Sealing joint strip and application method thereof

A technology of sealing strips and elastomers, applied in adhesives, polyurea/polyurethane adhesives, solar thermal devices, etc., can solve problems such as long curing time, unstable quality, and low bonding strength, and achieve excellent environmental performance , Excellent sealing effect, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

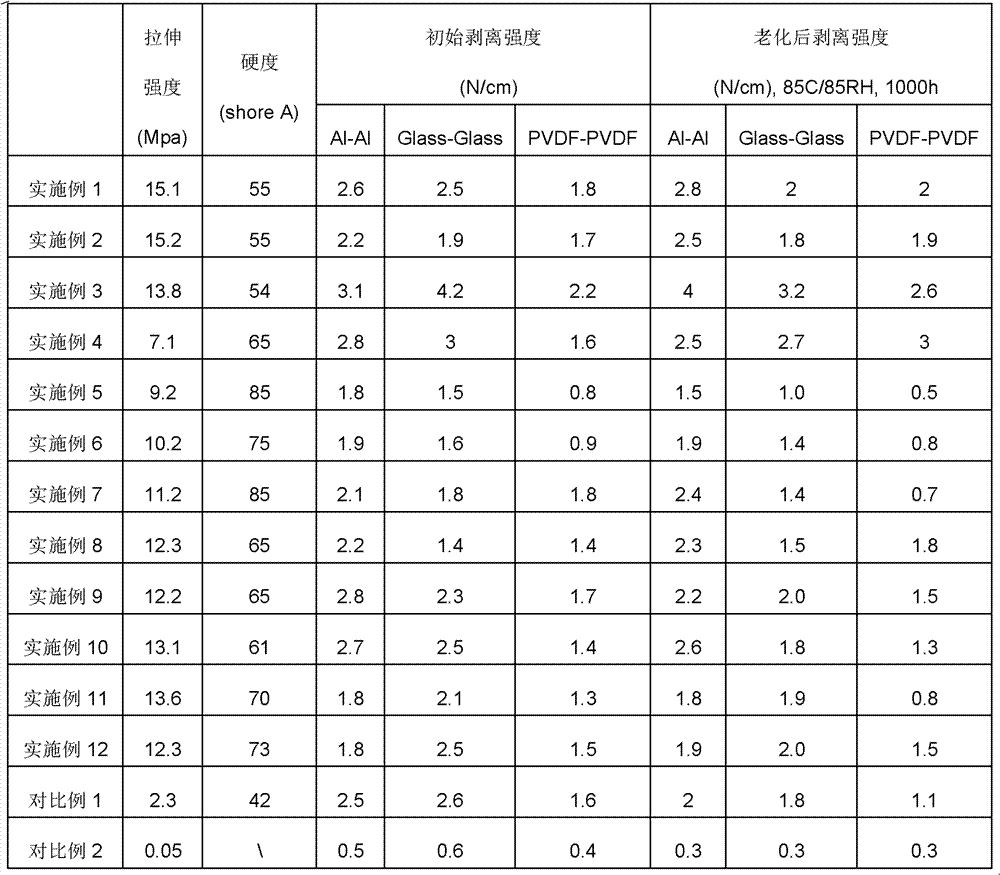

Examples

Embodiment 1

[0047] In terms of parts by mass, 0.6 parts of N-β (aminoethyl)-γ-aminopropyltrimethoxy base silane (Dow Corning, USA), and mix well. The obtained composition is processed into a continuous film or a U-shaped or C-shaped rubber strip through melt blending and extrusion molding.

Embodiment 2

[0049] In terms of parts by mass, 0.6 parts of γ-(2,3-glycidyloxy)propyltrimethoxy base silane (Dow Corning, USA), and mix well. The obtained composition is processed into a continuous film or a U-shaped or C-shaped rubber strip through melt blending and extrusion molding.

Embodiment 3

[0051] In terms of parts by mass, 0.6 parts of N-β (aminoethyl)-γ-aminopropyltrimethoxy Base silane (U.S. Dow Corning), add 30 parts of maleic anhydride grafted SEB S (U.S. Curton Polymers), 0.2 parts of antioxidant tetrakis (methylene (3,5-di-(tert)-butyl -4-Hydroxyhydrocinnamate)) methane (Nanjing Ningkang Chemical Co., Ltd.), 0.2 parts of light stabilizer bis(2,2,6,6-tetramethylpiperidinyl) sebacate (Nanjing Milan Chemical Co., Ltd. Co., Ltd.) and mix well. The obtained composition is processed into a continuous film or a U-shaped or C-shaped rubber strip through melt blending and extrusion molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com