Patents

Literature

79results about How to "Lower fuel consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

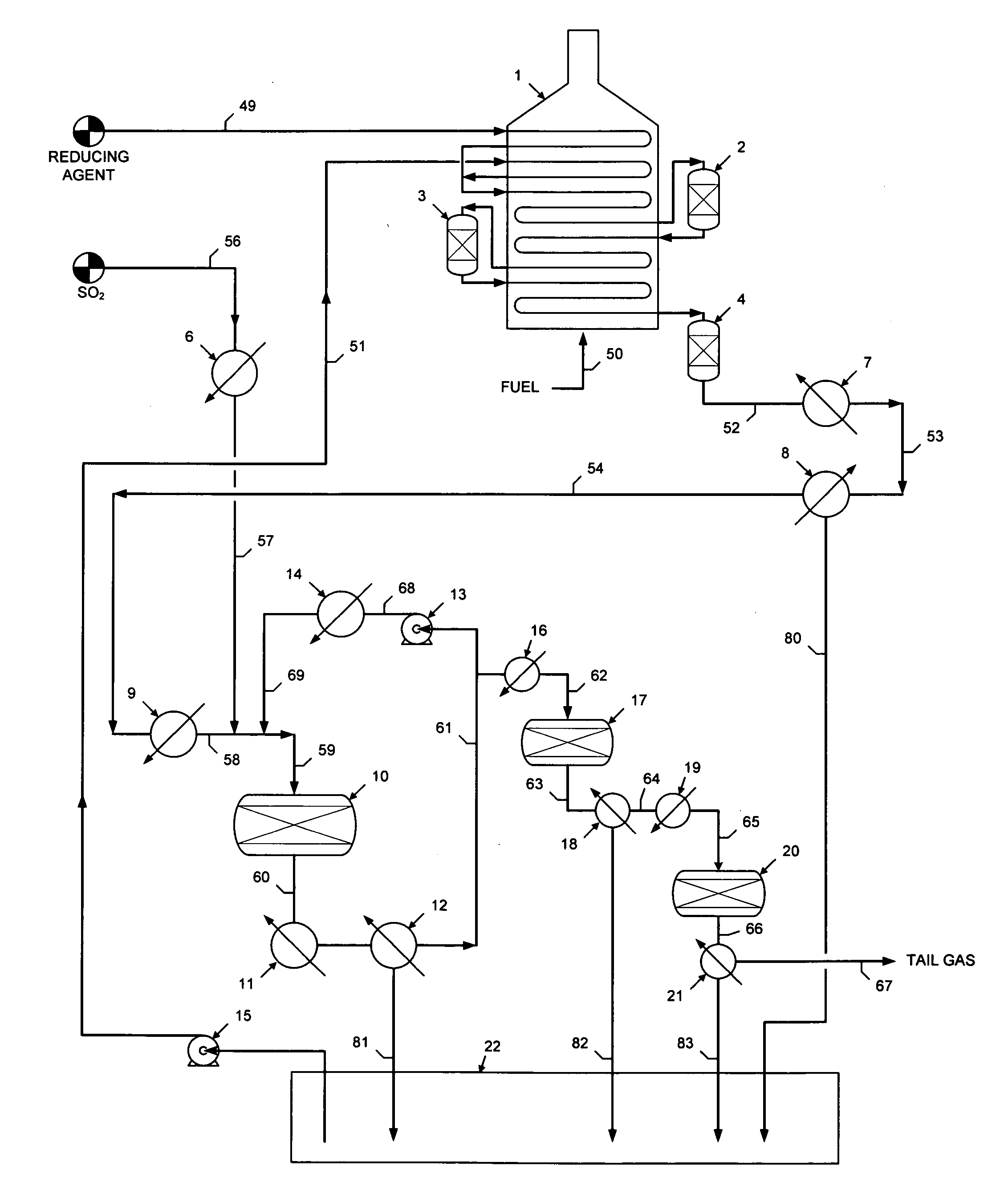

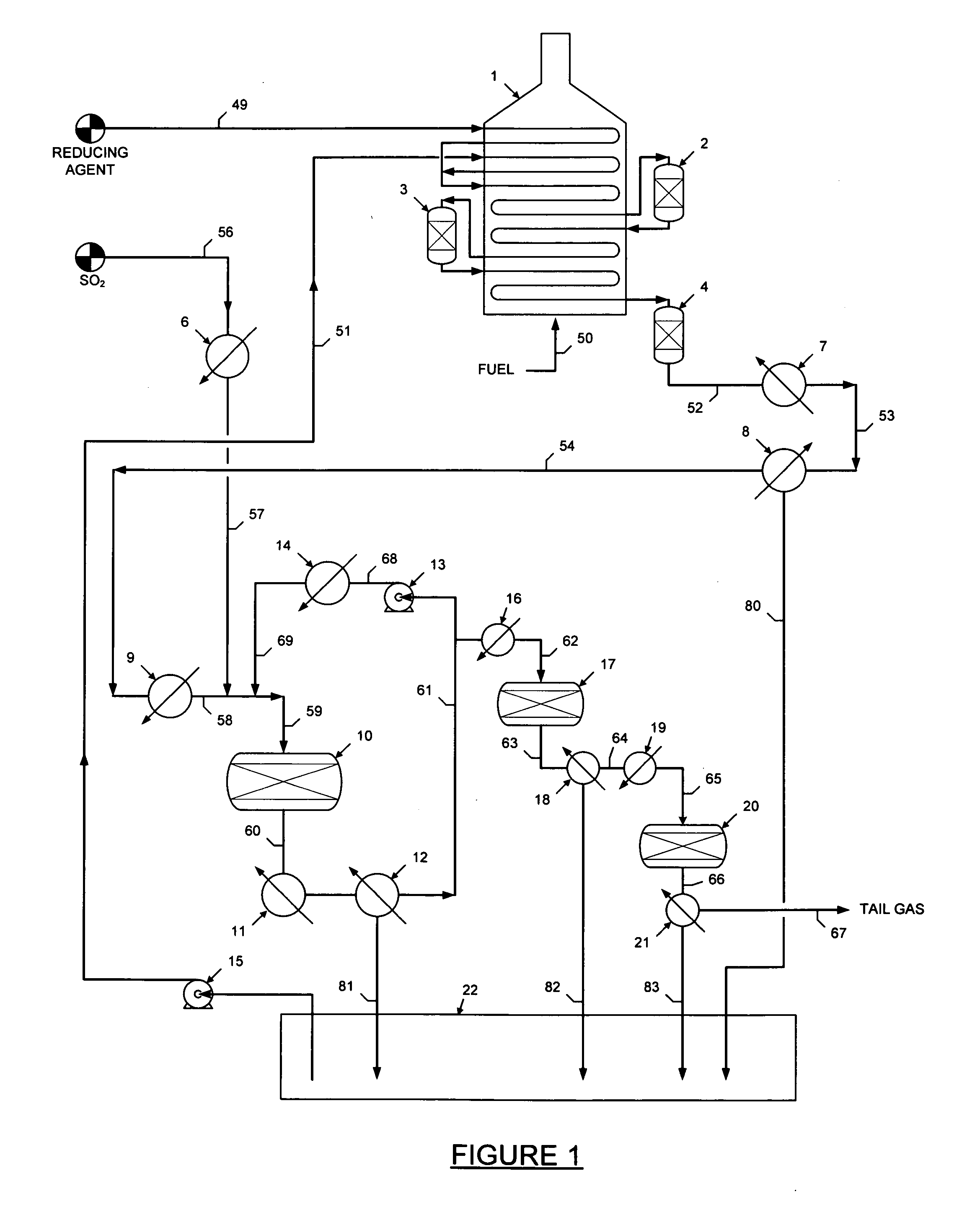

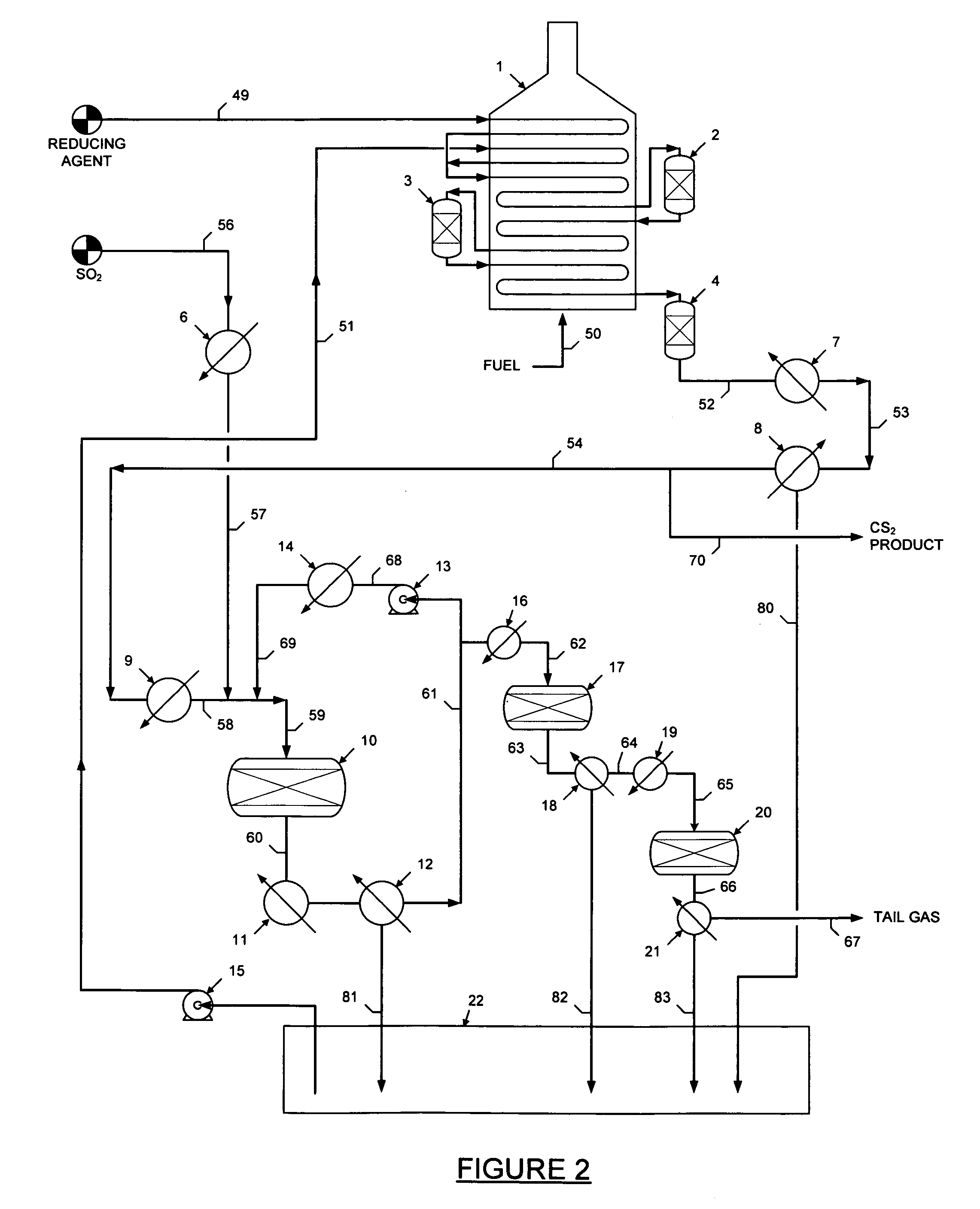

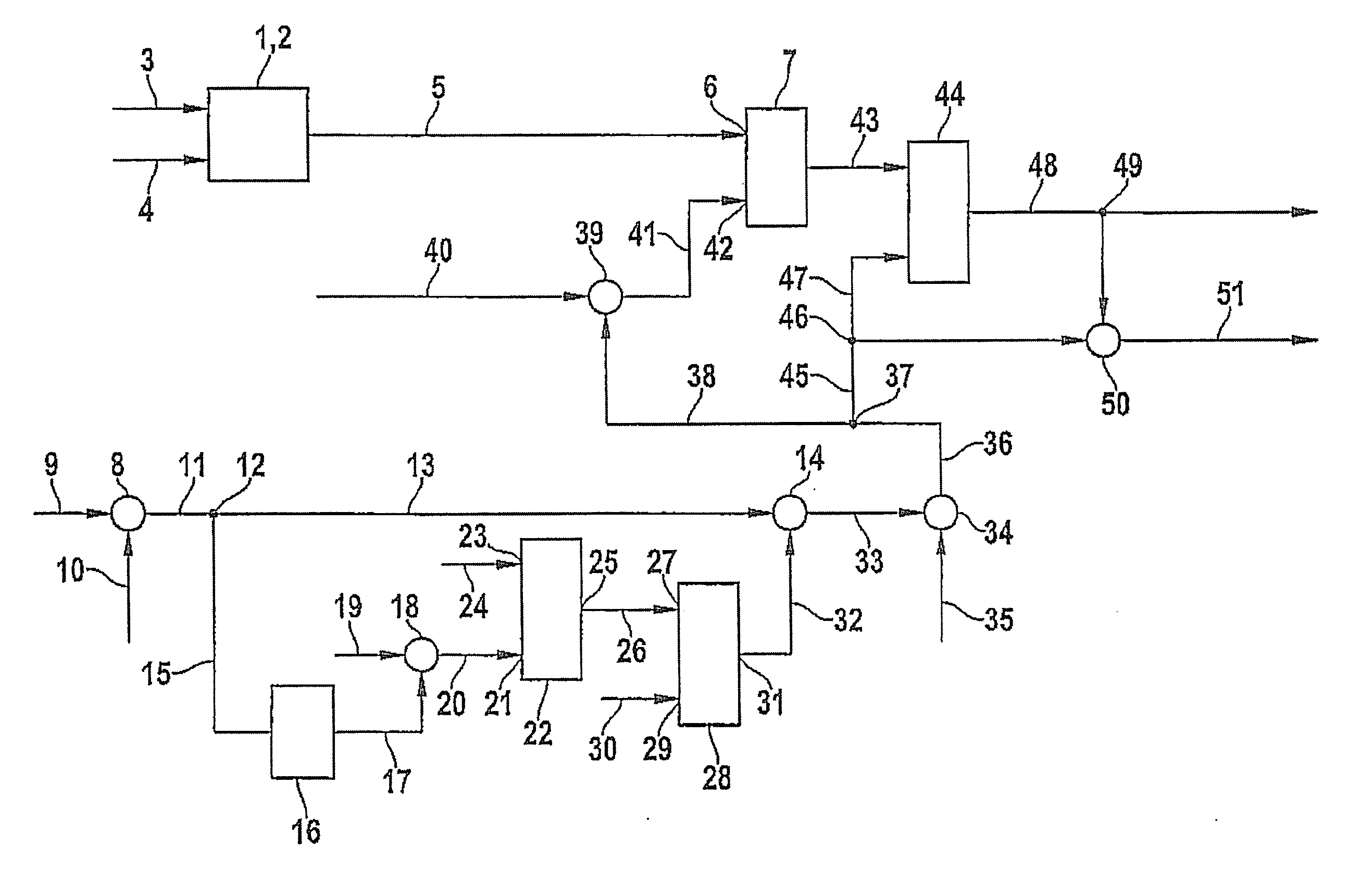

Process for the production of sulfur from sulfur dioxide

InactiveUS20060288919A1Lower fuel consumptionWell operational stabilityEmission preventionHydrogen sulfidesSulfur dioxideEnvironmental chemistry

The reduction of gas streams containing sulfur dioxide to elemental sulfur is carried out by contacting a reducing gas, such as natural gas, methanol or a mixture of hydrogen and carbon monoxide, with recycled sulfur to produce a stream containing hydrogen sulfide that may be reacted with the gas stream that contains sulfur dioxide. Gas streams with a molar concentration of sulfur dioxide from 1 to 100% may be processed to achieve nearly 100% sulfur recovery efficiency.

Owner:WORLEYPARSONS GROUP

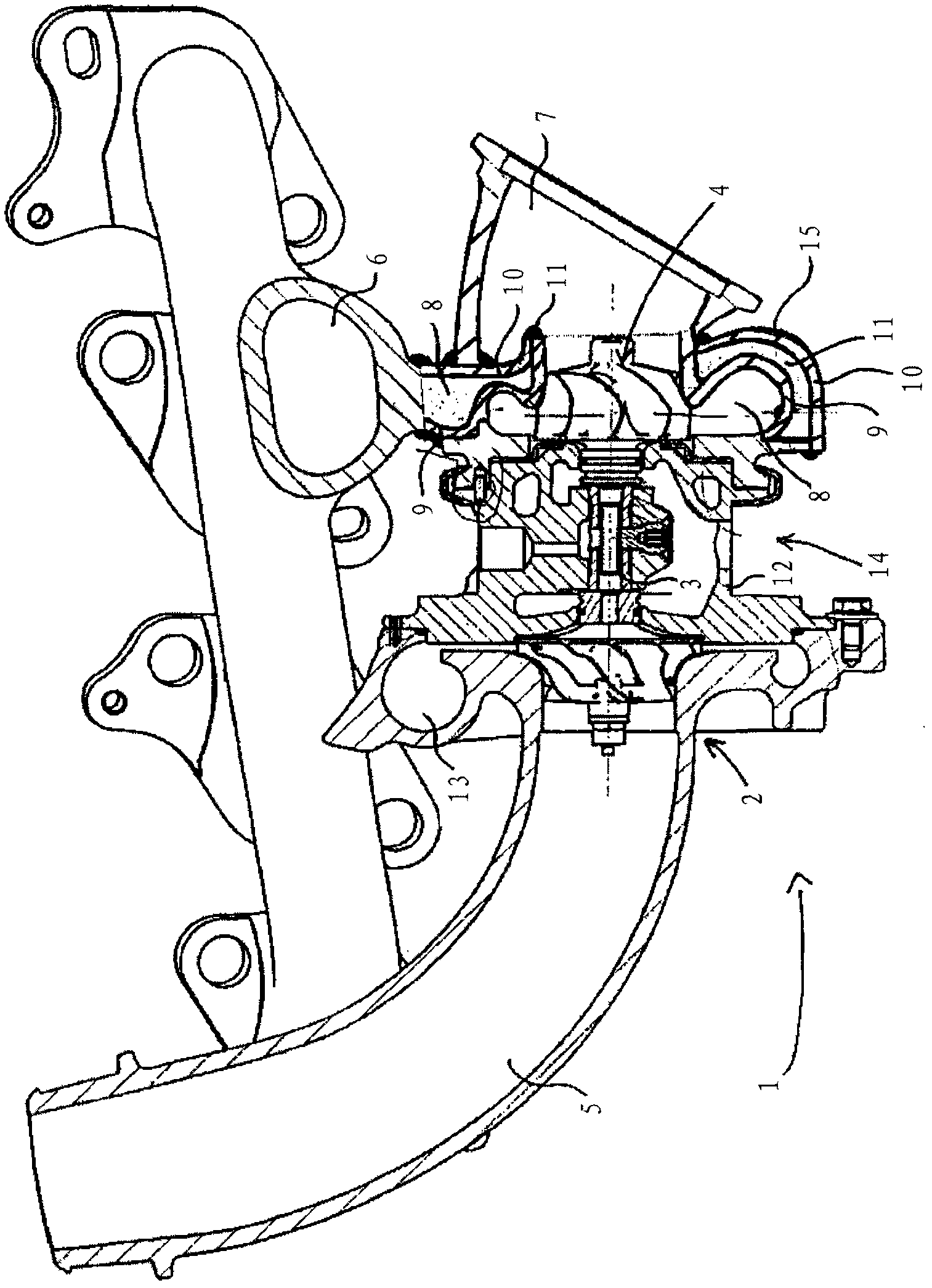

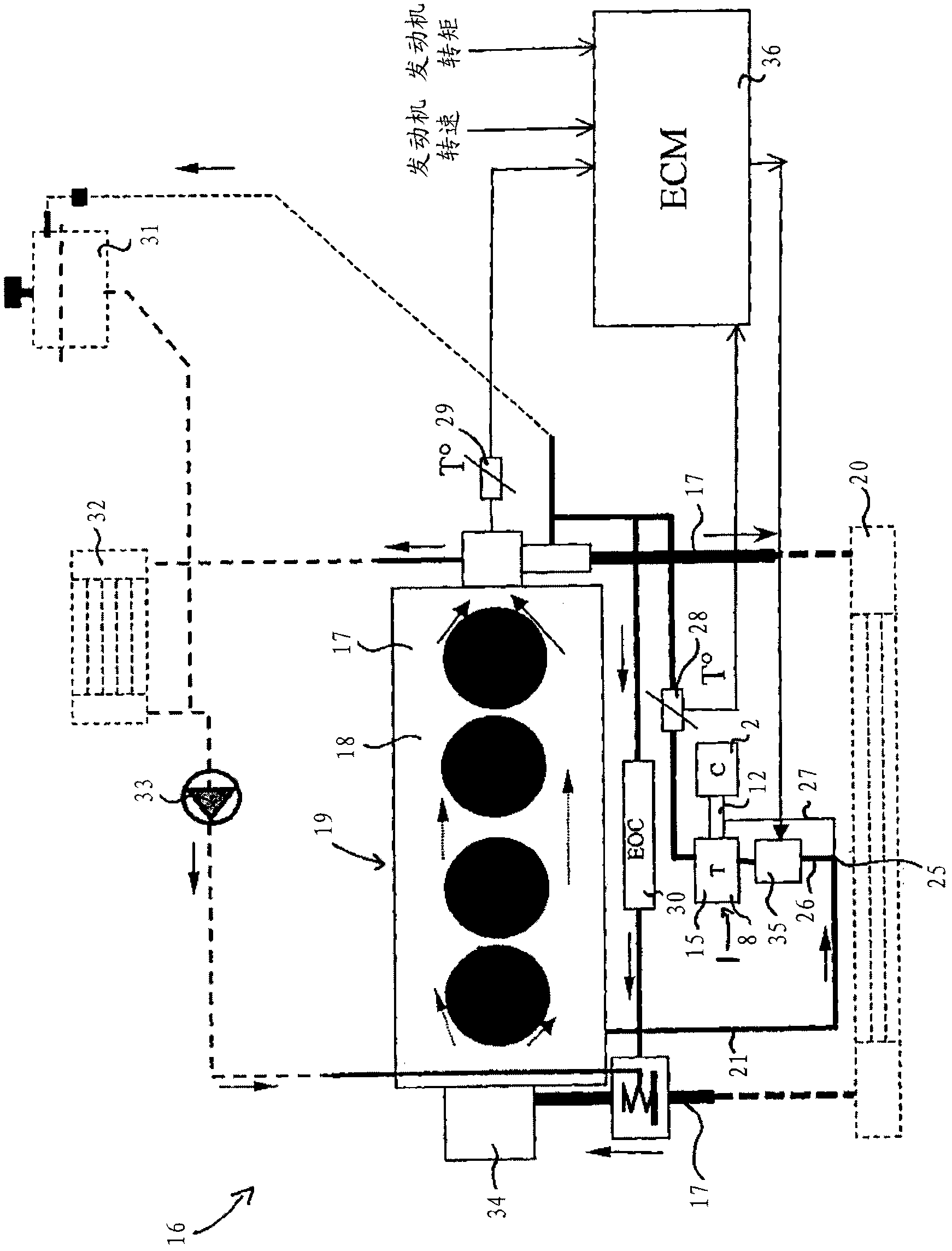

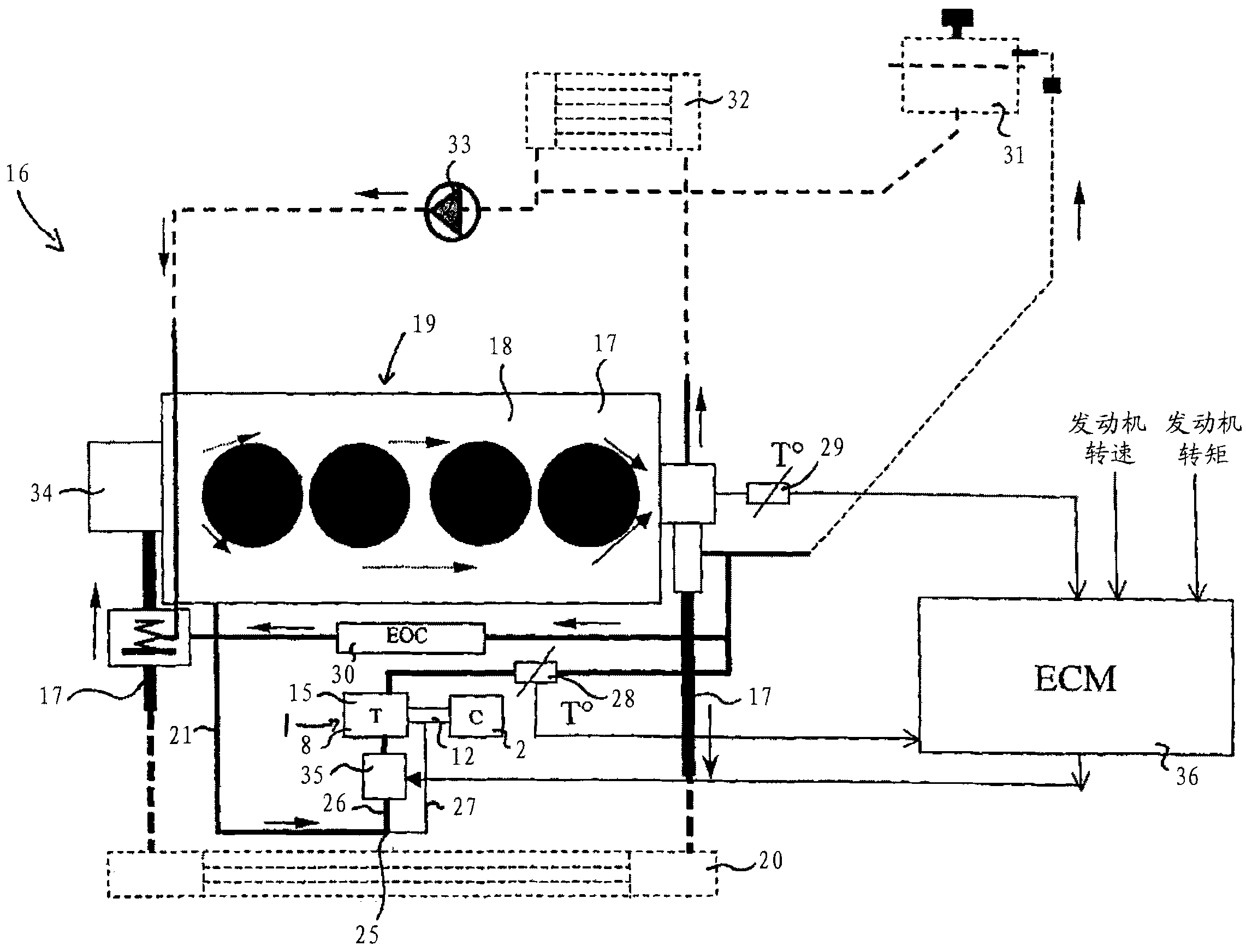

Fluid cooling system of a combustion engine charged by a turbocharger and method for cooling a turbine housing of a turbocharger

