shrinkage in the whole course from the plastic stage to a later hardening stage, and is ultrahigh in early strength, final strength and elasticity modulus, the 1d compressive strength of the material reaches up to 50MPa, the 28d compressive strength of the material can exceed 110MPa, and the 28d elasticity modulus of the material exceeds 45GPa, and therefore, the ultrahigh-strength grouting material is suitable for grouting of various important parts or areas with requirements on high strength and high modulus.

Owner:WUHAN UNIV OF TECH

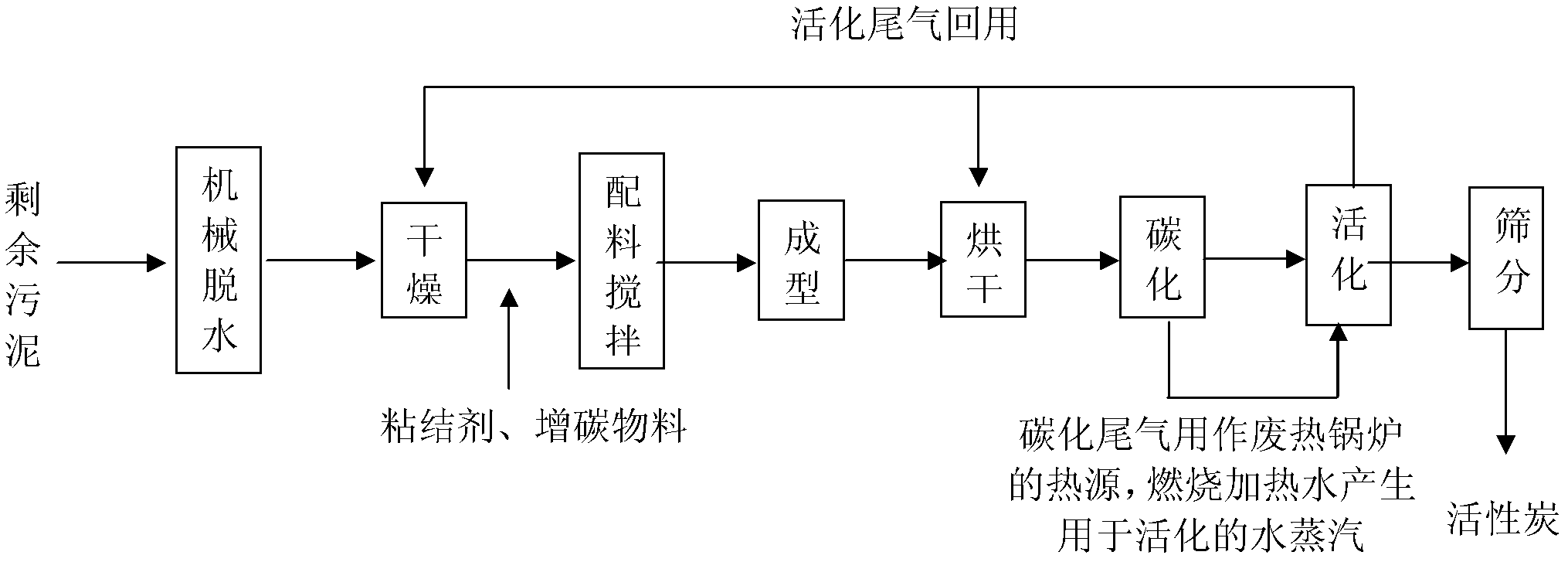

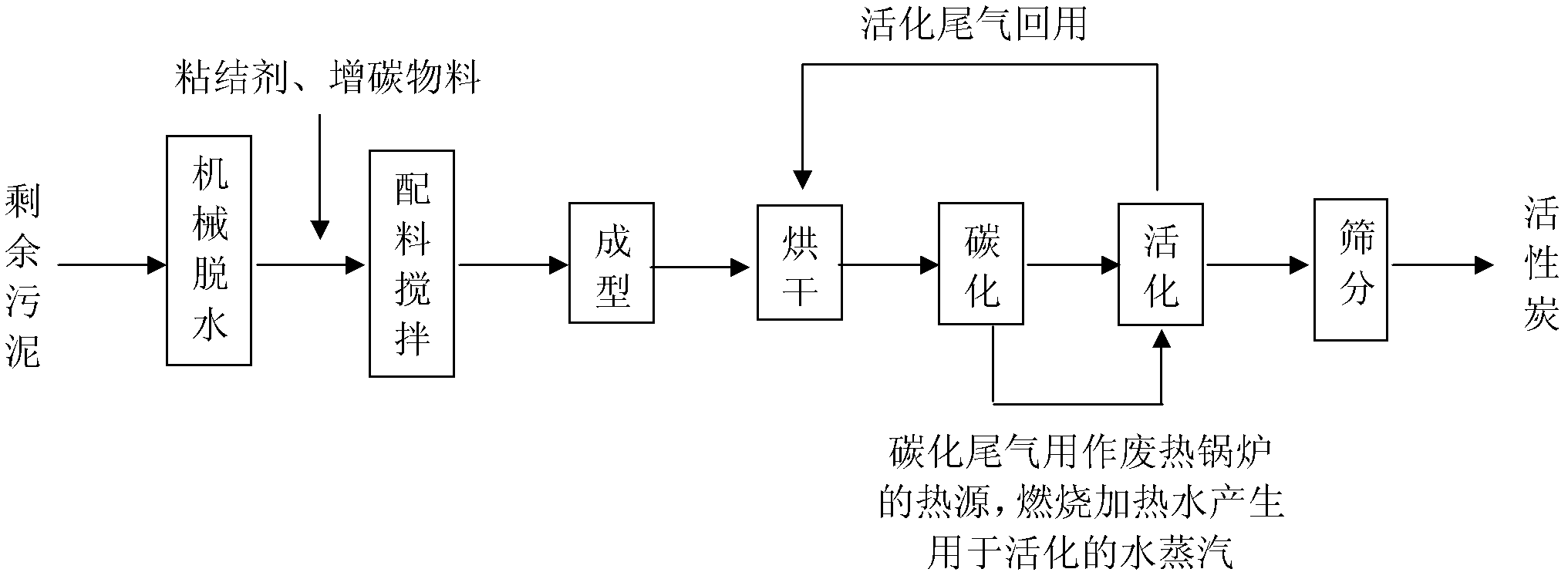

Method for preparing activated carbon by physical activation of excess sludge

InactiveCN102432007AAlleviate shortagesWide variety of sourcesCarbon compoundsEnergy inputActivated carbonSocial benefits

The invention relates to a recycling disposal of industrial solid waste, in particular a method for preparing activated carbon by physical activation of excess sludge. The method comprises taking excess sludge generated by sewage treatment as raw material, utilizing water vapour as activating gas and preparing sludge activated carbon by physical activation. The invention takes large amount of excess sludge generated by sewage treatment as raw material to prepare activated carbon and realizes highly efficient utilization of energy resources by multi-type excess heat recycling, therefore, the generated activated carbon product has low energy consumption. Compared with chemical activation, the physical activation has no large amount of waste water generation during the preparation process and the production process is clean and environment friendly. The invention has excellent economic, ecological and social benefits.

Owner:NANJING UNIV OF TECH

Artificial three-segment cultivating Paris Chinensis method

InactiveCN101248727AMajor risks can be mitigatedSeedlings grow fastSeed and root treatmentFertilising methodsInsect pestFarmyard manure

A method for manually-cultivating three-stage Rhizoma Paridis belonging to the technical field of agriculture includes primary seedling planting and raising, secondary seedling planting and raising, Rhizoma Paridis cultivation and field management, wherein, the primary seedling planting and raising includes the steps of presprouting of seeds and seed seedling raising, when tubers weigh 2g after 3 years, transplantation can be carried out. The secondary seedling planting and raising includes the steps that: the primary seedlings with 2g of tubers are transplanted in October and last third of November and transplantation can be carried out when the tubers are 15g after 3 years. The steps of Rhizoma Paridis cultivation and field management are that: the secondary seedlings are transplanted according to the proportion of 21,000 seedlings in per acre in October and last third of November, and mature Rhizoma Paridis can be dug after 3 years; farmyard manure is fertilized once or twice every May and last third of August with the amount of 3000kg per acre every time, or carbamide is fertilized or foliar fertilizer is sprayed for three times in the vigorous growth period; in the non-seed-collecting filed, ovaries are picked off after sepals unfold; commercial pesticide is used for preventing plant diseases and insect pests in the growth period of the Rhizoma Paridis. The method for manually-cultivating Rhizoma Paridis is characterized by less investment, early effect, good harvest, high efficient, etc., which can realize major production.

Owner:YUNNAN ACAD OF AGRI SCI

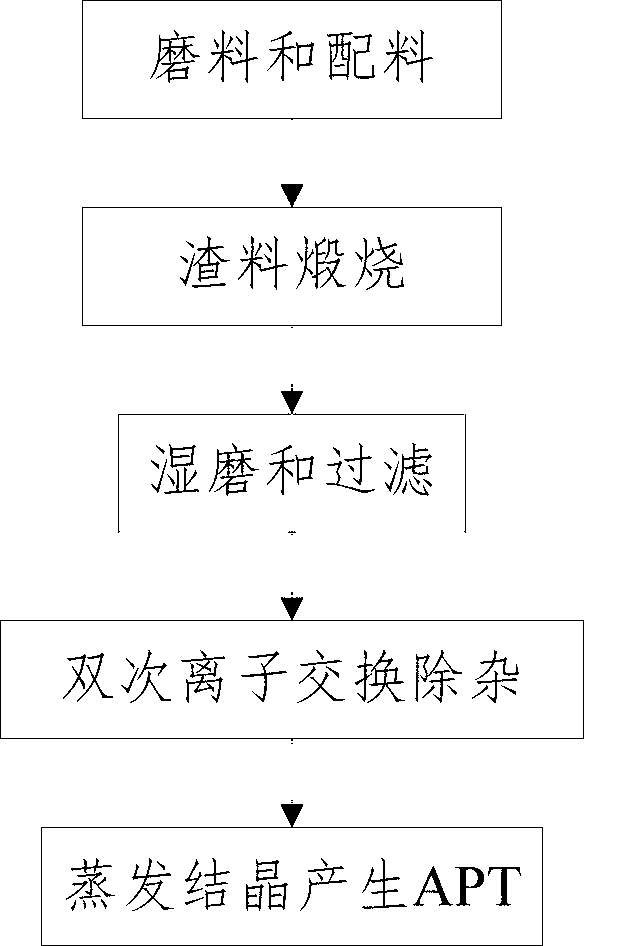

Method for regenerating APT (ammonium paratungstate) by use of APT waste low-grade tungsten slag

InactiveCN103103359AHigh recovery rateEasy to useProcess efficiency improvementAmmonium paratungstateSlag

The invention belongs to the field of tungsten resource recycling, and particularly relates to a method for regenerating APT (ammonium paratungstate) by the use of waste low-grade tungsten slag in an APT production process. The invention discloses a method for regenerating APT by use of APT waste low-grade tungsten slag, which is realized by improving the technological parameters of the traditional soda sintering method and comprises the following steps of: (a) grinding and dosing; (b) slag calcining; (c) wet grinding and filtering; (d) two-secondary ion exchange and impurity removal; and (e) evaporating and crystallizing to generate APT. The method provided by the invention can reduce resource waste, improve the utilization rate of resources, and can increase the economic benefits of an enterprise by recycling the APT waste low-grade tungsten slag; the method is suitable for treating the waste low-grade tungsten slag of which the WO3 grade is 2-10%, overcomes the shortcomings of the technology matching the waste and the tungsten concentrate raw material, and can effectively improve the recovery rate of tungsten and reduce environmental pollution; and through the invention, the service life of the tungsten resource of the country can be prolonged, the current situation of shortage in tungsten resource is relieved, the emission of waste can be effectively reduced, and environmental pollution is reduced.

Owner:陈泉兴

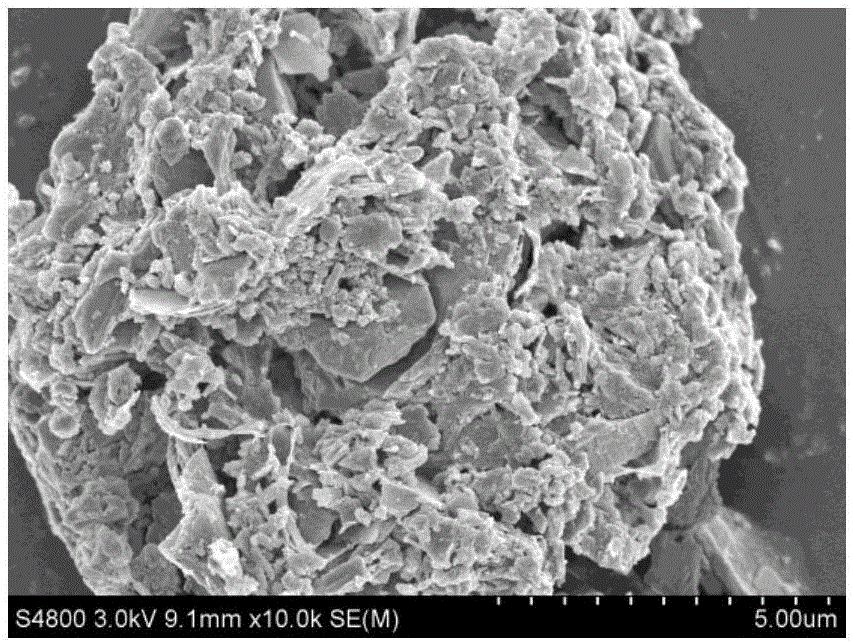

Preparation method of nanometer resin with high hygroscopy

The invention discloses a preparation method of nanometer resin with high hygroscopy, which comprises the following steps: adopting crylic acid monomers to carry out graft copolymerization on carboxymethylcellulose; adding organic quaternary ammonium salt to modify montmorillonoid; and preparing CMC / acrylic polymers / OMMT nanometer resin with high hygroscopy through an in situ intercalation polymerization method of aqueous solution. The adoption of the carboxymethylcellulose and the montmorillonoid reduces the dosage of the acrylic polymers, so that the cost is lowered; and after the nanometer resin with the high hygroscopy is dried, the absorption of pure water can be 500g / g, the absorption of normal saline can be 130g / g, the gelstrength can be 13 times of that of the graft copolymerization materials, so the resin has good biodegradation property and can be bio-degraded within 3-4 months and is a green and environment-friendly water retention product. In addition, the raw materials used in the invention, namely the carboxymethylcellulose and montmorillonoid have wide sources, excellent biocompatibility, can remit the shortage of oil resources, and has obvious cost advantages and wide application prospect.

