Patents

Literature

42results about How to "Requires more" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

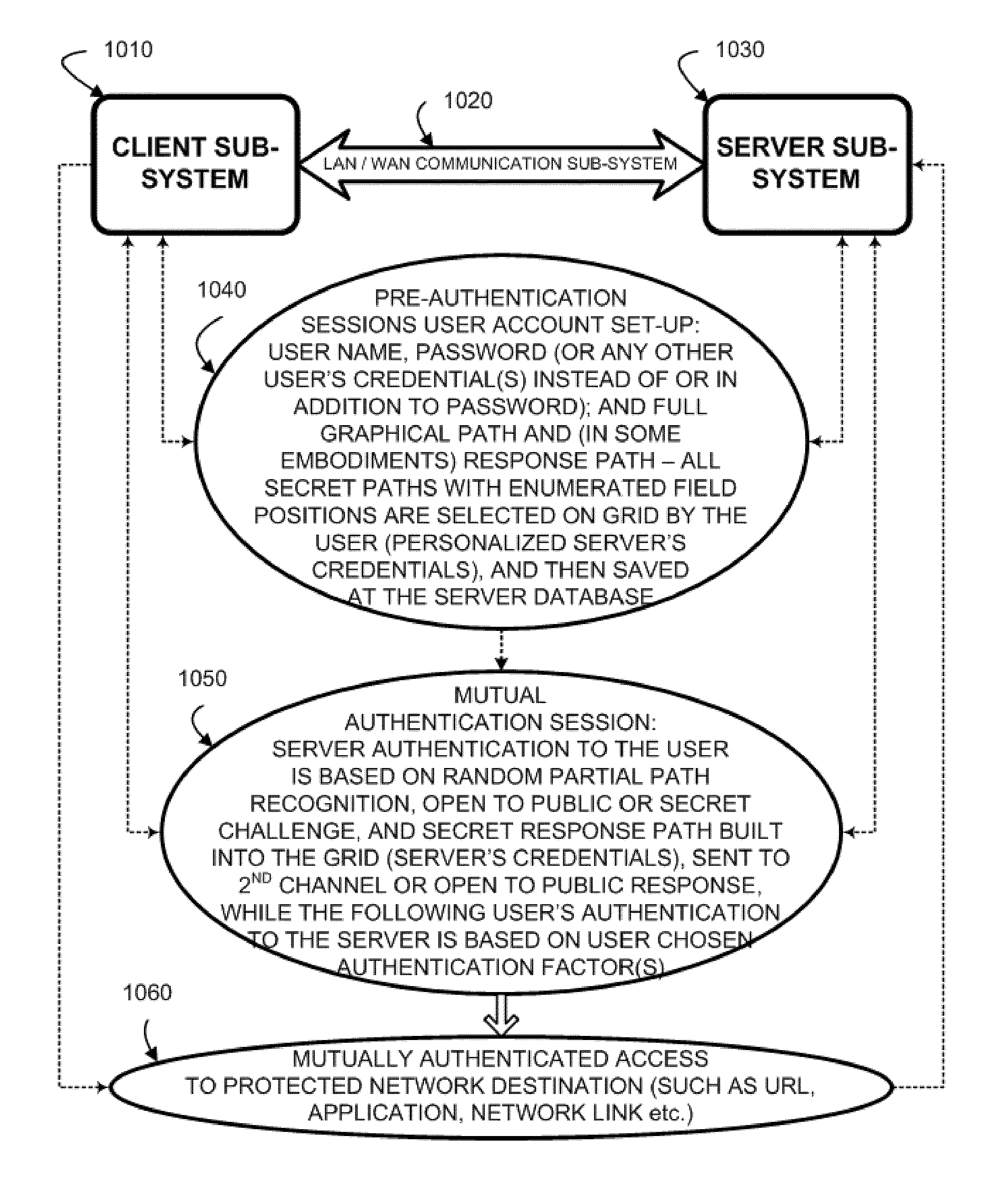

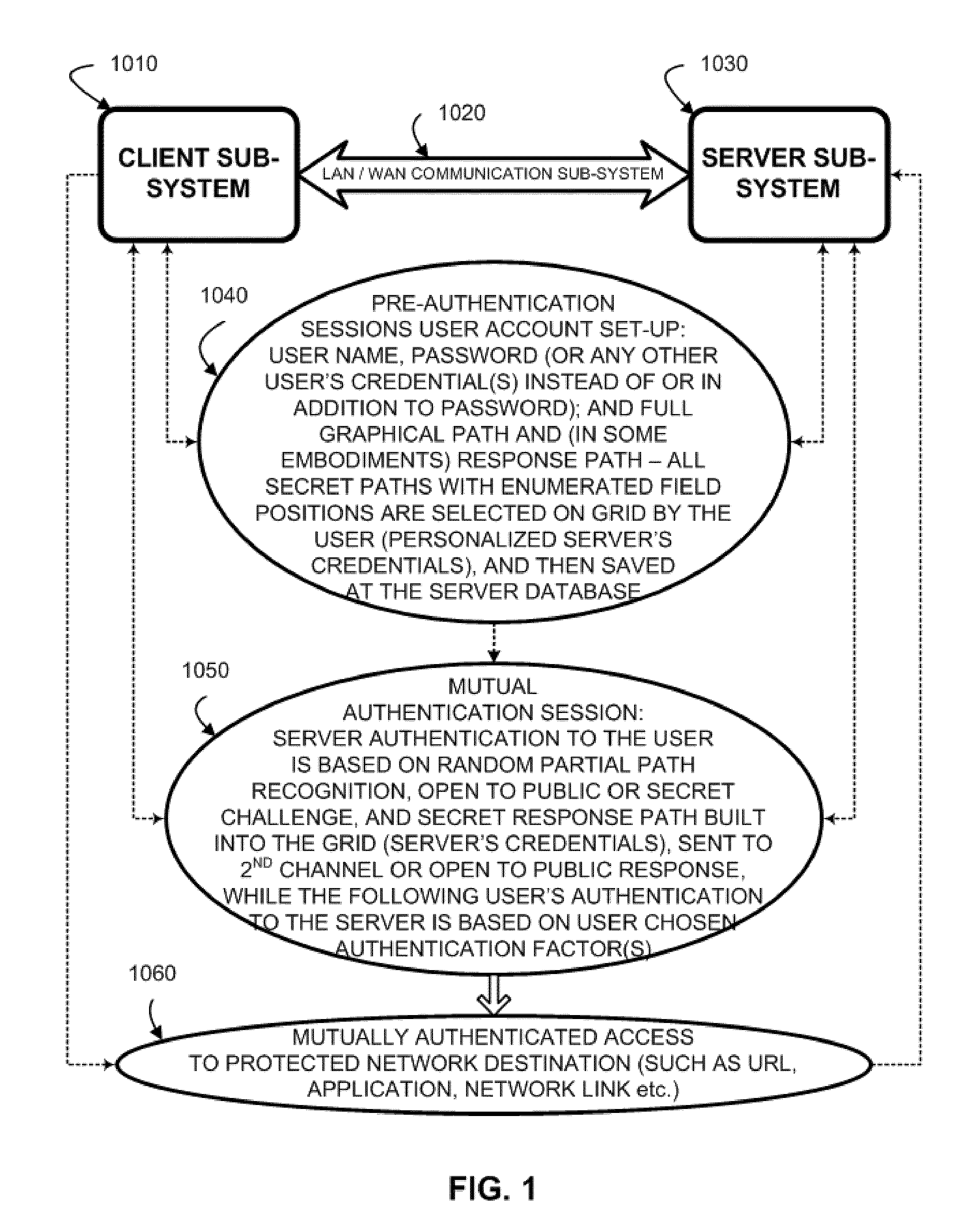

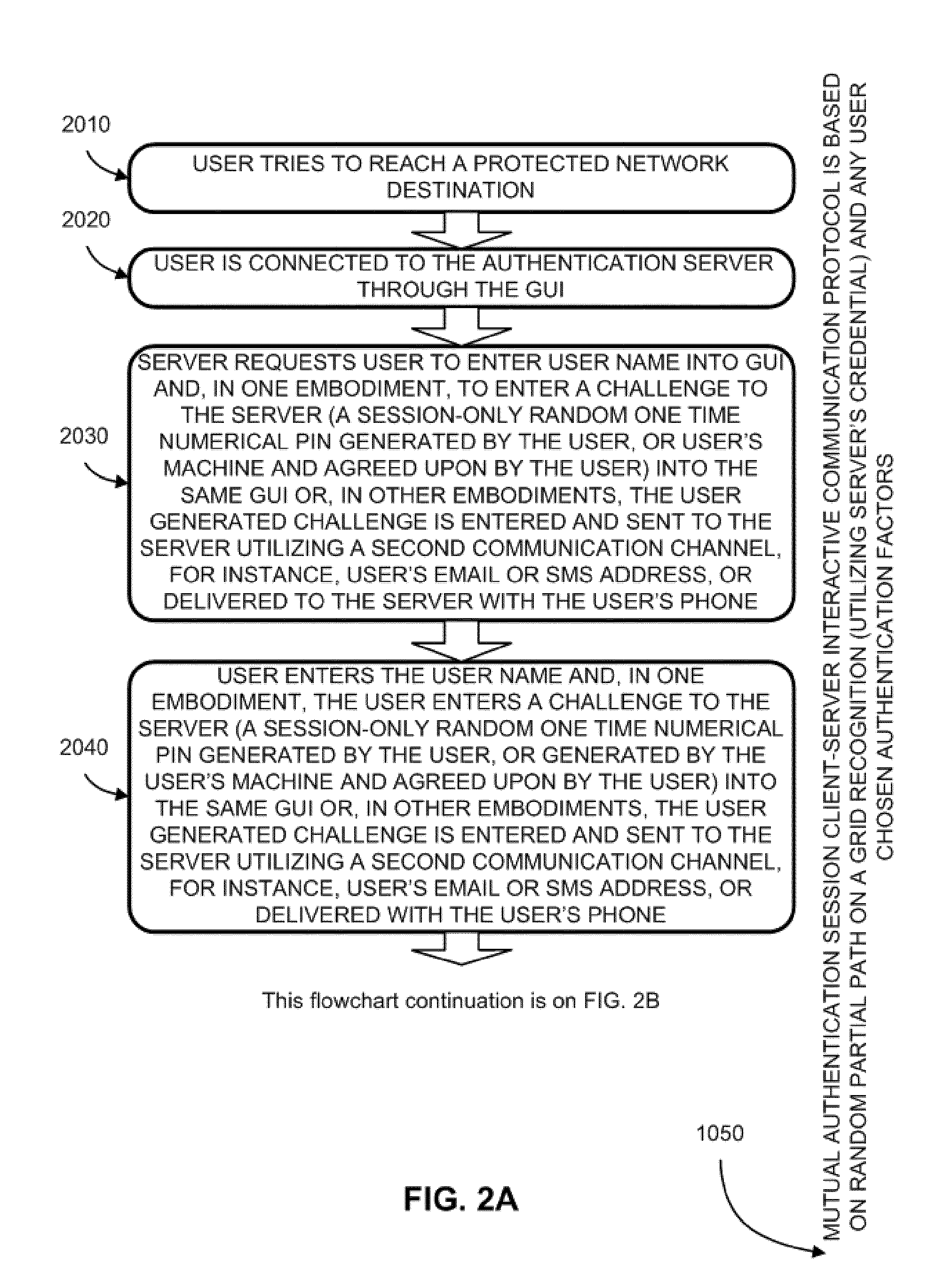

System and method for in- and out-of-band multi-factor server-to-user authentication

ActiveUS20110197070A1More versatile security requirementPracticalDigital data processing detailsUser identity/authority verificationUser authenticationClient-side

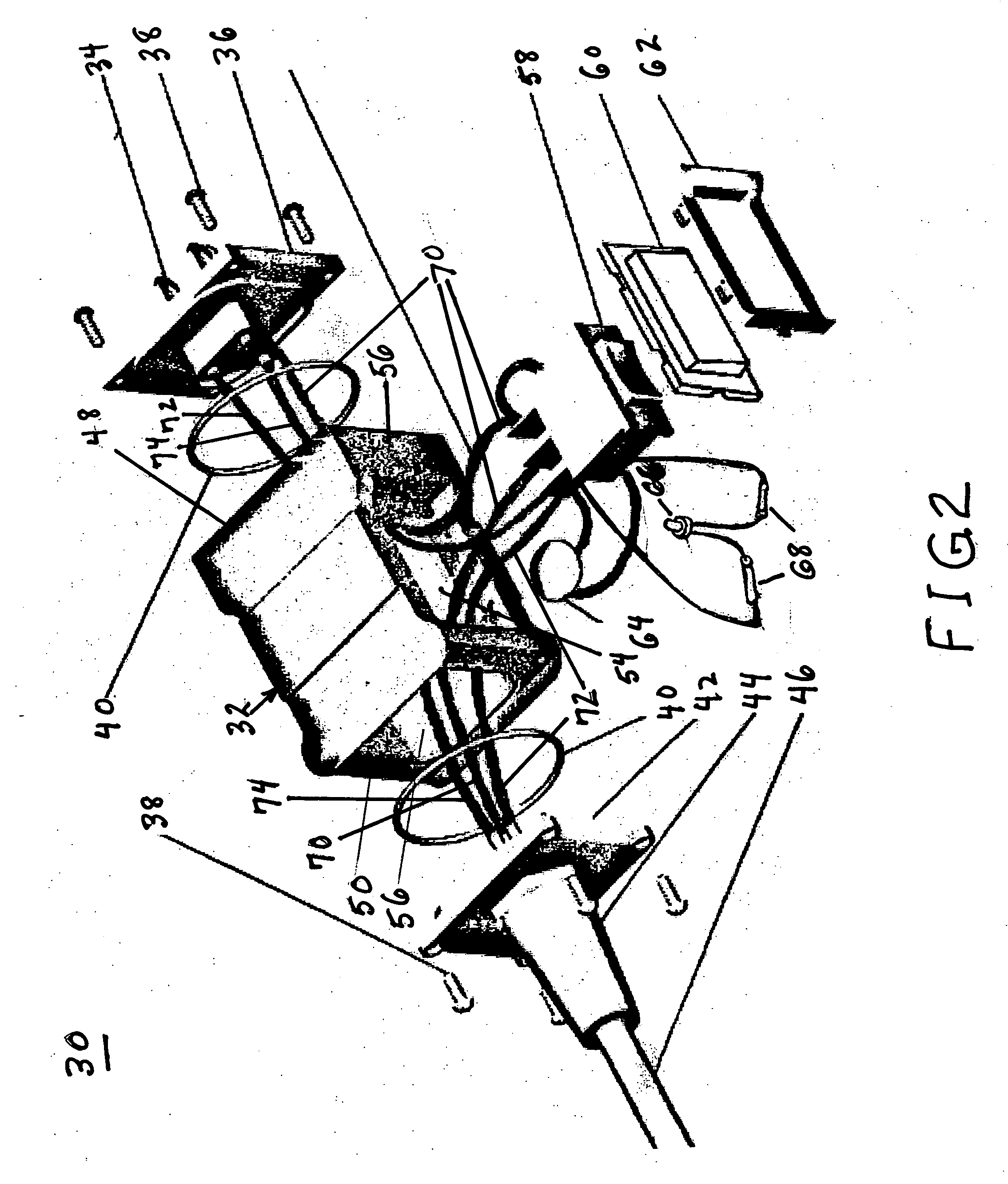

A method to authenticate a server to a client is provided, including in-band and out-of-band techniques. At least a first shared secret identifies a server path, including a plurality of pre-defined locations on a frame of reference (e.g. a grid). An authentication session is initiated upon receiving a client identifier at the server-side resources. A current session instance of the grid is presented to the client, populated with characters. The process includes sharing between the client and the server a challenge identifying a random subset of the plurality of predefined locations in the server path, and a response including characters that match the characters in the locations on the server path identified by the challenge. As a result, client is capable of verifying that the server has access to the first shared secret. Then a protocol is executed to authenticate the client to the server.

Owner:AUTHERNATIVE INC

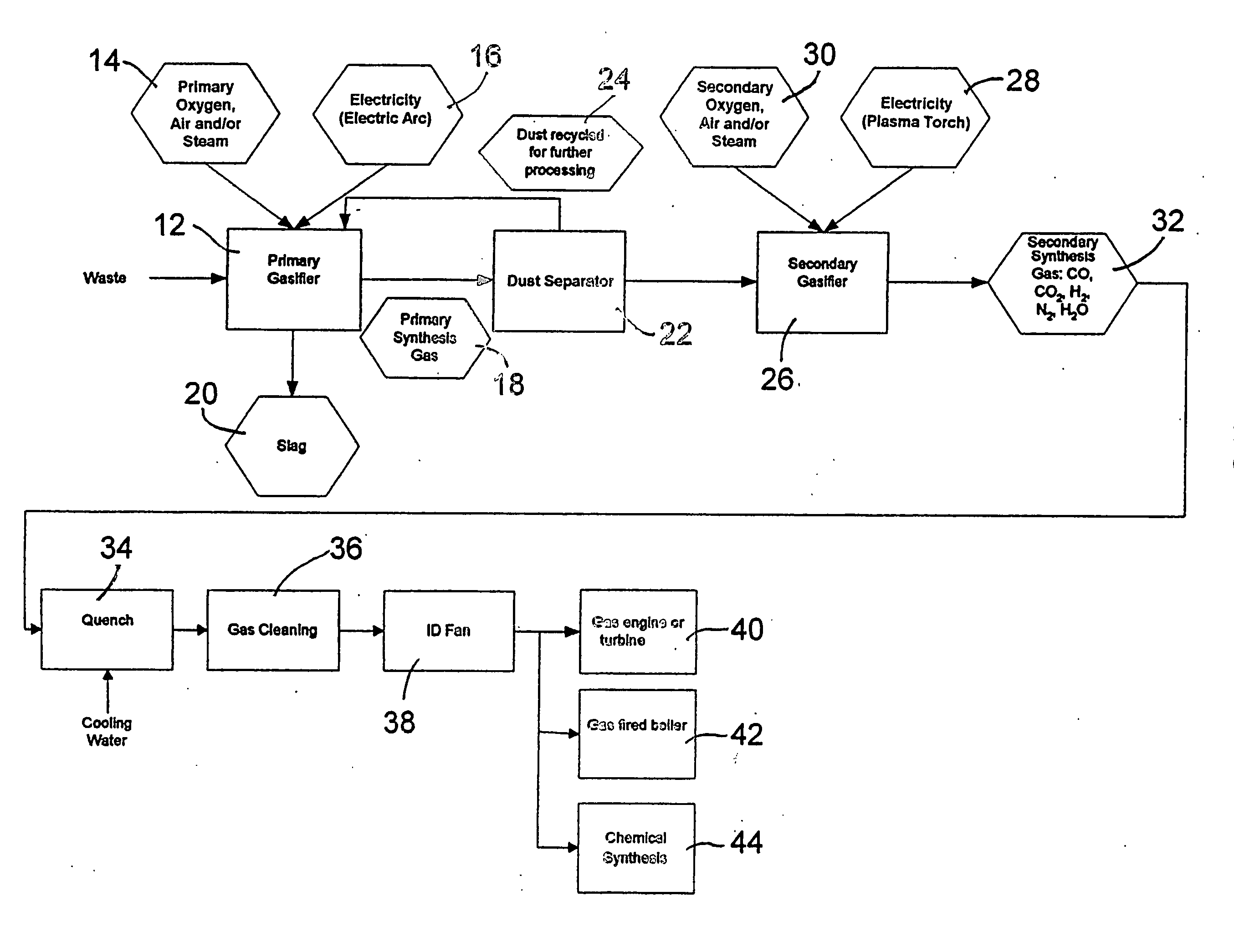

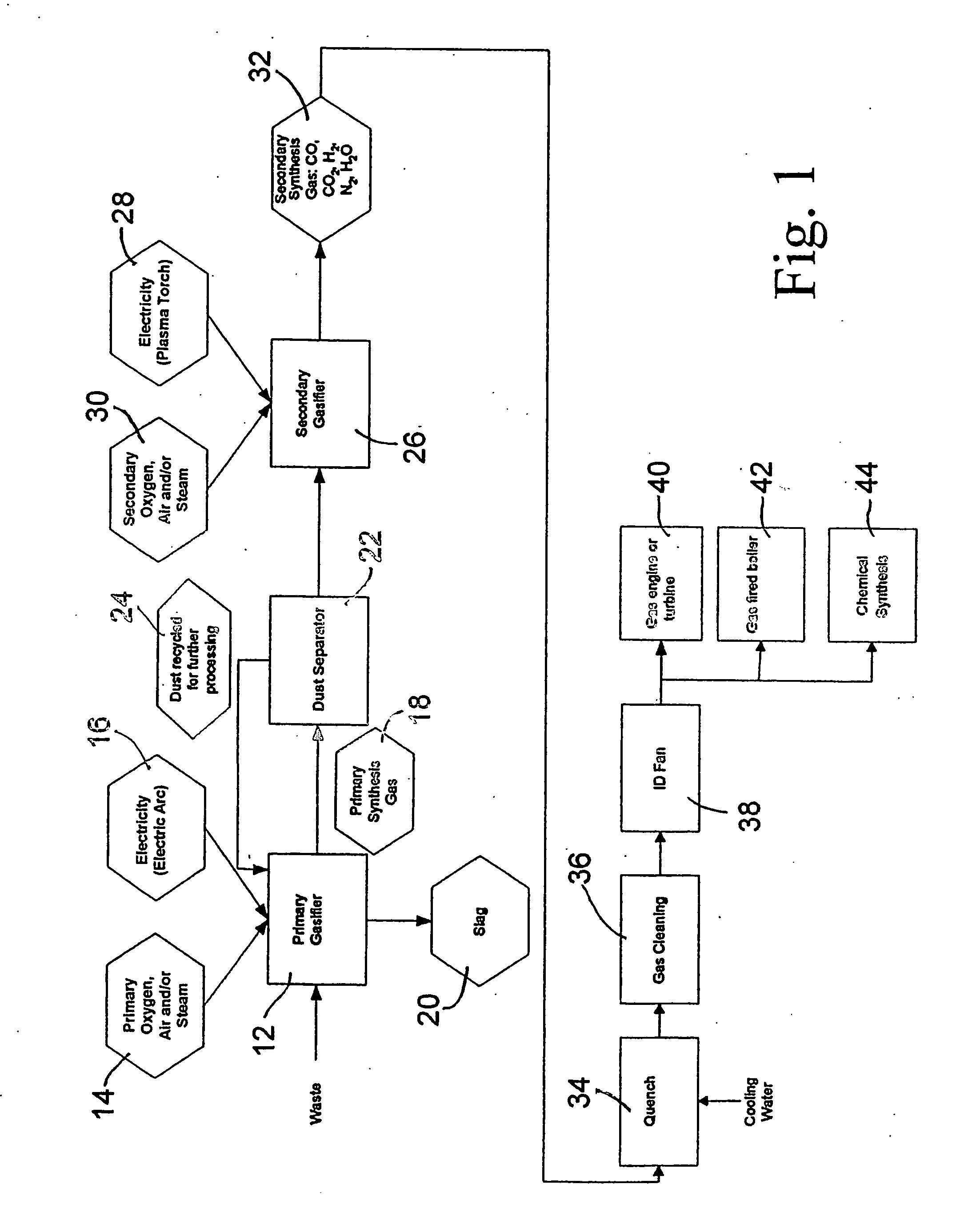

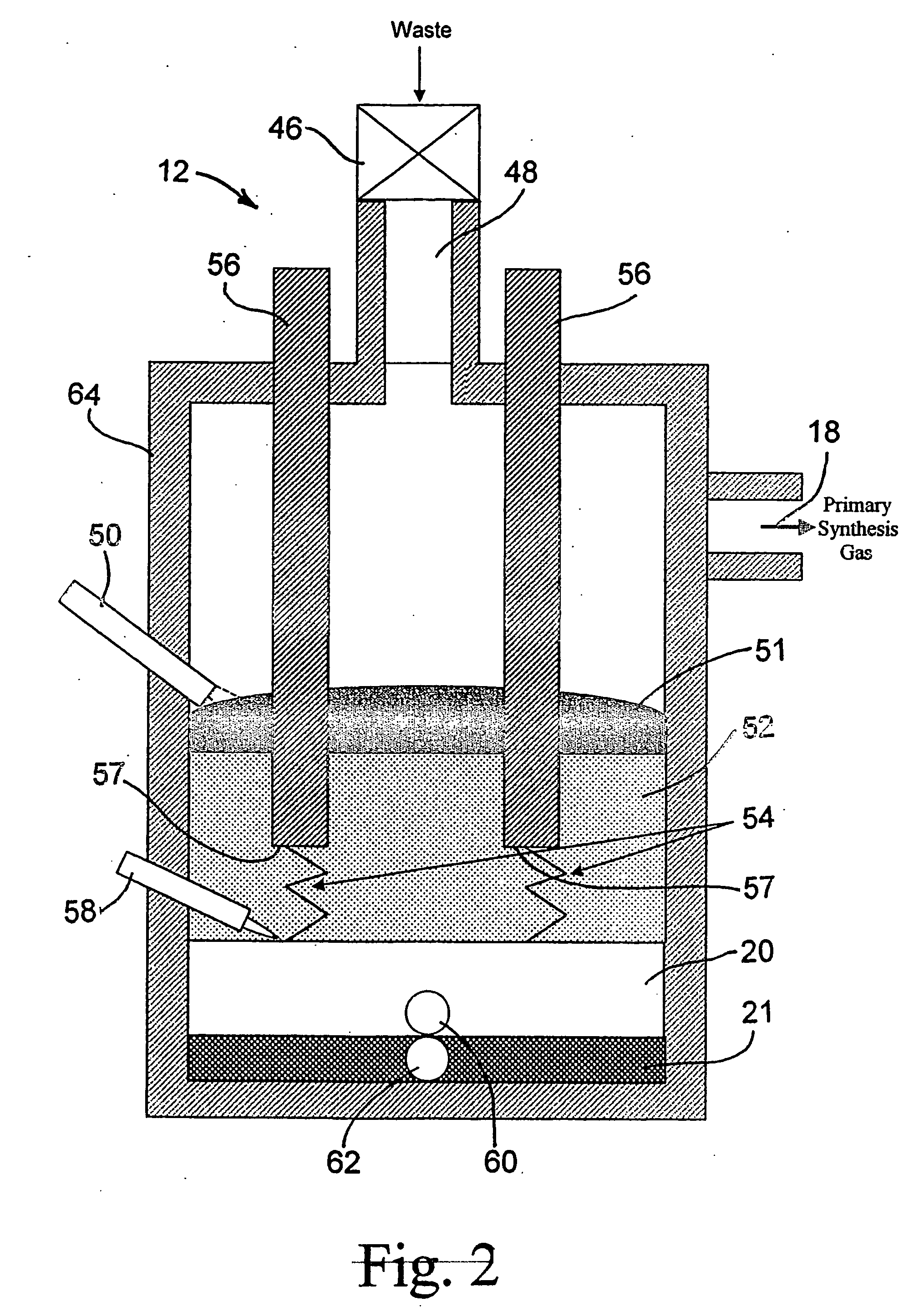

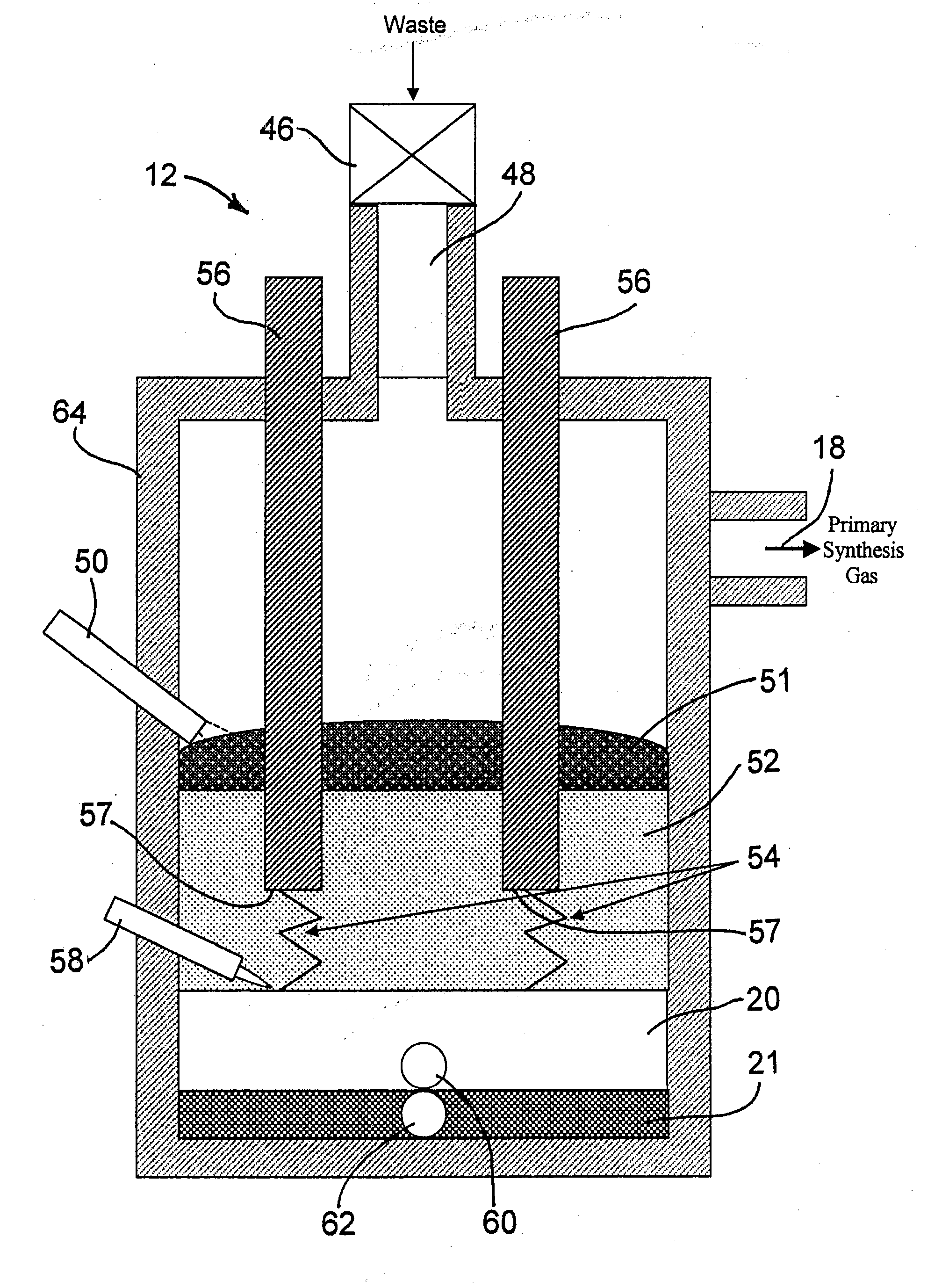

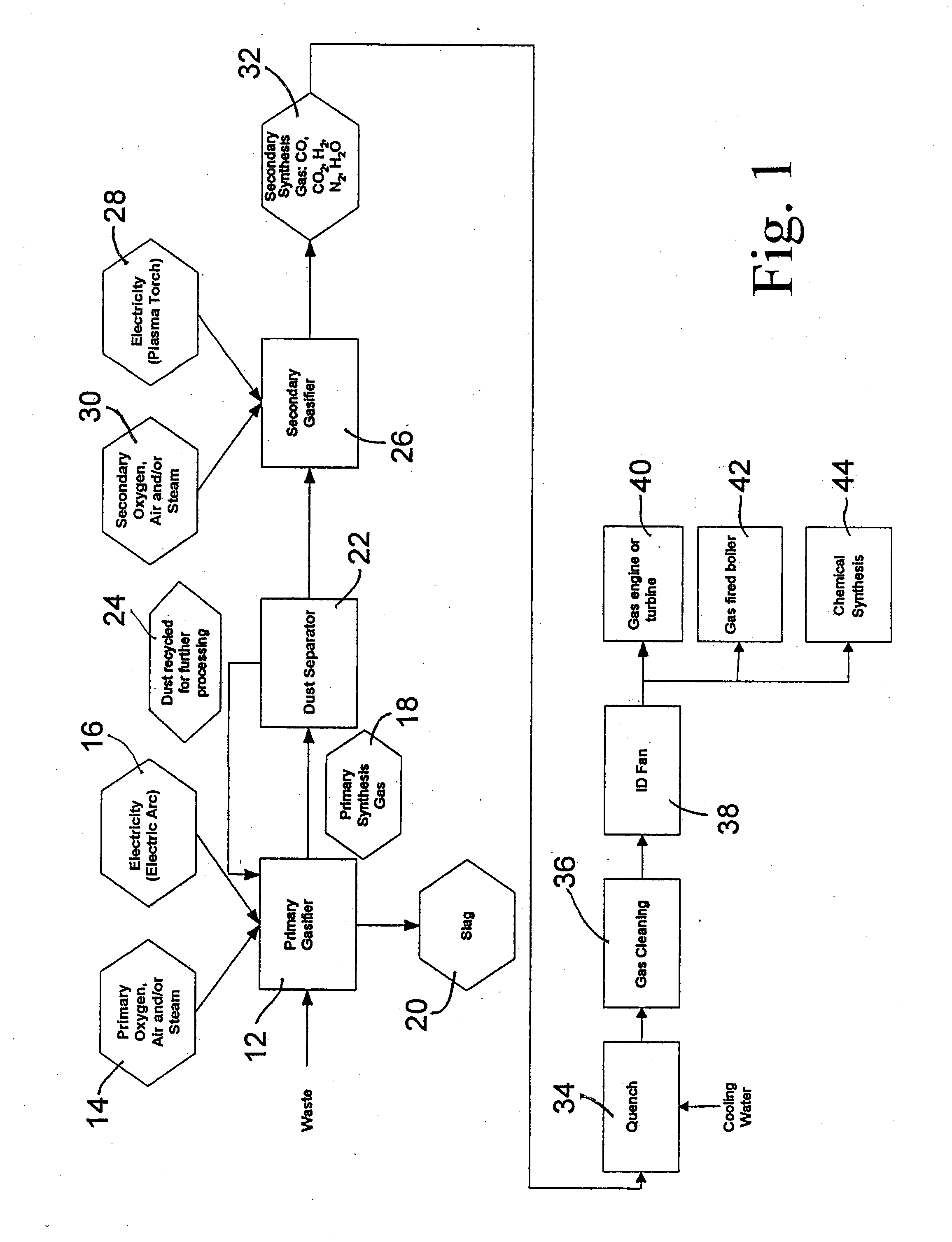

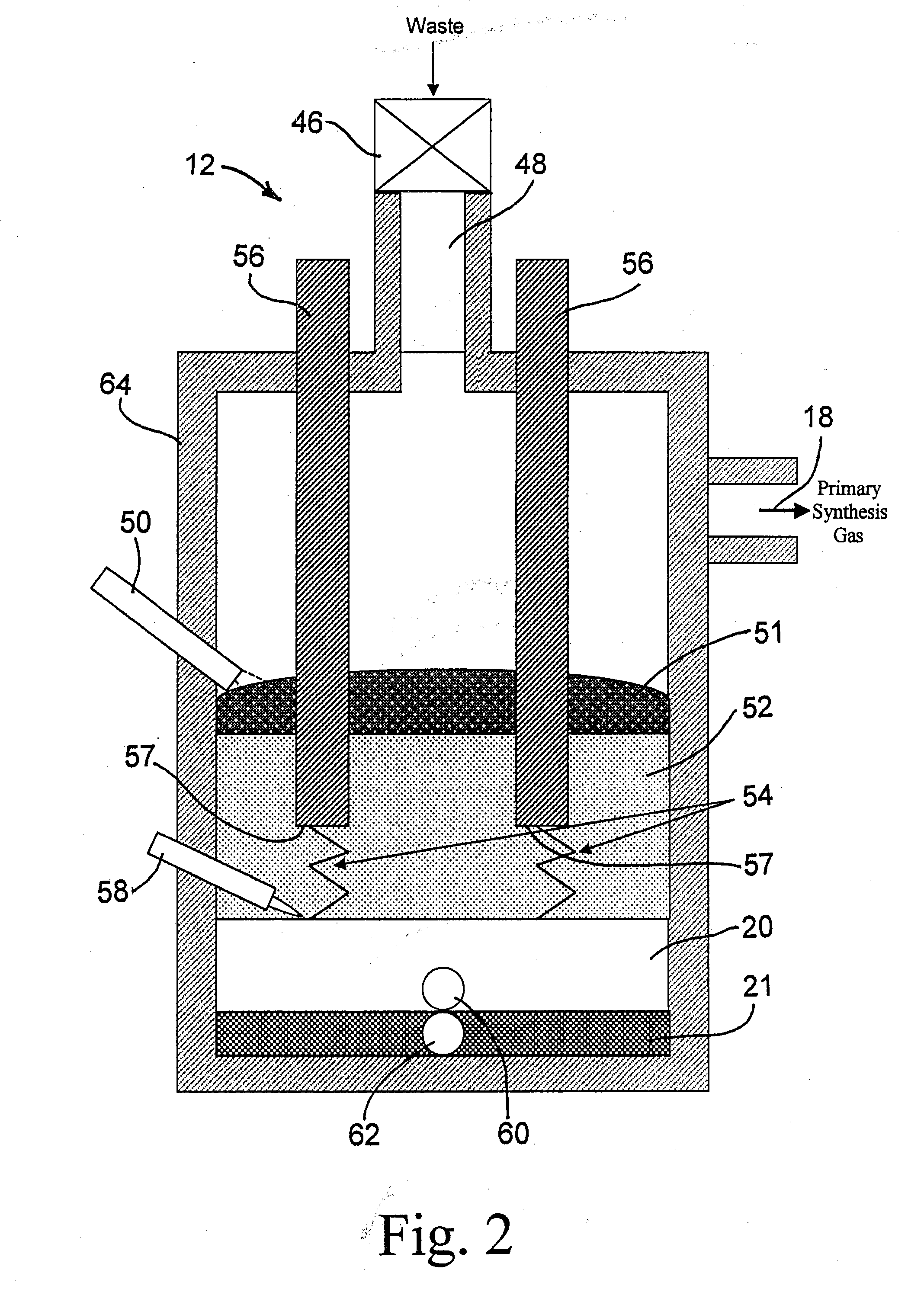

Two-Stage Plasma Process For Converting Waste Into Fuel Gas And Apparatus Therefor

InactiveUS20070272131A1Limited amountImprove energy efficiencyGasifier electrodesGasification processes detailsPlasma jetCyclone

A two-step gasification process and apparatus for the conversion of solid or liquid organic waste into clean fuel, suitable for use in a gas engine or a gas burner, is described. The waste is fed initially into a primary gasifier, which is a graphite arc furnace. Within the primary gasifier, the organic components of the waste are mixed with a predetermined amount of air, oxygen or steam, and converted into volatiles and soot. The volatiles consist mainly of carbon monoxide and hydrogen, and may include a variety of other hydrocarbons and some fly ash. The gas exiting the primary gasifier first passes through a hot cyclone, where some of the soot and most of the fly ash is collected and returned to the primary gasifier. The remaining soot along with the volatile organic compounds is further treated in a secondary gasifier where the soot and the volatile compounds mix with a high temperature plasma jet and a metered amount of air, oxygen or steam, and are converted into a synthesis gas consisting primarily of carbon monoxide and hydrogen. The synthesis gas is then quenched and cleaned to form a clean fuel gas suitable for use in a gas engine or a gas burner. This offers higher thermal efficiency than conventional technology and produces a cleaner fuel than other known alternatives.

