Patents

Literature

35results about How to "Minimal heat loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions and Methods of Using Same in Producing Heavy Oil and Bitumen

InactiveUS20070295640A1Reduce energy consumptionMinimal heat lossWorking-up pitch/asphalt/bitumen by chemical meansFluid removalFuel oilSolvent

deposition in a formation, wellbore, near wellbore region, and production tubing. Compositions of the invention comprise an asphaltene solvent and a viscosity reducing agent, the asphaltene solvent and viscosity reducing agent present in a ratio so as to substantially reduce viscosity of an asphaltene-containing material while substantially negating deposition of asphaltenes either in a reservoir, in production tubing, or both when mixed or otherwise contacting the asphaltene-containing material Methods of the invention comprise forcing a composition comprising an asphaltene solvent and a viscosity reducing agent to contact an asphaltene-containing hydrocarbon in an underground geologic formation, and producing from the formation a production composition comprising at least some of the treatment composition and at least some of the asphaltene-containing hydrocarbon under conditions sufficient to substantially negate deposition of asphaltenes in the formation.

Owner:SCHLUMBERGER TECH CORP

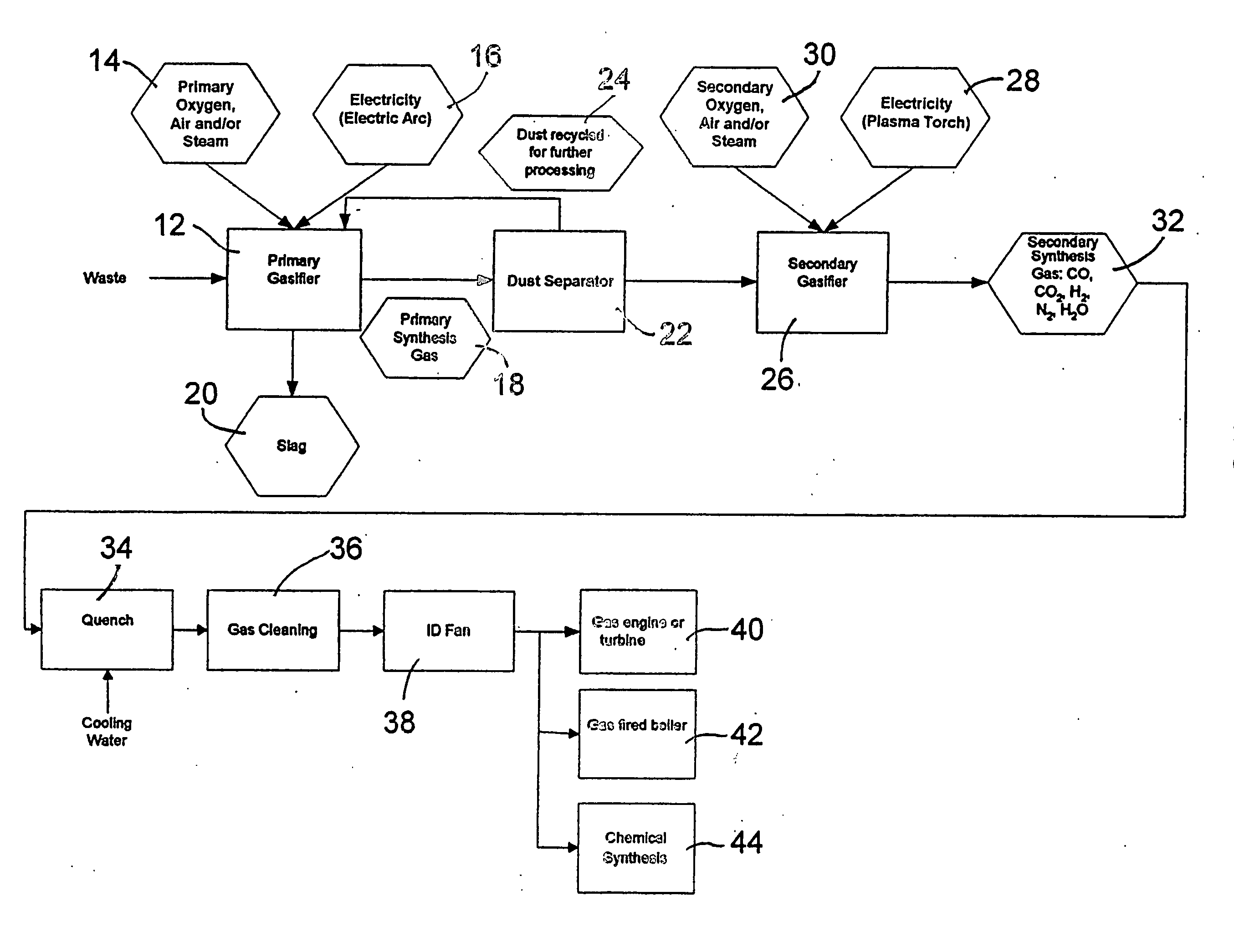

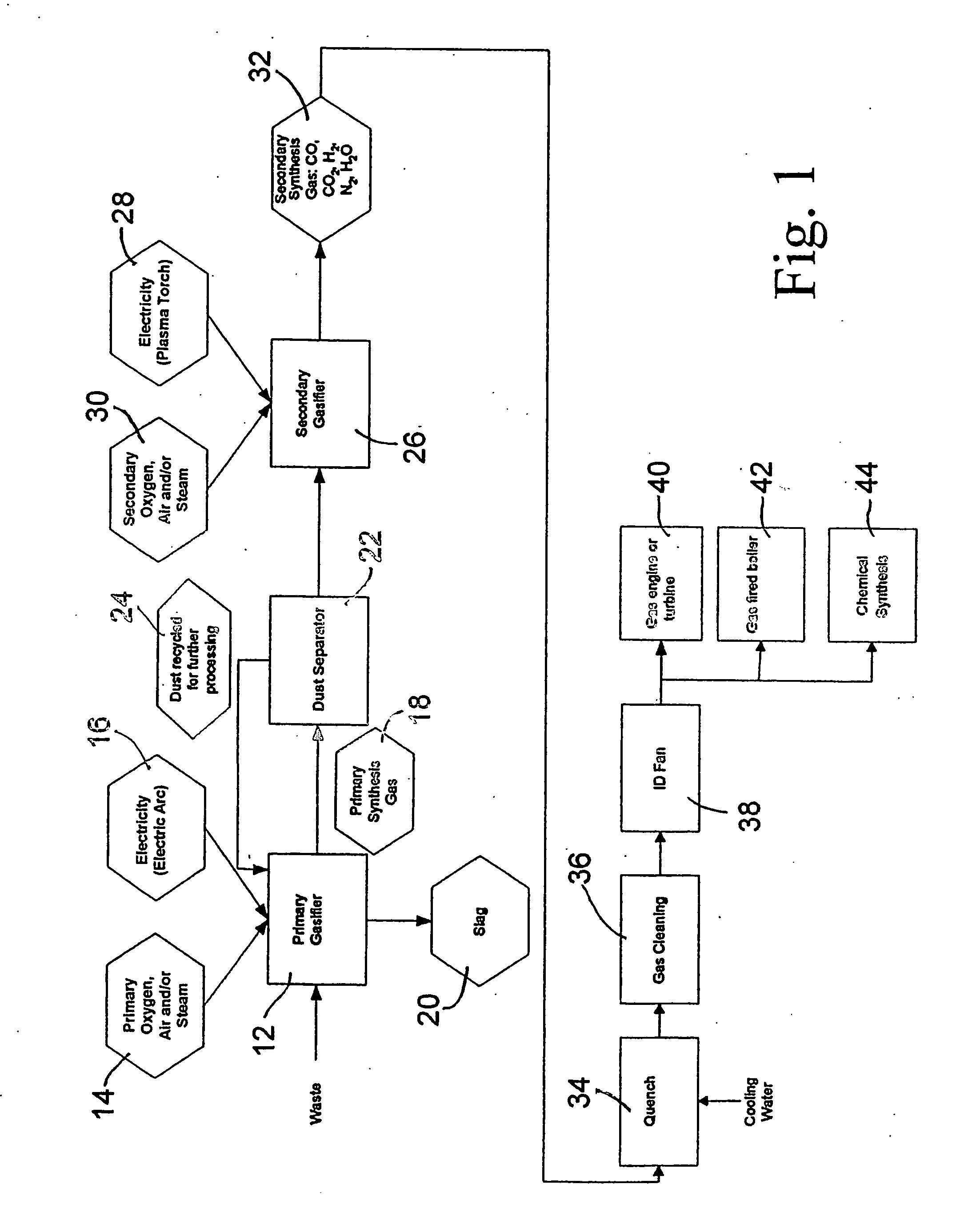

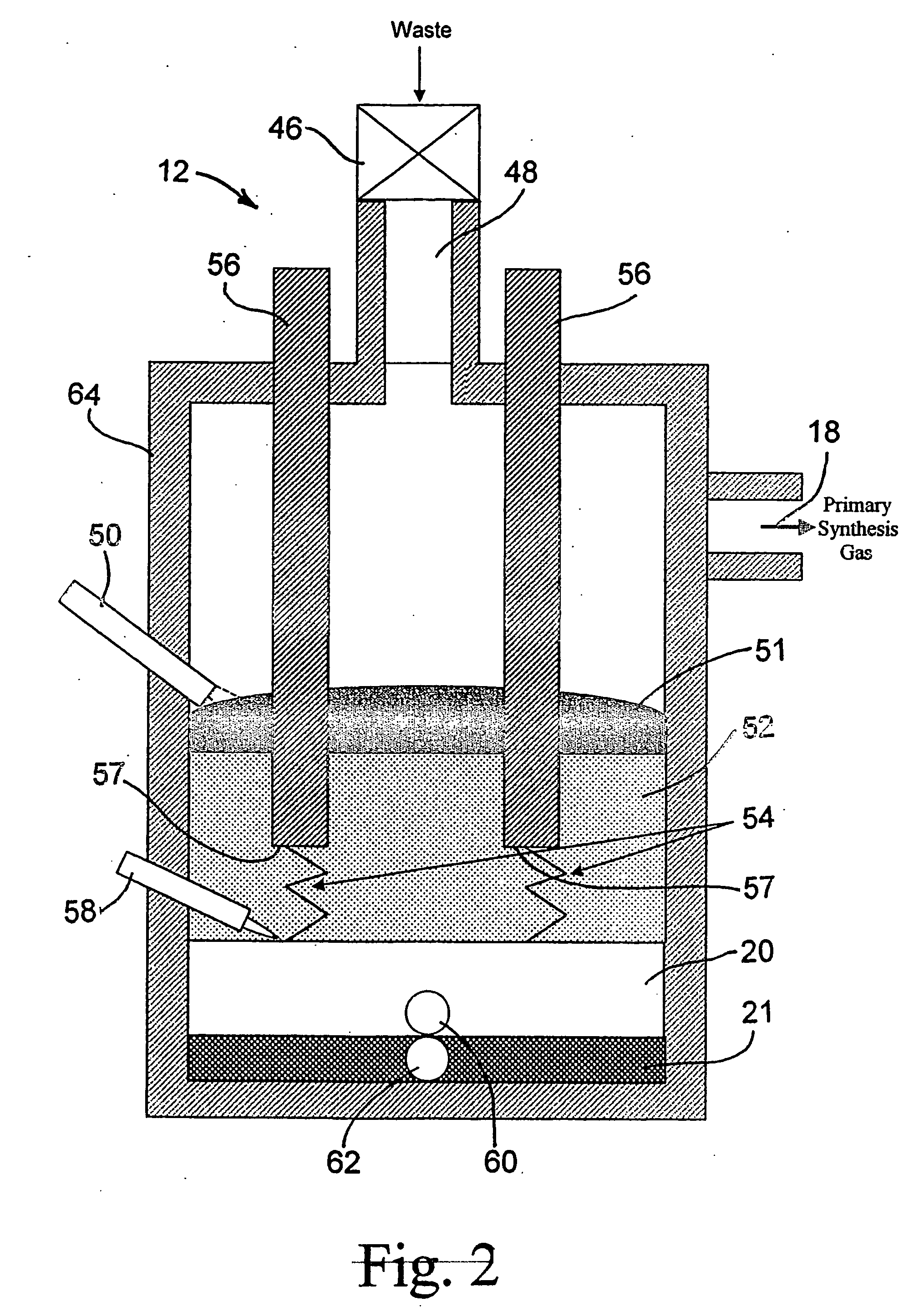

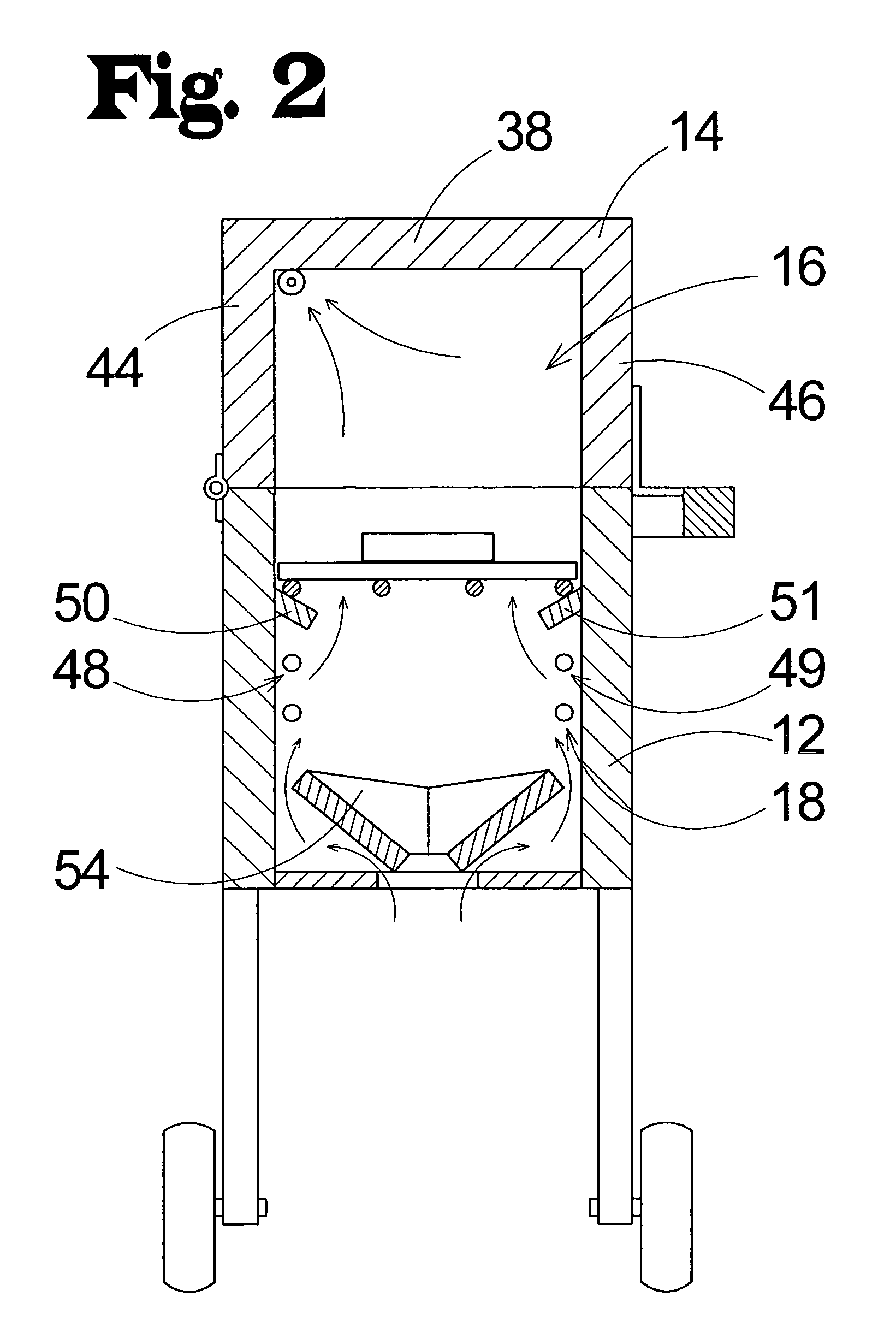

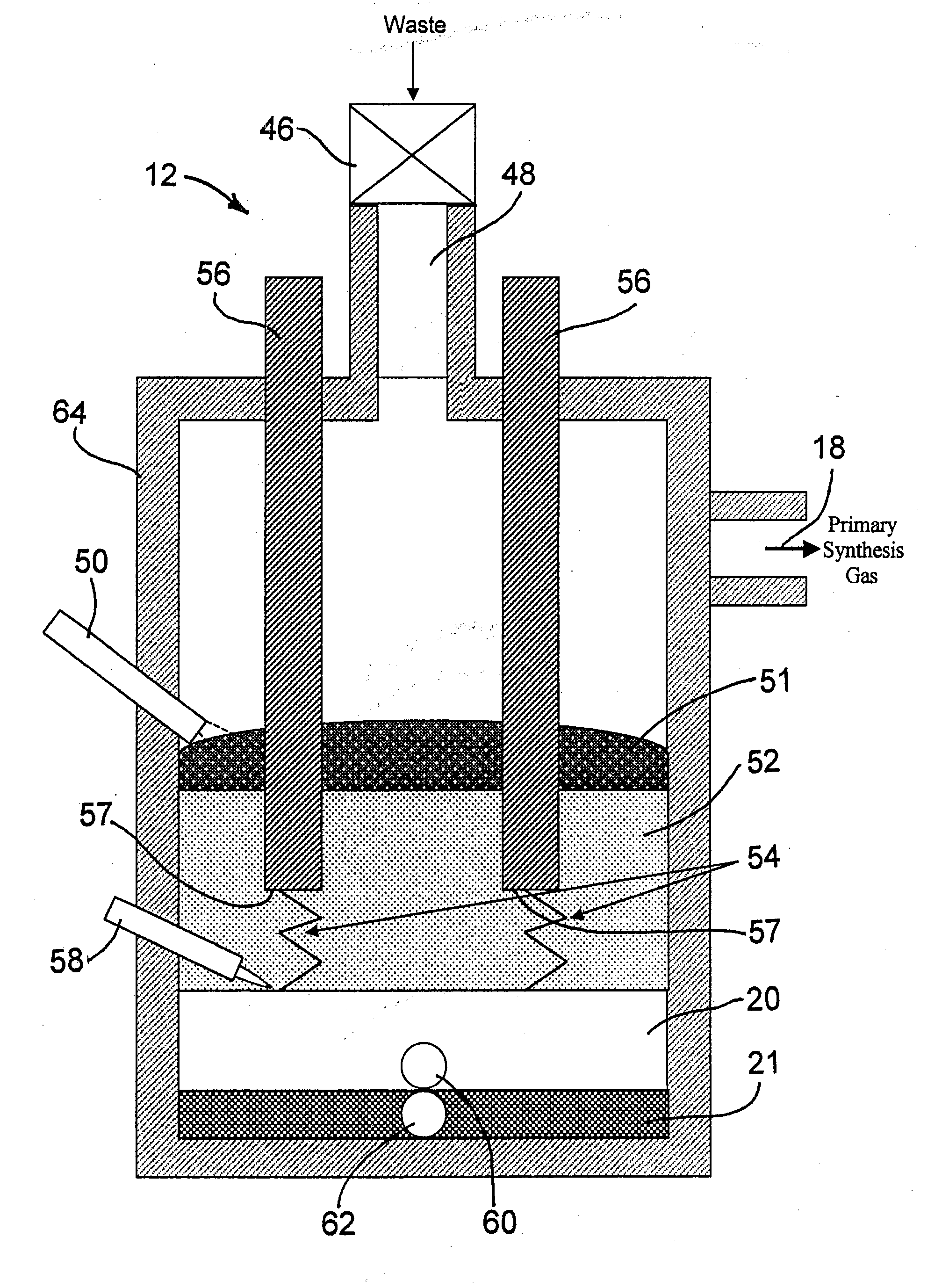

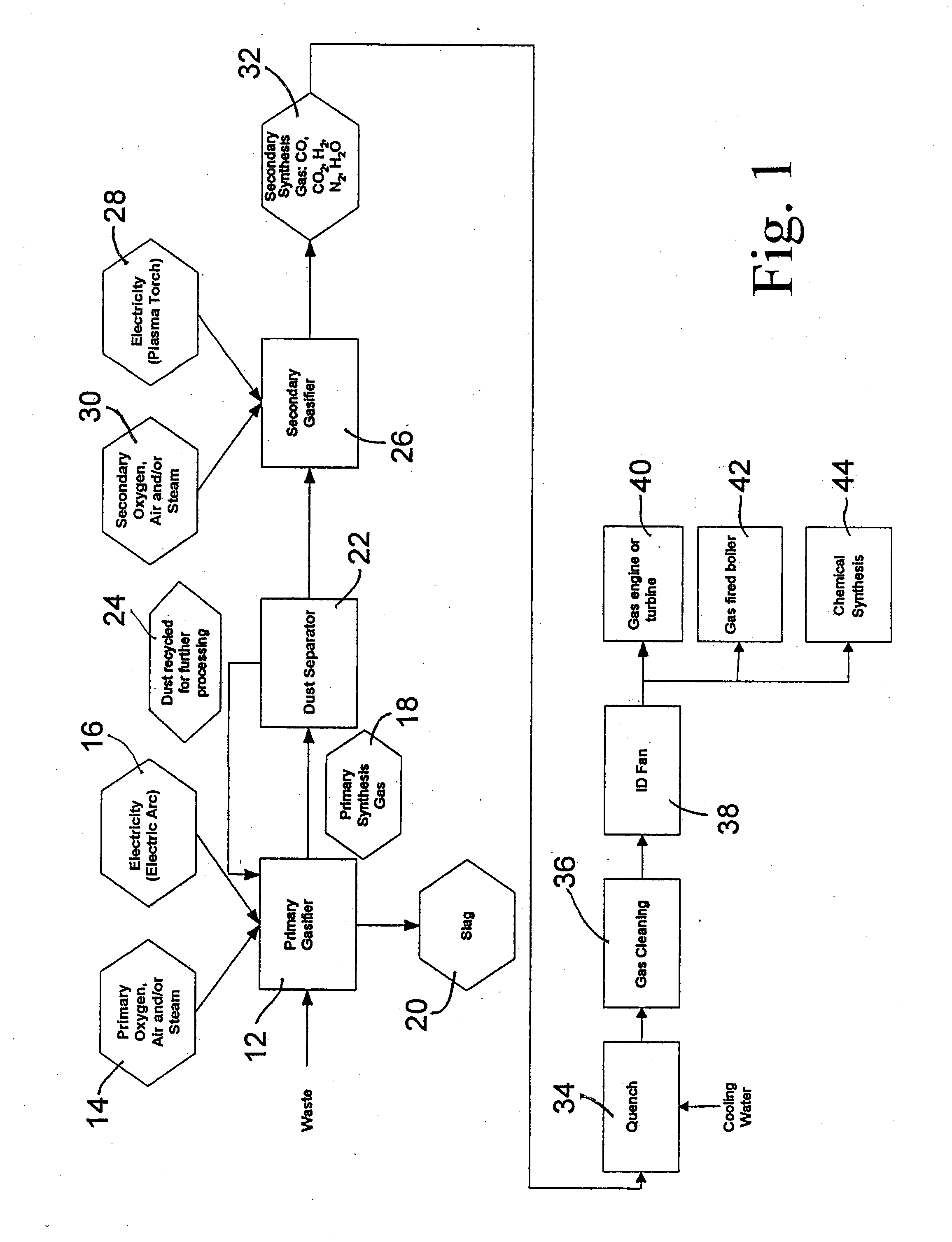

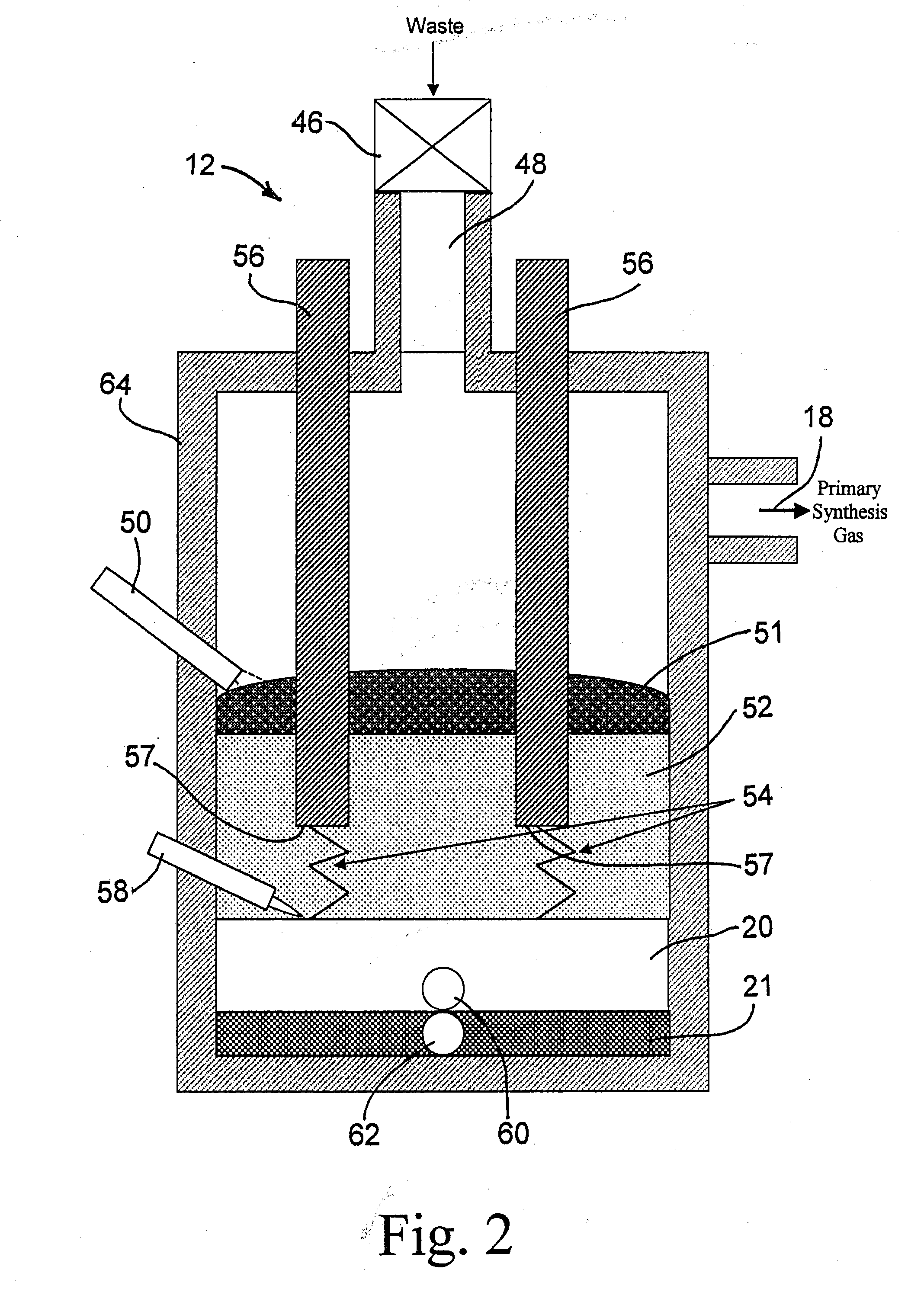

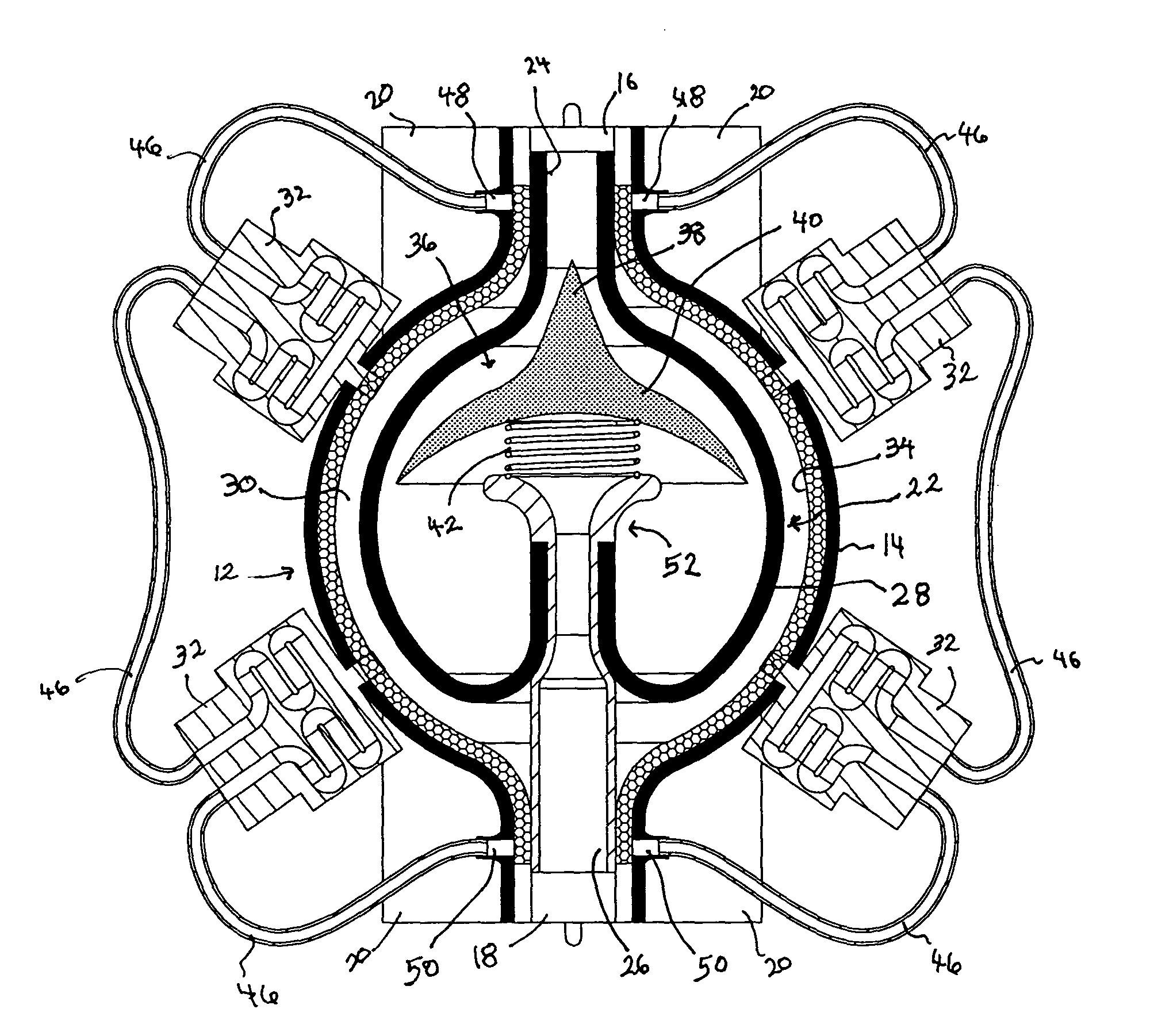

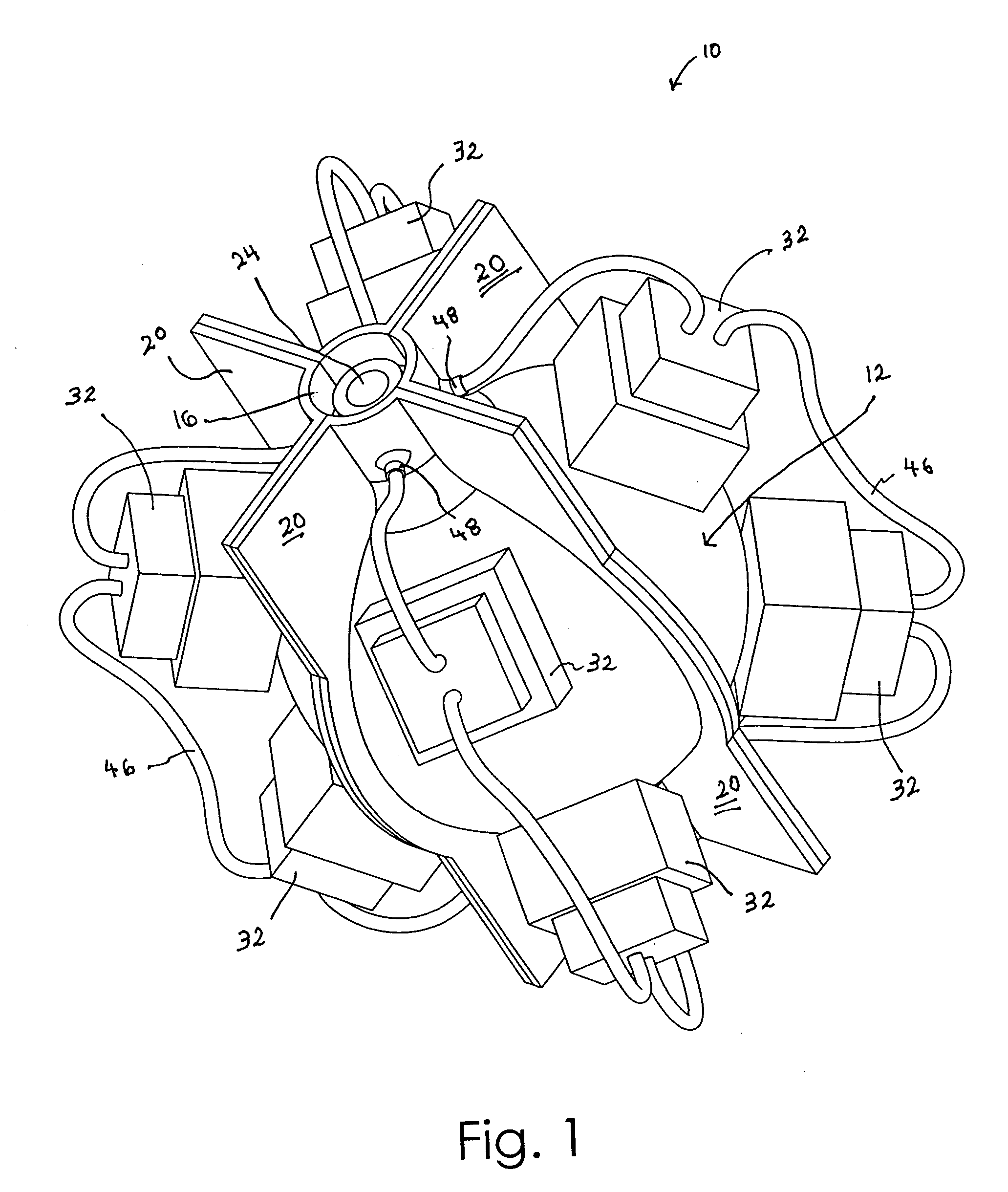

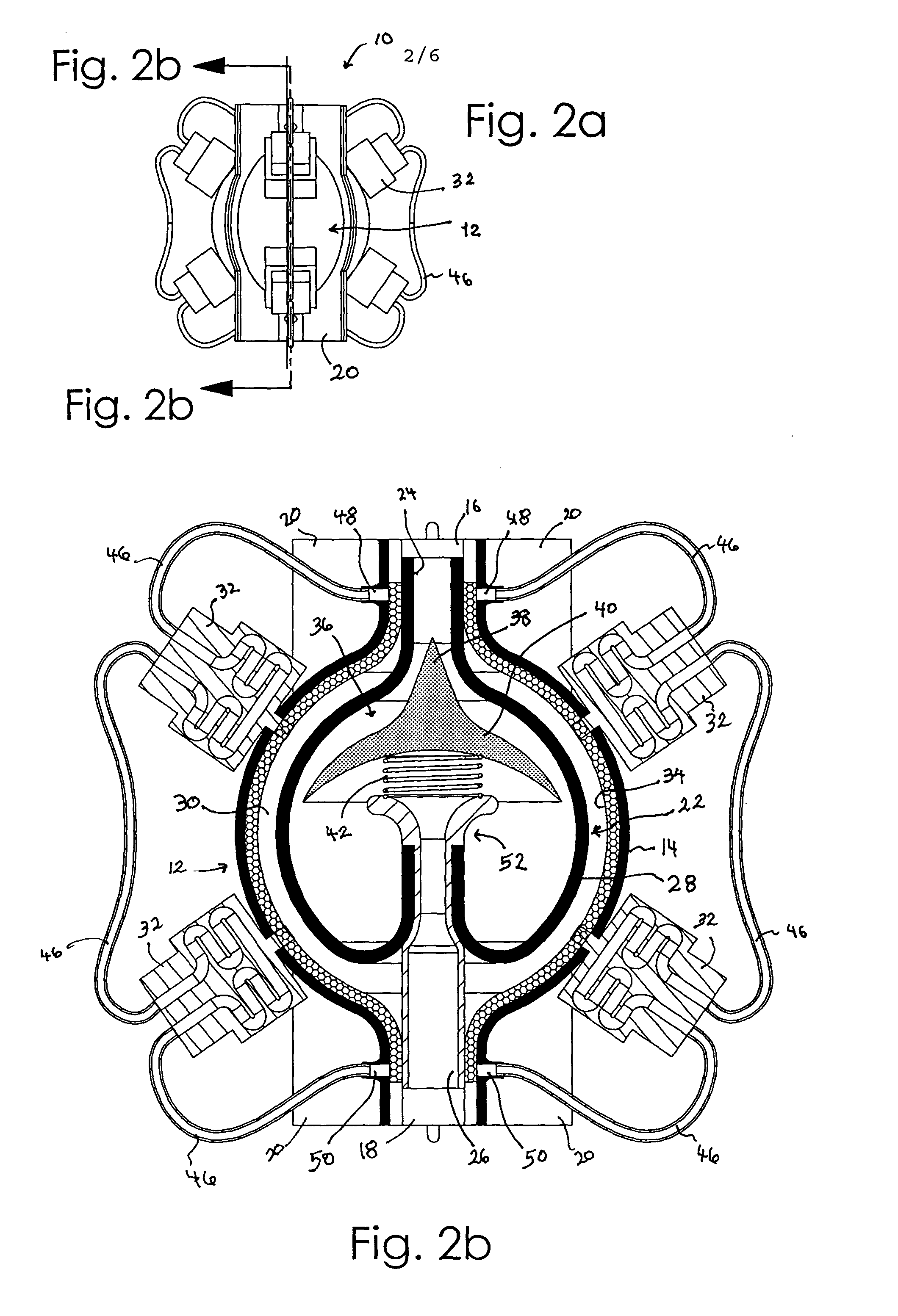

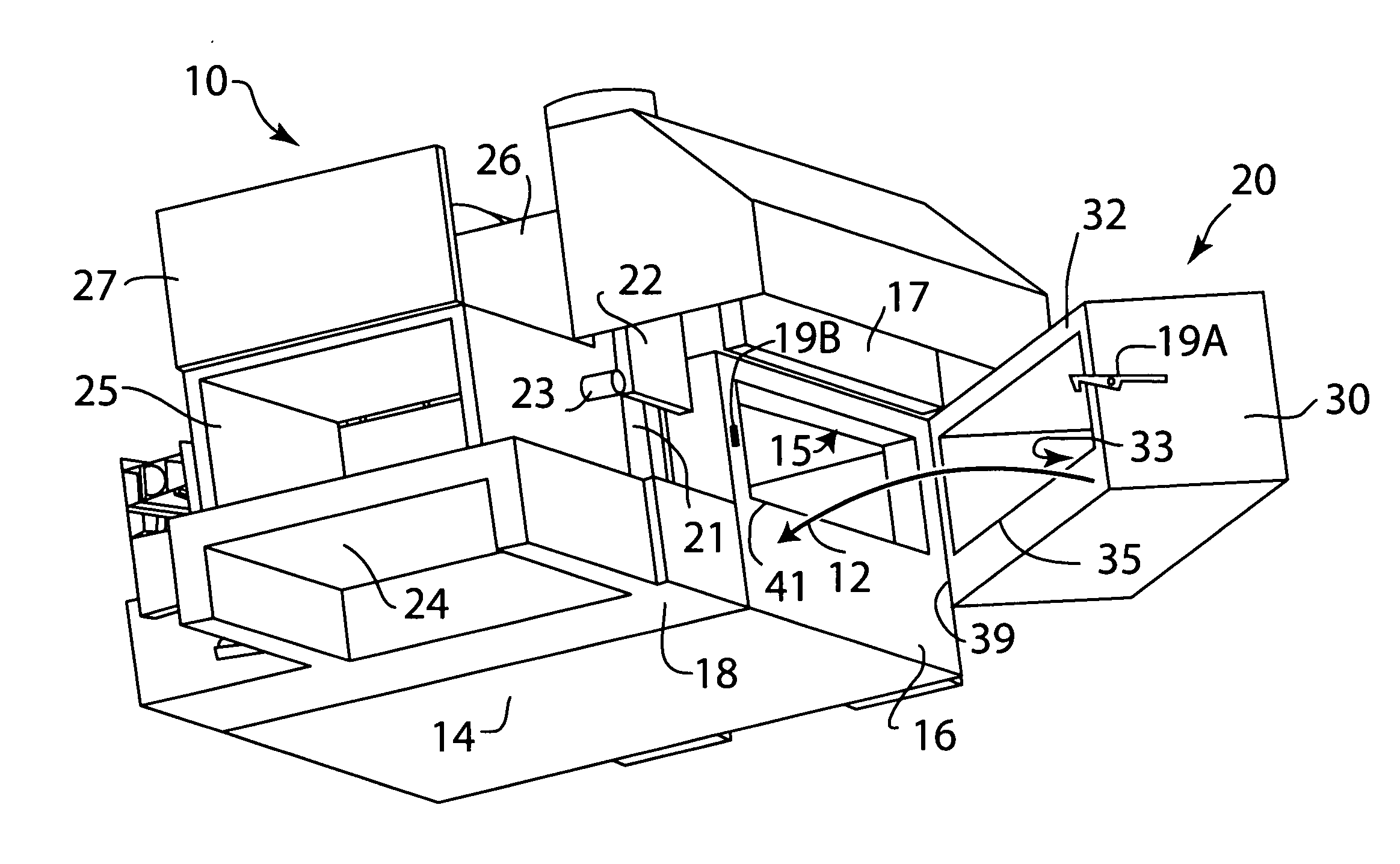

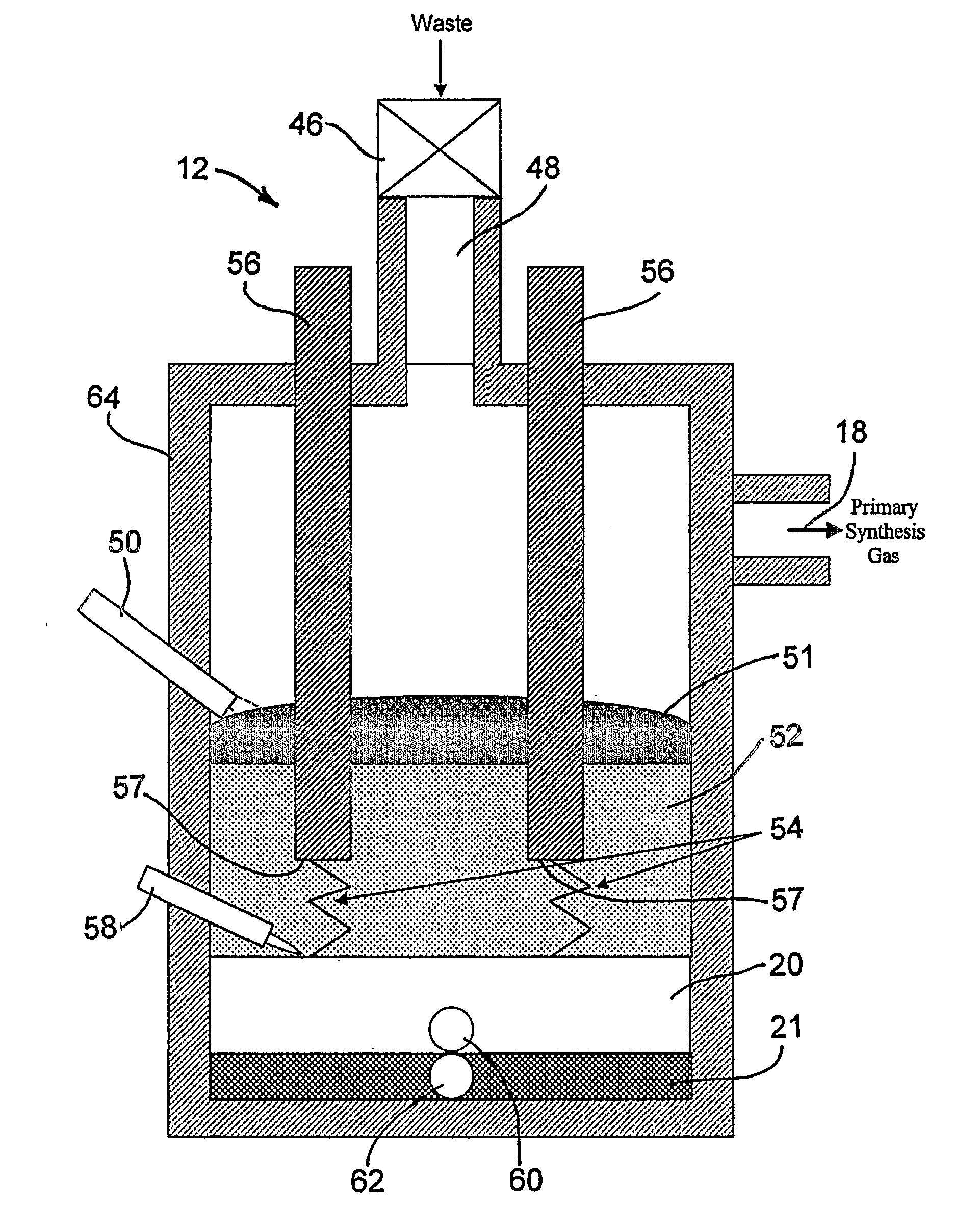

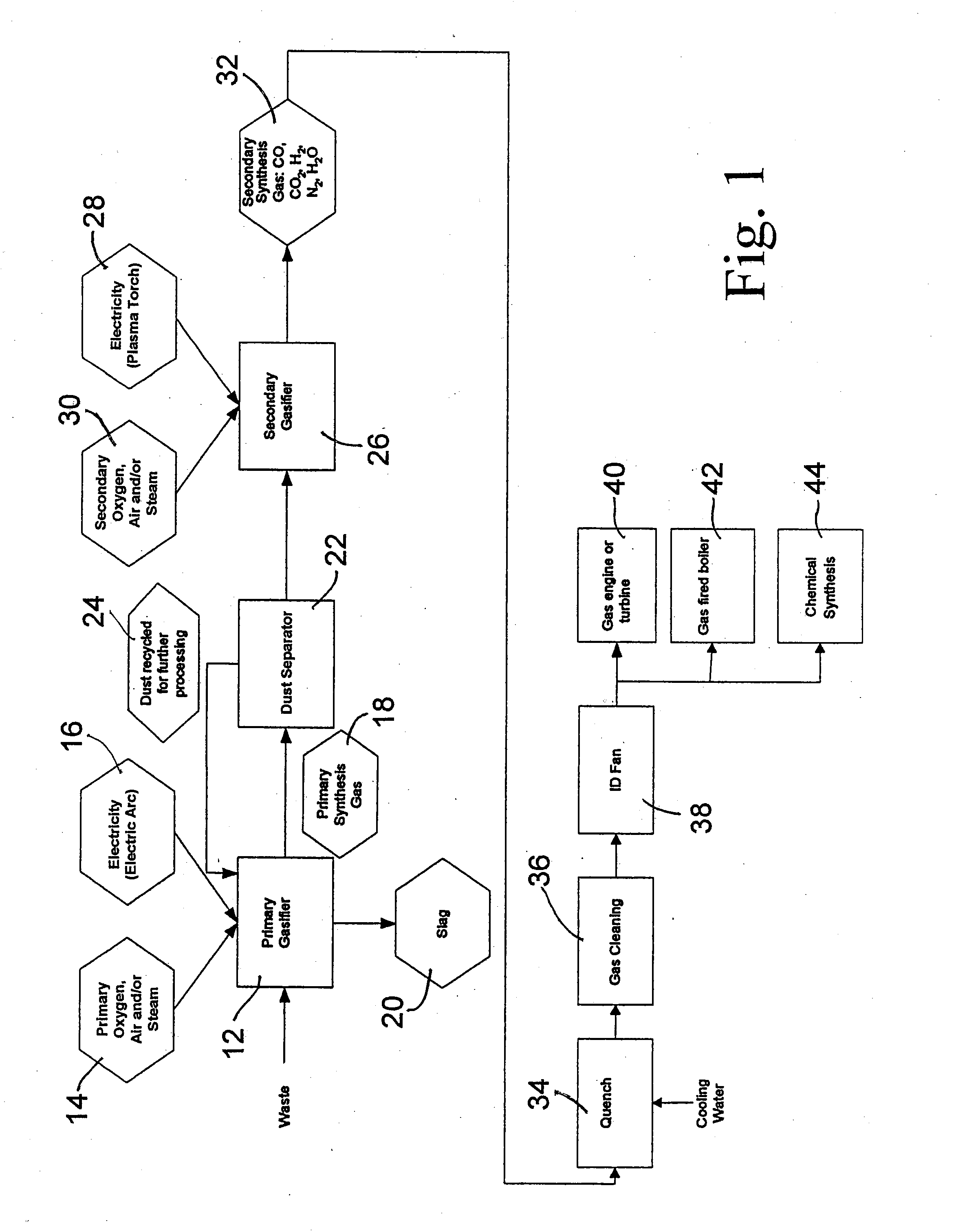

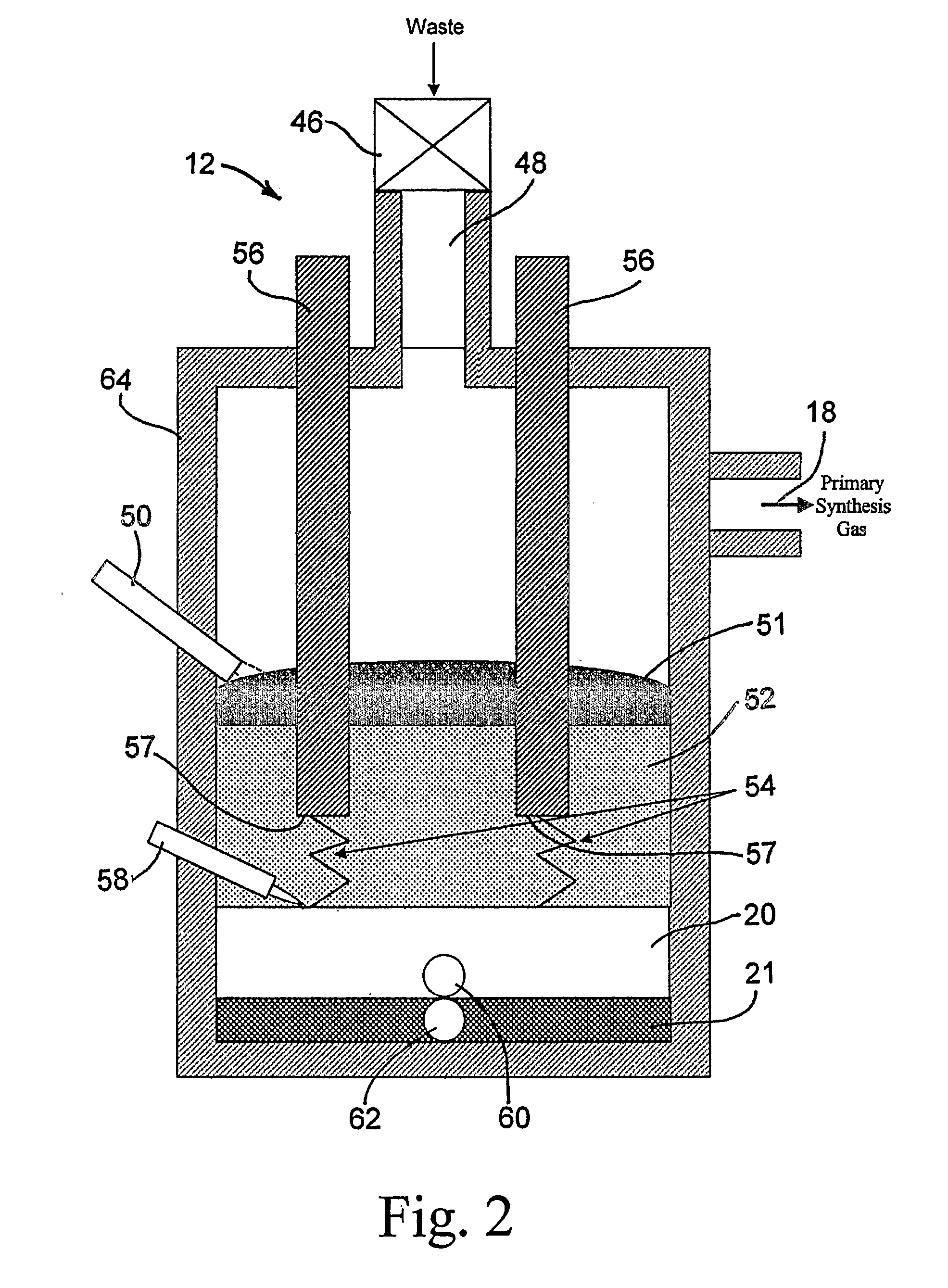

Two-Stage Plasma Process For Converting Waste Into Fuel Gas And Apparatus Therefor

InactiveUS20070272131A1Limited amountImprove energy efficiencyGasifier electrodesGasification processes detailsPlasma jetCyclone

A two-step gasification process and apparatus for the conversion of solid or liquid organic waste into clean fuel, suitable for use in a gas engine or a gas burner, is described. The waste is fed initially into a primary gasifier, which is a graphite arc furnace. Within the primary gasifier, the organic components of the waste are mixed with a predetermined amount of air, oxygen or steam, and converted into volatiles and soot. The volatiles consist mainly of carbon monoxide and hydrogen, and may include a variety of other hydrocarbons and some fly ash. The gas exiting the primary gasifier first passes through a hot cyclone, where some of the soot and most of the fly ash is collected and returned to the primary gasifier. The remaining soot along with the volatile organic compounds is further treated in a secondary gasifier where the soot and the volatile compounds mix with a high temperature plasma jet and a metered amount of air, oxygen or steam, and are converted into a synthesis gas consisting primarily of carbon monoxide and hydrogen. The synthesis gas is then quenched and cleaned to form a clean fuel gas suitable for use in a gas engine or a gas burner. This offers higher thermal efficiency than conventional technology and produces a cleaner fuel than other known alternatives.