Owner:SHAANXI UNIV OF SCI & TECH

Method for producing concrete active admixture by iron tailings

ActiveCN101121579AAlleviate the shortage of ultrafine slag powderLow costSolid waste managementMagnetResource consumption

The present invention relates to a method to produce concrete active mixing material using the waste iron to replace part of scoria. The method is to add 70 percent to 93 percent of the magnet quartz waste iron, 1 percent to 20 percent of calcareousness or calcium carbide residual or the mixture of the two materials, 1-10 percent of gypsum or semi-water gypsum or anhydrite or decarbolizing gypsum or phosphorus gypsum or fluorspar gypsum or the mixture of the two or more than the two and 0.1 - 5 percent of corroding together to be milled into 80um griddle residual less or equal to 3 percent; and the grain is to be made the reaction of heat liquid corroding reaction. The corroding production after being cooled is mixed with 10 -60 percent of scoria with the molar percent between 40 percent and 90 percent and then to be milled into 80um griddle residual less or equal to 0.5 percent; in this way, the active concrete mixture replaced with the scoria powder is obtained. The present invention can make the magnet quartz waste iron treated with resource mode, relax the lacking of the super thin scoria powder led by the much larger infusion for the casting of the concrete and decrease the manufacturing cost for the concrete; the method can enhance the use amount of the mixture, decrease the use amount of the cement and decrease the resource consumption and environment pollution led by the cement production.

Owner:河北科晖环境资源有限公司

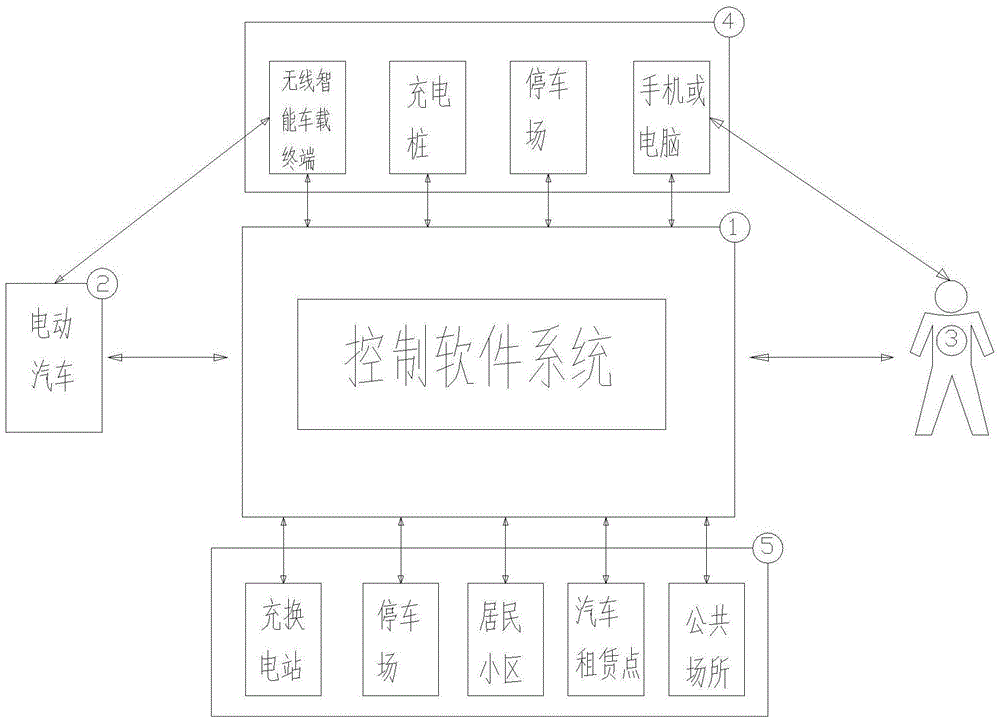

Electric vehicle sharing platform and intelligent control method

InactiveCN104915771AIntelligent chargingIntelligent car rentalResourcesEnvironmental issueCar sharing

The invention relates to an electric vehicle sharing platform and an intelligent control method and belongs to the electric vehicle charging technical field. The electric vehicle sharing platform is characterized in that the electric vehicle sharing platform includes an electric vehicle, a charging pile, a parking lot, a wireless intelligent vehicle-mounted terminal, a mobile phone or a computer and a control software system, wherein the control software system includes a management center cloud control system, a mobile phone APP, vehicle control middleware, charging pile middleware and parking lot middleware. A platform user logins the management center cloud control system through the mobile phone or the computer, and then, performs intelligent management and monitoring on the electric vehicle, the charging pile and the parking lot through the vehicle control middleware, the charging pile middleware and the parking lot middleware. With the electric vehicle sharing platform and the intelligent control method adopted, various kinds of resources of vehicles can be utilized fully and rationally, and fuel vehicles can be converted into more environmentally friendly electric vehicles, and private vehicles can be converted into the electric vehicles, and more people will choose renting vehicles rather than buying private vehicles, and finally energy shortage and social and environmental issues can be alleviated, and related operations such as vehicle renting, charging and parking can be completed.

Owner:WUHU HENGTIAN YIKAI SOFTWARE TECH CO LTD

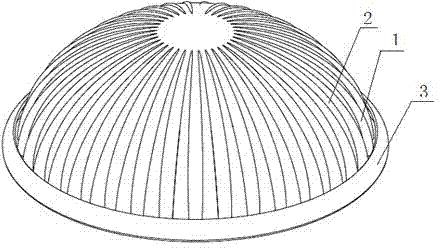

Moisture capture device

InactiveCN103205994ASolve water problemsReduce the temperatureDrinking water installationEnvironmental resistanceWater storage

The invention discloses a moisture capture device. The moisture capture device comprises a wave-shaped moisture condensation surface and a water storage device, wherein a radiation refrigeration material serves as a base plate of the moisture condensation surface, protruding portions of the wave-shaped moisture condensation surface are hydrophilic protruding portions, concave portions of the wave-shaped moisture condensation surface are hydrophobic concave portions, the water storage device is arranged at the bottom end of the moisture condensation surface, and droplets are formed by moisture captured by hydrophilic protruding portions, then transferred to hydrophobic concave portions after growing up and transferred to the water storage device along hydrophobic concave portions. The temperature of the condensation surface can be reduced quickly due to the radiation refrigeration material, the moisture in the air is captured by hydrophilic protruding portions and is condensed into droplets, and droplets are transferred to hydrophobic concave portions after growing up and are quickly transferred to the water storage device along hydrophobic concave portions. The device is simple in structure and environment-friendly, can be used in arid areas and semi-arid areas to mitigate the problem of water shortage to a certain extent and can be used in non-arid areas to provide domestic water and production water.

Owner:WUHAN UNIV

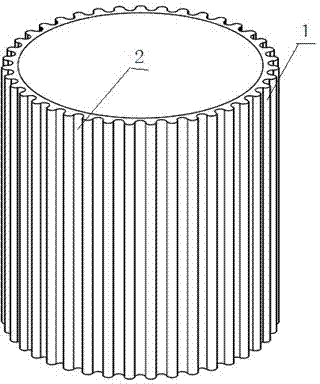

Mixed type electrochemical capacitor

InactiveCN103346021AAlleviate shortagesImprove power densityHybrid capacitor electrolytesHybrid capacitor electrodesHybrid typeHigh energy

The invention relates to a mixed type electrochemical capacitor, in particular to a mixed type electrochemical capacitor with high-energy density based on directional carbon nanotubes. The mixed type electrochemical capacitor structurally comprises a positive electrode, a negative electrode, a separating membrane and electrolytes, wherein the separating membrane and the electrolytes are arranged between the positive electrode and the negative electrode. The mixed type electrochemical capacitor is characterized in that the positive electrode of the mixed type electrochemical capacitor is composed of a directional carbon nanotube array directly growing on a conductive substrate and manganese oxide or polyaniline composite materials; the negative electrode of the mixed type electrochemical capacitor is composed of a modified directional carbon nanotube array or a directional carbon nanotube array directly growing on the conductive substrate and polypyrrole composite materials; the electrolytes of the mixed type electrochemical capacitor are nonaqueous electrolytes. The mixed type electrochemical capacitor has energy density capable of being compared to a secondary battery, and meanwhile has high power density and cycling stability. The current problem of energy shortage can be eased, and the mixed type electrochemical capacitor has high practical value, wide market prospect and considerable economic and social benefits.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

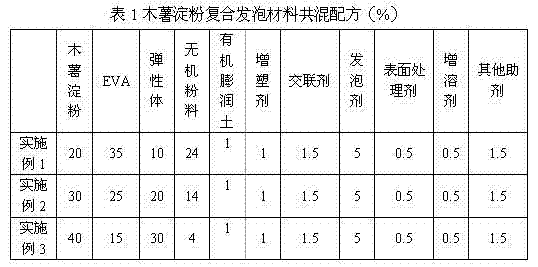

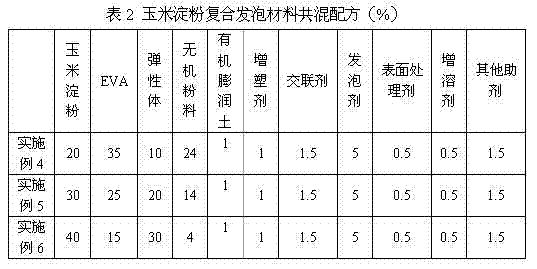

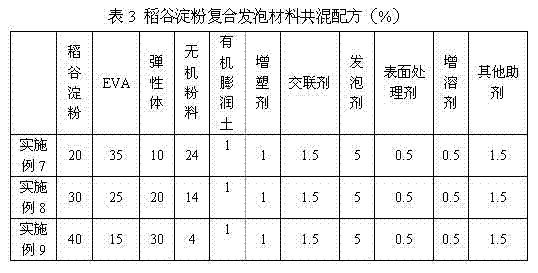

Starch composite foamed material and its production method

The invention provides a starch composite foamed material and its production method, which comprises the following components by mass fraction: 1% to 50% of starch; 10% to 60% of EVA; 1% to 50% of elastomer; 0 to 5% of organic bentonite; 0 to 50% of inorganic powder; 0.1% to 15% of plasticizer; 0.5 to 2% of cross-linking agent, 2 to 11% of composite foamed agent, 0 to 3% of surface conditioning agent, 0 to 5% of compatibilizer and 0 to 5% of other auxiliary agents. The production process is also disclosed. The starch composite foamed material can be widely used for manufacturing beach shoes, slippers, sports shoes and the like, and can be used for producing children picture mosaic, foam floor, and also can be used for package materials of precision electronic instruments, electric appliances and medical apparatus. The production of material is beneficial to environmental protection, and shortage phenomenon of plastic raw material can be alleviated. The production method is scientific and reasonable, the process is simple and strong operationality, and substantially improves degradability of a traditional EVA foamed material, realizes functionalization of EVA foamed material and enhances the added value of the products, the starch composite foamed material has wide application market prospects, obvious social benefit and economic benefit.

