Patents

Literature

199results about How to "Raise the initial temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

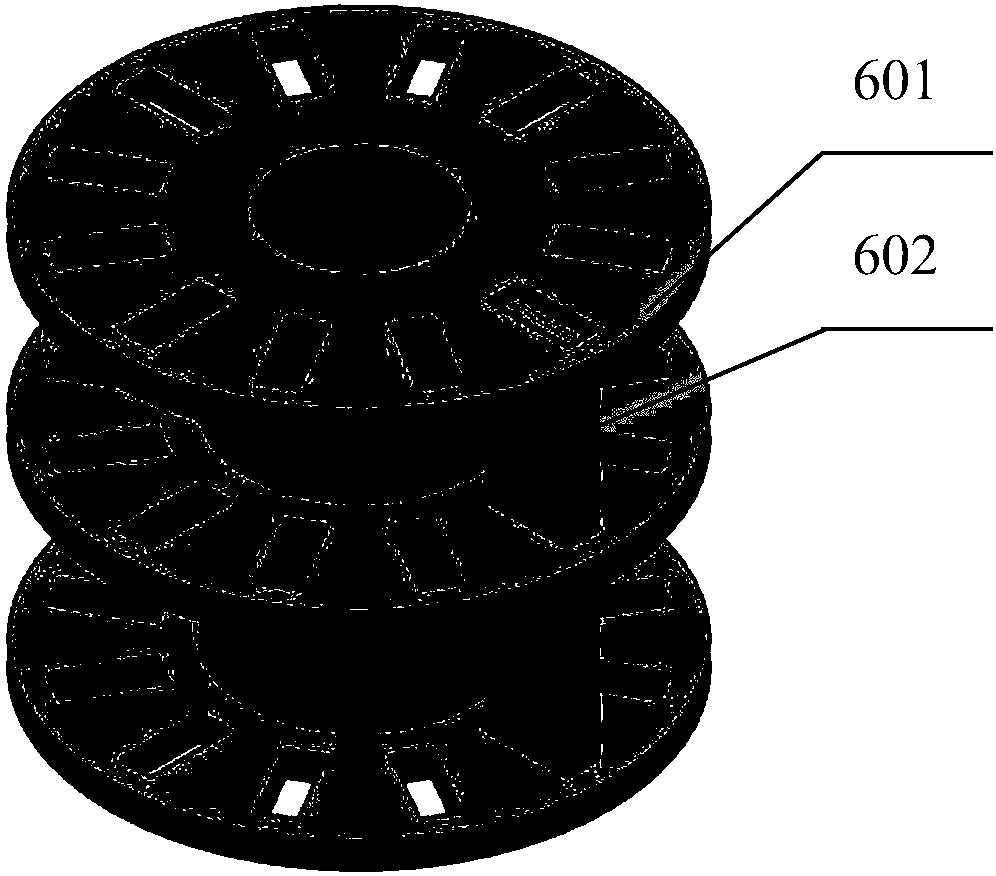

High-temperature expanded polymer microspheres and preparation method thereof

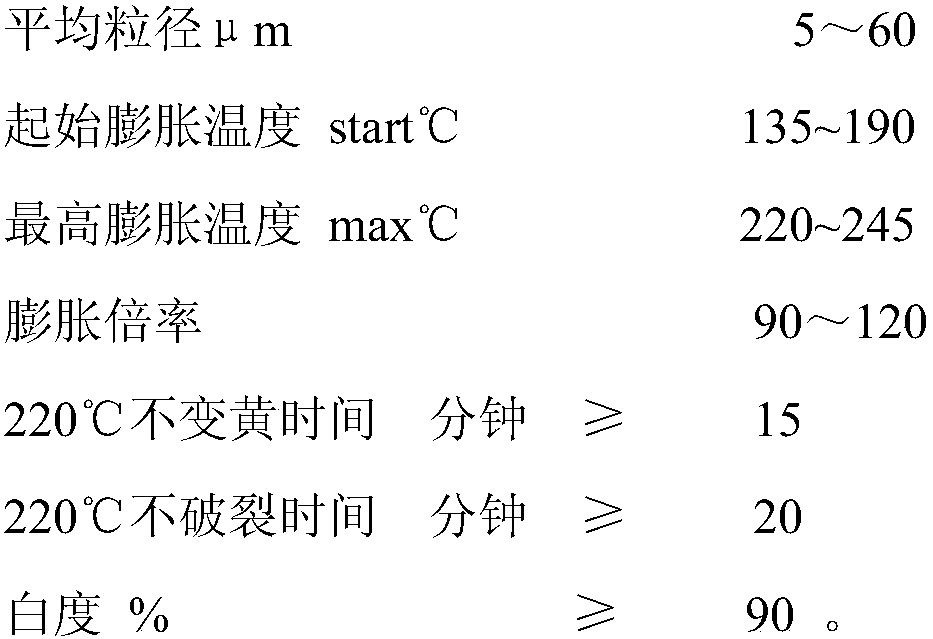

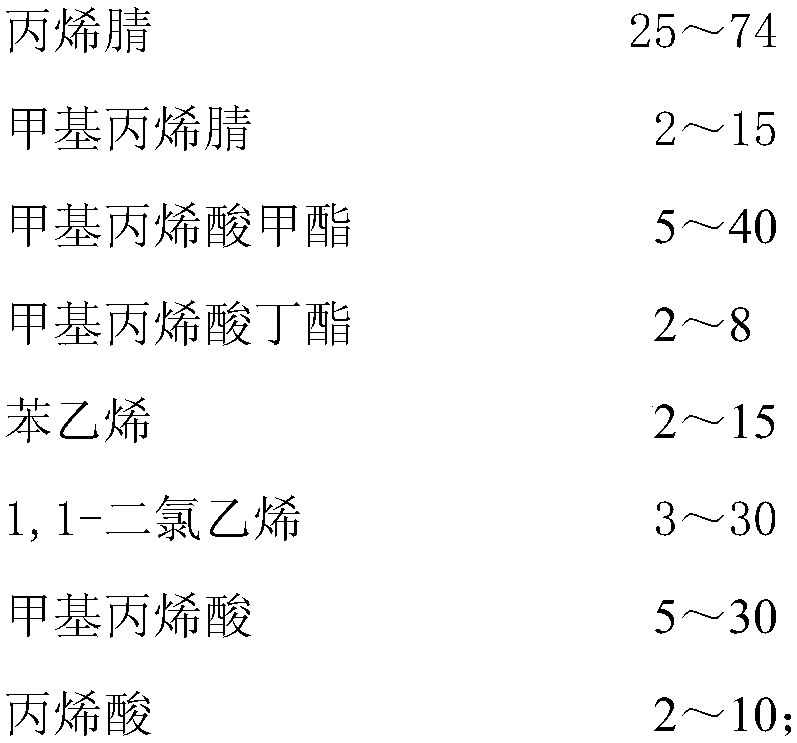

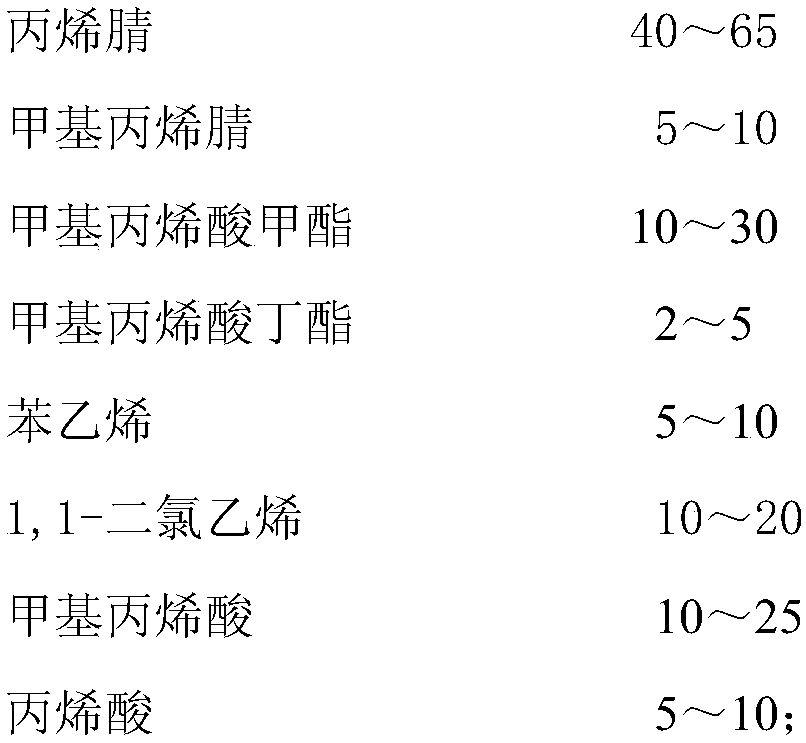

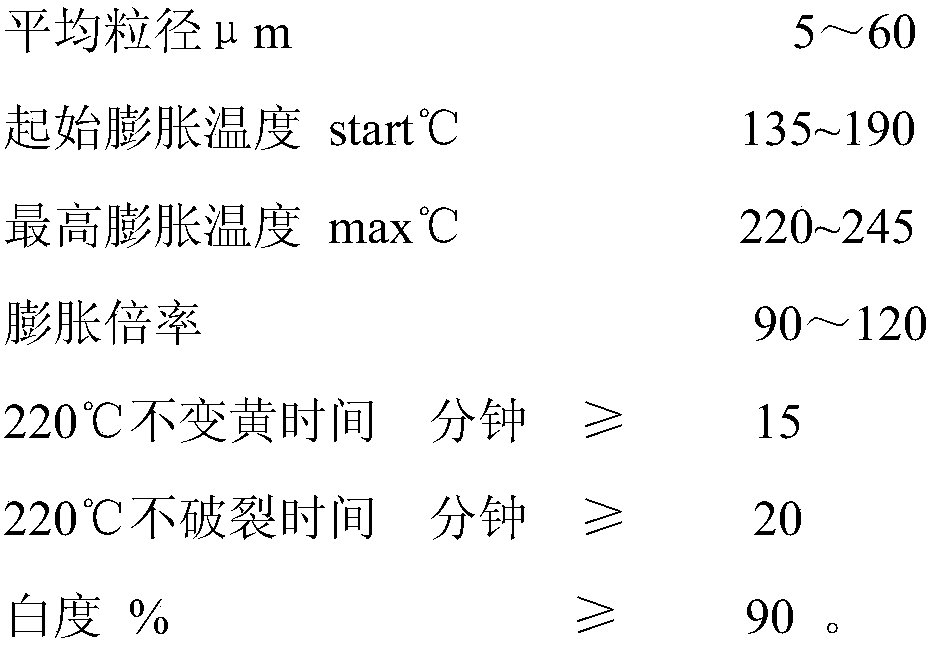

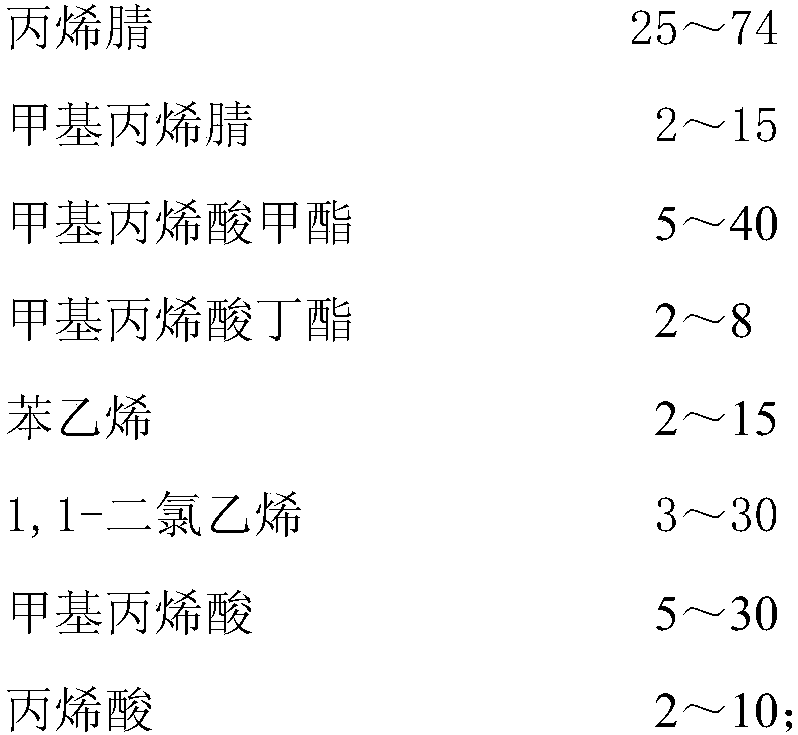

The invention provides high-temperature expanded polymer microspheres and a preparation method thereof and belongs to expandable particles. The high-temperature expanded polymer microspheres are prepared from a thermoplastic resin shell body and a foaming agent packaged in the shell body, wherein an oil-phase composition composed of a polymerizable monomer and a crosslinking agent can be dispersedinto a water-phase dispersed composition; in the presence of the foaming agent, the polymer microspheres coated with the foaming agent are directly prepared through carrying out suspension polymerization reaction and coating the foaming agent in situ; the high-temperature expanded polymer microspheres are characterized in that the oil-phase composition contains the polymerizable monomer and the crosslinking agent, and also comprises a silane coupling agent; the foaming agent is a mixture of isopentane, isooctane and n-octane; the high-temperature expanded polymer microspheres provided by theinvention have the advantages of complete core-shell structure, uniform grain diameter distribution, high foaming agent coating efficiency, good heat resistance of a shell-layer polymer, relatively high initial temperature in an expansion process, relatively high highest expansion temperature and high foaming ratio, have a relatively wide foam stabilizing temperature range, and are suitable for being applied to a thermoplastic resin, rubber or thermoplastic elastomer foaming and processing technology.

Owner:SHANDONG RUIFENG CHEM

Thermally-expandable polymer microsphere special for polyvinyl chloride resin foaming and preparation method thereof

The invention relates to a thermally-expandable polymer microsphere for polyvinyl chloride resin foaming and a preparation method thereof, and belongs to the field of expandable particles. The thermally-expandable polymer microsphere consists of a thermoplastic resin shell and a foaming agent encapsulated in the shell; an oil phase composition composed of a polymerizable monomer and a crosslinkingagent is dispersed in an aqueous phase dispersion composition; and in the presence of the foaming agent, the foaming agent is coated in situ through a suspension polymerization reaction to directly prepare the polymer microsphere coated with the foaming agent. The thermally-expandable polymer microsphere is characterized in that the oil phase composition comprises a silane coupling agent in addition to the polymerizable monomer and the crosslinking agent, and the foaming agent is a mixture of isopentane, isooctane and n-octane. The invention provides a thermally-expandable polymer microspherewhich has the advantages of complete core-shell structure, uniform particle size distribution, high foaming agent coating efficiency, good heat resistance of a shell polymer, high initial temperatureduring expansion, high maximum expansion temperature, high foaming ratio, and wide foam stabilizing temperature range, and is special for foaming polyvinyl chloride resin.

Owner:SHANDONG RUIFENG CHEM

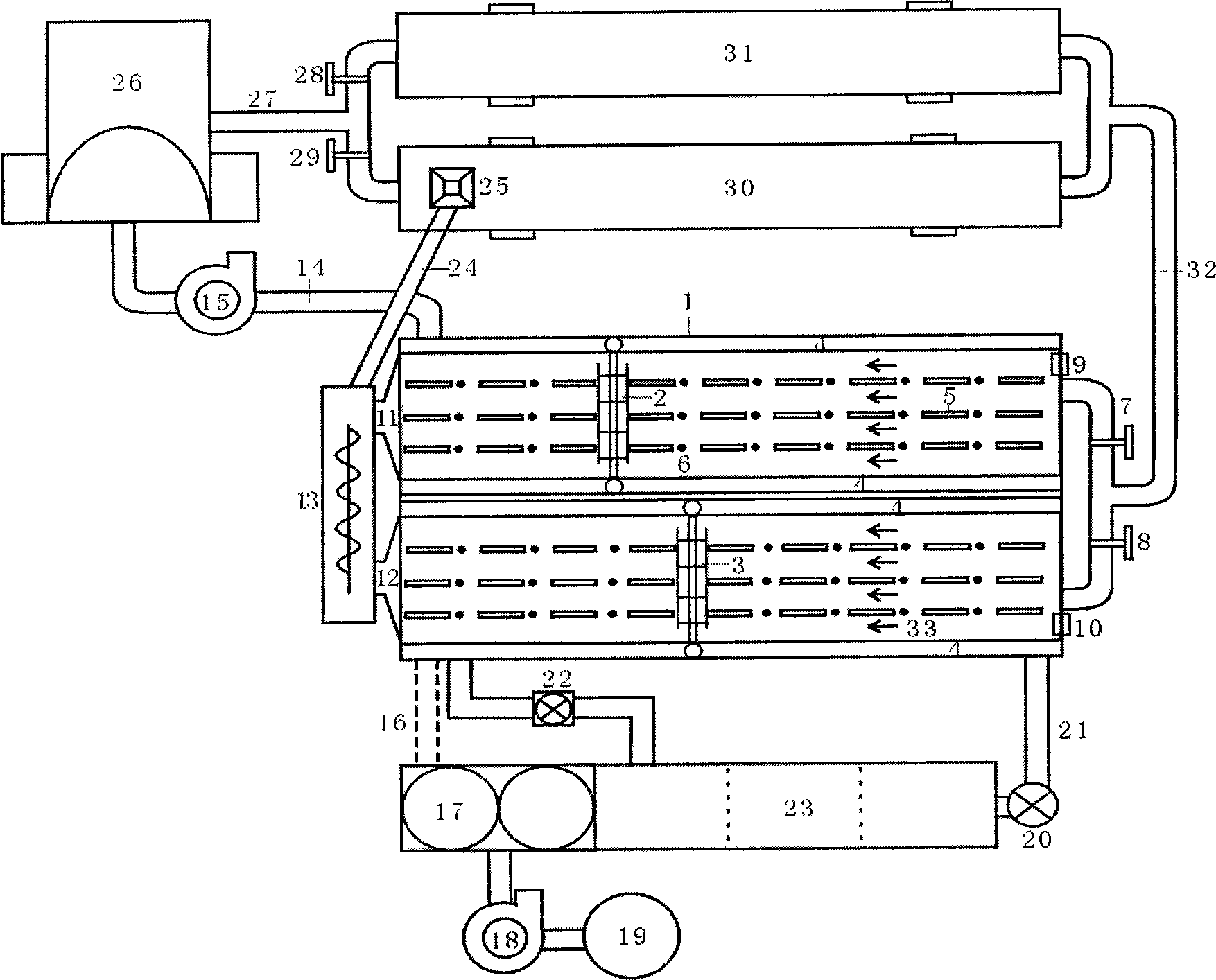

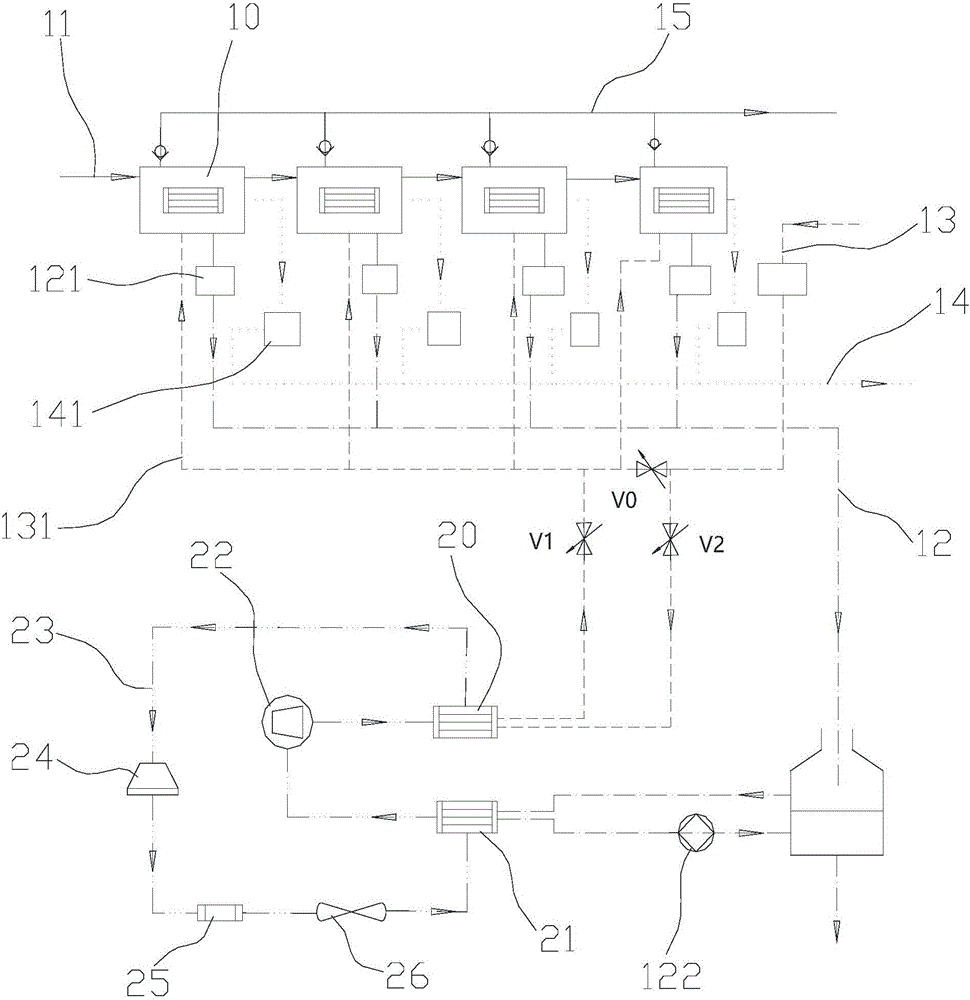

A double-effect cross flow MVR evaporation and concentration system

ActiveCN106068149ARaise the initial temperatureReduce differential pressureEvaporation with vapour compressionMultiple-effect evaporationEvaporationSingle effect