InactiveCN102135028AReduce heat loadLower fuel consumptionLiquid coolingCoolant flow controlCylinder blockEngineering

Owner:GM GLOBAL TECH OPERATIONS LLC

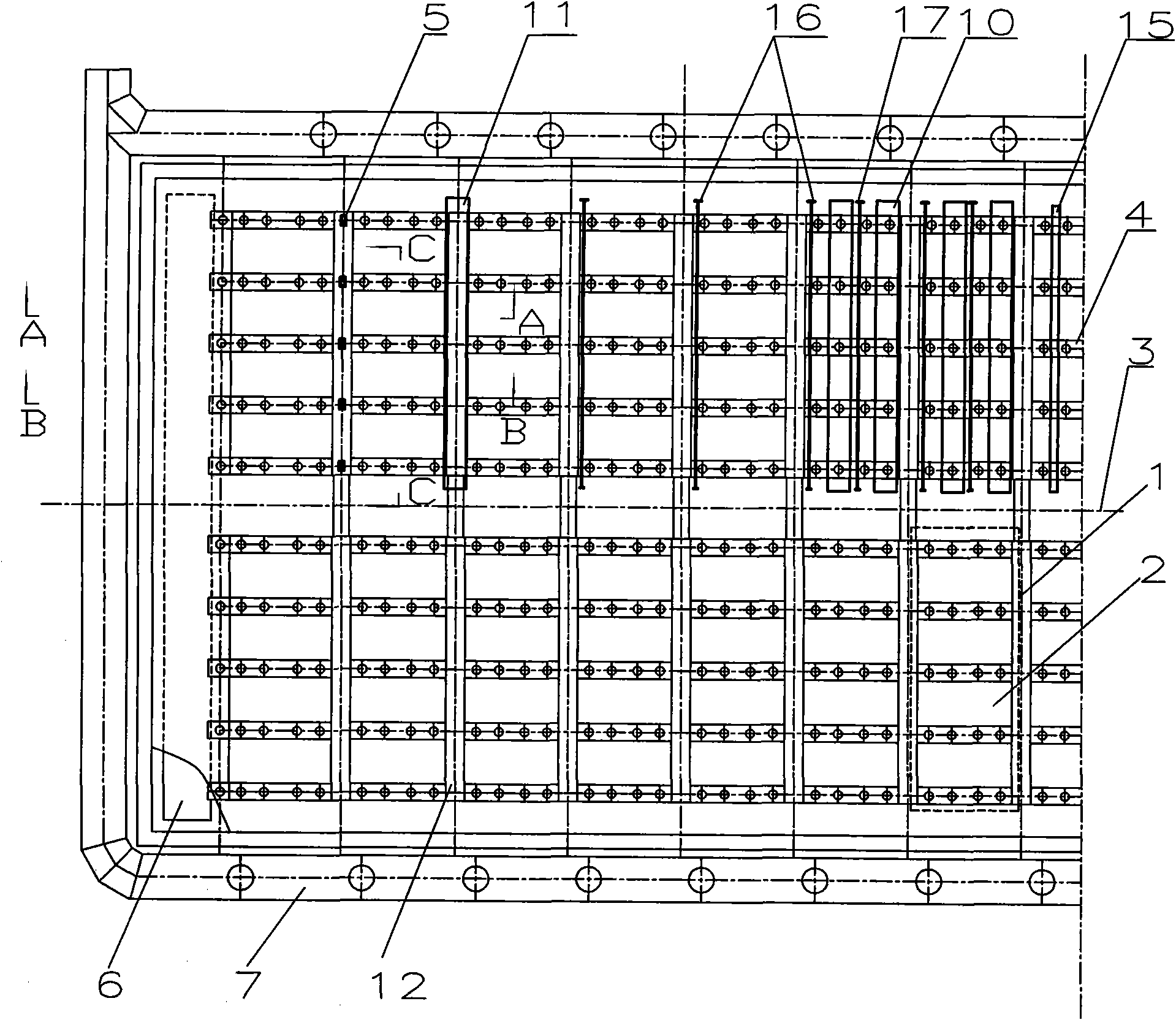

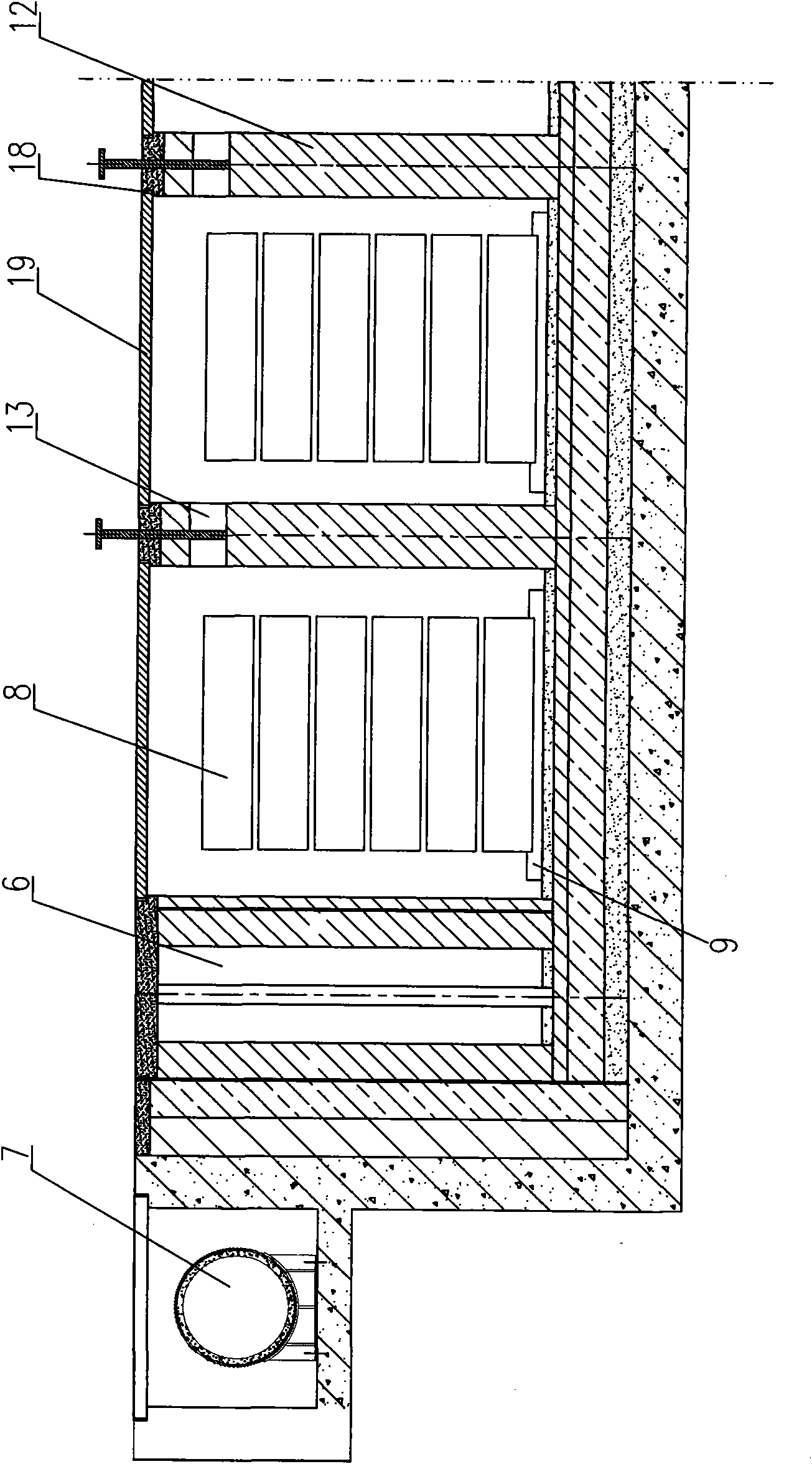

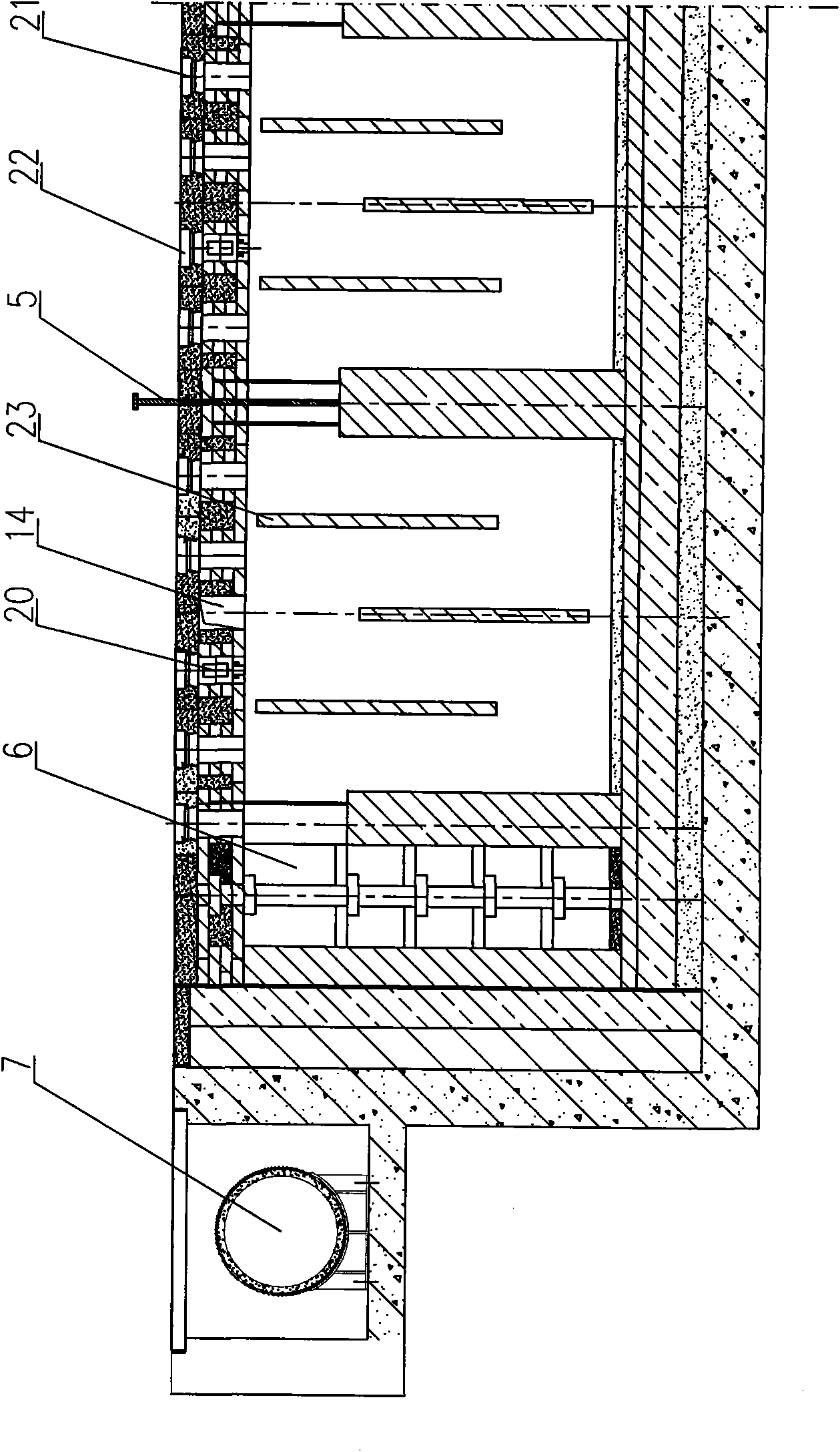

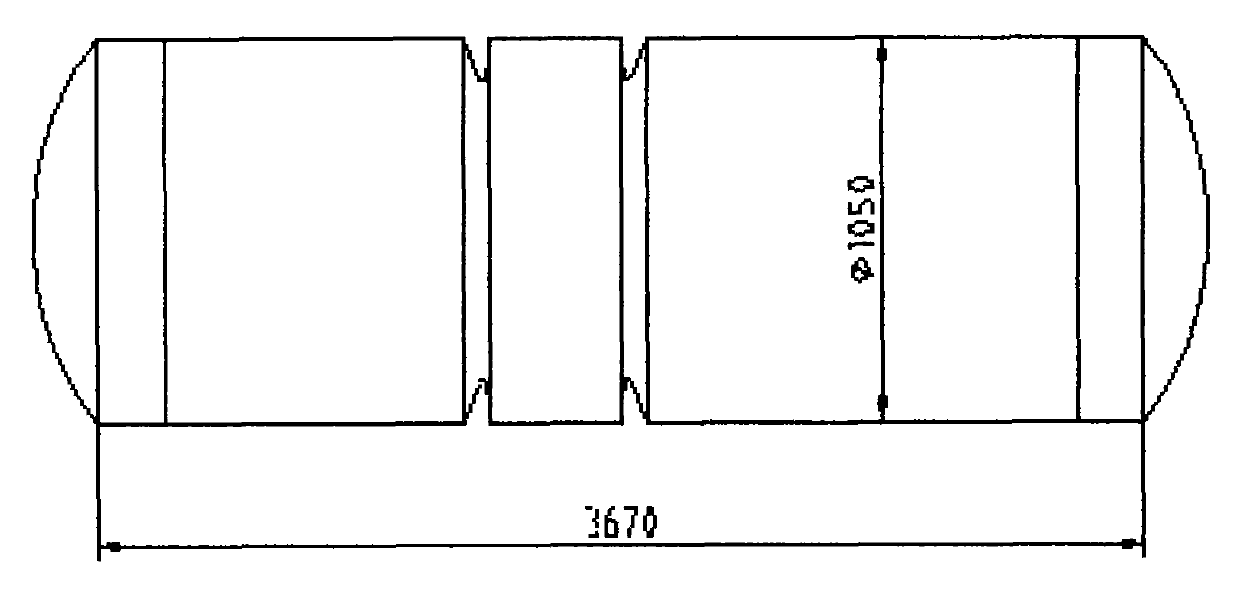

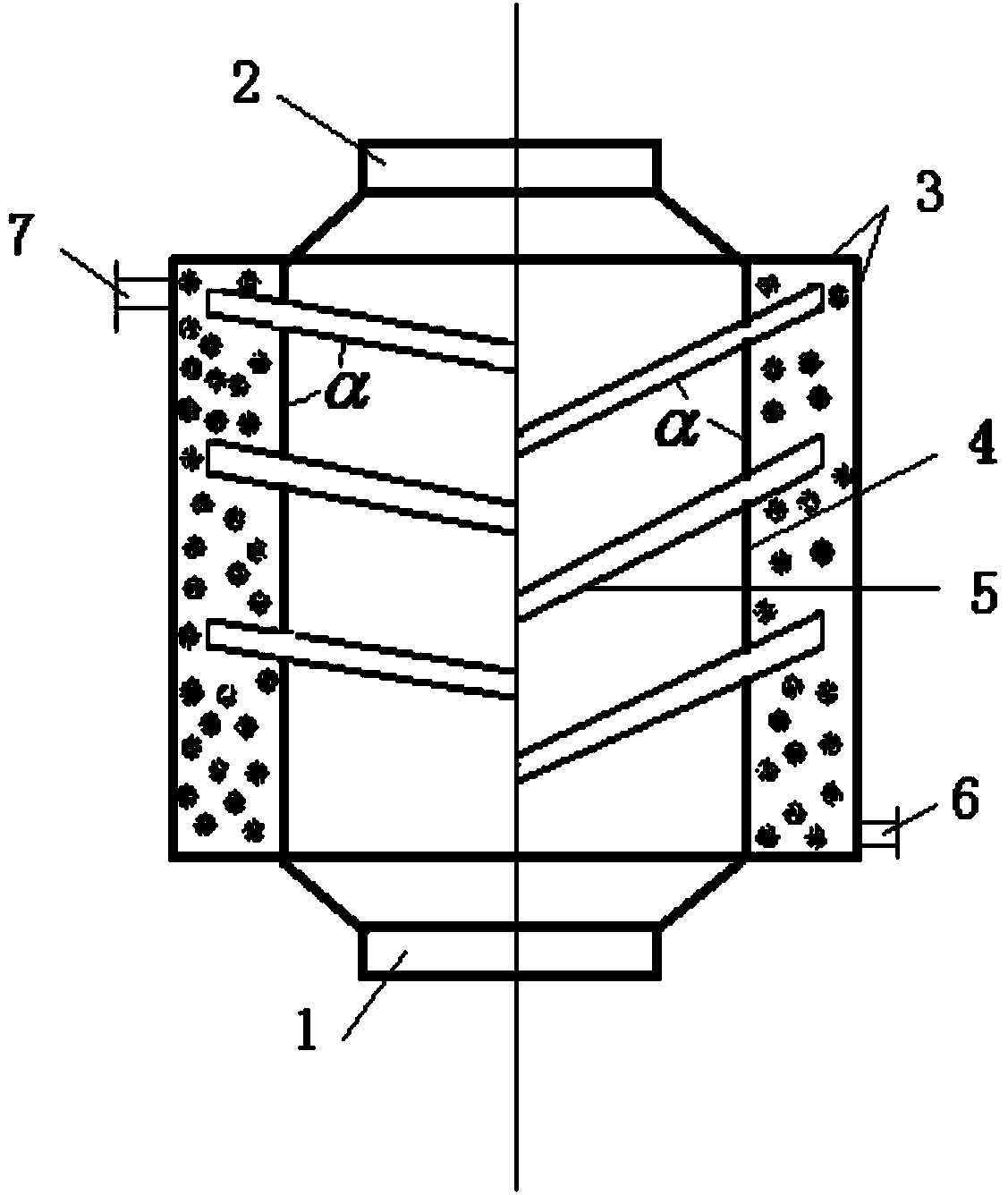

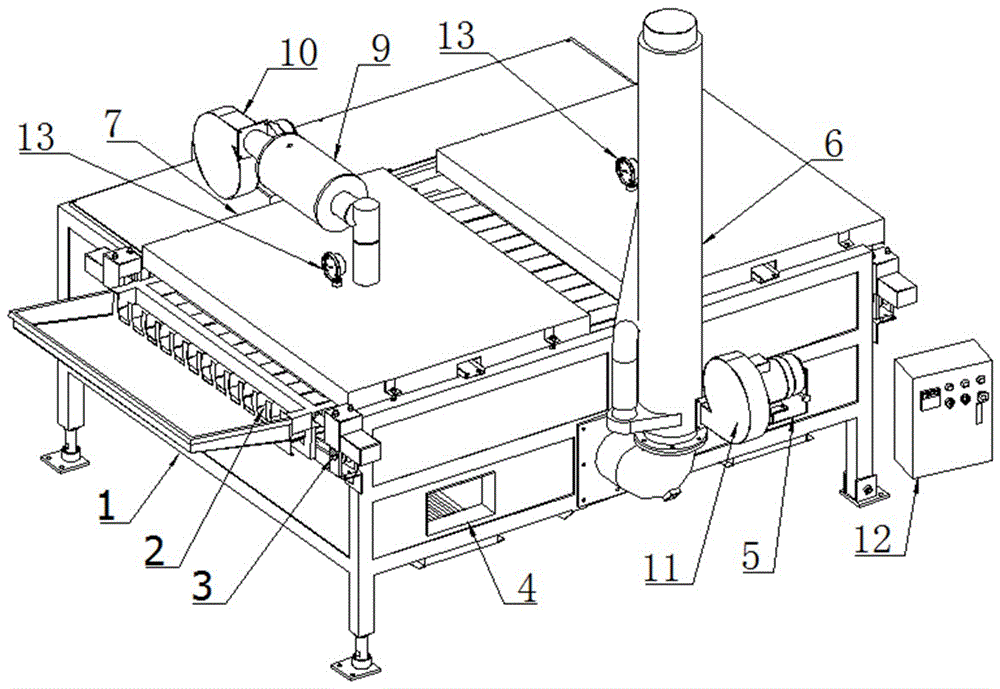

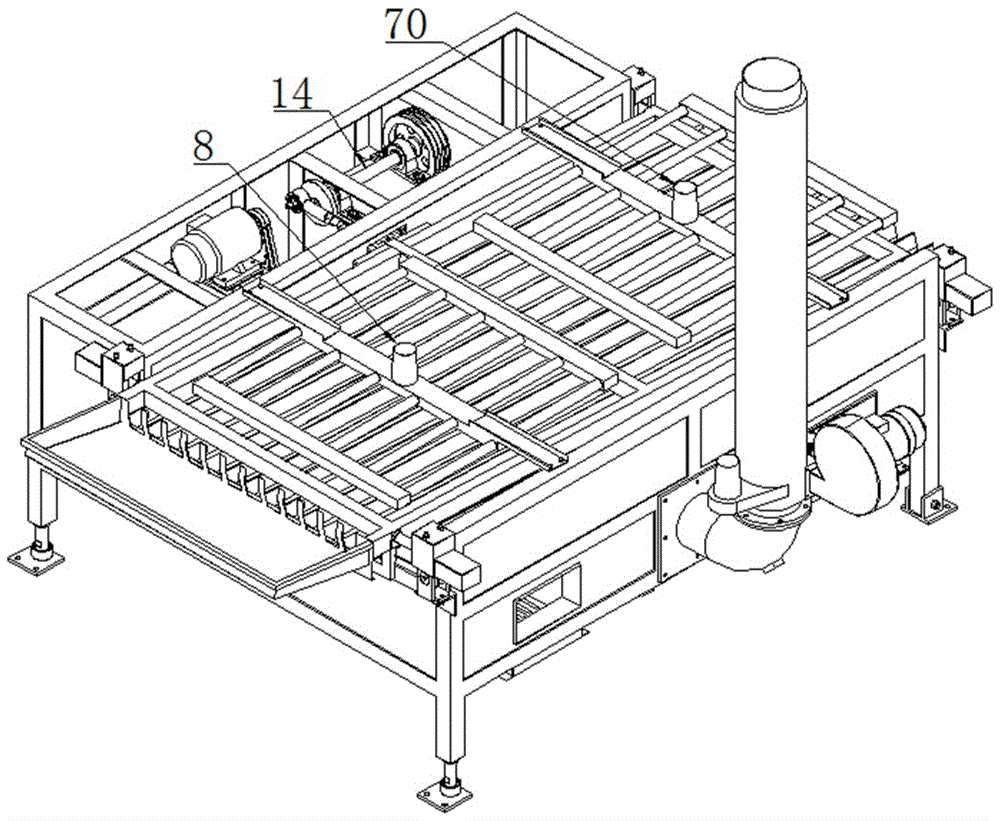

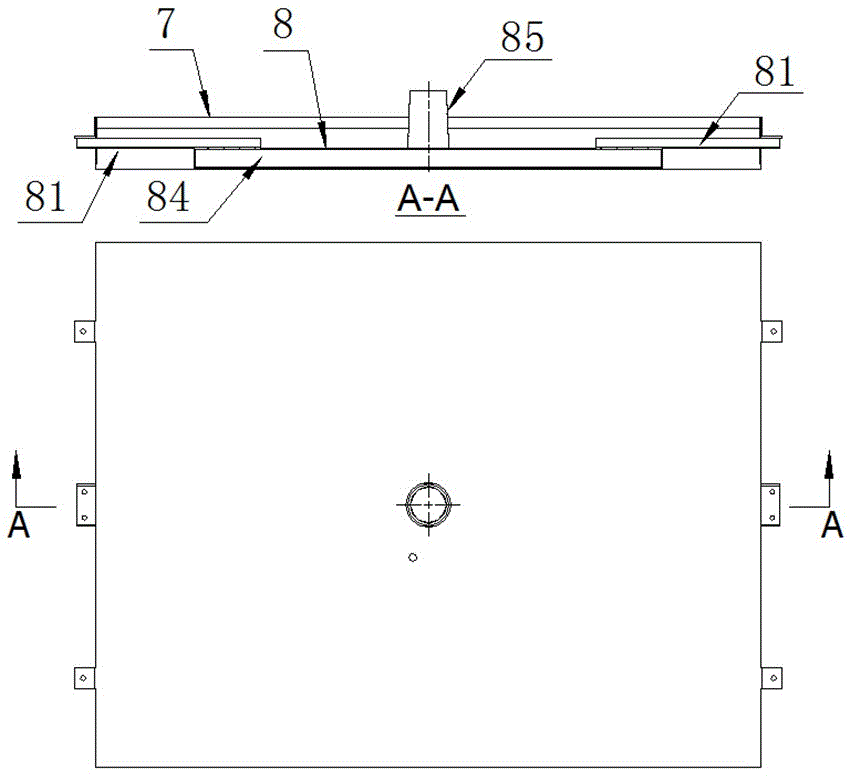

Secondary roasting furnace for carbon products and roasting method of secondary roasting furnace

InactiveCN102381696AEliminate environmental pollutionLower fuel consumptionChemical industryFlueAsphalt

The invention discloses a roasting furnace, and particularly relates to a secondary roasting furnace for carbon products. The secondary roasting furnace is structurally characterized in that two rows of furnace chambers are symmetrically arranged on two sides of a furnace central line in a furnace body, each row of furnace chambers consists of a plurality of single chamber bodies, each single furnace chamber body is divided into n-1 material tanks by n flame paths, each material tank comprises flame path walls on two sides, transverse walls at two ends and a material tank bottom, a light heat-insulation furnace cover for sealing is arranged on the top of each material tank, volatile matter balancing channels are arranged on upper portions of the flame path walls, volatile matter flowing channels are arranged on upper portions of the transverse walls, ends of the two rows of furnace chambers are connected by communicating flame paths, volatile matter flowing control gate discs are inserted into the volatile matter flowing channels from tops of the transverse walls, smoke vents are disposed on upper surfaces of the transverse walls and communicated with smoke discharge devices, the smoke discharge devices are communicated with a main smoke flue, and flame path gate discs are arranged among the flame path walls of the adjacent single furnace chamber bodies. Asphalt volatile matters generated during roasting are guided to the high-temperature flame paths to be completed burned, and environmental pollution due to the fact that asphalt smoke is discharged into the atmosphere is thoroughly eliminated.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

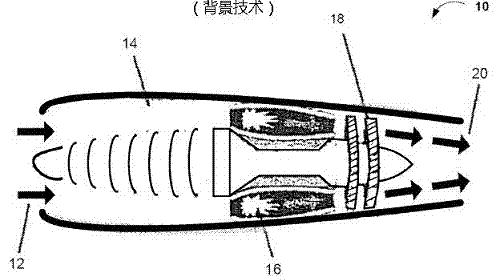

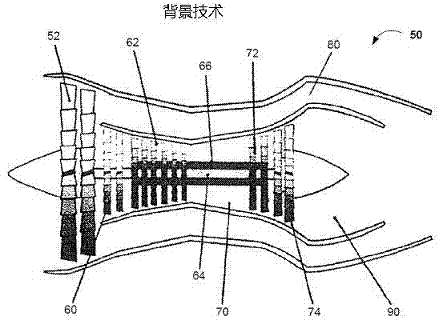

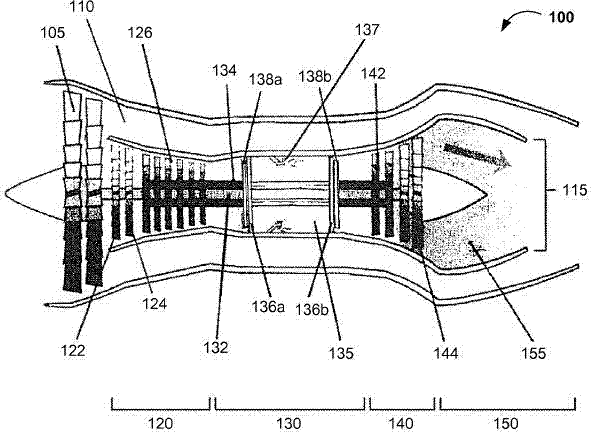

Internal detonation engine, hybrid engines including the same, and methods of making and using the same

InactiveCN104718354AImprove efficiencyLower fuel consumptionReciprocating combination enginesInternal combustion piston enginesAutomotive engineeringStator

Hybrid internal detonation-gas turbine engines incorporating detonation or pulse engine technology (such as an internal detonation engine), and methods of manufacturing and using the same are disclosed. The internal detonation engine includes a detonation chamber having a fuel igniter therein, a stator at one end of the detonation chamber having at least a first opening to receive fuel, a rotor adjacent to the stator, and an energy transfer mechanism configured to convert energy from igniting or detonating the fuel to mechanical energy. The detonation chamber and fuel igniter are configured to ignite or detonate a fuel in the detonation chamber. Either the stator or the detonation chamber has a second opening to exhaust detonation gas(es). The rotor has one or more third openings therein configured to overlap with at least the first opening as the rotor rotates.