Owner:PHOENIX HAUTE TECH

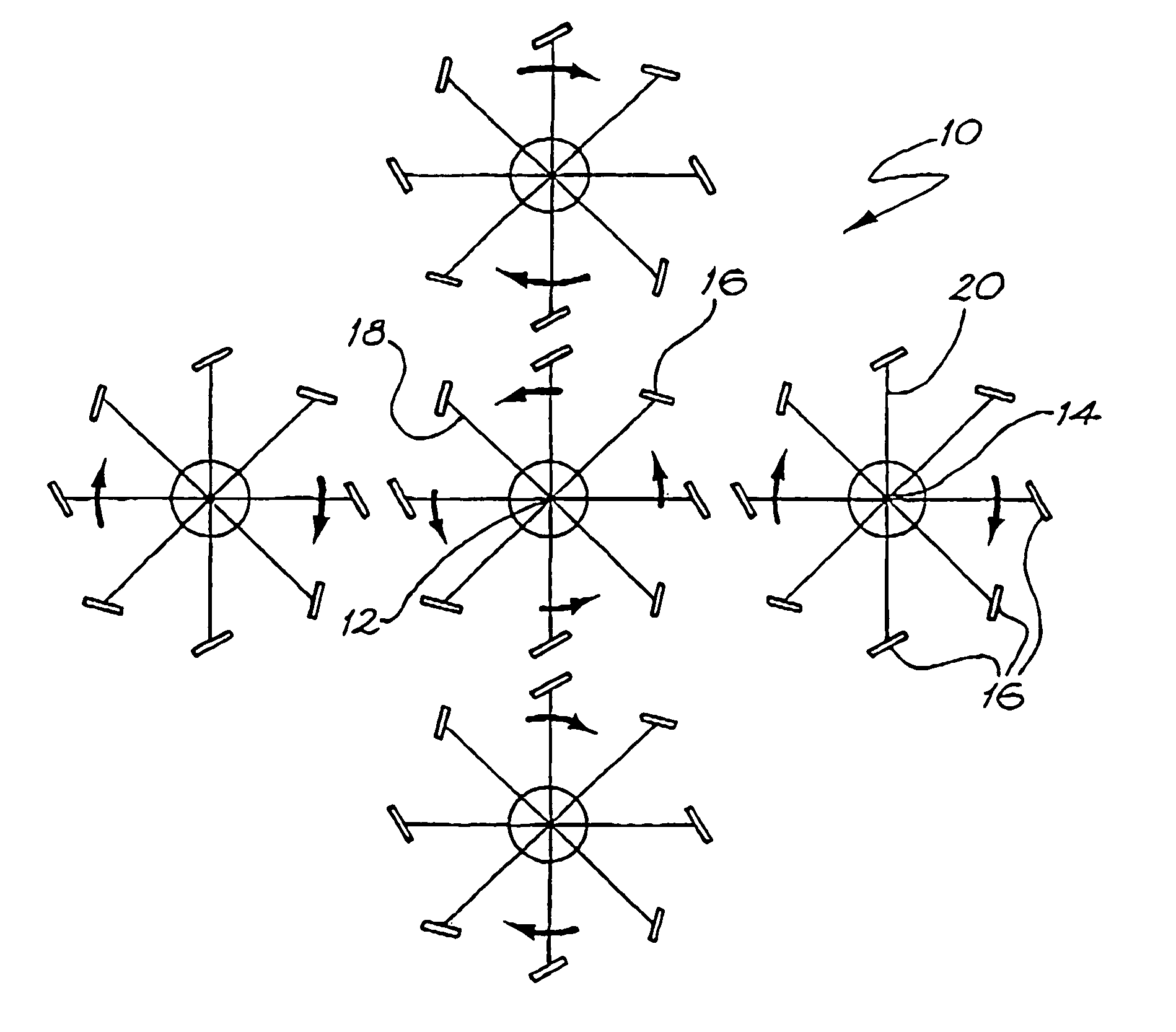

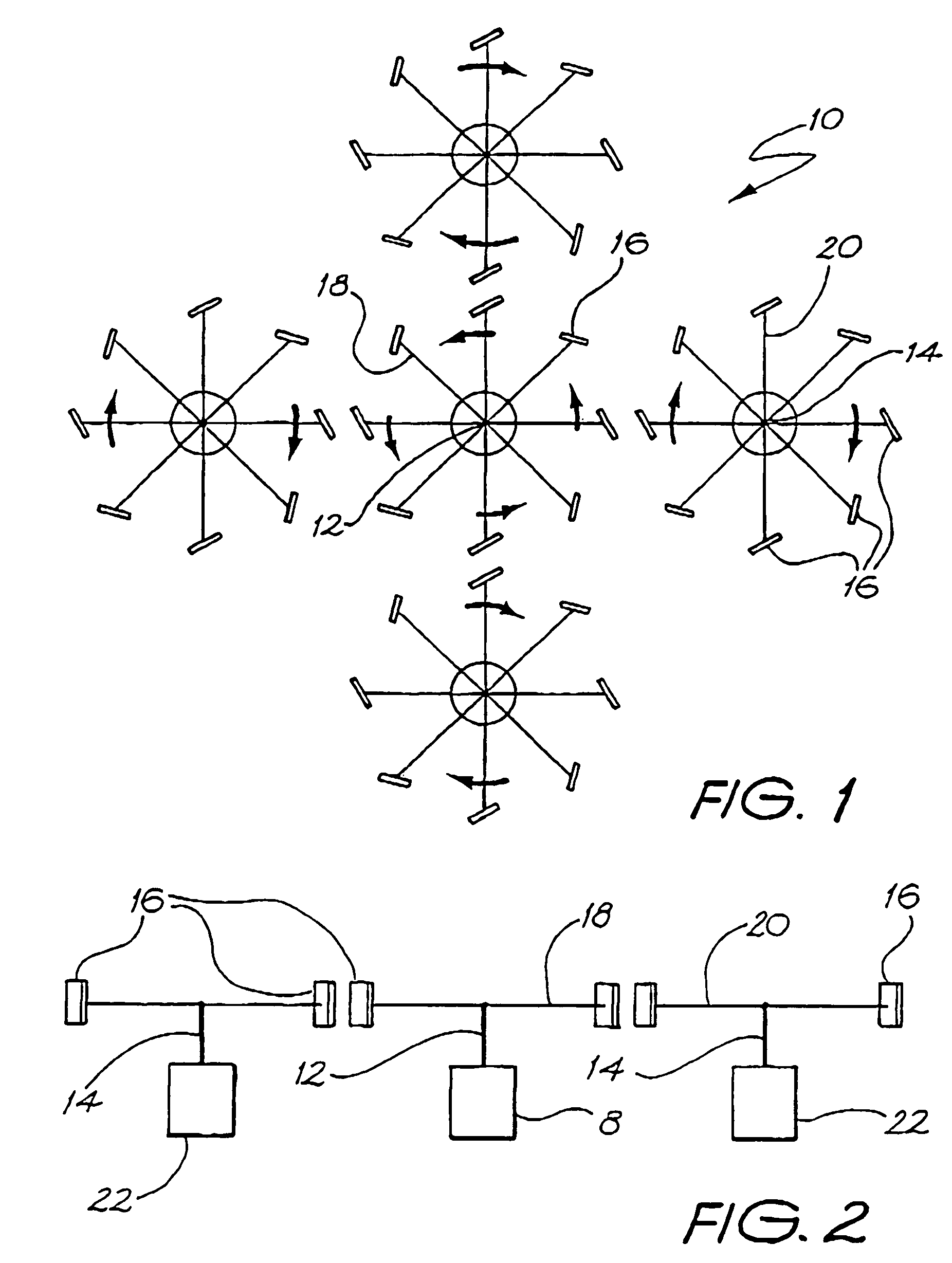

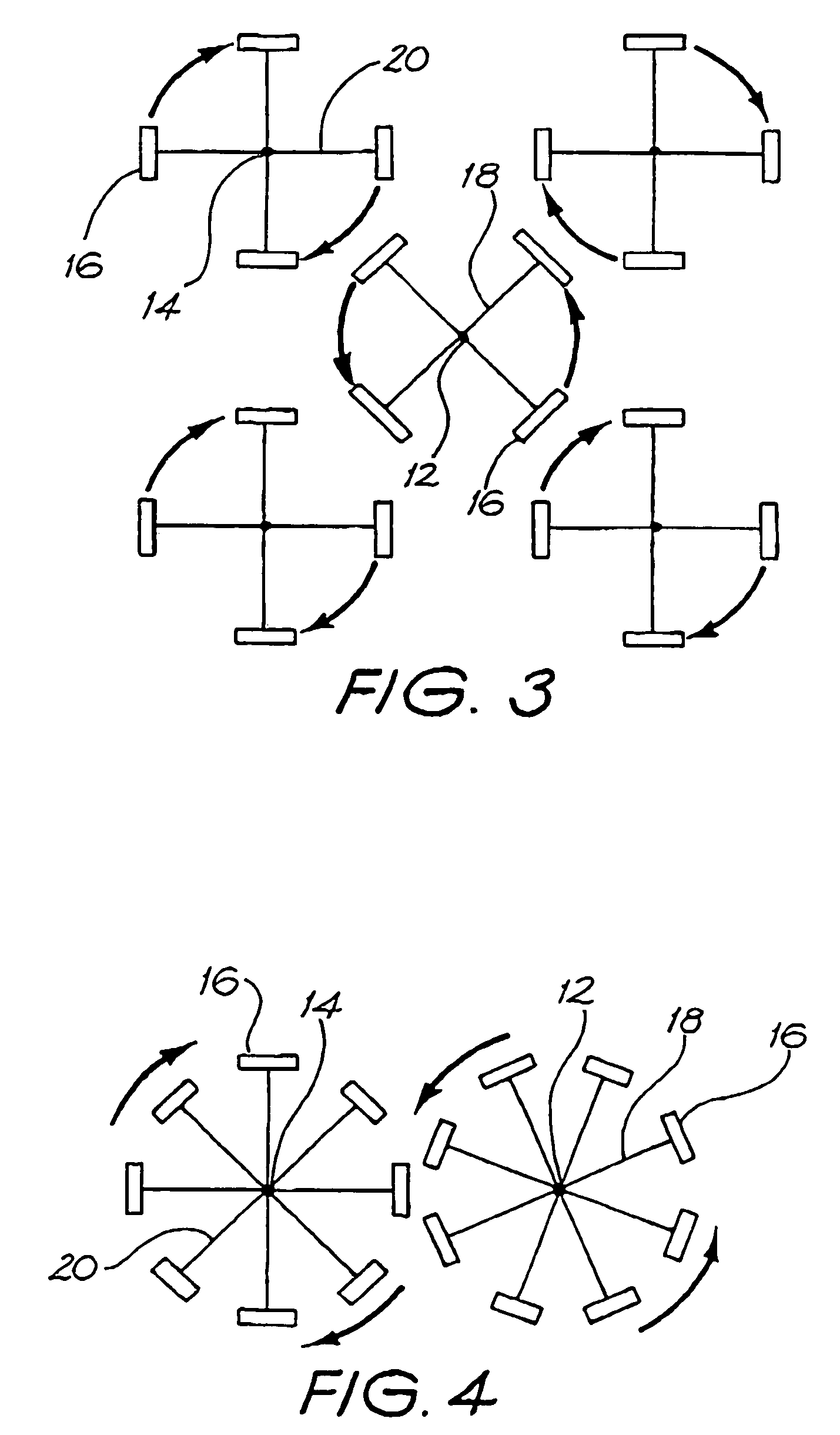

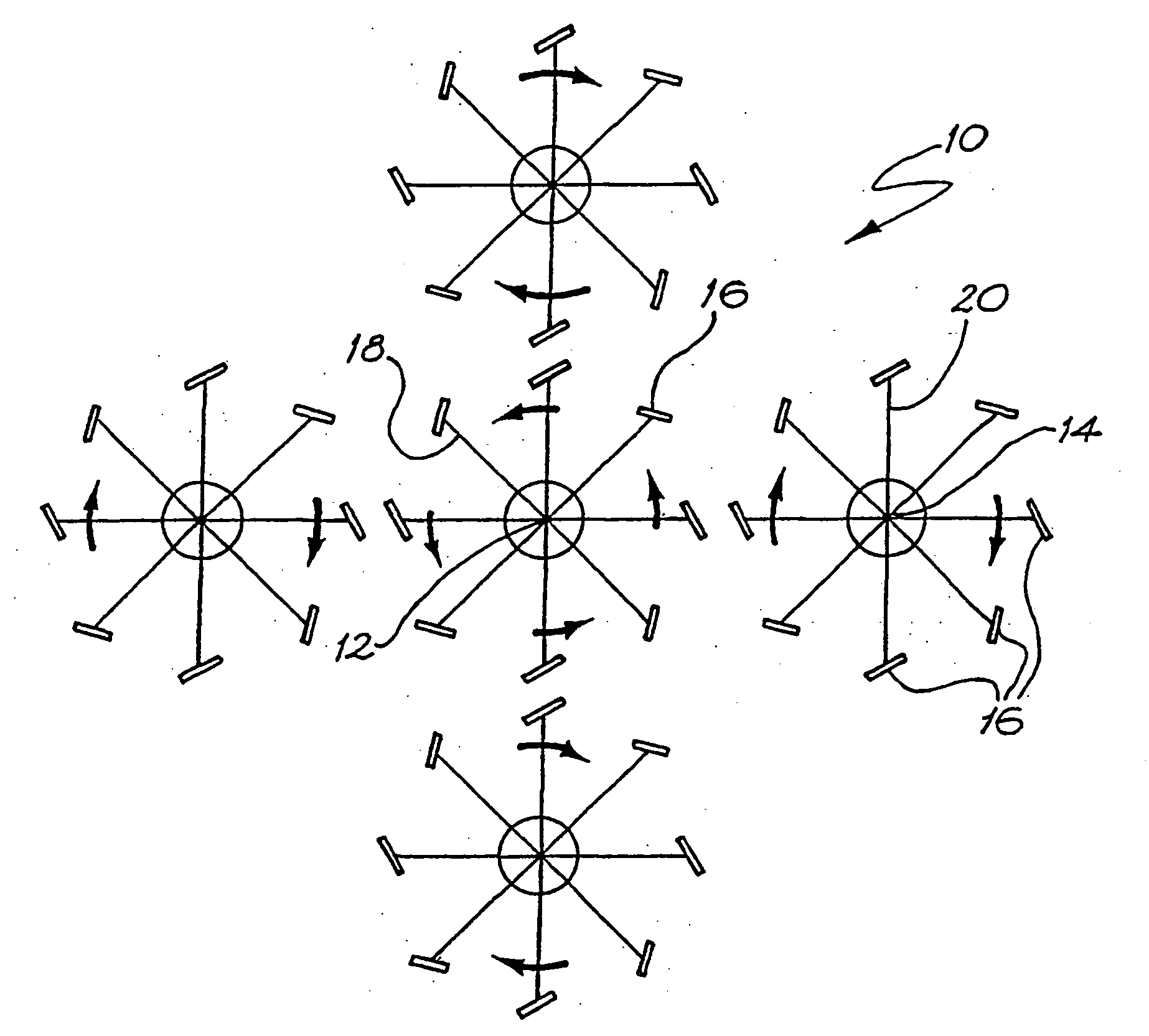

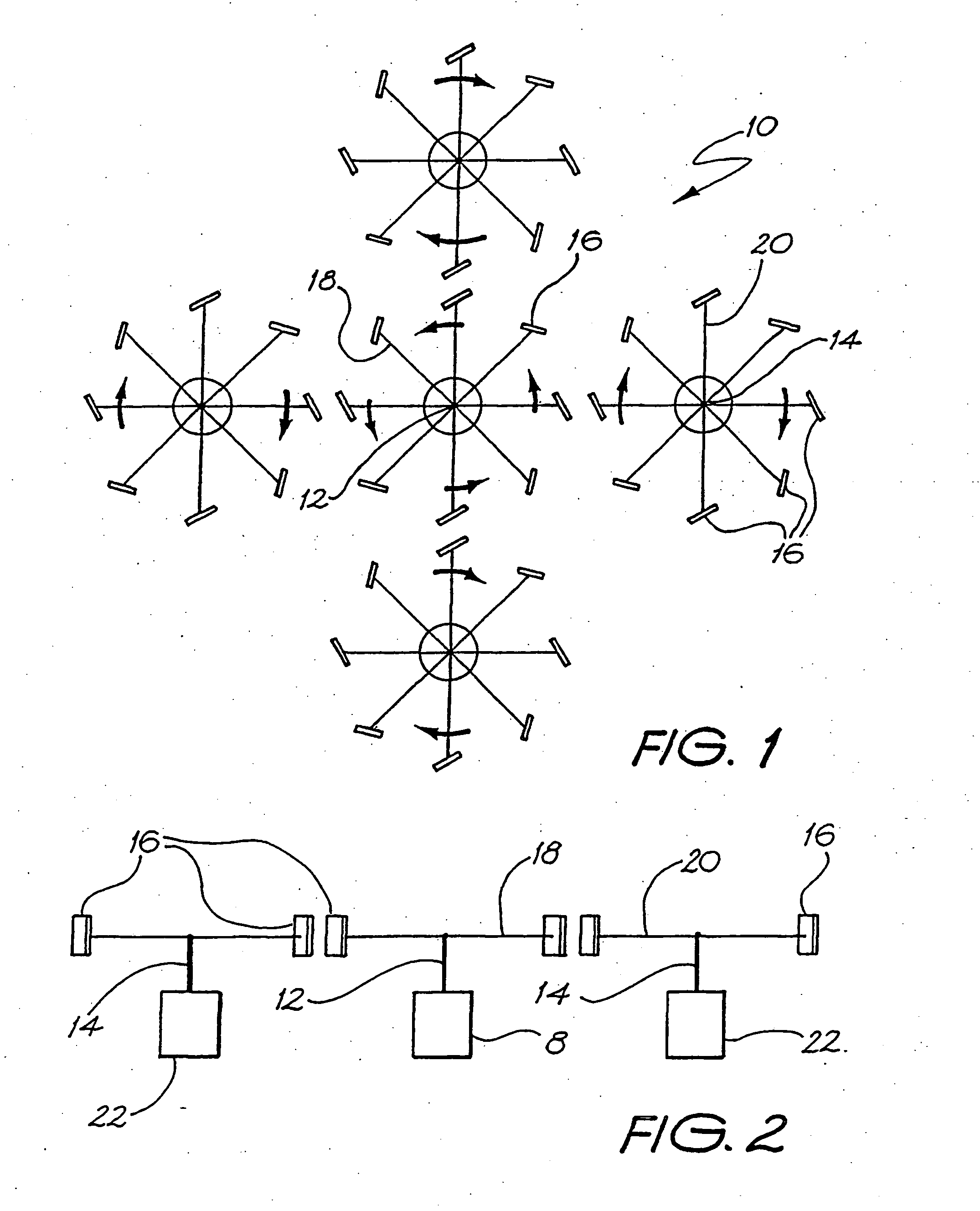

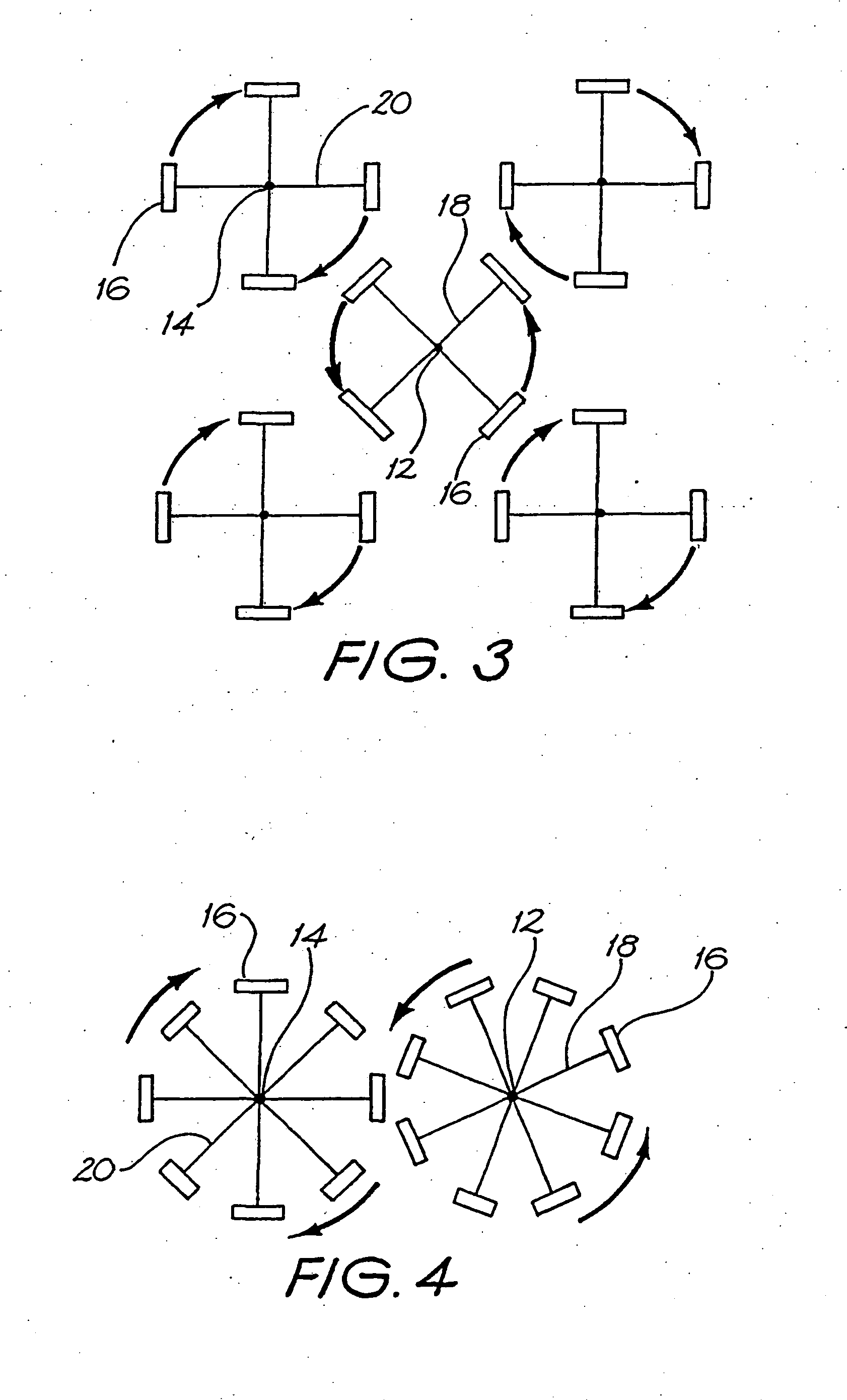

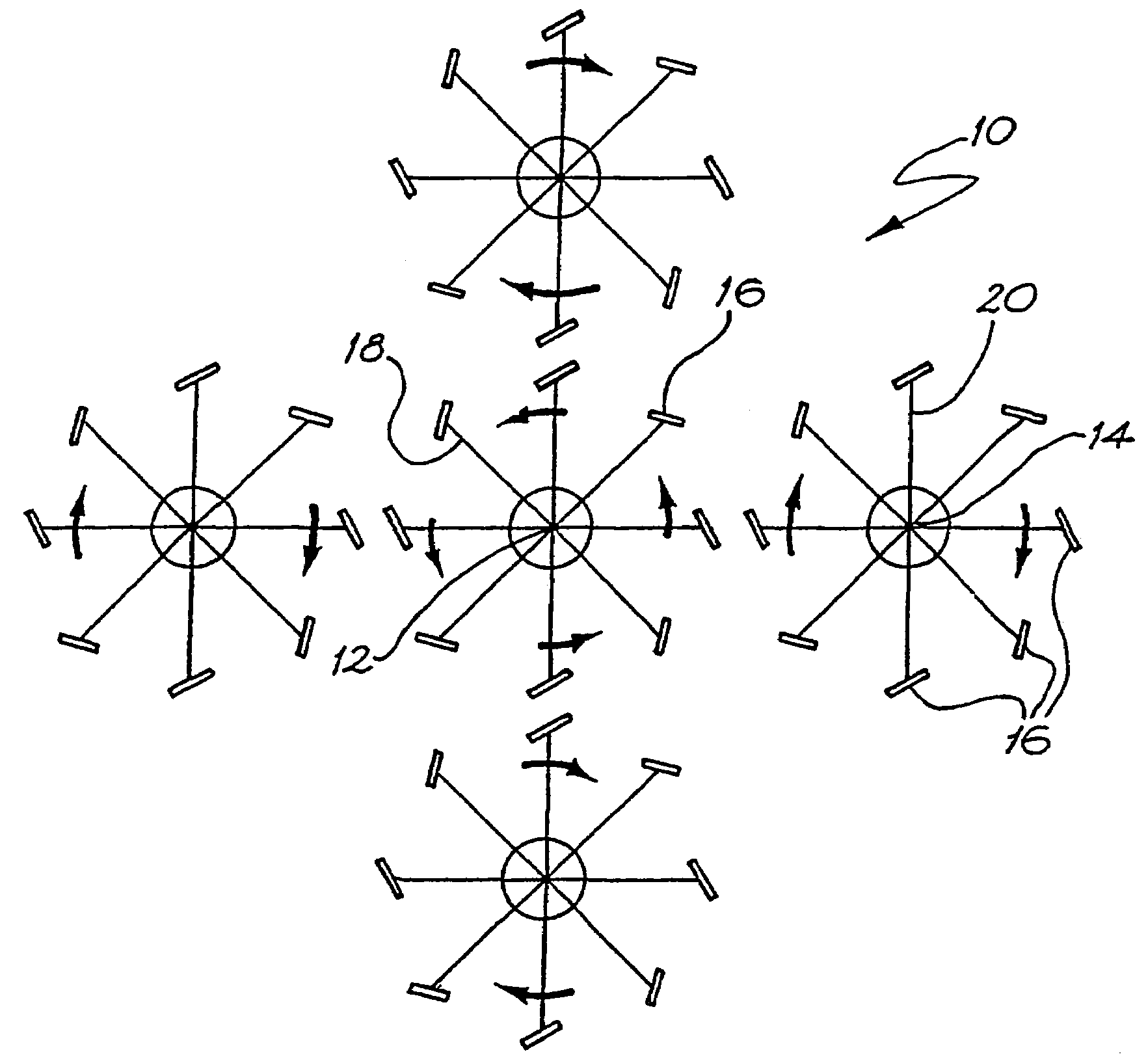

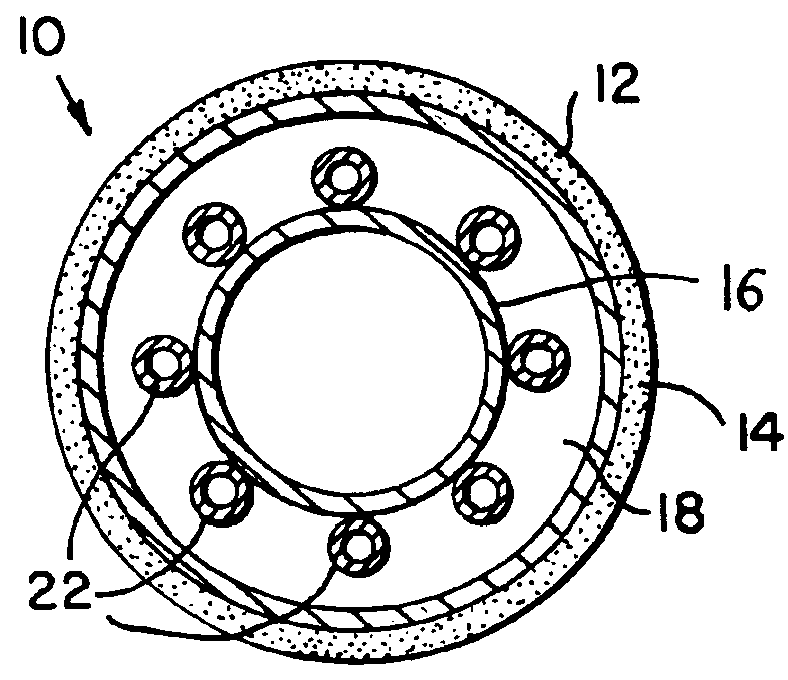

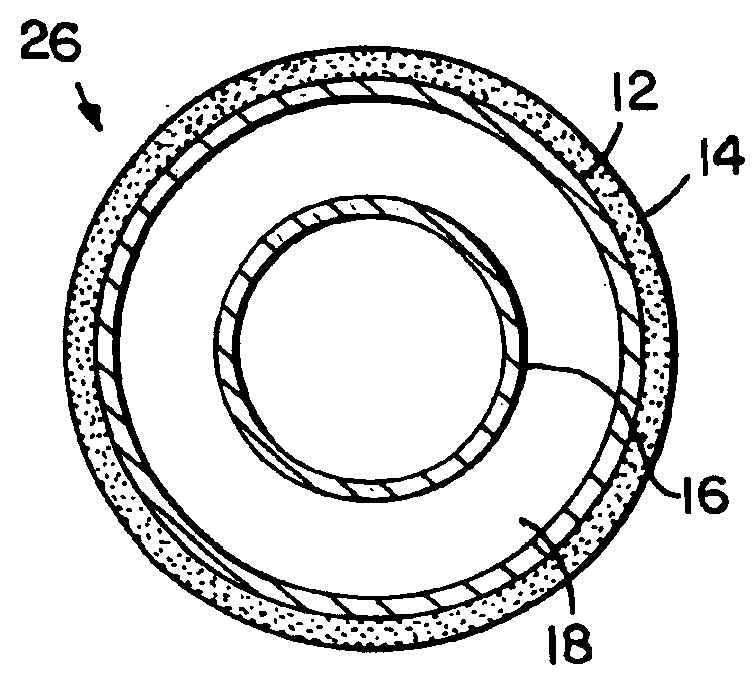

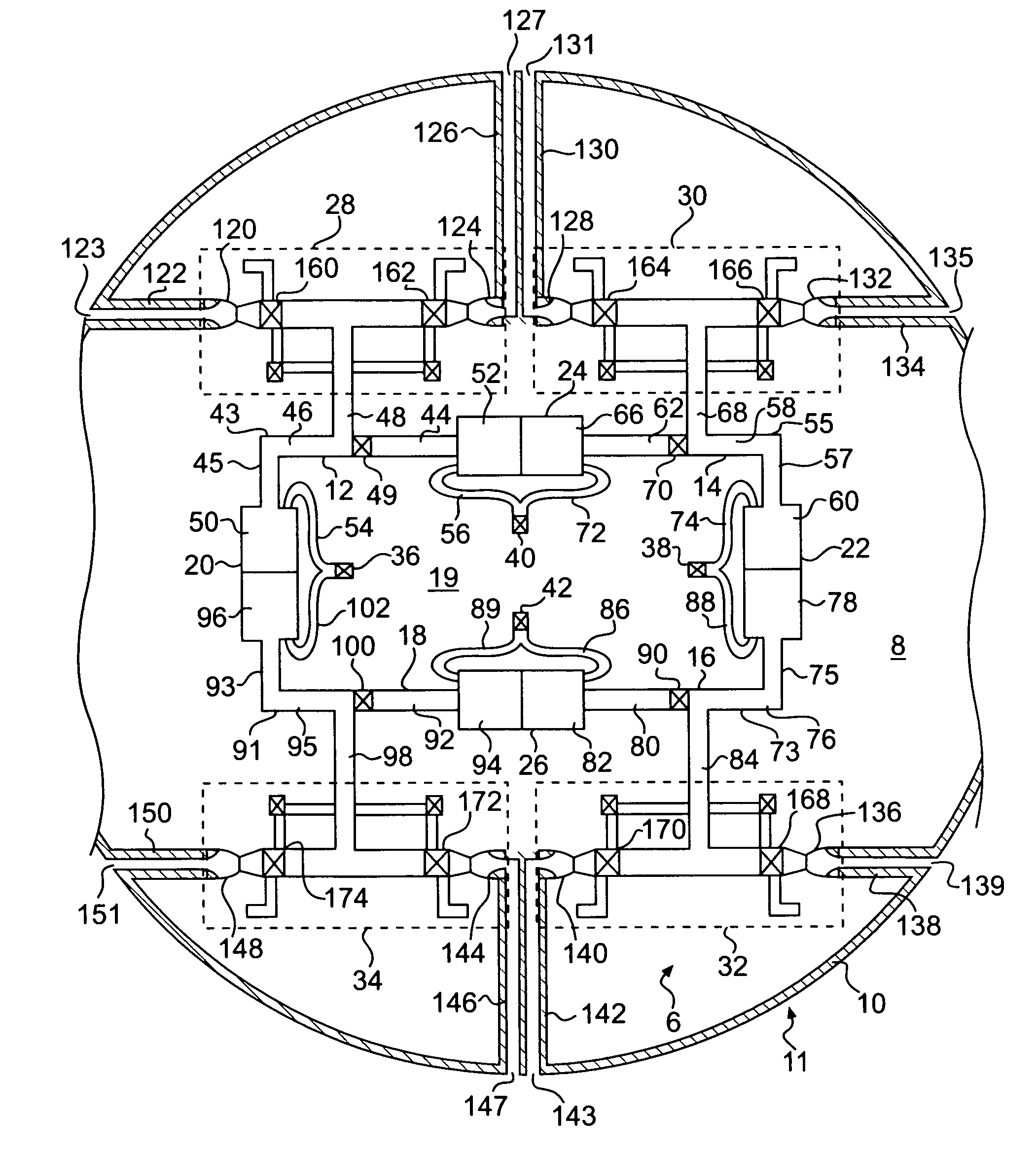

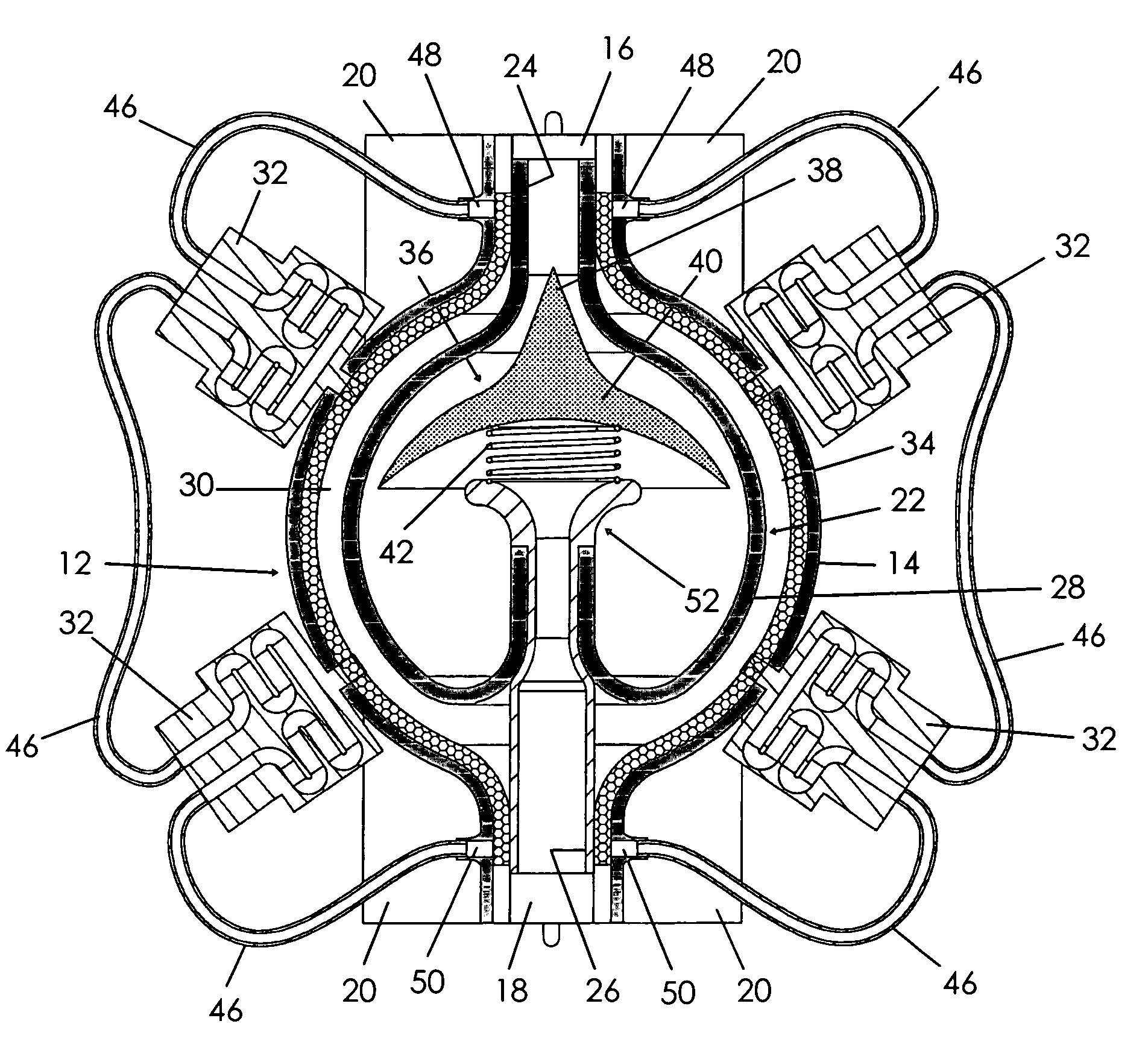

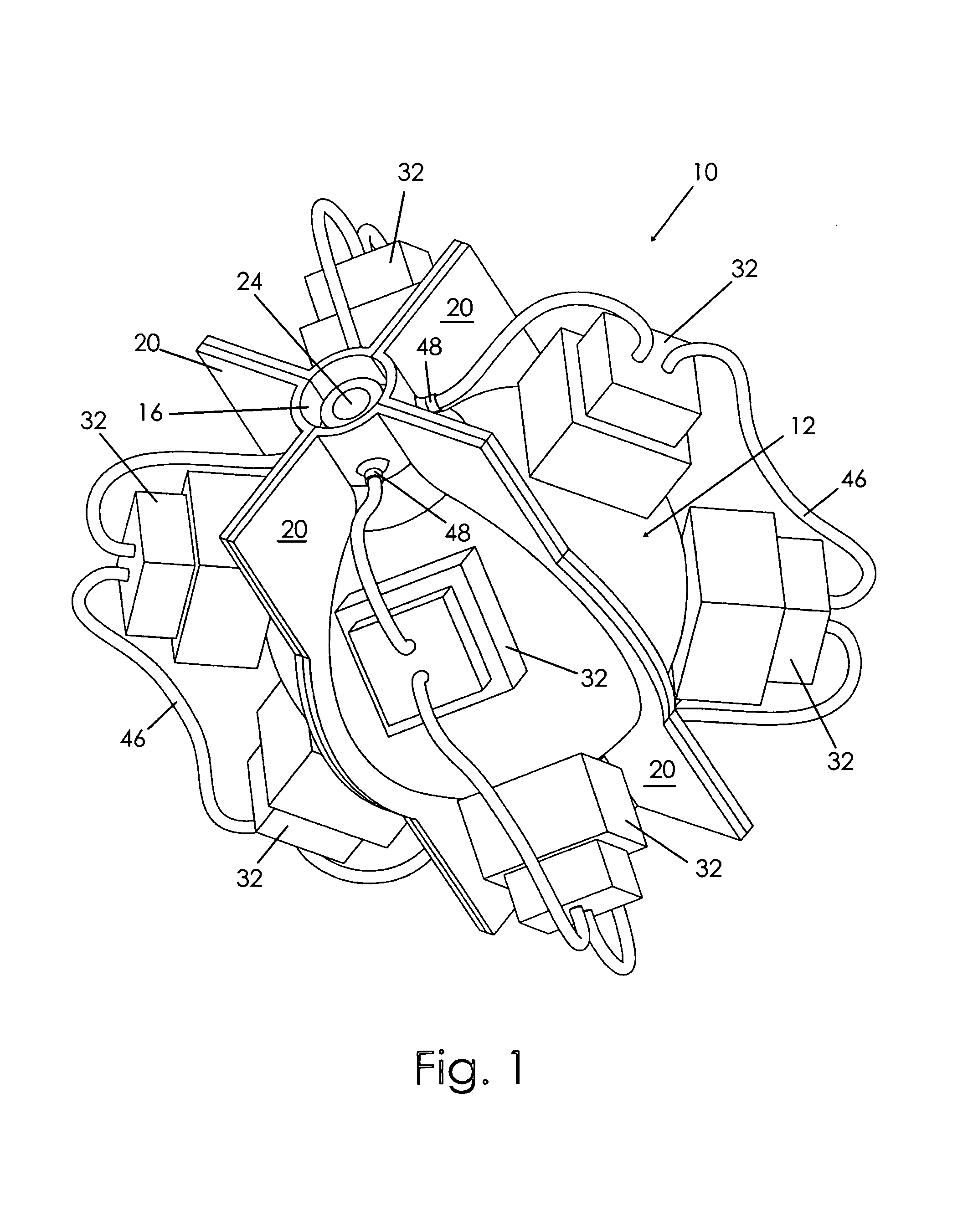

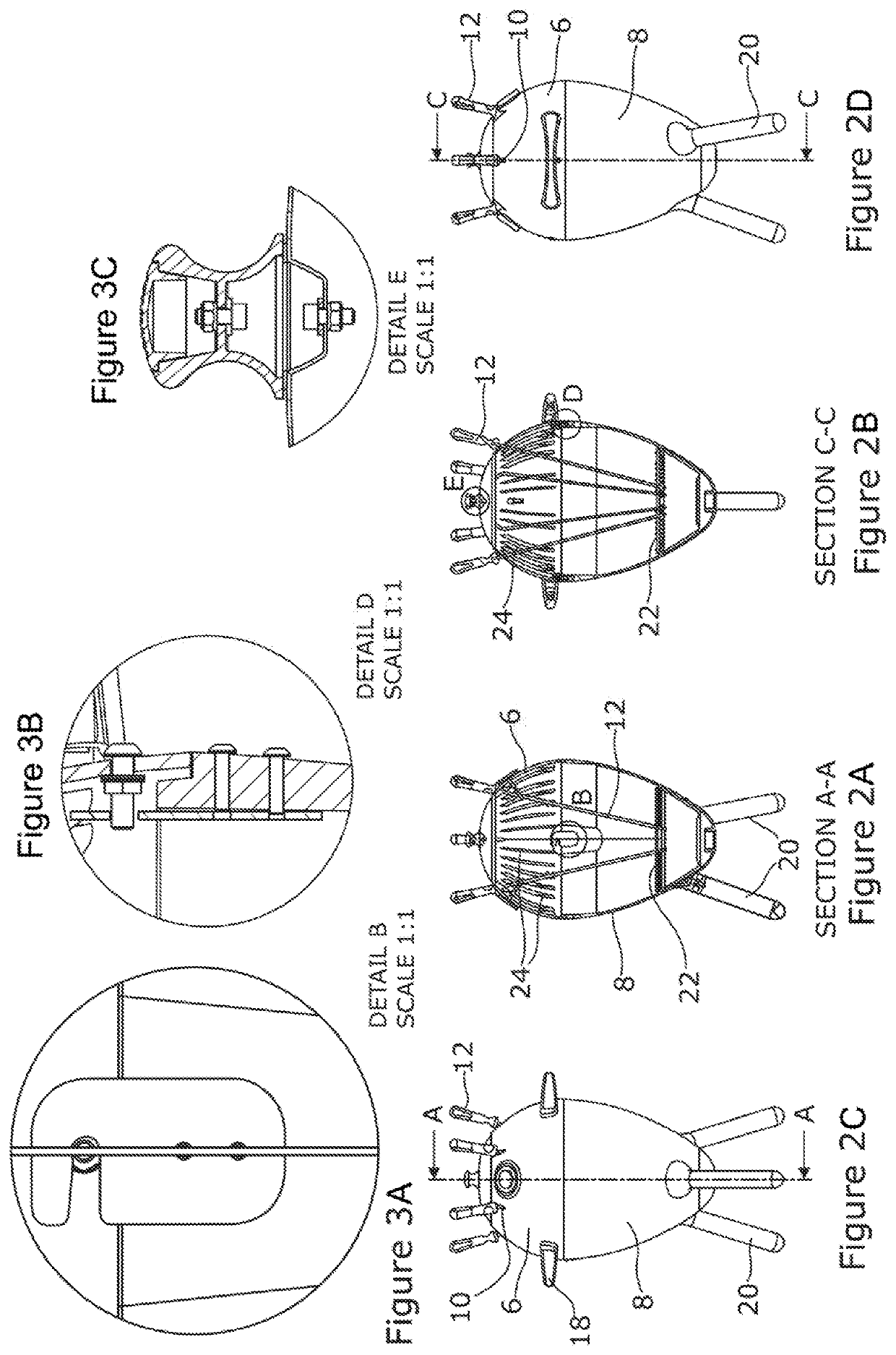

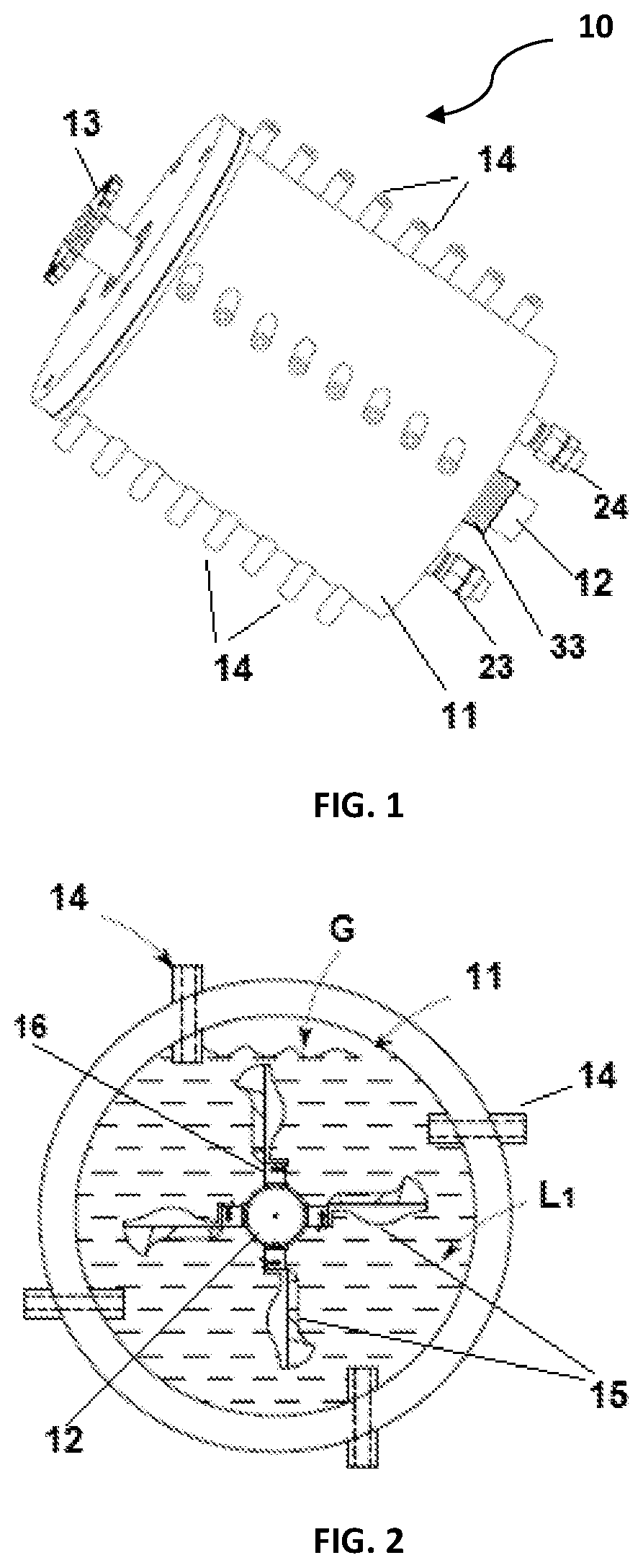

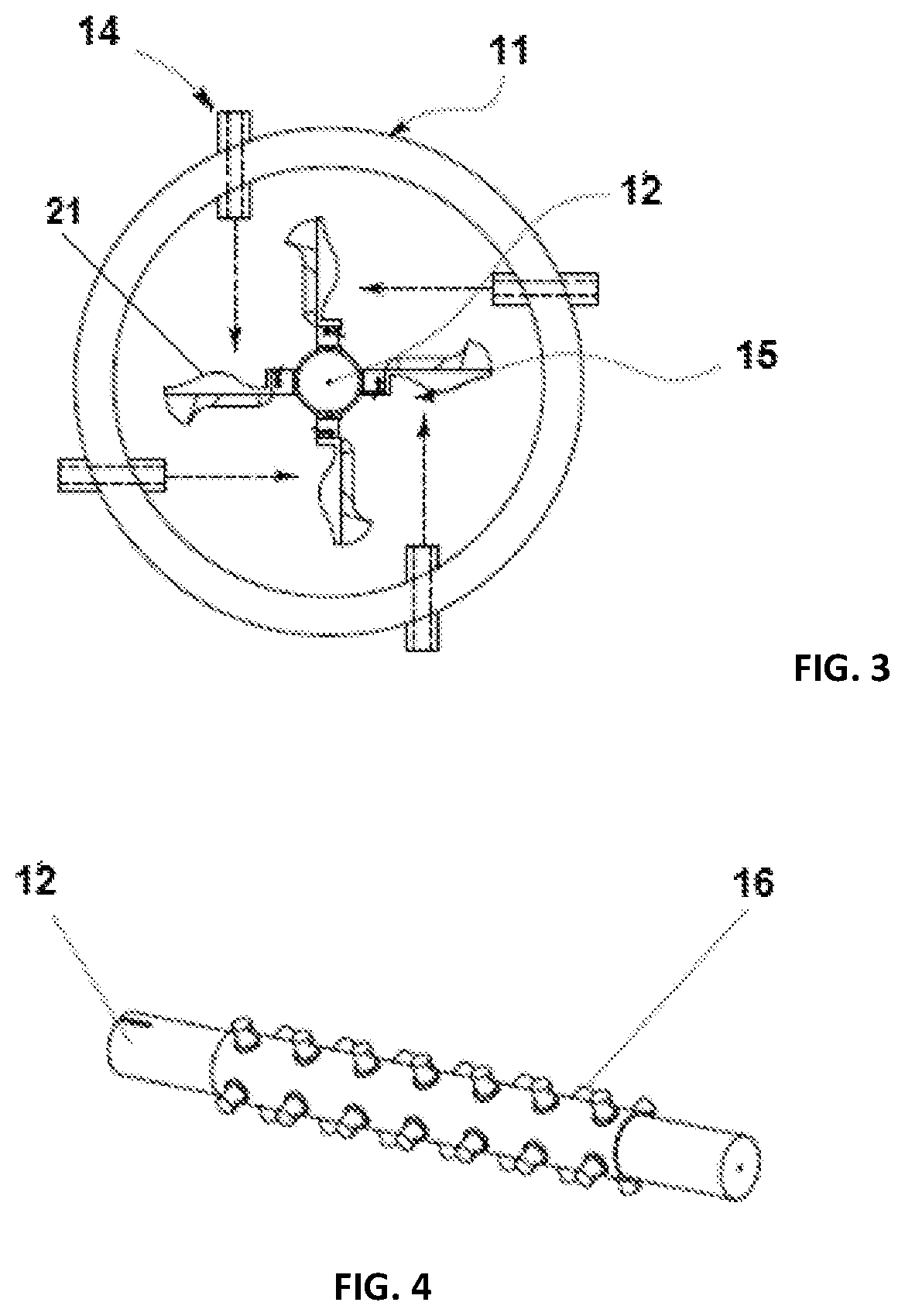

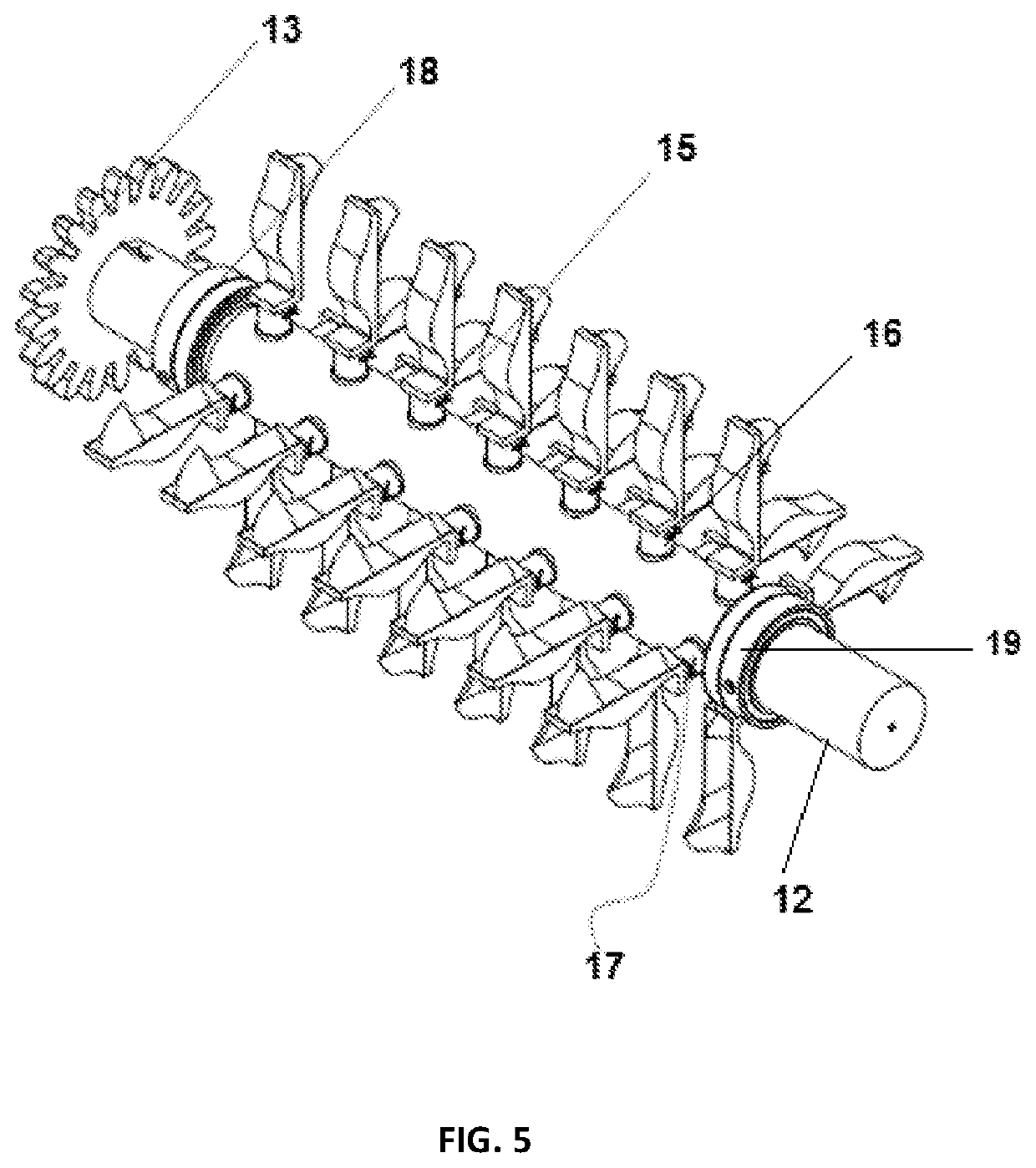

Drive apparatus

InactiveUS7024963B2Minimal heat lossIncrease its rotational inertiaMagnetic circuitGearingElectricityDrive shaft

An apparatus for inducing drive is shown that includes a primary drive shaft and four secondary drive shafts. The primary shaft and secondary shafts are fitted with magnets that are oriented such that when the primary shaft is rotated the secondary shafts are caused to rotate due to attractive or repulsive forces. The primary shaft is connected to and rotated by a rotational energy source such as a motor powered by electricity or a battery, although any source of energy to cause rotation of the primary shaft may be used. Each secondary shaft is fitted with two annular magnetic discs that are oriented to