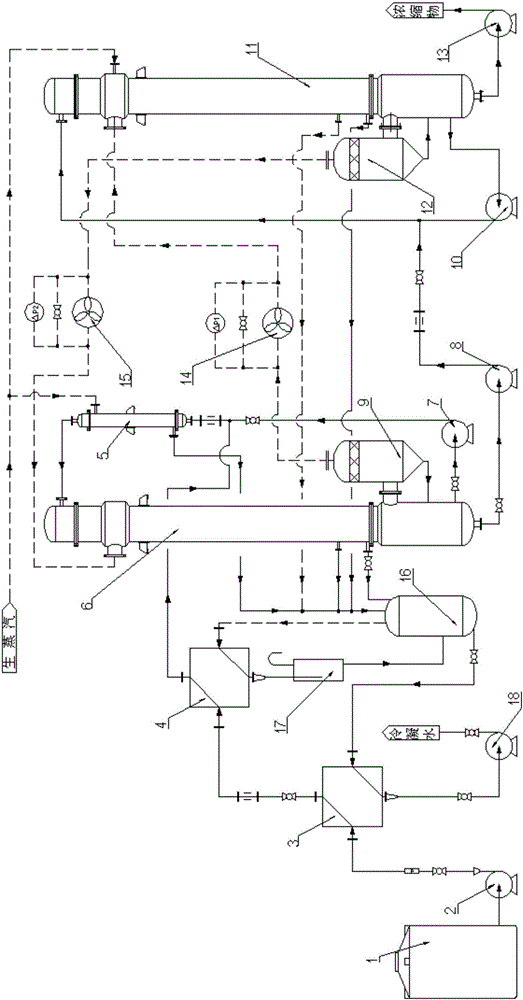

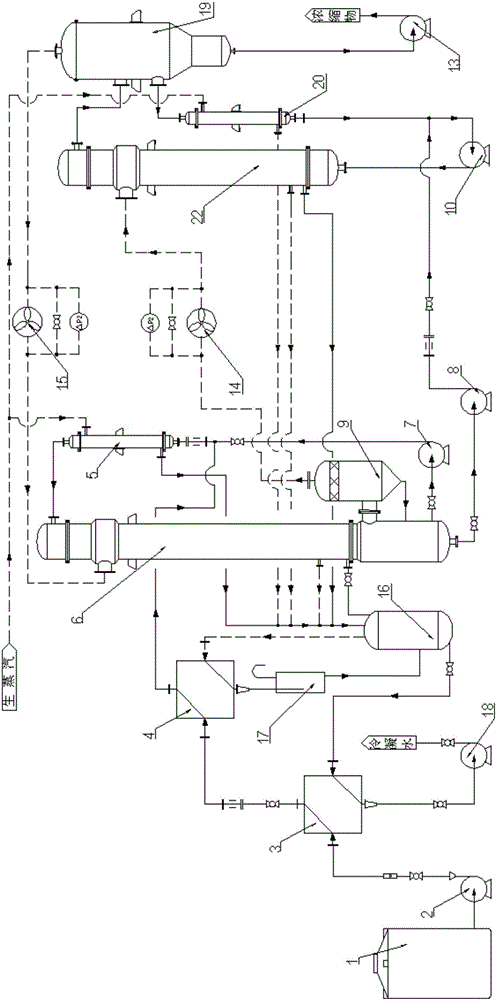

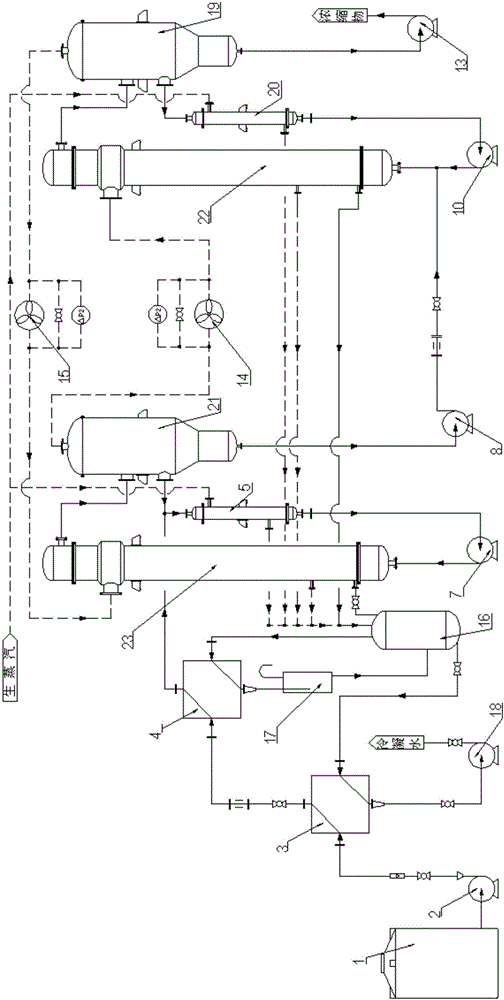

The invention discloses a double-effect cross-flow MVR evaporation and concentration system including a feed liquid flow subsystem, a cross-flow steam compression subsystem and a waste heat recovery subsystem. In the feed liquid flow subsystem, feed liquid is preheated by the waste heat recovery subsystem, and performs primary evaporation after reaching a bubbling point through live steam heating; generated secondary steam is compressed by a primary compressor to serve as a heat source of secondary evaporation; primarily concentrated feed liquid is sent to a secondary evaporator via a primary discharge pump for continuous evaporation and concentration; generated secondary steam is compressed by a secondary compressor to serve as a heat source of primary evaporation, and completion liquid is discharged out of the system via a secondary discharge pump. The feeding speed, the preheating temperature, the circulatory flow and the compressor working pressure difference of the system are under accurate control of a PLC. Compared with a single-effect MVR evaporation and concentration system, the system has the advantages that the steam compressor operation pressure difference is reduced, power consumption is saved by 25%-40%, the evaporation and concentration expenses are reduced and emission of carbon dioxide causing the greenhouse effect is greatly reduced.