Owner:布兰特·W-T·李

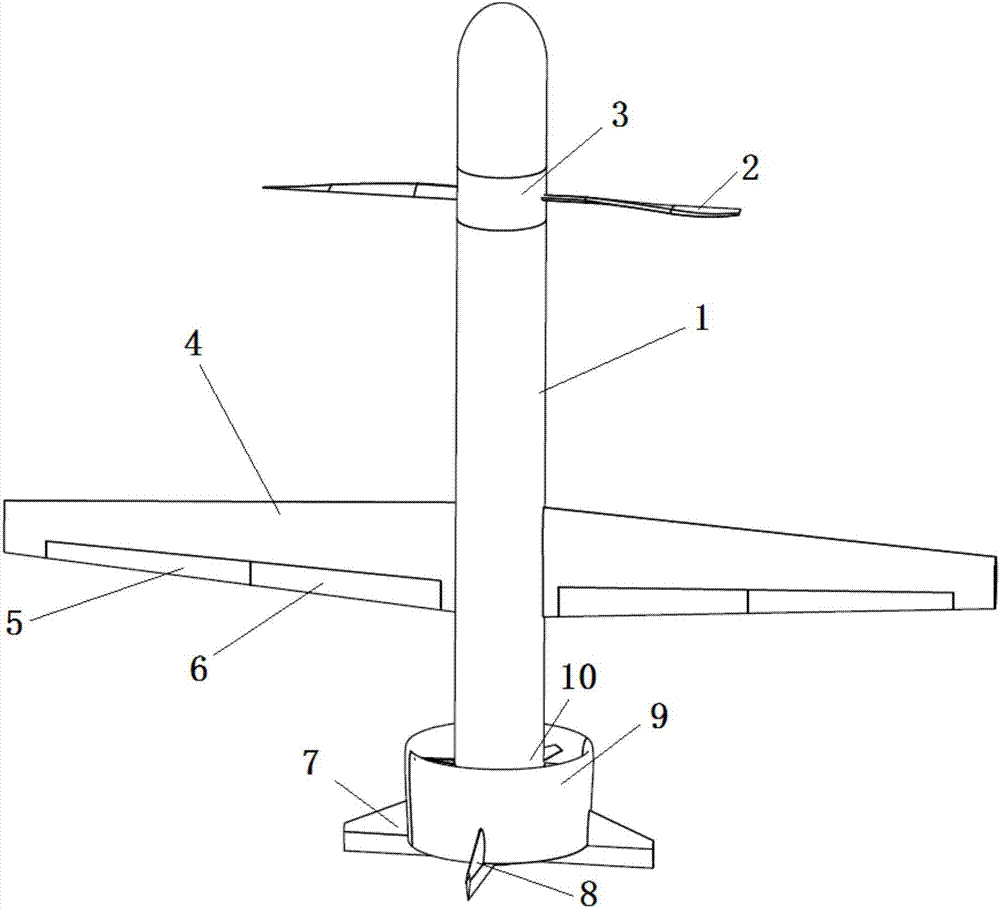

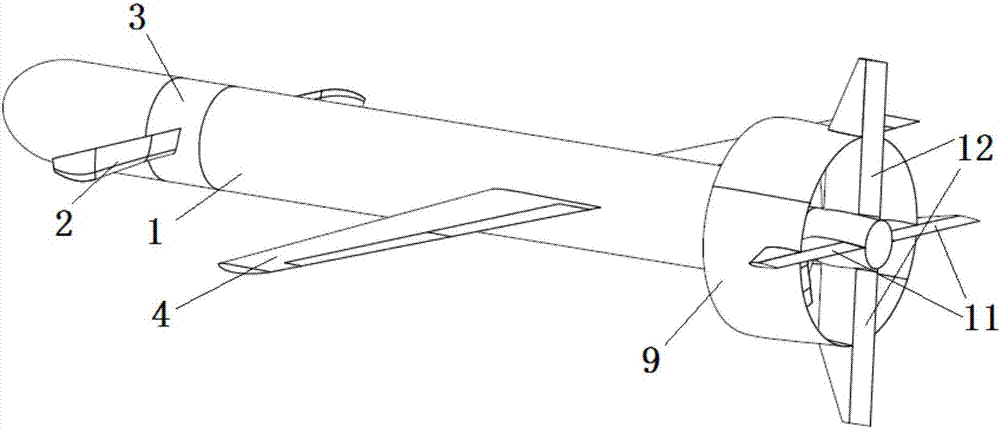

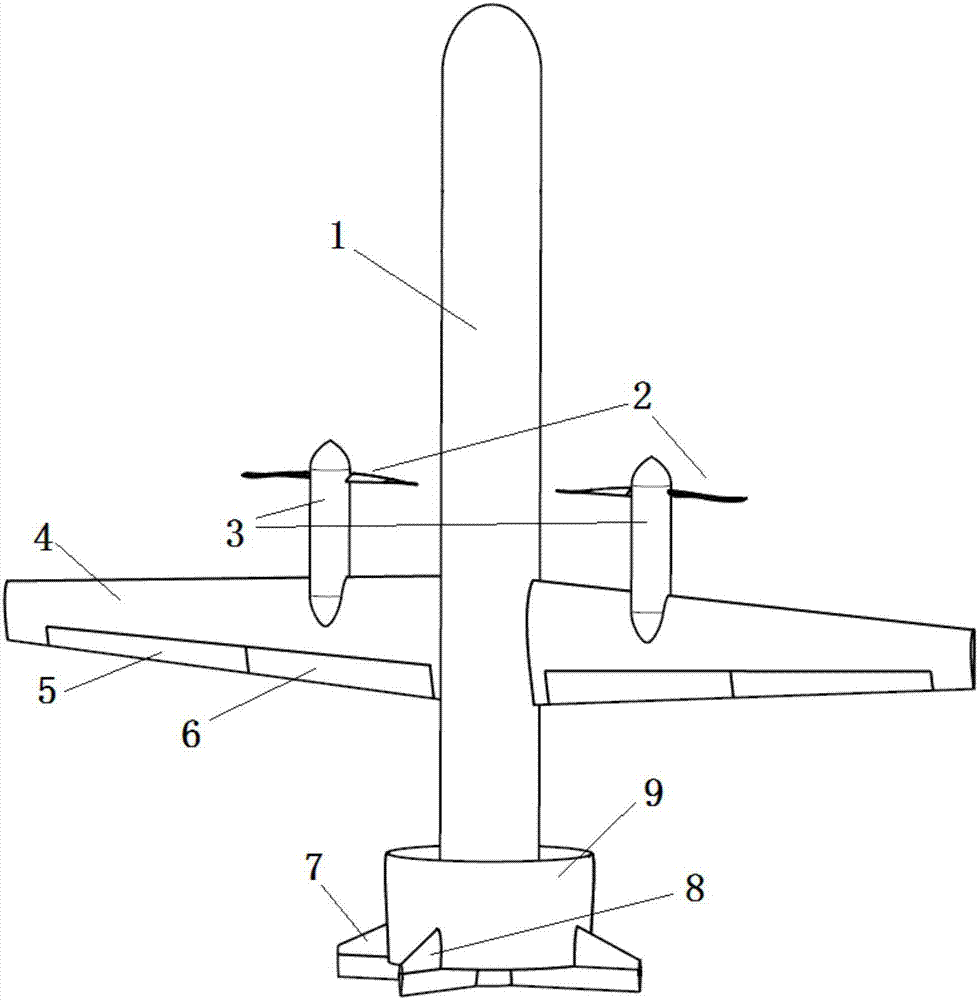

Hybrid power tail sitting type vertical takeoff and landing long-endurance unmanned aerial vehicle and flight control method thereof

ActiveCN107089328ALower fuel consumptionReduce powertrain weightVertical landing/take-off aircraftsElectric machineryTailplane

The invention provides a hybrid power tail sitting type vertical takeoff and landing long-endurance unmanned aerial vehicle and a flight control method thereof. The unmanned aerial vehicle comprises a fuselage, wings, a main driving motor, propellers, a piston power ducted propeller and tail wings mounted on a duct. According to the invention, two sets of power systems, namely a motor and a piston engine, are adopted; in a vertical takeoff and landing stage which is short in time and requires large power, the motor serves as driving power, the advantage of high power-weight ratio of the motor can be fully exerted, and thus the weight of the power systems is reduced; in a cruising flight stage, the tail piston engine and the ducted propeller system driven by the tail piston engine drive the unmanned aerial vehicle to fly forward, and the piston power and the ducted propeller system can be selected and designed according to the optimal cruising state without considering the vertical takeoff and landing state, so that the fuel consumption rate of the cruising state can be effectively reduced; in combination with high-aspect-ratio wings, long-time flight of the unmanned aerial vehicle can be ensured; and meanwhile, because the weight of the power systems is reduced, the empty weight ratio of the unmanned aerial vehicle can be reduced, and the loading capacity of the unmanned aerial vehicle can be effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

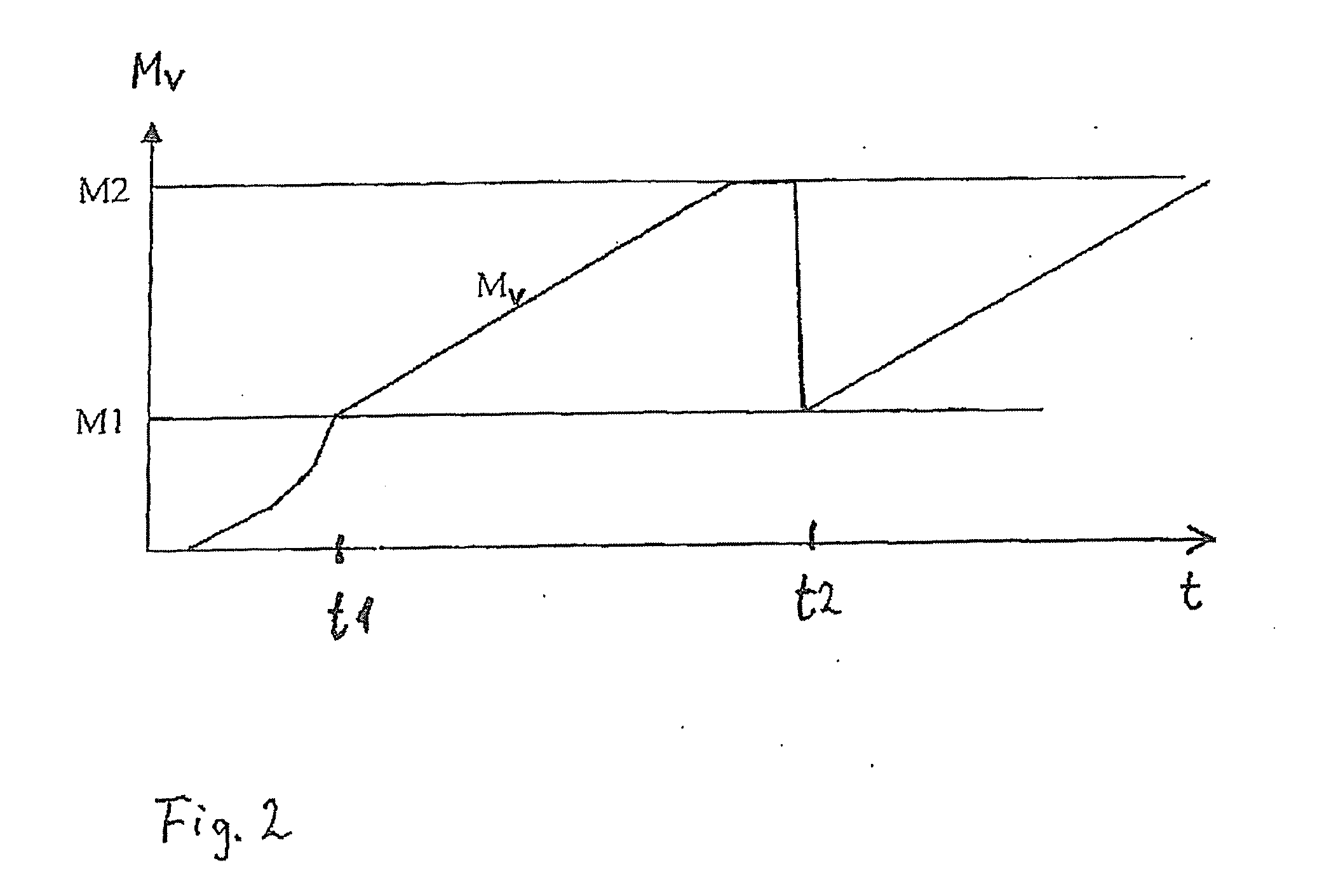

Method for operating a hybrid drive

InactiveUS20100012052A1Lower fuel consumptionAbsorbable drag torque is alsoSpeed controllerPropulsion using engine-driven generatorsDrag torqueHybrid drive

A method for operating a hybrid drive, developed as a parallel hybrid, and having a drive train, especially for a motor vehicle, having at least one internal combustion engine and at least one electrical machine device or a hydraulic machine device, a separating clutch being situated between the internal combustion engine and the electrical or hydraulic machine device and, as seen in the drive direction, the electrical or the hydraulic machine device is postconnected to the internal combustion engine, the separating clutch being separated in the overrun condition if a specifiable drag torque is able to be absorbed by the electrical or the hydraulic machine device.