vertically support the weight of the shaft (and any attachments / fittings thereto) above the alternating or generating device. The discs can be arranged to provide either an attractive or repulsive magnetic force between them.

Owner:THE GABRIELLE BAKEY FAMILY TRUST

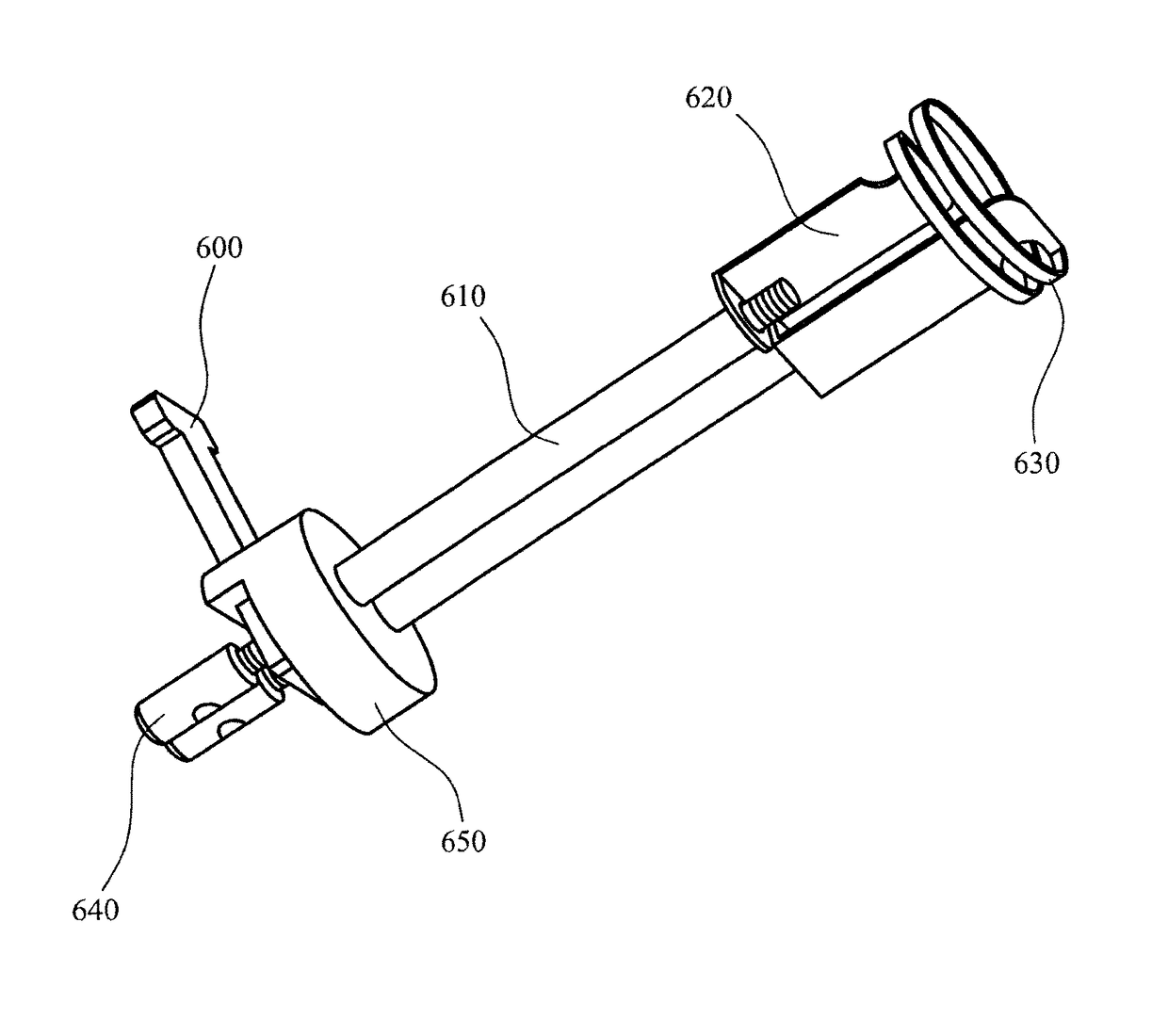

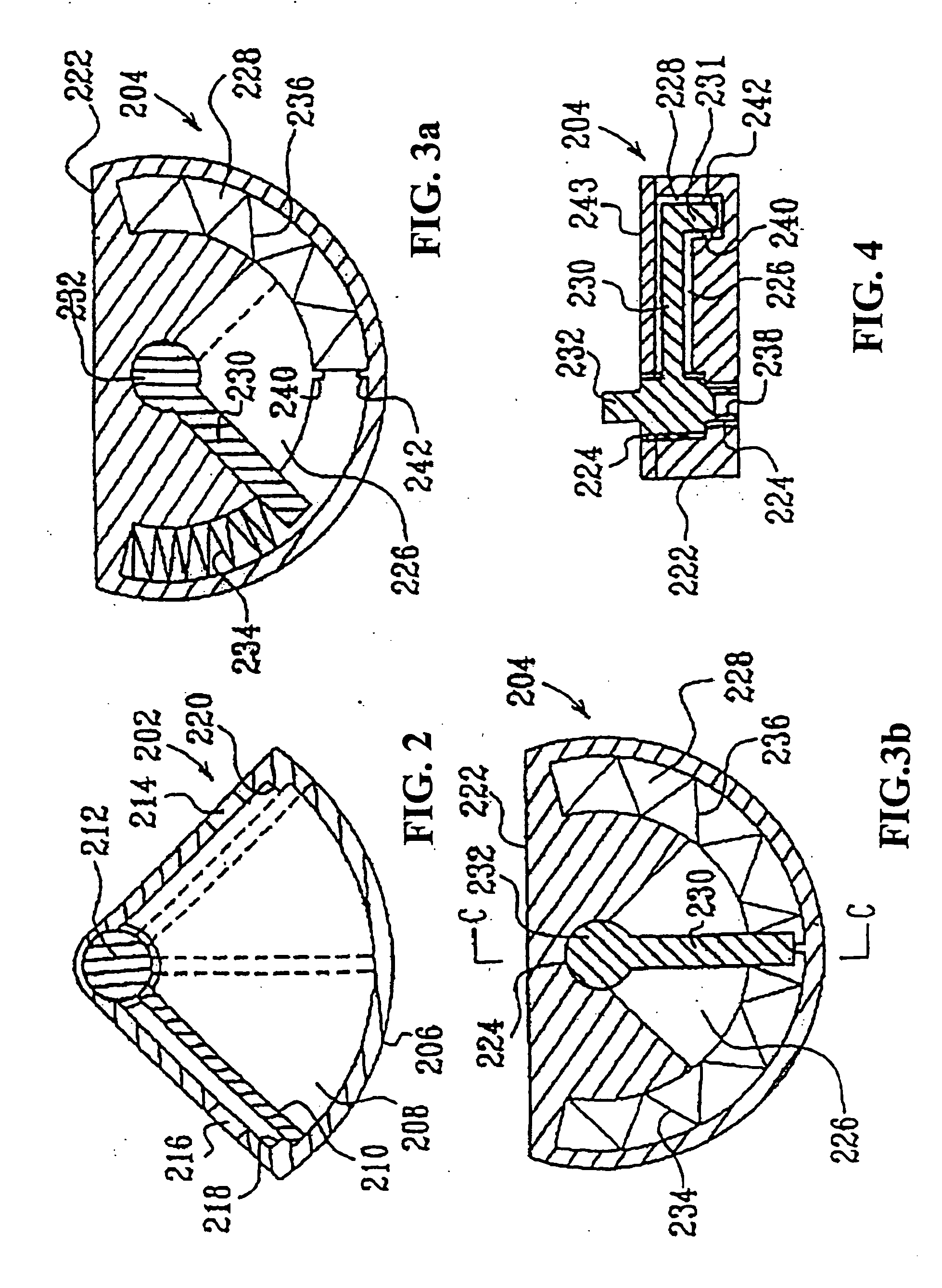

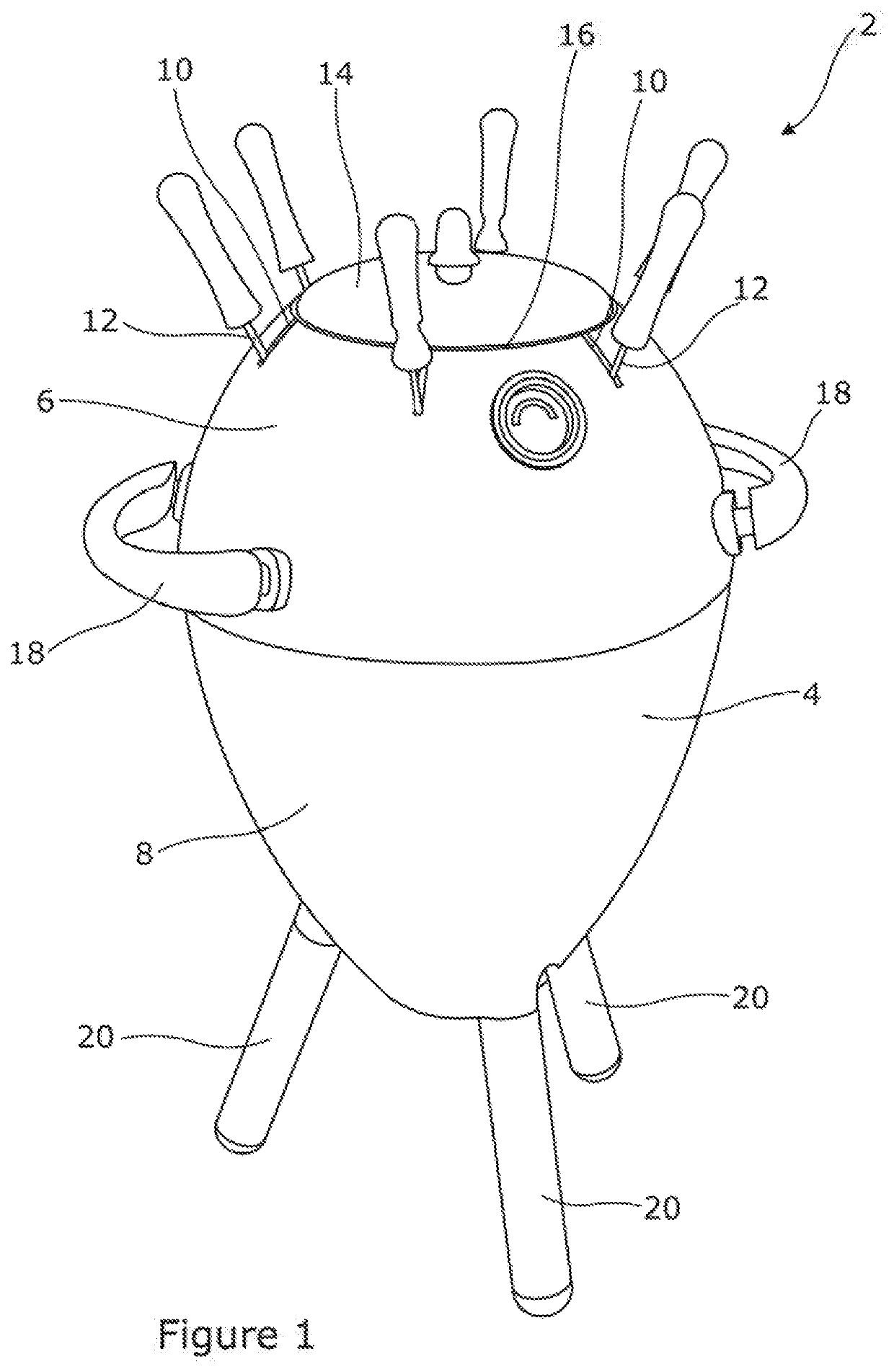

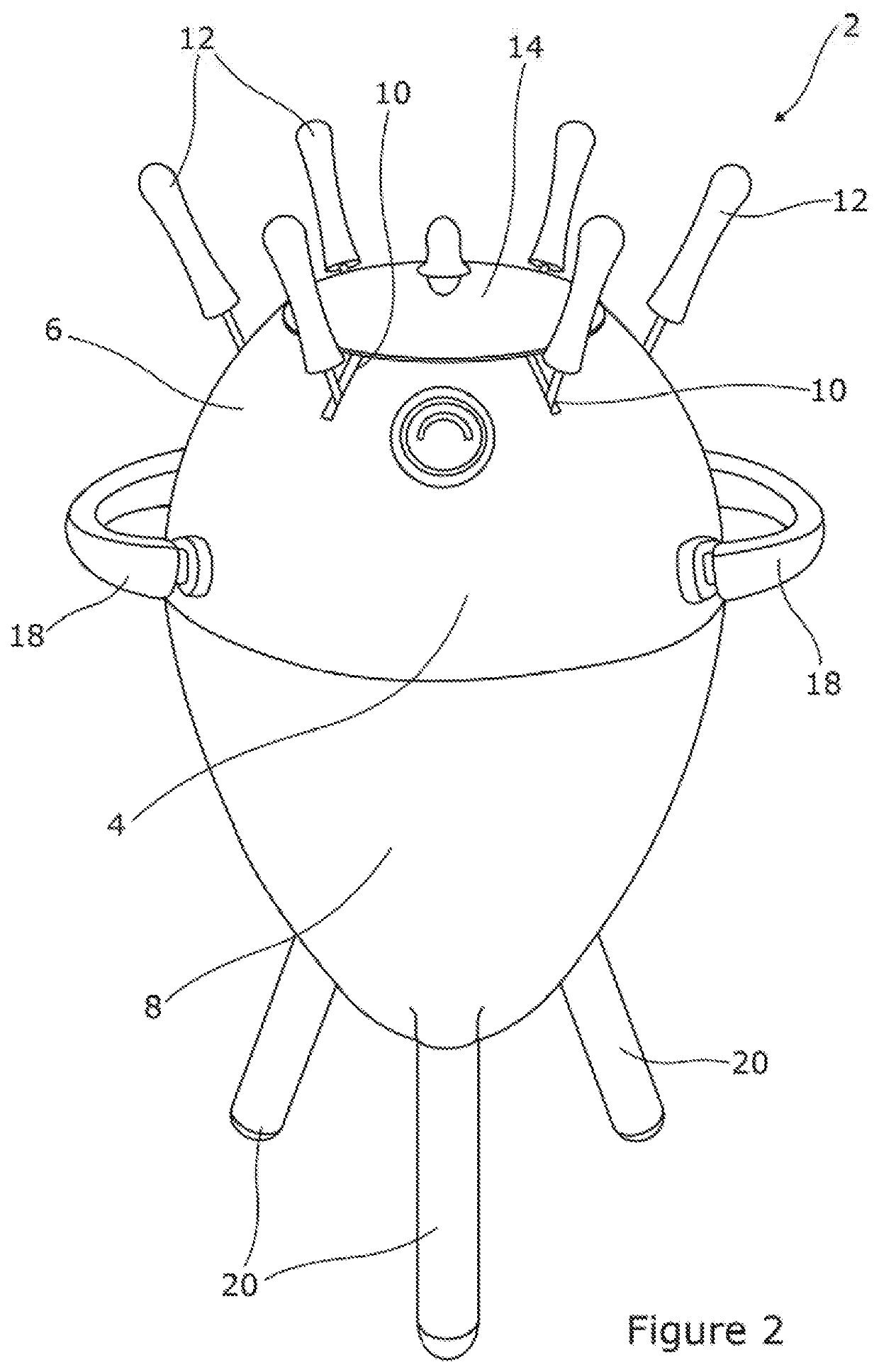

Aerosol generating device with heater assembly

ActiveUS9999247B2Efficient heatingMinimal heat lossTobacco treatmentTobacco pipesAerosolHeating element

An aerosol generating device is provided, including a housing configured to receive an aerosol-forming substrate having an internal cavity; a heating element configured to be received within the internal cavity of the substrate, and a positioning mechanism coupled to the heating element and to the housing being configured to move the heating element between a plurality of heating positions within the cavity. There is also provided an aerosol generating device including a housing configured to receive an aerosol-forming substrate, a heating element configured to heat a portion of the substrate, and a positioning mechanism configured to move the heating element from a first position next to a first portion of the substrate, to a second position remote from the substrate, and then to a third position next to a second portion of the substrate.