Owner:PHOENIX HAUTE TECH

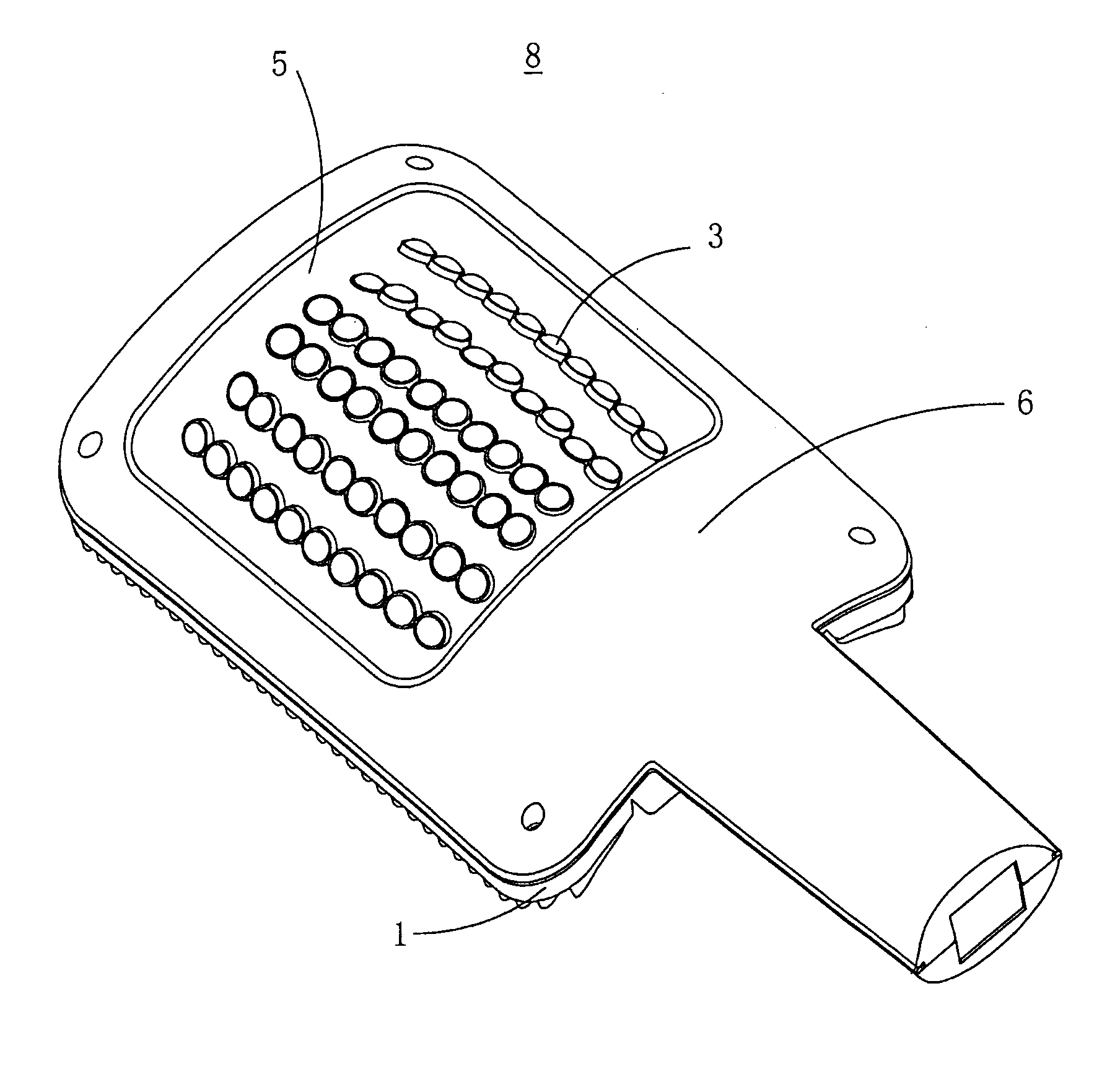

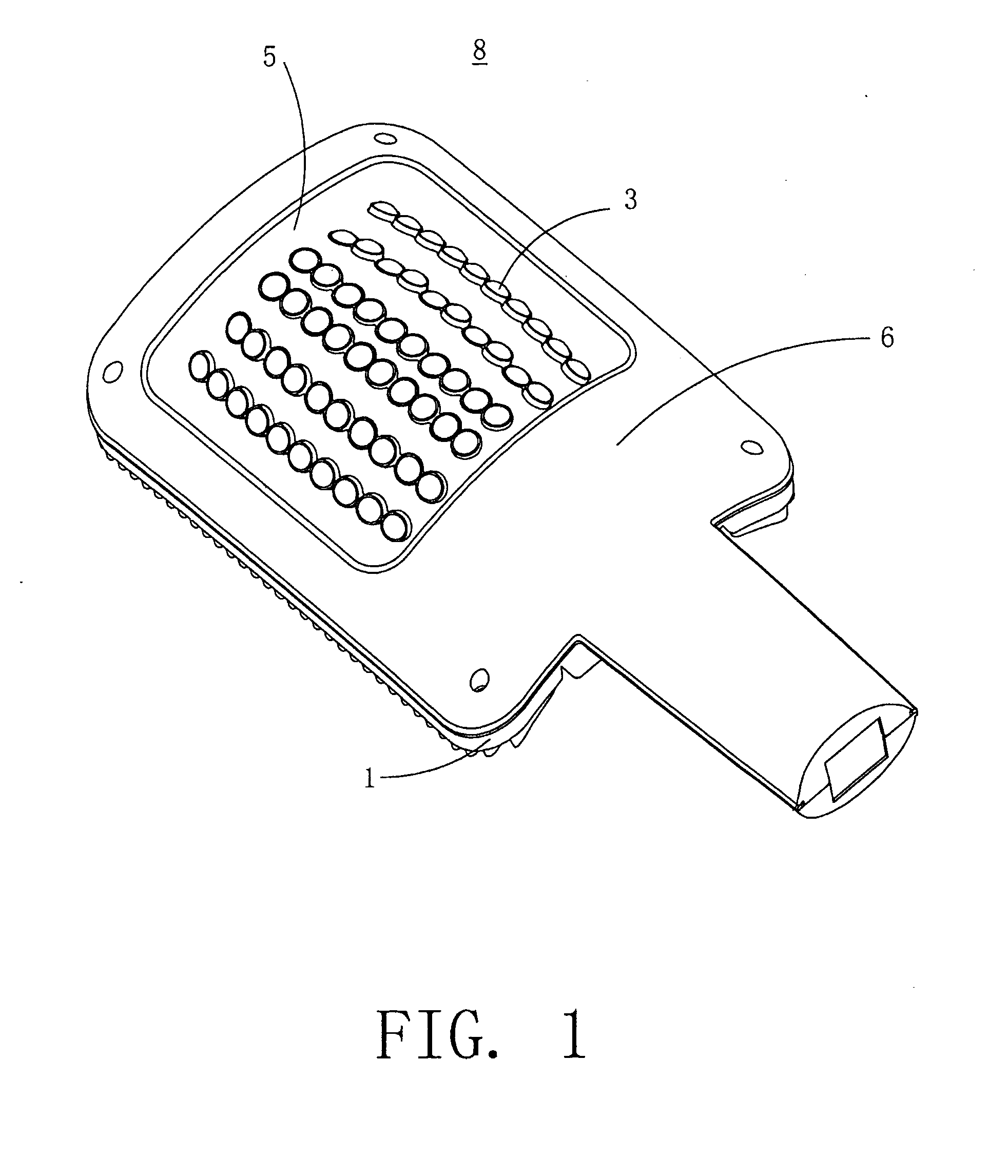

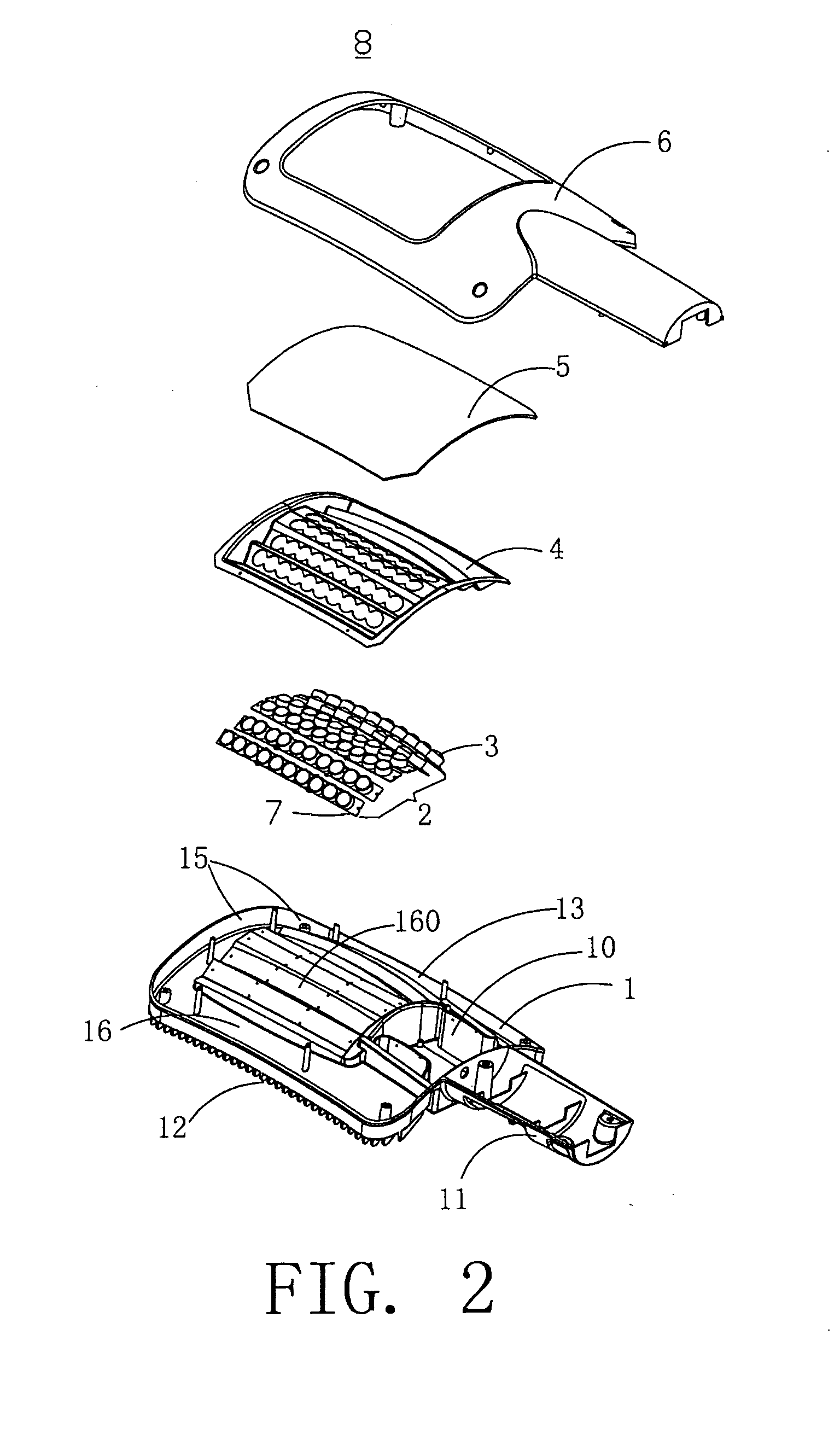

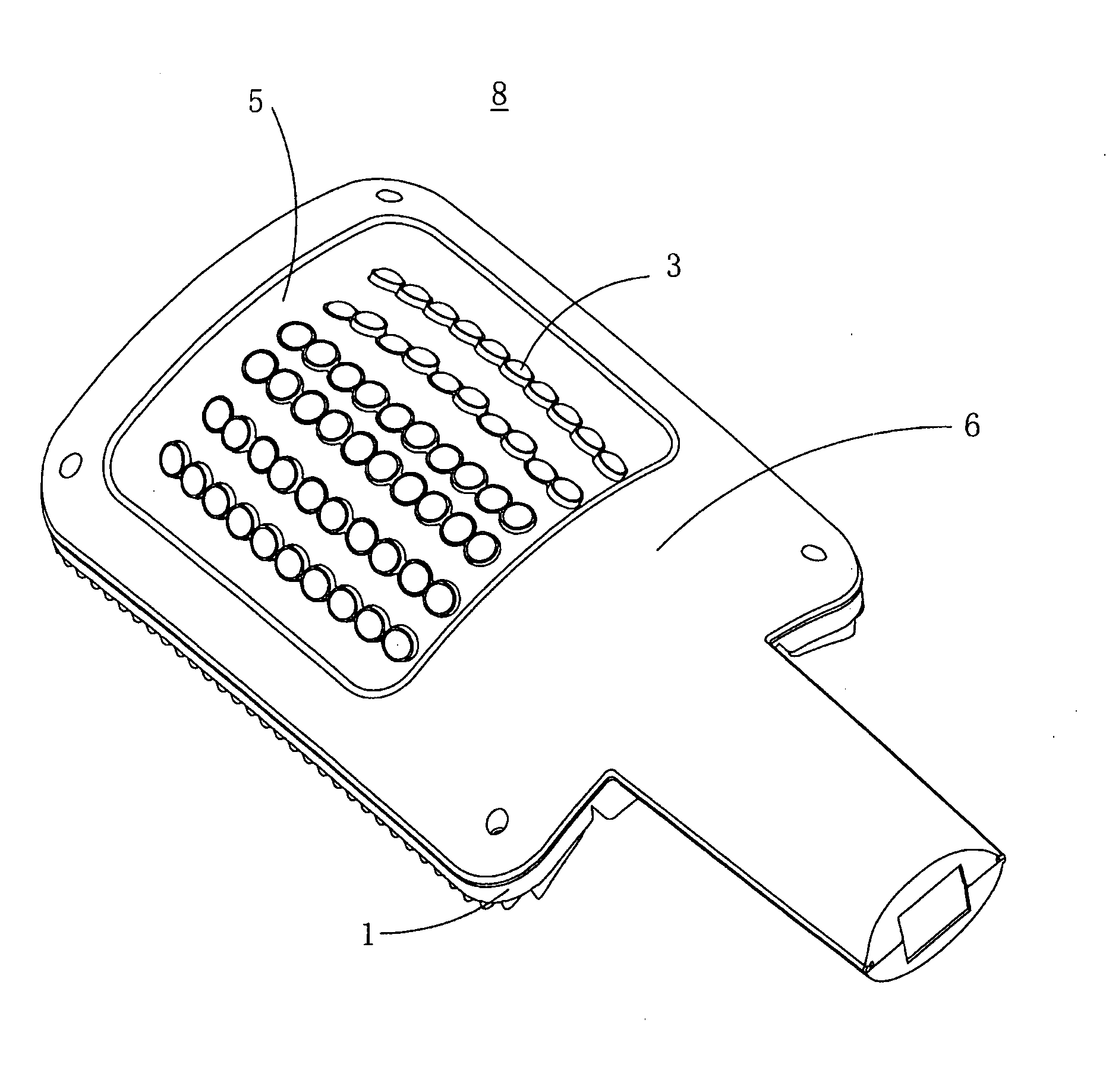

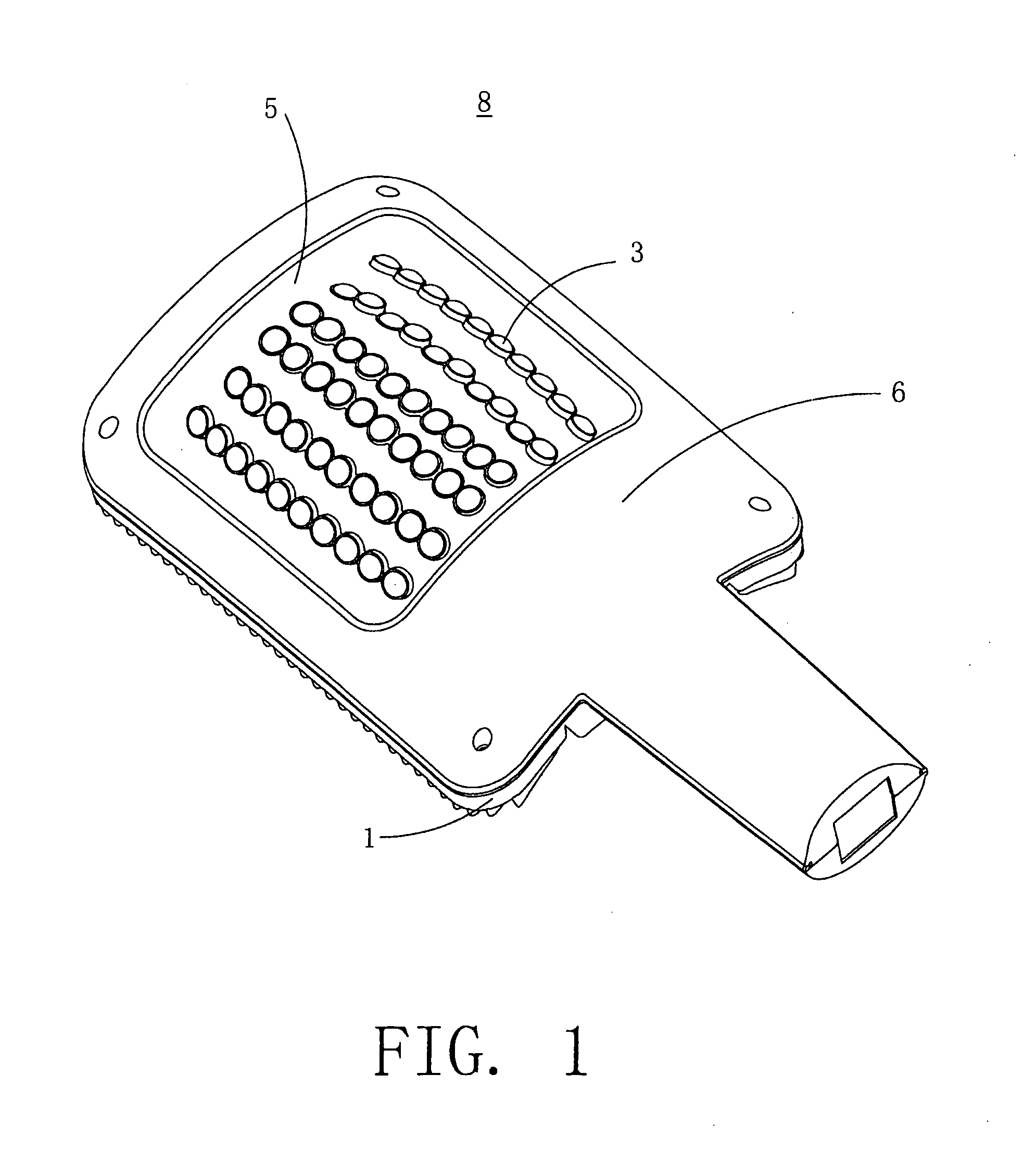

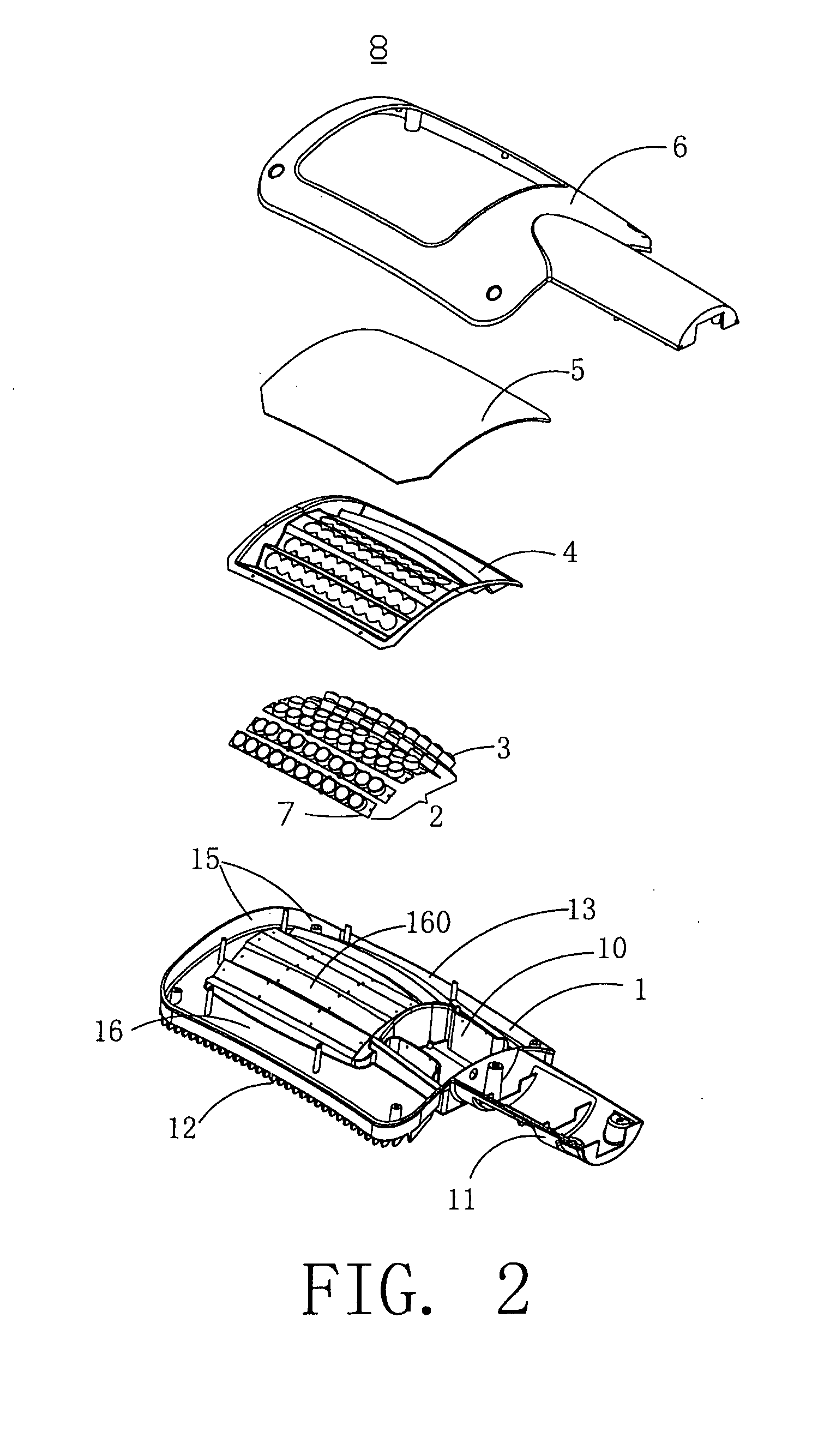

High-power light emitting diode (LED) street lamp and body frame thereof

InactiveUS20090034257A1Requires moreNon-electric lightingMechanical apparatusLight-emitting diodeLight emission

A high-power light emitting diode (LED) street lamp includes a body frame, a plurality of light emitting diode (LED) modules, and a base unit convexly positioned on the body frame along the light emission direction of the high-power light emitting diode (LED) street lamp. The light emitting diode (LED) modules have a plurality of light emitting diodes (LEDs), and at least one circuit board. The light emitting diodes (LEDs) are electrically connected to the at lease one circuit board. The base unit has a plurality of supporting surfaces which support the light emitting diode (LED) modules. The supporting surfaces are symmetrically positioned on a normal direction of an end surface of the base unit, and the light emitting diode (LED) modules are positioned on the adjacent supporting surfaces, respectively. The supporting surfaces further comprise a plurality of edge supporting surfaces positioned on the edges of the base unit. An angle formed by the light emission direction of the light emitting diodes (LEDs) on the edge supporting surfaces and the normal direction of the end surface of the base unit is in a range between 45 degrees to 60 degrees.

Owner:NINGBO ANDY OPTOELECTRONIC CO LTD

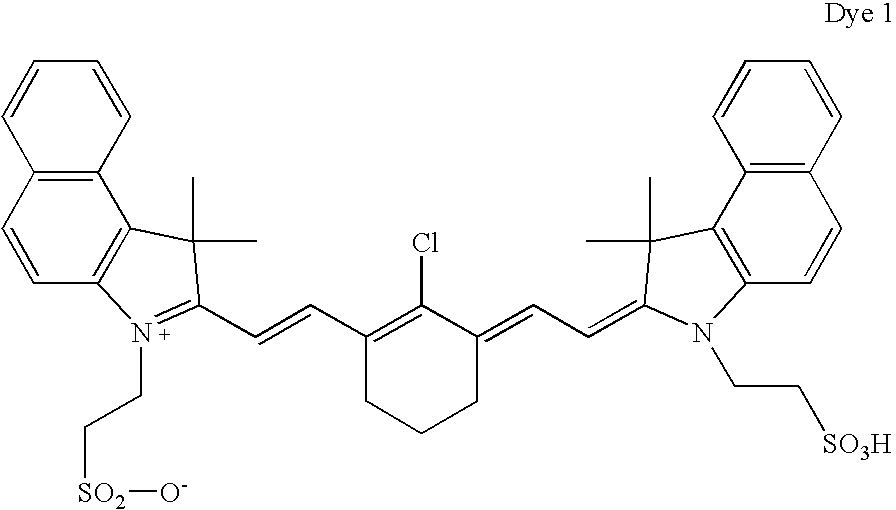

Negative-working thermal lithographic printing plate precursor comprising a smooth aluminum support

InactiveUS6983694B2High run lengthReduction of image wearPlate printingThermographyPolymer scienceSurface roughness

A negative-working lithographic printing plate precursor is disclosed which comprises a grained and anodized aluminum support having a hydrophilic surface and a heat-sensitive coating provided on the hydrophilic surface, the coating comprising hydrophobic thermoplastic polymer particles which are capable of forming a hydrophobic phase in the coating by heat-induced coalescence of the polymer particles. The support is characterized by a surface roughness, expressed as arithmetical mean center-line roughness Ra, which is less than 0.45 μm. The smooth surface enables to prepare a lithographic printing plate from the mentioned precursor, which is characterized by a high run length during printing.

Owner:AGFA OFFSET BV

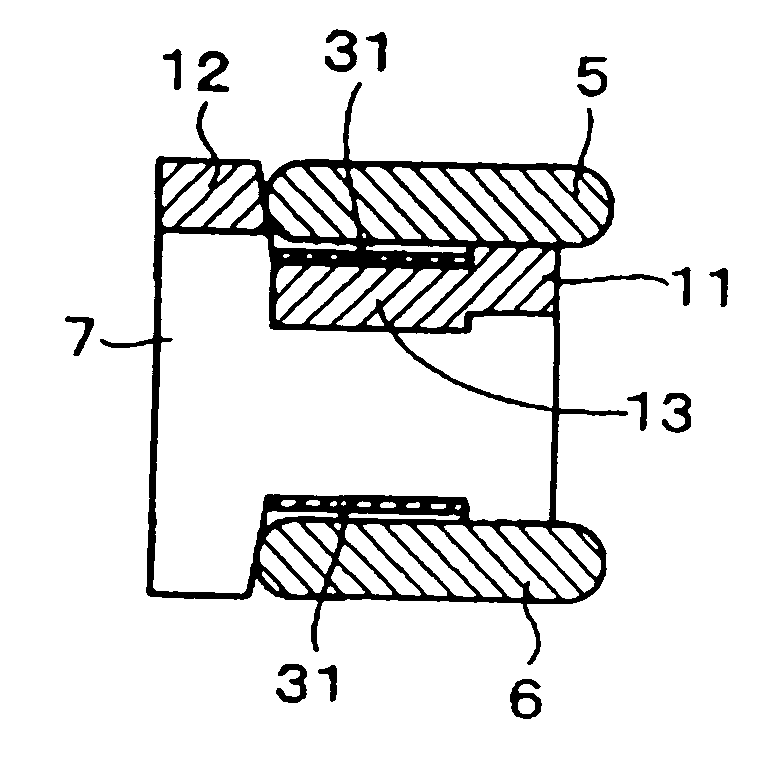

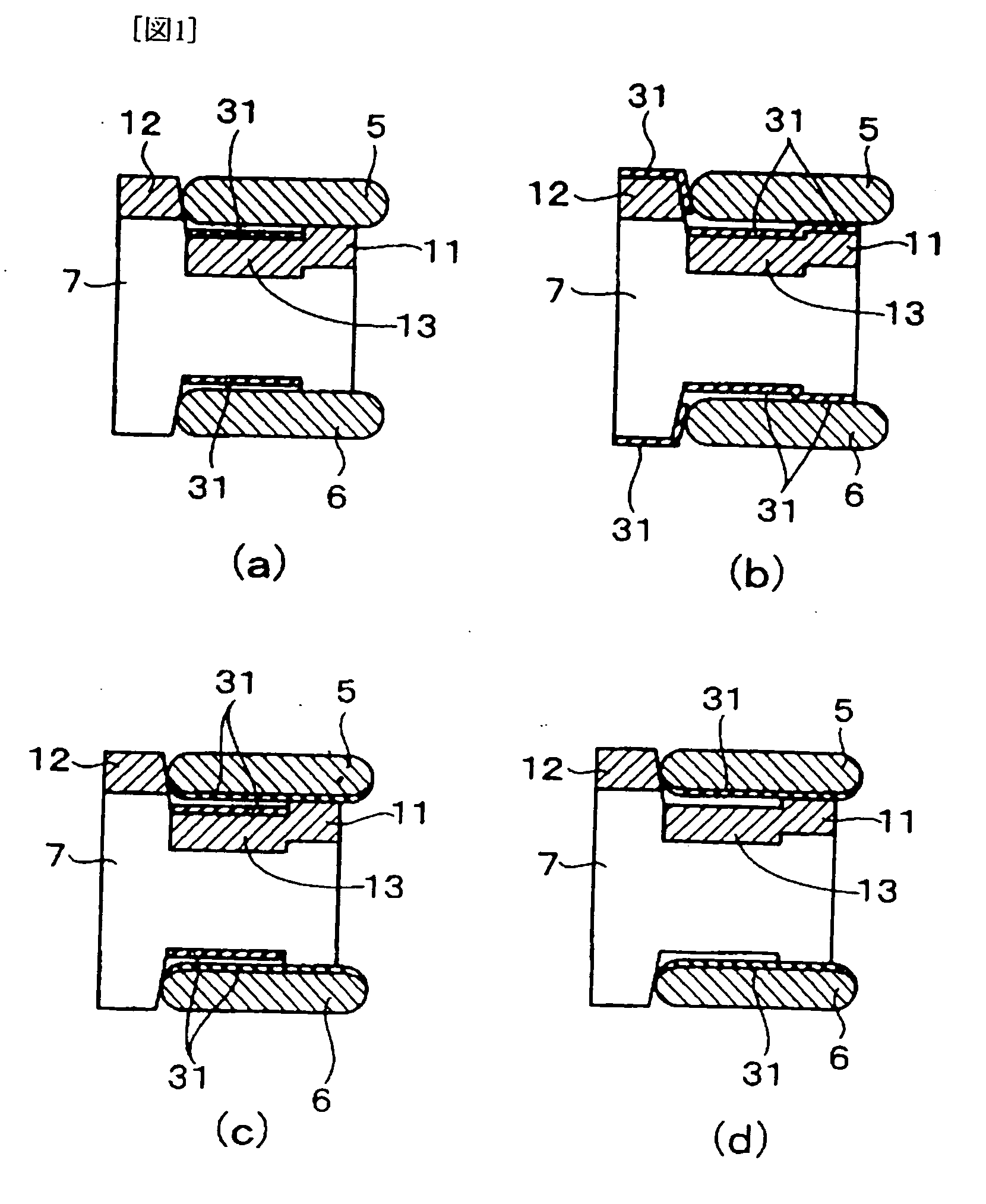

Three piece-combined oil ring

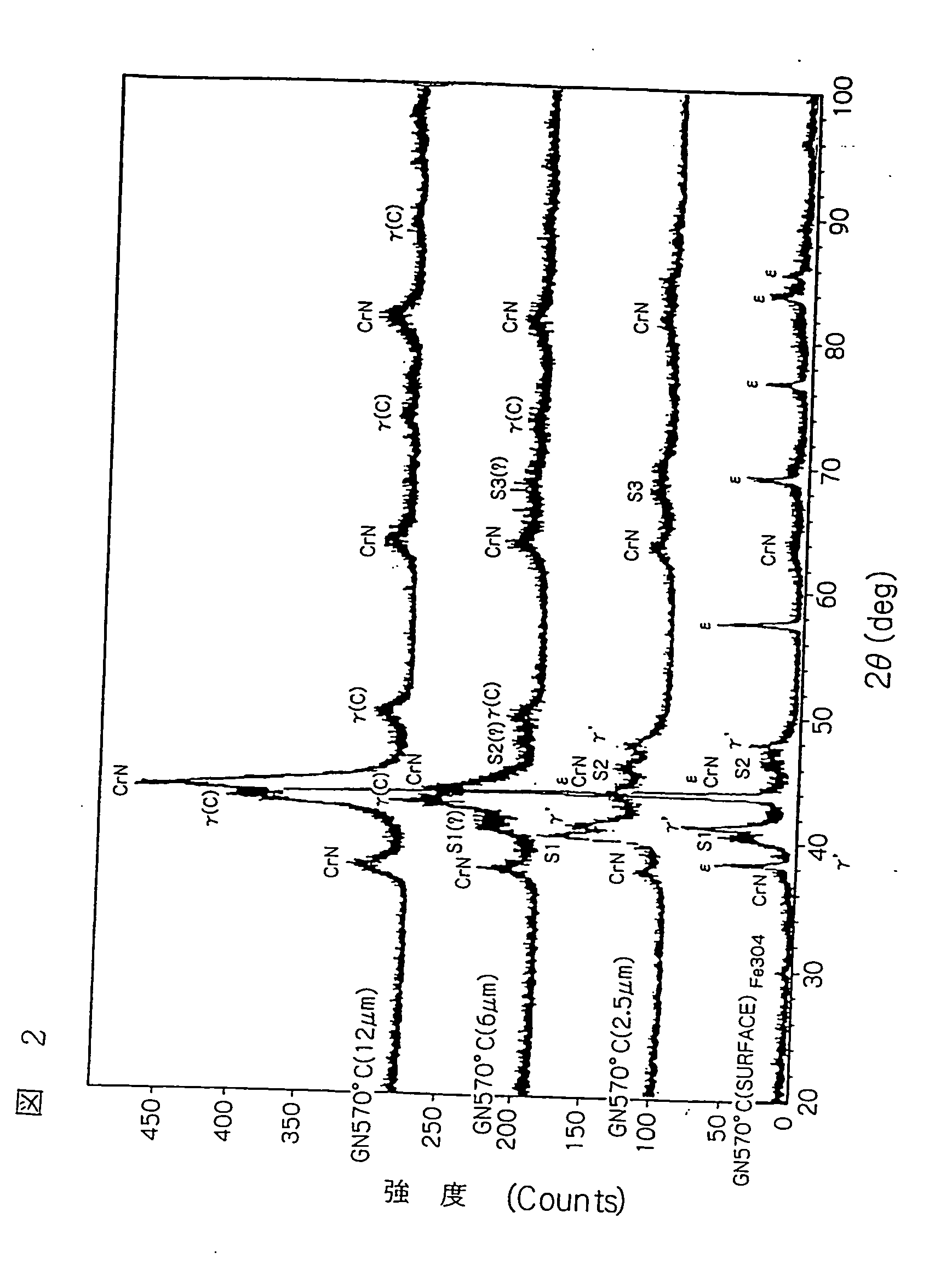

InactiveUS20060061043A1Poor corrosion-resistanceReduce tensionPiston ringsBraking action transmissionSurface layerX-ray

A three-piece combined oil-control ring comprises a pair of upper and lower side rails 222 in the axial direction and a spacer expander 224. The spacer expander is located between the side rails 222, and pushes the side rails from their inner peripheral side to generates the tension of the side rails 222. The ears of the spacer expander made of austenitic stainless steel in contact with inner peripheral surfaces of the side rails, are subjected to gas-nitriding at a temperature of 470° C. or higher to form a 10 to 60 μm thick gas-nitriding surface-layer comprising a phase having peaks at 2θ=40° and 2θ=46° by Cu—K α X-ray diffraction. In addition or alternatively, a resin coating film (31) is formed on at least surfaces of the spacer expander (7) faced to the side surfaces of the side rails or on at least surfaces of the side rails (5,6) faced to the spacer expander (7).

