Patents

Literature

19741results about How to "Promote environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

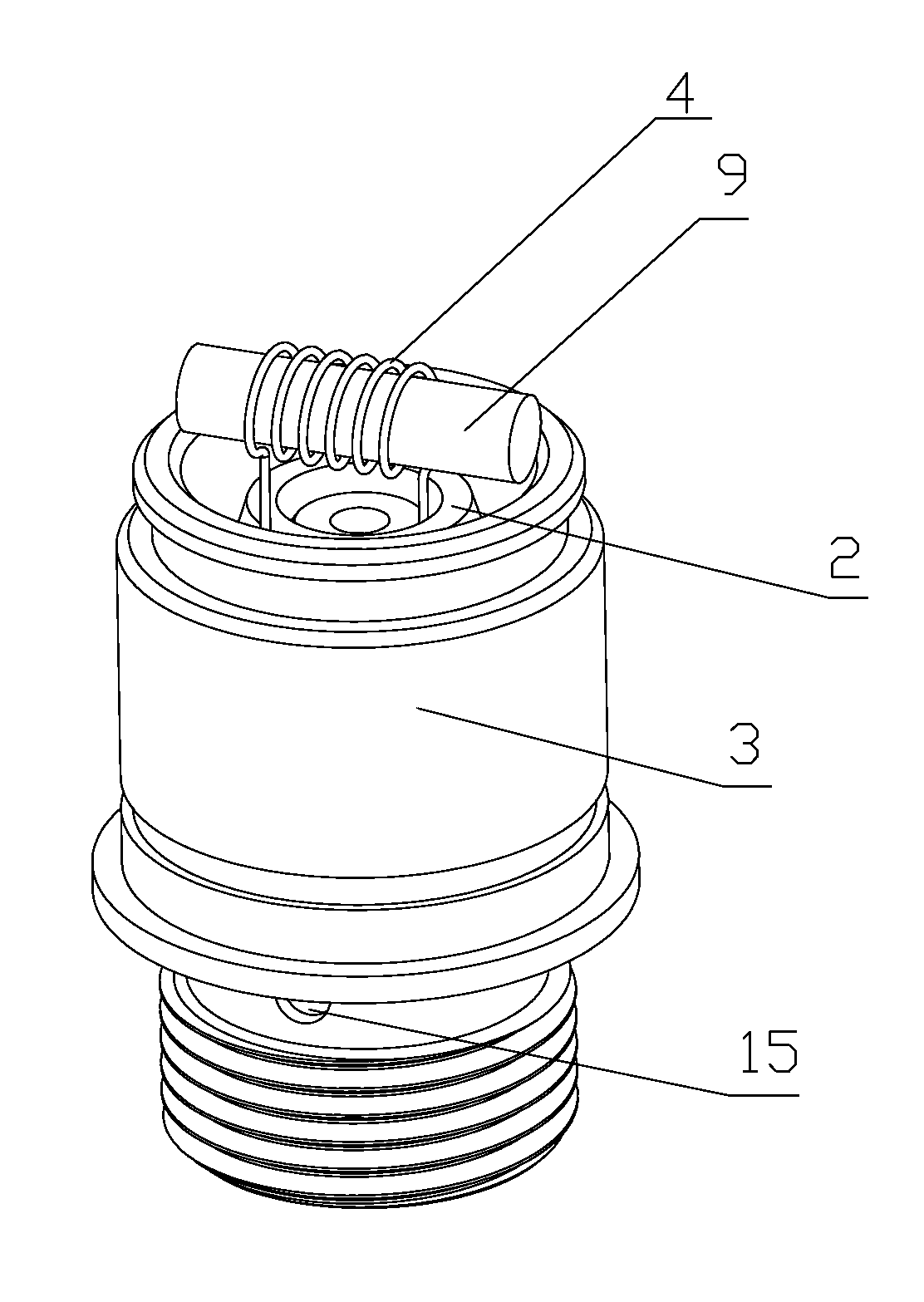

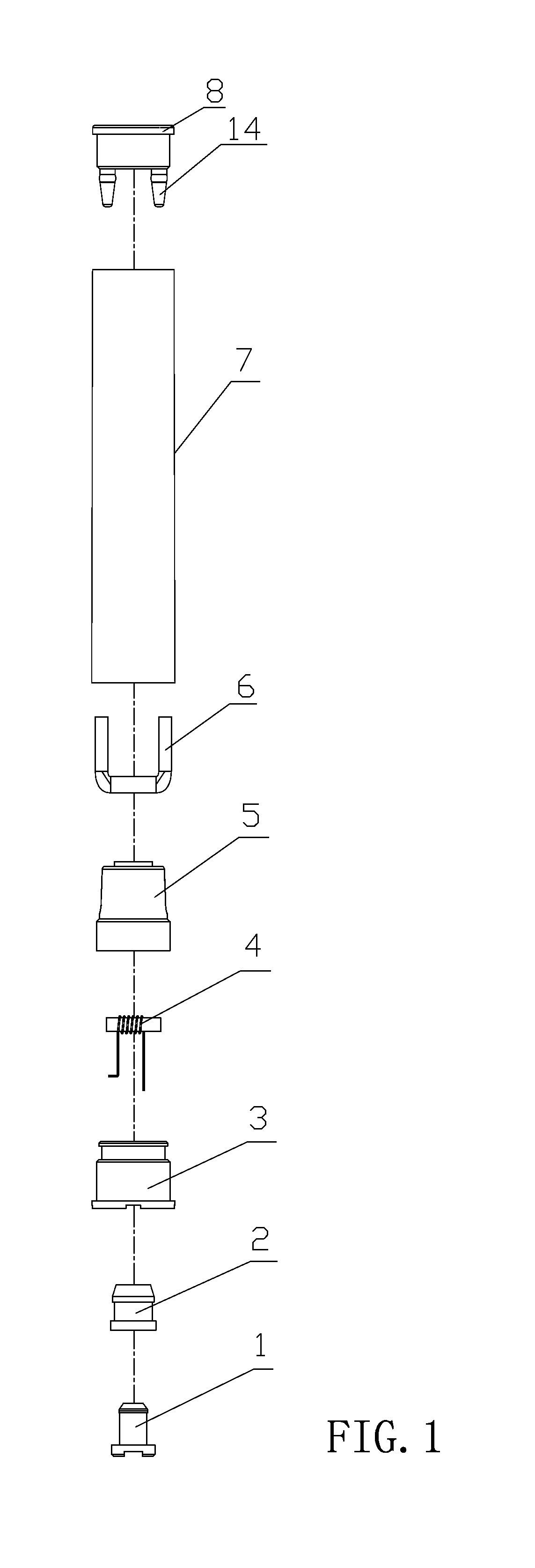

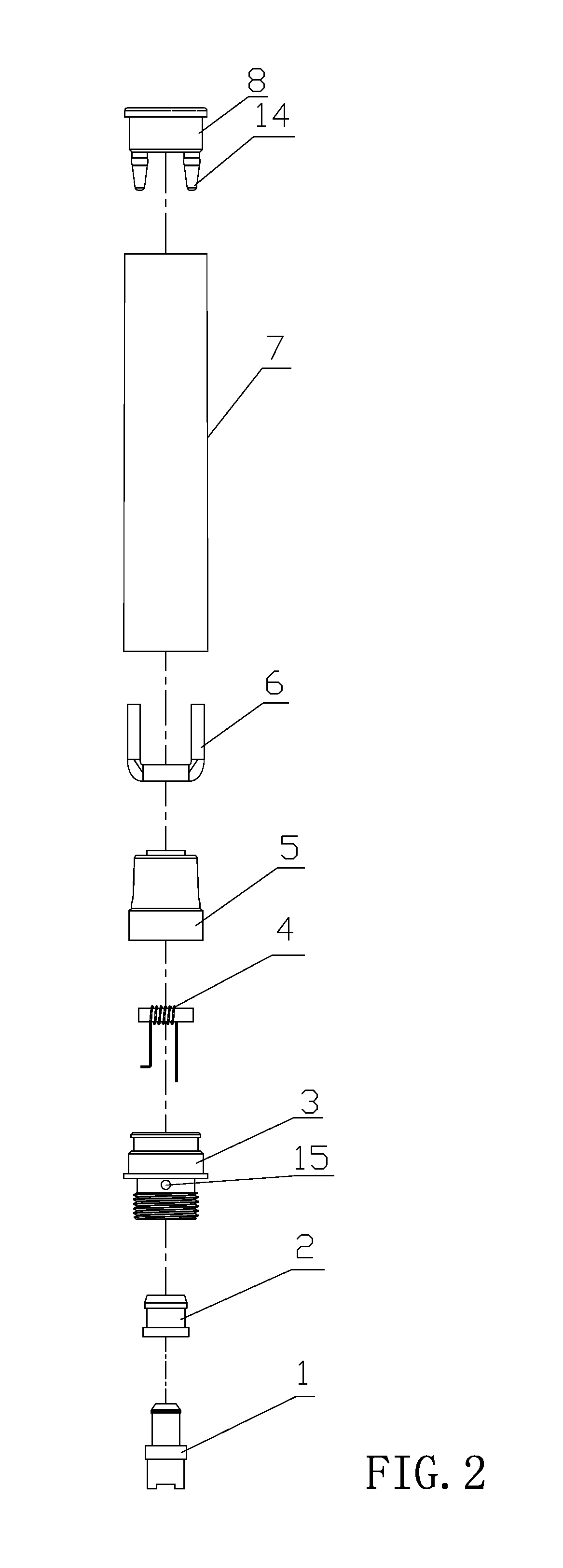

Atomizer for electronic cigarette

InactiveUS20130192618A1Easy to makeEasy to assembleTobacco pipesTobacco devicesMouth pieceElectronic cigarette

An atomizer for electronic cigarette comprises a mouth-piece, an atomization shell and a thread bushing. The atomization shell is a hollow pipe with its first end connected to the mouth-piece and second end sealed by a sealing sleeve and the thread bushing. An aerosol passage is provided inside the atomization shell. The aerosol passage has one end in communication with an orifice of the mouth-piece and another end communicating with the sealing sleeve muff-coupled to the thread bushing. The atomization shell has a first intermediary piece extending into the sealing sleeve for introducing tobacco liquid stored in the atomization shell into the sealing sleeve. An electric heater is provided between the sealing sleeve and the thread bushing. The electric heater heats up the tobacco liquid immerged in the first intermediary piece to make it atomized. The atomized tobacco liquid flows through the aerosol passage and is discharged through the mouth-piece.

Owner:LI YONGHAI +1

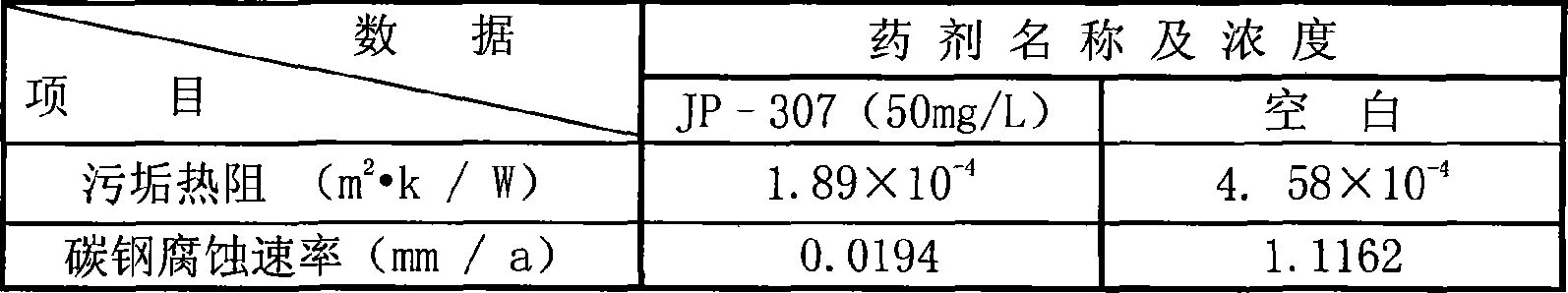

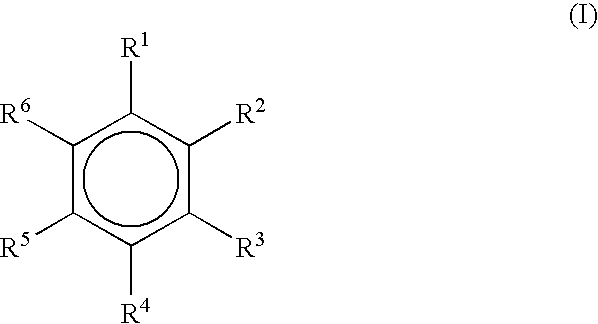

No-phosphate corrosion and scale inhibitor and its application

InactiveCN101066811AExcellent corrosion inhibition performanceIncrease polarityScale removal and water softeningNon-contaminated water treatmentPolyaspartic acidPhosphate

The present invention relates to no-phosphate corrosion and scale inhibitor and its application. The no-phosphate corrosion and scale inhibitor consists of polyaspartic acid and / or polyepoxy succinic acid 10-20 wt%, polymaleic anhydride 20-30 wt%, copolymer of acrylic acid and 2-acrylamido-2-methyl propenyl sulfonic acid 15-20 wt%, zinc salt 3-5 wt%, natural organic high molecular compound 5-12 wt%, molybdate 5-8 wt%, and other components 5-20 wt%. It has excellent corrosion retarding performance, high scale inhibiting performance and environment friendship.