Owner:PHILIP MORRIS PROD SA

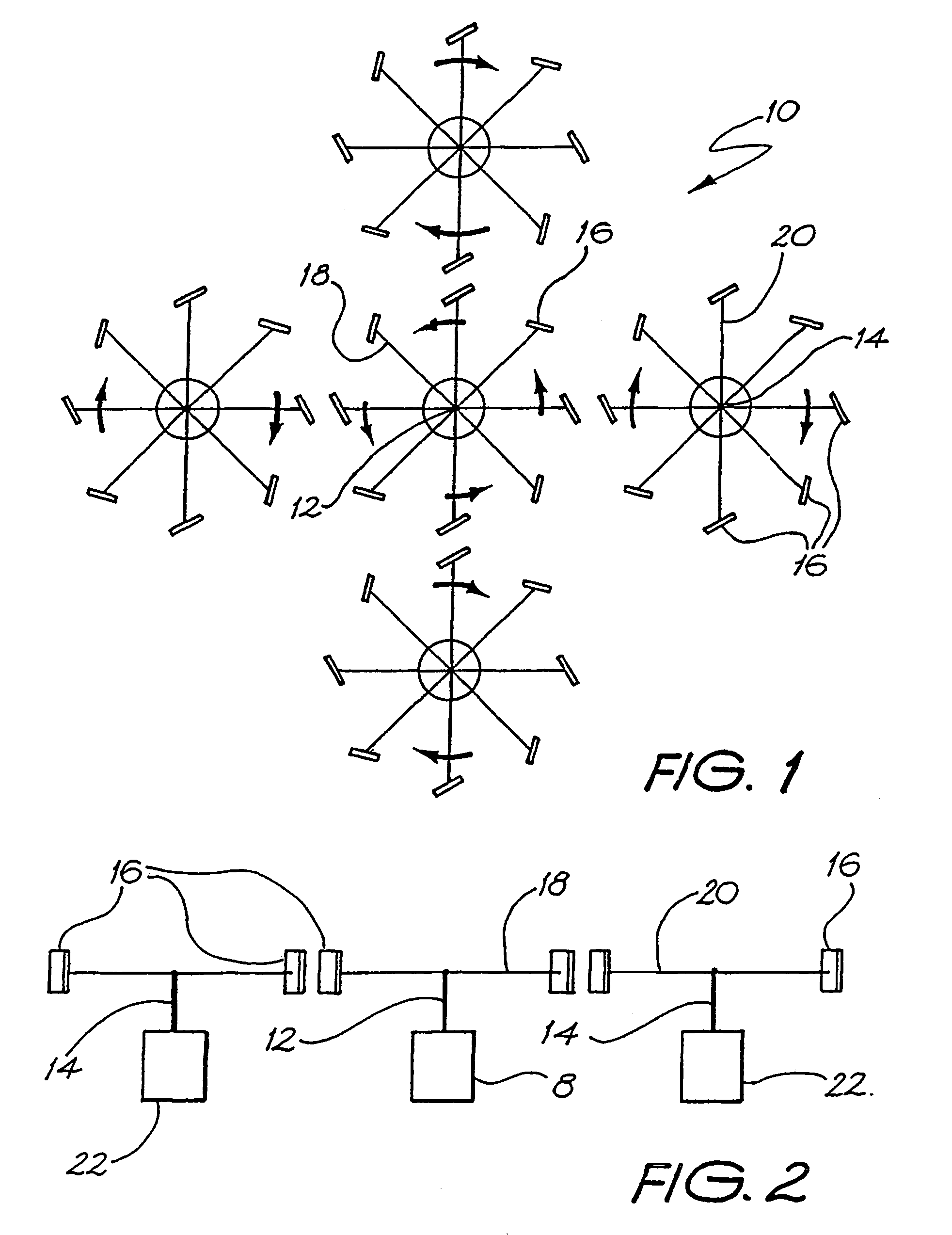

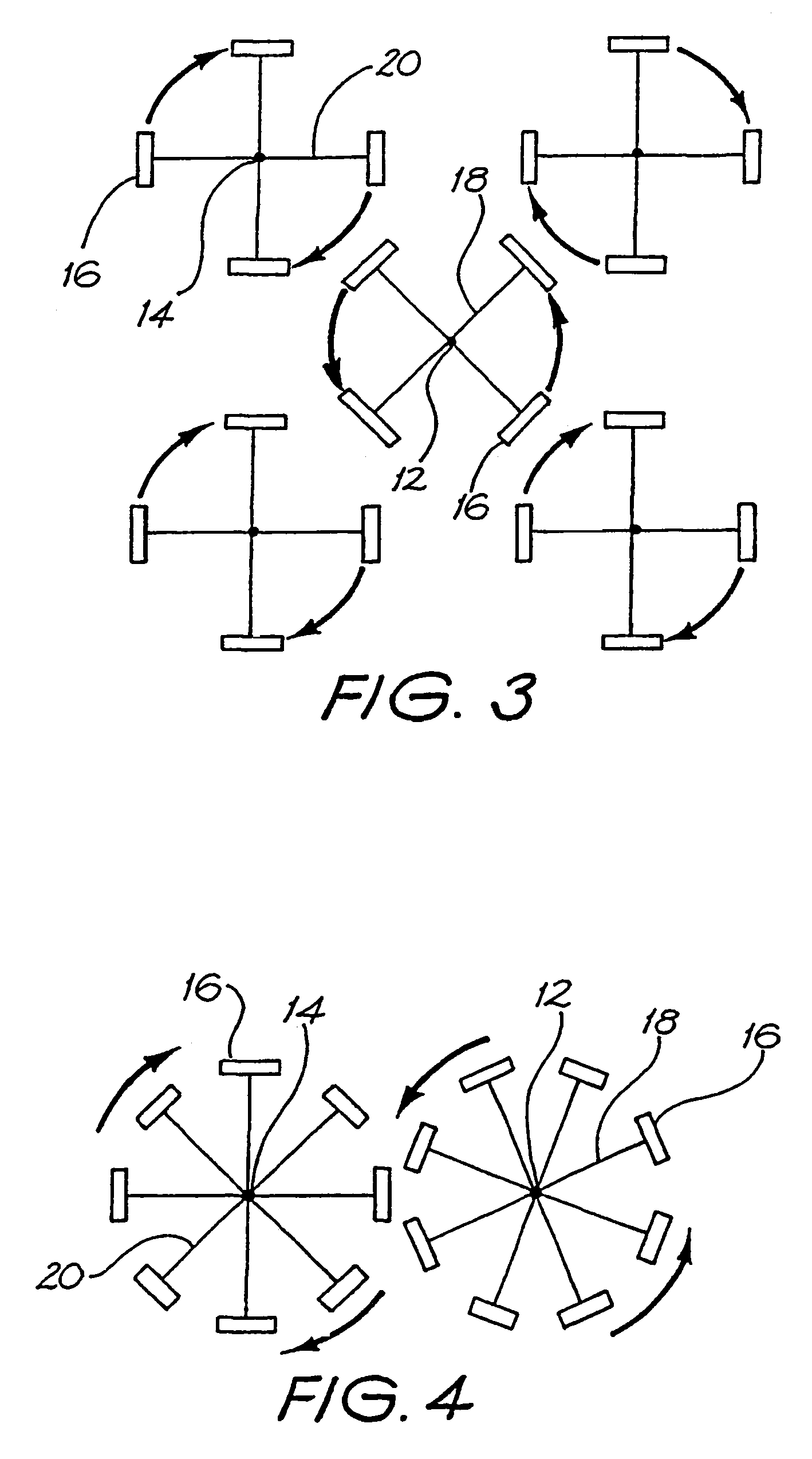

Drive apparatus

InactiveUS20060123936A1Improve performanceSmooth inductionDynamo-electric brakes/clutchesCircuit arrangementsMagnetElectricity

An apparatus for inducing drive is shown that includes a primary drive shaft and four secondary drive shafts. The primary shaft and secondary shafts are fitted with magnets that are oriented such that when the primary shaft is rotated the secondary shafts are caused to rotate due to attractive or repulsive forces. The primary shaft is connected to and rotated by a rotational energy source such as a motor powered by electricity or a battery, although any source of energy to cause rotation of the primary shaft may be used. Each secondary shaft is fitted with two annular magnetic discs that are oriented to vertically support the weight of the shaft (and any attachments / fittings thereto) above the alternating or generating device. The discs can be arranged to provide either an attractive or repulsive magnetic force between them.

Owner:FORCE FIELD LTD

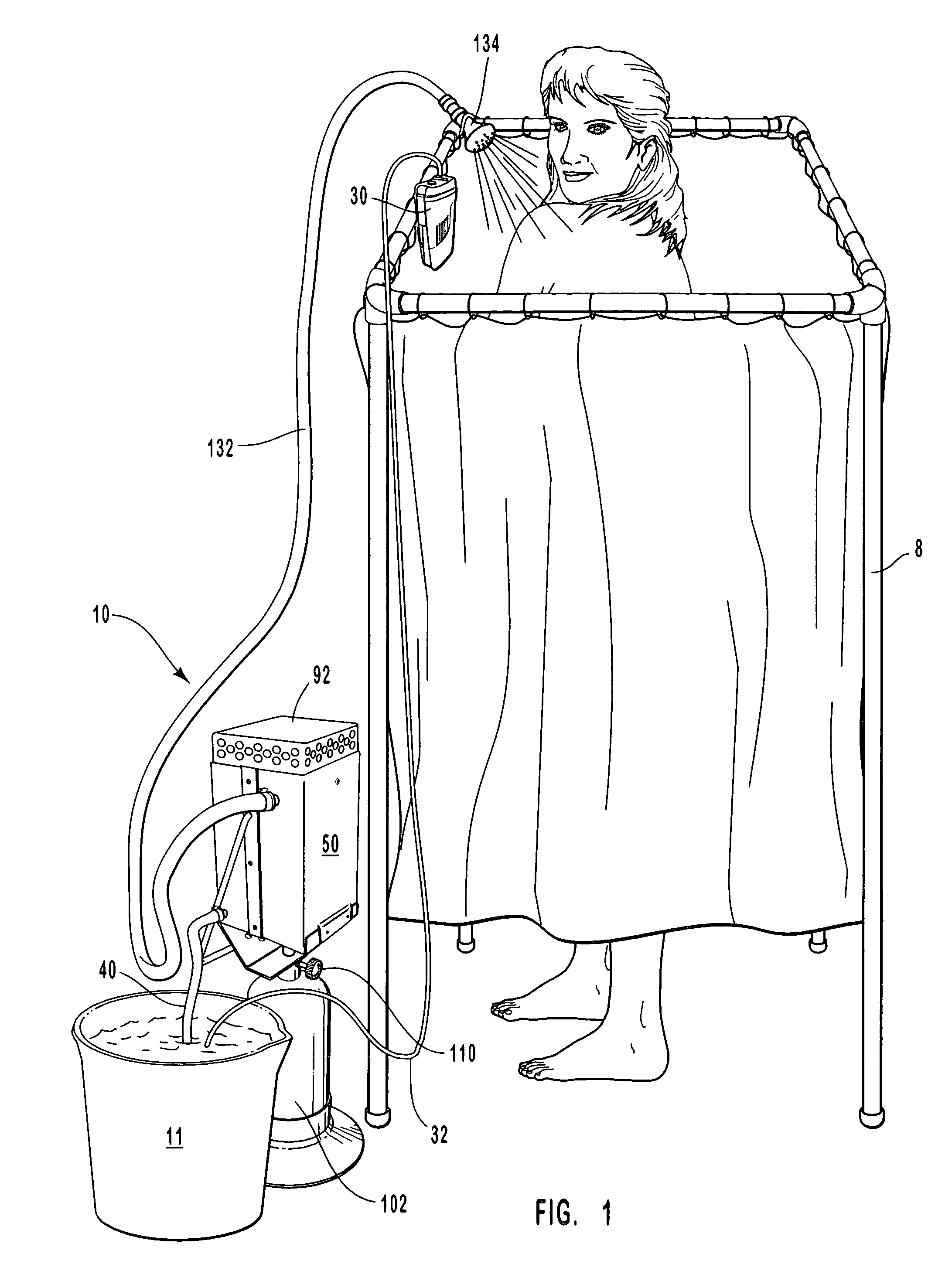

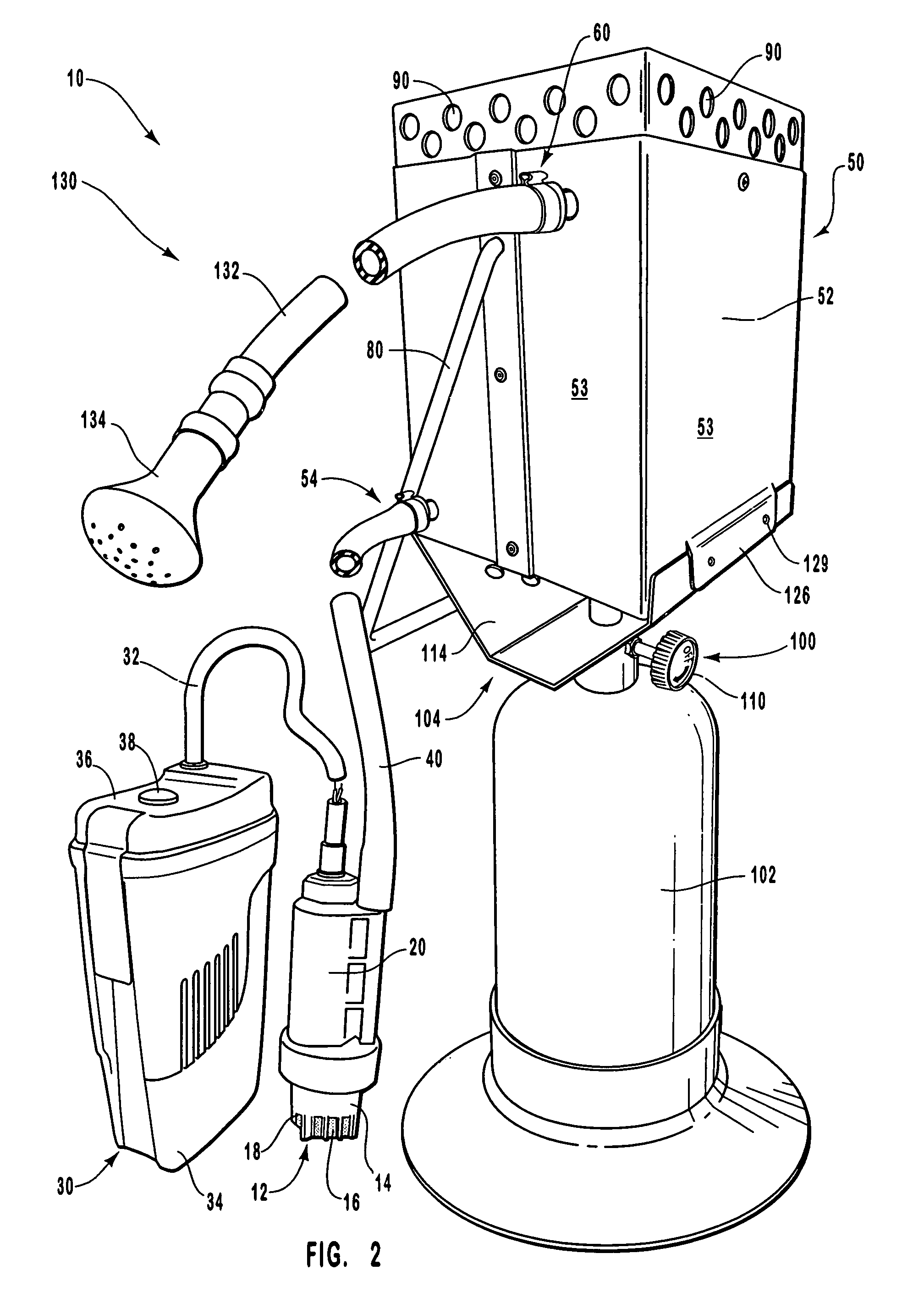

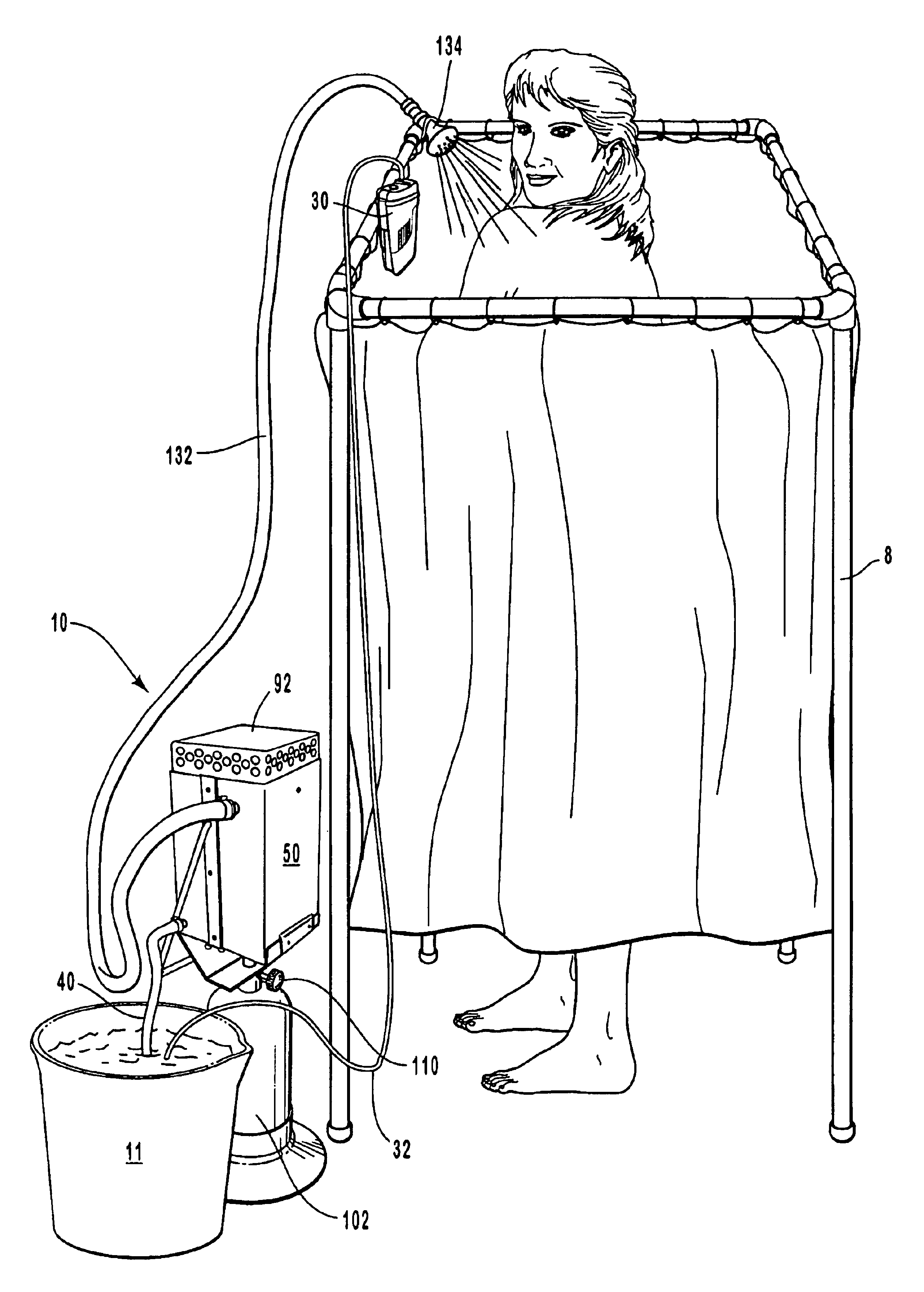

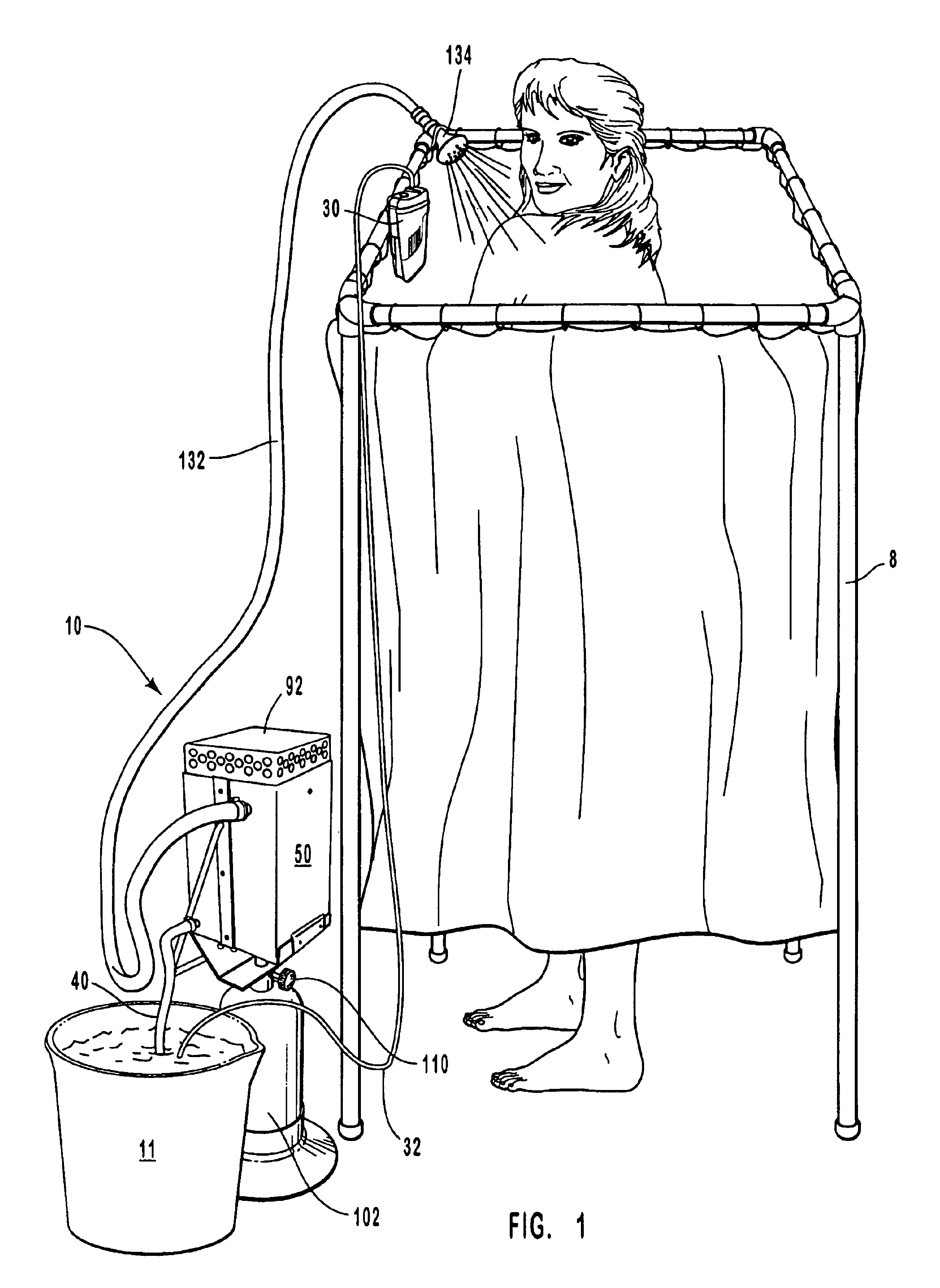

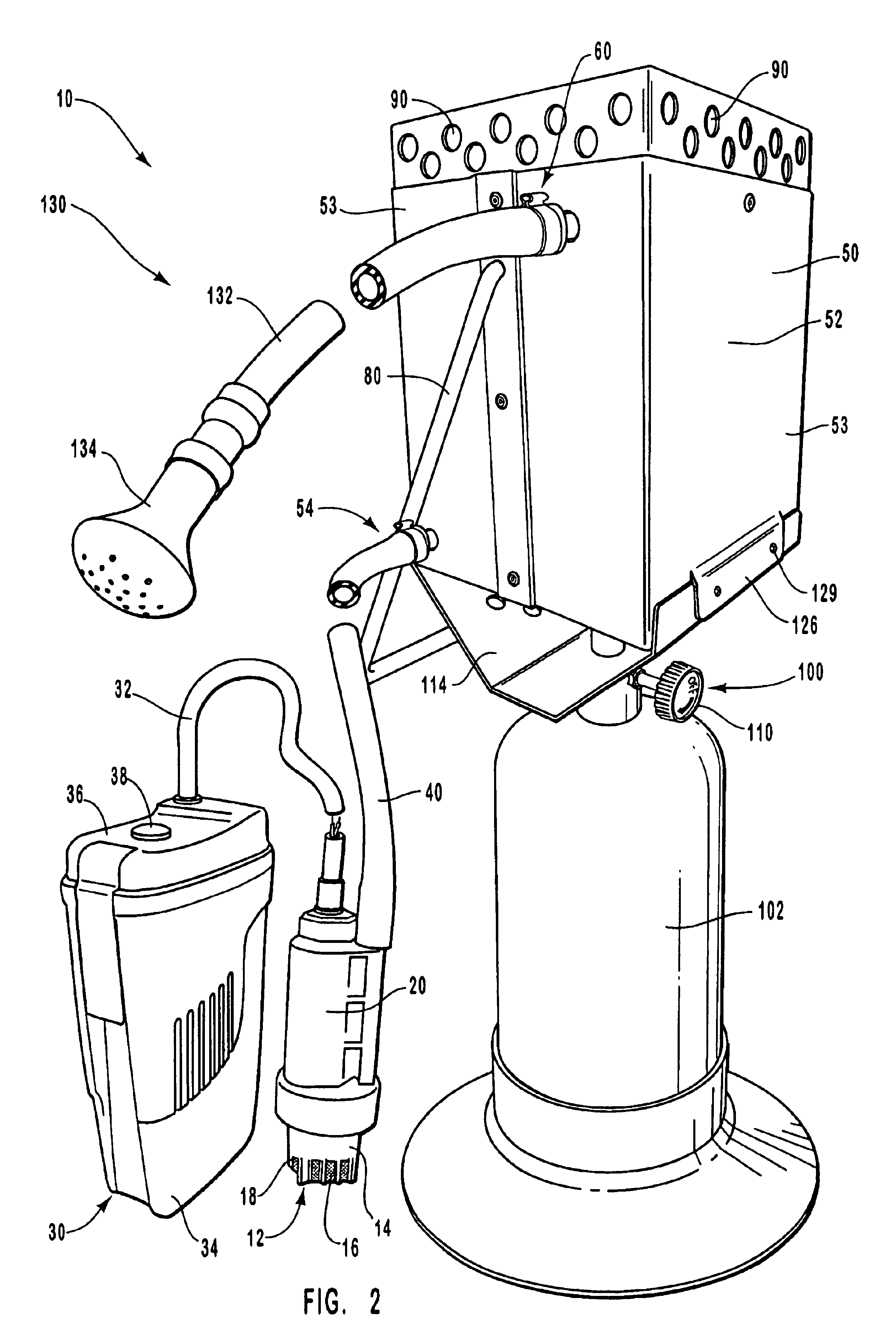

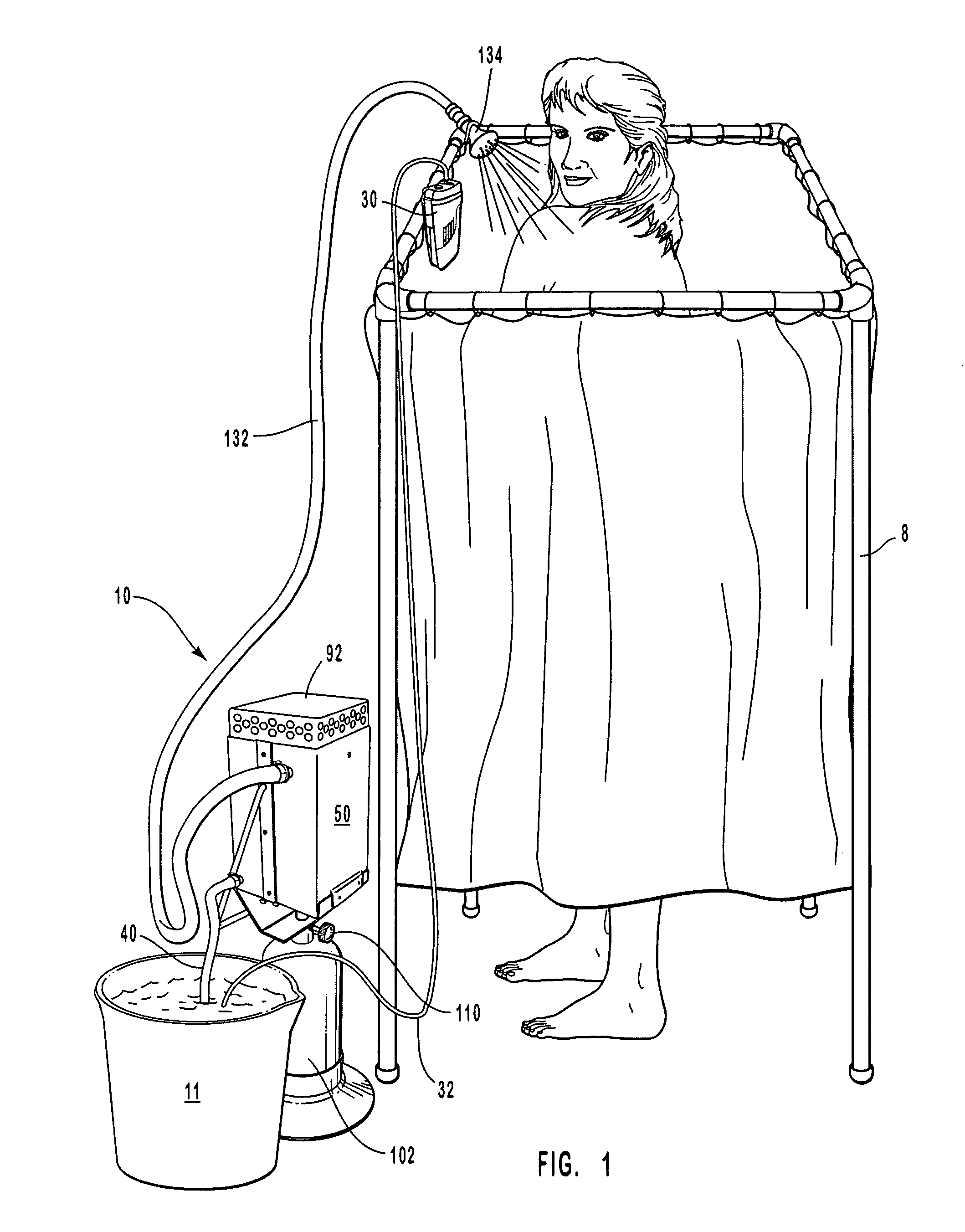

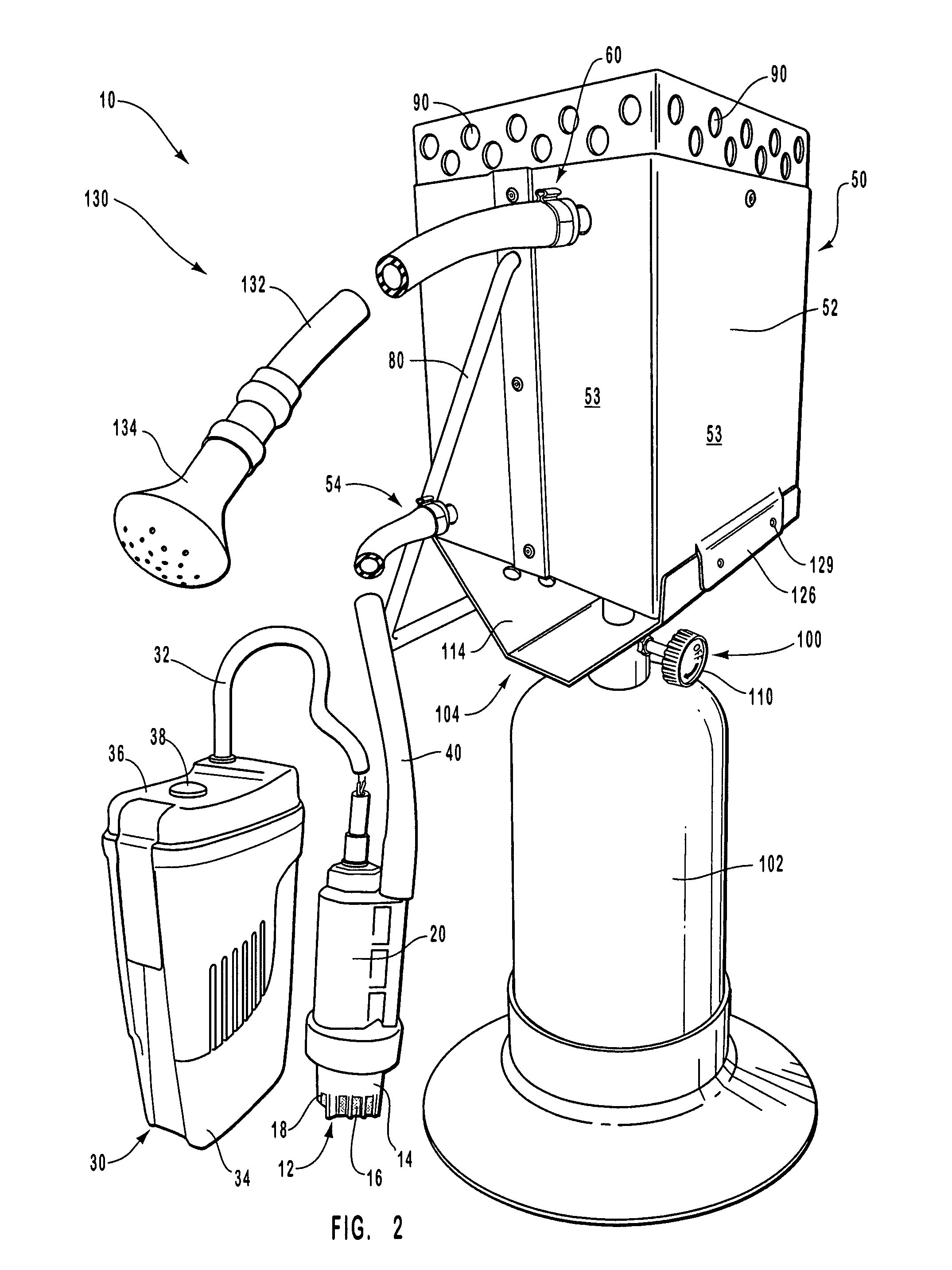

Portable water heater

A portable hot water heater for larger-scale applications including emergency use, situations involving hazardous materials, and the like. The hot water heater advantageously efficiently and rapidly heats large quantities of water for providing a stream of hot water for immediate use. The hot water heater includes a pump that can draw water from any suitable water source, a power source, a heating assembly that quickly and efficiently heats the water as it flows through the heating assembly. The heating assembly is attached to a shower head or other fixture.