Owner:JINJIANG CHENGCHANG SHOES

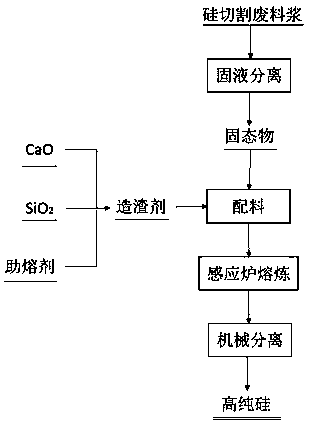

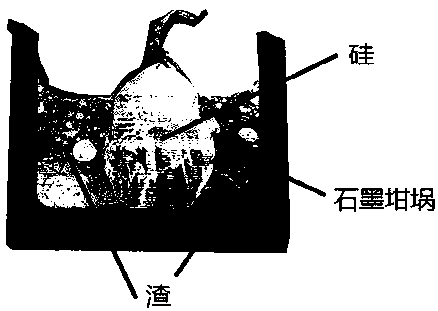

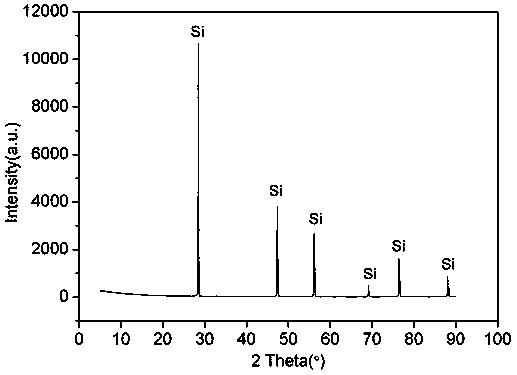

Recycling and purification method of silicon cutting waste material

InactiveCN109052407AAchieve recyclingAchieving processing powerSilicon compoundsPurification methodsSlag

The invention relates to a recycling and purification method of a silicon cutting waste material and belongs to the technical field of secondary resource circulation utilization of silicon materials.The recycling and purification method comprises the following steps: carrying out solid-liquid separation on silicon waste slurry in a silicon ingot cutting process, and drying to obtain a solid-statesilicon waste material; uniformly mixing CaO, SiO2 and a fluxing agent to obtain a slag-making agent; uniformly mixing the slag-making agent and the solid-state silicon waste material; putting a mixture into a medium frequency induction furnace; vacuumizing and then introducing argon gas; heating to 1450 to 1700 DEG C under an argon gas atmosphere condition and smelting at constant temperature for 0.5 to 4h; cooling along a furnace to obtain a fused block; separating silicon dreg of the fused block by adopting a diamond line cutting method to obtain high-purity silicon. According to the recycling and purification method, a silicon cutting waste material is subjected to slag-making and refining treatment of an induction furnace; separation and purification are carried out in the same operation step, and comprehensive recycling and purification treatment of a silicon-containing waste material in a silicon ingot cutting process is realized; the recycling and purification method has the characteristics of great production capability and high comprehensive recycling rate; wastes are changed into valuable things; the solar power generation cost can be reduced and a solar energy technology is easy to popularize.

Owner:KUNMING UNIV OF SCI & TECH

Transition gear and transition gear train

The invention relates to a transition gear and a transition gear train, aiming at providing the simple, practical and high-efficiency gear and the gear train used as a force conversion system for a reciprocating piston type heat engine. The transition gear is an incomplete gear with deformed tooth profile, and the tooth profile is deformed so that the transition gear can be the one with close contact and repeatedly changed speed direction and speed degree to form a gear pair. The transition gear train at least comprises one transition gear. In the rack transition gear train, the transition rack is in close contact with the tooth profile of the transition gear to make equidirectional or reversed motion or to be stationary so that the rack moving in a reciprocating manner can transfer the motion to the transition gear without rigid compact and the pushing force of fuel gas can be redistributed to drive a crankshaft to rotate.

Owner:黎耕

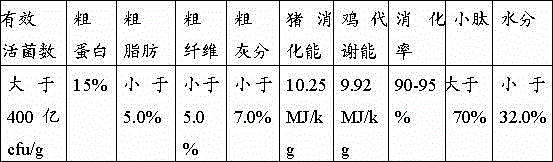

Animal feed additive and preparation method thereof

The invention discloses an animal feed additive and a preparation method thereof. The animal feed additive is prepared from the following raw materials in parts by weight: 5-10 parts of corn fiber, 15-20 parts of soybean curb residue, 12-15 parts of zeolite powder, 40-60 parts of corn sugar residue, 1 part of compound biological active enzyme, 1 part of saccharomycetes, 1 part of lactobacillus, 1 part of bacillus and 1 part of bifidobacterium, wherein the compound biological active enzyme comprises the following components: 20,000 IU / g of xylanase, 10,000 IU / g of pectinase, 400 IU / g of cellulose and 200 IU / g of protease. The preparation method comprises the steps of raw material weighing, pre-processing, mixing, dual fermentation and packaging. The animal feed additive disclosed by the invention can be used for improving the digestibility to promote the growth and development of animals, regulating the gastrointestinal micro-ecological balance to enhance animal immunity and improve disease resistance, improving animal feed intake, improving the cultivation environment to reduce respiratory diseases, and improving the quality and quantity of cultivated products.

Owner:黑龙江天予肽禾生物科技有限公司

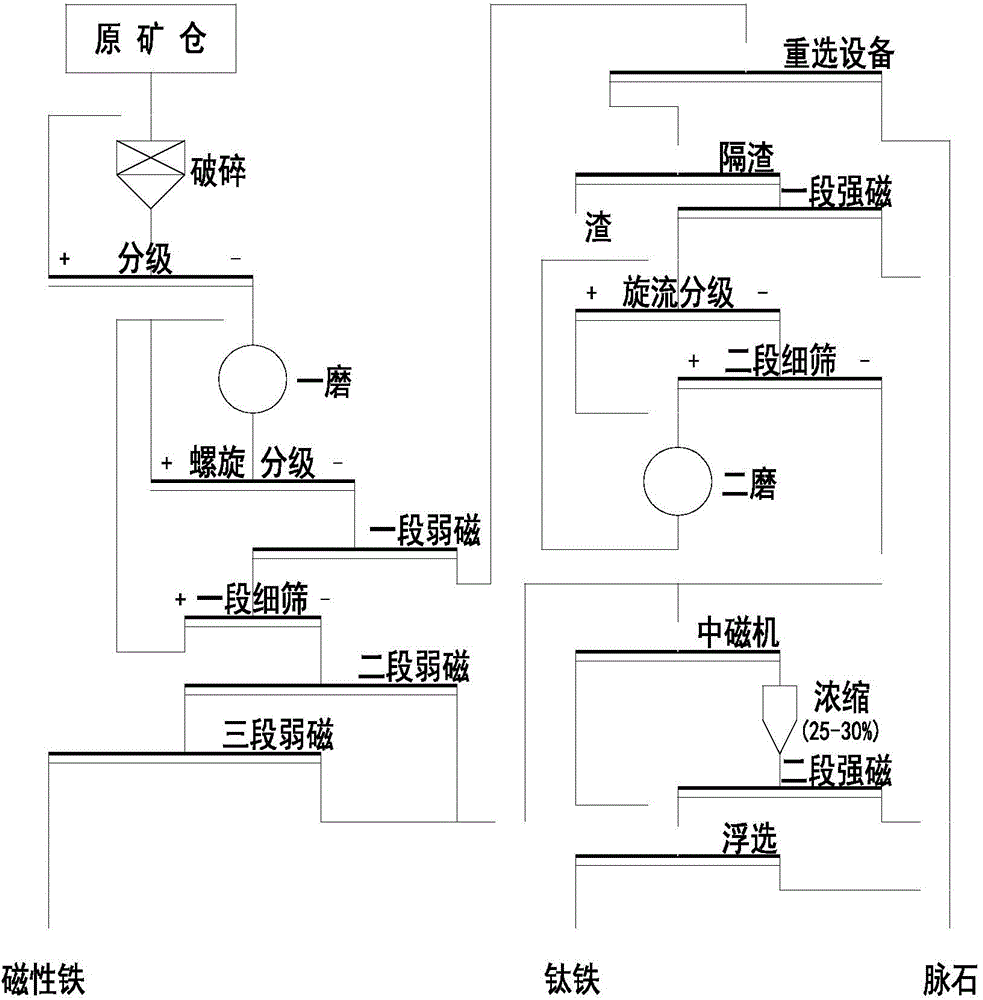

Ilmenite beneficiation method and equipment

InactiveCN104607296AGood beneficiation indexAlleviate the shortageGrain treatmentsWet separationIlmeniteEngineering

The invention provides an ilmenite beneficiation method and equipment, and is suitable for comprehensive utilization of low grade ilmenite resources. The method and the equipment provided by the invention can be used for separating materials by fully using three kinds of physical differences of useful components in ilmenite magnetic iron and ferrotitanium and useless gangues, such as magnetism, density and surface hydrophilicity, as well as the property of the stage degree of dissociation. In the whole separating process, by using a magnetic-gravity separation-flotation combined process, the magnetic iron which is the strongest in magnetism is separated by using a magnetic separating method firstly, and then the ferrotitanium is selected by using a method of gravity separation combined with strong magnetic combined flotation. In the whole separating process, a graded ore grinding and graded beneficiation method is adopted, and in the process of separating the ferrotitanium, ore is secondarily ground, so that the ferrotitanium containing part of impurities after strong magnetism in the first stage is further dissociated, and therefore, relatively good beneficiation indexes are obtained.

Owner:LONGI MAGNET CO LTD

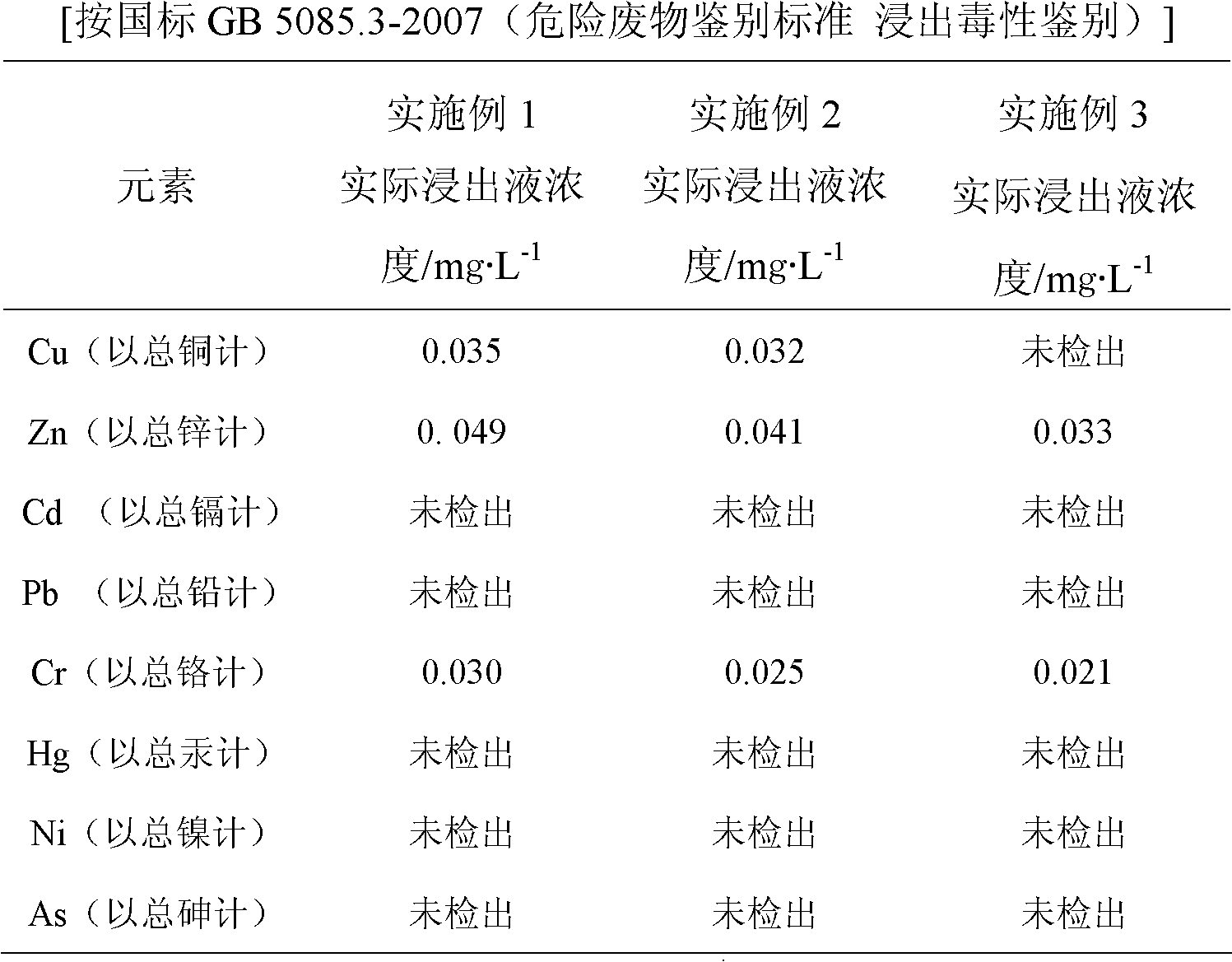

Process for preparing active carbon by adding husks into chemical sludge

InactiveCN102107872AAlleviate shortagesWide variety of sourcesSludge treatmentChemical industrySludge

The invention relates to a process for preparing active carbon by adding husks into chemical sludge. The process comprises the following steps of: drying residual sludge which is generated from sewage treatment in chemical industry and serves as a raw material; adding the husks; grinding; adding an activating agent; drying; performing carbonizing activation under the protection of inert gases; and cooling, washing and drying to prepare sludge-based active carbon. The active carbon is prepared from a great deal of the residual sludge which is generated from sewage treatment in chemical industry and serves as the raw material, so the discharge value of the residual sludge in the chemical industry is reduced, preparation cost of an active carbon adsorbent is reduced, and obvious environmental and economic benefits are achieved. The heavy metal concentration of the prepared active carbon is lower than the highest allowable leachate concentration stated in national standard GB 5085.3-2007 (hazardous waste identification standard leaching toxicity identification); and under a high-temperature pyrolysis condition, organic matters in the sludge can be completely mineralized. The active carbon prepared by the process can be applied in the fields of wastewater treatment, waste gas absorption and the like and has a wide market prospect.

Owner:NANJING UNIV OF TECH

Process for preparing EVA/PE/starch composite foam material

The invention discloses a making method of EVA / PE / starch composite foaming material, which comprises the following steps: adopting EVA and PE as main raw material and starch and inorganic flour as auxiliary material; allocating glycerin, crosslinking agent, foamer AC and surface modifier; kneading starch and glycerin in the high-speed stirrer to form gelatinized starch; fusing in the open-fusing machine with EVA, PE surface modifier and other raw materials; grafting surface modifier and EVA and PE in the fusing course; modifying the binding property of two-phase interface of EVA and PE; forming piece after fusing and plasticizing; cutting; weighing; placing in the flat vulcanizer to do vulcanization foaming; obtaining the product.