Owner:RIKEN CO LTD

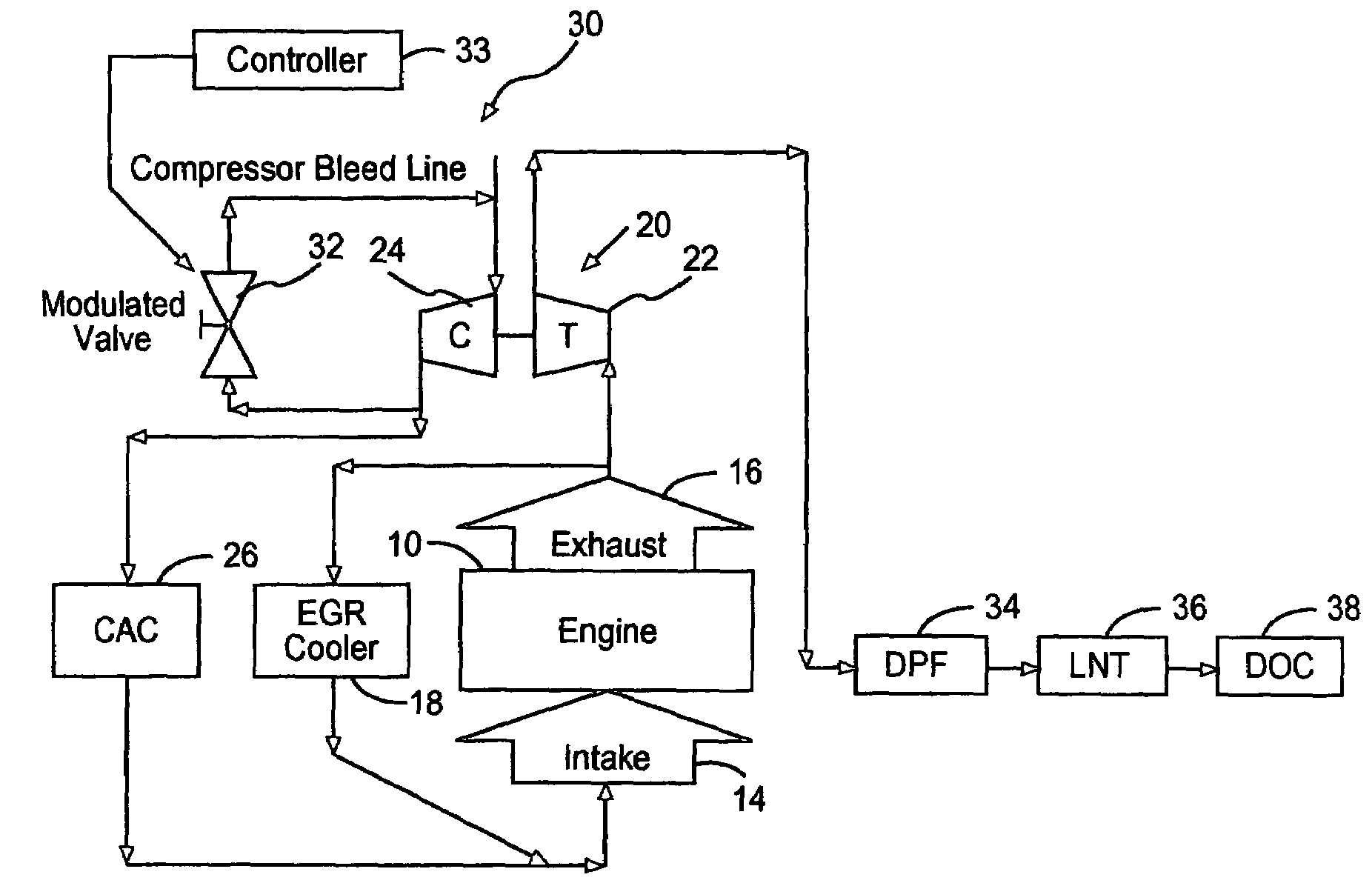

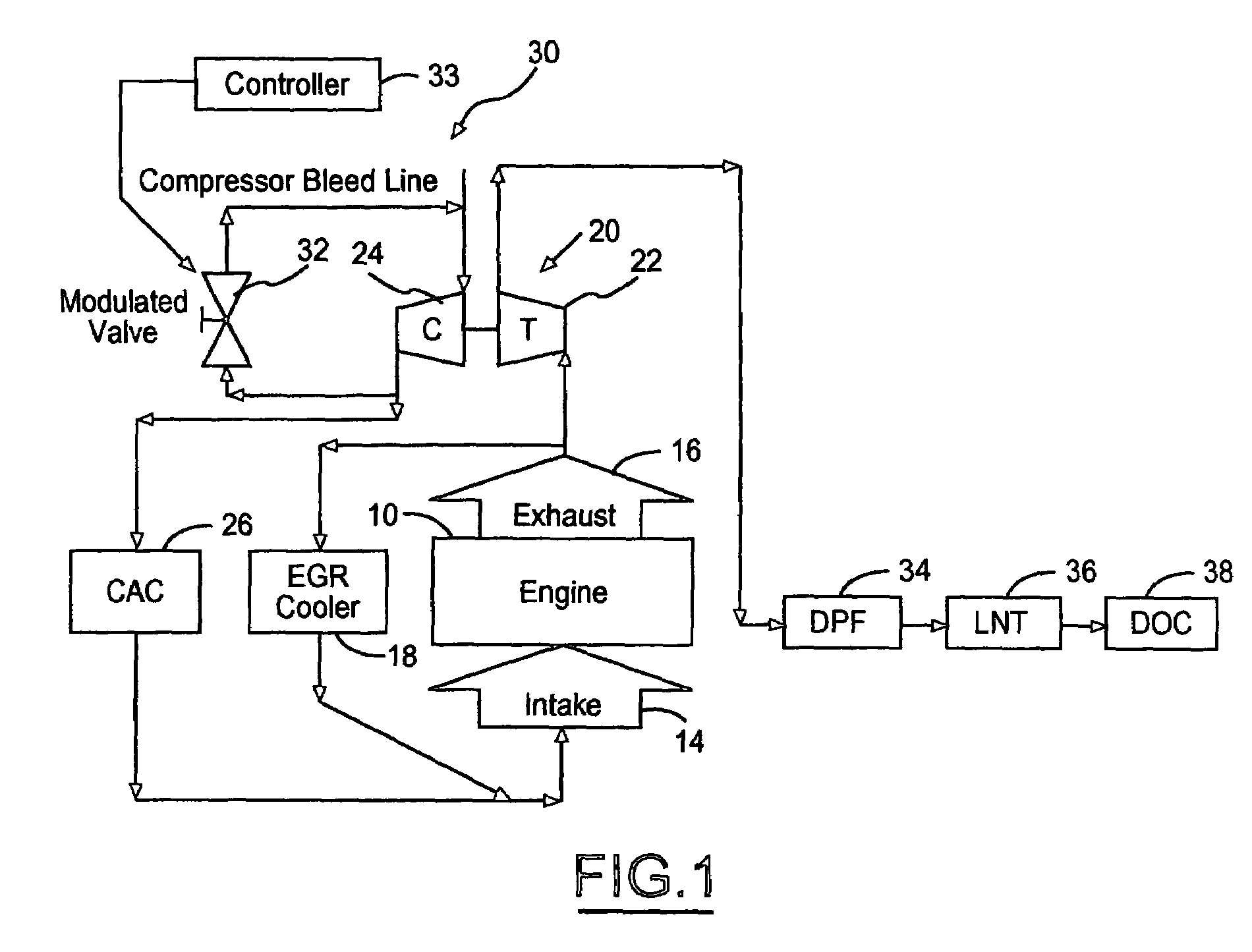

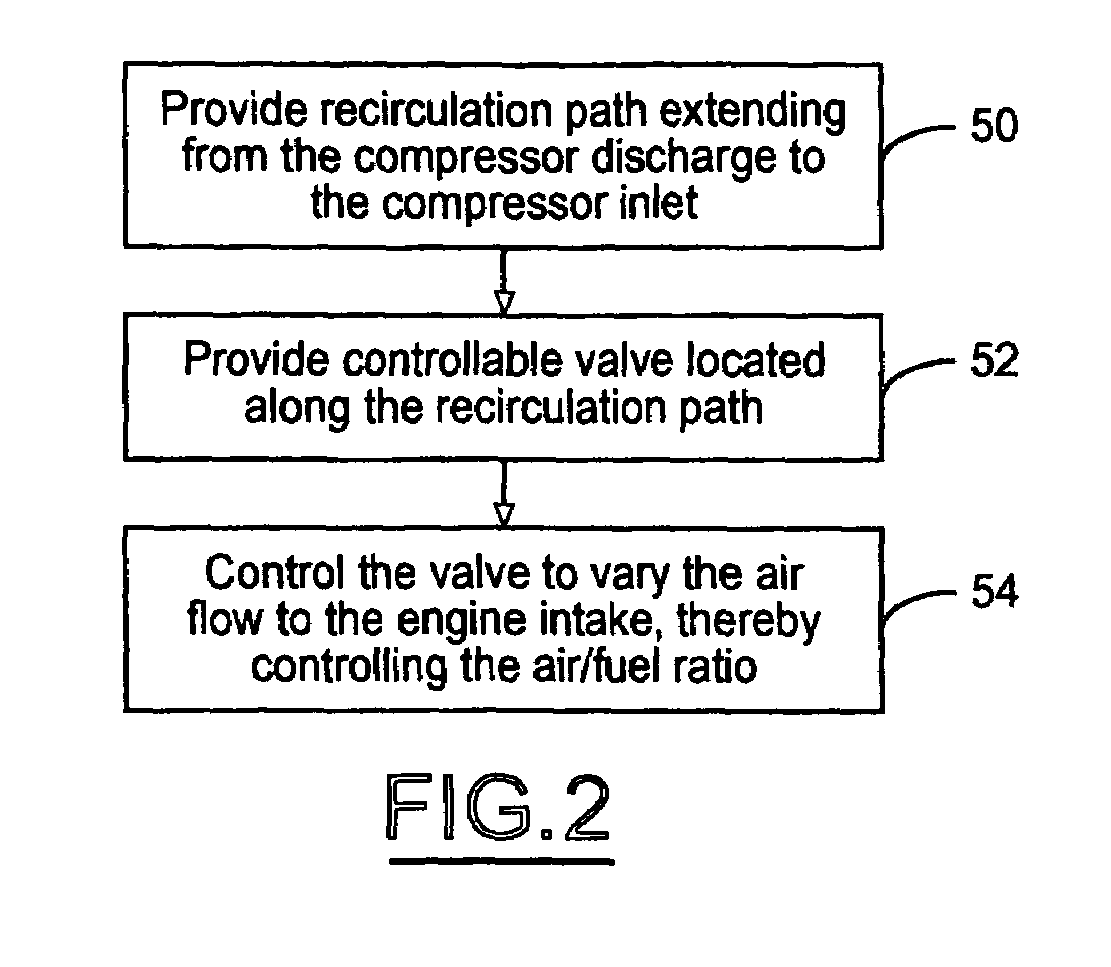

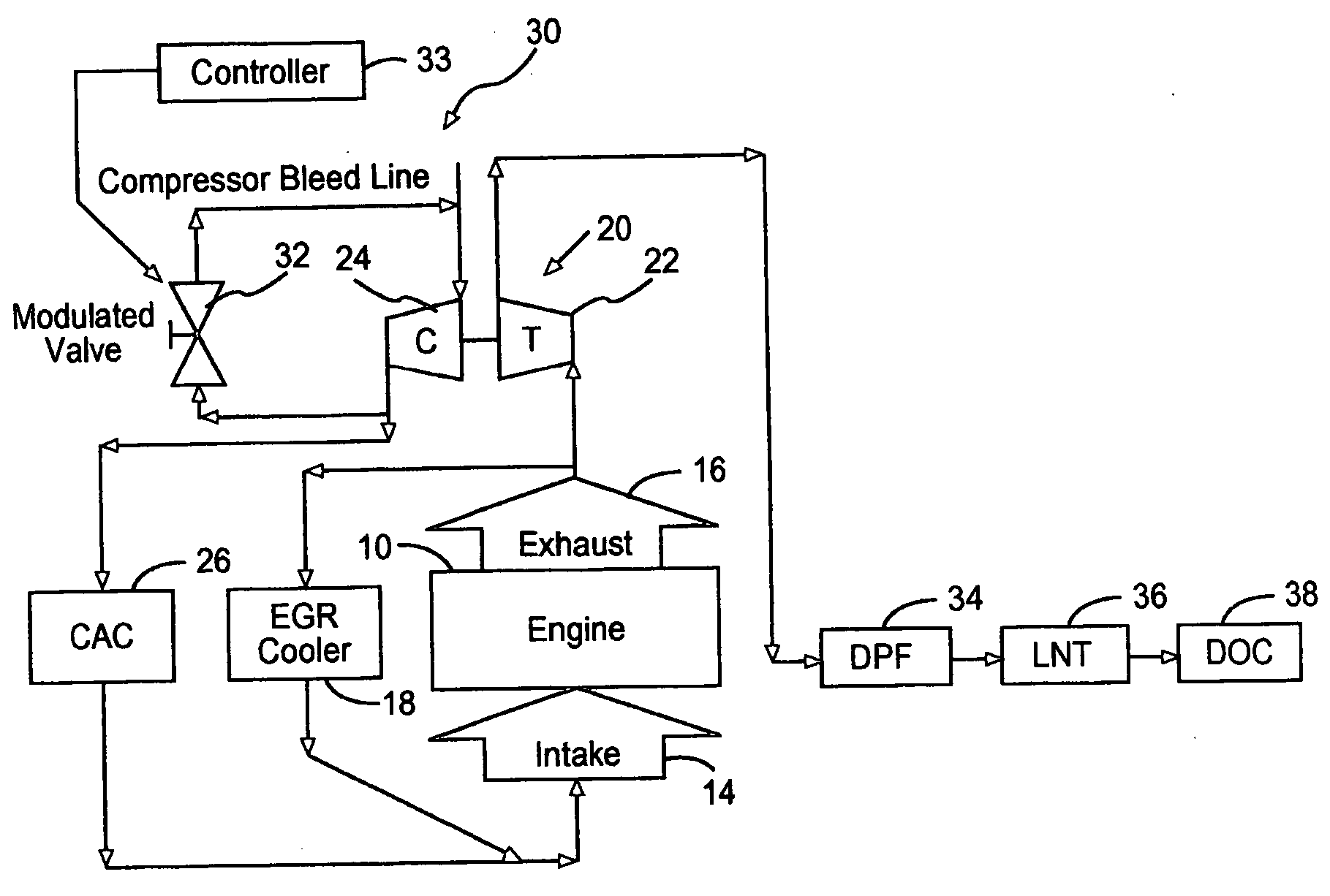

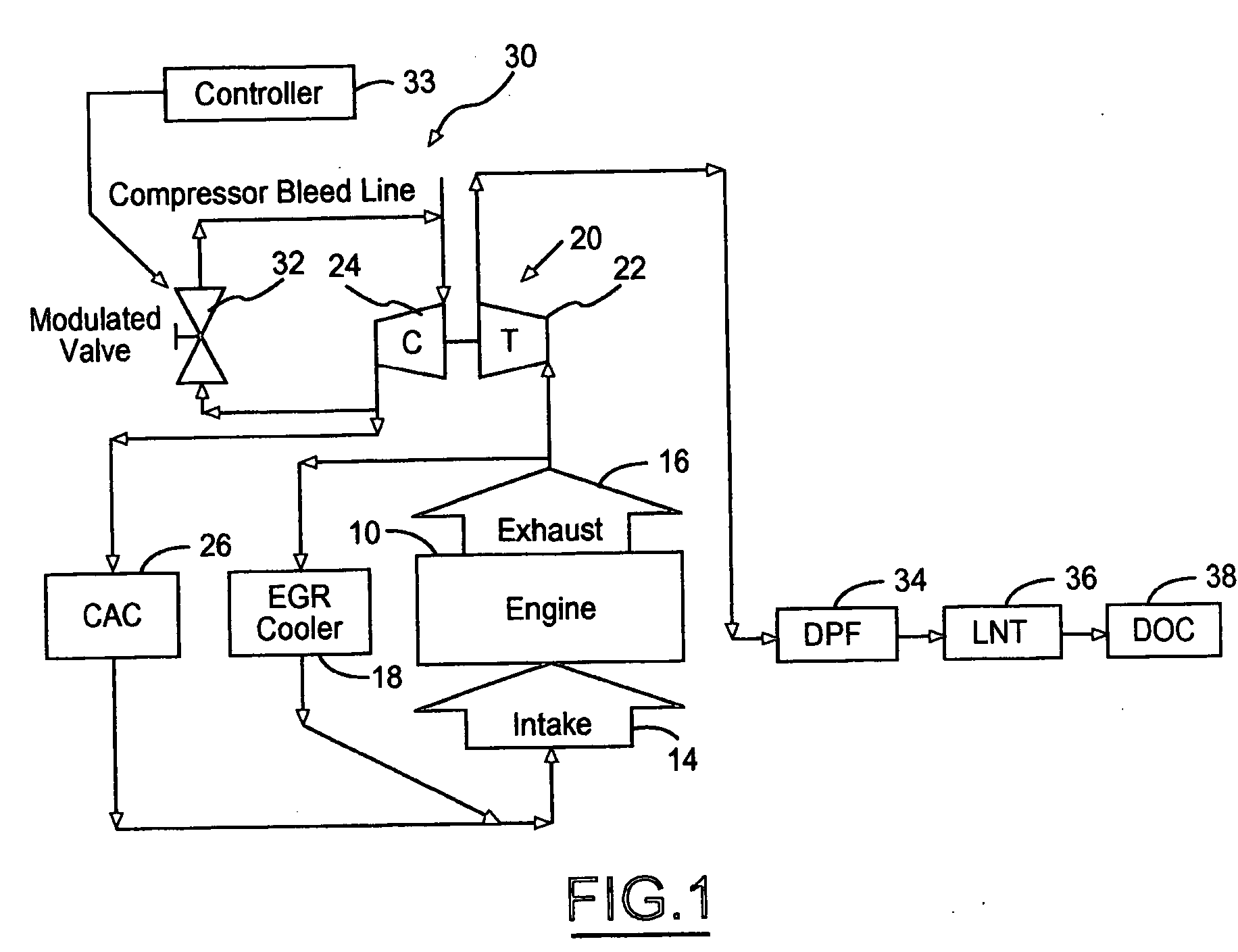

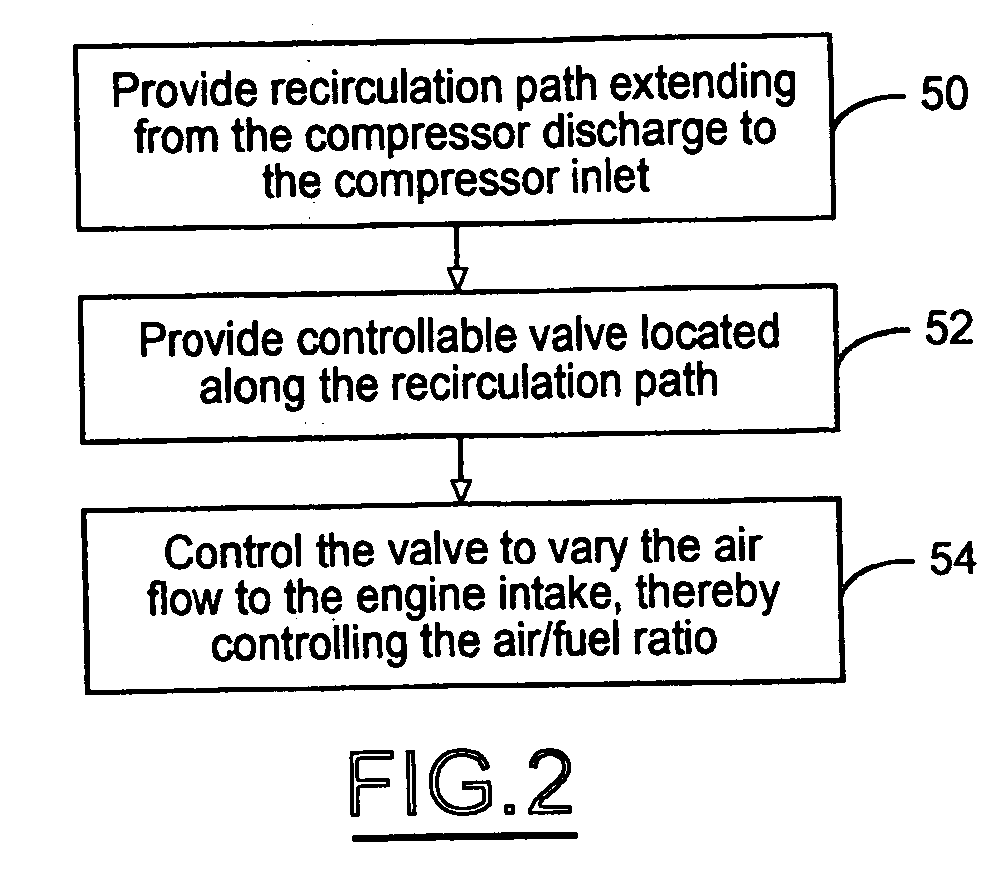

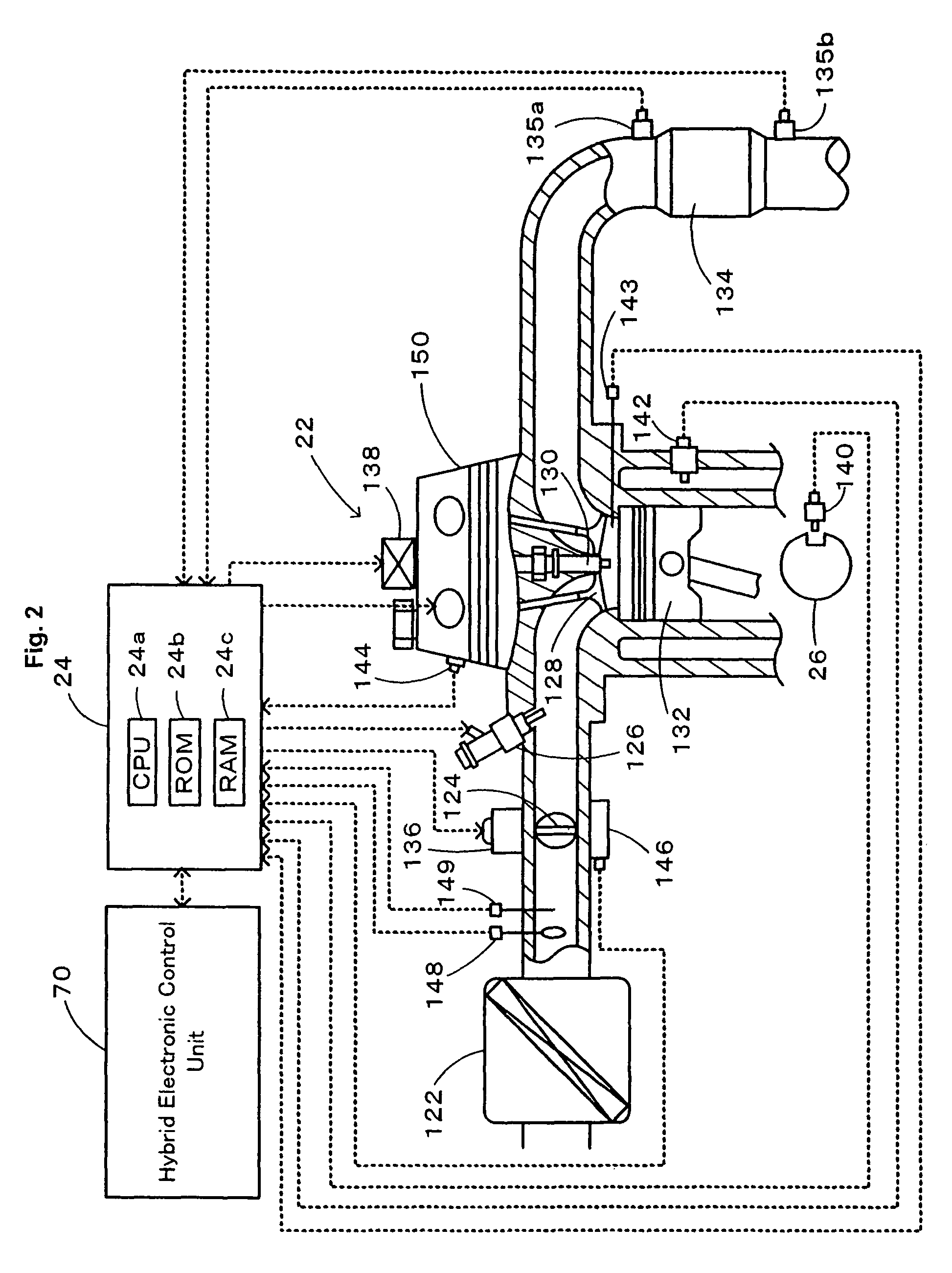

Method for controlling engine air/fuel ratio

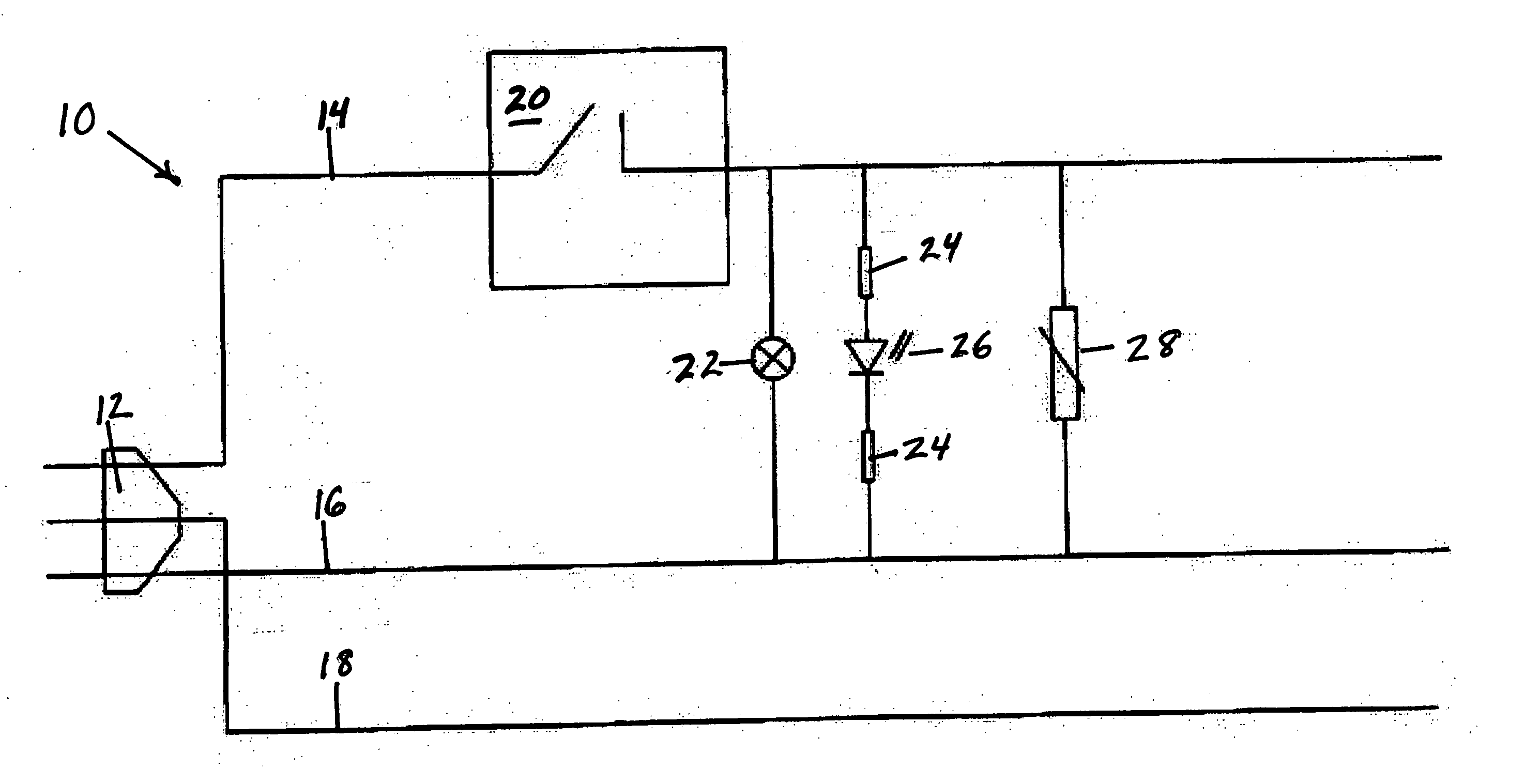

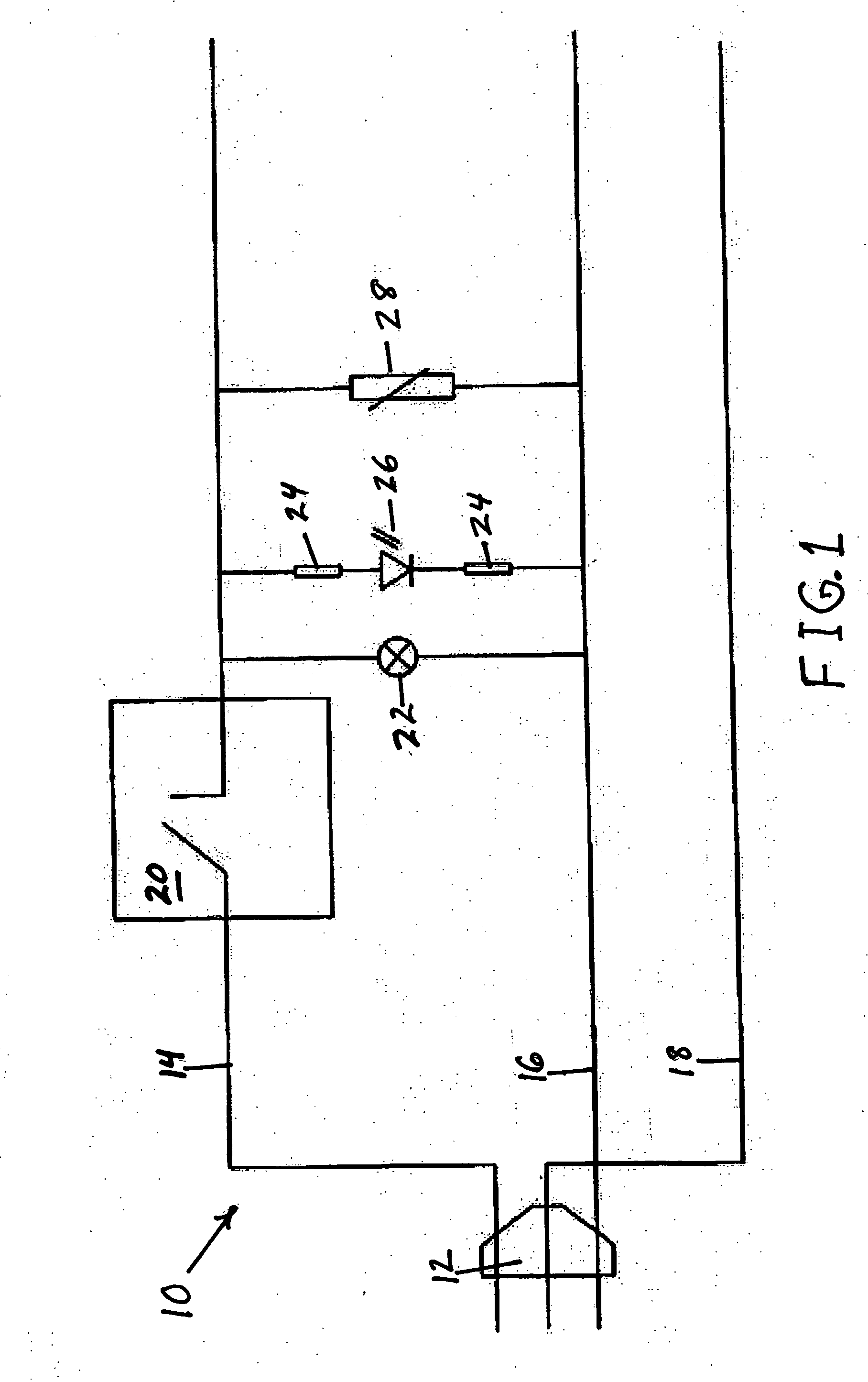

InactiveUS7080511B1Requires moreReduce the ratioElectrical controlInternal combustion piston enginesEngineeringControl valves

A system for controlling engine air / fuel ratio includes an engine, a compressor having an inlet receiving air. The compressor discharges air to the engine intake. A recirculation path is provided from the compressor discharge to the compressor inlet. A controllable valve is located along the recirculation path. A controller is programmed to control the valve to vary the air flow to the engine intake, thereby controlling the air / fuel ratio. Various applications for the compressor recirculation arrangement are possible.

Owner:DETROIT DIESEL CORP

High-power light emitting diode (LED) street lamp and body frame thereof

InactiveUS20090016055A1Improve the light distribution effectRequires moreNon-electric lightingMechanical apparatusElectricityLight emission

A high-power light emitting diode (LED) street lamp includes a body frame, a plurality of light emitting diode (LED) modules, and a base unit convexly positioned on the body frame along the light emission direction of the high-power light emitting diode (LED) street lamp. The light emitting diode (LED) modules have a plurality of light emitting diodes (LEDs), and at least one circuit board. The light emitting diodes (LEDs) are electrically connected to the at lease one circuit board to be served as the light emitting diode (LED) modules. The base unit has a plurality of supporting surfaces which support the light emitting diode (LED) modules. The supporting surfaces are symmetrically positioned on a normal direction of an end surface of the base unit, and the light emitting diode (LED) modules are positioned on the adjacent supporting surfaces, respectively. The supporting surfaces further comprise a plurality of first supporting surfaces adjacent to the normal direction of the end surface of the base unit, a plurality of second supporting surfaces adjacent to the first supporting surfaces, and a plurality of third supporting surfaces adjacent to the second supporting surfaces. An angle formed by the first supporting surfaces and the normal direction of the end surface of the base unit is in a range between 76 degrees to 86 degrees. An angle formed by the second supporting surfaces and the normal direction of the end surface of the base unit is in a range between 49 degrees to 59 degrees. An angle formed by the third supporting surfaces and the normal direction of the end surface of the base unit is in a range between 37 degrees to 47 degrees.

Owner:NINGBO ANDY OPTOELECTRONIC CO LTD

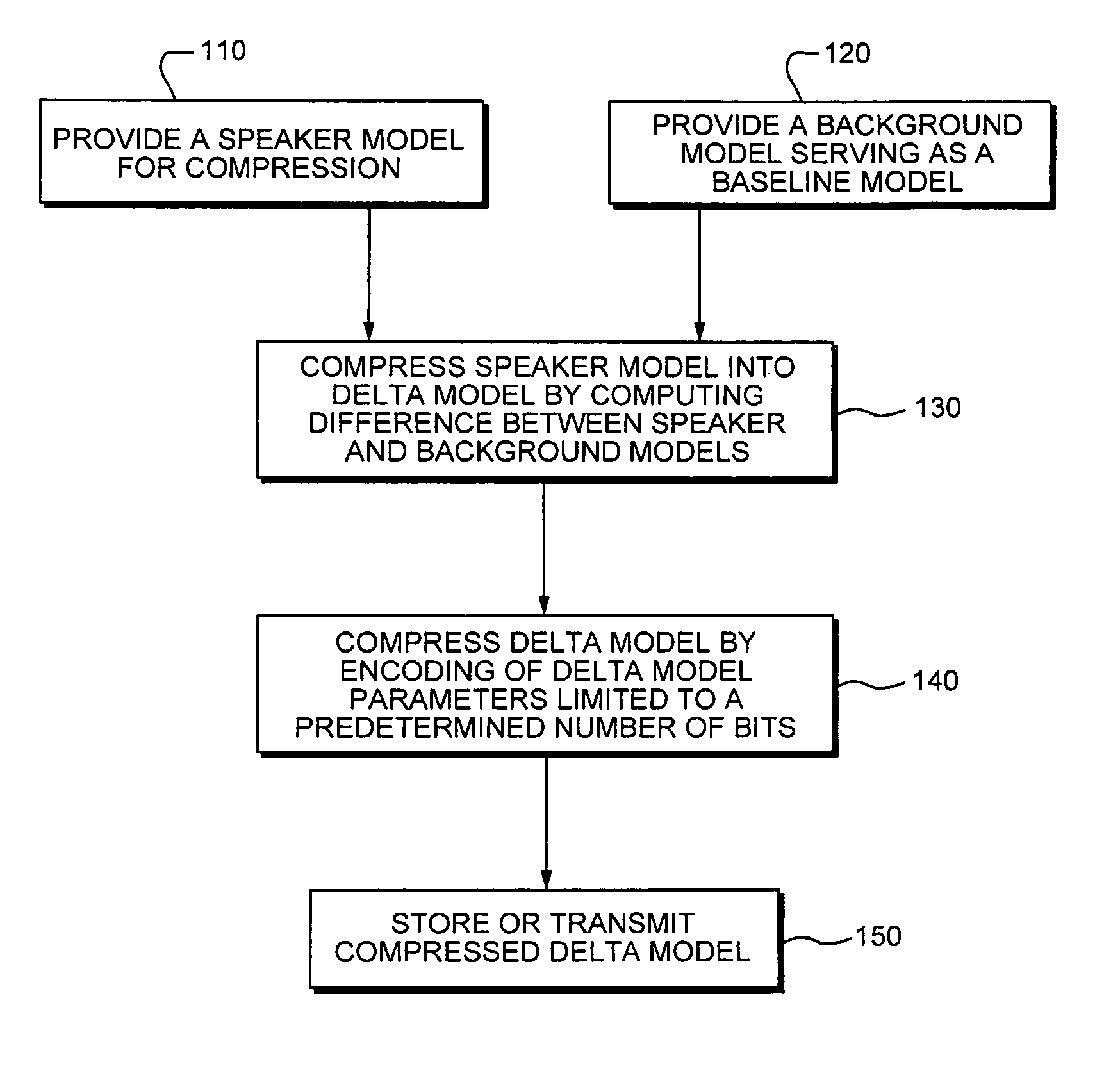

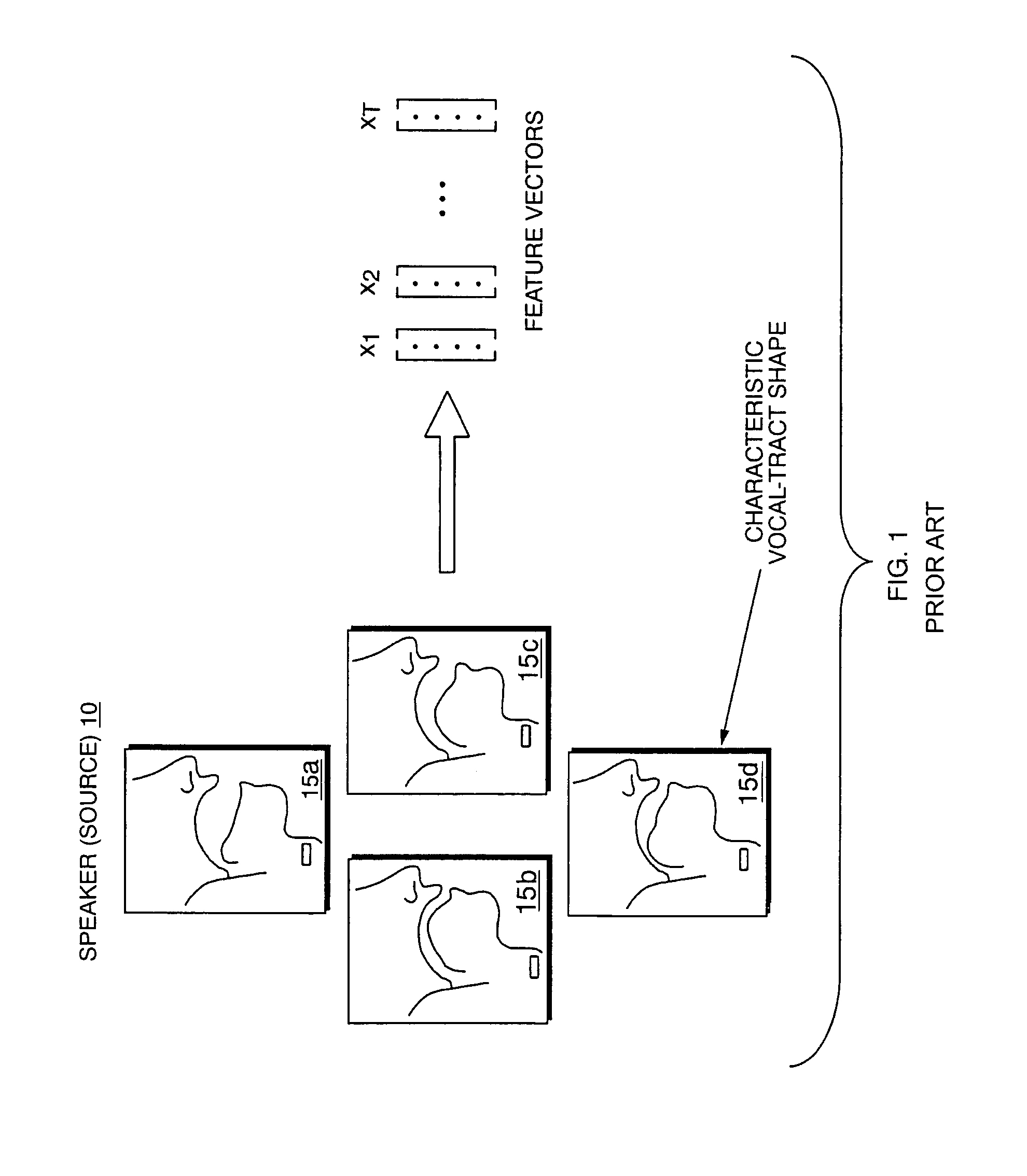

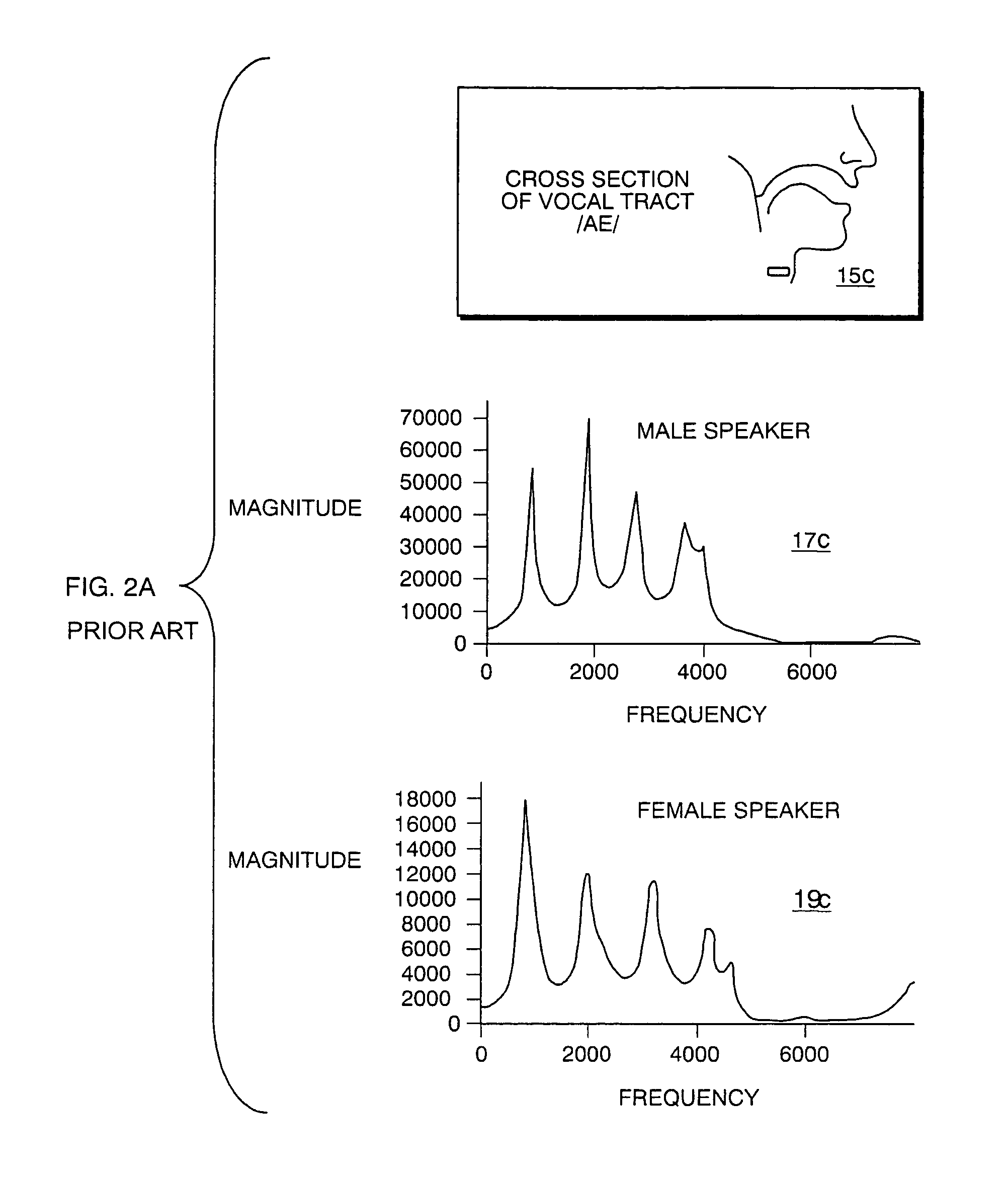

Method and apparatus for differential compression of speaker models

InactiveUS7379868B2Easy to storeLower requirementDigital data processing detailsSpeech recognitionAlgorithmDelta model

A differential compression technique is disclosed for compression individual speaker models, such as Gaussian mixture models, by computing a delta model from the difference between an individual speaker model and a baseline model. Further compression may be applied to the delta model to reduce the large storage requirements generally attributed to speaker models.