Owner:TAPH

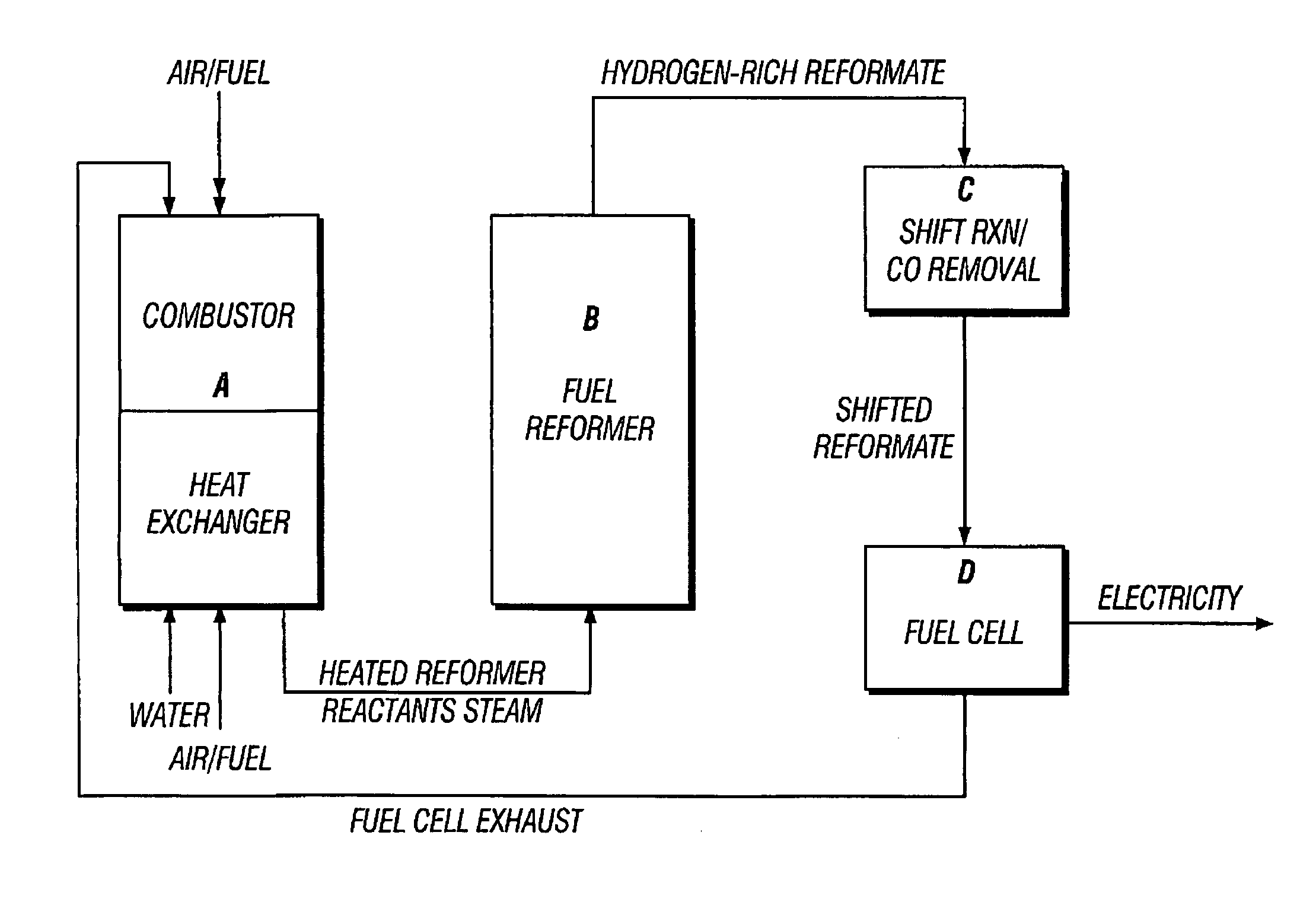

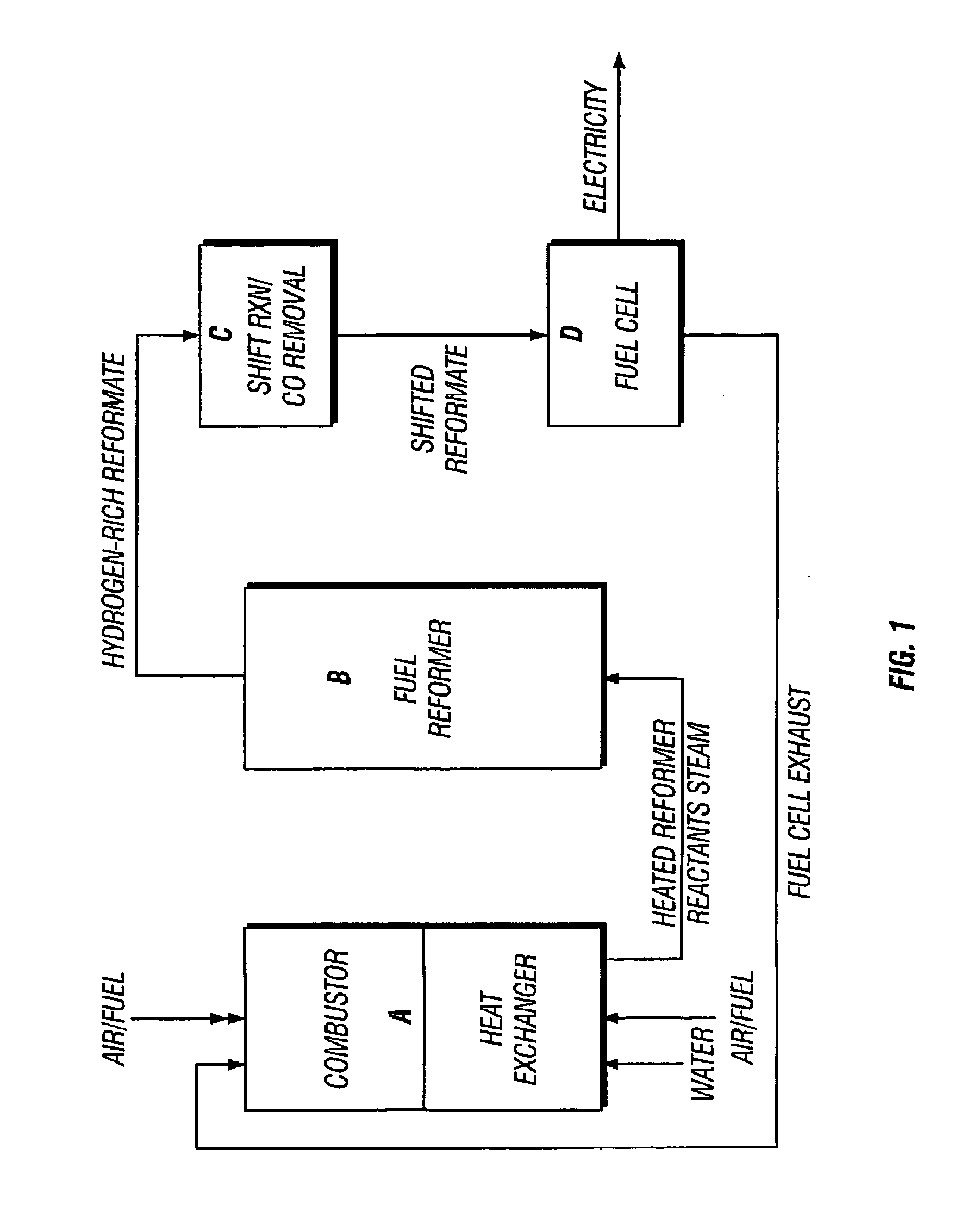

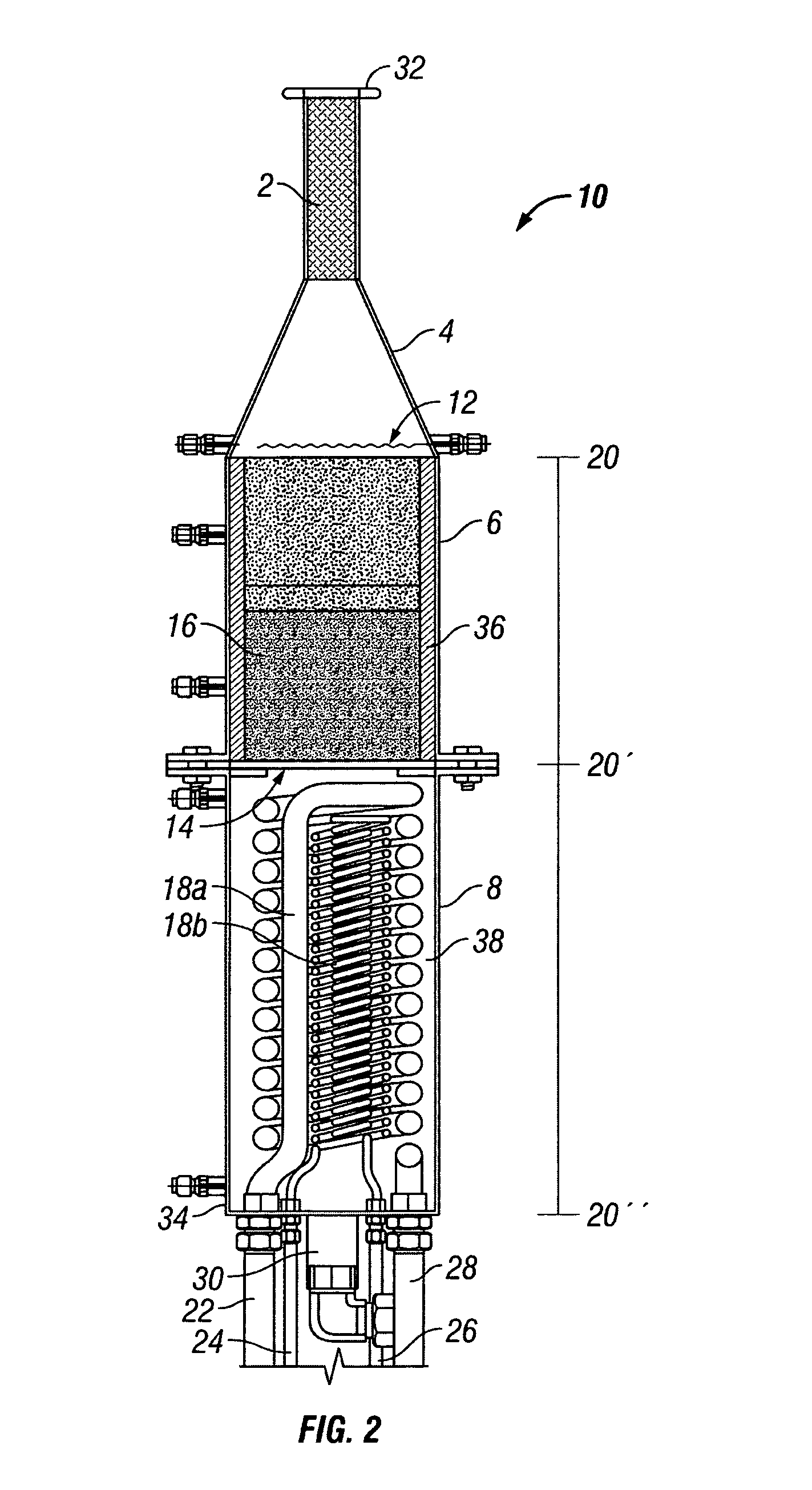

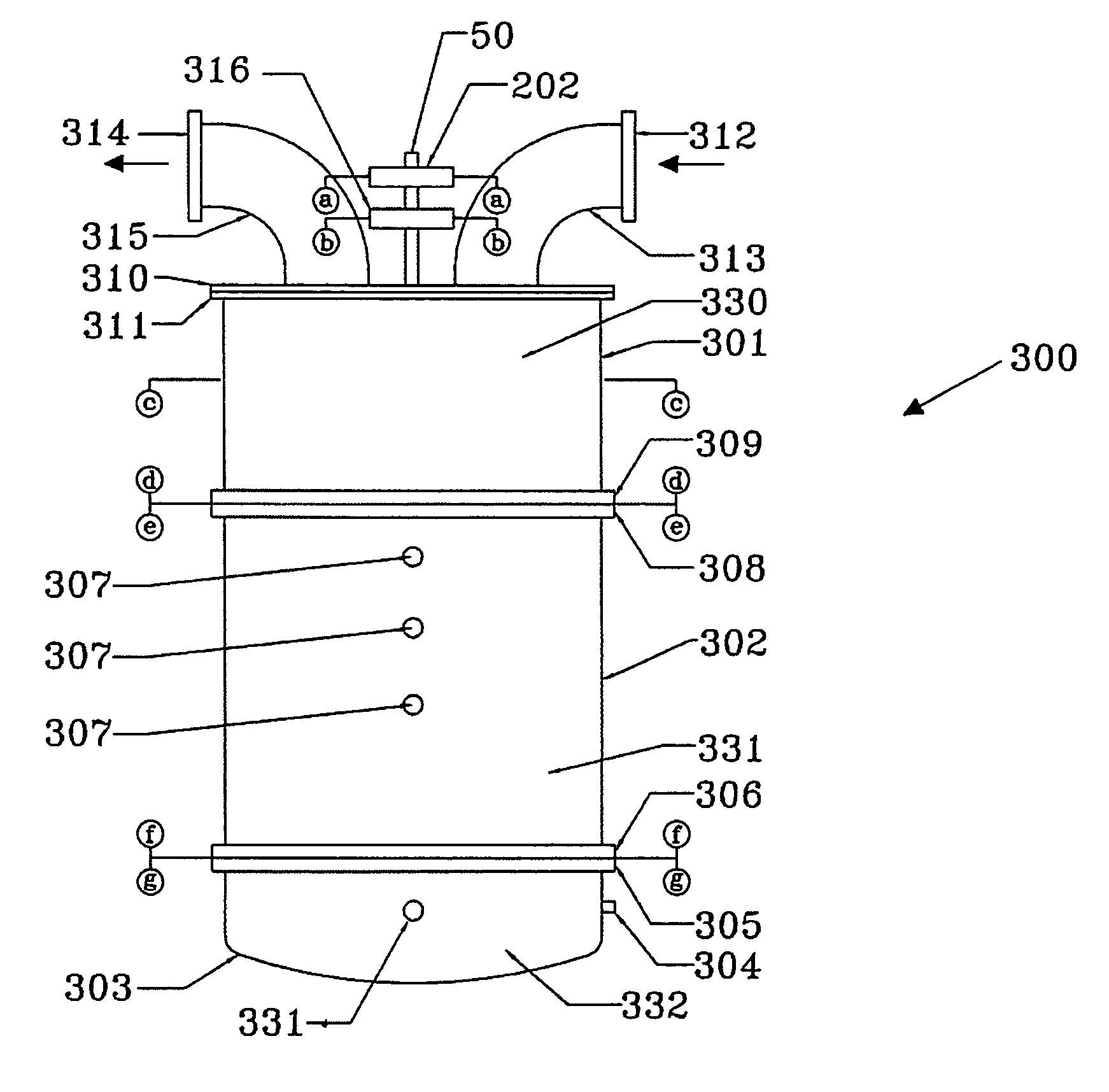

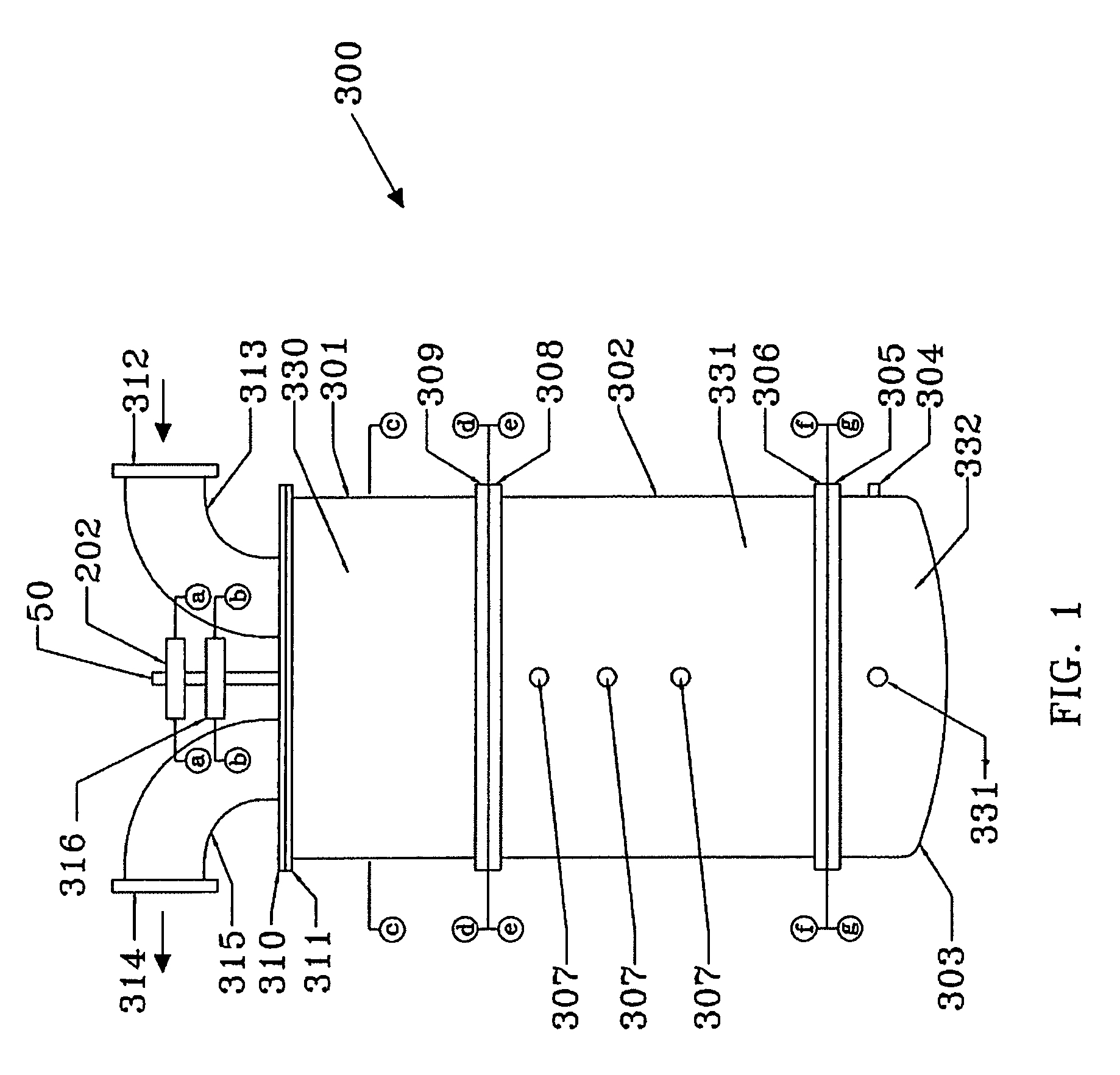

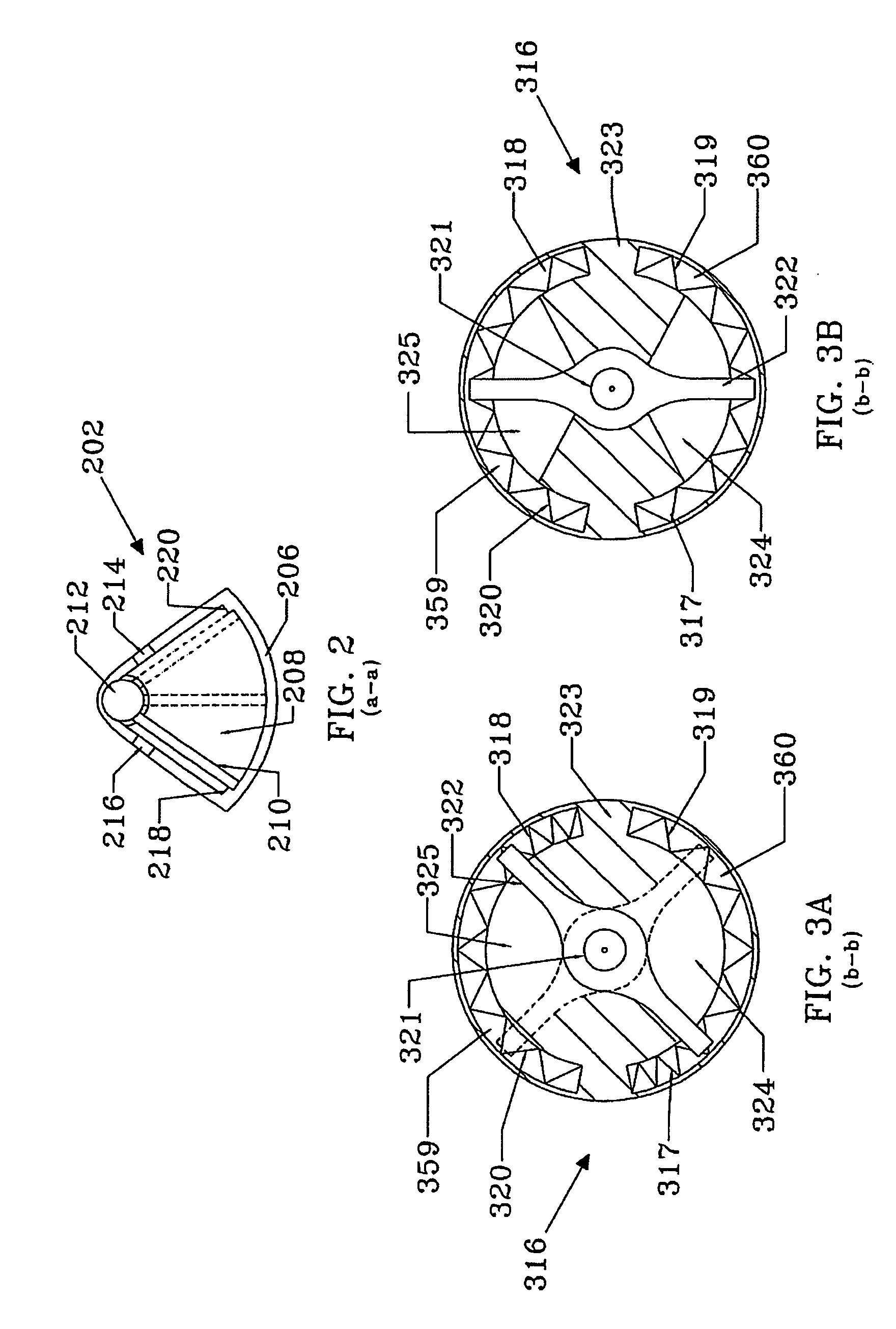

Method and apparatus for rapid heating of fuel reforming reactants

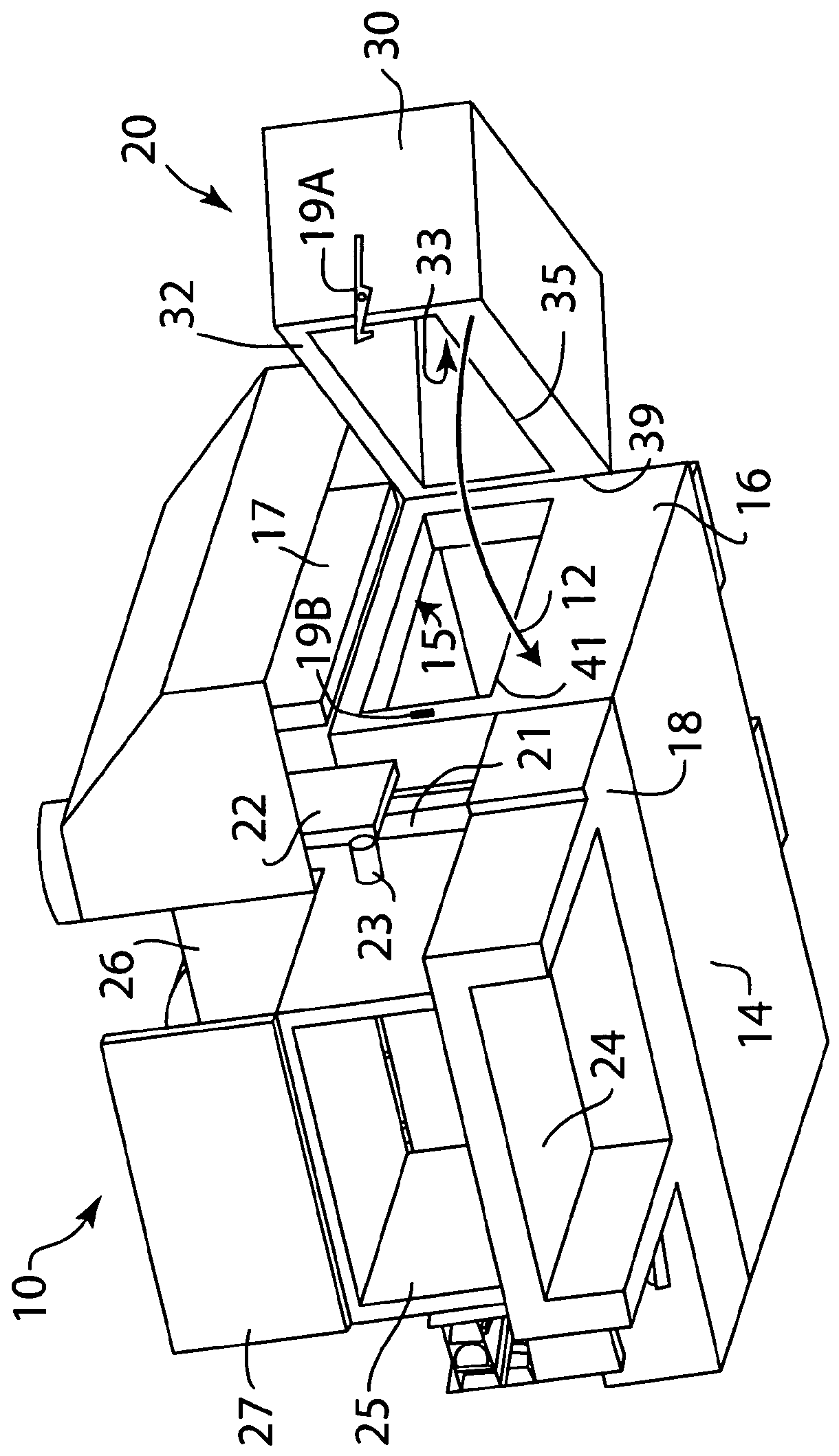

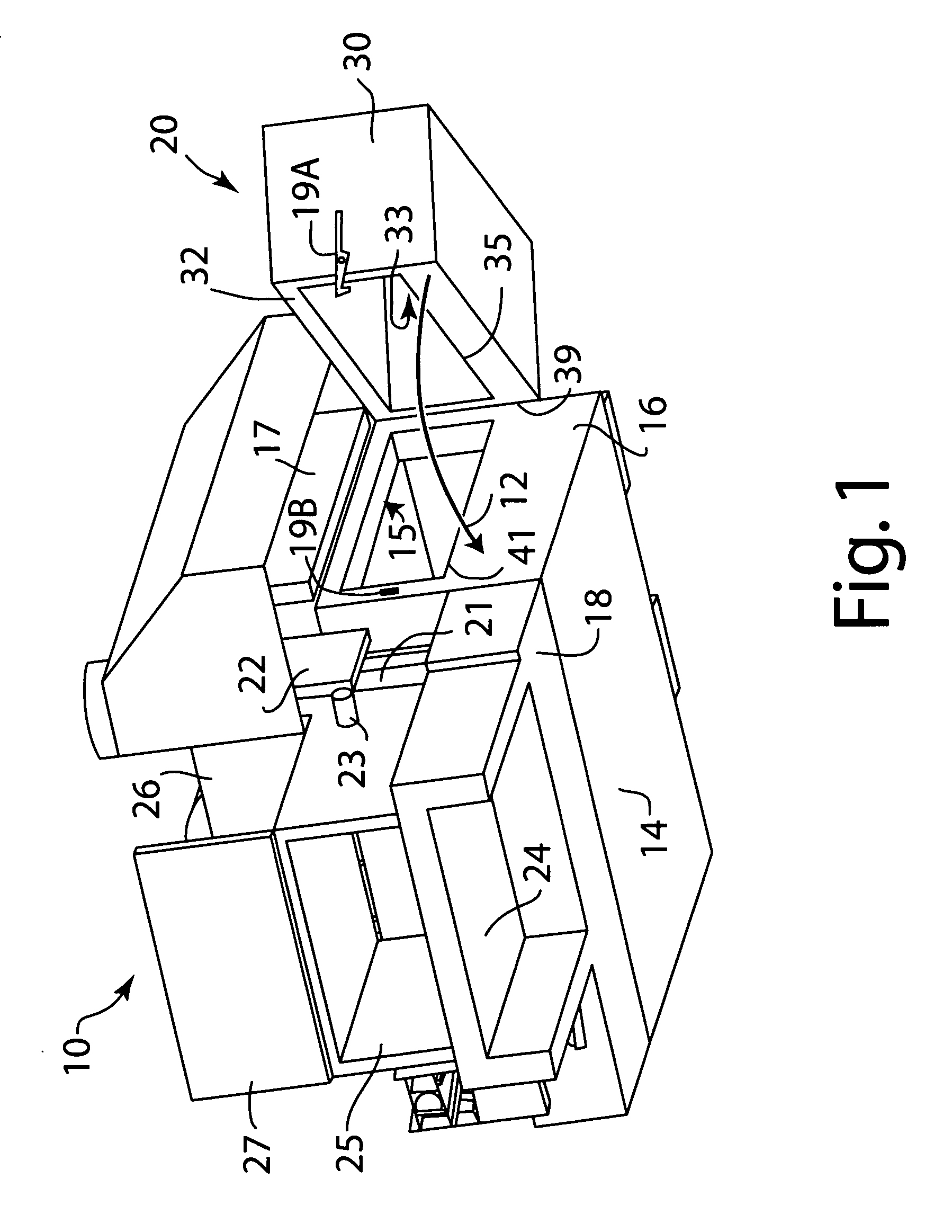

InactiveUS7235217B2Start fastMinimal heat lossGas modification by gas mixingHeat exchanger casingsCombustion chamberEngineering

Apparatus and method for rapidly heating one or more reactants for use in a fuel reformer. The apparatus includes a combustion section having an outer wall enclosing a combustion chamber and a catalyst disposed within the combustion chamber. A heat recovery section is in fluid communication with the combustion section and has an outer wall defining a heat recovery chamber. At least one heat exchanging element is located within the heat recovery chamber having an inlet for receiving a fuel reforming reactant and an outlet for directing a heated reactant out of the heat recovery section. The combustion section is elevated relative to the heat recovery section such that heated combustion gases are displaced down into the heat recovery section. The housing has an internal diameter of less than about 10 inches, or alternatively, has a length and a diameter in a ratio of between about 7:1 and about 4:1.

Owner:TEXACO INC

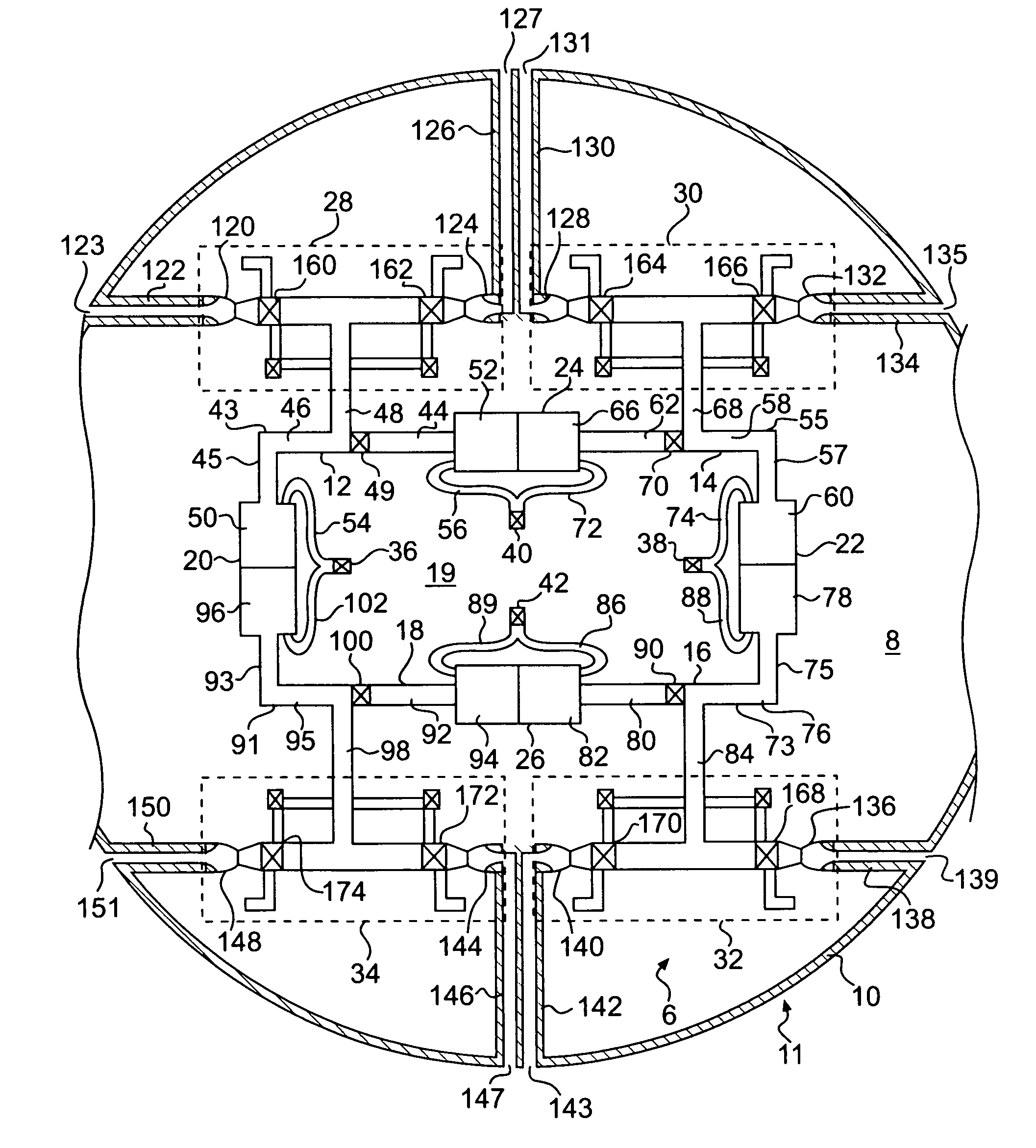

Drive apparatus

InactiveUS7421929B2Minimal heat lossIncrease its rotational inertiaDynamo-electric brakes/clutchesCircuit arrangementsElectricityDrive shaft

An apparatus for inducing drive is shown that includes a primary drive shaft and four secondary drive shafts. The primary shaft and secondary shafts are fitted with magnets that are oriented such that when the primary shaft is rotated the secondary shafts are caused to rotate due to attractive or repulsive forces. The primary shaft is connected to and rotated by a rotational energy source such as a motor powered by electricity or a battery, although any source of energy to cause rotation of the primary shaft may be used. Each secondary shaft is fitted with two annular magnetic discs that are oriented to vertically support the weight of the shaft (and any attachments / fittings thereto) above the alternating or generating device. The discs can be arranged to provide either an attractive or repulsive magnetic force between them.

Owner:FORCE FIELD LTD

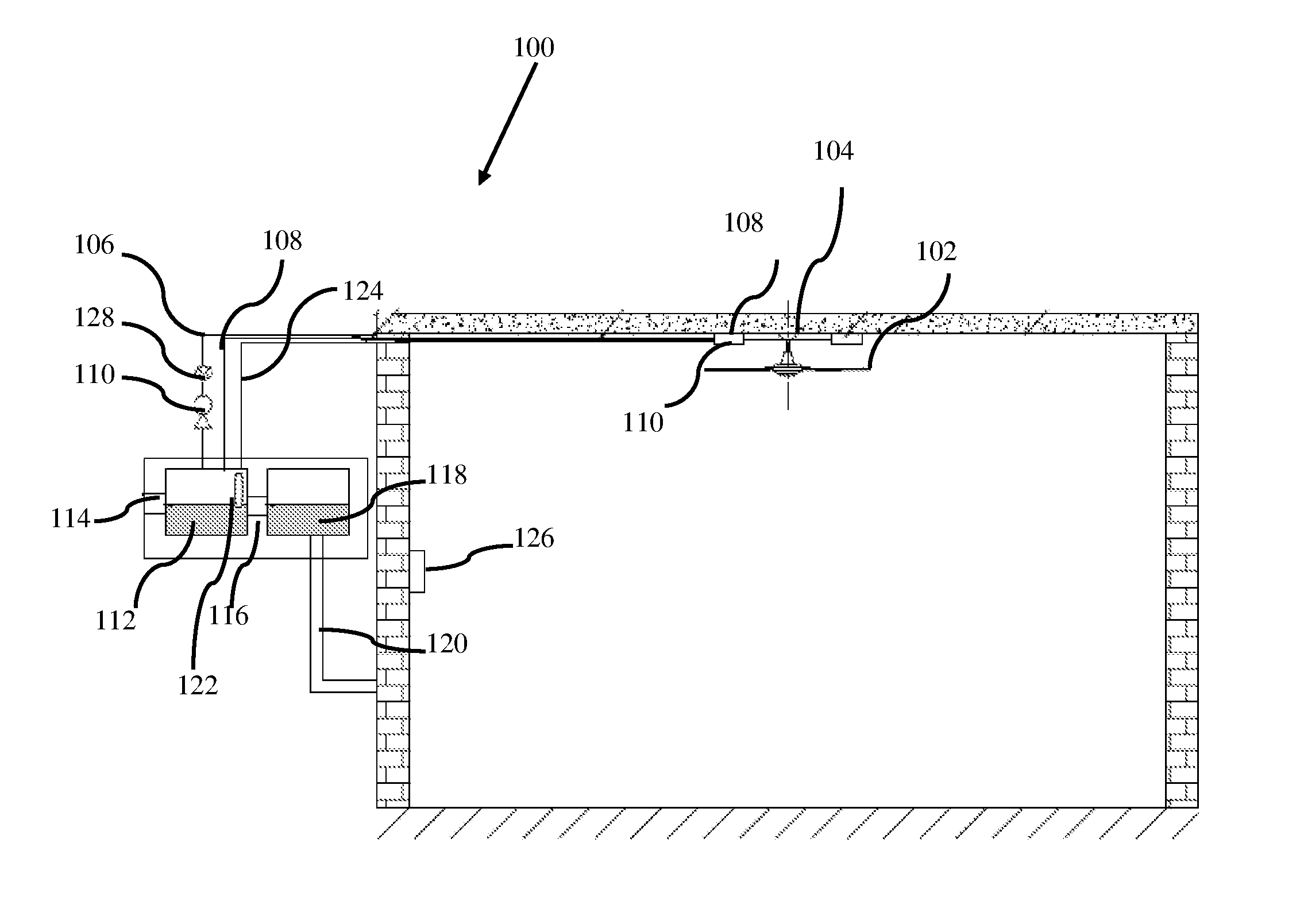

Active heating system for oil pipeline

InactiveUSH2139H1Energy consumption is minimizedShort timePipe heating/coolingFluid removalWaxPetroleum

A pipeline for transmitting oil or other substance which forms a solid residue such as wax when the substance is cooled, as in a subsea oil pipeline. Pass a tube through the interior of the pipeline, e.g., at the wall of the pipeline. Transmit heated liquid or water through the tube for heating the material being passed through the pipeline to a temperature which avoids or eliminates the solid residue and for heating the pipeline.

Owner:COFLEXIP

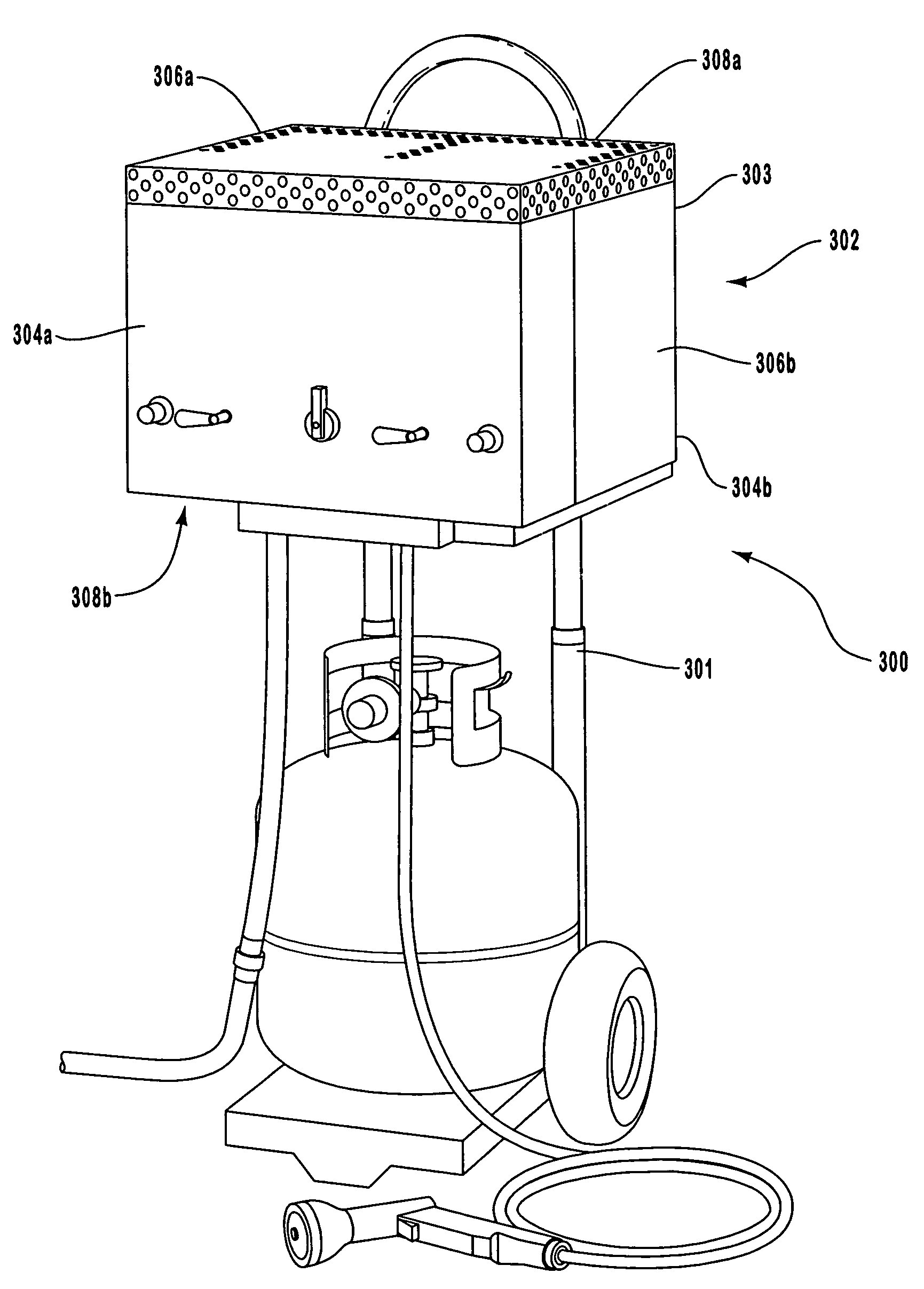

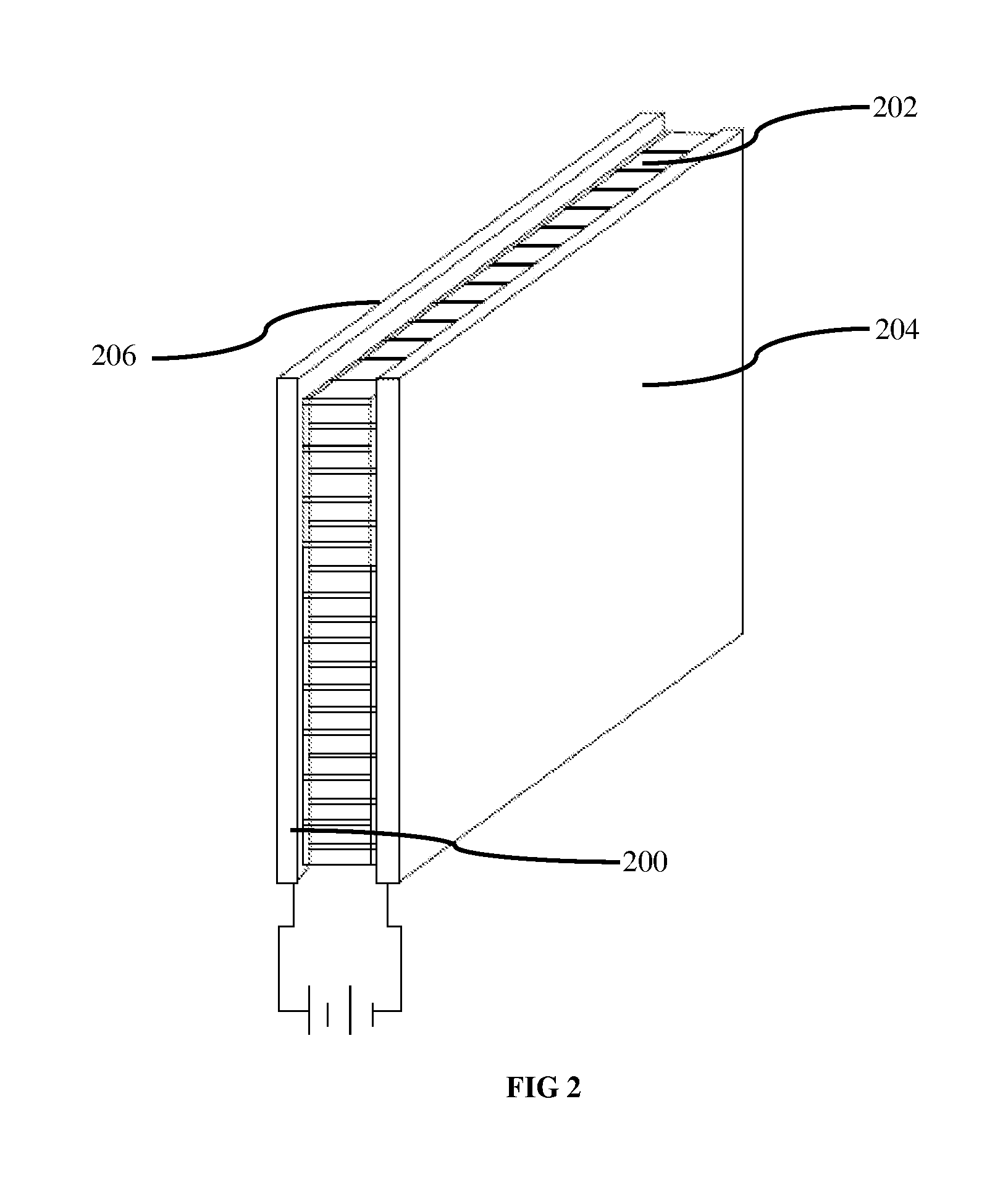

Portable water heater

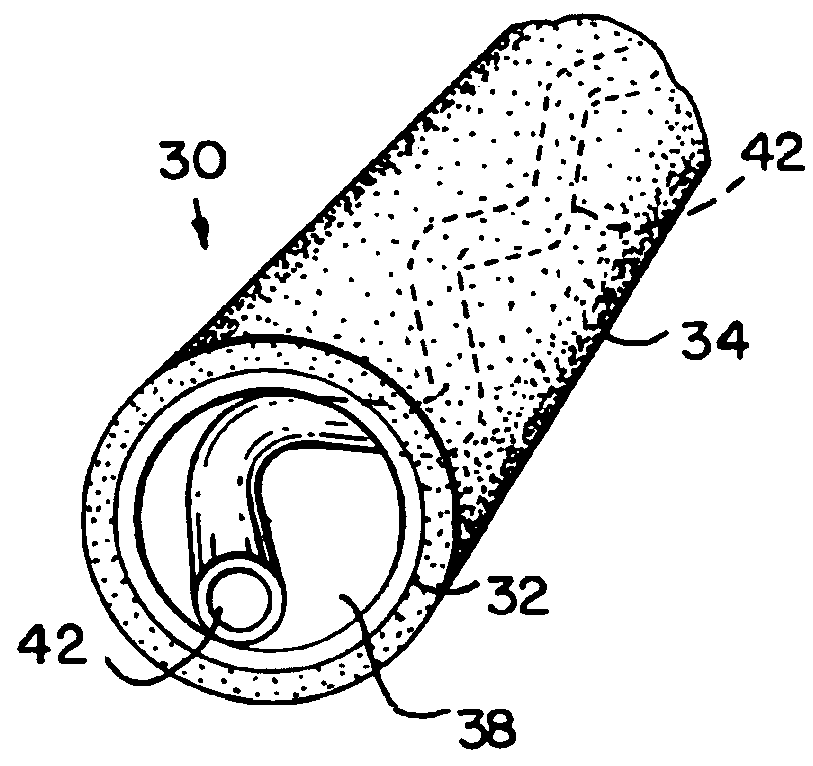

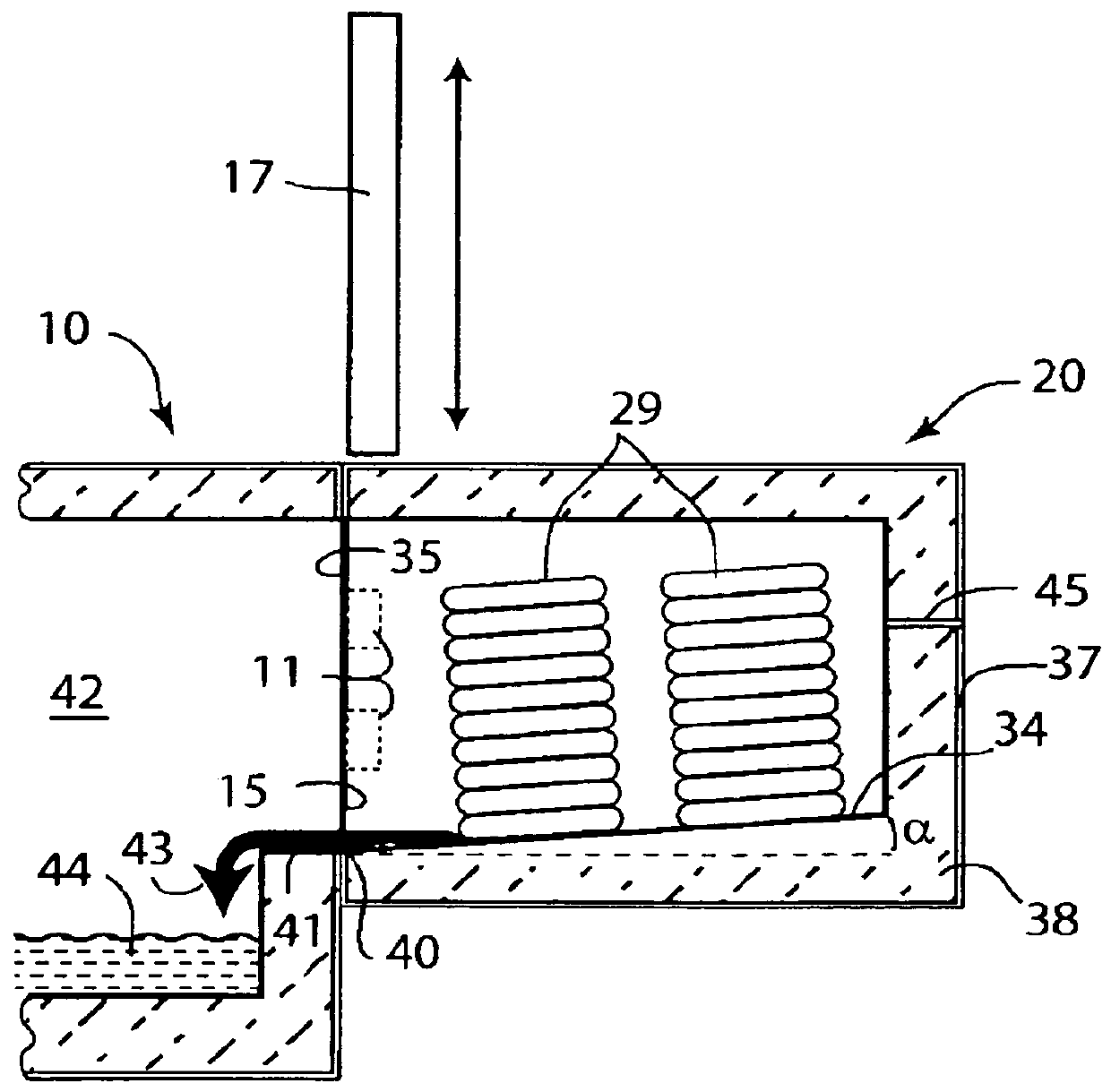

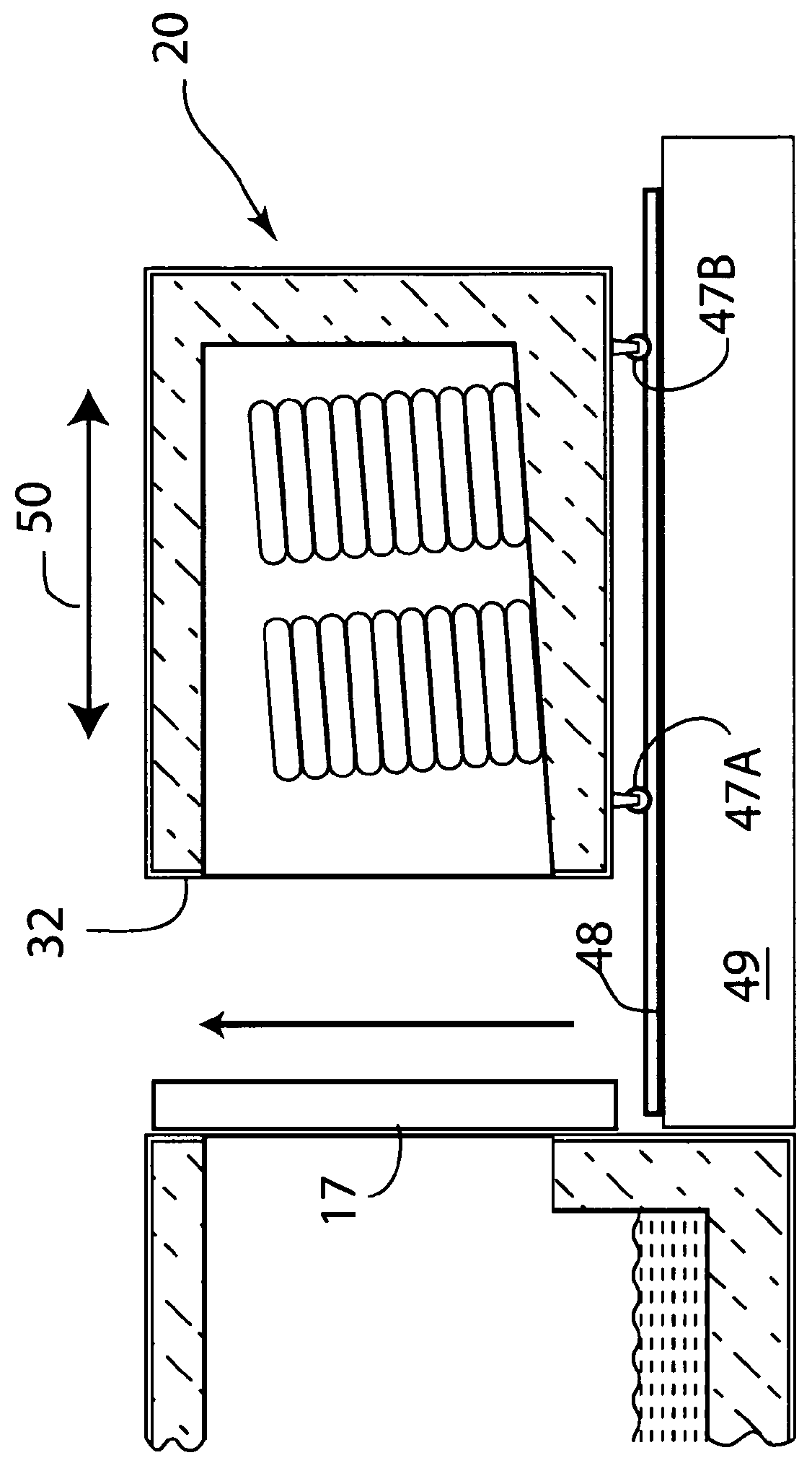

InactiveUS6978496B2Minimal heat lossProvides heated quickly and efficientlyBathsDouchesWater sourceEngineering

A portable hot water heater for use during camping, boating, hunting, hiking, fishing, backpacking, etc. The hot water heater advantageously efficiently and rapidly heats large quantities of water for hot showers, cooking and cleaning. The hot water heater includes a pump that can draw water from any suitable water source, a power source, a heating assembly that quickly and efficiently heats the water as it flows through the heating assembly. The heating assembly is attached to a shower head or other fixture.