Owner:FUZHOU UNIV

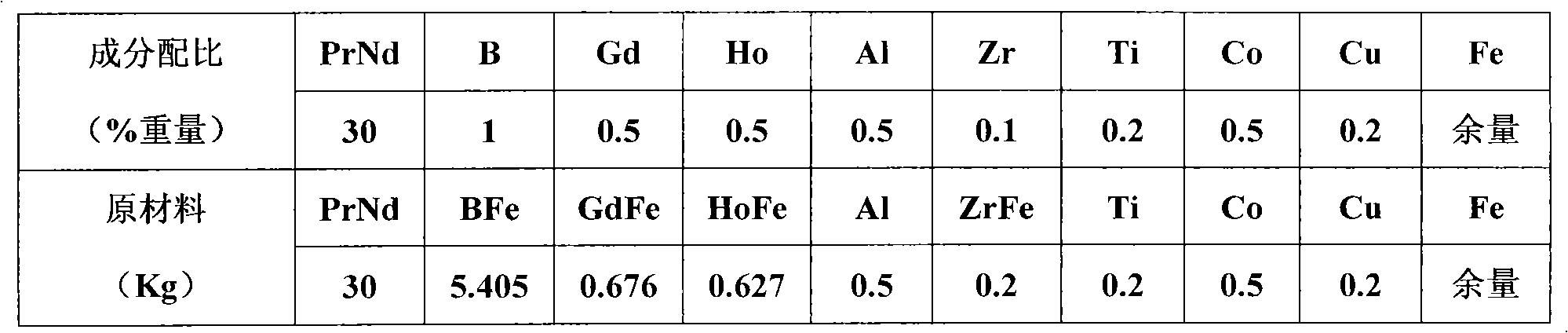

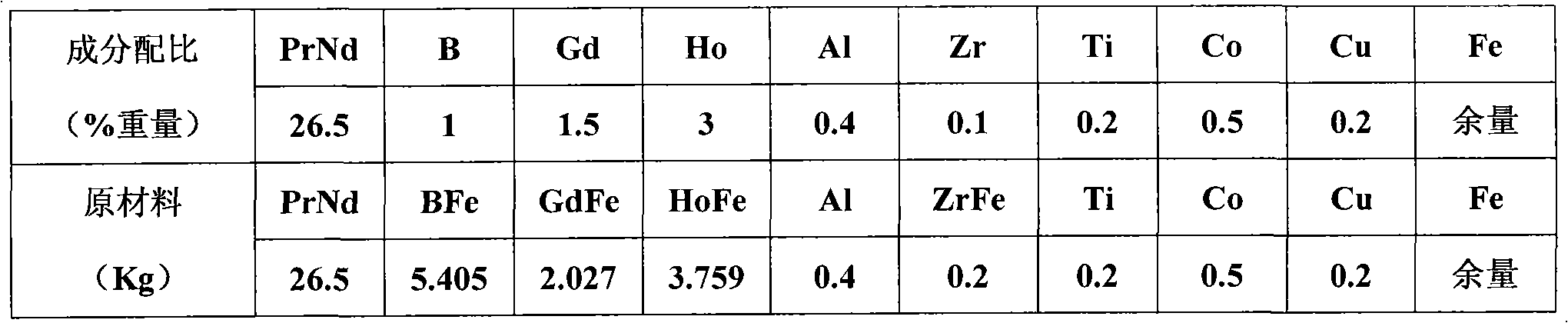

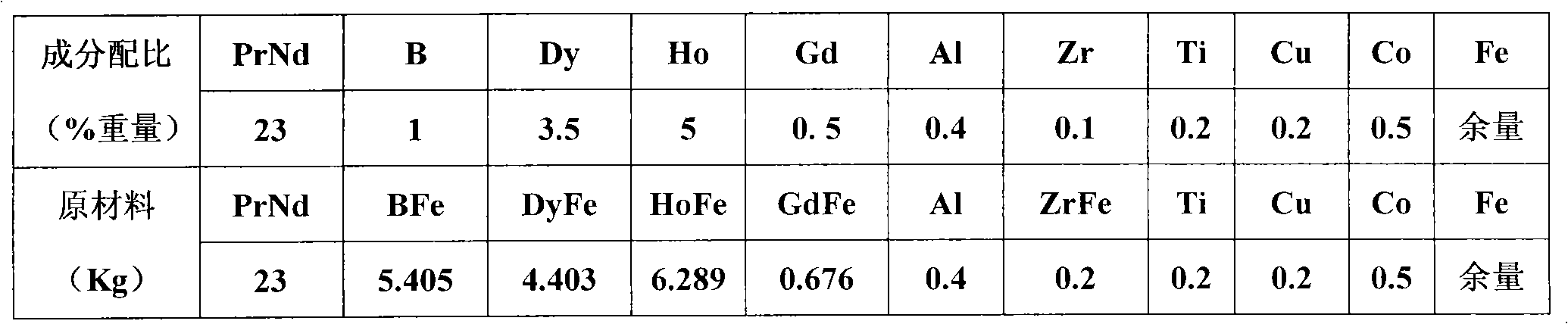

Medium-to-high grade neodymium-iron-boron magnet with composite addition of gadolinium and holmium

InactiveCN101552062AAlleviate shortagesPowder speed increasedInductances/transformers/magnets manufactureMagnetic materialsCobaltImpurity

The invention discloses a medium-to-high grade neodymium-iron-boron magnet with composite addition of gadolinium and holmium, which is composed of the following components by weight percentage: 20 percent-33 percent of praseodymium-neodymium alloy, 0.5 percent-10 percent of gadolinium, 0.5 percent-10 percent of holmium, 0.9 percent-1.2 percent of boron, 0.1 percent-0.8 percent of aluminum, 0.1 percent-0.5 percent of copper, 0.1 percent-0.5 percent of zirconium, 0.1 percent-0.5 percent of titanium, 0 percent-10 percent of dysprosium, 0 percent-3.0 percent of cobalt and the balance of iron and a small amount of inevitable impurities in materials. The medium-to-high grade neodymium-iron-boron magnet with composite addition of gadolinium and holmium has high corrosion resistance, square degree and magnetic energy product; furthermore, the powder discharging speed of the powder production procedure in the preparation process is fast, thereby shortening the production cycle, improving the magnetic performances of the magnet and enhancing the enterprise competitiveness.

Owner:宁波同创强磁材料有限公司

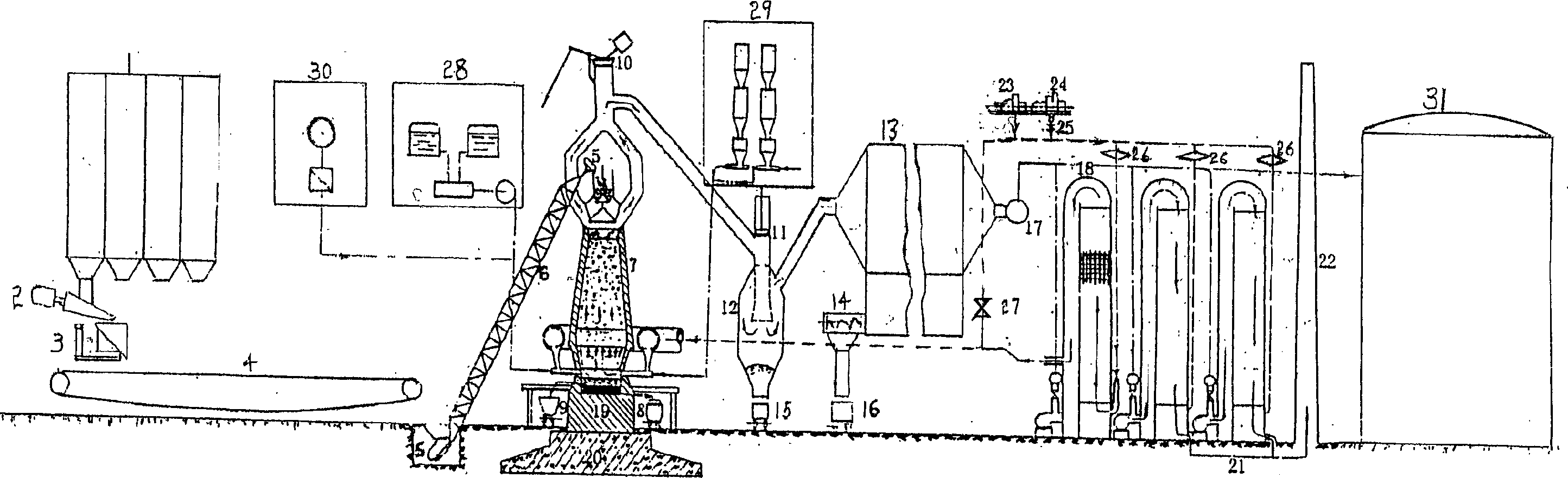

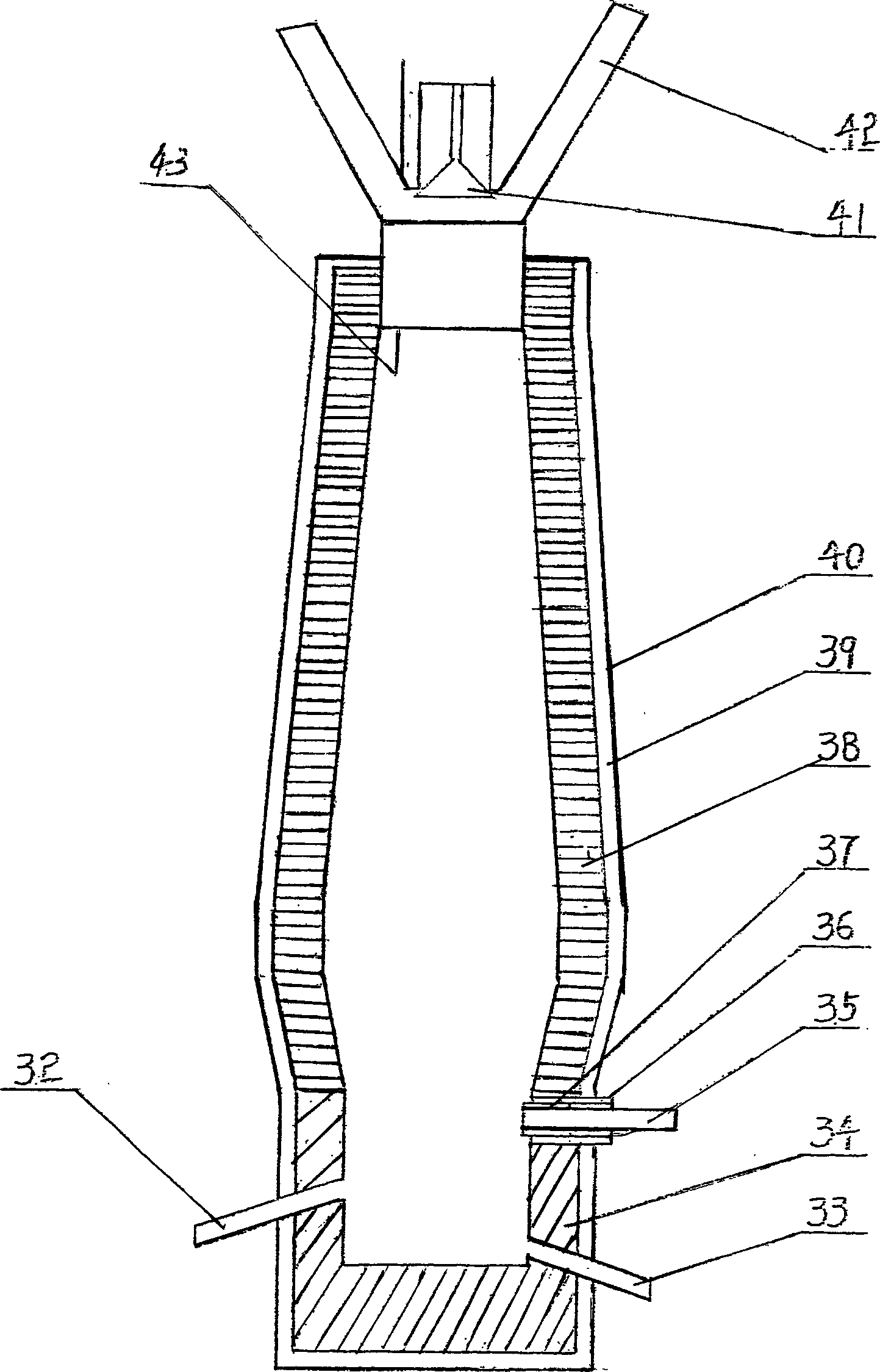

Method and apparatus for preparing calcium carbide by oxygen-fuel blowing of high furnace

InactiveCN1843907AReduce manufacturing costRealize the comprehensive utilization of resourcesChemical industryCalcium carbideFerrosiliconHearth

The invention relates to field of preparing calcium carbide with oxygen jetting in tower furnace. The calcium carbonate is heat decomposed into calcium oxide and reduced to calcium carbide by carbon material by jetting with preheating oxygen or oxygen-enriched air. The device comprises: tower furnace and systems of feeding, charging, oxygen producing, heating air, blasting air, oxygen enriching, jetting, cooling, cleaning and recoverying coal gas and recovering calcium carbide and ferrosilicon. The ration between said furnace height and furnace hearth diameter is less than or equal to 3.5, and diameter ratio between furnace hearth and furnace hearth is 0.8-1.1. The invention is to produce calcium carbide of 80%, the proportioning of raw material is lime carbonate: coke: fluorite =(1.2-2.0): (1.5-4.0): (0.039-0.046); jetting material is coal powder, light oil or natural gas; relative oxygen-enriched air amount, the xygen-enriched rate is 9-39%, and prepares side products of calcium carbide of more than 65%, ferrosilicon more than or equal to 54% and carbon monoxide of more than or equal to 54% at high temperature. The invention is characterized by energy saving, high quality and environmental protection.

