Fibrilia automobile inner decoration member and method of manufacturing the same

A technology for automobile interior parts and a production method, which is applied in the field of automobile interior parts manufacturing, can solve the problems of large consumption of chemical materials, environmental pollution, limited material resources, etc., and achieves small energy loss, low moisture content, and high modulus. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0039] The invention provides a method for manufacturing a hemp fiber automotive interior trim. The hemp fiber automotive interior trim is composed of hemp fiber and polypropylene fiber. The proportion of fibers used in the two materials is: jute fiber 45%, polypropylene fiber 55%. The production methods of two kinds of hemp fiber automotive interior parts are provided below.

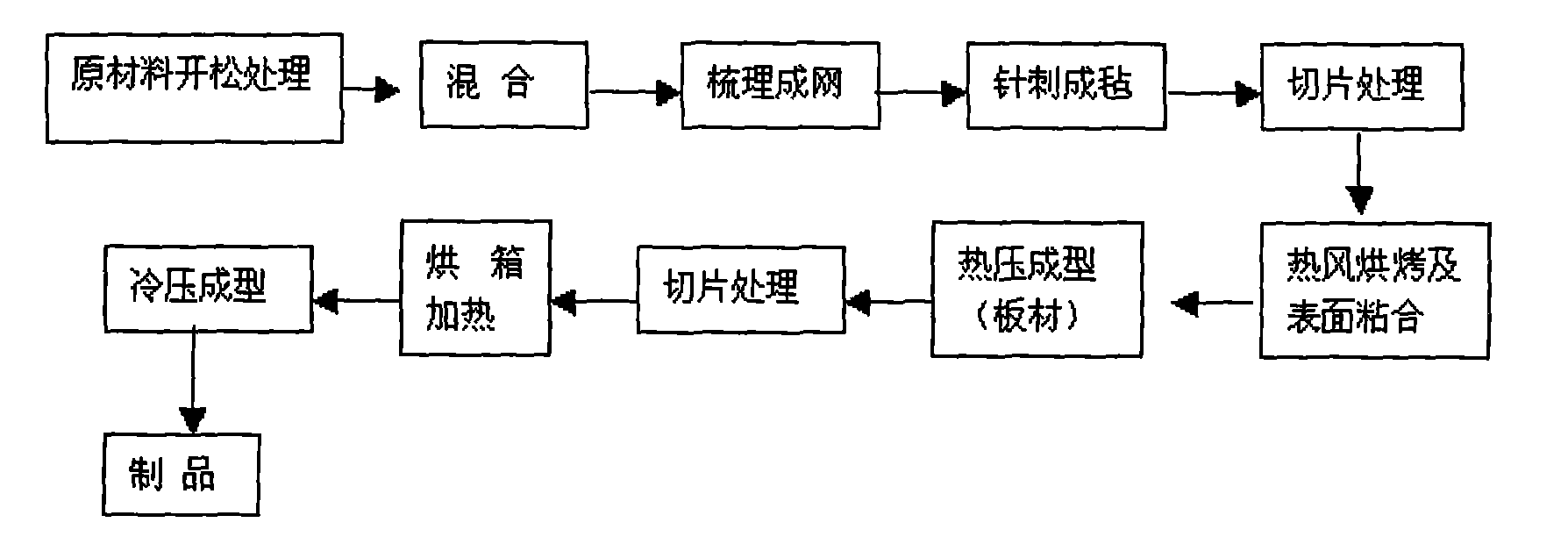

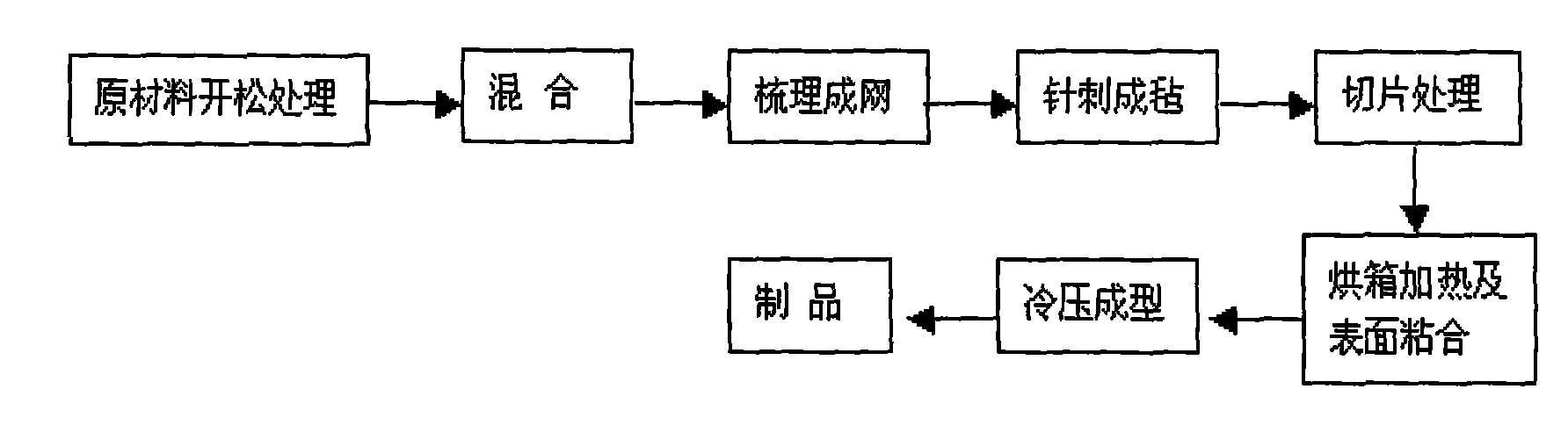

[0040] Method 1: if figure 1 As shown, the packaged raw materials are opened and loosened, jute fibers and polypropylene fibers are mixed in the carding machine according to the proportion, and the fibers are formed into a net at the same time, and then needled into a felt by a needle punching machine, and the felted product is processed. Slicing process, first baked by hot air and bonded on the surface, the bak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com