Owner:MASSACHUSETTS INST OF TECH

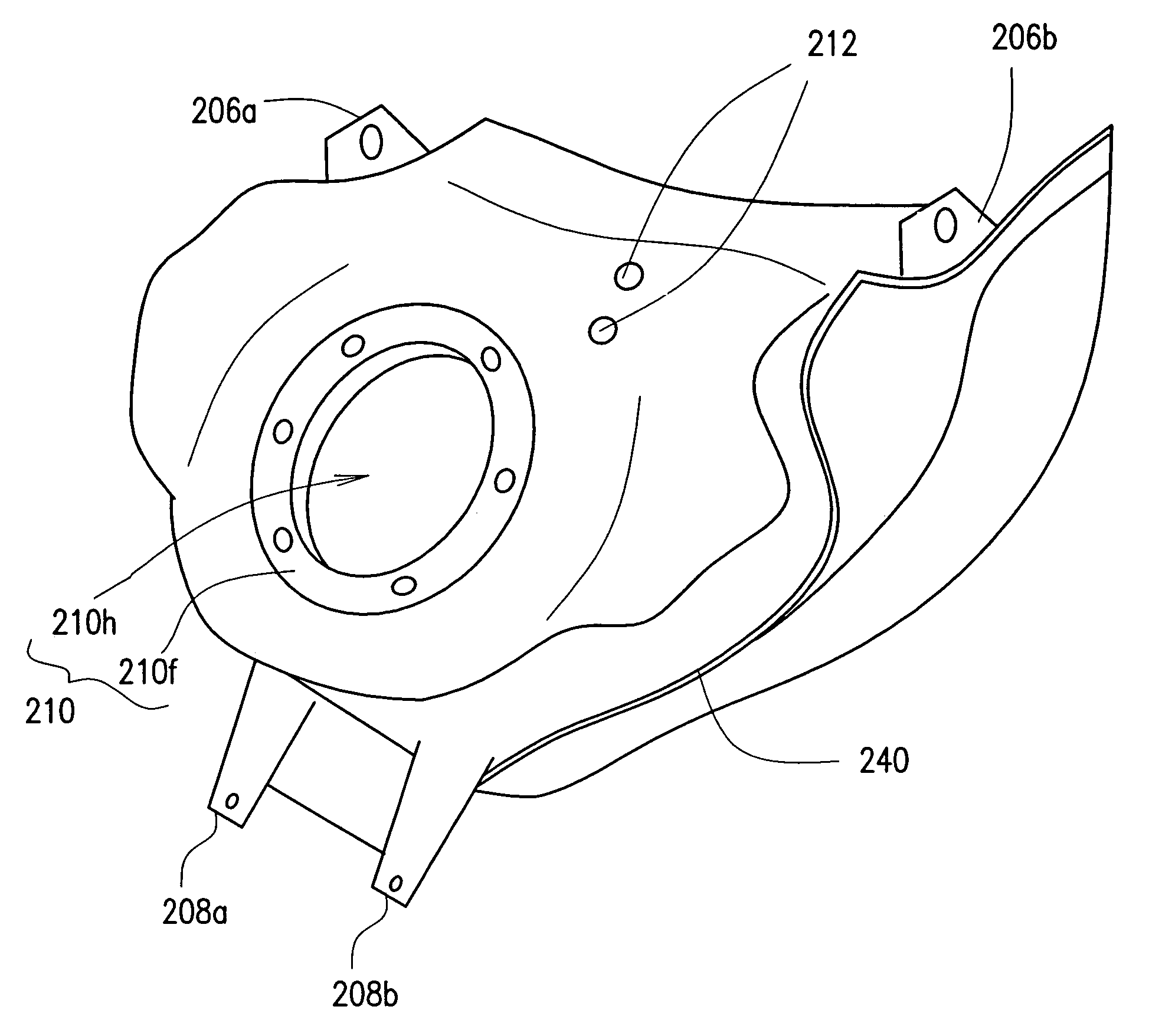

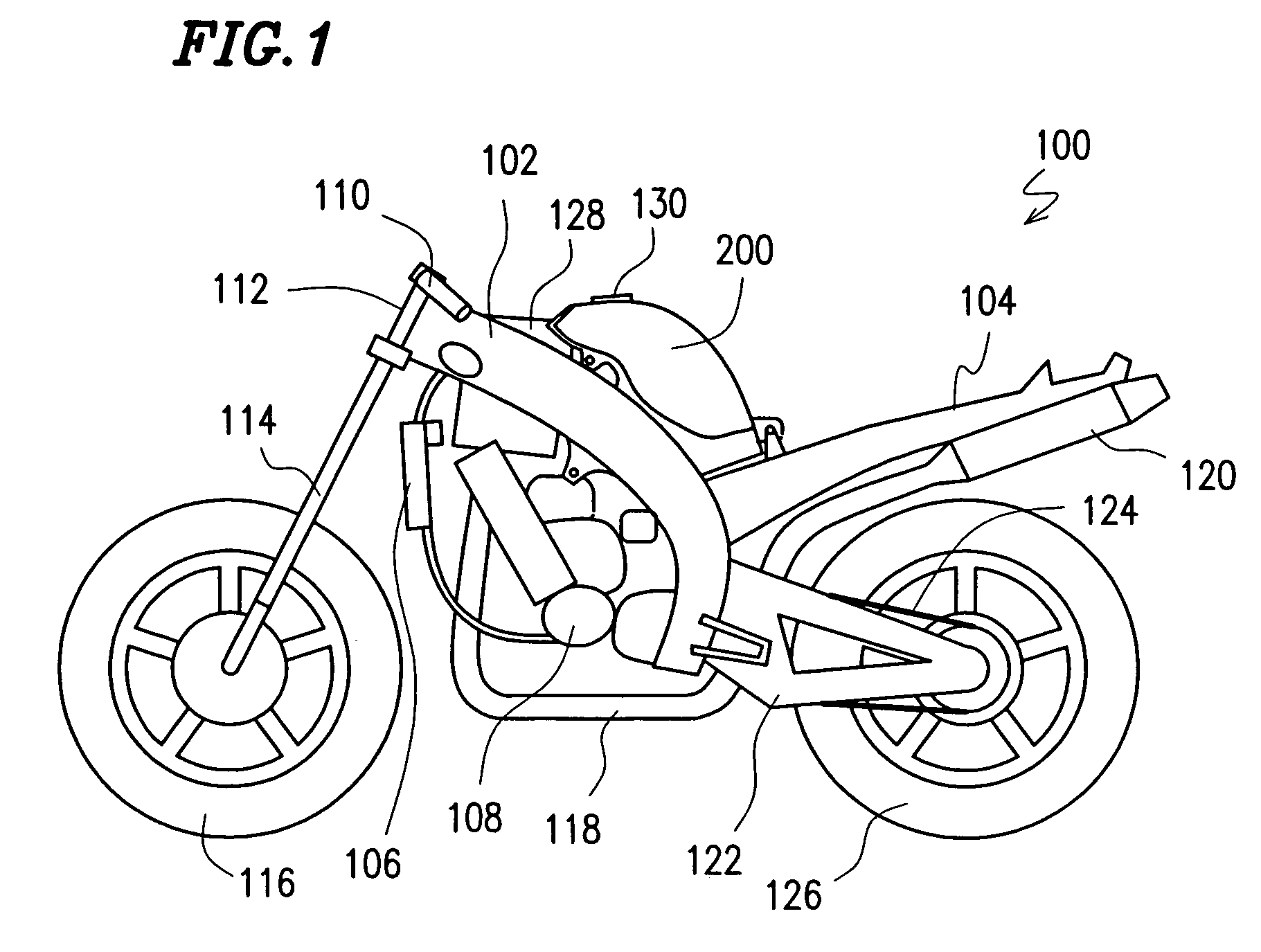

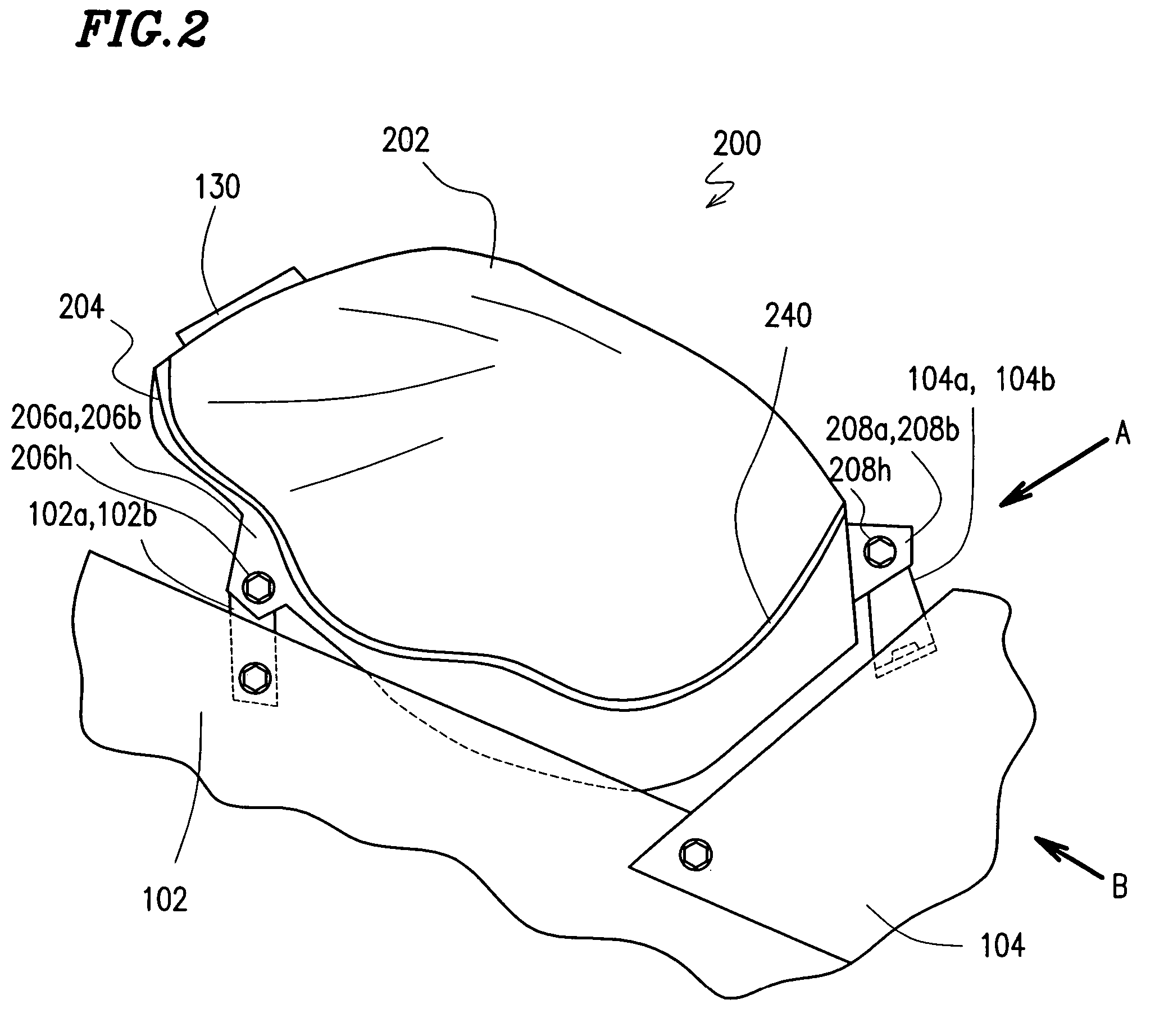

Motorcycle fuel tank

ActiveUS7390023B2High mechanical strengthGuaranteed uptimeTank vehiclesLarge containersFuel tankEngineering

A motorcycle fuel tank according to a preferred embodiment of the present invention includes an upper shell, and a lower shell including a body and fixing portions. The lower shell body is bonded to the upper shell and arranged to define a fuel storage space with the upper shell. The fixing portions are used to fix the lower shell body onto a motorcycle body. The lower shell is made of an aluminum alloy and the lower shell body and the fixing portions are formed by a casting process such that the fixing portions are integral with the lower shell.

Owner:YAMAHA MOTOR CO LTD

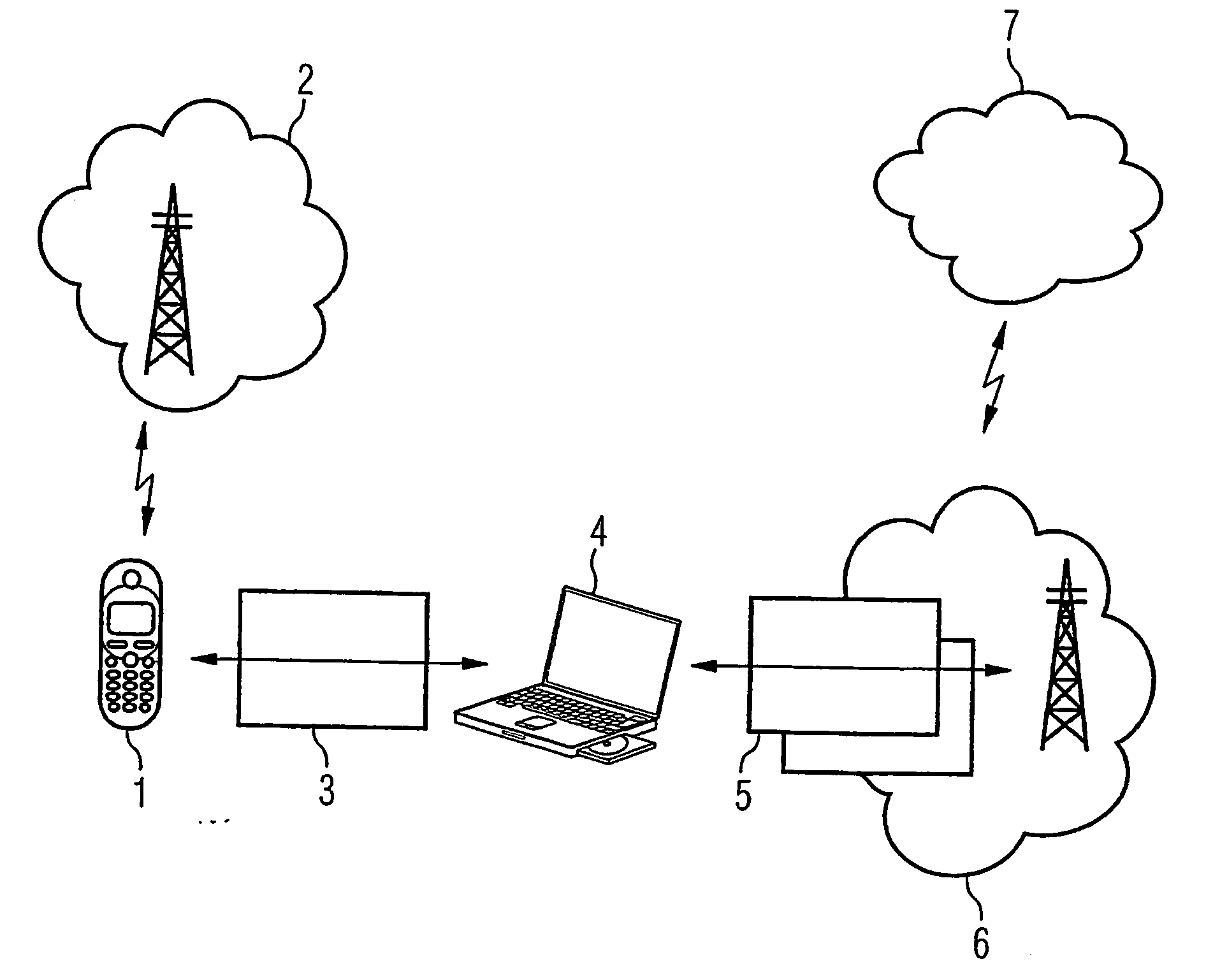

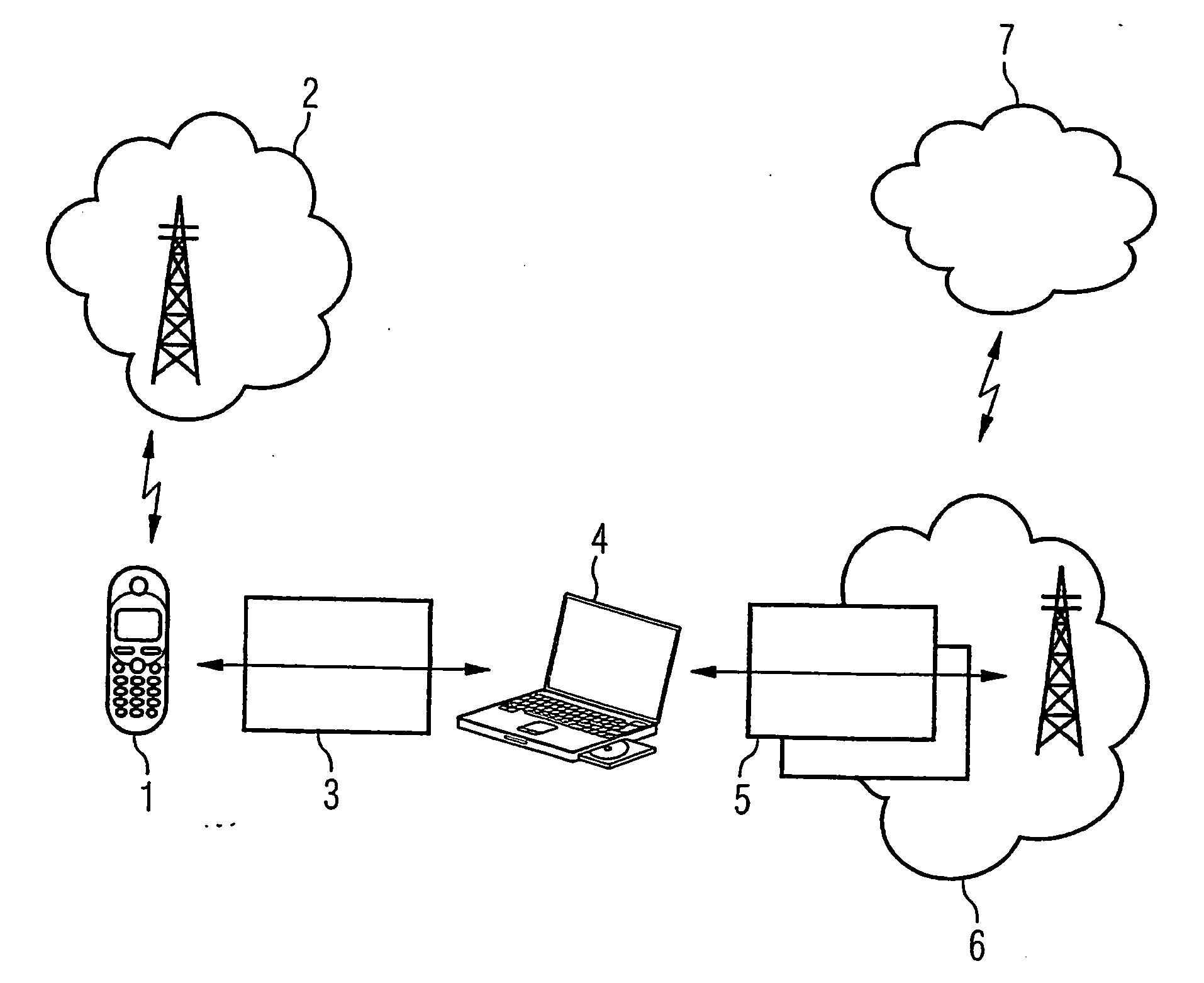

Method for safeguarding data traffic between a first terminal and a first and a second terminal and a second network

ActiveUS20070147618A1Requires moreNetwork topologiesData switching switchboardsData transmissionData traffic

To safeguard data transmission, a first terminal communicates in a first network with the aid of at least one session key and a second terminal communicates in a second network with the aid of at least one session key. The first terminal is connected to the second terminal through a local interface. In the first terminal, at least one first session key is determined and at least one second session key is derived from the first session keys. At least one second session key is transmitted to the second terminal through the local interface by a safety protocol. The second terminal is authenticated to the second network by at least one second session key or by the key derived from the second session key(s) through an authentication protocol.

Owner:SIEMENS AG

Method for controlling engine air/fuel ratio

InactiveUS20060150628A1Easy to controlRequires moreElectrical controlNon-fuel substance addition to fuelVALVE PORTEngineering

A system for controlling engine air / fuel ratio includes an engine, a compressor having an inlet receiving air. The compressor discharges air to the engine intake. A recirculation path is provided from the compressor discharge to the compressor inlet. A controllable valve is located along the recirculation path. A controller is programmed to control the valve to vary the air flow to the engine intake, thereby controlling the air / fuel ratio. Various applications for the compressor recirculation arrangement are possible.

Owner:DETROIT DIESEL CORP

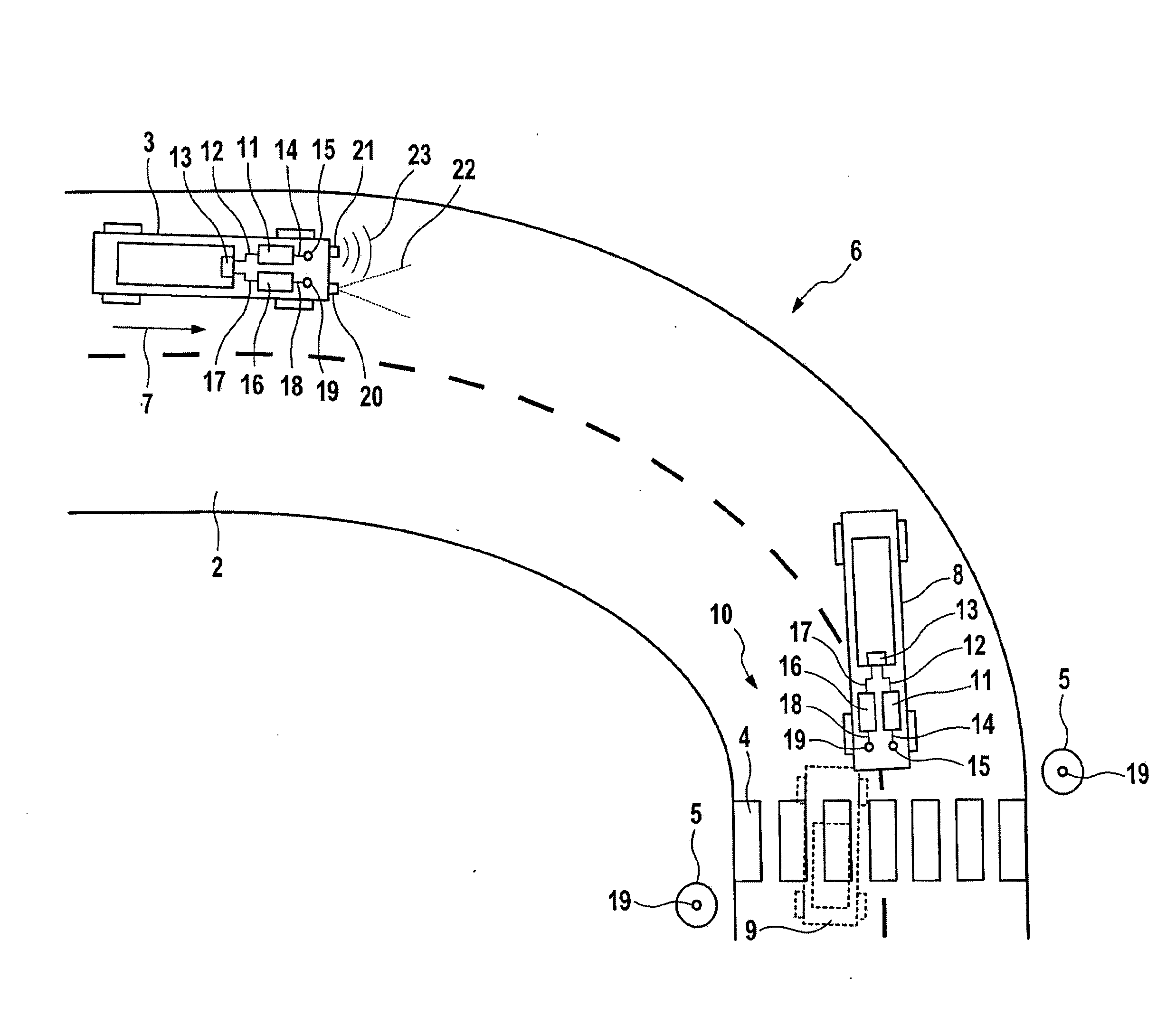

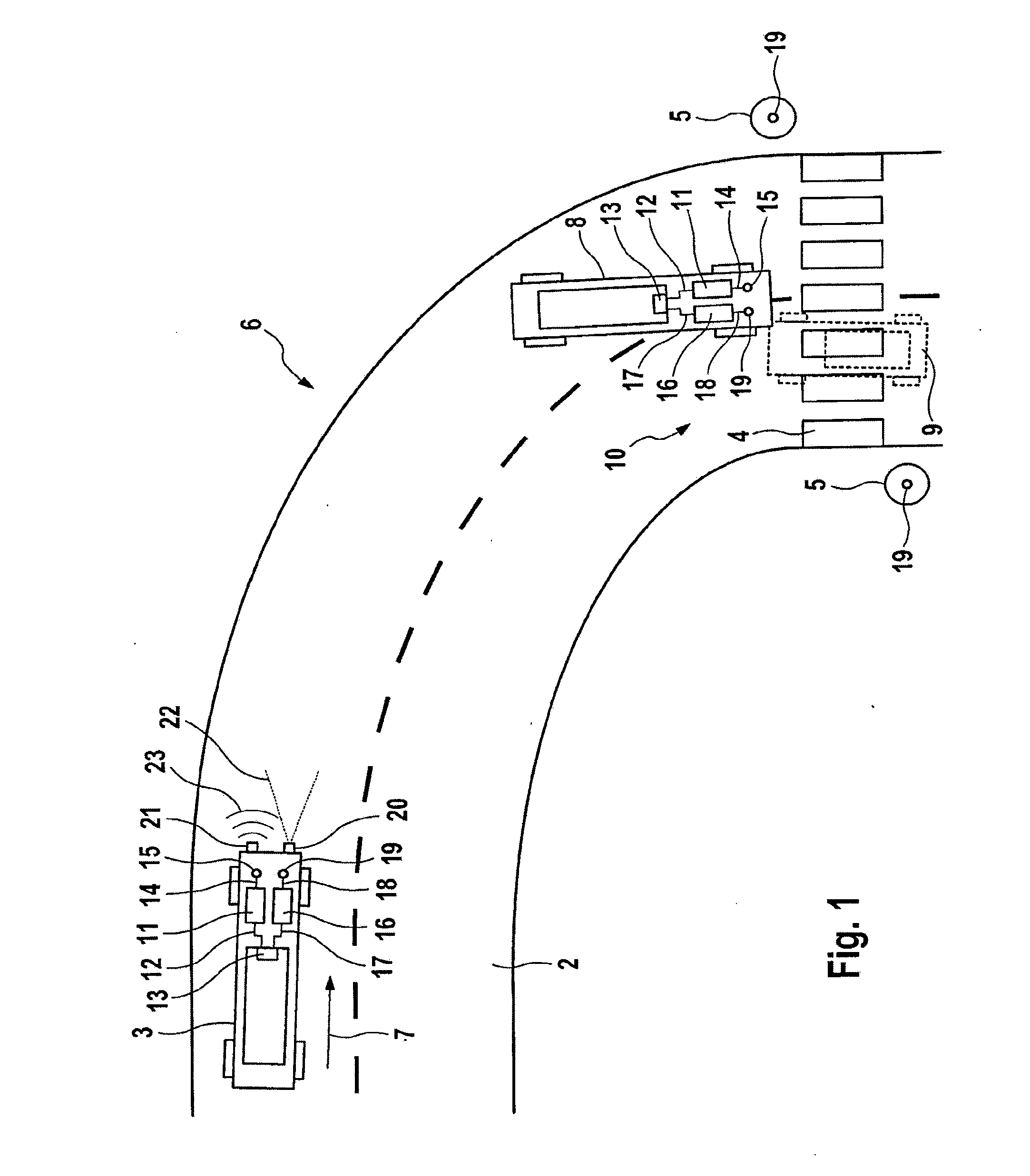

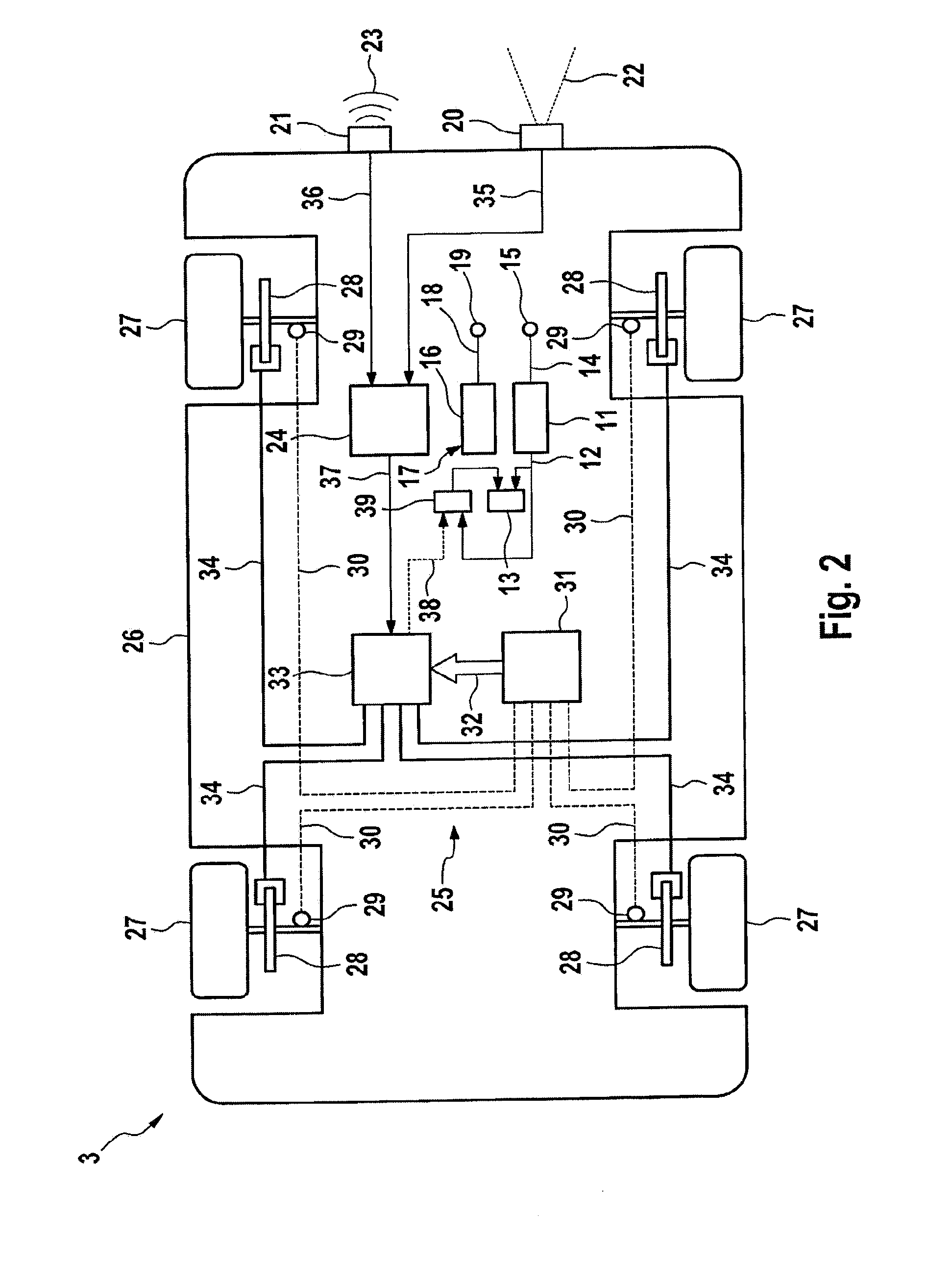

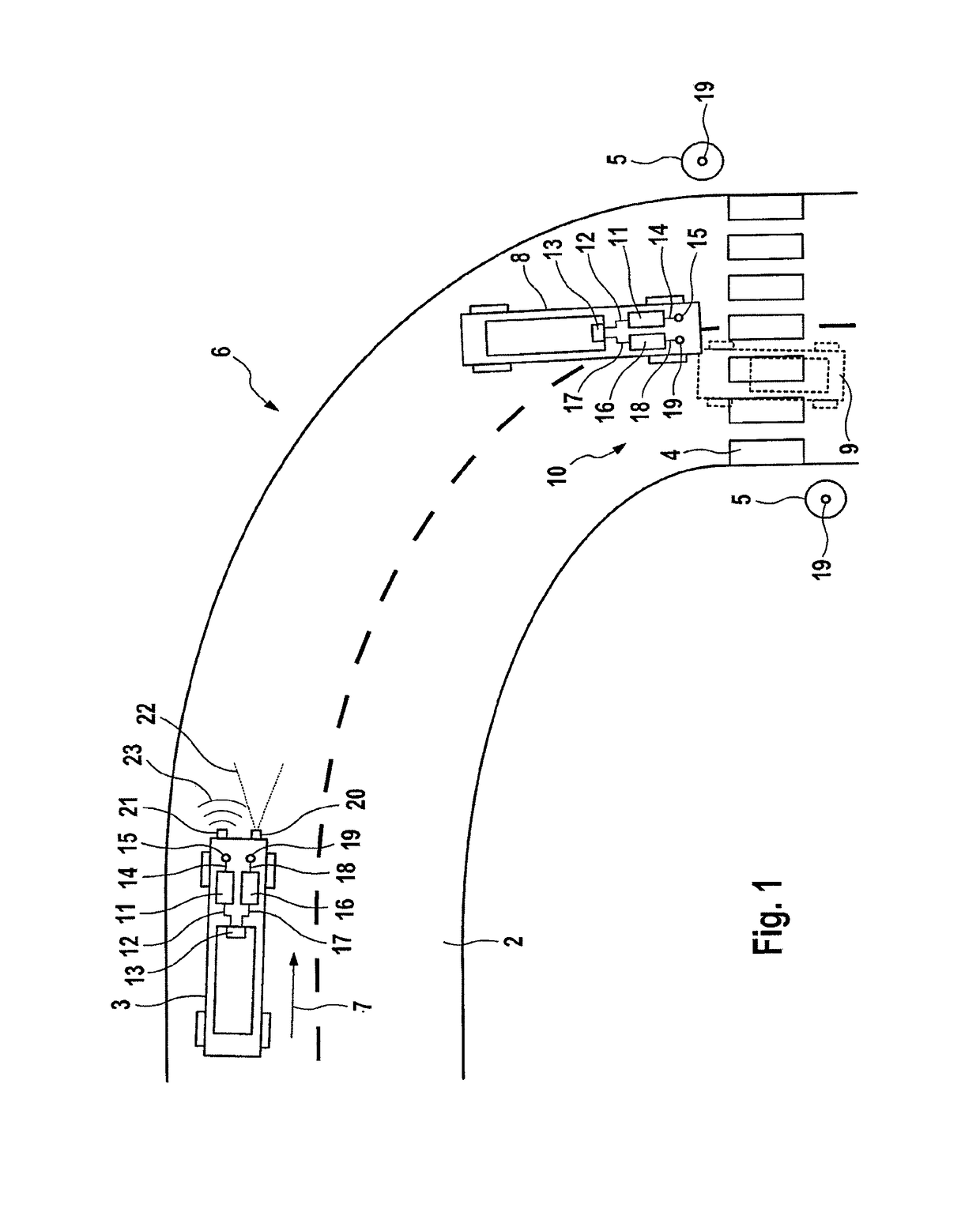

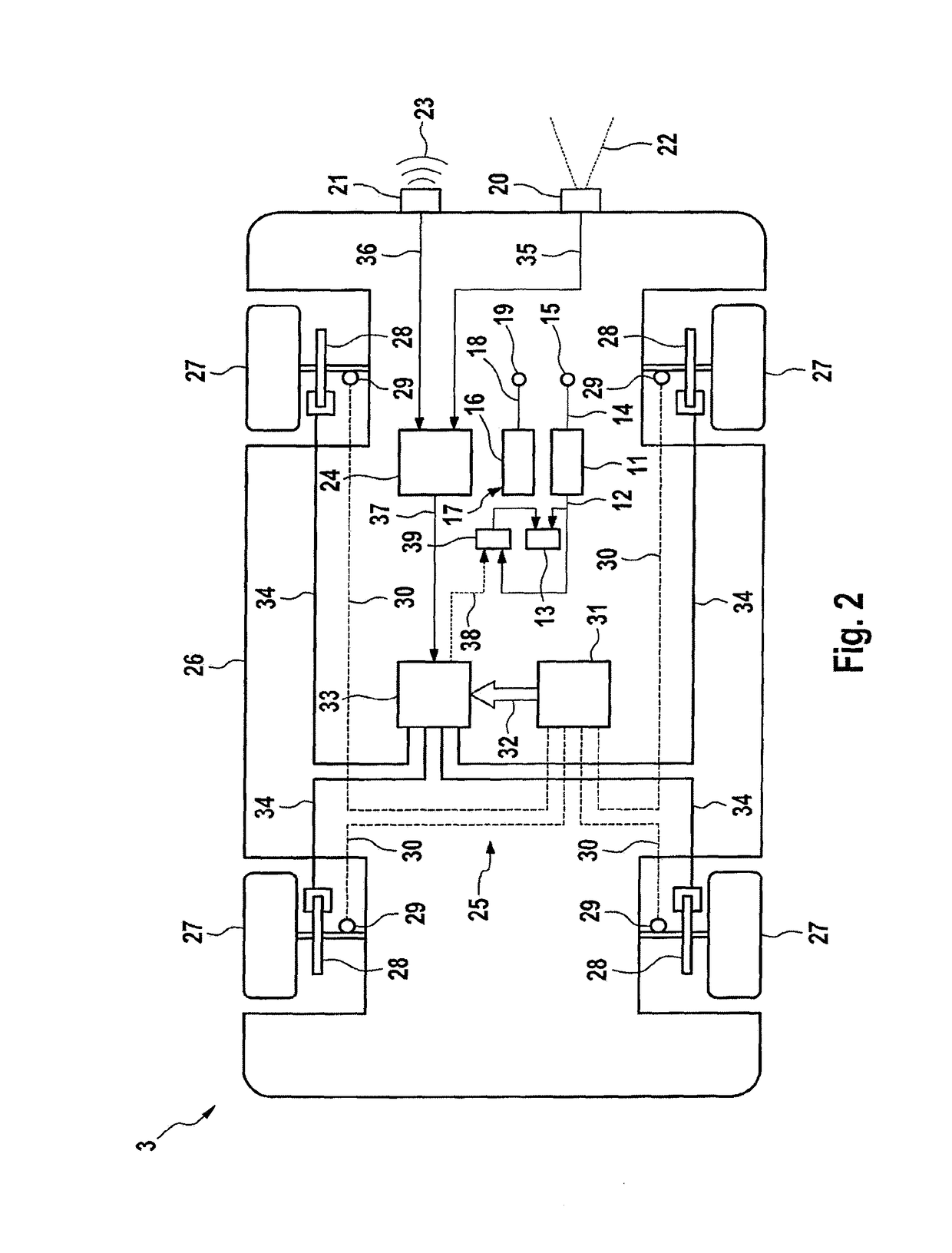

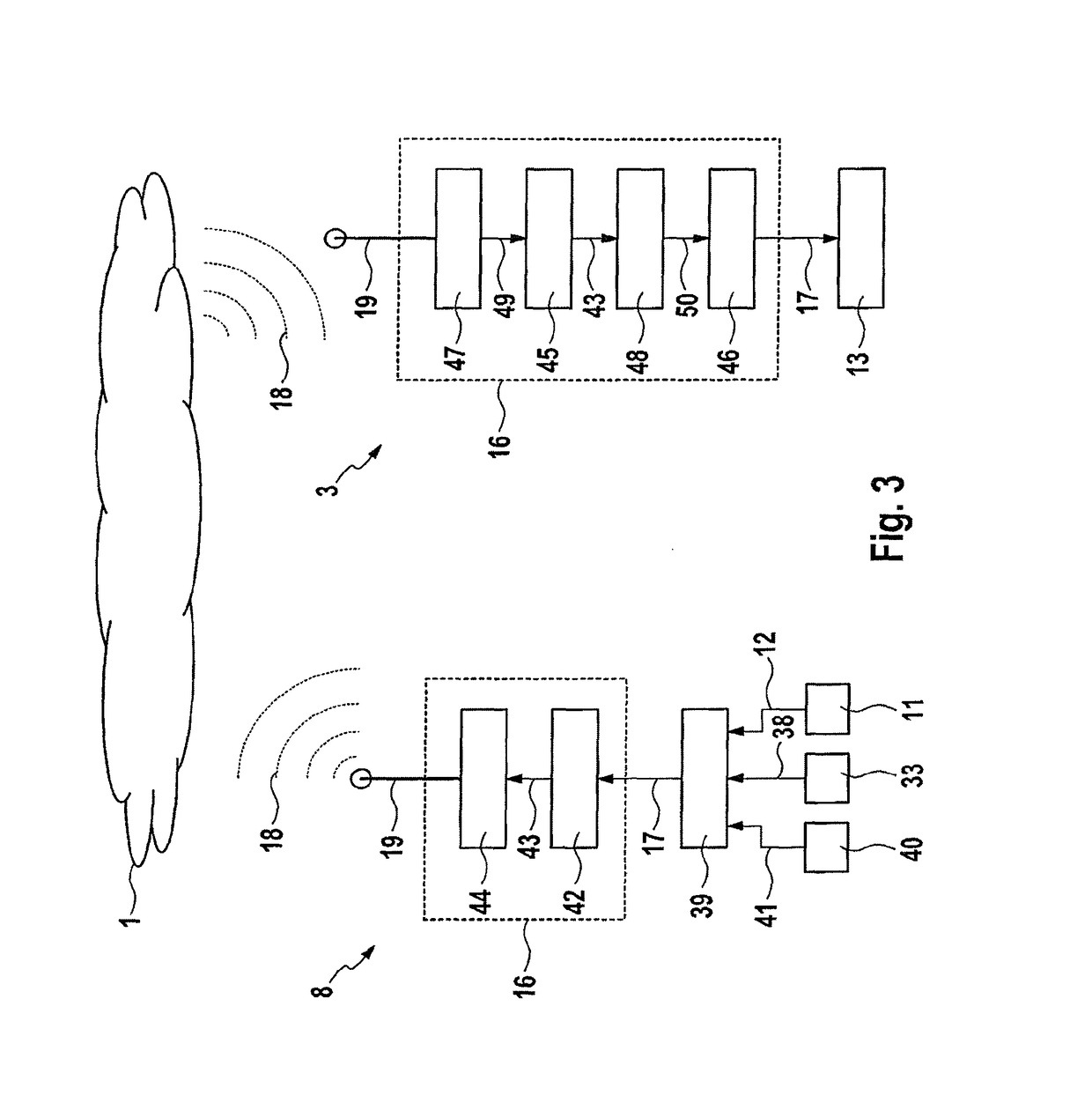

Car2x receiver filtering based on a receiving corridor in a geographic coordinate system

ActiveUS20160198303A1Easy to useReduce complexityRoad vehicles traffic controlParticular environment based servicesGeographic coordinate systemDecision threshold

A method for filtering a message transmitted between a transmitter and a receiver in a vehicular ad hoc network, the message containing at least one position of the transmitter, including: determining a position of the receiver by a global satellite navigation system in a predetermined coordinate system; determining a decision threshold for a maximum distance between the receiver and the transmitter in the predetermined coordinate system in which the position of the receiver was determined; and discarding the message if a distance between the position of the transmitter and the position of the receiver exceeds the decision threshold.

Owner:CONTINENTAL TEVES AG & CO OHG

Two-stage plasma process for converting waste into fuel gas and apparatus therefor

InactiveUS20110107669A1Limited amountImprove energy efficiencyGasifier electrodesGaseous fuelsCyclonePlasma jet

A two-step gasification process and apparatus for the conversion of solid or liquid organic waste into clean fuel, suitable for use in a gas engine or a gas burner, is described. The waste is fed initially into a primary gasifier, which is a graphite arc furnace. Within the primary gasifier, the organic components of the waste are mixed with a predetermined amount of air, oxygen or steam, and converted into volatiles and soot. The volatiles consist mainly of carbon monoxide and hydrogen, and may include a variety of other hydrocarbons and some fly ash. The gas exiting the primary gasifier first passes through a hot cyclone, where some of the soot and most of the fly ash is collected and returned to the primary gasifier. The remaining soot along with the volatile organic compounds is further treated in a secondary gasifier where the soot and the volatile compounds mix with a high temperature plasma jet and a metered amount of air, oxygen or steam, and are converted into a synthesis gas consisting primarily of carbon monoxide and hydrogen. The synthesis gas is then quenched and cleaned to form a clean fuel gas suitable for use in a gas engine or a gas burner. This offers higher thermal efficiency than conventional technology and produces a cleaner fuel than other known alternatives.