Owner:岳书才

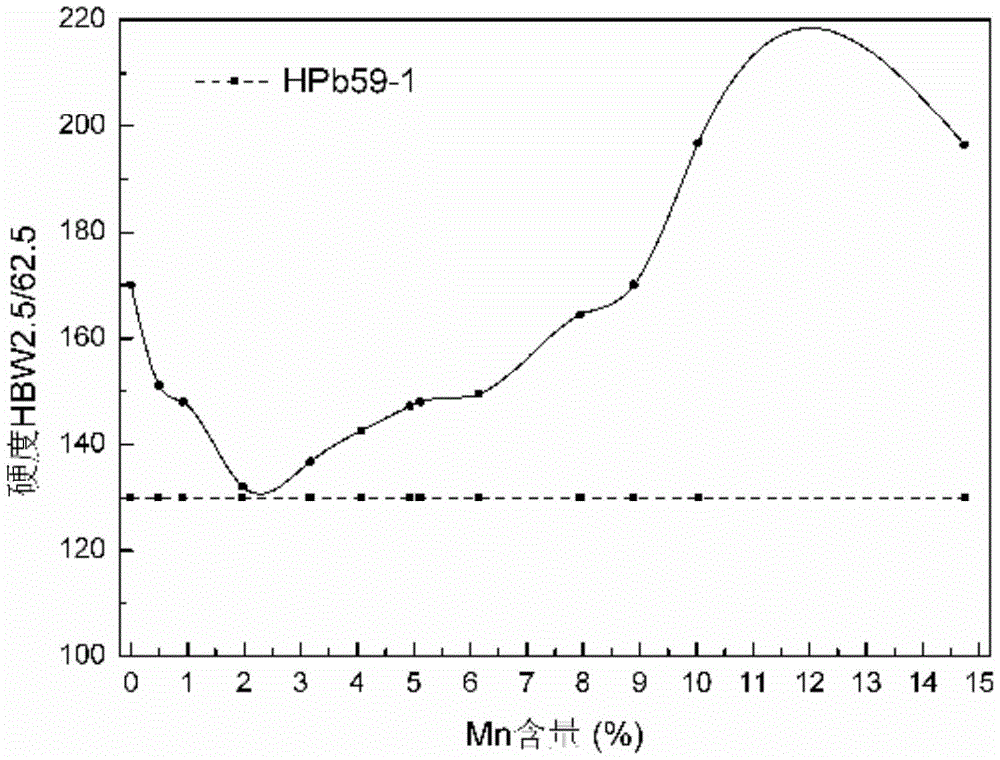

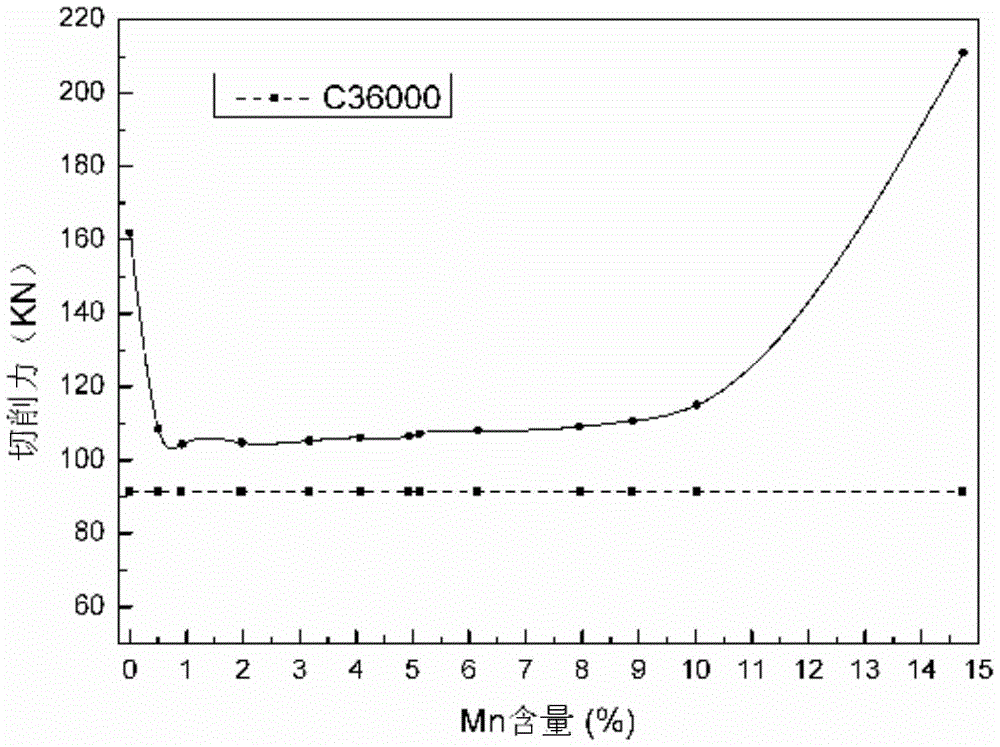

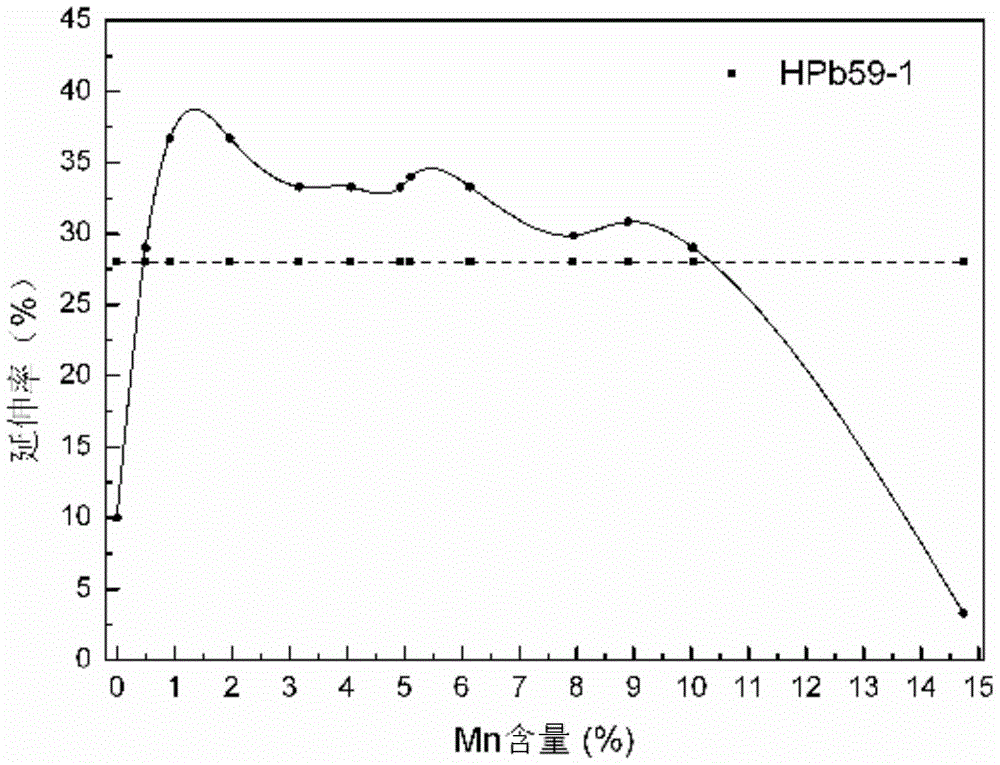

Machinable brass alloy and preparation method thereof

The invention relates to a machinable brass alloy and a preparation method thereof. The machinable brass alloy is characterized by including following components, by weight, 45-54 wt% of copper, 0.5-9.0 wt% of manganese and 37-53 wt% of zinc, wherein the total weight of the three metal components is not less than 95% and the weight of unavoidable impurities is not more than 0.1 wt%. The alloy also includes a Cu-Zn solid solution having a body-centered cubic structure and a Cu-Mn solution having a surface-centered cubic structure. The preparation method includes following main process: material preparation, smelting, continuous casting, skin stripping, pulling, stress removal and annealing, straightening, sizing and packaging. The machinable brass alloy is better in machinable and mechanical performances and is greatly reduced in alloy, can be used for replacing a machinable brass alloy in the prior art, and can alleviate the problems of shortage of copper resources and excess of zinc resources.

