Sludge storing and preheating system utilizing sludge drying tail gas afterheat

A sludge storage and sludge drying technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve problems such as large energy consumption, reduce operating costs, ensure discharge standards, and increase initial temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

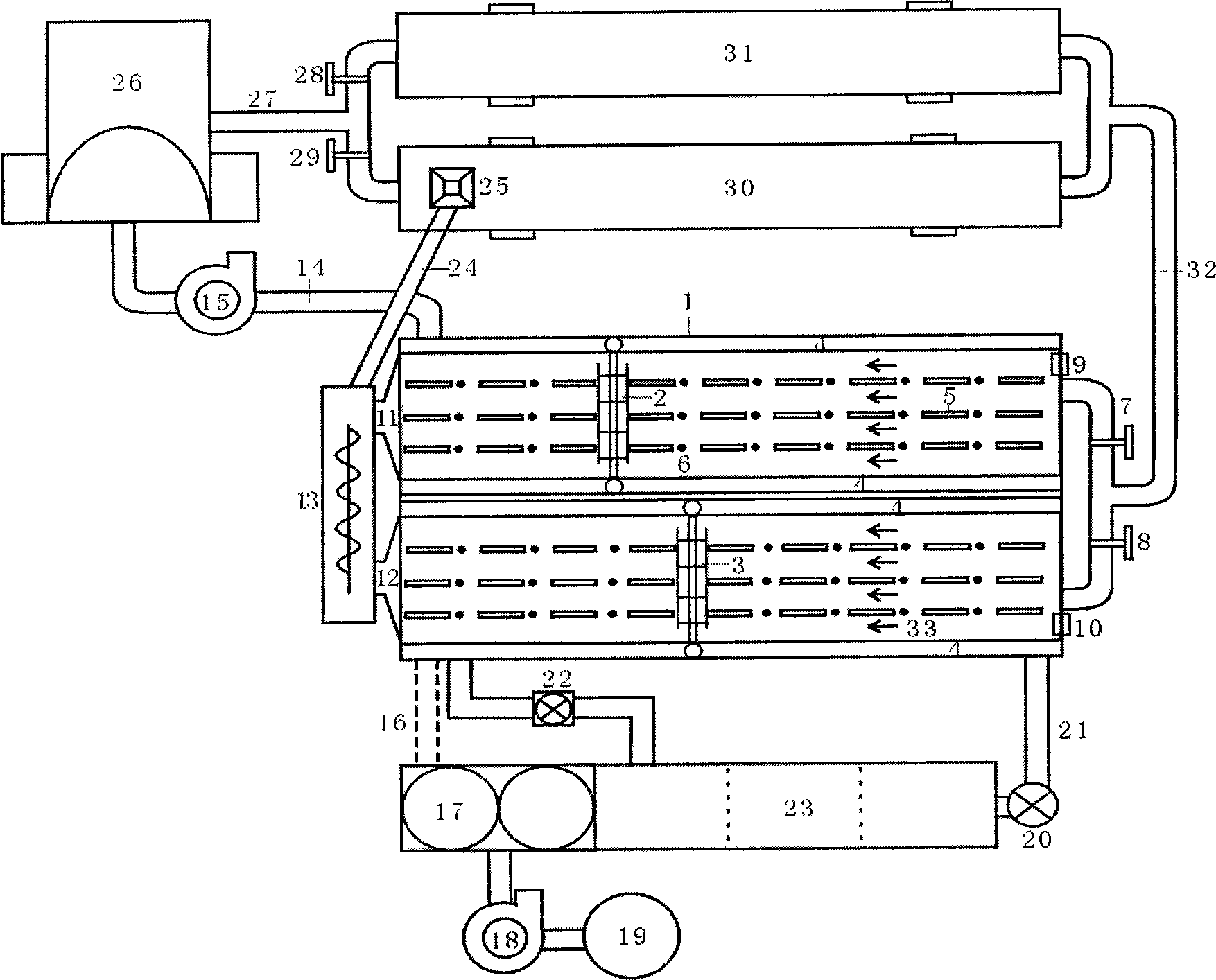

[0011] As shown in the attached figure, the sludge storage and preheating system using the waste heat of sludge drying tail gas has a closed sludge storage 1, and one end of the closed sludge storage 1 is provided with a first sludge input port 9 and a second The sludge input port 10, the closed sludge storage 1 is provided with a mud pusher rail 4, and the mud pusher rail 4 is equipped with a first mud pusher 2 and a second mud pusher 3, and the closed sludge The other end of the storage house 1 is provided with a first sludge output port 11 and a second sludge output port 12, the first sludge output port 11 and the second sludge output port 12 are connected with a sludge feeding device 13, and the sludge The feeding device 13 is connected to the sludge feed port 25 of the first sludge drying device 30 through a conveyor belt, and the first sludge drying device 30 and the second sludge drying device 31 pass through the third damper 28 and the second sludge drying device 31 res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com