Owner:JIANGMEN BAICHUAN ENVIRO TECH CO LTD

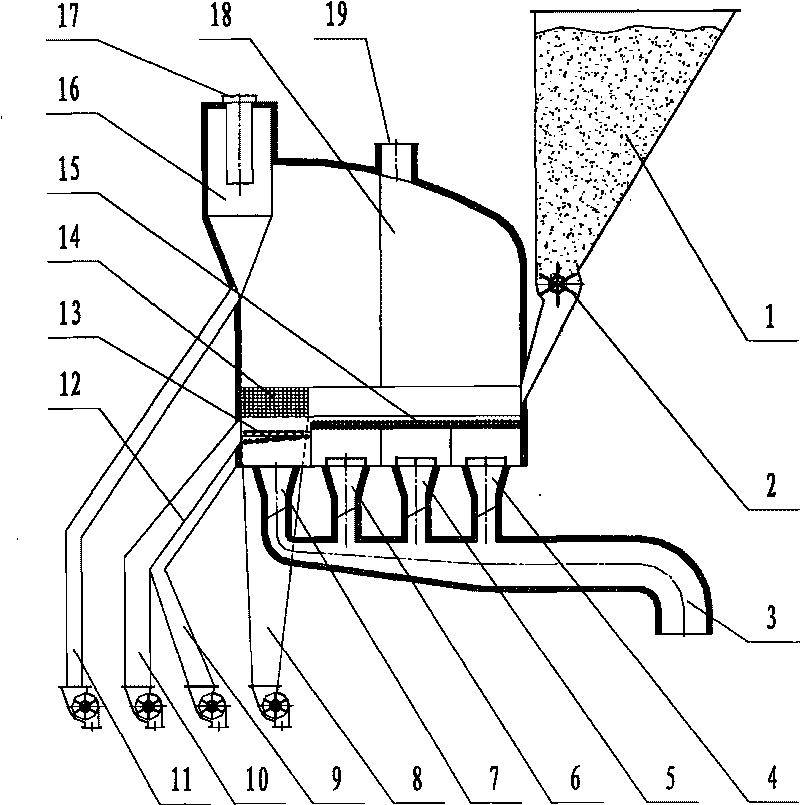

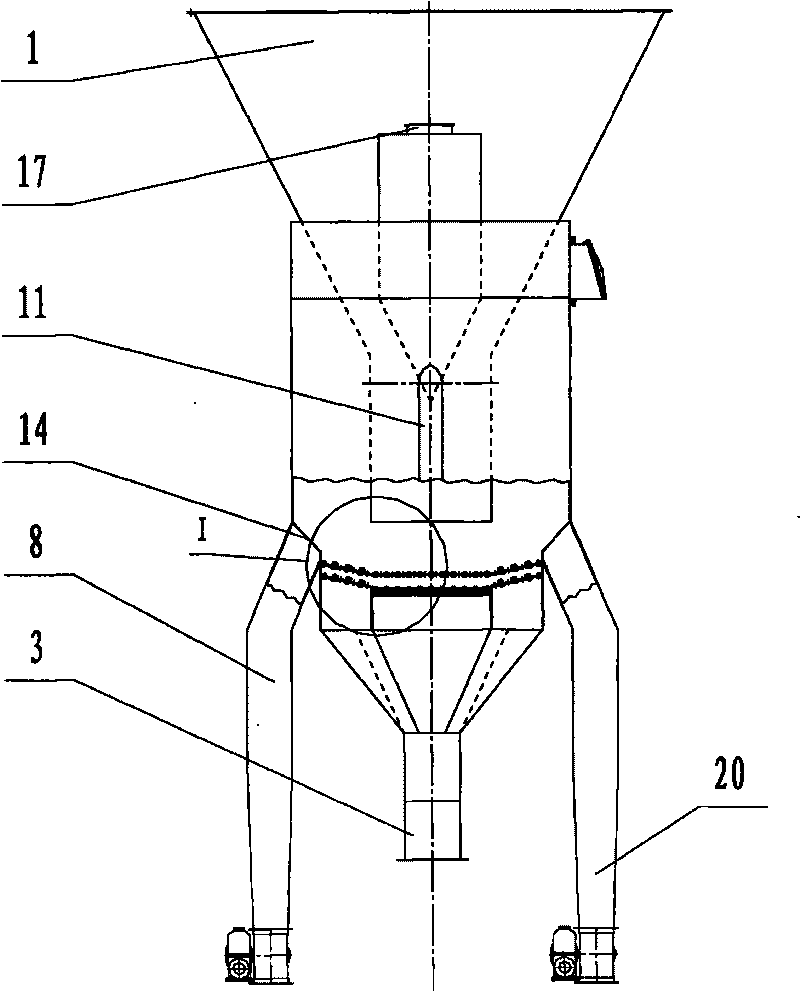

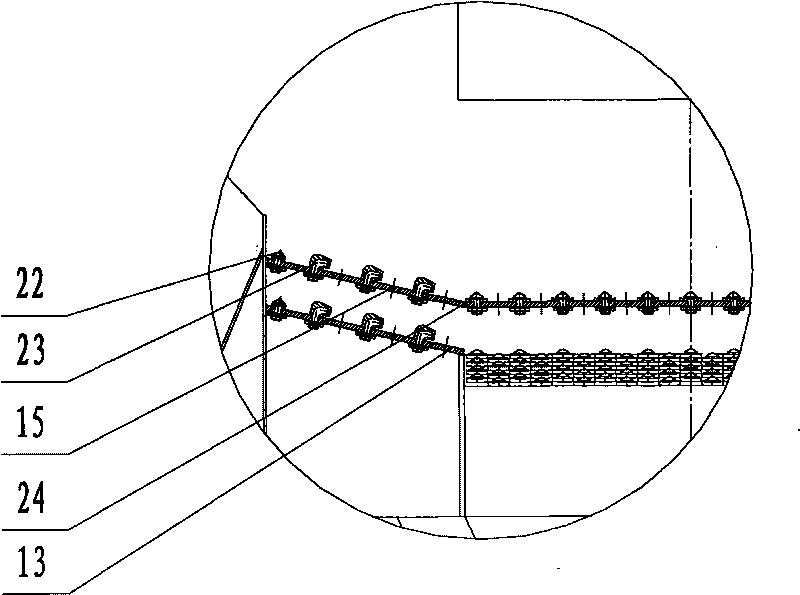

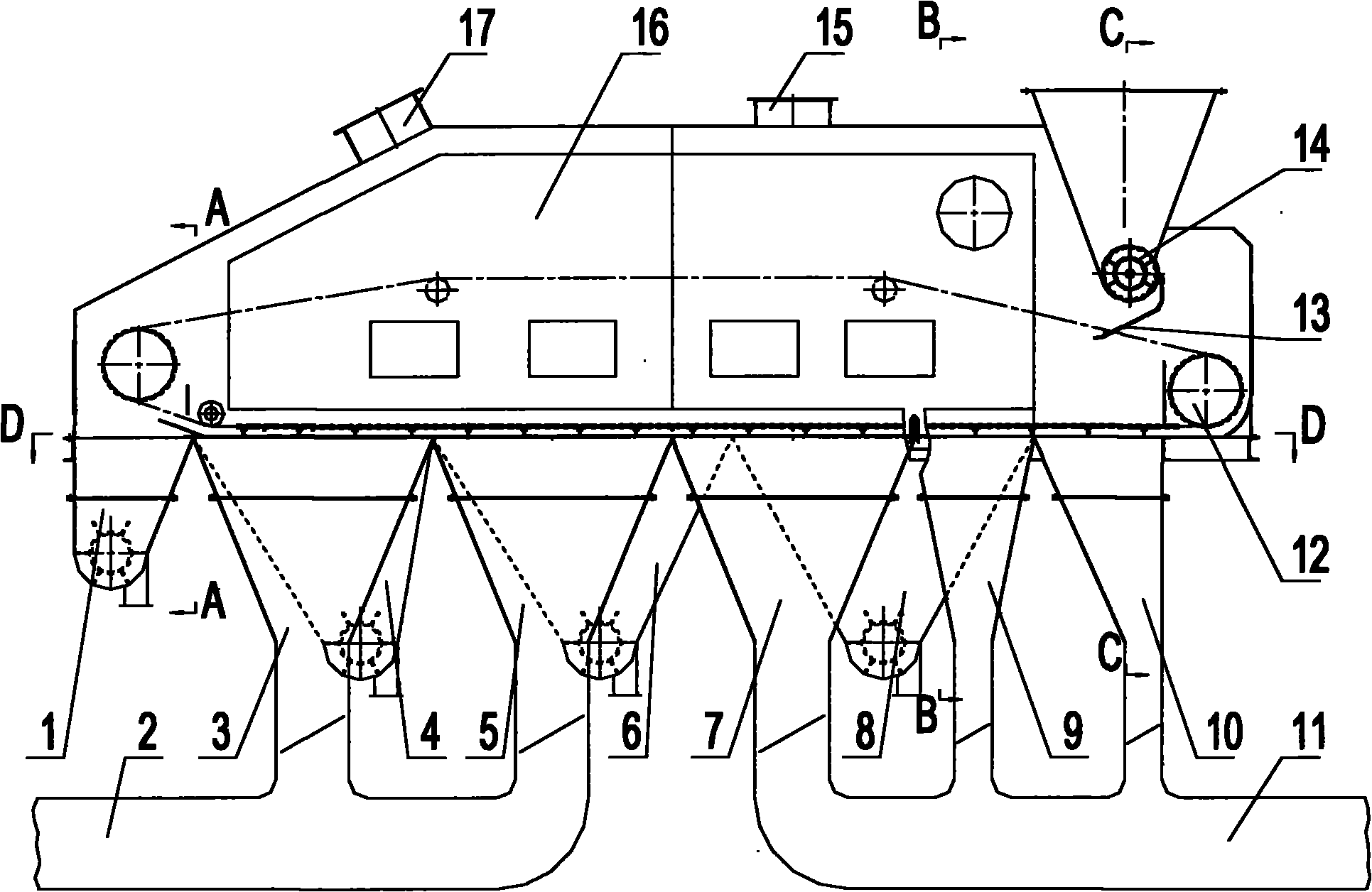

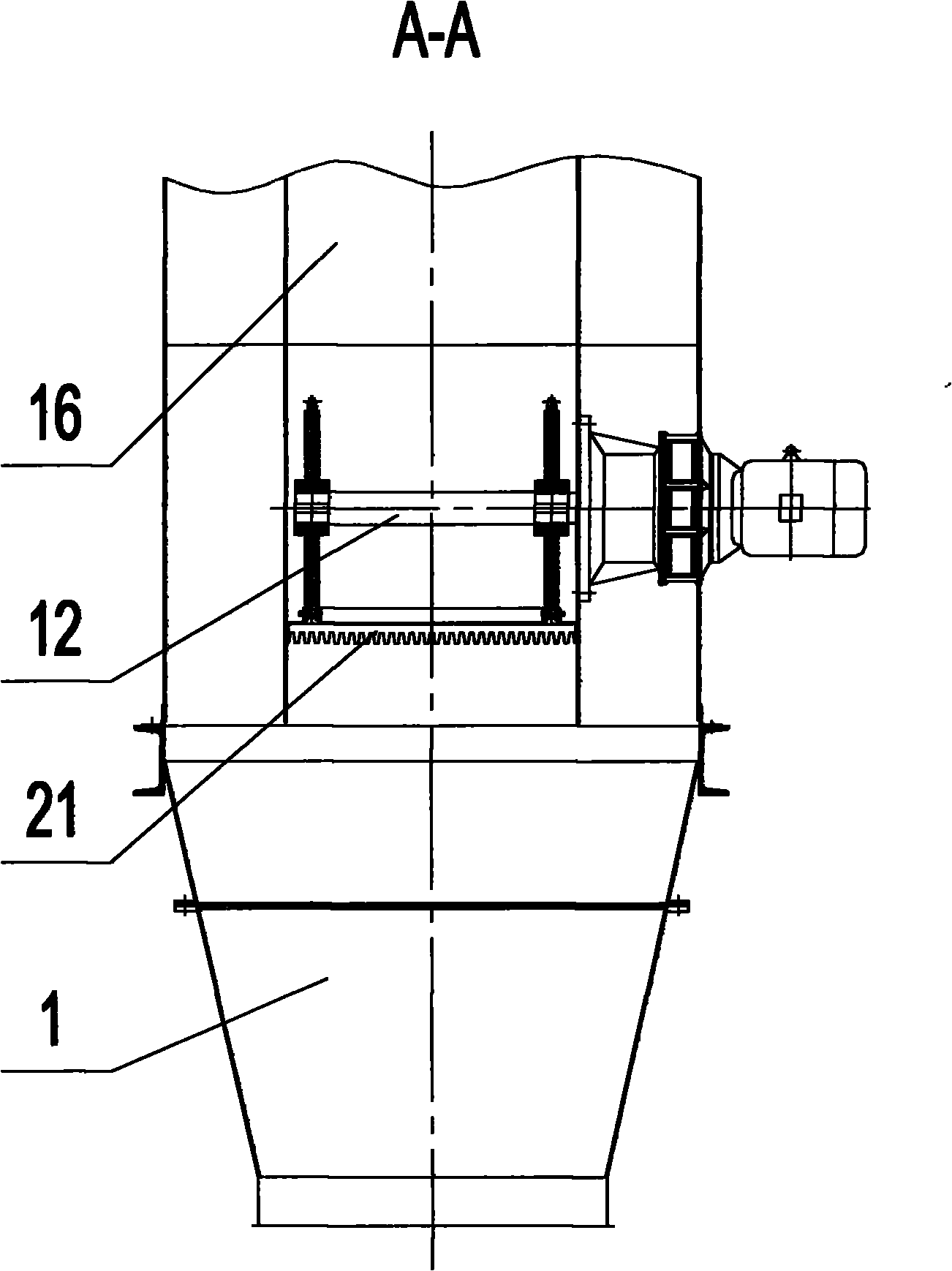

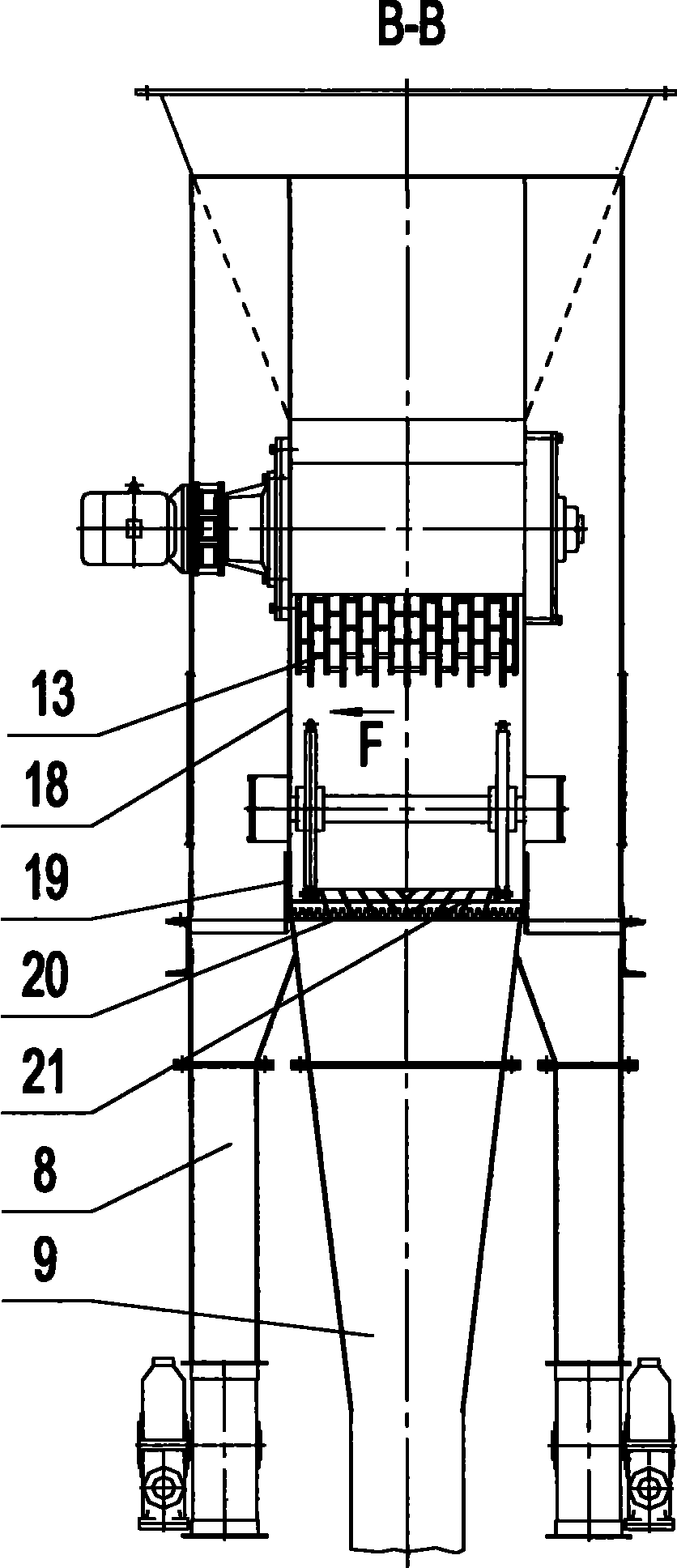

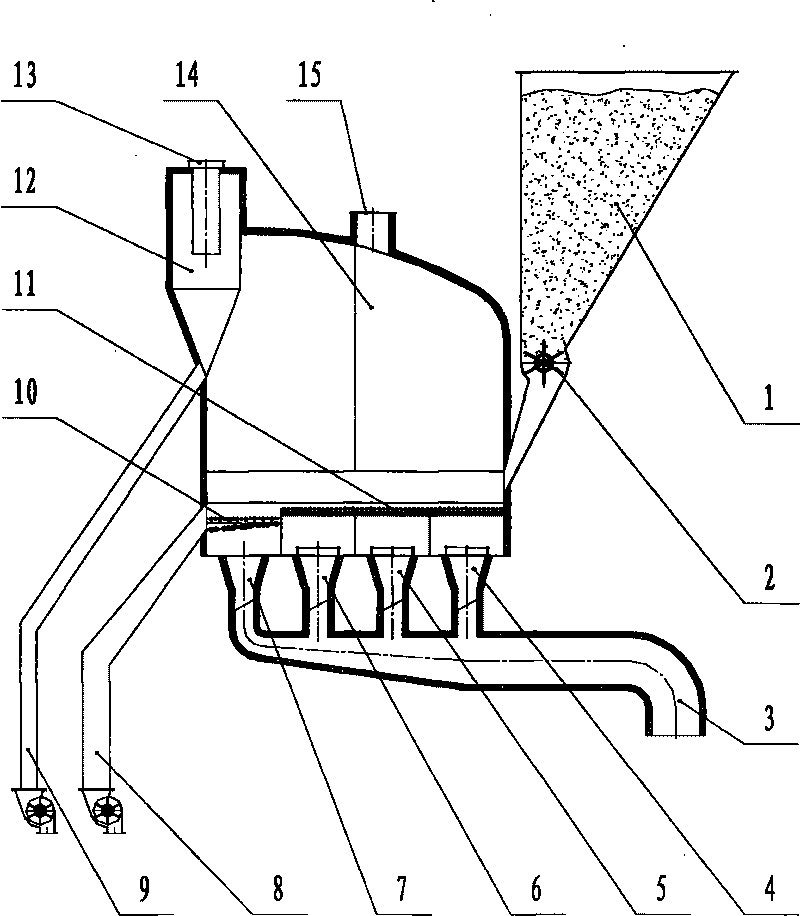

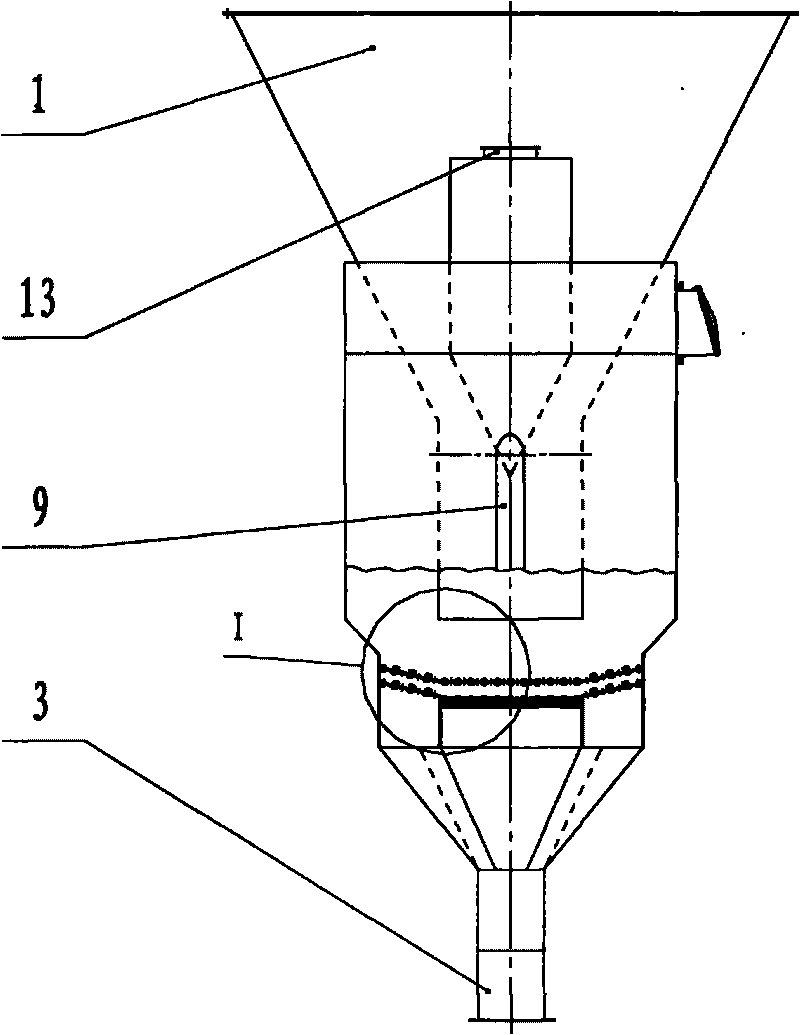

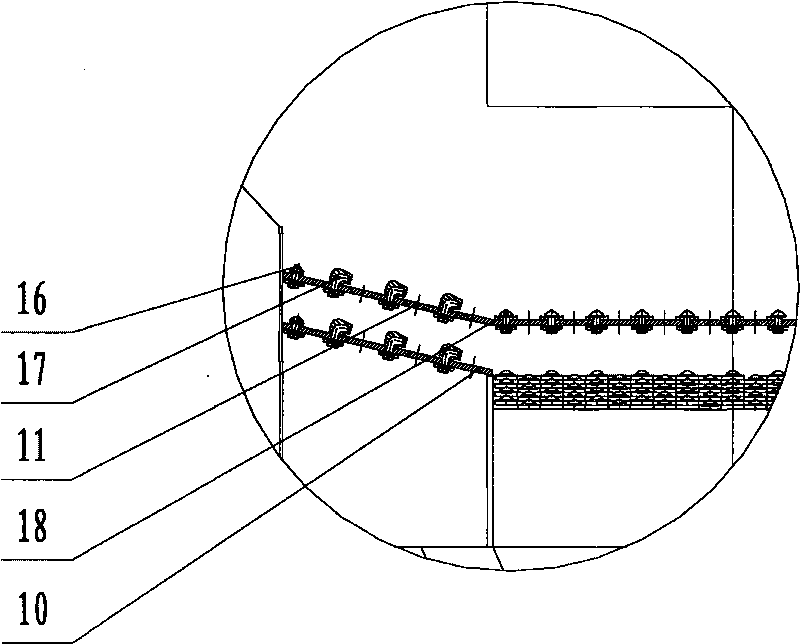

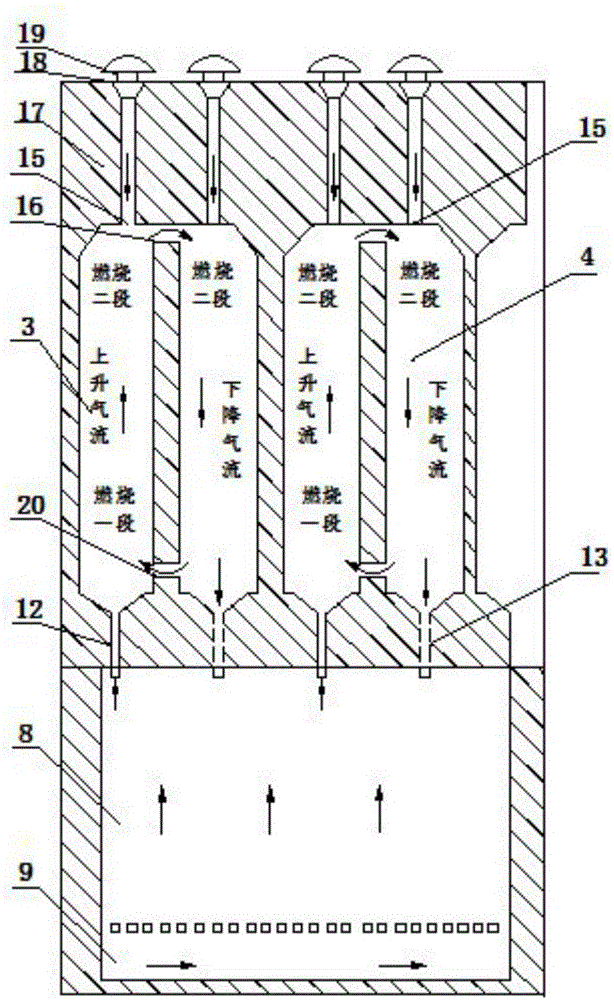

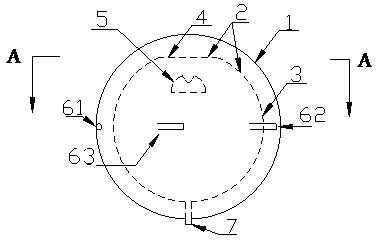

Full-boiling cyclone fluidized bed air separating damping machine and new air separating damping technology

ActiveCN101708493AImprove qualityIncrease moistureGas current separationDrying solid materials with heatProcess engineeringCoal

The invention relates to a full-boiling cyclone fluidized bed air separating damping machine and a new air separating damping technology. The full-boiling cyclone fluidized bed body arranged in a sealed case is divided into a drying section bed and an air separating section bed, wherein a drying section air compartment and an air separating air compartment are separately arranged below the two beds, a fine granule emission pipe is arranged on the upper side surface of the air separating section bed, and the tail part of the air separating section bed is communicated with a coarse granule emission pipe. The granular material is placed in the sealed case so that a great deal of moisture is taken away effluent gas and then the granular material is separately sent to the fine granule emissionpipe and the coarse granule emission pipe for central emission. The two aims of humidity-regulating and size-grading can be completed on one device, thus the machine and the new technology of the invention are especially suitable to be popularized in the coal moisture conditioning field of the coking industry.

Owner:长沙通发高新技术开发有限公司

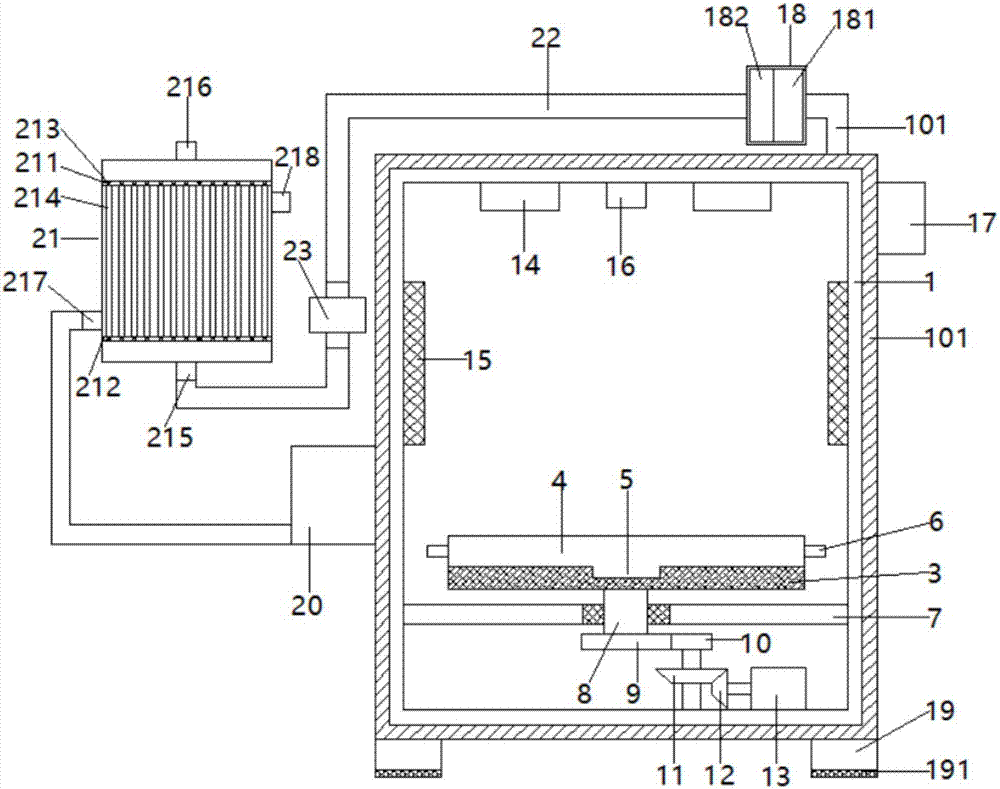

Domestic intelligent electric oven

InactiveCN106943034AImprove the baking effectImprove job stabilityRoasters/grillsAutomatic controlEngineering

The invention discloses a household intelligent electric oven, which comprises a box body, an insulation layer is arranged on the outer wall of the box body, and a partition board is horizontally arranged on the lower side inside the box body, and the partition board divides the box body into a baking cavity on the upper side and a baking chamber on the upper side. In the installation cavity on the lower side, a turntable is horizontally arranged at the center of the lower side of the box body, and a circular groove is opened at the center of the upper surface of the turntable. The limiting protrusion of the household electric oven of the present invention can effectively eliminate oil fume and reduce pollution during the baking process, can automatically control the baking temperature, improve the baking effect, and drive the food to rotate at a uniform speed during baking, so that The food is baked more evenly. Infrared heating and hot air are used for baking, which improves the baking efficiency, effectively reduces shock, improves stability, and improves the efficiency of heat use, avoids heat loss, and saves energy.

Owner:湖南鸣腾智能科技有限公司

Fluidized bed winnowing and moisture controlling machine and new winnowing and moisture controlling process

InactiveCN101786080AReduce moistureRaise the initial temperatureDrying solid materials with heatGas current separationGranularityFluidized bed

The invention relates to equipment and a process for adjusting the moisture of granular materials and grading the granularity, in particular to a fluidized bed winnowing and moisture controlling machine and a new winnowing and moisture controlling process which can simultaneously realize the reduction of water content of the granular materials and the grading according to the granularity of the granulated materials. Fine granular materials of the granular materials in the fluidized state are centrally discharged through a fine granule discharge pipe and other rough granular materials are scraped to a rough granule discharge pipe for centralized discharge, so the proper reduction of the water content can be realized while grading the granularity. The equipment and the process are applied to the field of coal moisture control in the coking industry, the dryness and quality improvement of lignitous coal in coal industry and the like.

Owner:长沙通发高新技术开发有限公司

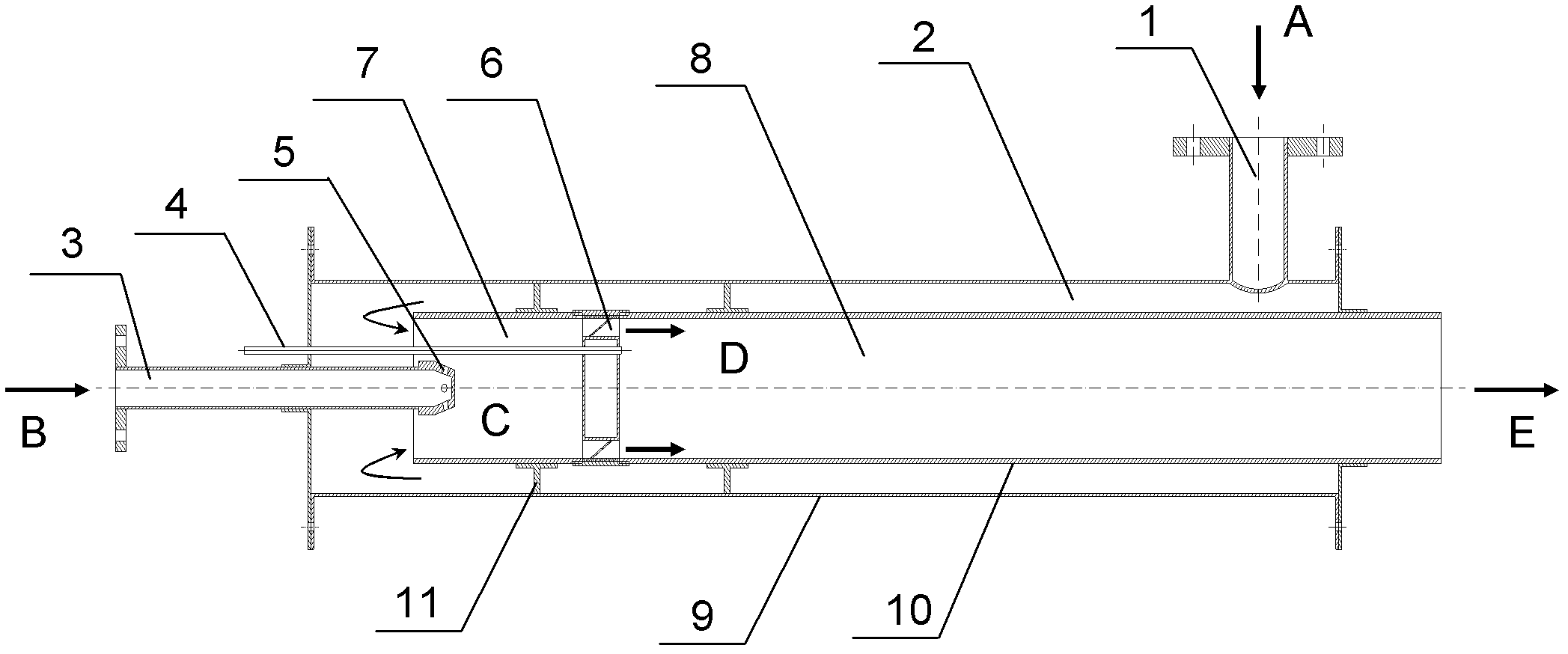

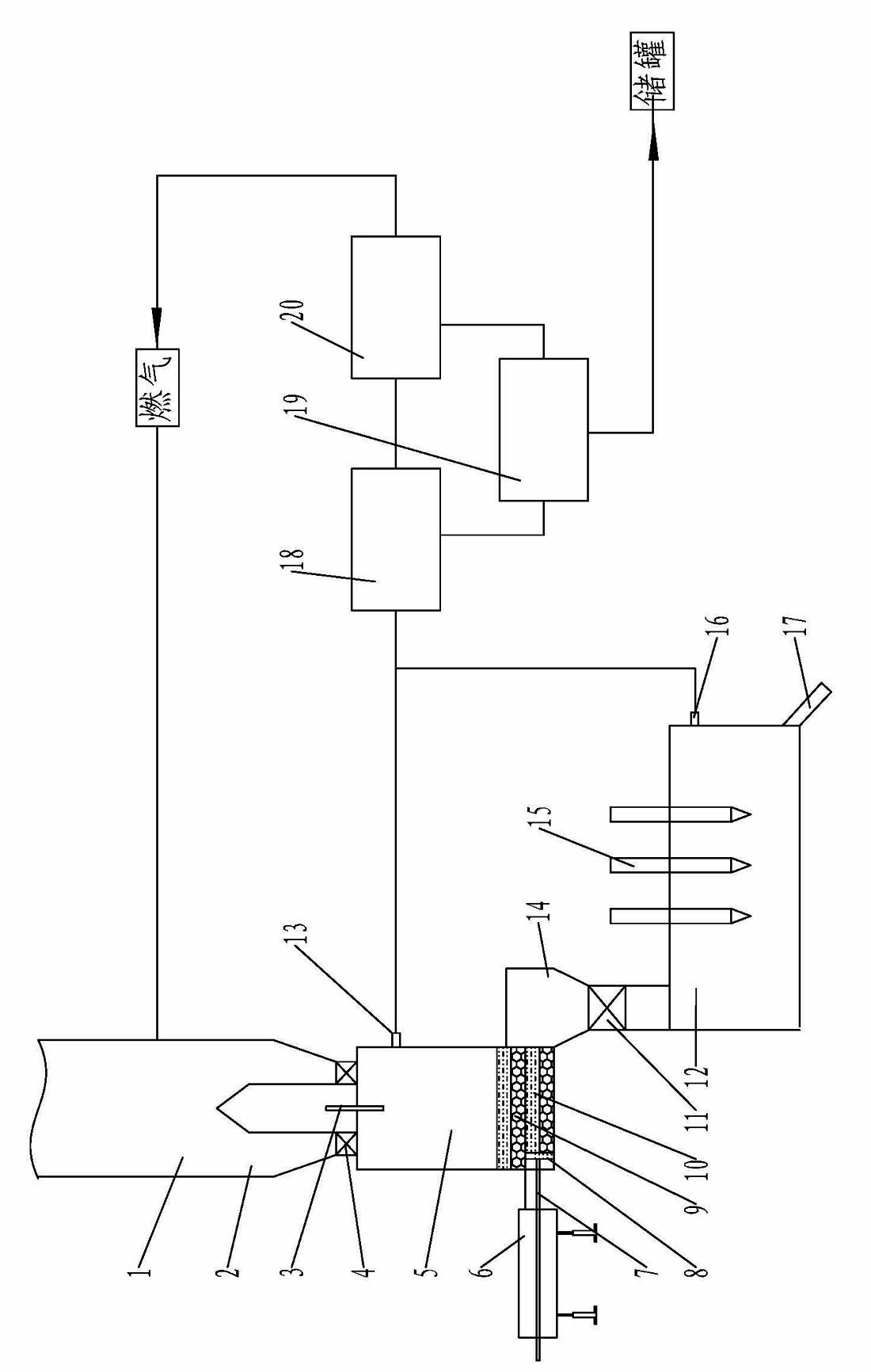

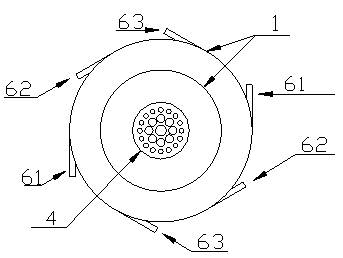

Self-backheating swirling burner for fuel gas with low heat value

InactiveCN102425793ARaise the initial temperatureImprove combustion performanceGaseous fuel burnerPetrochemicalPower engineering