Owner:NINGBO POWERWAY ALLOY MATERIAL

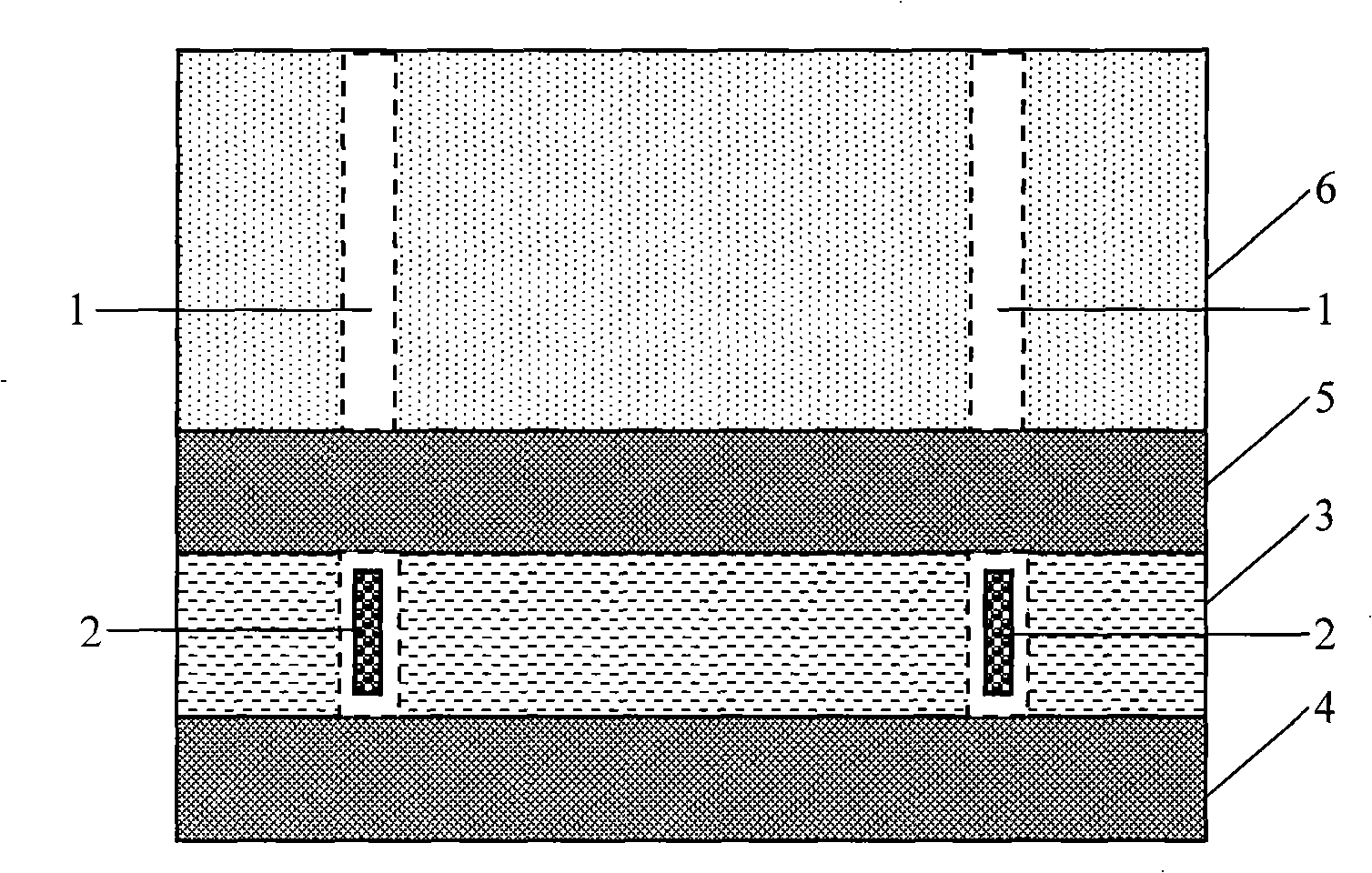

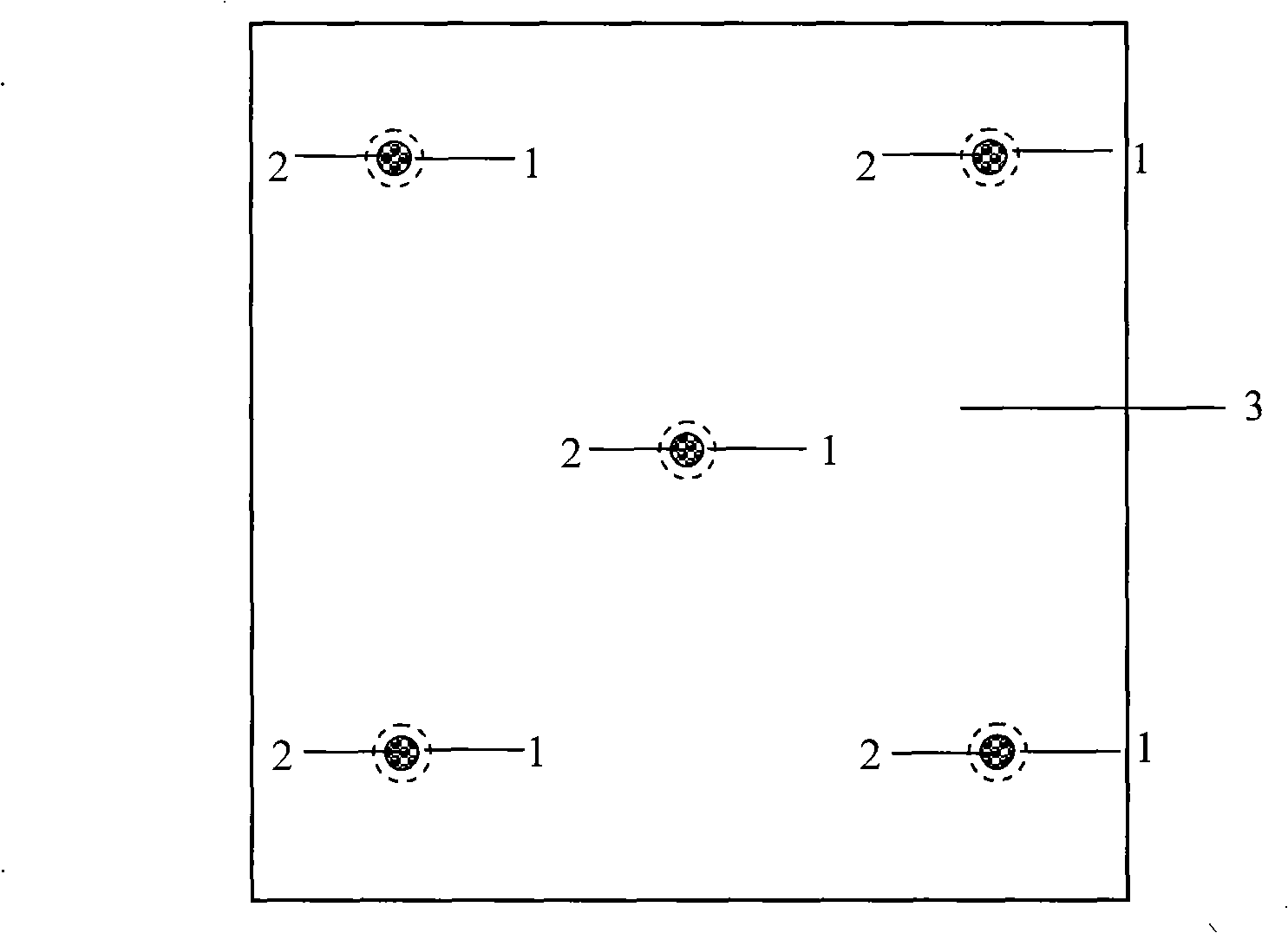

Method for blasting seepage enhancement for low infiltration sandrock -type uranium deposit

The invention discloses a method for explosion and leakage increase of a low permeability sandstone uranium deposit, which includes steps as follows: A. blast holes are drilled through the overburden, the top rock of occurrence terrane to the proper position of the occurrence terrane from surface. An underreamer is used to locally ream the blast holes at the occurrence terrane to meet charging requirement; B. blasting cartridges are arranged in the blast holes in an uncoupling way; the detonator is waterproof; uncoupling charge for explosion comprises radial uncoupling charge and axial uncoupling charge; C. after the blasting cartridges are arranged properly, hole seal measures shall be taken to build up the blast holes; D. the blasting cartridges are initiated through short delay blasting which comprises short delay blasting inside the blast holes and short delay blasting between the blast holes. The recovery factor and the yield per unit of in-situ Uranium leaching are improved; the uranium deposit resource of low permeability sandstone type is used completely, thus alleviating the shortages of uranium resources.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

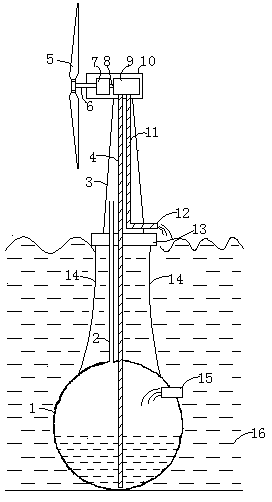

Sea wind-driven water-pumping energy-storage hydraulic power generation device

InactiveCN103410651AControl full load operationFull load reductionMachines/enginesEngine componentsWind drivenEngineering

A sea wind-driven water-pumping energy-storage hydraulic power generation device comprises a wind turbine, an energy storage ball, a water pumping pump and a hydraulic power generation unit. The wind turbine is built above the sea level, the energy storage ball is built on the seabed below the sea level, a seawater inlet is formed in the energy storage ball, the hydraulic power generation unit is arranged at the water inlet for power generation, and the water pumping pump can discharge the seawater in the energy storage ball, which impacts the hydraulic power generation unit, into the sea after power generation. According to the device, wind-driven water-pumping energy-storage and hydraulic power generation are combined, the combined usage of the two energy sources is achieved, and accordingly, impact of wind-driven generation on power grids can be prevented, energy storage through the water resource can be fully used, and problems during current combined wind and hydraulic power generation are solved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

