Full-boiling cyclone fluidized bed damping machine and new damping technology

A humidity conditioner and new process technology, applied in hearth type furnaces, drying solid materials, furnaces, etc., can solve the problems of low production capacity, high energy consumption, unsuitable for industrial large-scale production, etc., to save transportation costs, improve The effect of coal quality and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

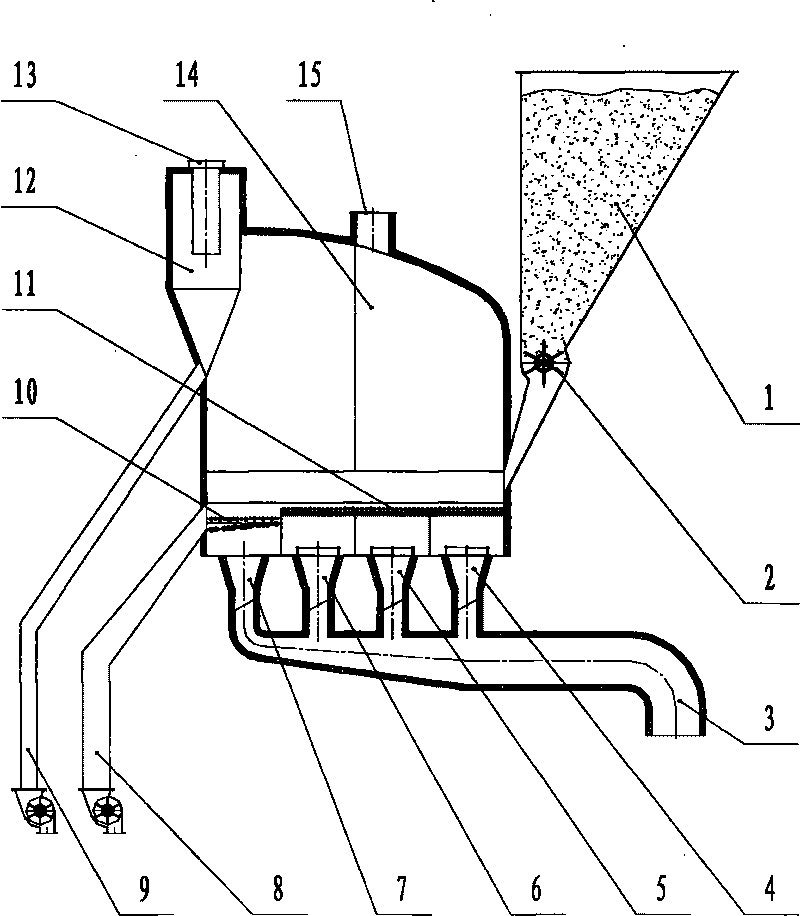

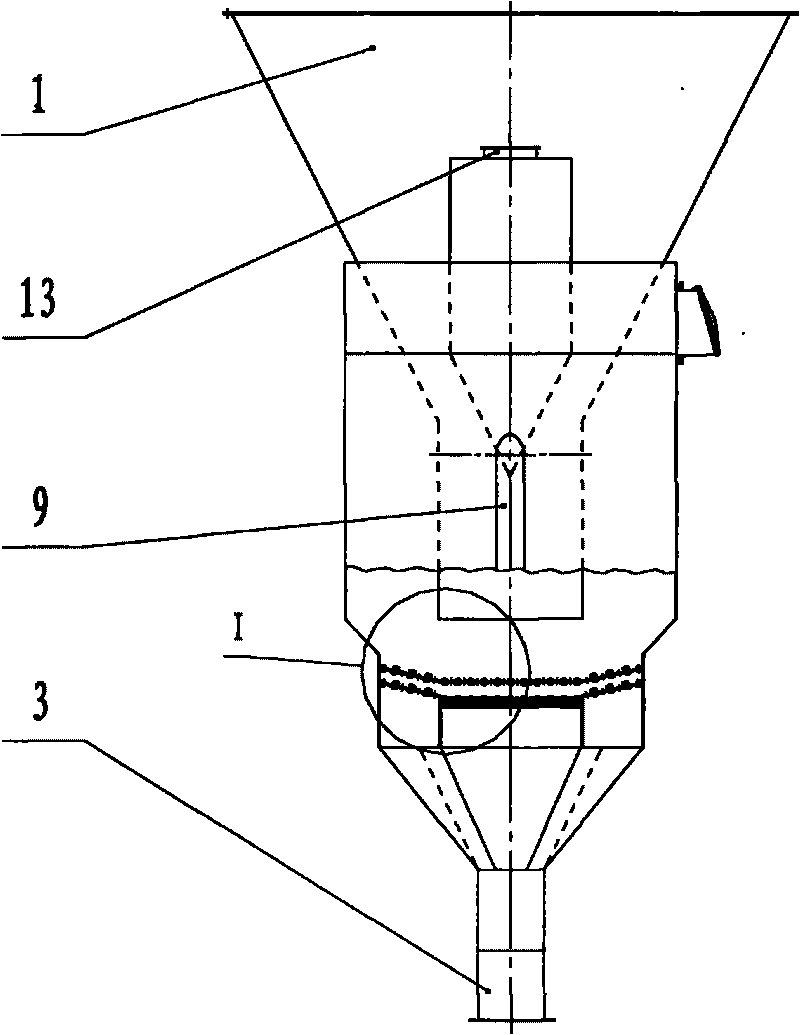

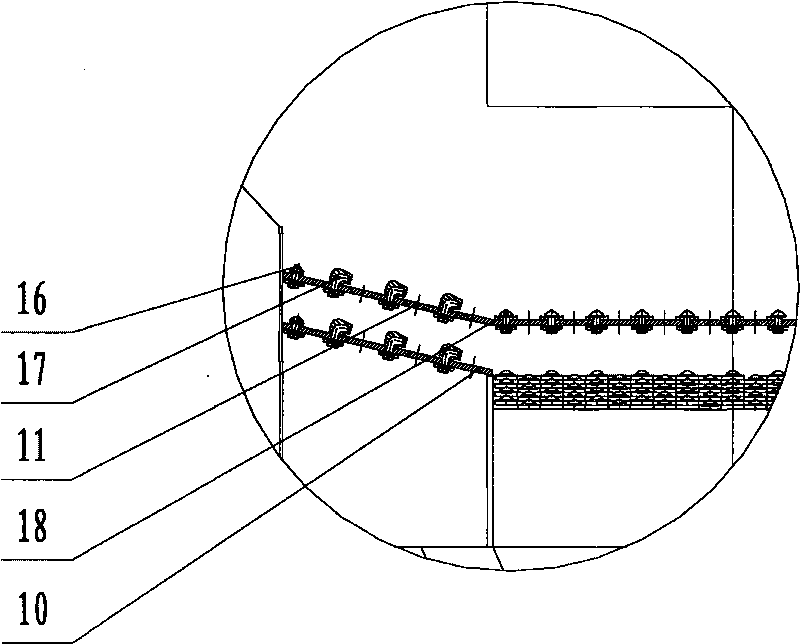

[0015] exist figure 1 , figure 2 and image 3 In the shown first embodiment, the body of the full-boiling swirling fluidized bed arranged in the closed casing (14) is divided into a drying front section bed (11) and a drying back section bed (10), and the drying front section The No. 1 air chamber (4) of the drying front section, the No. 2 air chamber (5) of the drying front section, the No. 3 air chamber (6) of the drying front section and the drying section are arranged under the bed (11) and the drying rear section of the bed (10). The back section air chamber (7), the tail of the drying back section bed (10) communicates with the dry granular material discharge pipe (8). The bed in the front drying section (11) and the bed in the back section of the drying section (10) are gradually higher on both sides of the depression in the middle in the direction of the cross section, and the bed in the back section of the drying section (10) is lower in the longitudinal section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com