Owner:ROBERT BOSCH GMBH

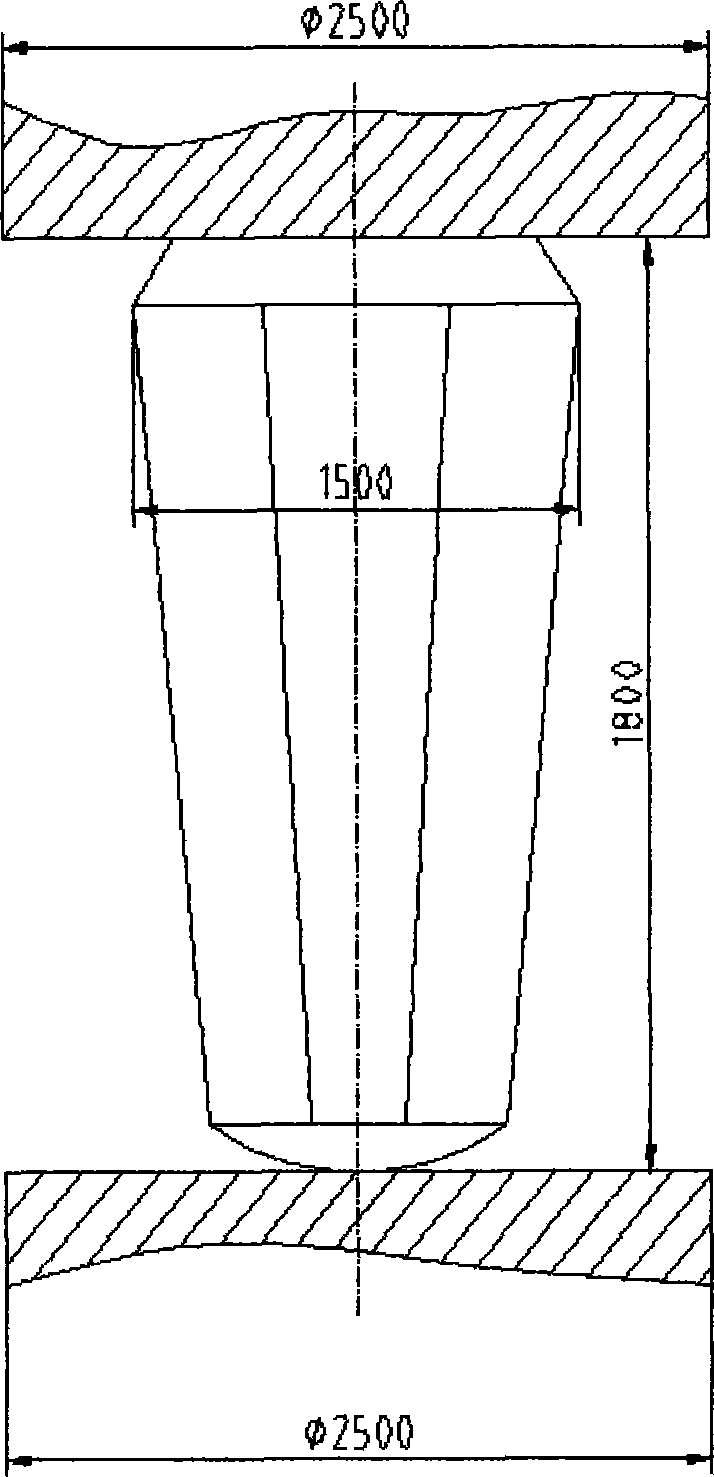

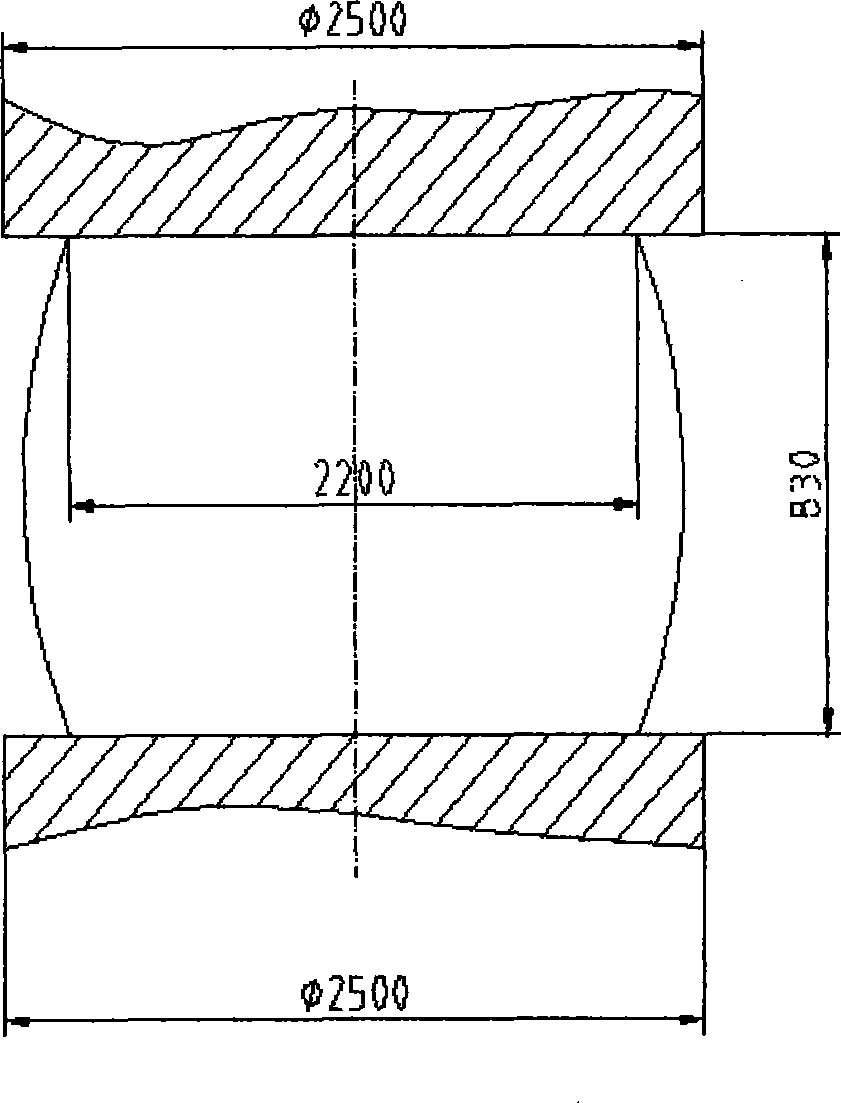

All-fiber-texture large-size one-piece flange fan main shaft forging method

ActiveCN104175063ALower fuel consumptionIncrease productivityMetal-working apparatusFurnace typesFiberForging

The invention discloses an all-fiber-texture large-size one-piece flange fan main shaft forging method which comprises the following steps of material selection, heating, primary firing forging, secondary firing forging, heat treatment after forging, rough turning, ultrasonic flaw detection, hardening and tempering, semifinishing, lossless flaw detection, body sampling, mechanical property testing and stable heat treatment. Compared with the conventional twice-forging and welded flange main shaft production method, the all-fiber-texture large-size one-piece flange fan main shaft forging method has the advantages that the welding working procedures are reduced, the time is saved, the raw material consumption is reduced, and the production cost is lowered; a forged flange main shaft is of an all-fiber-texture structure, so that the natural defects that the welded flange is low in balance property and easy to deform and the root is easy to break are totally overcome; a requirement of a large-size fan on the main shaft design is met.

Owner:陕西华威科技股份有限公司

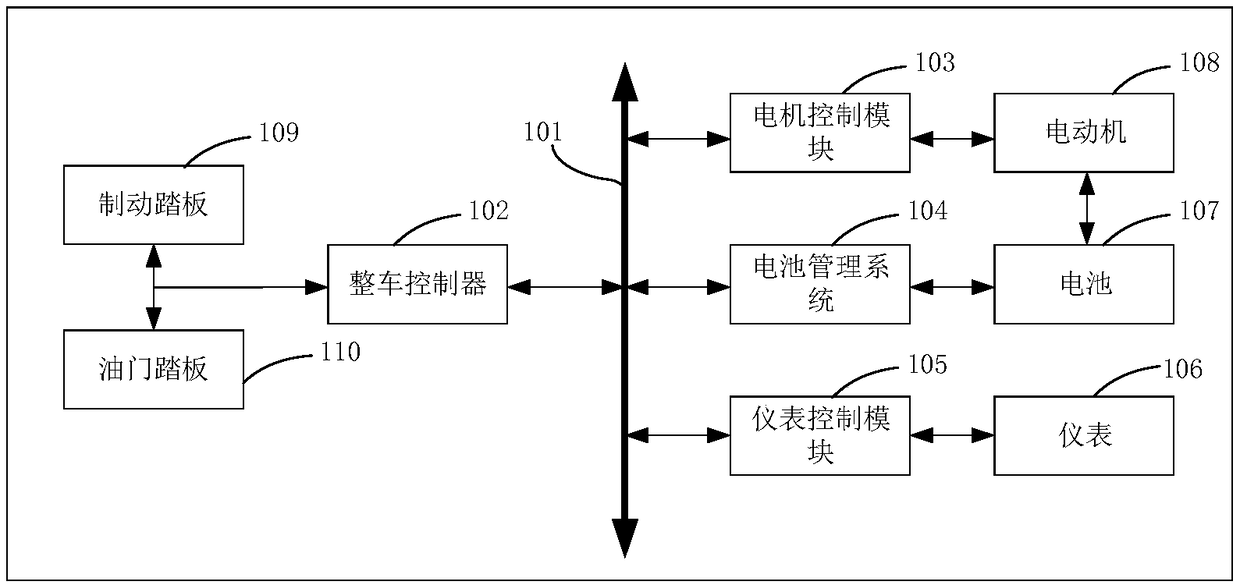

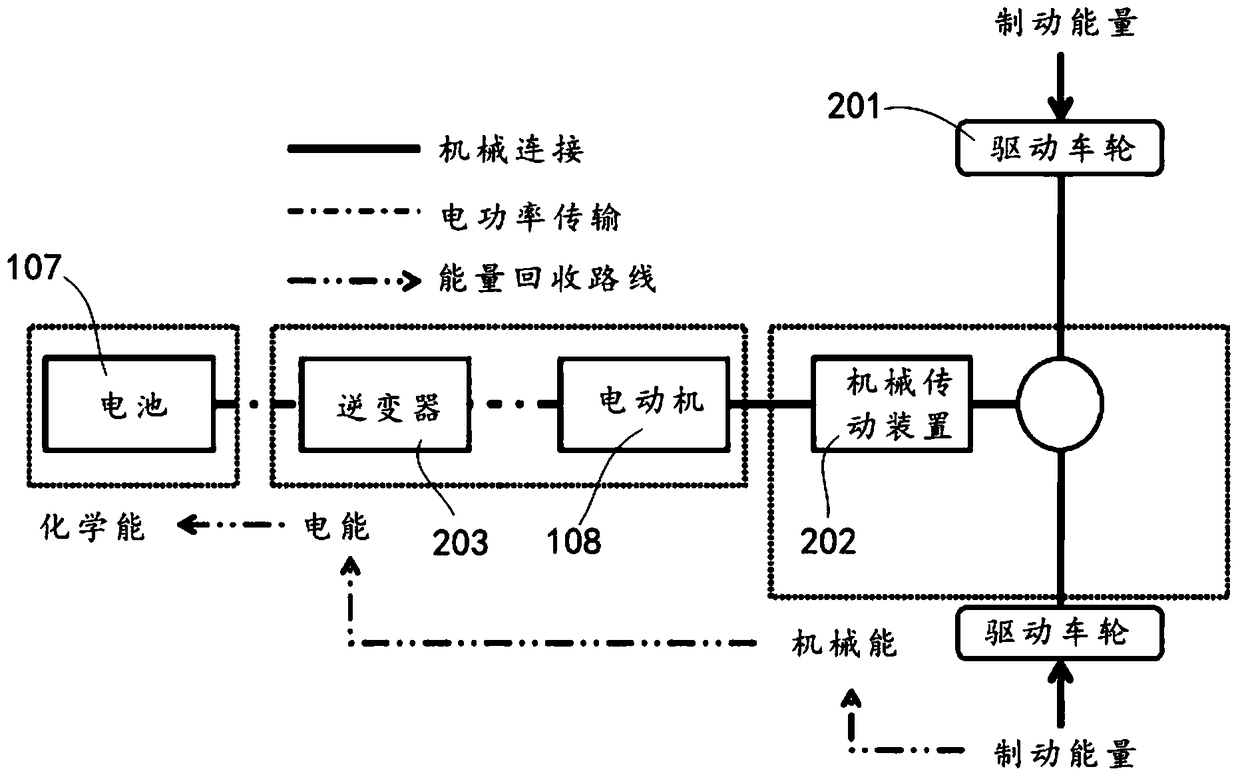

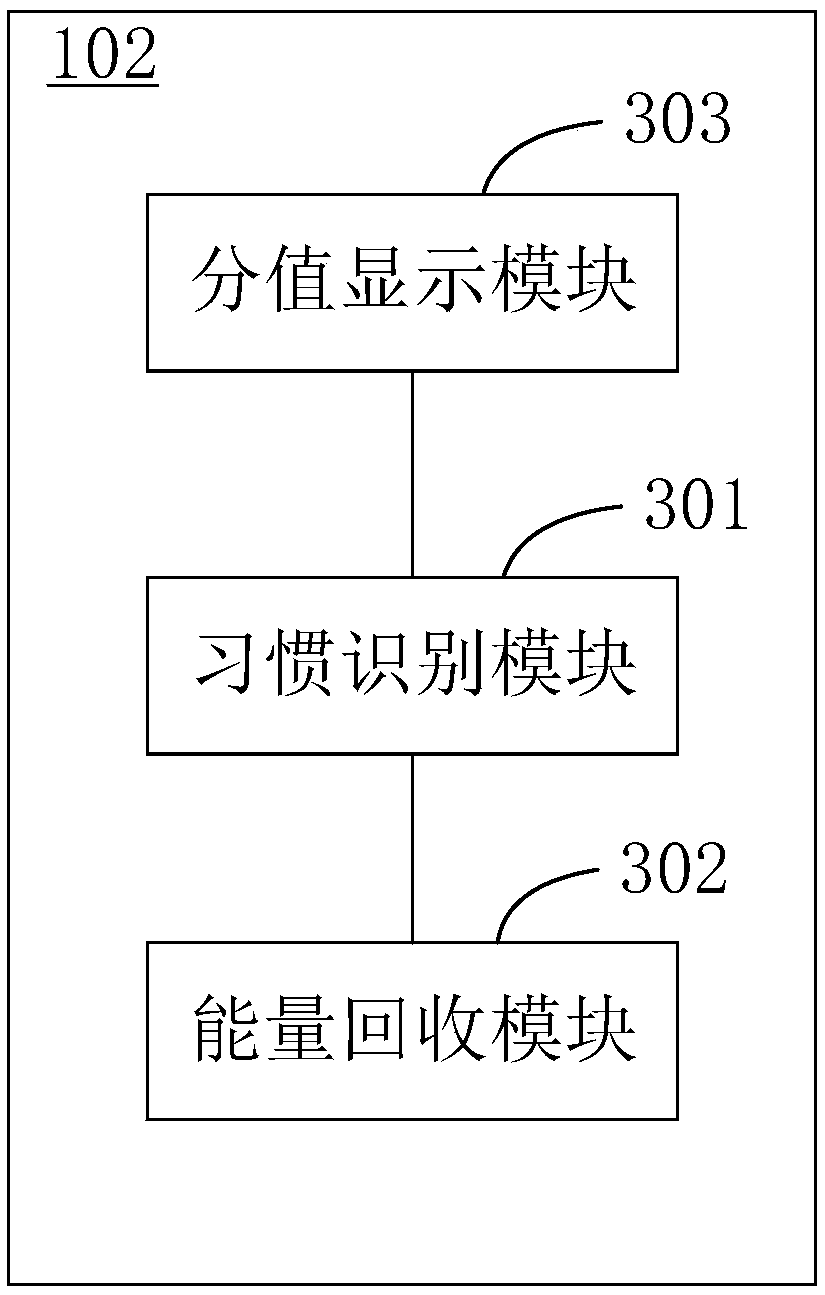

Driving habit recognition method, system and equipment for electric automobile and storage medium

ActiveCN108909719AImprove driving habitsLower fuel consumptionExternal condition input parametersDriver input parametersCurrent timeRoad condition

The invention discloses a driving habit recognition method, system and equipment for an electric automobile and a storage medium. The driving habit recognition method for the electric automobile comprises the steps that S100, a history driving habit score value of each unit time section before a unit time section of the current time is obtained by using a preset time length as a unit time section;and iteration is carried out on the history driving habit score values according to an iteration strategy to obtain a current driving habit score value of the current time, wherein the history driving habit score value is obtained according to a road condition type of a running road and a sliding coefficient in the unit time section; and S200, the electric automobile comprises an instrument; andthe current driving habit score value is displayed on the instrument.

Owner:AIWAYS AUTOMOBILE CO LTD

Pleonaste brick

ActiveCN102701759AGuaranteed comprehensive performanceLower fuel consumptionReducing atmosphereRefractory

The invention discloses a pleonaste brick which is manufactured in the manner that high-purity magnesite or fused magnesite and synthetic fused hercynite are taken as main raw materials, reduced iron powder, and fine fused magnesite powder, fine high-purity magnesite powder and an additive (namely lignin liquor) are added, pressed into a green brick after being uniformly mixed, dried, and fired at a lower temperature under the weakly reducing atmosphere. The pleonaste brick has the advantages that through the manner that air holes are sealed through low temperature sintering and fine powder addition, divalent iron protoxide in a brick body in prevented from being converted into ferric iron at a high temperature, iron protoxide capable of prompting the coating of a rotary cement kiln to be stable in the brick body exits in a divalent state to the limit, and the brick body has better coating hanging performance and toughness. The pleonaste brick prepared by the invention breaks through the traditional method that alkaline refractory products have to depend on the high temperature firing in achieving the chrome free treatment of the brick body, ensures the comprehensive performance of the chrome free brick fired in rotary cement kiln, and reduces the fuel consumption of the refractory material in the production process.

Owner:郑州真金耐火材料有限责任公司

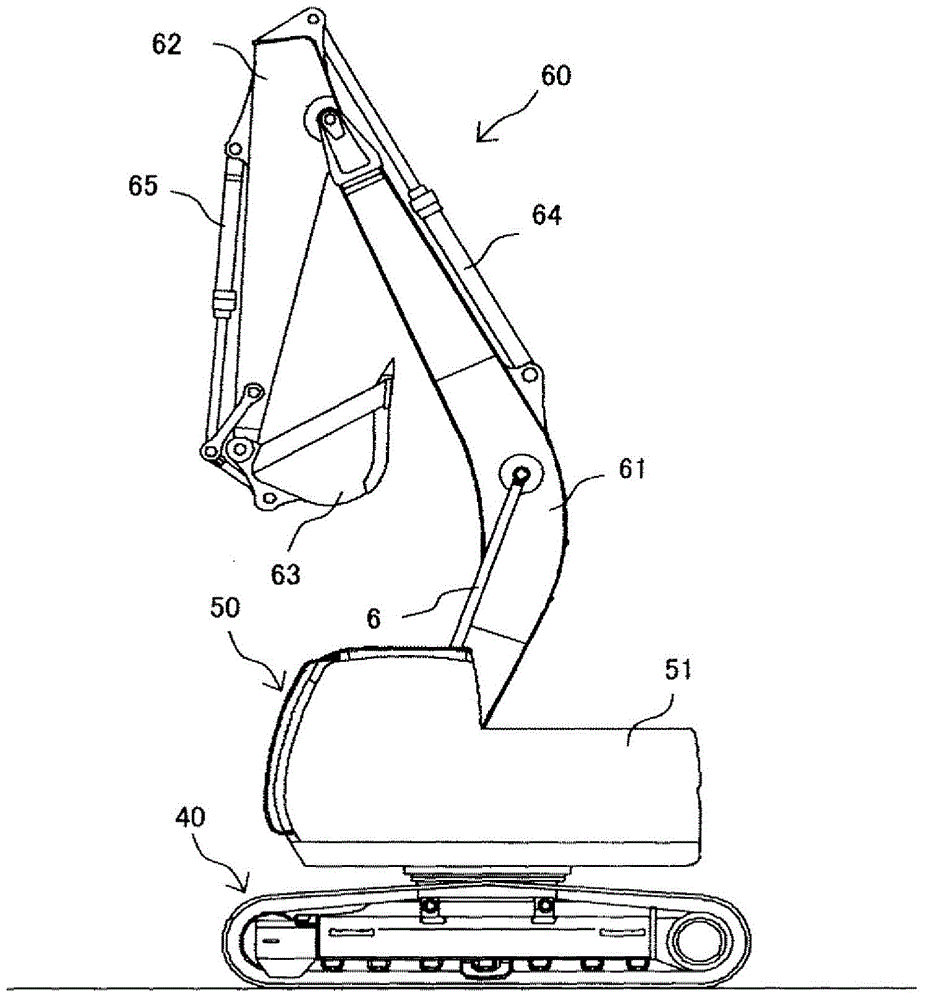

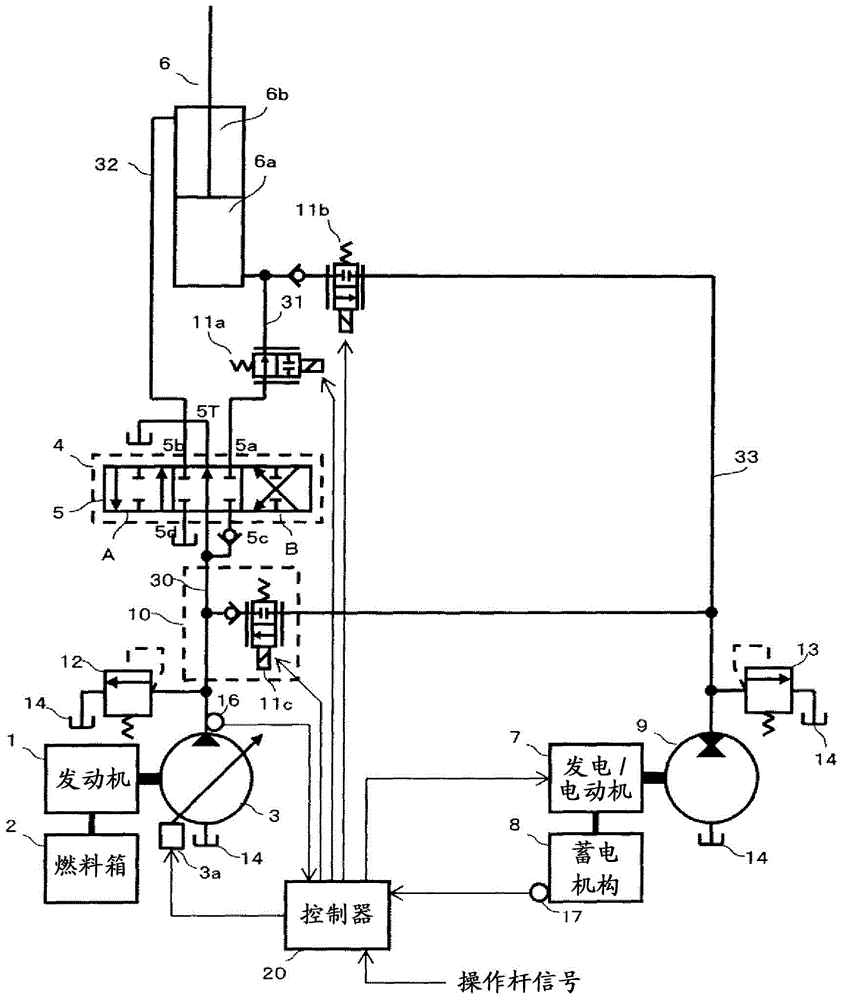

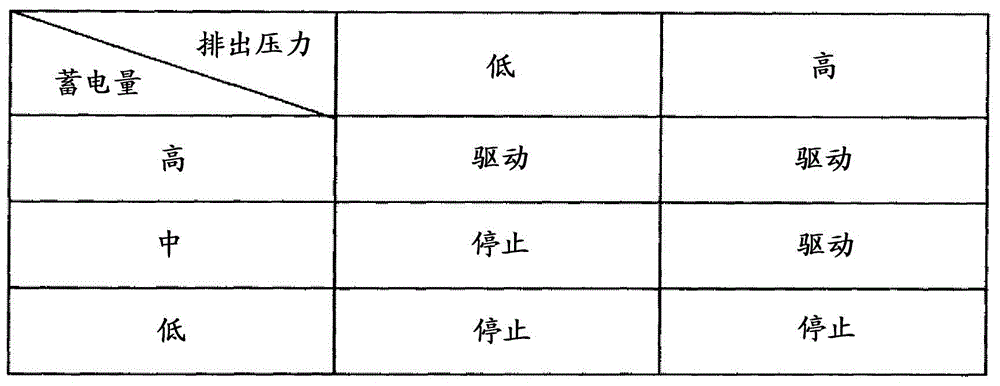

Construction machinery

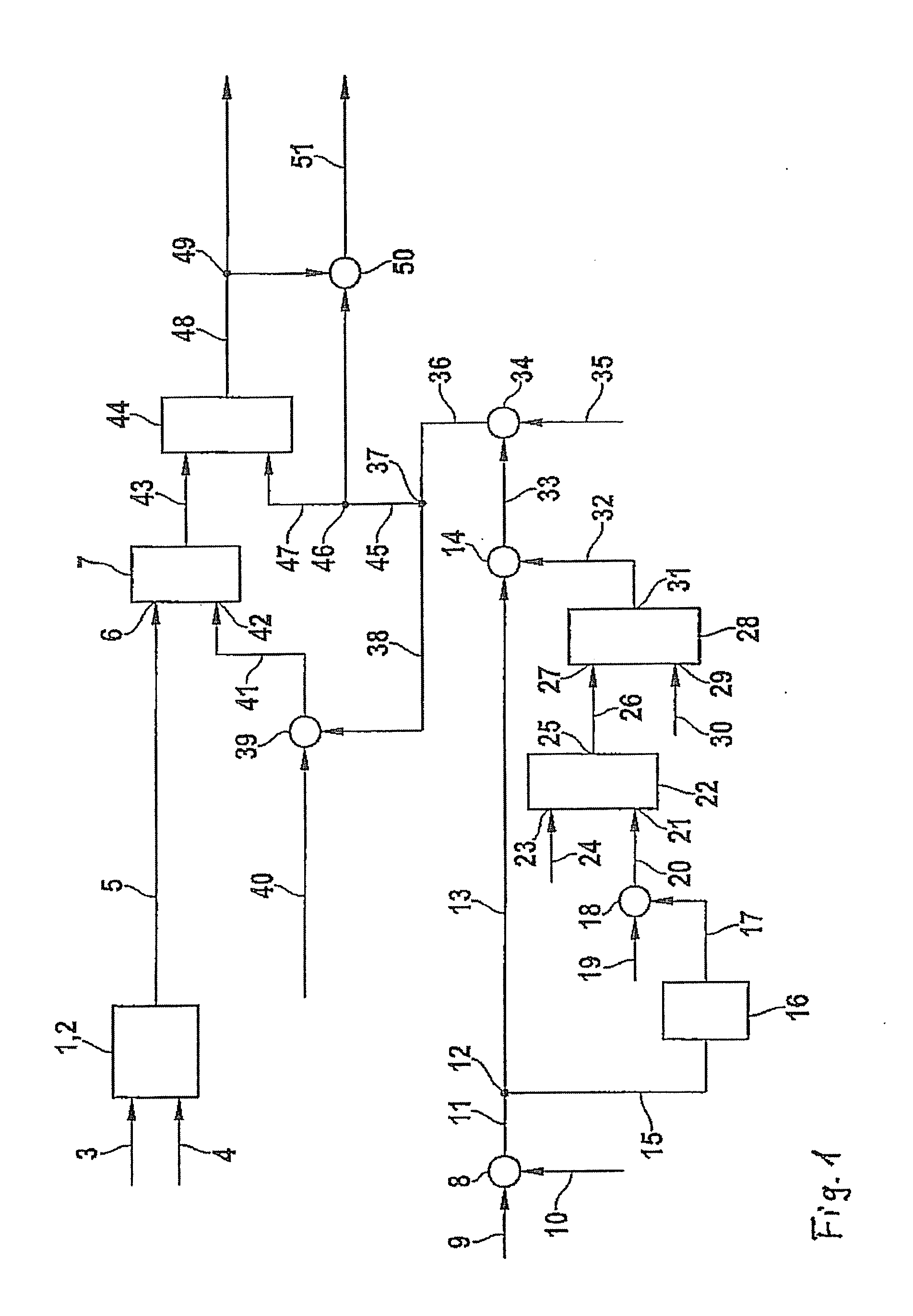

ActiveCN104105888ALower fuel consumptionExtended run timeServomotorsSoil-shifting machines/dredgersHydraulic pumpEnergy storage