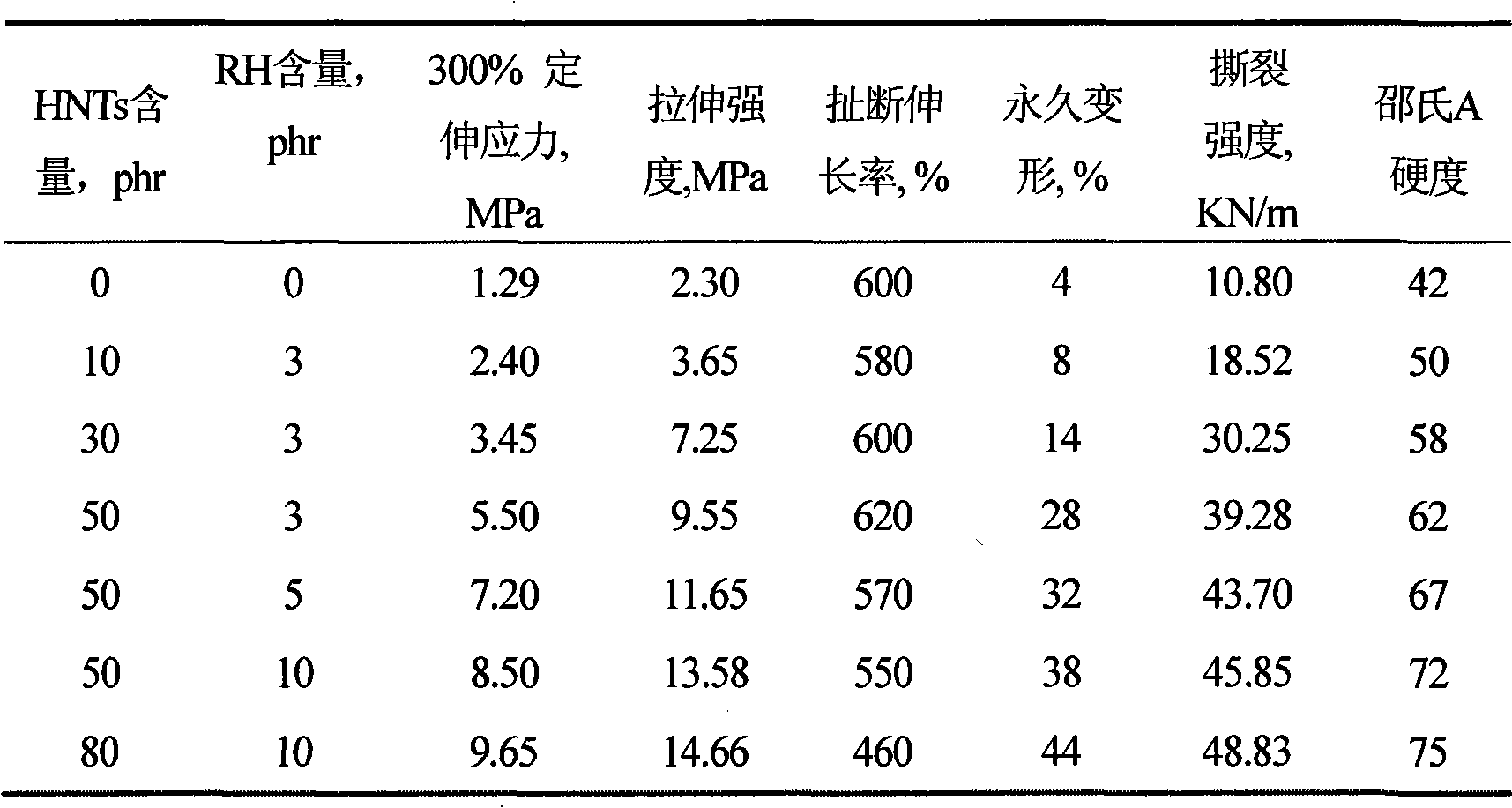

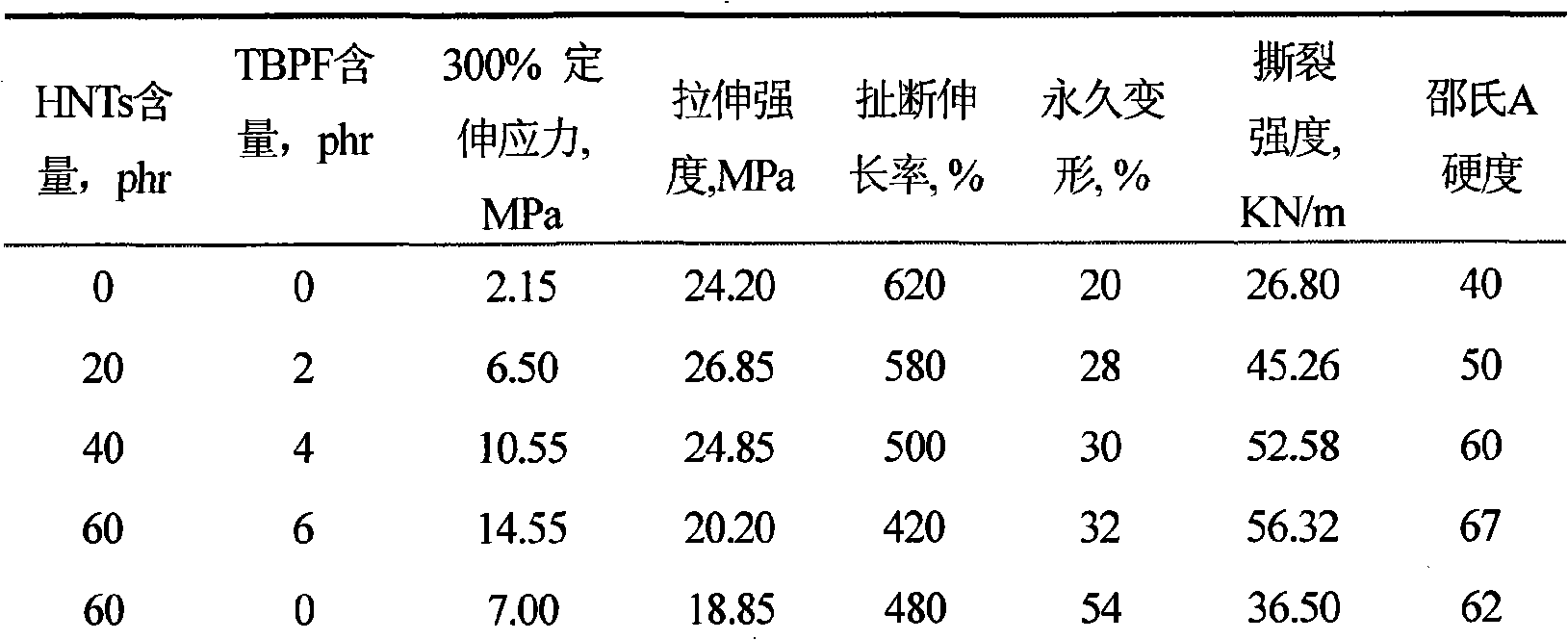

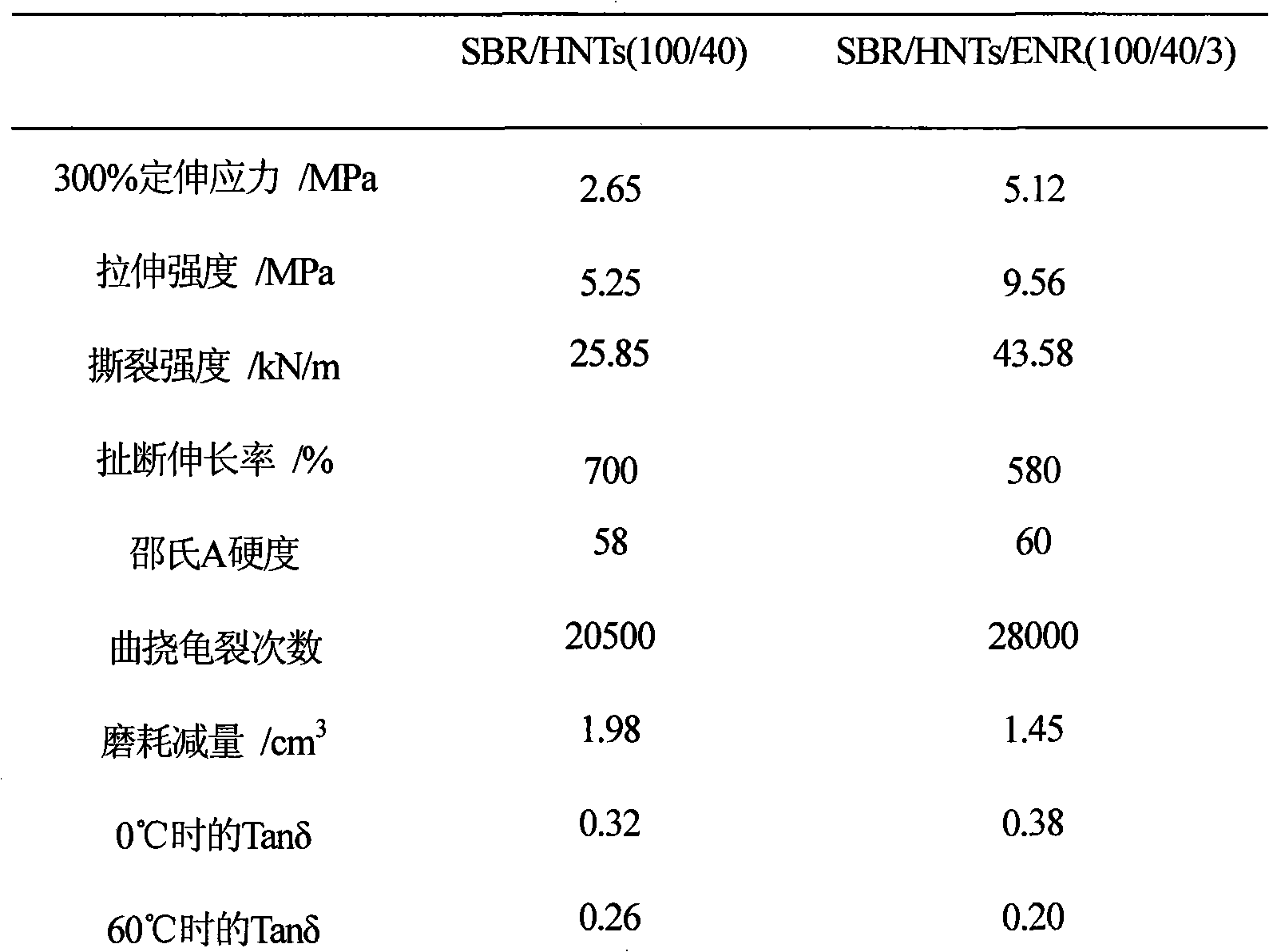

Preparation method for rubber/keramite nano-tube nano-composite material

The invention relates to preparation method of rubber / halloysite nanotube nano-composite material, the invention adopts the preparation method that the rubber, the halloysite nanotube and modifying agent are mixed according to the mass ratio of 100:5 to 100 : 0.5-20 through the ordinary rubber pugging equipment and technique, then the sulphation is performed through the ordinary sulphidizing process and equipment to realize the in-situ modification, and finally, the rubber / halloysite nanotube nano-composite material with nano-dispersion, good interfacial bonding and good performance. Wherein, the modifying agent comprises compound in-situ generated phenolic resin, alkyl phenolic resin, modified rubber, methacrylic acid metal salt and one or more than one mixture (s) in the sulfur-containing organosilane coupling agent. The preparation method of rubber / halloysite nanotube nano-composite material has the advantages that the defects that the rubber / halloysite nanotube nano-composite material is difficult to be dispersed, the interfacial bonding is not good, the performance can not be improved observably can be overcome, and the preparation method can be applied in a variety of rubber products, rubber toughening plastics and binding agents and the like.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method for papermaking argillaceous activated carbon adsorption material

InactiveCN105126756ALow process temperatureReduce entryOther chemical processesSludge treatment by pyrolysisSludgeShielding gas

The invention discloses a preparation method for a papermaking argillaceous activated carbon adsorption material. The preparation method comprises the following steps of concentrating, squeezing and drying biochemical sludge from a pulping and papermaking wastewater treatment plant until the water content is below 10 percent, and grinding, sieving and retaining sludge particles with the average grain diameter of 200 meshes; adding the sludge particles into an activating agent for activating treatment, and then performing dewatering and drying; placing the dried sludge particles into a pyrolyzing furnace; by taking nitrogen gas as protective gas, performing carbonizing treatment on the nitrogen gas under an anaerobic condition; washing a product subjected to the carbonizing treatment with a hydrochloric acid solution and then washing the product with distilled water to be neutral, and drying, grinding and sieving to prepare the papermaking argillaceous activated carbon adsorption material. The preparation method disclosed by the invention is simple, and breaks through a traditional technique of preparing activated carbon from coal and wood; the cost of raw materials is low, so that the contradiction that wood and energy in China are in shortage is alleviated; besides, the preparation method also opens up a new path for treating solid papermaking wastes.

Owner:SHAANXI UNIV OF SCI & TECH

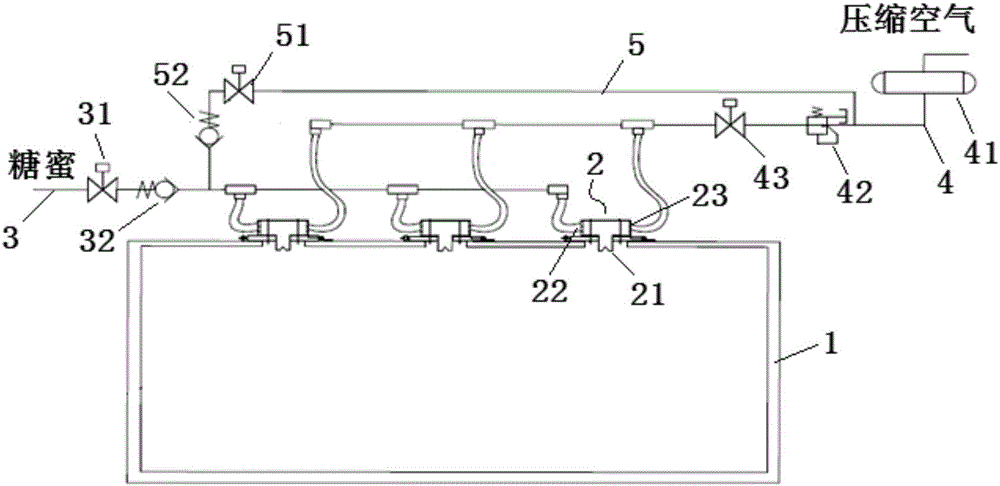

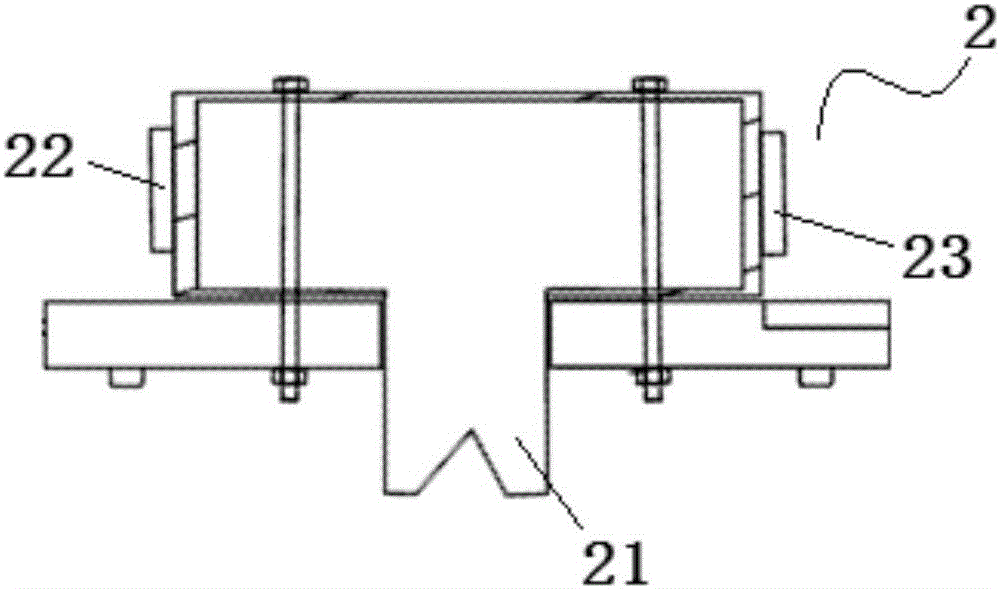

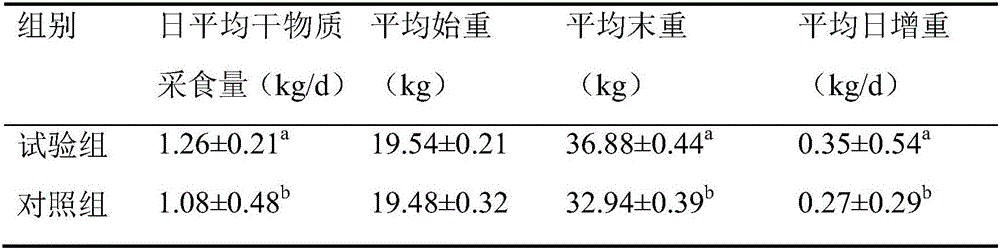

Total mixed pellet feed for meat sheep and manufacturing method and application of feed

InactiveCN106376738AImprove palatabilityIncrease feed intakeFood processingAnimal feeding stuffSodium bicarbonateSlurry

The invention discloses total mixed pellet feed for meat sheep and a manufacturing method and application of the feed. The feed comprises: 20.00-40.00% of straw, 0.00-30.00% of caragana korshinskii, 0.00-30.00% of sunflower shells, 0.00-30.00% of leymus chinensis, 10.00-30.00% of corn, 5.00-10.00% of molasses, 5.00-8.00% of soybean meal, 0.00-10.00% of cottonseed meal, 0.00-5.00% of sesame meal, 0.00-15.00% of maize germ meal, 0.00-5.00% of rapeseed meal, 0.00-8.00% of corn bran with slurry, 0.00-3.00% of wheat bran, 0.00-5.00% of rice bran, 0.00-20.00% of corn distiller's dried grains with soluble, 0.00-3.00% of bentonite, 0.40-0.80% of salt, 0.10-0.50% of calcium hydrogen phosphate, 0.50-1.50% of stone flour, 0.00-0.80% of slow-release protein, 0.50-1.50% of sodium bicarbonate, 0.04-0.08% of a mildew inhibitor, 0.40-0.50% of ammonium chloride, 1.00-3.00% of Chinese herbal medicine premix and 0.80-1.50% of meet goat fattening premix. The feed can replace common refined feeding and roughage, the breeding process is simplified, the breeding cost is saved, and the total mixed pellet feed can prevent the occurrence of rumen acidosis and urinary calculus of meet sheep.

