Transition gear and transition gear train

A technology of gear trains and gears, which is applied in the field of transition gears and transition gear trains, can solve the problems that the piston cannot be reciprocated and cannot be used as an internal combustion engine power conversion mechanism, etc., so as to alleviate the energy shortage, reduce the volume of the combustion chamber, and improve environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] 1. Implementation mode of transition gear:

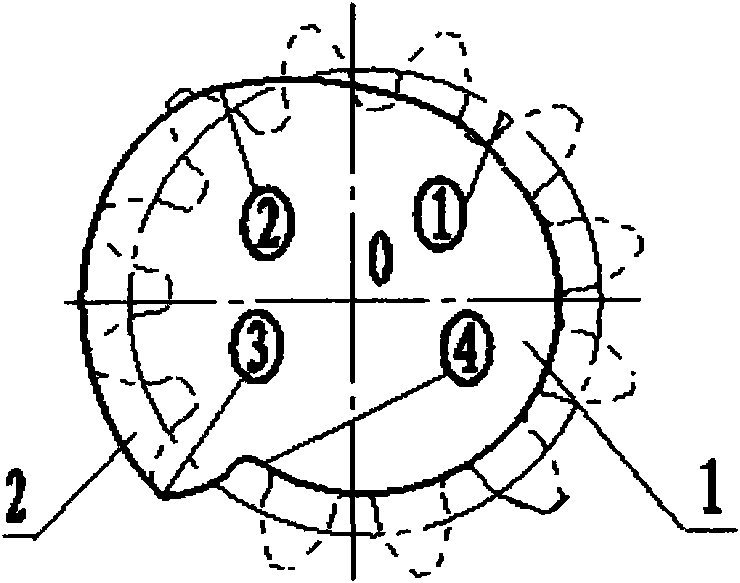

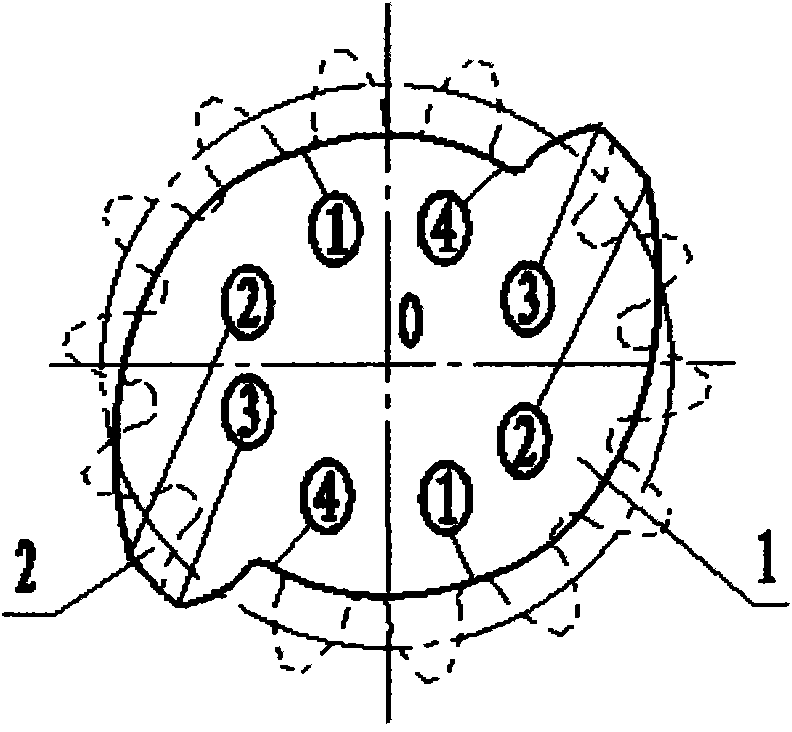

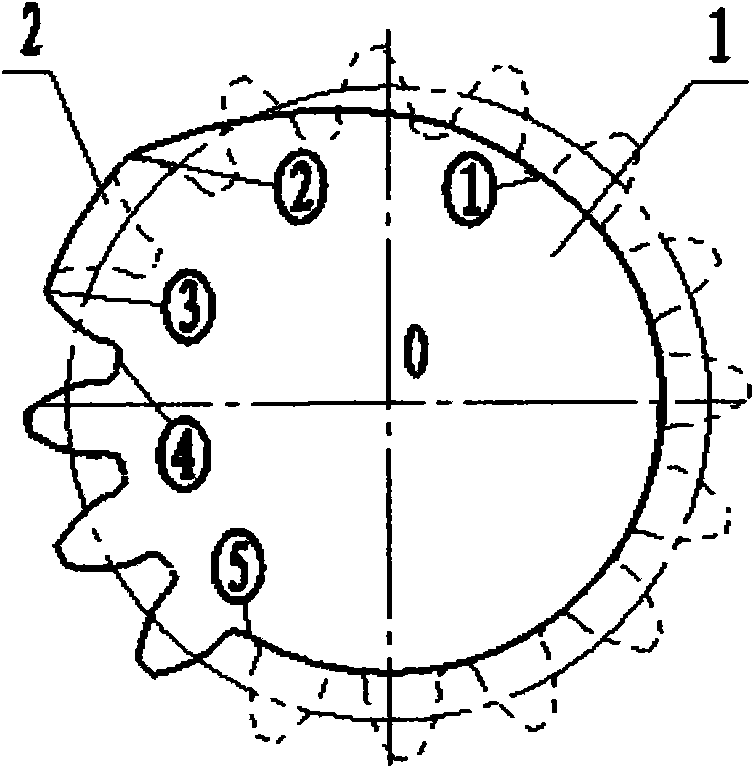

[0064] The transitional gear is deformed based on the tooth profile data of the usual gear pair as an example. Such as figure 1 , figure 2 , image 3 The dotted line in is the involute tooth profile of the unused parallel shaft gear pair, the toothless part ⑤-① or ④-① is the dedendum arc of the normal gear, and the normal tooth part ⑤-④ is the involute tooth profile , but the tooth height can be raised and lowered, and the tooth width increased (such as Figure 5 The tooth rack of the transition section ③-④ is an involute tooth profile, but the shape of the tooth profile can be changed according to the needs; the transition middle section ②-③ tooth profile is the tooth top of the involute gear, but it can be as follows figure 1 , Figure 4 Change the height and shape of part of the addendum in that way, and push the rack to continue to move forward to reach the end of the stroke; the transitional front section ①-② is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com