Construction machinery is provided which can significantly reduce fuel consumption through the efficient use of recovered energy. The construction machinery includes: a first hydraulic pump (3) and a second hydraulic pump (9) for discharging hydraulic fluid to operate an actuator (6); a second power source (7) for driving the second hydraulic pump (9); an energy storage means (8) for storing energy to drive the second power source (7); and a hydraulic fluid supply circuit (10) with a hydraulic fluid switching unit (11c) for receiving hydraulic fluid discharged from the first hydraulic pump (3) and hydraulic fluid discharged from the second hydraulic pump (9), and selecting one or both sources of hydraulic fluid to be supplied to the actuator (6). The construction machinery also includes a control device (20) for outputting switching instructions to the hydraulic fluid switching unit (11c) and for outputting drive instructions to the second power source (7) when the drive efficiency of the second hydraulic pump (9) and / or the amount of energy stored in the energy storage means (8) exceeds a predetermined set value.

Owner:NIHON KENKI CO LTD

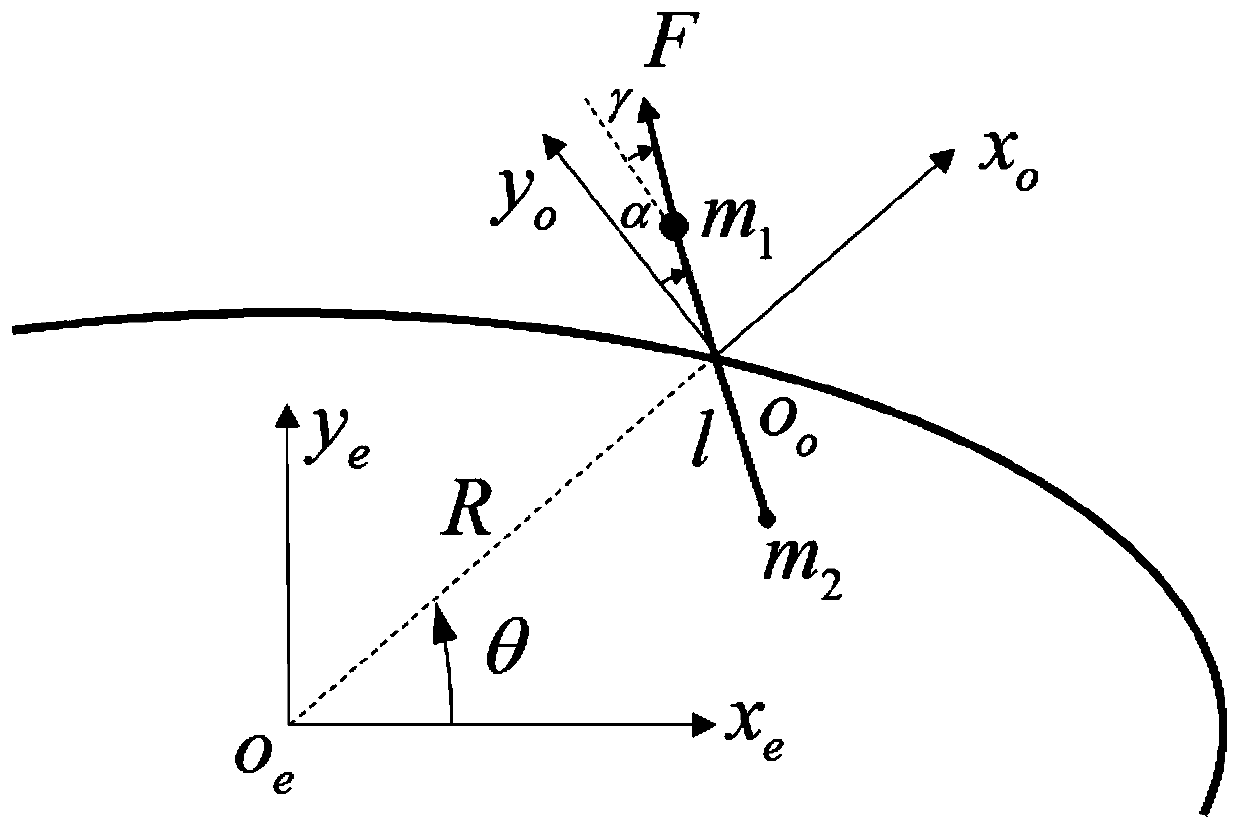

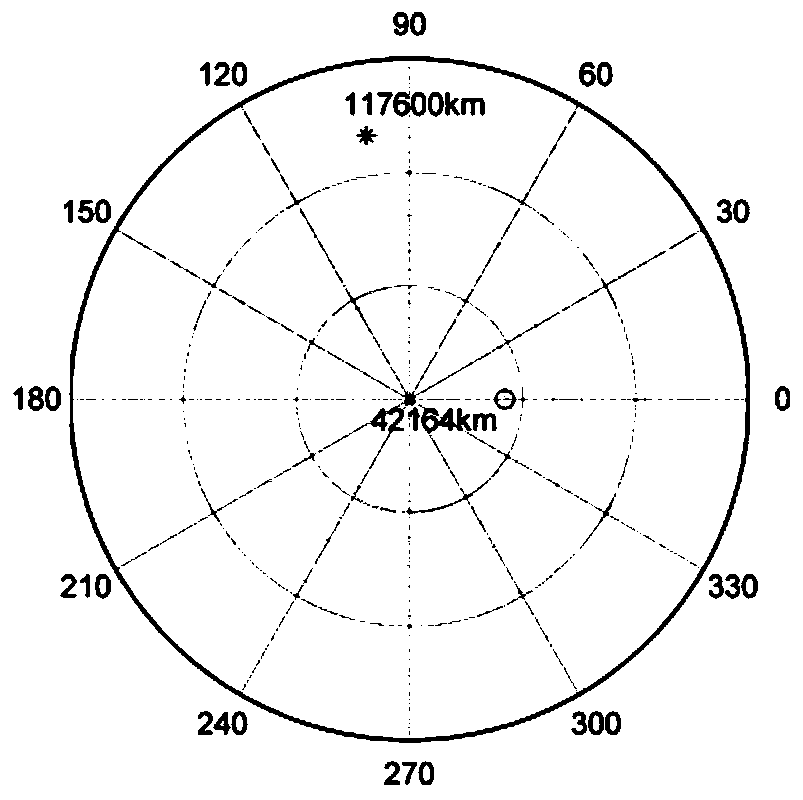

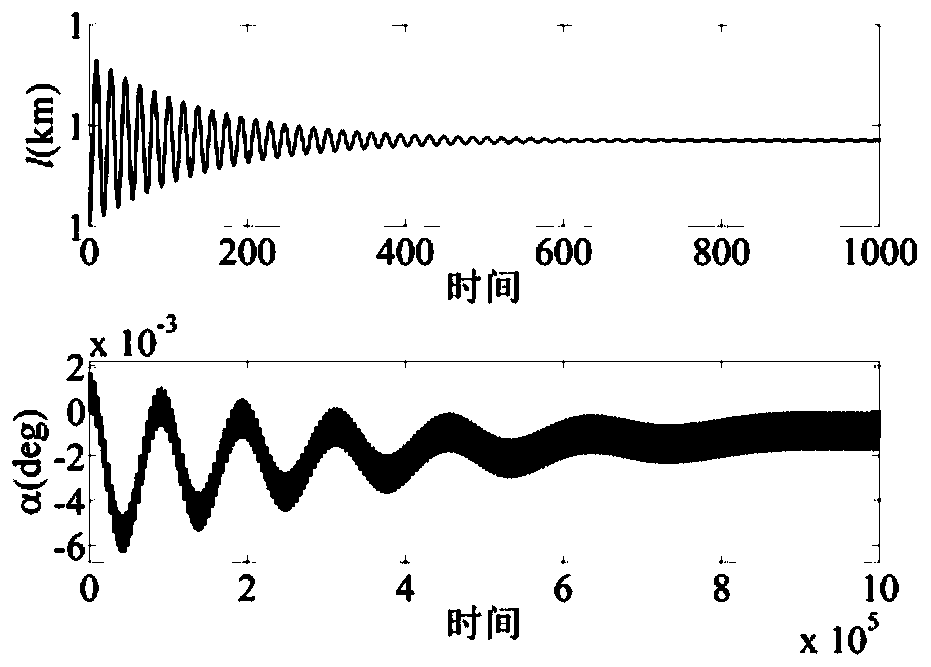

Optimal deorbit method for tethered towing of space debris

The invention discloses an optical deorbit method for tethered towing of space debris and belongs to the field of spacecraft attitude and orbit dynamics and control. The implementation method includes: establishing a coupling dynamics model of the in-plane orbit of a tethered towing system through a Lagrange method; solving the optimal fuel problem of transfer orbit by adopting an optimization method for orbit transfer and ensuring a wide range of optimal orbit transfer of the tethered towing while system stabilizing the altitude of tethered towing system; at the end of towing, controlling thedebris by swinging and releasing to enable the debris to gain the maximum initial velocity and fly to the farther orbit, and completing the debris removal task while reducing fuel consumption duringthe debris removal process. With the method, wide range optimal orbit transfer of the tethered towing system can be guaranteed, and meanwhile, the attitude of the tethered towing system can be kept stable to remove the space debris stably; besides, the final swing control makes the debris fly further into the orbit, and fuel consumption during the debris removal process is reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