Owner:TAPH

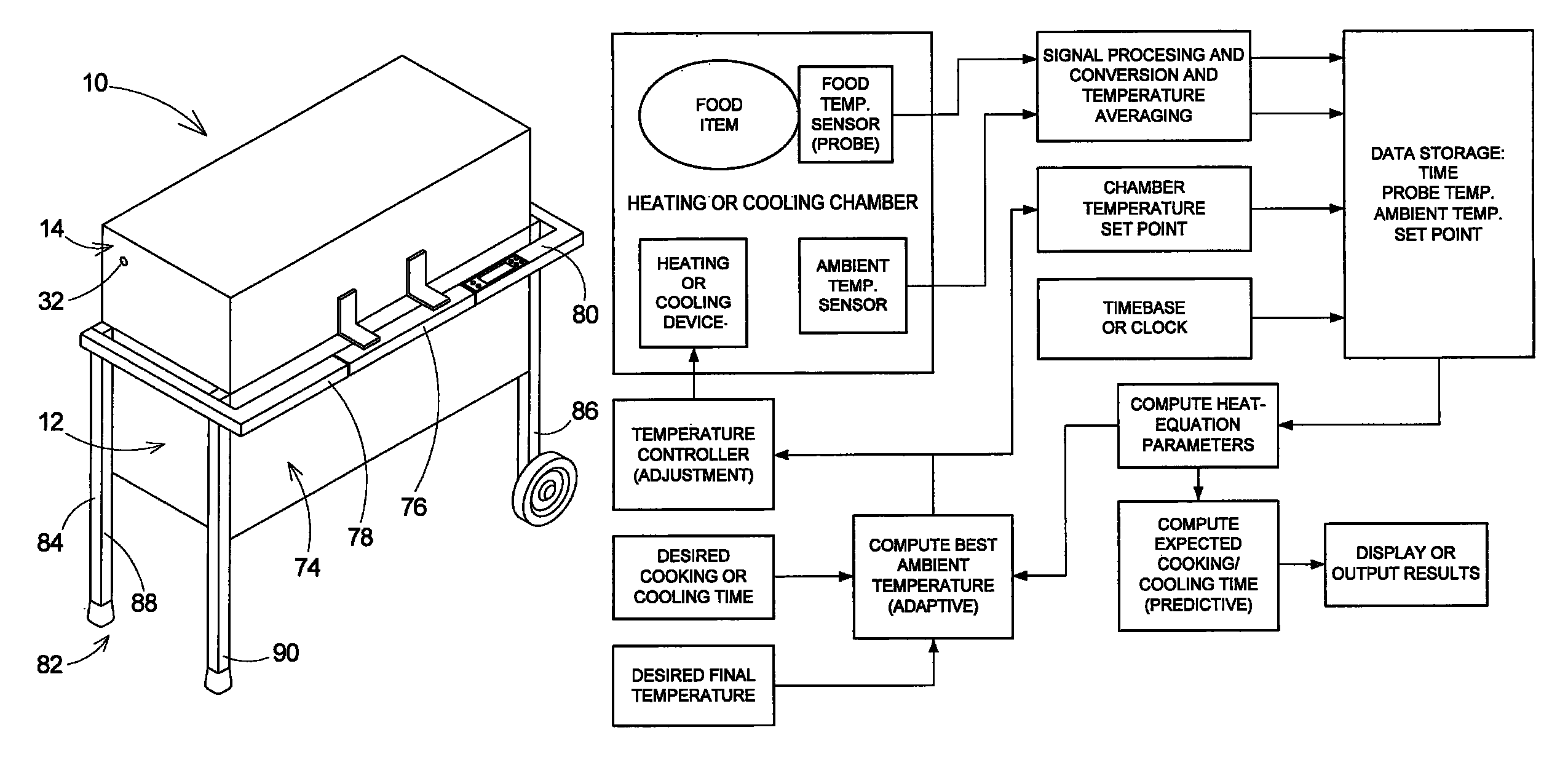

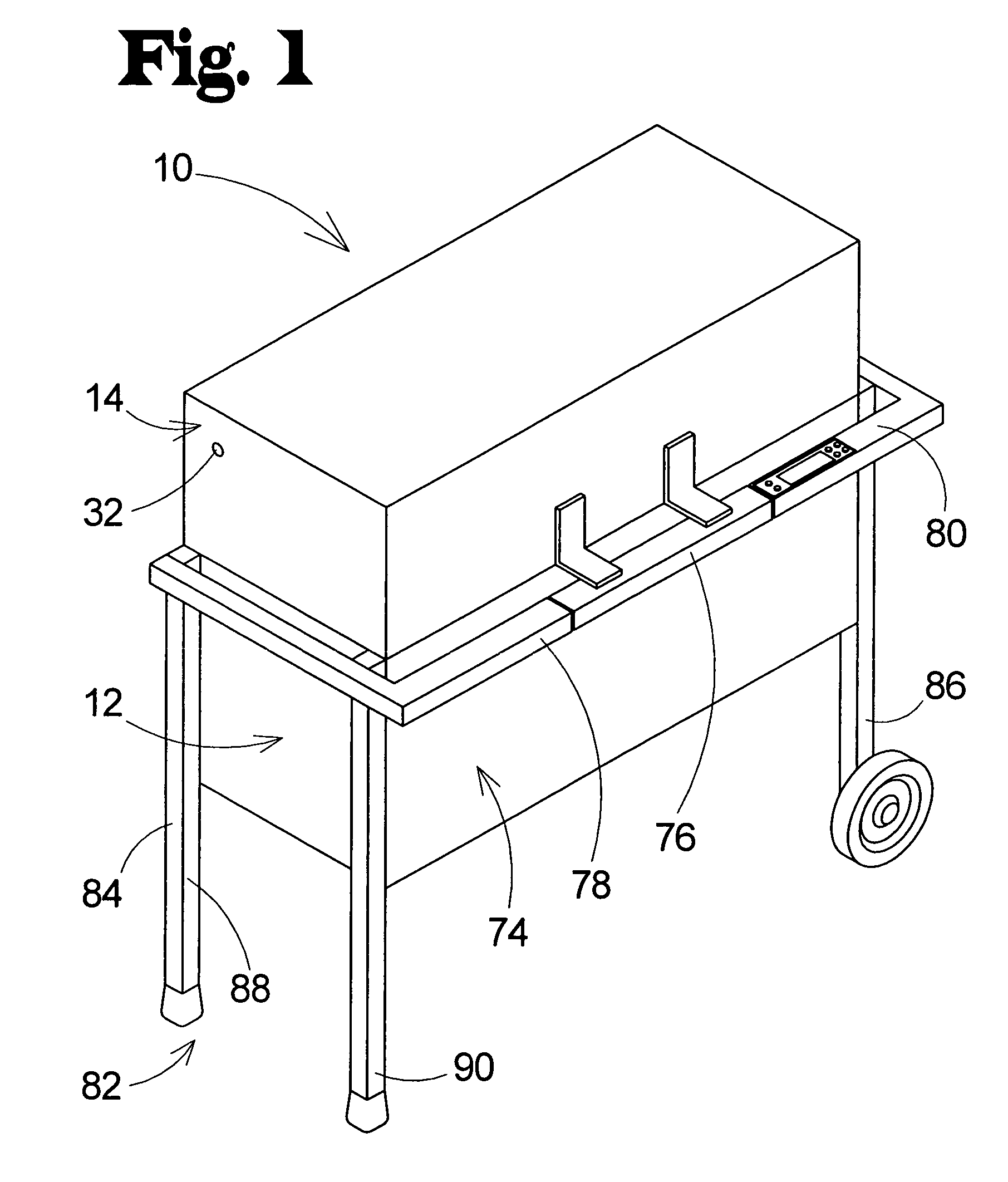

Electric grilling appliance

InactiveUS8624169B1Not overheat or burn or dry out the food being cookedEfficient heatingBoiling over preventionDomestic stoves or rangesFood temperaturesControl circuit

A heating appliance comprises a chamber portion defining a heating chamber, a lid portion, a heating apparatus to heat air in the heating chamber, a food temperature sensor to sense an internal temperature of an item located in the heating chamber, a user interface configured to receive designation of a desired time of completion of heating of the item from the user, and a control circuit configured to control the supply of power to the heating apparatus. The control circuit is in communication with the temperature sensor and the user interface. The control circuit may control the heating apparatus so that the internal temperature of the item reaches a predetermined temperature at the desired time of completion designated by the user. The control circuit may control the heating apparatus so that the internal temperature of the item is maintained at a predetermined temperature for a predetermined period of time before an end of the desired time of completion.

Owner:SORENSON WALLY B +1

Two-stage plasma process for converting waste into fuel gas and apparatus therefor

InactiveUS20110107669A1Limited amountImprove energy efficiencyGasifier electrodesGaseous fuelsCyclonePlasma jet

A two-step gasification process and apparatus for the conversion of solid or liquid organic waste into clean fuel, suitable for use in a gas engine or a gas burner, is described. The waste is fed initially into a primary gasifier, which is a graphite arc furnace. Within the primary gasifier, the organic components of the waste are mixed with a predetermined amount of air, oxygen or steam, and converted into volatiles and soot. The volatiles consist mainly of carbon monoxide and hydrogen, and may include a variety of other hydrocarbons and some fly ash. The gas exiting the primary gasifier first passes through a hot cyclone, where some of the soot and most of the fly ash is collected and returned to the primary gasifier. The remaining soot along with the volatile organic compounds is further treated in a secondary gasifier where the soot and the volatile compounds mix with a high temperature plasma jet and a metered amount of air, oxygen or steam, and are converted into a synthesis gas consisting primarily of carbon monoxide and hydrogen. The synthesis gas is then quenched and cleaned to form a clean fuel gas suitable for use in a gas engine or a gas burner. This offers higher thermal efficiency than conventional technology and produces a cleaner fuel than other known alternatives.

Owner:PYROGENESIS CANADA INC

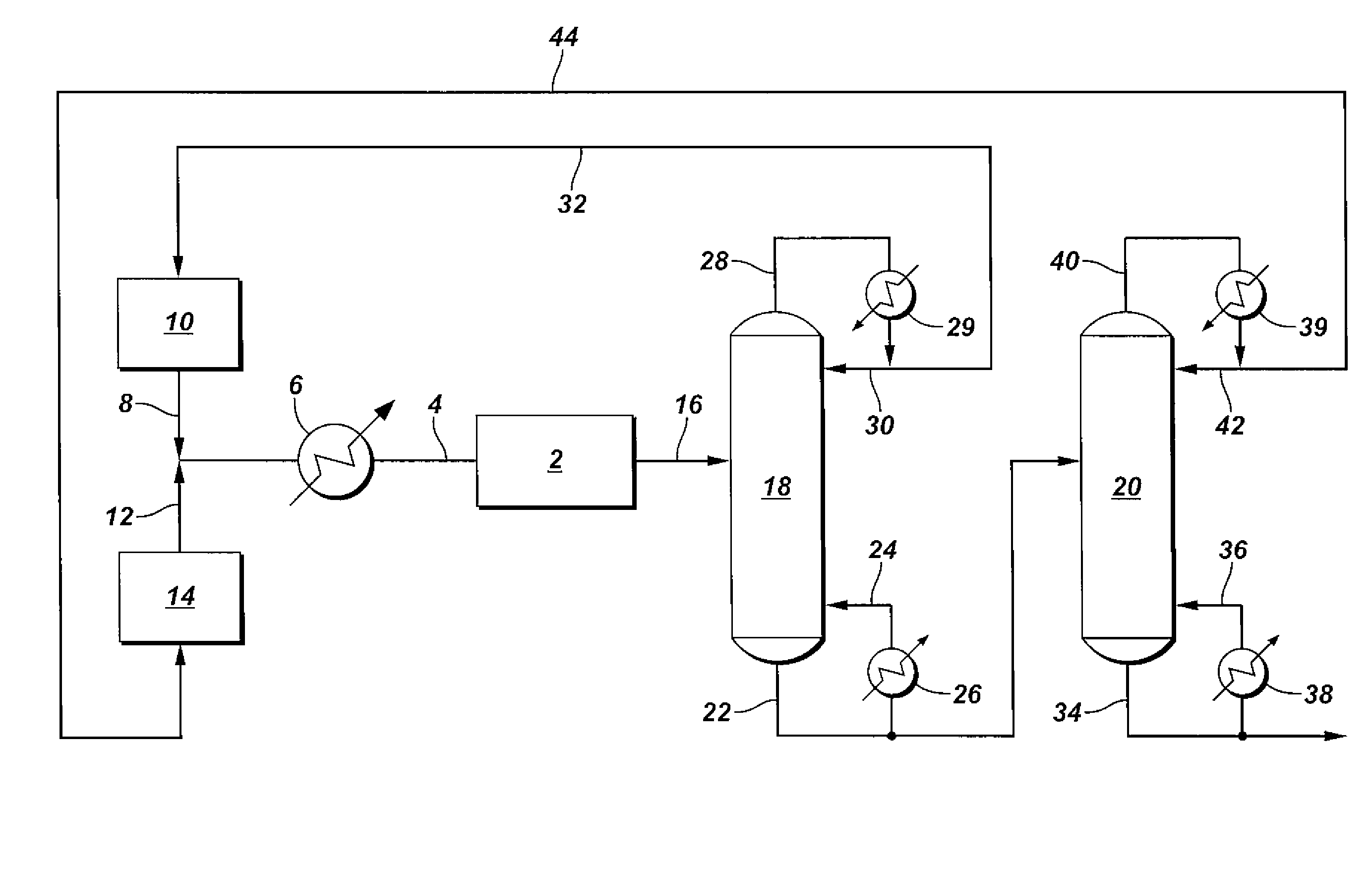

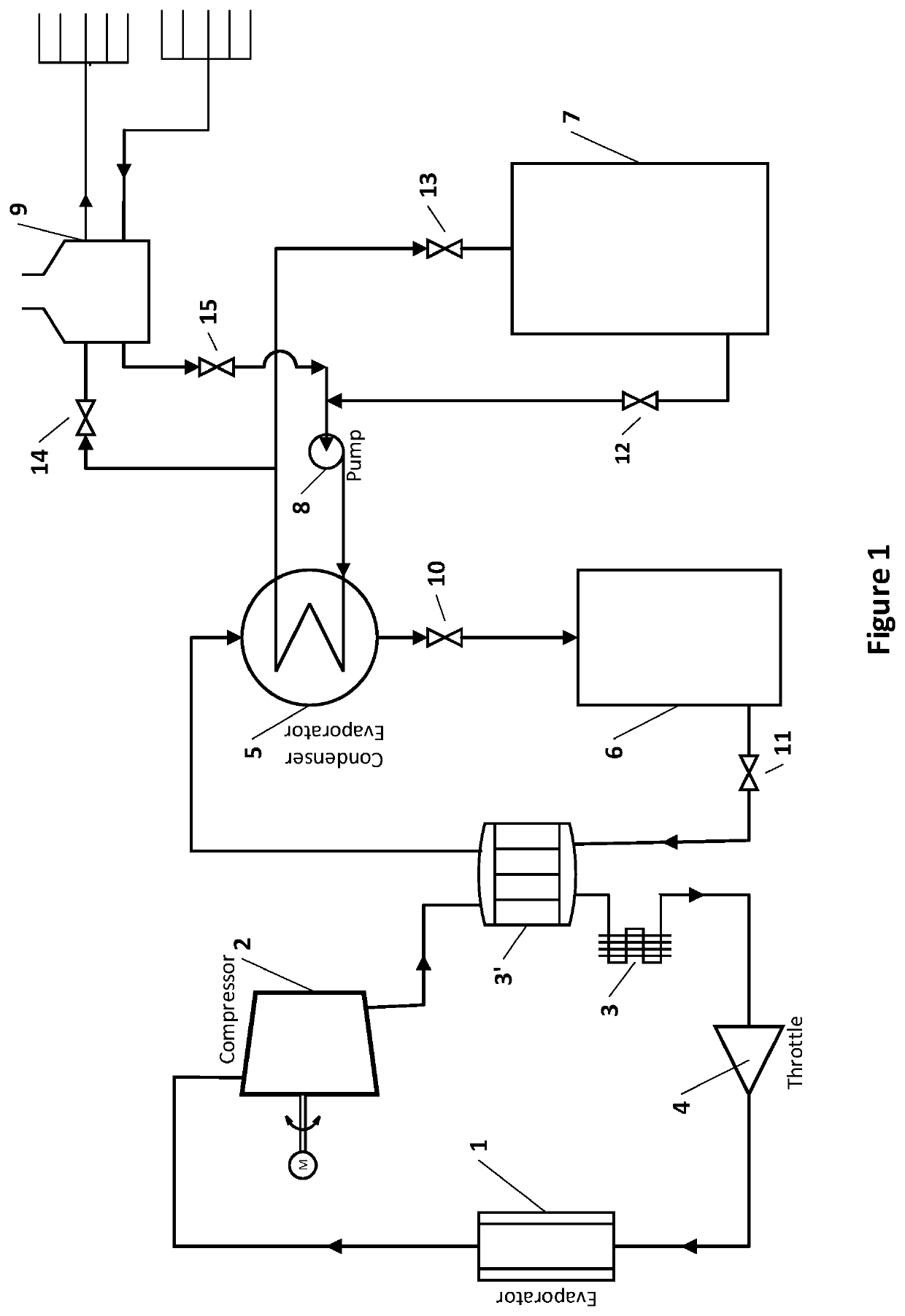

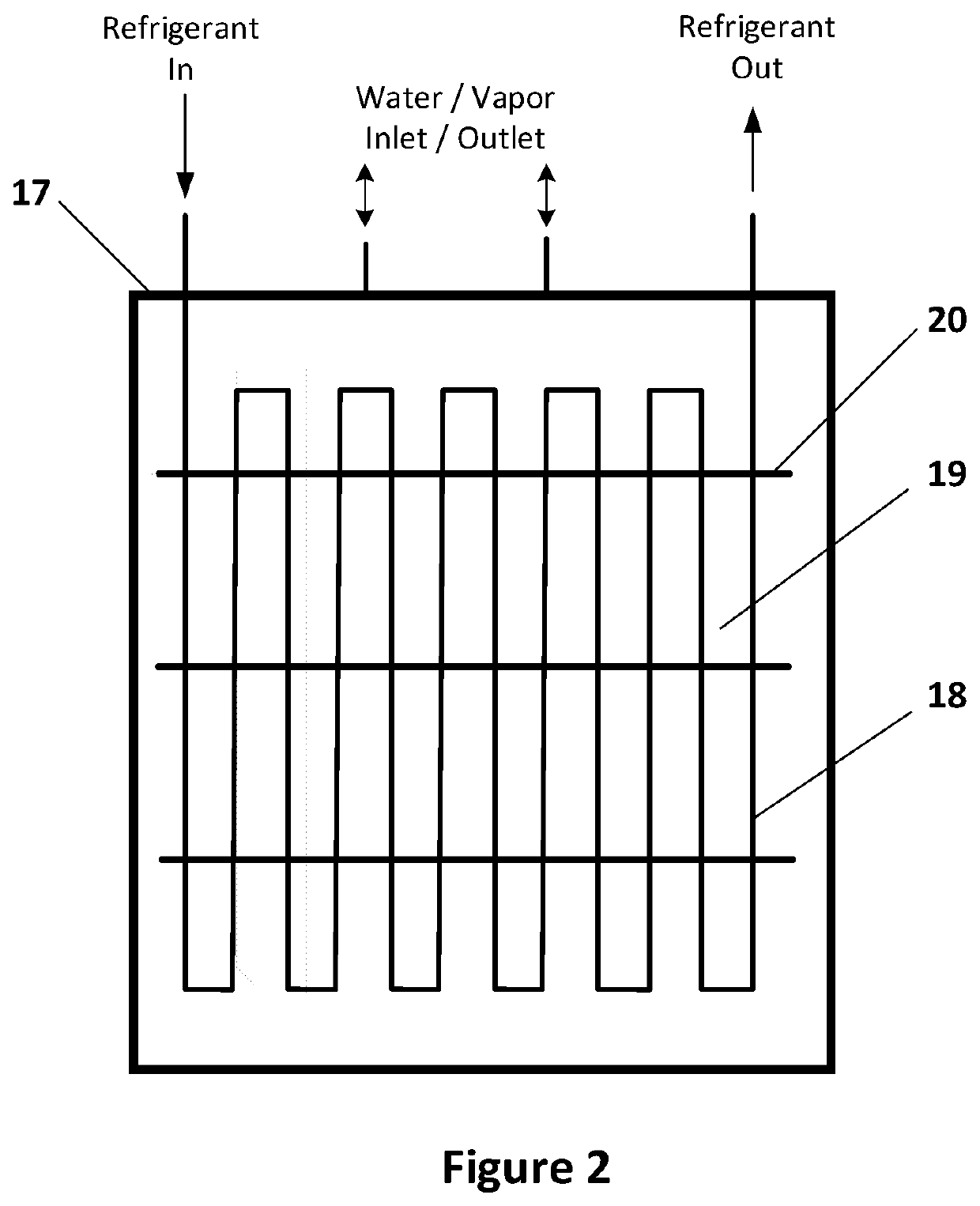

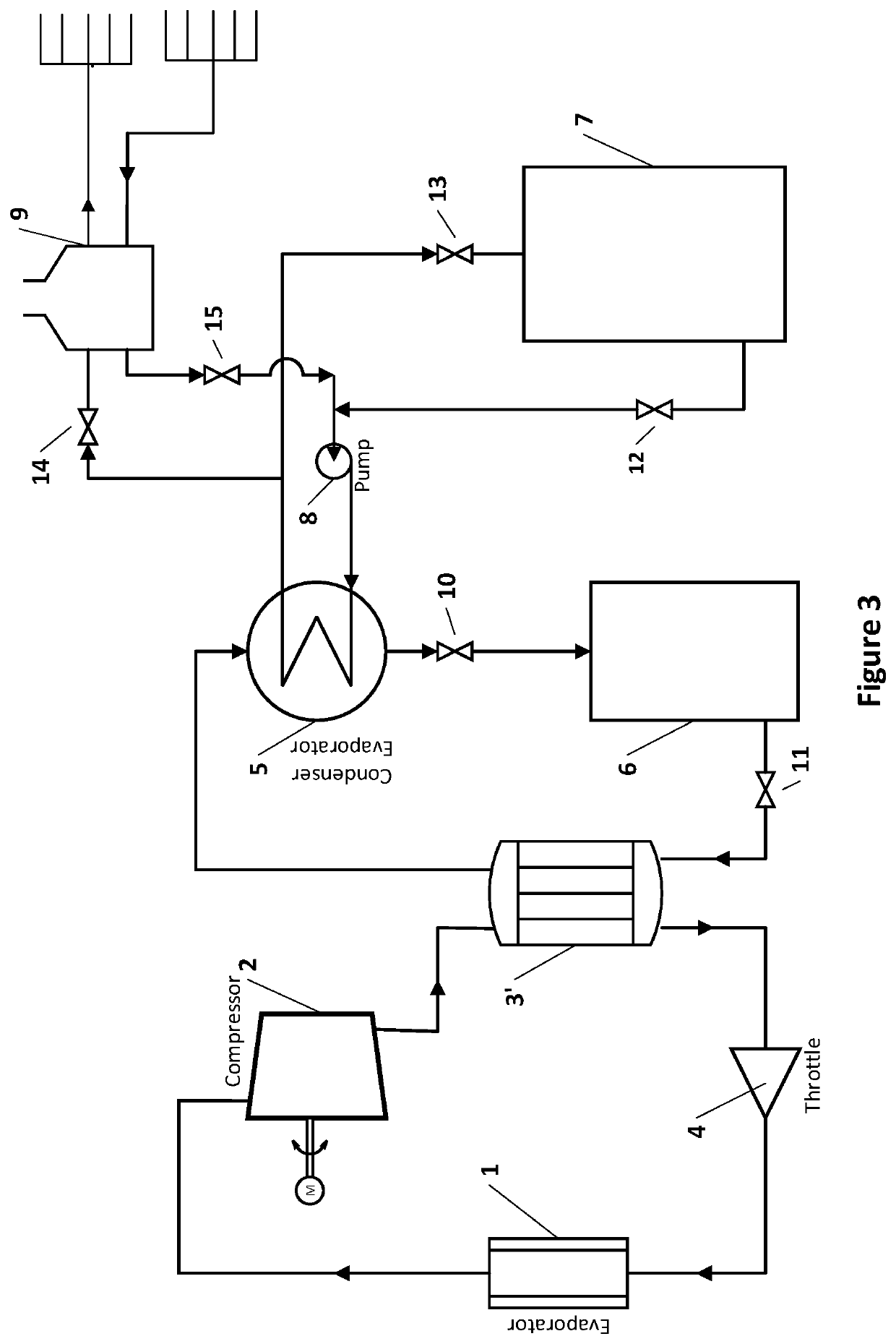

Integration of Thermochemical Heat Storage System with Waste heat Recovery Systems

InactiveUS20190383563A1Minimal heat lossCentral heating with accumulated heatHeat recovery systemsThermal energyWaste heat recovery unit

A waste heat recovery for use with refrigeration means and space heating / water heating to meet various seasonal demands on refrigeration and heating energy is disclosed. The system is intended for use with refrigeration means of the conventional type including a compressor and a condenser through which a compressible refrigerant is circulated. The system integrates a refrigeration system and a heating utilization system through a thermochemical system functioning as a heat transfer system and thermochemical energy storage system. Wherein the heat transfer system is used for absorbing the waste heat normally dissipated in the condenser and for discharging the recovered thermal energy to a heat utilization system for space heating and / or water heating, the thermochemical energy storage system is used for converting the waste heat collected into chemical energy for seasonal storage. The waste heat recovery system is designed with a feature that operations of the refrigeration system and the heat utilization system are de-coupled so that the refrigeration system and the heat utilization system can be operated independently at different times on demand. This feature makes implementation of the waste heat recovery system viable for more residential houses, commercial establishments, and industrial processes applications.

Owner:HE JUNYI DEREK +1

Post boost control power assembly

InactiveUS7875838B1Minimal heat lossLess heat lossCosmonautic vehiclesDirection controllersControl powerEngineering

A tubular distributor in a missile having a right-angled hollow tubular first section, the right-angled hollow tubular first section having a first leg and a second leg, a straight hollow tubular second section, an end of the first leg of the right-angled hollow tubular first section perpendicularly connected to a first end of the hollow tubular second section, a straight hollow tubular third section, a first end of the hollow tubular third section perpendicularly connected to the first end of the straight hollow tubular second section, and a close / open valve positioned within the straight hollow tubular third section, the close / open valve positioned between a gas generator and the straight hollow tubular second section.

Owner:NAVY U S NAVY AS REPRESENTED BY THE SEC OF THE

Further improved reversing flow catalytic converter for internal combustion engines

InactiveUS20060283173A1Compact structureEfficient executionInternal combustion piston enginesSilencing apparatusCombustionExhaust fumes

A further improved compact reversing flow catalytic converter with protection from overheating includes an improved valve unit which directs exhaust gases through a container filled with catalytic material to permit a bypass of catalytic material when a temperature of the material exceeds a predetermined threshold. The container defines a U-shaped gas passage that communicates with two chambers at the top of the container. The improved valve unit is mounted to the top of the container and includes two container chamber extension cavities, an improved intake cavity and an improved exhaust cavity. The improved valve unit includes an improved valve flapper and two conjoined valve walls each wall with two openings therethrough. The improved valve flapper rotates around normal central axis between a first, a second and third positions. When overheating of the catalytic material is predicted, a controller relinquishes control of the improved valve flapper and an improved center return mechanism rotates the improved valve flapper to a third position, in which each of the valve openings communicates with both inlet and exhaust ports so that the exhaust gas flow bypasses catalytic material. A fuel injection system under control of the controller is used so that measured amounts of fuel can be injected into the container reaction core to enhance oxidation. The catalytic material is thus protected from damage due to overheating. The advantage is a compact, reliable, highly efficient further improved catalytic converter that is inexpensive to manufacture, durable, and adapted for extended service life. The improved valve may driven by a stepper motor that moves and holds the valve to its three positions including bypass, forward and reverse flow. An alternate version also replaces the oxidizing flow-through monolith with an oxidizing filter trap.

Owner:SMART MUFFLER CORP

System and Method for Optimal Cooling by Thermo Electric Cooling Module (TEC) and an Electric Fan Thereof

ActiveUS20140305141A1Evenly distributedConducive to diversificationThermoelectric device with peltier/seeback effectMachines using electric/magnetic effectsCold sideThermoelectric cooling

The various embodiments of the present system disclose a system for an optimal cooling by a thermoelectric cooling module and an electric fan thereof. The system comprises a thermoelectric cooling module, an electric fan and a housing. The thermoelectric cooling module comprises a plurality of thermoelectric sub-modules, a hot side management module, a cold side management module and an integrated control module. The present invention provides an optimal cooling on the basis of an external weather condition. The present invention further provides an optimal cooling by implementing an efficient fluid circulation mechanism. The present invention also provides a dynamic management over the working of various modules of the said system.

Owner:ANANDHAKRISHNAN VAIDYANATHAN

Portable water heater

InactiveUS8887322B1Minimal heat lossProvides heated quickly and efficientlyBathsDouchesWater sourceEngineering

A portable hot water heater for larger-scale applications including emergency use, situations involving hazardous materials, and the like. The hot water heater advantageously efficiently and rapidly heats large quantities of water for providing a stream of hot water for immediate use. The hot water heater includes a pump that can draw water from any suitable water source, a power source, a heating assembly that quickly and efficiently heats the water as it flows through the heating assembly. The heating assembly is attached to a shower head or other fixture.

Owner:TAPH

Reversing flow catalytic converter for internal combustion engines

InactiveUS20060266025A1Compact structureEfficient executionInternal combustion piston enginesSilencing apparatusCombustionEngineering

A compact reversing flow catalytic converter with protection from overheating includes a valve unit which directs exhaust gases through a container filled with catalytic material to permit a bypass of catalytic material when a temperature of the material exceeds a predetermined threshold. The container defines a U-shaped gas passage that communicates with two ports at the top of the container. The valve unit is mounted to the top of the container and includes an intake and an exhaust cavity. The valve unit includes a valve disk having two openings therethrough. The valve disk rotates around perpendicular central axis between a first, a second and third positions. When overheating of the catalytic material is predicted, a controller relinquishes control of the valve disk and a center return mechanism rotates the valve disk to a third position, in which each of the openings communicates with both ports so that the exhaust gas flow bypasses catalytic material. The catalytic material is thus protected from damage due to overheating. The advantage is a compact, reliable, highly efficient catalytic converter that is inexpensive to manufacture, durable, and adapted for extended service life. An alternate version of the compact reversing flow controller is also described wherein the valve unit and container are essentially as described above but the valve disk is a four position disk with the fourth position blocking communication between the valve housing and the container isolating the monolith so that maximum heat is retained during engine shut down. The valve is driven by a stepper motor that moves and holds the valve to its four positions including block, bypass, forward and reverse flow. The alternate version also replaces the oxidizing flow-through monolith with an oxidizing filter trap and adds a fuel injection system under control of the controller so that measured amounts of fuel can be injected into the valve inlet to enhance oxidation.