The invention discloses a self-backheating swirling burner for a fuel gas with a low heat value. The structure comprises an outer barrel of a burner, an inner tube of the burner and a swirling generation device, wherein the outer barrel of the burner and the inner tube of the burner are coaxially configured, and the swirling generation device is arranged in the inner tube of the burner. The self-backheating swirling burner is characterized in that combustion air exchanges heat with the high-temperature smoke of a combustion chamber by virtue of an inner pipe wall to improve the temperature of the combustion air; and then after the combustion air enters a mixing chamber to be mixed with the fuel gas with a low heat value, the mixture begins rotating by virtue of the swirling generation device to obviously improve the combustion stability of the fuel gas with a low heat value to realize complete combustion. The burner can be applied to the technical field of thermal power engineering, can fully utilize various types of fuel gases generated in the industrial processes, such as metallurgy, petrochemical industry, biomass pyrogenation, waste gasification treatment and the like, and also can be used for burning a common fuel gas.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

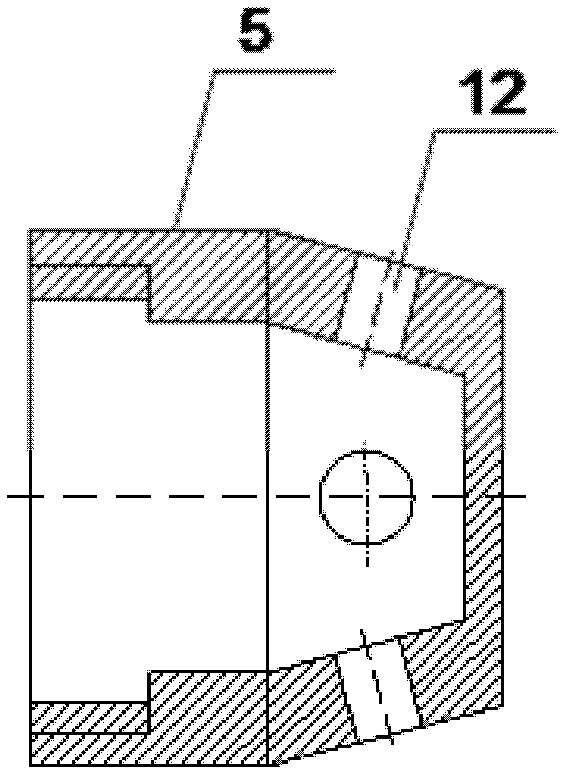

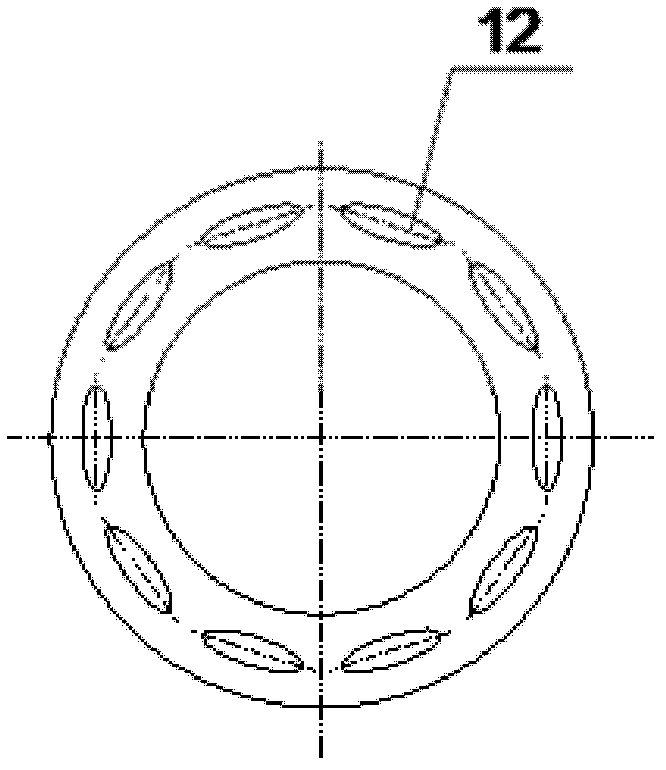

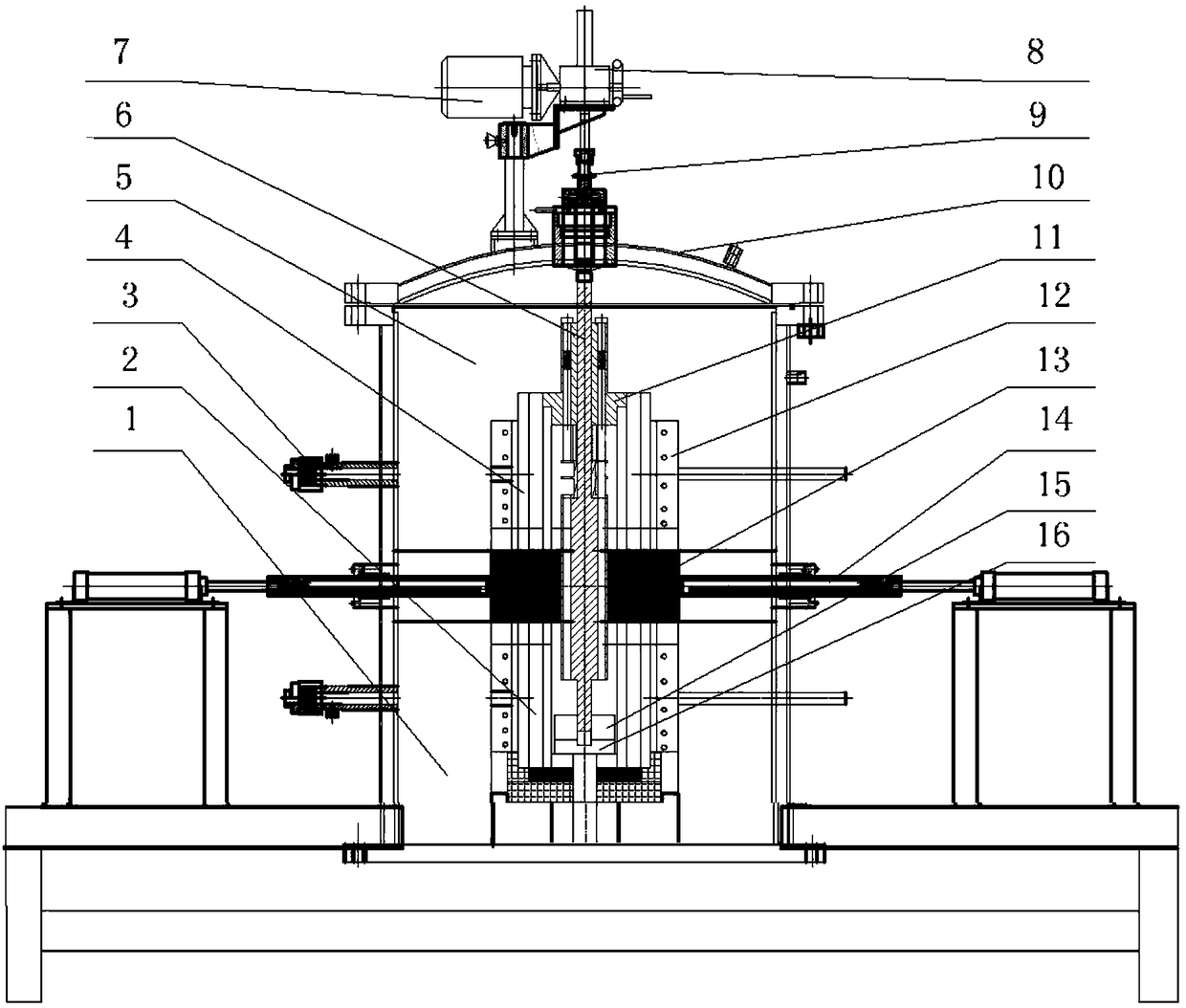

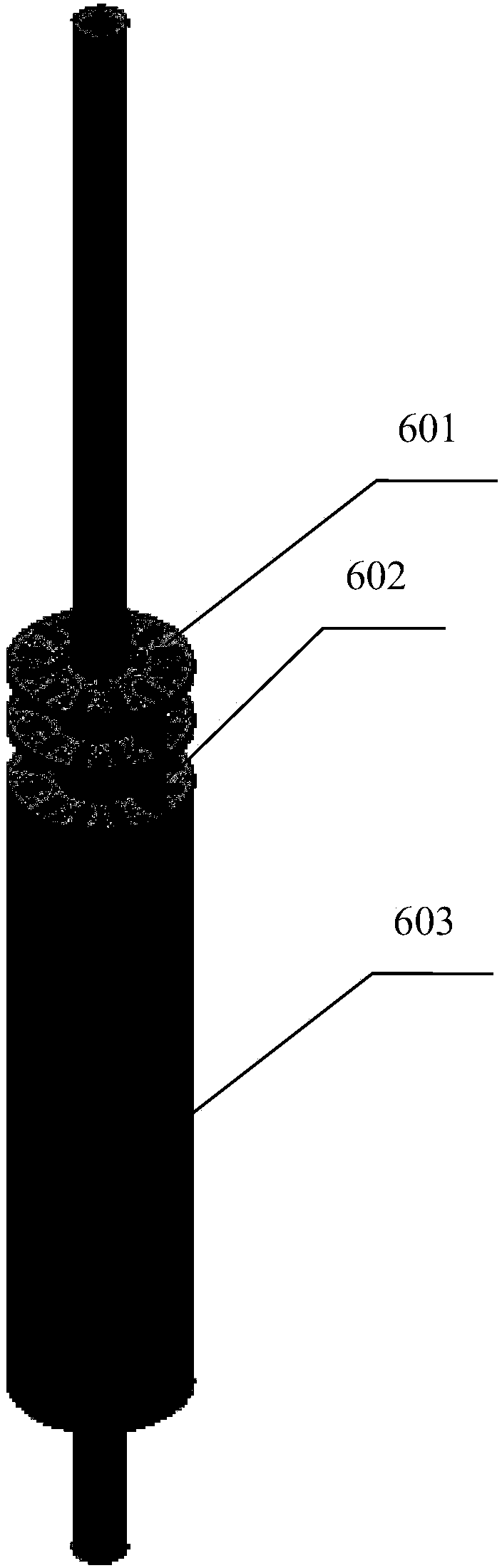

Massive thermal shock testing device of hyperthermal material

ActiveCN108132199AImprove efficiencyRaise the initial temperatureStrength propertiesFixed frameDrive shaft

The invention discloses a massive thermal shock testing device of a hyperthermal material. The device comprises an upper environment module and a lower environment module, wherein upper heating furnaces and lower heating furnaces are correspondingly arranged in the environment modules; a sealing partition is arranged between the two environment modules; and a specimen prepressing mechanism is mounted at the top of the upper heating furnace and comprises a fixing frame, screws, springs and push fingers. A specimen introduction mechanism is mounted between the upper heating furnace and the lowerheating furnace in a penetrating manner; the upper end of the specimen introduction mechanism is connected with a speed reducer via a transmission shaft and then connected with a motor; the specimenintroduction mechanism is equipped with specimen retainers, specimens and a specimen guide pipe; and a cushion is mounted at the bottom of the specimen introduction mechanism and supported by a tray.The device has the technical effects that the device can ensure controllable initial speeds of the specimens to be tested, achieve testing of the specimens in the same lot at the different initial speeds and perform massive thermal shock resistance testing of the specimens, is high in efficiency, and can ensure thermal shock testing environments of the specimens in the same lot are good in consistency and testing results are high in reliability.

Owner:CHONGQING UNIV

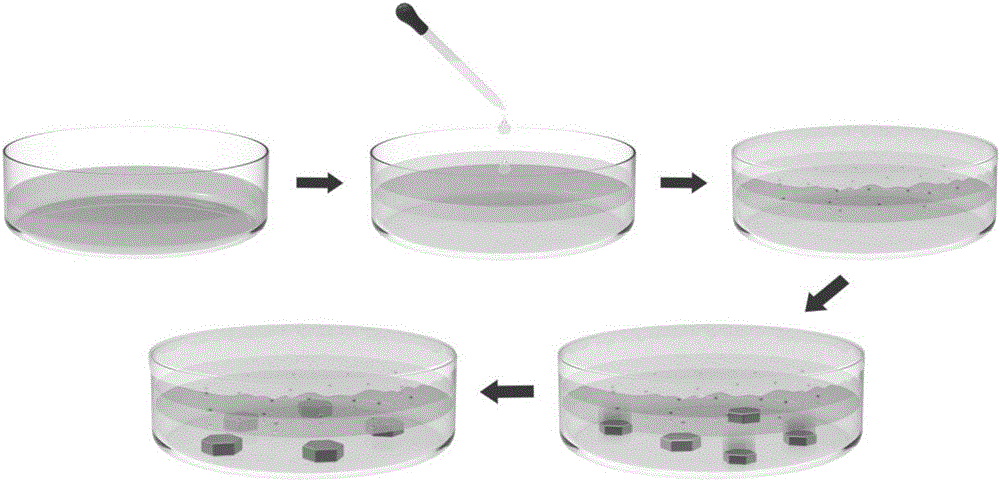

Method for growing perovskite monocrystal with liquid-liquid two-phase method

ActiveCN106319625AHigh crystallinityImprove stabilityPolycrystalline material growthFrom normal temperature solutionsSingle crystalCrystallinity

The invention relates to a method for growing a perovskite monocrystal with a liquid-liquid two-phase method. The method is simple in operation, low in requirement for surrounding environment, non-toxic and free of environmental pollution, and the obtained monocrystal is high in degree of crystallinity and high in stability. The method comprises the following steps: getting a solution providing a tin source, dropwise adding in an immiscible solution containing halides, reacting at the position of a formed separation interface, and growing the perovskite monocrystal. Two immiscible liquid phases are dropwise added to form layering in a liquid-liquid two-phase method reaction manner, the two phases quickly react at the layering position of the interface directly to grow an MASnI3 perovskite monocrystal, and the temperature regulation is restricted, so that the environmentally-friendly leady monocrystal with regular shape, high degree of crystallinity and high stability can be grown. The method has the characteristics of being simple in operation, quick in reaction, low in requirement for reaction, low in cost, high in success rate, non-toxic and pollution-free; and a new thought and a new method are provided for the development of the perovskite material.

Owner:SHAANXI NORMAL UNIV

Sludge storing and preheating system utilizing sludge drying tail gas afterheat

InactiveCN101066831ARaise the initial temperatureOvercoming bottlenecks that are difficult to implementSludge treatment by de-watering/drying/thickeningSludgeHigh pressure water

The present invention discloses sludge storing and preheating system utilizing the afterheat of sludge drying tail gas. The system consists of one upper part and one lower part, the upper part has a closed sludge storing household, a sludge shifter, a sludge shifter track, a sludge inlet, a sludge outlet and a gas exhaust unit; and the lower part has walls for supporting the bottom of the closed sludge storing household, a flue, a high pressure water pipe, and a water collecting and guiding set. The system with circulating utilization of energy can lower power consumption for drying sludge, reduce cost and lower the pollution load of sludge drying tail gas.