Owner:WUHAN JINPO CHEM TECH

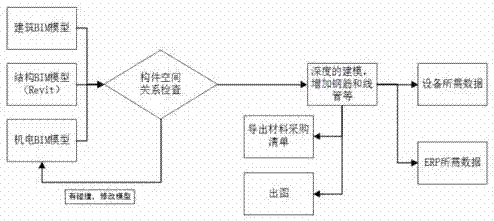

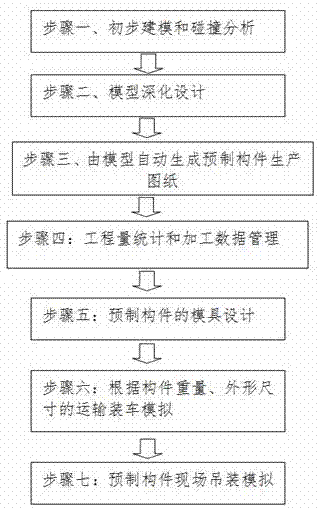

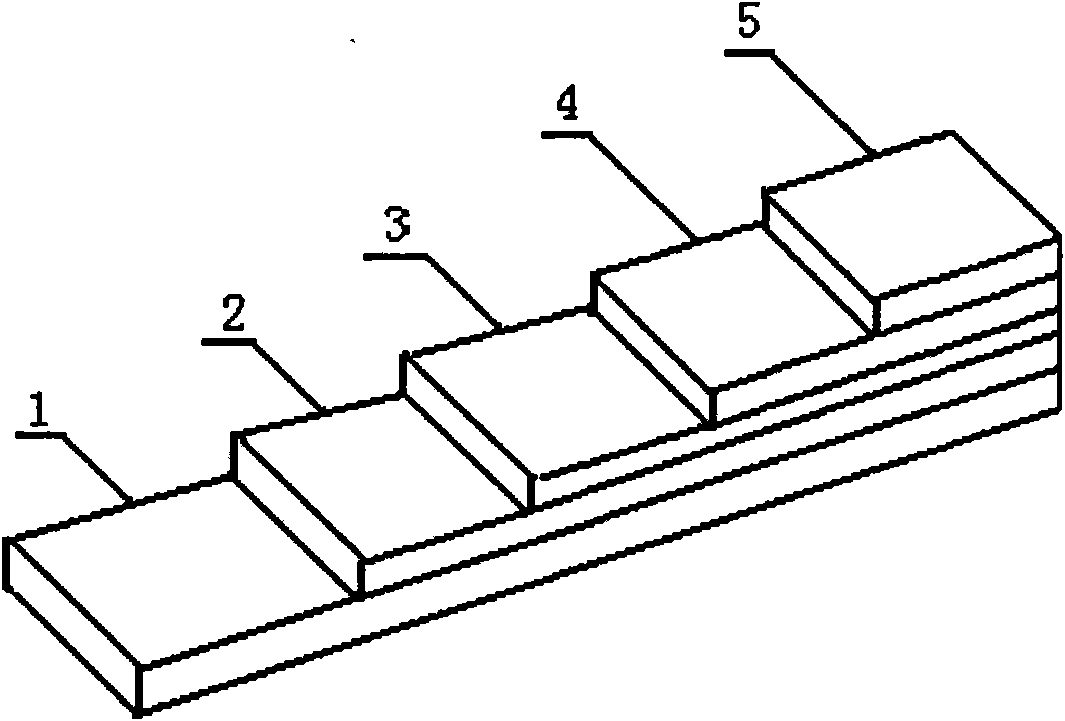

Assembled building deepening design method based on BII software

ActiveCN107967399AImprove accuracyImprove efficiencyGeometric CADSpecial data processing applicationsProduction drawingCollision analysis

The invention provides an assembled building deepening design method based on BII software. The assembled building deepening design method comprises the following steps of 1, conducting preliminary modeling and collision analysis; 2, conducting model deepening design; 3, automatically generating member production drawing through a model; 4, conducting engineering amount statistics and processing data management; 5, designing a mold of a prefabricated member; 6, conducting transportation vehicle-loading simulating and optimizing according to the member weight and the profile size; 7, conductingfield hoisting and simulating of the prefabricated member, and optimizing the hoisting sequence. Aiming at defects of an existing prefabricated member deepening design method, it is adopted that firstly, a three-dimensional model is modeled before deepening design drawing is drawn, a three-dimensional examination method is adopted, after the space conflict relation between the prefabricated member is excluded, the drawing is generated, a large amount of modification of the drawing is avoided, parts in the model all have the accurate three-dimensional size, material information and member subordination relationship, a member material list can be generated simply by conveying the information, and thus an accurate and efficient effect is achieved.

Owner:GUANGDONG JIAN YUAN CONSTR ASSEMBLY IND CO LTD

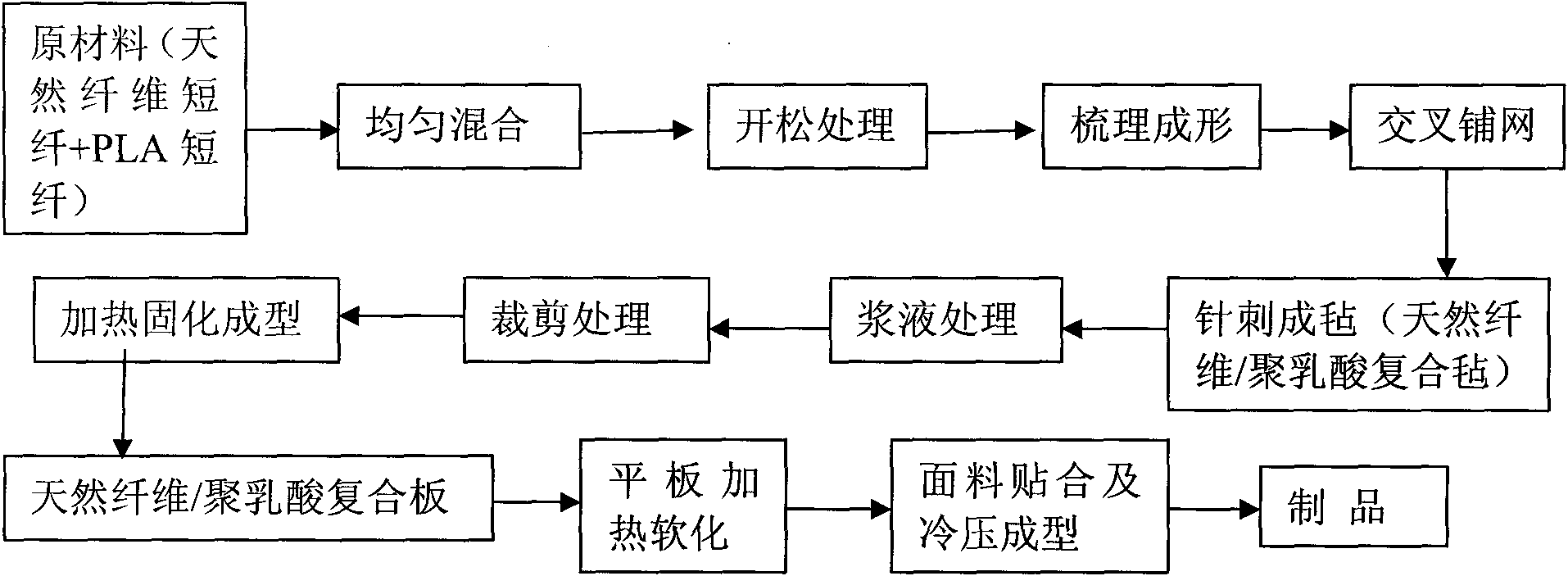

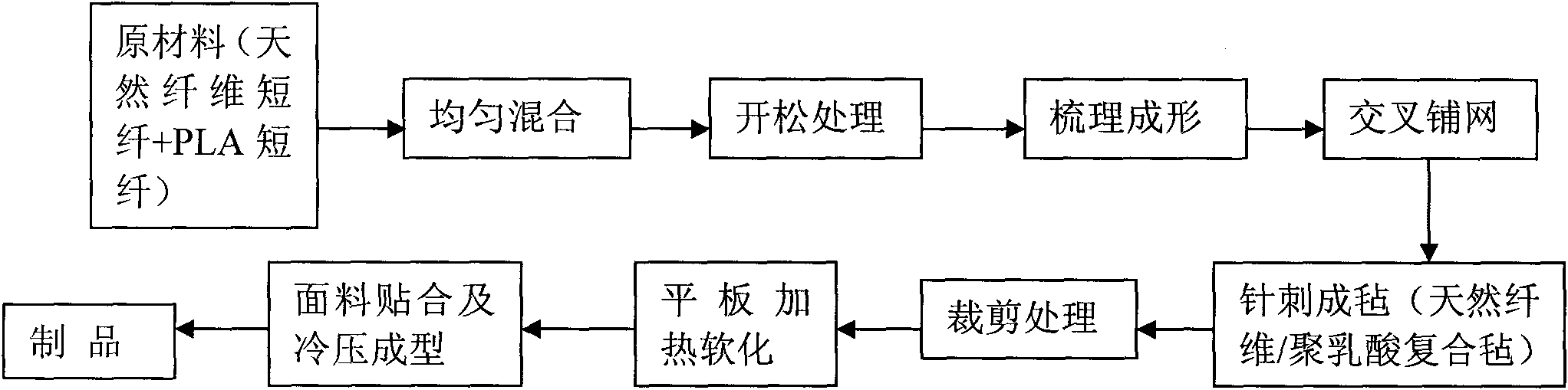

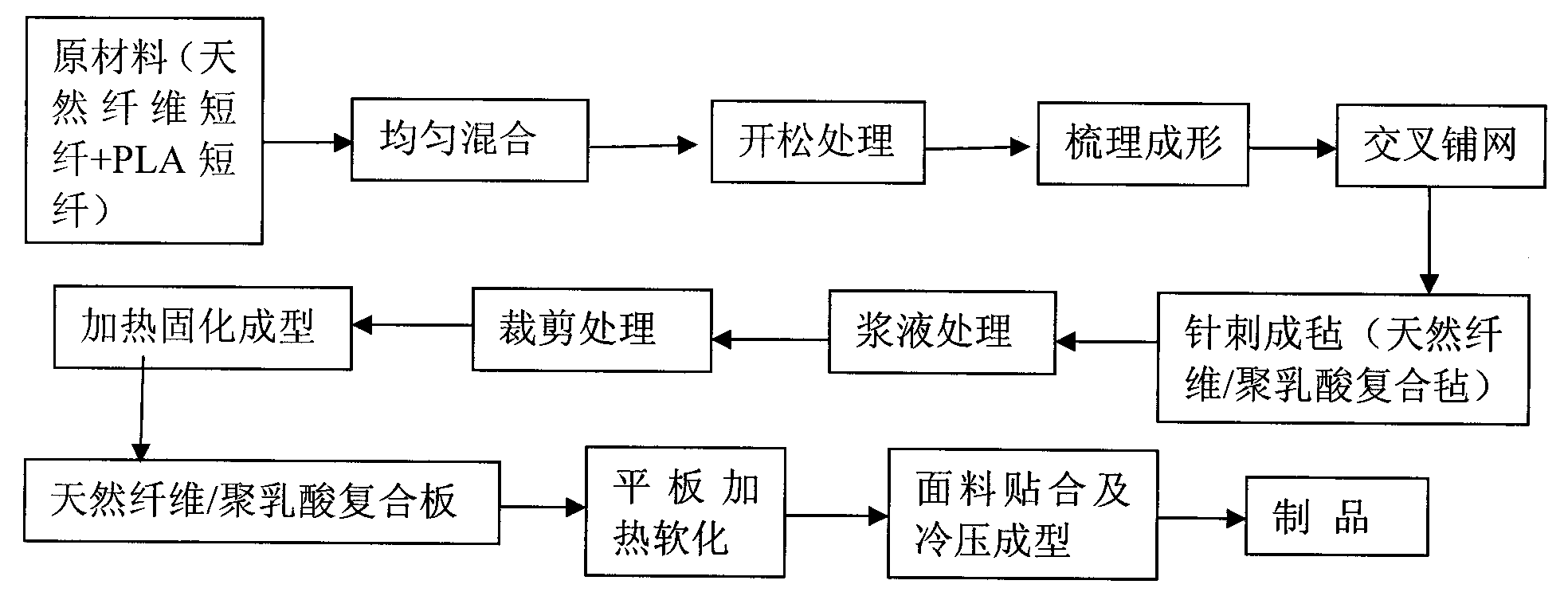

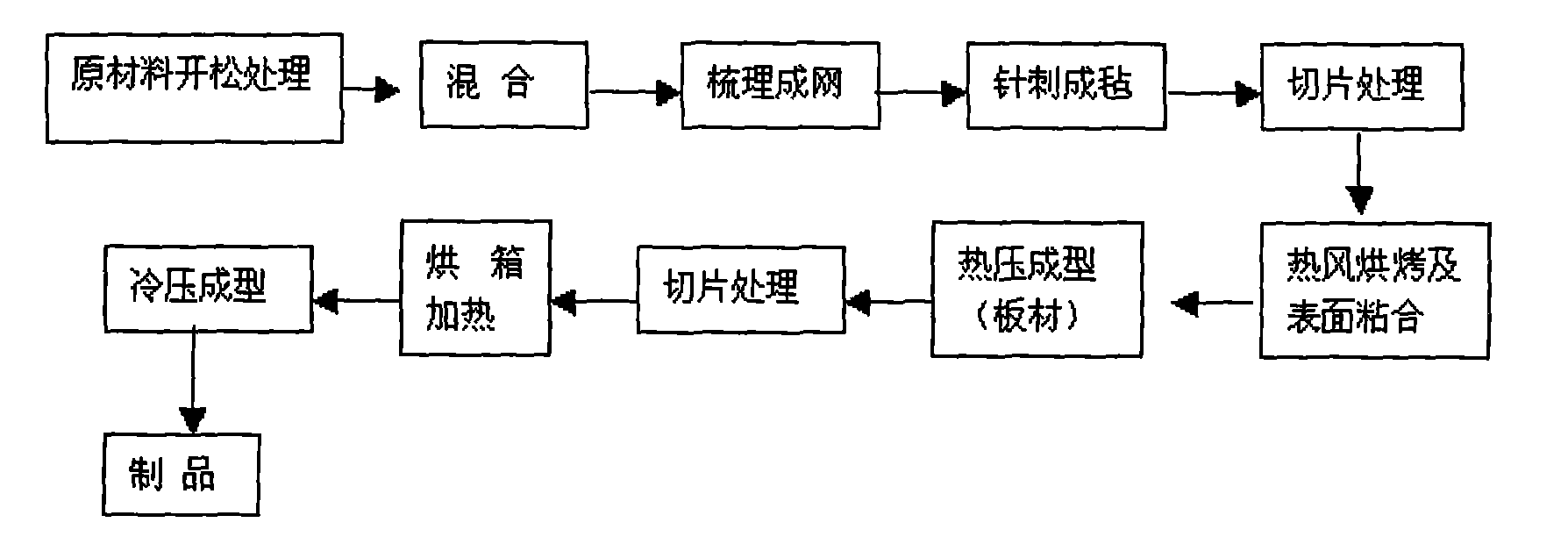

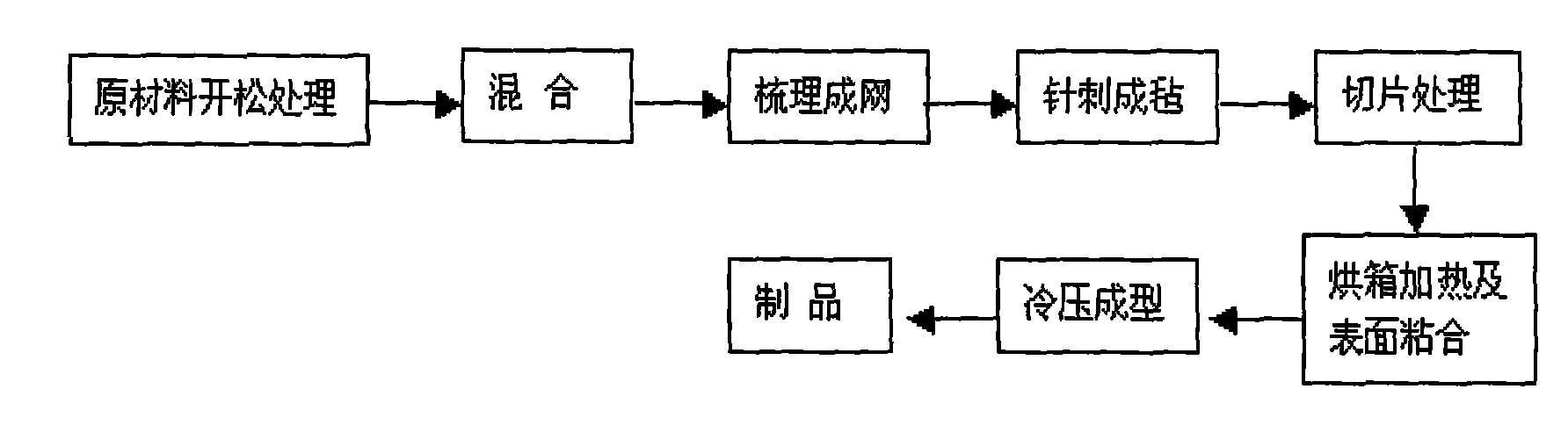

Composite material for automobile interior part and production method thereof

ActiveCN101812773ANo pollution in the processReduce lossVehicle componentsNon-woven fabricsMetallurgySlurry

The invention discloses a formula of a composite material for an automobile interior part. The formula consists of the following materials in percentage by weight: 40 to 60 percent of polylactic acid fiber and 40 to 60 percent of natural fiber. The production method of the invention comprises the following steps: uniformly mixing the raw materials; putting the mixture into an opener for opening, combing and shaping the obtained product, feeding the product into a lapping machine for cross lapping and feeding the cross-lapped product into a needling machine for needling to form a felt; immersing the fiber felt into a processing slurry; drying the immersed coiled material through hot blast and cutting the dried material into pieces of required size; placing the cut material into a mould for curing and shaping by heating; demoulding the material to form a composite plate; and softening the composite plate by flat panel heating, covering the plate with a surface decorative layer and performing cold molding on the plate through a product mould to manufacture the finished product finally; or softening the cut fiber felt by the flat panel heating directly, covering the plate with the surface decorative layer and performing the cold molding to manufacture the finished product finally. The composite material for the automobile interior part of the invention has the advantages of no toxicity, no pollution, simple processing technique, small energy consumption and high environment protection performance.