Owner:PYROGENESIS CANADA INC

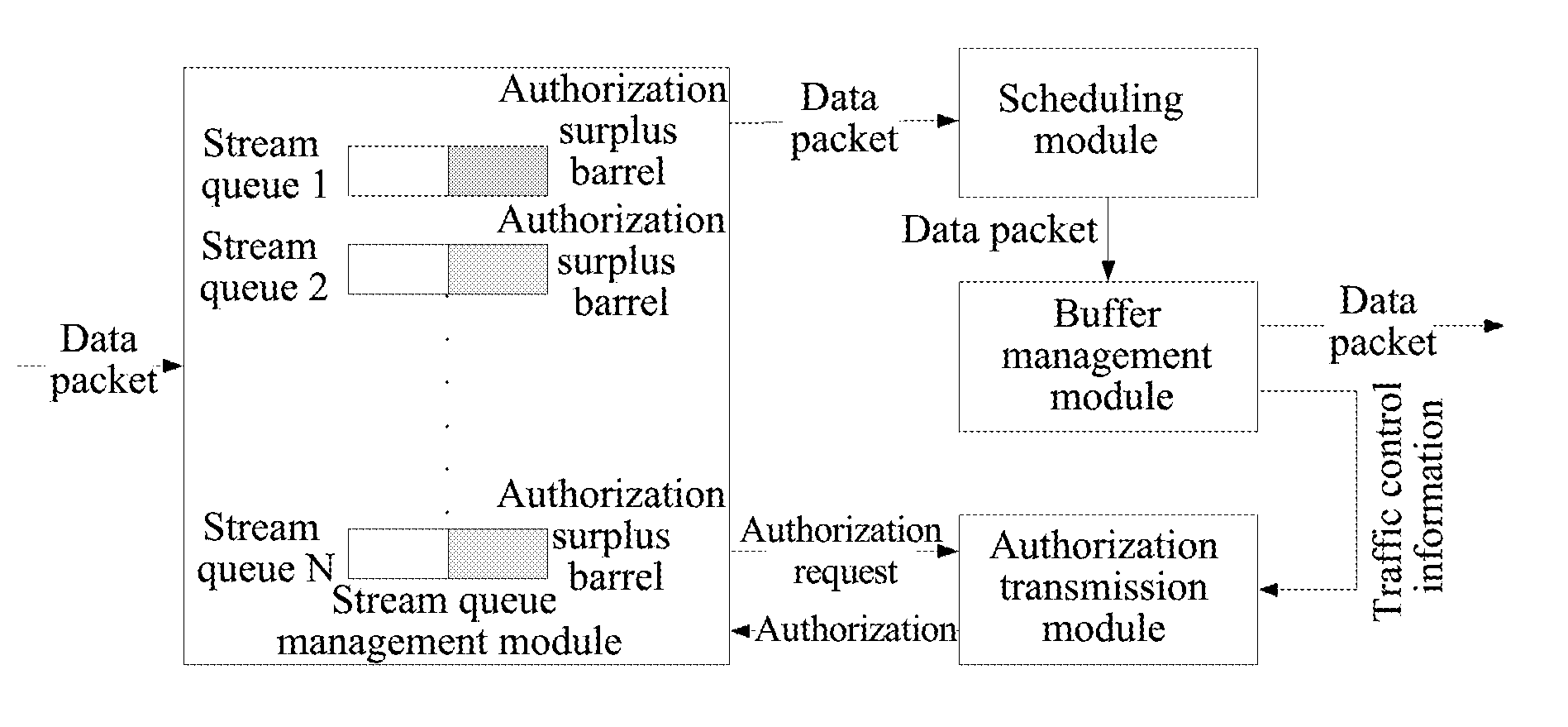

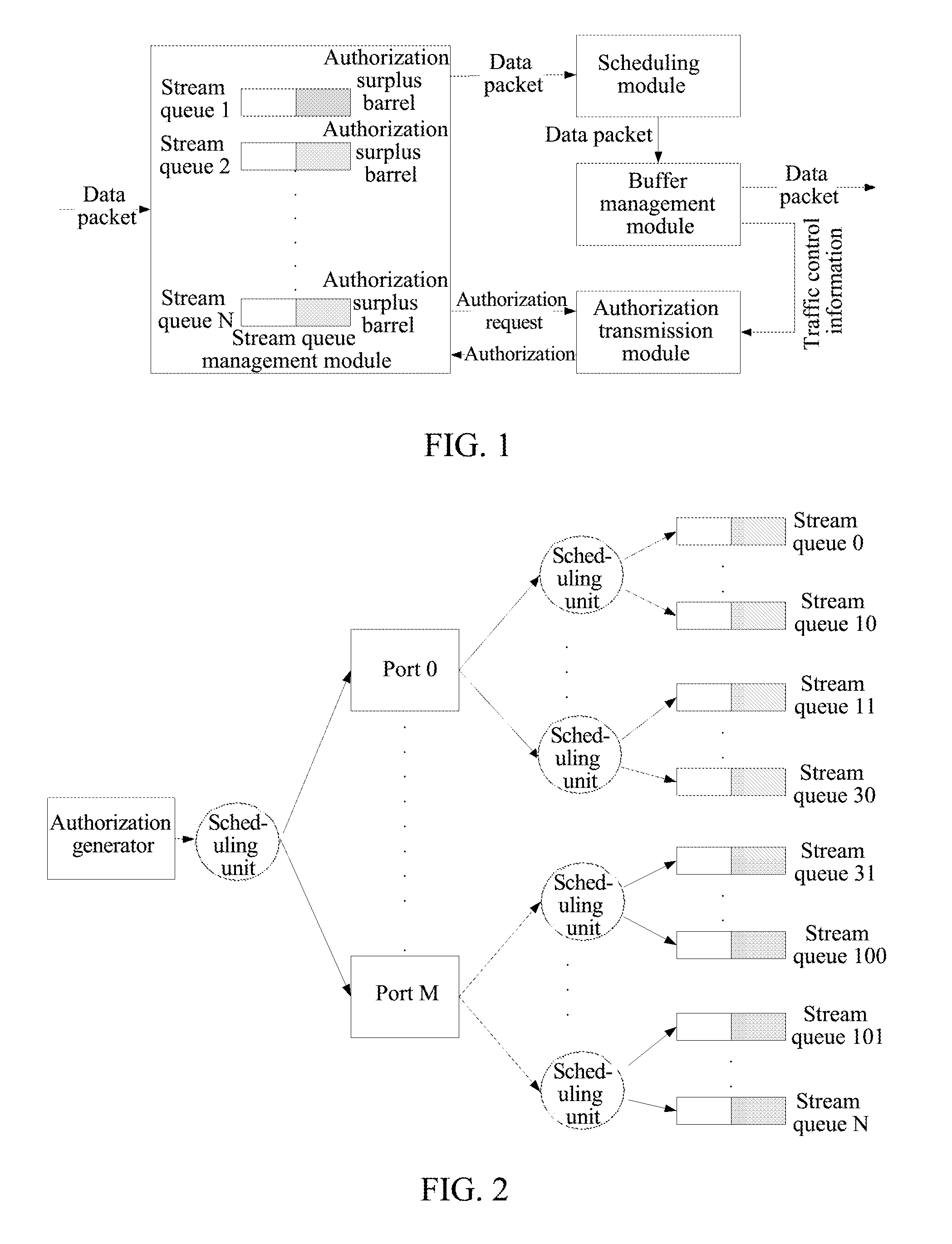

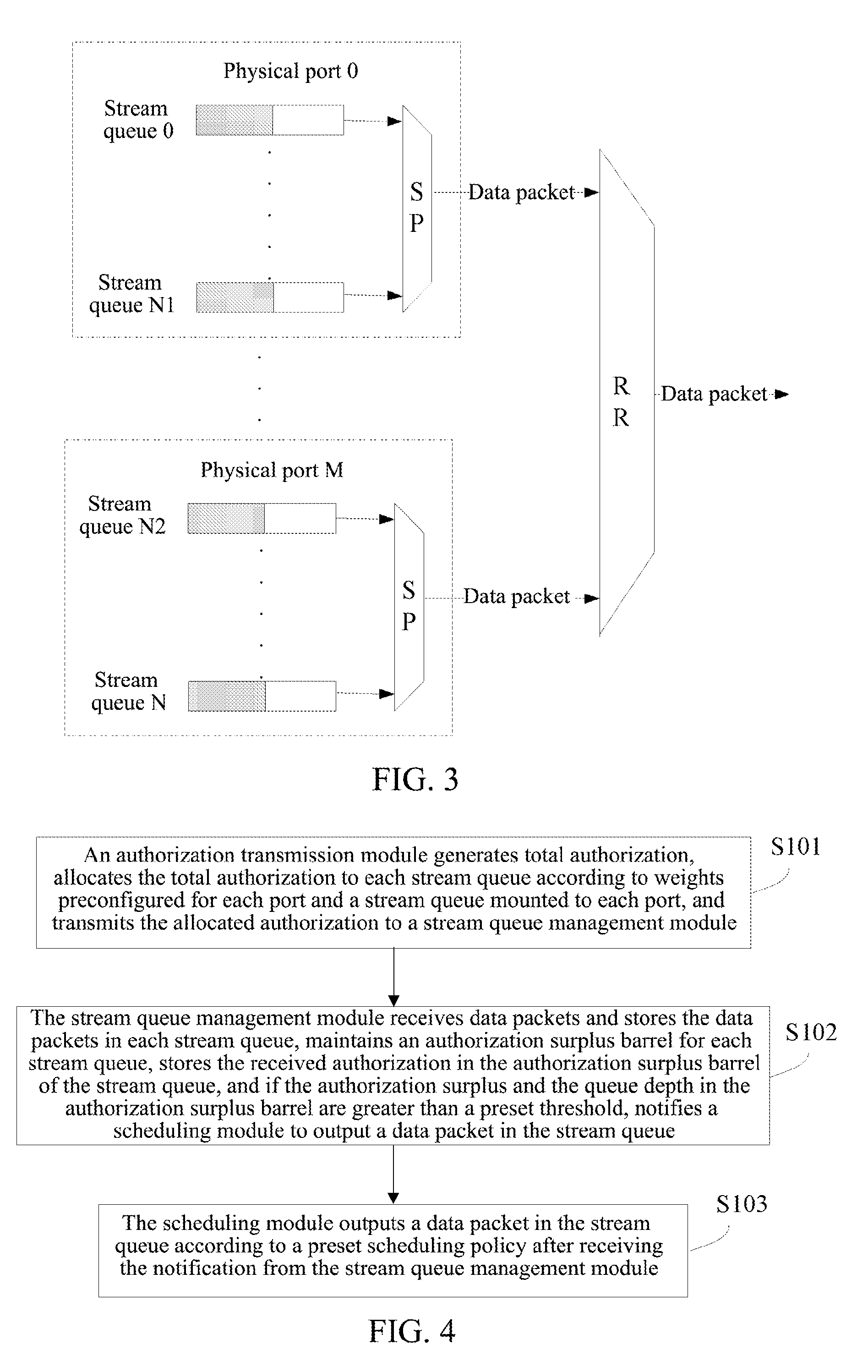

Flow scheduling device and method

ActiveUS20150058485A1Avoid problemsRequires moreDigital computer detailsData switching networksTraffic capacityNetwork packet

A method for traffic scheduling includes: authorizing a transmitting module to generate total authorization, allocating the total authorization to each stream queue according to weights preconfigured for each port and a stream queue mounted to each port, and transmitting the allocated authorization to a stream queue management module; the stream queue management module receiving data packets and storing the data packets in each stream queue, maintaining an authorization surplus barrel for each stream queue, storing the received authorization in the authorization surplus barrel of the stream queue, and if the authorization surplus and the queue depth in the authorization surplus barrel are greater than a preset threshold, notifying a scheduling module to output a data packet in the stream queue; and after receiving the notification from the stream queue management module, the scheduling module outputting a data packet in the stream queue according to a preset scheduling policy.

Owner:SANECHIPS TECH CO LTD

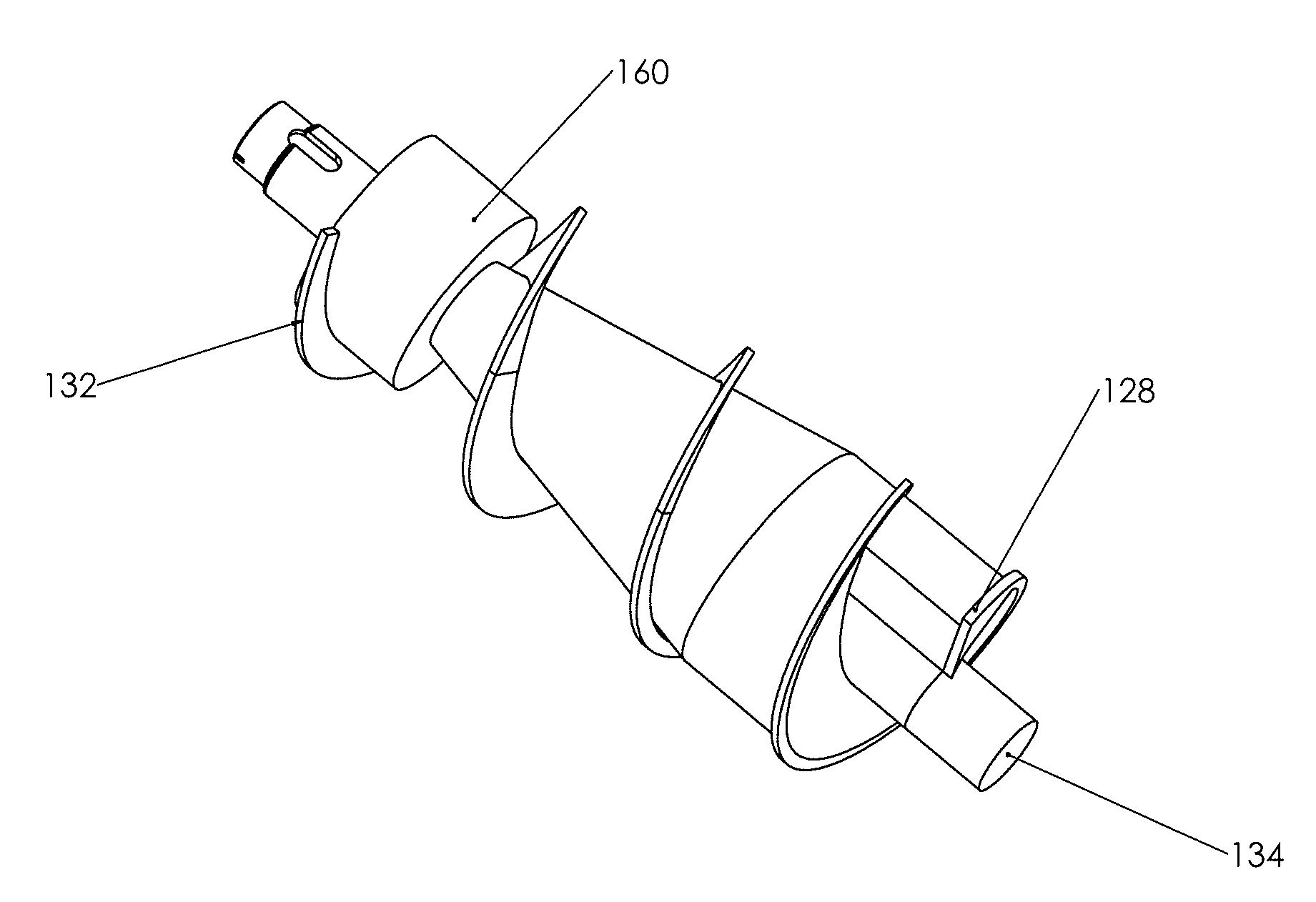

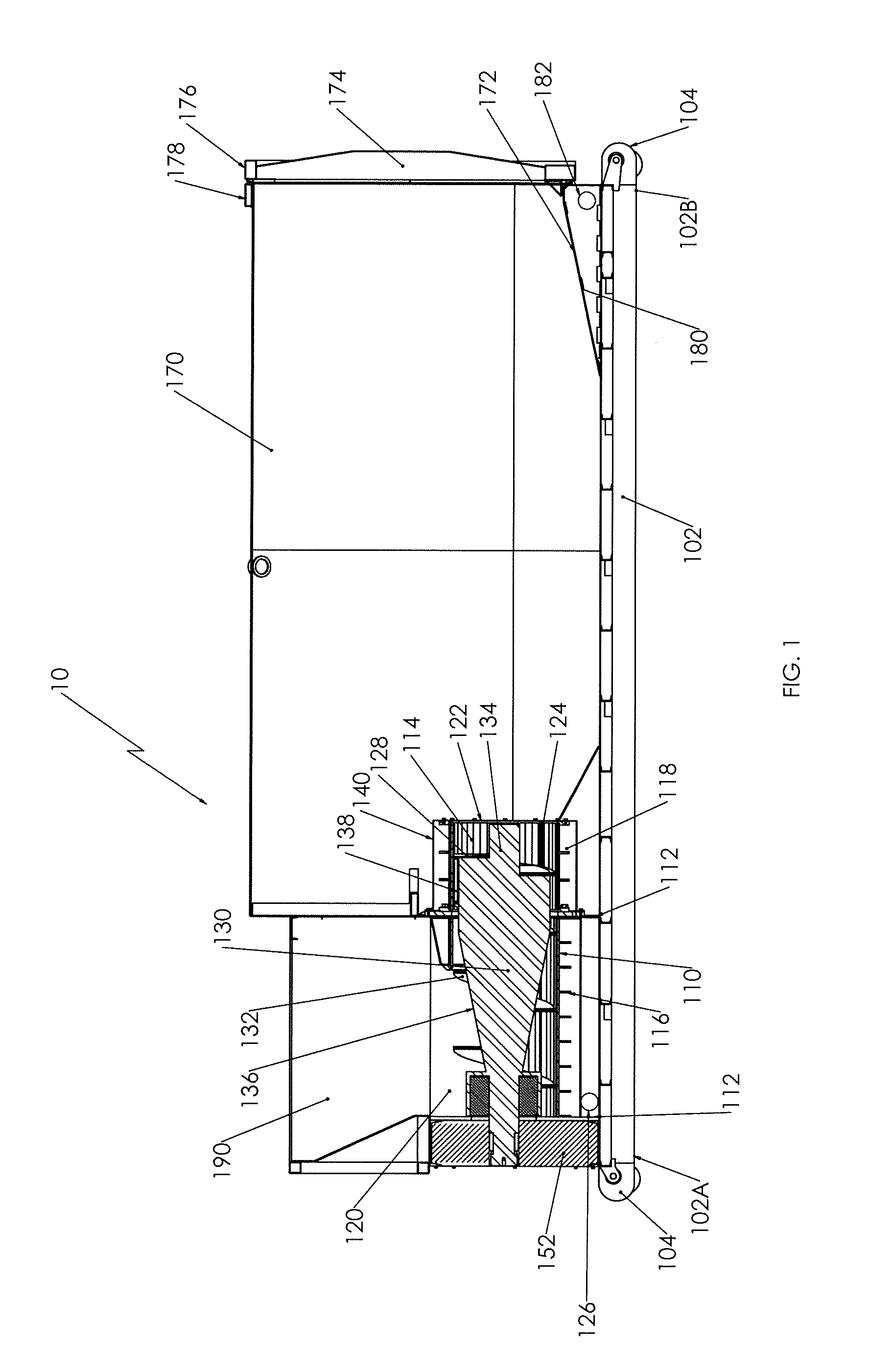

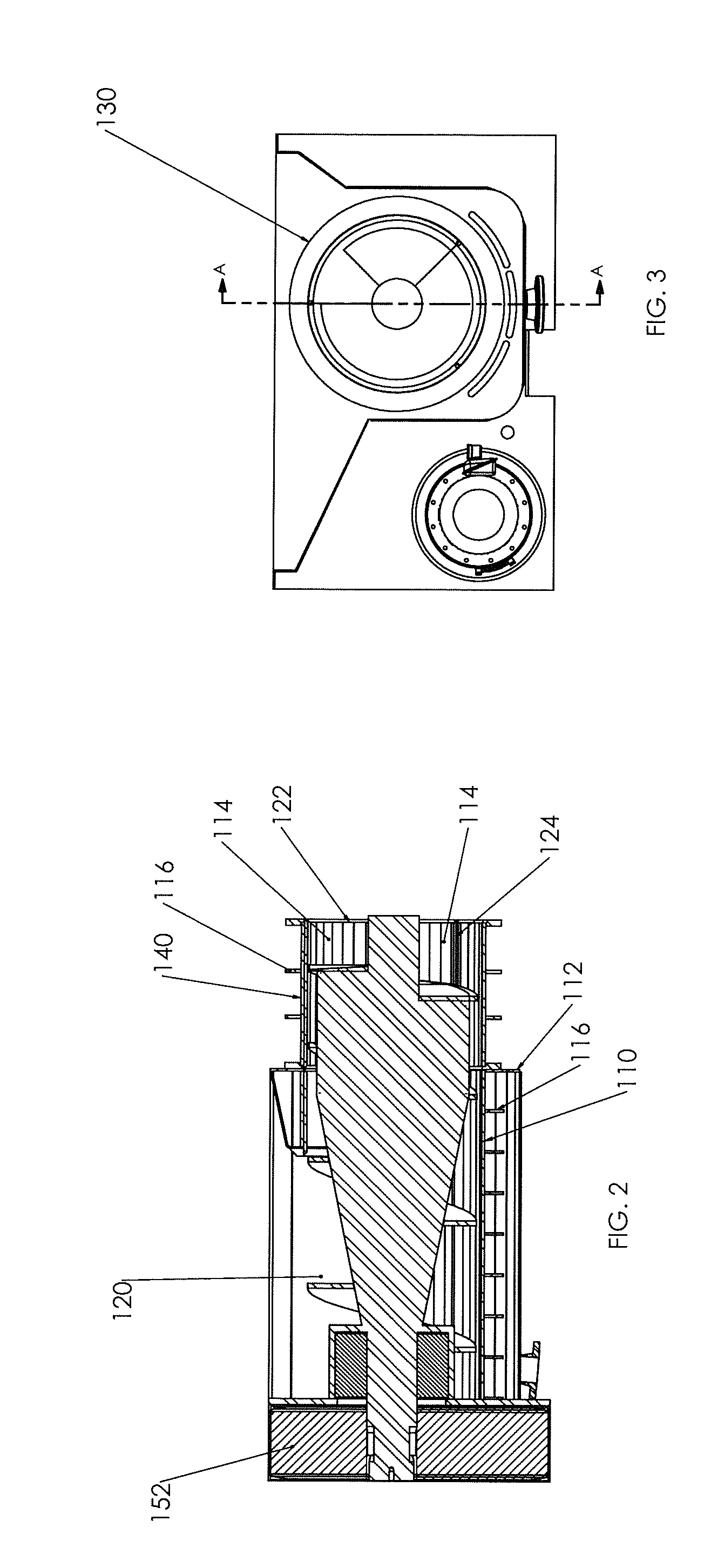

System and method for crushing and compaction

ActiveUS20120145012A1Increase efficiency and remedy problemReduce reliabilityBone cleaning devicesGrain treatmentsCantileverCrusher

An exemplary embodiment of a screw crusher may utilize a cantilevered screw with an inverse tapered shaft with flighting for conveying the product up the length of the shaft for compression. The screw may include an end flight configured to provide thrust to the product for further conveyance beyond the end of the screw or additional compaction when utilized with a receiving container. An exemplary embodiment of the screw crusher may utilize a single moving element in relation to a cylindrical tube for compression of the product. Also, an exemplary screw compactor may utilize a fixed replaceable restrictor tube section and an efficient screw design making it more cost effective and efficient to operate than other known compactors. Furthermore, an example of the screw crusher may be fitted with perforated or the preferred “V” Slotted tube to perform liquid removal in addition to the compaction of the material.

Owner:KOMAR IND LLC

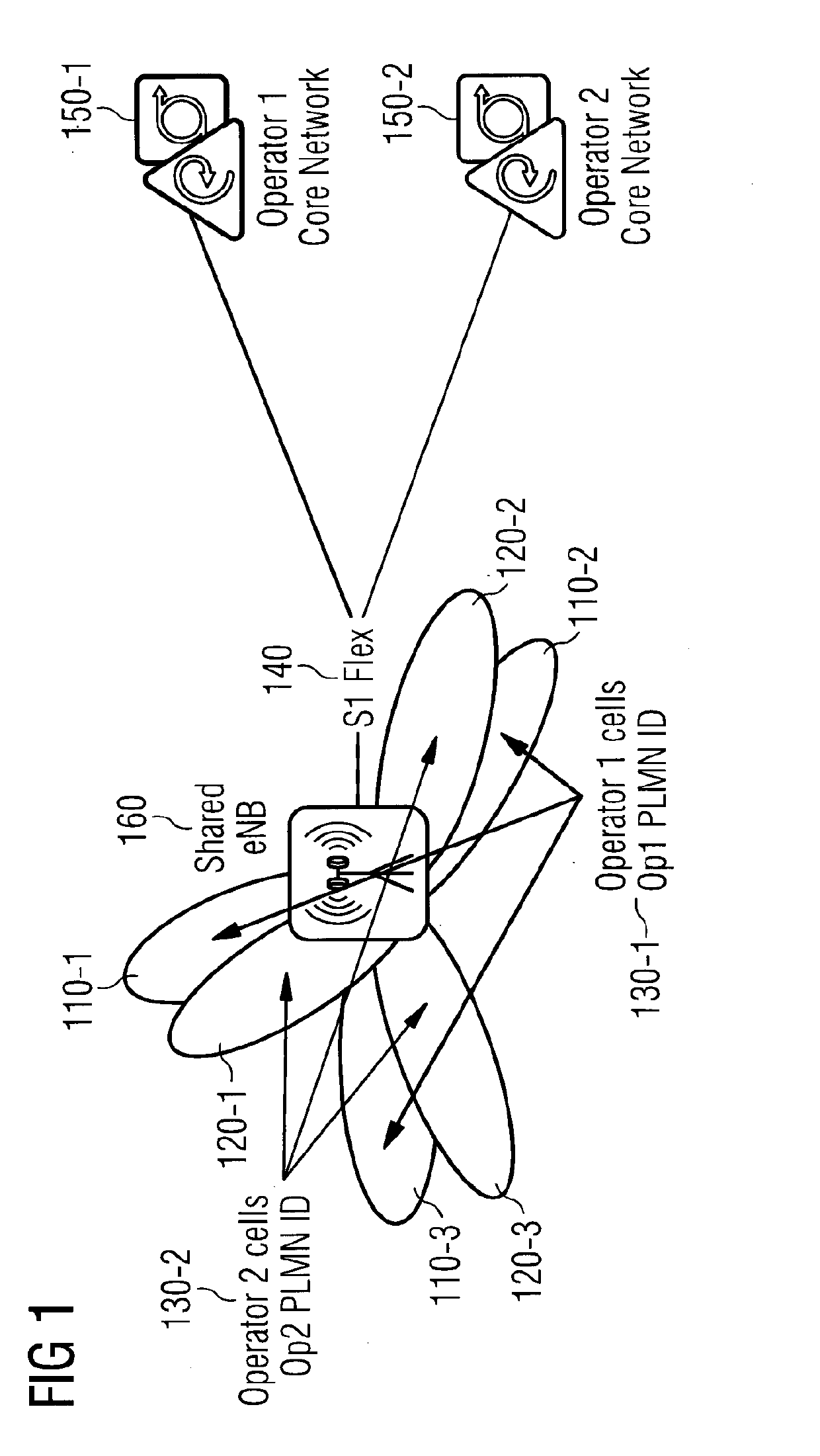

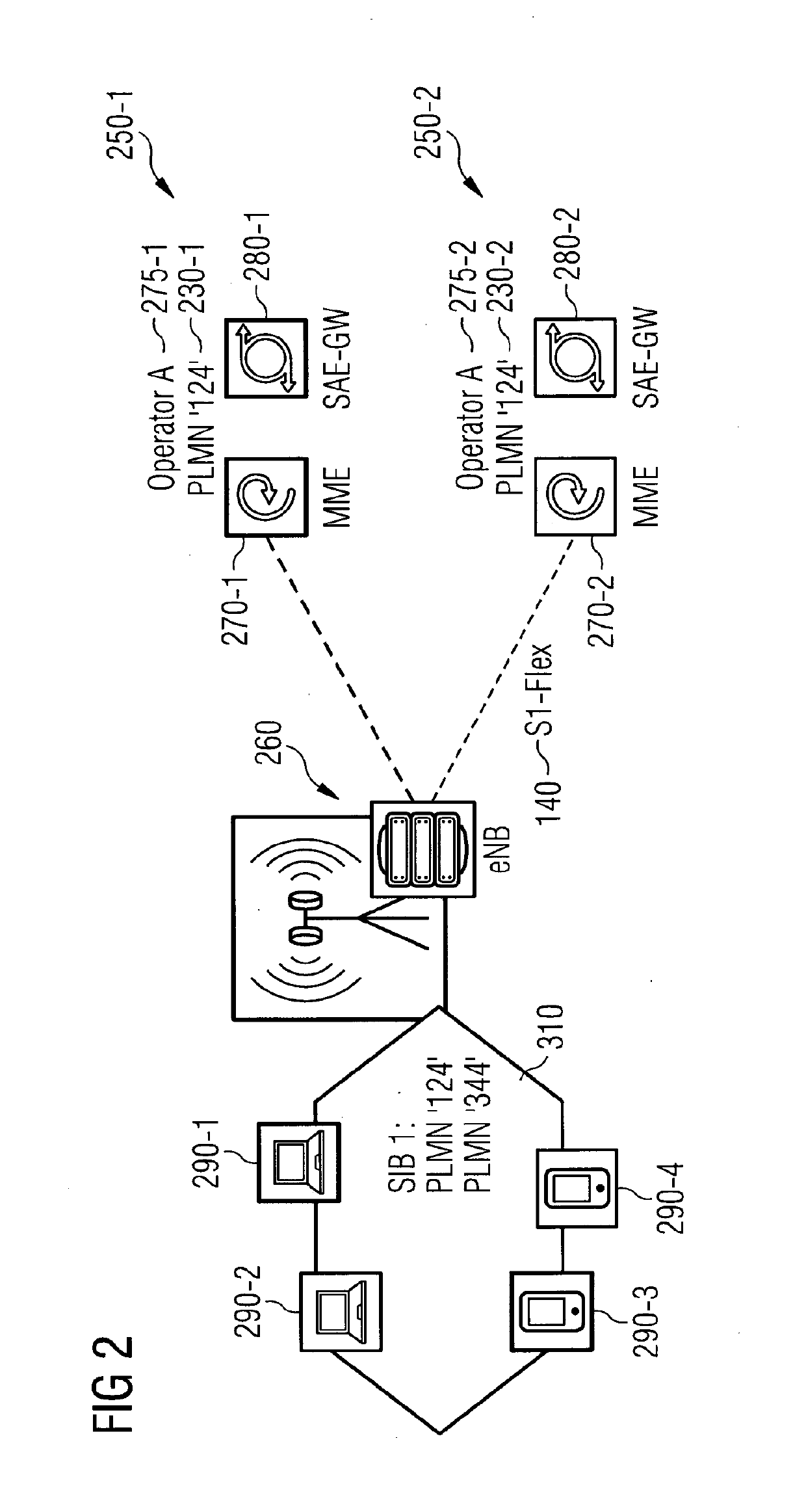

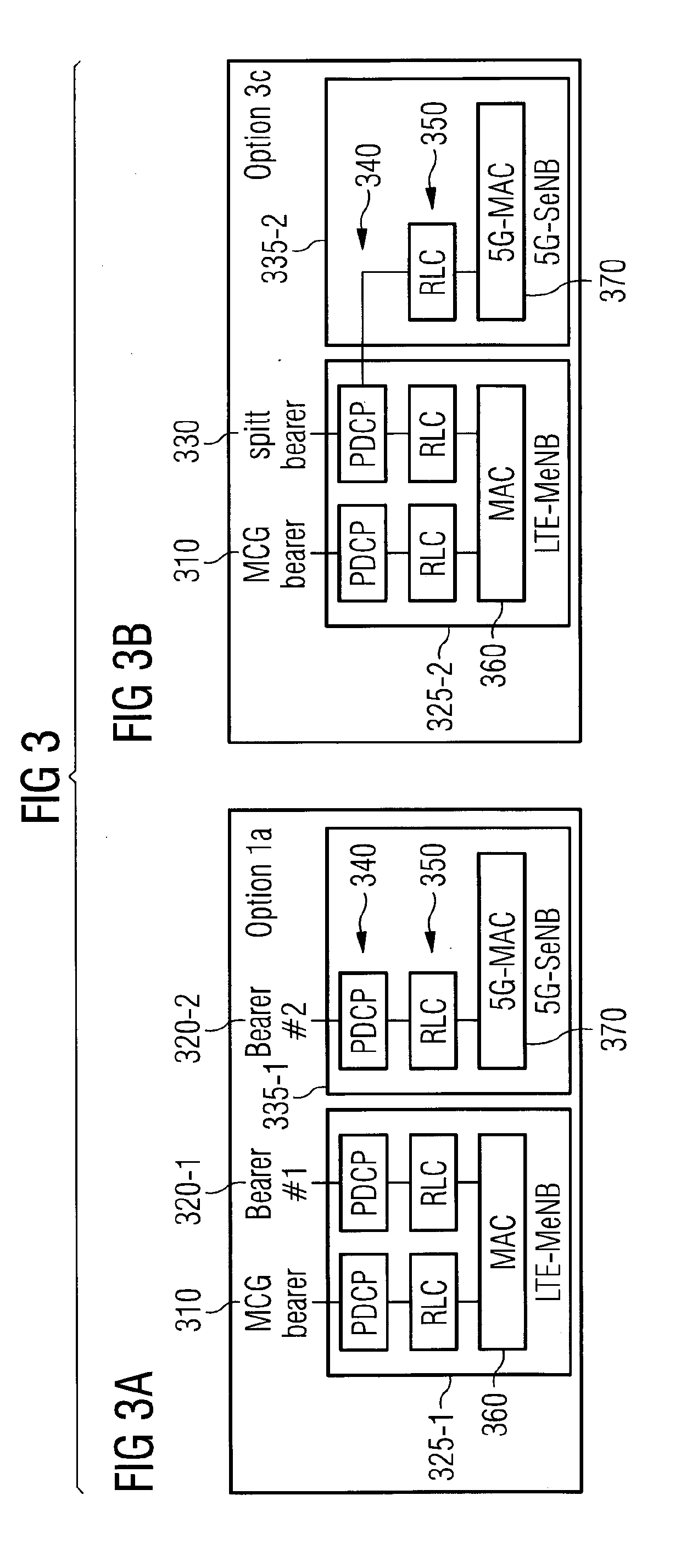

Implementing Radio Access Network Slicing in a Mobile Network

In one example, requirement(s) are determined for data flows though different logical instances of mobile networks. The data flows are between UE(s) and the logical instances of the mobile networks. Information for the determined requirement(s) is sent to a multiple node controller to allow the multiple node controller to output information to enable configuration of RRC. The configuration causes the RRC to cause radio subflow(s), which flow through different radio legs and to the UE(s), to satisfy the requirement(s). In another example, mapping is received that maps different logical instances of mobile networks and their associated service flows to radio subflows that flow through different radio legs and to UE(s). The radio subflows, which flow through different radio legs and to the UE(s), are caused to satisfy the requirement(s) for the data flows. Apparatus, methods, programs, and program products are disclosed.

Owner:NOKIA SIEMENS NETWORKS GMBH & CO KG

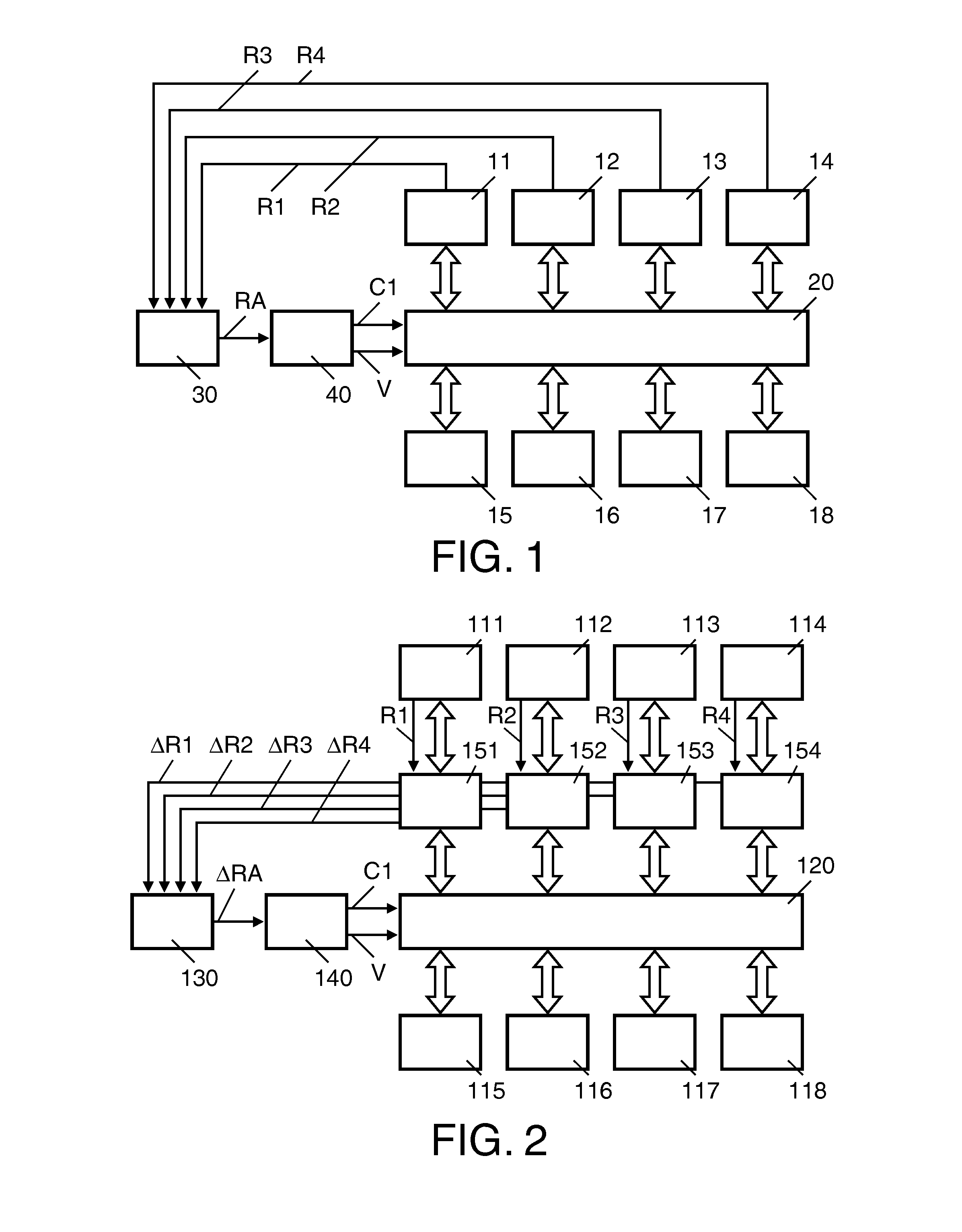

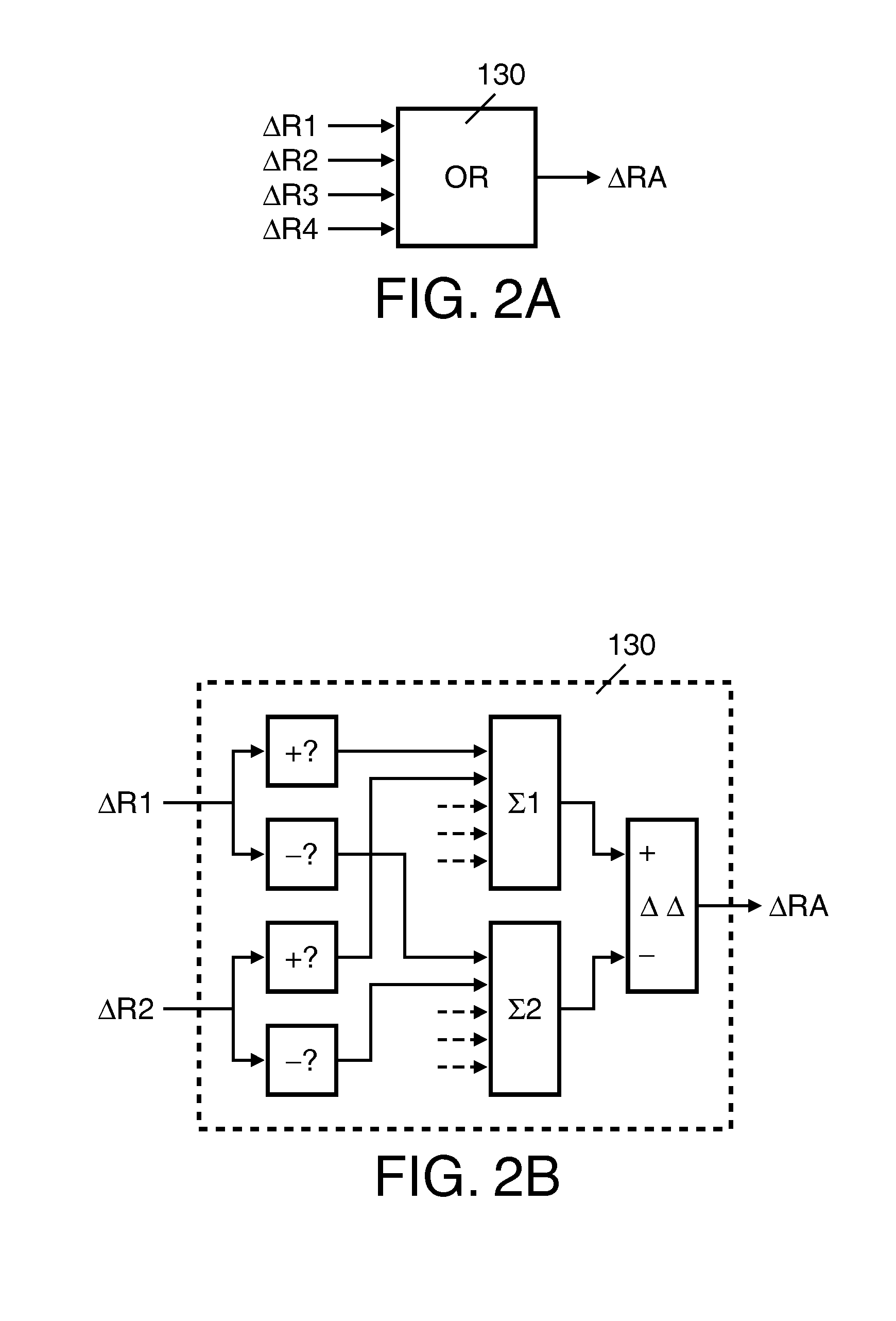

Data-processing system and data-processing method

InactiveUS20100211702A1Downsizing of facilityReduce power consumptionEnergy efficient ICTVolume/mass flow measurementData processing systemControl signal

A data-processing system is described comprising: A plurality of data-processing devices (11, 12, 13, 14) A data-handling facility (20) shared by the data-processing devices, An aggregation facility (30) for receiving signals (R1, R2, R3, R4) indicative for individual requirements from the data-processing devices for a performance of the shared data-handling facility and for providing a control signal (RA) indicative for a required activity level to meet the aggregated requirements, a control device (40) for controlling an activity level of the data-handling facility depending on the control signal (RA). Additionally a data-processing method is described.

