Production device for calcium carbide co-production coking product

A production device and calcium carbide technology, which is applied in the field of lime, coking and calcium carbide product production equipment, and calcium carbide co-production coking products. It can solve the problems of mutual utilization of heat energy, increase in transportation costs, and large energy waste, etc., to simplify the intermediate process. Effects of process and transportation costs, savings in transportation costs, and increased surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

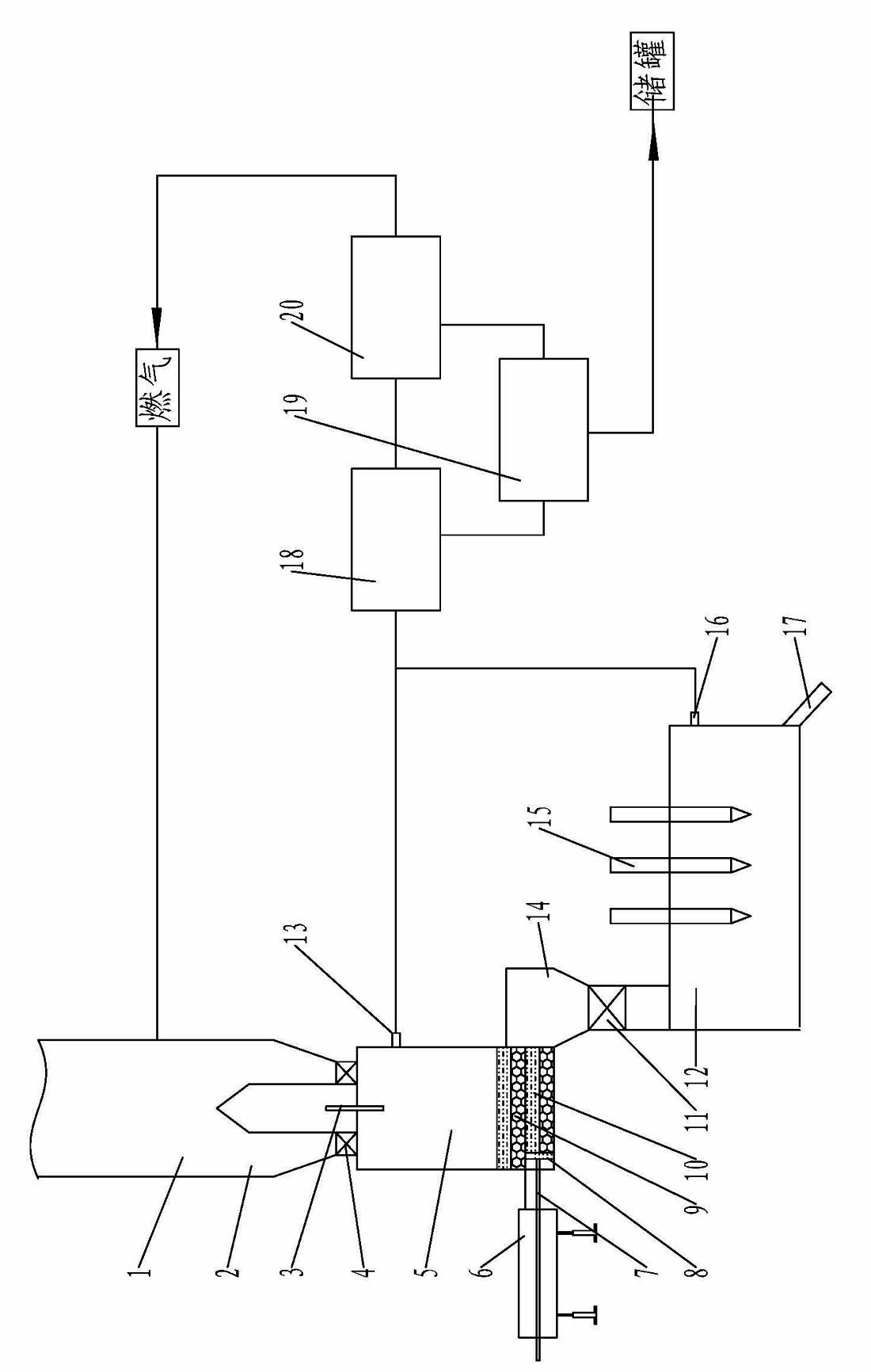

[0017] The production device of calcium carbide co-production coking product of the present invention is as figure 1 As shown, it includes a lime kiln 1 , a calcium carbide furnace 12 , a carbonization chamber 5 , a coking product separation device 18 , a hydrogen separation device 20 and a hydrogenation device 19 . The lime kiln is a beam type lime kiln, including a preheating zone, a calcination zone and a lime outlet 4, the lime outlet is provided with a material lock, and the calcination zone is provided with a fuel burner. The calcium carbide furnace is an electric arc furnace, including electrodes 15, calcium carbide furnace inlet 11, calcium carbide furnace outlet 17 and calcium carbide furnace gas outlet 16. The calcium carbide furnace inlet is provided with a material lock, and the calcium carbide furnace inlet is provided with a distributor. The carbonization chamber 5 is a semi-coke furnace, and the carbonization chamber is provided with a coal injection device 3, a...