Owner:ZHEJIANG UNIV

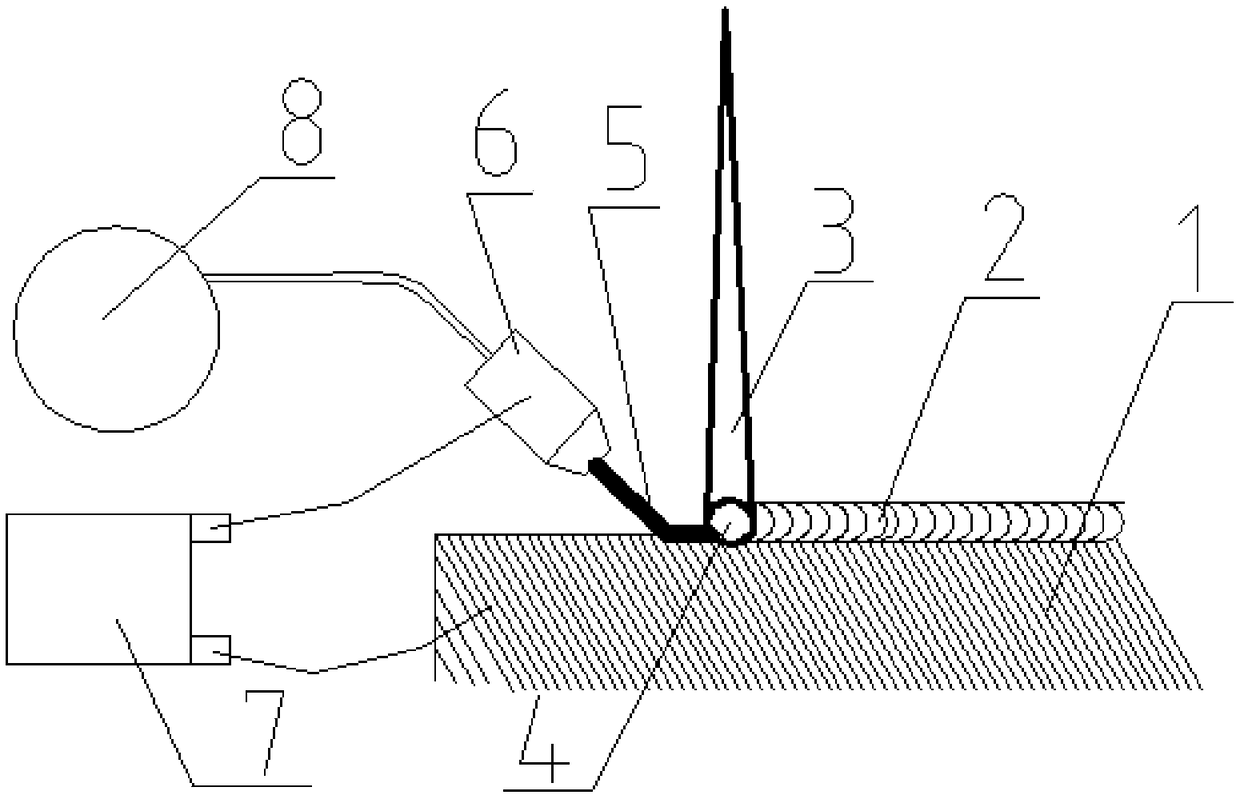

High-efficient wire material laser cladding method

InactiveCN109434286AImprove cladding efficiencyIncreased cladding line speedLaser beam welding apparatusLaser beamsMelting point

The invention provides a wire material laser cladding method. The wire material laser cladding method comprises the following steps that one electrode of a wire material heating device is connected with a workpiece, the other electrode of the wire material heating device is connected with a conductive nozzle, the wire material penetrates through the conductive nozzle and then makes contact with the surface of the workpiece, a laser beam and the wire material are placed in a certain angle with the surface of the workpiece respectively, the wire material heating device is started, the wire material is preheated to a certain temperature, a laser is started, and a laser beam generated by the laser is focused on wire material on the surface the workpiece, the laser energy is absorbed by the wire material, then a molten pool is instantly formed on the surface of the workpiece, the melting pool is controlled to move on the surface of the workpiece according to a preset path and a preset speed, and the laser cladding is completed. According to the method, the initial temperature and the cladding linear speed of the wire material are increased, the temperature of the wire material is increased to be close to the melting point before the wire material enters the laser beam, the wire material can melt to form a molten pool on the surface of the workpiece only by relatively small laser energy and relatively short irradiation time of the laser beam, and the wire cladding efficiency and quality are obviously improved, therefore the method has a wide popularization and application prospect.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

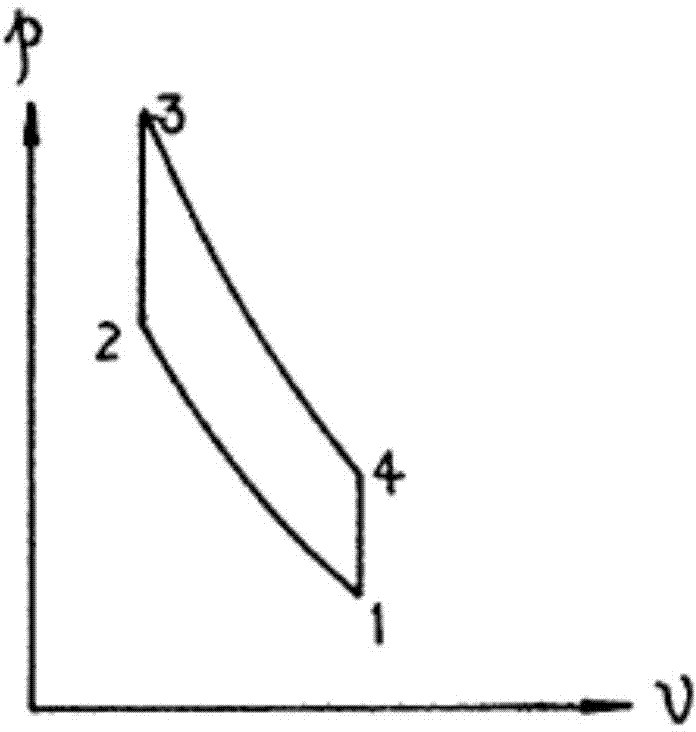

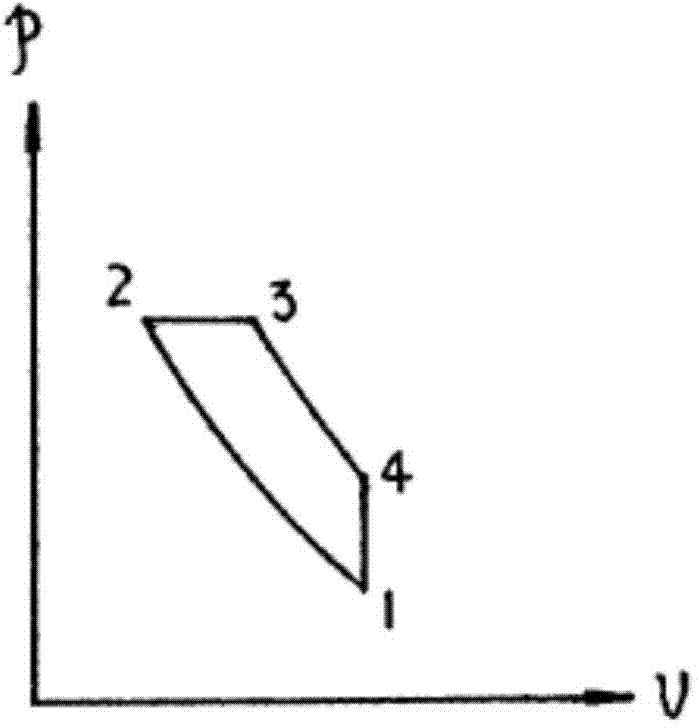

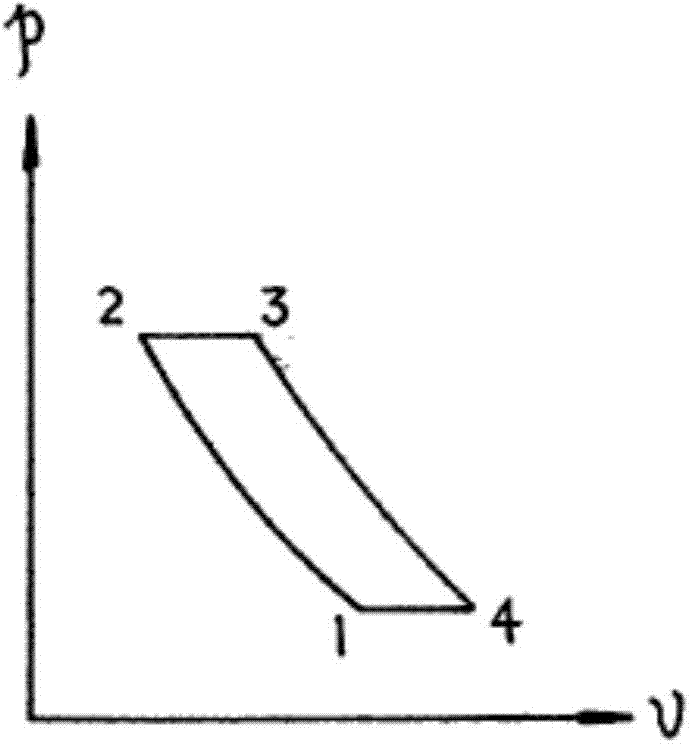

Semi-closed type timing constant-volume thermodynamic circulation method and system of prime motor

ActiveCN103883399AReduced Compression Power ConsumptionReduce fresh working fluid temperatureInternal combustion piston enginesGas turbine plantsThermal dilatationPrime mover

The invention provides a semi-closed type timing constant-volume thermodynamic circulation method and a semi-closed type timing constant-volume thermodynamic circulation system of a prime motor. The thermodynamic circulation method comprises six processes, namely multi-compression-stage intercooling, countercurrent heat exchanging, timing constant-volume burning, adiabatic expansion, aftercooling, and carbon dioxide and water removal. Heat-power conversion is achieved in the thermodynamic circulation. In the process of multi-compression-stage intercooling, compression power consumption is lowered; in the process of countercurrent heat exchanging, the enthalpy of an expanded working medium is recovered to participate in thermodynamic circulation; the process of timing constant-volume burning effectively inhibits the generation of harmful pollutants such as HC, CO, PM and NOx; in the process of adiabatic expansion, complete expansion for working is achieved; in the process of aftercooling, the working medium is further cooled to the environment temperature and the expansion ratio in the process of adiabatic expansion is enhanced; in the process of carbon dioxide and water removal, the carbon dioxide and the water generated in the process of timing constant-volume burning are removed; the remaining work mediums participate in the next thermodynamic circulation. By the method and the system, the direction is defined for designing a high-efficiency low-pollutant-emission and high-performance prime motor in the future.

Owner:GREEN ENERGY HIGH TECH GRP +5

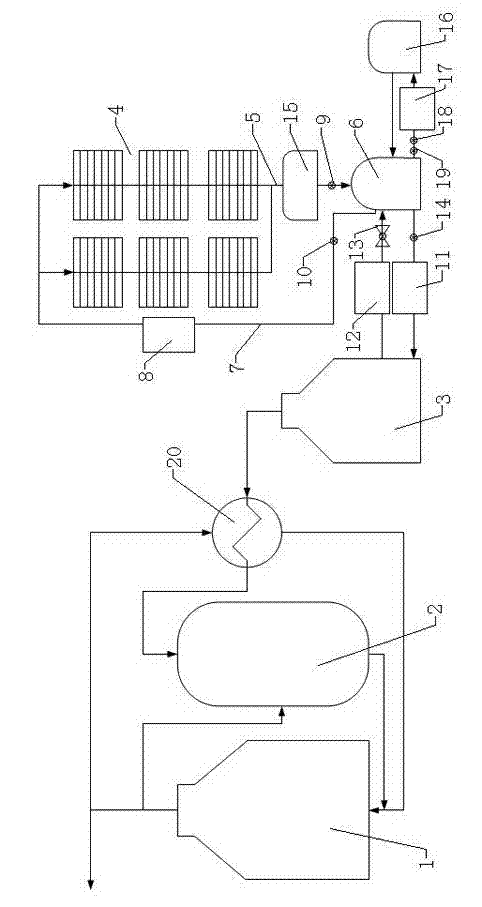

Solar boiler soft water preheating system

InactiveCN103175189ARaise the initial temperatureReduction of reflux steamLiquid degasificationControl systemEngineering

The invention discloses a solar boiler soft water preheating system. The solar boiler soft water preheating system comprises a boiler (1), deoxidizing equipment (2), a soft water box (3) and a solar thermal collector (4), and the solar boiler soft water preheating system is characterized in that the solar thermal collector (4) is connected with a heat storing water box (6) through a hot water pipe (5); and the heat storing water box (6) is connected with the solar thermal collector (4) through a water supplying pipe (7) which is provided with a water supplying pump (8), the hot water pipe (5) and the water supplying pipe (7) are respectively provided with a hot water temperature controller (9) and a water supplying temperature controller (10) which are respectively connected with a central control system, the heat storing water box (6) is connected with the soft water box (3) respectively through a water outlet pump (11) and a water supplementary pump (12), and the soft water box (3) is connected with the deoxidizing equipment (2) and the boiler (1) in sequence through a pipeline. The solar boiler soft water preheating system provided by the invention increases the initial temperature of soft water by utilizing renewable solar energy, is energy-saving and emission-reducing, saves non-renewable resources and reduces environmental pollution.

Owner:NANJING UNIV OF TECH

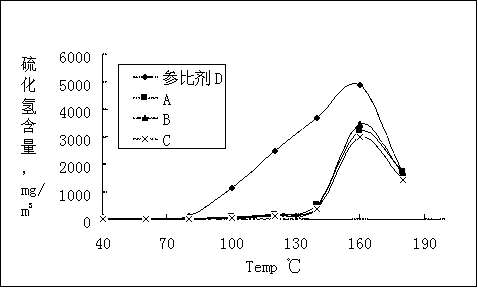

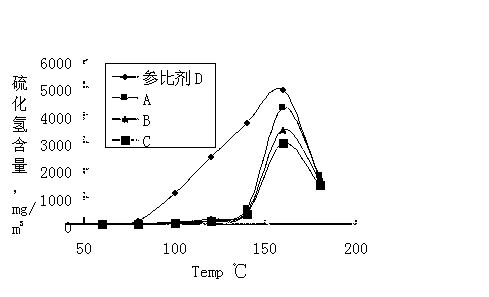

Preparation method of prevulcanization type catalyst

ActiveCN103100444ANo self-heatingNo flammability issuesCatalyst activation/preparationSimple Organic CompoundsVulcanization

The invention discloses a preparation method of a prevulcanization type catalyst. The method consists of: taking an oxidation state catalyst, adding an organic solvent and elemental sulfur, conducting heat treatment, then using an appropriate organic assistant to perform aftertreatment on the catalyst, thus obtaining the final prevulcanization type catalyst. The method enables the organic assistant and sulfur to form an organic compound, which does not decompose at low temperature, thus avoiding untimely contact of hydrogen and sulfur during startup activation, release of a hydrogen sulfide gas and the consequent influence on equipment air tightness. After high pressure air sealing, the compound of sulfur and the organic assistant decomposes. Hydrogen and sulfur react, the formed hydrogen sulfide and an active metal undergo catalyst activation in the pores of the catalyst, thus raising the initial temperature of vulcanization. After high pressure air sealing, activation oil is introduced to take away the heat generated by activation timely, thus avoiding temperature runaway of the catalyst bed and ensuring a smooth startup process. The catalyst prepared by the method involved in the invention is applicable to preparation of a petroleum fraction hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

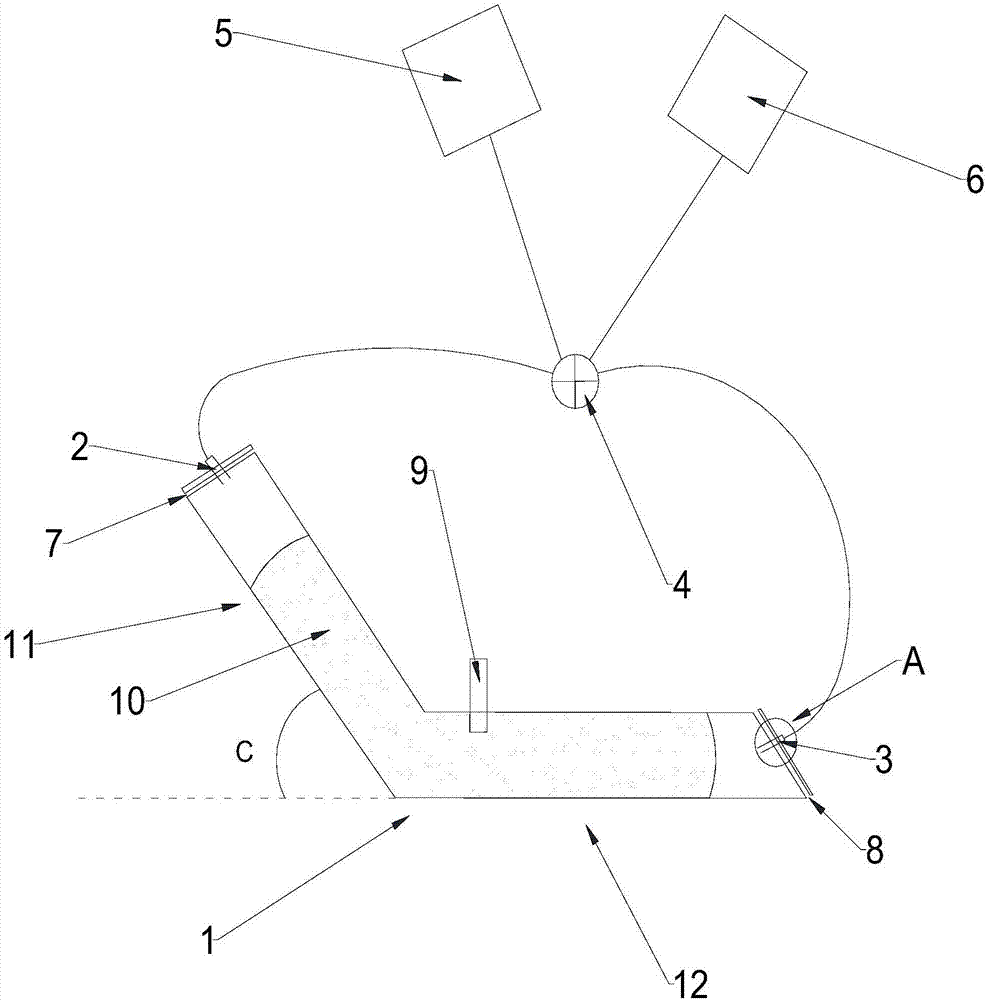

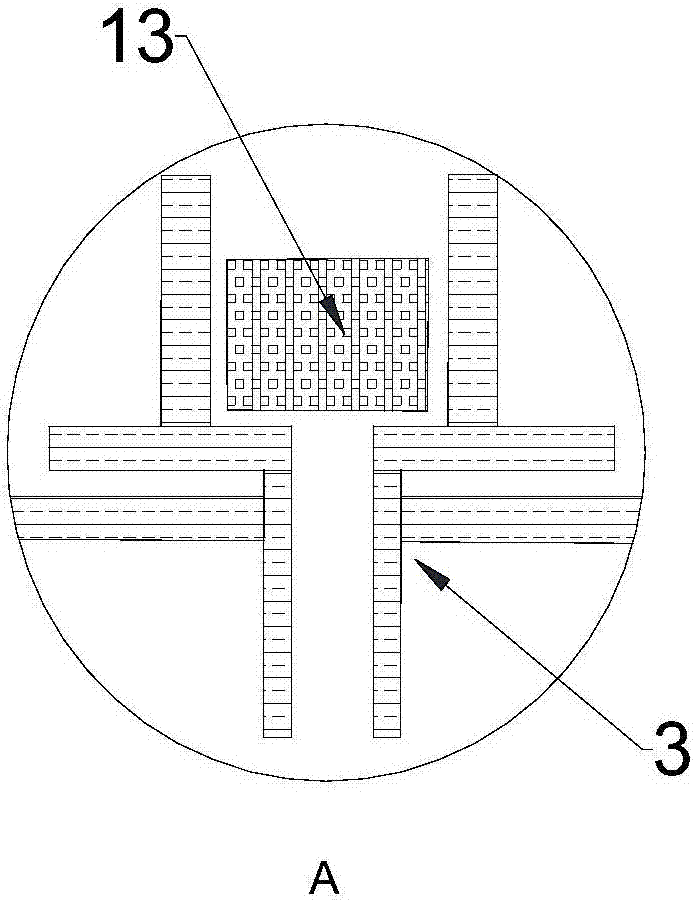

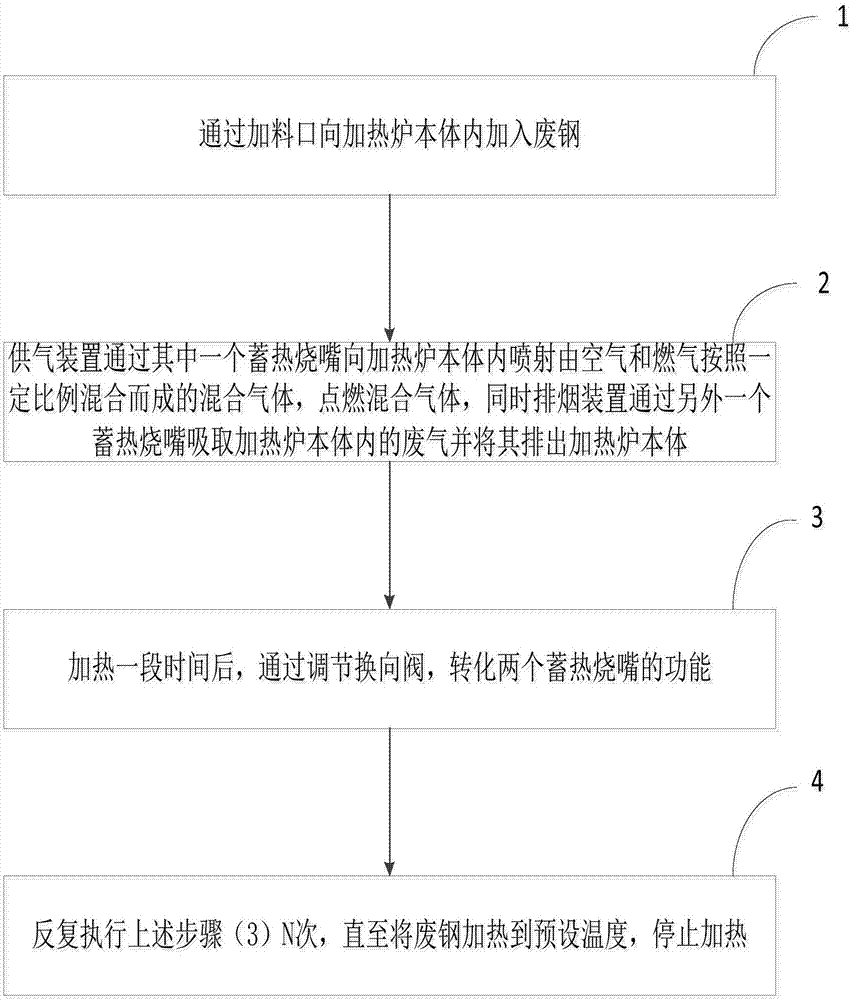

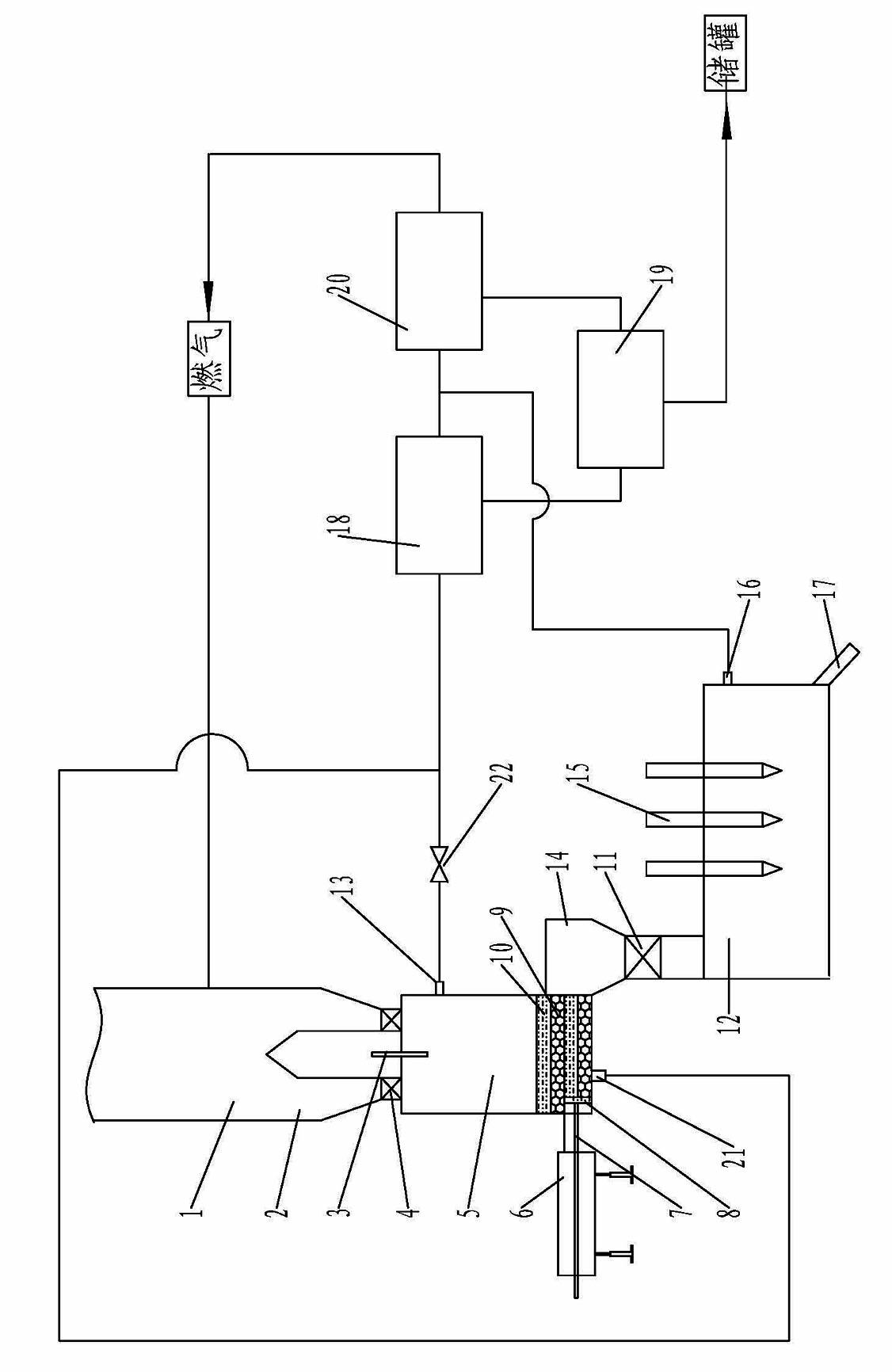

Method for heating steel scrap and increasing smelting steel scrap ratio

InactiveCN107385145ARaise the initial temperatureFast heatingManufacturing convertersGas emission reductionSmelting processHeating furnace

