Paddy field ridger

A technology for building ridges and paddy fields, which is applied in the fields of farming machinery, agricultural machinery and machinery, and applications, can solve the problems of easy collapse, low work efficiency, and long ridge building time, and achieves moderate bottom width, high production efficiency, and power. balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

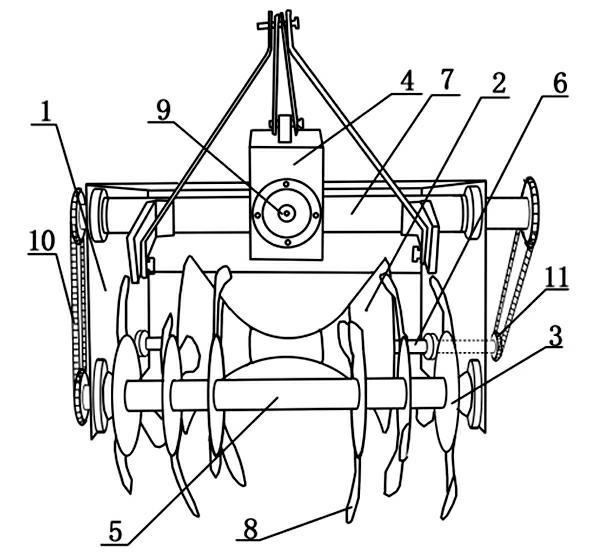

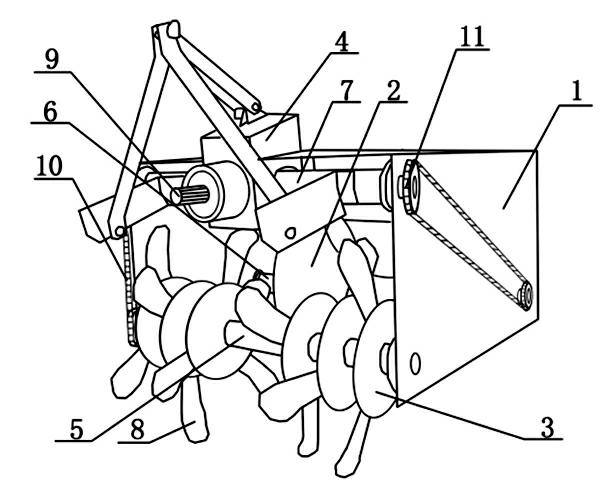

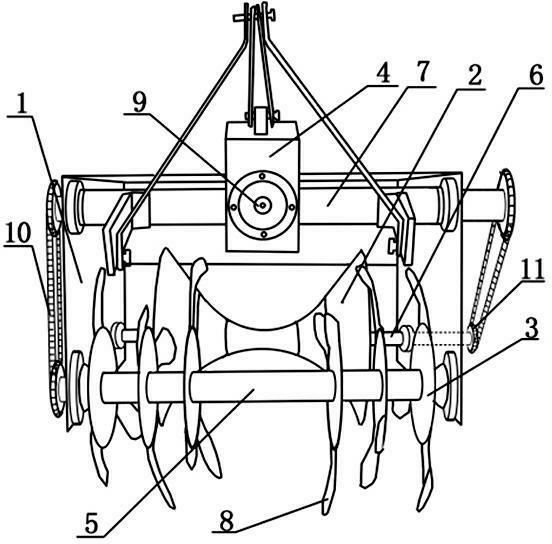

[0014] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

[0015] like figure 1 , figure 2 As shown, a kind of paddy field ridge building machine of the present invention comprises frame 1, field ridge device 2, reamer, gear box 4, and described frame 1 comprises front axle 5, rear axle 6, is provided with on frame 1 top Drive shaft 7, the middle part of the drive shaft 7 is provided with a gear box 4, and the front part of the gear box 4 is provided with an input shaft 9, and the input shaft 9 is connected with the output shaft of the engine to provide power for the whole paddy field ridge building machine. The gear 11 on one side of the transmission shaft 7 is connected with the gear 11 on the front axle 5 through a chain 10 , the gear 11 on the other side of the transmission shaft 7 is connected with the gear 11 on the rear axle 6 through a chain 10 , and the chain 10 on the gear 11 Drive front axle 5, rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com