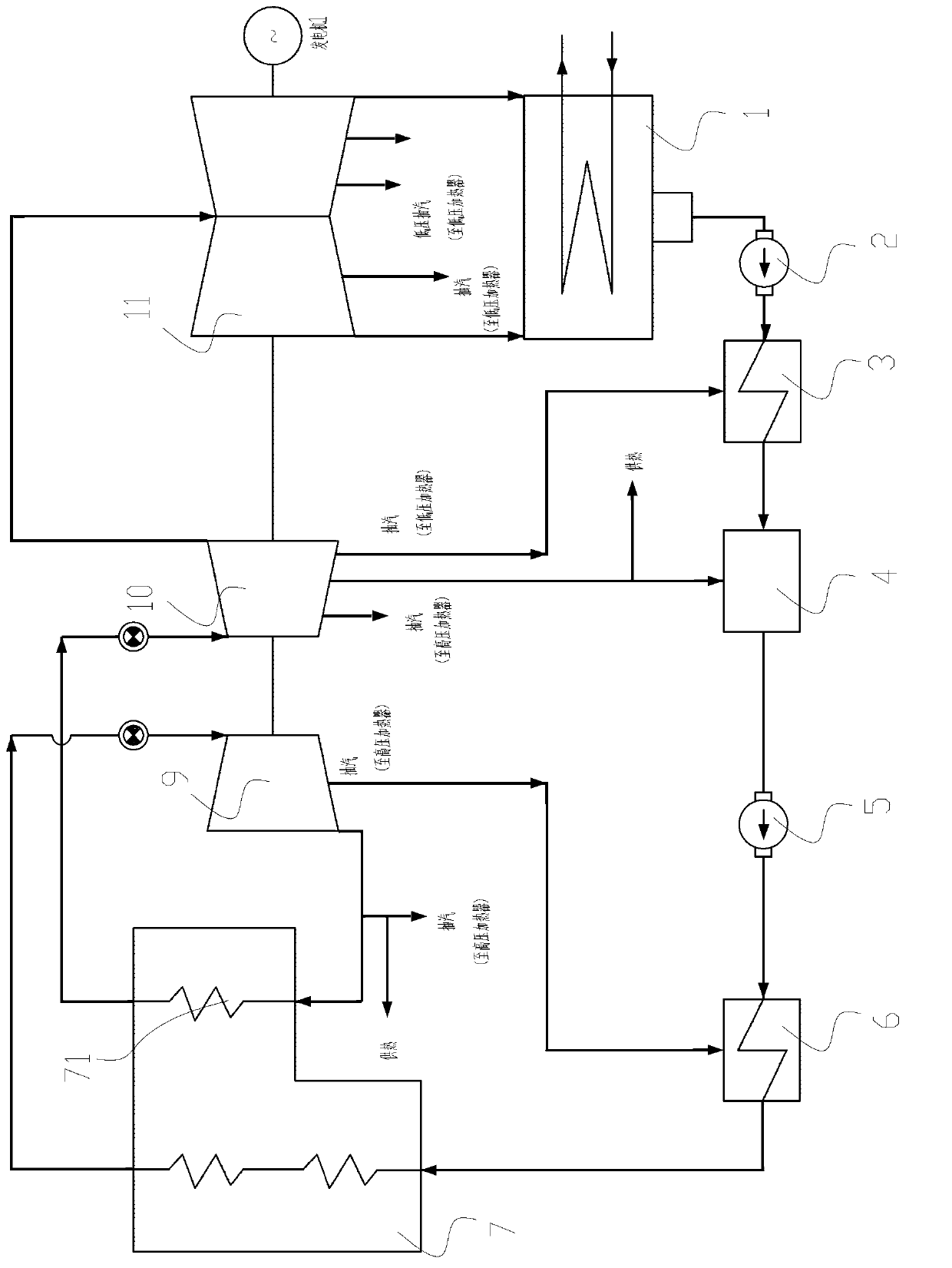

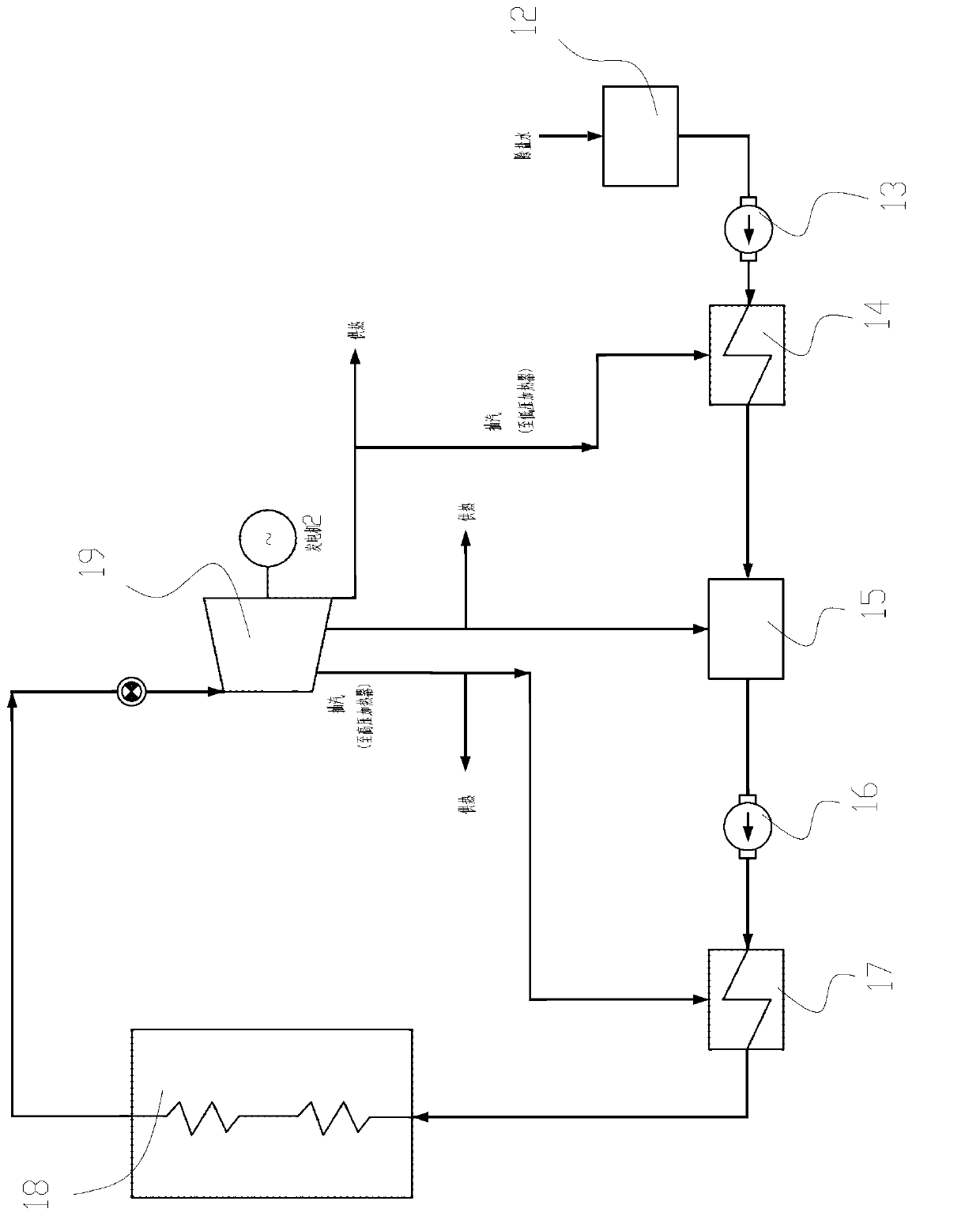

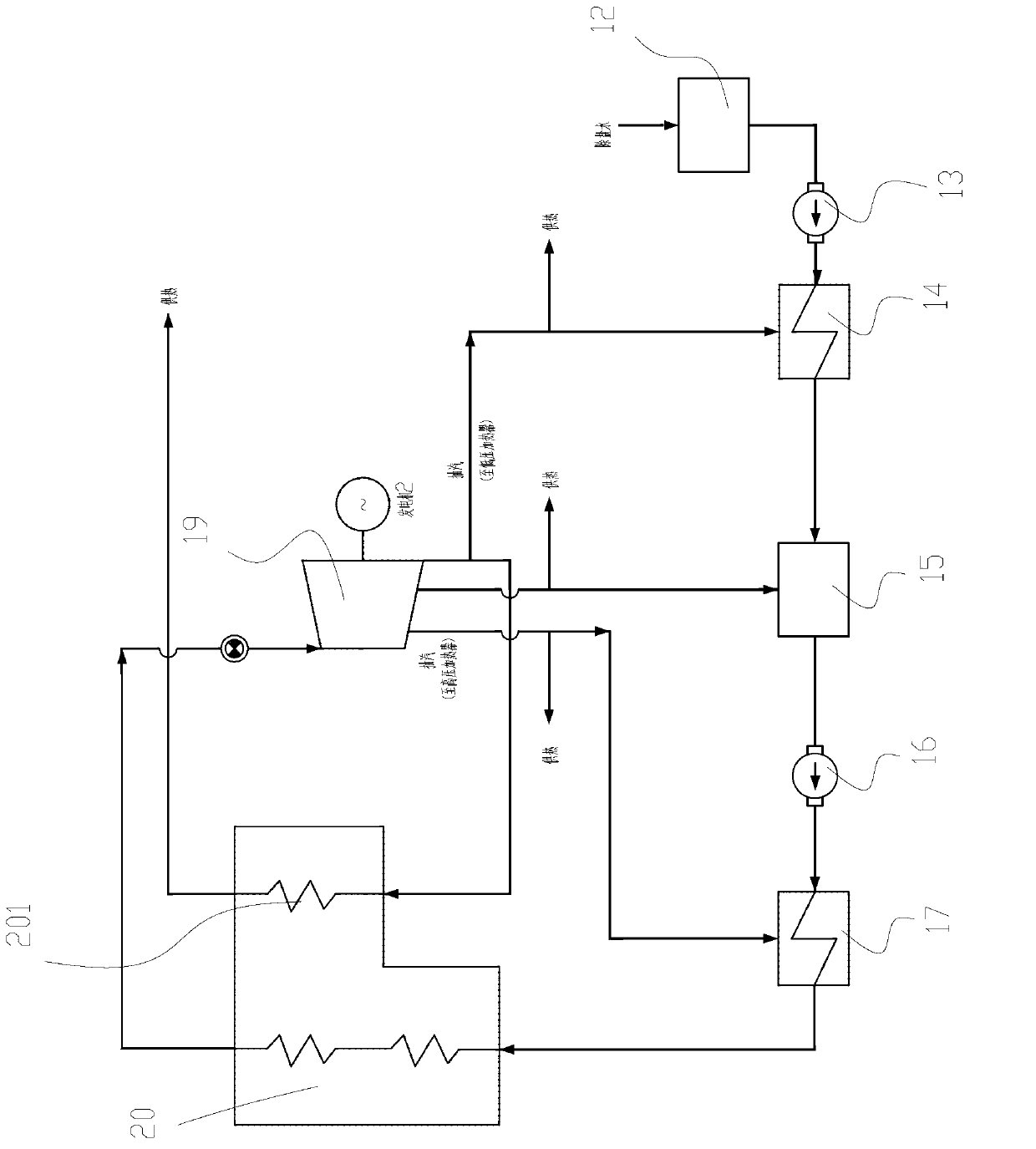

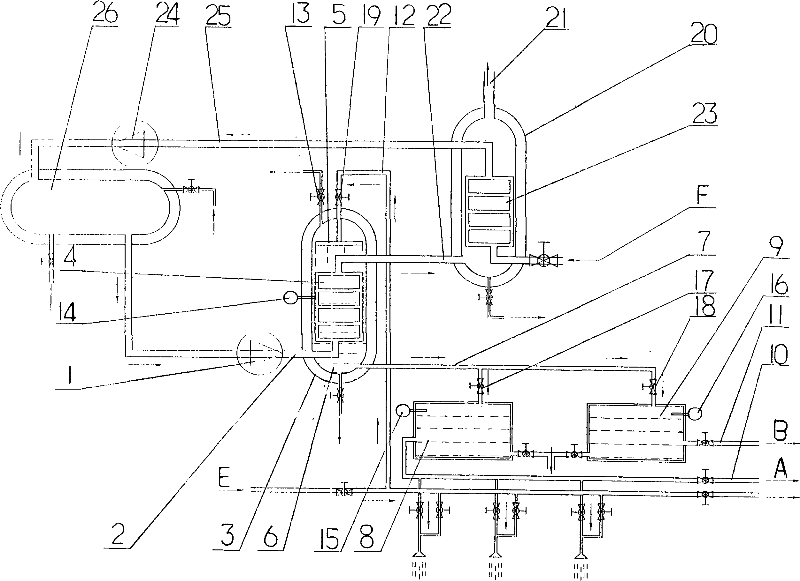

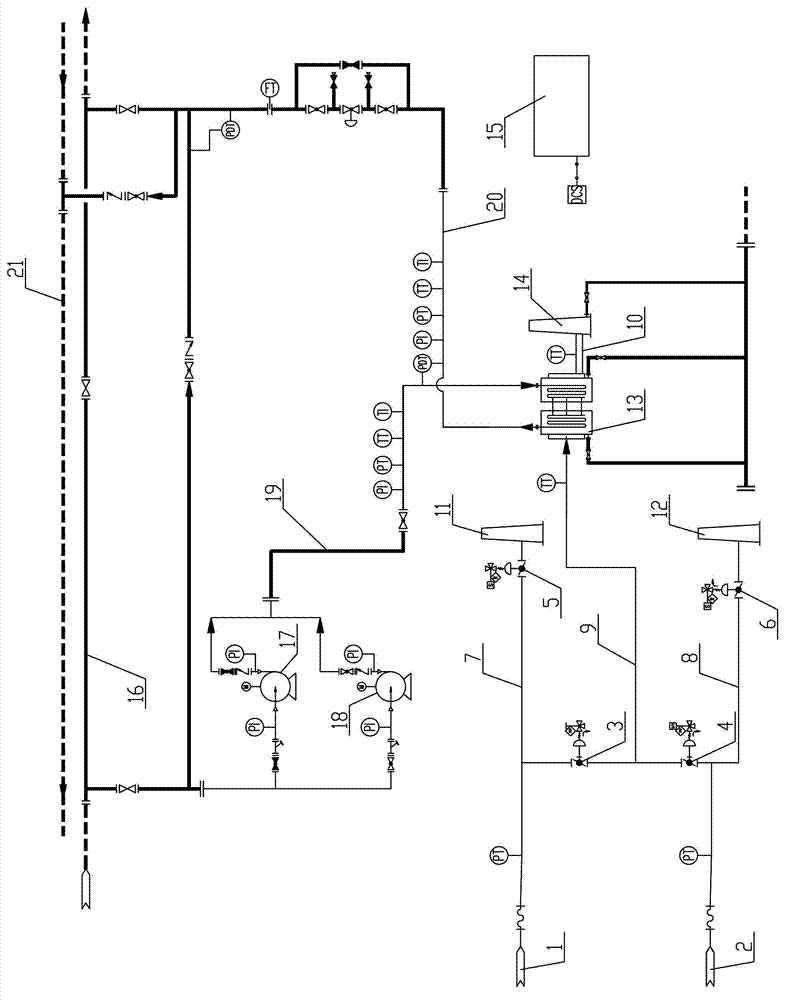

Thermal power plant combined heat system and thermal power plant

ActiveCN102828792AImprove thermal cycle efficiencyLower fuel consumptionSteam useCombined combustion mitigationEngineeringThermal cycle

The invention discloses a thermal power plant combined heat system and a thermal power plant. The thermal power plant comprises a primary reheat condensing steam unit and a backpressure unit; and the combined heat system comprises a heat system of the primary reheat condensing steam unit and a heat system of the backpressure unit, wherein the heat system of the primary reheat condensing steam unit and the heat system of the backpressure unit share a heat recovery system from a condenser to a deaerator; condensation water of the primary reheat condensing steam unit and the supplement demineralized water of the backpressure unit are divided into two paths through the shared heat recovery system; and one path enters the primary reheat condensing steam unit, and the other path enters the backpressure unit. According to the combined heat system, the requirements of industrial high capacity and high parameter heat supply can be simultaneously met, the thermal cycle efficiency is greatly improved, the fuel consumption is reduced, and the pollutant discharge is reduced; and meanwhile, the power plant investment can be greatly reduced.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST +1

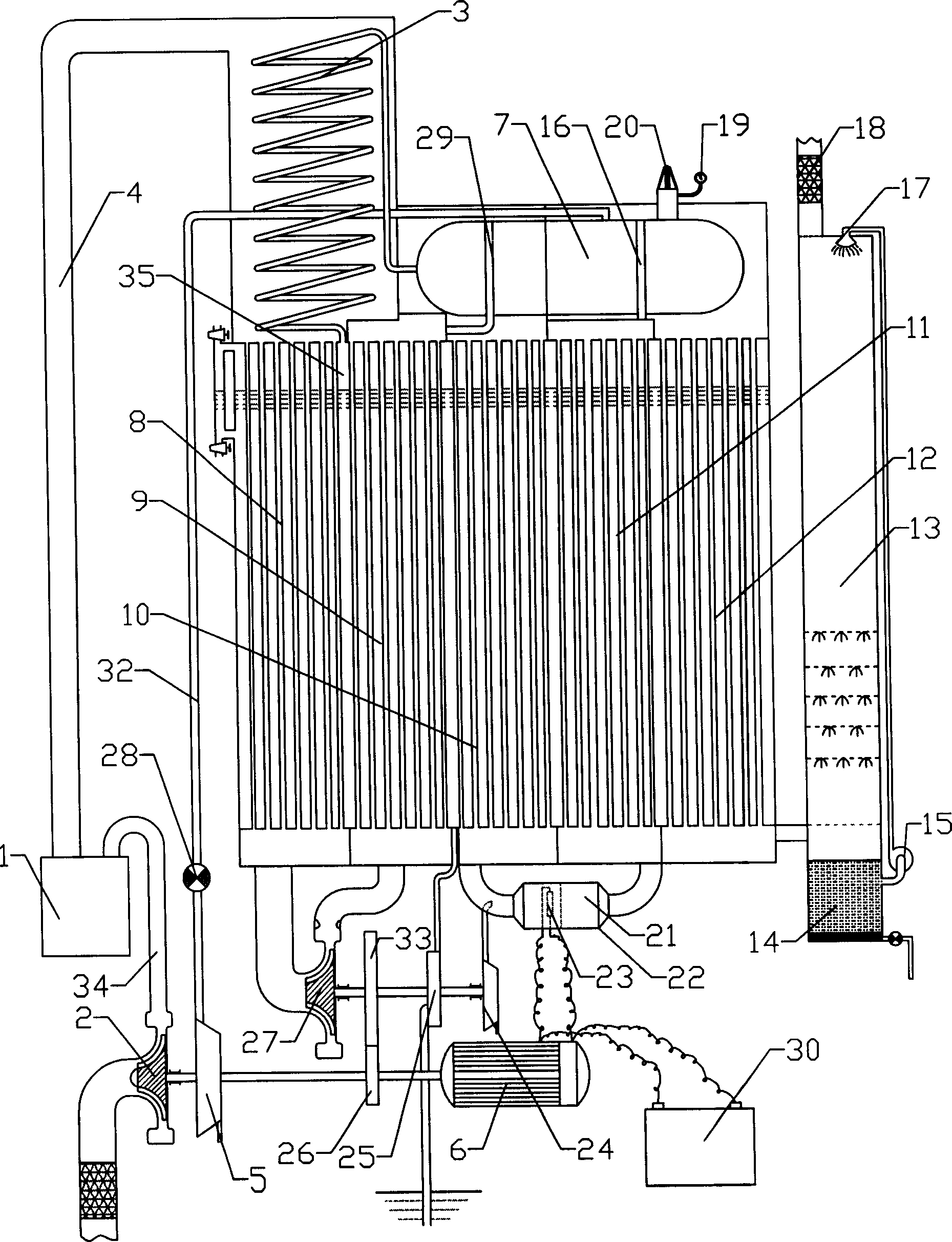

Wastegas steam turbine super charging system

InactiveCN1987064AImprove efficiencyLower fuel consumptionInternal combustion piston enginesExhaust apparatusHeat recovery steam generatorExhaust fumes

A waste gas boosting system for steam turbine has an air compressor connected with the air inlet tube of diesel engine, and a heat exchanging unit connected with the exhaust tube of diesel engine. Said heat exchanging unit consists of a casing, 5 heat exchangers, over-heat steam generator, and steam storage chamber with a steam output tube connected to steam turbine arranged coaxially with said air compressor.

Owner:张建元

Water treating agent of boiler

InactiveCN1854087AThe water quality is clear and free of impuritiesLower fuel consumptionTreatment using complexing/solubilising chemicalsEnvironmental chemistrySodium sulfites

A boiler water treatment chemical consists of sodium hydrate, monometallic sodium orthophosphate, hydroxyl-ethylene phosphoric acid, ethylenimine, hydrazine, sodium humate, sodium sulfite, sodium phosphate and deionized water. It has better water quality and saves energy sources.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

Testing device for rocket engine nozzle throat liner

ActiveCN112555058AHigh precisionLower fuel consumptionRocket engine plantsAutomotive engineeringProcess engineering

The embodiment of the invention provides a testing device for a rocket engine nozzle throat liner. The testing device comprises a test engine unit and at least two spray pipe units. The test engine unit is provided with a combustion chamber and an output end, the output end is provided with at least two gas channels, one end of each gas channel communicates with the combustion chamber of the testengine unit, and the other end communicates with the external environment of the test engine unit. Each spray pipe unit is detachably connected into the corresponding gas channel. Each spray pipe unitis used for correspondingly bearing different types of throat liner test pieces. The combustion chamber is used for generating the same real gas environment for simulating a rocket engine and testingdifferent types of throat liner test pieces. According to the embodiment of the testing device for the rocket engine nozzle throat liner, different types of throat liner test pieces can be ablated atthe same time in the same ablation test, the real same test environment is realized, the ablation performance comparison assessment precision of different types of throat liner test pieces can be greatly improved, and the test cost is reduced.

Owner:星河动力(北京)空间科技有限公司 +2

Method for making sintering bed charge by returning mine at high mixture ratio

The invention discloses a method for making a sintering bed charge by returning mine at a high mixture ratio. The method comprises the following steps of: mixing 50-75 percent by mass of sintering return mine serving as a major raw material with 10-35 percent by mass of high-grade fine particle iron-containing material, 5-20 percent by mass of iron-containing sludge and 5-10 percent by mass of bonding agent, and stirring; pressing a mixture into blocks on a ball press; and drying and baking to obtain the sintering bed charge. The high-grade fine particle iron-containing material is one or more of sheet iron, steel scale and high-grade concentrate fines, and the content of the material of which the granularity is less than 0.074 millimeters is over 85 percent. The bonding agent consists of 25-55 percent by weight of bentonite and 45-75 percent by weight of starch. The sintering productivity rises, the fuel consumption in a sintering procedure is lowered, and the production cost is reduced.

Owner:ANGANG STEEL CO LTD

Residual heat utilization device of boiler heat smoke method of using same

ActiveCN101038107ALower fuel consumptionEnergy savingCombustion technology mitigationWater heatersProcess engineeringHeat generation

The present invention relates to a boiler hot smoke and residual heat using device and a using method. Commonly, the hot smoke after heat generation is discharged to the atmosphere directly; there is no reasonable and effective technology for using residual heat. The present invention mainly includes a draft fan, a hot water generating tower, an air preheating tower, exchangers, a level meter, a blower, a hot water box for production, a life using hot water box, a valve and a pipeline. The reclaimed hot water is exchanged fully twice by the exchangers in the hot water generating tower and the air preheating tower, and then is used for production and life; the reclaimed hot air is used for boiler preheating in order to save fuel, the useable heat of the fuel is 1.2 times than before, and the maximum residual use is achieved. It is also a big contribution for resource saving and environment protection.

Owner:SHANGHAI FORWARD MASCH CO LTD

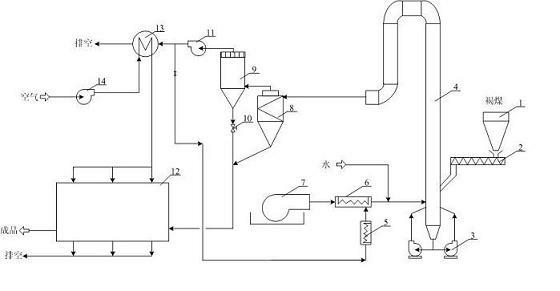

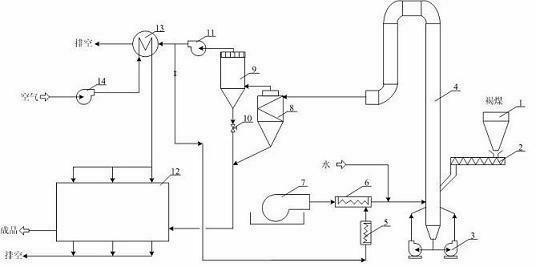

Air flow and high frequency combined lignite drying device and process

ActiveCN102661658ALower fuel consumptionReduce CO2 emissionsDrying machine combinationsDrying gas arrangementsProcess engineeringAirflow

The invention discloses an air flow and high frequency combined lignite drying device and an air flow and high frequency combined lignite drying process. The air flow and high frequency combined lignite drying device comprises an air flow dryer, a high frequency dryer, an external heat exchanger, a feeding device, a compression device, a dust removal system and a hot flue gas generation device, wherein a feeding part of the air flow dryer is connected with the feeding device; a flue gas inlet part of the air flow dryer is connected with the hot flue gas generation device; a discharge part of the air flow dryer is connected with the dust removal system; the dust removal system is connected with the high frequency dryer and the compression device I; the compression device I is connected with the external heat exchanger and the hot flue gas generation device; the external heat exchanger is connected with the high frequency dryer through a ventilation system and is also connected with the compression device II; and the external heat exchanger and the high frequency dryer can be emptied. The air flow and high frequency combined lignite drying device and method have the advantages of safety, energy conservation, high efficiency, environmental friendliness and the like.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

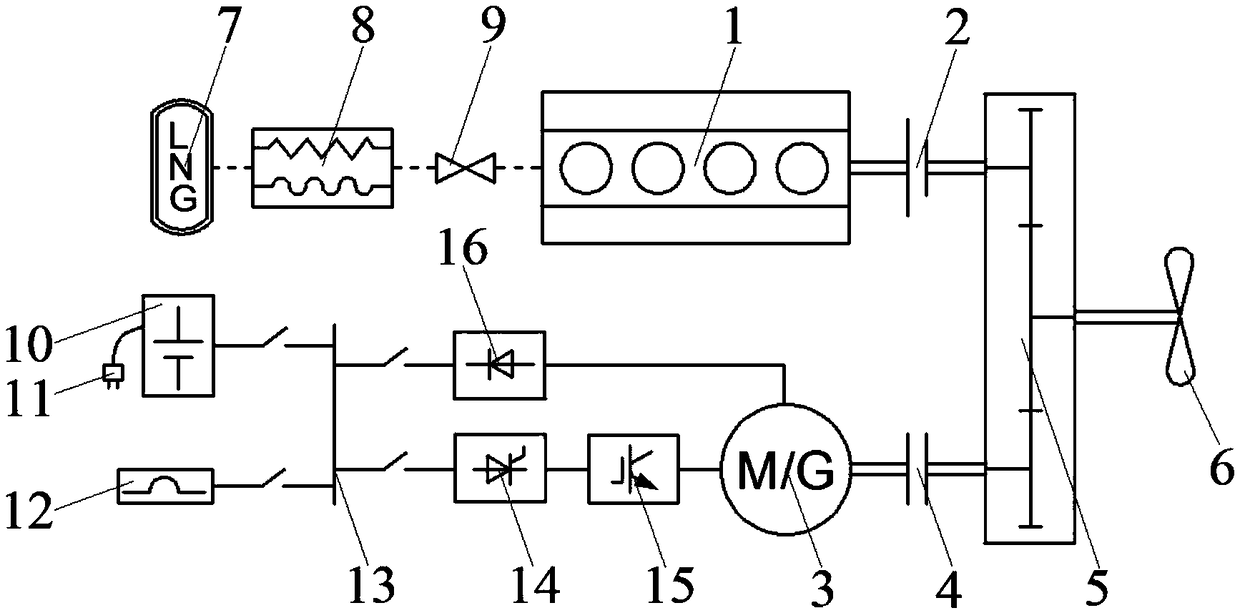

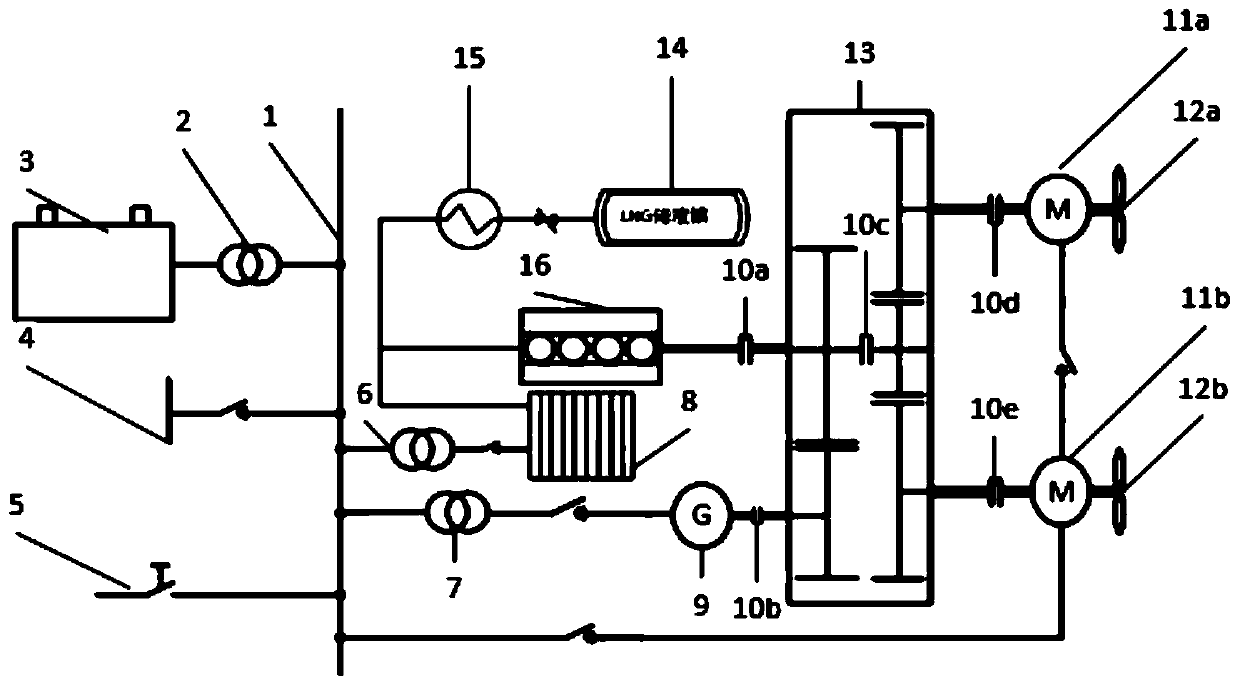

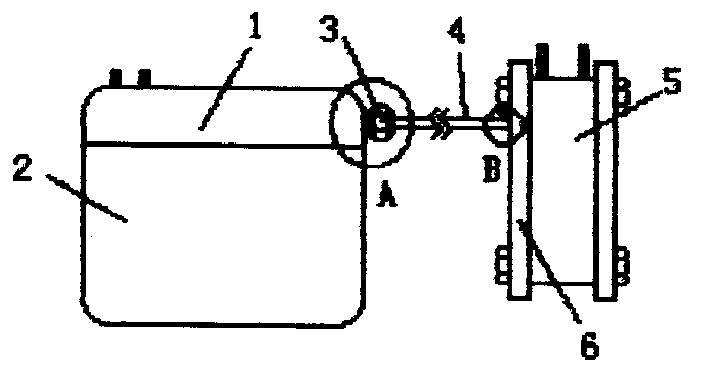

Single-engine single-propeller type gas-electric hybrid ship power system

InactiveCN108657405AWide power coverageLower fuel consumptionPropulsion based emission reductionPower plants using propulsion unit combinationsPropellerClutch

The invention provides a single-engine single-propeller type gas-electric hybrid ship power system. The single-engine single-propeller type gas-electric hybrid ship power system comprises a gas engine, a storage battery and a gearbox, the output end of the gas engine is connected with the input end of the gearbox through a permanent magnet coupler, the output / input ends of a reversible motor are connected with the input / output ends of the gearbox through a clutch, and the output end of the gearbox is connected with a propeller. A liquefied natural gas tank is connected with a gas supply devicein a gas mode, the gas supply device communicates with the interior of the gas engine, the storage battery, ship load, an inverter and a rectifier are all connected to a distribution board, the inverter is connected with the reversible motor through a frequency converter, and the reversible motor is electrically connected with the rectifier. The layout of various energy forms adopted by the single-engine single-propeller type gas-electric hybrid ship power system can meet the needs of ships in various environments and operating conditions, further improves the operation efficiency of the gasengine and the reversible motor, effectively reduces fuel consumption and emission of the gas engine, improves the dynamic response of the ships simultaneously, and the system has a wide range of application.

Owner:HARBIN ENG UNIV

High-efficiency denitration and plume elimination system for flue gas from sintering machine

PendingCN110152487AHigh specific surface areaLower fuel consumptionDispersed particle filtrationEngineeringAir blower

The invention discloses a high-efficiency denitration and plume elimination system for flue gas from a sintering machine. The system comprises a first bearing plate and a third bearing plate; and an air cylinder is installed at the top end of the first bearing plate, a second bearing plate is installed at the top end of a hydraulic rod, a connecting rod passing through a second sleeve cylinder isinstalled in the second sleeve cylinder through a third spring, an air blower is horizontally installed at one end of the top end of the third bearing plate, an air outlet pipe passing through a firstreaction box is installed at the output end of the air blower, a bag-type dust collector is installed on the top end of one part, located at one side, far away from the first reaction box, of a fourth reaction box, of the third bearing plate, and a second reaction box is installed at the top end of one part, far away from the bag-type dust collector, of a third reaction box, of the third bearingplate. According to the high-efficiency denitration and plume elimination system for the flue gas from the sintering machine provided by the invention, the third bearing plate transfers impact force generated by vibration to the first connecting rod and a fourth connecting rod, and the impact force generated by the vibration is eliminated by the third spring, a fourth spring and a second spring, so that the cushion shock absorption is facilitated.

Owner:无锡市东方环境工程设计研究所

Flue gas waste heat recovery device for heat pipes

InactiveCN103423862ALower fuel consumptionLower exhaust gas temperatureWater heatersPipingHeating system

The invention discloses a flue gas waste heat recovery device for heat pipes. The device comprises a water sleeve body formed by an inner casing and an outer casing. The set of heat pipes are welded on the inner wall of the water sleeve body, a flue gas inlet flange and a flue gas outlet flange are welded at the upper end and the lower end of the water sleeve body respectively, a water outgoing pipe is welded at the top of the water sleeve body, and a water ingoing pipe is welded at the bottom of the water sleeve body. The flue gas inlet flange is connected with a boiler flue gas outlet, and the flue gas outlet flange is connected with the root of a chimney. The water ingoing pipe and the water outgoing pipe are in series connection in a heating system water return pipe, and the water outgoing pipe is connected with a boiler water return port. The flue gas waste heat recovery device for heat pipes has the advantages of reducing fuel consumption of an atmospheric pressure boiler, reducing exhaust gas temperature, and improving operation heat efficiency of the boiler.