Owner:CHERY COMML VEHICLE ANHUI

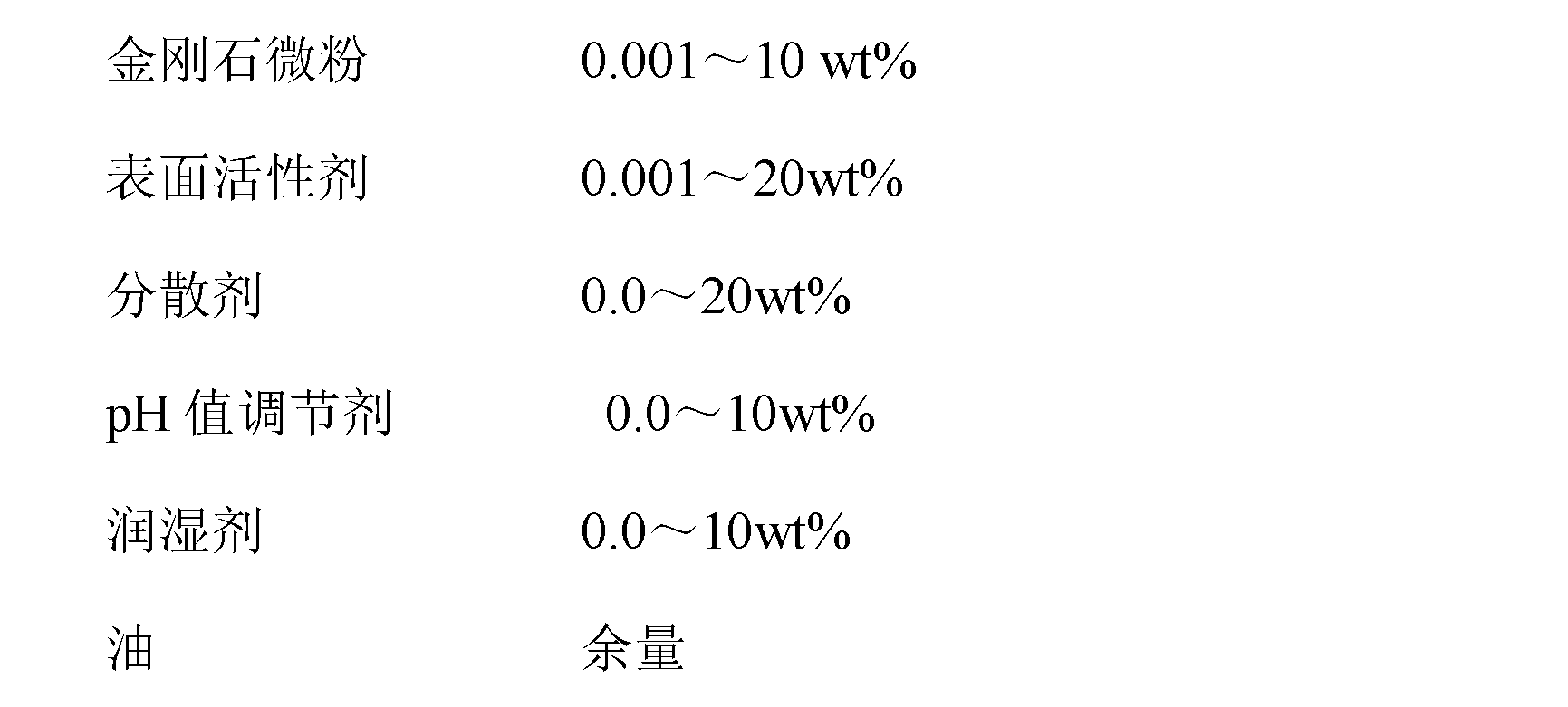

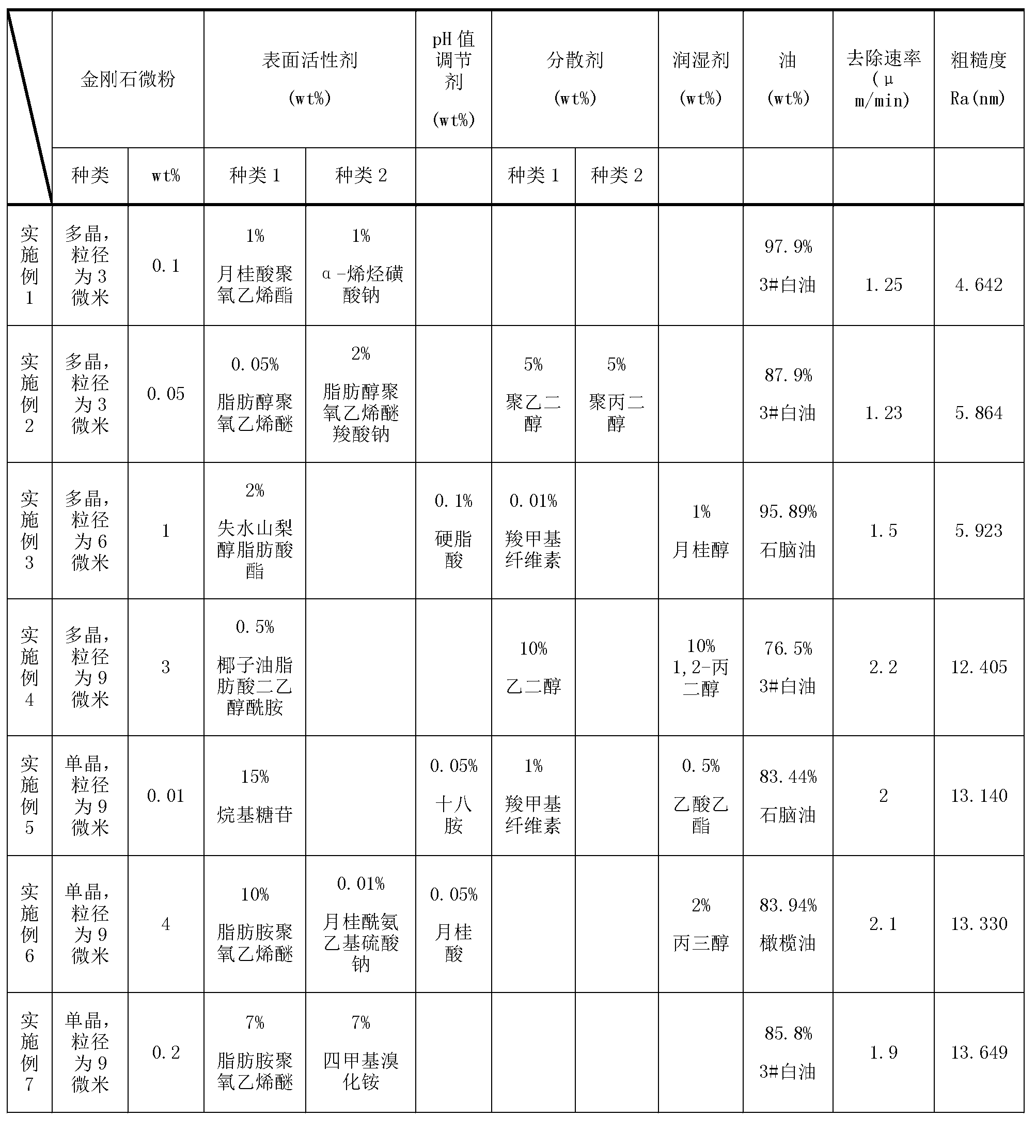

Oily diamond grinding liquid and preparation method thereof

InactiveCN103013345AImprove polishing efficiencyImprove matchPolishing compositions with abrasivesStable stateEnvironmental resistance

The invention discloses an oily diamond grinding liquid and a preparation method thereof, and belongs to the technical field of surface superfine grinding. The grinding liquid comprises the following components by weight percent: 0.001%-10% of diamond micro powder, 0.001%-20% of surface active agent, 0-20% of dispersant, 0-10% of pH value regulator, 0-10% of wetting agent and oil in balancing amount. The oily diamond grinding liquid is mainly applied to surface grinding and polishing of silicon carbide wafers, LED sapphire substrate slices, ceramic, optical fiber, dies, semi-conductor compound wafers and the like. By the use of the oily diamond grinding liquid provided by the invention, the polishing efficiency can be greatly improved; the dispersing performance is good; a uniform and stable state can be kept for a long time; the degree of finish of products polished with the oily diamond grinding liquid is high; the polishing effect is good; no ingredient harmful to human body is contained; the cleaning is easy; and the environmental protection is facilitated.

