Frost Protected Foundation System and Method of Using

a foundation system and frost protection technology, applied in the field of frost protection foundations, can solve the problems of increased winter heating costs for homeowners, increased heat loss, and prone to freezing of soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

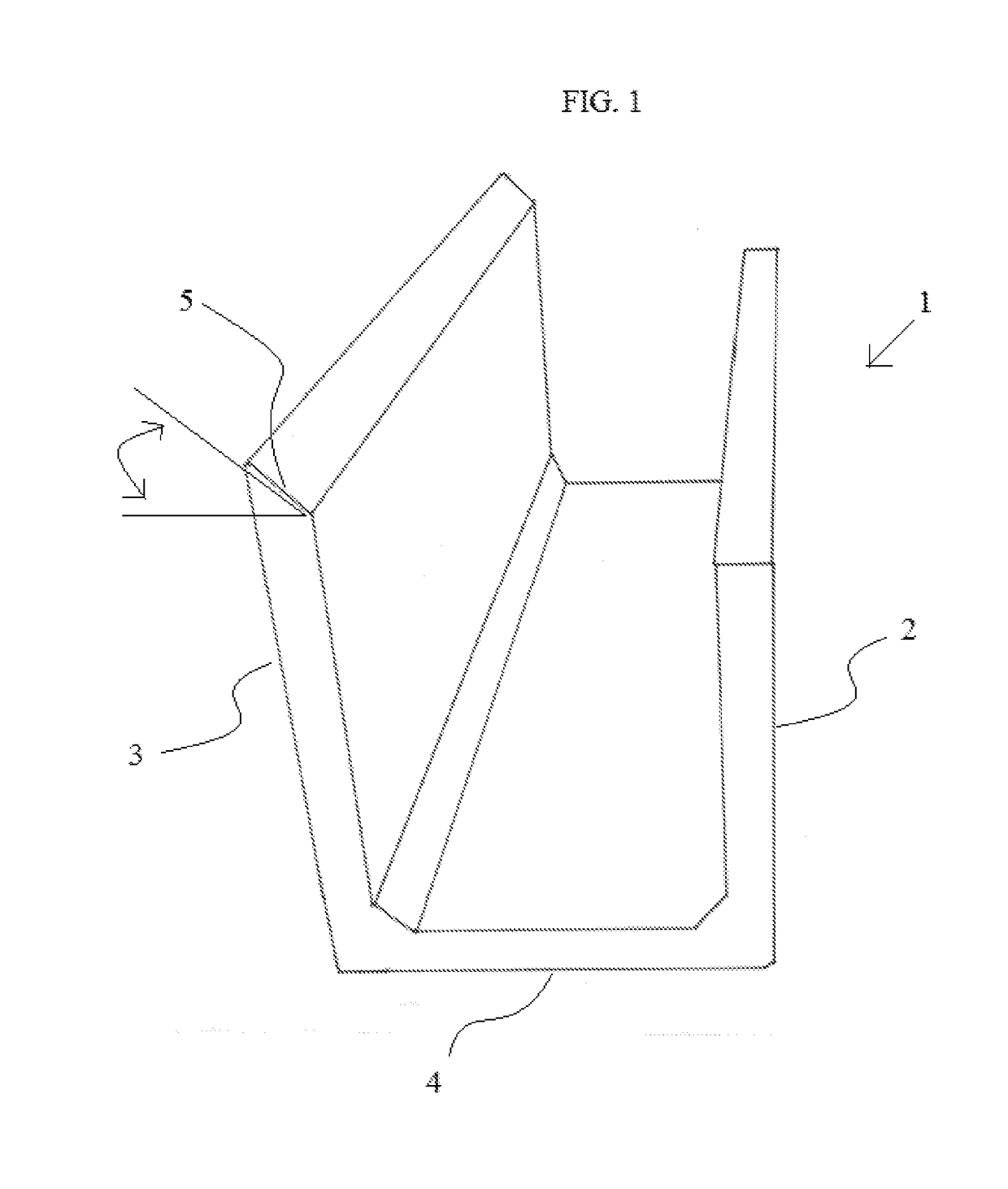

[0036]A slab on grade foundation was poured using the form 1 and bracket assembly 8. FIG. 11 shows the ground 35 at the job site was first leveled with earth moving equipment to be approximately the shape of the building that would subsequently be constructed on the foundation. Earth moving equipment may include a payloader, a skid steer loader, or the like. The perimeter of the leveled ground was excavated to create a trench that was slightly larger than the foam form 1. The trench was approximately four (4) feet wide and one and a half (1.5) feet deep. Two to four inches of pea gravel 36 was placed in the bottom of the trench to provide a level surface for placing the forms 1 on top of. Alternatively, one to twelve inches of pea gravel may be used. Using pea gravel is advantageous in that it provides a level surface for the form 1 to rest on and requires less labor, compared to leveling the dirt under the forms. The area between the vertical inner wall 2 and the ground 35 was fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com