Owner:陕西火王能源科技有限责任公司

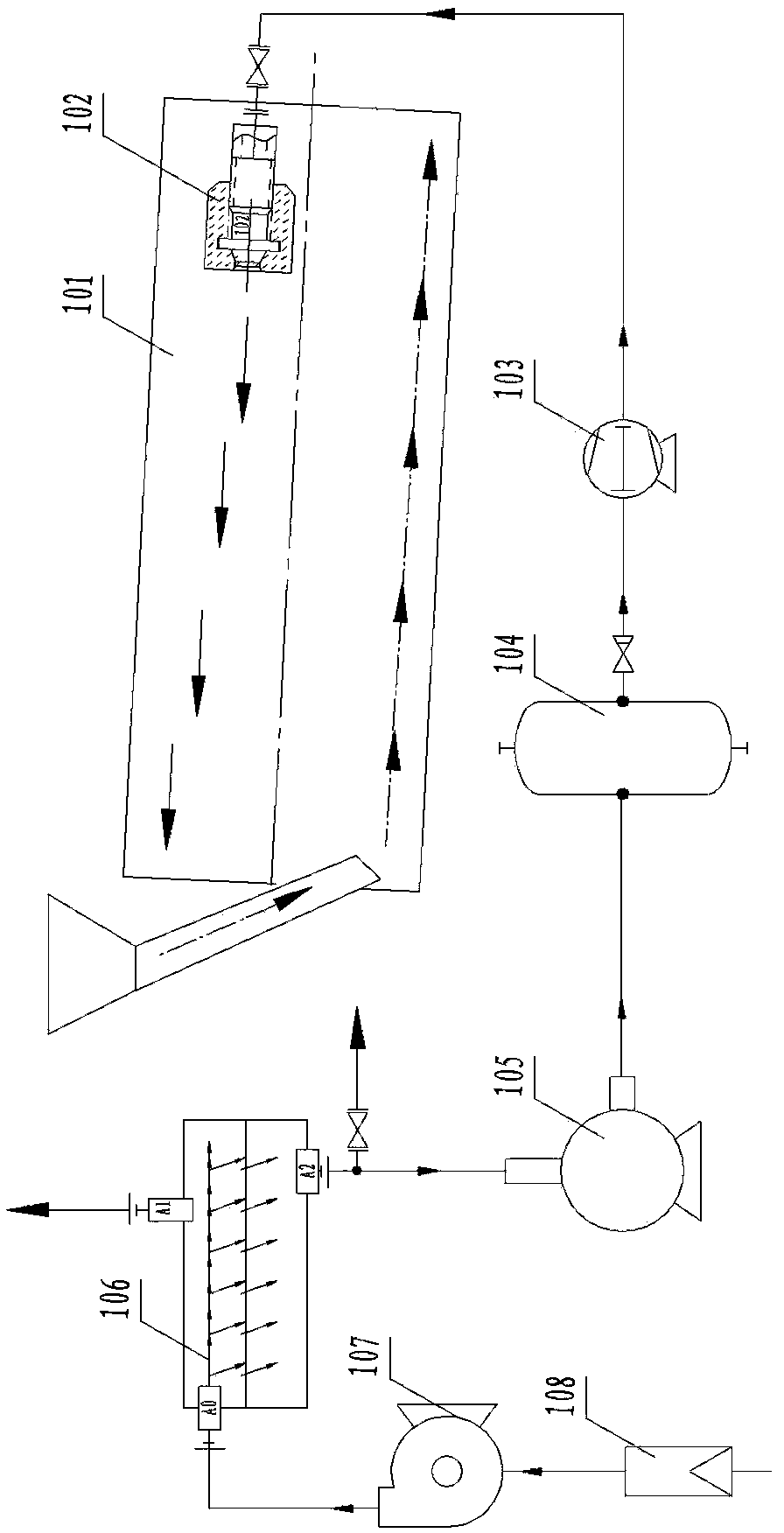

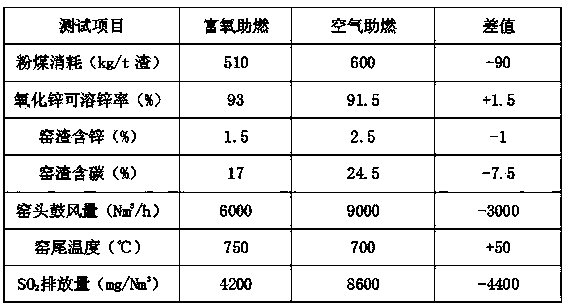

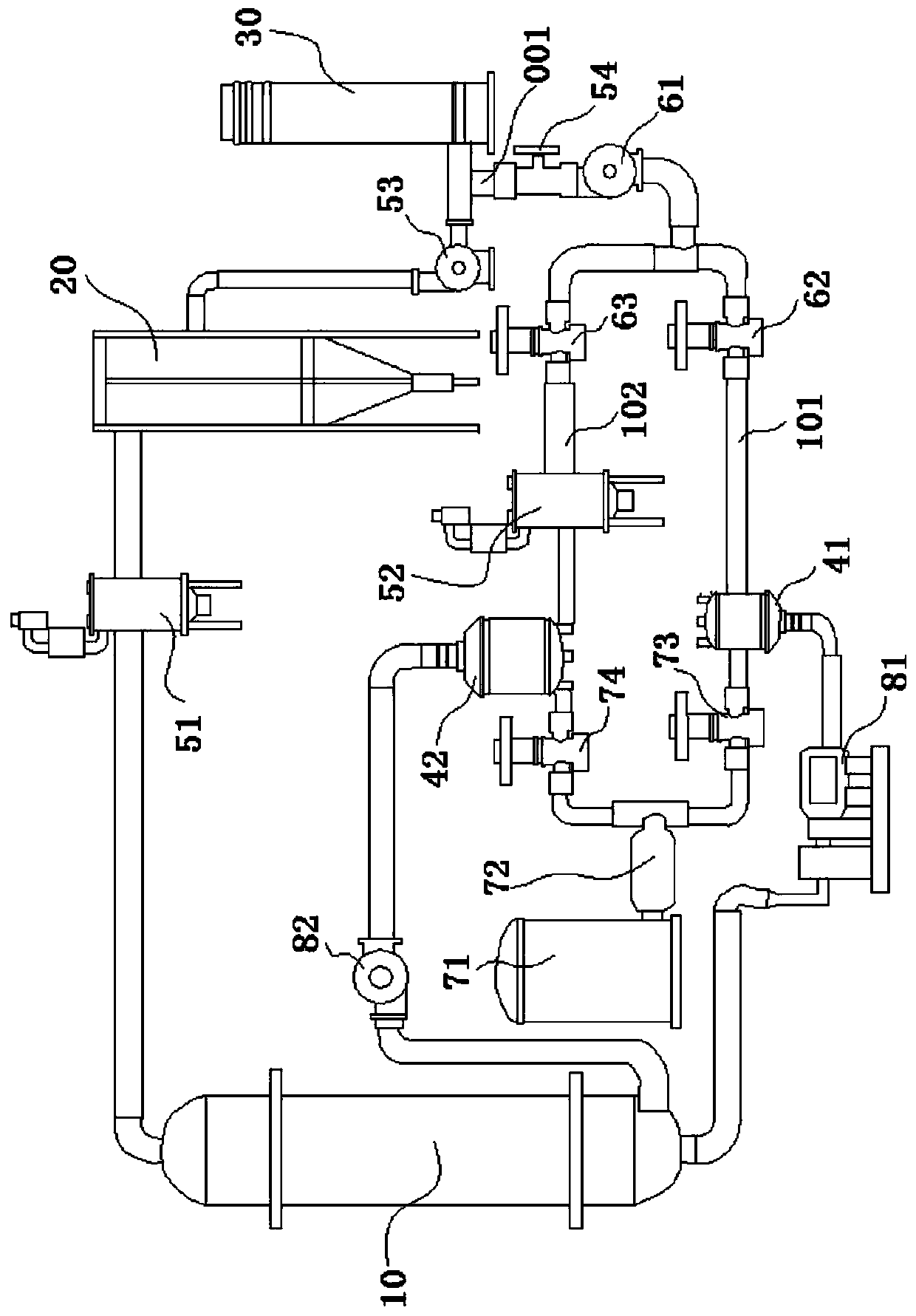

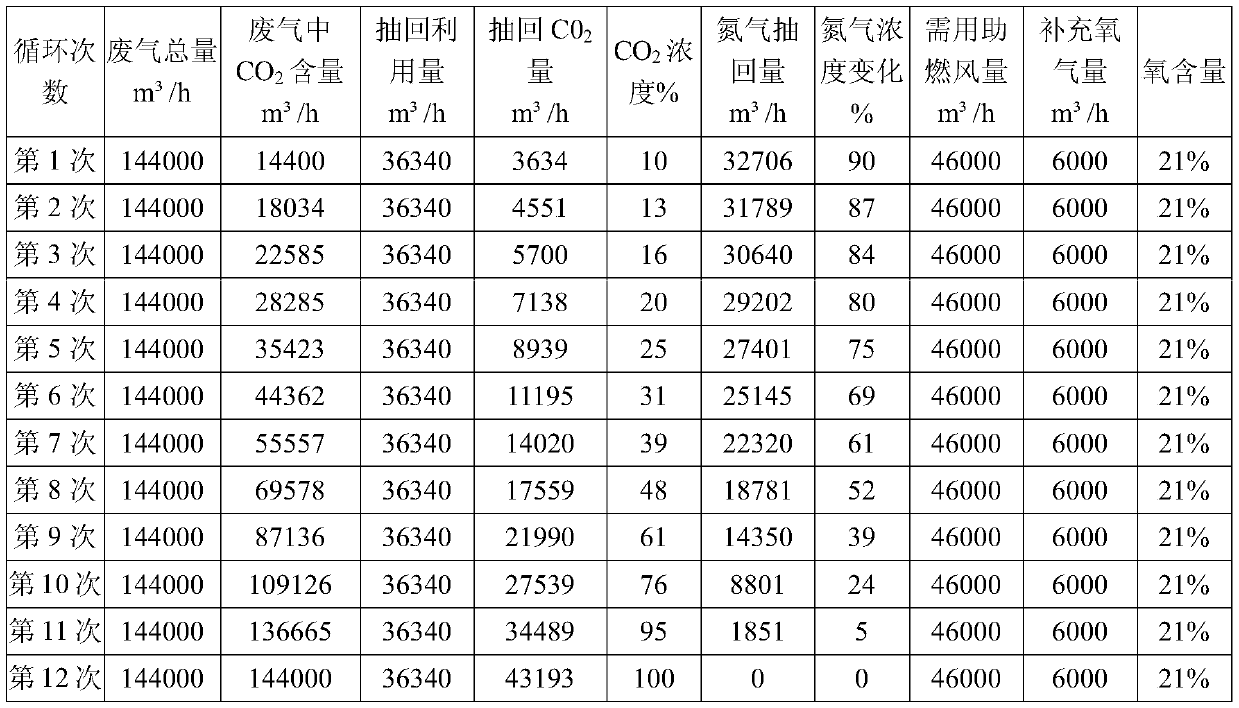

Oxygen-enriched combustion method of volatilization klin

InactiveCN104033892ALower fuel consumptionIncrease volatilityIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplySlagCoal

The invention discloses an oxygen-enriched combustion method of a volatilization klin and relates to the technical filed of klin equipment. The oxygen-enriched combustion method is implemented through an oxygen-enriched combustion device of the volatilization klin, and comprises the following steps: (1) preparing materials, namely mixing leaching slag and pulverized coal to obtain a mixture, wherein the moisture content of the leaching slag is less than 20%, the moisture content of the pulverized coal is less than 5% and the moisture content of the mixture is 12-18%; (2) preparing oxygen, namely preparing oxygen with a membrane separator, wherein the flow rate of the enriched oxygen is 3000-9000m<3> / / h and the concentration of the enriched oxygen is 22-30%; (3) supplying air, namely an air compressor supplies 0.1-0.2MPa compressed oxygen-enriched air and the mixture is combusted with the oxygen-enriched air through a nozzle in the cavity of the volatilization klin. According to the oxygen-enriched combustion method, the problem that during production of the volatilization klin, the production cost is high because valuable metal is not volatilized completely and large amount of energy is wasted, is solved.

Owner:广西聚为能源科技有限公司 +1

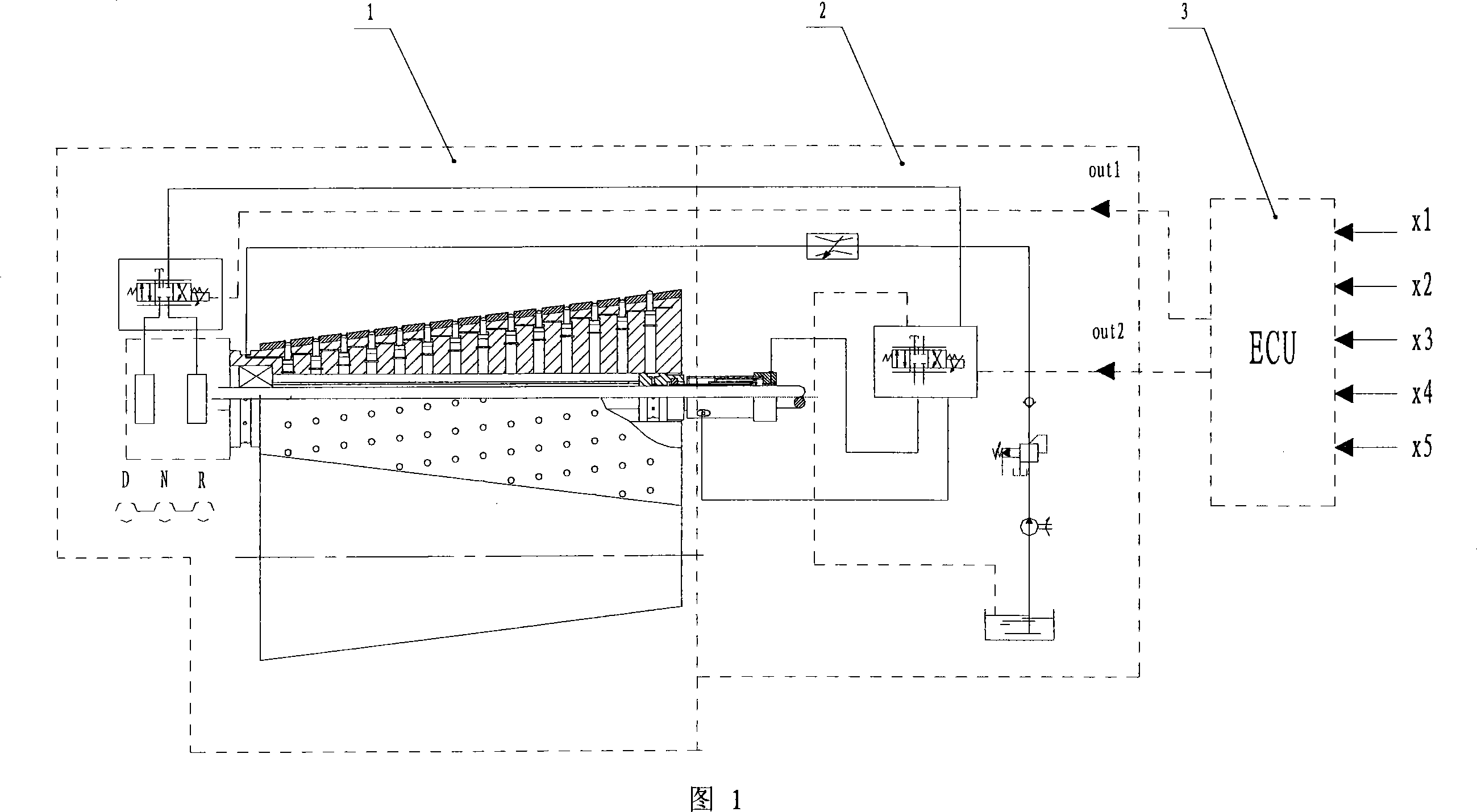

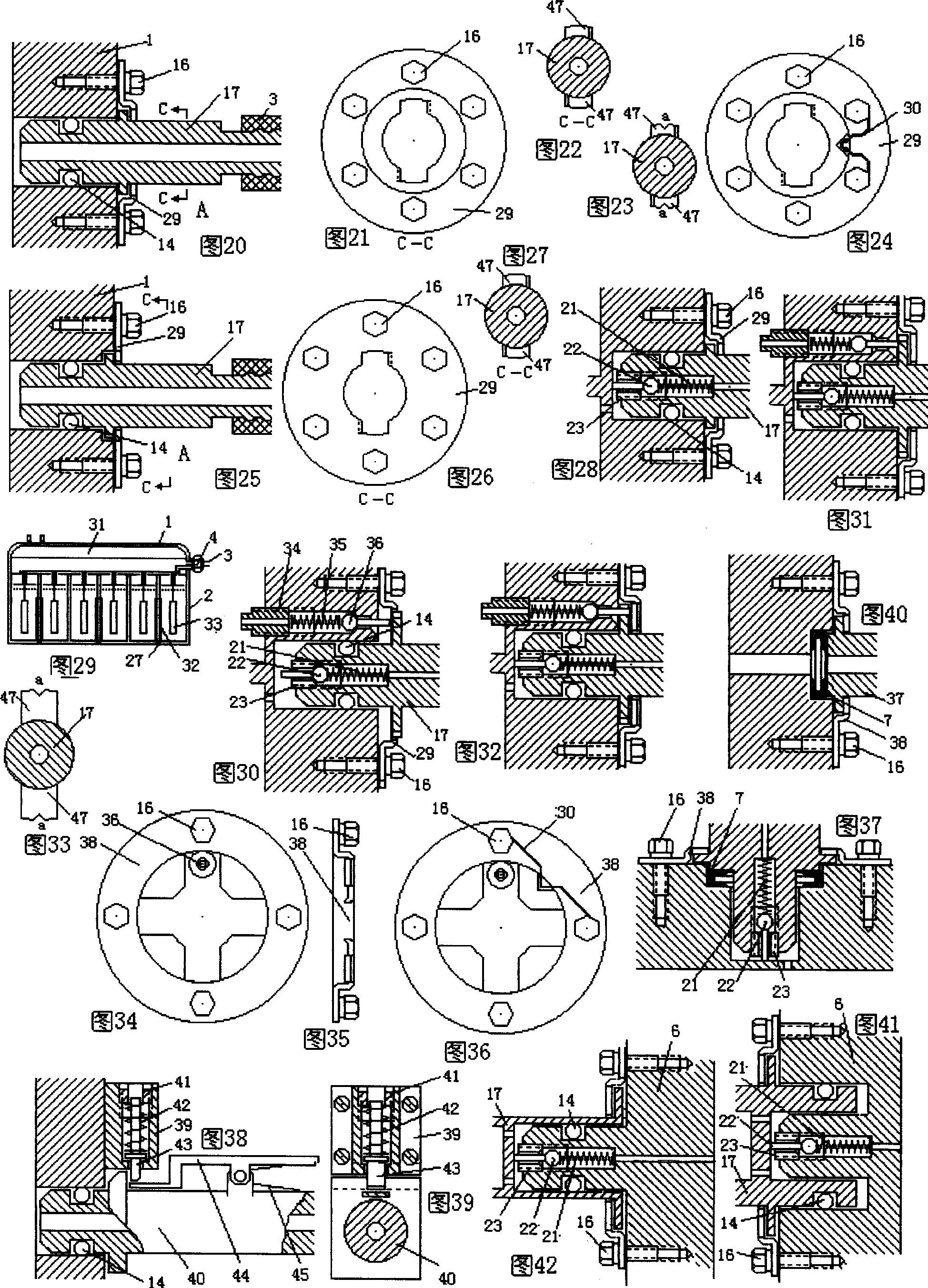

Hydraulic and mechanical automatic speed variator

The present invention relates to vehicle electronic control automatic speed variator field, especially relates to a hydraulic automatic mechanical speed variator device. The object is to conquer the fault that the existing vehicle electronic control automatic speed variator is complex in manufacturing technique and high in cost. The device is composed of a speed variator part, a hydraulic control part and a control unit, the control unit is connected to the speed variator and the hydraulic control part; the speed variator part includes an initiative awl table and a driven awl table that are accordance in external structure, inverse with each other, mounted with the surfaces are contacting with each other and parallel in axes, a gear box mounted at the left end of the initiative awl table and a gear shifting piston mounted in the internal main oil channel of the initiative awl table and a gear shifting selecting cylinder for driving the gear shifting piston, the initiative awl table and the driven awl table are machined with plural round holes with same position and diameter, the round holes of the initiative awl table is mounted with plural groups of plungers that can protrudes from the external surface through the round holes, the plunger oil channel is connected to the internal main oil channel of the initiative awl table.