Owner:TSINGHUA UNIV +2

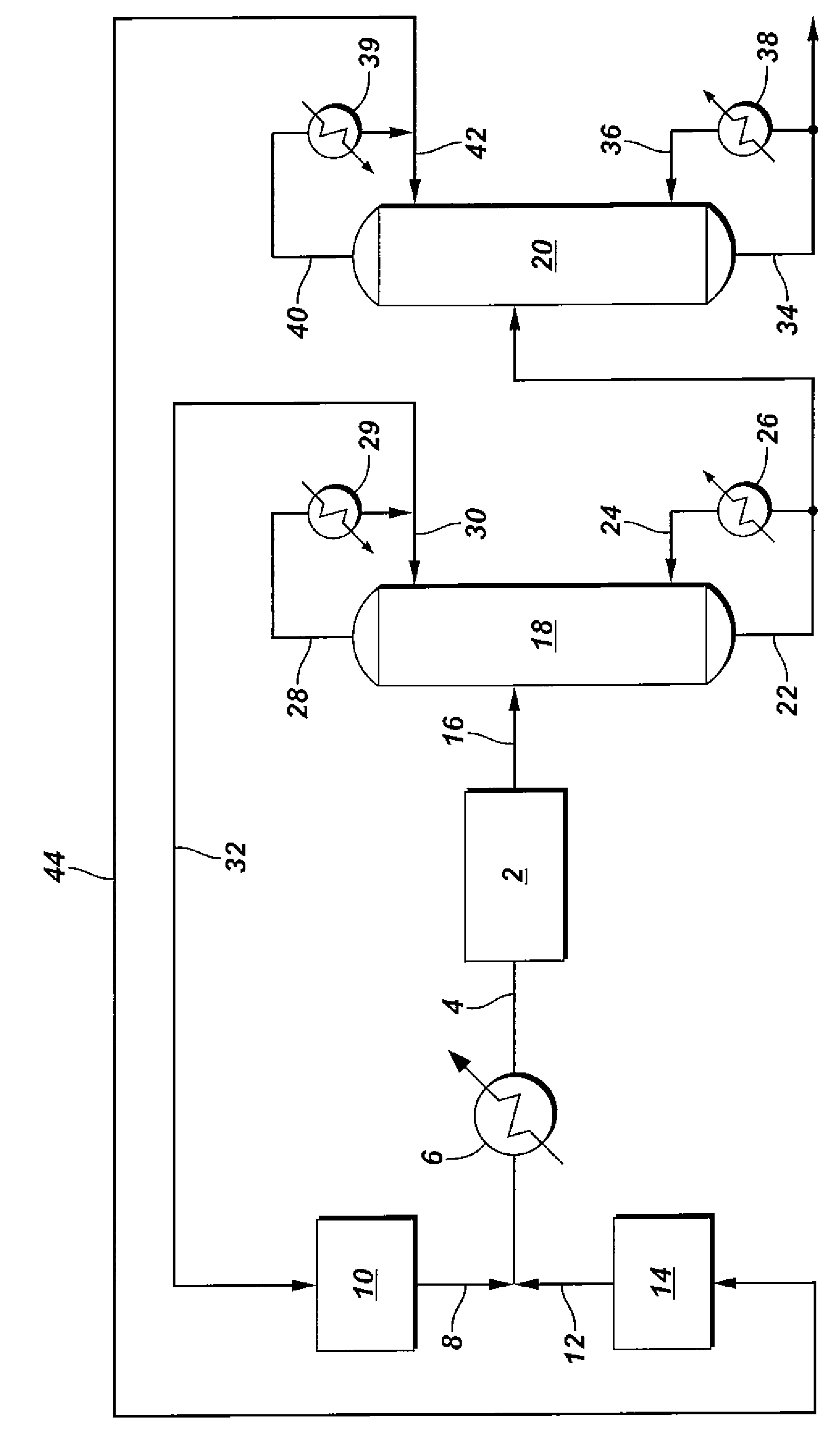

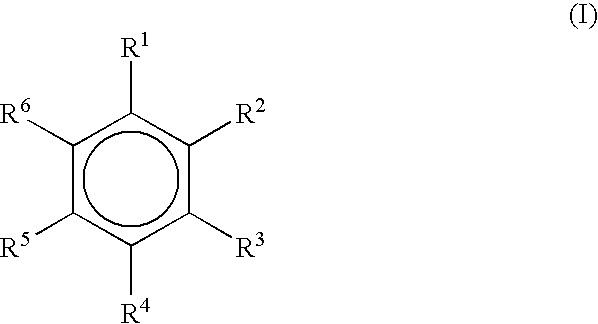

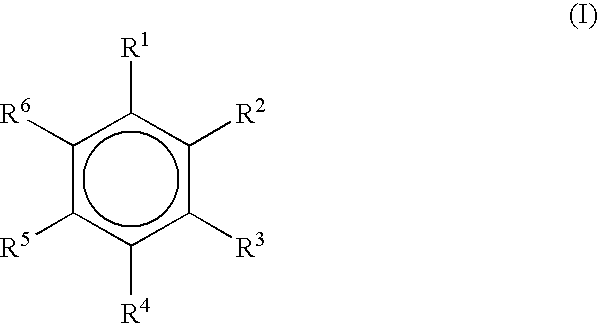

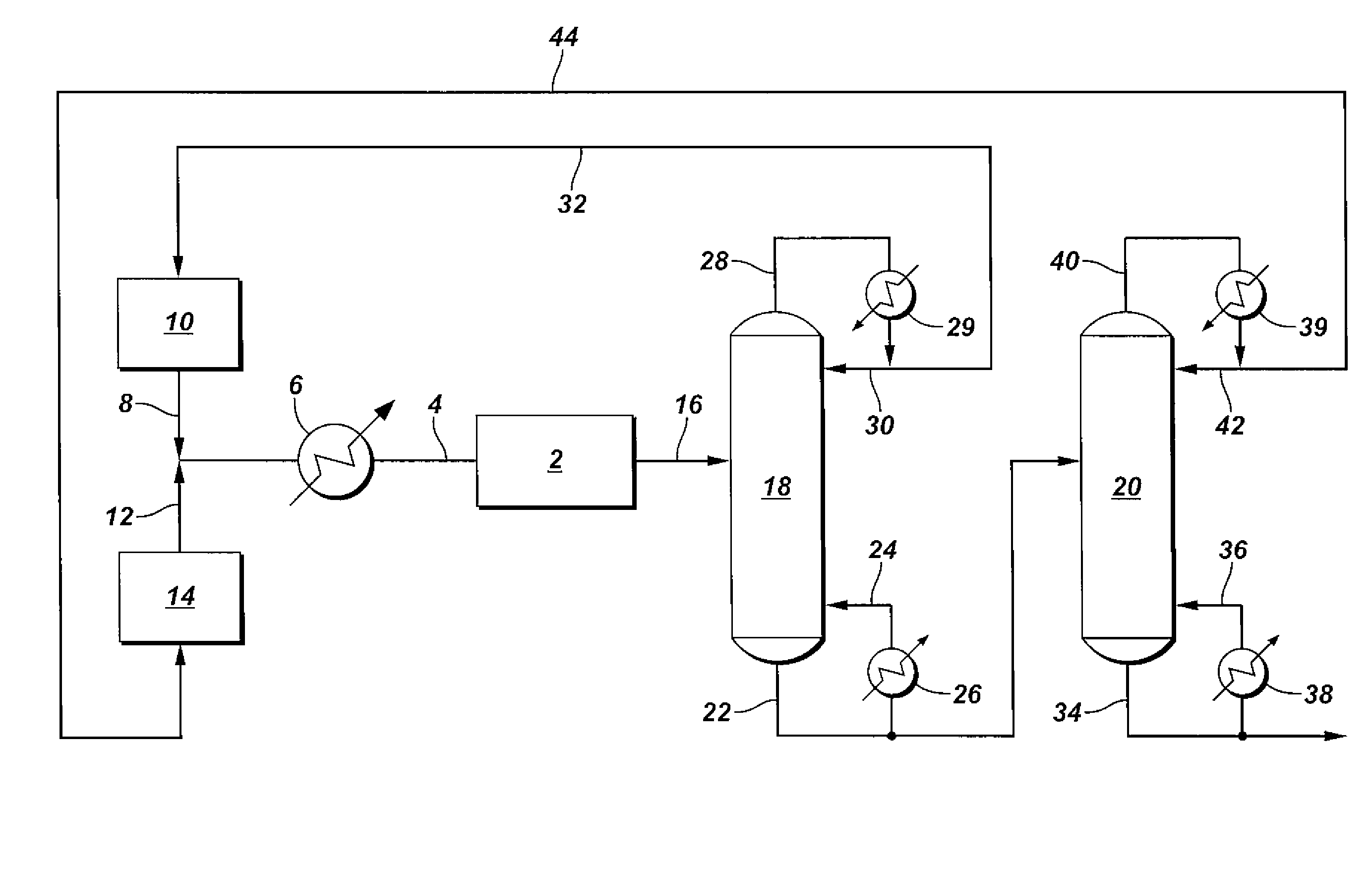

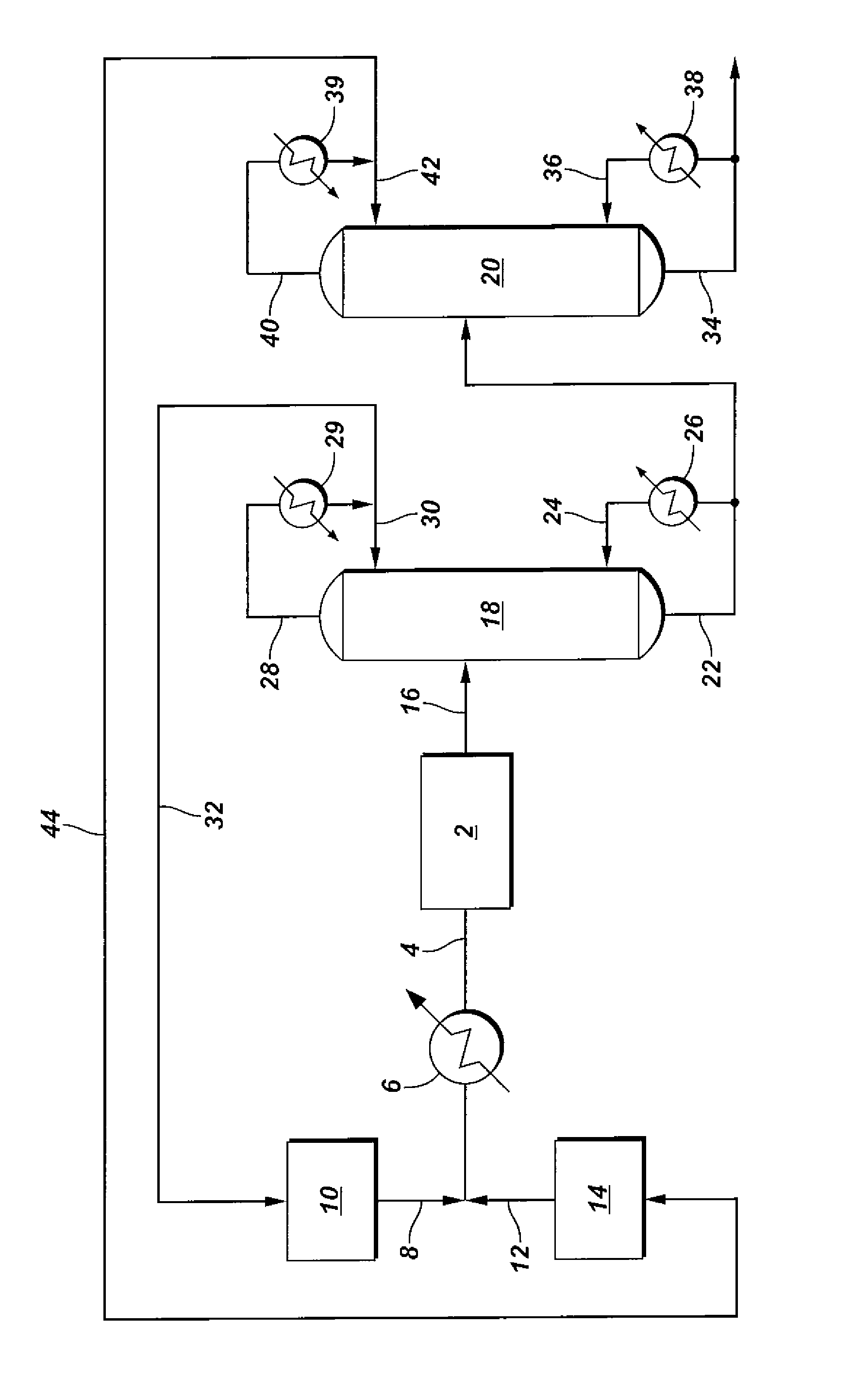

Compositions and methods of using same in producing heavy oil and bitumen

InactiveUS7691788B2Maximize the effectLarge volumeWorking-up pitch/asphalt/bitumen by chemical meansFluid removalFuel oilSolvent

Owner:SCHLUMBERGER TECH CORP

Compositions and Methods of Using Same in Producing Heavy Oil and Bitumen

InactiveUS20070295640A1Reduce energy consumptionMinimal heat lossWorking-up pitch/asphalt/bitumen by chemical meansFluid removalFuel oilSolvent

deposition in a formation, wellbore, near wellbore region, and production tubing. Compositions of the invention comprise an asphaltene solvent and a viscosity reducing agent, the asphaltene solvent and viscosity reducing agent present in a ratio so as to substantially reduce viscosity of an asphaltene-containing material while substantially negating deposition of asphaltenes either in a reservoir, in production tubing, or both when mixed or otherwise contacting the asphaltene-containing material Methods of the invention comprise forcing a composition comprising an asphaltene solvent and a viscosity reducing agent to contact an asphaltene-containing hydrocarbon in an underground geologic formation, and producing from the formation a production composition comprising at least some of the treatment composition and at least some of the asphaltene-containing hydrocarbon under conditions sufficient to substantially negate deposition of asphaltenes in the formation.

Owner:SCHLUMBERGER TECH CORP

Preparation of graft modification protein-based adhesive

InactiveCN101302410ASolve application problemsIncrease added valueGraft polymer adhesivesAdhesiveRedox

The invention relates to a method for preparing graft modification protein adhesives, belonging to the adhesive technical field. The method obtains the graft modification protein adhesives by adopting redox system initiator to react for a period of time at a certain temperature and linking vinyl monomer branched chains on a protein trunk chain. During the production and use processes, substances such as formaldehydes and so on are not released, thereby the method is favorable for environmental protection; and simultaneously the method can increase the added value of protein products and has important economic value. Because more hydrophobic groups are linked on the protein trunk chain, the interaction between the graft modification protein adhesives obtained and molecular groups on the wood surface is stronger and the adhesives are difficult to damage by water molecules, thereby the graft modification protein adhesives have good bonding strength and superior water resistance. The method widens the application environment and solves the problem which disturbs actual application of the protein adhesives for a long time, consequently having obvious technical advance.

Owner:JIANGNAN UNIV

Ultraviolet light cured transfer printing film and preparation method and application thereof

InactiveCN101941339AHigh material strengthGood weather resistanceDecorative surface effectsOrnamental structuresLacquerPrinting ink

The invention belongs to the field of decorative materials, and particularly relates to an ultraviolet light cured transfer printing film and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly coating or printing a mold release agent on a base load film, and performing infrared curing; uniformly coating or printing an ultraviolet light cured printing ink with a patterning function on a mold release agent layer, and performing curing through ultraviolet irradiation; or uniformly coating or printing an ultraviolet cured protective layer coating with anti-scratching and wear-resistant functions on the mold release agent layer first, then uniformly coating or printing the ultraviolet light cured printing ink with the patterning function on the mold release agent layer after the curing through the ultraviolet irradiation, and performing the curing through the ultraviolet irradiation; and uniformly coating or printing an ultraviolet light cured bottom color coating on an ultraviolet light cured printing ink decorative pattern layer, and performing the curing through the ultraviolet irradiation to obtain the ultraviolet light cured transfer printing film which can be used for producing an ultraviolet light cured transfer printing film decorative board. The ultraviolet light cured transfer printing film has high material strength, and has the advantages of high weathering resistance, high environmental protection, rich colors and patterns, full lacquer film, high hardness, scratch resistance, easy cleaning, noninflammability and the like.

Owner:ZHUHAI DONGCHENG UV MATERIALS

Bamboo powder filling biodegradable compound material and preparation method thereof

The invention relates to a bamboo powder filling biodegradable compound material and a preparation method thereof. The bamboo powder filling biodegradable compound material comprises the following raw materials in part by mass: 30 to 80 parts of biodegradable resin, 20 to 70 parts of bamboo powder, 1 to 19 parts of plasticizer, 0.6 to 6 parts of interface modifier and 4 to 12 parts of aids. The preparation method comprises the following steps of: uniformly mixing the biodegradable resin, bamboo powder, plasticizer, interface modifier and auxiliary agent by using a mixer according to formula proportion; performing melt blending and granulation of the obtained mixture by using a screw extruder to obtain particles; and processing the particles by using an injection molding machine, a sheet extrusion forming machine, a blow molding machine or a film blowing machine, and molding in molds of different shapes to obtain the bamboo powder filling biodegradable compound materials of different shapes. The method has the advantages of high production efficiency and low cost; and the powder filling biodegradable compound material prepared by the method has the advantages of high environmentally-friendly property and economy and excellent usability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing environment-friendly type organosilicon modified acrylic ester binding agent

InactiveCN101423735APromote environmental protectionImprove stabilityFibre treatmentEster polymer adhesivesPolymer scienceAdhesive

The invention relates to a method for preparing an environment-friendly silicone-modified acrylate adhesive. Raw materials of the preparation method comprise a basic monomer, a modified monomer and an auxiliary agent, wherein the basic monomer comprises a hard monomer, a soft monomer and a crosslinking monomer; the modified monomer comprises a silane monomer, a coupling agent and inorganic nano-powder; the crosslinking monomer is glycidyl acrylate or glycidyl methacrylate; and the grain diameter of the inorganic nano-powder is less than 80 nanometers. In the preparation method, the crosslinking monomer adopts the glycidyl acrylate or the glycidyl methacrylate so as to be environment-friendly. The product prepared by the method is a nanometer / silicone double-modified molecular composite polymer material. The molecular composite material is combined with the advantages of two polymer materials, namely silicone and polyacrylic ester and an inorganic nanometer material, and has better performance and broad application.

Owner:WUHAN TEXTILE UNIV

A kind of Chinese herbal medicine feed for laying hens and preparation method thereof

InactiveCN102273551AReasonable formulaEasy to prepare and operateFood processingAnimal feeding stuffDiseaseWheat gluten

The invention relates to a Chinese herbal medicinal forage for a laying hen and a preparation method thereof. The Chinese herbal medicinal forage for the laying hen comprises two parts of a raw material pulvis which comprises soybean meal, wheat bran, corn, wheat gluten powder, carrot powder, a feed of visceral organs of fresh fish, and the like and a Chinese herbal medicinal additive which comprises raw materials of honeysuckle flower, phellodendron, Radix Codonopsis, bitter apricot kernel, licorice, fructus forsythiae, isatis root and the like. The preparation method comprises the followingsteps: sequentially crushing above raw materials, mixing, stirring, crushing, drying, stirring, bulking, and producing the hard particulate forage. The preparation method has the advantages of reasonable formula, convenient preparation and operation, good environmental protection effect and the like. The Chinese herbal medicinal forage, which can promote the metabolism level of an individual of the laying hen, has good prevention and treating effects on diseases of cold, bird flu, new castle disease, white diarrhea, gastritis, proctoptosia, red and swollen arse and bad digestive system of thelaying hen, and can obviously improve the immunological competence of the laying hen and effectively solve an epidemic prevention problem of a large-scale laying hen culturing farm, accords with production requirements of nuisance free eggs and has a high cost performance.

Owner:SHAANXI FUTURE GREEN AGRI ANIMAL HUSBANDRYDEV

Pesticide auxiliary agent

ActiveCN1701663AWith characteristicsHave made significant progressBiocideAnimal repellantsActive agentSolvent

Disclosed is a pesticide auxiliary agent whose raw material includes (by mass ratio) plant oil 100, auxiliary solvent 0-50, surface active agent 5-55, the auxiliary agent can be made into the dosage forms of oil miscible concentrate, oil solution, hot mist, aerosol, low-volume spraying agent, pesticide, germicidal agent, sterilizing agent, hygienic pesticide and plant growth agent.