Embodiment 2

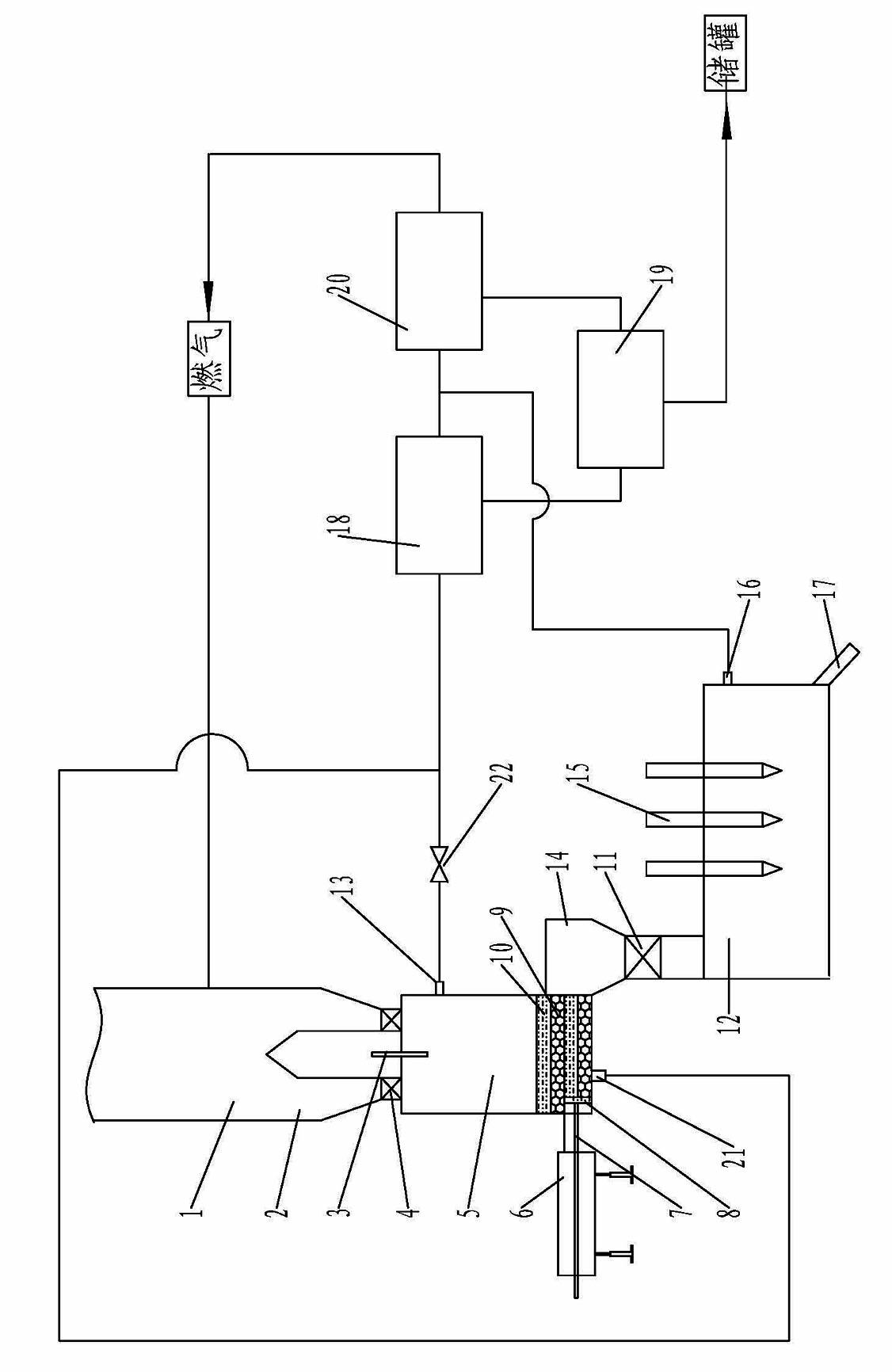

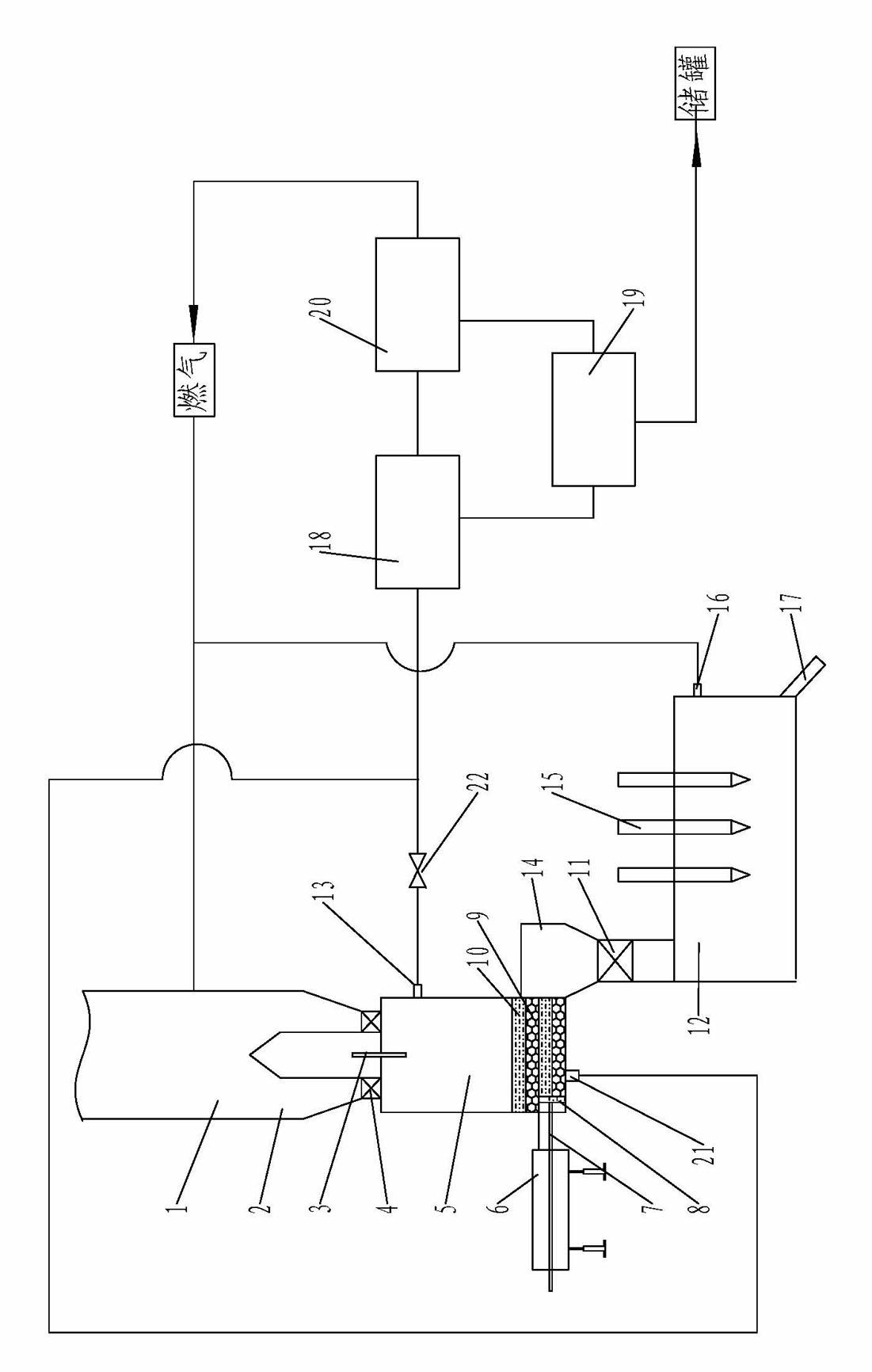

[0021] Another embodiment of the present invention is as figure 2As shown, the carbonization chamber 5 is a coking furnace, and the carbonization chamber is equipped with a coal injection device 3 , a discharge machine 6 , a coking product outlet 13 , a coking product lower outlet 21 , a coke outlet and a hopper 14 . The coking product outlet 13 and the feed port pipeline of the coking product separation device 18 are provided with a valve 22, and the coking product lower outlet 21 is connected to the feed port of the coking product separation device. The calcium carbide furnace gas outlet 16 is connected to the gas inlet of the hydrogen separation device 20 . Other equipment processes are the same as in Embodiment 1. Another embodiment of the present invention is as image 3 As shown, the calcium carbide furnace gas outlet 16 is directly connected to the fuel burner of the calcining zone of the lime kiln.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com