Owner:范巨新

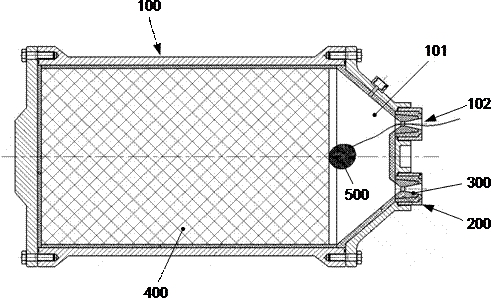

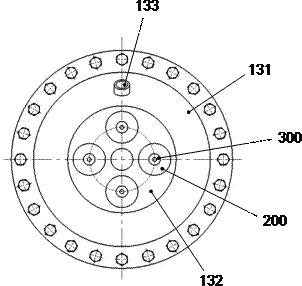

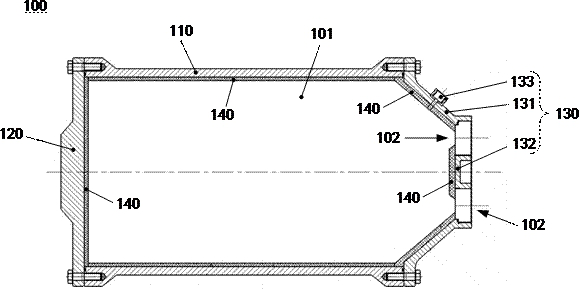

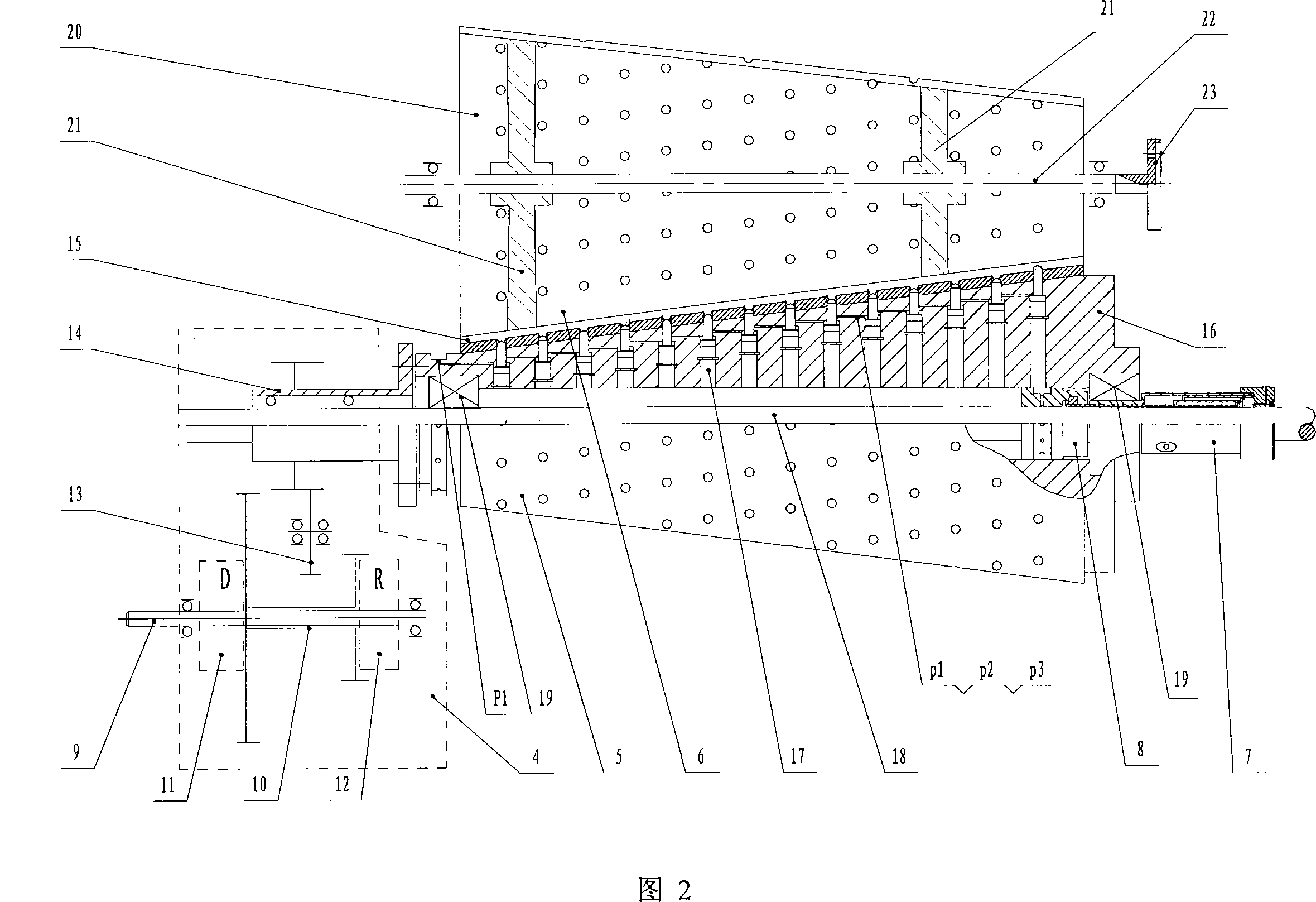

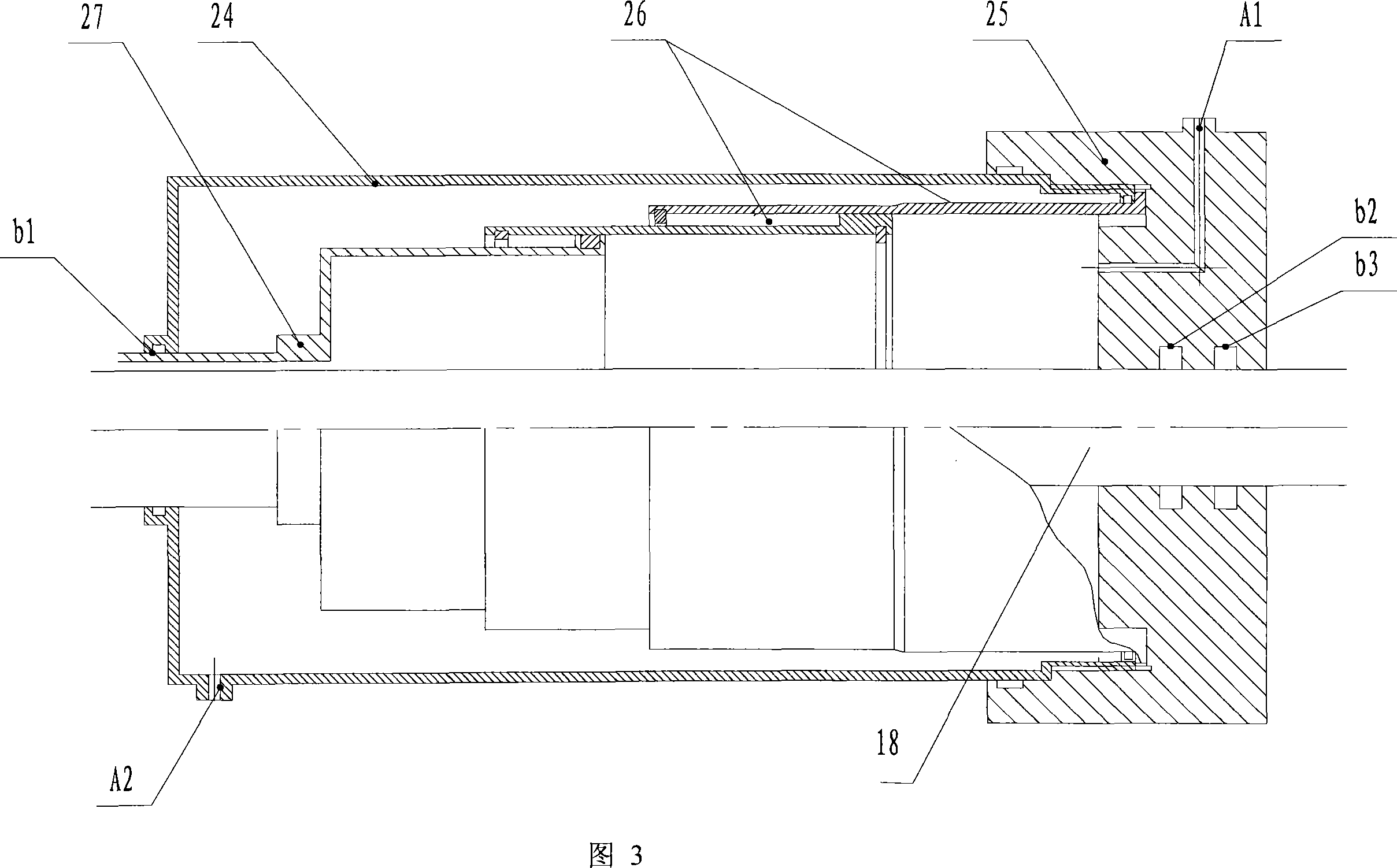

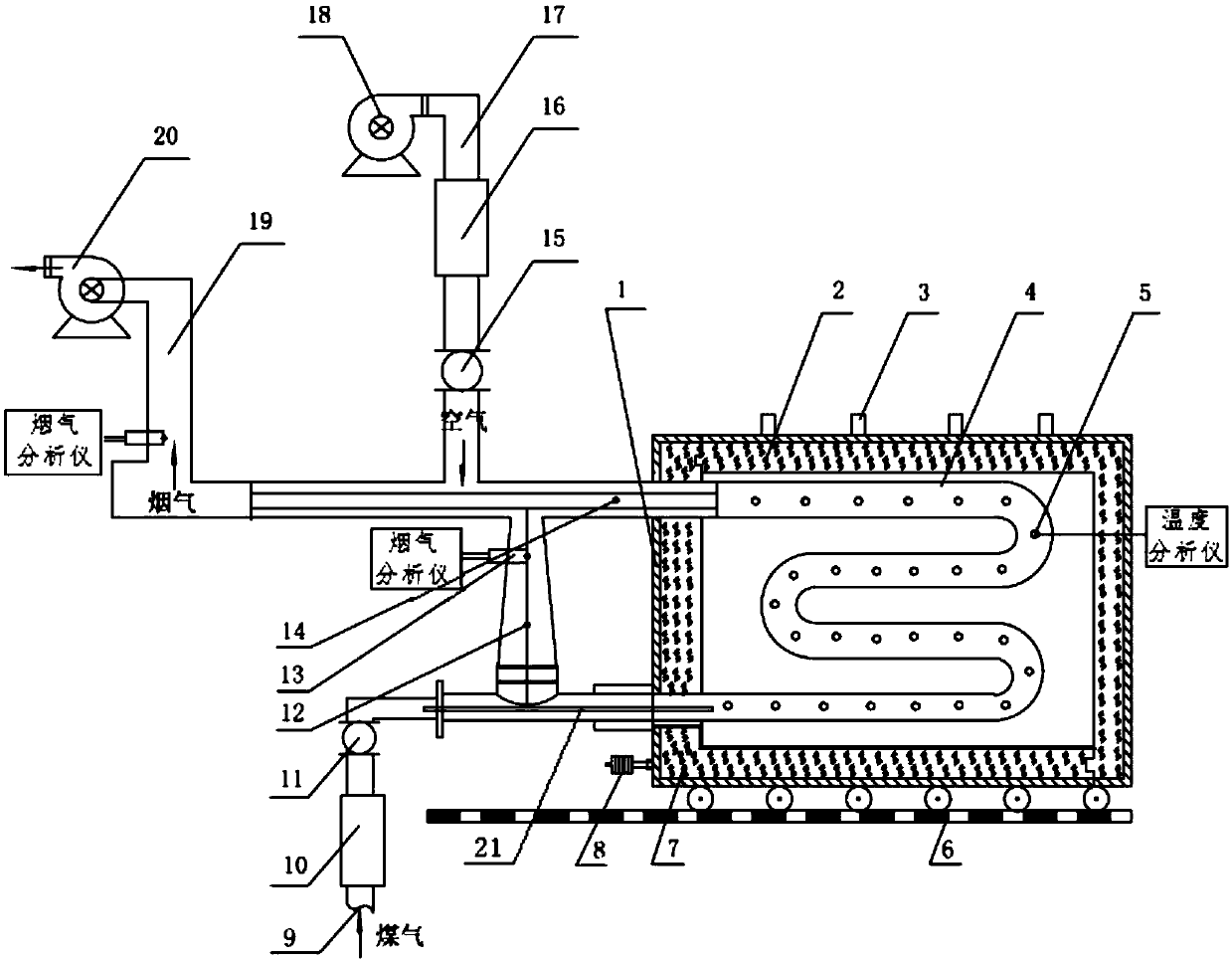

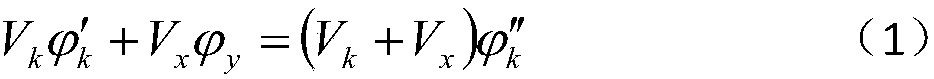

Radiant pipe combustion performance thermal simulation test furnace and method

ActiveCN108826989AImprove combustion efficiencyLower fuel consumptionStructural/machines measurementCharge manipulationPollutantControl models

The invention relates to a radiant pipe combustion performance thermal simulation test furnace and a method. The test furnace comprises a furnace body, a movable end wall, a radiant pipe, a slideway,a trolley bottom, a heat exchanger, a preheating air pipe and a radiation pipe burner. Compared with the prior art, the radiant pipe combustion performance thermal simulation test furnace and the method has the beneficial effects that the combustion performance of the radiant pipe of a continuous annealing furnace in actual production can be detected, the detection result can be used for optimizing combustion parameters of the continuous annealing furnace combustion control model, the combustion efficiency of the radiant pipe is improved, the efficiency of the heat exchanger is improved, the fuel consumption is reduced, the emission amount of NOx pollutants is reduced, and energy conservation and environmental protection are facilitated; and in addition, in a new product development designprocess of a radiant pipe complete device, the selection of thermal parameters is also a very important experiment method, the heating effect of the new product is improved, and the heating quality of thin strip steels is ensured.

Owner:ANGANG STEEL CO LTD

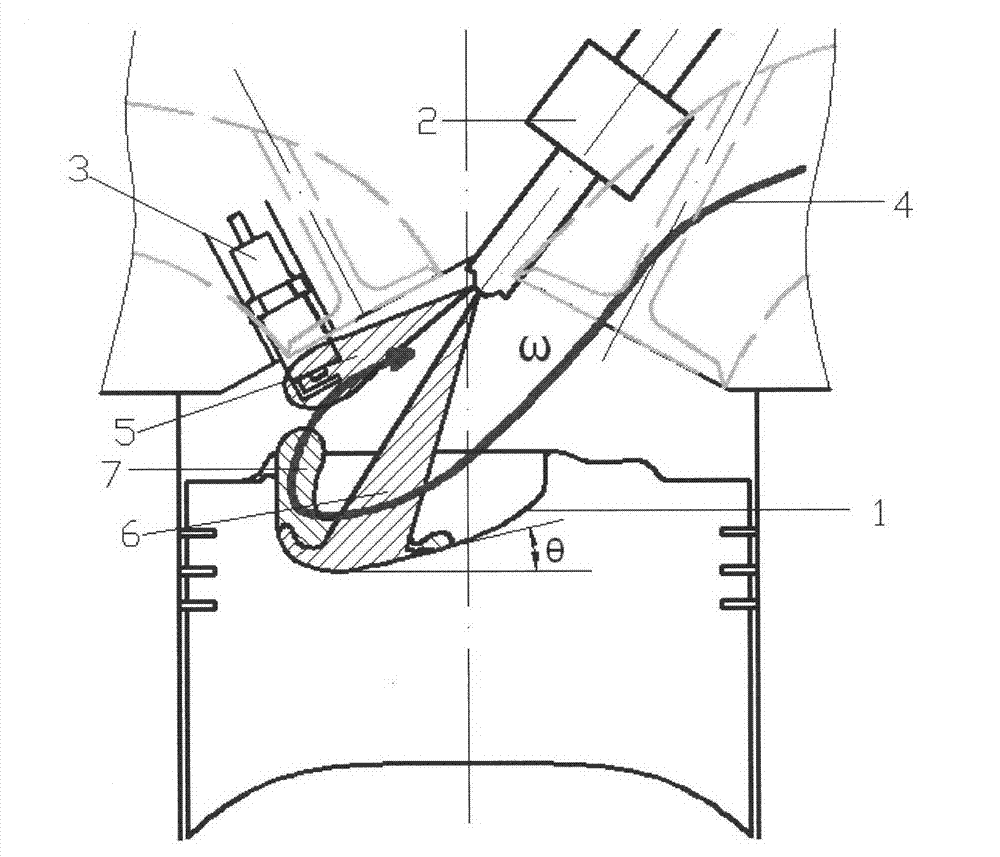

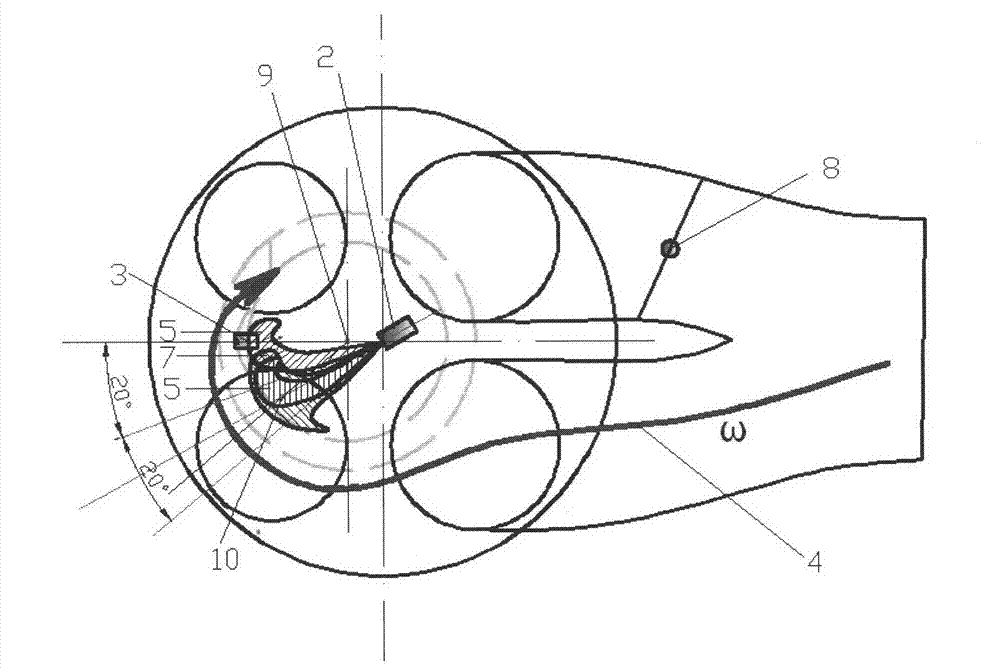

Forming method of mixed gas of layered lean-burn spraying-wall face combined-guiding LPG direct injection supercharged engine

InactiveCN103362691ALower fuel consumptionReduce consumption rateInternal combustion piston enginesFuel supply apparatusCombustion chamberMixed gas

The invention relates to a forming method of mixed gas of a layered lean-burn spraying-wall face combined-guiding LPG direct injection supercharged engine. The method is mainly characterized in that a large-inclination-angle bottom-face pit is formed in the top of a piston, the center of the pit deviates from the axis of a cylinder, and the symmetry axis (the bottom) of the pit deflects downward by 40 degrees in the anti-clockwise direction; three-hole spray nozzle high-pressure center injection is adopted, part of LPG is injected to the position close to a sparking plug electrode to directly form the combustible mixed gas in a spraying guiding mode at the later stage of the compression process, and the other part of fuel injected into the combustion chamber pit provided with the large-inclination-angle bottom face goes upward along with a piston to the position close to a sparking plug to form the combustible mixed gas in a wall-face guiding mode under the action of entrainment vortex and air intake vortex in the pit; under the partial load work condition, one air intake valve is closed, and air flow enters a cylinder only through the other air intake valve to form air intake vortex. Under the large load condition, the two air intake valves are opened at the same time, the air intake early stage ((70 degrees CA ATDC) LPG injection is adopted to form homogeneous mixed gas in the cylinder. Under the cold starting and turbine heating conditions, the air intake early stage LPG injection is also adopted. In comparison with an existing engine, the lean-burn limit (air-fuel ratio A / F > 60:1) of the layered mixed gas is further widened, and fuel consumption can be reduced by more than 10%. The method is also applicable to a layered lean-burn direct injection supercharged gasoline engine.

Owner:许伯彦 +2

Single-engine double-propeller gas-electric hybrid ship power system with fuel cell

InactiveCN109878682AWide power coverageLower fuel consumptionPower plants using propulsion unit combinationsTransmission with mechanical gearingPropellerClutch

The purpose of the invention is to provide a single-engine double-propeller gas-electric hybrid ship power system with a fuel cell. The system includes a gas engine, a generator, motors, the fuel cell, a storage battery, clutches, a gear case, propellers, a natural gas storage and supply device, a substation device, a shore power device, a ship power grid, and a ship load. The gas engine is connected to the gear case through the clutch. The motors and the generator are connected to the gear case through the clutches. The propellers are directly connected to output ends of the motors. An electric power source is the fuel cell, the storage battery and the generator. The single-engine double-propeller gas-electric hybrid ship power system with the fuel cell adopts a plurality of energy form arrangements, has a plurality of working modes, can meet requirements of ships in various environment and working conditions, can maintain the gas engine and the motors in a high efficiency zone all the time, reduces the fuel consumption and discharge of the ship power system, improves the power response of ships, and enlarges seaworthiness of the ships.

Owner:HARBIN ENG UNIV

Turbine residual heat recycling and utilizing system

InactiveCN102758703AIncrease temperatureLower fuel consumptionInternal combustion piston enginesPipeline systemsProcess engineeringAtmospheric pollutants

The invention discloses a turbine residual heat recycling and utilizing system which mainly comprises a residual heat boiler, a hot oil circulating pump, a smoke valve and a field control disc. High-temperature smoke discharged by a turbine motor is used as a heat source and the residual heat of smoke is recycled; heat-conducting oil is introduced to a residual heat boiler heat exchanging disc through a hot oil circulating pump and the heat-conducting oil in a residual heat boiler heat exchanging coiled pipe is heated by utilizing the high-temperature smoke; and after the heat-conducting oil is heated, the heat-conducting oil is returned to a heat-conducting oil system. According to the turbine residual heat recycling and utilizing system disclosed by the invention, the heat energy in turbine smoke can be recycled and the heat-conducting oil can be heated by effectively utilizing the residual heat of the smoke, so that the temperature of the heat-conducting oil is improved, the consumption of fuel is reduced, the load of a previous heat medium boiler is reduced, and the normal maintenance of the heat medium boiler and the normal operation of a hot oil system are guaranteed; and therefore, the risk of safely operating the previous heat medium boiler is reduced, the safety operating factor of equipment is improved and the pressure of outputting crude oil is relieved. Meanwhile, the emission of atmospheric pollutants is further reduced, and energy conservation and emission reduction are realized.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Firewood-burning type waste-heat utilization continuous fixation tea strip tidying machine with electric hot air

InactiveCN106387130ALower fuel consumptionLower energy costsPre-extraction tea treatmentAir heatersEnergy costCombustion chamber

The invention discloses a firewood-burning type waste-heat utilization continuous fixation tea strip tidying machine with electric hot air. The firewood-burning type waste-heat utilization continuous fixation tea strip tidying machine comprises a machine frame, a groove pot, roller assemblies, hot air distributors, an electric hot air generator, combustion chambers, a waste heat recovery device, fans and a transmission device, wherein the combustion chambers are located below the groove pot, and dried firewood low in price is combusted in the combustion chambers to be used as main hot source; the groove pot is driven by the transmission device and the roller assemblies to sing left and right in a width direction; and two hot air distributors are arranged above the groove pot, and high-temperature hot air is fed through the fans by the electric hot air generator and the waste heat recovery device to be used as an auxiliary hot source. The firewood-burning type waste-heat utilization continuous fixation tea strip tidying machine is low in fuel consumption, low in energy cost and easy to operate, besides, labor is saved, and the human cost is reduced; due to reasonable allocation of the hot sources, the output rate and the superior product rate of finished tea are greatly increased, and the yield can be increased by 10% or above; and the added value of each jin of dried tea can be increased by 5-20 yuan, the market application range is enlarged, and the scale benefits are increased.

Owner:YUEXI COUNTY GREAT WALL MACHINERY

Gas connecting structure of double fuel cell sets

InactiveCN1440089ALower fuel consumptionReduce consumptionFuel and primary cellsHybrid cell detailsEngineeringElectrical and Electronics engineering

A connecting structure of gas for a set of double fuel batteries consists of the gas channel between a "metal-air" battery and a hydrogen-oxygen fuel battery and the connectors of the gas channel. One end of the gas channel is connected by the connectors of the gas channel to the cover of the "metal-air" battery, the other end of the gas channel is firmly connected to the inlet of the hydrogen ofthe hydrogen-oxygen fuel battery. The hydrogen generated during discharging of the "metal-air" battery is sent to the hydrogen-oxygen fuel battery to reuse, making use of the power source of the battery sufficiently and saving the fuel of the battery.

Owner:顾晓青

Limekiln hot air circulation system

PendingCN109721259AImprove heat utilization efficiencyLower fuel consumptionNitrogen oxidesSulfur dioxide

The invention relates to a limekiln hot air circulation system. The system comprises a limekiln, a deduster and a chimney, a hot air circulation outlet is arranged between the deduster and the chimney, and the hot air circulation outlet is respectively connected with a combustion-supporting gas primary wind pipeline and a combustion-supporting gas secondary wind pipeline; a first gas mixer is arranged in the combustion-supporting gas primary wind pipeline, and the first gas mixer is provided with an oxygen input port connected with an oxygen supply device; and a second heat exchanger for reducing the temperature of flue gas is arranged in the combustion-supporting gas secondary wind pipeline, and an oxygen input port connected with the oxygen supply device is arranged in the second gas mixer. The high-temperature heat-carrying flue gas generated by the limekiln is partially recycled, the oxygen content in the combustion-supporting air is changed, and the temperature of the heat-carrying flue gas is used to achieve secondary utilization of carbon monoxide in the flue gas, so the heat utilization efficiency of the limekiln is increased, the fuel consumption is reduced, and the totalemission amount of the flue gas is reduced; and nitrogen oxides and sulfur dioxide participate in reactions in the cycle calcination process in order to realize low-discharge amount control.

Owner:高雷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com