Owner:FUJIAN NUODE BIOTECH

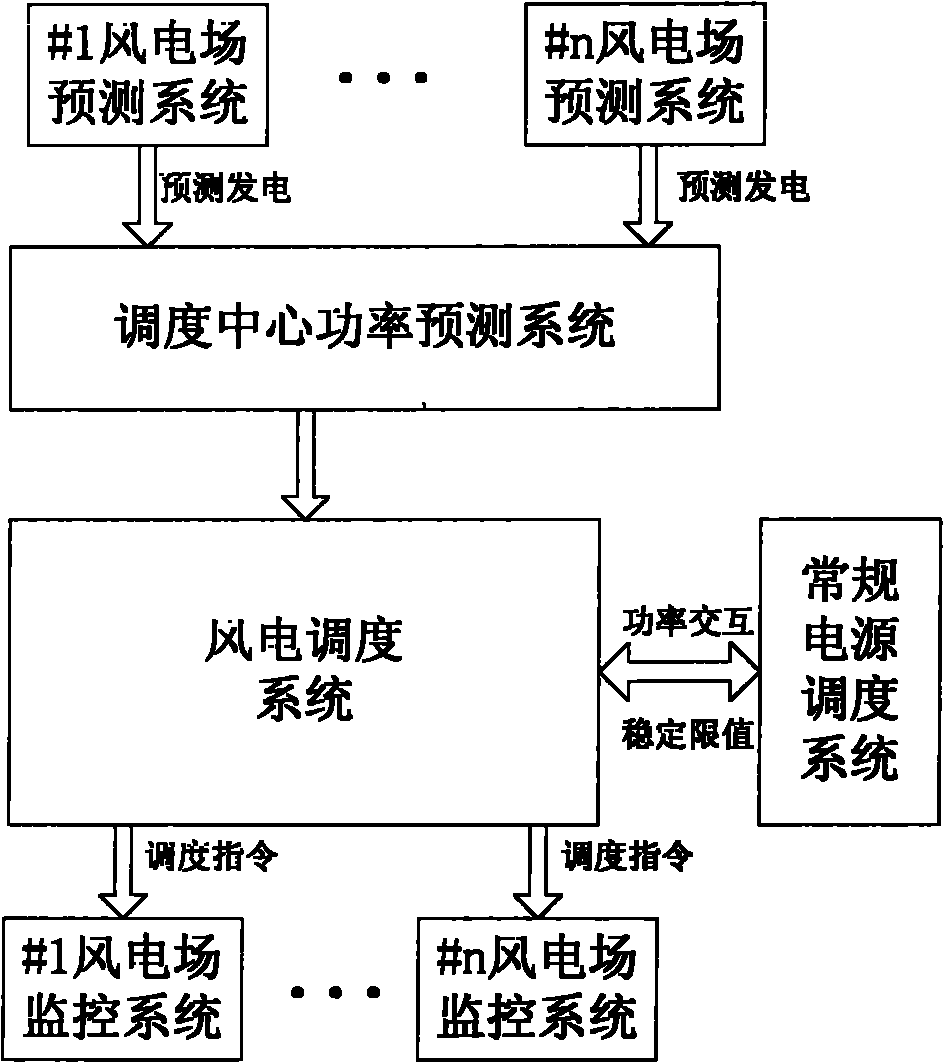

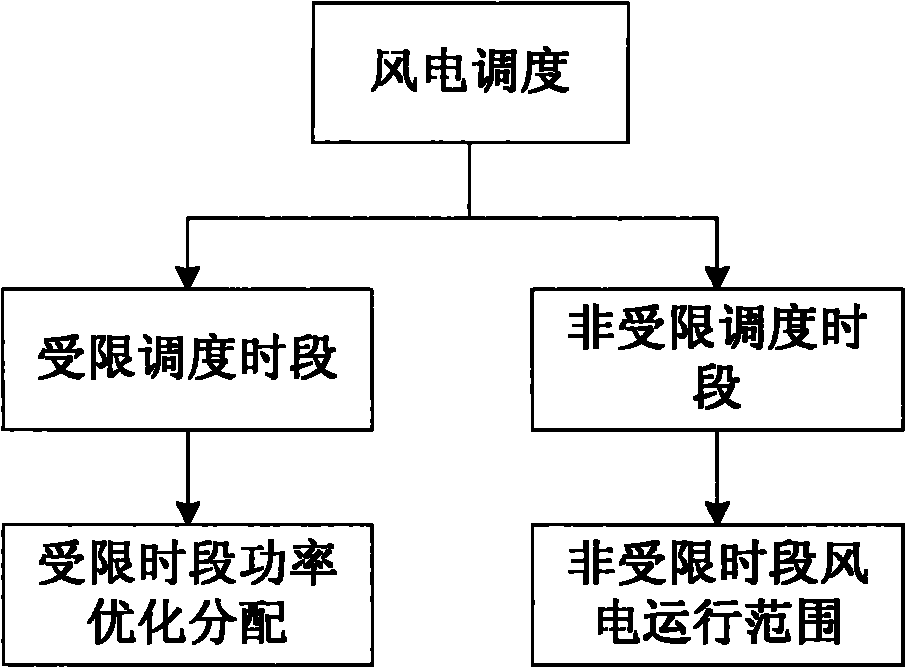

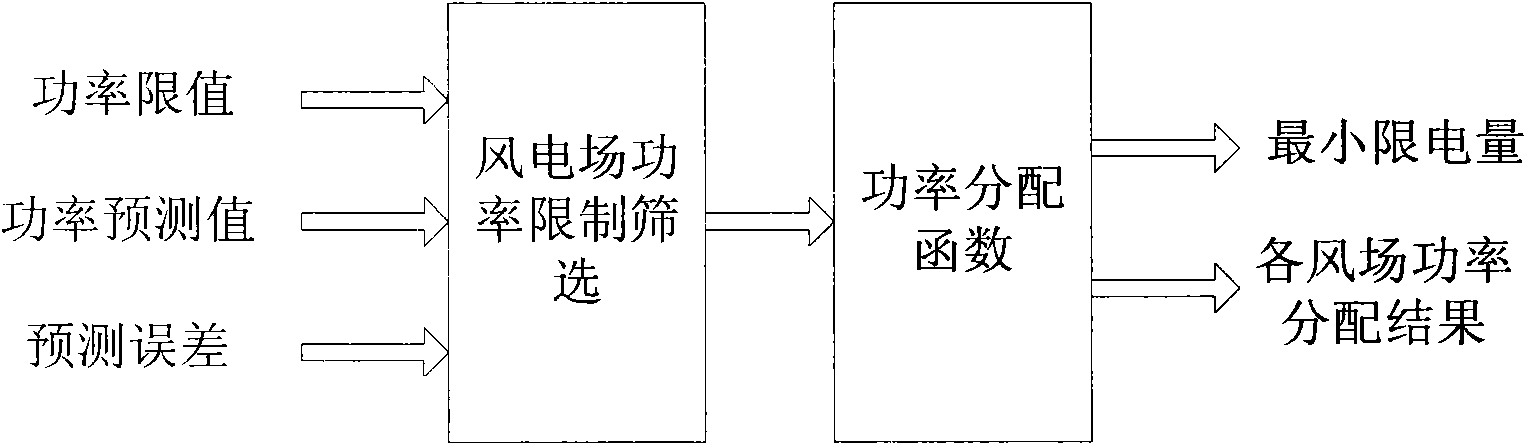

Wind power optimal scheduling method based on power forecast

ActiveCN102097828AIncreased power contributionSafe and stable operationSingle network parallel feeding arrangementsWind energy generationElectricityPower station

The invention provides a wind power optimizing scheduling method based on power forecast, which is applied to a power scheduling operation schedule solution containing wind power. In the method, the power forecast curve of a wind power station are utilized; the peak regulation capacity and the safe and stable limit of a system are calculated, so that scheduling of total output of the wind power within the scheduling range is divided into restricted time interval scheduling and non-restricted time interval scheduling; for the non-restricted time interval scheduling, the error scope of the forecast power generation is considered based on a forecast power generation curve; and for the restricted time interval scheduling, wind power forecast errors are considered based on the restriction of the aggregate limit of the wind power stations and the forecast power generation output of each wind power station, thus optimizing power generation power limit value allocation of each wind power station, so that the system can maximally digest the wind power under the condition of meeting the requirement of safe and stable operation. A wind power scheduling curve is executed by the power generation of the wind power station so as to strength safety and stability of the power grid operation, intensify the digestion capacity of the wind power and maximally utilize the wind power.

Owner:CHINA ELECTRIC POWER RES INST +1

Thermal-insulating external-wall coating of nano-composite water and its production

InactiveCN101029206AImprove insulation performanceGood weather resistanceFireproof paintsEmulsion paintsRefractive indexSlurry

A water nan-composite thermal-insulating coating for external wall and its production are disclosed. The coating consists of water, polymer emulsion, high-refractive index pigment, filler, nano-tin-antimony oxide slurry, nano-SiO2, wet dispersant, filming accessory, pH adjuster, thickener, de-foaming agent, anti-freezing agent and mildew-proof bactericide. It's cheap and simple, has excellent wash and weather resistances, better thermal-insulating performance, safe storage and no environmental pollution. It can be used for apparatus surface and architecture external wall.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for preparing oxidized graphene coated film

InactiveCN102173145AHigh transparencyImprove securitySynthetic resin layered productsCoatingsGraphene coatingMetallurgy

The invention provides a method for preparing an oxidized graphene coated film, which comprises the following steps of: adding oxidized graphene into water, and performing ultrasonic treatment and stirring simultaneously to obtain colloid suspension of the oxidized graphene, wherein 1mg of oxidized graphene is added into 1mL of water; and coating the colloid suspension of the oxidized graphene onthe surface of a general film in a spraying or rolling mode, drying to form an oxidized graphene film, coating a plurality of layers, and after the uppermost oxidized graphene coating is dried to form a film, covering a layer of general film on the uppermost oxidized graphene film to obtain the oxidized graphene coated film. The method has the advantages that: the oxidized graphene coated film prepared by the method has good transparency, high safety, good environment friendliness, and excellent barrier property; the barrier property to CO2 gas is greatly improved particularly; and the methodis used for packaging foods and medicines with higher requirement on barrier property.

