Coal with improved combustion properties

a technology of combustion properties and coal, applied in the petroleum industry, liquid carbonaceous fuels, solid fuels, etc., can solve the problems of low thermal efficiency, achieve the effects of improving carbon burnout, reducing carbon content in ash, and reducing activation energy for oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0027]Iron (II) phthalocyanine (0.1-0.2 g) was dissolved in concentrated sulphuric acid (50-60 ml). A sample of brown coal (˜2 g) (2-3 mm grain size) was stirred in this solution for 2 hours at room temperature and left overnight to soak. After stirring, the coal with the deposited phthalocyanine was filtered off. The residual concentration of iron (II) phthalocyanine was determined by UV / visible spectrophotometric analysis. The quantity of the deposited iron-based additive was determined by the difference in concentrations of the starting and residual solutions. The filtered coal was washed with water to neutral pH and air-dried to constant weight over 72-144 hours. Calculations showed that 0.2% of iron (II) phthalocyanine was deposited on the coal. This corresponds to about 200 ppm of iron. After drying, the sample of coal was ground to dust in a mortar for DTA / DTG analysis.

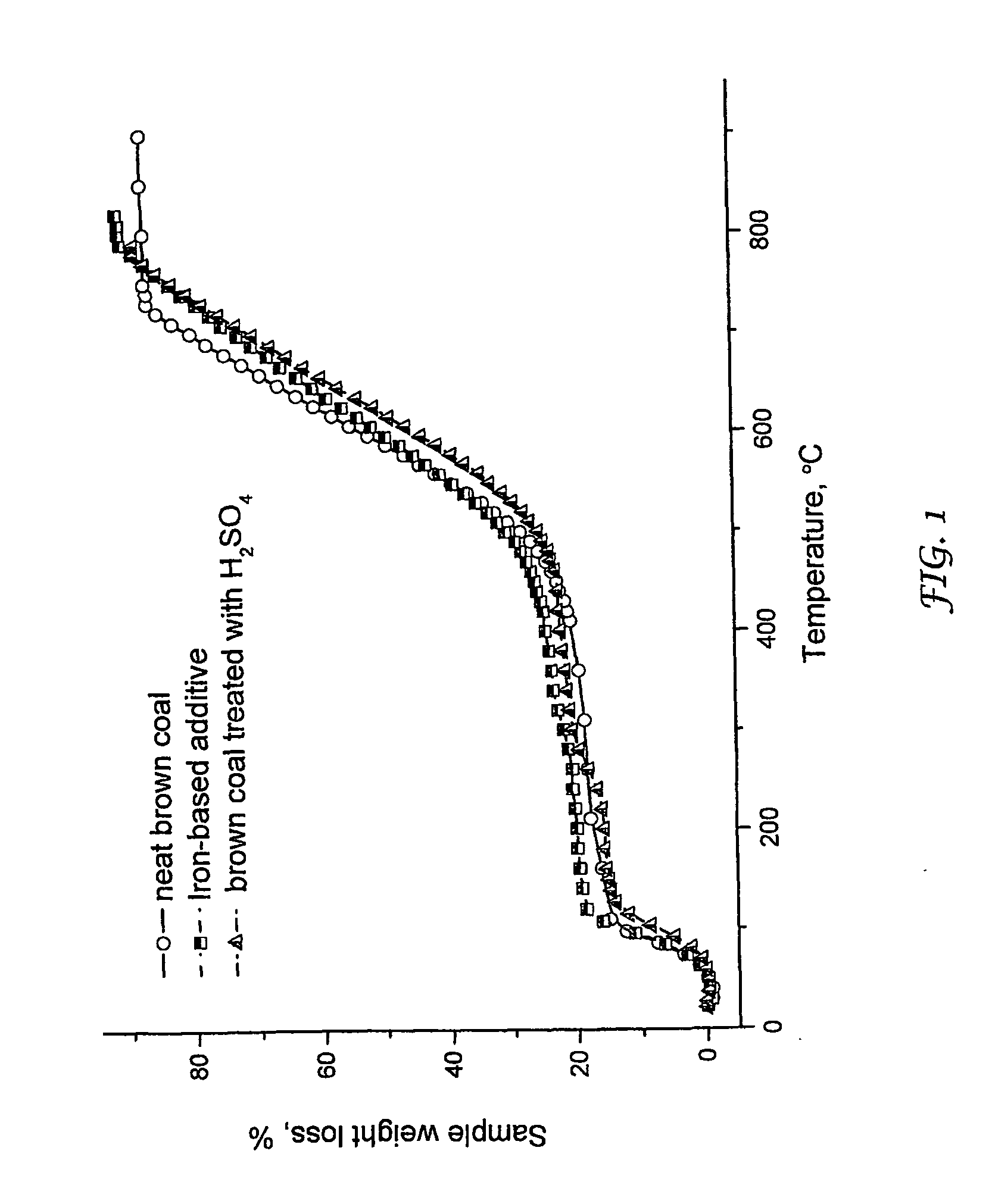

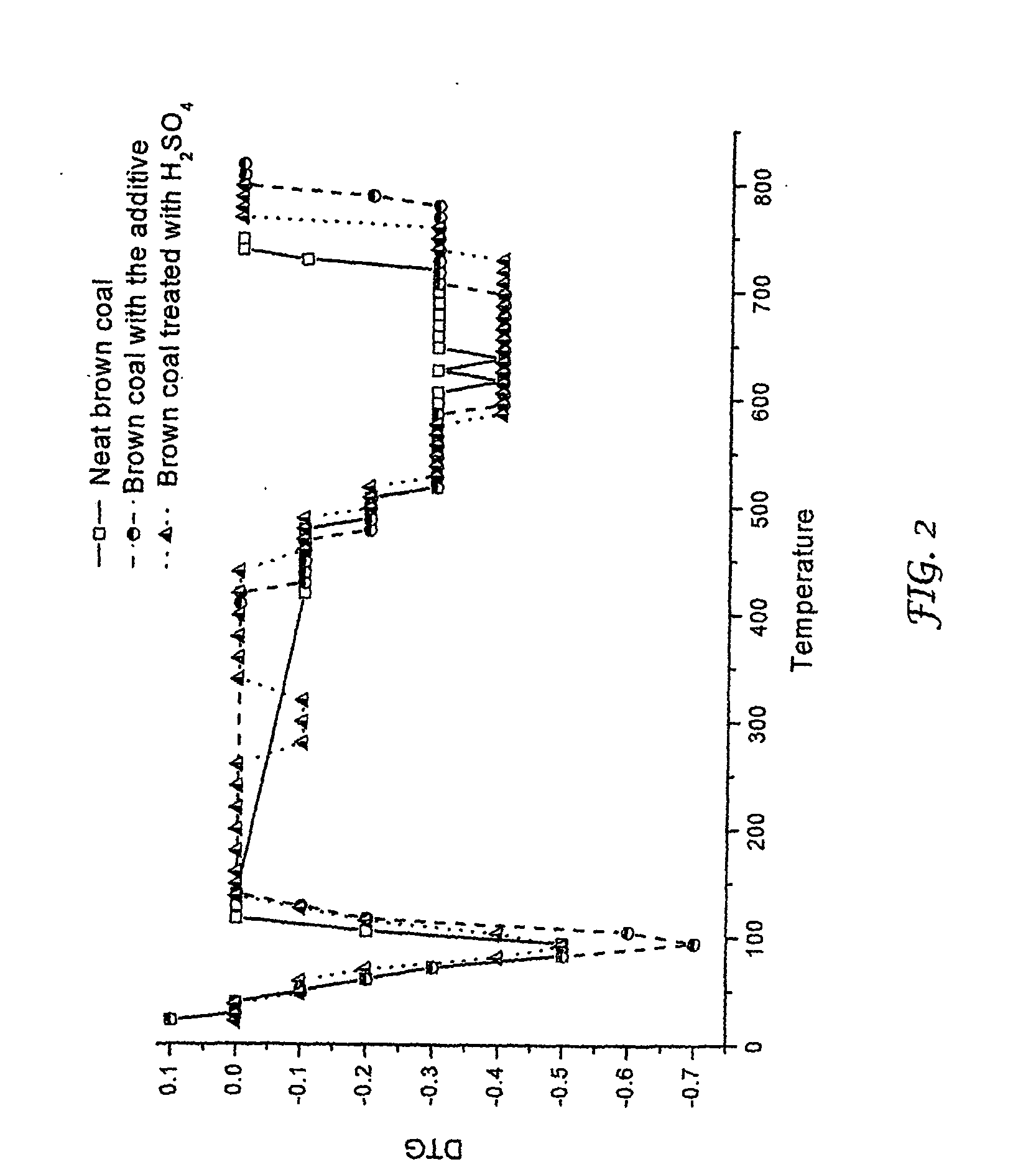

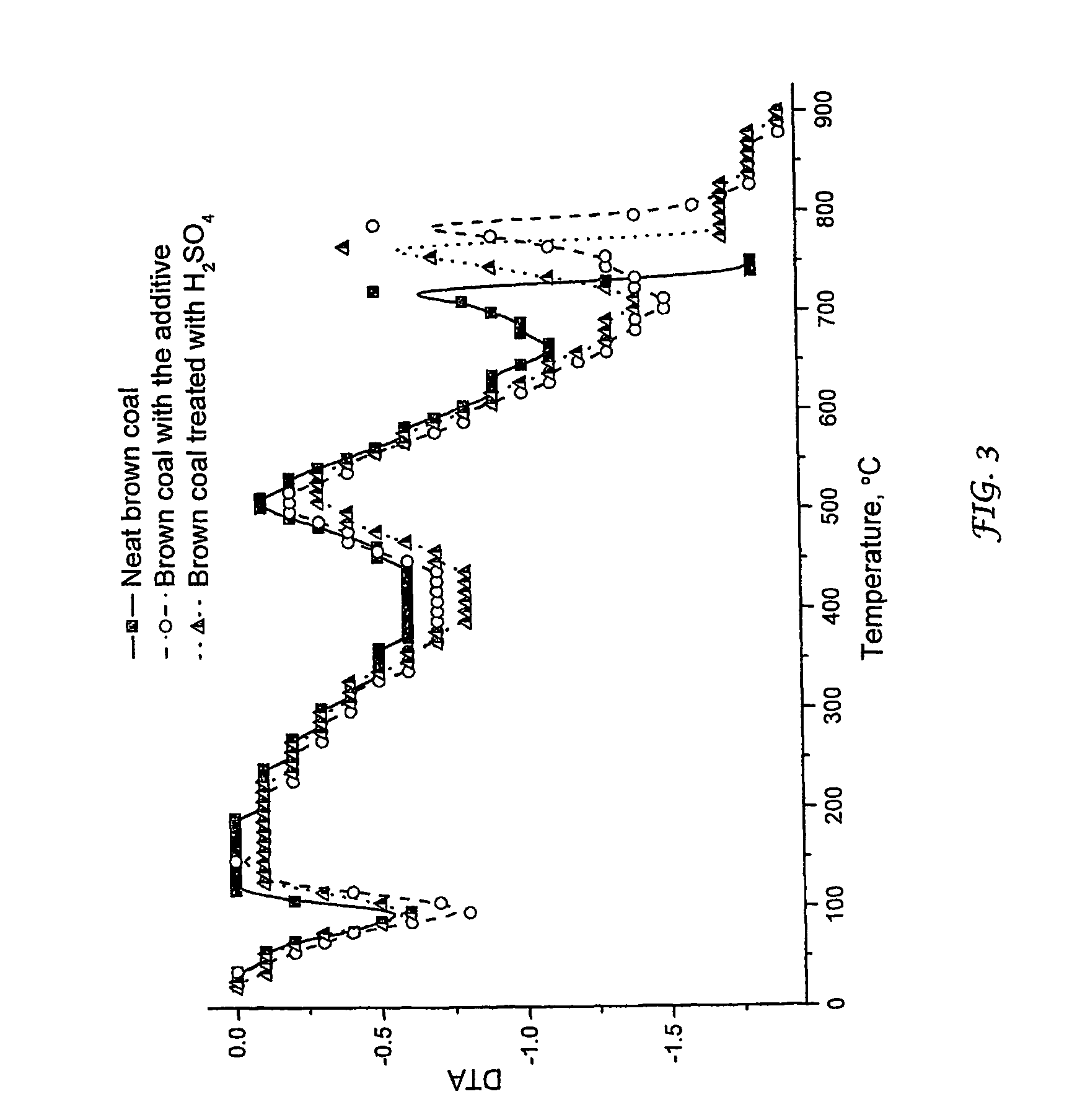

[0028]Comparative measurements were made on untreated (‘neat’) brown coal and on brown coal treated under th...

example 2

[0042]As for Example 1 but using cobalt phthalocyanine disulphonate as the metal porphyrin and distilled water instead of sulphuric acid as the fluid carrier.

[0043]Results are shown in FIGS. 7-11.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| combustion properties | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com