Owner:NXP BV

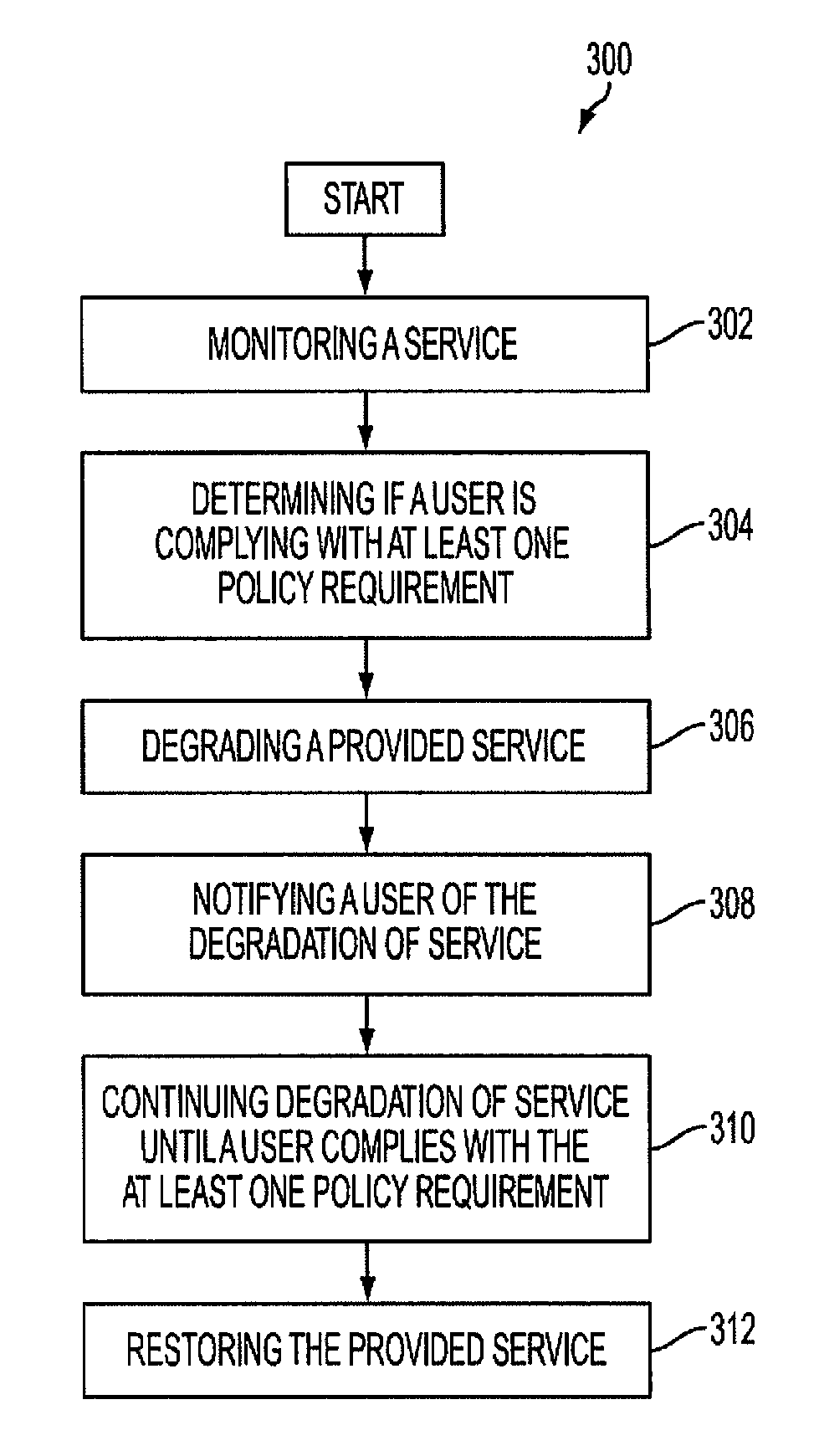

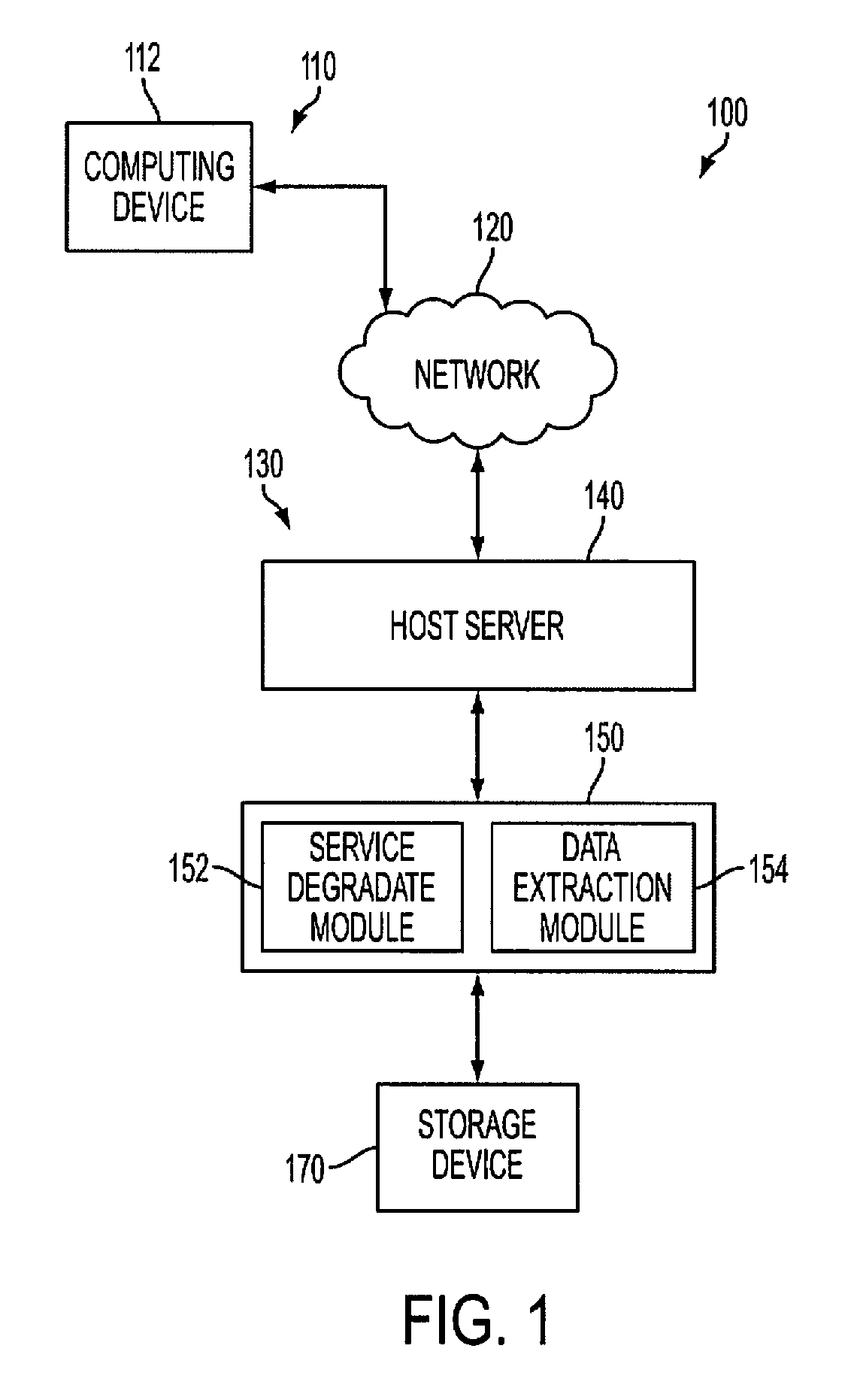

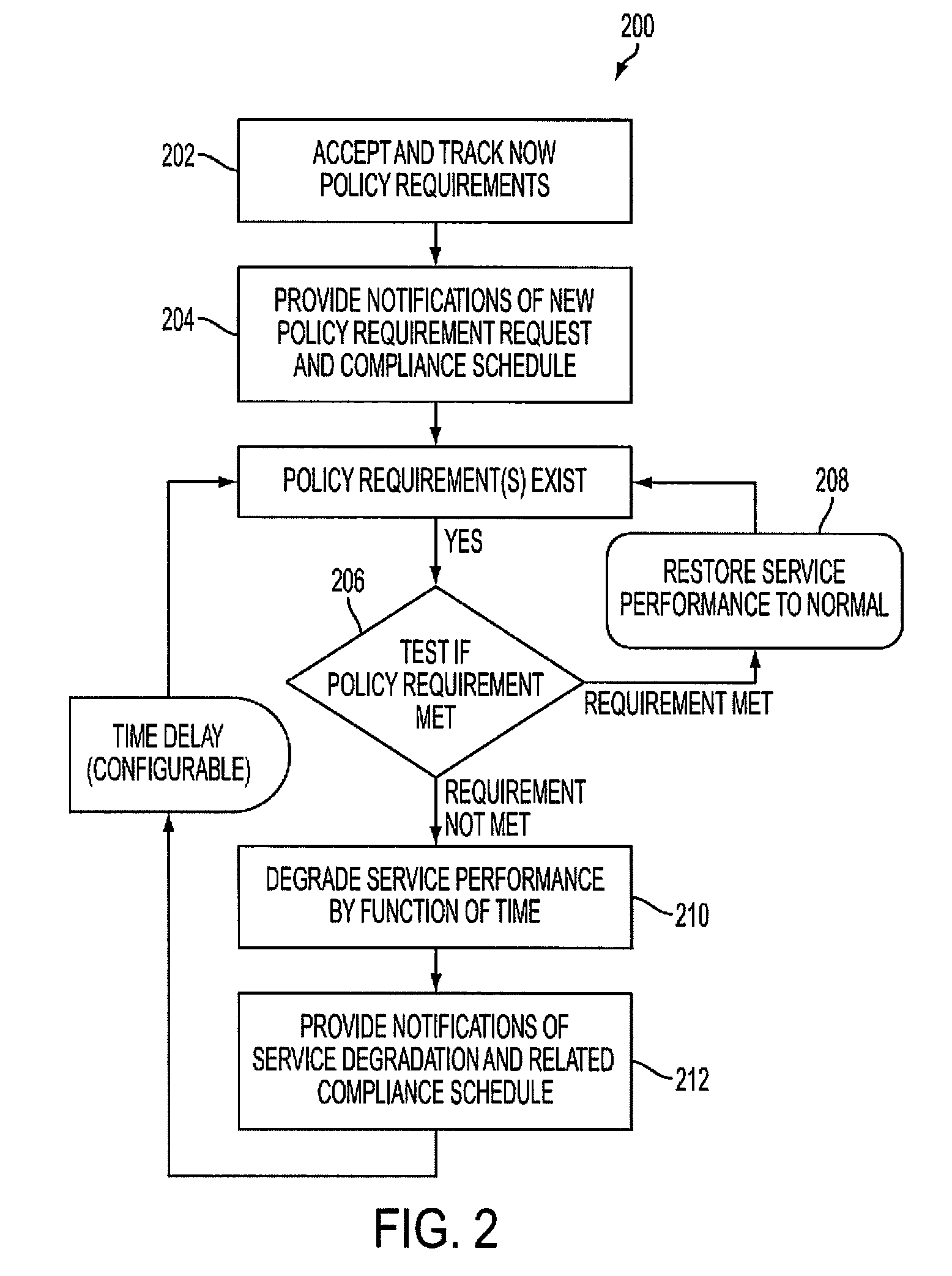

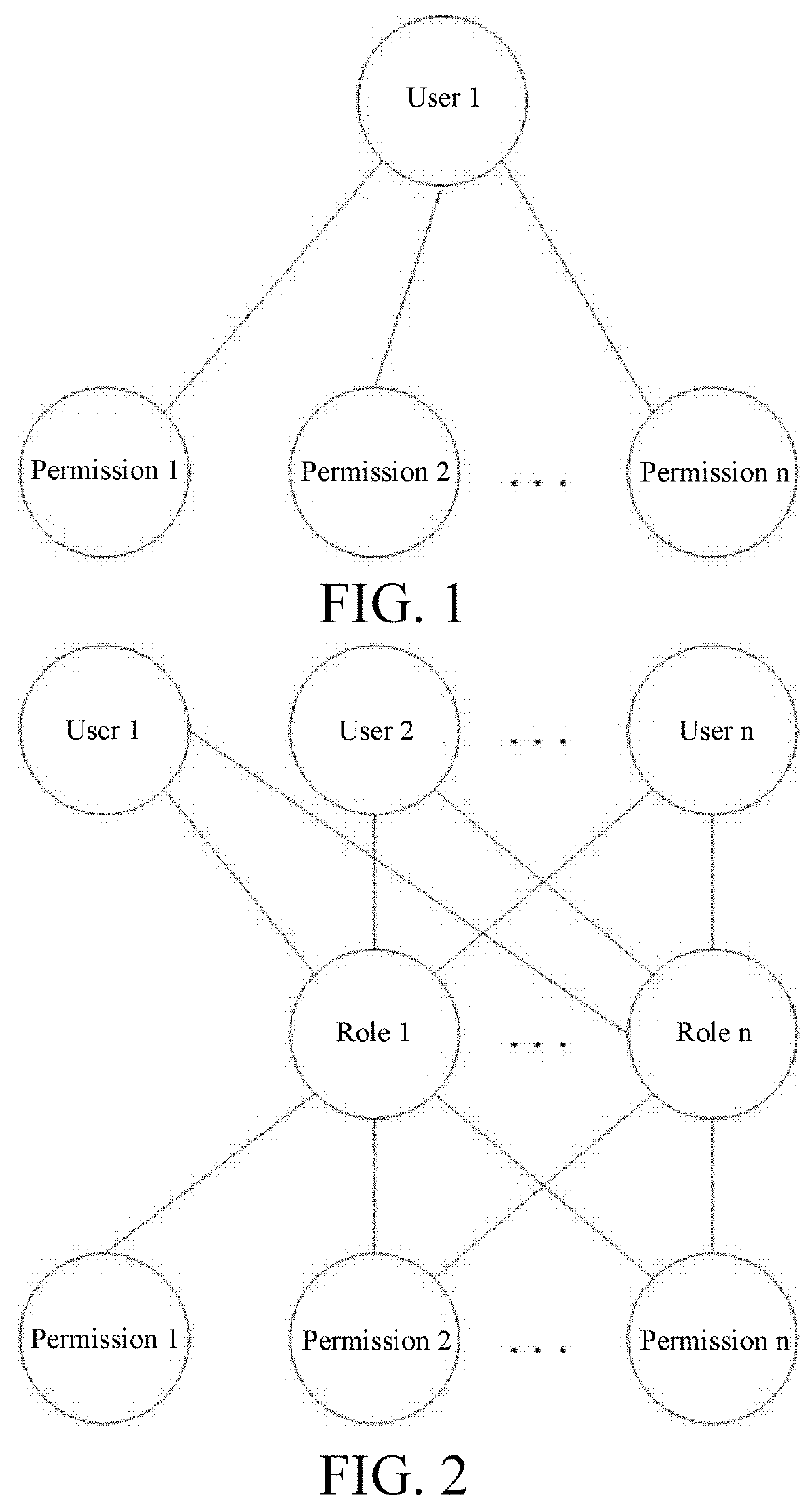

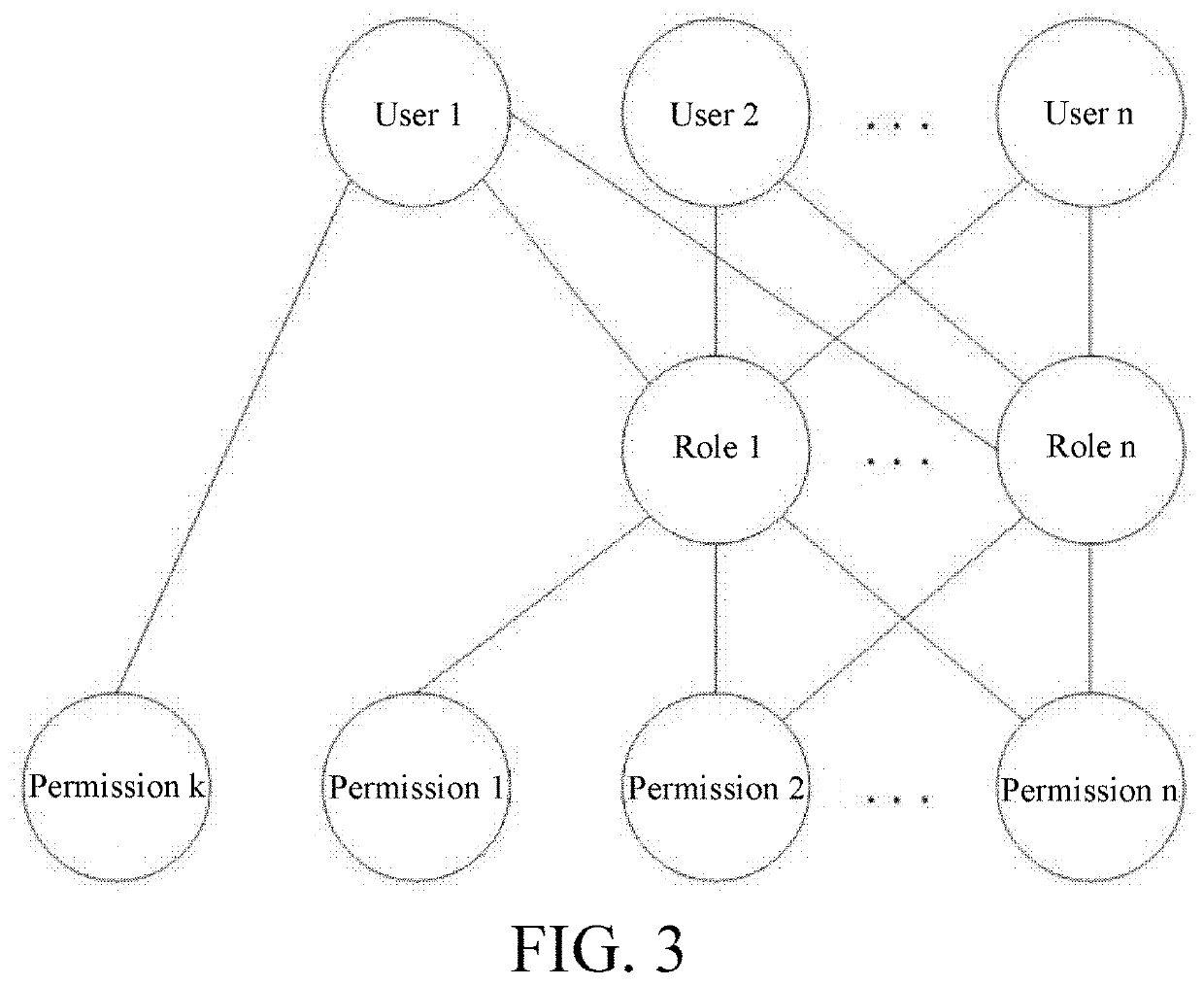

Apparatus, system, and method for enforcing policy requirements associated with a service

ActiveUS20100132050A1Requires moreDigital data processing detailsUser identity/authority verificationService provisionApplication software

A computer-readable medium having stored thereon a plurality of instructions including instructions that when executed by a processor enable a service provider to track and enforce policy requirements associated with a provided service of the service provider. The application software configured to provide notification of the policy requirements and to trigger an intentional degradation of the provided service as a function of time when a user fails to comply with at least one of the policy requirements.

Owner:XEROX CORP

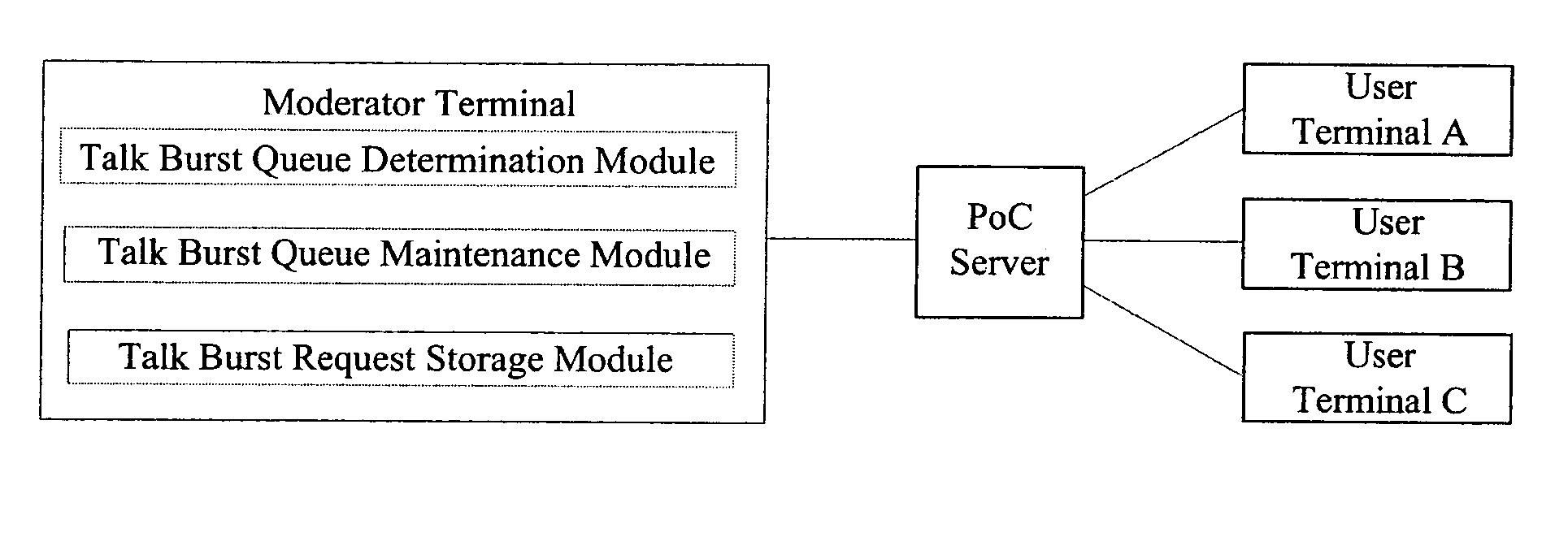

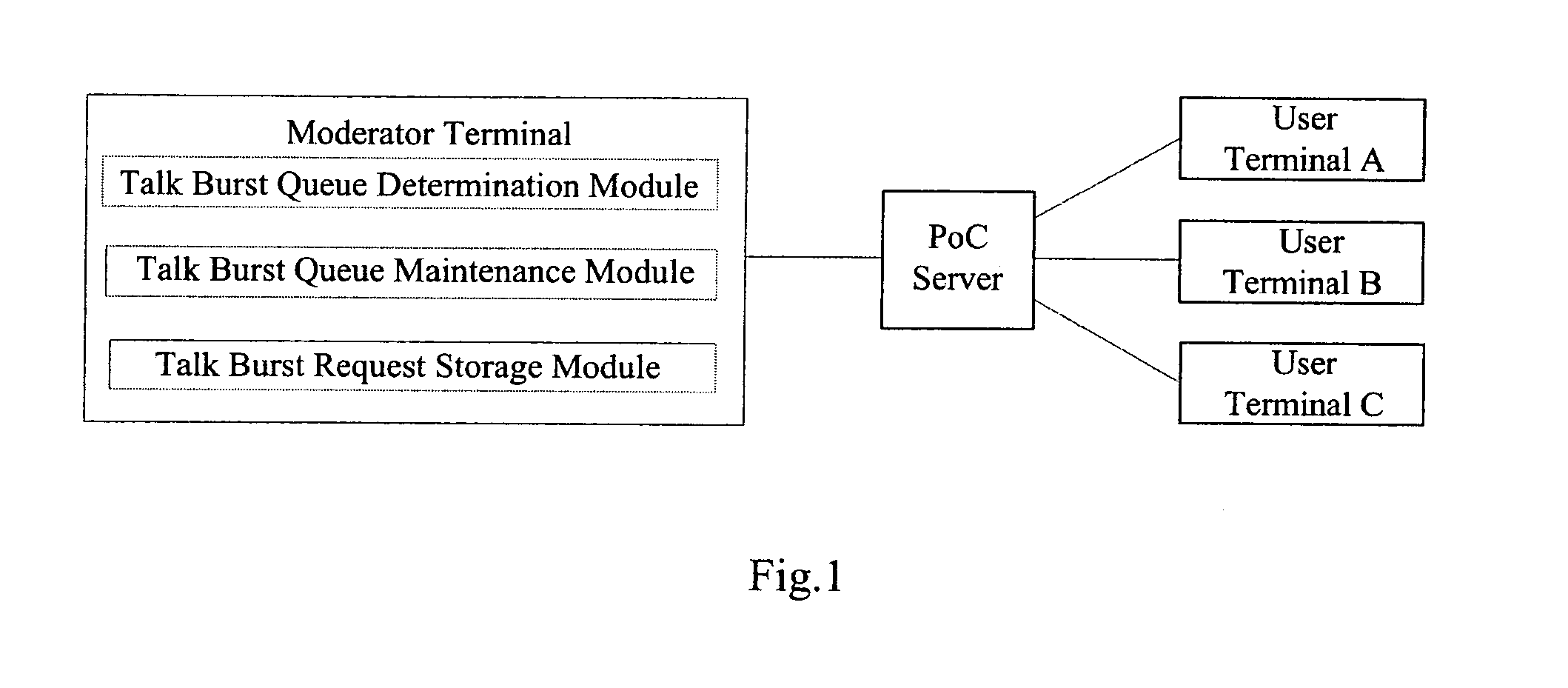

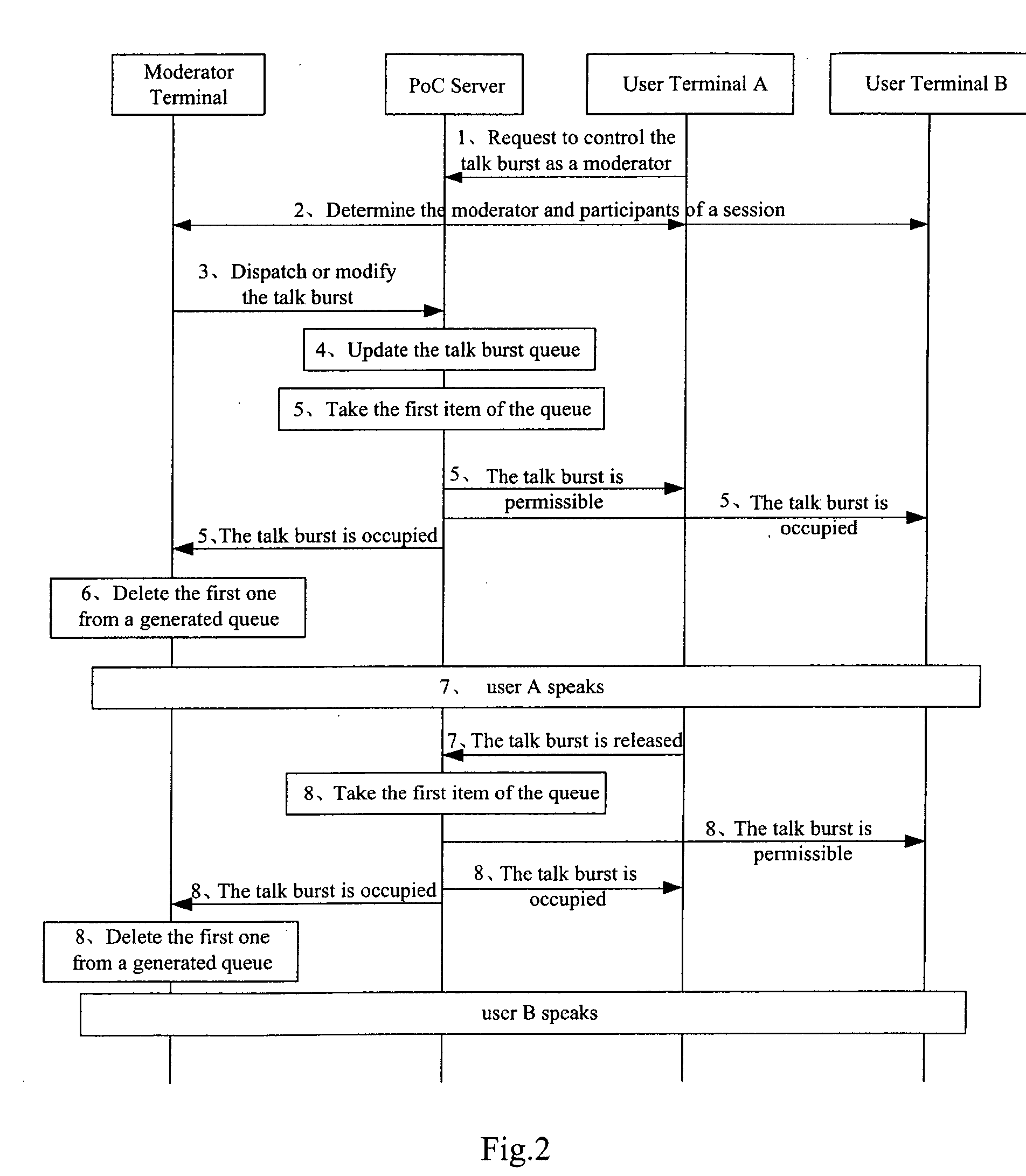

Method and a system for talk burst control and an moderator terminal therefor

InactiveUS20070161393A1Satisfies requirementRequires moreConnection managementBroadcast service distributionComputer scienceEmbedded system

A method and a system for talk burst control in wireless PoC in the field of group talk technology and a moderator terminal therefore, wherein the method comprises: determining, by a moderator terminal, a talk burst sequence and delivering a talk burst dispatch message to a PoC server; dispatching, by the PoC server, the talk burst to a user terminal according to the talk burst dispatch message. According to the method and the system of the invention, the operation on talk burst control will be more flexible and the requirements of a scheduling system will be met more satisfactorily.

Owner:HUAWEI TECH CO LTD

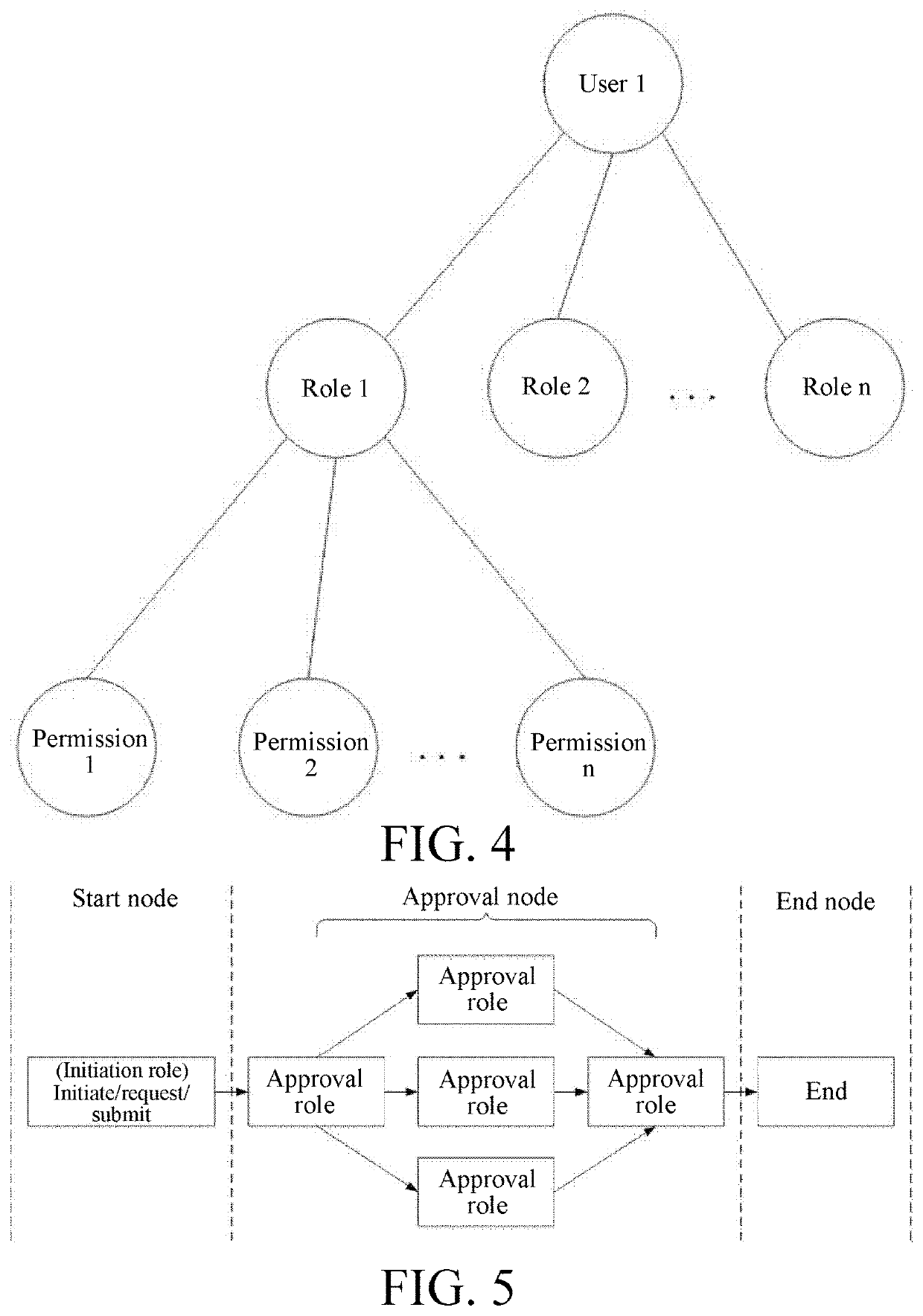

Method for setting approval procedure based on base fields

PendingUS20200134527A1The process is simple and clearEasy to understandComputer security arrangementsResourcesSoftware engineeringData science

A method for setting an approval process based on basis fields is disclosed in the present invention, including a step of creating an approval process: S1: selecting a form corresponding to the approval process; S2: selecting a basis field for the approval process, where one basis field can be selected by one or more approval processes; and S3: setting a field value set of the selected basis field of the approval process, wherein each field value can only exist in a field value set of one approval process under the basis field. During relation to the approval process, it is determined, according to the field value of the basis field in the approval form, the approval form belongs to which approval process's field value set of the corresponding basis field. In the present invention, when a form is submitted to be approved in an approval process, the form may be automatically related to an approval process according to a field value of a basis field in the form. The process is determined according to content of the basis field in the form, which is simple, clear, and easy to operate. The basis field in the form is changeable, so that different approval requirements in actual management can be met.