Owner:XIAN UNIV OF TECH

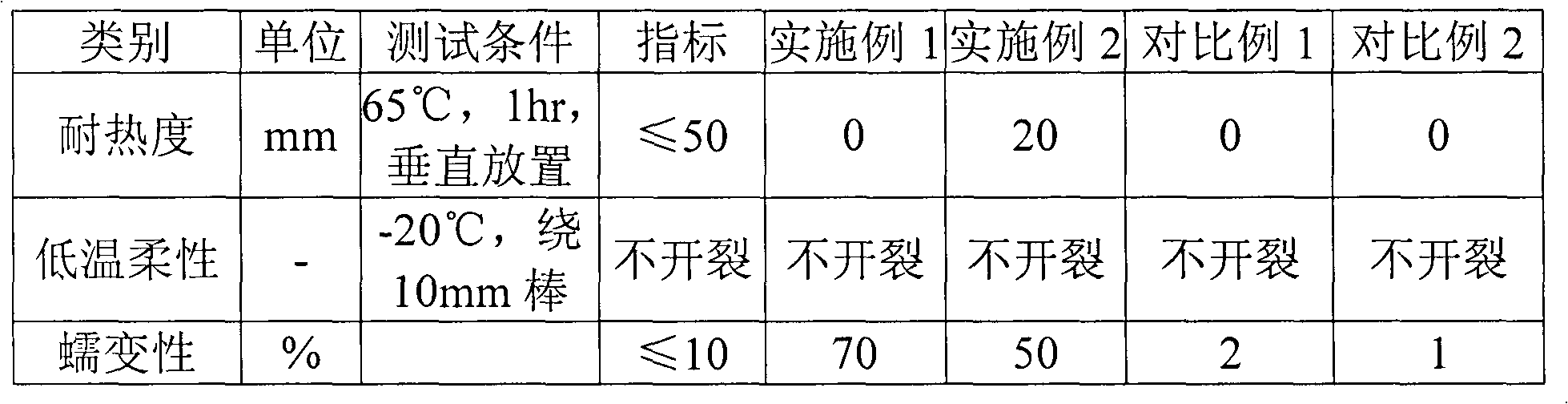

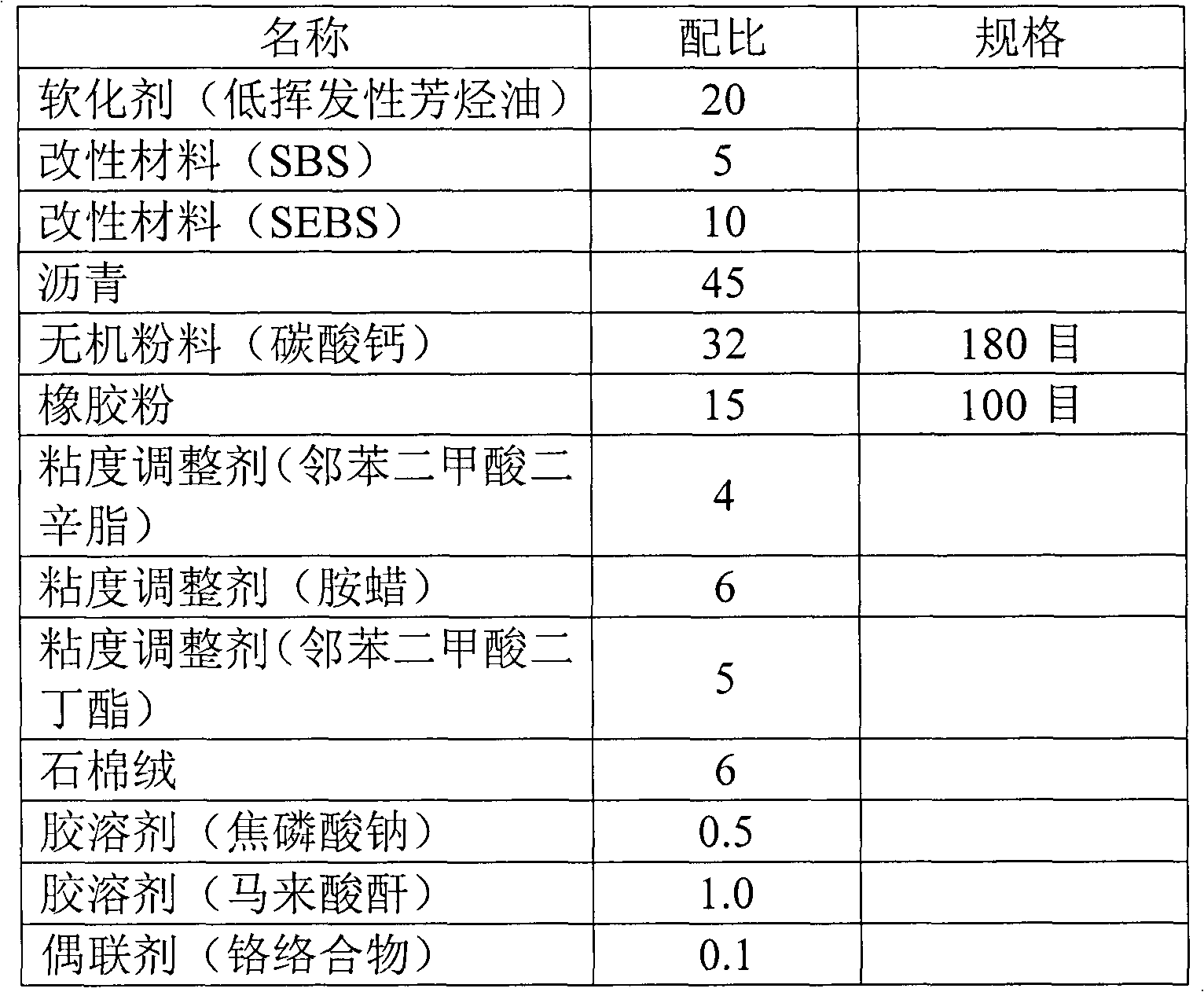

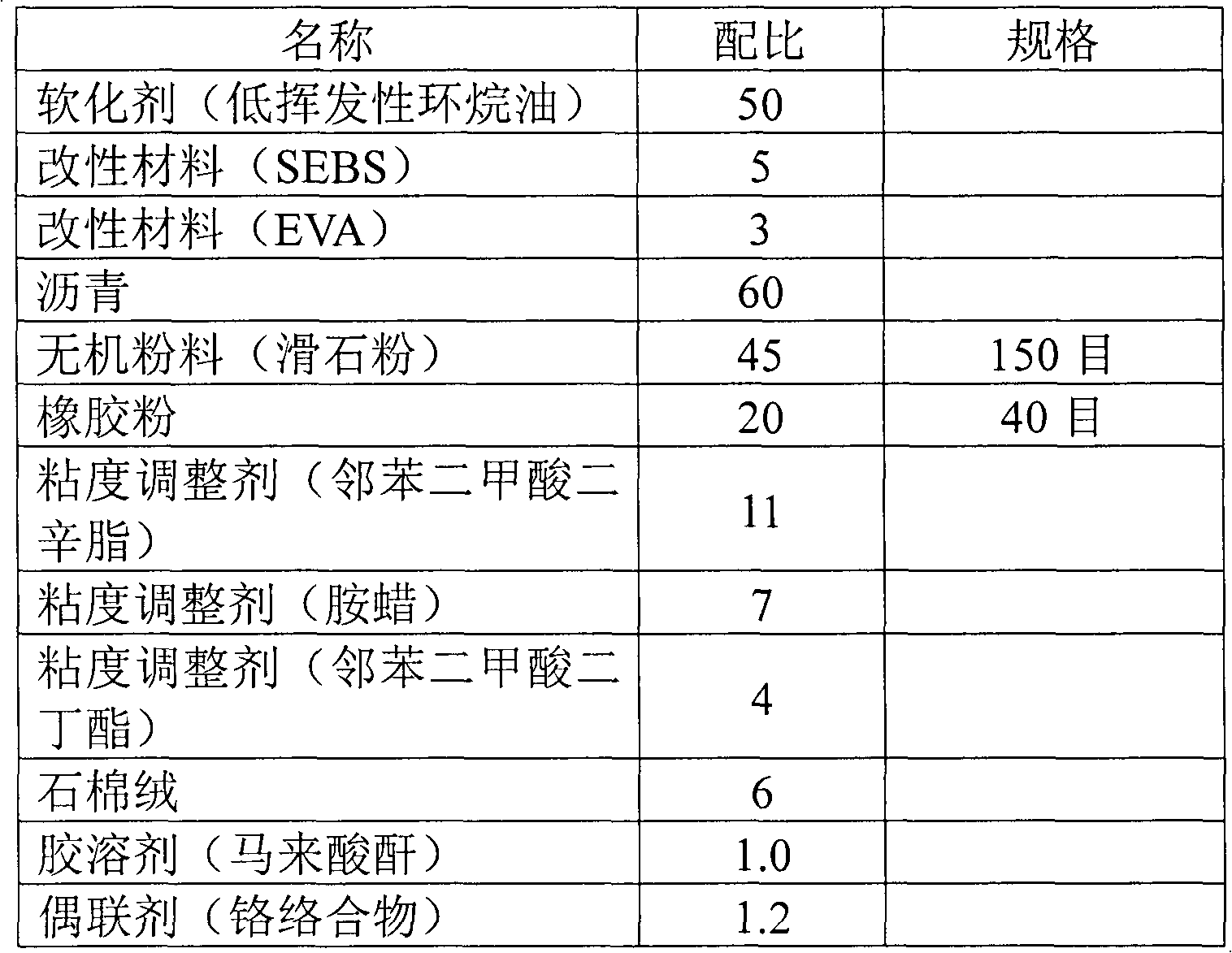

Modified asphalt composition with creeping characteristic and preparation method thereof

InactiveCN102020859AAvoid rapid agingExtended service lifeBuilding insulationsBituminous waterproofingMaterials science

The invention provides a modified asphalt composition with a creeping characteristic, which comprises the following components in parts by weight: 15-60 parts of asphalt, 3-15 parts of modifying material, 5-30 parts of rubber powder, 15-60 parts of softening agent, 15-60 parts of inorganic powder, 3-25 parts of viscosity regulating agent, 0.3-1.5 parts of peptizing agent and 0.1-2 parts of coupling agent. A preparation method of the modified asphalt composition comprises the following steps of: adding the softening agent into a reaction kettle, heating to 170 to 200 DEG C, adding the modifying material, agitating, adding the asphalt and the rubber powder, and agitating for 1-2 h to obtain an intermediate raw material; levigating the intermediate raw material to 150-250 meshes, and putting back to the reaction kettle; and finally, adding the inorganic powder, the viscosity regulating agent, the peptizing agent and the coupling agent into the reaction kettle, agitating and dispersing uniformly. The modified asphalt composition has the characteristics of excellent water-proof performance, strong binding capability and continuous binding capability, large elongation percentage and good low-temperature flexibility.

Owner:ZHEJIANG WOPUMAN HIGH NEW MATERIALS

Preparation method for graphene oxide with high barrier property and polymer nanocomposite film

The invention provides a preparation method for graphene oxide with high barrier property and a polymer nanocomposite film. The preparation method comprises the following steps: graphene oxide is added in solvent for stirring to obtain a colloidal suspension of graphene oxide during the ultrasonic processing at the temperature of 20 to 45 DEG C; a polymer is added in the colloidal suspension of graphene oxide for stirring during the ultrasonic processing at the temperature of 20 to 120 DEG C, until the polymer is completely dissolved to obtain a solution of graphene oxide / polymer; and after air bubbles in the solution of graphene oxide / polymer are removed, the graphene oxide / polymer nanocomposite film is obtained by a casting method or blow molding method. The carbon dioxide transmission coefficient of the prepared nanocomposite film containing graphene oxide is reduced by more than 150 times, and the prepared nanocomposite film containing graphene oxide can be used for packaging food and drugs with higher requirements of barrier property.

Owner:XIAN UNIV OF TECH

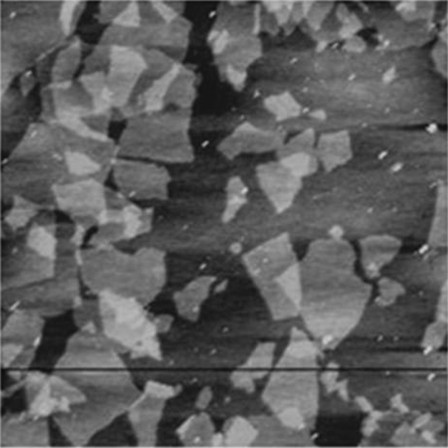

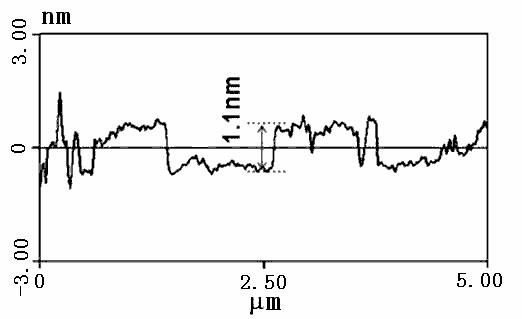

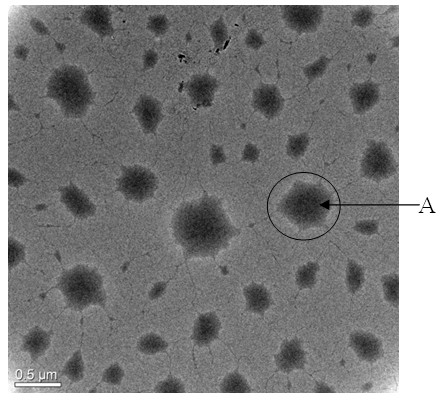

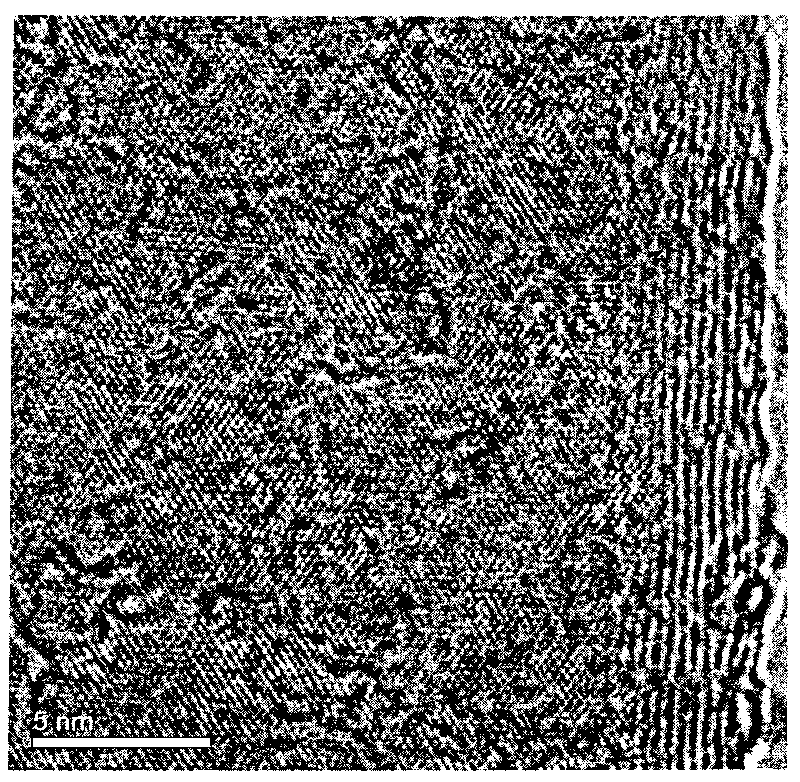

Method for preparing multi-layer graphene

ActiveCN101746755AImprove conductivityImprove thermal conductivityUltrasonic dispersionMaterials science

The invention relates to a method for preparing multi-layer graphene, and belongs to the technical field of carbon materials. The multi-layer graphene is prepared from expanded graphite serving as a raw material through ultrasonic dispersion, solid-liquid separation and drying. The thickness of the multi-layer graphene prepared by the method is between 1 and 10nm; the number of layers is between 2 and 20 layers; and the aperture is mainly between 6 and 50nm. The multi-layer graphene has the characteristics of high electrical conductivity, high heat conductivity, high electromagnetic wave absorptivity, wear resistance and the like. The method has the advantages of simpleness, convenient operation and low production cost, capability of reducing production energy consumption, no three wastes emission, environmental friendliness and convenient popularization and application. The multi-layer graphene prepared by the method can be used as the electrode materials of batteries and super capacitors, can also be used as the conductive agents of high molecular materials, ceramic materials, silicate materials and the like, and can also be used as the conductive agents of lithium batteries, alkaline batteries and nickel-metal hydride batteries.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Method for processing regenerated polyester staple fiber by using waste polyester textile

ActiveCN102899729AImprove qualityHigh strengthFilament forming substance formingMelt spinning methodsPolyesterPolymer science

The invention relates to a method for producing regenerated polyester staple fibers, in particular to a method for processing regenerated polyester staple fibers through a physical method by using waste polyester textiles. The method for processing regenerated polyester staple fibers by using waste polyester textiles comprises the following steps of: conducting color matching, proportioning and drying to friction materials produced by using the recovered waste polyester textiles; squeezing and fusing the dried friction materials to obtain fusant; primarily filtering the fusant, feeding the fusant into a high-vacuum tempering and viscosity-regulating reaction kettle; filtering the fusant, feeding the fusant into a spinning manifold and metering spinning; and after spun nascent fibers are bundled, conducting oiling through a dipping tank and a drawing tank, steam secondary drawing, overlapping, curling, relaxed heat setting, cutting and packing to obtain the regenerated polyester staple fibers. By adopting the method for processing regenerated polyester staple fiber by using waste polyester textiles, the technical problem of producing high-quality regenerated polyester staple fibers by using the recovered textiles is solved, the cost of raw materials for producing the regenerated polyester staple fibers is decreased and the problem of recovering the waste polyester textiles is solved.

Owner:余姚大发化纤有限公司

Exterior wall composite insulation heat-proof plastering material

InactiveCN101229970ARealize resource utilizationImprove protectionSolid waste managementFiberResource utilization

The invention relates to compound thermal insulation plastering material for external wall, which consists of a compound cementing material and a lightweight aggregate. The compound cementing material consists of cement, active admixture, lime powder, promoter, surfactant, anti-crack and waterproof agent, water retaining agent, flame retardant, re-dispersible emulsion powder, alkali-resistance fiber and coal flying ash cenosphere; the lightweight aggregate consists of EPS grain and expanded perlite. The invention has the advantages of low density, thermal performance, high strength, good impact resistance, bond strength and low shrinkage. The compound cementing material adopts a plurality of polymeric cementing materials, allows the insulation material to have good bond performance and simultaneously ensures falling and slipping resistance performance. The invention has good water resistance and high softening coefficient. By using cement-based cementing material as main material and organic reinforced material and waterproof component as auxiliary materials, the invention has a hydrophobic rate more than 98 percent and a softening coefficient more than 0.7. The invention can save energy and protect environment. A great deal of industrial waste residue is used in the materials, which can save a great number of energy, realize resource utilization of the waste residue and is in favor of environmental protection.

Owner:SHANGHAI TONGBIAO INSULATION TECH

Edible collagen food packaging film and preparation method thereof

InactiveCN102093722AEasy to degradeEnvironmental protection is goodFlexible coversWrappersSide effectPlasticizer

The invention provides an edible collagen food packaging film and a preparation method thereof. The preparation method comprises the following steps: firstly, stirring a 5-30wt% collagen solution and a 0.1-3wt% modifier solution at the temperature of 30-60 DEG C to react for 30-60 minutes, thus obtaining a compound solution; then adding a plasticizer and an auxiliary additive into the compound solution, then continuing to stir for 20-40 minutes at the temperature of 30-60 DEG C so as to obtain a mixed solution; and pouring the mixed solution in a die, molding, drying for 5-15 hours at the temperature of 40-80 DEG C, so as to obtain the edible collagen food packaging film. The edible collagen food packaging film has the advantages of better mechanical property, better heat stability, better moisture barrier property, safety, effectiveness and no side effect; wastes can be degraded and do not cause environment pollution; and the edible collagen food packaging film can be widely applied to the fields of various food packaging and medicament packaging, and has a good market application prospect.