The invention relates to a method for heating steel scrap and increasing the smelting steel scrap ratio. The method comprises the following steps that firstly, the steel scrap is added to a heating furnace body through a feeding opening; secondly, a gas supply device sprays mixed gas formed by mixing air and fuel according to a certain proportion into the heating furnace body through one of regenerative burners, the mixed gas is ignited, and meanwhile an exhaust device sucks waste gas in the heating furnace body through the other regenerative burner and exhausts the waste gas out of the heating furnace body; thirdly, after the mixed gas is heated for a period of time, the functions of the two regenerative burners are converted by adjusting a reversing valve; and fourthly, the steps mentioned above are repeated for 3N times till the steel scrap is heated to the preset temperature, and at the moment, heating is stopped. According to the heating method, the steel scrap in the steel scrap heating furnace is preheated, the initial temperature of the steel scrap entering a converter is increased, the converter temperature rising speed is increased, the smelting efficiency of the converter is improved, the proportion of the steel scrap in the raw materials in the smelting process is increased, and the smelting cost is lowered.

Owner:安徽盛博冶金环保科技有限公司

Full-boiling cyclone fluidized bed damping machine and new damping technology

ActiveCN101709913AFully and evenly regulated humidityEasy for industrial mass productionDrying solid materials with heatHearth type furnacesBrown coalProcess engineering

The invention relates to a full-boiling cyclone fluidized bed damping machine and a new damping technology. The full-boiling cyclone fluidized bed body arranged in a sealed case is divided into a drying front section bed and a drying back section bed, wherein a drying front section air compartment and a drying back section air compartment are separately arranged below the two beds, and the tail part of the drying back section bed is communicated with a dried granular material emission pipe. The granular material is placed in the sealed case so that a great deal of moisture is taken away by hot air and then the granular material is sent to the dried granular material emission pipe for central emission, thus the drying effect is complete and uniform and the industrial production is easy to realize. The damping machine and the damping technology of the invention are especially suitable for the coal moisture conditioning field of the coking industry and the brown coal quality upgrading and drying field of the coal industry, and have good economic and social benefits.

Owner:长沙通发高新技术开发有限公司

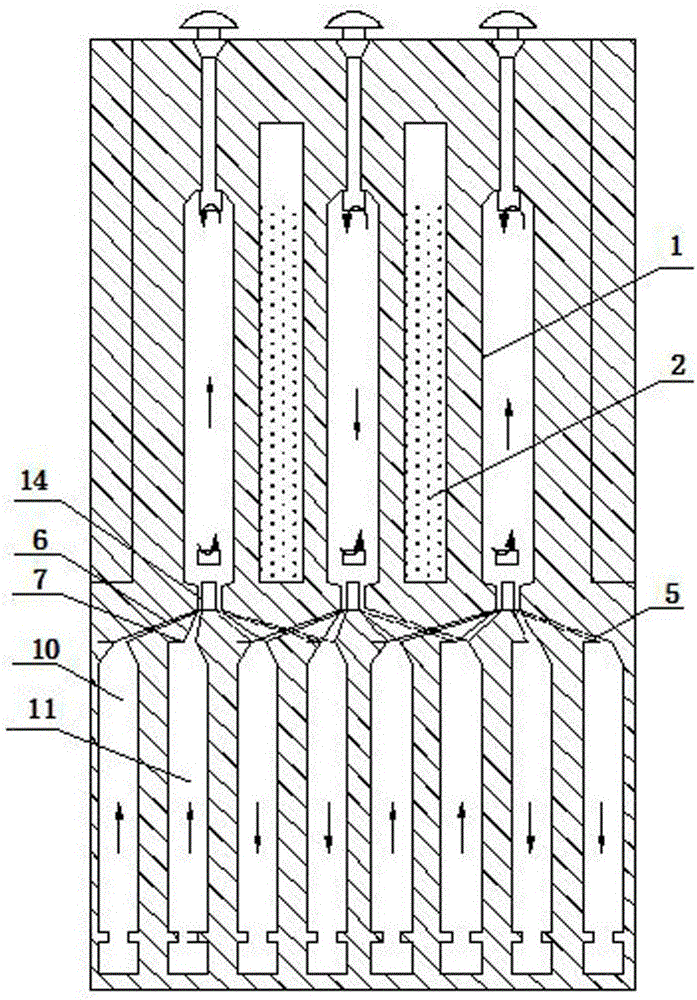

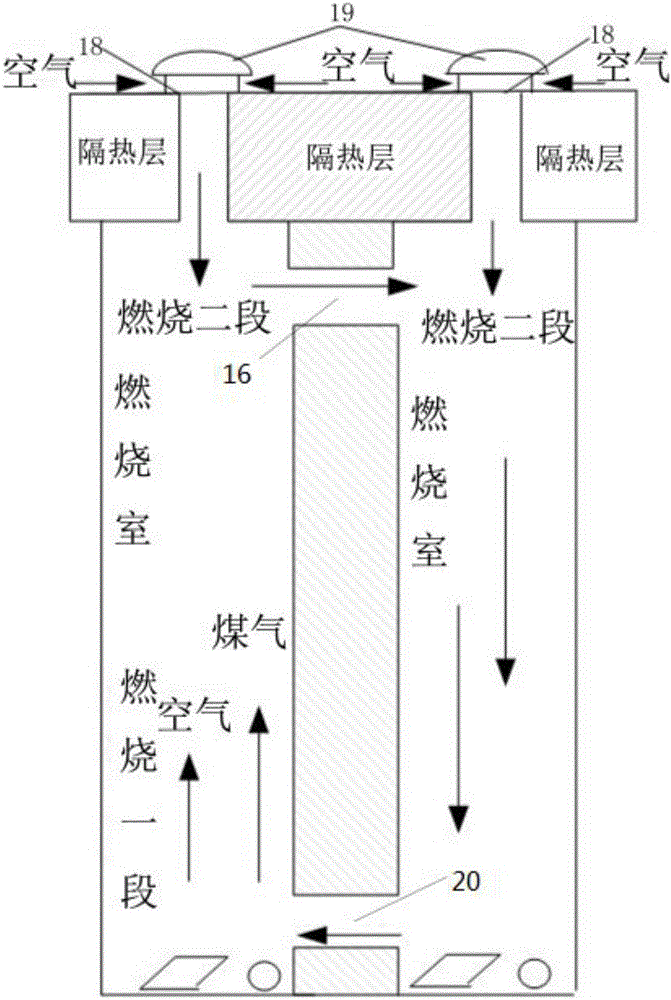

Coking furnace heating method and device capable of reducing generation of NOx

InactiveCN106190184ARealize staged combustionLow retrofit costCombustible gas coke oven heatingEnergy inputBrickCarbonization

The invention provides a coking furnace heating method and device capable of reducing generation of NOx. Vertical flues are double connected, coal for coking is put in a carbonization chamber and refined to be coke, coking furnace gas is downwards injected, air is supplied to the vertical flues in a segmented manner and mixed with the coking furnace gas for combustion, waste gas after segmented combustion enters each downdraft vertical flue after being turned through a crossing hole, and complete combustion is performed at the top of the downdraft vertical flue; after complete combustion, the waste gas enters an adjacent heat storage chamber through inclined channels of the downdraft vertical flues and exchanges heat with lattice bricks, the cooled waste gas enters a small flue through adjustable grate holes, and finally, the waste gas is discharged through a branch flue, a main flue and a chimney. Segmented combustion of coking furnace gas can be realized, adjustment is performed according to the combustion condition, the coke quality is improved, heat loss is reduced, the heat efficiency is improved, high temperature points in the vertical flues are reduced, generation of NOx is reduced, and environmental protection is realized.

Owner:HUNAN QIANMENG INTELLIGENT INFORMATION TECHCO LTD

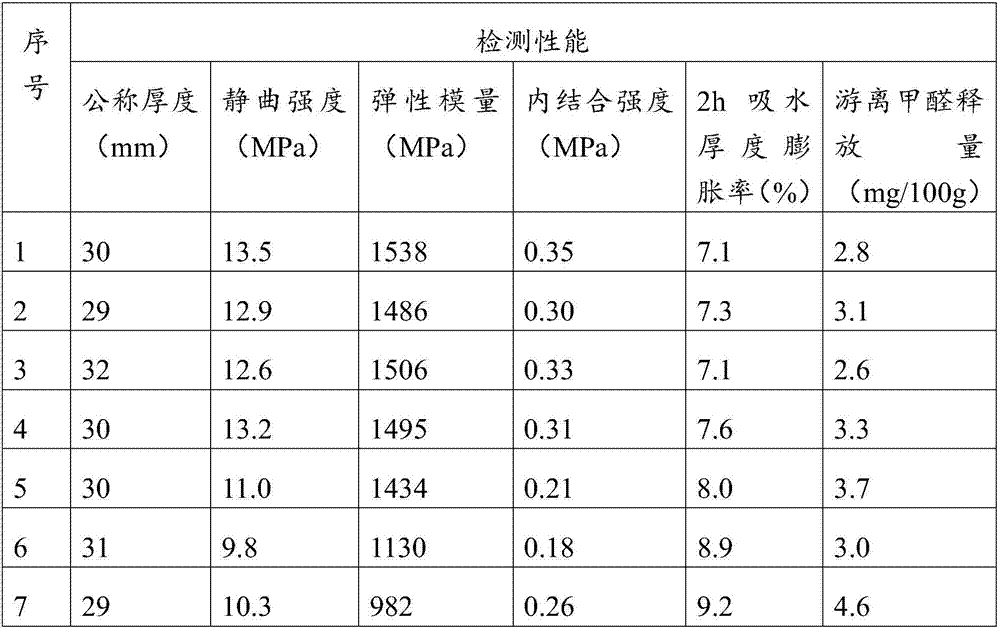

Production method of particleboard

InactiveCN107379205AIncrease profitAdd channelFlat articlesDomestic articlesWood shavingsEngineering

The invention discloses a production method of a particleboard. The production method comprises the following steps of (1) wood shaving preparation; (2), drying and screening; (3) glue application; (4) laying and precompression; (5) hot press molding; and (6) edge sawing and sanding. According to the production method provided by invention, rough core layer wood shavings subjected to glue application are pretreated, and then procedures including laying, precompression and hot press molding are carried out, so that the hot pressing time can be effectively reduced, the hot press molding ratio is increased, and the production efficiency is improved; the particleboard prepared by the production method is low in cost and free formaldehyde releasing quantity and high in strength at the same time; and the production method provided by the invention is capable of effectively improving the quality of a particleboard product and increasing the benefit of an enterprise and is worthy of popularization.

Owner:广西祥盛家居材料科技股份有限公司

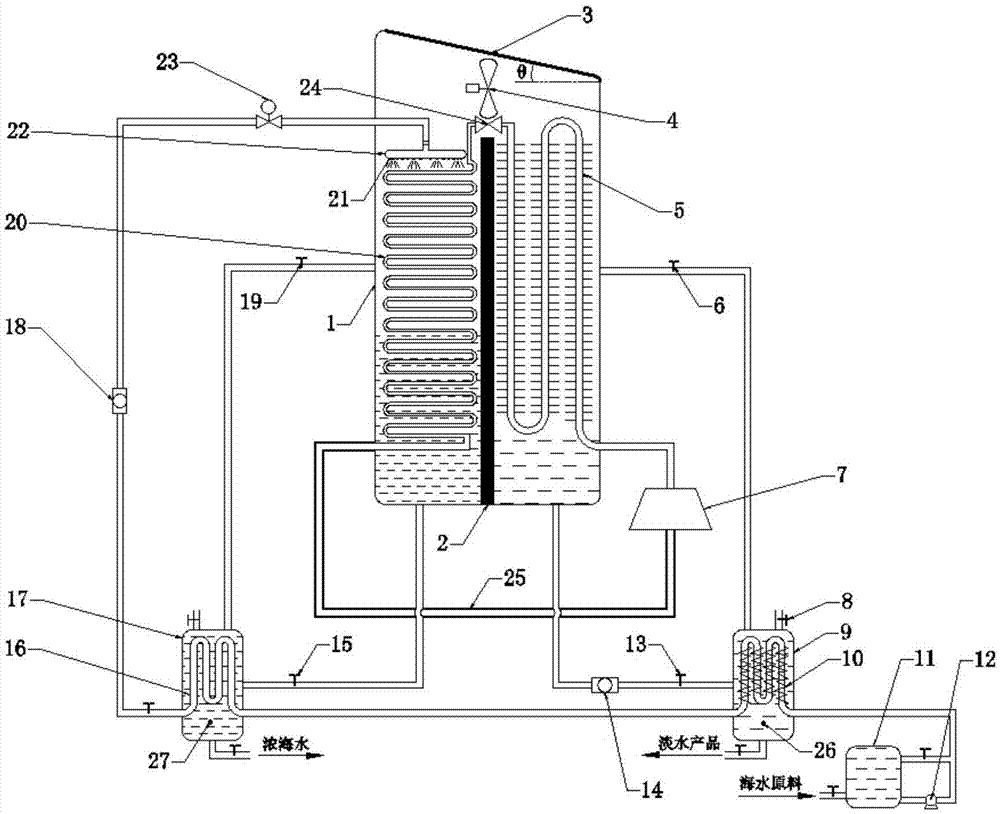

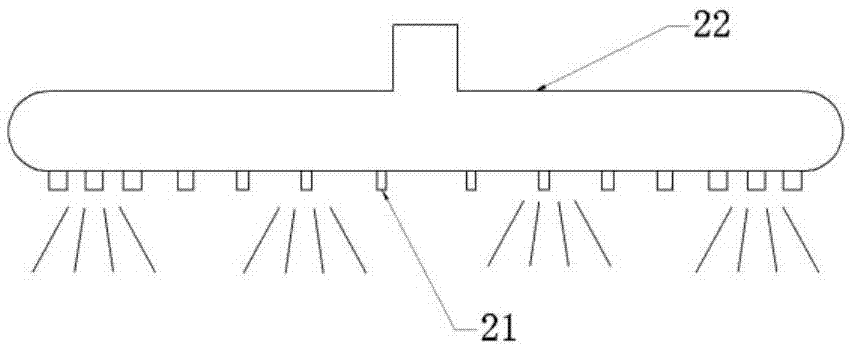

Heat pump type seawater desalination apparatus with step preheating, and control method thereof

ActiveCN105439232ASpray evenlyPrevent drynessGeneral water supply conservationSeawater treatmentFresh water organismCoupling

The invention discloses a heat pump type seawater desalination apparatus with step preheating, and a control method thereof. The apparatus comprises an evaporative condenser, a finned evaporator, a rolling rotor compressor, an axial flow fan, a primary preheater and a secondary preheater. The apparatus is mainly characterized in that step preheating of seawater is carried out by the primary preheater and the secondary preheater, and heat of freshwater and concentrated seawater is recovered to improve the initial temperature of seawater evaporation and the heat utilization rate of a system; and a sprayer and the evaporative condenser are arranged in a coupling manner, so membrane high-efficiency evaporation of seawater on the surface of the condenser is realized. The apparatus has the characteristics of simple structure, safety, reliability, low running cost, high heat utilization rate and good energy saving effect.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

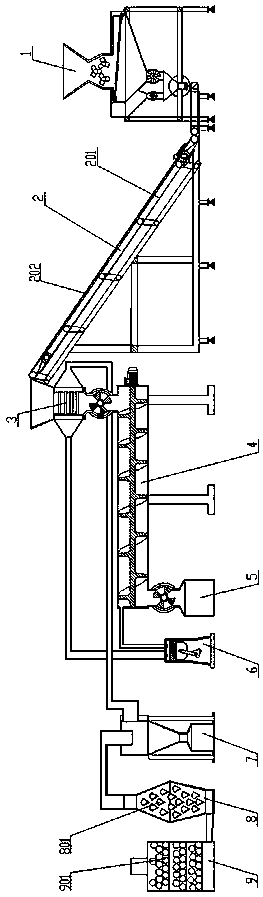

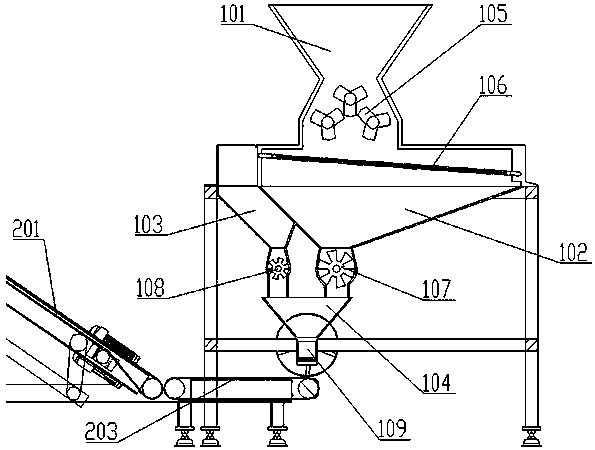

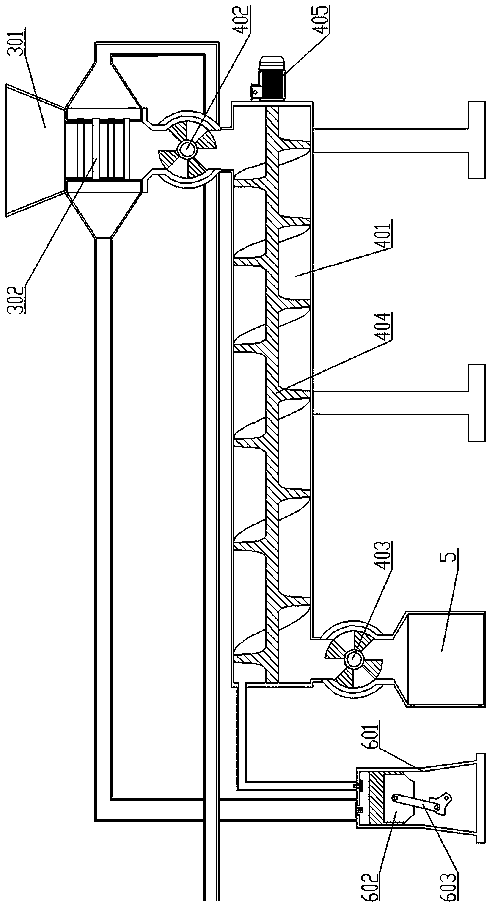

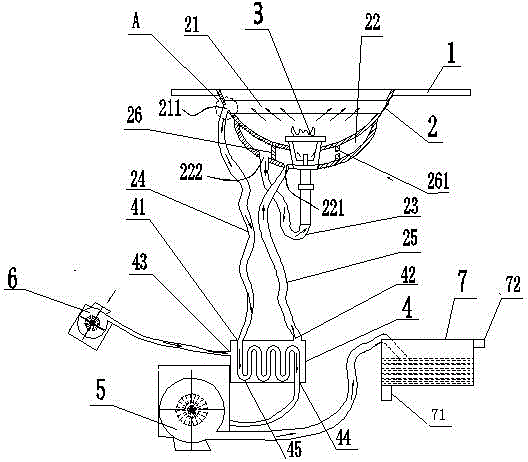

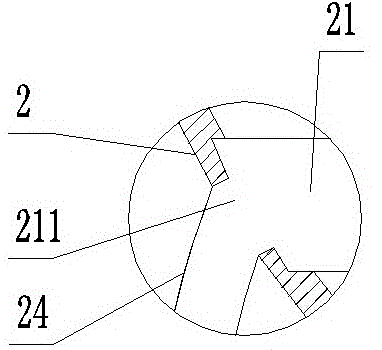

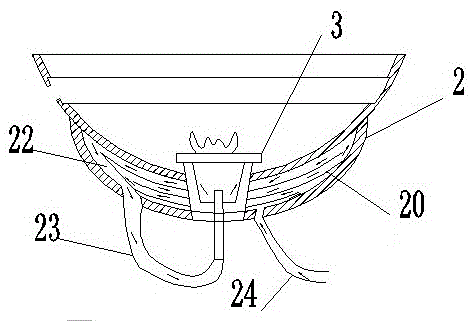

Negative-pressure thermal desorption treatment system for mercury contaminated soil

ActiveCN111558611ATo achieve the effect of desorptionGuaranteed desorption effectContaminated soil reclamationGrain treatmentsCyclonic spray scrubberThermal desorption

A negative pressure thermal desorption treatment system for mercury contaminated soil comprises a pretreatment device, a feeding device, a waste heat utilization heat exchanger, a negative pressure heating device, a soil collecting box and an air extractor. The pretreatment device is used for crushing soil and mixing the soil with a catalyst; the feeding device conveys the soil from the pretreatment device to the waste heat utilization heat exchanger; the waste heat utilization heat exchanger is used for preheating the soil and enabling the soil to fall into the negative pressure heating device; the negative pressure heating device is used for carrying out thermal desorption treatment on the soil and enabling the soil to fall into the soil collecting box; the air extractor extracts hot airin the negative pressure heating device to form negative pressure in the negative pressure heating device; the air extractor is connected with an air inlet of the waste heat utilization heat exchanger, hot air flows into the waste heat utilization heat exchanger to exchange heat with the soil; and an air outlet of the waste heat utilization heat exchanger is sequentially connected with a cyclonedust collector, a condensing device and a tail gas treatment device. Safe and efficient negative pressure thermal desorption treatment can be conducted on mercury-containing soil.