Owner:CHENGDU QIANNIUCAO INFORMATION TECH CO LTD

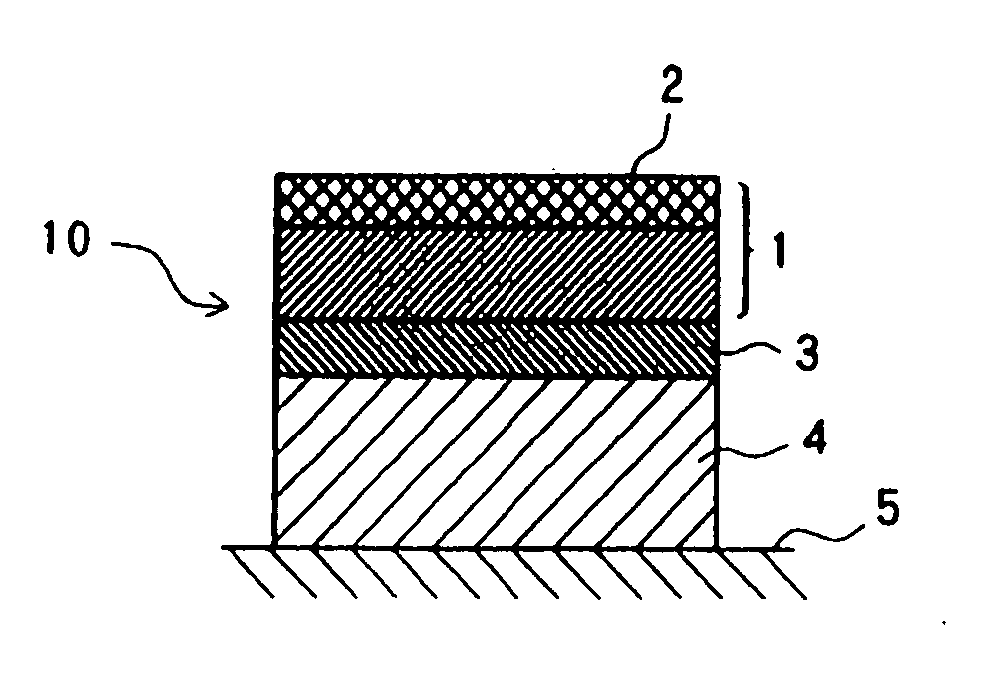

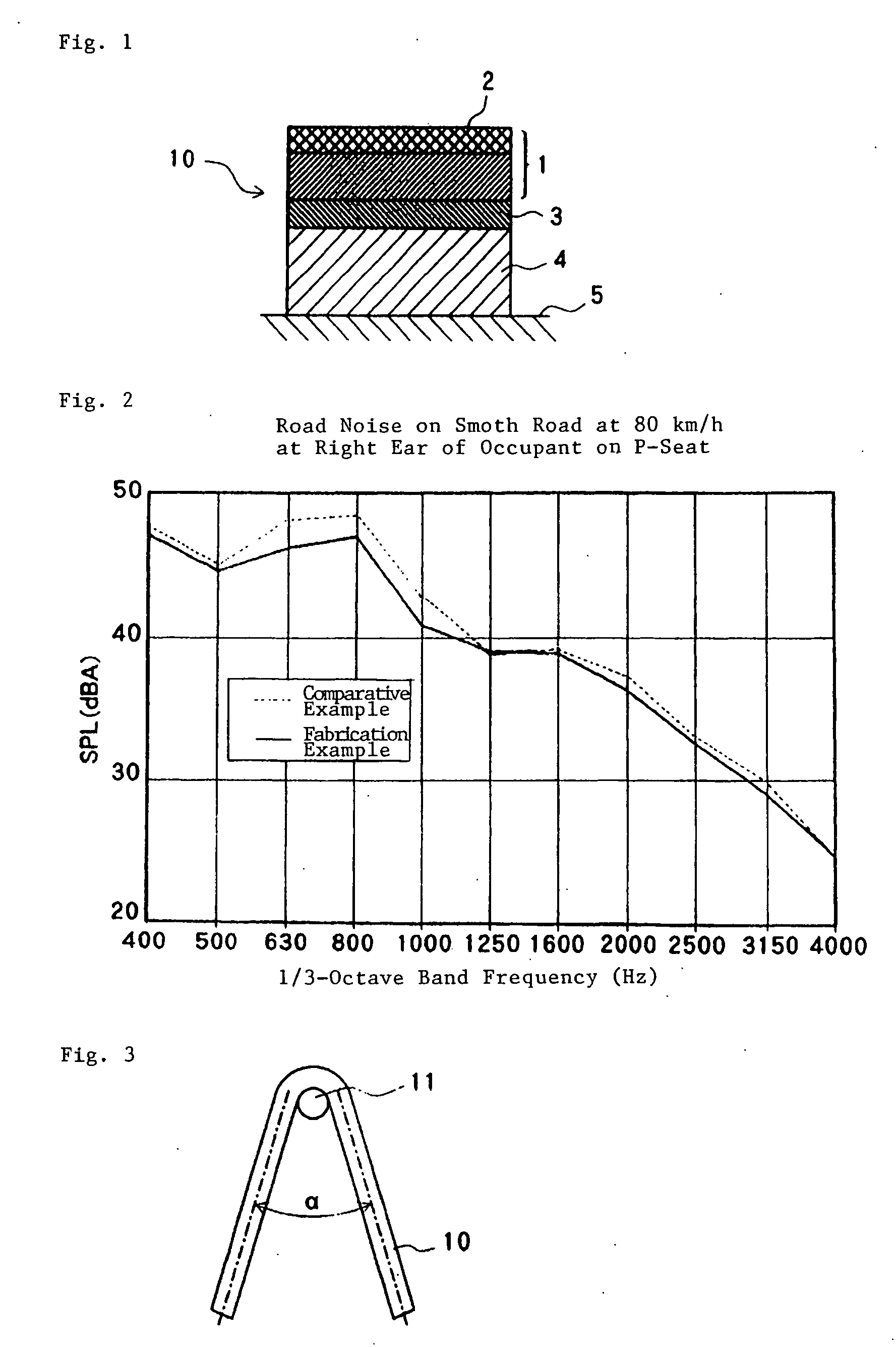

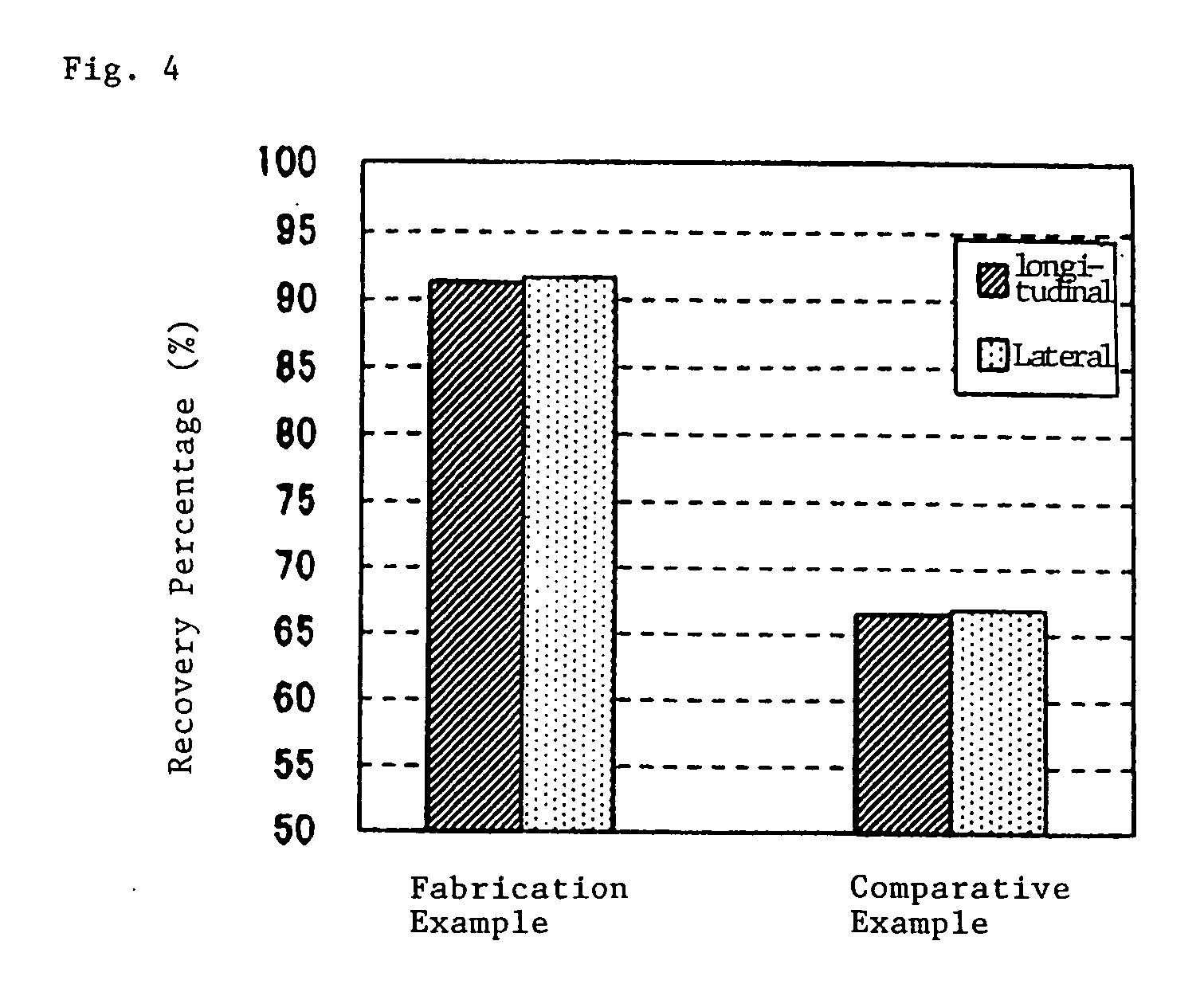

Formed mat

InactiveUS20060240732A1Prevent wrinklingHeighten wear resistanceVehicle arrangementsSynthetic resin layered productsEngineeringVolumetric Mass Density

Owner:HAYASHI TELEMPU CO LTD

Weather-resistant surge protector plug

InactiveUS20060056126A1Effective protectionRequires moreCoupling device detailsEmergency protective arrangement detailsOvervoltageMoisture

The specification discloses a weather-resistant surge protector plug for protecting an outdoor electrical device connected on its load side from spurious or excessive transient voltages or surges or both on an electrical line above a predetermined value, on its line side or its hot side. The surge protector plug contains, within the plug housing, an MOV and an on / off switch having a re-settable circuit breaker. The on / off switch acts to interrupt current to the device at the option of the user, and also to re-set the circuit breaker after the occurrence of an overvoltage condition. An indicator light indicates whether the switch is on or off. The plug housing is made of weather-resistant and materials and is further designed and constructed to be water or moisture resistant. An electrical circuit is are also disclosed. The lightning and surge protection as provided by this invention may also be rendered into a sold state chip device.

Owner:MELTZER EDWARD

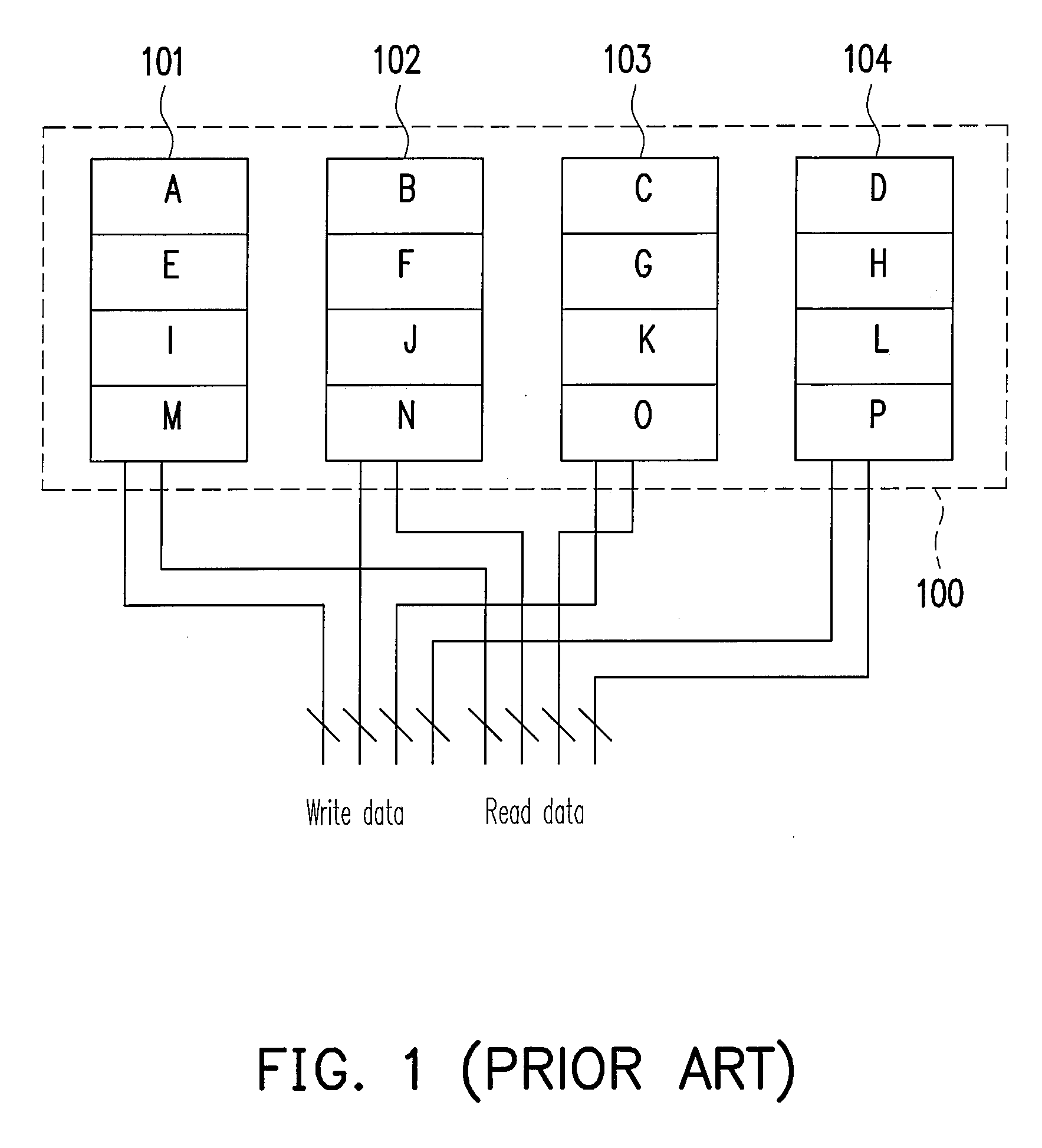

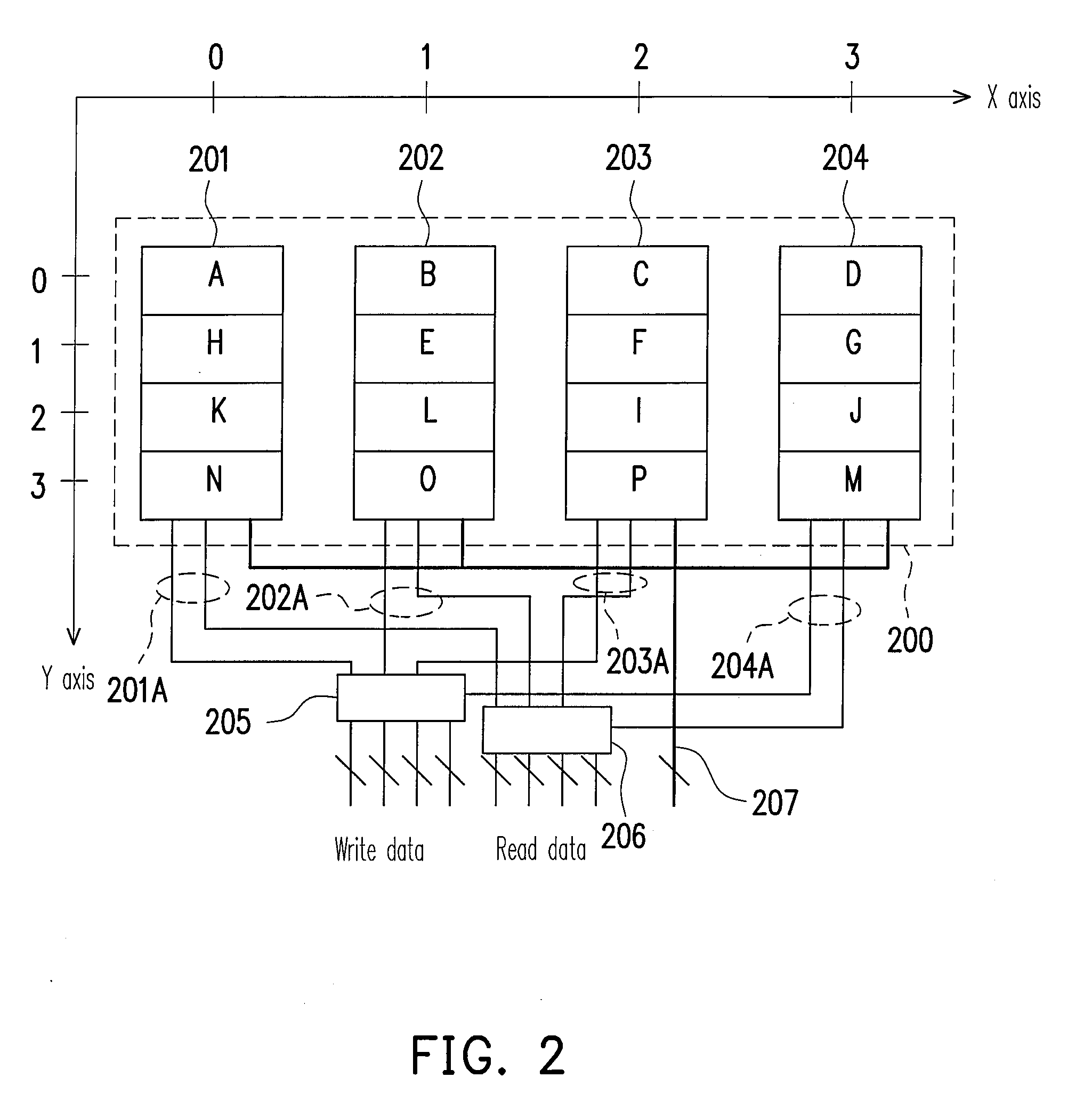

Method for memory address arrangement

InactiveUS20090006807A1Avoid restrictionsImprove performanceMemory adressing/allocation/relocationDigital storageMemory addressComputer architecture

A method for memory address arrangement is provided. Data of different Y coordinates is moved to operation units divided by different X coordinates, or data of different X coordinates is moved to operation units divided by different Y coordinates, so as to realize the function of simultaneously longitudinally and laterally reading and writing a plurality of batches of data, thereby preventing the limitation of only longitudinally or laterally reading and writing a plurality of batches of data.

Owner:NOVATEK MICROELECTRONICS CORP

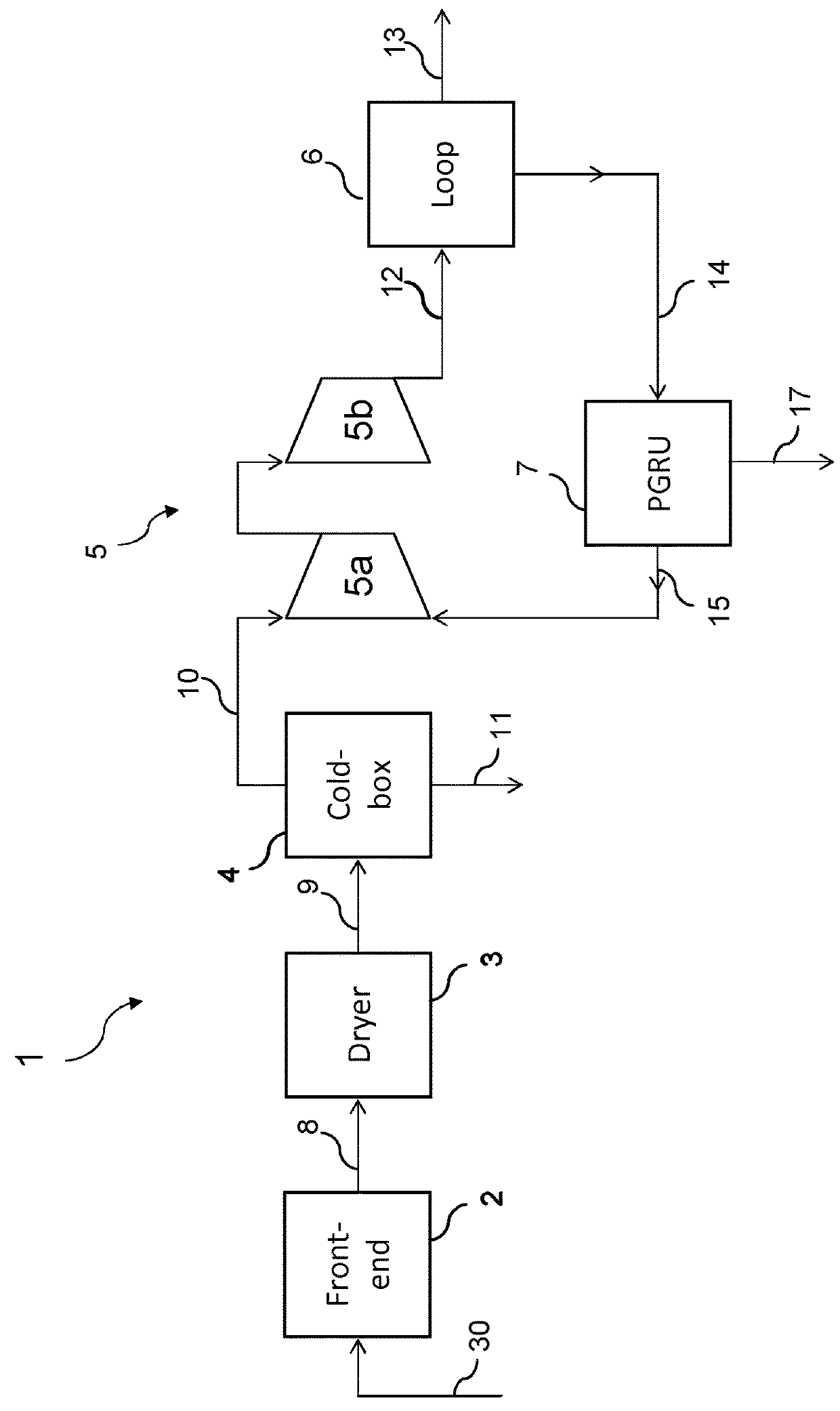

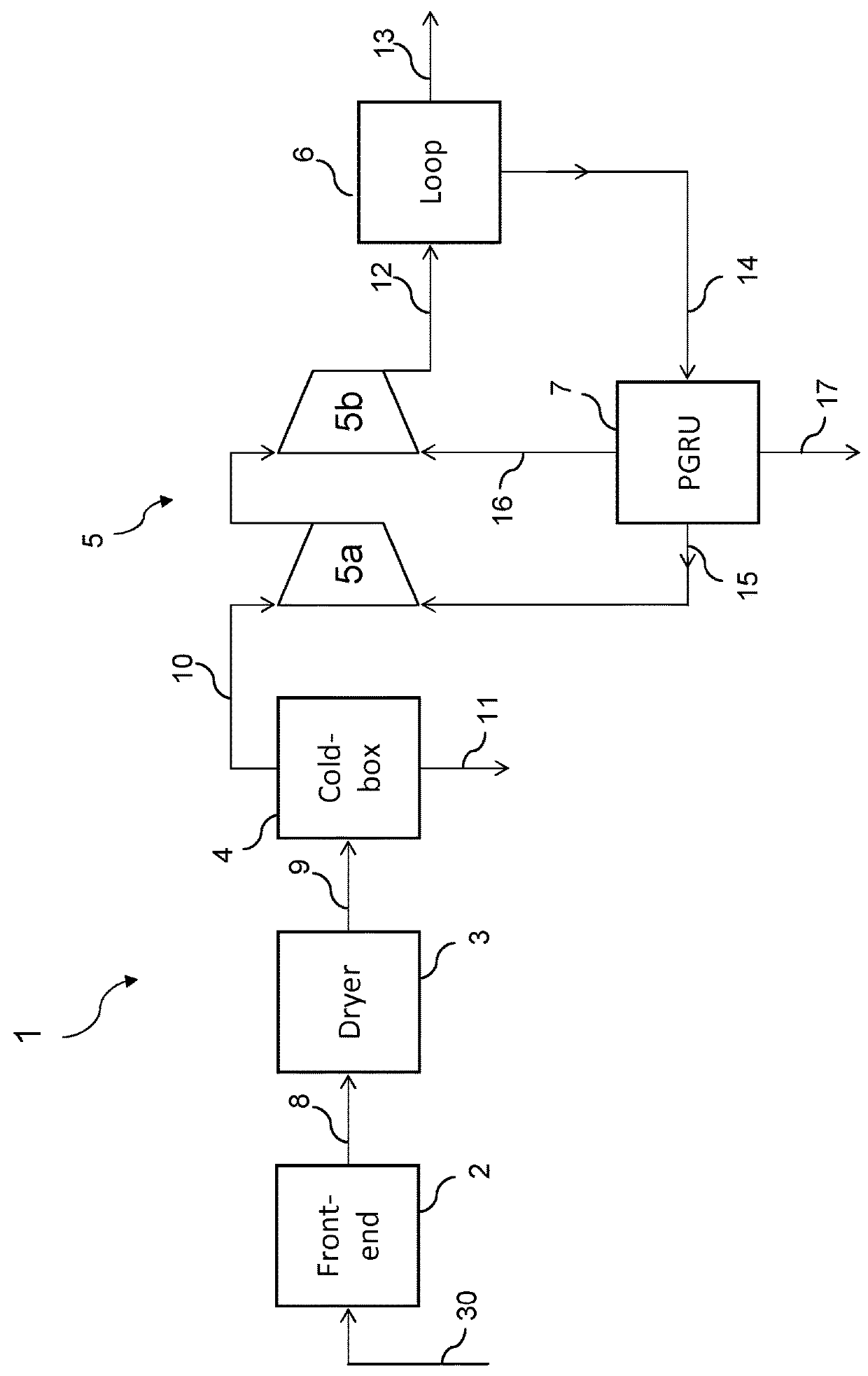

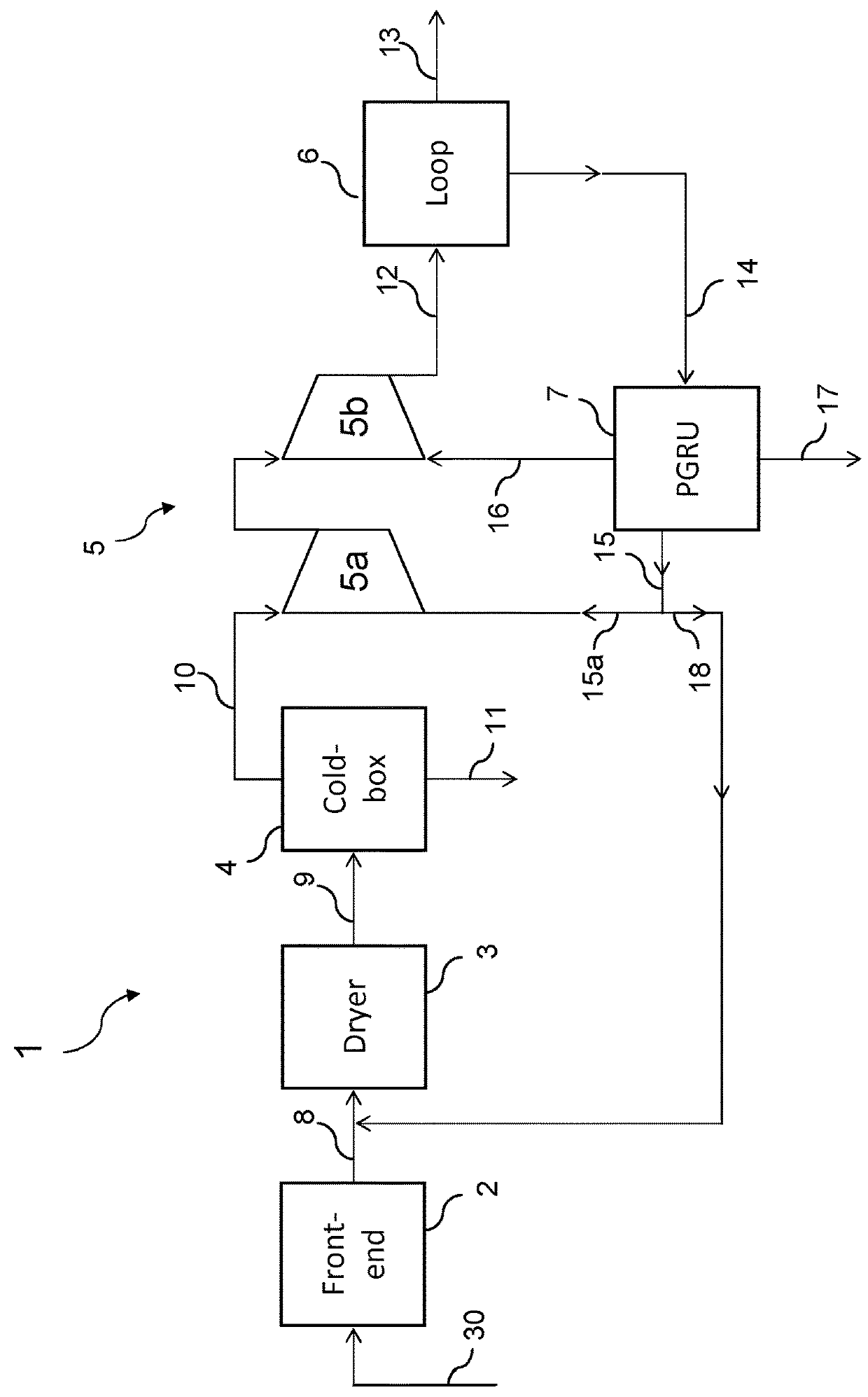

Plant and process for ammonia production with cryogenic purification, and related method of revamping

ActiveUS20180266758A1Small pressure lossHigh suction pressureSolidificationLiquefactionHydrogenAmmonia production

Process for the synthesis of ammonia from a make-up gas containing hydrogen and nitrogen, said process comprising: generation of a synthesis gas (8) containing hydrogen and nitrogen in a molar ratio lower than 3, inside a front-end section (2); a first cryogenic purification, designed to remove nitrogen and raise said molar ratio; conversion of the synthesis gas into ammonia (13) inside a high-pressure synthesis loop (6), with extraction from said loop of a purge stream (14) containing hydrogen and inert gases; wherein at least a portion of said purge stream (14) undergoes a further purification in order to recover at least part of the hydrogen contained therein, obtaining at least one stream (15, 15a, 16, 18) containing recovered hydrogen which is recycled to the process.

Owner:CASALE SA

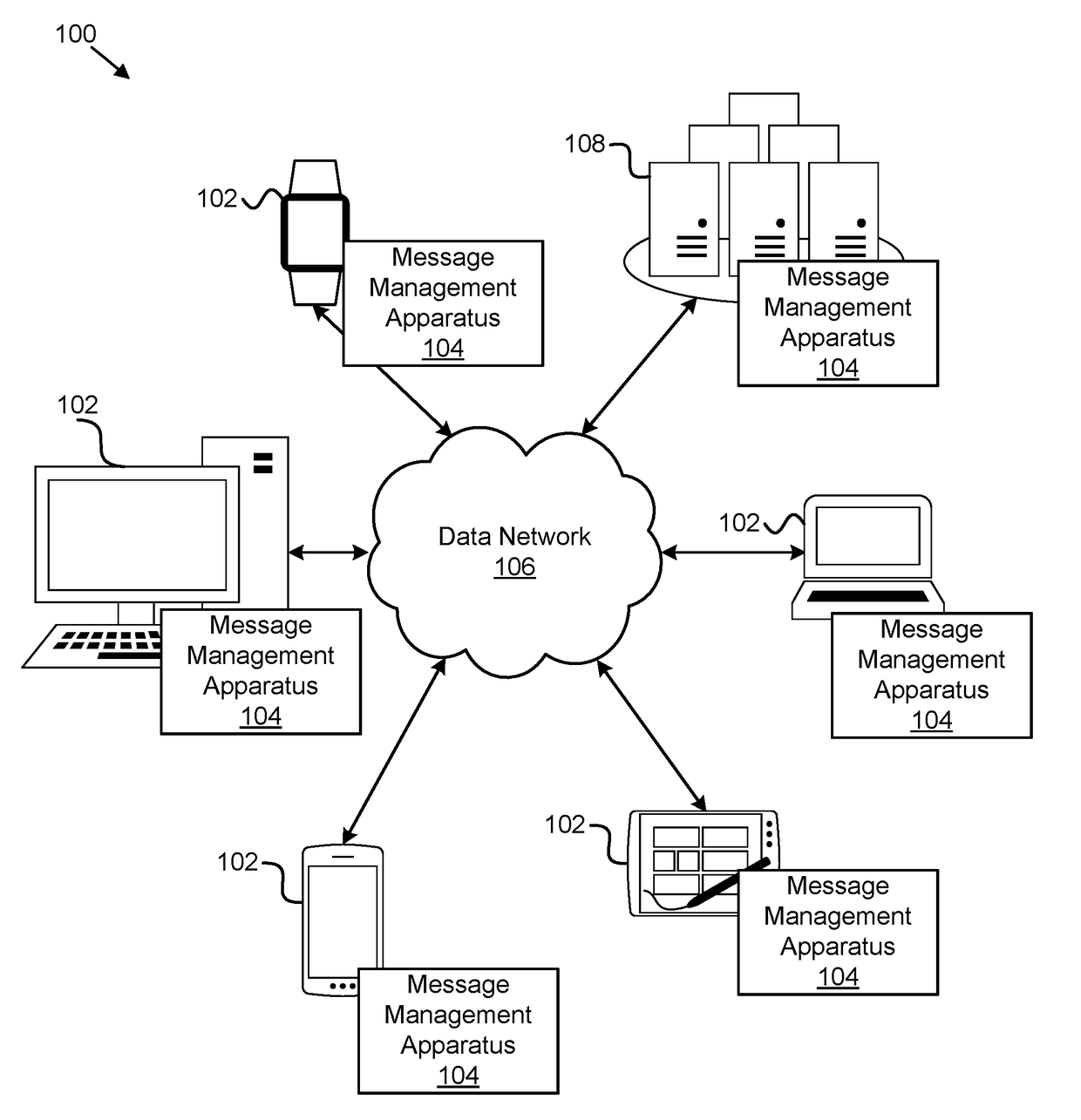

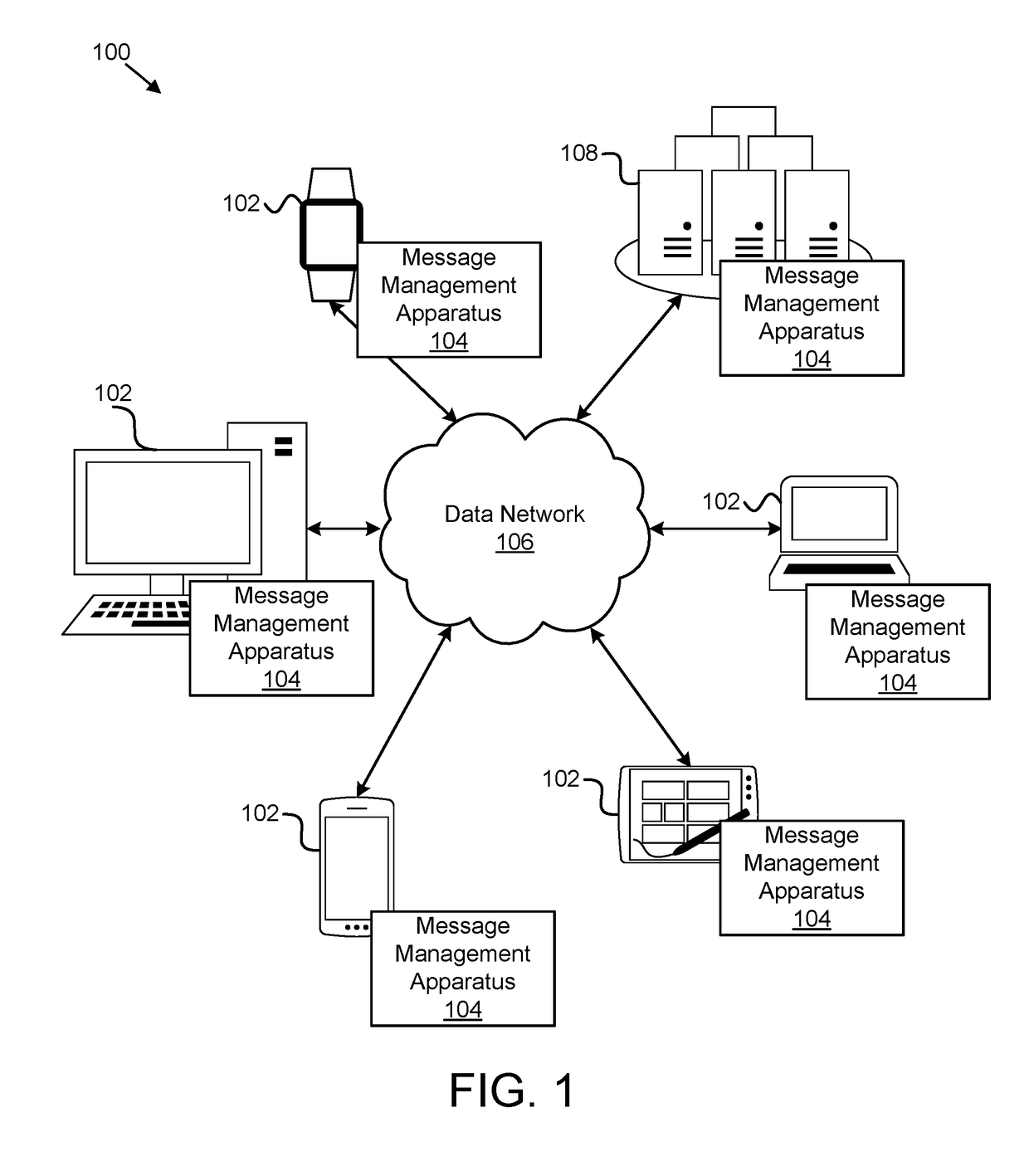

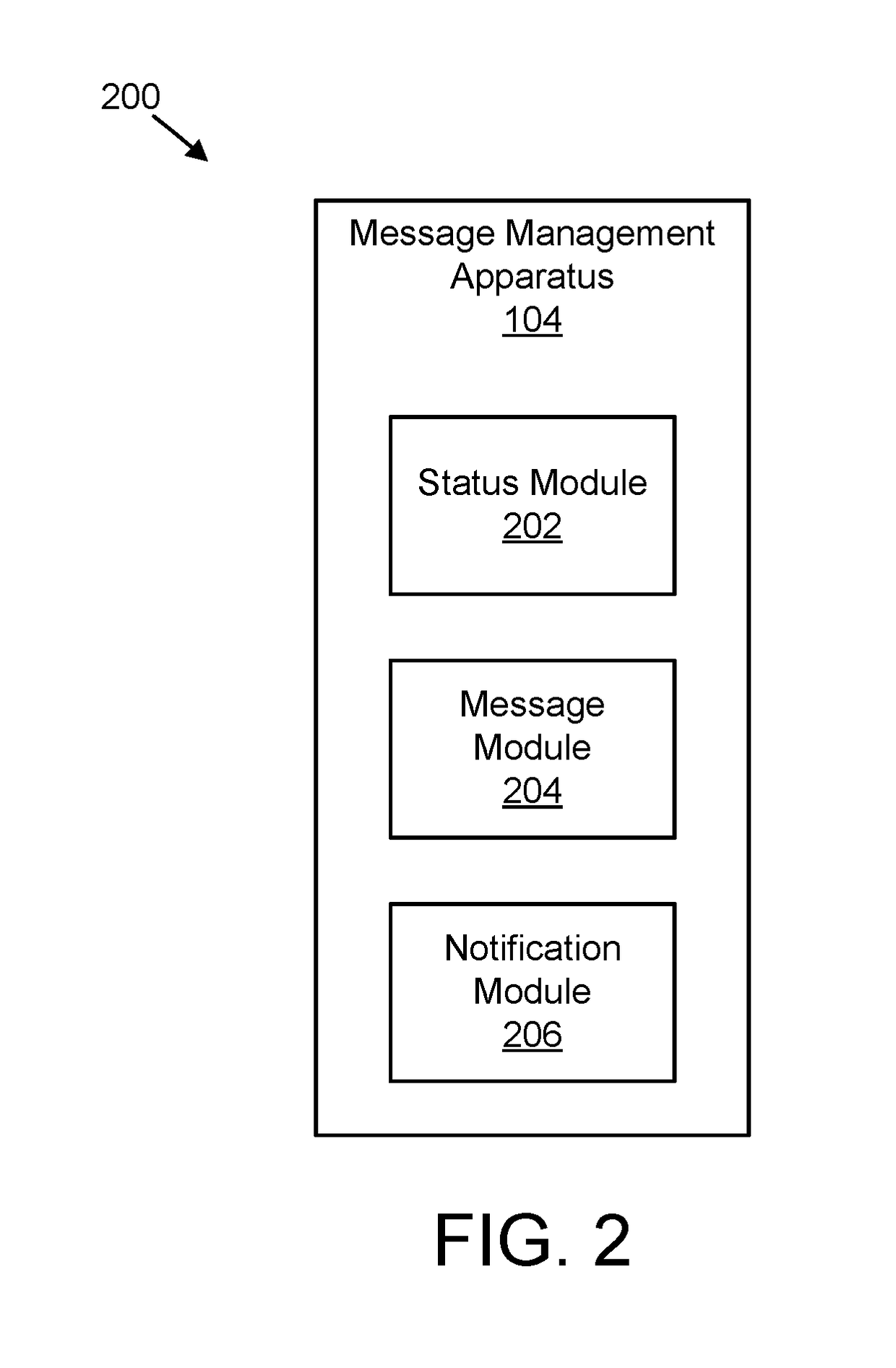

Sending messages to an unavailable device

An apparatus, system, method, and program product are disclosed for sending messages to an unavailable device. The apparatus includes a status module that determines that a recipient device for a message is unavailable to receive the message. The apparatus includes a message module that sends the message to an intermediate device for storage until the recipient device is available to receive the message in response to determining that the recipient device is unavailable to receive the message. The apparatus includes a notification module that sends a notification to the recipient device that the message is available to access from the intermediate device.