Owner:SICHUAN UNIV

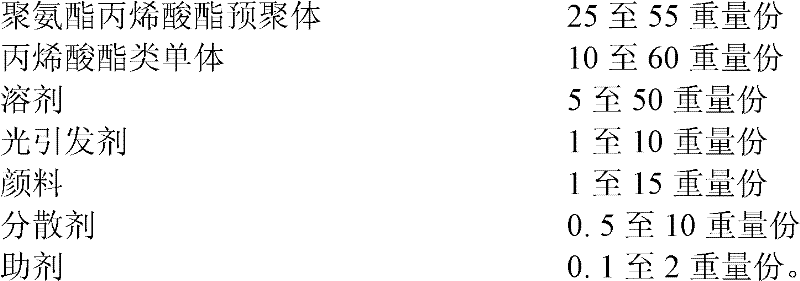

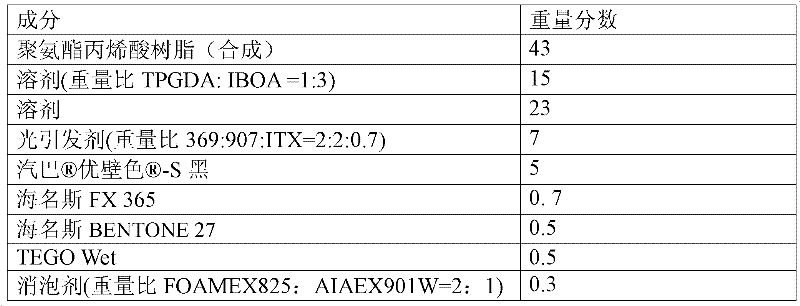

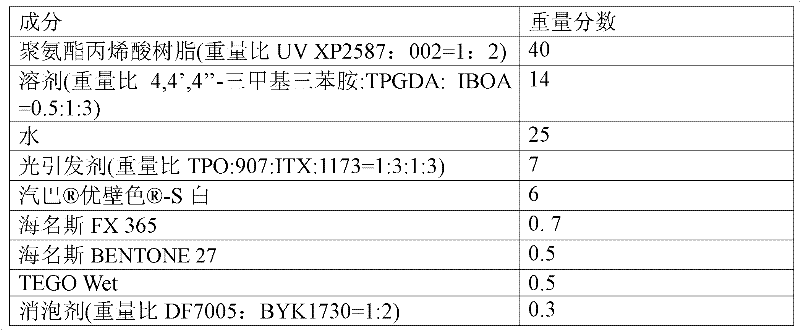

Colorful ultraviolet (UV) light solidifying paint

InactiveCN102212311AEasy constructionFast constructionPolyurea/polyurethane coatingsUltravioletUrethane acrylate

The invention provides a colorful ultraviolet (UV) light solidifying paint. The paint comprises the following components in parts by weight: 25-55 parts of polyurethane acrylate prepolymer, 10-60 parts of acrylate monomer, 5-50 parts of solvent, 1-10 parts of photoinitiator, 1-15 parts of pigment, 0.5-10 parts of dispersing agent and 0.1-2 parts of auxiliary, wherein the acrylate monomer is a mixture of a single-functionality monomer, a double-functionality monomer and a high-functionality monomer. According to the invention, the paint is used so as to overcome the problems such as large volatility, difficult construction and the like in the existing colorful UV light solidifying paint, has the characteristics of low volatile organic compound (VOC), good decorative effect, rapid curing speed and the like, is easy to construct, is suitable for flow line production, and can be used for decoration of base materials such as plastic, wood, metal and the like.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

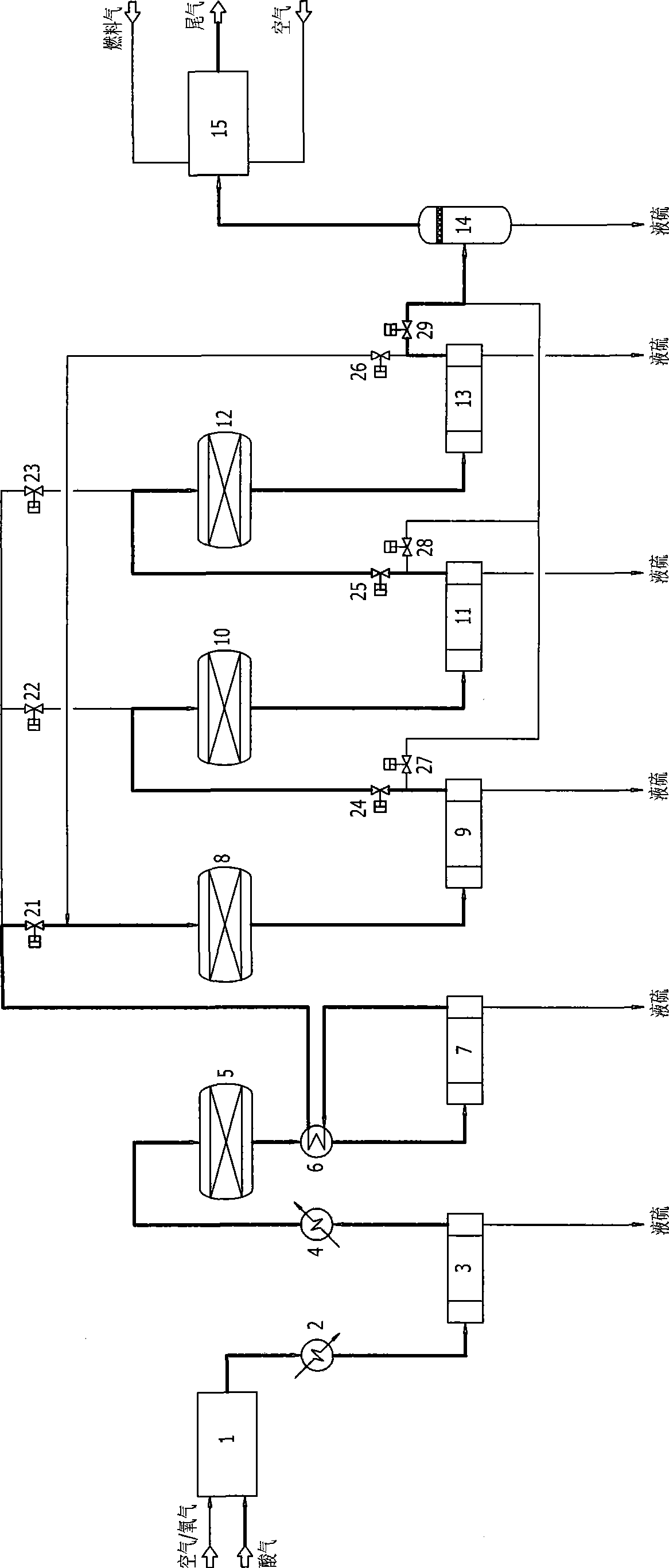

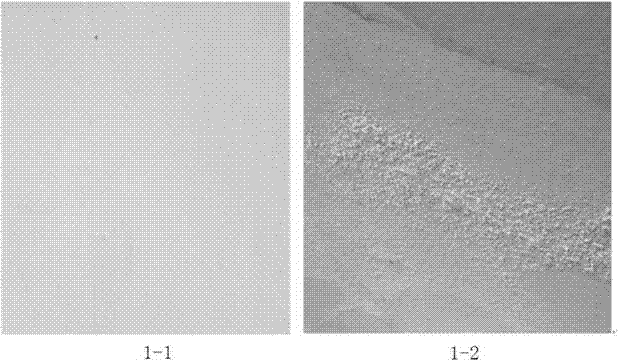

Low temperature Claus sulfur recovery process and device therefor

InactiveCN101519192AAchieve regenerationImprove conversion rateEnergy inputSulfur preparation/purificationReaction temperatureOxygen

Owner:CHENGDU SEPMEM SCI & TECH

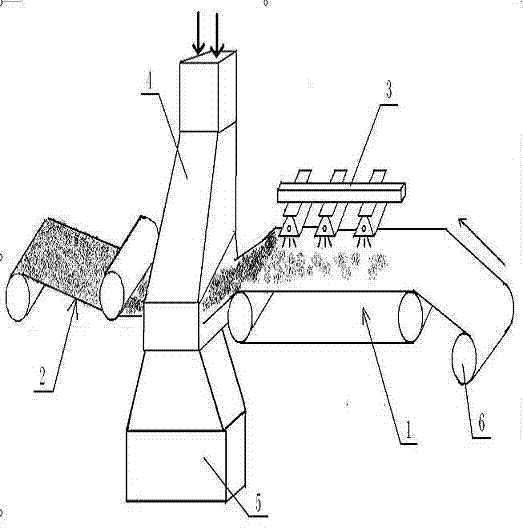

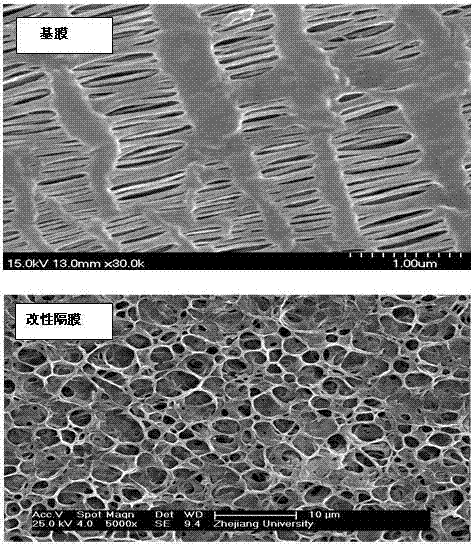

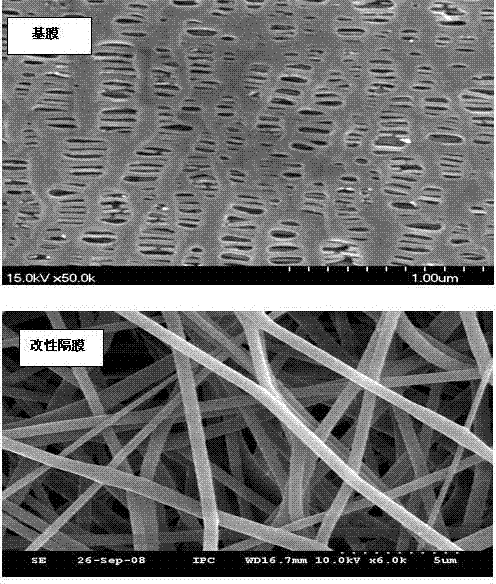

Preparation method of modified diaphragm for lithium-ion secondary battery as well as product and preparation device thereof

ActiveCN102218871AOvercome the disadvantages of poor mechanical propertiesHigh strengthSynthetic resin layered productsFilament/thread formingFiberPolyolefin

The invention discloses a preparation method of a modified diaphragm for a lithium-ion secondary battery as well as a prepared modified diaphragm and a preparation device and is aimed to solve the problem of lithium battery modified diaphragms in the prior art. The method concretely comprises the following steps of: (1), evenly dispersing special fiber or oxide and a binder into an organic solvent to prepare composite mixed liquid, and adding a cosolvent into the organic solvent; (2) evenly spraying the composite mixed liquid obtained in the step (1) on a polyolefin base membrane to form a primary composite membrane through an electrostatic spinning method; and (3), drying the primary composite membrane obtained in the step (2) and recycling the solvent, and then finally obtaining the finished product. The preparation method is convenient to operate and environmental friendly, can realize large-scale production and has strong feasibility.

Owner:WANXIANG 123 CO LTD

Aqueous organic-inorganic composite coating and preparation method thereof

The invention discloses an aqueous organic-inorganic composite coating, comprising the base materials of water-soluble film-forming material, pigment, filler, additive and water. The aqueous organic-inorganic composite coating is specifically composed of the following component, by weight: 15-25 parts of potassium silicate, 10-20 parts of styrene-acrylic emulsion, 0.2-0.5 part of stabilizer, 0.2-0.5 part of dispersing agent, 0.3-0.6 part of defoaming agent, 0.2-0.5 part of film-forming additive, 0.2-0.5 part of antifreeze, 0.1-0.3 part of thickening agent, 14-20 parts of titanium dioxide, 15-25 parts of heavy calcium, 5-10 parts of talcum powder and 20-25 parts of water. The invention has the following advantages: high film hardness, no cracking, excellent weather fastness, lasting replenished film, no addition of preservatives, excellent environmental protection performance, long recoating period of film and resource saving. In addition, the product has minimal construction resistance, and is easy for painting, promotion and application. The aqueous organic-inorganic composite coating has wide application range, and can be applied to coating of basement, underground parking, inner wall and outer wall.

Owner:广东嘉宝莉科技材料有限公司

Spray polyurea high-performance waterproof paint and preparation method thereof

InactiveCN101818019AFast curingHigh strengthPolyurea/polyurethane coatingsDiluentUltimate tensile strength

The invention relates to a spray polyurea high-performance waterproof paint which is characterized by comprising component A and component B, wherein the component A comprises semi-prepolymer formed by the reaction between 70-35 parts of polyisocyanate and 30-50 parts of polyether glycol, and 0-15 parts of diluent based on parts by weight; the component B comprises 50-70 parts of amine-terminated polyether, 20-40 parts of amine chain extender and 5-10 parts of filler; and the volume ratio between the component A and the component B is 1:1. Compared with the common spray polyurea high-performance waterproof paint, the spray polyurea high-performance waterproof paint has higher tensile strength, elongation at break, tearing strength and other physical properties, and not only is applicable to waterproof projects of common building projects, basic facilities and the like, but also is especially suitable for high-difficulty waterproof projects of large basic facility construction such as a high speed railway, a subway, a tunnel, water conservancy project and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

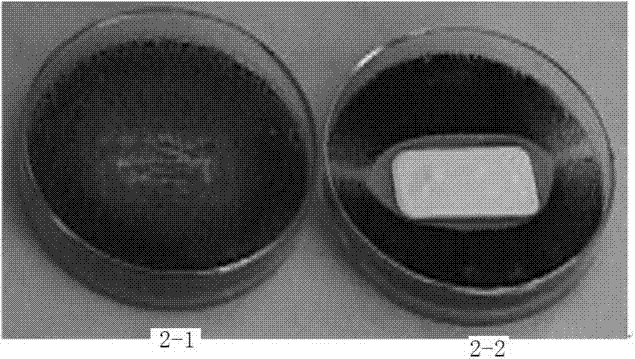

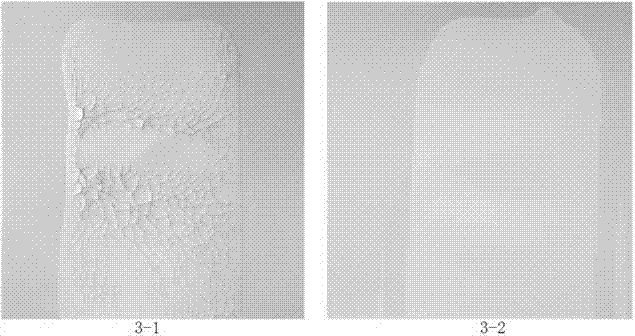

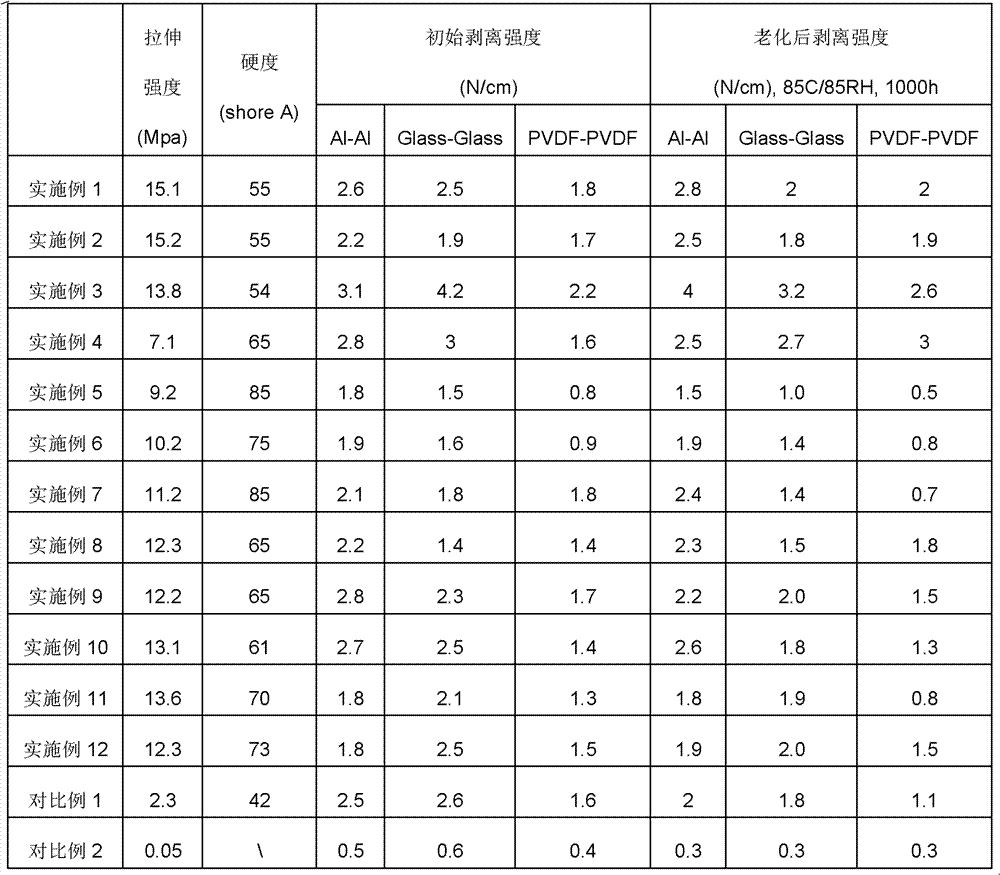

Sealing joint strip and application method thereof

InactiveCN102775944AImprove sealingDurableNon-macromolecular adhesive additivesSolar heat devicesElastomerEngineering