Owner:HENAN UNIV OF SCI & TECH

Flue gas waste heat recovery cooker

InactiveCN104154558APromotes more complete combustionSave fuelCombustion processIndirect carbon-dioxide mitigationPollutantZero emission

The invention relates to a flue gas waste heat recovery cooker which comprises a combustion chamber arranged in a cooking bench and a combustor located in the combustion chamber. The flue gas waste heat recovery cooker further comprises a heat exchange device for heat exchange between high-temperature flue gas exhausted from the combustion chamber and air. The heat exchange device is provided with a flue gas inlet and an air outlet. The upper portion of the combustion chamber is connected with the flue gas inlet through a pipeline, and the air outlet is communicated with the interior of the combustor. According to the flue gas waste heat recovery cooker, the high-temperature flue gas generated through combustion in the combustion chamber and waste heat on the inner wall of the combustion chamber are used for secondary heating on oxygen-bearing air, so that the initial temperature of oxygen-bearing air entering the combustion chamber is greatly increased, fuel can be saved and the flame temperature can be increased; an interlayer is arranged in a heating cavity, the travel of high-temperature oxygen-bearing air in the heating cavity is increased, and the heat exchange effect of high-temperature oxygen-bearing air is improved; a waste gas treatment device is arranged, waste gas pumped out of an exhaust fan is absorbed and treated through waste gas treatment liquid, zero emission of pollutants is achieved, and environmental protection is achieved.

Owner:HUBEI ZHONGRUITIANHENG ENERGY SAVING TECH DEV

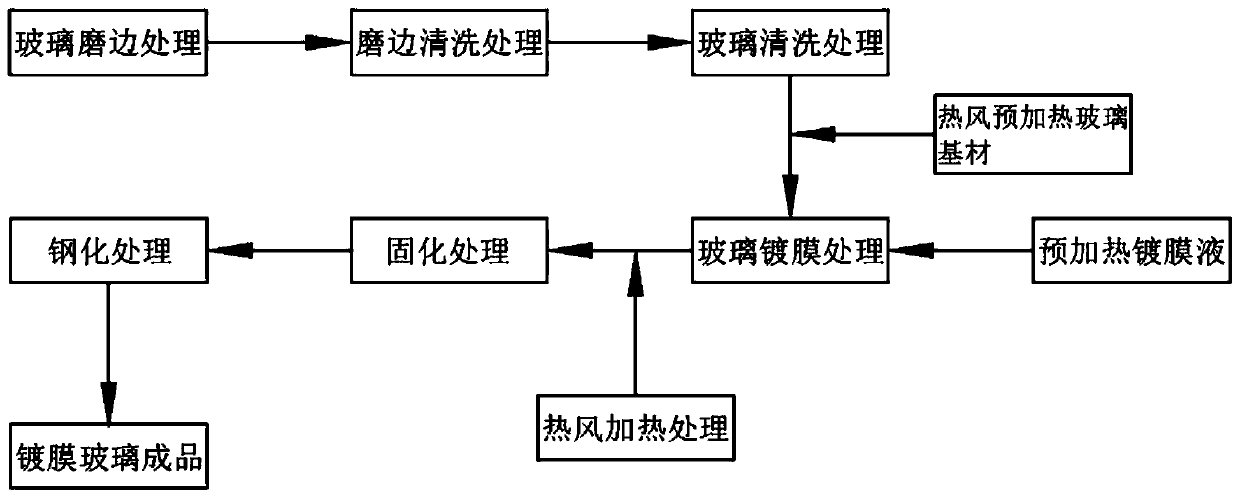

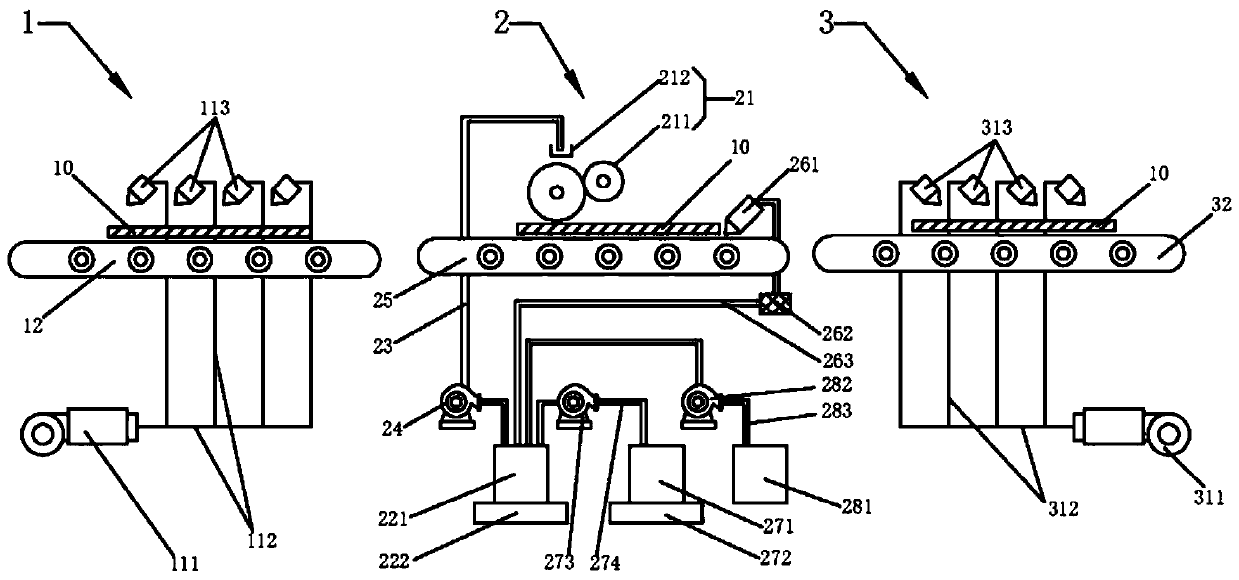

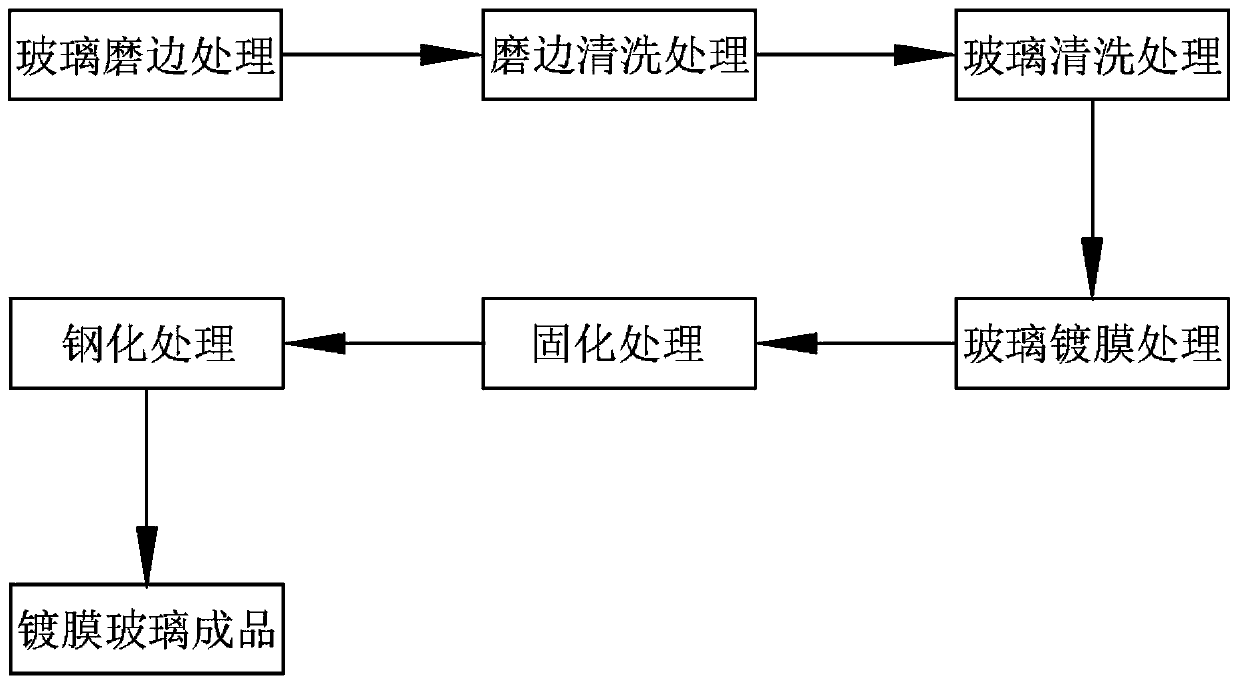

Preheating method and equipment for coated glass production

The invention relates to the technical field of coated glass, in particular to a preheating method and equipment for coated glass production. The preheating method comprises the following steps: S1, preheating a glass substrate: spraying hot air on the surface of the glass substrate until the temperature of the glass substrate is 40-60 DEG C; S2, preheating a coating solution, namely heating the coating solution to 30-40 DEG C, and coating the heated coating solution on the surface of the glass substrate preheated in the step S1; and S3, conducting post-heating treatment, specifically, adopting hot air for blowing and spraying the glass base material coated with the coating liquid in the step S2, so that the temperature of the glass base material reaches 50-70 DEG C, and the preheated coated glass is prepared for standby application and waiting for curing. The preheating method disclosed by the invention is simple to operate, high in production efficiency and low in production cost, the volatilization rate uniformity of the solvent in a wet film state can be accelerated, the adhesive force between the film layer and the glass substrate is improved, and the light transmittance, weather resistance and hardness of the film layer are improved.

Owner:DONGGUAN CSG SOLAR GLASS +1

Preparation method of vulcanization type catalyst

ActiveCN103100395ASimple production processReduce manufacturing costPhysical/chemical process catalystsRefining to eliminate hetero atomsInorganic saltsVulcanization

The invention discloses a preparation method of a vulcanization type catalyst. The method comprises: adopting a dipping solution containing a sulfide precursor of active metal Mo or W and an inorganic salt of Ni or Co to dip a needed catalyst carrier, and then conducting after-treatment under certain vacuum degree and temperature, thus obtaining the vulcanization type catalyst. The method can control vulcanization of the catalyst under an appropriate temperature in a startup activation process, thus avoiding untimely vulcanization of the active metal, release of a hydrogen sulfide gas and the consequent influence on equipment air tightness. Meanwhile, in the after-treatment process, redundant water in catalyst pores are removed to prevent excess water in recycle hydrogen from influencing the catalyst activity during activation and corroding equipment. The catalyst prepared by the method provided in the invention is applicable to preparation of a petroleum fraction hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

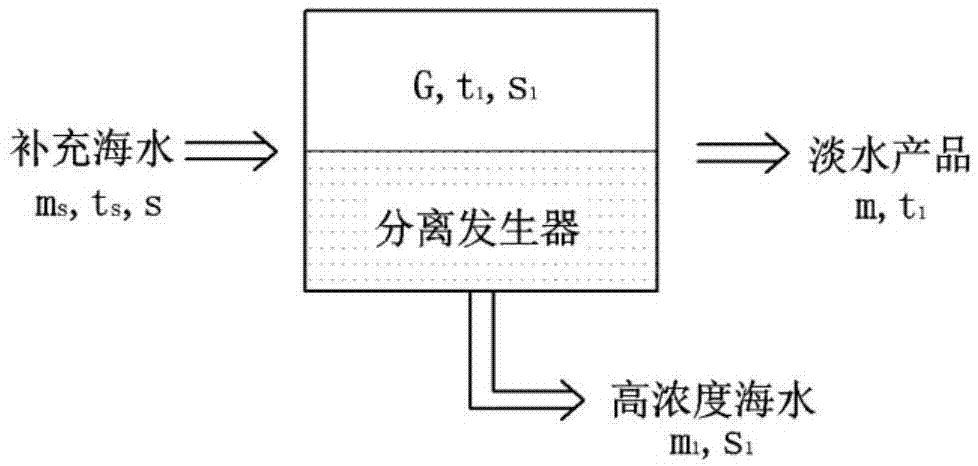

Seawater desalination system with waste heat recovery device

InactiveCN105819532ARaise the initial temperatureReduce the burden onGeneral water supply conservationSeawater treatmentWaste heat recovery unitFresh water

Provided is a seawater desalination system with a waste heat recovery device .The seawater desalination system comprises effect chamber evaporators, a heat source, a seawater pipeline, a fresh water pipeline and a strong brine pipeline; a heat pump system comprises a heat transfer working medium fluid pipeline, a heat transfer heat pump compressor, a heat pump condenser and a heat pump evaporator, the two ends of the heat transfer working medium fluid pipeline are connected to the input end and the output end of the heat pump compressor respectively, the heat pump condenser is installed on the side, close to the input end of the heat pump compressor, of the working medium fluid pipeline, the heat pump evaporator is installed on the side, close to the output end of the heat pump compressor, of the working medium fluid pipeline, the section, located in the heat pump condenser, of a seawater pipeline is a seawater pipe coil, and the section, located on the heat pump evaporator, of the strong brine pipeline is a strong brine pipe coil .According to the seawater desalination system with the waste heat recovery device, heat energy in high-temperature strong brine to be discharged is utilized, heating is conducted on seawater to be evaporated through the heat pump system, the initial temperature of seawater is increased, a burden of the heat source is reduced, and meanwhile the influence of emissions to the adjacent sea areas is reduced.

Owner:SHANGHAI JIAOYING ENERGY TECH

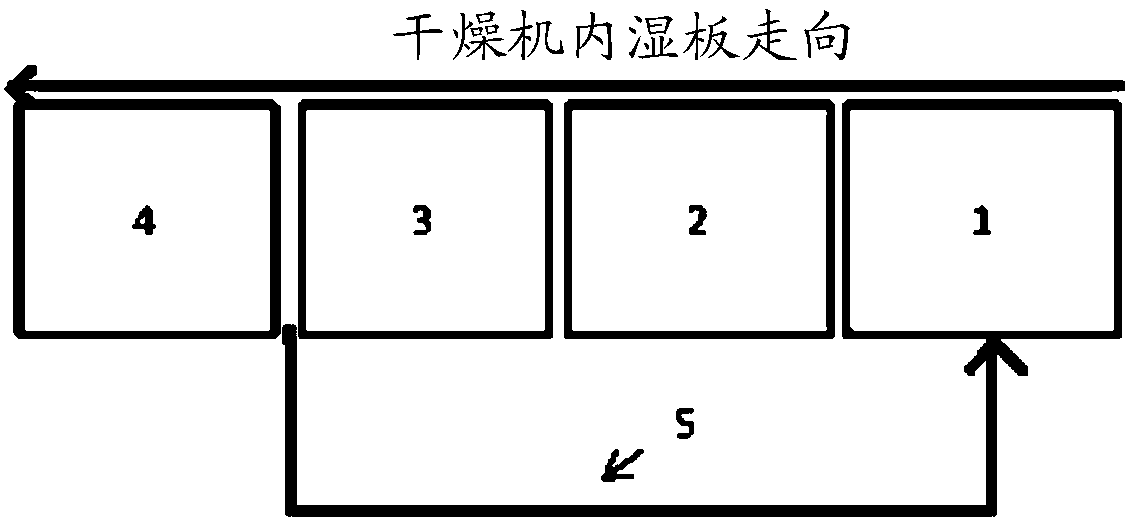

Gypsum board drying machine and application thereof

ActiveCN110645772AReduce pittingImprove appearance qualityDrying gas arrangementsCeramic shaping apparatusExhaust fumesEngineering

The invention relates to a gypsum board drying machine and an application thereof. The drying machine comprises an inlet preheating section, a drying machine first area, a drying machine second ares and a drying machine third area which are sequentially arranged, and further comprises a second heat exchanger, a second preheating fan, a second waste gas fan and a hot air pipeline, wherein the second heat exchanger is arranged at the joint of the drying machine second area and the drying machine third area, the second preheating fan is connected with the second heat exchanger and is used for blowing external air into the second heat exchanger, the second waste gas fan is connected with the drying machine second area and the second heat exchanger and is used for blowing wet hot gas dischargedfrom the drying machine second area into the second heat exchanger, so that the wet heat gas and the external air are subjected to heat exchange in the second heat exchanger, and the hot air pipelineis connected with the inlet preheating section and the second heat exchanger and is arranged to introduce hot air obtained after heat exchange into the inlet preheating section. The gypsum board drying machine has the advantages that the problem of pits in a gypsum board surface can be effectively solved, meanwhile, the production efficiency is improved, the energy consumption is reduced, and theproduction cost is reduced.