Owner:LENOVO ENTERPRISE SOLUTIONS SINGAPORE

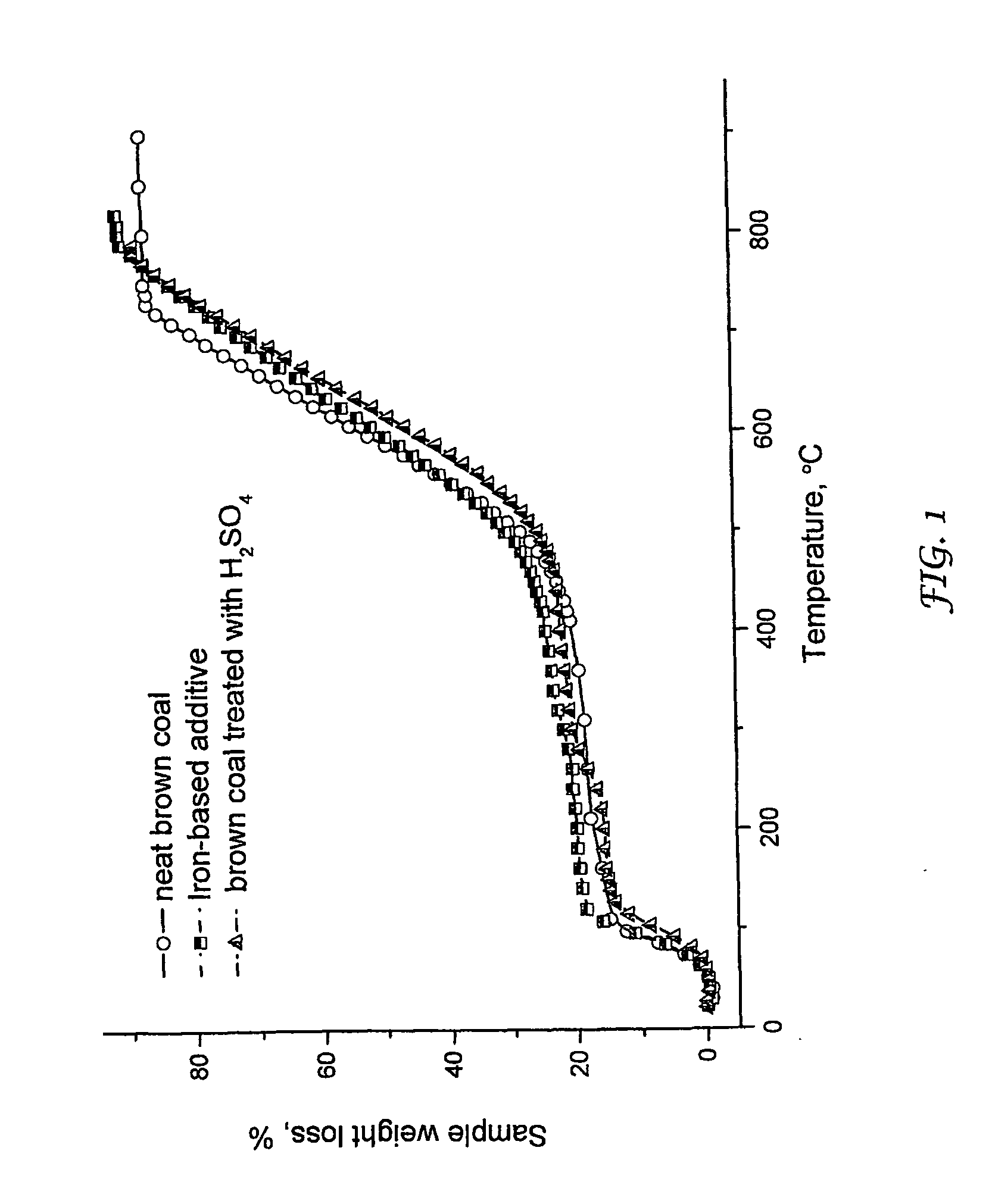

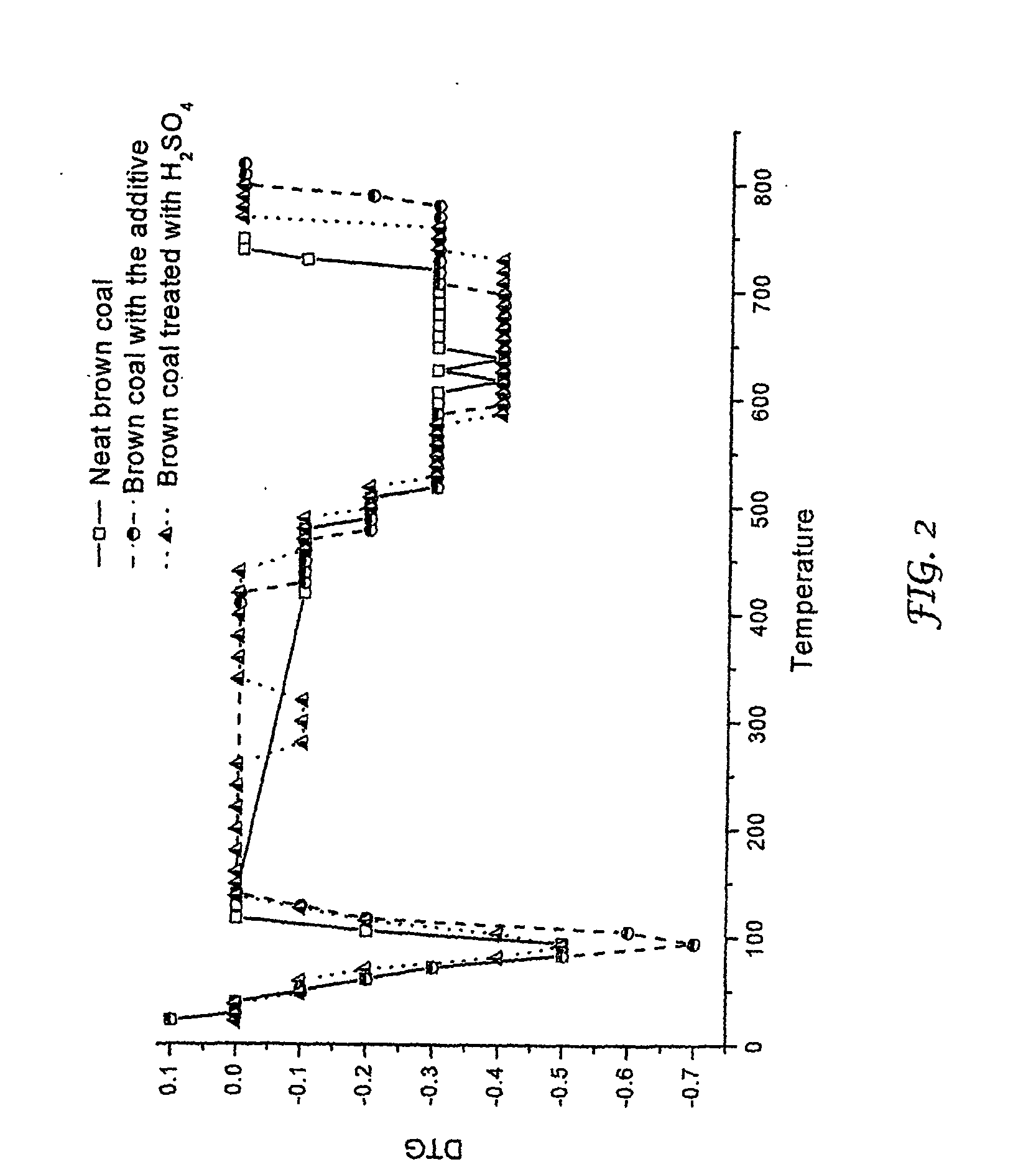

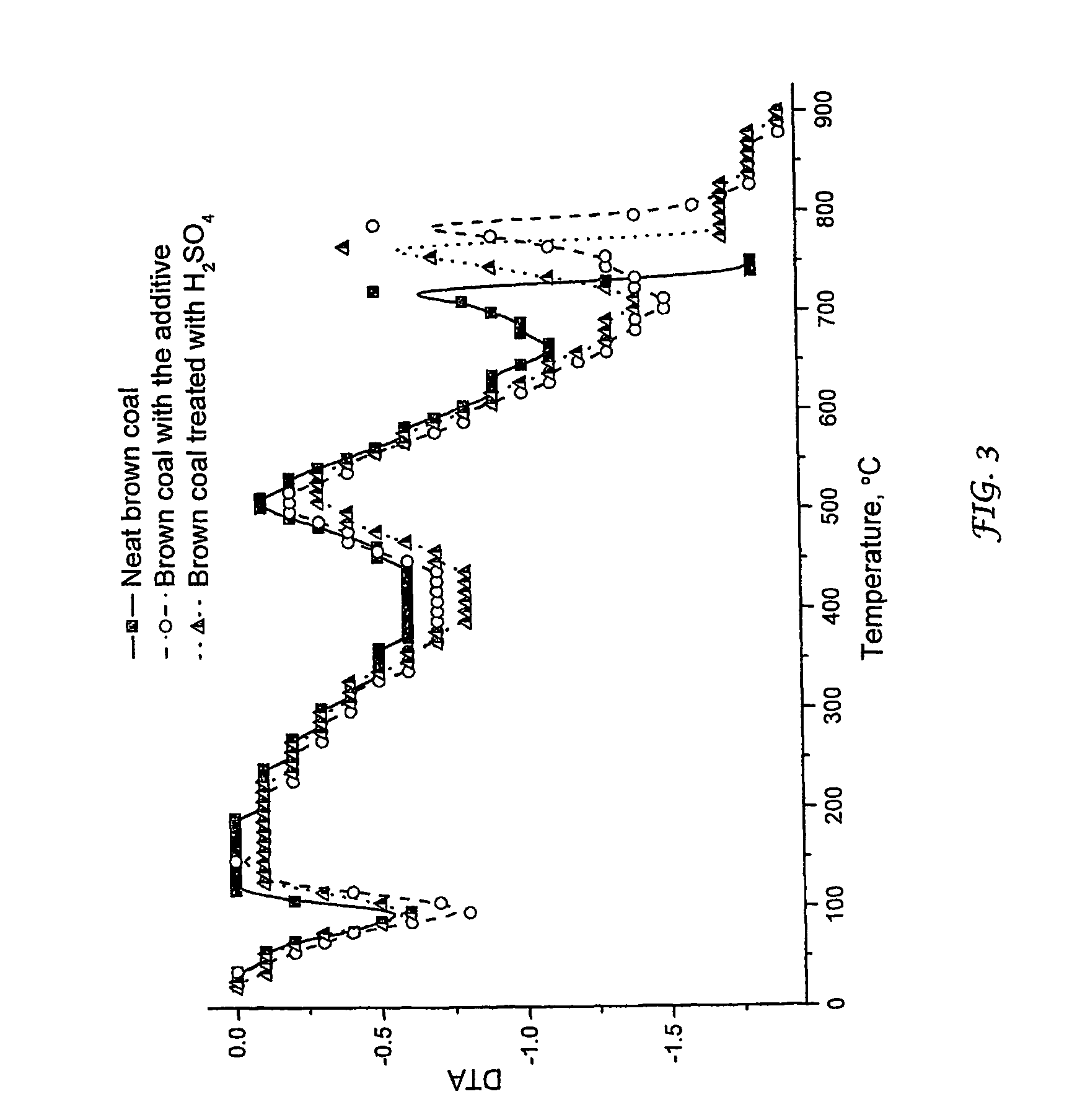

Coal with improved combustion properties

InactiveUS20090277080A1Improve combustion performanceReduce carbon contentSolid fuelsLiquid carbonaceous fuelsCombustionPorphyrin

Owner:AQUAFUEL RES LTD

CAR2X receiver filtering based on a receiving corridor in a geographic coordinate system

ActiveUS10225690B2Reduce complexityReduce needArrangements for variable traffic instructionsParticular environment based servicesGeographic coordinate systemDecision threshold

A method for filtering a message transmitted between a transmitter and a receiver in a vehicular ad hoc network, the message containing at least one position of the transmitter, including: determining a position of the receiver by a global satellite navigation system in a predetermined coordinate system; determining a decision threshold for a maximum distance between the receiver and the transmitter in the predetermined coordinate system in which the position of the receiver was determined; and discarding the message if a distance between the position of the transmitter and the position of the receiver exceeds the decision threshold.

Owner:CONTINENTAL TEVES AG & CO OHG

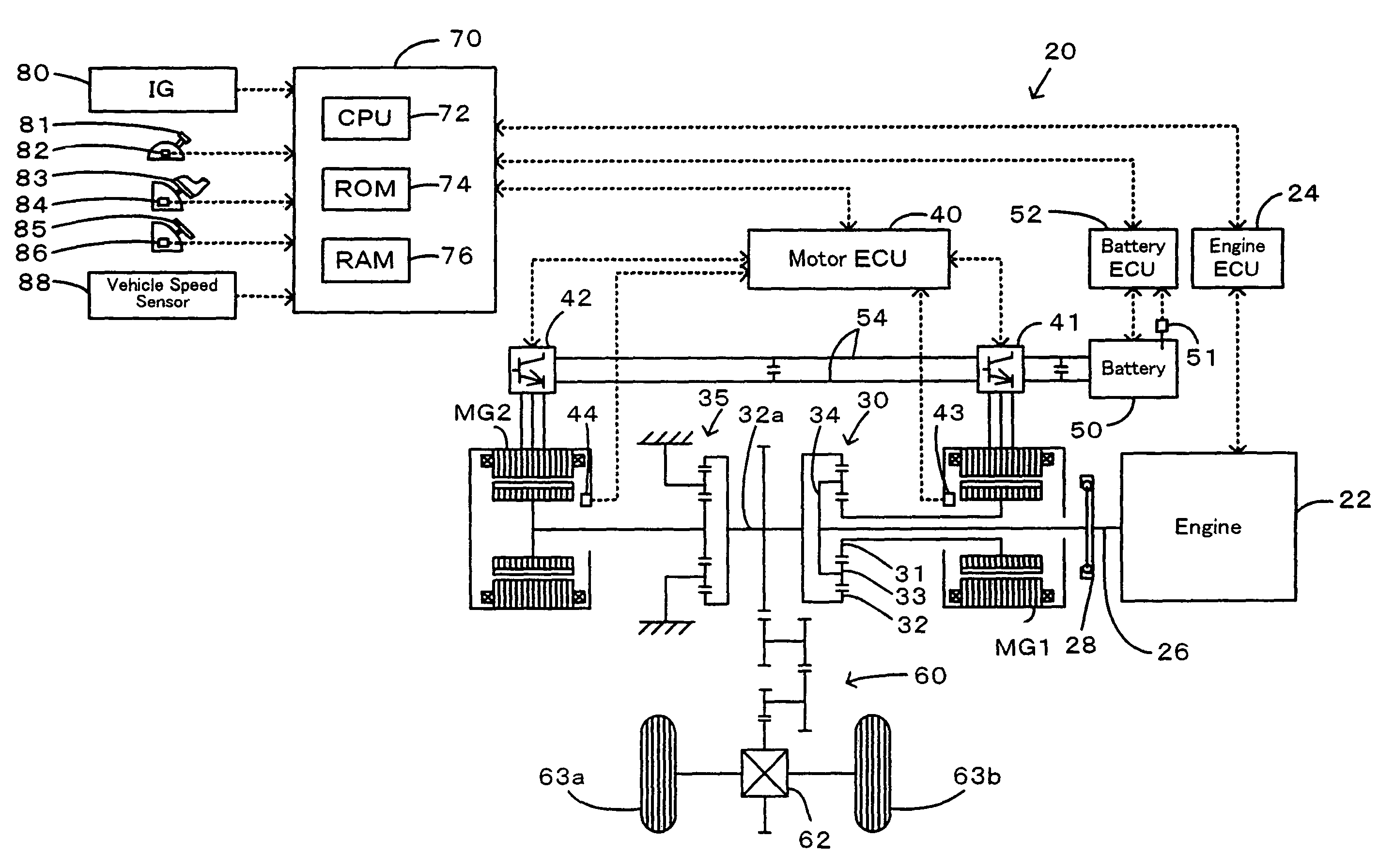

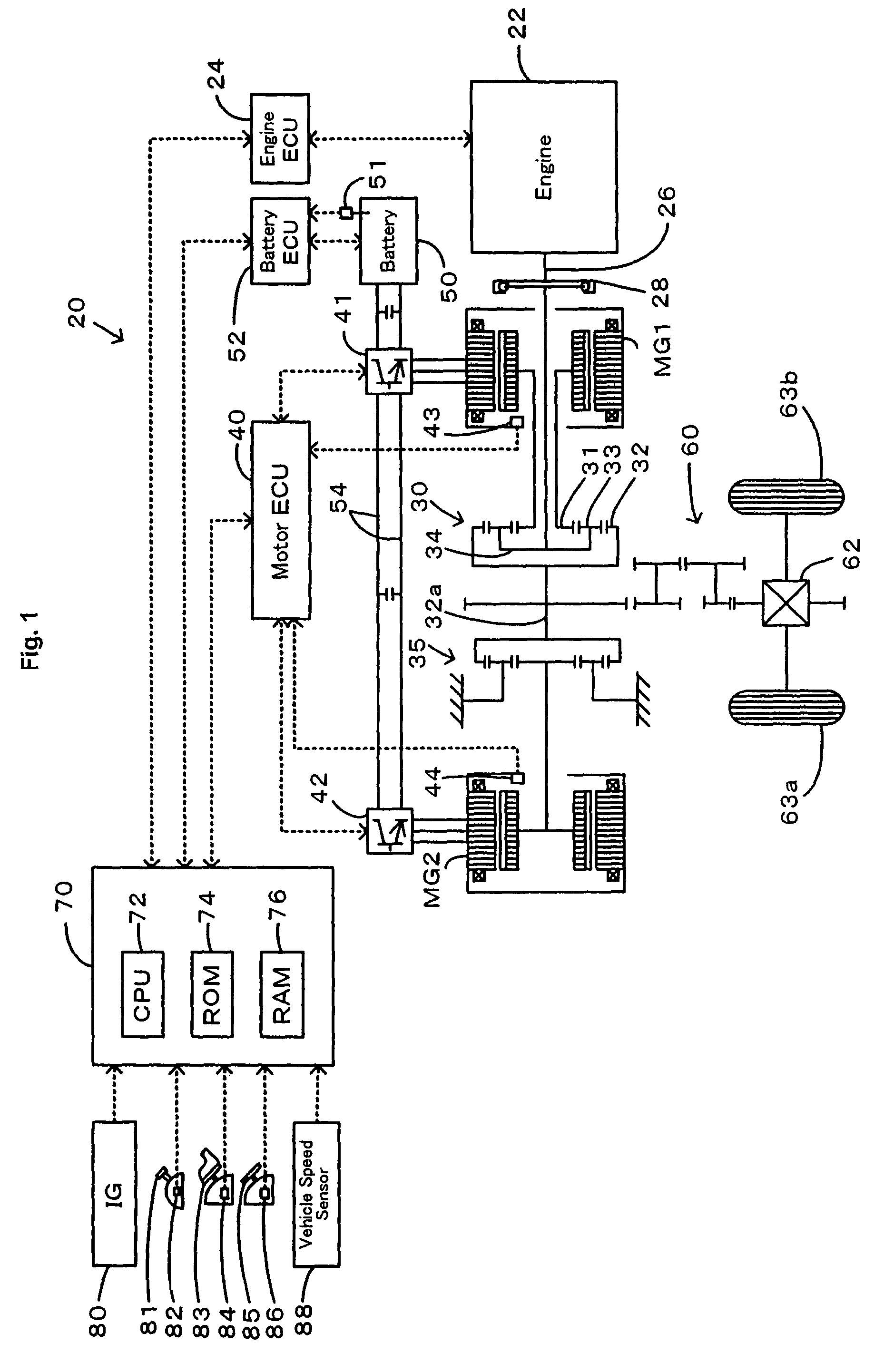

Internal combustion engine apparatus, vehicle and control method of internal combustion engine apparatus

InactiveUS7845333B2InhibitionInhibit outputInternal combustion piston enginesDigital data processing detailsEngineeringIgnition timing

When a condition for the prediction of the occurrence transient knocking has held, that is, when a cooling water temperature θw is not less than a threshold value θwref and an intake air flow Qa is not less than a threshold value Qaref and a deviation of the intake air flow ΔQa is not less than a threshold value ΔQaref (S550 to S570), ignition is performed with timing on the delay angle side compared to timing FT1 by a delay angle amount α that tends to decrease as an amount increase coefficient Kf increases (S600 to S680). Because of this, it is possible to suppress the occurrence of knocking without causing the ignition timing to be delayed more than necessary. As a result of this, it is also possible to suppress the worsening of drivability.

Owner:TOYOTA JIDOSHA KK

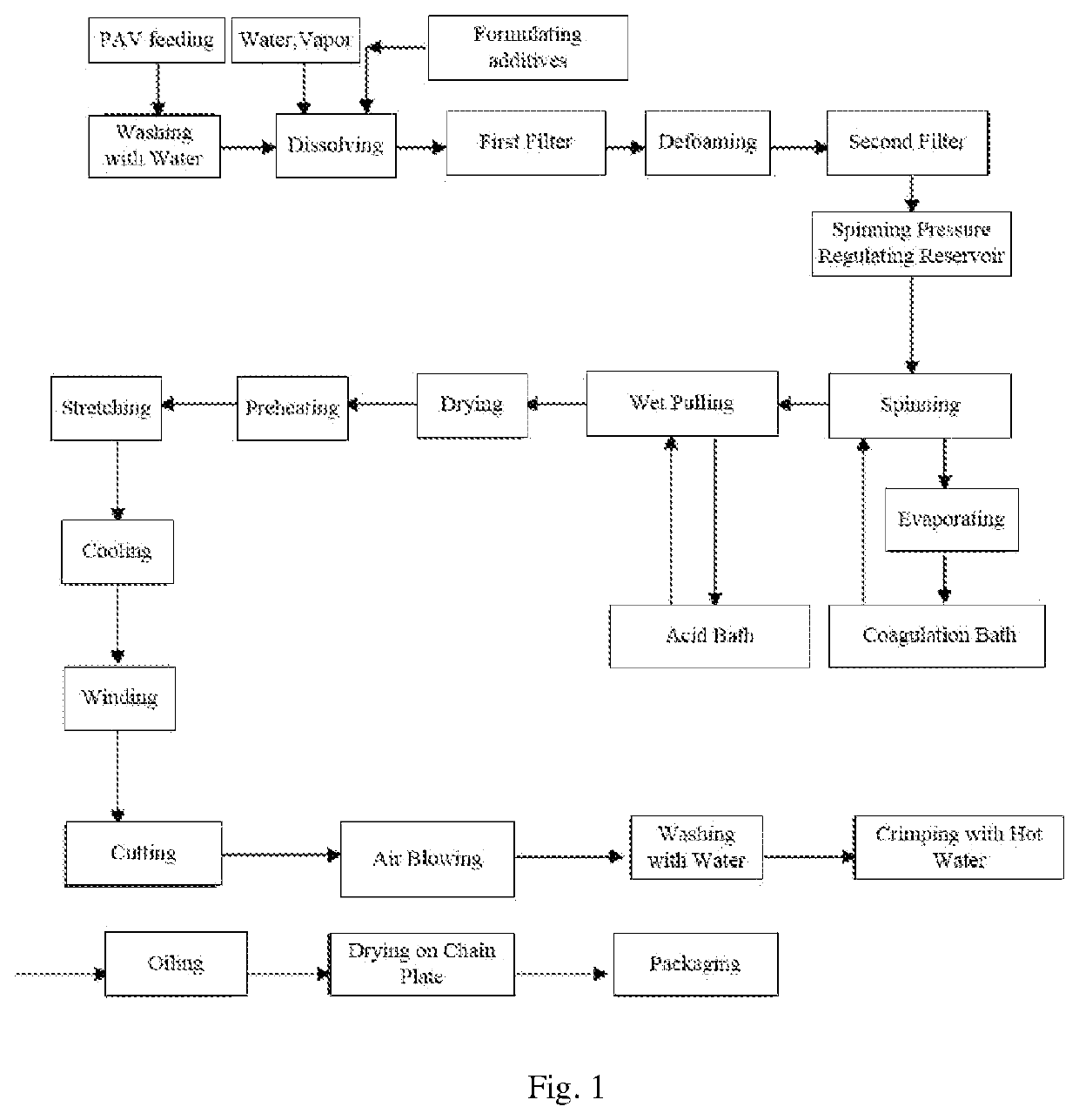

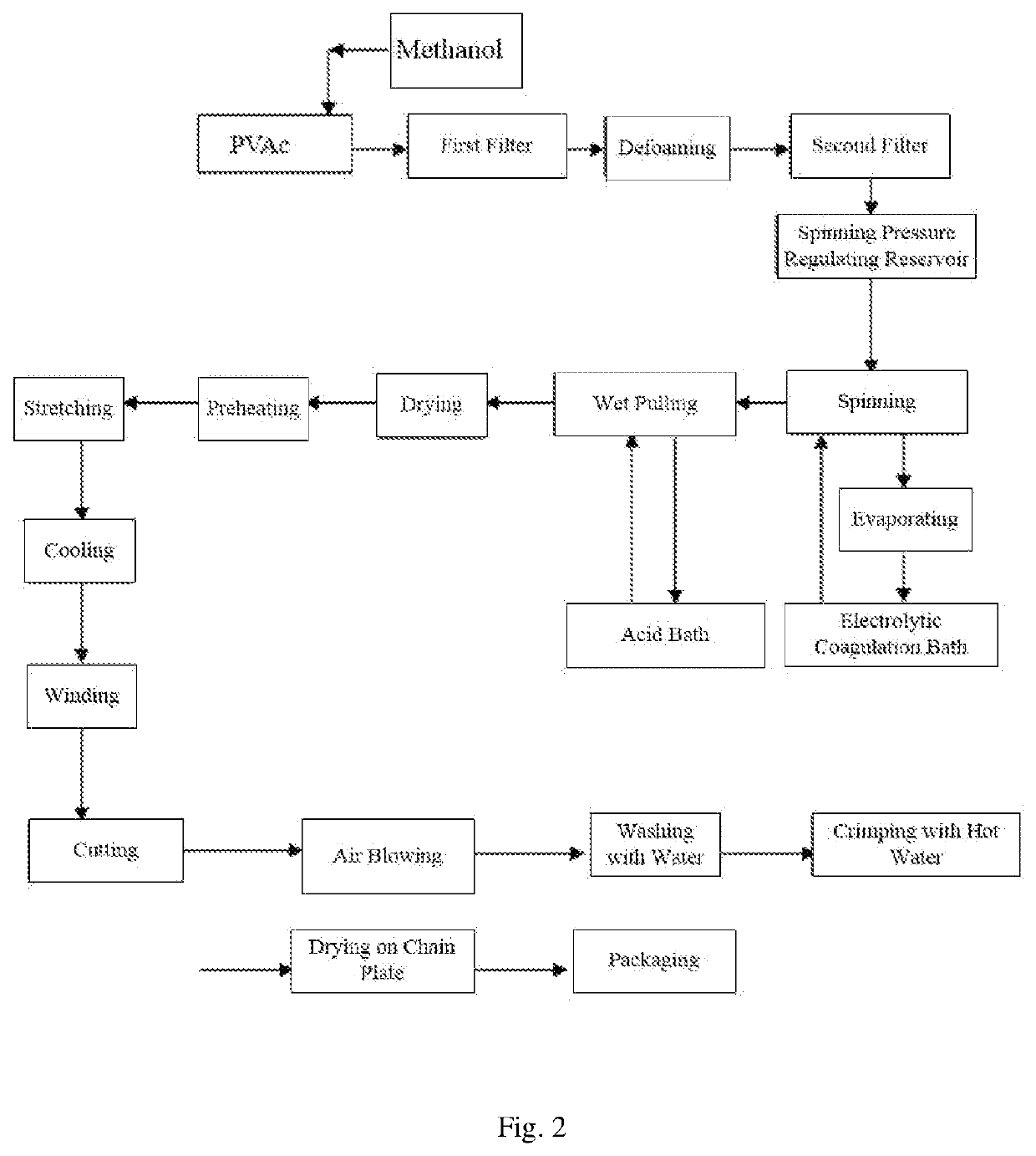

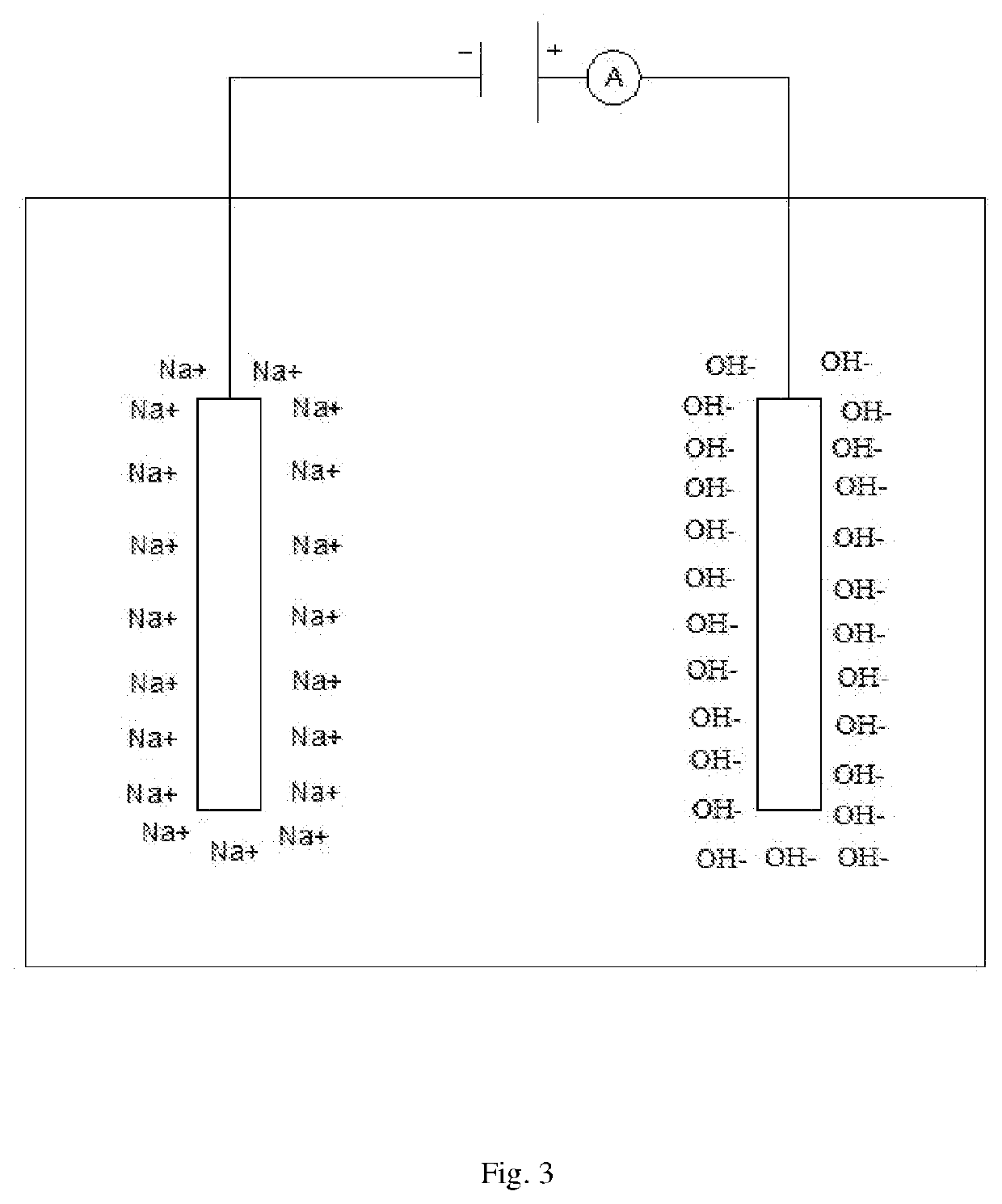

Preparation method of pva fiber

PendingUS20210214475A1High purityReduce the presence of impuritiesArtificial filament physical treatmentMonocomponent synthetic polymer artificial filamentFiberSpinning

A preparation method of PVA fiber comprises the following steps: preparing a spinning dope; PVAc is used as a raw material, and dissolved with addition of methanol before filtration, and then the spinning dope is obtained; spinning; the spinning dope is injected into a spinneret, and the ejected fibers are brought into a direct current electrolytic cell, and undergo a series of reactions of alcoholysis, electrolytic catalytic alcoholysis, and the levering of the alcohol; and the solution formulation in the electrolytic coagulation bath comprises alkali, alcohol and water; acid bath; through stretching, drying, washing with water, crimping with hot water and packaging, a finished polyvinyl alcohol fiber product is formed. The mirabilite is not needed in the coagulation bath, and PVA is obtained by the alcoholysis of PVAc in an electrolytic cell, and the produced PVA fibers present high purity and few impurities.

Owner:ZHENDE MEDICAL CO LTD

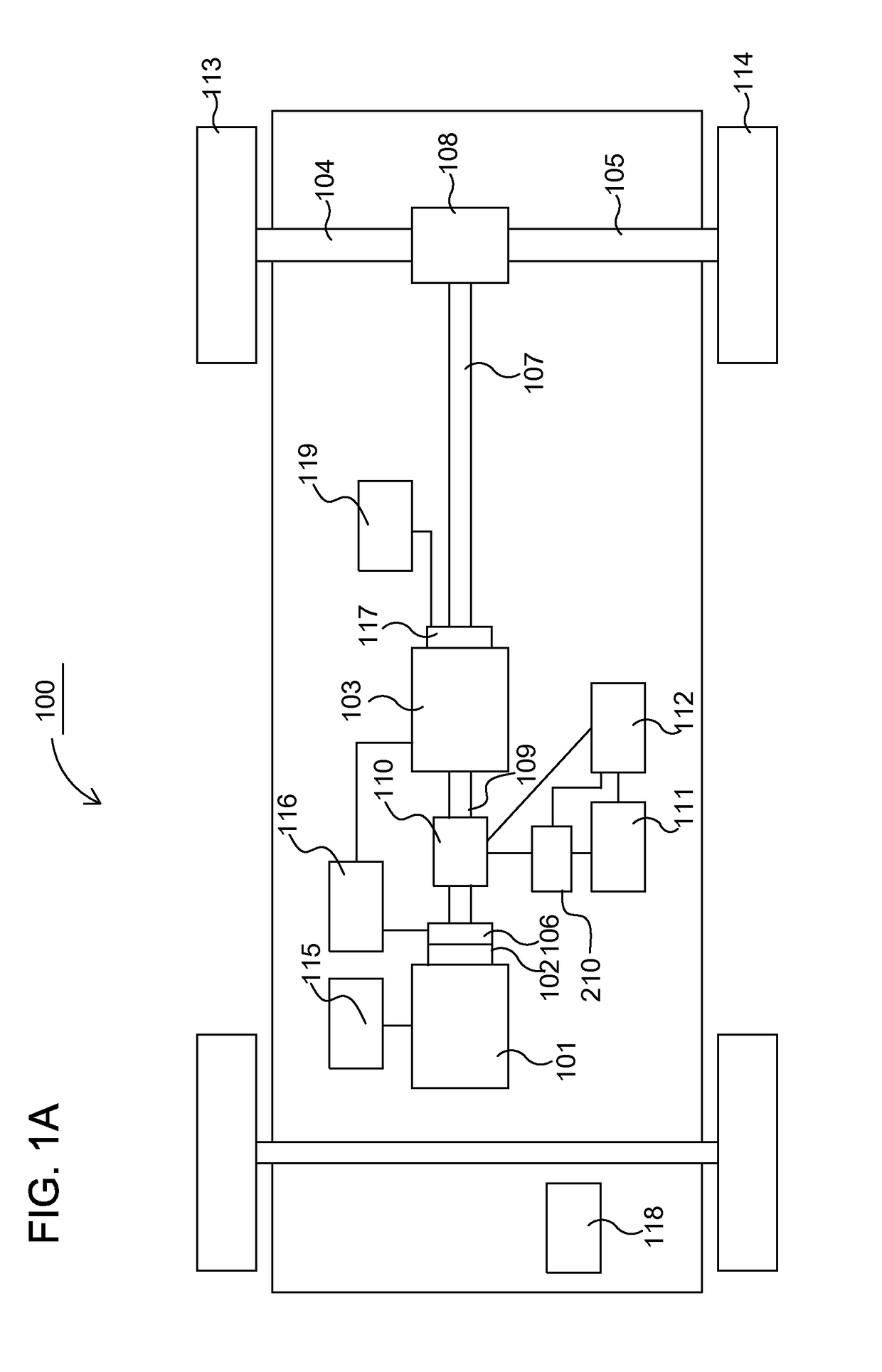

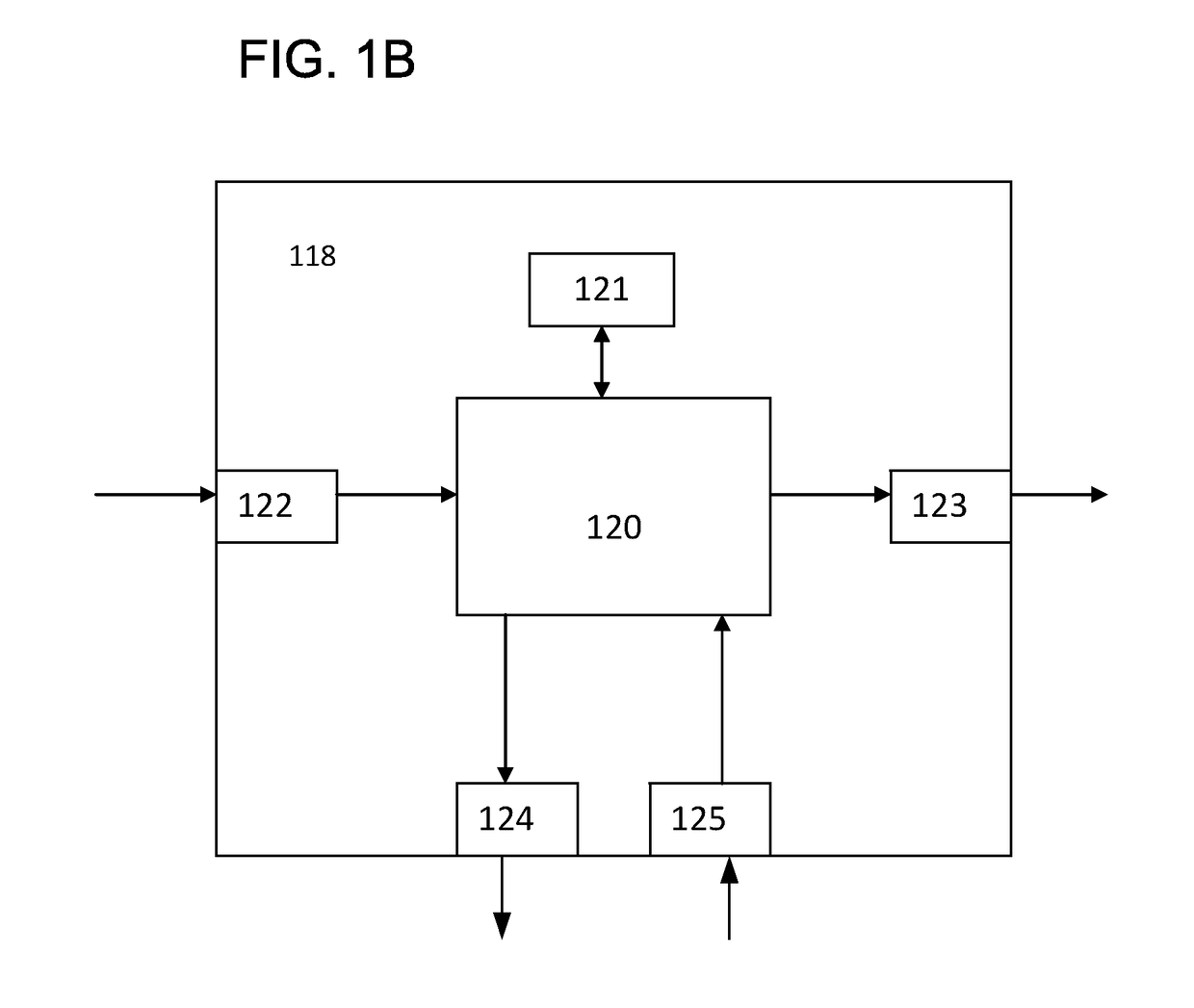

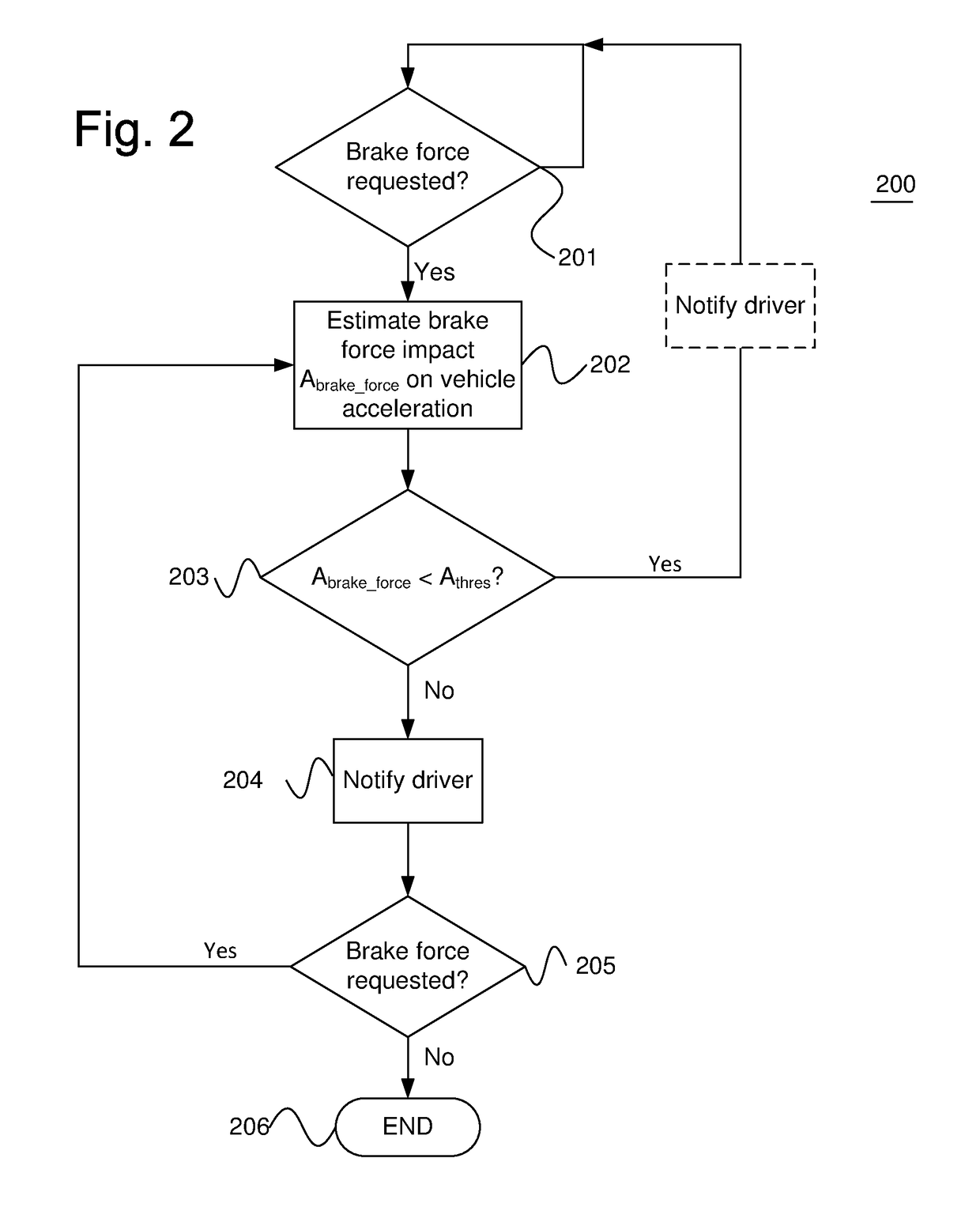

Method and device for determining a measure of brake system usage during operation of a vehicle

ActiveUS20180345982A1A large amountRequires moreHybrid vehiclesVehicle sub-unit featuresSystem usageBraking system

A method, system and computer program product are provided for determining a measure of brake system usage during operation of a vehicle, the vehicle comprising a power source for generating a motive force for propulsion of the vehicle in a first direction of travel, and driver controllable means for requesting a brake force that acts against a movement of the vehicle in the first direction of travel. When a driver of the vehicle requests a brake force, the method comprises determining an influence on the vehicle acceleration caused by the request for brake force; and determining, based on the determined influence, a measure of brake system usage of the vehicle, the measure indicating a level of economical driving, wherein a particular level is arranged to depend on the magnitude of the influence on the vehicle acceleration caused by the request for brake force.

Owner:SCANIA CV AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com