Owner:SMART MUFFLER CORP

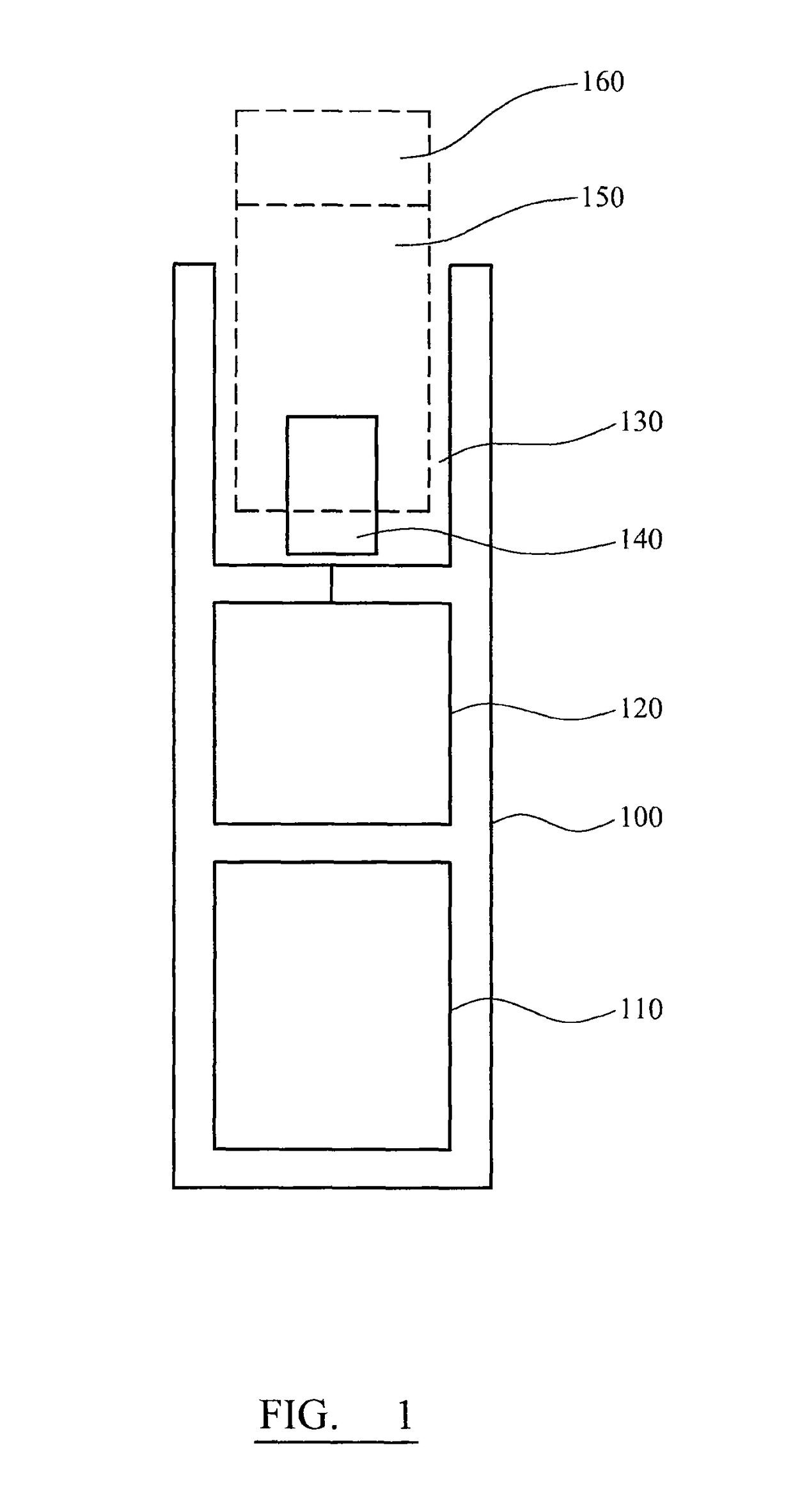

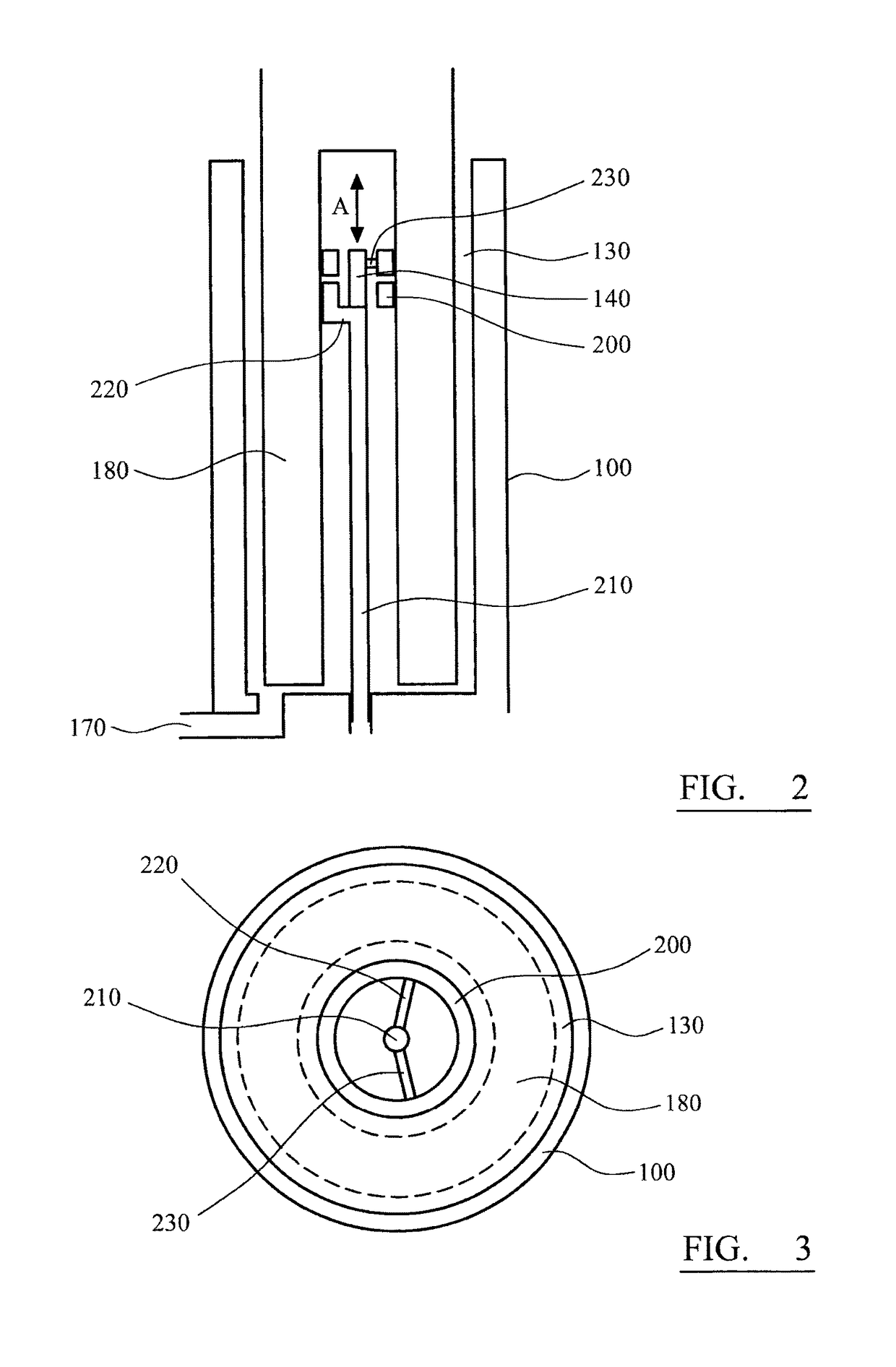

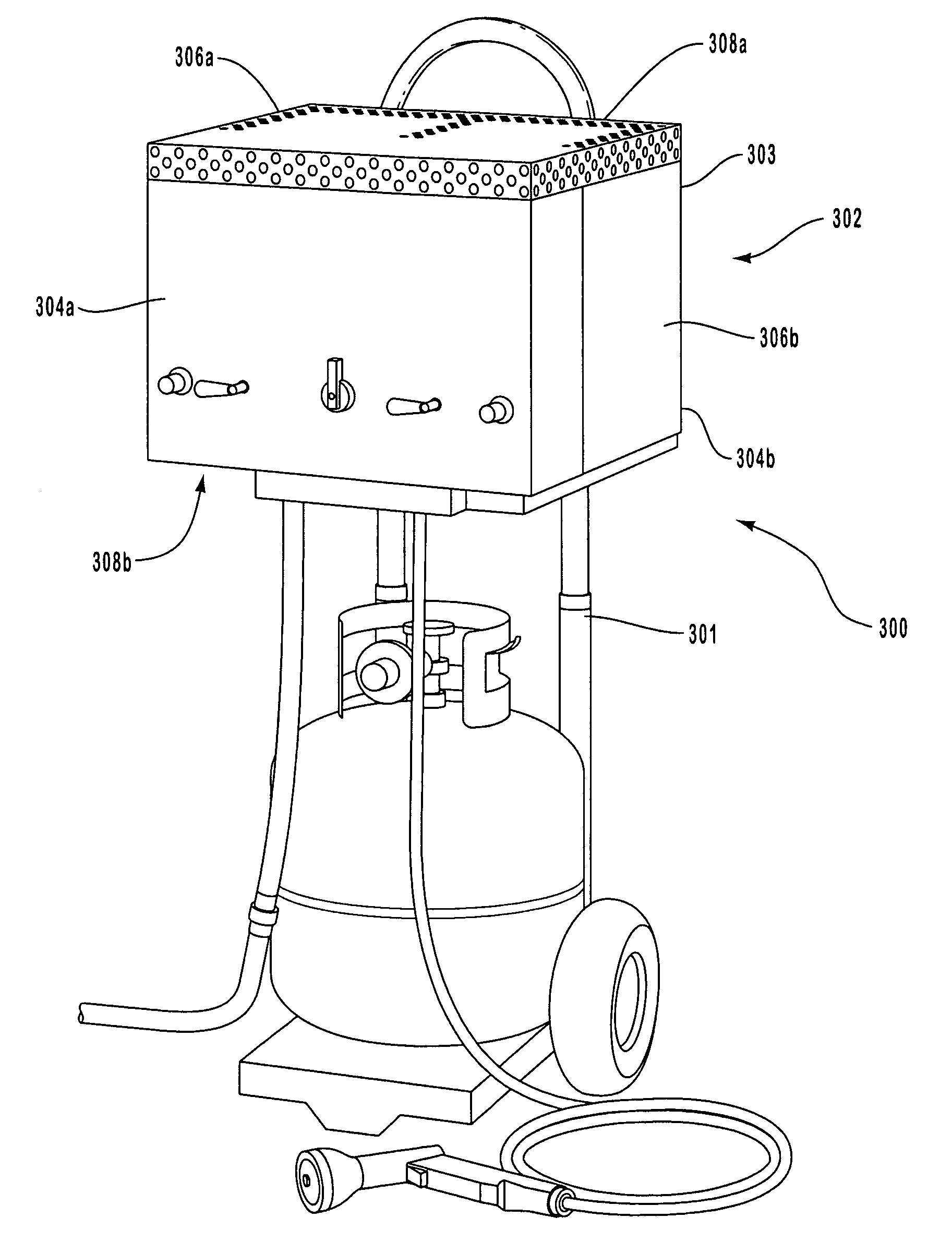

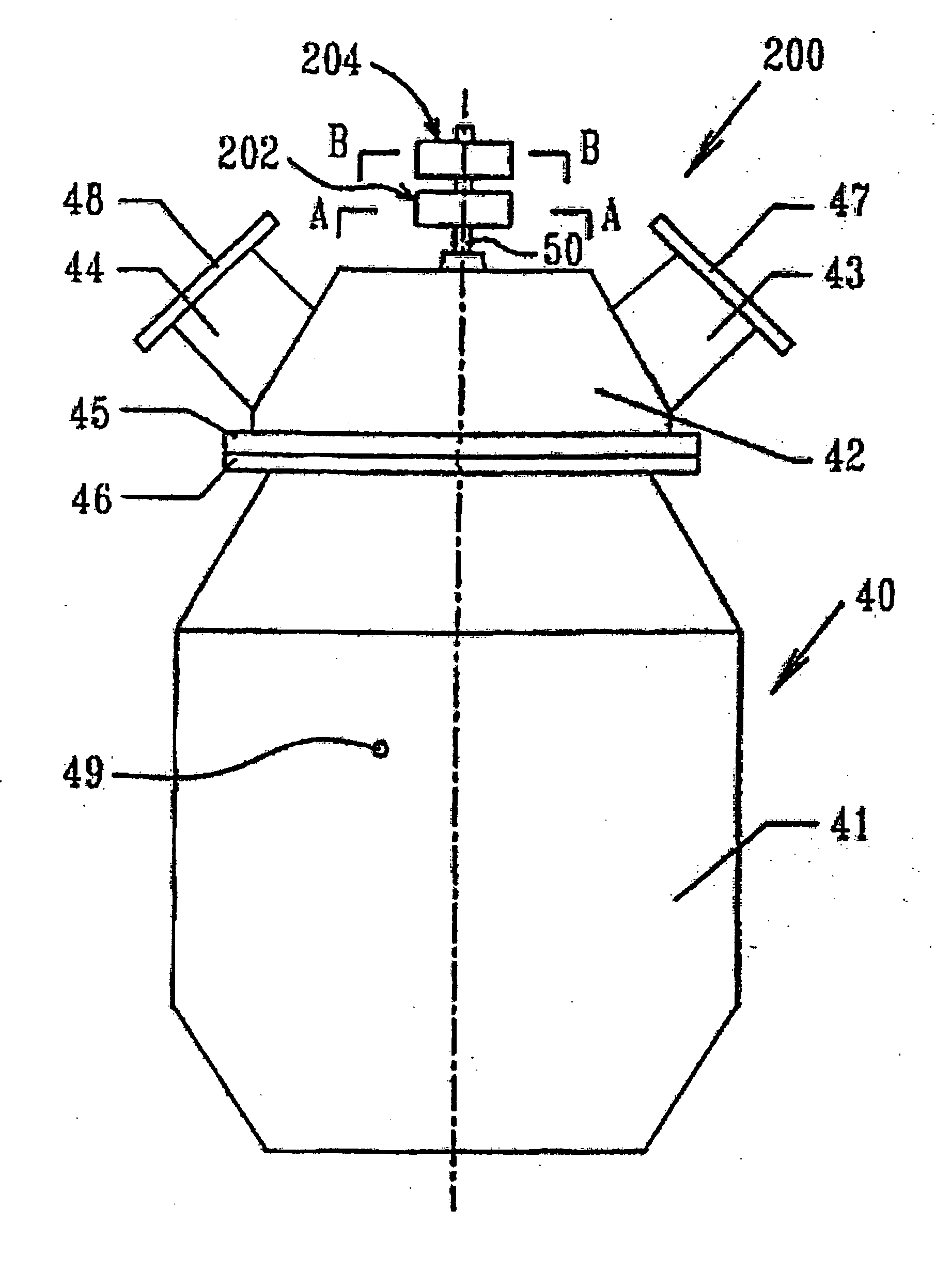

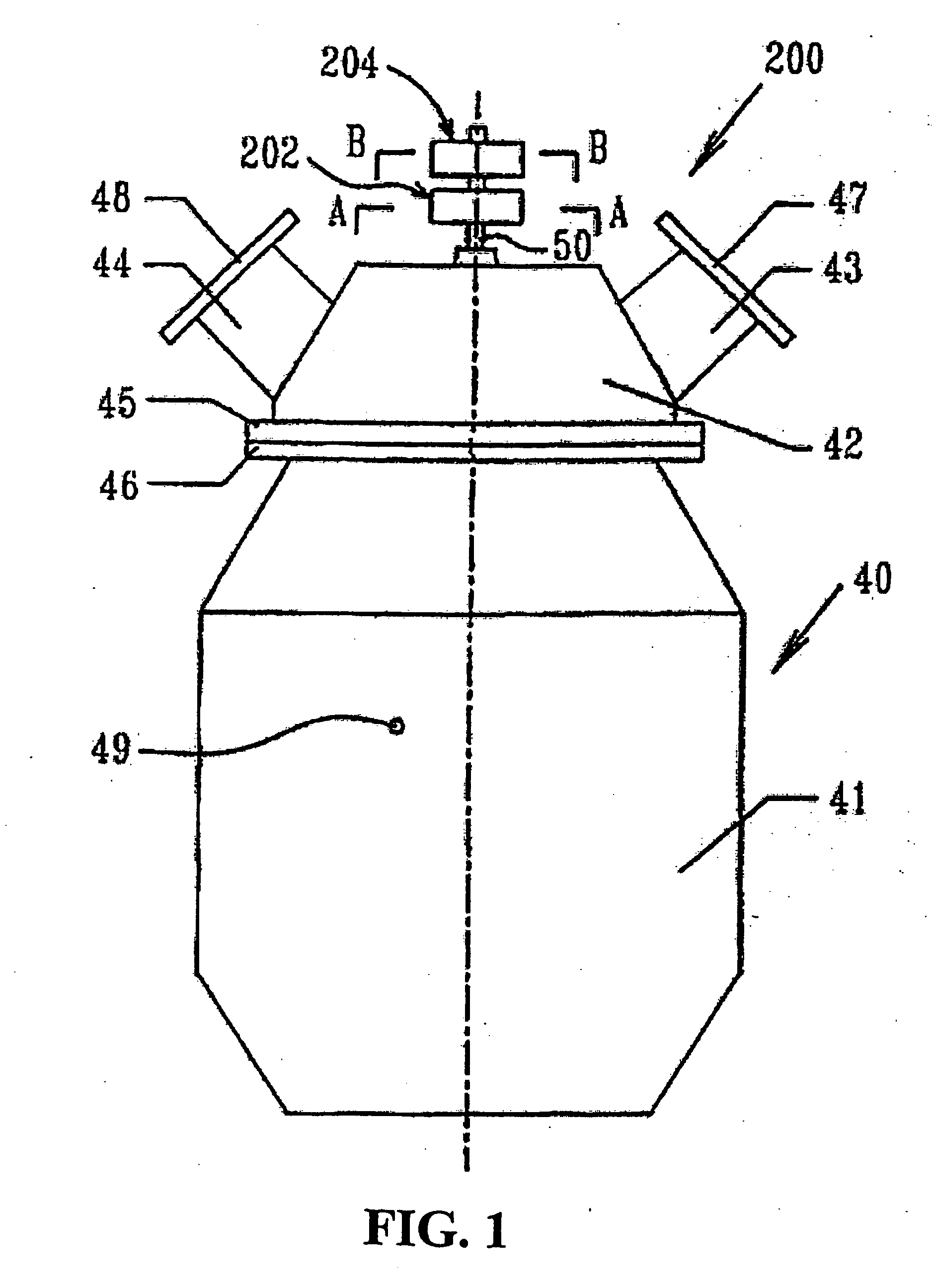

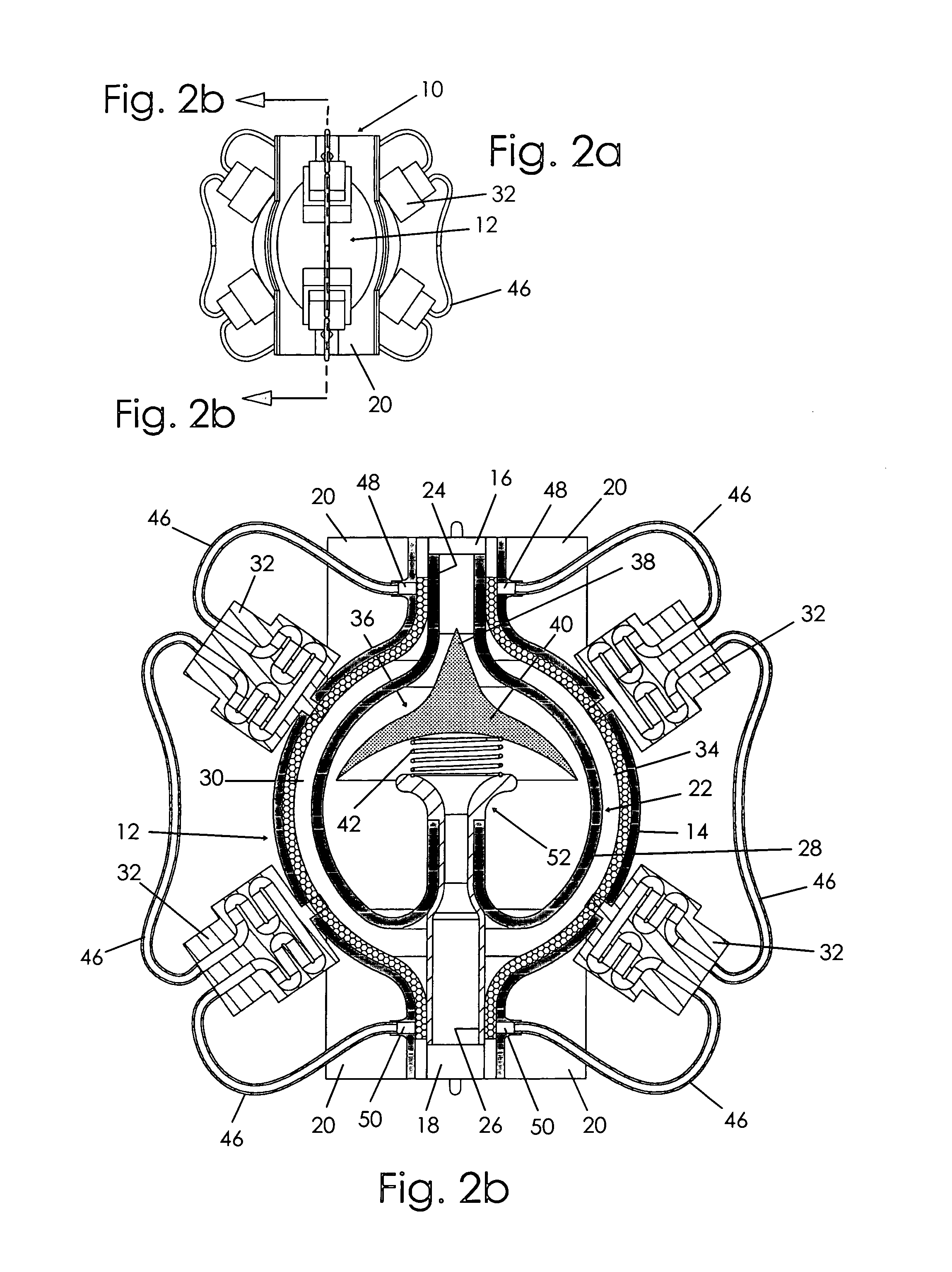

Microwave water heating system

InactiveUS20050061807A1Reduce heat lossImprove microwave heating efficiencyMicrowave heatingStream flowWater source

A microwave water heating system includes a metal casing having an outer wall defining an interior casing chamber. An inner housing is positioned within the casing and includes an outer wall displaced from the casing outer wall to form an insulating vacuum space. The inner housing includes an inlet port connected to an upstream water source and an outlet port connected to a downstream conduit. The casing and inner housing include generally spherical configurations. The inner housing is configured to induce a vortex of a water stream flowing between inlet and outlet ports. At least one magnetron is mounted to the casing for transmitting microwaves into the inner housing for heating the water stream at the vortex. A float valve in the inner housing allows the water stream to flow and be heated upon demand as the valve operates according to upstream and downstream pressure differentials.

Owner:COTTEN WILLIAM

Frost Protected Foundation System and Method of Using

InactiveUS20190048555A1Improve efficiencyEasy to stackProtective foundationForms/shuttering/falseworksFrostEngineering

A shallow foundation form and method of using are provided. The form is useful for pouring concrete slab foundations and results in a frost protected foundation with improved thermal characteristics. The form may include brackets to hold rebar at various locations. The brackets are designed to avoid the use of fastening devices, such as wire ties. When used to pour a concrete foundation, the form and brackets reduce construction material input costs, reduce the amount of skilled labor required, and reduce the amount of time required to pour a foundation.

Owner:JAHNKE DONALD JAMES

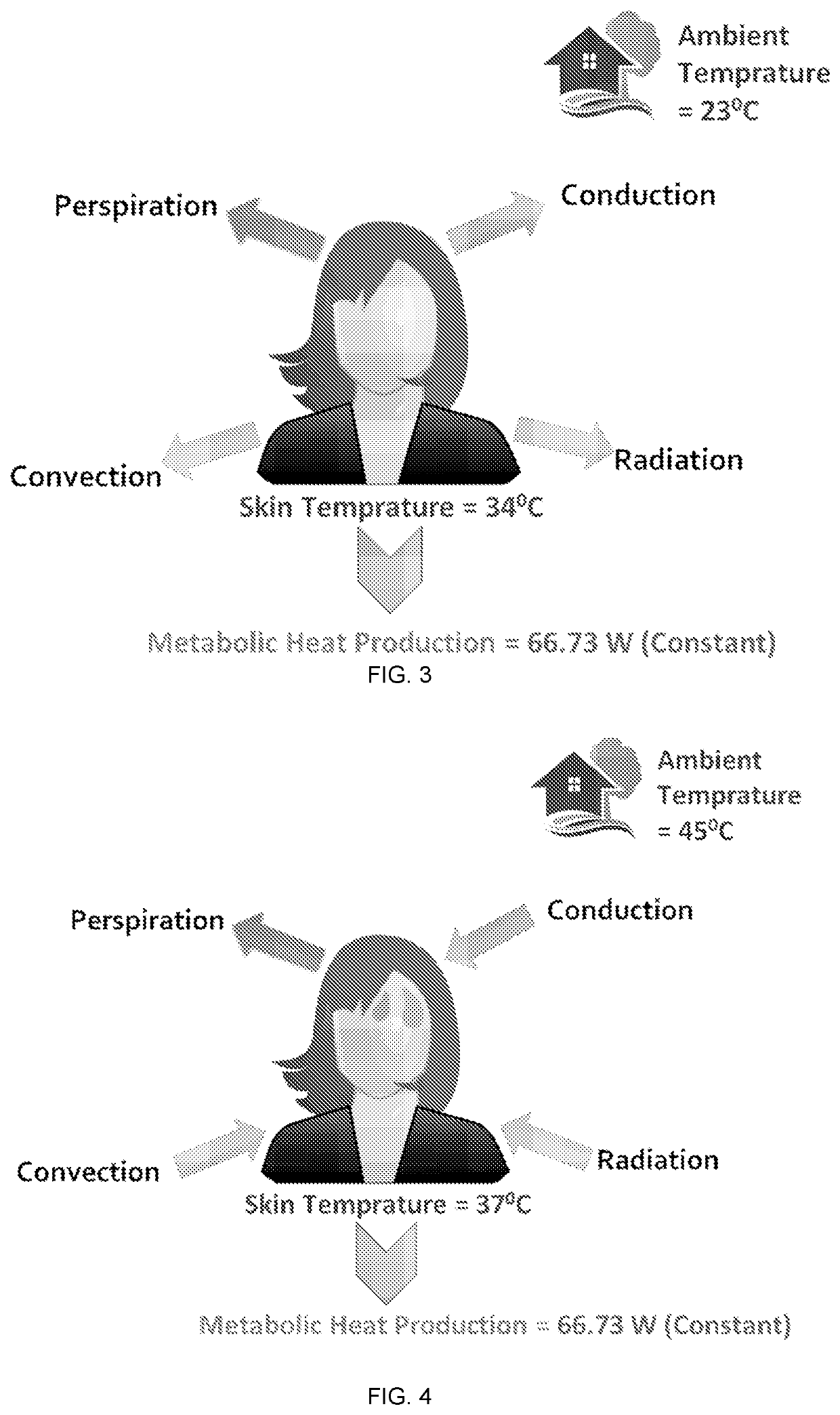

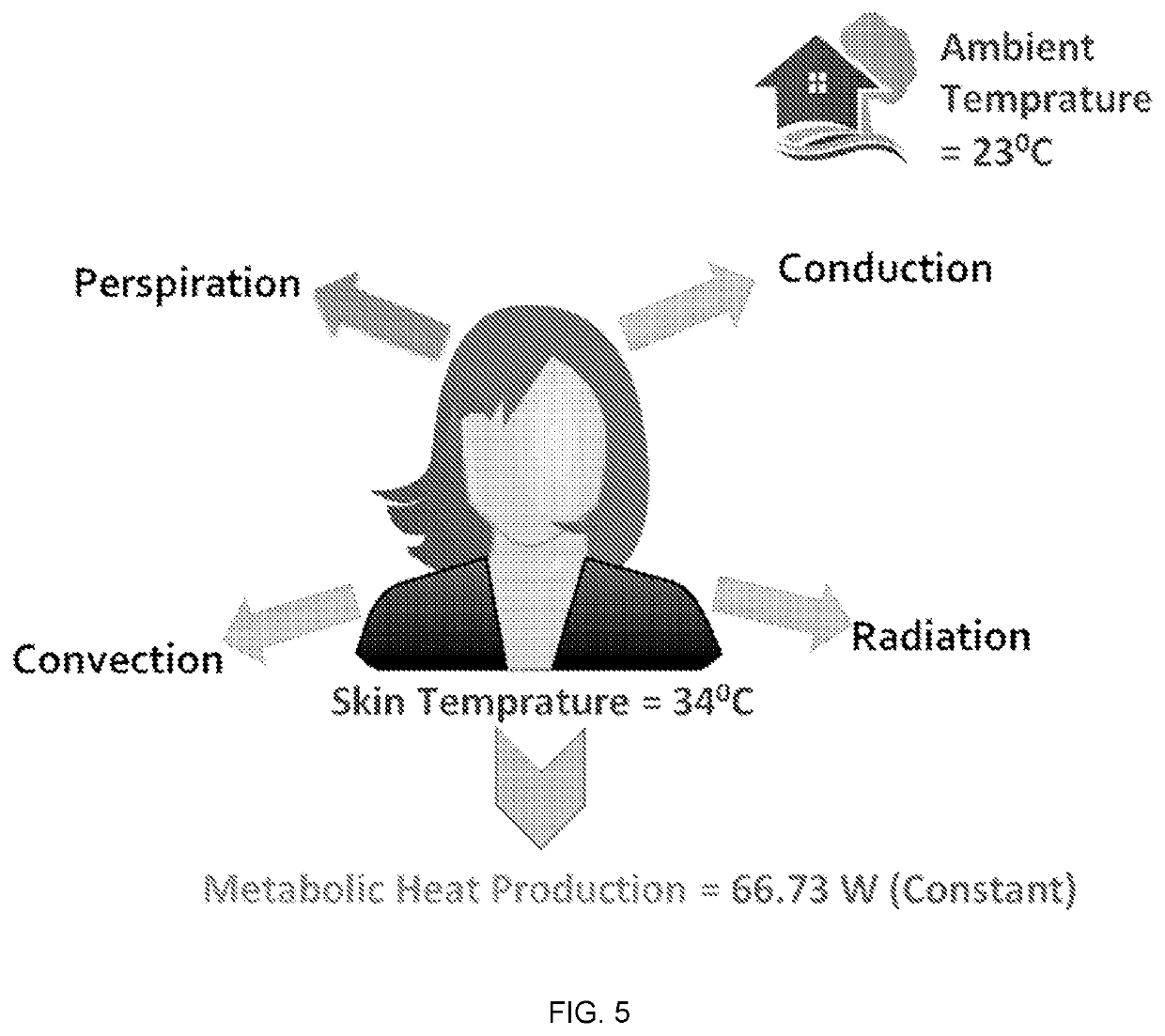

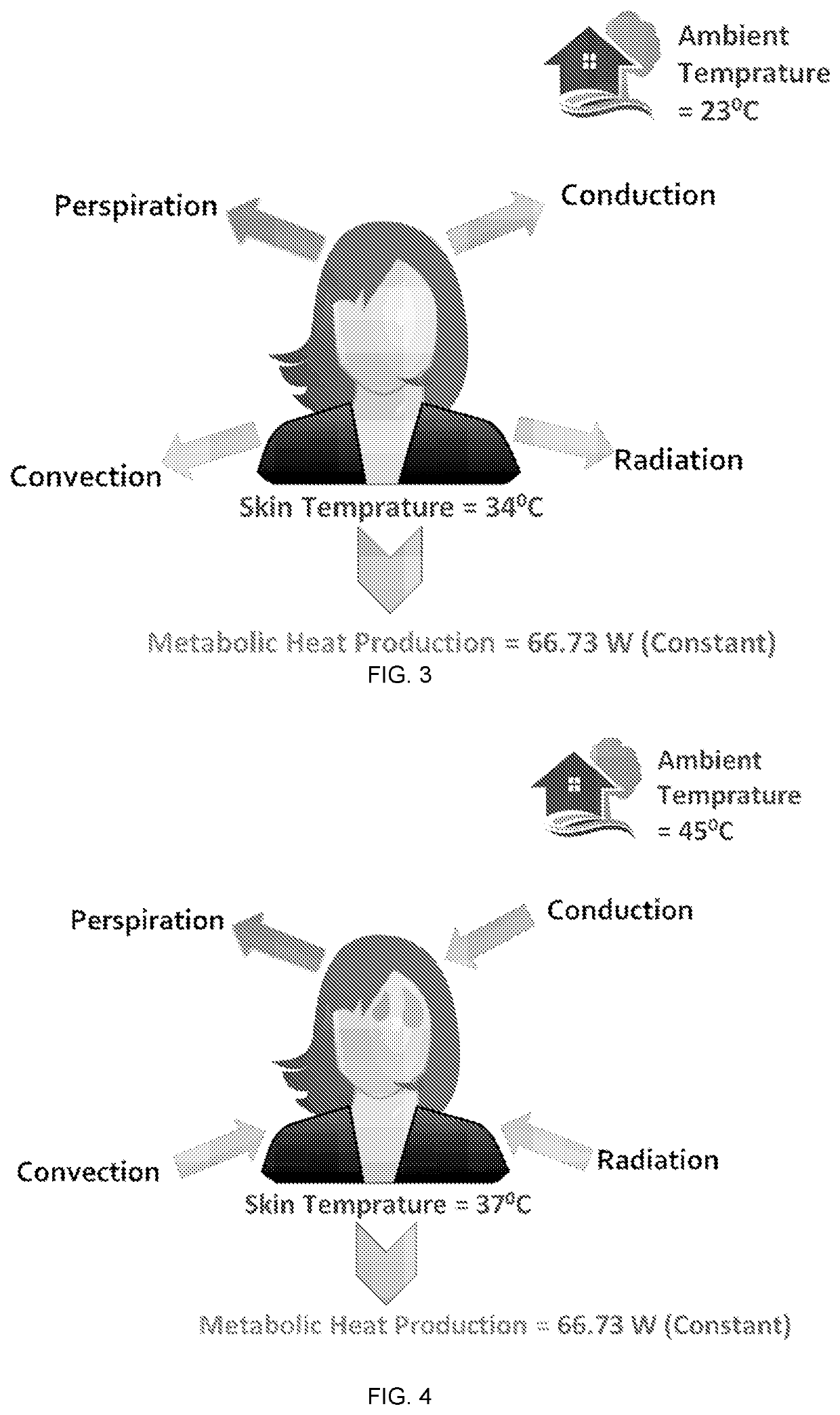

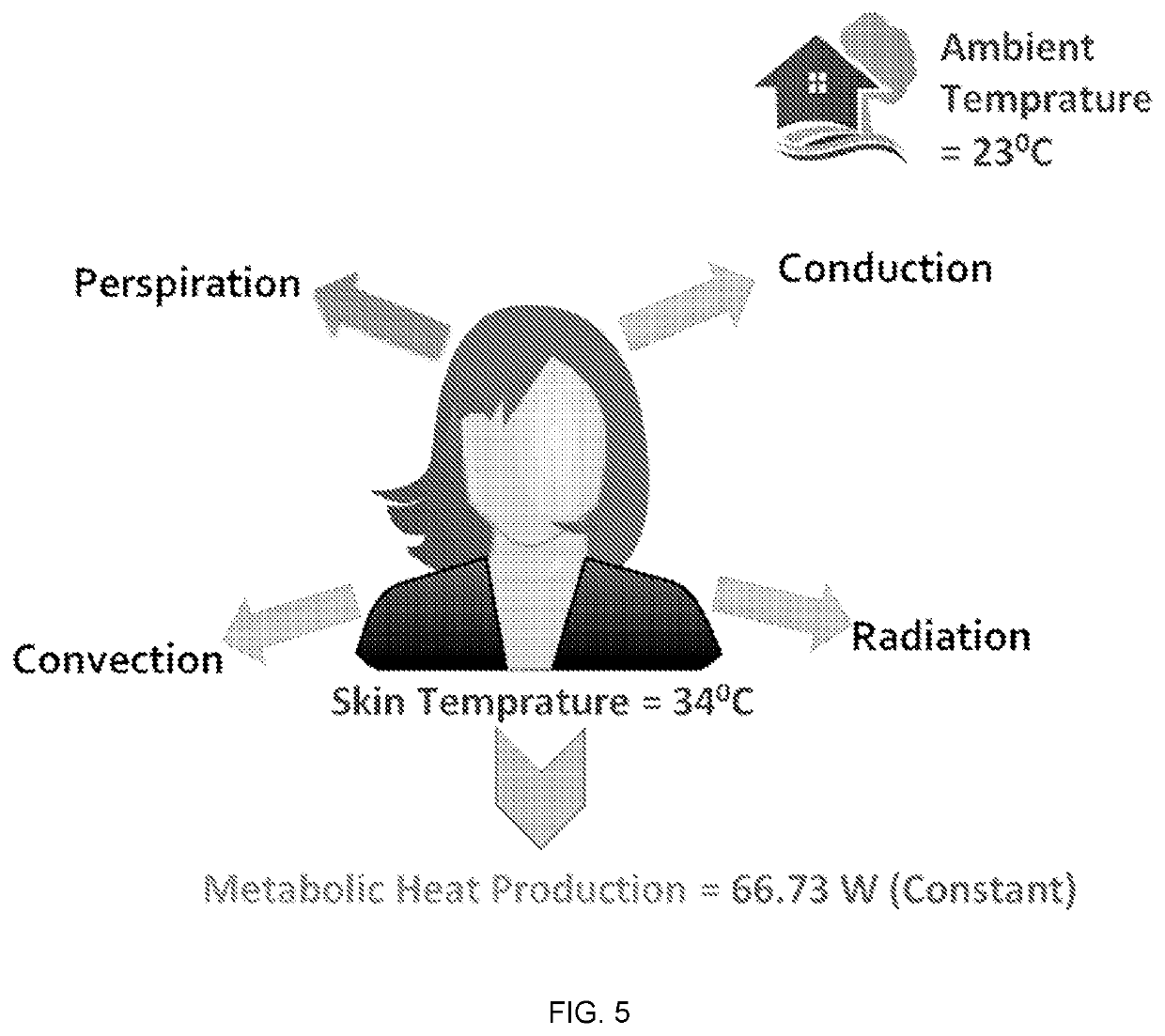

Garment for reducing hot flushes or relieving associated symptoms

ActiveUS20210251312A1Minimal heat lossGarment special featuresProtective garmentYarnPhysical medicine and rehabilitation

A wearable device, such as a garment or containing garment portions, for managing and / or reducing the symptoms of a hot flash in a subject. The device comprises: a first set of components, each comprising a fabric comprising a cooling yarn; a second set of components, each comprising a quick-dry wicking fabric; and a third set of components, each comprising a phase change material fabric, wherein the first set of components are adapted to cover at least a neckline region and a peripheral region that extends adjacently around the armpit and the clavicle of the subject; the second set of components are adapted to cover at least the abdominal muscles and the lumbar regions of the subject; and the third set of components are adapted to cover at least the mammary and the dorsum regions of the subject.

Owner:MAS INNOVATION

Microwave water heating system

A microwave water heating system includes a metal casing having an outer wall defining an interior casing chamber. An inner housing is positioned within the casing and includes an outer wall displaced from the casing outer wall to form an insulating vacuum space. The inner housing includes an inlet port connected to an upstream water source and an outlet port connected to a downstream conduit. The casing and inner housing include generally spherical configurations. The inner housing is configured to induce a vortex of a water stream flowing between inlet and outlet ports. At least one magnetron is mounted to the casing for transmitting microwaves into the inner housing for heating the water stream at the vortex. A float valve in the inner housing allows the water stream to flow and be heated upon demand as the valve operates according to upstream and downstream pressure differentials.

Owner:COTTEN WILLIAM

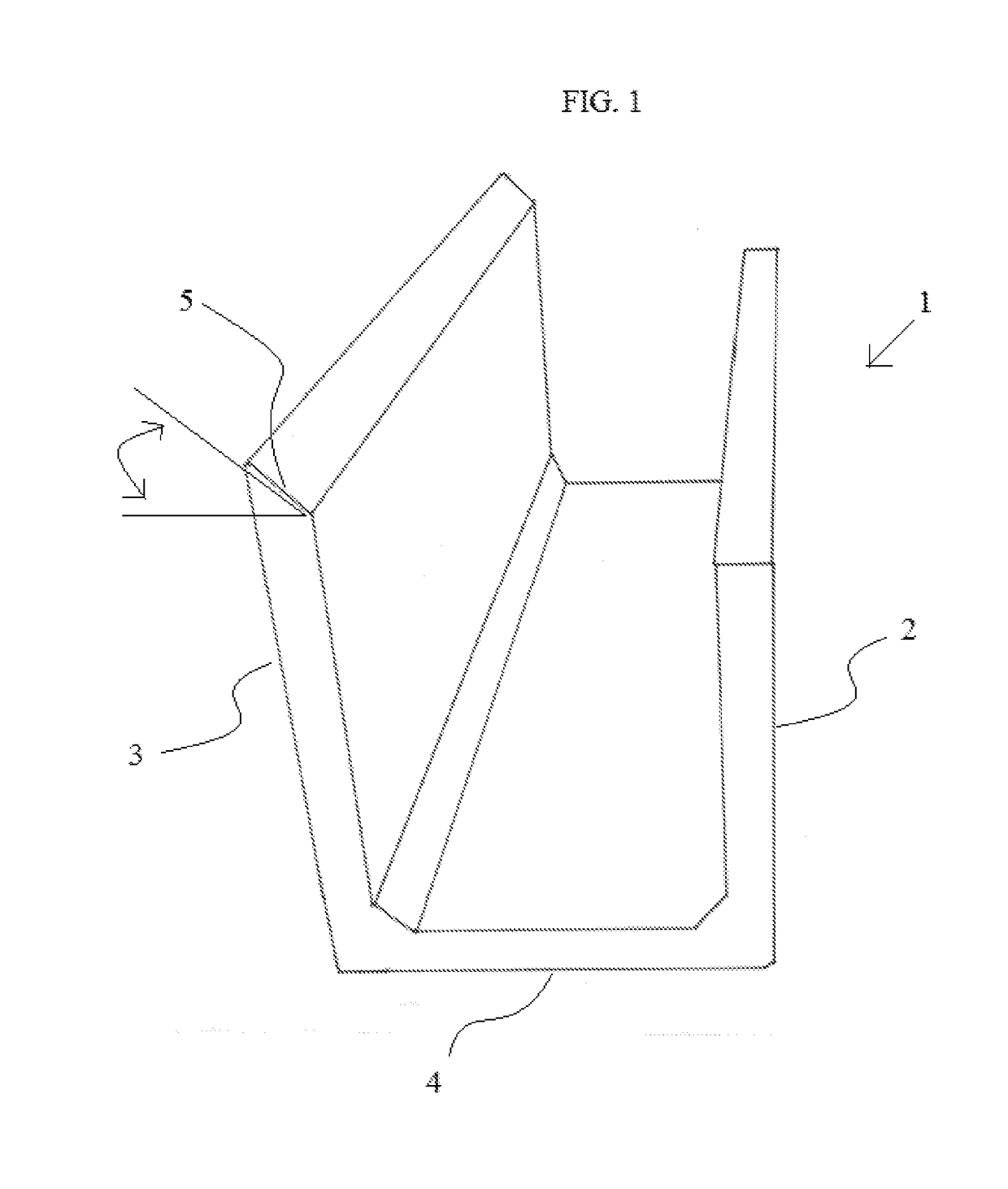

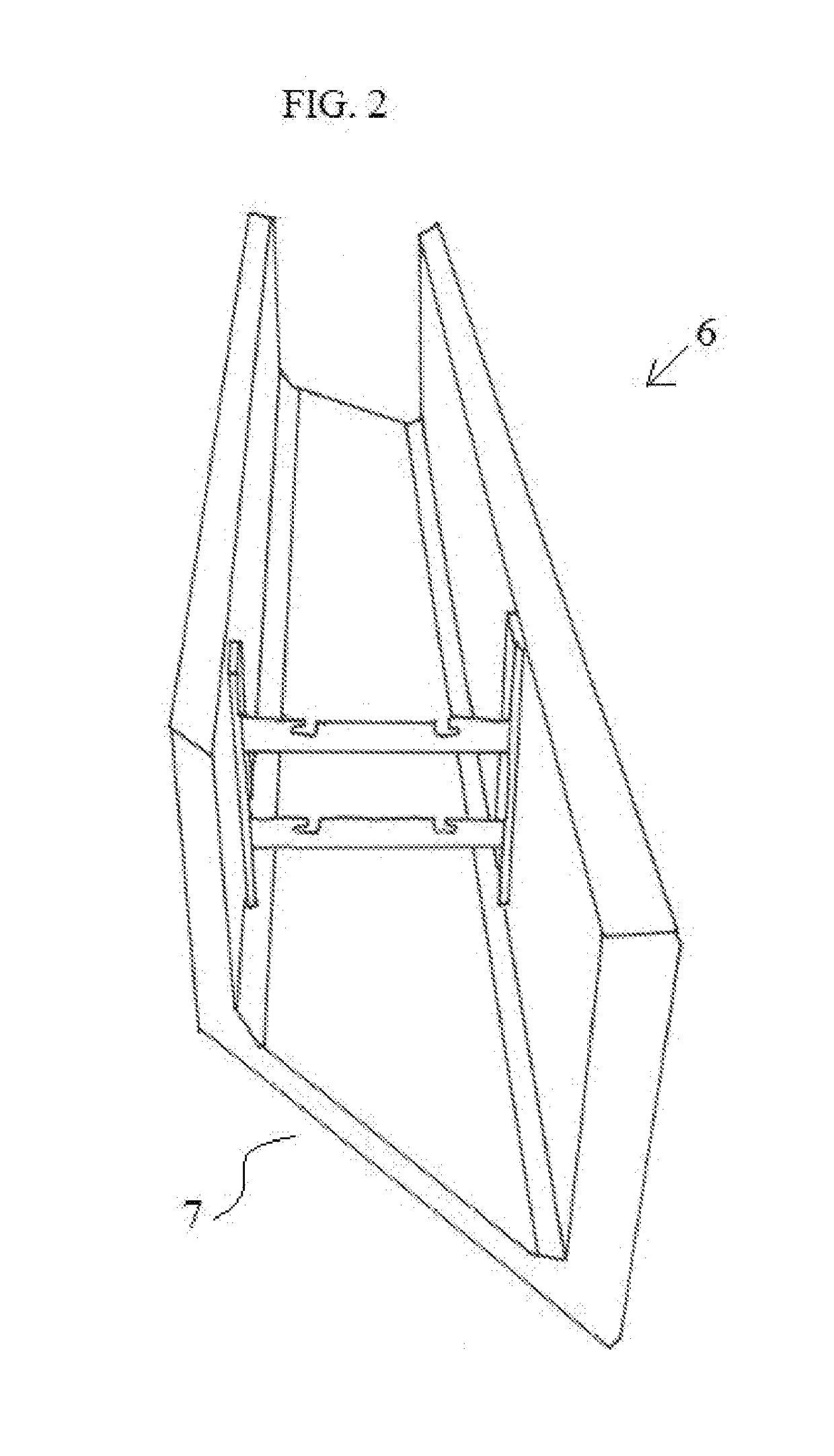

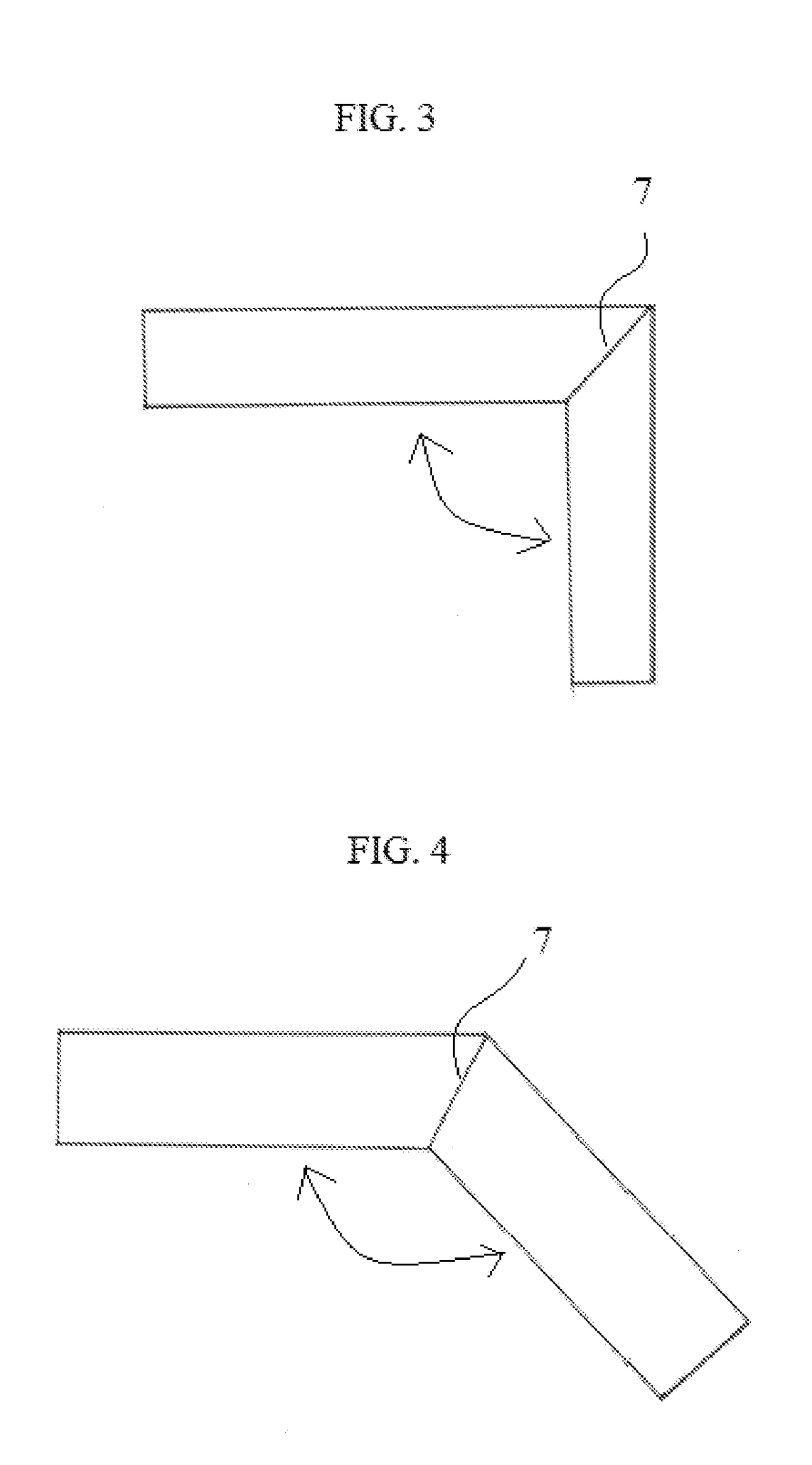

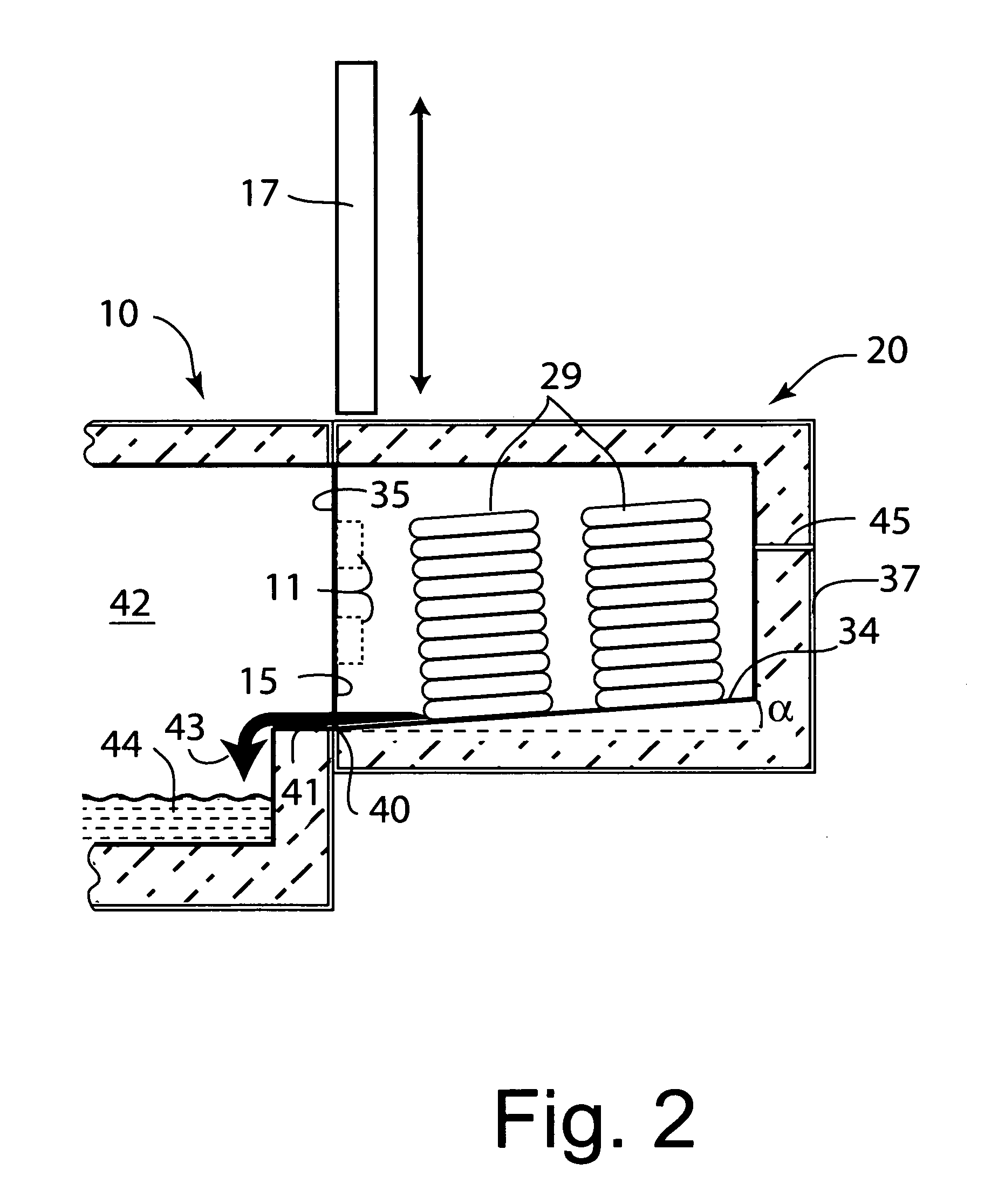

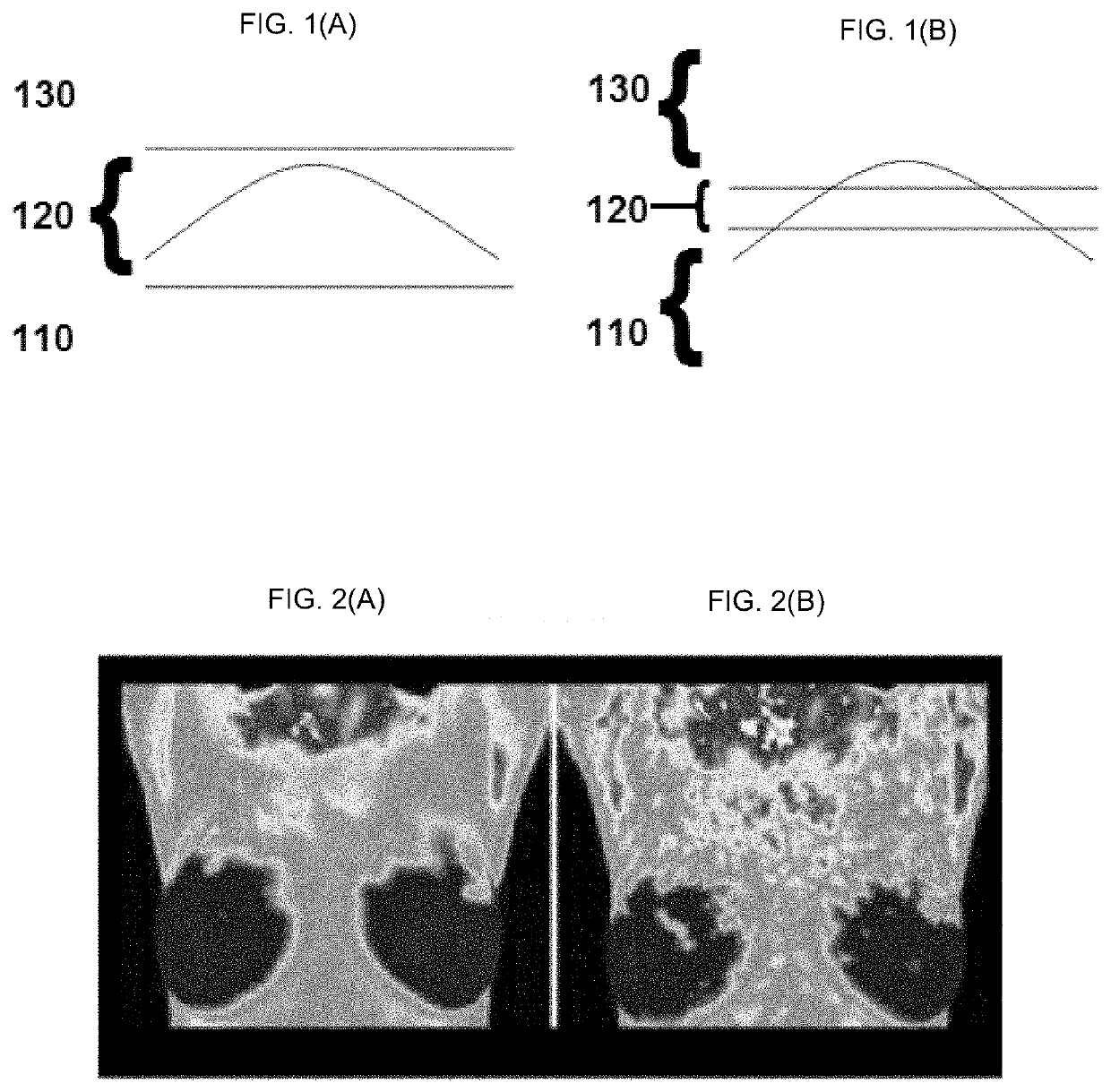

Movable sweat hearth for metal melting furnace

ActiveUS8414825B2Inhibit gas flowPrevent leakageCharge manipulationPreheating chargesHearthMolten metal