Owner:BEIJING JIUZHOU DADI BIOLOGICAL TECH GRP

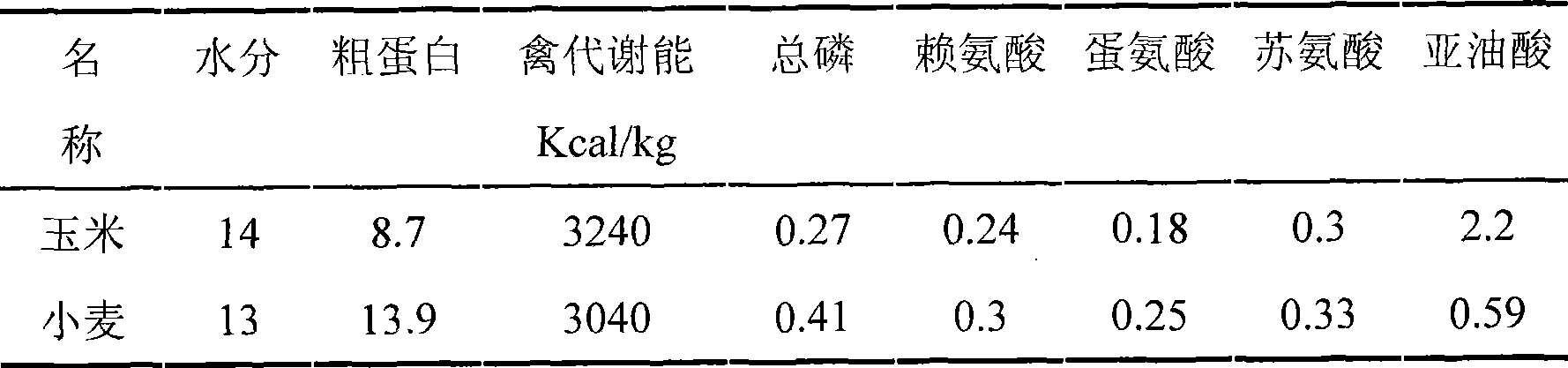

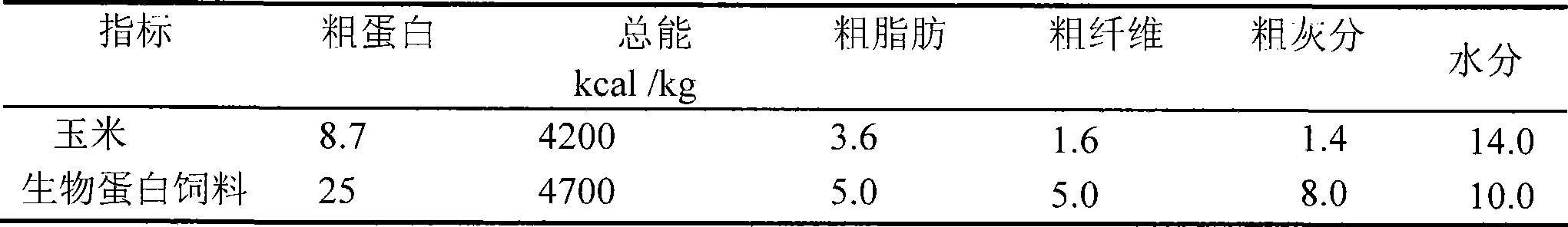

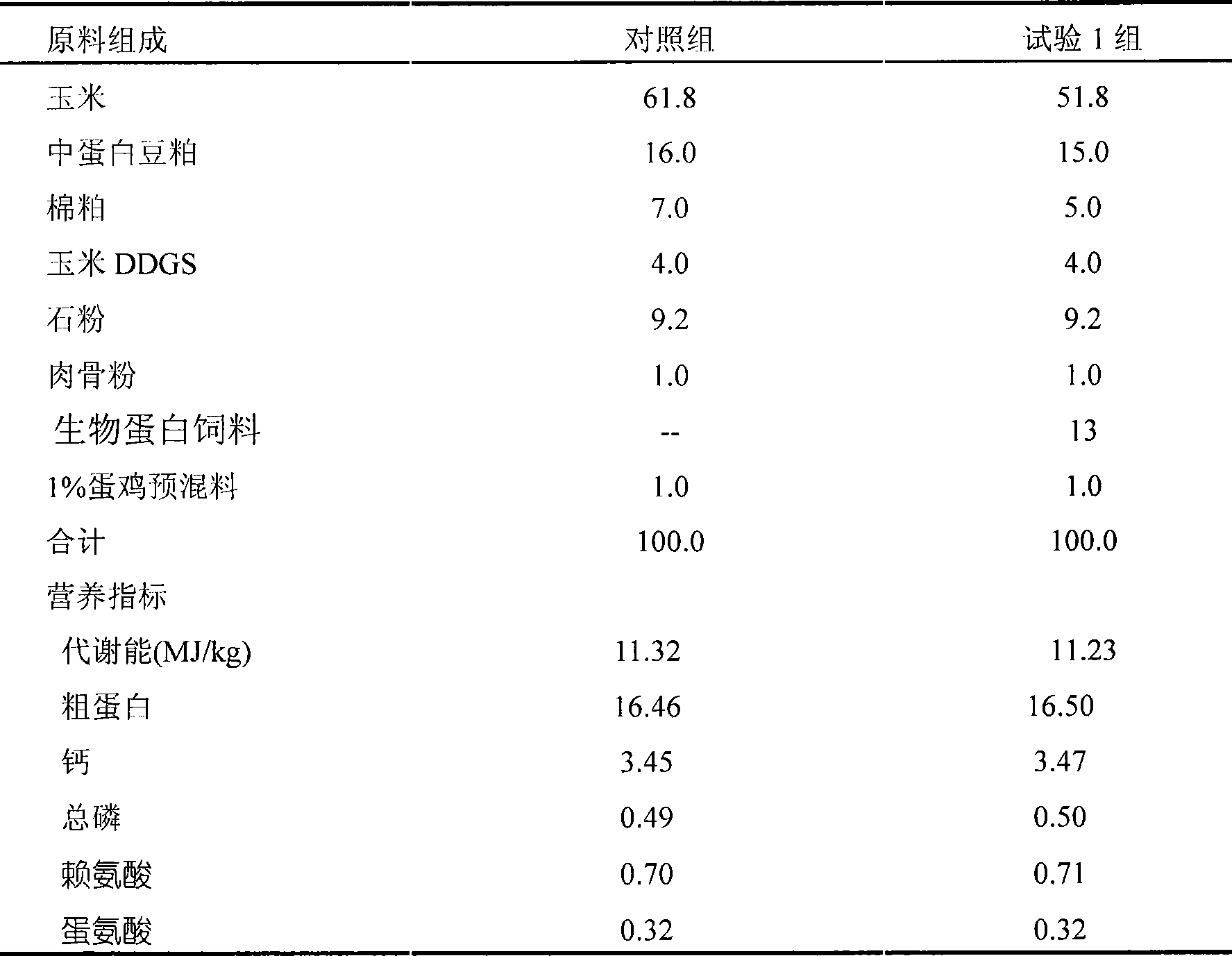

Feedstuff for laying hens and use thereof in producing laying hens

InactiveCN101449746AFully utilized resourcesLower cholesterol levelsFood processingAnimal feeding stuffNutrientNutritional composition

The invention discloses forage for laying hen and application thereof in laying hen production. The forage is prepared by following weight of components: 50-53 parts of corn, 12-18 parts of middle protein soybean meal, 4-6 parts of cotton meal, 4-6 parts of corn DDGS, 9-10 parts of stone powder, 0.8-1.2 parts of meat bone meal, 11-15 parts of biological protein forage and 0.8-1.2 parts of 1% laying hen premix. The biological protein forage provided by the present invention is light brown forage raw material with high quality, high energy and high protein, and has concentrated fragrance and strong palatability, so animal likes the forage. Content of thalline protein, peptide and free amino acid of the forage is high, and nutrient composition absorptivity is high. Simultaneously the raw material contains a large amount of beneficial microorganism and unknown growth factor, thereby improving micro-ecological environment in intestinal tract, increasing resistivity and disease resistance of animal, and reducing content of antibiotic medicament in the forage.

Owner:河南商都生物技术股份有限公司

Method for pretreating waste mineral oil and performing hydrogenation regeneration to produce lubricating base oil

ActiveCN106350112AEfficient removalSimple stepsTreatment with hydrotreatment processesLubricant compositionPretreatment methodPetroleum product

The invention discloses a method for pretreating waste mineral oil and performing hydrogenation regeneration to produce lubricating base oil. The method is characterized in that: pretreatment of the waste mineral oil sequentially comprises the following steps of performing sedimentation dehydration, washing, centrifuging by using a disc-type centrifuge, centrifuging by using a horizontal centrifuge, evaporating by using a scraping film evaporator, and performing reduced pressure distillation; preheated lubricating base oil enters a hydrogenating device, enters a pre-hydrogenation protection reactor first and then enters the hydrorefining reactor to produce the high-grade lubricating base oil. By the method for pretreating the waste mineral oil and performing hydrogenation regeneration to produce the lubricating base oil, various non-ideal components in the waste lubricating oil can be effectively removed only after pretreatment provided by the invention; the method is simple in steps and is convenient to operate; manpower and material resources are saved; the lubricating base oil product is good in quality and high in yield, wastes are not produced, and no pollution is caused to the environment; operating conditions are relatively mild, using requirements on equipment are lowered, the regenerating efficiency is increased by 10-15%, continuous operation of the equipment is facilitated, and pollution of the waste oil on the environment and shortage of a petroleum product are relieved.

Owner:新疆聚力环保科技有限公司

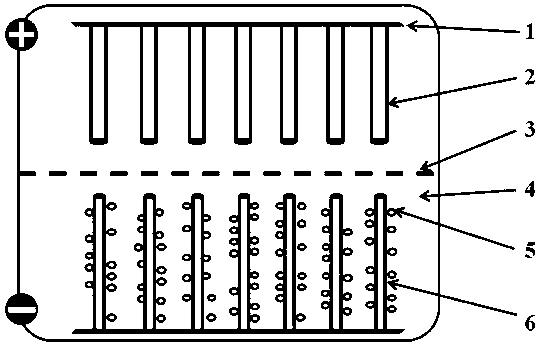

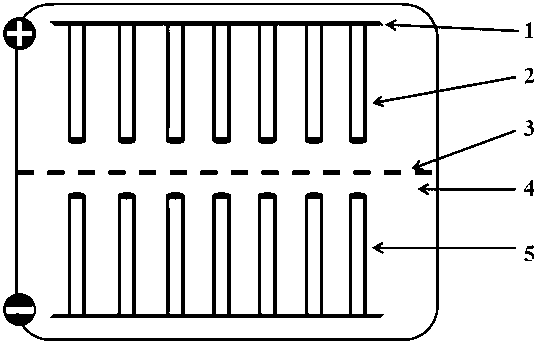

Oxygen evolution electrode

InactiveUS20080116064A1Reduce manufacturing costAlleviate shortagesMachining electrodesMultiple component coatingsElectrolysisOxygen

Disclosed is an oxygen evolution anode for evolving oxygen without chlorine evolution in electrolysis of aqueous solutions of sodium chloride having high performance and durability with decreased amount of the precious metal(s) in the intermediate layer to decrease manufacturing cost and to ease problem of the resources. The oxygen evolution anode comprises an electroconductive substrate, an intermediate layer and an electrocatalyst. The intermediate layer prepared by calcination consists of multiple oxide of the platinum group element(s), Sn and Sb, with the Sn / Sb ratio of 1-40 and with the sum of Sn and Sb of 90 cationic % or less. The electrocatalyst is prepared by anodic deposition and consists of 0.1-3 cationic % of Sn, 0.2-20 cationic % of Mo and / or W and the balance of Mn.

Owner:DAIKI ATAKA ENG

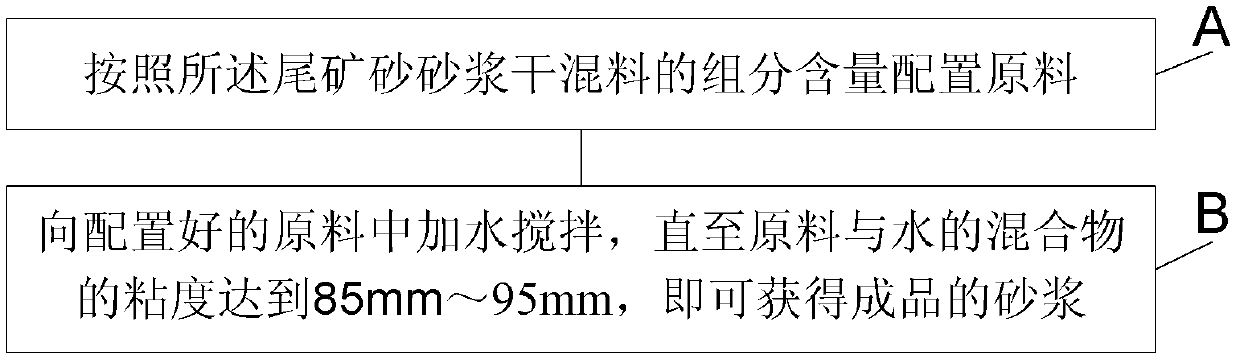

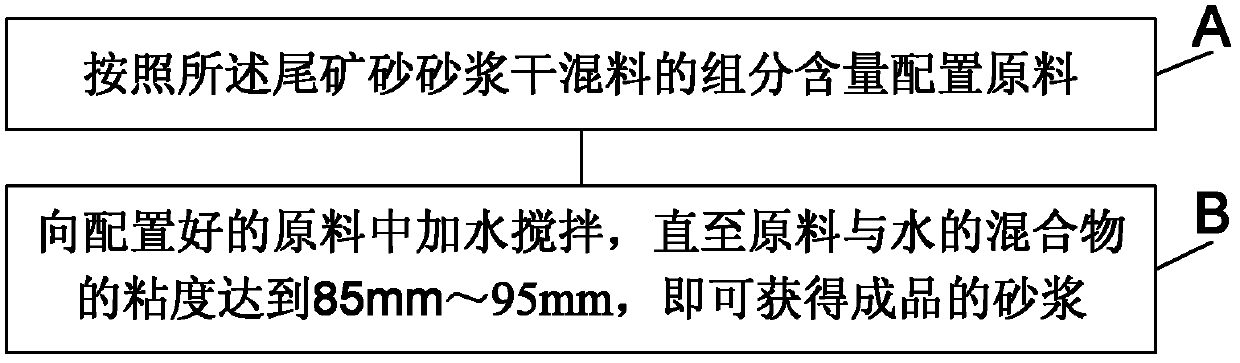

Tailing sand mortar dry blend and mortar preparation method thereby

InactiveCN102603248ARealize the rational application of resourcesImprove water retentionCellulosePortland cement

The invention discloses a tailing sand mortar dry blend and a mortar preparation method thereby. The tailing sand mortar dry blend comprises the following raw materials of common portland cement, sand, cellulose ether, naphthalene formaldehyde water reducer and re-dispersible latex powder, wherein the mass ratio of the common portland cement to the sand is 1:2-1:4; the mass of the cellulose ether accounts for 0.02-0.1% of the total mass of the common portland cement and the sand; the mass of the naphthalene formaldehyde water reducer accounts for 0.5-1.2% of total mass of the common portland cement and the sand; the mass of the re-dispersible latex powder is 0.05-0.4% of the total mass of the common portland cement and the sand; and the sand comprises 60-80wt% of tailing sand and the balance of natural sand. According to the embodiment of the tailing sand mortar dry blend, the use amount of the natural sand in the mortar is reduced, and the problem that the natural sand is in shortage is alleviated. In addition, the recycling reasonable application of the tailing sand is realized, and the preparation cost of the mortar is lowered.

Owner:北京建筑工程学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com