Owner:HUAINAN BEIXIN BUILDING MATERIAL +1

Production device for calcium carbide co-production coking product

ActiveCN102583378AReduce manufacturing costEfficient use ofChemical industryCalcium carbideLime kilnCoke

The invention relates to a production device for a calcium carbide co-production coking product. The production device comprises a lime kiln, a calcium carbide furnace, a carbonization chamber, coking product separation equipment, hydrogen separation equipment and hydrogenation equipment, wherein a lime outlet is connected with a feed port of the carbonization chamber; a coke outlet of the carbonization chamber is connected with an inlet of the calcium carbide furnace; a coking product outlet of the carbonization chamber and a gas outlet of the calcium carbide furnace are connected to the coking product separation equipment; a gas outlet of the coking product separation equipment is connected to the hydrogen separation equipment, and a liquid outlet is connected to the hydrogenation equipment; a hydrogen outlet of the hydrogen separation equipment is connected to the hydrogenation equipment. A discharge port of the hydrogenation equipment is connected to a product storage tank; and a fuel outlet of the hydrogen separation equipment is connected to a fuel burner of a lime kiln calcining zone. The production device is combined with the lime kiln and carbonization equipment through the calcium carbide furnace, and production of the calcium carbide co-production coking product is realized, so that the transportation cost is saved, the energy is effectively utilized, resource is saved, the production cost of calcium carbide and coking product is reduced, and the economic benefit of the enterprise is increased.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

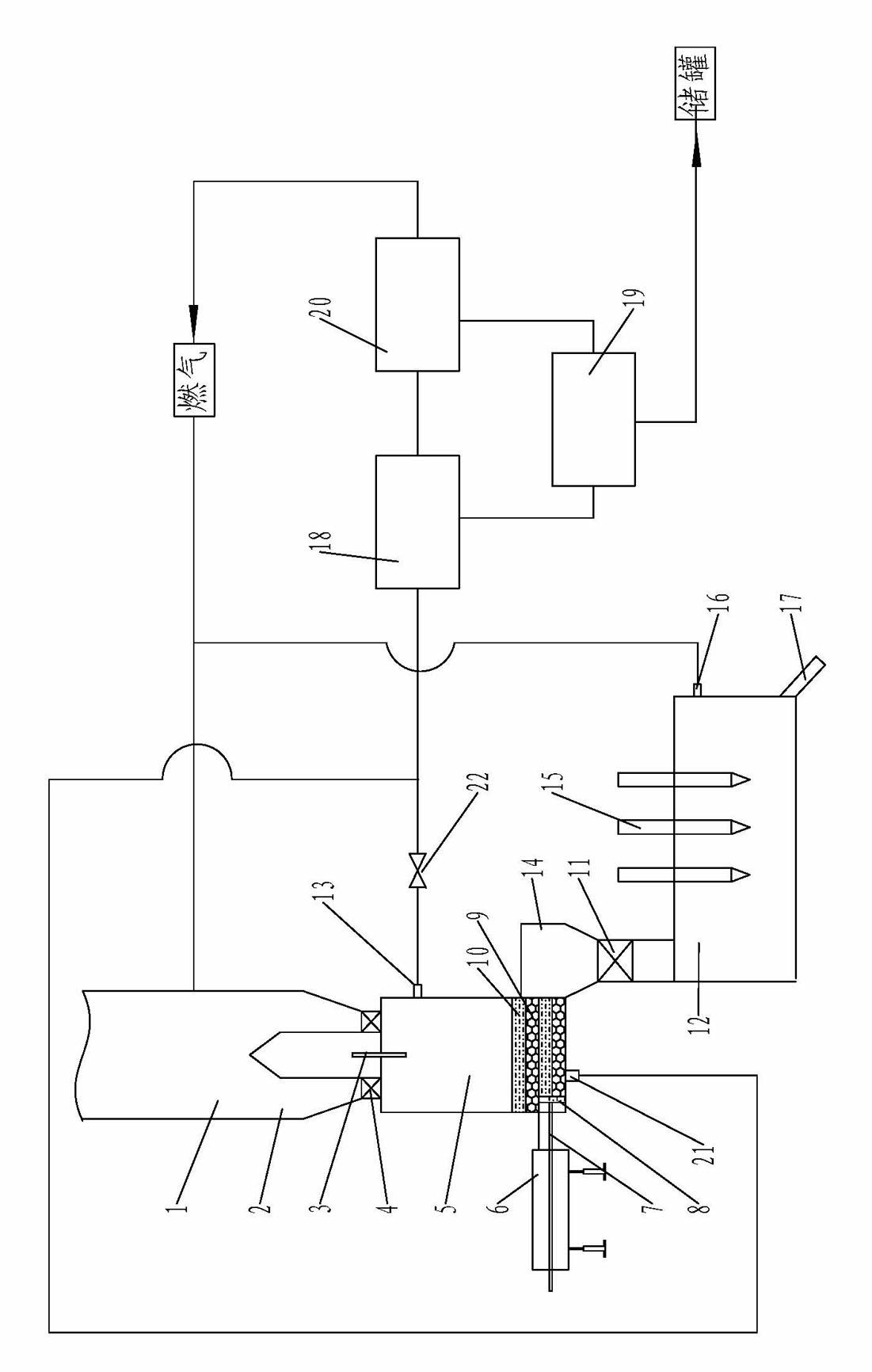

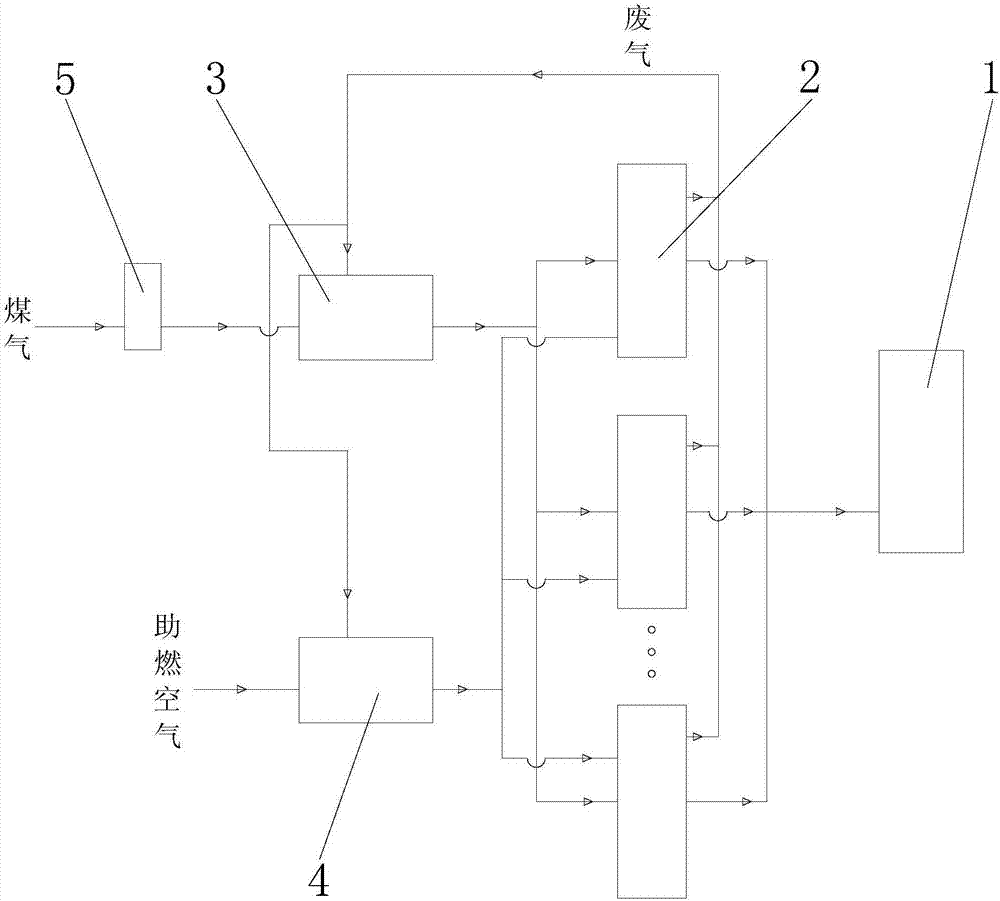

Blast furnace hot blast stove system

InactiveCN107488771ARaise the initial temperatureIncrease productionBlast furnace detailsHeating stovesCombustionAir temperature

The invention discloses a blast furnace hot blast stove system. The blast furnace hot blast stove system comprises a plurality of hot blast stoves and is characterized in that the multiple hot blast stoves are connected to a blast furnace in parallel; coal gas is preheated by a coal gas preheating device and then conveyed to each hot blast stove by a corresponding distribution pipeline; combustion air is preheated by an air preheating device and then conveyed to each hot blast stove by a corresponding distribution pipeline; and the coal gas passes through a dust removal device and then is conveyed to the coal gas preheating device. The blast furnace hot blast stove system preheats the coal gas and smoke, the initial temperature of the combustion air is effectively improved, the air temperature level is greatly improved, the stability of temperature of the blast furnace is ensured, the air temperature of the hot blast stoves is increased so as to reduce the coke ratio advantageously, the iron and steel output is improved, energy is saved, and the production cost is reduced.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

V-shaped gap type hemispherical blunt body micro-combustor with hydrogen permeation and combustion stabilization functions

The invention discloses a V-shaped gap type hemispherical blunt body micro-combustor with the hydrogen permeation and combustion stabilization functions. The micro-combustor comprises an outer spherical body, an inner spherical body and a blunt body. At least one set of gas inlet channels are formed in the peripheral direction of the middle of the outer spherical body. Each gas inlet channel of each set is composed of a fuel gas inlet, an air inlet and a hydrogen inlet. A gas outlet channel is formed in the bottom of the outer spherical body, and another gas outlet channel is formed in the bottom of the inner spherical body. The inner spherical body is composed of a segment and a round multi-hole panel. The segment is made of a hydrogen permeation material. The round multi-hole panel is provided with a plurality of round holes. The blunt body is a hollow hemispherical body and is arranged on the upper portion in the inner spherical body. The top of the blunt body is provided with a V-shaped gap. The micro-combustor enables gas of micro flow to generate catalytic combustion reaction fast and efficiently. Due to the blunt body, the premixed gas forms a return flow zone in the back of the blunt body; according to the characteristics of low speed and high temperature of the rear return flow zone of the blunt body, near fuel is lighted so that the purpose of combustion stabilization can be achieved, the blow-off limit of the fuel can be improved greatly, and the combustion efficiency is improved.

Owner:CHONGQING UNIV

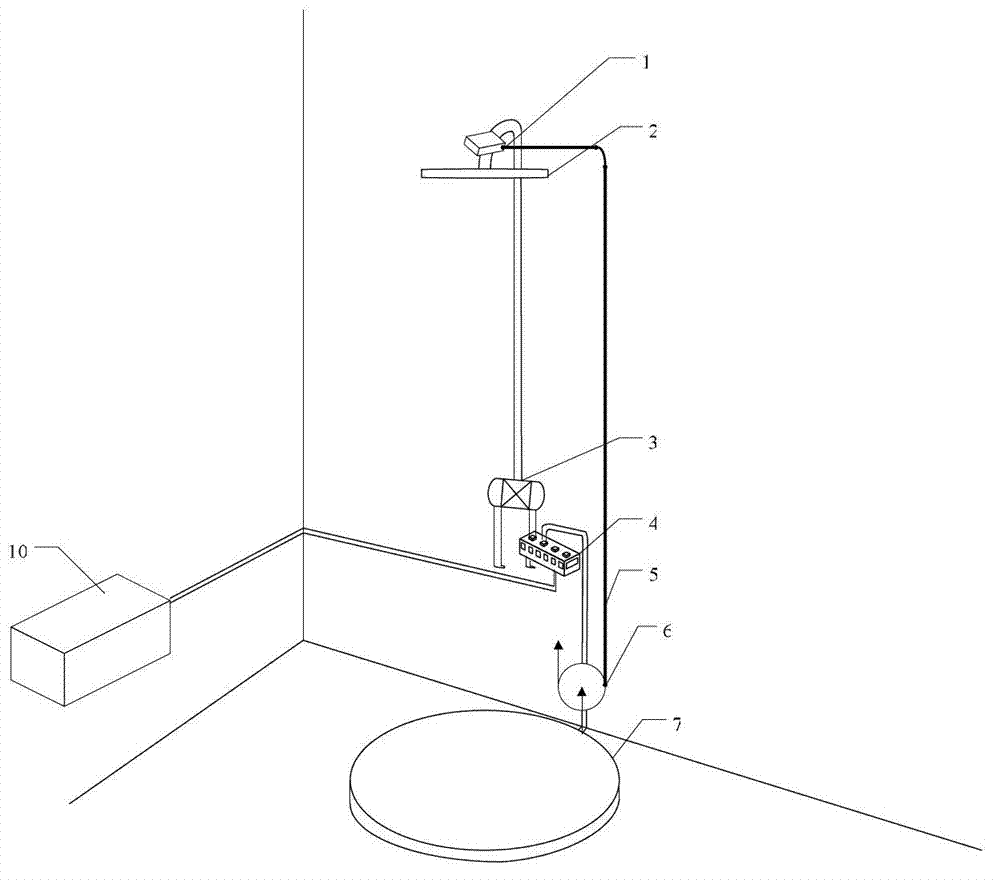

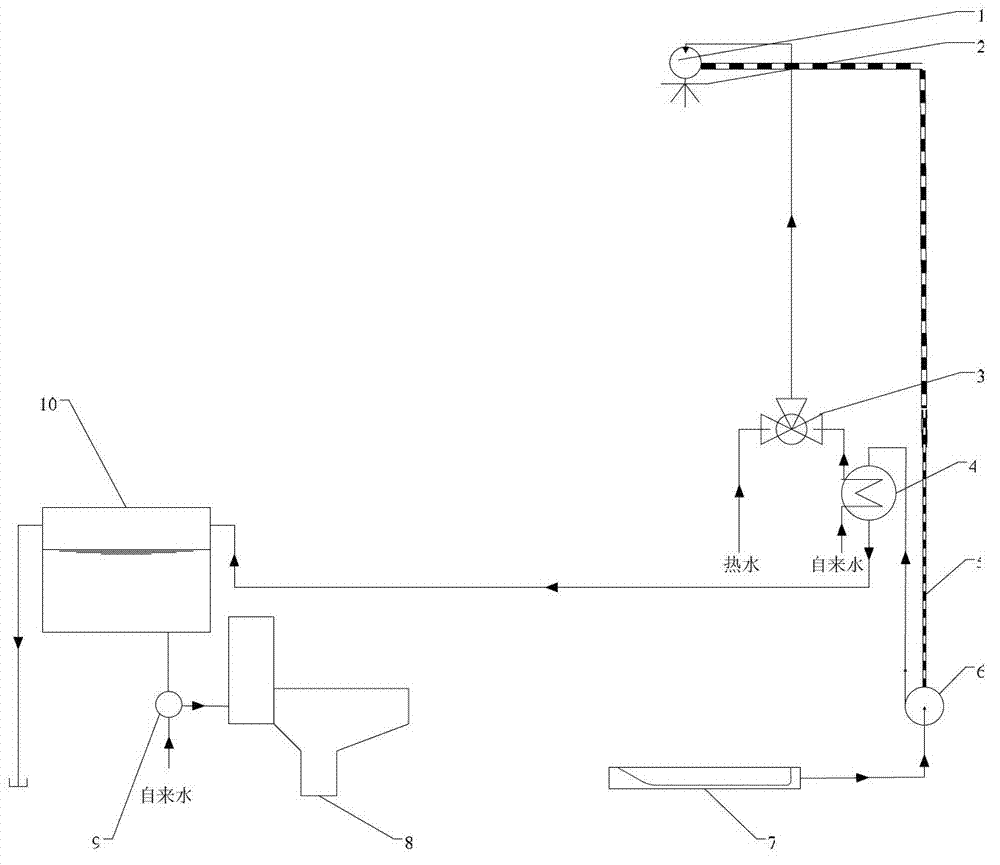

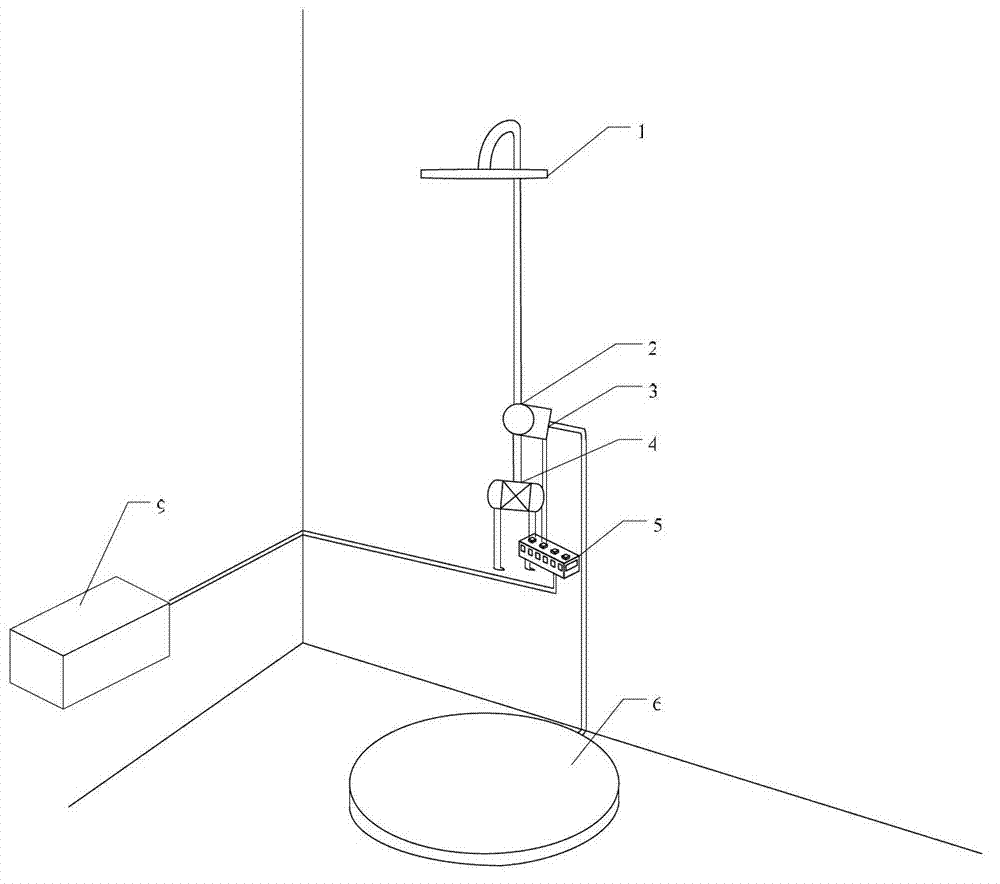

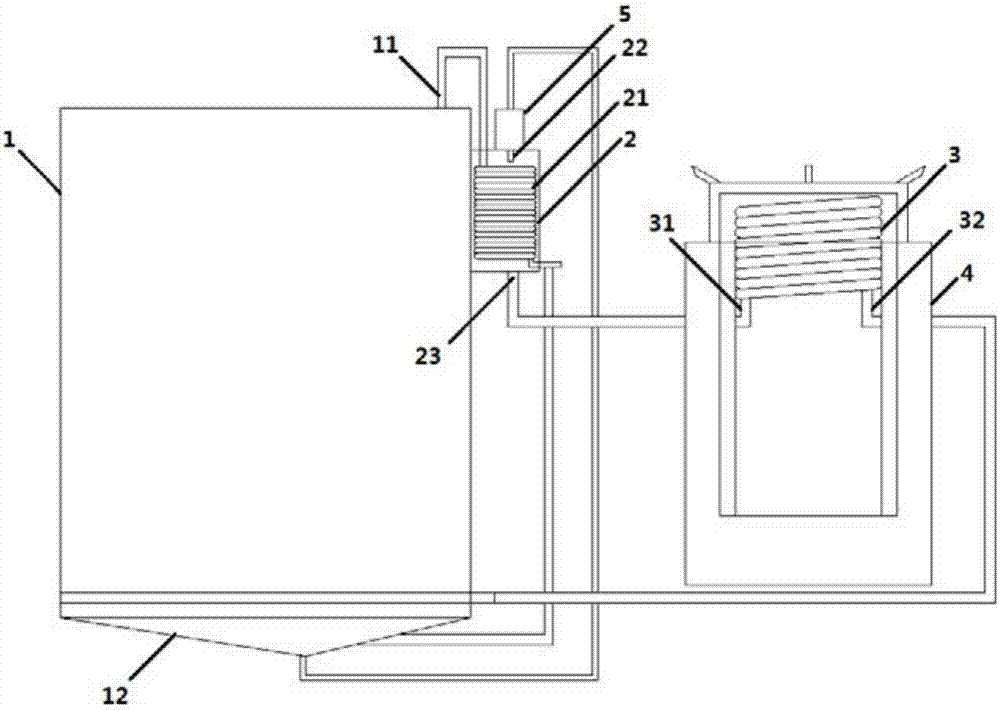

Water power based recycling device for shower wastewater and heat energy

InactiveCN102828547AReduce consumptionEmission reductionOther heat production devicesDomestic plumbingWater sourceTap water

The invention discloses a water power based recycling device for shower wastewater and heat energy. The water power based recycling device is a full-automatic comprehensive recycling device for the shower wastewater, which can save the running water and the energy required by heating water, can reduce the quantity of wastewater effluent and can utilize the water power. The hydraulic energy for discharging shower water is utilized as the energy source for collecting the shower wastewater; the shower wastewater after being filtered is pressurized; the shower wastewater enters a heat exchanger through a pipeline; the heat exchanger is utilized to exchange the heat of the collected shower wastewater at higher temperature with the heat of the low-temperature entering water of a shower system, so as to increase the initial temperature of the low-temperature entering water of the shower system; the cooled shower wastewater flows into a recycled wastewater storage device and is used as a water source for flushing a closestool; the shower wastewater is reused, the running water is saved, the sewage discharge and the energy consumption are reduced, and the purpose of saving the energy source and the running water is achieved; the water power based recycling device is safe and reliable and is convenient to realize; and the water power based recycling device has better economic benefit.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Rice steaming box capable of recycling steam heat

PendingCN107374336ARaise the initial temperatureImprove energy efficiencySteam cooking vesselsWarming devicesEngineeringSteaming

The invention discloses a rice steaming box capable of recycling steam heat. The rice steaming box capable of recycling steam heat comprises a rice steaming box body and a water tank, wherein a heat exchange tube is arranged in the water tank; one end of the heat exchange tube is connected with a steam discharging tube of the rice steaming box body; a water inlet tube and a water outlet tube are arranged on the water tank; the water inlet tube is connected with an external water supply tube; and the water outlet tube is connected with a water inlet of a steam generating device of the rice steaming box body. Water in the water tank is preheated by afterheat of steam discharged from the rice steaming box, the initial temperature of the water which enters a heating tube is increased, required heat for generation of steam is reduced, the energy utilization rate is increased, and energy consumption and costs are reduced.

Owner:池州信安电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com