Exemplary embodiments provide a movable sweat hearth for use with a metal melting furnace having a wall provided with a metal-loading entrance. The sweat hearth includes a hearth body movable relative to the furnace into and out of contact with the wall of the furnace at the entrance. The body has exterior walls enclosing a hollow interior except at a furnace-engagable side wall of the hearth body provided with an opening communicating with the interior. The interior has a floor adapted to support a charge of scrap metal, and the opening is positioned relative to the floor to allow molten metal to drain from the interior through the opening. The floor is arranged at an angle to horizontal to slope in a downward direction towards the opening when the container is moved into sealing engagement with the wall of the furnace with the opening aligned with the furnace entrance. Other exemplary embodiments relate to a combination of a movable sweat hearth as described above and a metal melting furnace having a front wall provided with a furnace entrance.

Owner:NOVELIS INC

Movable sweat hearth for metal melting furnace

Exemplary embodiments provide a movable sweat hearth for use with a metal melting furnace having a wall provided with a metal-loading entrance. The sweat hearth includes a hearth body movable relative to the furnace into and out of contact with the wall of the furnace at the entrance. The body has exterior walls enclosing a hollow interior except at a furnace-engagable side wall of the hearth body provided with an opening communicating with the interior. The interior has a floor adapted to support a charge of scrap metal, and the opening is positioned relative to the floor to allow molten metal to drain from the interior through the opening. The floor is arranged at an angle to horizontal to slope in a downward direction towards the opening when the container is moved into sealing engagement with the wall of the furnace with the opening aligned with the furnace entrance. Other exemplary embodiments relate to a combination of a movable sweat hearth as described above and a metal melting furnace having a front wall provided with a furnace entrance.

Owner:NOVELIS INC

Garment for reducing hot flushes or relieving associated symptoms

ActiveUS11206877B2Minimal heat lossGarment special featuresProtective garmentYarnPhysical medicine and rehabilitation

A wearable device, such as a garment or containing garment portions, for managing and / or reducing the symptoms of a hot flash in a subject. The device comprises: a first set of components, each comprising a fabric comprising a cooling yarn; a second set of components, each comprising a quick-dry wicking fabric; and a third set of components, each comprising a phase change material fabric, wherein the first set of components are adapted to cover at least a neckline region and a peripheral region that extends adjacently around the armpit and the clavicle of the subject; the second set of components are adapted to cover at least the abdominal muscles and the lumbar regions of the subject; and the third set of components are adapted to cover at least the mammary and the dorsum regions of the subject.

Owner:MAS INNOVATION

Cooking Apparatus

PendingUS20220015573A1Maximize heat generationBreaking up air flowSolid fuel combustionRoasting apparatusEngineeringMechanical engineering

Owner:MISTRY BHARATKUMAR

Two-stage plasma process for converting waste into fuel gas and apparatus therefor

InactiveUS20150028258A1Limited amountImprove energy efficiencyGasifier electrodesHydrogenPlasma jetCyclone

A two-step gasification process and apparatus for the conversion of solid or liquid organic waste into clean fuel, suitable for use in a gas engine or a gas burner, is described. The waste is fed initially into a primary gasifier, which is a graphite arc furnace. Within the primary gasifier, the organic components of the waste are mixed with a predetermined amount of air, oxygen or steam, and converted into volatiles and soot. The volatiles consist mainly of carbon monoxide and hydrogen, and may include a variety of other hydrocarbons and some fly ash. The gas exiting the primary gasifier first passes through a hot cyclone, where some of the soot and most of the fly ash is collected and returned to the primary gasifier. The remaining soot along with the volatile organic compounds is further treated in a secondary gasifier where the soot and the volatile compounds mix with a high temperature plasma jet and a metered amount of air, oxygen or steam, and are converted into a synthesis gas consisting primarily of carbon monoxide and hydrogen. The synthesis gas is then quenched and cleaned to form a clean fuel gas suitable for use in a gas engine or a gas burner. This offers higher thermal efficiency than conventional technology and produces a cleaner fuel than other known alternatives.

Owner:PYROGENESIS CANADA INC

Fluid driven motor device

ActiveUS10941754B2Minimal heat lossEnergy efficiencyHydro energy generationEngine componentsElectric machineGear wheel

A fluid driven motor device is provided, which does not use a magnet or an armature coil, includes a motor casing chamber containing a fluid mixture, a shaft disposed within the chamber, and a plurality of ray guns arranged on the periphery of the chamber, and a unidirectional gear assembly. The shaft has a plurality of cell holders, onto which a corresponding plurality of membrane cells is attached. Each membrane cell holds a predetermined quantity of a liquid. The membrane cells expand continuously based on the firing of the subatomic rays by the plurality of ray guns causing the shaft to rotate. The device has several advantages such as being very energy and heat efficient, having lesser weight as compared to conventional electromagnetic coil based motors.

Owner:SAFAR SAMIR HANNA

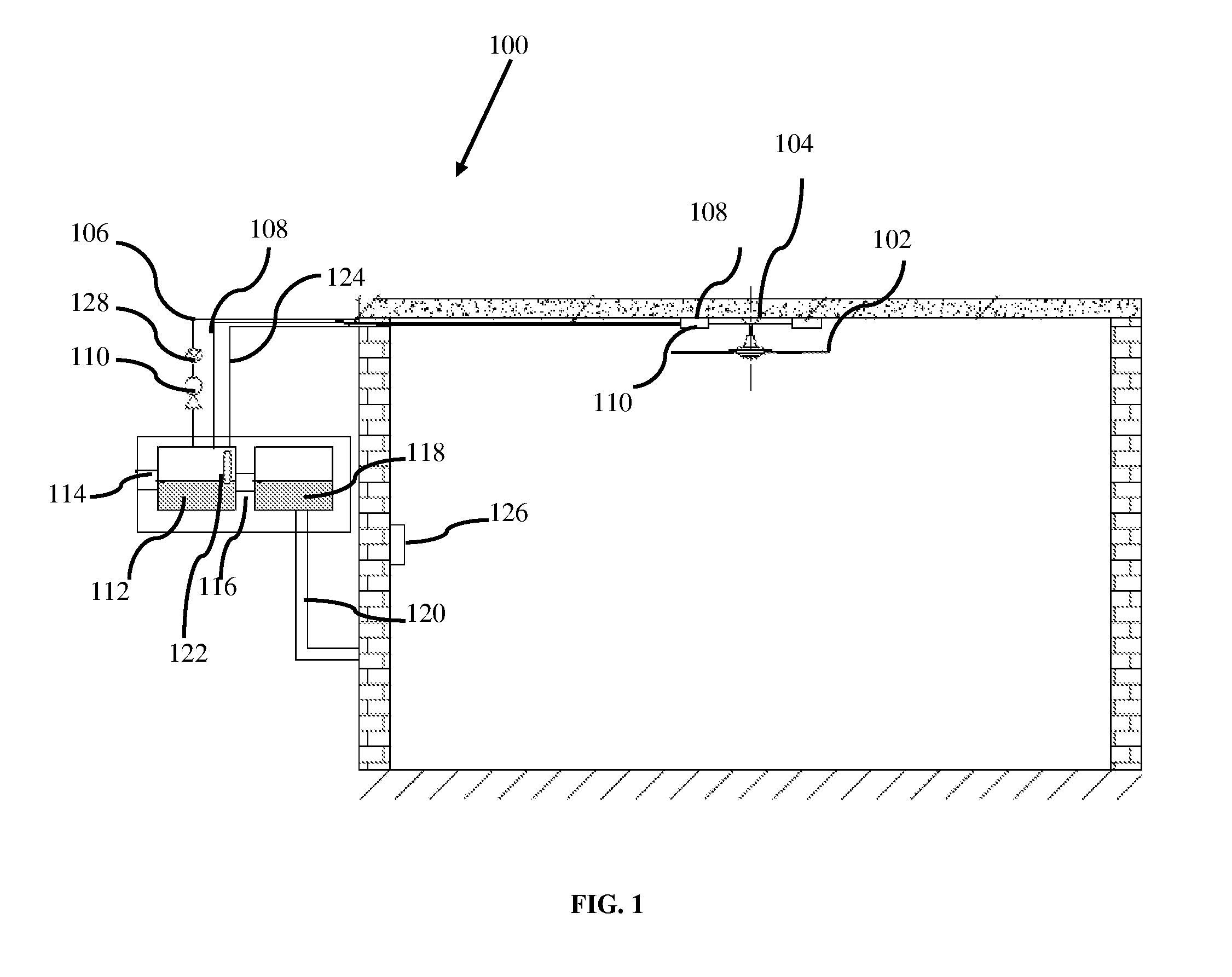

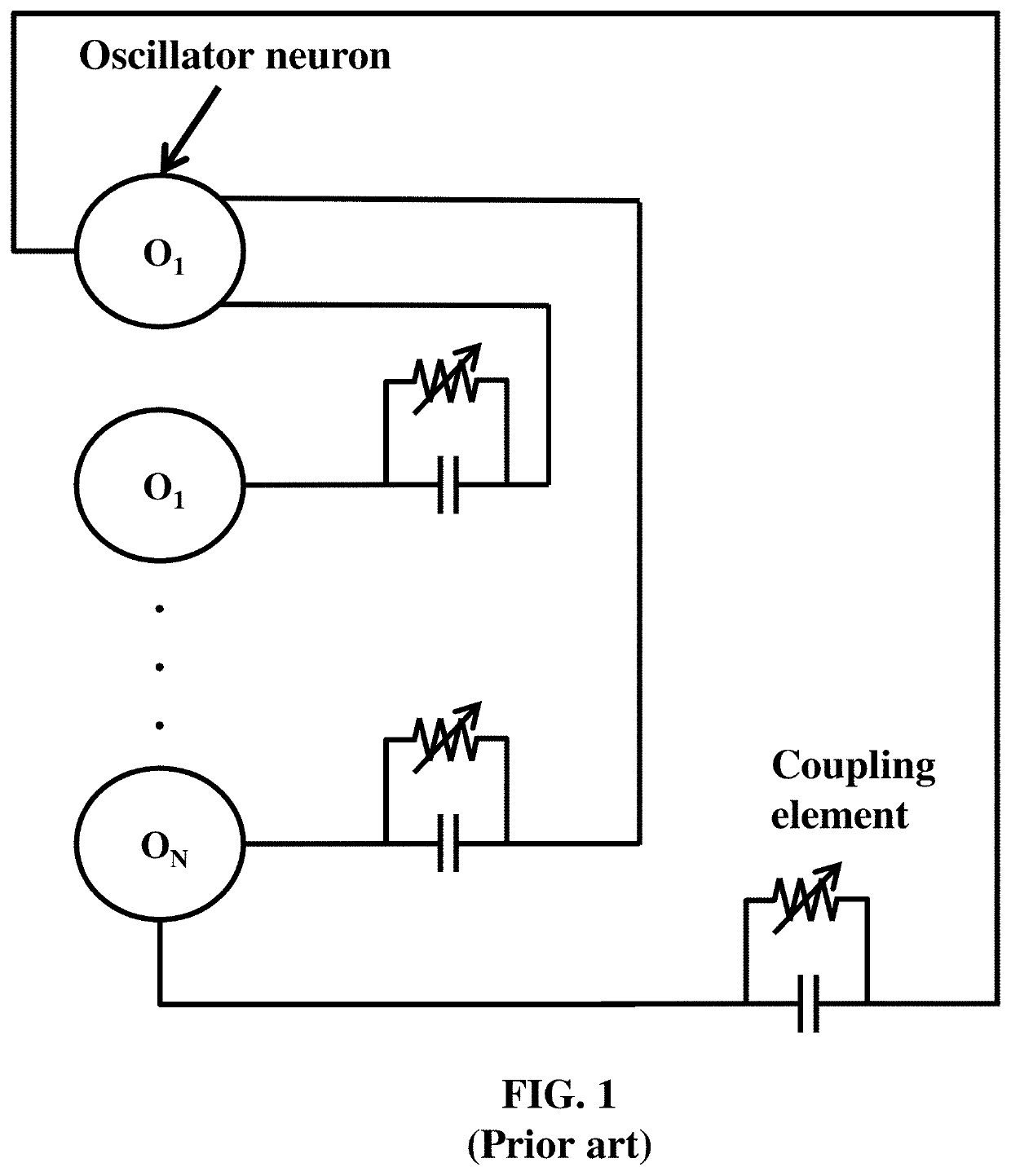

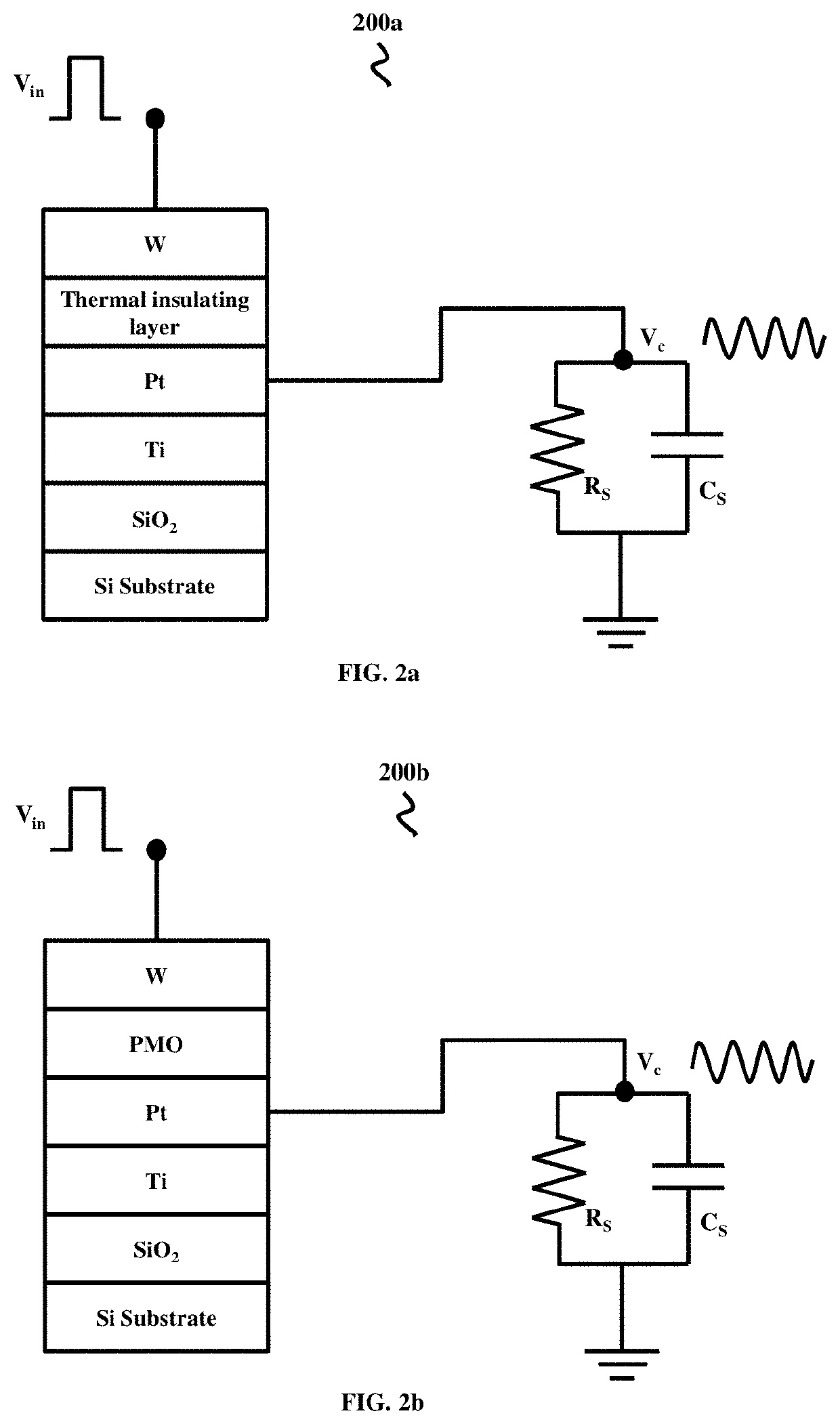

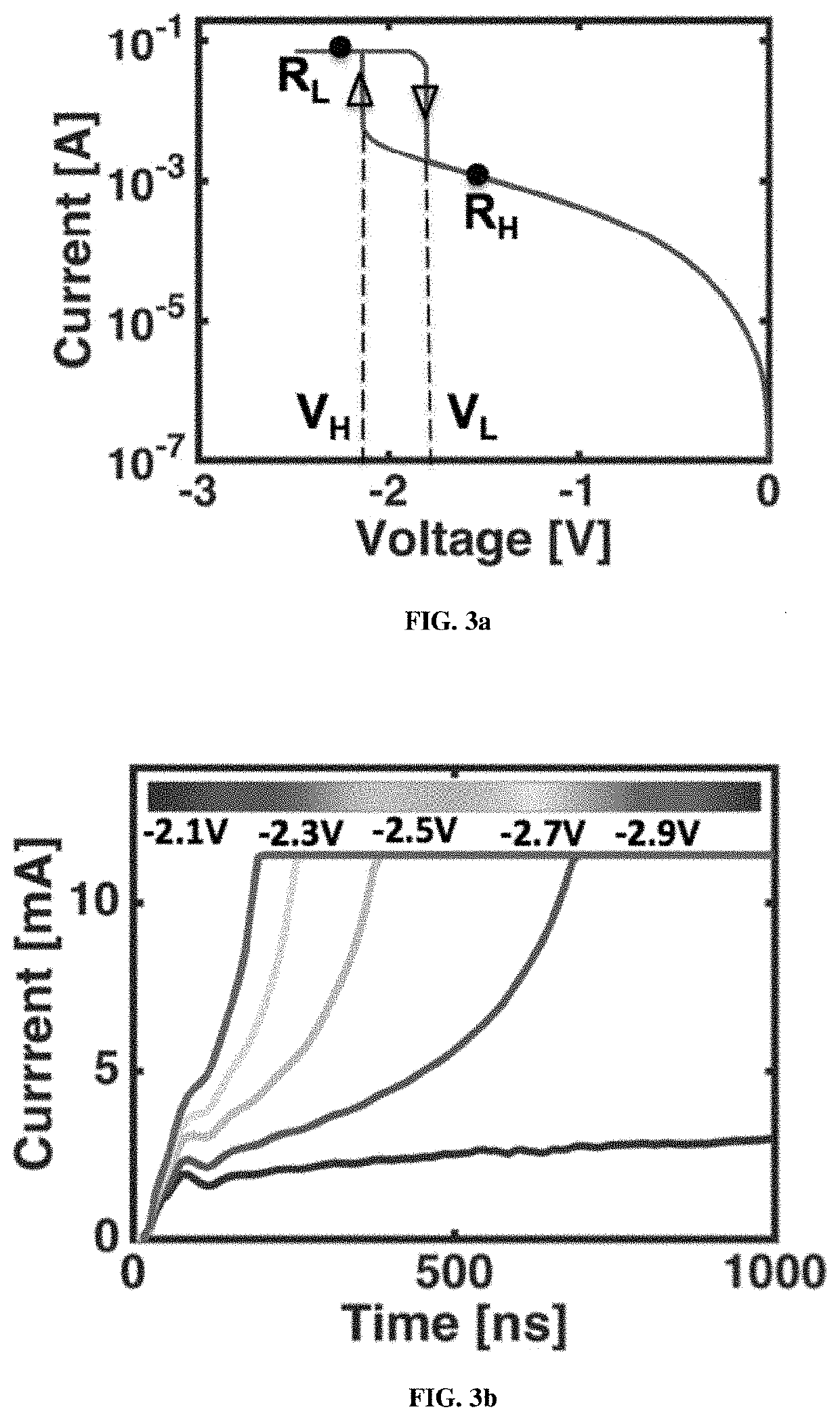

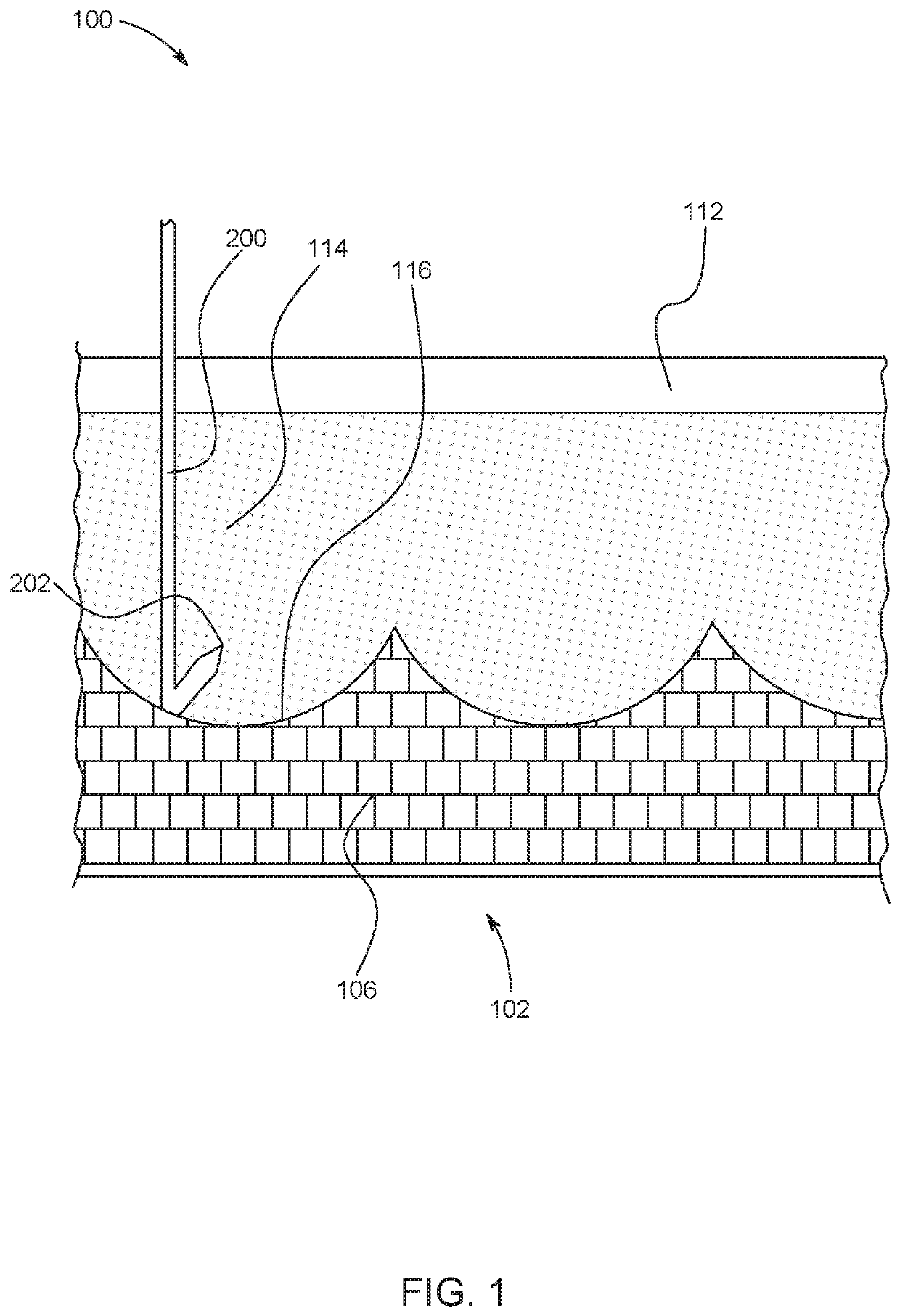

Method for fabricating neuron oscillator including thermal insulating device

ActiveUS20210242831A1Minimal heat lossNoise generationNeural architecturesConvertersElectrical resistance and conductance

Accordingly the embodiments herein provide a method for fabricating a neuron oscillator (200a). The neuron oscillator (200a) includes a thermal insulating device connected with a resistor and a capacitor in series to produce self-sustained oscillations, where the resistor and the capacitor are arranged in parallel manner. The neuron oscillator (200a) eliminates a requirement of an additional compensation circuitry for a consistent performance over a time under heating issues. Additionally, an ON / OFF ratio of the neuron oscillator (200a) improves to a broader resistor range. Further, a presence of tunable synaptic memristor functionality of the neuron oscillator (200a) provides a reduced fabrication complexity to a large scale ONN. An input voltage required for the neuron oscillator (200a) is low (2-3 V) which makes it suitable to use with existing circuitries without using any additional converters. Additionally, an amplitude of the oscillations is a significant fraction of an applied bias which eliminates a need for an amplification.

Owner:INDIAN INSTITUTE OF TECHNOLOGY BOMBAY

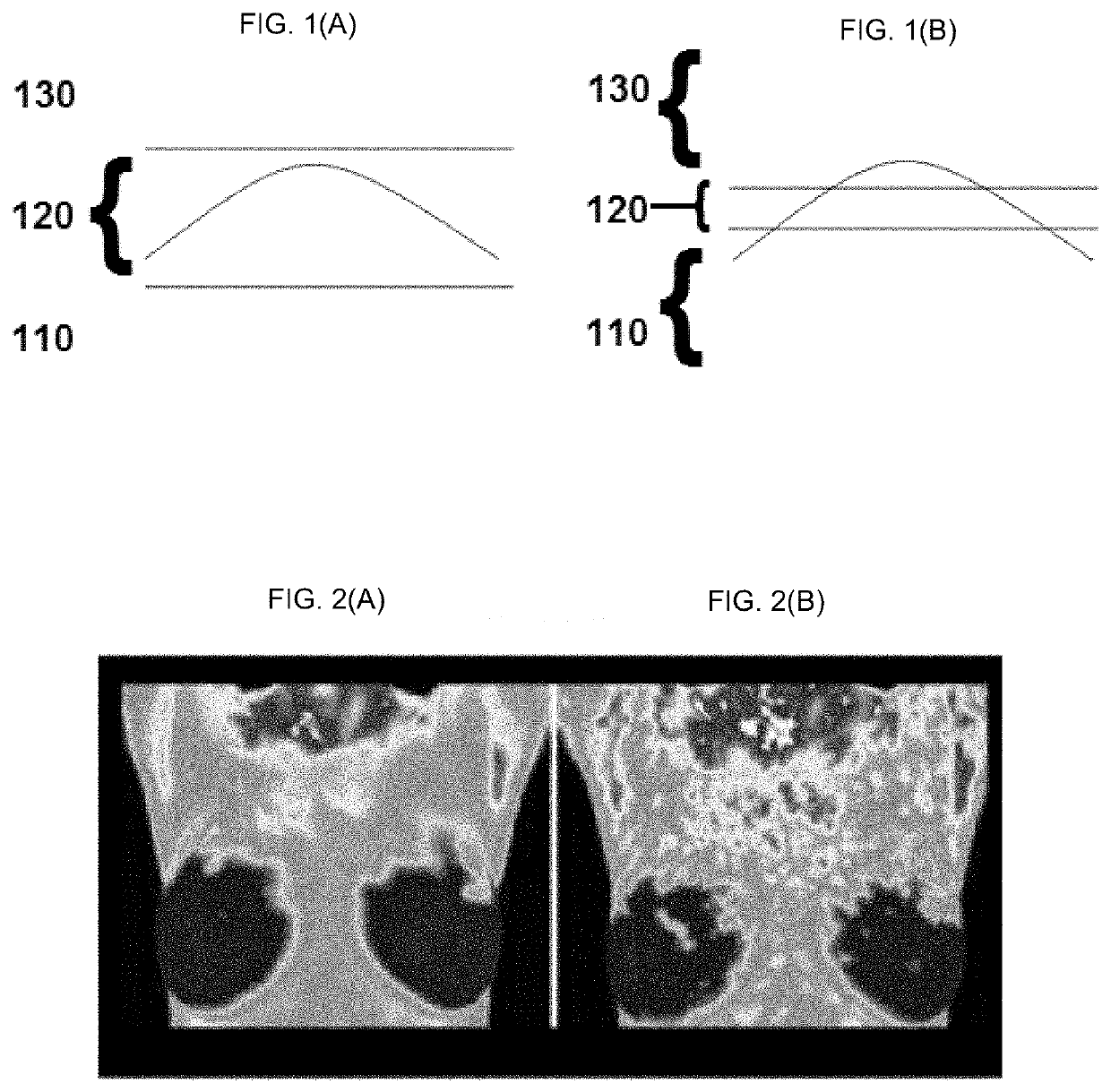

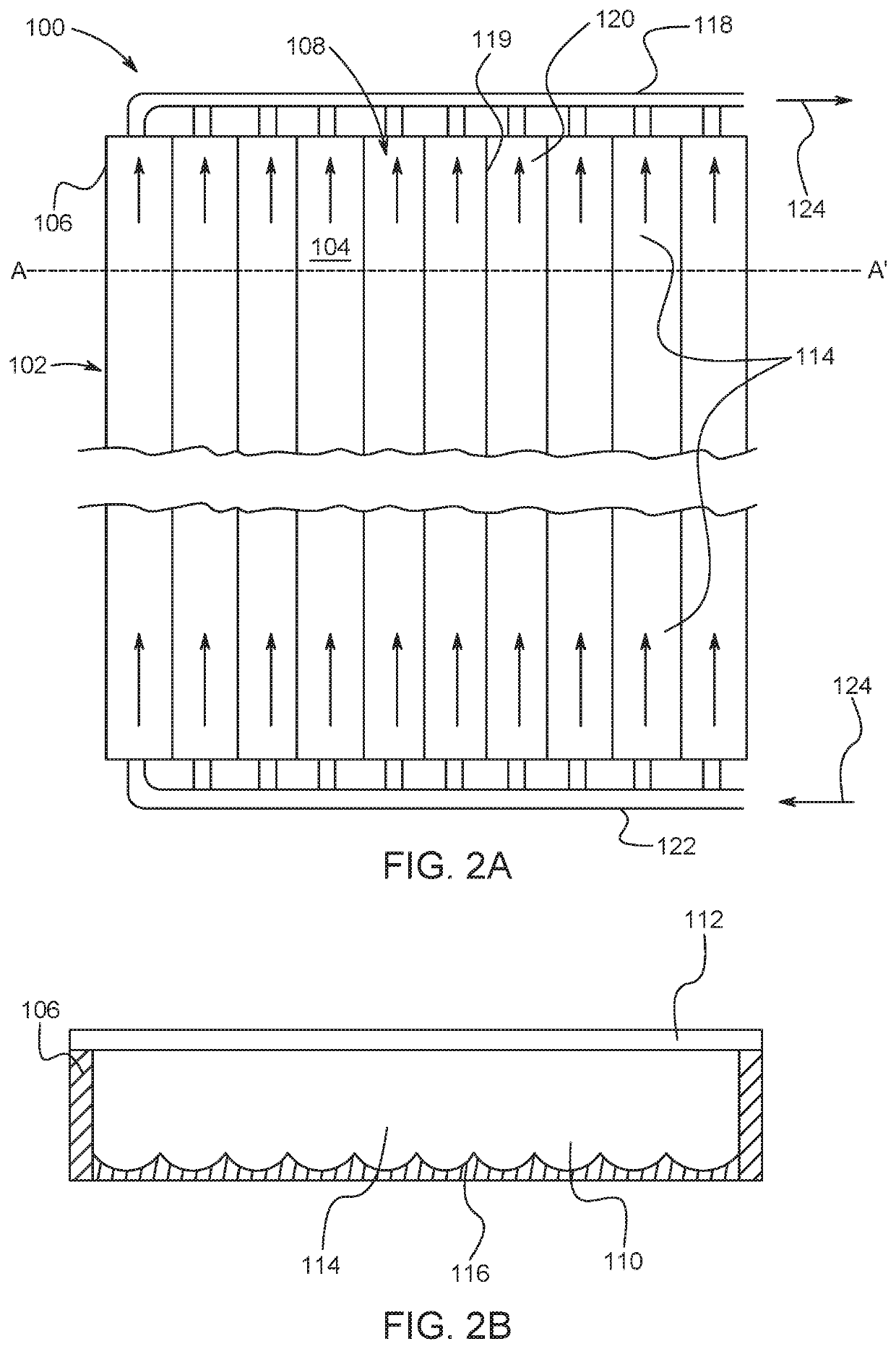

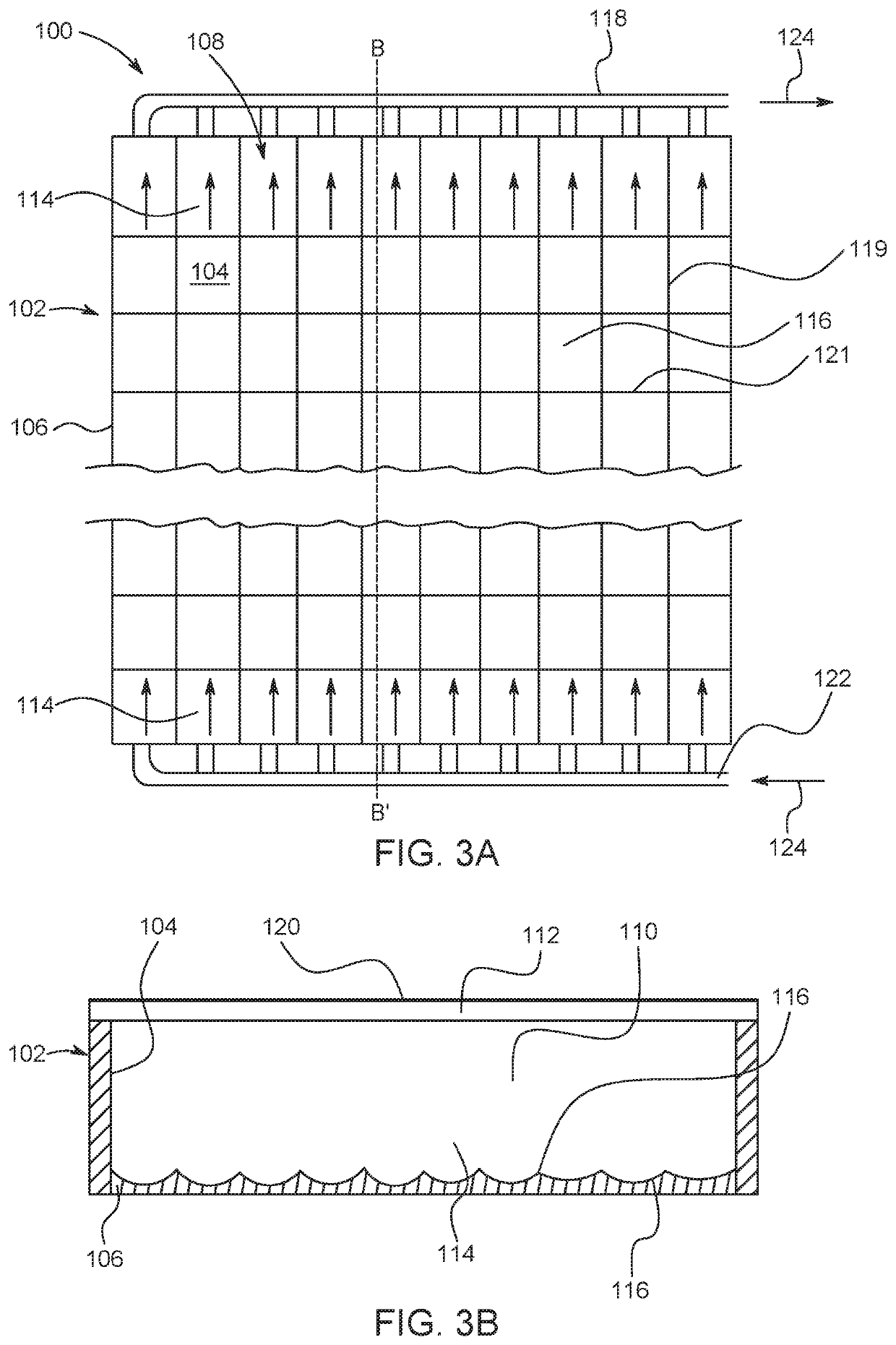

Solar thermal collecting system

ActiveUS10823459B1Reduce heat lossMinimal heat lossSolar heating energySolar heat storageEngineeringAtmospheric sciences

A solar thermal collecting system captures solar radiation into a vessel containing an opaque or partially opaque fluid medium. The solar radiation is reflected and intensified using interior parabolic reflectors inside the vessel to generate hot zones throughout the fluid medium; and the generated heat in the fluid medium is transported to a separate system designed to utilize the heat with minimal heat loss. The system of the present invention comprises a vessel that contains the fluid medium. An at least partially transparent or translucent lid enables passage of solar radiation into the vessel. The lid may have integrated solar panels to generate power from solar radiation. Multiple reflective parabolic reflectors integrated in the vessel focus solar radiation throughout the fluid medium to create hot zones that intensifies heating the fluid medium. The vessel is resilient to withstand variances in pressure and temperature. After fluid medium absorbs heat, an insulated conduit transports the heated fluid medium for storage or other beneficial uses such as conversion to power with minimal heat loss.

Owner:FREEMAN WALTER B

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com