The invention provides a sealing joint strip which is used for heat bonding of a solar battery assembly or a flat-plate solar heat collector with a border. The sealing joint strip is characterized by comprising the following components by mass: 100 parts of thermoplastic polymer elastomer and 0.1 to 10 parts of a silane coupling agent. During utilization, the sealing joint strip can be pressed at a position where the solar battery assembly or the flat-plate solar heat collector and the border joint in the assembling process of a solar module and is then laid aside or treated at a certain temperature for a period of time so as to finish heat bonding, which allows good sealing and fixing effects of the sealing joint strip to be obtained. The application method for the sealing joint strip is characteristic of simpleness, high efficiency and environment friendliness. The sealing joint strip and the application method can also be used for the flat solar heat collector.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

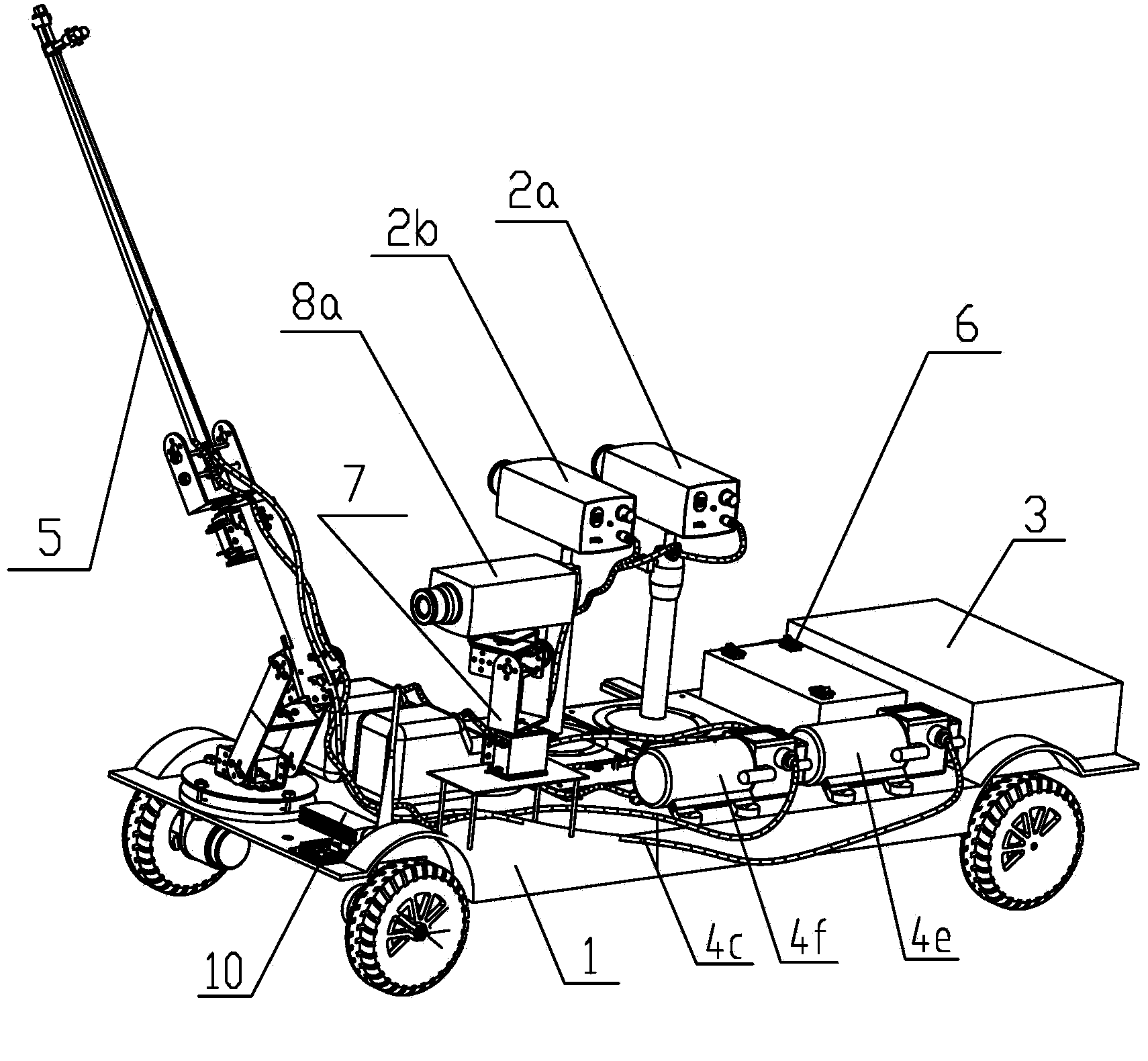

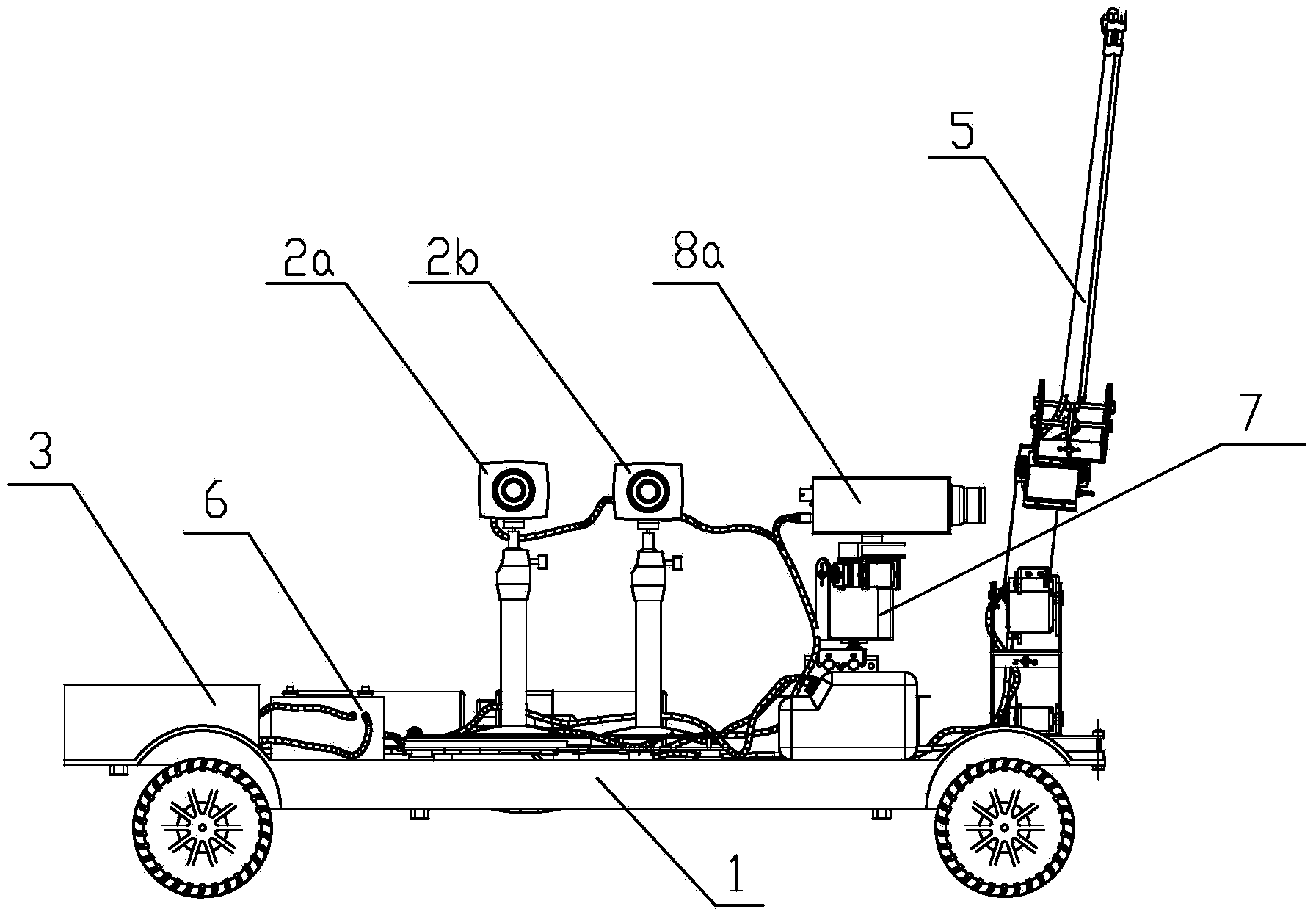

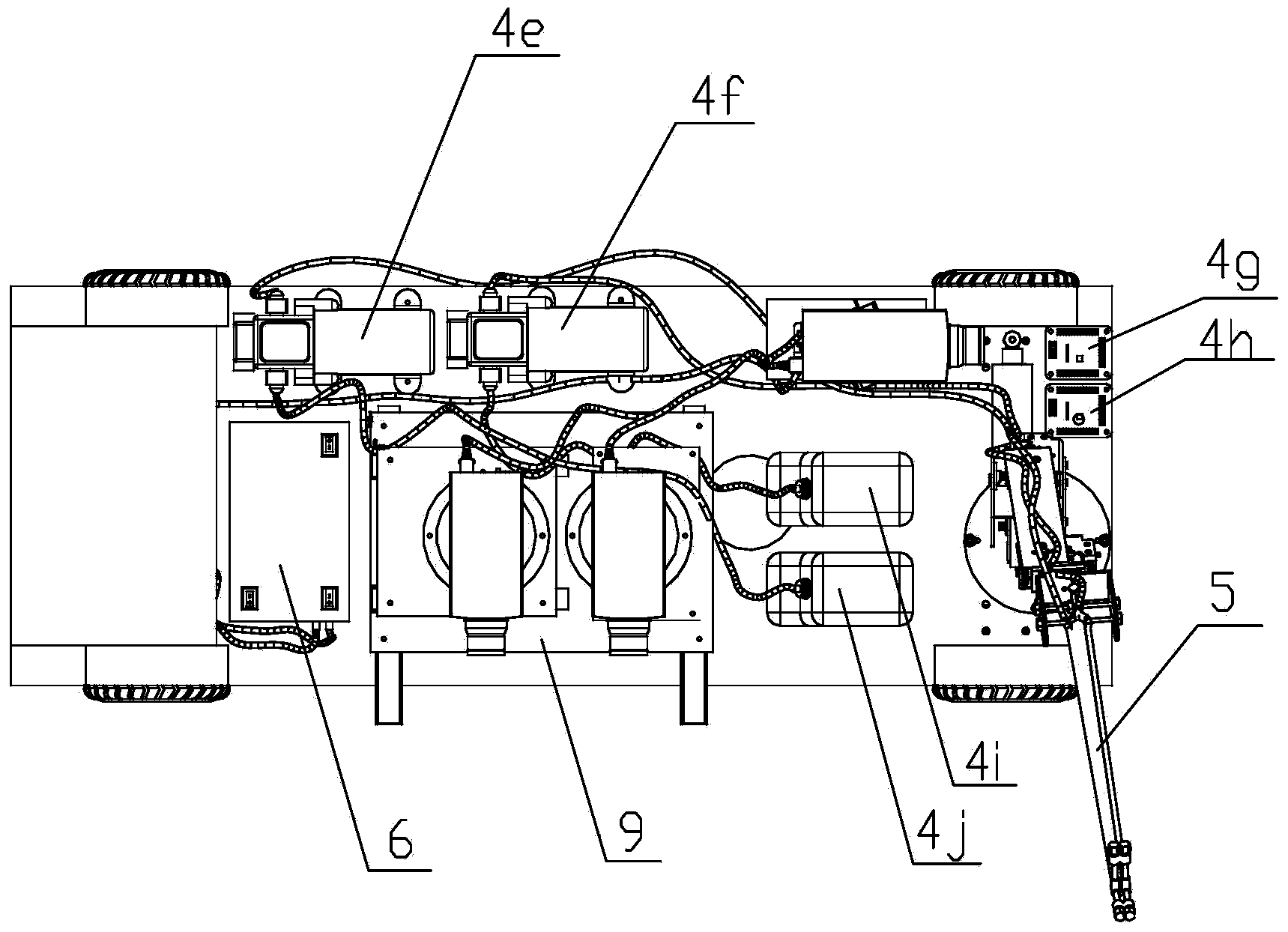

Intelligent spraying method based on image processing and spraying robot based on image processing

ActiveCN103918636AReduce labor intensityLow costManipulatorInsect catchers and killersPesticide residueDisinfectant

The invention provides an intelligent spraying method based on image processing and a spraying robot based on image processing. Through the method, the spraying robot can correctly distinguish specific crops and weeds and carry out targeted spraying according to the distribution condition of the crops and the weeds needing to be sprayed, that is, the spraying robot sprays weed killer on the weeds and sprays corresponding disinfectant and other pesticides on the crops, and consequently intelligent spraying without human interference is achieved. Meanwhile, a wireless video transmission mode is additionally adopted, and a worker can monitor and control the spraying robot by holding a monitor in hand. Thus, the intelligent spraying robot not only reduces the labor intensity of the workers and spraying cost but also reduces the use quantity of the pesticides and pesticide residues in the soil environment and has an immeasurable significance in improving spraying intellectualization and modernization of agriculture and accelerating agriculture precision in our country.

Owner:QINGDAO AGRI UNIV

Fibrilia automobile inner decoration member and method of manufacturing the same

ActiveCN101549671ANo pollution in the processReduce lossMonocomponent cellulose artificial filamentSuperstructure subunitsRaw materialPolypropylene fiber

The present invention relates to a fibrilia automobile inner decoration member and a method of manufacturing the same, the steps is that implementing a opening treatment to packaged raw material, mixing jute fiber and polypropylene fiber according to proportionality in a cotton opener, and fiber netting simultaneously; then needling to form a felt by a needle machine, and implementing a sliced sheet treatment to the product after felting; baking and heating the felt directly in a baking oven to bond the surface, the baking temperature is from 180 to 200 DEG C; then cold press molding by a product mold, finally manufacturing a finished product; or preparing the belt into a sheet material to store, then baking and heating the sheet material, and a corresponding product molding according to requirements.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com